Self-lubricating wear-resistant compound coating on surfaces of titanium and titanium alloy and preparation method thereof

A composite coating and titanium alloy technology, applied in the direction of surface reaction electrolytic coating, device for coating liquid on the surface, coating, etc., can solve the problems of poor wear resistance, etc., achieve a wide range of applications, reduce wear, and wear resistance Grinding performance improvement effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

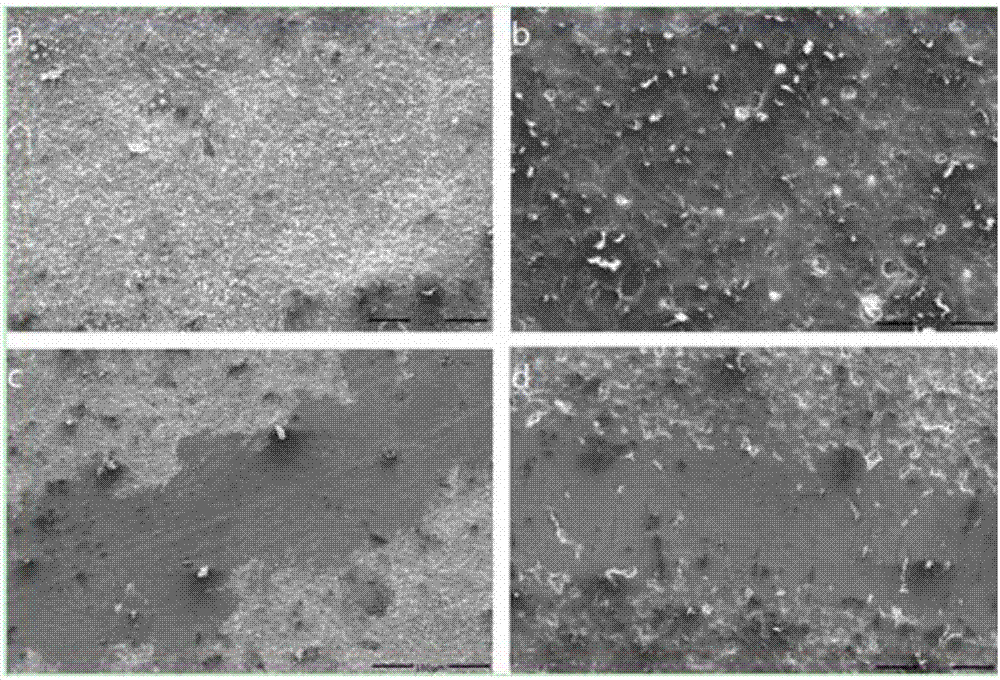

Image

Examples

Embodiment 1

[0029] (1) Use sandpaper or grinding wheels with a particle size of less than 600 mesh to polish the surface of titanium and titanium alloy parts to remove defects with large surface sizes, so that the surface roughness is lower than 0.1, and use a polishing cloth to polish the surface of titanium and titanium alloy parts to form a mirror surface.

[0030] (2) Use a chemical solution containing 20-30g / L of nitric acid and 10-15g / L of hydrofluoric acid to fully clean titanium and titanium alloys at 25-35°C for 5-10 minutes, and then use ethanol to clean them for 10 minutes under the action of ultrasonic waves. After more than a minute, take it out, rinse it under running water, and dry it.

[0031] (3) Use a Nd:YAG pulse-based light puncher to punch holes on the surface of the sample after the treatment in step (2).

[0032] (4) The sodium aluminate-sodium phosphate system is used as the electrolyte.

[0033] (5) Plasma electrolytic oxidation treatment is performed on the surf...

Embodiment 2

[0039] (1) Use sandpaper or grinding wheels with a particle size of less than 600 mesh to polish the surface of titanium and titanium alloy parts to remove defects with large surface sizes, so that the surface roughness is lower than 0.1, and use a polishing cloth to polish the surface of titanium and titanium alloy parts to form a mirror surface.

[0040](2) Use a chemical solution containing 20-30g / L of nitric acid and 10-15g / L of hydrofluoric acid to fully clean titanium and titanium alloys at 25-35°C for 5-10 minutes, and then use ethanol to clean them for 10 minutes under the action of ultrasonic waves. After more than a minute, take it out, rinse it under running water, and dry it.

[0041] (3) Use a Nd:YAG pulse-based light puncher to punch holes on the surface of the sample after the treatment in step (2).

[0042] (4) The sodium aluminate-sodium phosphate system is used as the electrolyte.

[0043] (5) Plasma electrolytic oxidation treatment is performed on the surfa...

Embodiment 3

[0049] (1) Use sandpaper or grinding wheels with a particle size of less than 600 mesh to polish the surface of titanium and titanium alloy parts to remove defects with large surface sizes, so that the surface roughness is lower than 0.1; use a polishing cloth to polish the surface of titanium and titanium alloy parts to form a mirror surface.

[0050] (2) Use a chemical solution containing 20-30g / L of nitric acid and 10-15g / L of hydrofluoric acid to fully clean titanium and titanium alloys at 25-35°C for 5-10 minutes, and then use ethanol to clean them for 10 minutes under the action of ultrasonic waves. After more than a minute, take it out, rinse it under running water, and dry it.

[0051] (3) Use a Nd:YAG pulse-based light puncher to punch holes on the surface of the sample after the treatment in step (2).

[0052] (4) Using sodium silicate-sodium phosphate system as electrolyte;

[0053] (5) Plasma electrolytic oxidation treatment is performed on the surface textured ti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Contact angle | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com