Rubber covered roller of island structure and preparation method thereof

A technology of sea-island structure and rubber roller, applied in the field of sea-island structure rubber roller and its preparation, can solve the problems of insignificant effect of friction coefficient, uneven force on materials, non-abrasion resistance, etc., so as to solve the problems of poor bonding reliability and friction The effect of uniform and maintaining elongation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0049] The invention relates to a sea-island structure rubber roller. The rubber layer of the sea-island structure rubber roller is prepared by kneading a matrix compound rubber and individual granule rubber. The master compound rubber and the individual granule rubber use nitrile rubber as the raw material, and the master compound rubber is obtained through mixing, and the individual granule rubber is obtained through mixing, vulcanization, crushing and sieving. Heat the matrix rubber mixture and cover the rolls; add the individual granules in batches, and wait until the individual granules are completely integrated into the matrix rubber to obtain the rubber layer of the sea-island structure rubber roller.

[0050] In the processing process of this embodiment, it is ensured that the elongation of the matrix compound is 220% higher than that of the individual granules, and the Shore A hardness of the matrix compound is 14 degrees lower than that of the individual granules. Th...

Embodiment 2

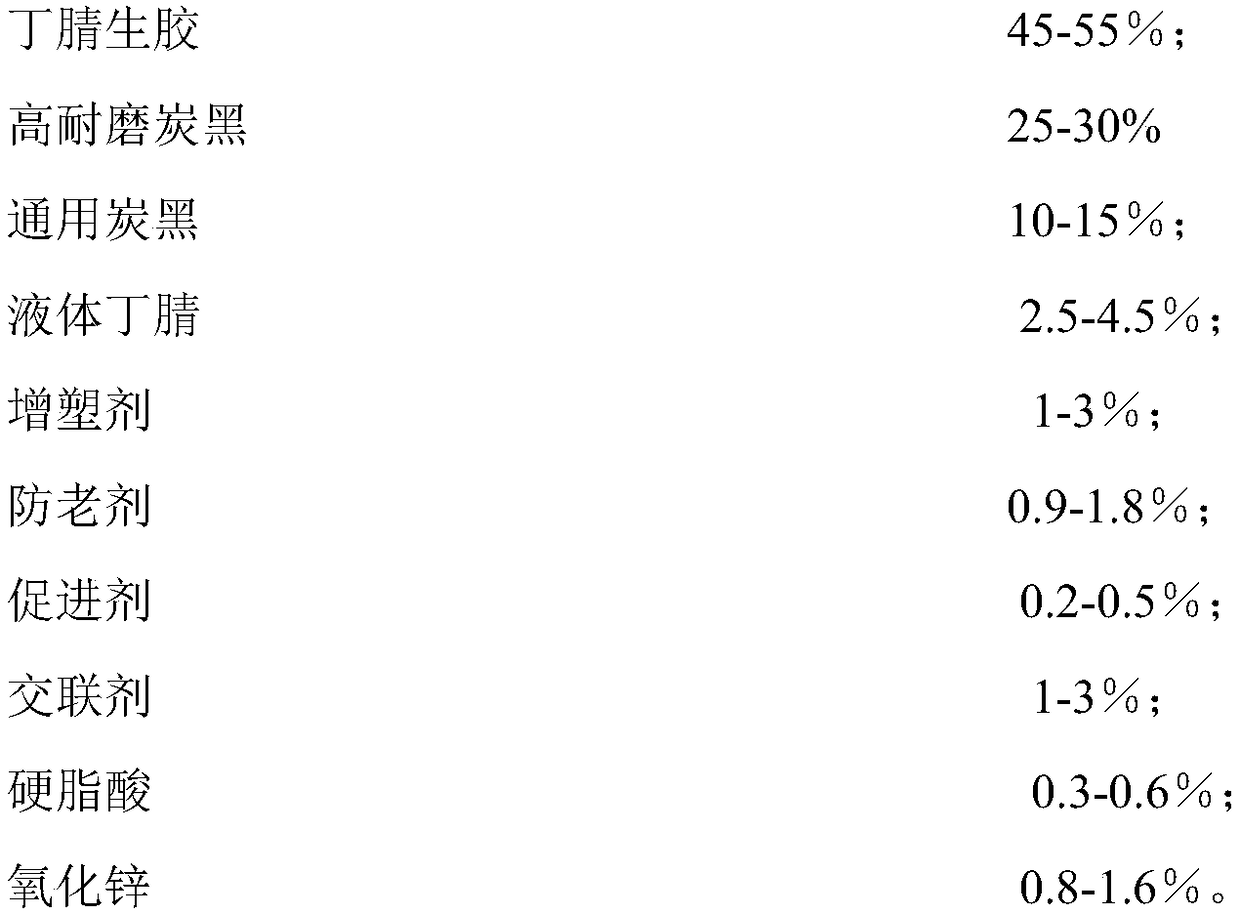

[0053] Master compound rubber component raw material table in the embodiment 2-4 of table 1

[0054] Raw materials for master mix components

Example 2

Example 3

Example 4

Example 5

Nitrile rubber

33.75kg

37.50kg

41.25kg

37.50kg

High wear-resistant carbon black

22.50kg

18.75kg

20.18kg

18.83kg

General purpose carbon black

13.73kg

7.50kg

7.5kg

11.25kg

liquid nitrile

1.88kg

3.38kg

1.88kg

2.25kg

plasticizer

0.75kg

2.25kg

0.75kg

1.5kg

Antiaging agent

0.68kg

1.35kg

0.90kg

0.75kg

Accelerator

0.15kg

0.38kg

0.23kg

0.30kg

crosslinking agent

0.75kg

2.25kg

1.13kg

1.50kg

stearic acid

0.23kg

0.45kg

0.30kg

0.38kg

Zinc oxide

0.60kg

1.20kg

0.90kg

0.75kg

[0055] Individual granule glue component raw material table in the embodiment 2-4 of tab...

Embodiment 3

[0068] A sea-island structure rubber roller. The rubber layer of the sea-island structure rubber roller is prepared by mixing a matrix rubber mix and individual granule rubber. The component weights of the matrix rubber mix and individual granule rubber are shown in Table 1 and Table 2. In the antioxidant, the ratio of MB to ZMMBI is 2:1; in the crosslinking agent, the ratio of dicumyl peroxide and sulfur is 3:1.

[0069] The preparation method of the sea-island structure rubber roller of embodiment 3, concrete preparation process is as follows:

[0070] (1) Mixing: Weigh the component raw materials of the matrix rubber compound and the component raw materials of the individual granule rubber respectively, and mix to prepare the matrix rubber compound and the individual rubber compound respectively, and park;

[0071] (2) Vulcanization: vulcanize the individual compounded rubber to obtain individual vulcanized rubber sheets;

[0072] (3) Pulverization: the individual vulcaniz...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com