Patents

Literature

102results about How to "Prevent cooling and solidification" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

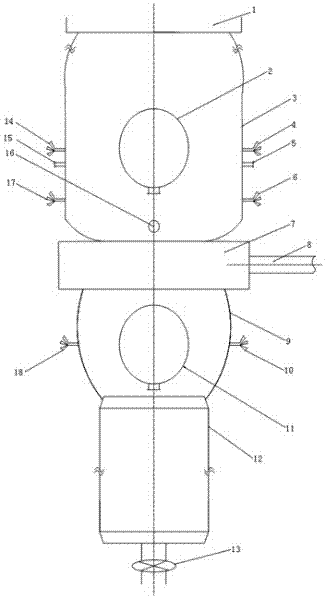

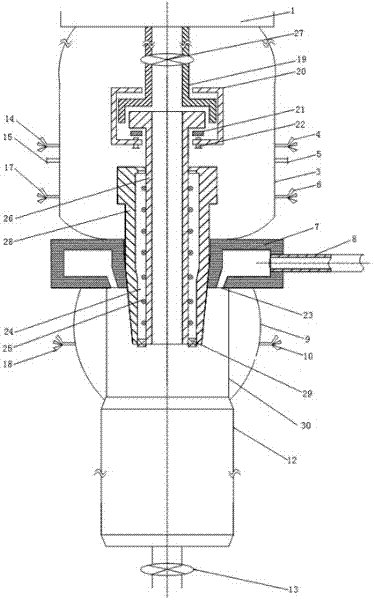

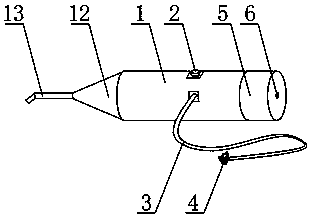

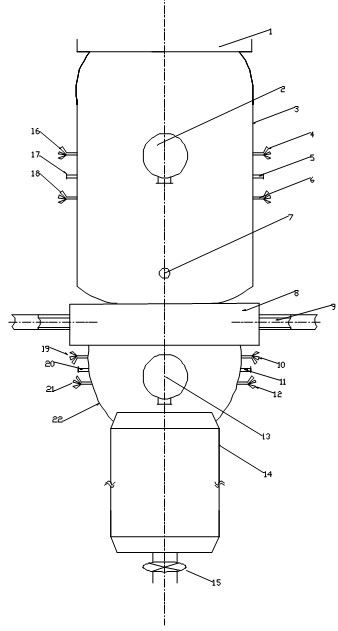

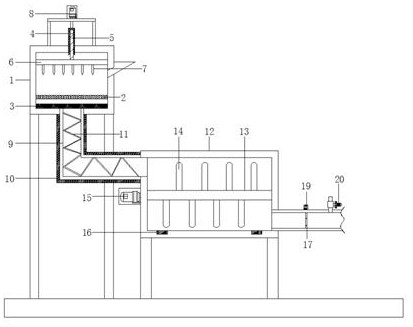

Totally closed gas atomization pulverization device

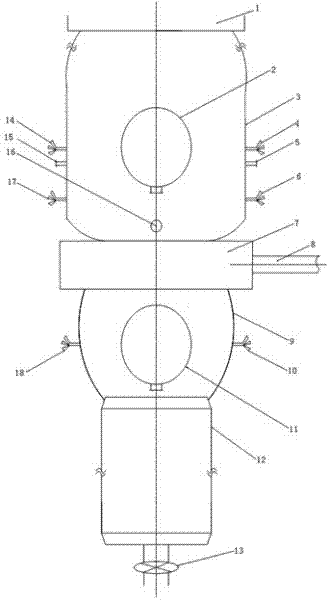

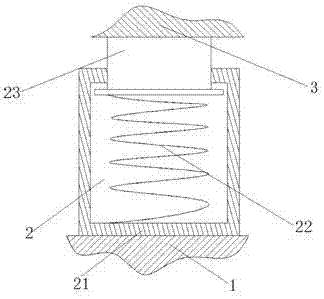

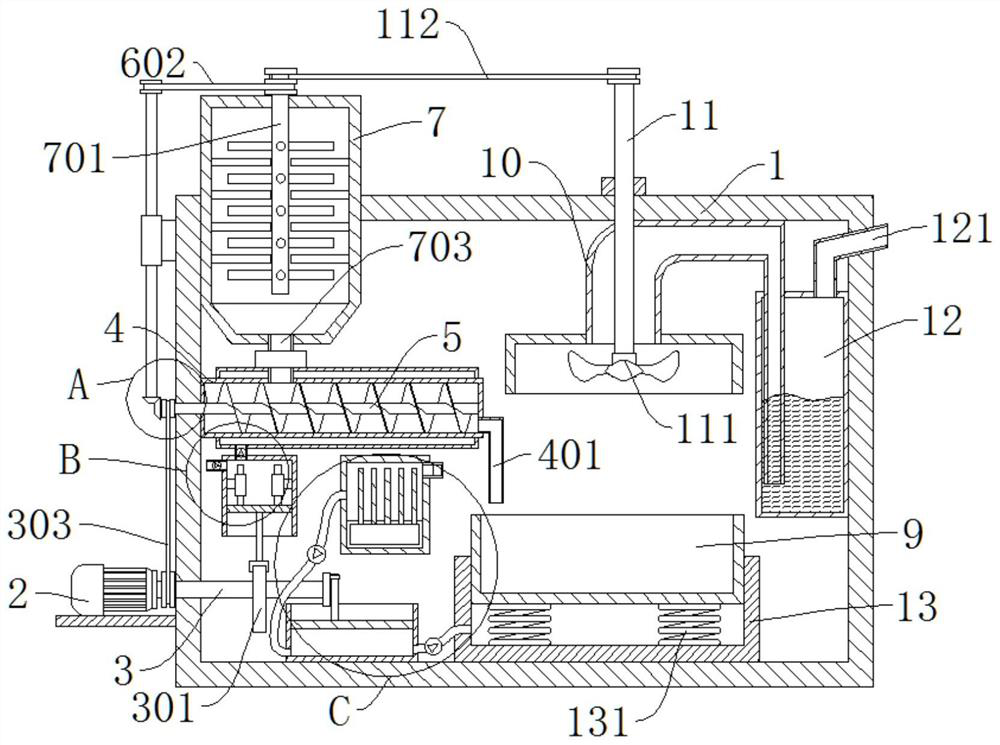

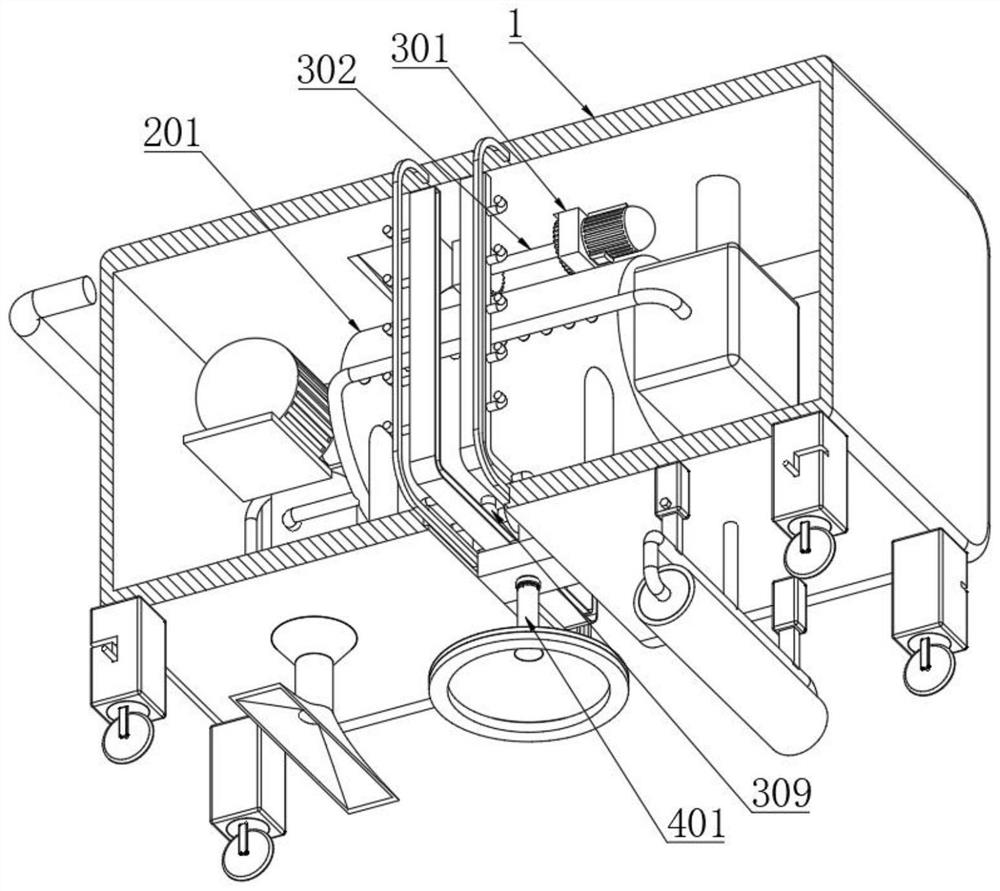

The invention discloses a totally closed gas atomization pulverization device. The device comprises a heat insulation crucible, an atomizer, an atomization tower, a telescopic plastic pipe A, a telescopic plastic pipe B and the like, wherein the atomizer is arranged in the telescopic plastic pipe A; the telescopic plastic pipe A is respectively connected with the heat insulation crucible and the upper surface of a nozzle of the atomizer in a sealed mode; the atomization tower is connected with the lower surface of the nozzle through the telescopic plastic pipe B in the sealed mode; and two half metal cylindrical barrels are arranged in inner and outer metal grooves on the lower surface of the nozzle and on the atomization tower, so that a totally closed system structure is formed. The structure can prevent oxide and nitride from being formed on the atomizer and blocking the atomizer. The totally closed gas atomization pulverization device has the advantages that: the device has a simple structure and is convenient to install, blocking is effectively prevented, the quality of powder is improved, and the like.

Owner:SHANGHAI INST OF TECH

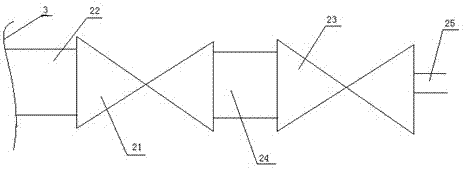

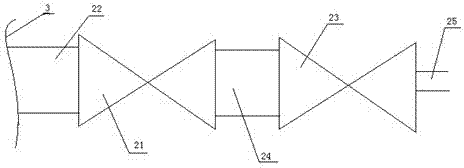

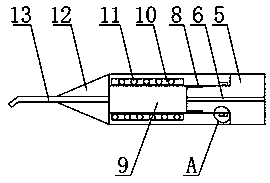

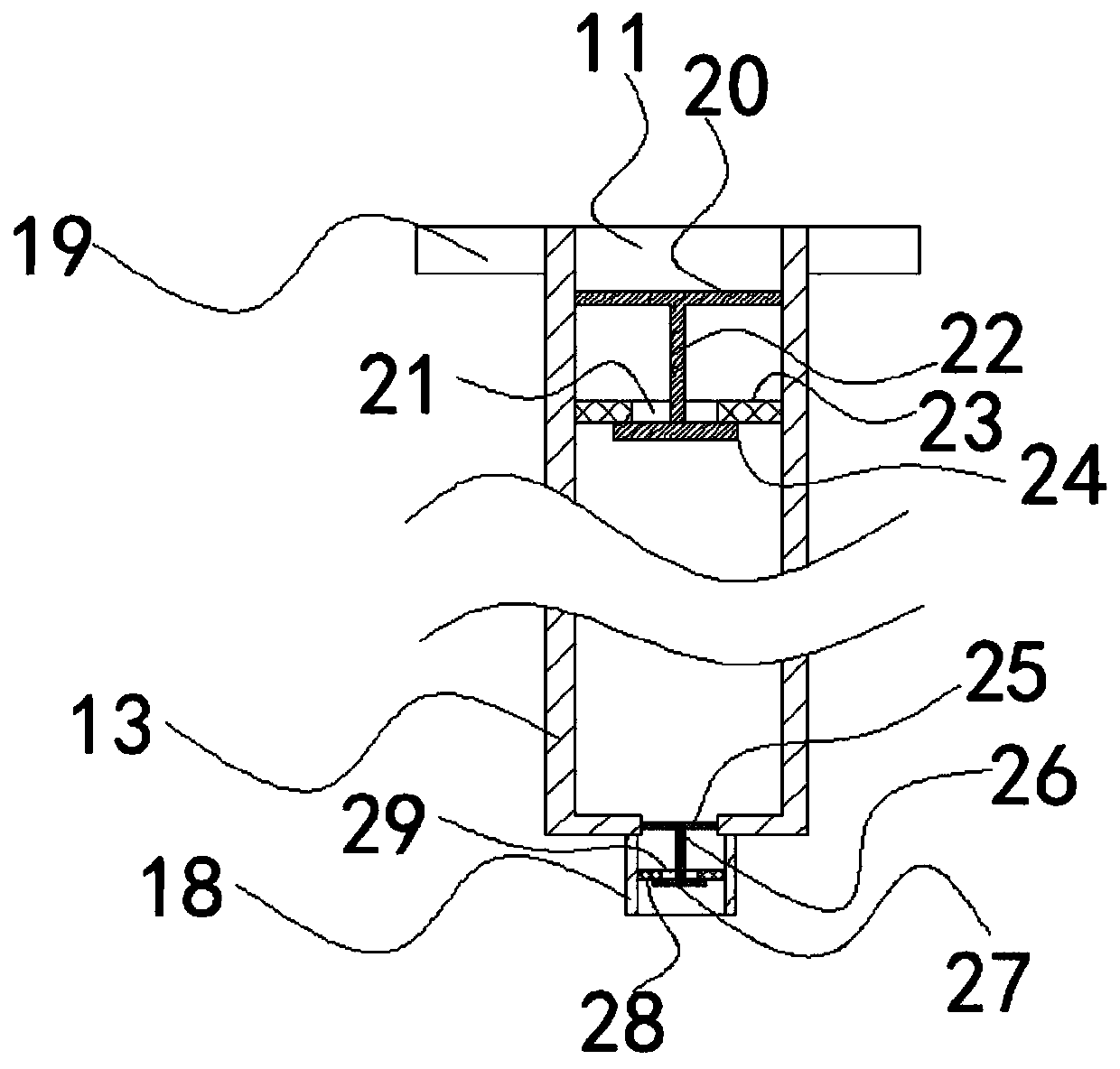

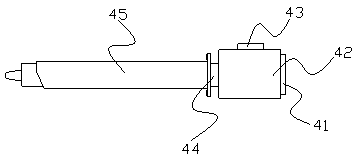

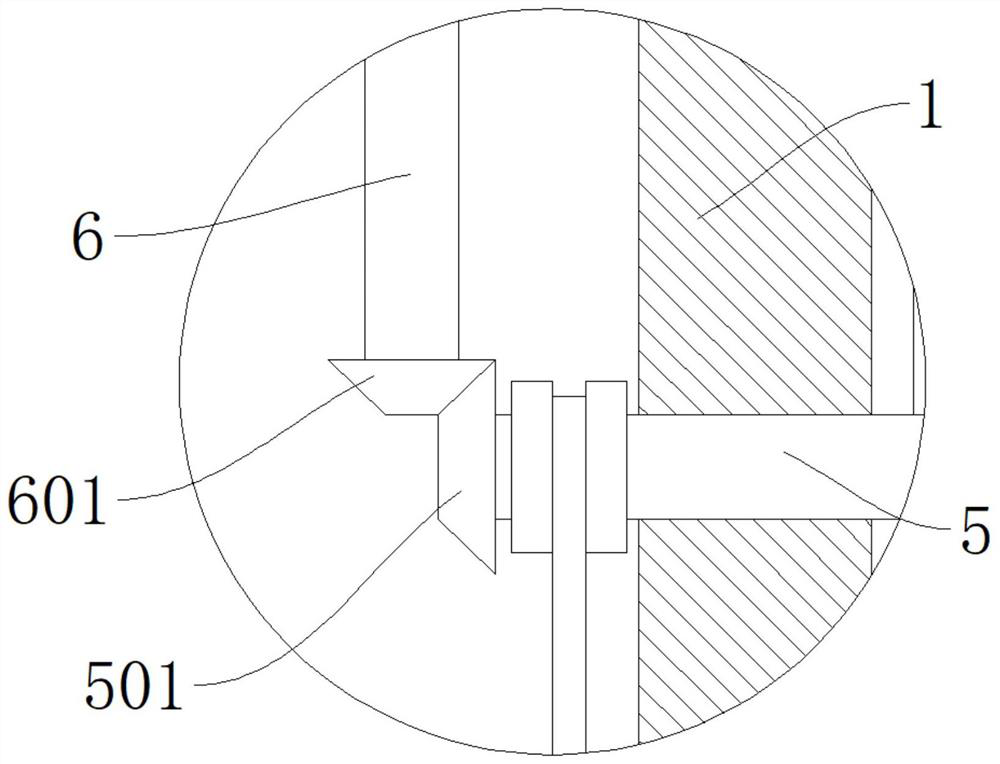

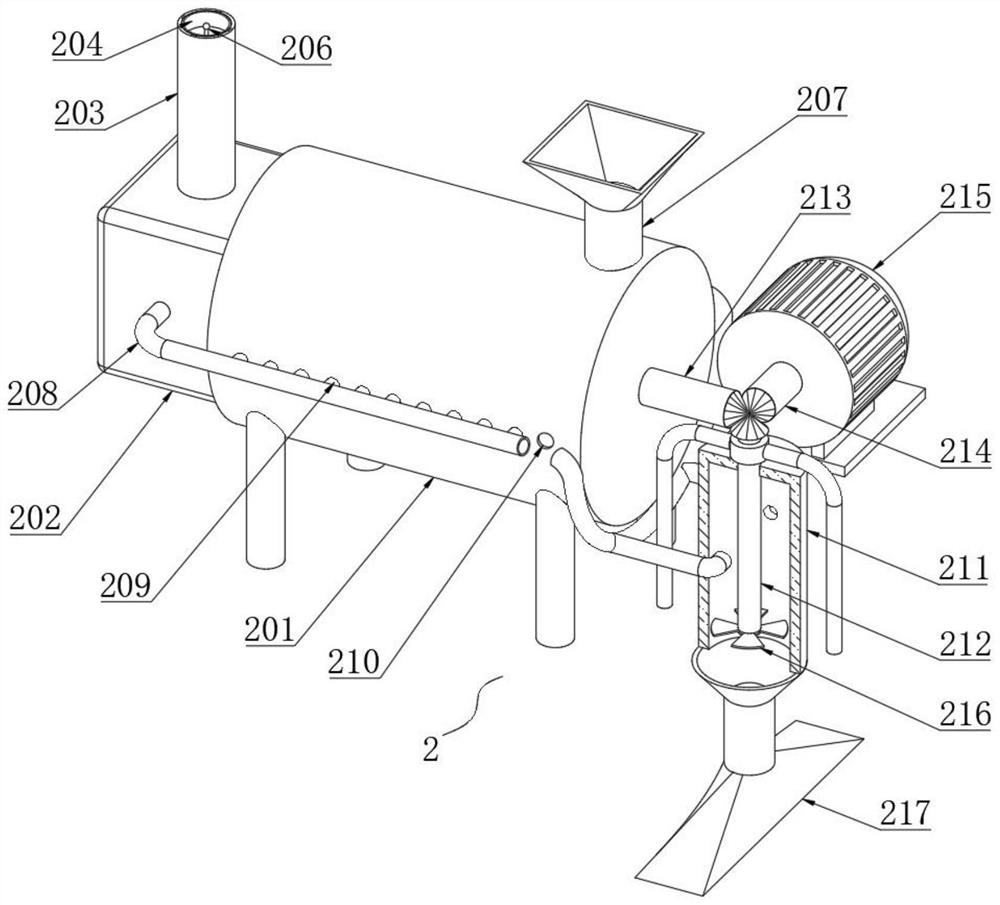

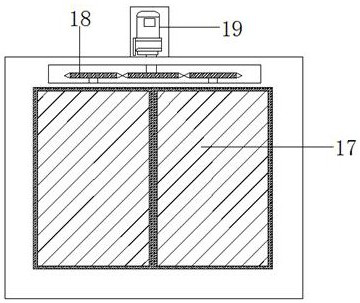

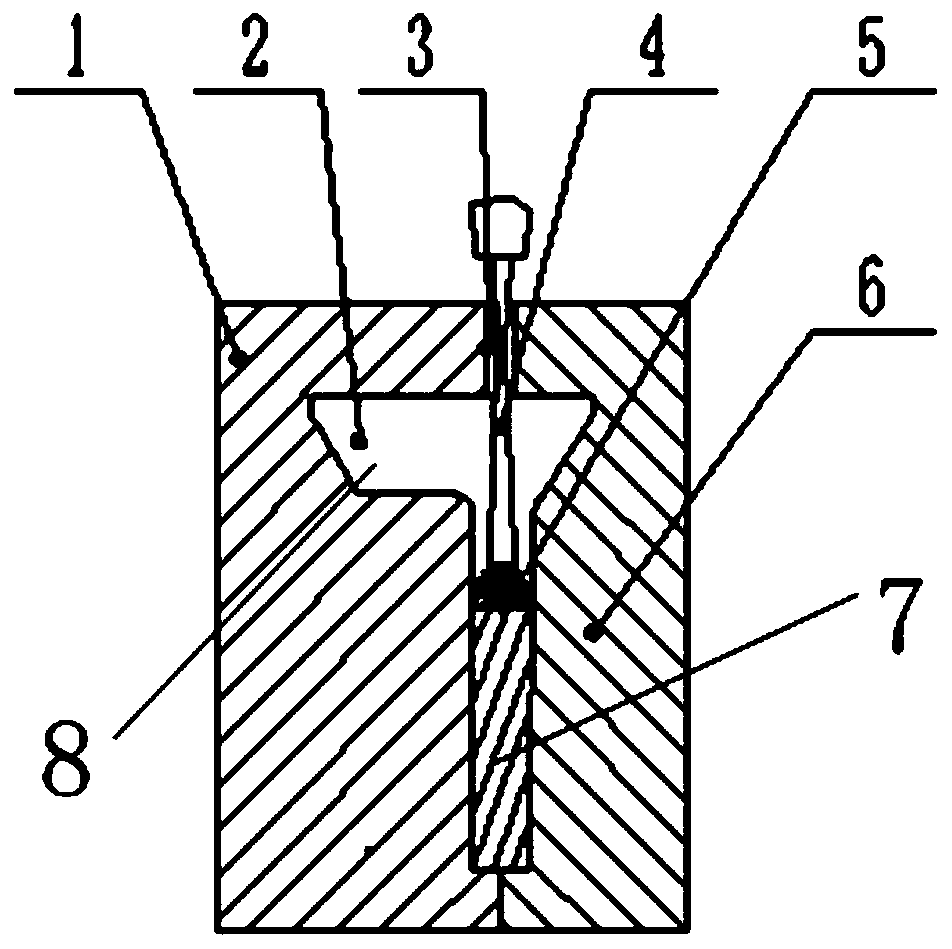

Atomizer capable with nozzle and flow guide tube prevented from blockage

The invention discloses an atomizer with a nozzle and a flow guide tube prevented from blockage. The atomizer is composed of a flow guide tube, a metal jacket, a nozzle, a heating body A, a ceramic sealing ring, a metal sealing ring, a gasket and the like, wherein a gap between the flow guide tube and the metal jacket is provided with the heating body A; a heating body B is arrange each of gaps of the two Laval-structure air outlet tubes of the nozzle; the inner surface of the metal jacket is provided with a metal reflection film or a sprayed white reflection coating; the lower end part of the metal jacket and the lower end part of the flow guide tube are level; the end part of a gap between the lower end part of the metal jacket and the lower end part of the flow guide tube is sealed by the ceramic sealing ring; and the end parts of the gaps between the two Laval-structure air outlet tubes of the nozzle are in threaded connection and sealed by the metal sealing ring. The atomizer has the functions of effectively preventing metal and alloy from being blocked and solving the blockage problem, is suitable for melt flow guidance for metal or alloy atomization, has the advantages of simple structure and the like, and is convenient to install, and the production efficiency can be improved.

