High-entropy alloy powder used on surface of riding wheel of rotary cement kiln, preparation method thereof and coating preparation method

A cement rotary kiln and high-entropy alloy technology, which is applied in metal material coating process, coating, fusion spraying, etc., can solve the problem that the coating quality and surface continuity cannot meet the production and use requirements, and the uniformity of powder components Insufficient, high powder oxidation, etc., to achieve excellent comprehensive performance, uniform components, high bonding strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

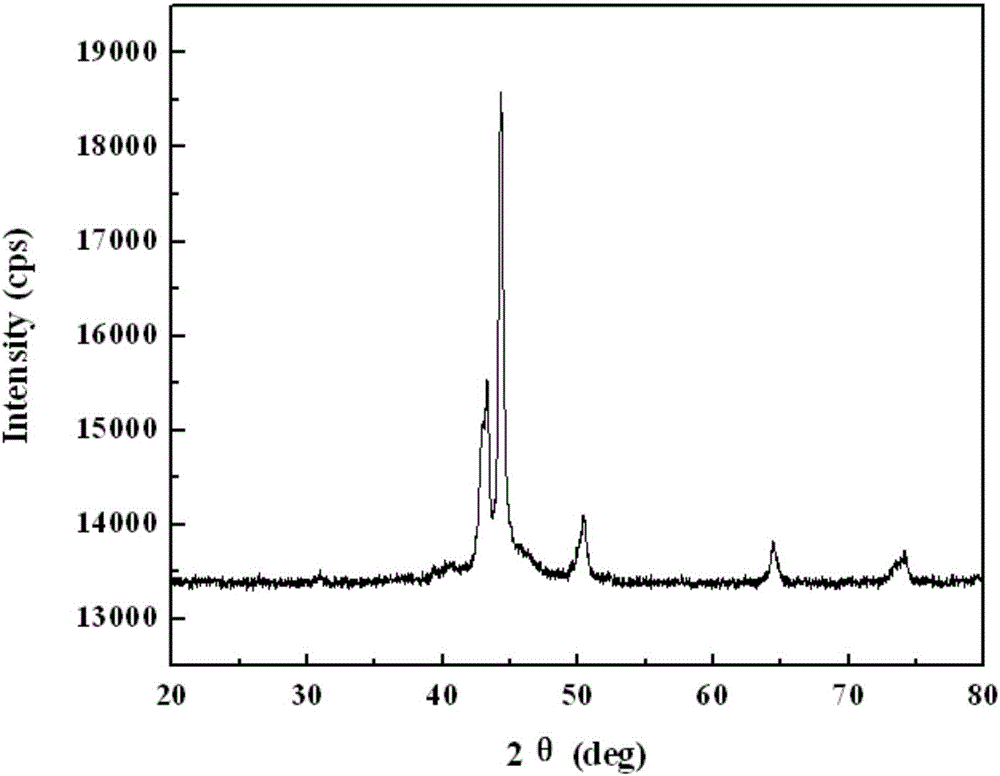

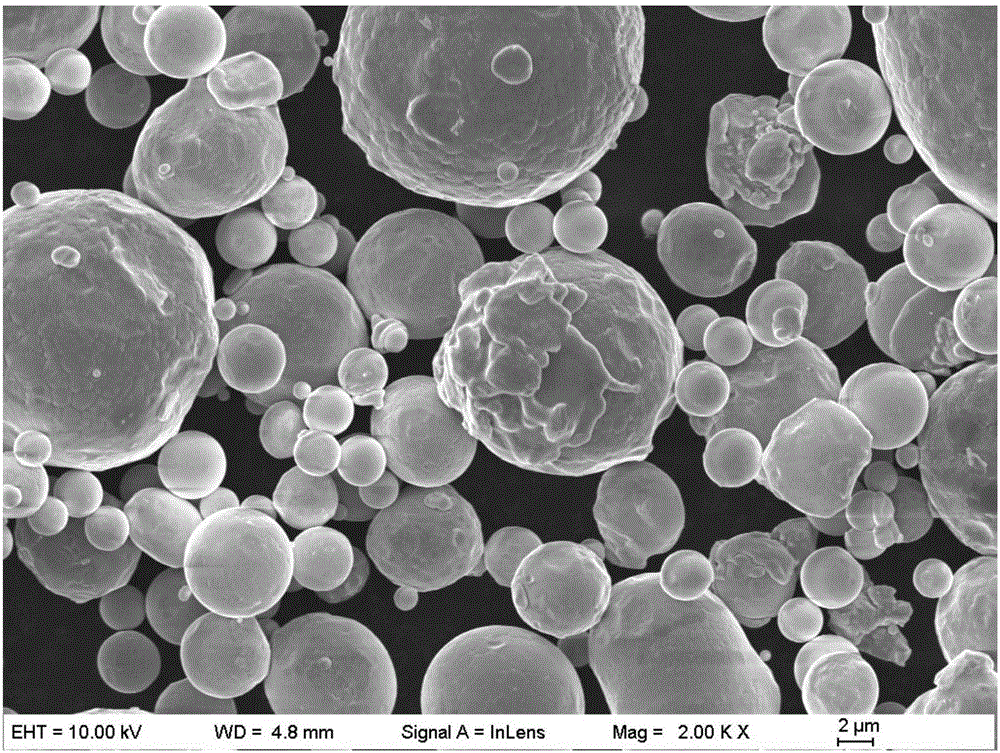

[0027] The present invention proposes a high-entropy alloy powder for the surface of a cement rotary kiln supporting wheel, and its chemical composition includes: Fe: 19%, Al: 19%, Cr: 18%, Mn: 19%, Ni: 20.4 %, W: 3%, B: 0.6%, C: 1%.

[0028] The present invention also proposes a method for preparing high-entropy alloy powder for the surface of the supporting wheel of the cement rotary kiln, comprising the following steps:

[0029] S1. Weigh 19 kg of iron ingot, 19 kg of aluminum ingot, 18 kg of chromium ingot, 19 kg of manganese ingot, 17.15 kg of nickel ingot, 3 kg of metal tungsten, 3.85 kg of nickel-boron alloy and 1 kg of carbon powder according to the melting point. Put them into the medium frequency induction melting furnace in sequence from low to high, and evacuate to 1.5×10 -3 MPa, then filled with argon, and smelted for 60 minutes under the condition of argon pressure of 1.1 atmospheric pressure to obtain a metal liquid;

[0030] S2. Send the metal liquid into the...

Embodiment 2

[0035] The present invention proposes a high-entropy alloy powder for the surface of a cement rotary kiln supporting wheel, and its chemical composition includes: Fe: 18%, Al: 17.7%, Cr: 19%, Mn: 20%, Ni: 19 %, W: 4%, B: 0.8%, C: 1.5%.

