Patents

Literature

38results about How to "High water removal rate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

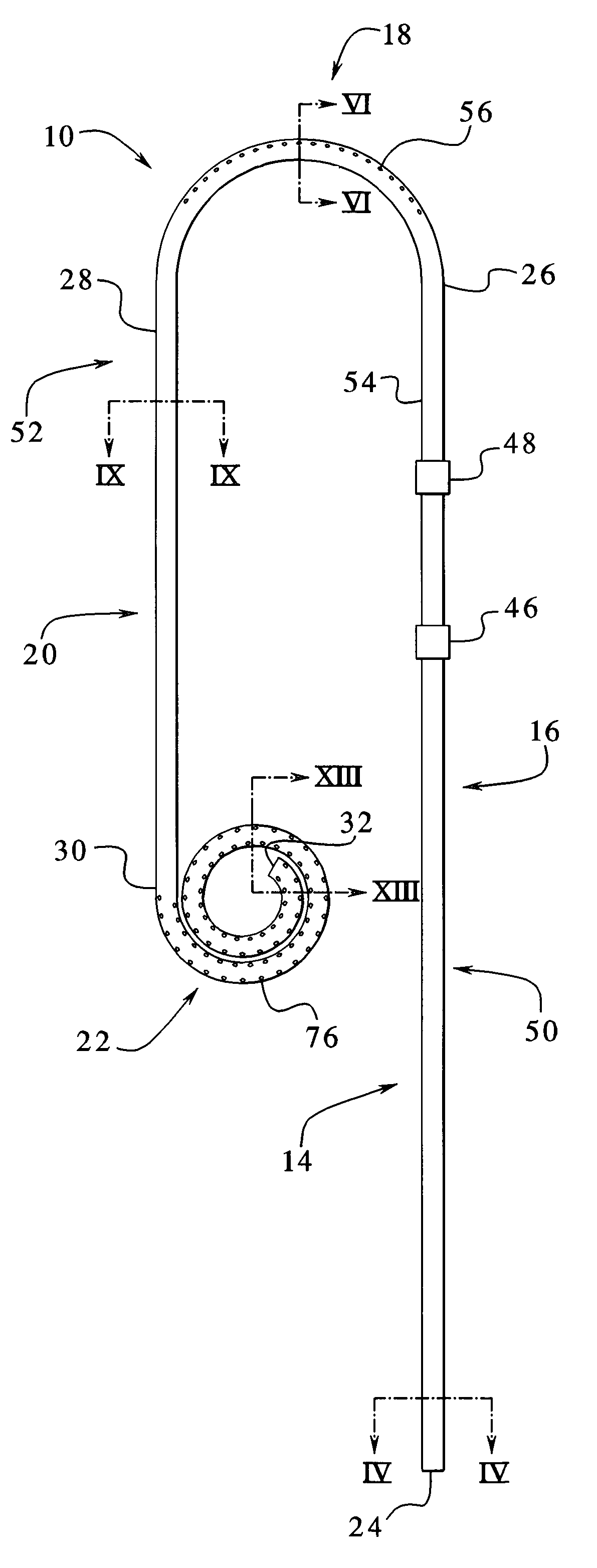

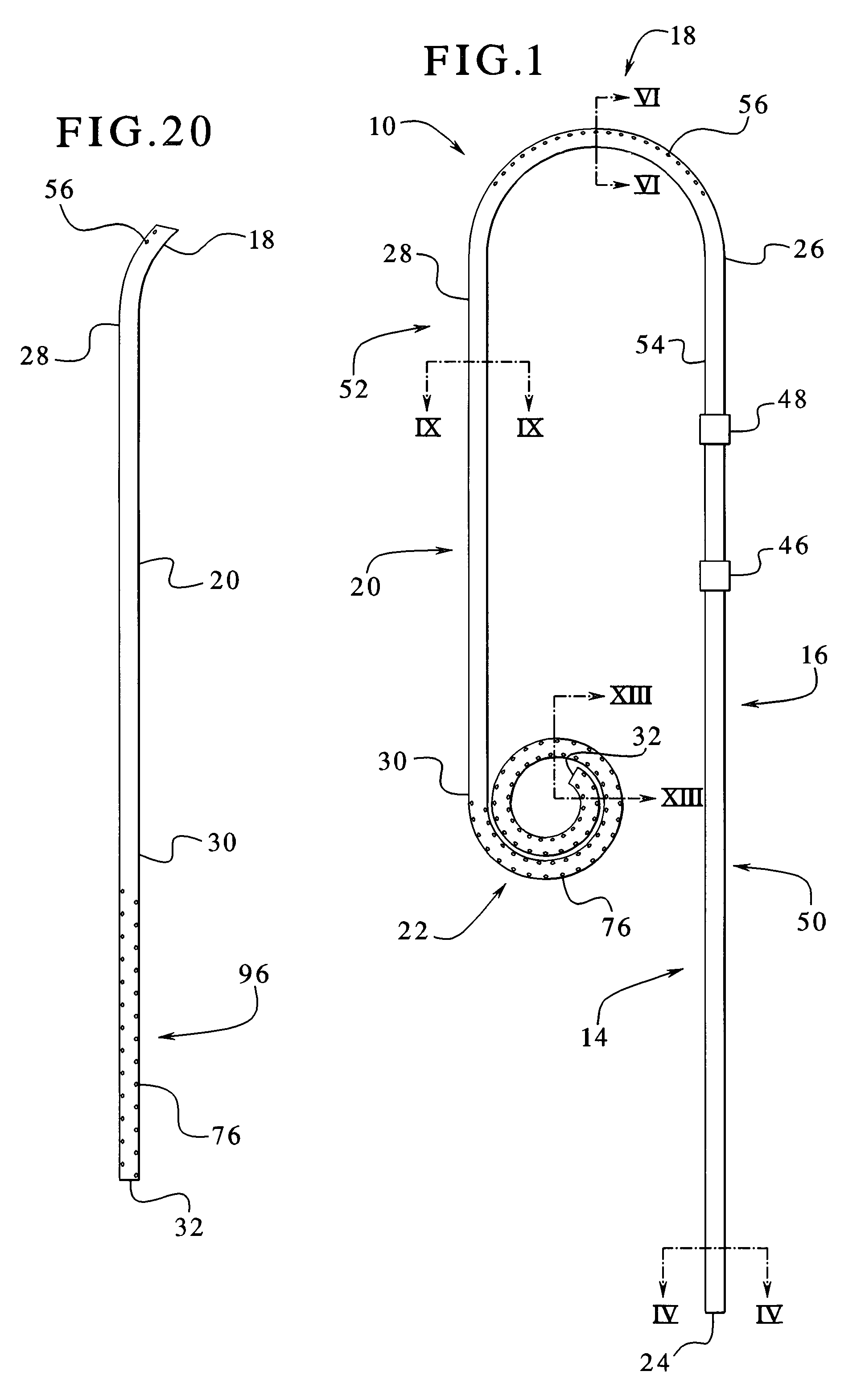

Peritoneal dialysis catheters

InactiveUS6976973B1Well mixedMinimize shuntingMedical devicesCatheterPeritoneal dialysis catheterCatheters dialysis

A catheter suitable for use in performing peritoneal dialysis. The catheter is a dual lumen catheter which allows for continuous flow peritoneal dialysis. Dialysate flows through the catheter into the patient via one lumen and simultaneously flows through the catheter out of the patient via the second lumen. The dual lumen dialysis catheter has a flexible tube which has an implantable portion extending from an external patient portion. Both of the lumens have openings in the external patient portion for connecting to a supply and drain of dialysate, respectively. The implantable portion has a preformed curved segment which has an outlet for the first lumen to flow dialysate into the patient's peritoneal cavity. The implantable portion has an opening for the second lumen at the distal end to flow dialysate out of the peritoneal cavity and removal from the patient. The catheter facilitates mixing of fresh and spent dialysate inside the peritoneal cavity by inflowing fresh dialysate into the cavity at a location substantially separated from the cavity outflow location, and by directing the inflow of dialysate into the cavity opposite the cavity outflow location.

Owner:BAXTER INT INC

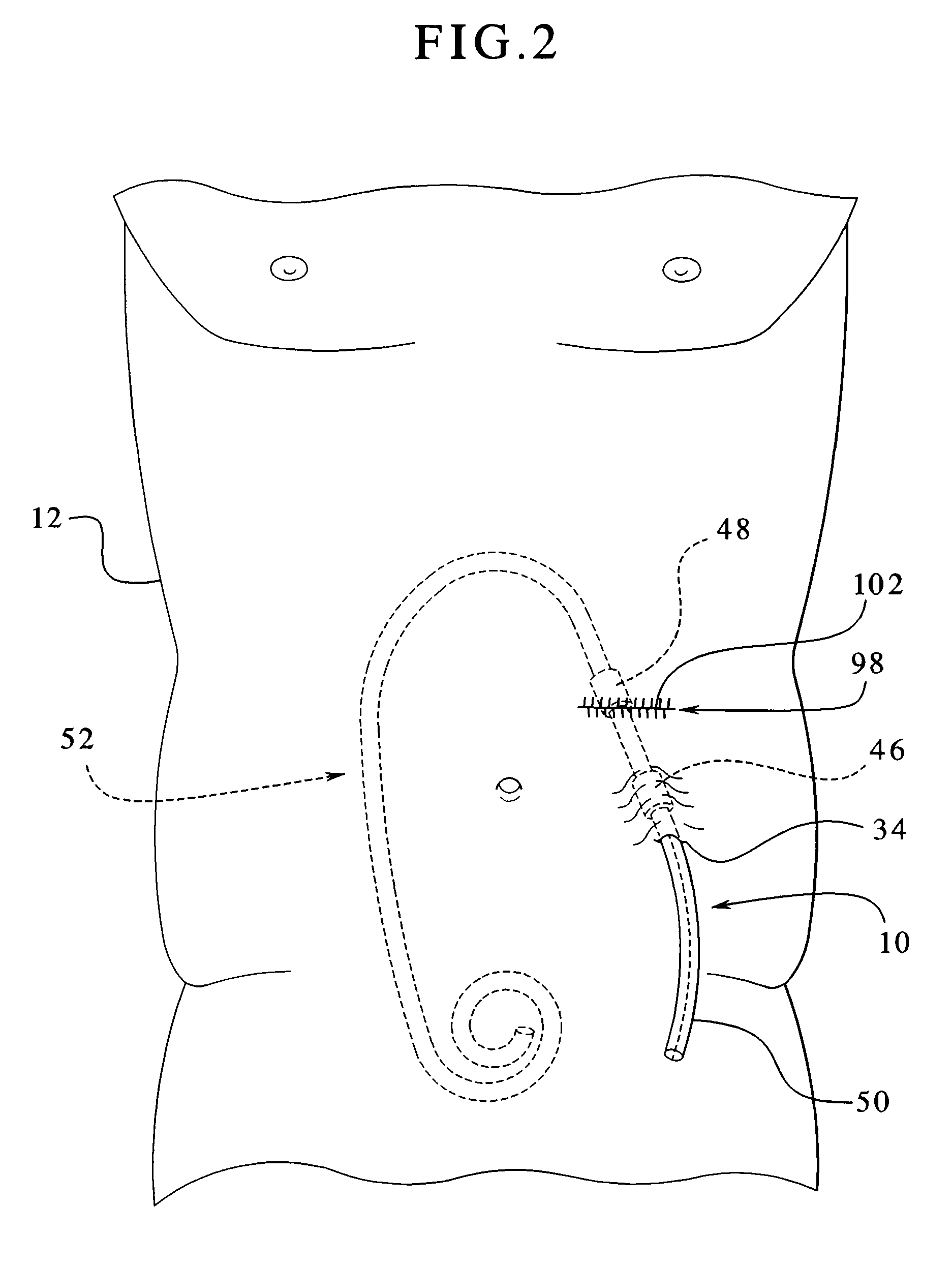

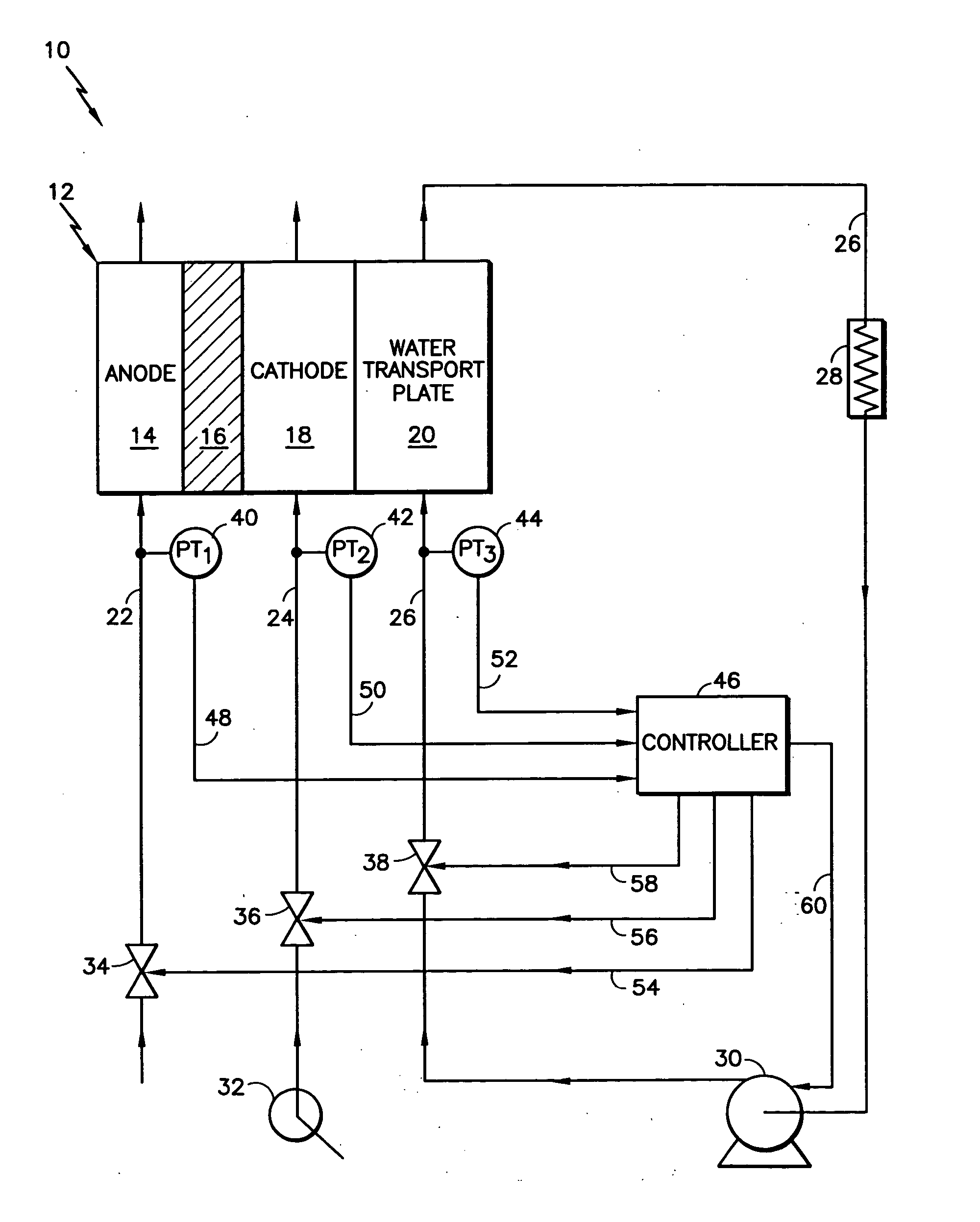

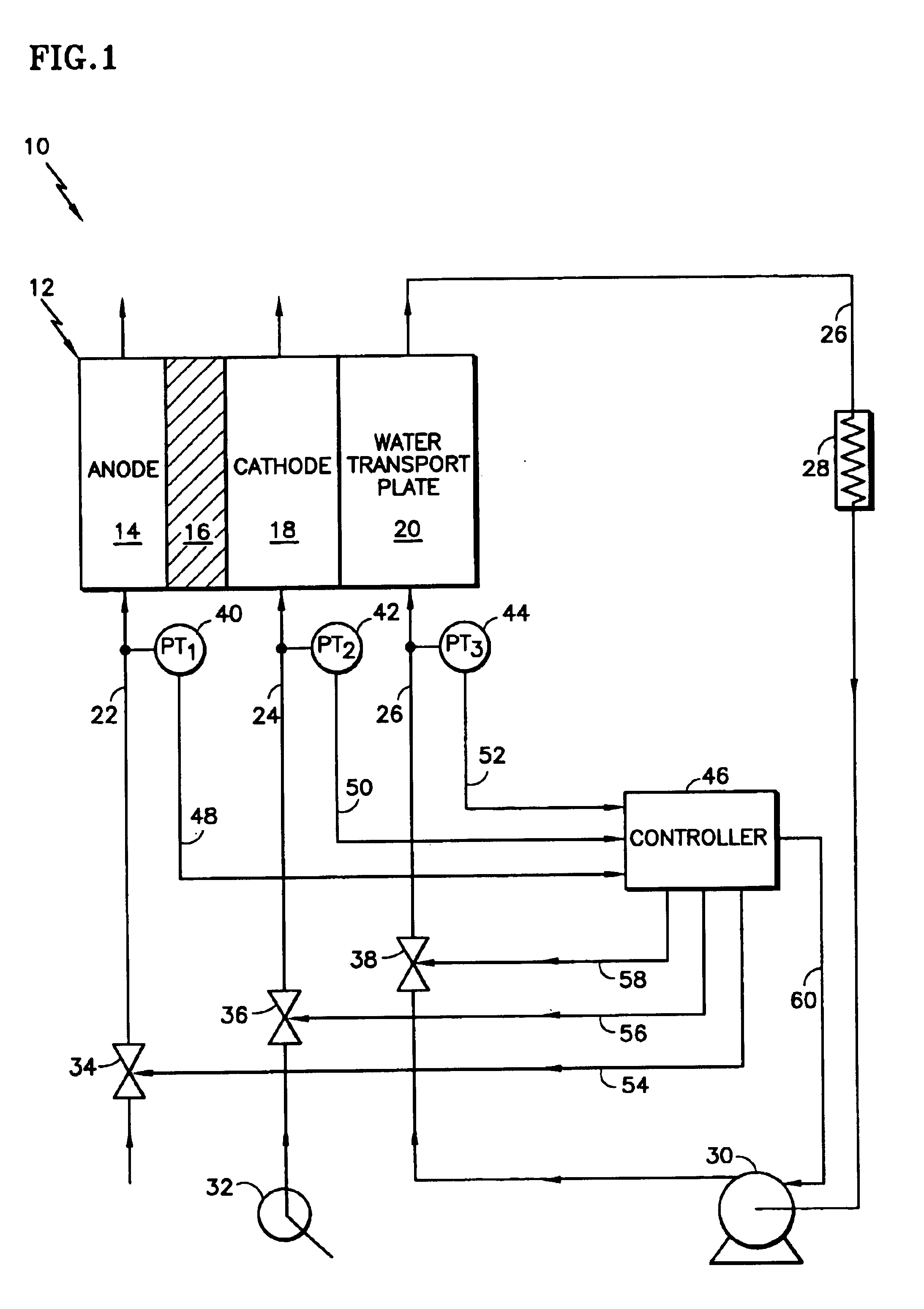

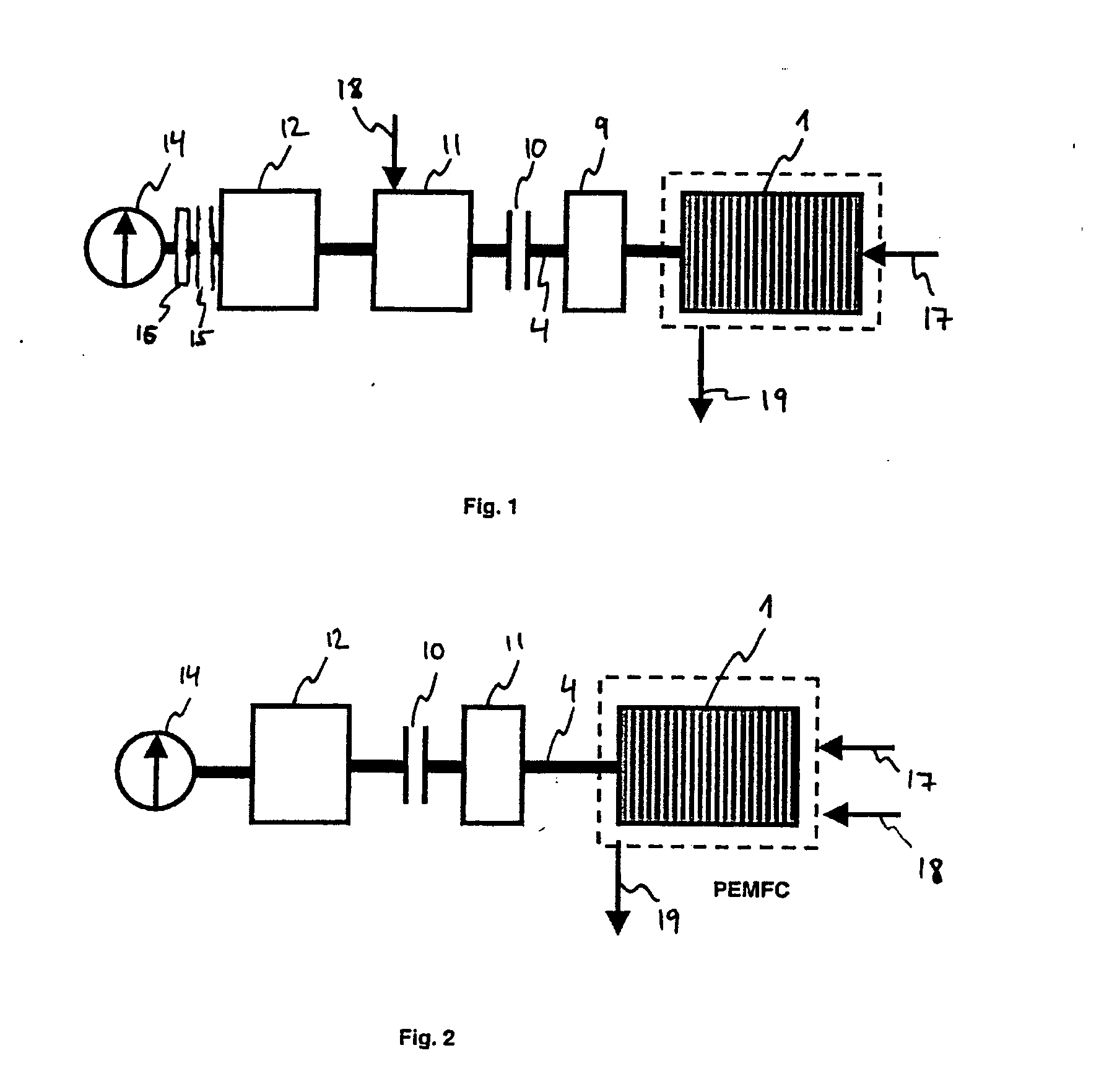

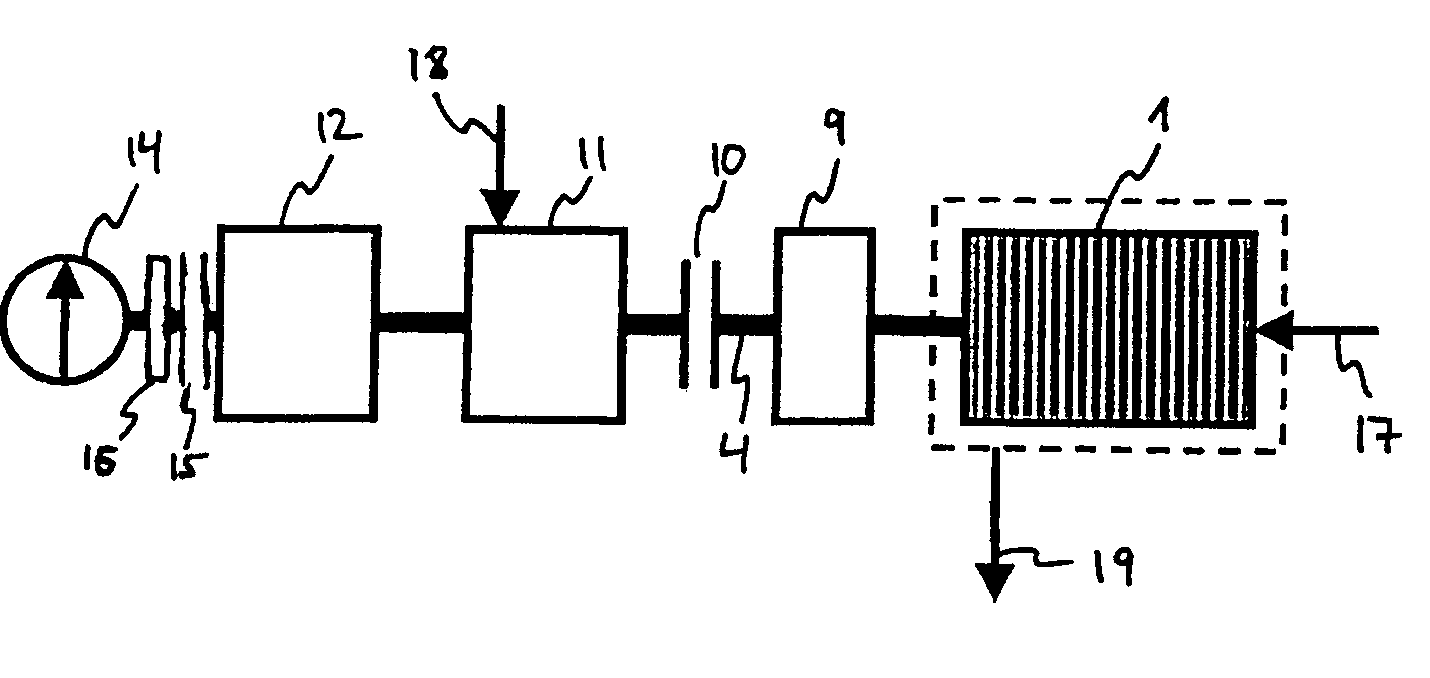

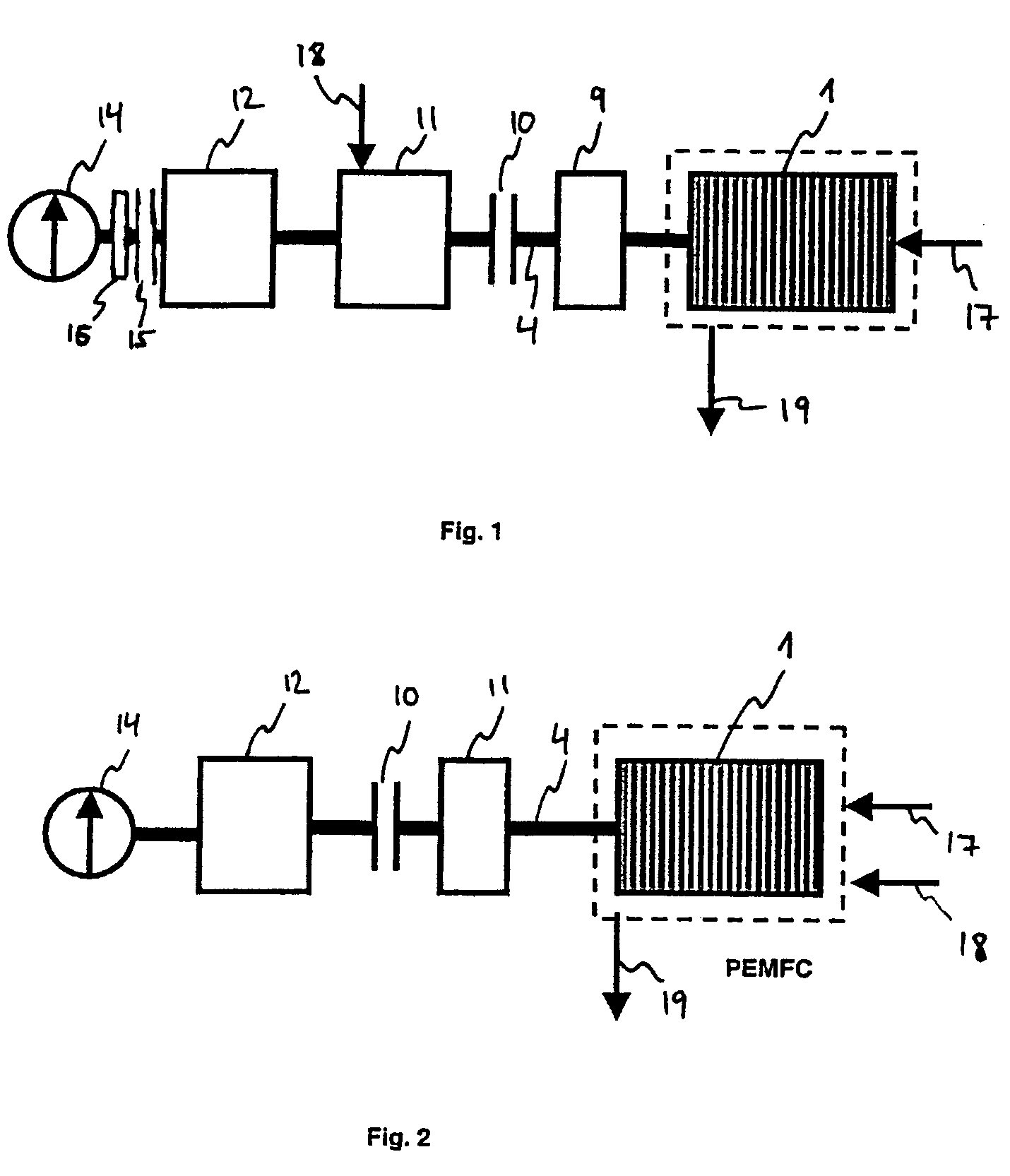

Fuel cell having interdigitated flow channels and water transport plates

InactiveUS20010004501A1Increasing migrationHigh water removal rateCell electrodesWater management in fuel cellsEngineeringWater transport

The present invention is a fuel cell power plant that includes a fuel cell having a membrane electrode assembly (MEA), which is disposed between an anode support plate and a cathode support plate, and porous water transport plates adjacent the anode and cathode support plates. The porous water transport plates have interdigitated flow channels for the reactant gas streams to pass therethrough and conventional flow channels for a coolant stream to pass therethrough. The fuel cell power plant also has means for creating a pressure differential between the reactant gas streams and the coolant stream such that the pressure of the reactant gas streams is greater than the coolant stream. Incorporating the interdigitated flow channels into the porous water transport plates and operating the fuel cell at a pressure differential allows the coolant water to saturate the water transport plates thereby forcing the reactant gases into the anode and cathode support plate. This, in turn, increases the mass transfer of such gases into the support plates, thereby increasing the electrical performance of the fuel cell. Current densities of about 1.6 amps per square meter are achieved with air stochiometries of not over 2.50.