Owner:SHANGHAI LUOKE CENT CONTROLLED ENERGY SAVING TECH CO LTD

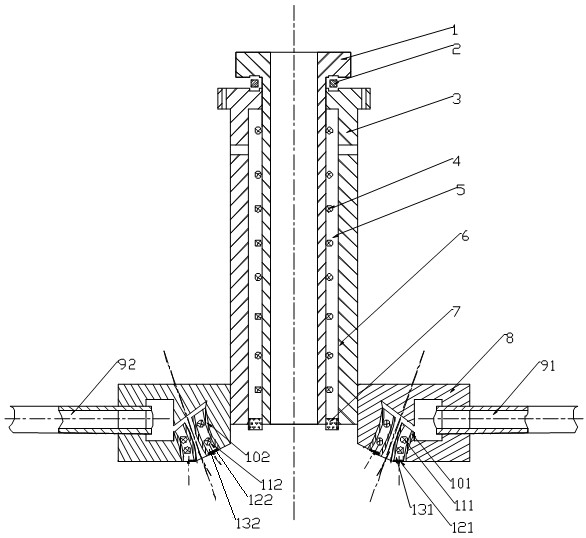

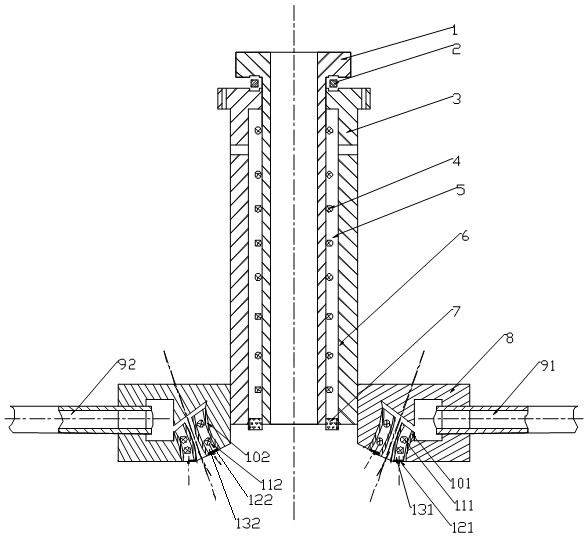

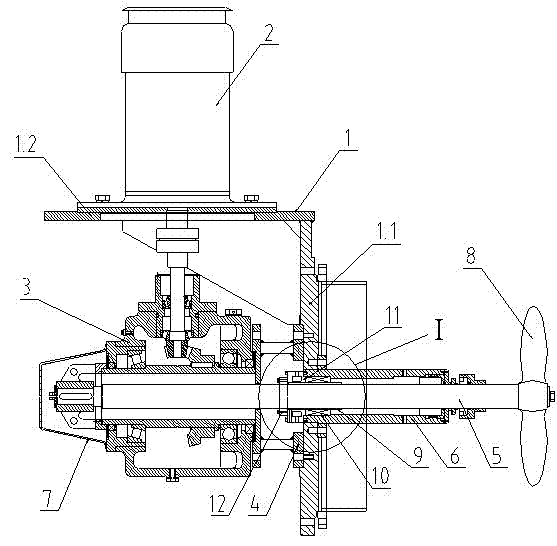

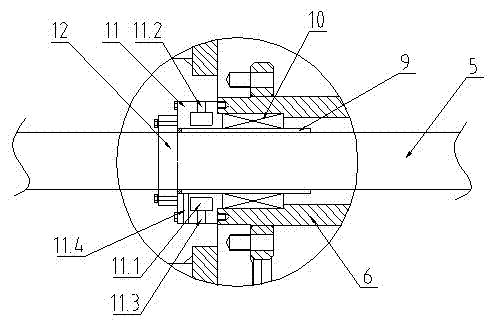

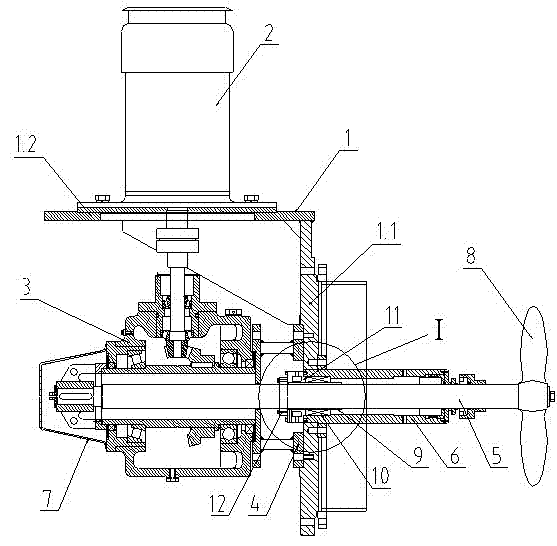

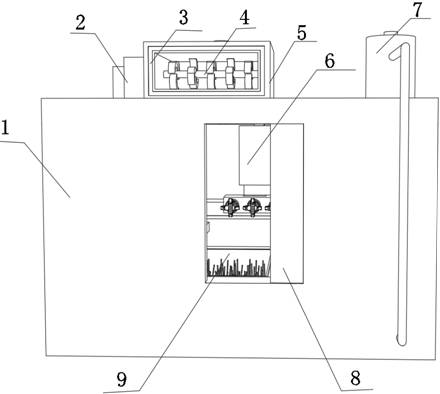

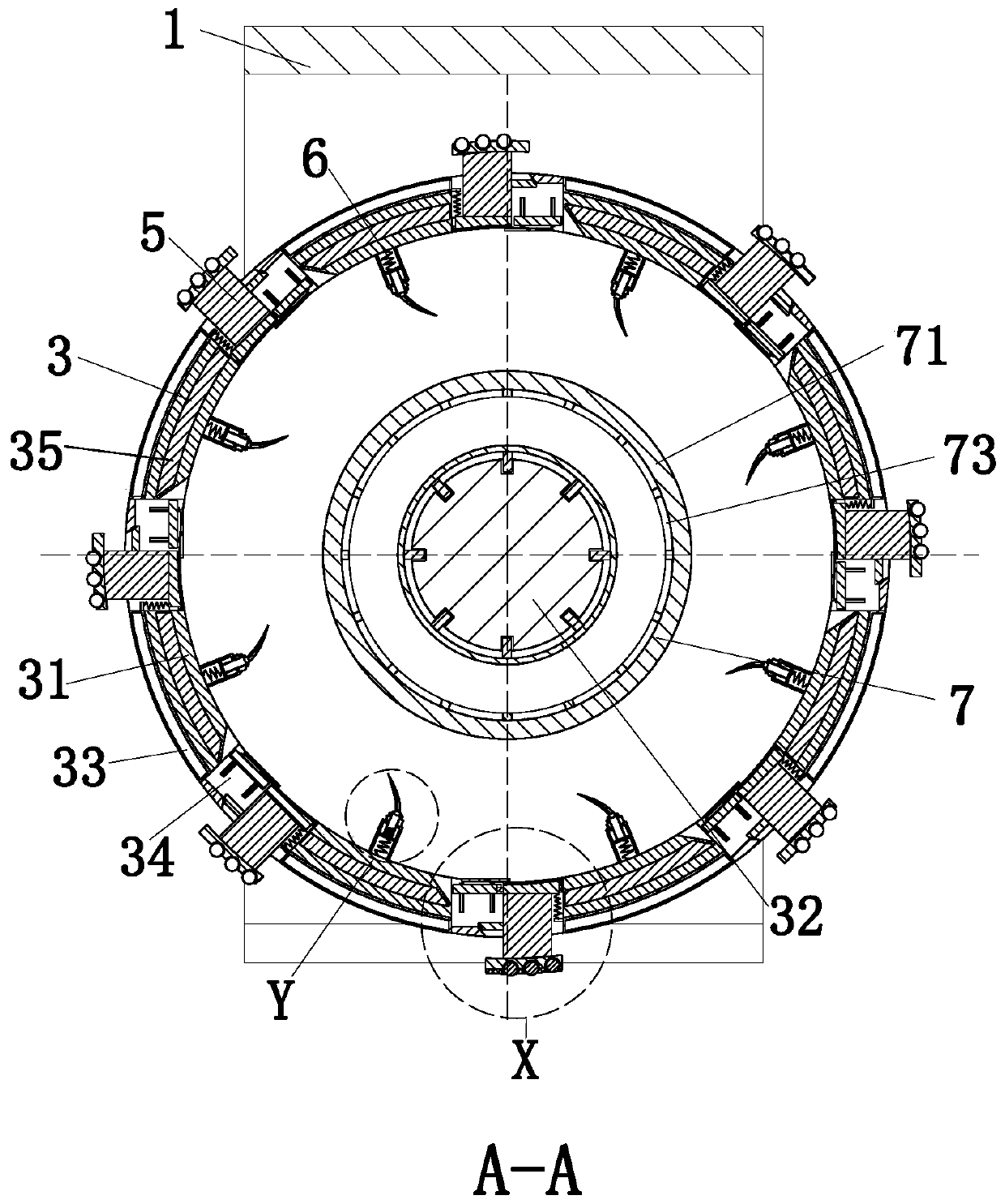

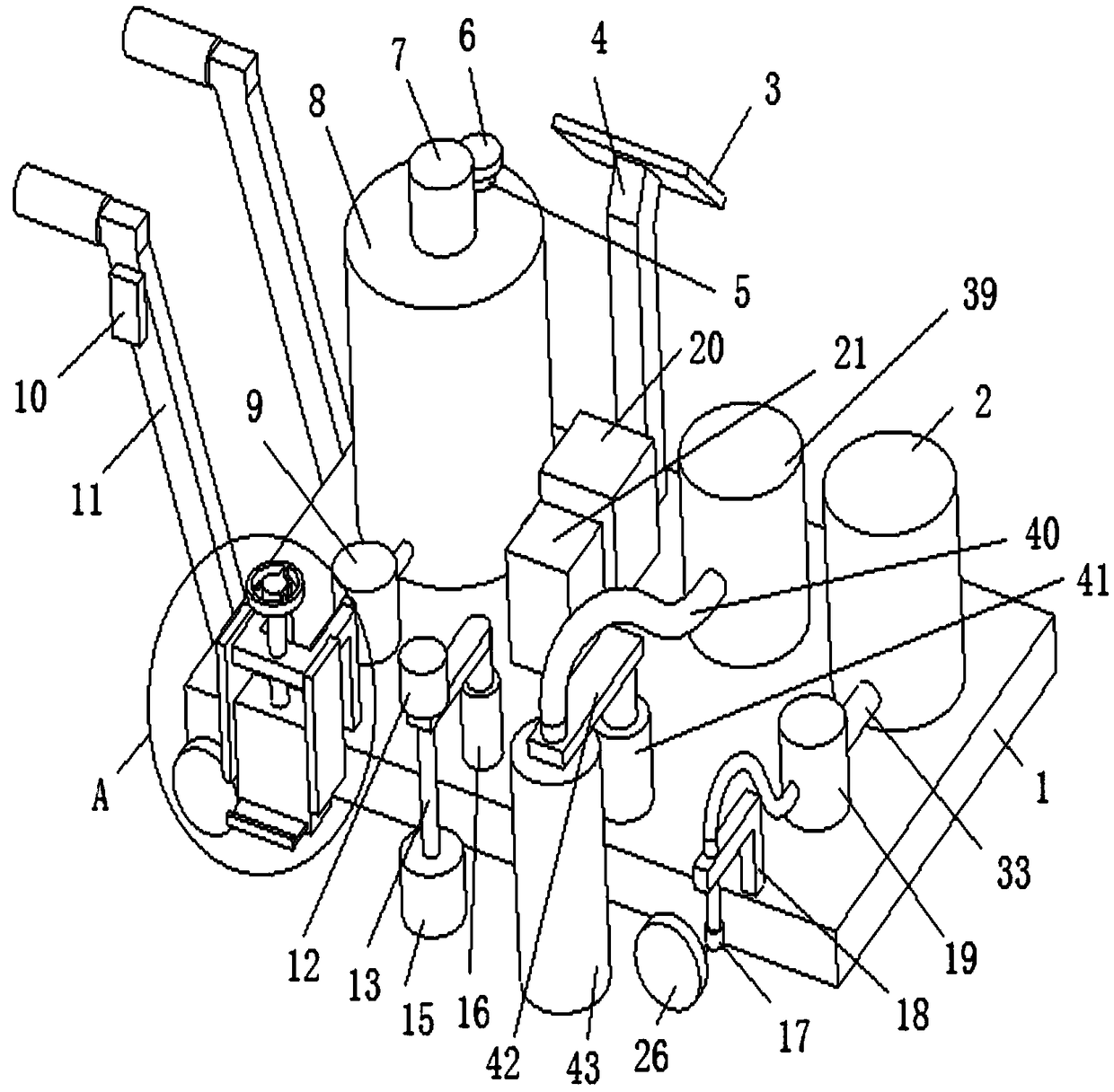

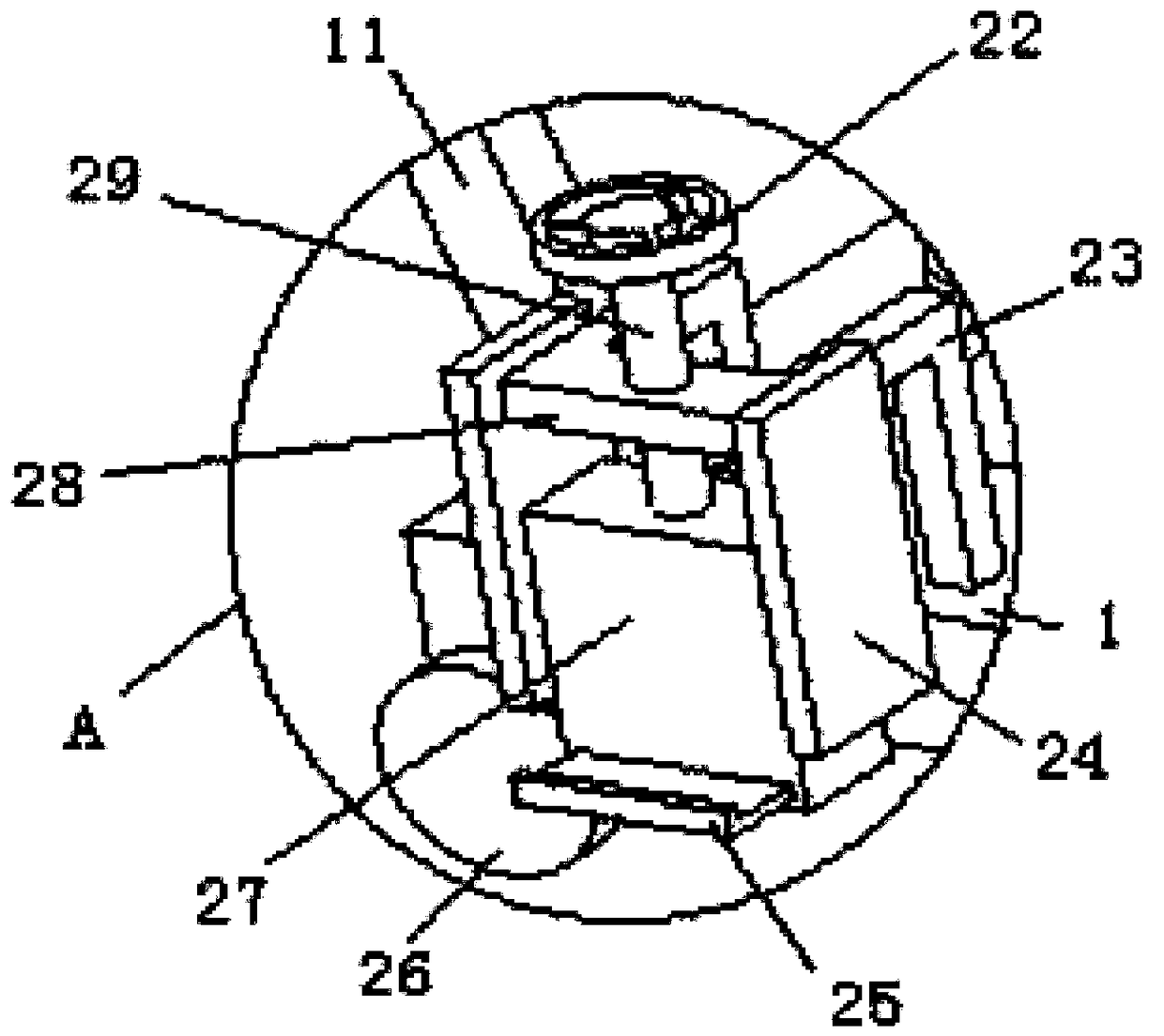

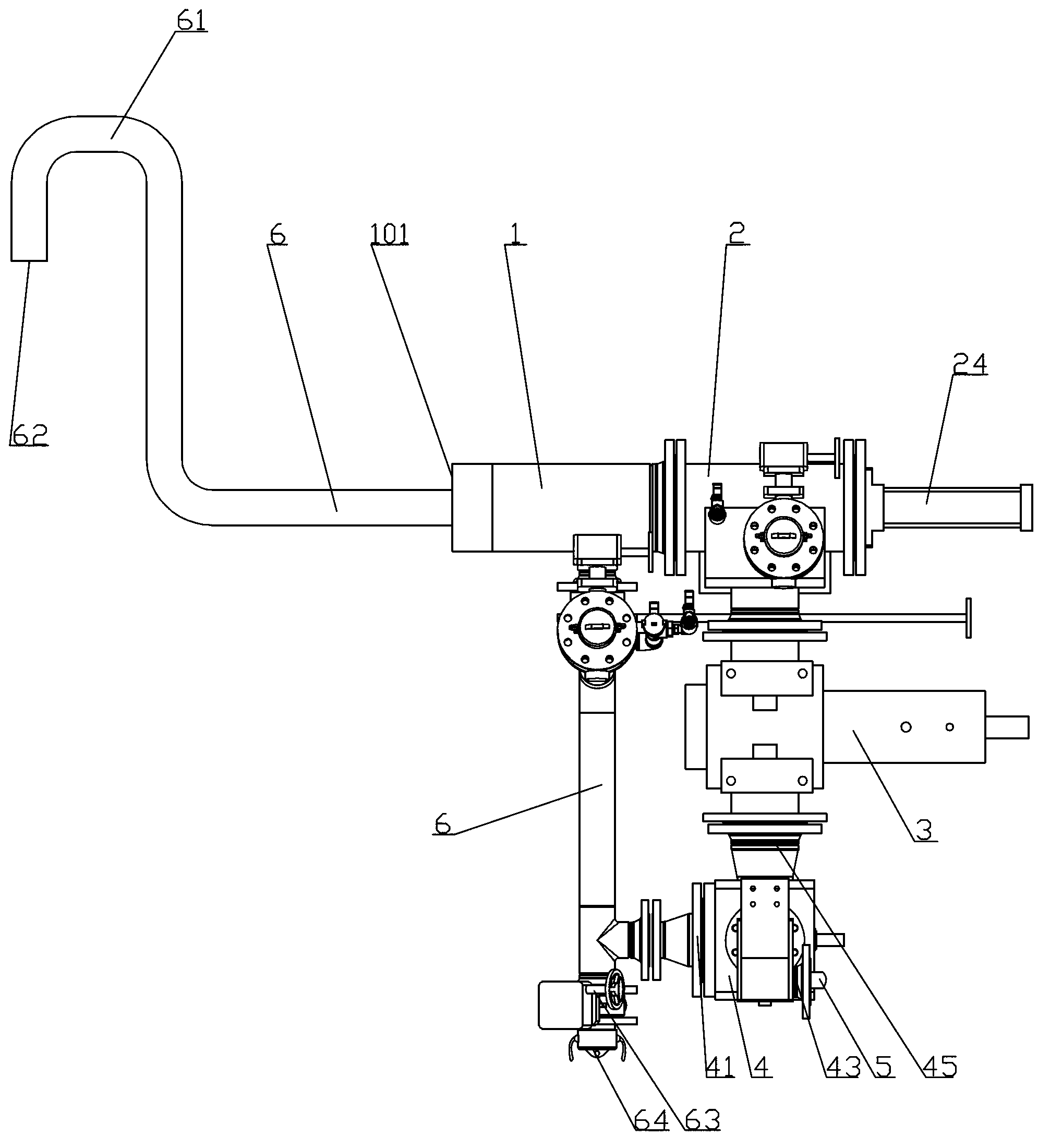

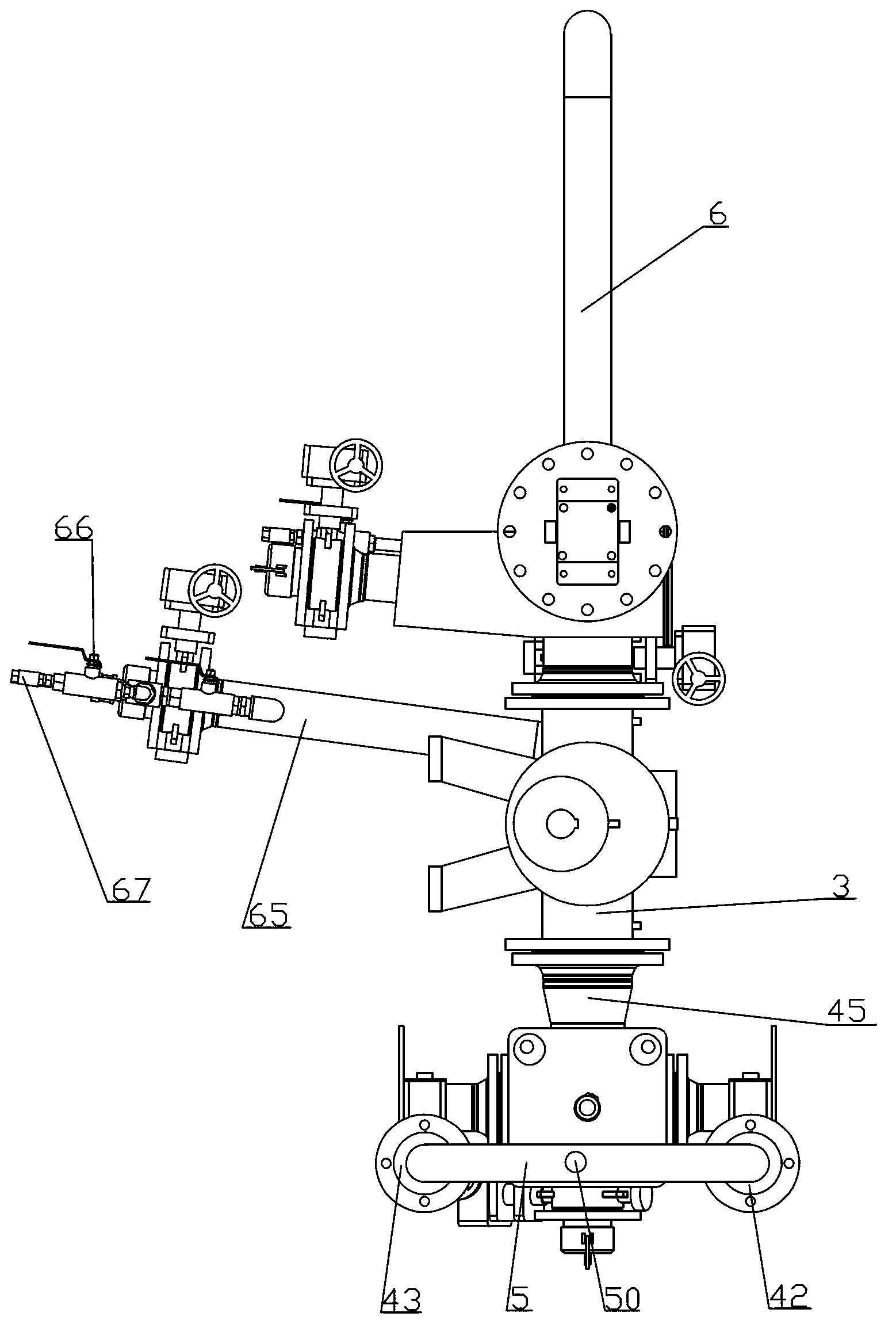

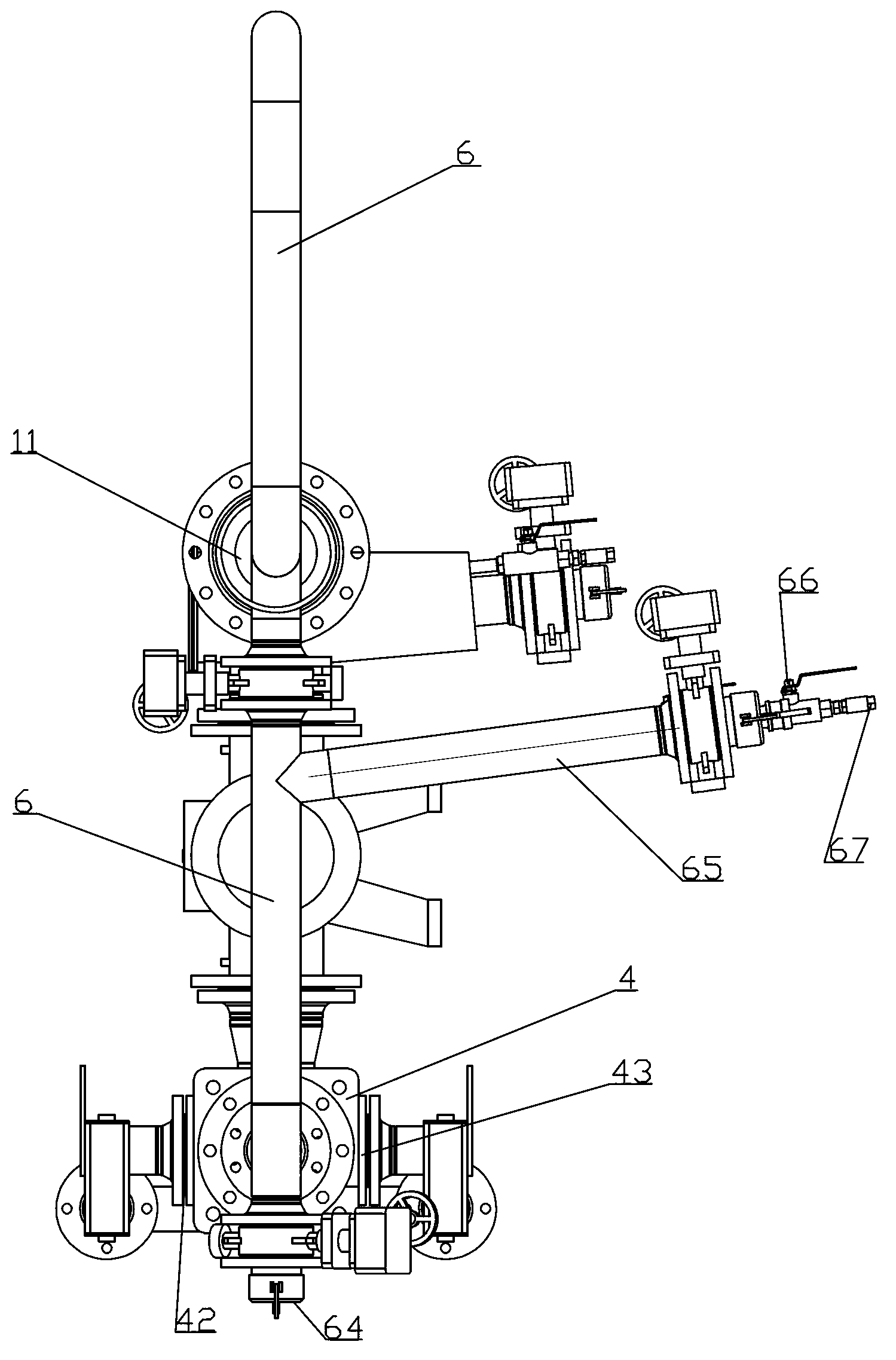

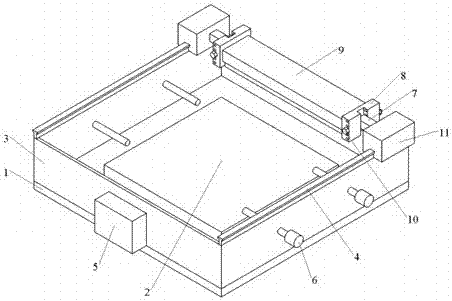

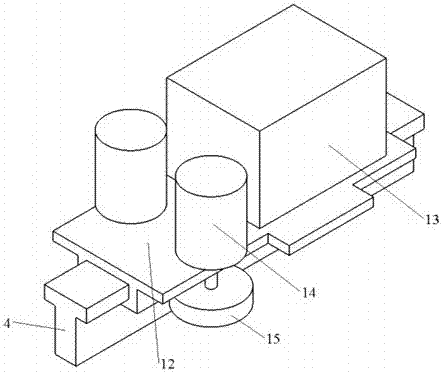

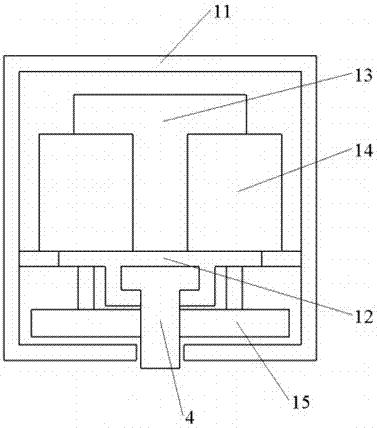

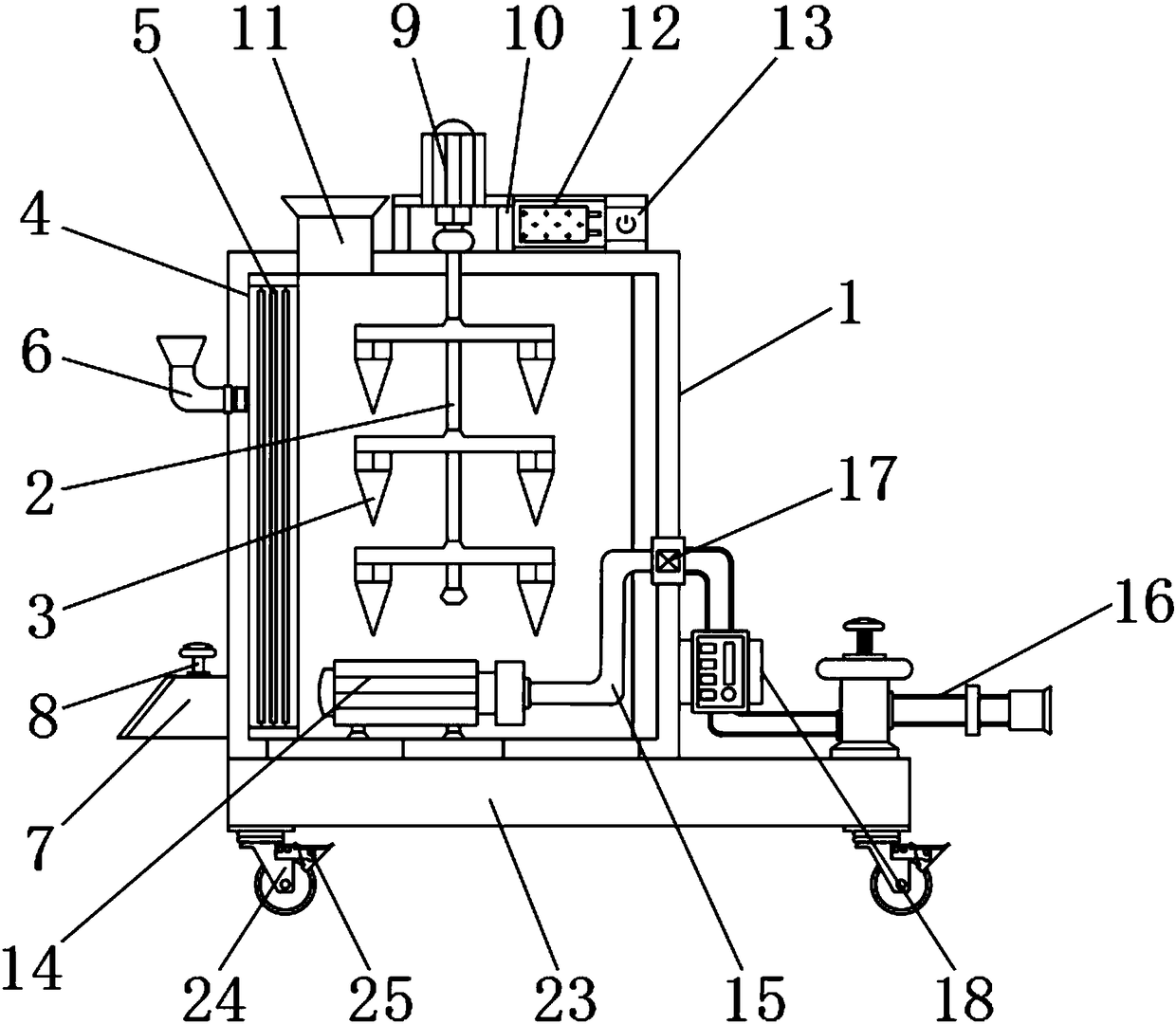

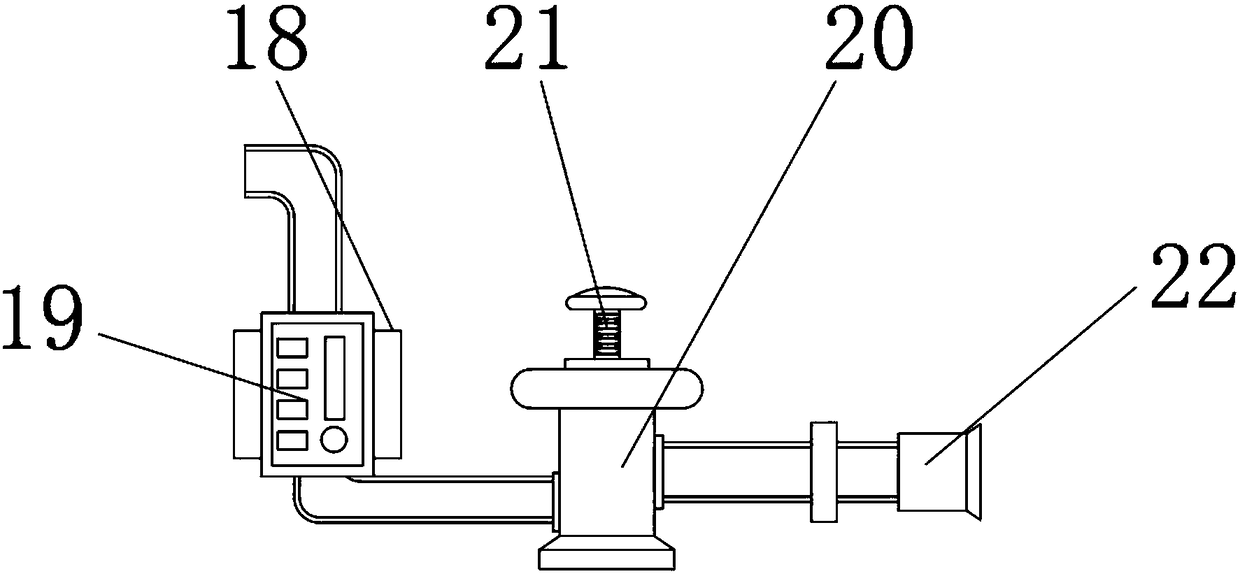

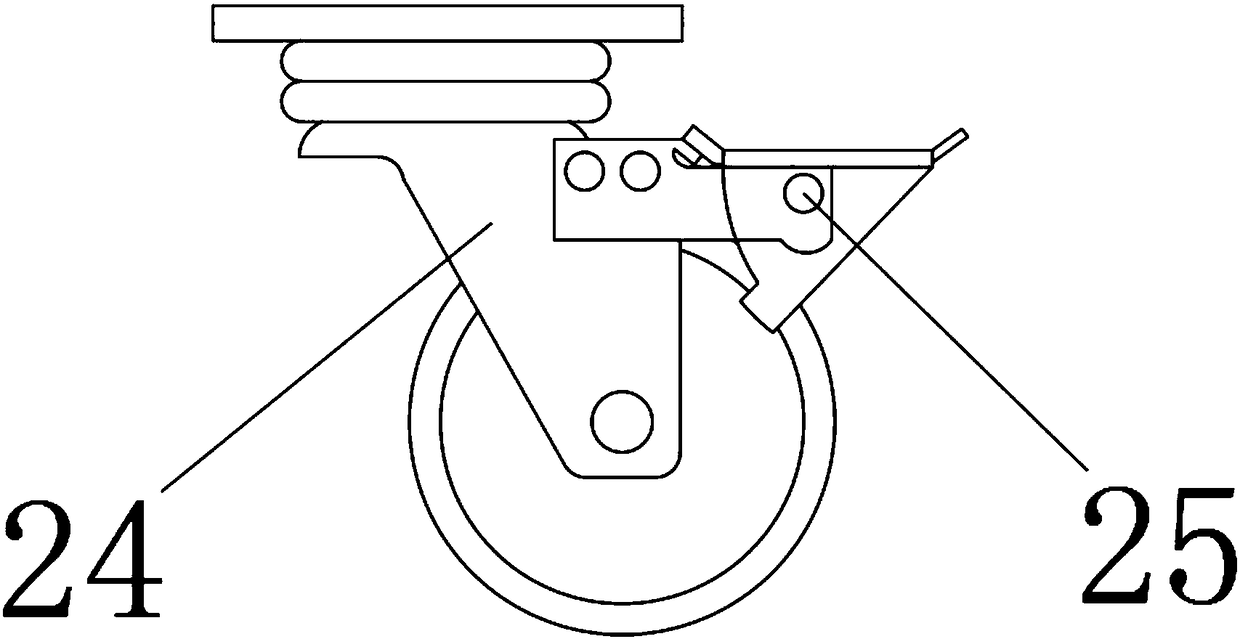

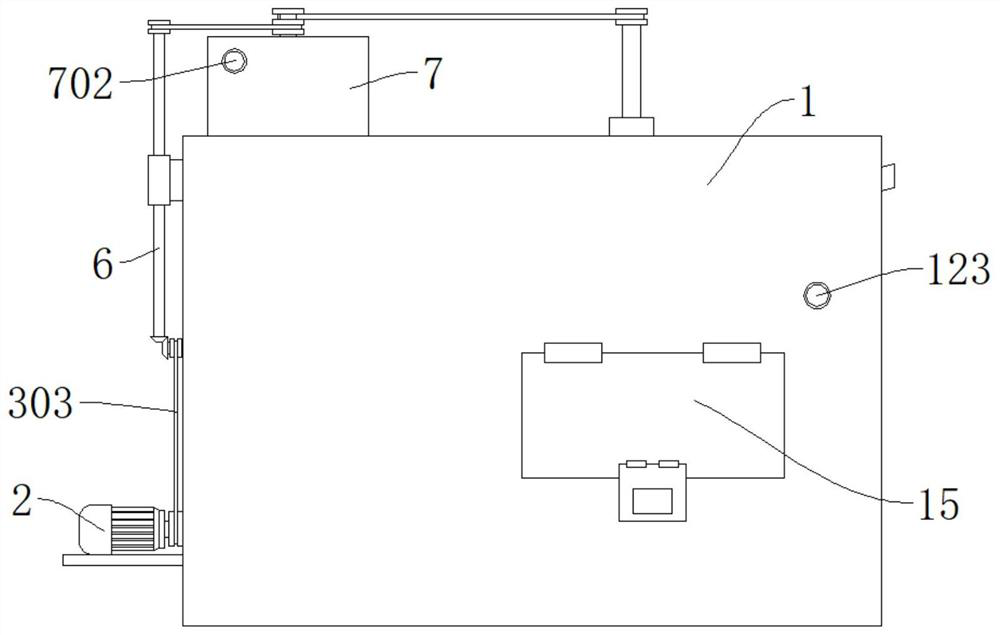

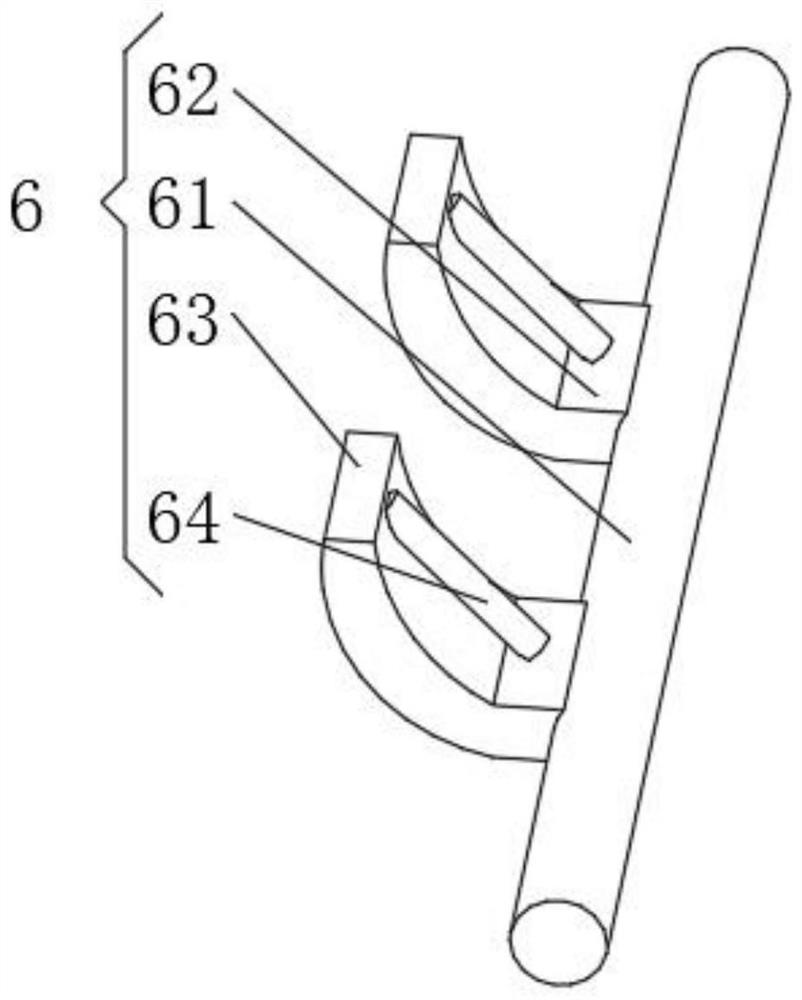

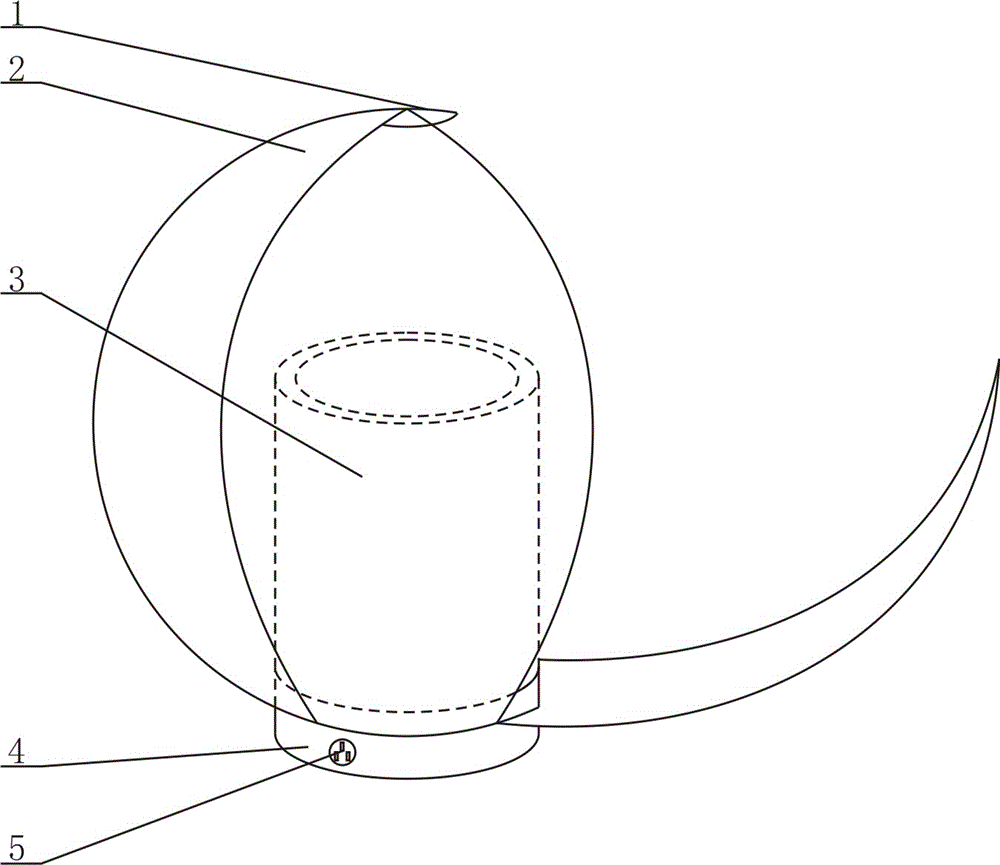

Side inserted agitator

ActiveCN102233242APrevent cooling and solidificationRotary stirring mixersMixer accessoriesImpellerTransverse plane

The invention relates to an agitator, in particular to a side inserted agitator, is mainly used for blending products in storage tanks and / or preventing precipitation in petroleum refining enterprises, chemical enterprises, storage and transportation companies and the like, and belongs to the technical field of agitation machinery. The agitator comprises a bracket (1), a motor (2), a reduction gearbox (3), a spindle (5) and an impeller (8), wherein the bracket (1) comprises a vertical plate (1.1) and a transverse plate (1.2); the motor (2) is fixedly arranged on the transverse plate (1.2); anouter extending bearing (6) and a shaft sleeve (9) are sleeved on the spindle (5); one end of an outer extending bearing (7) is connected with the vertical plate (1.1); a mechanical seal (10) is fixedly sleeved on the shaft sleeve (9); and a fixed flange (11) is arranged outside the mechanical seal (10). The side inserted agitator has the advantage that the mechanical seal is hardly damaged, and can be applied to agitating asphalt, paraffin and other colloidal materials.

