Water-scrubbing resistant artificial leather and preparation method thereof

An artificial leather and water-resistant technology, applied in the field of artificial leather, can solve the problems of not easy to clean, fall off, poor wear resistance, etc., and achieve the effect of enhancing scratch resistance, improved adhesion, and good wear resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

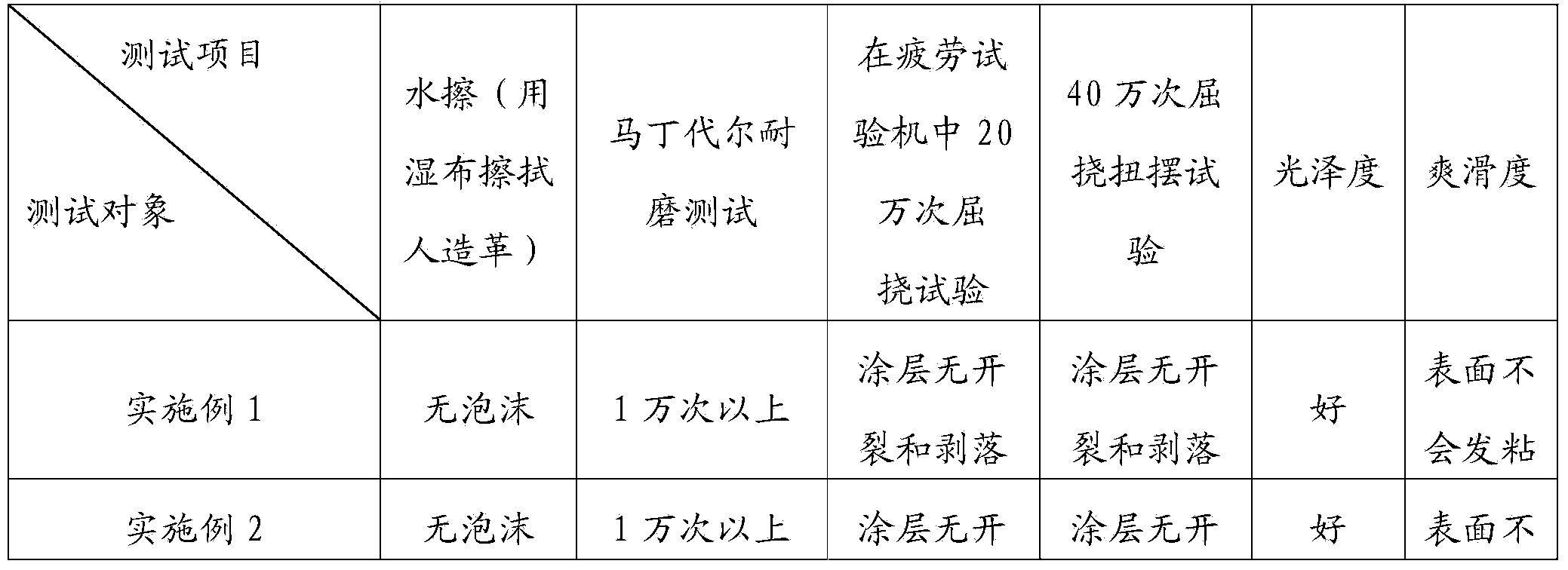

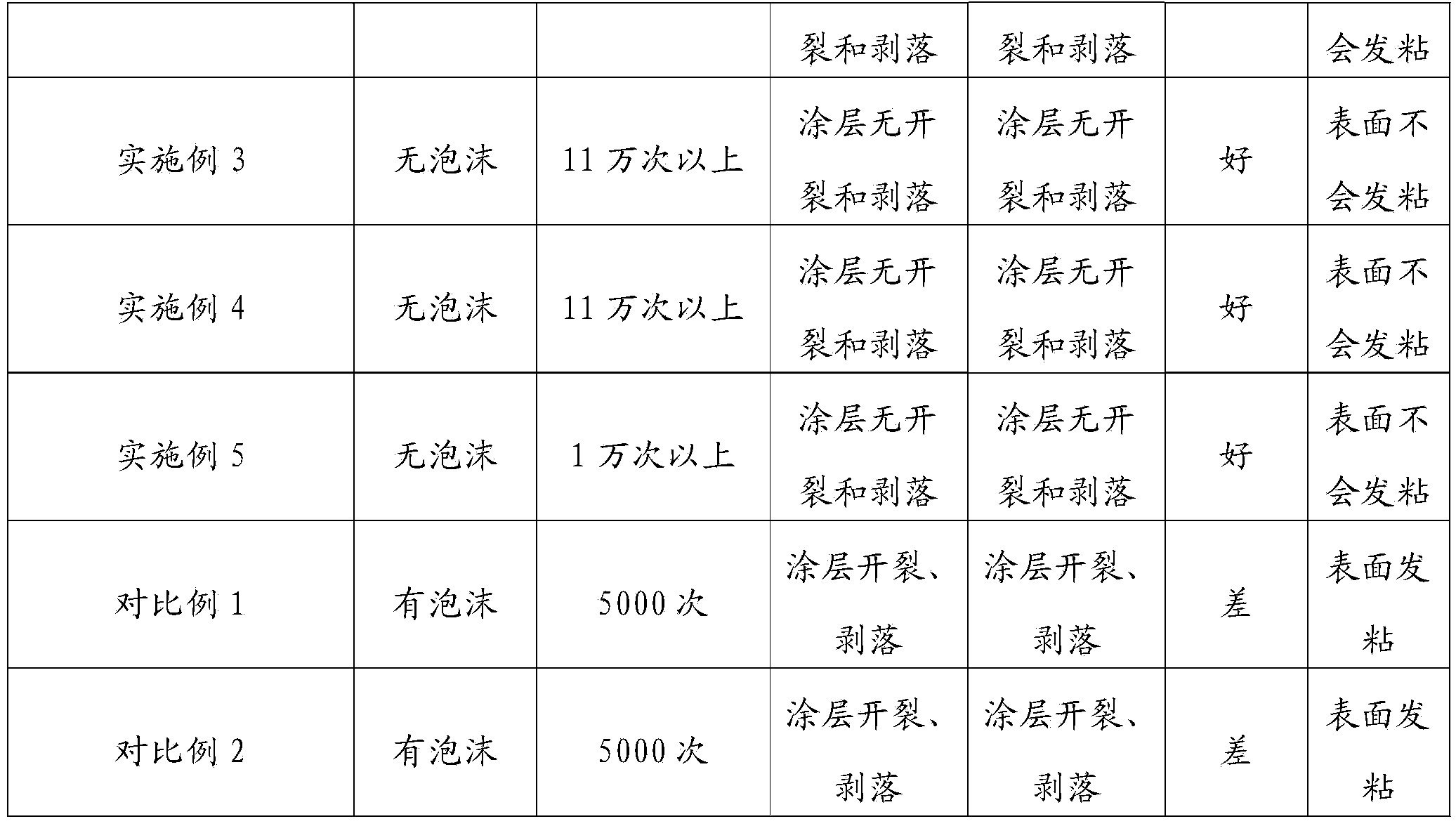

Examples

Embodiment 1

[0042] (1) Select base cloth and release paper;

[0043] Prepare the polyurethane surface layer slurry: fully stir and mix the polyurethane resin of 100 parts by weight and the dimethylformamide of 60 parts by weight;

[0044] Preparation of polyvinyl chloride foam slurry: fully stir 100 parts by weight of polyvinyl chloride resin, 70 parts by weight of dioctyl phthalate (DOP), 80 parts by weight of filler and 5 parts by weight of foaming agent mix;

[0045] Preparation of polyurethane bonding materials;

[0046] Preparation of surface treatment agent: the neutralizing agent (the model produced by Taiwan Jiaqian Chemical Co., Ltd. is the water-based neutralizing agent of SOPHI. ) and 0.1 parts by weight of leveling agent (model 825 leveling agent produced by Deqian Enterprise Co., Ltd.) are fully stirred and mixed.

[0047] (2) Evenly coat the prepared polyurethane surface layer slurry on the selected release paper, and form the polyurethane surface layer after drying at 10...

Embodiment 2

[0053] (1) Select base cloth and release paper;

[0054] Prepare the polyurethane surface layer slurry: fully stir and mix the polyurethane resin of 100 parts by weight and the dimethylformamide of 80 parts by weight;

