Air inlet duct assembly for automobile and air inlet mechanism

An air intake and assembly technology, applied in the field of the air intake system of a motor vehicle, can solve the problems of increasing airflow resistance, engine water intake, and shortening the service life of the air filter, so as to increase the water removal rate and increase the air intake. Air volume, the effect of reducing wind resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

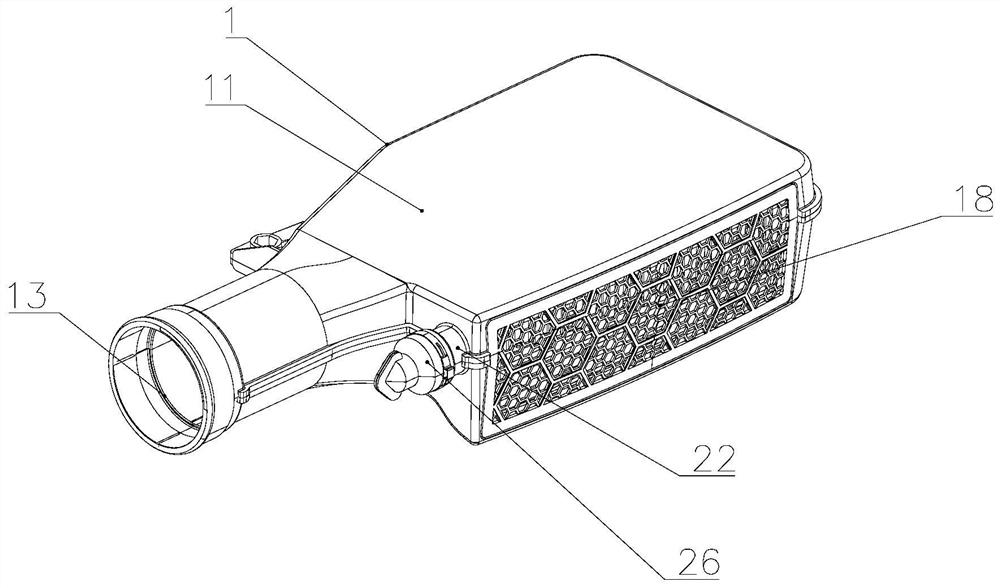

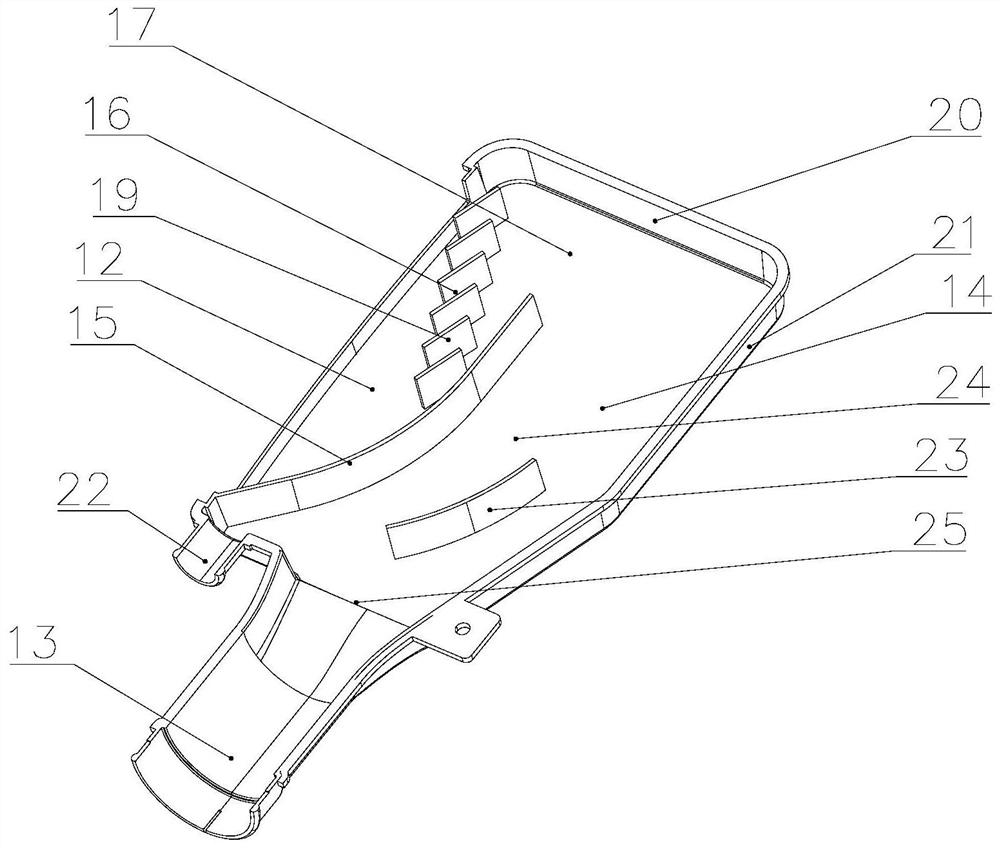

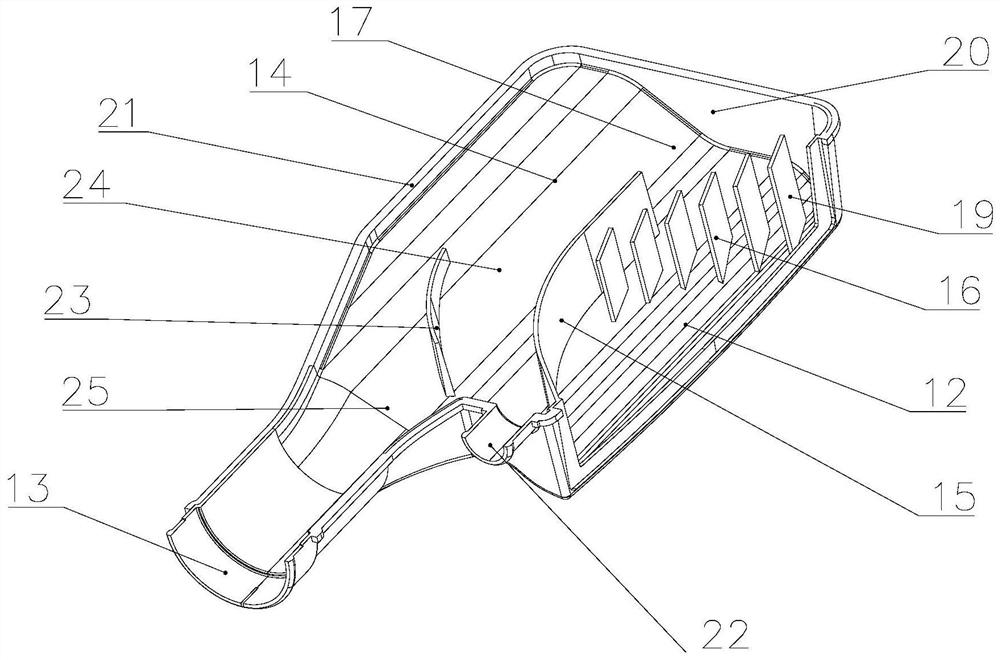

[0056] refer to Figure 1-3 , the embodiment of the present application discloses an air inlet assembly 1 for automobiles, which includes an air inlet casing 11, a first air inlet 12 is arranged on the side wall of the air inlet casing 11, and the air inlet casing The bottom wall of 11 is provided with air outlet 13, and air inlet casing 11 forms air inlet cavity 14, and the first separating plate 15 and separating grid 16 are arranged in the air inlet cavity 14, and first separating plate 15 separates from first air inlet 13 The bottom bends inwards and extends upwards, the top of the first separation plate 15 forms the second air inlet 17 with the inner wall of the air inlet casing 11, and the separation grid 16 is inclined inward from the top of the first air inlet 12 and arranged downwards Extending, the separation grid 16 is arranged outside the second air inlet 17 , and the bottom end of the separation grid 16 is not higher than the top end of the first separation plate ...

Embodiment 2

[0073] Test the sample of the rapid production assembly after the completion of the intake port design stage, the intake port assembly 1 of the preferred embodiment, the inside of the intake port RP sample S = 11155mm 2 ;S outer = 16377mm 2 , wherein, the inside of S is the effective air intake area of the separation grid 16, and the outside of S is the effective opening area of the porous isolation cover 18.

