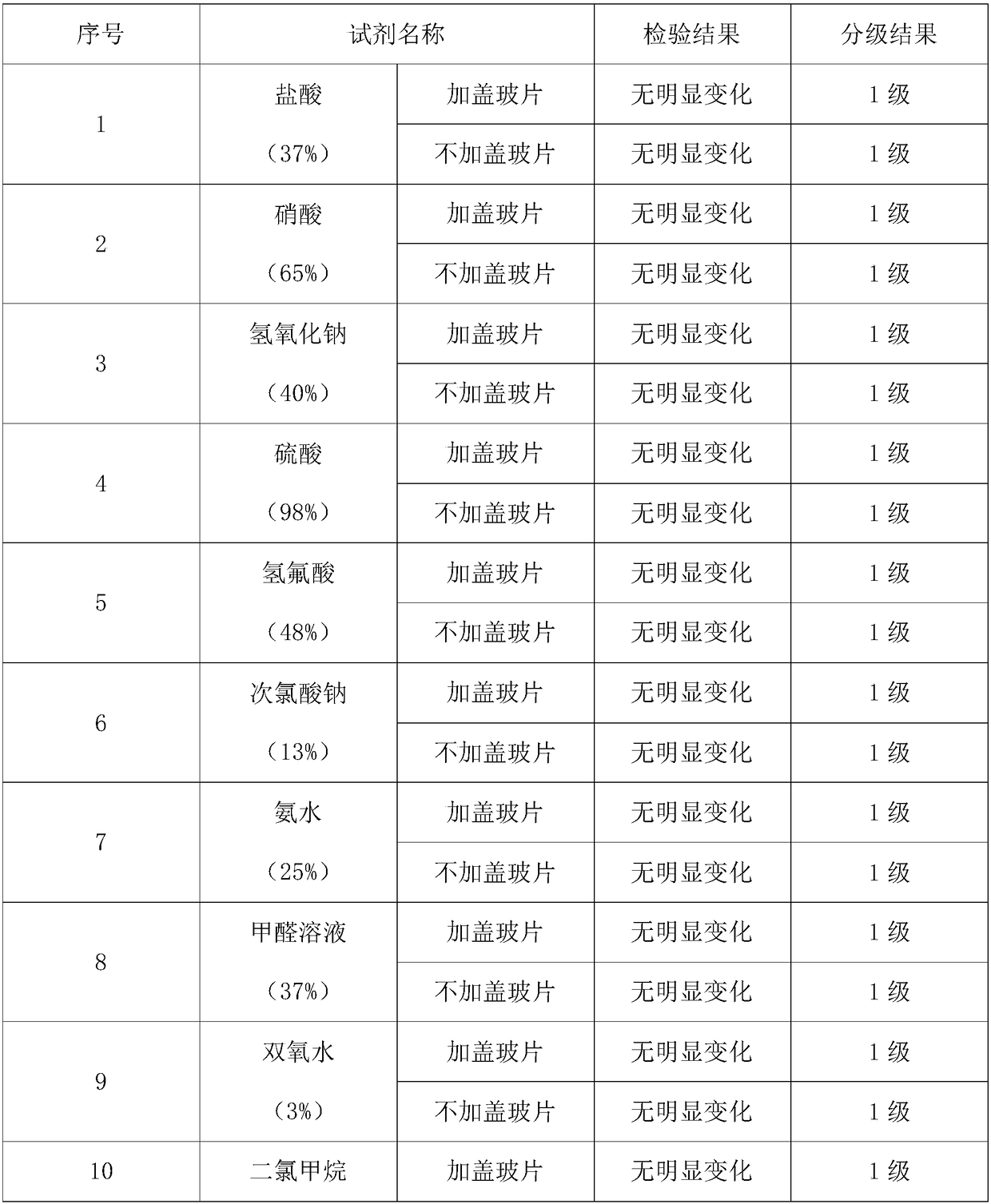

Patents

Literature

45results about How to "Avoid abrasion" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

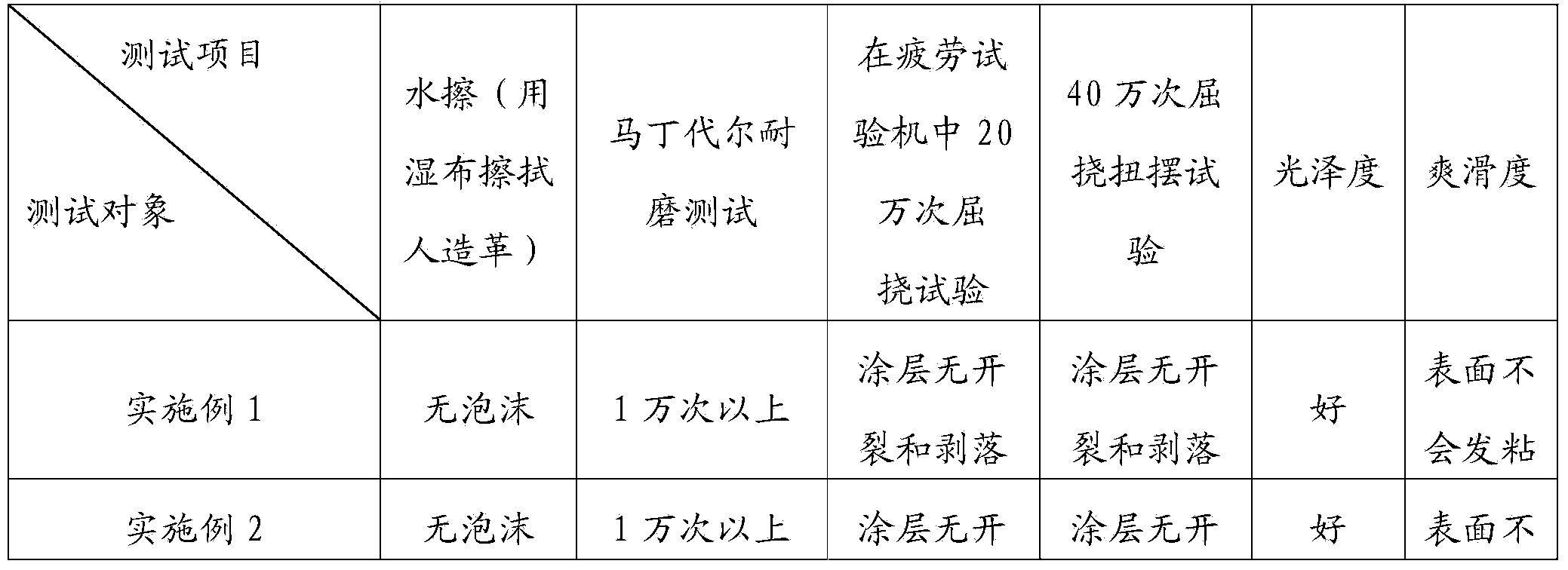

Water-scrubbing resistant artificial leather and preparation method thereof

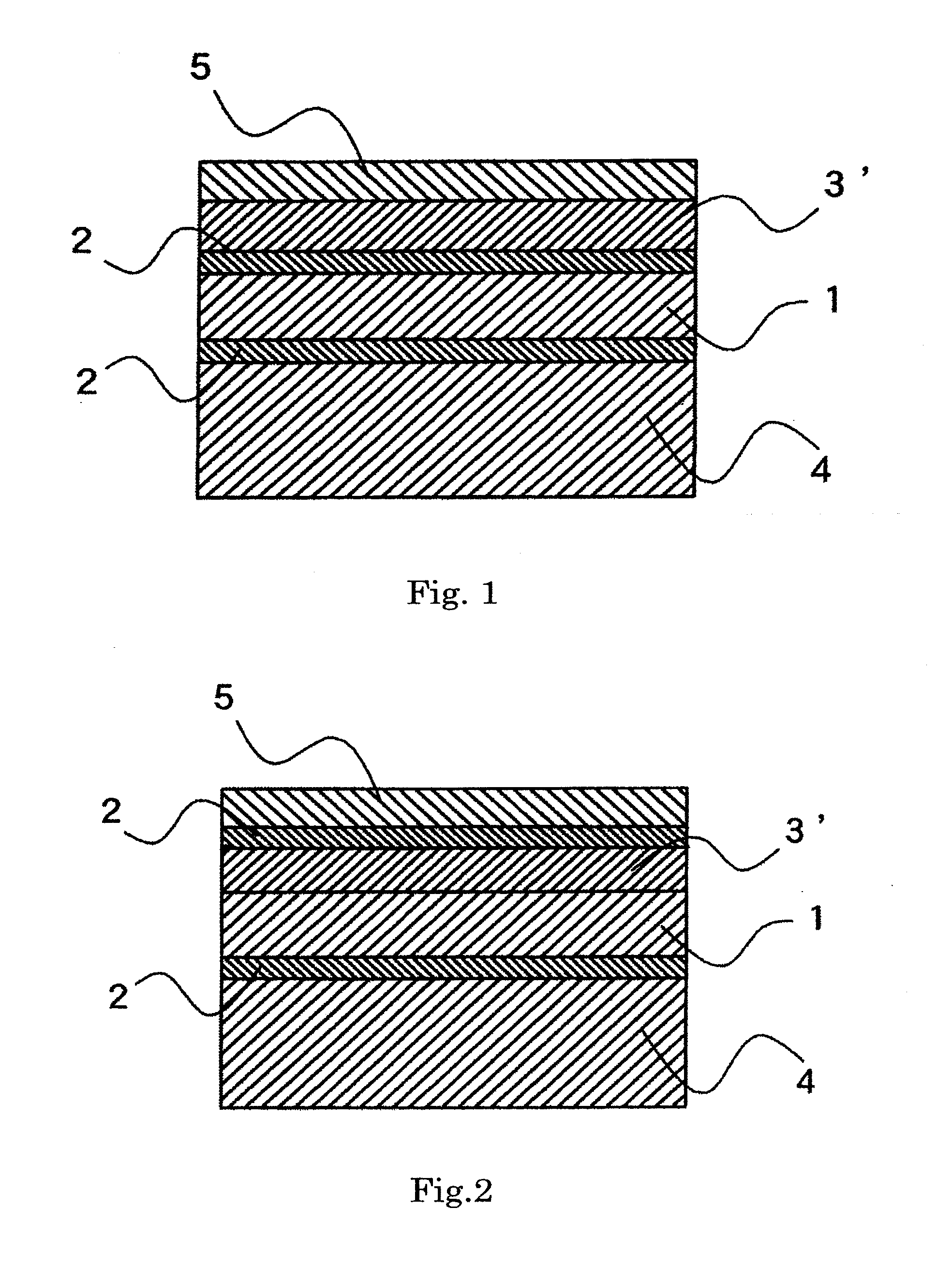

ActiveCN103643532AAvoid crackingNot easy to fall offLamination ancillary operationsSynthetic resin layered productsOrganic solventSurface layer

The invention relates to water-scrubbing resistant artificial leather and a preparation method thereof. The artificial leather comprises a surface layer, a foaming layer, an adhesion layer and a base cloth layer, wherein the surface of the surface layer is coated with a coating; the surface layer is formed by drying slurry on a polyurethane surface layer; the coating is formed by drying a surface treating agent; the surface treating agent comprises polyurethane resin, an organic solvent, a neutralizing agent and a leveling agent. The preparation method of the artificial leather comprises the following steps: sequentially forming the polyurethane surface layer, the foaming layer, the adhesion layer and the base cloth layer on release paper; removing the release paper to obtain a semi-finished product of artificial leather; applying the prepared surface treating agent to the surface of the semi-finished product of artificial leather; and drying, cooling and shaping to obtain a finished product of artificial leather. According to the water-scrubbing resistant artificial leather, the polyurethane surface layer and the surface treating agent which is composed of the polyurethane resin, the organic solvent, the neutralizing agent and the leveling agent are adopted so that the adhesion between the coating and the surface of the artificial leather is greatly improved, and the coating is unlikely to crack and fall off, resistant to water scrubbing, smooth in surface and good in wearing resistance.

Owner:FUJIAN POLYTECH TECH CO LTD

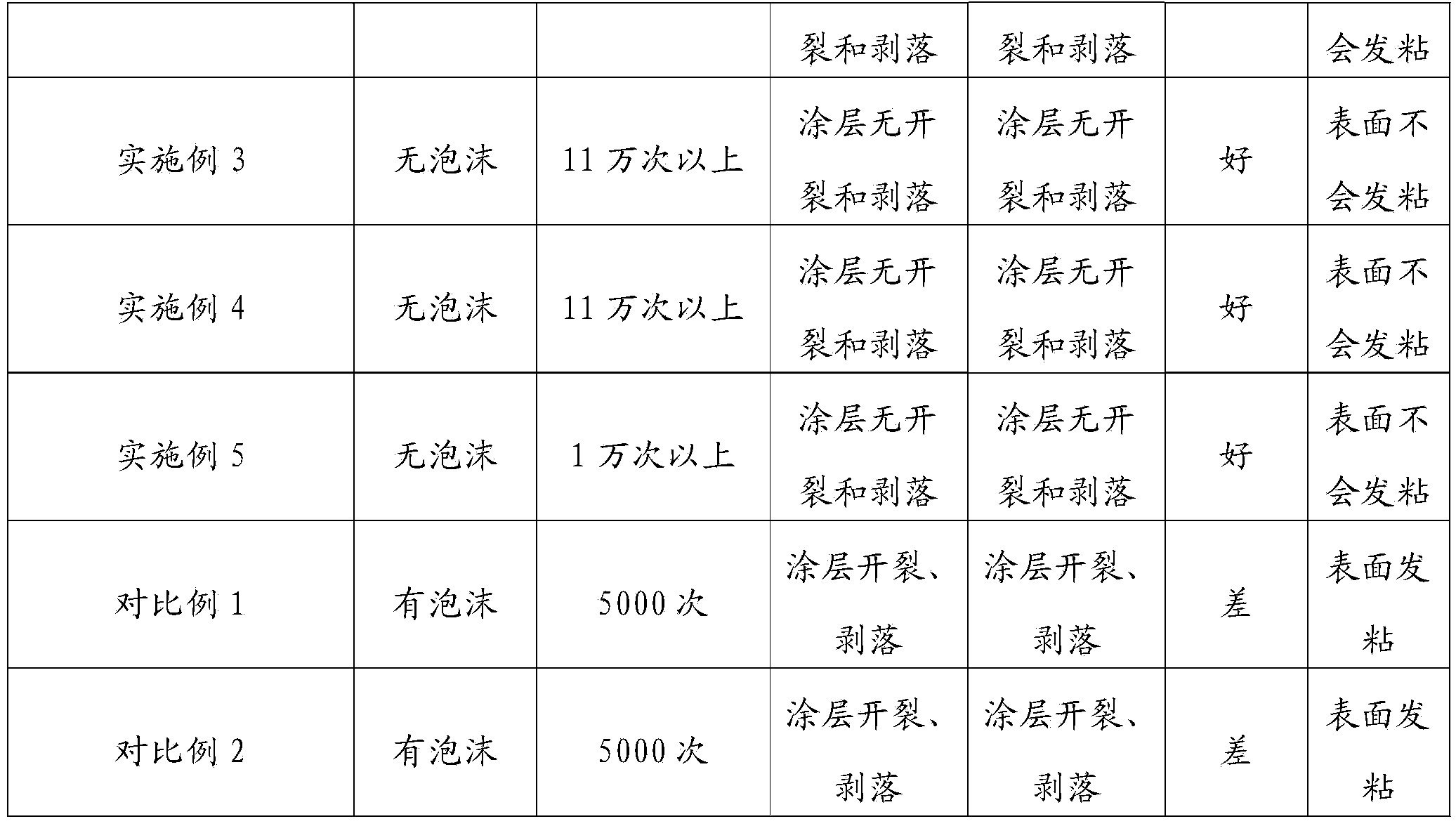

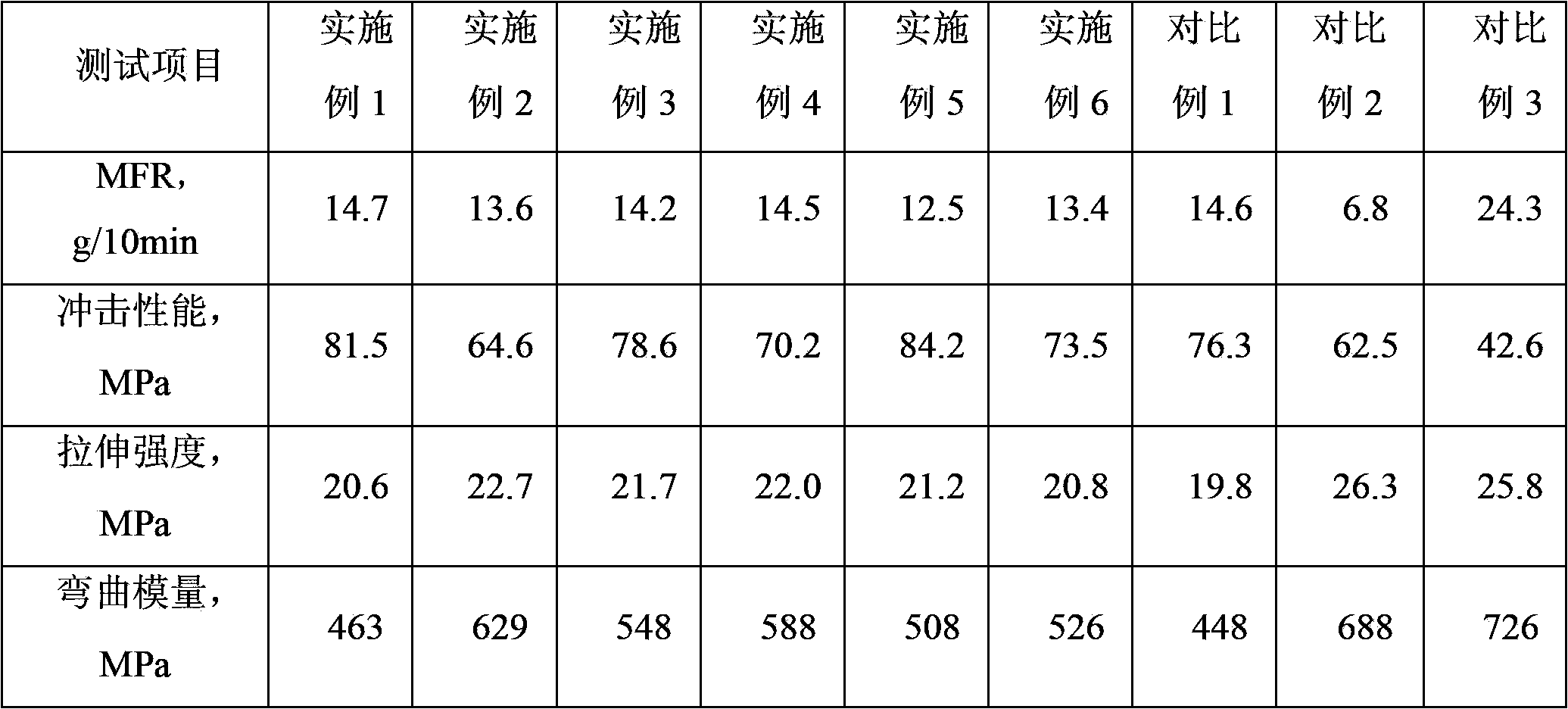

Polyethylene composite for drip irrigation pipes

ActiveCN103665508AHigh strengthGood flexibilityClimate change adaptationWatering devicesLow-density polyethyleneAntioxidant

The invention discloses a polyethylene composite for drip irrigation pipes, belongs to the technical field of high polymer materials, and particularly relates to a polyethylene composite. The polyethylene composite is characterized by comprising the following components in parts by weight: 40-60 parts of high-density polyethylene resin, 20-30 parts of high-pressure polyethylene resin, 10-30 parts of metallocene polyethylene resin, 0.15-1.2 parts of antioxidant, and 1.2-3 parts of carbon black. The composite, besides having good strength, flexibility, processability and aging resistance, has excellent abrasion resistance, ESCR (environmental stress cracking resistance) and puncture resistance and good high-temperature hydrostatic performance.

Owner:CHINA PETROLEUM & CHEM CORP

Catalyst for low-temperature SCR (Selective Catalytic Reduction) denitration and preparation method of catalyst

ActiveCN103170344AGood activity at low temperatureAvoid abrasionDispersed particle separationMetal/metal-oxides/metal-hydroxide catalystsVanadium(V) oxideTreatment costs

The invention relates to a catalyst for low-temperature SCR (Selective Catalytic Reduction) denitration. The catalyst is composed of titanium dioxide, vanadium pentoxide, molybdenum trioxide and an assistant, wherein the assistant is one or more of transition metal silicates. The invention further relates to a preparation method of the catalyst. The low-temperature SCR denitration catalyst provided by the invention is excellent in low temperature activity, and is capable of performing the denitration reaction at a low temperature, reducing the reaction energy consumption and lowering the treatment cost. Furthermore, the raw materials of the catalyst provided by the invention are easily available and low in cost, and the preparation process is simple.

