Water-vapor separation device and cleaning equipment

A technology for water vapor separation and cleaning equipment, which is applied in the cleaning field and can solve problems such as increasing the cost of the suction fan, affecting the service life of the suction fan, and affecting heat dissipation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

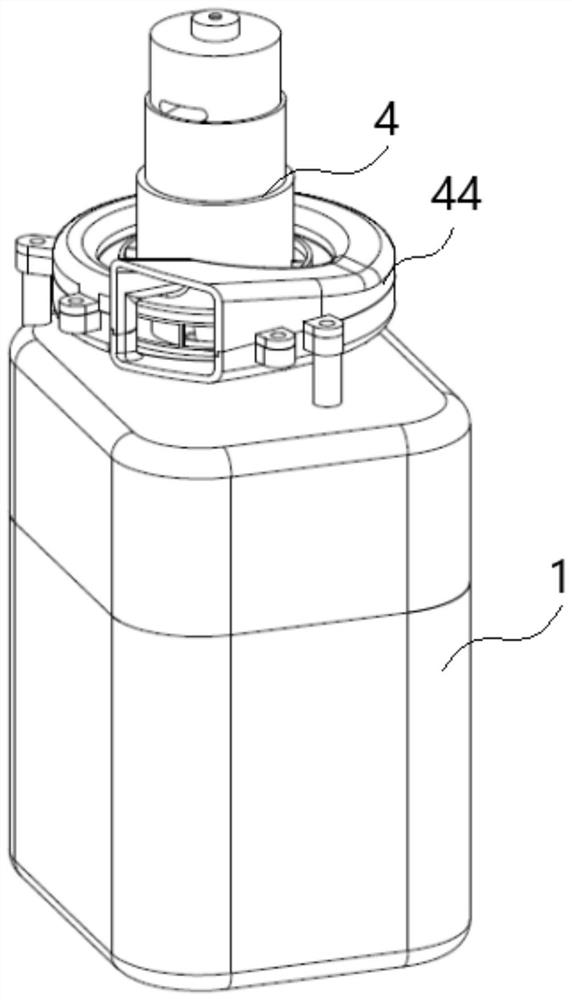

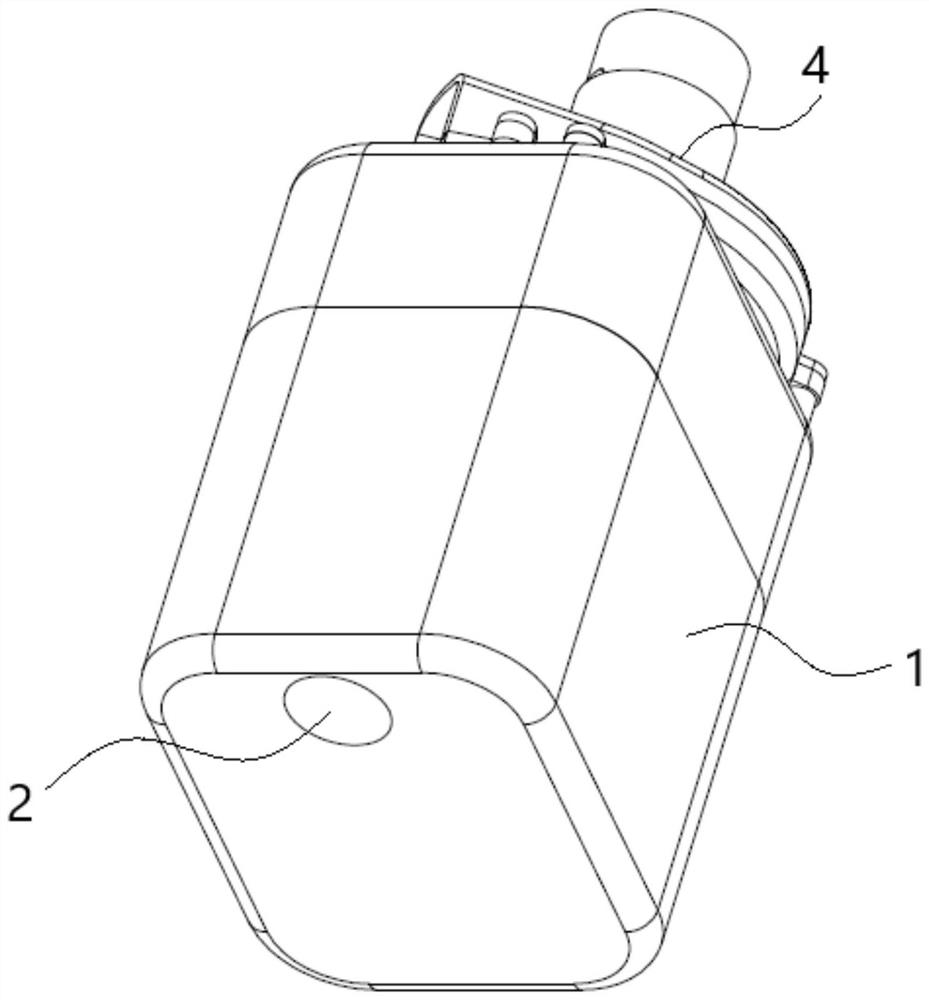

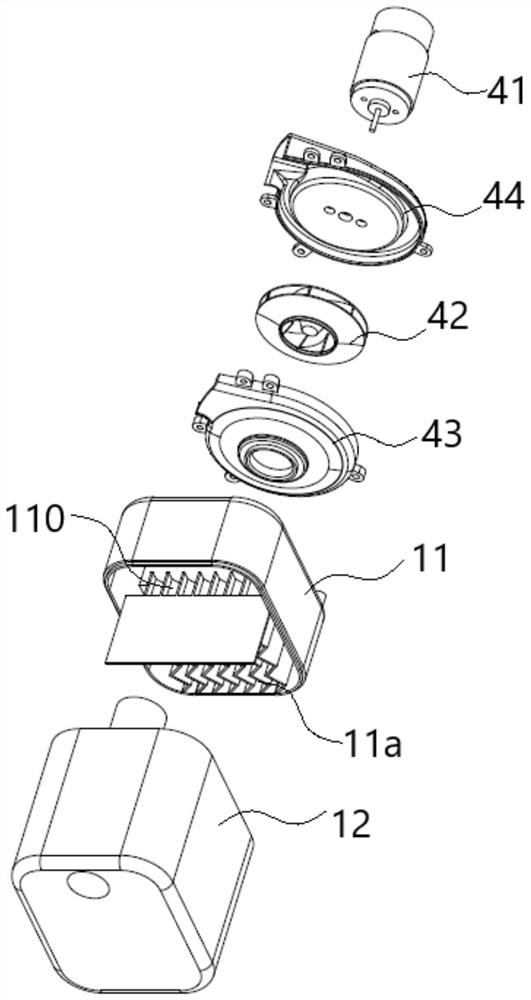

[0035] Example 1: see figure 1 , figure 2 , image 3 and Figure 4 A water vapor separation device 1 shown (in combination with Figure 5 shown), including the water vapor separation installation housing 13 respectively provided with the water vapor separation area 1a and the liquid collection area 12, the water vapor separation installation housing 13 (can use a cover plate type split installation structure, the figure has been shown, but not marked ) is installed and connected with the suction fan 4 as a whole; the water vapor separation area 1a includes a water vapor separation part 11 connected to the air flow inlet end 11b, the air flow outlet end 11c and the liquid outlet end 11a respectively, and the air flow inlet end 11b is connected to the suction channel 2 through the suction channel 2. The suction port 3 is communicated; the air flow outlet end 11c is communicated with the air inlet of the suction fan 4; the liquid collection area 12 is matched with the liquid ...

Embodiment 2

[0045] Embodiment 2: the remaining schemes of this embodiment 2 are the same as the above embodiment 1, the difference is that please refer to Image 6 , Figure 7 and Figure 8 In the shown water vapor separation device 1', in this embodiment 2, the water vapor separation part includes