Patents

Literature

210results about How to "Reduce power usage" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for controlling power consumption

InactiveCN103488152AReduce power usageEfficient managementProgramme total factory controlElectricity priceWork period

The invention discloses a method for controlling power consumption. The method comprises the steps that an intelligent power consumption control center monitors the situation of staff, temperature, humidity, photometric brightness and the like indoors in real time by using a control sensor, and the intelligent power consumption control center determines whether related electric appliances are started up or not and the temperature value of running of the related electric appliances by acquiring temperature data and other data; furthermore, the working periods of the electric appliances can be set, before one related electric appliance is started up, whether current time is within the working periods of the electric appliance or not is judged preferentially, and the electric appliance is not started up if not; besides, according to the corresponding relationships between set electricity prices and time periods, and according to the corresponding relationships between power consumption and electricity prices, total power consumption and periodic power consumption are calculated after the power consumption of all the electric appliances are acquired; whether the total power consumption exceeds a preset value or not is judged, if yes, a warning module is used for sending a prompt to a user, and the user is informed of the current power consumption and electric charges; according to the preset power consumption weight of all the electric appliances, some of the electric appliances are shut down. According to the method for controlling the power consumption, the household appliances can be effectively managed, and electric energy is saved.

Owner:STATE GRID CORP OF CHINA +2

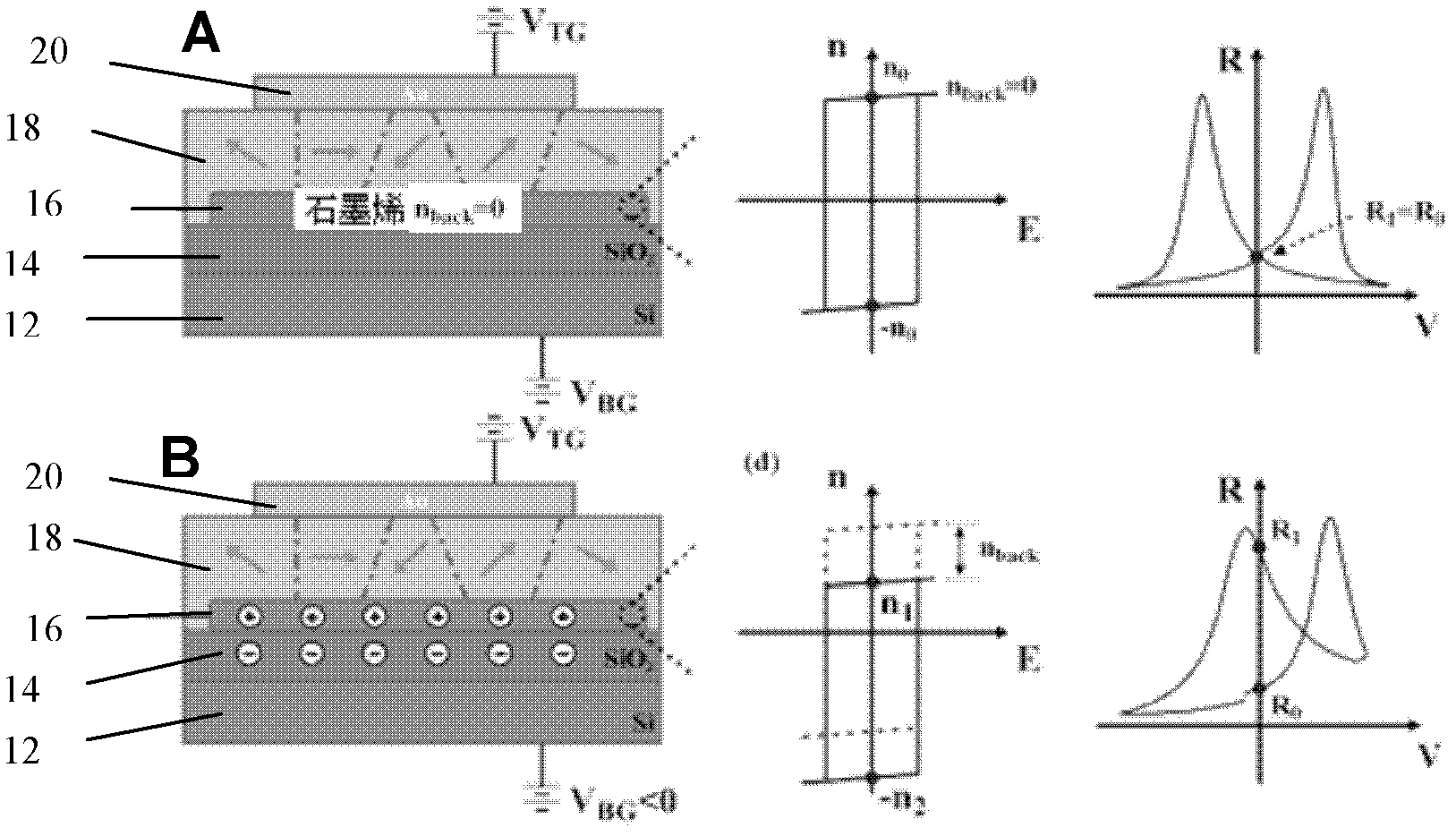

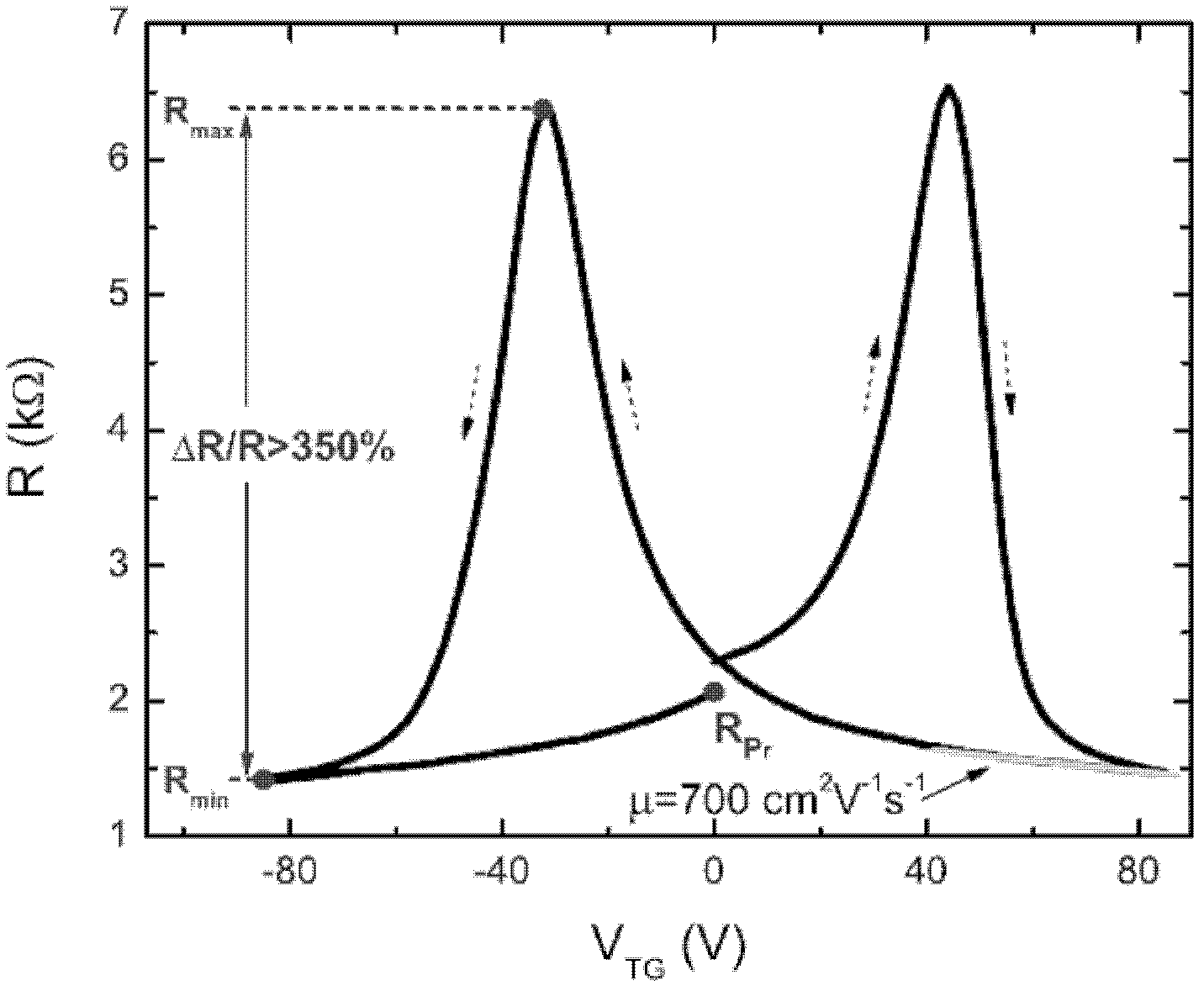

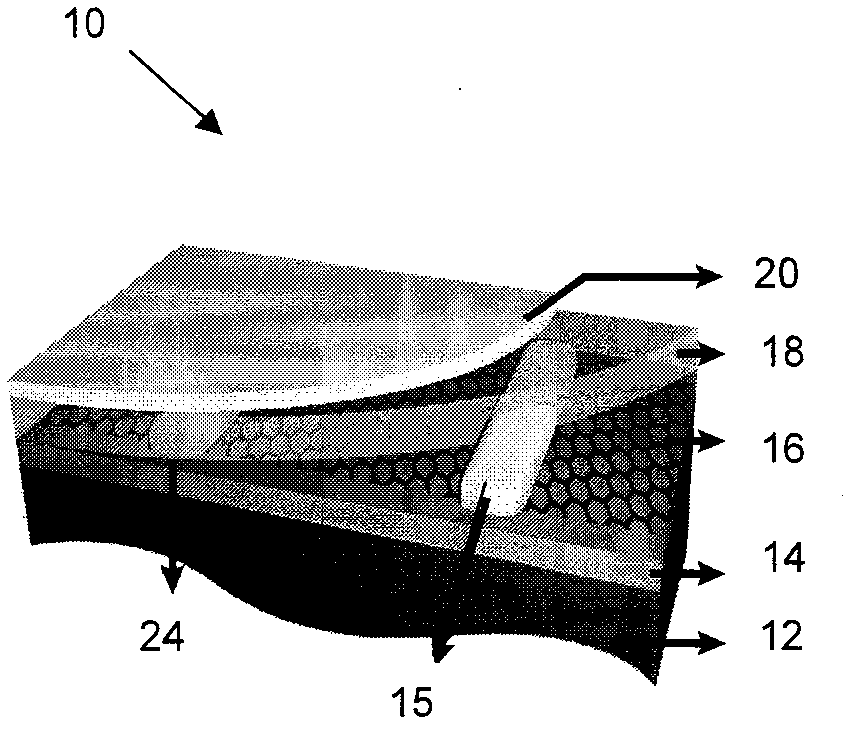

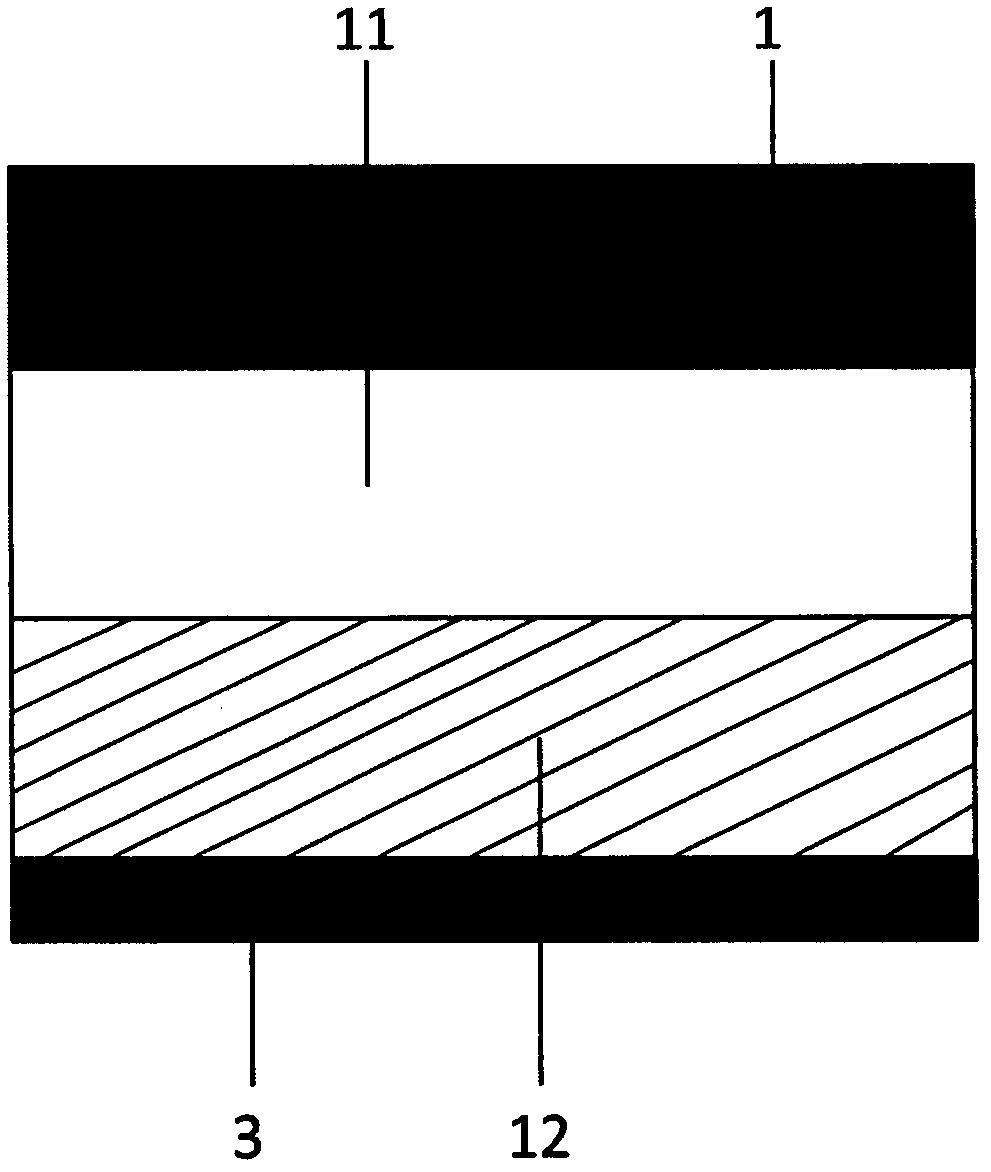

Graphene memory cell and fabrication methods thereof

InactiveCN102257610AReduce power consumptionNon-destructiveTransistorNanoinformaticsHigh resistanceElectrical resistance and conductance

The disclosed memory cell (10) comprises a graphene layer (16) having controllable resistance states representing data values of the memory cell (10). In one exemplary embodiment a non-volatile memory is provided by having a ferroelectric layer (18) control the resistance states. In the exemplary embodiment, binary '0's and ' 1 ' are respectively represented by low and high resistance states of the graphene layer (16), and these states are switched in a non-volatile manner by the polarization directions of the ferroelectric layer (18).

