Patents

Literature

316 results about "Porous pipe" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

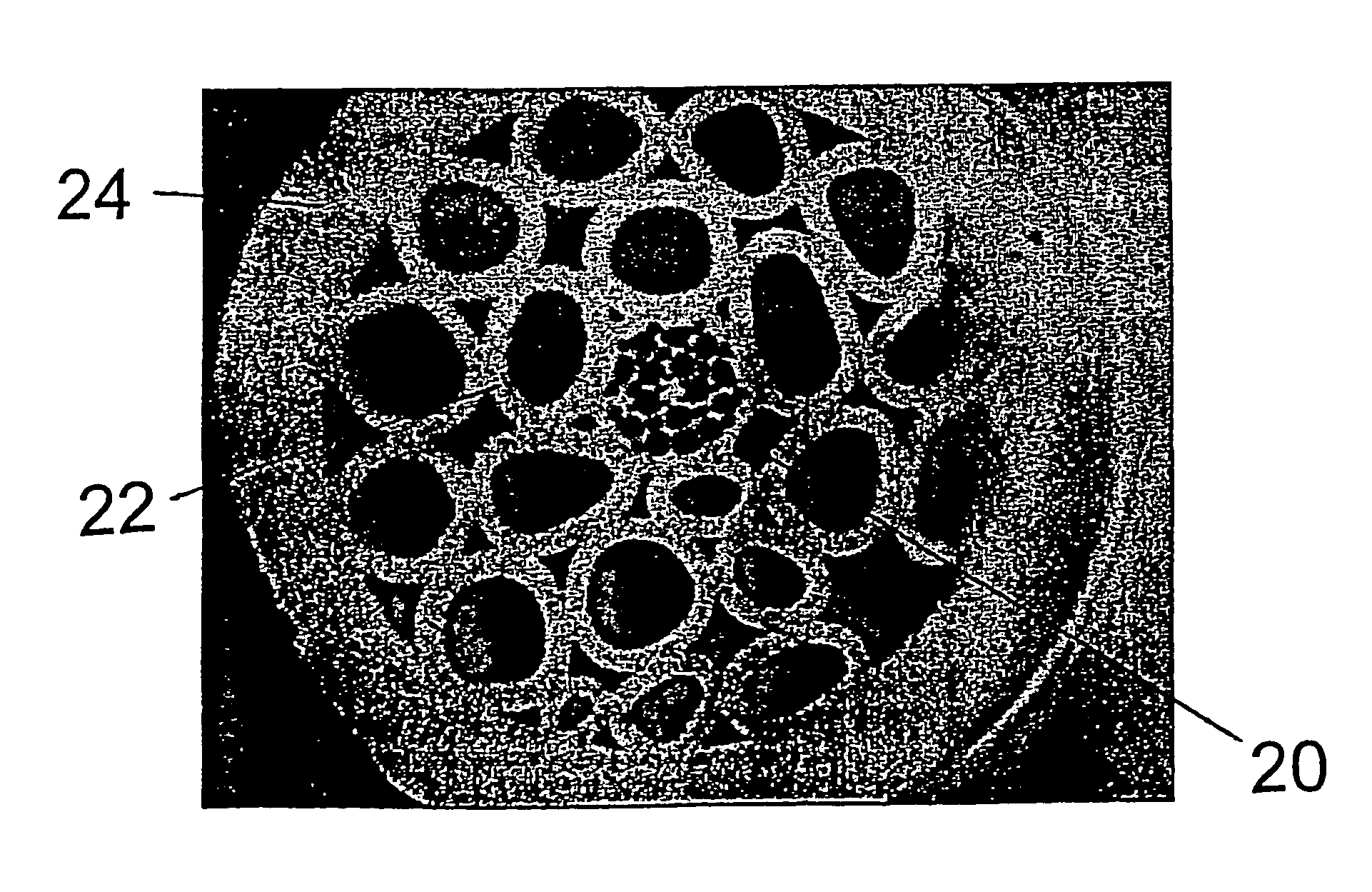

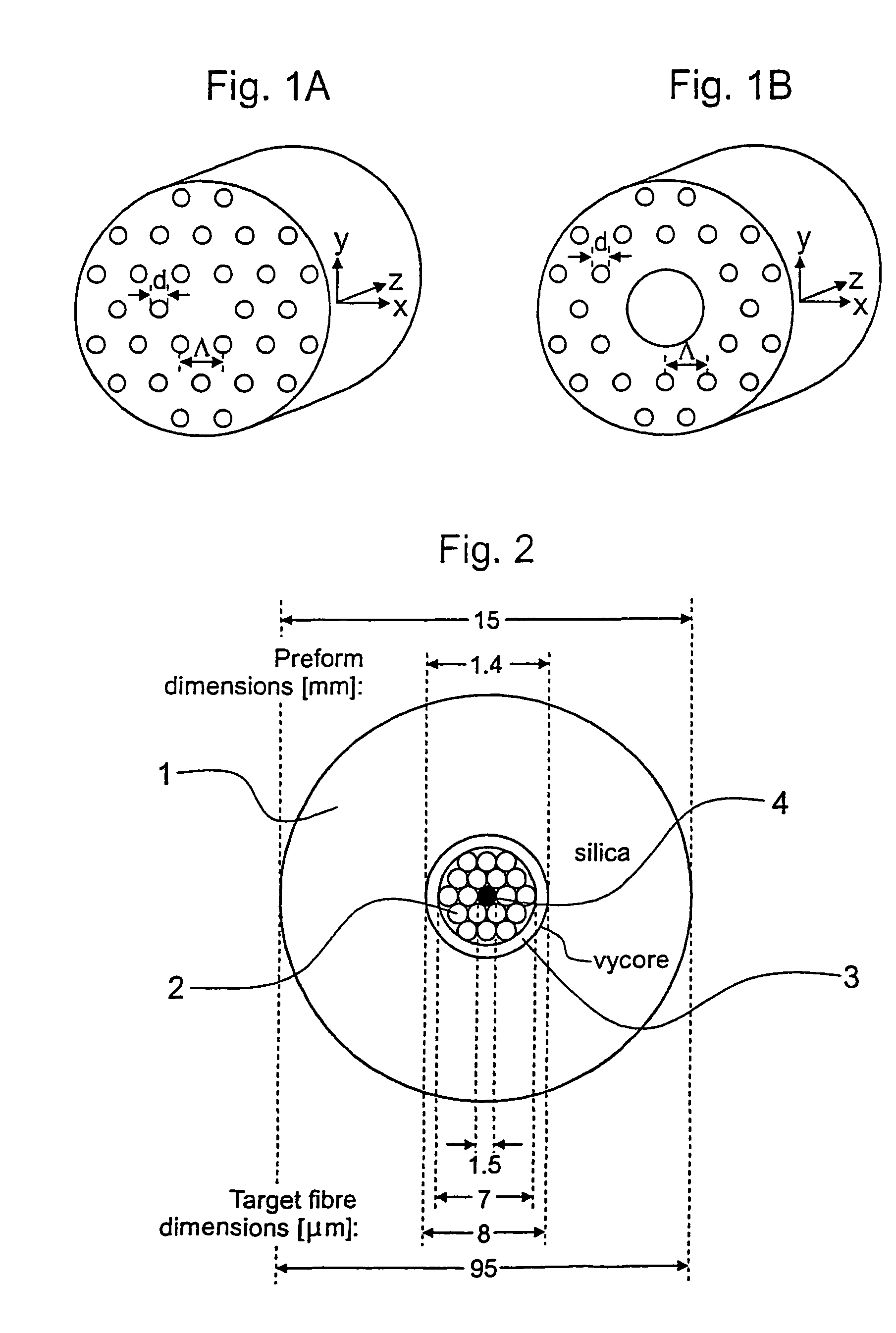

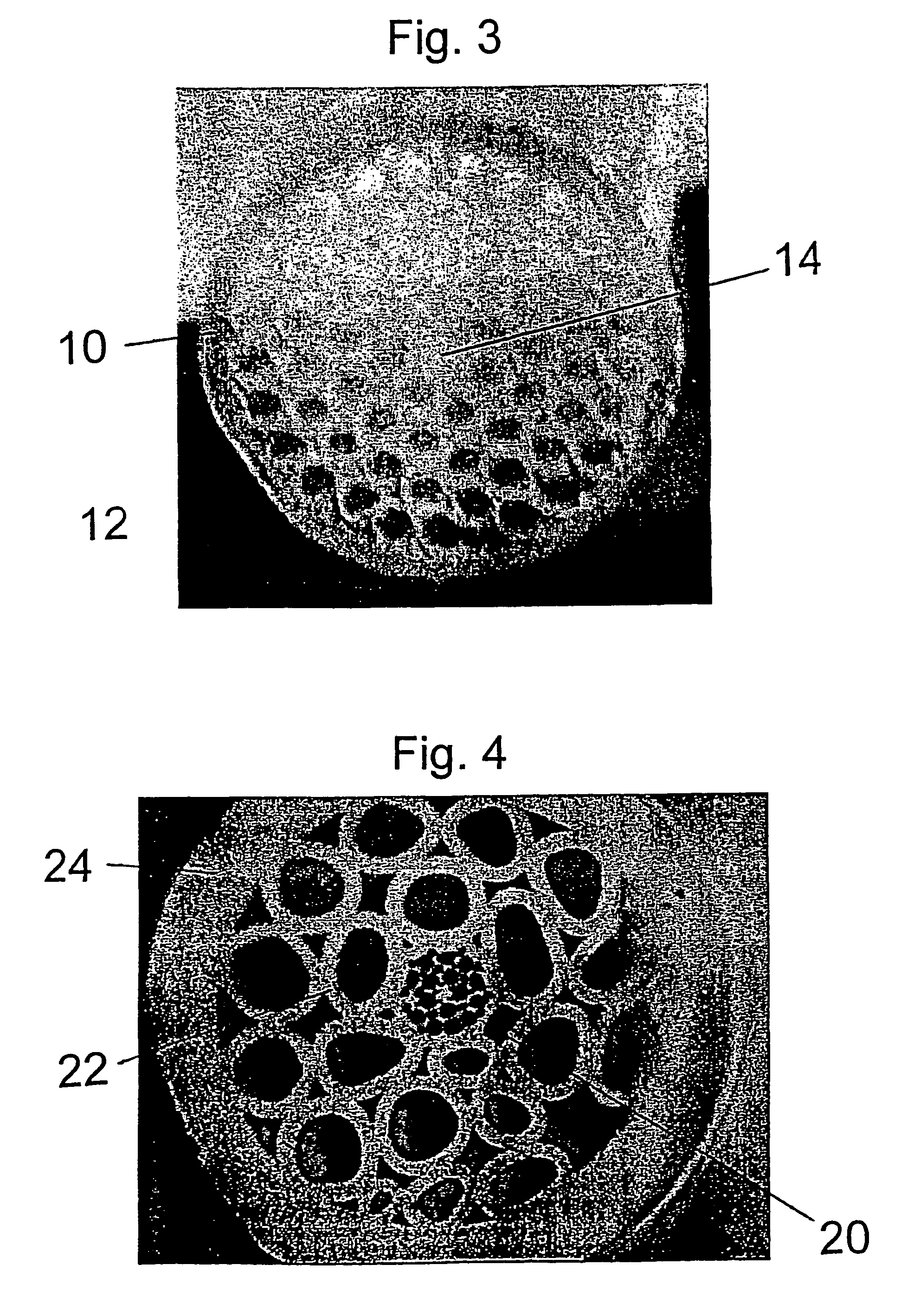

Holey optical fibres

An optical fiber structure having a holey fiber arranged in a holey outer support structure made up of holey tubes encased in a thin walled outer jacket. The holey fiber may have a solid core surrounded by a holey cladding having a plurality of rings of holes. With the invention it is possible to produce robust, coated and jacketed fibers with microstructured core features of micrometer size relatively easily using existing fiber fabrication technology. This improvement is a result of the outer holey structure which reduces the thermal mass of the supporting structure and makes it possible to reliably and controllably retain small hole features during the fiber fabrication process.