Owner:TIANJIN RENDE SCI

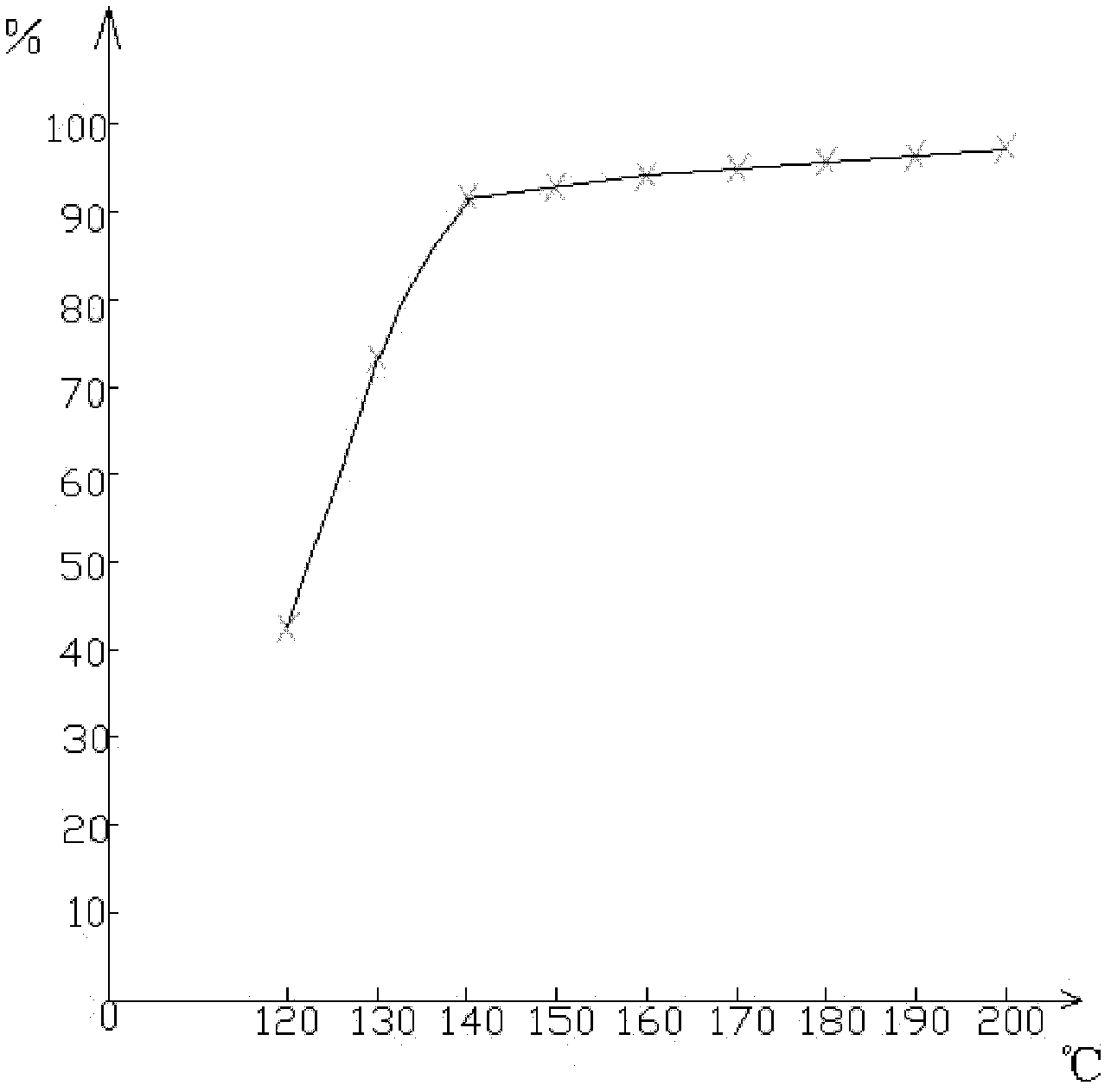

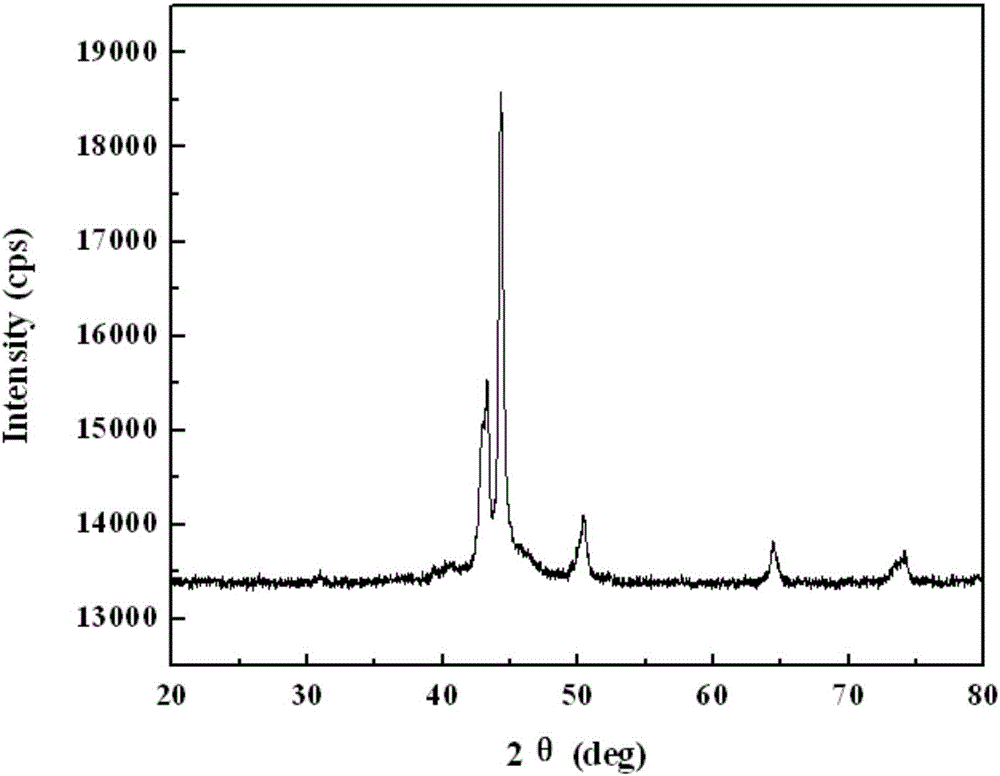

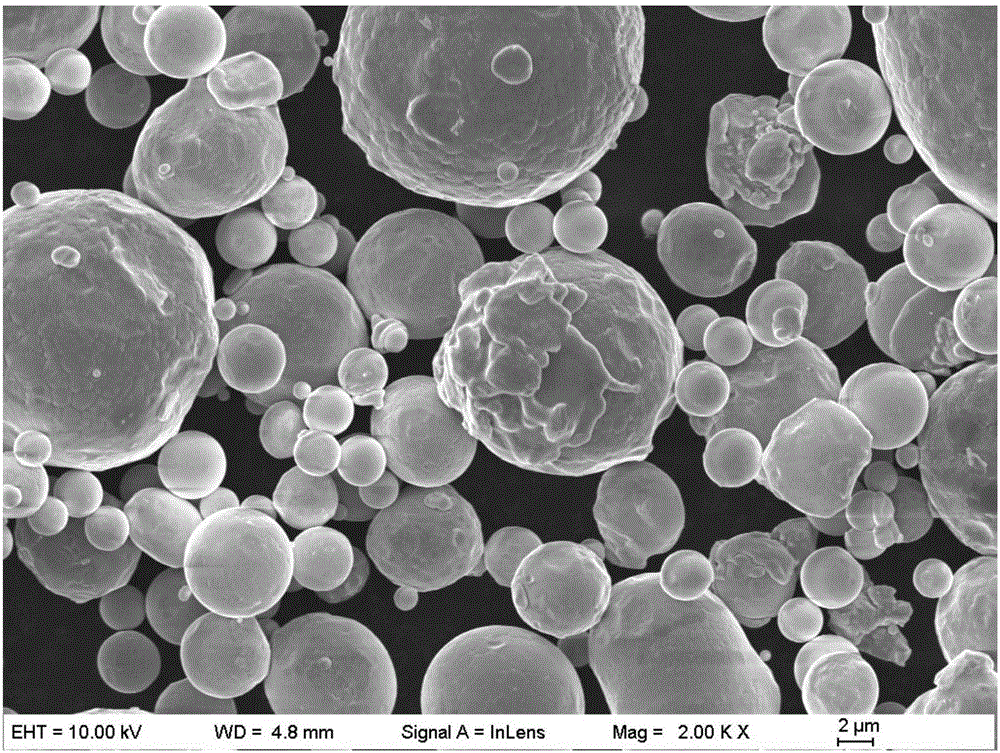

High-entropy alloy powder used on surface of riding wheel of rotary cement kiln, preparation method thereof and coating preparation method

ActiveCN106191621AHigh hardnessImprove wear resistanceMolten spray coatingChemical compositionHigh entropy alloys

The invention discloses high-entropy alloy powder used on the surface of a riding wheel of a rotary cement kiln, a preparation method thereof and a coating preparation method. The alloy powder comprises, by weight, 18%-20% of Fe, 17%-19% of Al, 17%-19% of Cr, 19%-20% of Mn, 19%-21% of Ni, 2.8%-4% of W, 0.6%-0.8% of B and 1.0%-2% of C. The alloy powder is prepared through a medium-frequency induction melting atomization one-step method. The high-entropy alloy powder and the preparation method thereof have the characteristics that pollution is small, environmental protection is realized, the steps are simple and energy consumption is low. A coating obtained through the hypersonic flame spraying process is suitable for the surface of the riding wheel of the rotary cement kiln. Bonding strength of the coating and a base body is high, the heat effect on the base body is small, tissue is good, and abrasion resistance of the riding wheel is improved after repair.

Owner:ANHUI RUITAI NEW MATERIALS TECH +1

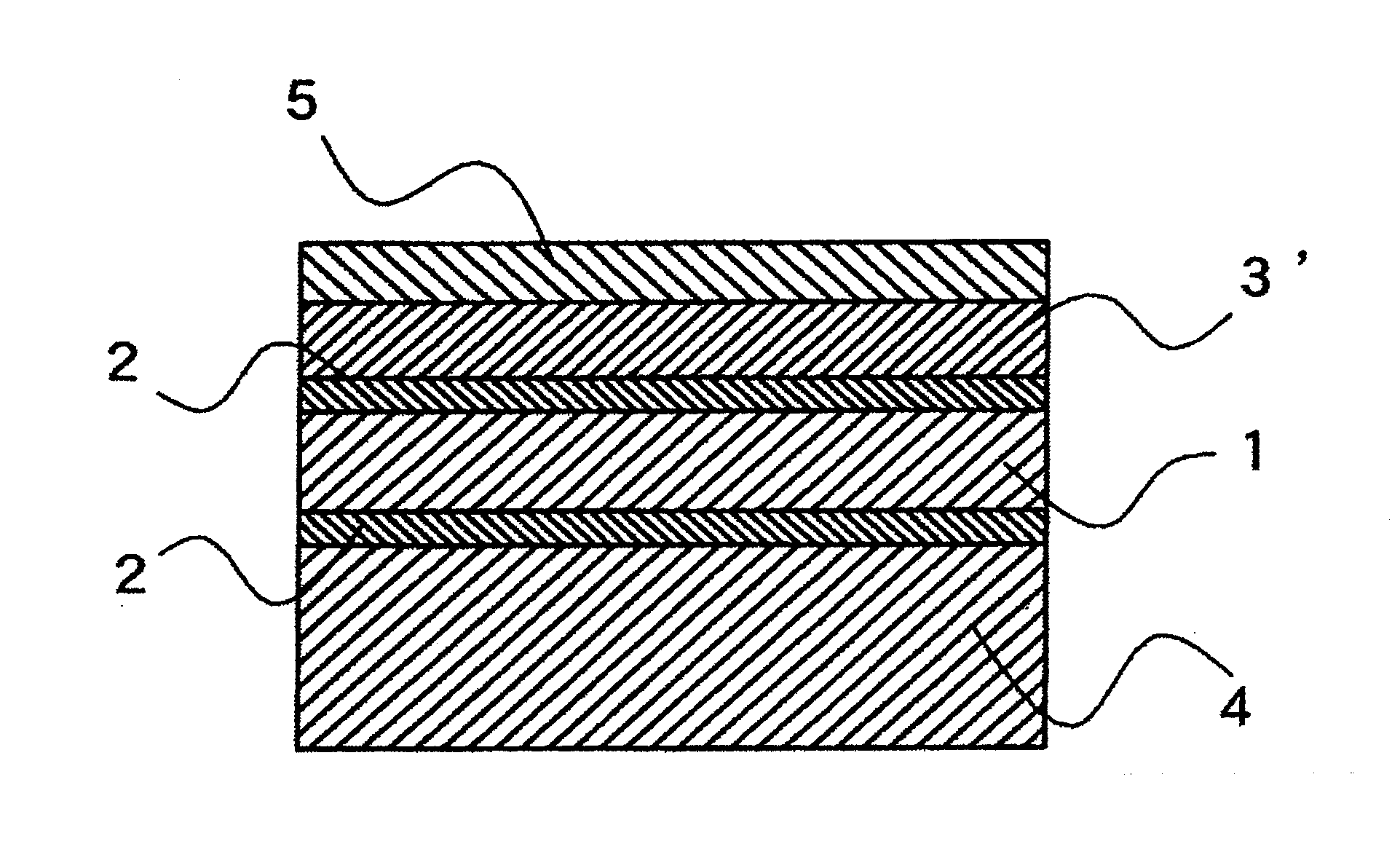

Optical resin composition, optical resin material using the same, optical filter for image display device, and image display device

InactiveUS20120120347A1Improve impact absorption performanceHigh transparencyOptical filtersCoatingsDiacrylate esterBiopolymer

An optical resin composition that is transparent, has suitable adhesion and necessary impact absorption for protection of an image display device etc., not affecting constituent materials of a image display panel, and being excellent in reliability, can be used to provide an optical resin material using the same. The optical resin composition contains (A) a first acrylate derivative that is a compound having one polymerizable unsaturated bond in its molecule, (B) a second acrylate derivative that is a compound having two or more polymerizable unsaturated bonds in its molecule, and (C) an acrylate derivative polymer, and an optical resin material produced by curing reaction of the optical resin composition.

Owner:HITACHI CHEM CO LTD

Wearable ultrahigh molecular weight polyethylene tubular product and preparation method thereof

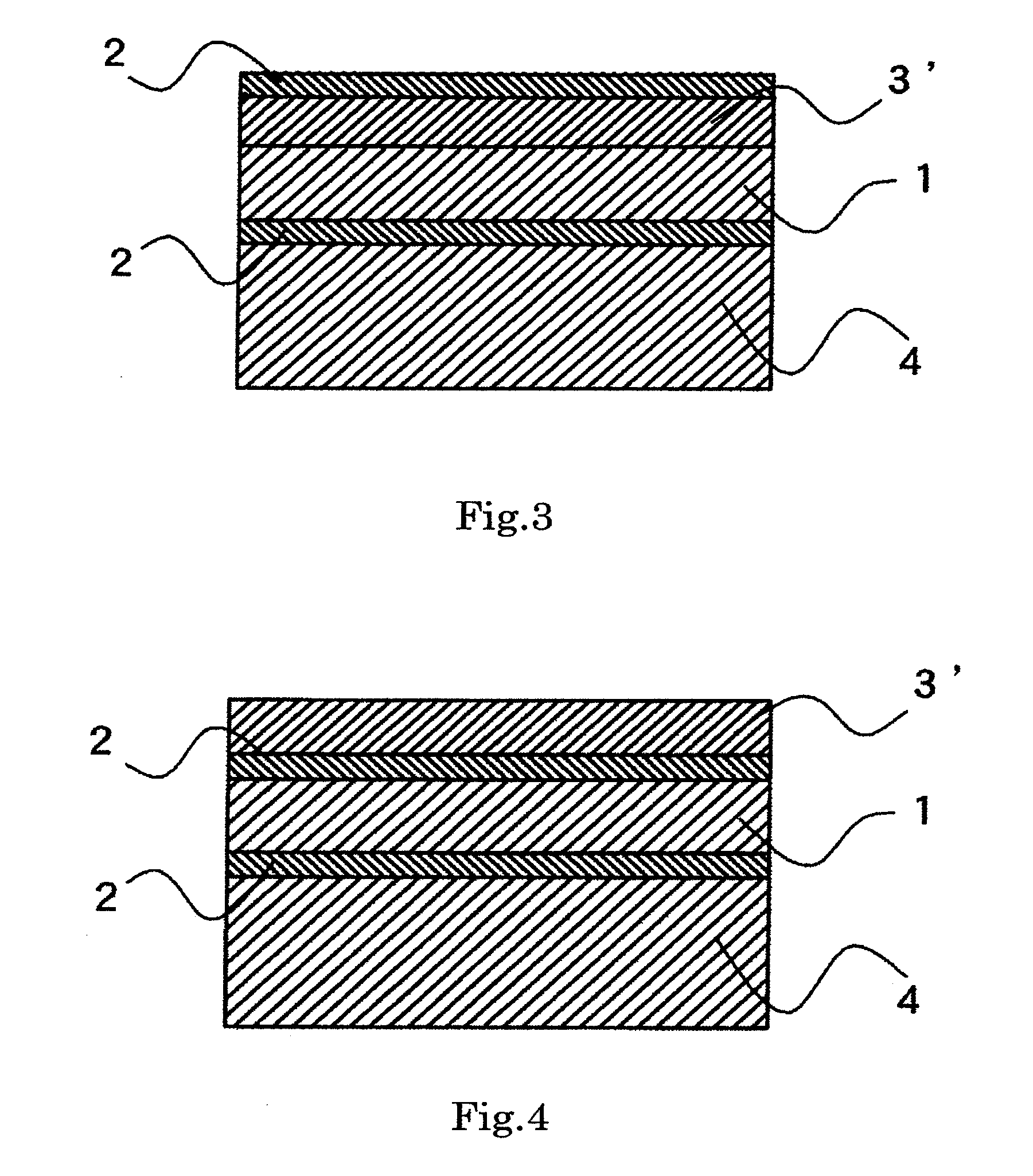

InactiveCN101696291AImprove toughnessGood chemical stabilityRigid pipesChemical industryPolymer science

The invention discloses a wearable ultrahigh molecular weight polyethylene tubular product and a preparation method thereof, belonging to a composite of macromolecular compounds, and comprising the following raw material components in parts by weight: 95-98 parts of ultrahigh molecular weight polyethylene with viscosity-average molecular weight of 2800,000-2850,000, 1.8-4.8 parts of polyethylene wax with molecular weight of 1,000-1,500, and 0.1-0.3 part of carbon black. The invention provides the wearable ultrahigh molecular weight polyethylene tubular with performances of corrosion resistance, anti-adhesion, compression resistance, impact resistance, high surface hardness, good abrasion resistance, high mechanical strength, high heat distortion temperature, convenient process, long service life and low manufacture cost, and a preparing method thereof with simple manufacturing process and low production cost. As the substitute of steel tubes, the invention meets the market requirements, overcomes the defects of poor performances of corrosion resistance, abrasion resistance and anti-adhesion in the prior steel tubes, and is widely applied to the transportation of wastewater, waste residue and corrosive medium in the industries such as metallurgy, electric power, paper-making, chemical industry, machine, petroleum and the like.

Owner:沂源县联创工贸有限公司

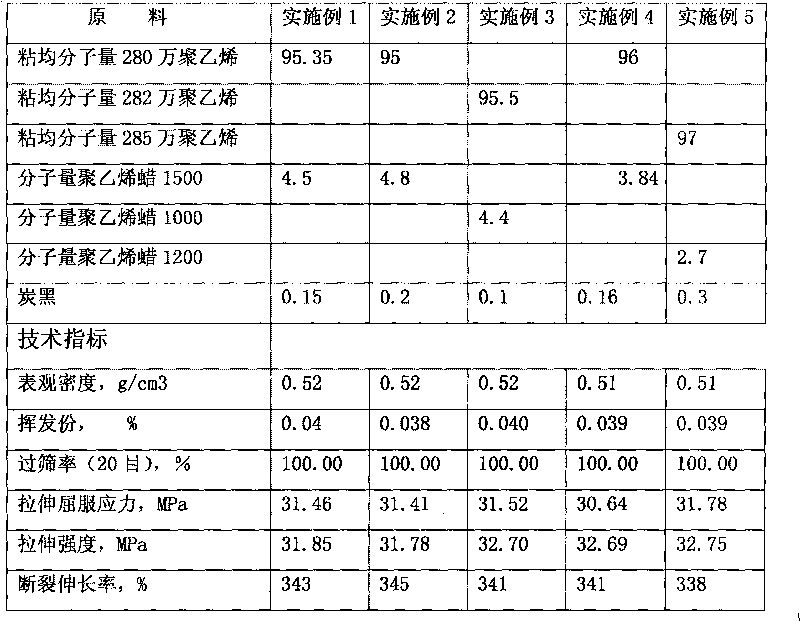

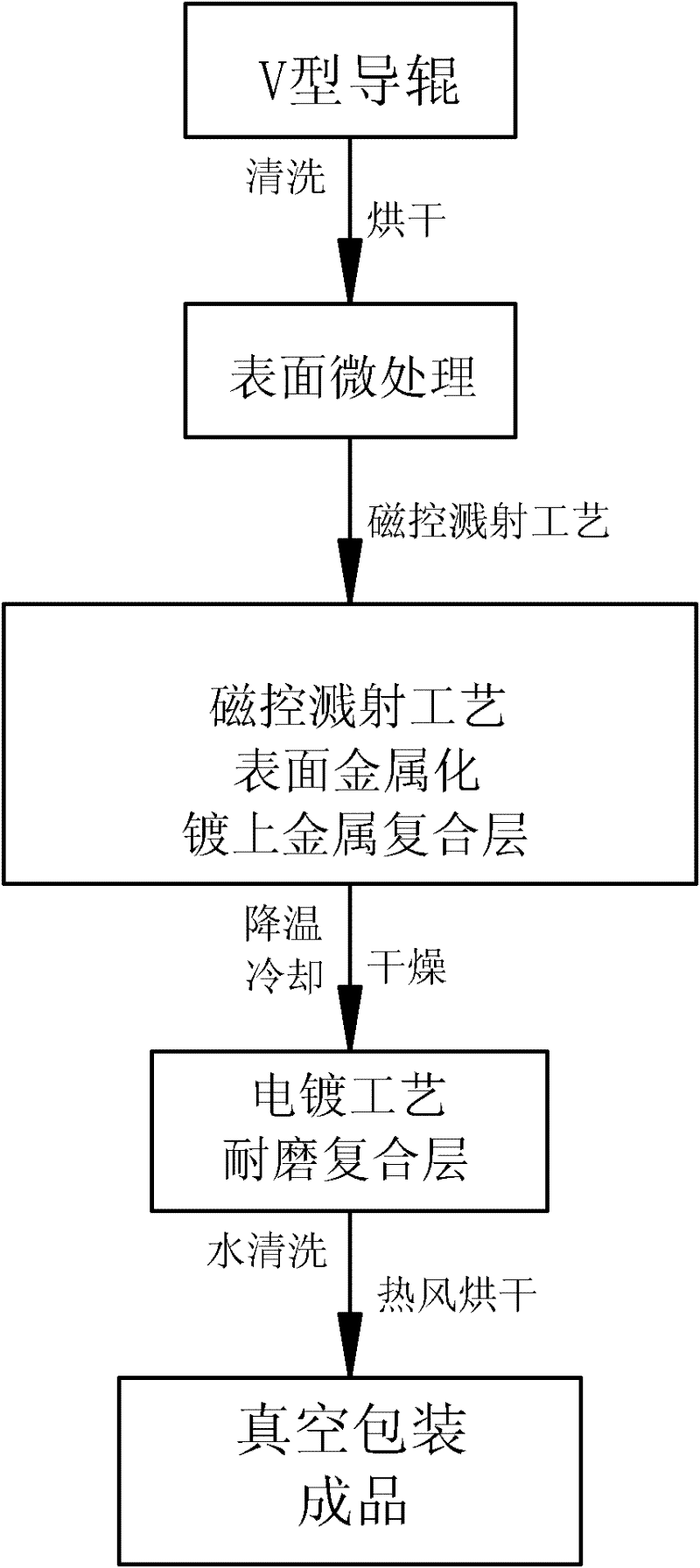

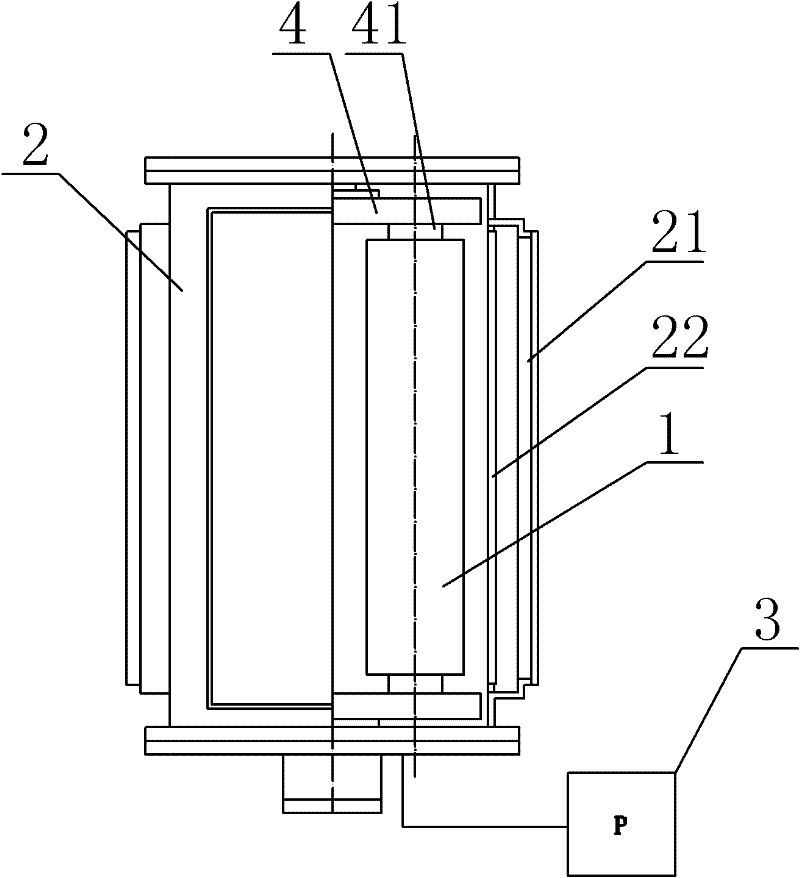

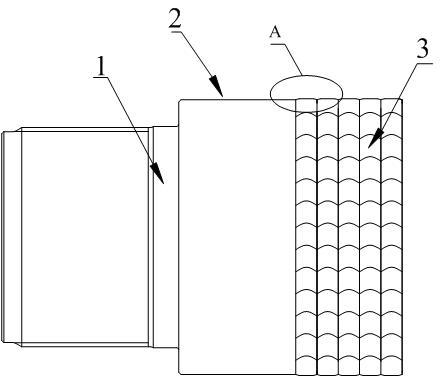

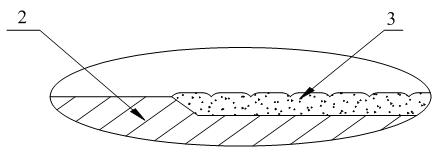

Solar silicon wafer wire cutting guide roller and manufacturing method and special film coating machine and electroplating machine

InactiveCN102225598AReduce wearExtended service lifeFinal product manufactureVacuum evaporation coatingWear resistantWire cutting

The invention relates to a solar silicon wafer wire cutting guide roller and a manufacturing method and a special film coating machine and an electroplating machine. the method comprises the following steps of: making a V-shaped guide roller base body made from composite polyurethane, plating a metal composite layer on the surface of the V-shaped guide roller base body, and plating a wear-resistant composite layer on the surface of the metal composite layer,wherein the metal composite layer is compounded by one or more then one of nickel, titanium, copper and chromium, the wear-resistant composite layer is a antiseize polymer in which wear-resistant particles are contained. According to the invention, under the condition of not changing the existing cutting technique, the service life of the V-shaped guide roller manufactured by the invention is prolonged, the replacement frequency can be reduced, the cutting yield is stabilized, the equipment utilization ratio is improved, and the overall cutting cost is lowered.