[0055] Preparation of polyvinyl chloride foam slurry: fully stir 100 parts by weight of polyvinyl chloride resin, 70 parts by weight of dioctyl phthalate (DOP), 80 parts by weight of filler and 5 parts by weight of foaming agent mix;

[0056] Preparation of polyurethane bonding materials;

[0057] Preparation surface treatment agent: the neutralizing agent (the model that Taiwan Jiaqian Chemical Co., Ltd. produces is the water-based neutralizing agent of SOPHI.A2012 of the polyurethane resin of 100 weight parts, the dimethylformamide of 80 weight parts, ) and 0.1 parts by weight of leveling agent (model 825 leveling agent produced by Deqian Enterprise Co., Ltd.) are fully stirred and mixed.

[0058] (2) Evenly coat the prepared polyurethane surface layer slu...

Embodiment 3

[0064] (1) Select base cloth and release paper;

[0065] Prepare the polyurethane surface layer slurry: fully stir and mix the polyurethane resin of 100 parts by weight and the dimethylformamide of 60 parts by weight;

[0066] Preparation of polyvinyl chloride slurry: fully stirring and mixing 100 parts by weight of polyvinyl chloride resin and 60 parts by weight of dioctyl phthalate;

[0067] Preparation of polyvinyl chloride foam slurry: fully stir 100 parts by weight of polyvinyl chloride resin, 70 parts by weight of dioctyl phthalate (DOP), 80 parts by weight of filler and 5 parts by weight of foaming agent mix;

[0068] Preparation of polyurethane bonding materials;

[0069] Preparation of surface treatment agent: the neutralizing agent (the model produced by Taiwan Jiaqian Chemical Co., Ltd. is the water-based neutralizing agent of SOPHI. ) and 0.1 parts by weight of leveling agent (model 825 leveling agent produced by Deqian Enterprise Co., Ltd.) are fully stirred an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com