Patents

Literature

51results about How to "Reduce liquid content" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Defluidizing lost circulation pills

InactiveUS20110278006A1Reduce liquid contentReduce lossesSolid waste managementFluid removalFiberMedicine

A slurry for treating a wellbore that includes a base fluid; at least one fibrous structure; and a plurality of calcium silicate particles is disclosed. Methods of reducing loss of wellbore fluid in a wellbore to a formation using an LCM pill having calcium silicate particles therein is also disclosed.

Owner:MI

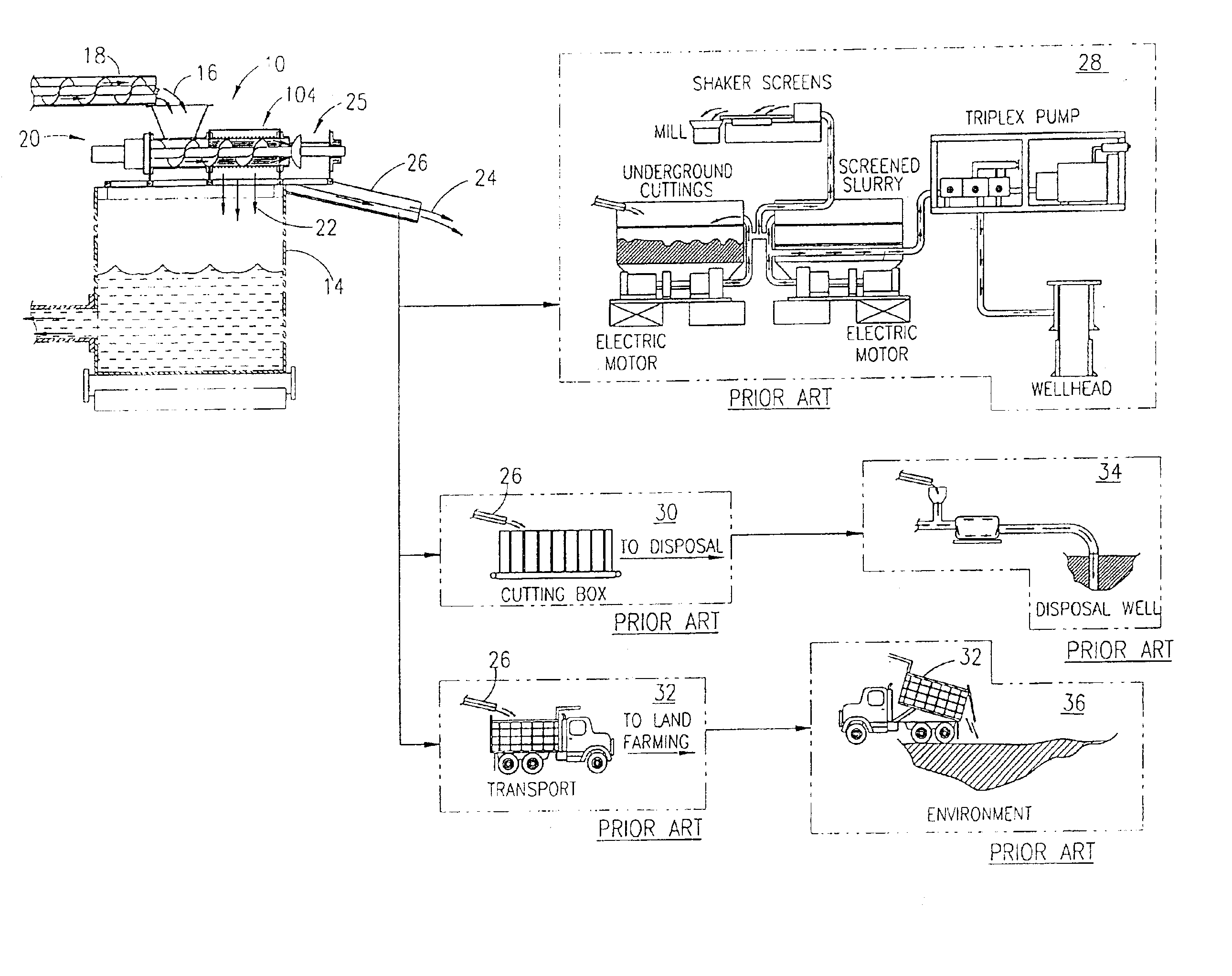

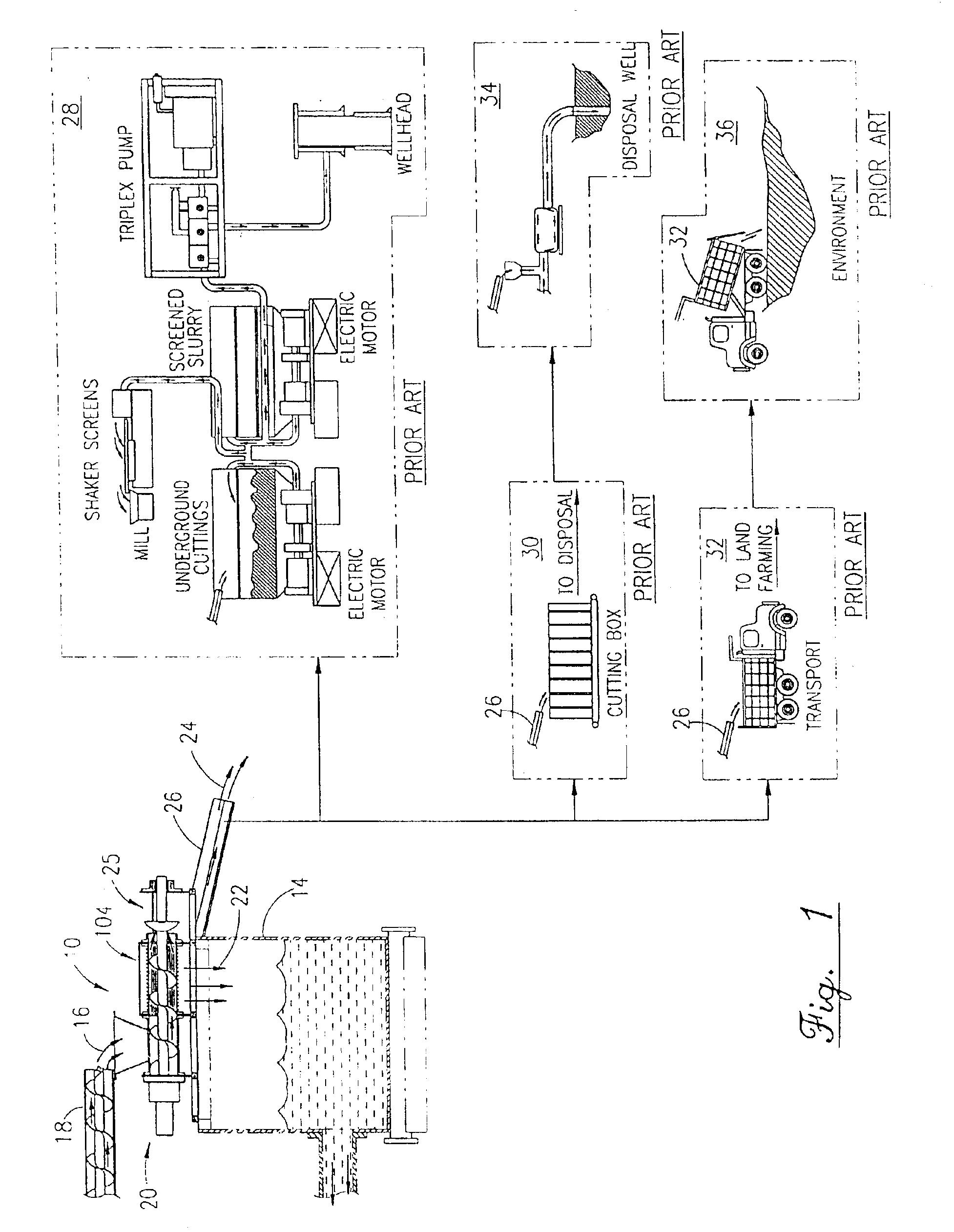

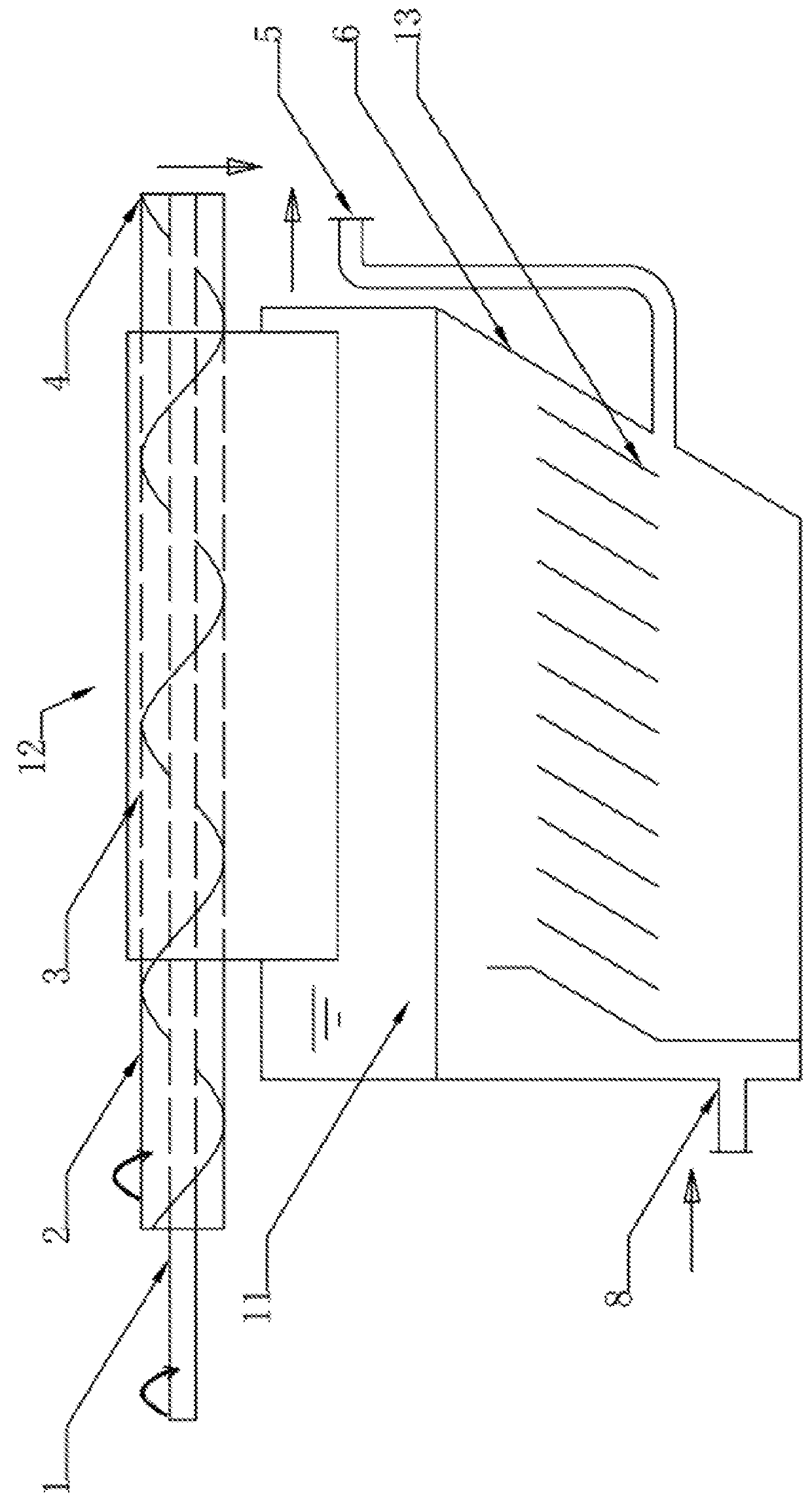

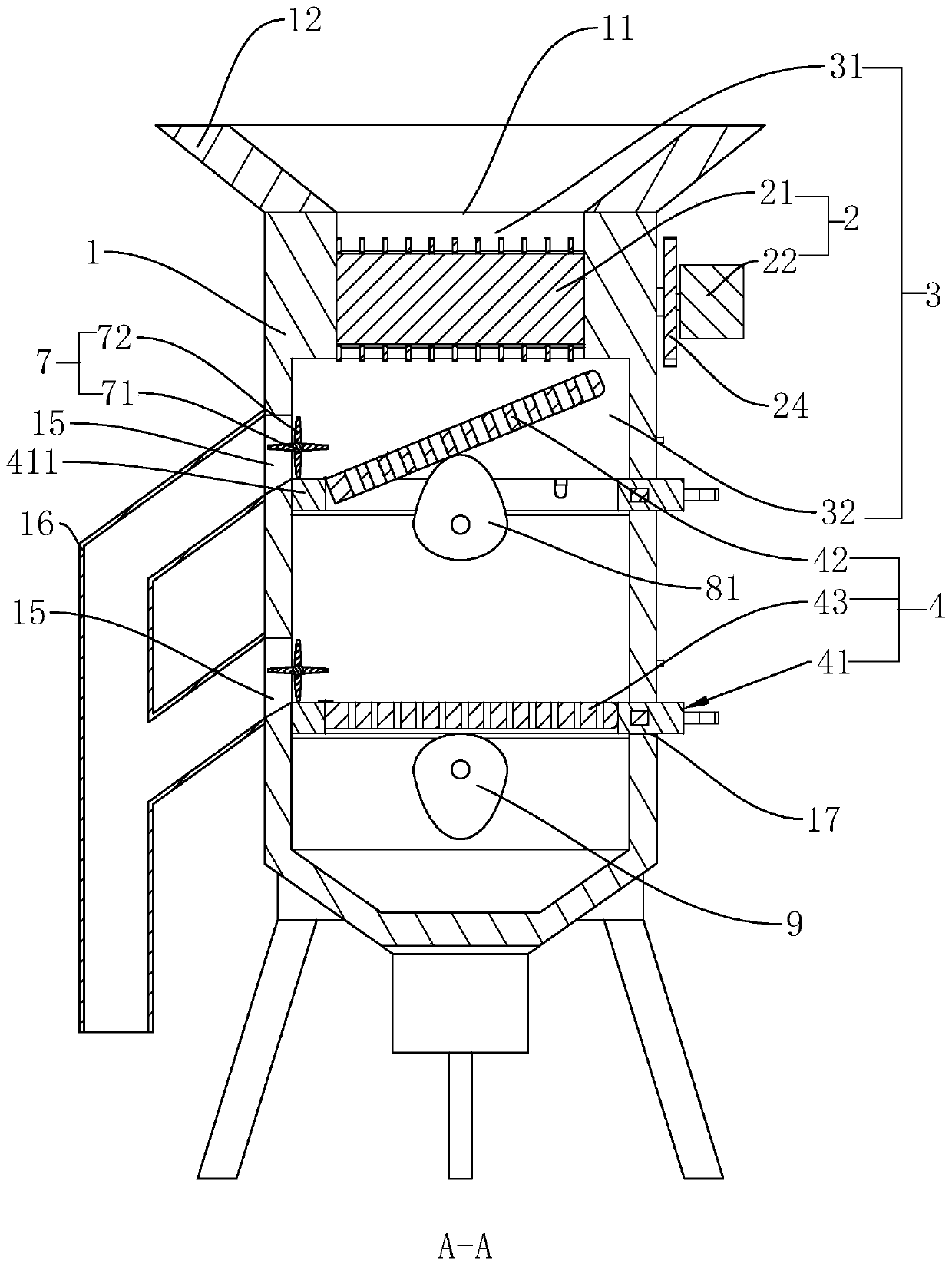

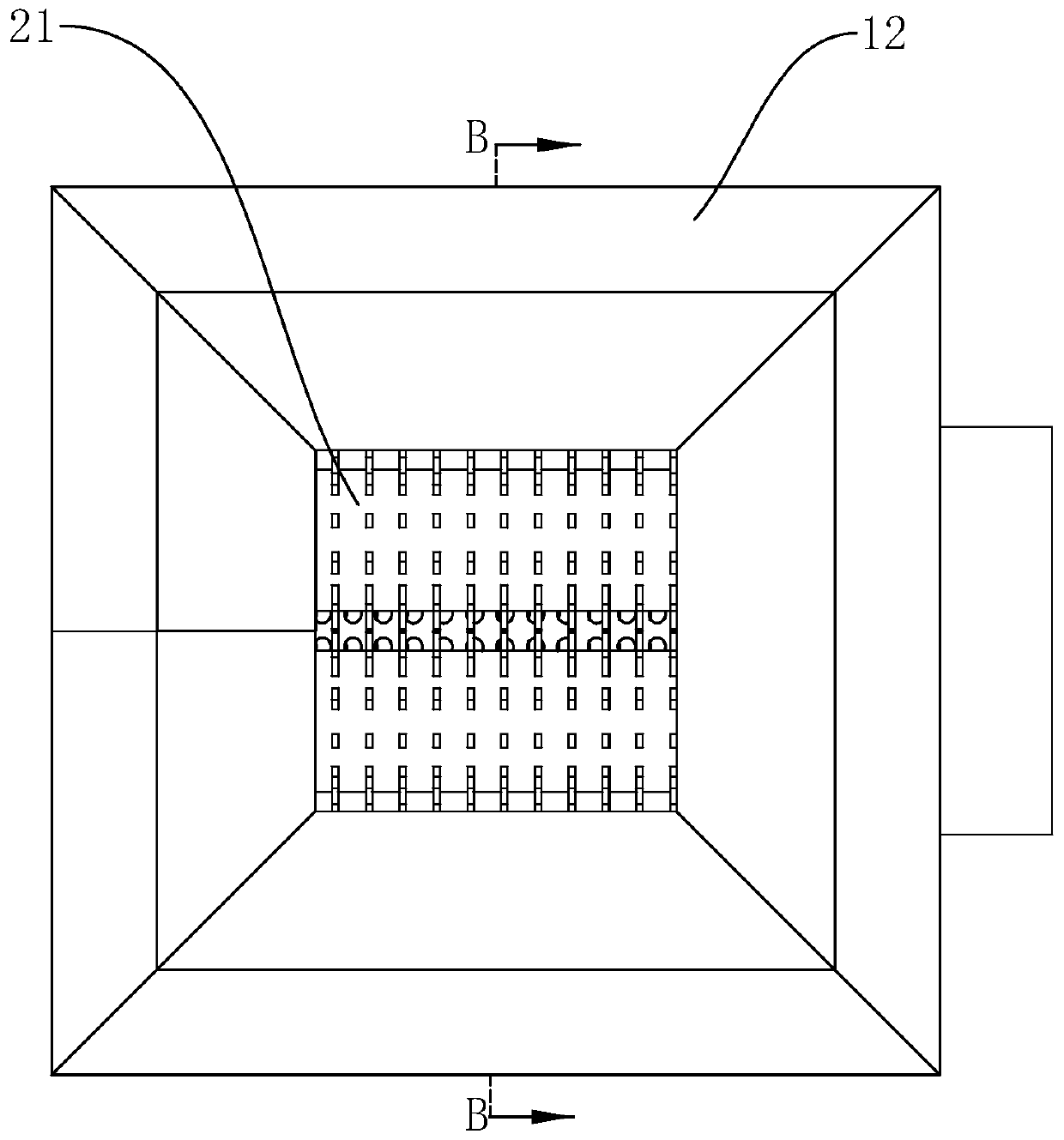

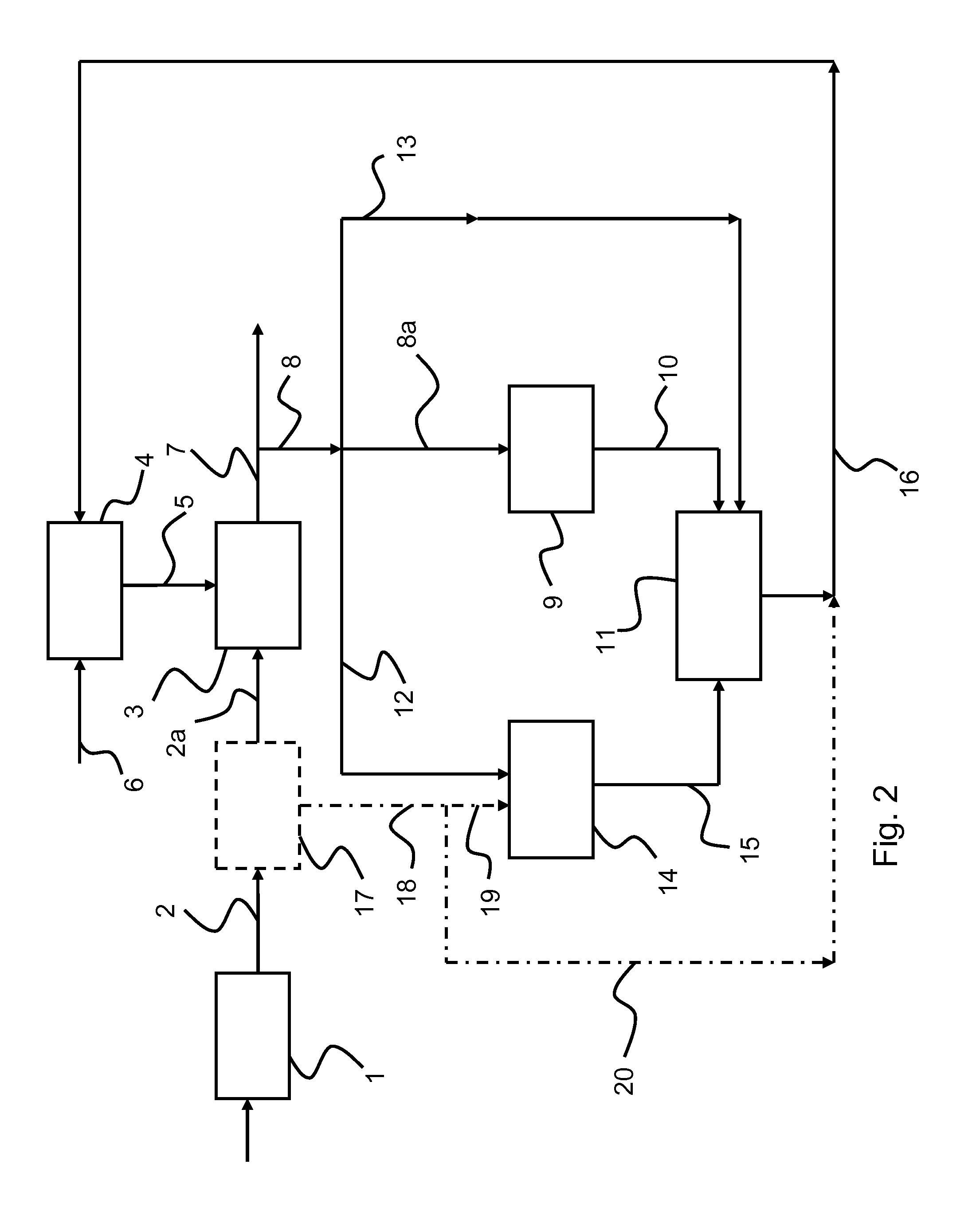

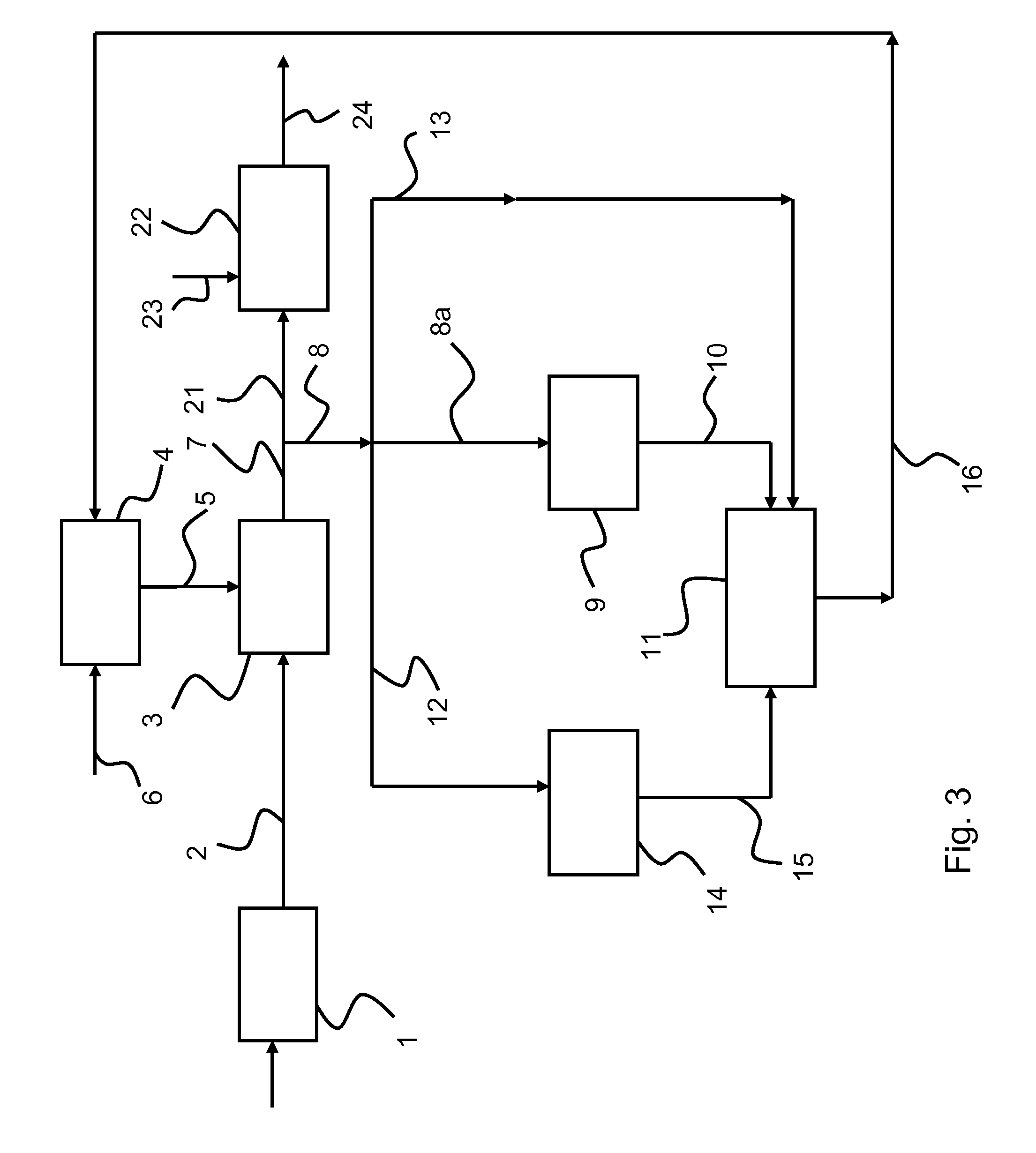

Drilling fluid recovery and cuttings processing system

InactiveUS6910411B2Reduce liquid contentDischarge volume reductionFlushingDrilling compositionProcess systemsDistillation

A drill cuttings slurry process system is disclosed for defluidizing earth drill cuttings, thereby extracting valuable drilling additives and returning them to the drilling system while producing a dense, drier material which may be discharged directly in the environment at or near the well being drilled or chemically treated for distillation and / or better dissolution into the environment, thereby reducing, cost in transportation and environmental treatment chemicals thus reducing environmental contamination. The system comprising a cuttings press having solids / fluids separation a dryer and / or a retort for flashing off any residual petroleum residue and moisture, a fines grinder and a chemical injection system. The retort including an analyzer system for weighing and determining rate of throughput and analyzing the cuttings for residual petroleum residue content prior to discharge to environment or further refinement prior to reinjection into the well or transport to environmental depository sites.