Owner:AUDI AG

Stabilized and Lyophilized Radiopharmaceutical Agents For Destroying Tumors

InactiveUS20070248533A1Easy to refactorReduces predictabilityPowder deliveryNervous disorderAbnormal tissue growthDiagnostic radiopharmaceuticals

A novel method is set out of preparation of radioactive diagnostic radiopharmaceutical in a stable, shippable, lyophilized form by an apparatus designed to rapidly flash freeze and dehydrate a radiopharmaceutical composition to minimize auto radiolysis. The method proposes rapid cooling and removal of ambient vapor, and then ultra cold removal when the potential of explosive liquid oxygen is eliminated. The radioactive diagnostic radiopharmaceutical requires no further cold or refrigerated storage, including with respect to shipping, subsequent to stabilization. The preferred composition can be reconstituted “on site” by the addition of a suitable diluent to bring the radiopharmaceutical complex into solution at a desired concentration.

Owner:KUPERUS JOHN H +2

Method of preserving lyophilized microorganisms for transport, storage and recovery of viable microorganisms

InactiveUS20060177426A1Improve stability and recoveryVapor pressureBiocideDead animal preservationLaboratory TechnologistFree space

Incorporation of a microbial cell suspension throughout a fibrous network provides a physical environment that allows greater removal of water during lyophilization or desiccation thereby yielding a device with improved stability and recovery of viable microbial cells. Strands of appropriate fibers in a tightly knit network absorb aqueous cell suspensions by a capillary effect rather than absorption. When vapor pressure is decreased by vacuum during lyophilization or by air moved during desiccation, the surface tension is affected at the fiber / water interface, which results in increased water removal, by a “reverse capillary” effect. Thus bound and free water removal is increased. Therefore, incorporation of the use of a network of fibers in conjunction with a preservation matrix containing sensitive microbial cells provides a means of producing a preserved product with increased stability at both extreme and routine storage temperatures and greater efficacy for the end user. The invention also provides a means for recovery of viable microbial cells by direct inoculation to solid or liquid culture media as recommended for use in performance or quality control testing of culture media, stains, identification kits, maintenance of stock cultures and in the evaluation of bacteriological procedures. Additionally, the device can be used to mimic clinical specimens in clinical or industrial proficiency testing surveys that test the ability of laboratory technologists to properly perform diagnostic procedures.

Owner:GIBSON CECIL +1

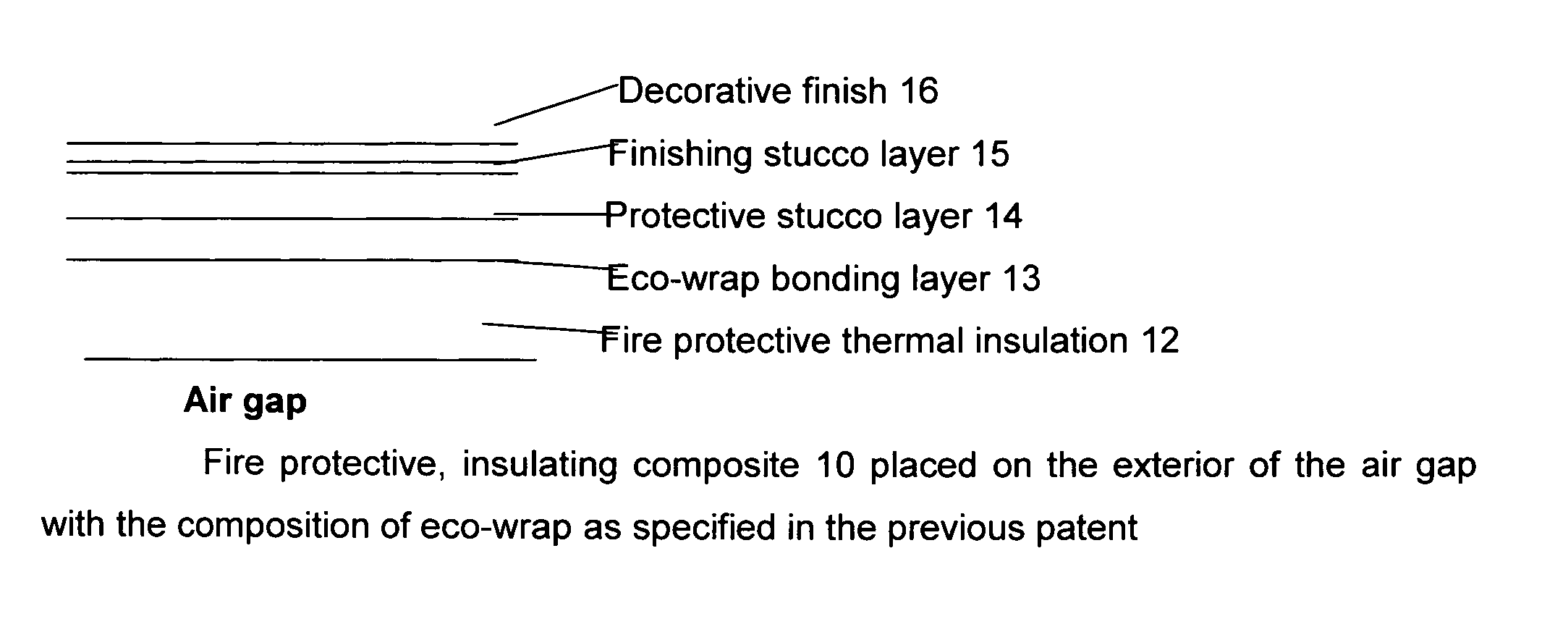

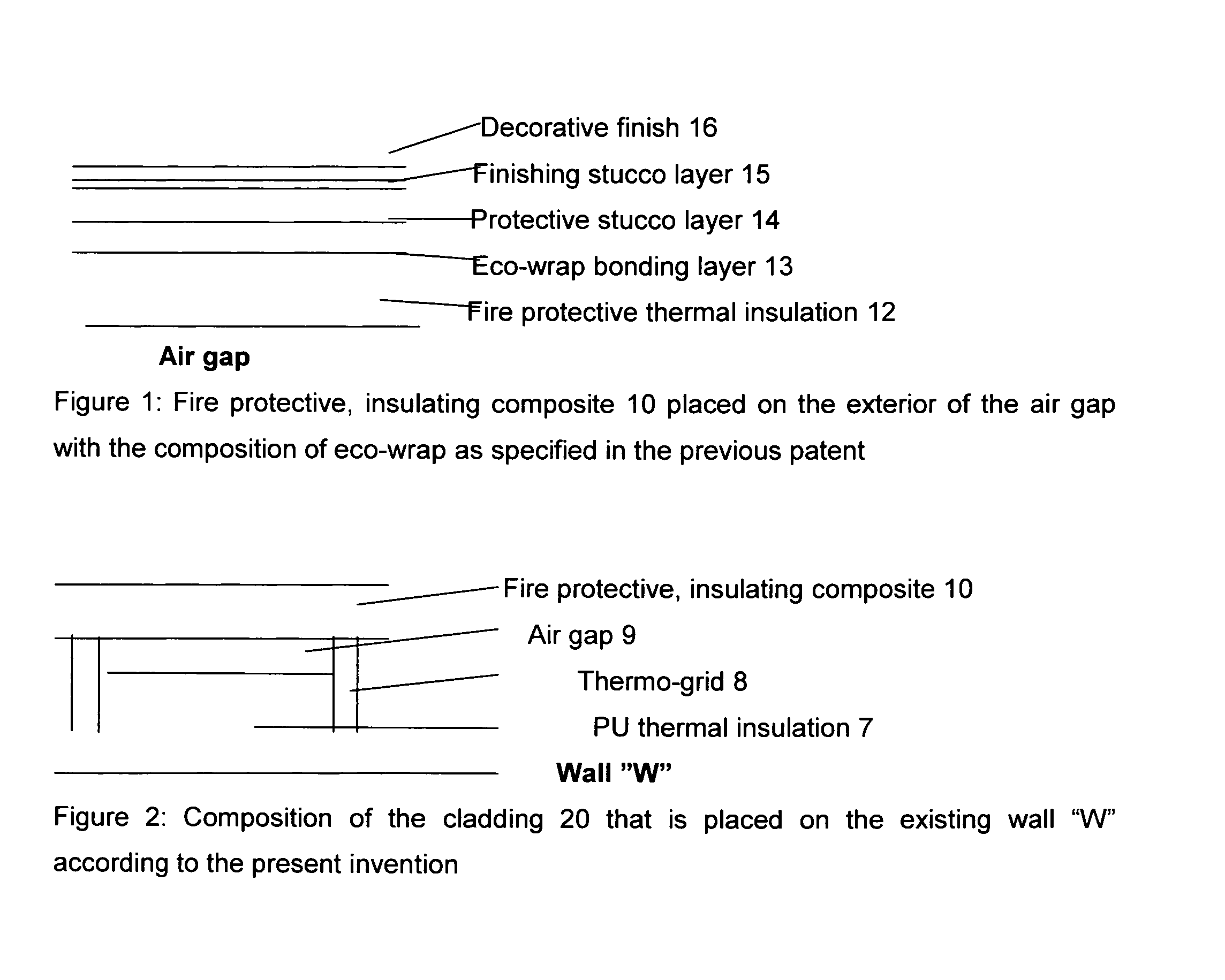

Continuous thermal insulation and fire protective composite placed on thermo-grid designed for wind load transfer

InactiveUS20120317914A1Avoid enteringEfficient use ofCeilingsLamination ancillary operationsStrappingWater vapor

The present invention relates to construction materials and more specifically, to a continuous composite exterior insulation system and cladding used in the construction of building walls and structure, to control heat transfer, rain-water penetration, air and water vapor transmission while providing fire protection to a building enclosure. This invention relates to a thermal upgrade of existing and new buildings. The wall substrate is arranged for receipt of subsequent layers of cladding materials. Thermo-grid of insulated composite strapping is mounted on the surface of the said wall and a layer of continuous insulation e.g. polyurethane foam is applied between the thermo-grid strapping leaving a thin air gap between it and the next layer of the fire protective composite.

Owner:BOMBERG MARK +1

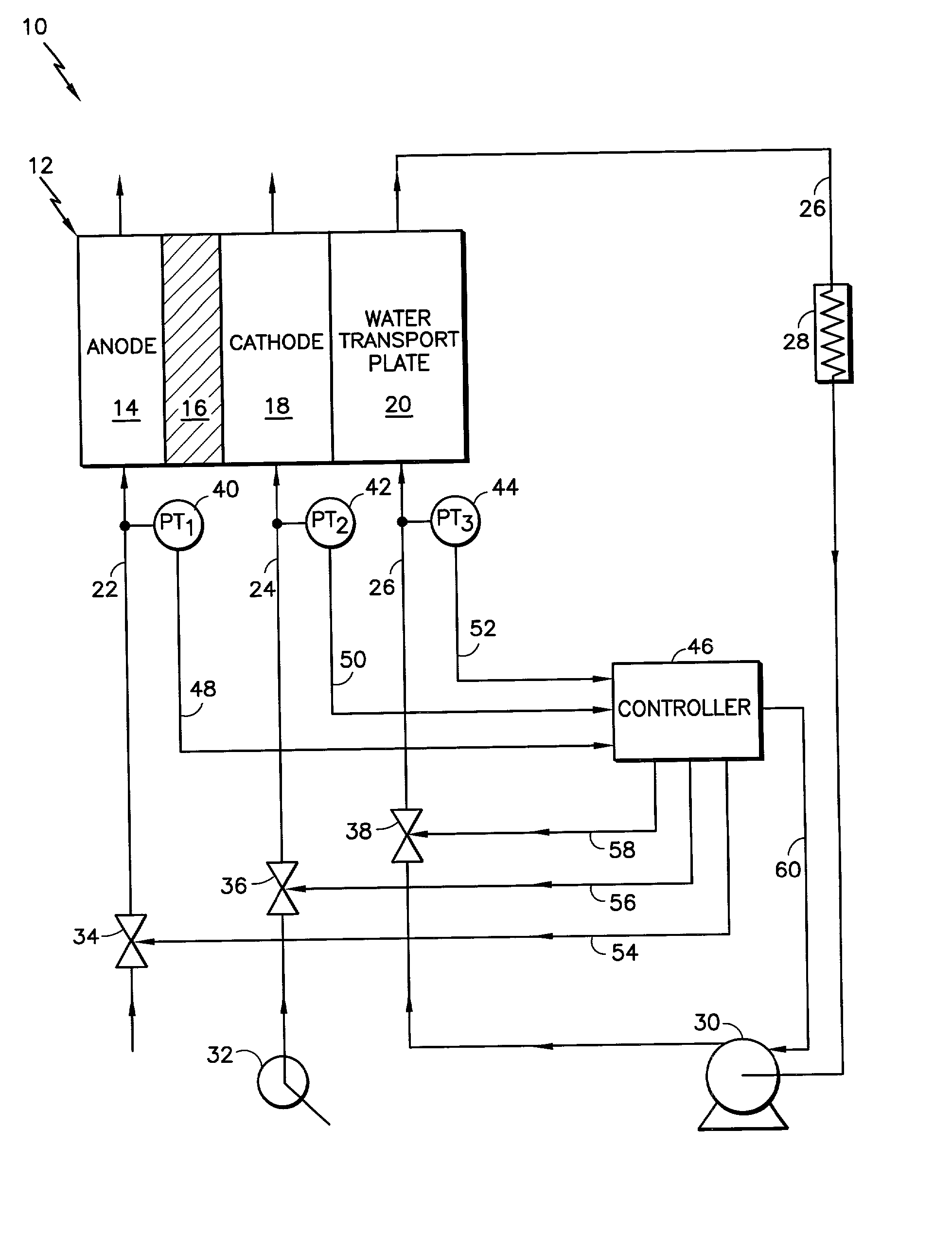

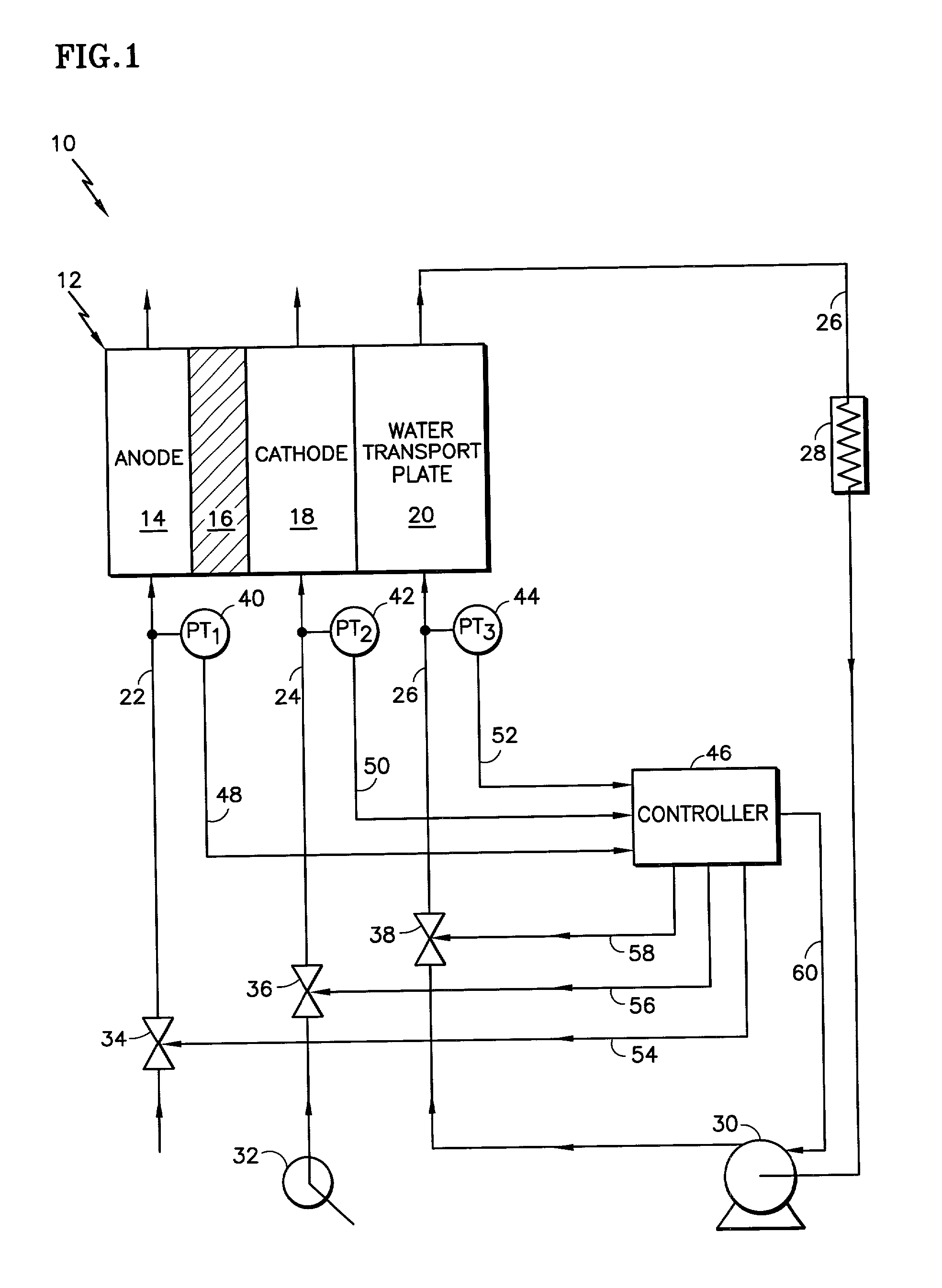

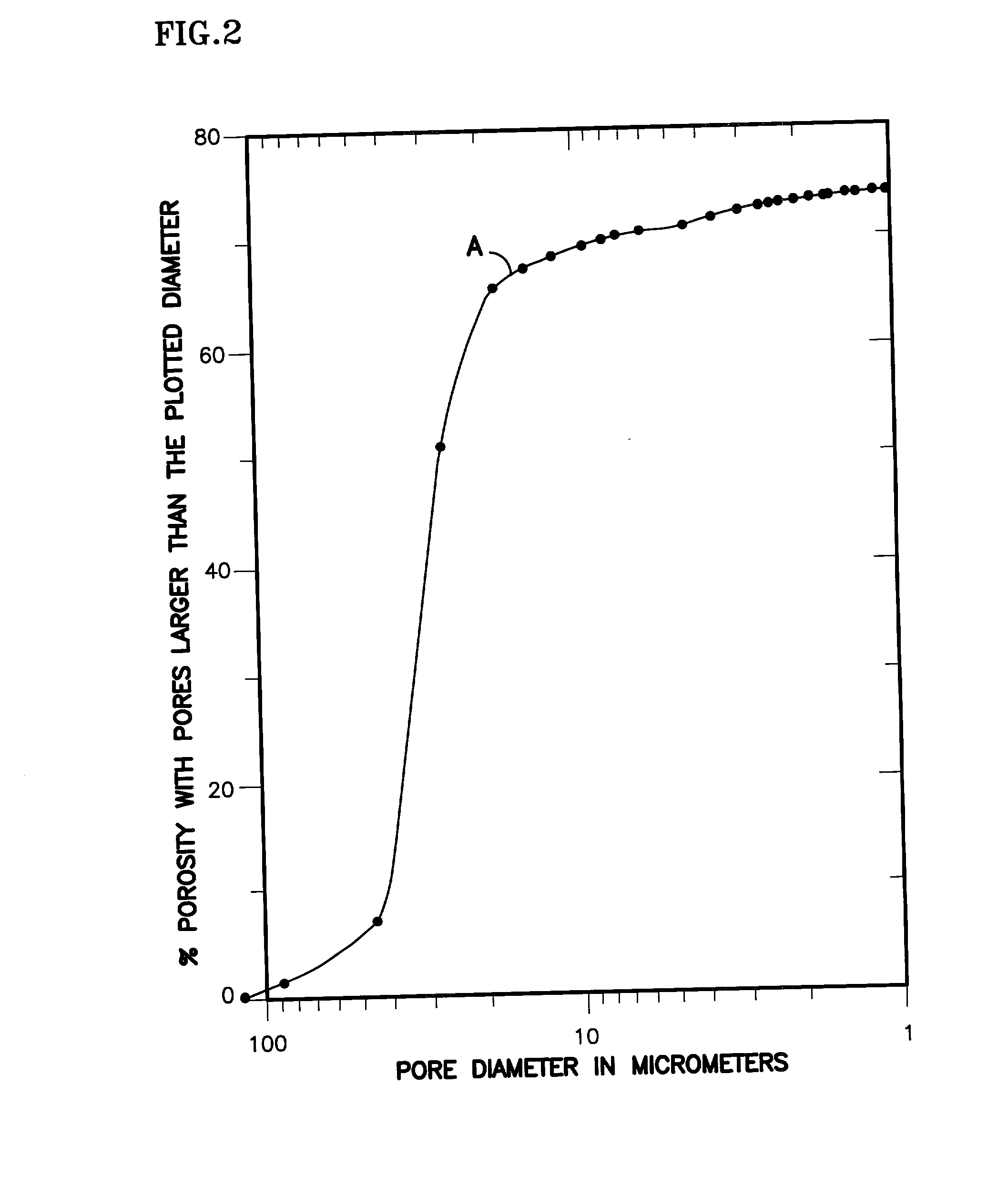

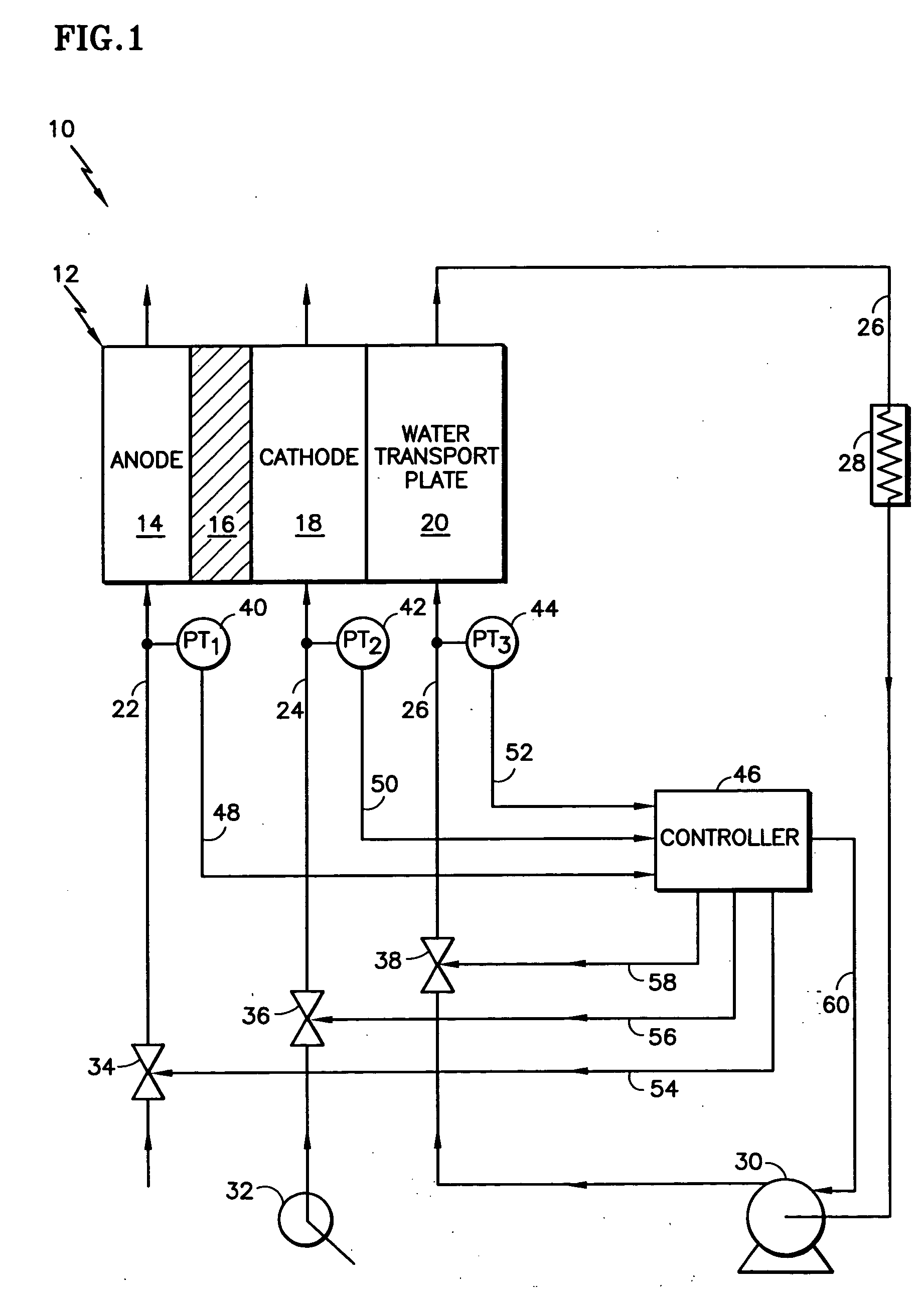

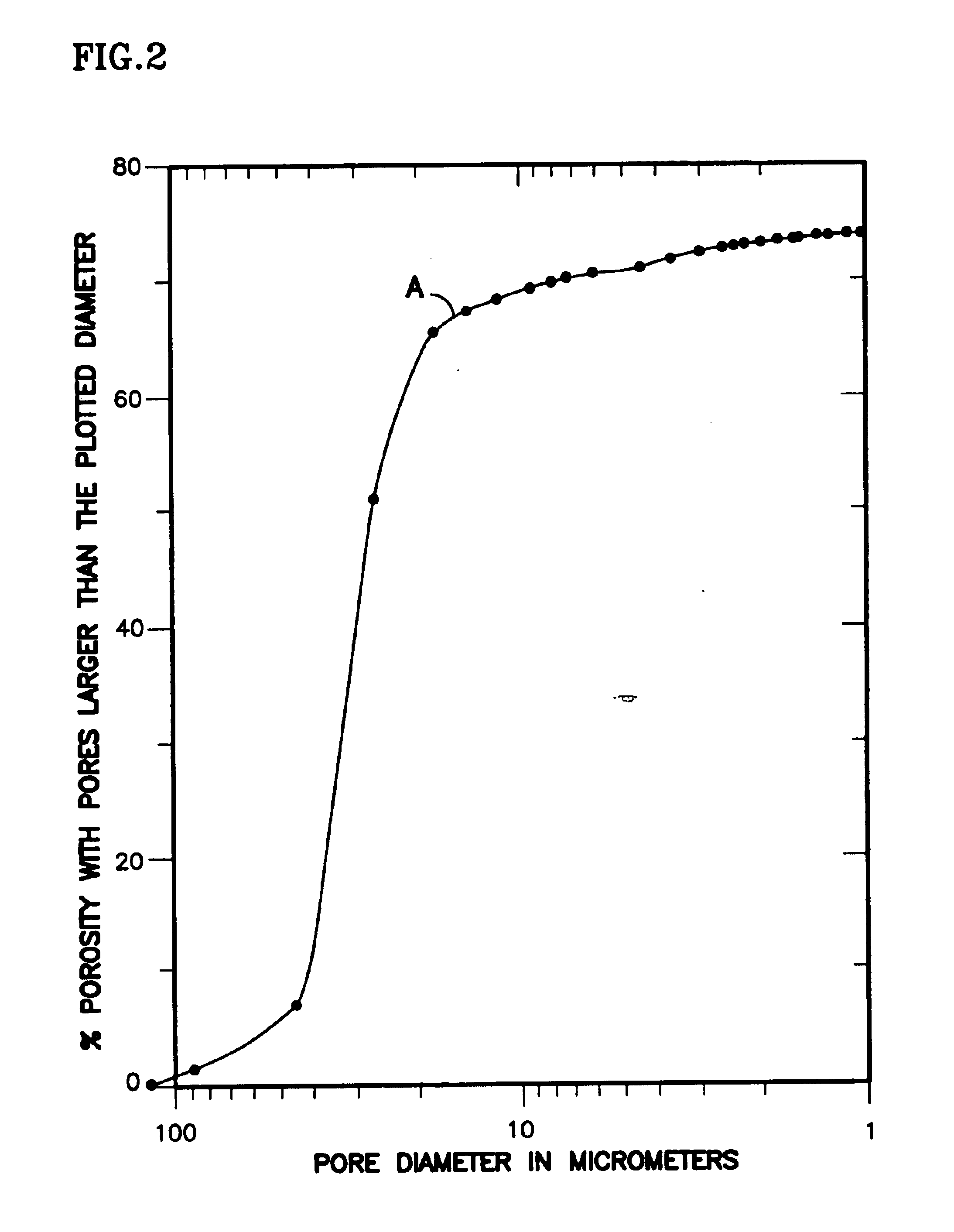

Fuel cell having a hydrophilic substrate layer

InactiveUS20020071978A1Enhance migrationImprove removal of waterCell electrodesWater management in fuel cellsElectrical efficiencyMembrane configuration

