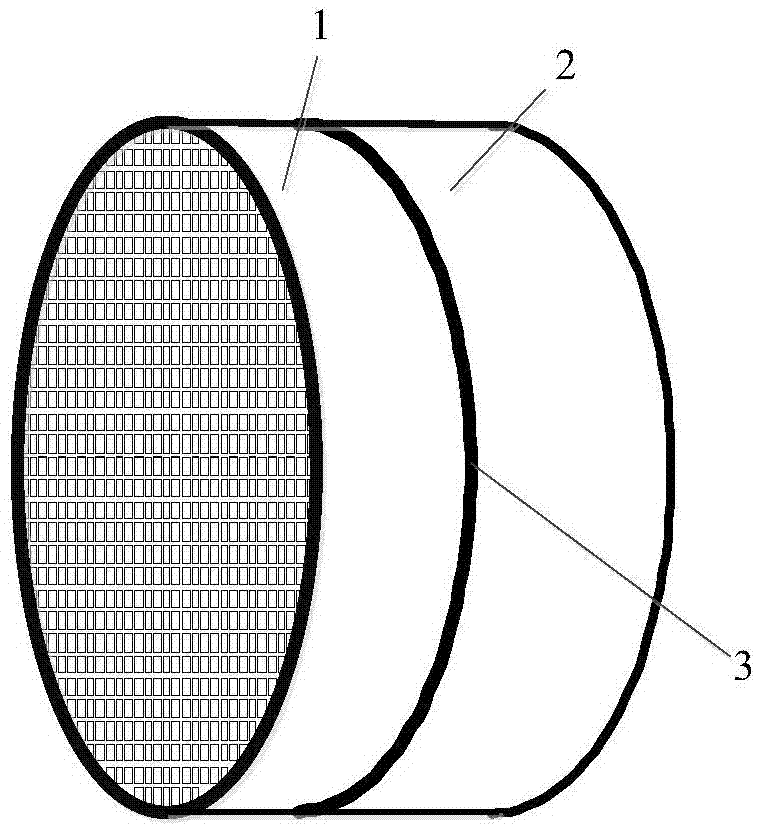

Compound VOCs absorbing concentration turning wheel and use method thereof

A technology of concentrating runners and runners, which is applied in separation methods, chemical instruments and methods, and other chemical processes, and can solve problems such as the inability to satisfy the complete adsorption of components, and achieve cost reduction, low cost, and equipment occupancy effect of space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

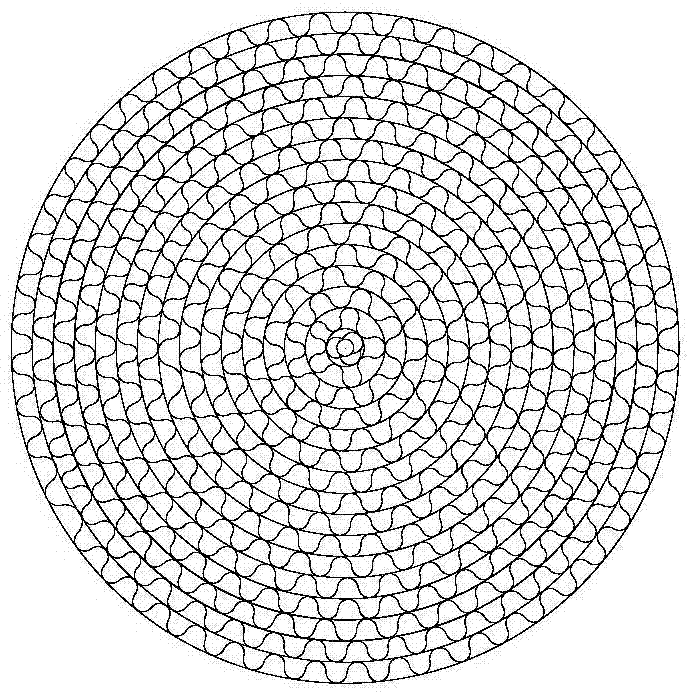

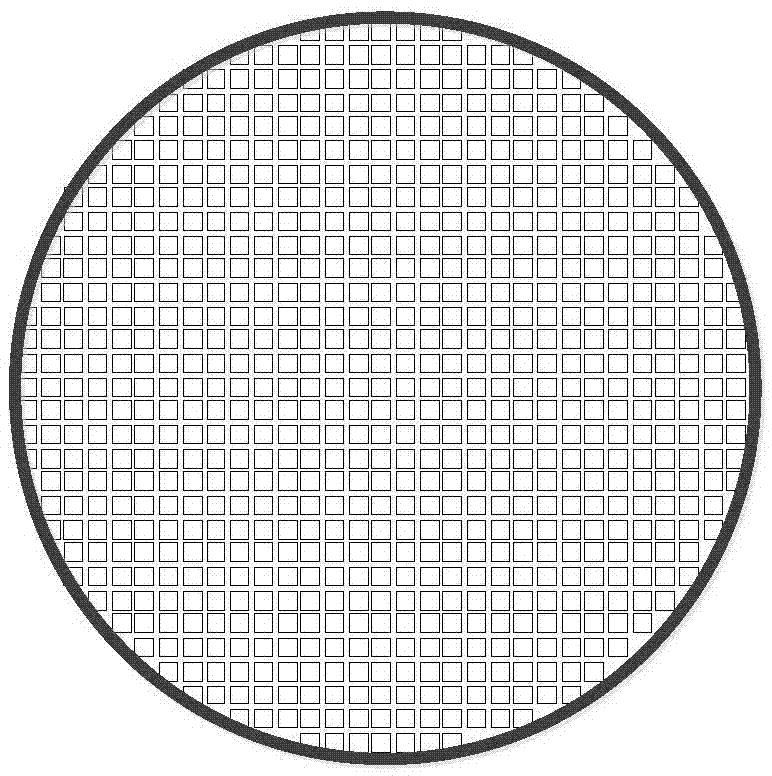

Method used

Image

Examples

Embodiment 1

[0041] combine Figure 6 As shown, the multi-component VOCs waste gas 7 enters the honeycomb activated carbon adsorption area, and most of the organic waste gas such as dust, moisture and odor is absorbed, and then passes through the molecular sieve runner, the waste gas is further purified, and the purified gas 10 is emptied Or for other purposes. During this process, the thickness ratio and total thickness of the honeycomb activated carbon runner and the molecular sieve runner are designed and adjusted according to the exhaust gas components and on-site working conditions, and various parameters are adjusted in due course according to the operating conditions. When the adsorption is saturated, it enters the desorption area, and the air 4 and the outlet gas 8 of the cooling area are heated by the electric heating device 9 to become high-temperature air with a temperature of 100-300°C, which is preferentially desorbed from the molecular sieve runner, and the high-temperature a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com