Owner:UNIV OF SOUTHAMPTON

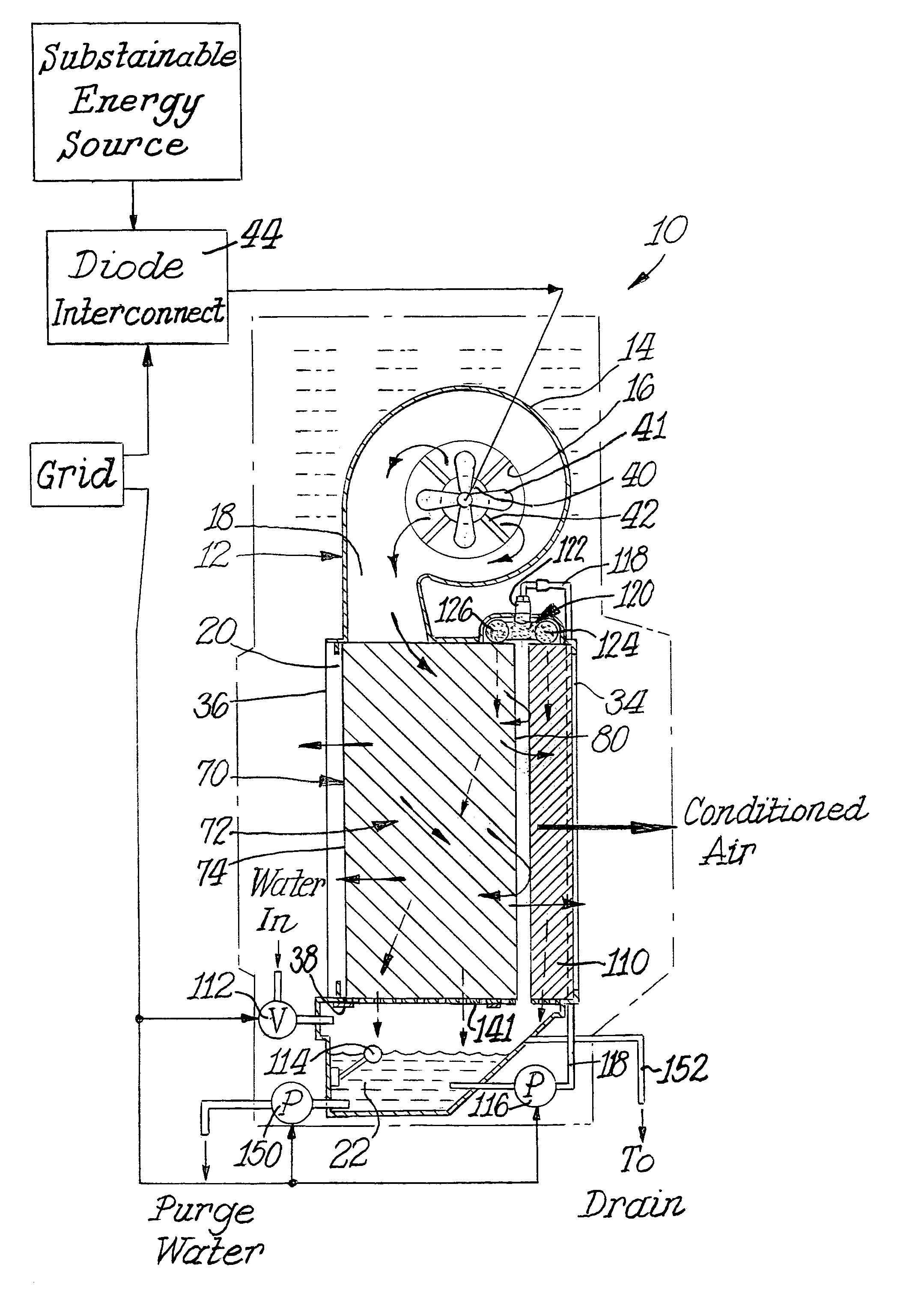

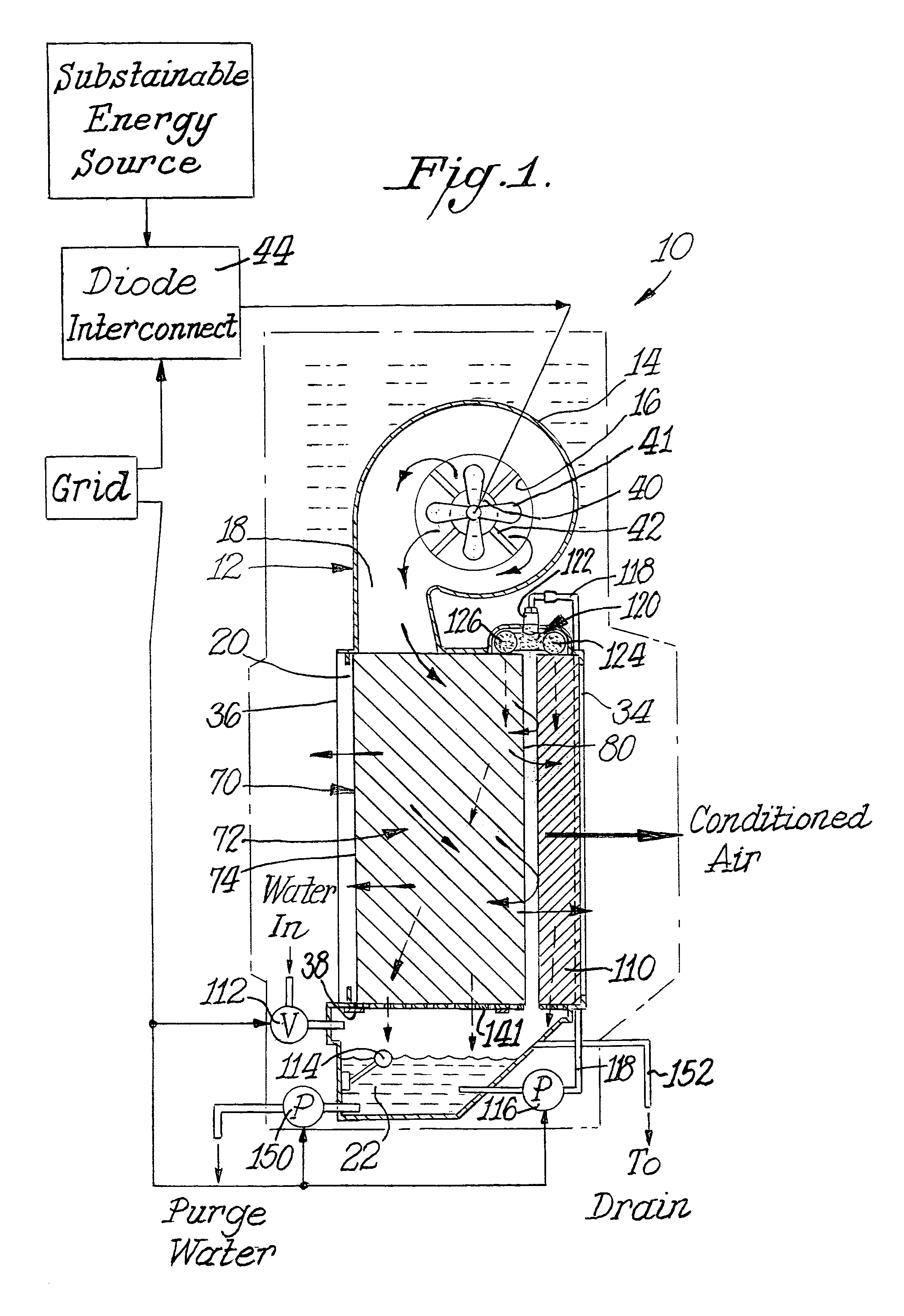

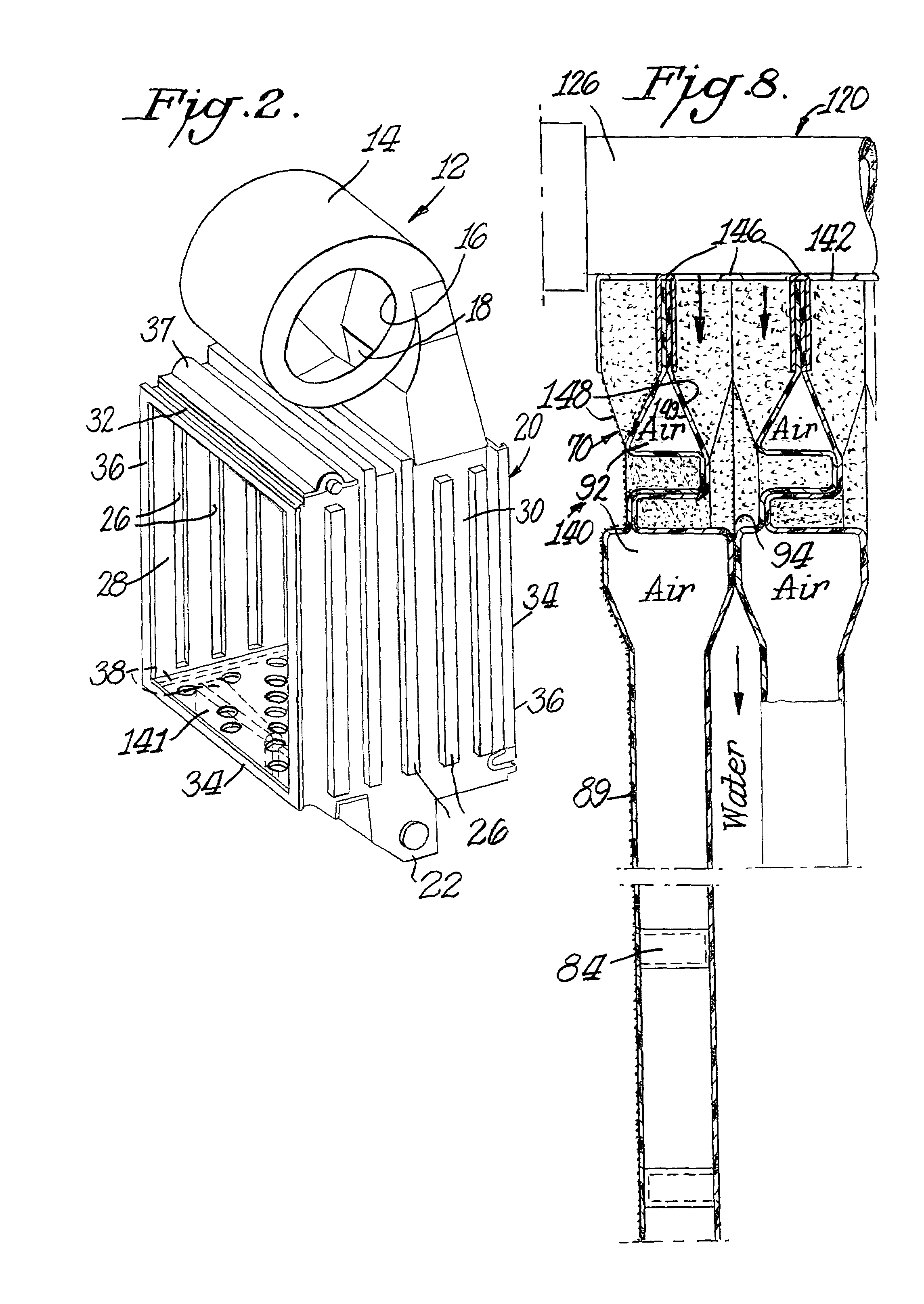

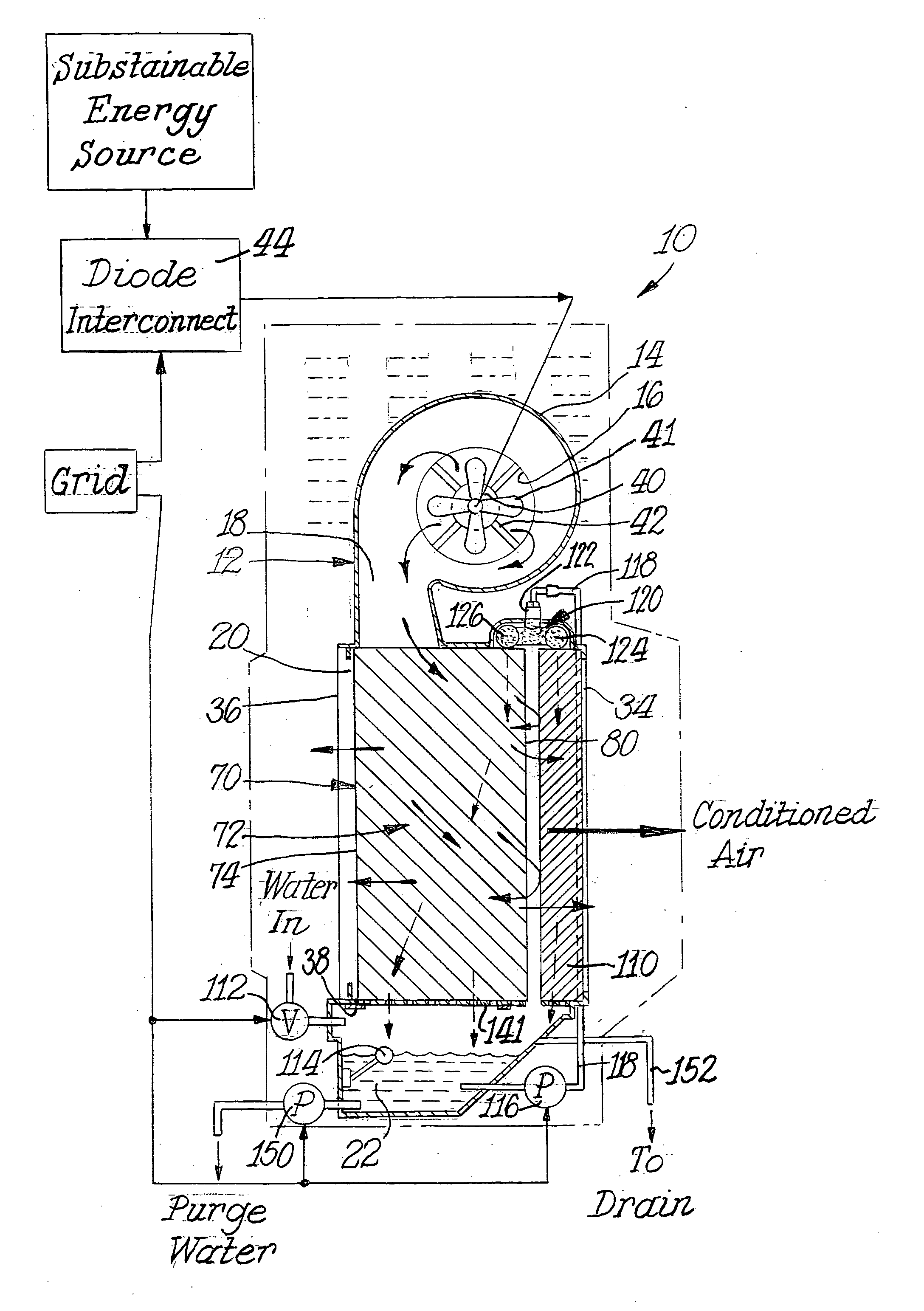

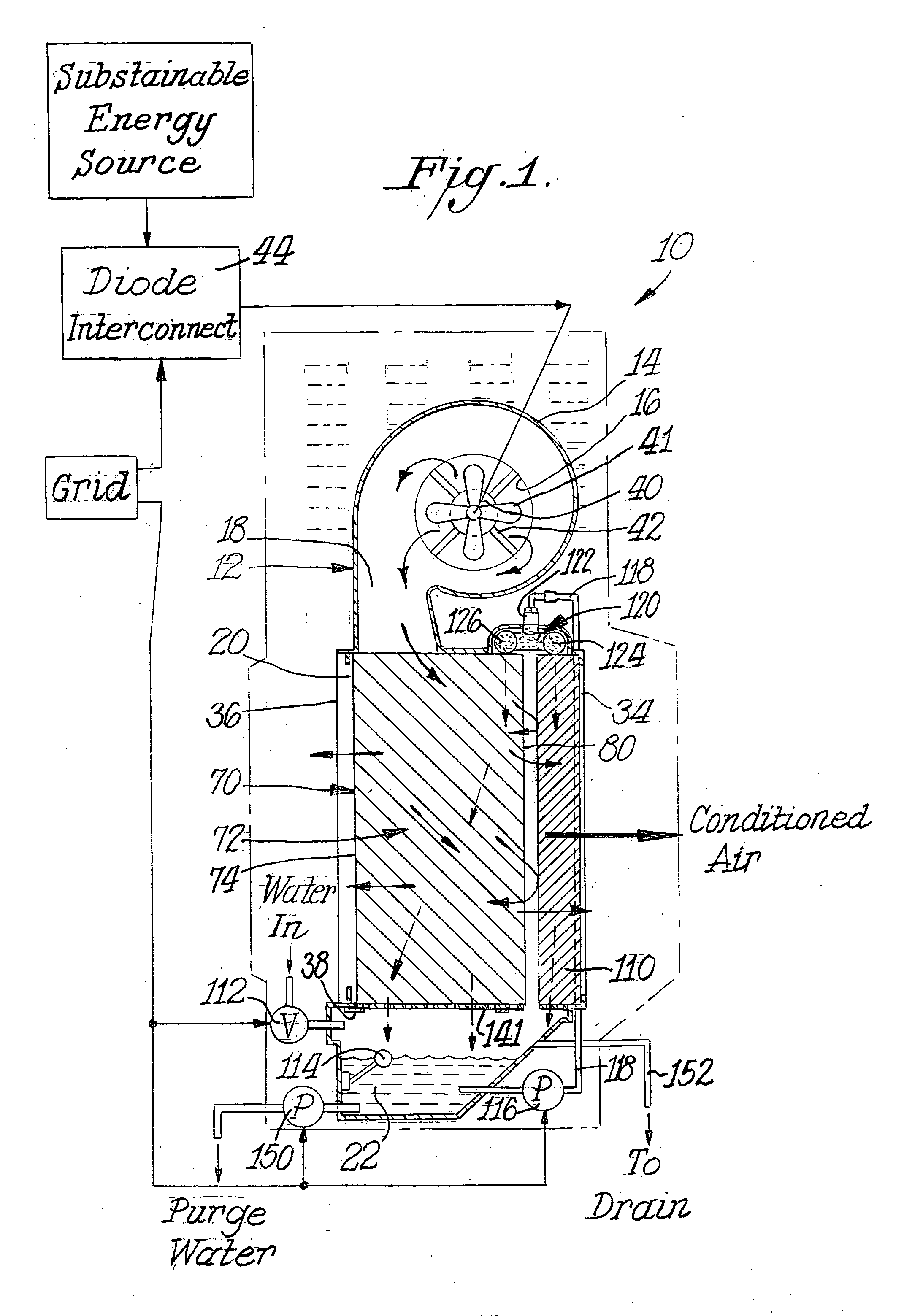

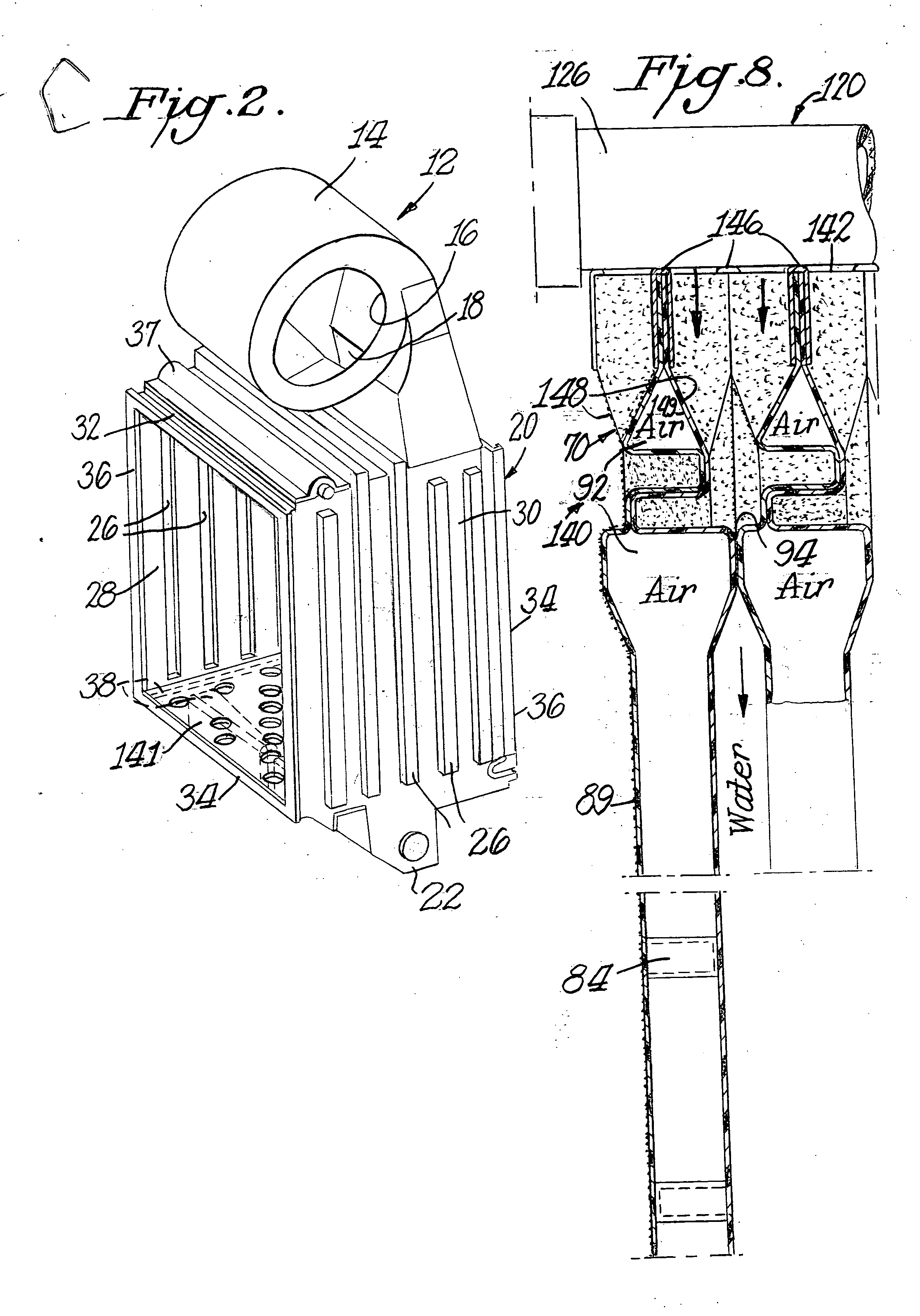

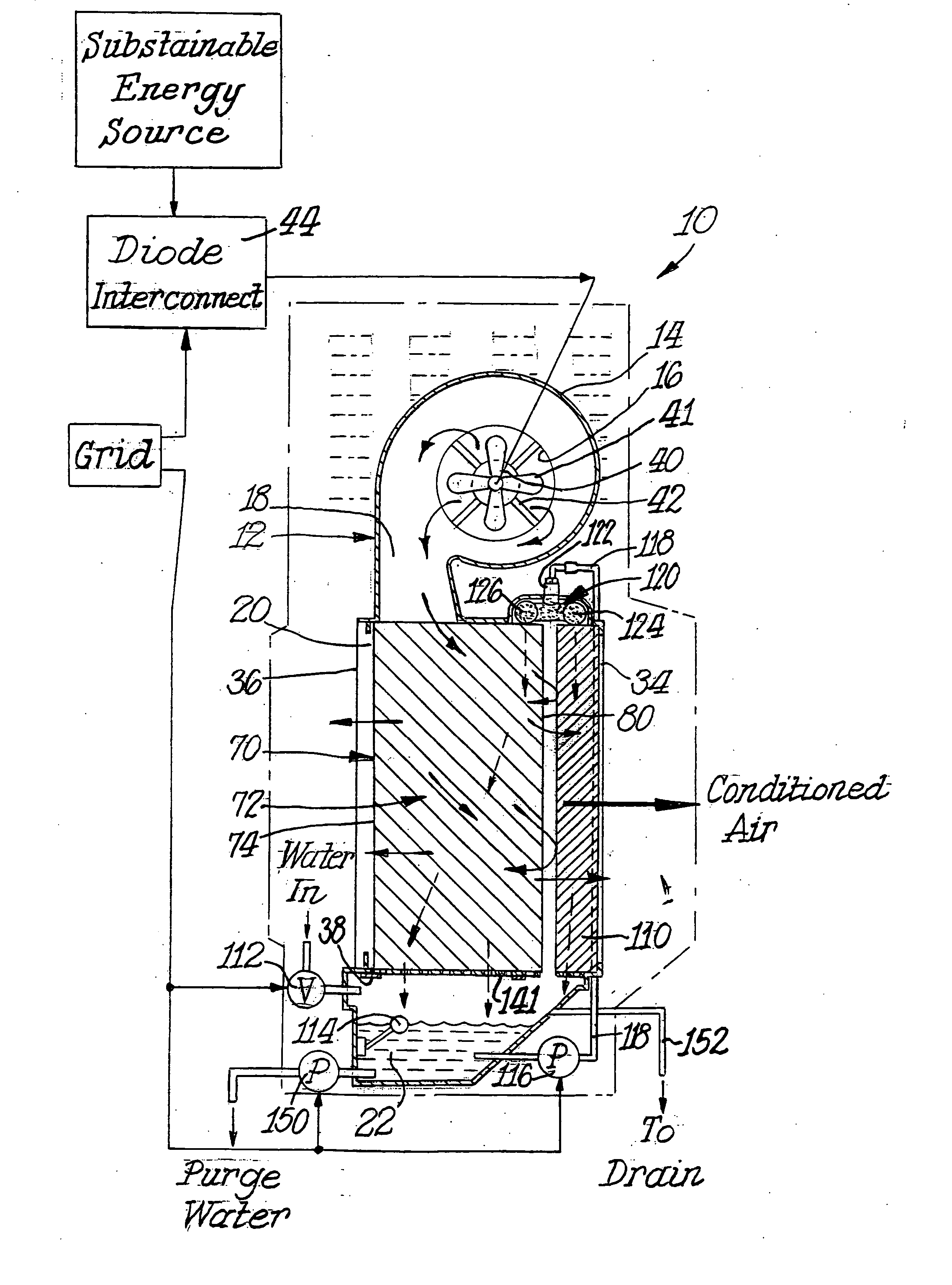

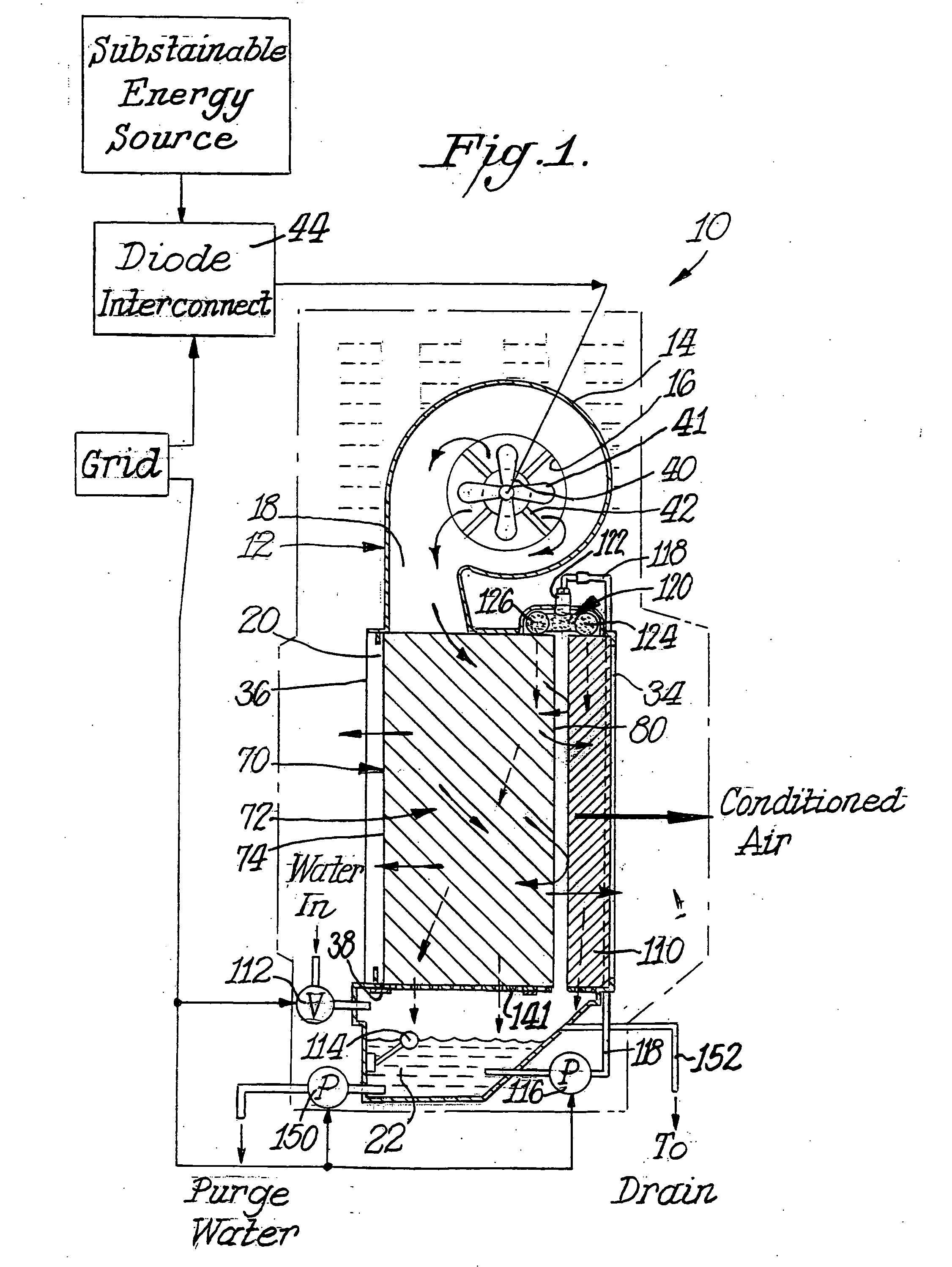

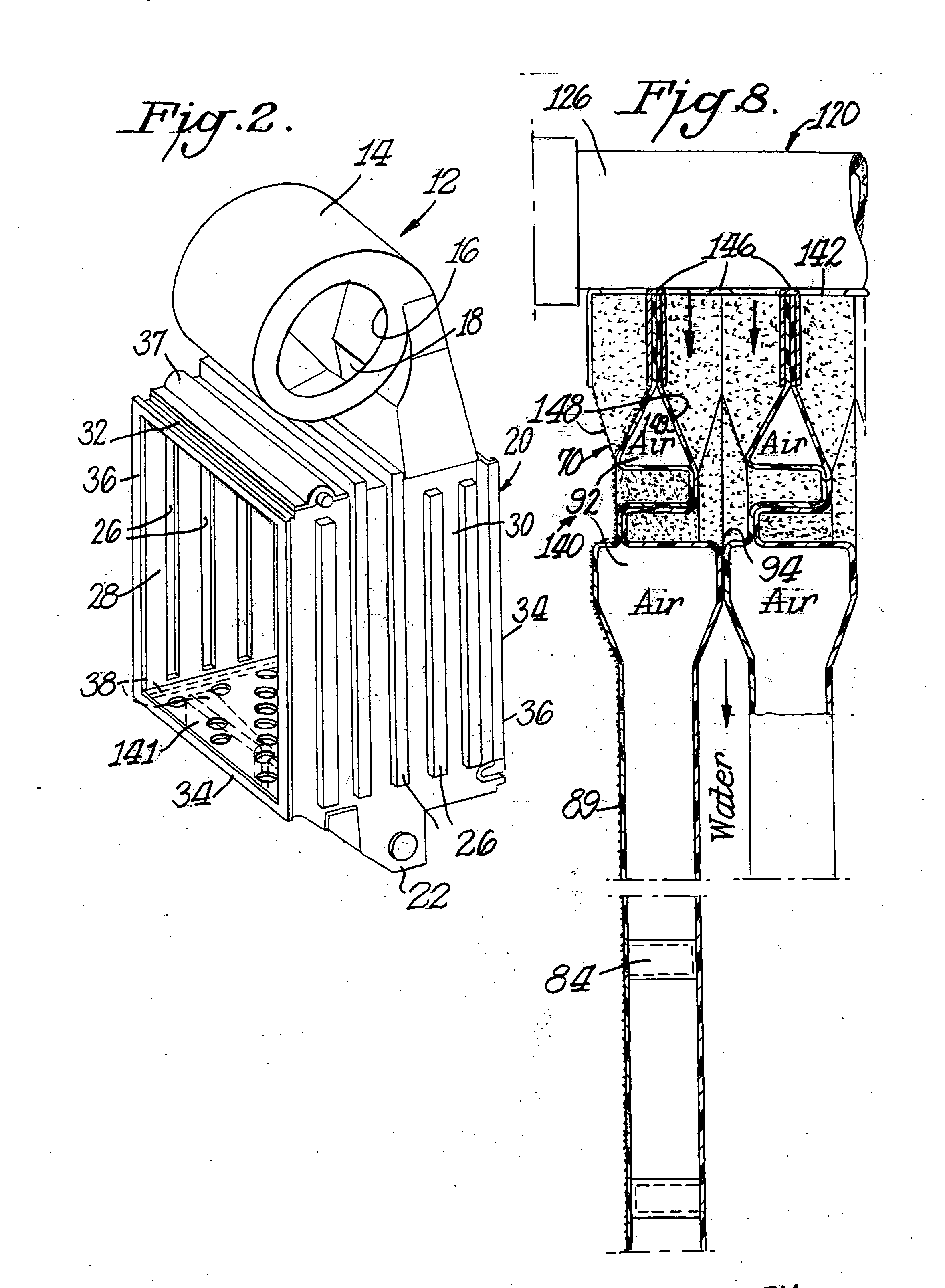

Indirect-direct evaporative cooling system operable from sustainable energy source

InactiveUS7143597B2Reduce the amount requiredImprove cooling effectFree-cooling systemsStationary conduit assembliesPower gridProcess engineering

Improved means for powering and increasing evaporative cooling in an indirect-direct evaporative cooling (IDEC) apparatus are disclosed. Sustainable energy from solar energy mixed with grid power, when needed, power the IDEC device. These DC and AC power sources are seamlessly merged in a unique diode interconnect unit. Improved means for evaporative cooling include a rayon-based flocking on the wet side of molded plastic indirect evaporative cooling plates. Separate wet and dry passages through those plates are facilitated by a unique means for clamping the upper ends of the plates. These clamping means also add to the structural integrity of an array of plates so that the array can be inserted in and removed from a housing containing other operational components of the IDEC such as fan, direct cooling plates and water distribution means. Applicants IDEC utilizes improved porous piping that allows uniform and continuous distribution of water to all wet passages within both the indirect and direct stages of the IDEC. Operational controls for the system limit the potential water damage caused by overflow of water from the IDEC housing.

Owner:SPEAKMAN

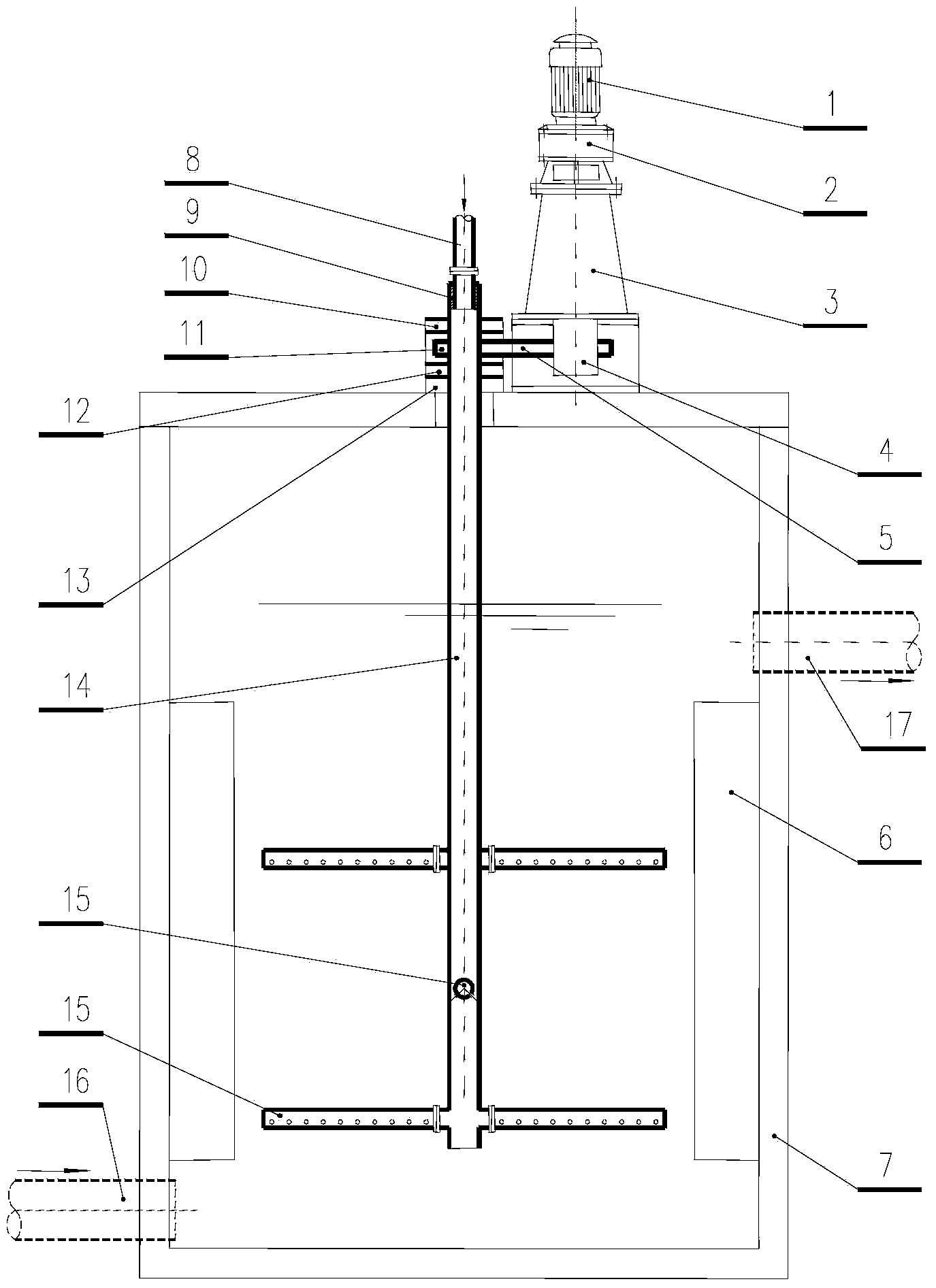

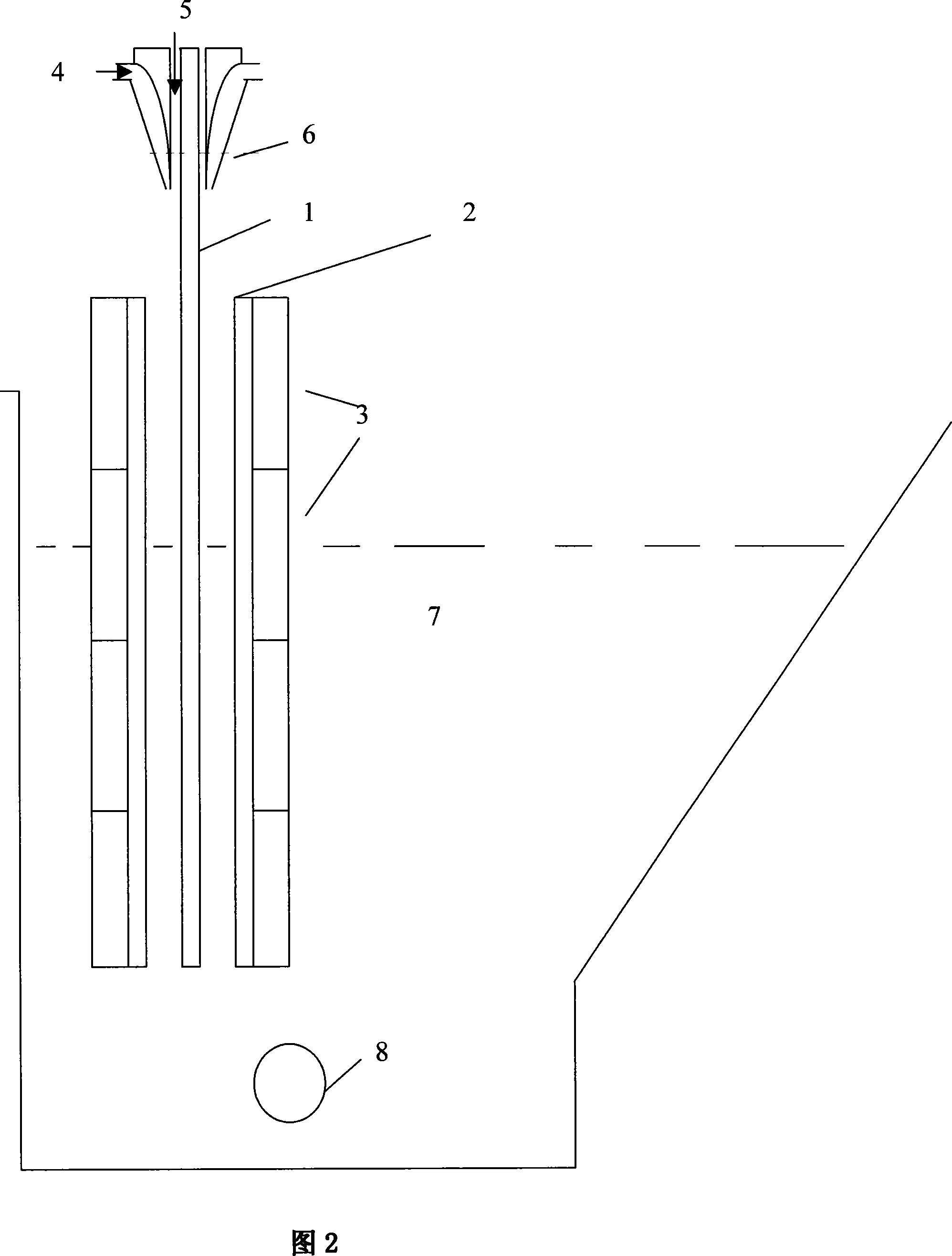

Mechanical mixing stirrer

ActiveCN103521110AWell mixedReduce dosageRotary stirring mixersMixer accessoriesEngineeringMechanical engineering

The invention discloses a mechanical mixing stirrer, and mainly aims to provide the mechanical mixing stirrer having the advantages of high mixing uniformity degree, reliable operation, and convenient construction and installation. The mechanical mixing stirrer comprises a drive mechanism; the drive mechanism drives a stirring shaft through a transmission mechanism; the stirring shaft is of a hollow structure, is connected with a drug feeding pipe, is insertedly provided with a plurality of strip-shaped porous pipes at intervals, and is communicated with the porous pipes. The mechanical mixing stirrer enables a drug liquid to be mixed uniformly, has the advantages of decreased drug using amount, simple manufacture, flexible manufacture, and low maintenance cost, and saves power consumption.

