Patents

Literature

67results about How to "Smooth coating surface" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

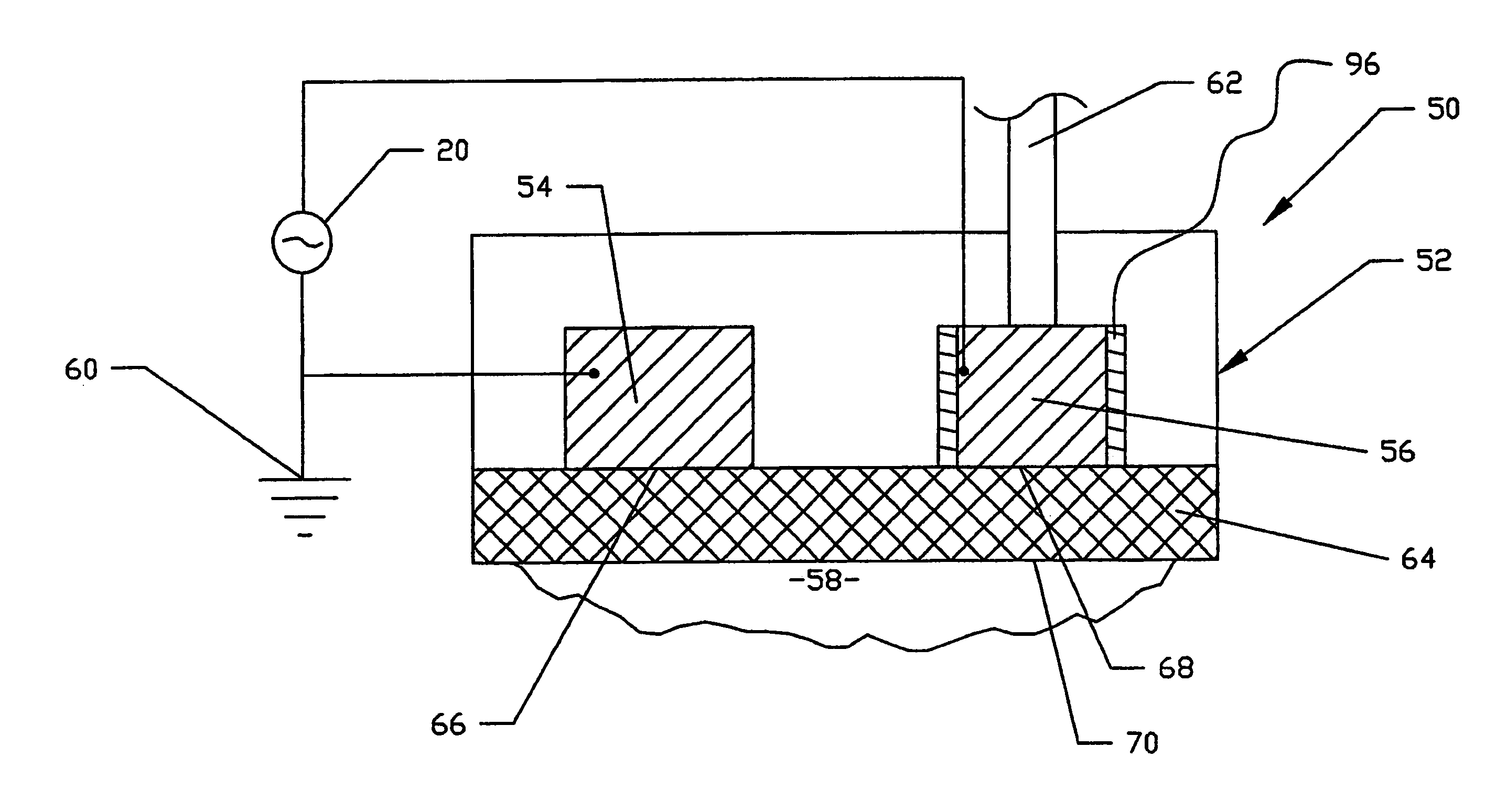

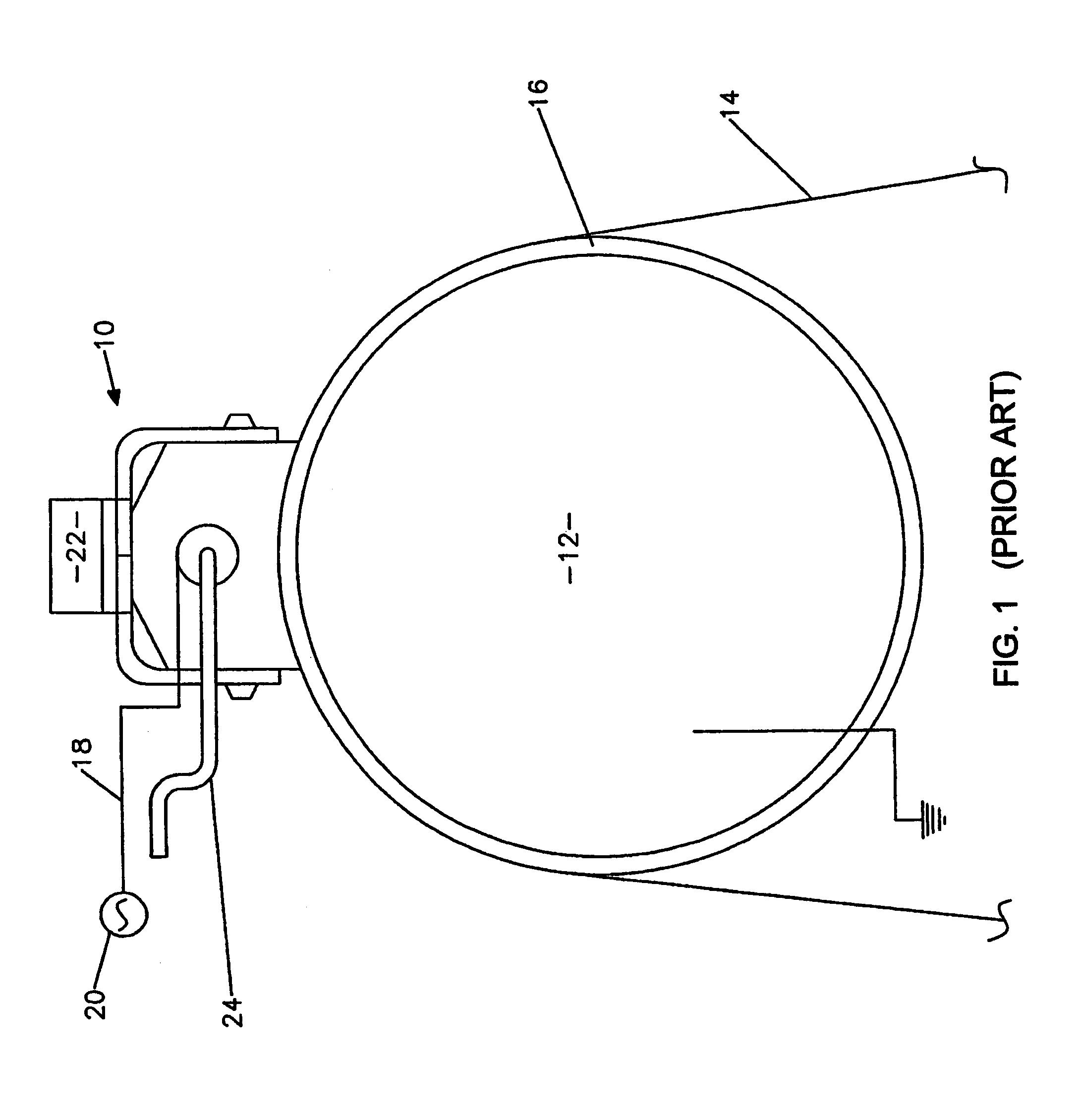

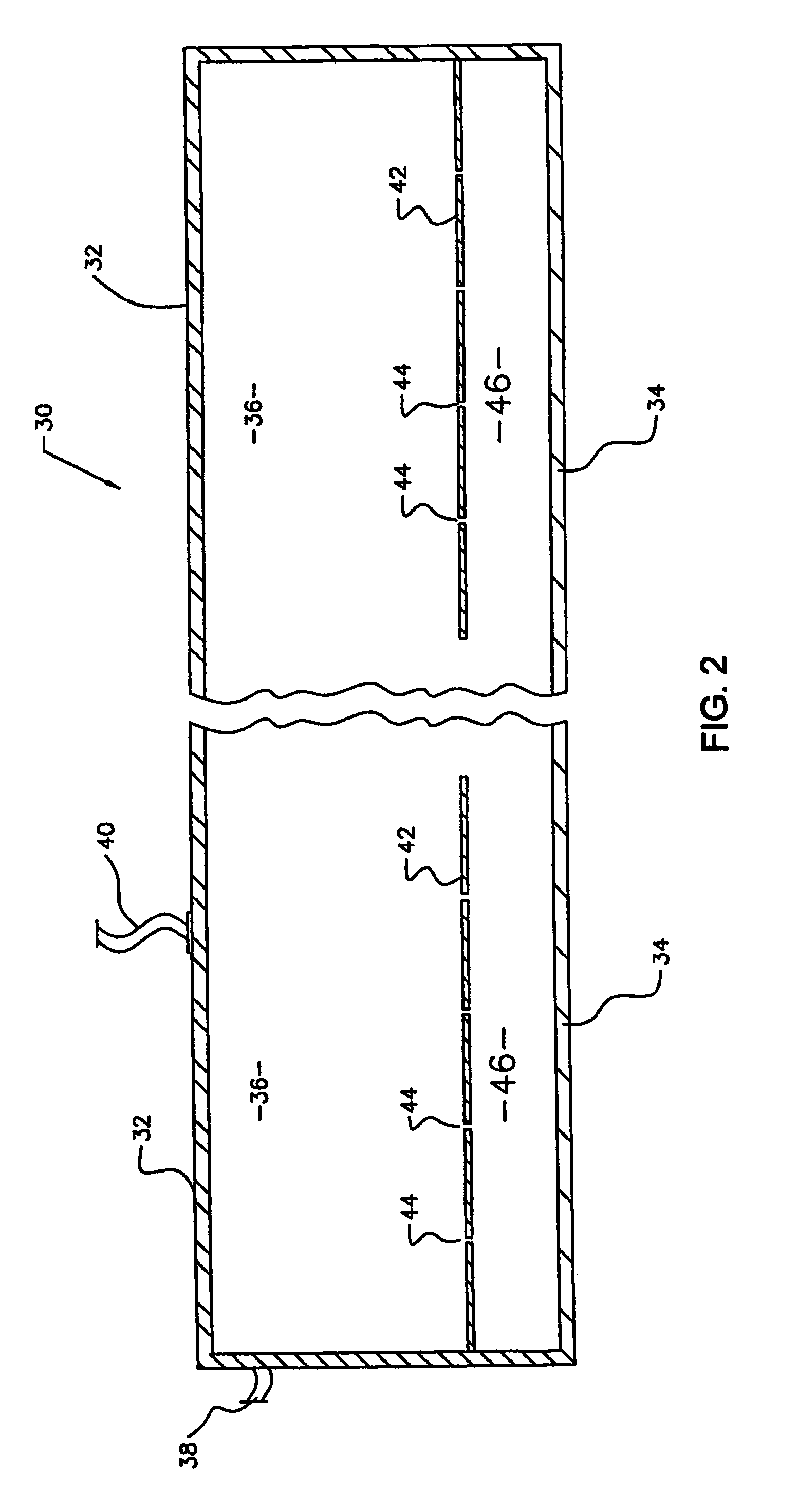

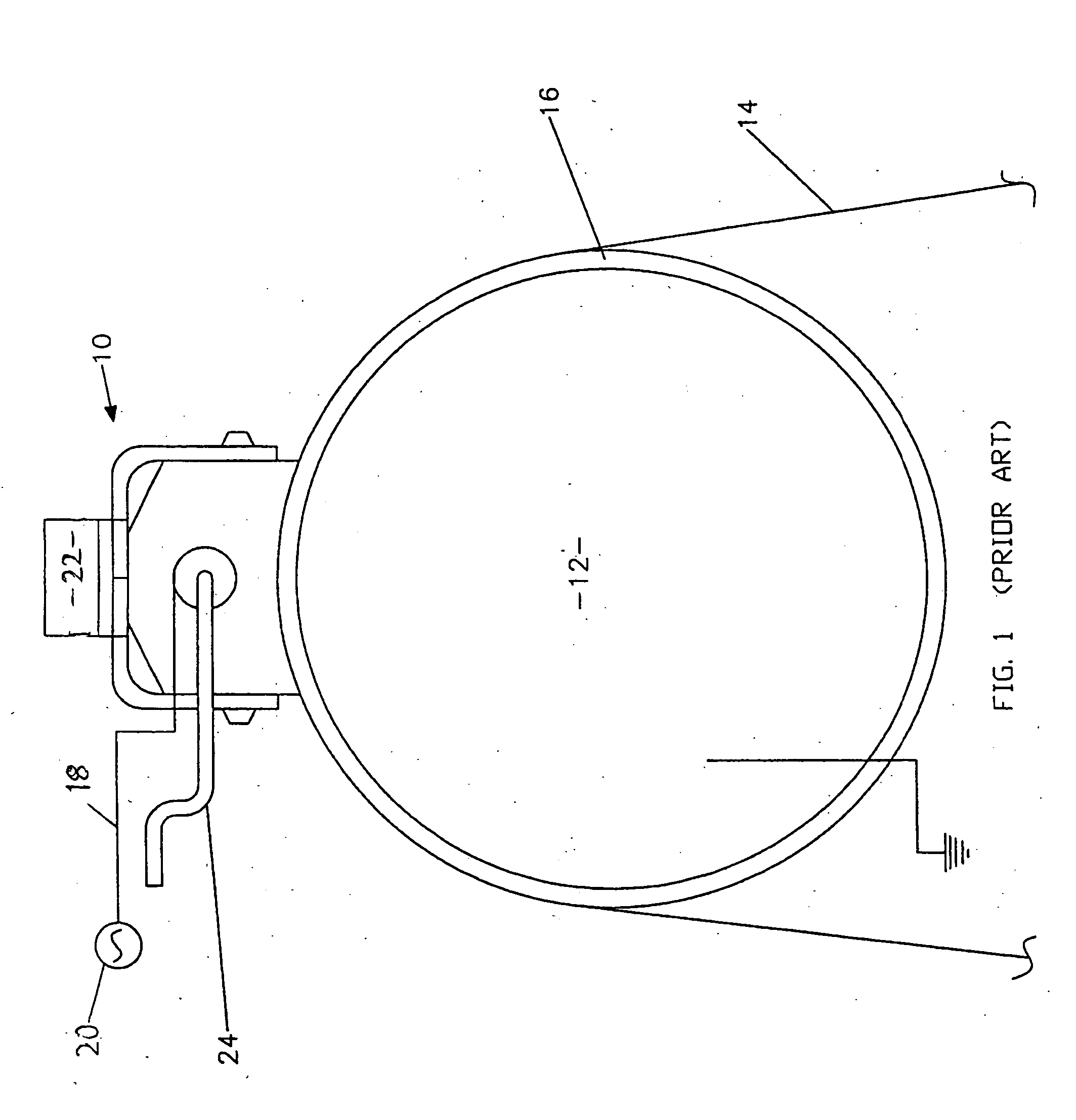

Atmospheric glow discharge with concurrent coating deposition

InactiveUS7067405B2Improve adhesionImprove curingElectric discharge tubesSemiconductor/solid-state device manufacturingMetallic electrodeGas phase

A plasma is produced in a treatment space by diffusing a plasma gas at atmospheric pressure and subjecting it to an electric field created by two metallic electrodes separated by a dielectric material, a precursor material is mixed with the plasma, and a substrate film or web is coated by vapor deposition of the vaporized substance at atmospheric pressure in the plasma field. The deposited precursor is cured by electron-beam, infrared-light, visible-light, or ultraviolet-light radiation, as most appropriate for the particular material being-deposited. Plasma pre-treatment and post-treatment steps are used to enhance the properties of the resulting coated products. Similar results are obtained by atomizing and spraying the liquid precursor in the plasma field.