Owner:江苏柯恒石化电力机械有限公司

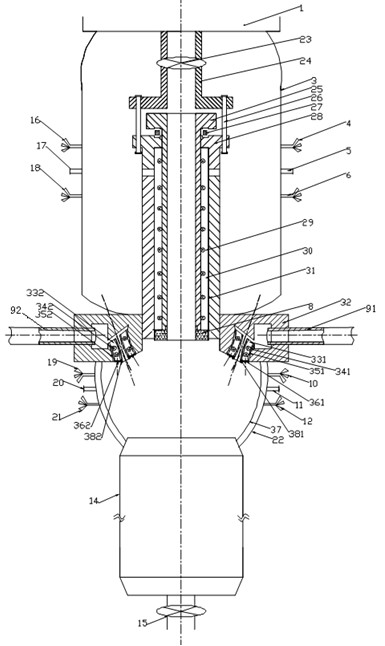

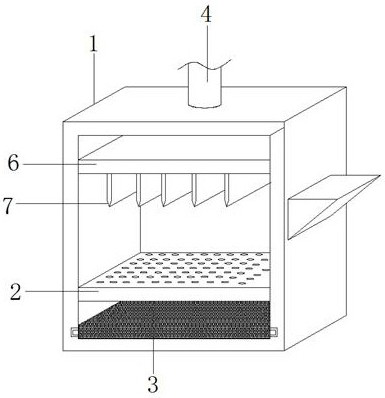

Totally-enclosed gas atomizing powder making device for preventing high-melting-point substance from being blocked

The invention discloses a totally-enclosed gas atomizing powder making device for preventing a high-melting-point substance from being blocked. The device comprises a heat-preserving crucible, an atomizer, an atomizing tower, a telescopic plastic pipe A, a telescopic plastic pipe B and the like, wherein the atomizer is arranged in the telescopic plastic pipe A; the telescopic plastic pipe A is hermetically connected with the heat-preserving crucible and the upper surface of a nozzle of the atomizer respectively; and the atomizing tower is hermetically connected with the lower surface of the nozzle through the telescopic plastic pipe B, so that a totally-enclosed system structure is formed, and the formation of a high-melting-point substance on the atomizer and caused blockage of the atomizer can be prevented. A heating body is arranged in a gap between a honeycomb duct of the atomizer and a metal jacket, so that nozzle blockage caused by a metal or an alloy can be solved by electrifying. When the atomizer is blocked, the problem of blockage can be solved by replacing a ceramic circular ring. The totally-enclosed gas atomizing powder making device for preventing the high-melting-point substance from being blocked disclosed has the advantages of simple structure, convenience for installing, effective prevention and solving of blockage, improvement on the powder quality, and the like.

