Patents

Literature

291results about How to "Reduce cooling area" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

LED streetlight structure

InactiveUS7641363B1Extended service lifeIncrease heat dissipation structurePlanar light sourcesMechanical apparatusPlastic materialsEngineering

The present invention discloses an LED streetlight structure, which comprises: a heat-conduction pipe frame, an upper casing, a lower casing, a light concentration plate, and a transparent cover. The upper and lower casings are made of a plastic material and pivotally coupled to each other. The heat-conduction pipe frame has a heat-dissipation seat with main heat-dissipation fins. Two stabilizer boxes with fins are respectively arranged at two sides of the heat-dissipation seat. Heat-dissipation lamp sets insert through the bottom of the heat-dissipation seat. The present invention installs the main heat-dissipation fins on heat-conduction pipe frame and installs the fins on the stabilizer boxes to increase heat-dissipation area. Further, an auxiliary heat-dissipation ventilation device is arranged above the heat-conduction pipe frame and made of aluminum, and aluminum itself benefits heat dissipation. Furthermore, air can be compulsively conducted to the main heat-dissipation fins, then can enhance the dissipation effect.

Owner:LI HONG TECHNOLOGICAL

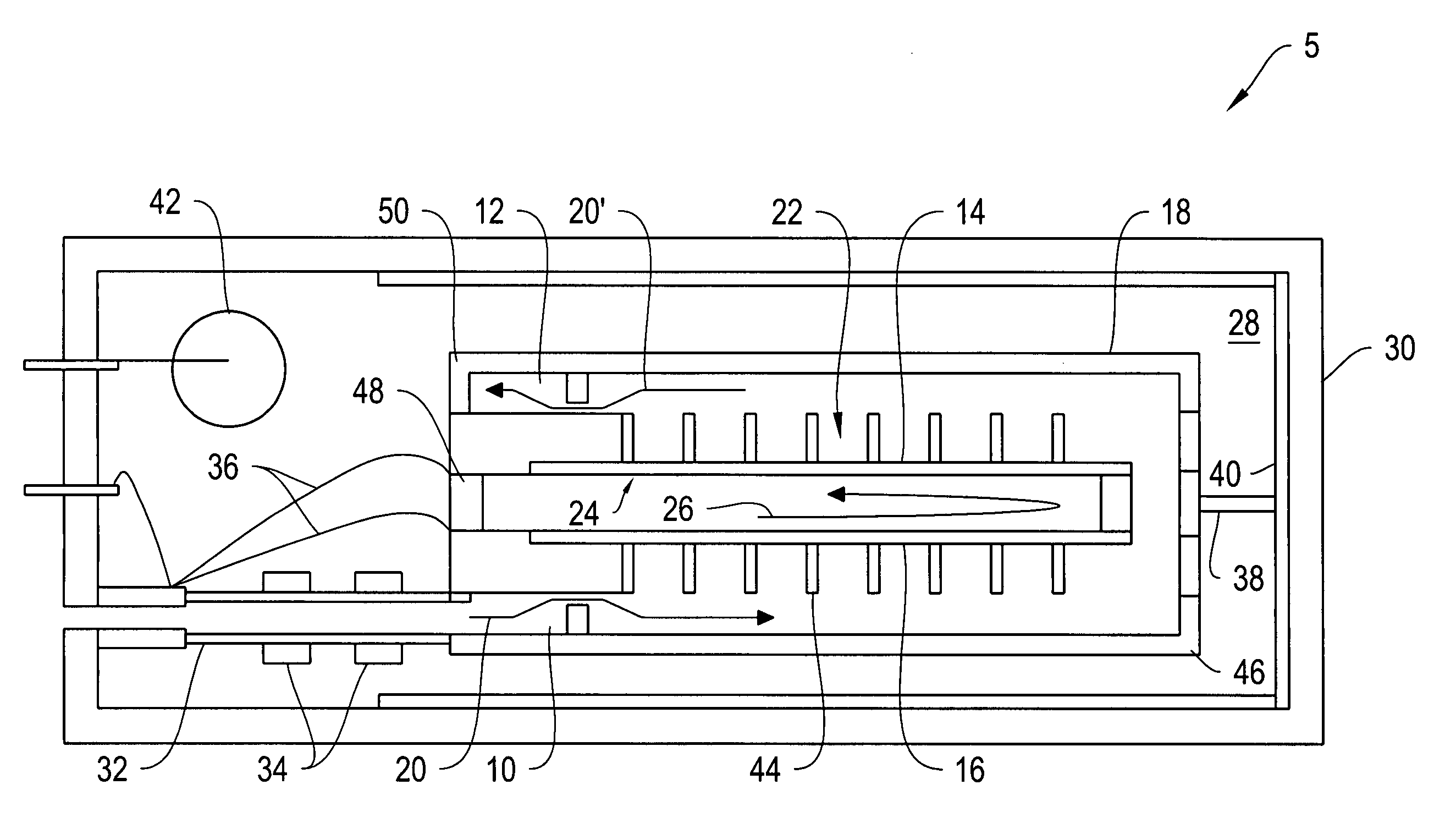

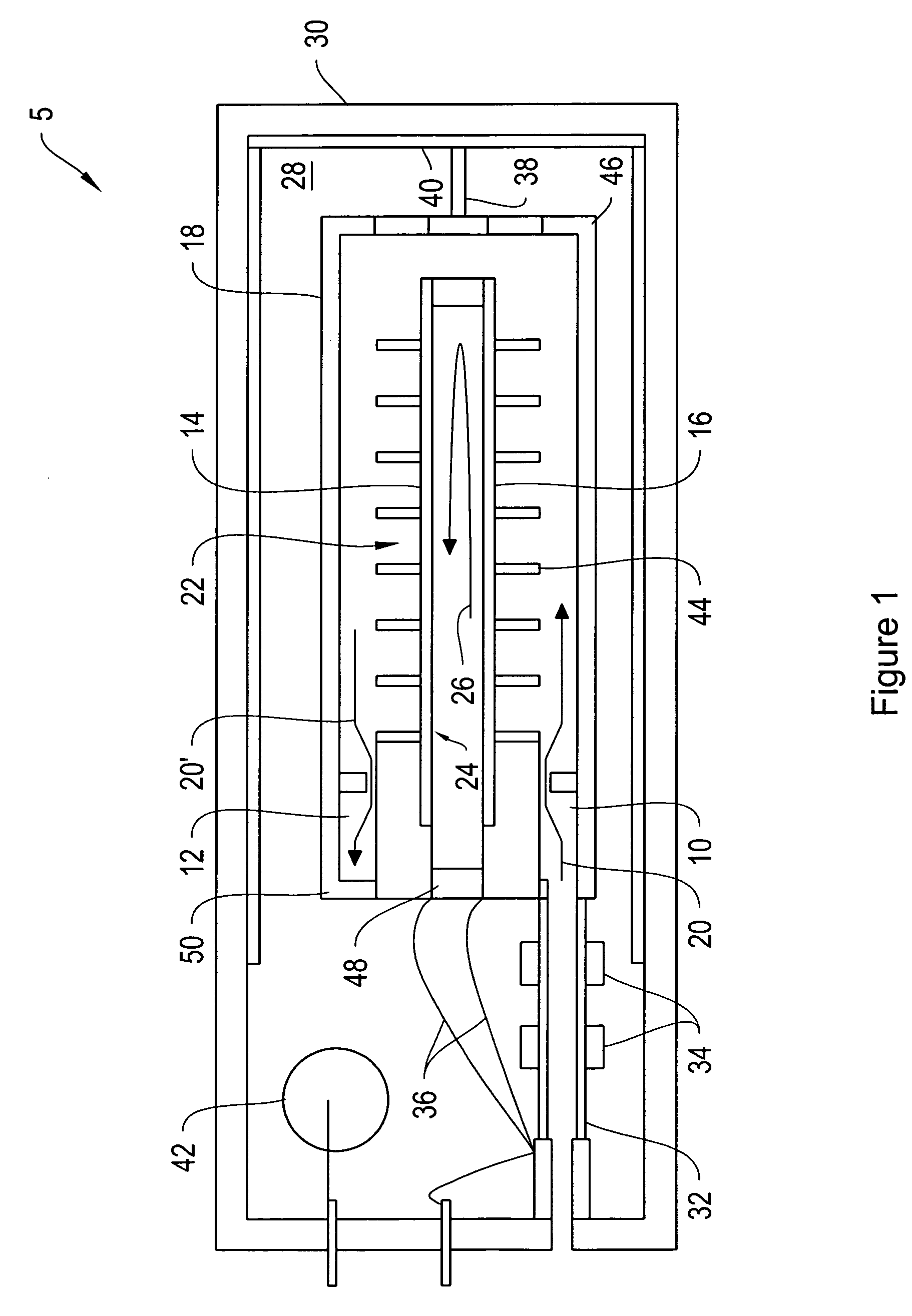

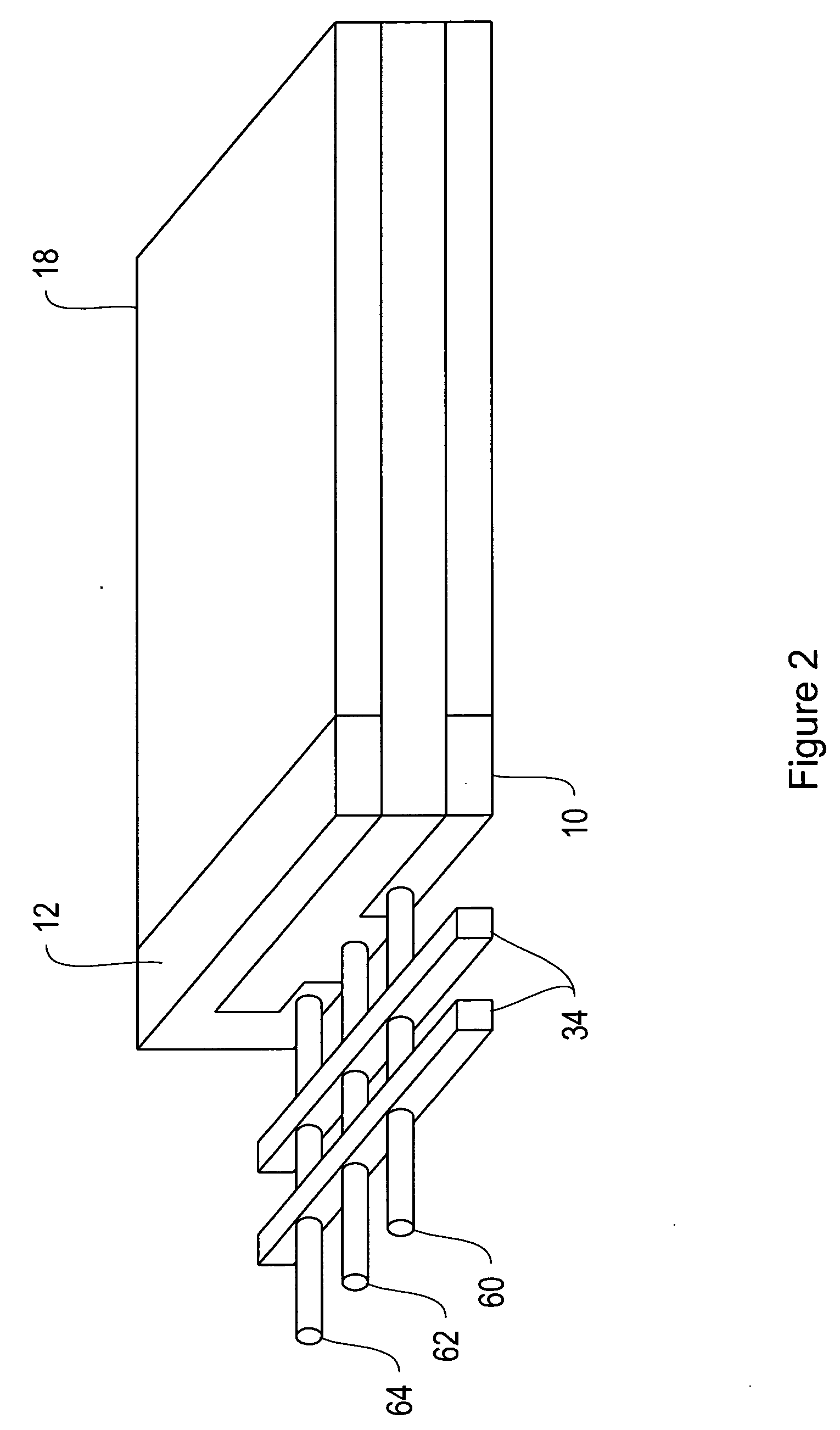

Fuel cell apparatus and methods

InactiveUS20060263665A1Fuel efficiencyImprove thermal efficiencyFuel cell heat exchangeRegenerative fuel cellsFuel cellsThermal insulation

Fuel cells having an efficient means of thermal insulation such that all of the components requiring high temperature operation are contained within a single housing and whereby such thermal insulation is disposed exterior to such housing.

Owner:LILLIPUTIAN SYST

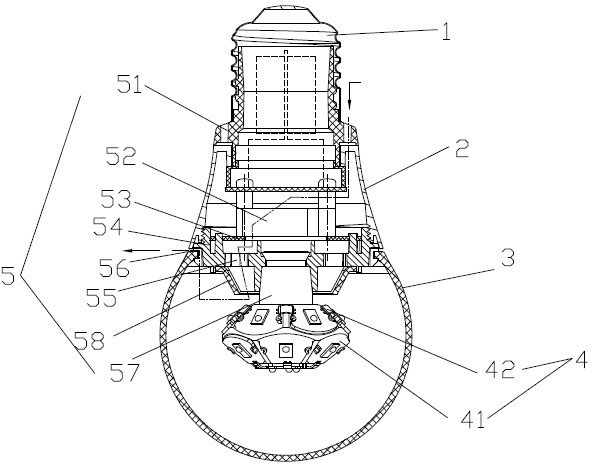

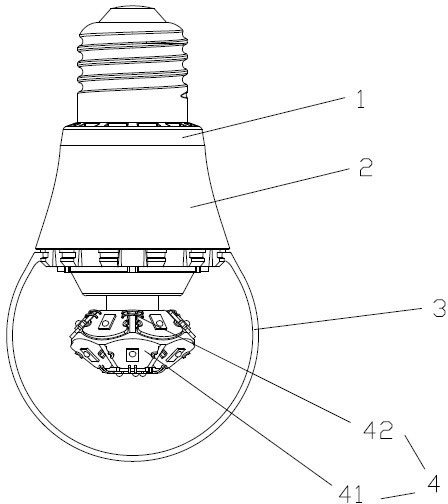

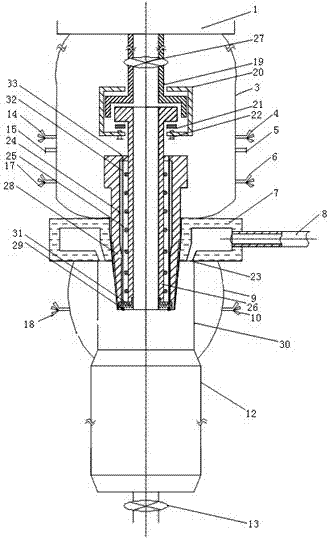

Large-luminosity-angle spherical bulb with diamond light-emitting surfaces

ActiveCN102128370AAchieve coolingIncrease the light transmission anglePoint-like light sourceLighting heating/cooling arrangementsEngineeringLight head

The invention provides a large-luminosity-angle spherical bulb with diamond light-emitting surfaces, comprising a lamp head insulating body, a lamp body, a lamp shade, a diamond polyhedron and LED (Light-Emitting Diode) light-emitting component and an in-bulb cooling device, wherein the lamp body connects the in-bulb cooling device and the lamp head insulating body; the lamp shade is matched with the in-bulb cooling device; the diamond polyhedron and LED light-emitting component is arranged near the center in the lamp shade and is combined by substrates, flexible connecting bridges, a diamond polyhedral heat-conducting installing body; the substrates are provided with LED light sources, and the front surfaces of the substrates are provided with welding points used for connecting; the flexible connecting bridges are connected among the substrates through circuits; the diamond polyhedral heat-conducting installing body is diamond-like and has N sides, can be used for fixing a light-emitting component and can be set into any angle and shape; and the in-bulb cooling device is communicated with the lamp head, the lamp body and the lamp shade to form an airflow inlet and outlet channel. In the large-luminosity-angle spherical bulb provided by the invention, the lamp shade is designed into a shape larger than a hemisphere, which can increase a light-transmitting angle, the LED light-emitting component is made into a diamond structure so as to realize multidirectional positive and negative surface irradiation, and the in-bulb cooling device can carry out forced air-cooling on the in-bulb radiating fins and radiating fins in the lamp body.

Owner:SICHUAN LIANKAI LIGHTING CO LTD

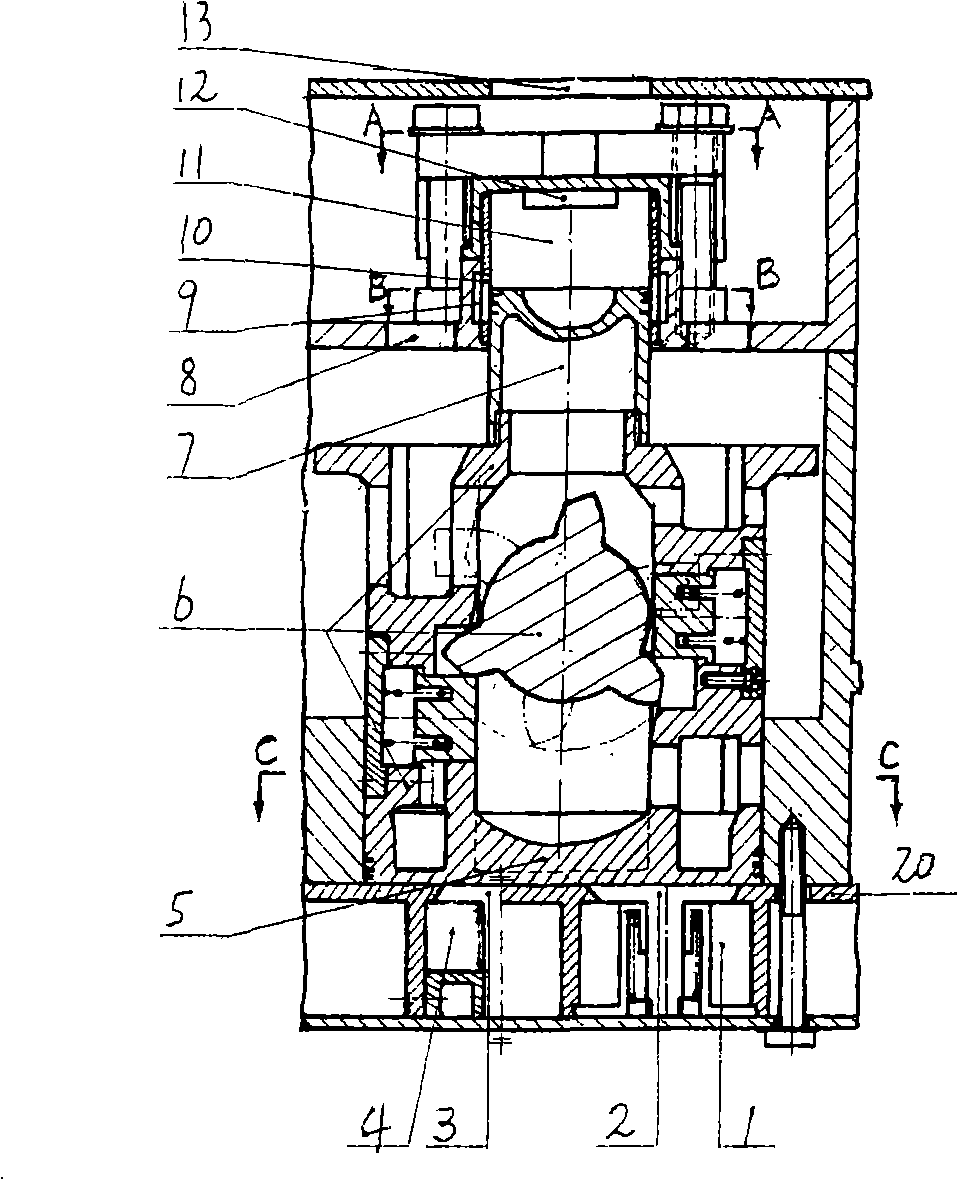

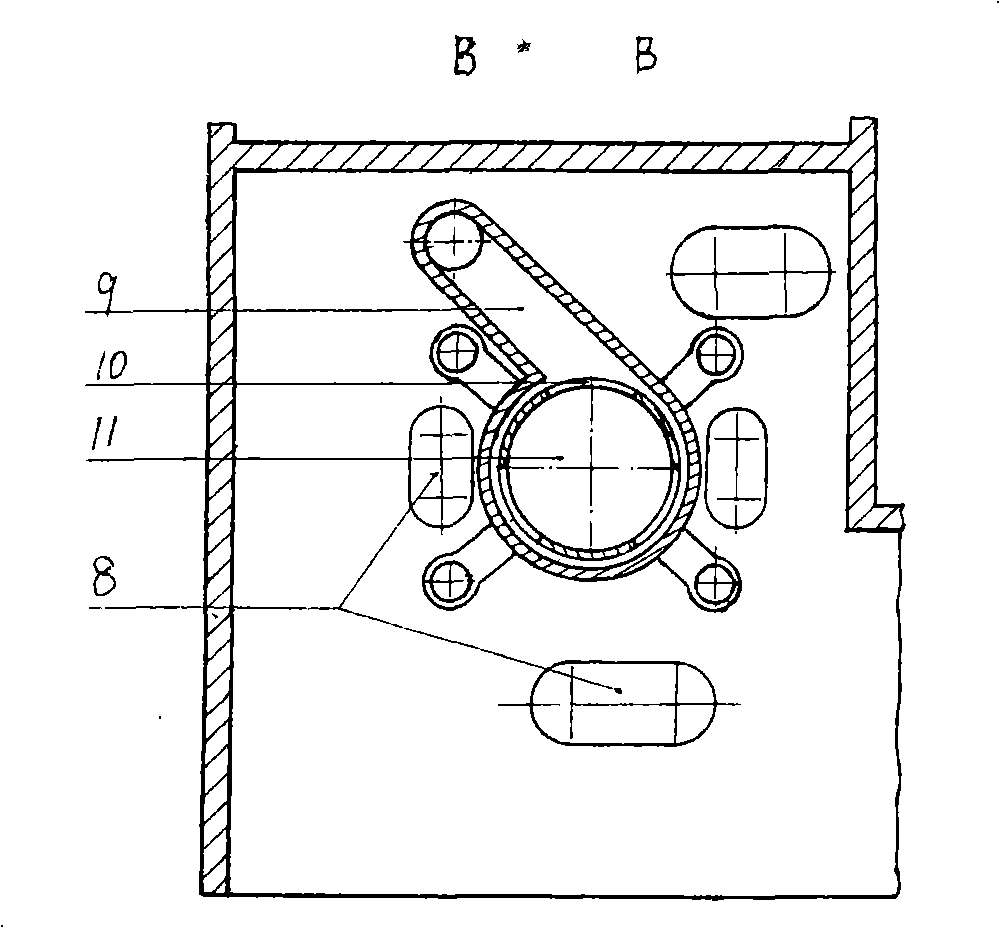

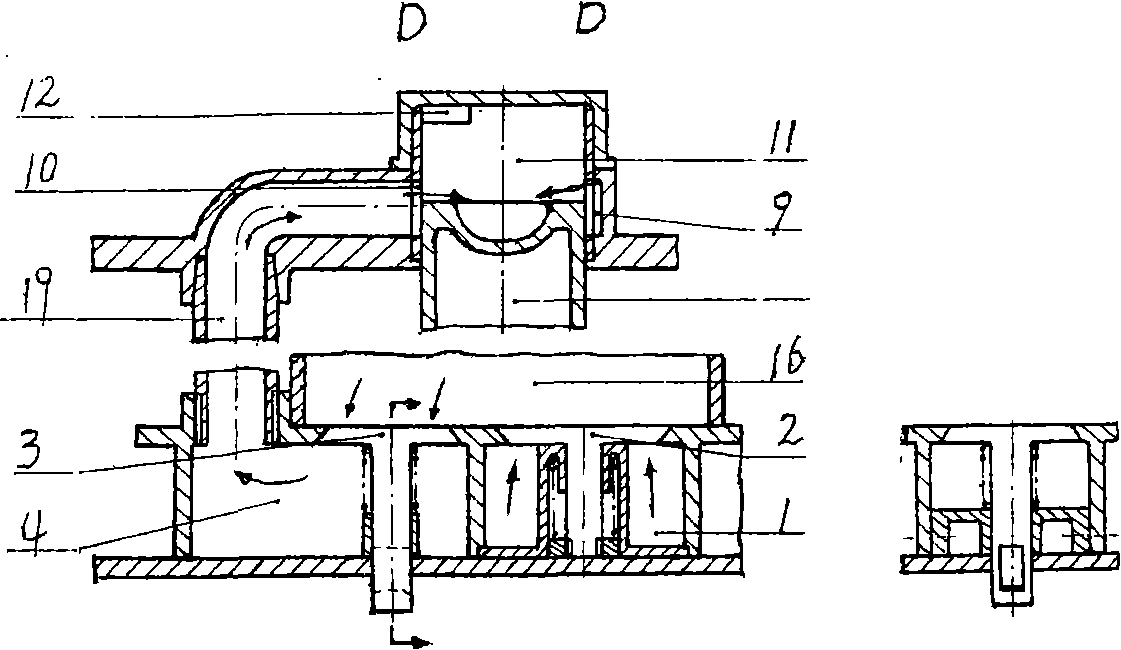

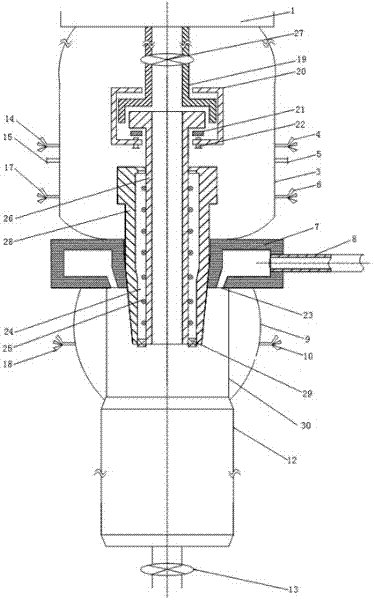

Piston reciprocating internal-combustion engine working substance flow system and its device

InactiveCN101289956AHigh thermal efficiencyEasy to achieve coolingNon-fuel substance addition to fuelInternal combustion piston enginesAir compressionControl set

The invention discloses a working substance flowing system of a piston reciprocating internal combustion engine and regulation and control setting thereof. An upper end of a frame moving up and down along the rotation of a power shaft is connected with an engine cylinder piston [7]; the lower end of the frame is made into a pressure cylinder piston [5]; an air inlet pipe[14], an air inlet check valve[2] and an air compression check valve[3] are arranged on a bottom cover plate of the pressure cylinder; air sucked from the air inlet pipe[14] by the pressure cylinder is sprayed by water mist for intercooling in compression; compressed air is stored in an air storage channel, tangentially supplied to an air inlet[10] of an engine cylinder sleeve; a rod head of the air compression check valve[3] is connected with the compressed air regulating and controlling device. An exhaust port [12] of the engine cylinder is arranged in the rear side of the cylinder top; a pressurized air bypass channel tightly pressed on the lower side of a flashboard-type exhaust valve [21] and an air suction check valve [22] of the upper side of a vent-pipe inlet cool an exhaust system and exhaust air and have the effects of both decontamination and preventing an exhaust gas turbine from surging. The supercharging mechanism has compact structure, indirect transmission, stable pressurization and cooling function; the working substance flowing system is provided with the regulating and controlling device with optimized performance and is convenient to the actualization of a small and medium sized engine.

