Patents

Literature

152results about How to "Uniform friction" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

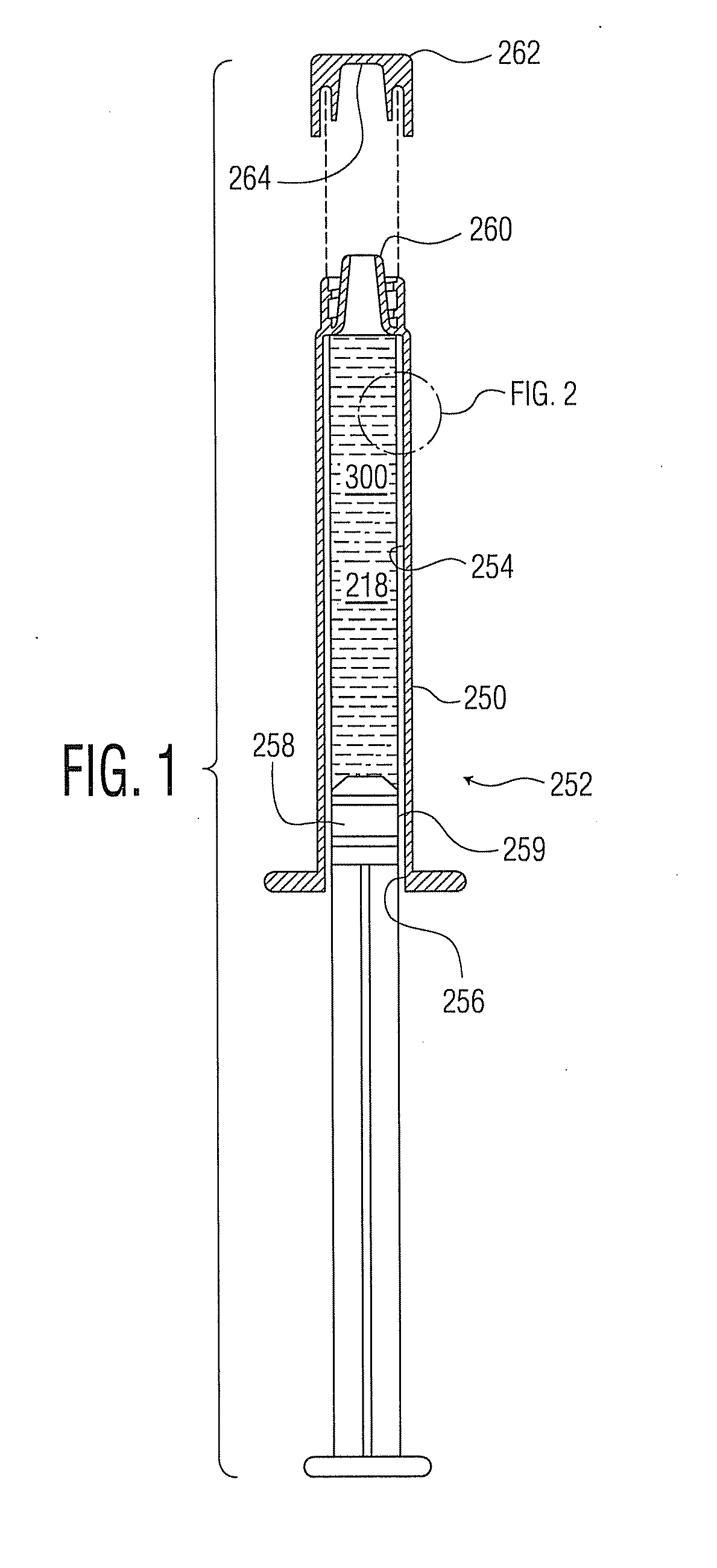

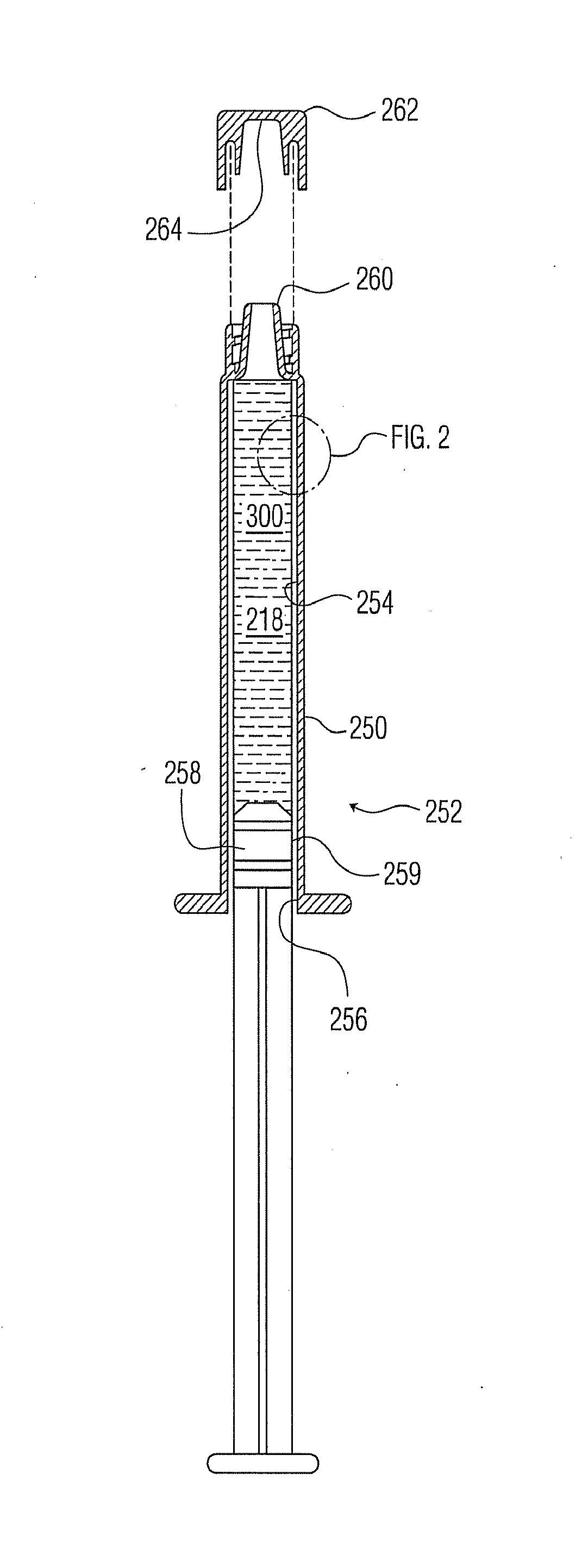

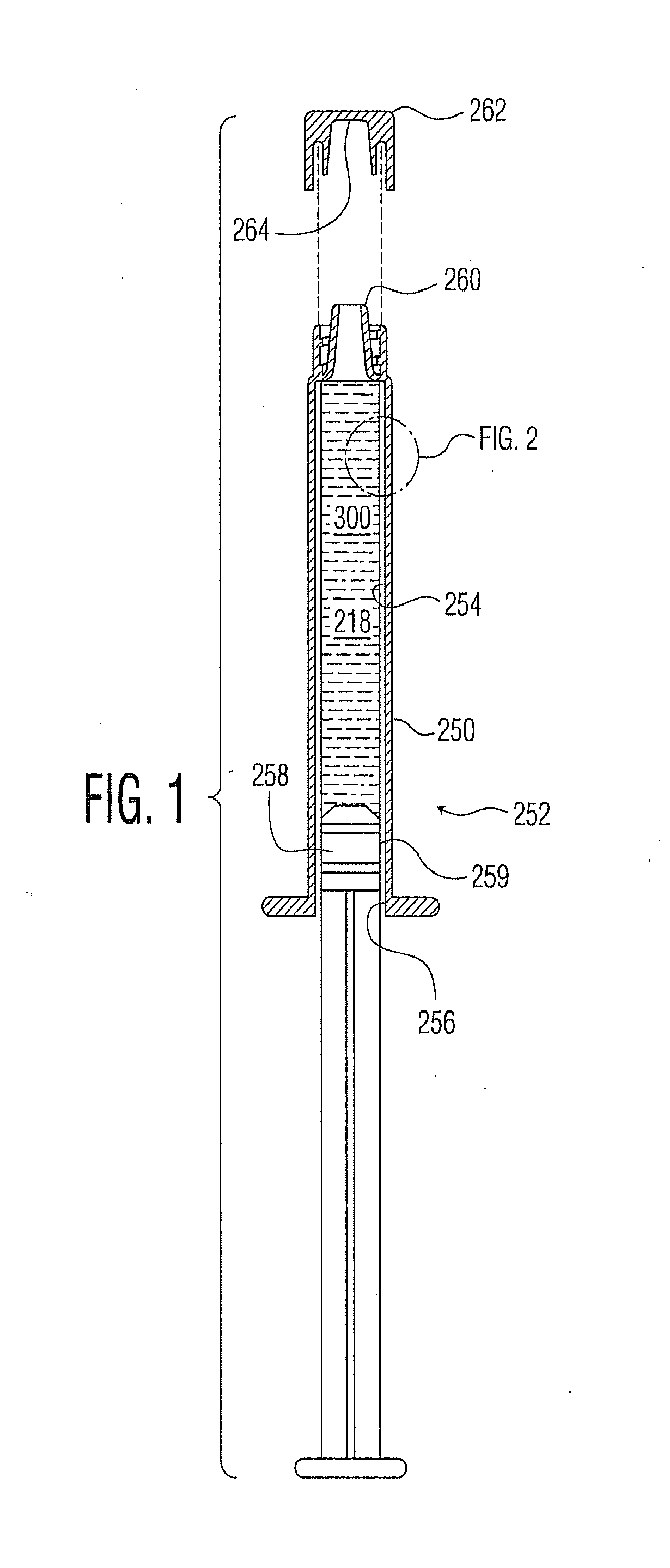

Plasma or CVD pre-treatment for lubricated pharmaceutical package, coating process and apparatus

ActiveUS20140249484A1Improve the lubrication effectReduce sliding frictionInfusion syringesSurgeryPolymer sciencePre treatment

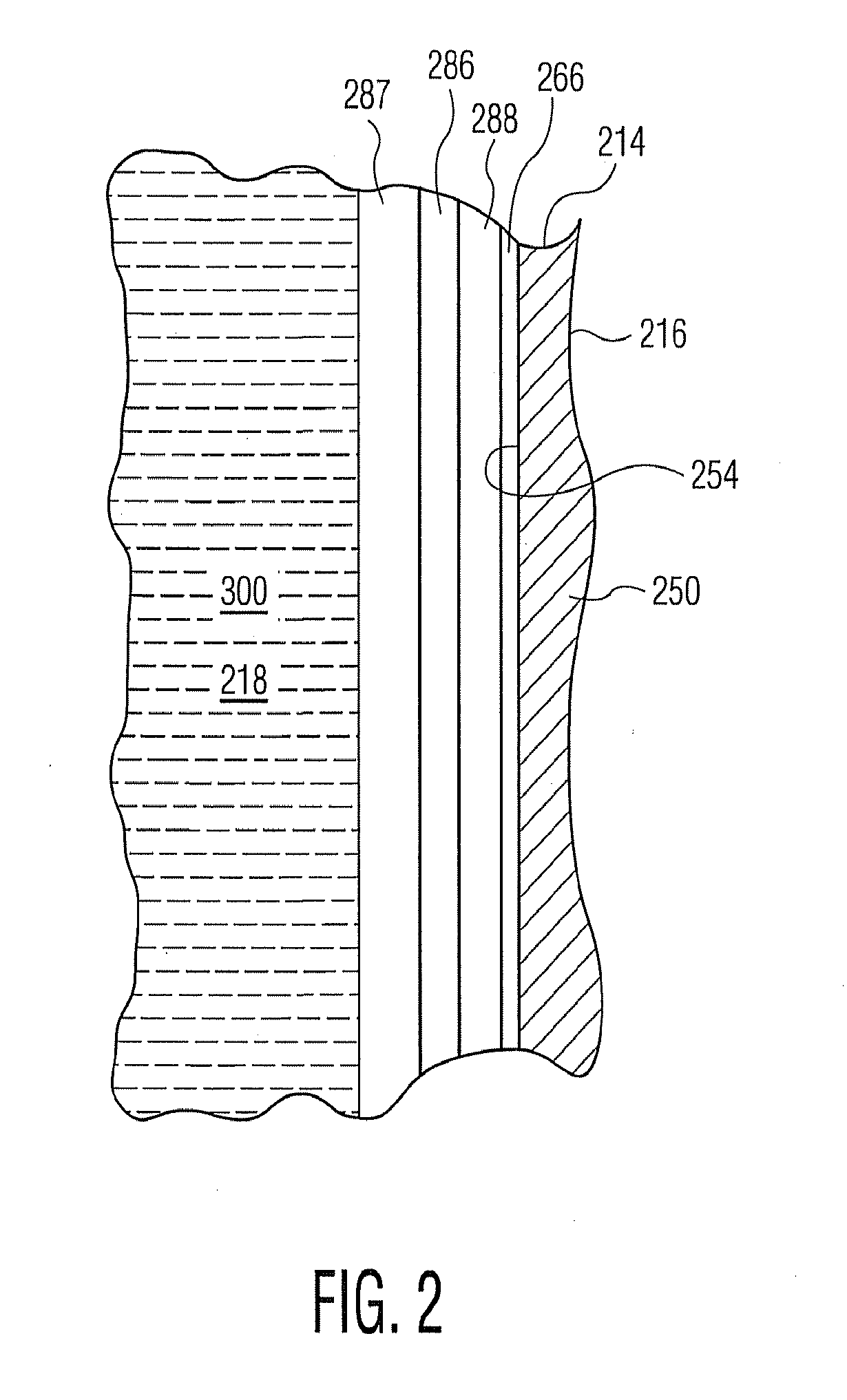

An article is described including an article surface, a primer coating or layer of SiOx, SiOxCy or SiNxCy applied to the article surface, and a deposit of lubricant applied to the primer coating or layer. The primer coating or layer of SiOx, SiOxCy or SiNxCy is applied by chemical vapor deposition of a polysiloxane or polysilazane precursor in the presence of oxygen. A first deposit of lubricant is applied to the primer coating or layer. The primer coating or layer improves the adhesion or wetting of the lubricant on the surface to be lubricated. Examples of such an article are a prefilled syringe having a barrel with a lubricated interior portion and a plunger tip that slides along it. Another example of such an article is a vial having a lubricated opening to receive a septum. Another aspect of the invention is a method of making such an article.