Owner:BAKER HUGHES INC

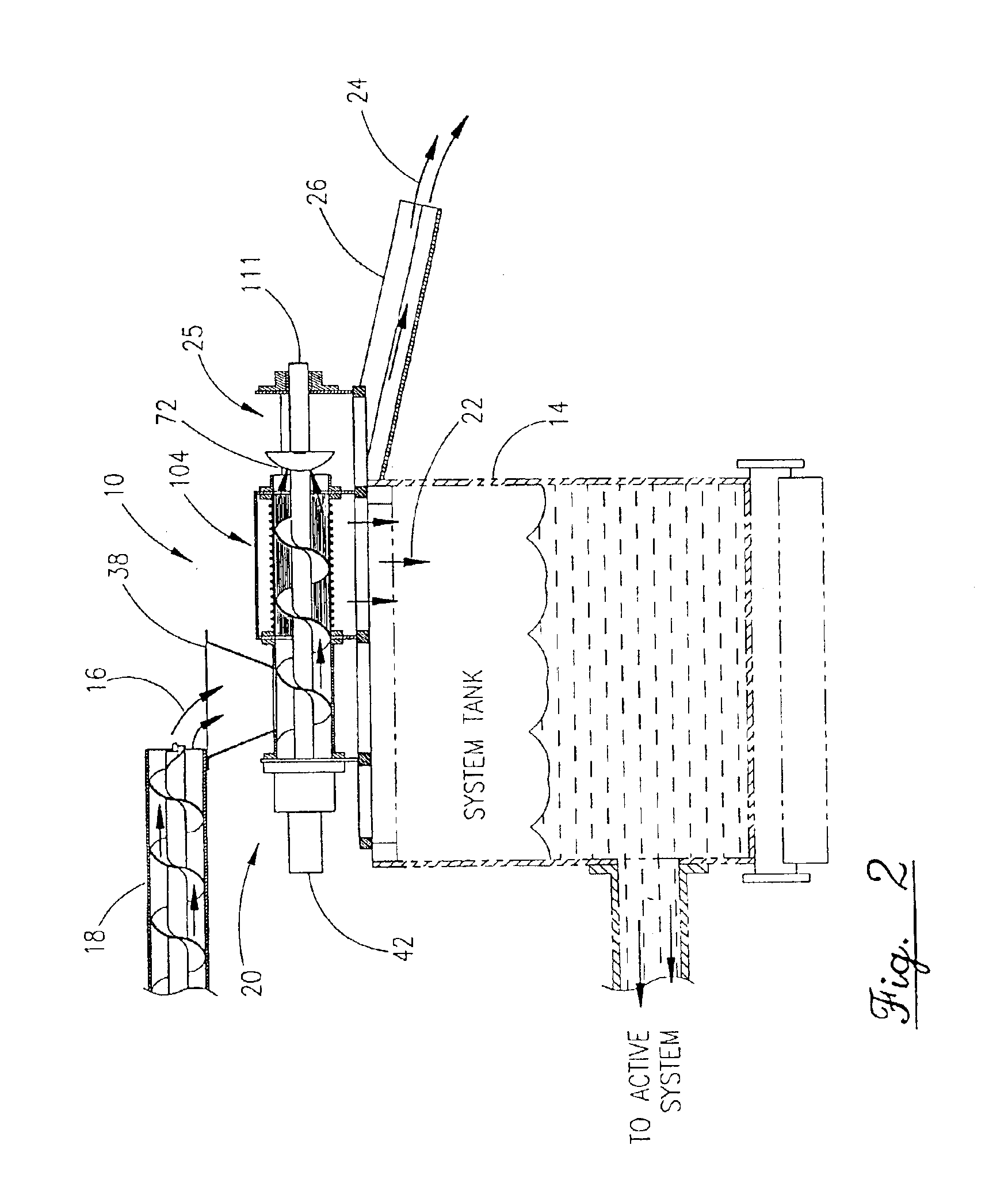

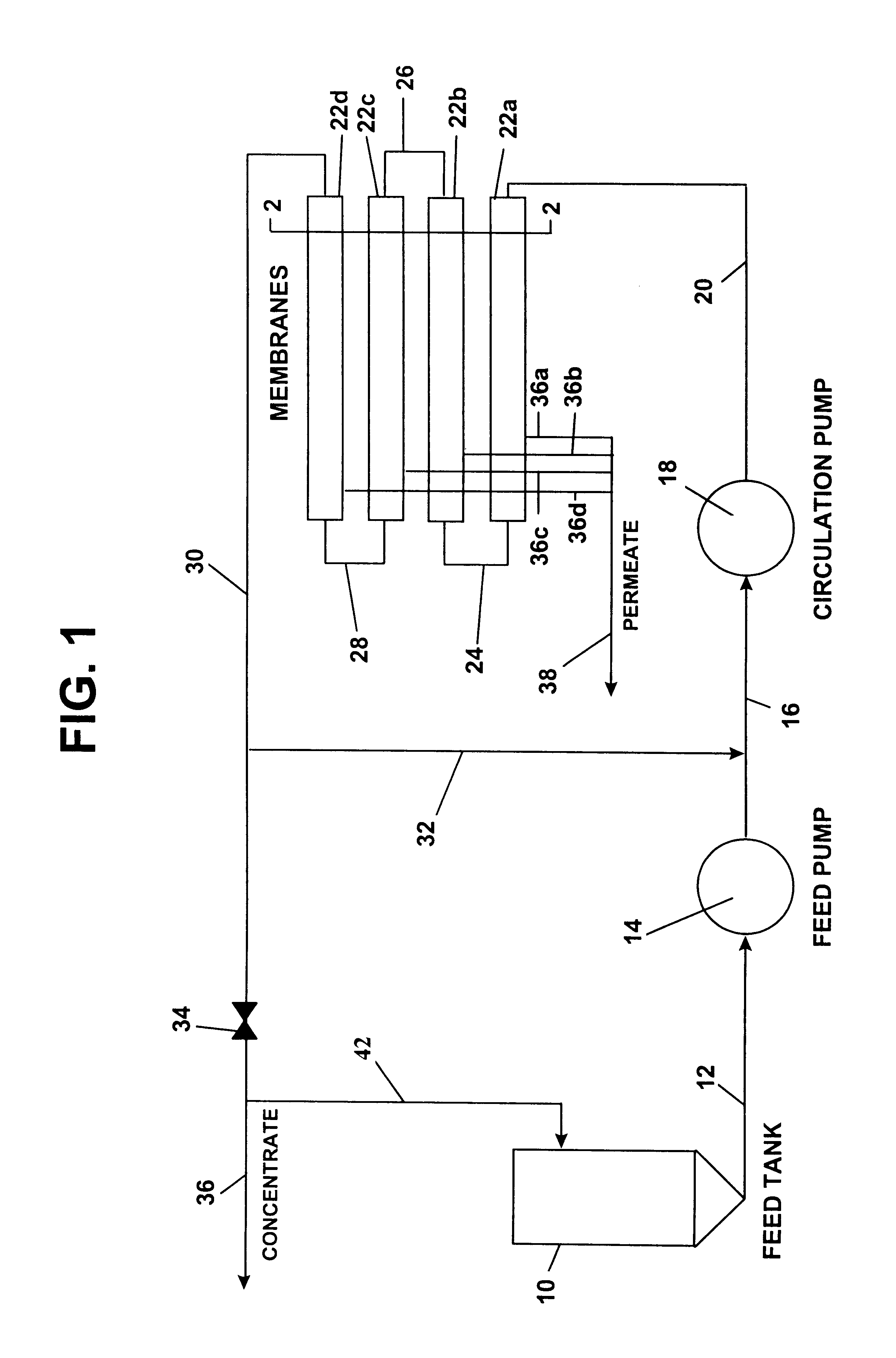

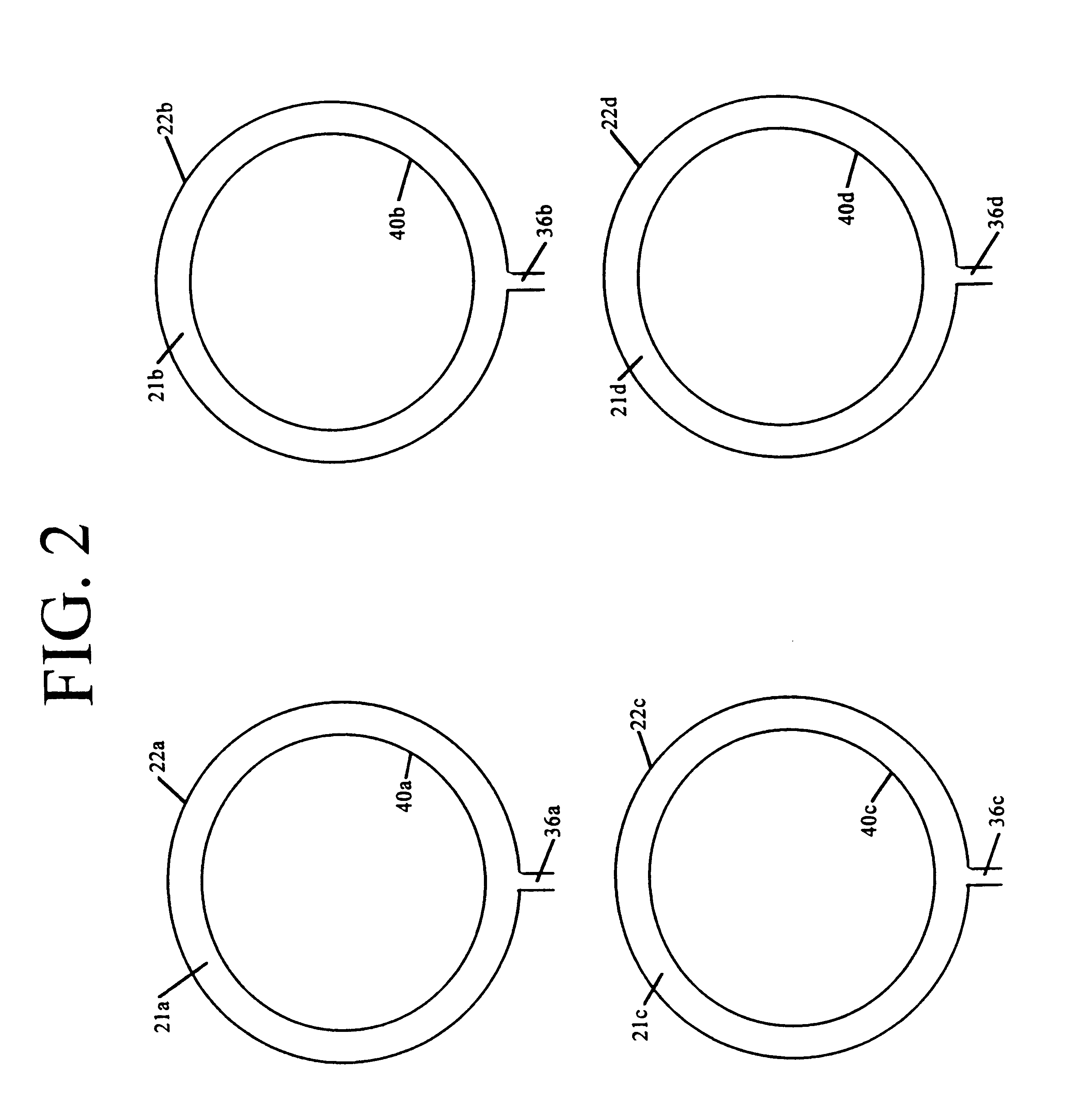

Apparatus and process for the separation of liquids and solids

InactiveUS6110390AReduce liquid contentPrevent buildupLiquid separation auxillary apparatusUltrafiltrationFiltrationSystem pressure

A liquid solid separation apparatus having a porous metal pipe sealed inside a non-porous metal pipe which allows a portion of the liquids, e.g., hydrocarbons and water to pass through the first pipe into the non porous pipe from which they are removed while solids are retained within the porous pipe. In the process there is a system pressure which aids in the filtration and a circulating velocity which removes the detained solids. Preferably a portion of these solids with reduced liquid content are recycled back to the system, mixed with fresh feed. By recycling a porion of the recovered solid concentrate the velocity of the flow in the system kept constant and the system itself is stabilized.

Owner:ENVIRONMENTAL SAFEGUARDS

Foodstuffs containing mucorales fungi

InactiveUS20030157219A1Retain it shapeReduce liquid contentFungiProteins working-up by texturisingMucoralesRNA

The preparation of an edible substance for use in a foodstuff is described which comprises fungal cells of the order Mucorales. The cells are grown in a fermentor vessel in an aqueous liquid which is mixed during fermentation, and fermentation allowed to finish. The fungal cells are kept in the vessel and allowed to ripen, the cells' own RNAses reducing the intracellular RNA content. Fungi of this order may thus have a low RNA content and therefore no heating step, to reduce their RNA content, is necessary. The fungal cells are removed and processed into the edible substance. This substance is then processed into a foodstuff. This avoidance of heat has also resulted in better tasting foodstuffs.

Owner:DSM NV

Apparatus and process for the separation of liquids and solids

InactiveUS6375843B1Reduce liquid contentPrevent buildupLiquid separation auxillary apparatusUltrafiltrationFiltrationSystem pressure

A liquid solid separation apparatus having a porous metal pipe sealed inside a non-porous metal pipe which allows a portion of the liquids, e.g., hydrocarbons and water to pass through the first pipe into the non porous pipe from which they are removed while solids are retained within the porous pipe. In the process there is a system pressure which aids in the filtration and a circulating velocity which removes the detained solids. Preferably a portion of these solids with reduced liquid content are recycled back to the system, mixed with fresh feed. By recycling a porion of the recovered solid concentrate the velocity of the flow in the system kept constant and the system itself is stabilized.

Owner:ENVIRONMENTAL SAFEGUARDS

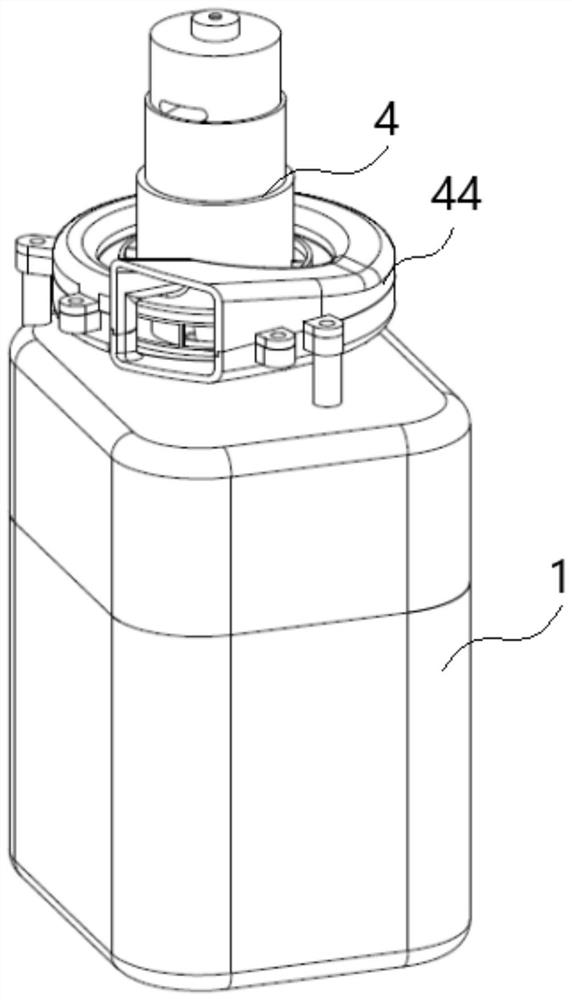

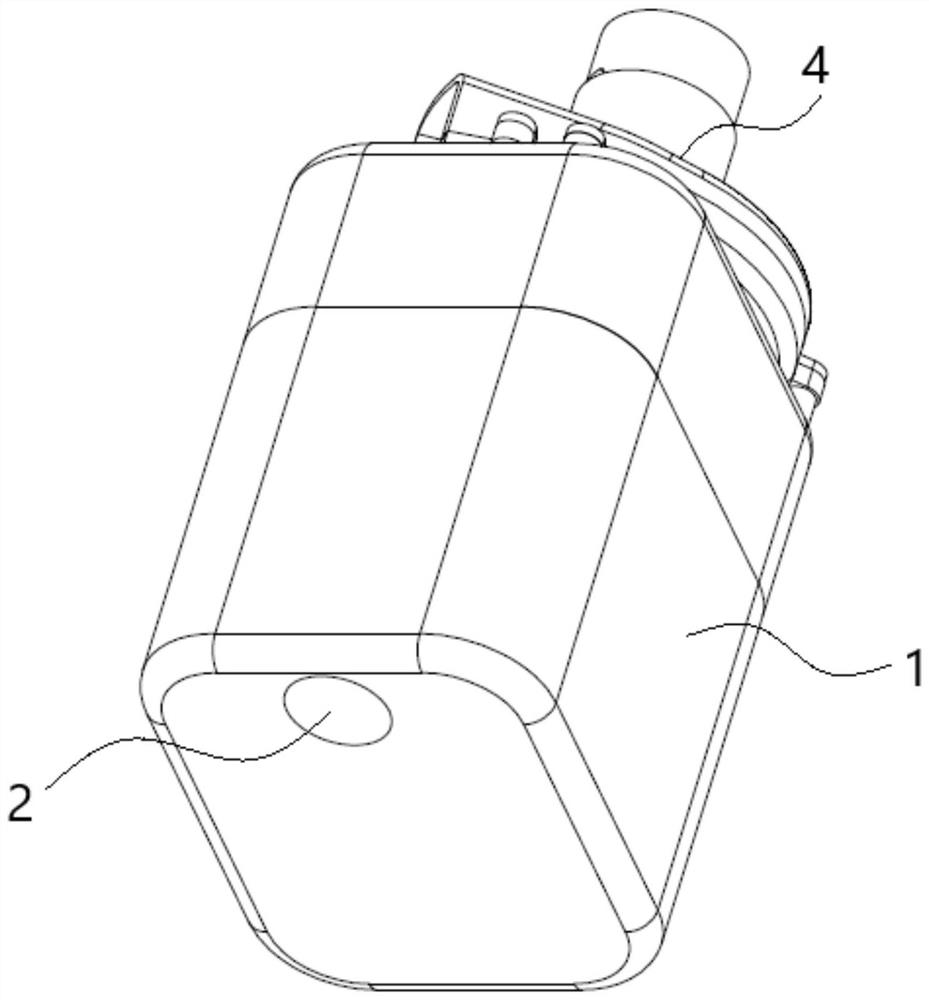

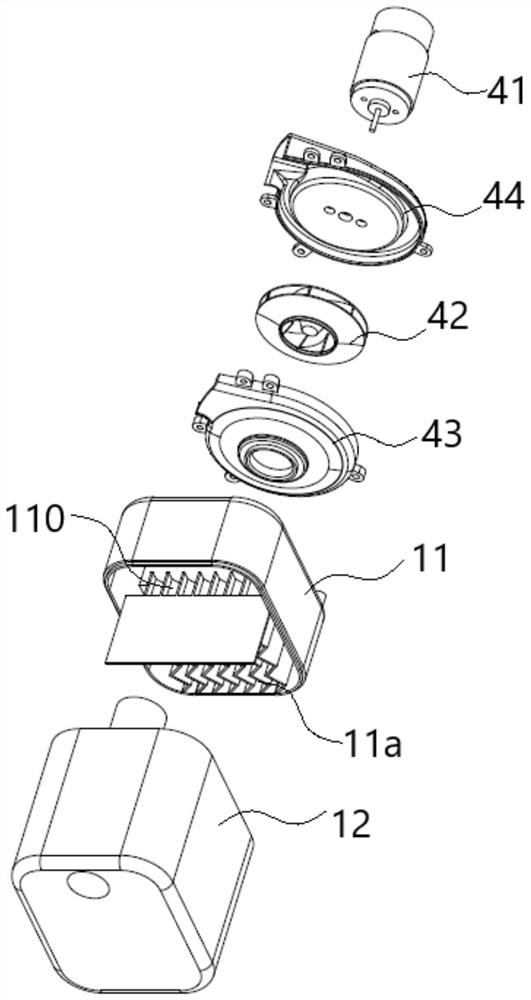

Water-vapor separation device and cleaning equipment

PendingCN113317734AGuaranteed service lifeHeat dissipation effectCarpet cleanersFloor cleanersEnvironmental engineeringMechanical engineering

The invention discloses a water-vapor separation device and cleaning equipment. The water-vapor separation device comprises a water-vapor separation mounting shell which is provided with a water-vapor separation area and a liquid collection area, wherein the water-vapor separation mounting shell is connected with a suction fan; the water-vapor separation area comprises a water-vapor separation part which is respectively connected with an airflow inlet end, an airflow outlet end and a liquid outlet end, and the airflow inlet end is communicated with a suction port through a suction channel; the airflow outlet end is communicated with an air inlet of the suction fan; and the liquid collection area is correspondingly matched with the liquid outlet end for collecting liquid. According to the invention, the liquid content of airflow entering the suction fan can be effectively avoided or greatly reduced, the service life of the suction fan is ensured, and negative effects on the heat dissipation performance of the suction fan are avoided.

Owner:WUXI NEWSTART CONTROLS TECH CO LTD

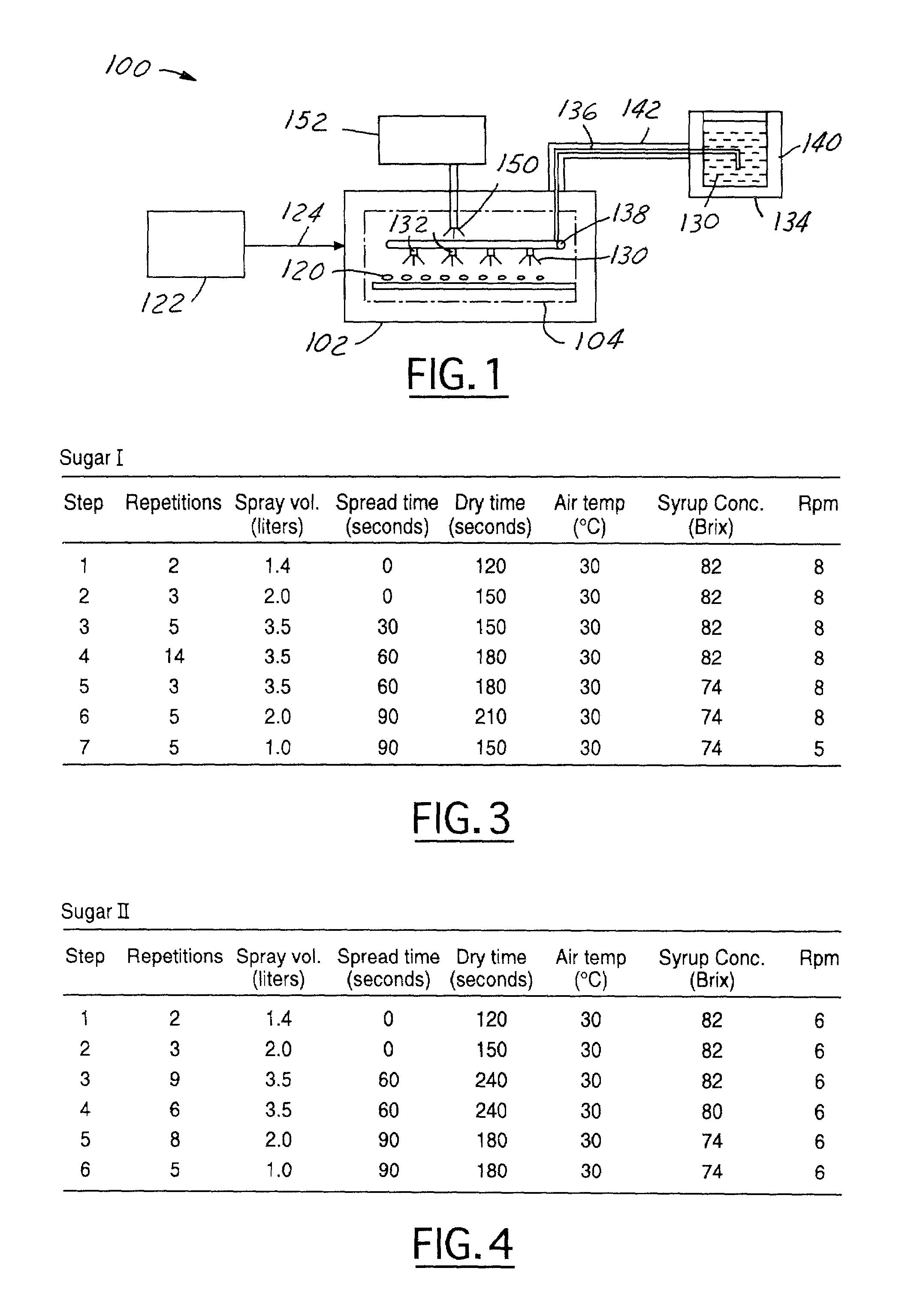

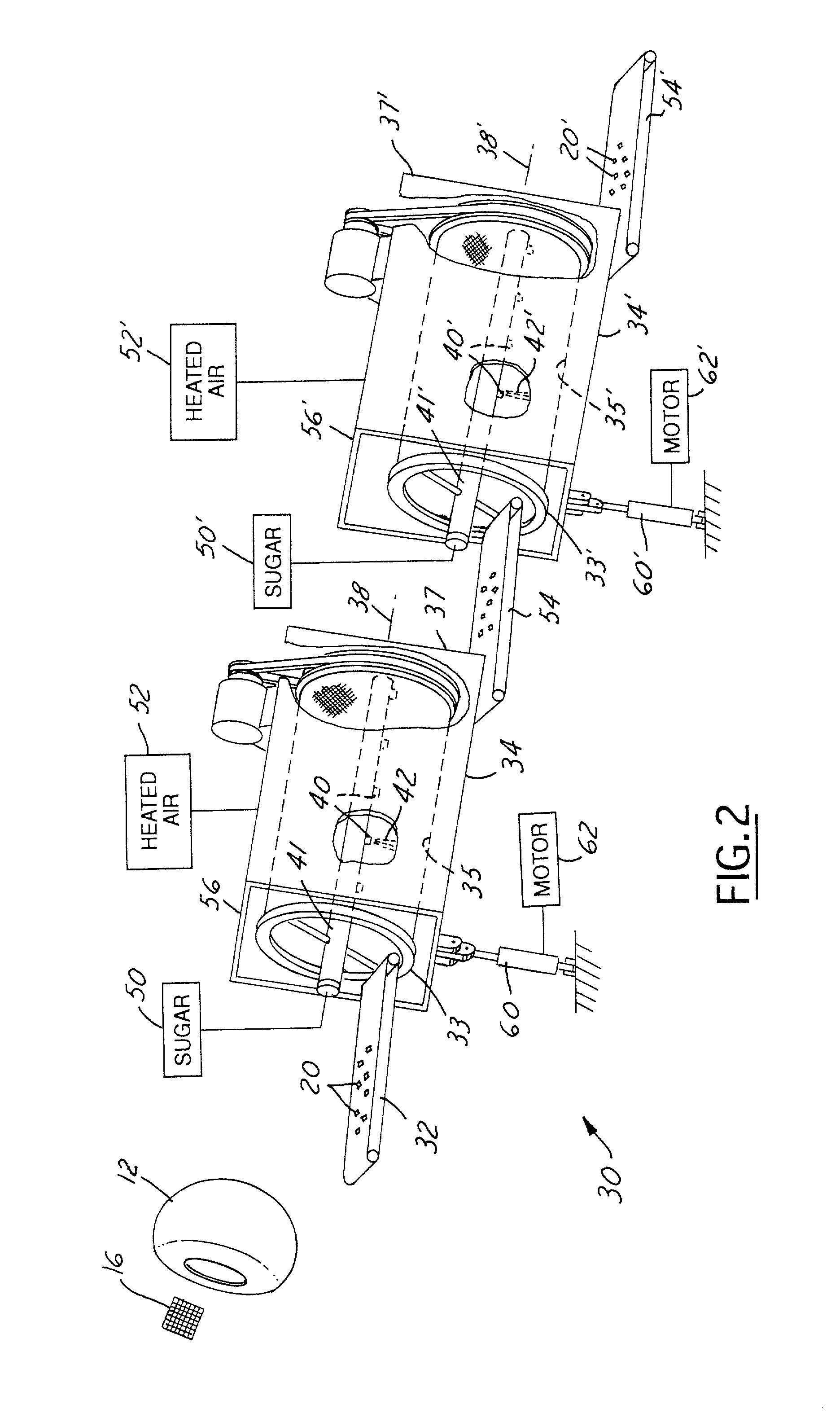

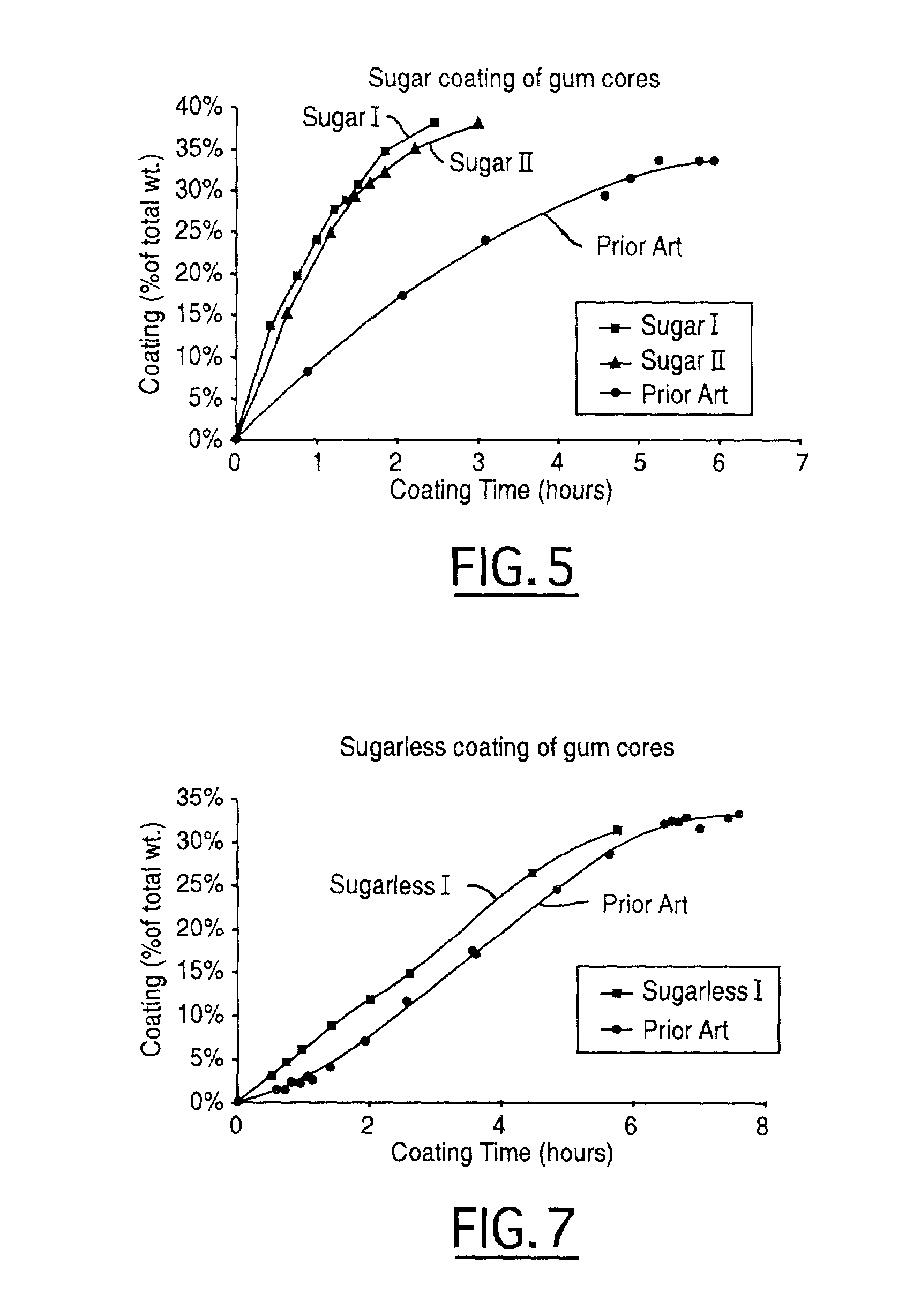

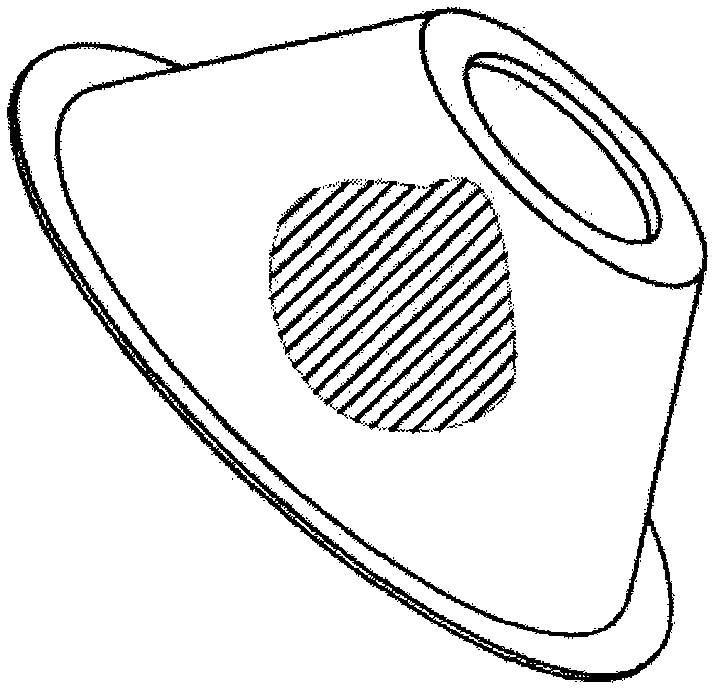

High speed coating of gum cores

InactiveUS7537792B2Simple coating processIncrease speedContainers for annular articlesConfectionerySugarSolid content

A system and process for coating pieces or cores of confectionery material, such as chewing gum, with a sugar-based coating or a sugarless-based coating. The solid content of the sugar or sugarless material in the syrup solution is increased, thus reducing the water content and allowing the successive coating layers to be dried more quickly. The syrup solution is maintained at an elevated temperature in order to prevent the syrup solids from precipitating or crystallizing out of solution.