Owner:SIGMA LAB OF ARIZONA

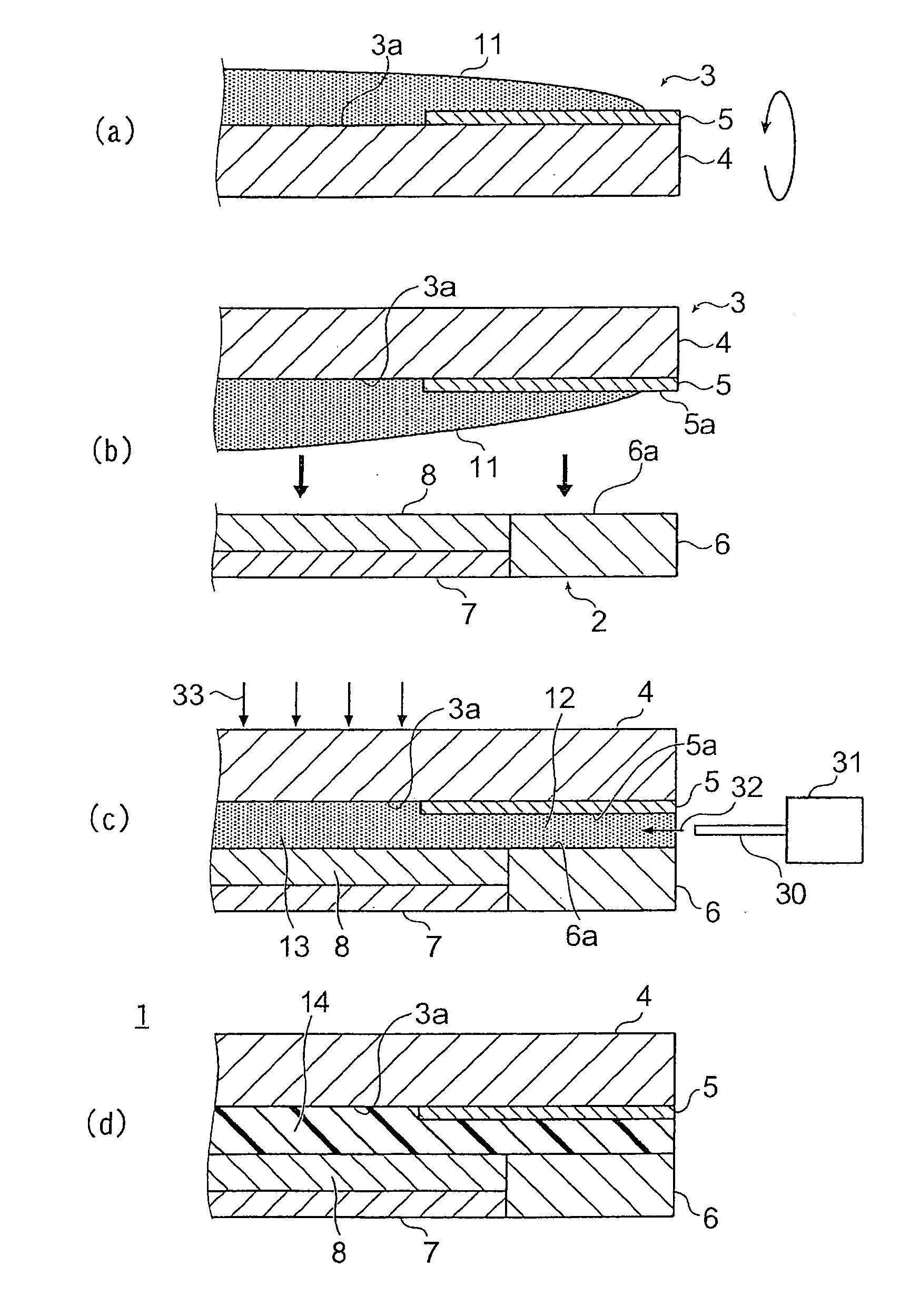

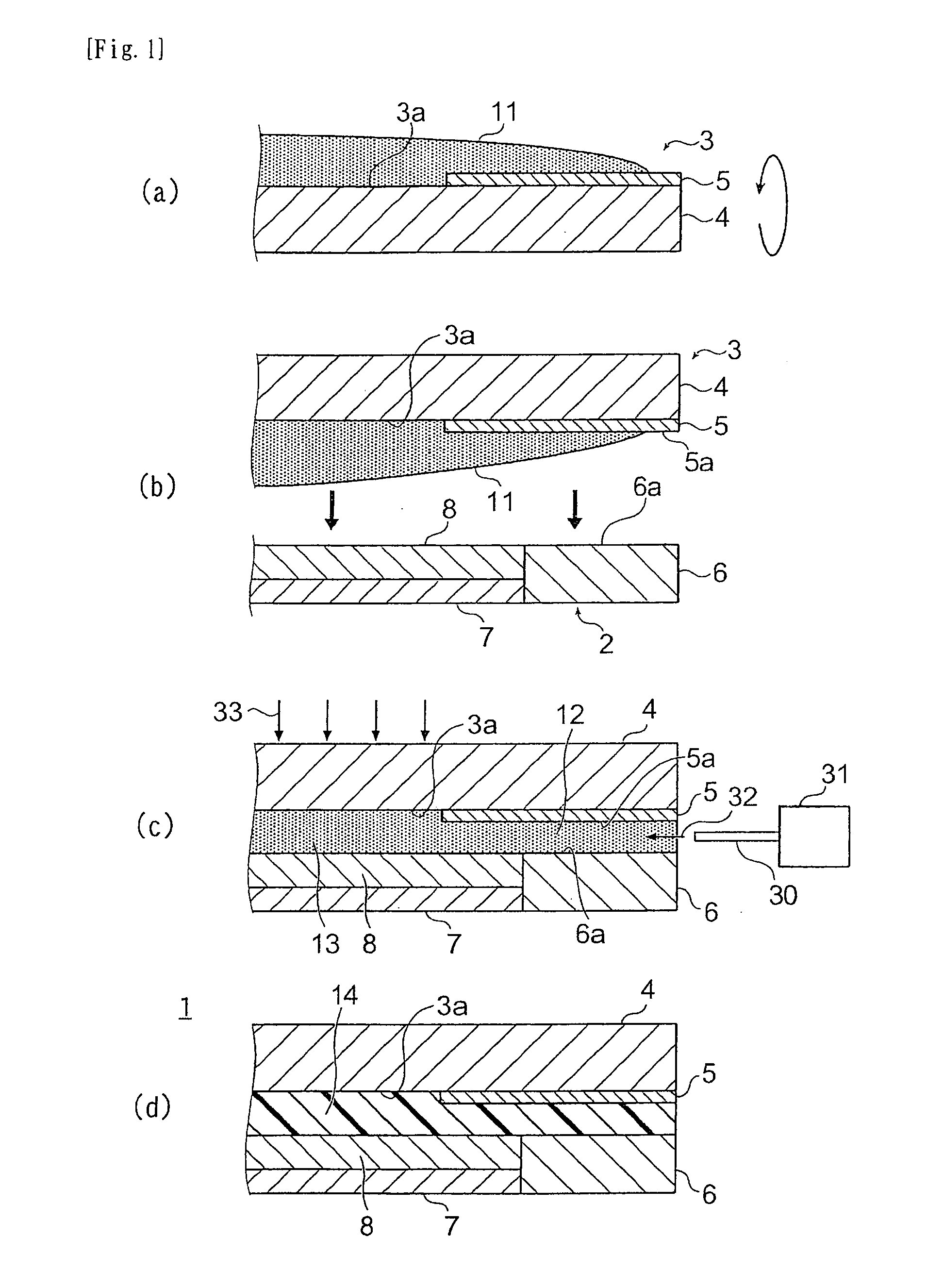

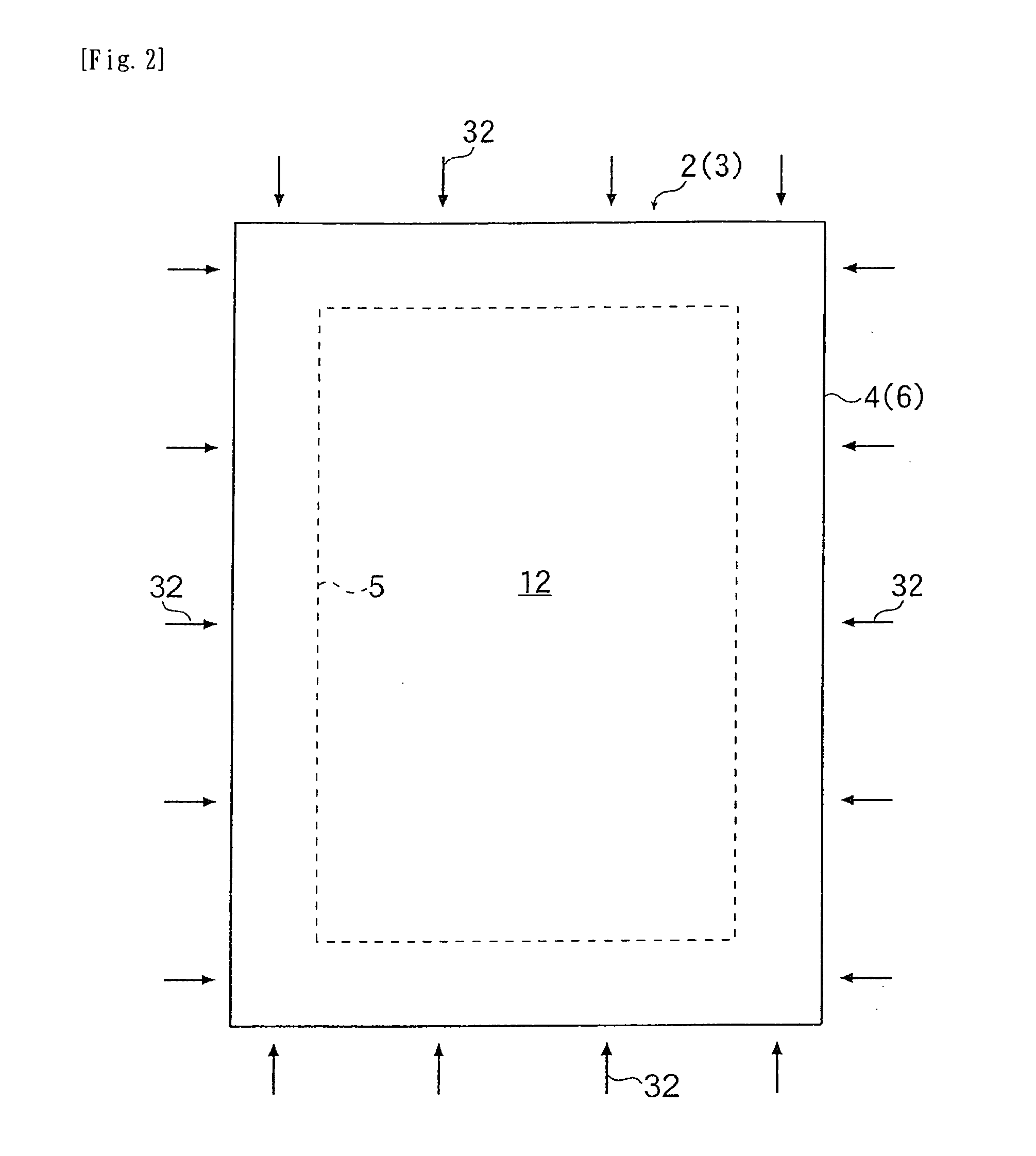

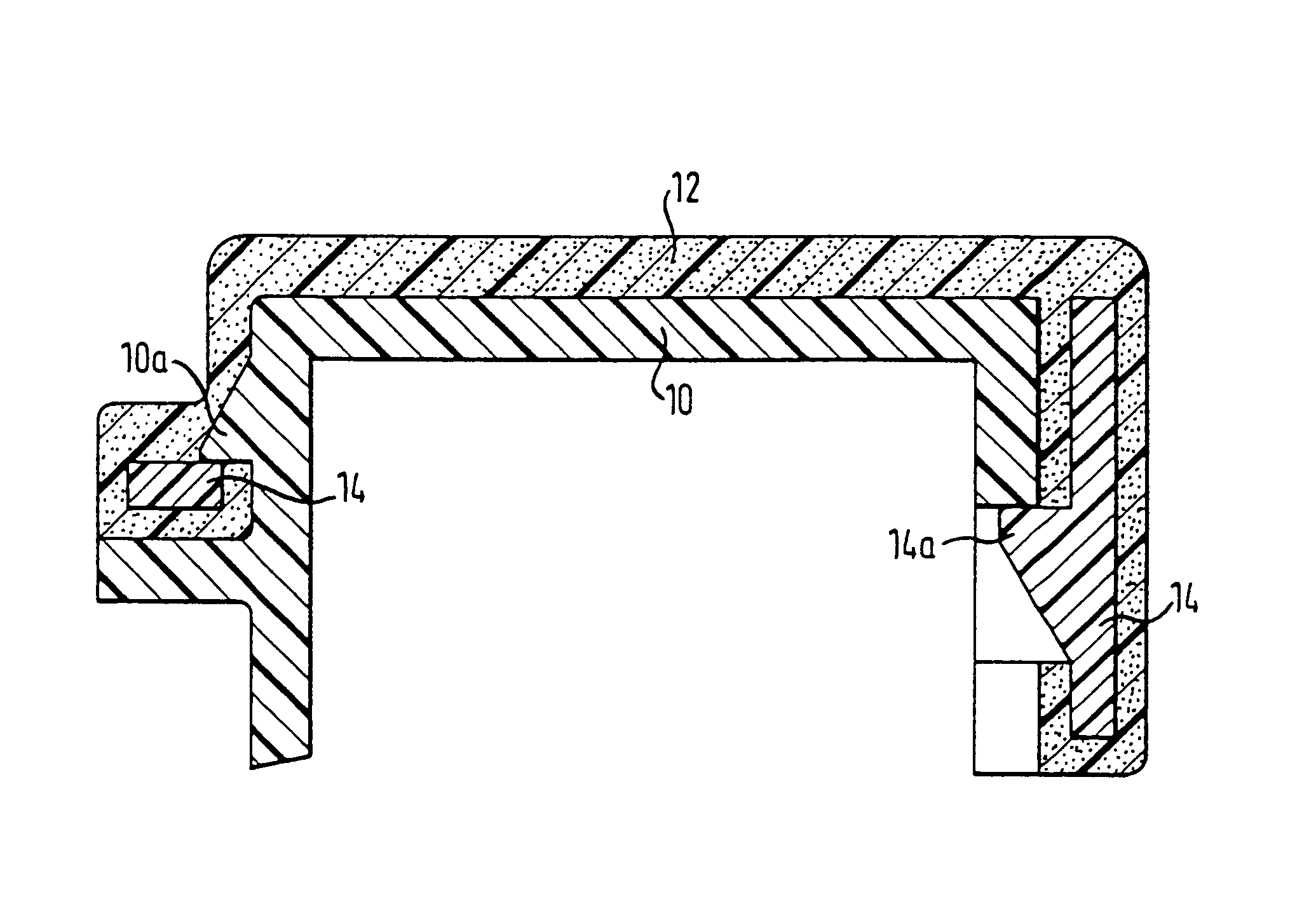

Method for producing image display apparatus

ActiveUS20100098839A1Increase brightnessIncrease contrastSpecial surfacesCoatingsOptical transmittanceEngineering

In the production of a thin image display apparatus by filling a curable resin composition between a protective part and a base and then curing the resin, the present invention enables a high-luminance and high-contrast image to be displayed in which display defects resulting from deformation of an image display part are not produced, the curable resin composition has a uniform thickness, and air bubbles are prevented from becoming mixed in the curable resin composition. A method for producing such an image display apparatus including the steps of coating a curable resin composition onto a base having an image display part or onto a light-transmitting protective part arranged on the image display part, arranging the base and the protective part to face each other in close proximity, and forming a cured resin layer between the base and the protective part by curing the curable resin composition, wherein as the curable resin composition, a resin composition is used which has a curing shrinkage ratio of 5% or less, a cured product storage modulus of 1×107 Pa or less at 25° C., and a light transmittance of the cured resin layer in a visible region of 90% or more, and the curable resin composition coated onto the base or the protective part has a pattern with a prescribed shape.