Owner:肖光宇

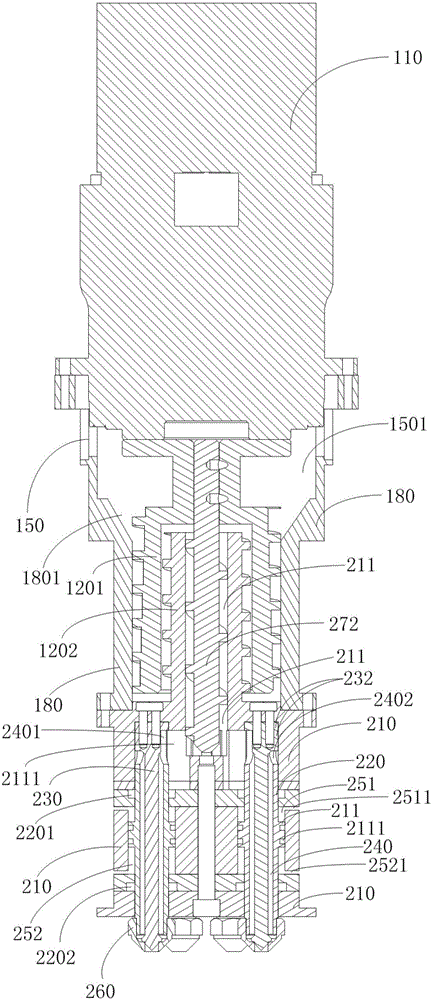

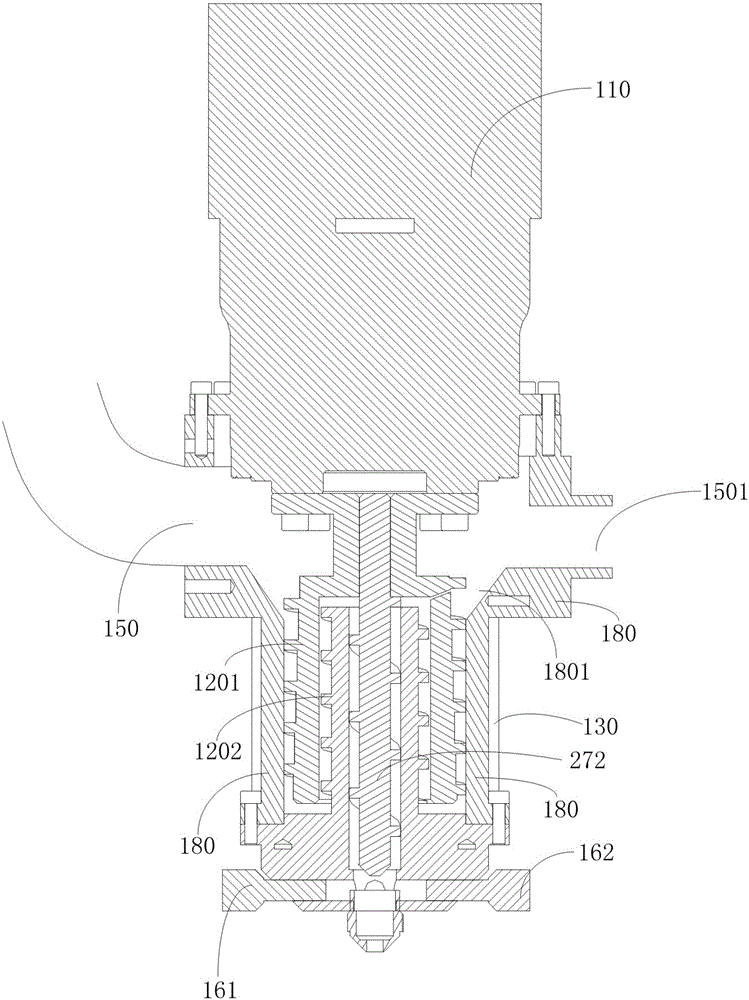

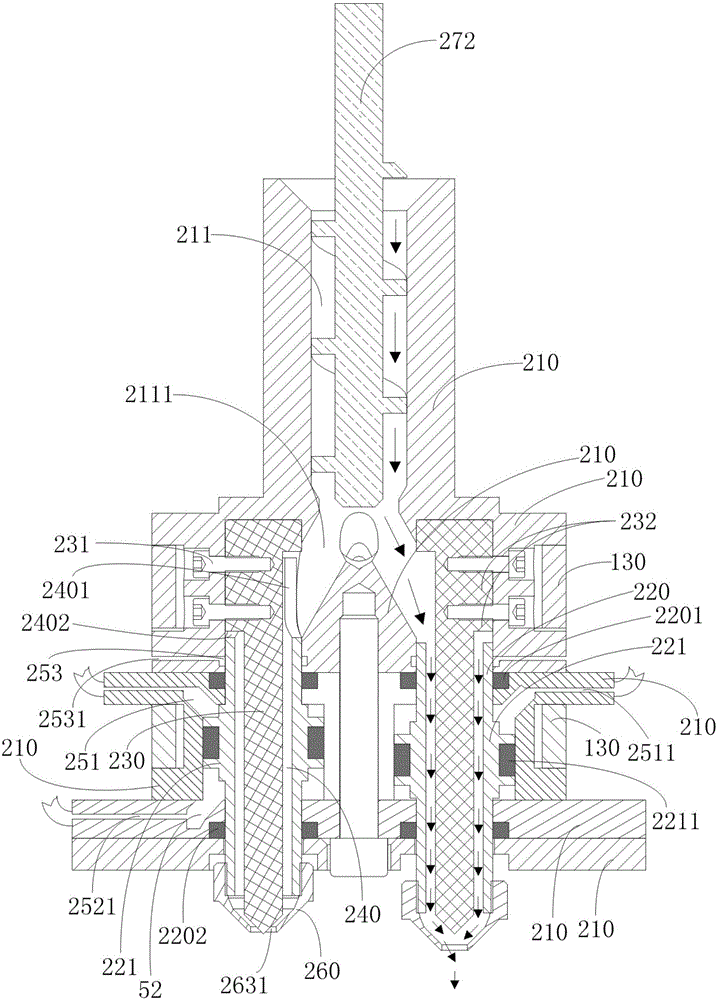

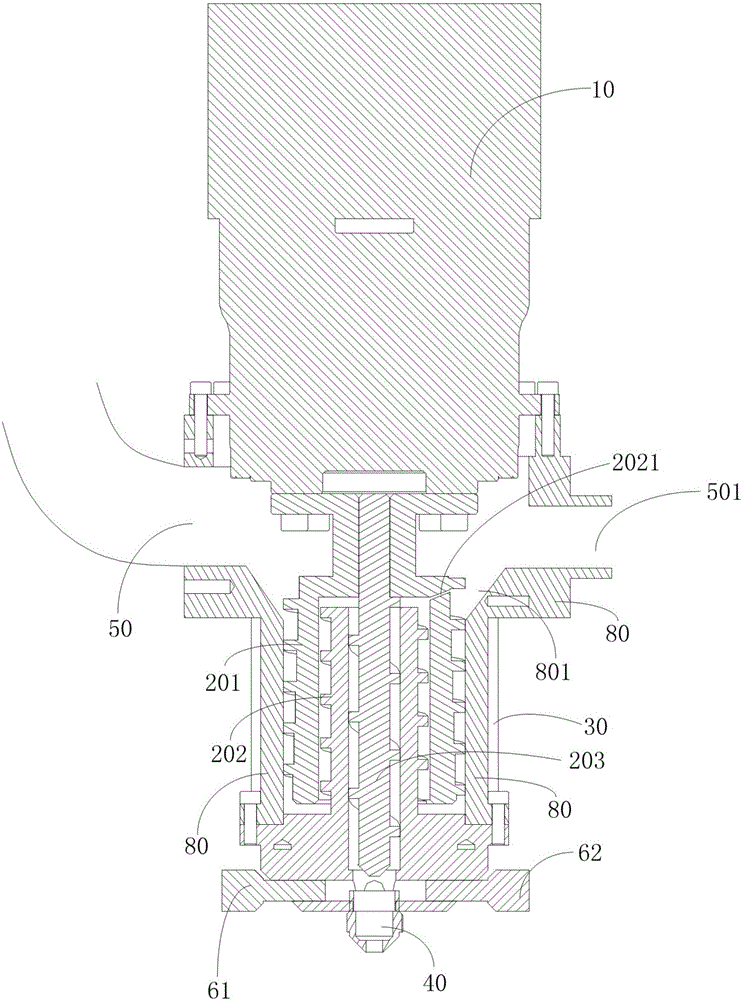

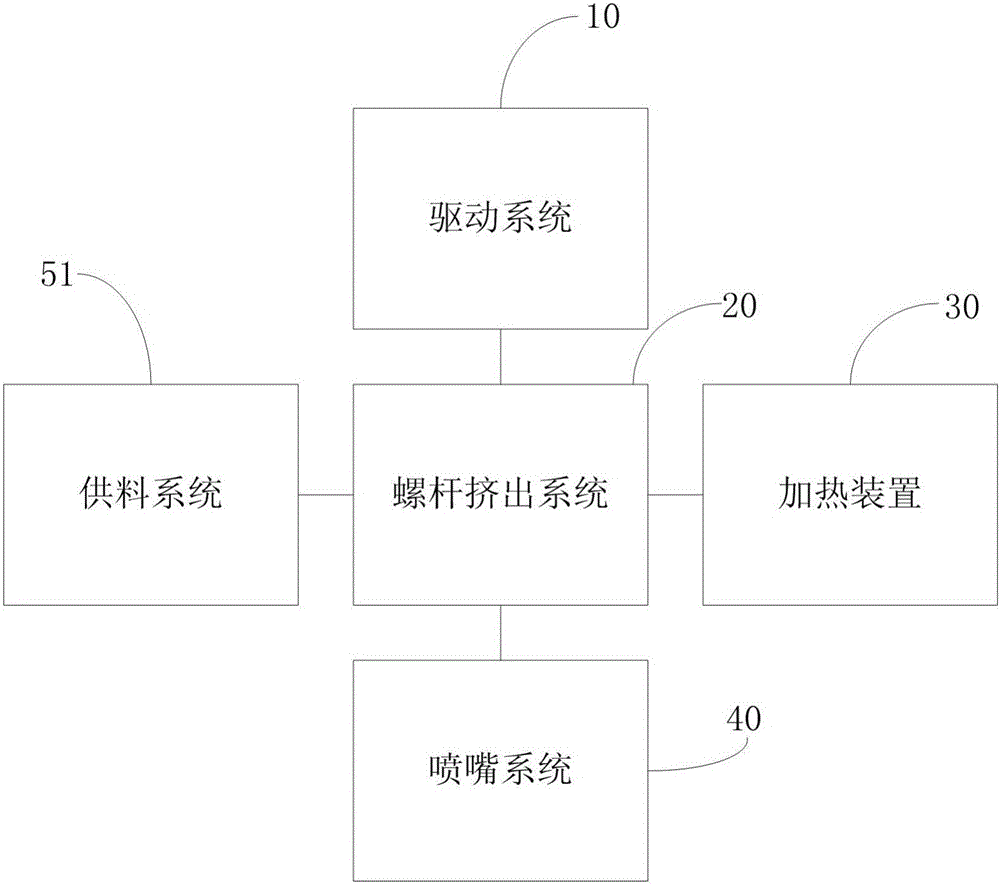

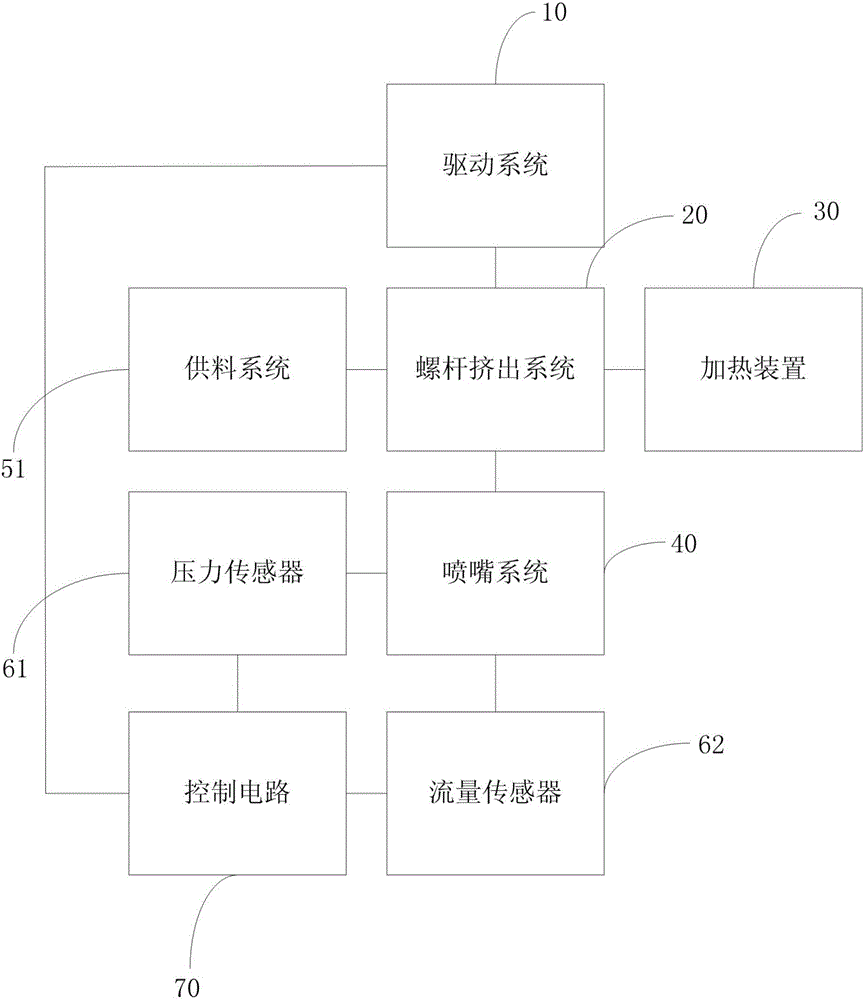

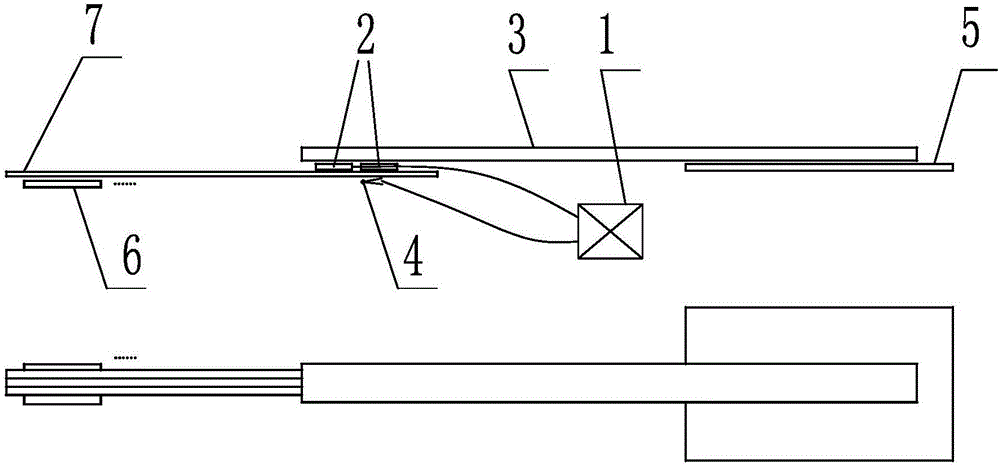

Printing head for 3D printing, control system, 3D printer and printing method

The invention discloses a printing head for 3D printing. The printing head comprises a machine shell, a screw extruding system, an installation seat, barrels, valve needles and spray nozzles. A drive system is arranged at one end of the machine shell. The screw extruding system is arranged in the machine shell and is composed of at least two screws which are embedded internally and externally, and at least one screw is driven by the drive system. The installation seat is mounted below the screw extruding system. One or more inner holes are distributed in the installation seat in the axial direction, and a discharge outlet is formed in the top or the side face of each inner hole. The barrels are mounted in all the inner holes of the installation seat correspondingly, the barrels extend out from one end of the installation seat, and barrel feeding openings are formed in the top ends of the barrels. Valve cavities are formed in the barrels. The valve needles penetrate through all the valve cavities of the barrels to be mounted on the installation seat, and the gaps between the valve needles and the valve cavities form discharging channels communicating with the feeding openings of the barrels. The spray nozzles are arranged at the tail ends of all the barrels. The printing head for 3D printing is light in weight, small in size, capable of achieving high printing precision and printing speed, novel in design, high in practicability and high in economic value.

Owner:浙江光镀智造科技有限公司

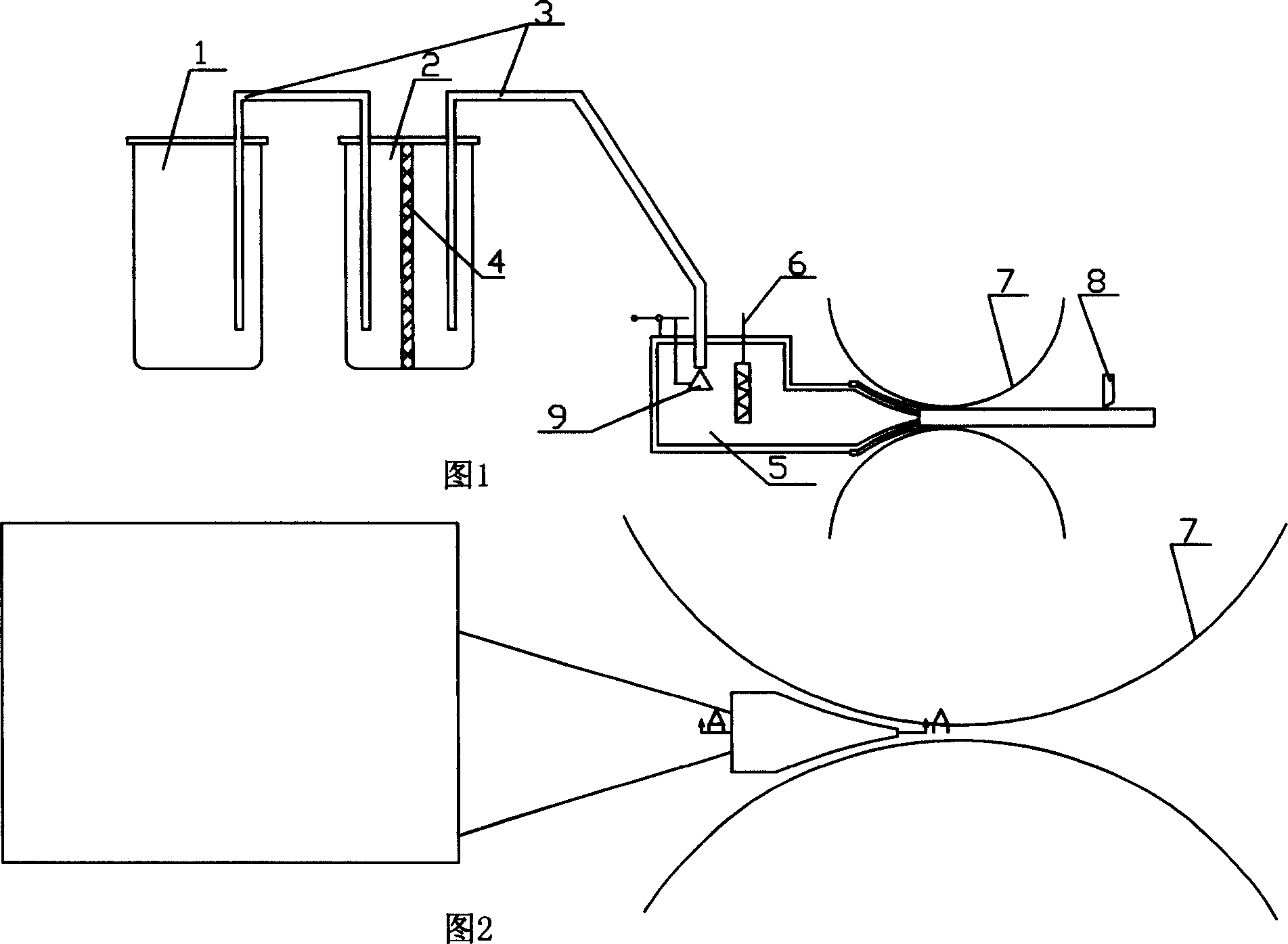

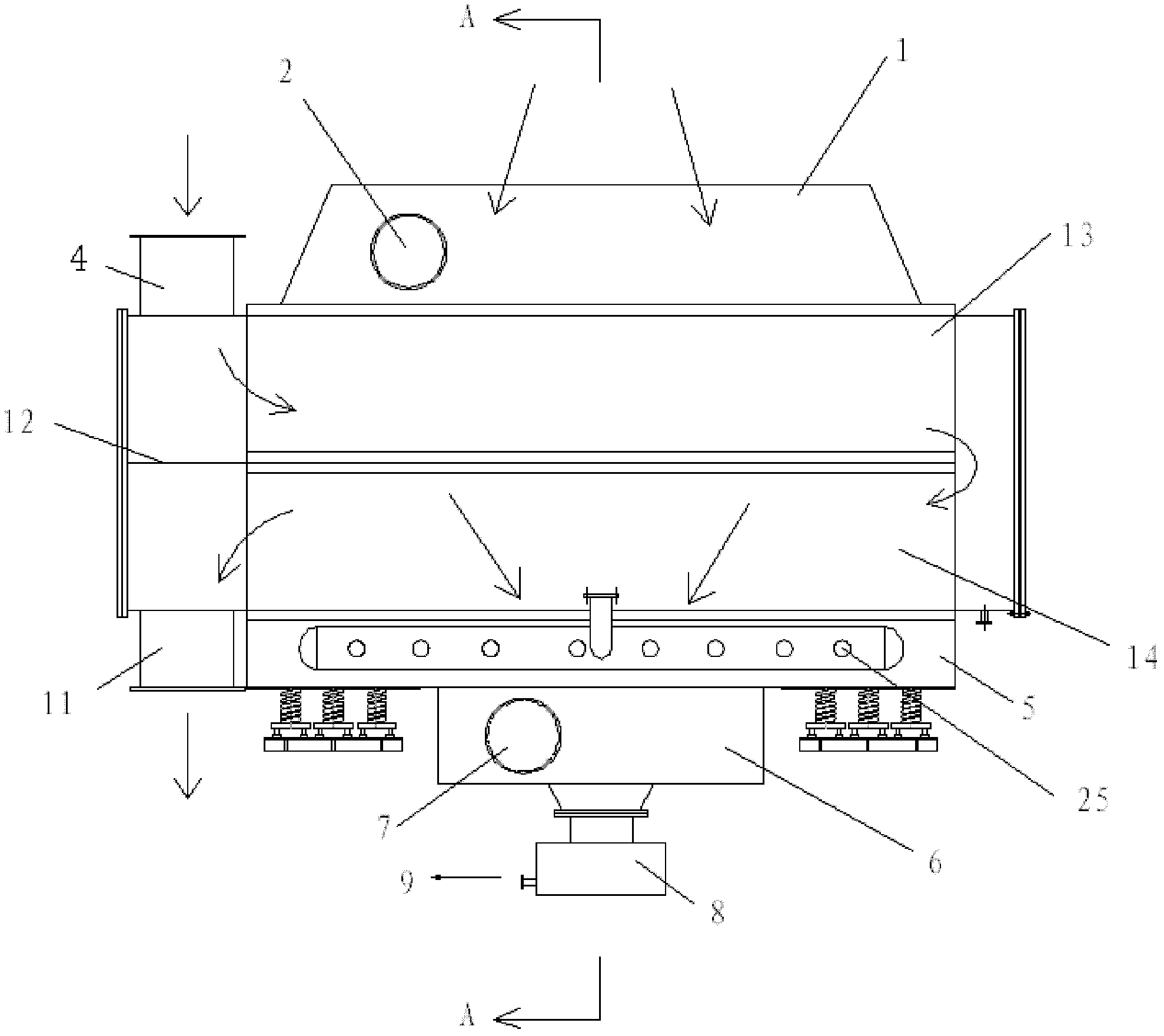

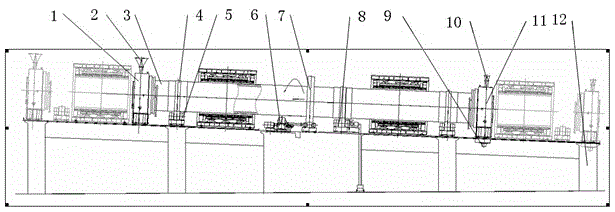

Magnesium alloy twin-roll continuous casting system for manufacturing magnesium alloy plate

A conticasting system with dual Mg-alloy rollers for producing Mg-alloy plate is disclosed. Its technology includes such steps as smelting Mg-alloy, holding temp. delivering to front box with constant temp and level and protecting gas, and flowing in casting-rolling mill. Its apparatus is composed of smelting furnace, temp-keeping heater, delivering system, front box, flowing outlet, casting-rolling mill and shear mechanism. Its advantages are high productivity and high safety.