Owner:INTERCONTINENTAL GREAT BRANDS LLC

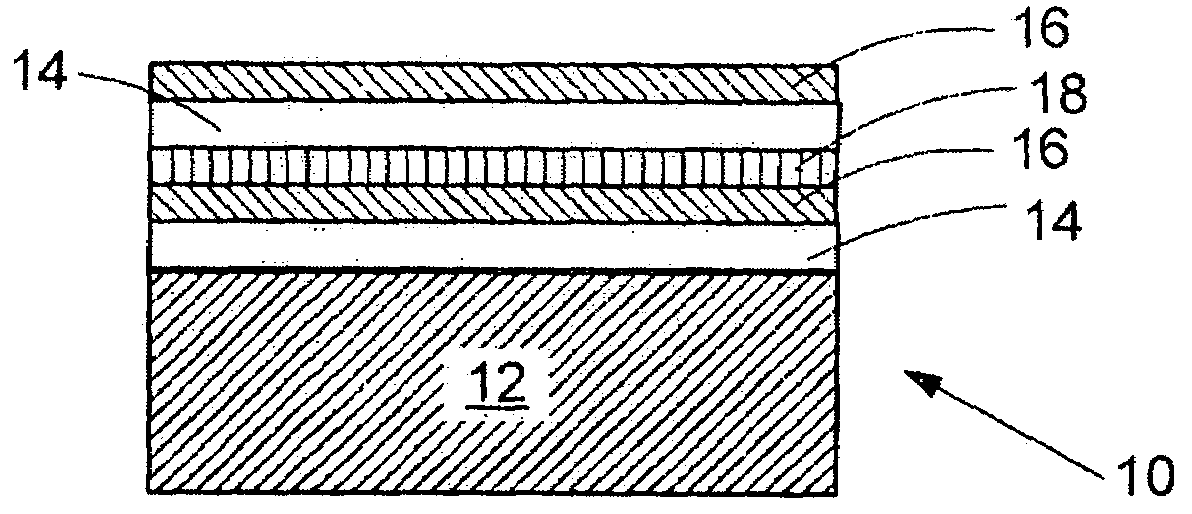

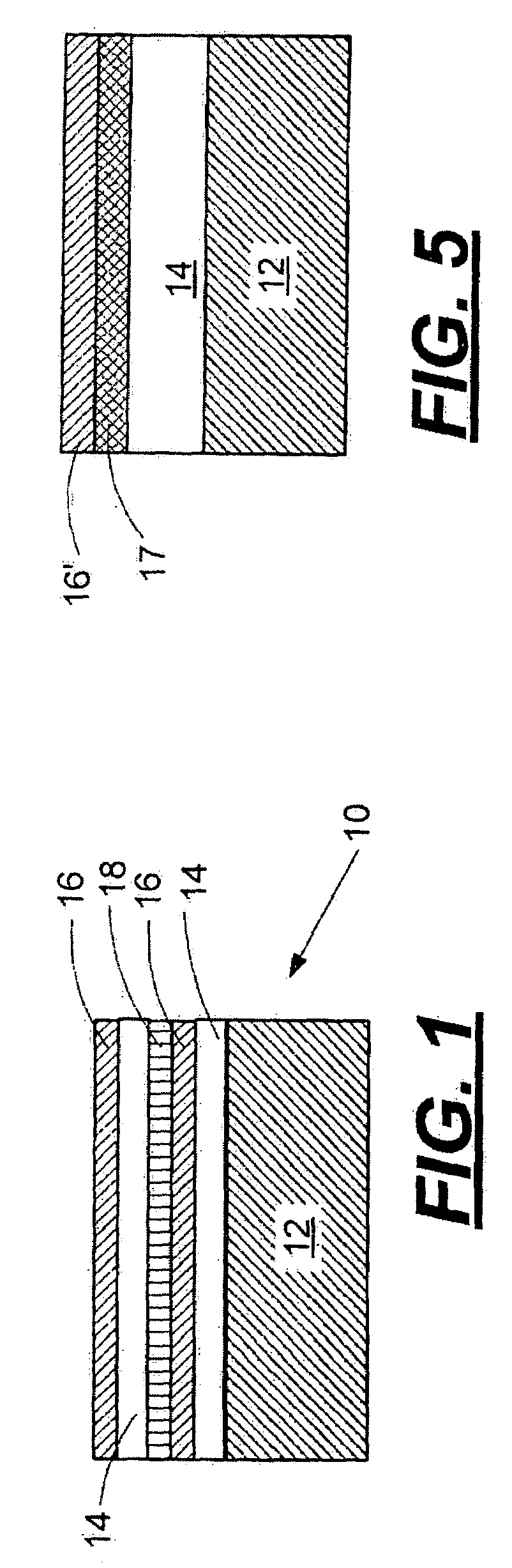

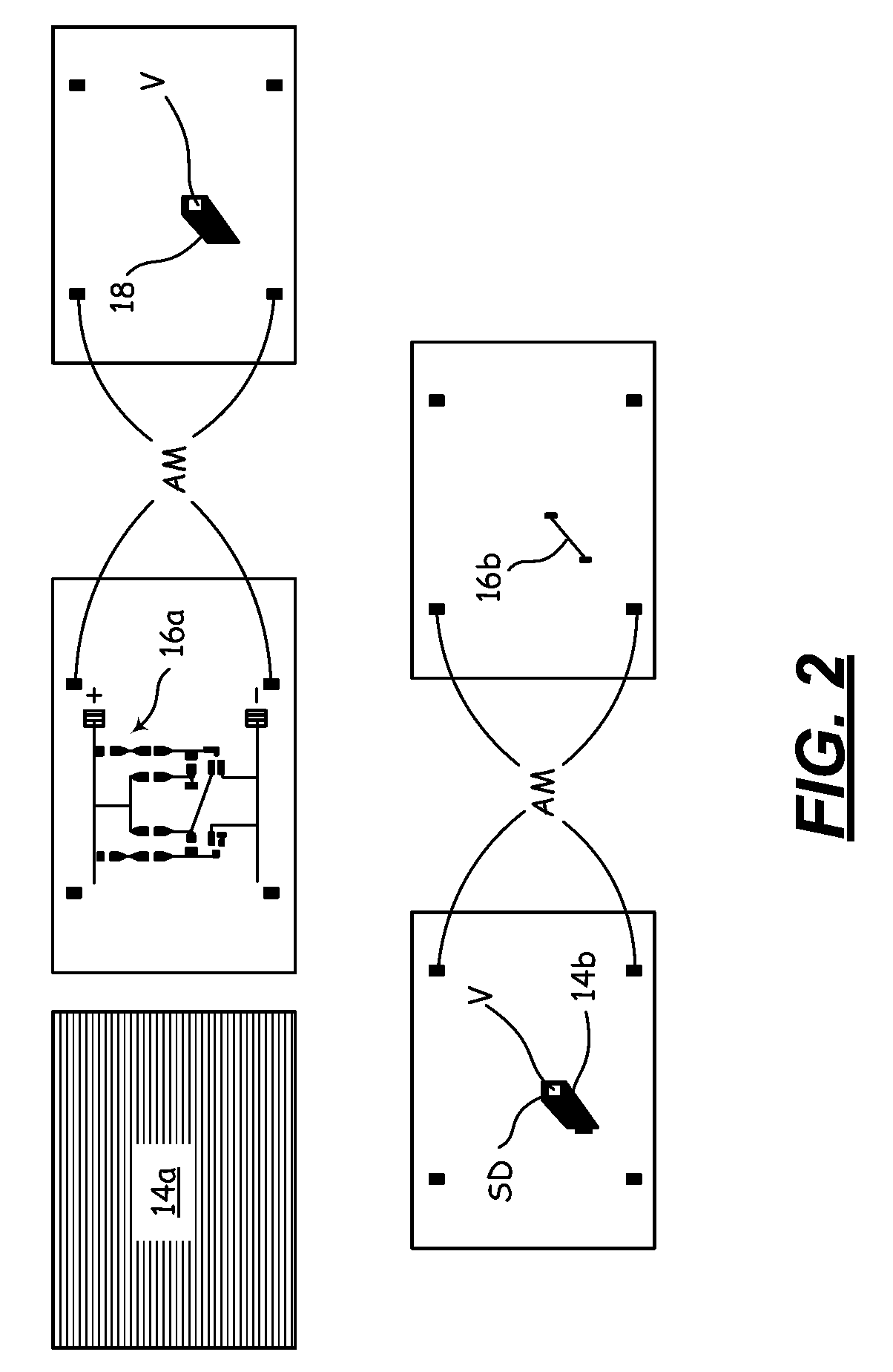

Fluid composition receiving layer for printed conductive layers and methods therefor

InactiveUS20080044634A1Reduce liquid contentPrinted electric component incorporationPrinted circuit aspectsCarrier fluidFluid composition

Printed circuits having conductive traces applied adjacent to a substrate, such as one where the traces have a resistivity of from about 1 to about 0.1 ohms / square, and methods for forming a fluid composition receiving layer adjacent to a substrate. One such method includes depositing a primary treatment fluid having a particle dispersion and a binder in a carrier fluid adjacent to at least a portion of a substrate to provide a treated substrate having a fluid composition receiving layer. The primary treatment fluid is deposited in a pattern using a: micro-fluid ejection head. After deposition, the carrier fluid content of the fluid composition receiving layer is reduced.

Owner:LEXMARK INT INC

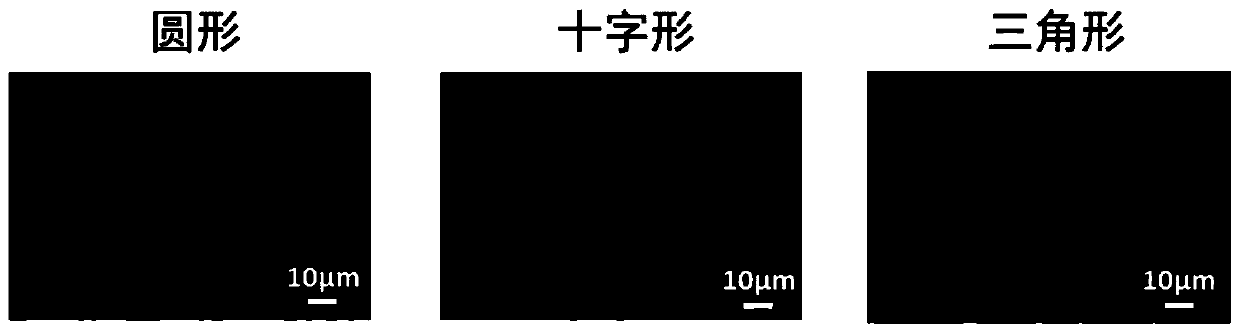

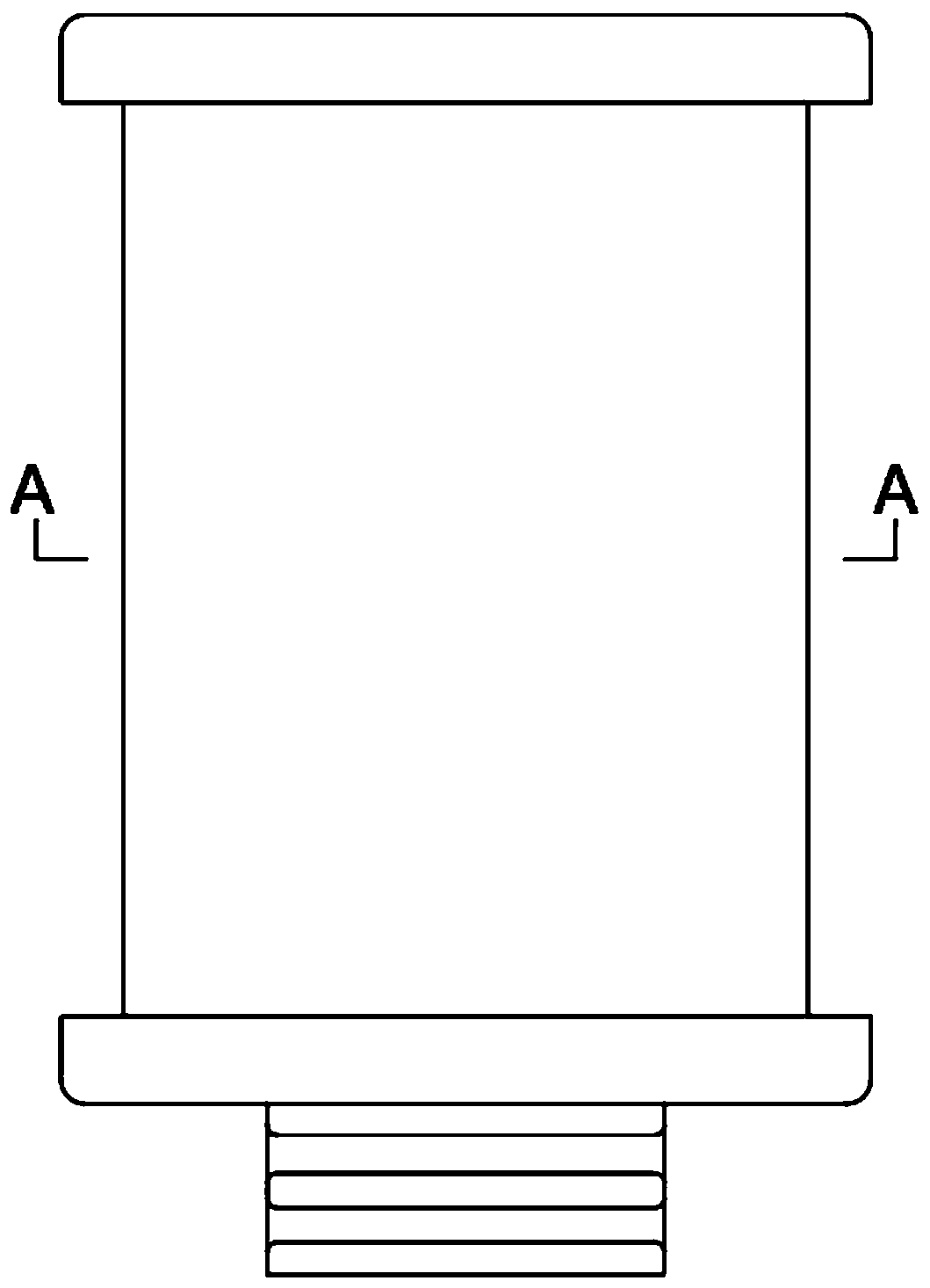

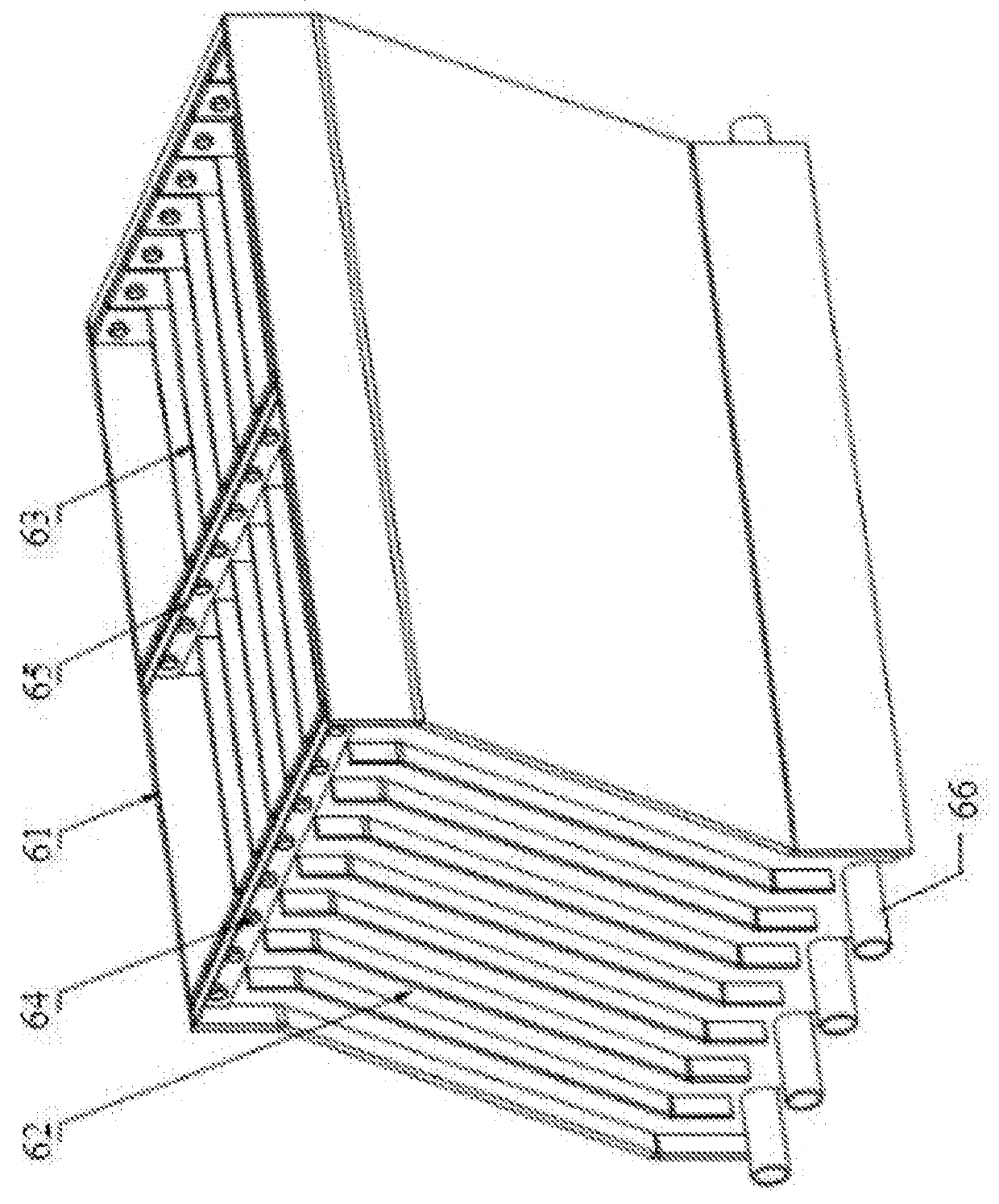

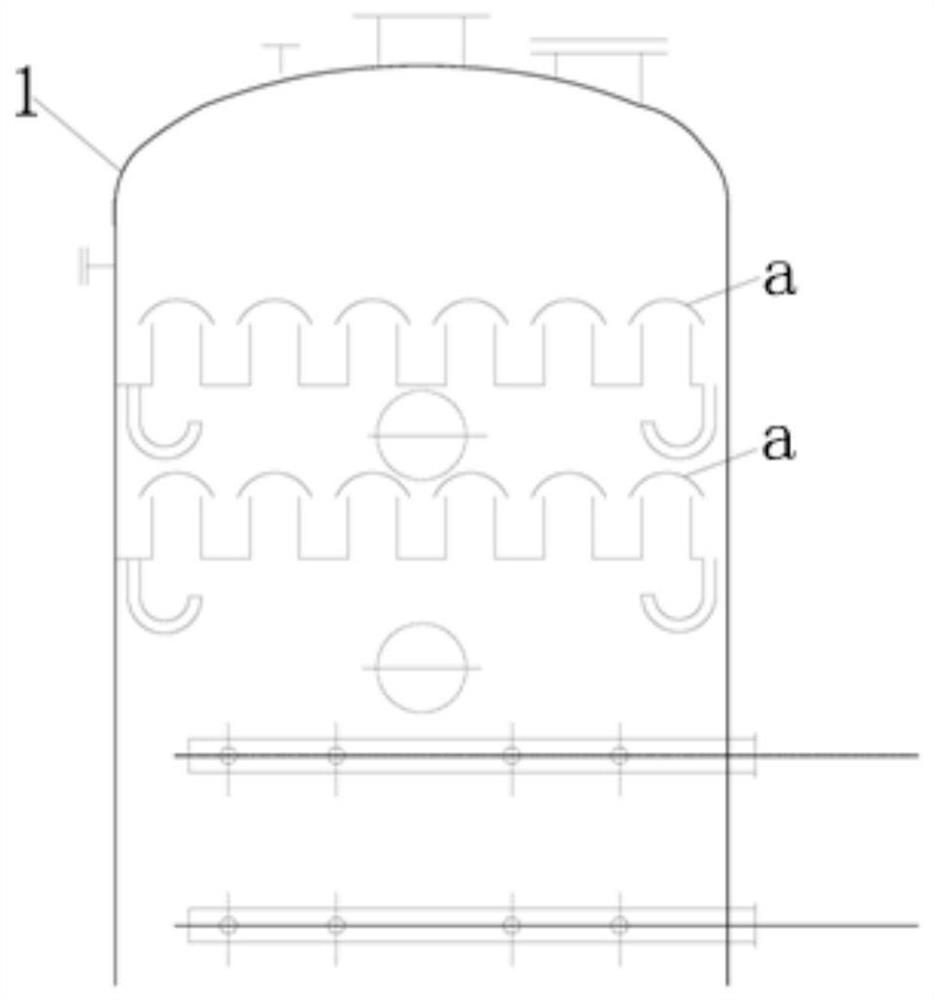

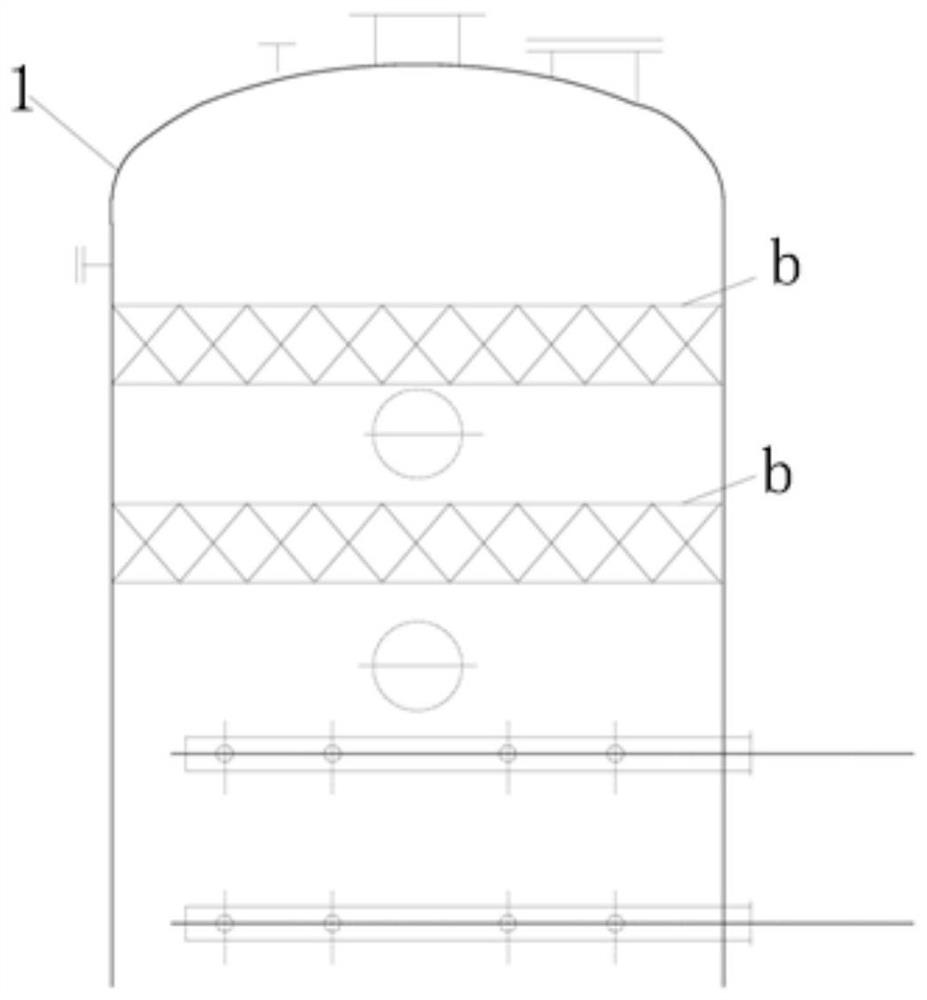

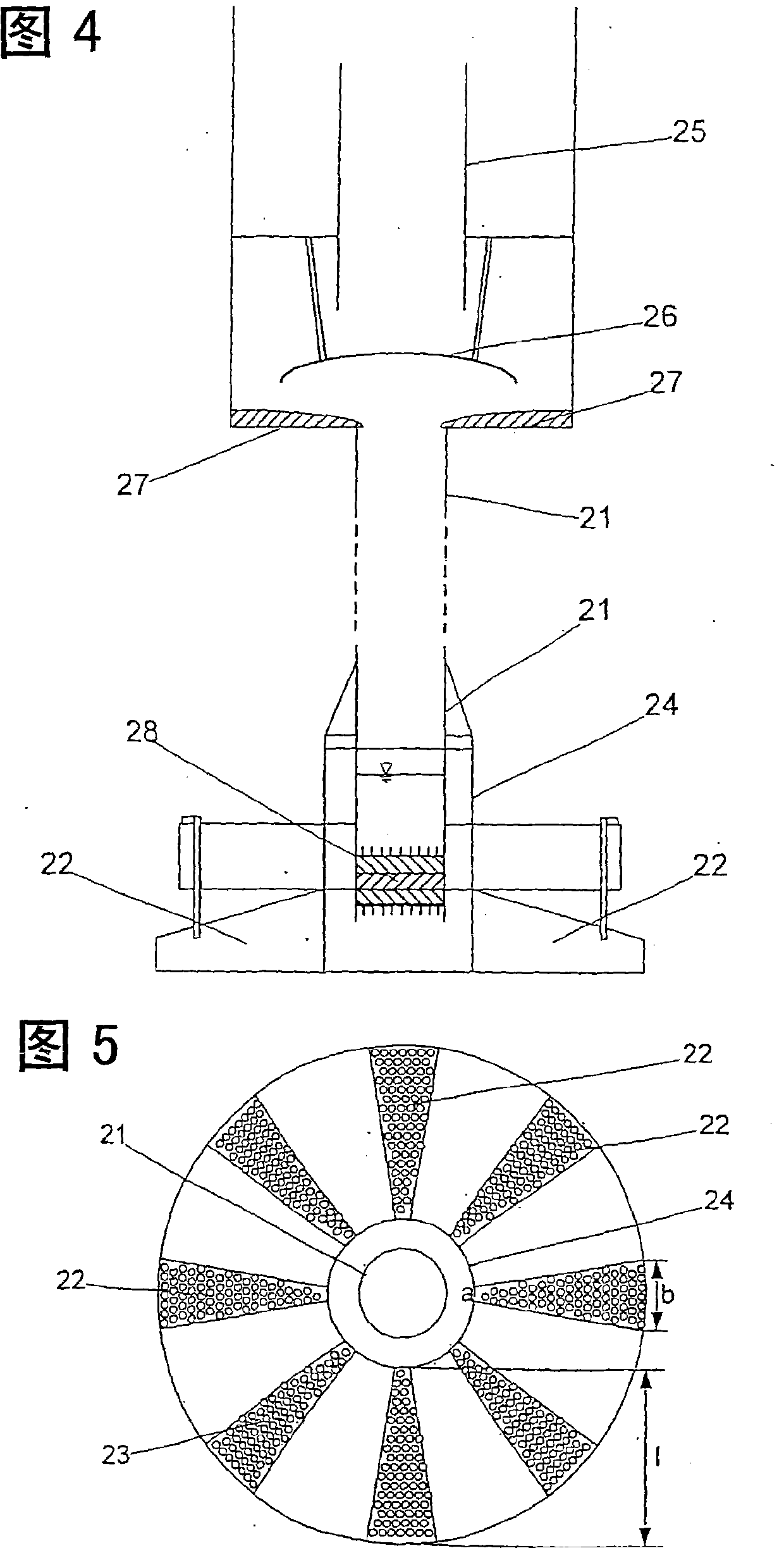

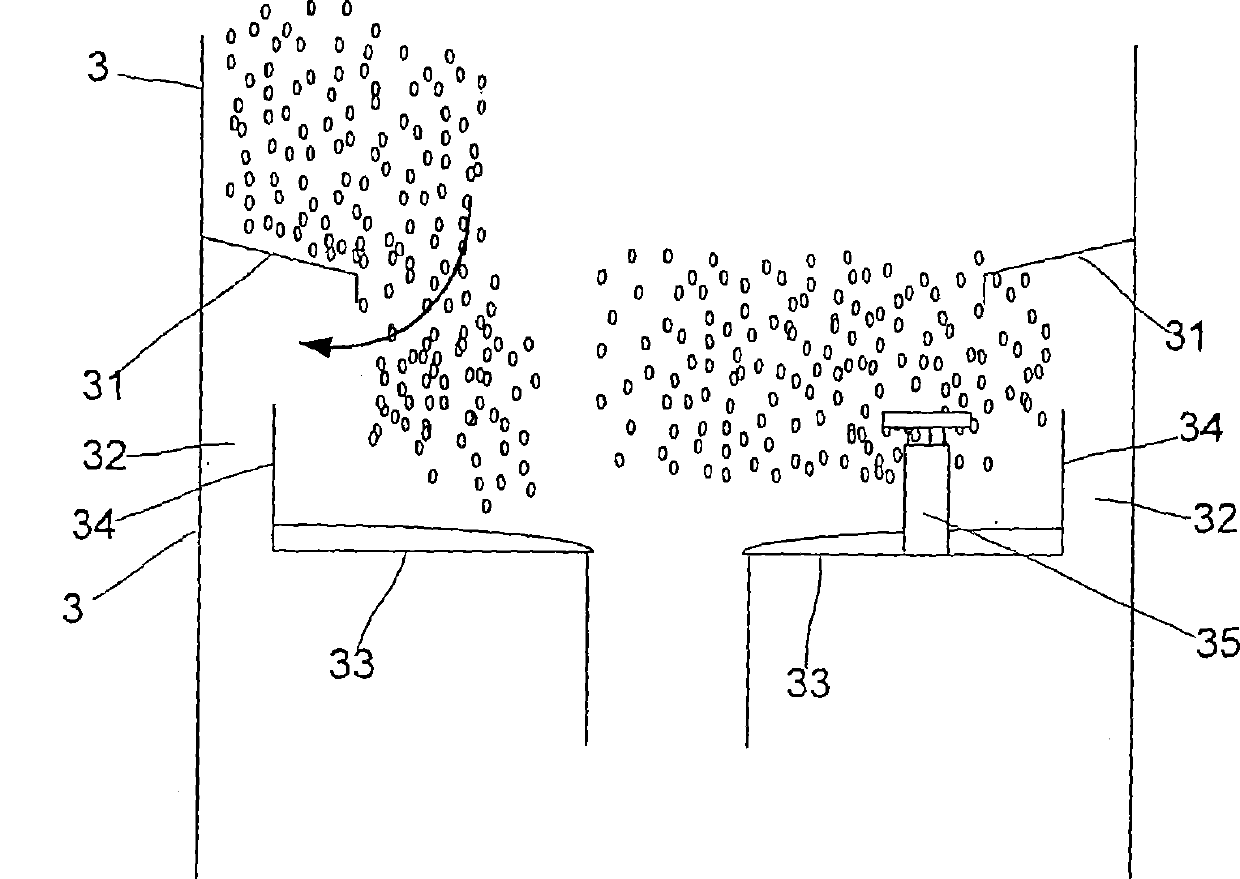

Gas-liquid coalescence filter element and application and filtering device containing gas-liquid coalescence filter element

PendingCN110917749AImprove interception effectSolve the problem of excessive pressure dropDispersed particle filtrationFiberEngineering

The invention provides a gas-liquid coalescence filter element and application and a filtering device containing the gas-liquid coalescence filter element. The filter element comprises a pre-separation layer, a coalescence layer and a liquid discharging layer which are sequentially arranged in the airflow direction. The pore diameter of the pre-separation layer is 8-12 [mu] m, the thickness of thepre-separation layer is 1-2 mm, the pre-separation layer is formed by profiled fibers and the whole pre-separation layer has hydrophobicity and lipophobicity. The pore diameter of the coalescence layer is 3-8 [mu] m, the thickness of the coalescence layer is 0.4-0.6 mm, the coalescence layer is formed by profiled fibers and the coalescence layer is divided into a hydrophobic and oleophobic area and a hydrophilic and oleophylic area which are arranged at intervals in the circumferential direction. The pore diameter of the liquid discharging layer is 10-20 [mu] m, the thickness of the liquid discharging layer is 2-3 mm, the liquid discharging layer is formed by profiled fibers, the air inlet side is a hydrophilic and oleophylic area, and the air outlet side is a hydrophobic and oleophobic area. The filter element can be used for filtering a gas-liquid mixture. The filtering device containing the filter element can remarkably reduce the filtering pressure drop while improving the filtering efficiency.

