Linear vibration casting machine

A linear vibration, casting machine technology, applied to casting equipment, equipment for feeding molten metal into molds, manufacturing tools, etc., can solve problems such as blocked feeding pipes, inconvenient discharge of molten metal, and impact on quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

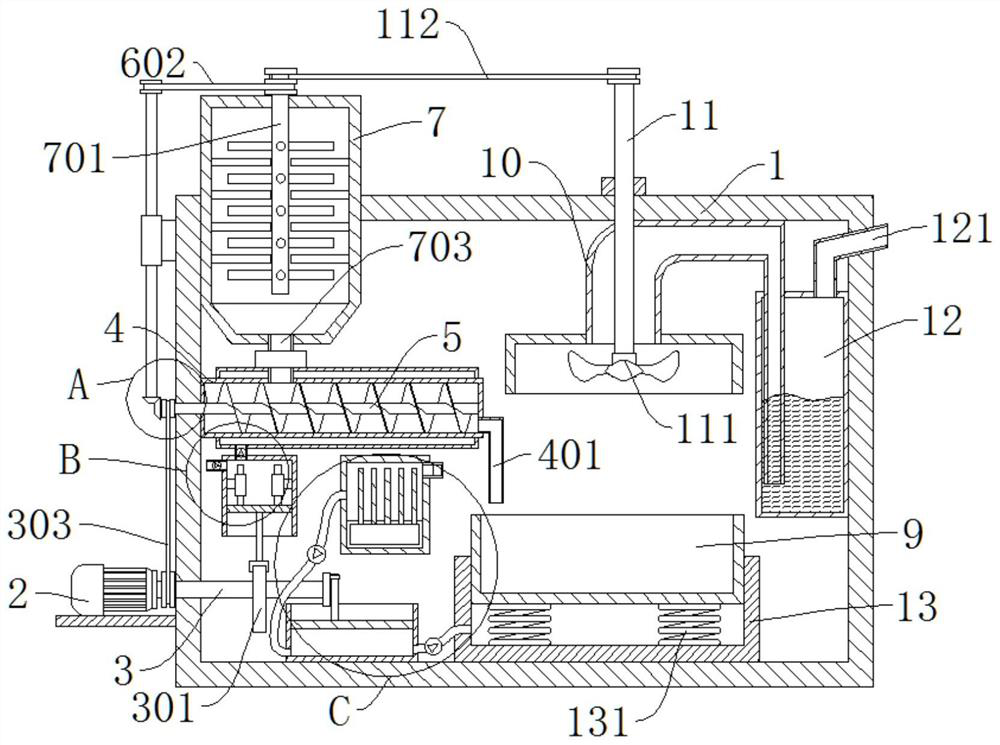

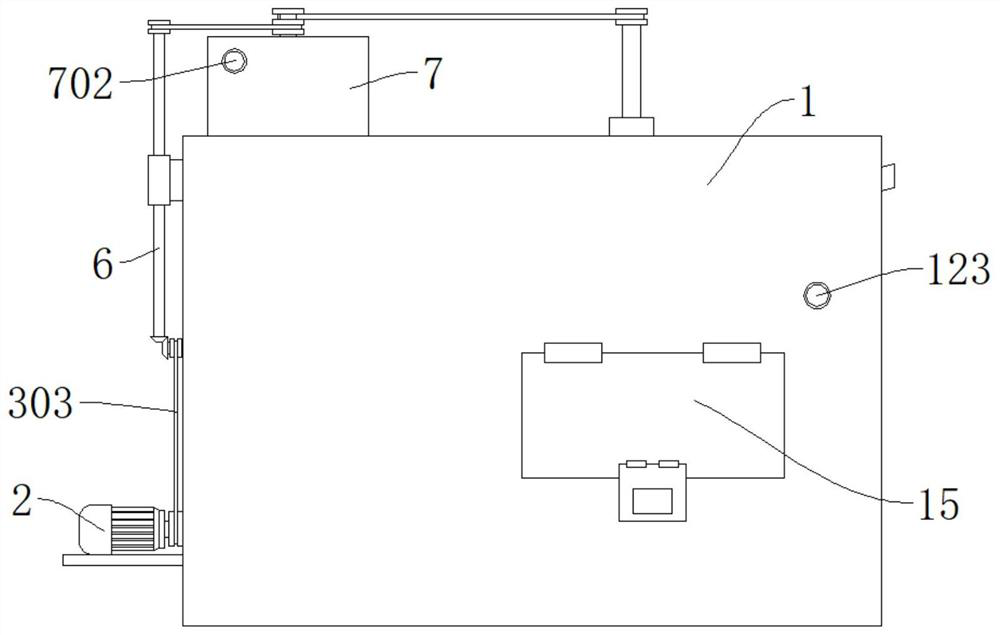

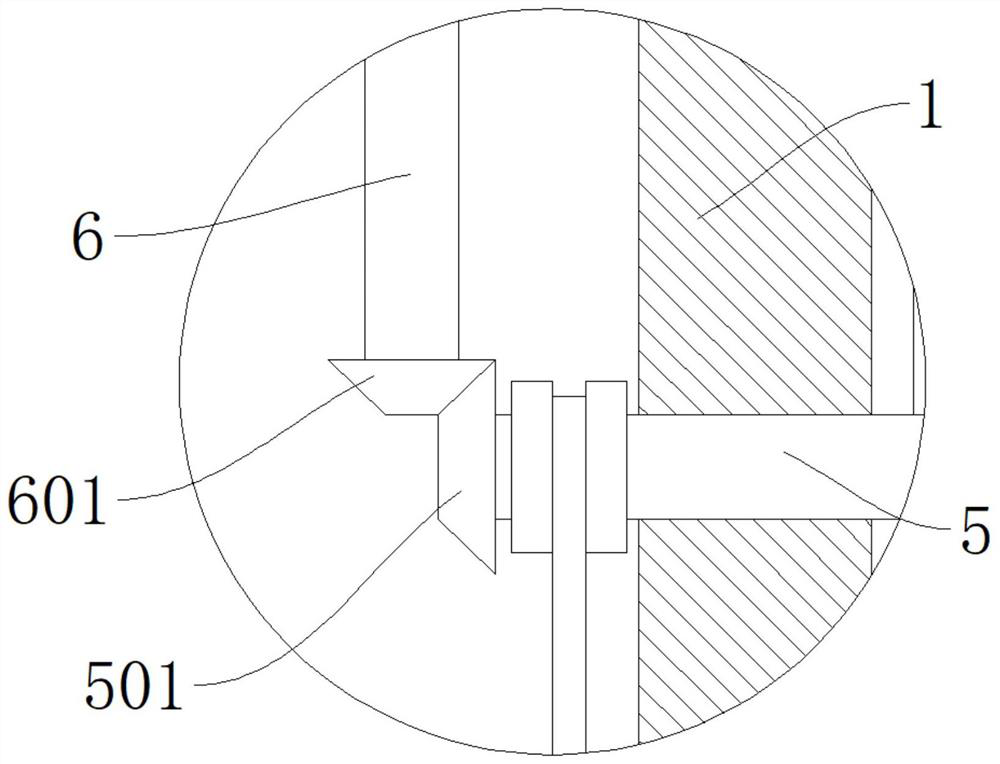

[0036] refer to Figure 1-5 , a linear vibration casting machine, comprising a box 1, a mixing box 7 is provided on the box 1, a stirring shaft 701 is arranged in the mixing box 7, a feeding pipe 702 is provided on the mixing box 7, and a stirring box 7 is provided in the box 1 The feed pipe 4 is connected with a pusher shaft 5 in rotation in the feed pipe 4, and the pusher shaft 5 is provided with a screw propulsion blade, and a feed pipe 703 is connected between the feed pipe 4 and the mixing box 7, and the feed pipe 703 A control valve is arranged on the top, a bevel gear 501 is arranged on the pushing shaft 5, a second rotating shaft 6 is rotatably connected to the side wall of the box body 1, and a driven gear 601 is arranged at the lower end of the second rotating shaft 6, and the driven gear 601 and the bevel gear 501, the second transmission belt 602 is connected between the second rotating shaft 6 and the stirring shaft 701, the side wall of the box body 1 is provided...

Embodiment 2

[0039] refer to figure 1 , 4 , a linear vibration casting machine, basically the same as Embodiment 1, furthermore, the transmission mechanism includes a cam 301, and the cam 301 is fixedly connected to the first rotating shaft 3, and the heating mechanism includes a first gas cylinder 