Owner:SI02 MEDICAL PRODS

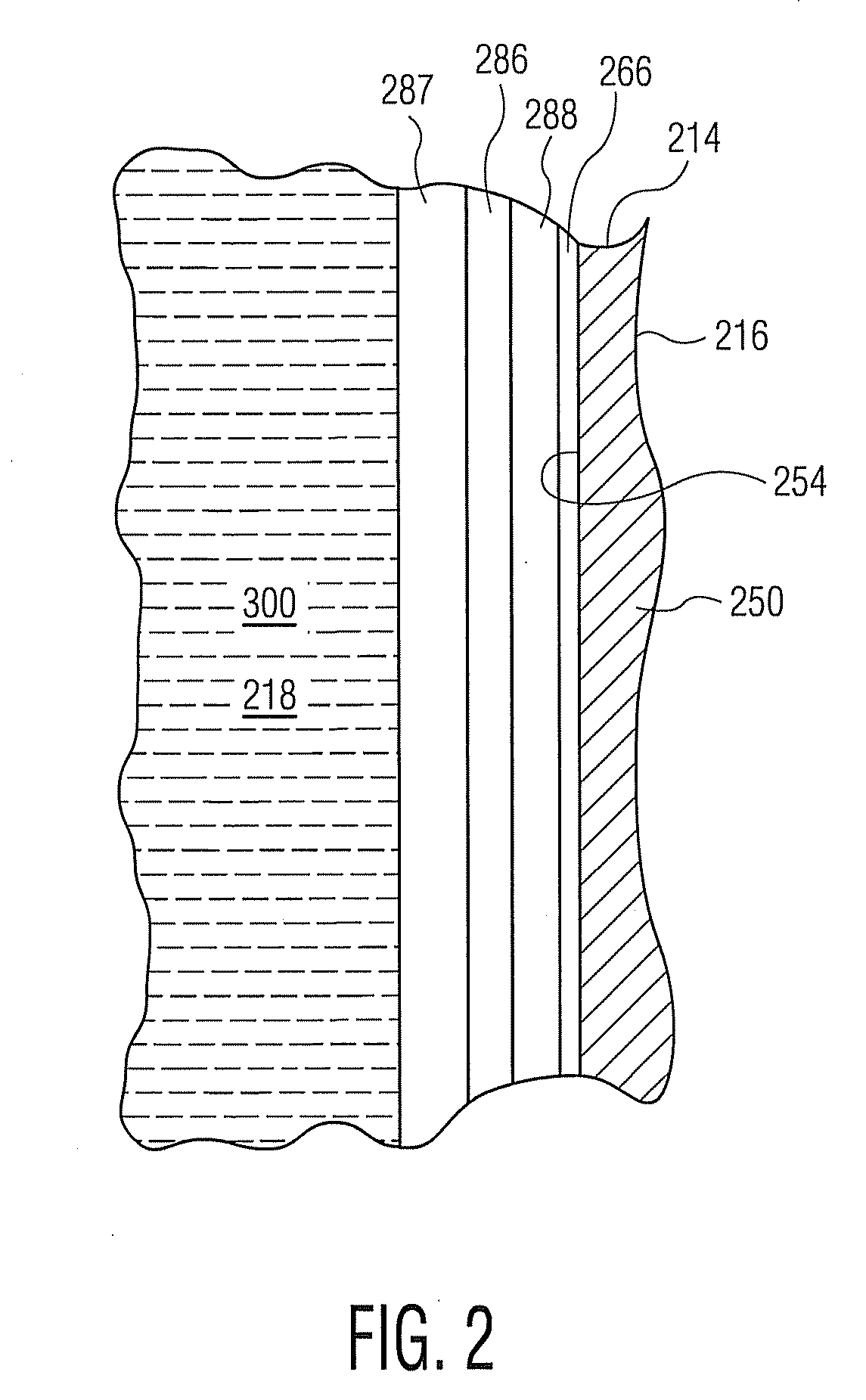

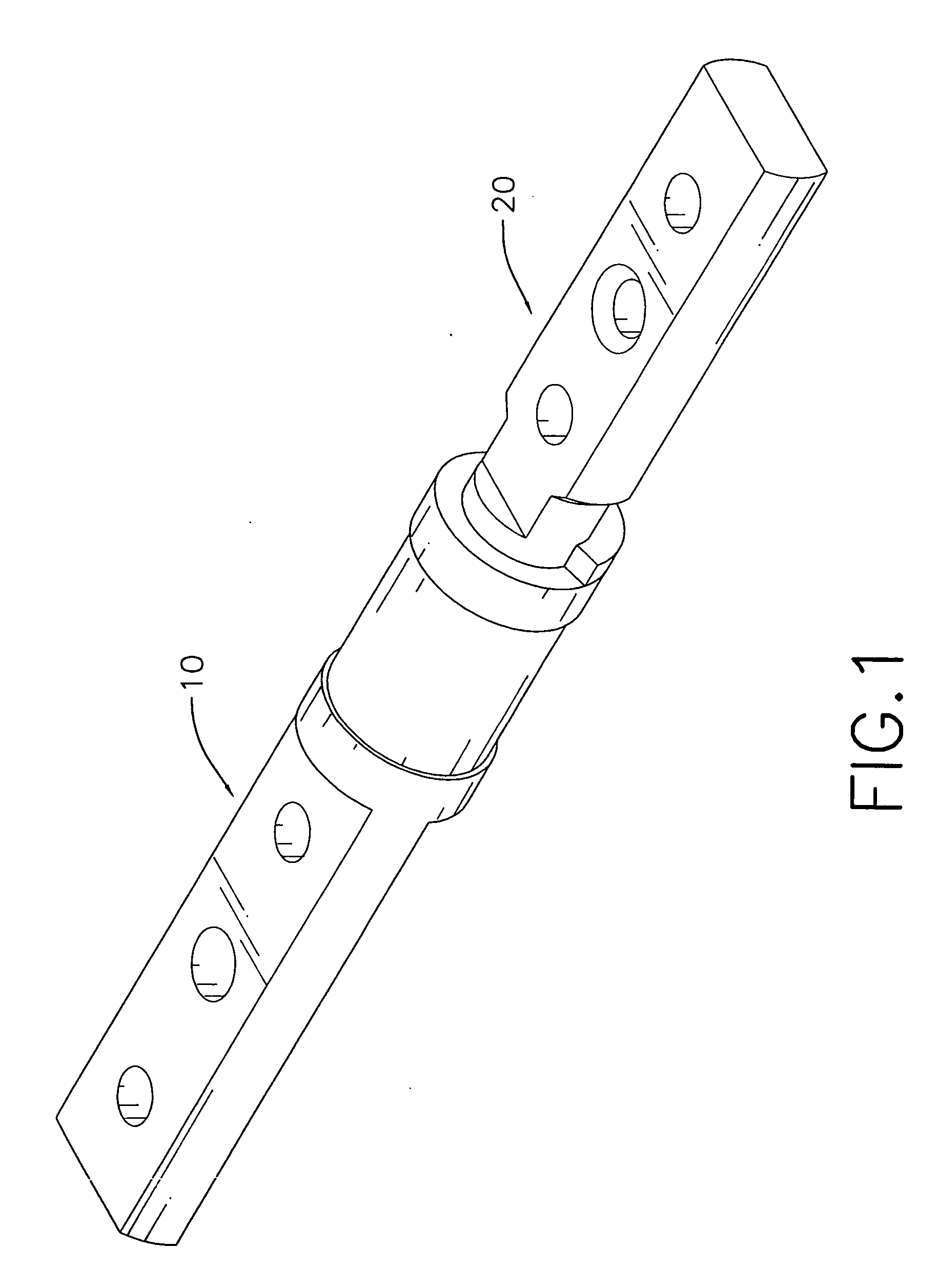

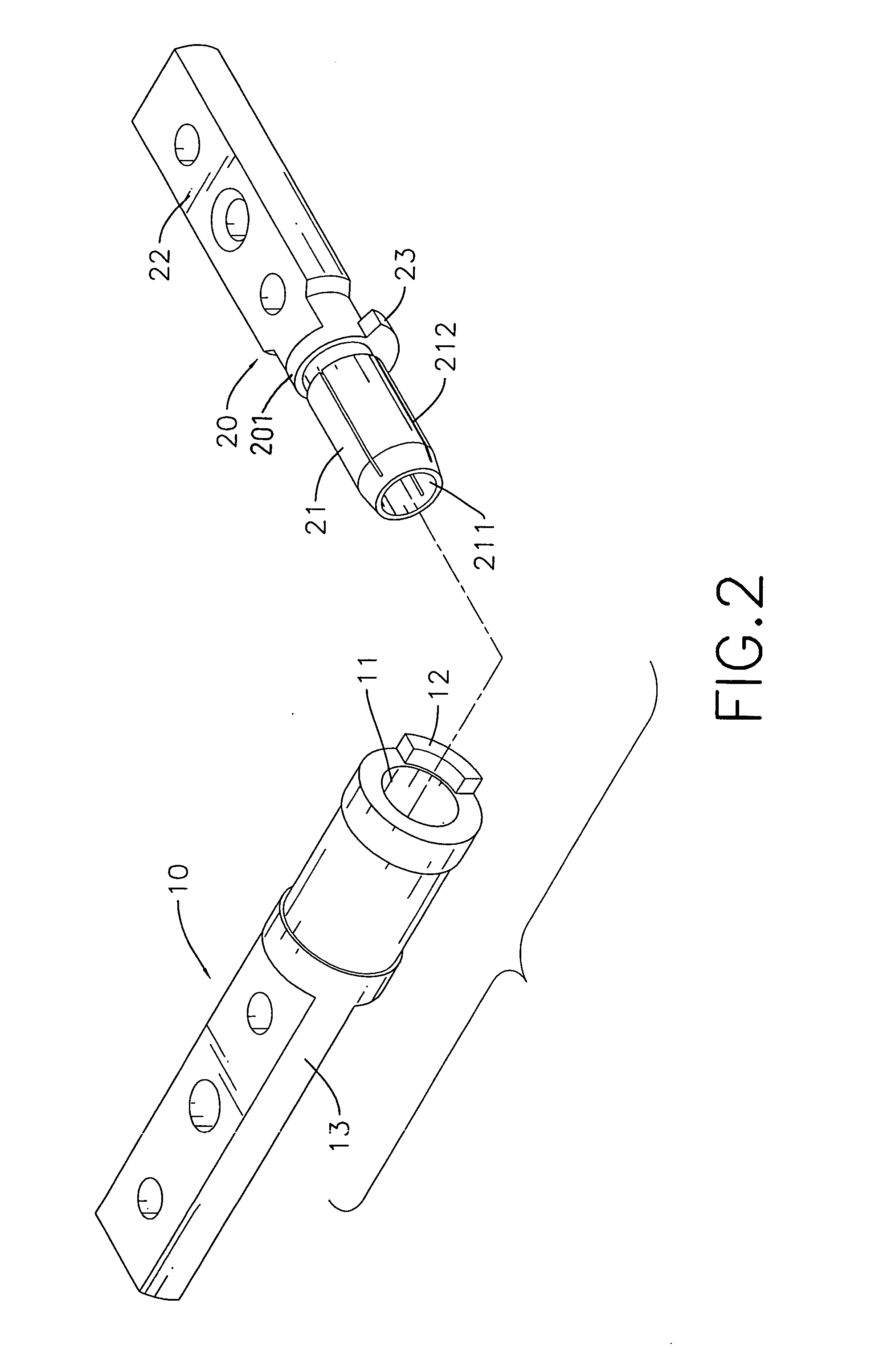

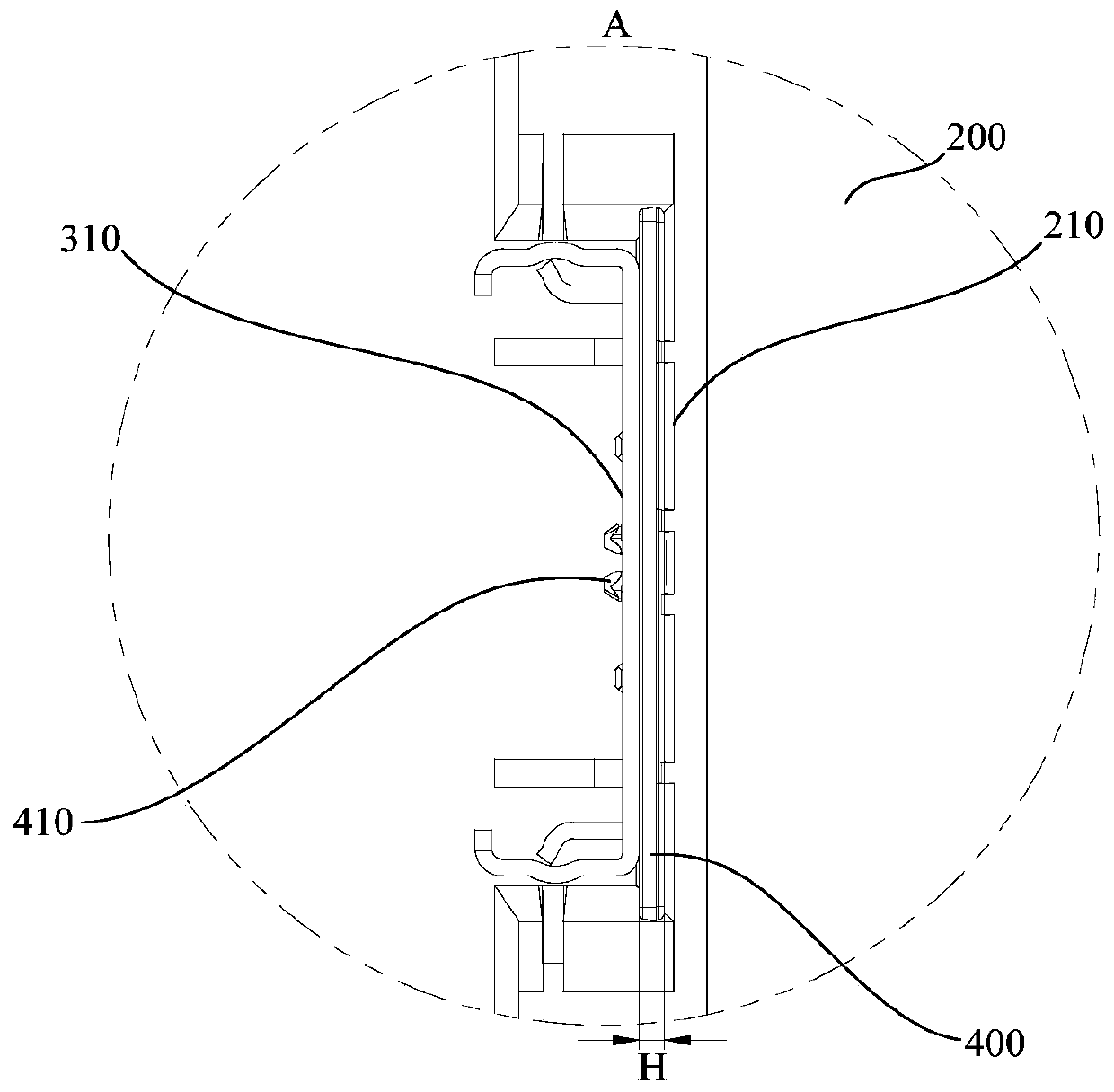

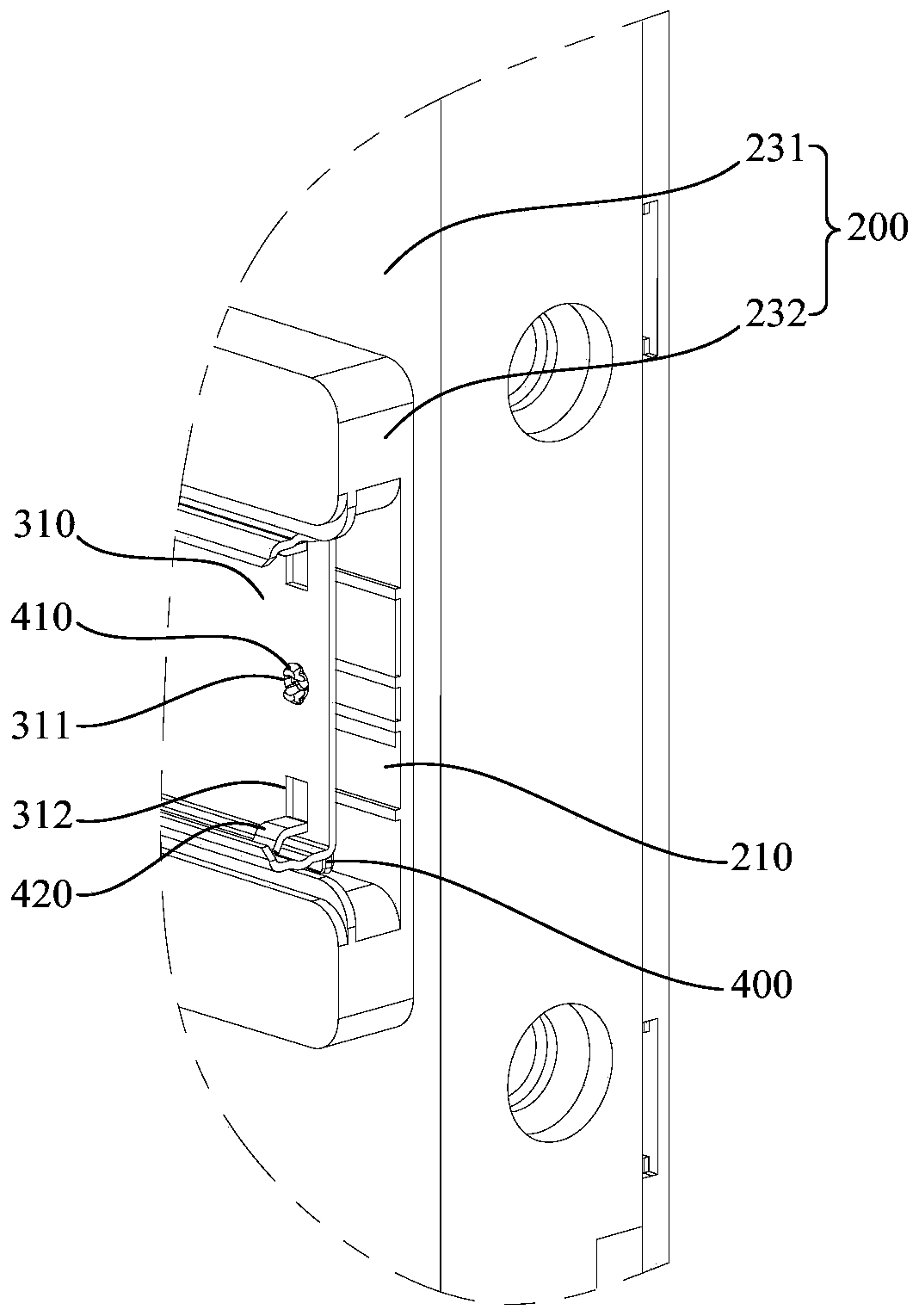

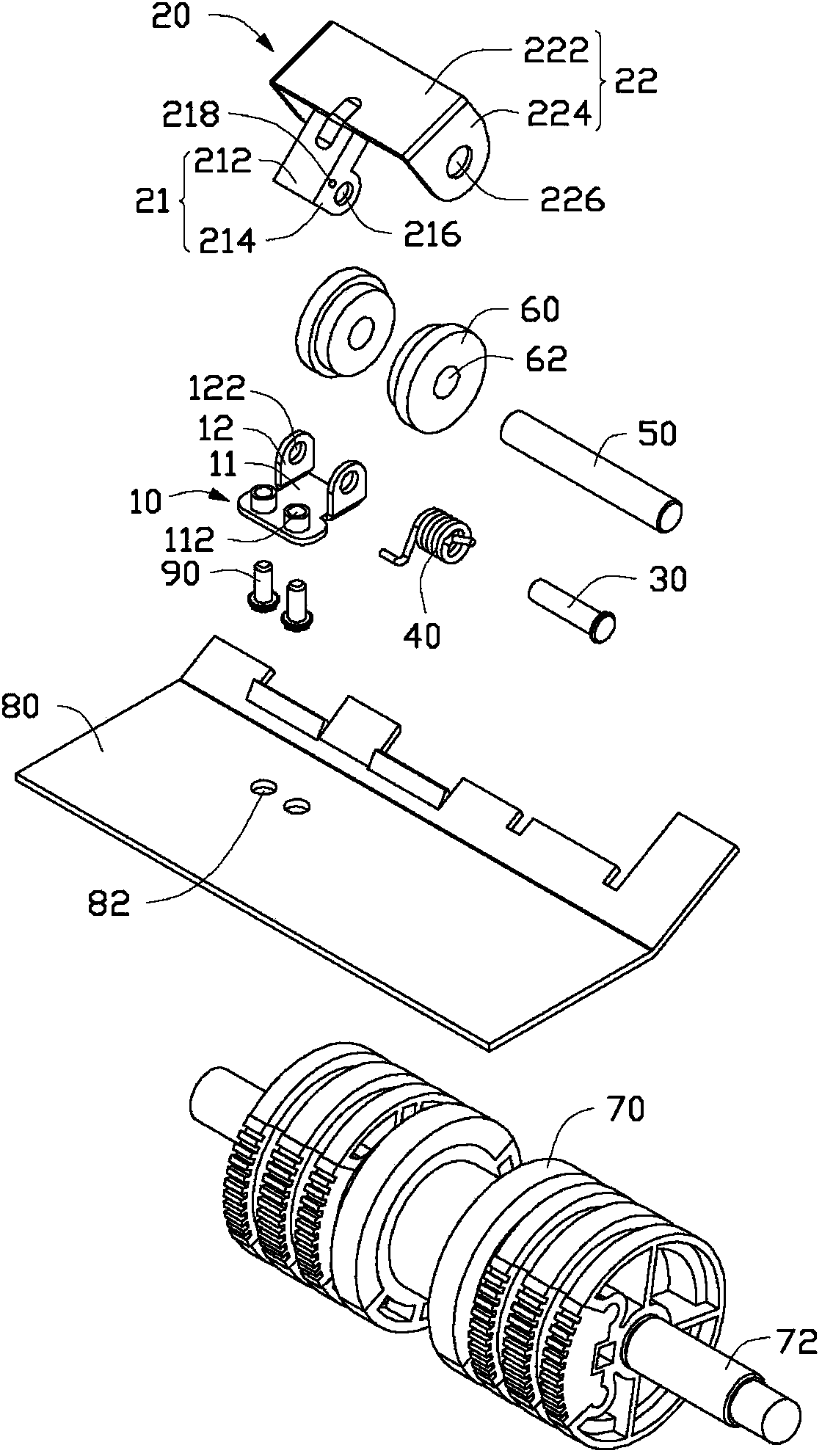

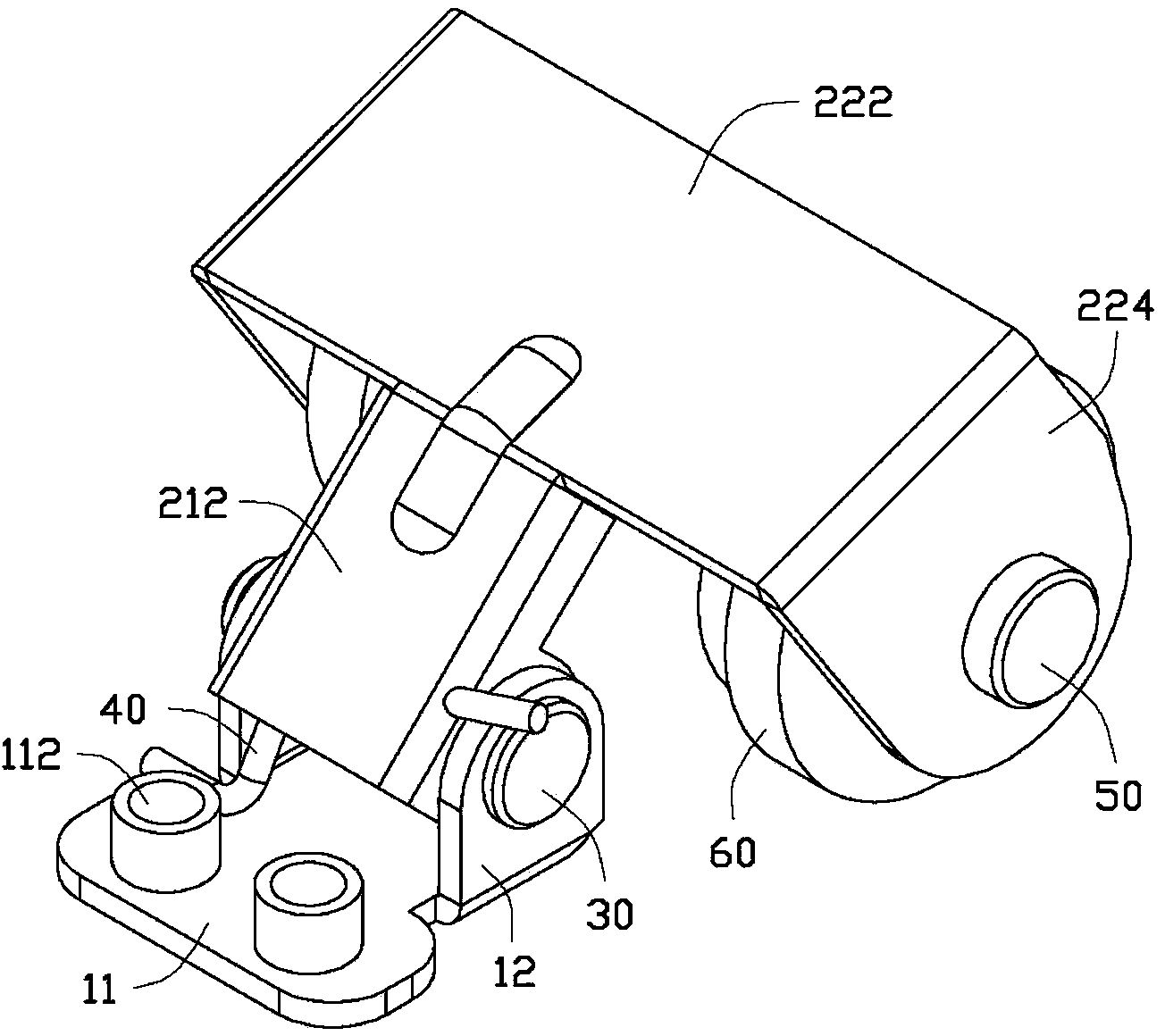

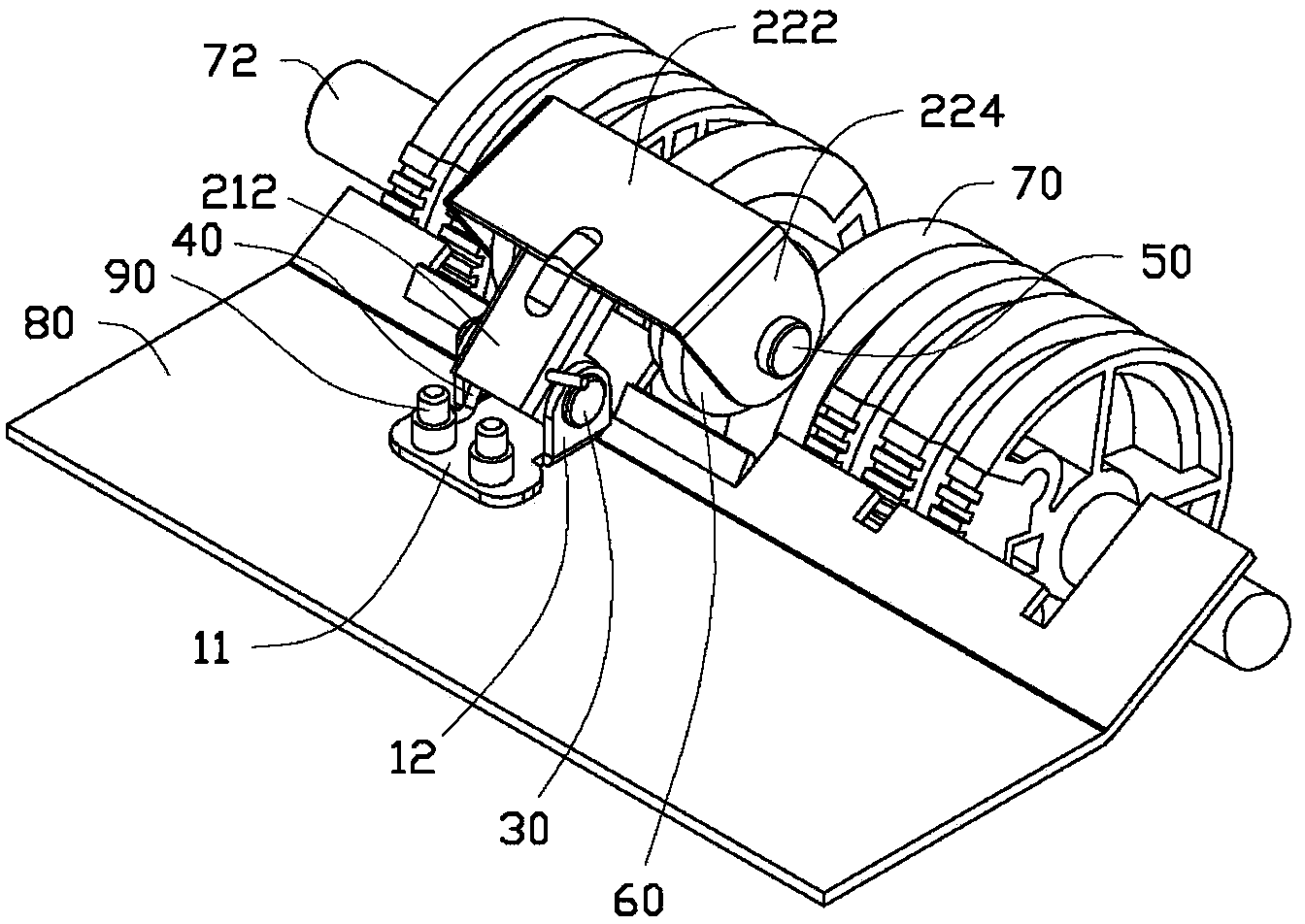

Hinge

InactiveUS20060236504A1Uniform frictionMaintain frictionWing fastenersDetails for portable computersHinge angleBiomedical engineering

A hinge has a sleeve and a shaft and is mounted between a cover and a base of an electrical device. The sleeve is hollow, is attached to the base and has an internal diameter. The shaft is attached to the cover, is mounted pivotally in the sleeve and has a hollow torsion rod. The torsion rod has an external diameter, an opening end and multiple slots. The external diameter of the torsion rod is bigger than the internal diameter of the sleeve to provide friction. The slots are formed in the torsion rod without communicating with the opening end to provide uniform friction. Because the torsion rod is hollow to provide spaces for the torsion rod to be deformed, the torsion rod maintains its shape. Therefore the torsion rod provides uniform friction with the sleeve.

Owner:SHIN ZU SHING

Specific crystallizer casting powder for sulphur free-cutting steel and production method thereof

The invention discloses a specific crystallizer casting powder for sulphur free-cutting steel and production method thereof, mass percents of chemical components thereof are as follows: 29-35% of CaO, 25-30% of Sio2, 2-5% of MgO, 3-5% of Al2O3, 2-6% of Fe2O3, 5-11% of NaO?, 0-2% of Li2O, 5-9% of CaF2?, 0-5% of MnO, 0.5-2.0% of Al grey, 0-2% of B2O3, 5-11% of solid carbon, and allowance is building material adhesive and water. The sulphur free-cutting steel has low high-temperature strength and high crack sensitivity, and the casting powder should have properly high basicity. Basicity of a slag is improved, so that diffusion velocity is accelerated, and absorption of impurities in molten steel is benefited. So, improvement of basicity is an effective means for improving absorption of the impurities and control of surface longitudinal crack.