Owner:CHINA UNIV OF PETROLEUM (BEIJING)

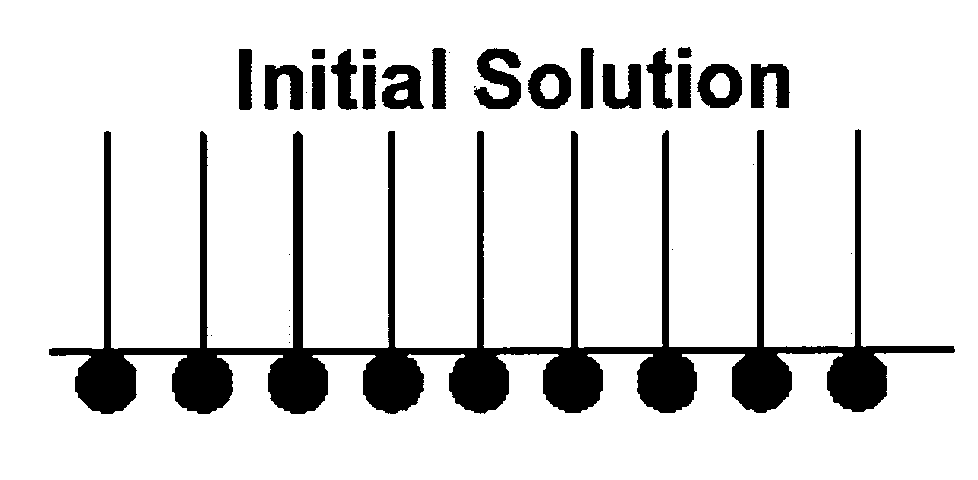

Process for enhanced liquid extraction from fabrics

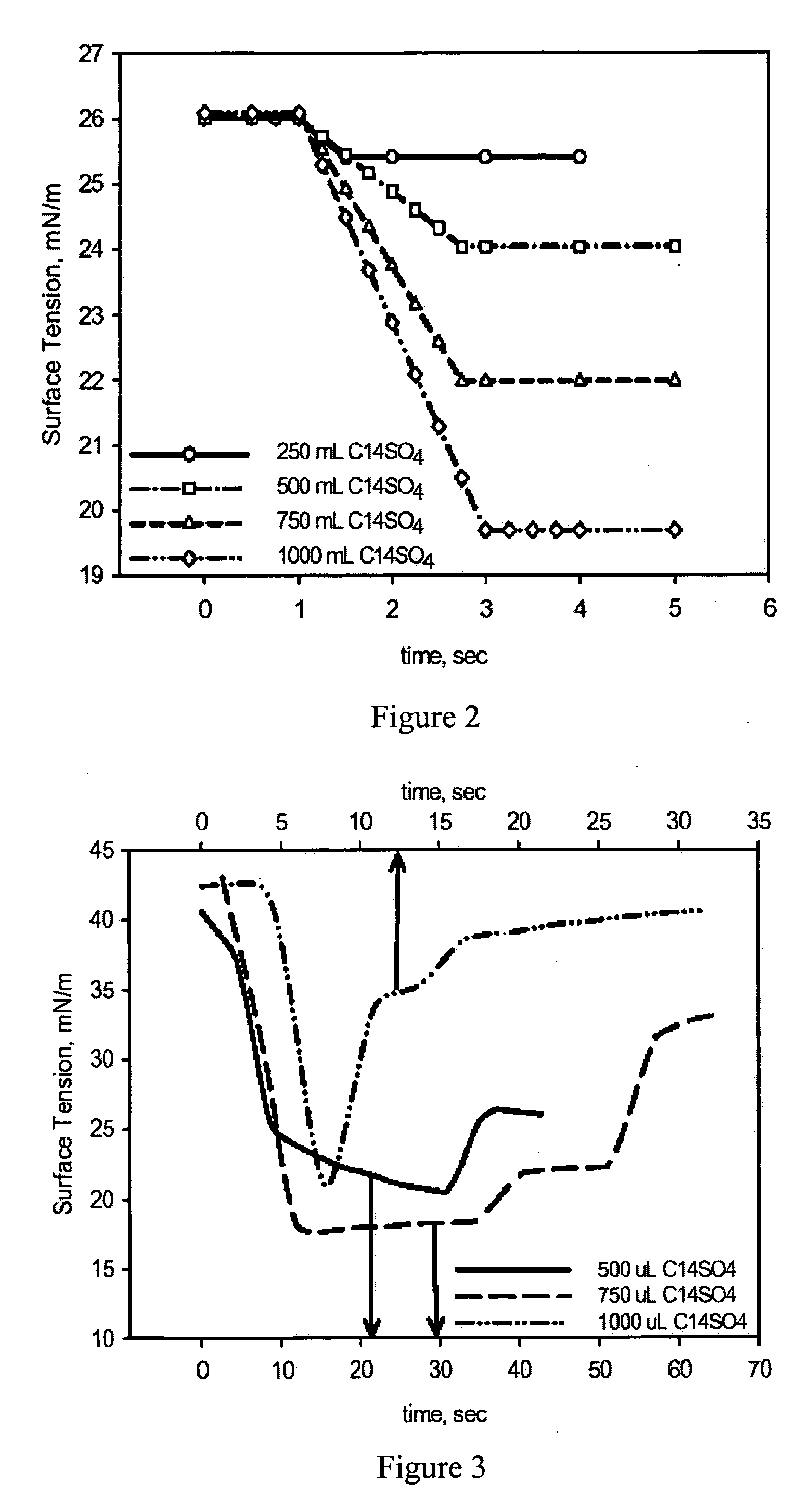

InactiveUS20060157088A1Substantial chain length compatibilityReduce surface tensionCationic surface-active compoundsNon-ionic surface-active compoundsAir liquid interfaceSurface layer

A process of extracting liquid from a fabric having a first content of liquid includes the steps of creating a surfactant surface layer including at least one surfactant at an air-liquid interface of the liquid on the fabric, wherein the surface layer has a first surface tension, and adding at least one co-surfactant different from the surfactant. The surfactant and said co-surfactant have substantial chain length compatibility. The co-surfactant reduces the surface tension at the air-liquid interface. The fabric is then subjected to mechanical extraction for a period of time to reduce the liquid content of the fabric from the first content of liquid to a second liquid content.

Owner:UNIV OF FLORIDA RES FOUNDATION INC

A method and apparatus for separating magnetic material from a slurry

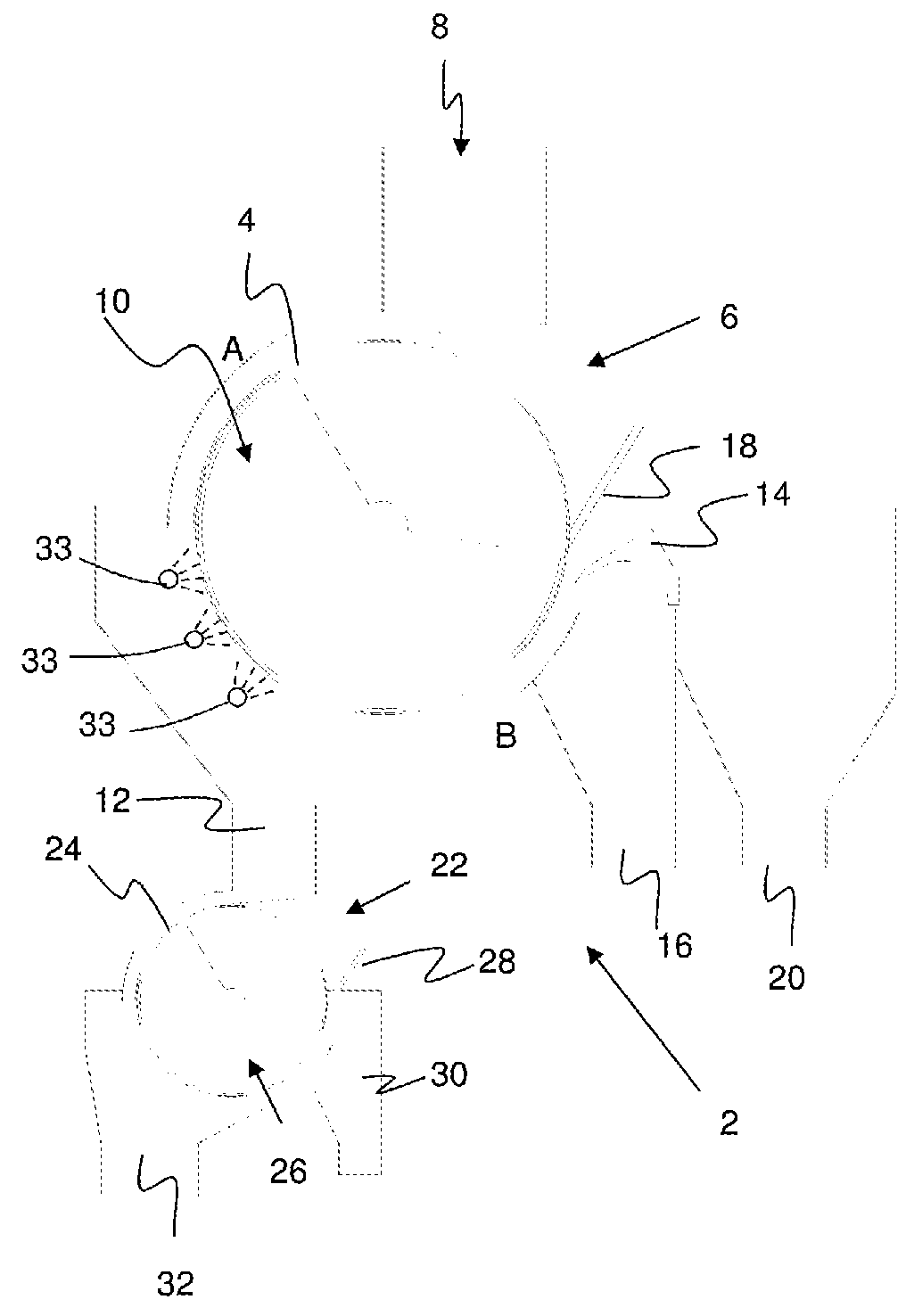

ActiveUS20160030947A1Efficiently reprocessedNot to wasteWater/sewage treatment by magnetic/electric fieldsMultistage water/sewage treatmentSlurryMechanical engineering

A method and apparatus for separating magnetic material from a slurry is disclosed, the method including the steps of providing a first moving surface, depositing the slurry onto the first moving surface, attracting at least a portion of the magnetic material of the slurry onto the first moving surface by first magnetic means, arranging the first moving surface such that liquid from the slurry is removed due to the portion of the magnetic material being attracted to the moving surface by the first magnetic means to form a magnetic material cake, separating an inner portion of the magnetic material cake from an outer portion of the magnetic material cake, with respect to the first moving surface, such that the inner portion has a lower liquid content than the outer portion.

Owner:STEINERT AUSTRALIA

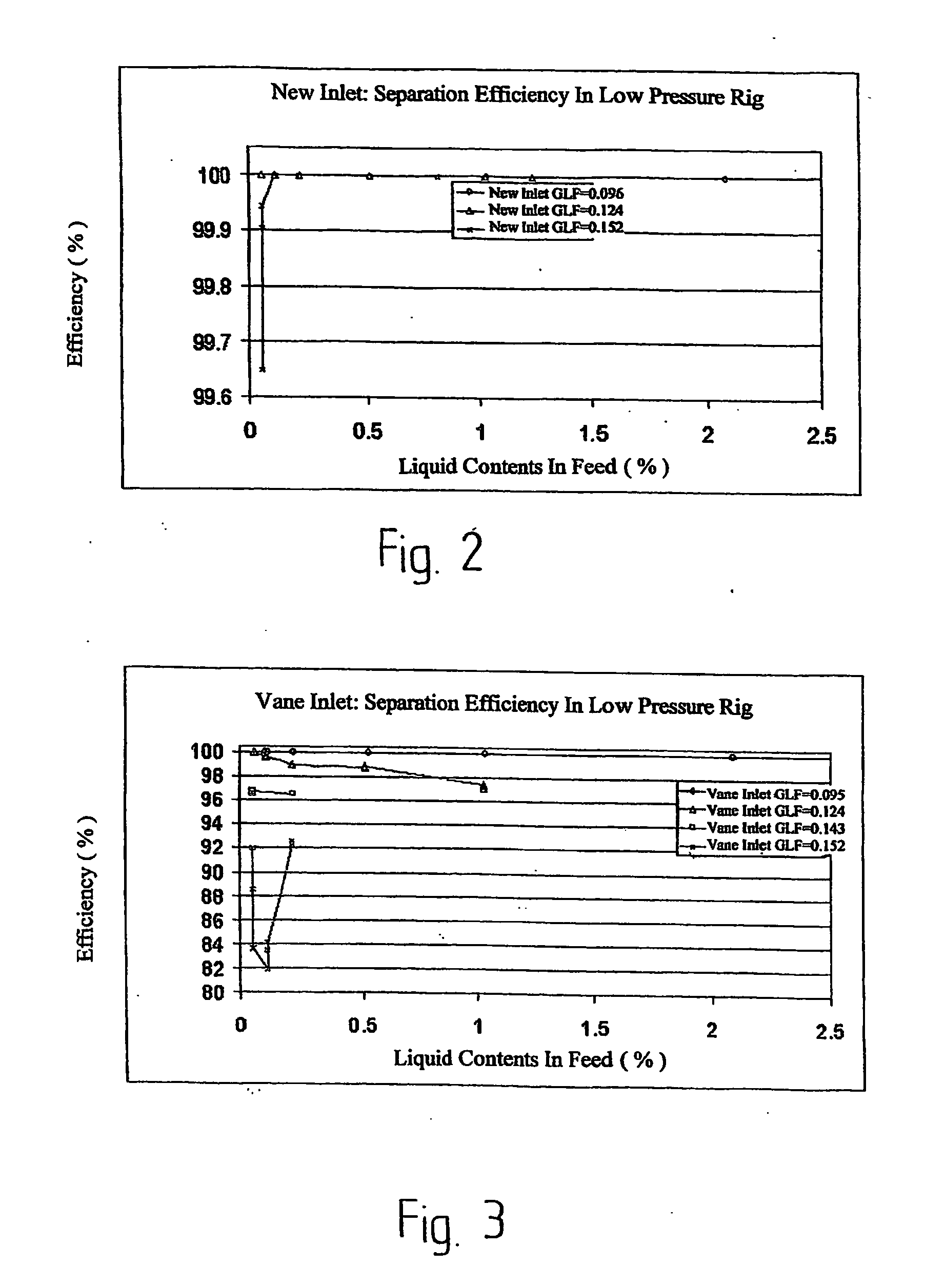

Scrubber

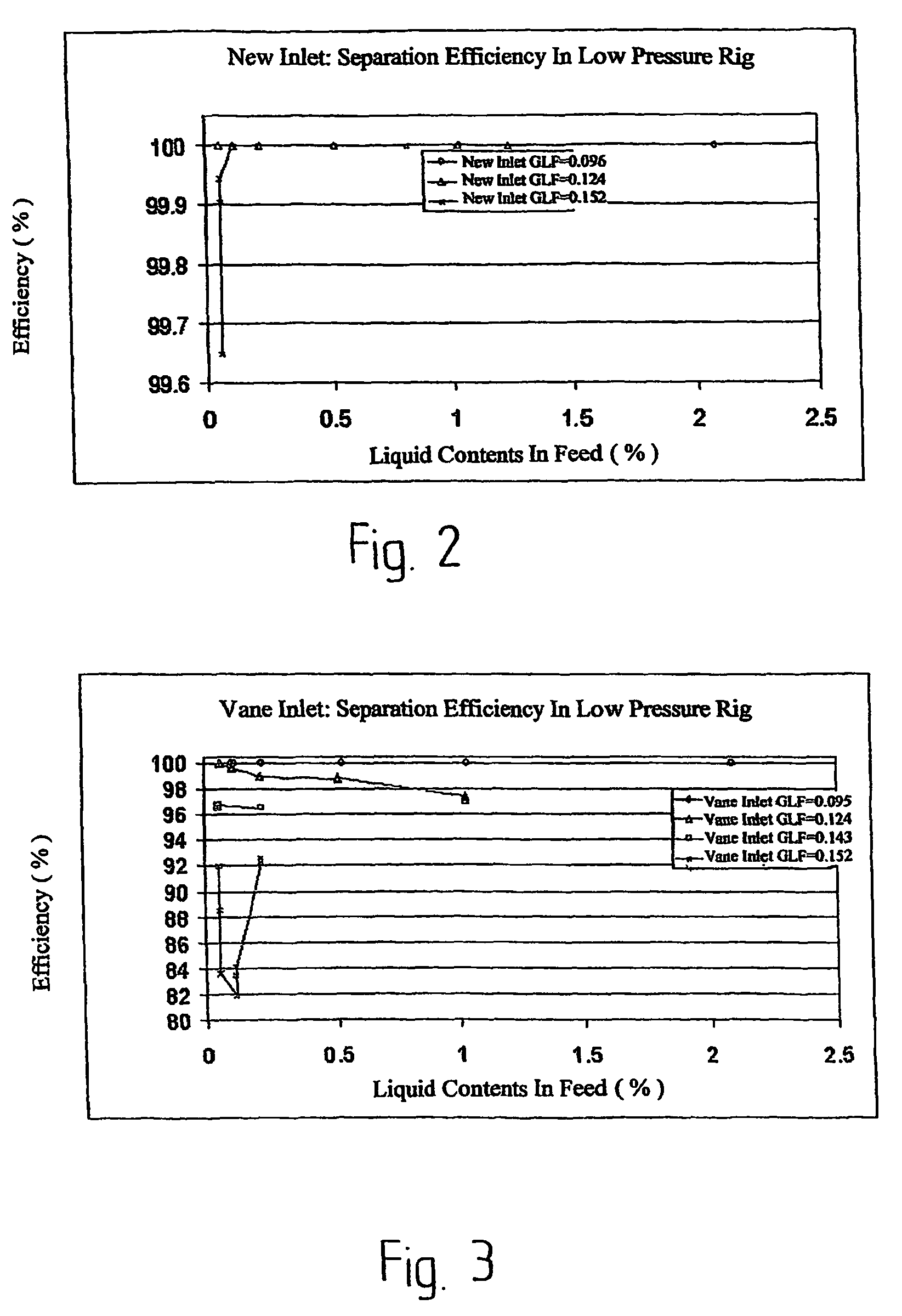

ActiveUS20060117959A1Avoid unnecessary pressure lossHigh viscosityReversed direction vortexUsing liquid separation agentEngineeringLiquid phase

Scrubber for separation of liquid phase and any other constituents from a fluid flow that in substance is comprising a gas, which scrubber is formed as a standing vessel with round cross section, with oulet for liquid from the bottom and outlet for gas from the top. The scrubber is distinguished in that it is comprising: a fluid inlet that either is tangetially oriented to the inner wall of the scrubber or equipped with a deflection plate, such that introduced fluid is directed tangentially horizontal or with a small downward slope along the inner wall of the scrubber, into and through a fluid way arranged as a downwards directed spiral within the scrubber, along the inner wall, from a level over or at the inlet to a level at or close to the outlet for liquid, with opening for gas escape inwards of the center of the scrubber. The scrubber according to the invention results in very low liquid entrainment.

Owner:DEN NORSKE STATS OLJESELSKAP AS

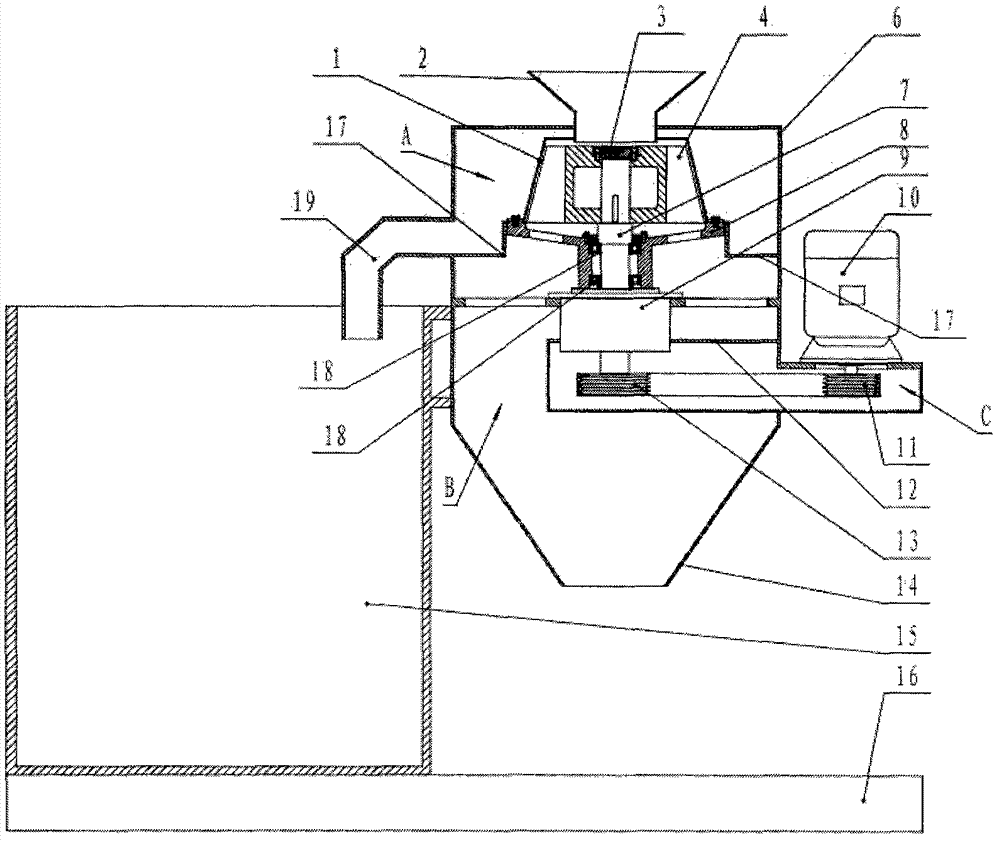

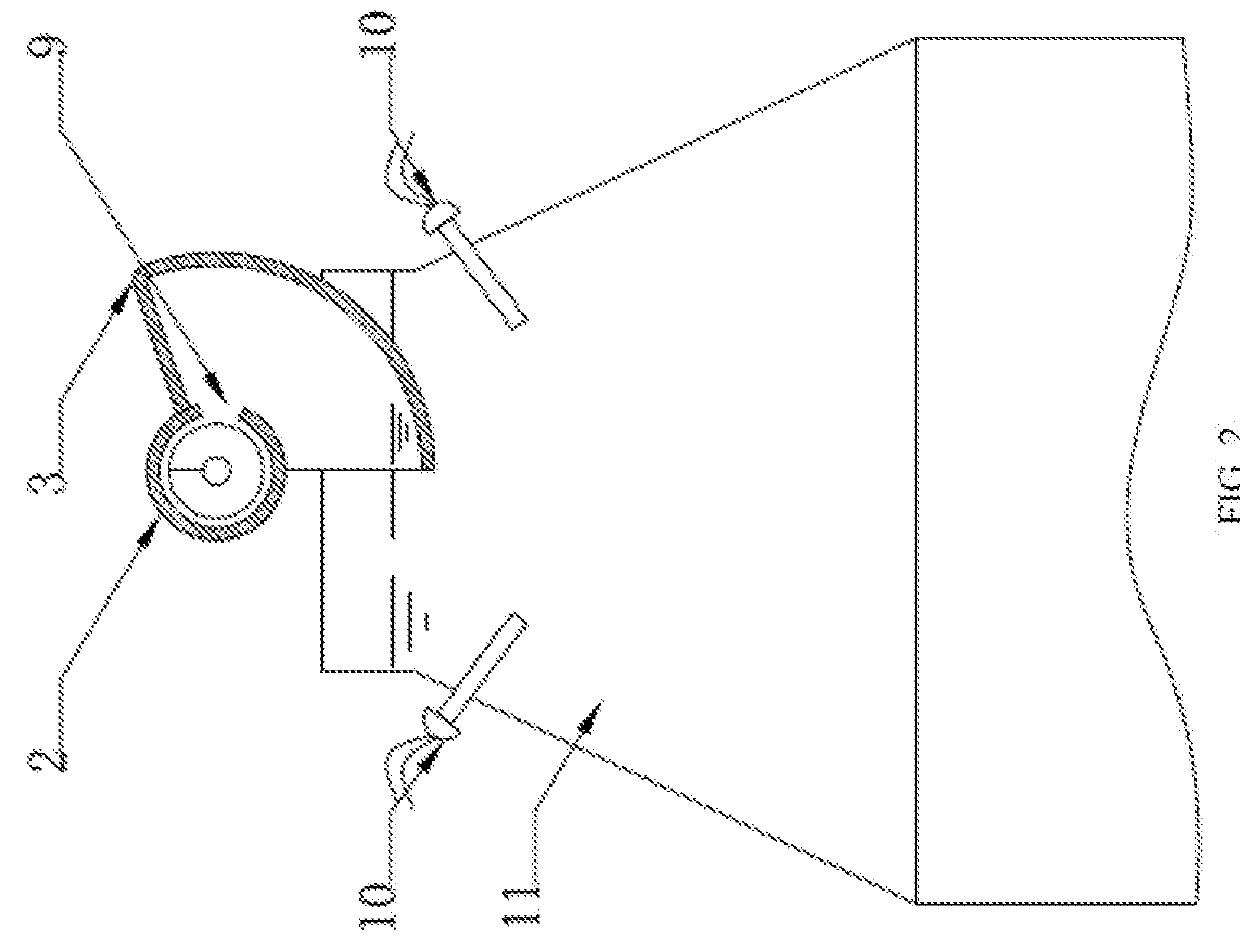

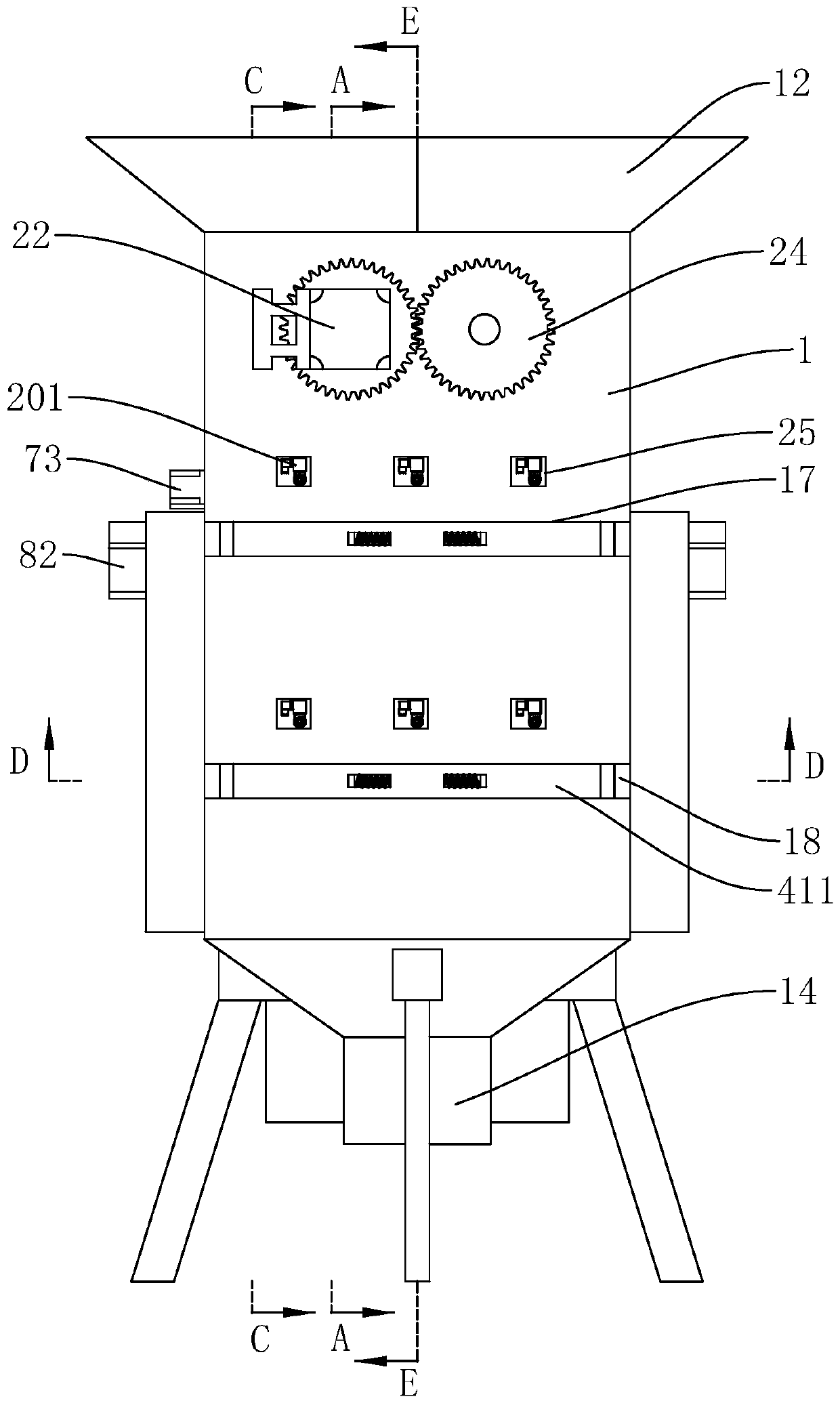

Oil drilling cutting dryer

InactiveCN103191834ASolve environmental problemsSolve resource problemsRotary centrifugesOil drillingPetroleum

An oil drilling cutting dryer belongs to the technical field of solid-liquid separation equipment and aims to solve the problem that conventional solid-liquid separation equipment is unreasonable in structural design, causes environmental pollution and wastes resources. The oil drilling cutting dryer adopts the structure that a conical screen cloth is fixed on a rotating arm, a central shaft is mounted in a shaft hole of the rotating arm, a scraping device is mounted on the central shaft, a transmission is fixed on a dryer housing, a motor is connected with the input shaft of the transmission, the transmission is connected with the rotating arm and the central shaft, baffles are connected to the interior of the housing of a dryer baseframe and divide the housing into a wet cavity, a dry cavity and a transmission cavity, a feed hopper is fixed at the top of the dryer housing, and a discharge hopper is fixed at the bottom of the dryer housing. The oil drilling cutting dryer has a simple structure, is suitable for solid-liquid separation and recovery of oil drilling cuttings, as well as solid-liquid separation in other applicable industries.