Owner:FUJIAN HUAMEI NEW TECH DEV

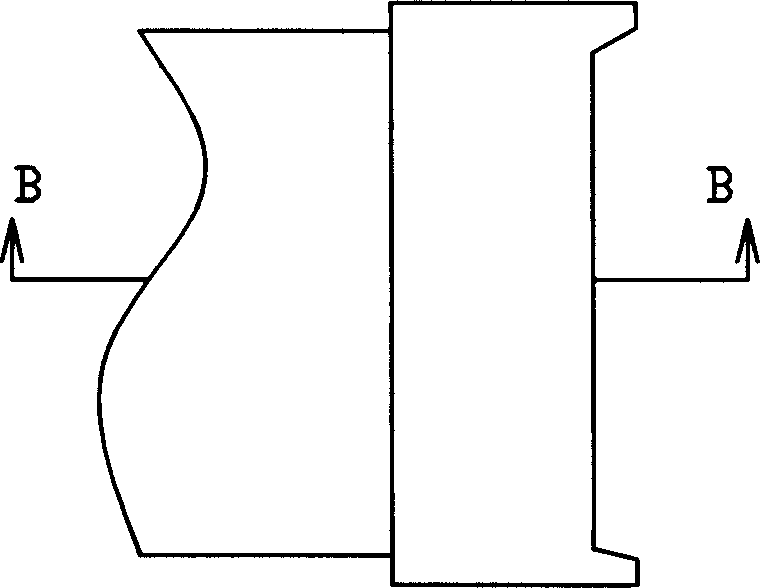

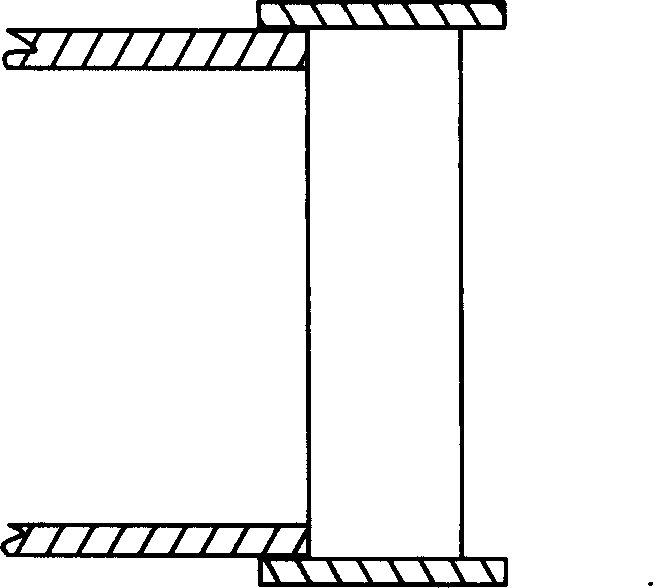

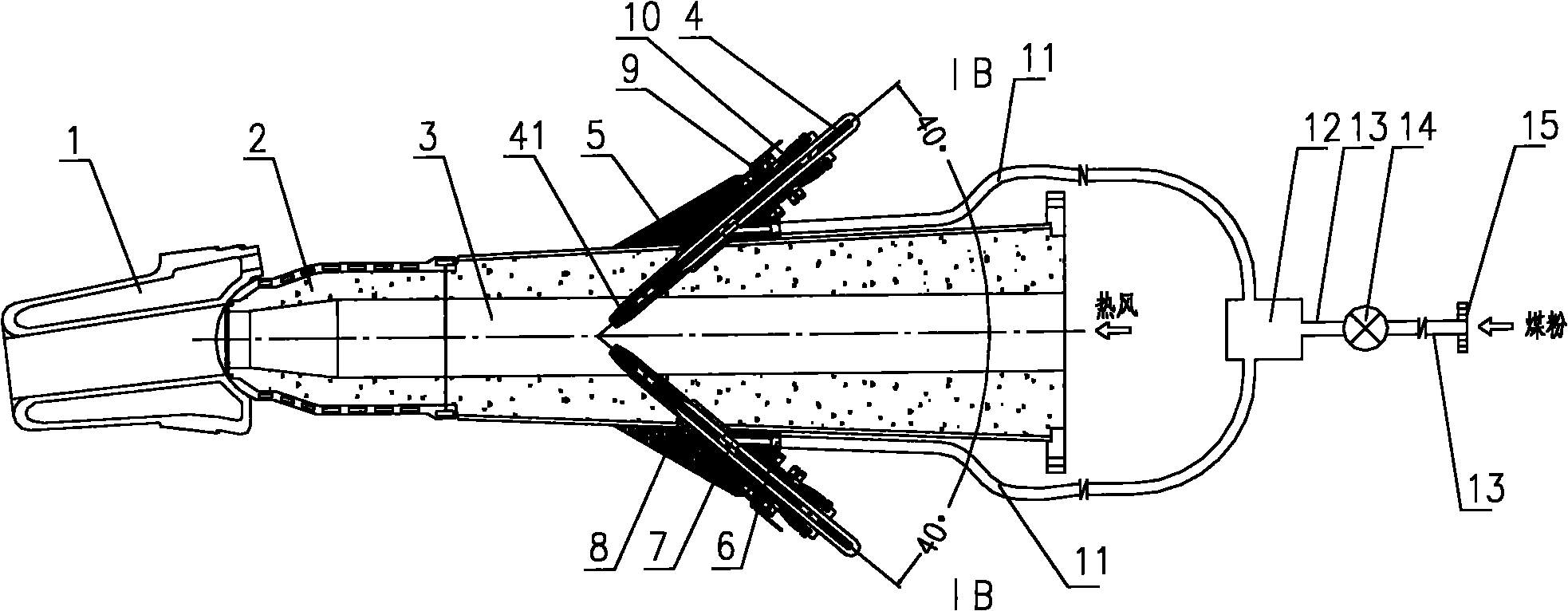

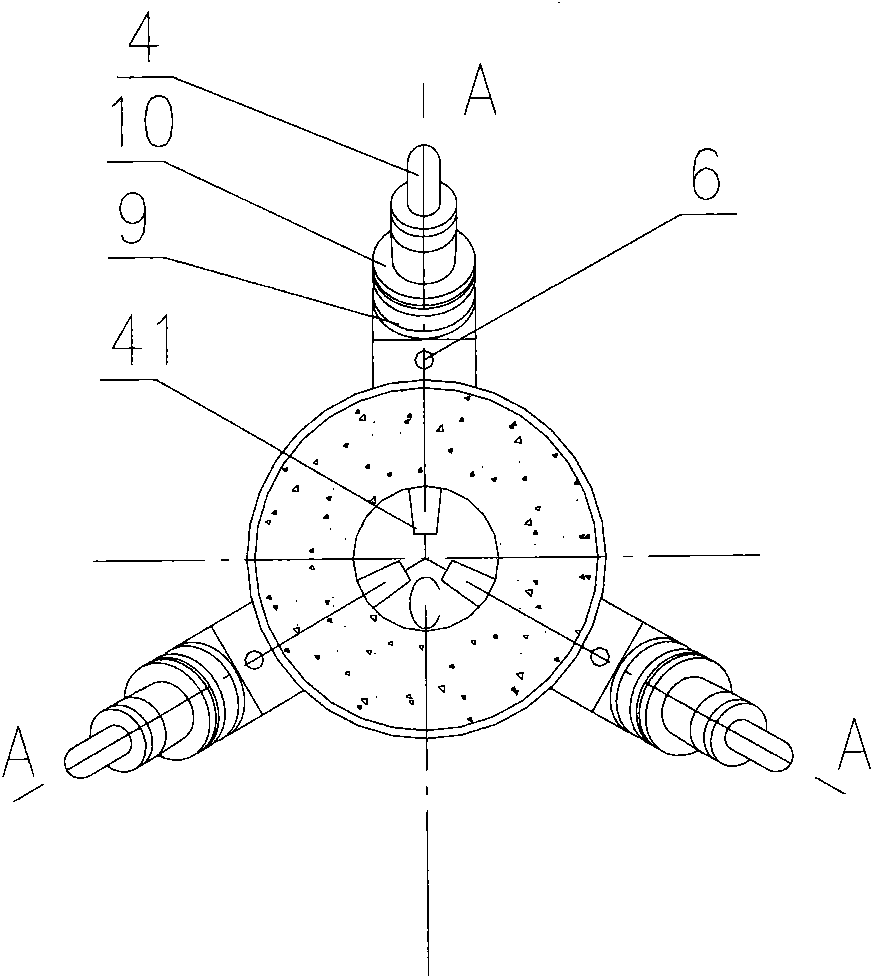

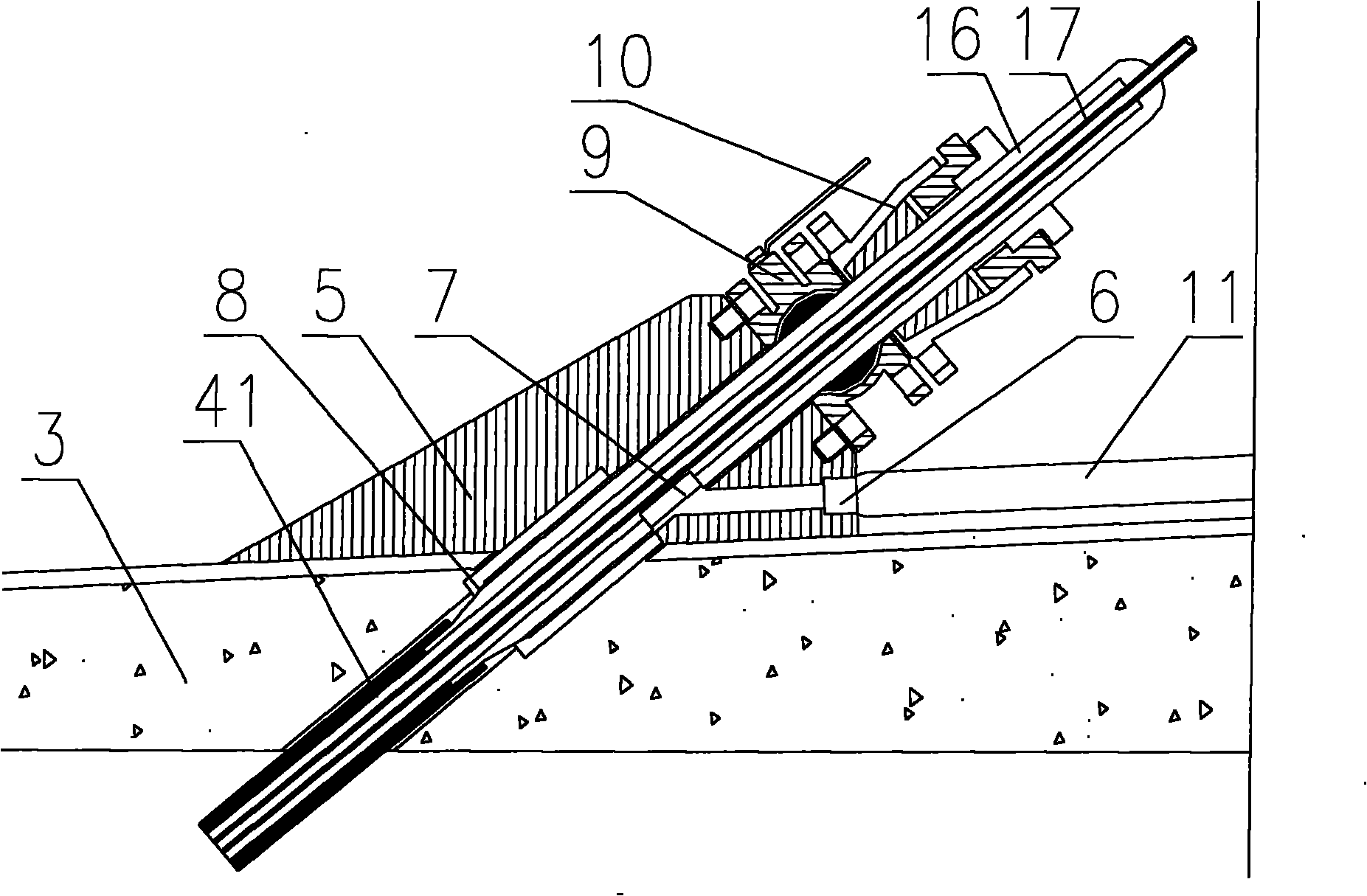

Method and device for blast furnace to blow coal powder

InactiveCN102485913AEnhance heat and mass transferExtended stayTuyeresBlast furnace detailsBall valveNew device

The invention puts forward a method and device for a blast furnace to blow coal powder. Characterized by employment of several short spray guns, a large incidence angle, accurate positioning of spray guns, small heat radiation and long life of blowpipes, and adoption of ceramic nozzles, the new method and new device of the invention aims to eliminate various defects in prior art, such as small coal powder incidence angle, restriction by high speed hot airflow, inadequate mixing with hot air, long length and long service life of spray guns, large heat radiation and short service life of blowpipes, and hard use of oxygen-coal lances, etc. According to the invention, on the blowpipes of each air ports, each short spray gun is inserted into each installation seat, and coal powder blown into a blast furnace enters from blowing inlets positioned on a lateral side of each installation seat, then reaches the inside of each short spray gun through coal spraying holes that are disposed on tube walls of the short spray guns and are over against the blowing inlets, and is finally blown into the furnace through each short spray gun. The device of the invention at least comprises: a blowpipe with a coal powder precombustion function, short spray guns, installation seats, ball valves, locking devices, coal conveying branch pipes, a distributor, a small ball valve, a coal conveying pipe, and an inlet connecting piece.

Owner:张昭贵

One-shot forming process for preparing split-blip brush wire

InactiveCN101011200APrevent penetrationIncrease productivityFibre treatmentCurling-ironsPolyesterLithium hydroxide

The invention relates to a method for preparing dual-sharp printing wires by one time. The invention comprises that sheathing a film outside the polyester wires to form wire beam to be cut into wire cake; packing the wire cake by the politef coat, and be tied by the beam; immerging the wire cake in the processing liquid of shaping kettle, for 25-35min at 115-128Deg. C, while the processing liquid is formed by mixing caustic soda, caustic potash, or lithium hydrate and water, and the processing liquid is added as 28-42%; taking out the wire cake, removing the coat, washing in water to remove the left liquid and corrosion material, arranging into fixed support to be dewatered by dewatering machine, dried or baked by bake oven to be packed into final product. The invention has high efficiency and low cost, without pollution.

Owner:王小芳

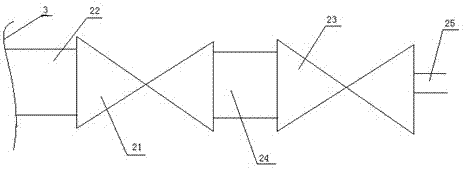

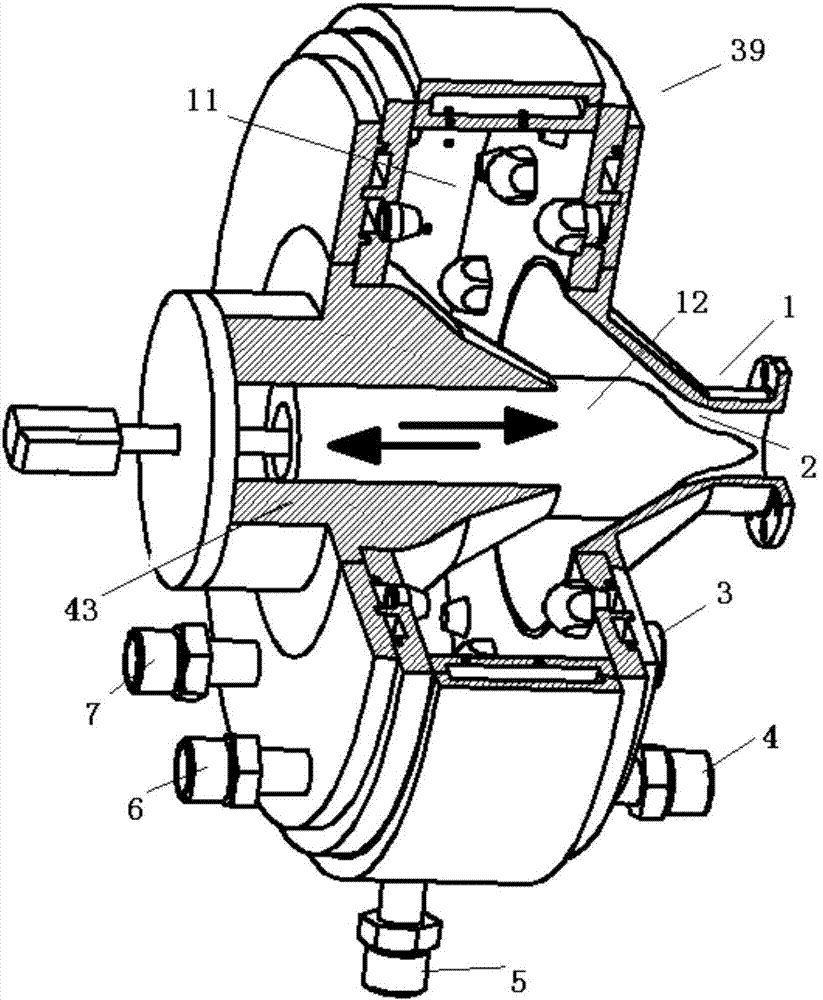

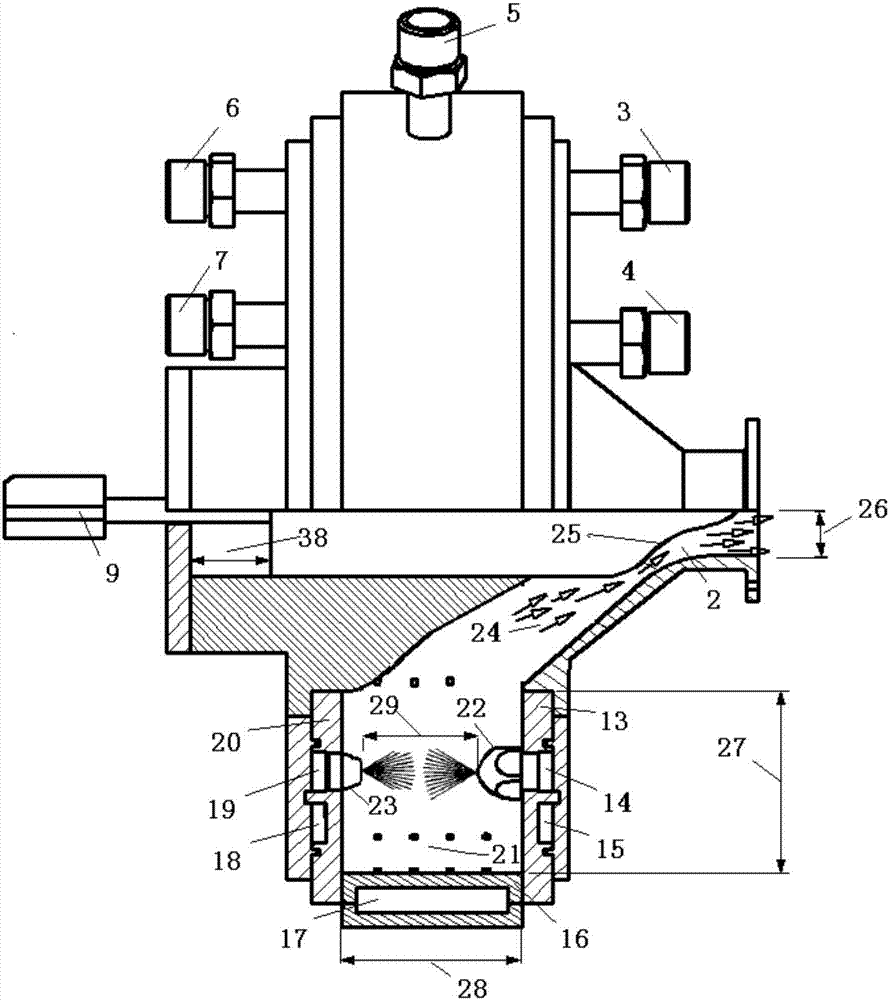

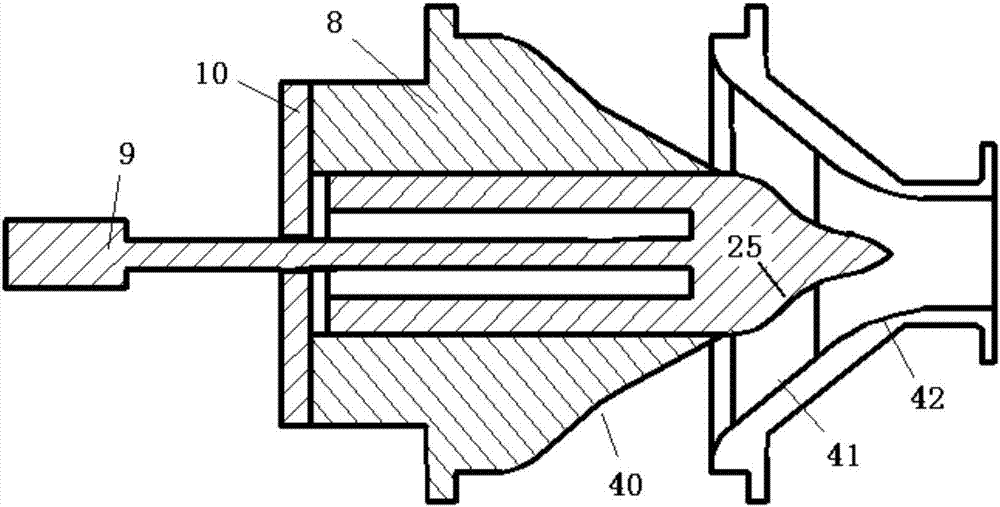

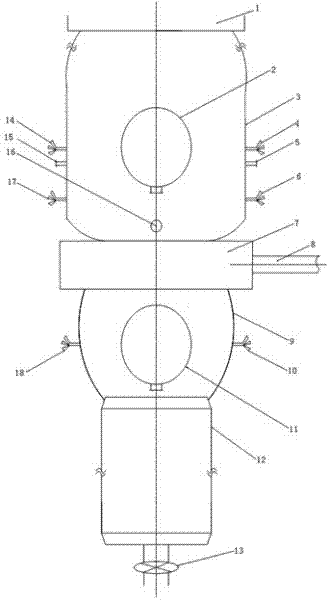

On-line adjustable fuel gas generator adopting jet flow collision combustion mode

ActiveCN105020050APromote fragmentationPromote atomizationRocket engine plantsJet flowCombustion chamber

The invention discloses an on-line adjustable fuel gas generator adopting a jet flow collision combustion mode. The on-line adjustable fuel gas generator is composed of a circular groove combustion chamber, a contraction section and an adjusting plug-cone component, wherein an adjusting plug cone is located on the head portion of the fuel gas generator, and is coaxially installed with the contraction section; the circular groove combustion chamber is formed by combining a front jet panel, a rear jet panel and a body cooling panel; the adjusting plug-cone component is composed of the adjusting plug cone, an action sleeve and a fixed disk; and the adjusting plug cone can move back and forth in the action sleeve, and the adjusting plug cone and the contraction section surface are designed in a matched manner. The on-line adjustable fuel gas generator adopting the jet flow collision combustion mode has the beneficial effects that the structure is compact, the length of the combustion chamber is short, the requirements of the structural size and the cooling area of the combustion chamber are greatly reduced, the fuel gas generator can be suitable for on-line adjustment on various combustion conditions of fuel gas generators of a ground testing system in the aerospace industry, the excellent flame stabilization and the fuel gas mixing ability are achieved, and the exit flow field is uniform.