Owner:SHANGHAI INST OF TECH

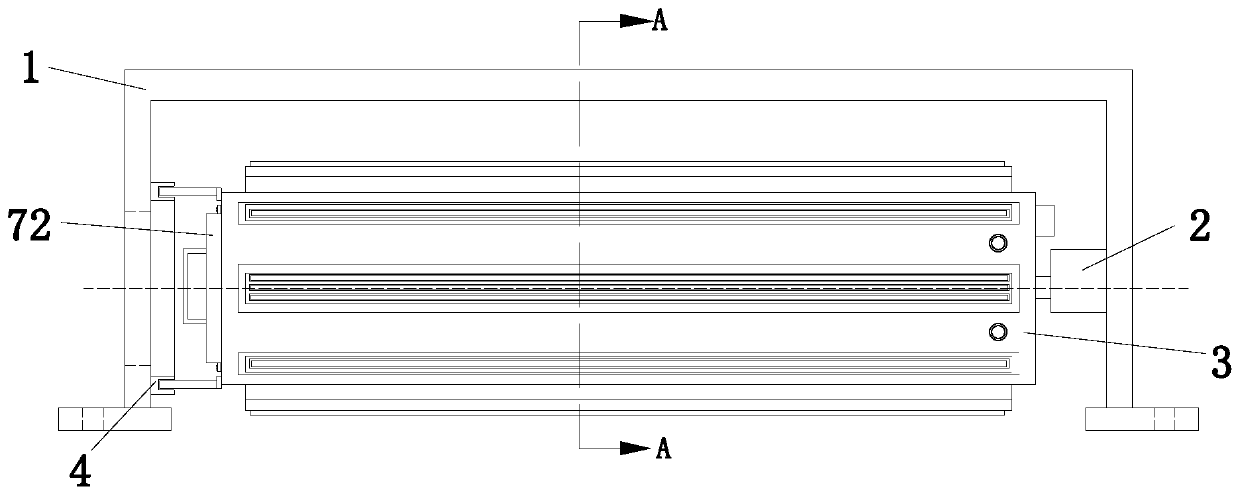

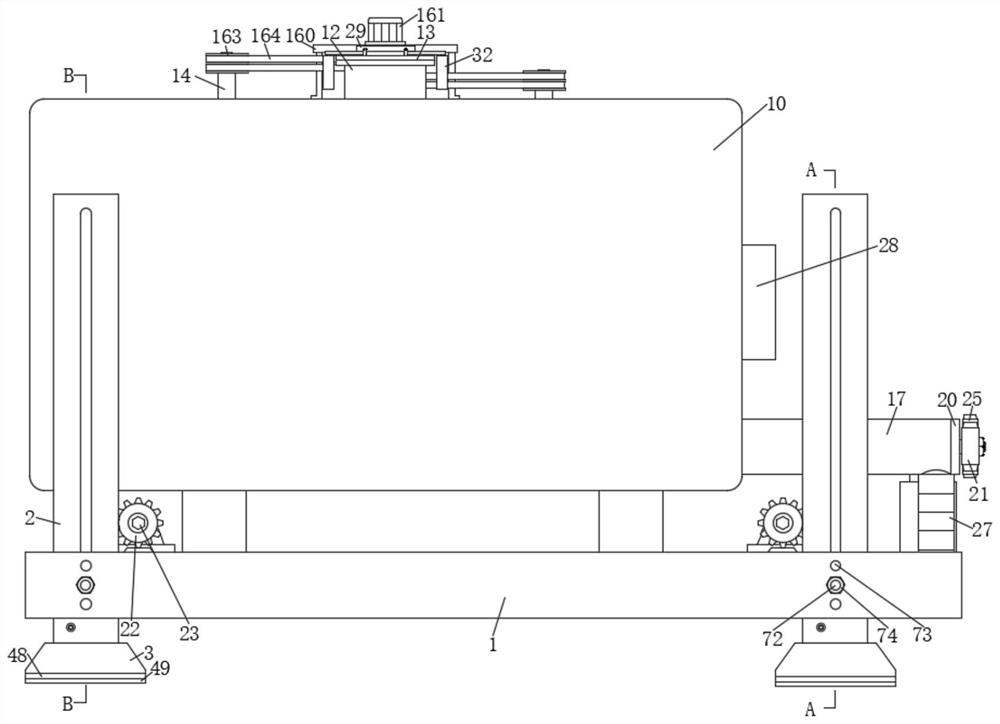

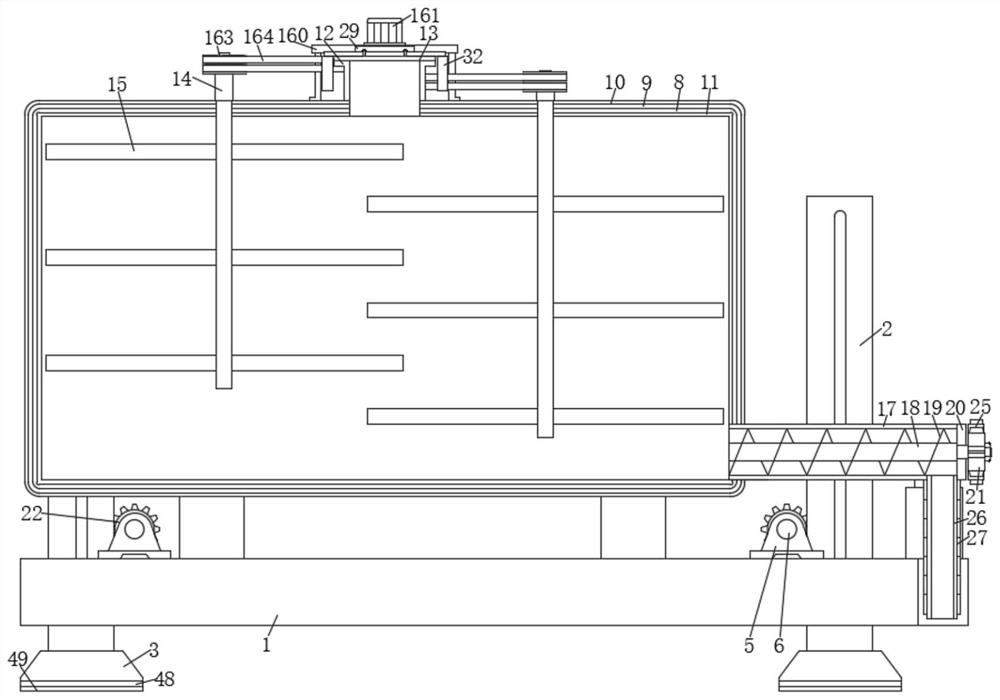

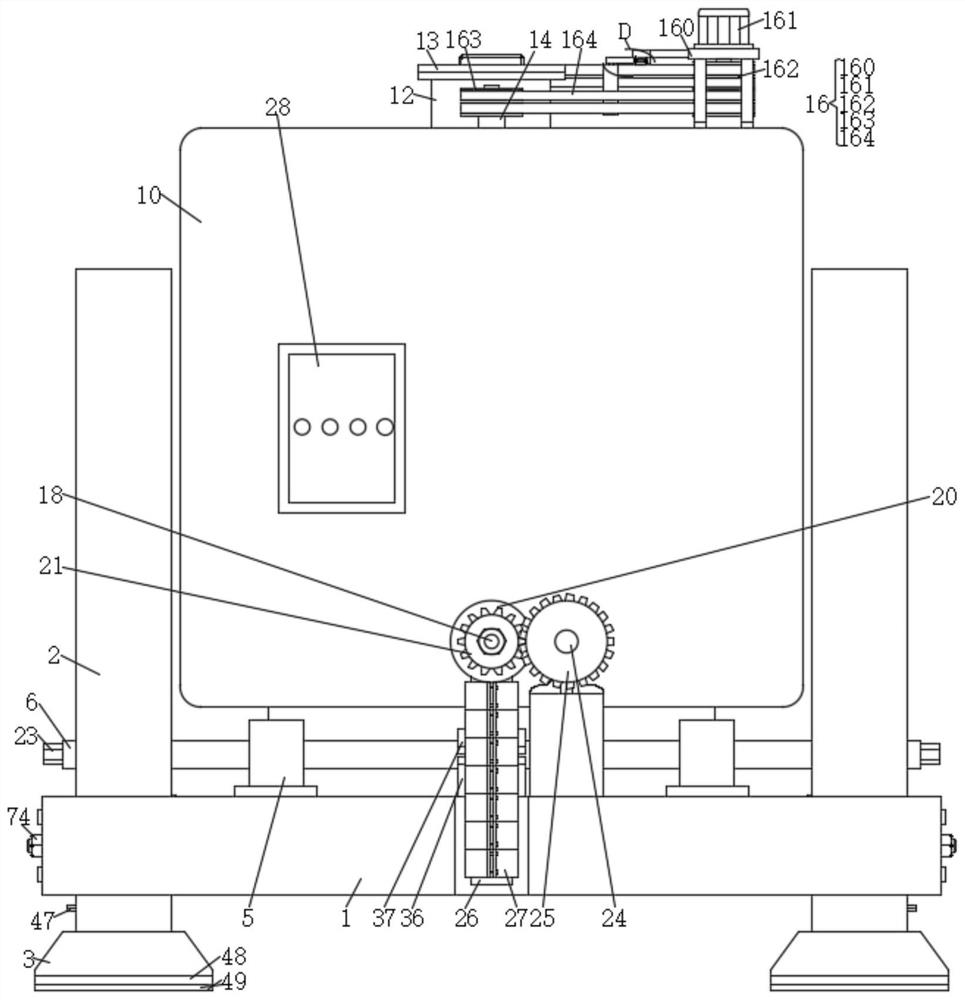

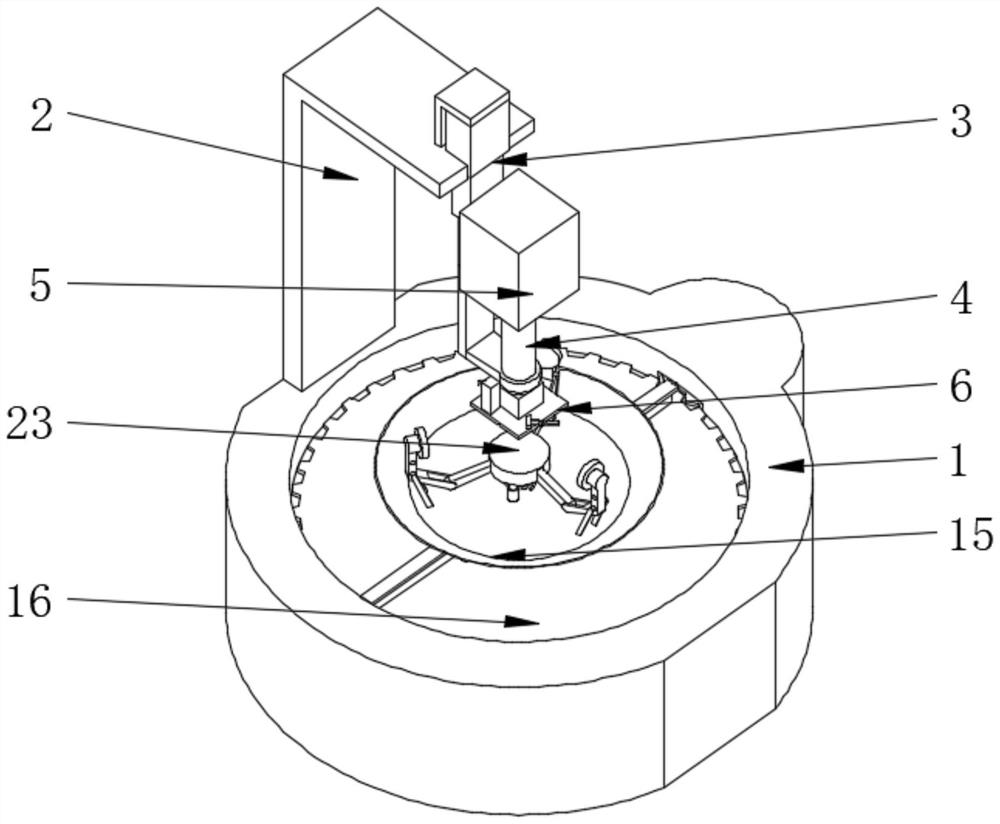

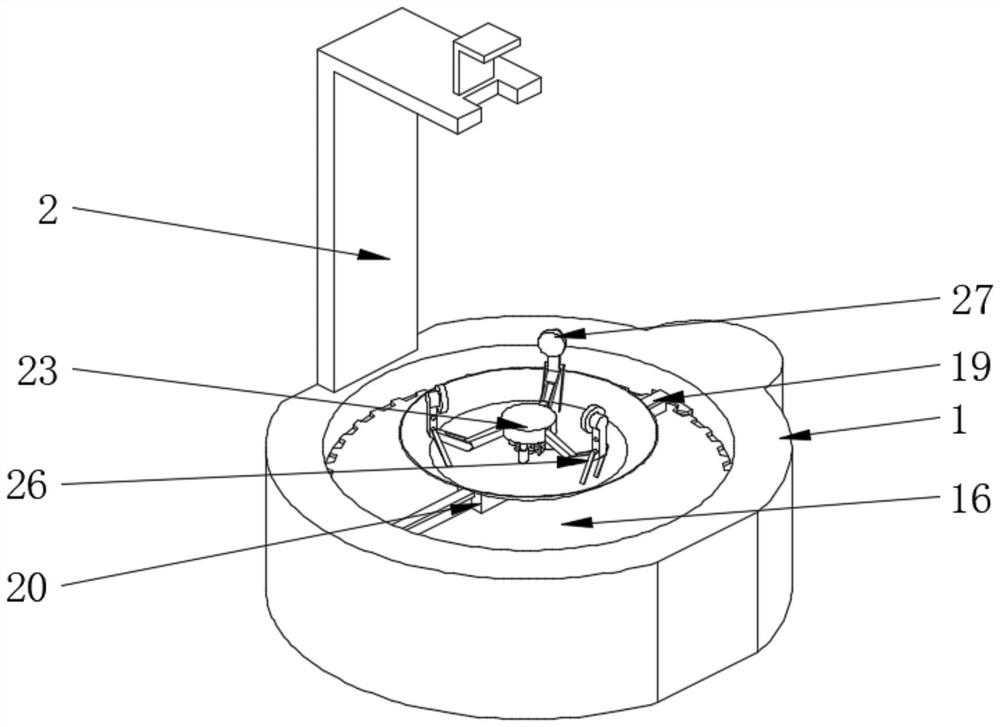

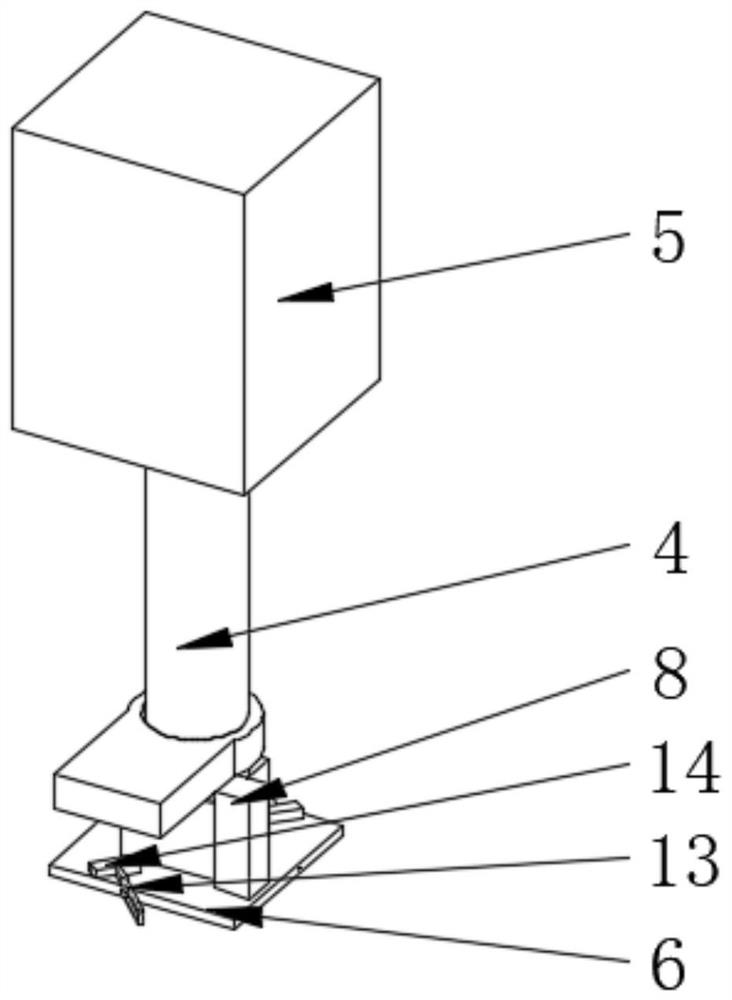

Paint plating device and paint plating method for valve machining

ActiveCN112371428AAccelerate solidificationQuality assurancePretreated surfacesCoatingsHydraulic cylinderGear wheel

The invention discloses a paint plating device and a paint plating method for valve machining, relates to the technical field of valve machining, and aims at solving the problem that paint is easily accumulated at a contact point. The device comprises a machine body; a first electric sliding groove is formed in the inner wall of the top of the machine body; a hydraulic cylinder is arranged on theinner wall of the first electric sliding groove; the extending end of the hydraulic cylinder is rotatably connected with a connecting base through a connecting column; a third motor is arranged on theinner wall of the bottom of the connecting base; and three gears are arranged on the inner wall of one side of the connecting base. The paint plating method for the device comprises the following steps that the paint is added to a first material box; a valve is placed in a net box; and a cleaning spraying member and a second motor are started to drive the net box to complete cleaning and spin-drying in the rotating process. In the air blowing process, the valve rotates continuously at the same time to accelerate solidification of the valve after feeding; and no acting point exists in the solidification period of the feeding position of the valve, and therefore the situation of paint accumulation is avoided, and the quality and efficiency of paint plating are guaranteed.

Owner:林仙夫

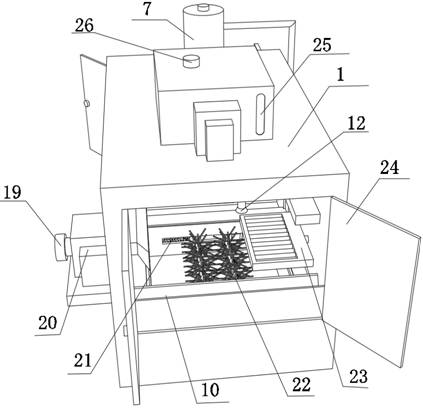

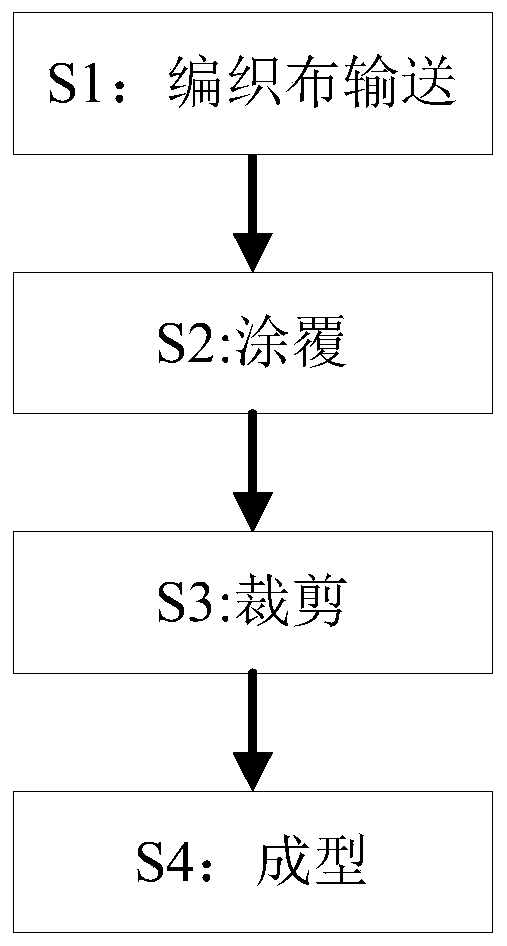

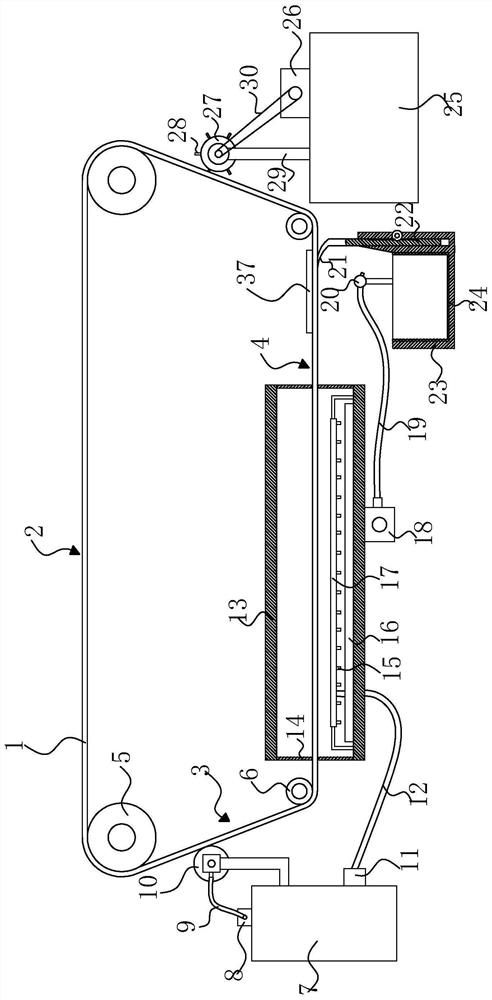

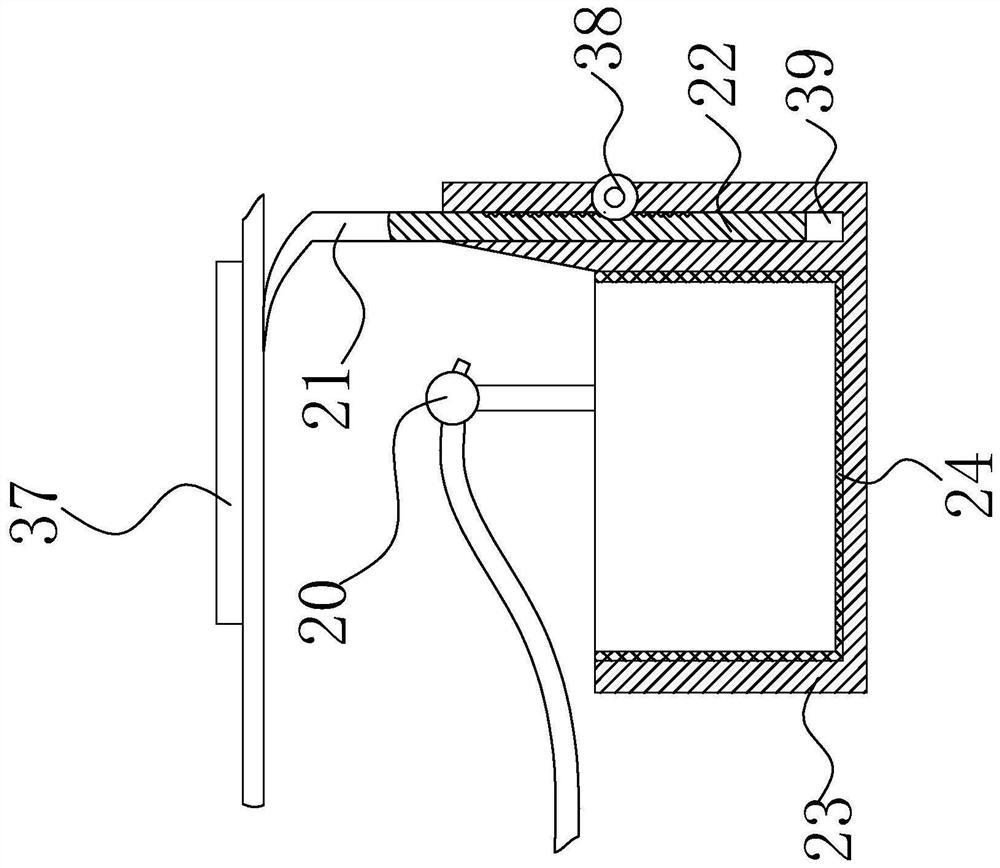

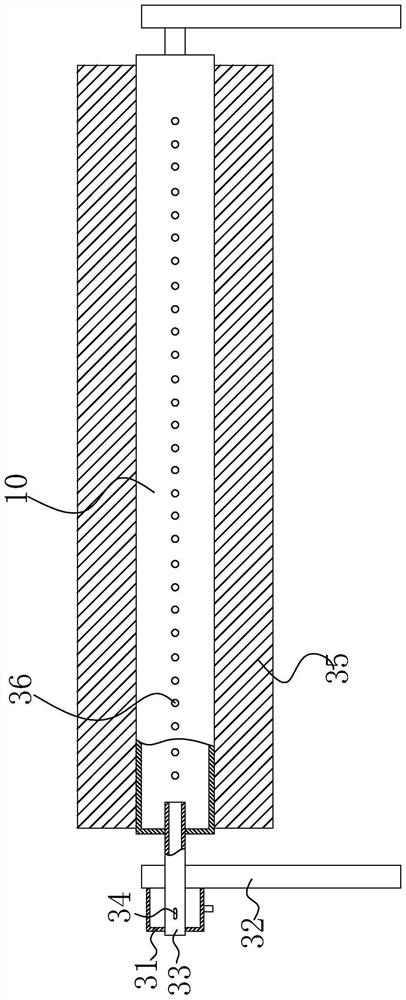

Manufacturing process of two-in-one composite plastic woven cloth

ActiveCN110479535AEffective controlAvoid cooling and solidificationLiquid surface applicatorsCoatingsEngineeringPortal frame

The invention provides a manufacturing process of two-in-one composite plastic woven cloth, wherein a portal frame, a motor, a coating roller, an annular sliding chute, discharging devices, swing devices and a heat conduction cylinder are matched to complete operation. In the existing coating process, in general, a resin solution is directly poured onto the woven cloth, coating is carried out through the coating roller, and due to the fact that the concentration of the resin solution is high, it is difficult for the resin solution to drip, the single pouring amount of the resin solution is always unequal, and the pouring amount cannot be effectively controlled; and the temperature of the resin solution in hot melting state is higher, the phenomenon of cooling and solidification often occurs when the resin solution to be poured out is cooled, and when the resin solution is poured onto the woven cloth, the amount of the resin solution at each position of the woven cloth is unequal, and consequently the thickness of each position of a rolling layer of the woven cloth is uneven during rolling of the coating roller, With the manufacturing process of the two-in-one composite plastic woven cloth, the above problems can be solved.