Owner:DEXERIALS CORP

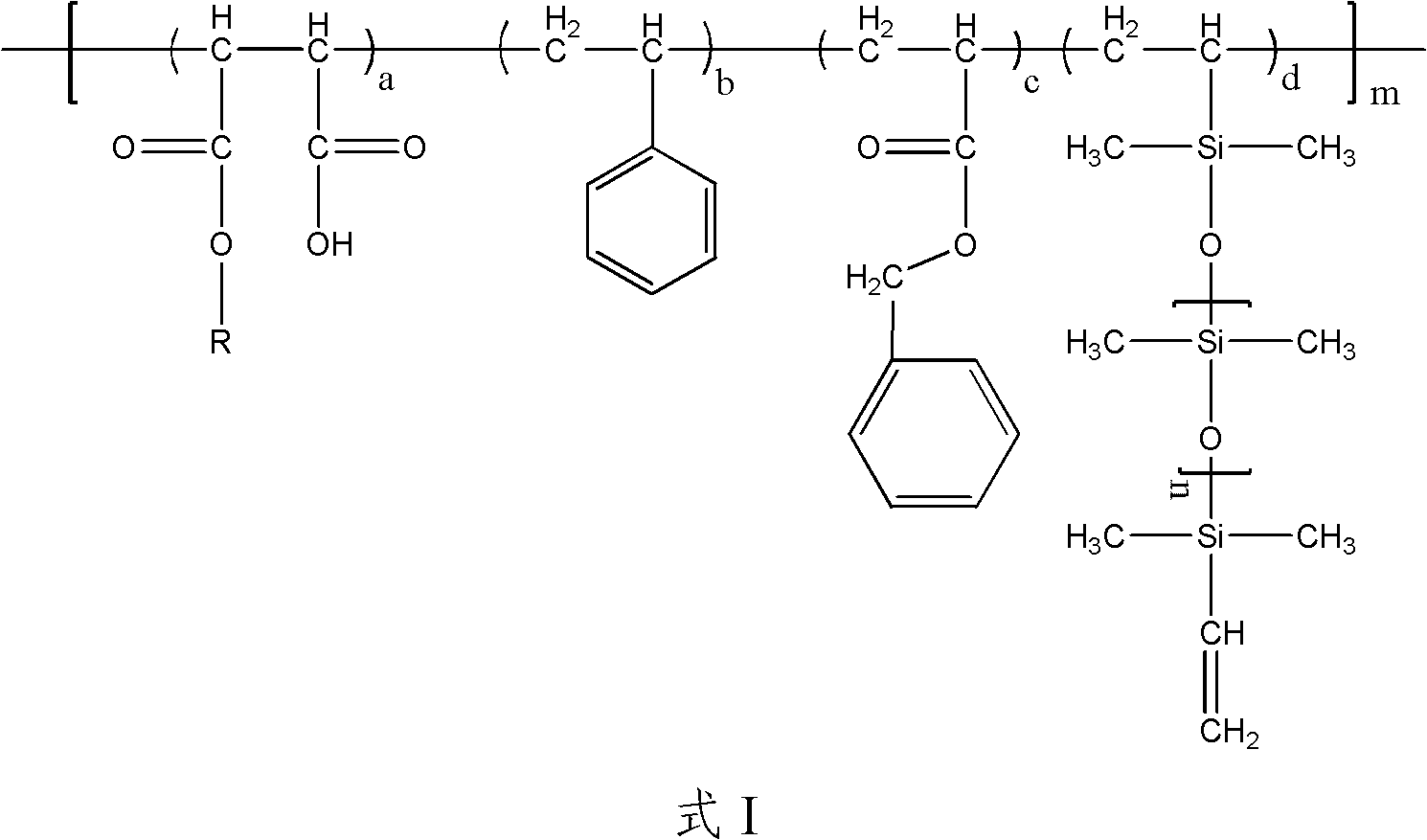

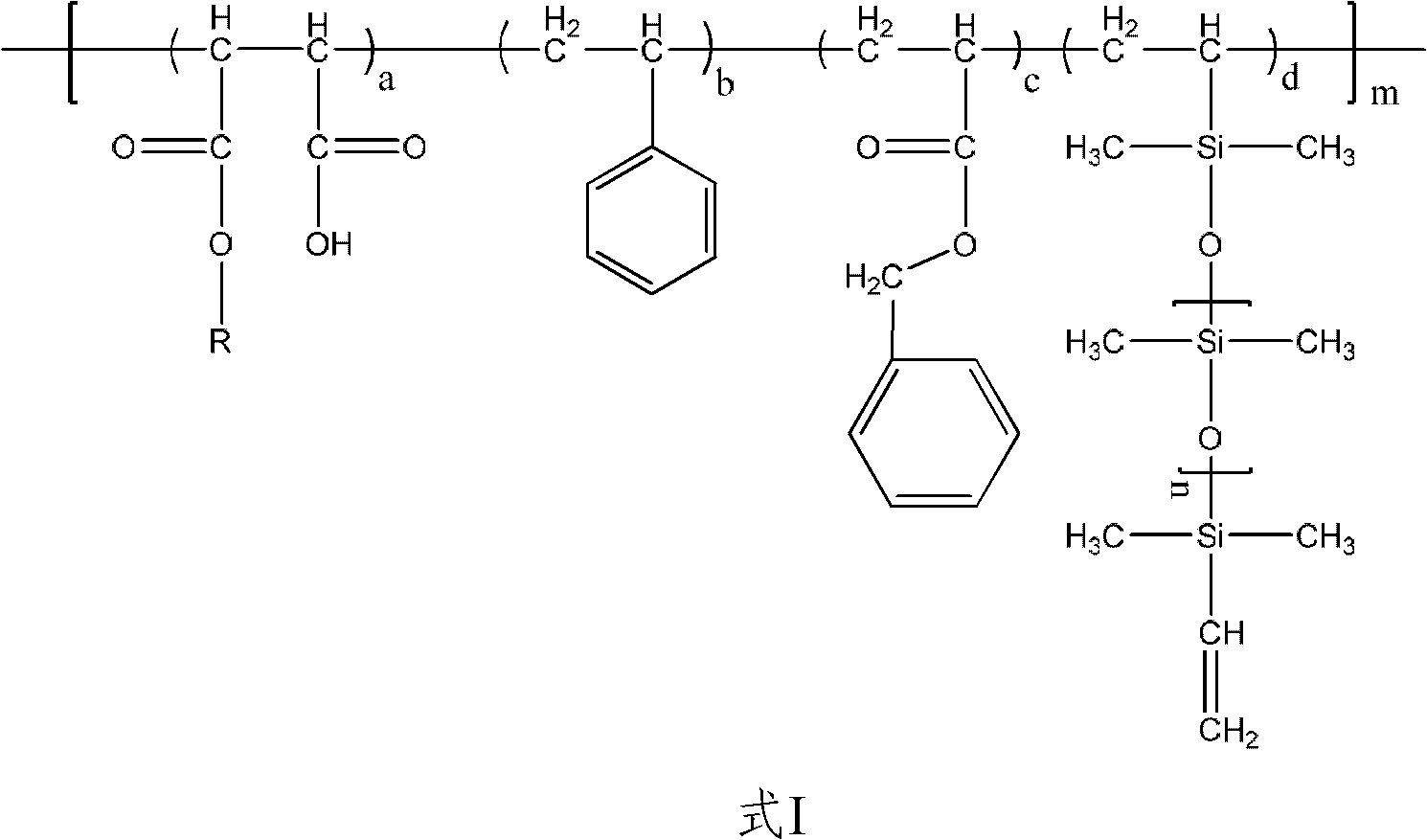

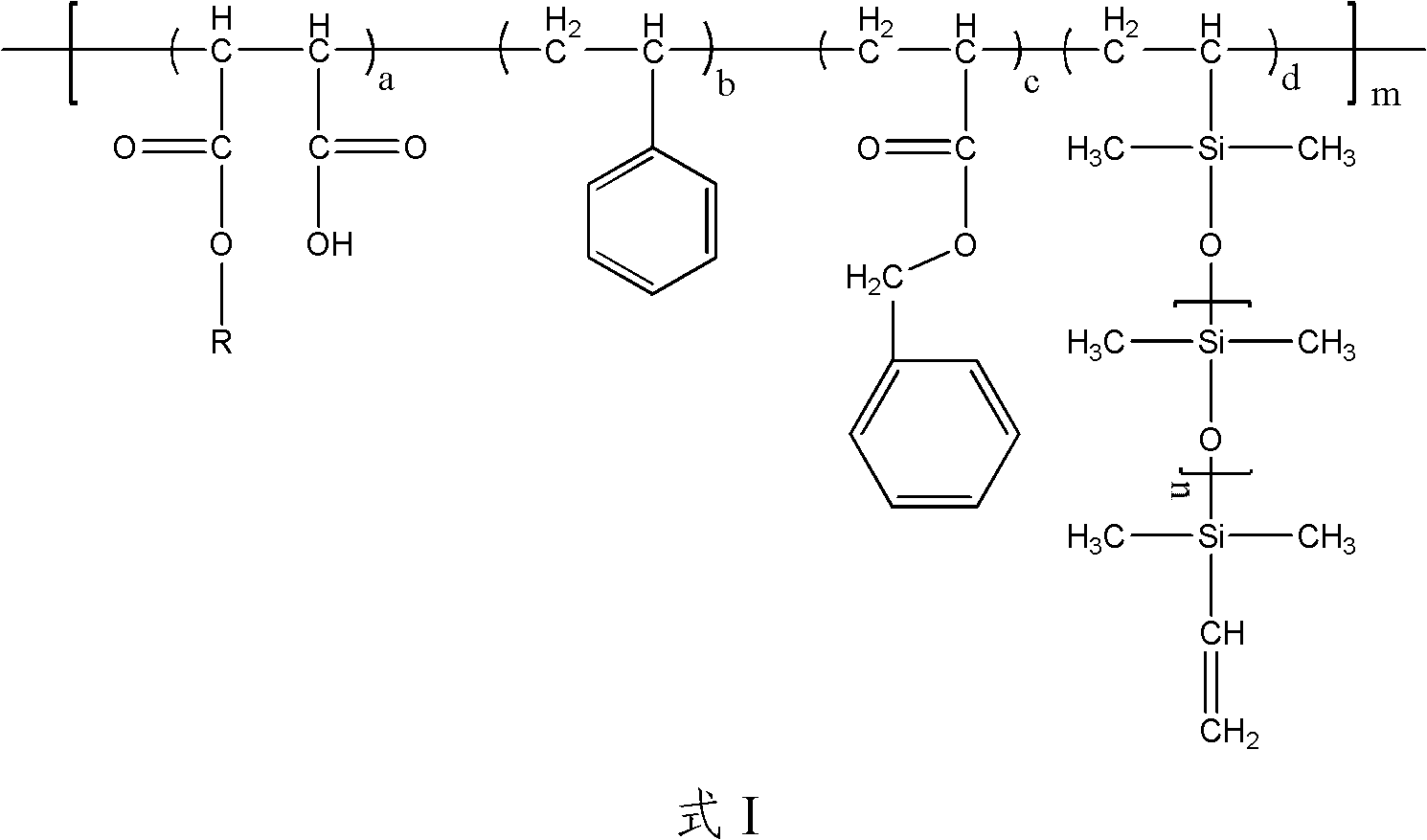

Alkali soluble resin, photosensitive resin composition containing it and application thereof

ActiveCN102875745ASmooth coating surfaceImprove flexibilityOptical filtersPhotomechanical apparatusHydrogenColor gel

The invention discloses an alkali soluble resin and its preparation method. The alkali soluble resin has a chemical structural formula shown in formula 1, wherein a is an integer ranging from 1 to 5, b is an integer ranging from 1 to 5, c is an integer ranging from 1 to 10, d is an integer ranging from 1 to 10, m is an integer ranging from 1 to 30, n is an integer ranging from 1 to 10, and R is hydrogen, alkyl, alkoxy or an acrylic group. The alkali soluble resin has a weight-average molecular weight of 3500-35000. The invention also discloses a photosensitive resin composition containing the alkali soluble resin, and a color photoresist glue that contains the photosensitive resin composition and is used for color filters, as well as a display device containing the color photoresist glue, which has the advantage of a level and smooth coating surface.

Owner:BOE TECH GRP CO LTD

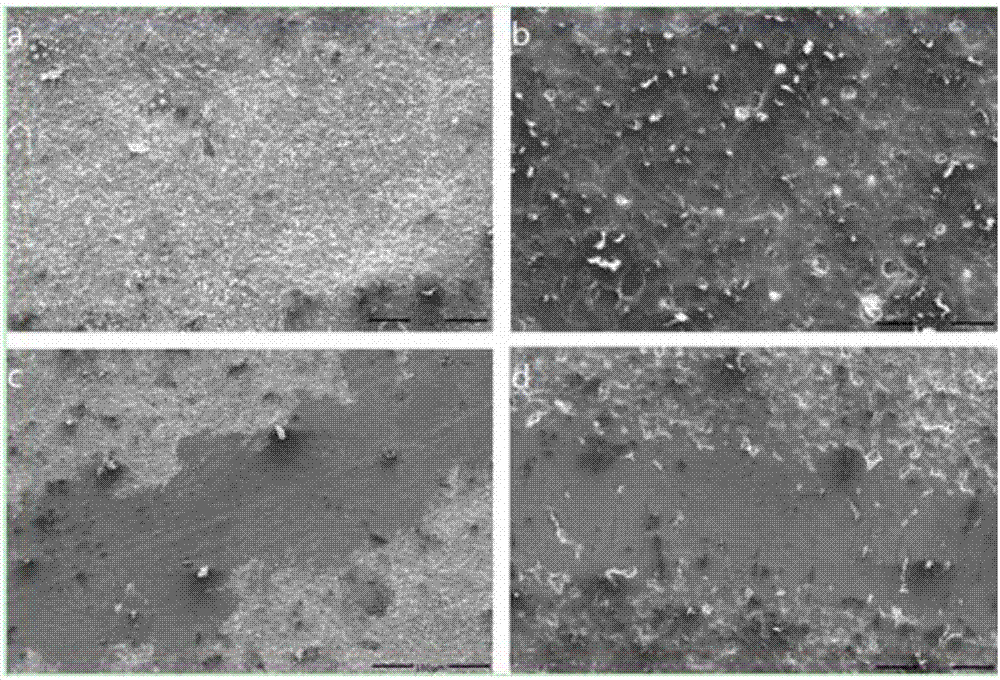

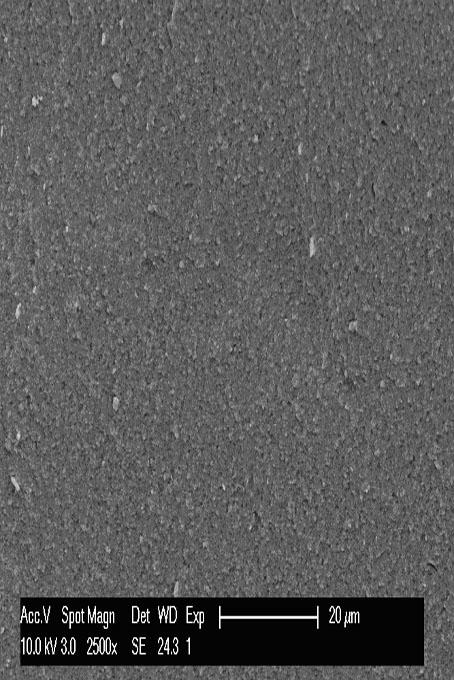

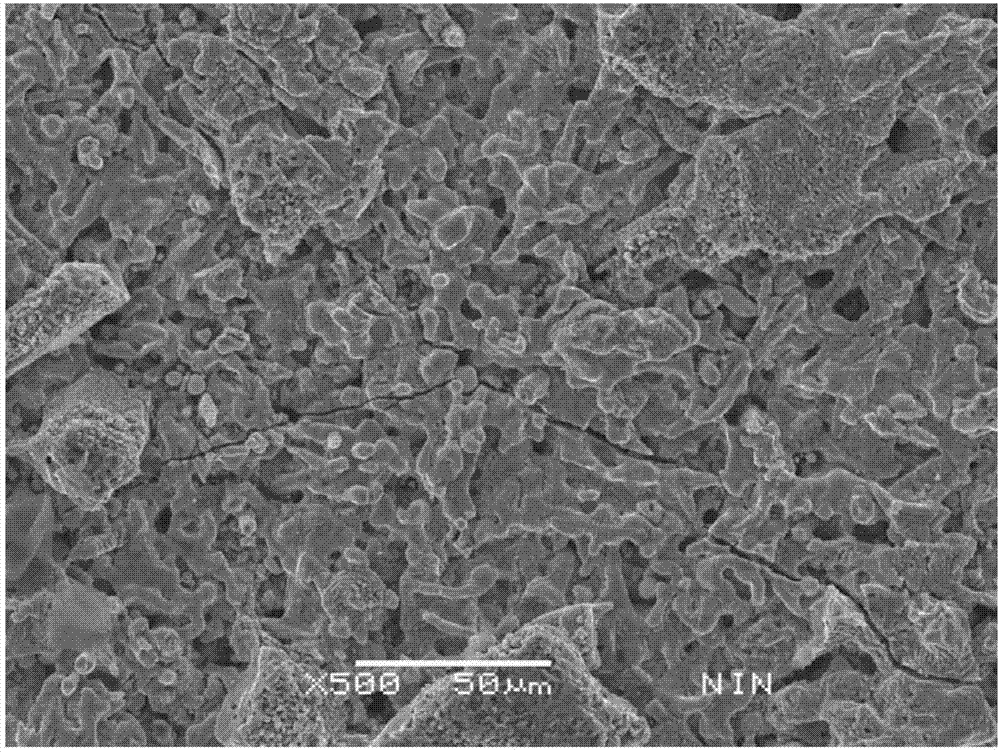

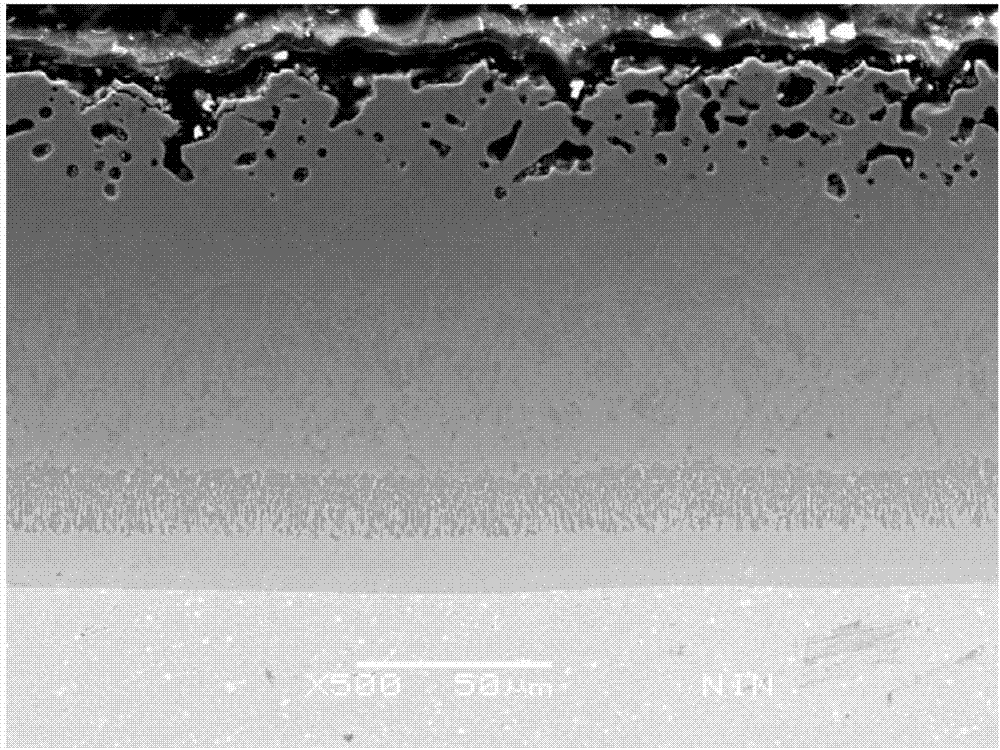

Self-lubricating wear-resistant compound coating on surfaces of titanium and titanium alloy and preparation method thereof

InactiveCN107281544AHigh bonding strengthReduce wearSurface reaction electrolytic coatingPretreated surfacesPlasma electrolytic oxidationDoped graphene

The invention discloses a self-lubricating wear-resistant compound coating on surfaces of titanium and titanium alloy and a preparation method thereof. The compound coating comprises a surface of a titanium and titanium alloy substrate, an oxidized ceramic coating and a self-lubricating coating which are successively connected. The titanium and titanium alloy substrate has a textured surface pre-treated by a Nd:YAG pulse laser puncher, the oxidized ceramic coating is a hard oxidized ceramic coating generated by means of plasma electrolytic oxidation, and the self-lubricating coating is an ultra high molecular weight polyethylene coating doped with graphene. By adding graphene into the ultra high molecular weight polyethylene coating to form a laminar compound structure, the surface wettability of the coating is improved, the frictional coefficient and the wear rate of the coating are reduced, and the frictional property of the surface of the coating is improved. According to the invention, the wear-resistant compound coating which is high in hardness and low in frictional coefficient and the wear rate can be prepared on the surface of the titanium and titanium alloy, and the coating is level, smooth and compact in surface and has good wear-resistant and corrosion-resistant properties.

