Ternary Nano catalyst in use for cellular carrier of full metal, preparation method and coating process

A nano-catalyst and honeycomb carrier technology, which is applied in metal/metal oxide/metal hydroxide catalysts, chemical instruments and methods, physical/chemical process catalysts, etc., can solve the problem that the bonding strength between the carrier and the catalytic active layer cannot reach the catalytic to achieve high anti-aging performance, uniform particle size, and good low-temperature activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

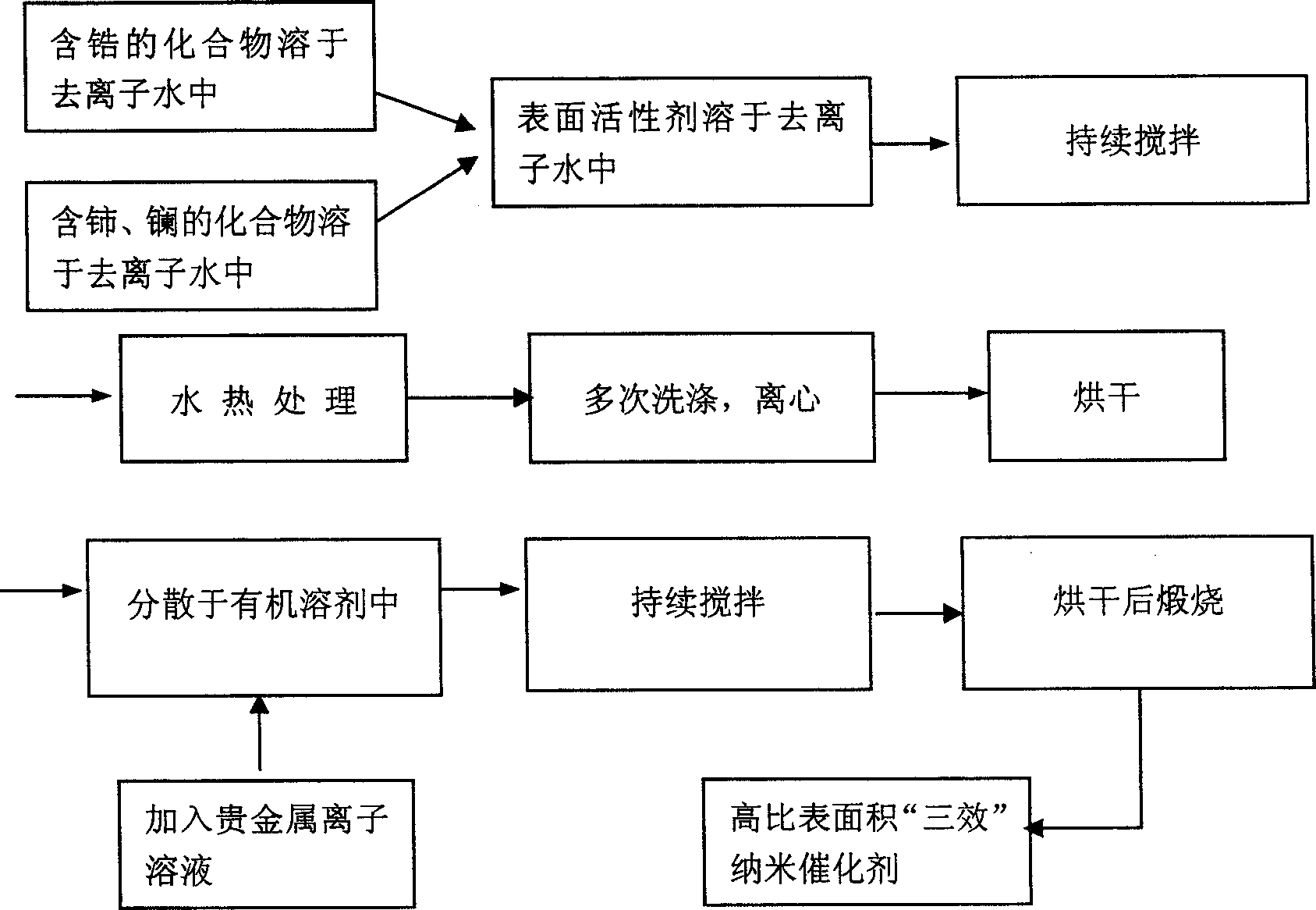

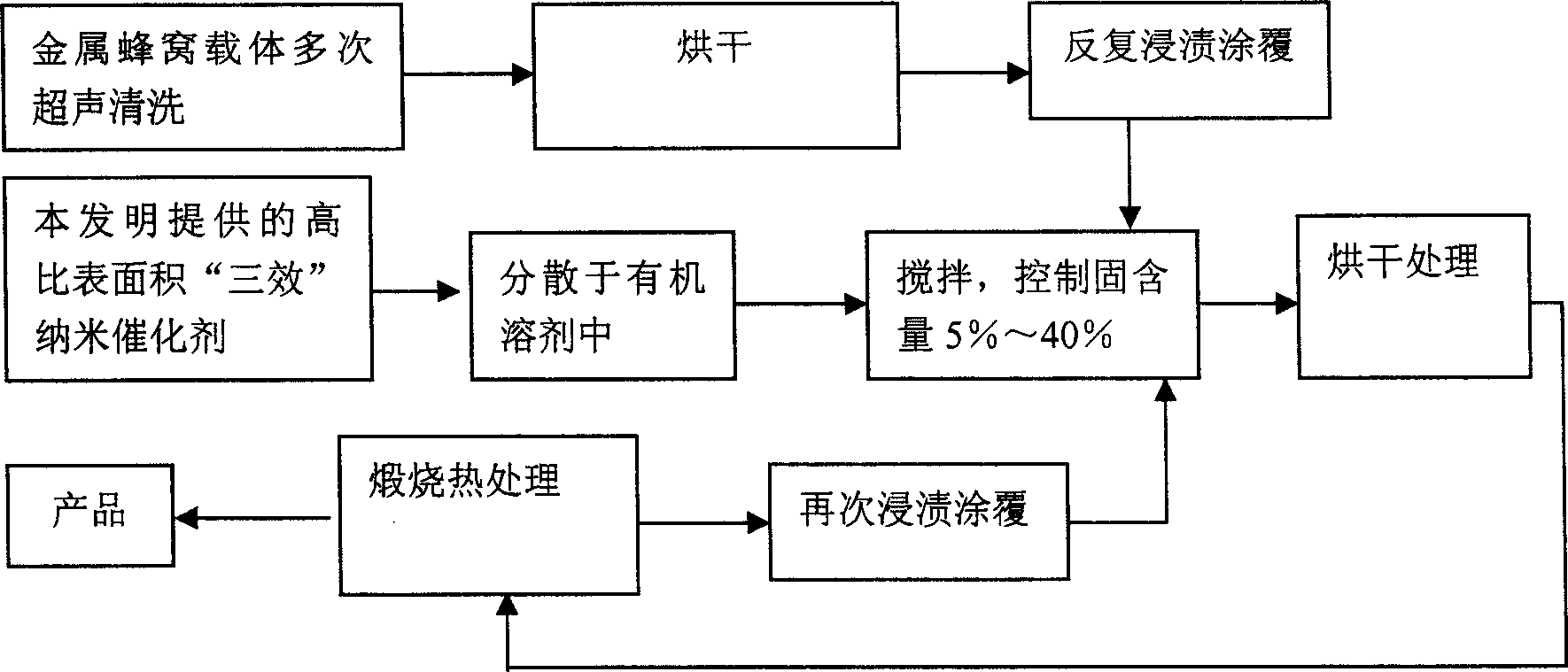

Method used

Image

Examples

Embodiment 1

[0042] The zirconium source is zirconium sulfate tetrahydrate; the cerium source is cerium nitrate hexahydrate; the lanthanum source is lanthanum nitrate; the surfactant is polyoxyethylene polyoxypropylene copolymer. According to the formula ratio (weight ratio): 1Zr(SO 4 ) 2 : 4Ce(NO 3 ) 3 : 1La(NO 3 ) 3 : 3 Surfactant: 150H 2 O; carry out hydrothermal crystallization treatment at 120°C for 24 hours; synthesize a composite precursor sample of nano-lanthanum oxide, cerium oxide and zirconia with high specific surface area and high dispersion, and disperse in an organic solvent after centrifugation and drying. At the same time, a solution containing platinum, palladium and rhodium ions (1-3 wt%) is added, stirred for 3 hours, and dried by centrifugation. After drying at 100°C for 2 hours, calcining in a muffle furnace to remove the organic surfactant, to obtain the prepared lanthanum oxide, cerium / zirconia composite nano-three-way catalytic material, calcining temperature...