Owner:NAT UNIV OF SINGAPORE

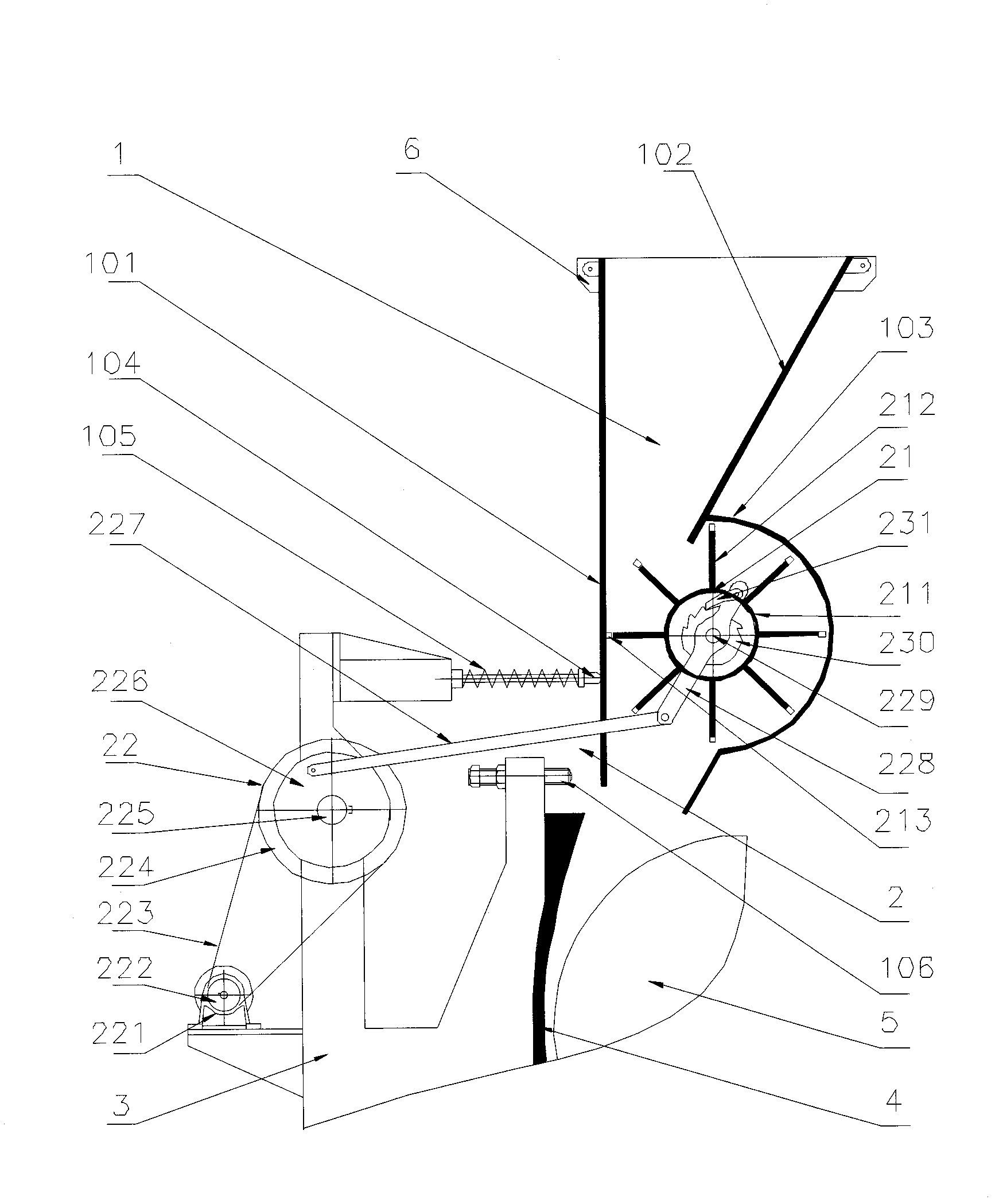

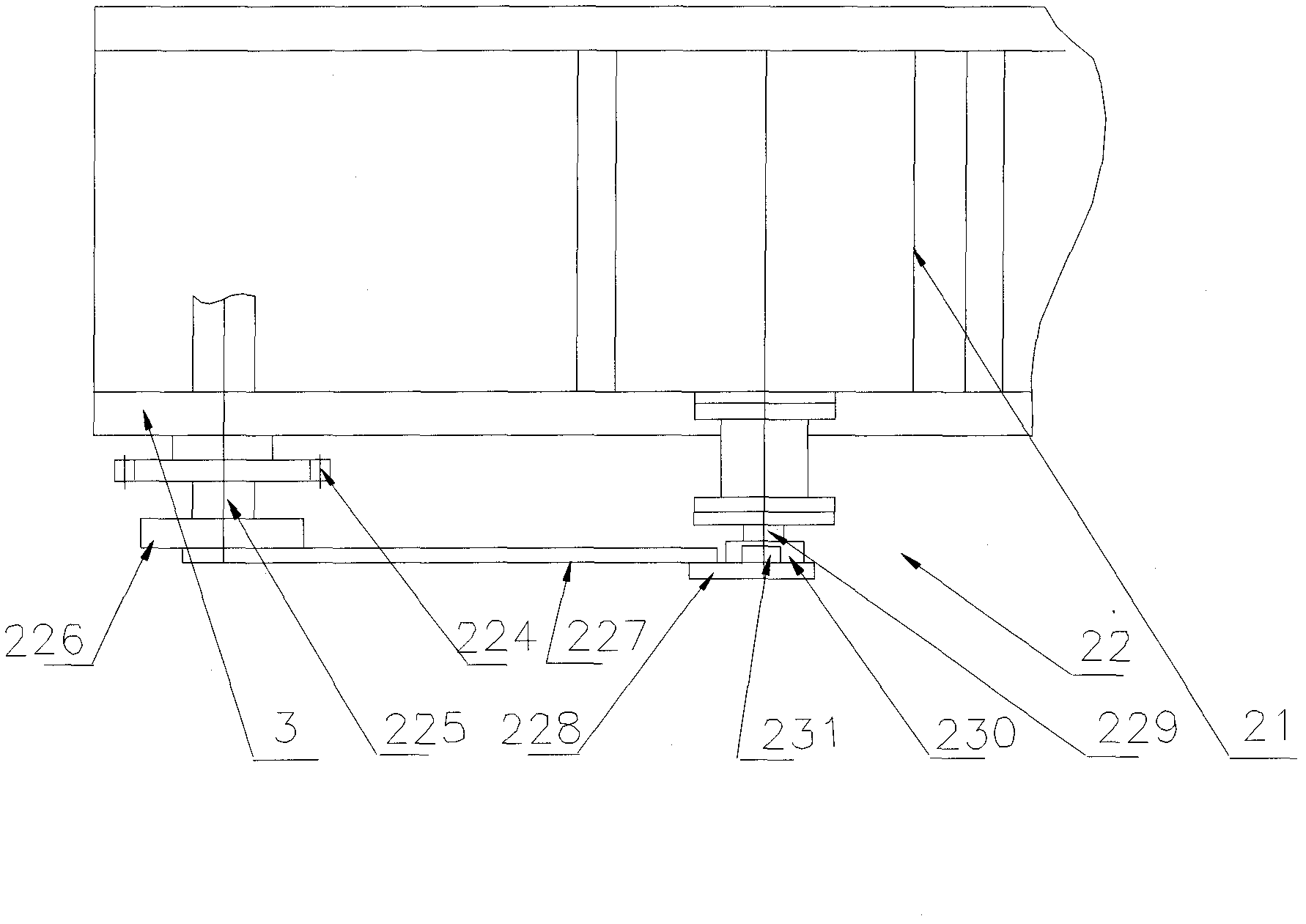

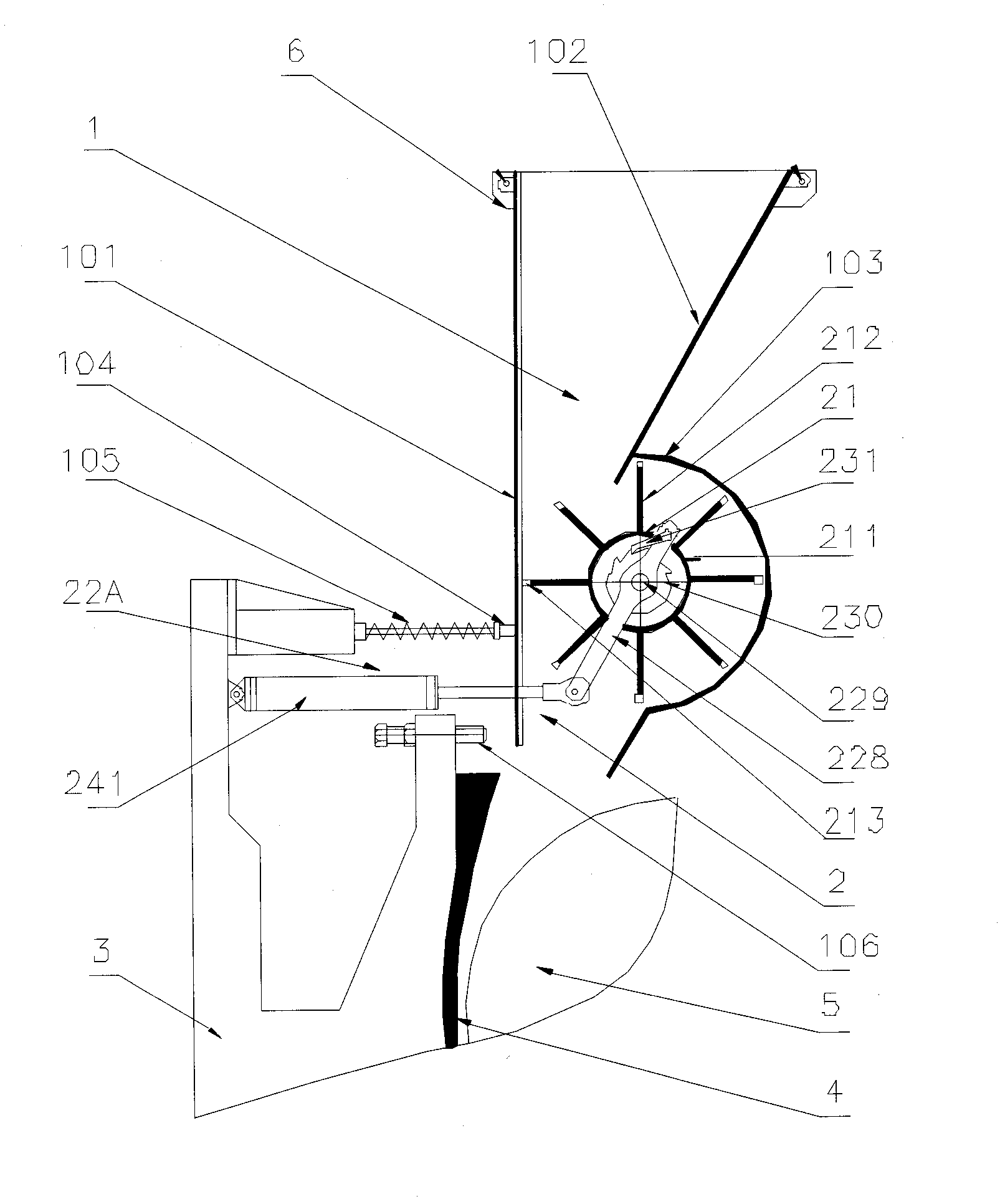

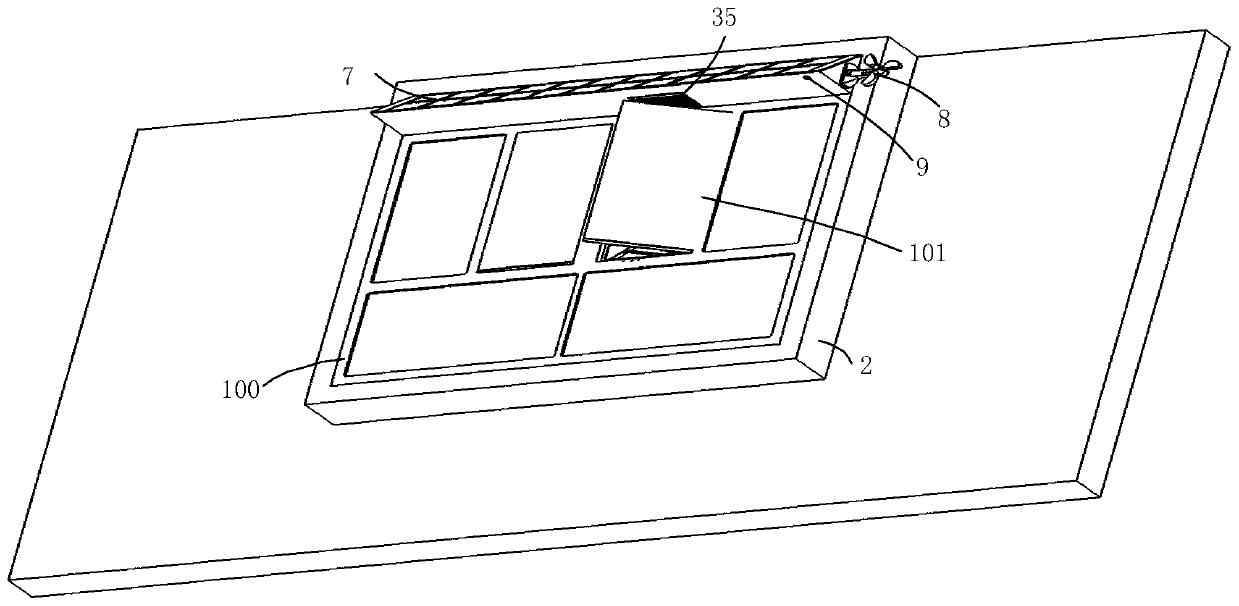

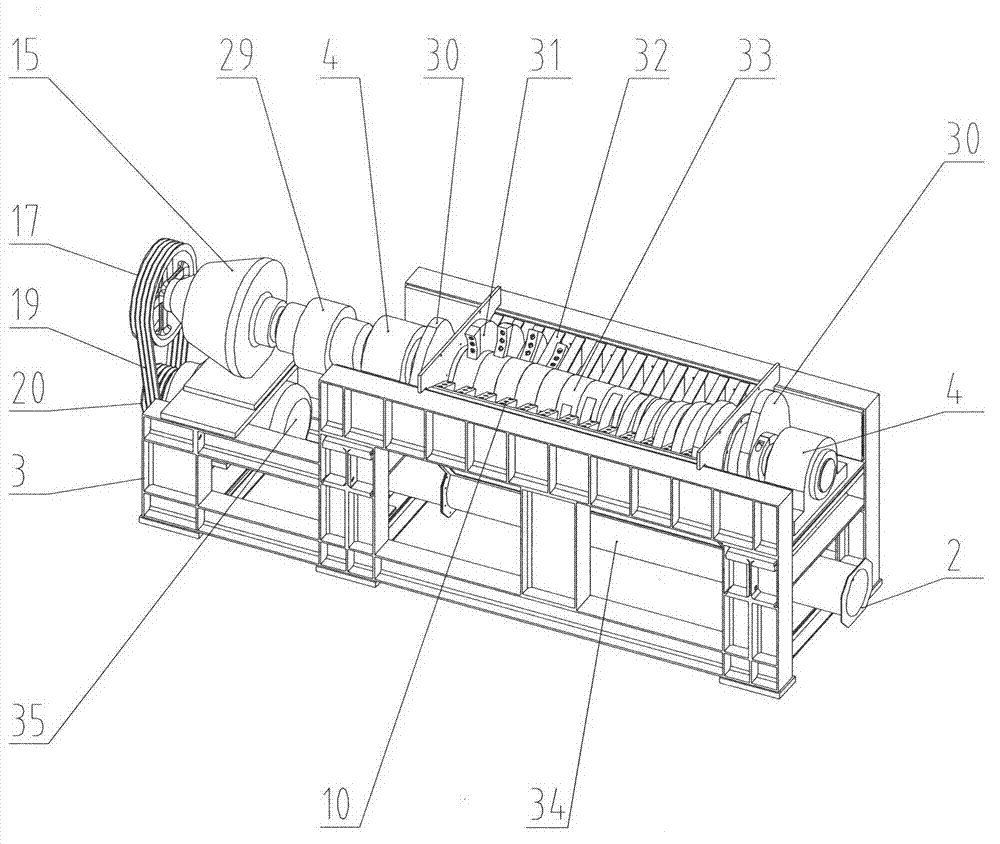

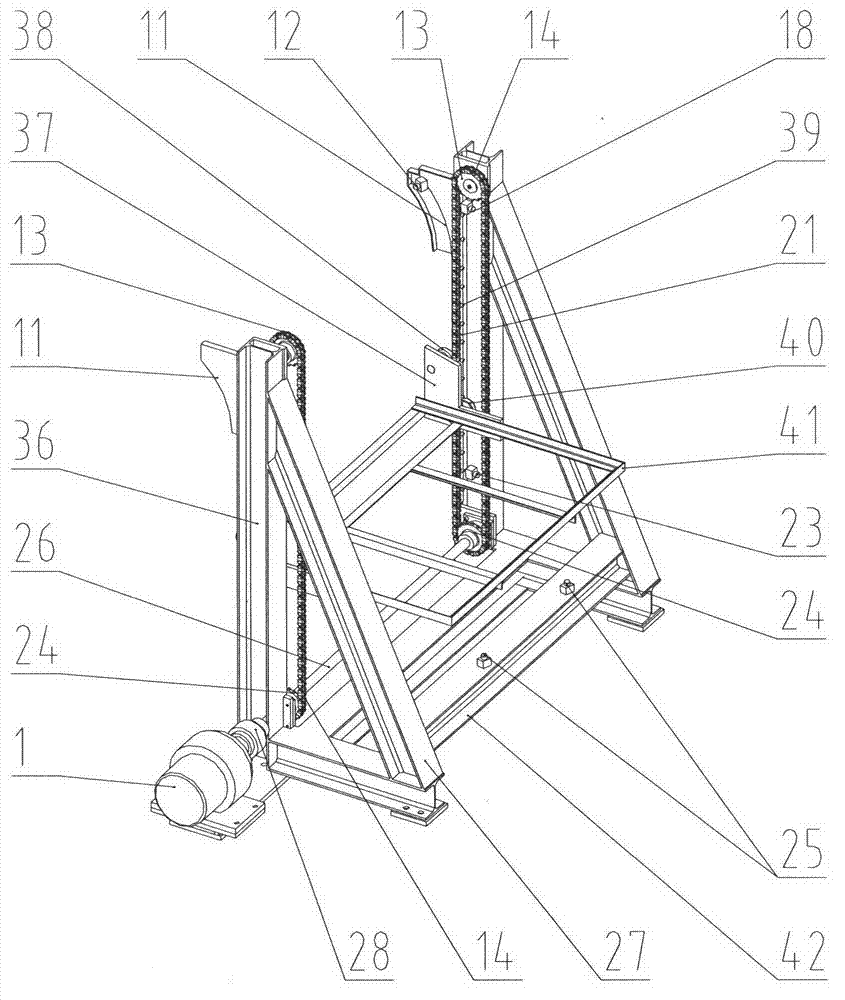

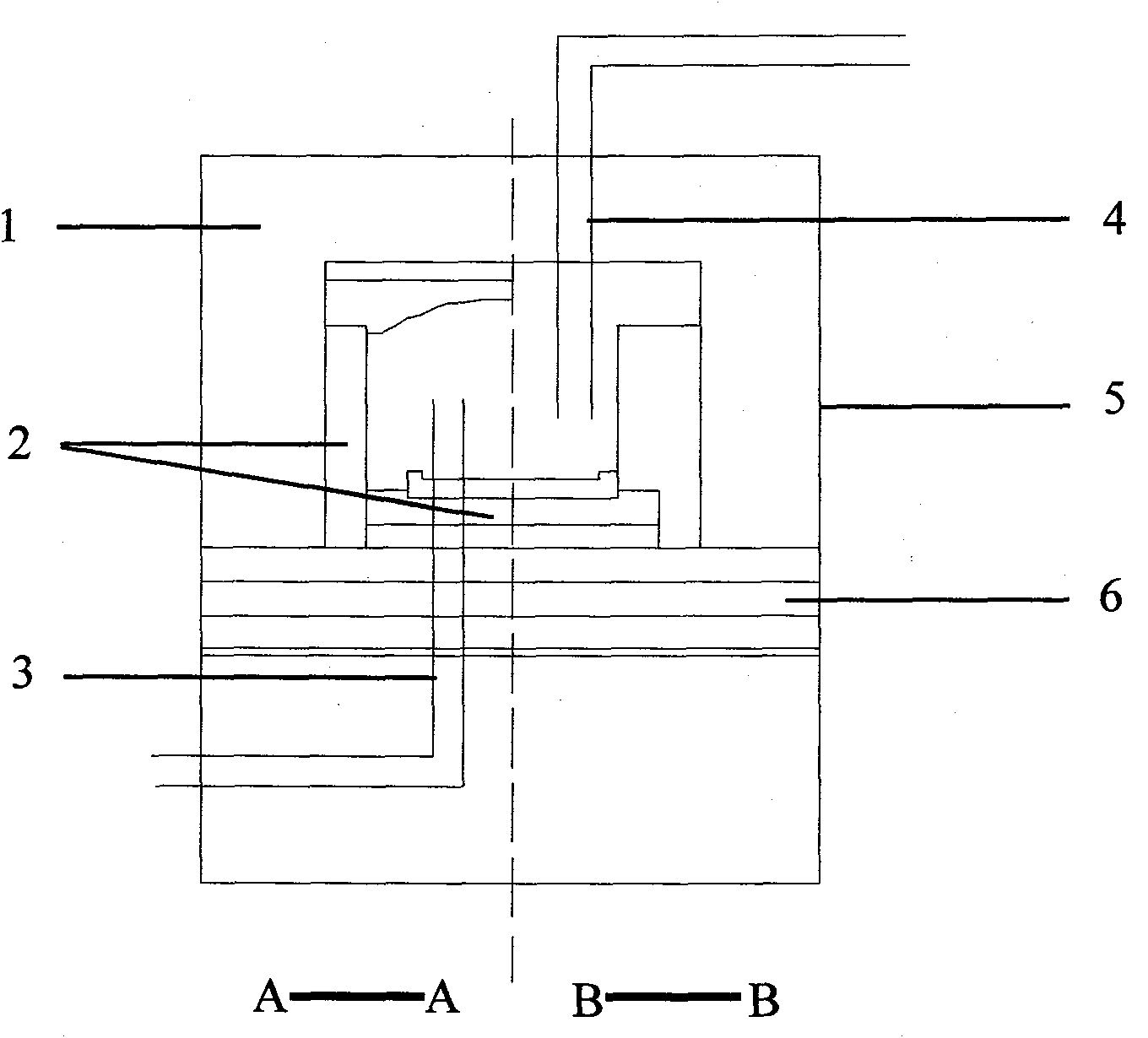

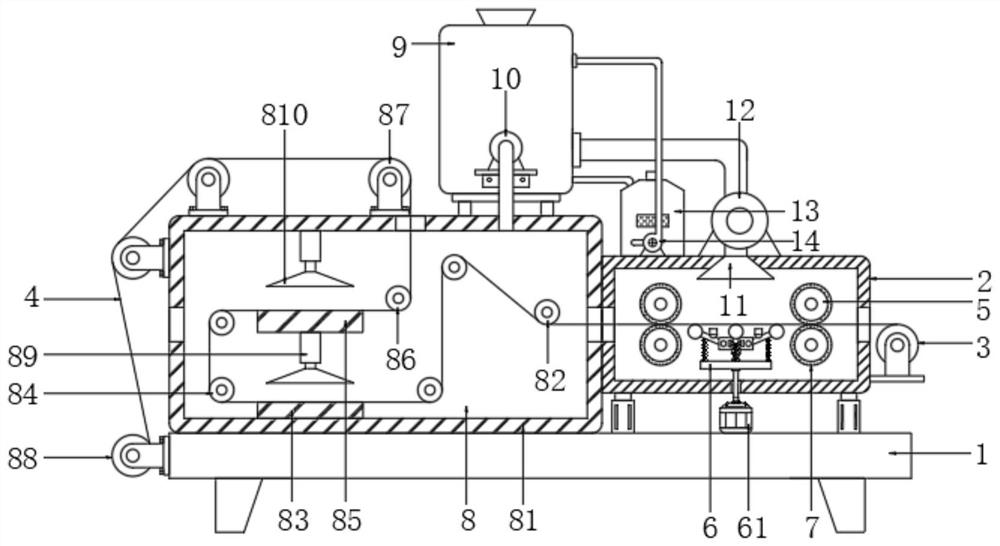

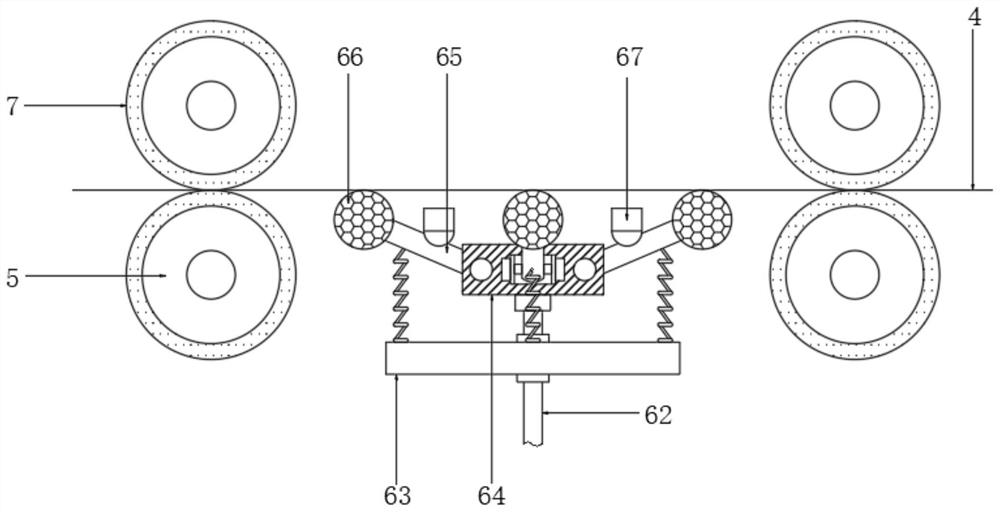

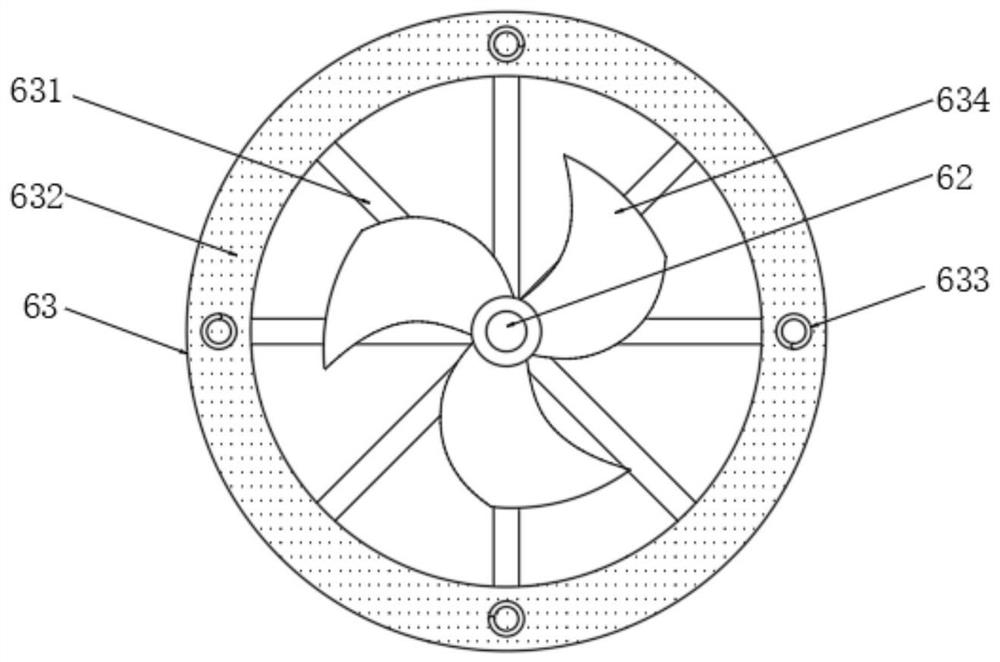

Feeding device of material crushing apparatus

A feeding device of a material crushing apparatus comprises a deformed bunker and an intermittent feeding mechanism, wherein one side of the deformed bunker is provided with a pendulous movable straight plate, the upper end of the movable straight plate is hinged to a fixed hopper lower edge, the other side of the deformed bunker is provided with a fixed semicircular plate and a movable inclined plate, the fixed semicircular plate makes a semicircular cavity, the upper end of the movable inclined plate is hinged to the fixed hopper lower edge, the lower end of the movable inclined plate is laid on the upper edge of the fixed semicircular plate in an inclined manner, and the outside of the movable straight plate is provided with a bunker plate resetting device; and the intermittent feeding mechanism comprises a uniform feeder and a stepping driving part, the uniform feeder is positioned in the cavity of the fixed semicircular plate and comprises a central ring and a plurality of separation plates fixed on the central ring in an equant manner, the central ring is arranged on the wheel shaft of a frame, the length of each of the separation plates can realize a case that the outer ends of the separation plates can successively move the movable inclined plate and the movable straight plate in the rotation of the separation plates, the outer end of the one of the separation plates props against the movable straight plate in the pause of the separation plates, and the stepping driving part intermittently pushes the uniform feeder to rotate. The feeding device realizes the uniform and quantitative feeding and the smooth production, and is suitable for the feeding of large-granule materials.

Owner:卢小平 +1

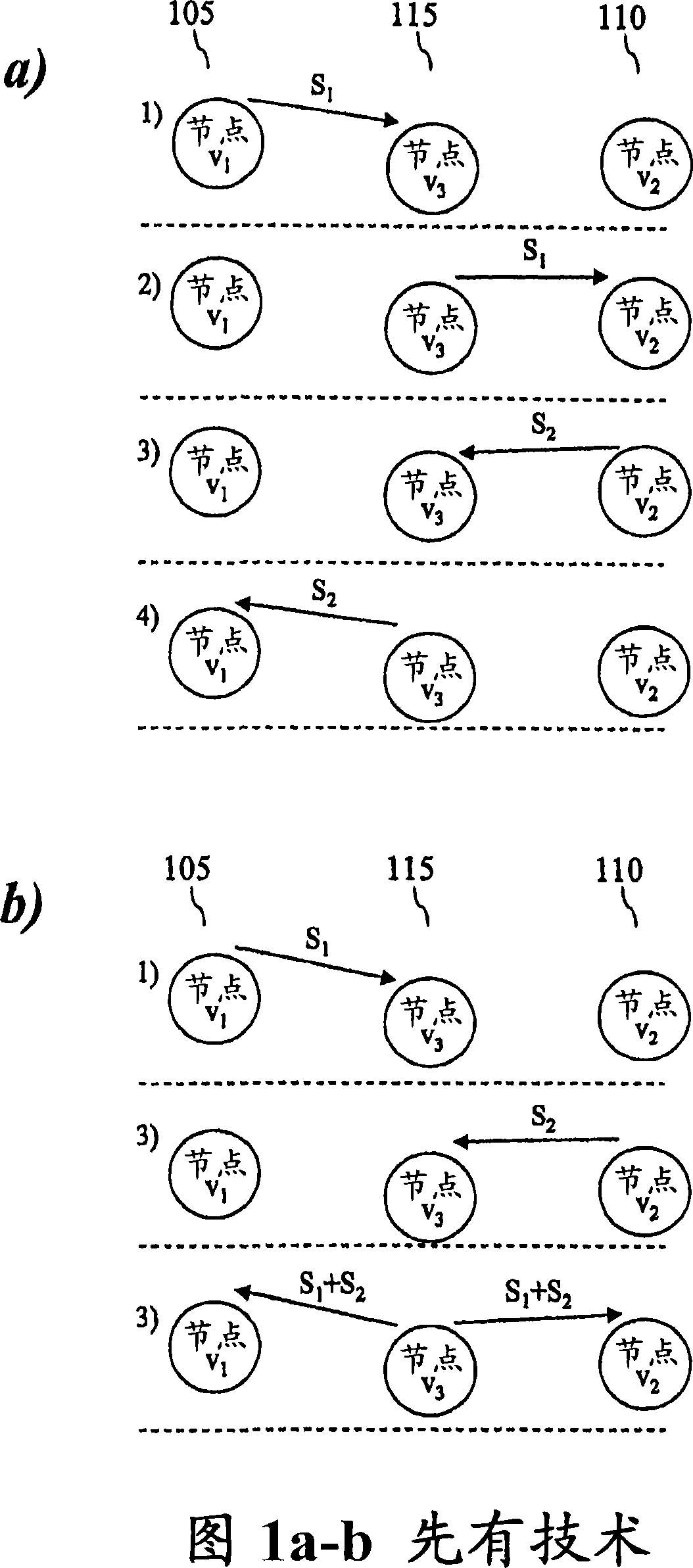

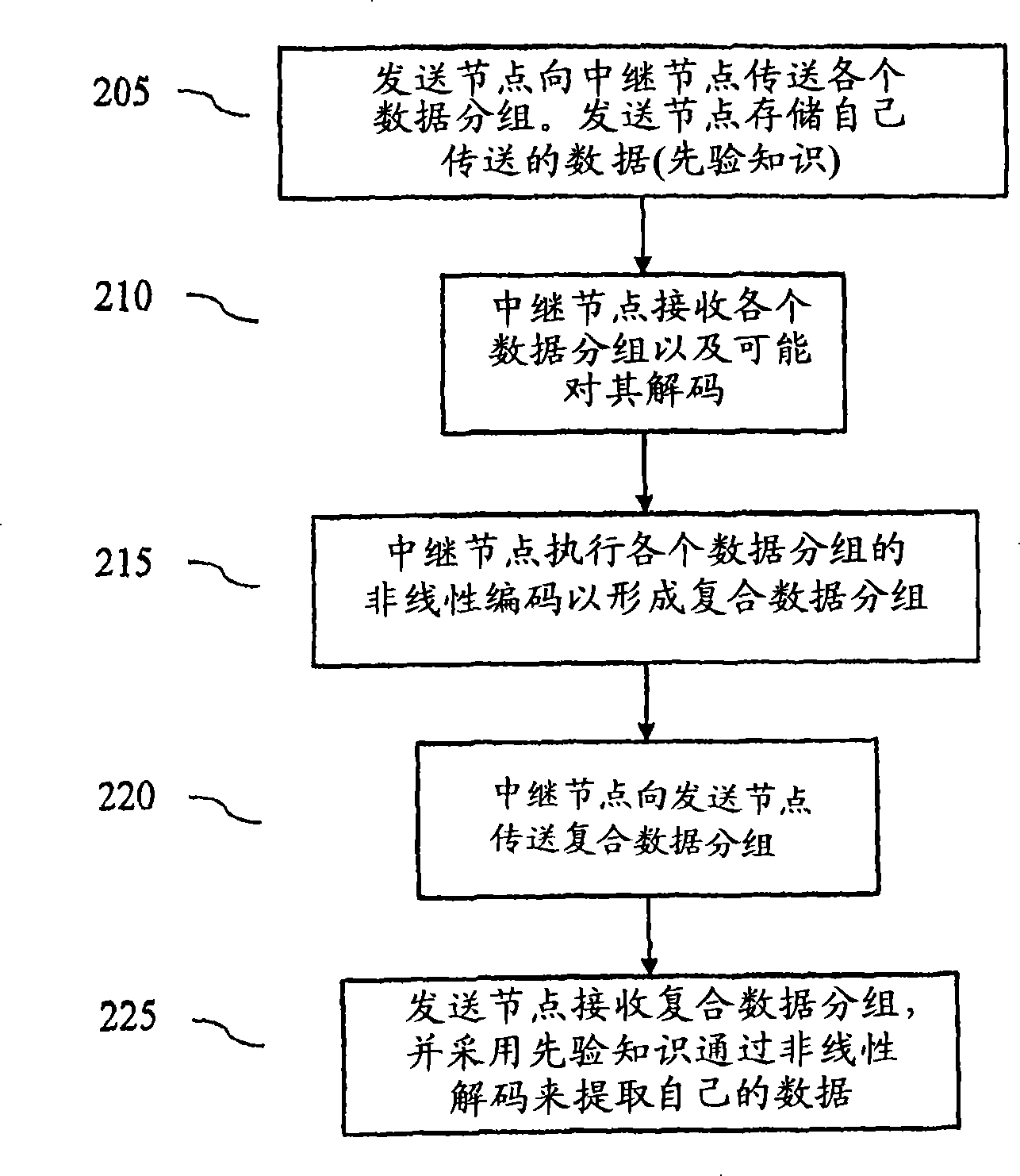

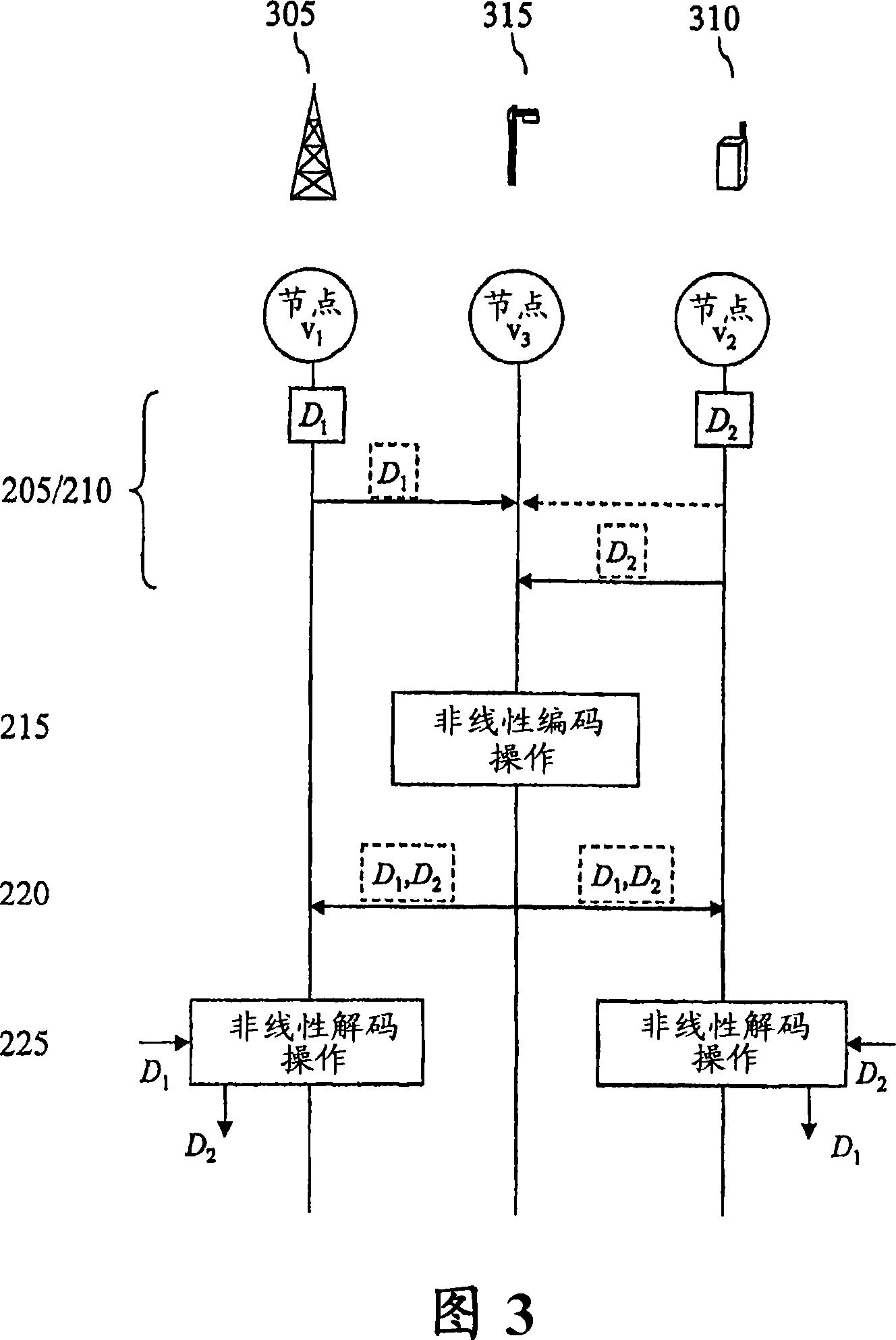

Method and arrangement for bi-directional relaying in wireless communication systems

InactiveCN101128997AIncrease flexibilityImprove throughputActive radio relay systemsCode conversionTelecommunicationsCommunications system

The present invention relates to methods and arrangements in a relaying radio node and / or in a sending / receiving radio node, adapted for use in a relaying communication system. The relaying node is in bidirectional communication with at least a first and a second sending / receiving radio node, and the relaying radio node receives at least a first signal carrying at least first data and a second signal carrying at least second data. The relaying node generates (215) a reduced representation of at least the first and second signal, with a reduced information content as compared to the first and second data, by a joint non-linearly encoding operation, and transmits (220) the reduced representation to at least the first and the second communication node. The first and second sending / receiving node can extract data from the reduced representation by a non-linear decoding operation (225) using stored a priori information.

Owner:TELEFON AB LM ERICSSON (PUBL)

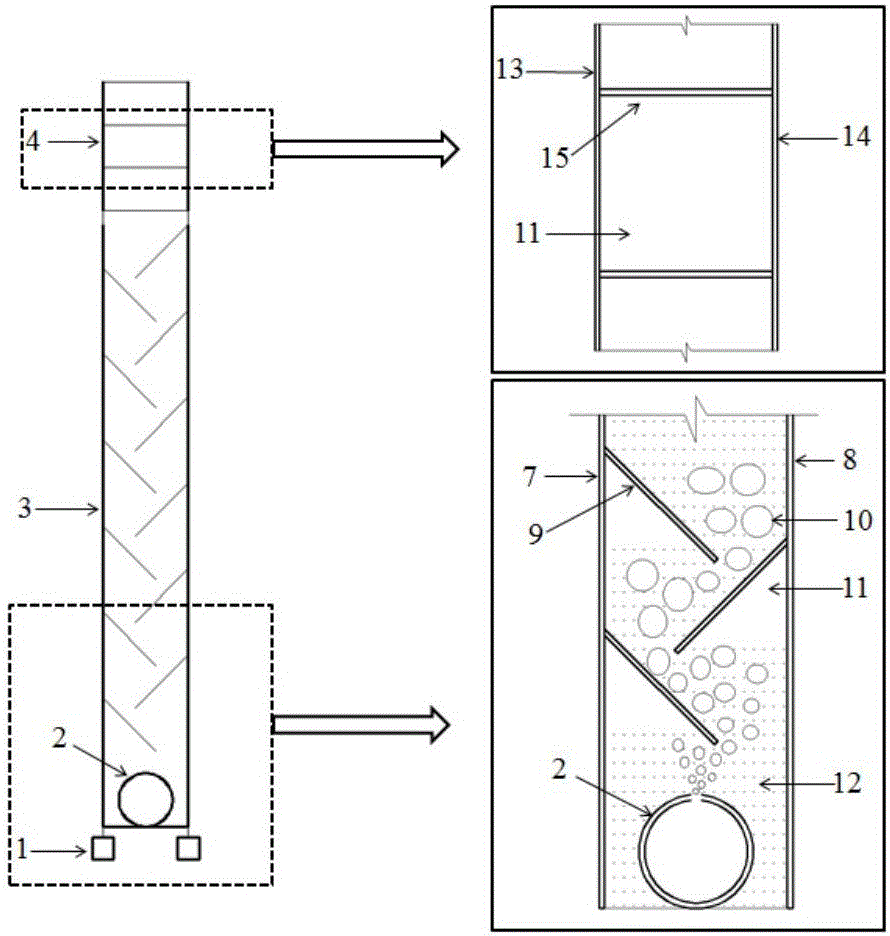

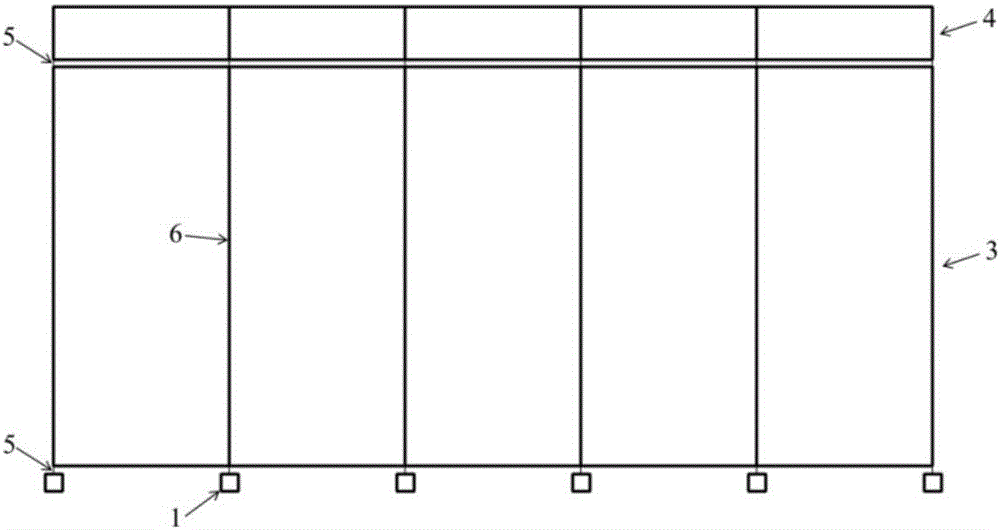

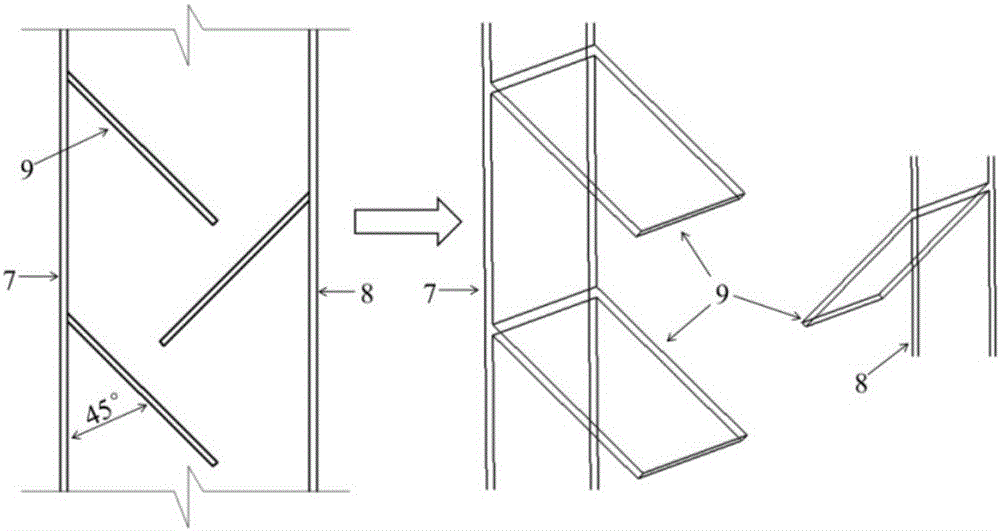

Air buffer device used for eliminating underwater near-distance explosion shock waves

The invention provides an air buffer device used for eliminating underwater near-distance explosion shock waves. The air buffer device comprises a counterweight, a gas ejector pipe, a maze type bubble channel and a flexible gasbag, wherein both the lower end and the upper end of the maze type bubble channel are open; the lower end of the maze type bubble channel is fixedly arranged on the gas ejector pipe, and the upper portion of the maze type bubble channel is connected with the flexible gasbag; the gas ejector pipe is connected with the counterweight; a gas ejecting hole of the gas ejector pipe is positioned inside the maze type bubble channel; and floating force, generated in water, of the flexible gasbag is greater than gravity, borne in water, of the maze type bubble channel. According to the air buffer device provided by the invention, air buffers which are staggered front and rear are formed in the vertical direction, and sudden change of wave impedance between an air medium and a surrounding water medium is utilized, so that a pressure peak value of shock waves can be attenuated by 90% or more, and therefore, safety of nearby hydraulic structures and other protected targets is protected, and the air buffer device has the advantages of being good in energy dissipation effect, energy-saving, environmentally friendly, and the like.

