Device for evaluating images of weld spots on a carrier material

A technology for carrying materials and solder joints, which is used in measurement devices, welding monitoring devices, analysis materials, etc., can solve the problems of image quality, imprint reflection, etc., and achieve the effect of improved quality, compact structure, and compact design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

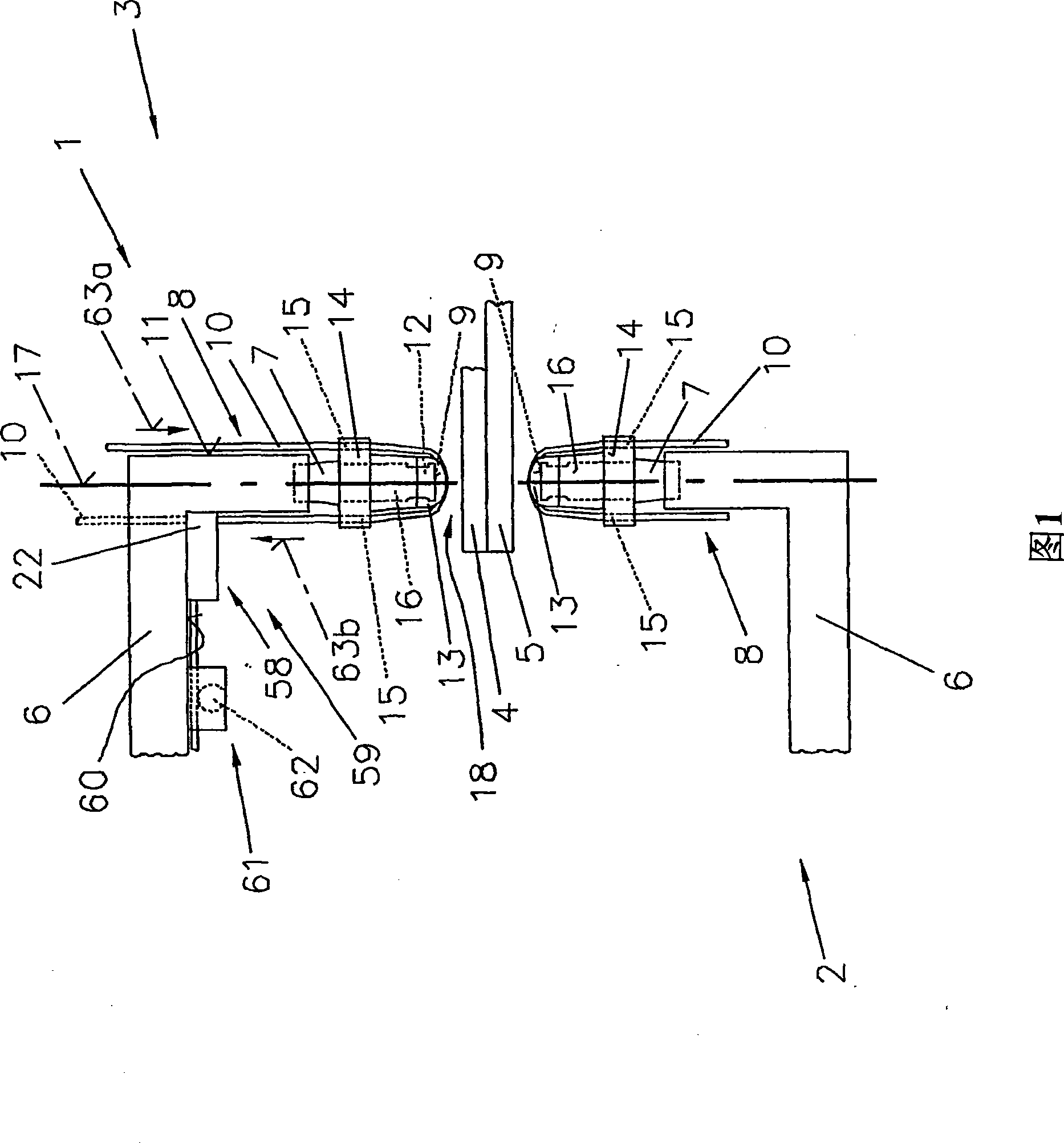

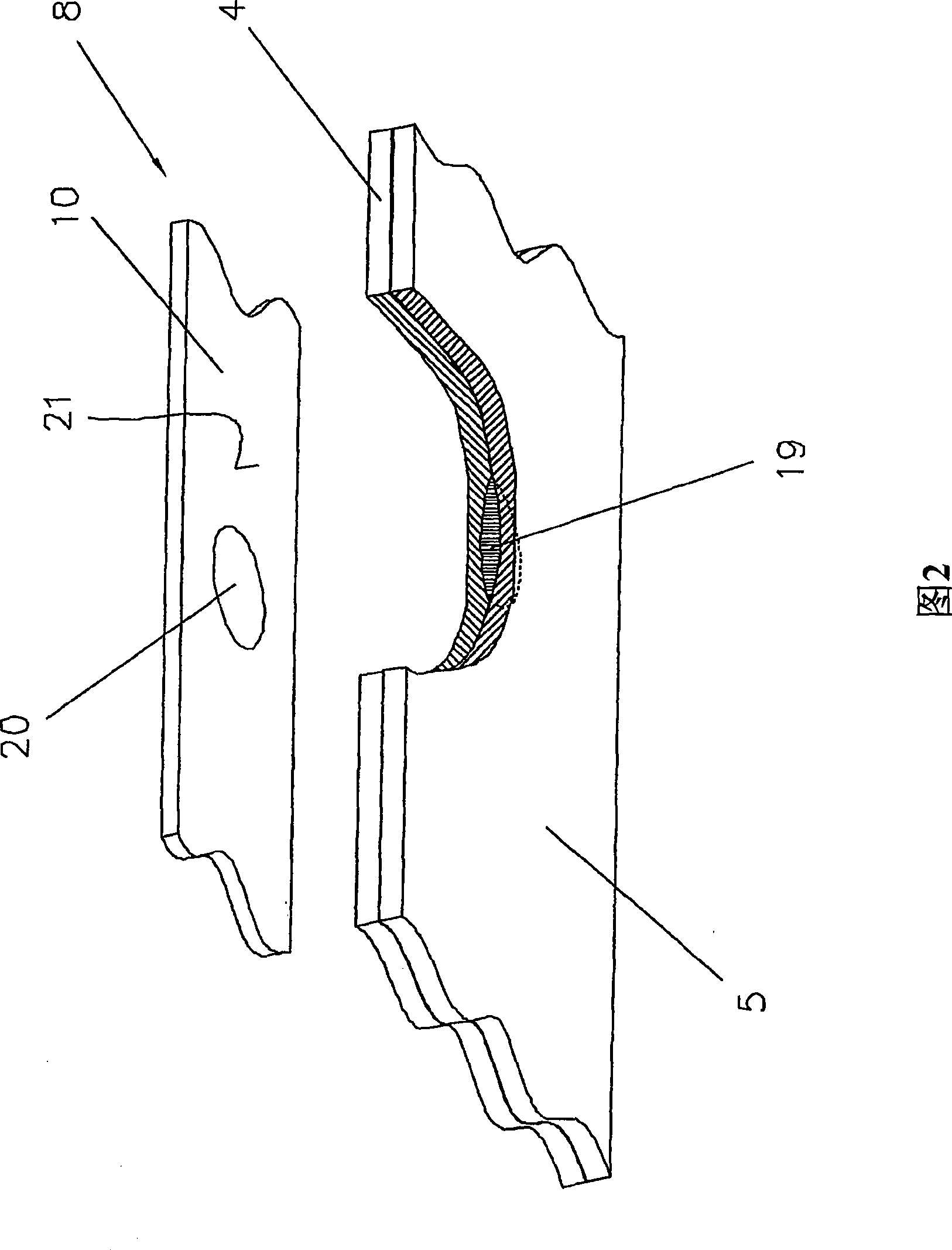

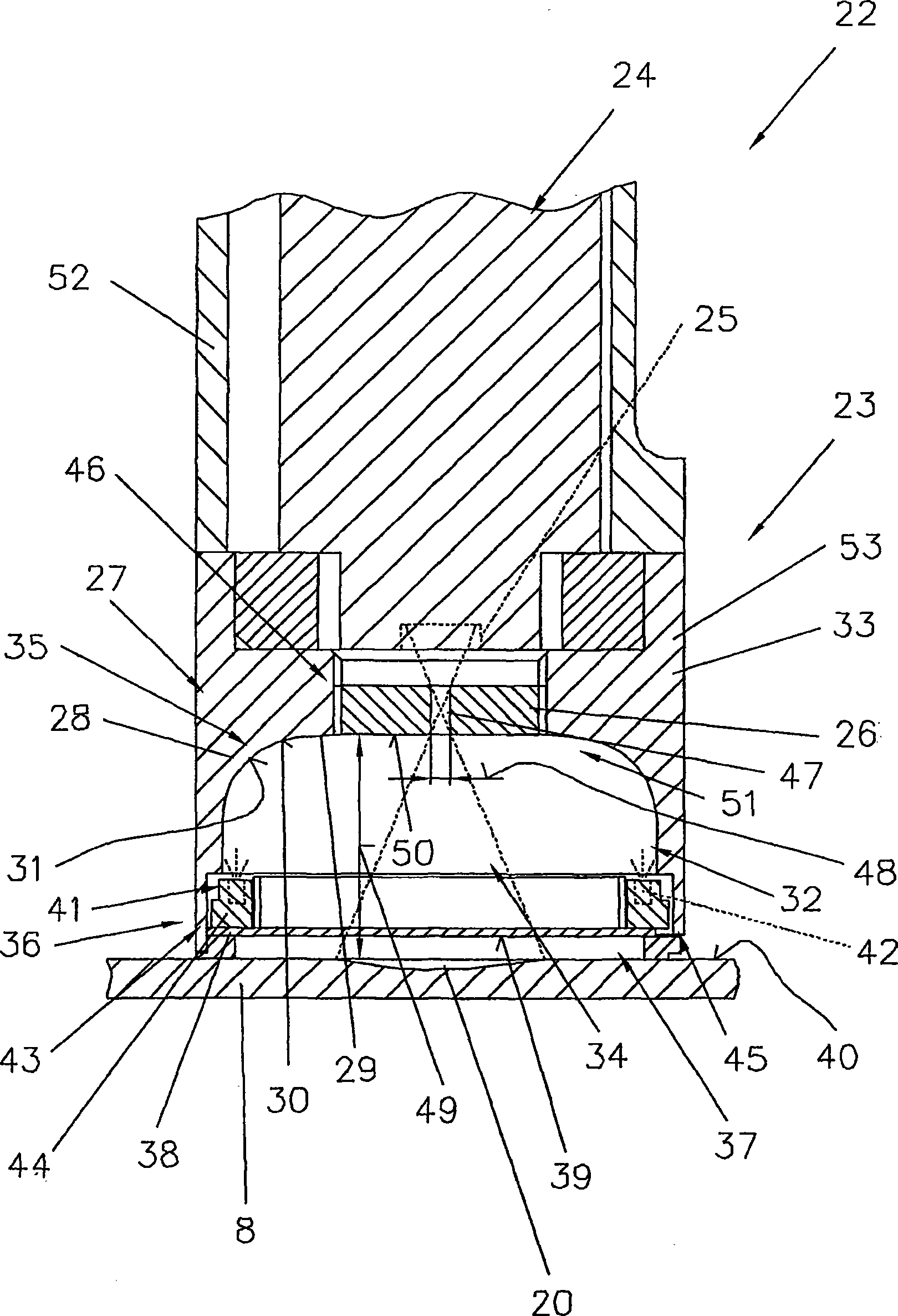

[0037] FIG. 1 shows a welding tool 1 in the form of a welding torch 2 of a spot welding device 3 for resistance welding of at least two components, for example metal sheets 4 and 5 . Preferably, the welding tool 1 is used in robotic applications for automatic generation of spot welded joints. The welding tool 1 has, for example, two curved or L-shaped holding arms 6 for each receiving an electrode 7 which is connected to a power supply of a spot welding device 3 not shown in the figures. Furthermore, the welding tool 1 is designed to receive and guide a carrier material 8 which is guided through the tip 9 of the electrode 7 via at least one holding arm 6 . Preferably, the carrier material 8 comprises a metal foil or strip 10 which is deformable and displaceable in its longitudinal direction along the surface 11 of the holding arm 6 . For moving and / or conveying the carrier material 8, the welding tool 1 and / or the welding device 3 comprises a positioning unit, eg as will be d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com