Owner:浙江兴澳科技有限公司

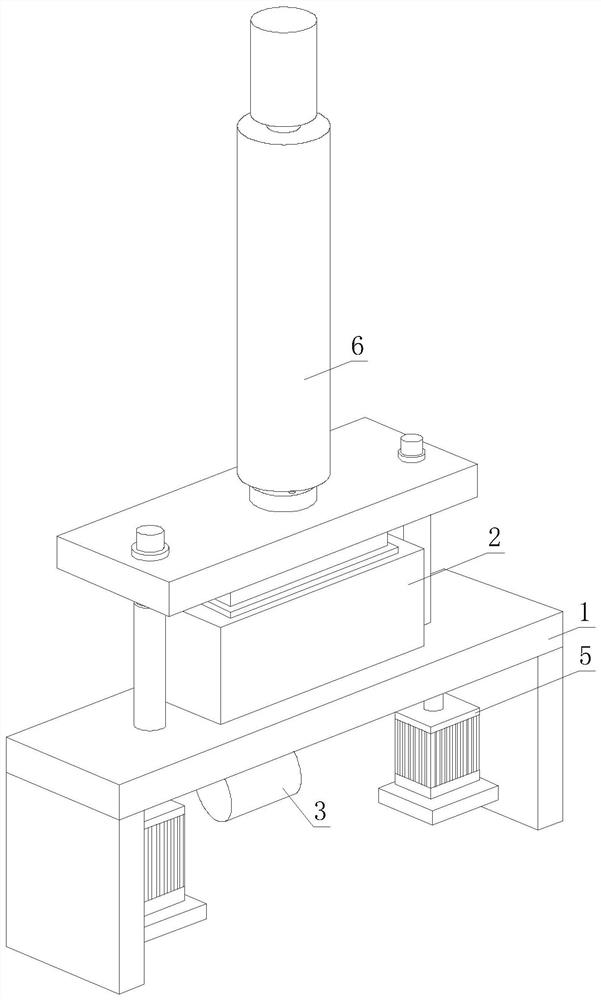

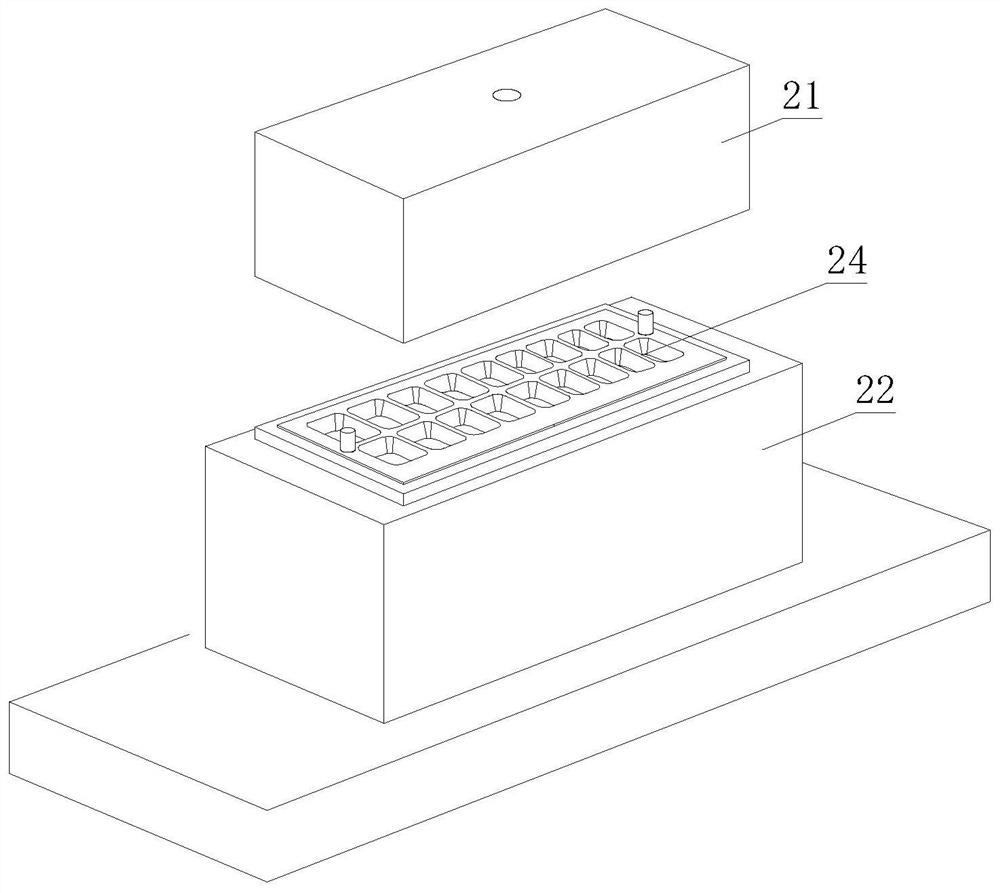

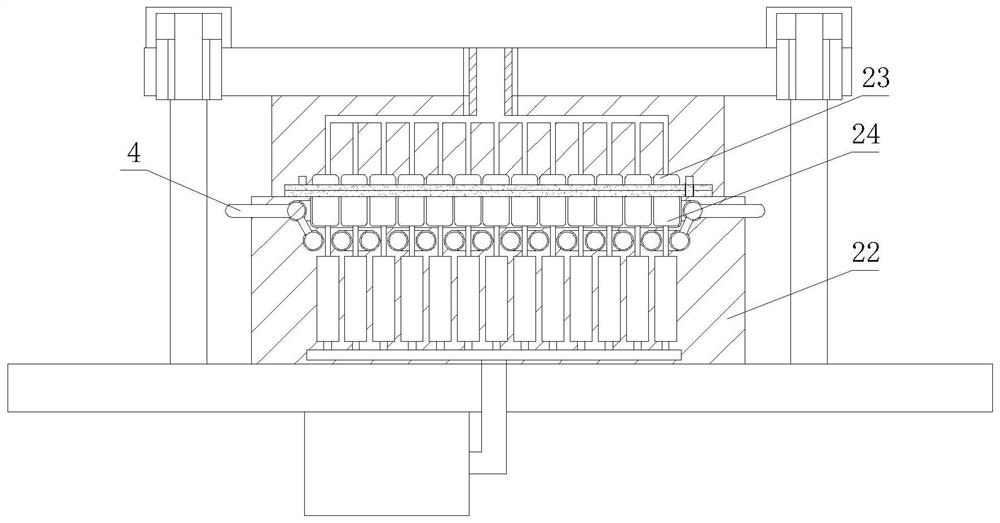

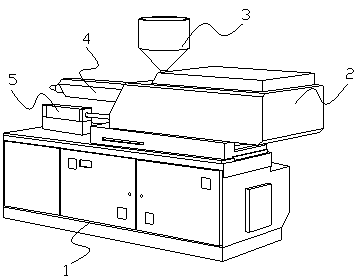

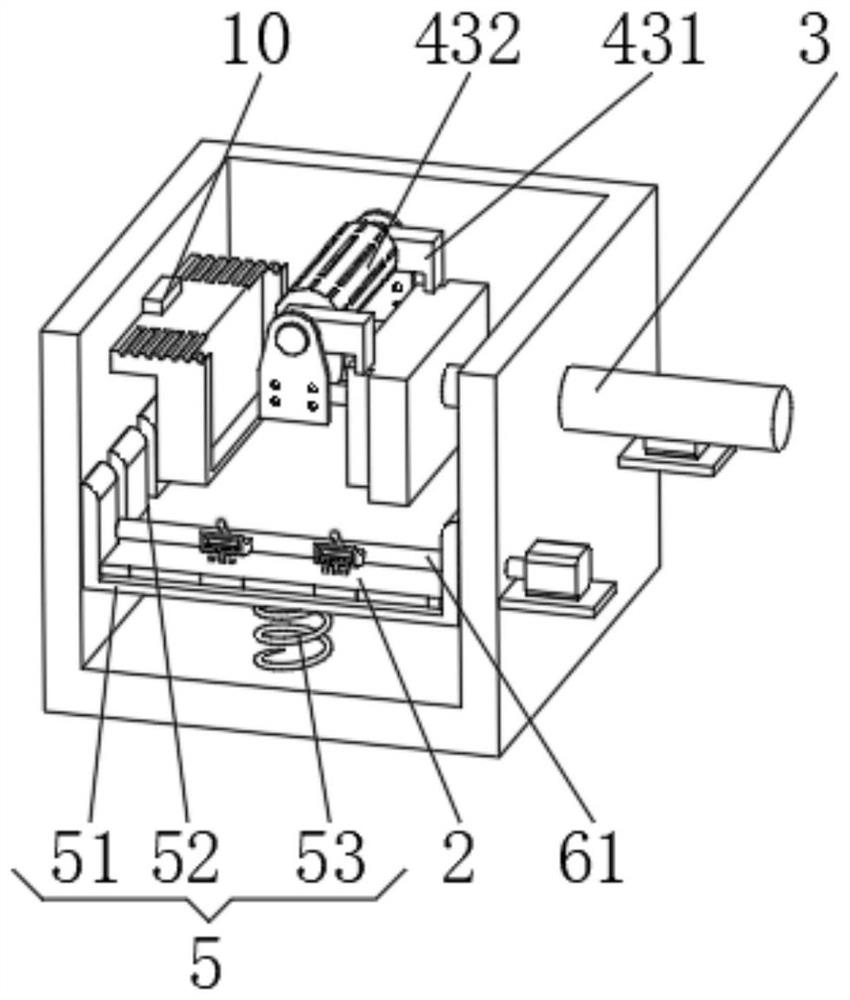

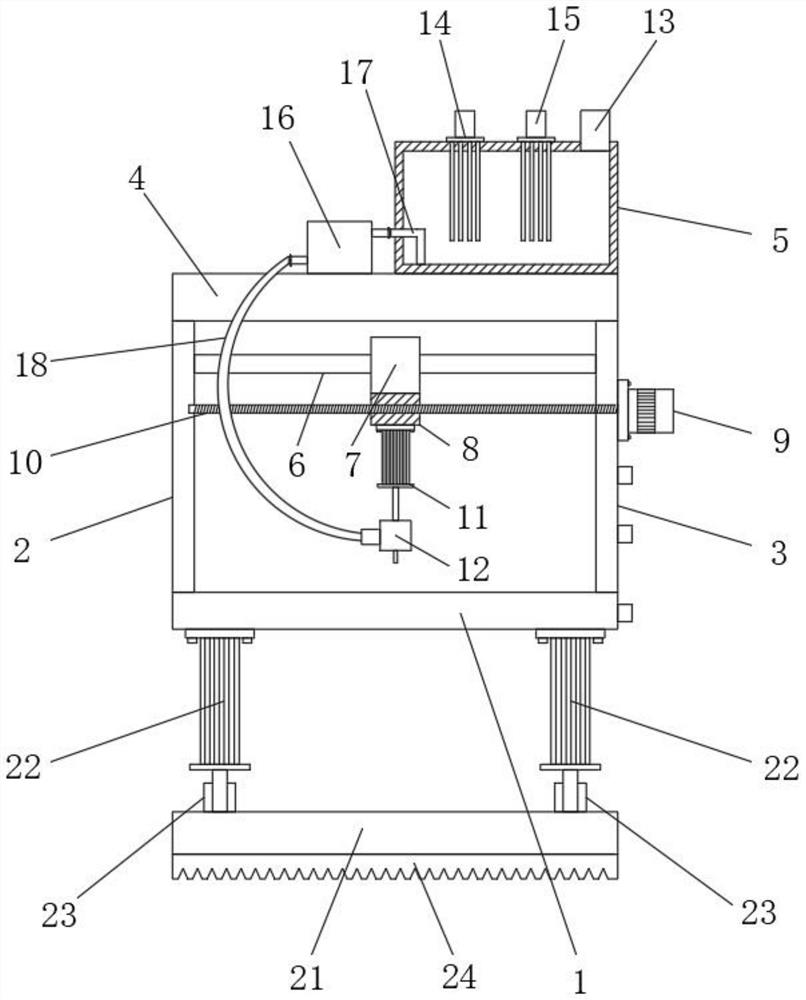

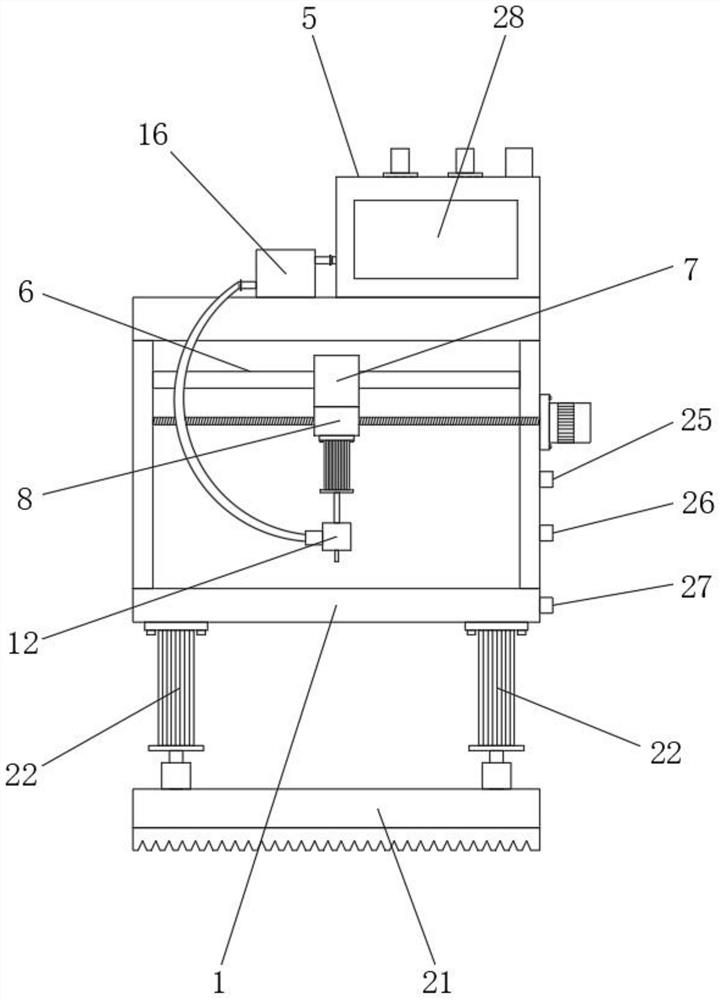

Forming curing mold for plastic-sealed diode production and implementation method of forming curing mold

InactiveCN113085098AEasy to placeEffective placementDomestic articlesInjection molding processMechanical engineering

The invention discloses a forming curing mold for plastic-sealed diode production and an implementation method of the forming curing mold, and belongs to the technical field of plastic-sealed diode production. The forming curing mold comprises a base, wherein a curing mold assembly is arranged above the base, a demolding ejection assembly is arranged on the lower portion in the curing mold assembly, a cooling assembly is arranged in the curing mold assembly, a power assembly is connected to the upper portion of the curing mold assembly, and an injection molding assembly is connected to the upper portion of the power assembly above the curing mold assembly. According to the forming curing mold for plastic-sealed diode production and the implementation method of the forming curing mold, injection molding liquid is prevented from leaking, the quality of plastic-sealed objects is improved, the demolding efficiency is improved, the inconvenience of manual demolding is reduced, and the effect of rapid curing is achieved; water resource waste is reduced through circular cooling, and the cooling efficiency is also greatly improved; and the mechanical energy of an upper mold base is effectively guided, the pressing precision is improved, the joint closing efficiency is guaranteed, the injection molding efficiency is improved, the situation that internal liquid solidifies to block an inner groove in the next injection molding process can be avoided, and the dredging efficiency is improved.

Owner:赣龙微电子科技(定南)有限公司

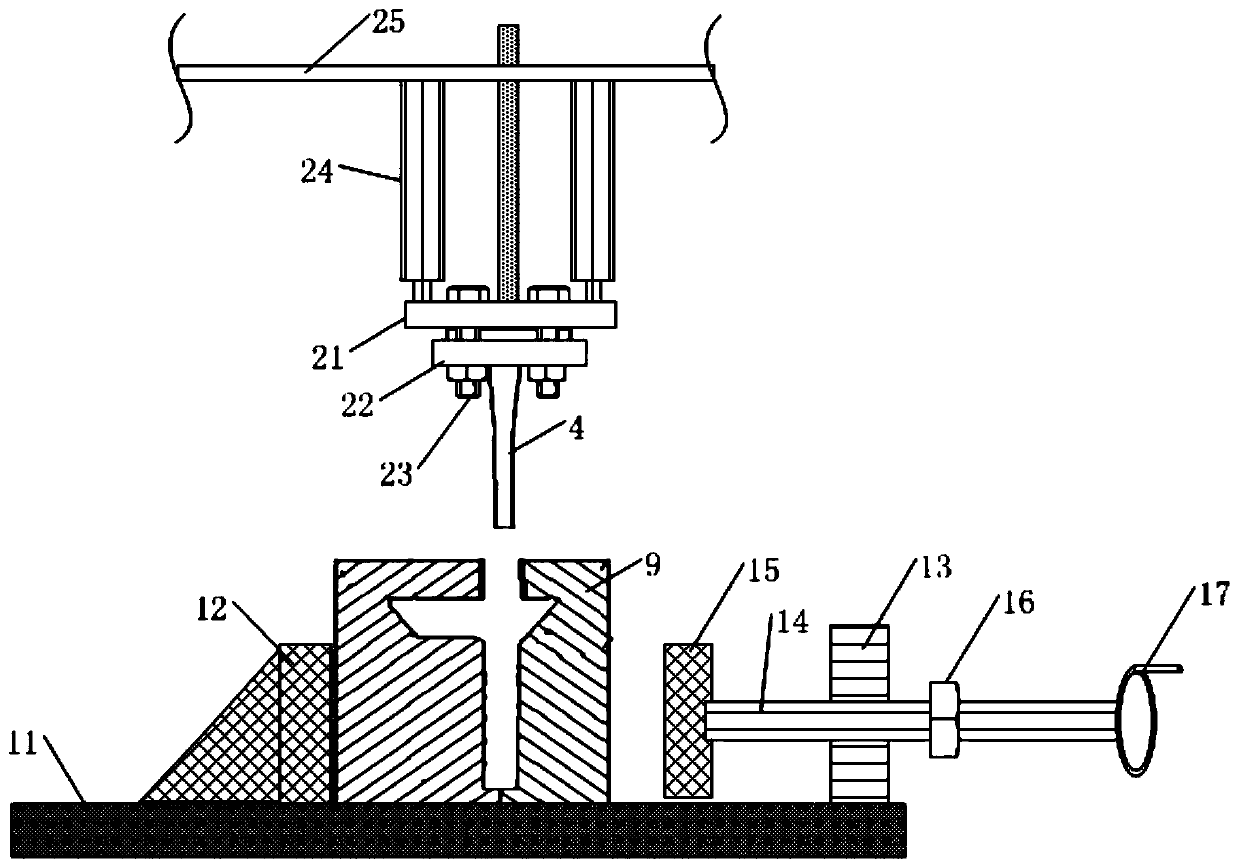

Efficient lead-acid storage battery cast-welding production process

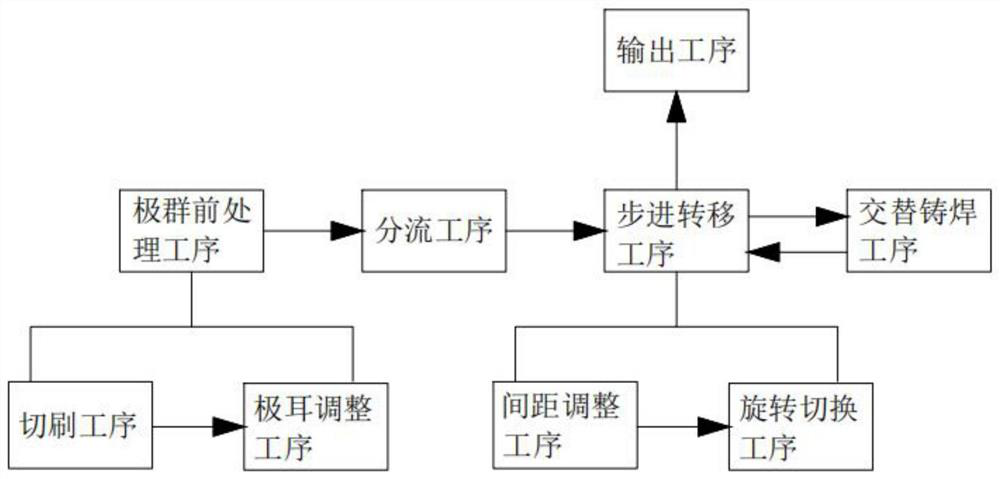

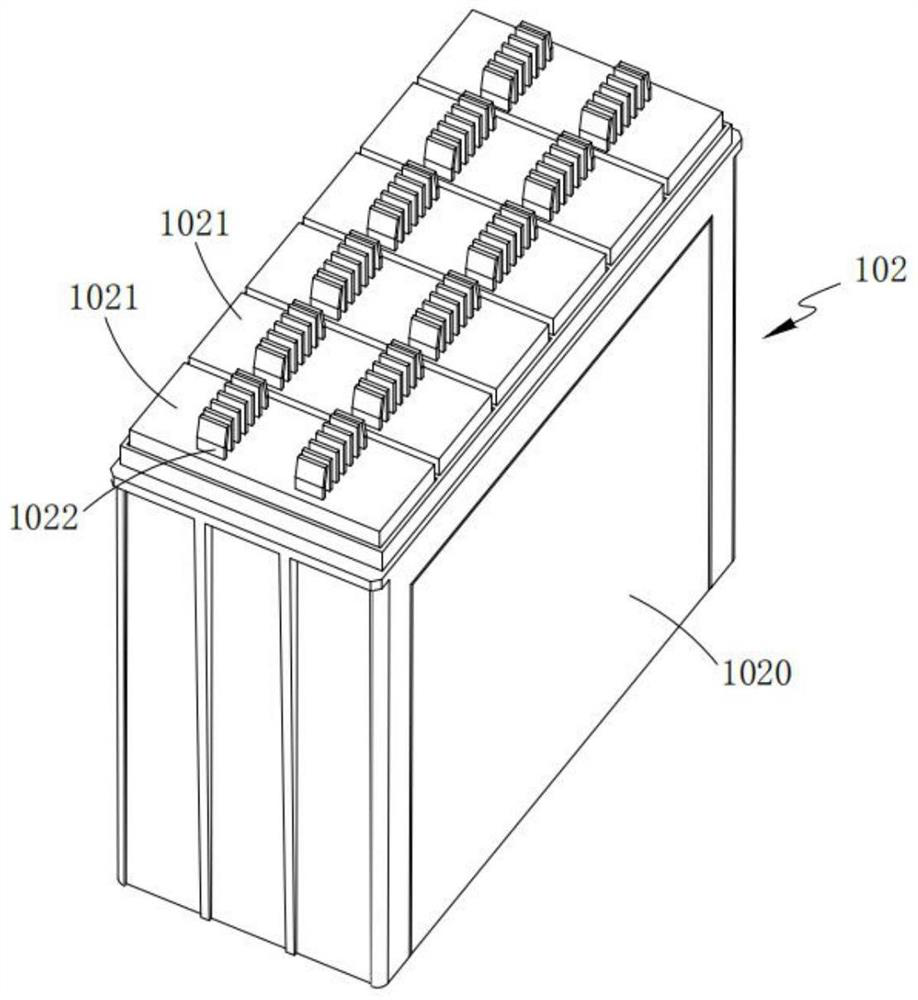

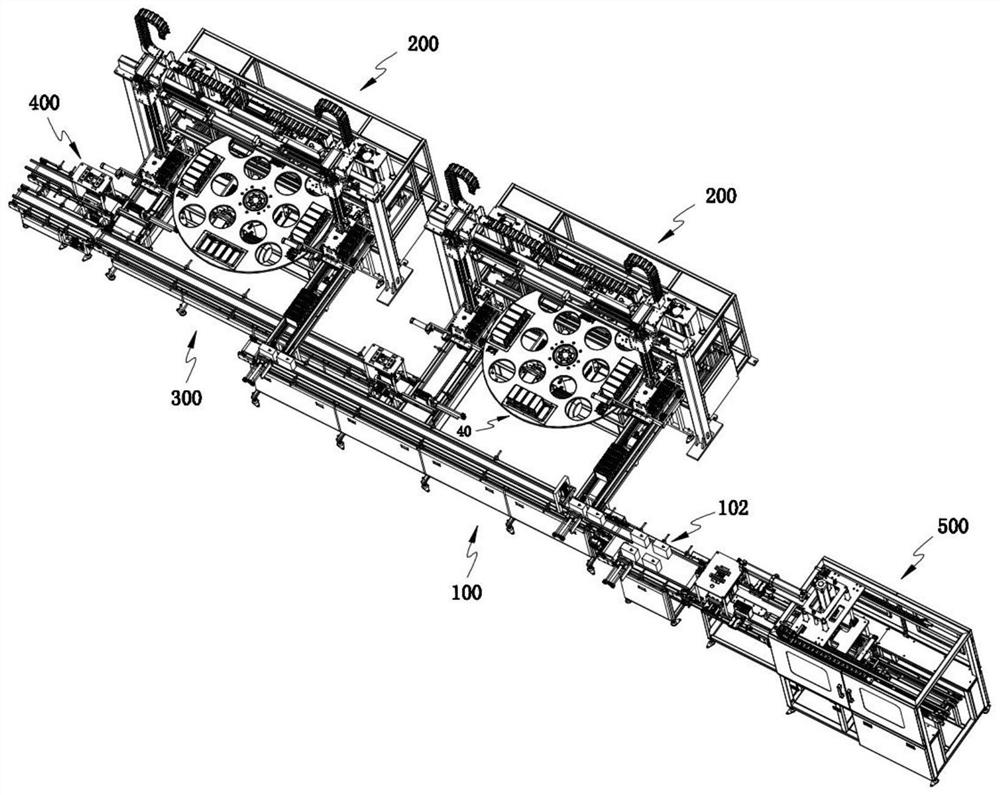

ActiveCN112756588ARealize flow operationShorten production timeCasting plantsFinal product manufactureEngineeringProcess engineering