Owner:NANJING UNIV OF SCI & TECH

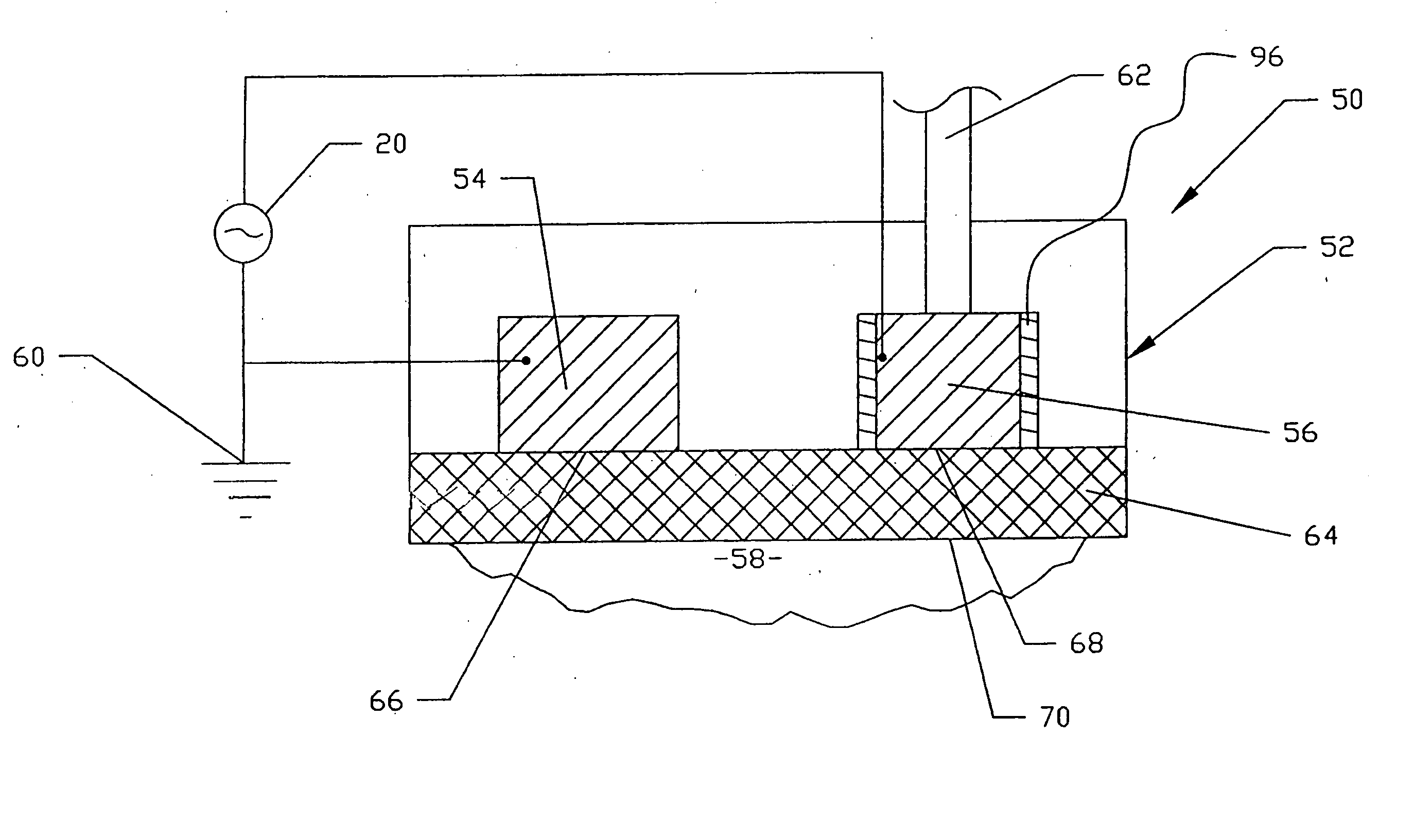

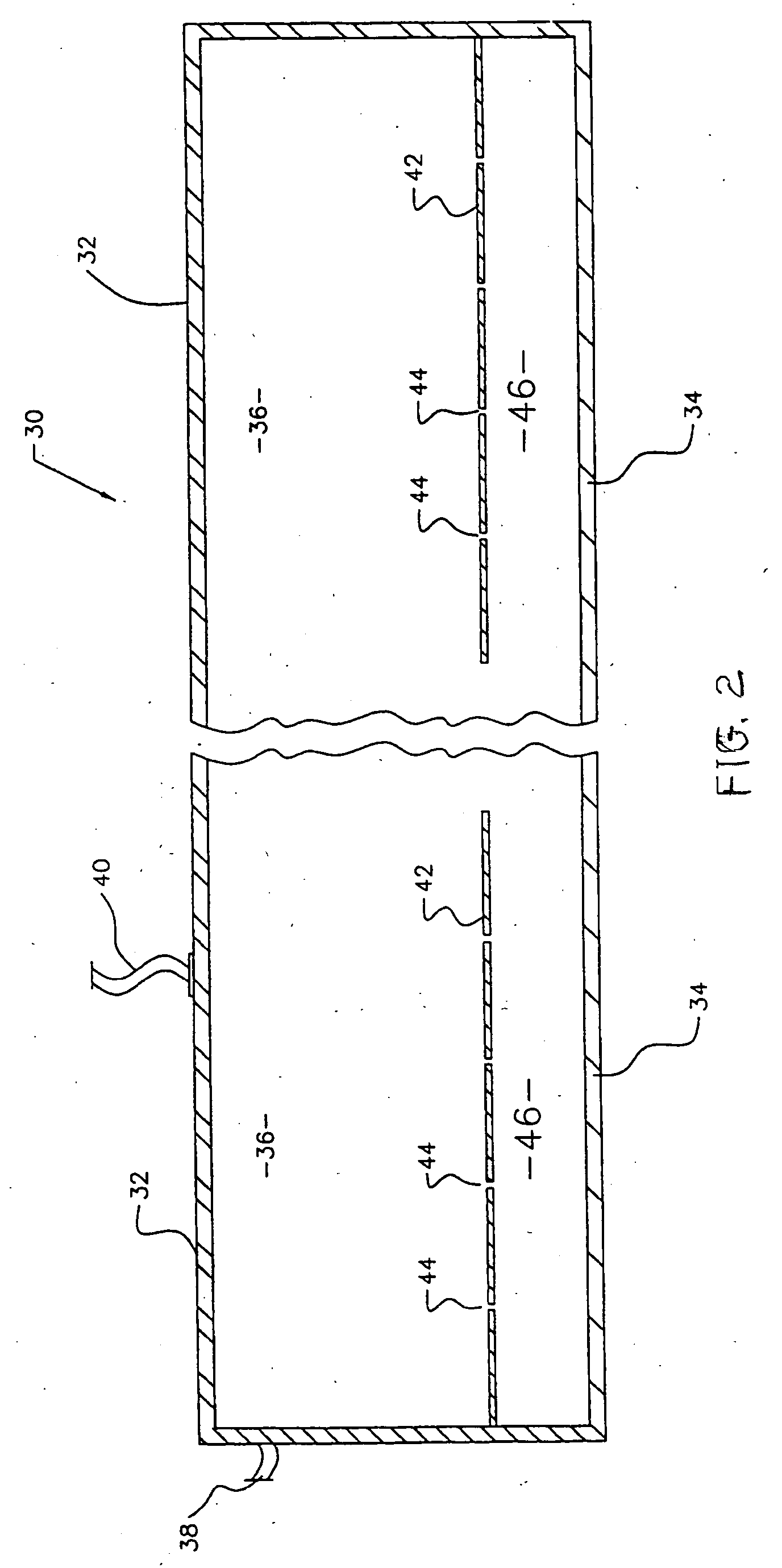

Atmospheric glow discharge with concurrent coating deposition

InactiveUS20050020038A1Improve curingSmooth coating surfaceElectric discharge tubesFrom solid stateMetallic electrodeGas phase

A plasma is produced in a treatment space by diffusing a plasma gas at atmospheric pressure and subjecting it to an electric field created by two metallic electrodes separated by a dielectric material, a precursor material is mixed with the plasma, and a substrate film or web is coated by vapor deposition of the vaporized substance at atmospheric pressure in the plasma field. The deposited precursor is cured by electron-beam, infrared-light, visible-light, or ultraviolet-light radiation, as most appropriate for the particular material being-deposited. Plasma pre-treatment and post-treatment steps are used to enhance the properties of the resulting coated products. Similar results are obtained by atomizing and spraying the liquid precursor in the plasma field.

Owner:SIGMA LAB OF ARIZONA

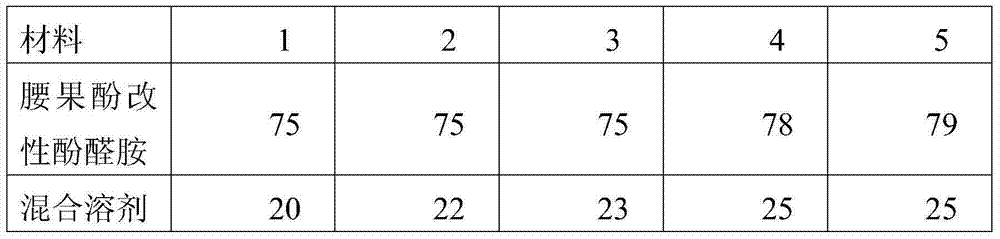

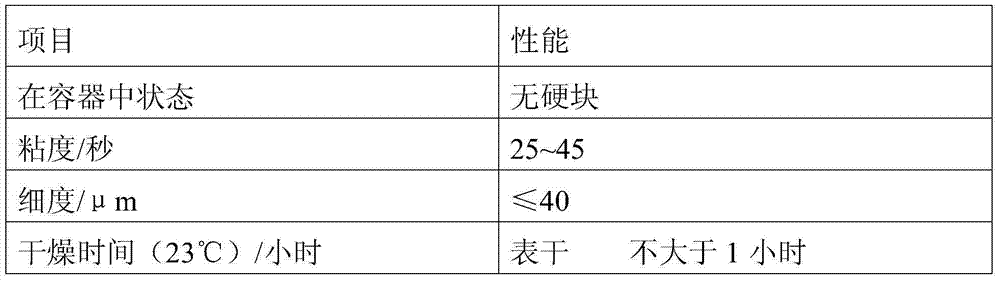

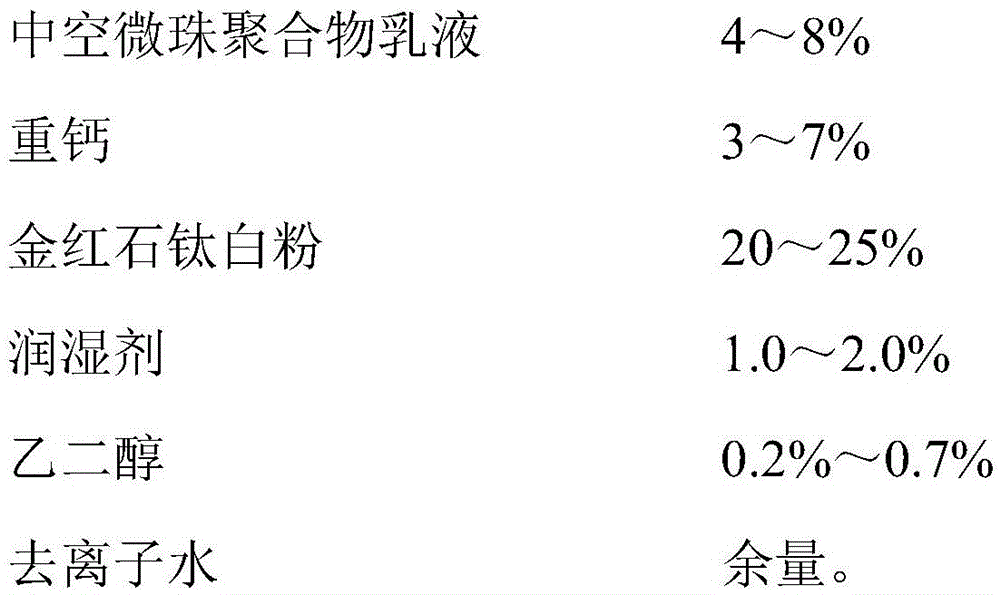

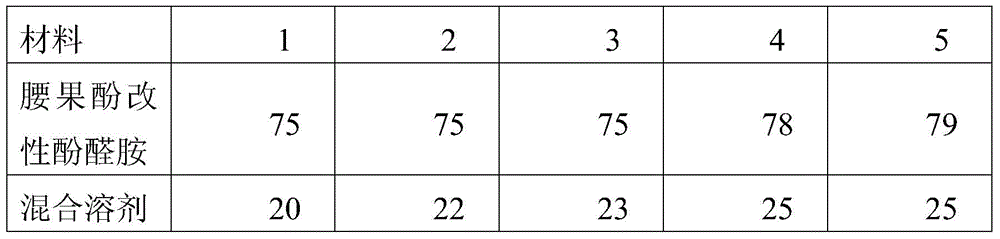

Anticorrosive paint coated under rusted and moist conditions

InactiveCN103756512AImprove protectionIncrease crosslink densityAnti-corrosive paintsEpoxy resin coatingsEpoxySolvent

The invention discloses an anticorrosive paint coated under rusted and moist conditions and particularly discloses a bicomponent epoxy anticorrosive paint which can be coated on rusted and moist steel surfaces and can play a protective role. The anticorrosive paint comprises a component A and a component B, wherein the component A is composed of the following components in parts by weight: 25-28 parts of epoxy resin, 33-36 parts of pigment and filler, 3.5-5 parts of rust transforming agent, 30-35 parts of mixed solvent and 0.5-1.5 parts of auxiliaries; and the component B is composed of the following components in parts by weight: 75-80 parts of modified mannich amide hardener and 20-25 parts of mixed solvent. The weight ratio of the component A to the component B is (90-100): (1-1.2), and the component A and the component B are mixed before being used.

Owner:SHANGHAI DATONG TABERNACLE NEW ENERGY SAVING MATERIALS CO LTD

Conductive coating

ActiveCN103587164AGood film formingImprove securitySynthetic resin layered productsElectrically-conductive paintsPhosphoric acidSulfide

The invention provides a conductive coating which comprises a bottom layer and a surface layer, wherein the bottom layer is prepared by components in parts by weight as follows: 70 parts of polytetrafluoroethylene emulsion, 6.8-7.1 parts of phosphoric acid, 6.8-7.2 parts of chromic acid, 0.7-1.0 part of lauryl sodium sulfate, 1.6-2.0 parts of chromium sesquioxide, 8-9 parts of water, 0.5-0.8 part of polyphenylene sulfide, 5-7.5 parts of graphite and 1-2.5 parts of conductive black; and the surface layer is prepared by components in parts by weight as follows: 90 parts of polytetrafluoroethylene emulsion, 0.7-0.9 part of lauryl sodium sulfate, 10-11 parts of water, 2-2.5 parts of polyphenylene sulfide, 5-7.5 parts of graphite and 1-3 parts of conductive black. The obtained conductive coating has a smooth surface and large adhesive force with a metal mold, and is high in hardness, difficult to scratch and good in conductivity; and the demolding effect is good after the metal mold is sprayed, and the quality of a finished product is guaranteed.

Owner:湖北三江航天江河橡塑有限公司

Surface metallization method for foamed plastic by adopting high-power pulse magnetron sputtering

ActiveCN103122452ACompact structureReduce the binding forceVacuum evaporation coatingSputtering coatingLow temperature depositionSurface engineering

The invention relates to a surface metallization method for foamed plastic by adopting high-power pulse magnetron sputtering and belongs to the technical field of material surface engineering. The surface metallization method for the foamed plastic by adopting high-power pulse magnetron sputtering comprises the following steps of: firstly carrying out pre-treatment of surface sealing, cleaning, drying and distressing on the surface of foamed plastic, then loading samples, vacuumizing, and degassing; carrying out pre-sputtering to clean a foamed plastic workpiece and sputtering a target material; depositing a metal coating by adopting high-power pulse magnetron sputtering, wherein a metal coating with high ionization rate is deposited on the surface of the foamed plastic workpiece at a low temperature by controlling pulse configuration, frequency, charging voltage and sputtering / cooling time, and a metal coating with smooth surface, compact structure and high cohesion between film and substrate material is prepared; and finally cooling, taking away the foamed plastic workpiece, and inspecting properties of the metallized foamed plastic such as surface appearance, hardness and cohesion between film and substrate material. The surface metallization method for the foamed plastic by adopting high-power pulse magnetron sputtering has the advantages that the surface metallization method is applicable to various metallized coatings; the coating is smooth and compact in surface and high in cohesion between film and substrate material; the sputtering temperature and the deposition temperature are low, and a foamed plastic substrate can not deform; and the surface metallization method is safe and environment-friendly, and no chromic acid reagent which contains Cr<6+> and is related in a chemical plating process is used.

Owner:DALIAN UNIV OF TECH

Surface antiseptic treating agent for cable bridge frame

InactiveCN101085889ARaise the ratioOvercome the problem of poor scratch resistanceCellulose coatingsAnti-corrosive paintsWear resistantRare earth

The invention relates to a kind of corrosion-resistant and erosion resistant coating material, which in detail is a corrosion-resistant material for cable bridge surface. The invention adds flaky zinc powder concentration for traditional dacromet coating formulation, adds penetrating agent, surface active agent, hardening agent and rare earth material. The coating layer on the surface is characterized by high adhesion power, good wearing resistant performance, good antiweatherability and stable chemically-resistant property, and suitability for wild environment utilization for a long time, which as long as 30 years.

