Wear-resistant cylinder body of triangular rotor engine and machining method thereof

A triangular rotor and processing method technology, which is applied to combustion engines, machines/engines, internal combustion piston engines, etc., can solve the problems of wear-resistant layer falling off, insufficient wear resistance, easy to fall off, etc., to improve wear resistance and increase engine speed. service life, avoiding the effect of insufficient wear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The following are specific embodiments of the present invention and in conjunction with the accompanying drawings, the technical solutions of the present invention are further described, but the present invention is not limited to these embodiments.

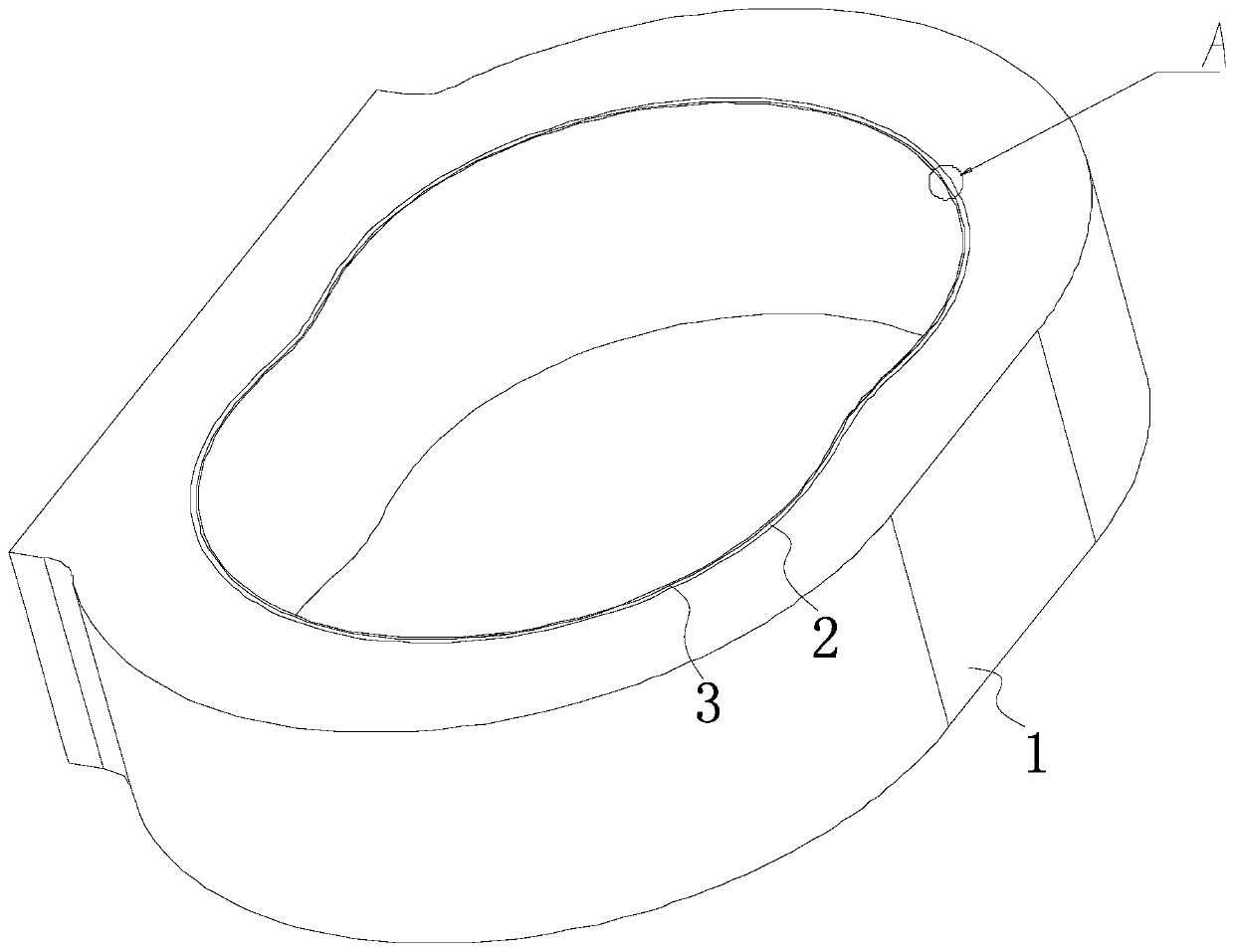