Owner:HENAN TONGYU METALLURGY MATERIALS GRP

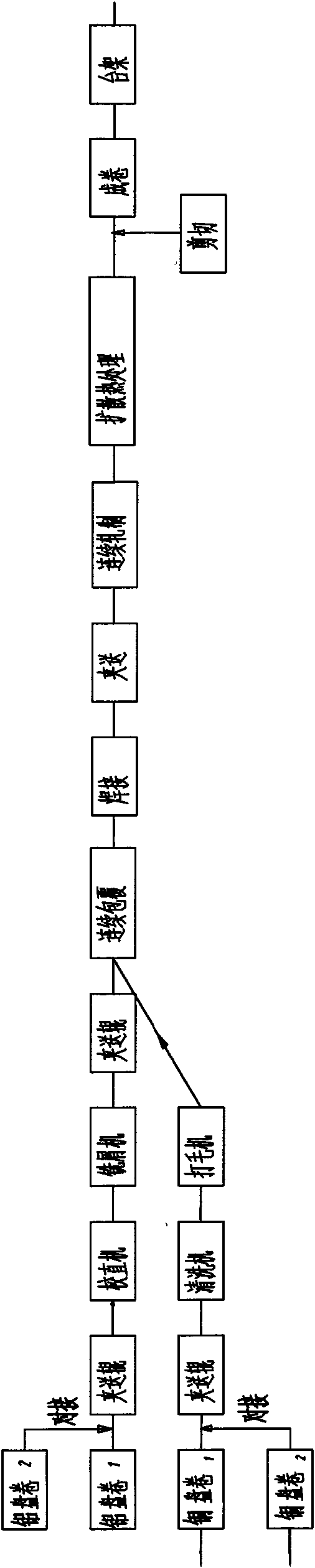

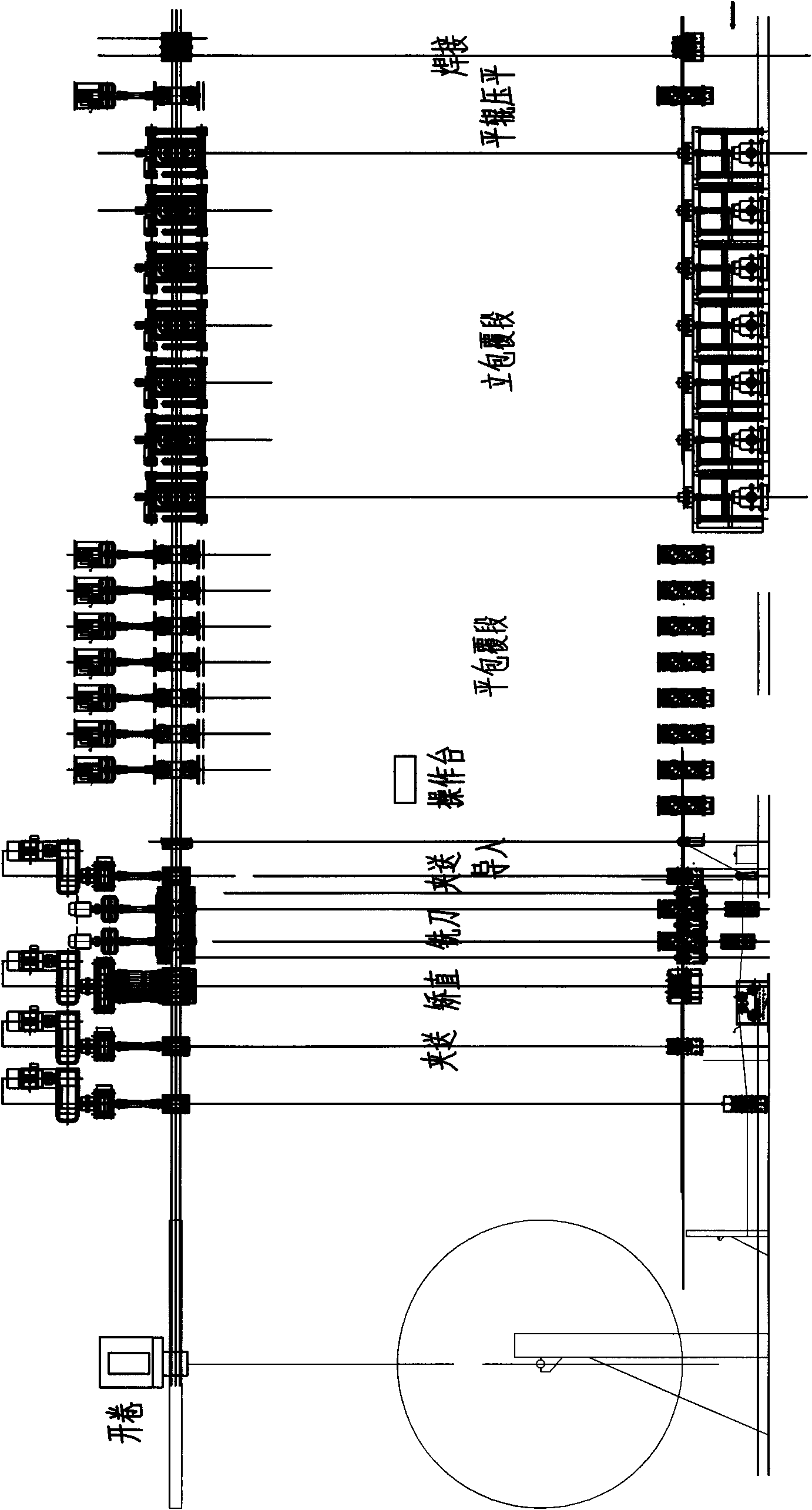

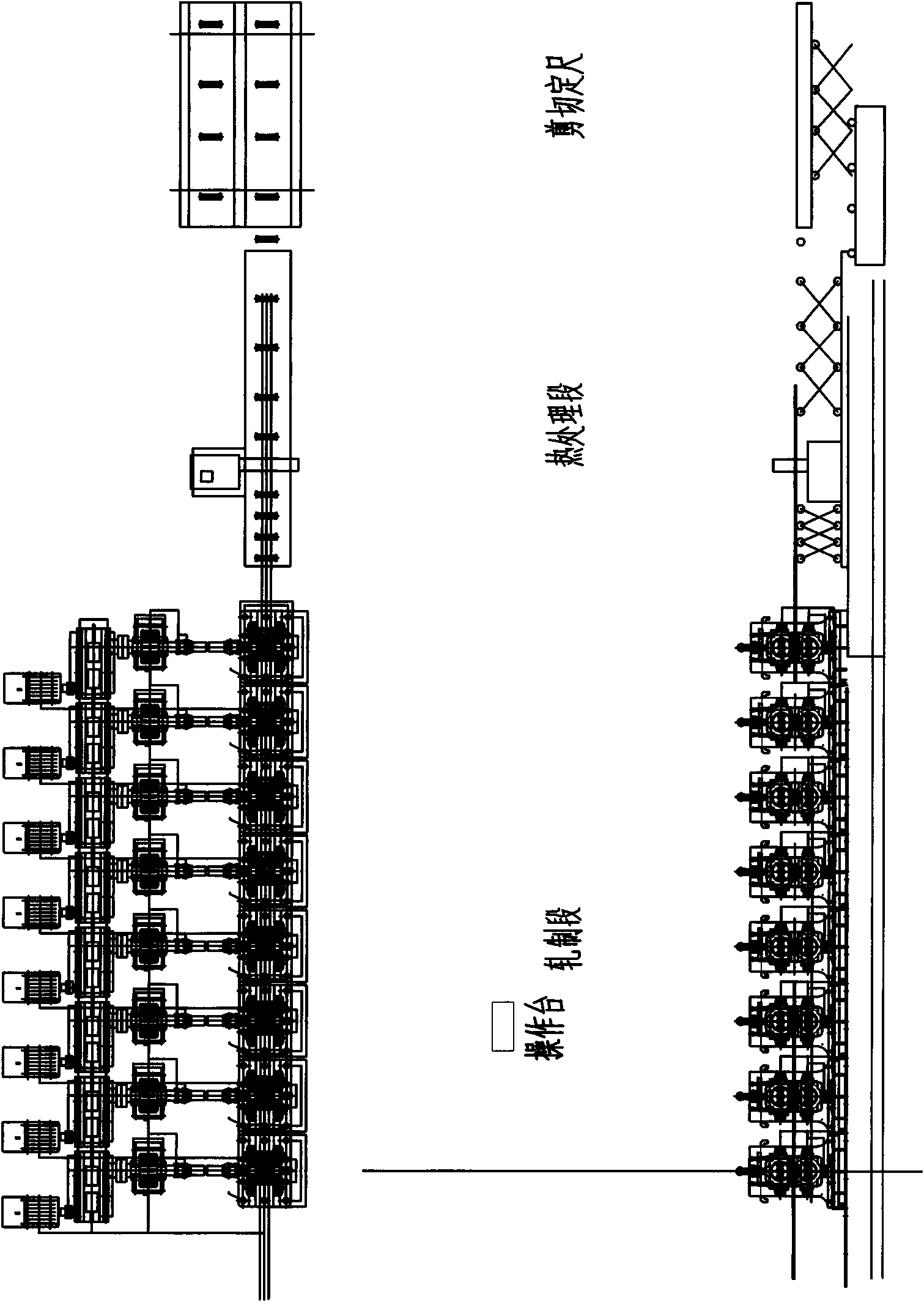

Continuous metallurgical composite production process for copper-clad aluminum rows

InactiveCN101685687AUniform thicknessFull and uniform metallurgical bondingSingle bars/rods/wires/strips conductorsMetal/alloy conductorsCopper coatingEconomic benefits

The invention relates to a continuous metallurgical composite production process for copper-clad aluminum rows. The process comprises a pretreatment step, a continuous coating step, a welding step, acontinuous rolling step, an on-line automatic monitoring step and a diffusion heat treatment step, thereby achieving the following technical effects of: (1) ensuring full uniform combination of coppersheets and aluminum rows, as well as uniform thickness of copper coating; and (2) greatly improving finished-product rate and ensuring yield and quality. Therefore, the production process solves theproblem of producing the copper-clad aluminum rows with various specifications, is particularly applicable to the manufacture of large-size copper-clad aluminum rows, and has huge economic benefit.

Owner:谢洪善 +1

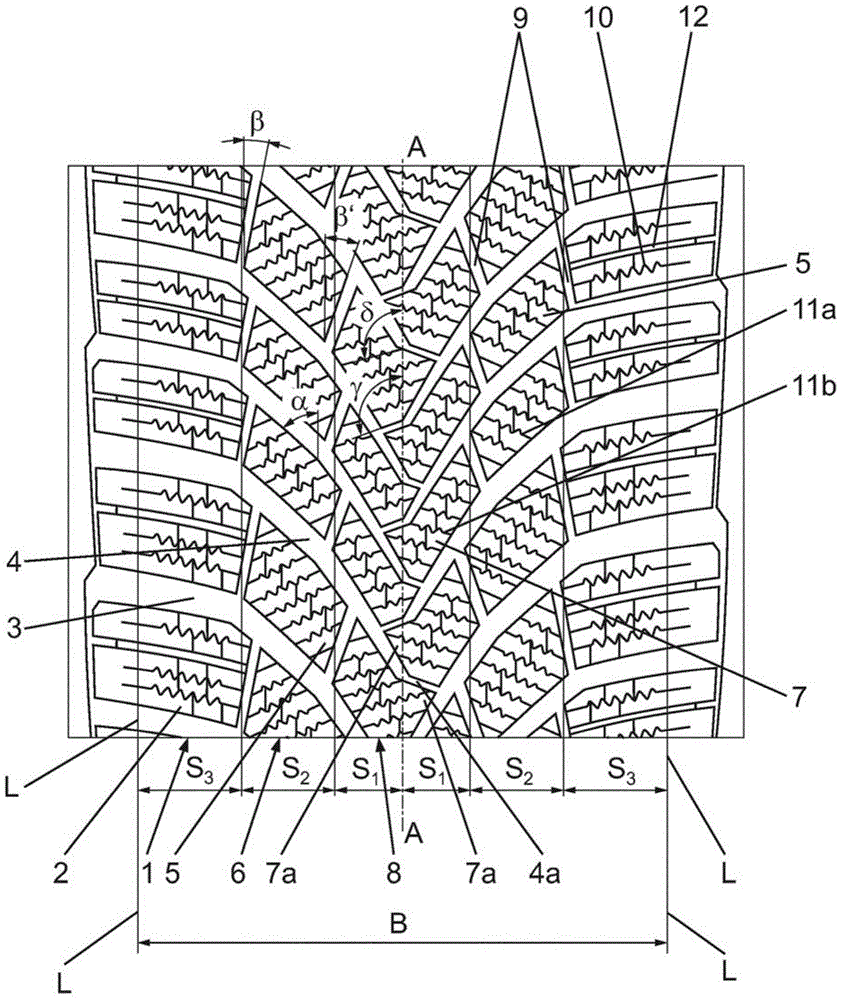

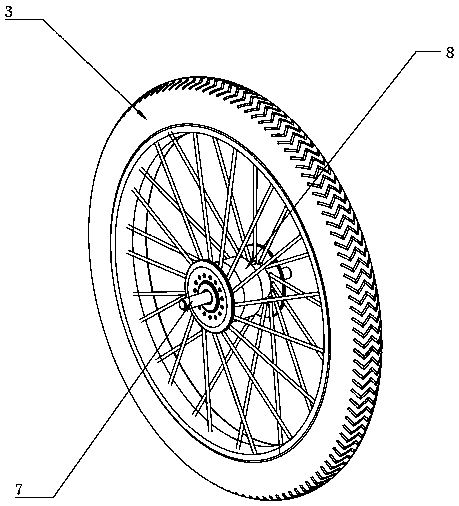

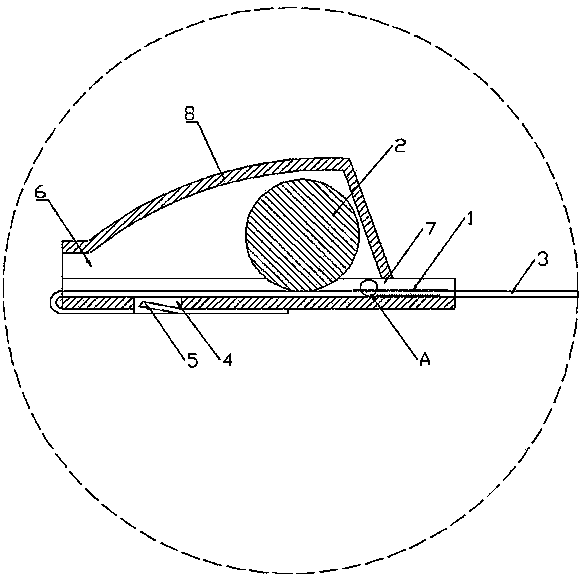

Pneumatic vehicle tyre

ActiveCN103958220AHigh Durable KilometersAverage service lifeTyre tread bands/patternsGround contactLateral region

The invention relates to a pneumatic vehicle tyre, in particular to a tyre for passenger cars having a tread which is divided into profile positives by grooves, channels (3, 4) and the like, for example a plurality of profile blocks (2, 5, 7) and which has a smaller profile depth in its central region than in the lateral regions. Given division of each tread half-between the tyre equator (A-A) and the tread edge (L) bounding the ground contact patch width (B)-into three circumferential sections (S1, S2, S3). A first circumferential section (S1) of the three circumferential sections which runs adjacent to the tyre equator (A-A) has a width of 15 % of the ground contact patch width (B); and the two further circumferential sections (S2, S3) each has a width of 17.5 % of the ground contact patch width (B), in each case a relatively small portion of the positive face of the tread half is located in the first and in the second circumferential section (S1, S2) than in the third circumferential section (S3) and the circumferential rigidity is in each case smaller in the first and in the second circumferential section (S1, S2) than in the third circumferential section (S3).

Owner:CONTINENTAL REIFEN DEUTSCHLAND GMBH

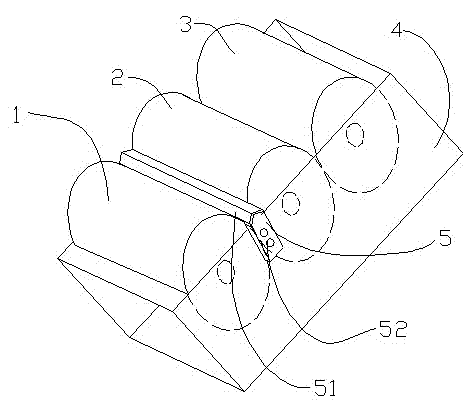

Three-roller machine

InactiveCN102513181AAvoid accidental injuryEven forceGrain treatmentsEngineeringMechanical engineering

The invention provides a three-roller machine, belonging to the technical field of machinery, comprising a rear roller, a middle roller, a front roller, a frame, and a stopper device, wherein the stopper device comprises a barrier strip and a connection assembly, the barrier strip is a straight strip with an inverted V-shaped cross section and is arranged above a line close to the rear roller and the middle roller and parallelly to the respective axis of each roller, the two extended V-shaped edges of the barrier strip are close to the outer cylindrical surfaces of the rear roller and the middle roller, and the connection assembly is connected with the two ends of the barrier strip to fix the barrier strip on the frame. According to the invention, materials can uniformly flow in the rear roller and the middle roller, and various metal objects and hard sundries are effectively prevented from entering between the running rear roller and the middle roller.

Owner:苏州冰心文化用品有限公司

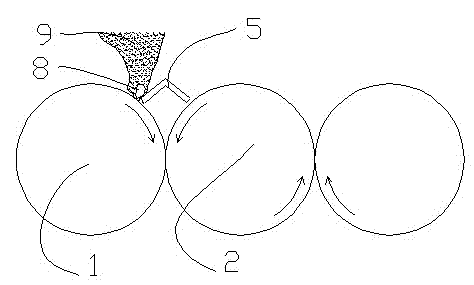

Chenille spinning machine

The invention discloses a chenille spinning machine for spinning chenille yarns. Firstly, knitting wools for spinning the chenille yarns wind an inverted triangle distance cutting sheet through a high-speed swiveling head, and the width of the neck portion of the distance cutting sheet depends on the length of pile yarns. Subsequently, a pressure roller is fed into a grey yarn rack, two core yarns are discharged, one of the core yarns forms a surface layer core yarn of the chenille yarns, and the other one of the core yarns forms a base layer core yarn of the chenille yarns. The knitting wools on the distance cutting sheet are pushed to blades through roller pieces, the blades move in the middle of the neck portion of the distance cutting sheet, and the knitting wools are cut by means of the blades. The cut knitting wools are sideward clamped between the surface layer core yarn and the base layer core yarn, and flaky knitting wools between the two core yarns are scattered towards all sides to form the chenille yarns through downward use of swiveling of reeling spindles. The chenille spinning machine has the advantages of being convenient to operate, high in production efficiency, large in reeling volume, safe, and reliable.