Owner:HUATIAN ENG & TECH CORP MCC

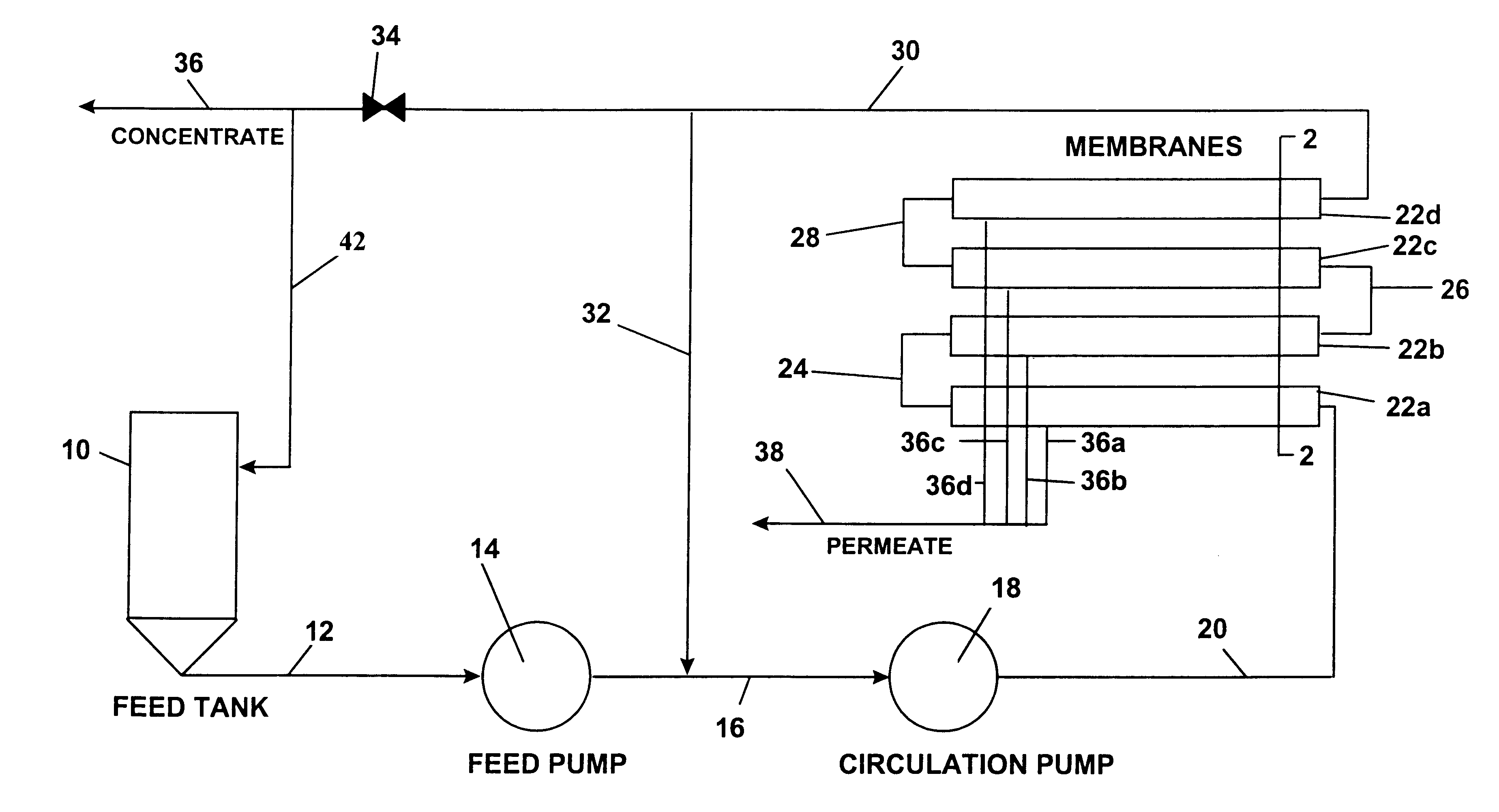

Apparatus and process for the separation of liquids and solids

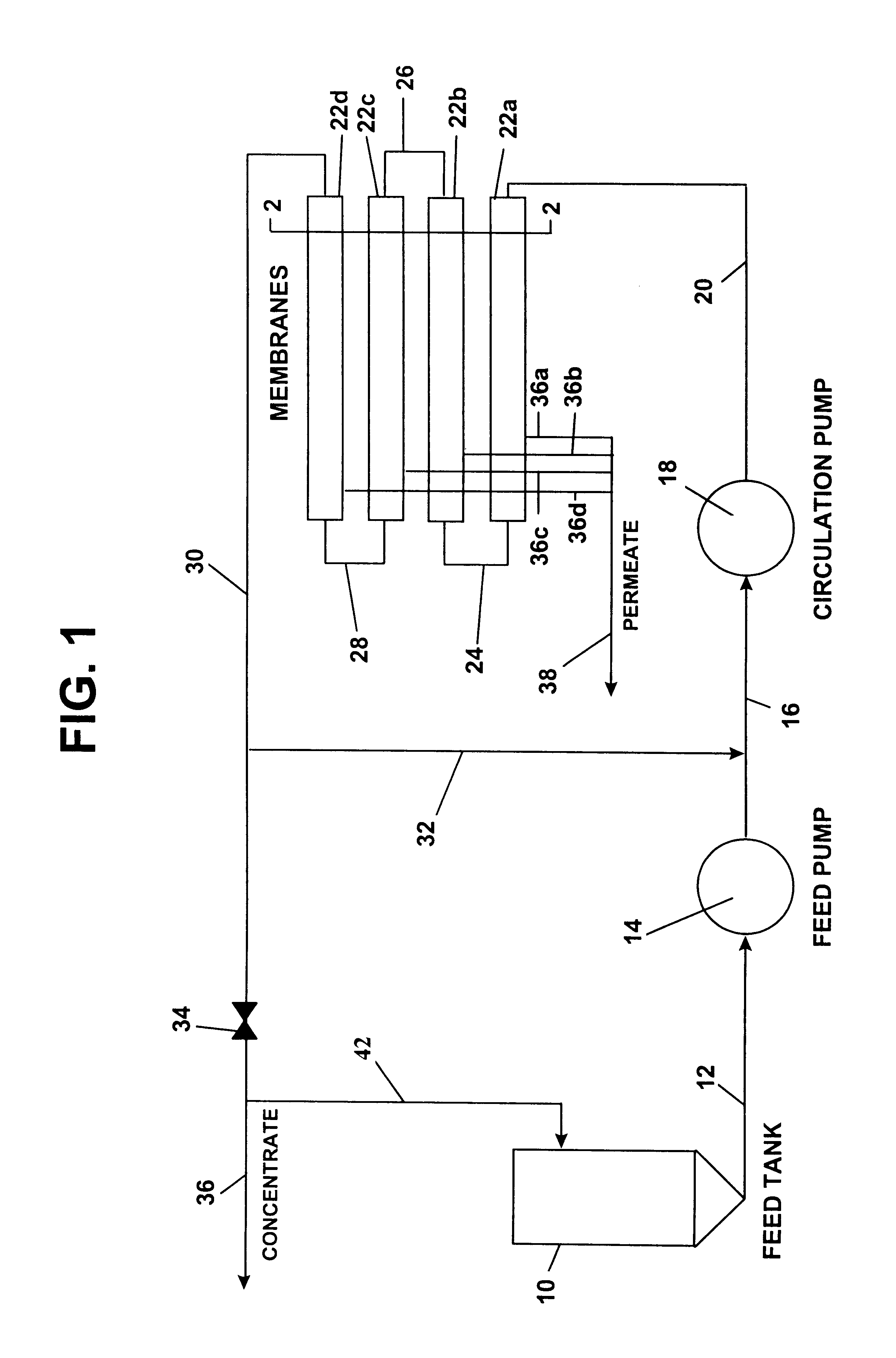

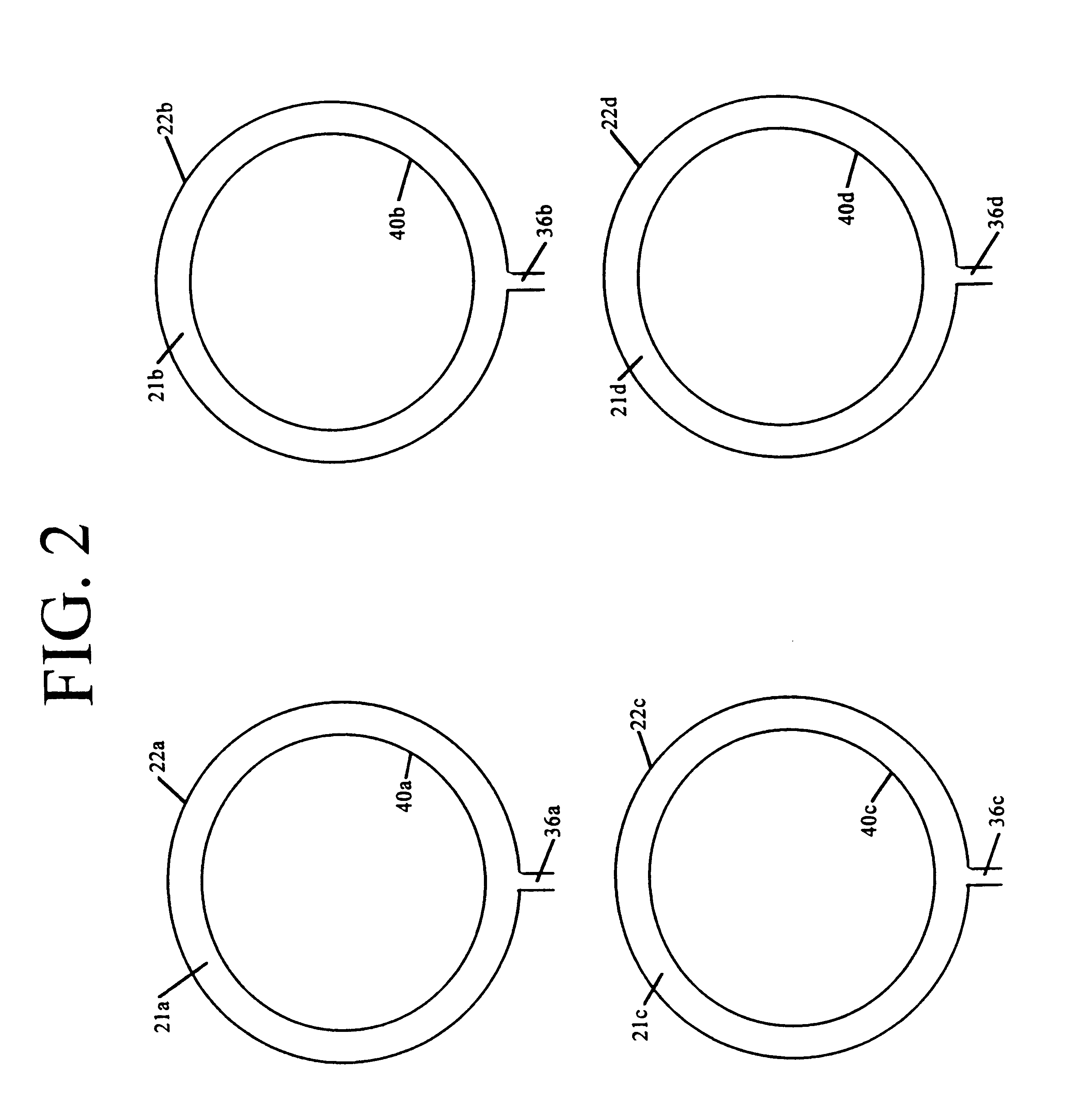

InactiveUS6110390AReduce liquid contentPrevent buildupLiquid separation auxillary apparatusUltrafiltrationFiltrationSystem pressure

A liquid solid separation apparatus having a porous metal pipe sealed inside a non-porous metal pipe which allows a portion of the liquids, e.g., hydrocarbons and water to pass through the first pipe into the non porous pipe from which they are removed while solids are retained within the porous pipe. In the process there is a system pressure which aids in the filtration and a circulating velocity which removes the detained solids. Preferably a portion of these solids with reduced liquid content are recycled back to the system, mixed with fresh feed. By recycling a porion of the recovered solid concentrate the velocity of the flow in the system kept constant and the system itself is stabilized.

Owner:ENVIRONMENTAL SAFEGUARDS

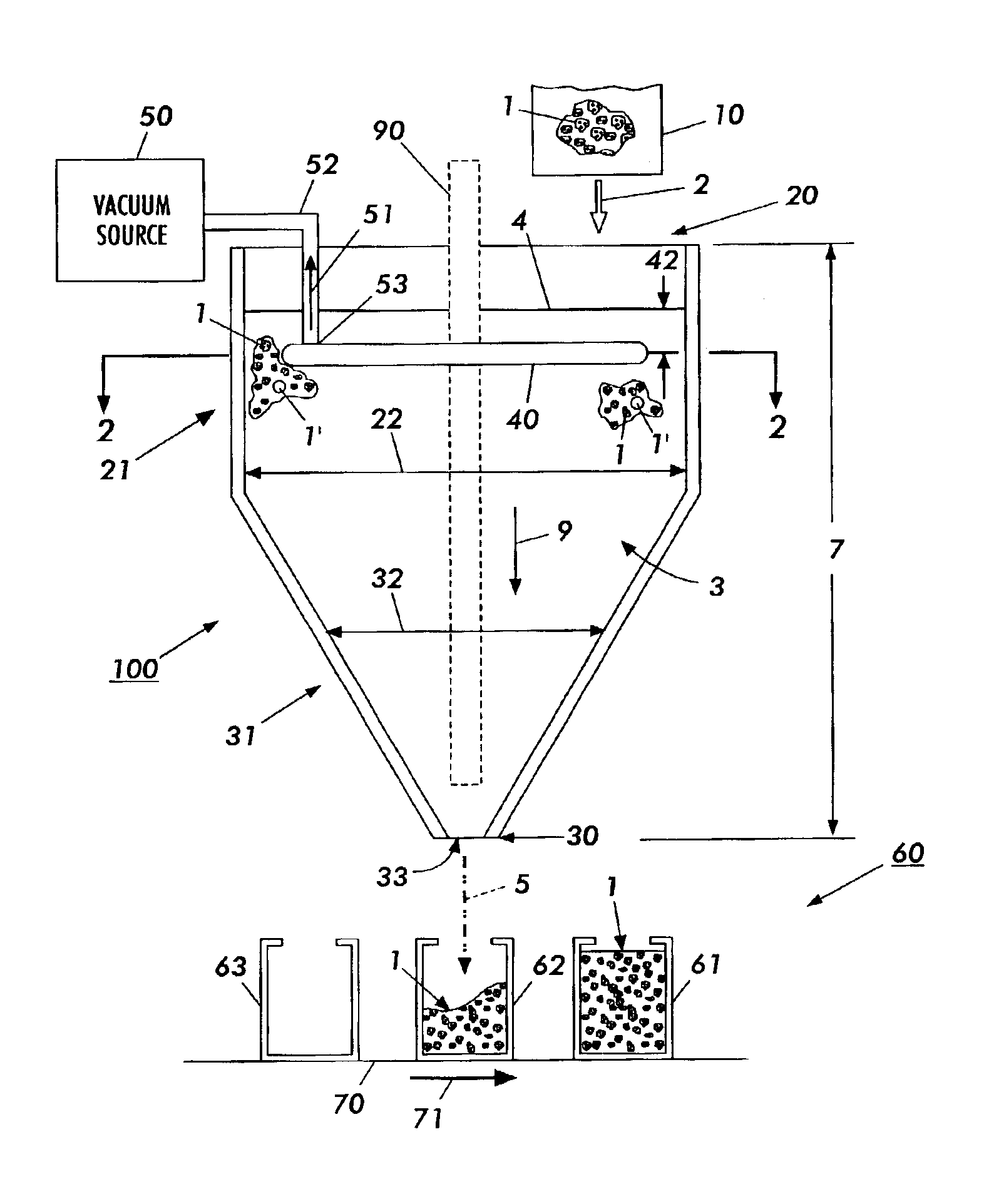

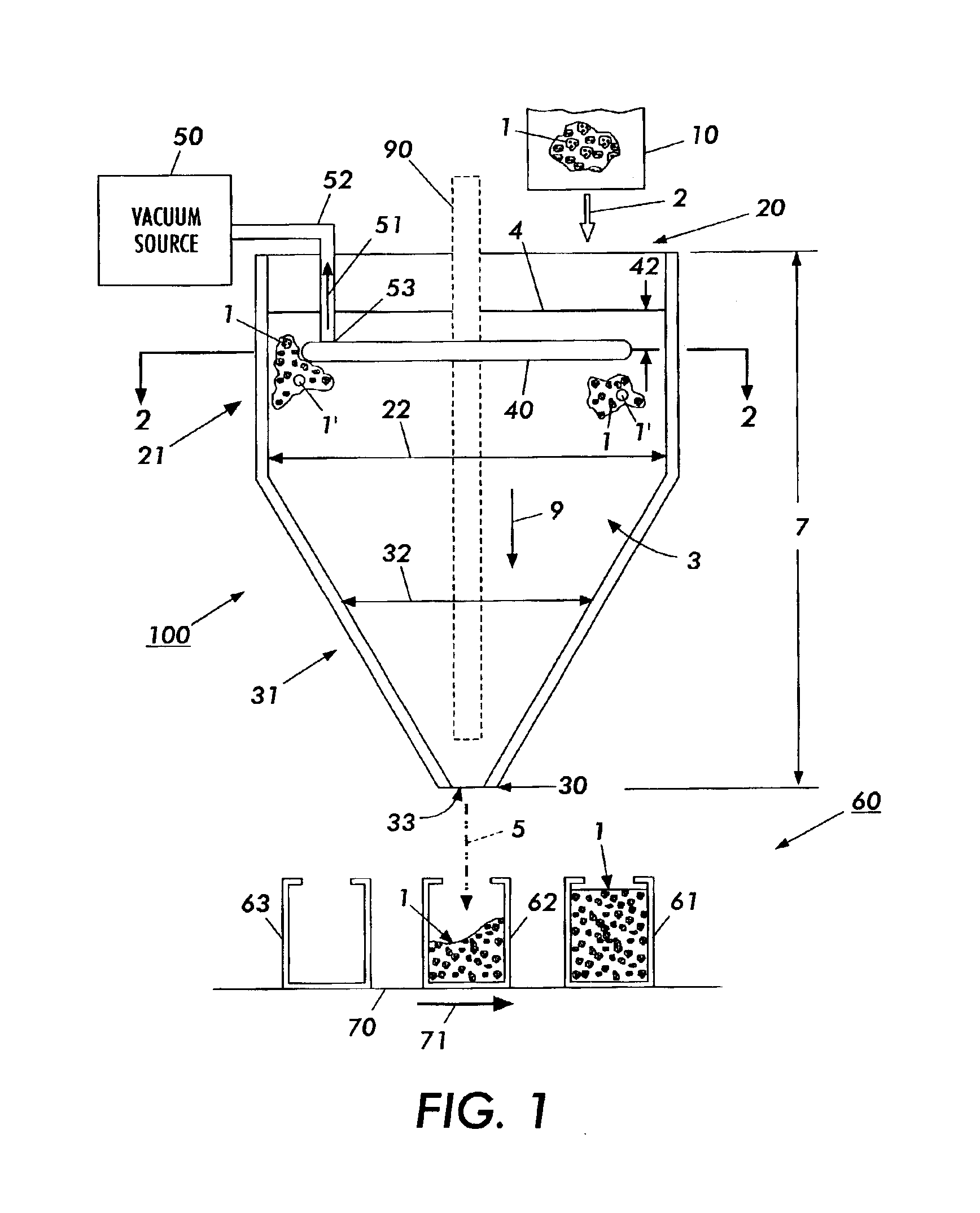

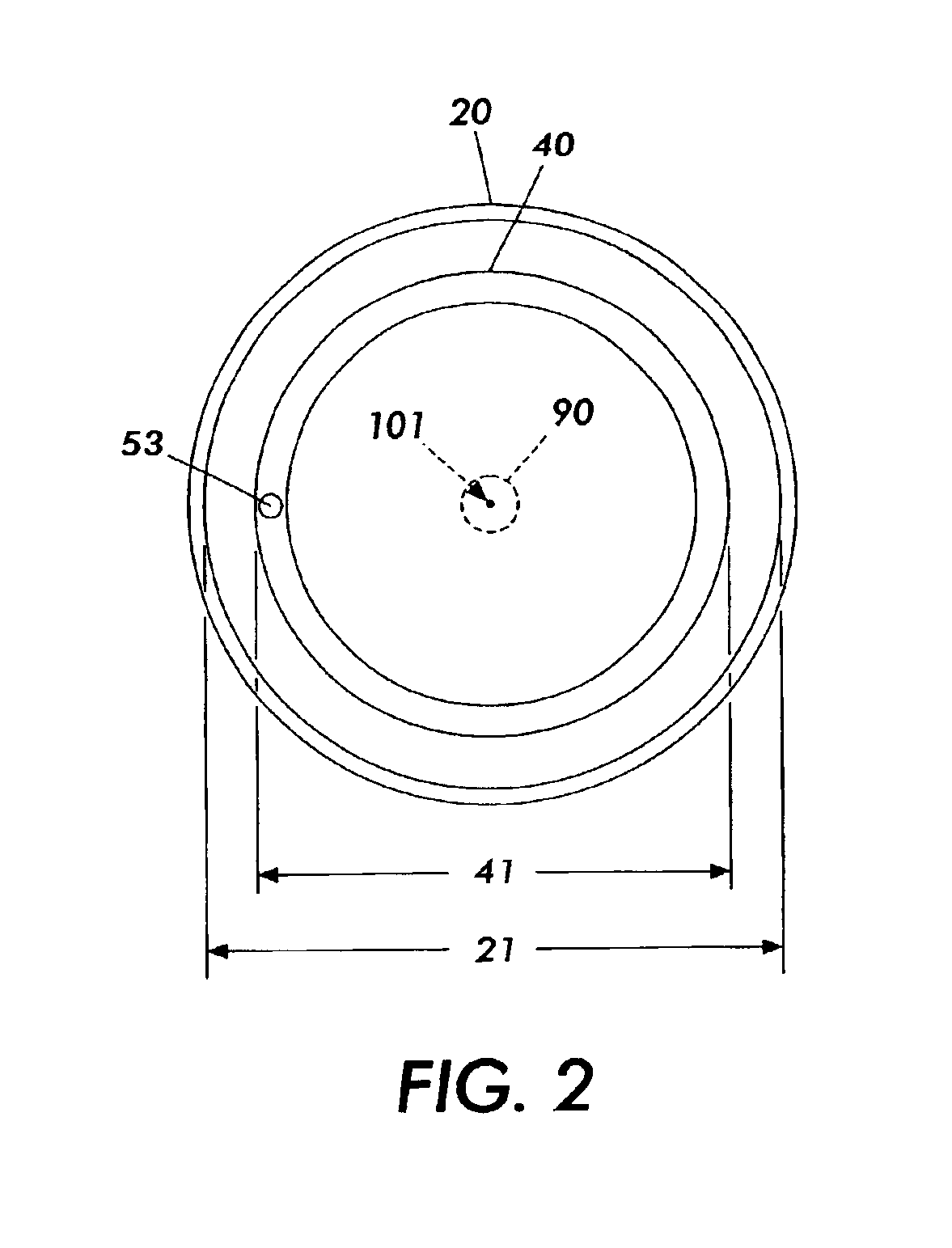

Method of dispensing particles, a particle filling line, and apparatus for dispensing particles

A particle filling line comprises a vertical conduit that is arranged to dispense particles to one or more containers that are disposed on an included movable conveyor belt. The conduit includes a conduit hollow, a conduit top and a conduit bottom that defines an outlet. Particles supplied to the conduit top flow through the outlet to fill the containers. The conduit is filled with particles. The particles include a particle spacing air. The particle spacing air is reduced by means of a porous tube that is fixed in the conduit hollow and coupled to a vacuum source. After reducing the particle spacing air, the particles flow through the outlet to be received in the containers.

Owner:XEROX CORP

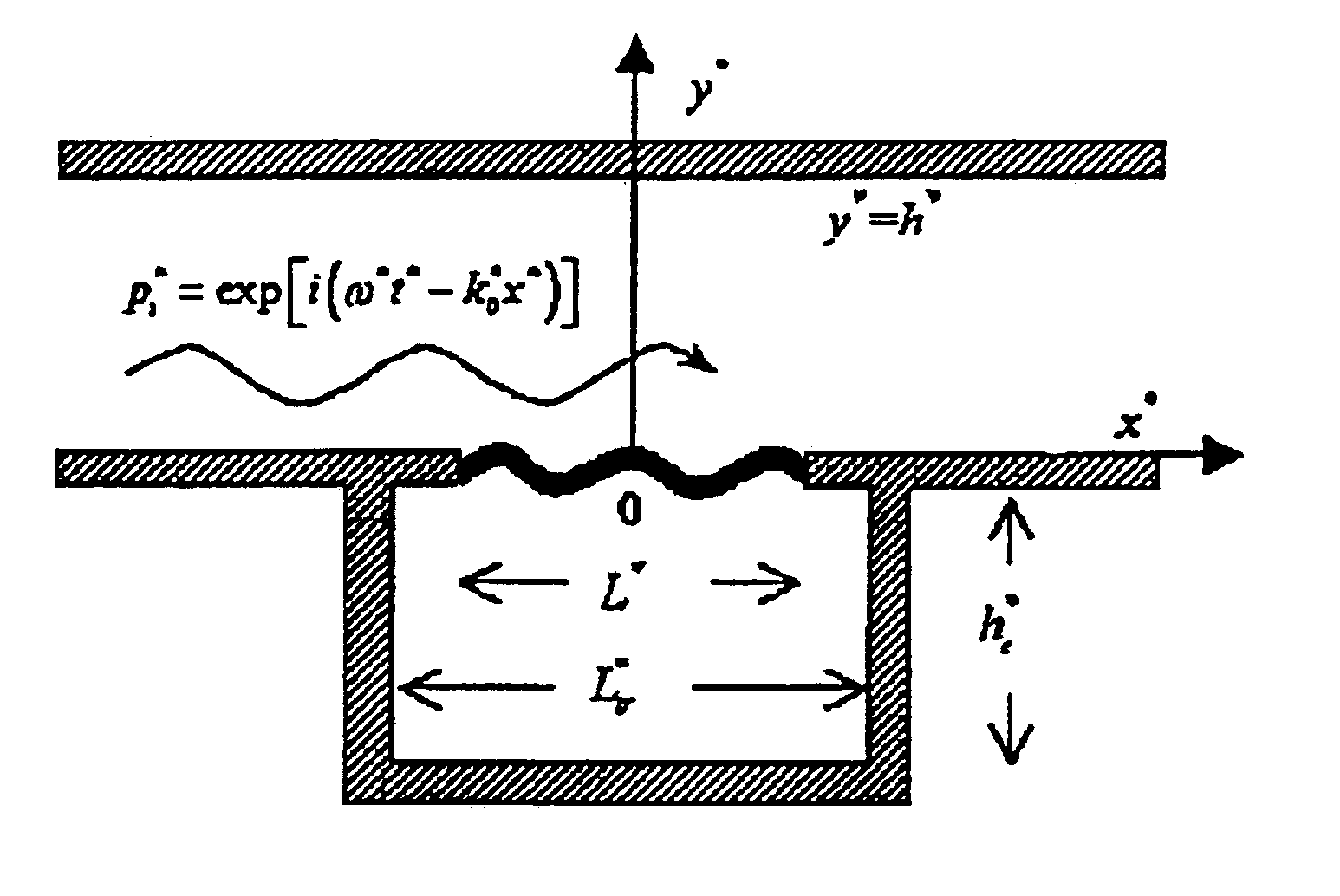

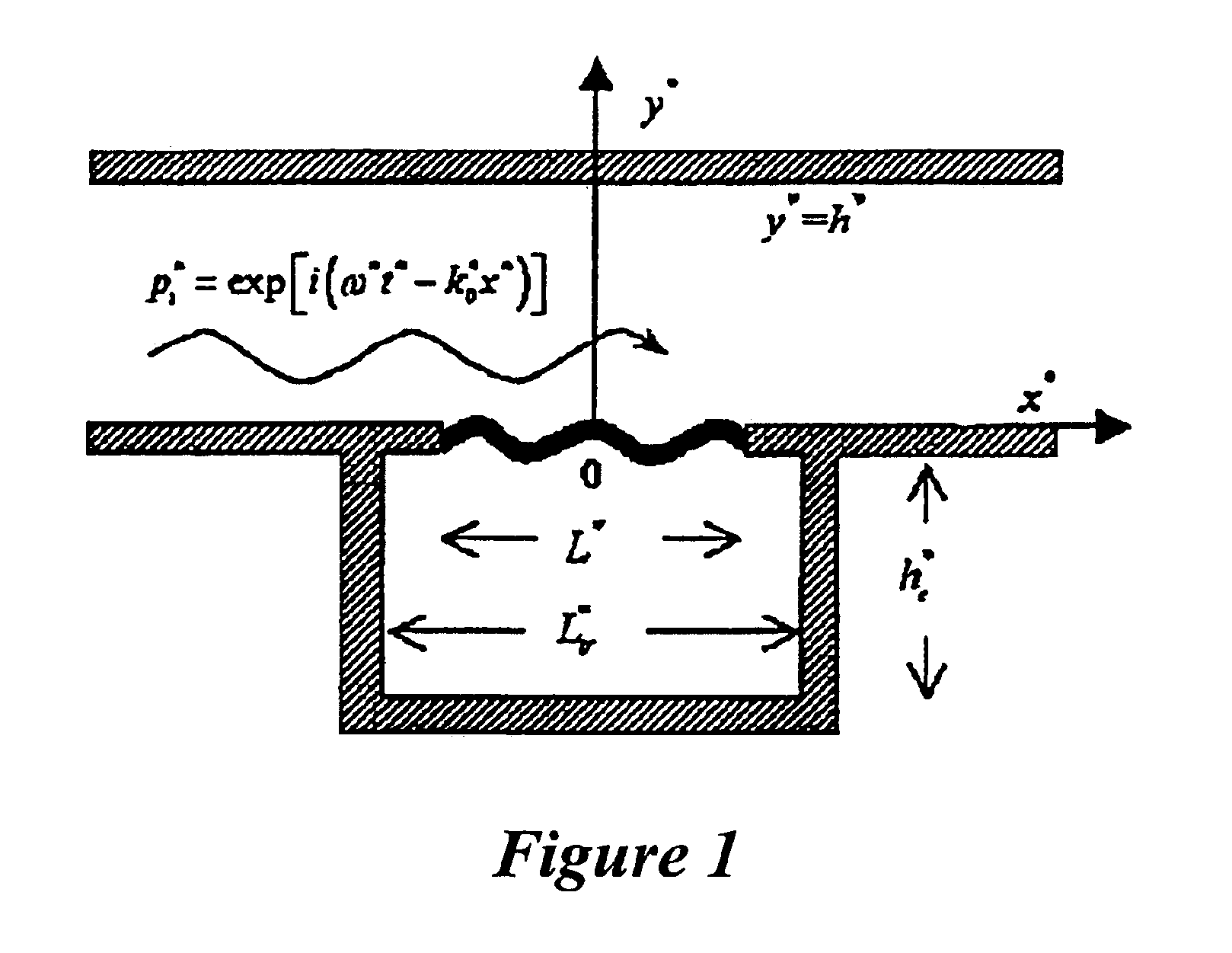

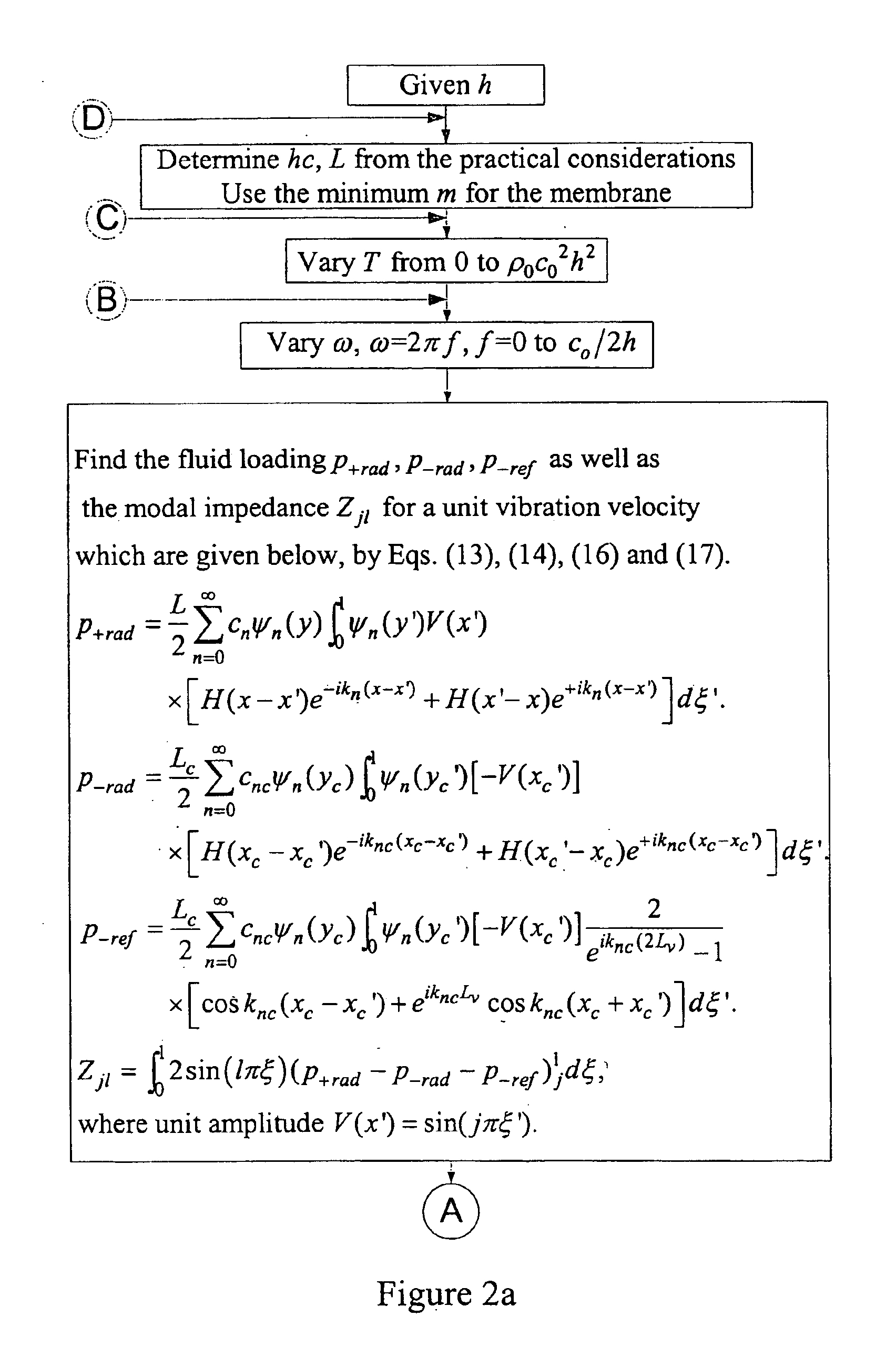

Methods for designing a chamber to reduce noise in a duct

InactiveUS6988057B2Reduce noiseNoise figure or signal-to-noise ratio measurementAmplifier modifications to reduce noise influenceIntermediate frequencyThin membrane

Low-frequency duct noise is relatively difficult to deal with by passive methods such as porous duct lining. Reactive methods like expansion chamber are rather bulky, while compact resonators are to narrow-banded. This invention shows that a suitably stetched thin membrane backed by a slender cavity can achieve a satisfactory performance from low to medium frequencies over an octave band.

