Indirect-direct evaporative cooling system operable from sustainable energy source

a technology of sustainable energy source and evaporative cooling system, which is applied in the direction of air humidification system, lighting and heating apparatus, heating type, etc., can solve the problem of water dribbling down in a rather uncontrolled fashion out of the slots, and achieve the effect of reducing power consumption, high efficiency cooling, and facilitating the use of twin power sources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

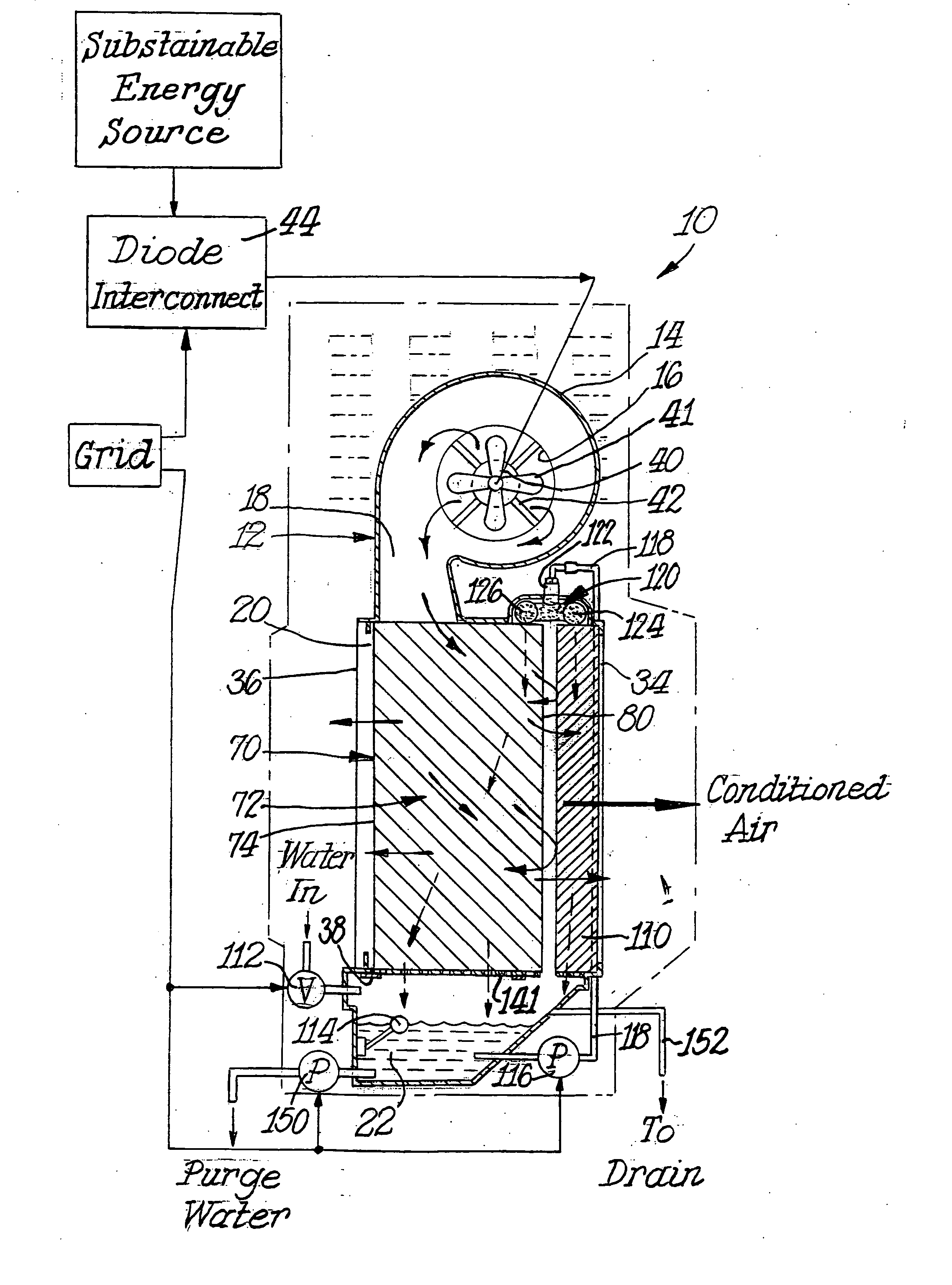