Owner:WUHAN UNIV

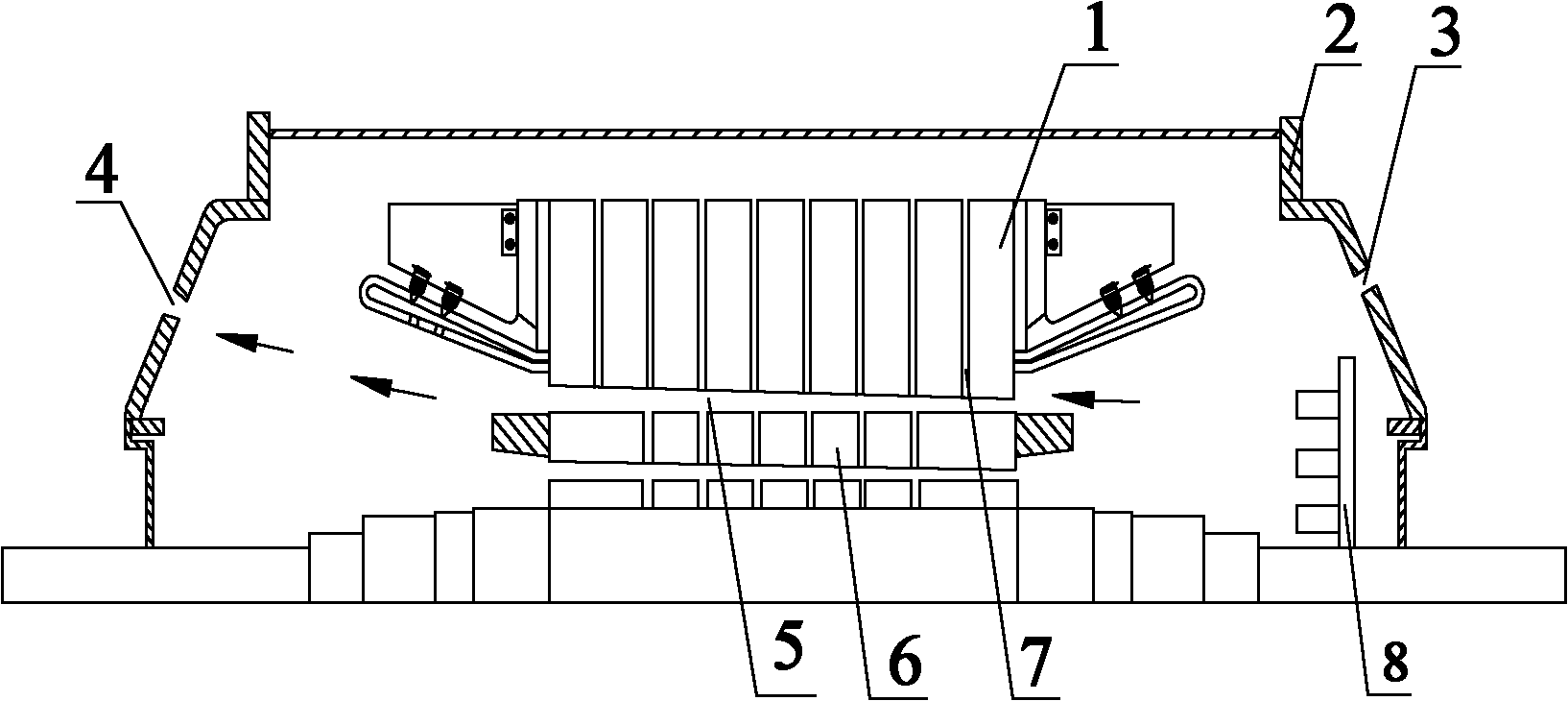

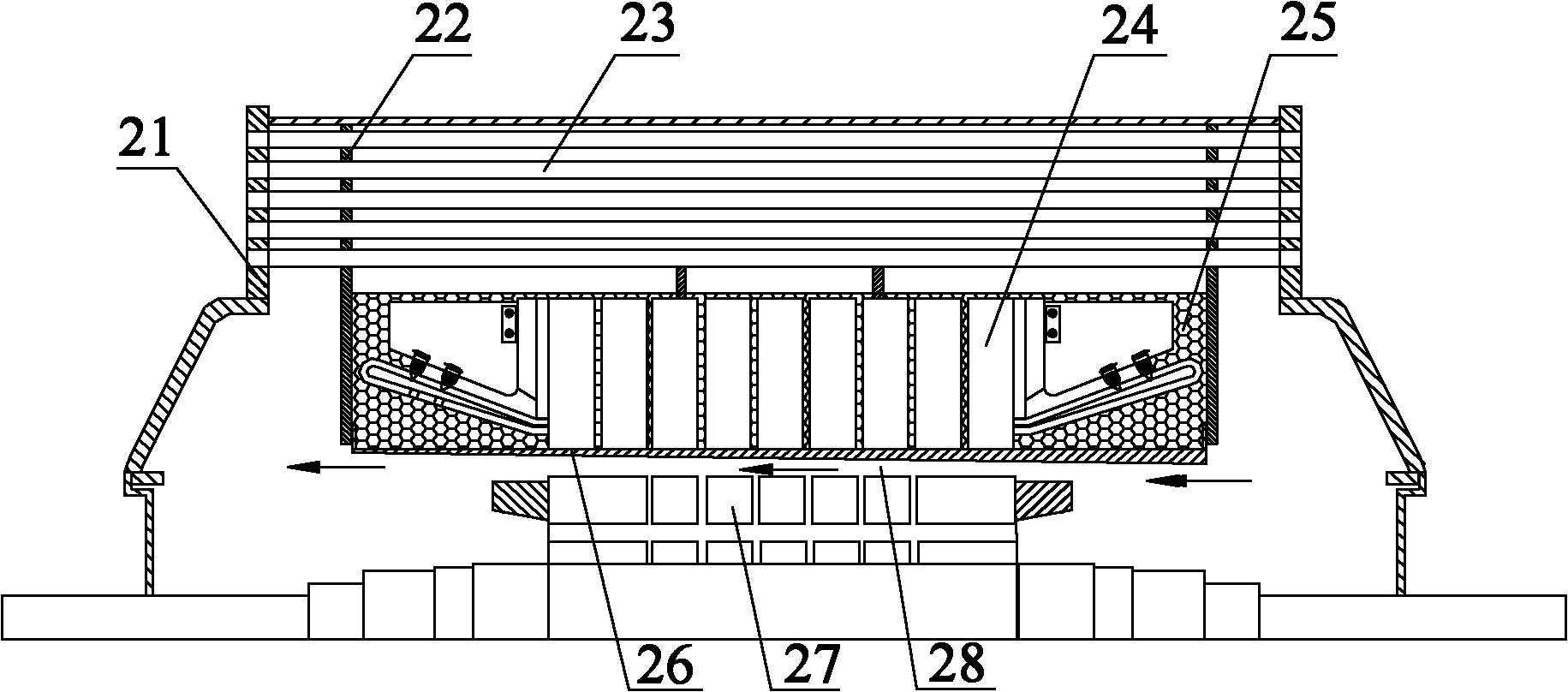

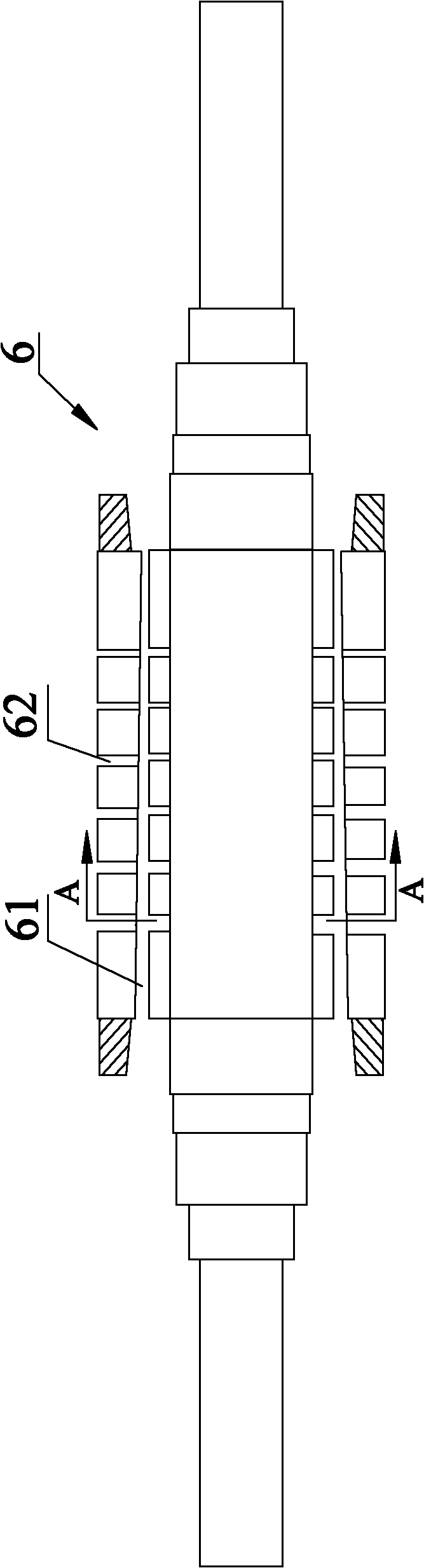

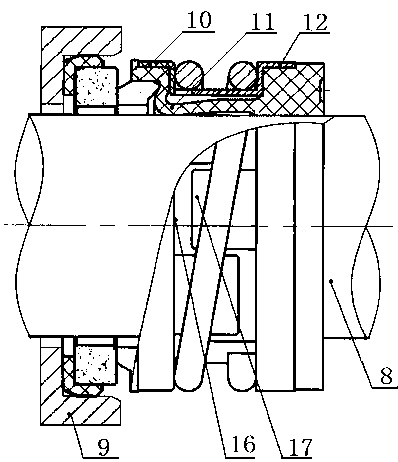

Motor air cooling structure and horizontal motor

ActiveCN102025222AAvoid negative influenceImprove cooling efficiencyCooling/ventillation arrangementCooling temperatureCooling efficiency

The invention provides a motor air cooling structure. An air gap between a stator and a rotor is a wedge-shaped one, a small port of the wedge-shaped air gap is arranged at the low temperature side of the rotor, and a big port of the wedge-shaped air gap is arranged at the high temperature side of the rotor. By adopting the motor air cooling structure provided by the invention, the wedge-shaped air gap is formed between the stator and the rotor, cooling temperature uniformity and cooling efficiency of the stator and the rotor are improved, and structure is simple. Besides, the invention provides a horizontal motor with the air cooling structure, and the horizontal motor has higher work efficiency and work stability compared with a motor with an air cooling structure in the prior art.

Owner:MCC XIANGTAN HEAVY IND EQUIP

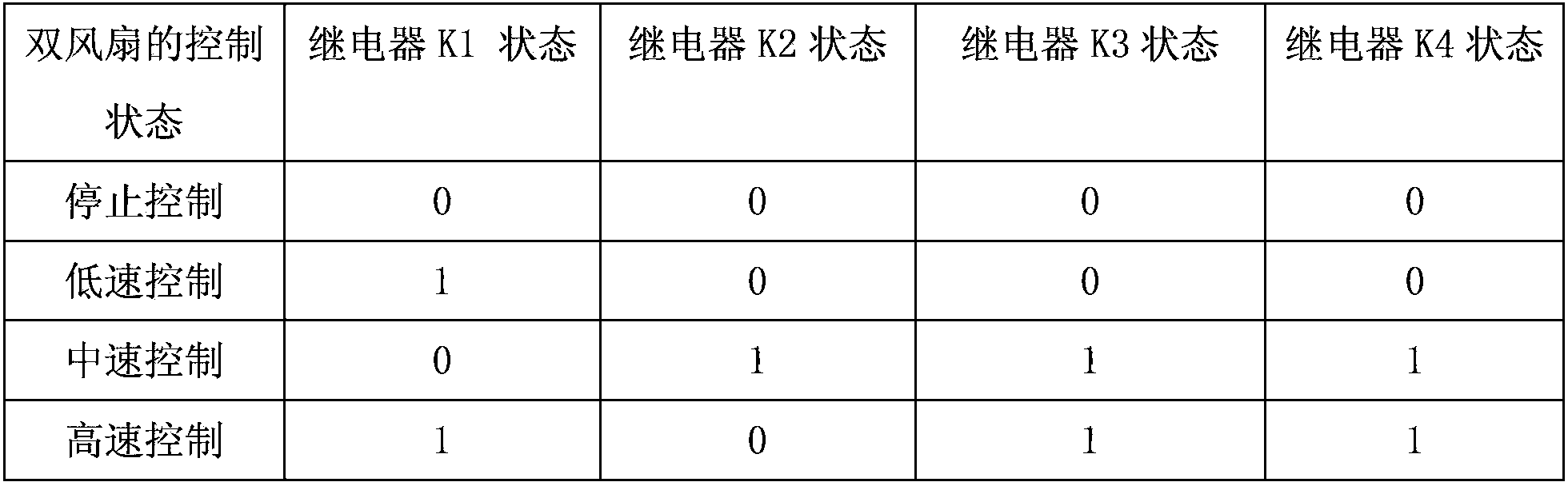

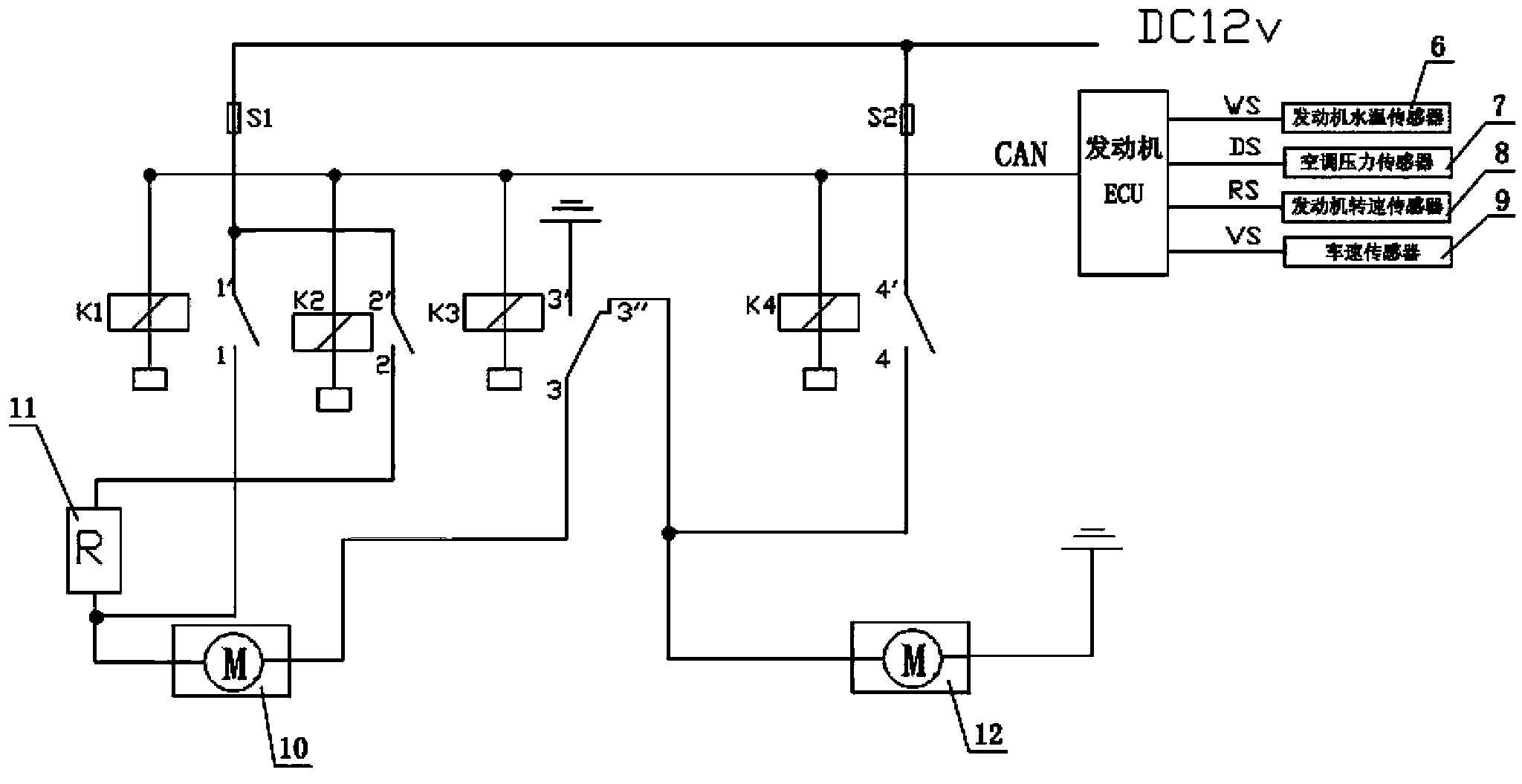

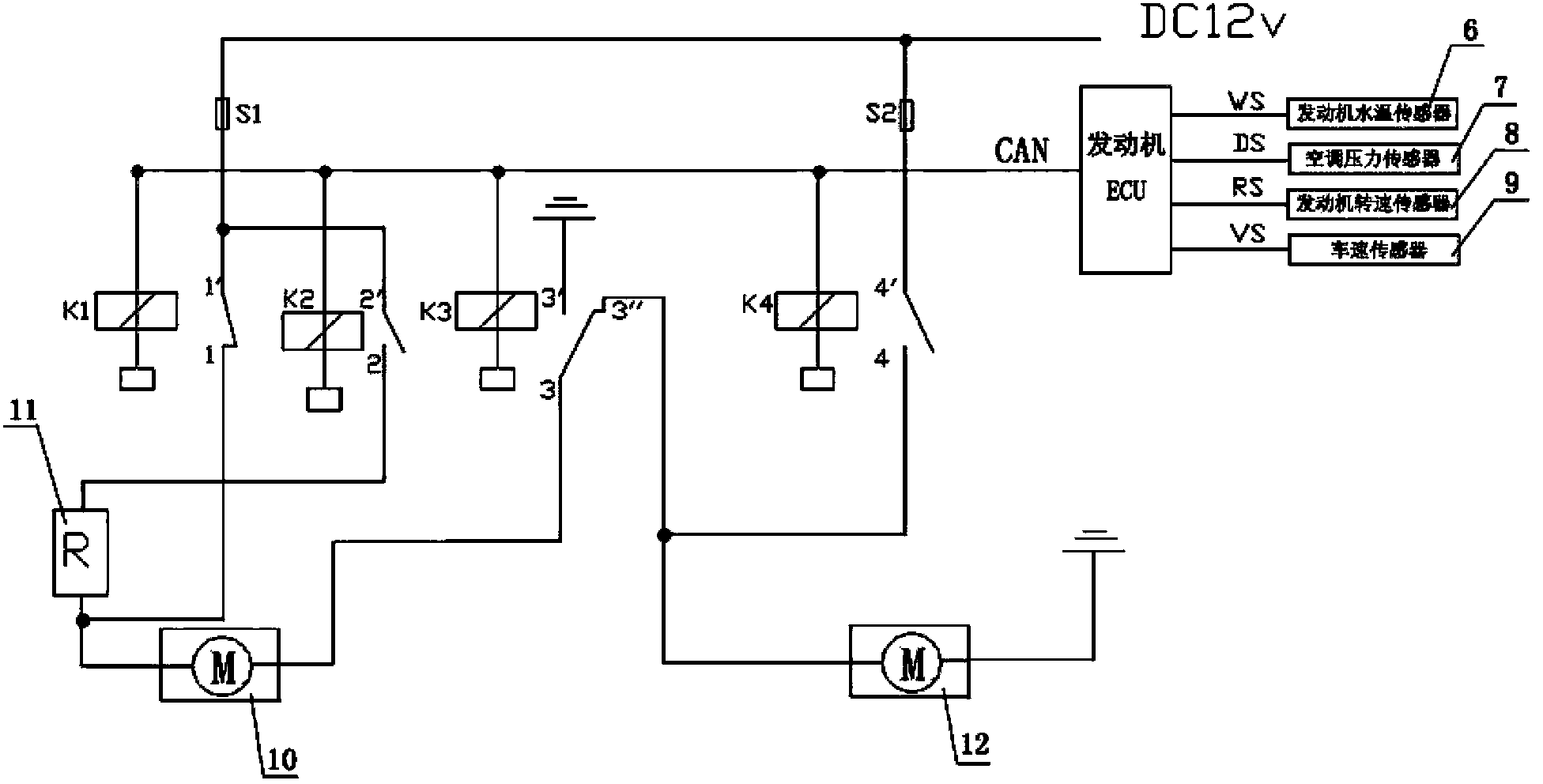

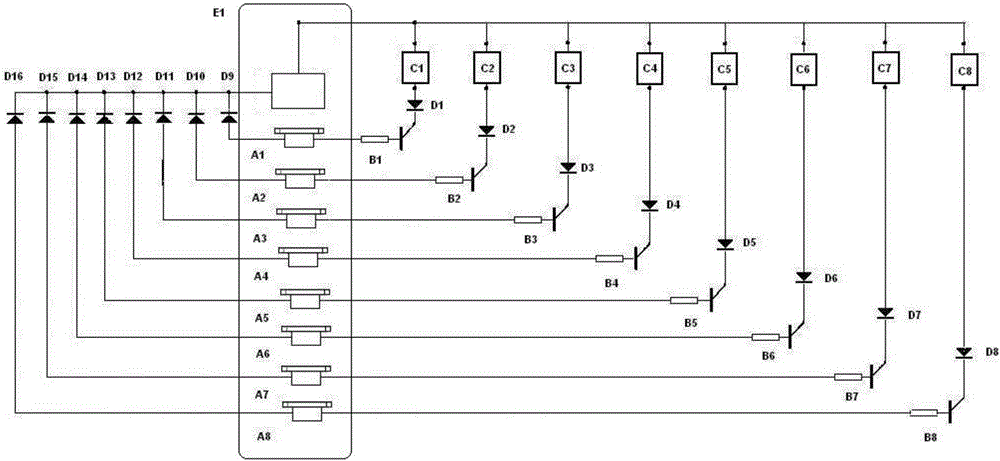

Automotive double-fan three-level speed control circuit and control method

ActiveCN103775186AReduce power usageReduce noiseCoolant flow controlMachines/enginesThree levelElectrical resistance and conductance

The invention discloses an automotive double-fan three-level speed control circuit and a control method. The automotive double-fan three-level speed control circuit comprises relays, a first electric fan, a second electric fan, an engine ECU (Electronic Control Unit) and an adjustable resistor; an input end of the engine ECU obtains motor water temperature signals, air conditioner pressure signals, motor rotating speed signals and vehicle speed signals in real time; an output end of the engine ECU is connected with coils of the relays K1, K2, K3 and K4 through a CAN (Controller Area Network) bus to control conduction or disconnection of the relays K1, K2, K3 and K4; the first electric fan is connected with the second electric fan in a series mode to achieve low speed control; the first electric fan which is connected with the adjustable resistor in a series mode is connected with the second electric fan in a parallel mode to achieve intermediate speed control; the first electric fan is connected with the second electric fan in a parallel mode to achieve high speed control. Under some specific working condition, the noise value of fan operation is reduced through the intermediate speed control mode meanwhile temperature reducing is satisfied and meanwhile the service power of the fans is reduced.

Owner:CHONGQING CHANGAN AUTOMOBILE CO LTD

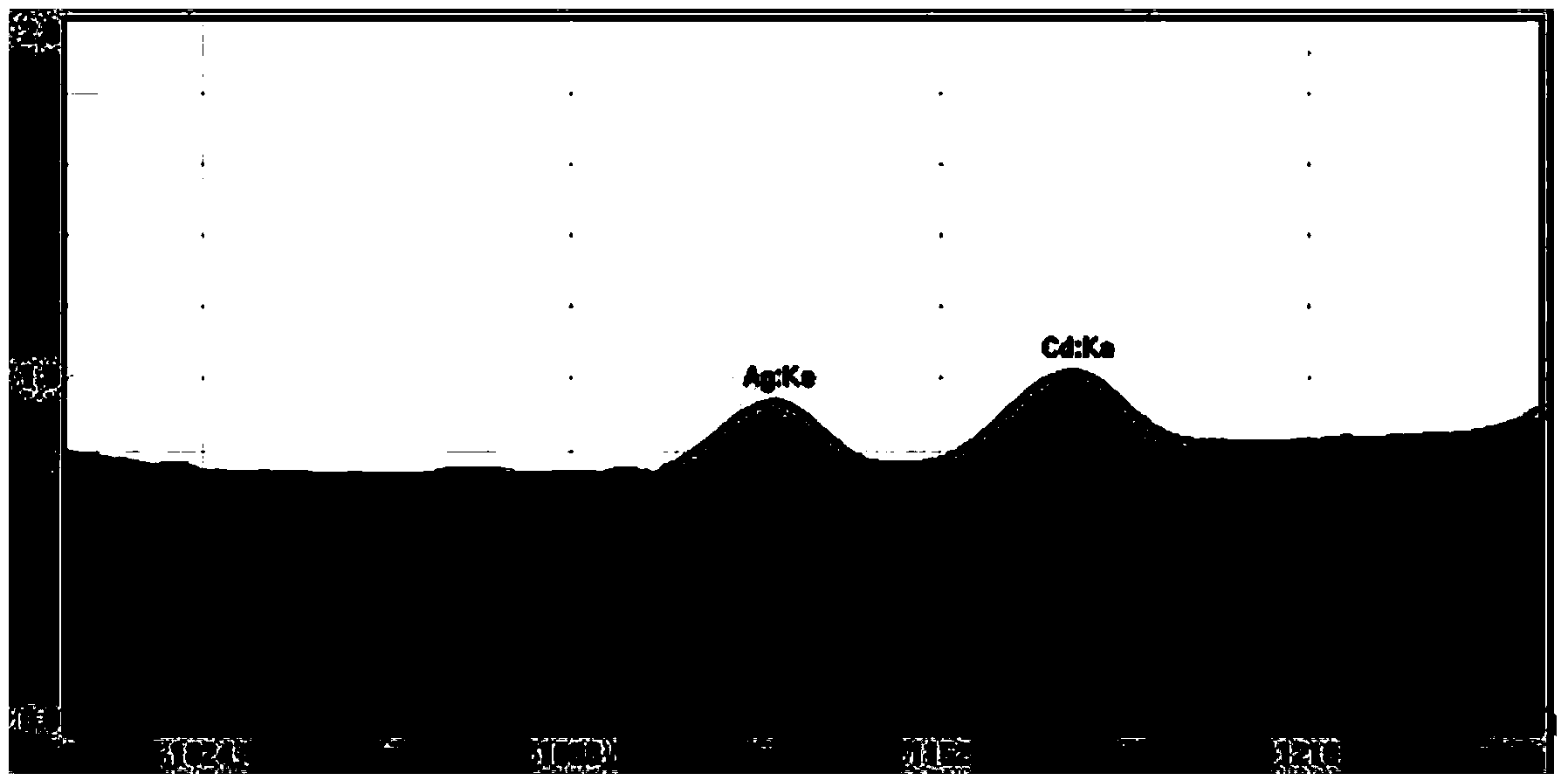

Fast analyzer for nondestructive measuring heavy metal cadmium in foods and analyzing method

ActiveCN103822935AReduced form requirementsGuaranteed identityMaterial analysis using wave/particle radiationFood specimenSoft x ray

The invention relates to a fast analyzer for nondestructive measuring heavy metal cadmium in foods and an analyzing method, and belongs to the technical field of food safety detection. The fast analyzer comprises an X-ray fluorescence analysis mechanism, an analyzer case, a specimen cup and an intelligent controlling mechanism. The analyzing method comprises the following steps: specimens are put into the specimen cup, and the specimen cup is put into the detection hole of the analyzer case; the X-ray fluorescence analysis mechanism is adopted to measure; the content of cadmium in the specimens is calculated by the intelligent controlling mechanism; the X-ray fluorescence analysis mechanism is an X-ray fluorescence analysis mechanism with high power energy dispersion; the specimens are powdery or granular specimens without chemical digestion or enrichment pretreatment. According to the invention, the fast analyzer has the following advantage: the pretreatment is not needed to be carried out on food specimens, the purpose that the heavy metal cadmium in the food specimens is detected can be realized; the fast analyzer has the characteristics of non-destruction, directness, rapidness, high sensitivity, convenience for field measurement and the like.

