High friction coefficient synthetic materials and preparation method thereof

A technology with high friction coefficient and synthetic materials, which is applied in the field of friction material preparation, can solve the problems that cannot meet the requirements of high-speed and heavy-duty railway vehicle braking components, the friction performance is not stable enough, and cannot meet the braking requirements, etc., to achieve good durability Abrasion resistance, reduction of wheel damage, and stable friction performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] This embodiment provides a high friction coefficient synthetic material, which can be used to prepare high friction parts such as brake shoes of railway wagons. The material is formed by compounding the following components by weight ratio in an internal mixer after treatment The polymer composite material, each component is specifically:

[0028] Nitrile rubber 8~13, styrene-butadiene rubber 2~10, cresol modified resole phenolic resin 5~10, steel fiber 15~30, magnesium oxide 10~15, calcined petroleum coke 5~10, silicon carbide 2~5 , mineral fiber 10-25, calcium hydride 5-10, barium sulfate 10-20, graphite 5-10, molybdenum disulfide 1-5, carbon black 1-5, sulfur 1-3, accelerator 1-3.

[0029] Among them, the mineral fiber can be green iron mineral fiber; the accelerator can be rubber accelerator, such as: thiuram TMTD.

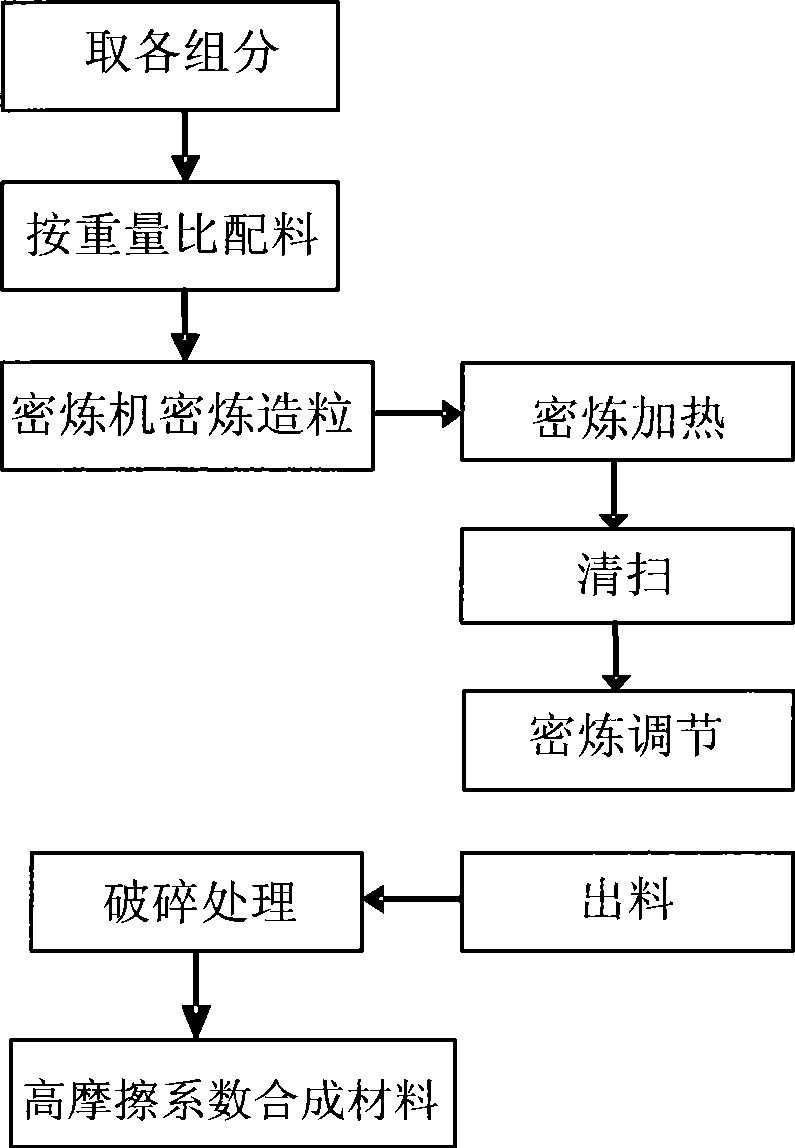

[0030] The preparation process of the above-mentioned high friction coefficient synthetic material, such as figure 1 As shown, the specific steps can...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com