Owner:ZHEJIANG DONGXING TEXTILE MACHINERY

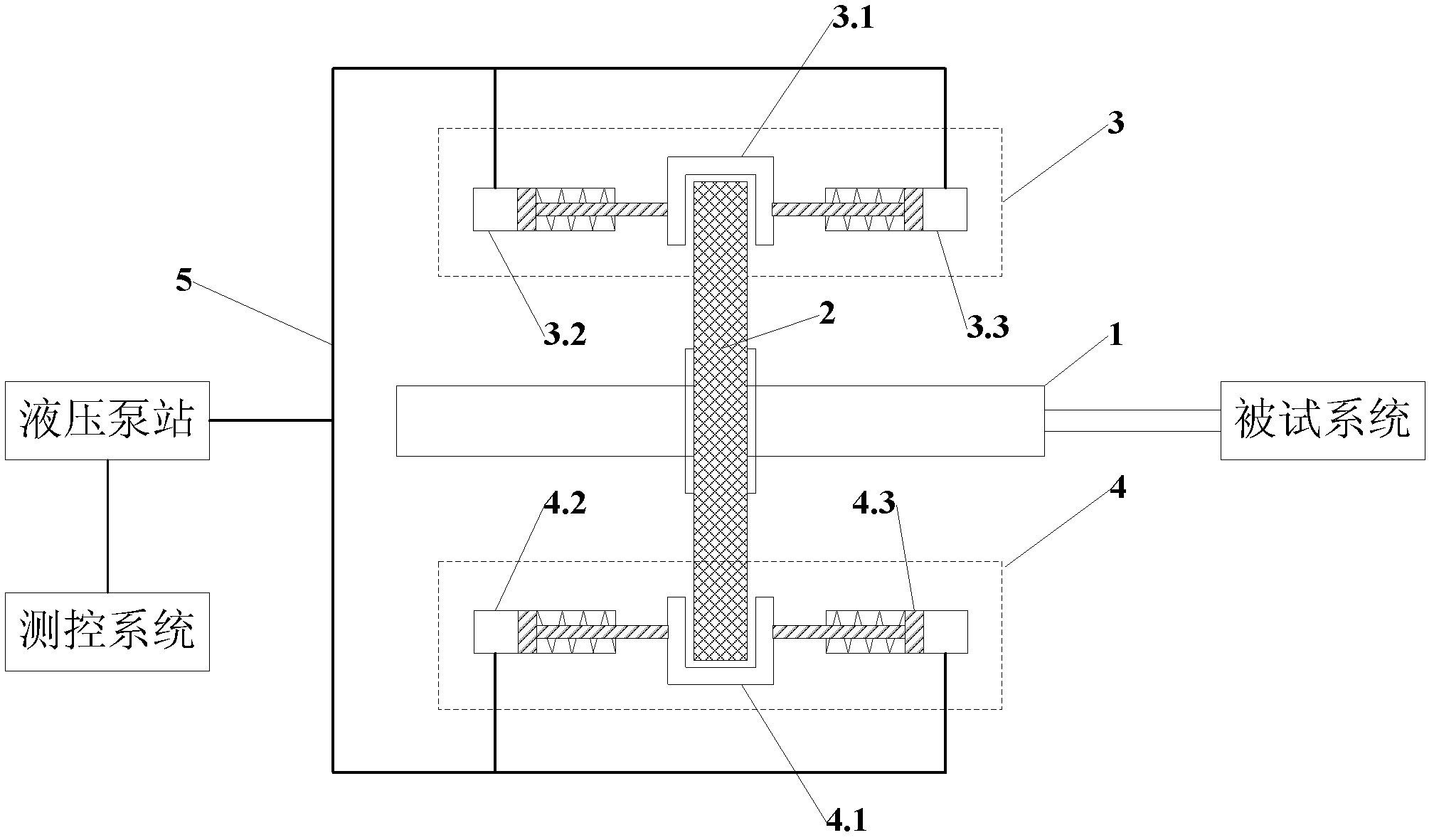

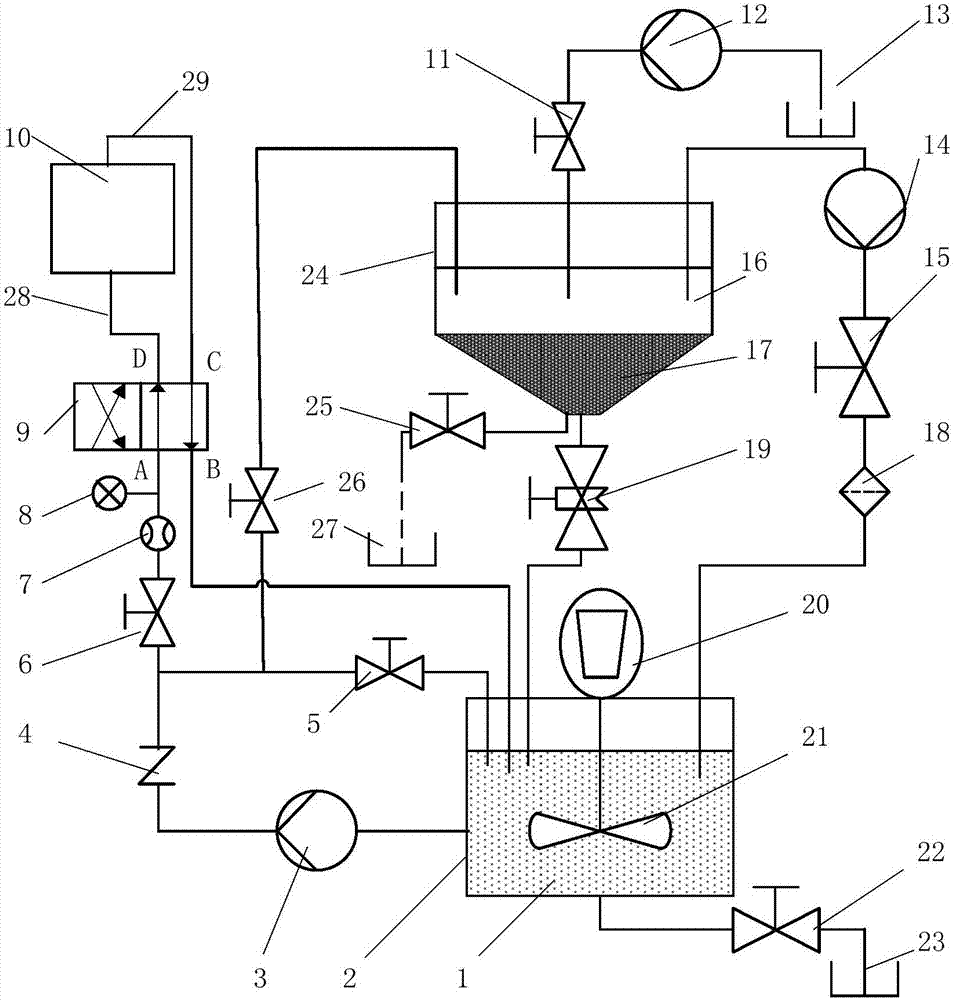

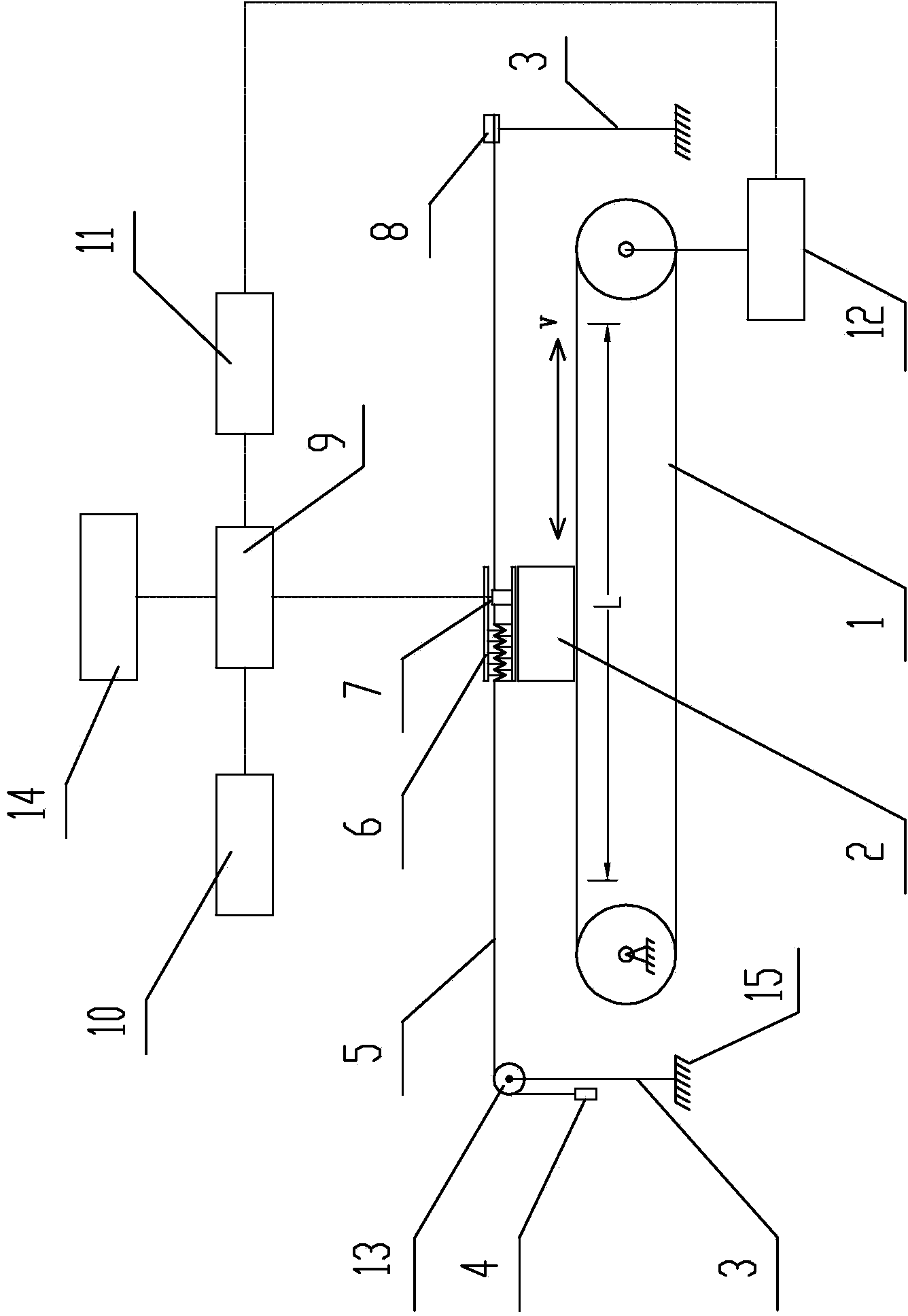

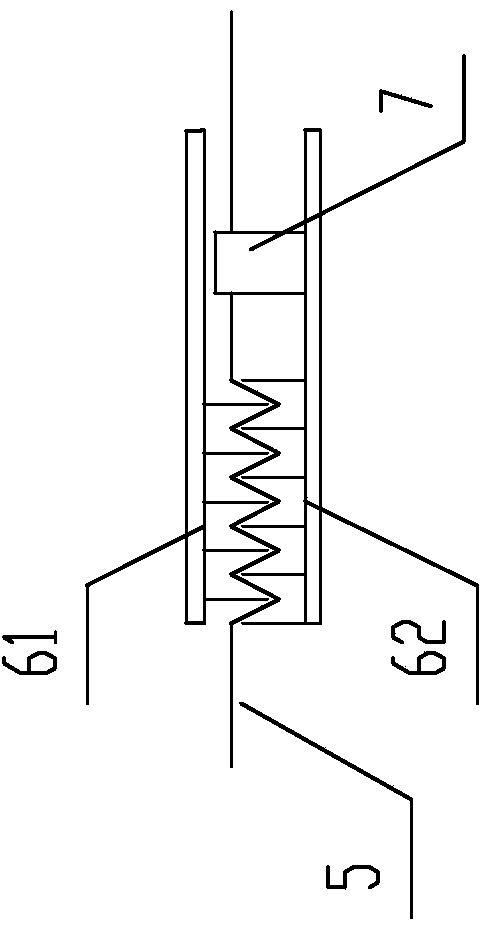

Friction loading apparatus and method thereof

InactiveCN102426110AMeet the needs of friction loadsReflect actual performanceStructural/machines measurementControl systemHydraulic pump

The invention, which belongs to the mechatronics field, provides a friction loading apparatus and a method thereof. The apparatus comprises: a hydraulic pump station, a brake mechanism and a measurement and control system. The brake mechanism comprises: a rotating shaft, a brake disc and two groups of brake calipers. Each group of the brake caliper comprises one brake pad and two brake pistons. The method comprises the following steps: firstly, correctly installing a tested system on a test station; then through the measurement and control system, starting the hydraulic pump station, adjusting a system test pressure so that hydraulic oil drives the brake pistons to move towards a direction of the brake pads and the brake pads are extruded, generating a loading force because of the friction between the brake pads and the brake disc and real-timely calculating the friction loading force through the hydraulic oil pressure; finally, reducing the system test pressure through the measurement and control system so that the friction force of the brake pads and the brake disc reduced to zero. By using the apparatus and the method of the invention, the tested system can be applied with the friction load corresponding to an actual condition. Actual performance of the tested system can be reflected. An apparatus structure is simple and application is convenient.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

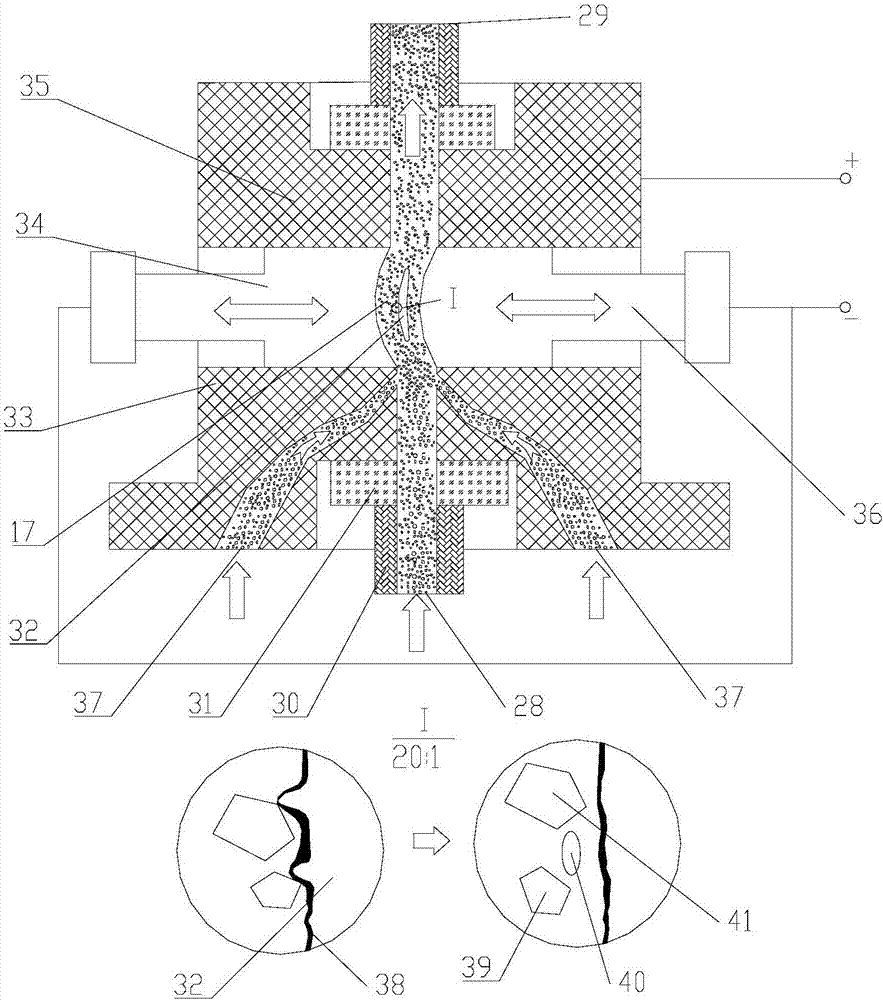

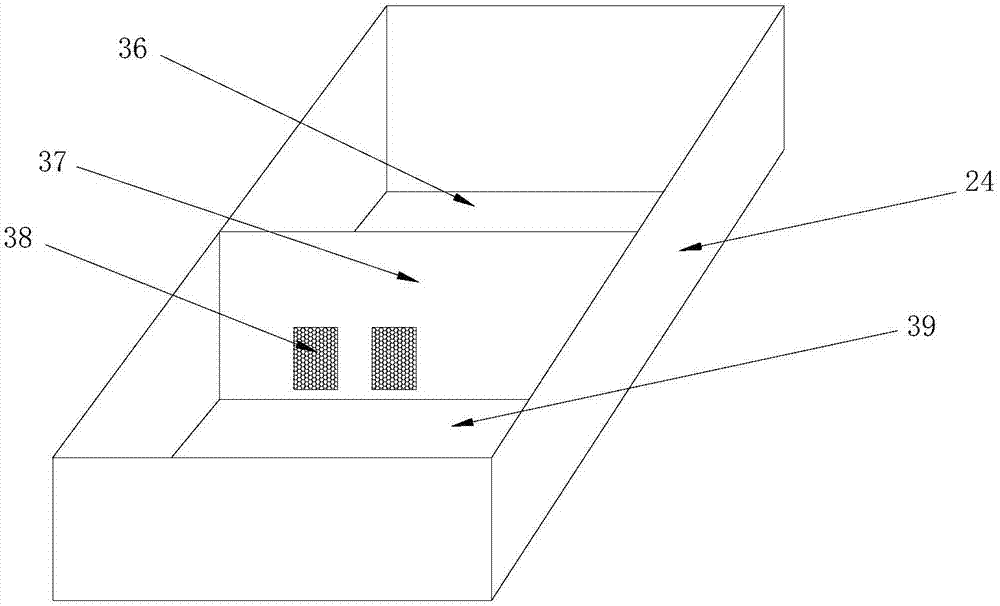

Vibration auxiliary abrasive particle flowing electrolysis micro grinding composite finishing process method

The invention relates to a vibration auxiliary abrasive particle flowing electrolysis micro grinding composite finishing process method, and belongs to the field of electrolysis machining. The method is characterized in that on the basis of the electrolysis polishing principle and the abrasive particle flow finishing process principle, the vibration auxiliary abrasive particle flowing electrolysis micro grinding composite finishing process method is provided, electrolytes mixed with abrasive particles with different grain diameters and in different shapes enter a runner at a certain speed and certain pressure, workpiece anodes and tool cathodes are assisted in vibration, meanwhile, power source machining voltage is adjusted to enable the anode potential to be in the anode workpiece polarization curve passivation area, and the vibration electrolysis polishing method and the abrasive particle flow finishing machining method are effectively composited; on the one hand, the electrolysis effect is used for generating the passivation film on the surface of the anode workpiece; on the other hand, the abrasive particles are driven to flow through the electrolytes, the passivation film and protrusions on the surface of the workpiece are subject to micro grinding, the protrusions are subject to electrodissolution, and the surface of the workpiece has the macro flattening effect.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

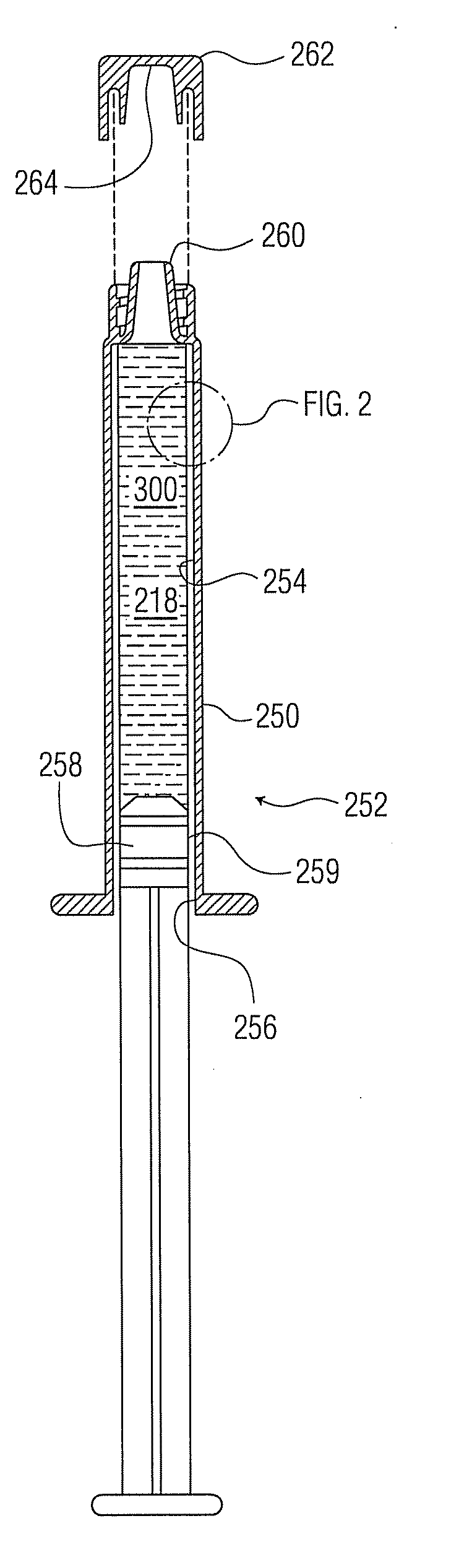

Plasma or CVD pre-treatment for lubricated pharmaceutical package, coating process and apparatus

InactiveUS20160015898A1Improve the lubrication effectEasy to drainInfusion syringesSurgeryPre treatmentLubricant

A syringe comprising a wall having a generally cylindrical interior surface defining a lumen with a primer coating or layer between 1 and 1000 nm thick of SiOx Cy Hz, in which x is from about 0.5 to about 2.4, y is from about 0.6 to about 3, and z is from about 2 to about 9, on at least a portion of the interior surface, the primer coating or layer having an outside surface facing the interior surface of the barrel and an inside surface facing the lumen. A deposit of fluid lubricant on the inside surface of the primer coating or layer is further provided.