Owner:蒙特集团(香港)有限公司

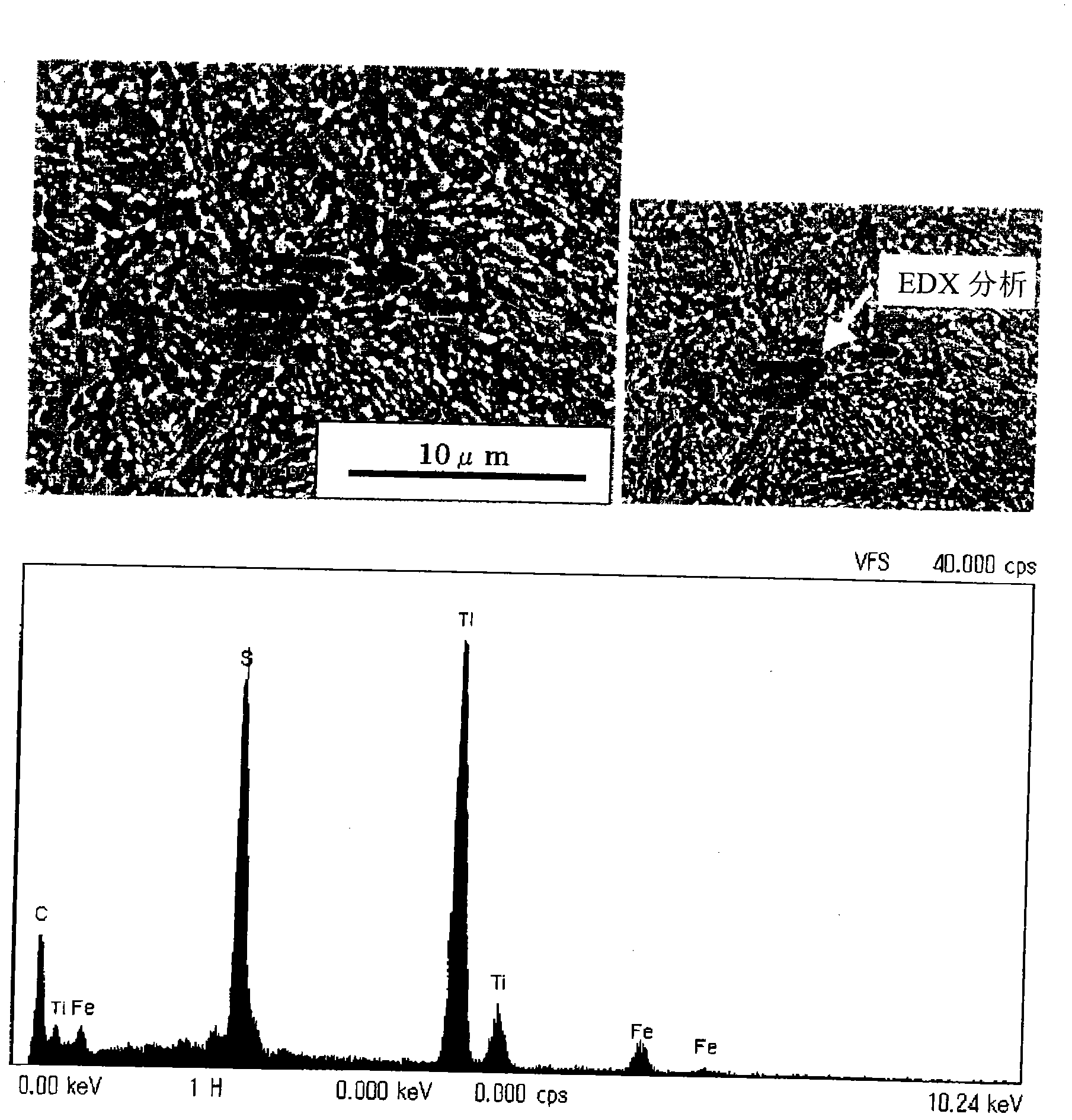

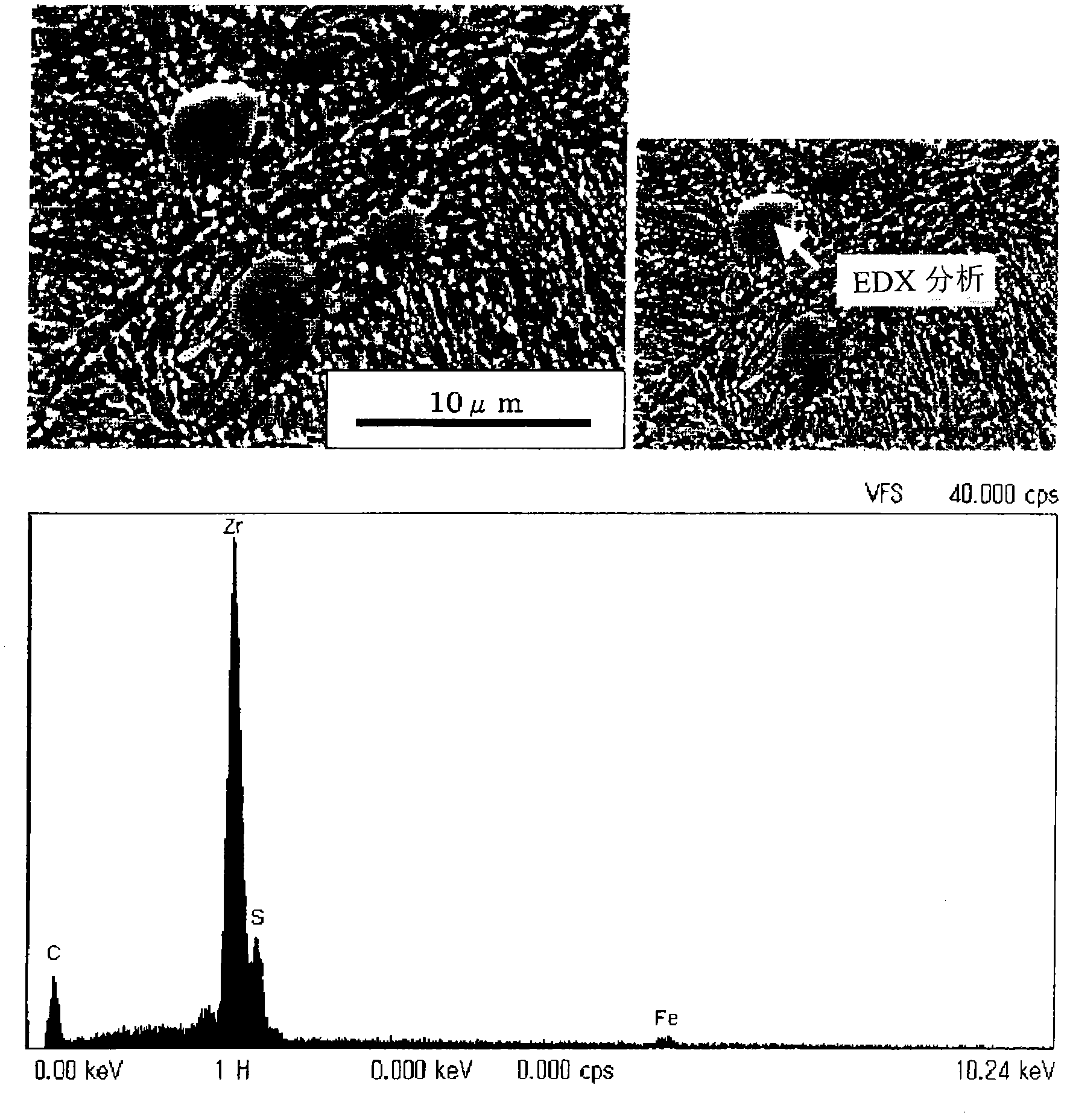

Piston ring material for internal combustion engine

ActiveCN101978085AGood self-lubricating performanceWith wear resistancePiston ringsFurnace typesManganeseInternal combustion engine

A piston ring material is provided which retains excellent mechanical properties and processability, which are required of piston ring materials, and has wearing resistance and scuffing resistance, which are sliding properties required of piston rings. The piston ring material, which is for use in internal combustion engines, contains, in terms of mass%, 0.3-0.8% carbon, 0.1-3.0% silicon, 0.1-3.0% manganese, 0.01-0.3% sulfur, 0.1-2.0% chromium, and 0.05-2.0% the sum of titanium and / or zirconium, with the remainder being iron and incidental impurities. The titanium and / or zirconium contained in the piston ring material and the sulfur contained therein satisfy the following relationship. [Ti (%) + 1 / 2Zr (%)] / S (%) = 5.0 Preferably, the material may contain one or more members selected from up to 1.0% copper, less than 3.0% molybdenum, up to 1.0% aluminum, and less than 2.0% nickel, in terms of mass%.

Owner:PROTERIAL LTD

Optical resin composition, optical resin material using the same, optical

InactiveUS20140023799A1Improve impact absorption performanceHigh transparencyLiquid crystal compositionsOptical filtersPolymer scienceAcrylate ester

The invention provides an optical resin composition being transparent, having suitable adhesion and necessary impact absorption for protection of an image display device etc., not affecting constituent materials of a image display panel, and being excellent in reliability, and an optical resin material using the same.Disclosed is an optical resin composition containing (A) a first acrylate derivative that is a compound having one polymerizable unsaturated bond in its molecule, (B) a second acrylate derivative that is a compound having two or more polymerizable unsaturated bonds in its molecule, and (C) an acrylate derivative polymer, and an optical resin material produced by curing reaction of the optical resin composition.

Owner:RESONAC CORP

Glass fiber reinforced plastic and production process thereof

The invention discloses a glass fiber reinforced plastic and a production process thereof, and relates to the technical field of glass fiber reinforced plastics, wherein the glass fiber reinforced plastic is prepared from the following components in parts by weight: 100-200 parts of unsaturated polyester, 100-150 parts of epoxy resin, 100-150 parts of phenol-formaldehyde resin, 50-100 parts of glass fibers, 50-100 parts of carbon fibers, 20-30 parts of polystyrene, 30-50 parts of polyethylene, 100-200 parts of aluminum hydroxide, 100-200 parts of magnesium hydroxide, 1-5 parts of a curing agent, 1-2 parts of a coupling agent, 1-2 parts of a lubricant dispersant, 1-4 parts of a compatibilizer and 100-200 parts of rock flour. A plastic mold is selected from an internal-external double-layermold, a plastic raw material of the carbon fibers is wrapped outside a plastic raw material of the glass fibers, and the alkali-free glass fibers are used. The glass fiber reinforced plastic has the glass fiber advantages of high strength, good corrosion resistance and good electrical insulation, and also has the carbon fiber advantages of high elastic modulus and high heat resistance; at the sametime, a flame retardant is added to the material to ensure that the plastic is not burned at high temperature and the overall performance and quality of the plastic are improved.

