Acid-modified CeO2-based SCR (Selective Catalytic Reduction) catalyst for denitration and preparation method of acid-modified CeO2-based SCR catalyst

An SCR catalyst, acid modification technology, applied in chemical instruments and methods, physical/chemical process catalysts, separation methods, etc., can solve the problems of large biological toxicity, narrow operating temperature window, etc., and achieve excellent low temperature activity and excellent selectivity. , the effect of easy industrial production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

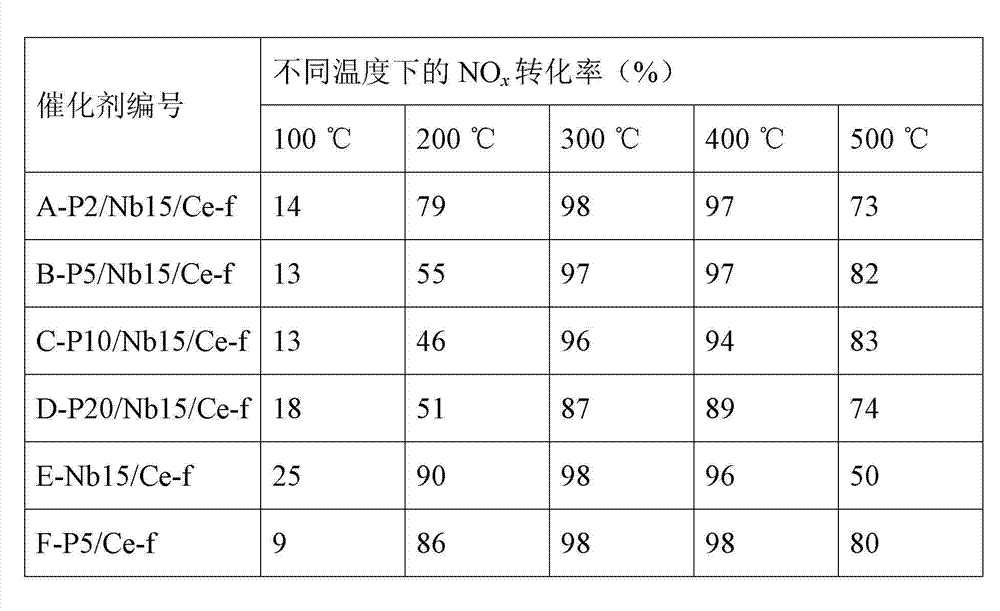

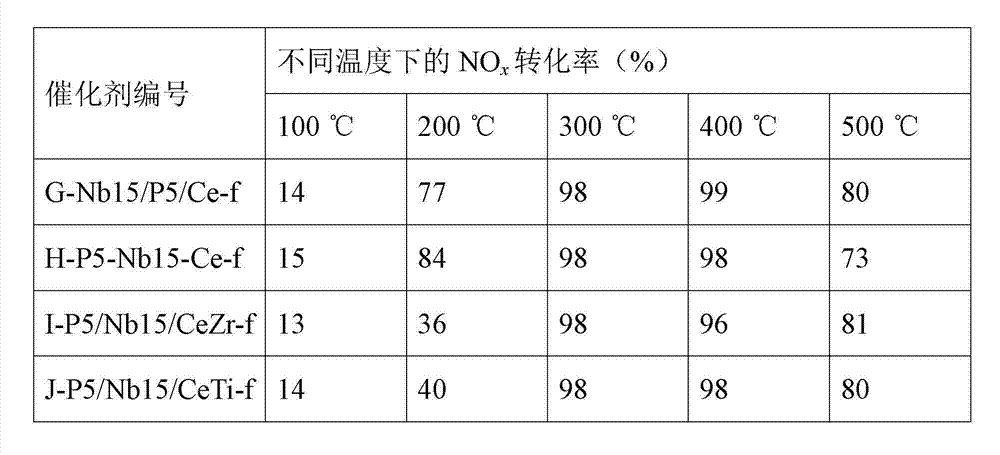

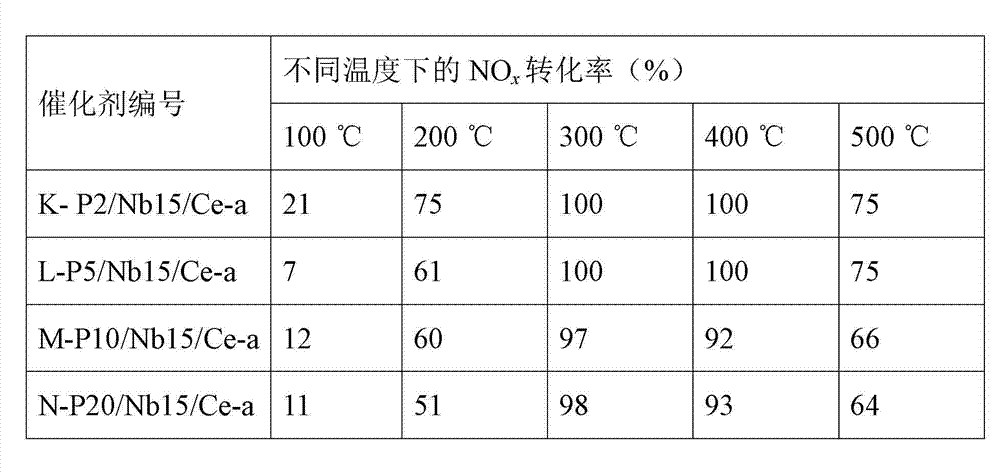

Embodiment 1-4

[0040] Take a certain amount of Ce(NO 3 ) 3 ·6H 2 O, zirconium acetate and water were mixed at a mass ratio of 40:10:50 at a stirring speed of 500 r / min to prepare slurry A. The 200-mesh cordierite honeycomb ceramic carrier was soaked in the slurry for 30 min, and the excess solution in the channels was blown out with high-pressure gas to ensure that the cells of the honeycomb were connected, and then the carrier was dried at 110 °C for 2 h; after repeating the above steps 3 times, The carrier was calcined at 550 °C for 3 h, and the active component was CeO 2 Active coating carrier B, CeO 2 The load is 100 g / L, accounting for CeO 2 The total mass of the cordierite carrier and the carrier is 10%, and the water absorption rate of the carrier at this time is measured to be 25 wt%. Configure the required niobium oxalate (C 12 h 7 NbO 24 ) Salt solution C, and use this solution to load Nb on the surface of carrier B by excessive impregnation method 2 o 5 The carrier of th...

Embodiment 5