Owner:SI02 MEDICAL PRODS

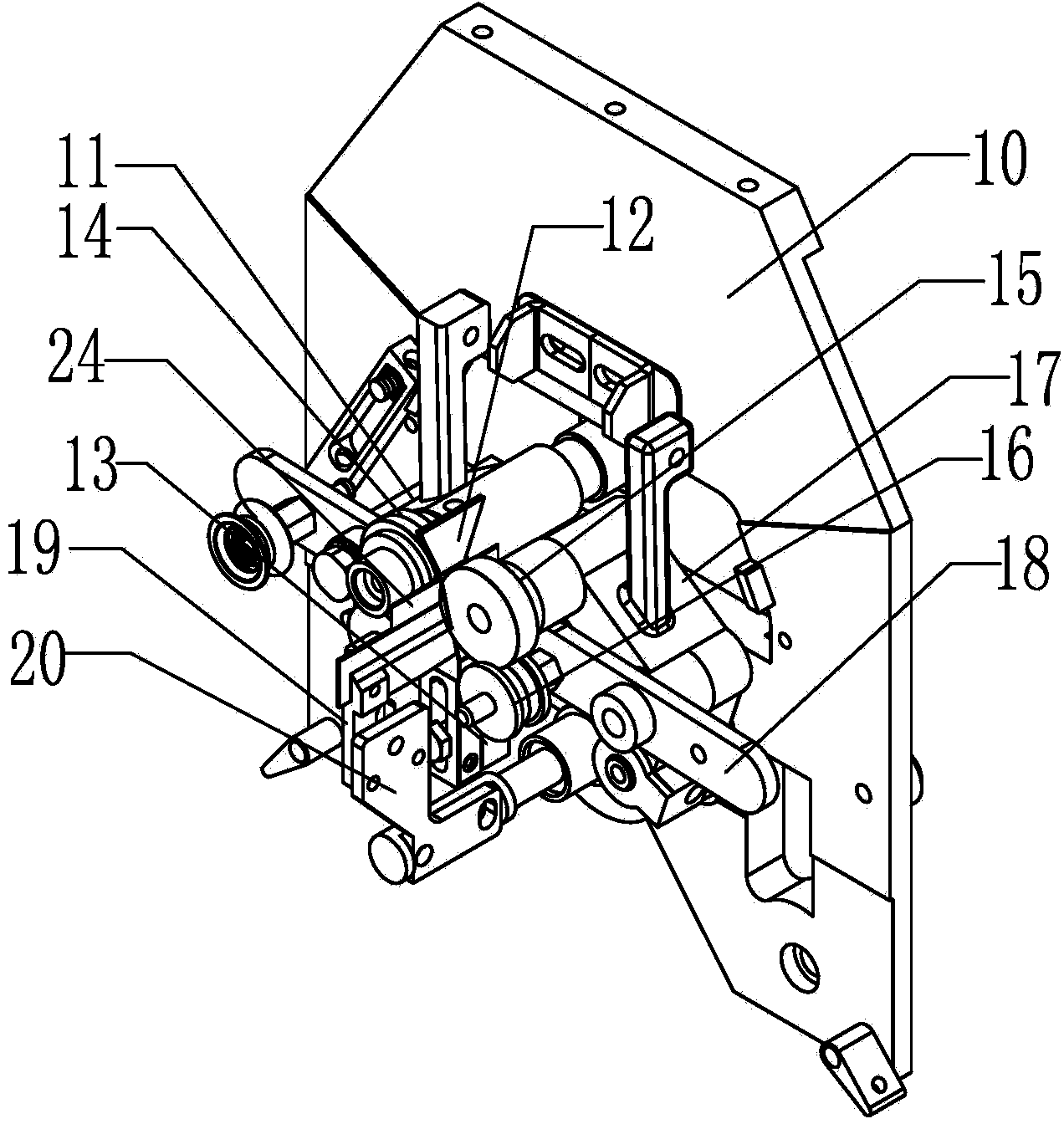

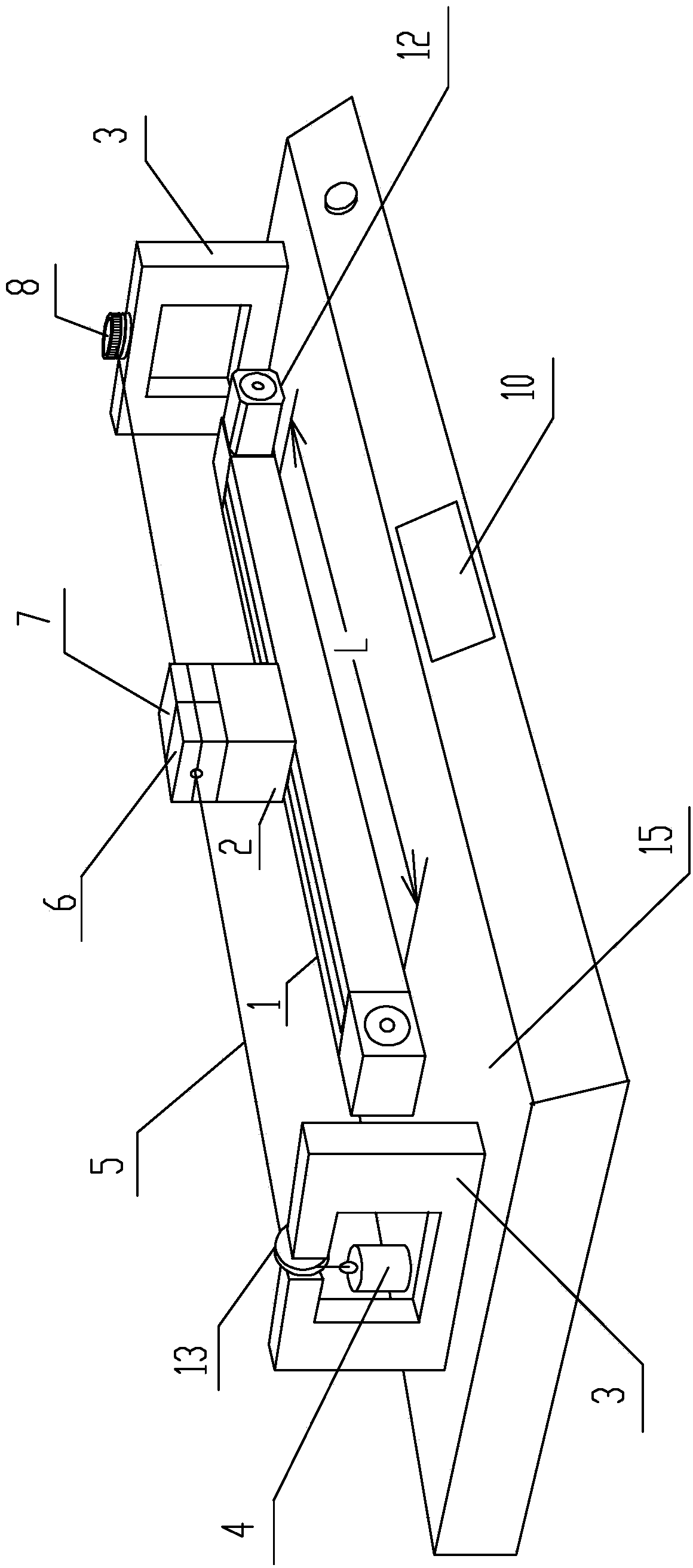

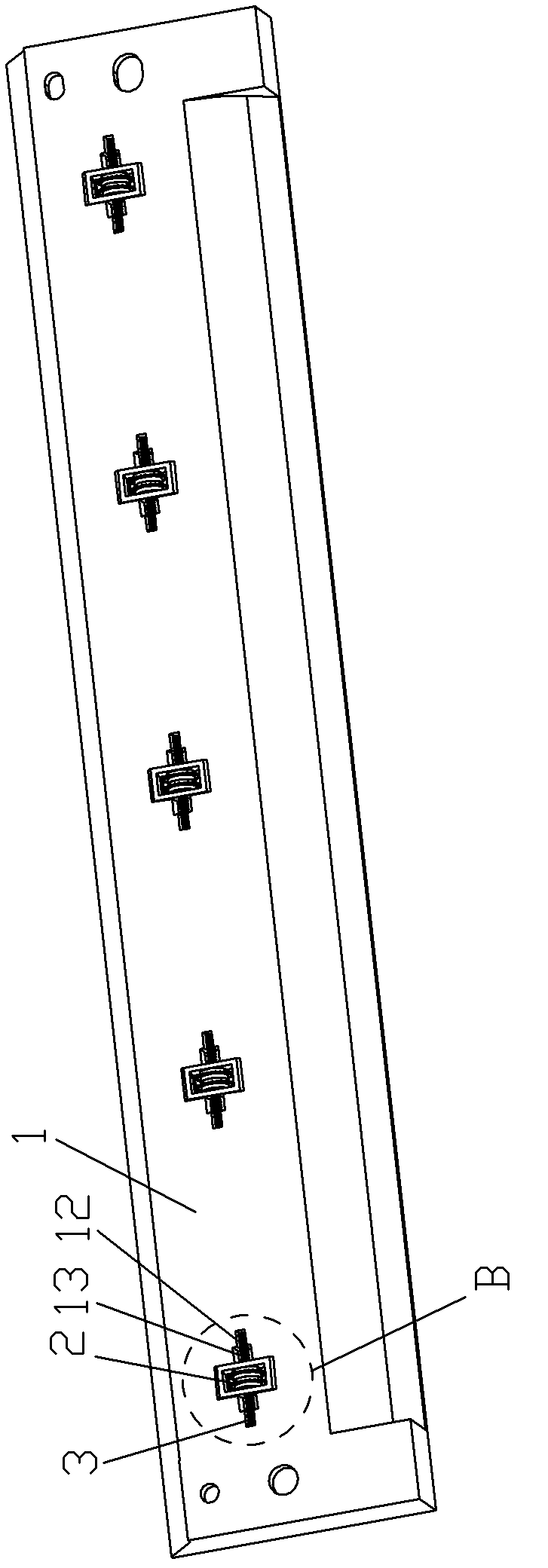

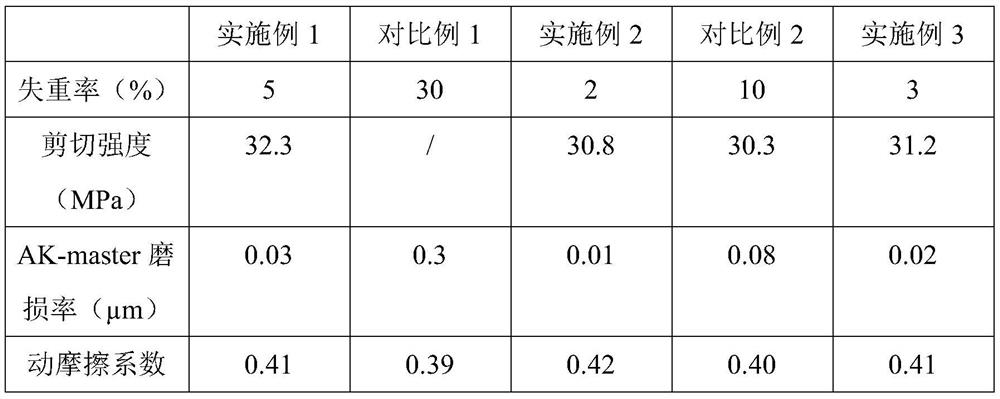

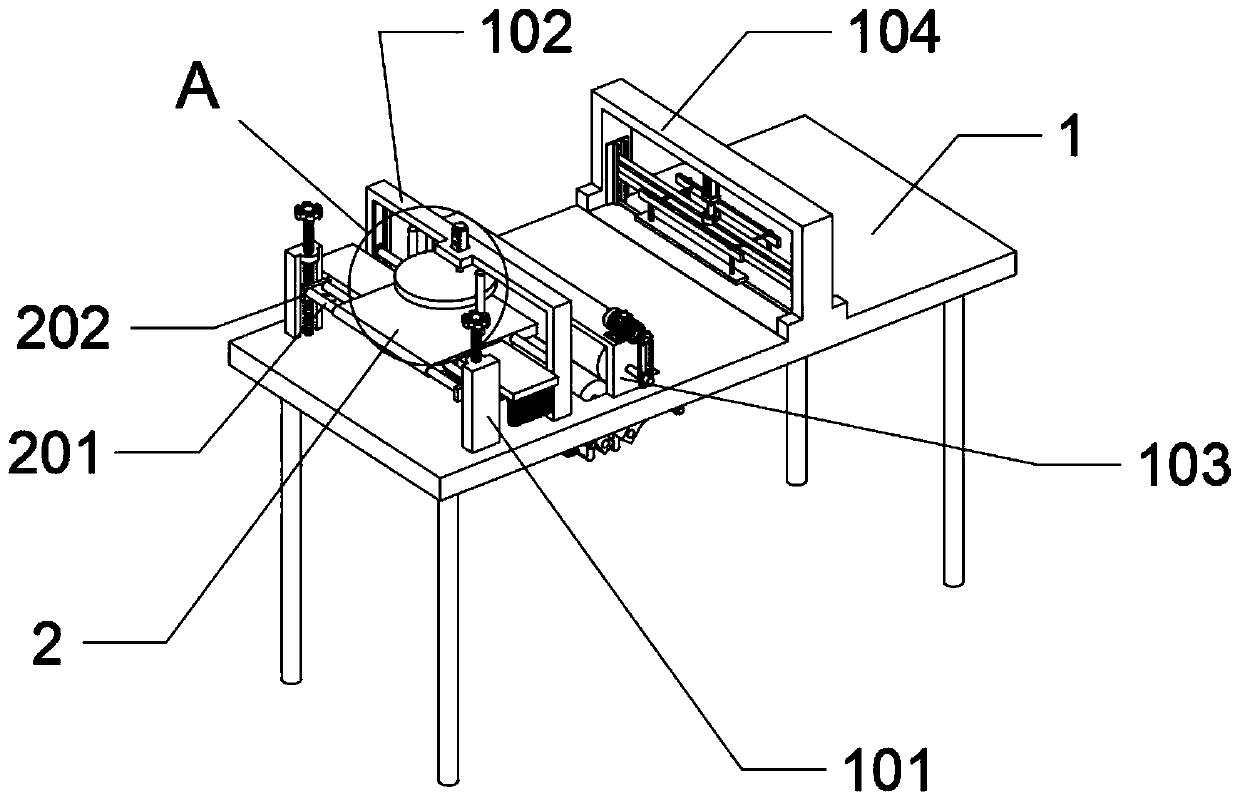

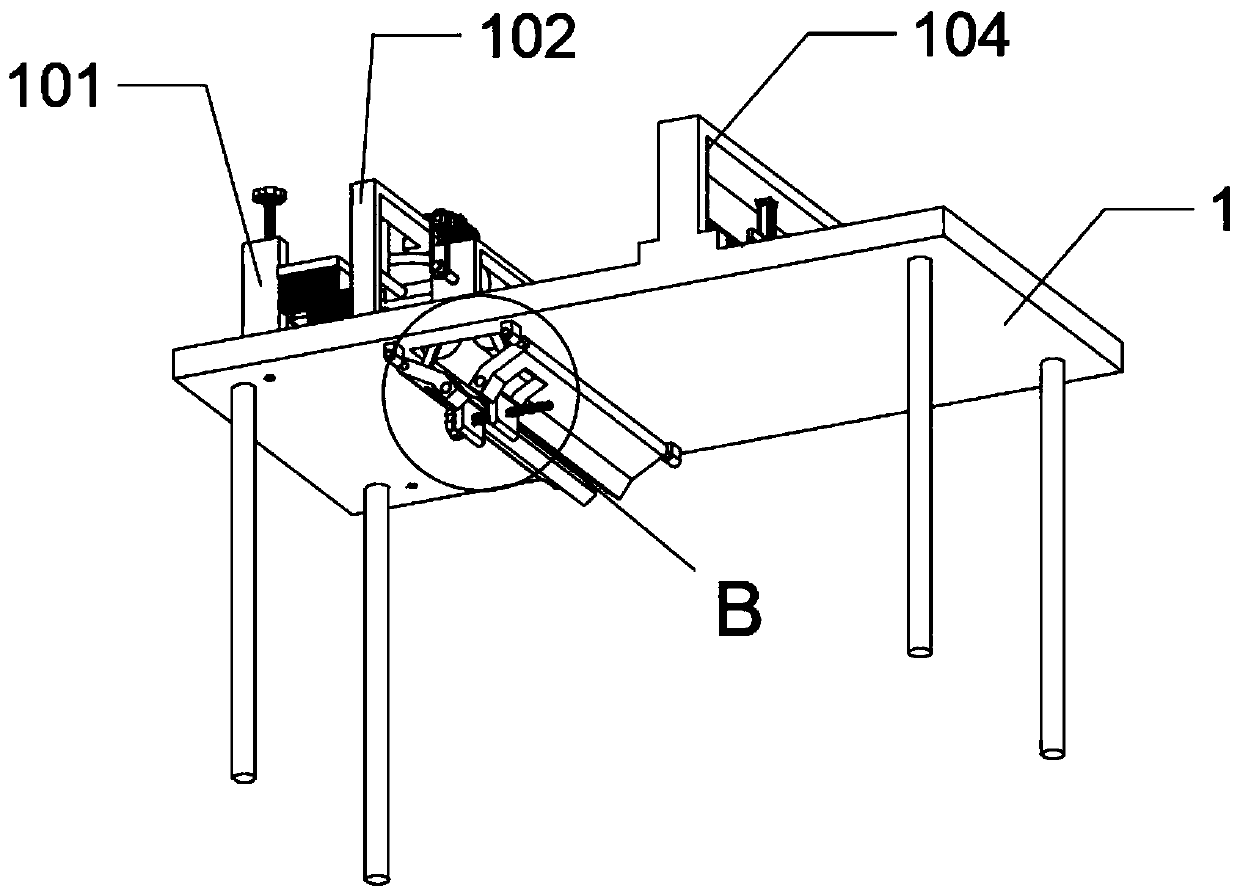

Automatic inspection device for raw silk cohesion and method for inspecting raw silk cohesion

ActiveCN104132890AUniform frictionOvercoming the defects of uneven frictionUsing mechanical meansMaterial analysisControl systemTouchscreen

The invention relates to an automatic inspection device for raw silk cohesion. The automatic inspection device comprises a reciprocating linear sliding table, a reciprocating sliding block, raw silk support frames, a raw silk tension weight, a friction blade group, a silk guiding pulley and an automatic inspection control system, wherein the automatic inspection control system is composed of a capacitive silk density sensor, a touch screen, a programmable controller, a motor driver, a sliding table motor and a computer. A method for inspecting the raw silk cohesion comprises the following steps: one end of a raw silk strip to be inspected is fixed to one raw silk support frame through a silk clamping nut, and the other end of the raw silk strip to be inspected penetrates through the capacitive silk density sensor and the friction blade group, then passes through the silk guiding pulley fixedly mounted on the other raw silk support frame, and finally is hooked on the raw silk strip tension weight; the reciprocating linear sliding table is utilized to drive the friction blade group on the reciprocating sliding block so as to carry out constant-linear-speed reciprocating friction on the raw silk strip to be inspected at constant uniform speed; meanwhile, the following capacitive silk density detection sensor is utilized to detect the splitting condition of the raw silk strip to be inspected caused by friction; the programmable controller determines the cohesion performance of raw silk.

Owner:柳州市自动化科学研究所

Friction type torque limiting structure

InactiveCN104863990ASimple structureCompact structureAutomatic clutchesEngineeringMechanical equipment

The invention relates to a friction type torque limiting structure, in particular to a torque overload protection device, namely, when transmission torque exceeds a certain limited value, the friction type torque limiting structure slips to provide overload protection for equipment, and belongs to the technical field of mechanical equipment. The friction type torque limiting structure comprises a spacing shaft, friction plates, a transmission piece and a torque adjustment piece, wherein the spacing shaft neck portion of the spacing shaft is sleeved with the transmission piece, on end of the spacing shaft neck portion of the spacing shaft is connected with the torque adjustment piece through an external thread, one of the friction plates is arranged between the transmission piece and a flange portion of the spacing shaft, and the other friction plate is arranged between the transmission piece and the torque adjustment piece. According to the friction type torque limiting structure, the assembly and the setting of slipping torque are easy, and occupied space is small; a compressing position is on the middle portion of each friction plate, the friction generated through pressure is uniform, the accuracy of the set overload slipping torque is high, and even if the friction type torque limiting structure is used for a long term and slipped for multiple times, the set torque repeated accuracy is still high.

Owner:无锡创明传动工程有限公司

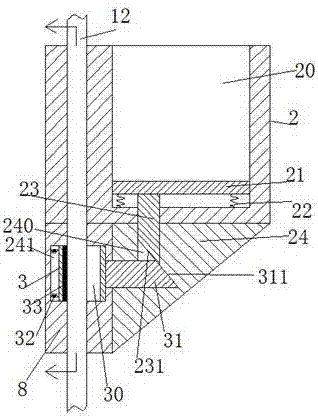

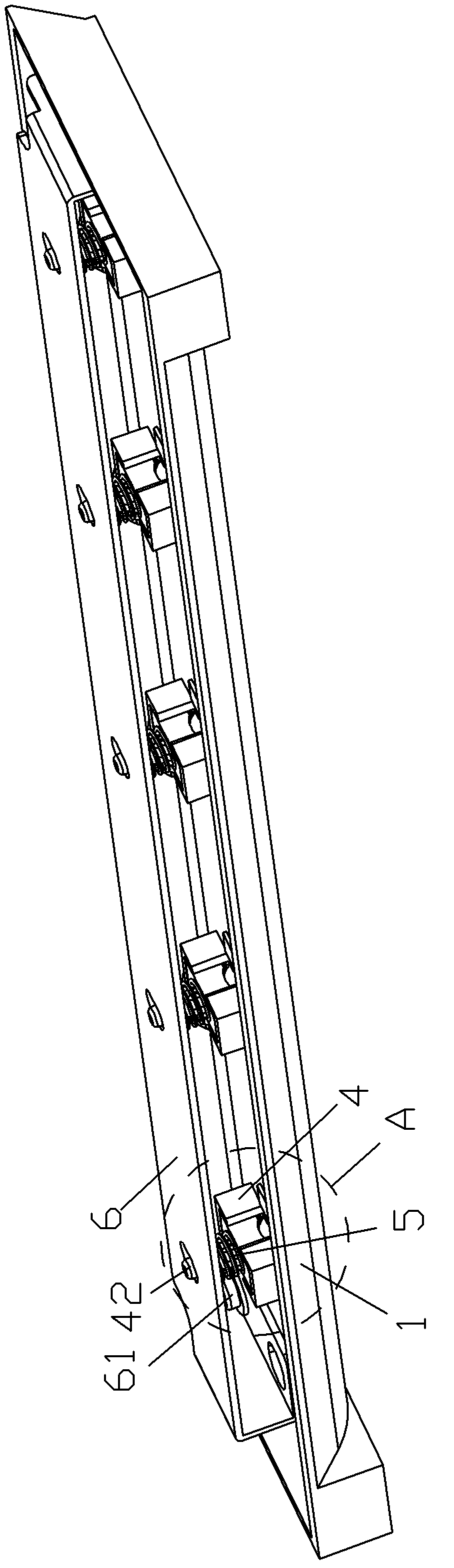

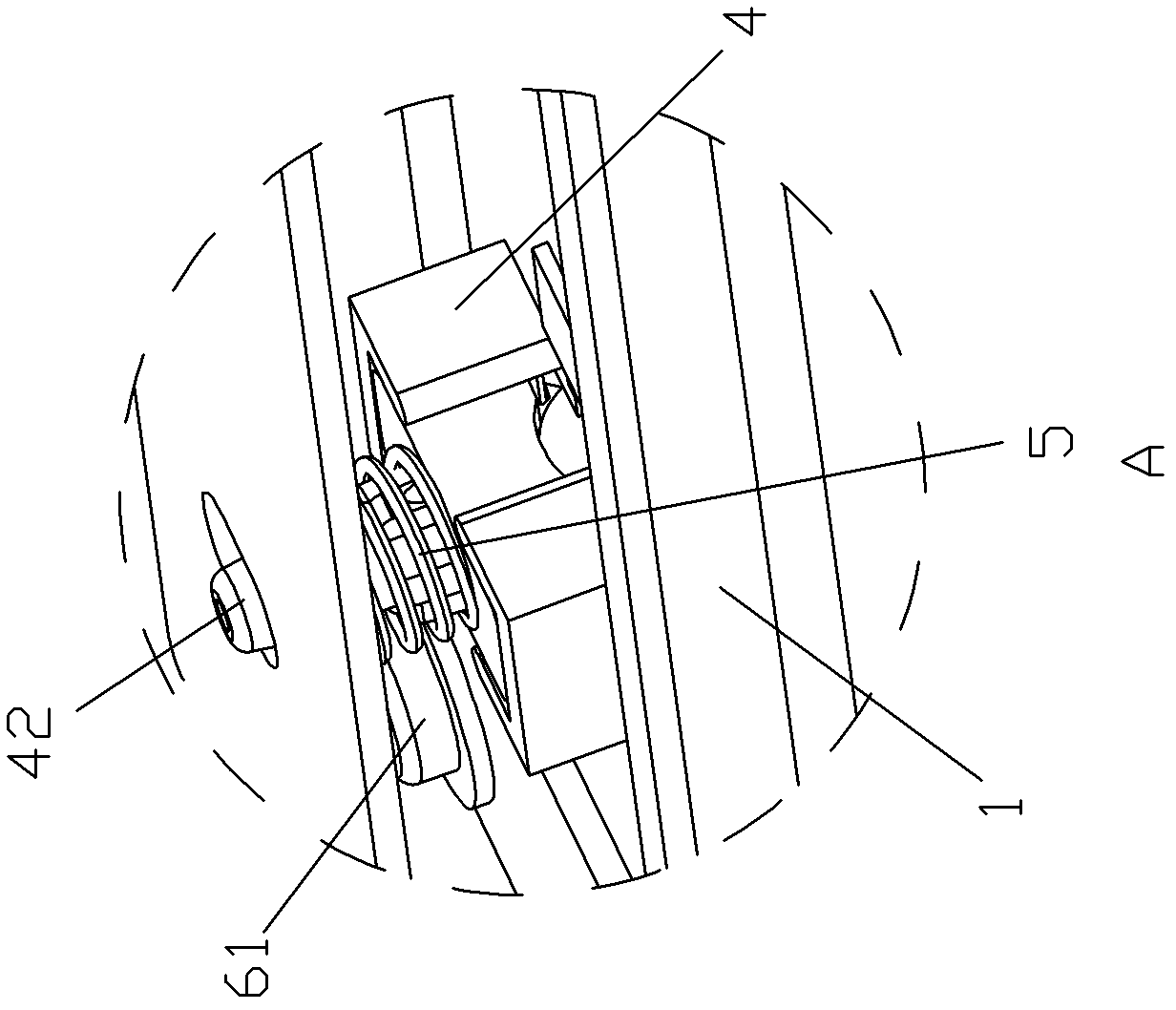

Building material transporting device

Disclosed is a building material transporting device. The building material transporting device comprises a base plate and a top plate, wherein the base plate is fixedly installed on the ground, and the top plate is fixedly installed on the roof of a building. Two guide rods and a lifting threaded rod are fixedly installed between the base plate and the top plate, wherein the guide rods are symmetrical in a left-and-right mode, and the lifting threaded rod is located between the guide rods. A lifting frame is installed on the lifting threaded rod, and guide holes are symmetrically formed in the left side and the right side of the lifting frame, and matched with the guide rods. Guide sleeves are further installed on the guide rods in a sliding mode, and the upper ends of the guide sleeves are fixedly connected with the lower end of the lifting frame. A triangular plate is further fixedly installed between the front ends of the guide sleeves and the bottom end of the lifting frame, and a transverse groove and a longitudinal groove which is communicated with the transverse groove are formed in the triangular plate. A sliding plate is installed in a cavity of the lifting frame in the mode that the sliding plate can slide up and down. Sliding grooves which extend in a front-and-rear mode are formed in the guide sleeves, sliding frames are installed in the sliding grooves in a sliding mode, empty grooves which allow the guide rods to pass through are formed in the sliding frames, the rear end wall of each empty groove is set to be an arc-shaped surface, and arc-shaped friction plates are fixedly installed on the arc-shaped surfaces.