[0074] Compared with the air inlet assembly 1, the first air inlet 12 is provided for the air inlet housing, the first air inlet 12 is directly equipped with a separation grid 16, and the downstream of the first air inlet 12 in the air inlet chamber 14 is set The first separation plate 15, that is, the difference between the air inlet assembly 1 and the comparison air inlet assembly 1 includes: the separation grid 14 of the air inlet assembly 1 is installed on the first air inlet 12, while the comparison air inlet The separation grille 14 of the assembly 1 is insta...

Embodiment 3

[0089] refer to Figure 5-7 The difference between this embodiment and Embodiment 1 is that the first miscellaneous outlet 27 is arranged on the first side wall 28 of the air inlet casing 11, close to the bottom wall of the air inlet casing 11, and the first miscellaneous outlet The port 27 and the first air inlet 12 are arranged on opposite sides of the first separation plate 15, and a resonant cavity 29 is arranged inside the first separation plate 15; a second separation plate 23 is also arranged in the air intake chamber, and the second separation plate 23 Arranged above the air outlet 13 , the second separation plate 23 includes a front separation plate, a middle separation plate and a rear separation plate connected in sequence, and the opening between the front separation plate and the rear separation plate faces the air outlet 13 . The second separation plate 23 performs secondary removal of impurities such as water in the airflow, and the moisture in the airflow hitti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com