Owner:孔繁明

Coating material and method for producing the same

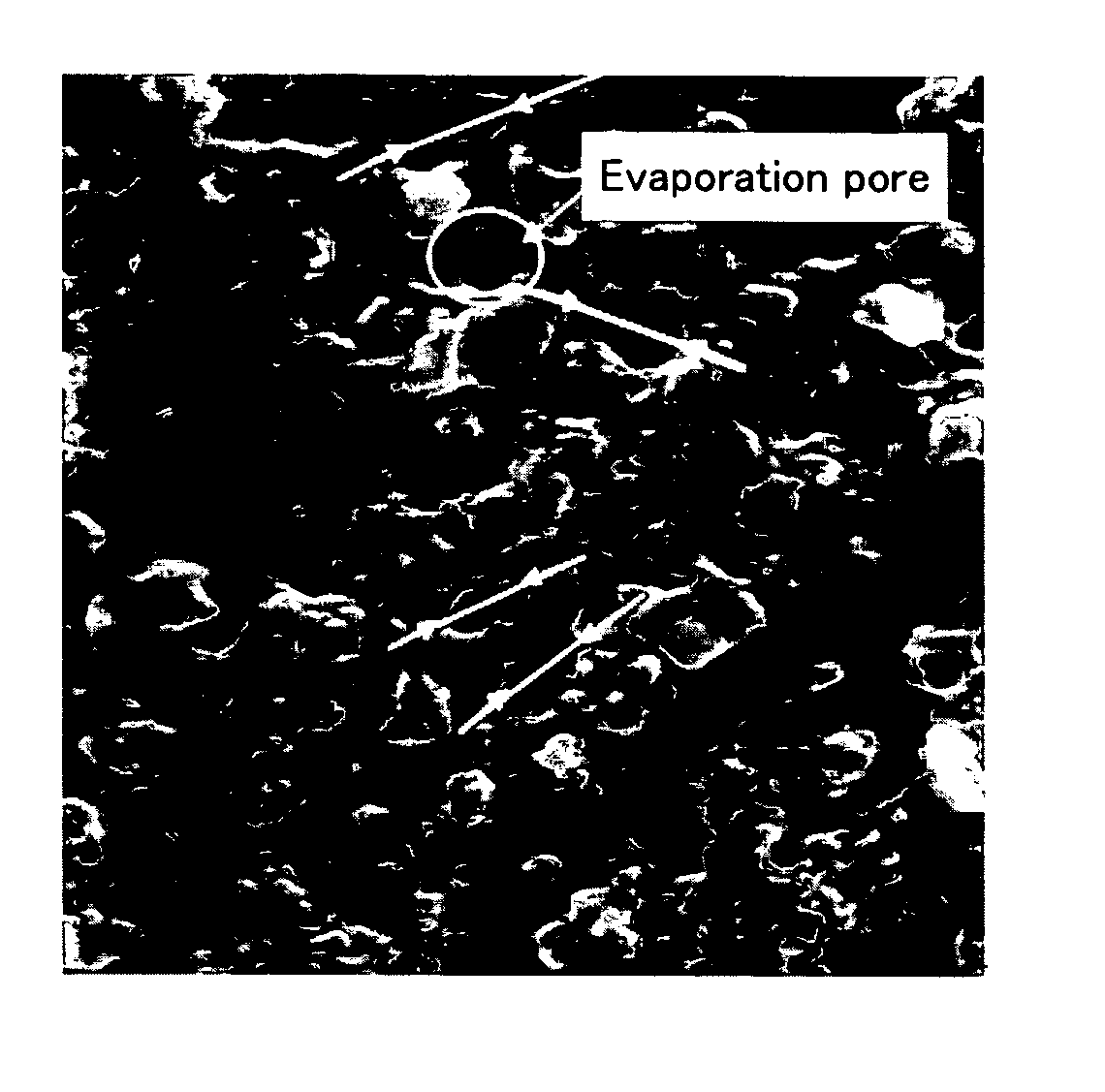

InactiveUS20080206496A1Superior coating glossinessExcellent glossinessPattern printingAblative recordingCoated surfaceEvaporation

To provide a coating material capable of making a coating surface smoother, improving glossiness and being suitably used especially as a thermosensitive recording material, and a method for producing the same. As a means for realizing the foregoing, there is a coating material produced by a multilayer simultaneous coating process, including: an outermost coating surface having moisture evaporation pores, wherein the moisture evaporation pores are 1.5 μm or less in average diameter. And there is a method for producing the coating material, including: simultaneously depositing two or more types of coating solutions over a continuously running web, and drying the coating solutions, wherein a coating solution which constitutes a coating other than an outermost coating surface is formed of a dispersion solution, and dispersed particles contained in the dispersion solution are 1 μm or less in average diameter.

Owner:RICOH KK

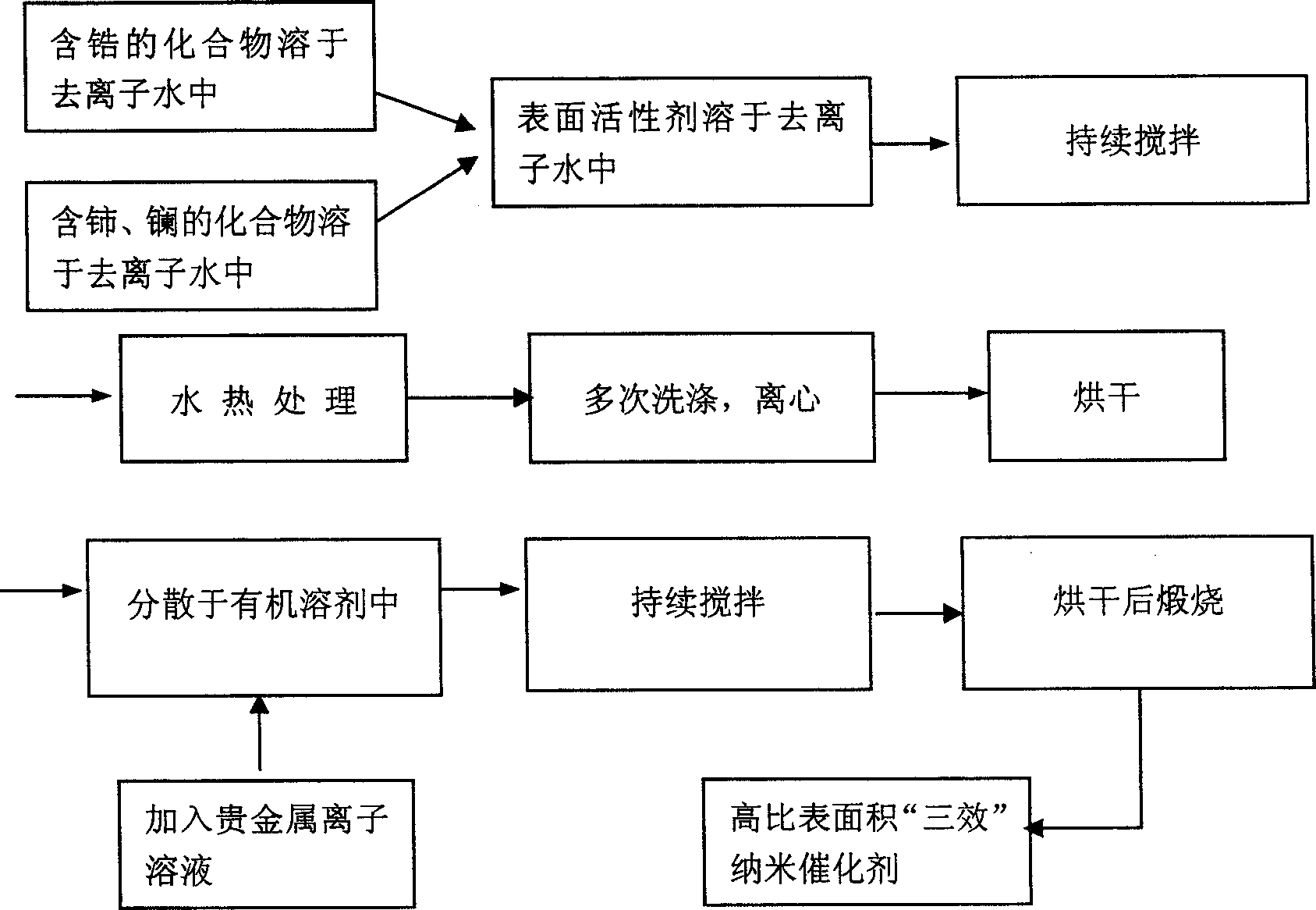

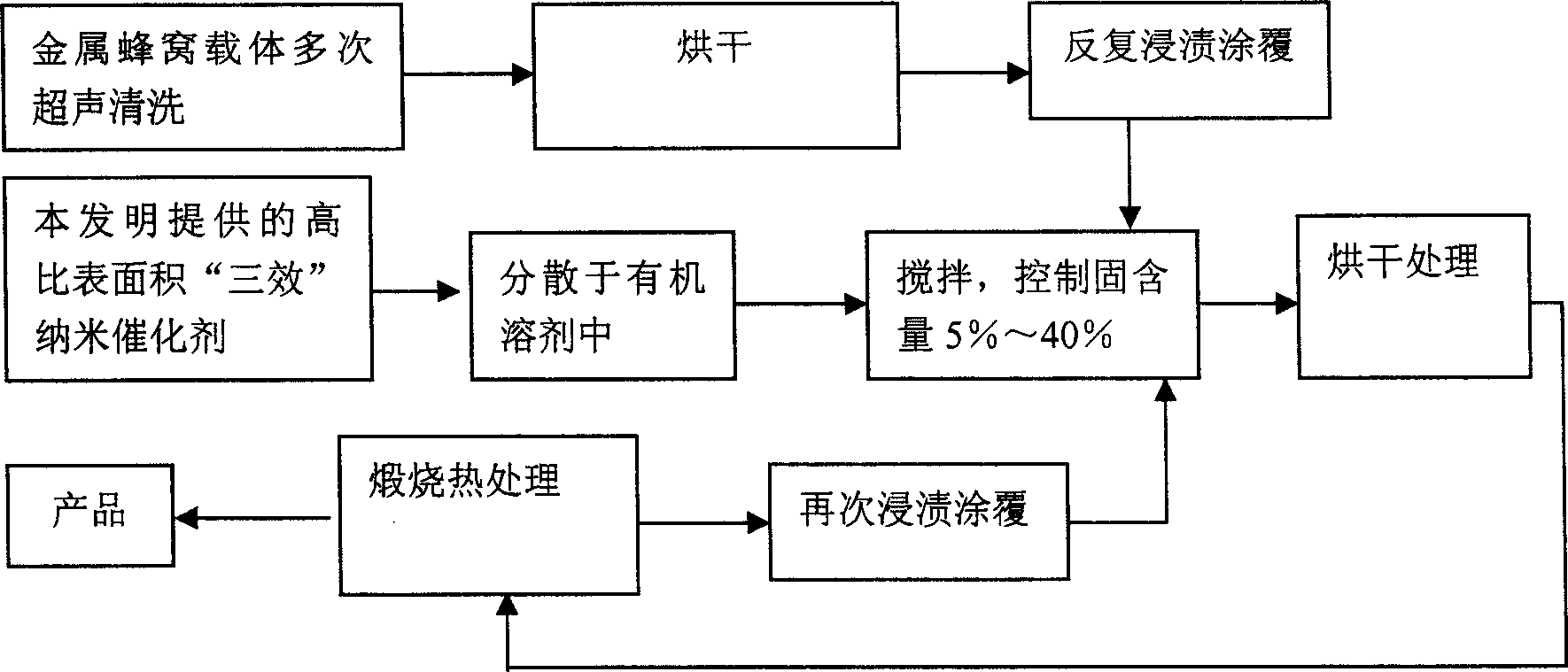

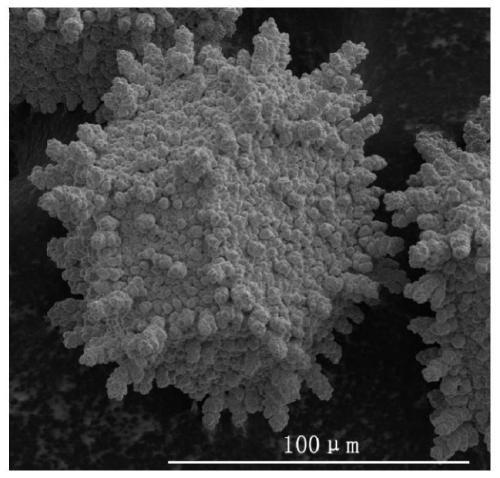

Ternary Nano catalyst in use for cellular carrier of full metal, preparation method and coating process

InactiveCN1915489ACoating Process AdvantagesGood activity at low temperatureDispersed particle separationMetal/metal-oxides/metal-hydroxide catalystsNano catalystOrganic solvent

A three-element nano-catalyst for the metallic cellular carrier used to treat the tail gas of car is proportionally prepared from lanthanum oxide, zirconium oxide and cerium oxide through dissolving them in deionized water, adding surfactant, hydrothermal treating, washing, filtering, dispersing it in organic solvent, adding the solution of noble metal, stirring, baking and calcining. Its coating technology includes such steps as ultrasonic cleaning of metallic cellular carrier multiple times, dispersing said nano-catalyst in organic solvent, stirring, baking, coating and calcining.