[0042] Take a certain amount of Ce(NO 3 ) 3 ·6H 2 O, zirconium acetate and water were mixed at a mass ratio of 40:10:50 at a stirring speed of 500 r / min to prepare slurry A. The 200-mesh cordierite honeycomb ceramic carrier was soaked in the slurry for 30 min, and the excess solution in the channels was blown out with high-pressure gas to ensure that the cells of the honeycomb were connected, and then the carrier was dried at 110 °C for 2 h; after repeating the above steps 3 times, The carrier was calcined at 550 °C for 3 h, and the active component was CeO 2 Active coating carrier B, CeO 2 The load is 100 g / L, accounting for CeO 2 The total mass of the cordierite carrier and the carrier is 10%, and the water absorption rate of the carrier at this time is measured to be 25 wt%. Configure the required niobium oxalate (C 12 h 7 NbO 24 ) Salt solution C, and use this solution to load Nb on the surface of carrier B by excessive impregnation method 2 o 5 The modified coat...

Embodiment 6

[0044] Take a certain amount of Ce(NO 3 ) 3 ·6H 2 O, zirconium acetate and water were mixed at a mass ratio of 40:10:50 at a stirring speed of 500 r / min to prepare slurry A. The 200-mesh cordierite honeycomb ceramic carrier was soaked in the slurry for 30 min, and the excess solution in the channels was blown out with high-pressure gas to ensure that the cells of the honeycomb were connected, and then the carrier was dried at 110 °C for 2 h; after repeating the above steps 3 times, The carrier was calcined at 550 °C for 3 h, and the active component was CeO 2 Active coating carrier B, CeO 2 The load is 100 g / L, accounting for CeO 2 The total mass of the cordierite carrier and the carrier is 10%, and the water absorption rate of the carrier at this time is measured to be 25 wt%. According to the calculated water absorption configuration required (H 3 PO 4 ) solution D, and use this solution to support P on the cooled catalyst by the equal volume impregnation method 2 o ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com