Device and process applied to hydrogen peroxide extraction

A hydrogen peroxide, extraction technology, applied in the directions of peroxide/peroxyhydrate/peroxyacid/superoxide/ozone, inorganic chemistry, non-metallic elements, etc., can solve the problem of high production cost, large size, separation Problems such as poor effect, to achieve the effect of short residence time, reduced load, and improved safety control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

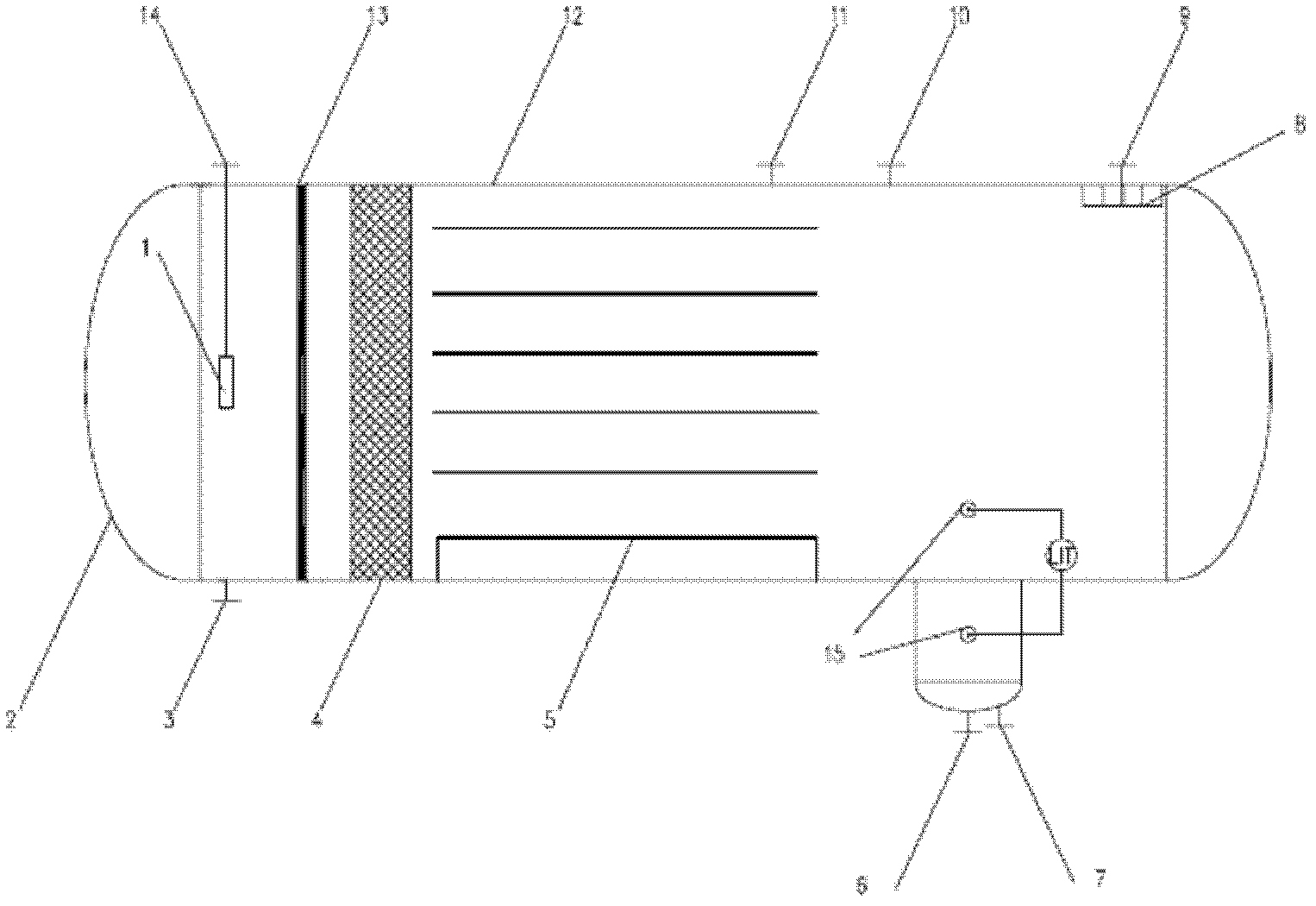

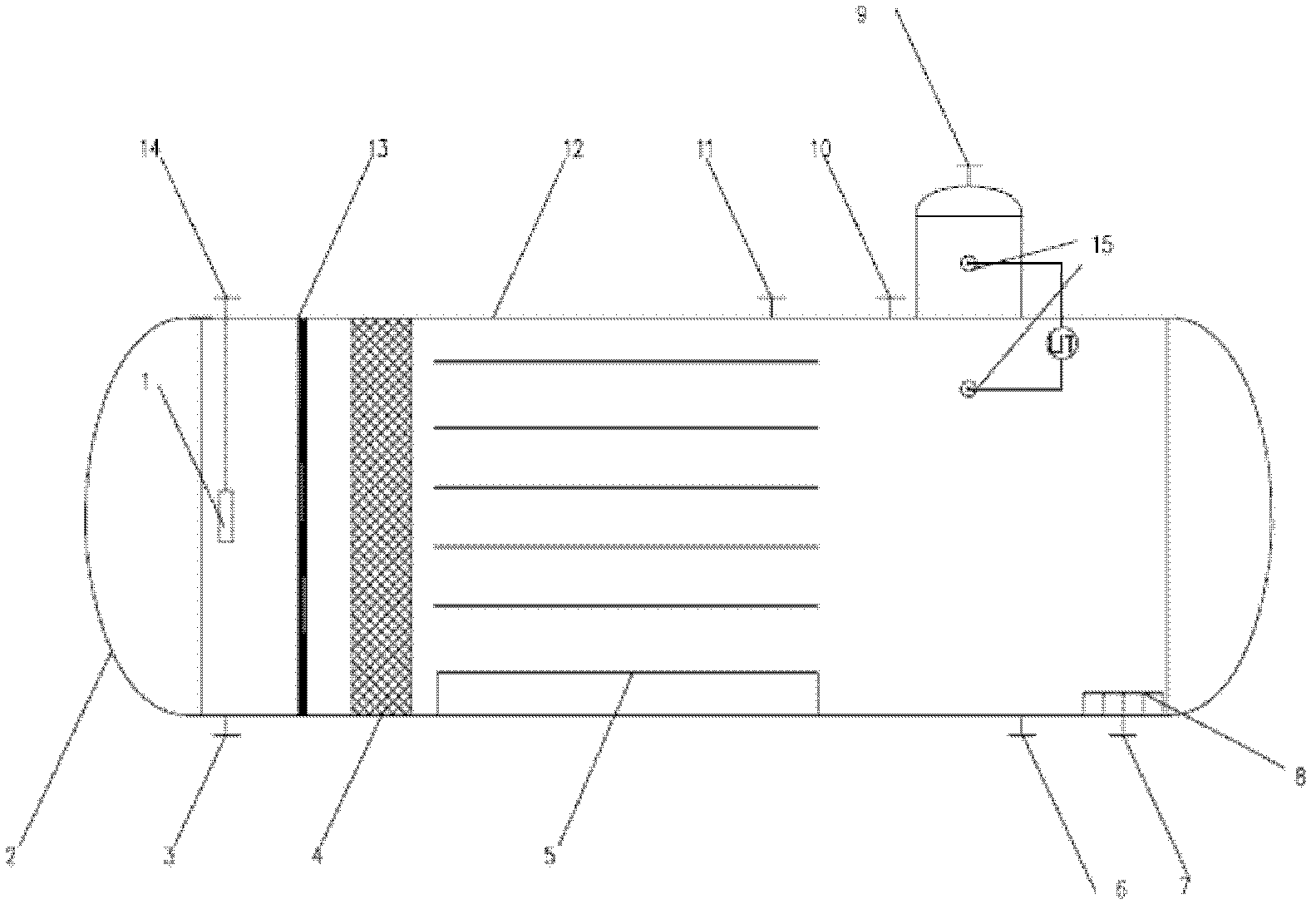