Owner:SHANGHAI INST OF CERAMIC CHEM & TECH CHINESE ACAD OF SCI

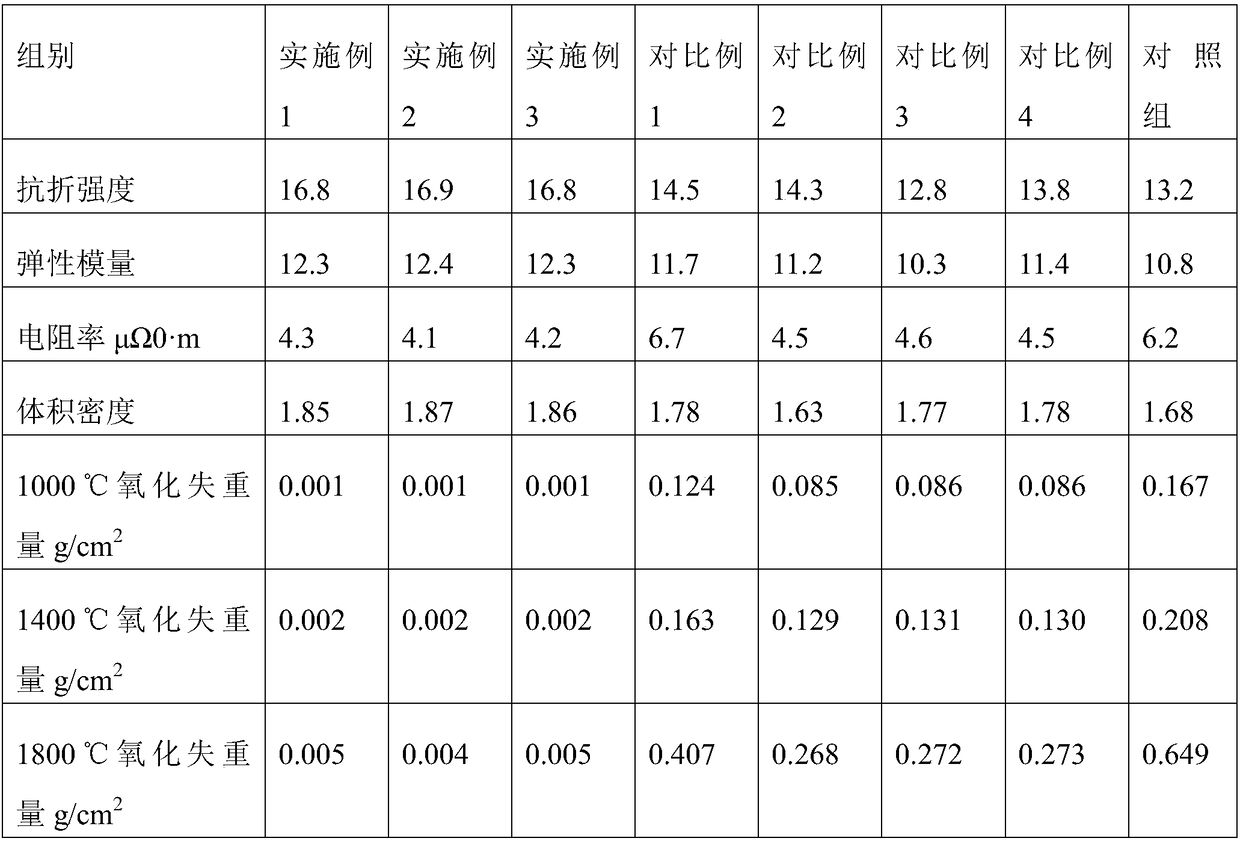

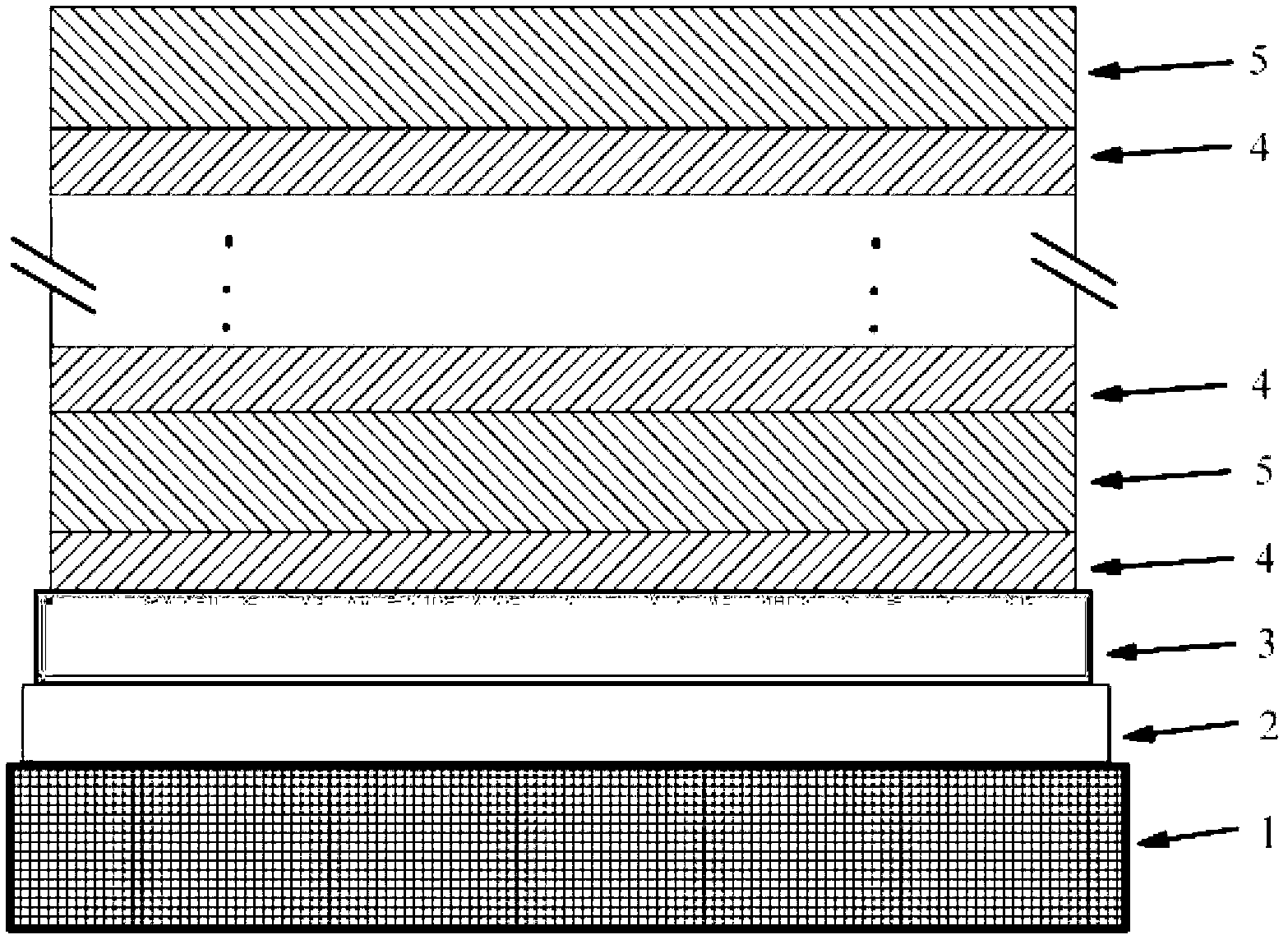

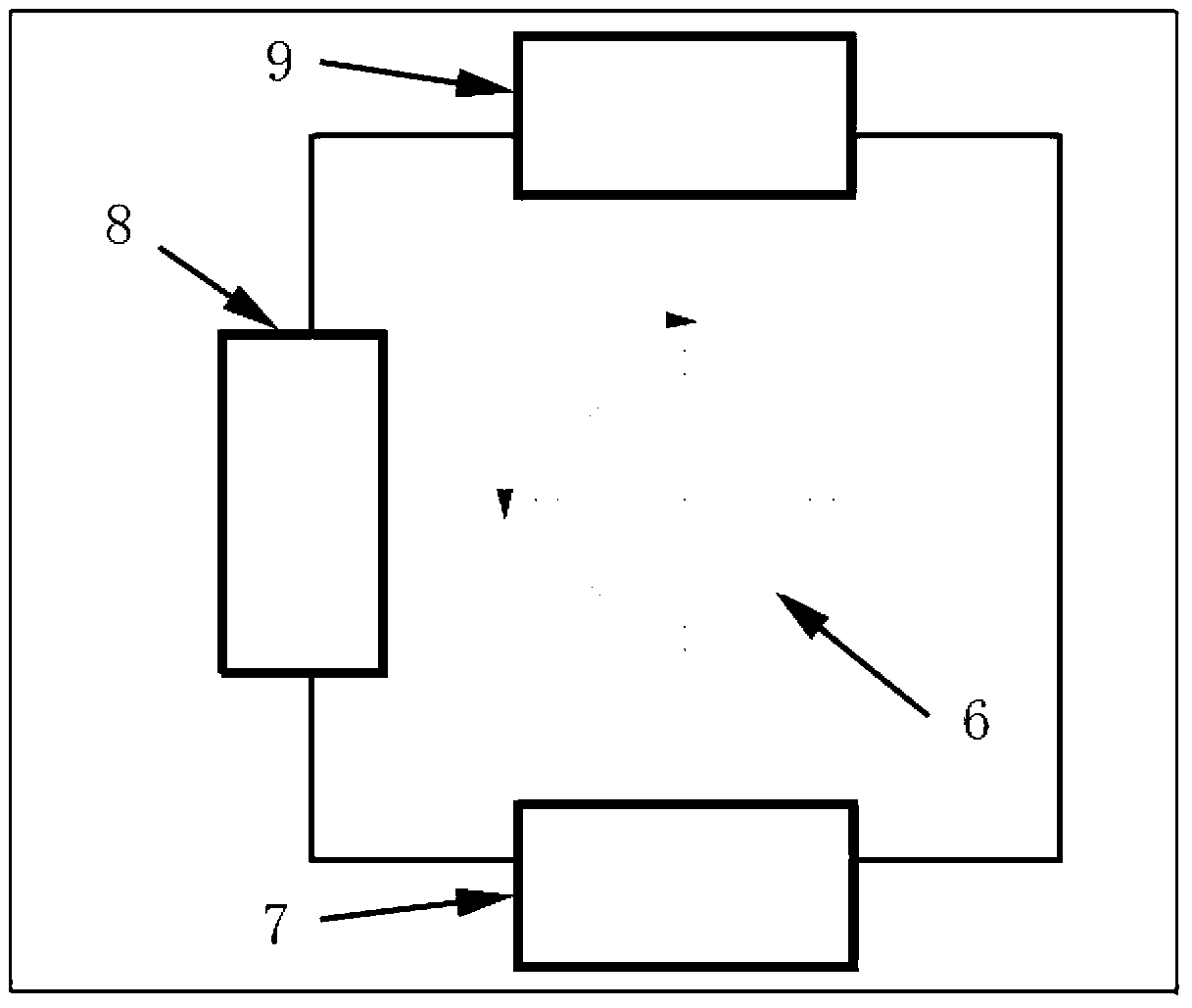

Graphite electrode nanometer antioxidant and preparation method thereof

The invention belongs to the technical field of graphite electrodes, and provides a graphite electrode nanometer antioxidant and a preparation method thereof. The graphite electrode nanometer antioxidant is prepared from the following components in parts by weight: 20 to 30 parts of water, 20 to 30 parts of nano-oxide ceramic powder, 15 to 20 parts of graphene, 10 to 20 parts of dispersant, 10 to15 parts of film-forming additive, 6 to 12 parts of stabilizer and 5 to 10 parts of polyhedral oligomeric silsesquioxane, wherein the dispersant is polyethylene glycol; the film-forming additive is thiol-based chitosan; the stabilizer is a mixture of zinc borate and polyetherimide in the mass ratio of 2 to 1. By adopting the graphite electrode nanometer antioxidant, the problem of conductivity decrease of a graphite electrode after introduction of the graphite electrode under the risks of peeling and falling off due to cracks generated in the heating process of a generated antioxidation layersince the antioxidation temperature is not high during use of the graphite electrode nanometer antioxidant in the prior art is solved.

Owner:河北弘华节能科技有限公司

Nanometer multilayer coating and preparation method thereof

InactiveCN103215542AHigh hardnessSmooth coating surfaceVacuum evaporation coatingSputtering coatingHardnessCoating

The invention discloses a nanometer multilayer coating. The nanometer multilayer coating is characterized in that the coating at least comprises a settled layer, wherein the settled layer is formed by alternately settling a TiAlSiN sub-layer and a CrAlN sub-layer; and the atom content of Si in the TiAlSiN sub-layer is 2-12 percent; and the CrAlN sub-layer contains a nanocrystalline CrAlN tissue having a B1 structure. The invention also discloses a preparation method of the nanometer multilayer coating. Compared with the prior art, the nanometer multilayer coating has the advantages of high hardness, high flexibility, high heat stability and high oxidizability resistance.

Owner:CHINA WEAPON SCI ACADEMY NINGBO BRANCH

Silicone release coating composition and low release force emulsion silicone release coating for films and papers having cured release coating

ActiveUS20170145256A1Reduce release forceMaintain good propertiesPaper coatingEmulsion paintsPolymer scienceActive agent

A silicone release coating composition comprises:(A) 100 weight parts of an organopolysiloxane fluid having a viscosity at 25° C. of 50 to 10,000 mPa·s and an alkenyl content of 0.10 to 3.0 wt %;(B) 0.5-40 weight parts of a diorganopolysiloxane represented by the average structural formula (1):Rc3SiO(RbRcSiO2 / 2)n1(Rc2SiO2 / 2)n2SiRc3 (1)wherein Rb is an alkenyl group; Rc is an alkyl group or a phenyl group; n1 provides an alkenyl content of 0.05 to 0.80 wt. %; n2 is at least 1; and n1+n2 provides this component with a viscosity at 25° C. of 5,000 to 150,000 mPa·s;(C) an organohydrogenpolysiloxane that has a viscosity at 25° C. of 1 to 1,000 mPa·s, at least two silicon-bonded hydrogen atoms in each molecule, and an alkyl group or a phenyl group for its silicon-bonded organic groups;(D) a hydrosilylation reaction catalyst in a catalytic amount;(E) a surfactant;(F) water; and(G) an inhibitor.

Owner:DOW SILICONES CORP +1

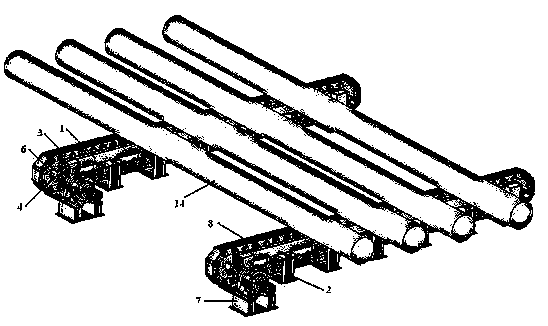

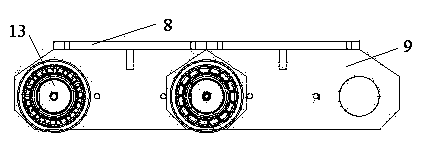

Steel pipe inner coating solidifying device used for high-temperature environment

InactiveCN103447213ANovel structureBeautiful shapePretreated surfacesCoatingsSteel tubeFrequency changer

The invention discloses a steel pipe inner coating solidifying device used for a high-temperature environment and aims to solve the problems of the prior art. The steel pipe inner coating solidifying device comprises a sliding rail, supports, a chain, a driving wheel, a driven wheel, a driving rod and a frequency changer, each support is of a hollow structure in the shape of a Chinese character 'kou', the sliding rail is supported by the supports, the driving wheel and the driven wheel are arranged at two ends of the sliding rail, one end of the chain is nested in the driving wheel while the other end of the same is nested in the driven wheel through the sliding rail, and the frequency changer is connected with the driving wheel through the driving rod. The steel pipe inner coating solidifying device is easy to operate, safe, stable and capable of realizing continuous solidifying processes, and product quality is guaranteed.

Owner:PANYU ZHUJIANG STEEL PIPE LIANYUNGANG

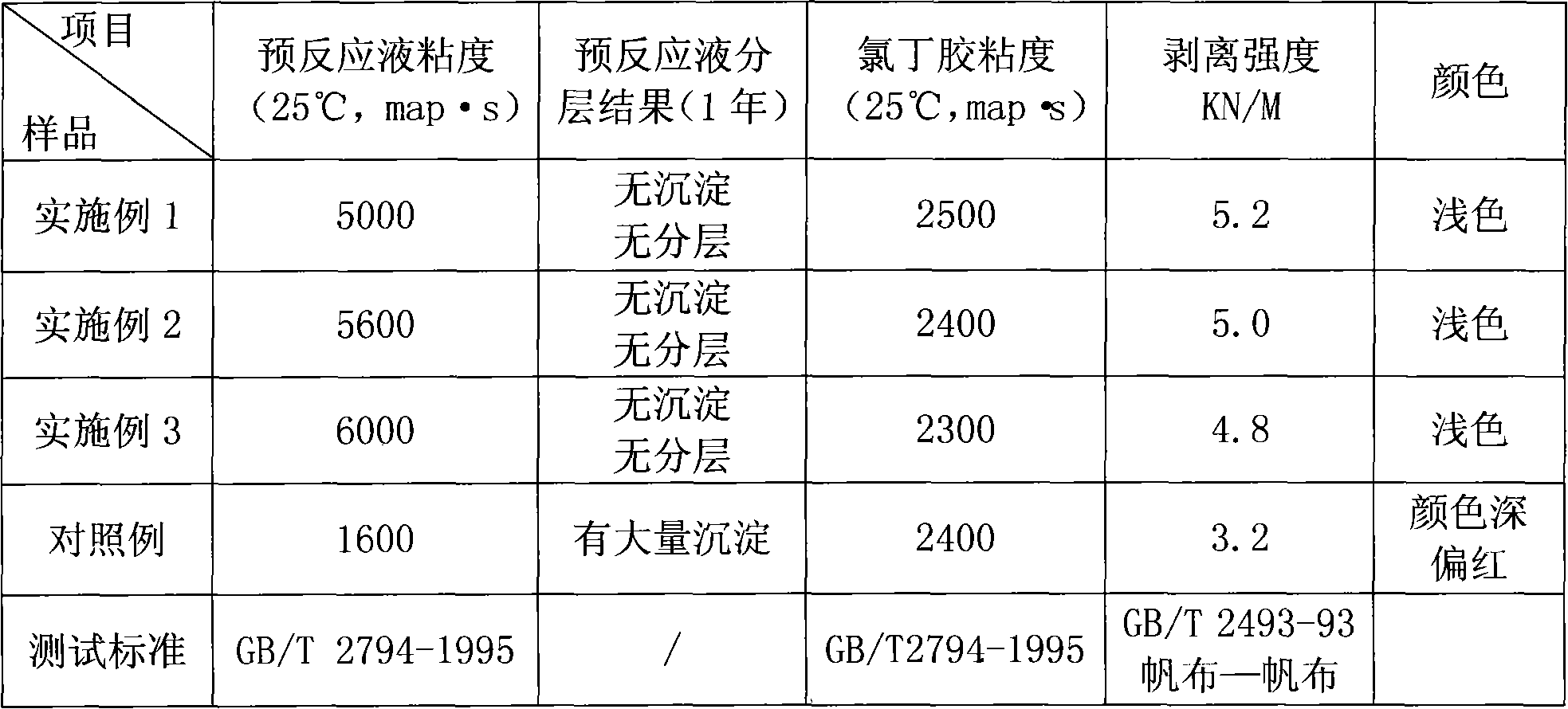

Nano chlorobutadiene rubber adhesive and preparation method thereof0}

The invention relates to a nano neoprene adhesive and preparing method thereof. The nano neoprene adhesive is prepared by stirring, pre-reacting, high speed shearing, and mixing chloroprene rubber, phenol resin, nano magnesium oxide, cyclohexane, 120 # solvent gasoline, toluene, ethyl acetate, acetone and catalyst. The invention uses nano magnesium oxide, which replaces traditional light magnesium oxide, as chelating agent for pre-reaction to improve storage stability of pre-reacting liquid and increase adhesion strength of glue. By using high speed shearing to replace traditional glue refining technique, energy is saved, intensity of labor is reduced, and production efficiency is improved. The production possessed advantages of high binding strength, good storage stability, not easy to stratification, and good painting property.

Owner:HUNAN SHENLI IND

Process for preparing automobile heat-isolation glass

InactiveCN104556719AGood physical propertiesStrong adhesionEpoxy resin coatingsDriver/operatorMembrane surface

The invention discloses a process for preparing automobile heat-isolation glass and relates to the field of rubber. The process comprises the preparation of nanometer antimony-doped tine dioxide size, the preparation of a component A, the preparation of a component B, the preparation of an epoxy transparent heat-isolation glass coating and the preparation of an epoxy transparent heat-isolation glass film. In the preparation process, the proportion, aging time, maintenance time and the like of the raw materials are controlled strictly, so that the prepared heat-isolation glass is excellent in physical and chemical properties, the film is smooth in surface and high in adhesive force, the glass is high in hardness and acid-resistant, alkali-resistant, stain-resistant and aging-resistant performances, long in service life, relatively high in light transmission for visible light and excellent in light transmittance performance, vague sense is avoided, a driver can have a good visual field, the coated glass has an excellent heat-isolation performance, can maintain the temperature in a vehicle well, and is stable in performance, and the whole preparation process is simple, can implement automatic production easily and achieves a high production efficiency.

Owner:DANYANG CITY FEIYUE VEHICLE ACCESSORY

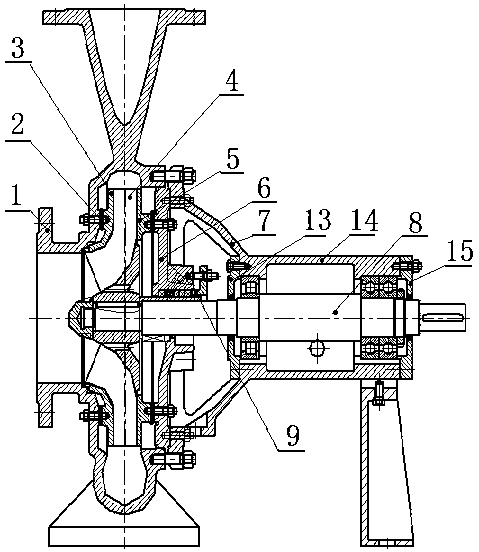

Novel wear-resistant and corrosion-resistant chemical centrifugal pump

The invention discloses a novel wear-resistant and corrosion-resistant chemical centrifugal pump which is applied to transport corrosive liquid containing solid particles and other fiber media in papermaking, chemical engineering, food, environmental engineering and other industries. A pump shaft is fixedly arranged on a bearing box of a suspension; two ends of the bearing box are respectively provided with a front gland and an end cover fixedly; a mechanical seal is arranged between a pump cover and the pump shaft; an impeller is fixedly arranged on one end of the pump shaft; the pump body is fixedly arranged on the suspension; a front lining board is arranged between the pump body and the impeller; a rear lining board is arranged between the pump cover and the impeller; a hard alloy layer is respectively sprayed on each of the front lining board and the rear lining board which are made of corrosion-resistant and wear-resistant materials, so that the wear-resistant performance of the front lining board and the rear lining board are further improved; and meanwhile, the surfaces of the coatings are smoother, so that the friction force and resistance of a flow through object are reduced, serous fluid can pass quickly, the use power of a water pump is reduced, the use efficiency is improved and the energy-saving effect is significant.

Owner:JIANGSU XINYUE PUMP IND MFG

A kind of putty powder with high waterproof, high hardness and high adhesion for building exterior wall

The invention relates to the technical field of building materials, and is a high-waterproof, high-hardness, high-adhesion putty powder for building exterior walls, which is composed of the following raw materials in parts by weight: 20-30 parts by weight of white cement, and 8-20 parts by weight of calcium bicarbonate , talc powder 25~35, gray calcium powder 20~30, paraffin wax 0.08~0.12, quartz powder 5~12, propylamine 0.05~0.1, hydroxypropyl methylcellulose 0.15~0.2, wood fiber 0.05~0.1 rubber powder 0.2~ 0.35, pigment 0.05-0.1, the product formula of the invention is reasonable, the preparation method is simple, and the product performance is excellent, which effectively solves the problem of the low hardness, poor waterproof performance and weak adhesion of the existing putty powder for external walls, which is easy to cause construction workers to repeat construction Or the problem of high wall repair rate; the putty powder coating scraped by the product of the present invention has hardness comparable to that of granite, and good waterproof performance, strong adhesion, and almost zero repair rate, which is suitable for wide application.