8, and the first gas cylinder 8 A first piston 801 is slidably connected, and a first push rod 802 is fixedly connected to the lower end of the first piston 801. The end of the first push rod 802 away from the first piston 801 is slidably connected to the outer wall of the cam 301. Friction rod 803, friction ring 804 is provided in the first gas cylinder 8, friction rod 803 and friction ring 804 are slidingly connected, the first gas cylinder 8 is provided with a first air inlet pipe 805, the first gas cylinder 8 and the heating pipe 402 are connected with The first exhaust pipe 806, the first air intake pipe 805 and the first exhaust pipe 806 are all provided with check valves, the first exhau...

Embodiment 3

[0041] refer to figure 1 , 5 , a linear vibrating casting machine, which is basically the same as that of Embodiment 1, furthermore, a shock absorbing groove 13 is provided in the box body 1, the mold 9 is slidably connected in the shock absorbing groove 13, and a spring 131 is provided at the bottom of the mold 9, The end of the spring 131 away from the mold 9 is fixedly connected to the inner wall of the shock-absorbing groove 13. The setting of the shock-absorbing groove 13 and the spring 131 is convenient for shock absorption during the falling process of the casting material, so as to prevent the casting material from splashing when it falls on the mold 9. At the same time, the mold 9 vibrates under the pressure of the casting material, so that the casting material entering the mold 9 can be better and evenly laid in the mold 9, and the vibration of the mold 9 can greatly reduce the air bubbles inside the casting material and improve the quality of the finished product of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com