Owner:THE HONG KONG POLYTECHNIC UNIV

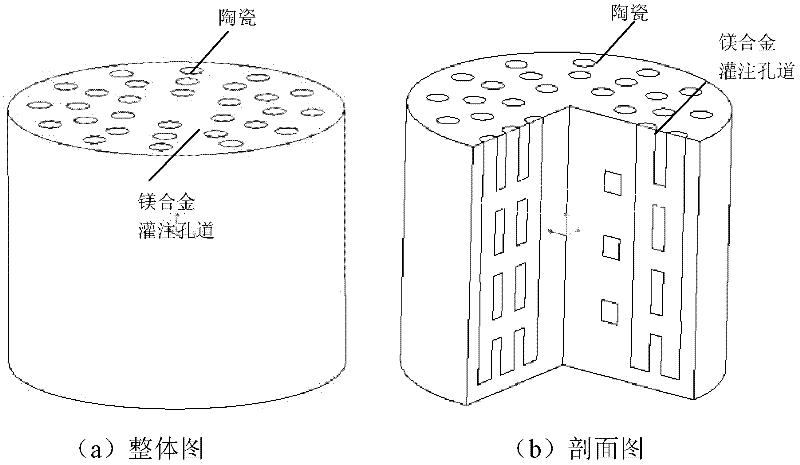

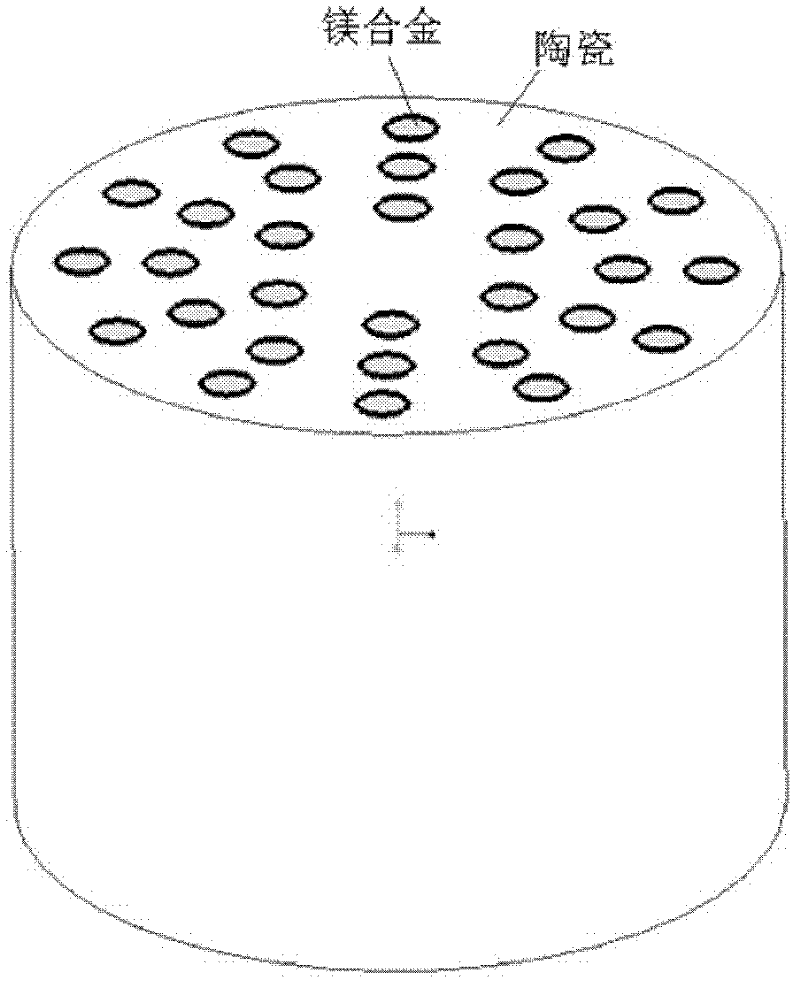

Magnesium alloy/biological ceramic bone bracket based on photocuring and gel casting and forming method of bone bracket

InactiveCN102335460AImprove early mechanical propertiesMeet growthBone implantBiomechanicsGel casting

The invention discloses a magnesium alloy / biological ceramic bone bracket based on photocuring and gel casting and a forming method of the bone bracket. The method comprises the following steps of: establishing computer-aided design (CAD) models of the bracket and a bracket negative model through shape correlation and microstructure simulation by using reverse engineering and CAD according to the structures of different bone defect parts and the analysis results of biomechanics; making a resin bracket negative model by a photocuring technology; filling ceramic slurry into the bracket negative model by a gel casting process, curing and sintering at a high temperature to make a biological activity ceramic framework with mutually-communicated porous pipelines; and casting molten magnesium alloy into the porous pipelines of the biological activity ceramic framework by a vacuum suction casting method, cooling for solidification, and thus obtaining the magnesium alloy / biological ceramic simulation composite structure bone bracket. The internal microstructure of the made bracket consists of the mutually-communicated pipelines, the magnesium alloy is filled in the pipelines to increase the early mechanical property of the composite bracket, and the pipelines filled with the magnesium alloy become mutually-communicated pore passages as the magnesium alloy is corroded and degraded, so that the requirements of organization growth, nutrition and metabolism are met.

Owner:XI AN JIAOTONG UNIV

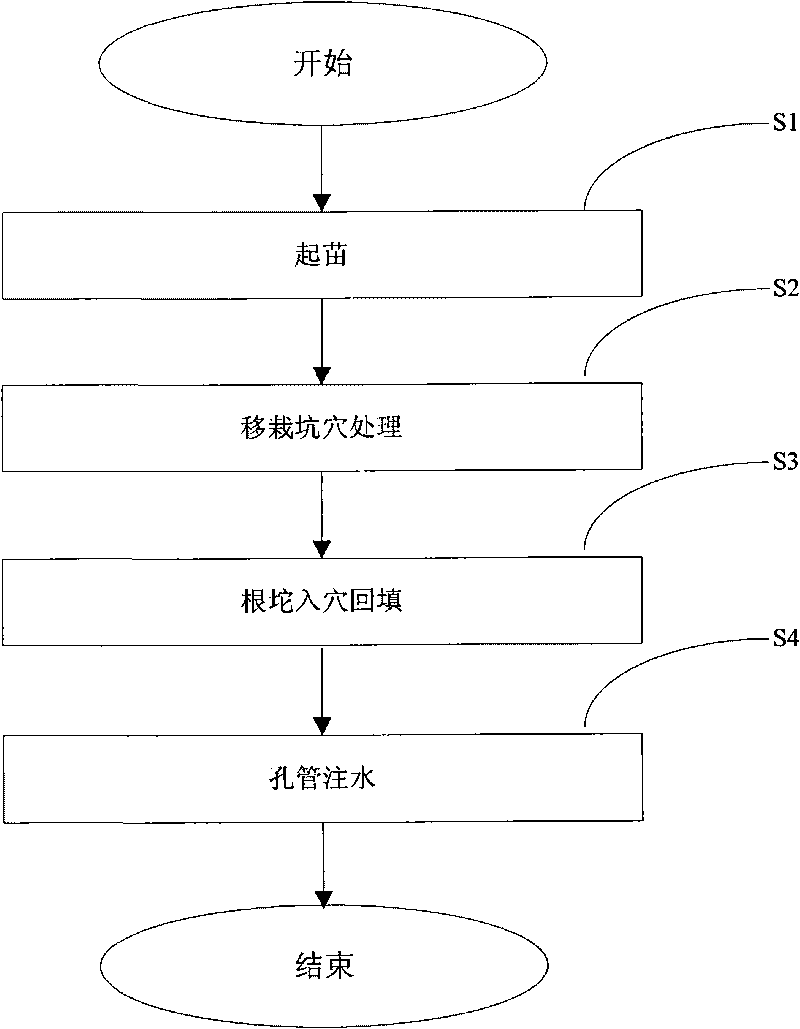

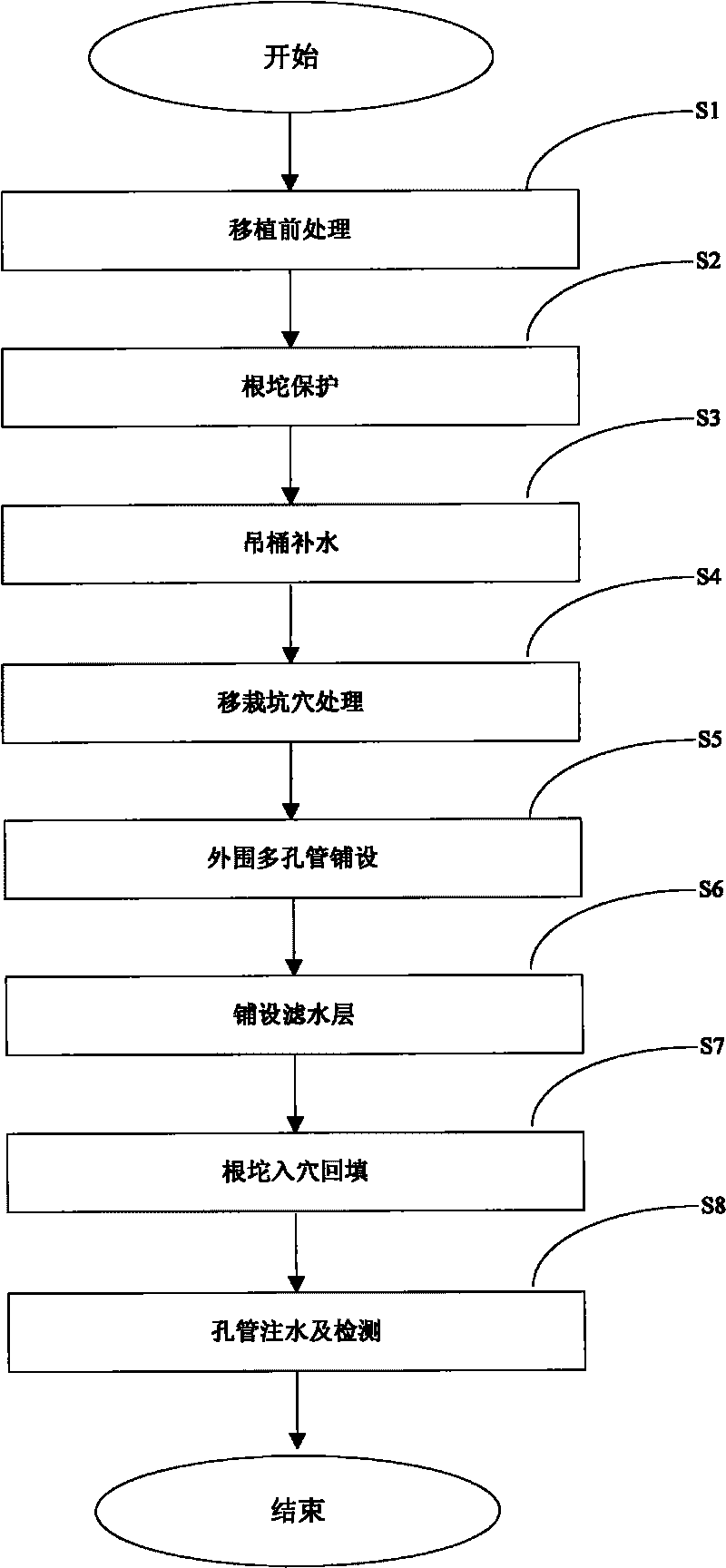

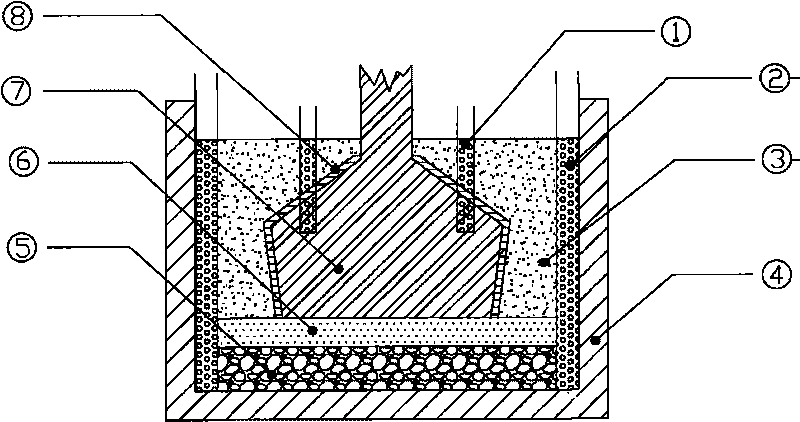

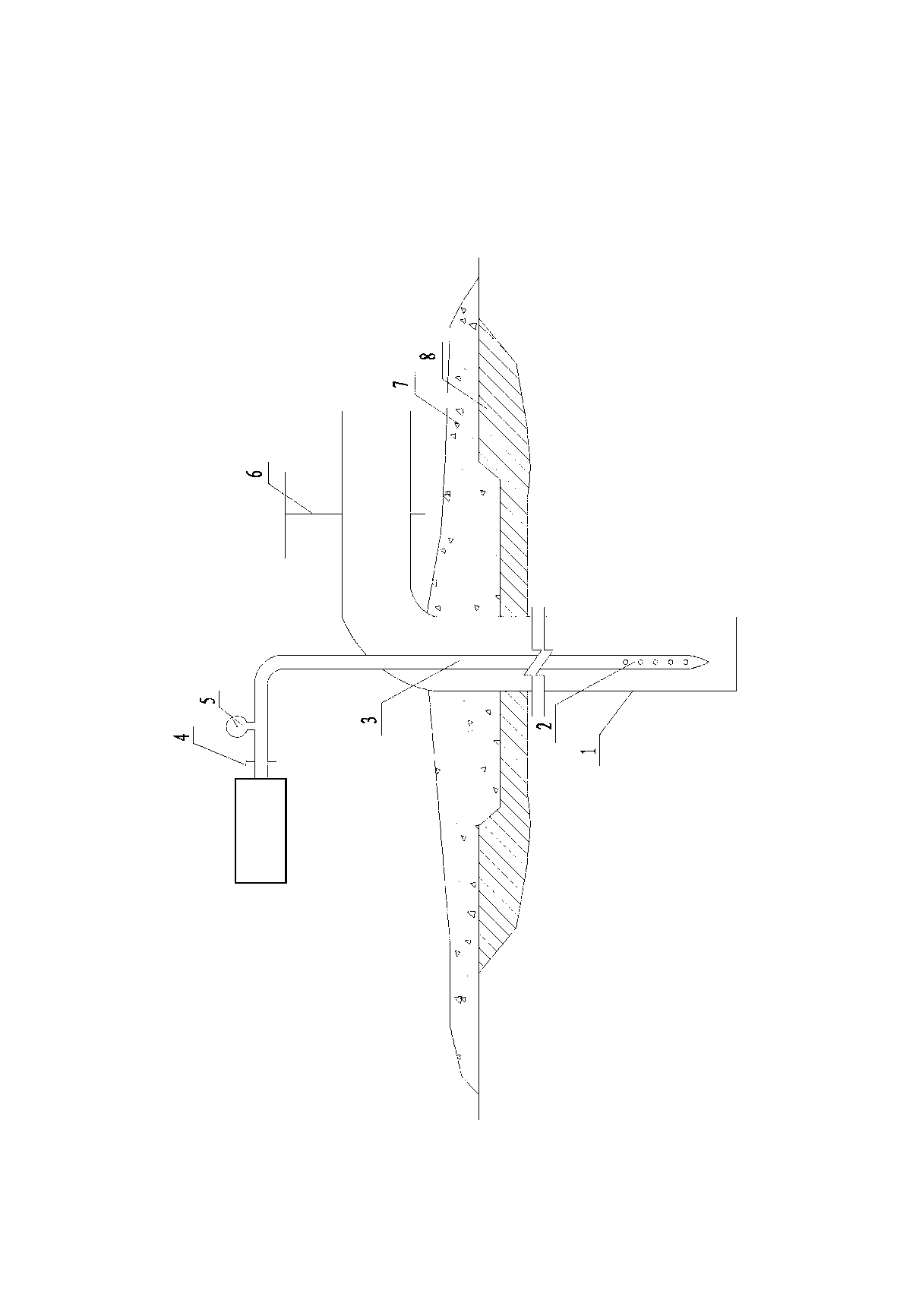

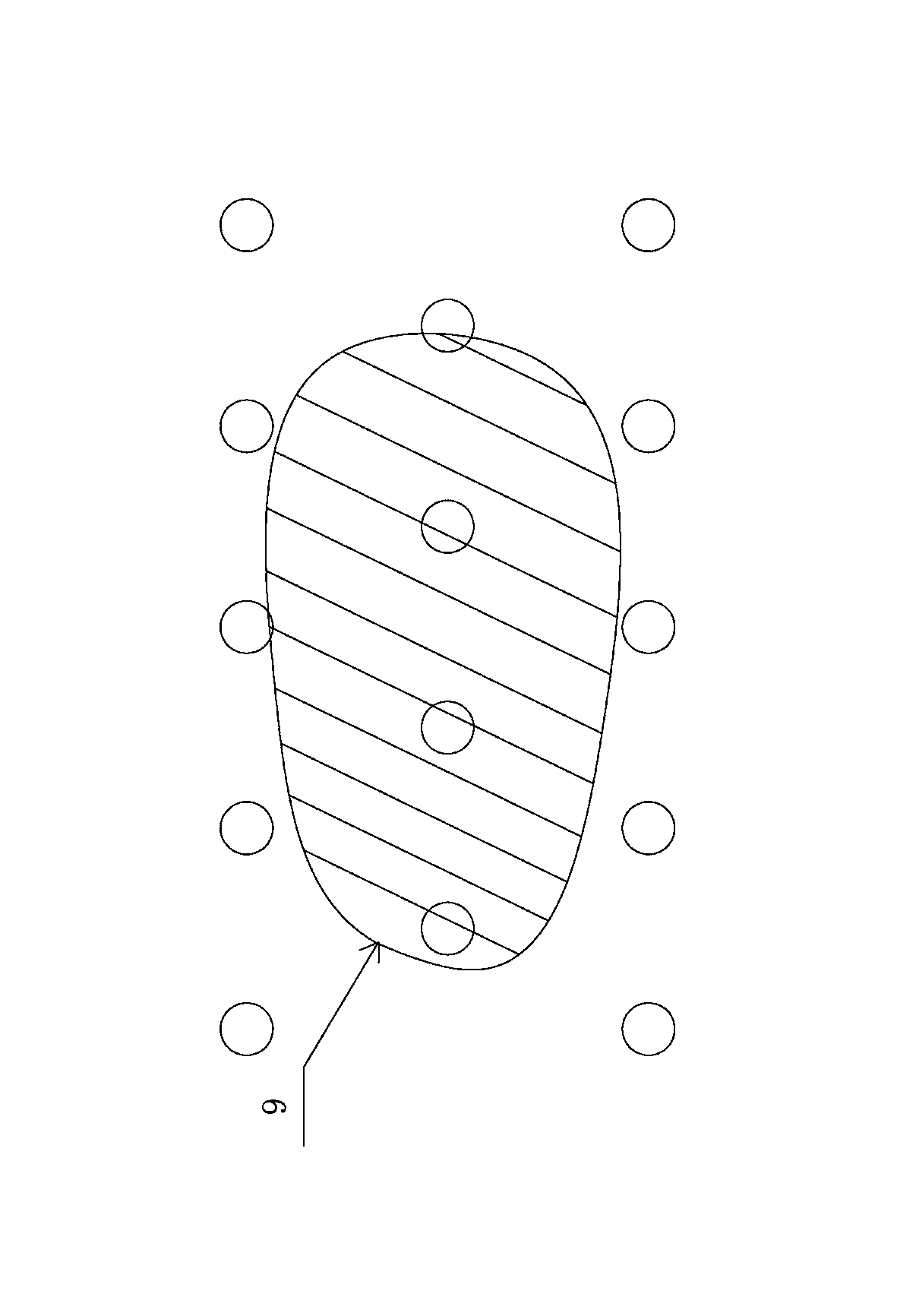

Method and system for transplanting big trees

The invention relates to a method and a system for transplanting big trees. The method comprises the following steps: S1, lifting seedlings, namely digging out roots of the big trees to be transplanted, and performing disinfection and water retaining treatment; S2, treating transplanting pits; S3, putting the roots into the pits and backfilling, namely vertically arranging peripheral porous pipes at the peripheries of the transplanting pits, positioning the roots of the big trees into the transplanting pits, backfilling nutrient soil into the transplanting pits, compressing the soil, and inserting internal porous pipes to the roots of the big trees; and S4, injecting water into the porous pipes, namely simultaneously injecting water into the peripheral porous pipes and the internal porous pipes until the moisture content is saturated. The method and the system for transplanting the big trees have obvious water retaining effect and simple implementation, and can prevent waterlogging.

Owner:SHENZHEN TECHAND ECOLOGY & ENVIRONMENT CO LTD

Indirect-direct evaporative cooling system operable from sustainable energy source

InactiveUS20060000227A1Reduce power consumptionReduce the amount requiredFree-cooling systemsStationary conduit assembliesPower gridImproved method

Improved means for powering and increasing evaporative cooling in an indirect-direct evaporative cooling (IDEC) apparatus are disclosed. Sustainable energy from solar energy mixed with grid power, when needed, power the IDEC device. These DC and AC power sources are seamlessly merged in a unique diode interconnect unit. Improved means for evaporative cooling include a rayon-based flocking on the wet side of molded plastic indirect evaporative cooling plates. Separate wet and dry passages through those plates are facilitated by a unique means for clamping the upper ends of the plates. These clamping means also add to the structural integrity of an array of plates so that the array can be inserted in and removed from a housing containing other operational components of the IDEC such as fan, direct cooling plates and water distribution means. Applicants IDEC utilizes improved porous piping that allows uniform and continuous distribution of water to all wet passages within both the indirect and direct stages of the IDEC. Operational controls for the system limit the potential water damage caused by overflow of water from the IDEC housing.

Owner:SPEAKMAN

Indirect-direct evaporative cooling system operable from sustainable energy source

InactiveUS20070017241A1Reduce the amount requiredImprove cooling effectFree-cooling systemsStationary conduit assembliesPower gridProcess engineering

Improved means for powering and increasing evaporative cooling in an indirect-direct evaporative cooling (IDEC) apparatus are disclosed. Sustainable energy from solar energy mixed with grid power, when needed, power the IDEC device. These DC and AC power sources are seamlessly merged in a unique diode interconnect unit. Improved means for evaporative cooling include a rayon-based flocking on the wet side of molded plastic indirect evaporative cooling plates. Separate wet and dry passages through those plates are facilitated by a unique means for clamping the upper ends of the plates. These clamping means also add to the structural integrity of an array of plates so that the array can be inserted in and removed from a housing containing other operational components of the IDEC such as fan, direct cooling plates and water distribution means. Applicants IDEC utilizes improved porous piping that allows uniform and continuous distribution of water to all wet passages within both the indirect and direct stages of the IDEC. Operational controls for the system limit the potential water damage caused by overflow of water from the IDEC housing.

Owner:SPEAKMAN

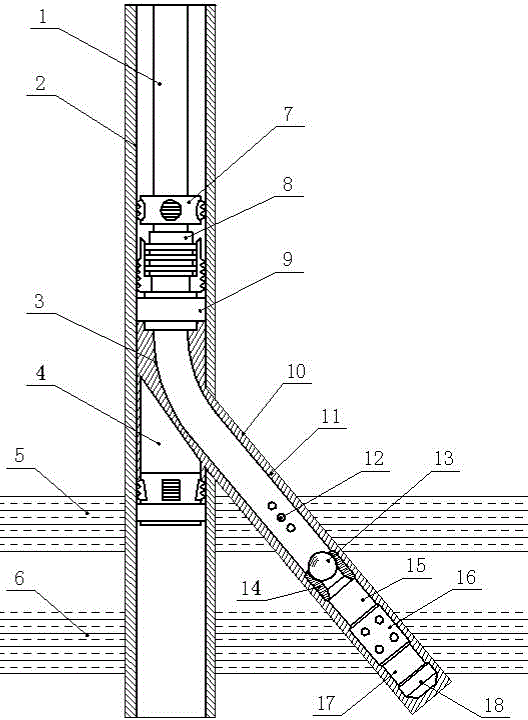

Side-tracking slim hole layered fracturing string and side-tracking slim hole layered fracturing method

ActiveCN106223917AReliable isolationFilling the gap in layered fracturing technologyFluid removalSealing/packingWell cementingPetroleum engineering

The invention provides a side-tracking slim hole layered fracturing string which comprises a sleeve, a first oil pipe, a tubing anchor, a fracturing plug and a tail string, wherein the first oil pipe, the tubing anchor, the fracturing plug and the tail string are arranged in the sleeve and are sequentially connected from top to bottom; the sleeve is provided with a flank hole; the upper end of the tail string is connected with the fracturing plug, and the lower end of the tail string passes through the flank hole; the tail string consists of a hanger, a second oil pipe, a ball seat, a third oil pipe, a soluble porous pipe, a fourth oil pipe and a tail pipe shoe which are sequentially connected from top to bottom; the hanger is connected with the fracturing plug. The invention also provides a fracturing method. A fracturing tool is not needed to be fed, not only can the large-displacement fracturing construction requirement be met, but also downhole tool feeding risks can be avoided, and meanwhile perforating operation at a lower reservoir stratum is omitted; compared with a well cementation sliding sleeve layered fracturing method, the risk that the sliding sleeve cannot be opened is avoided, furthermore, the side-tracking slim hole layered fracturing method has the characteristics that the blank of layered fracturing technology in feeding tail strings with an inner diameter of 76mm into a slim hole with an inner diameter of 118mm and cementing the well by using cement is filled.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

Low temp sintering method for surface porous pipe

The low-temp. sinterring method of surface perforated pipe includes the following steps: brushing base component required for sintering perforated layer with glue liquor, spraying the alloy copper tin powder on the base component brushed with glue liquor, after dried placing said base component into heating furnace with protective atmosphere, introducing hydrogen gas to make protection and heating to 400-500 deg.C, heat-insulating for 5-30 min., then quickly heating to 670-700 deg.C and heat-insulating for 60-90 min., and cooling under the protective atmosphere so as to can obtain the invented surface perforated pipe. The tin content in the described alloy copper tin powder is 9-13 wt%.

Owner:EAST CHINA UNIV OF SCI & TECH

Multi-water level vegetation evapotranspiration measuring device

InactiveCN101598587AAchieve separationSatisfied with precise measurementMachines/enginesLevel indicatorsVegetationEngineering plastic

The invention relates to a vegetation evapotranspiration measuring device, in particular to a device for measuring vegetation evapotranspiration, soil evaporation and water surface evaporation at multiple water levels. The device consists of a cultivating system and a water supply system, and comprises parts such as a cultivating vat made of an ABS engineering plastic material, a water supply pipe, a porous pipe and a Malpighian bottle with a scale. Fixed-water level water supply at different water levels is realized by adjusting the height of the Malpighian bottle. The change of the water levels in the Malpighian bottle is recorded before and after an experiment; and conversion is carried out by combining a cross-sectional area ratio of the Malpighian bottle to the cultivating vat to obtain water consumption for vegetation evapotranspiration in the cultivating vat. Different cultivating vats are compared in water consumption to obtain water consumption for underlaying surface (a water surface or soil) evaporation and the water consumption for vegetation transpiration so as to realize the separation a vegetation transpiration capacity from a soil evaporation capacity. The device has mechanical connection, simple structure, low cost, stability, reliability convenient maintenance and strong practicality and accuracy up to 0.1 mm and can completely meet accurate measurement of a vegetation evapotranspiration capacity and an underlaying surface evaporation capacity.

