Composite metal porous pipe and preparing method thereof

A composite metal and porous tube technology, which is applied in separation methods, chemical instruments and methods, filtration and separation, etc., can solve the problems of few researches and few reports on metal porous membranes, and achieve simple operation steps, simple equipment, and air permeability coefficient high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

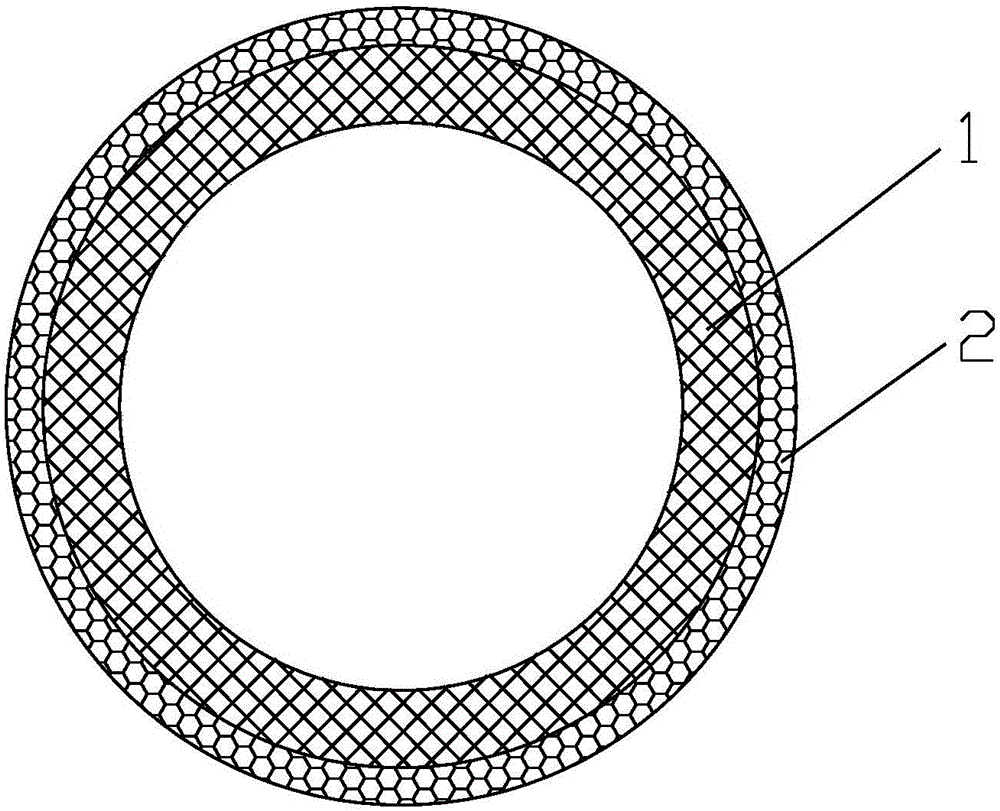

[0029] like figure 1 As shown, this embodiment includes a wire mesh pipe 1 and a powder porous functional layer 2 attached to the wire mesh pipe 1; The wall thickness of 1 is 3.8mm, the aperture of wire mesh tube 1 is 200μm, the outer diameter of wire mesh tube 1 is 45mm, and the tube length is 1200mm; the thickness of the powder porous functional layer 2 is 15μm, and the aperture is 0.5μm, which is breathable rate 20m 3 / (m 2 ·KPa·h); The wire mesh is a stainless steel wire mesh.

[0030] The preparation method of the composite metal porous pipe of the present embodiment comprises the following steps:

[0031] Step 1. Lay seven stainless steel wire meshes with a pore diameter of 200 μm to obtain a wire mesh assembly, then roll the wire mesh assembly into a tubular shape, and then roll the rolled wire mesh assembly into a joint at the joint of the tubular wire mesh assembly Welding to obtain a wire mesh pipe; the rolling speed is 50m / h; the welding adopts argon arc welding...

Embodiment 2

[0039] like figure 1 As shown, this embodiment includes a wire mesh pipe 1 and a powder porous functional layer 2 attached to the wire mesh pipe 1; The wall thickness of 1 is 1.5mm, the aperture of wire mesh tube 1 is 20 μm, the outer diameter of wire mesh tube 1 is 120 mm, and the tube length is 600 mm; the thickness of the powder porous functional layer 2 is 200 μm, the aperture is 22 μm, and the gas permeability 50m 3 / (m 2 ·KPa·h); The wire mesh is a nickel mesh.

[0040] The preparation method of the composite metal porous pipe of the present embodiment comprises the following steps:

[0041] Step 1. Lay three nickel screens in layers to obtain a wire mesh assembly, then roll the wire mesh assembly into a tubular shape, and then weld the joints of the rolled into a tubular wire mesh assembly to obtain a metal mesh assembly. Wire mesh pipe; the rolling speed is 60m / h; the welding adopts argon arc welding, and the whole welding process is protected by high-purity argon;...

Embodiment 3

[0049] like figure 1As shown, this embodiment includes a wire mesh pipe 1 and a powder porous functional layer 2 attached to the wire mesh pipe 1; The wall thickness of 1 is 2.5 mm, the aperture of wire mesh tube 1 is 100 μm, the outer diameter of wire mesh tube 1 is 30 mm, and the tube length is 700 mm; the thickness of the powder porous functional layer 2 is 600 μm, the aperture is 20 μm, and the air permeability 30m 3 / (m 2 ·KPa·h); the wire mesh is titanium mesh.

[0050] The preparation method of the composite metal porous pipe of the present embodiment comprises the following steps:

[0051] Step 1. Lay 5 titanium screens in layers to obtain a wire mesh assembly, then roll the wire mesh assembly into a tubular shape, and then weld the joints of the rolled into a tubular wire mesh assembly to obtain a metal mesh assembly. Wire mesh pipe; the rolling speed is 30m / h; the welding adopts argon arc welding, and the whole welding process is protected by high-purity argon; ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Wall thickness | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

| Outer diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com