Owner:钢研纳克江苏检测技术研究院有限公司

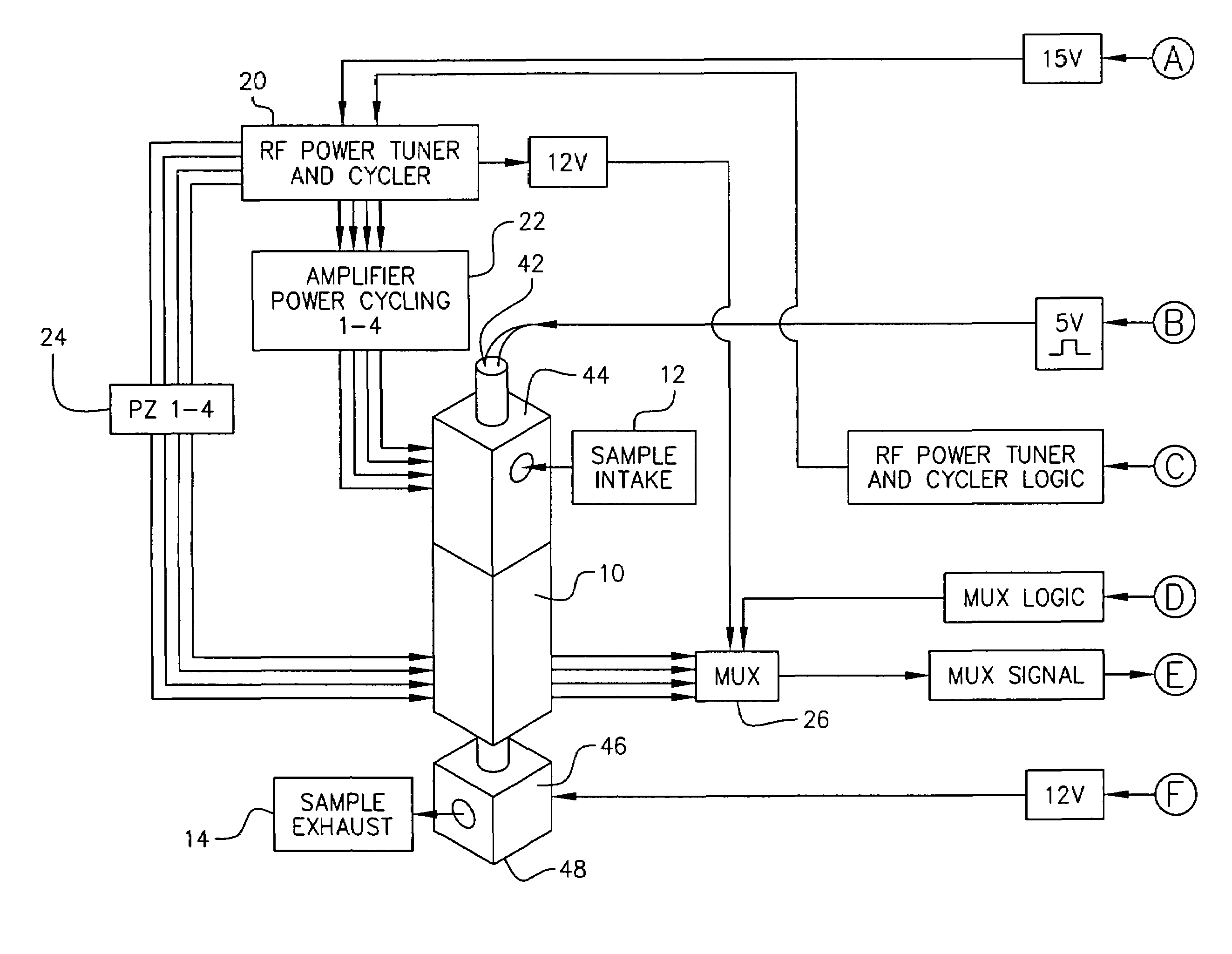

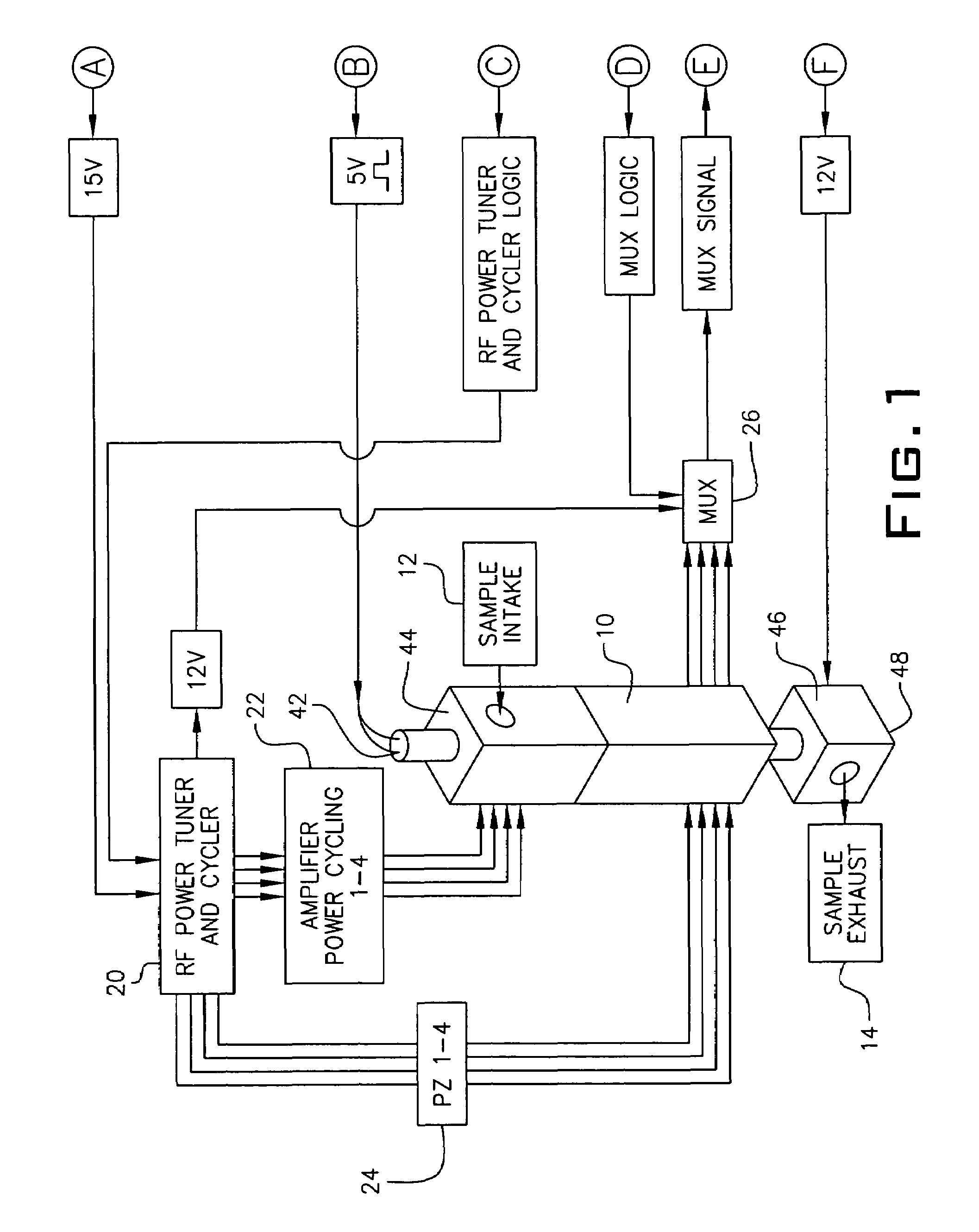

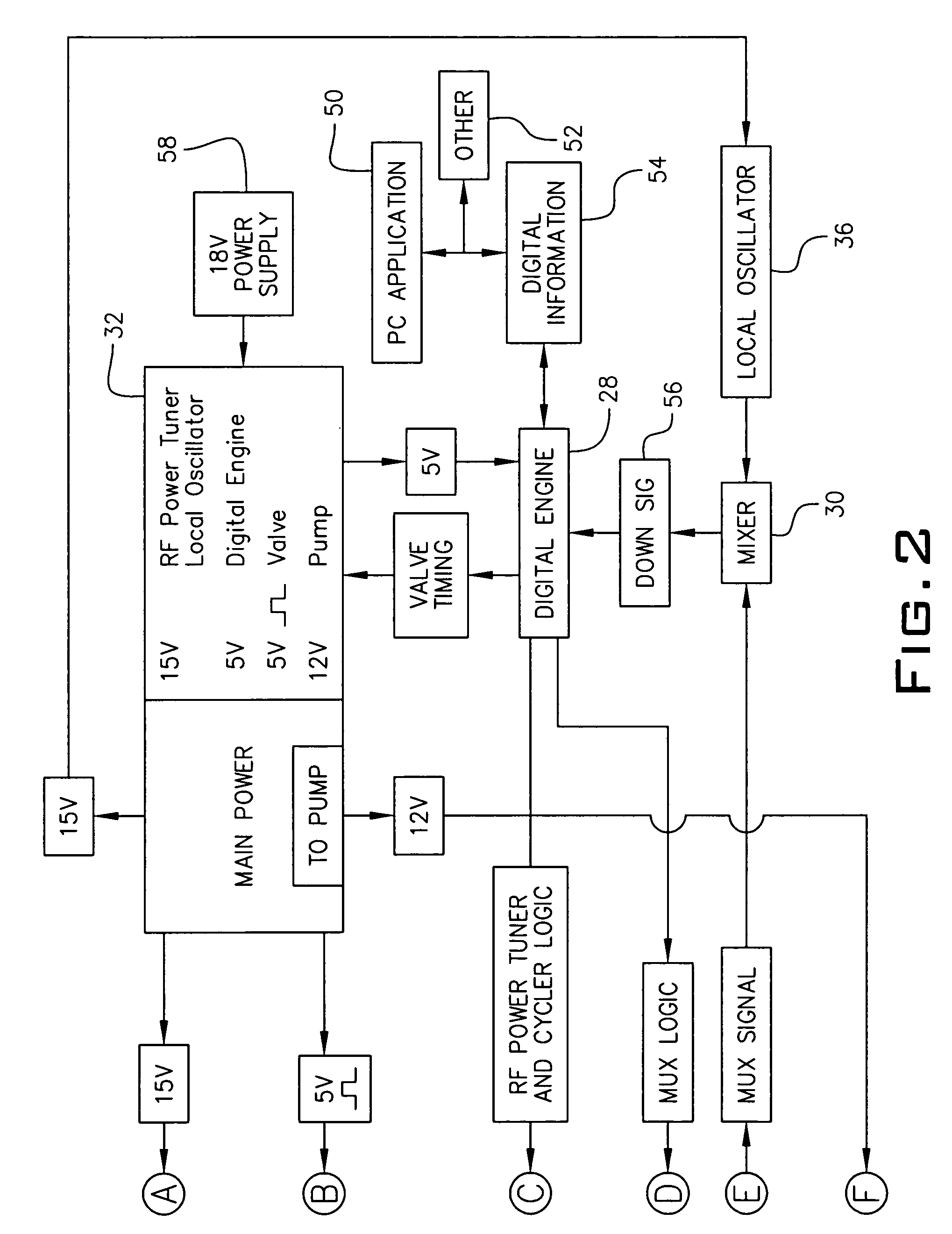

Chemical agent detector

InactiveUS6931913B2Reduce RF NoiseReduce noiseAnalysing fluids using sonic/ultrasonic/infrasonic wavesPiezoelectric/electrostriction/magnetostriction machinesAcoustic waveSurface acoustic wave

A chemical agent detector utilizing surface acoustic wave (SAW) sensors for detecting the presence of a multitude of chemical agents by sampling ambient air is provided. A pressure-differential manifold having an air intake port, an exhaust port, a valve and a pump is used to draw the ambient air into the manifold to be tested. A plurality of SAW sensors mounted on sensor driver boards which are in turn mounted on the manifold come into contact with the ambient air sample. Each SAW sensor is coated with a substance that has an affinity for detecting a particular chemical agent. Each SAW sensor driver board generates a continuous RF signal which emits a frequency shift if a particular chemical agent is detected. A power cycler module turns each sensor driver board on and off such that only one sensor driver board is powered-on at a given point in time. An RF multiplexor receives the continuous RF signals generated by the sensor driver boards and outputs one of the RF signals to a microprocessor based upon a timing signal generated by the microprocessor. The microprocessor interprets the frequency shift as the detection of a chemical agent and provides an alarm that a particular chemical agent has been detected.

Owner:CONSTELLATION TECH

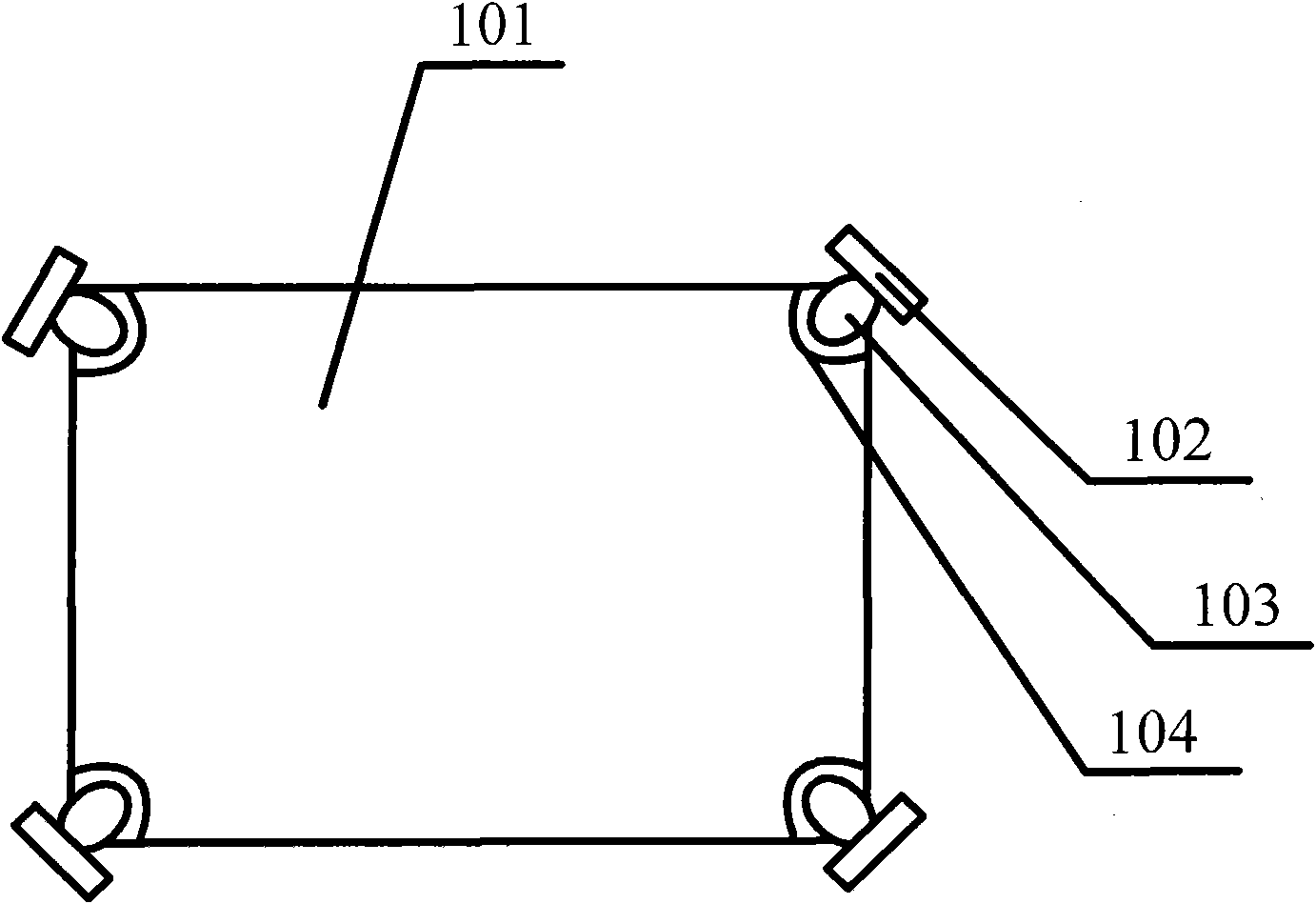

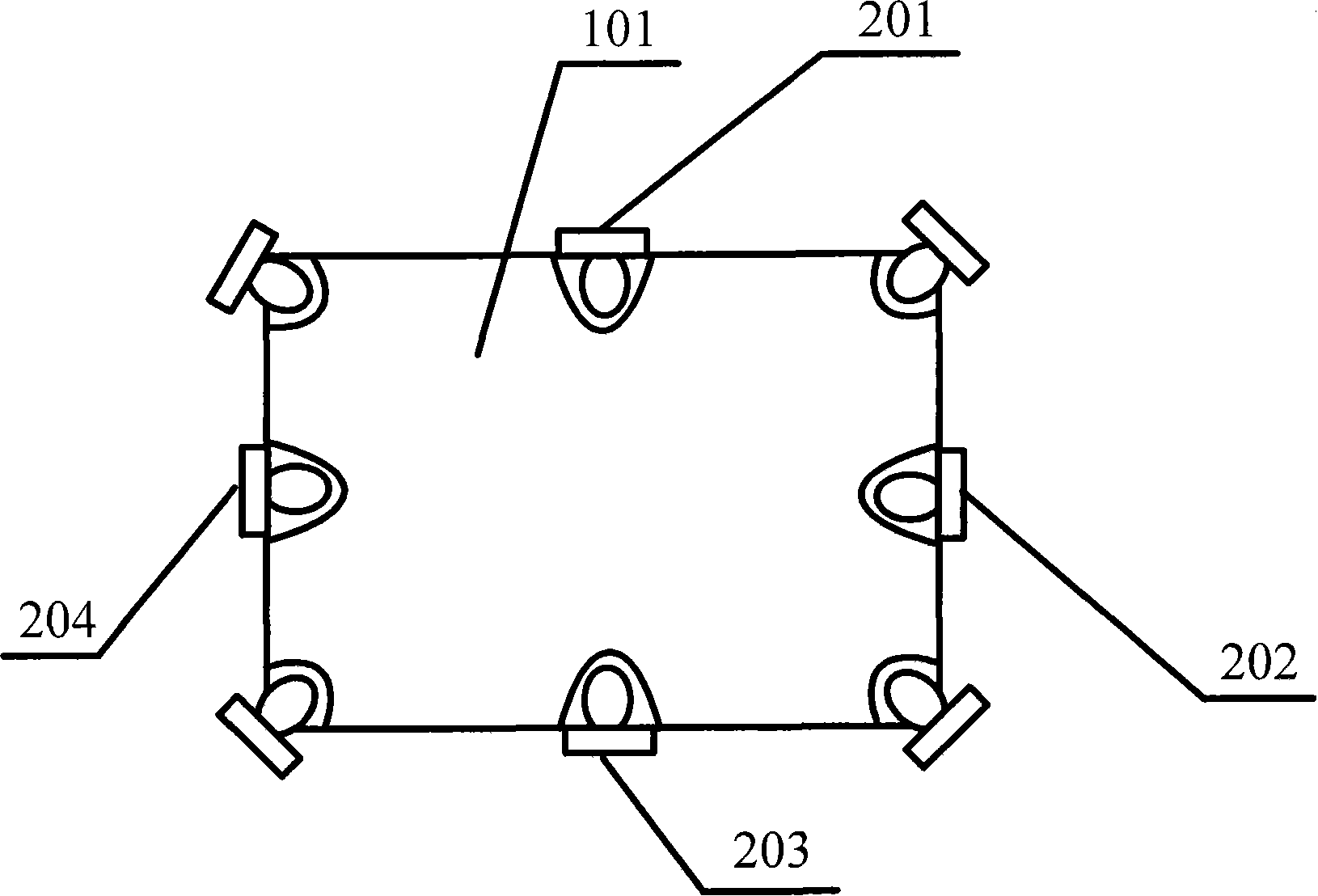

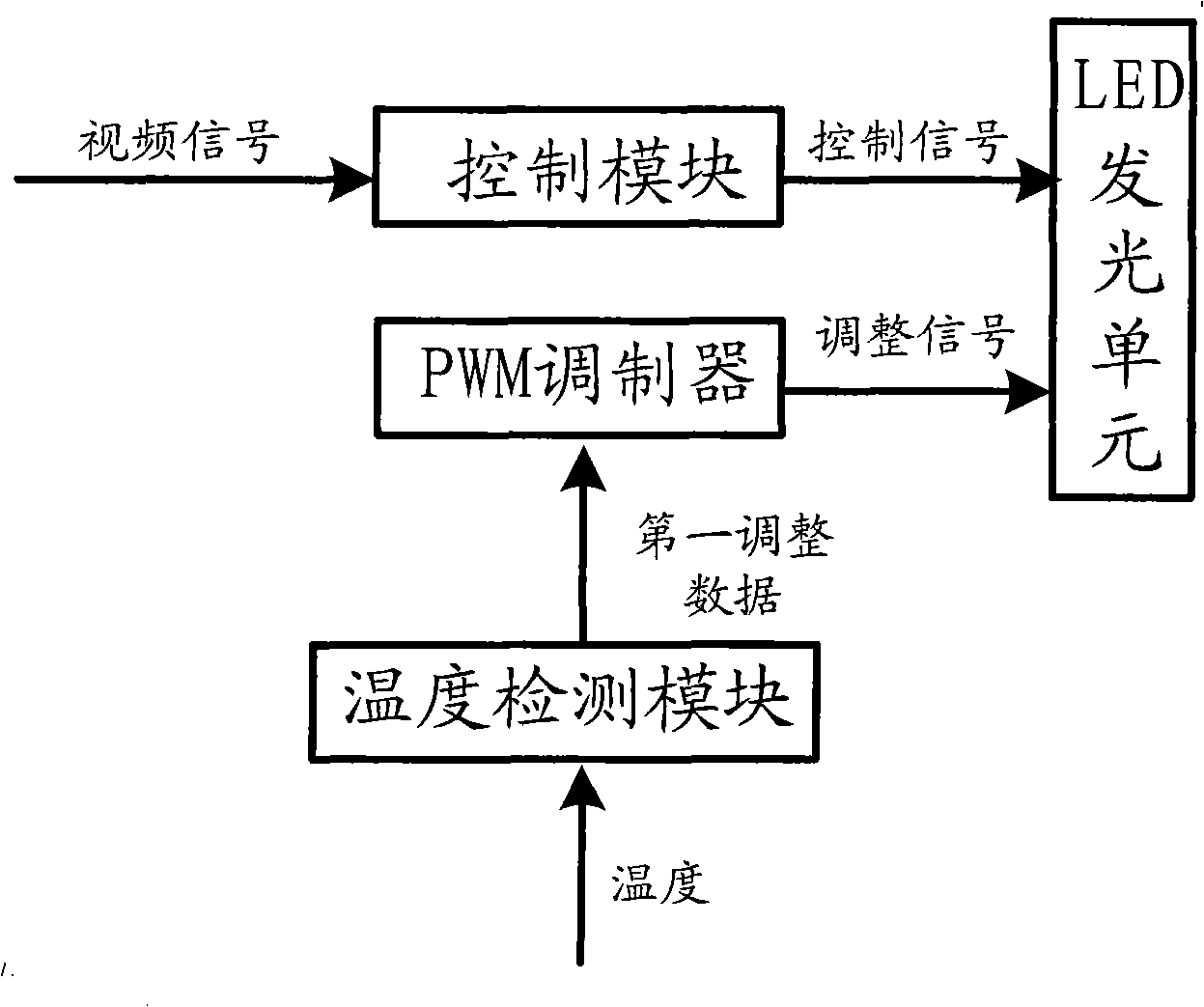

LED backlight module used for liquid crystal display

InactiveCN101806977AReduce power usageReduce power consumptionNon-linear opticsLiquid-crystal displayControl signal

The invention discloses an LED backlight module used for a liquid crystal display, which comprises at least four light-emitting units, a light guide plate and a regulation unit, wherein each LED light-emitting unit is provided with red, blue and green LEDs; the light guide plate is in a rectangular shape, four point angles of the light guide plate are respectively provided with an LED light-emitting unit, light outlet surfaces of two LED light-emitting units arranged diagonally are arranged oppositely; grooves containing the light outlet surfaces of the corresponding LED light-emitting units are arranged corresponding to each LED light-emitting unit, and the shape and the size of the groove are consistent with those of the light outlet surface of the LED light-emitting unit, which is correspondingly contained by the groove; the regulation unit comprises a control module and a PWM modulator; the control module is used for generating a control signal to control each LED light-emitting unit; and the PWM modulator is used for generating a regulation signal to regulate the LED brightness of each LED light-emitting unit. The invention has the advantages of small power consumption, high light emitting efficiency, uniform light emitting and good light emitting effect.