Owner:PLA PEOPLES LIBERATION ARMY OF CHINA STRATEGIC SUPPORT FORCE AEROSPACE ENG UNIV

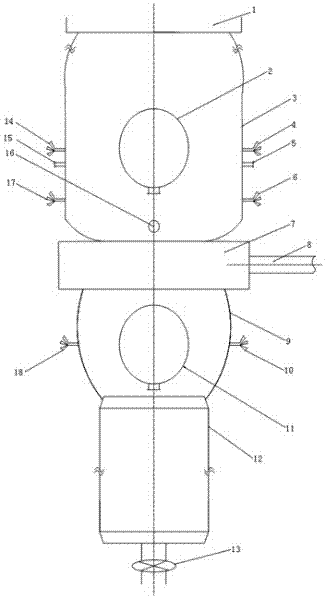

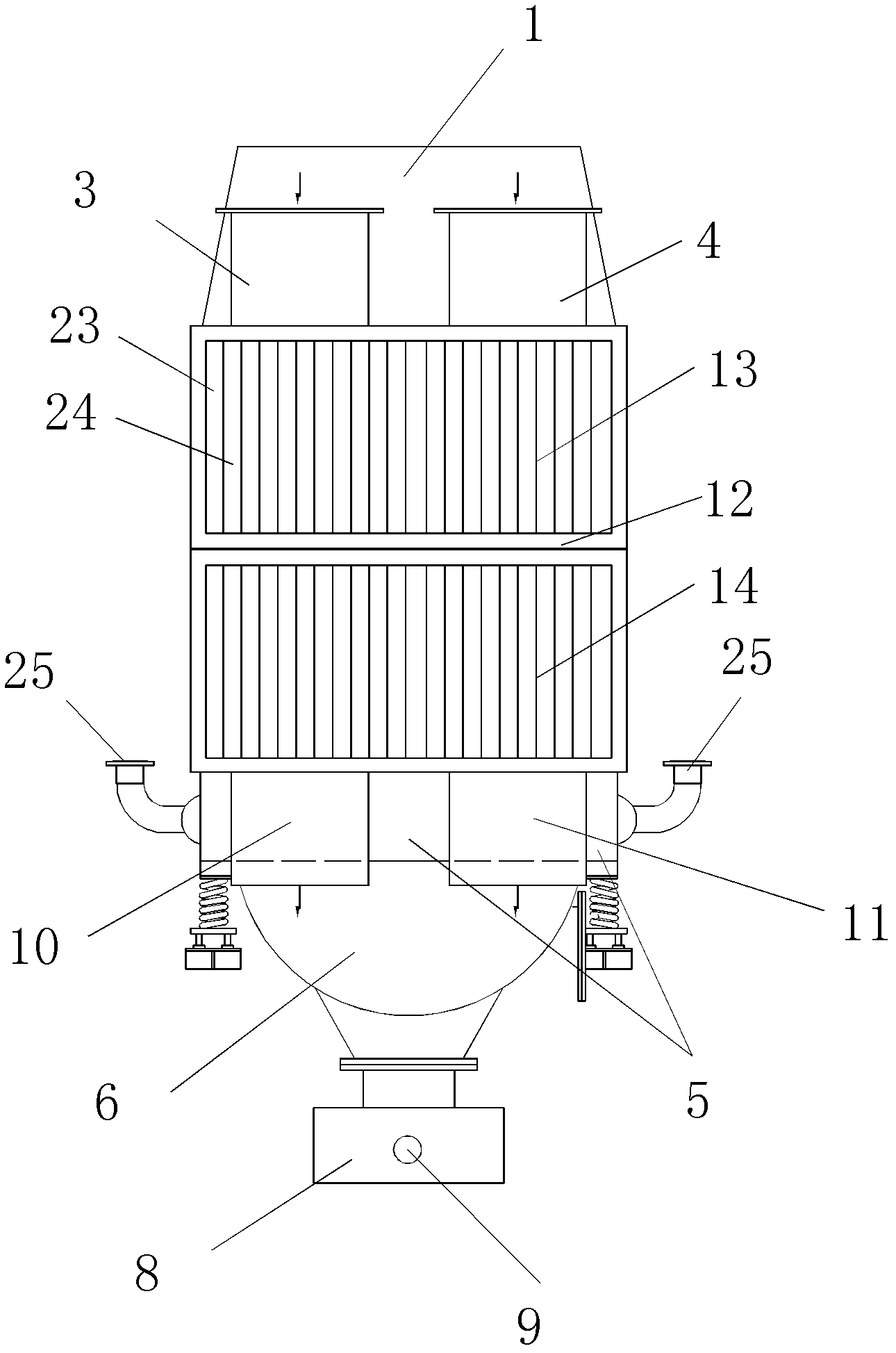

Vertical sewage treatment device and method

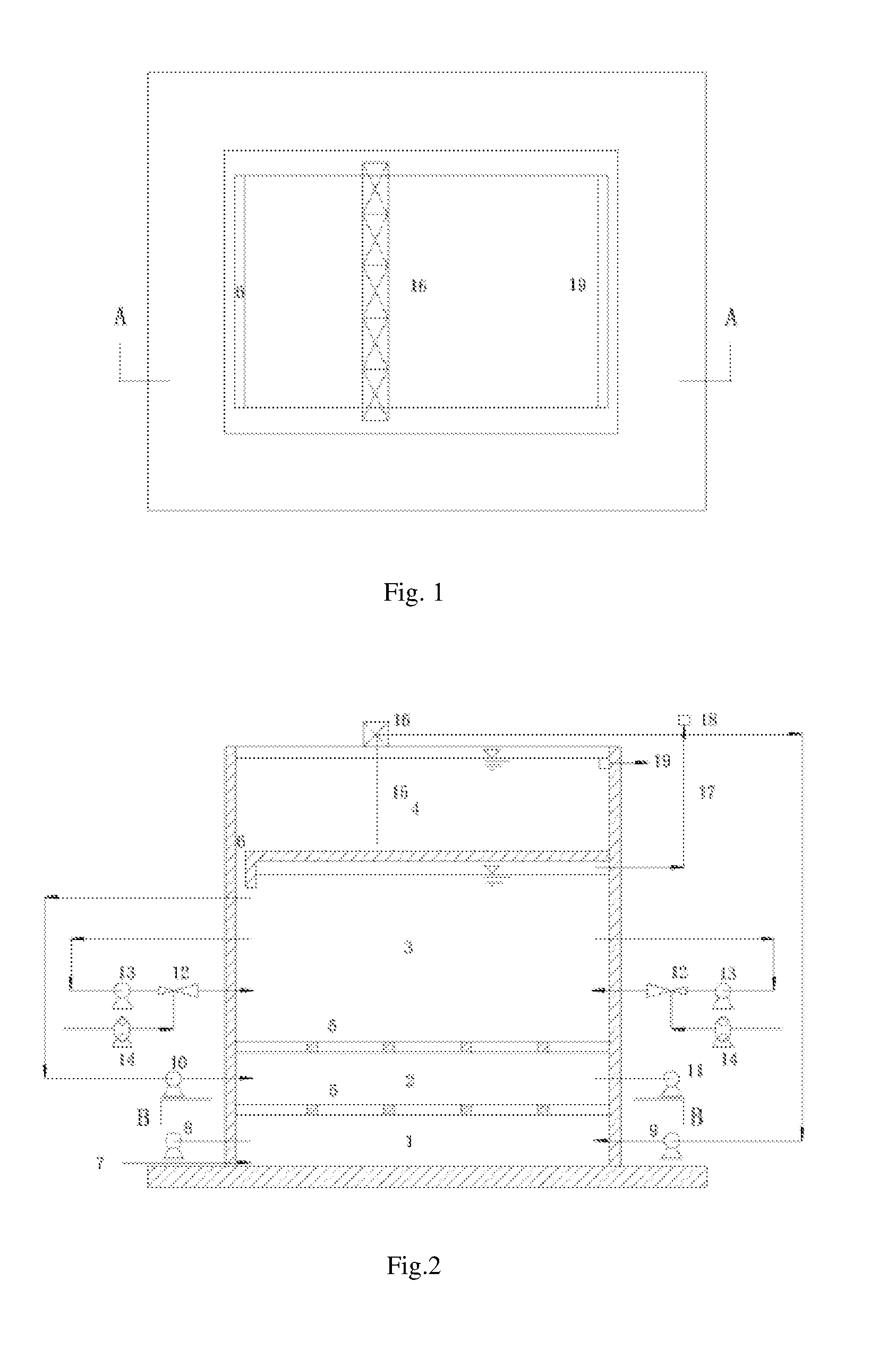

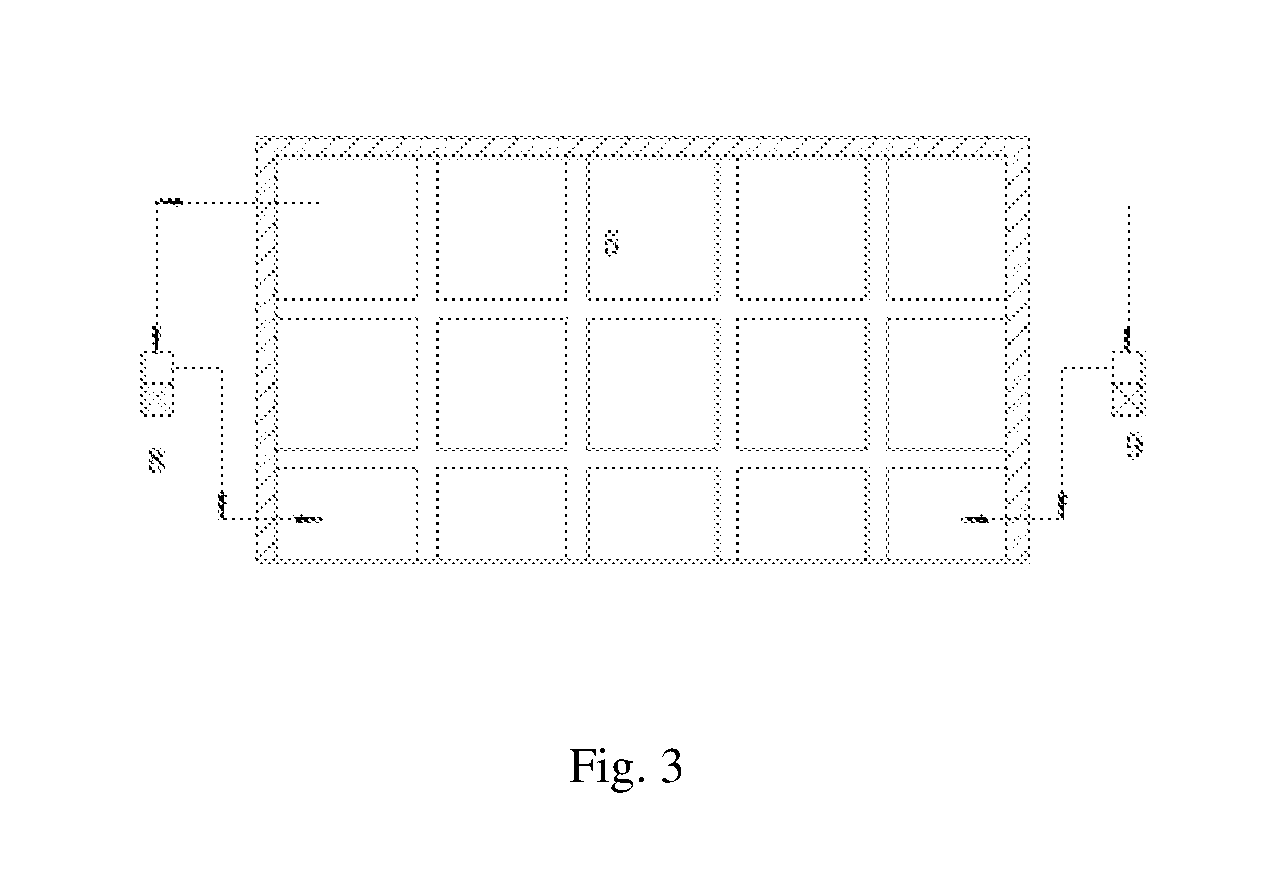

ActiveUS20160376178A1Improve oxygenation efficiencyReduce occupancyBiological treatment apparatusTreatment with aerobic and anaerobic processesAnaerobic chamberHeat losses

The present invention provides a vertical sewage treatment device including an anaerobic chamber, an anoxic chamber, an aerobiotic chamber, and a secondary precipitation chamber, wherein the anaerobic chamber, the anoxic chamber, the aerobiotic chamber, and the secondary precipitation chamber are vertically arranged in sequence from the bottom to the top. According to another aspect, the present invention also provides a sewage treatment method using the foregoing vertical sewage treatment device. The sewage treatment device and method of the present invention have the advantages such as a reduced occupied area, improved oxygenation efficiency, a decreased head loss, a reduced invalid structure volume, and a low heat loss.

Owner:CHINESE RES ACAD OF ENVIRONMENTAL SCI

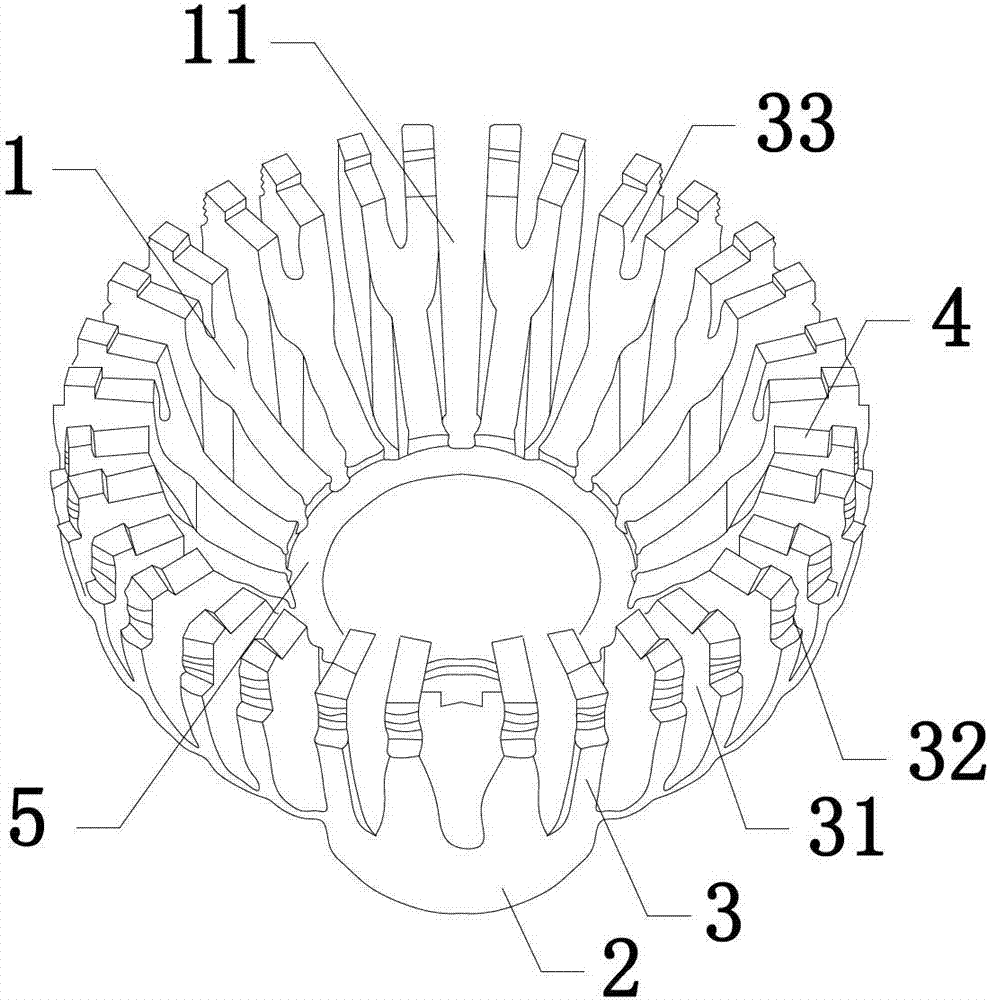

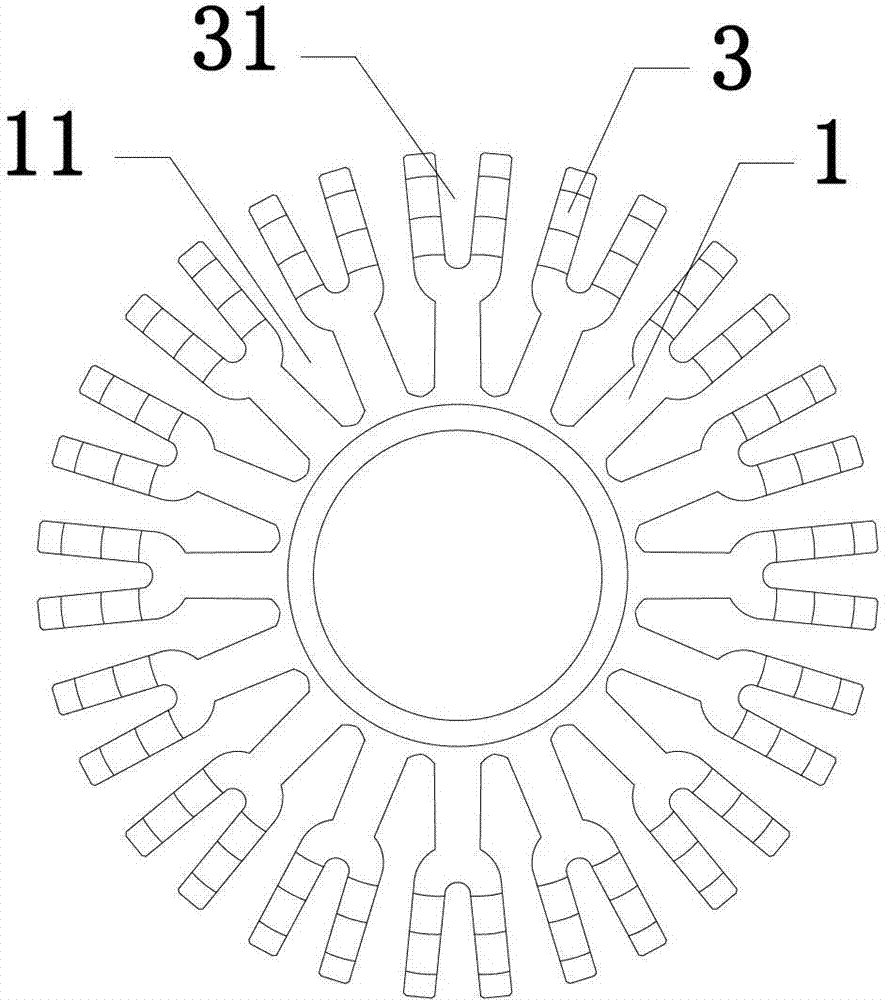

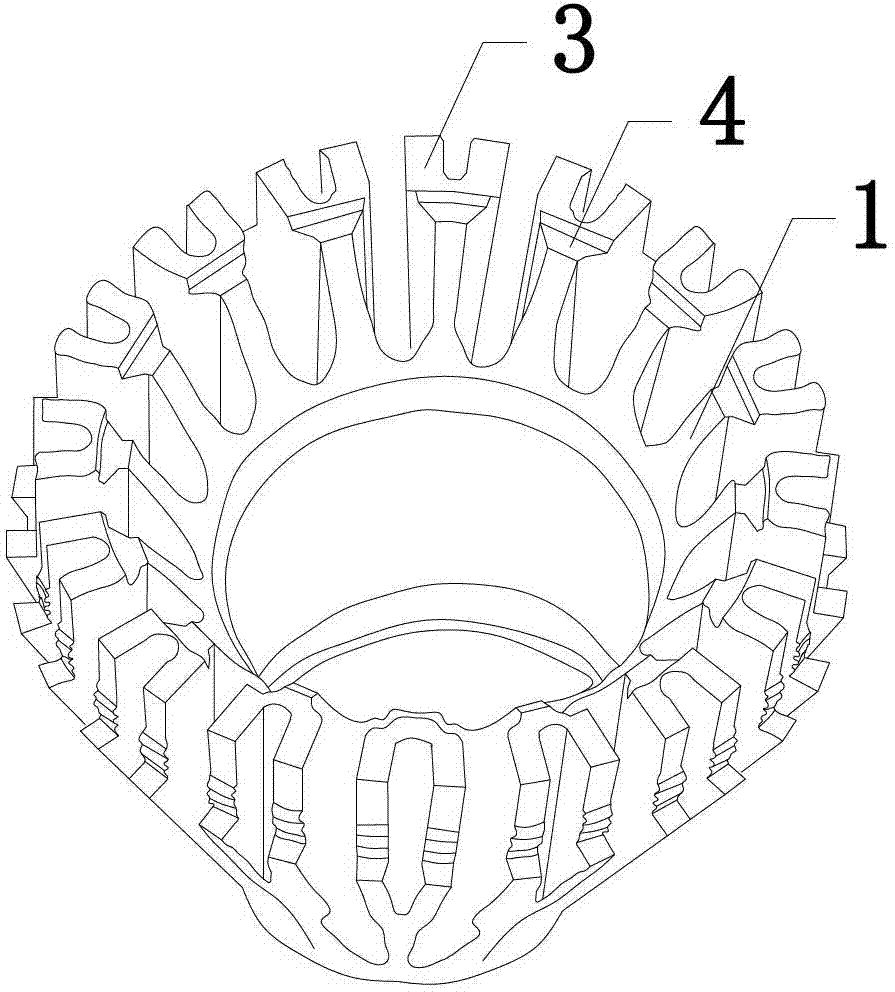

Radiating shell of LED lamp

InactiveCN103206695AIncrease cooling areaImprove cooling efficiencyPoint-like light sourceLighting heating/cooling arrangementsEngineeringHeat sink

The invention aims at providing a radiating shell for improving radiating efficiency of an LED lamp. The radiating shell comprises a tubular heat absorbing core and multiple radiating fins radially arranged around the heat absorbing core, a main ventilation groove is formed between each two adjacent radiating fins, the multiple radiating fins extend towards a same end of the heat absorbing core and form a cavity used for holding devices by surrounding at the end, the cavity and the main ventilation grooves are communicated, the outside of each radiating fin is at least provided with two radially-arranged fins, and auxiliary ventilation grooves are formed among the fins on a same radiating fin. The structure of the radiating shell is improved by additionally arranging the fins on the radiating fins, so that radiating effect of the radiating shell is greatly improved.

Owner:GUANGDONG ECORISING TECH

Multifunctional composite thermal-insulating layer

ActiveCN105864581AIncreased durabilityReduce heat lossThermal insulationPipe protection by thermal insulationThermal bridgeHeat losses

The invention provides a multifunctional composite thermal-insulating layer which comprises a pipe or an equipment base, at least one thermal-insulating layer, at least one internal protective layer, and at least one isolating layer. The internal protective layer is used for absorbing swell and supporting the whole thermal-insulating structure to prevent the same from collapsing. The isolating layer made of a high-temperature-resistant emitting material has effects of corrosion resistance and air-tightness, and further has effects of reducing heat-transfer coefficient and thermal conductivity of metal materials, isolating heat conduction and thermal bridge of pipe supports and hangers and improving heat barriers. Specifically, the isolating layers, the internal protective layers and the thermal-insulating layers are sequentially arranged on the outer side of the pipe or equipment base; the internal protective layers and the thermal-insulating layers are composited and interactive with each other, are arranged alternatively to overcome heat loss caused by irradiation, conduction and convection; joints of the different layers are staggered with one another to realize non-convection heat dissipation; and every two adjacent layers are made from different materials. The multifunctional composite thermal-insulating layer solves the problems about heat loss caused by irradiation, conduction and convection.