Owner:梧州理想科技有限公司

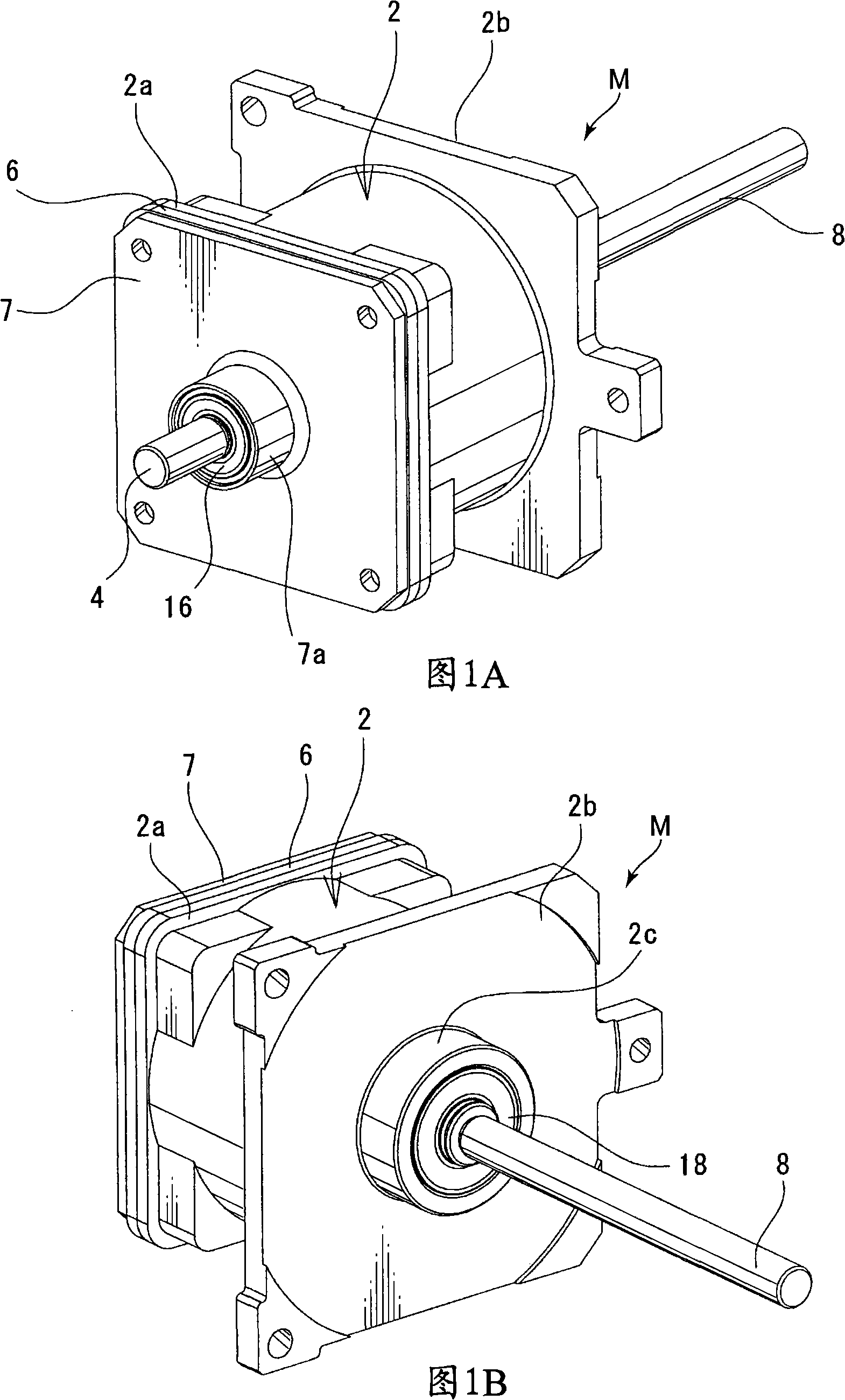

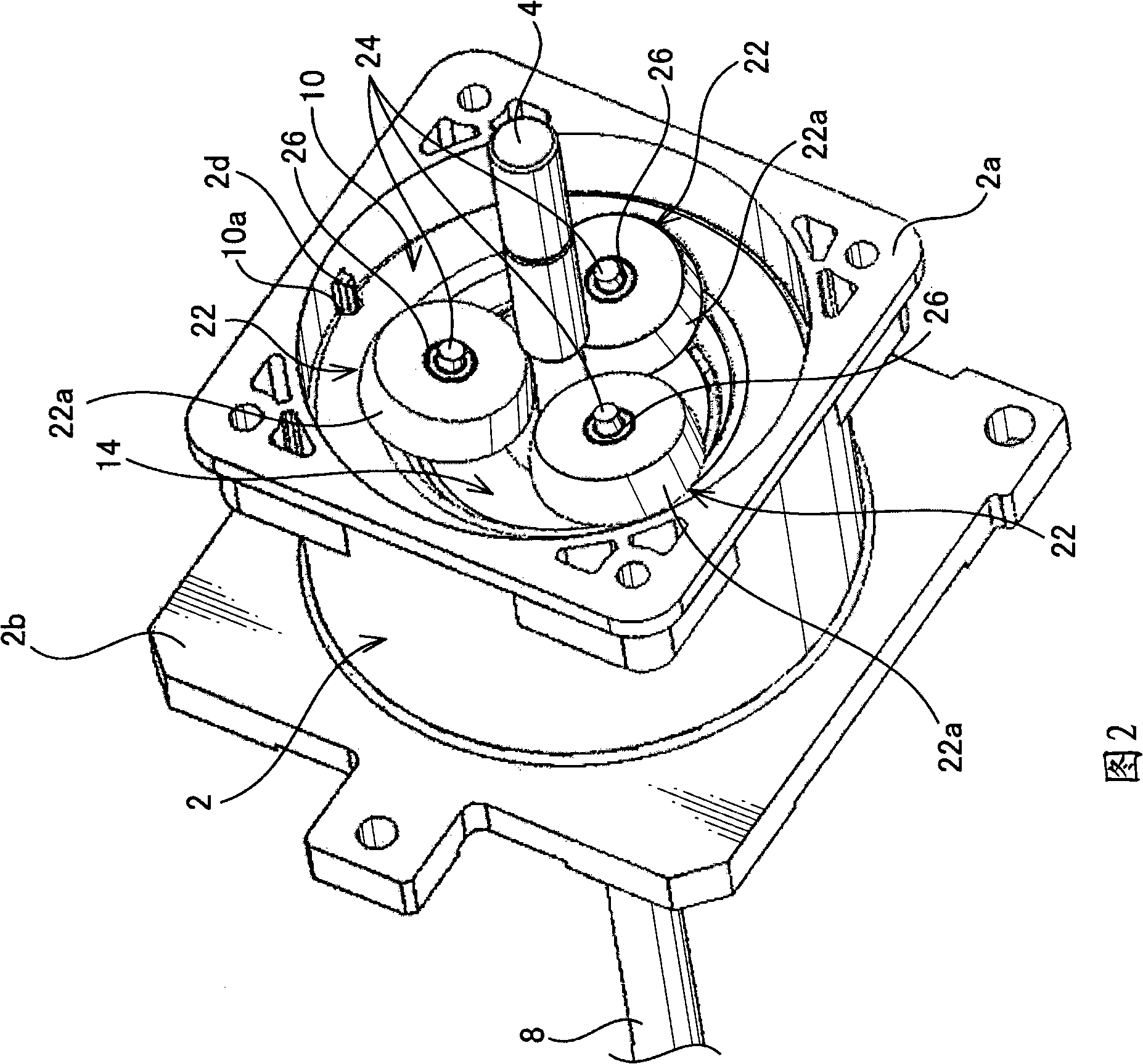

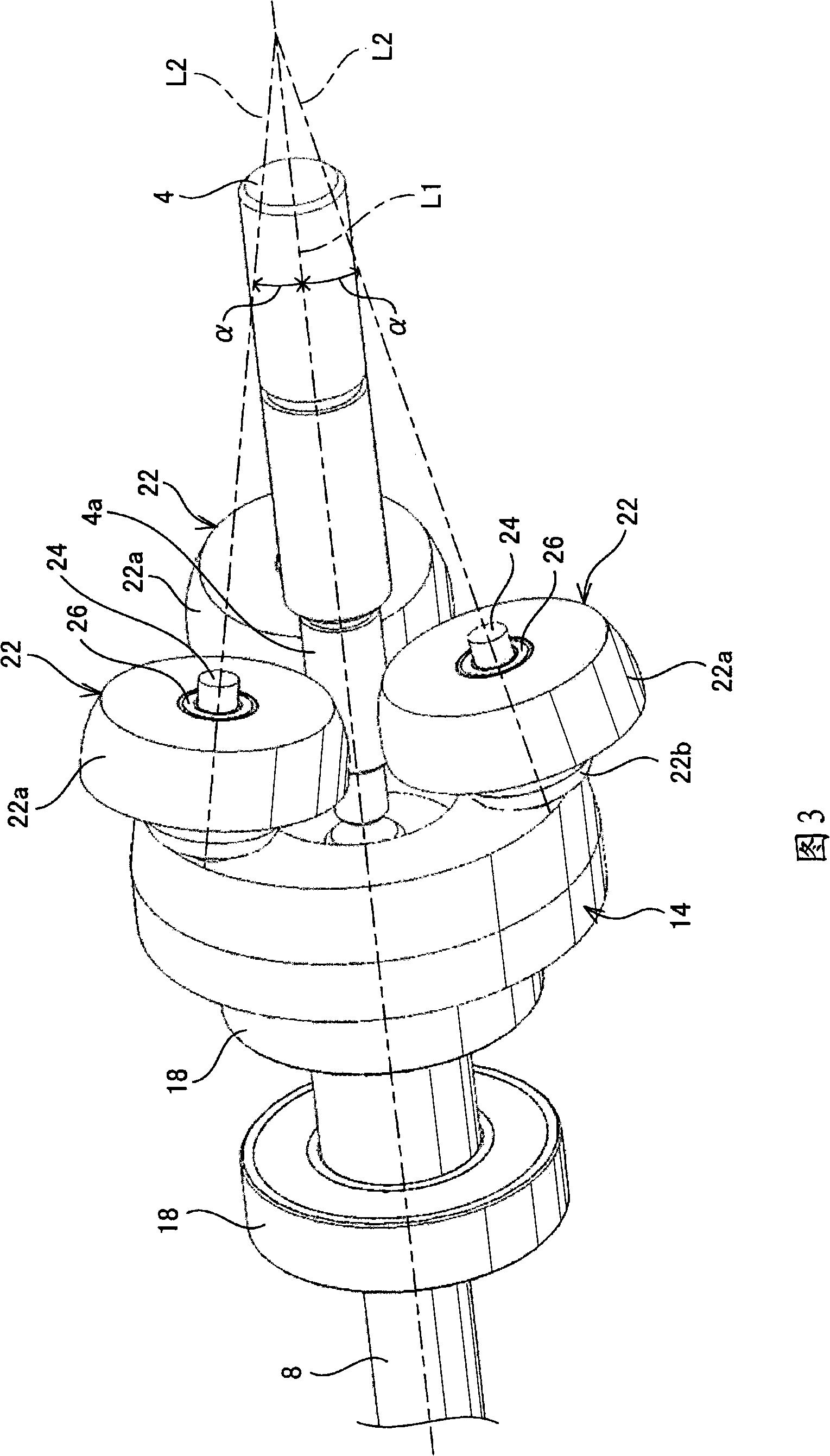

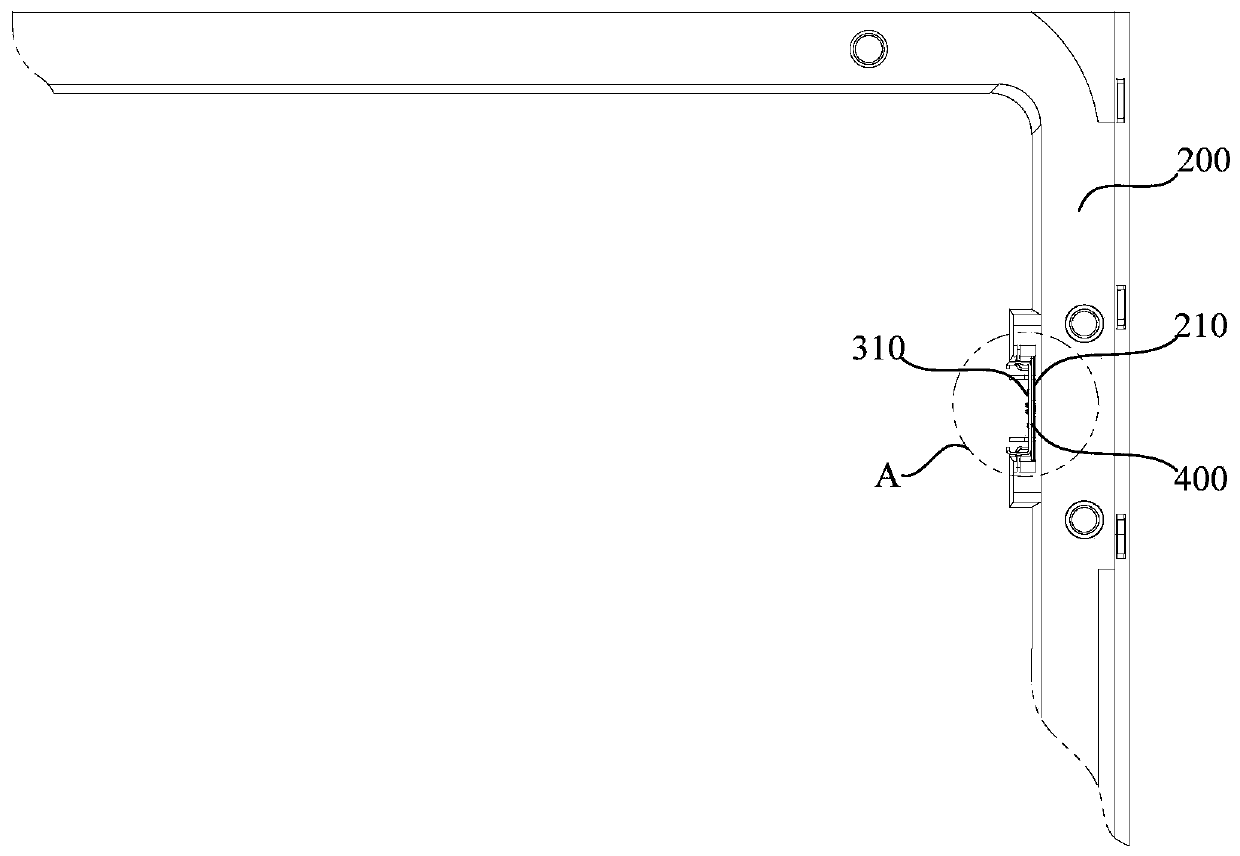

Driving-force transmission mechanism and image forming apparatus equipped therewith

InactiveCN101334097AUniform frictionGear lubrication/coolingElectrographic process apparatusEngineeringFriction force

The invention provides a traction-drive force transmission mechanism and a image forming device equipped with the same. The traction-drive force transmission mechanism, includes a sun roller rotatable about a first axis and a plurality of shafts. Each is disposed on an adjacent axis inclined relative to the first axis. Planetary rollers are disposed along an outer peripheral surface of the sun roller and are supported respectively by the shaft. A carrier holds each of the shafts in the inclined posture and is adapted to be rotated about the first axis together with the planetary rollers. A pressing member pressingly moves each planetary roller in a direction for reducing a distance to the first axis so as to press each planetary roller against the outer peripheral surface of the sun roller. Thus a driving force can be transmitted to a traction force between the sun roller and each of the planetary rollers.

Owner:KYOCERA DOCUMENT SOLUTIONS INC

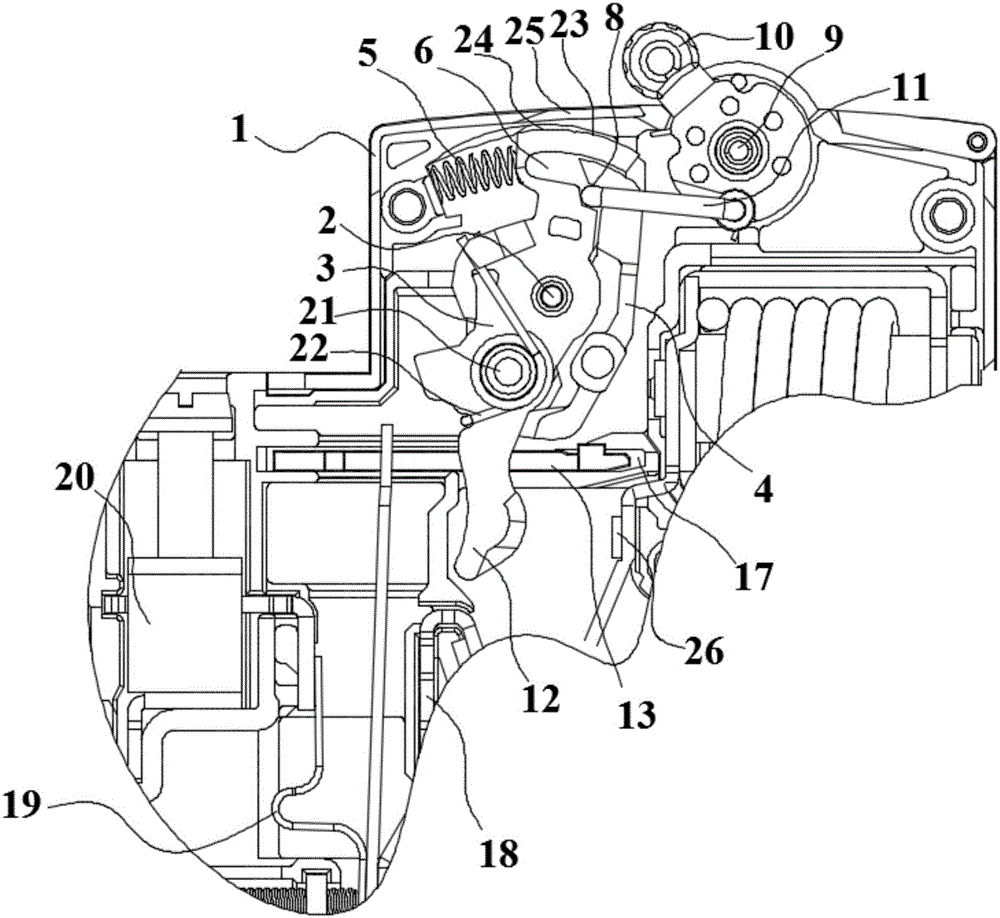

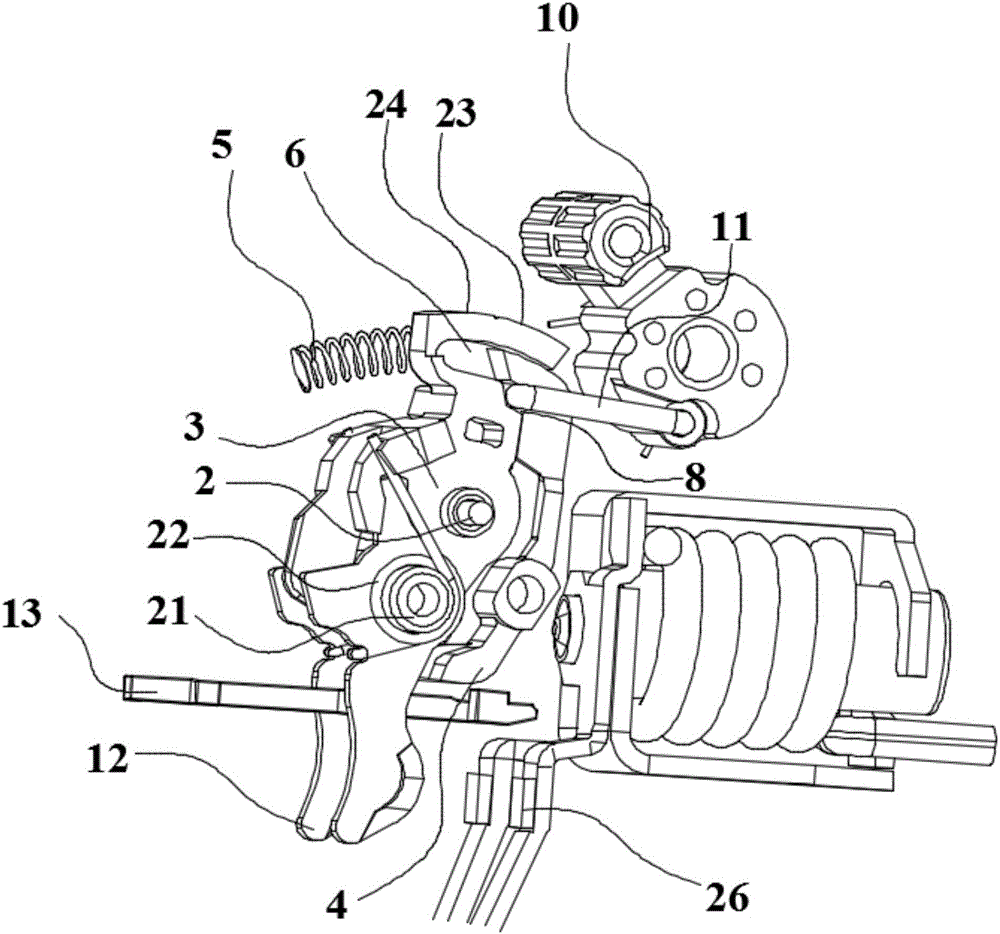

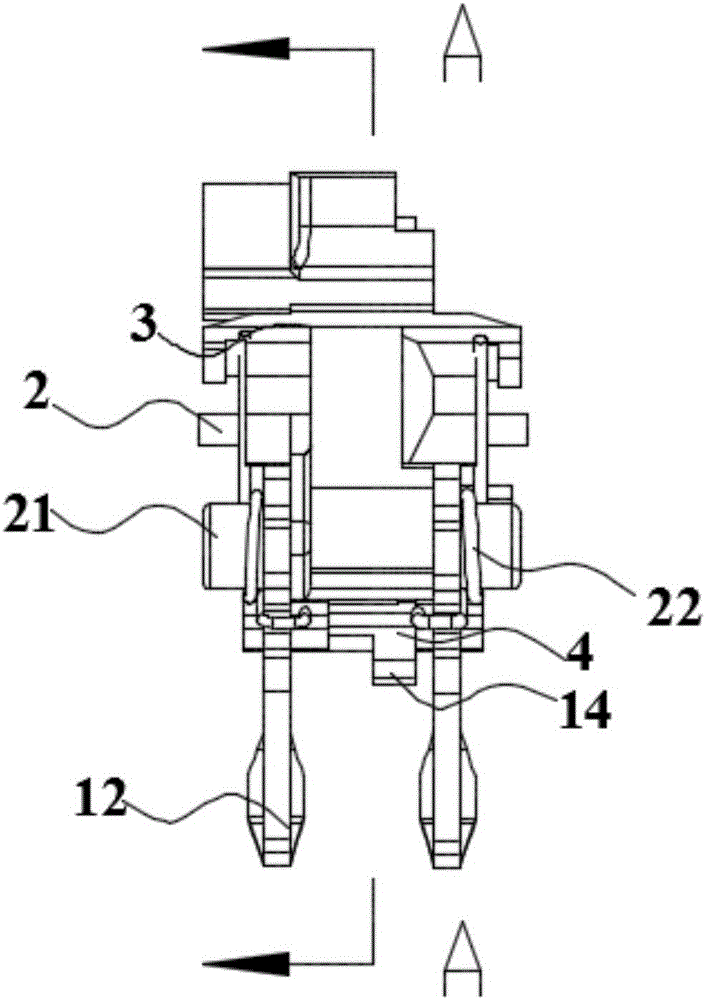

Operating mechanism of electrical protection apparatus

InactiveCN105742128ASimple structureEasy to useProtective switch operating/release mechanismsEngineeringMechanical engineering

The invention relates to an operating mechanism of an electrical protection apparatus. The operating mechanism comprises a shell and a handle arranged in the shell, wherein a bracket and a lock catch are coaxially and rotationally arranged in the shell; an axial torsion spring is arranged on the bracket shaft, wherein the two ends of the axial torsion spring props against and presses the bracket and the lock catch respectively; one end of the bracket props against a bracket spring while the other end of the bracket spring props against the shell; a bracket end groove is formed in the side wall, propping against one end of the bracket spring, of the bracket; one end of the lock catch extends into the bracket end groove to form an opening-closing hole; the handle is in transmission connection with the opening-closing hole through a U-shaped pushing rod; when the handle is opened, one end of the push rod is locked through the opening-closing hole; when the handle is closed, the push rod is pushed to overcome the locking force of the opening-closing hole to slide to the bracket end groove and to push the bracket to rotate; a moving contact is connected with the relative end of one end, propping against the bracket spring, of the bracket; one end, far from the bracket end groove, of the lock catch props against a sliding block for limiting the rotation of the lock catch; and the sliding block is connected with a thermal releasing apparatus. The operating mechanism of the electrical protection apparatus is simple in structure, low in abrasion and long in service life.

Owner:YUEQING ZHISHUN ELECTRIC CO LTD

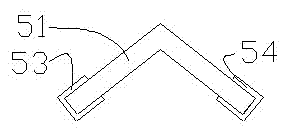

Headset connecting structure and headset

ActiveCN106358106AImprove qualityGlides steadily and smoothlyMicrophonesLoudspeakersDual actionSound production

The invention relates to the technical field of a headset structure and discloses a headset connecting structure and a headset. The headset connecting structure is used for connecting a head band and sound production units of the headset and comprises a magnetic sliding arm, a sliding track and a casing covering the periphery of the sliding track, wherein the tail end of the magnetic sliding arm can slide to extend into the sliding track from the head end of the sliding track, the head end of the magnetic sliding arm is fixedly connected with the head band, and the tail ends of the casing are connected with the sound production units; the magnetic sliding arm is covered with a seamless sleeve, and iron-based parts in adsorption matching with left and right sides of magnetic sliding arm are arranged in the sliding track and attached to the seamless sleeve. The headset comprises the head band, the sound production units and the headset connecting structure for connecting the head band and the sound production units. According to the headset connecting structure and the headset, the iron-based parts arranged in the sliding track are in adsorption matching with the magnetic sliding arm movably extending into the sliding track, so that the magnetic sliding arm slides smoothly under the dual actions of magnetic force and frictional force, and the use effect of a user is improved.