Owner:CANGZHOU HUAYOU FEIDA SOLIDS CONTROL EQUIP

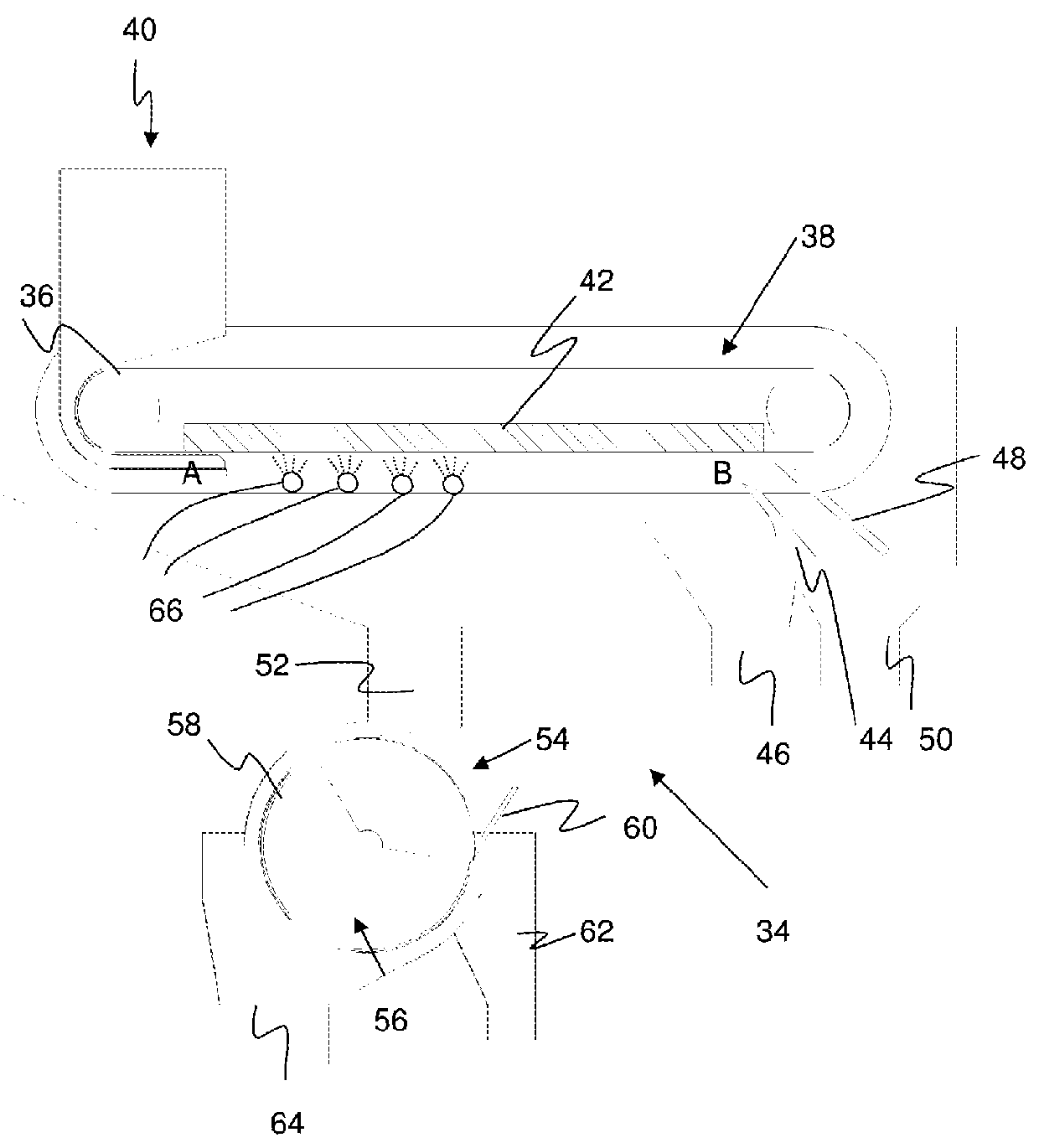

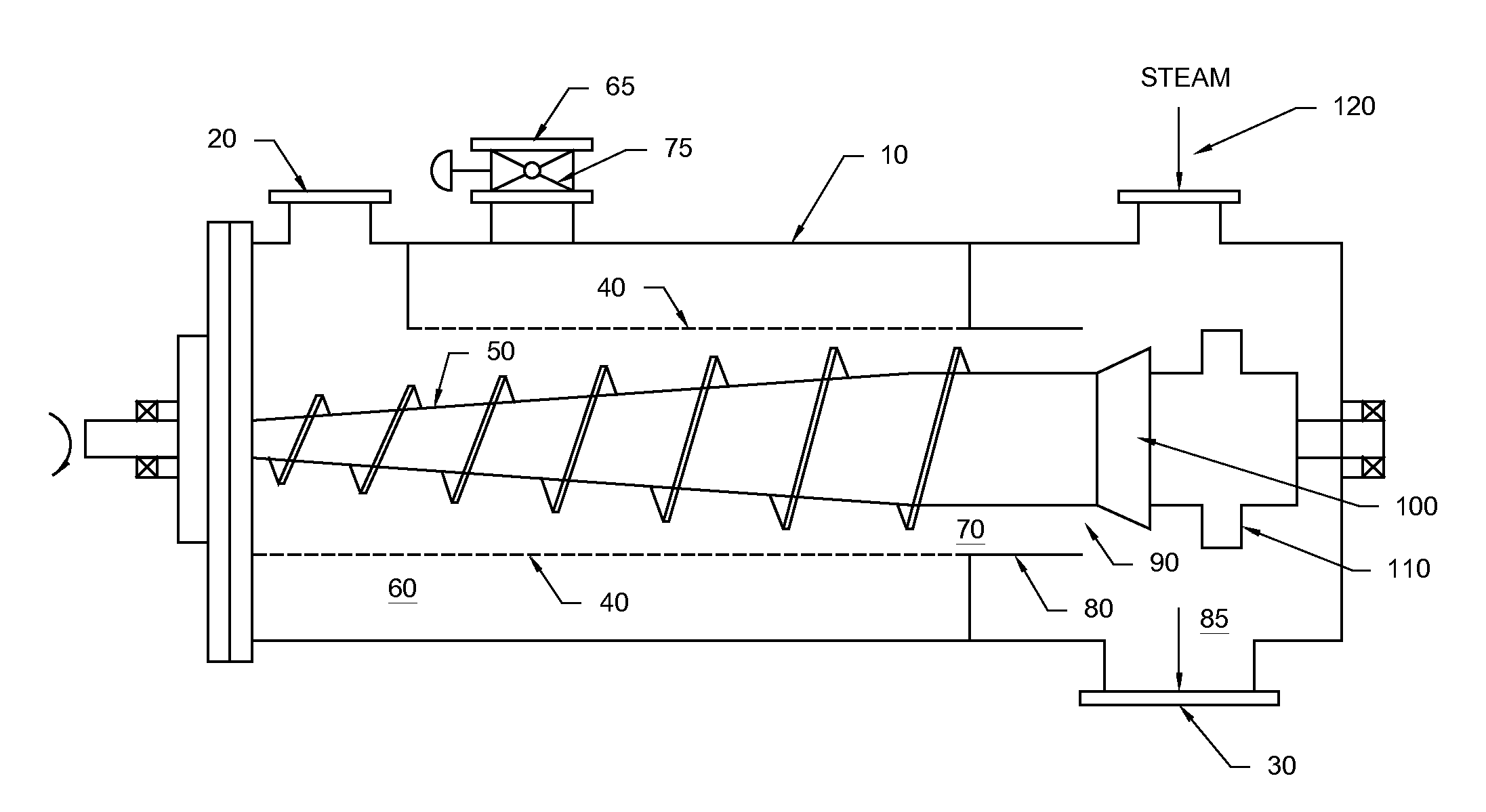

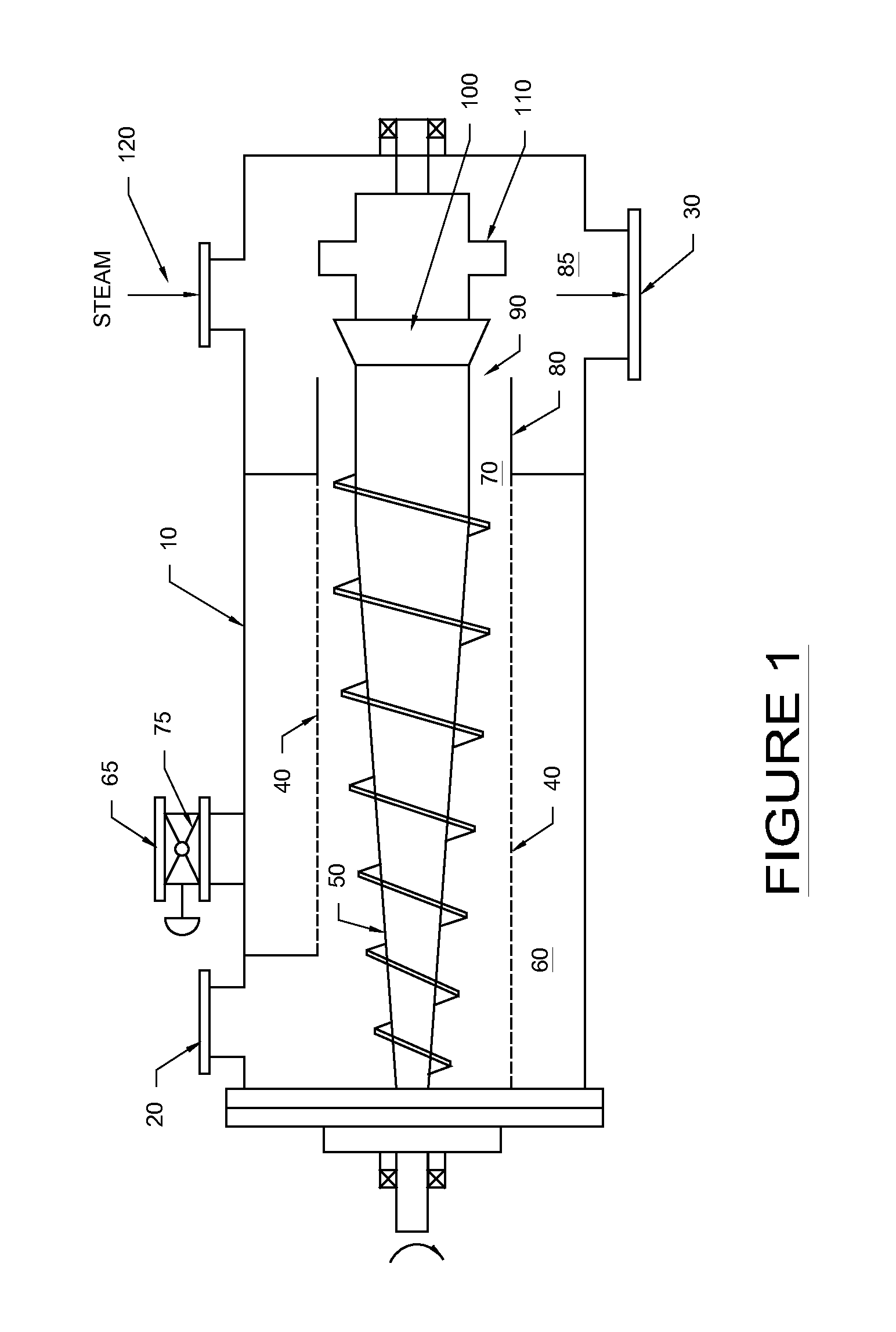

Method for removing liquid from a slurry

ActiveUS20150165709A1Reduce liquid contentPurification using adsorption agentsSludge treatmentDifferential pressureSlurry

The method includes the following steps: (i) feeding a slurry into the inlet of a press; (ii) removing liquid from the slurry as the slurry advances through a deliquefying section of the press, thereby producing a pressate stream; (iii) forming a plug of material as the slurry is advanced through a plug formation section of the press; (iv) advancing the plug of material to a discharge section of the press; and (v) removing additional liquid from the plug of material by operating the press so that the pressure in the discharge section of the press is greater than the pressure of the pressate stream by at least 2 psi. There is also described a method for controlling discharge consistency from a press, without provision of discharge restrictors, by varying a pressure differential between a discharge section of the press and a pressate stream.

Owner:IOGEN ENERGY CORP +1

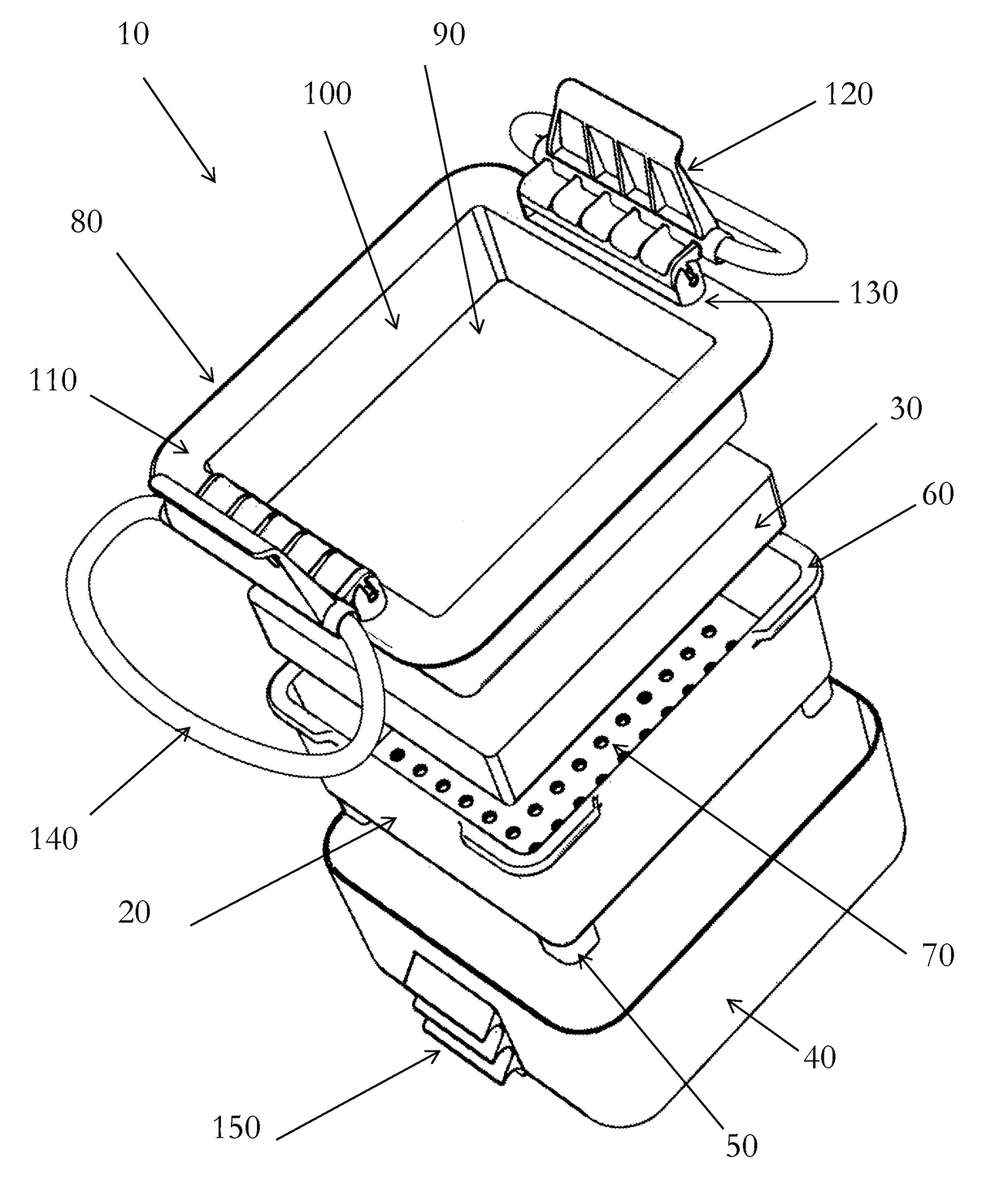

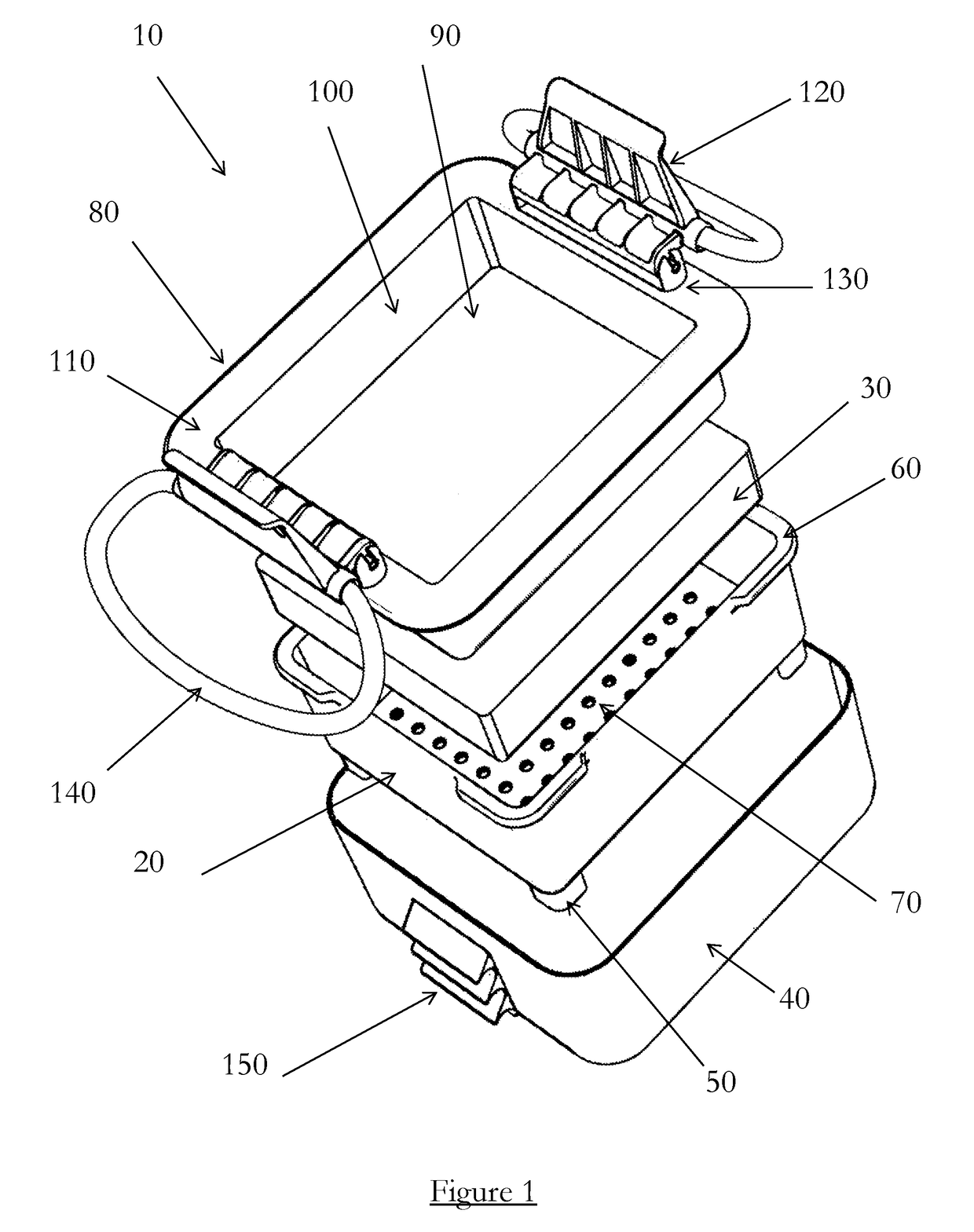

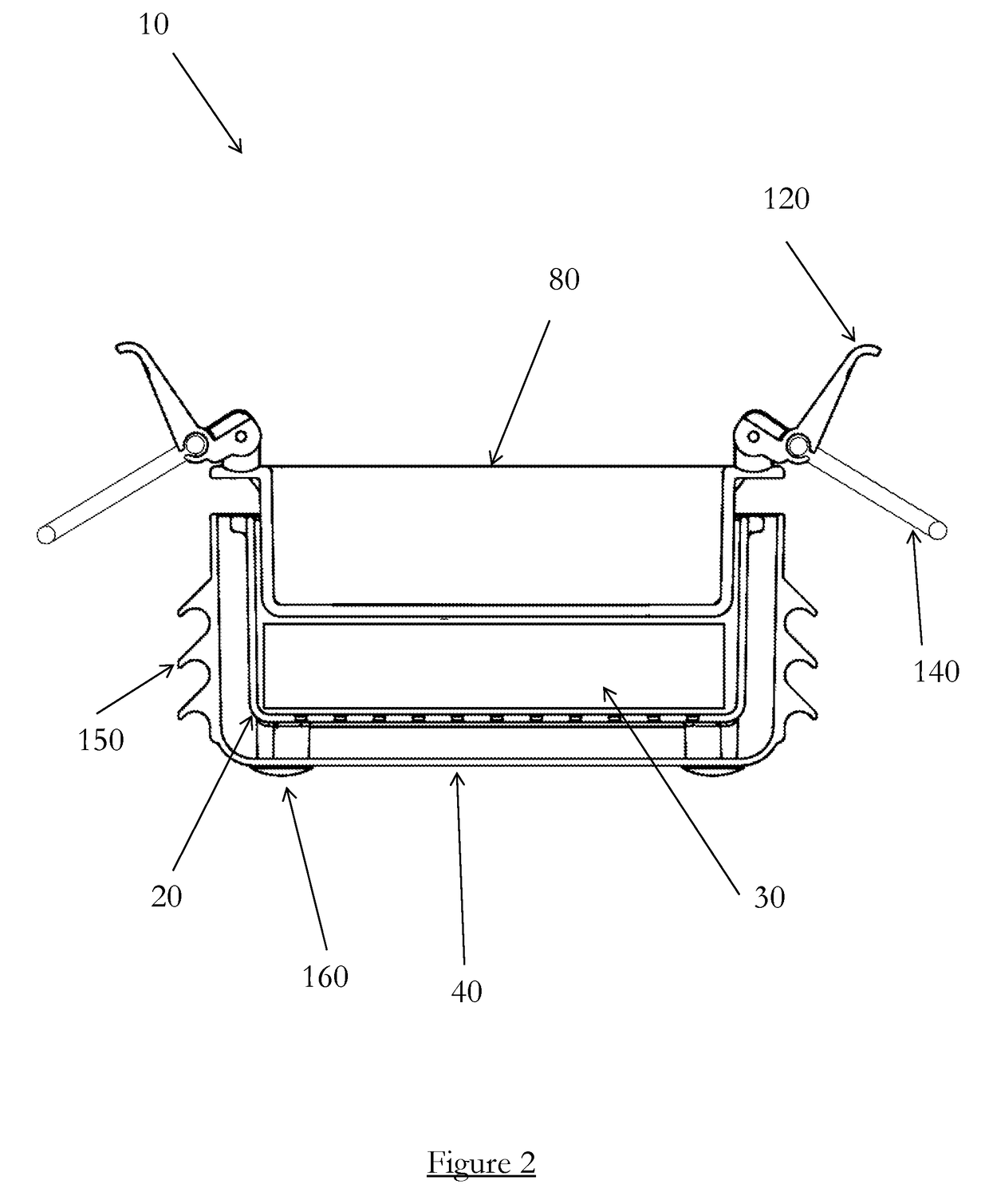

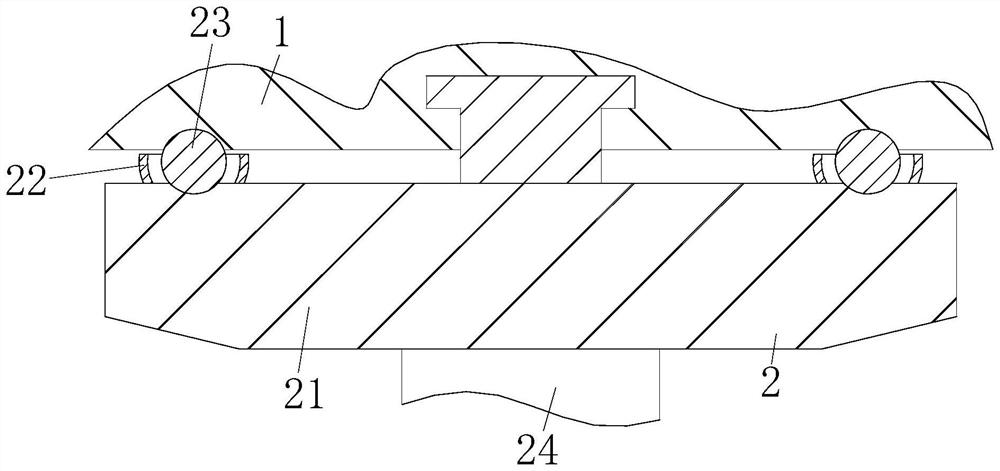

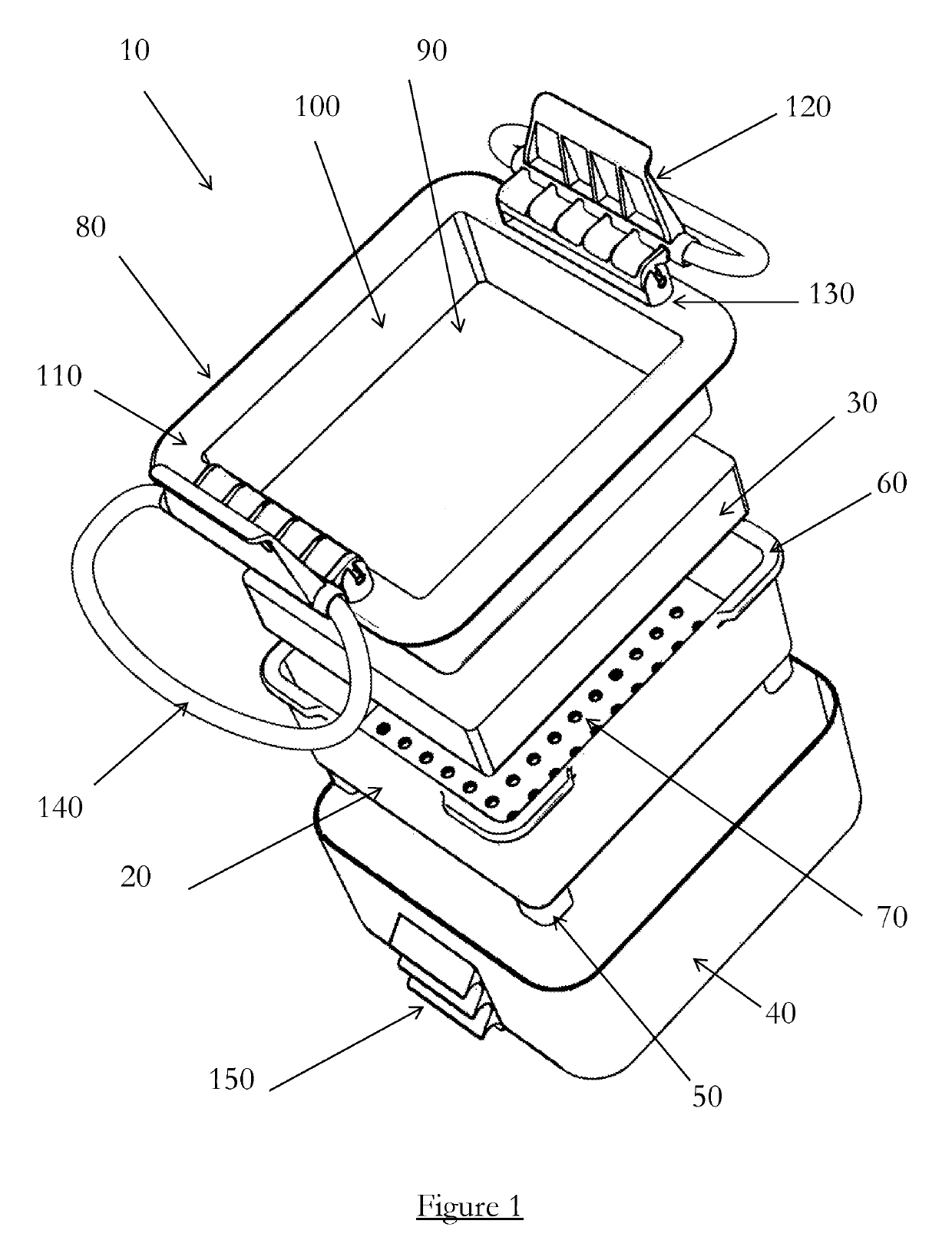

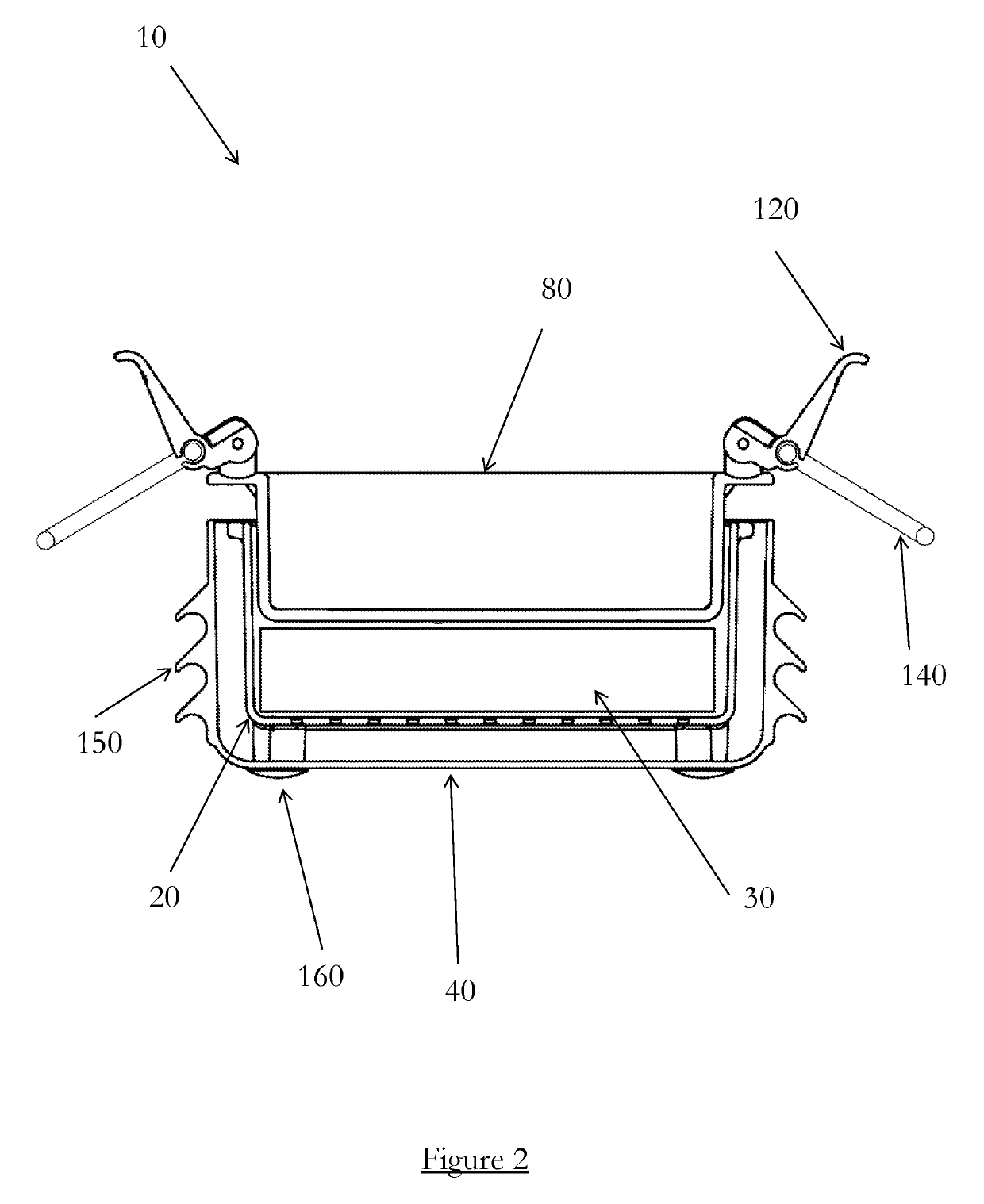

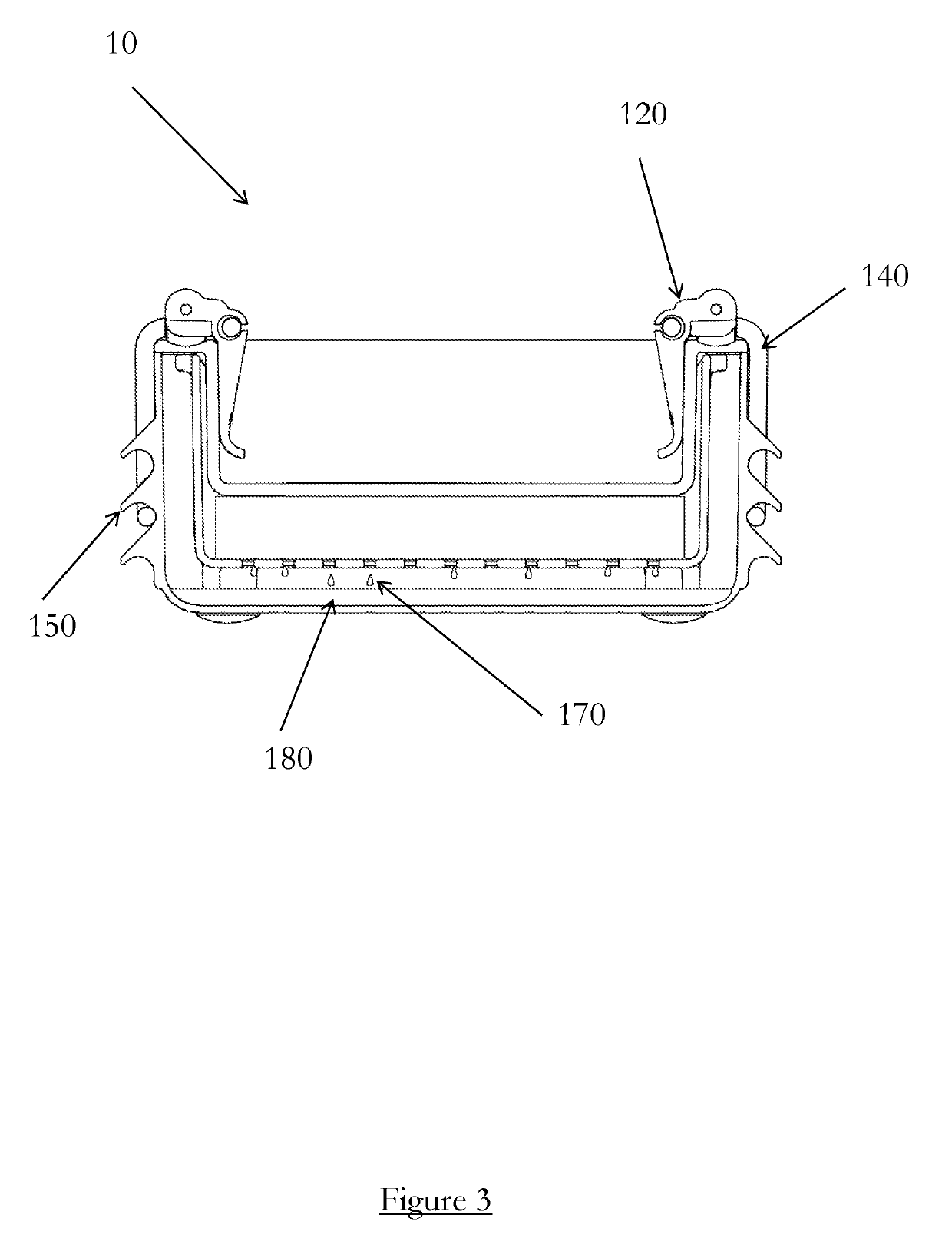

Tofu press and method of removing liquid from tofu

ActiveUS20170318856A1Function increasePrevent accidental spillageFood shapingPressesBiomedical engineeringLiquid content

Tofu is typically sold saturated in liquid, and in order for the tofu to take on a desired flavour, the liquid content of the tofu must first be reduced. The present invention provides a method of reducing the liquid content of tofu and a tofu press 10, comprising: a tray 20 for receiving tofu 30 therein; a pressure member 80 for applying pressure to the tofu 30 within the tray 20; and a toggle latch 120 releasably coupleable between the tray 20 and the pressure member 80 such that pressure is applied to the tofu 30 within the tray by the pressure member 80.