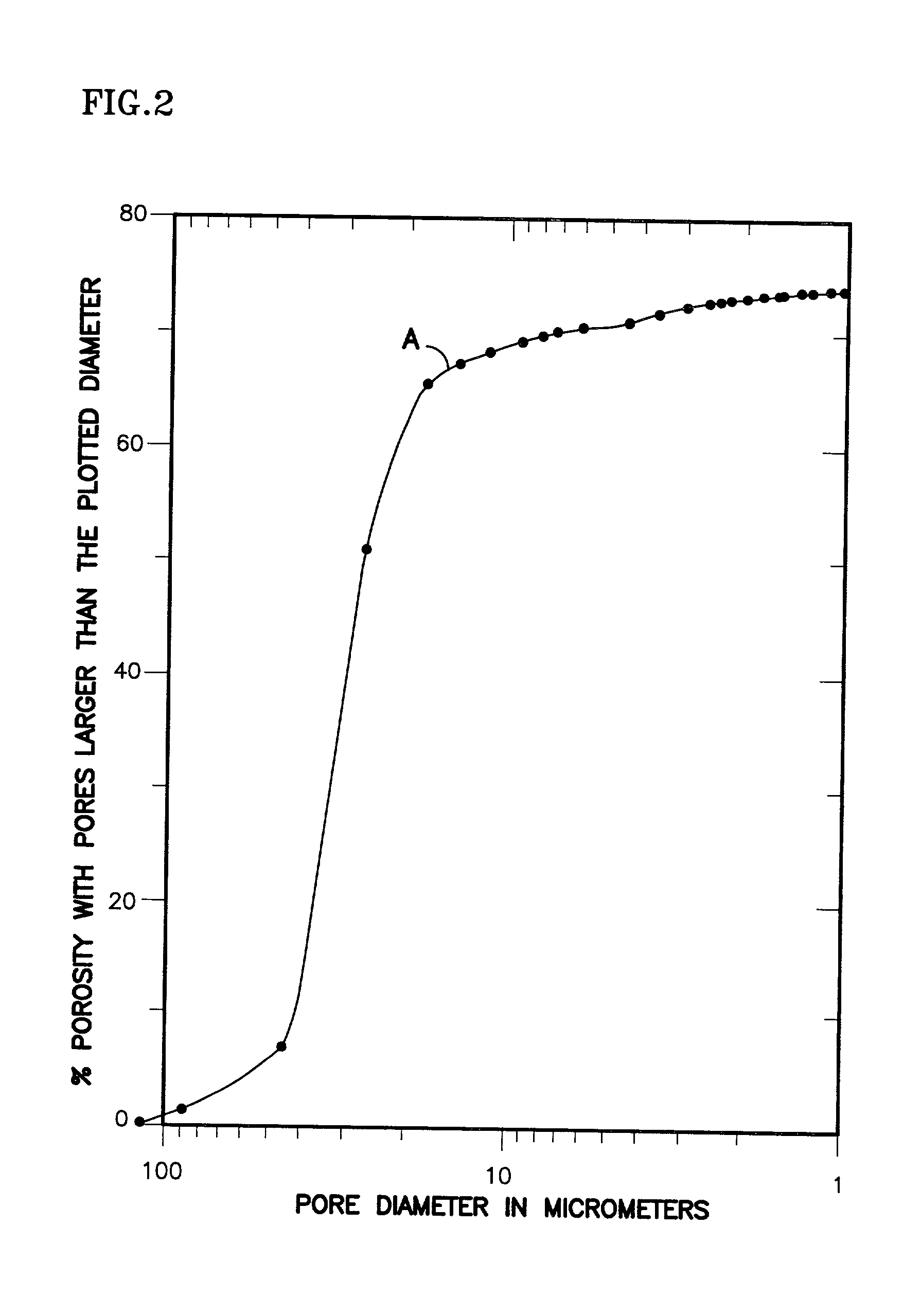

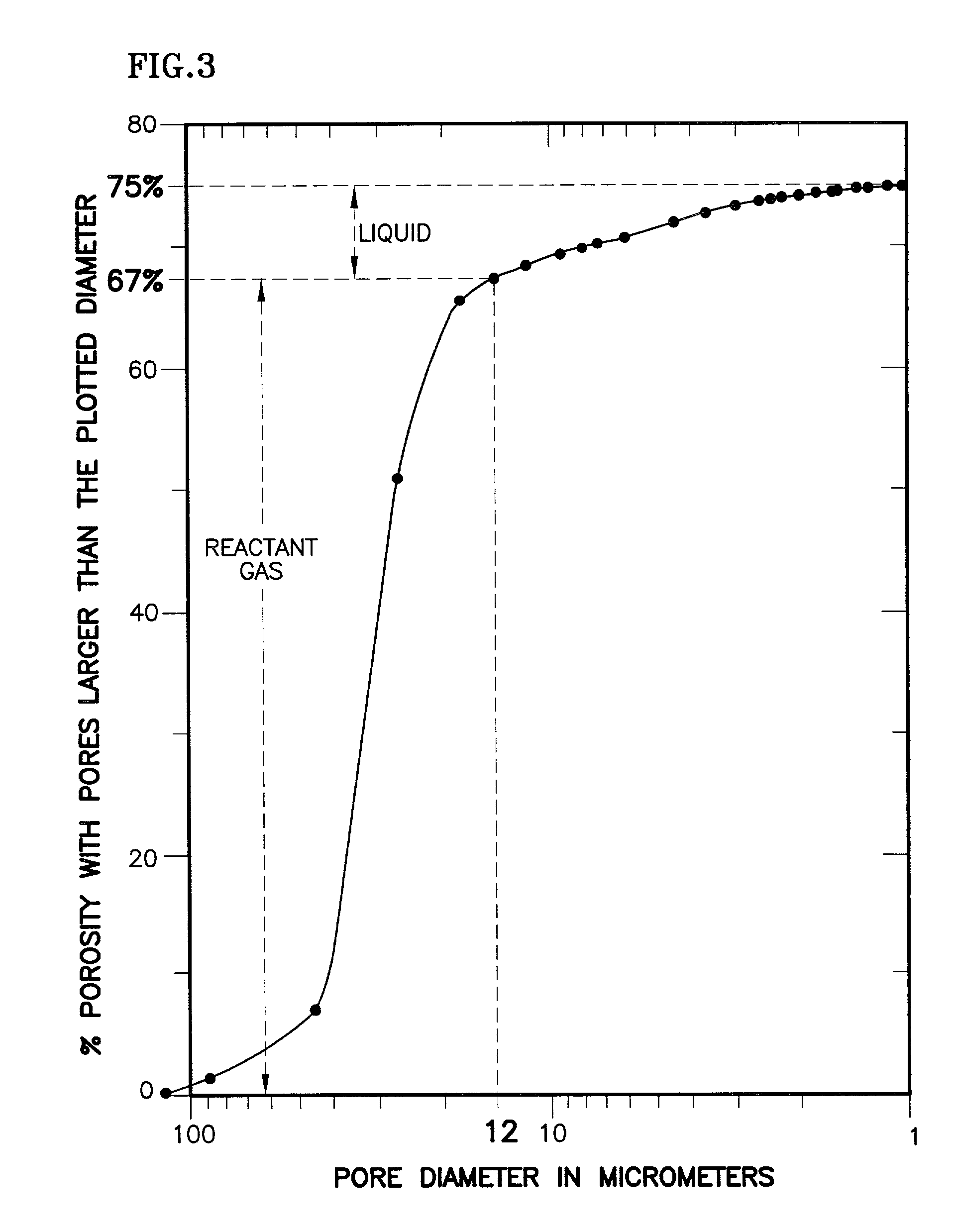

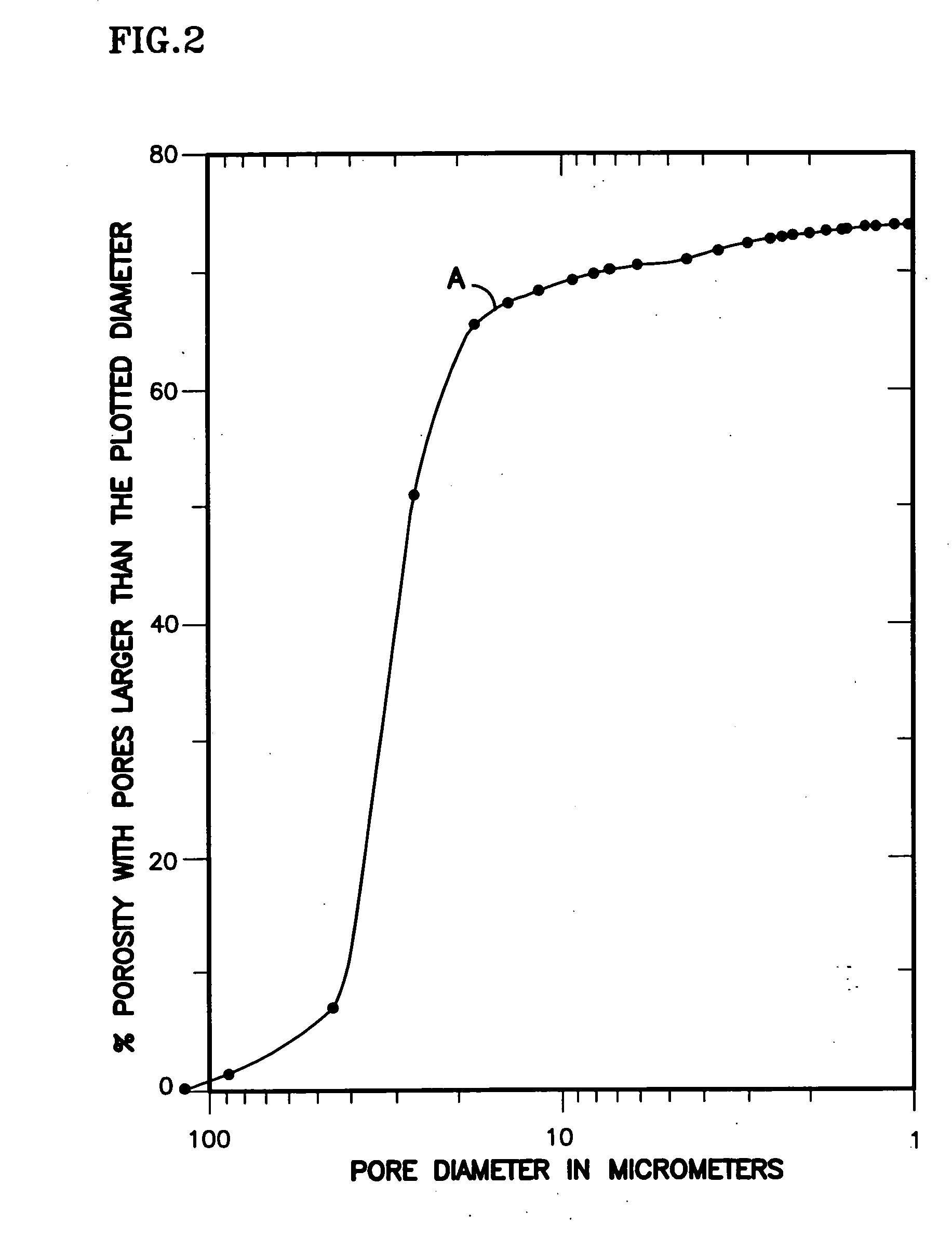

Fuel Cell Having a Hydrophilic Substrate Layer A fuel cell power plant includes a fuel cell having a membrane electrode assembly (MEA), disposed between an anode support plate and a cathode support plate, the anode and / or cathode support plates include a hydrophilic substrate layer having a predetermined pore size. The pressure of the reactant gas streams is greater than the pressure of the coolant stream, such that a greater percentage of the pores within the hydrophilic substrate layer contain reactant gas rather than water. Any water that forms on the cathode side of the MEA will migrate through the cathode support plate and away from the MEA. Controlling the pressure also ensures that the coolant water will continually migrate from the coolant stream toward the anode side of the MEA, thereby preventing the membrane from becoming dry. Proper pore size and a pressure differential between coolant and reactants improves the electrical efficiency of the fuel cell.

Owner:INT FUEL CELLS

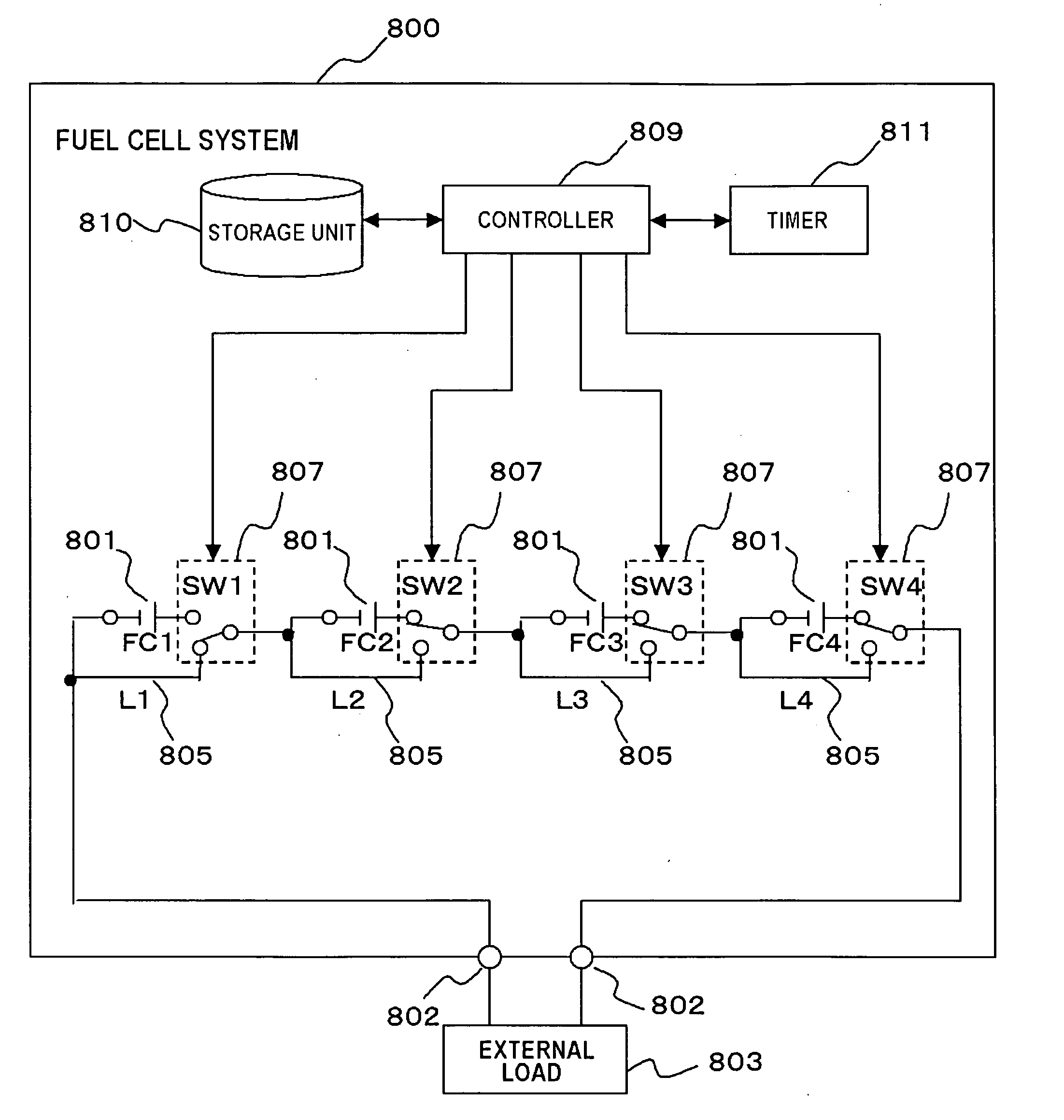

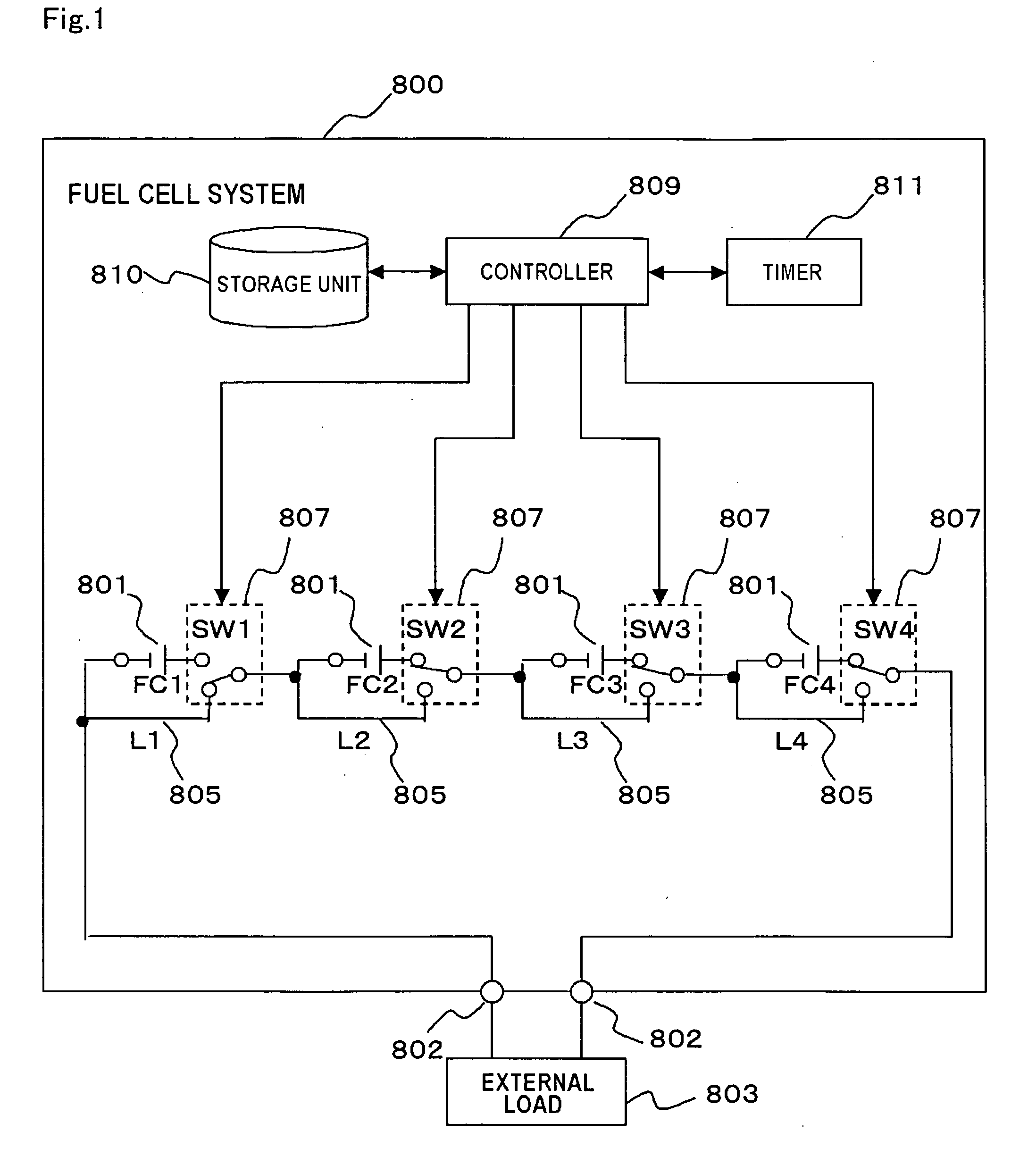

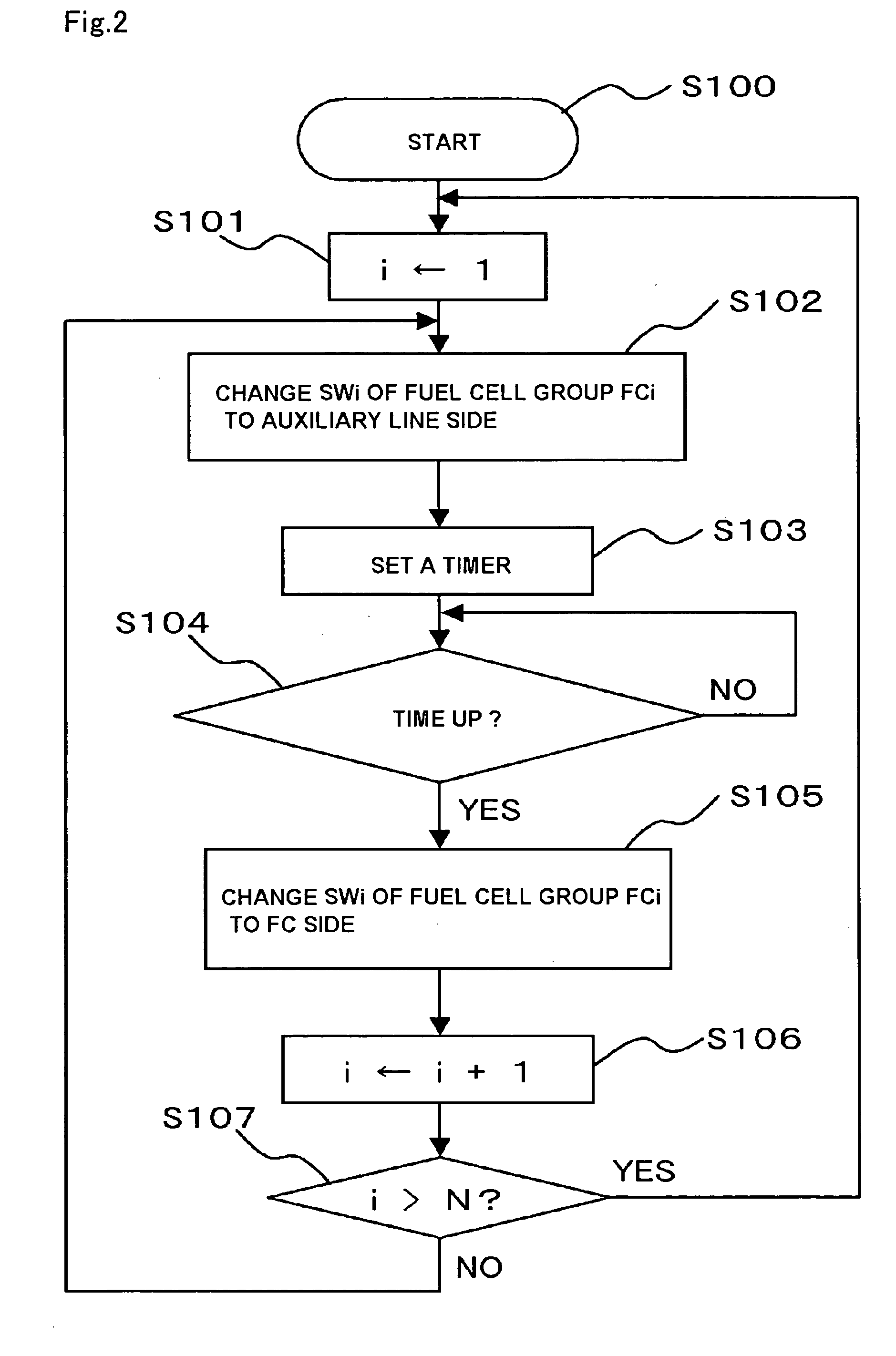

Fuel cell system and method of operating the same

InactiveUS20050142406A1High water removal rateStable outputFuel cells groupingFuel cell auxillariesFuel cellsAutomotive engineering

The present invention provides a fuel cell system capable of supplying a stable power. In a fuel cell system, a plurality of fuel cell groups which supply a power to an external load are mutually electrically connected in series, as well as electrically connected to the external load. At least one fuel cell group is selected out of the plurality of fuel cell groups, and the selected fuel cell group is electrically disconnected from the external load.

Owner:NEC CORP

Fuel cell having a hydrophilic substrate layer

InactiveUS20040106034A1Increasing migrationHigh water removal rateCell electrodesWater management in fuel cellsFuel cellsPressure difference

A fuel cell power plant includes a fuel cell having a membrane electrode assembly (MEA), disposed between an anode support plate and a cathode support plate, the anode and / or cathode support plates include a hydrophilic substrate layer having a predetermined pore size. The pressure of the reactant gas streams is greater than the pressure of the coolant stream, such that a greater percentage of the pores within the hydrophilic substrate layer contain reactant gas rather than water. Any water that forms on the cathode side of the MEA will migrate through the cathode support plate and away from the MEA. Controlling the pressure also ensures that the coolant water will continually migrate from the coolant stream toward the anode side of the MEA, thereby preventing the membrane from becoming dry. Proper pore size and a pressure differential between coolant and reactants improves the electrical efficiency of the fuel cell.

Owner:AUDI AG

Exterior building wall insulation systems with hygro thermal wrap

InactiveUS20110256786A1Accelerated dryingRaise transfer toWeft knittingLayered productsFreeze thawingWater vapor

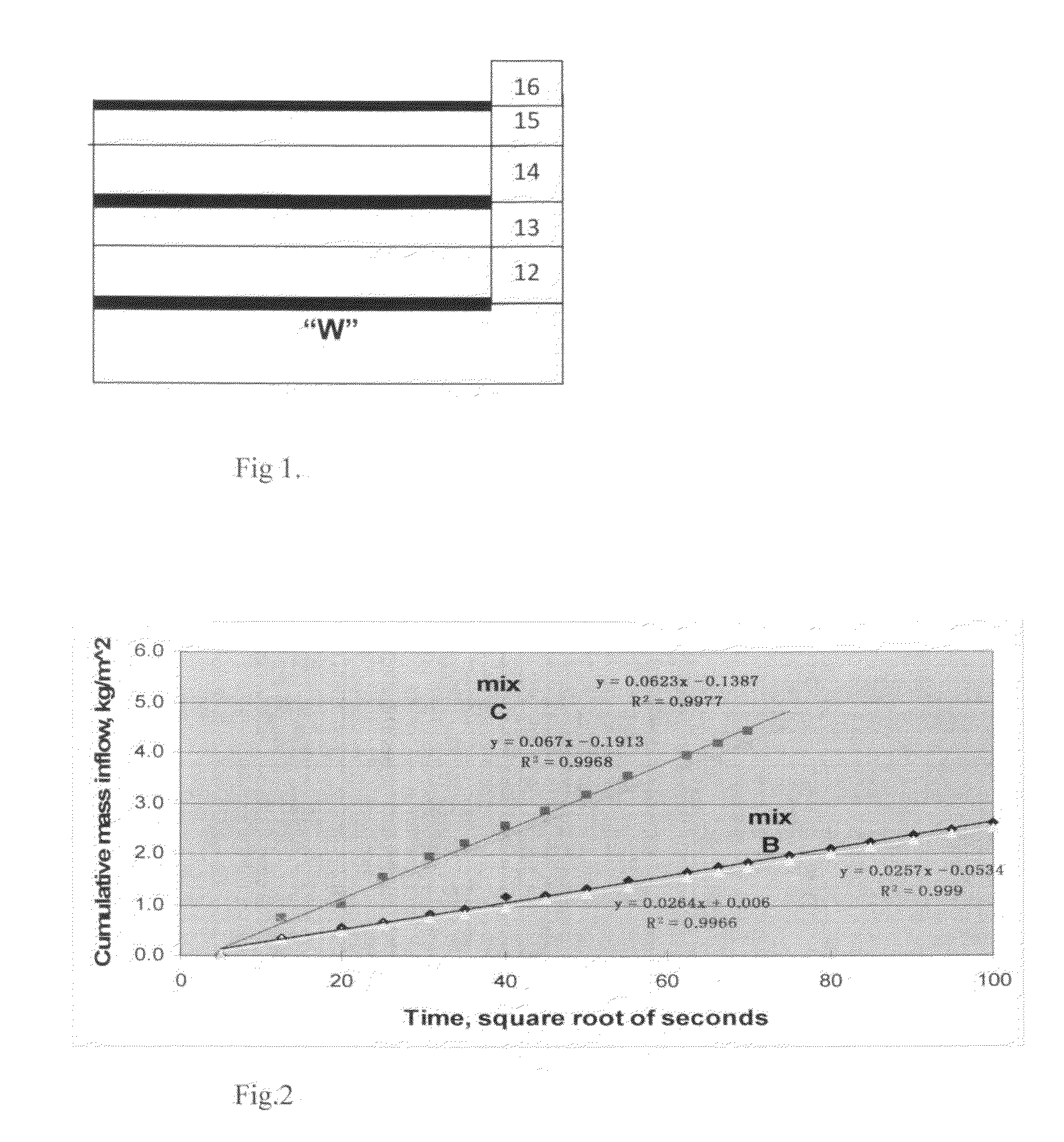

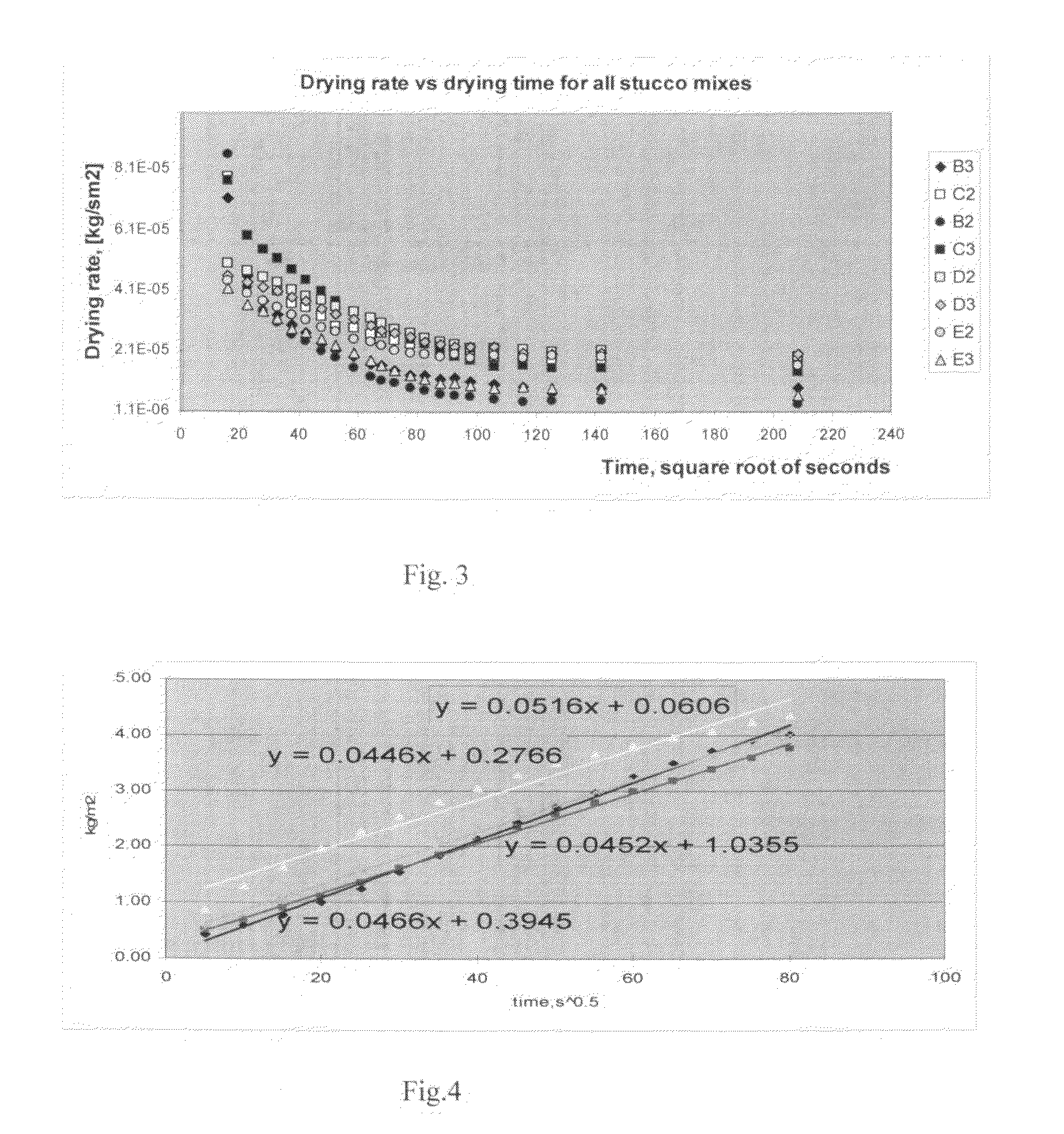

A composite, layered, thermal insulation and cladding system and method to construct a hygro thermal (HT) wrap. The external insulation system controls the passage of heat, air, liquid water, water vapor, and moisture permeability of the system with the change of the moisture content in some materials. The HT wrap comprises at a material mix applied in two layers, with or without additional surface treatments. The inventive method includes the material combinations and their fiber diameter or particle size in such a manner that the microstructure of HT wrap will provide pore space for retention of the initially added water, permit expansion of the freezing water (thereby improving freeze-thaw durability), provide the interruption in the crack propagation (because the brittle inorganic matrix of the binders is prone to cracking), and provide a degree of elasticity needed to accommodate movements caused by the polyurethane foam or other substrates.