The invention relates to the technical field of storage battery production equipment, in particular to an efficient lead-acid storage battery cast-welding production process which is characterized by comprising the following steps: S1, a shunting procedure: a storage battery is automatically conveyed forwards by a feeding conveying system, and a plurality of cast-welding production systems are arranged on the side of the feeding conveying system; and S2, a cast-welding alternating procedure: each cast-welding production system comprises a cast-welding mechanism, a plurality of sets of lead dipping mechanisms and cast-welding molds which are arranged in one-to-one correspondence with the lead dipping mechanisms and can be conveyed and transferred between the cast-welding mechanism and the corresponding lead dipping mechanisms, the cast-welding mechanisms bear storage battery packs conveyed by a shunting mechanism in a shunting mode, the cast-welding molds obtain molten lead liquid from the lead dipping mechanisms to the cast-welding mechanisms to be subjected to cast-welding work with the storage battery packs, and the multiple cast-welding molds alternately change the cast-welding mechanisms to convey the lead liquid needed by cast-welding. Cast-welding flow production of the storage battery is achieved, the cast-welding molds are matched to alternately conduct cast-welding on the cast-welding mechanisms, and the production time is shortened.

Owner:长兴金润科技有限公司

Road pavement marking method on basis of road pavement guide line marking device

The invention relates to the technical field of road pavement marking, in particular to a road pavement marking method on the basis of a road pavement guide line marking device. The road pavement guide line marking device comprises a bottom plate. A storage shell is arranged on a side of the upper end of the bottom plate, a ball is connected with the lower end of a threaded rod, a movable plate isconnected with the outer side of the ball by a ball groove, the end, which is far away from a first pump, of a discharge pipe penetrates a through hole and is connected with a spray gun, and withdrawal barriers are inserted in two sides of the movable plate. The road pavement marking method has the advantages that to-be-marked pavements can be swept by a sweeping brush, accordingly, marking effects can be improved, manual sweeping can be omitted, and the work efficiency can be improved; the to-be-marked pavements can be washed by a spray nozzle, accordingly, sticky objects can be brushed awayby the sweeping brush, and the marking effects can be improved; the storage shell has a heating function, and accordingly raw materials can be prevented from being cooled and solidified in long-timeuse; original guide lines can be cleared, the road pavement guide line marking device is simple in structure and convenient to use, energy can be saved, the amount of hand labor can be reduced, and the marking efficiency can be improved.

Owner:山西永泰峰达建设工程有限公司

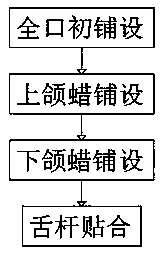

Dental metal base waxing method

InactiveCN110123469AThe overall thickness is thinDoes not affect aestheticsDental prostheticsWaxUltimate tensile strength

The invention relates to the technical field of base waxing, and discloses a dental metal base waxing method. The method comprises the steps of full mouth initial spreading, maxillary wax spreading, mandibular wax spreading, and tongue sticking. The dental metal base waxing method has a thin thickness and does not affect the appearance. after a rear bracket is installed, broken phenomenon of the rear bracket due to not enough intensity cannot be generated, through the effect of a waxing device, the solid wax is melted, in the process of and waxing, the process of waxing is more convenient, andthe separation of a top cover and the waxing device body is facilitated by the function of the fastening structure, the splicing is relatively stable, and the wax addition is more convenient and comprehensive. Through the action of a wax melting device, during the a spreading process of a smooth wax sheet, the smooth wax sheet can be heated and melted for spreading, so that the spreading of the smooth wax sheet is more convenient, and the method brings better use prospect.

Owner:合肥卓越义齿制作有限公司

Asphalt cyclic spraying device

InactiveCN103215879AIncrease temperaturePrevent cooling and solidificationRoads maintainenceEngineeringControl valves

The invention relates to an asphalt cyclic spraying device which comprises a material feed channel communicated with an asphalt tank. According to the technical key point, one end of the material feed channel is connected with a material feed control valve body; the material discharge end of the material feed control valve body is communicated with an asphalt pump, and asphalt supply and asphalt non-supply between the asphalt pump and the material feed channel are controlled by the material feed control valve body; the material discharge end of the asphalt pump is communicated with an asphalt control valve body provided with a plurality of gears for controlling backflow or spraying of the asphalt; a first material outlet, a second material outlet, a third material outlet and a material inlet are formed in the asphalt control valve body; the material inlet is communicated with the material discharge end of the asphalt pump; the first material outlet is communicated with a backflow pipeline for leading the asphalt back to the asphalt tank; the second material outlet and the third material outlet are communicated with each other through a communicating pipeline; and the communicating pipeline is communicated with a spraying device. The asphalt cyclic spraying device can control the asphalt to backflow and then to be sprayed, so that the spraying temperature of the asphalt is guaranteed, and the asphalt cyclic spraying device can easily control the asphalt.

Owner:GUANGDONG ESUN HEAVY IND CO LTD

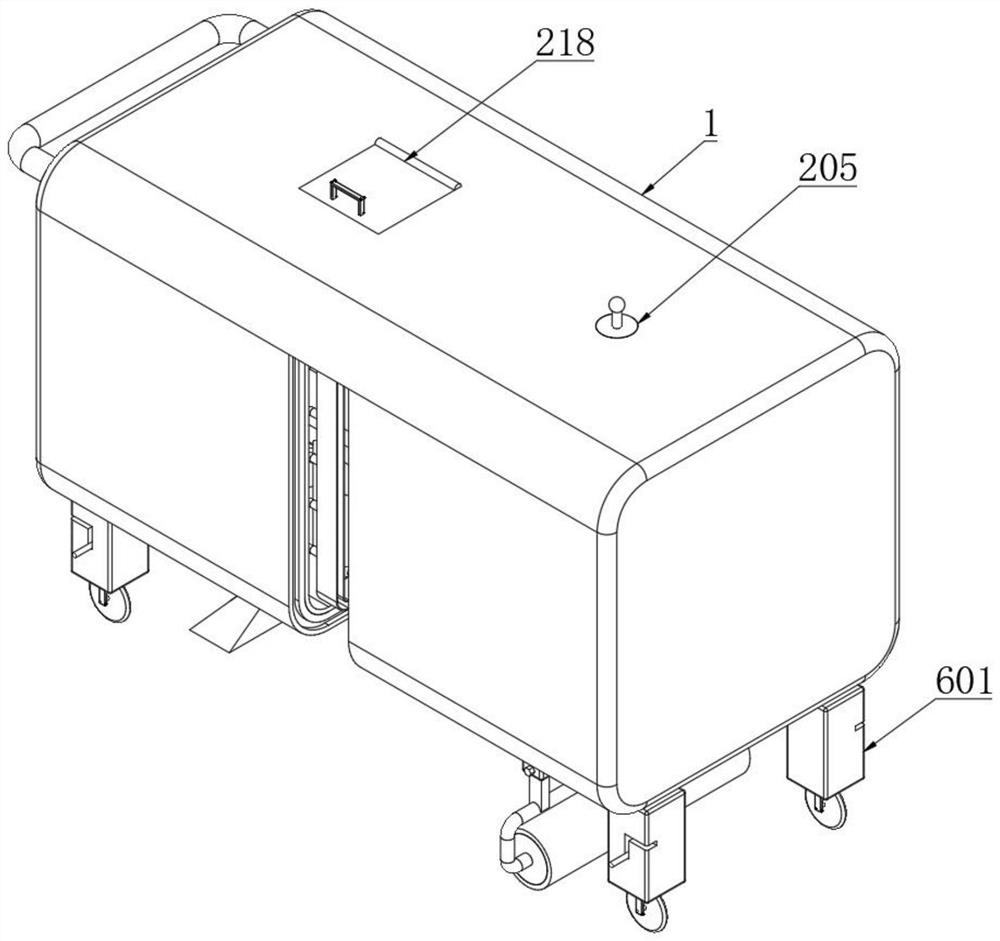

Hot asphalt conveying and storing device with anti-blocking function

ActiveCN112455945AEvenly heatedPrevent cooling and solidificationLarge containersTank wagonsGear driveGear wheel

The invention relates to the technical field of engineering machinery, in particular to a hot asphalt conveying and storing device with an anti-blocking function. The device comprises a base, first through grooves are formed at the four corners of the upper surface of the base, supporting columns are inserted into the first through grooves, and the lower ends of the four supporting columns penetrate through the first through grooves and are provided with roller mechanisms; bottom foot sleeves are arranged at the outer sides of the roller mechanisms in a sleeving manner, the upper portions of the bottom foot sleeves are fixedly connected with the supporting columns, supporting plates are symmetrically arranged at the left side and the right side of the upper surface of the base correspondingly, a transmission shaft is rotatably arranged between every two adjacent supporting plates, the two ends of each transmission shaft penetrate through the outer side of the corresponding supporting plate and are sleeved with first gears correspondingly, and the two ends of each transmission shaft are connected with first rotating heads; and grooves communicating with mounting grooves are formed at the four corners of the base, locking mechanisms are arranged in the grooves, and tooth grooves matched with the first gears are formed at one sides of the supporting columns. The device can be conveniently loaded on and unloaded from a moving vehicle, so that a transport vehicle is not idle, and meanwhile, a pipeline for conveying asphalt is prevented from being blocked.

Owner:永康市正永沥青混凝土有限公司

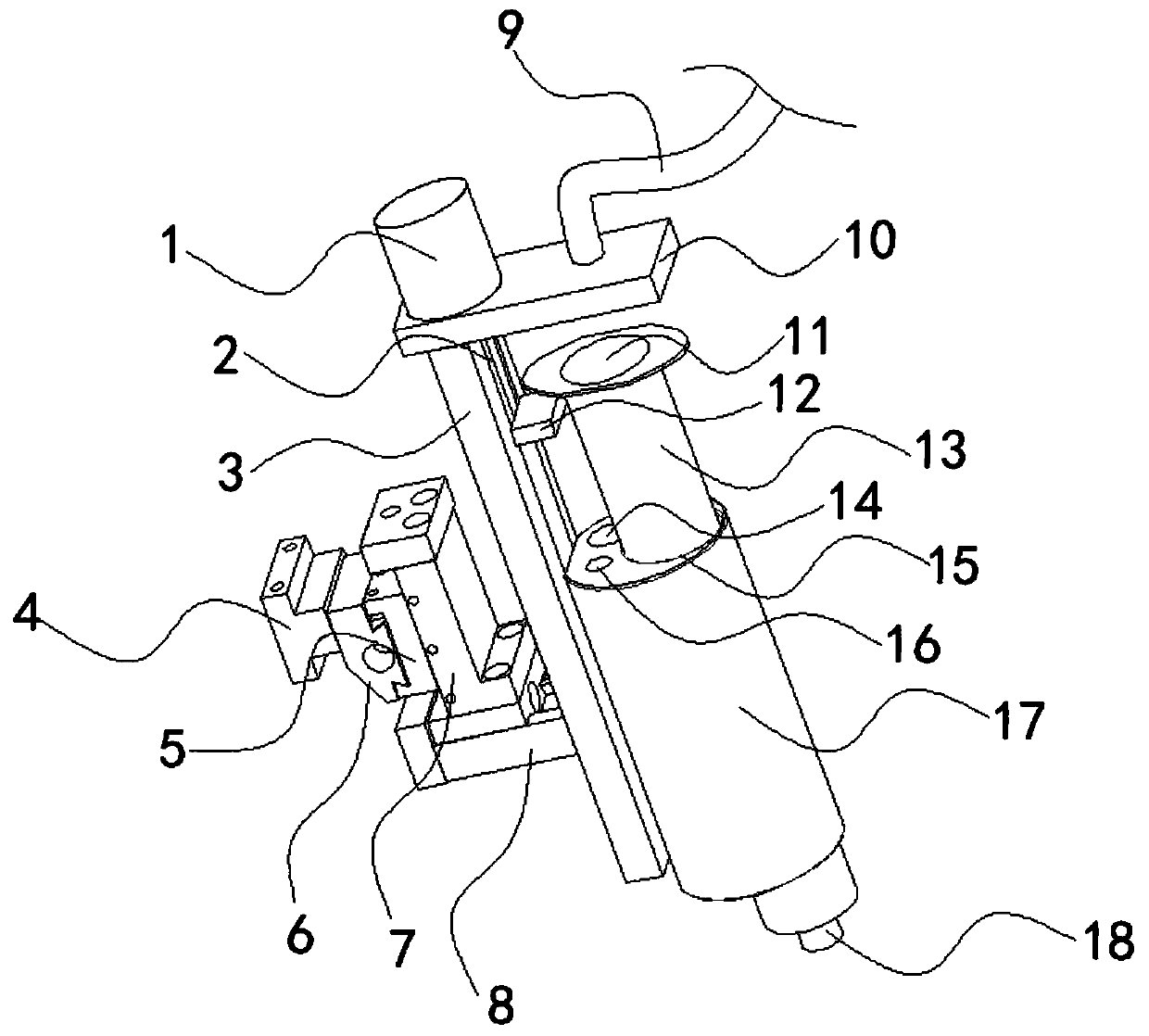

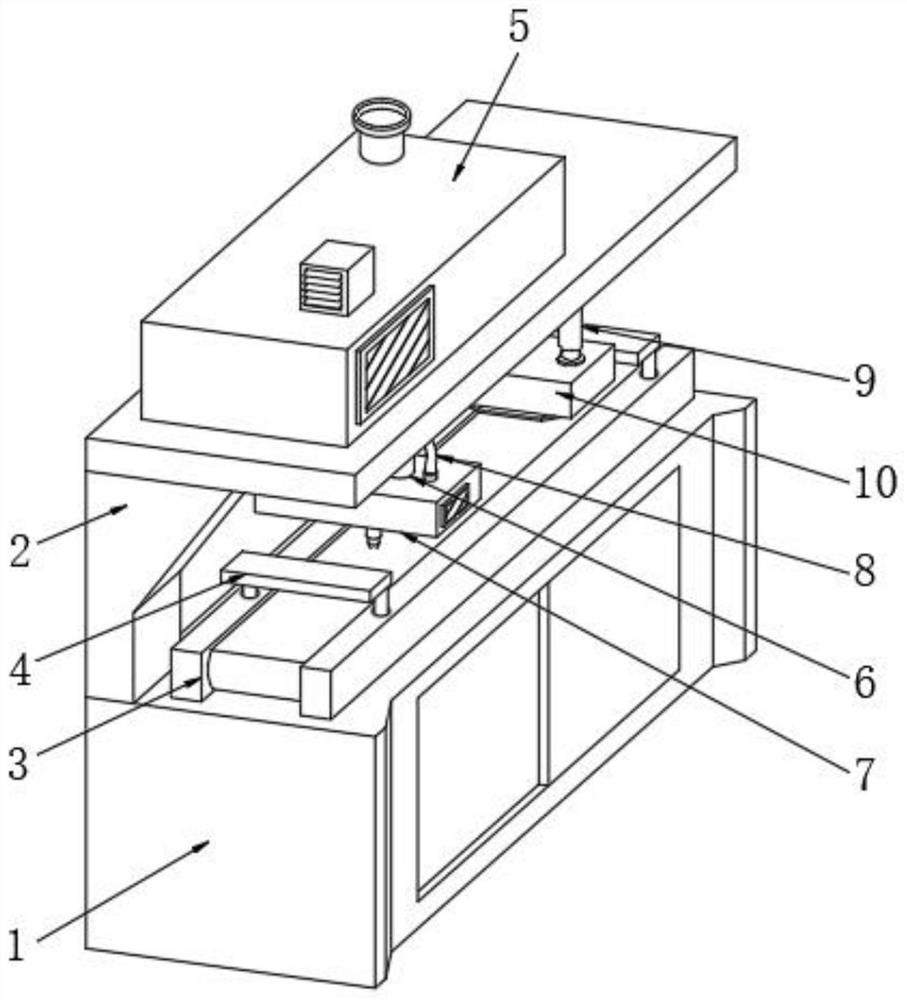

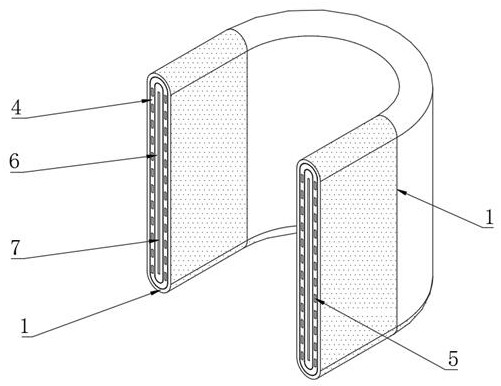

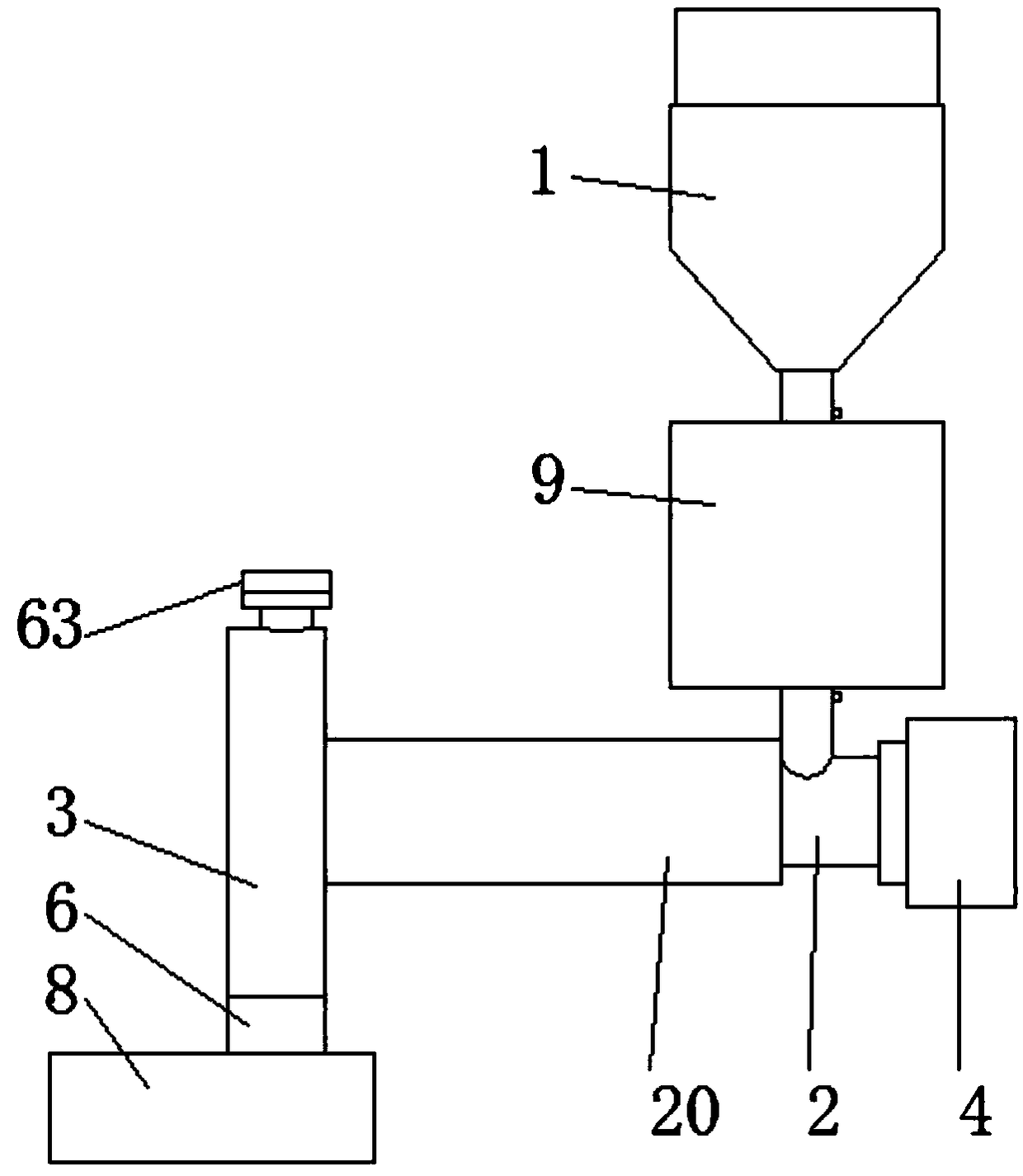

Adhesive dispensing device

ActiveCN110170424APrevent escapePrevent spoilageLiquid surface applicatorsCoatingsAdhesiveEngineering

The invention provides an adhesive dispensing device. The adhesive dispensing device comprises a position fine adjustment device, a support frame, a heating cylinder, an adhesive dispensing cylinder,a lifting block, a drive mechanism and a pressurization air pipe, wherein the position fine adjustment device is connected with the support frame, the heating cylinder is detachably arranged on the lower portion of the support frame, a stop block is arranged at the top of the support frame, the pressurization air pipe penetrates through the stop block, one side, facing the heating cylinder, of thesupport frame, is provided with a guide rail along the vertical direction, the lifting block is arranged on the guide rail and can slide up and down, a through hole is formed in the heating cylinder,the adhesive dispensing cylinder is arranged in the through hole in up and down sliding mode, the upper end and the lower end of the adhesive dispensing cylinder are exposed out of the through hole,an opening is formed in the top of the adhesive dispensing cylinder, an adhesive outlet pipe is arranged at the bottom of the adhesive dispensing cylinder, and a first dummy plate and a first siliconepart are arranged in the adhesive outlet pipe. The adhesive dispensing device aims at solving the problems that an existing adhesive dispensing mode is uneven in adhesive dispensing and enables adhesive to overflow.