Owner:韩松

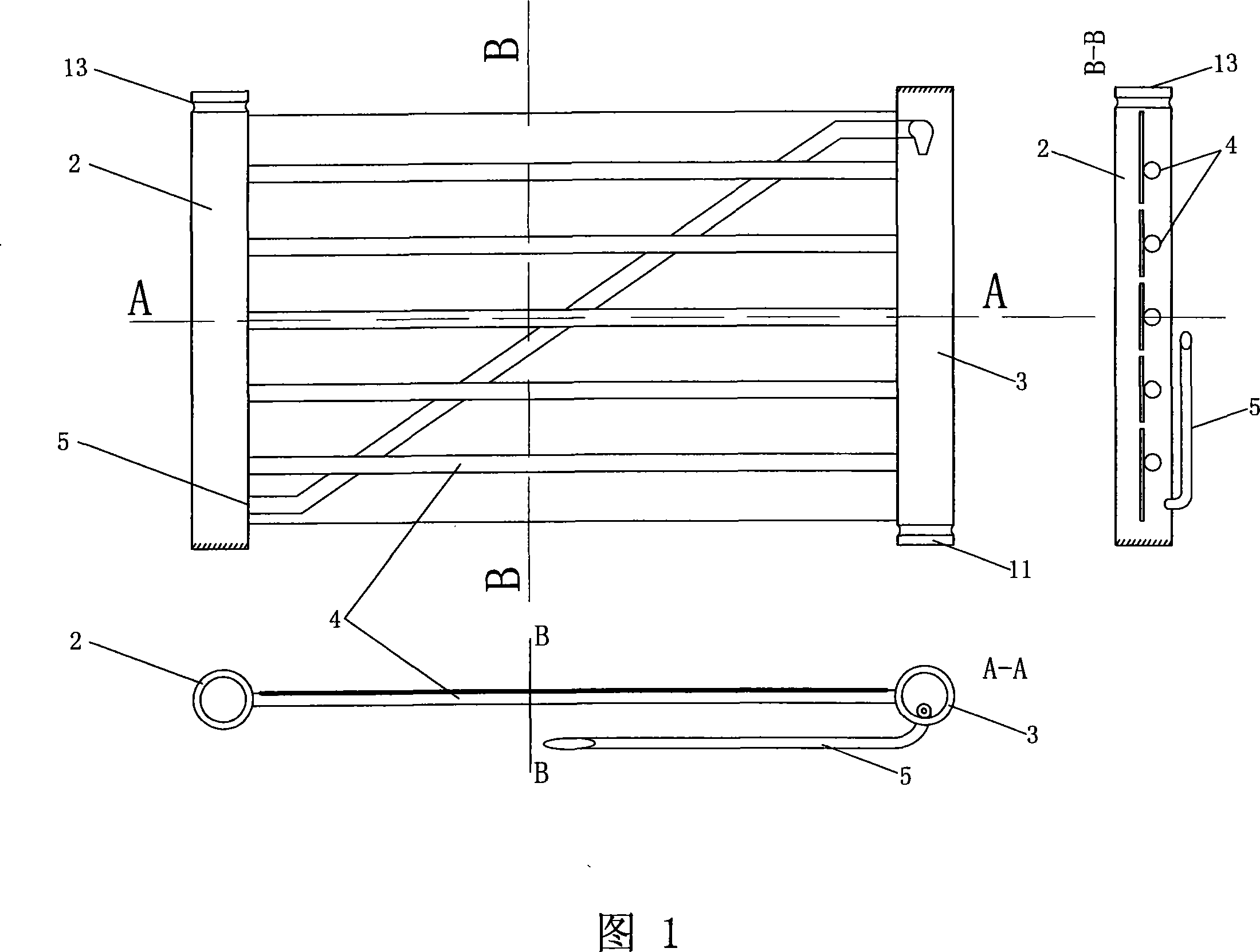

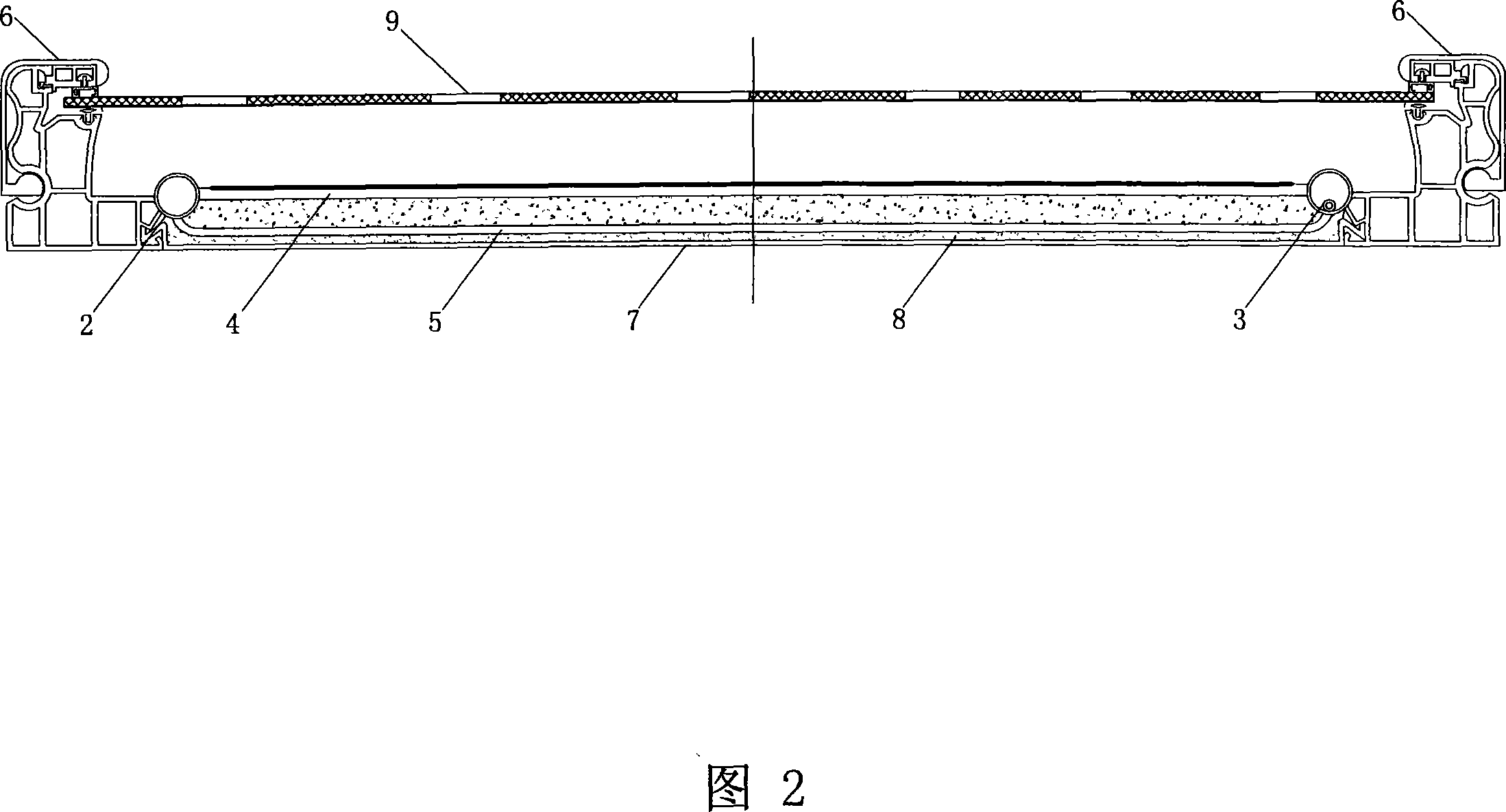

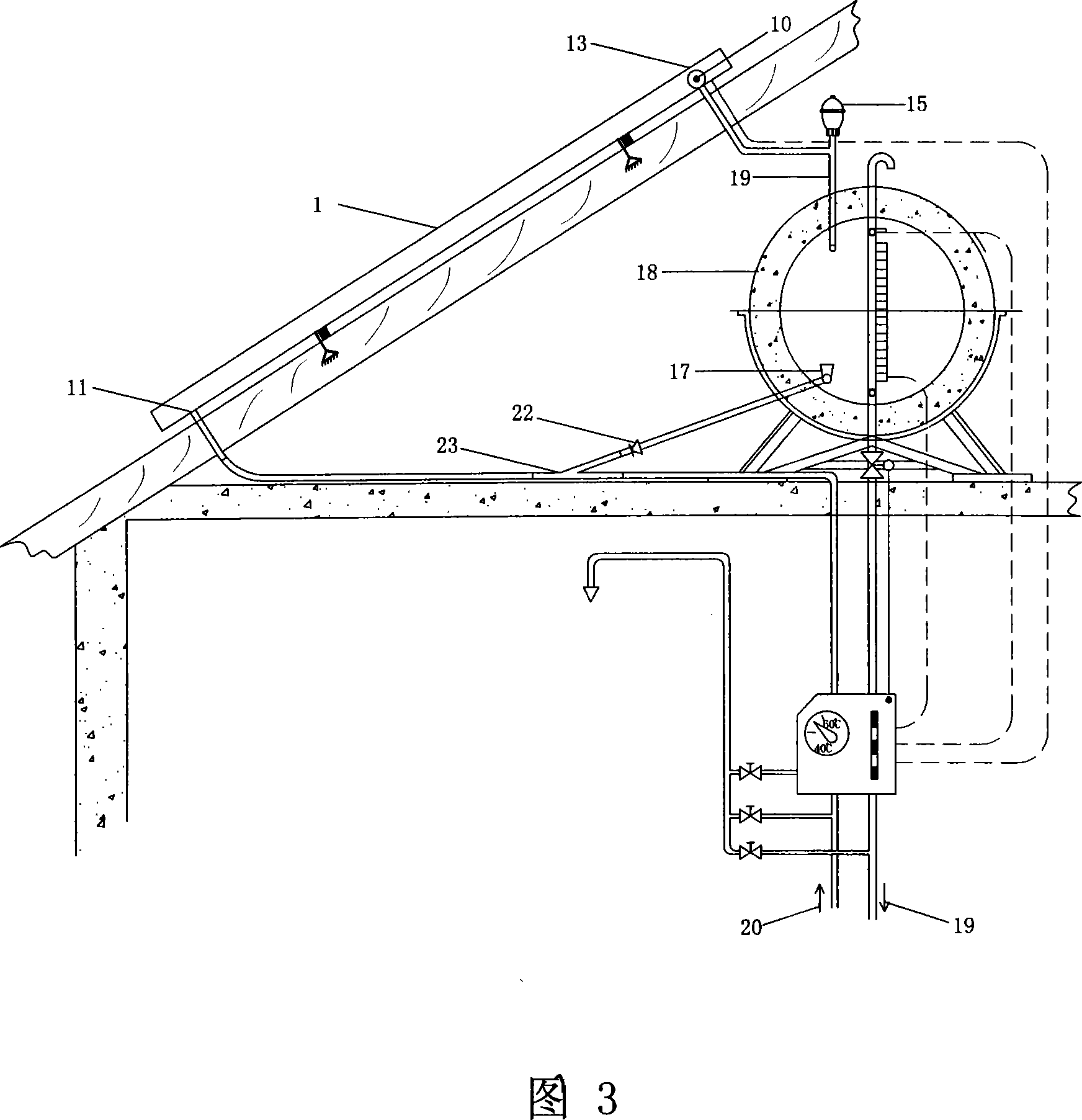

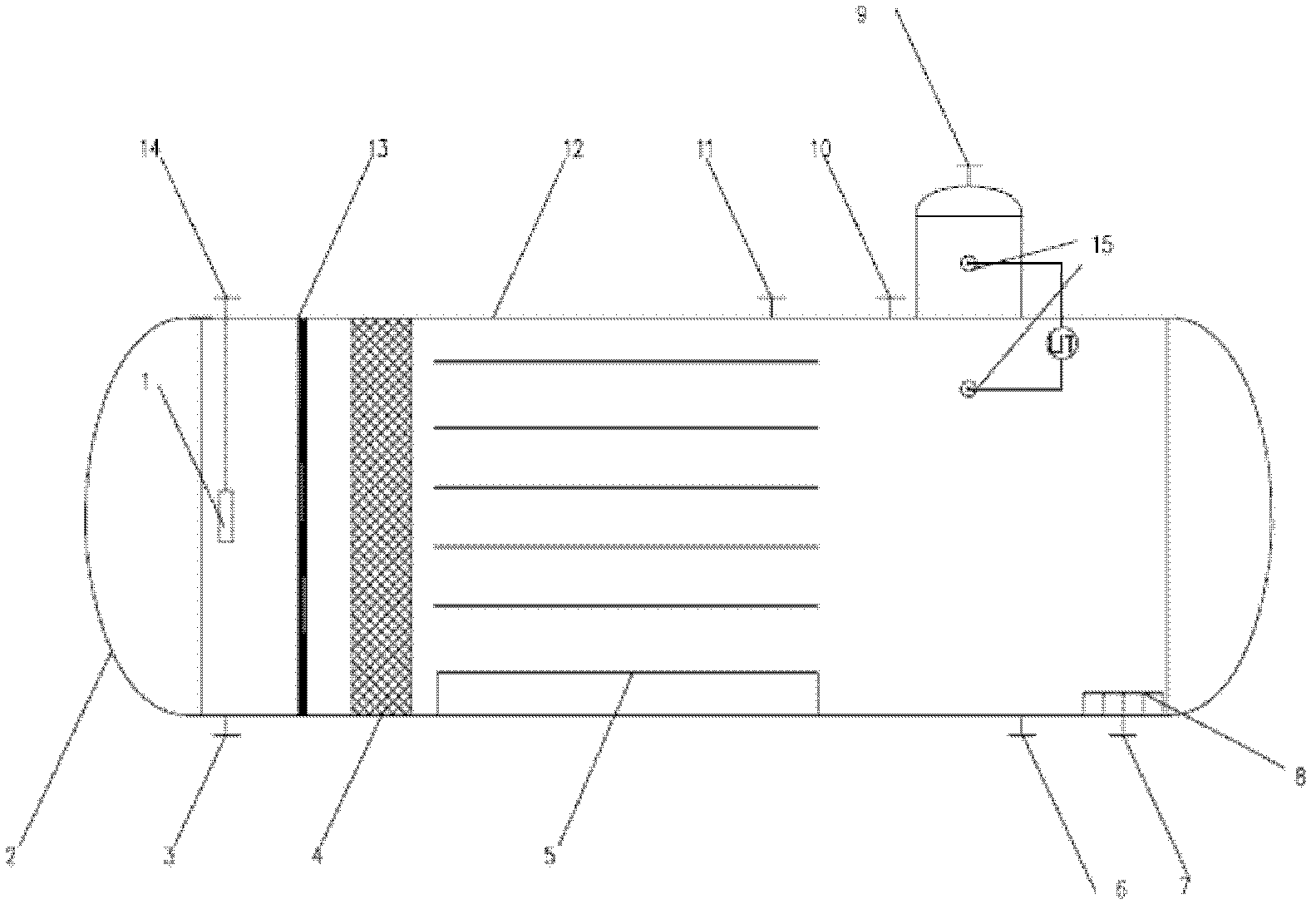

Tube sheet type system integrated solar water heater

InactiveCN101144654AGuarantee the quality of water supplyEasy accessSolar heat devicesSolar thermal energy generationSolar waterWater resources

The invention relates to a tube plate type system integrated solar water heater, which can highly integrate the natural circulation mechanism within the range of a tube plate type heat collector, thereby leading the tube plate type solar hot water system to realize the separation of the collection and the storage, the simple combination, and coordinated installation. A heat insulation water tank which operates effectively is integrally and shadily installed on the building; a heat insulation water tank which goes into household is hung on the wall in the split way, and is shadily installed according to the design requirements of the building. The tube plate type integrated heater which realizes the integrated and integral structure can choose an adaptive patent stand base system according to the existing building installation condition, and can be simply, coordinately and directly anchored on the tiling slope roof, the even building root or the balcony guard rail. The system installed on the even building root can simply adjust the established angle and the azimuth angle which face the sun according to the sunshine condition, in addition, the heat emission residual water of the previous night in the water tank arranged on the stand base on the even building root can automatically operate the passive second circulation heating, to save the water resources and guarantee the quality of water supply.

Owner:涂济民

Composite insulating layer with cavity structures

InactiveCN106195529ALow thermal conductivityImprove insulation effectThermal insulationPipe protection by thermal insulationGratingEngineering

The invention provides a composite insulating layer with cavity structures. The composite insulating layer comprises a pipeline or equipment substrate and at least one insulating layer, wherein block ratings or supports are arranged between the pipeline or equipment substrate and the insulating layer to form part of the cavity structures; block gratings or supports are arranged between the insulating layers to form the rest cavity structures. According to the composite insulating layer with the cavity structures, provided by the embodiment of the invention, as air has a favorable heat insulation effect, equivalently, air layers are added to a common insulating layer structure, and the heat insulation effect of the air layers per se are better than that of the traditional insulating layers, the cost is lowered, heat loss is reduced, successful normal production is guaranteed, the expenditure on frequently replacing the insulating layers is reduced for enterprises, and a certain economical benefit is created.

Owner:BEIJING ENJI ENERGY SAVER TECH

Totally closed gas atomization pulverization device

The invention discloses a totally closed gas atomization pulverization device. The device comprises a heat insulation crucible, an atomizer, an atomization tower, a telescopic plastic pipe A, a telescopic plastic pipe B and the like, wherein the atomizer is arranged in the telescopic plastic pipe A; the telescopic plastic pipe A is respectively connected with the heat insulation crucible and the upper surface of a nozzle of the atomizer in a sealed mode; the atomization tower is connected with the lower surface of the nozzle through the telescopic plastic pipe B in the sealed mode; and two half metal cylindrical barrels are arranged in inner and outer metal grooves on the lower surface of the nozzle and on the atomization tower, so that a totally closed system structure is formed. The structure can prevent oxide and nitride from being formed on the atomizer and blocking the atomizer. The totally closed gas atomization pulverization device has the advantages that: the device has a simple structure and is convenient to install, blocking is effectively prevented, the quality of powder is improved, and the like.

Owner:SHANGHAI INST OF TECH

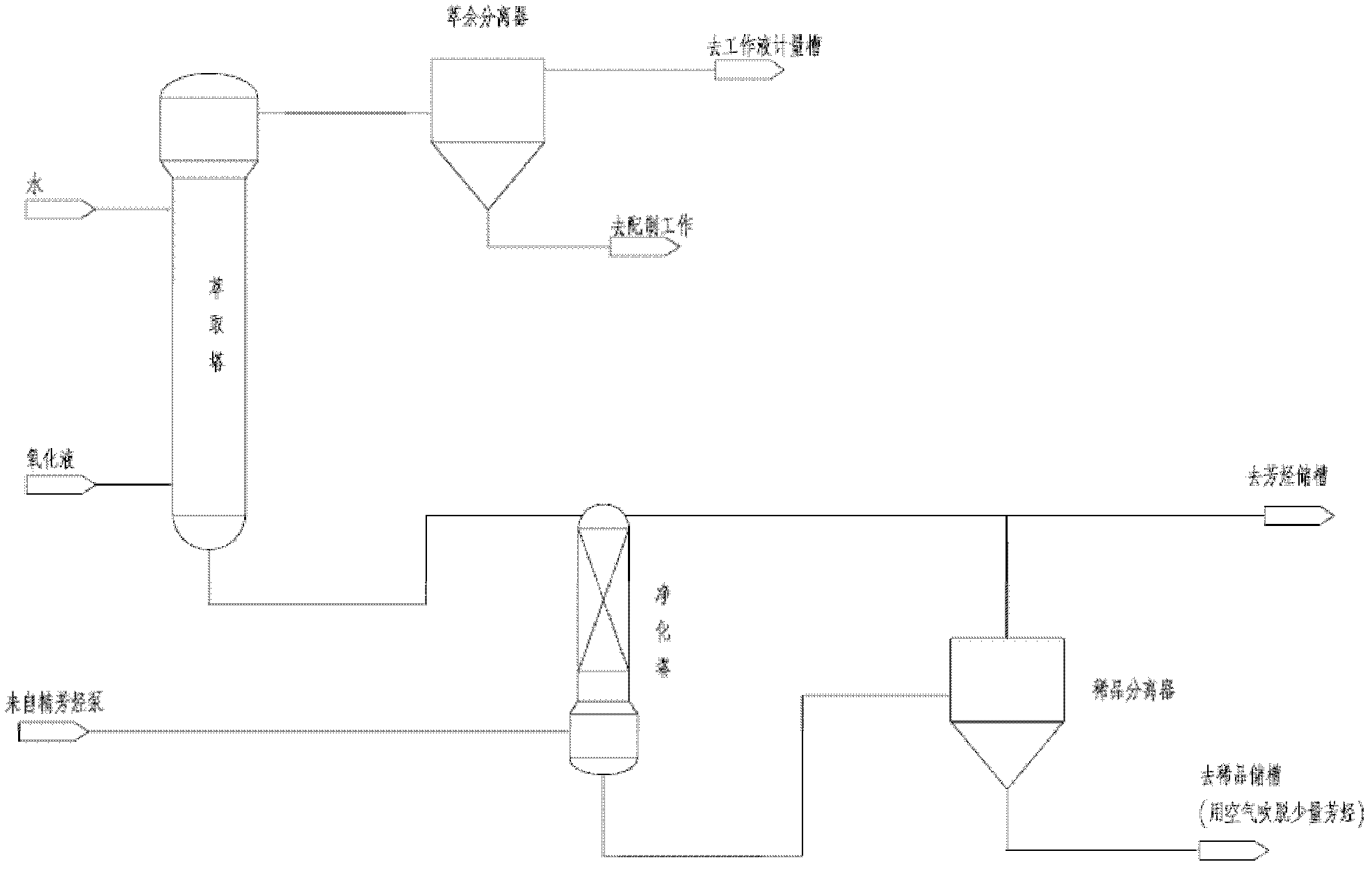

Device and process applied to hydrogen peroxide extraction

ActiveCN102491281AExtended stayShort stayPeroxides/peroxyhydrates/peroxyacids/superoxides/ozonidesFiberProcess engineering

The invention provides a device and process applied to hydrogen peroxide extraction. The device comprises a stock solution tank, a separating tank, a liquid distributor, a rectifier, a liquid drop multiplication fiber filler assembly, a special plate group separating assembly and an anti-vortex baffle plate assembly, wherein the liquid drop multiplication fiber filler assembly and the special plate group separating assembly are arranged in the separating tank; the separating tank is provided with a small dispersed phase discharge barrel for stabilizing a two-phase interface and preventing discharging inclusion of a dispersed phase; and the anti-vortex baffle plate assembly is arranged in the separating tank and is used for preventing discharging vortex, stabilizing flow field in the separating tank and enhancing a separating effect. The separating equipment can reach dozens of ppm in maximum. Due to the adoption of a rare product phase separator, separating time is shortened, equipment size is reduced, and the load of subsequent air blow-off aromatic hydrocarbon and the emission of aromatic hydrocarbon can be lowered.

Owner:SHANGHAI ANHORN ENVIRONMENTAL TECH CO LTD

Polycrystalline silicon ingot and casting method thereof

ActiveCN102965727AImprove performanceQuality improvementPolycrystalline material growthSingle crystal growth detailsMolten stateThermal insulation

The invention discloses a polycrystalline silicon ingot and a casting method thereof, and applies to an ingot furnace which is provided with a top heater, and a thermal insulation bottom plate is arranged at the bottom periphery of a heat radiation platform. The casting method comprises the following steps of: loading a silicon material in a crucible, and heating the silicon material to a molten state; reducing the power of the top heater on the polysilicon ingot furnace, simultaneously opening a shutter to the angle of 25 degrees to 35 degrees gradually, and reducing the surface temperature of a silicone fluid in the molten state to 1400 DEG C-1450 DEG C so that the silicone fluid at the bottom starts crystallizing; continuing gradually opening the shutter to the maximum opening vertical angle, and keeping a stable silicone fluid crystallization rate, wherein the opening speed rate of the shutter is less than the opening speed rate of the shutter in the second step, and the opening speed rate of the shutter is gradually reduced; and maintaining the maximum opening of the shutter until crystallization is finished. The polycrystalline silicon ingot and the casting method thereof provided by the invention solve the problem that the peripheral impurities of the silicon ingot are distributed in a scattering manner through changing a oriented polycrystalline silicon crystallizing process, the property of the polycrystalline silicon ingot is improved, the polycrystalline silicon ingot with good quality and high compound output rate is prepared, the utilization ratio of the silicon material is improved, and the manufacturing cost of the silicon ingot is reduced.

Owner:YINGLI ENERGY CHINA

Atomizer capable with nozzle and flow guide tube prevented from blockage

The invention discloses an atomizer with a nozzle and a flow guide tube prevented from blockage. The atomizer is composed of a flow guide tube, a metal jacket, a nozzle, a heating body A, a ceramic sealing ring, a metal sealing ring, a gasket and the like, wherein a gap between the flow guide tube and the metal jacket is provided with the heating body A; a heating body B is arrange each of gaps of the two Laval-structure air outlet tubes of the nozzle; the inner surface of the metal jacket is provided with a metal reflection film or a sprayed white reflection coating; the lower end part of the metal jacket and the lower end part of the flow guide tube are level; the end part of a gap between the lower end part of the metal jacket and the lower end part of the flow guide tube is sealed by the ceramic sealing ring; and the end parts of the gaps between the two Laval-structure air outlet tubes of the nozzle are in threaded connection and sealed by the metal sealing ring. The atomizer has the functions of effectively preventing metal and alloy from being blocked and solving the blockage problem, is suitable for melt flow guidance for metal or alloy atomization, has the advantages of simple structure and the like, and is convenient to install, and the production efficiency can be improved.

Owner:SHANGHAI LUOKE CENT CONTROLLED ENERGY SAVING TECH CO LTD

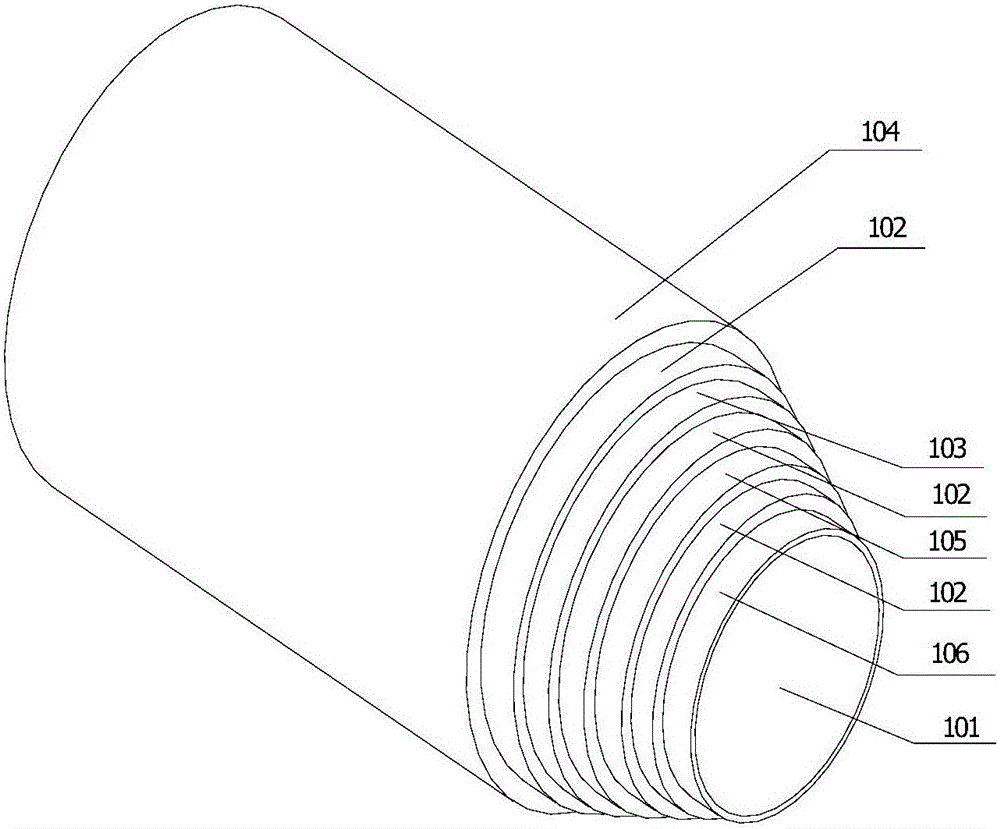

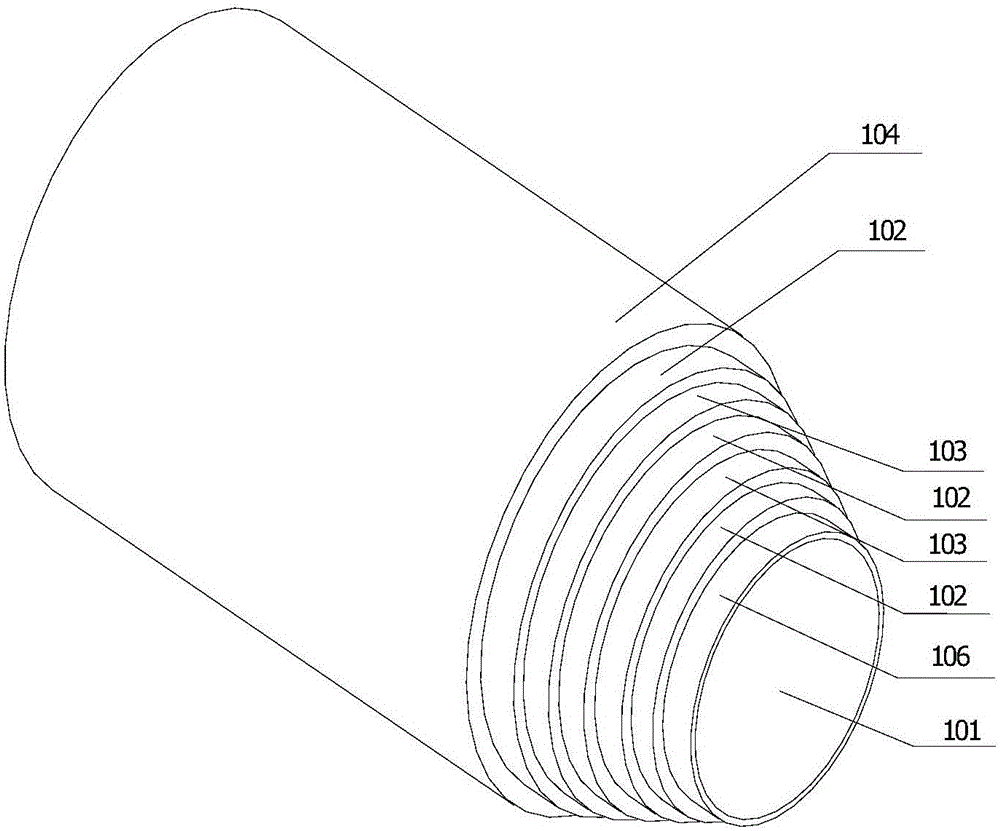

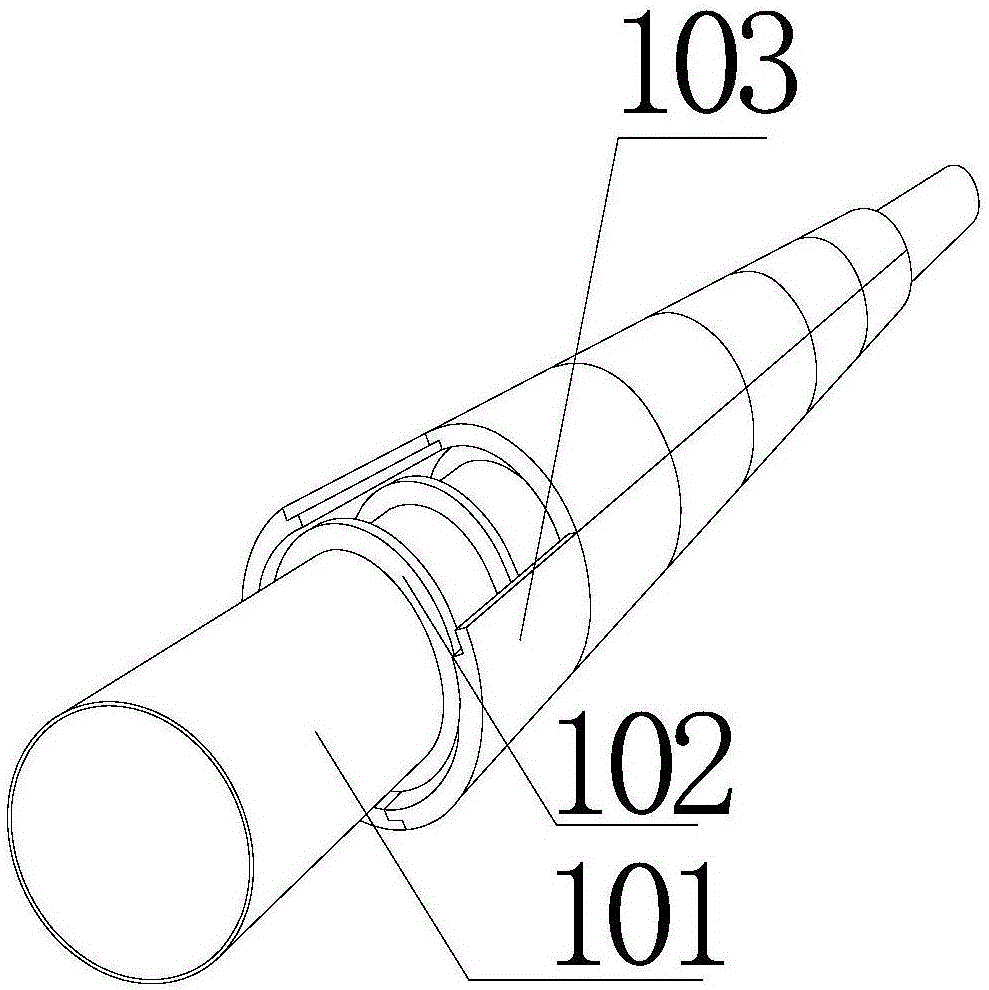

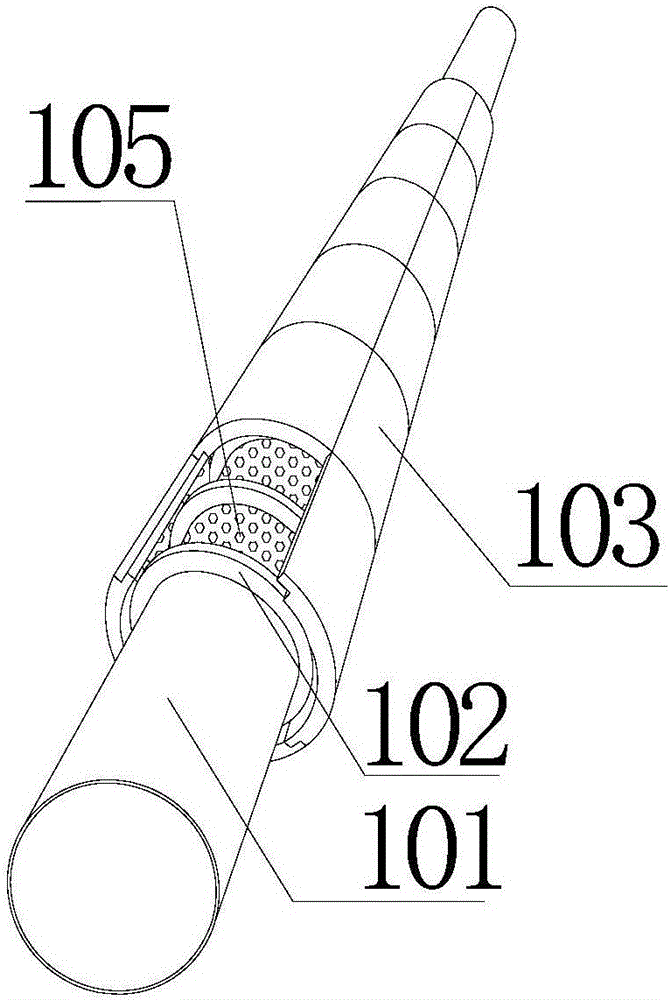

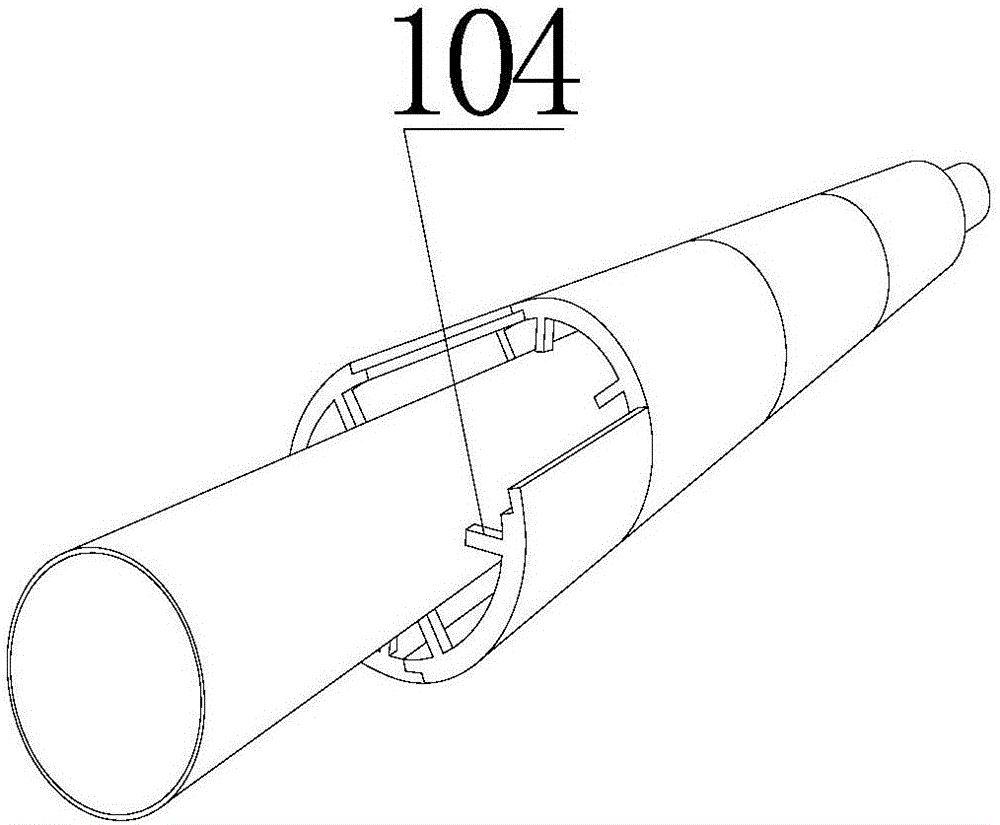

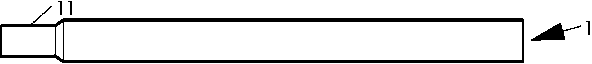

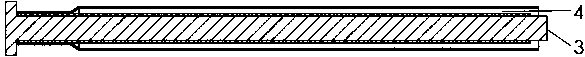

Heat pipe, manufacturing method of heat pipe and equipment comprising heat pipe

InactiveCN109764708AFlexible approachRich technical meansIndirect heat exchangersWaste productEnergy consumption

The invention discloses a heat pipe, a manufacturing method of the heat pipe and equipment comprising the heat pipe, mainly relates to a capillary core of the heat pipe and a manufacturing method of the capillary core, and belongs to the technical field of heat conduction. According to the manufacturing method, a positioning tool and a metal net are mainly used, metal powder is arranged and limited in a specific space position in a pipe shell, and the technical problems that in the sintering process in which a traditional method is adopted, the metal powder is bonded with a core rod, when thecore rod is pulled out after sintering, the capillary core is prone to damage, and even a waste product occurs, and the technical problems that core rod is used for separating the reducing atmospherefrom the metal powder, so that the reducing effect is poor, secondary sintering is generally needed, and the energy consumption and the thermal pollution are large can be comprehensively or correspondingly solved; and the technical situations that the capillary core of the sintered layer is damaged due to the deformation processes of bending, flattening and the like can be relieved or avoided, andthe process route in which bending is carried out first, and then sintering is carried out can be realized. The method is applied to manufacturing of the heat pipes (including hot columns and ultra-thin heat pipes). The heat pipe is applied to equipment or a device requiring heat transfer or heat dissipation through the heat pipe.