Owner:BOMBERG MARK

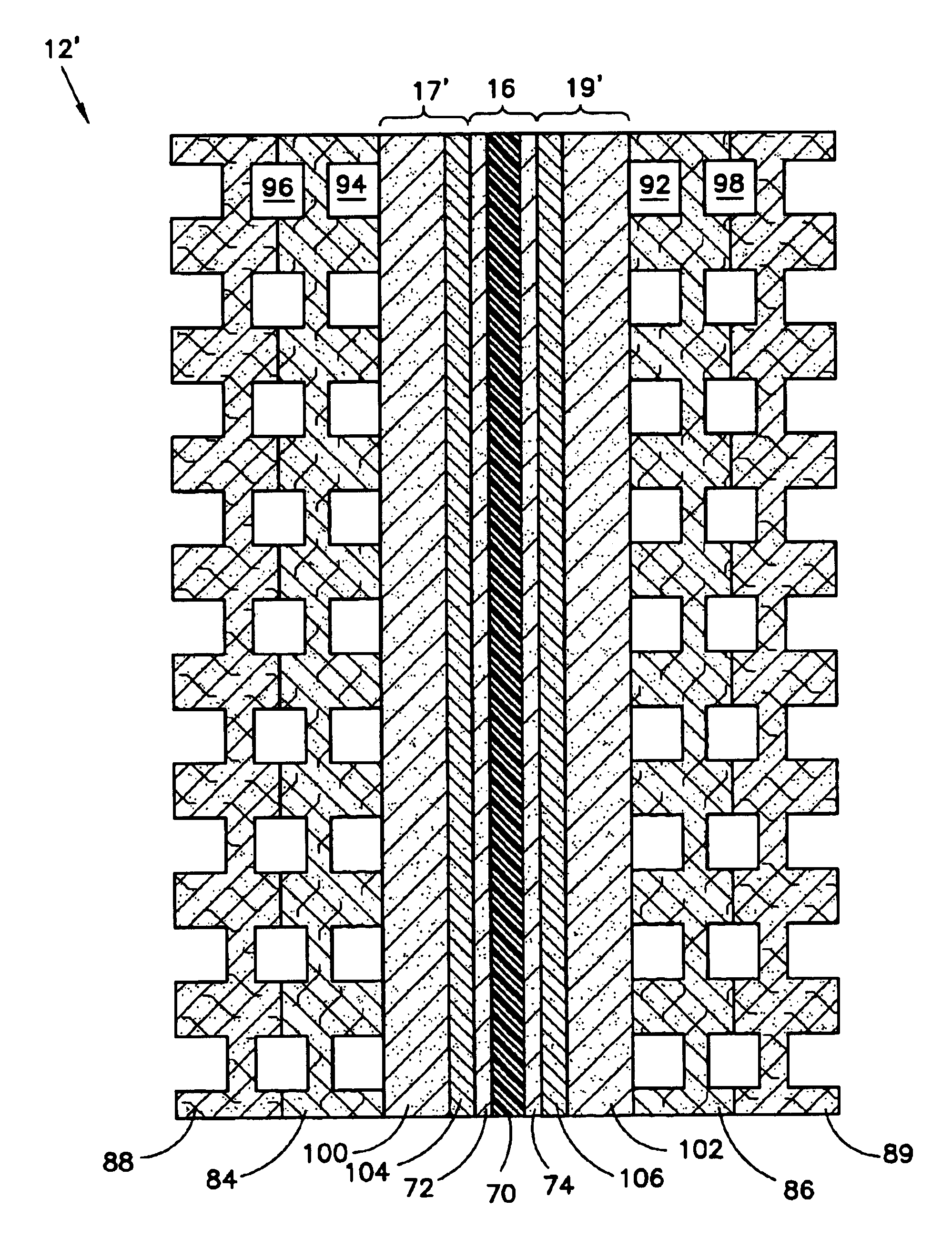

Fuel cell having interdigitated flow channels and water transport plates

InactiveUS6780533B2Increasing migrationHigh water removal rateCell electrodesWater management in fuel cellsWater transportEngineering

A fuel cell power plant includes a fuel cell having a membrane electrode assembly (MEA), which is disposed between anode and cathode support plates. Porous water transport plates or the support plates have interdigitated flow channels for the reactant gas streams to pass through and conventional flow channels for coolant streams to pass through. The pressure of the reactant gas streams is greater than the coolant stream which, within the porous water transport plates allows the coolant water to saturate the water transport plates thereby forcing the reactant gases into the anode and cathode support plates. This, in turn, increases the mass transfer of such gases into the support plates, thereby increasing the electrical performance of the fuel cell. Current densities of about 1.6 amps per square centimeter are achieved with air stochiometries of not over 2.50.

Owner:AUDI AG

Acoustic building material employing chitosan

InactiveUS20130234058A1Promotes even distributionThorough contactCeilingsConstruction materialUltimate tensile strengthMaterials science

A cast ceiling tile and method for manufacture incorporates chitosan in an amount sufficient to provide improved strength.

Owner:USG INTERIORS INC

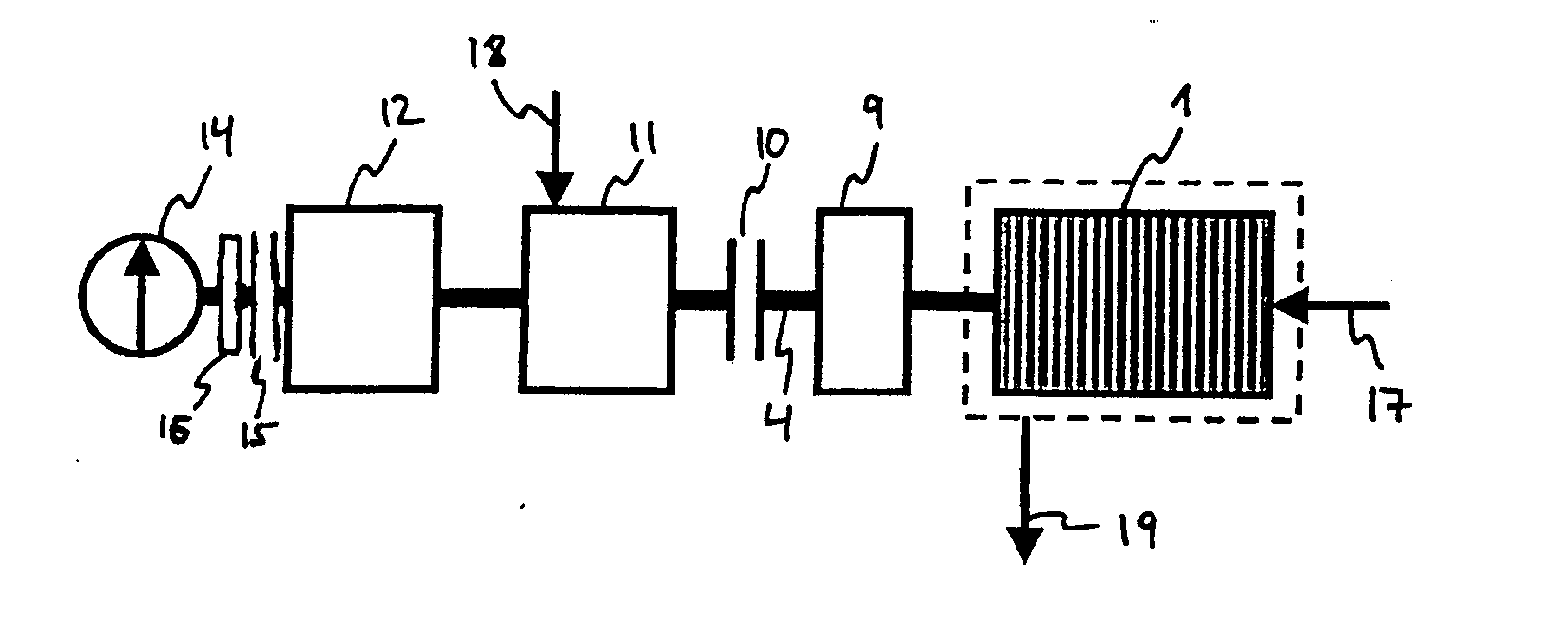

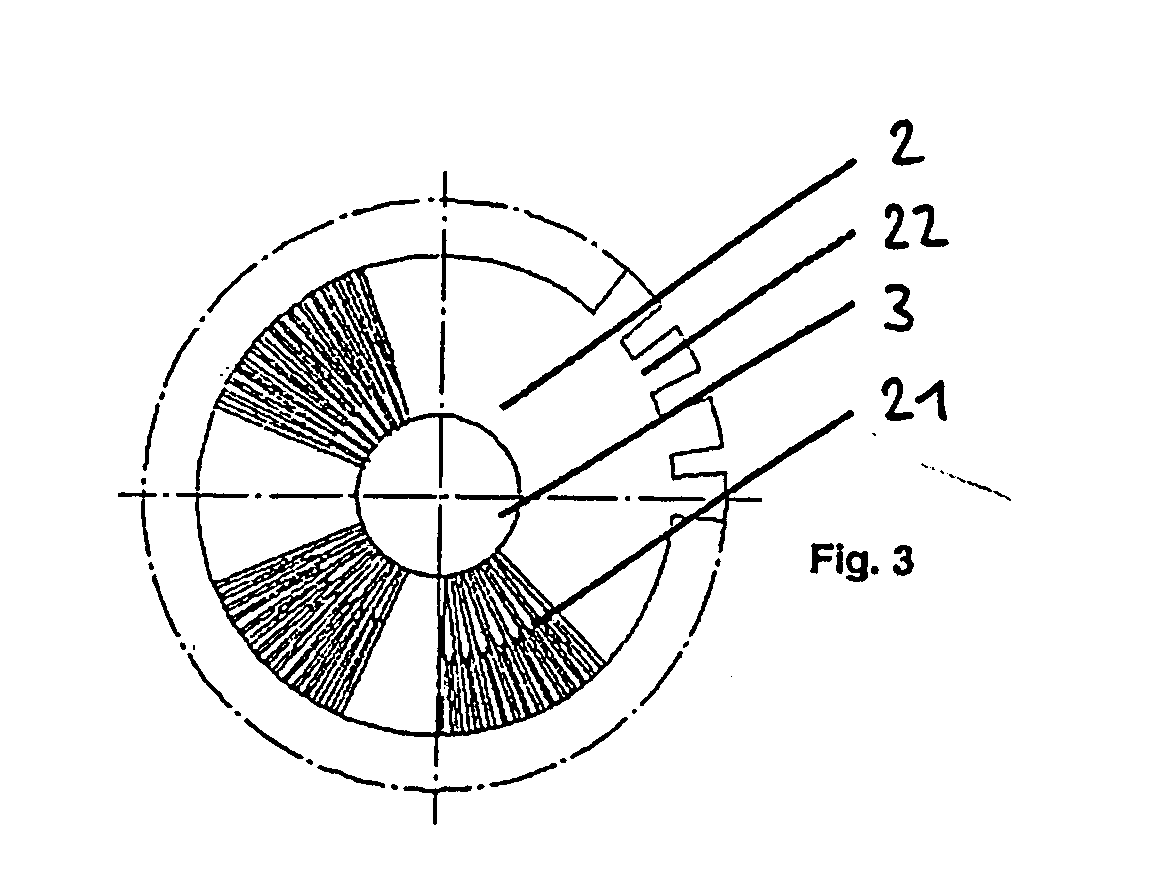

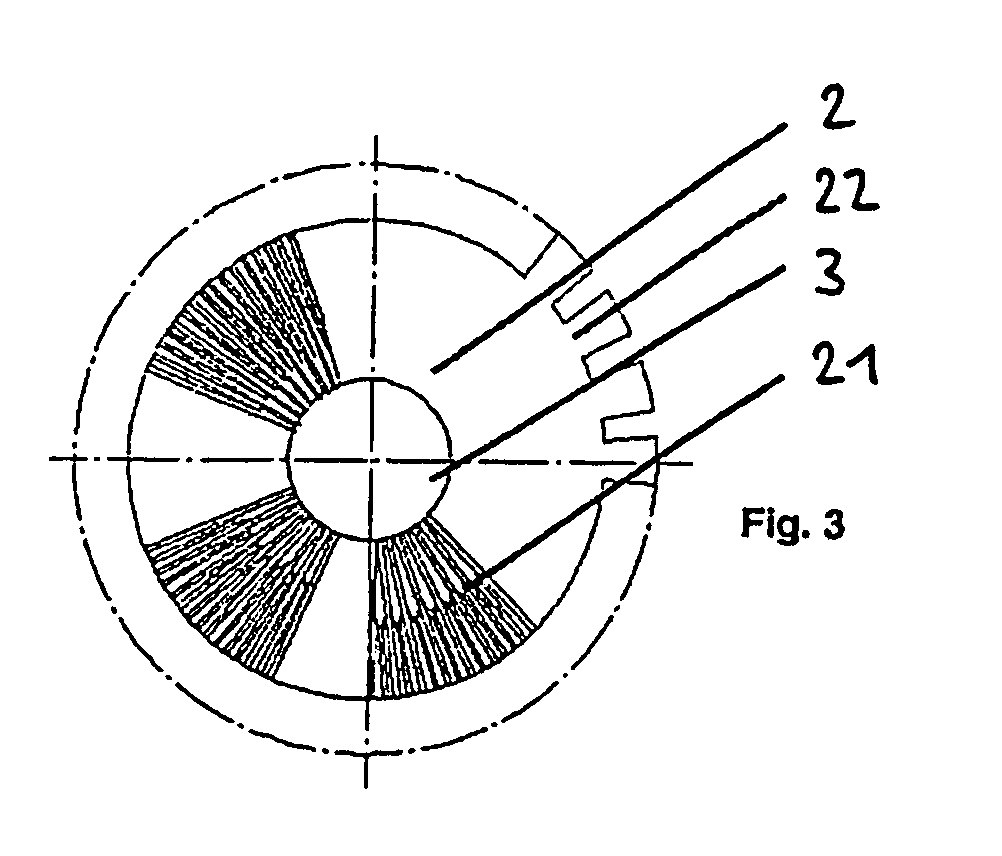

Fuel cell system

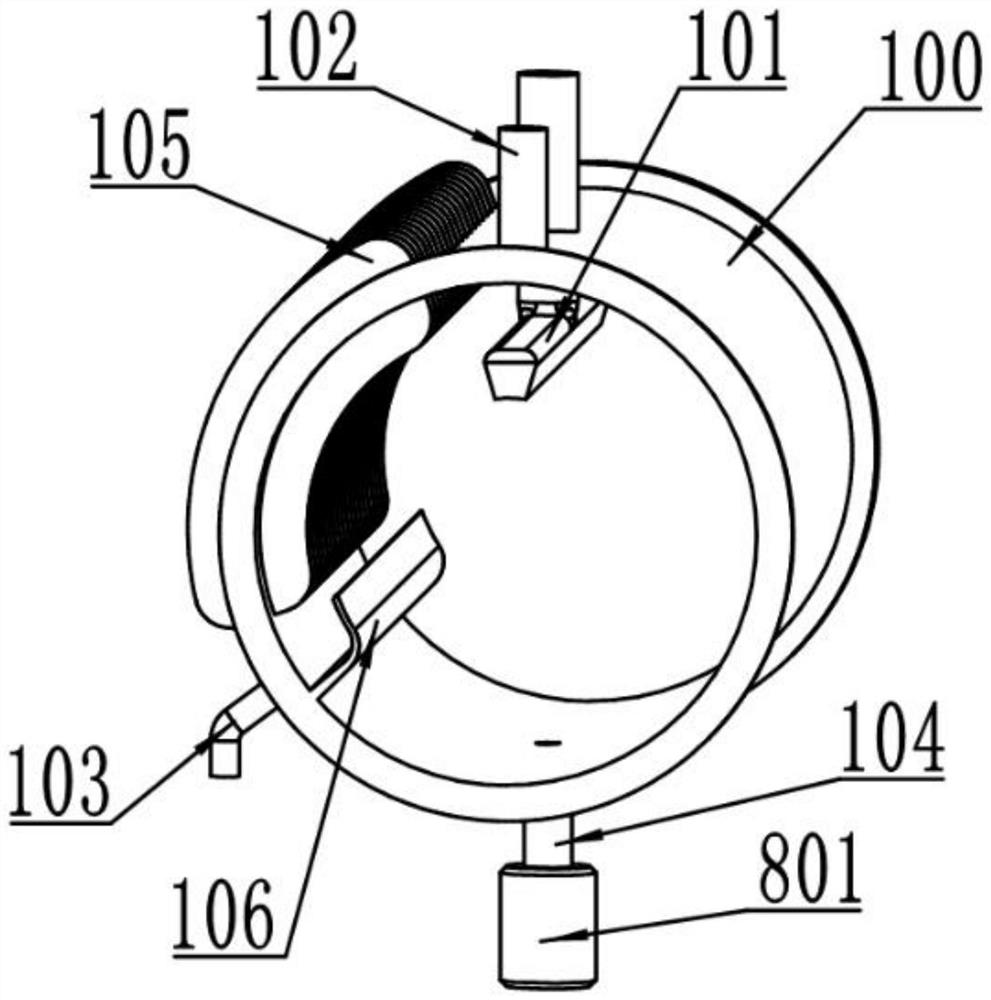

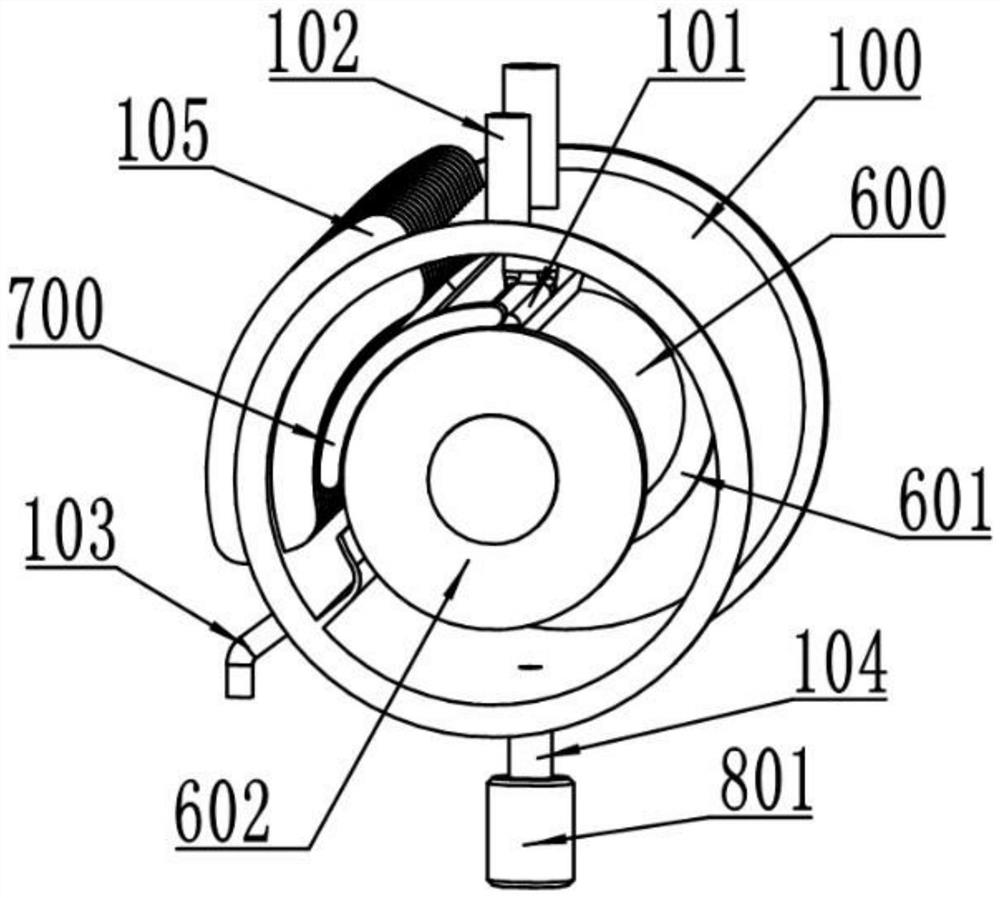

ActiveUS20060099477A1High water removal rateGood removal effectFuel cell heat exchangeFuel cell shape/formElectrochemical responseFuel cells

For operation, PEMFCs require among other things a compressor for the cathode air, and a system for removing the water which is generated on the cathode side as a result of the electrochemical reaction. According to an embodiment of the present invention the removal of water is supported in that the fuel cell is made to rotate by way of an electric motor so that the water contained in the cathodes of the fuel cell can be extracted by centrifugal force. To this effect the air channels on the cathode side are arranged so as to extend radially or in a spiral shape from the inside towards the outside. In this way the efficiency of the fuel cell can be significantly improved.

Owner:AIRBUS OPERATIONS GMBH

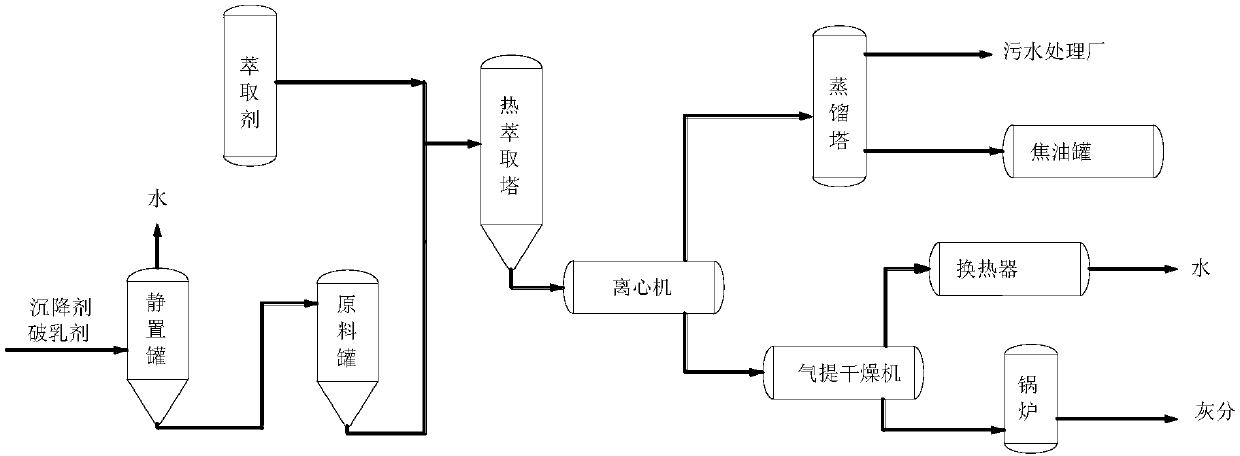

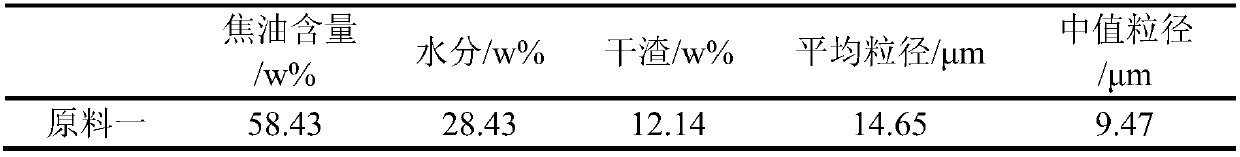

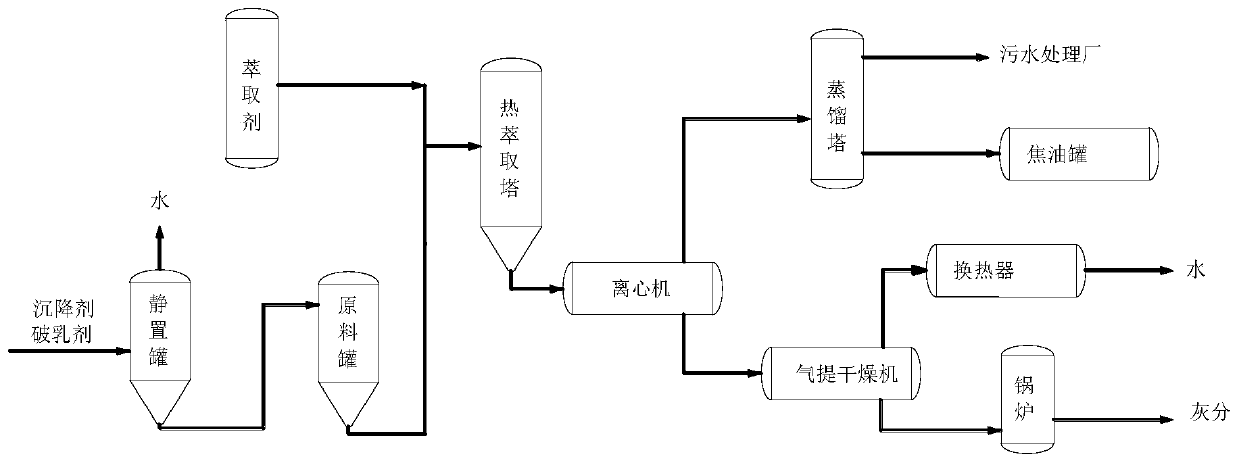

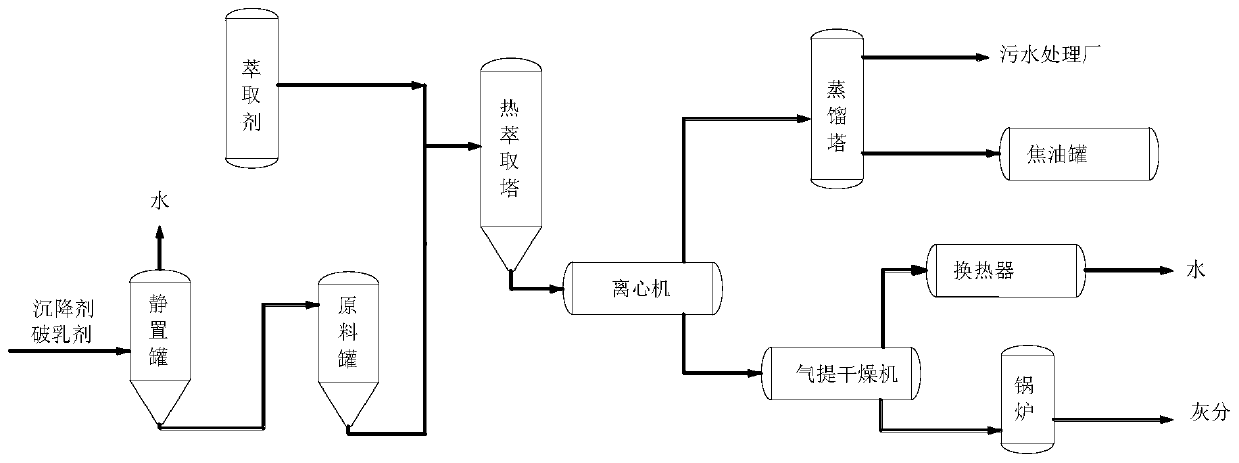

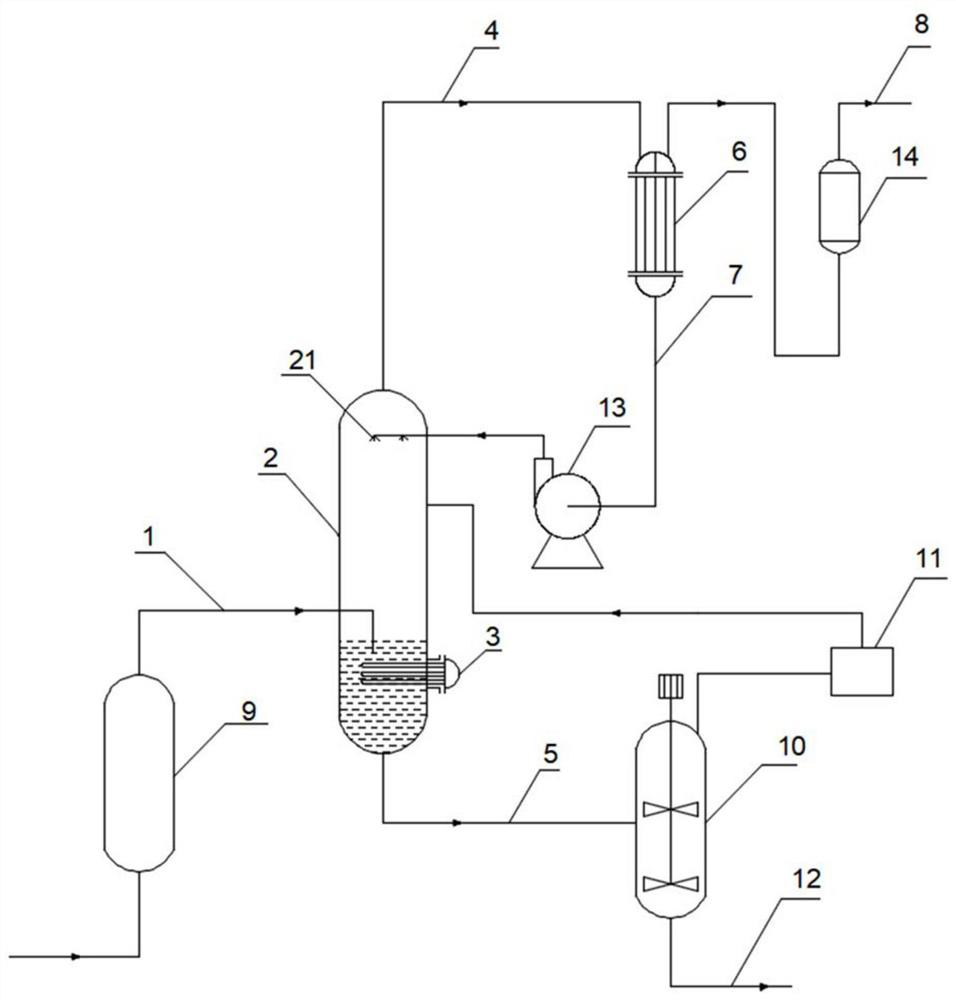

Resourceful treatment process of tar residue

ActiveCN107557044AAchieve three-phase separationEasy to separateTar working-up by water removalTar working-up by distillationSolventWater content

The invention provides a resourceful treatment process of tar residue. The resourceful treatment process is characterized in that demulsification dehydration, solvent extraction and centrifugal separation are taken as the core, distillate oil, obtained at the temperature of 200-230 DEG C, of coal tar is used as a main extracting agent, a small amount of crude benzene and industrial naphthalene areadded so as to form a composite extracting agent, and the proportion of all the components used in the process is as follows: 90-95wt / % of the distillate oil, obtained at the temperature of 200-230 DEG C, of the coal tar, 4.1-9.7wt / % of the crude benzene and 0.3-0.9wt / % of the industrial naphthalene; a technology of combining heat extraction and centrifugation is adopted under the conditions thatthe temperature of the demulsification dehydration is 35-55 DEG C, extraction temperature is 55-60DEG C, the pressure is 101.325kPa, the pump circulating flow rate is 15-20m<3> / h, the extraction timeis 3-4h, the centrifuge rotating speed is 2500-3000r / min, and the like, so that the recovery rate of tar in the tar residue reaches up to 95% or above. The resourceful treatment process is verified to be capable of well adapting to the raw material tar residue with water content of 20-60% in the aspect of raw material adaptability; the extracting agent used in the process does not need to be recovered after oil-water-residue separation is finished, can be directly used as an oil product component in the oil so as to be stored and utilized, and does not need to be recycled, so that the separation link is simplified, waste is avoided, and energy is saved; the resourceful treatment process effectively solves the problems of the tar residue in the aspects of energy utilization and environment-friendly treatment.