Owner:深圳市中庆微科技开发有限公司

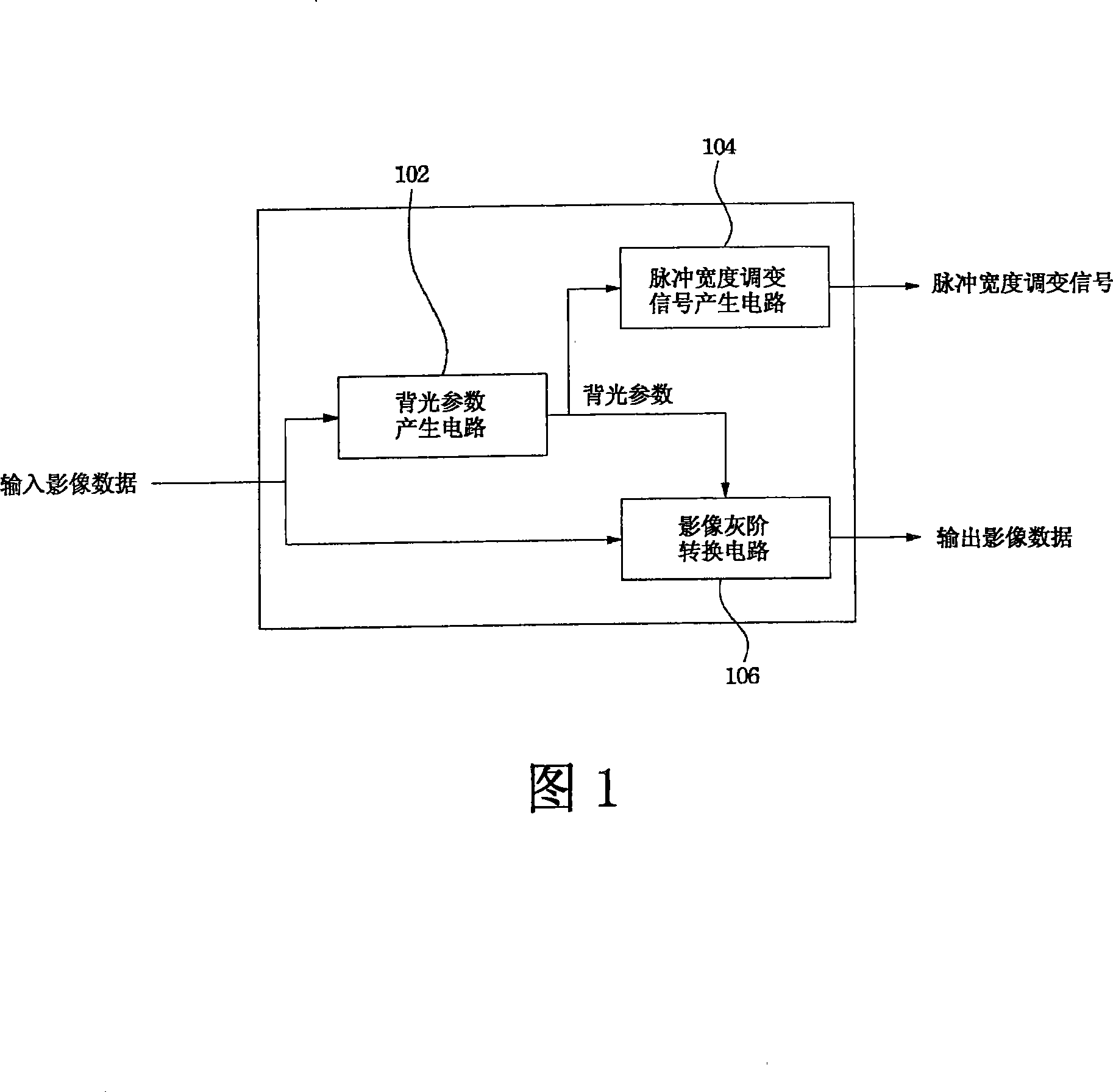

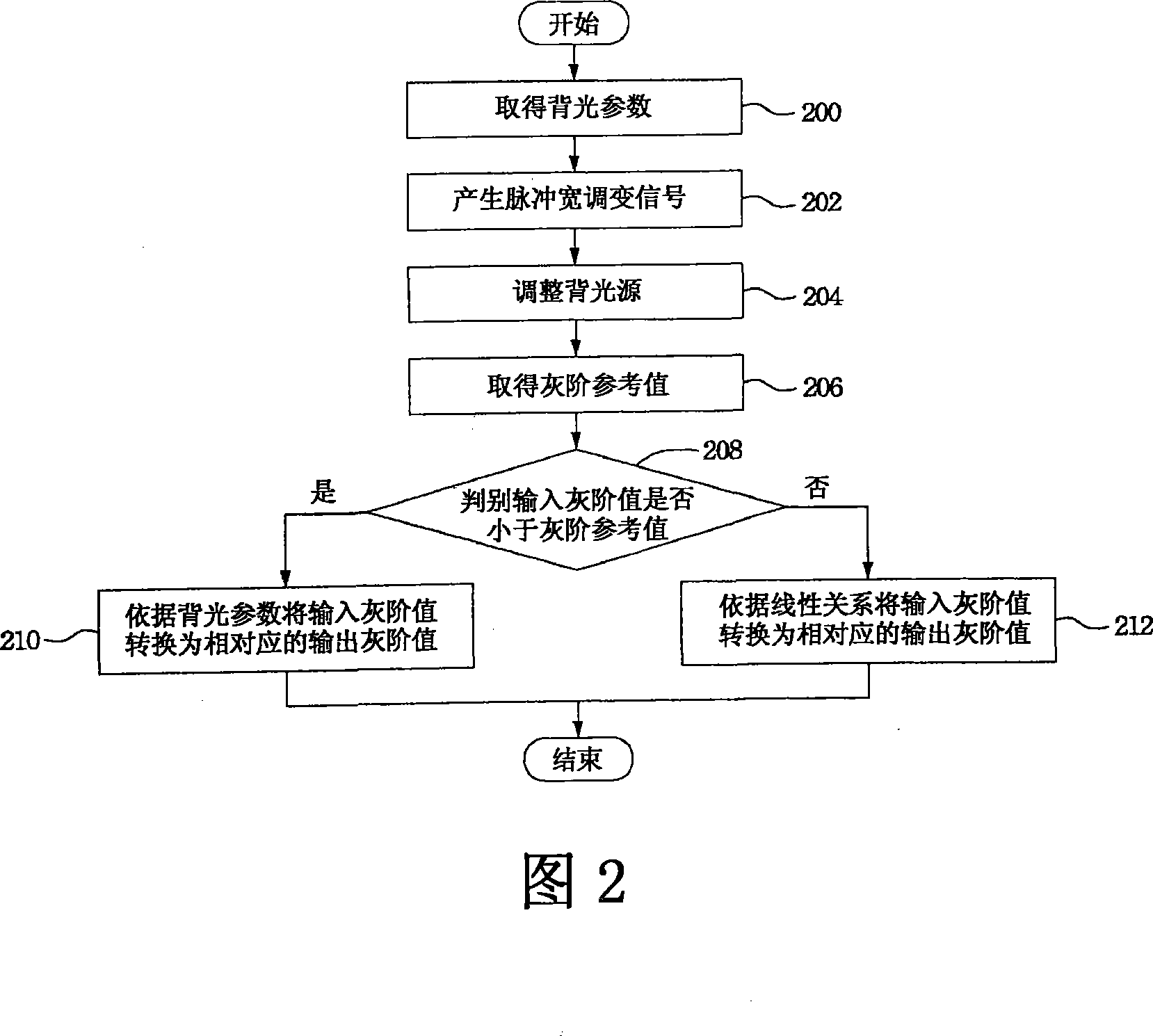

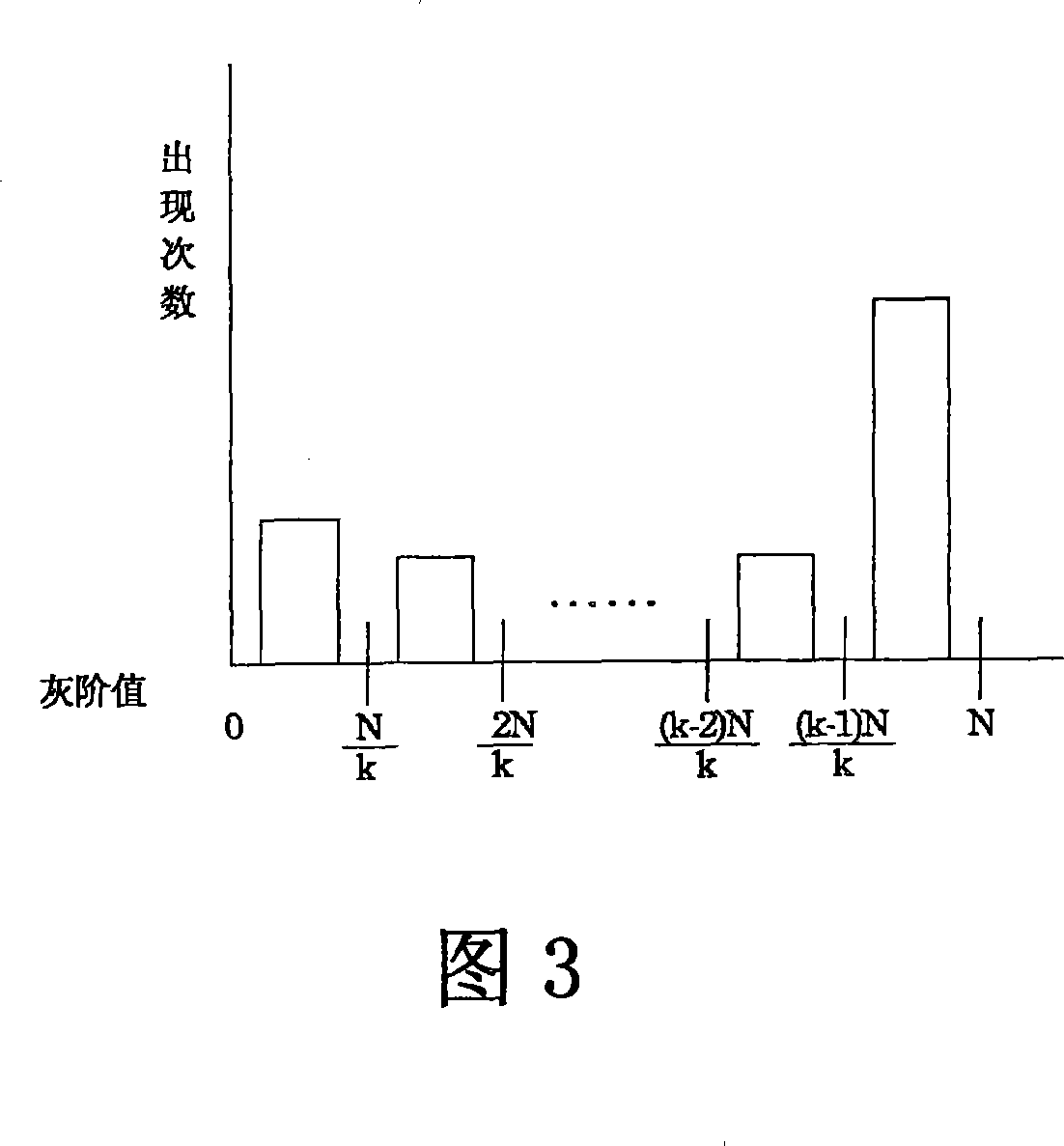

Image processing method in LCD

ActiveCN101162573AIncrease contrastImprove color levelsCathode-ray tube indicatorsLiquid-crystal displayImaging processing

The invention relates to a method for processing images of a liquid crystal display (LCD), comprising the following steps that: backlighting parameters are obtained according to image datum; a backlighting source is adjusted against the backlighting parameters; a gray reference value is obtained against the adjusted backlighting source, wherein the gray reference value between a first gray boundary value and a second boundary value; when the gray value of the image datum is between the gray reference value and the first gray boundary value, the gray value of the image data is converted into a corresponding output gray value against the backlighting parameters; when the gray value of the image data is between the gray reference value and the second gray boundary value, the gray value of the image data is converted into a corresponding output gray value against a linear relation. The invention can improve contrast degree of the image and increase the color levels displayed by the image so as to highlight the image.

Owner:AU OPTRONICS CORP

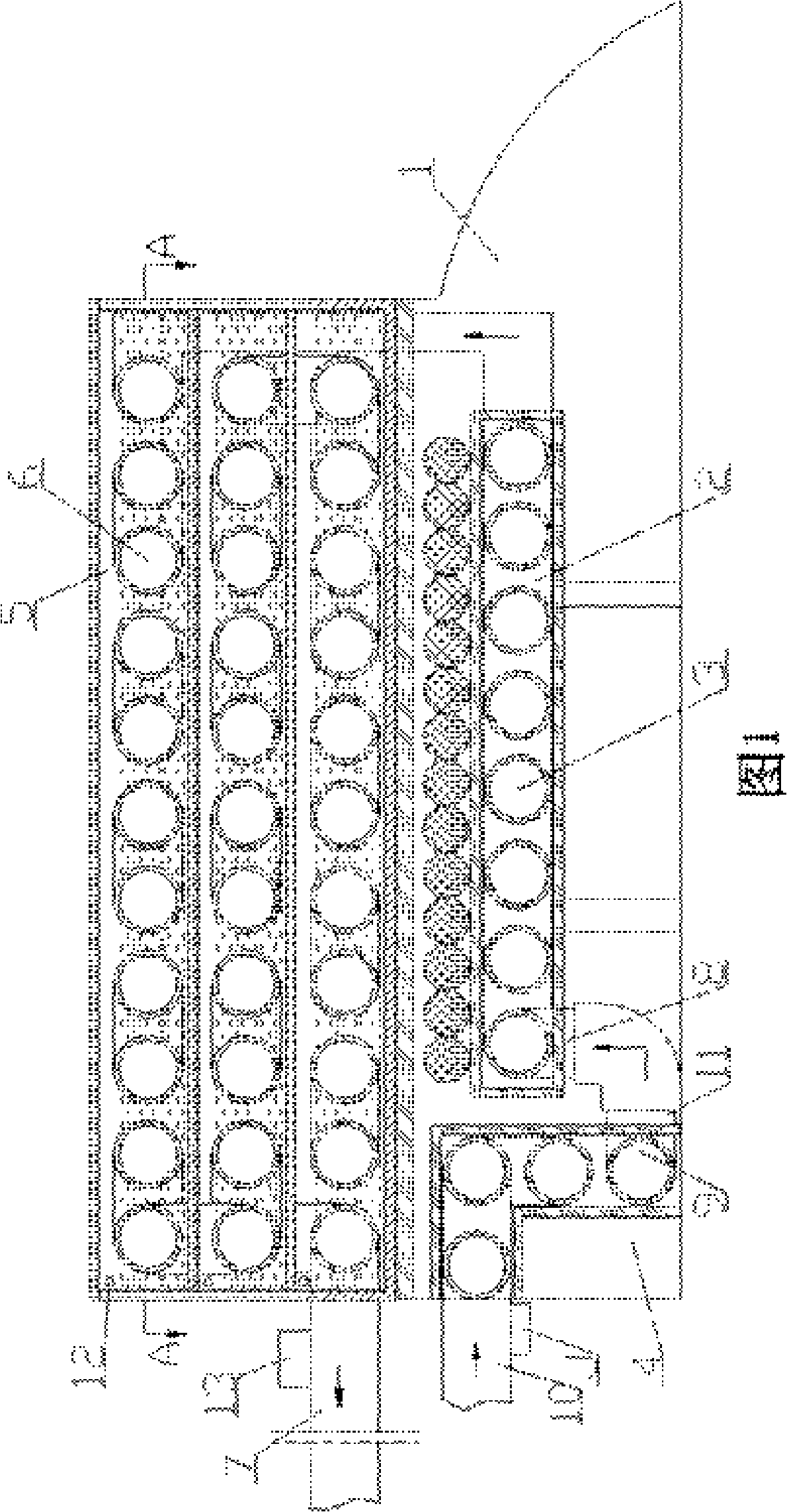

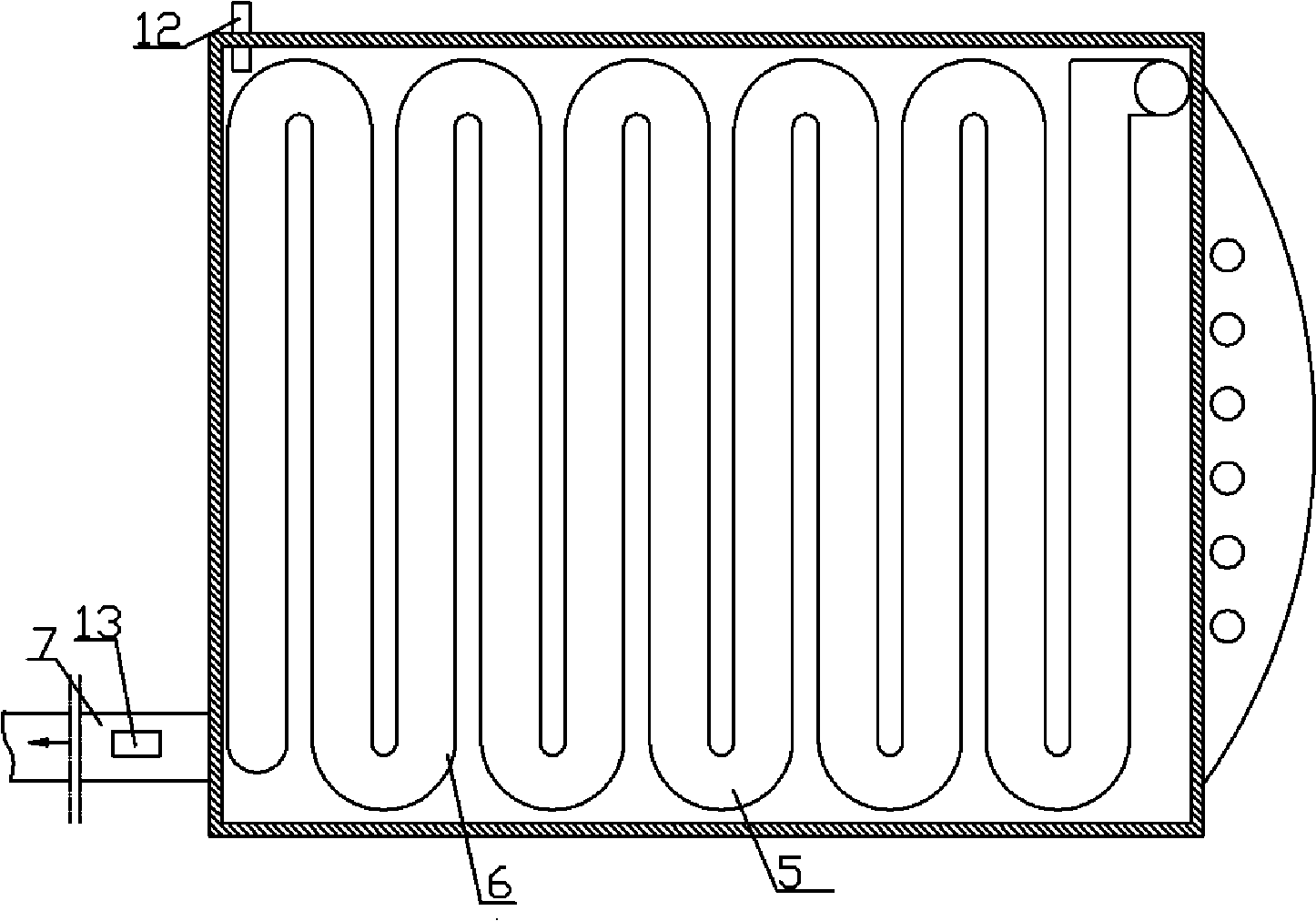

High-efficiency, energy-conserving and electromagnetical instantaneously heated type safety water heater and method for manufacturing same

The present invention discloses a high-efficient energy-saving instant-heating safety heater and a production method thereof, wherein, the heater adopts an electromagnetic oven to heat, and is characterized in that the surface of an electromagnetic oven tray is provided with a sealed box body that is made of iron material or stainless steel material and is provided with two layers or more that are separated from each other; each layer of the sealed box body is provided with water and provided with the disc-shaped heat-conducting pipe that is made of the copper pipe, and the heat conducting pipes inside each layer of the sealed box body are communicated with each other; at the same time, the electromagnetic coil supporting plate that is arranged inside the electromagnetic oven adopts the ceramic material to be made into an electromagnetic coil supporting plate with a water cycling passage; the outlet of the water cycling passage of the supporting plate is connected with a water inlet of the heat conducting pipe that is arranged inside the most upper layer of the sealed box body, so that the water that flows inside the heat conducting pipe can be rapidly heated. The electromagnetic oven is used to heat, so that the electricity not only can be completely separated from the water, so as to improve the security of the user, but also can improve the energy source utilization rate.

Owner:陈述河

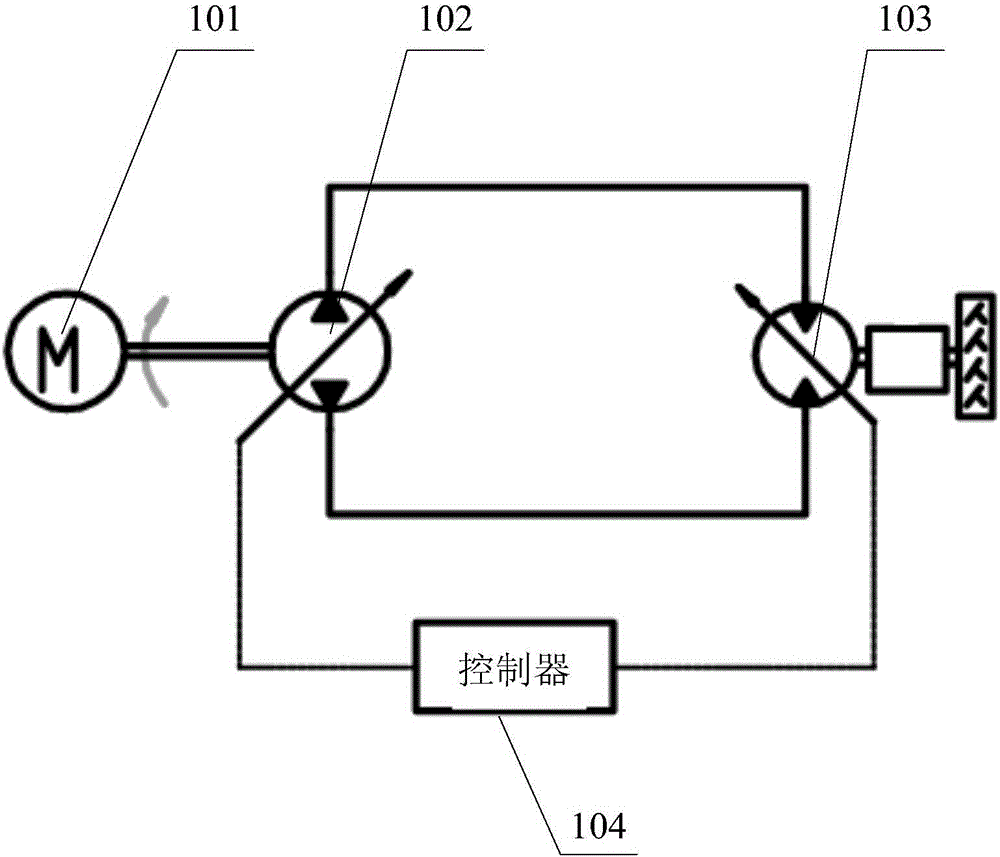

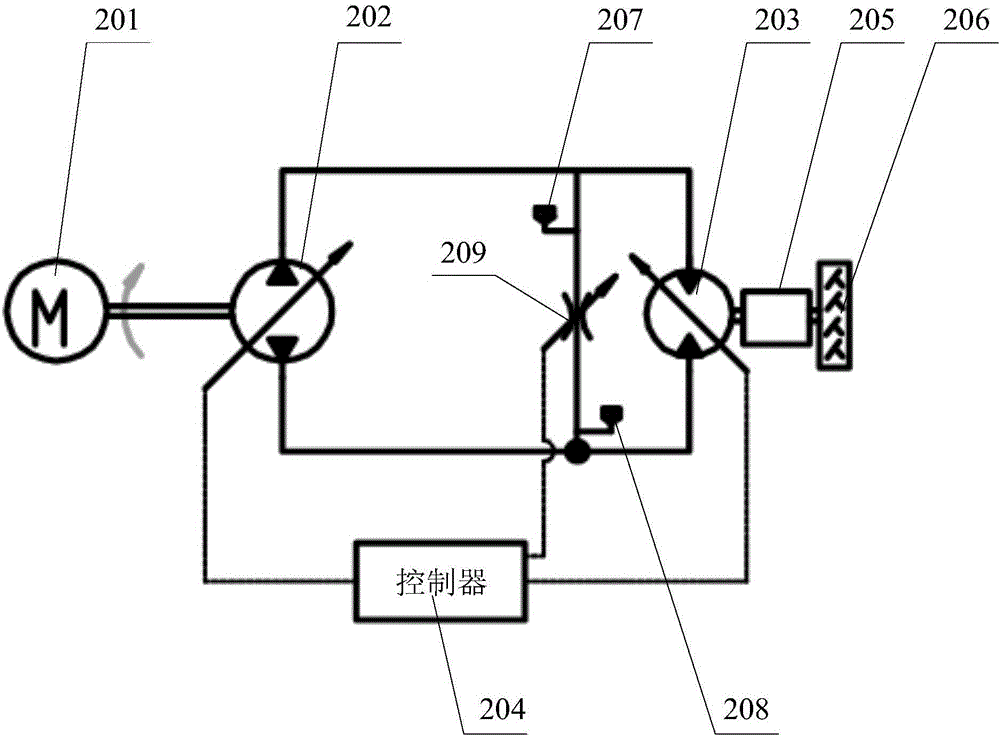

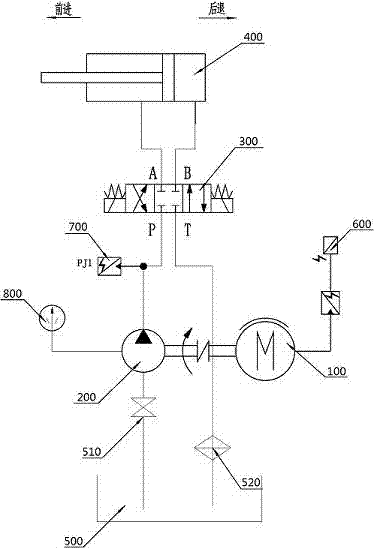

Hydraulic closed system, hydraulic closed walking system and hydraulic closed winding system

The embodiment of the invention discloses a hydraulic closed system. The hydraulic closed system comprises a hydraulic pump, a hydraulic motor, a third pipeline and a throttling valve, wherein an oil outlet of the hydraulic pump communicates with an oil inlet of the hydraulic motor through a first pipeline, and an oil outlet of the hydraulic motor communicates with an oil inlet of the hydraulic pump through a second pipeline; one end of the third pipeline communicates with the first pipeline, and the other end of the third pipeline communicates with the second pipeline; and the throttling valve is connected in series with the third pipeline. As for the normal working conditions, the displacement of the hydraulic pump can be reduced under the condition of keeping the original output speed unchanged, so that the service power of an engine can be lowered, and accordingly, the energy consumption can be reduced. As for the motored conditions of the hydraulic pump, the throttling valve can be opened and kept at a certain opening degree, meanwhile, displacement changes of the hydraulic pump are adjusted to reduce overspeed 'running away' phenomena while keeping the output speed of the hydraulic motor not reduced. The invention further discloses a hydraulic closed walking system and a hydraulic closed winding system.

Owner:WEICHAI POWER CO LTD

Turnover kiln with air distribution system arranged at bottom

The invention provides a turnover kiln with an air distribution system arranged at the bottom. The air distribution system is composed of a kiln body annular interior wall, annular heat suction main air ducts, heat suction branch air ducts, an annular heat sending main air duct, heat sending branch air ducts, moisture discharge openings and a heat sending draught fan desulfuration and dust removing device. By means of opening of a plurality of air brakes fixedly distributed in the heat suction main air ducts and the heat sending main air duct and by means of reasonable joining of air used for drying and roasting in a kiln furnace moving on the annular bottom of the kiln, waste heat can be fully utilized, the aim of conducting artificial drying and one-time palletizing and burning can be achieved, and therefore kiln loading and kiln discharging can be conducted outside the kiln. The air distribution system can thoroughly solve the difficult problem of high-temperature corrosion resistance of the kiln body steel structure and can scientifically and efficiently conduct desulfuration and dust removing, the primer can more easily enter the bottom of the kiln, positive-pressure moisture discharge is achieved, green bodies can be rapidly and evenly dried, unnecessary intermediate process links and devices are omitted, the diameter of the kiln can be large or small, and the turnover kiln is more suitable for small-scale investment and plant construction. The turnover kiln can be specially used for sintering non-bearing air bricks when the diameter of the kiln is small, one and a half times of palletizing and burning can be achieved through natural drying bricks when the diameter of the kiln is large, and the turnover kiln is also suitable for automatic kiln stacking conducted through mechanical hands.

Owner:寿阳县大胜窑炉科技有限公司

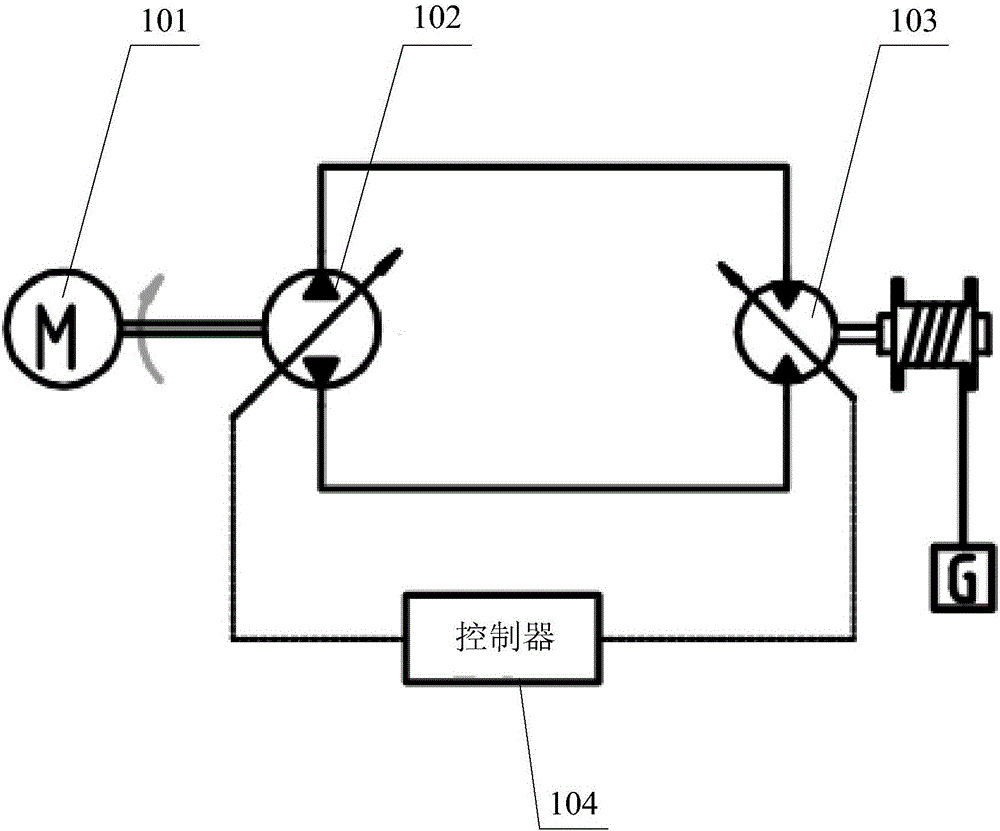

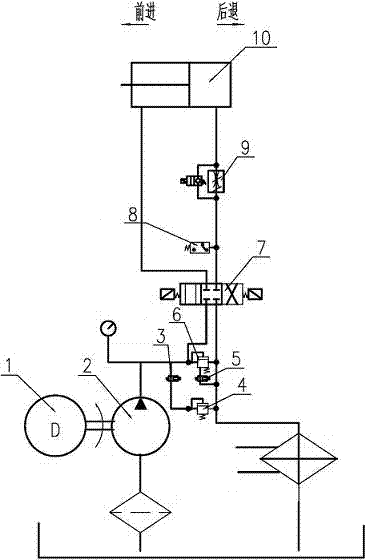

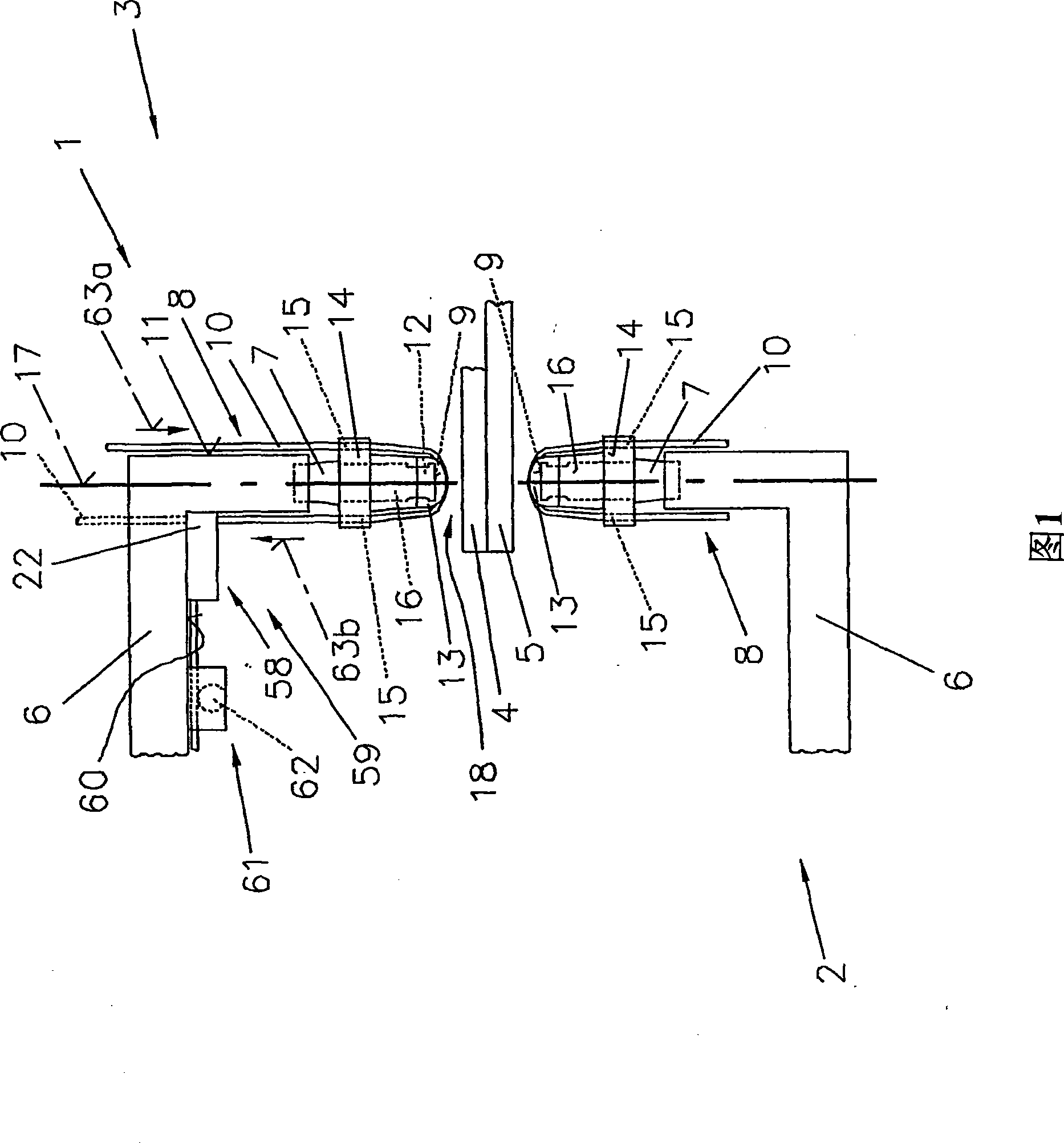

Servo hydraulic system of friction welding machine

InactiveCN103042304AImprove stabilityEasy to storeServomotorsNon-electric welding apparatusFriction weldingLoop control

The invention aims to provide a servo hydraulic system of a friction welding machine. The servo hydraulic system comprises a servo motor, a hydraulic pump, an electromagnetic directional valve and a main oil cylinder, wherein the main cylinder and the electromagnetic directional valve are mutually connected, a P end of the electromagnetic directional valve is connected to an oil tank via the hydraulic pump, the hydraulic pump and the servo motor are mutually connected, and a T end of the electromagnetic directional valve is connected to the oil tank. By adjusting pressure and flow quantity via a servo controller, storage of multiple groups of parameters and welding of products in multiple specifications are facilitated, by comparing feedback of a pressure sensor with parameters set by the servo controller, pressure closed-loop control of a hydraulic system of the friction welding machine is realized, utilization power of the system is reduced, energy consumption is saved, the hydraulic system is simplified, stability of the hydraulic system is improved, hidden fault danger is reduced, and purpose of the servo hydraulic system of the friction welding machine is achieved.