Owner:宁国中信零部件有限公司

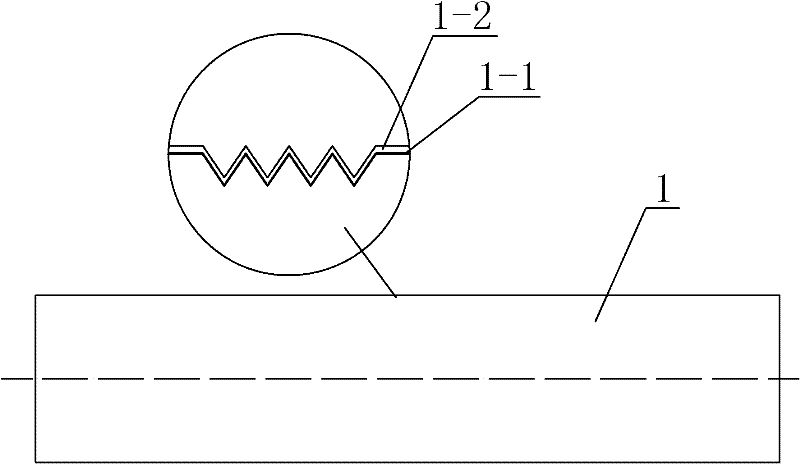

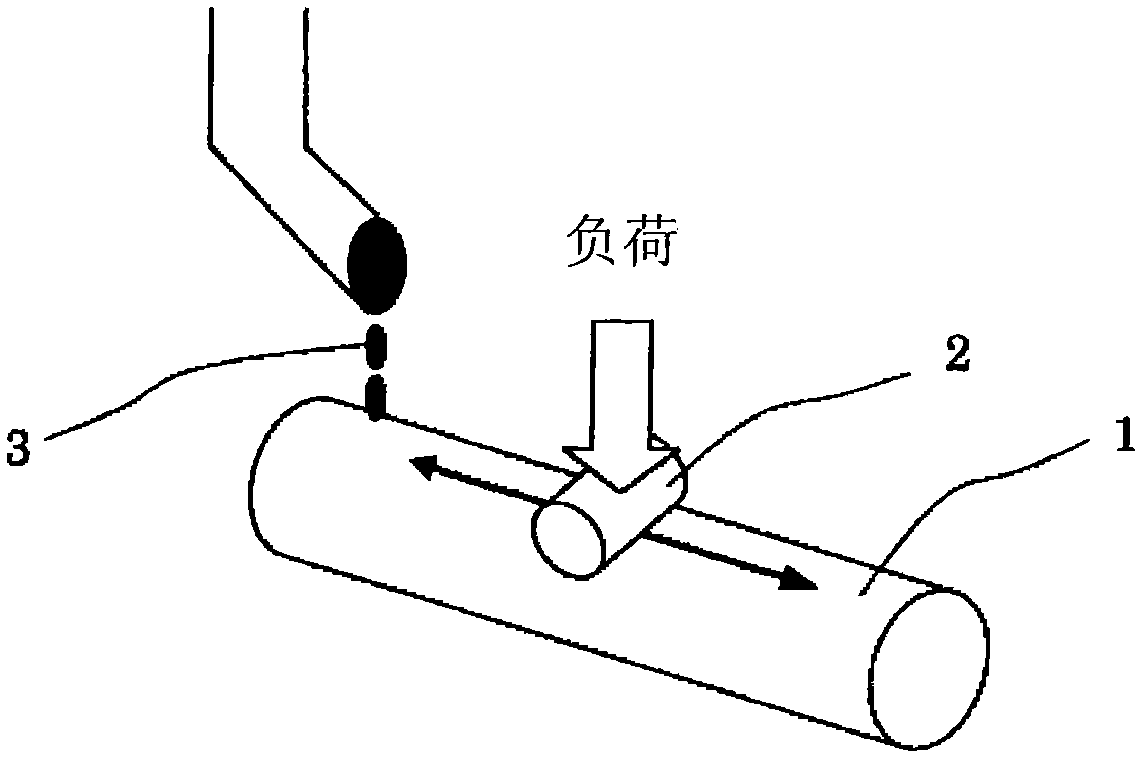

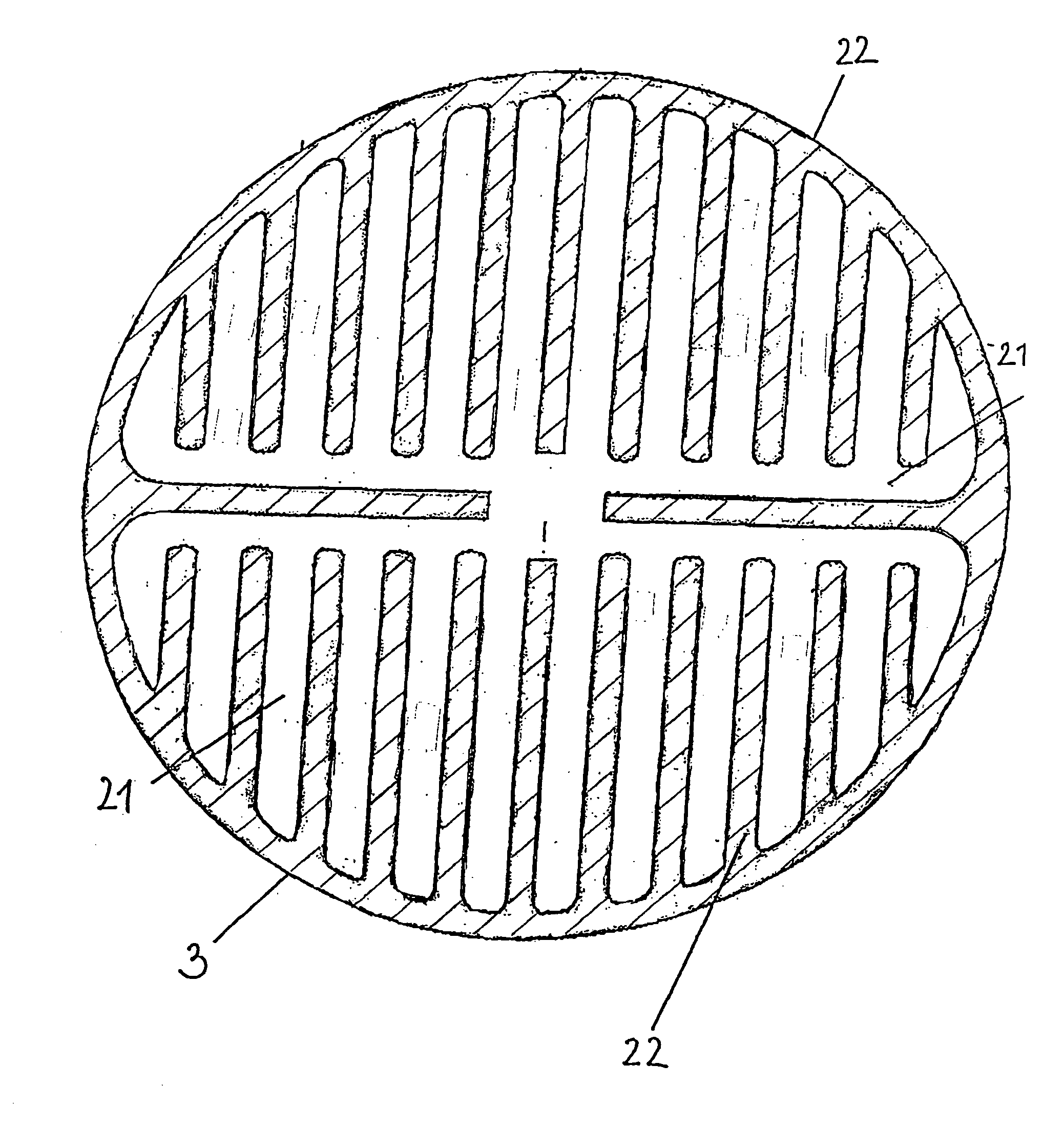

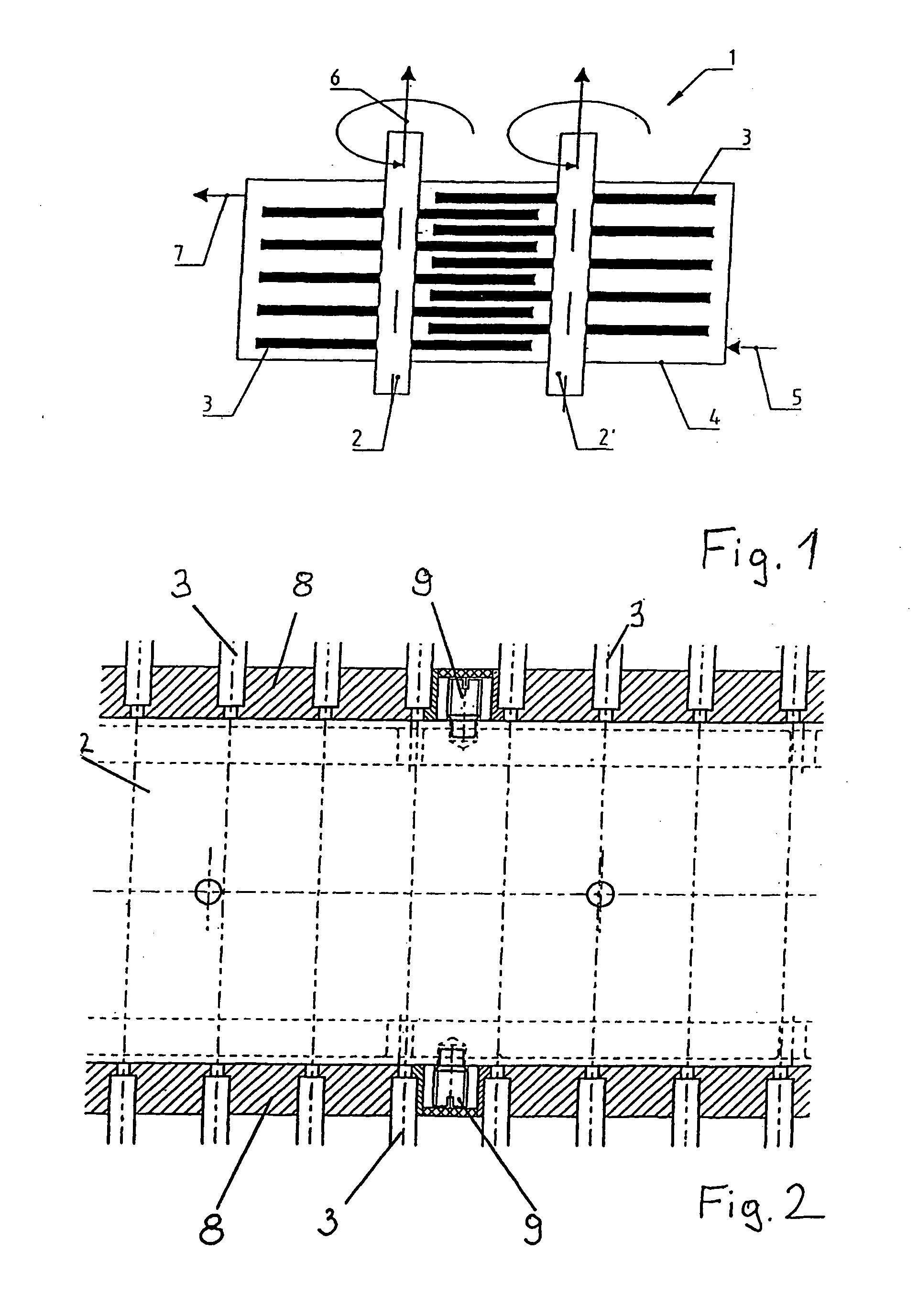

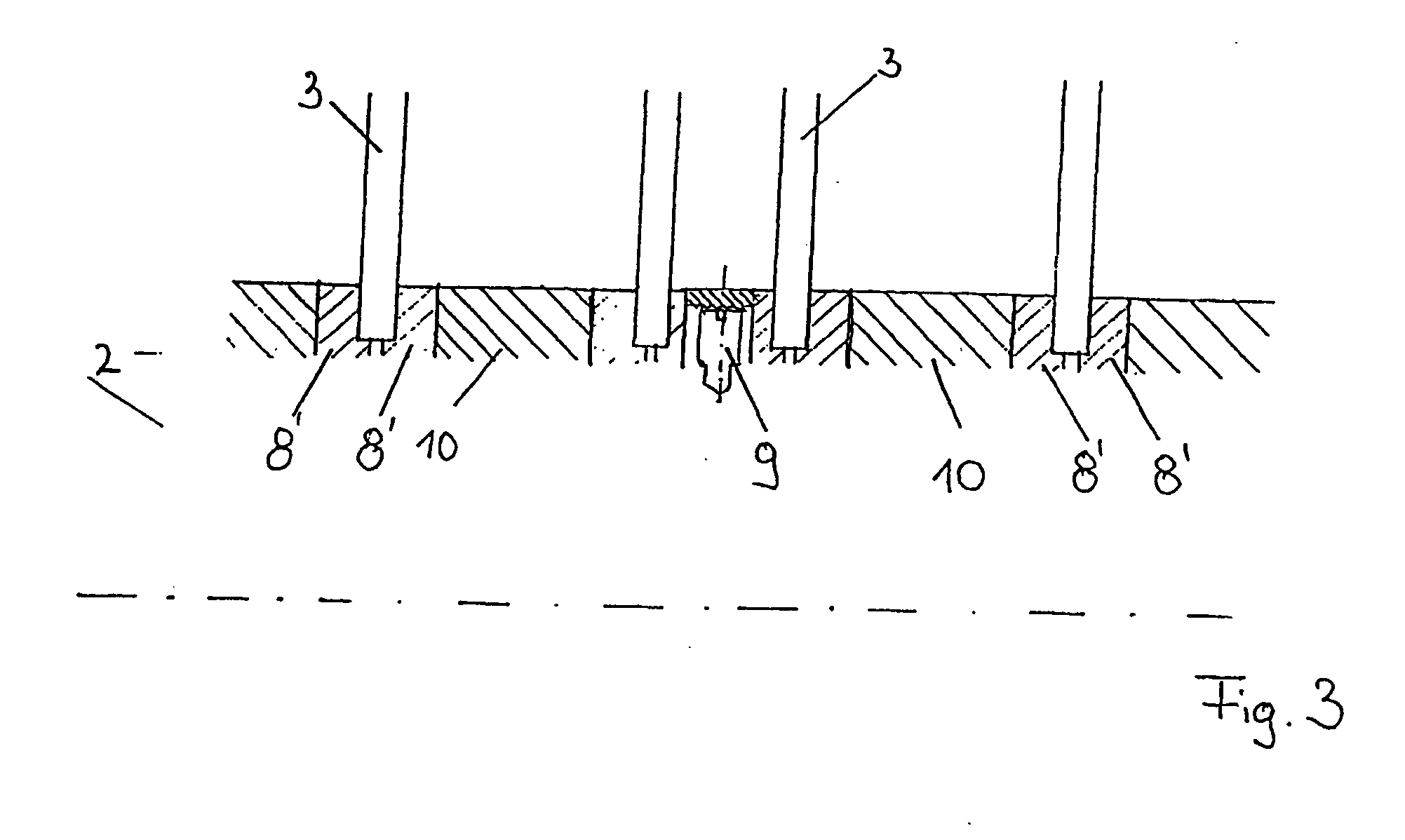

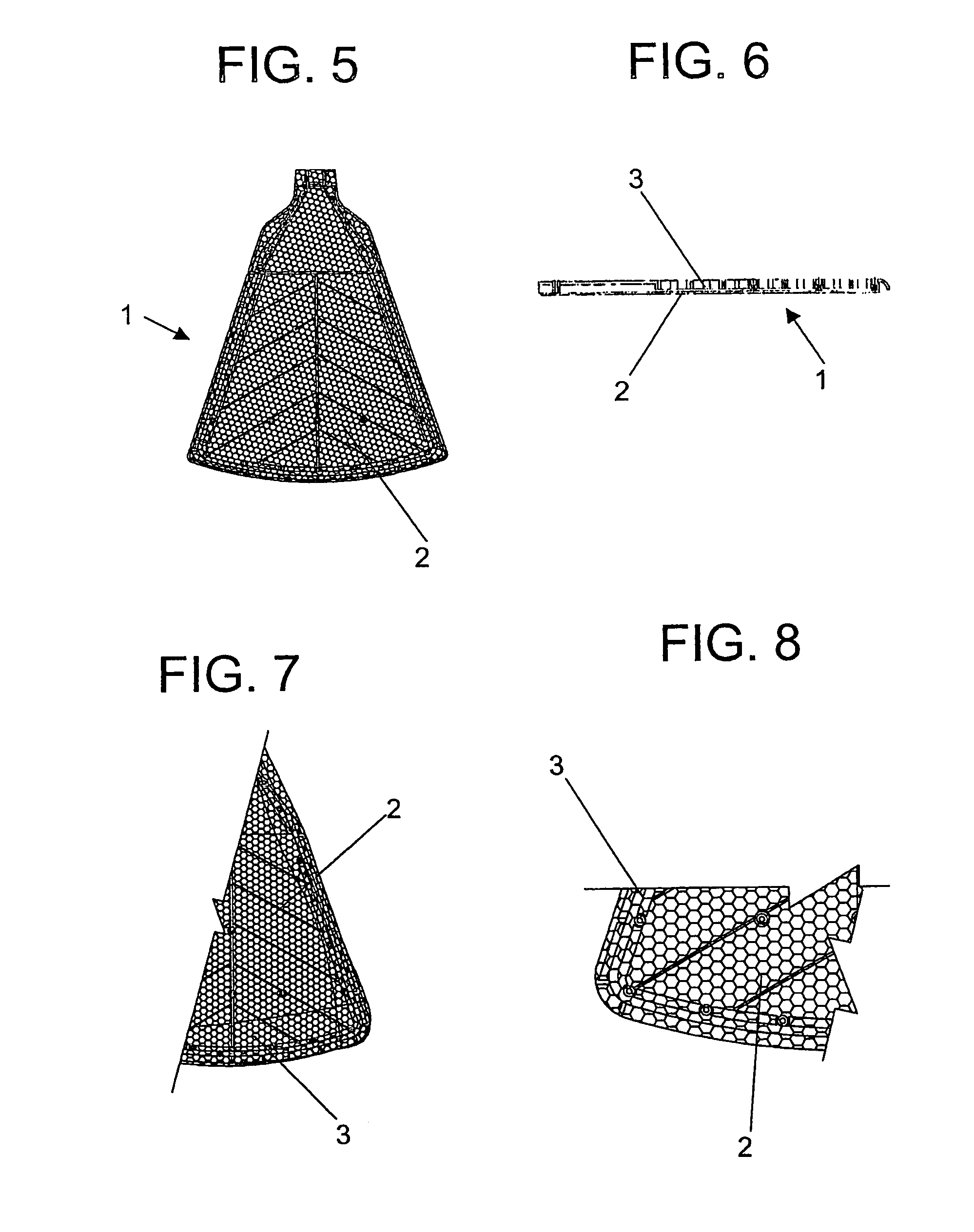

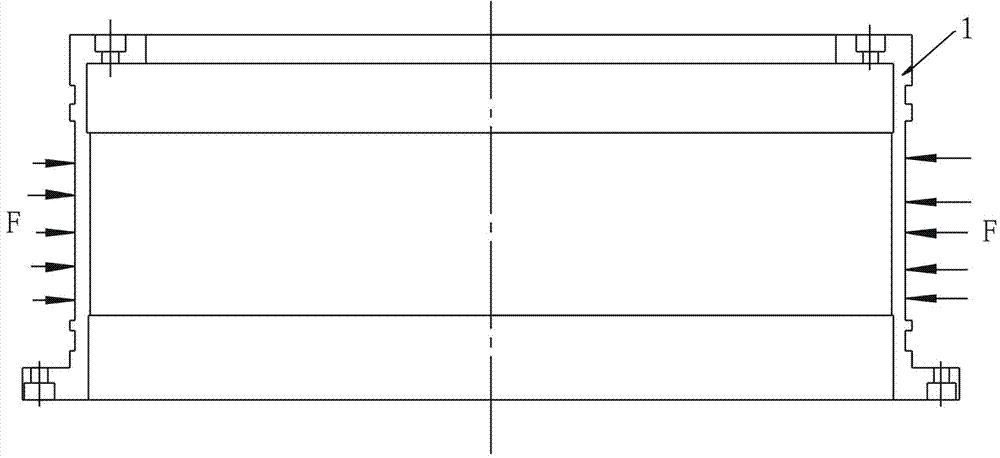

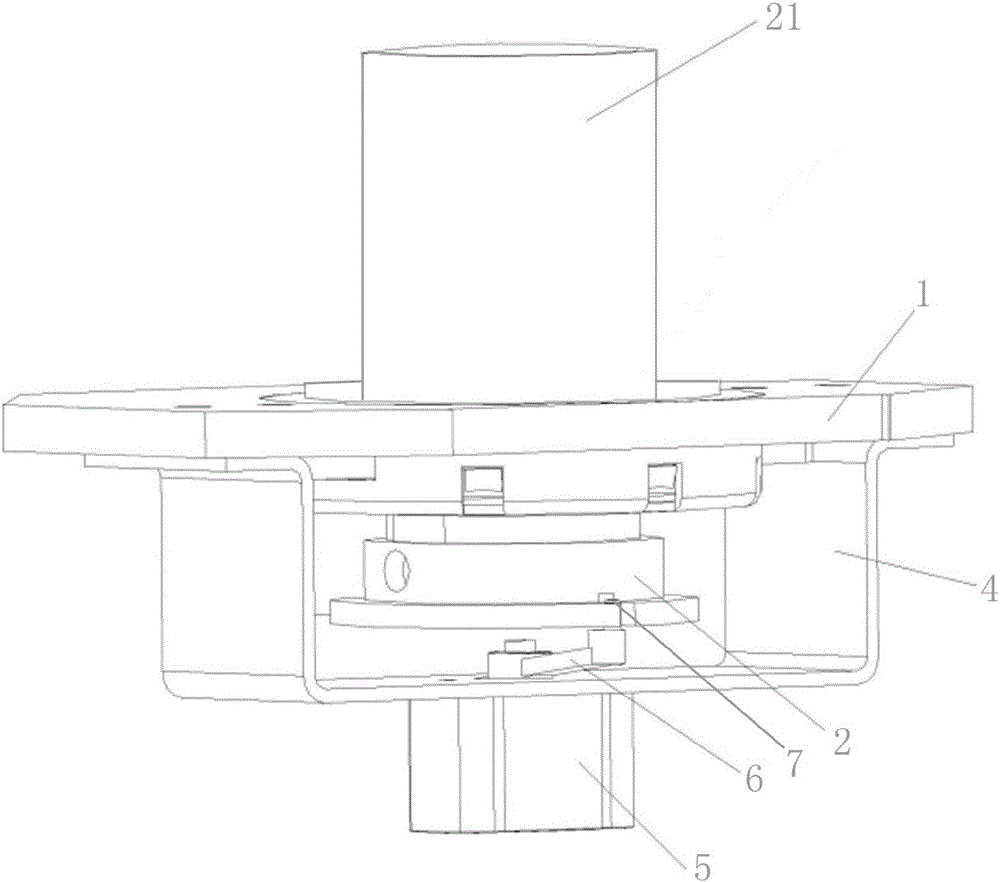

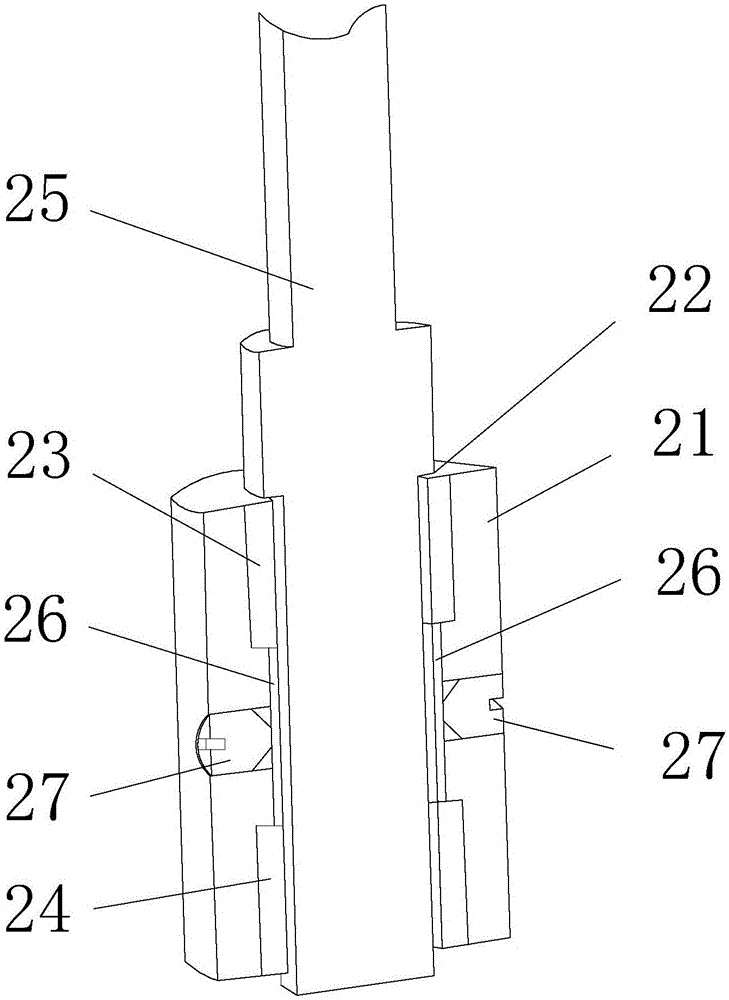

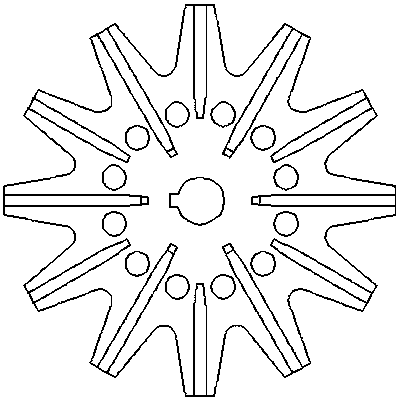

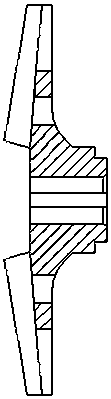

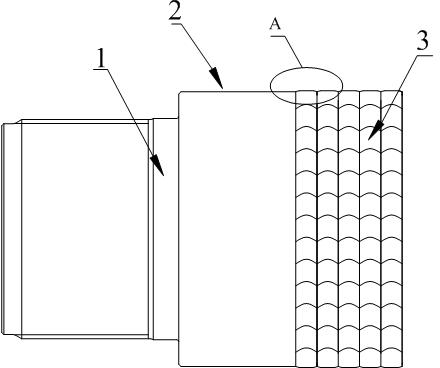

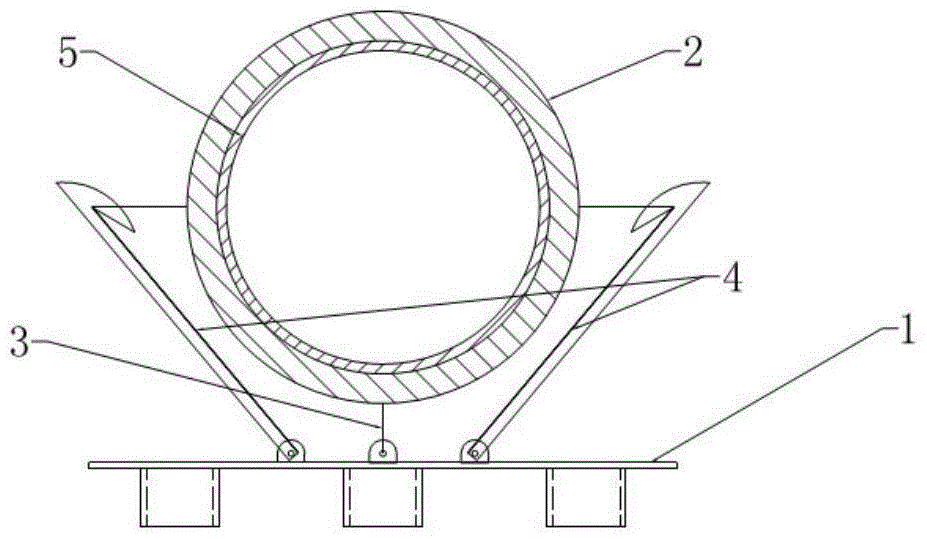

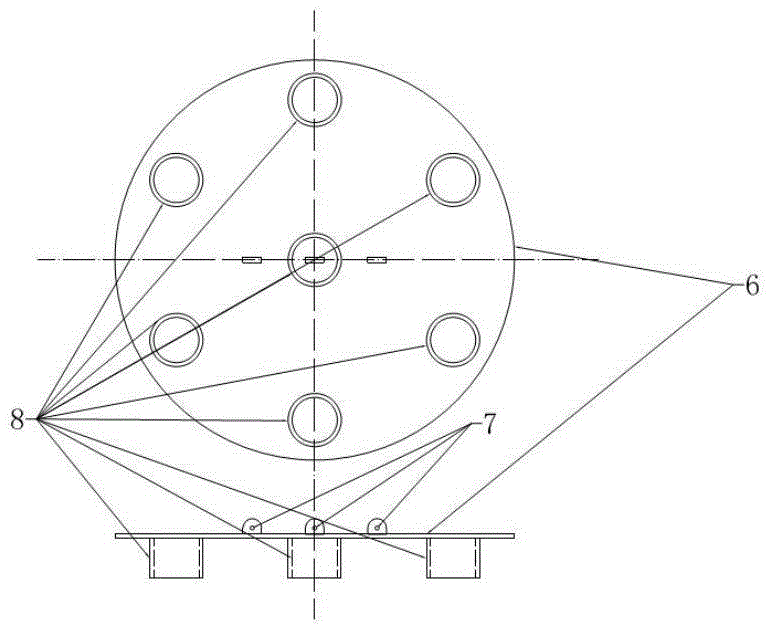

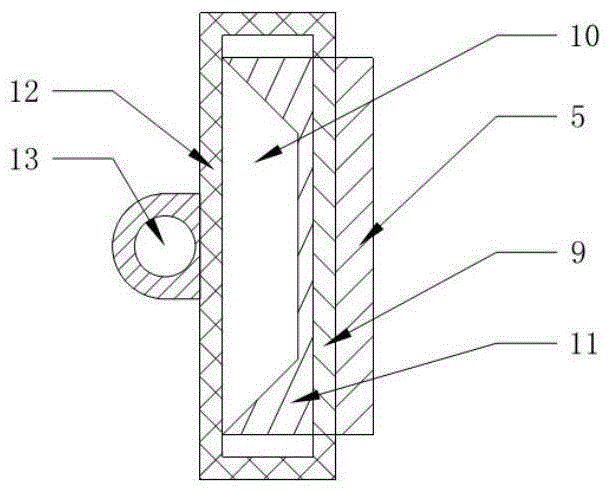

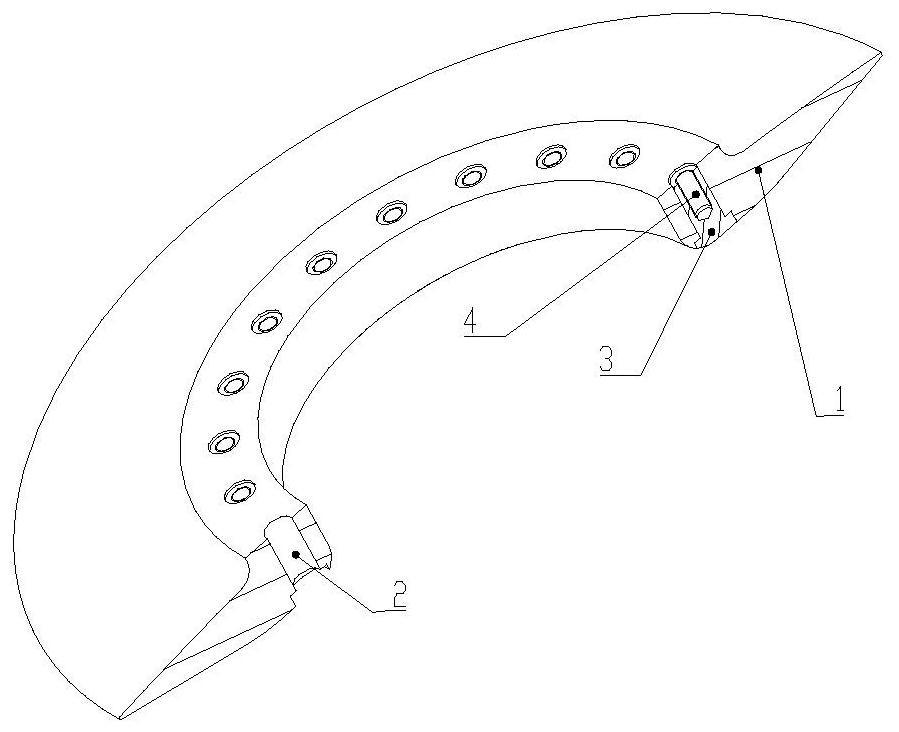

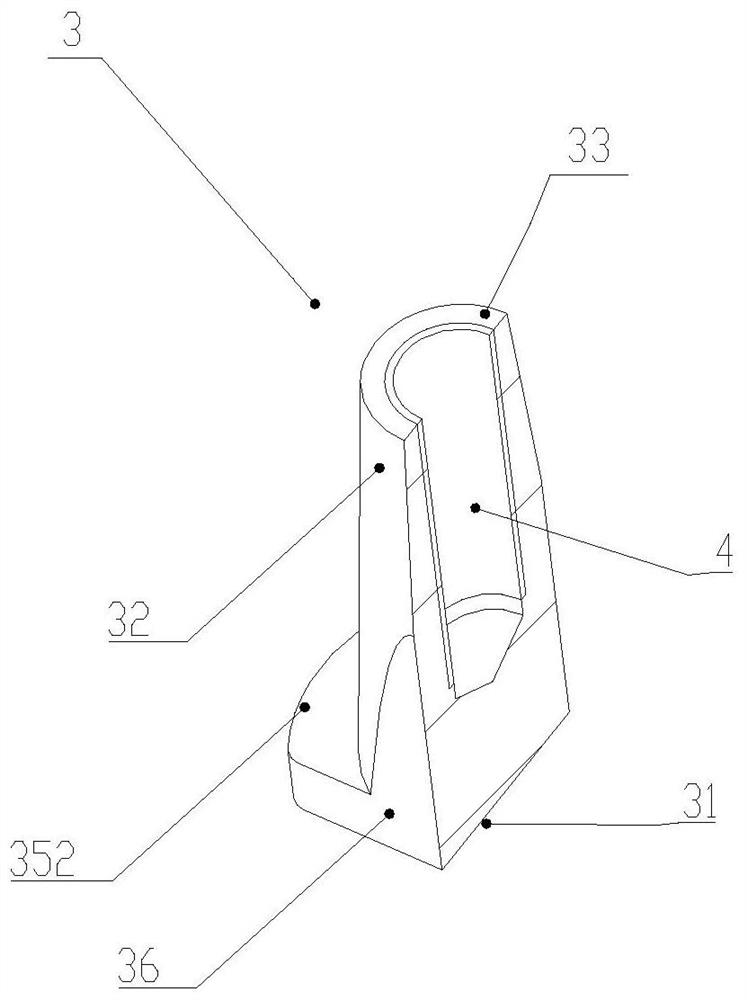

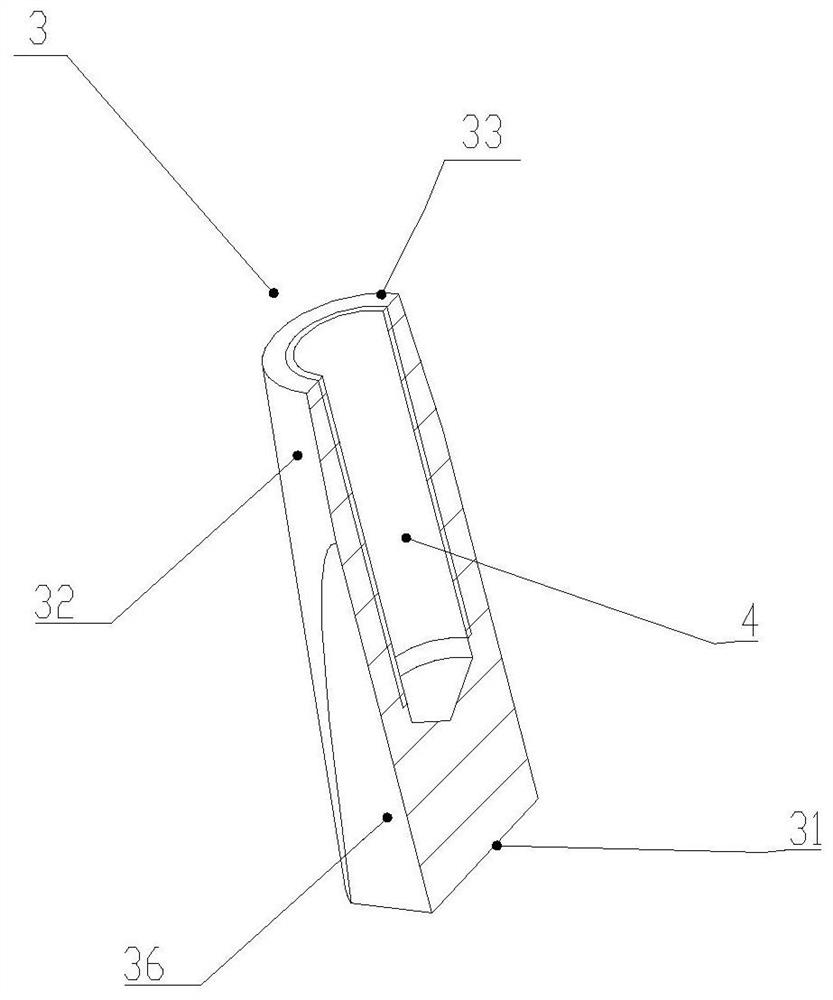

Filter disc

InactiveUS20070056895A1Low costAvoid abrasionSemi-permeable membranesTransducer detailsEngineeringMechanical engineering

A filter (1) with several rotating filter discs (3) mounted on a shaft (2) and which are provided with a porous filter medium. In one aspect it is characterised by elastomer elements (8, 8′) being mounted on the shaft (2) as spacers between the individual filter discs (3). In another aspect, the invention refers to a filter disc (3) for a filter (1) of this kind, wherein the disc (3) has a rigid support body with distinct drainage channels (21) leading to a central opening for receiving the shaft (2) and an attached surrounding filter medium or membrane (23).