Owner:NORTHWEST UNIV(CN)

Method for improving the removal of water

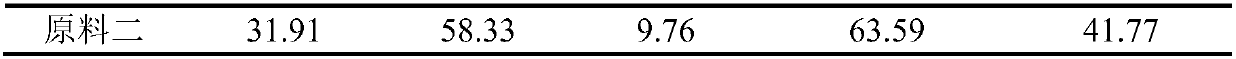

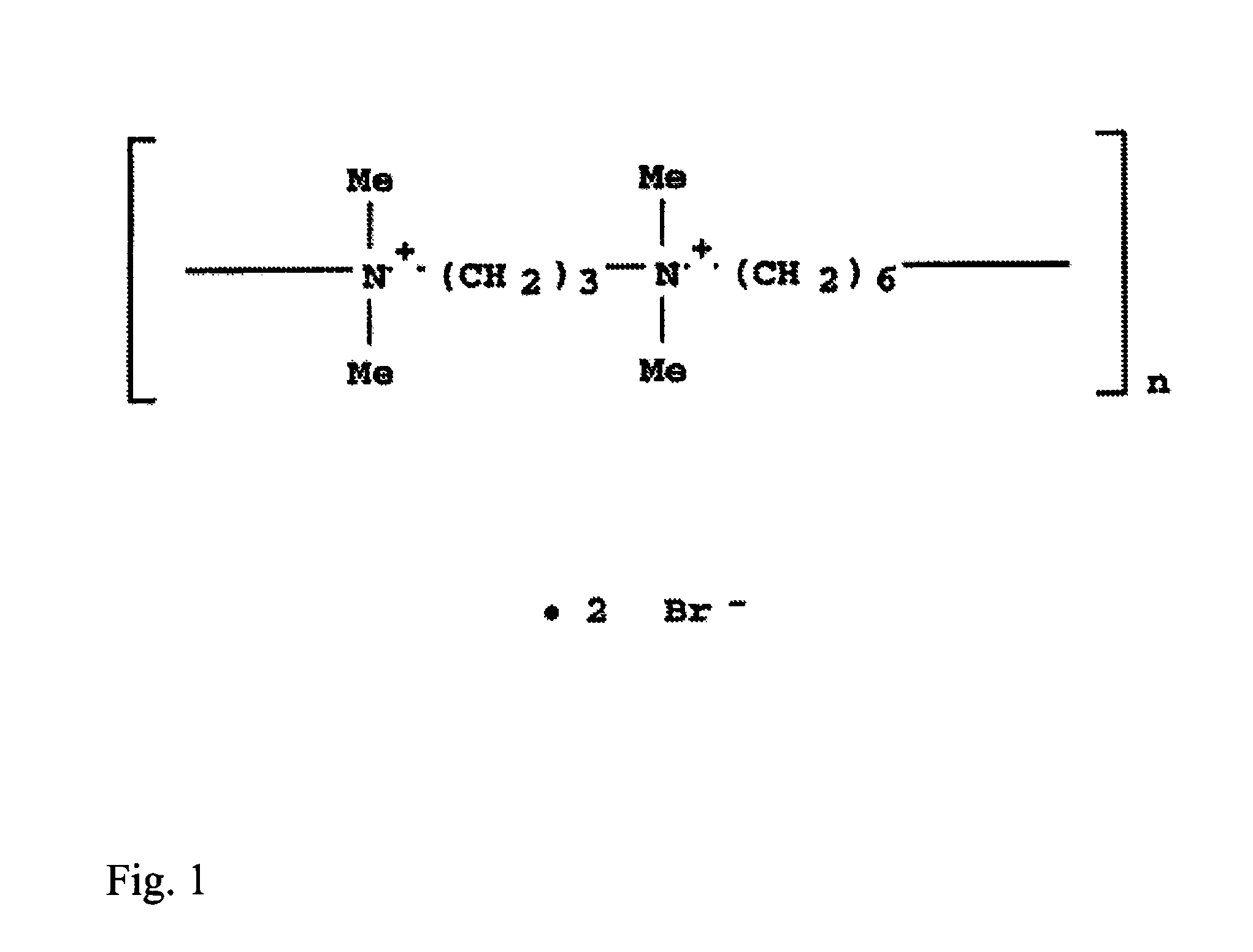

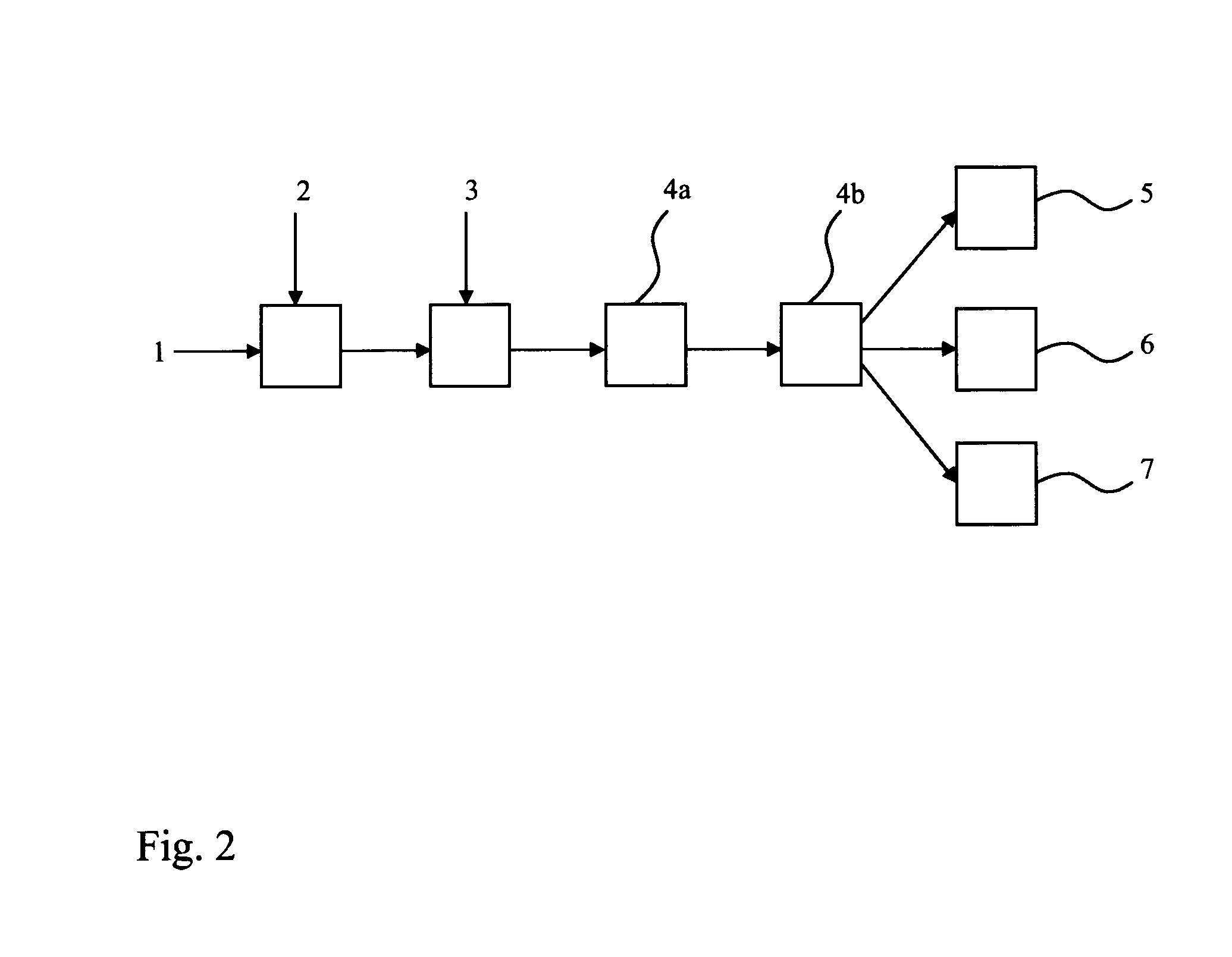

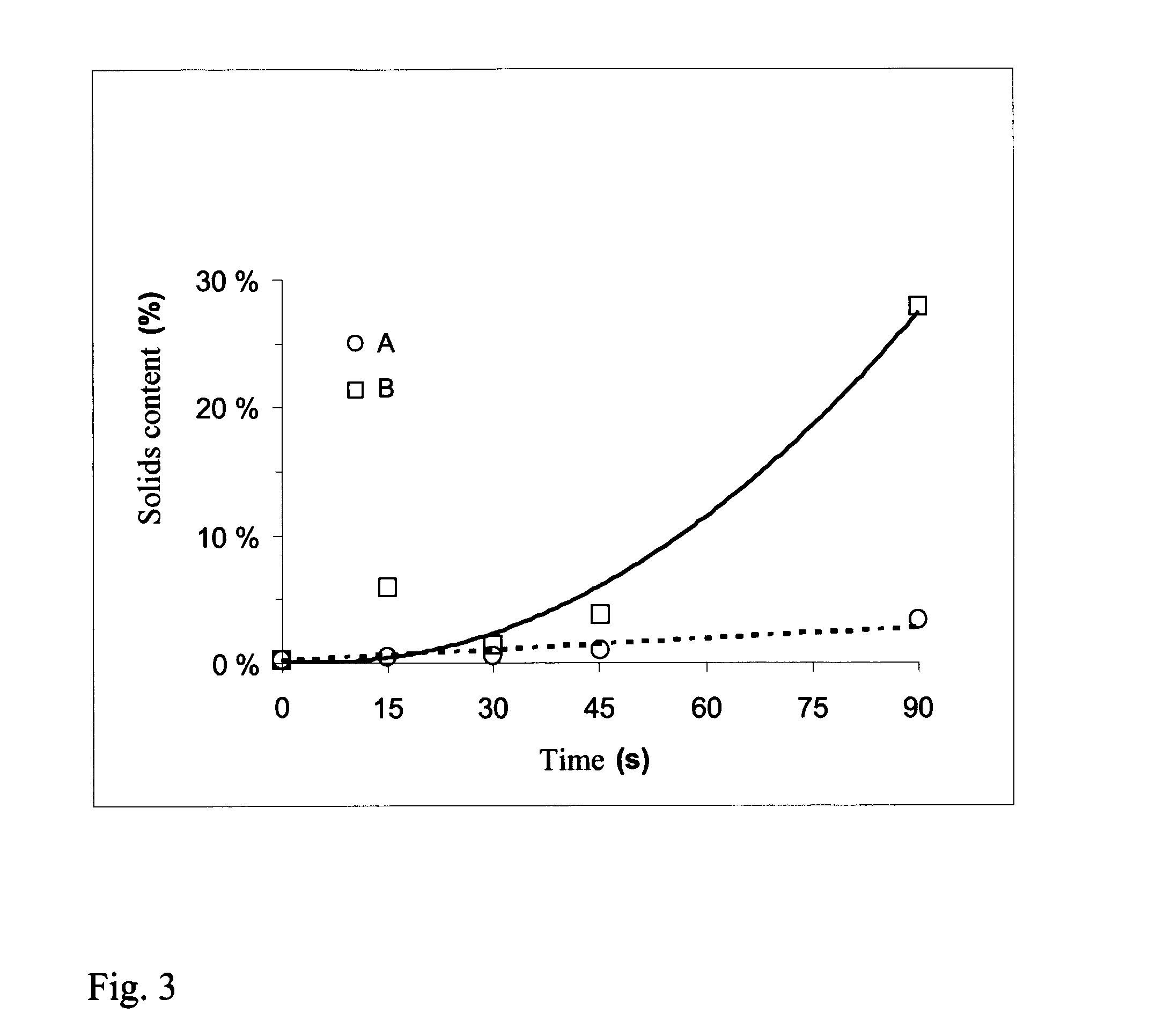

InactiveUS20130180679A1Accelerates the removal of moistureAffects structuralSpecial paperPaper after-treatmentCelluloseCationic polyelectrolytes

The invention relates to a method for improving the removal of water in a composition containing microfibrillated cellulose. According to the invention, a cationic polyelectrolyte that has a low molecular weight and a molecular weight of less than 10000 is provided in the composition containing microfibrillated cellulose.

Owner:UPM-KYMMENE OYJ

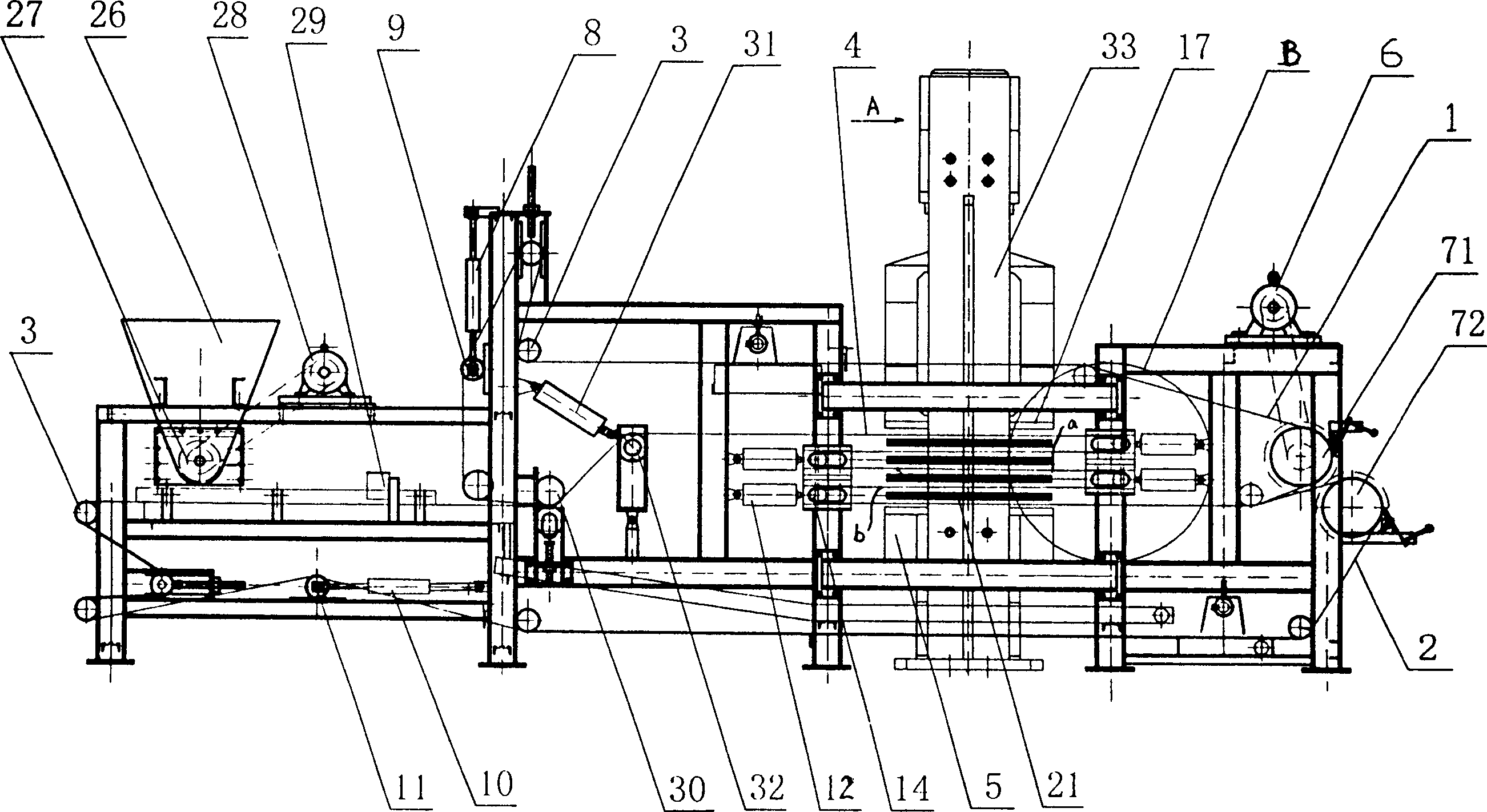

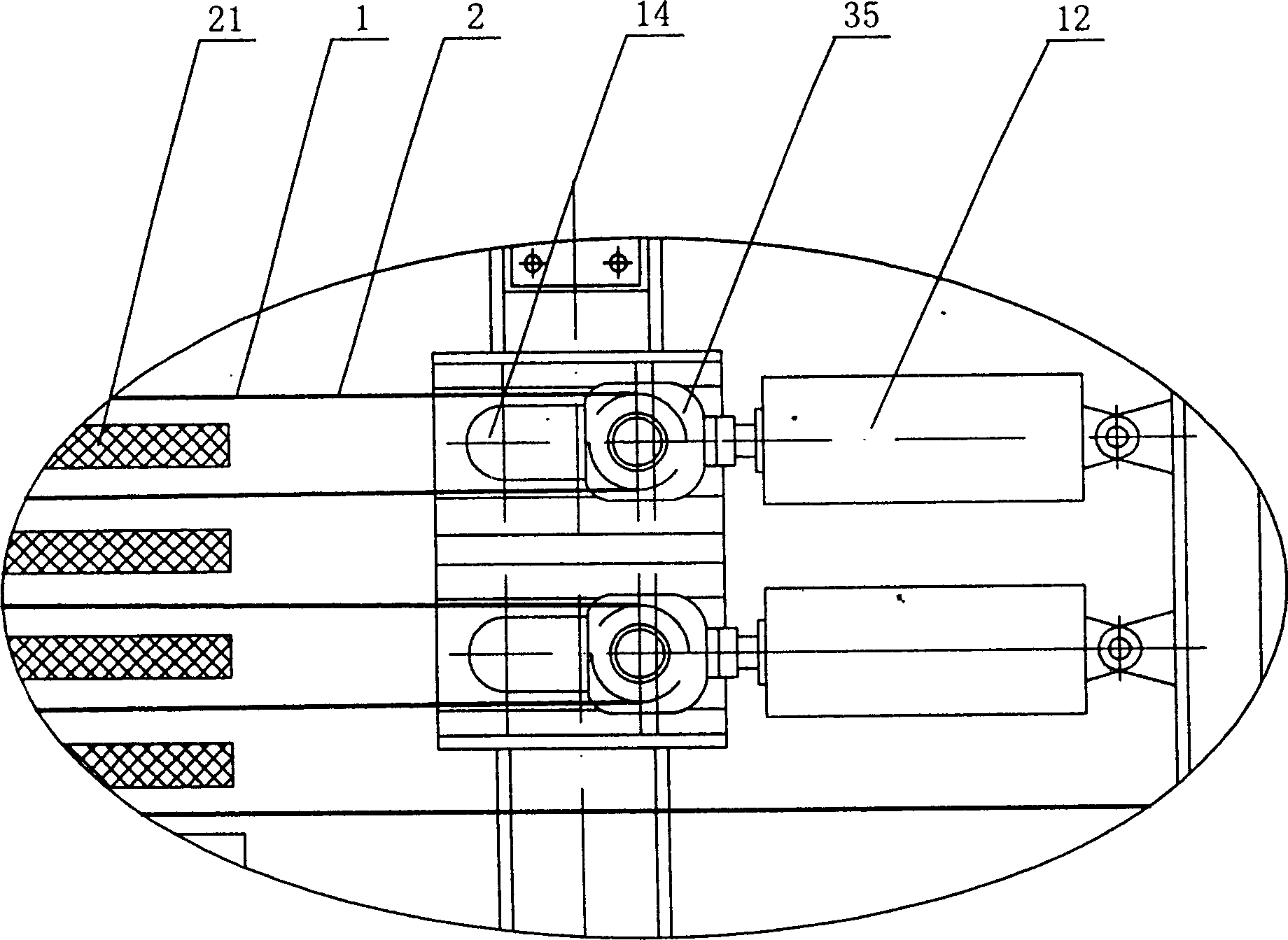

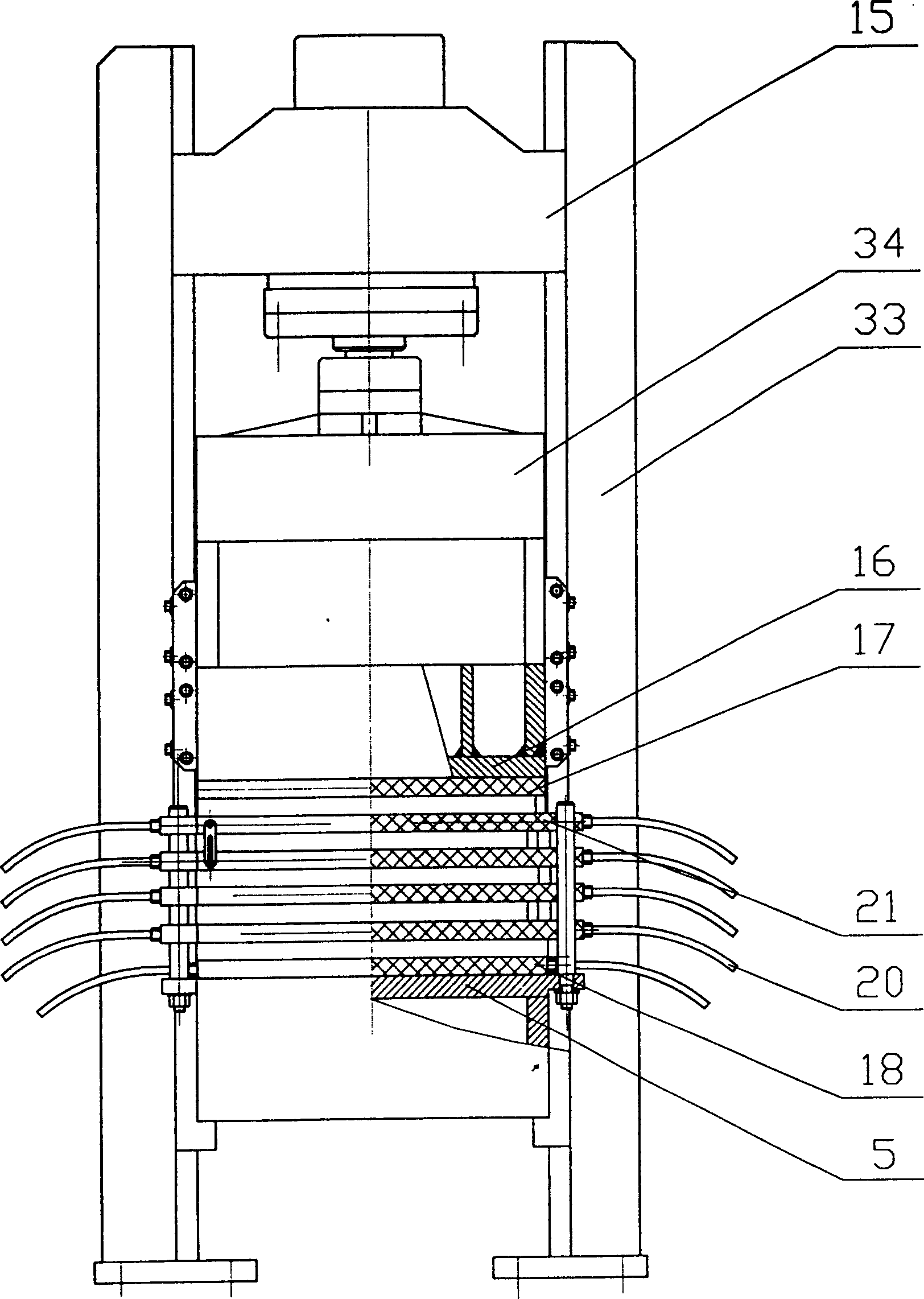

High-efficient strong filter press

InactiveCN1817405AShorten the lengthHigh water removal rateFiltration separationReciprocating motionEngineering

An efficient strong press filter for removing water from material is composed of the endless material conveying netted band and its power unit, guide rollers, the deviation correcting unit and S-shaped press region, where there are press bearing table, upper and lower press plates, and releasing and stretching unit for netted band.