Owner:SHANGHAI SHENGCHUN MACHINERY

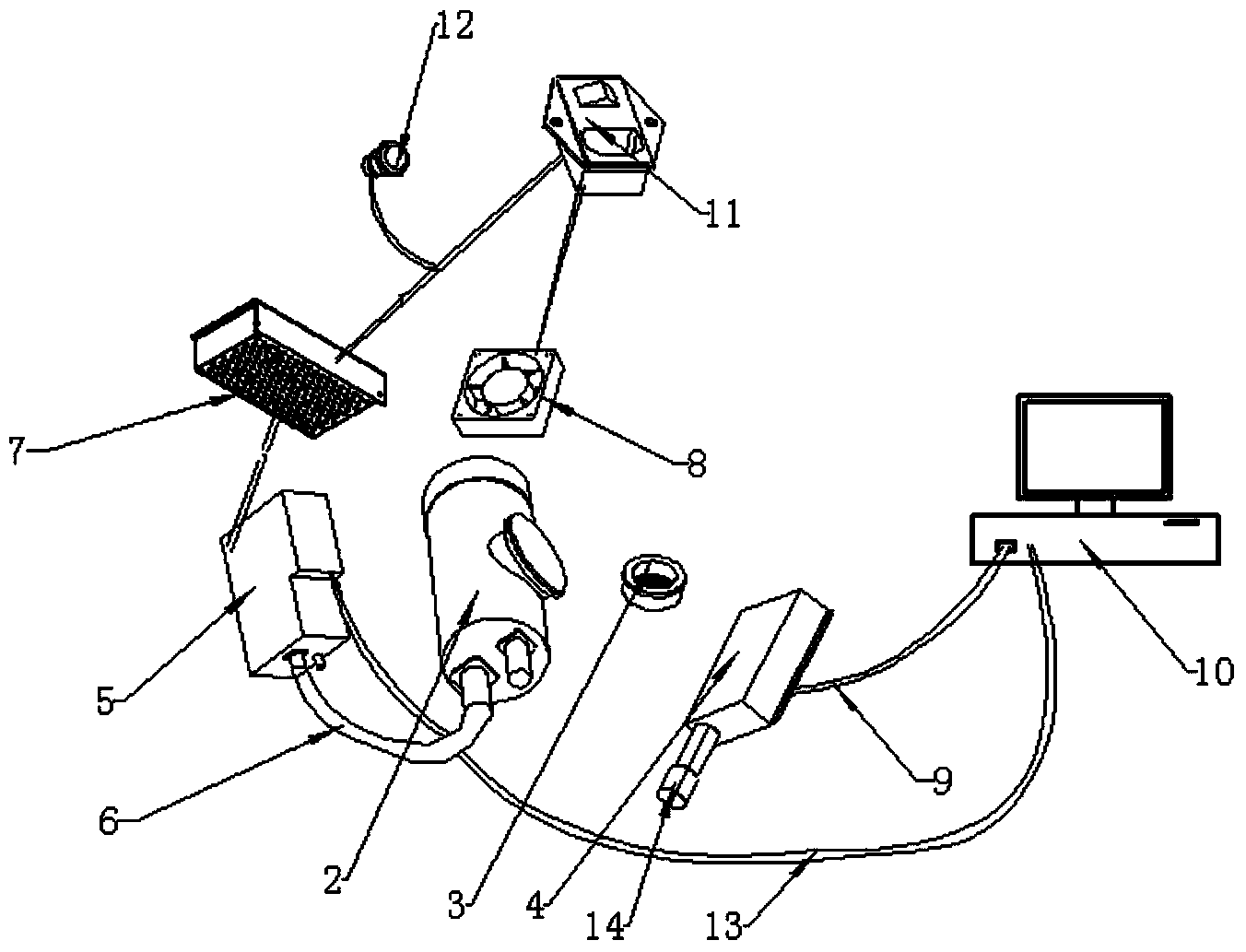

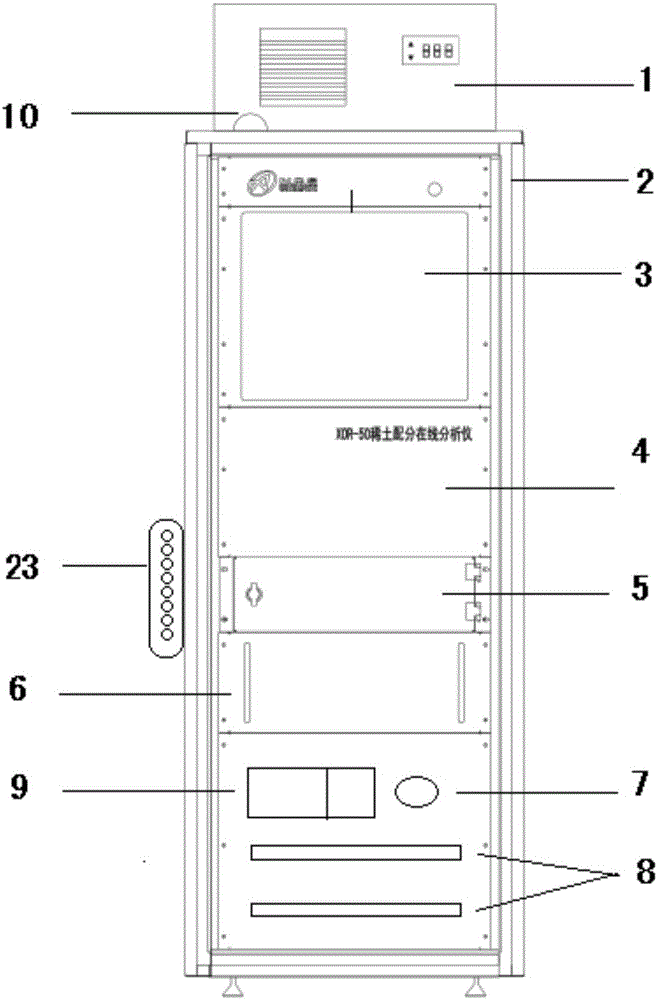

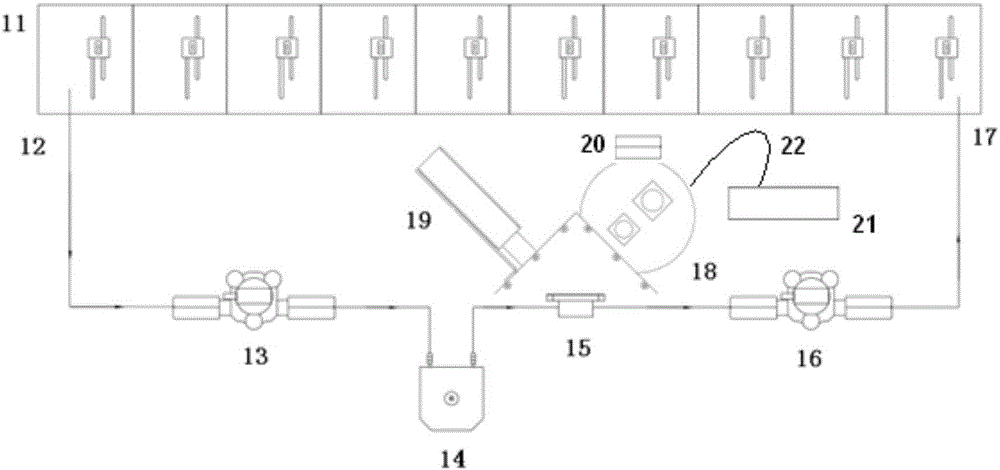

Rare-earth smelting and separation process mass partition quantity online monitor

ActiveCN105136831AWide measurement rangeRelatively small errorMaterial analysis using wave/particle radiationAutomatic controlRare earth

The invention provides a rare-earth smelting and separation process mass partition quantity online monitor, and belongs to the technical field of rear-earth hydrometallurgy. The online monitor comprises a single-flow-path or multi-flow-path automatic sampling system, an X-ray fluorescence analysis system, a data processing system and an automatic control system. A sampling pump introduces a water phase in a cascade-stage extraction tank into a detection tank, after a sample is conveyed to the detection tank, irradiation is conducted on the sample through X rays generated from an X-ray light tube, and characteristic X-ray fluorescence of rear-earth L series is motivated and received through an SDD-type detector. The detected sample flows into an extraction tank body again through a sample conveying pipeline. The data processing system is connected to the detector of the analyzer through a signal cable and transmits a collected signal to a computer, calculation is conducted through a data processing module of computer software, and then the mass partition quantity of all rear-earth elements of the sample is output and uploaded to a main control room. Online monitoring on partition changes of all the rear-earth elements in the extraction tank of the rear-earth smelting and separation process is achieved, data are accurate and reliable, and the sensitivity is high.

Owner:NCS TESTING TECH

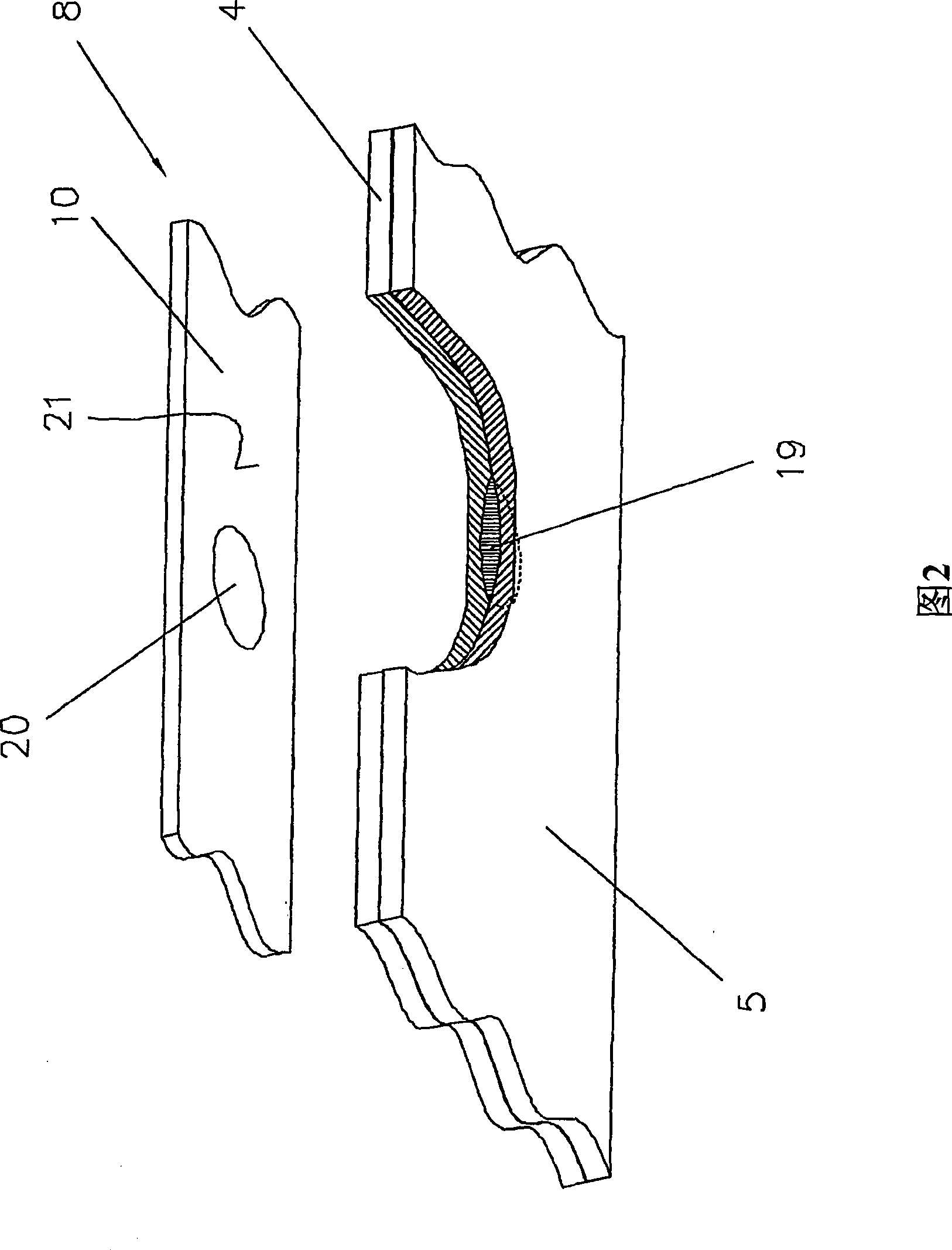

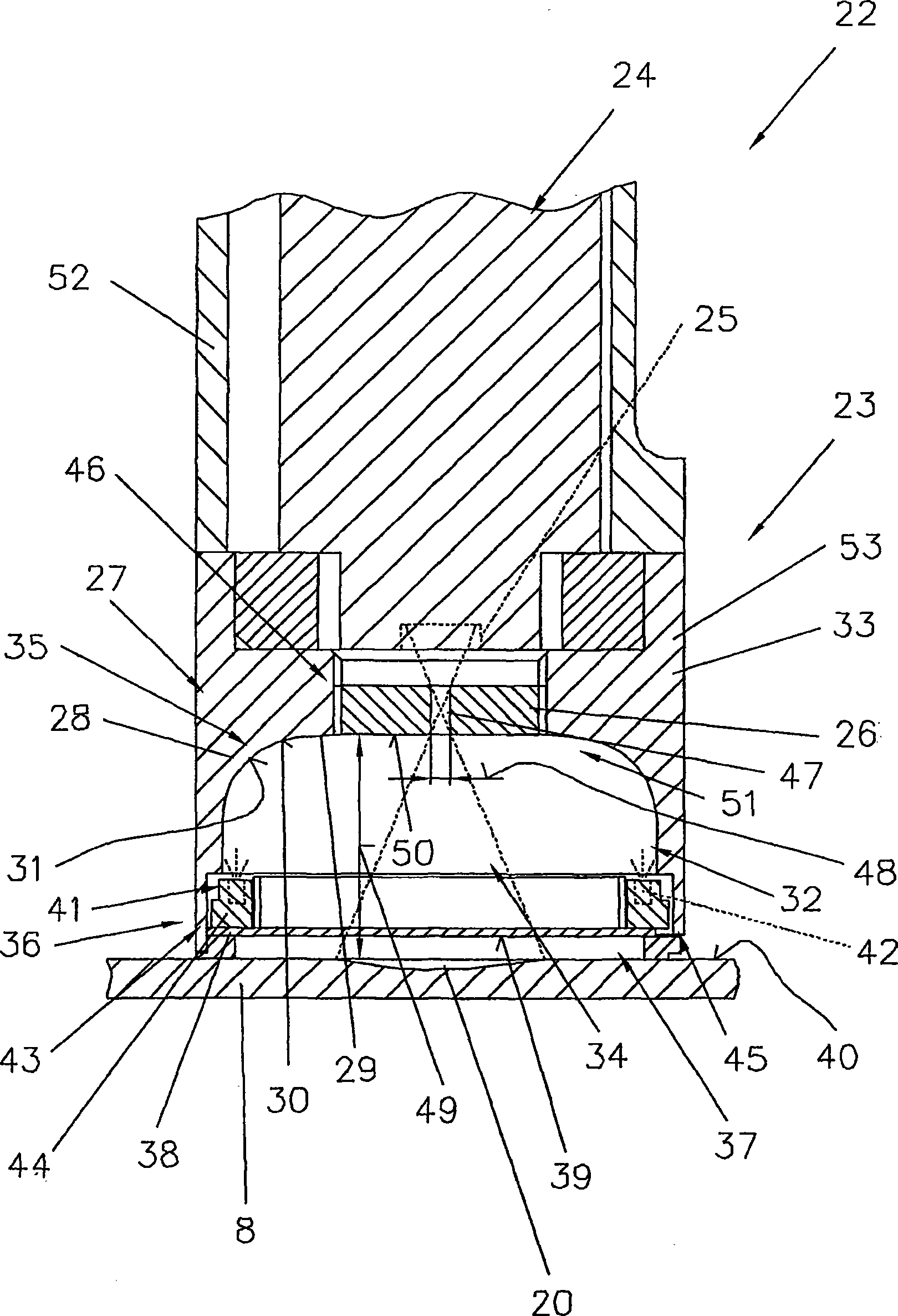

Device for evaluating images of weld spots on a carrier material

InactiveCN101454112ACompact structureCompact designOptically investigating flaws/contaminationWelding monitoring devicesEngineeringOptical quality

The invention relates to a device (22) for evaluating an image (20), produced on a carrier material (8) by the spot welding of a weld spot (19) using an optical image detection unit (23), comprising a camera (24) consisting at least of a detection means (25) and a lens (26). To provide an evaluating device (22) with which the optical quality examination of spot welded joints can be improved, the image detection unit (23) has an illuminating means (27) with a diffuser (28) for the diffuse and homogeneous illumination of the image (20) of the spot weld on the carrier material (8). The invention also relates to a welding tool (1) for a spot welding unit, in particular a welding gun (2), having an evaluating device (22) for analyzing an image (20) of a spot weld (19) on a carrier material (8).

Owner:FRONIUS INTERNATIONAL GMBH

Phase-change heat-storage energy-saving electric water heater

InactiveCN101943466AReduce energy consumptionExtend the on-off cycleChemical industryHeat-exchange elementsEngineeringHigh heat

The invention discloses a phase-change heat-storage energy-saving electric water heater and belongs to the technical field of household appliances. The water heater comprises a shell, an insulating layer, an inner tank, a magnesium rod, a sewage draining exit, a hot water outlet, a cold water inlet, a leakage protection switch, a temperature controller and an electric heating pipe, wherein the insulating layer between the shell and the inner tank is a composite insulating layer which consists of a polyurethane foam heat-preservation layer and a phase-change heat storage layer; the energy saving of a water storage electric water heater is realized by the double insulation of heat storage and heat insulation; the polyurethane foam heat-preservation layer is positioned between the shell and the phase-change heat storage layer which is tightly attached to the outer side of the inner tank; the composite insulating layer is 25 to 45mm thick; and the thickness ratio of the phase-change heat storage layer to the polyurethane foam heat-preservation layer is 0.4 to 0.8. The electric water heater has the advantages of capability of improving the energy saving level in a water storage and heat preservation process and reducing power consumption, high heat utilization ratio, safety and low cost, and is environmentally friendly and convenient for operation.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

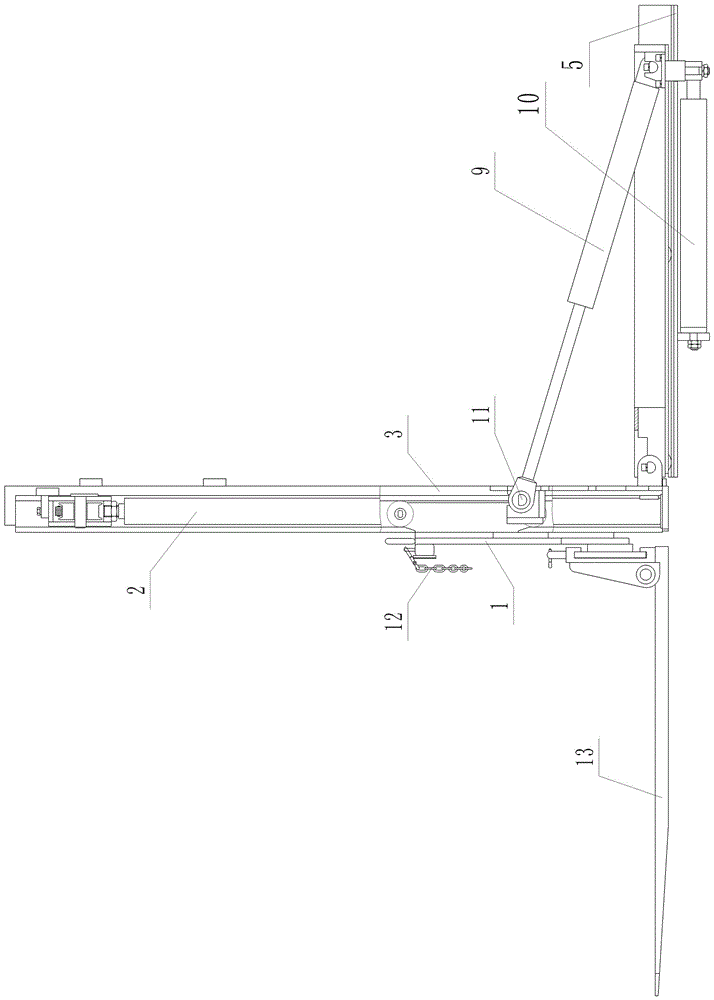

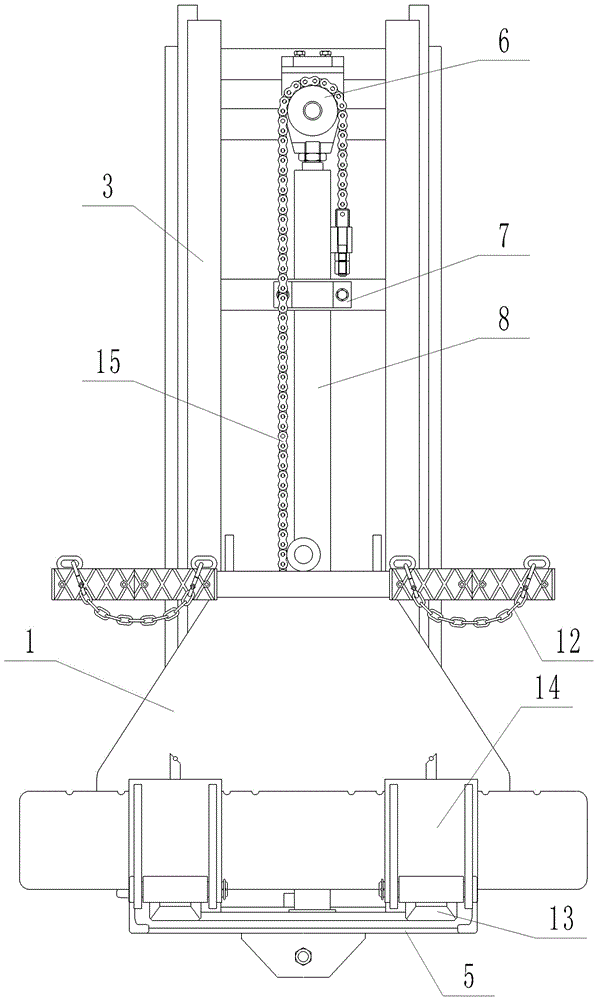

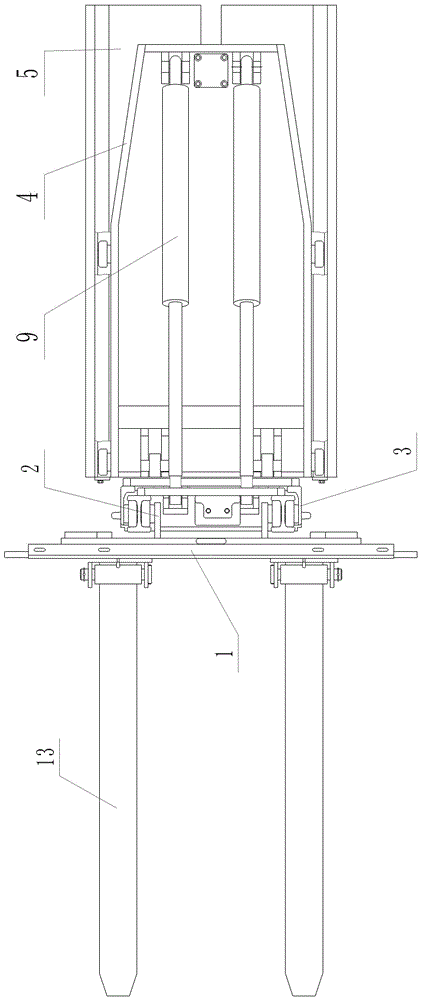

Front fork and portal double-folding device capable of moving forwards and backwards

ActiveCN105858546ALighten the counterweightReduce power usageLifting devicesVehicle framePallet fork

The invention discloses a front fork and portal double-folding device capable of moving forwards and backwards. The front fork and portal double-folding device capable of moving forwards and backwards is characterized in that the device comprises a pallet fork, an inner portal, an outer portal and a guide rail forklift frame; the pallet fork comprises a front fork and a pallet fork carrier; the front fork is rotatably connected with the pallet fork carrier; the inner portal and the outer portal are slidably connected in a matched mode, the inner portal and the outer portal are vertically arranged, and the inner portal and the outer portal can rotate around the lower portion of the outer portal; the guide rail forklift frame is horizontally arranged, and the outer portal and the guide rail forklift frame are slidably connected in a matched mode; and the pallet fork carrier is arranged on the inner portal, and the pallet fork carrier is slidably connected with the inner portal in a matched mode through a lifting assembly. According to a forklift provided with the device, forklift transportation is slightly limited, the weight of the whole forklift is low, and the using cost and transportation cost are low.

Owner:GUILIN FUHUA METAL

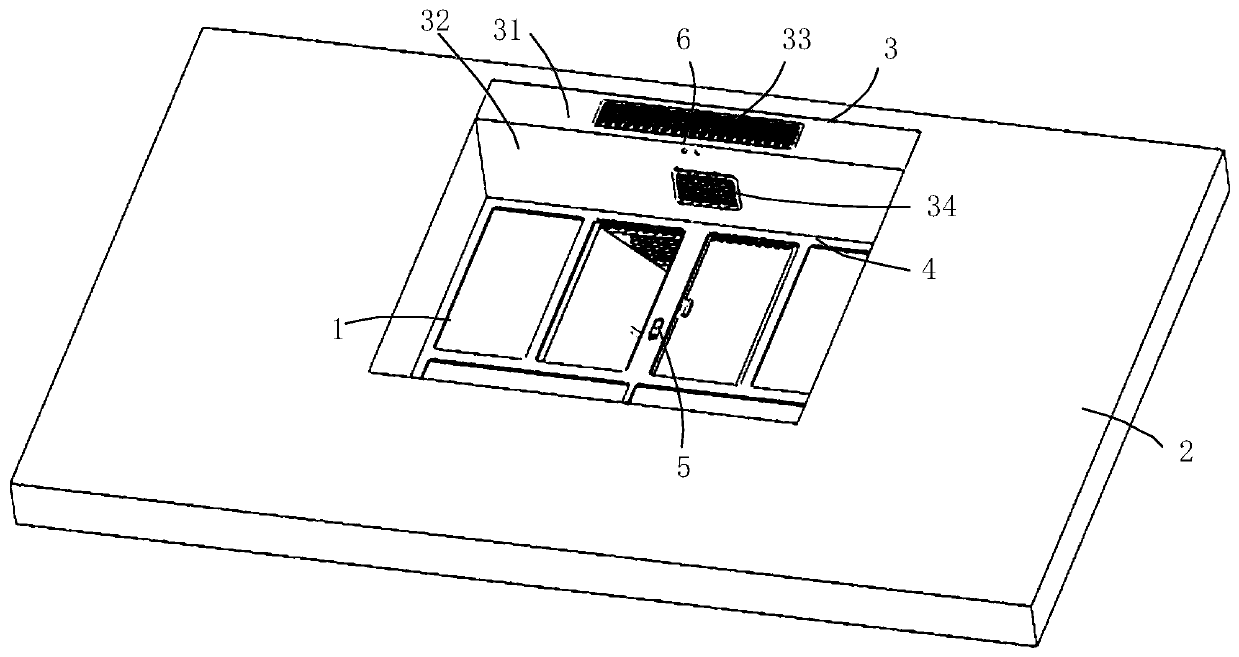

Intelligent integrated window

PendingCN110512988ASmall temperature differenceReduce power usageTelevision system detailsBatteries circuit arrangementsOutdoor temperatureEngineering

The invention provides an intelligent integrated window. According to the intelligent integrated window, the functions of a window, a hidden window automatic switcher, air purification, photovoltaic power generation and energy storage, automatic sun shading, security monitoring, an AI sensor and the like are integrated, the indoor space is saved, the using cost is lowered, living comfort is improved, and the more systematic effect is achieved; by adopting technologies such as mixed-flow air purification, energy recovery, intelligent temperature control and the AI sensor, the window is automatically opened and closed when wind and rain come, the window is automatically closed when children climb the window, the phenomena of indoor and outdoor temperature difference, condensate water and freezing are reduced, the dynamic conditions outside the window are monitored in real time, innocence of throwing objects in high building is self-proofed, APP remote control is achieved, and the more intelligent effect is achieved; by adopting photovoltaic power generation and energy storage technologies, power generated during the day is used for a system motor, surplus power is stored in a storagebattery and automatically discharged at night for a system, meanwhile, heat generated during working of a photovoltaic energy storage system is utilized comprehensively, and by adopting mixed-flow purification and energy comprehensive utilization technologies, the more energy-saving effect is achieved.