Owner:WUXUE ZHEWU CALCIUM IND CO LTD

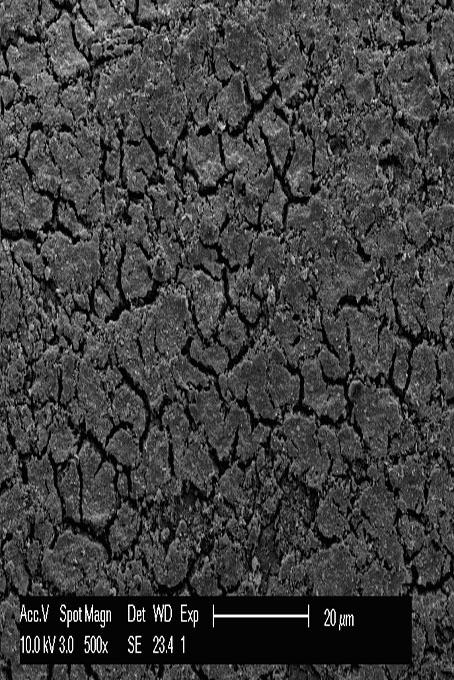

Hydrogenation catalyst using cellular titanium dioxide as carrier and preparation method thereof

ActiveCN102626621AImprove bindingImprove thermal stabilityOrganic compound preparationCarboxylic compound preparationBenzaldehydeAldehyde formation

The invention discloses a hydrogenation catalyst using a cellular titanium dioxide as a carrier and a preparation method thereof. The catalyst is characterized by comprising cellular titanium dioxide carrier, TiO2-C composite coating and precious metal Pd. The TiO2-C composite coating has a thickness of 1-100 mum, a load of 1-10% of the weight of the cellular titanium dioxide carrier and an abscission rate no more than 3%. The precious metal Pd has a load of 0.1-1% of the weight of the cellular titanium dioxide carrier and a load depth of 1-100 muM. Compared with a prior art, the invention has the following advantages: first, the TiO2-C composite coating has high adhesion rate with cellular titanium dioxide carrier, and has smooth coating surface, no crack and low coating abscission rate; second, immersion depth of the precious metal Pd can be effectively regulated by controlling the thickness of the TiO2-C composite coating; and third, the catalyst has the advantages of simple preparation technology, good hydrogenation performance and suitability for industrialized production. The hydrogenation catalyst of the invention is suitable to be used as a hydrogenation catalyst for aromatic aldehydes like crude terephthalic acid or p-carboxy benzaldehyde.

Owner:CHINA PETROLEUM & CHEM CORP +1

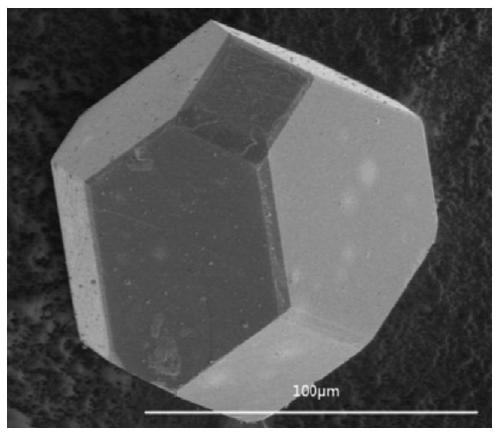

Modified diamond particles, modification method and application as reinforced phase and obtained metal-based composite material

ActiveCN110438457AImprove liquidityHigh particle energyVacuum evaporation coatingSputtering coatingHeat conductingHeat resistance

The invention discloses modified diamond particles, a modification method and an application as reinforced phase and an obtained metal-based composite material and belongs to the field of composite materials. The modification method of the modified diamond particles adopts vacuum rolling coating equipment and the particles are stirred in a roller, so that the coating uniformity of the diamond particles is improved. By adopting a multi-arc ion coating process, plasmas are generated on the surface of a target material directly, so that energy of particles attached to a matrix is high, the coating compactness is high, and a carbide is formed more easily by a metal and the diamonds, and therefore, mechanical bonding is converted into metallurgical bonding, and the interface heat resistance canbe reduced greatly. By carrying out coating by means of a magnetron sputtering method, the surface of the multi-arc ion coating is improved, so that the surface is leveler, the flowability of the diamond particles is increased, the hot press molding ability is improved and formation of pores is reduced. On the other hand, the multi-arc ion coating metal is prevented from being diffused to a matrix metal, so that the heat conducting property of the matrix is reduced. According to the modified diamond particles, a coating is compact and is unlikely to fall off.

Owner:苏州博志金钻科技有限责任公司

Component

InactiveUS7018702B2Smooth coating surfaceRecord information storageHigh-tension/heavy-dress switchesSoft materialsMaterials science

A component including a base body of a relatively hard material and a coating of a relatively soft material, wherein the coating covers at least a main surface area of the base body. The main surface area is delimited by an outer periphery and an edge portion of the coating extends from the periphery and comprises a reinforcement made of a relatively hard material and engages the base body.

Owner:TRW AUTOMOTIVE ELECTRONICS & COMPONENTS GMBH & CO KG

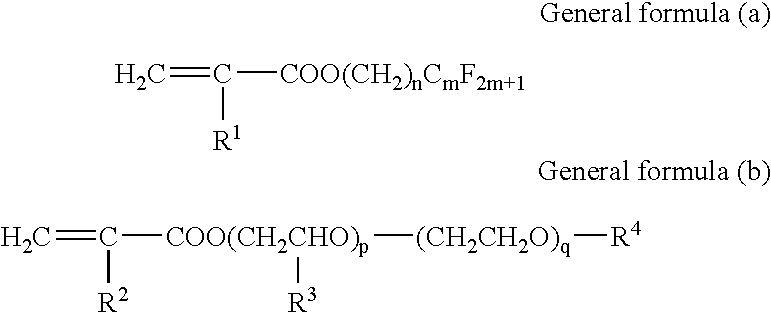

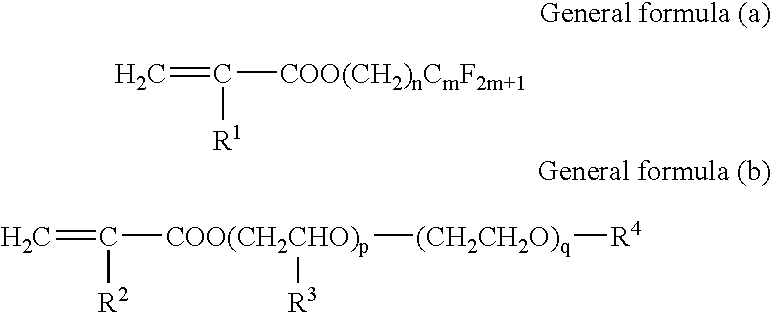

Image forming material

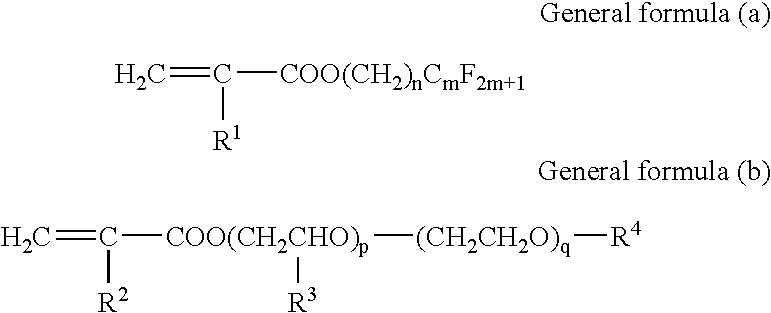

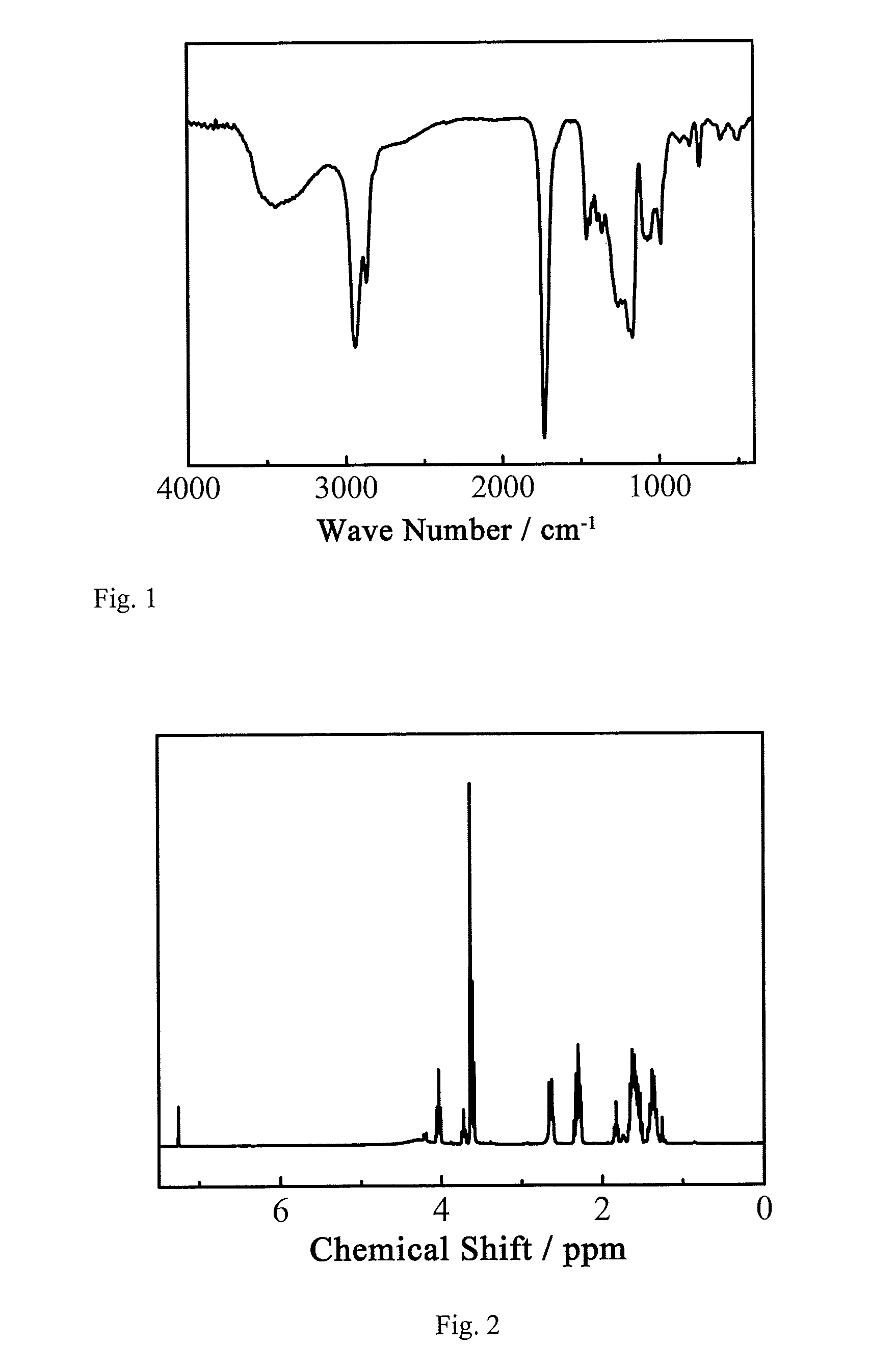

ActiveUS7435531B2Improved contact characteristicsIncrease speedPhotosensitive materialsOptical filtersImage formationCopolymer

The present invention relates to an image forming material in which at least an alkali-soluble thermoplastic resin layer and a photosensitive resin layer are formed on a support in this order. At least the thermoplastic resin layer of the image forming material includes a copolymer comprising monomers represented by the following general formula (a) and the following general formula (b), a content ratio by mass of the monomers represented by general formula (a) to the monomers represented by general formula (b) is in a specific range.

Owner:FUJIFILM CORP +1

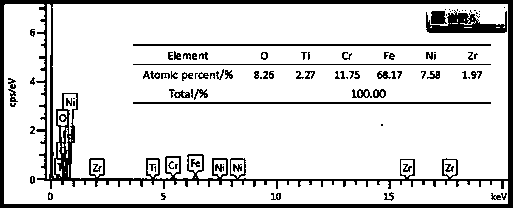

Zr modified silicide coating on refractory metal surface and preparation method thereof

ActiveCN108004539AGood compatibilityEasy to prepareHeat inorganic powder coatingAcid washingDegreasing

The invention discloses a Zr modified silicide coating on a refractory metal surface. The Zr modified silicide coating comprises the following components of Ti, W, Cr, Zr, Nb and Si. The invention further discloses a preparation method of the coating. The preparation method comprises the following steps that 1, polishing, sand blasting, degreasing and acid washing are carried out on refractory metal; 2, composite suspension slurry is prepared; and 3, the slurry is placed on the refractory metal surface in advance to obtain a preset layer, then high-temperature fusion sintering is carried out to prepare the preparation method of the coating, the Zr modified silicide coating is good in compatibility with a refractory metal matrix, the coating is suitable for Nb, Nb alloy, W, W alloy, Ta, Taalloy, Mo or Mo alloy, the thickness of the coating is controllable, the coating is in metallurgical bonding with the matrix, coating can be realized on a surface of a special-shaped hot end part andan inner surface of the part, and the prepared coating can provide no less than 200h protection for the refractory metal material under the oxidation condition of 1100-1500 DEG C or provide short-timeprotection in an ablation environment.

Owner:NORTHWEST INSTITUTE FOR NON-FERROUS METAL RESEARCH

Method for preparing main chain scission-type polysilyl (METH)acrylate resin and application thereof

ActiveUS20160185913A1Effective controlAccurately metAntifouling/underwater paintsPaints with biocidesPolyesterPolymer science

A method for preparing a main chain scission-type polysilyl (meth)acrylate resin and application thereof. The method comprises: a cyclic monomer, vinyl monomer and vinyl silyl ester monomer are mixed in a solvent at a formulation ratio, then added a composite initiator in a mass percentage of 0.01-5% based on the total amount of the monomers, and reacted at a temperature of 25-150° C., and under the protection of argon or nitrogen gas, so as to prepare the main chain scission-type polysilyl (meth)acrylate resin, wherein the monomers are consisted of 5-95% by mass of cyclic monomer, 0-90% by mass of vinyl monomer and 5-95% by mass of vinyl silyl ester monomer. The resulting resin can not only be hydrolyzed on the side chain silyl ester segment under the effect of the sea water, but also occur chain scission on the main chain polyester segment under the effect of the seawater, so as to solve the dependency of the traditional self-polishing material on the sailing speed, effectively control the release of the antifouling agent at a constant rate, ensure the active substance preserved on the coating surface of the ships, and properly meet the antifouling requirements on the low sailing speed ships, submarines and off-shore oil platform facilities.

Owner:SOUTH CHINA UNIV OF TECH

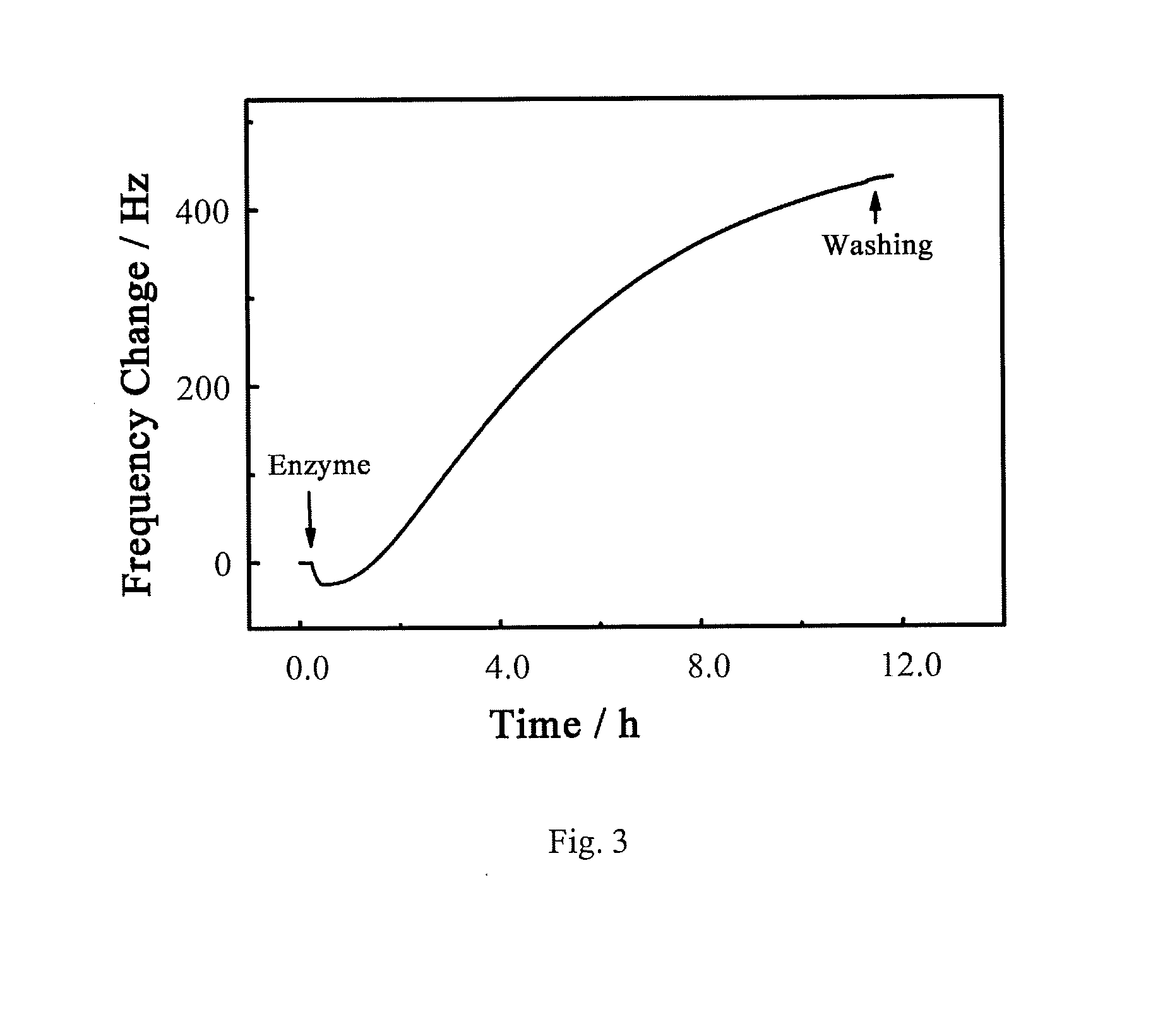

Liquid deposition preparing method for anti-corrosion TiO2-ZrO2 coating and anti-corrosion metal with anti-corrosion TiO2-ZrO2 coating

InactiveCN105369223AEffective isolation of contactsIsolated contactLiquid/solution decomposition chemical coatingWater bathsDistilled water

The invention discloses a liquid deposition preparing method for an anti-corrosion TiO2-ZrO2 coating. (NH4)2TiF6, H3BO3, Zr(SO4)2 and (NH4)2S2O8 serve as raw materials, metal is deposited for 5 h to 48 h under the water bath condition at the temperature ranging from 20 DEG C to 80 DEG C according to a liquid deposition method, the deposited metal is washed through distilled water and aired and is then put in a high-temperature muffle furnace, the temperature is increased to 400 DEG C to 800 DEG C, calcination is kept for 1 to 5 hours, and therefore the TiO2-ZrO2 coating is prepared on the surface of the metal. Through tests, when prepared stainless steel with the TiO2-ZrO2 coating is compared with untreated stainless steel, the corrosion current density of a polarization curve of the stainless steel with the coating in a terrestrial heat aqueous solution is reduced by about one order of magnitude, the polarization resistance of the stainless steel is improved by 15 to 23 times, the annual corrosion rate is increased by 80% to 90%, and the good corrosion resistant effect is achieved.