Owner:TOFUTURE

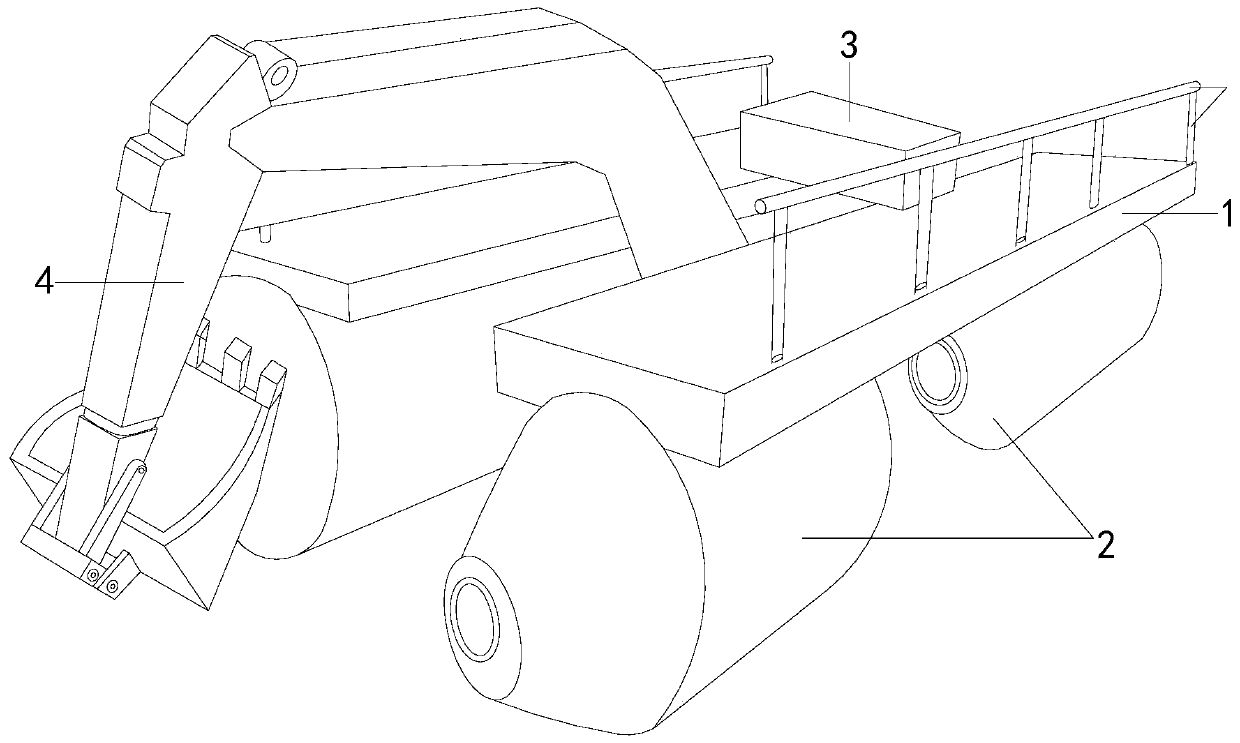

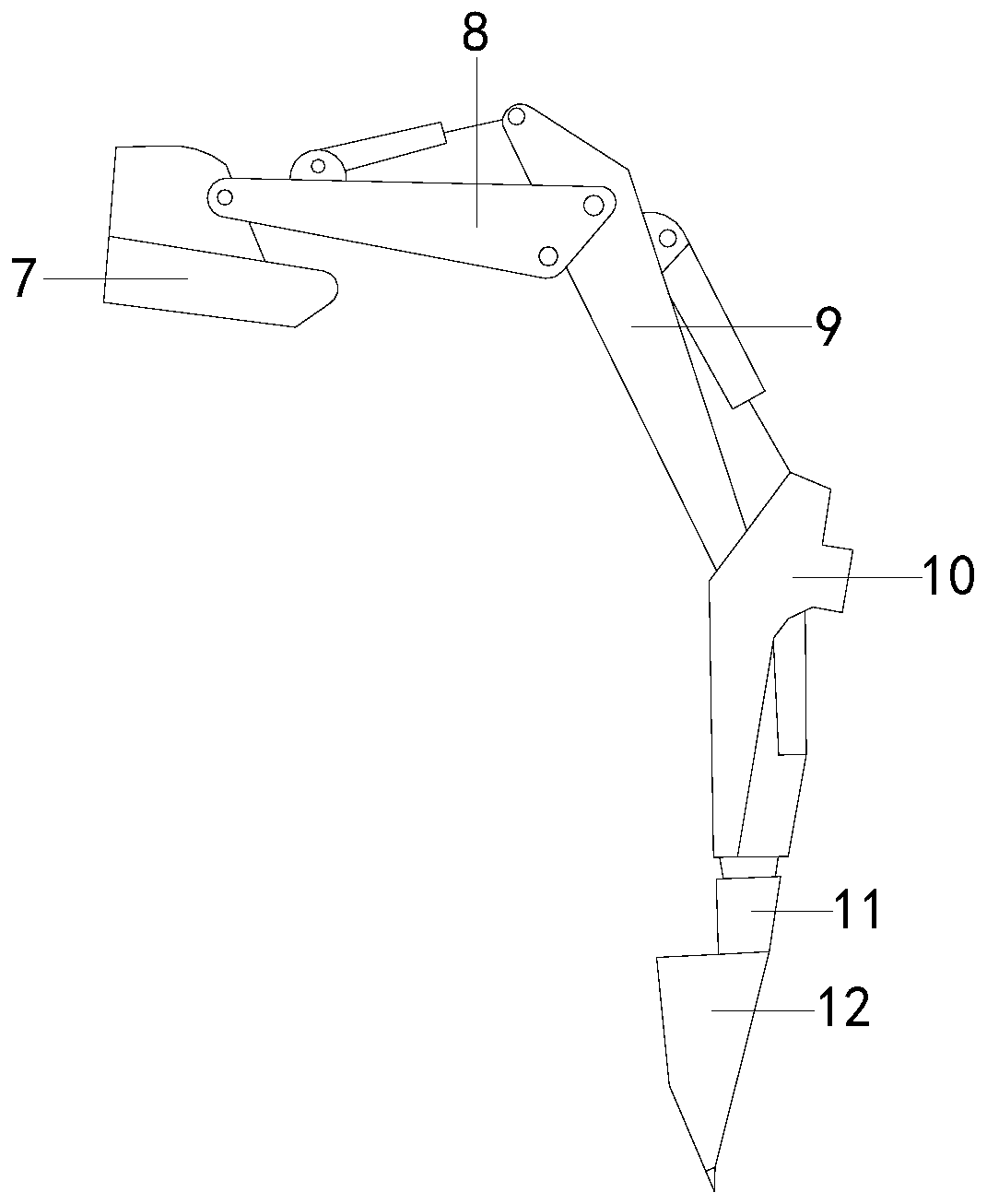

Water project silt cleaning equipment having functions of digging and spading

InactiveCN111058503ASolve the accumulationAvoid the disadvantage of slow movementMechanical machines/dredgersUnderwaterEnvironmental engineering

The invention discloses water project silt cleaning equipment having functions of digging and spading. The water project silt cleaning equipment structurally comprises a water entering machine frame,buoys, a power machine tank and a silt cleaning mechanism, wherein the buoys are separately arranged on two sides of the bottom of the water entering machine frame; the power machine tank is located at a center point position of the surface of the water entering machine frame; and the water entering machine frame is mutually connected with the silt cleaning mechanism. The water project silt cleaning equipment disclosed by the invention has the beneficial effects that a traditional digging manner is replaced by a novel underwater silt spading manner, so that underwater silt can be effectively borne, and the situation that the silt slides off from the structure once again is prevented; besides, a specific drainage mechanism is adopted, so that the disadvantage that the silt cleaning mechanism moves slowly under water caused by that a great quantity of water bodies infiltrate in the silt can be avoided; and besides, the liquid content is reduced, so that the situation that in the moving process, a great quantity of water bodies are mixed with the silt to drip from a railway carriage, and pollution is generated can be avoided.

Owner:谢 志坚

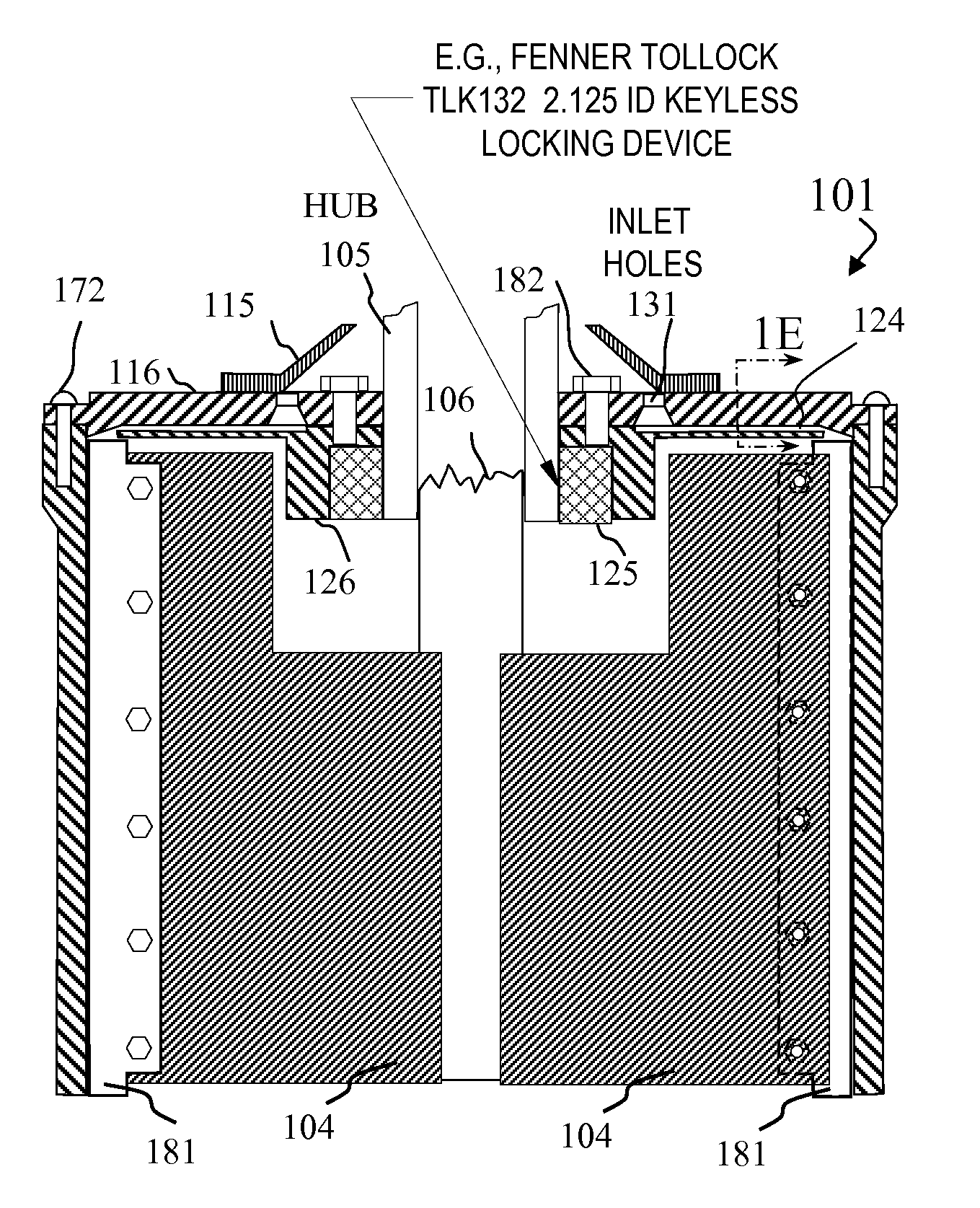

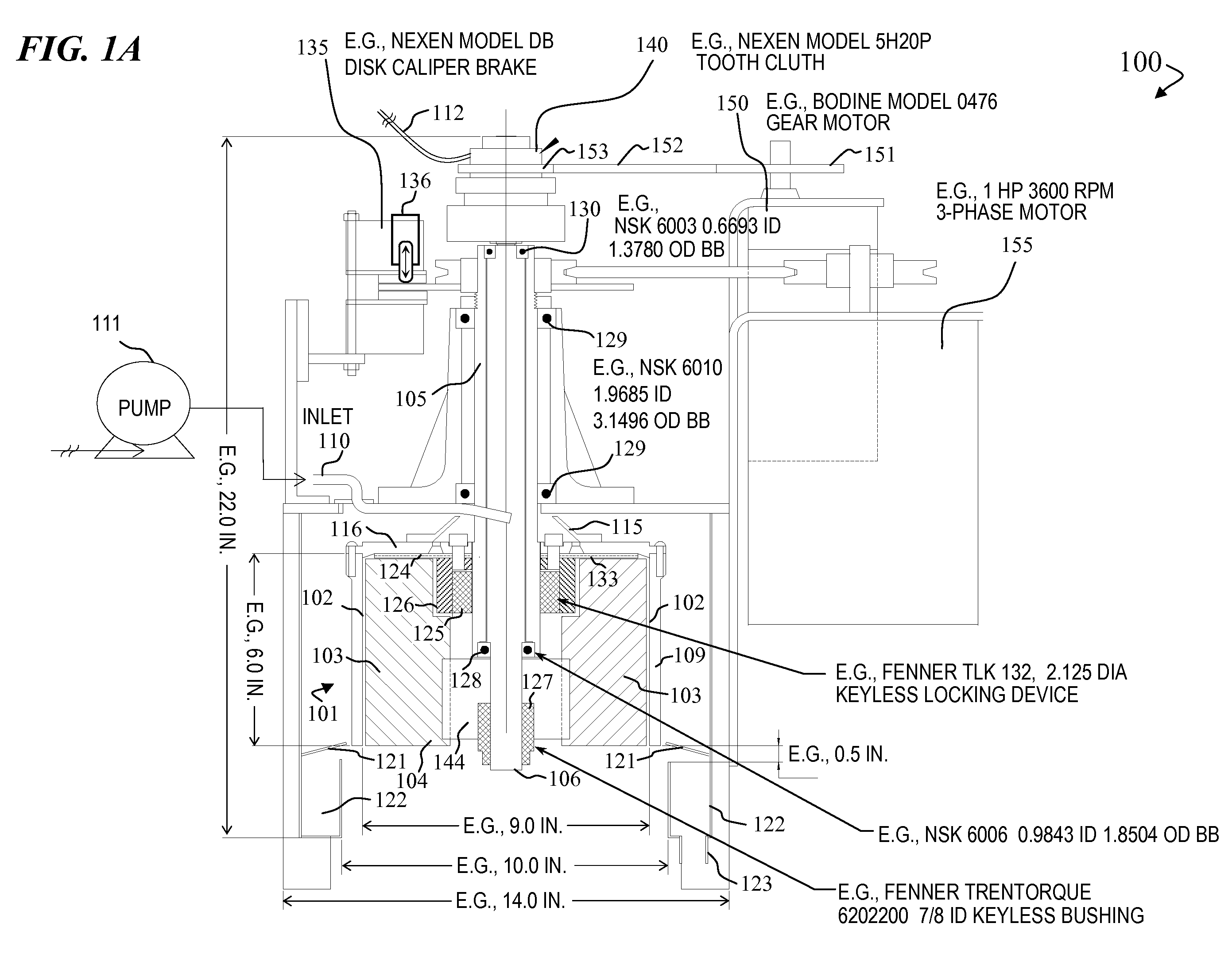

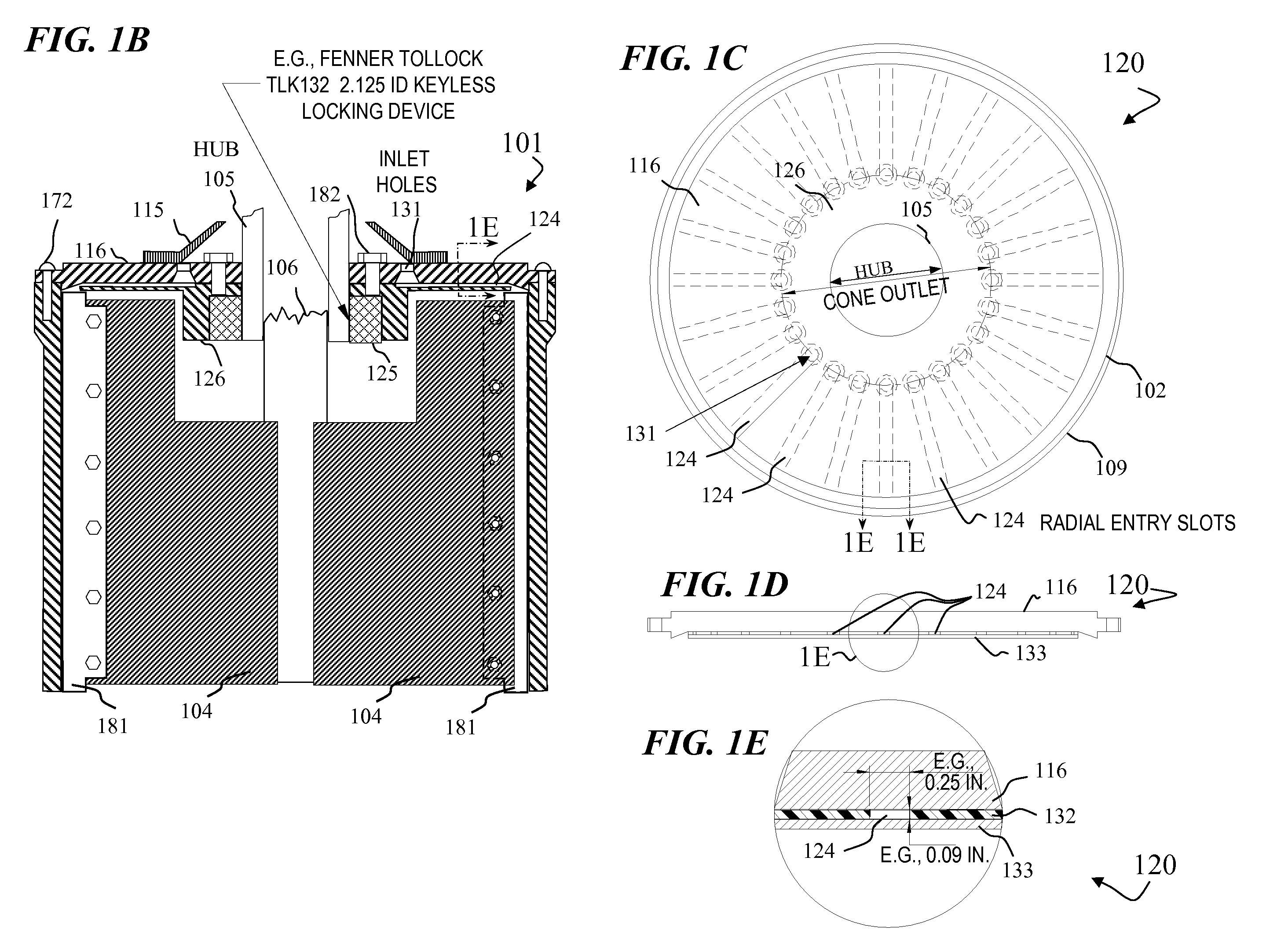

Methods and apparatus for centrifuging dry solids

InactiveUS20080026926A1Reduce fluid contentReduce needRotary centrifugesPurge ConcentrateParticulates

The present invention provides a self-cleaning drying centrifuge for removing fluid from a concentrated particulate-filled fluid and peeling mostly dried particulate (solid) material from the centrifuge. In some embodiments, a high-efficiency centrifuge performs an initial separation and concentration of small particles from a contaminated fluid, and outputs a clarified fluid for reuse, and periodically purges concentrated particulates with high fluid content. The purged concentrate is then fed into the present invention's drying centrifuge, which substantially reduces the remaining fluid content. In some embodiments, the drying centrifuge is periodically stopped and one or more internal blades (peelers) are rotated around the inner wall of the drying centrifuge bowl to peel the accumulated solids, which drop into a collection container. In some embodiments, partial peelers are arranged in a balanced configuration, but each peel portions of the bowl not peeled by others, to reduce the brake size needed to hold the bowl.