Owner:ZEGG HERBERT +1

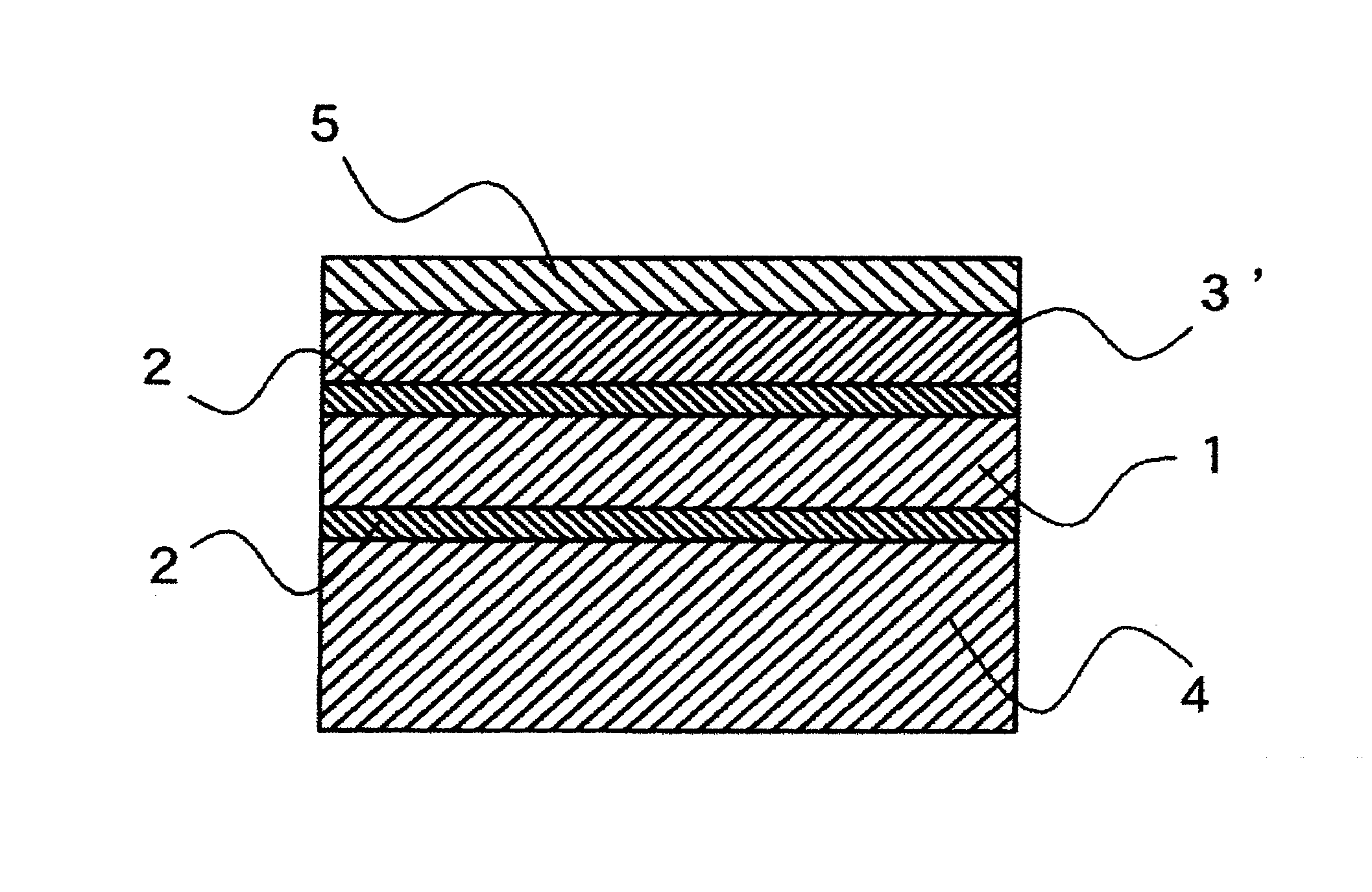

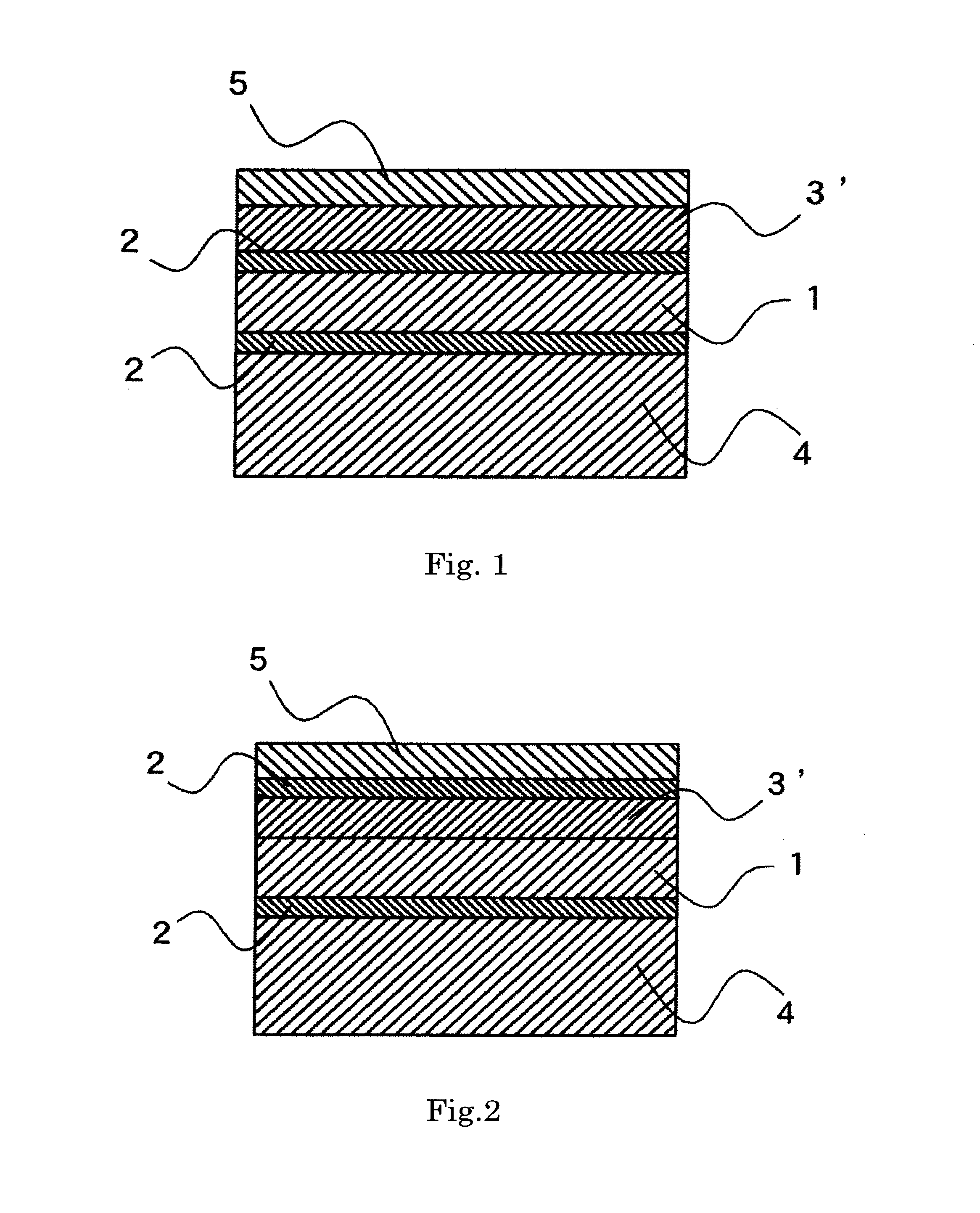

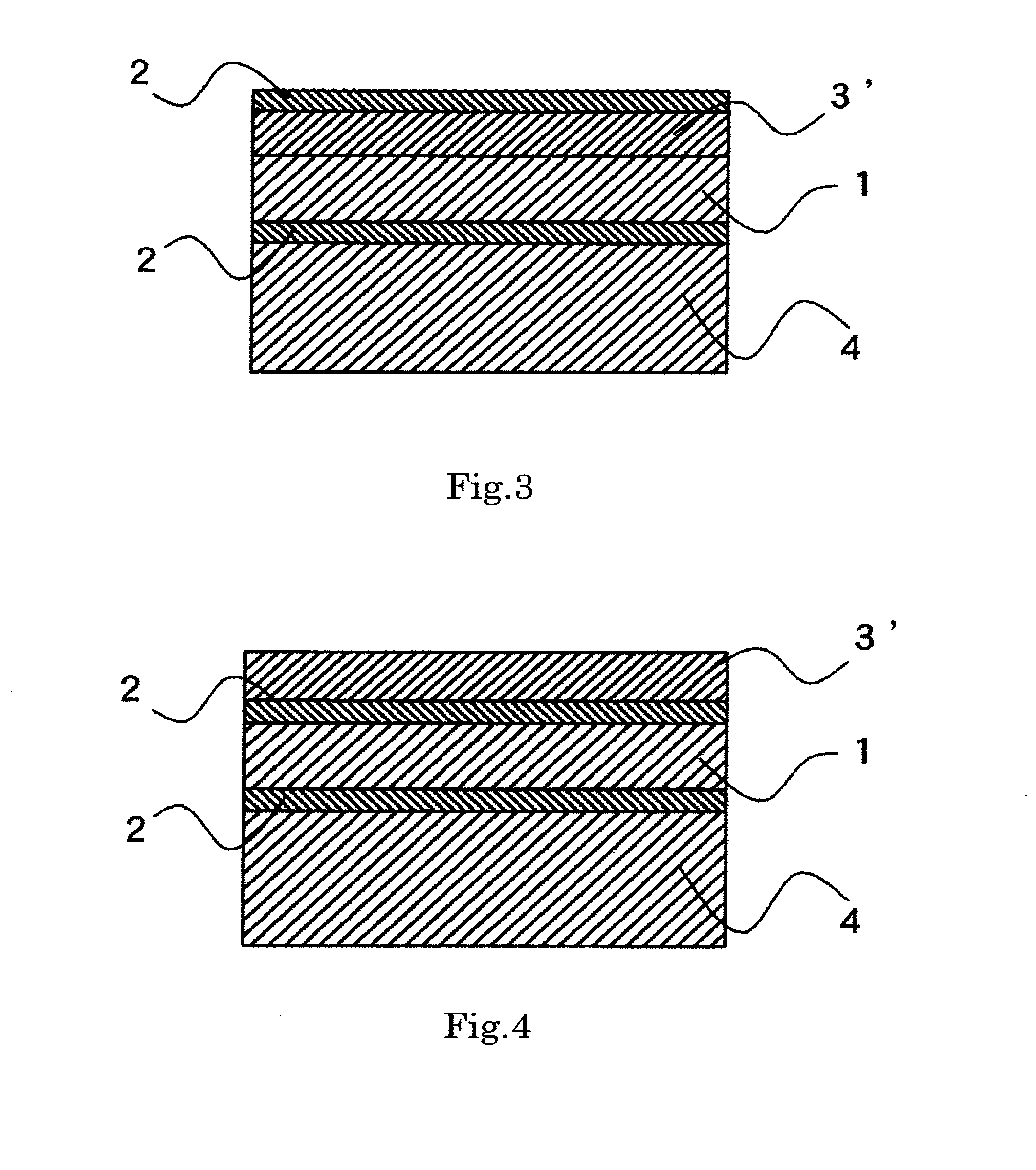

Anti-wear synchronous belt

InactiveCN109466139ABarrier piercingPrevent wear and tearConveyorsSynthetic resin layered productsPolyurethane elastomerAdhesion process

The invention relates to an anti-wear synchronous belt which comprises a polyurethane base layer, wherein a core rope framework is arranged in the polyurethane base layer; a wear-resistant polyurethane layer is arranged on the surface of the polyurethane base layer; the wear-resistant polyurethane layer is an organosilicone modified polyurethane elastomer; the thickness of the wear-resistant polyurethane layer is 1-10mm. The preparation method of the anti-wear synchronous belt comprises the following steps: preparing and integrally molding the polyurethane and the core rope framework by virtueof extrusion molding so as to obtain the polyurethane base layer; adhering the wear-resistant polyurethane layer to the surface of the polyurethane base layer by virtue of a hot melt adhesion process. Compared with the prior art, the anti-wear synchronous belt disclosed by the invention has the advantages of being light in weight, excellent in impact resistance, wear-resistant, cut-resistant andthe like, and can be widely applied to the driving conveying industry.