Owner:江西盛达尔新能源开发有限公司

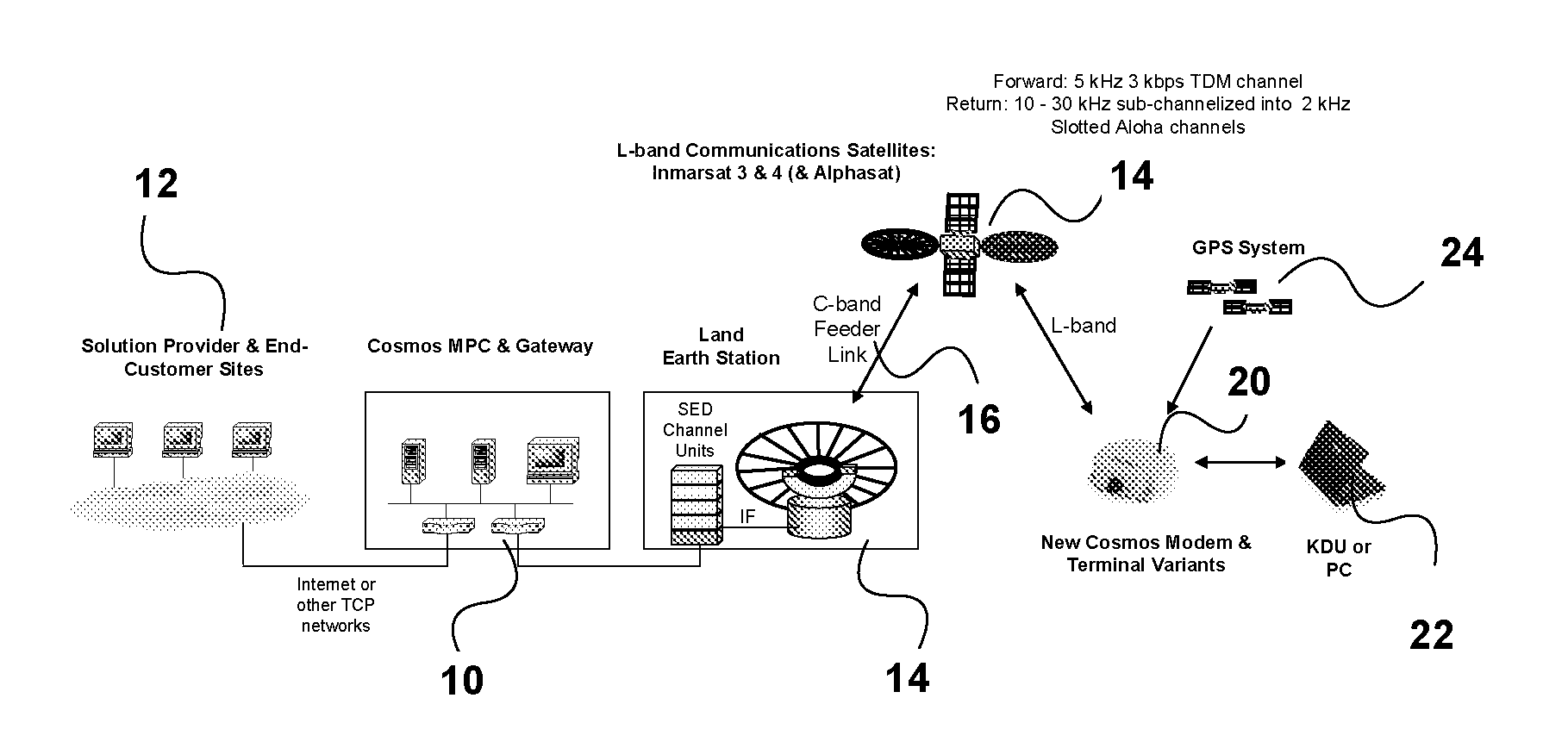

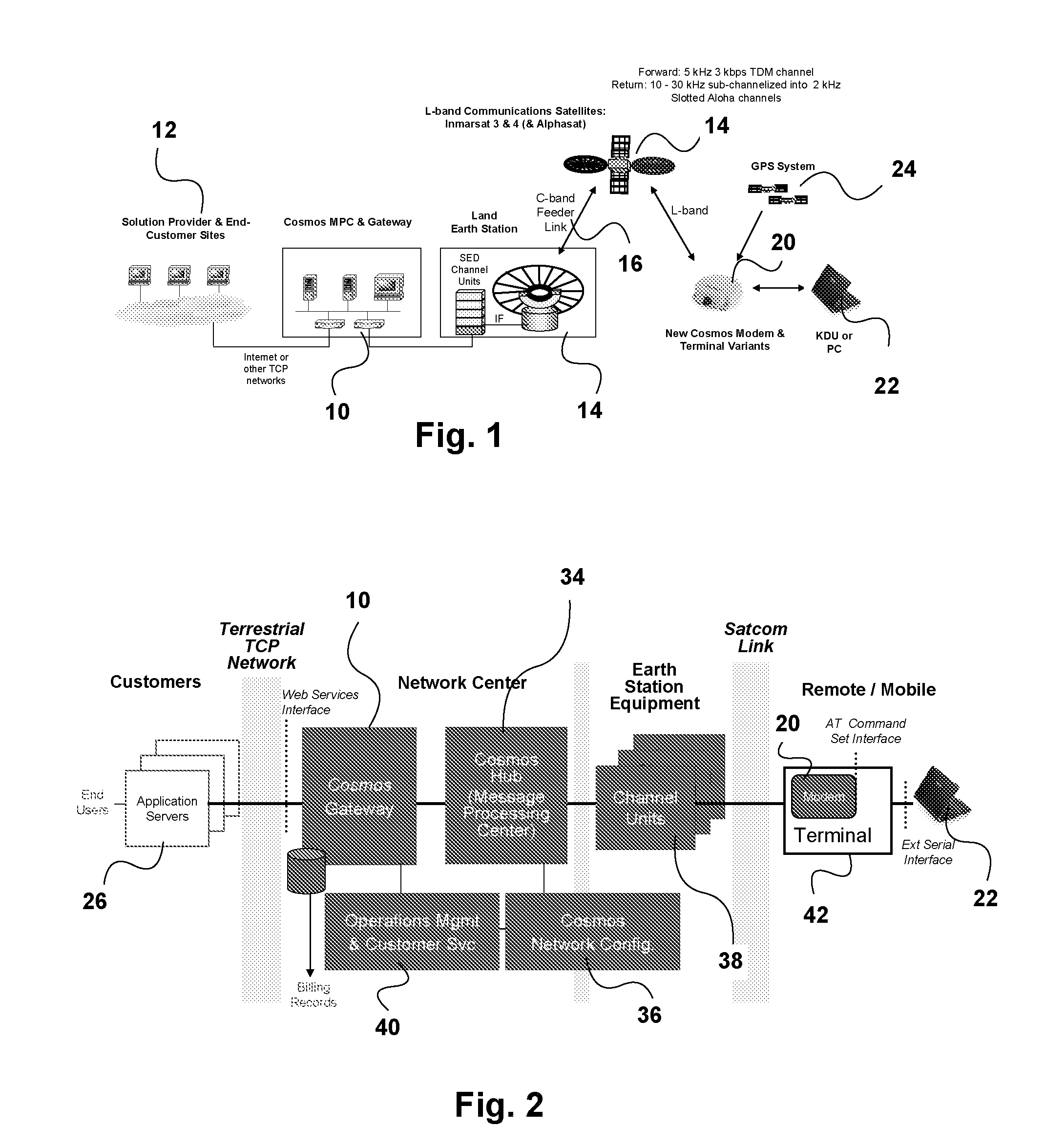

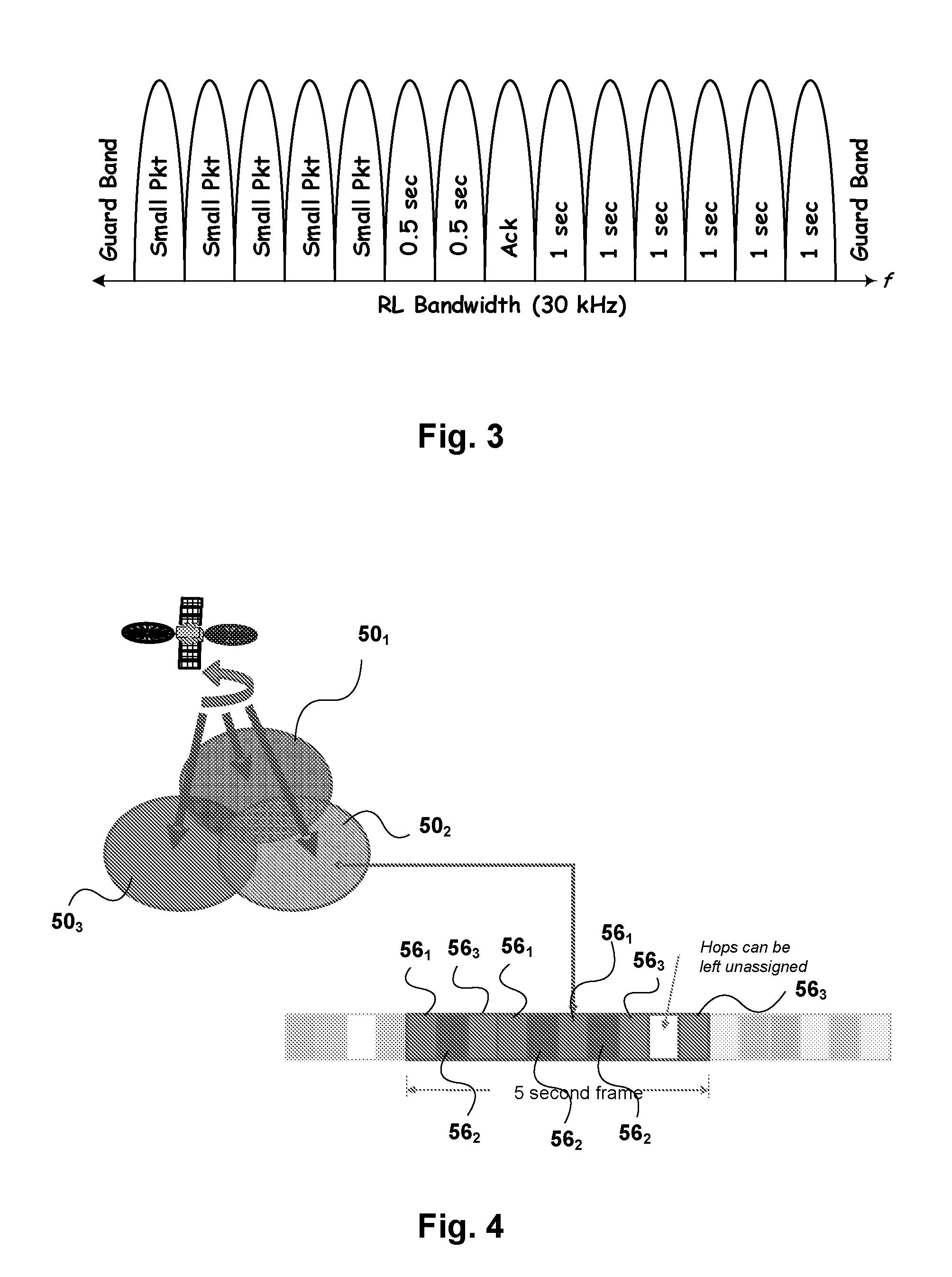

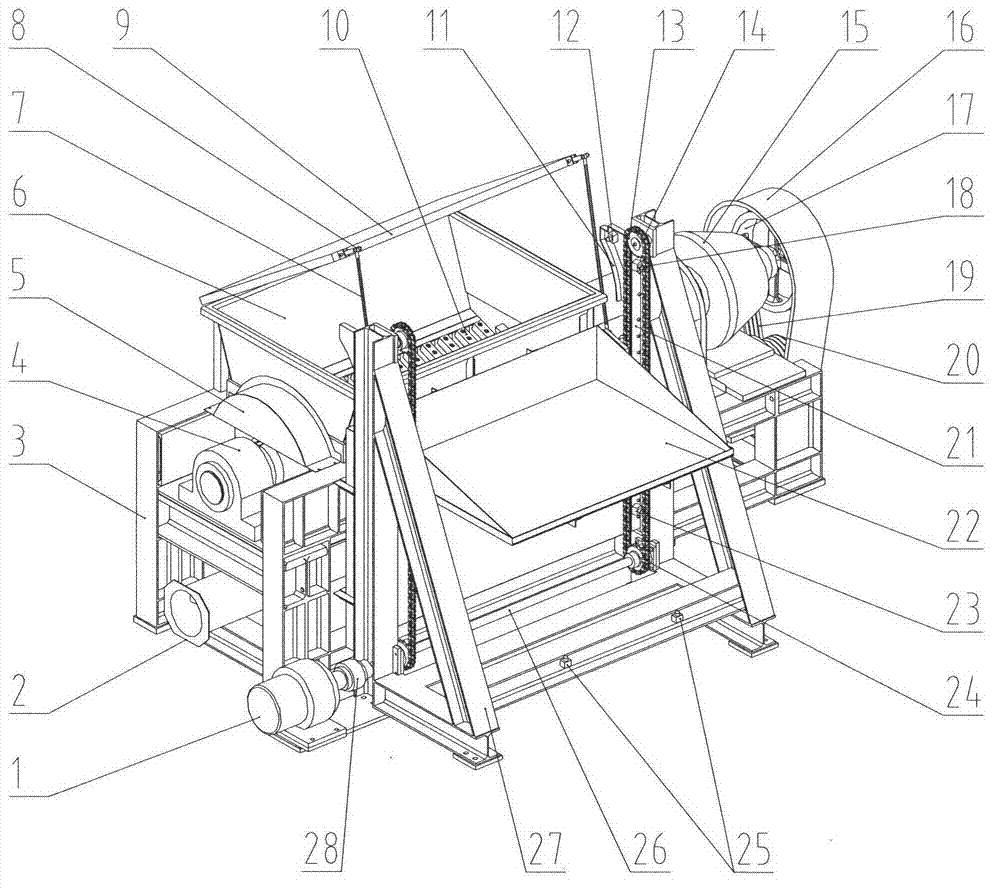

Satellite-based messaging system

ActiveUS20130021900A1Reduce power consumptionHeavy loadError preventionFrequency-division multiplex detailsTelecommunicationsTransport medium

In a satellite-based messaging system messages are exchanged between a ground station and mobile terminals over a wide geographic area covered by multiple satellite beams. Each beam contains one or more carrier frequencies. A message processing center is configured to provision a frame comprising a plurality of subframes to carry data over a forward link to the mobile terminals; hop between beams in the forward link and assign each subframe within a frame to a specific satellite beam; provision a transport medium in the form of virtual carriers each defined by one or more carrier frequency / beam hop combinations, wherein each virtual carrier is assigned a unique virtual carrier identifier; and notify the mobile terminals of carrier frequency / hop combinations for assigned virtual carrier identifiers.

Owner:2201028 CANADA INC

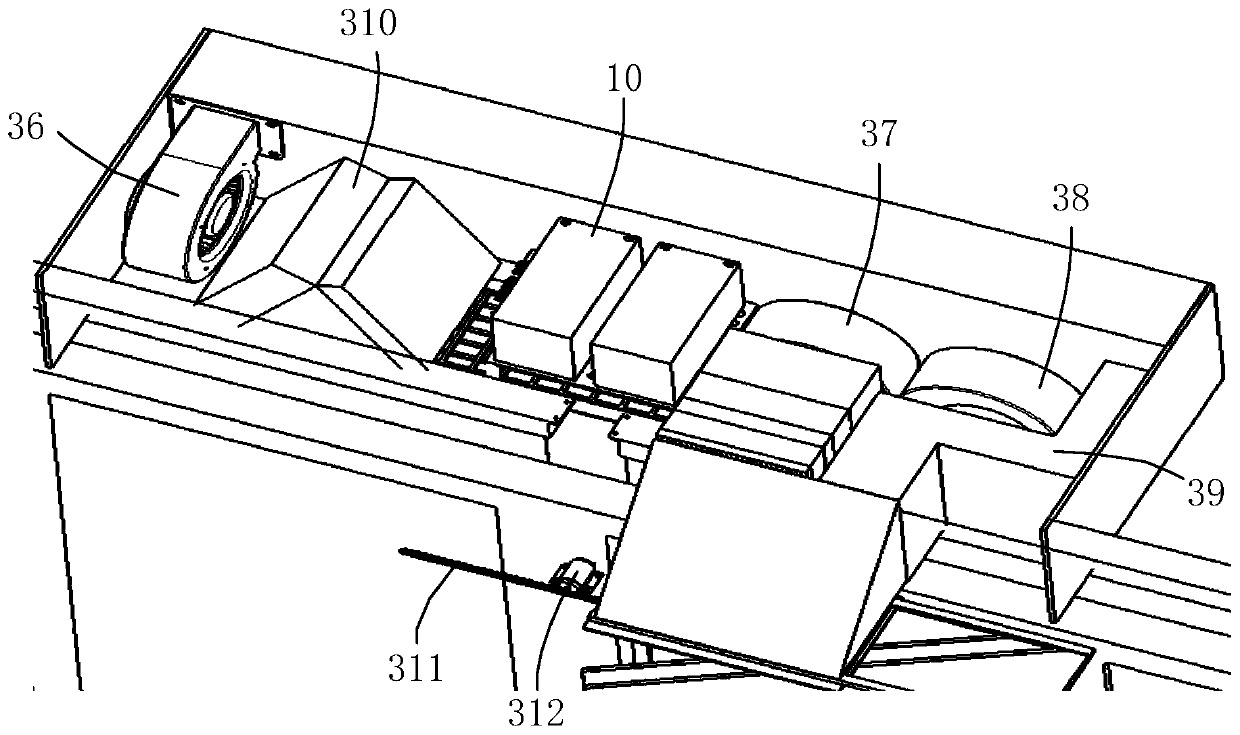

Low-energy consumption animal crushing machine

The invention discloses a low-energy consumption animal crushing machine, which comprises a feeding hole, a frame, a hob shaft, a balance wheel, a left fixed knife, a right fixed knife, a screw conveyer, a power transmission device and a feeding mechanism, wherein the feeding mechanism consists of a speed-reducing motor, a coupler, a chain wheel, a chain, a chain transmission shaft, a hopper and a bracket; an inner raceway and a front raceway are formed on an upright post of the bracket; two sides of the hopper are provided with a front roller and a rear roller; a covering cap which is automatically opened and closed on the feeding hole is connected with the hopper through a connecting rod; the screw conveyer is adjacent to the hob shaft and is positioned below the hob shaft; and a rotating axis of the screw conveyer is parallel to an axis of the hob shaft. By the adoption of single-stage crushing of a single hob shaft, the service efficiency is low, and the power supply conditions of a farm can be met; and moreover, the equipment is fully equipped, the feeding and crushing of large animal carcass and crushed material output can be automatically finished.

Owner:大幸(保定)废弃资源利用股份有限公司

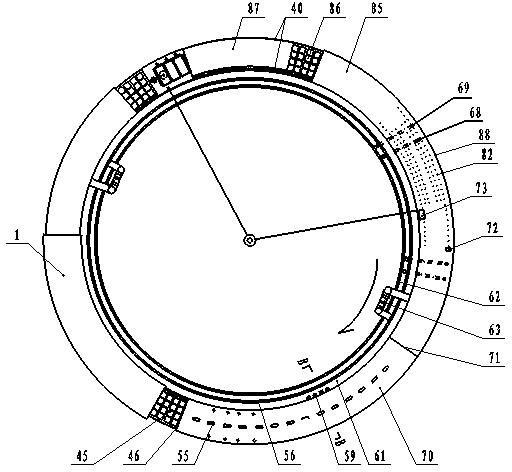

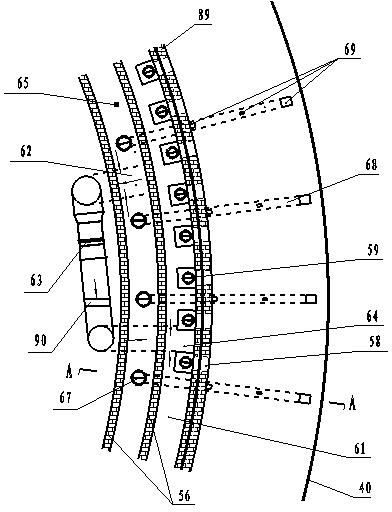

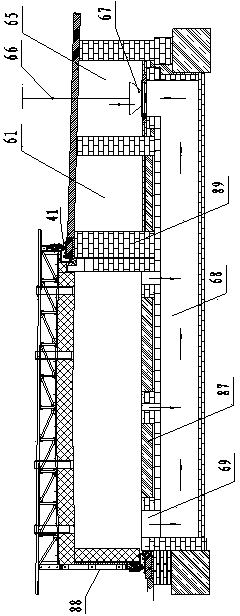

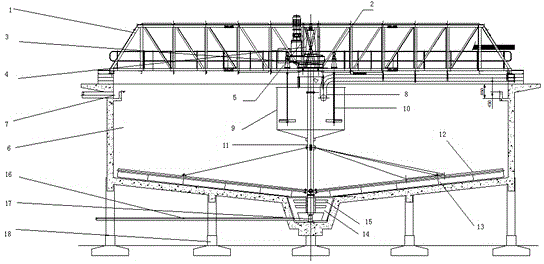

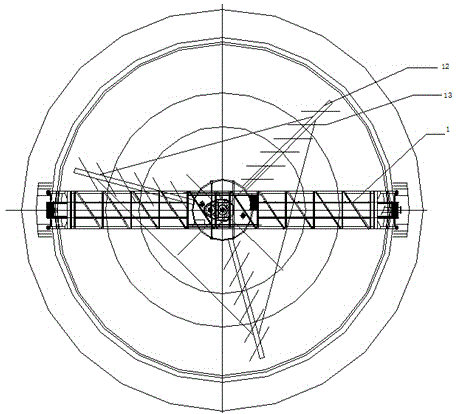

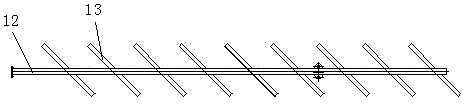

Arc-shaped scraper plate center transmission mud scraper

The invention relates to an arc-shaped scraper plate center transmission mud scraper. The mud scraper comprises a support, a sewage barrel, a service bridge, a main driving motor, a speed reducer, a center transmission shaft, flocculation mixers, a flocculation barrel and a scraper arm. The service bridge is arranged at top of the sewage barrel, the sewage barrel is arranged on the support, a loop of the overflow weirs are arranged at the surrounding of the sewage barrel, a center bearer is arranged at the center of the service bridge, the main driving motor and the speed reducer are fixed on the center bearer, the flocculation mixers are respectively arranged at two sides of the center bearer, a stirring device is connected with the lower end of the flocculation mixer, a water inlet pipeline is arranged between the service bridge and the sewage barrel, an outlet of the water inlet pipeline is placed in the flocculation barrel, an outlet of the overflow weir is arranged at the upper part of the side wall of the sewage barrel, an output shaft of the motor is connected with the speed reducer, a base plate of the sewage barrel is the tapered base plate, a downwardly recessed mud collecting cavity is arranged at a top angle position of the tapered base plate, the mud collecting cavity is the tapered cavity, the scraper plate employs an arc-shaped structure, and an anticorrosion coating layer is arranged on the scraper plate.