Owner:BEIJING NORMAL UNIVERSITY

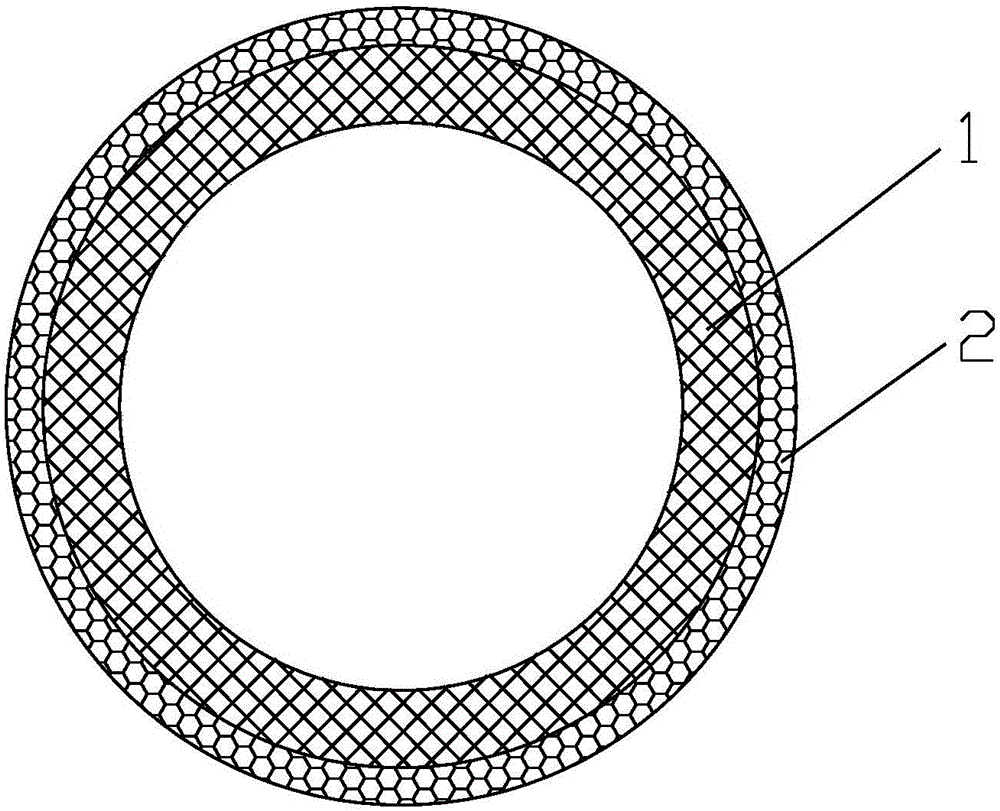

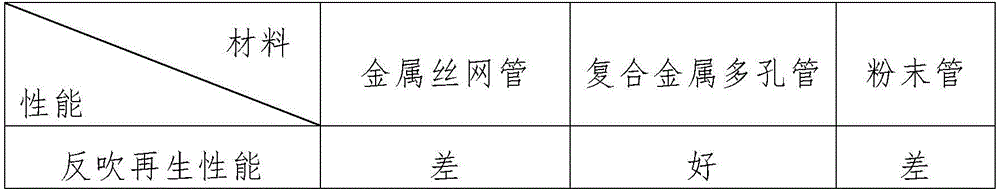

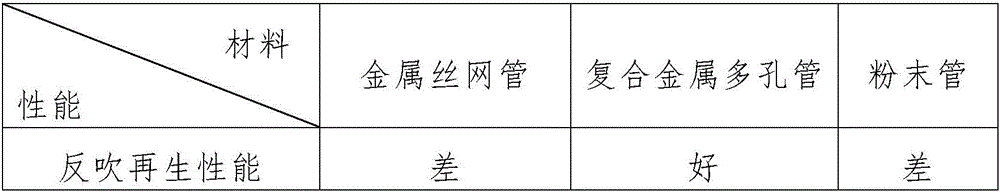

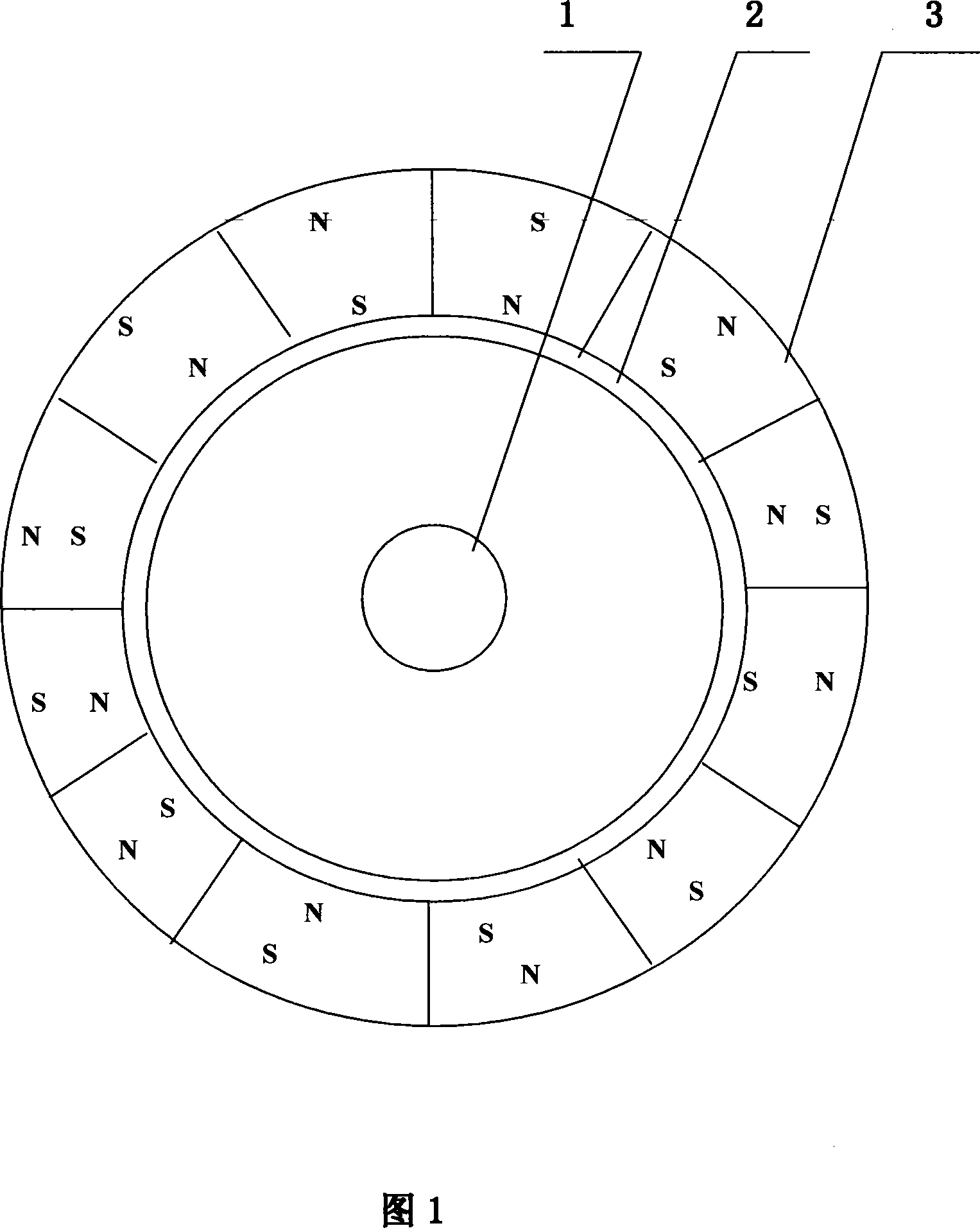

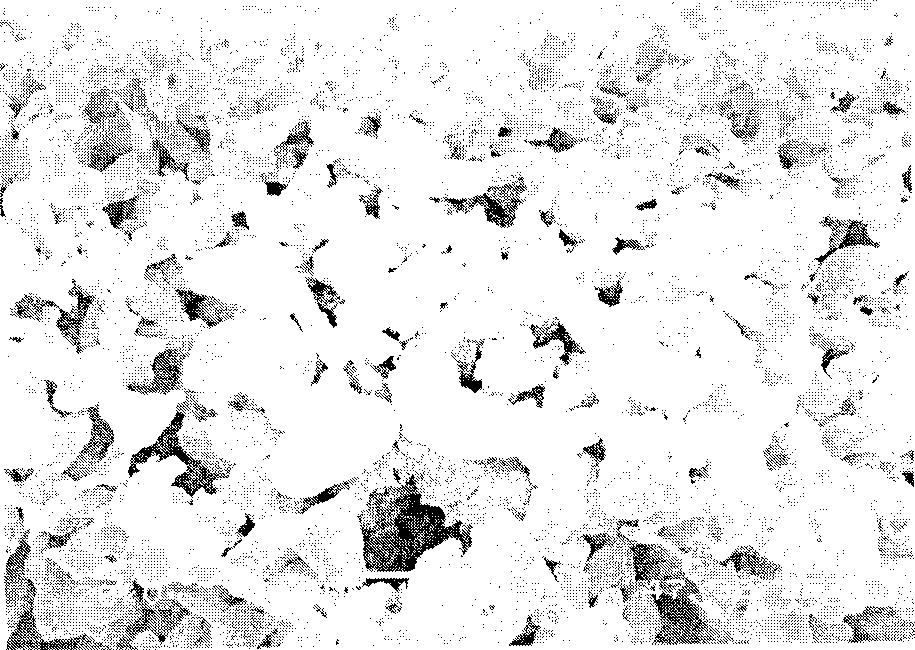

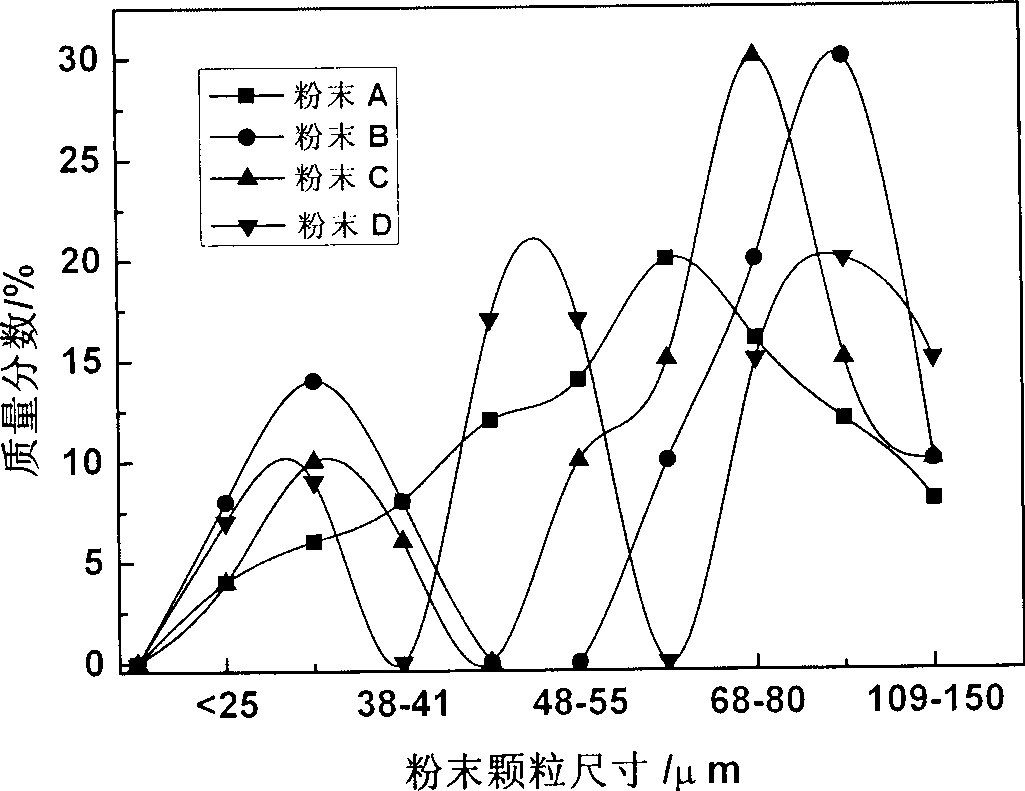

Composite metal porous pipe and preparing method thereof

ActiveCN106041101AHigh filtration precisionImprove breathabilityMembrane filtersFiltration separationPore diameterPermeability coefficient

The invention discloses a composite metal porous pipe which comprises a metal wire net pipe and a powder porous functional layer attached to the metal wire net pipe. The metal wire net pipe is formed by laying 3-7 layers of metal wire nets in a stacked manner and then rolling the metal wire nets. The wall thickness of the metal wire net pipe ranges from 1.5 mm to 3.8 mm, the hole diameter of the metal wire net pipe ranges from 20 microns to 200 microns, and the outer diameter of the metal wire net pipe ranges from 20 mm to 120 mm. The thickness of the powder porous functional layer ranges from 15 microns to 600 microns, the hole diameter of the powder porous functional layer ranges from 0.5 micron to 22 microns, and the air permeability is not smaller than 20 m<3> / (m<2>. KPa. h). In addition, the invention discloses a method for preparing the composite metal porous pipe. The composite metal porous pipe has the beneficial effects that the filtering precision is high, the permeability coefficient is high, and the reverse blowing and regeneration performance is good; and the hole diameter range can be adjusted according to use conditions, the application range is wide, and practical value is high.

Owner:NORTHWEST INSTITUTE FOR NON-FERROUS METAL RESEARCH

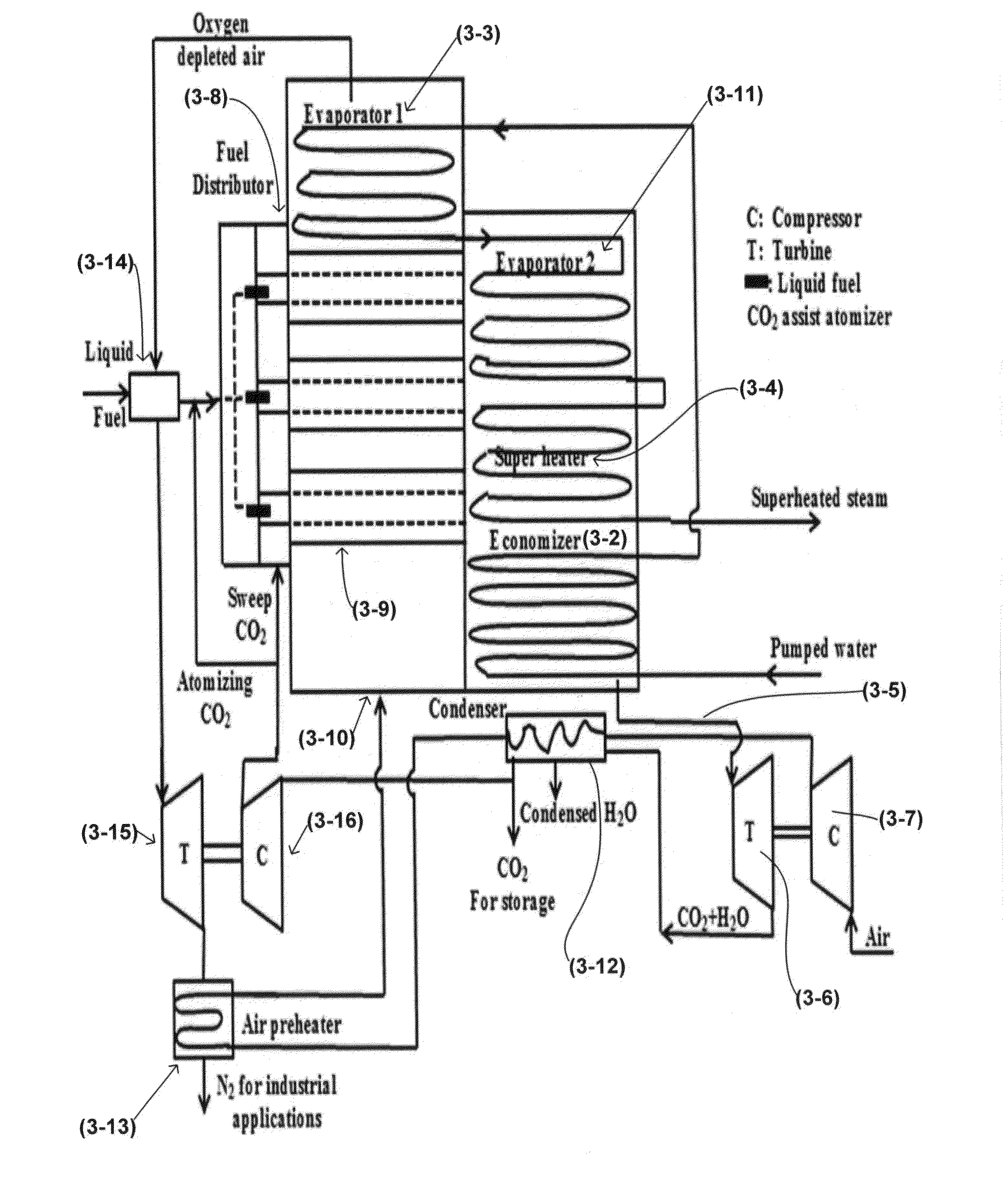

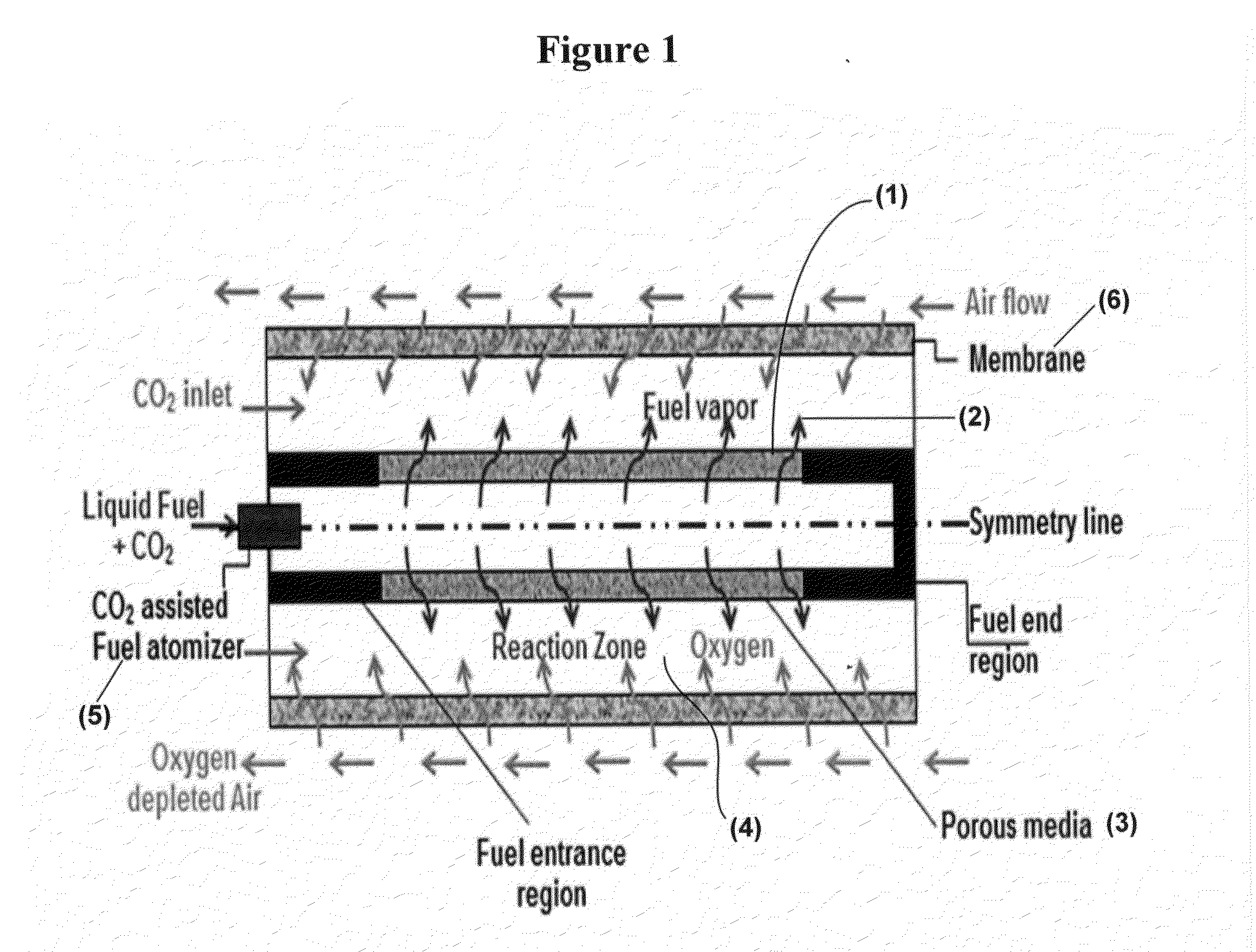

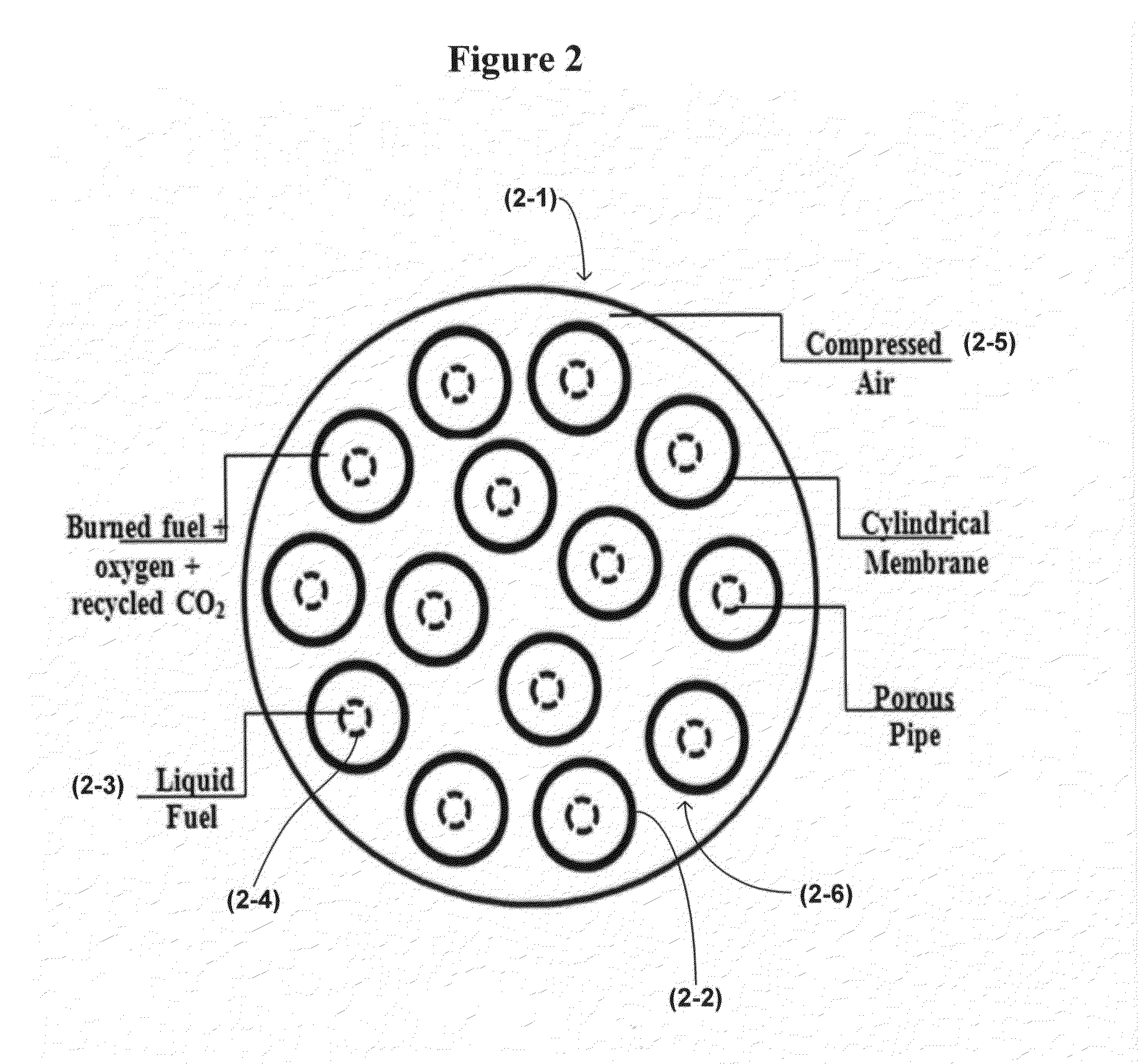

Carbon-free low-nox liquid fuel oxygen transport rector for industrial water tube boilers

ActiveUS20150176487A1Combustion using gaseous and pulverulent fuelSemi-permeable membranesSmall dropletLiquid fuel

An oxygen transport reactor for boiler furnaces and gas turbine combustors that utilizes a liquid fuel that is oxidized as a gaseous fuel in a membrane reactor. A liquid fuel is introduced by vaporizing the fuel inside a porous pipe surrounded by an annulus reaction zone which is surrounded by an annulus air zone. An oxygen transport membrane separates the annulus reaction zone containing the porous vaporized fuel and sweeping CO2 from the air feed side zone. Oxygen is transported from the outer annulus through the membrane to the annulus reaction zone containing the vaporized fuel and sweeping CO2. Fuel is first cracked to very small droplets in the intake fuel atomizer utilizing part of the intake CO2 then completely vaporized inside the porous pipe utilizing the heat coming from the surrounding reaction zone. The oxygen transport reactor is applicable for carbon free boiler furnaces and gas turbine combustors which utilize oxygen transport reactors for combined oxygen separation and combustion.