Owner:胡杭虎

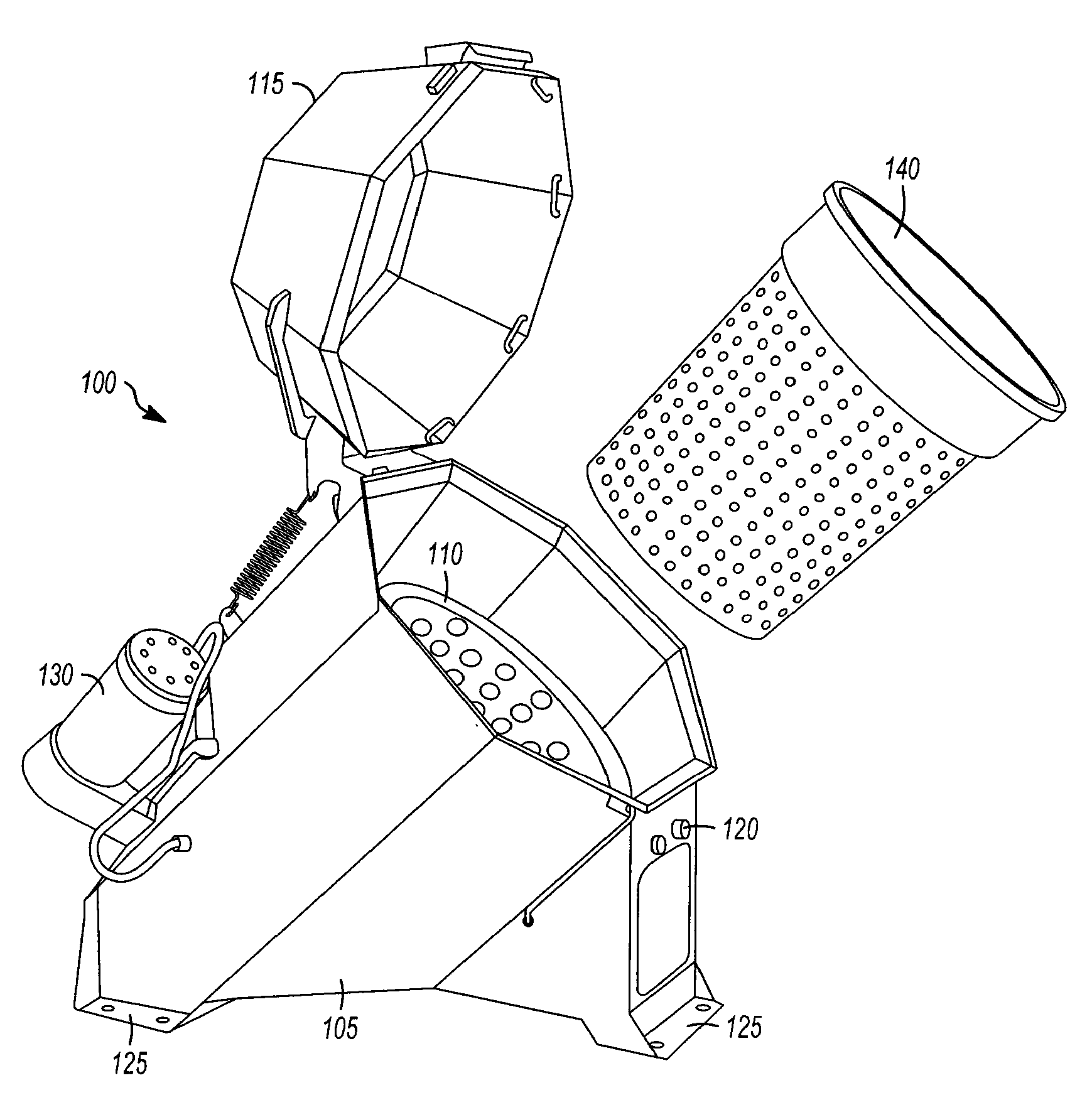

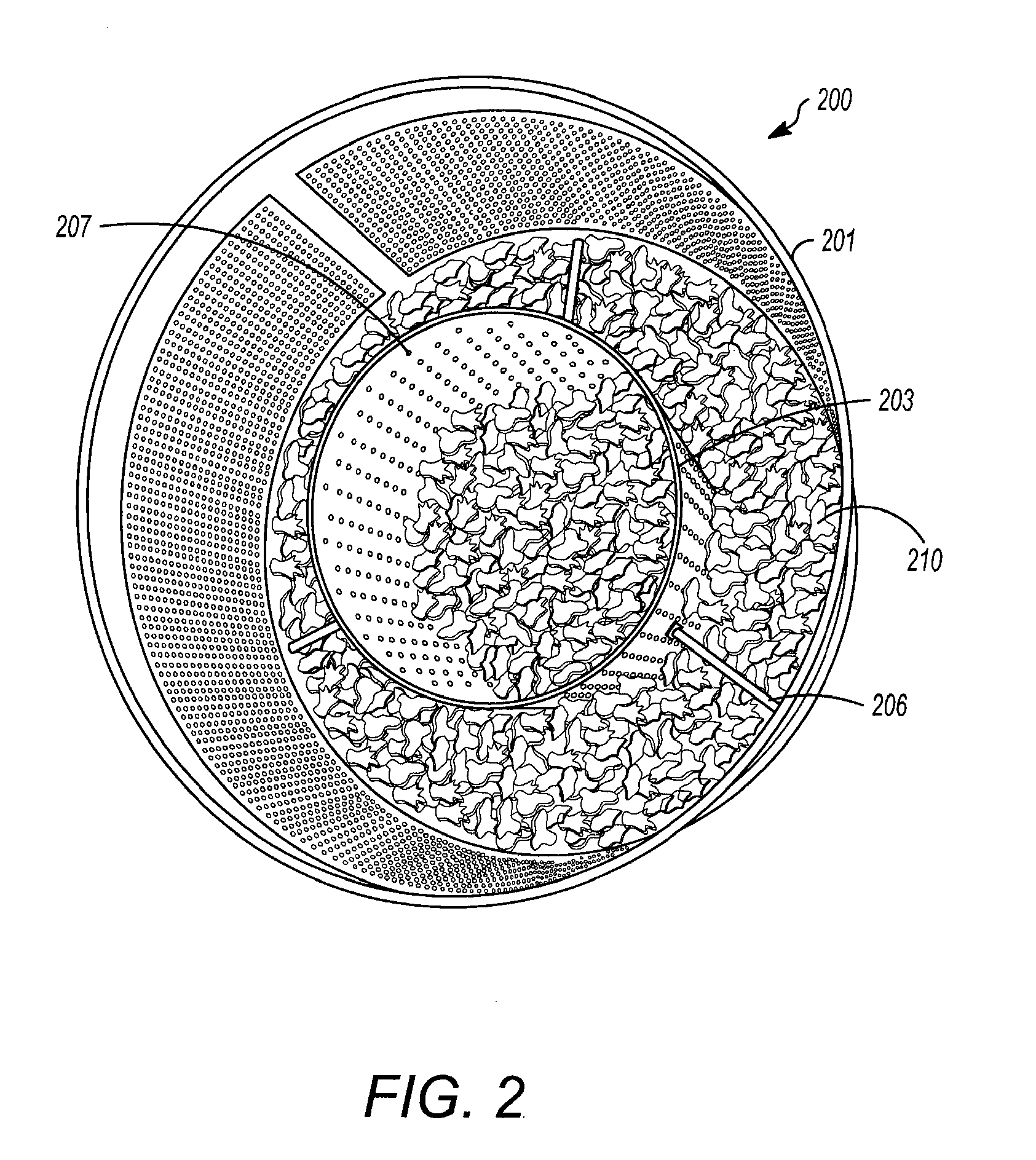

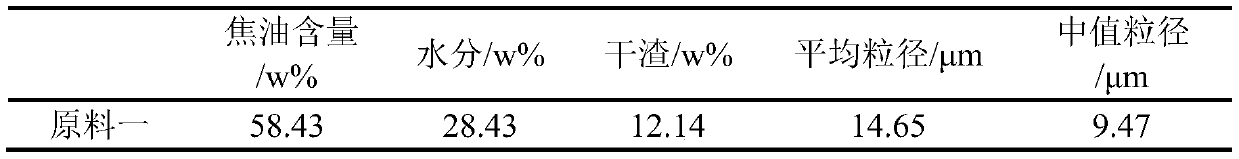

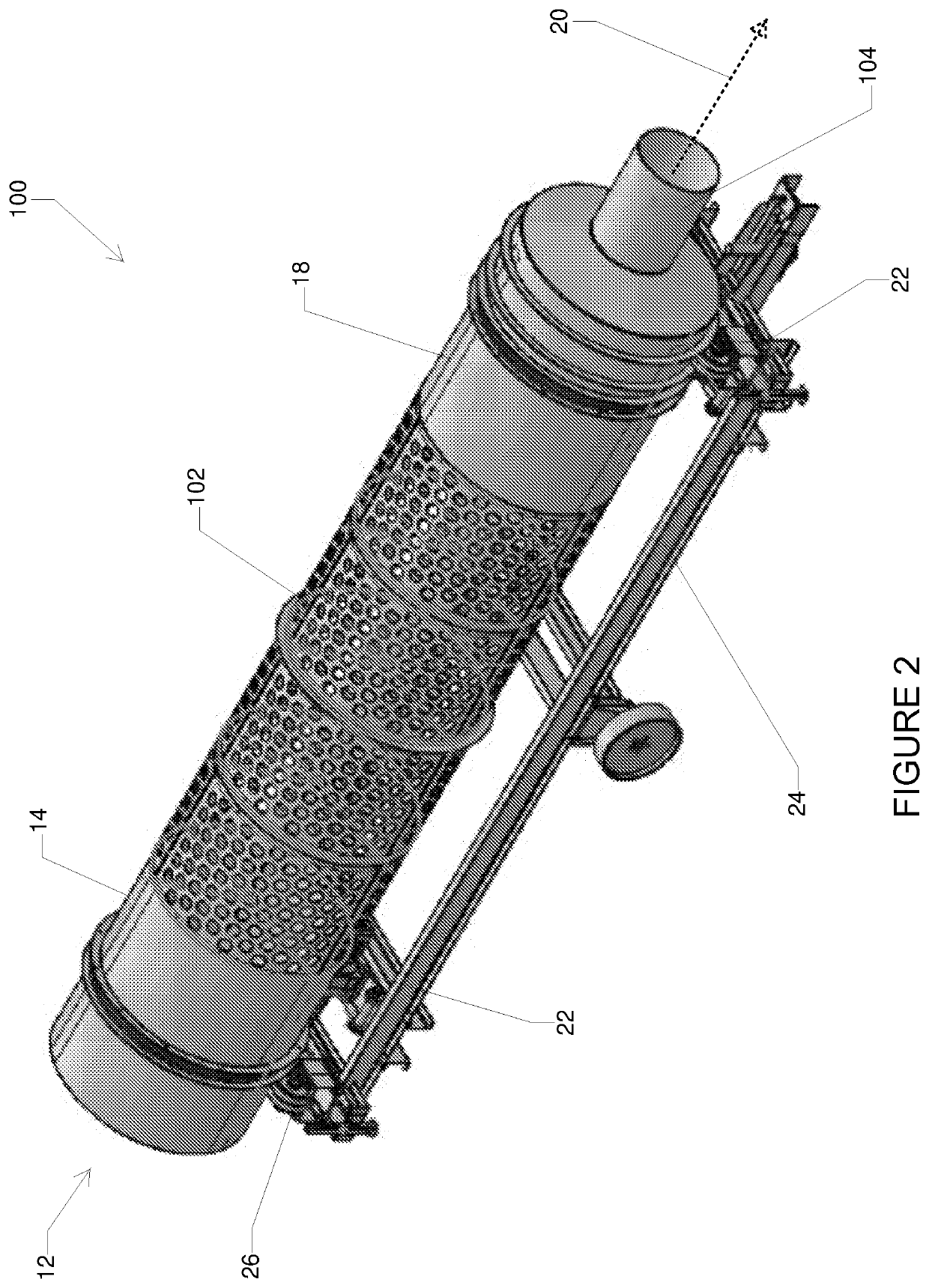

Vertical drum drier

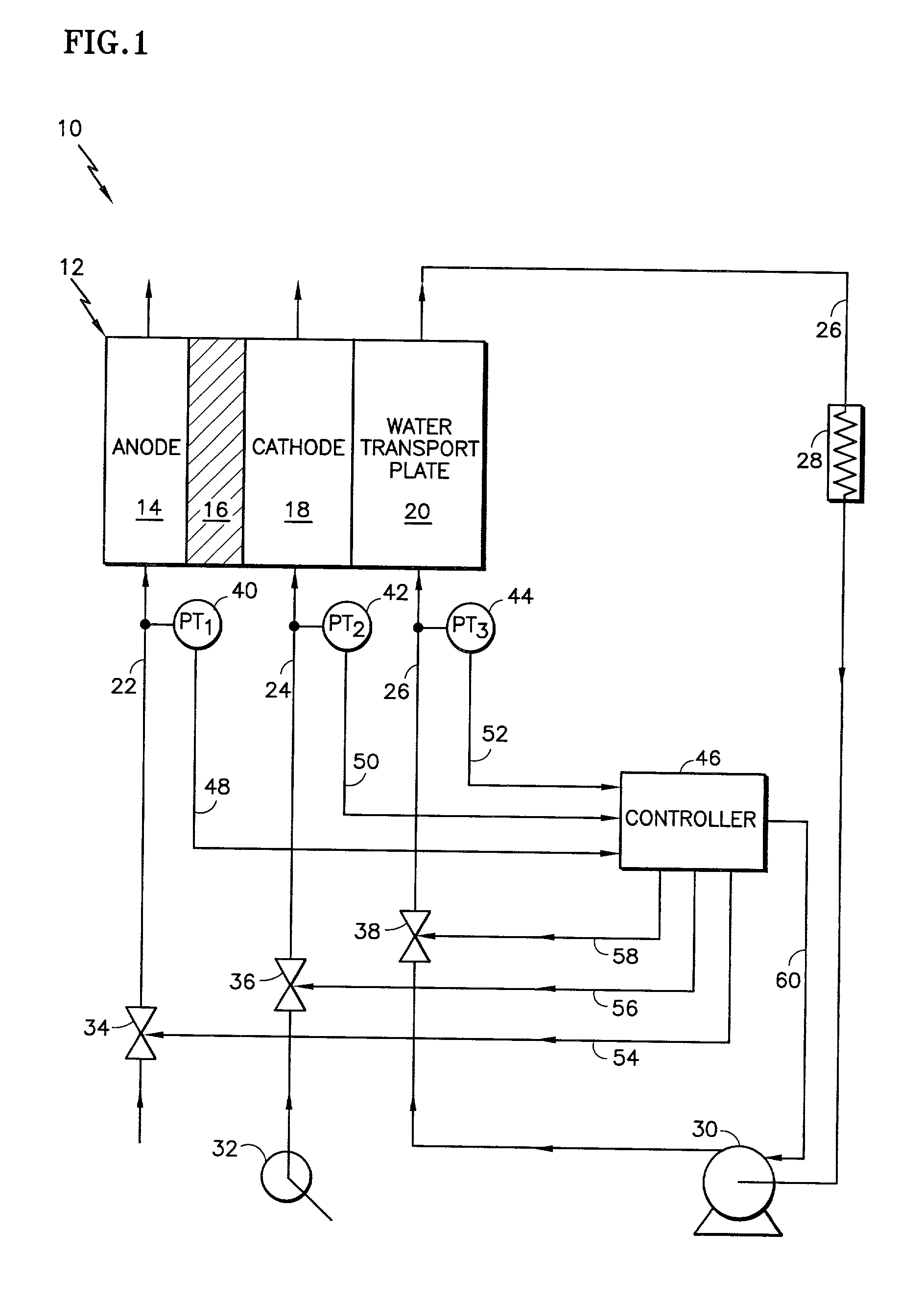

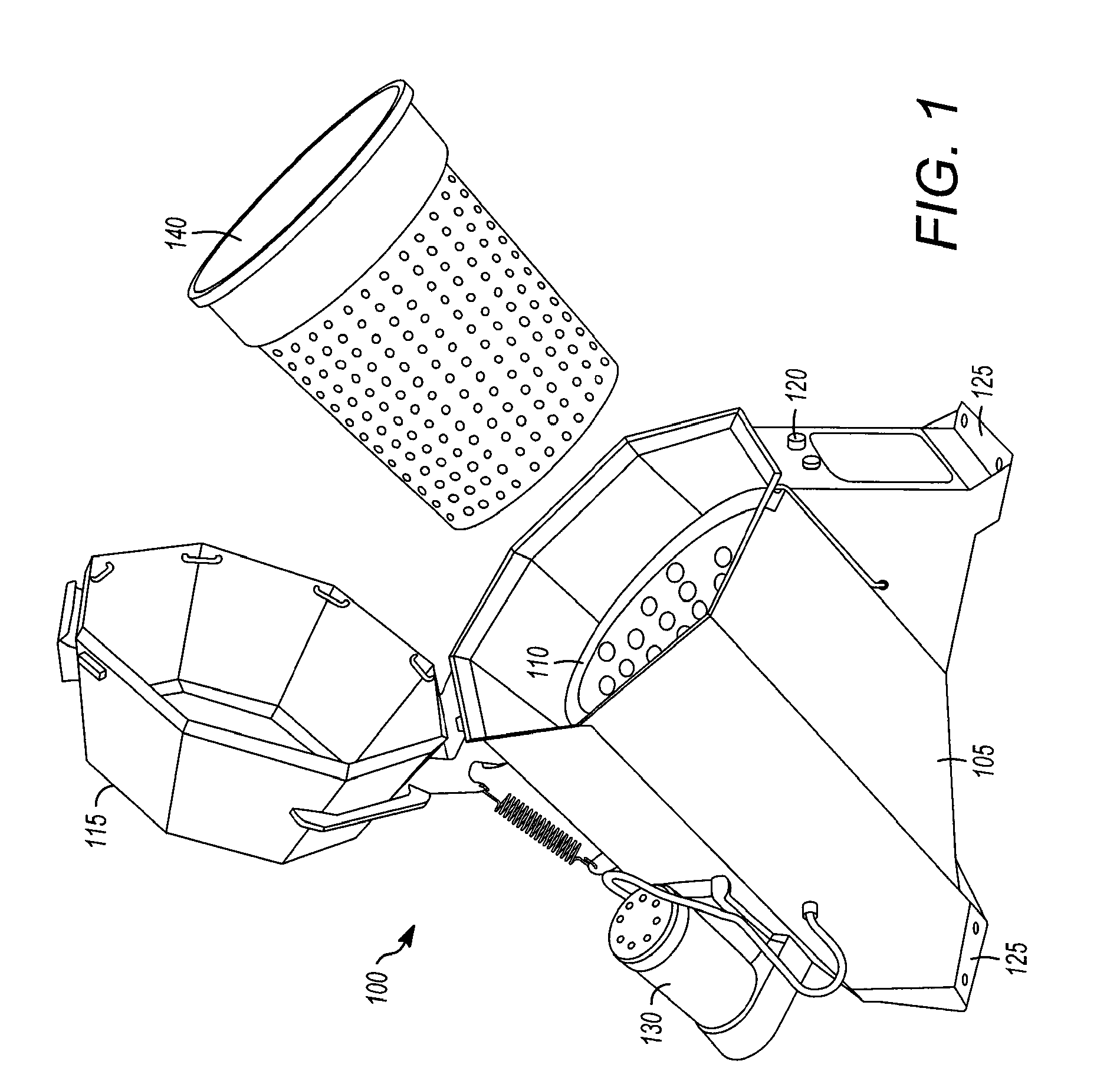

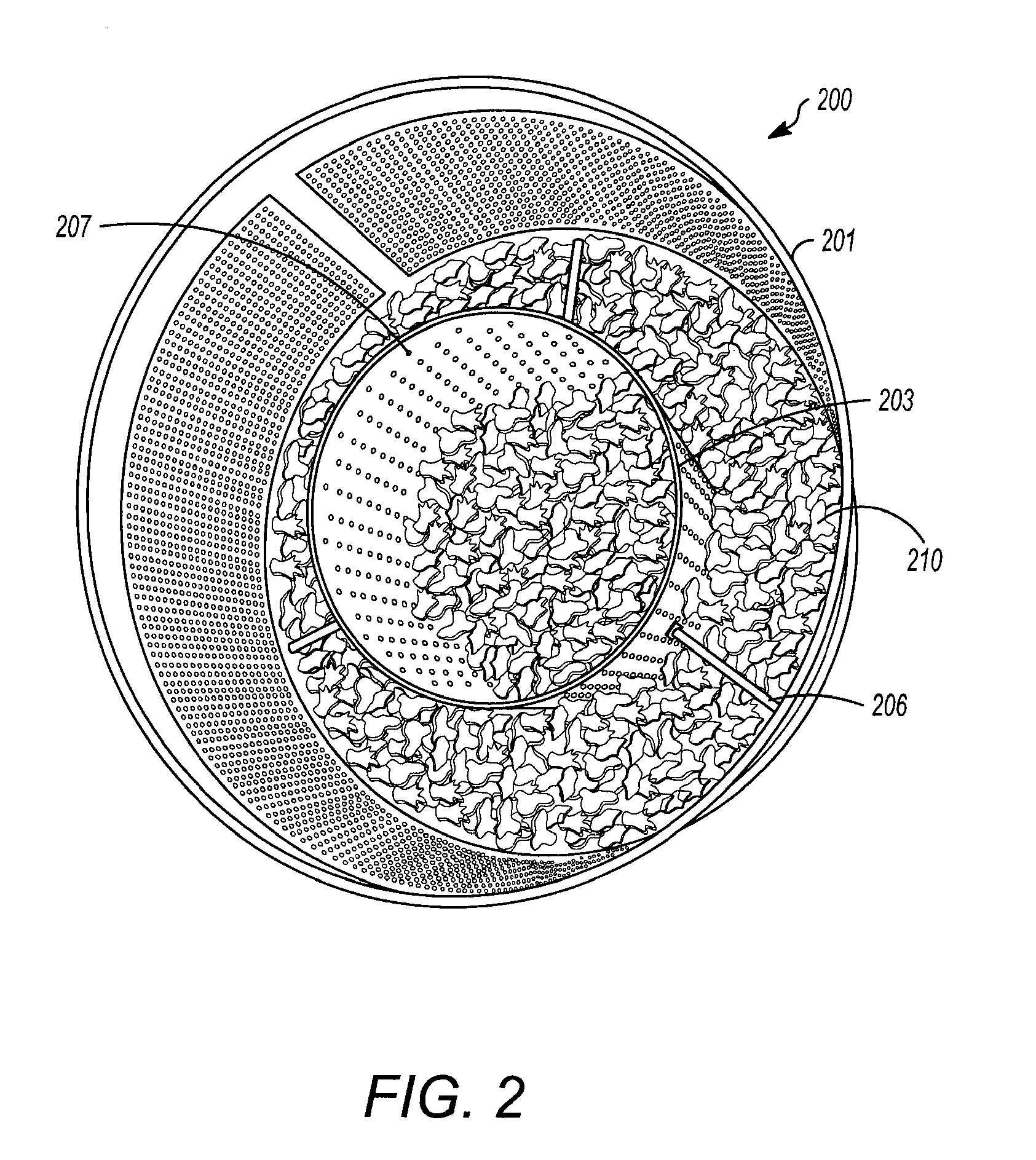

InactiveUS20110023320A1Extended shelf lifeGreat aesthetic appealDrying solid materials without heatDrying machines with non-progressive movementsEngineeringMechanical engineering

A method and apparatus for drying produce in a centrifugal drier is described. The drier includes a housing and a drum configured to receive a multi-volume basket. The method includes loading produce into a first volume and a second volume of the multi-volume basket. The basket may include perforated walls, a closed lower end, and an open upper end. The interior volume of the basket is divided into at least a first volume and a second volume by a perforated inner divider that is oriented concentrically to the basket walls. The first volume is disposed inside the inner divider. The second volume is disposed between the inner divider and the basket walls. A drive assembly rotates the drum and the basket, loaded with produce in the first and second volumes, to cause fluids to drain out of the produce to yield dried produce.

Owner:DOLE FRESH VEGETABLES

Sludge biological drying method

InactiveCN105016600AHigh water removal rateFast absorptionSludge treatment by de-watering/drying/thickeningSludge processingFiberSludge

The invention provides a sludge biological drying method, which comprises the following steps: 1)removing impurity and homogenizing; 2)performing acidolysis treatment on sludge; 3)conditioning surface active substance; 4)adding a filler: adding the filler crude wood chip in the processed sludge and fully stirring; and 5)adding a composite microbe preparation: adding a composite microbe preparation in processed sludge, wherein the composite microbe preparation is prepared by carbon source and composite microbe inocula according to mass part of 2: 1. An employed ventilation mode is intermittence ventilation by a blower, under condition of certain ventilation quantity, ventilation rate is adjusted from large rate to small rate, and the moisture clearance of the material is increased by 3%. drying method is carried out on the sludge by employing an addition method of an acidulate agent and microbe, fiber component and protein component in sludge can be partially hydrolyzed to nutrition component which can be rapidly used by thalline, drying efficiency is increased, and drying effect is improved.