Owner:CHONGQING UNIV OF TECH

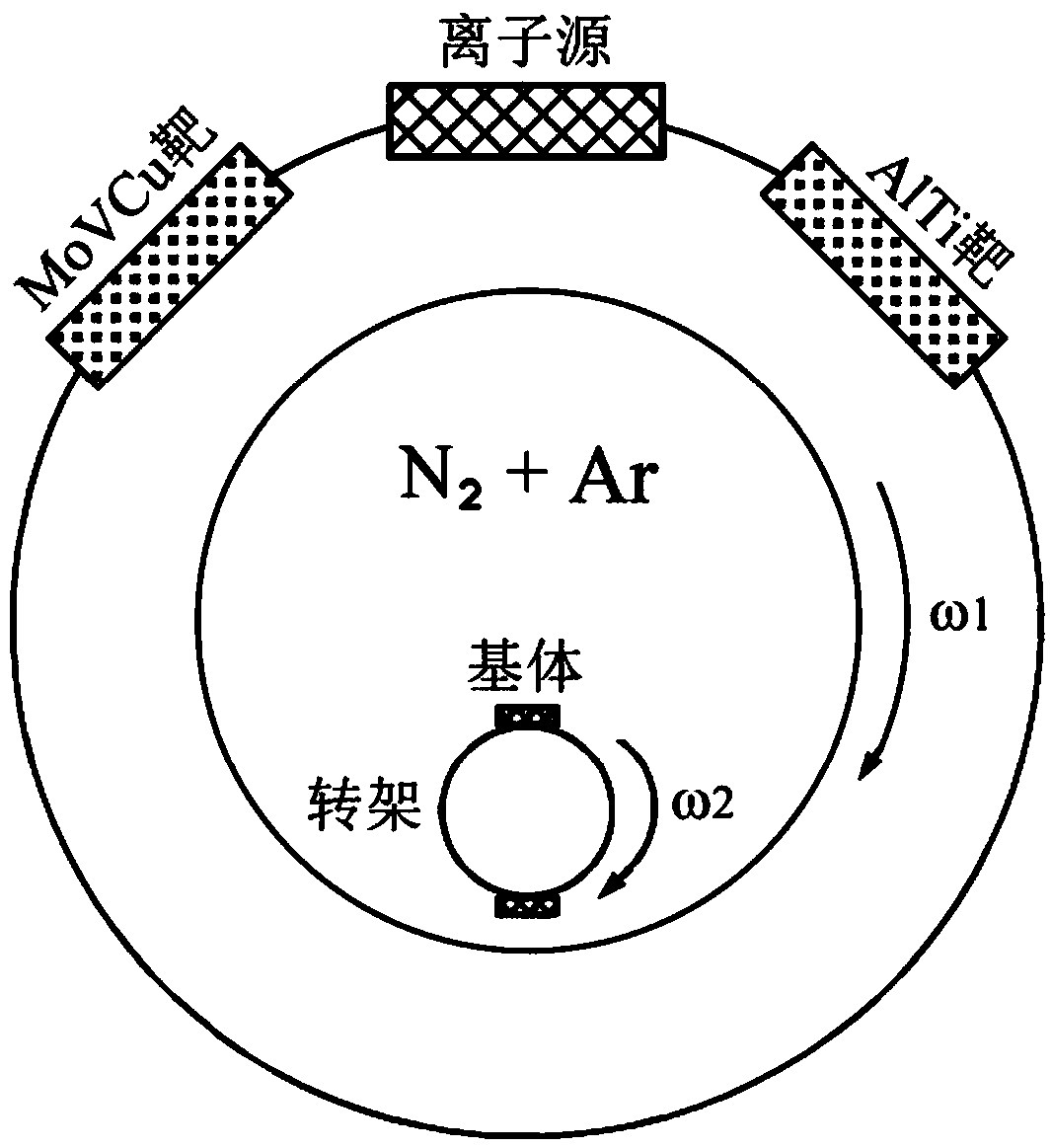

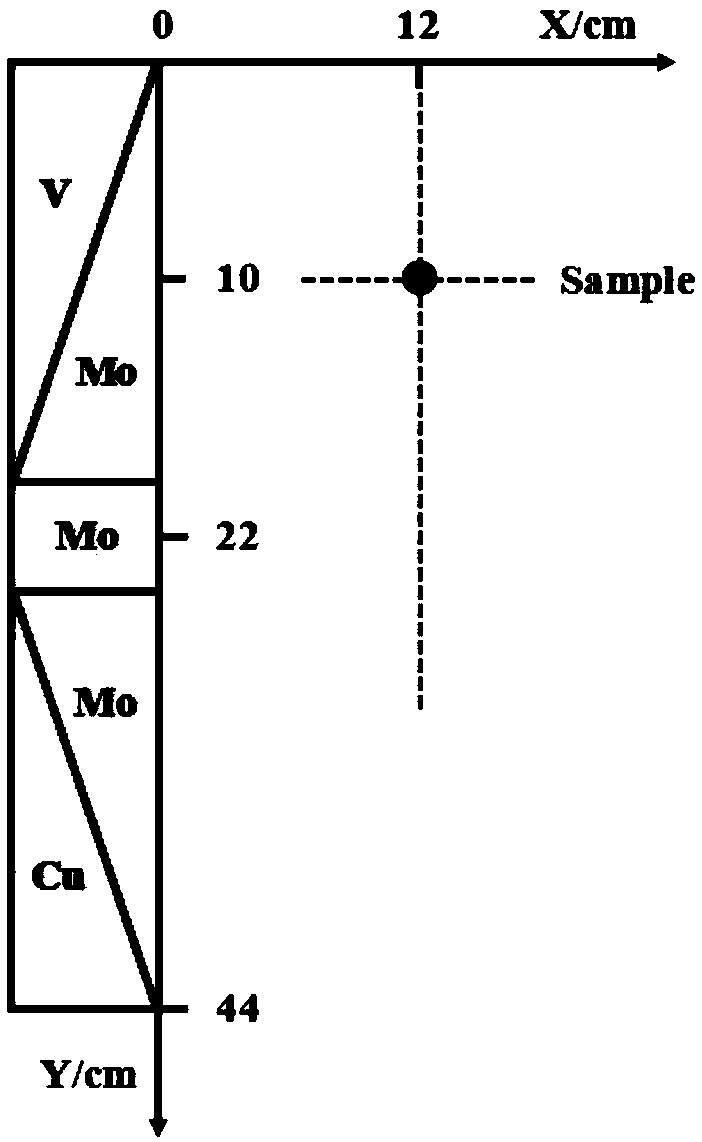

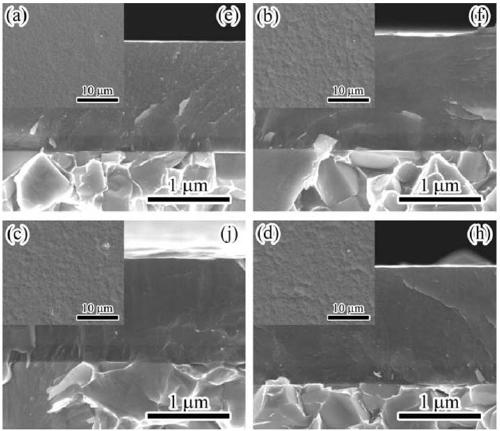

A nanometer multi-layer AlTiN/MoVCuN coating and a preparing method and applications thereof

ActiveCN108930022AImprove performanceSmooth coating surfaceVacuum evaporation coatingSputtering coatingSputter depositionTransition layer

The invention belongs to the technical field of preparation of cutter coatings and surface protective coatings, and discloses a nanometer multi-layer AlTiN / MoVCuN coating and a preparing method and applications thereof. The coating includes, from bottom to top, a substrate matrix, a Cr bombardment implanted layer, a CrN transition layer and a nanometer multi-layer AlTiN / MoVCuN coating formed by alternative deposition of AlTiN middle layers and MoVCuN middle layers in a ratio of 3:2 with a modulation period being 0.6-2.4 nm. Nanometer multi-layer and nanometer composite structures are combinedto design a nanometer multi-layer lubricating hard coating, a multi-layer multi-component nanometer composite coating prepared by a bipolar pulse magnetron sputtering deposition technique assisted bya positive electrode layer ionic source is adopted, and the disclosed coating has smooth surfaces, a compact structure, a low friction coefficient, and a self-lubricating effect.

Owner:GUANGDONG UNIV OF TECH

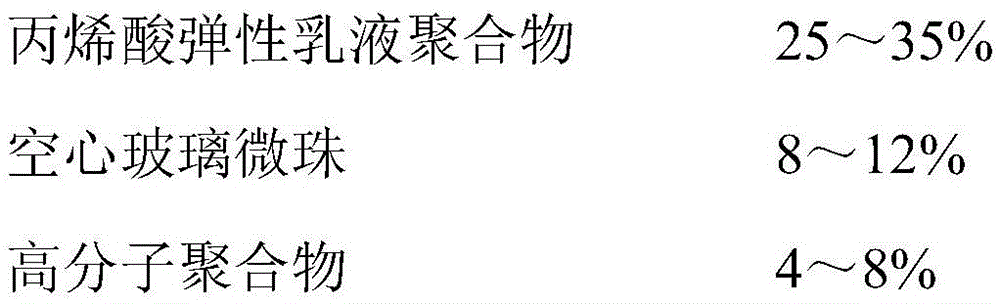

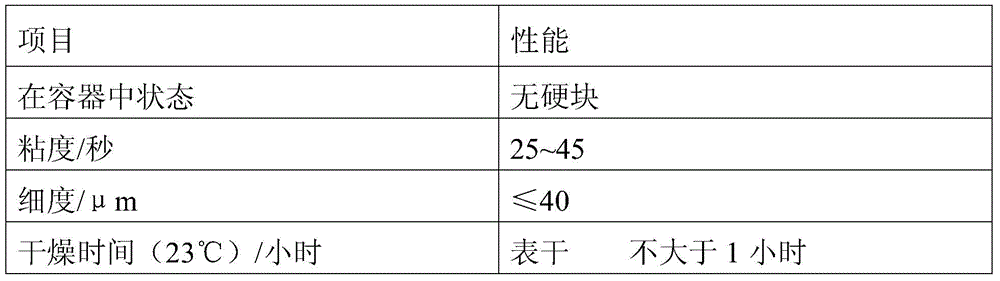

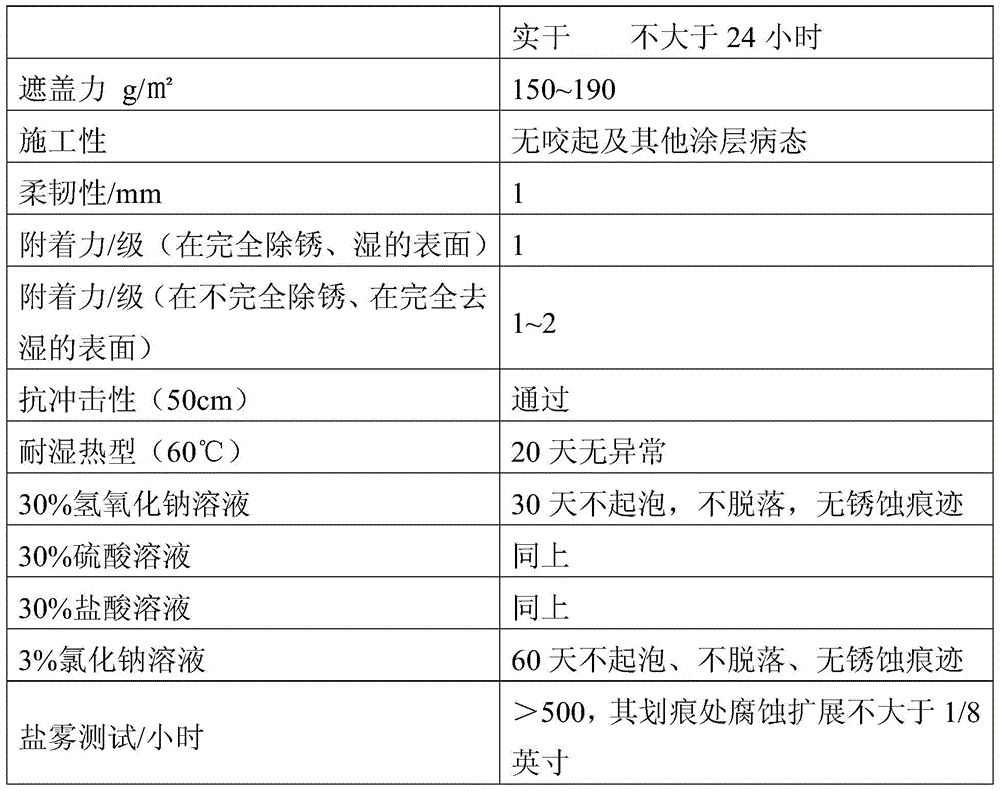

External wall heat-insulation low-carbon energy-saving paint

InactiveCN105602375AExcellent film elongation at breakGood stain resistanceAntifouling/underwater paintsPaints with biocidesWeather resistanceEmulsion

The invention discloses an external wall heat-insulation low-carbon energy-saving paint which is compounded from an acrylic elastic emulsion polymer, small-particle-size hollow glass microspheres, a high-molecular polymer, a hollow microsphere polymer emulsion, a low-HLB (hydrophile-lipophile balance)-value wetting agent, ethylene glycol and other components. The paint production process is simple. The coated film formed by the prepared paint has the advantages of ultrahigh heat reflectivity, smooth surface, no roughness, pollution resistance, excellent weather resistance and high storage stability, and is a thinly-coated smooth-type heat-reflection heat-insulation paint which satisfies the standards for many nations.

Owner:ZHONGSHAN MOORE CHEM IND CO LTD

Silicone release coating composition and low release force emulsion silicone release coating for films and papers having cured release coating

ActiveUS10155883B2Reduce release forceMaintain good propertiesPaper coatingEmulsion paintsPolymer scienceActive agent

A silicone release coating composition comprises:(A) 100 weight parts of an organopolysiloxane fluid having a viscosity at 25° C. of 50 to 10,000 mPa·s and an alkenyl content of 0.10 to 3.0 wt %;(B) 0.5-40 weight parts of a diorganopolysiloxane represented by the average structural formula (1):Rc3SiO(RbRcSiO2 / 2)n1(Rc2SiO2 / 2)n2SiRc3 (1) wherein Rb is an alkenyl group; Rc is an alkyl group or a phenyl group; n1 provides an alkenyl content of 0.05 to 0.80 wt. %; n2 is at least 1; and n1+n2 provides this component with a viscosity at 25° C. of 5,000 to 150,000 mPa·s;(C) an organohydrogenpolysiloxane that has a viscosity at 25° C. of 1 to 1,000 mPa·s, at least two silicon-bonded hydrogen atoms in each molecule, and an alkyl group or a phenyl group for its silicon-bonded organic groups;(D) a hydrosilylation reaction catalyst in a catalytic amount;(E) a surfactant;(F) water; and(G) an inhibitor.

Owner:DOW SILICONES CORP +1

Corruption coatings with rust band wet paint

InactiveCN103756512BImprove protectionIncrease crosslink densityAnti-corrosive paintsEpoxy resin coatingsEpoxySolvent

The invention discloses an anticorrosive paint coated under rusted and moist conditions and particularly discloses a bicomponent epoxy anticorrosive paint which can be coated on rusted and moist steel surfaces and can play a protective role. The anticorrosive paint comprises a component A and a component B, wherein the component A is composed of the following components in parts by weight: 25-28 parts of epoxy resin, 33-36 parts of pigment and filler, 3.5-5 parts of rust transforming agent, 30-35 parts of mixed solvent and 0.5-1.5 parts of auxiliaries; and the component B is composed of the following components in parts by weight: 75-80 parts of modified mannich amide hardener and 20-25 parts of mixed solvent. The weight ratio of the component A to the component B is (90-100): (1-1.2), and the component A and the component B are mixed before being used.

Owner:SHANGHAI DATONG TABERNACLE NEW ENERGY SAVING MATERIALS CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com