Owner:AA IND BELTING (SHANGHAI) CO LTD

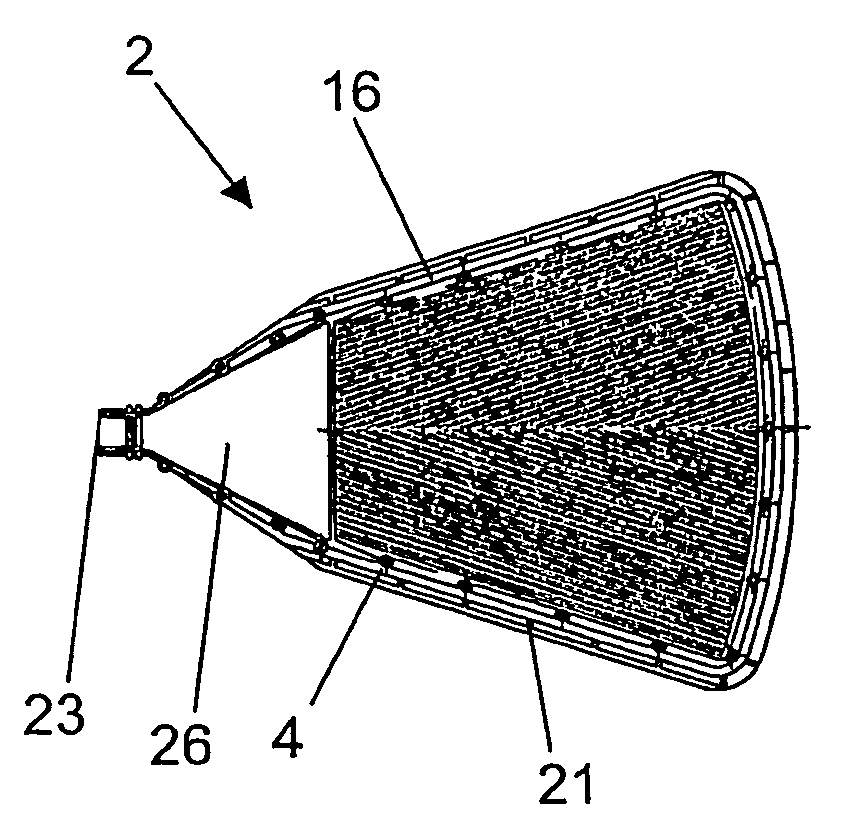

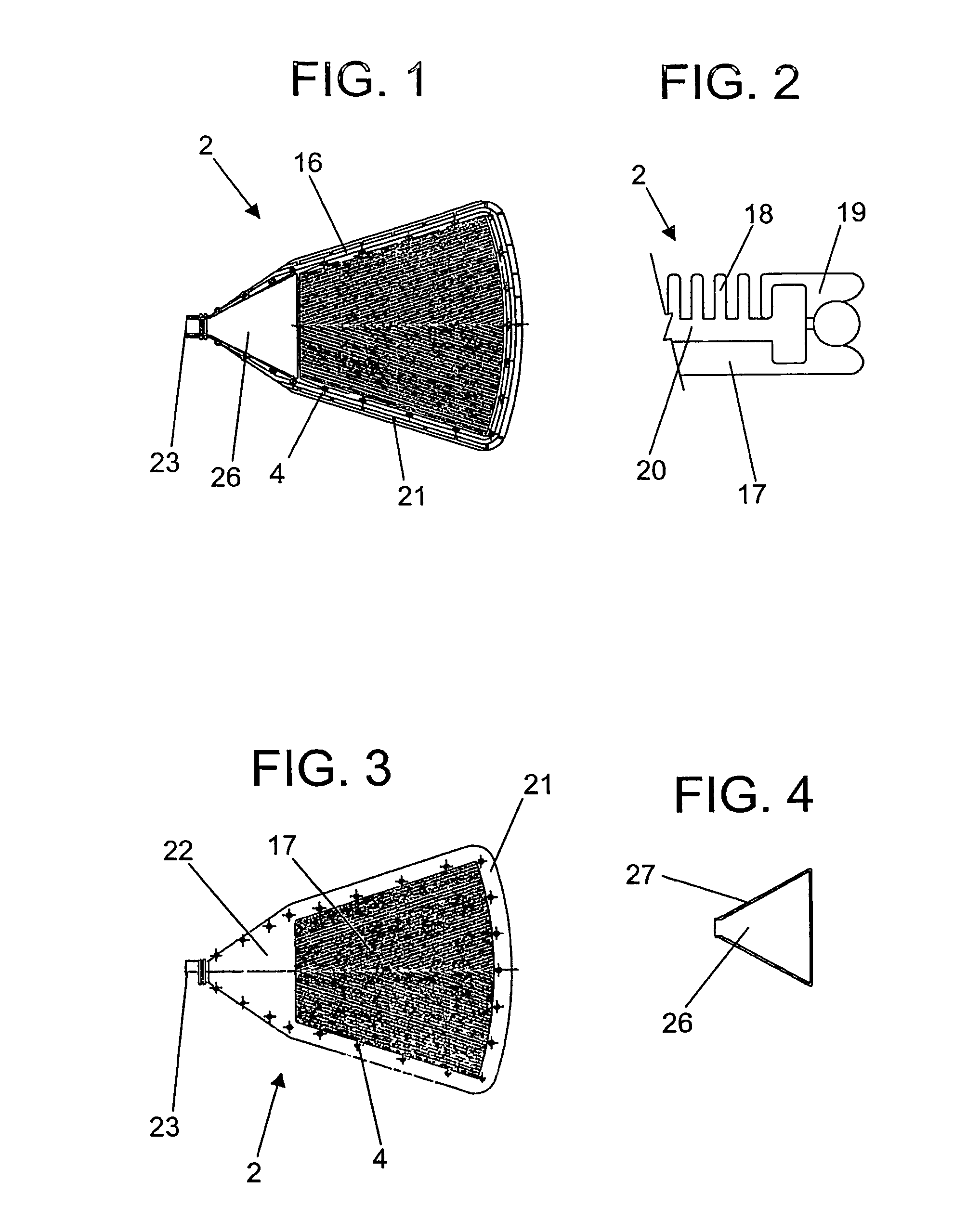

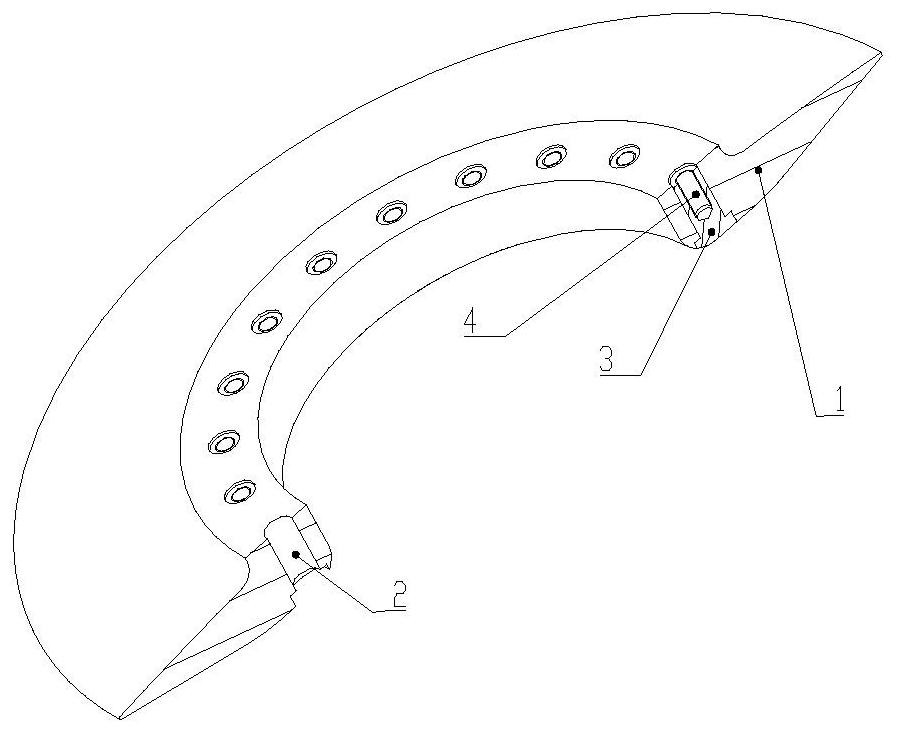

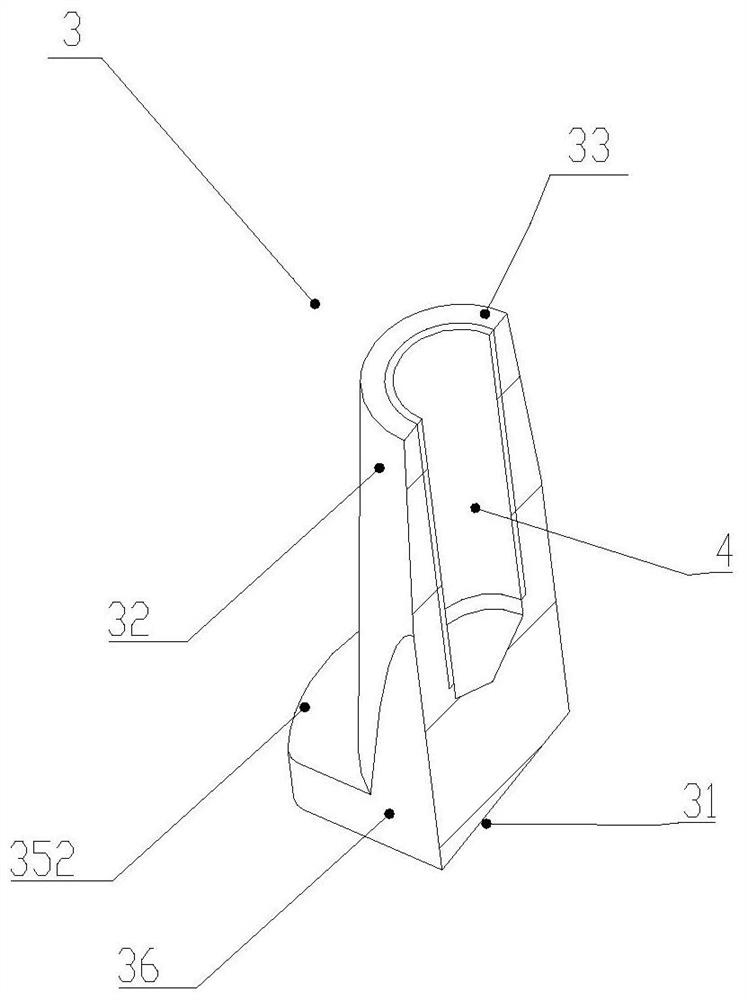

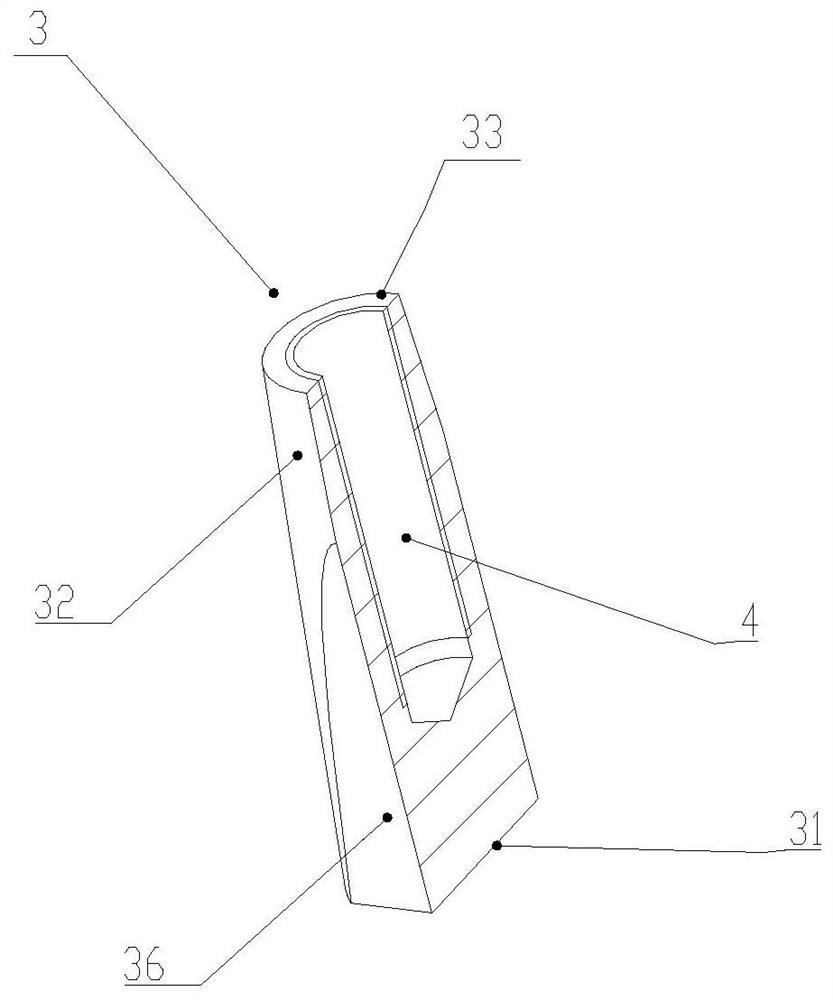

Sector for vacuum rotating filters and similars

A filtering sector (1) provided with two generating elements (2), obtained preferentially of polymeric material highly resistant to abrasion of mining products finely dispersed in the liquid filtrate, drained through the bi-foliar permeable film element (3), which covers the two grating elements (2), which are provided with lowered cylindrical holes (4) distributed along its extension, a par of grating elements (2) this one united through self-locking pins (5) which receives internally, through its frontal end, a locking counter-pin (11). Each grating element (2) formed by perimeter element (16) has a large edge (21) and, in the internal funneling of the grating elements (2), inserts (26), preferentially elastomeric or polymeric of high resistance to abrasion of the minerals finely disperse in the drained filtrate.

Owner:CASFIL IND E COMERCIO

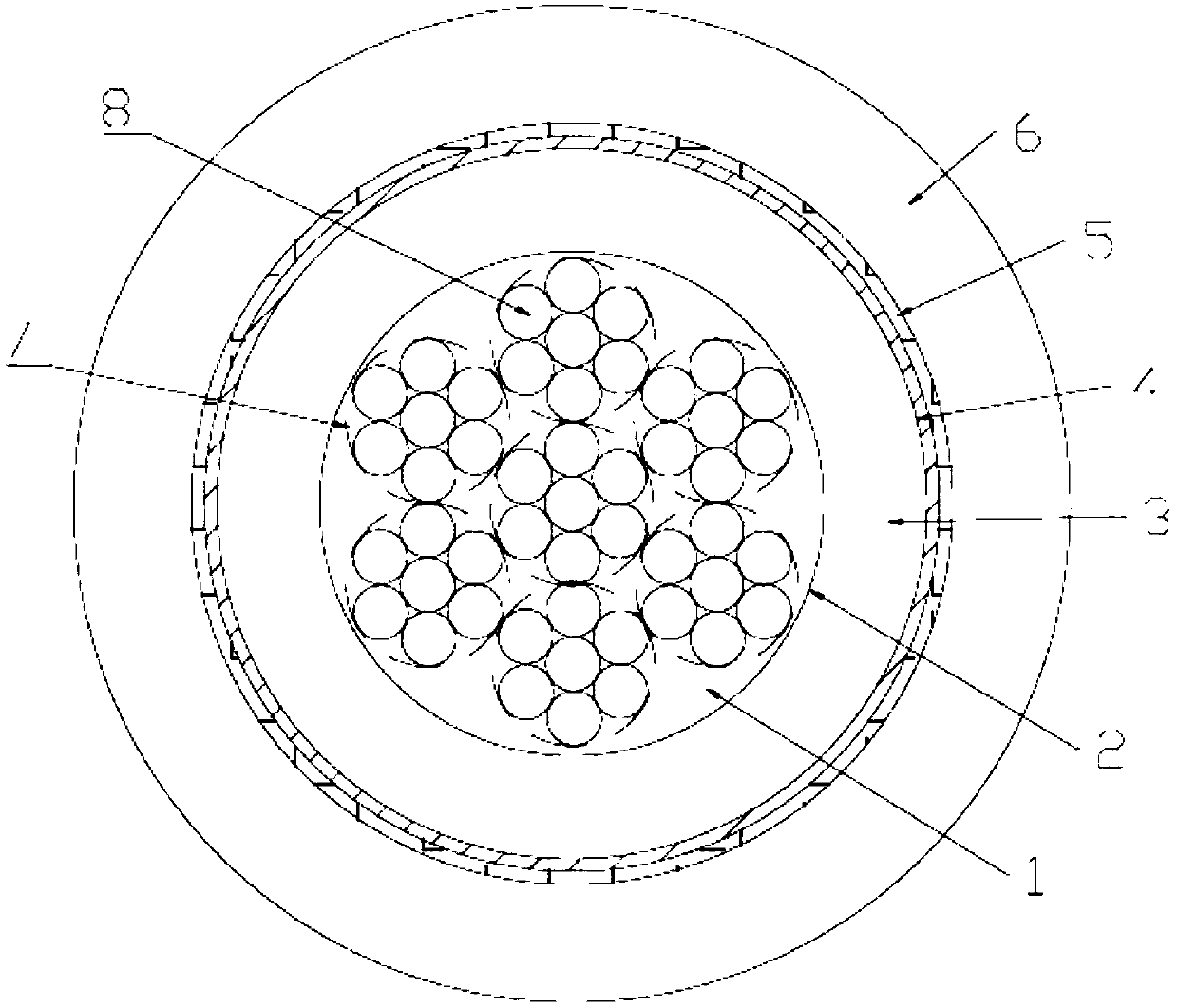

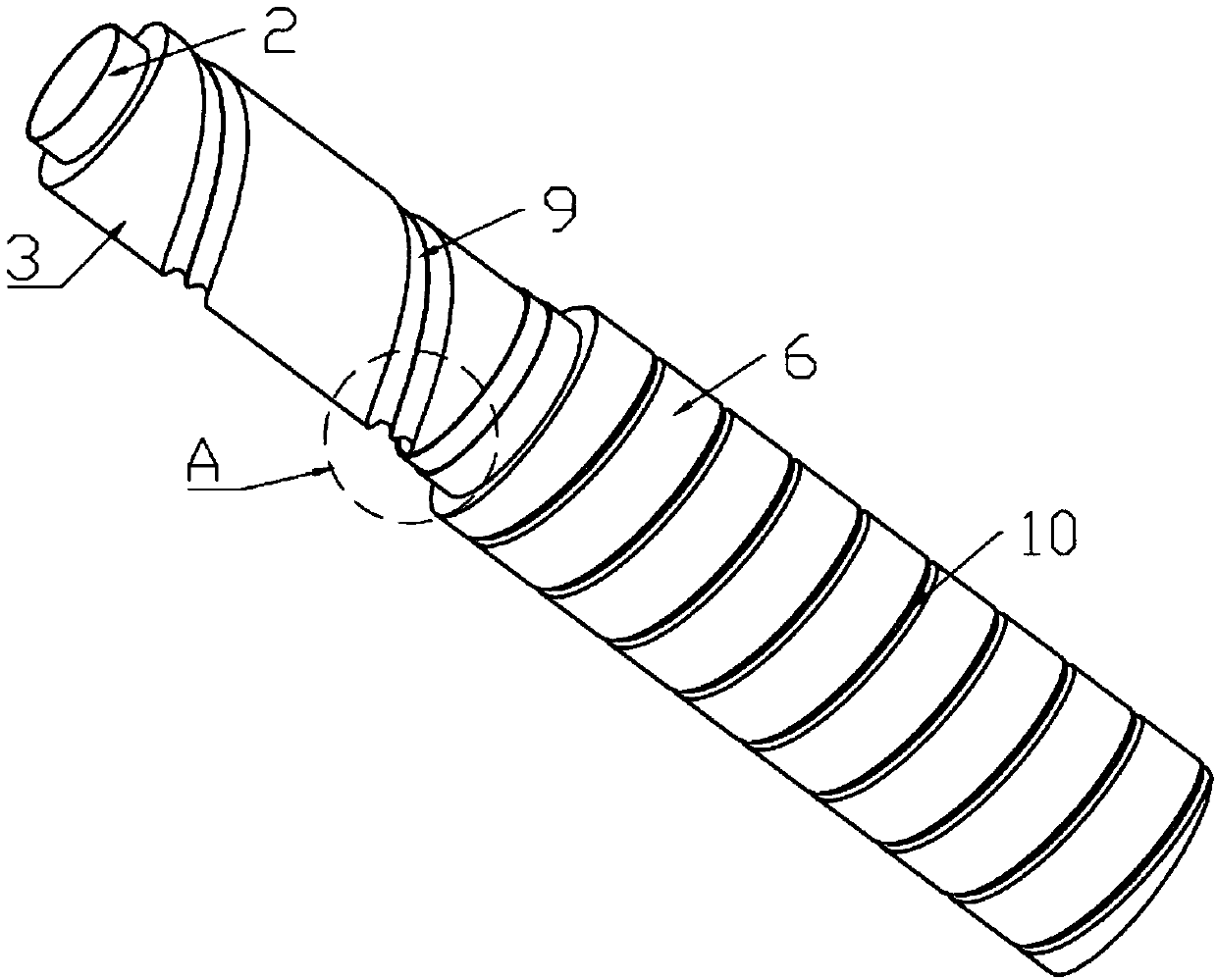

Sand inclusion steel-plastic complex cable guide pipe

A sand inclusion steel-plastic complex cable guide pipe comprises a glass reinforced plastic pipe and a sand inclusion pipe arranged therein, wherein the sand inclusion pipe comprises an inner pipe and a quartz sand layer which is composed of quartz sand grains and is extruded onto the outer surface of the inner pipe; the quartz sand layer covers the outer surface of the inner pipe in the circumferential direction and extends to two ends in the axial direction. According to the invention, the quartz sand layer is additionally arranged between the inner pipe and the glass reinforced plastic pipe to tightly integrate the inner pipe and the glass reinforced plastic pipe; the friction between the inner pipe and the glass reinforced plastic pipe is greatly increased to avoid sliding of the inner pipe from an outer pipe; the sand inclusion steel-plastic complex cable guide pipe has good mechanic performance, high intensity, corrosion resistance, heat resistance, inflaming resistance, insulation property and anti-aging property, and not only exerts the advantages of the glass reinforced plastic pipe, but also avoids the deficiencies of poor wear resistance and filoselle; as the cable can penetrate easily, the condition that the cable is stuck is avoided.

Owner:SHANDONG ZHONGBO PIPES

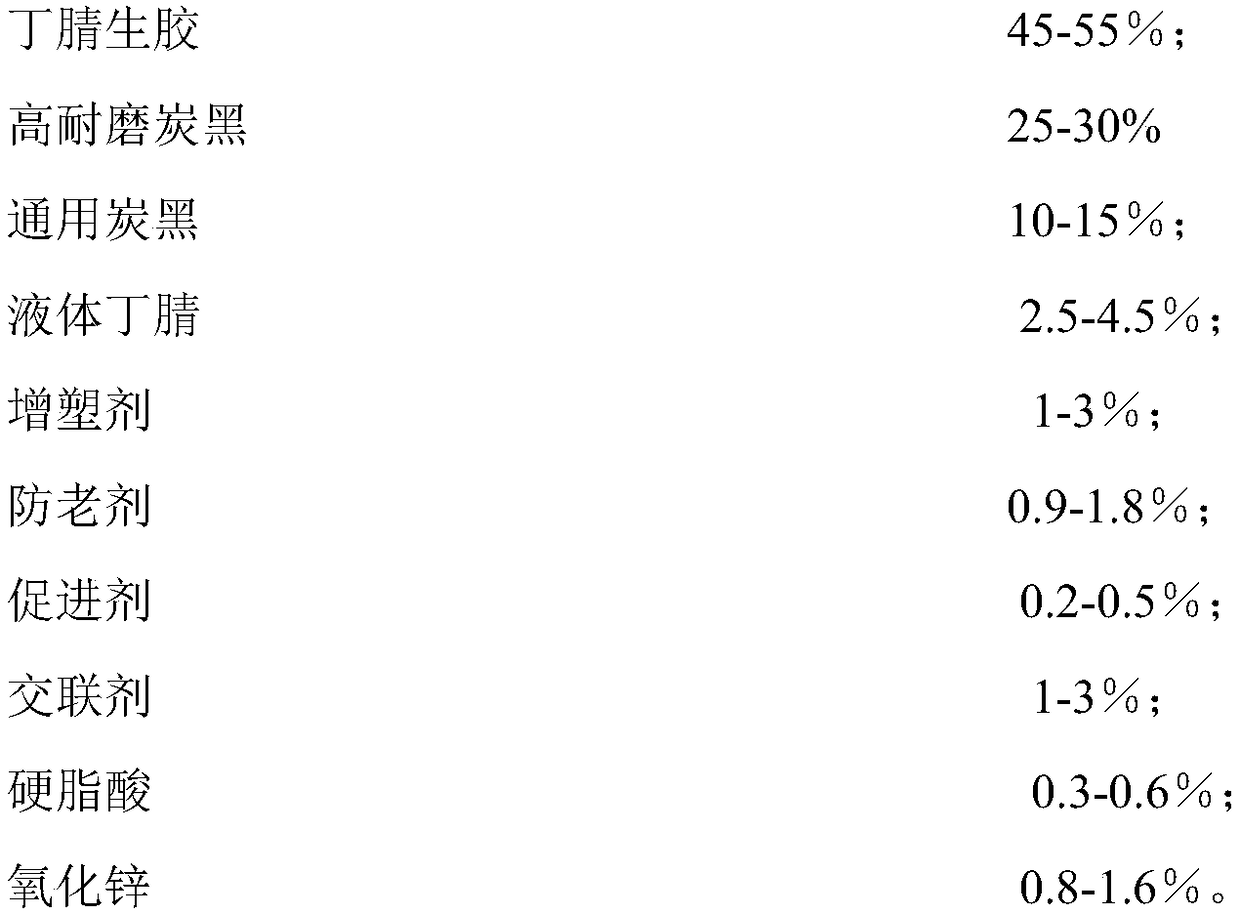

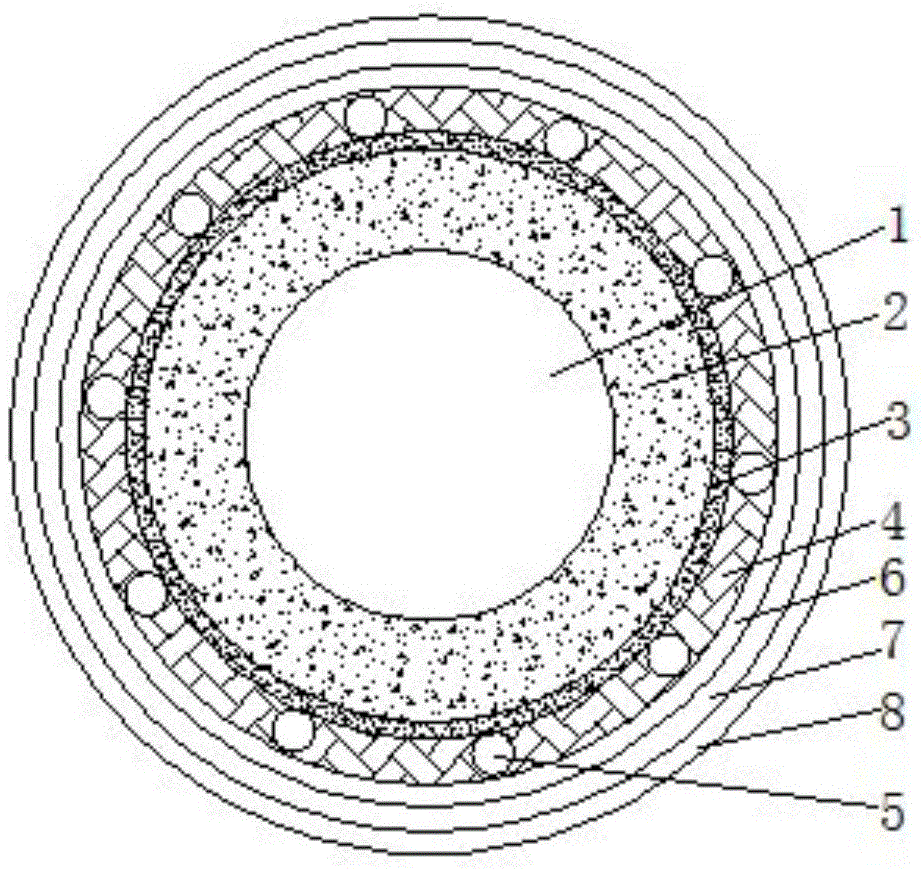

Rubber covered roller of island structure and preparation method thereof

ActiveCN108948459AIncrease coefficient of frictionImprove wear resistanceDomestic articlesPolymer scienceHardness