Owner:刘康

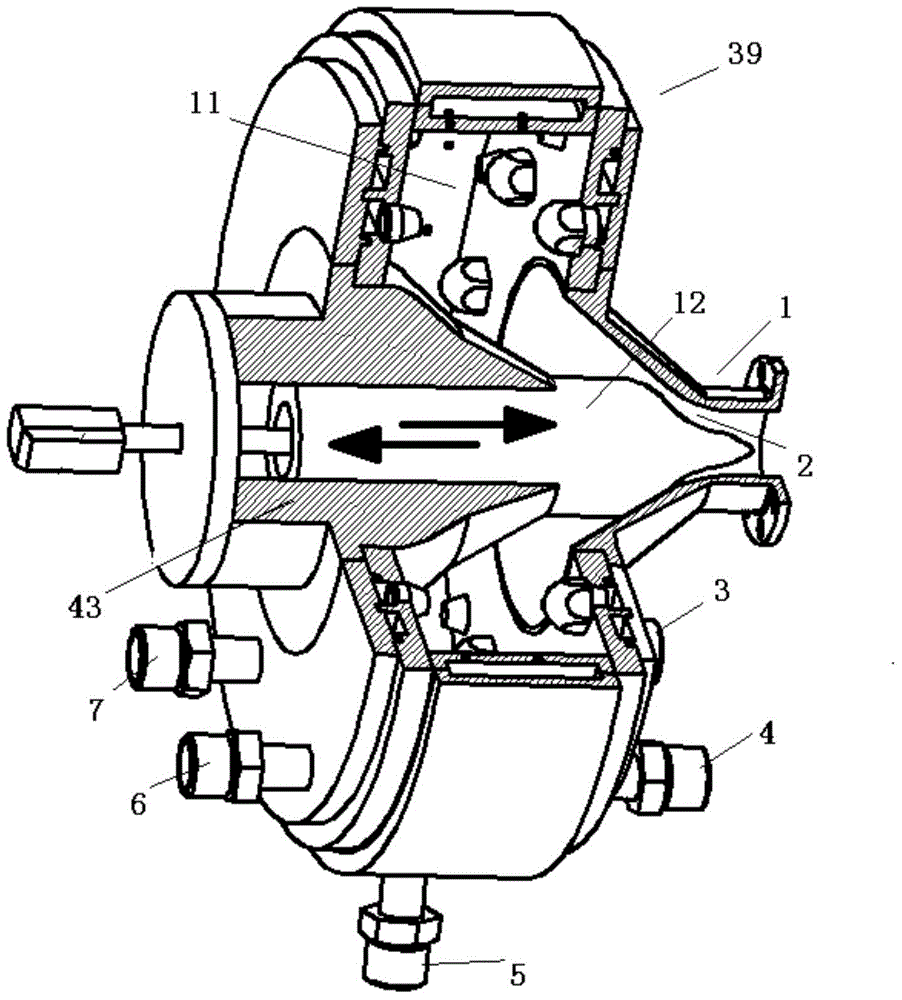

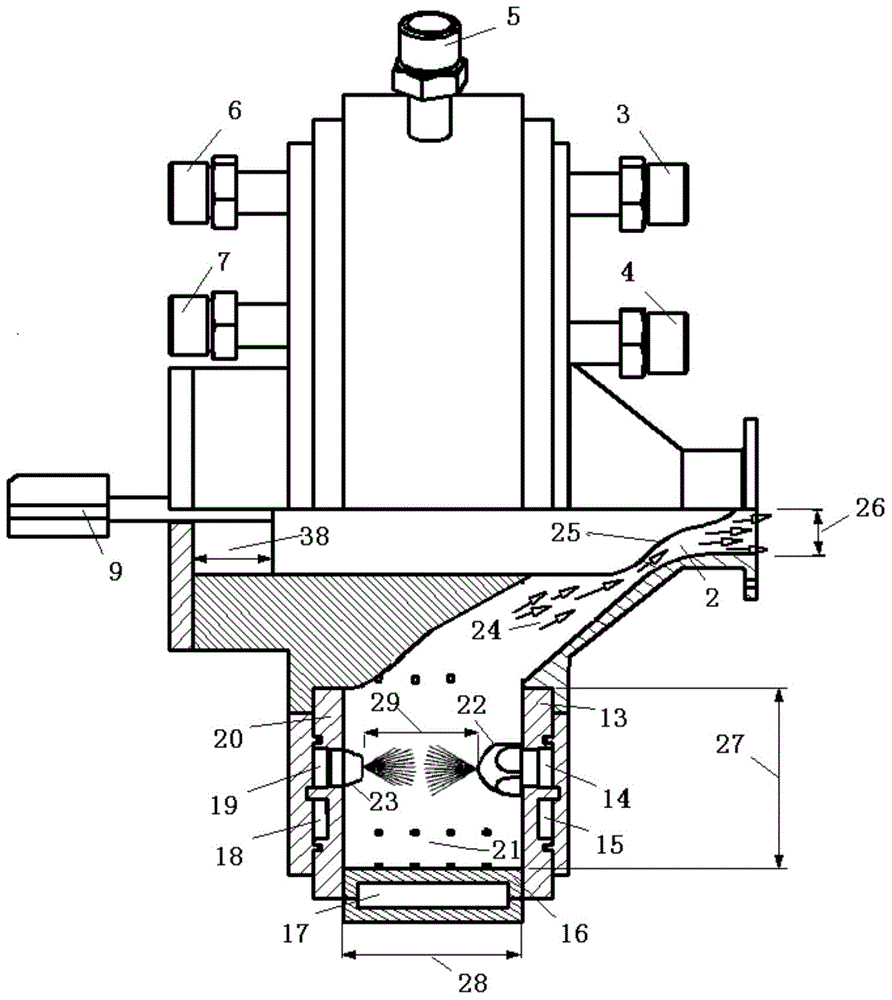

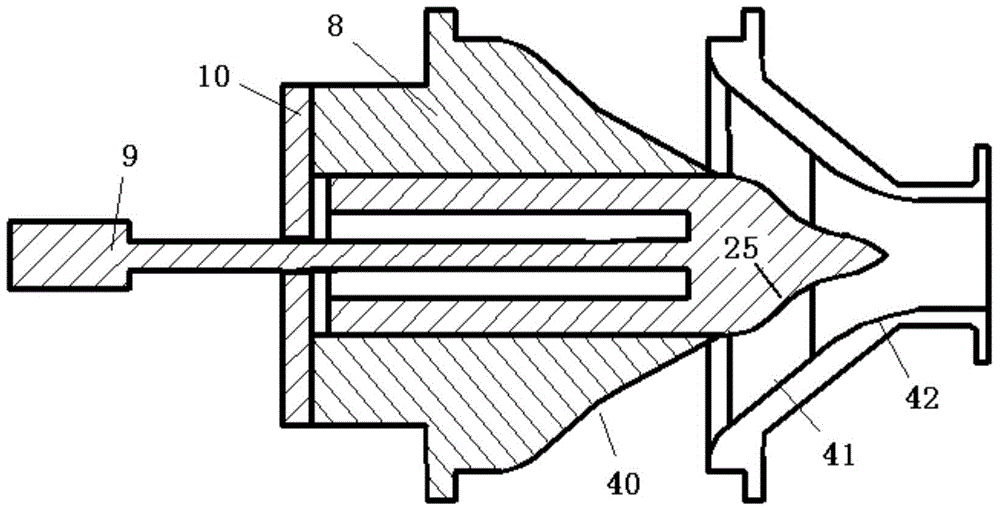

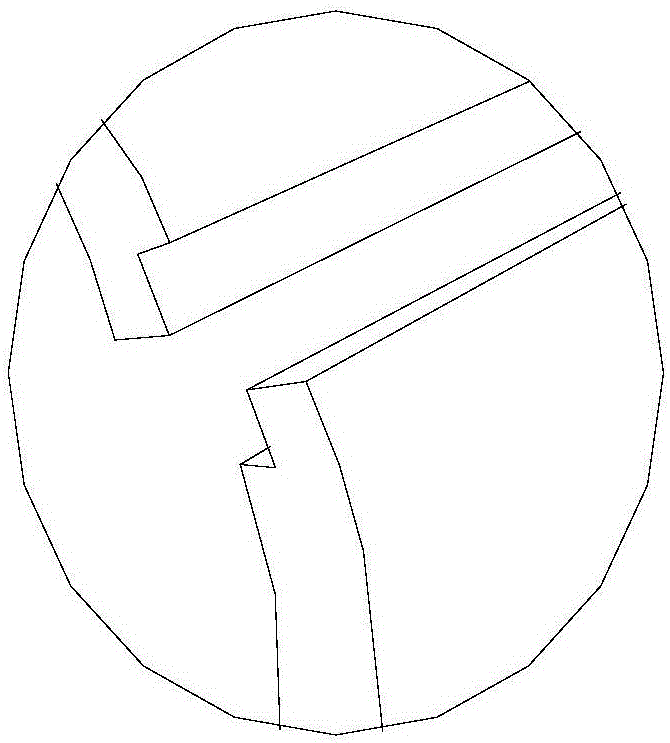

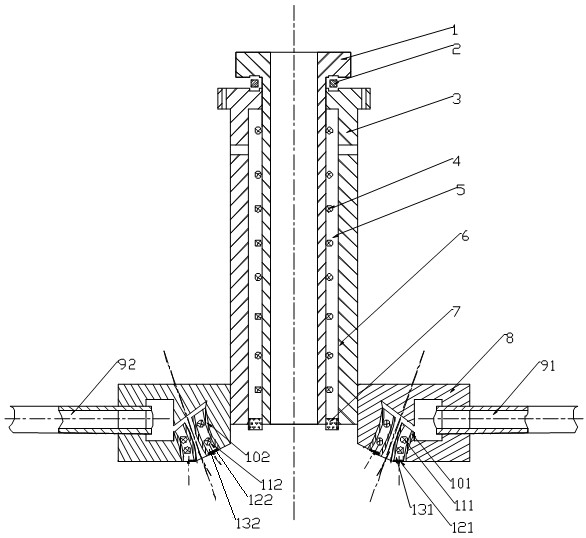

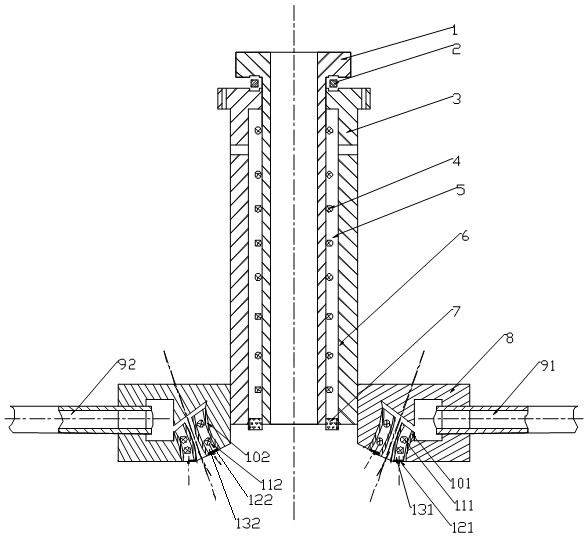

Online adjustable fuel gas generator adopting jet flow collision combustion manner

InactiveCN107013943APromote fragmentationPromote atomizationContinuous combustion chamberPilot systemCombustion chamber

The invention provides an online adjustable fuel gas generator adopting a jet flow collision combustion manner. The online adjustable fuel gas generator is composed of an annular slot combustion chamber, a convergence segment and an adjustment plug cone, and the adjustment plug cone is located at the head of the combustion chamber; the combustion chamber is of an annular-slot-shaped structure and is composed of a front jet panel, a rear jet panel and a side body portion cooling panel; a plurality of sets of rotational flow type air feeding holes of different rotation directions are formed in the side body portion cooling panel of the combustion chamber to provide liquid film type regeneration cooling for the combustion chamber body portion and enhance mixing of fuel gas; and the adjustment plug cone molded surface and the convergence segment molded surface are designed in a matched manner, the adjustment plug cone can move front and back, the relative position is manually set, or the size of the outlet throat portion is subjected to online self-adaption adjustment based on combustion chamber pressure. The online adjustable fuel gas generator is compact in structure, the length of the combustion chamber is small, the structural size and cooling area requirements of the combustion chamber are greatly lowered, the online adjustable fuel gas generator can be adapted to online adjustment of fuel gas generators of ground test systems in the aerospace field in various combustion working conditions and has excellent flame stability and fuel gas mixing capacity, and an outlet flow field is uniform.

Owner:PLA PEOPLES LIBERATION ARMY OF CHINA STRATEGIC SUPPORT FORCE AEROSPACE ENG UNIV

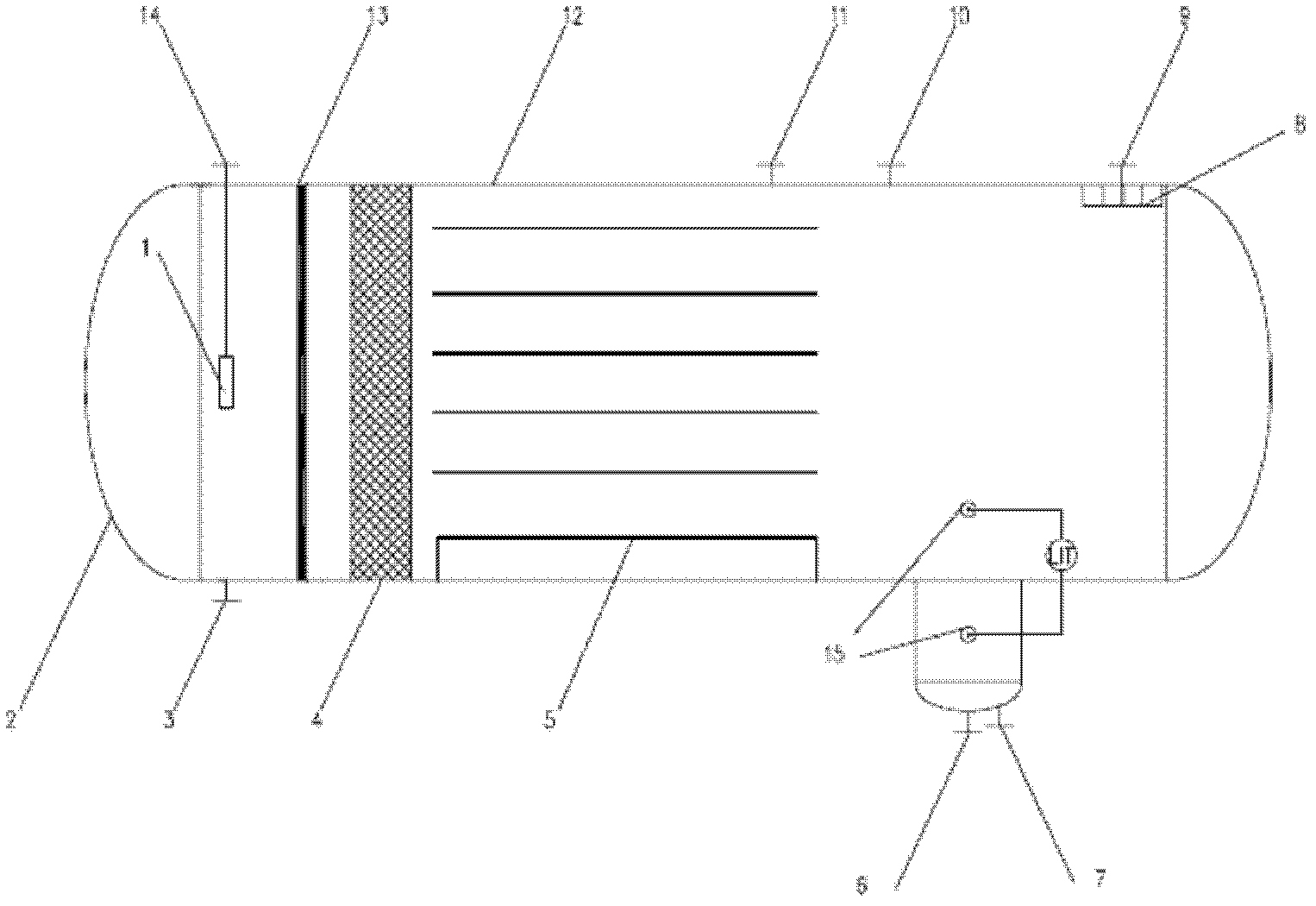

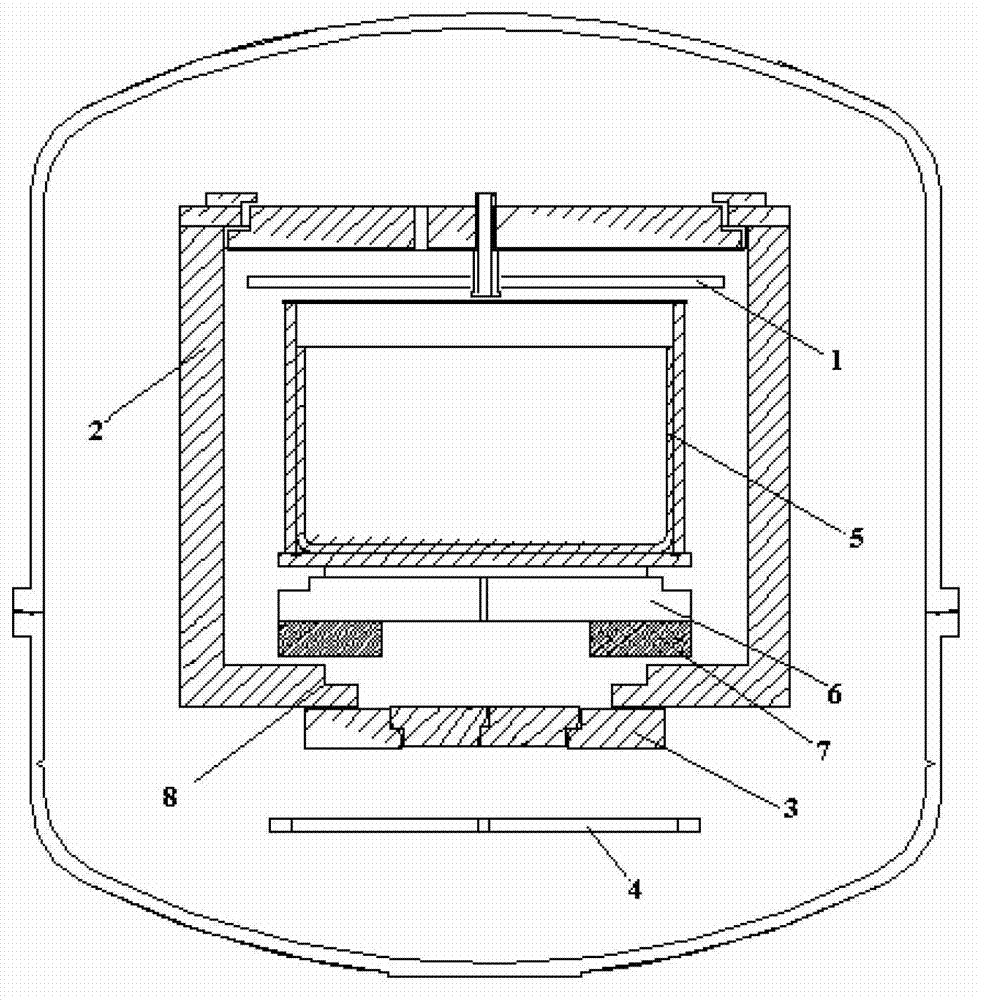

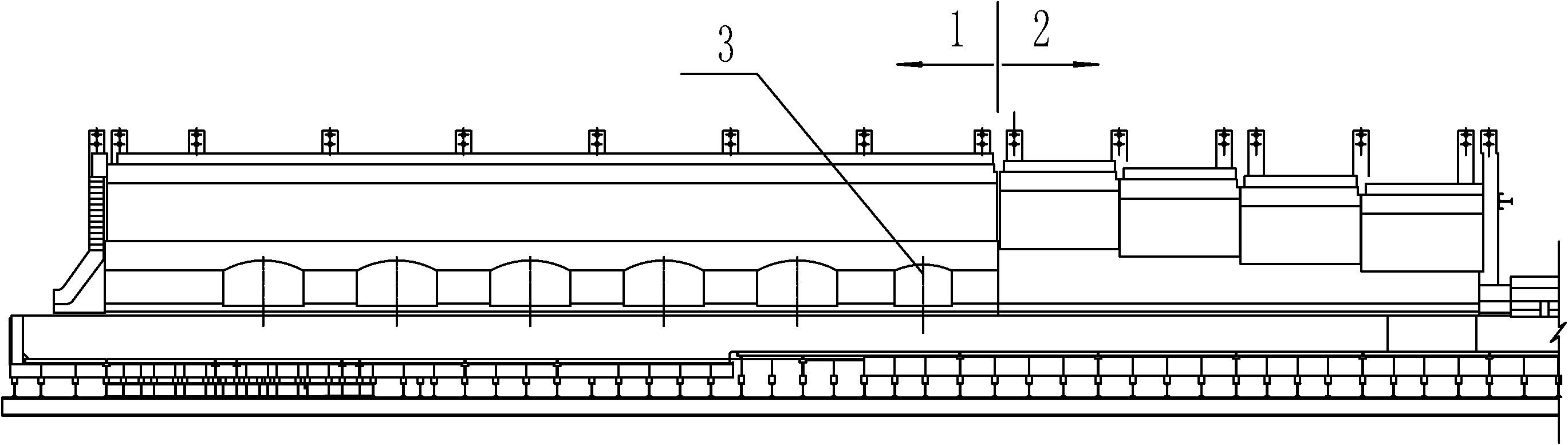

All-welded plate shell type stainless steel condenser and application thereof

ActiveCN102425958AOvercoming Heat Transfer Performance DeteriorationReduce cooling areaSteam/vapor condensersSteam engine plantsPower stationEngineering

The invention provides an all-welded plate shell type stainless steel condenser and application thereof. The all-welded plate shell type stainless steel condenser is a key device in a thermodynamic system of a power plant. Concave-convex multi-point type stainless steel sheets are adopted in a high-vacuum negative-pressure rectangular case at a dead steam part; two sheets are provided with longitudinal welding lines between which tops of convex grooves are opposite to each other, so as to form a dead steam path which is of single flow path type; the other two sheets are provided with transverse welding lines, between which bottoms of concave grooves are opposite to each other, so as to form a circulation cooling water path which is separated into two equal flow paths by a case separator; the height of the convex grooves is equal to the depth of the concave grooves and is not less than 6mm; small convex grooves are arranged among convex grooves and small concave grooves are arranged among concave grooves. The dead steam exchanges heat with the circulation cooling water in a fair flow / cross flow manner from top to bottom by virtue of flow paths at two sides of the sheets, and is condensed into water and flows downwards in a mode of beads, and water gathered in a steam gathering chamber and a water gathering chamber flows out through a heat well condensed water outlet. The condenser has the advantages of compact structure, material saving, light weight, low production cost, short investment return period and is worthy of popularization and application in large scale.

