Tubular oxygen sensor Pt inner electrode coating process and equipment used in process

An oxygen sensor and a coating process technology, which is applied to the Pt inner electrode coating process of a tubular oxygen sensor and the equipment used in its processing, can solve the problems of low production efficiency, uneven thickness and width of the coating layer, platinum electrode slurry Material gram weight and other issues to achieve the effect of improving production efficiency and ensuring consistency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

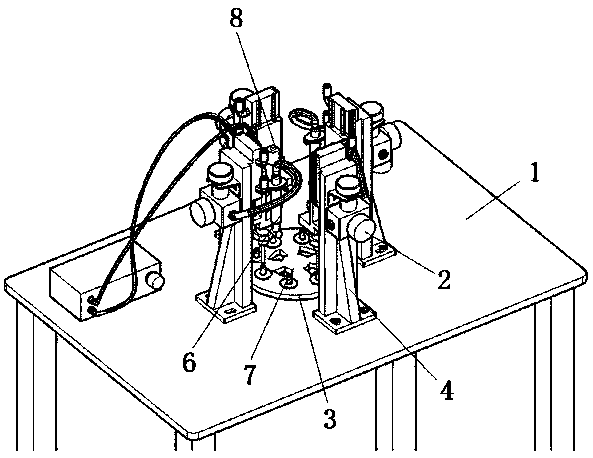

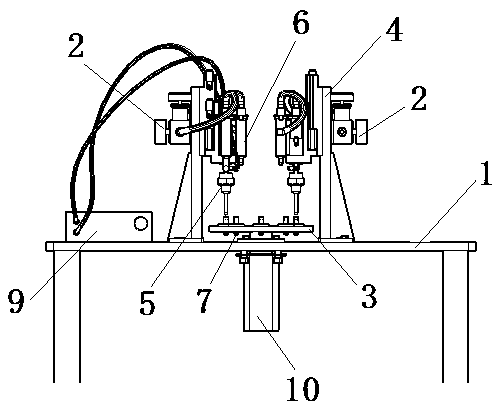

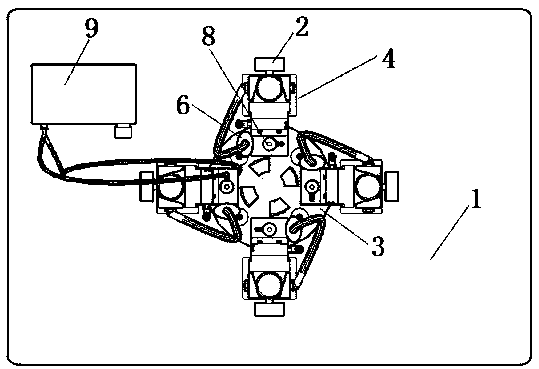

[0026] A kind of tubular oxygen sensor Pt inner electrode coating process, comprises the following steps:

[0027] Step 1, mixing Pt powder and binder to make slurry;

[0028] Step 2: Use 0.2-50MPa compressed air to atomize the slurry, the atomization time is 10-50s, and spray the atomized slurry inside the zirconium tube body to form a ring-shaped inner electrode;

[0029] Step 3. Place the zirconium tube blank on the centrifugal disc of the centrifuge, rotate at a speed of 500-5000 rpm, and form the lead wire of the vertical line on the outermost side of the inner wall of the zirconium tube blank with the slurry;

[0030] Step 4: Sinter the zirconium tube body in a furnace, and cool naturally in the air after sintering to obtain the finished product.

[0031] According to another embodiment of the present invention, it further includes that in step 1, the particle size of the Pt powder is 0.05-0.5 μm, and the solid content of the slurry is 40-80%.

[0032] According to ano...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com