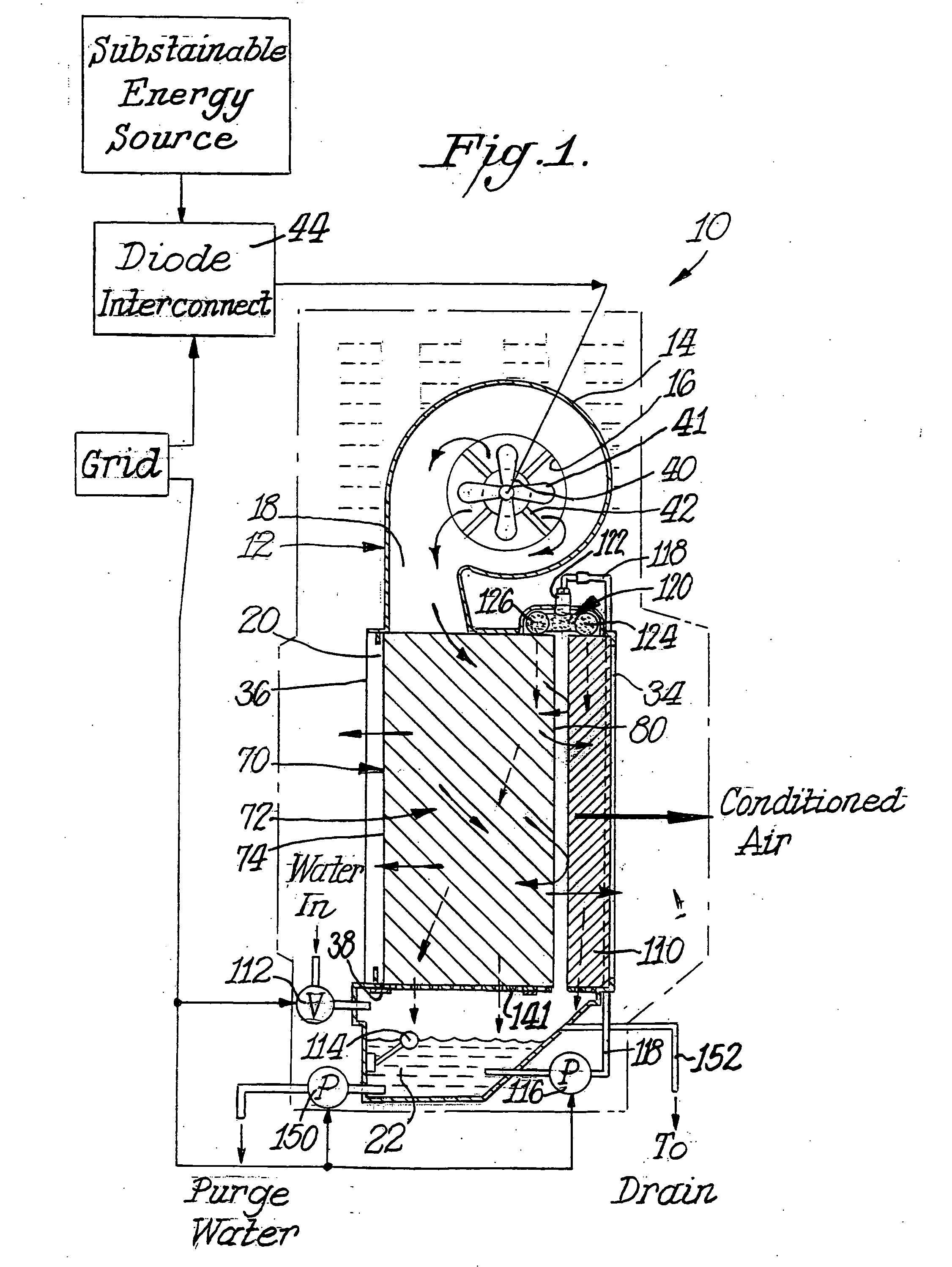

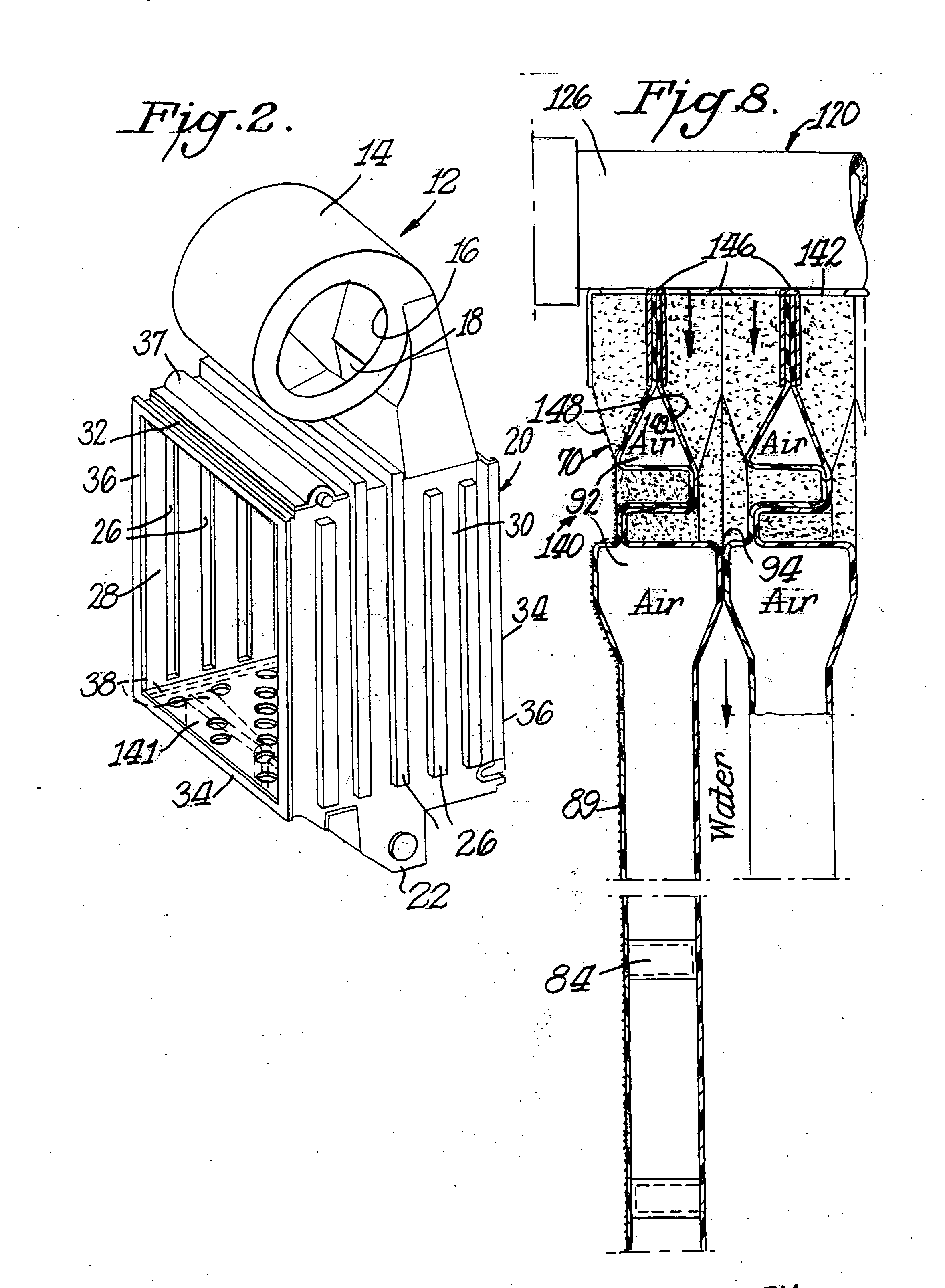

[0032] The basic components of applicants' IDEC 10 are schematically illustrated in FIG. 1. These components are preferably housed in a cabinet 12 which is molded as a single plastic part as shown in FIG. 2. This one piece plastic construction of the cabinet 12 promotes ease of manufacture and reduces corrosion issues as noted in Davis II. This approach also facilitates assembly and replacement of parts in the cabinet of 12.

[0033] For simplicity sake, the arrangement and function of basic sections of the cabinet 12 will be described in a top-to-bottom sequence. The upper end 14 (as viewed in FIG. 1) of the cabinet 12 has a volute shape with a generally circular outside air inlet 16 and a larger, generally rectangular air outlet discharge 18. The air outlet discharge 18 transitions into the larger, generally rectangular cross-sectional body 20 of cabinet 12. A reservoir chamber 22 at the bottom of cabinet 12 rounds out the basic sections of the cabinet 12, which is preferably formed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com