Plastic film extruding forming machine

An extrusion molding machine and plastic film technology, applied to flat products, household utensils, and other household utensils, etc., can solve the problems of large screw rotation driving force, increased equipment cost, and long delivery pipe, so as to improve the quality of plastic film , Reduce equipment cost, the effect of low equipment cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

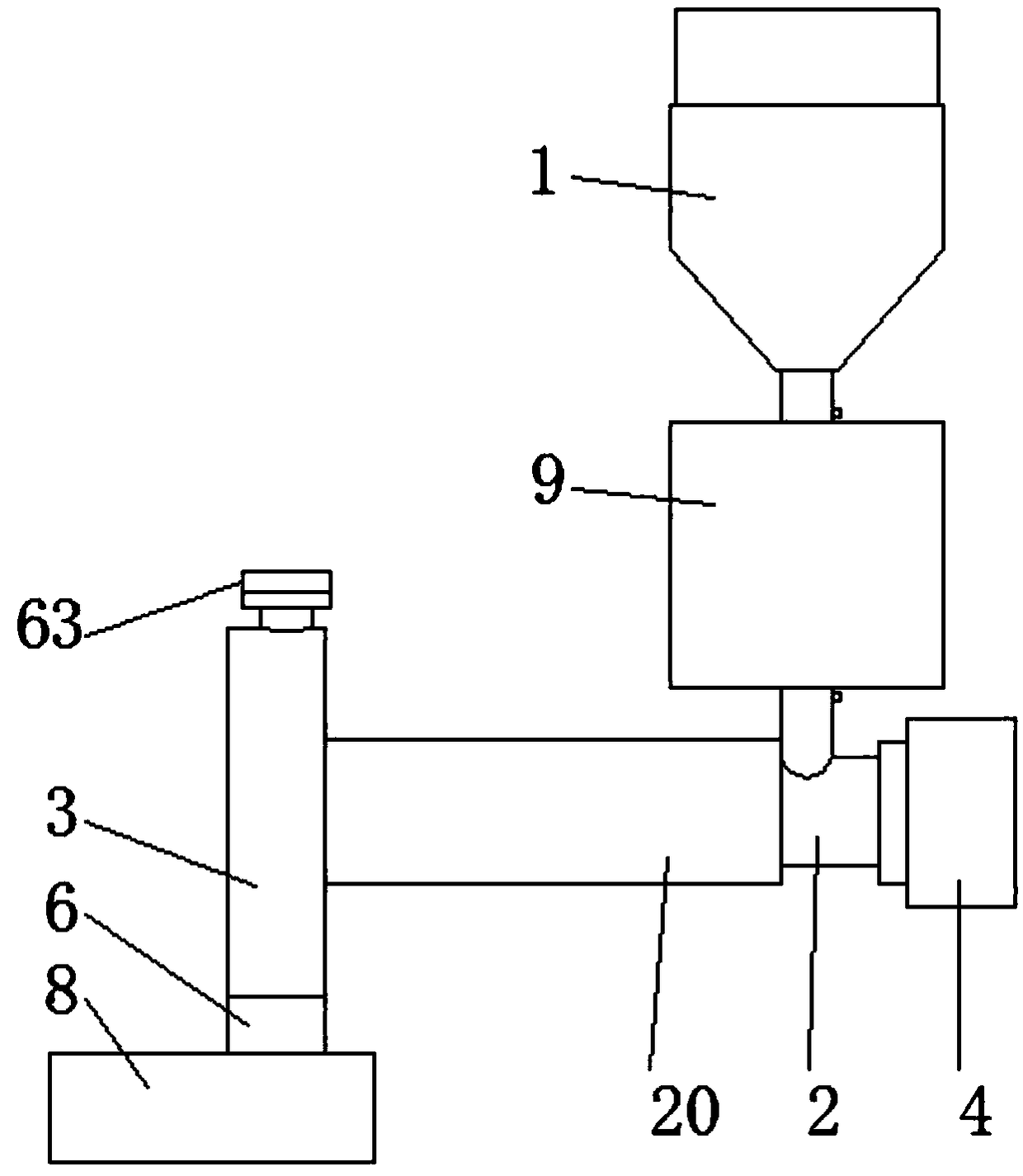

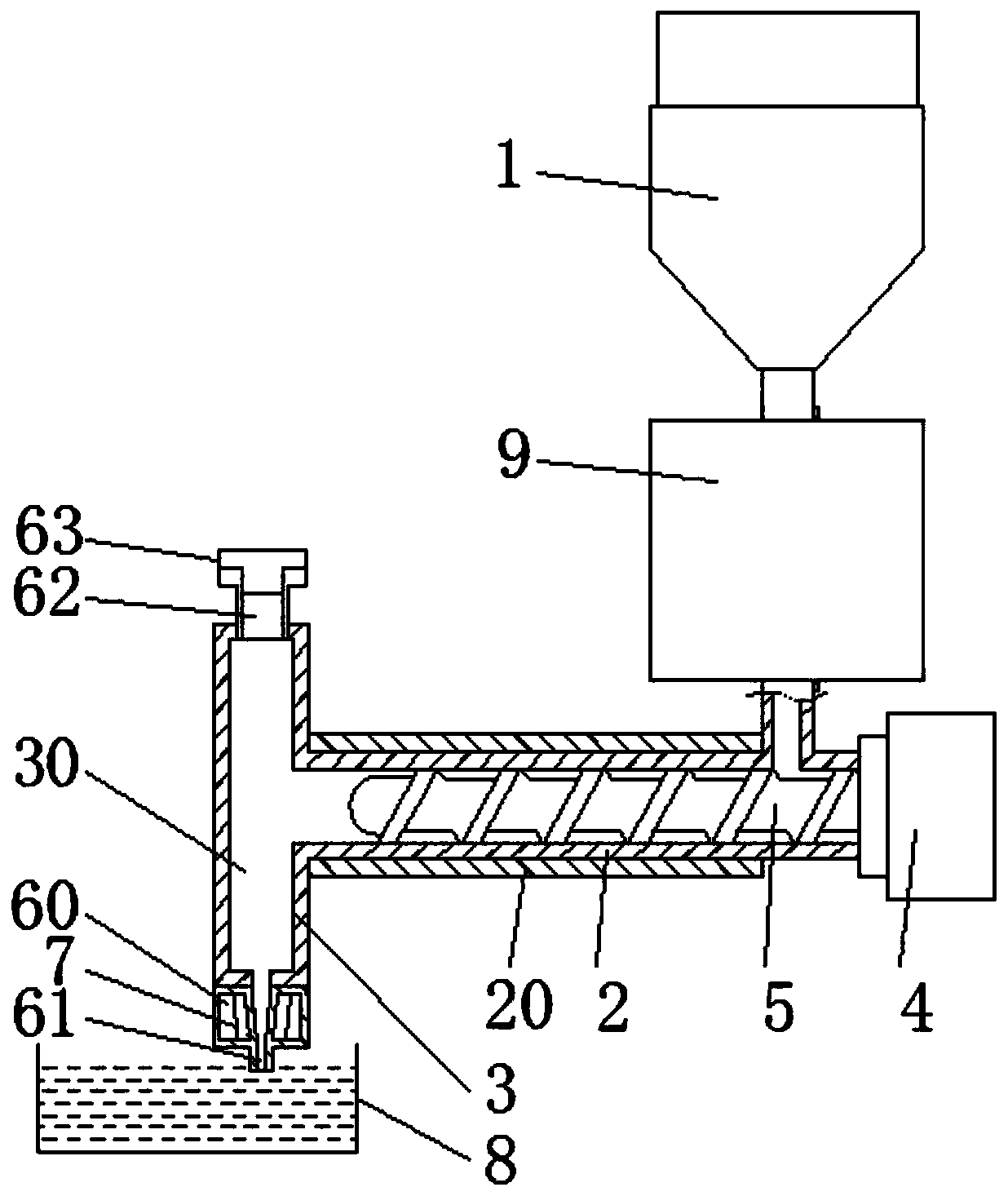