Owner:JIANGSU WATER ENVIRONMENTAL PROTECTION

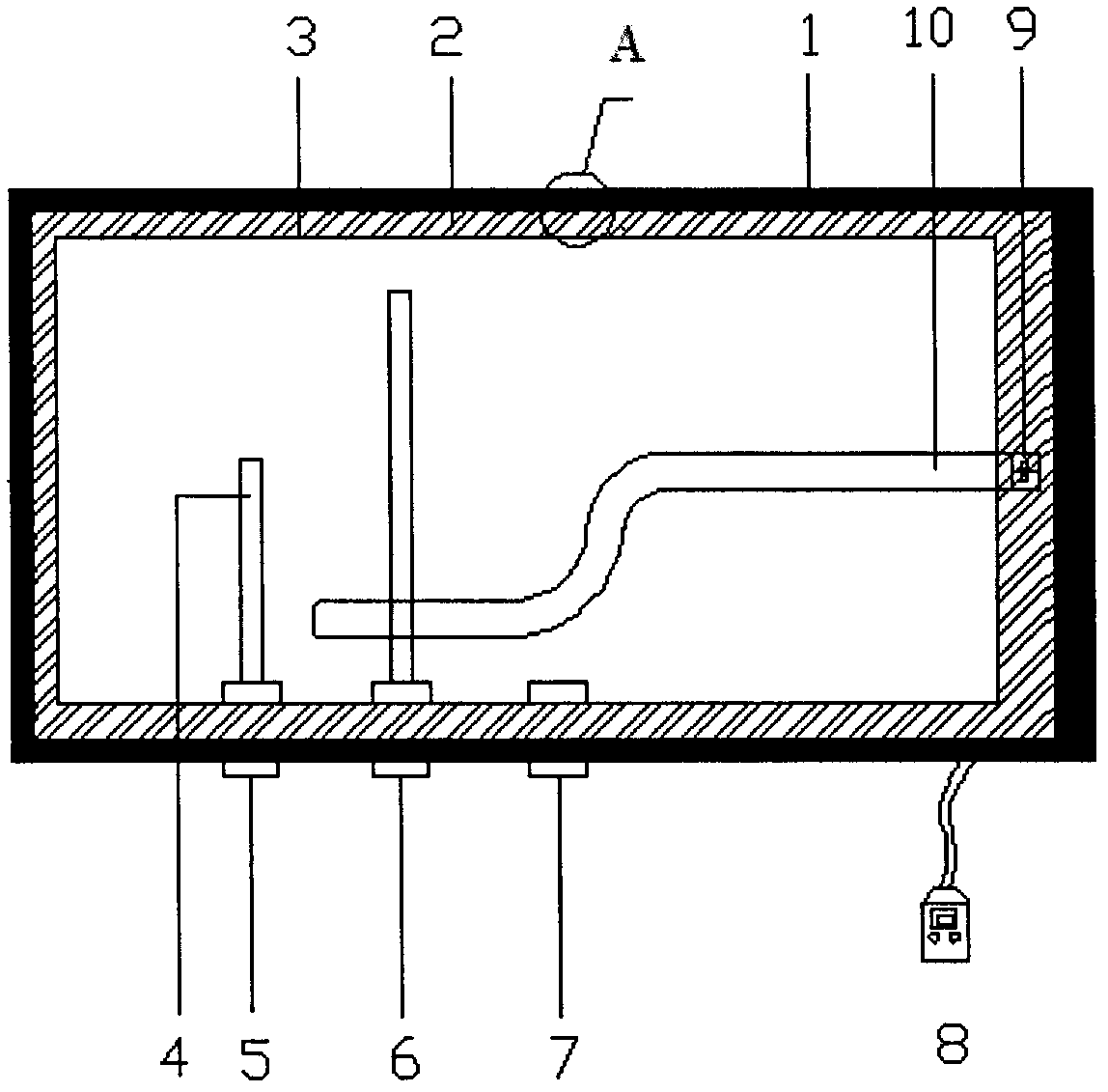

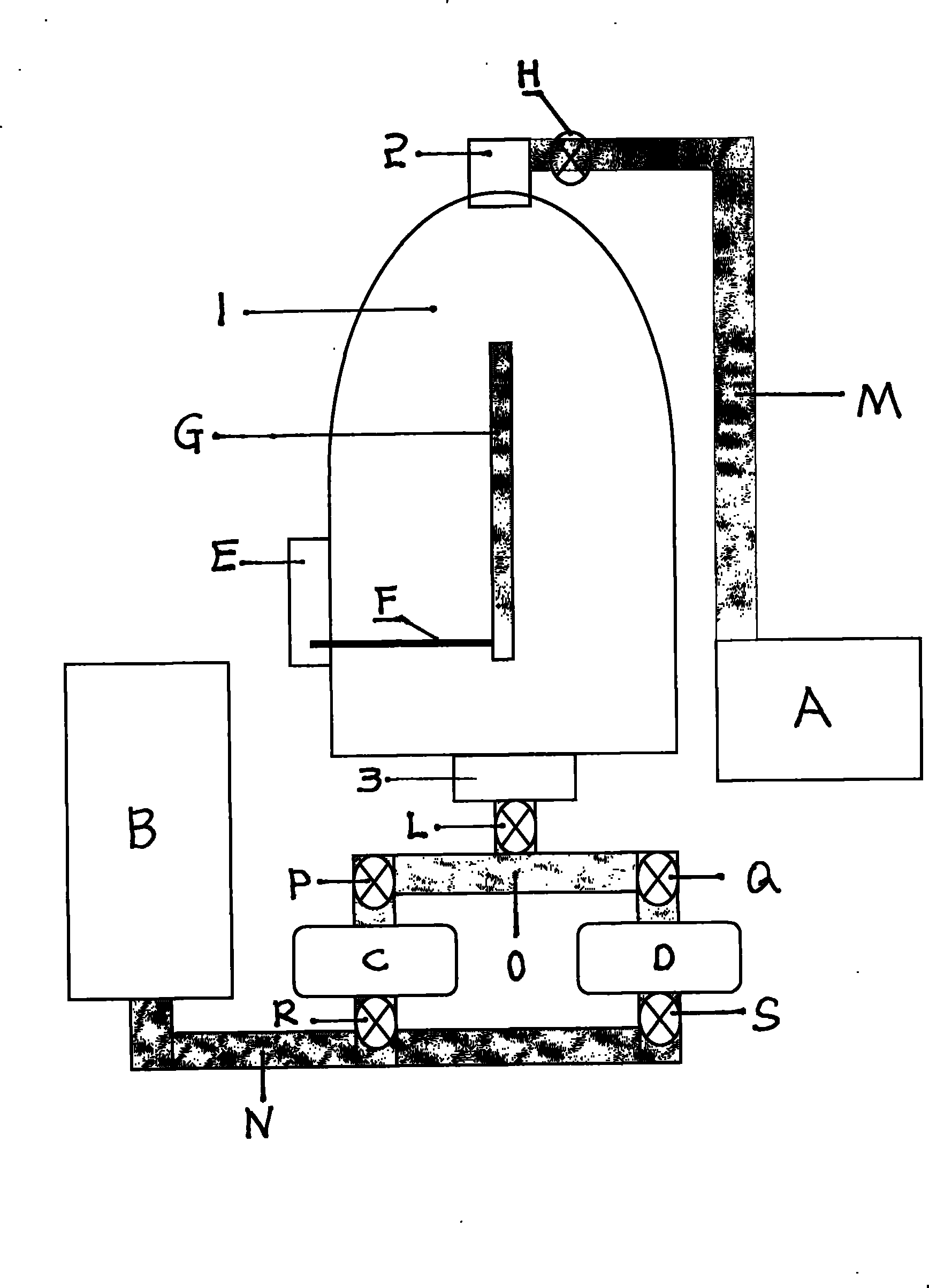

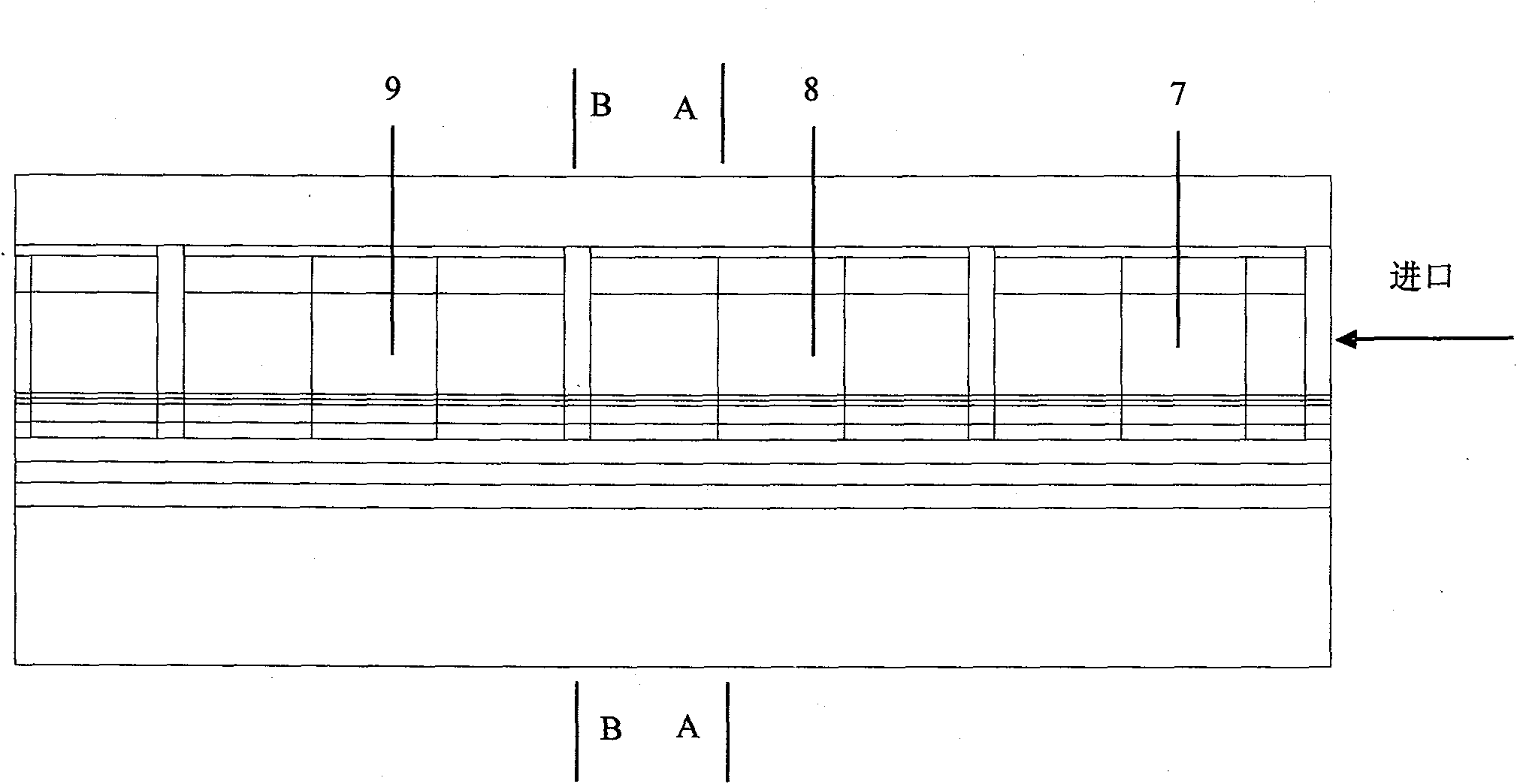

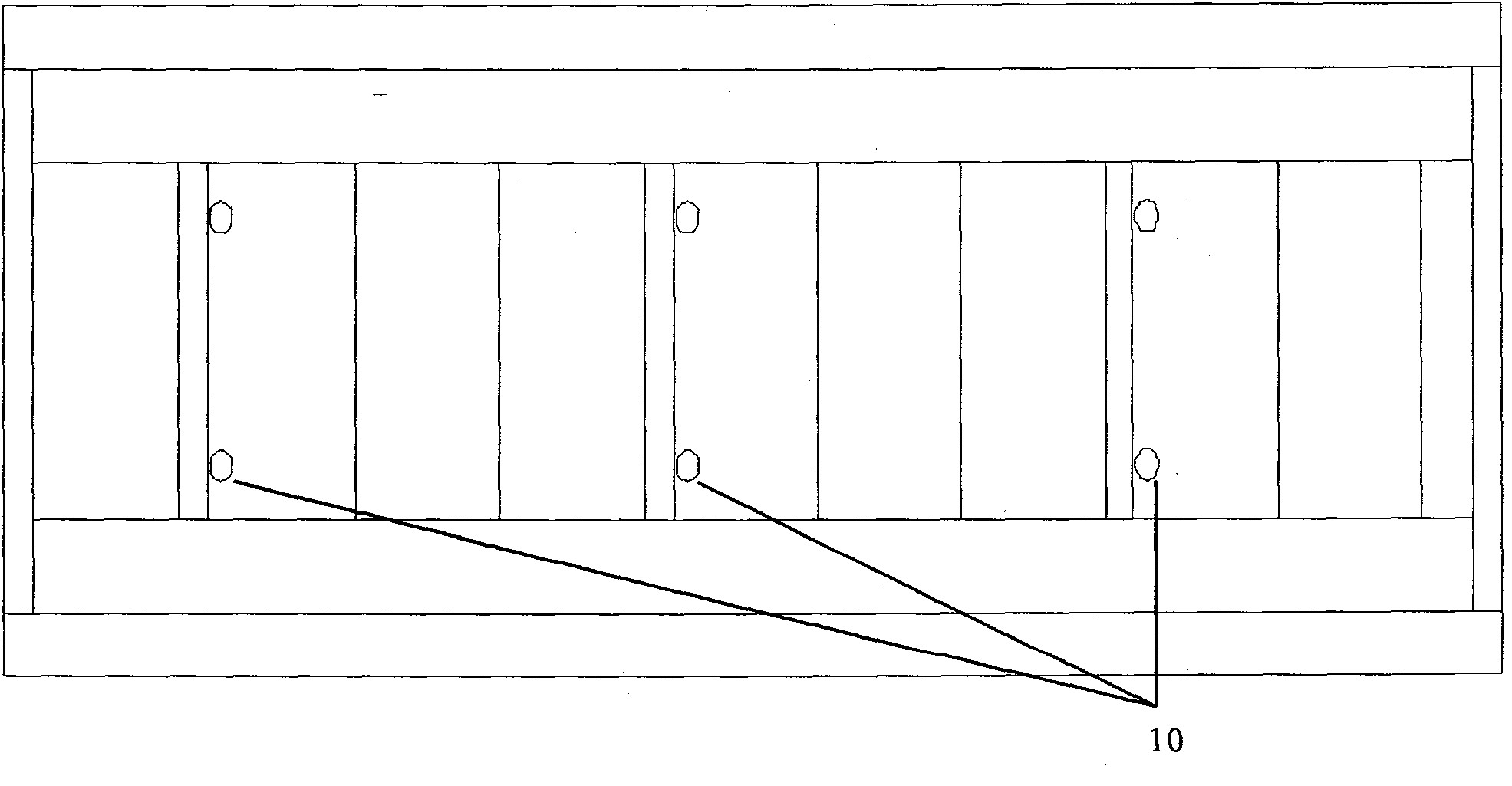

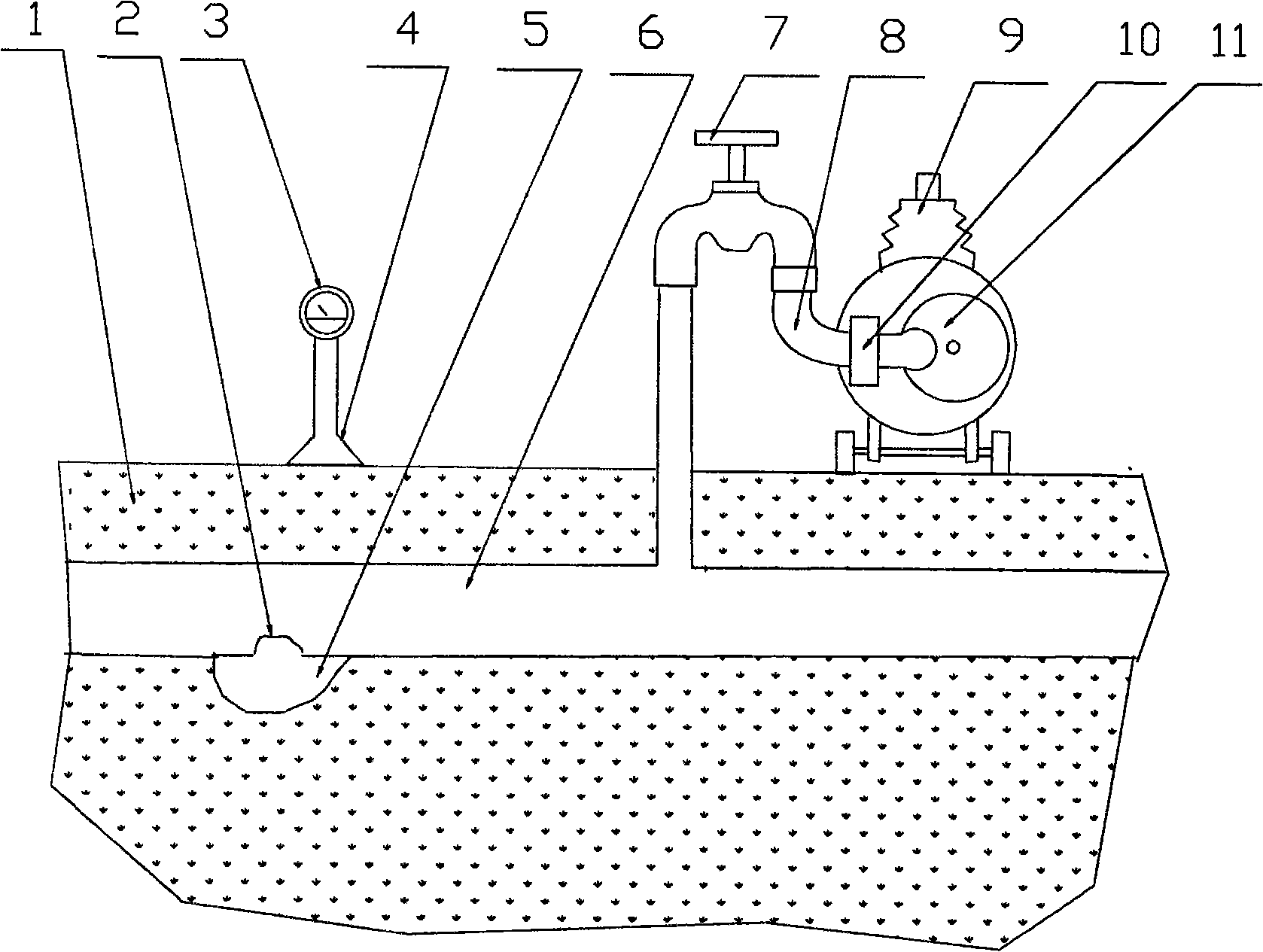

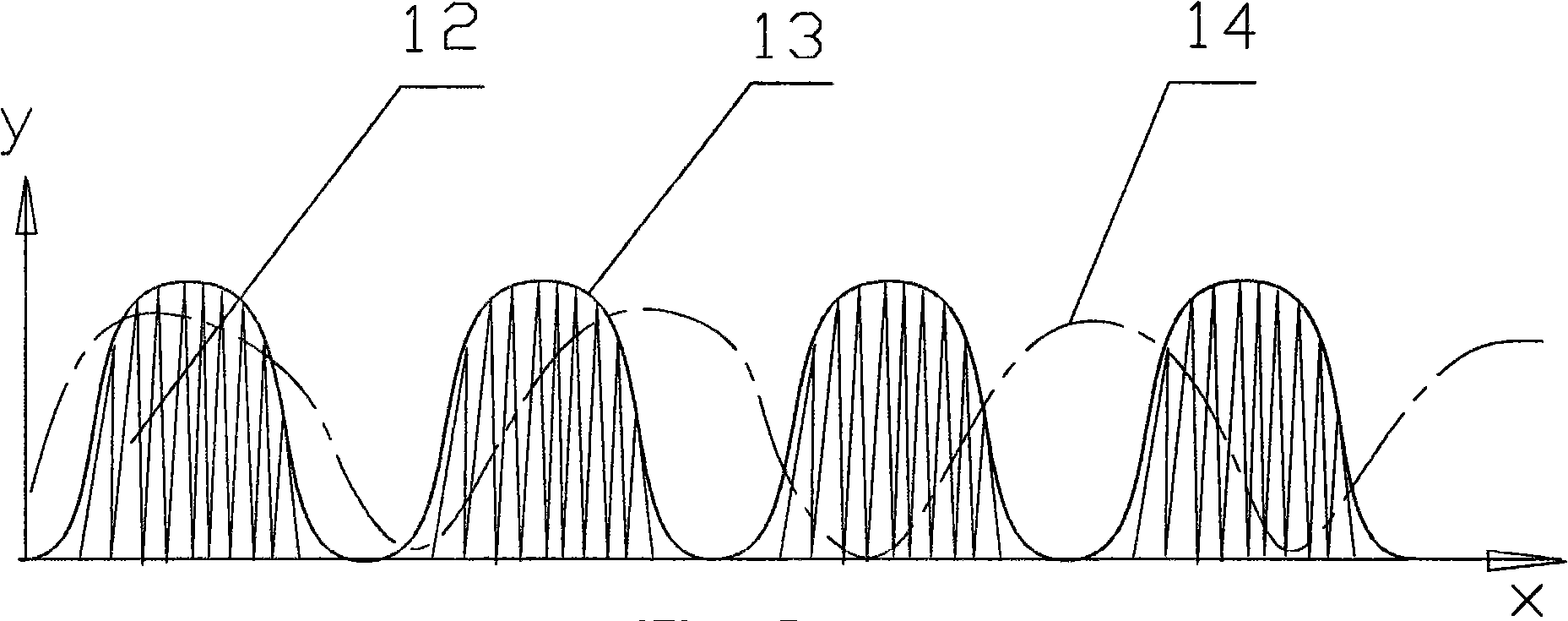

Storage method for intelligent insect-prevention vacuum cycle ozone tempering and refreshing grains

InactiveCN102132728AEasy to useEasy to operateFood processingEdible seed preservationVacuum pressurePesticide residue

The invention provides a storage method for intelligent insect-prevention vacuum cycle ozone tempering and refreshing grains, which can realize intelligent real-time and networking monitoring and regulation on all function indexes of temperature, humidity, pressure, fungus damage, insect damage, pesticide residual hazard and the like during the whole process of grain storage, can be completely handled without dead corners for the stored grains through alternative work of vacuum pressure reduction as well as high-pressure ozone and ozone humidity, thus achieving the purposes of long-time damage prevention, old elimination, freshment and quality preservation, and being convenient to use, simple to operate and obvious in practical application effect and can not be limited and influenced by different geographic locations, seasons change, grain storage facilities, and the like; compared with the traditional grain storage and preservation method, the storage time can be doubled; the one-time investment is less, the usage cost is extremely low; and the equipment is reasonable in design, is compact and portable, occupies small space, and is energy-saving and environment-friendly.

Owner:李和翼

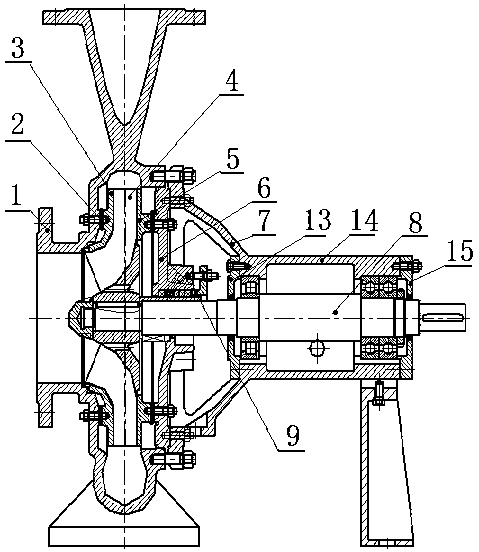

Novel wear-resistant and corrosion-resistant chemical centrifugal pump

The invention discloses a novel wear-resistant and corrosion-resistant chemical centrifugal pump which is applied to transport corrosive liquid containing solid particles and other fiber media in papermaking, chemical engineering, food, environmental engineering and other industries. A pump shaft is fixedly arranged on a bearing box of a suspension; two ends of the bearing box are respectively provided with a front gland and an end cover fixedly; a mechanical seal is arranged between a pump cover and the pump shaft; an impeller is fixedly arranged on one end of the pump shaft; the pump body is fixedly arranged on the suspension; a front lining board is arranged between the pump body and the impeller; a rear lining board is arranged between the pump cover and the impeller; a hard alloy layer is respectively sprayed on each of the front lining board and the rear lining board which are made of corrosion-resistant and wear-resistant materials, so that the wear-resistant performance of the front lining board and the rear lining board are further improved; and meanwhile, the surfaces of the coatings are smoother, so that the friction force and resistance of a flow through object are reduced, serous fluid can pass quickly, the use power of a water pump is reduced, the use efficiency is improved and the energy-saving effect is significant.

Owner:JIANGSU XINYUE PUMP IND MFG

Full fiber ceramic body glue discharging method and kiln

InactiveCN101798229AFast glue removalGood degumming effectFurnace typesCeramicwareCeramicProduct gas

The invention discloses a full fiber ceramic body glue discharging method. A ceramic biscuit containing organic matters is subject to heating up, glue discharging under heat reservation and reheating in a full fiber ceramic body glue discharging kiln to convert organic matters in the biscuit into gas to be discharged; the biscuit forms a porous body with certain strength and compact structure; meanwhile, the body is not obviously bent and deformed, thus being convenient for the body to form a dense body with intact shape in the sintering process and improves product yield. Glue discharging heat reservation temperature can be 600-1000 DEG C. The kiln has simple structure and convenient operation and maintenance; the utilization ratio of the kiln is low and is only 60-70% of similar products abroad; compared with the glue discharging kiln with other structures, the kiln of the invention has low cost; thus, the kiln can be widely applied to the glue discharging process of the ceramic biscuit and can be used for the sintering production of low-temperature ceramics.

Owner:LUOYANG SHENJIA KILN +1

Magnetic suspension resistance type elevator

Provided is a magnetic suspension resistance type elevator. According to the magnetic suspension resistance type elevator, the magnetic suspension resistance type elevator and electromagnetic materials are combined. According to a system, vertical movement of the magnetic suspension resistance type elevator serves as magnetic induction line cutting movement. In the system, the whole elevator hoistway can become an annular multi-ring coil, magnetic substances can be installed on an elevator body, when the annular multi-ring coil is energized, perpendicularly-upward acting force can be provided for the magnetic suspension resistance type elevator, and the magnetic suspension resistance type elevator moves upwards. Acting force borne by the magnetic suspension resistance type elevator is controlled through control over electric current. When the magnetic suspension resistance type elevator descends, the magnetic suspension resistance type elevator carries out the magnetic induction line cutting movement through gravity, gravitational potential energy can be converted into electric energy, the electric energy is stored in a switching type capacitor, the capacitor carries out saturated discharging to generate reverse current, and the magnetic suspension resistance type elevator decelerates due to opposite force. The system can save energy, and can prevent emergencies from occurring through the advantages of the system, when the magnetic suspension resistance type elevator is in emergency, the magnetic suspension resistance type elevator can carry out independent operation, and safety of passengers is ensured.

Owner:郑有志

Water pipe man-made sound wave leakage checking method

InactiveCN101303268ALight weightReduce power usageDetection of fluid at leakage pointSound producing devicesWater useLeaking water

The present invention discloses a method for detecting leakages on water pipes by using artificial sound waves. An air compressor with a low-frequency air pressure generator is provided. A gap degassing switch with a degassing outlet connected with a water-using valve port of a water pipe is provided in a degassing channel of the air compressor. An acoustic vibration receiver which is sensitive to the frequency of the low-frequency air pressure generator and which is characterized in that artificial sound waves easy to penetrate the layer of earth can be generated in a chamber formed by water leakage after that a water-air compound with certain frequency waves is filled into the chamber is provided on the ground of the water pipe to be tested. Therefore, the matter leaked from the ventage is only water before the compressed air is filled into the water pipe, while most of the matter leaked from the ventage is air and the amount of water is reduced after the compressed air is filled into the water pipe, and the compressed air leaked from the ventage forms a large area of impact force on the wall around and generate big airflow impact noise because the compressed air has a light deadweight. Therefore, not only the cost of a leak detecting device can be reduced, but also leaked water having tiny noise can be detected by using the method in the present invention.

Owner:陈宜中

Textile fabric dedusting and ironing device and using method

InactiveCN112359544AImprove dust removal effectLow costMechanical cleaningPressure cleaningMechanical engineeringManufacturing engineering

The invention discloses a textile fabric dedusting and ironing device and a using method, and belongs to the technical field of textile fabrics. The textile fabric dedusting and ironing device comprises a base, wherein a dedusting box is fixedly connected to the right side of the top of the base, a feeding roller is arranged on the right side of the dedusting box, a textile fabric is wound aroundthe feeding roller, the left end of the textile fabric penetrates through the dedusting box, cleaning rollers are evenly arranged in the dedusting box, the bottom of the textile fabric is movably connected with a fabric flipping assembly, cleaning brushes are evenly arranged on the outer sides of the cleaning rollers, the opposite sides of the upper and lower sets of cleaning brushes make contactwith the top and the bottom of the textile fabric correspondingly, and connecting rods are driven to rotate through a rotating shaft. When the connecting rods pass by a stop block every time, plasticballs can continuously flip the textile fabric through the elastic force of supporting springs, dust which is not prone to being brushed off on the textile fabric can be flipped off by flipping the textile fabric, the dedusting effect of the textile fabric is improved, and the dedusting efficiency is improved.

Owner:王玉立

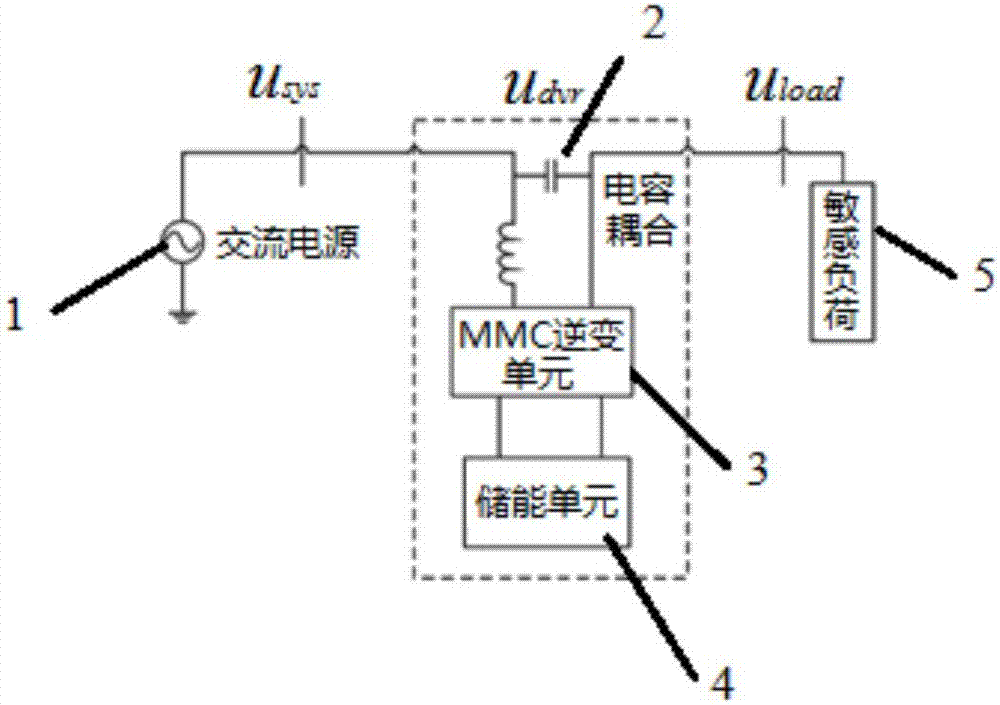

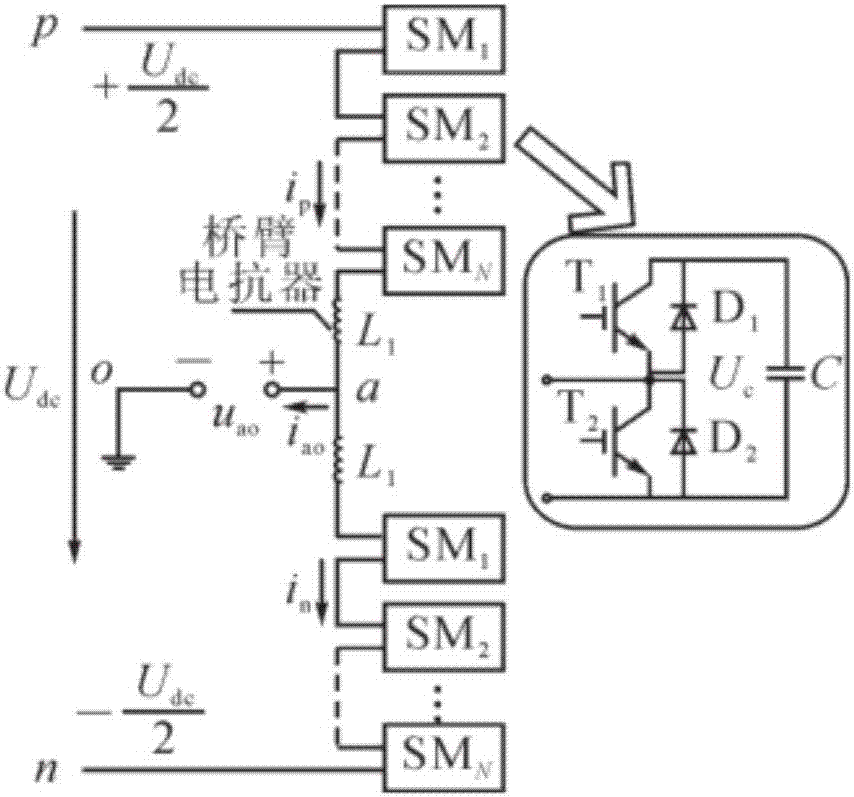

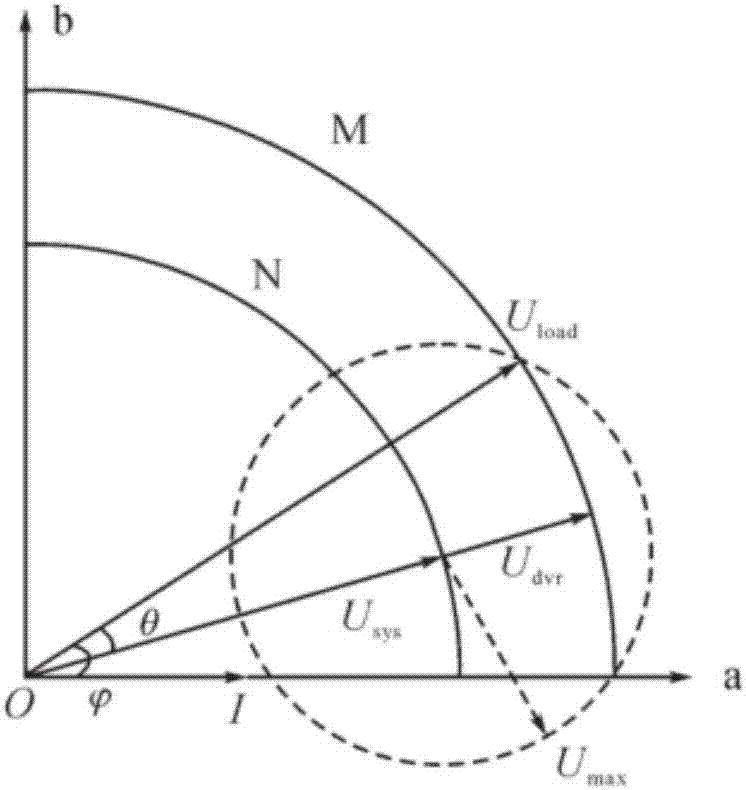

Dynamic voltage adjusting device and method based on modular multi-level inverter

PendingCN107154631AHigh degree of modularityEasy to expandAc-dc conversionAc network load balancingModularitySingle phase

The invention relates to a dynamic voltage adjusting device and method based on a modular multi-level inverter, and the device comprises a main circuit and a DSP control circuit. The main circuit comprises an energy storage unit, an MMC inversion unit, and a capacitor coupling unit. The energy storage unit provides energy for a compensator, and the MMC inversion unit is provided with a modular multi-level structure. A single-phase topological structure comprises an upper bridge arm and a lower bridge arm. Each bridge arm comprises a plurality of submodules which are in series connection and have the same structure, and one bridge arm reactor. The voltage waveform which meets the requirements is outputted through controlling the on / off of a switching device in each submodule, and the capacitor coupling unit is used for inhibiting the impact on a load from the voltage fluctuation of a system. Compared with the prior art, the device is low in switching frequency, is low in switching loss, is small in output harmonic, and is good in application prospect.

Owner:SHANGHAI UNIVERSITY OF ELECTRIC POWER

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com