Owner:SHENZHEN GRANDSUN ELECTRONICS

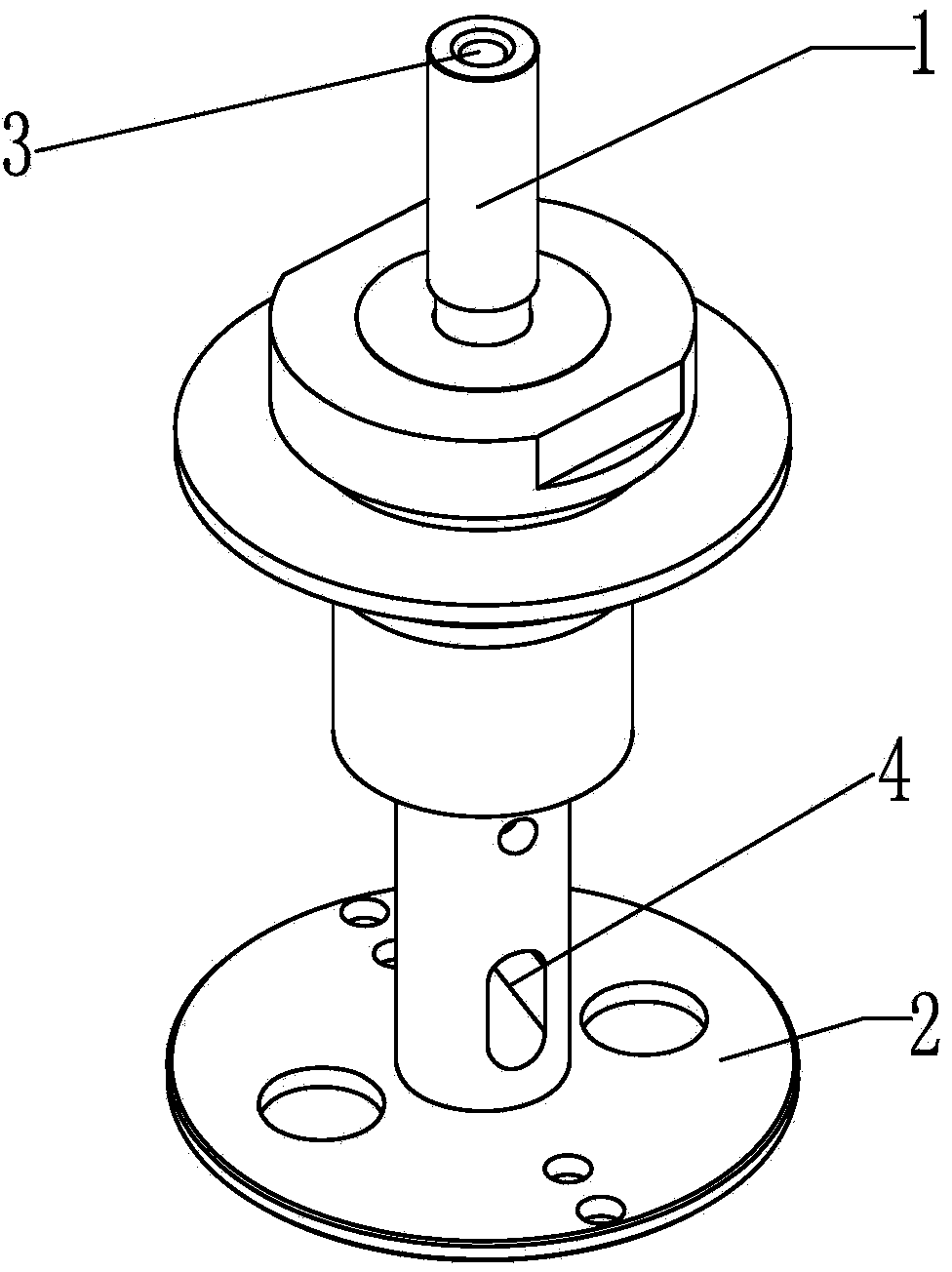

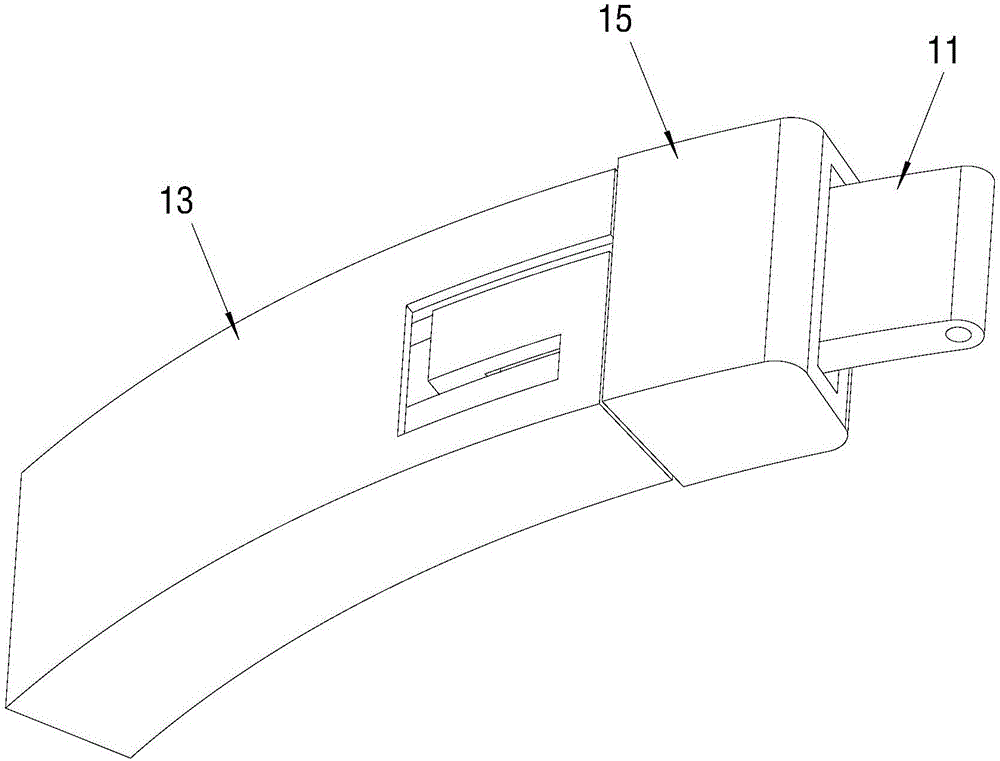

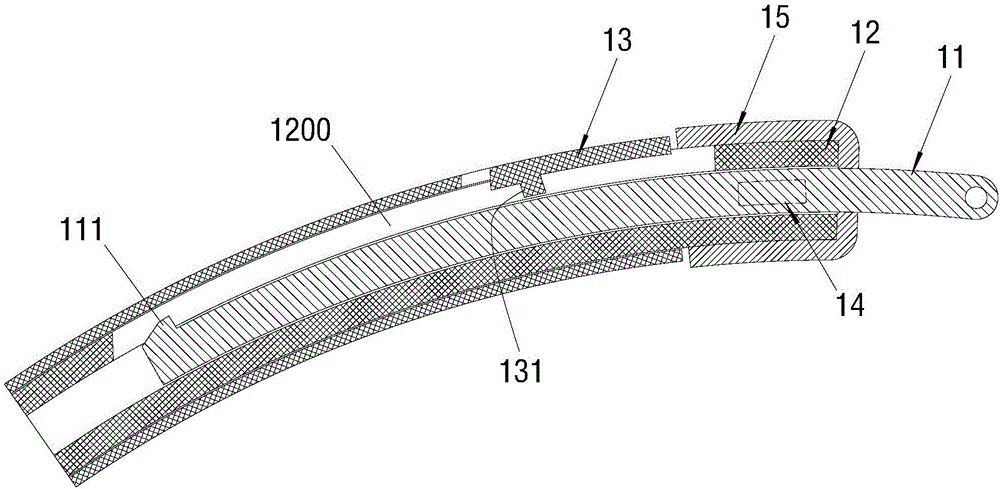

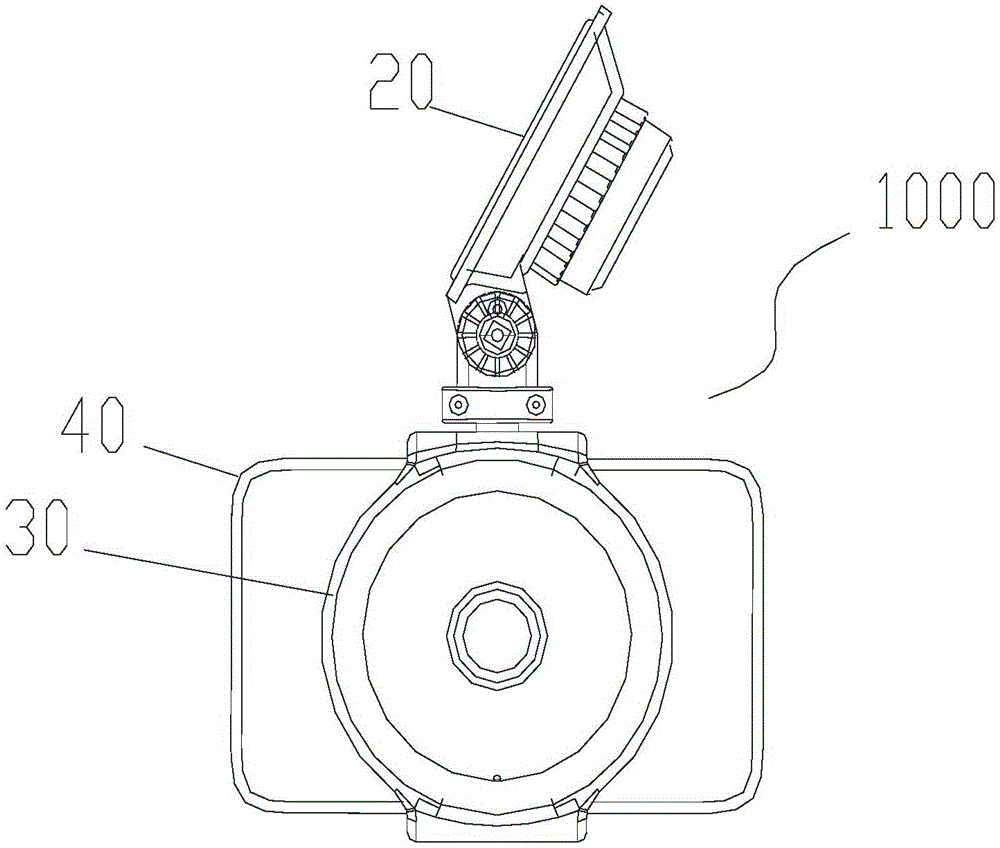

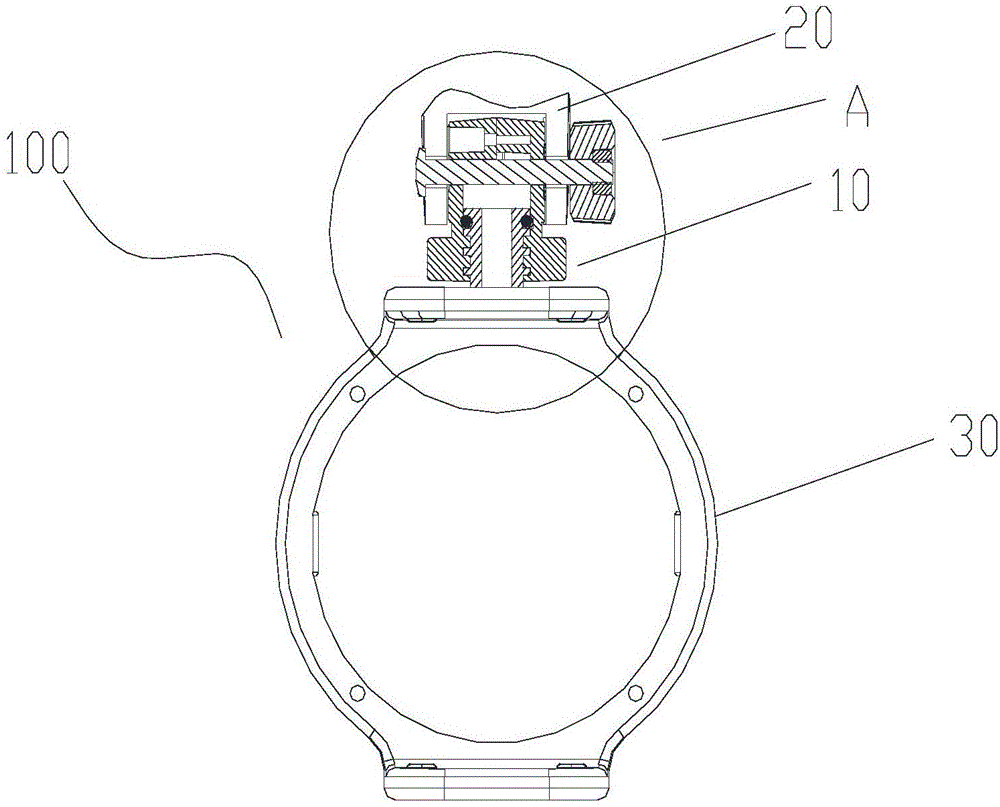

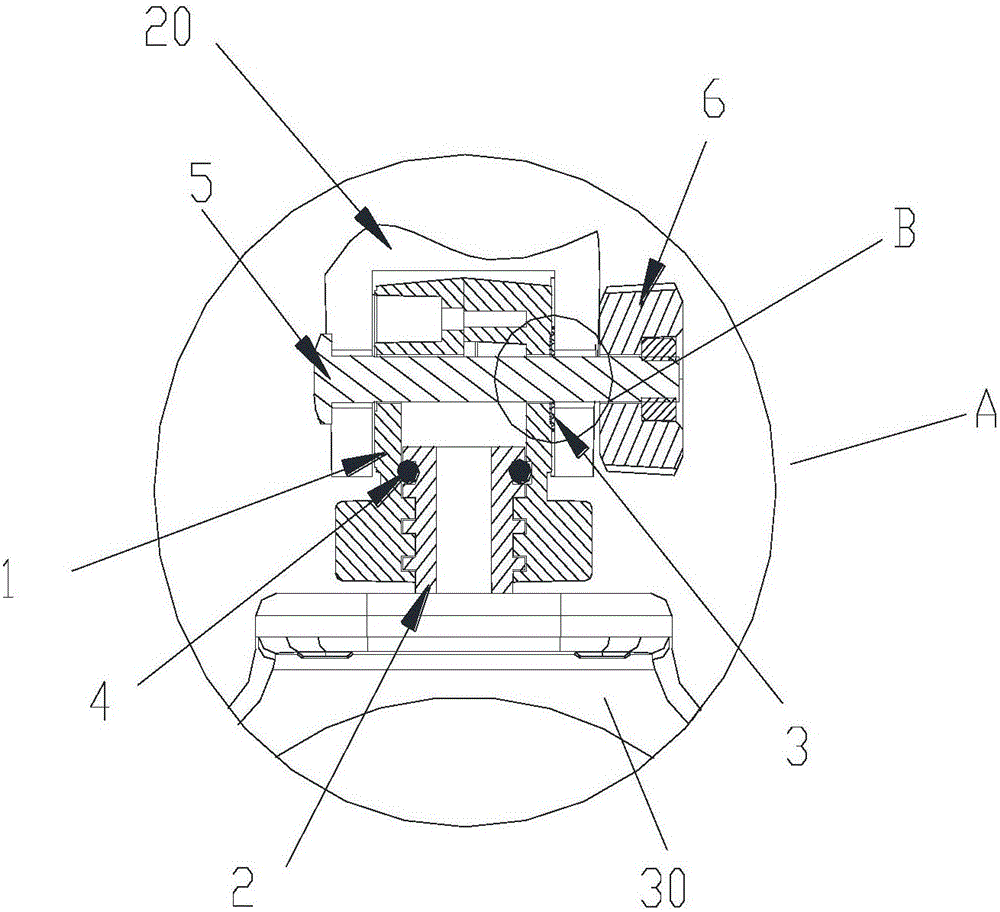

Rotary assembly, support and image pickup device suite

ActiveCN106314306ASmooth rotationUniform frictionRegistering/indicating working of vehiclesVehicle componentsVertical planeFriction force

The invention provides a rotary assembly. The rotary assembly comprises an upper rotary part and a lower rotary part which are rotationally connected in a sleeved manner, and a pre-pressing part for carrying out pre-pressing to generate friction force is arranged at the sleeved position of the upper rotary part and the lower rotary part. Due to the fact that the upper rotary part and the lower rotary part are rotationally sleeved, the upper rotary part and the lower rotary part can relatively rotate by 360 degrees. Furthermore, the upper rotary part is provided with a connecting part for conveniently adjusting the connecting angle between the upper rotary part and an external fixing part, and the connecting part enables the rotary assembly to rotate by 180 degrees in the vertical plane. In addition, the invention provides a rotary support adopting the rotary assembly and an image pickup device suite adopting the rotary support. The image pickup device suite is easy to install; preferably, an automobile data recorder is adopted as an image pickup device, and due to the fact that the rotary assembly is adopted, the shooting range of the automobile data recorder can be effectively widened.

Owner:BEIJING QIHOO TECH CO LTD

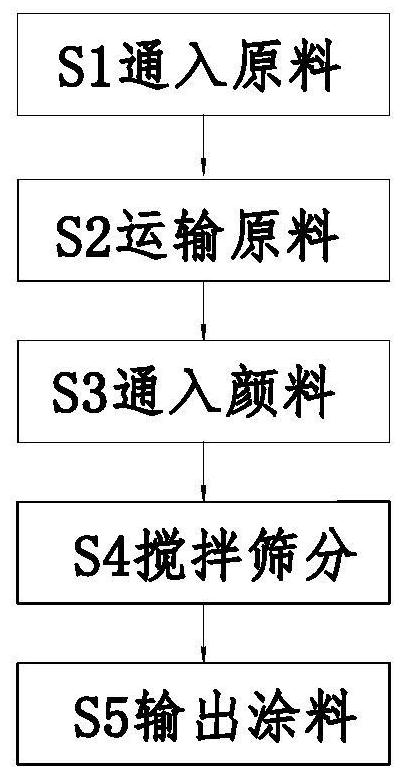

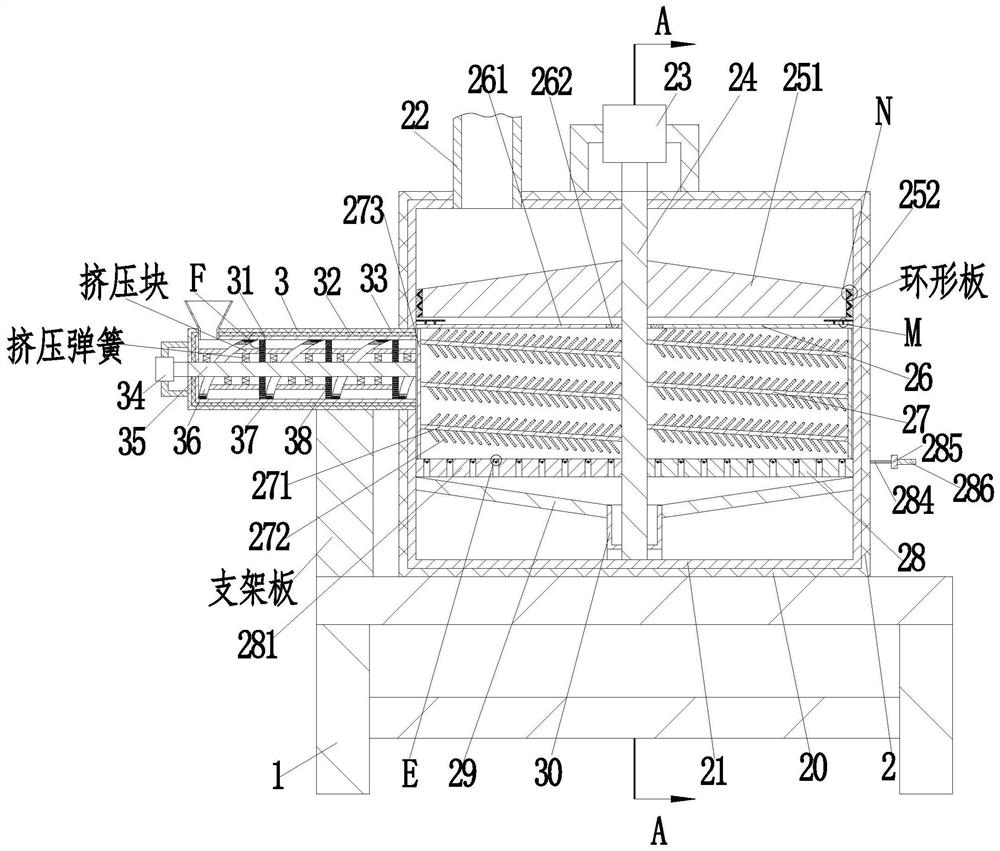

Polyurethane coating preparation method

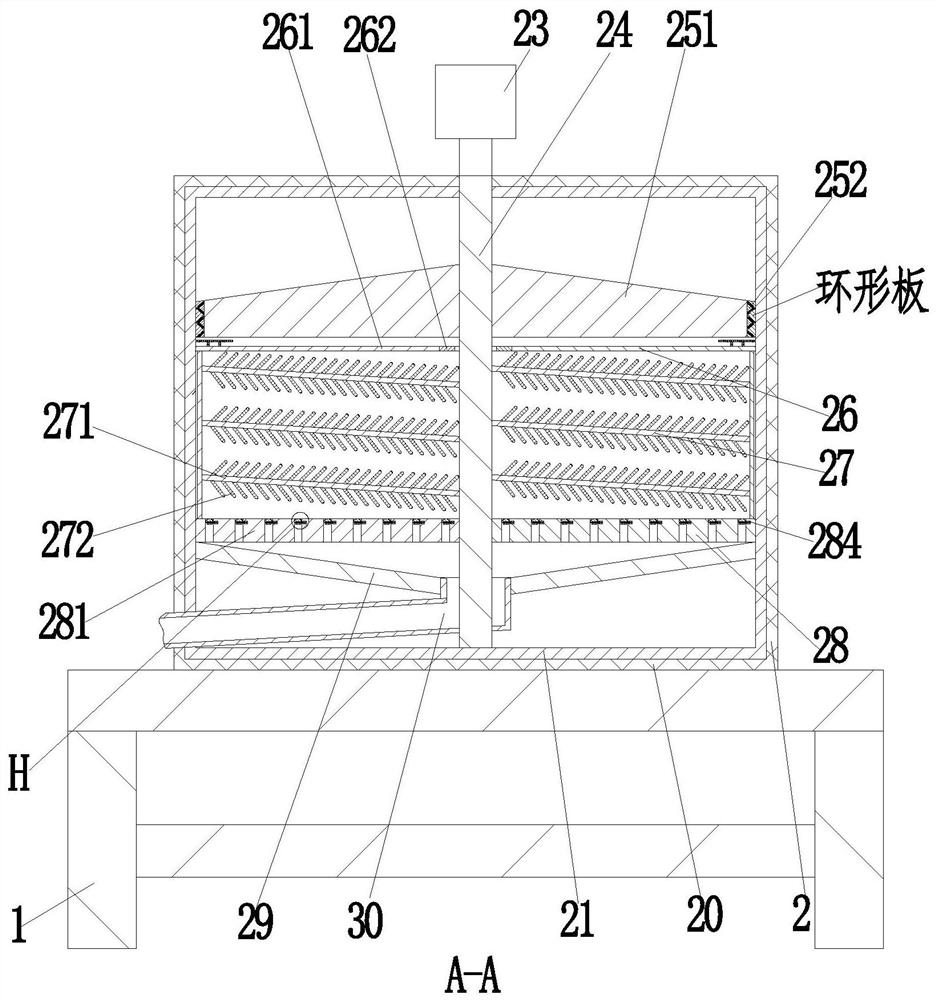

InactiveCN112808137AAvoid accumulationPrevent impact on production qualityTransportation and packagingMixing methodsPolymer scienceEmulsion

The invention relates to a polyurethane coating preparation method, which comprises a workbench, a preparation device and a heating device; the preparation device is fixedly installed at the upper end of the workbench, the heating device is fixedly installed at the left end of the preparation device, the preparation device is fixedly installed at the upper end of the workbench, and the heating device is fixedly installed at the left end of the preparation device; the preparation device comprises a heat preservation plate, a cylindrical plate, a feeding pipe, a first motor, a rotating column, a grinding frame, a screening plate, a stirring frame, a screening circular plate, a conical barrel and a discharging pipe. According to the invention, the pigment is ground through the preparation device, and meanwhile, the pigment and a mixed emulsion of polyurethane and auxiliaries are stirred and mixed and are sieved, so that accumulation of pigments is prevented. The polyurethane and the auxiliaries are heated through the heating device, and meanwhile, the heated mixture is screened, so that the situation that solid polyurethane enters the preparation device along with liquid polyurethane, thereby preventing influence on the production quality.