Owner:霍普科技(天津)股份有限公司

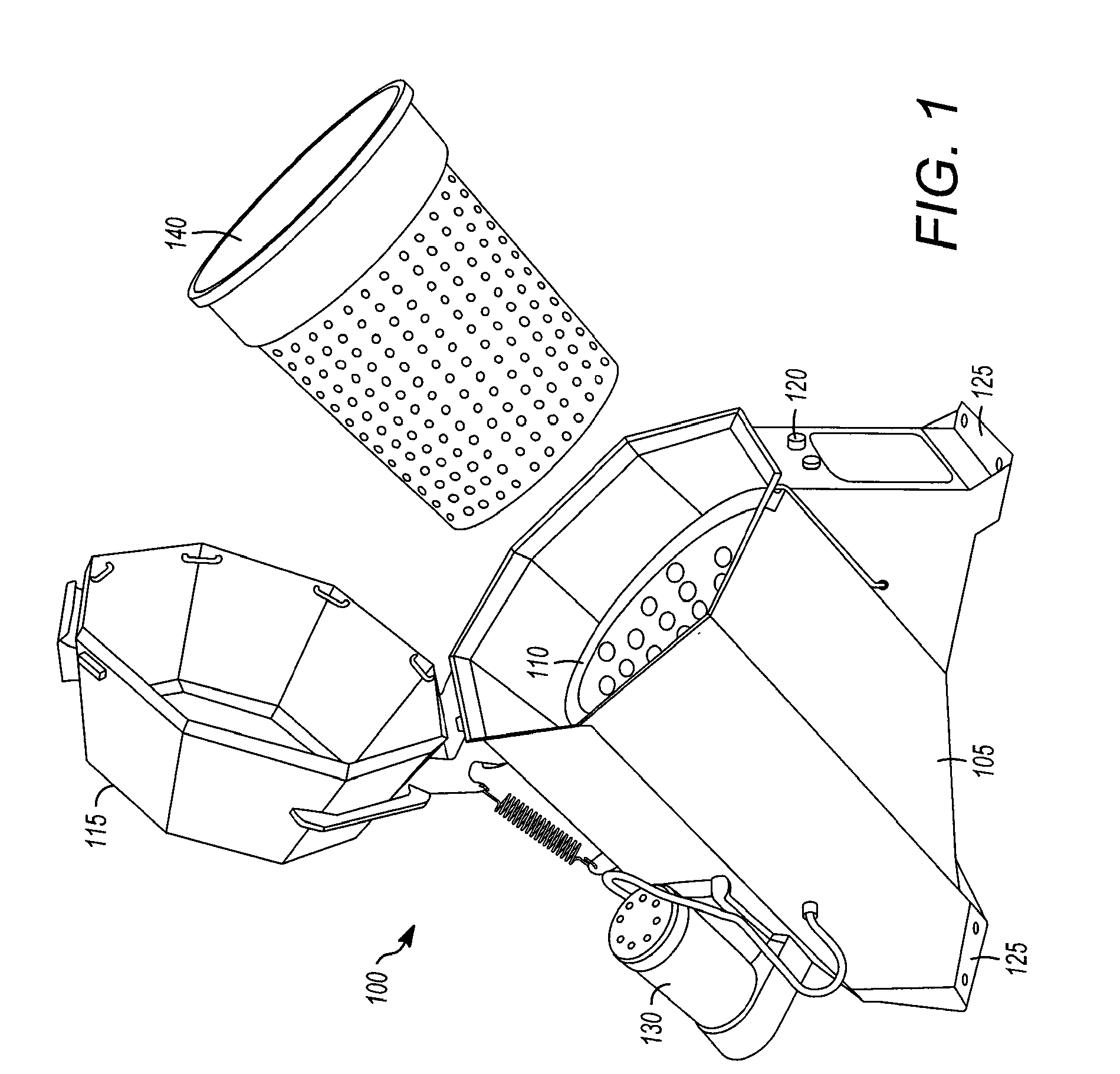

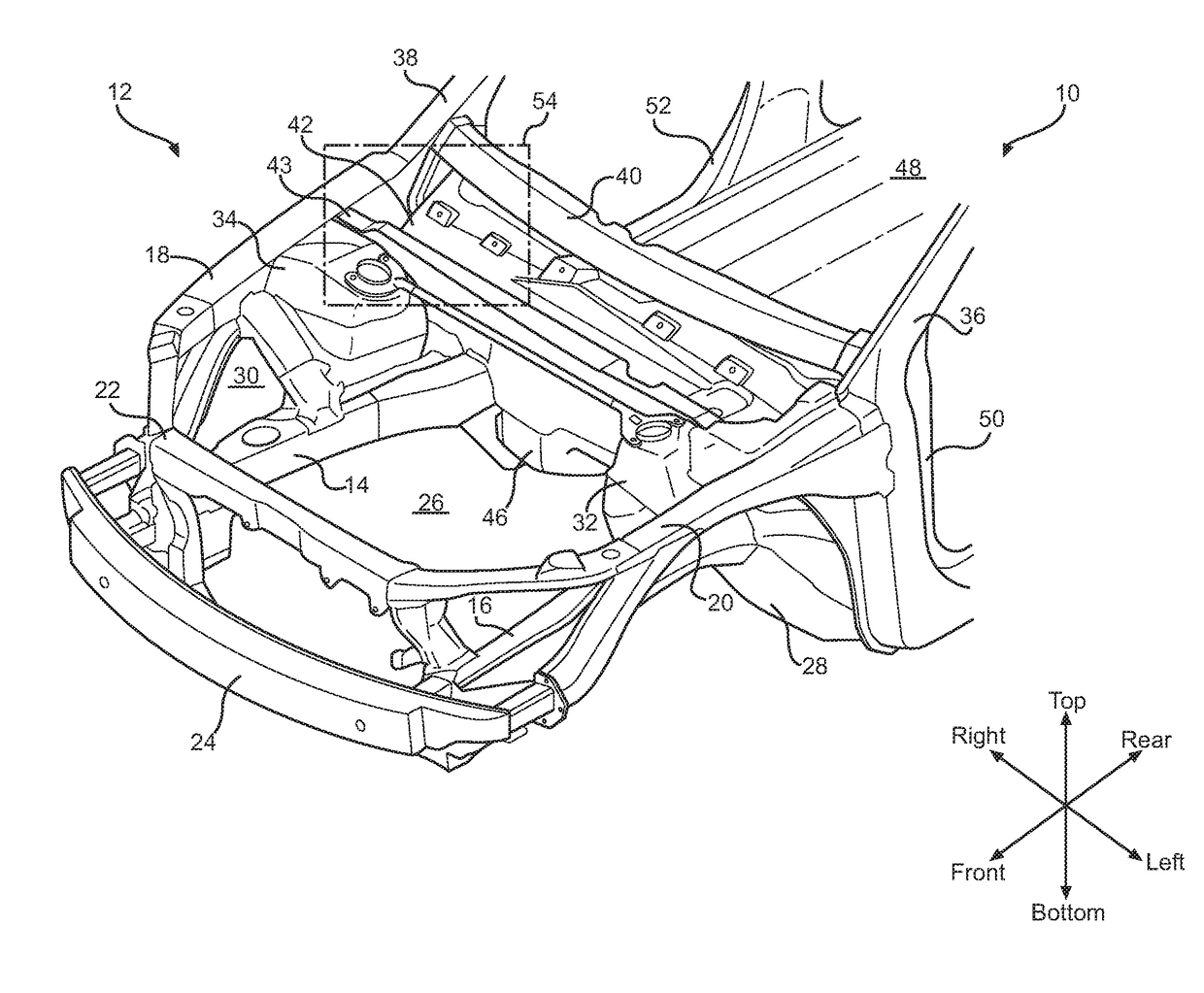

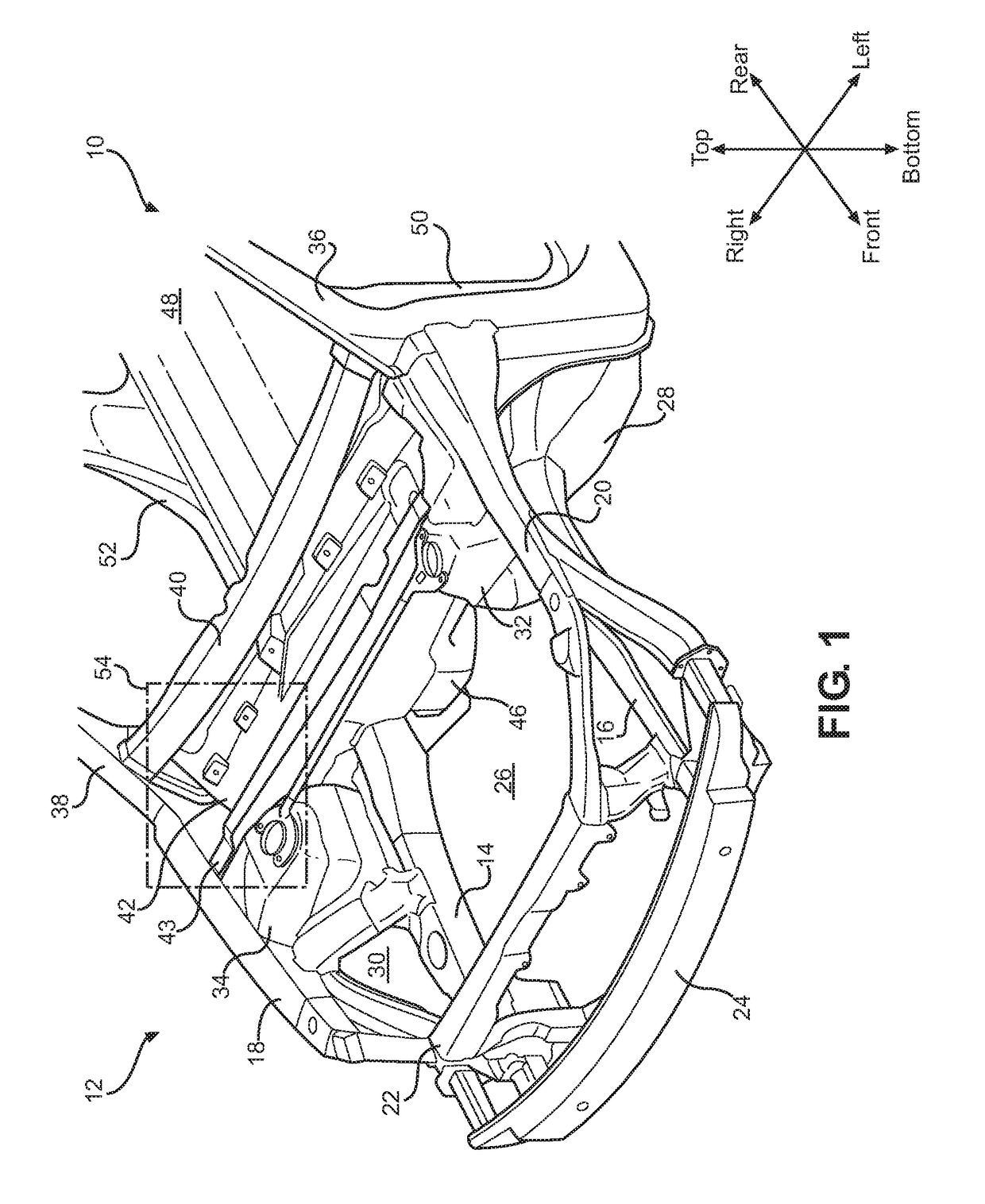

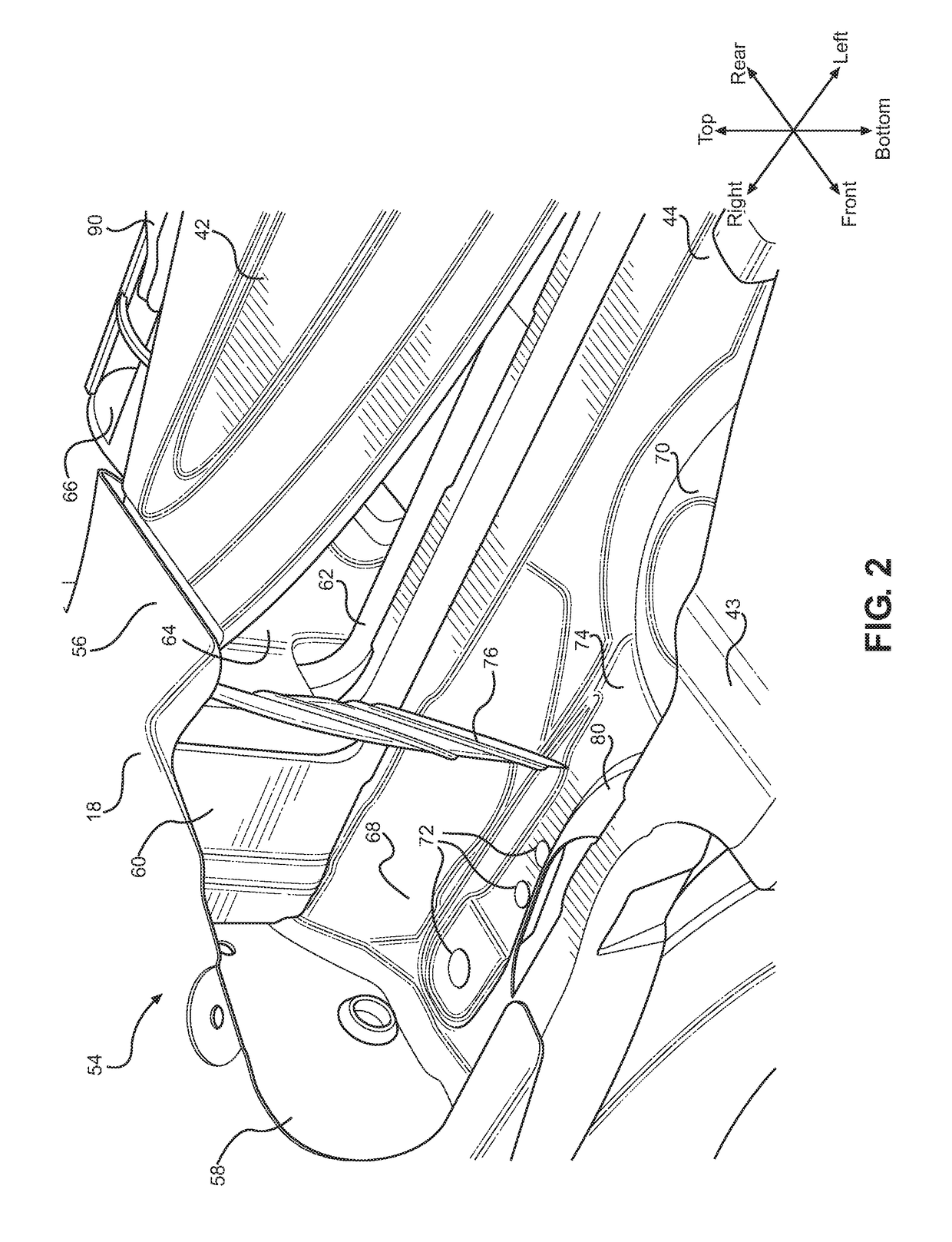

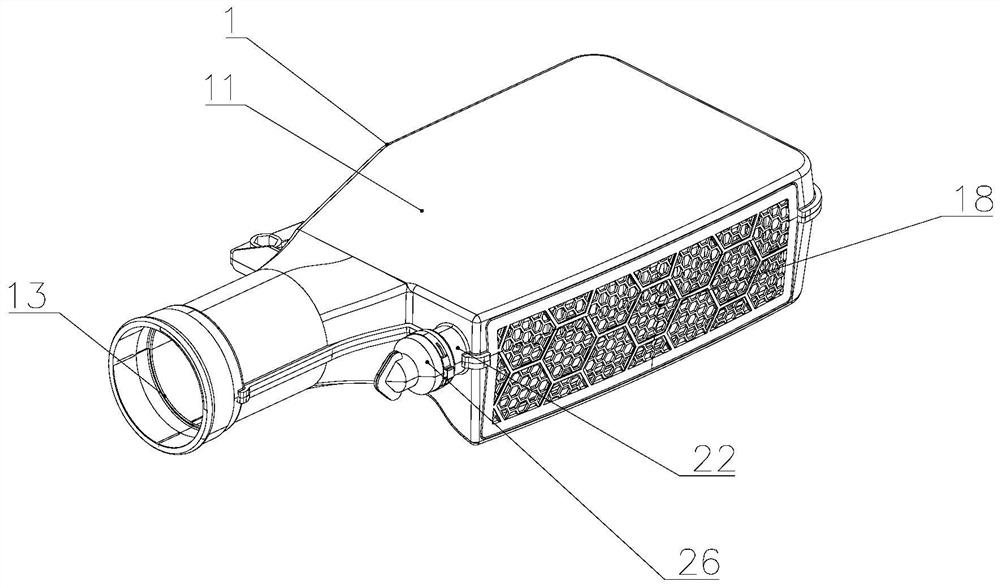

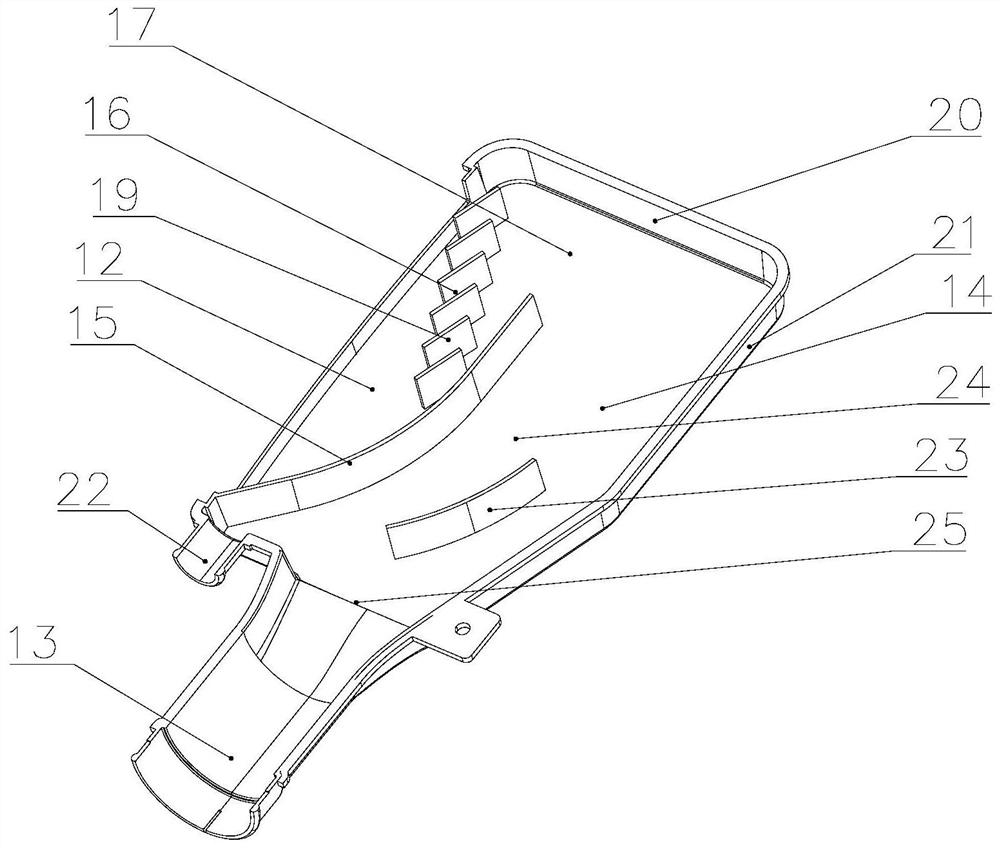

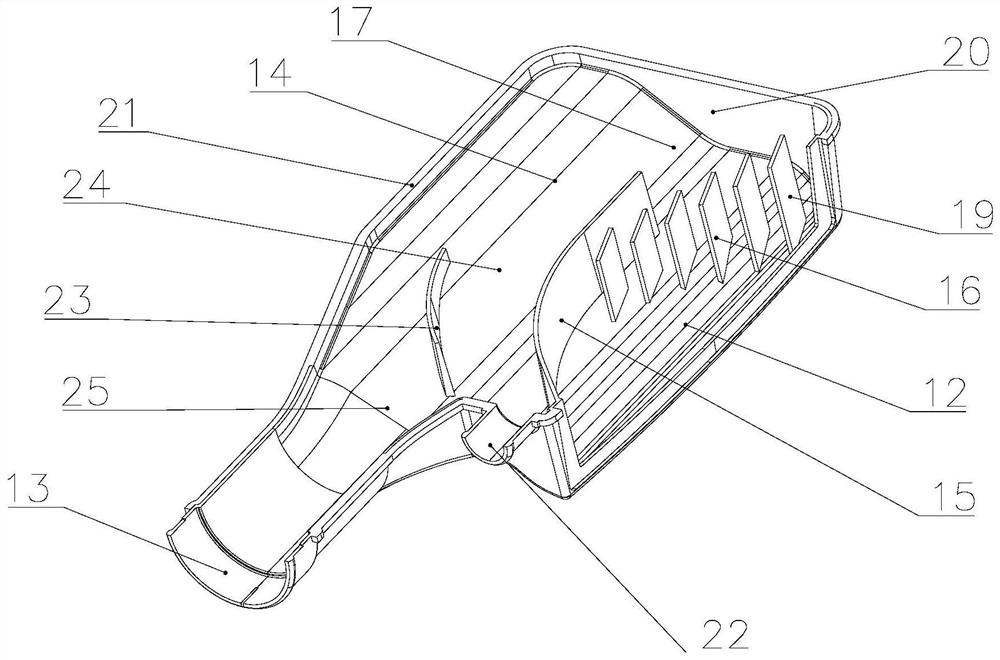

Vehicle air intake apparatus, and methods of use and manufacture thereof

ActiveUS20170232820A1Easy to disassembleAmount of water it takesAir-treating devicesVehicle heating/cooling devicesEngineeringAirflow

Some embodiments are directed to a deflector for use with a vehicle air intake system that directs air from a vehicle exterior to a vehicle interior. The deflector can include a base configured for attachment to a region of an interior wall of an air compartment adjacent a perimeter of a drain. The deflector can also include a barrier wall connected to the base and including an inner surface that is disposed over the drain when the base is attached to the interior wall of the air compartment. The barrier wall can be shaped to define a concavity between the drain and the inner surface. The barrier wall can define an air stream opening that is disposed to direct air traveling from the drain and through the concavity toward a section of the interior wall of the air compartment that opposes a shield.

Owner:HONDA MOTOR CO LTD

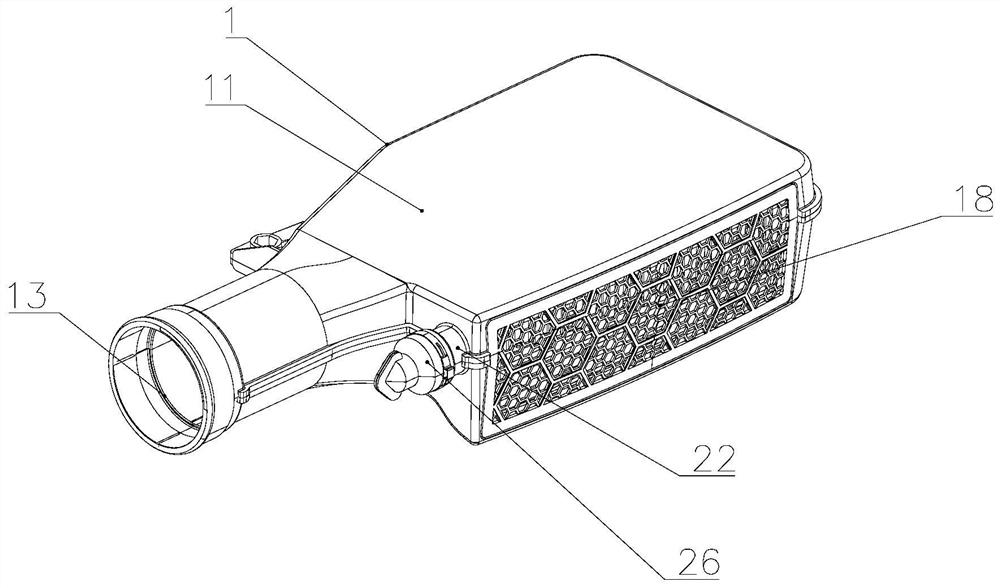

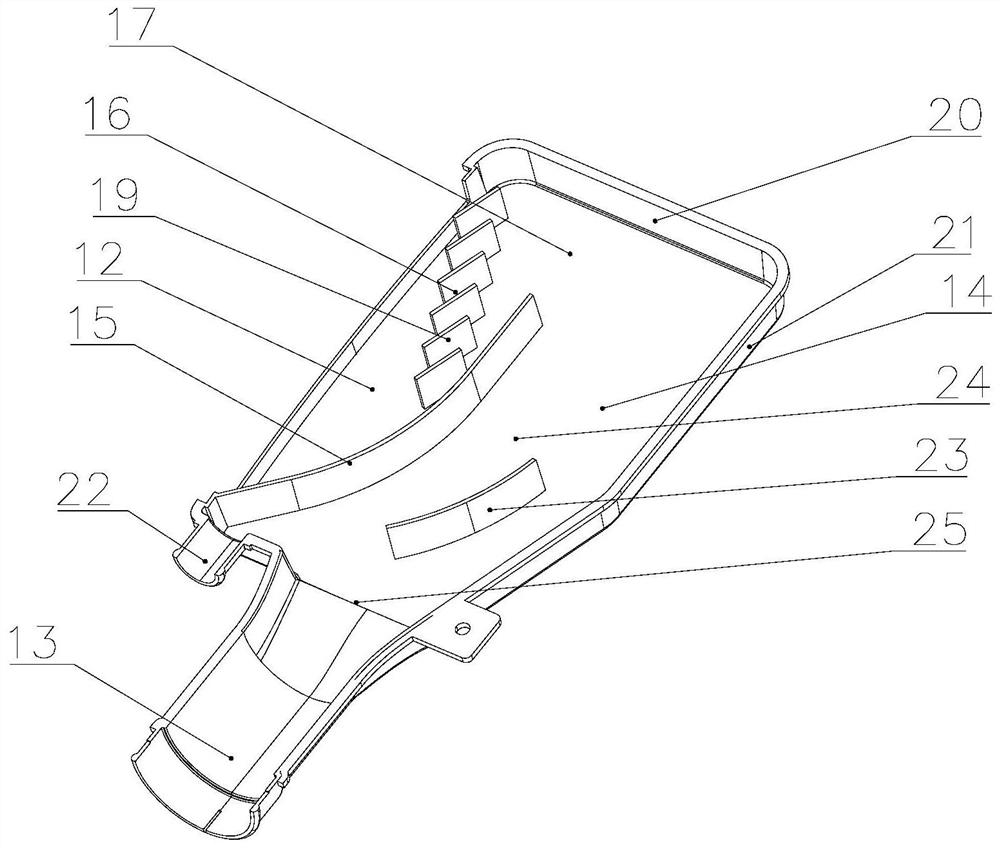

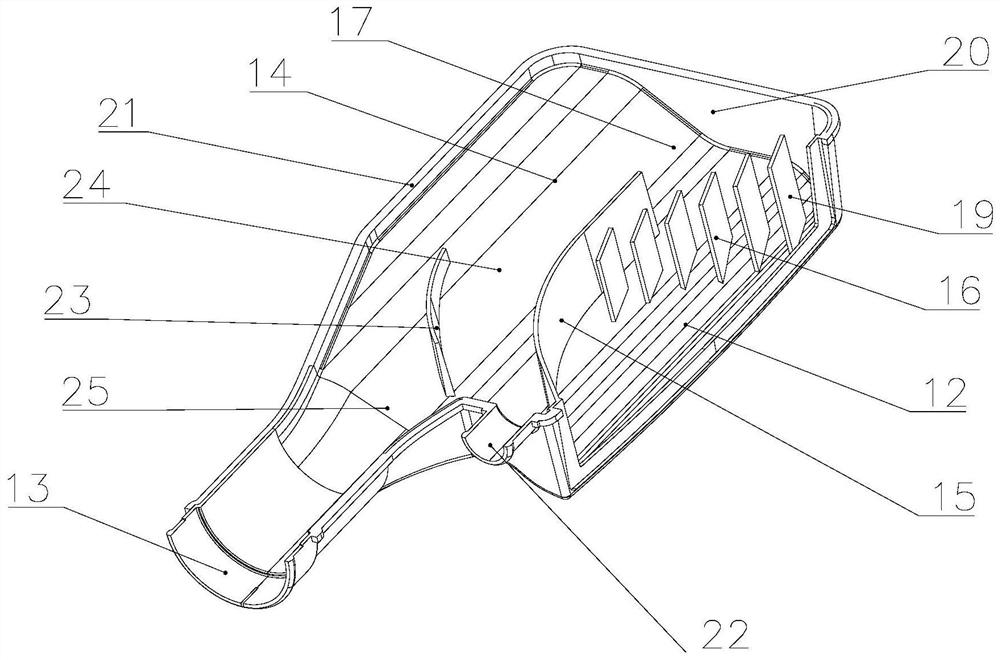

Air inlet duct assembly for automobile and air inlet mechanism

ActiveCN112253343AReduce wind resistanceReduce energy consumptionMachines/enginesAir cleaners for fuelMarine engineeringAir filter

The invention discloses an air inlet duct assembly for an automobile and an air inlet mechanism, and belongs to the technical field of air inlet systems of motor vehicles. The air inlet duct assemblyfor the automobile comprises an air inlet duct shell; a first air inlet port is formed in the side wall of the air inlet duct shell; an air outlet port is formed in the bottom wall of the air inlet duct shell; an air inlet cavity is formed in the air inlet duct shell; a first separation plate and separation grids are arranged in the air inlet cavity; the first separation plate is bent inwards fromthe bottom of the air inlet port and extends upwards; the top end of the first separation partition plate and the inner wall of the air inlet duct shell form a second air inlet; the separation gridsincline inwards from the top of the air inlet port and are arranged and extend downwards; the separation grids are arranged on the outer side of the second air inlet port; and the bottom ends of the separation grids are not higher than the top end of the first separation partition plate. The air inlet duct assembly for the automobile is high in filtering and impurity removing efficiency, small inair resistance and low in energy consumption; noises is low; and the air inlet duct assembly of the air inlet mechanism and an air filter do not need to be connected through a corrugated pipe, the manufacturing cost is low, and the assembly tolerance is small.

Owner:山东统亚模塑科技实业有限公司

A kind of tar residue resource treatment process

Owner:NORTHWEST UNIV

Method for the chemoenzymatic production of fatty acid esters

InactiveUS20100159538A1Highly synergisticHigh water removal rateOrganic-compounds/hydrides/coordination-complexes catalystsFermentationAlcoholChemo enzymatic

A chemoenzymatic process for the production of fatty acid esters comprising partially esterifying one or more fatty acid esters, under mild temperatures with an enzymatic catalyst, and optionally in the presence of one or more inert solvents, with a 1- to 5-fold molar excess of one or more water-containing aliphatic alcohols with boiling points between 60° C. and 120° C., then removing the water and unreacted alcohol(s) from the resulting pre-esterification product, followed by additional esterification up to 99.7%, chemically-catalyzed with, e.g., an acid or tin salt at slightly higher temperatures, optionally using one or more inert solvents, with a 1- to 4-fold molar excess of the same one or more aliphatic alcohols as employed in the preliminary esterification step.

Owner:COGNIS IP MANAGEMENT GMBH

Vertical drum drier

InactiveUS8234795B2Extended shelf lifeGreat aesthetic appealDrying solid materials without heatDrying machines with non-progressive movementsEngineeringMechanical engineering

A method and apparatus for drying produce in a centrifugal drier is described. The drier includes a housing and a drum configured to receive a multi-volume basket. The method includes loading produce into a first volume and a second volume of the multi-volume basket. The basket may include perforated walls, a closed lower end, and an open upper end. The interior volume of the basket is divided into at least a first volume and a second volume by a perforated inner divider that is oriented concentrically to the basket walls. The first volume is disposed inside the inner divider. The second volume is disposed between the inner divider and the basket walls. A drive assembly rotates the drum and the basket, loaded with produce in the first and second volumes, to cause fluids to drain out of the produce to yield dried produce.

Owner:DOLE FRESH VEGETABLES INC

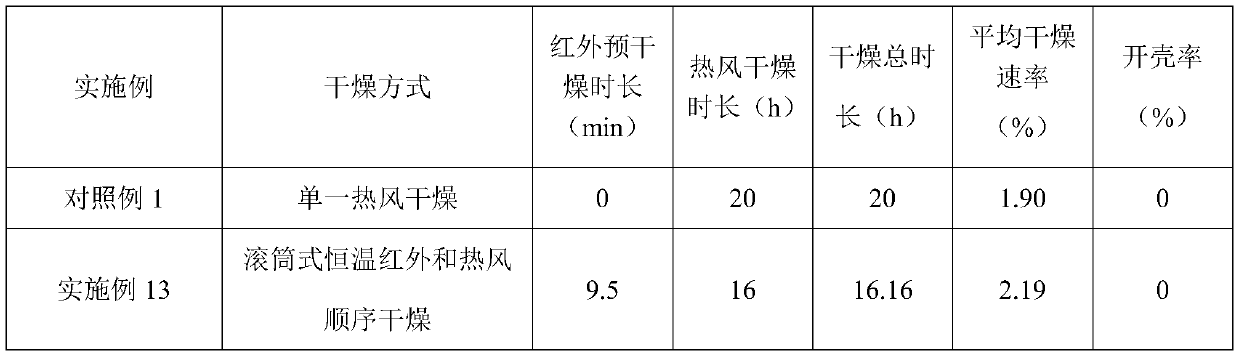

Method for sequentially drying walnuts through drum-type constant-temperature infrared rays and hot air

InactiveCN111059875AGuaranteed uniformityAvoid cracking and other bad phenomenaDrying gas arrangementsDrying chambers/containersWalnut NutThermodynamics

The invention discloses a method for sequentially drying walnuts through drum-type constant-temperature infrared rays and hot air and relates to the technical field of agricultural product and food processing. The method comprises the steps that the distance between an infrared generator and a sample is adjusted to 30 cm; the infrared radiation temperature is adjusted to 450 DEG C; the drum speedis adjusted to 25 Hz; and fresh green husk-removed walnuts are pre-dried by infrared rays (9.5 min), and then immediately transferred to 43 DEG C, and continue to be subjected to hot air drying for 16h under the condition of the wind speed of 3m / s to obtain walnut products sequentially dried through drum-type constant-temperature infrared rays and hot air. Compared with single hot air drying (20h), the total time is shortened by 19.2%. Through the innovative design of drum-type catalytic infrared pre-drying, the drying time is greatly shortened, and energy conservation and environmental protection are achieved.

Owner:JIANGSU UNIV

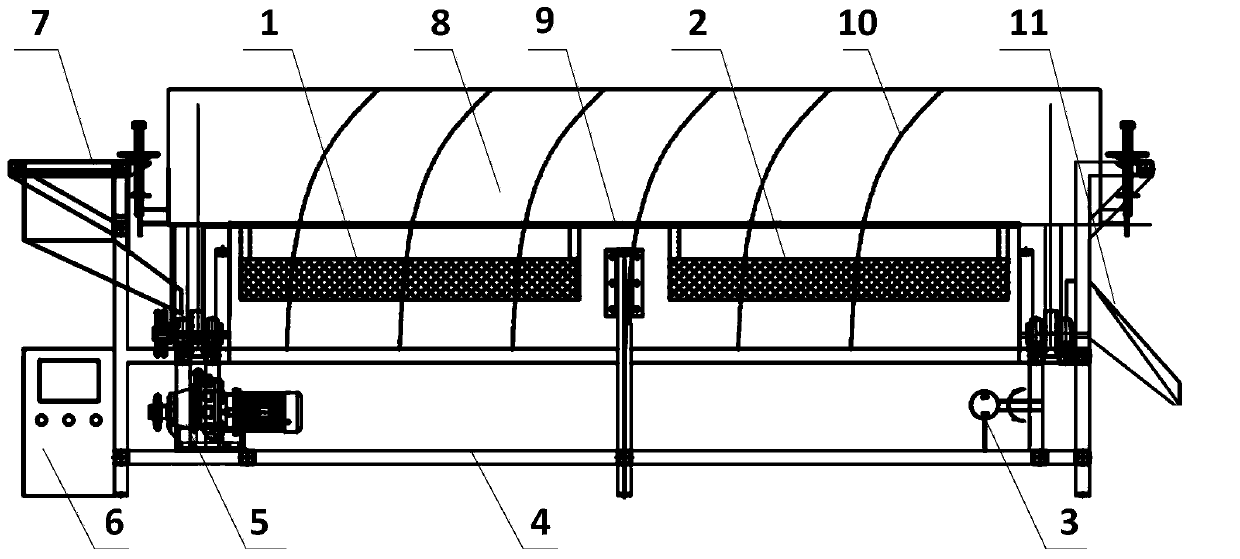

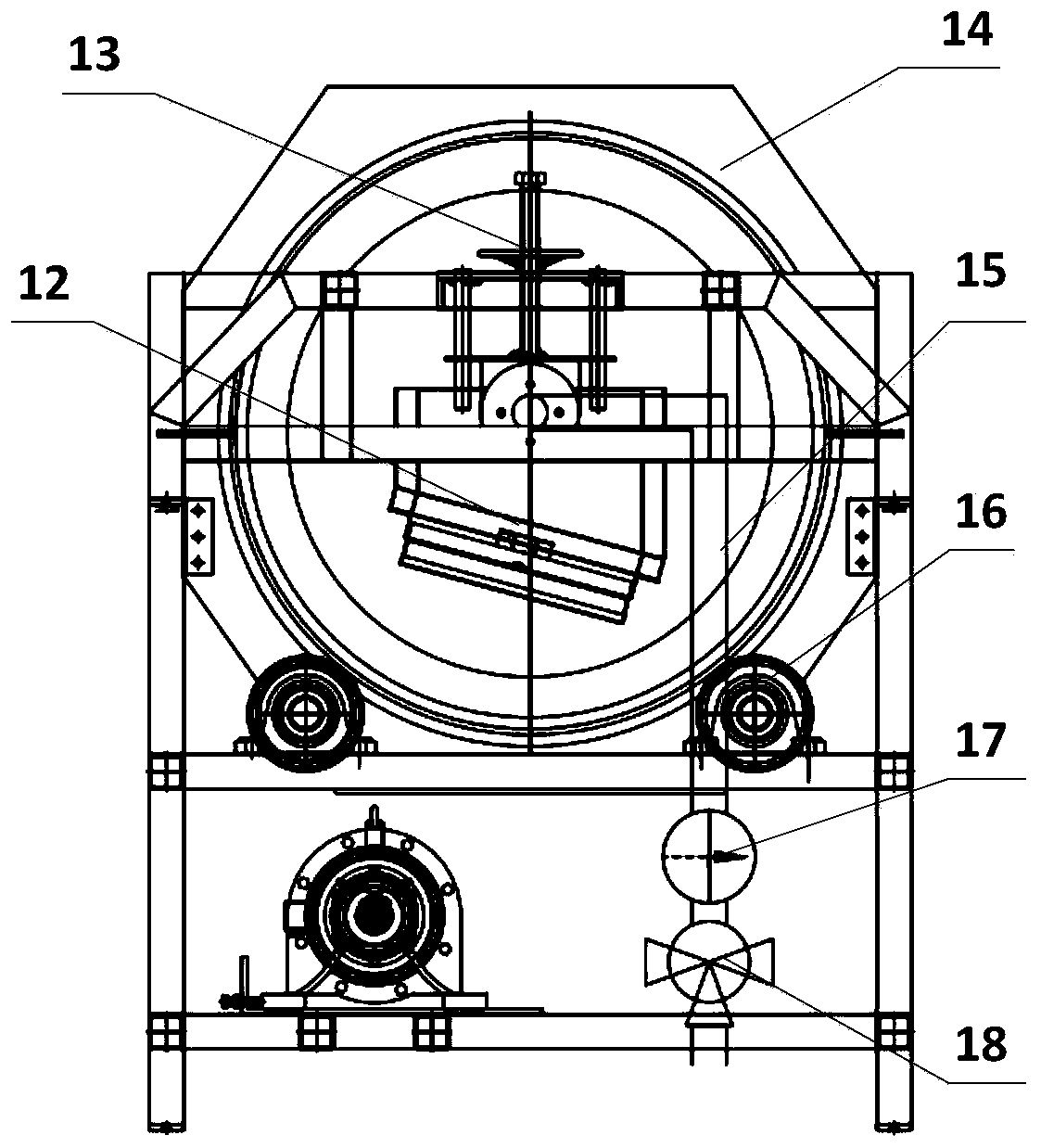

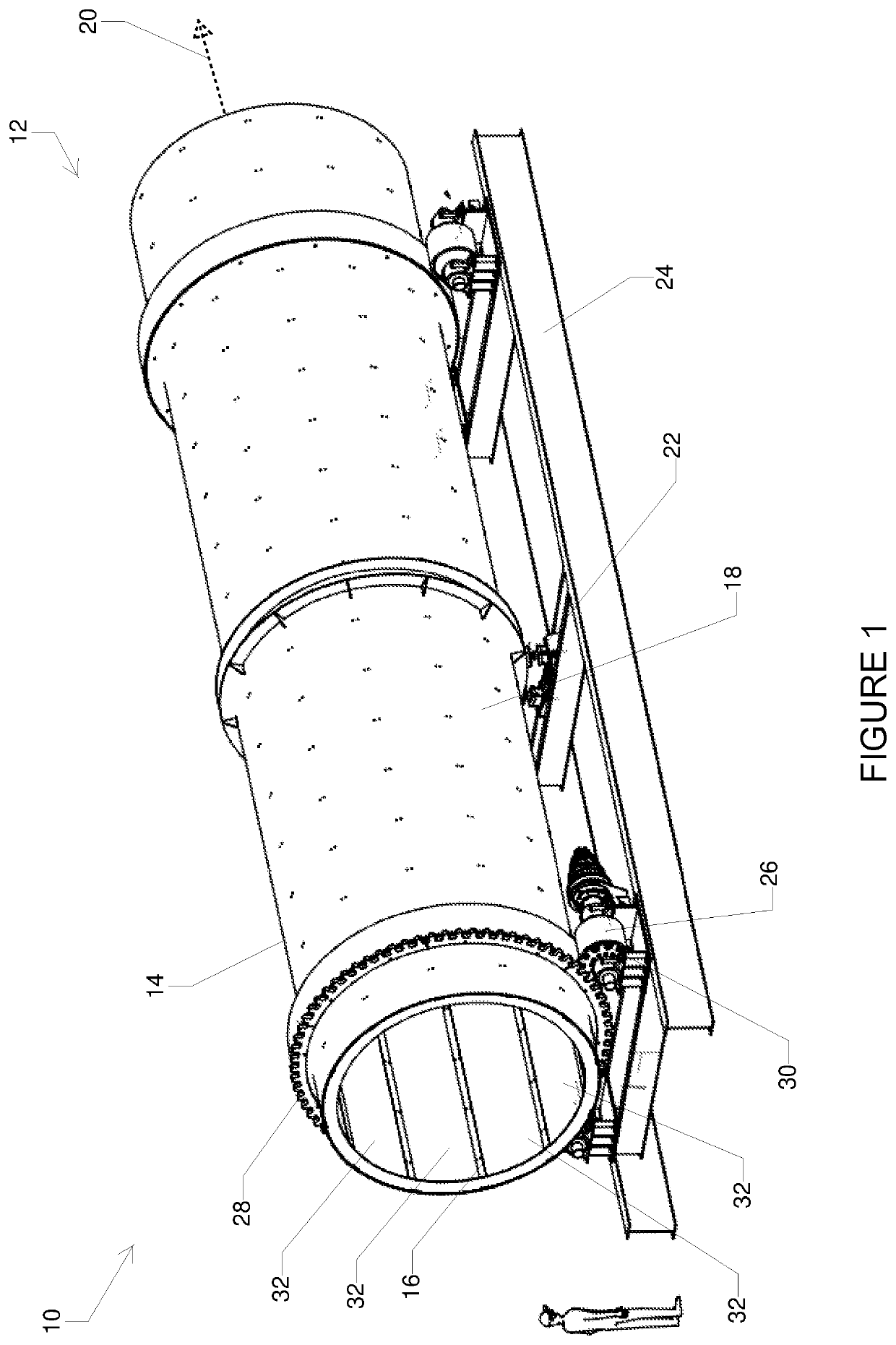

Pellet Processing Drum

PendingUS20220057139A1High water removal rateGood removal effectDrying solid materials with heatDrying solid materials without heatEngineeringMechanical engineering