Owner:KING FAHD UNIVERSITY OF PETROLEUM AND MINERALS

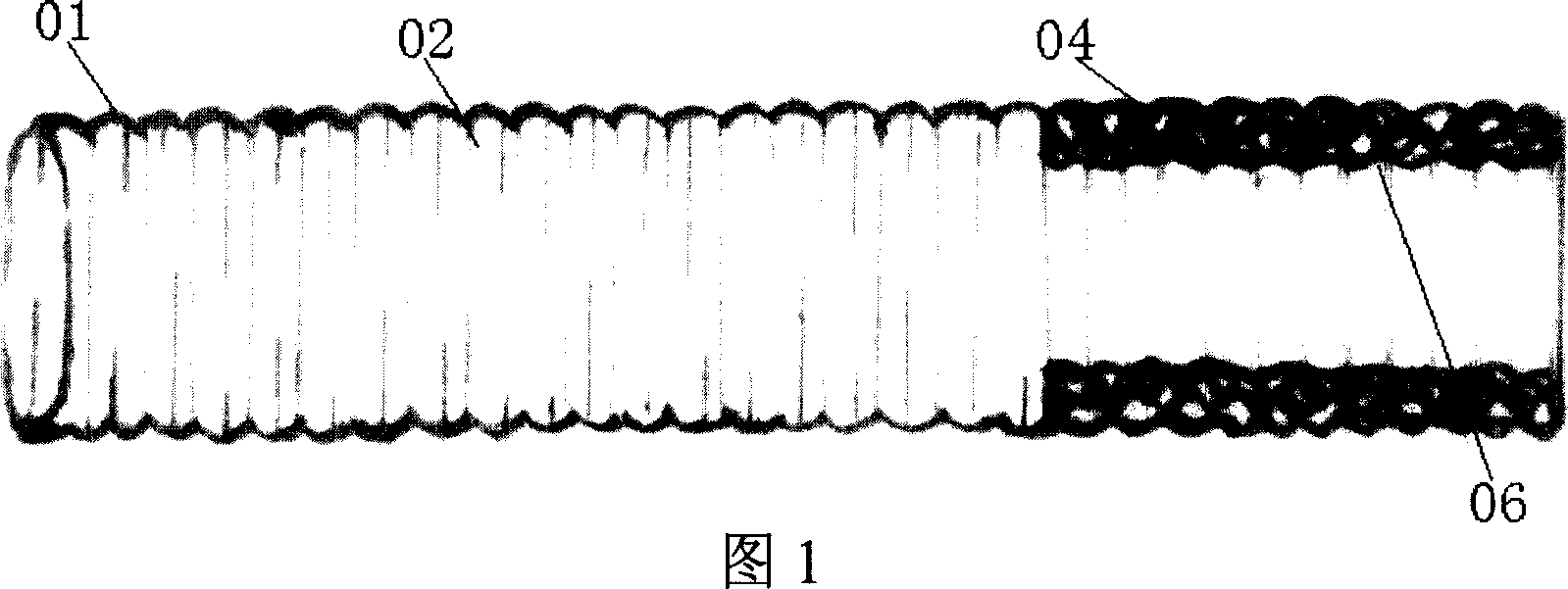

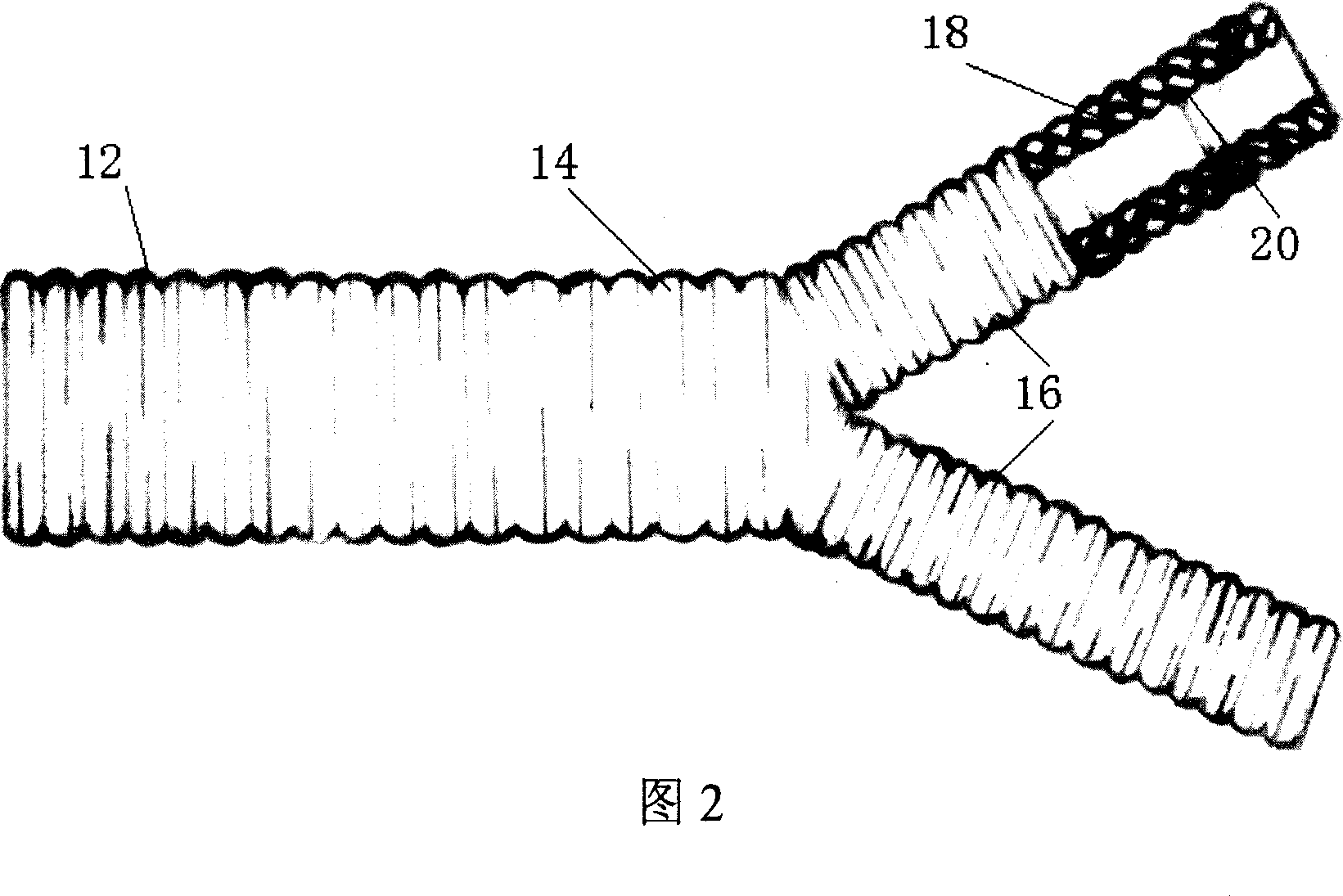

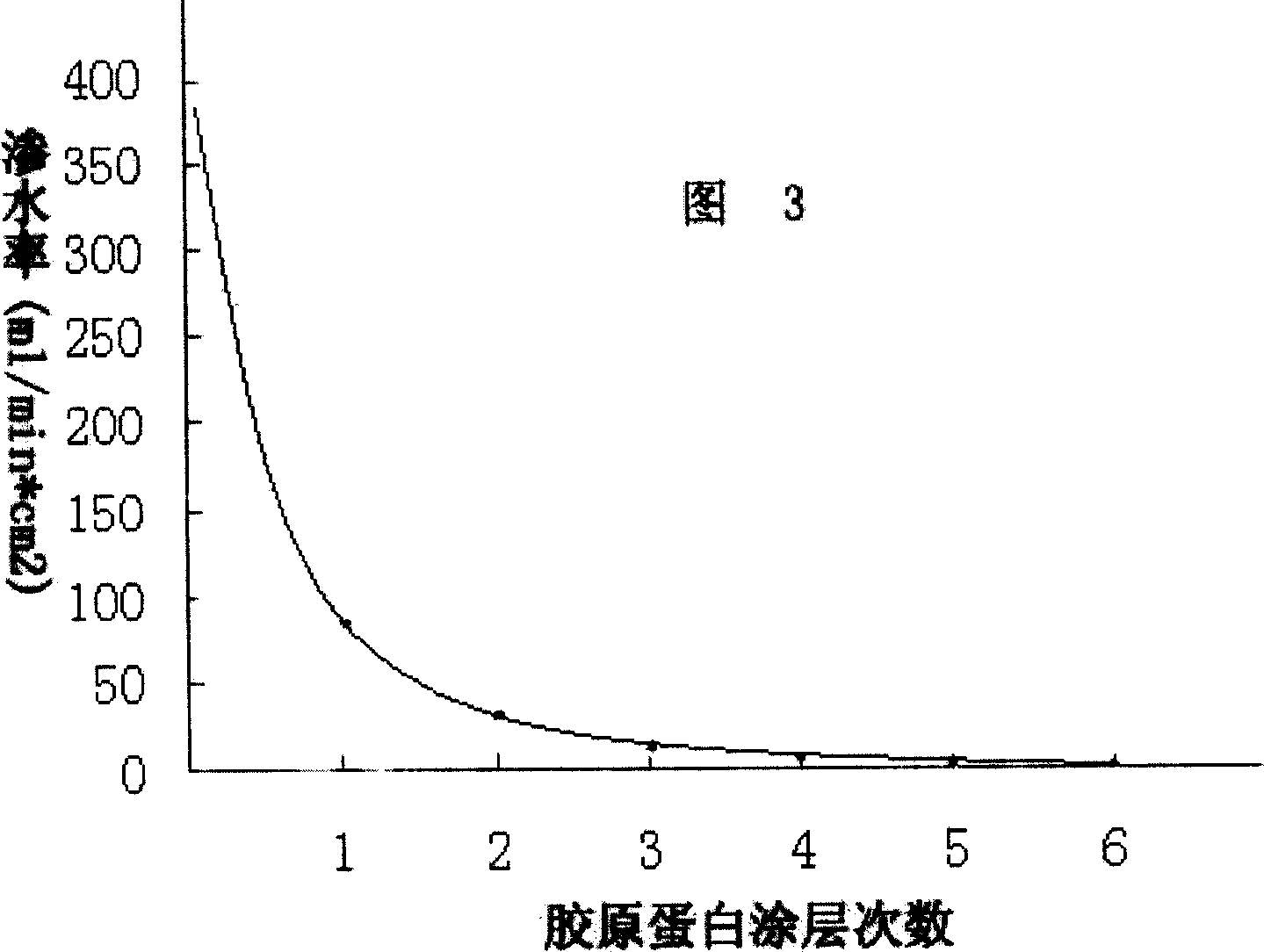

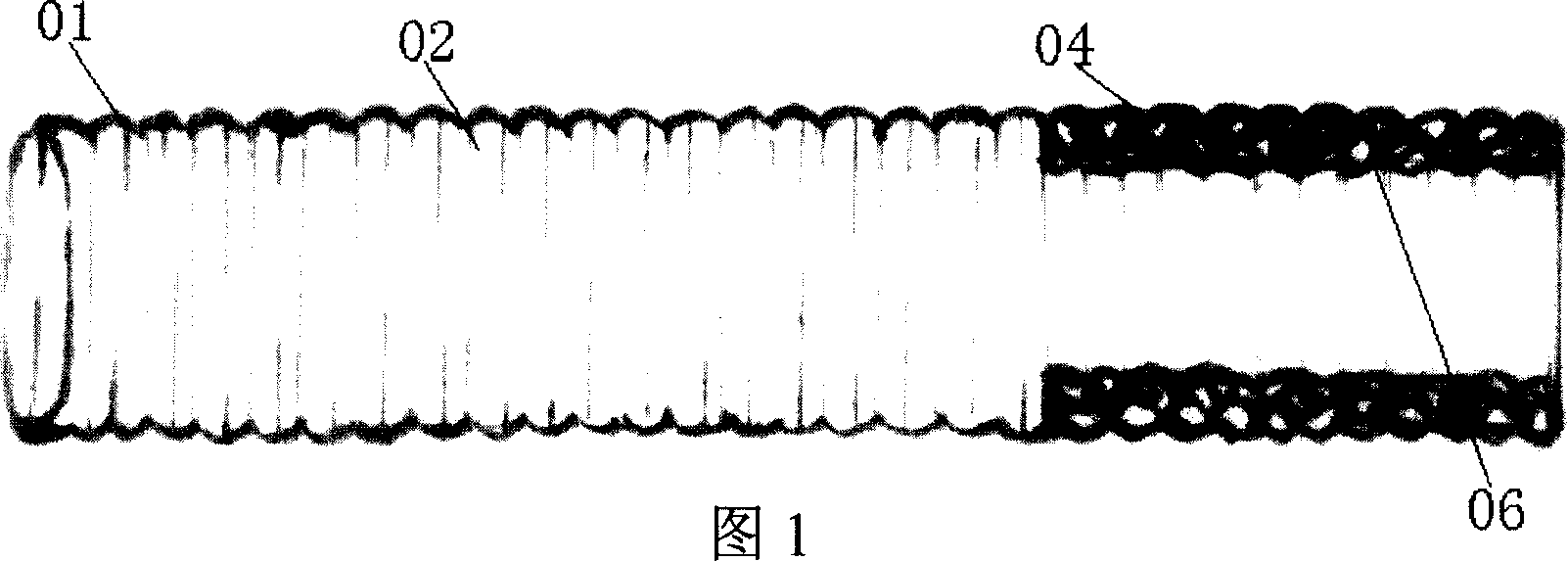

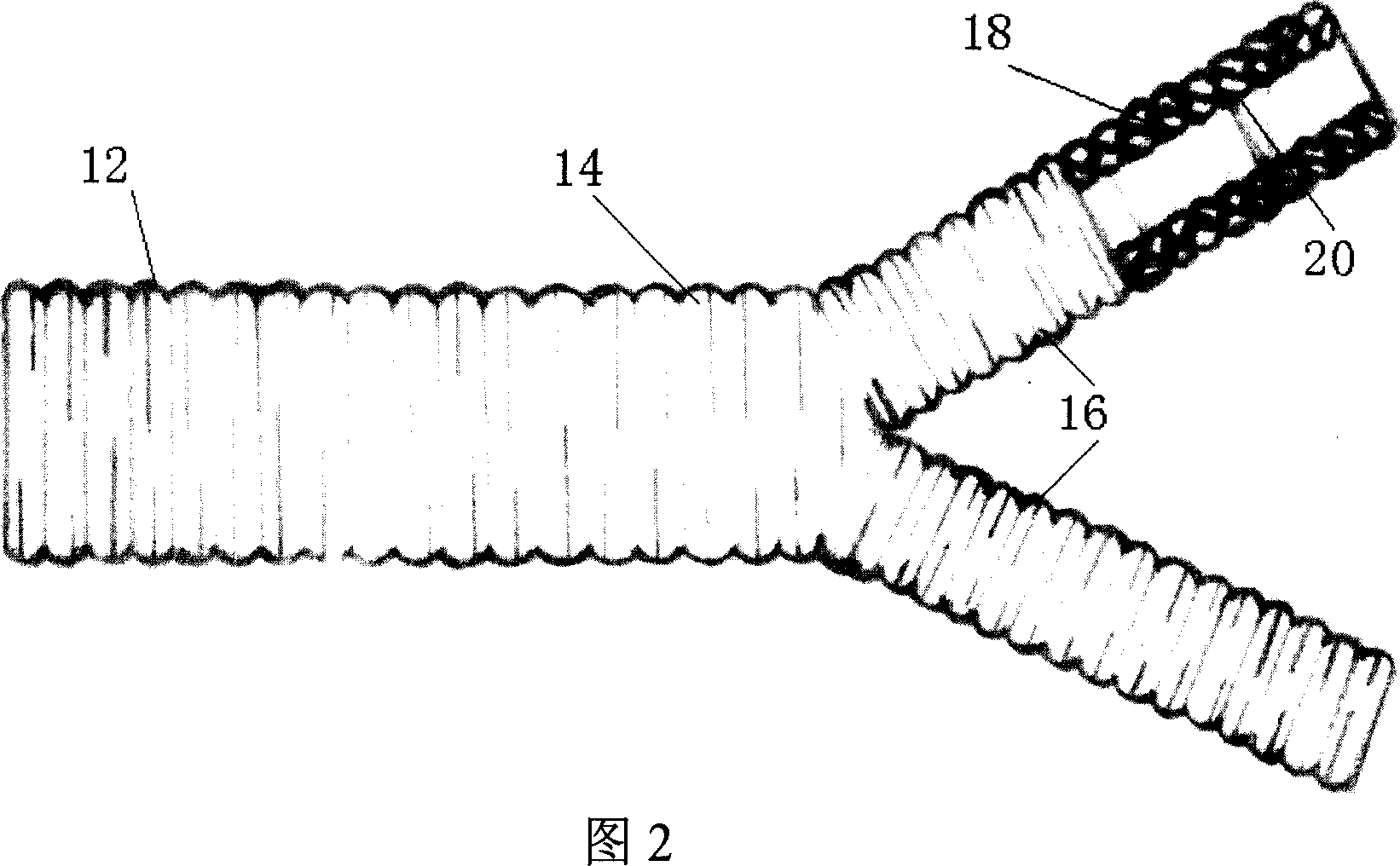

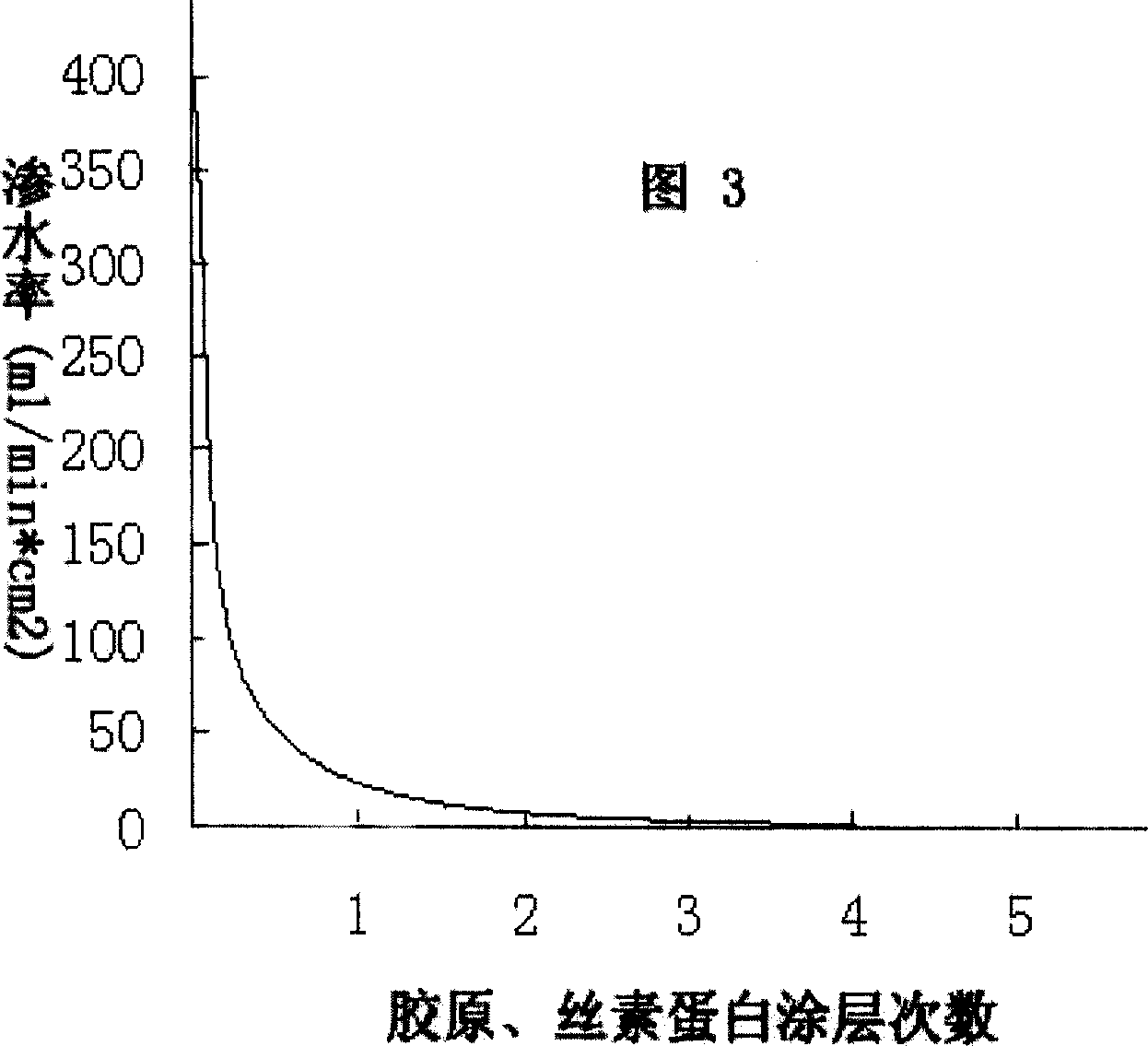

Artificial blood vessel collagen pre-coagulation coating

The invention discloses a pre-coating method of artificial vessel collagen, which comprises the following steps: synthesizing vessel prosthese through woven or knitted elastic porous pipe structure, coating the collagen liquid with elasticizer for at least three times, setting the collagen in the base bottom evenly, drying to fix the collagen through heat-hinging method.

Owner:郑军 +2

Apparatus and process for the separation of liquids and solids

InactiveUS6375843B1Reduce liquid contentPrevent buildupLiquid separation auxillary apparatusUltrafiltrationFiltrationSystem pressure

A liquid solid separation apparatus having a porous metal pipe sealed inside a non-porous metal pipe which allows a portion of the liquids, e.g., hydrocarbons and water to pass through the first pipe into the non porous pipe from which they are removed while solids are retained within the porous pipe. In the process there is a system pressure which aids in the filtration and a circulating velocity which removes the detained solids. Preferably a portion of these solids with reduced liquid content are recycled back to the system, mixed with fresh feed. By recycling a porion of the recovered solid concentrate the velocity of the flow in the system kept constant and the system itself is stabilized.

Owner:ENVIRONMENTAL SAFEGUARDS

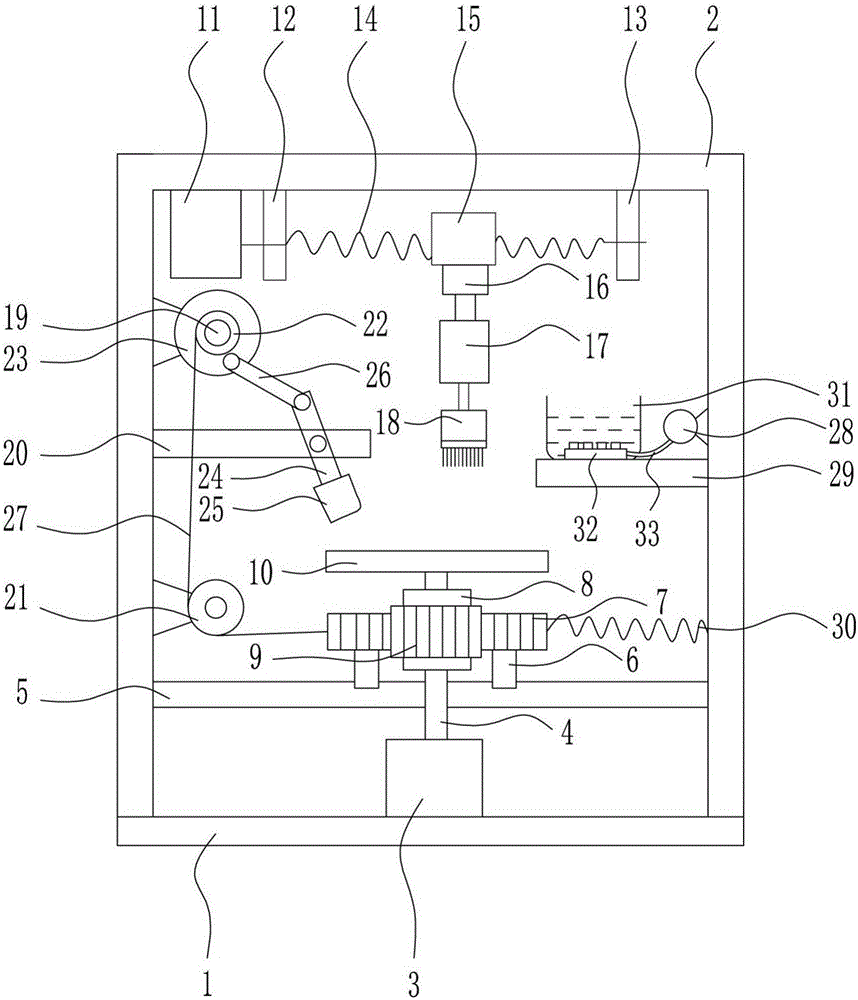

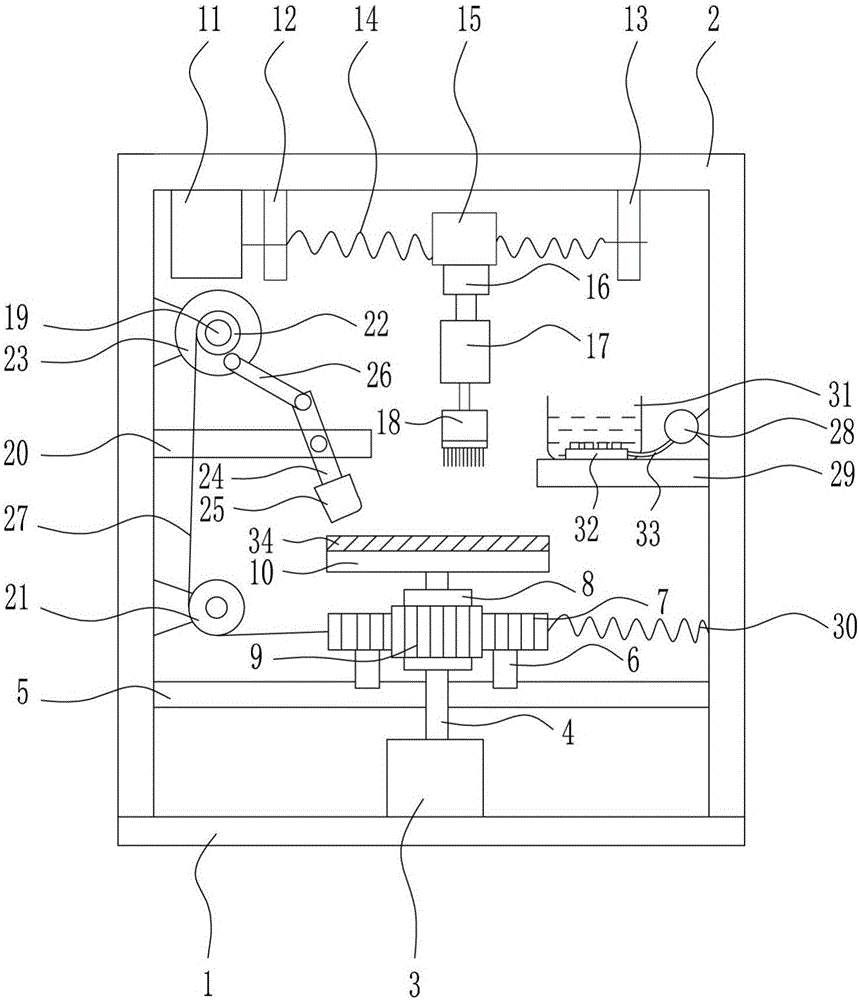

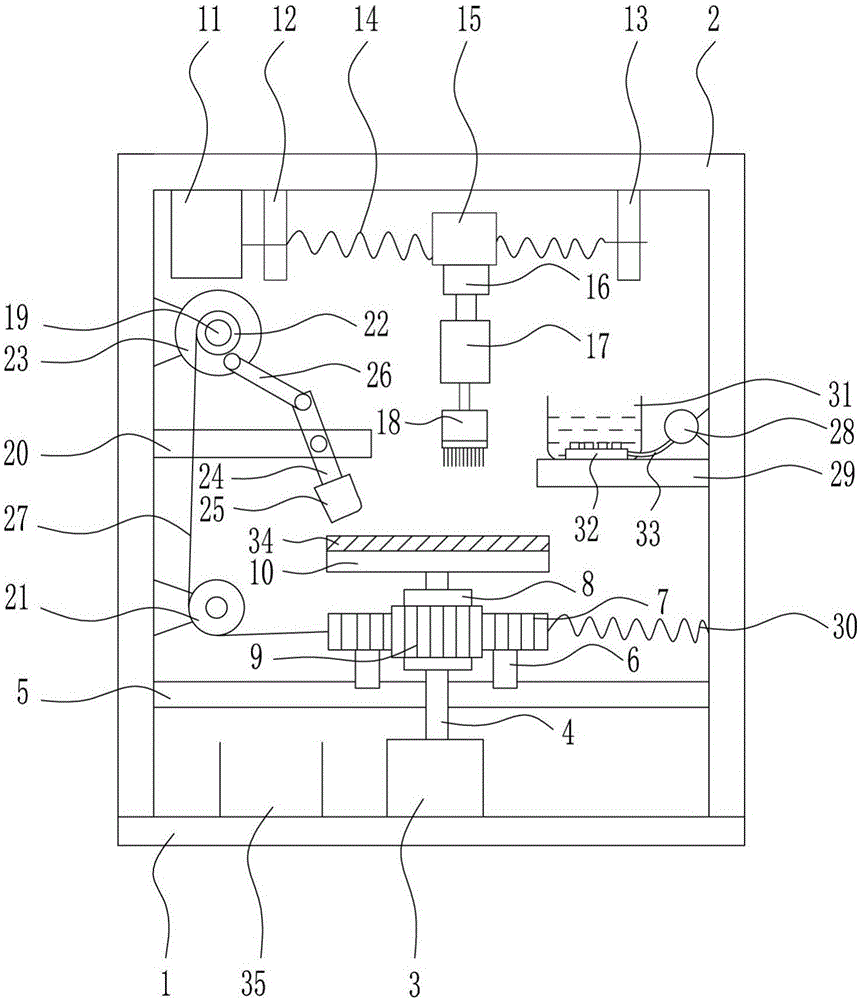

Efficient care device for leather shoes

The invention relates to a care device for leather shoes, in particular to an efficient care device for the leather shoes. The technical problems that an efficient care device for the leather shoes is poor in nursing, cannot keep original luster and is unreasonable in care time need to be solved. In order to solve the above-mentioned problems, the efficient care device for the leather shoes is provided. The efficient care device for the leather shoes comprises a bottom plate, an n-shaped support, a first bearing pedestal, a rotating shaft, a sliding rail, sliding blocks, a rack, a one-way clutch, a gear, a containing plate, a first motor, a second bearing pedestal, a third bearing pedestal, a lead screw, a nut, a second motor, a cylinder, a wool brush, a third motor, a first supporting rod, a pulley, a reel, a disk, a swinging rod, an oily shoe cleaning towel, a connecting rod, a guy wire, an air pump, a second supporting rod, a spring, an oil tank, a porous pipe and an air pipe, and the n-shaped support is arranged on the top of the bottom plate. According to the efficient care device for the leather shoes, the effects of being good in nursing, capable of keeping the original luster and reasonable in care time are achieved.

Owner:张浩杰

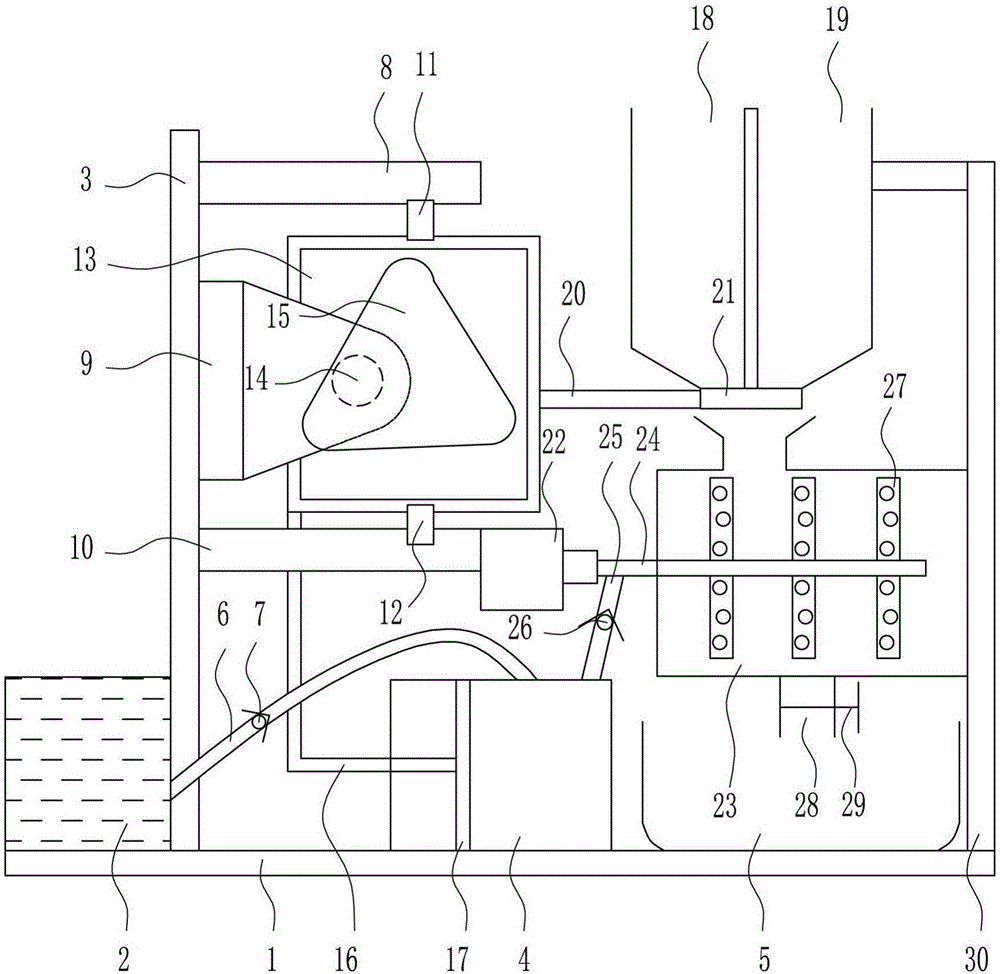

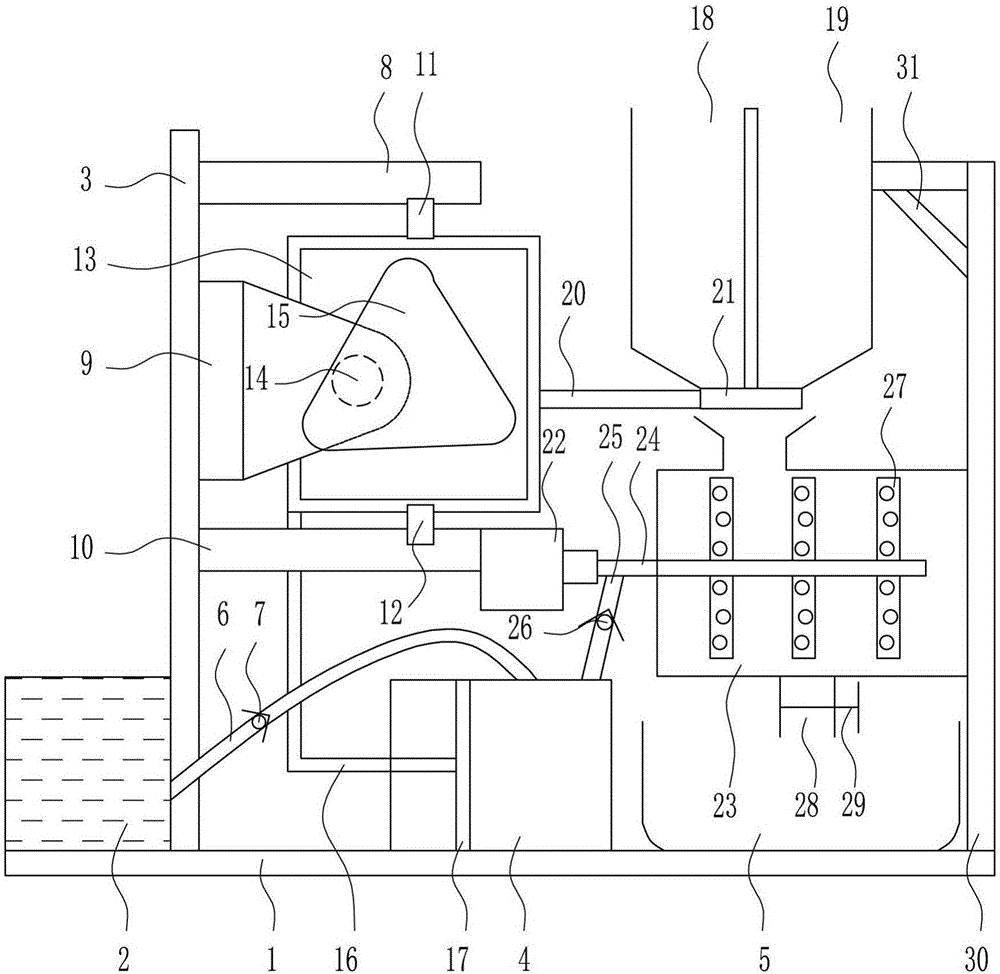

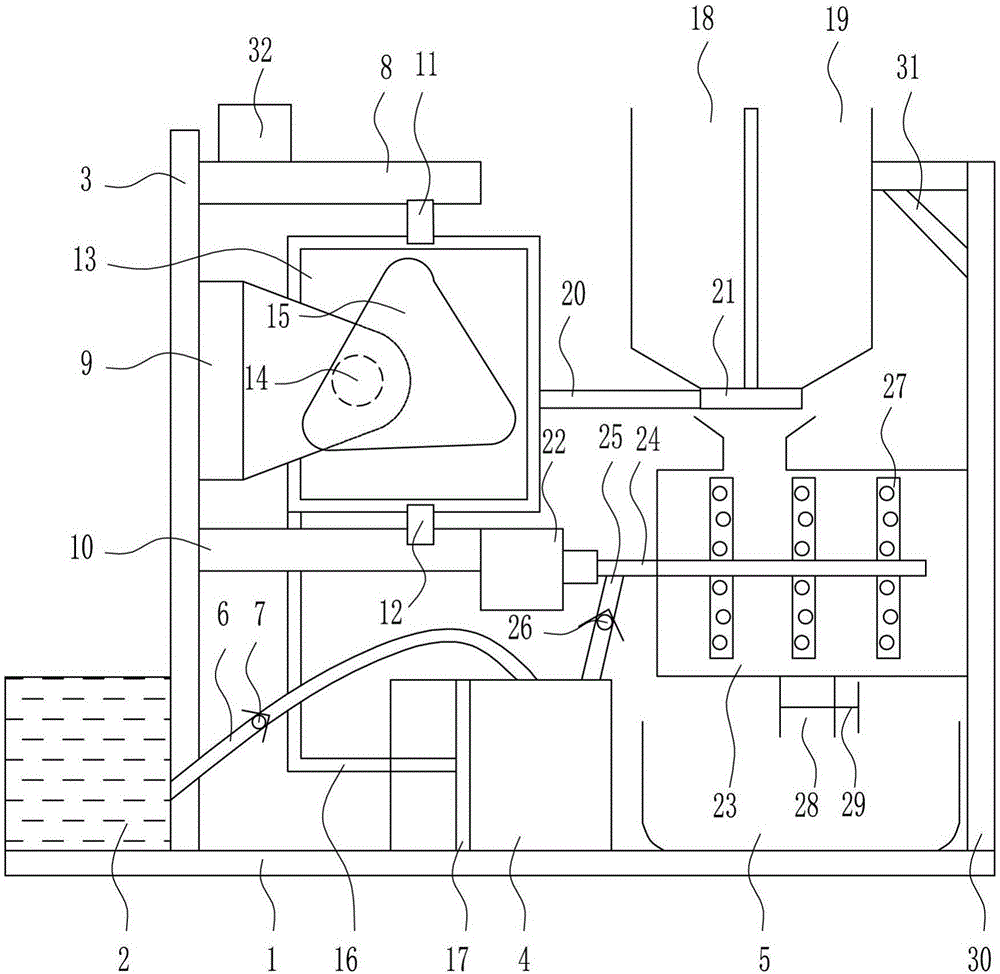

Discharging and stirring device for animal husbandry

InactiveCN106179022AStir wellStir in timeRotary stirring mixersTransportation and packagingEngineeringCylinder block

The invention relates to a stirring device for the animal husbandry, in particular to a discharging and stirring device for the animal husbandry, and aims to provide the discharging and stirring device which is used for the animal husbandry and can realize uniform discharge, timely stirring of feed and integrated stirring and water addition. The discharging and stirring device for the animal husbandry comprises a bottom plate, a water tank, a left frame, a cylinder block, a collecting frame, a water inlet pipe, a first one-way valve, a first sliding rail, a mounting seat, a second sliding rail, a first sliding block, a second sliding block and the like; the water tank, the left frame, the cylinder block, the collecting frame and a right frame are sequentially arranged on the bottom plate from left to right; the water inlet pipe is connected between the top of the cylinder block and the lower part of the right side of the water tank; the first one-way valve is arranged in the water inlet pipe. A porous pipe performs stirring and sprays water to realize more even stirring while discharging, and the device has the effects of being capable of realizing uniform discharging, timely stirring of feed and integrated stirring and water addition.