Owner:北京市京海换热设备制造有限责任公司

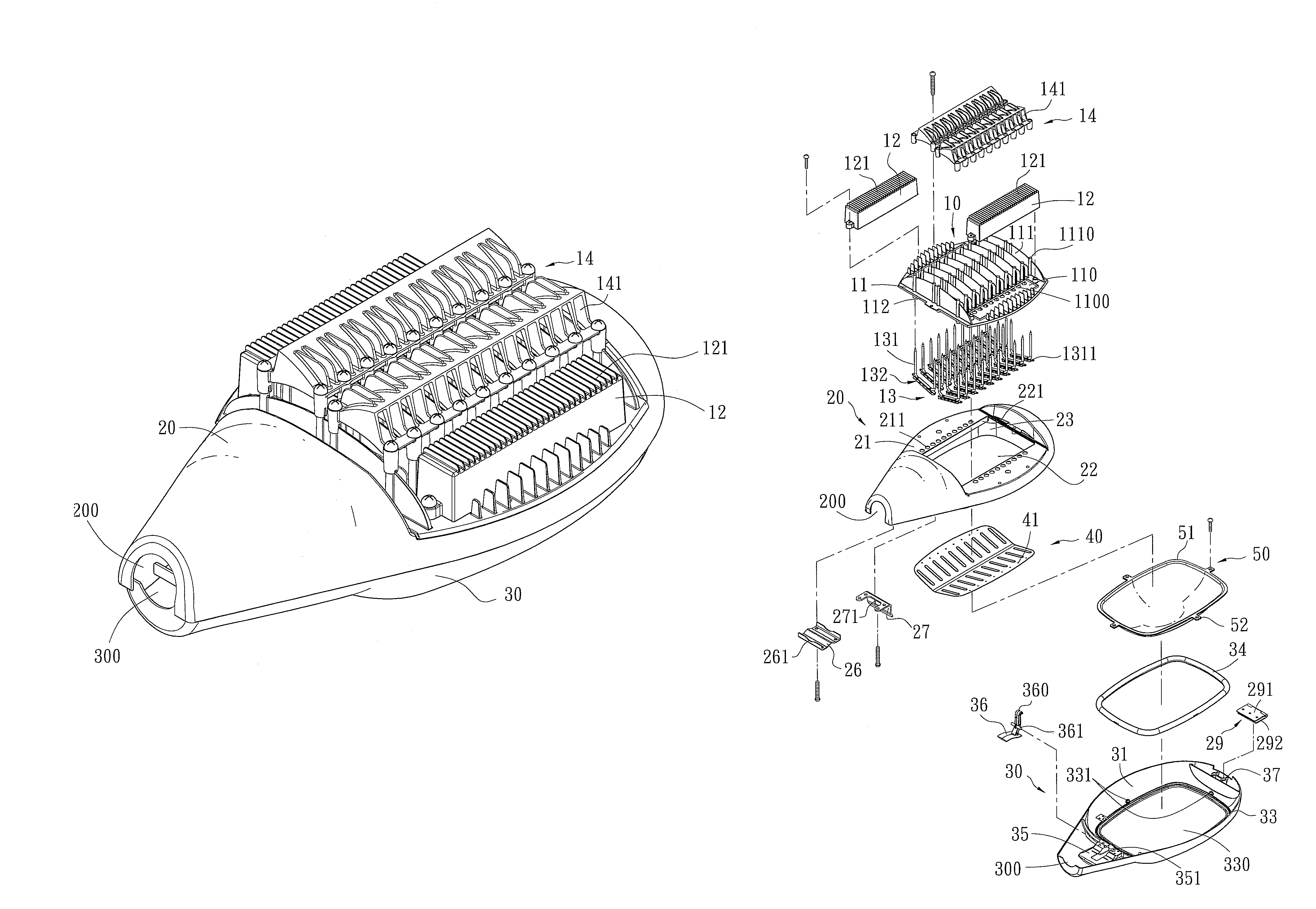

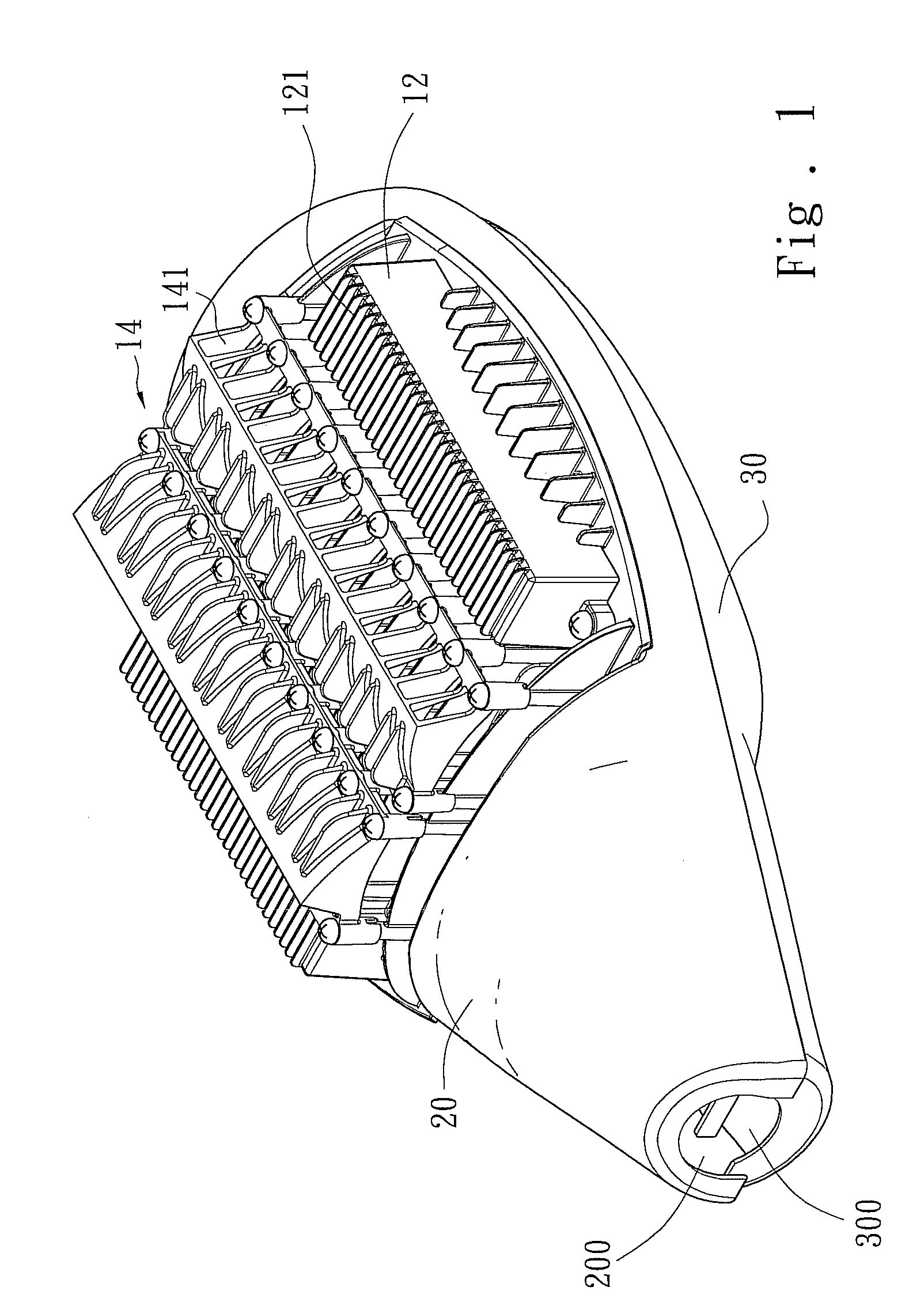

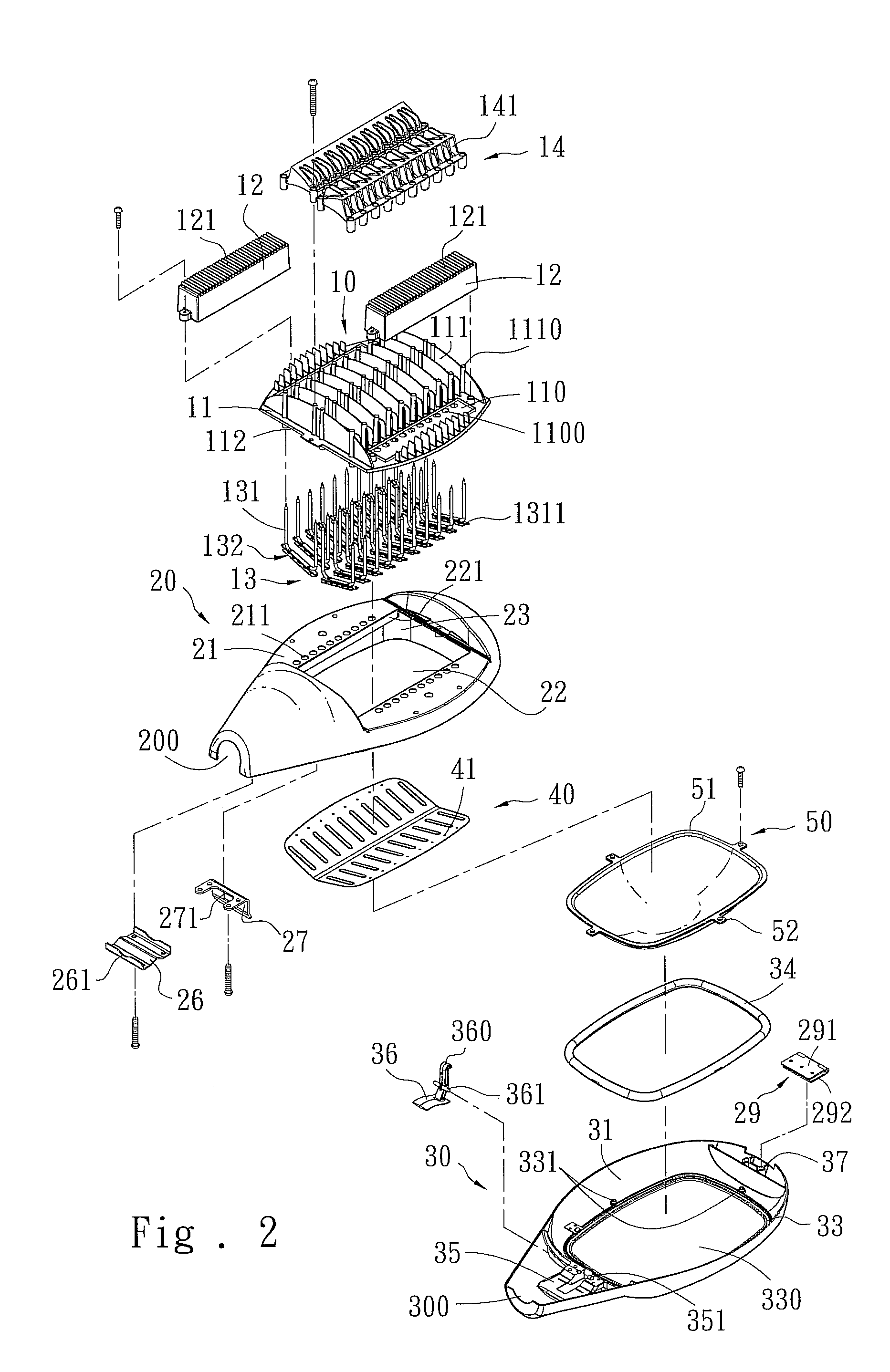

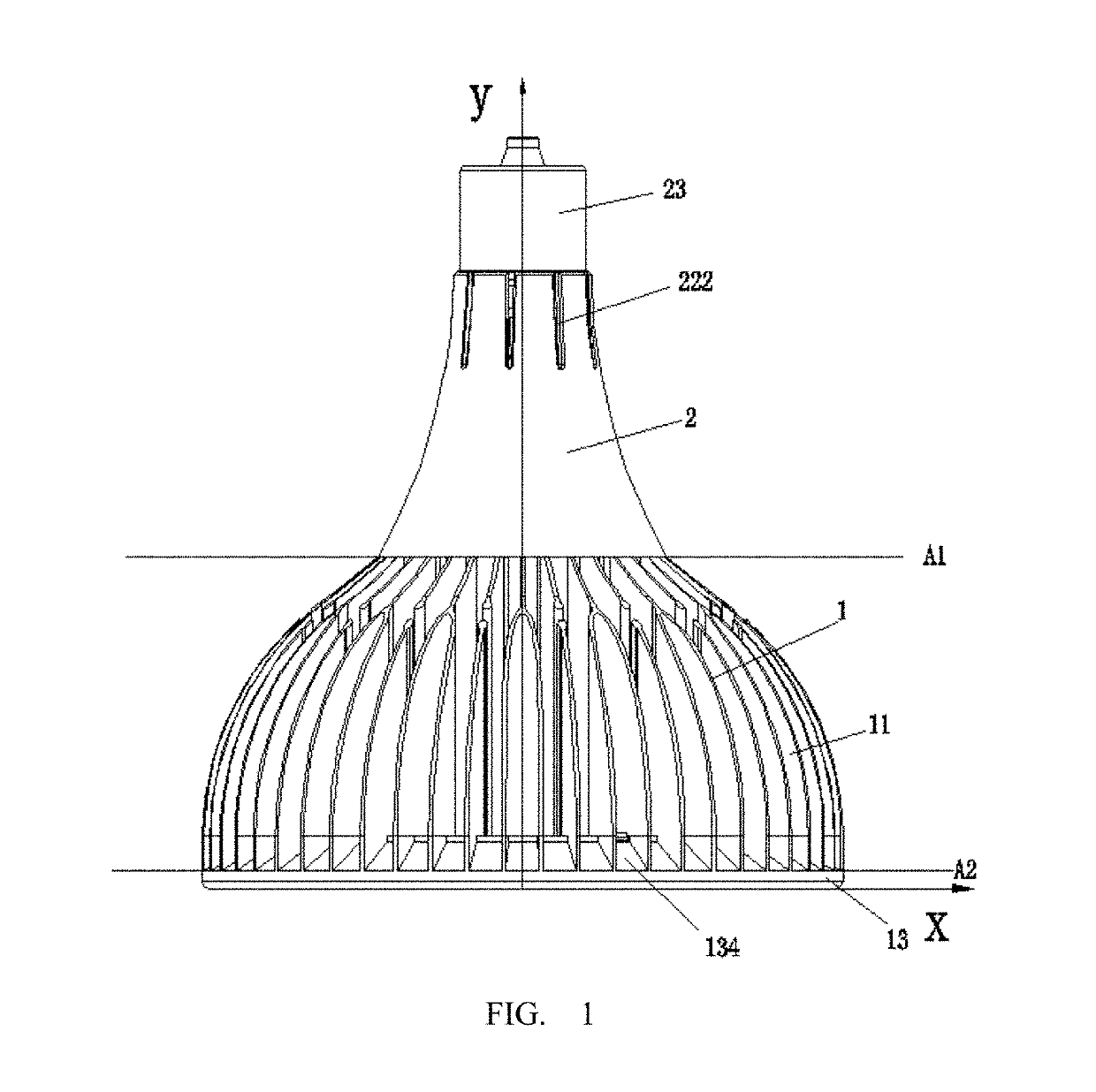

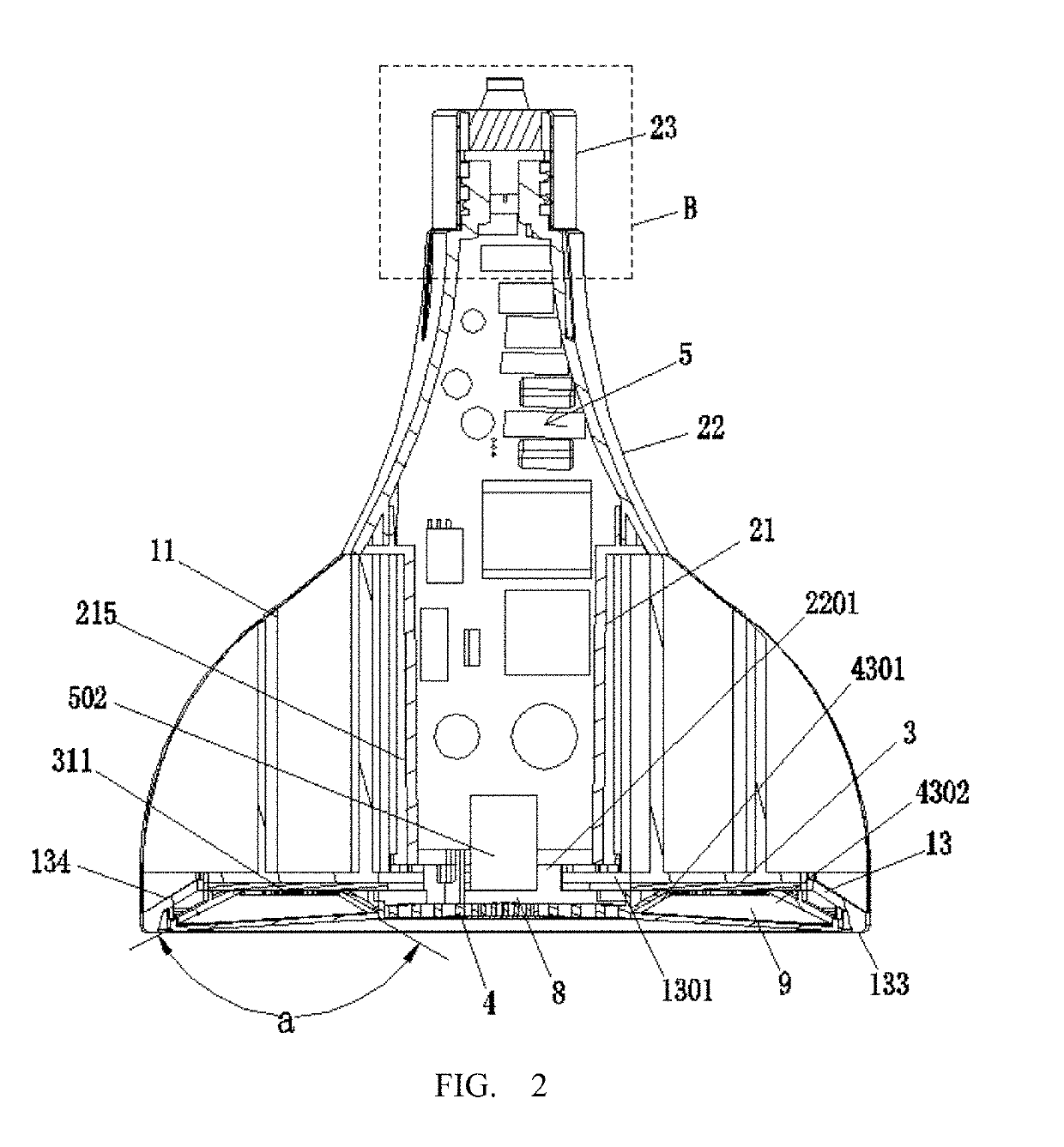

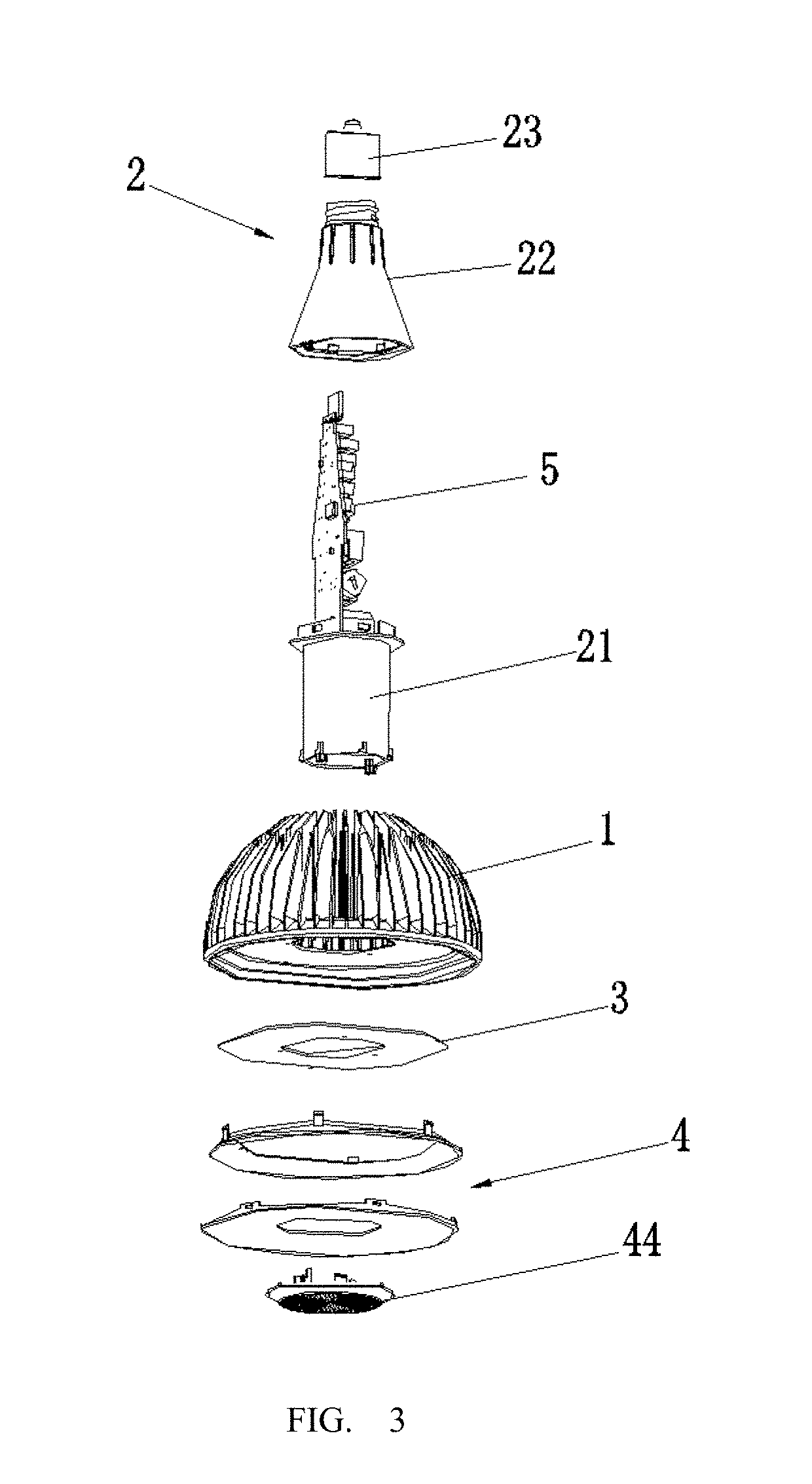

LED lamp

ActiveUS20190242569A1Enhanced convectionImprove efficiencyMultiple-port networksPlanar light sourcesEngineeringLamp shell

An LED lamp includes: a lamp shell; a passive heat dissipating element having a heat sink, and the heat sink including fins and a base and connecting to the lamp shell; a power source disposed in the lamp shell; and a light board connecting to the heat sink and including LED chips electrically connected to the power source. A chamber of the lamp shell is formed with a first heat dissipating channel. The first heat dissipating channel has a first air inlet at an end of the lamp shell. Another end of the lamp shell has a heat dissipating hole. A second heat dissipating channel is formed in the fins and base. The second heat dissipating channel has a second air inlet. Air flows into the second air inlet, passes through the second heat dissipating channel and flow out from spaces between every adjacent two of the fins.

Owner:JIAXING SUPER LIGHTING ELECTRIC APPLIANCE

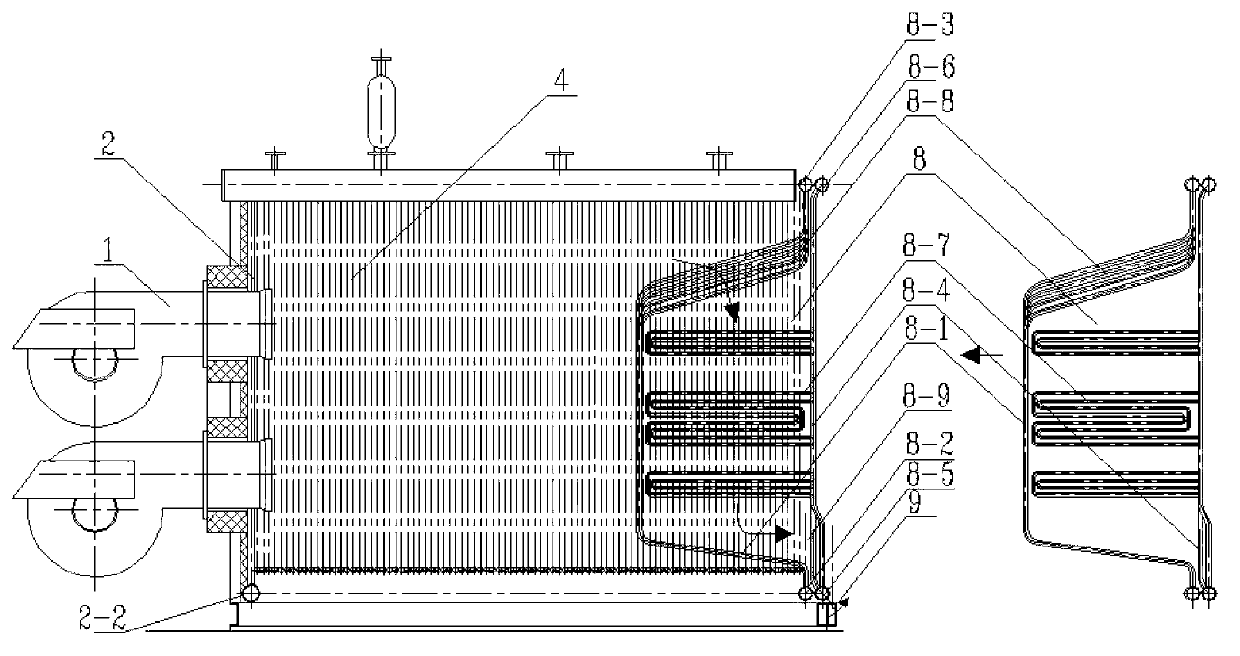

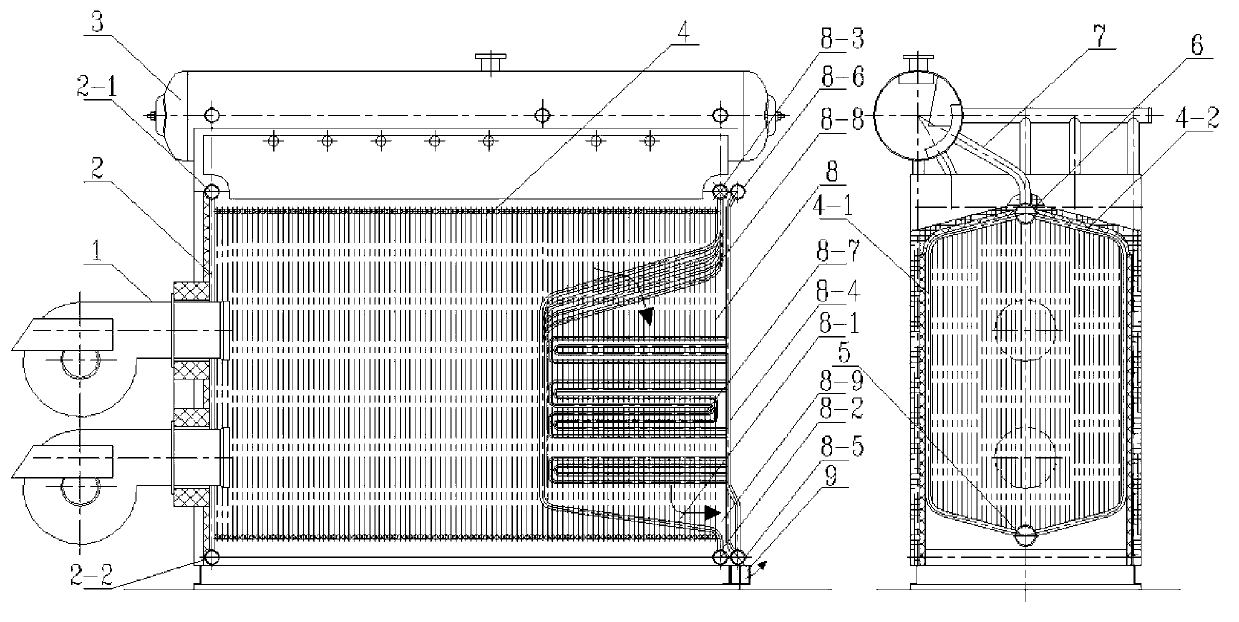

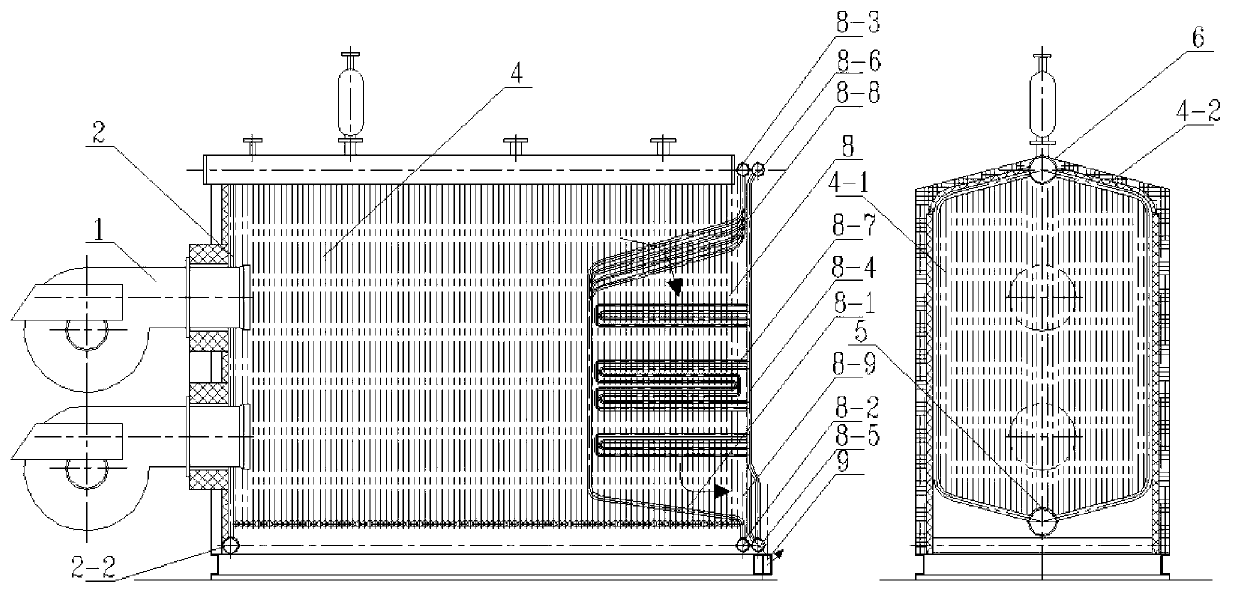

Embedded modularized assembly water pipe fuel oil and fuel gas boiler

ActiveCN103277781AReduce welding workloadShorten the installation cycleWater heatersSteam boilersButt jointEngineering

The invention relates to an embedded modularized assembly water pipe fuel oil and fuel gas boiler which comprises a radiating heated face module and a convection heated face module embedded in the radiating heated face module. The radiating heated face module comprises a radiating heated face front wall, a left wall and a right wall. A structure with an O-shaped section is composed of the left wall, the right wall, a side wall lower header and a side wall upper header. The convection heated face module comprises a convection heated face front wall and a convection heated face rear wall. The convection heated face front wall is used as a radiating heated face rear wall at the same time. A U-shaped pipe-bundle-type flag-type heated face is arranged on the convection heated face rear wall. When the boiler is a boiler with a small capacity or a medium capacity, rapid assembly can be fully achieved. When the boil is a boil with a medium capacity or a large capacity, the boiler is divided into a radiating heated face segment and a convection heated face segment for isolated transportation and embedded integral assembly is carried out on spot. Modularized butt joint can be achieved without any welding, an installation period is short and operation and maintenance are simple, convenient and easy to achieve. Moreover, whole sealing performance of the whole boiler is good, heat loss is obviously reduced and heat efficiency of the boiler is effectively improved.