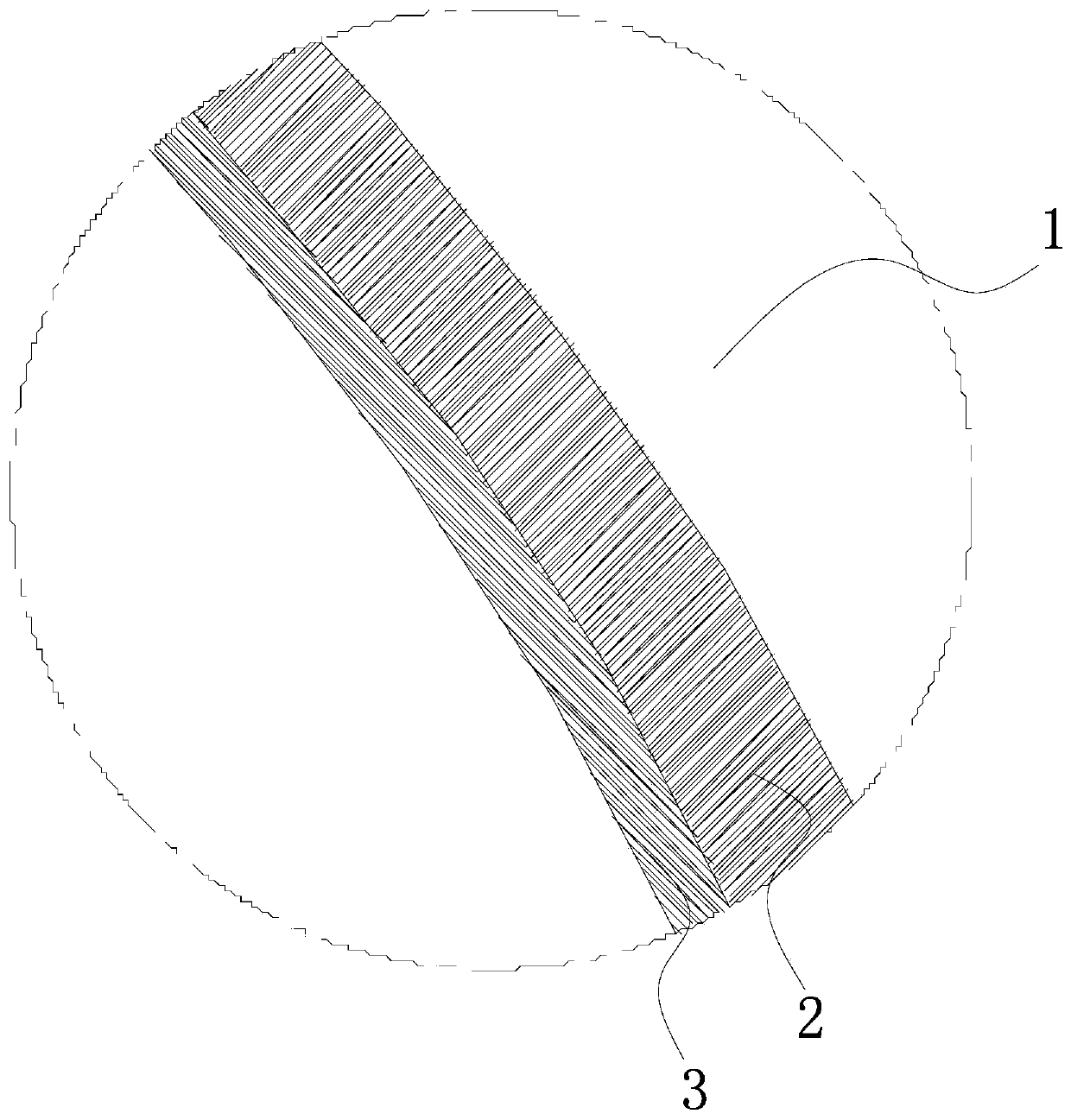

[0020] Such as figure 1 and figure 2 As shown, the wear-resistant cylinder of the triangular rotor engine and its processing method include a cylinder base 1, a transition layer 2 and a wear-resistant layer 3, the transition layer 2 is arranged on the inner surface of the cylinder base 1, and the The wear-resistant layer 3 is arranged on the inner side of the transition layer 2 .

[0021] Preferably, the transition layer 2 is made of stainless steel, and the thickness of the transition layer 2 is between 3mm and 4mm.

[0022] A method for processing a wear-resistant cylinder block of a triangular rotor engine, comprising the following steps;

[0023] S1, the transition layer 2 is precision cast by investment, and its o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com