Owner:季虎

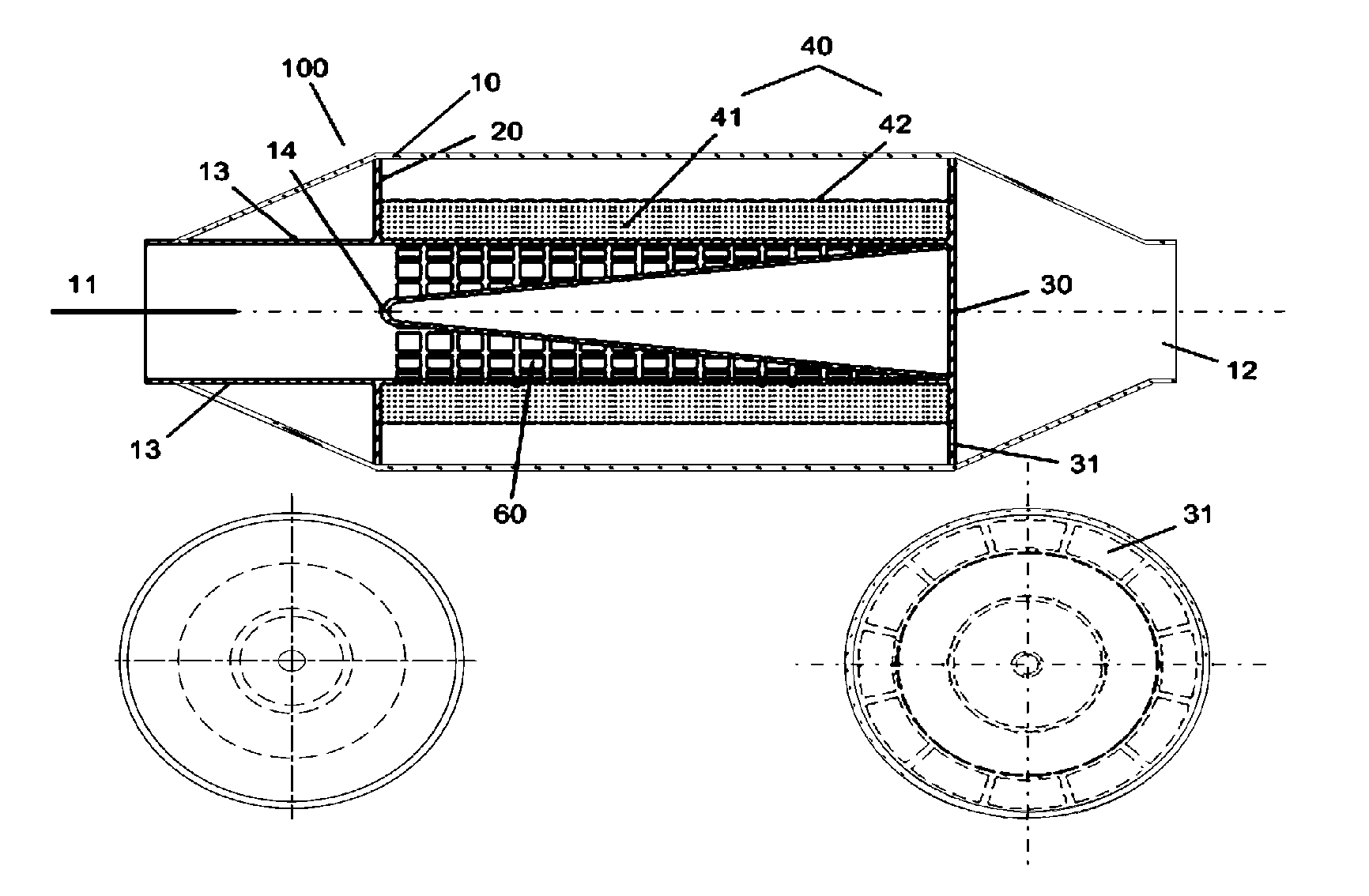

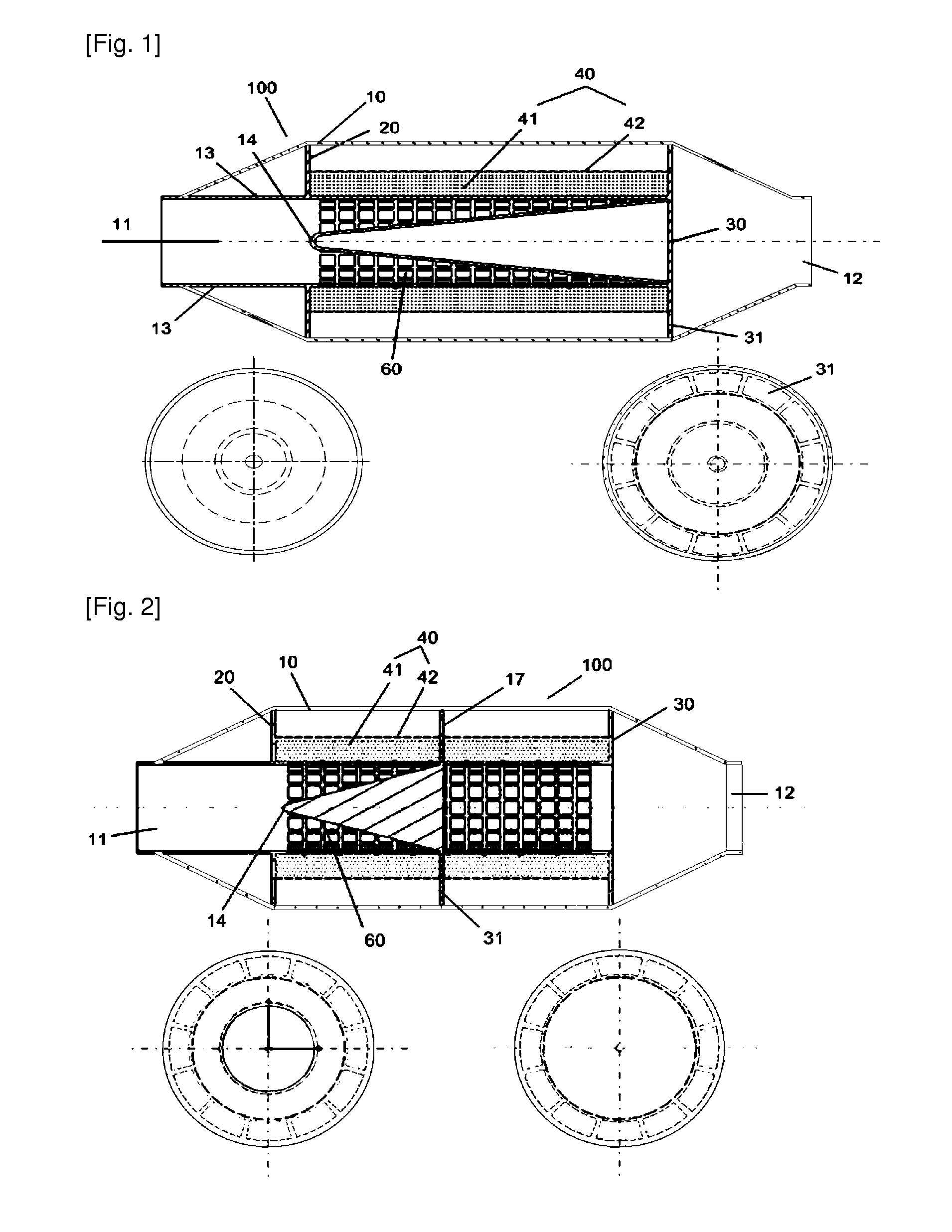

Filter device for filtering automobile exhaust gas

InactiveUS20110113755A1Increased durabilityUniform flow rateDispersed particle filtrationSilencing apparatusEngineeringMetal foam

A filter device for filtering automobile exhaust gas includes a case, front and rear support flanges mounted inside the case, and the filter member mounted between the front and rear support flanges. The front and rear support flanges are fixed vertically to the front and rear end portions of the filter member, respectively. The filter member includes a laminated or rolled-up metallic foam filter and a metallic mat or a jacket wrapping around the metallic foam filter. The porous pipe mounted inside the filter member is formed with a plurality of holes. The porous pipe is structured such that the width thereof decreases gradually towards the rear end portion or increase gradually towards the rear end portion, or the holes in the rear end portion are smaller, or a conical member is inserted in the inside space, or a pyramidal member is inserted in the inside space.

Owner:ALANTUM CORP

Process of preparing tubular porous membrane with high permeating flux

The present invention is process of preparing tubular porous membrane with high permeating flux. The process includes the following steps: mixing certain amount of additive, solvent, polymer and magnetic material through vibrating in certain temperature to compound homogeneous suspension; defoaming; wet or dry spinning to form capillary membrane or wet and dry phase converting to coat porous pipe to form membrane; and applying 100-18000 gauss cross magnetic field during evaporating and coagulating to form membrane. The tubular porous membrane with high permeating flux may be applied alone or as the porous support material for composite membrane.

Owner:HUBEI UNIV OF TECH

Processing method for foundation pit piping

InactiveCN103061349AGuarantee the construction progressPrevent collapseFoundation engineeringSlurryBuilding construction

The invention relates to a processing method for foundation pit piping. The object of the processing method is to block water gushing channels and close big water gushing points through chemical grouts so as to prevent the under water below a foundation pit pouring into the foundation pit, and accordingly create conditions for a dry construction. The technical scheme of the processing method includes the steps of: a) distributing holes within a water gushing area; b) sequentially aligning and drilling the holes through a drill and timely pressing steel sleeves into the holes in the drilling process, wherein a water outlet valve is mounted at a water outlet of an elbow which is positioned at the upper end of the steel sleeve inside which grouting pipeline equipment is installed; c) after finishing the pressing of the steel sleeves, firstly blanketing the openings of the holes with clay, then covering the clay with concrete or mortar and sealing gaps with cotton and quick-drying cement; d) after the concrete strength is reached, closing the water outlet valves and using a grout pump to grout the water soluble polyurethane slurry into a hole enclosed by the steel sleeves through a grouting pipe and a shot grout porous pipe. The processing method for foundation pit piping is applicable to the pit construction process of high buildings.

Owner:ZHEJIANG HUADONG CONSTR ENG

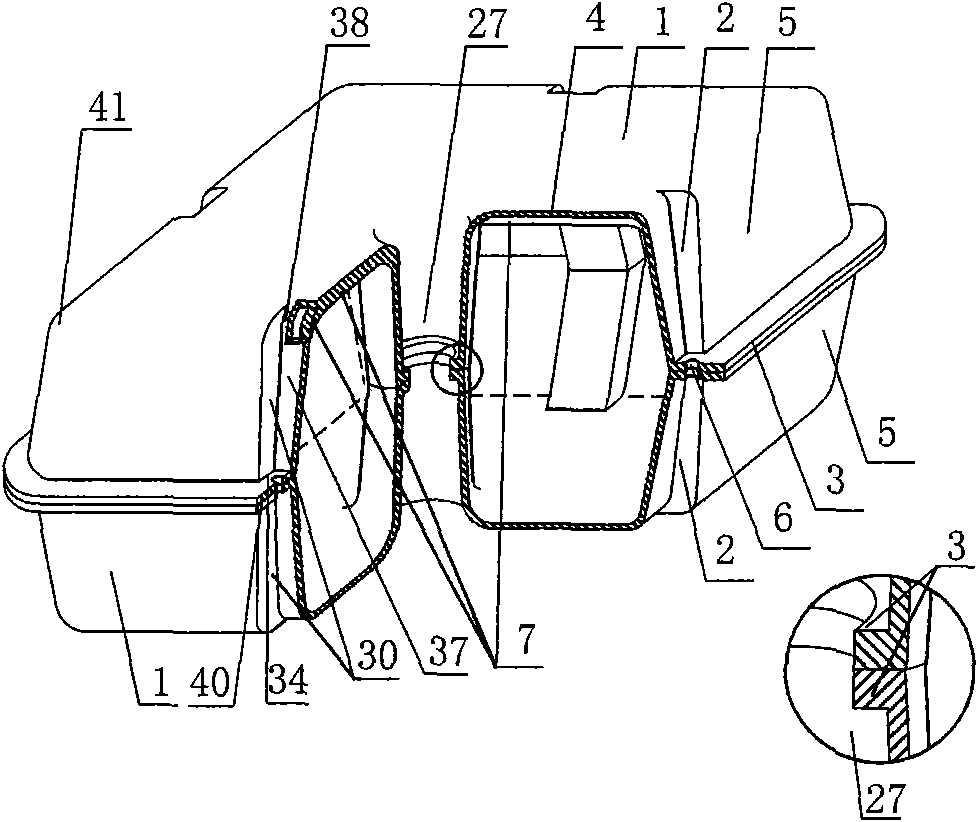

Concrete pore-forming core mould

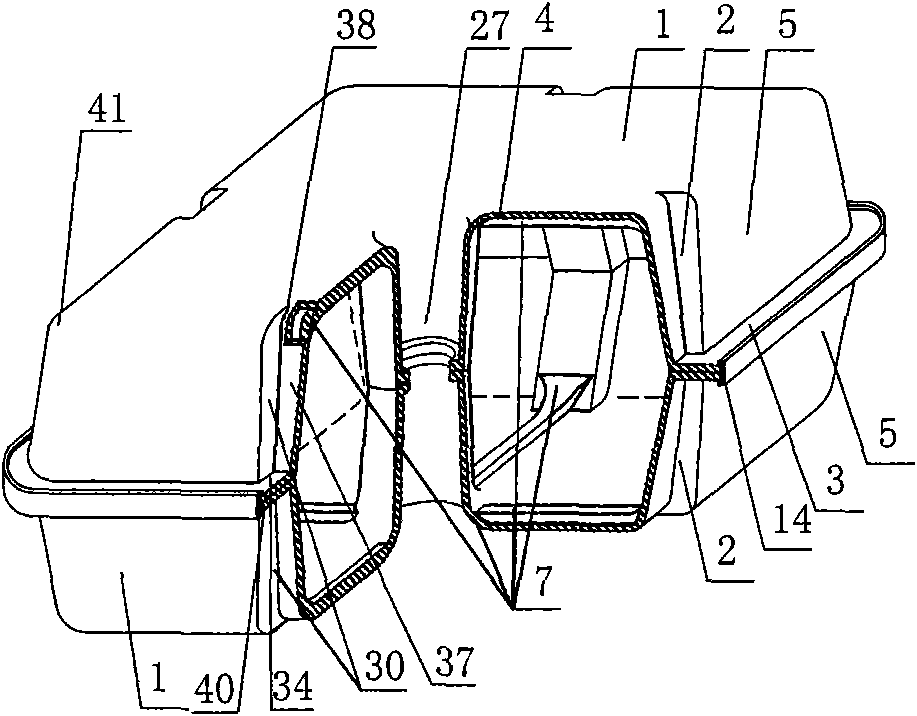

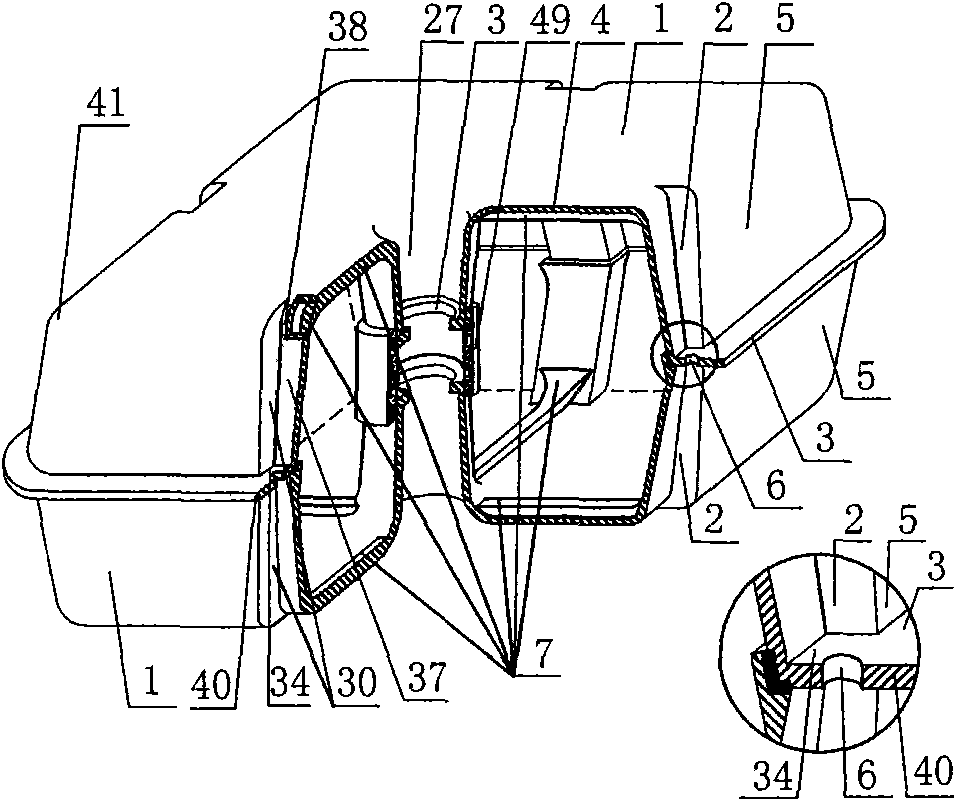

The invention discloses a concrete pore-forming core mould. The concrete pore-forming core mould comprises basin-shaped members (1), wherein each basin-shaped member (1) consists of a basin bottom plate (4) and a basin side wall (5) and is also provided with a raised edge (3); the basin side wall (5) is provided with a vertical groove (2); the two basin-shaped members (1) are relatively closed to form a sealed cavity; and the core mould is characterized in that the middle part of the basin-shaped member (1) is provided with a porous pipe (27). Thus, the porous pipe can play a part in reinforcing the middle part of the basin-shaped member; moreover, when the core mould is applied to a floor, the concrete above and below the core mould can be connected integrally through the porous pipe by means of the pores, so the overall performance of the floor is improved; the basin side wall is provided with the vertical groove, which has an effect of structural reinforcement on the core mould per se, so the core mould is difficult to deform in the use; and when the pore-forming core mould is applied to cast-in-place concrete slabs, the aim of the invention is fulfilled. The core mould can be manufactured from materials such as plastic rubber, concrete, steel and the like, is suitable to be used in hollow floors, roofs, walls, base slabs and bridges of cast-in-place reinforced concrete or pre-stressed reinforced concrete, and is particularly suitable to be used in the hollow floors.

Owner:湖南邱则有专利战略策划有限公司

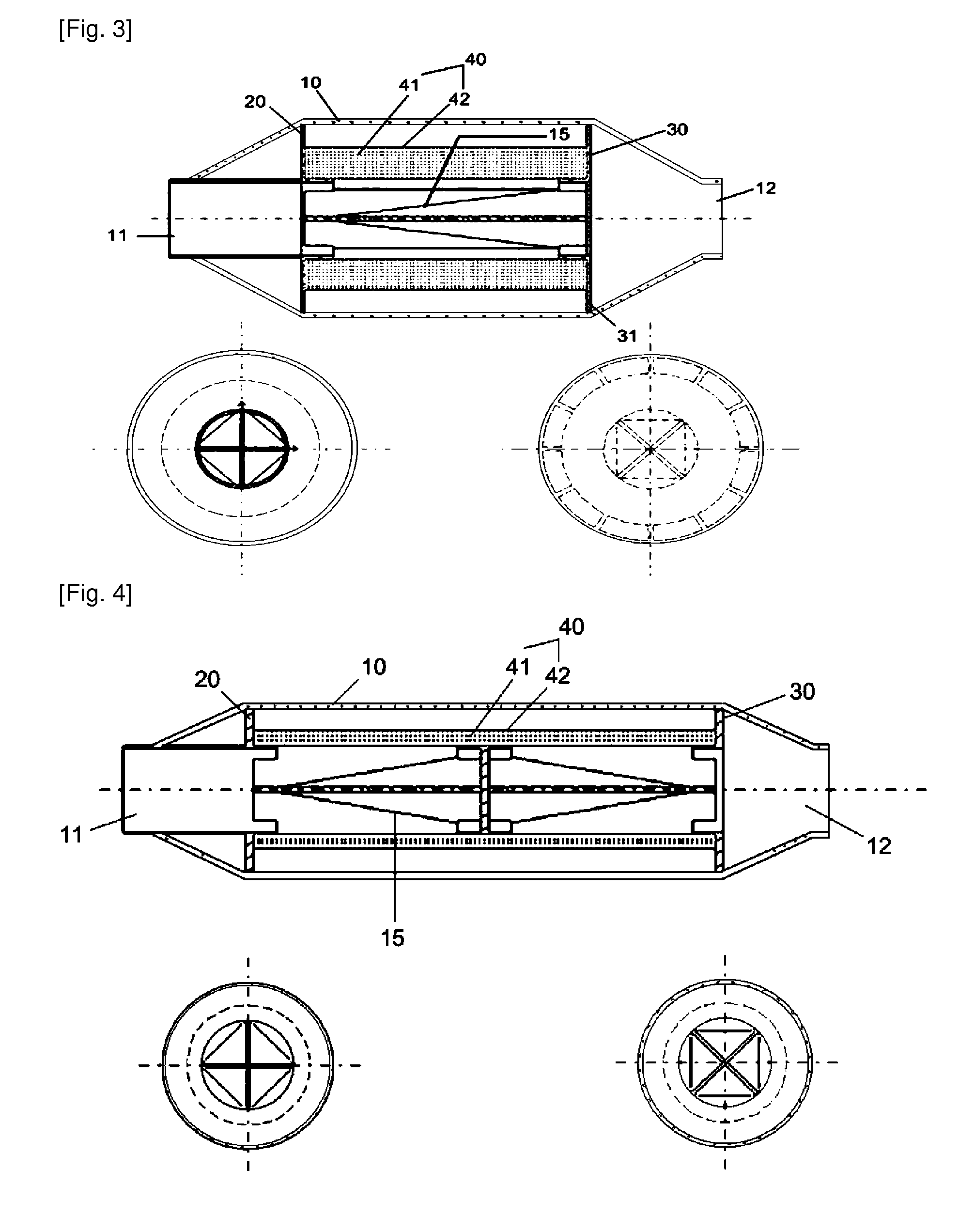

Carbon-free low-NOx liquid fuel oxygen transport reactor for industrial water tube boilers

ActiveUS9383096B2Combustion using gaseous and pulverulent fuelSemi-permeable membranesSmall dropletLiquid fuel

An oxygen transport reactor for boiler furnaces and gas turbine combustors that utilizes a liquid fuel that is oxidized as a gaseous fuel in a membrane reactor. A liquid fuel is introduced by vaporizing the fuel inside a porous pipe surrounded by an annulus reaction zone which is surrounded by an annulus air zone. An oxygen transport membrane separates the annulus reaction zone containing the porous vaporized fuel and sweeping CO2 from the air feed side zone. Oxygen is transported from the outer annulus through the membrane to the annulus reaction zone containing the vaporized fuel and sweeping CO2. Fuel is first cracked to very small droplets in the intake fuel atomizer utilizing part of the intake CO2 then completely vaporized inside the porous pipe utilizing the heat coming from the surrounding reaction zone. The oxygen transport reactor is applicable for carbon free boiler furnaces and gas turbine combustors which utilize oxygen transport reactors for combined oxygen separation and combustion.

Owner:KING FAHD UNIVERSITY OF PETROLEUM AND MINERALS

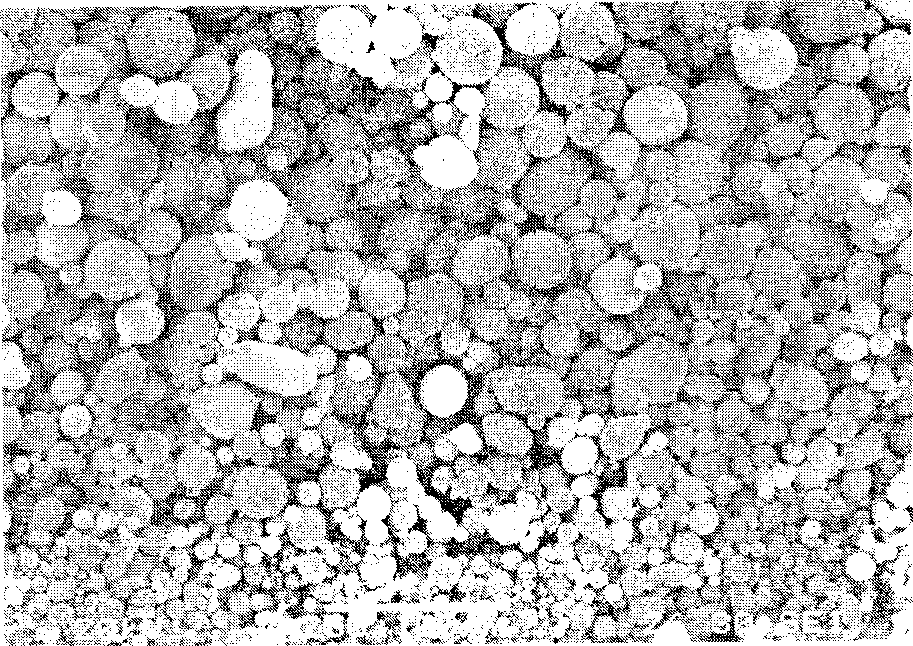

Method of manufacturing gradual-change bore diameter stainless steel antipriming pipe

ActiveCN101428346AImprove breathabilityGuaranteed filtration accuracyFiltration separationPolyvinyl alcoholSS - Stainless steel

The invention provides a preparation method for a stainless steel perforated pipe with gradually-varied aperture, the invention adopts the preparation process that stainless steel powder is mixed with a certain polyvinyl alcohol solution to prepare stainless steel powder suspension, and getter is added into the suspension and poured into a two-piece-type opening and closing rigid pipe die made of stainless steel after even stirring, which centrifugally takes shape on a centrifuge, thereby preparing a green body of the stainless steel perforated pipe with gradually-varied aperture grads; the green body is dried in a blast-type baking oven, and then the demoulding is performed; the green body of the stainless steel perforated pipe after drying is sintered in a vacuum stove, the sintering atmosphere adopts vacuum, and the stainless steel perforated pipe with gradually-varied aperture grads is prepared after cooling. The invention has the advantages that the demoulding attainment rate of the green body of the stainless steel perforated pipe with gradually-varied aperture is greatly enhanced, and the filtering precision of the perforated pipe is ensured; meanwhile, the air transmission coefficient of the stainless steel perforated pipe with gradually-varied aperture is enhanced, and the preparation method solves the phenomenon of the reciprocal relationship between the filtering precision of the stainless steel perforated pipe and the transmission performance in the filtration, separation and application process.

Owner:NORTHWEST INSTITUTE FOR NON-FERROUS METAL RESEARCH

Artificial blood vessel silk fibroin and collagen blending pre-coagulation coating

The invention discloses a stratified pre-condensing coating method of artificial vessel collagen and silk protein, which comprises the following steps: synthesizing vessel prosthesis through woven or knitted elastic porous pipe structure, using three-layered coating technology to coat collagen and reinforcer liquid on the internal wall of vessel prosthesis. The vessel prosthesis of silk protein liquid vessel needs composite reinforcer, which is coated in the base layer evenly to expose in the formaldehyde steam after drying.

Owner:郑军 +2

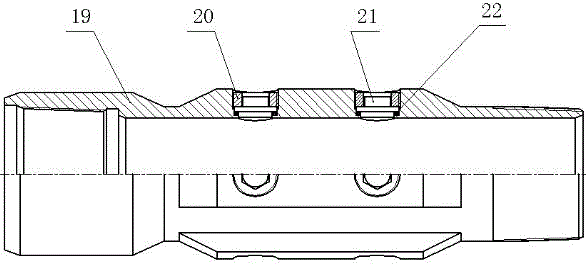

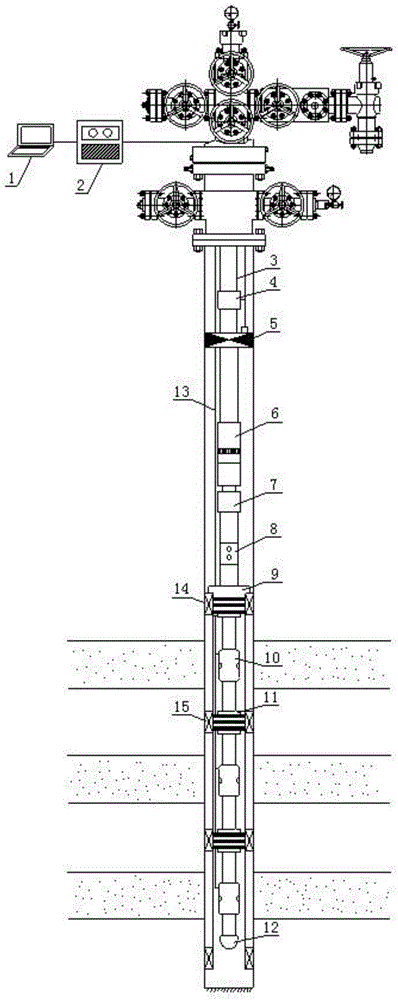

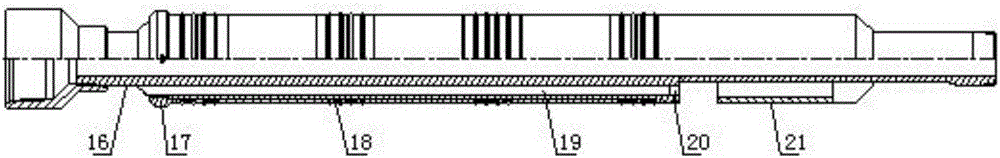

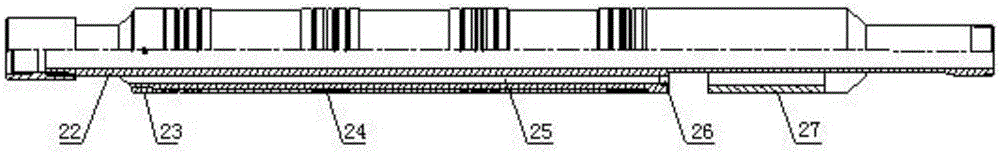

Highly-deviated well intelligent layered oil recovery string and work method thereof

ActiveCN106761604ARealize online stepless regulationSolve the general joint miningDrilling rodsFluid removalProduction stringPetroleum engineering

The invention discloses a highly-deviated well intelligent layered oil recovery string. The string comprises a layered production string body, the layered production string body comprises a porous pipe and a round plug, and a passing cable positioning seal, a plurality of layered production allocation devices and at least one passing cable insertion seal are arranged between the porous pipe and the round plug; each layered production allocation device is connected with a ground controller through a steel armored cable, the ground controller is connected with an upper computer, each layered production allocation device corresponds to one oil layer, and sealing between different layers is achieved through the passing cable positioning seal and the passing cable insertion seals. A work method of the string includes the steps that pigging is conducted; joint debugging testing of the layered production allocation devices is normal, and the string and the steel armored cables are put into a well; examining seal is conducted on the string; a pump is started for production; fixed-point acidification is conducted. By means of the string, online stepless regulation of highly-deviated well layered oil recovery can be achieved, and fixed-point acidification can be conducted according to production requirements.