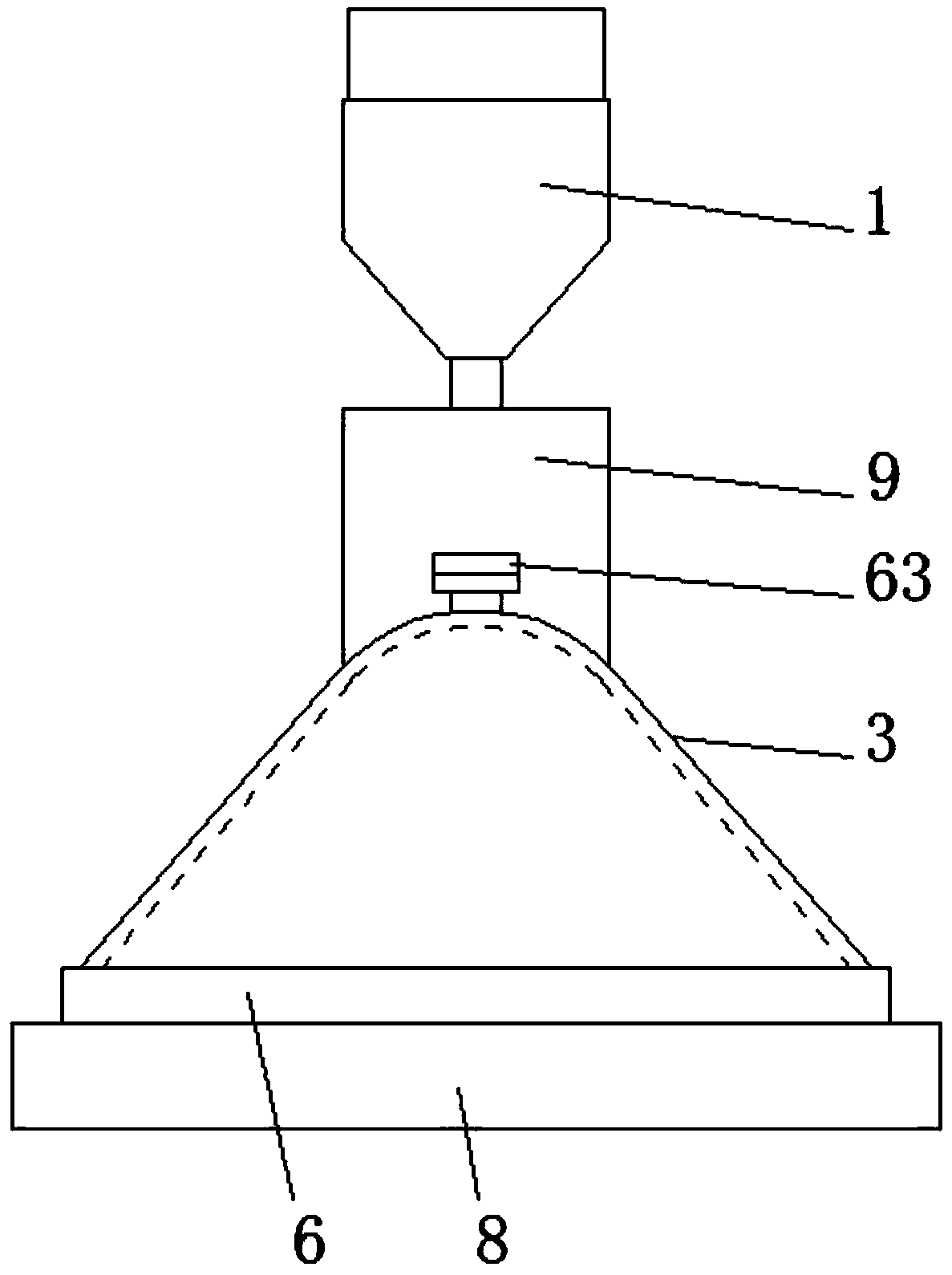

[0027] refer to Figure 1~3 As shown, a plastic film extrusion molding machine includes a hot-melt hopper 1 and a conveying pipe 2. The two ends of the conveying pipe 2 are respectively provided with an extruder head 3 and a driving motor 4. The driving motor 4 is connected to a Inside, the extrusion screw 5 used to push the plastic solution, the drive motor 4 drives the extrusion screw 5 to rotate in a fixed axis, the screw thread of the extrusion screw 5 is adapted to the inner wall of the delivery pipe 2, and the hot melt hopper 1 is in the delivery pipe 2 One end close to the driving motor 4 communicates with the delivery pipe 2 .

[0028] A plastic film extrusion molding machine of the present invention can use a hot-melt hopper 1 outside the conveying pipe 2 to melt plastic particles into a plastic liquid, and then transport the melted plastic liquid into the conveying pipe 2. Push extrusion under the action of rotation to make plastic film. Solid plastic particles are...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com