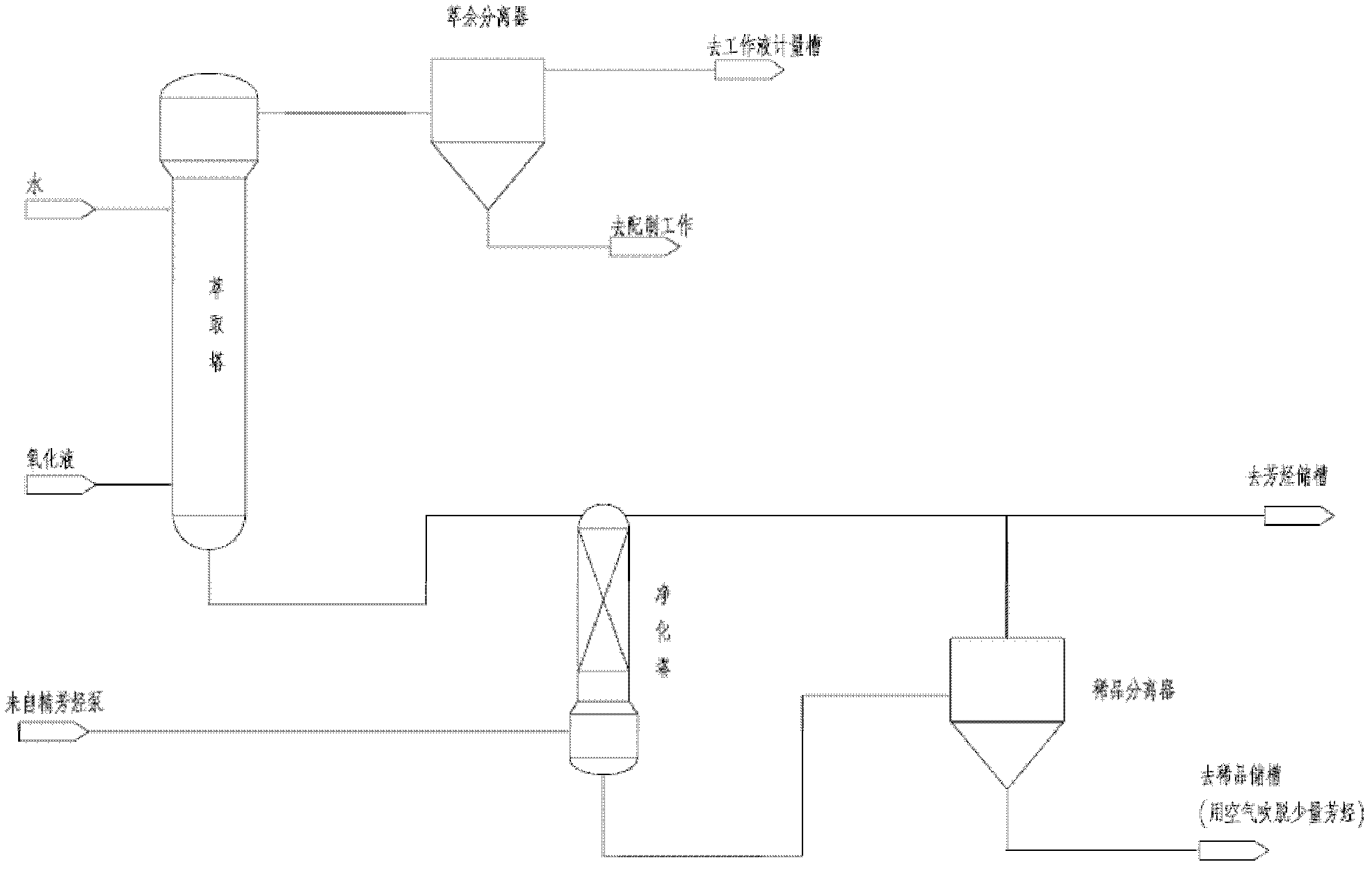

[0027] A device and process applied to hydrogen peroxide extraction, characterized in that its structure includes a raw liquid tank 2, a separation tank 12, a liquid distributor 1, a rectifier 13, a droplet multiplying fiber packing component 4, a special plate group separation component 5, Vortex baffle assembly 8. The droplet multiplying fiber packing assembly 4 and the separation special plate group separation assembly 5 are arranged in the separation tank. The separation tank 12 is provided with a small cylinder for discharging the dispersed phase, which stabilizes the interface between the two phases and prevents the material from being entrained by the lye; the separation tank is equipped with an anti-vortex baffle 8 to stabilize the flow field in the separation tank and enhance the separation effect. After the raw material enters the raw liquid tank 2, it enters the separation tank 12 through the rectifier 13, and the droplet multiplication and separation process is car...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com