Owner:南京金三力辊业科技有限公司

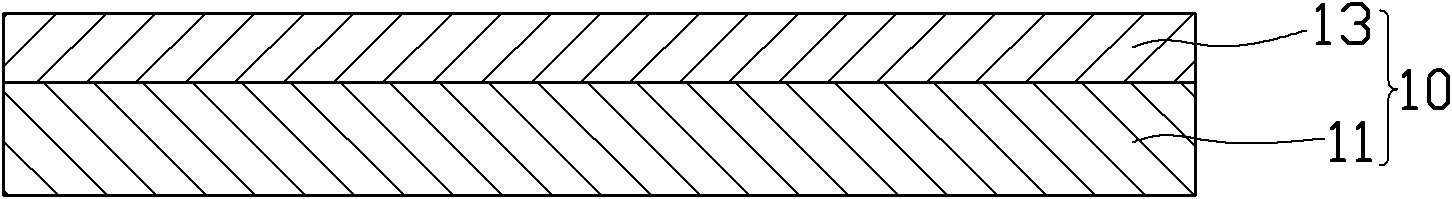

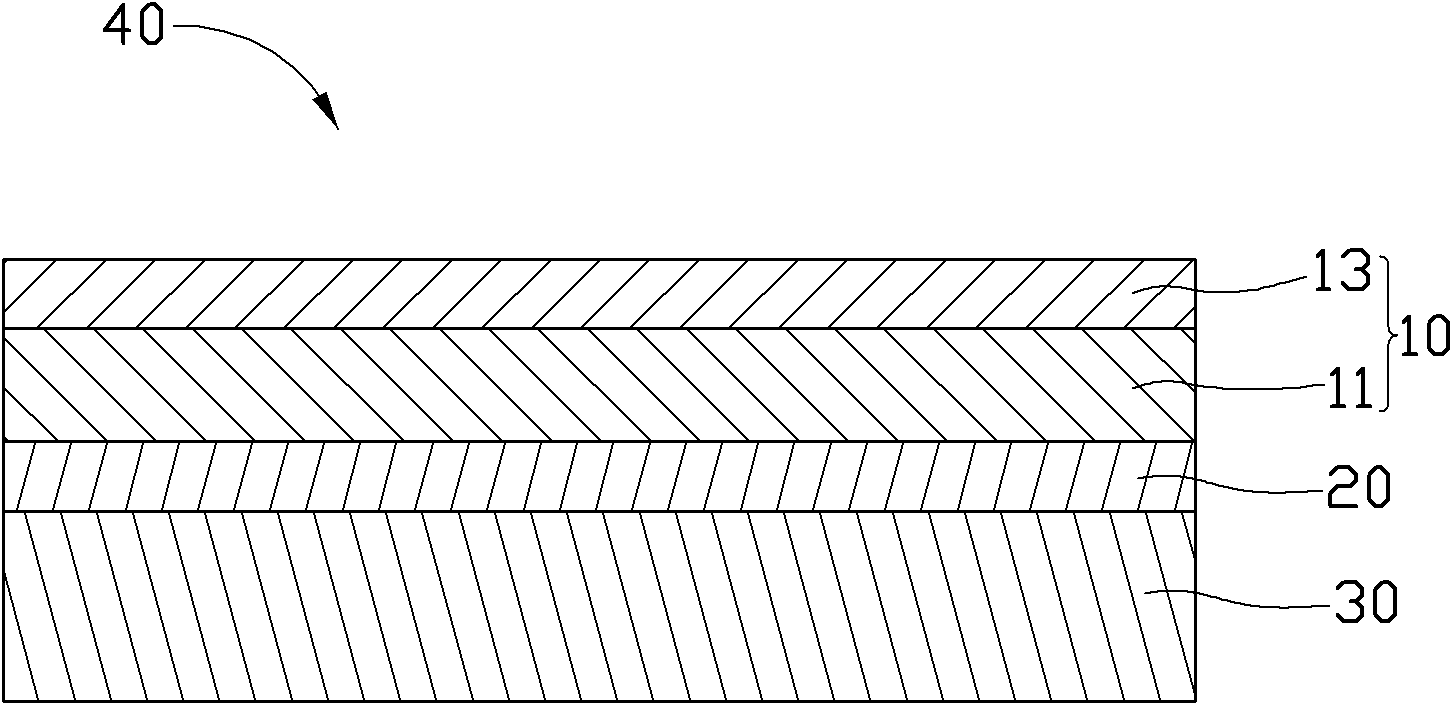

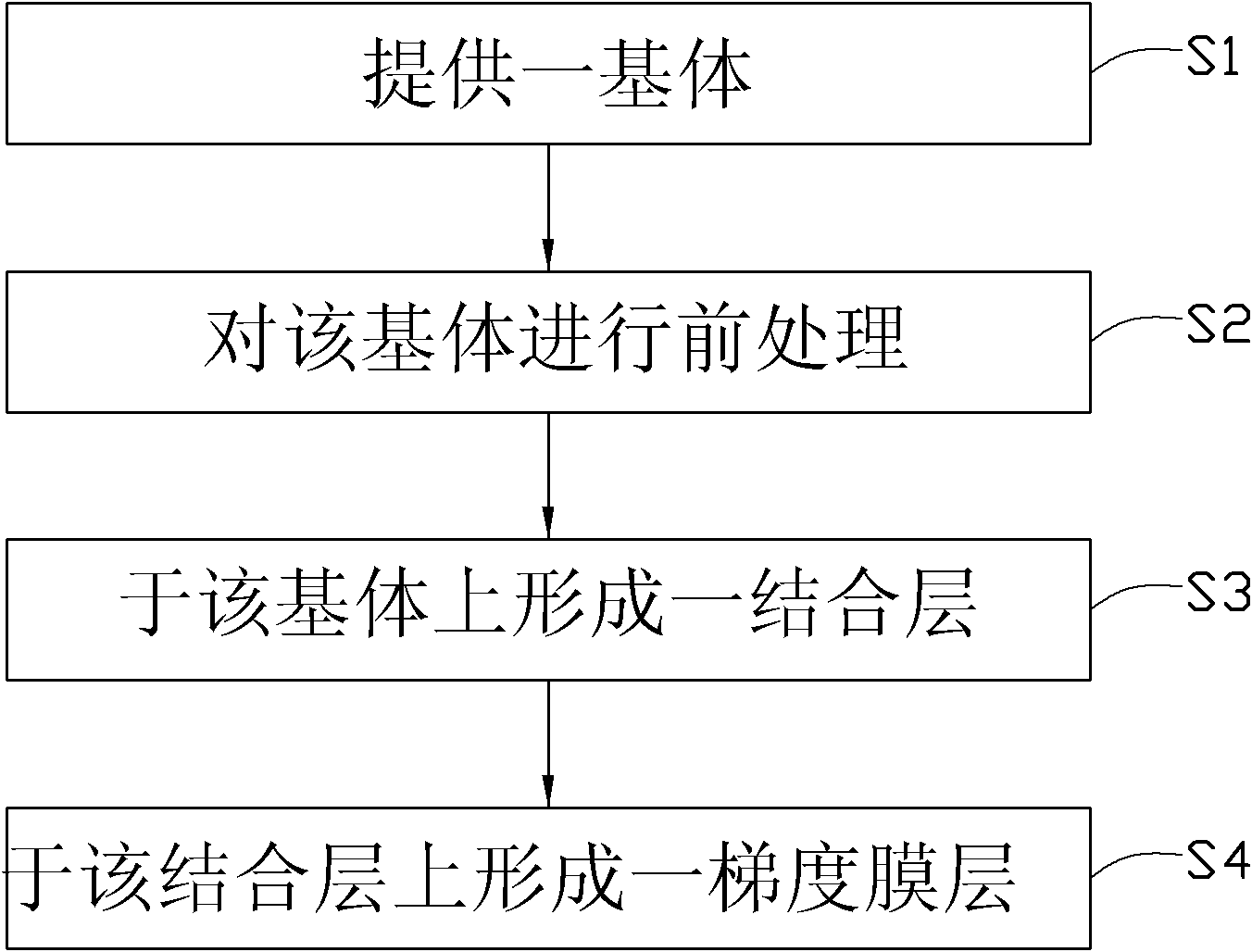

Coating, covered part with the coating and preparation method of covered part

InactiveCN102373426AImprove bindingImprove toughnessLayered productsVacuum evaporation coatingHardnessWear resistance

The invention provides a coating which comprises a ZrBN gradient coating and has high hardness, good corrosion resistance and wear resistance. The invention also provides a covered part with the above coating. The covered part comprises a hard matrix and a coating formed on the hard matrix. The coating contains the ZrBN gradient coating formed on the hard matrix. In addition, the invention also provides a preparation method of the above covered part.

Owner:HONG FU JIN PRECISION IND (SHENZHEN) CO LTD +1

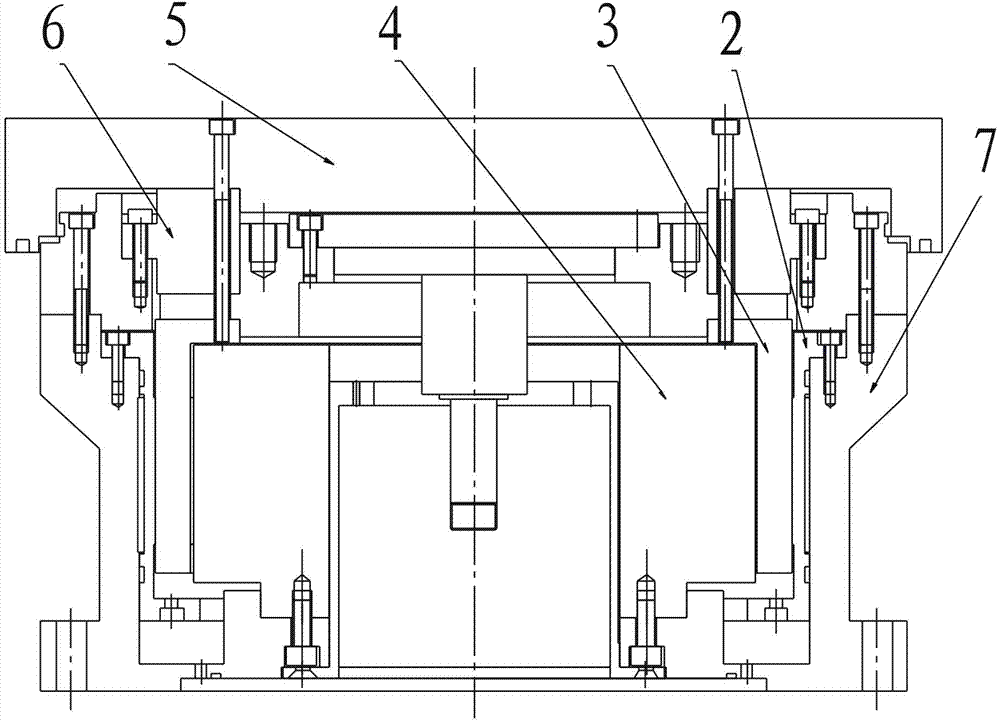

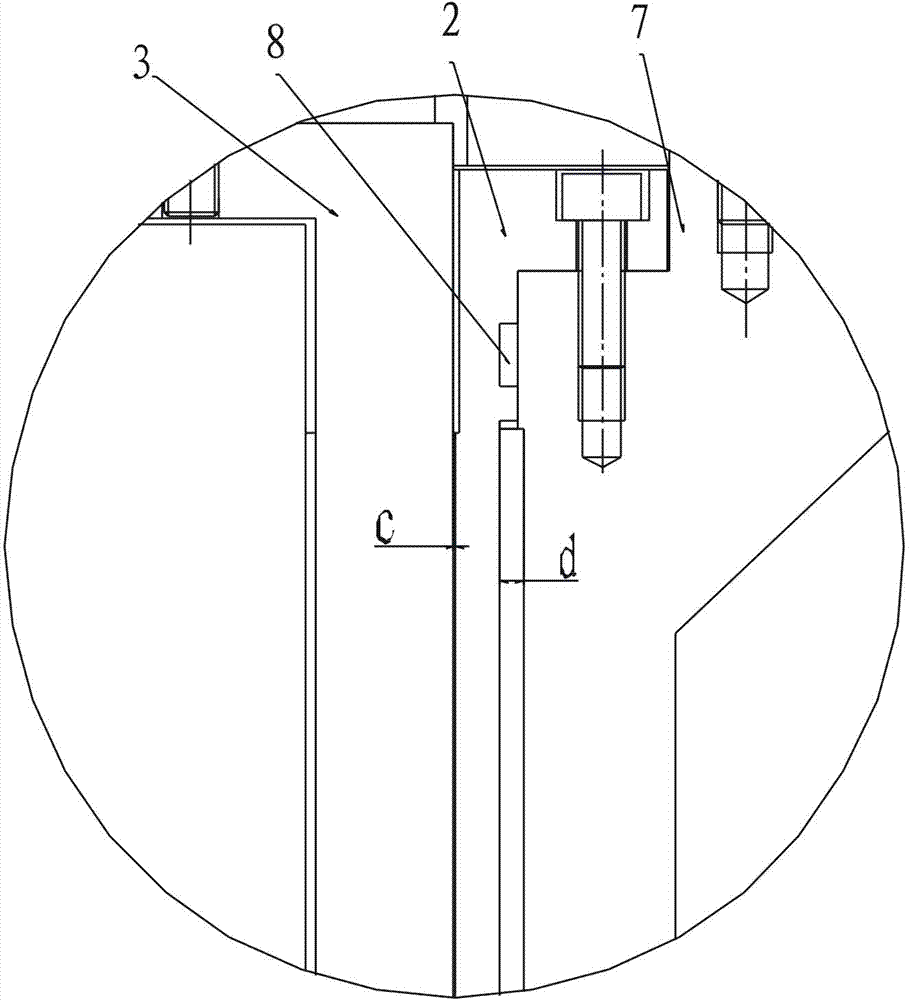

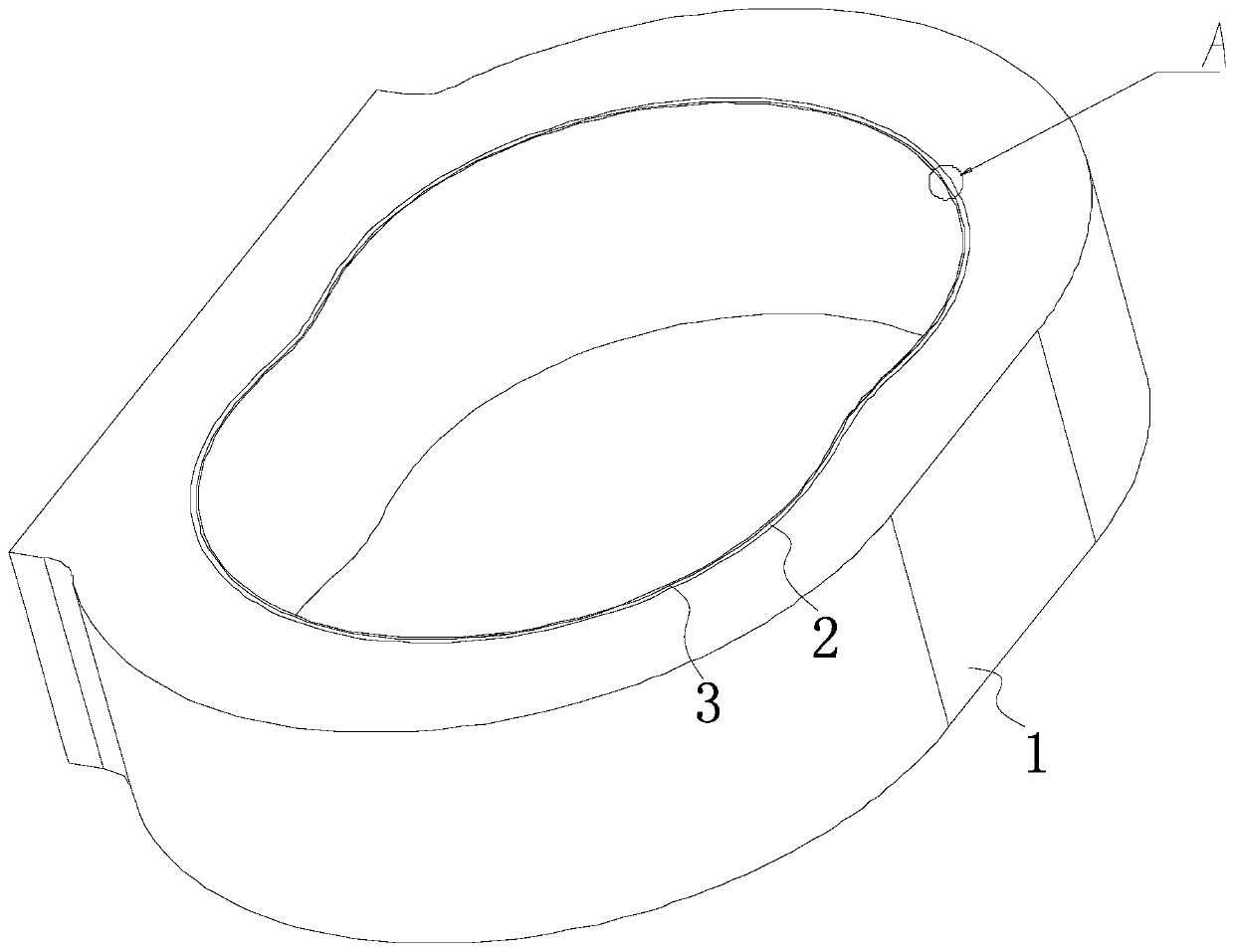

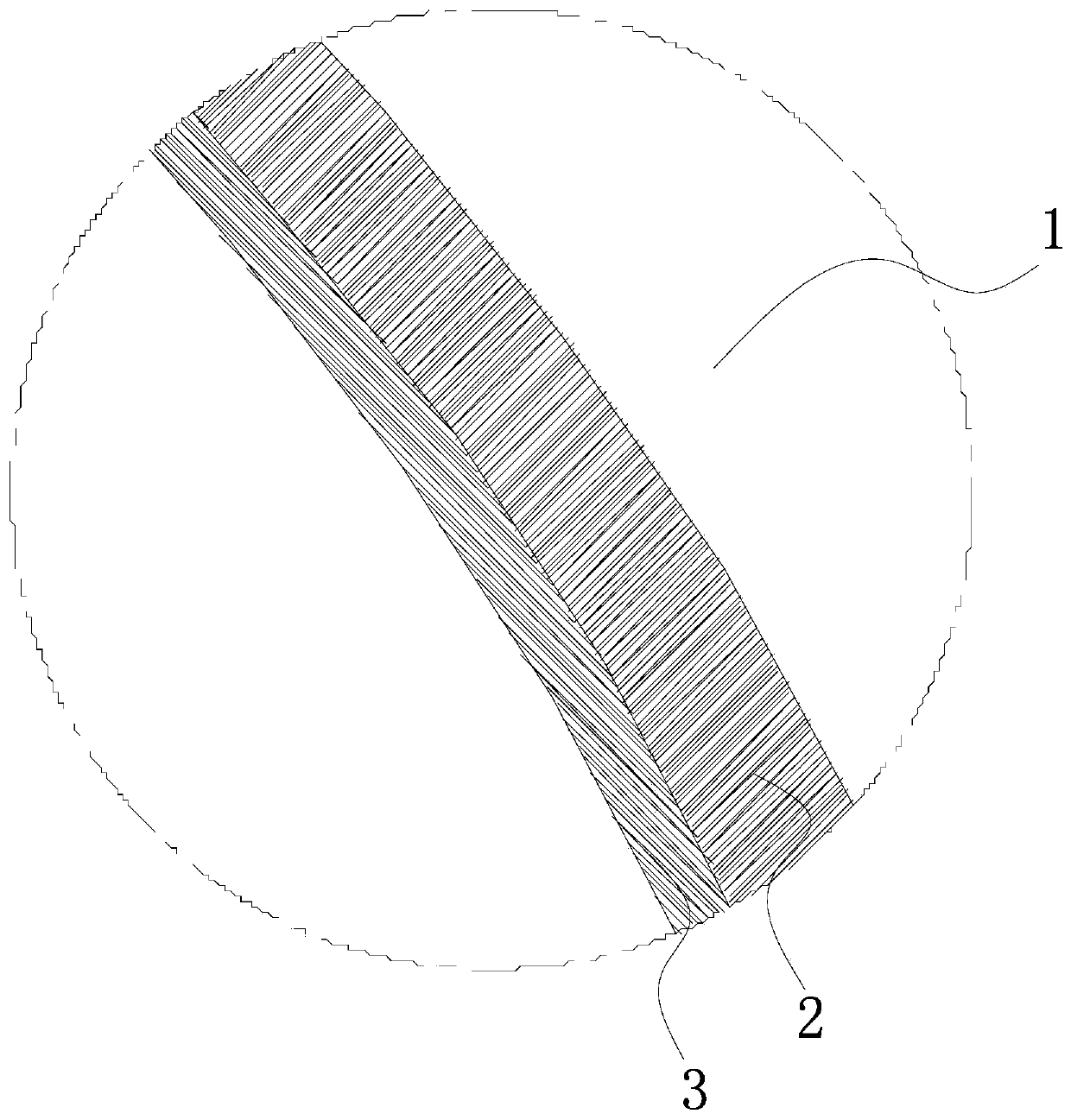

Thin-wall braking sleeve of direct drive rotary table and manufacturing method

InactiveCN103883647AProne to elastic deformationSolve deformation difficultiesBraking membersBrake actuating mechanismsThin walledHydraulic pressure

The invention relates to a thin-wall braking sleeve of a direct drive rotary table and a manufacturing method. A main body of the thin-wall braking sleeve of the direct drive rotary table is an annular cylinder, and the cross section of the annular cylinder is an oval ring. In the height direction of the oval ring, an external gap d is reserved between the outer edge of the oval ring and the inner wall of a case body, and an internal gap c is reserved between the inner edge of the oval ring and the outer wall of a motor rotor, wherein the external gap d is larger than the internal gap c and is filled with hydraulic oil. When the external gap d is filled with the hydraulic oil and the radial hydraulic pressure is generated, at least one action point on the inner wall surface of the annular cylinder is attached to the outer wall of the motor rotor under the effect of the hydraulic pressure in the circumferential direction of the oval ring, so that friction force is generated. On the premise of guaranteeing the strength and the abrasive resistance of the thin-wall braking sleeve, the thin-wall braking sleeve generates elastic deformation easily, and therefore braking of the direct drive rotary table is easy, safe and reliable, and oil leakage is avoided.