Embodiment 2

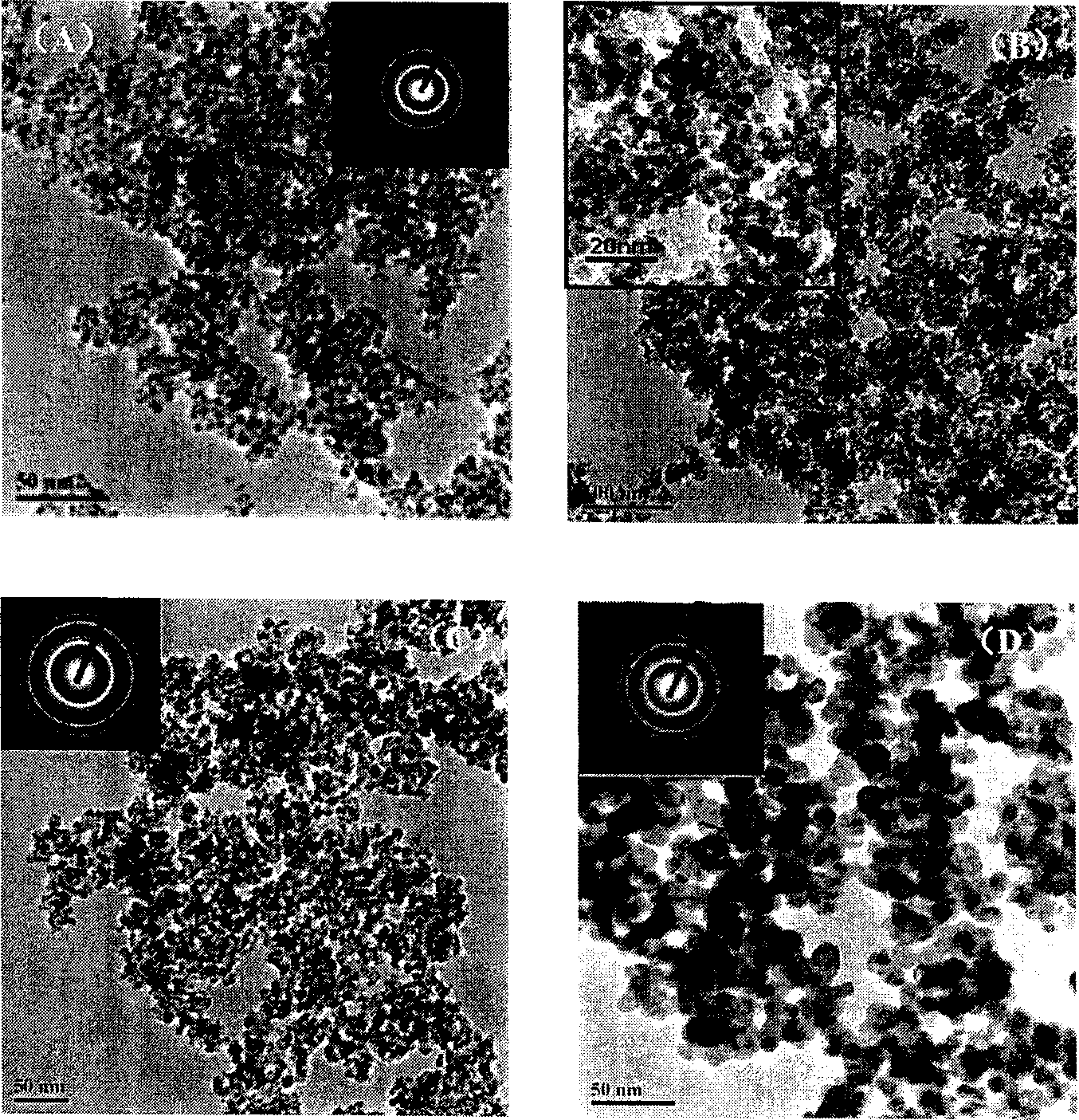

[0044]The proportion of the formula remains unchanged, and the samples without heat treatment after hydrothermal treatment, the transmission electron microscope photos and the electron diffraction patterns of the corresponding areas are as follows: image 3 a, XRD diffraction pattern as Figure 4 as shown in a. It can be seen that the sample without heat treatment also presents uniformly distributed cubic phase nanocrystals, and the composite oxide has the highest specific surface area and pore capacity.

Embodiment 3

[0046] No surfactant was added to the formula, and the other proportions and process remained unchanged. The specific surface area and pore volume structure parameters of the samples heat-treated at 500 °C are shown in Table 2. It can be seen that the specific surface area and pore volume of the sample without added surfactant are significantly reduced compared with Embodiment 1 after being calcined at 500 degrees. Stability is very beneficial.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com