Novel wear-resistant and corrosion-resistant chemical centrifugal pump

A corrosion-resistant, centrifugal pump technology, applied in the field of centrifugal pumps, can solve the problems of wear resistance that cannot be effectively improved and solved, the back lining plate cannot play a wear-resistant role, and the conveying efficiency is reduced, etc., to achieve significant energy-saving effect, avoid The effect of tearing, reducing power usage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

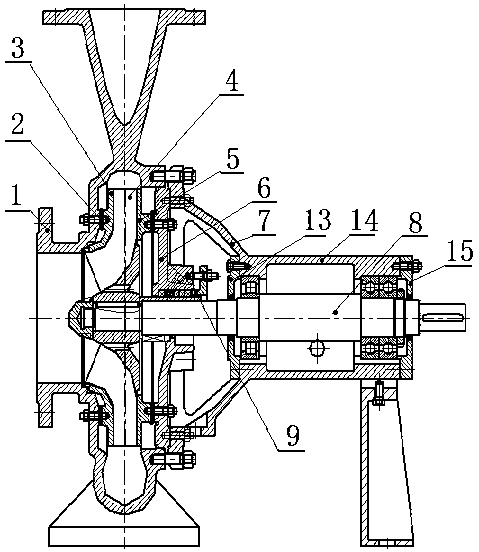

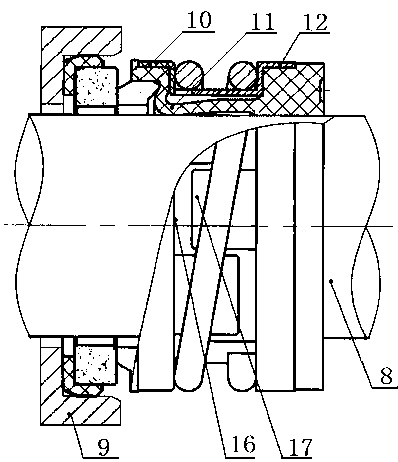

[0018] From figure 1 and figure 2 It can be seen from the figure that the new wear-resistant and corrosion-resistant chemical centrifugal pump includes a pump body 1, an impeller 4, a pump shaft 8, a suspension 7 and a pump cover 6, and the pump shaft 8 is fixed on the bearing housing 14 of the suspension 7, The two ends of the bearing box 14 are respectively fixed with a front gland 13 and an end cover 15, the pump cover 6 is fixed on the suspension 7, and a mechanical seal 9 is arranged between the pump cover 6 and the pump shaft 8 , the impeller 4 is fixed on one end of the pump shaft 8, the pump body 1 is fixed on the suspension 7; a front liner 3 is arranged between the pump body 1 and the impeller 4, the front liner 3 is fixed on the pump body 1; a rear liner 5 is arranged between the pump cover 6 and the impeller 4, and the rear liner 5 is fixed on the pump cover 6; it is characterized in that: the front The liner 3 and the back liner 5 are sprayed with a hard alloy ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com