[0036] The present invention also proposes a method for preparing high-entropy alloy powder for the surface of the supporting wheel of the cement rotary kiln, comprising the following steps:

[0037] S1. Weigh 18 kilograms of iron ingots, 17.7 kilograms of aluminum ingots, 19 kilograms of chromium ingots, 20 kilograms of manganese ingots, 14.7 kilograms of nickel ingots, 4 kilograms of metal tungsten, 5.1 kilograms of nickel boron alloys and 1.5 kilograms of carbon powder according to the melting point. Put them into the medium-frequency induction melting furnace in order of low to high, and vacuumize to 1.2×10 -3 MPa, then filled with argon, and smelted for 80 minutes under the condition of argon pressure of 1.1 atmospheric pressure to obtai...

Embodiment 3

[0041] A high-entropy alloy powder for the surface of a cement rotary kiln supporting wheel proposed by the present invention, its chemical composition includes: Fe: 20%, Al: 17%, Cr: 17%, Mn: 19.5%, Ni: 21 %, W: 2.8%, B: 0.7%, C: 2%.

[0042] The present invention also proposes a method for preparing high-entropy alloy powder for the surface of the supporting wheel of the cement rotary kiln, comprising the following steps:

[0043] S1. Weigh 20 kilograms of iron ingots, 17 kilograms of aluminum ingots, 17 kilograms of chromium ingots, 19.5 kilograms of manganese ingots, 17.2 kilograms of nickel ingots, 2.8 kilograms of metal tungsten, 4.5 kilograms of nickel-boron alloys and 2 kilograms of carbon powder according to the melting point. Put them into the medium frequency induction melting furnace in sequence from low to high, and evacuate to 1.5×10 -3 MPa, then filled with argon, and smelted for 70 minutes under the condition of argon pressure of 1.1 atmospheric pressure to ob...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| oxygen content | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com