a flow isolation unit and an air flow centrifugal unit respectively installed inside the water vapor separation installation housing 13', wherein the pump connected to the air flow inlet port 11b The suction channel 2' uses a tangential air inlet 2a' to achieve primary centrifugal separation of the liquid in the airflow entering the water vapor separation zone 1a'; specifically, preferably, in this embodiment, the flow blocking unit includes a cylindrical flow blocking part 120, the air flow centrifugal unit includes a centrifugal impeller 130 (also referred to as a separation blade) installed and connected to the flow partition and a centrifugal cone 140 (also referred to as a sinking cone) i...

Embodiment 3

[0048] Embodiment 3: the remaining schemes of this embodiment 3 are the same as the above embodiment 2, the difference is that please refer to Figure 9 and Figure 10 In the shown water vapor separation device 1", in the present embodiment 3, the airflow centrifugal unit includes a curved surface centrifugal part 150, the airflow inlet end 11b (non-tangential air inlet structure) is located below the curved surface centrifugal part 150, and the airflow inlet end 11c is located The top of the curved surface centrifugal part 150; the water-vapor separation installation housing 13' (the rib shape that is beneficial to the water-vapor separation can be provided at its upper end part) and the middle part extends upwardly to the inner side of the inner passage housing 131 (from the liquid collection area 12' to the The water vapor separation zone 1a") forms the suction channel 2 (part of the channel section belonging to the suction channel) communicated with the air inlet port 11b,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com