Owner:ADVANCED PRODS LAB

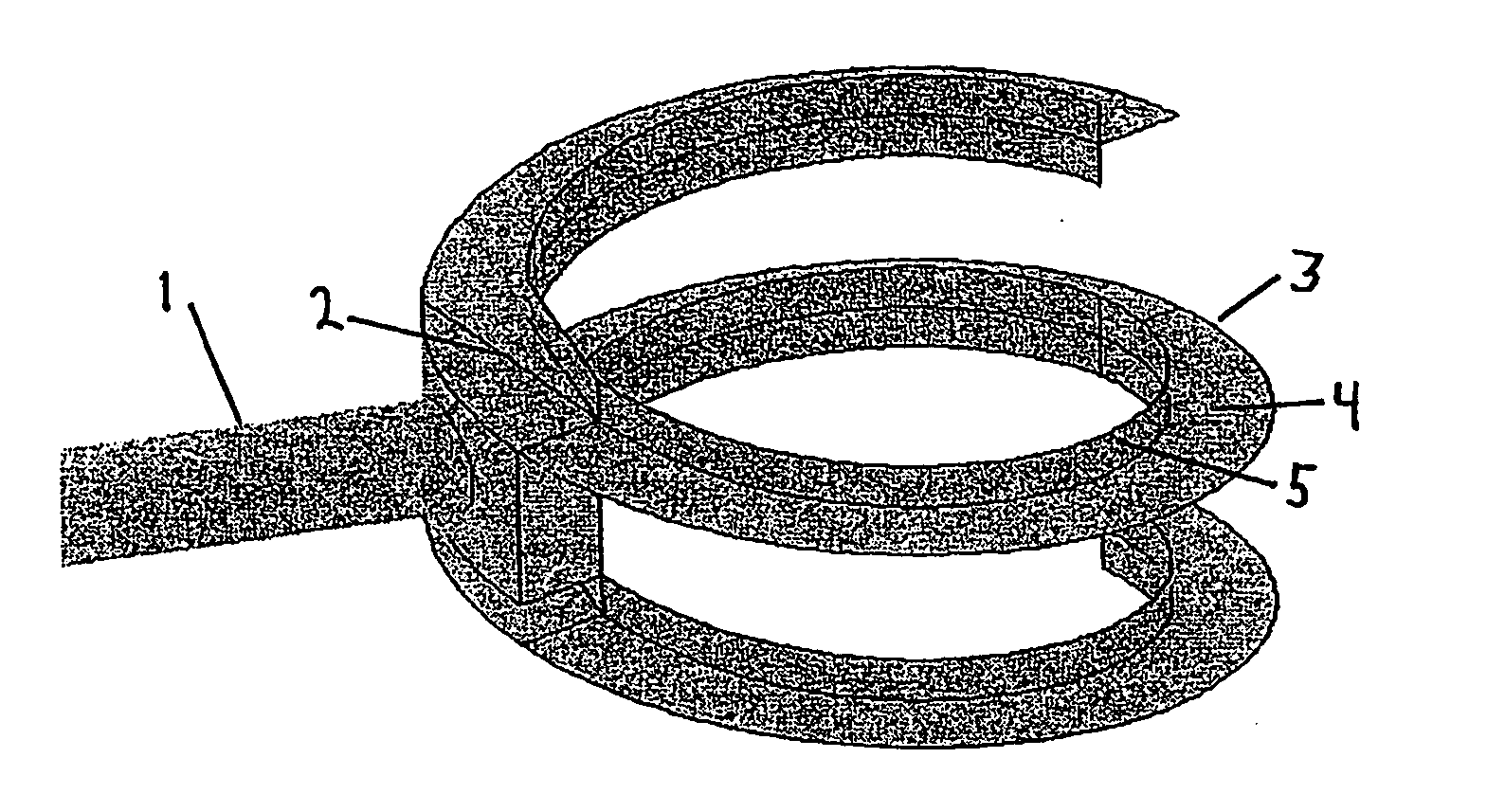

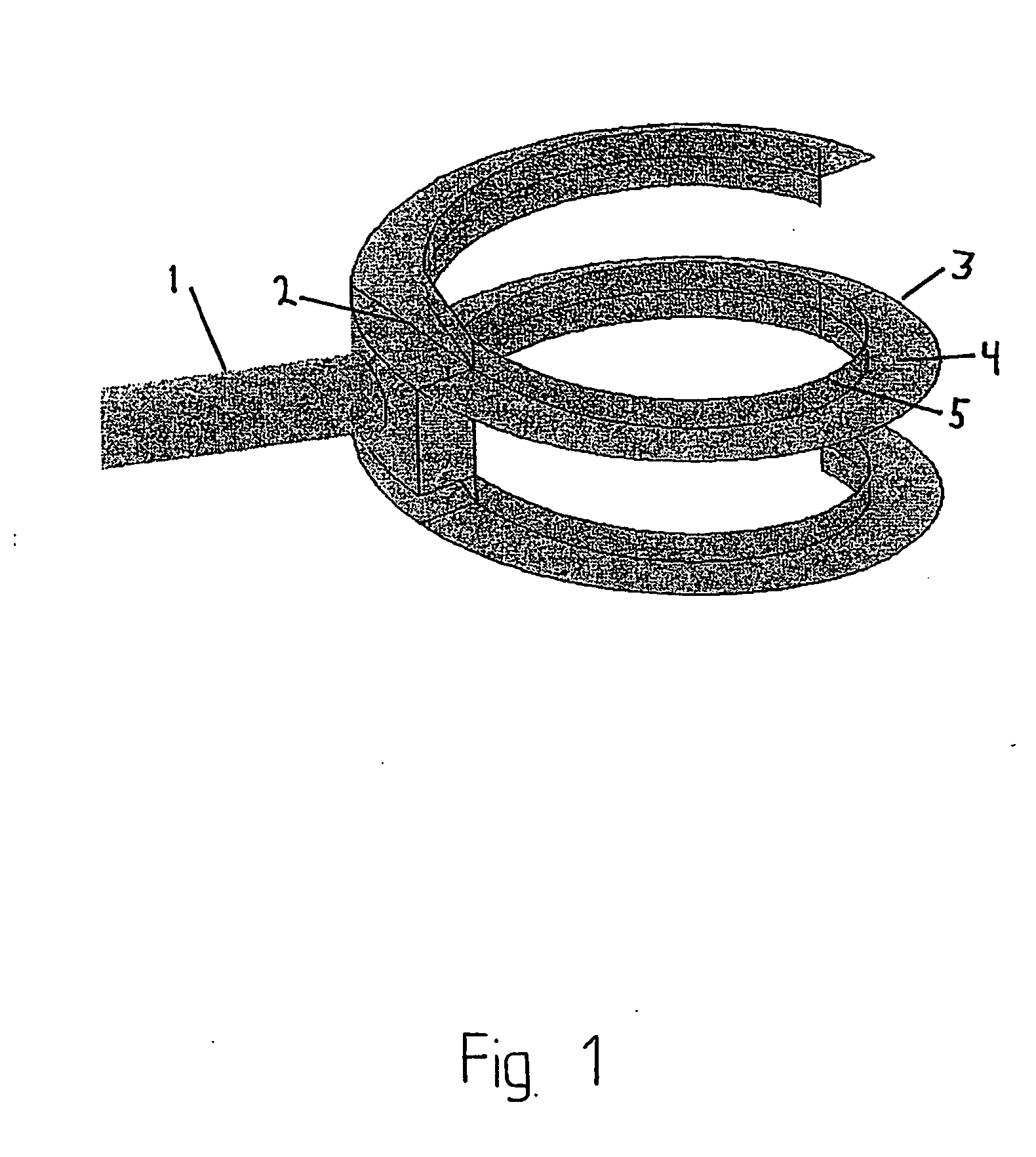

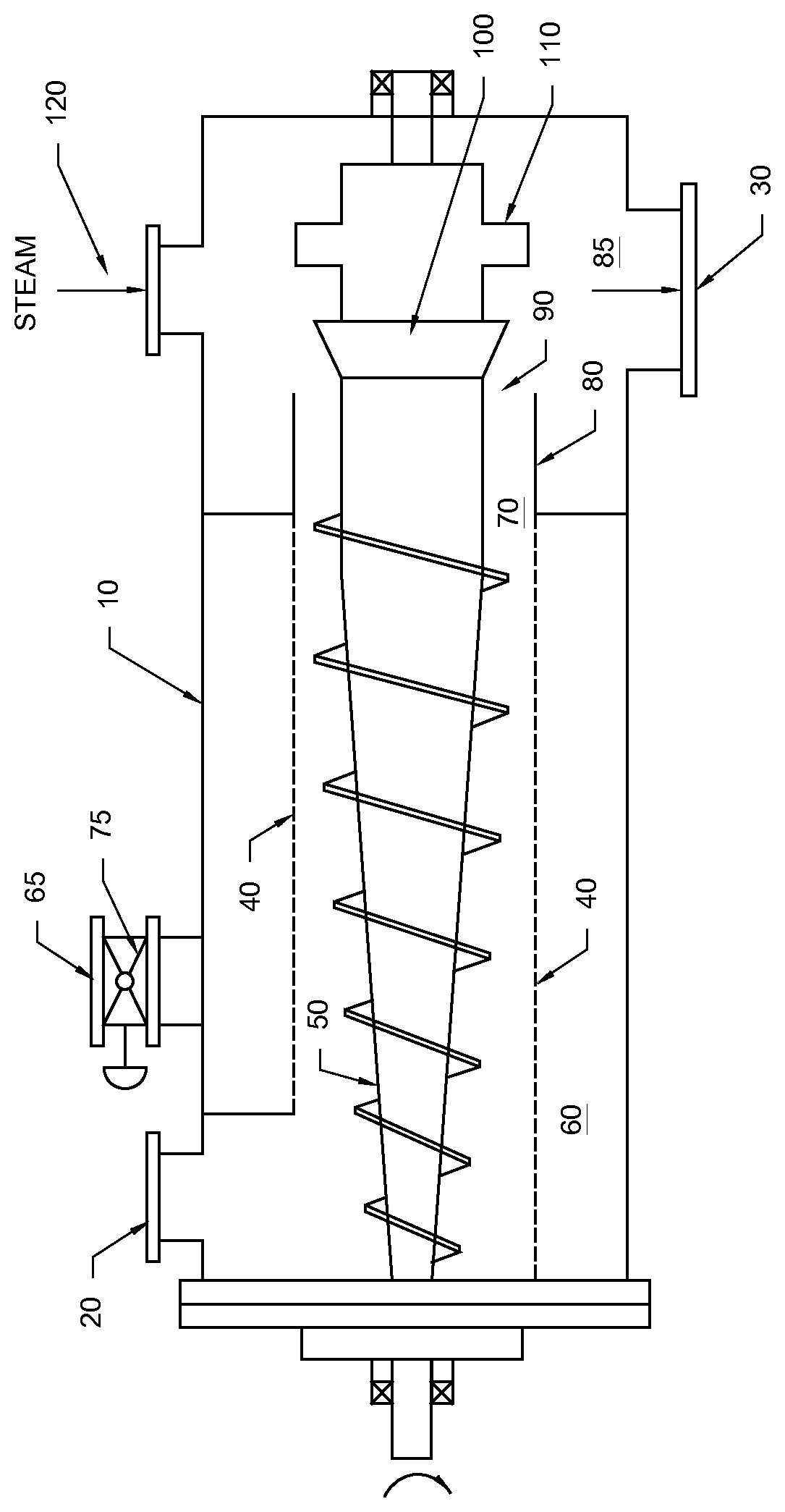

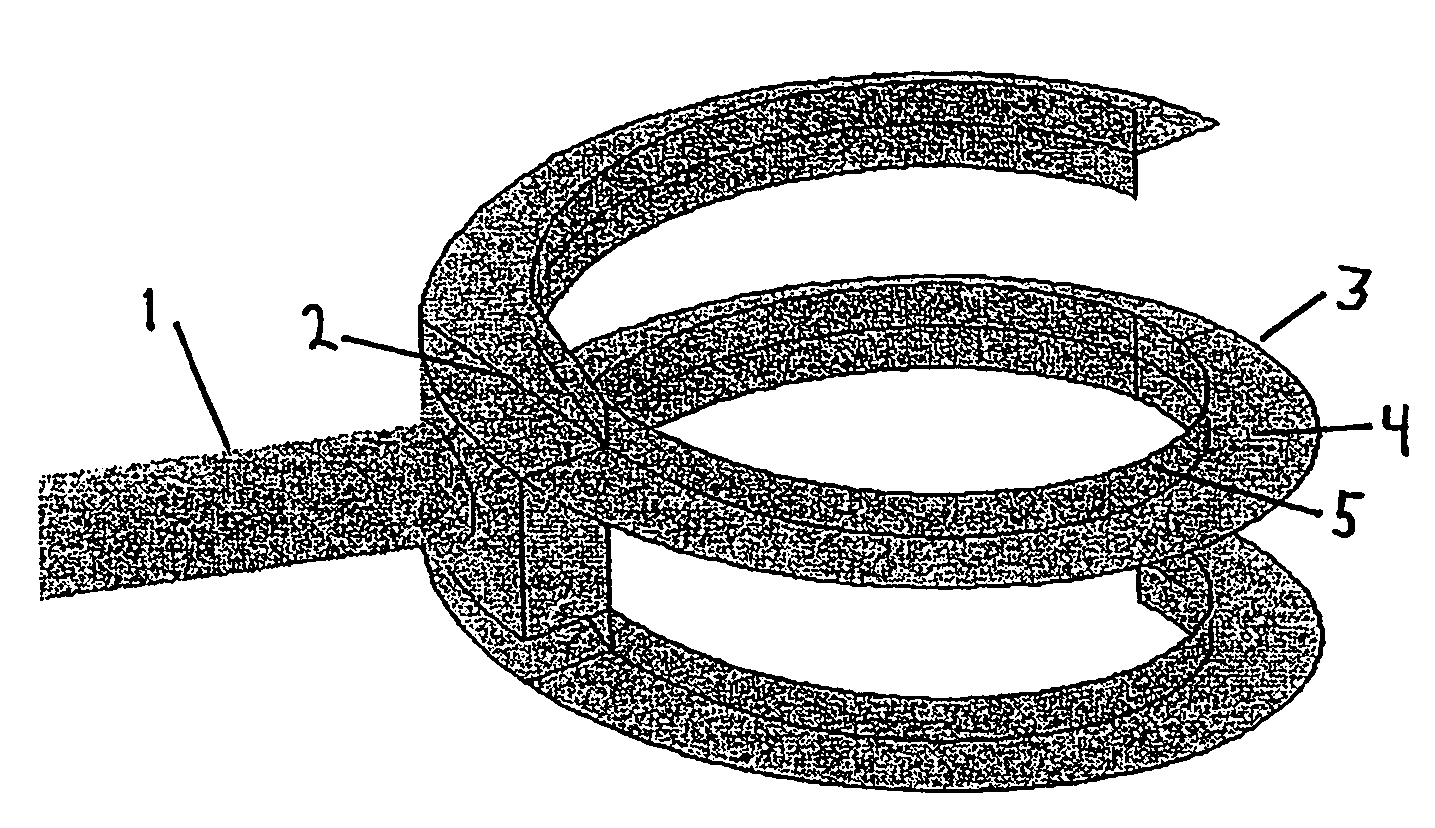

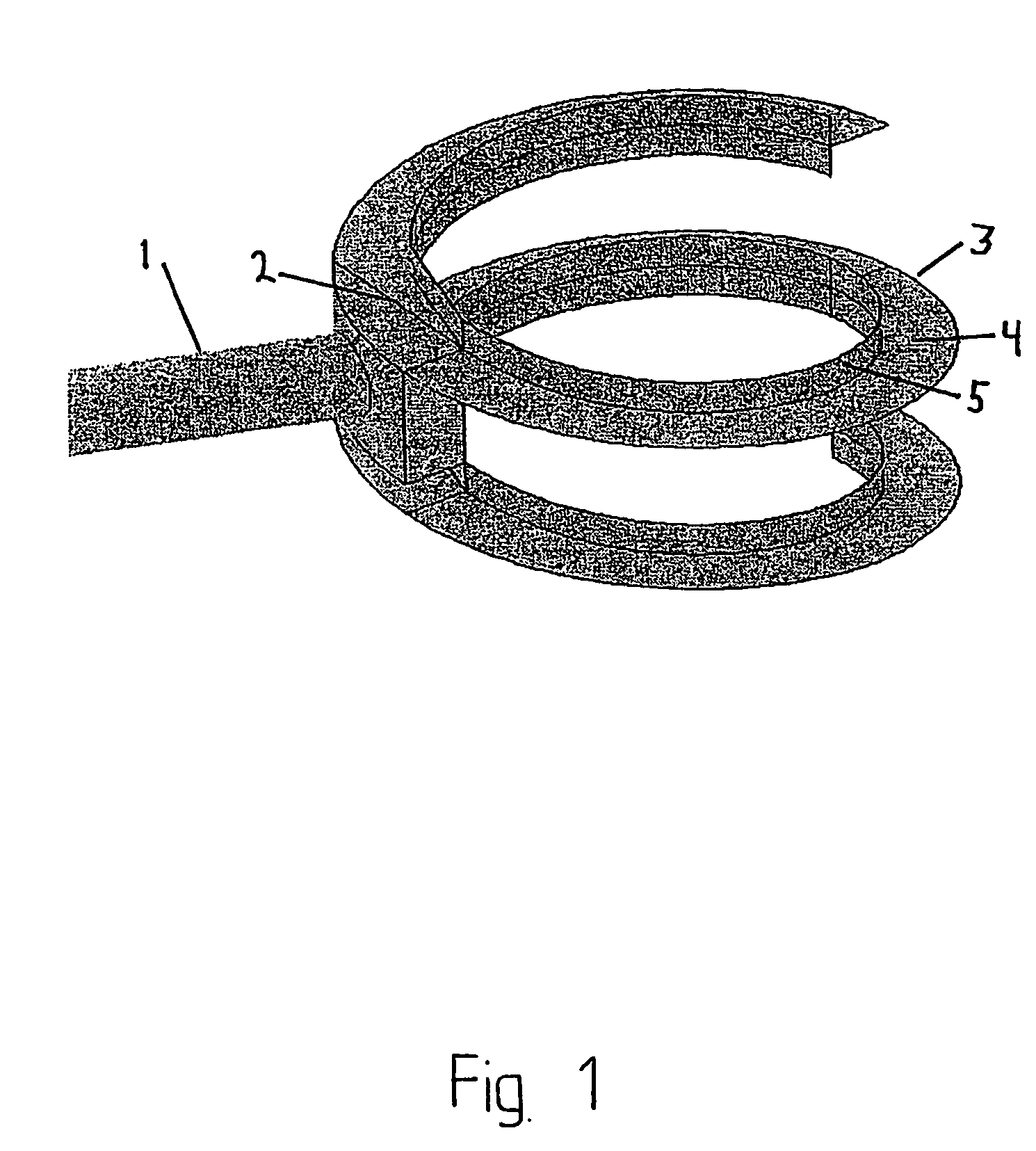

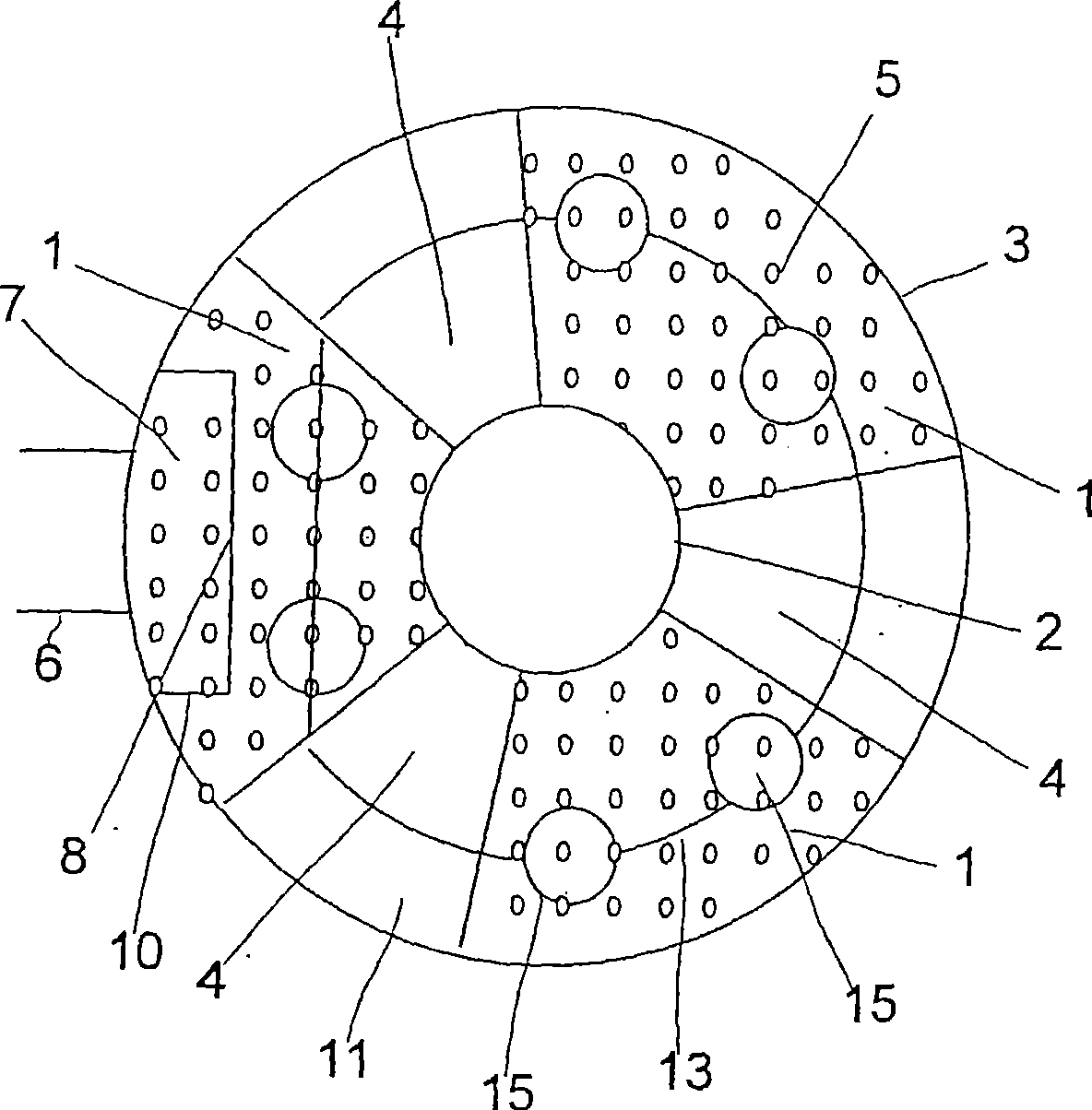

Scum concentration device

ActiveUS20180104621A1High interferenceHigh concentrationSettling tanks feed/dischargeLiquid separationBlood collectionMarine engineering

A scum or floating oil concentration device comprises a scum or floating oil concentration cone (11) and a scum or floating oil conveyor (12). Said scum or floating oil conveyor (12) is arranged above said scum or floating oil concentration cone (11). Said scum or floating oil conveyor (12) comprises a conveying helix (1) rotating around a shaft, a scum or floating oil conveying pipe (2) and a skimmer (3). Said conveying helix (1) is arranged inside said scum or floating oil conveying pipe (2). An opening is arranged on said scum or floating oil conveying pipe (2). Said skimmer (3) is arranged at said opening of said scum or floating oil conveying pipe (2). An inclined separation plate (13) and a scum or floating oil collection and concentration system are further provided in the present invention.

Owner:DALIAN BAY WATER TREATMENT TECH

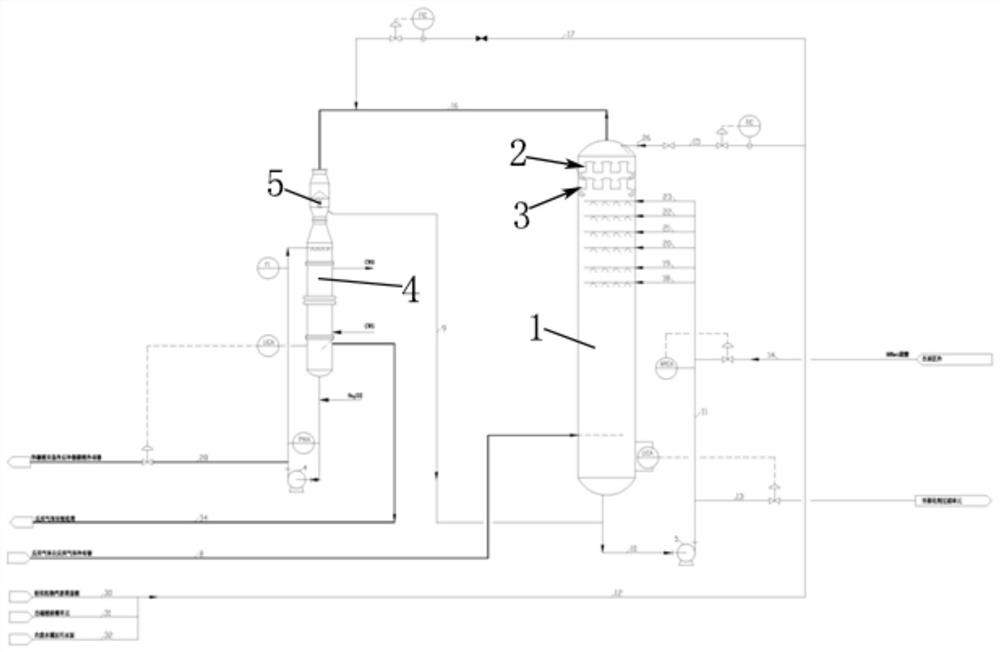

Method for removing acidic liquid in gas phase at top of quench tower of acrylonitrile device

The invention relates to a method for removing acidic liquid in a gas phase at the top of a quench tower of an acrylonitrile device. A first-layer gas-liquid separation tower internal part and a second-layer gas-liquid separation tower internal part are arranged in the top of a quench tower, a quench tower demister is arranged between a quench tower top gas phase outlet and an inlet of a quench after-cooler, and a quench tower top gas phase passes through the quench tower top gas phase outlet to the quench tower demister and then is sent into the quench after-cooler. The method provided by theinvention can effectively remove the acidic liquid in the gas phase at the top of the tower.

Owner:中石油吉林化工工程有限公司

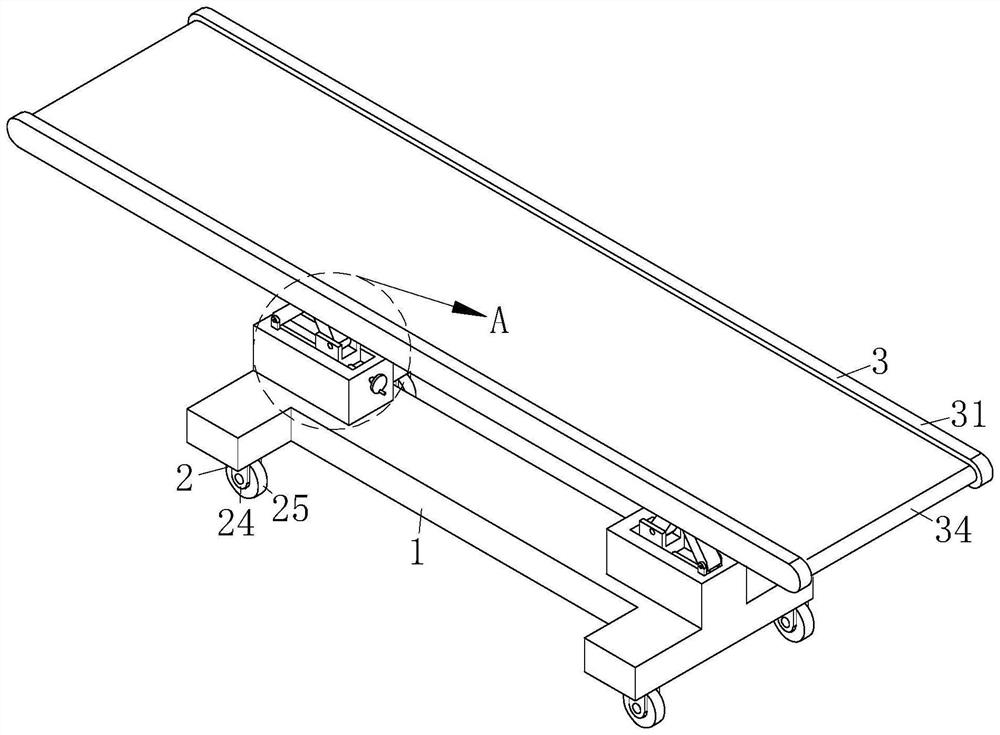

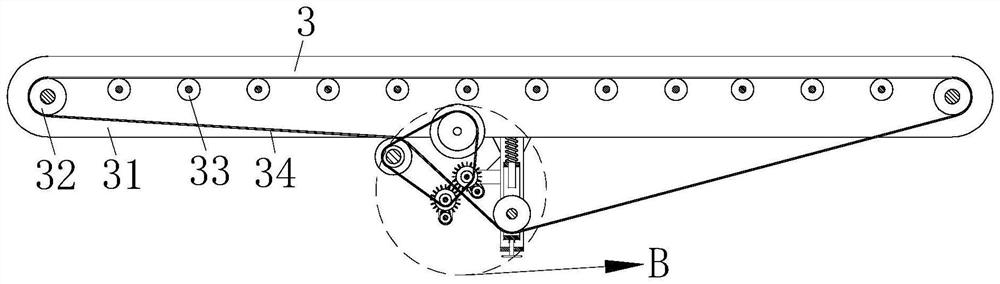

Adjustable conveying device for conveying, loading and incinerating garbage

Owner:邳州市交控新能源发展有限公司

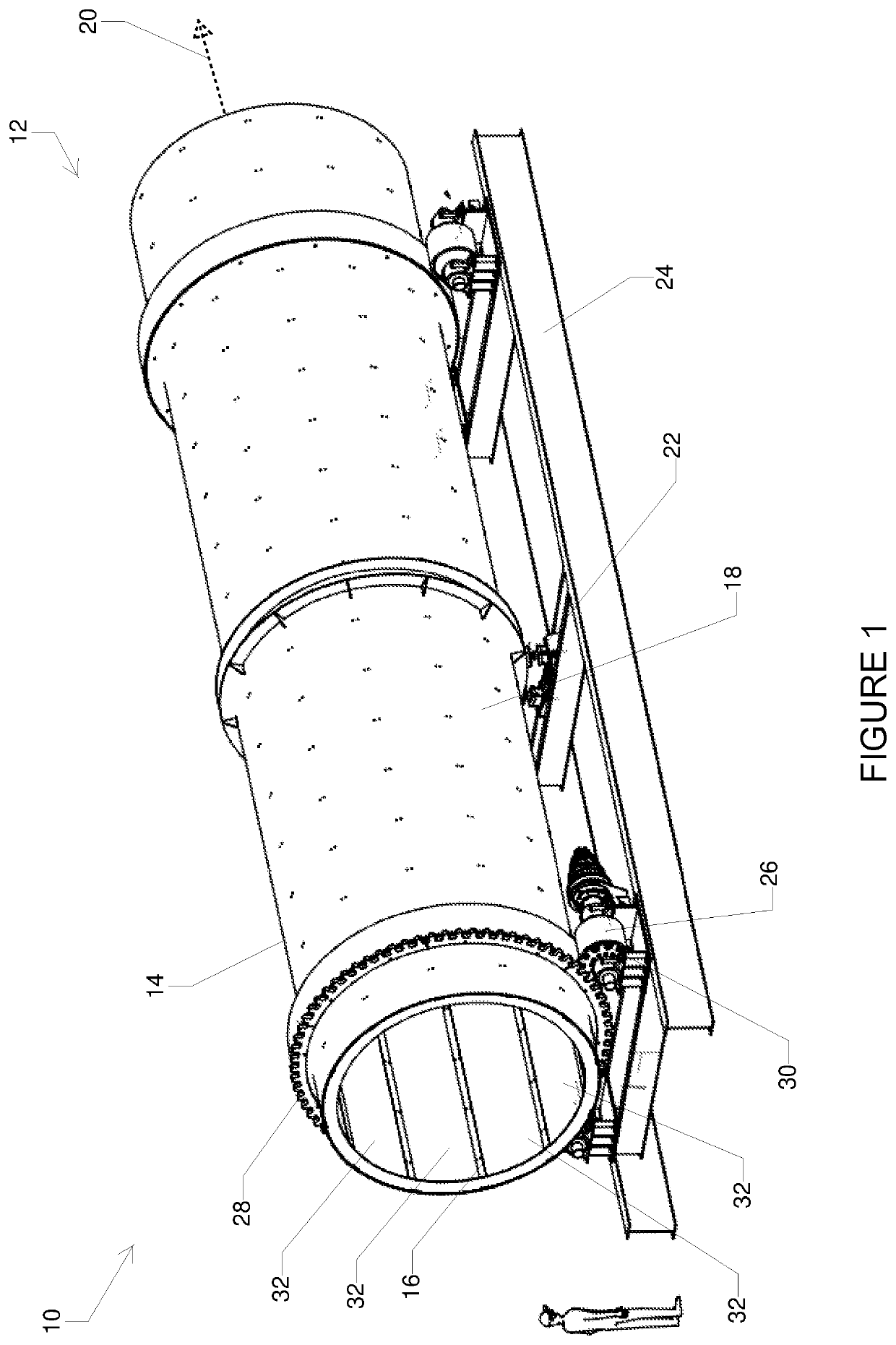

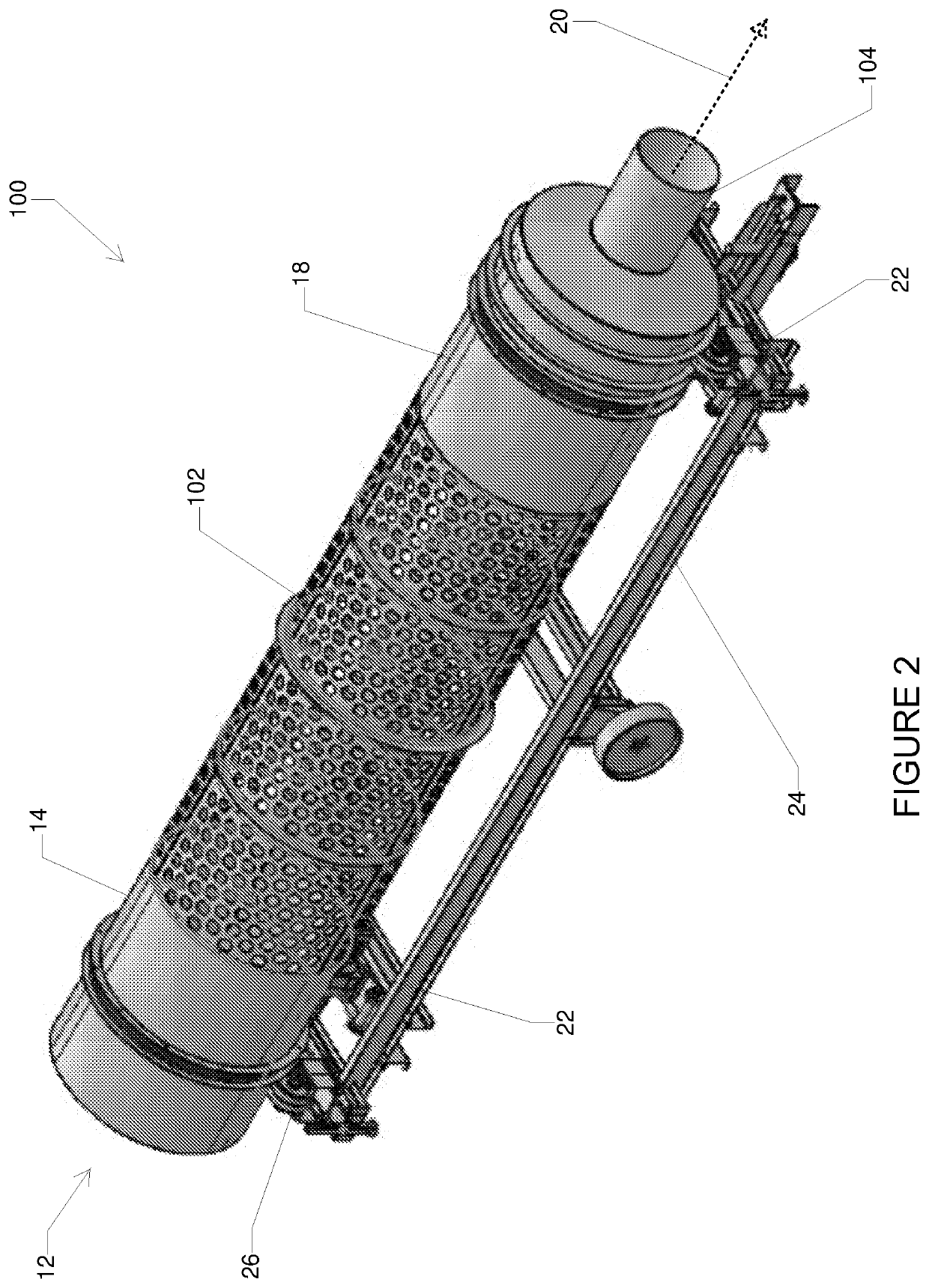

Pellet Processing Drum

PendingUS20220057139A1High water removal rateGood removal effectDrying solid materials with heatDrying solid materials without heatEngineeringMechanical engineering

The present invention relates to a desiccation apparatus, the apparatus comprising: a hollow drum mounted for revolution about a substantially longitudinal axis, the drum comprising a shell having an interior surface and an exterior surface; and a means to generate airflow through the hollow drum.