Owner:WUHAN POLYTECHNIC UNIVERSITY

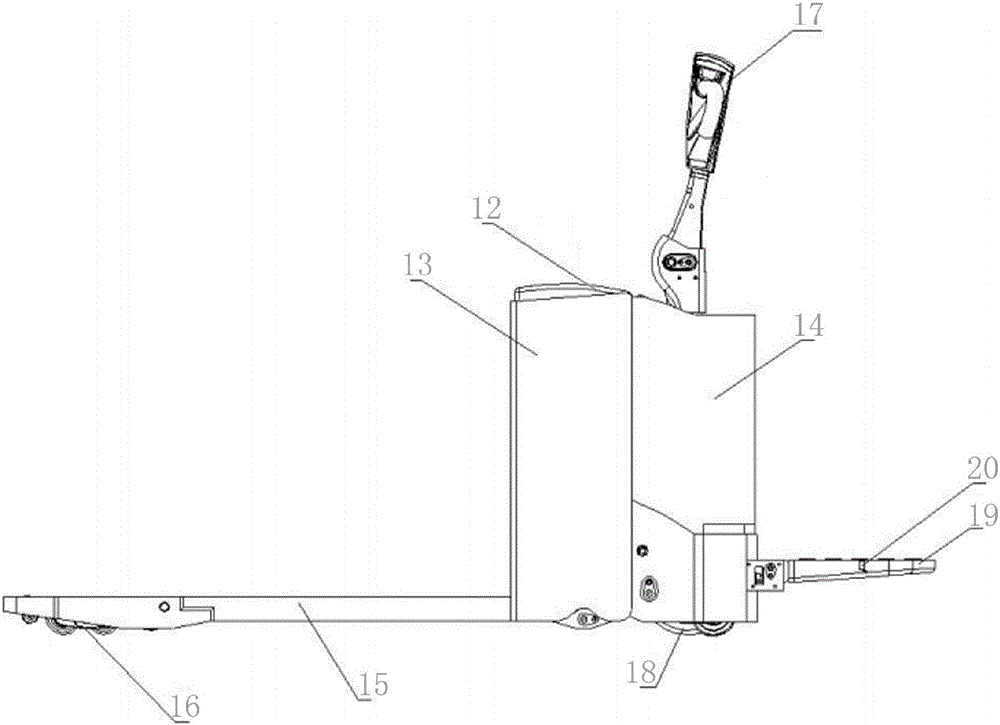

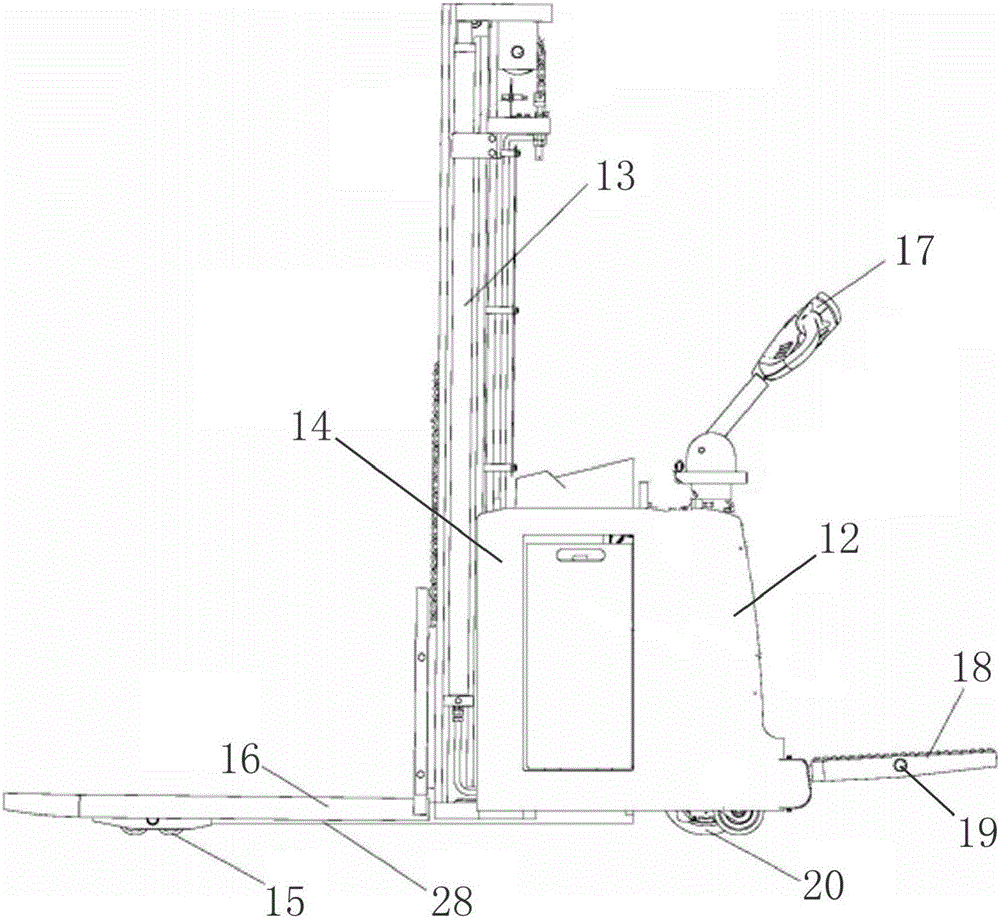

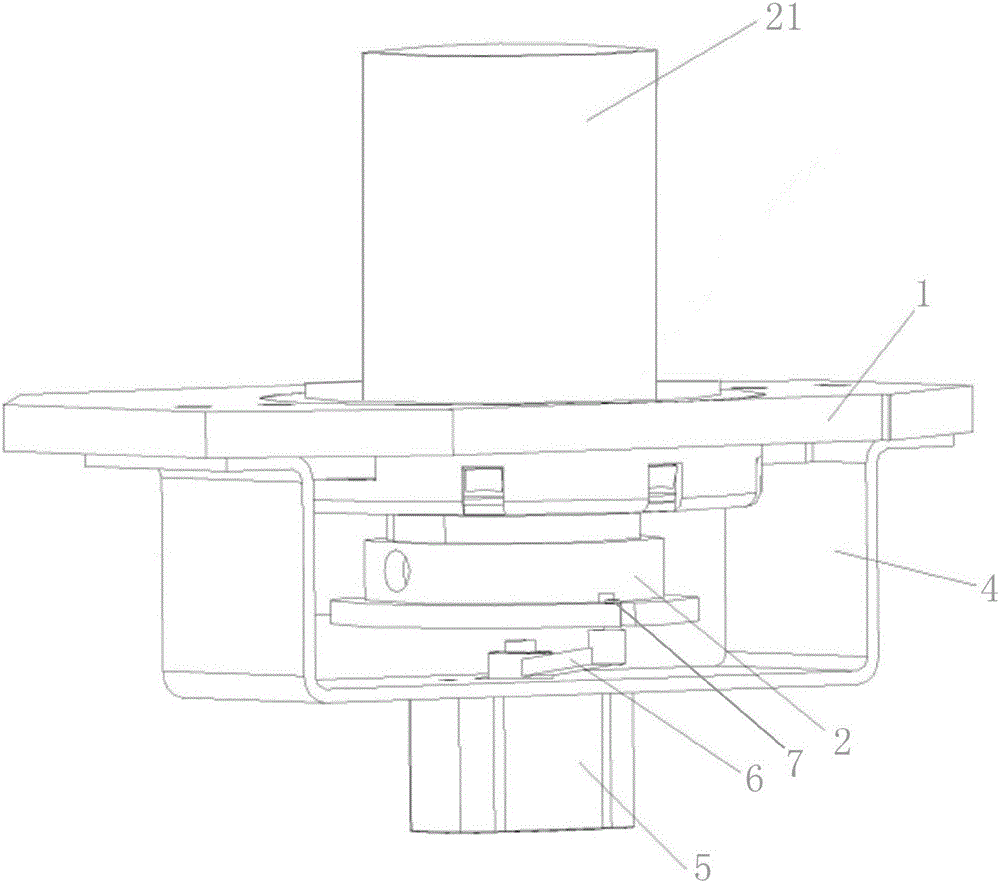

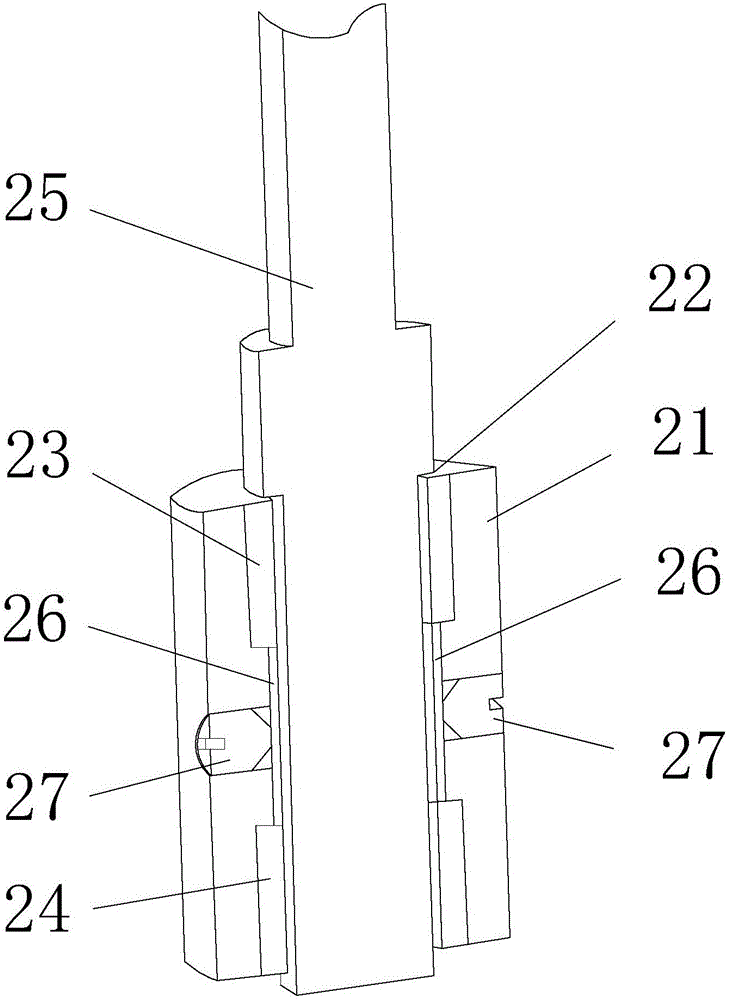

Stand-on type electrically-steering carrier

InactiveCN106080757ASimple structureReasonable designLifting devicesElectrical steeringPotentiometerVehicle frame

The invention provides a stand-on type electrically-steering carrier, comprising a carrier body; the carrier body is divided into an electric cabinet and a mechanical box; the mechanical box is internally provided with an electric driving mechanism and an electric steering mechanism; a pedal is connected with the rear end of the mechanical box and is provided with a pressure sensor; the electric steering mechanism comprises a rotating seat installed on a frame body; an axle hole is formed in the rotating seat, and an upper bearing, a lower bearing and a rotating shaft are arranged in the axle hole; a damping belt is wound on the rotating shaft; a tightening piece is arranged on the side wall of the rotating seat and is connected with the damping belt; a swivel plate is fixedly installed at the bottom end of the rotating shaft, and a nick is formed in the outer side of the swivel plate; a mounting plate is fixed on the bottom surface of the frame body, a potentiometer is fixedly installed under the mounting plate, and the axis of the potentiometer is the same as that of the rotating shaft; a rocker is arranged above the potentiometer, and the outer end of the rocker is connected with a locating pillar clamped in the nick. According to the stand-on type electrically-steering carrier, hand feeling of the electrically-steering is improved; the stand-on type electrically-steering carrier is sensitive in resistance adjustment, and the potentiometer is high in accuracy, so that vehicle manufacturing error is avoided, and the possibility of forced work of the potentiometer is reduced.

Owner:ANHUI YUFENG WAREHOUSING EQUIP

Resin adhesive for bonding thermosetting plastics and thermoplastic plastics and preparation method and application thereof

ActiveCN103450820AGreat ability to resist ground subsidenceStrong ability to resist ground subsidenceNon-macromolecular adhesive additivesOrganic non-macromolecular adhesiveThermoplasticAcrylonitrile

The invention relates to an adhesive and particularly discloses a resin adhesive for bonding thermosetting plastics and thermoplastic plastics and a preparation method and application thereof. The resin adhesive for bonding the thermosetting plastics and the thermoplastic plastics is prepared from the following raw materials in parts by weight: 800-1,000 parts of o-xylene or m-xylene, 280-450 parts of chlorinated polypropylene, 15-42 parts of styryl diethoxysilane, 2-6 parts of acrylonitrile, 1-3.5 parts of di-tert-butyl ether peroxide, 5-15 parts of acrylic acid and 4-6 parts of dimethacrylate-diester. The resin adhesive and the preparation method thereof have the beneficial effects that the raw materials are easily purchased, the cost is low, the toxicity is low, the use is convenient, the bonding is firm, a glass fiber reinforced plastic pipe which is formed through winding glass fibers after the glass fibers are subjected to resin infiltration is tightly combined with an inner pipe so as to form an integer, the split slippage of the inner pipe and an outer pipe is avoided, the coefficient of heat conductivity is large, and the heat resistance is good, so that the problem of bonding between the thermosetting plastics and the thermoplastic plastics is solved effectively, and the resin adhesive is used for bonding the thermosetting plastics (especially glass fiber reinforced plastics) and the thermoplastic plastics (especially polypropylene materials).

Owner:山东呈祥电气有限公司

Connecting structure of composite material joint

The invention discloses a connecting structure of a composite material joint. The connecting structure comprises a composite material joint body and a metal insert, the end face of the composite material joint body is provided with an installation hole for an external connecting piece to penetrate through. The outer bottom face and the outer side face of the metal insert are completely wrapped inthe composite material joint body, and a threaded hole used for being connected with the external connecting piece is formed in the outer top face of the metal insert. According to the connecting structure, the metal insert with the threaded hole is embedded into the composite material joint body; and the external connecting piece is connected with the composite material joint through the threadedhole in the metal insert, the defects that the composite material joint body is low in threaded strength, not resistant to abrasion and the like can be overcome, the bearing capacity is higher, and it is guaranteed that the composite material joint body cannot be damaged in the repeated disassembling and assembling process of the composite material joint and the external connecting piece.

Owner:THE GENERAL DESIGNING INST OF HUBEI SPACE TECH ACAD

Wear-resistant and corrosion-resistant centrifugal pump impeller coating and its preparation method and application

ActiveCN105602356BReduce construction costsEasy constructionLiquid surface applicatorsWax coatingsEpoxySilicic acid

The invention discloses a wear and corrosion resisting centrifugal pump impeller coating layer and a preparation method and application thereof. The centrifugal pump impeller coating layer comprises a base layer coating and a surface layer coating. The base layer coating is prepared from, by weight, 11-15 parts of heavy calcium carbonate powder, 3-8 parts of aluminum oxide, 20-27 parts of octyl epoxy stearate, 10-16 parts of nano barium sulfate and 8-13 parts of dimethyl formamide. The surface layer coating is prepared from, by weight, 5-9 parts of silicon dioxide, 3-8 parts of zirconium silicate, 18-25 parts of epoxy resin, 14-20 parts of chlorinated paraffin, 20-27 parts of polypropylene resin and 5-10 parts of cobaltous hydroxide. All the raw materials in the base layer coating are placed into a ball mill to be subjected to ball milling, sieving and ultrasonic oscillation to obtain the base layer coating. The raw materials, except for the chlorinated paraffin, in the surface layer coating are ball-milled and sieved, then the chlorinated paraffin is added, ultrasonic oscillation and heat treatment are carried out, and therefore the surface layer coating is obtained. A centrifugal pump impeller is high in corrosion resistance and wear resistance, the service life is prolonged, the production process is stable and reliable, the coating layer construction cost is reduced, and construction is convenient.

Owner:HEFEI AINUOWEI MACHINERY EQUIP

Stand-on type electrically-steering stacker

InactiveCN106080756AFeel goodImprove accuracyLifting devicesElectrical steeringVehicle frameEngineering

The invention provides a stand-on type electrically-steering stacker, comprising a mechanical box and an electric cabinet, wherein a lifting mechanism is arranged at the front end of the electric cabinet; a pedal and a pressure sensor are arranged at the rear end of the mechanical box; the mechanical box is internally provided with an electric driving mechanism and an electric steering mechanism; a handle is arranged above the mechanical box and is connected with the electric steering mechanism; the mechanical box is internally provided with a frame body; the electric steering mechanism comprises a rotating seat installed on the frame body, and the rotating seat is internally provided with an upper bearing, a lower bearing and a rotating shaft; a damping belt is wound on the rotating shaft; a tightening piece is arranged on the side wall of the rotating seat and is connected with the damping belt; a swivel plate is fixed at the bottom end of the rotating shaft, and a nick is formed in the outer side of the swivel plate; a mounting plate is fixed on the bottom surface of the frame body, and a potentiometer is fixed under the mounting plate; a rocker is arranged on the potentiometer, and the outer end of the rocker is connected with a locating pillar clamped in the nick. According to the stand-on type electrically-steering stacker, the damping belt is additionally arranged in an axle hole, so that hand feeling is improved during the rotation of the handle; the stand-on type electrically-steering carrier is sensitive in resistance adjustment, and the potentiometer is high in accuracy, so that misoperation is avoided.

Owner:ANHUI YUFENG WAREHOUSING EQUIP

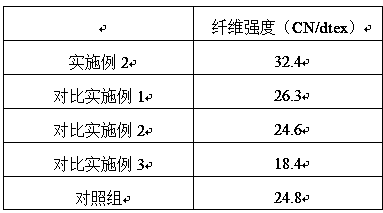

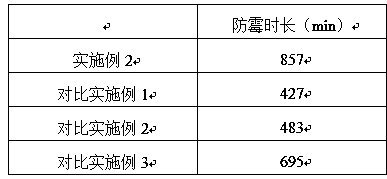

Production method of fibers for antibacterial and durable mattress fabric

InactiveCN110359109AExtended service lifeAvoid sexual fragilityGlass making apparatusFlame-proof filament manufactureFiberGlass fiber

The invention discloses a production method of fibers for antibacterial and durable mattress fabric. The production method includes the steps of firstly, preprocessing original bamboo fibers; secondly, performing ion injection; thirdly, modifying glass fibers; fourthly, blending; fifthly, spinning and setting. The production method has the advantages that the original bamboo fibers and the glass fibers are subjected to special treatment and then blended, the advantages of the two fibers are kept, the defects of the two fibers are overcome, the defects that the original bamboo fibers are shortin service life, and the glass fibers are brittle and poor in wear resistance are overcome, the bacterial resistance, breathability, flame retardance and strength of the fibers for the mattress fabricare enhanced evidently, and the service life of the final product is prolonged.

Owner:阜阳皖春家俬有限公司

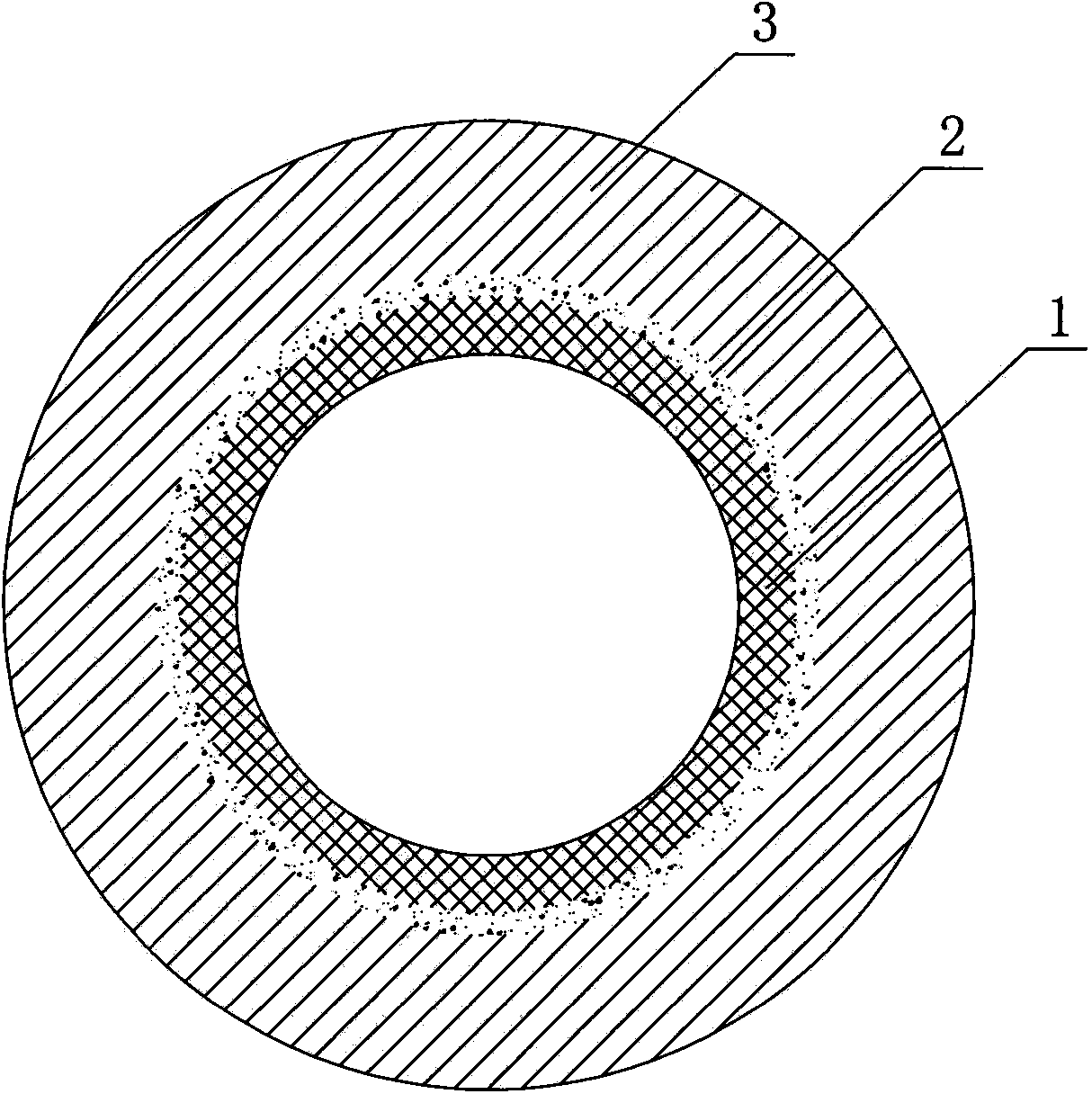

Wear-resistant cylinder body of triangular rotor engine and machining method thereof

ActiveCN110080876AExtend your lifeImprove wear resistanceInternal combustion piston enginesCombustionWear resistant

The invention belongs to the field of internal combustion engines, and provides a wear-resistant cylinder body of a triangular rotor engine and a machining method thereof. The wear-resistant cylinderbody of the triangular rotor engine comprises a cylinder body base body, a transition layer and a wear-resistant layer, the transition layer is arranged on the inner side surface of the cylinder bodybase body, and the wear-resistant layer is arranged on the inner side surface of the transition layer. Compared with the prior art, the wear-resistant cylinder body of the triangular rotor engine andthe machining method thereof have the advantages that the wear resistance of the cylinder body is improved, the transition layer is used for connecting the cylinder body base body and the wear-resistant layer, so that the problem that the wear-resistant layer falls off and the wear resistance is insufficient due to insufficient binding force when the wear-resistant layer and the cylinder body basebody material are directly bonded is solved, and the service life of the engine is prolonged.

Owner:NINGBO UNIV

Front connector of high air-pressure down-the-hole hammer

InactiveCN102434113AExtended service lifeAvoid abrasionDrilling rodsBorehole drivesMaximum diameterWear resistant

The invention provides a front connector of a high air-pressure down-the-hole hammer. A wear resistant material layer is welded on an excircle with the maximum diameter on the front end of the front connector, the welding seam direction of the wear resistant material layer is along the axis of the front connector or along the circumference of the front connector, or forms an angle of inclination with the axis of the front connector, and the wear resistant material layer is a tungsten carbide wear resistant welding rod. By welding the wear resistant material layer with a certain thickness on the excircle on the front end of the front connector, when a hammer works, the high speed returning debris firstly scours and abrades the wear resistant material layer welded on the surface of the front connector under the action of a high pressure gas, thus avoiding that the front end of the front connector directly withstands the violent scouring and abrasion of the debris and greatly increasing the service life of the front connector.

Owner:SHAREATE TOOLS

Flexible oil-resistant dual-layer high-voltage cable for new-energy vehicle

PendingCN107731371AAvoid spreadingDistribute stressPower cables with screens/conductive layersFlexible cablesTinningInsulation layer

The invention discloses a flexible oil-resistant dual-layer high-voltage cable for a new-energy vehicle. A six-type-conductor in a compound stranding form is adopted and is coated with an insolating layer, the isolating layer is coated with a silicon gel layer, the silicon gel layer is coated with a tinned copper weaving shielding layer, the tinned copper weaving shielding layer is coated with analuminum foil shielding layer, and the aluminum foil shielding layer is coated with an XLPO insulation layer. The insulation layer is formed by winding cotton paper around the six-type-conductor, andthe weaving angle of the tinned copper weaving shielding layer is 50 degrees. The overlapping ratio of the cotton paper winding is larger than or equal to 30%, and the moisture absorption rate of thecotton paper is smaller than 3%. The flexible oil-resistant dual-layer high-voltage cable has the advantages that the flexibility is high, the insulation layer does not easily crack, the interferenceis not generated, and the flexible oil-resistant dual-layer high-voltage cable is suitable for being widely applied and popularized.

Owner:王秀云

Energy-saving low-loss anti-interference wire cable

InactiveCN105609172AAvoid lossAchieve thermal protectionClimate change adaptationPower cables with screens/conductive layersGlass fiberElectrical conductor

The invention discloses an energy-saving low-loss anti-interference wire cable. The energy-saving low-loss anti-interference wire cable comprises a conductor, wherein a glass fiber insulating layer, a silica gel protective layer and a packing layer are wrapped on the outer surface of the conductor in sequence; the packing layer is formed by laminating ceramic powder, mica and asbestos, and reinforcing ribs are further additionally arranged in the packing layer; an electromagnetic shielding layer is wrapped on the outer surface of the packing layer; an anti-radiation layer and a rubber insulating outer skin layer are wrapped on the outer surface of the electromagnetic shielding layer in sequence; the anti-radiation layer is made of metal wires, and has a good anti-radiation performance; the wire cable is provided with the rubber insulating outer skin layer, so that insulation, tensile resistance, impact resistance and radiation isolation of the wire cable are solved, and the wire cable has a good bending performance and also isolates external radiation; a waterproof film formed by spraying a polyurethane waterproof coating is arranged on the outer side of the rubber insulating outer skin layer; the waterproof film achieves a waterproof effect effectively, so that the wire cable is protected; and meanwhile, the wire cable is effectively protected by the reinforcing ribs and the rubber insulating outer skin layer, so that the wire cable is prevented from causing loss due to external reasons.

Owner:FUJIAN NANSHENG CABLE CO LTD

A connection structure of a composite material joint

Owner:THE GENERAL DESIGNING INST OF HUBEI SPACE TECH ACAD

Method for reducing load of rod mill and abrasion to inner chamber of rod mill

The invention relates to the technical field of application of a rod mill, and discloses a method for reducing the load of the rod mill and abrasion to an inner chamber of the rod mill. The method comprises the following steps: (1) additionally arranging an electromagnetic band type iron separator and transforming magnetic separation equipment; (2) improving the stability of a steel rod; (3) manufacturing a steel slag screening device and sorting and smashing steel slag; (4) adjusting the metal grade and a transmission device; (5) storing and managing the metal after recovery; and (6) checkingthe modification result. According to the method for reducing the load of the rod mill and the abrasion to the inner chamber of the rod mill, the steel slag is conveyed to the interior of the screening device for primary crushing and secondary crushing before entering the rod mill, so that the steel slag is prevented from excessively abrading the steel rod when entering the rod mill and the consumption of the steel slag is reduced, and the effect of reducing the material consumption is achieved; and due to the fact that the metal grade and the transmission device are adjusted, matched equipment of a belt conveyor can have good abrasion resistance, and accordingly the problems that the consumption of a grinding rod and an auxiliary plate of the rod mill is high and the abrasion of the matched equipment of the belt conveyor is serious are effectively solved.

Owner:CHENGYU VANADIUM TITANIUM TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com