Owner:CHINA NAT OFFSHORE OIL CORP +2

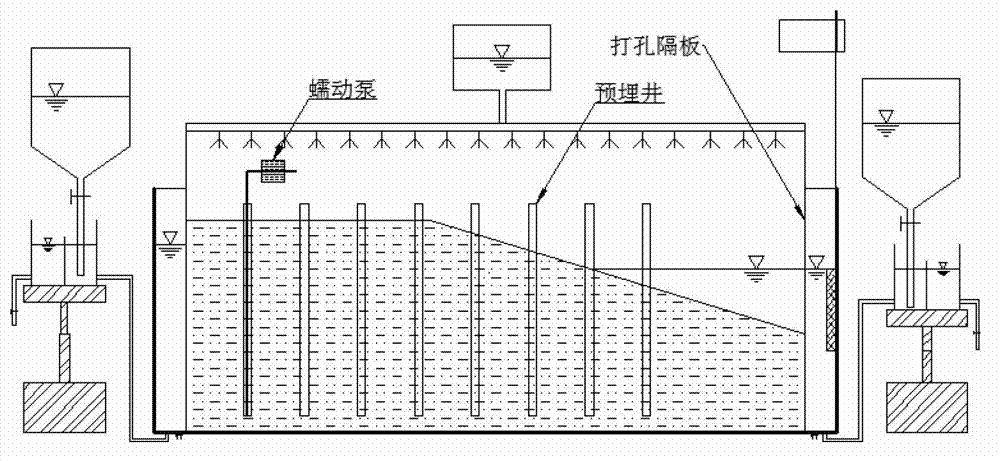

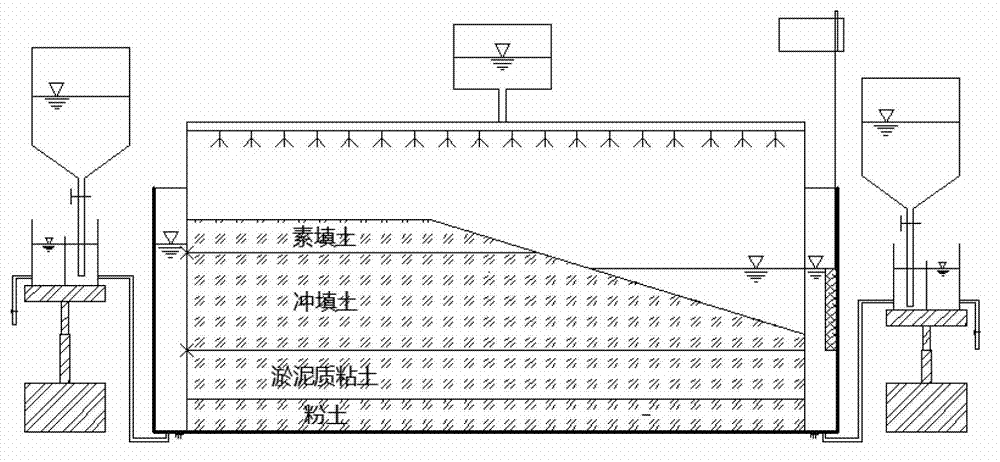

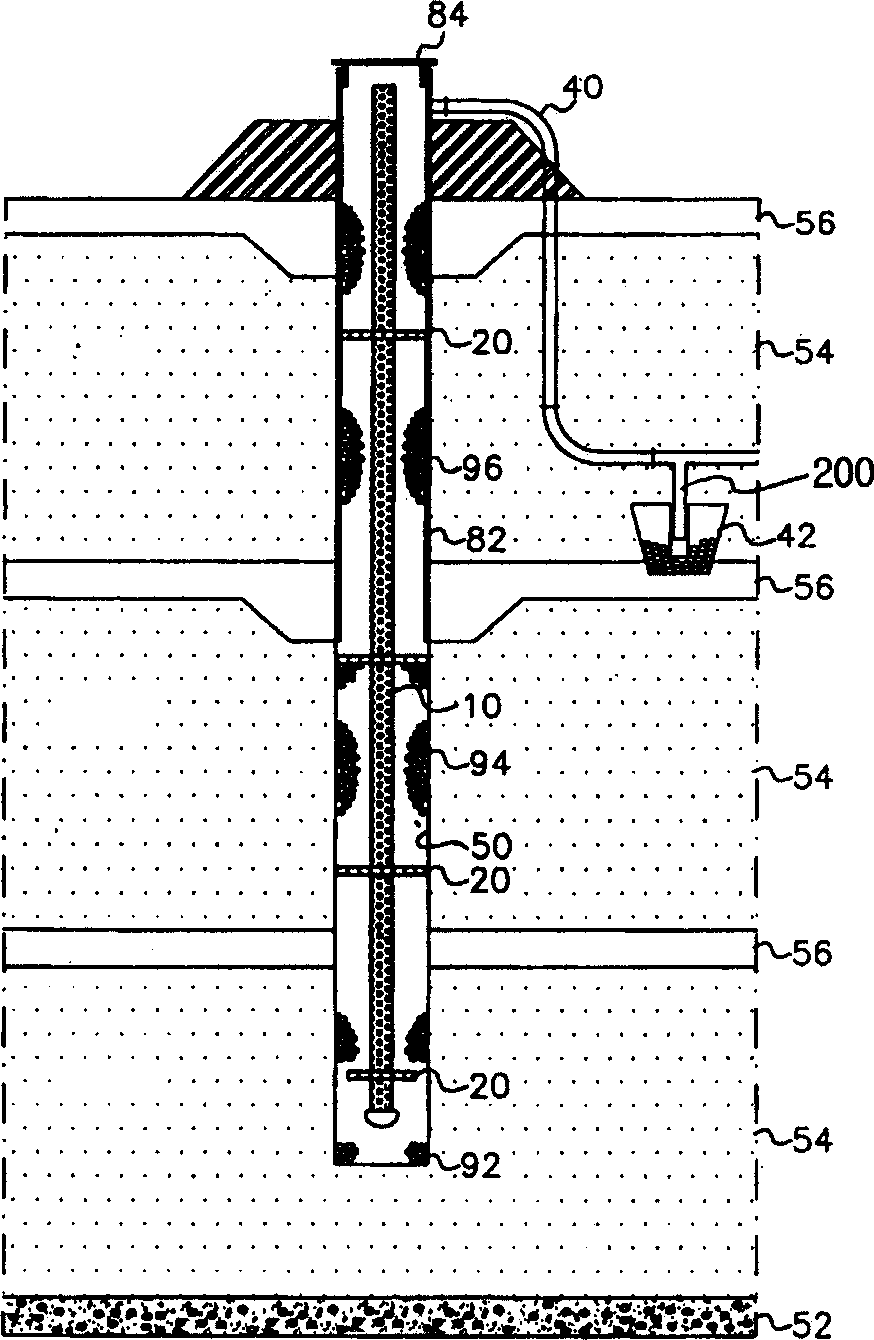

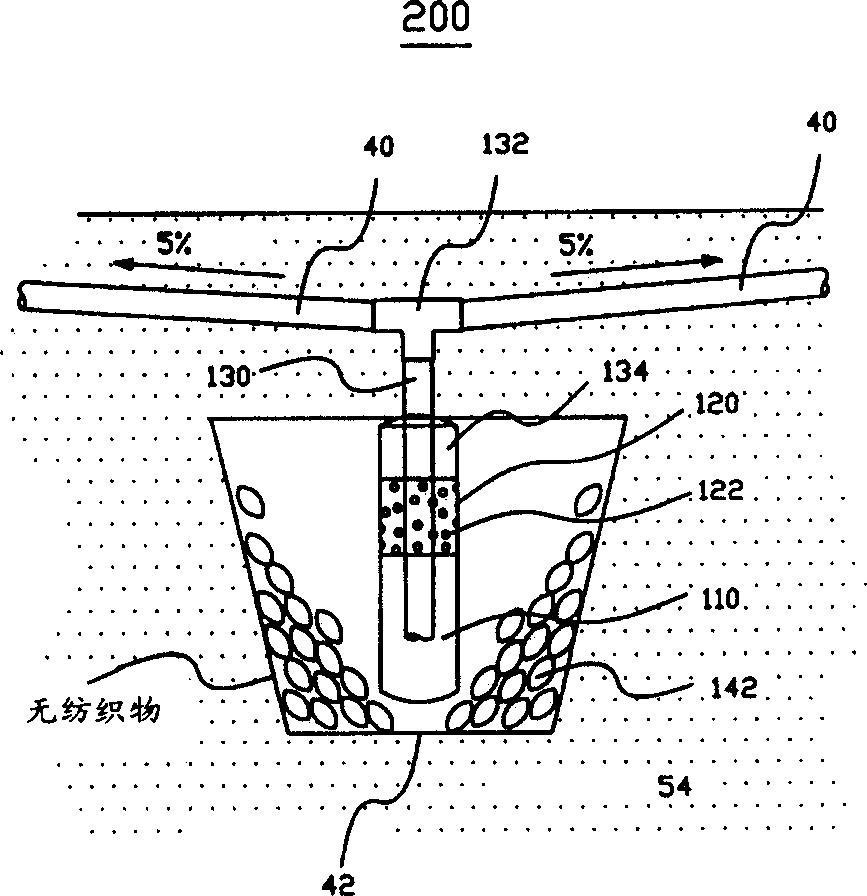

Vertical well pipe for assisting in efficiently extracting groundwater in low permeable aqueous medium in laboratory and usage method of vertical well pipe

InactiveCN103046528AGuaranteed cleanlinessIncrease the pumping rateIn situ soil foundationPorous pipeEnvironmental geology

The invention discloses a vertical well pipe assisting in efficiently extracting groundwater in a low permeable aqueous medium in a laboratory and a usage method of the vertical well pipe. With an ordinary well pipe improved, a rubber plug with two holes are added on a nozzle, and one hole serves as an air inlet and outlet port while the other hole serves as an insertion hole for an pumping hose. The inner portion of a porous pipe part positioned on the lower portion of the well pipe is of the structure of double layers, and washing cotton is used for filling the inner portion of a cylindrical ring while macroporous membrane is used for being stuck on an inner ring. The outer portion of the porous pipe is distributed with pores unevenly and asymmetrically. When the well pipe is vertically arranged, owing to symmetric distribution, water flow is fast due to the effect of groundwater flow; owing to the asymmetric distribution, cumulative amount in pumping can be increased, flow rate can be reduced, area of the water contact surface is expanded, pressure is increased, and therefore the siphon effect of the hose is improved.

Owner:TIANJIN UNIV

Gas discharging apparatus for waste reclaimed land

A gas discharge device for a landfill site is disclosed having a condensate drain for removing condensate from hazardous and explosive gases generated in the landfill site. The gas discharge device at this landfill site includes: a gas collection pipe, located inside the garbage layer, to collect the gas generated by the garbage layer; a gas delivery pipe, connected to the upper part of the gas collection pipe, and to discharge the gas collected in the gas collection pipe ; and a condensate drain connected to the gas collecting pipe and separating the condensate from said gas by gravity, wherein the condensate drain comprises: a waterproof pipe having an opening in its upper portion; a porous pipe with the opening of the waterproof pipe and having a plurality of drainage holes in its side; and a connecting piece connecting the porous tube to the gas delivery tube in such a way that water can flow.

Owner:SUDOKWON LANDFILL SITE MANAGEMENT CORP

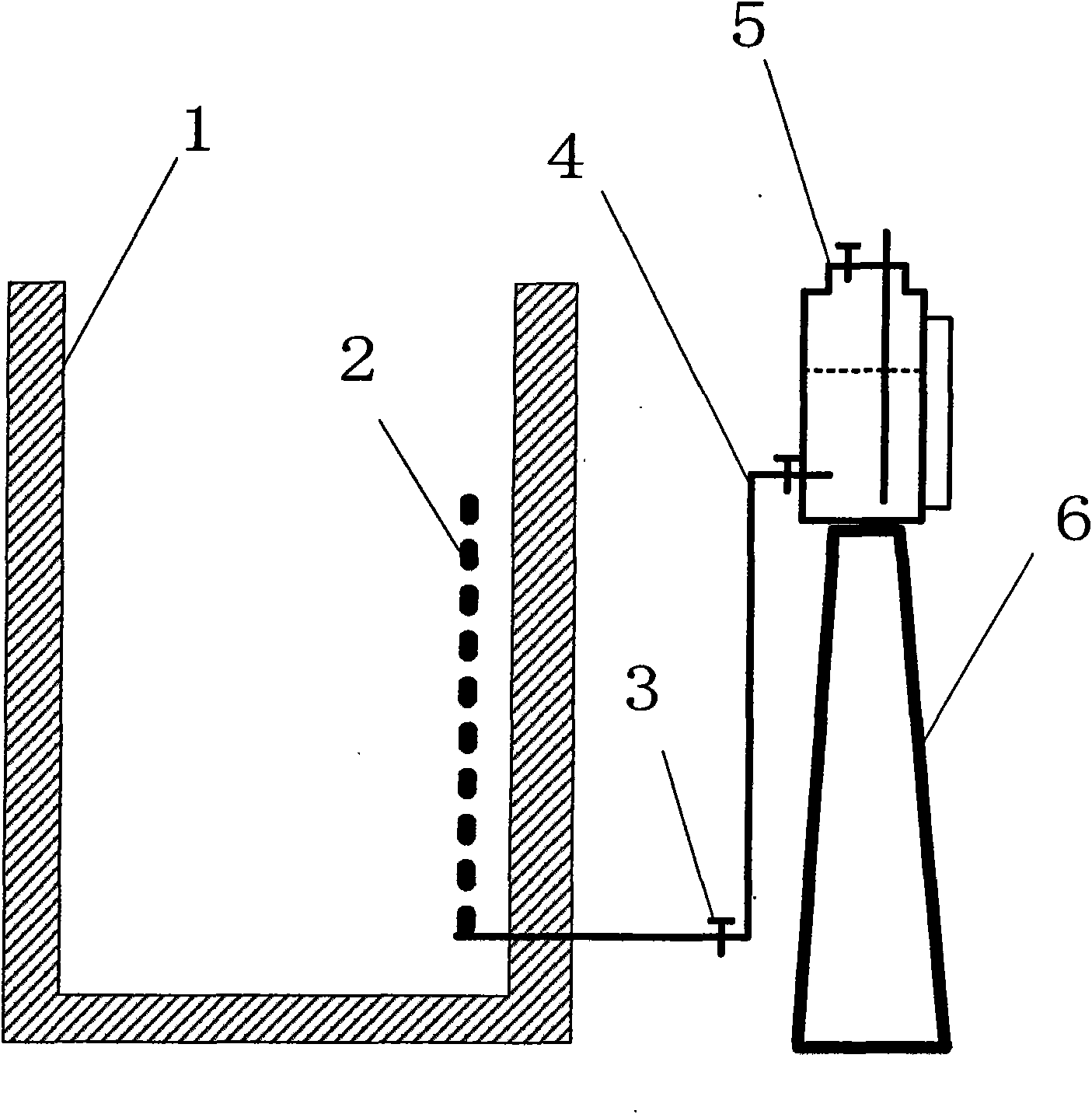

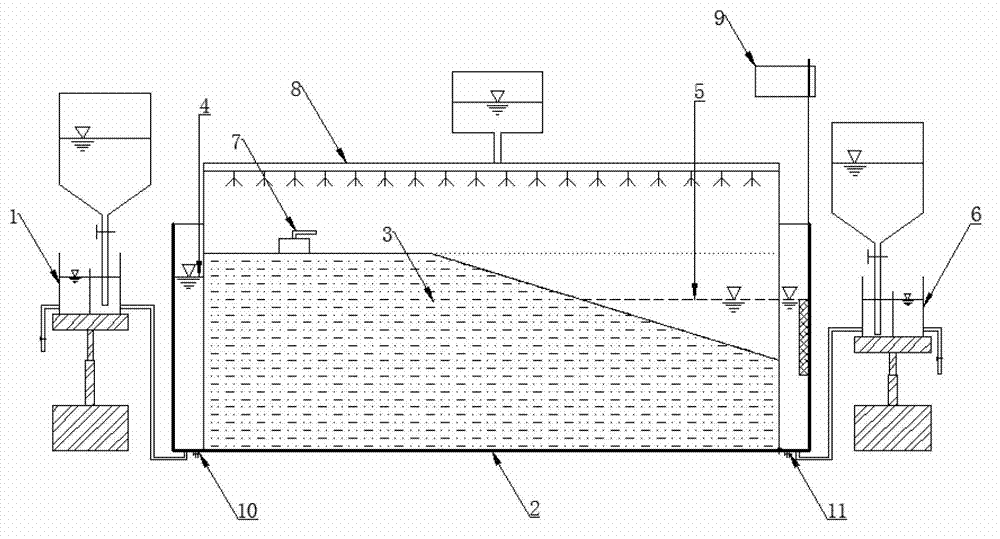

Systems of subirrigation

InactiveCN1520717ACurb savingsReliable underground irrigationWatering devicesCultivating equipmentsSubsurface irrigationSubirrigation

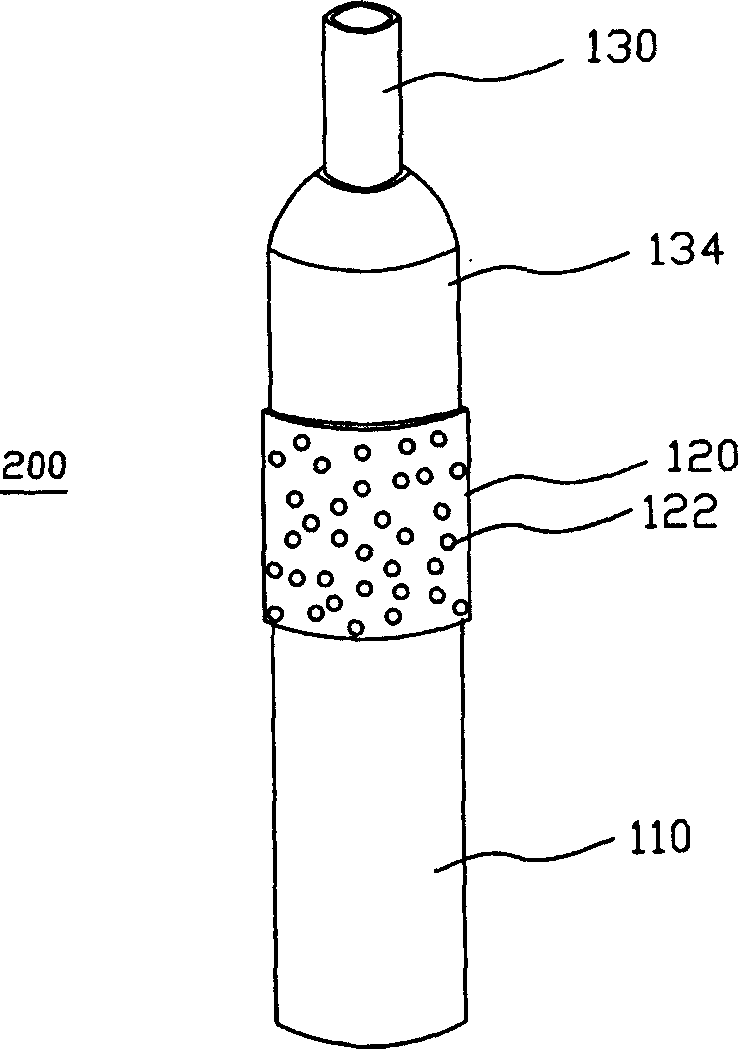

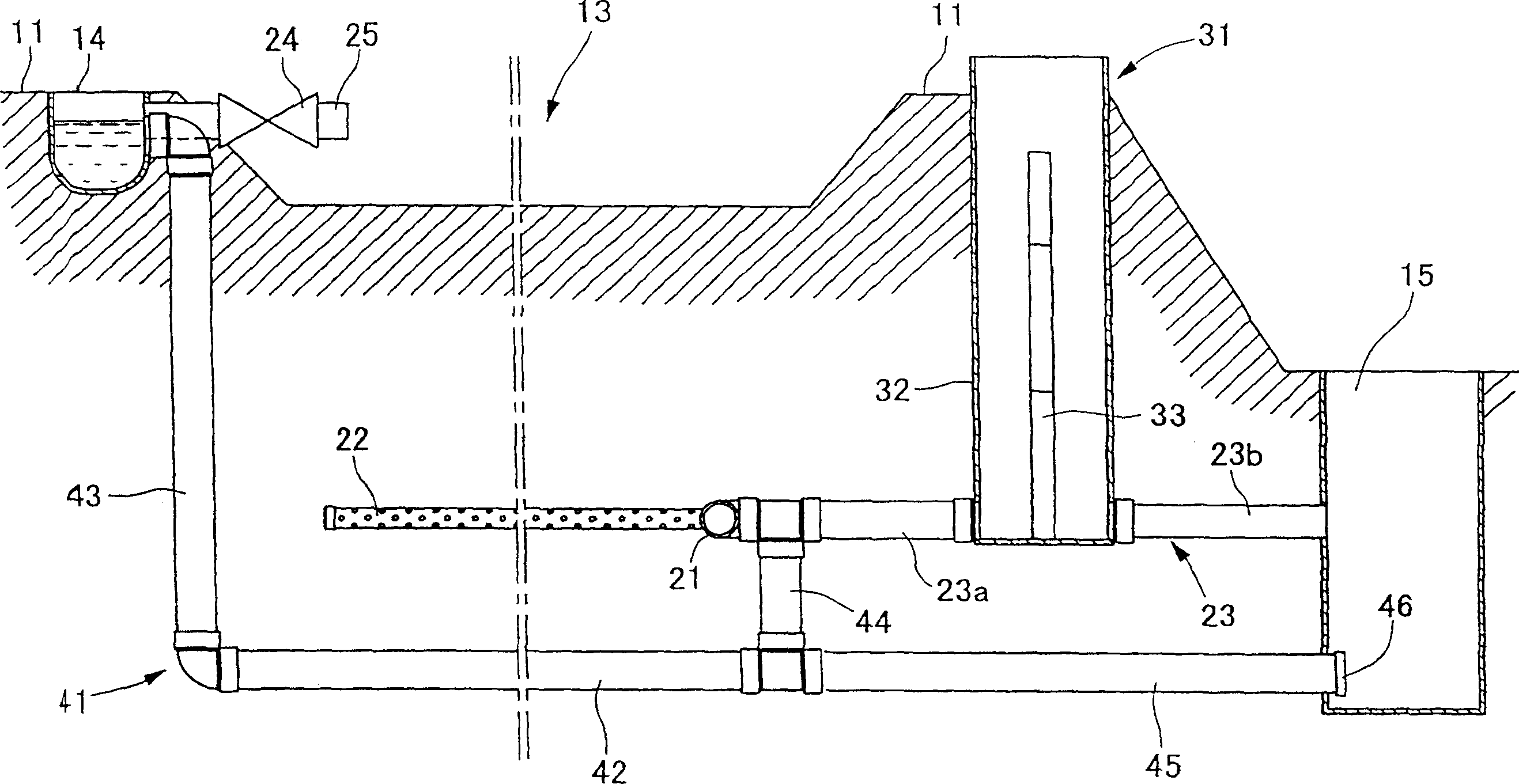

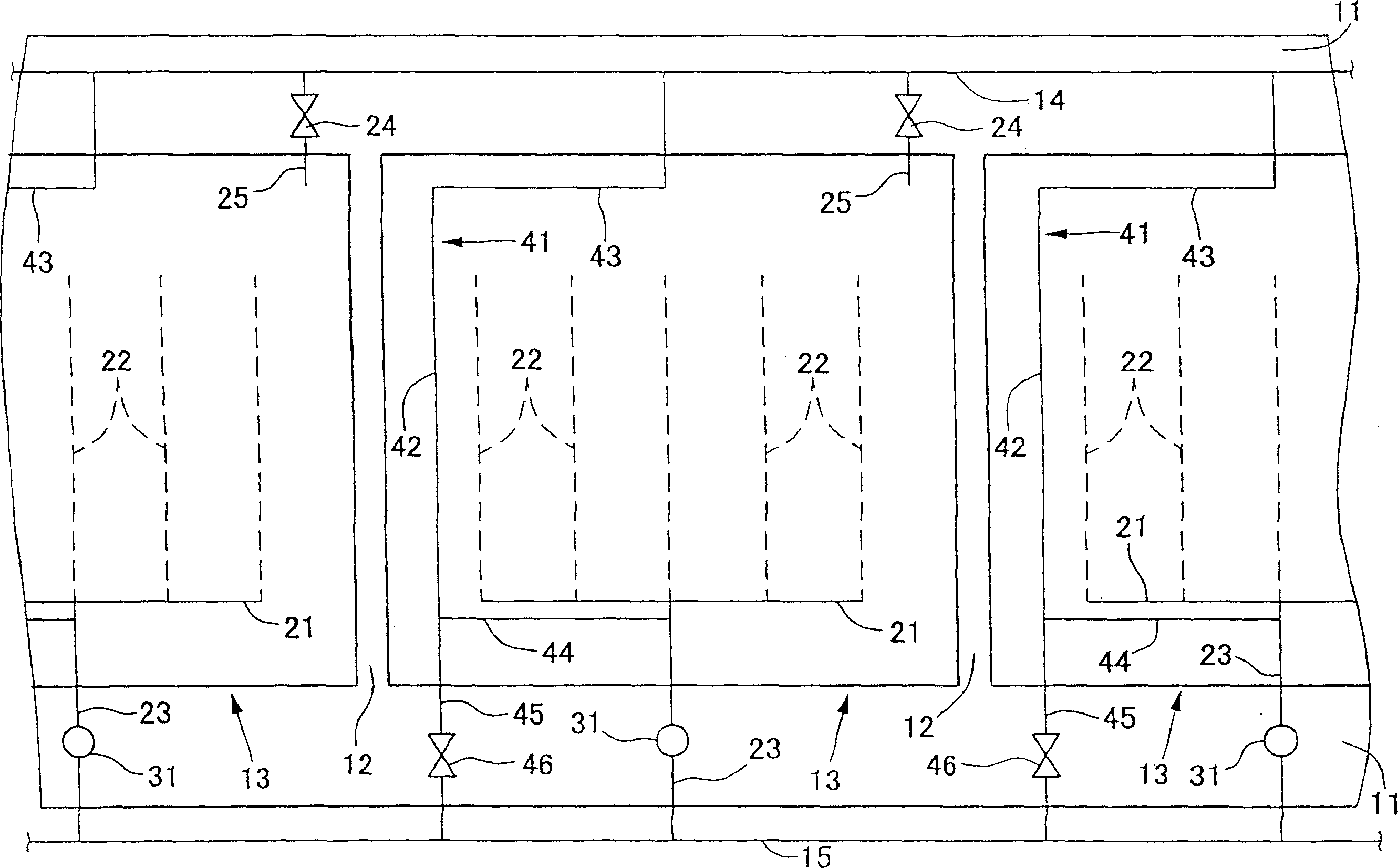

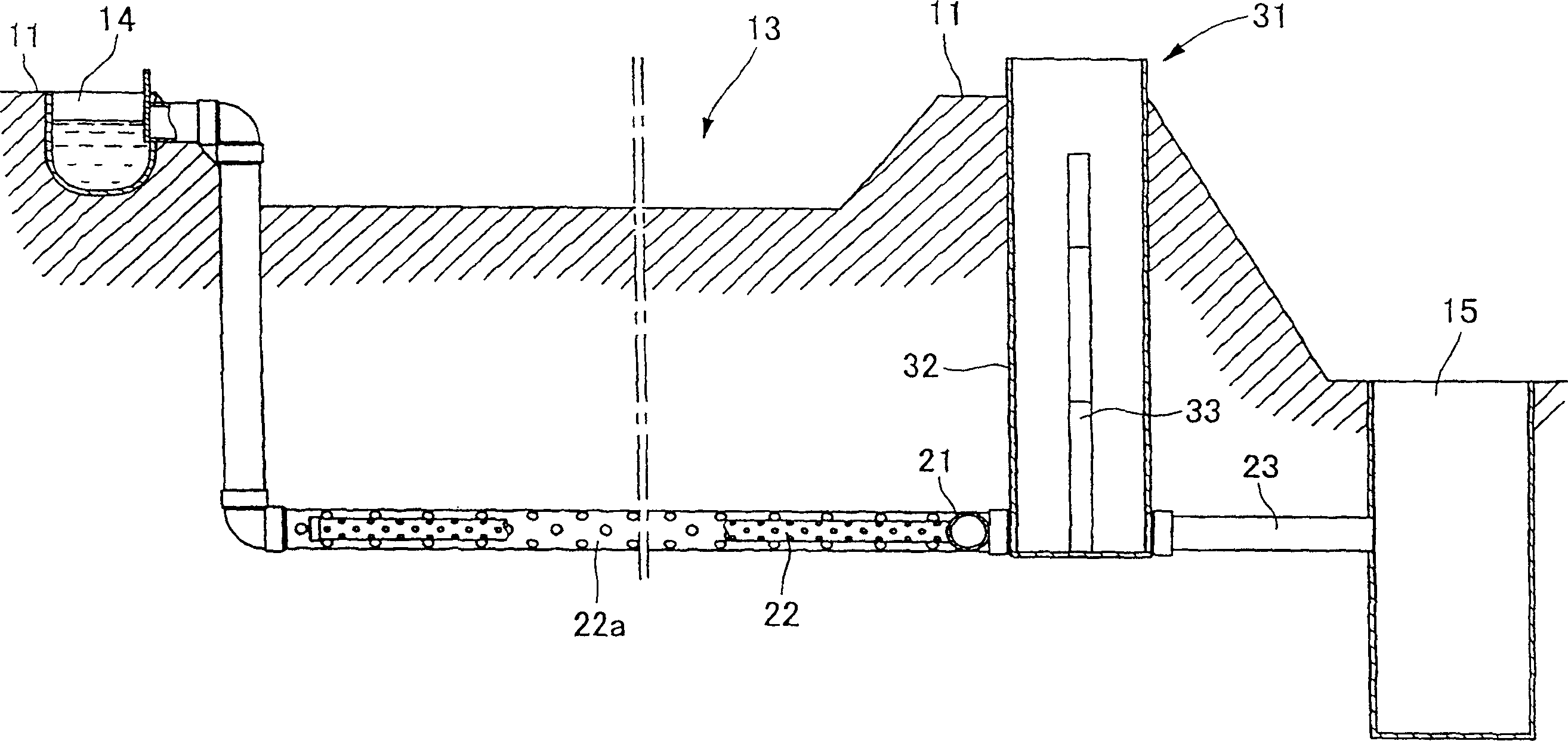

This underground irrigation system comprises the following steps: embedding a porous pipe 22 into the ground of the fields (cultivation areas 13), setting up a water level setting tool 31 on the lower-stream side of the porous pipe, regulating a drainage water level by the water level setting tool to set the water level of the field, embedding an underground water supply pipe 41 for supplying water for use from a water supply channel 14 into the ground of the field, connecting the underground water supply pipe 41 with the porous pipe 22 at the drainage side of the porous pipe to supply the water for use from the underground water supply pipe to the porous pipe.

Owner:KUBOTA CI CO LTD +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com