Owner:PELLETON GLOBAL RENEWABLES LTD

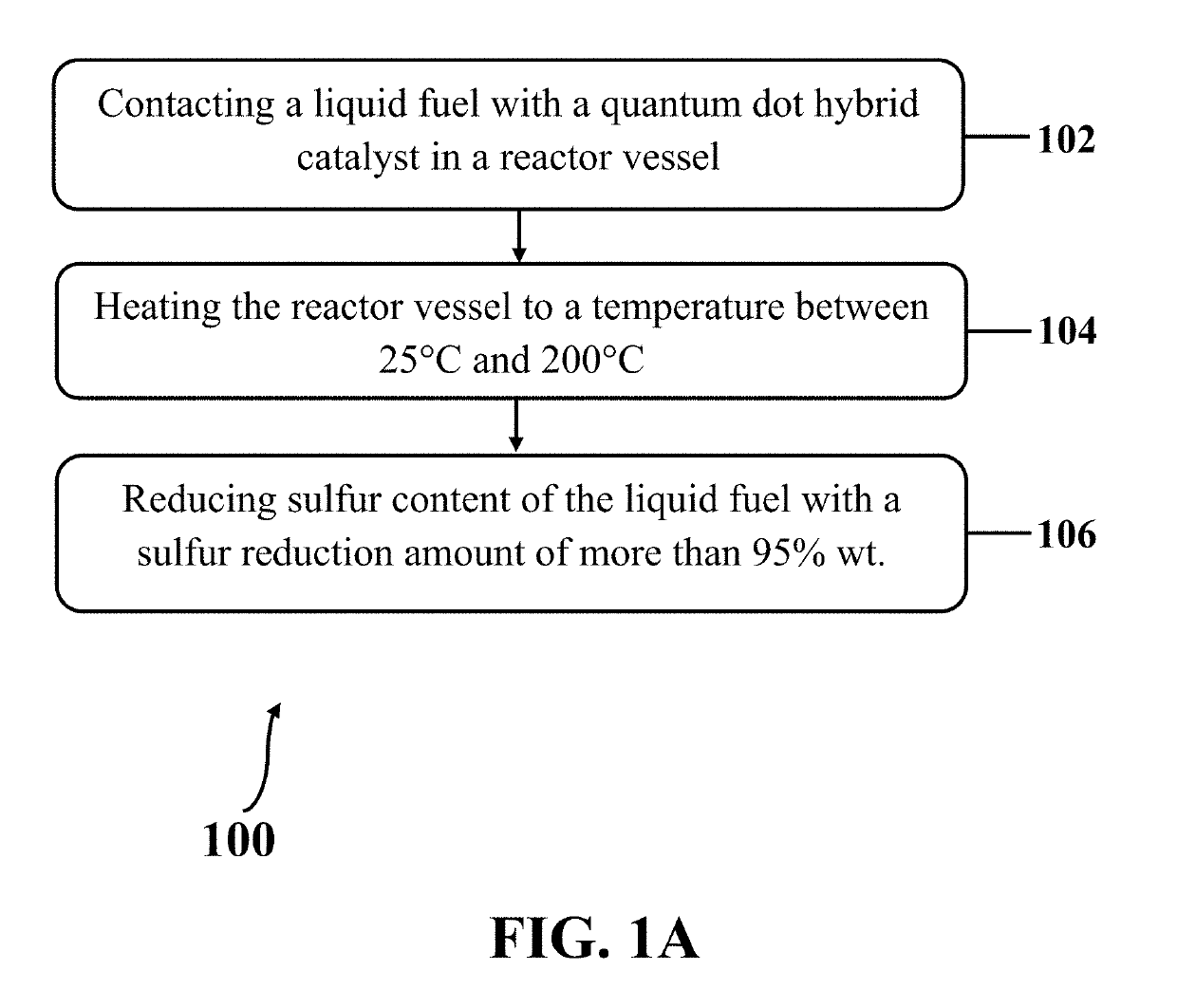

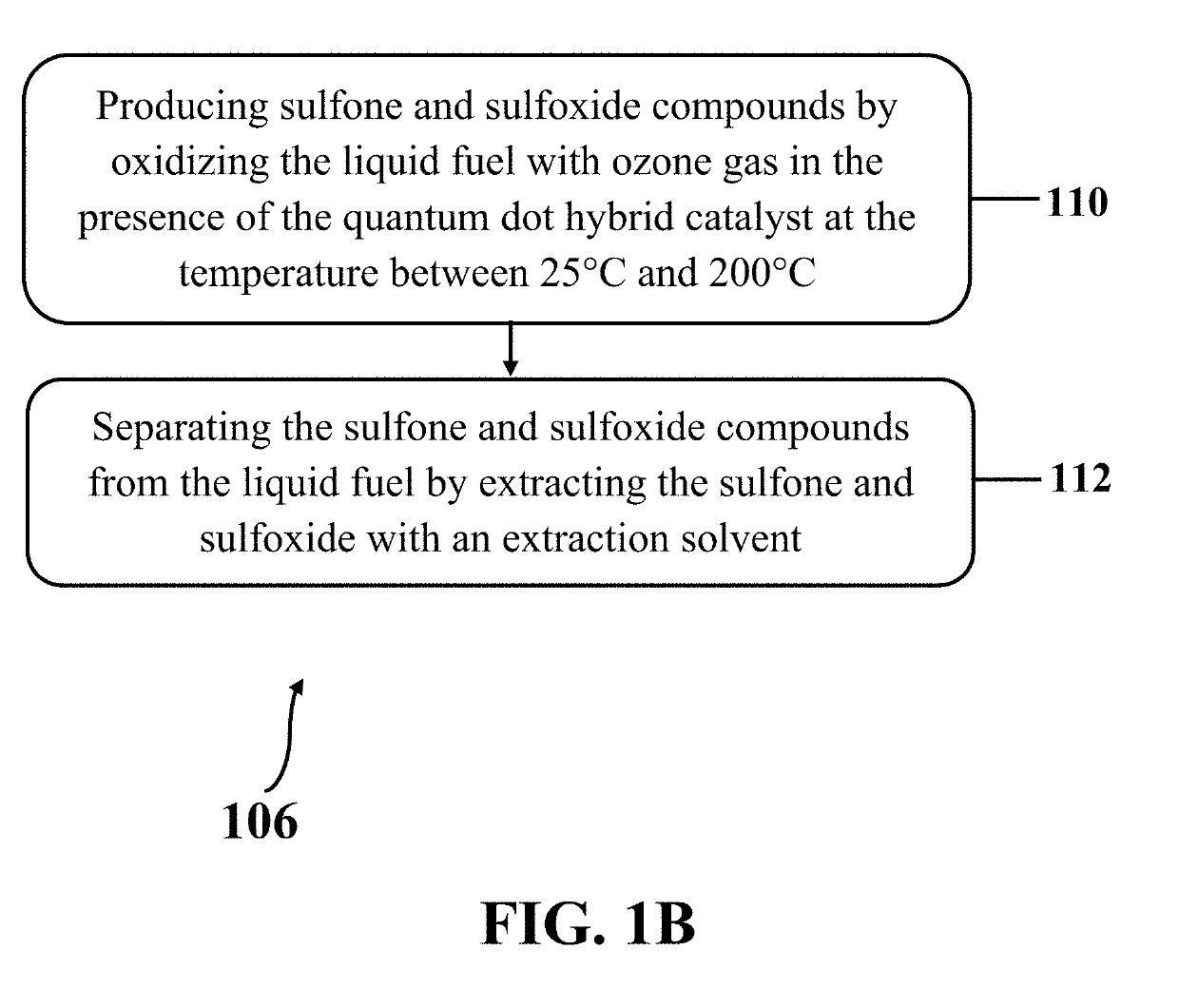

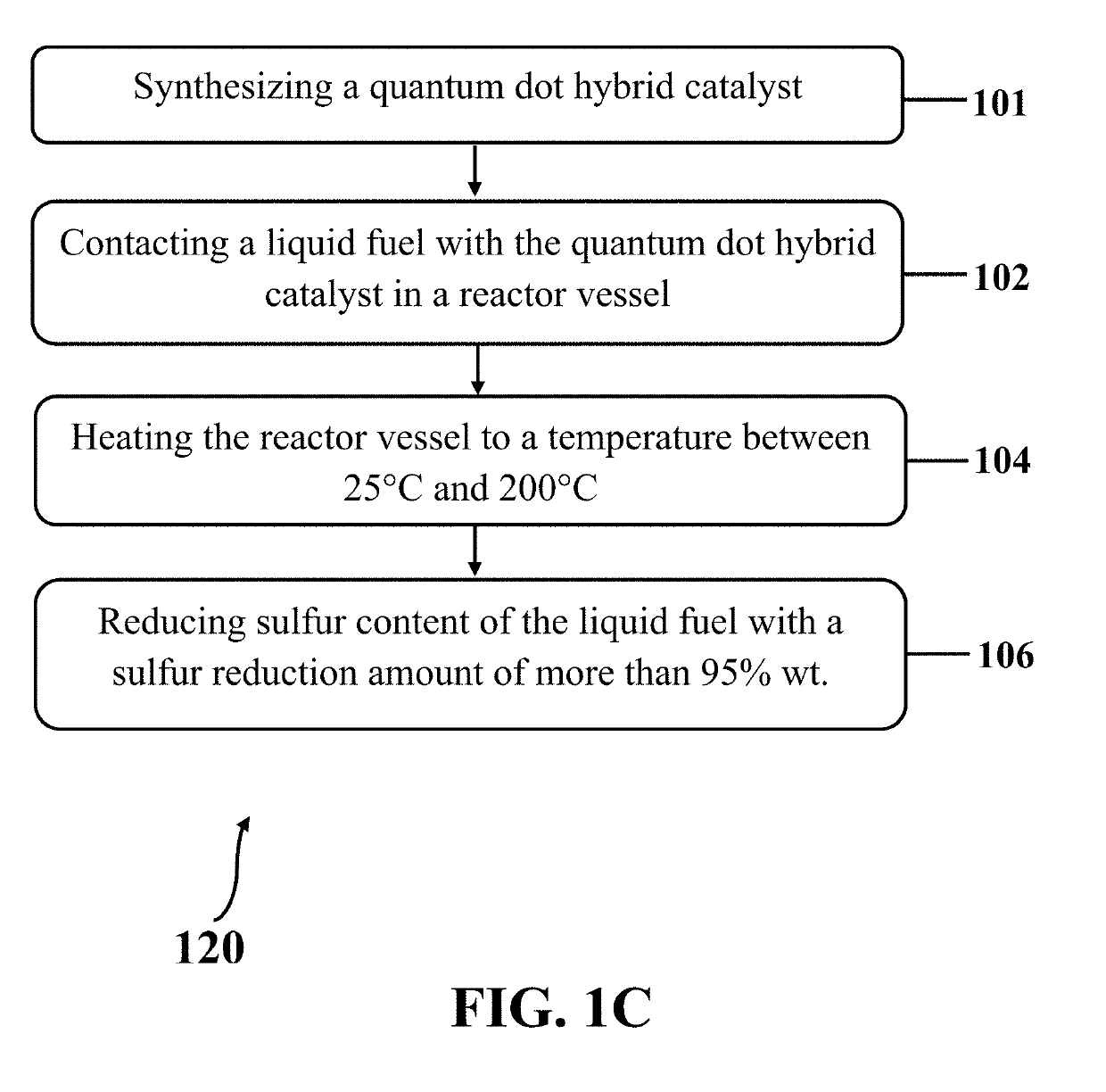

Oxidative desulfurization of liquid fuels using metal sulfide quantum dots/graphen oxid hybrid nanocatalyst

ActiveUS20190194556A1Reduce sulfur contentReduce liquid contentRefining with oxygen compoundsCatalyst activation/preparationNano catalystQuantum dot

A method for oxidative desulfurization of liquid hydrocarbon fuels is disclosed. The method includes contacting a liquid fuel with a quantum dot hybrid catalyst including metal sulfide quantum dots intercalated over graphene oxide layers in a reactor vessel, heating the reactor vessel to a temperature between 25° C. and 200° C., and reducing sulfur content of the liquid fuel with a sulfur reduction amount of more than 95% wt. Reducing the sulfur content of the liquid fuel with the sulfur reduction amount of more than 95% wt. includes producing sulfone and sulfoxide compounds by oxidizing the liquid fuel with ozone gas in the presence of the quantum dot hybrid catalyst at the temperature between 25° C. and 200° C., and separating the sulfone and sulfoxide compounds from the liquid fuel by extracting the sulfone and sulfoxide with an extraction solvent.

Owner:SAFAEI MAHMOUDABADI ZOHAL +4

Method for removing liquid from a slurry

The method includes the following steps: (i) feeding a slurry into the inlet of a press; (ii) removing liquid from the slurry as the slurry advances through a deliquefying section of the press, thereby producing a pressate stream; (iii) forming a plug of material as the slurry is advanced through a plug formation section of the press; (iv) advancing the plug of material to a discharge section of the press; and (v) removing additional liquid from the plug of material by operating the press so that the pressure in the discharge section of the press is greater than the pressure of the pressate stream by at least 2 psi. There is also described a method for controlling discharge consistency from a press, without provision of discharge restrictors, by varying a pressure differential between a discharge section of the press and a pressate stream.

Owner:IOGEN ENERGY CORP +1

Household garbage treatment equipment

InactiveCN111346418APrevent rotationGuaranteed normal rotationGrain treatmentsMoving filtering element filtersStructural engineeringRefuse Disposals

The invention relates to household garbage treatment equipment which comprises a machine body and a smashing assembly used for smashing garbage; an inner cavity is formed in the machine body, the smashing assembly is arranged in the inner cavity; a discharge hole is formed in the side part of the machine body; a separation piece for separating solid-liquid garbage is arranged on the cavity wall ofthe inner cavity; the separation piece is positioned below the smashing assembly; the machine body is provided with an installation opening for the separation piece to penetrate into the inner cavity. The separation piece comprises a connecting frame and a first filter plate; a first filter hole is formed in the first filter plate; the connecting frame comprises a frame body and a groove formed in the inner side wall of the frame body. The end, facing the discharging port, of the first filter plate is hinged to the end of the frame body, an extending block used for being embedded into the groove is arranged on the side of the first filter plate, a rotation limiting assembly used for limiting rotation of the first filter plate is arranged on the frame body, and a first driving assembly used for driving the first filter plate to rotate in a reciprocating mode is arranged on the machine body. The equipment has the effect of preventing liquid in garbage from polluting the environment along the way in the transportation process of the crushed garbage.

Owner:深圳深南环境发展有限公司

Scrubber

ActiveUS8066804B2Easy to separateReduced liquid fractionReversed direction vortexUsing liquid separation agentEngineeringScrubber

A scrubber for separation of liquid phase and any other constituents from a fluid now that in substance includes a gas. The scrubber is formed as a standing vessel with round cross section, with an outlet for liquid from the bottom and an outlet for gas from the top. The scrubber is distinguished in includes a fluid inlet that either is tangentially oriented relative to the inner wall of the scrubber or equipped with a deflection plate, such that introduced fluid is directed tangentially horizontal or with a small downward slope along the inner wall of the scrubber, into and through a fluid way arranged as a downwards directed spiral within the scrubber, along the inner wall, from a level over or at the inlet to a level at or close to the outlet for liquid, with an opening for gas escape inwards toward the center of the scrubber. The scrubber according to the invention results in very low liquid entrainment.

Owner:DEN NORSKE STATS OLJESELSKAP AS

Tofu press and method of removing liquid from tofu

ActiveUS10238139B2Increase pressureEasy to storeCheese manufactureFood shapingBiomedical engineeringLiquid content

Tofu is typically sold saturated in liquid, and in order for the tofu to take on a desired flavour, the liquid content of the tofu must first be reduced. The present invention provides a method of reducing the liquid content of tofu and a tofu press 10, comprising: a tray 20 for receiving tofu 30 therein; a pressure member 80 for applying pressure to the tofu 30 within the tray 20; and a toggle latch 120 releasably coupleable between the tray 20 and the pressure member 80 such that pressure is applied to the tofu 30 within the tray by the pressure member 80.

Owner:TOFUTURE

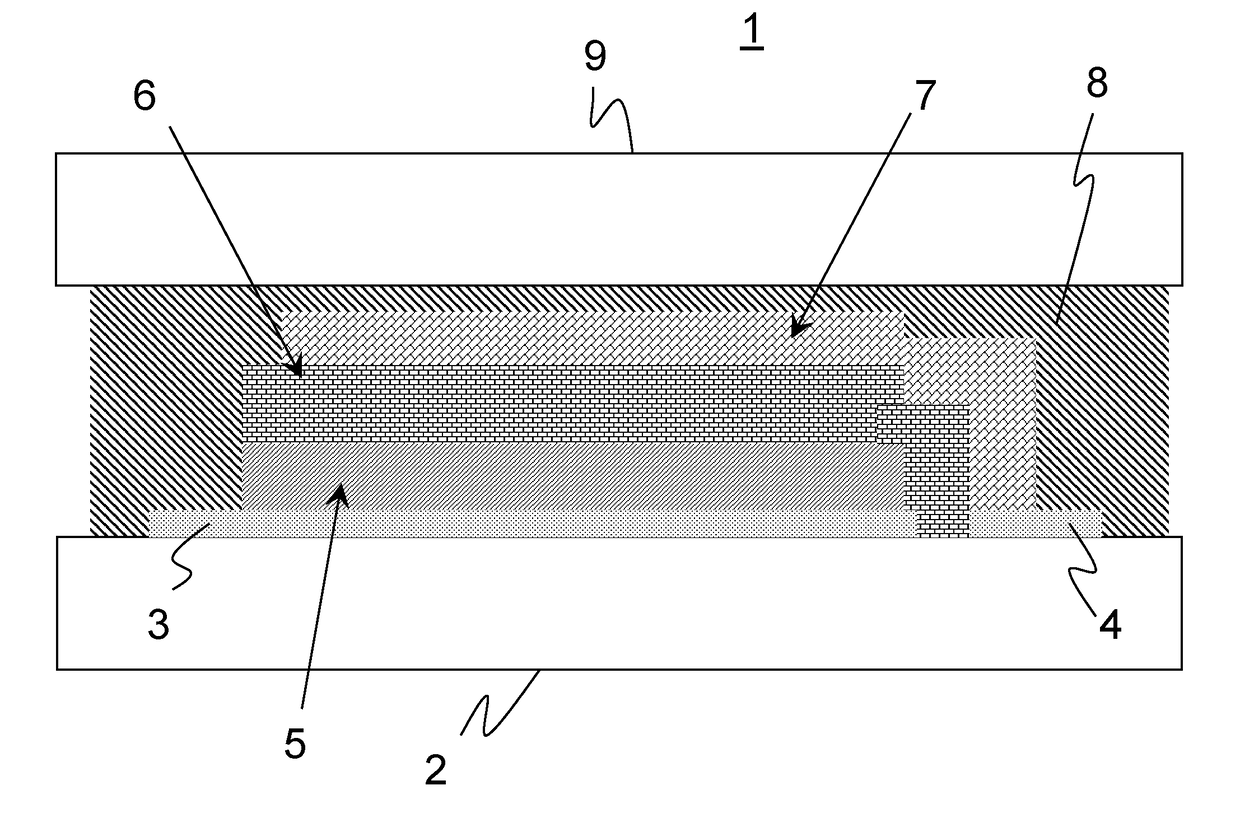

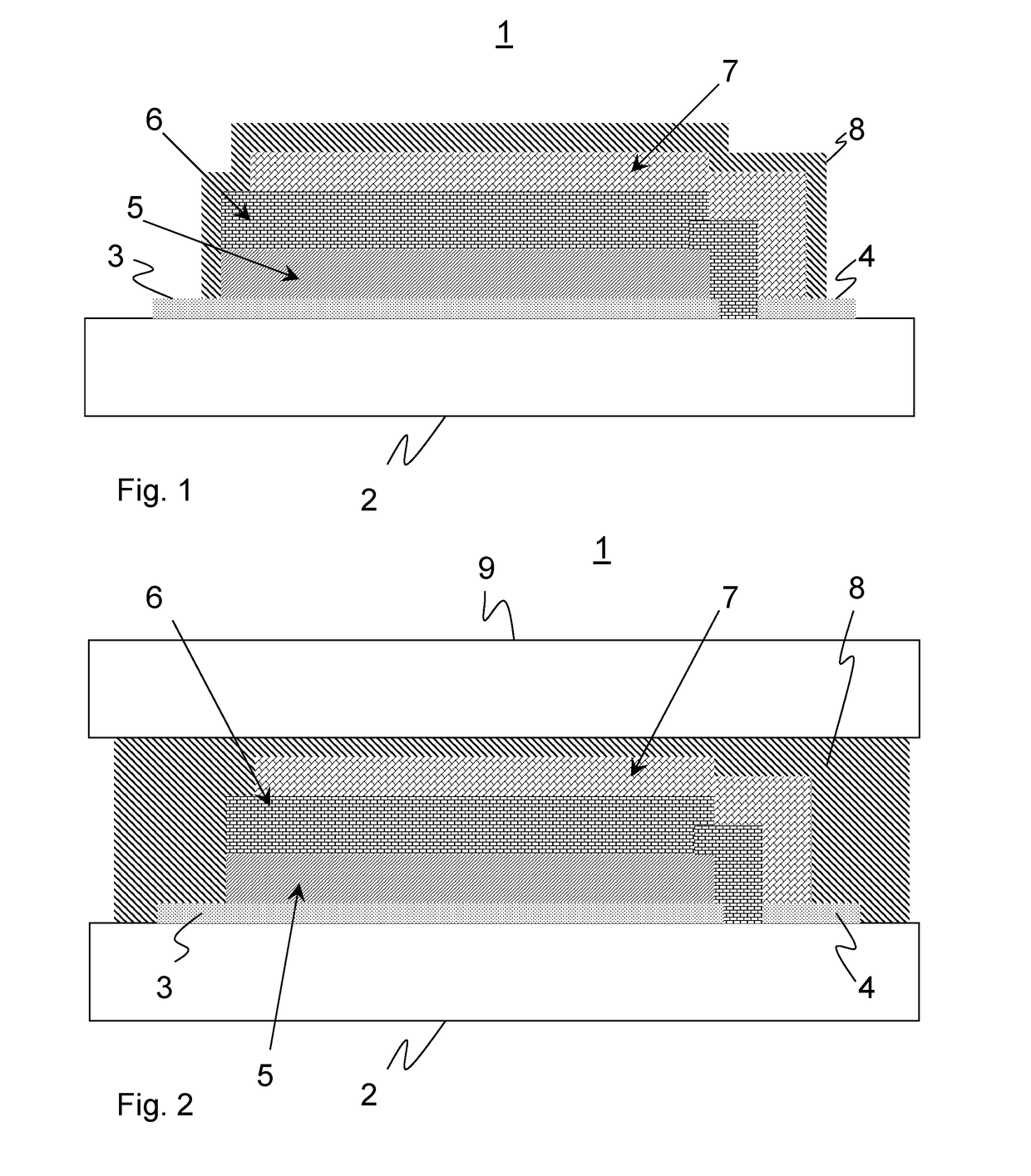

Thin film battery having low fluid content and an increased service life

InactiveUS20170104188A1Extended service lifeReduce contentFinal product manufactureSmall-sized cells cases/jacketsElectrical batteryEngineering

A thin film battery is provided that has an increased service life and low fluid content. The fluid content is at most 2000 ppm, preferably at most 500 ppm, particularly preferably at most 200 ppm, and most preferably at most 50 ppm. An inorganic, silicon-containing, in particular silicate, substantially fluid-free material for thin film batteries are provided, as well as methods for producing such thin film batteries.

Owner:SCHOTT AG

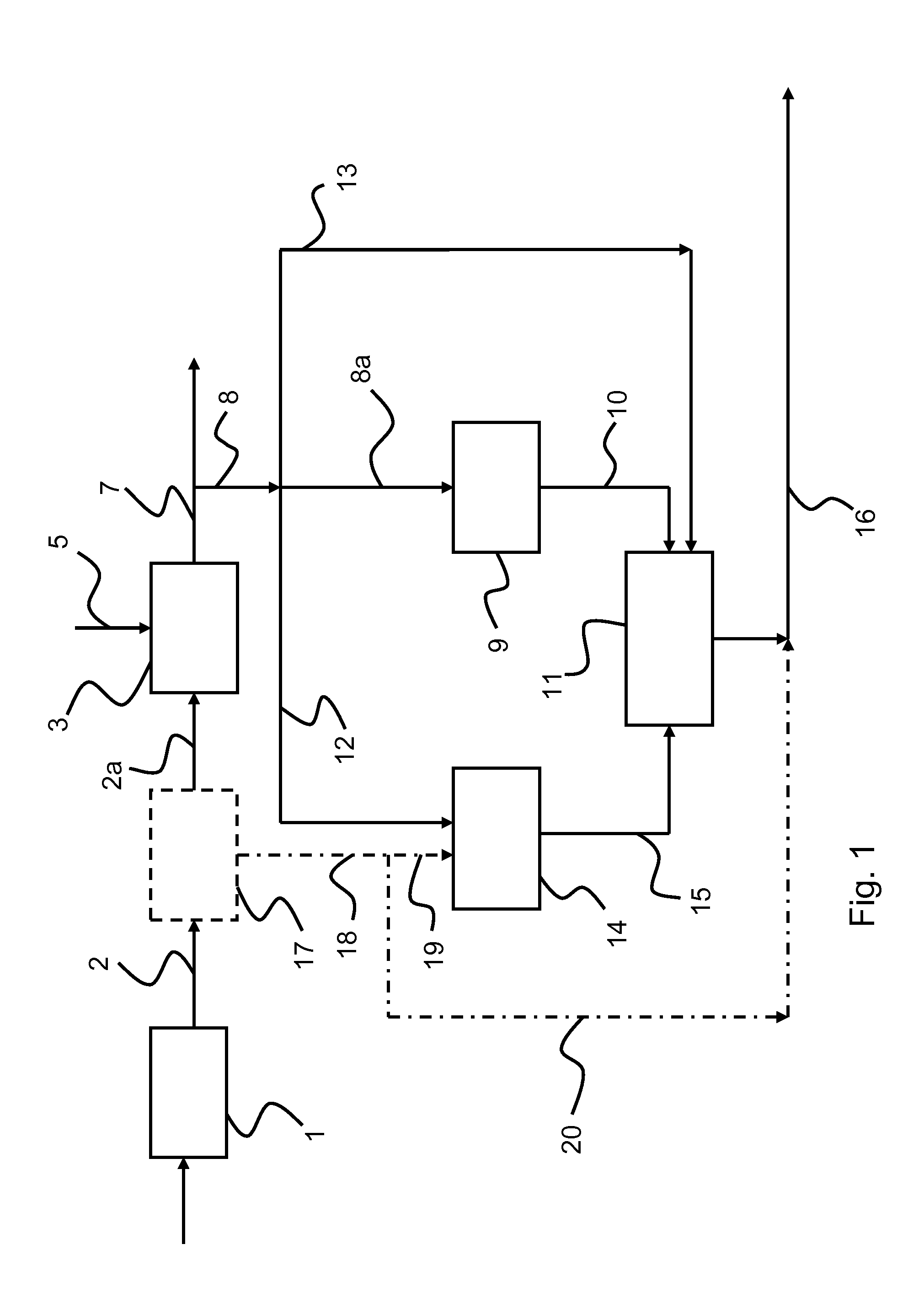

Process for the production of oligosaccharides from lignocellulosic biomass

A process for producing oligosaccharides from lignocellulosic biomass, having the following steps:a) pre-treating the biomass in a pre-treatment reactor (1) in order to provide an effluent containing a pre-treated substrate;b) enzymatic hydrolysis of the pre-treated substrate contained in the effluent from step a) in a reactor, in the presence of cellulases such that a hydrolysate containing glucose, cellulases and water is produced;c) removing at least a portion of the hydrolysate from step b) comprising a liquid fraction;d) reducing the water content of said portion of the hydrolysate in step c) such that the liquid fraction of the hydrolysate has a water content of less than 65% by weight with respect to the total weight of the liquid fraction;e) incubating the hydrolysate from step d) at a temperature in the range 40° C. to 70° C. for the time necessary to produce an effluent enriched in oligosaccharides.

Owner:INST FR DU PETROLE

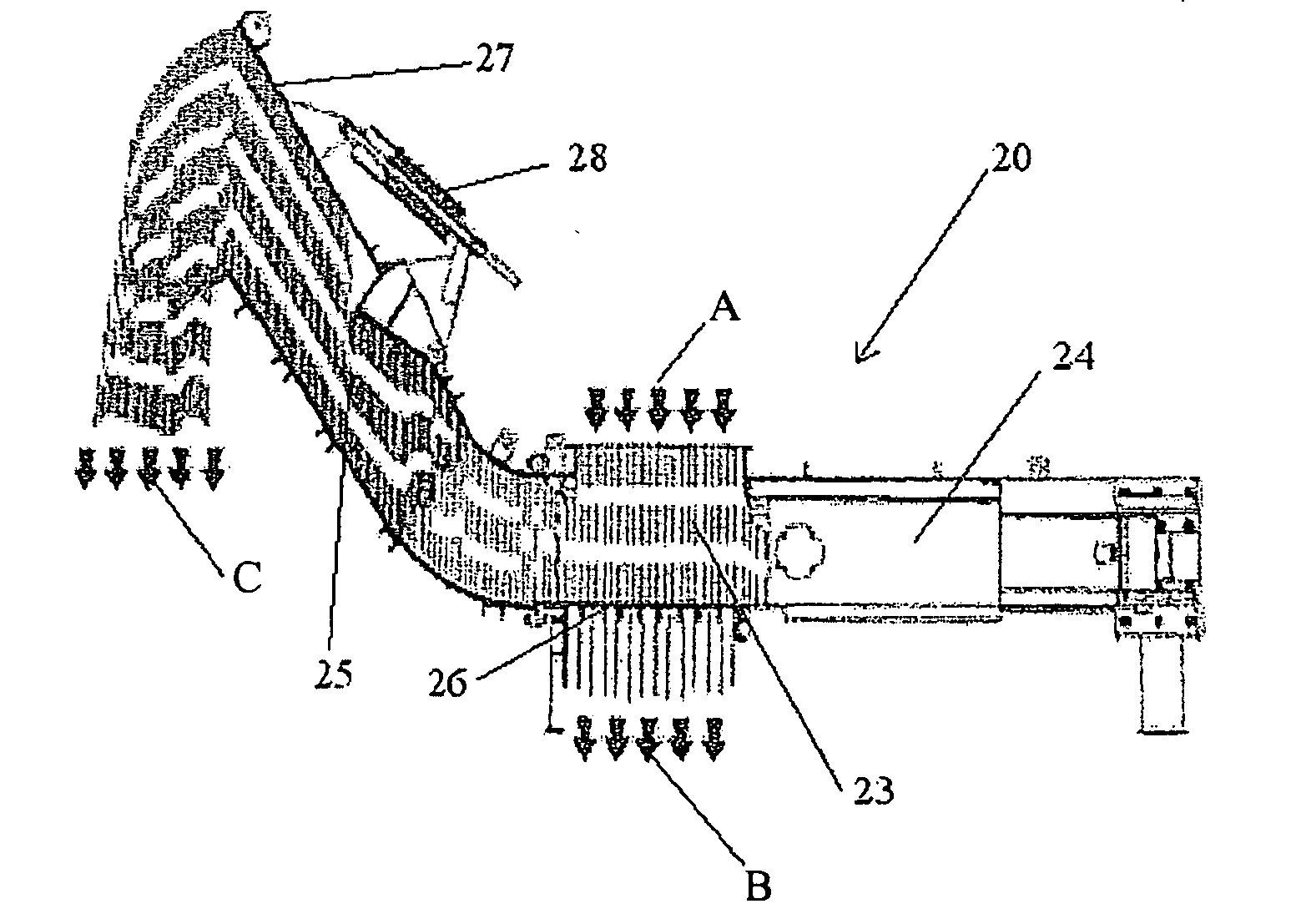

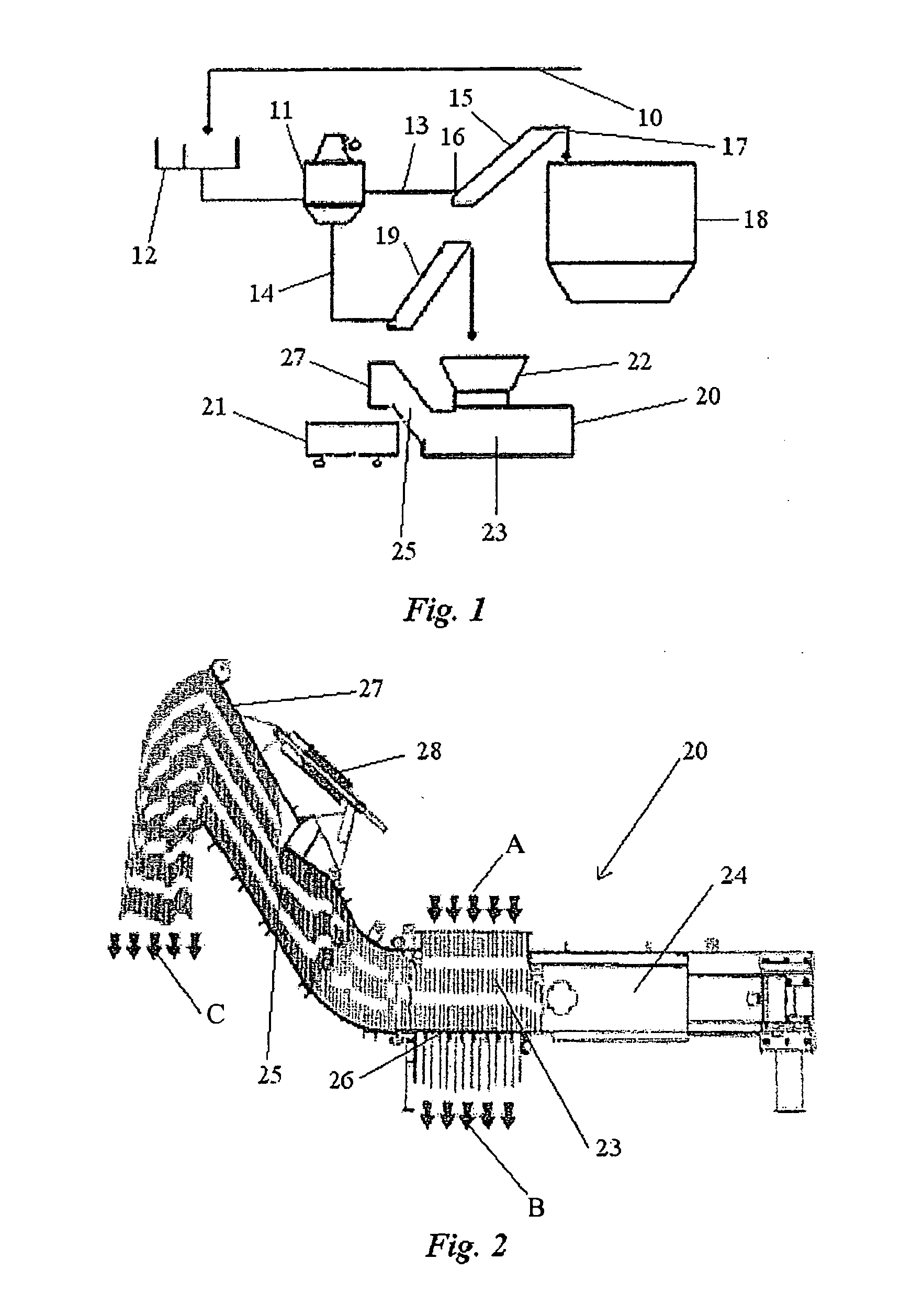

Method and apparatus for the integrated cleaning of a paper-pulp processing plant

InactiveUS20090272504A1Easy disposalReduce liquid contentFats/resins/pitch/waxes removal in pulpDryer sectionHigh densityProcess engineering

A method for the integrated cleaning of a paper-pulp processing plant including one or more high density cleaners comprising the steps of supplying the rejected flow (10) from one of the high density cleaners to a screening centrifugal separator (11); screening out contaminants in the separator (11) using a screen hole size of less than 3.5 mm; thickening any fibrous material accepted by the separator (11) and returning same to stock being processed in the processing plant; and recovering liquid (B) from any material (A) rejected by the separator (11) prior to disposing of the material. The invention further comprises an apparatus for performing the method.

Owner:INDAL TECH & SERVICES

Rolled heat exchanger

InactiveCN101006316BIncrease preloadIncrease liquid contentSolidificationLiquefactionPlate heat exchangerMain channel

The invention relates to a rolled heat exchanger comprising several pipes wound around a central pipe, a casing delimiting the external space around the pipes and a liquid distributor for distributing liquid in the external space. According to the invention, the liquid distributor is embodied in the form of a pipe manifold comprising a main channel (21) and several distributing arms (22) which are fluidically connected thereto.

Owner:LINDE AG

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com