Owner:广东迈特盛科技有限公司

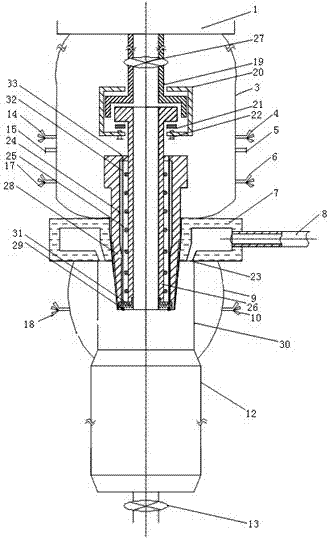

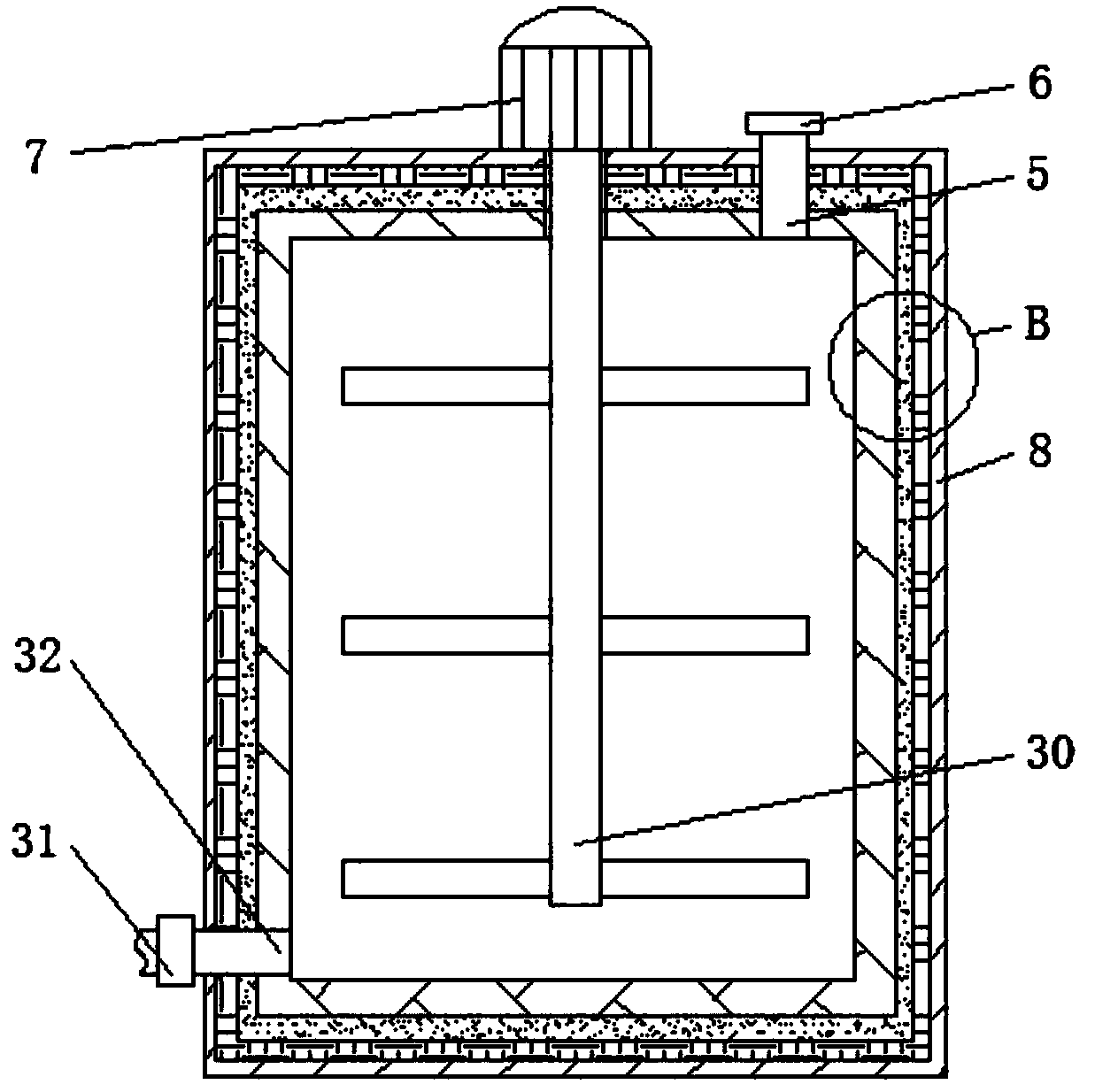

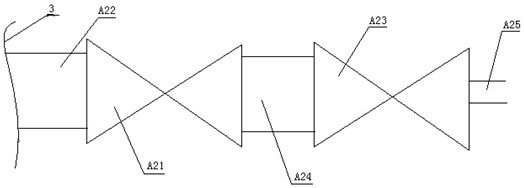

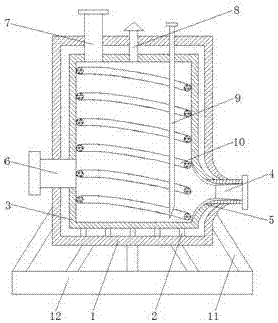

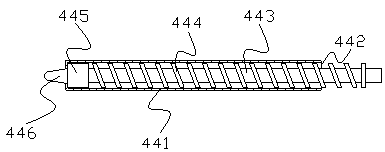

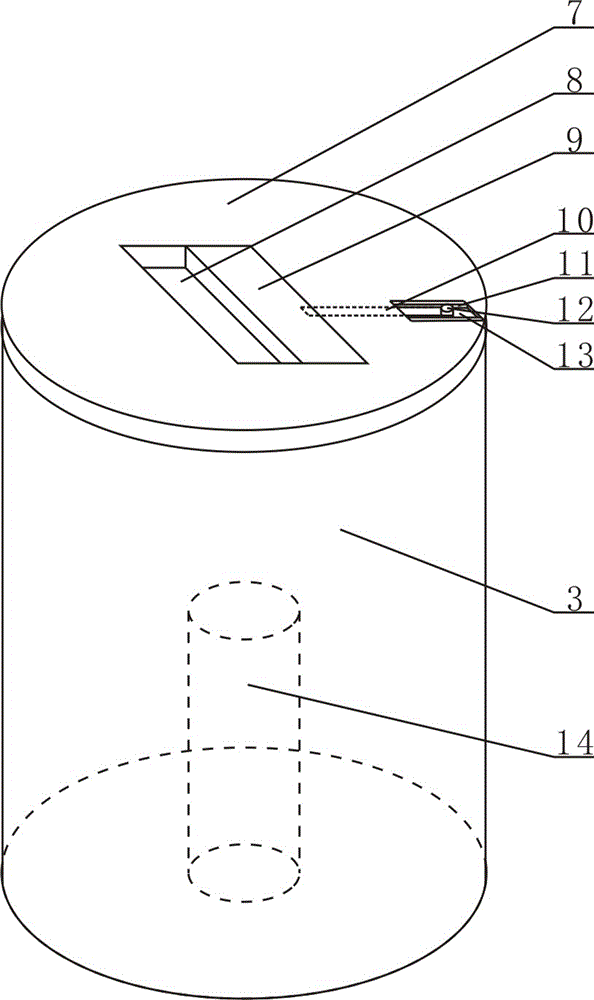

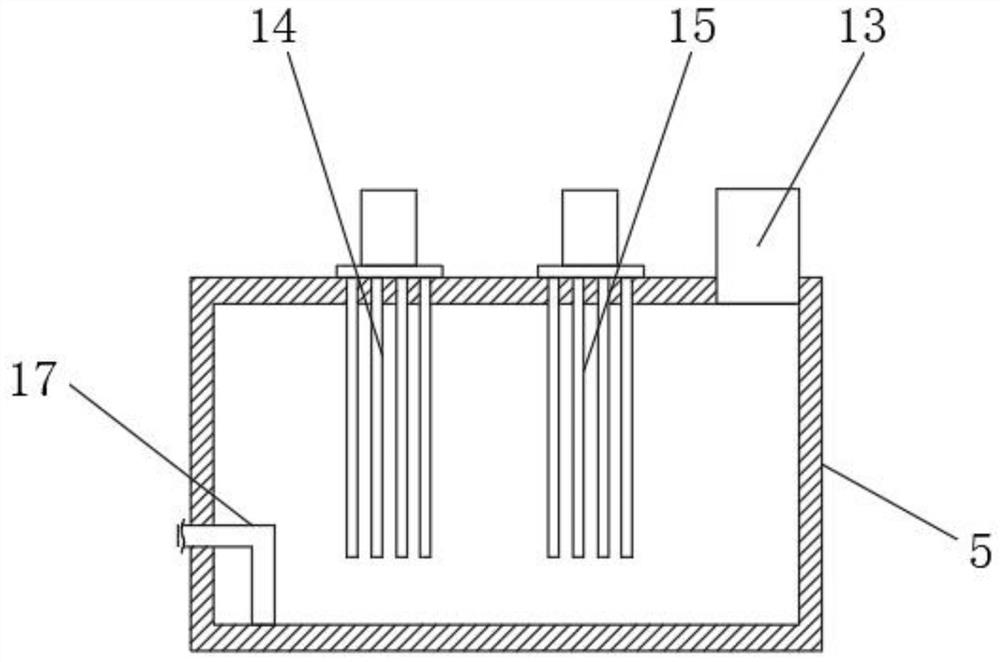

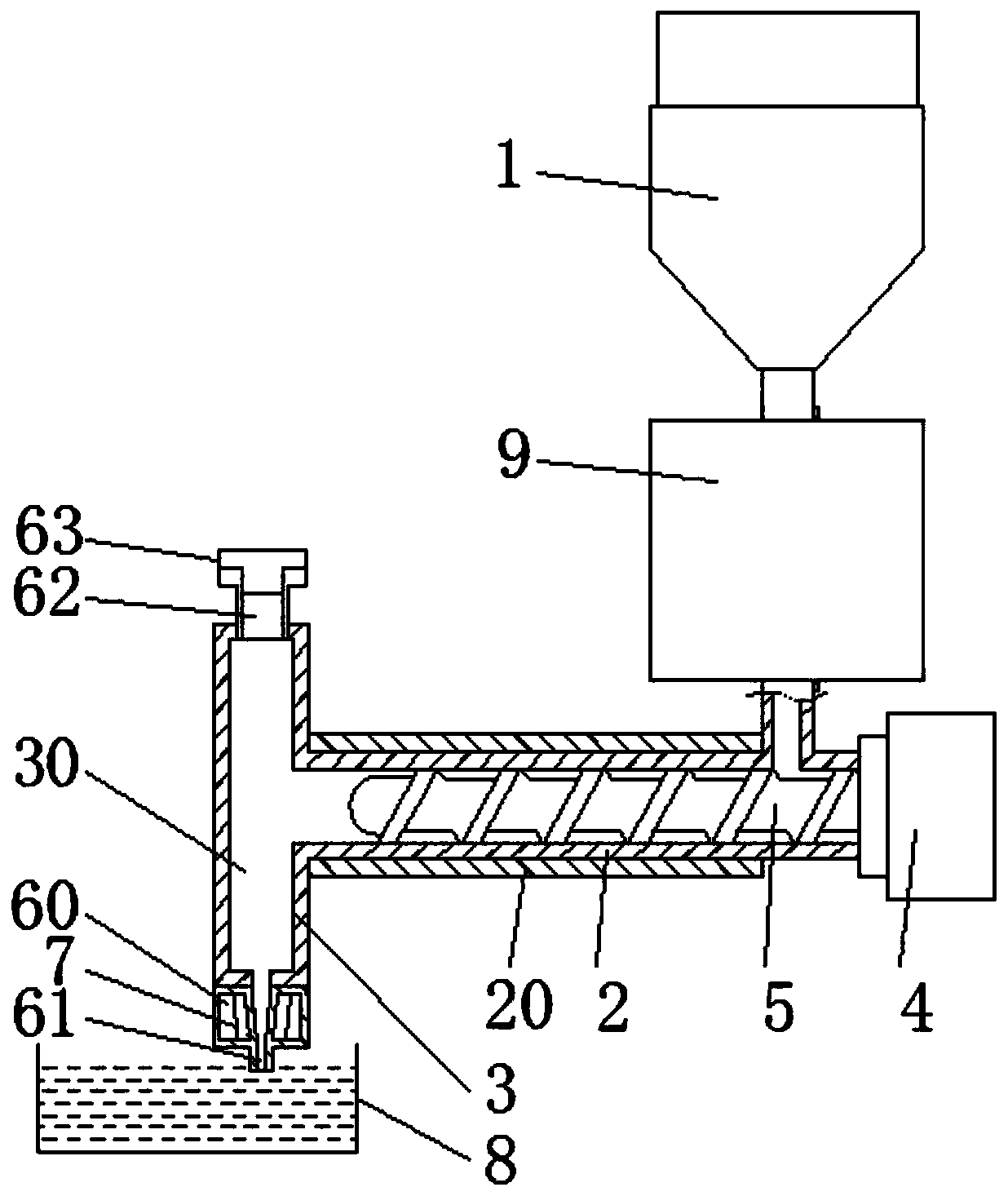

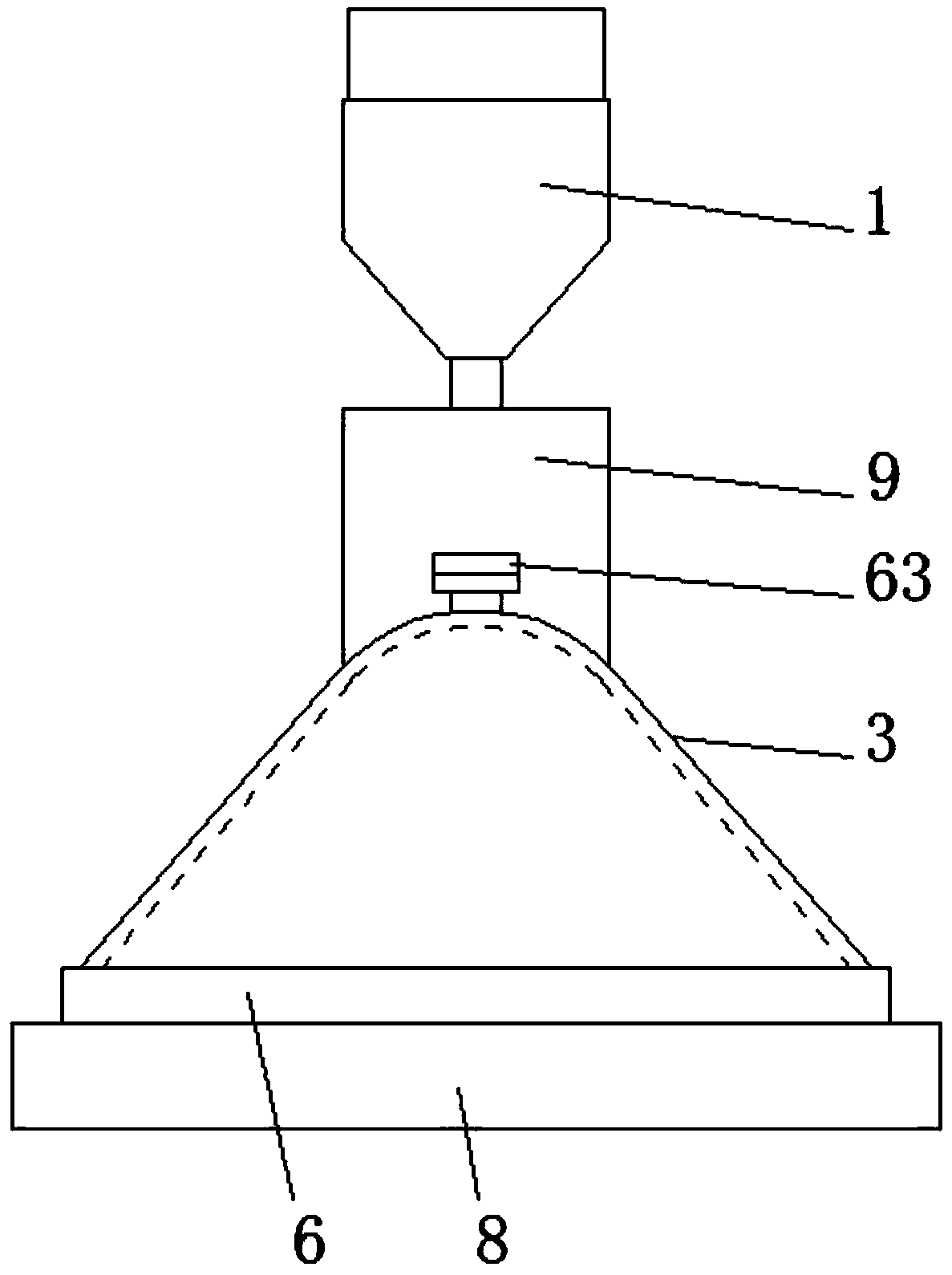

Totally-enclosed gas-atomizing powder preparation device for solving blockage of nozzle and liquid guiding pipe caused by high-melting-point material

InactiveCN102554246APlay a role in heat preservationPrevent cooling and solidificationCrucibleEngineering

The invention discloses a totally-enclosed gas-atomizing powder preparation device for solving blockage of a nozzle and a liquid guiding pipe caused by a high-melting-point material. The totally-enclosed gas-atomizing powder preparation device consists of a heat-preserving crucible, an atomizer, an atomizing tower, a retractable plastic pipe A, a retractable plastic pipe B, a vacuum pump and the like, wherein the atomizer is installed in the retractable plastic pipe A, the retractable plastic pipe A is hermetically connected with the heat-preserving crucible and the upper surface of a nozzle of the atomizer, and the retractable plastic pipe B is hermetically connected with the atomizing tower and the lower surface of the nozzle, so that a totally-enclosed system structure, which can prevent the high-melting-point material from being generated on the atomizer, is formed; a gap is maintained between the liquid guiding pipe and a metal outer sleeve and used for installing a heating element A, and a heating element B is installed in a gap between the air outlet pipes of two Laval structures of the nozzle, so that the heating element A and the heating element B can be used for solving the problem of blockage caused by the high-melting-point material when being simultaneously powered on. The totally-enclosed gas-atomizing powder preparation device for solving the blockage of the nozzle and the liquid guiding pipe caused by the high-melting-point material, provided by the invention, has the advantages that the structure is simple, the installation is convenient, the blocking problem can be effectively avoided and solved, the powder quality can be improved and the like.

Owner:SHANGHAI INST OF TECH

Industrial processing gumming machine based on Internet-of-Things control

InactiveCN111871698AEasy to collectEasy to receiveLiquid surface applicatorsCoatingsEngineeringMechanical engineering

The invention relates to the technical field of gumming devices, and discloses an industrial processing gumming machine based on Internet-of-Things control. The industrial processing gumming machine comprises a device base, an L-shaped supporting arm is fixedly installed in the middle of one side of the upper portion of the device base, and a right-angle frame is fixedly installed at one end of the upper portion of the L-shaped supporting arm; and a first electric push rod is fixedly mounted in the right-angle frame, and the bottom of the first electric push rod is fixedly connected to a sleeve rod. According to the industrial processing gumming machine based on Internet-of-Things control, a sliding rod is driven by a second electric push rod to slide in a sliding sleeve, two tightening devices are oppositely engaged to a certain extent, and the glue outlet diameter of glue in a glue outlet mechanism is adjusted and changed through joining of the two tightening devices; and a spiral heating pipe is heated through a heater device, the liquidity of the glue in a glue outlet hose is guaranteed through the spiral heating pipe, and the phenomenon that the glue is cooled and solidified in the transmission process in the glue outlet hose is avoided.

Owner:广州狸园科技有限公司

High-temperature fused salt storage tank device

InactiveCN107963351AGuaranteed temperatureReduce lossLarge containersTank wagonsMolten saltEngineering

The invention discloses a high-temperature molten salt storage tank device, which comprises a first shell, a shock absorbing device and a second shell. The double-layer structure of the first shell and the second shell can play a role of heat insulation, reducing The heat is lost through the surface of the storage tank, which enhances the heat preservation effect. The lower part of the side wall of the first shell is provided with a discharge pipe, and the inner wall of the discharge pipe is welded with a deflector. The first shell and the second shell are connected with the discharge pipe. The connection of the pipe is provided with rounded corners, so that the discharge port forms a smooth and gradual channel to prevent the precipitated crystals from blocking the discharge port. A manhole is provided on the side wall of the first shell away from the discharge pipe. The first The top of the housing is installed with a feed pipe, a safety valve and a liquid level gauge in sequence. The bottom of the liquid level gauge extends to the bottom of the inner cavity of the second housing. A heating tube is set inside the second housing. An electric heating wire is arranged inside, and the heating pipes are arranged in a spiral shape from top to bottom along the inner wall of the second housing to increase the heat conduction area.

Owner:新昌县城关海顺机械厂

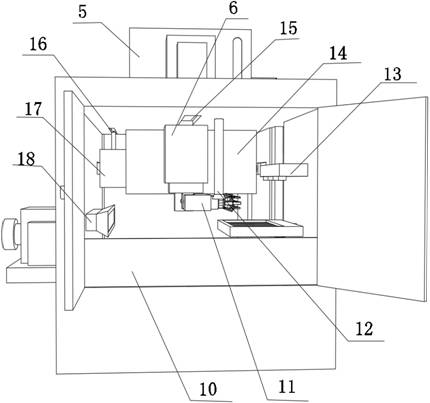

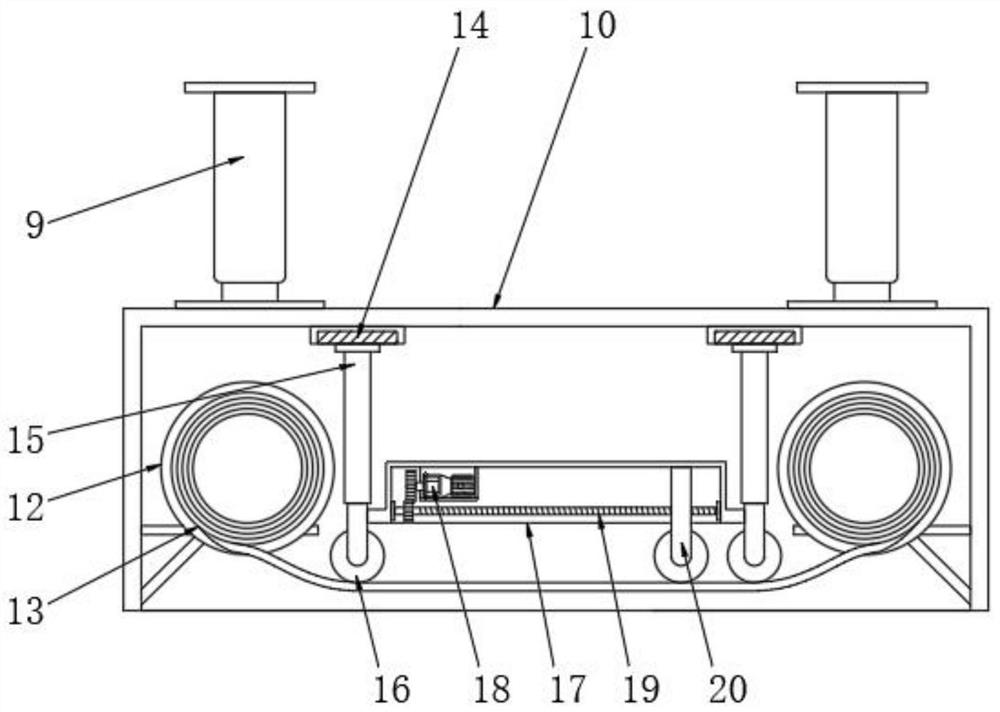

Flow-casting mold cleaning device

InactiveCN107457949APrevent cooling and solidificationEasy to operateCoatingsAgricultural engineeringCasting mold

The invention discloses a flow-casting mold cleaning device. The flow-casting mold cleaning device comprises a base, a rack, a heating device, a control device, fixing devices, guide rails, a power device, an adjusting device and a brush; the base is provided with the rack and the heating device; the control device is arranged on the outer side of the rack; the fixing devices are arranged on two sides of the rack; the guide rails are arranged on two sides of the upper portion of the rack; the power device is arranged on the guide rails; the power device comprises a driver, a sliding block, a motor, a rubber wheel and a shell; the adjusting device comprises an adjusting base, a bolt and a connection rod; the connection rod is connected with the shell; the connection rod is connected with the adjusting base through the bolt; the adjusting base and the brush are connected; and the control device is connected with the heating device and the driver. The flow-casting mold cleaning device is simple in structure, easy to operate and feasible.