Owner:XI AN JIAOTONG UNIV

Multi-gyring extruder for 3D printing and control system

ActiveCN105965895AShorten the lengthLittle increase in diameterAdditive manufacturing apparatusGlass shaping apparatusControl systemMiniaturization

The invention discloses a multi-gyring extruder for 3D printing. The multi-gyring extruder for 3D printing comprises a housing and a screw extruding system, wherein a driving system is arranged at one end of the housing; the screw extruding system is arranged in the housing and comprises at least two screws which are correspondingly embedded at the inside and outside; at least one screw is driven through the driving system. According to the multi-gyring extruder, the length is greatly reduced, so that the size of an industrial 3D printer can be further reduced. The multi-gyring extruder for the 3D printing is stable in flow output, high in accuracy, low in energy consumption, high in heat energy utilization rate, light in weight, small in size, high in heating efficiency, novel in design, high in practicability, easy to popularize and apply, and extremely high in economic value.

Owner:浙江光镀智造科技有限公司

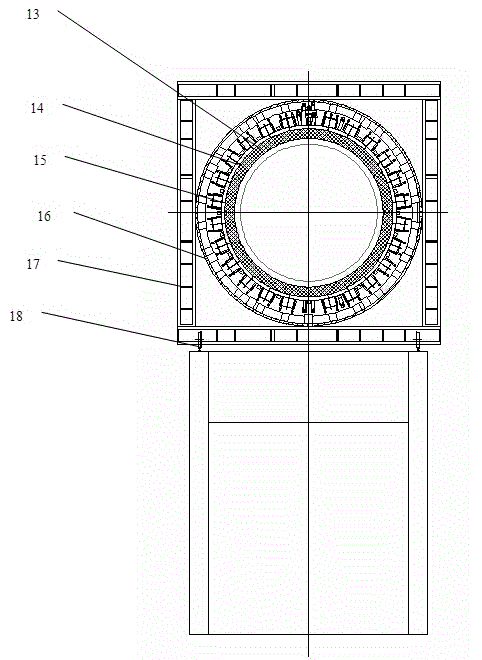

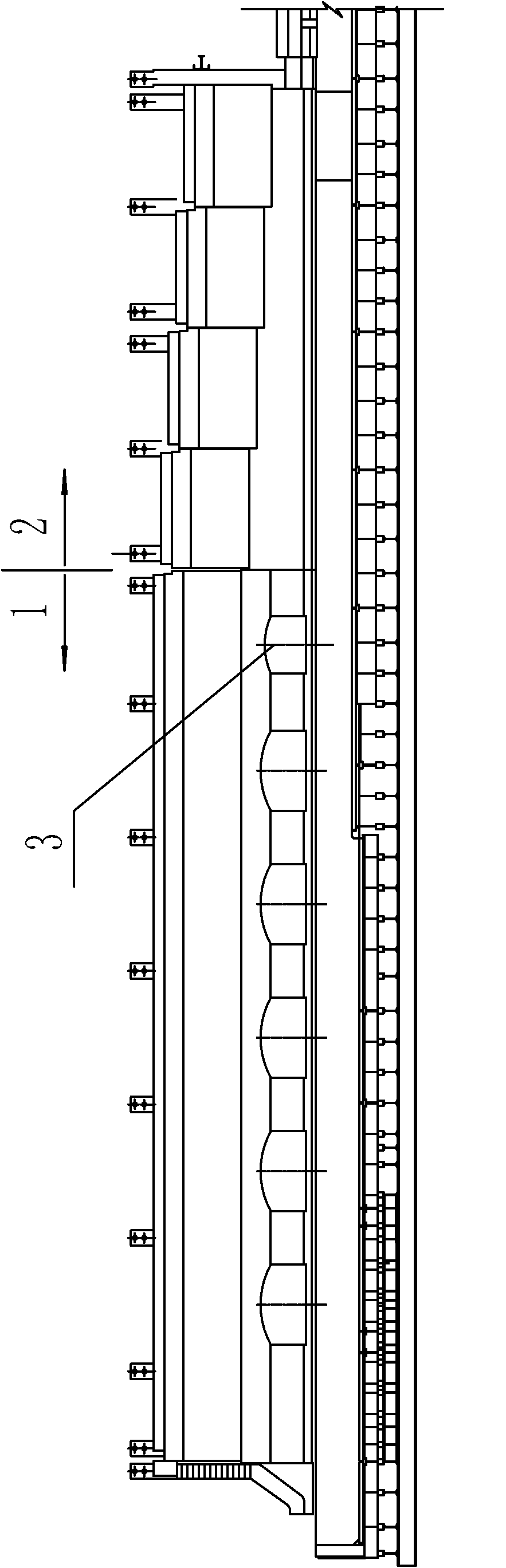

Energy-saving and environment-friendly mercury metallurgy electromagnetic induction roasting rotary kiln with size of phi 2000*18 meters

ActiveCN104880059ASimplify fuel procurement transportation and security managementAvoid polluting the environmentRotary drum furnacesAutomatic controlElectromagnetic induction

The invention relates to an energy-saving and environment-friendly mercury metallurgy electromagnetic induction roasting rotary kiln with the size of phi 2000*18 meters. The energy-saving and environment-friendly mercury metallurgy electromagnetic induction roasting rotary kiln comprises a kiln head cover, a mercury ore feeding hopper, a high-temperature alloy steel inner container kiln barrel, a wheel belt, a movable carrier wheel group, a transmission device, a gear pair, a fixed carrier wheel group, a track and cement piles. The energy-saving and environment-friendly mercury metallurgy electromagnetic induction roasting rotary kiln has the advantages that the energy is clean, and the problems that a mercury metallurgy rotary kiln roasted by a coal furnace is low in production efficiency, severe in environmental pollution, high in energy consumption and the like is solved. The energy is used and distributed conveniently. Compared with a mode of heating by fuel, gas and the like, the heating mode of the energy-saving and environment-friendly mercury metallurgy electromagnetic induction roasting rotary kiln has the characteristics that heat efficiency is high, sensible heat is not taken out by smoke or ash, and a kiln body is simple and compact in structure, small in heat dissipation area, low in heat dissipation loss, easy to control and regulate automatically and high in kiln temperature control precision, and meets requirements of a narrow calcining temperature process. The production efficiency is high, energy consumption is reduced, and emission of environmental pollutants is reduced. The energy-saving and environment-friendly mercury metallurgy electromagnetic induction roasting rotary kiln is an innovation of energy conservation, environmental protection and an equipment technology of a mercury metallurgy kiln.

Owner:朱兴发

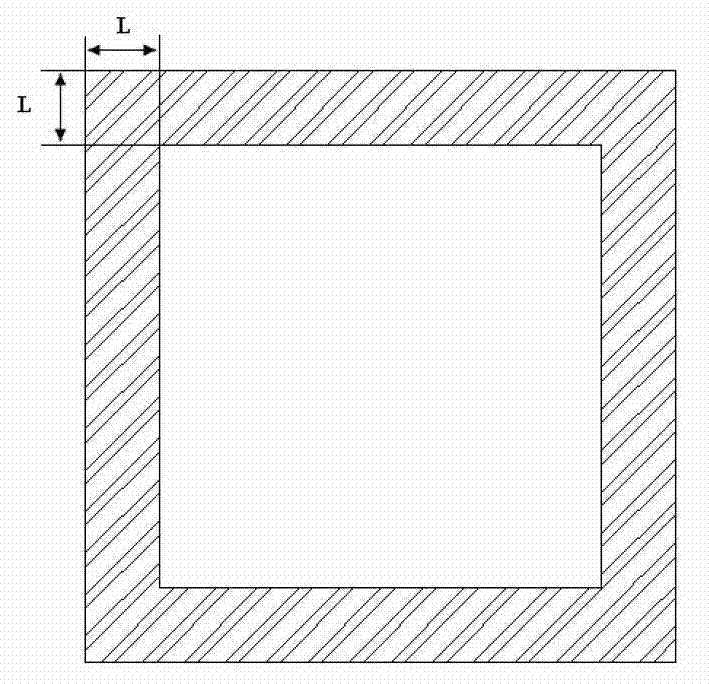

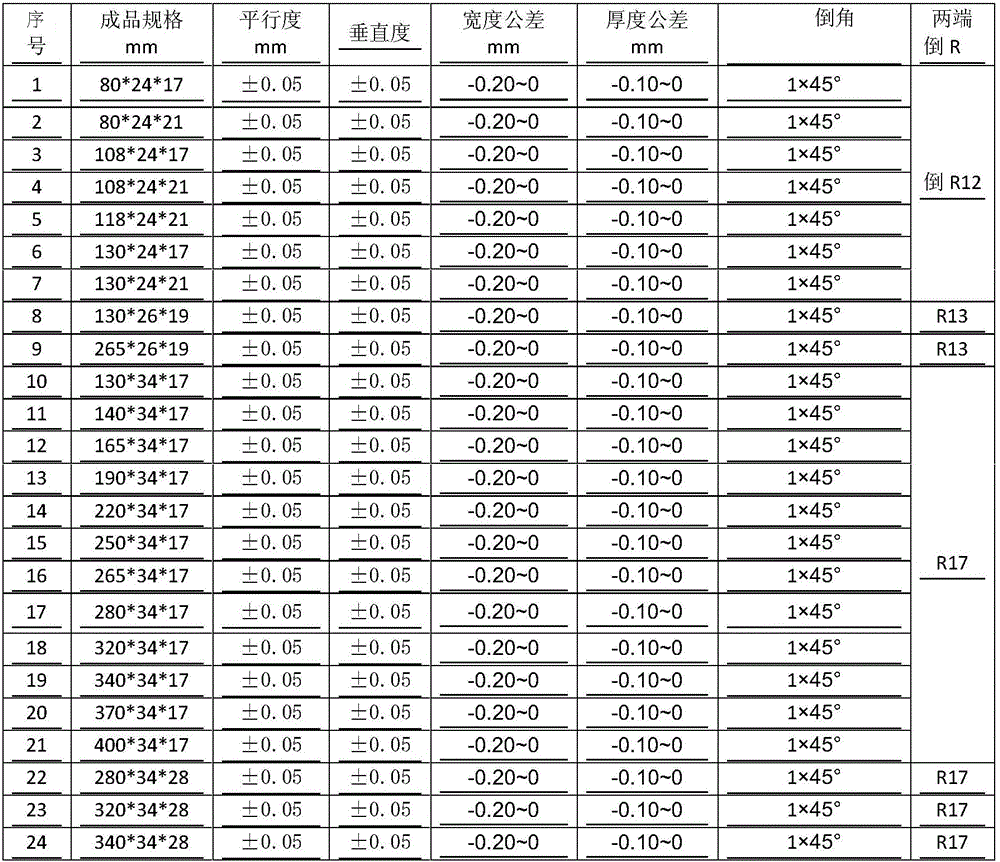

High temperature and high pressure resistant alkali-free aluminosilicate glass for high pressure liquidometer

InactiveCN106800370AImprove uniformityReduce cooling areaGlass furnace apparatusGlass drawing apparatusTemperature resistancePetrochemical

The invention discloses high temperature and high pressure resistant alkali-free aluminosilicate glass for a high pressure liquidometer, and is characterized in that the high temperature and high pressure resistant alkali-free aluminosilicate glass for the high pressure liquidometer comprises the oxide components by the mass percentage: (55-65)% of SiO2, (14-25)% of Al2O3, (3-8)% of B2O3, (5-12)% of CaO, (4-10)% of MgO, (3-8)% of BaO, (0.2-0.5)% of As2O3, (0.2-0.5)% of Sb2O3, (0.1-0.3)% of NaNO3, and (0.2-0.5)% of ZrO2. The glass contains no alkali metal oxides in the composition, has the advantages of high temperature resistance, high pressure resistance, high tenacity, high Young modulus, good chemical stability, suitable expansion coefficient of physical tempering, high transparency and the like, and is applied in requirements of high temperature and high pressure resistant glass view windows for harsh work condition environments of high temperature and high pressure steam liquidometer observation windows, high pressure pipeline view mirrors, deep-sea exploration equipment observation windows and the like in steel metallurgy, petrochemical engineering, thermal power plants and other industries.

Owner:南京神童特种玻璃技术有限公司

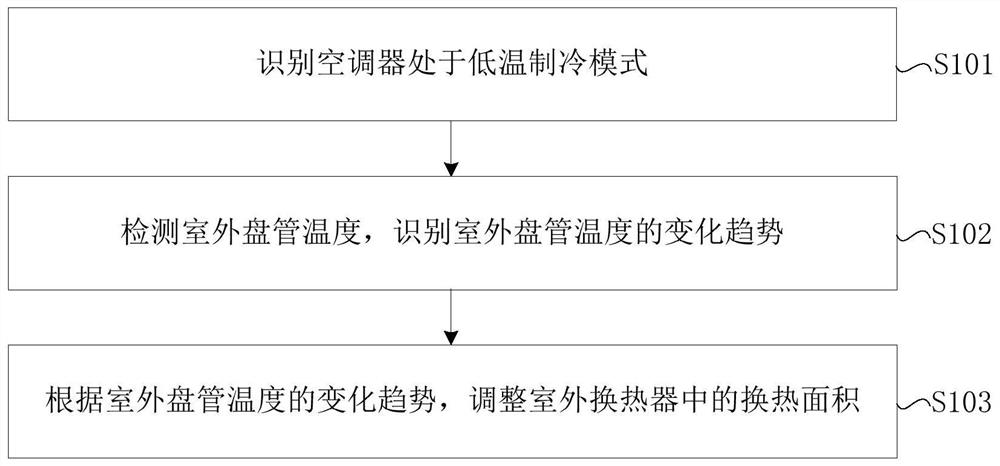

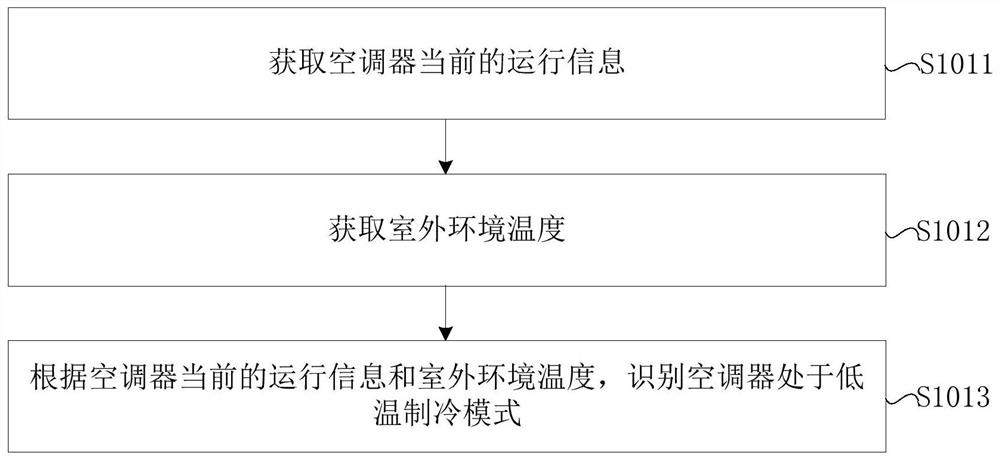

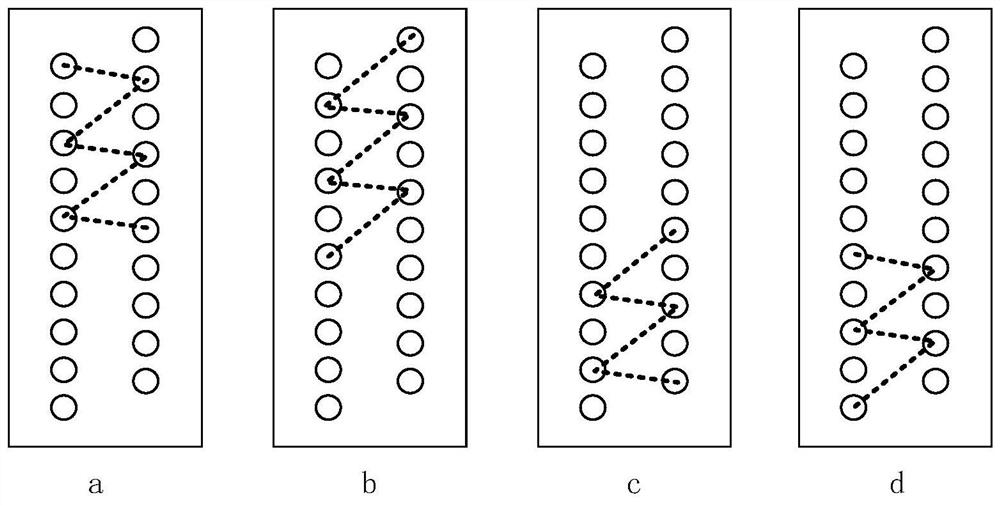

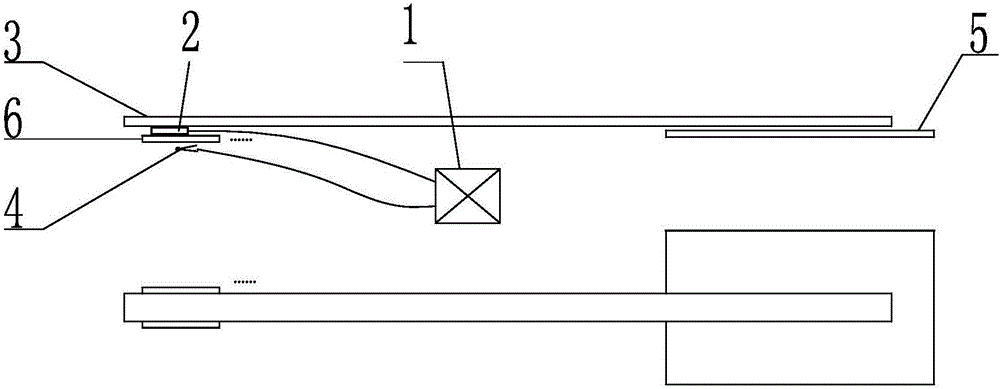

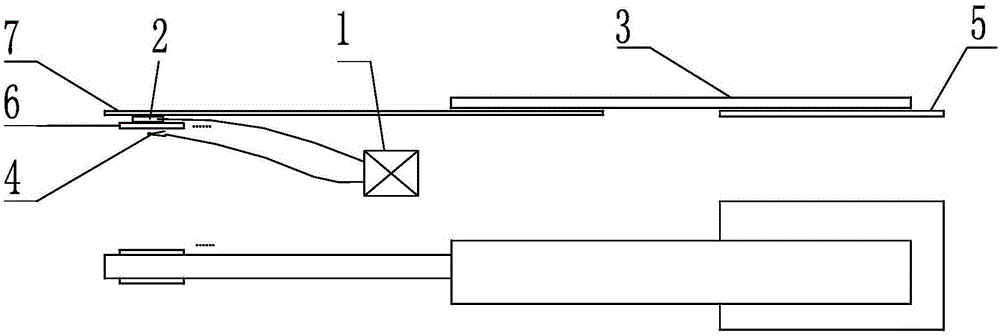

Control method and device of air conditioner, air conditioner and electronic equipment

ActiveCN112577164AOvercoming the technical problems of frequent start and stop of outdoor fansGuaranteed cooling effectMechanical apparatusSpace heating and ventilation safety systemsProcess engineeringControl room

The invention discloses a control method and device of an air conditioner and the air conditioner. The method comprises the following steps: recognizing that the air conditioner is in a low-temperature refrigeration mode; detecting the temperature of an outdoor coil pipe, and identifying the change trend of the temperature of the outdoor coil pipe; and adjusting the heat exchange area in an outdoor heat exchanger according to the change trend of the temperature of the outdoor coil pipe. According to the control method and device, after the air conditioner is identified to be in the low-temperature refrigeration mode, the change trend of the temperature of the air conditioner can be determined based on the temperature of the outdoor coil pipe, then the adjustment mode of the heat exchange area in the outdoor heat exchanger is determined according to the change trend of the temperature of the outdoor coil pipe, and the heat exchange area of the outdoor heat exchanger is controlled to bedynamically adjusted along with the change trend of the temperature of the outdoor coil pipe without depending on the start and stop of an outdoor fan to control the flow direction of heat, so that the phenomenon of frosting on the surface of the outdoor coil pipe in the low-temperature refrigeration mode is avoided, the technical problem that the outdoor fan of the air conditioner needs to be frequently started and stopped in the low-temperature refrigeration mode is solved, and the refrigeration capacity of the air conditioner is guaranteed.

Owner:GD MIDEA AIR-CONDITIONING EQUIP CO LTD +1

Temperature control device for periodical working heat source in spaceflight

ActiveCN106444917ACompensation heat power is smallReduce heat leakageAuxillary controllers with auxillary heating devicesEfficient regulation technologiesWork periodTemperature control

The invention relates to a low-power-consumption high-precision temperature control device for a periodical working heat source in spaceflight, wherein the temperature control device belongs to the field of temperature control technology of the periodical working heat source in a spaceflight field. Particularly the temperature control device is suitable for conditions of short working time and long idle time of the periodical working heat source. The temperature control device is composed of thermoelectric refrigerator, a phase change heat tube, a heat radiating panel, a temperature sensor and a control circuit. The cold surface of the thermoelectric refrigerator is connected with the heat source, and the heat surface is connected with one end of a phase change heat tube. The other end of the phase change heat tube is connected with the heat radiating panel. An active temperature control loop which is composed of the thermoelectric refrigerator, the control circuit and the temperature sensor that is bound on the heat source decides for making the thermoelectric refrigerator perform forward working for refrigerating or perform backward working for heating. The temperature control device has advantages of low power consumption and small heat radiation area.

Owner:BEIJING RES INST OF SPATIAL MECHANICAL & ELECTRICAL TECH

Horizontal flame melting furnace

InactiveCN102140005AReduce cooling areaReduce fuel usageGlass furnace apparatusManufacturing lineMelting furnace

The invention discloses a horizontal flame melting furnace which consists of a melting part and a clearing part and is characterized in that the height of a breast wall of the clearing part which is close to the last pair of small furnaces in the melting part gradually descends to lead a main crown of the clearing part to take the shape of a step. In the horizontal flame melting furnace, the height of the main crown of the clearing part is reasonably designed according to the effects of the clearing part and the last pair of small furnaces and the melting mechanism of the last pair of small furnaces so as to achieve the effect of energy saving, consumption reduction, emission reduction and efficiency increasing; and the horizontal flame melting furnace can reduce energy by about 3% according to the condition of a production line put into production.

Owner:HUAERRUN GLASS IND

Totally-enclosed gas atomizing powder making device for preventing high-melting-point substance from being blocked

The invention discloses a totally-enclosed gas atomizing powder making device for preventing a high-melting-point substance from being blocked. The device comprises a heat-preserving crucible, an atomizer, an atomizing tower, a telescopic plastic pipe A, a telescopic plastic pipe B and the like, wherein the atomizer is arranged in the telescopic plastic pipe A; the telescopic plastic pipe A is hermetically connected with the heat-preserving crucible and the upper surface of a nozzle of the atomizer respectively; and the atomizing tower is hermetically connected with the lower surface of the nozzle through the telescopic plastic pipe B, so that a totally-enclosed system structure is formed, and the formation of a high-melting-point substance on the atomizer and caused blockage of the atomizer can be prevented. A heating body is arranged in a gap between a honeycomb duct of the atomizer and a metal jacket, so that nozzle blockage caused by a metal or an alloy can be solved by electrifying. When the atomizer is blocked, the problem of blockage can be solved by replacing a ceramic circular ring. The totally-enclosed gas atomizing powder making device for preventing the high-melting-point substance from being blocked disclosed has the advantages of simple structure, convenience for installing, effective prevention and solving of blockage, improvement on the powder quality, and the like.

Owner:SHANGHAI INST OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com