The present invention relates to a desiccation apparatus, the apparatus comprising: a hollow drum mounted for revolution about a substantially longitudinal axis, the drum comprising a shell having an interior surface and an exterior surface; and a means to generate airflow through the hollow drum.

Owner:PELLETON GLOBAL RENEWABLES LTD

Rotatable fuel cell system

ActiveUS7807315B2Improve efficiencyHigh water removal rateFuel cell heat exchangeFuel cell shape/formElectrochemical responseFuel cells

For operation, PEMFCs require among other things a compressor for the cathode air, and a system for removing the water which is generated on the cathode side as a result of the electrochemical reaction. According to an embodiment of the present invention the removal of water is supported in that the fuel cell is made to rotate by way of an electric motor so that the water contained in the cathodes of the fuel cell can be extracted by centrifugal force. To this effect the air channels on the cathode side are arranged so as to extend radially or in a spiral shape from the inside towards the outside. In this way the efficiency of the fuel cell can be significantly improved.

Owner:AIRBUS OPERATIONS GMBH

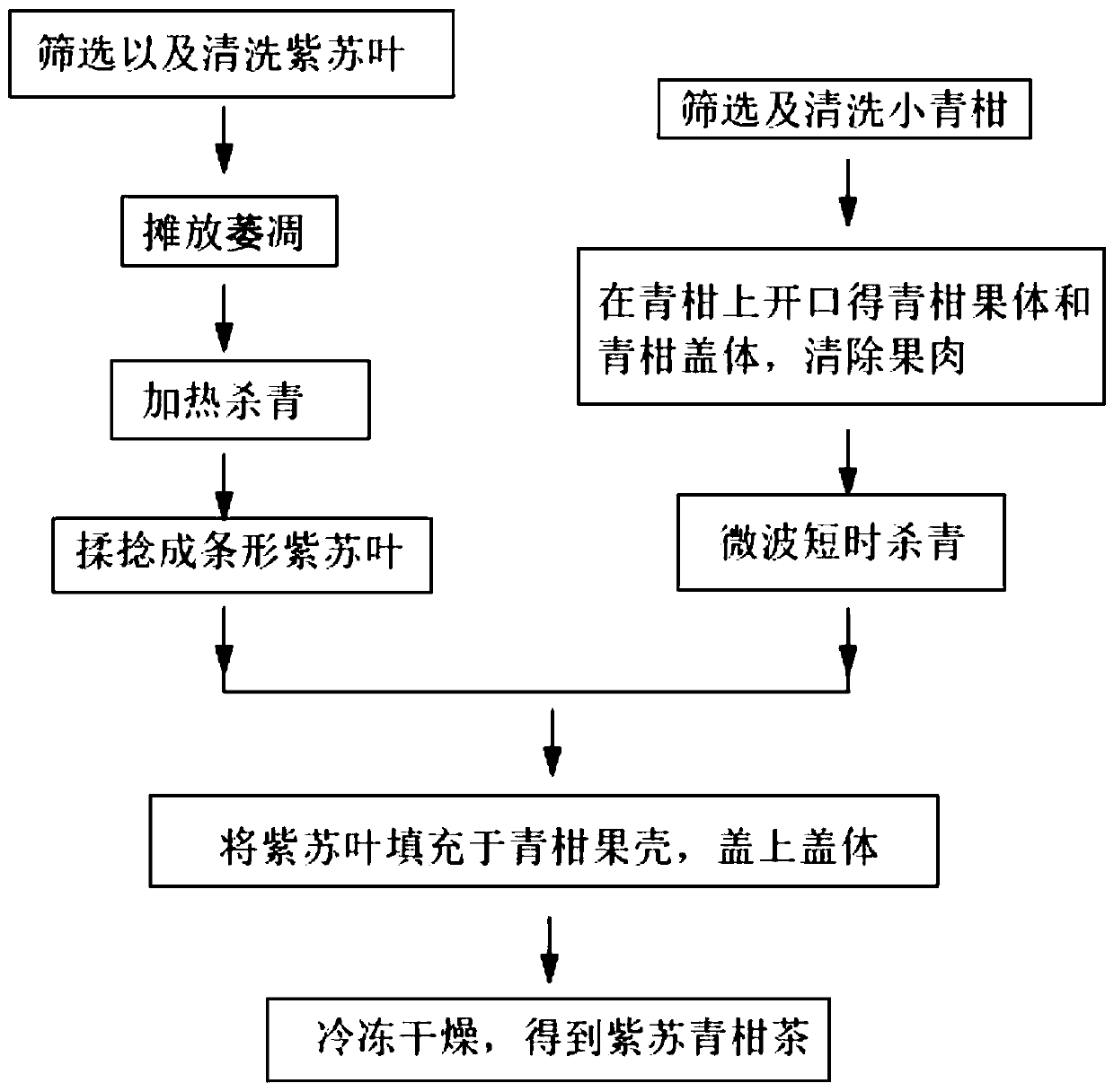

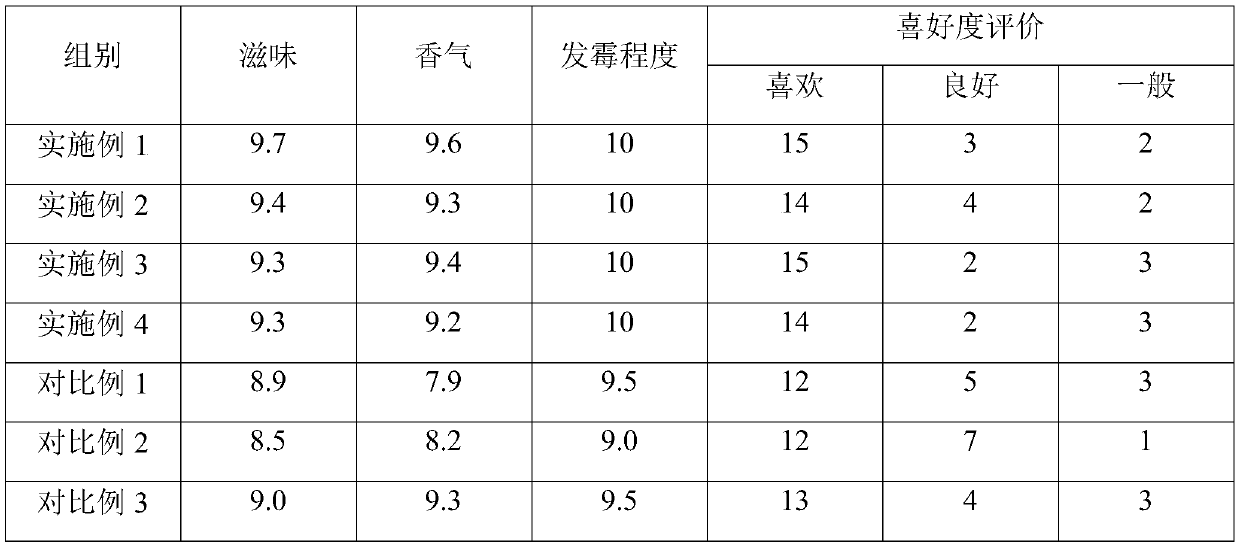

Purple perilla and lime tea and preparing method thereof

The invention belongs to the technical field of tea processing, and particularly discloses a purple perilla and lime tea and a preparing method thereof. The purple perilla and lime tea is prepared byfilling Xinhui small limes of which pulp is fished out with purple perilla leaves and then conducting freeze drying. The preparing method comprises the steps of screening and pretreatment of purple perilla, pretreatment of the limes, tea packaging and freeze drying. The prepared purple perilla and lime tea has the fragrance of the purple perilla leaves and the fruit aroma of the limes, the mouthfeel of existing purple perilla teas is improved, and the defects of green and astringency of the small limes are also overcome. The freeze drying technology is adopted for drying the purple perilla leaves and the small limes, the color, fragrance and taste of the purple perilla and lime tea can be preserved to the greatest extent, various stages of nutritional ingredients can be reserved, and the damage degree to active ingredients is small.

Owner:鄂伦春自治旗大杨树荣盛商贸有限责任公司

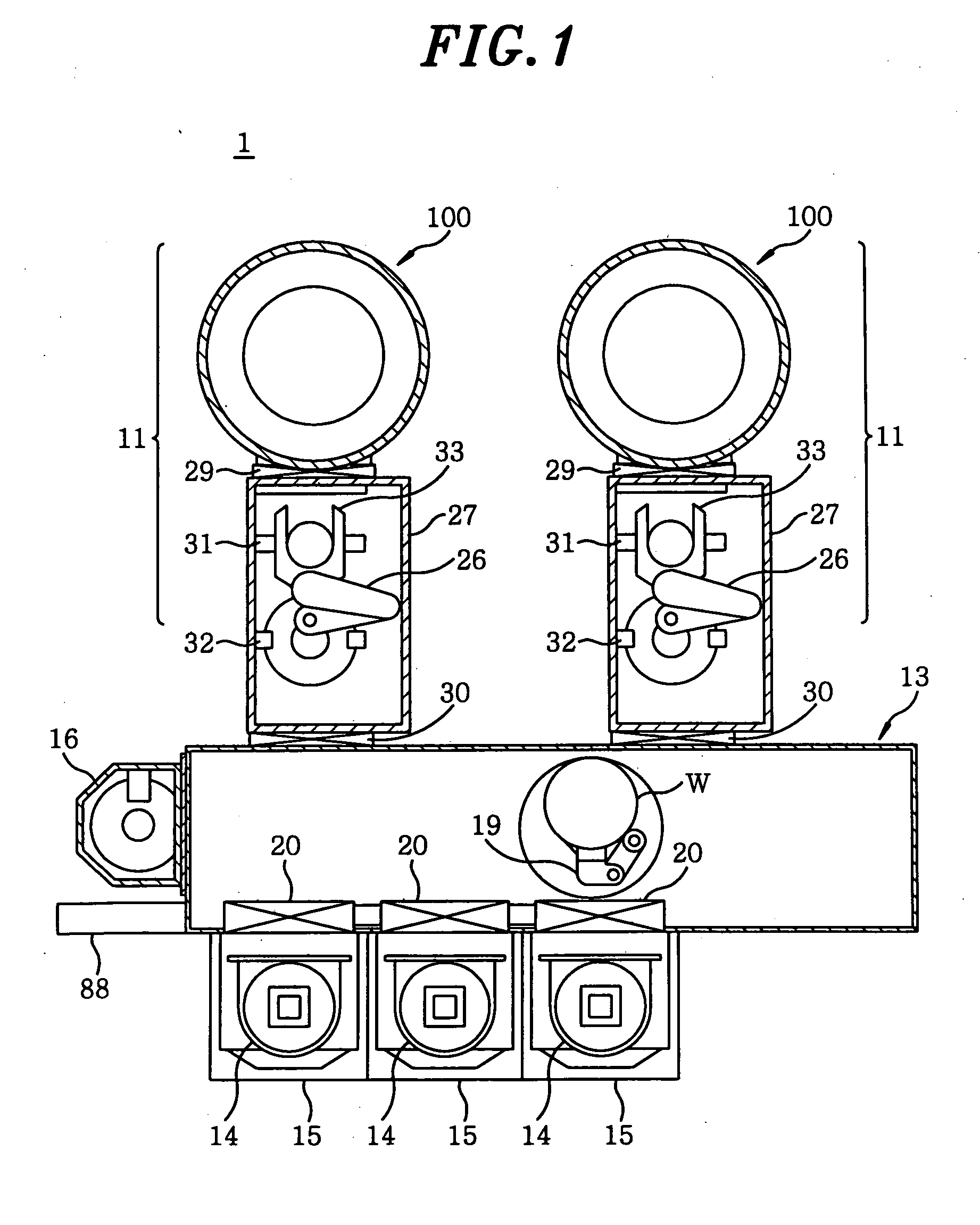

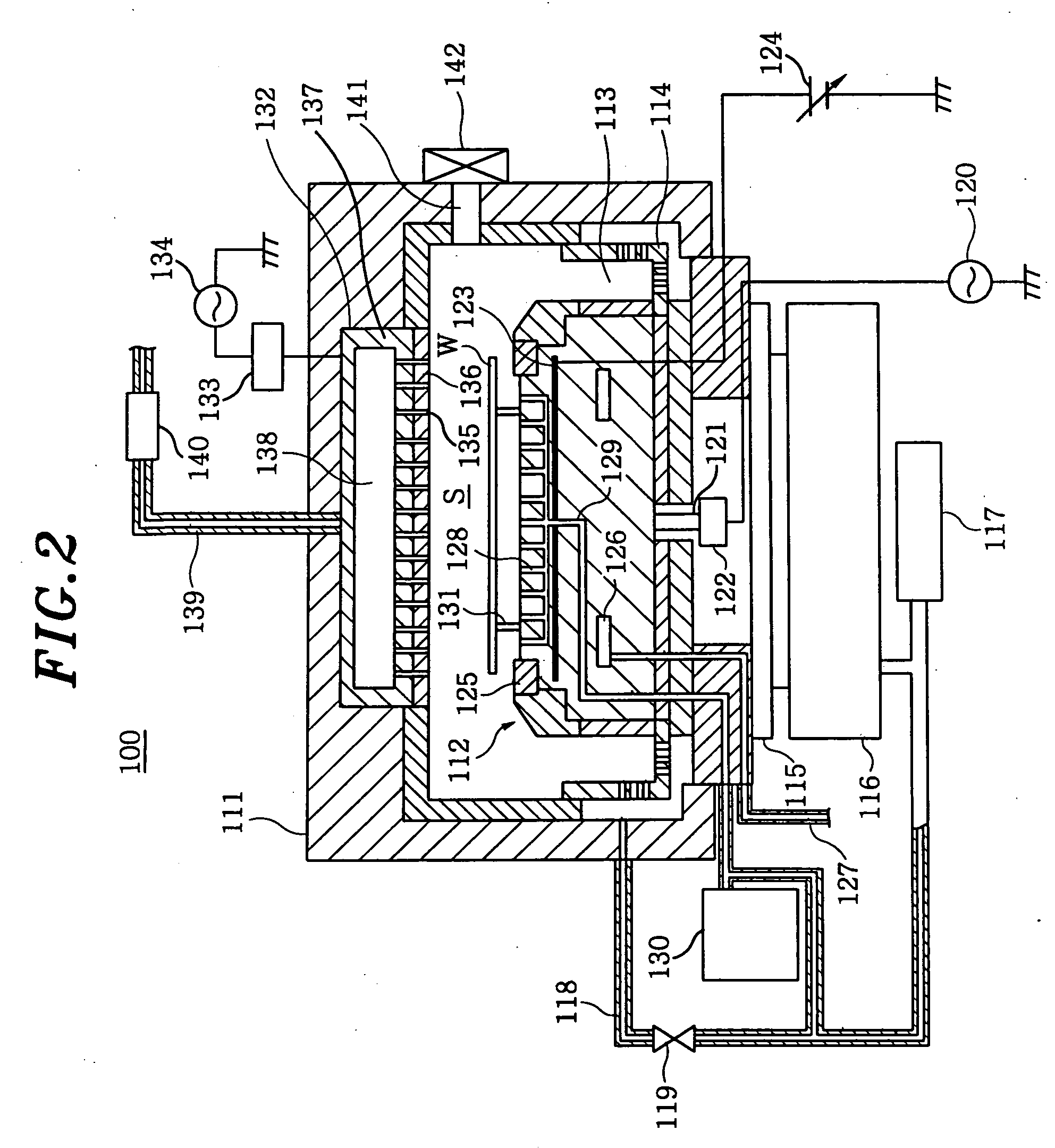

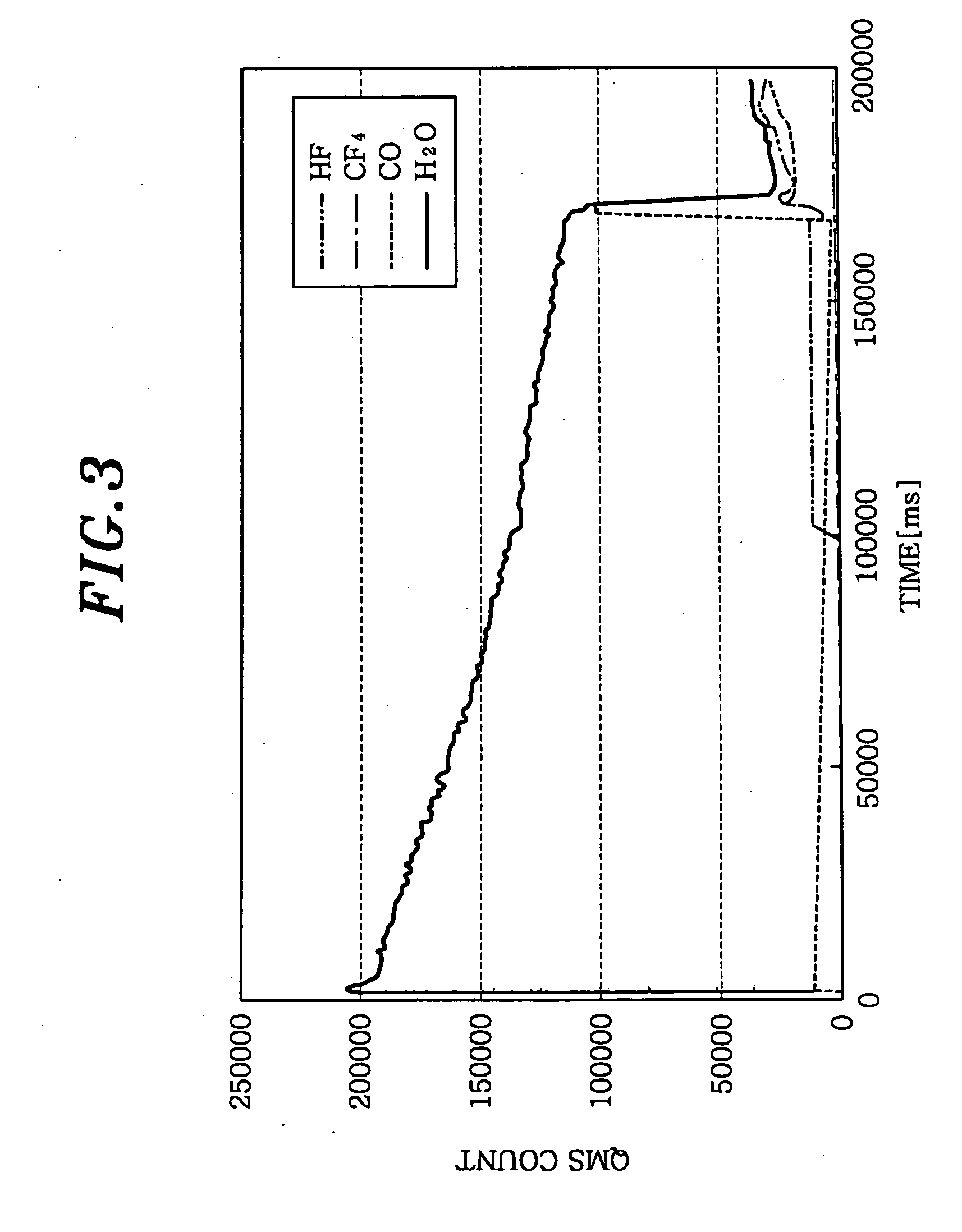

Method for removing water molecules from vacuum chamber, program for executing the method, and storage medium storing the program

ActiveUS20060210469A1Good removal effectEfficient water removalPreparation by dehalogenationChlorine/hydrogen-chloride purificationHalogenProduct gas

A method for removing water molecules from a vacuum chamber for carrying out a process on a target object in vacuum includes the steps of introducing into the vacuum chamber a water molecule removal gas including at least a reduction gas which reduces the water molecules to produce hydrogen molecules and a halogen-based gas which reacts with the produced hydrogen molecules to produce acid, exhausting gases in the vacuum chamber measuring an amount of water molecules present inside the vacuum chamber, and determining whether or not the measured amount of water molecules is greater than or equal to a threshold value, wherein if the measured amount of water molecules is greater than or equal to the threshold value, the water molecule removal gas is introduced into the vacuum chamber in the introducing step.

Owner:TOKYO ELECTRON LTD

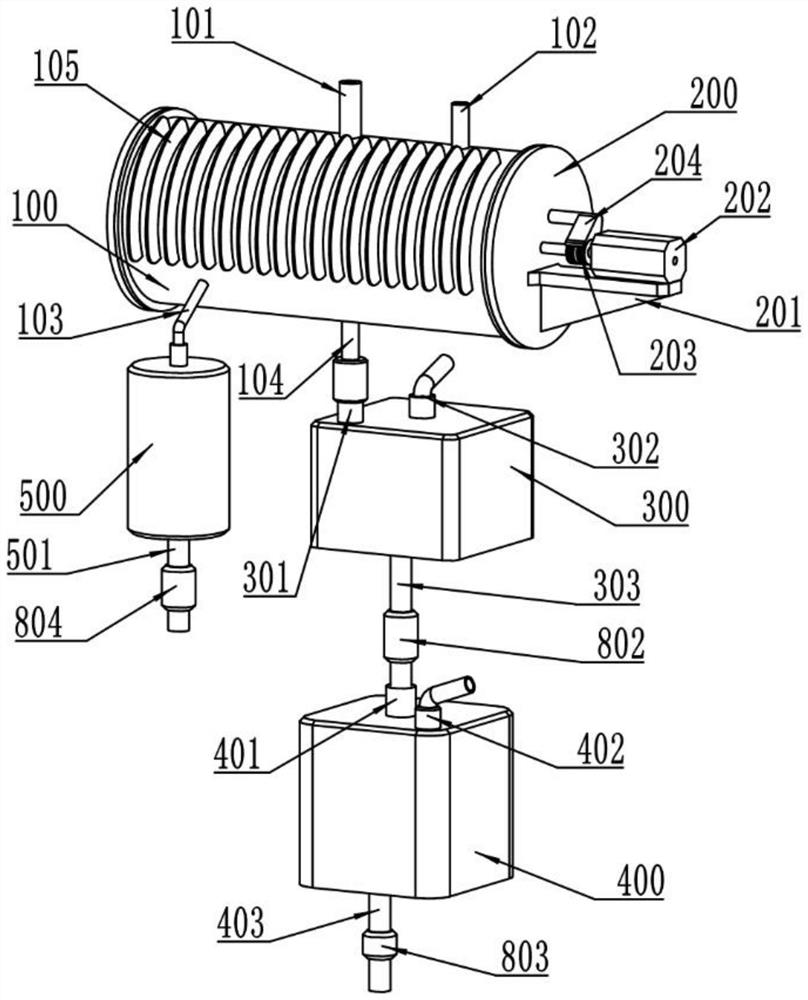

A kind of sucrose-6-ester production device and production method

ActiveCN112704891BWon't overflowHigh water removal rateEsterified saccharide compoundsSugar derivativesSolvent vaporSucrose

The invention belongs to the technical field of sucrose-6-ester production, in particular to a sucrose-6-ester production device and a production method, which solves the problem that a large amount of non-polar auxiliary is needed in the sucrose-6-ester synthesis method in the prior art. Solvent or gas (or solvent vapor) that can remove water causes problems such as reduced production efficiency and increased by-products. The sucrose-6-ester production device includes: a distillation tank, a right side cover, a storage tank, a reaction tank, and a cooling tank. Water collection tank, heating column, heating scraper group; the distillation tank is set horizontally, its right end is open, the top of the distillation tank is provided with a feed pipe and a vacuum pump connection port 1, and the bottom of the distillation tank is provided with a water outlet pipe and a discharge pipe. tube one. In the present invention, the first reaction mixture is evaporated to remove water at low pressure by forming a vacuum environment in the distillation tank, avoiding the use of gas or solvent vapor capable of removing water in this link, effectively reducing the process flow and production cost.

Owner:ANHUI JINGHE IND

A kind of intake duct assembly and intake mechanism for automobile

ActiveCN112253343BReduce wind resistanceReduce energy consumptionMachines/enginesAir cleaners for fuelAir filterStructural engineering

The application discloses an air intake port assembly for an automobile and an air intake mechanism, which belong to the technical field of the air intake system of a motor vehicle. The intake port assembly for automobiles includes an intake port housing, the side wall of the intake port case is provided with a first air inlet, the bottom wall of the intake port case is provided with an air outlet, and the intake port case forms an intake cavity , a first separation plate and a separation grille are arranged in the air inlet cavity, the first separation plate is bent inward from the bottom of the air inlet and extends upward, and the top of the first separation partition and the inner wall of the air inlet shell form a second air inlet , the separation grille is inclined inward from the top of the air inlet and extends downward, the separation grille is arranged on the outside of the second air inlet, and the bottom end of the separation grille is not higher than the top of the first separation partition. The automobile air intake assembly of the present application has high filtration and impurity removal efficiency, small wind resistance, low energy consumption, and low noise; the air intake assembly of the air intake mechanism and the air filter do not need to be connected by a bellows, and the preparation cost low, and tight assembly tolerances.

Owner:山东统亚模塑科技实业有限公司

Hydrogen for polycrystalline silicon production, impurity removal method and system, and polycrystalline silicon production method and system

PendingCN113321183AHigh water removal rateAfter-treatment apparatusHydrogen separation at low temperaturePhysical chemistryImpurity

The invention provides hydrogen for polycrystalline silicon production, an impurity removal method and system and a polycrystalline silicon production method and system. The impurity removal method comprises the following steps of introducing hydrogen for polycrystalline silicon production into boiling trichlorosilane to enable part of internal water to react with trichlorosilane; enabling a gas phase escaping from the trichlorosilane to be in contact with sprayed and atomized trichlorosilane so as to enable residual water vapor to react with trichlorosilane to obtain a dewatered gas phase; and condensing the dewatered gas phase to liquefy the vaporized trichlorosilane in the dewatered gas phase so as to obtain the impurity-removed hydrogen for polycrystalline silicon production. According to the invention, on the premise that external impurities are not introduced, the moisture in the hydrogen for polycrystalline silicon production is dried to be less than 1PPm.

Owner:INNER MONGOLIA XINTE SILICON MATERIAL CO LTD +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com