Owner:HARBIN UNIV OF SCI & TECH

Glue removing and cleaning equipment for producing sanitary towels

ActiveCN112722769AAvoid damageEasy to scrape offSteam generation heating methodsCleaningStructural engineeringMechanical engineering

The invention discloses a glue removing and cleaning equipment for producing sanitary towels. The equipment comprises main rollers and auxiliary rollers, a conveying belt is wound around the main rollers and the auxiliary rollers, the section, located between the two main rollers, of the conveying belt is a gluing section, the section, located between the two auxiliary rollers, of the conveying belt is a glue removing section, oblique side sections connected to both sides of the gluing section and the glue removing section, a cleaning assembly is arranged on the oblique side sections on the left side, a secondary scraping assembly is arranged on the oblique side sections on the right side, a colloid softening device and a scraper assembly are arranged on the glue removing section from left to right, the colloid softening device comprises a heating box, a spraying pipe and a heating plate, openings are formed in the two sides of the heating box, the conveying belt penetrates through the heating box, a heating plate is fixedly connected to the bottom of the inner side of the heating box, a spraying pipe is fixedly installed in the heating box and located above the heating plate, and a atomizing nozzle on the spraying pipe faces the heating plate.

Owner:QUANZHOU LUOJIANG DISTRICT HUIFENG SANITARY CO LTD

Preparation process of infantile diarrhea ointment

InactiveCN112043764ALow costAvoid loss of potencyAnthropod material medical ingredientsDigestive systemInfantile diarrheaOfficinalis

The invention discloses a preparation process of infantile diarrhea ointment, and relates to the technical field of ointment. The preparation process comprises the following steps that S1, raw materials are prepared, wherein the infantile diarrhea ointment comprises the following raw materials of, by weight, 30-35 parts of cinnamon, 20-23 parts of radix aucklandiae, 20-28 parts of folium artemisiae argyi, 15-20 parts of radix bupleuri, 12-15 parts of gallnut, 10-13 parts of cortex magnoliae officinalis, 12-14 parts of golden cypress and 7-10 parts of mint; and S2, the radix aucklandiae, the folium artemisiae argyi, the radix bupleuri, the golden cypress and the mint are crushed and are sieved with a 110-mesh sieve to obtain radix aucklandiae fine powder, folium artemisiae argyi fine powder, radix bupleuri fine powder, golden cypress fine powder and mint fine powder to be stored for later use. According to the preparation process, the antidiarrheic ointment is low in cost and free of side effects, peculiar smells of the ointment can be shielded through the mint powder, discomfort to children is prevented, when the ointment is used, a cool and comfortable feeling is achieved, and irritant side effects of the ointment on the children can be prevented.

Owner:安徽宝华药业有限公司

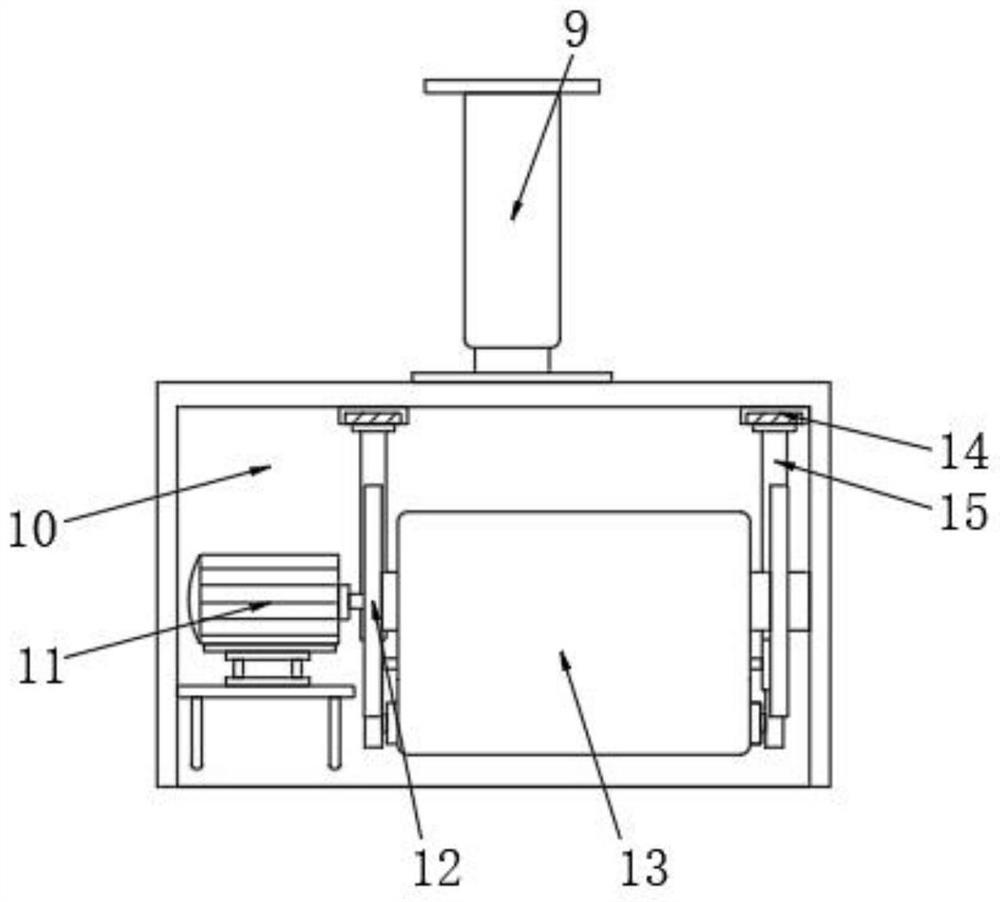

Secondary-heating energy-saving injection molding injection device

The invention discloses a secondary-heating energy-saving injection molding injection device. The device structurally comprises a case, a driving box, a hopper, an injection mechanism and an air cylinder. The driving box is horizontally mounted on the upper end of the case and is mechanically connected with the case. The hopper is vertically mounted on the upper end of the driving box and penetrates through the inner side, the injection mechanism is embedded and mounted on the left side of the driving box and is mechanically connected with the driving box, the air cylinder is horizontally mounted on the upper end of the case, and the right end is connected with the left end of the driving box; the injection mechanism comprises a connecting end, a heating box, a filling port, a conveying structure and a heat insulation cover; the connecting end is mounted on the right end of the heating box, the filling port is formed in the upper end of the heating box in a penetrating manner, the right end of the conveying structure is embedded on the inner side of the heating box, the heat insulation cover is arranged on the outer side of the conveying structure in a covering manner and is mechanically connected with the conveying structure, the conveying structure is arranged on the left side of the heating box, plastic can be better heated and melted, partial cooling and solidifying are prevented, more energy is saved while secondary interval heating is carried out, and the injection head is better prevented from being blocked.

Owner:沪金(苏州)实业有限公司

Grouting equipment for manufacturing of plastic products

InactiveCN108582610APrevent cooling and solidificationIncrease delivery speedEngineeringElectromagnetic heating

The invention discloses grouting equipment for manufacturing of plastic products. The grouting equipment comprises mixing blades, an electromagnetic heating plate, a material adding port, a slurry pump, an electromagnetic batcher and moving wheels. The electromagnetic heating plate is installed at one side of the mixing blades. The slurry pump is arranged below the material adding port. The movingwheels are installed below the electromagnetic batcher. The grouting equipment has a scientific and reasonable structure and is safe and convenient to use. With the arrangement of the mixing blades,plastic raw stock and additives are fully stirred and mixed. With the arrangement of the electromagnetic heating plate, the plastic raw stock is prevented from being cooled and solidified. With the arrangement of the material adding port, additives are convenient to add. With the arrangement of the slurry pump, the conveying speed of the plastic raw stock during pouring is increased. With the arrangement of the electromagnetic batcher, pouring amount of the plastic raw stock during pouring is convenient to regulate and control. With the arrangement of the moving wheels, the grouting equipmentis simpler and more convenient during moving and carrying processes.

Owner:海宁市晨丰橡塑有限公司

Linear vibration casting machine

PendingCN112808986APrevent cooling and solidificationMolten metal conveying equipmentsProcess engineeringControl valves

The invention discloses a linear vibration casting machine, and belongs to the field of metallurgical equipment. The linear vibration casting machine comprises a box body, a stirring box is arranged on the box body, a stirring shaft is arranged in the stirring box, a feeding pipe is arranged on the stirring box, a conveying pipe is arranged in the box body, a pushing rotating shaft is rotationally connected into the conveying pipe, a spiral propelling blade is arranged on the pushing rotating shaft, a guide pipe is connected between the conveying pipe and the stirring box, and a control valve is arranged on the guide pipe. According to the linear vibration casting machine, molten raw materials are conveniently stirred through the stirring box and are prevented from being solidified, the molten raw materials in the conveying pipe are conveniently pressurized and pushed through the pushing rotating shaft and the spiral propelling blade, bubbles in the raw materials are removed, meanwhile, the raw materials in the conveying pipe are conveniently and completely discharged, and a heating pipe, a transmission mechanism and a heating mechanism are arranged, so that the conveying pipe is conveniently heated, and the raw materials in the conveying pipe are prevented from being cooled and solidified in the transferring process.

Owner:谢剑波

Surface coating spraying device for road construction bridge

ActiveCN112439619AScientific and reasonable structureEasy to usePretreated surfacesCoatingsRotational axisHeat conducting

The invention discloses a surface coating spraying device for a road construction bridge. The device comprises a shell, wherein a stirring and drying mechanism is arranged at the inner side of the shell, and the stirring and drying mechanism comprises a material storage box, an electric heating box, an air-inlet pipe, a filtering box, a sealing cover, a handle, a feeding pipe, a ventilating pipe,a through pipe, a heat conducting piece, a fixing pipe, a connecting shaft, a stirring shaft, a rotating shaft, a rotating motor, fan blades, an air blowing cover and a dustproof cover. According to the device, through the arrangement of the stirring and drying mechanism, workers can stir and heat the materials at the inner side of the material storage box so that the phenomenon that the materialsare cooled and solidified in the placing process is avoided, the situation that the materials cannot be normally sprayed and used due to cooling and solidification of the materials is avoided, the drying treatment of the sprayed materials for the workers is facilitated, the sprayed materials on the ground are prevented from being rolled and treaded, the problem that a fan needs to be installed inthe using process of the spraying device is solved, and the spraying device has multiple effects.

Owner:王磊

Refractory material compression molding device

InactiveCN113815096AIncrease heightReduce wasteRotary stirring mixersAuxillary shaping apparatusCompression moldingRefractory

The invention discloses a refractory material compression molding device. The refractory material compression molding device comprises a material containing box, wherein a lifting plate is connected between the two sides of the inner wall of the material containing box in a sliding mode, an oil cylinder is fixedly connected to one side of the material containing box, one end of the oil cylinder penetrates through the material containing box and extends into the material containing box, a pressing device, a lifting device and a mixing device are arranged in the material containing box, the pressing device is provided with a pressing female die, the pressing female die is fixedly connected with the inner wall of the material containing box, and the lifting device is provided with an elastic film. The invention relates to the technical field of material processing. According to the refractory material compression molding method, the purpose of a material mixing function is achieved, the problem of uneven mixing caused by the fact that raw materials are prone to being deposited at the corners of a container is solved, the refractory material on the inner wall of equipment can be cleaned, waste of the refractory material is reduced, the refractory material can be heated, the refractory material is prevented from being cooled and solidified, and the refractory material can be conveniently pressed and formed.

Owner:淮北卓本科技有限责任公司

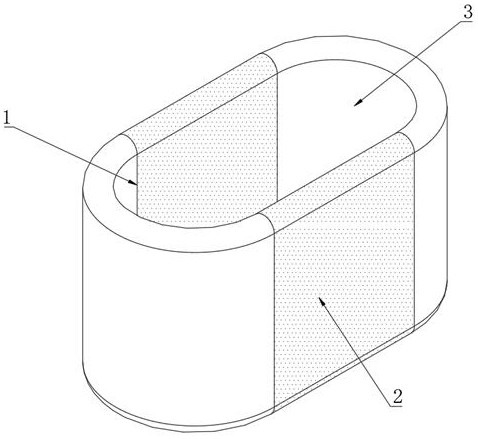

High-barrier flame-retardant composite sealing sleeve and preparation device thereof

ActiveCN112157968AScientific and reasonable structureEasy to useDomestic articlesRubber layered productsEngineeringMechanical engineering

The high-barrier flame-retardant composite sealing sleeve comprises a flame-retardant outer layer, frosted outer layers are symmetrically embedded into the outer side of the flame-retardant outer layer, heat-resistant rubber outer layers are symmetrically embedded into the positions, corresponding to the two sides of the frosted outer layers, of the outer side of the flame-retardant outer layer, and a barrier inner layer is bonded to the inner side of the flame-retardant outer layer. The storage sleeve is scientific and reasonable in structure and safe and convenient to use, through the arrangement of the flame-retardant outer layer, the frosted outer layer and the heat-resistant rubber outer layer, the flame-retardant and anti-skid performance of the storage sleeve can be improved, and the storage sleeve is high in practicability and easy to popularize and apply. Through the arrangement of the blocking inner layer, the blocking strips, the soft inner layer and the embedded blocking plate, the blocking effect of the sealing sleeve can be improved, the inflaming retarding and blocking effects on internal sealed objects are improved, the influence of external stimulation on the internal sealed objects is reduced, and the protection performance on the internal sealed objects is improved.

Owner:YANGZHOUSRKLE INDAL

Multi-disc type tank containing device for wax sealing of spina gleditsiae branches

InactiveCN106386192AQuick Wax TreatmentPrevent cooling and solidificationGraftingCultivating equipmentsWaxBiochemical engineering

The invention relates to a multi-disc type tank containing device for wax sealing of spina gleditsiae branches, which belongs to the field of agricultural equipment. The multi-disc type tank containing device is composed of a base, a connector, a wrapping device and a tank body, wherein the connector is arranged on the base, the wrapping device is arranged on the surface of the base, the wrapping device is composed of a clamping block, a fixed plate and a clamping head, the tank body is arranged on the base, a heating rod is arranged in the tank body, one end of the tank body is connected with the base, a cover is arranged on the other end of the tank body, a groove and an outlet are formed in the cover, a baffle is arranged at the outlet, the baffle is connected with a push-pull device, the push-pull device is composed of a push-pull rod, a limiting block and sliding ways, the sliding ways are respectively arranged on both sides of the groove, the push-pull rod is arranged between the two sliding ways, and the limiting block is arranged on the push-pull rod. The multi-disc type tank containing device has the advantages of simple structure and convenience in operation, wax-sealed treatment can be quickly performed on the collected spina gleditsiae branches, wax juice can be prevented from being cooled and solidified in a wax-sealed process, the wax-sealed efficiency is improved, and the wax-sealed operation of working personnel is greatly facilitated.

Owner:河南豫博药业科技有限公司

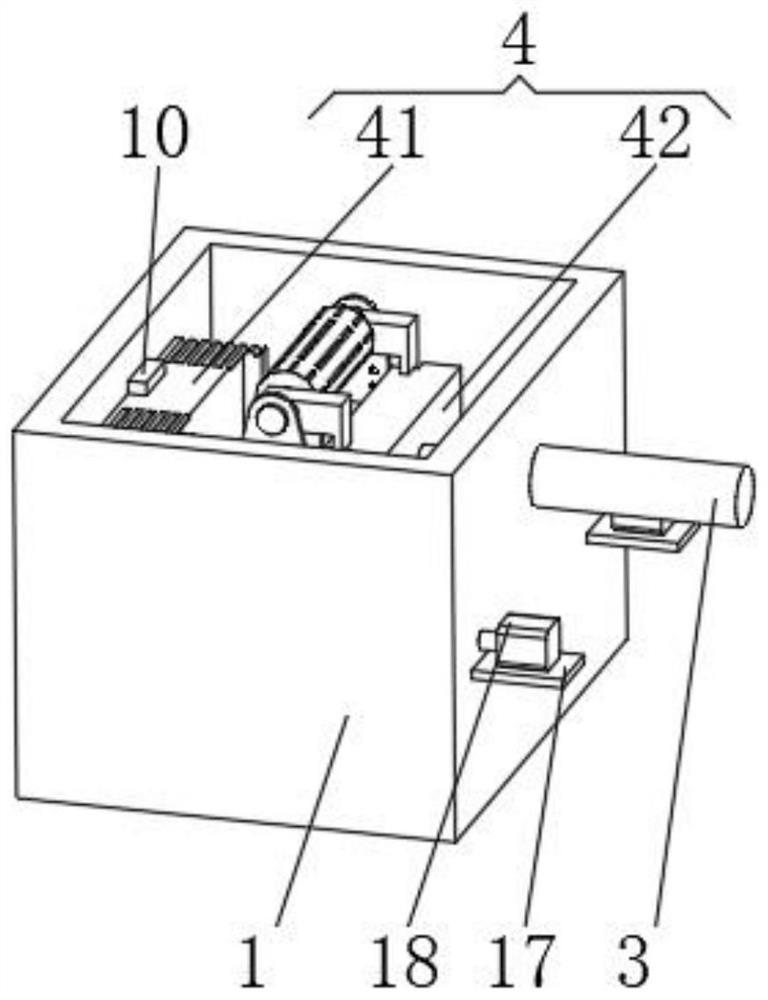

VARTM process resin flow control system and method

The invention discloses a VARTM process resin flow control system and method.The VARTM process resin flow control system comprises a bottom plate, melting equipment, conveying equipment, stirring equipment and flow control equipment, the melting equipment comprises a box body, the box body is welded to the top of the bottom plate, a feeding port is formed in the outer wall of one side of the box body, a feeding groove is welded to the outer wall of one side of the box body, and an electric heating plate is welded to the inner wall of the box body; and holes distributed at equal intervals are formed in the electric heating plate, a filter screen in sliding connection with the inner wall of the box body is arranged below the electric heating plate, a threaded groove is formed in the outer wall of the top of the box body, and the control method comprises fixed installation, system no-load detection and system load detection. The electric heating plate works to heat and melt resin, a cutting blade cuts the resin and accelerates the resin melting speed, a stirring shaft stirs the melted resin and keeps the resin fluidity, a gear motor drives a baffle to rotate, the resin flow is changed according to needs, operation is convenient, time is saved, the maintenance cost is lower, and the production cost can be saved.

Owner:苏州红典新材料科技有限公司

Epoxy resin dispensing device for manufacturing electronic components

InactiveCN112570207ARealize long-distance dispensingHeight adjustableLiquid surface applicatorsCoatingsEpoxyRubber material

The invention discloses an epoxy resin dispensing device for manufacturing electronic components, and belongs to the technical field of electronics. The epoxy resin dispensing device comprises a firstbase, and top plates are transversely welded to the tops of a first vertical plate and a second vertical plate. A sliding rod is transversely welded to the upper portion between the first vertical plate and the second vertical plate, a fixing block is welded to the bottom of the sliding block, a servo motor is connected to the upper portion of the side wall of the second vertical plate through screws, and a threaded rod is welded to the output end of the servo motor. A first electric cylinder is fixed to the bottom of the fixing block, and a rubber box is welded to the end of a piston rod ofthe first electric cylinder. Through forward and reverse rotation of the servo motor, the first electric cylinder and the rubber box can be driven to move left and right, so that long-distance dispensing of the rubber box is realized. The first electric cylinder can adjust the height of the rubber box through extension and retraction of a piston rod. Under the heating action of two heating copperpipes, rubber material in the rubber box can be heated and insulated, and the rubber material is prevented from being cooled and solidified. According to the invention, a second electric cylinder canadjust the use height of the equipment.

Owner:邵阳方邦瑞电子科技有限公司

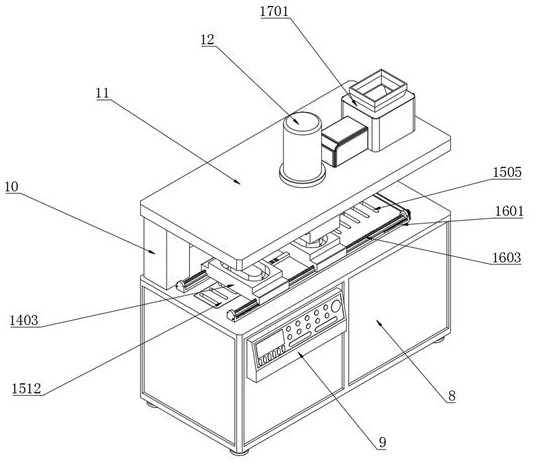

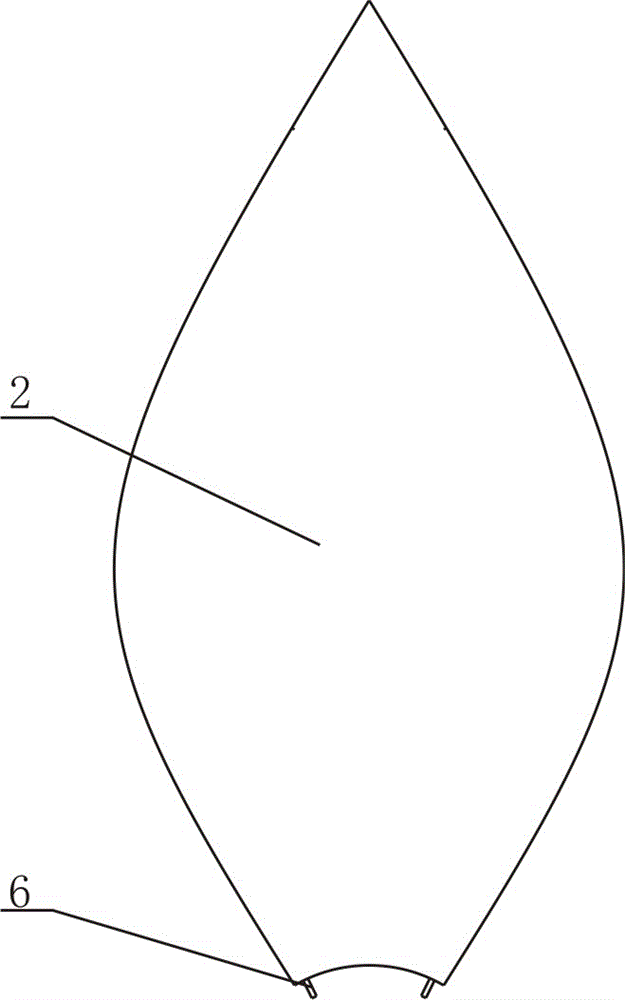

Preparation mold mechanism of forward curved vane of shot blasting machine and preparation method

PendingCN109913865APrevent cooling and solidificationImprove production efficiencyFurnace typesHeat treatment furnacesSolid particleHardness

The invention provides a preparation mold mechanism of a forward curved vane of a shot blasting machine and a preparation method. A vane substrate is configured as vane substrate solid particle powderwith the particle size ranging from 10 microns to 50 microns; the surface of the cavity wall of a preparation mold cavity is coated with a fluorocarbon resin release agent; a supersonic speed cold spray Laval nozzle extends into an injection hole of a preparation mold, solid particles are sprayed into the mold cavity, and the cavity is filled with the particles to form a vane rough blank; and mold opening is carried out, and the vane rough blank is subjected to water toughening treatment. By means of the preparation mold mechanism and the preparation method, the vane molding preparation method is improved, high efficiency is achieved, the hardness and compactness of the shot blasting machine are improved, the wear resistance of the vane is improved, and the service life is prolonged.

Owner:SHANDONG KAITAI SHOT BLASTING MACHINERY

Plastic film extruding forming machine

The invention discloses a plastic film extruding forming machine. The machine comprises a thermal melting hopper and a conveying pipe, wherein an extruding machine head and a driving motor are correspondingly arranged at two ends of the conveying pipe; the driving motor is electrically connected to an extruding screw, and the extruding screw is positioned in the conveying pipe and is used for pushing and extruding molten plastic; screw threads of the extruding screw fits the inner wall of the conveying pipe; and the thermal melting hopper at one end, close to the driving motor, of the conveying pipe communicates with the conveying pipe. The machine has the characteristics of being low in equipment cost, and capable of improving the quality of a plastic film.

Owner:衡东县中湖包装有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com