Owner:李腾飞

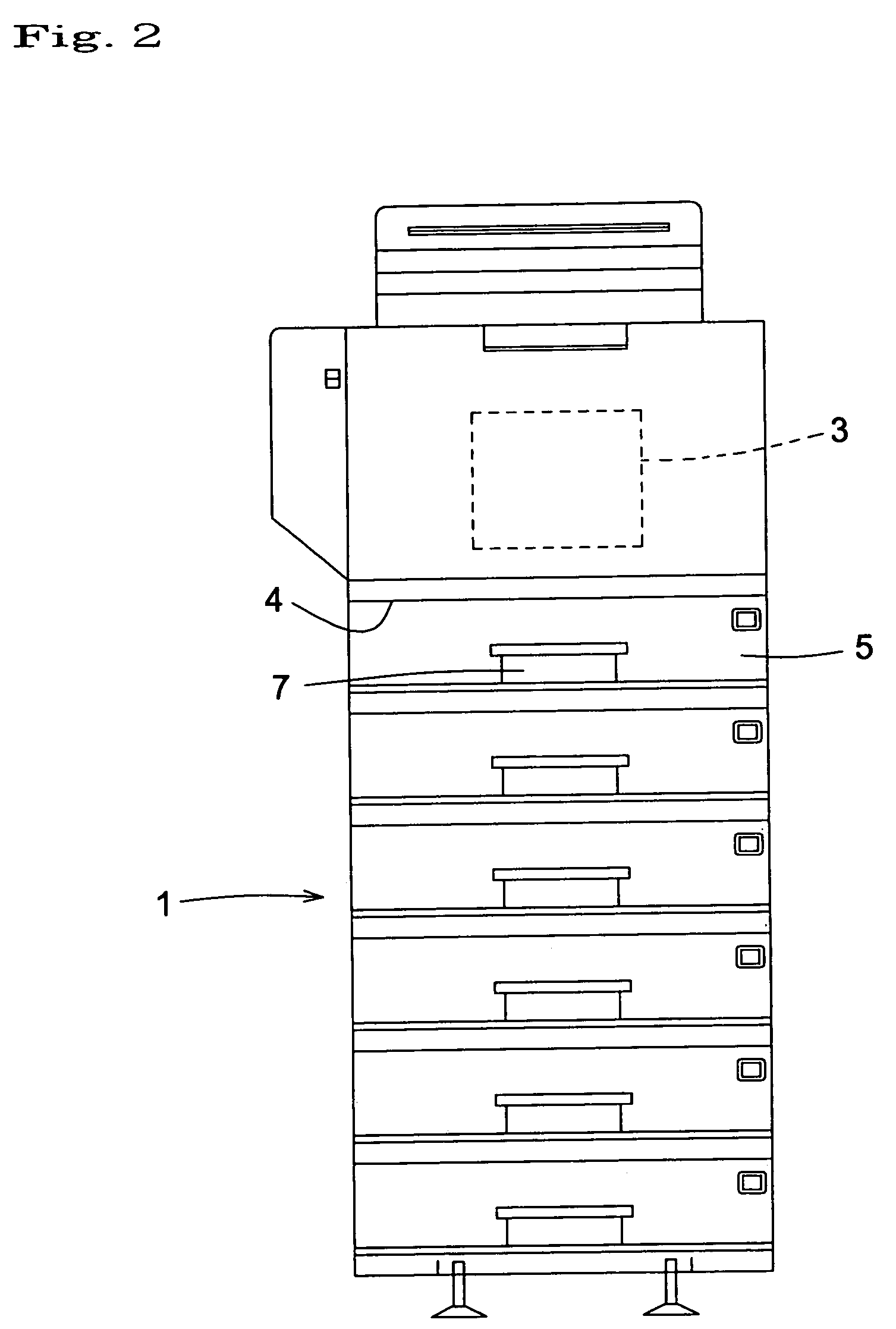

Upper paper guider of printer

ActiveCN102616005AExtended service lifeCompact and reasonable structureOther printing apparatusRubber ringPulp and paper industry

The invention discloses an upper paper guider of a printer, which comprises a mainboard and a star wheel. The star wheel consists of a toothed wheel and a smooth wheel arranged on the toothed wheel by means of injection molding, an elastic shaft penetrates through the star wheel, the star wheel is placed in a mounting groove on the mainboard via the elastic shaft, a press cake is connected onto the smooth wheel of the star wheel in an abutted manner, a groove for holding the toothed wheel is arranged on an end surface of the press cake, which contacts with the star wheel, a compression spring is connected to the top end of the press cake, one end of a compression spring is connected to the top end of the press cake, the other end of the compression spring is connected to the lower side of a pressure plate in an abutted manner, and the pressure plate is fixedly mounted onto the mainboard. The star wheel is elastically fixed onto the mainboard of the upper paper guider, accordingly, the star wheel can be automatically lifted up according to the thickness of a printed medium under the wheel, squeezing force and friction force of a lower paper guiding roller pressing on the printed medium are uniform, abrasion of a rubber ring on the surface of the lower paper guiding roller is reduced, and the upper paper guider is simple in structure, convenient in installation and applicable to equipment such as a laser or ink-jet printer, a copier, a scanner and the like required in printing.

Owner:KONG YUE ELECTRONICS & INFORMATION IND XIN HUI

Carbon-ceramic brake disc with wear-resistant and anti-oxidation coating and preparation method of carbon-ceramic brake disc

ActiveCN113277869AHigh bonding strengthUniform compositionBraking discsFriction liningOxidation resistantCarbon composites

The invention discloses a carbon-ceramic brake disc with a wear-resistant and anti-oxidation coating and a preparation method of the carbon-ceramic brake disc. The preparation method comprises the following steps that grooving treatment is conducted on the upper surface and the lower surface of a carbon / carbon composite material disc body, then coating slurry is brushed in a groove in the upper surface till the groove in the upper surface is filled with the coating slurry, and then the carbon / carbon composite material disc body is turned over, the groove in the lower surface is coated with the coating slurry till the groove in the lower surface is filled with the coating slurry, thus the carbon / carbon composite material disc body containing the coating slurry is obtained, curing, carbonization and ceramization treatment are sequentially conducted, and the carbon-ceramic brake disc is obtained. The preparation process of the wear-resistant and oxidation-resistant coating is simple, large-scale industrial mass production is easy to realize, the coating is bright and smooth in appearance, the bonding strength between the coating and the disc body is high, the size precision is easy to accurately control, and the problem that the size is easy to control inaccurately when the ceramic brake disc is subjected to machining treatment can be effectively solved.

Owner:HUNAN SHIXIN NEW MATERIALS CO LTD

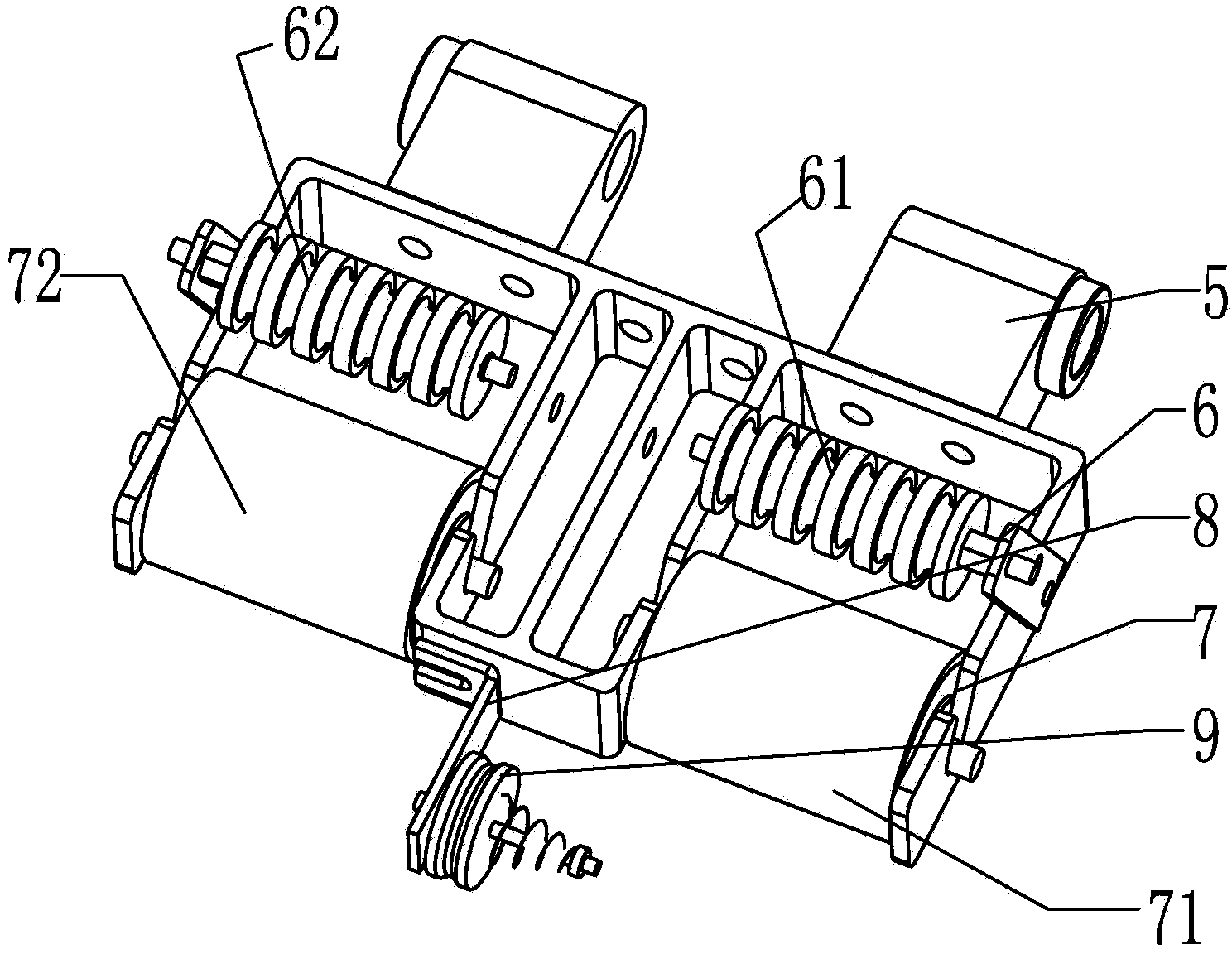

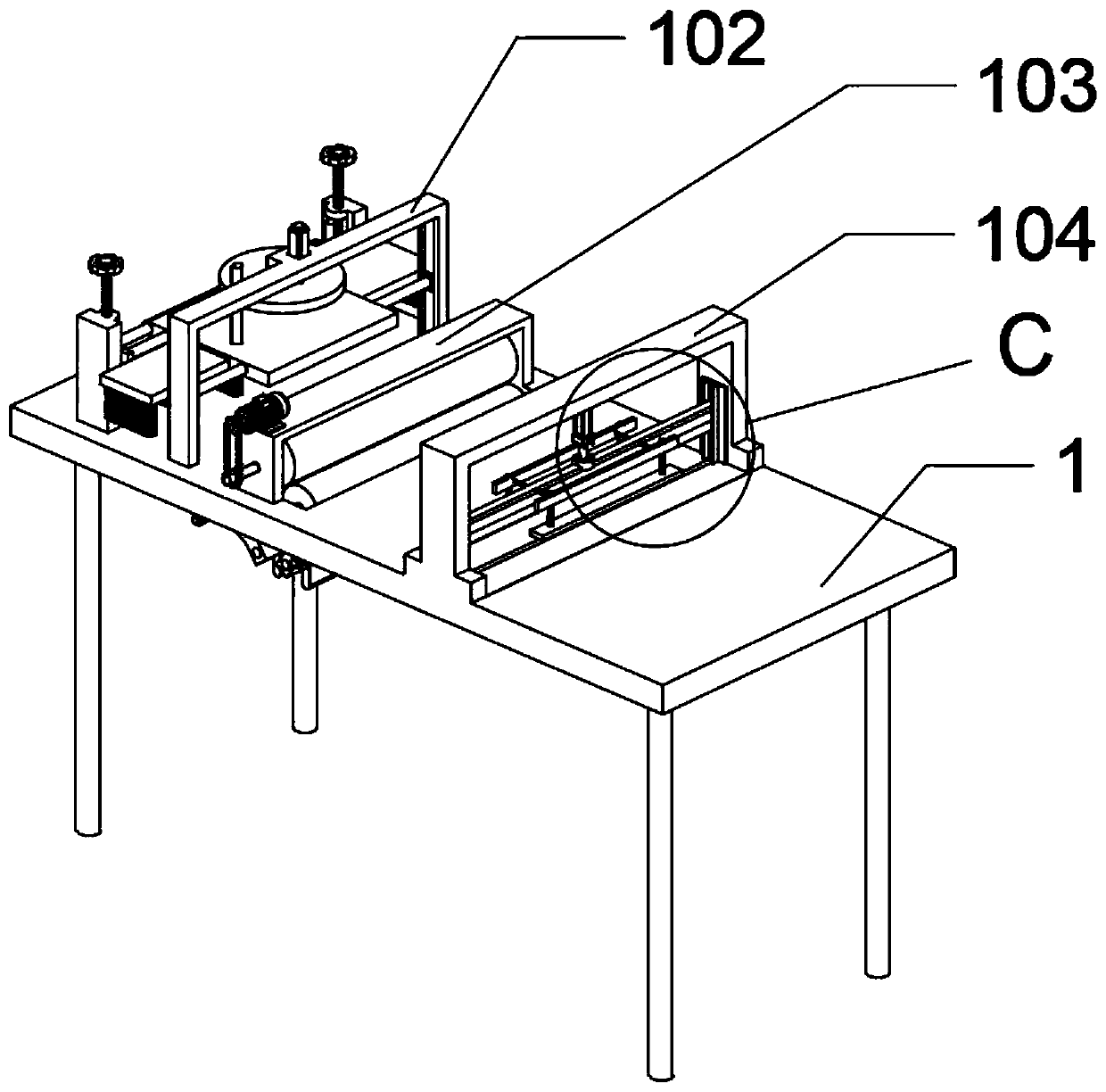

Processing device based on automobile seat cover

InactiveCN110421604AEasy to processUniform frictionMechanical cleaningPressure cleaningCamMaterials processing

The invention provides a processing device based on an automobile seat cover. The processing device comprises a workbench, two groups of frames A, a frame B, a frame C, a frame D, a moving plate, a guide rod, an eccentric wheel, a bottom wheel frame, a balance buckle, a bottom wheel, an electric cylinder, a tool rest, a blade, an auxiliary frame, a pressing edge, a guide rail and a cutting seat; the top of the workbench is fixedly provided with the frames A, the frame B, the frame C and the frame D through welding; and a roller is movably arranged inside the frame C through a rotating shaft, and a motor is arranged at the top of the frame C and is movably connected with the frame C in a chain transmission mode. By setting the moving plate and the eccentric wheel, the automatic reciprocating cleaning function is provided for the processing device, the moving plate is moved through an equal-diameter cam structure, the surfaces of seat cover materials are cleaned, the dust falling in theconveying process is removed, the friction force is uniform, the cleaning effect is good, the automation degree is higher, and the material processing of the seat cover is facilitated.

Owner:湖北增金汽车零部件有限公司

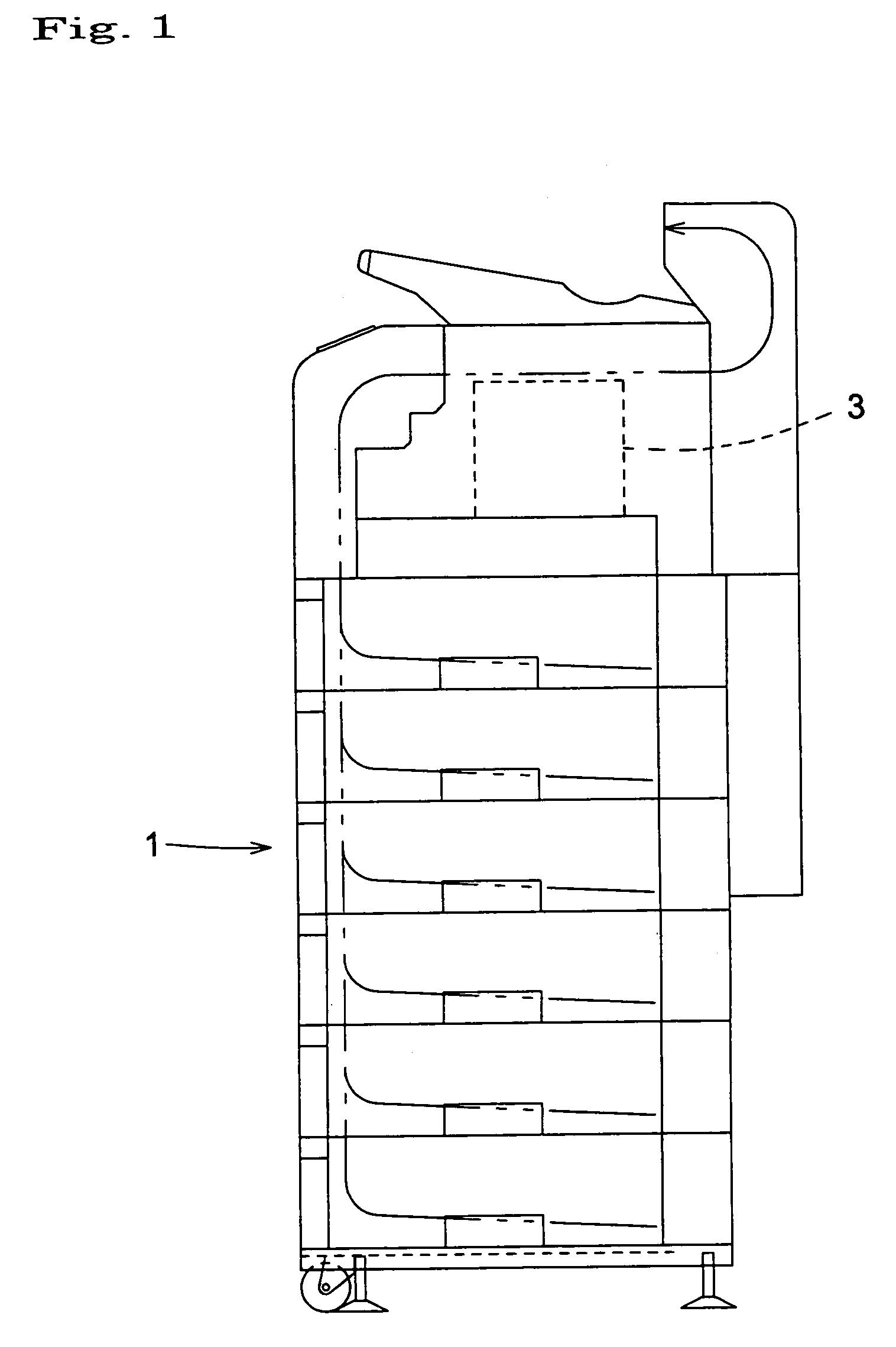

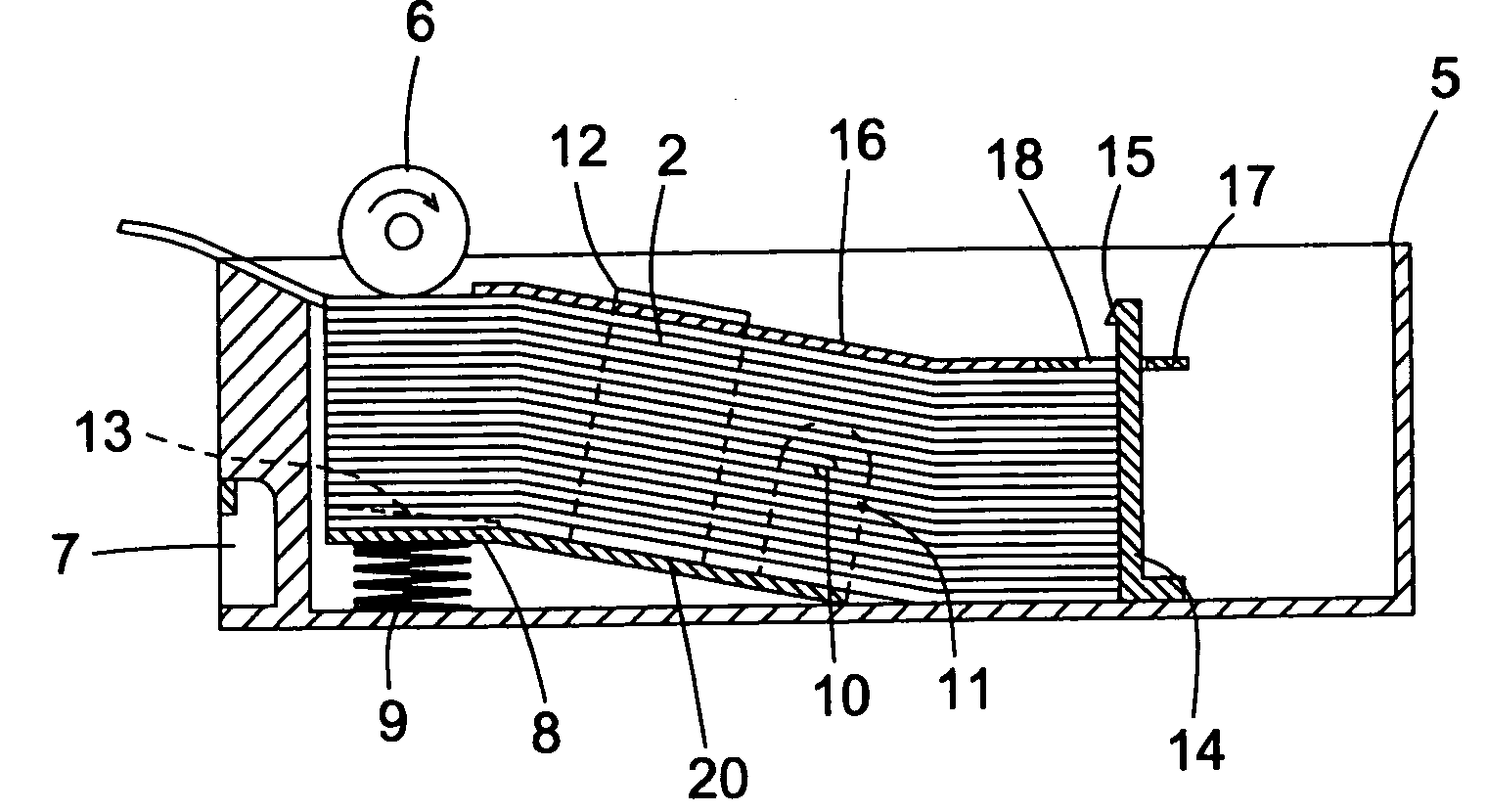

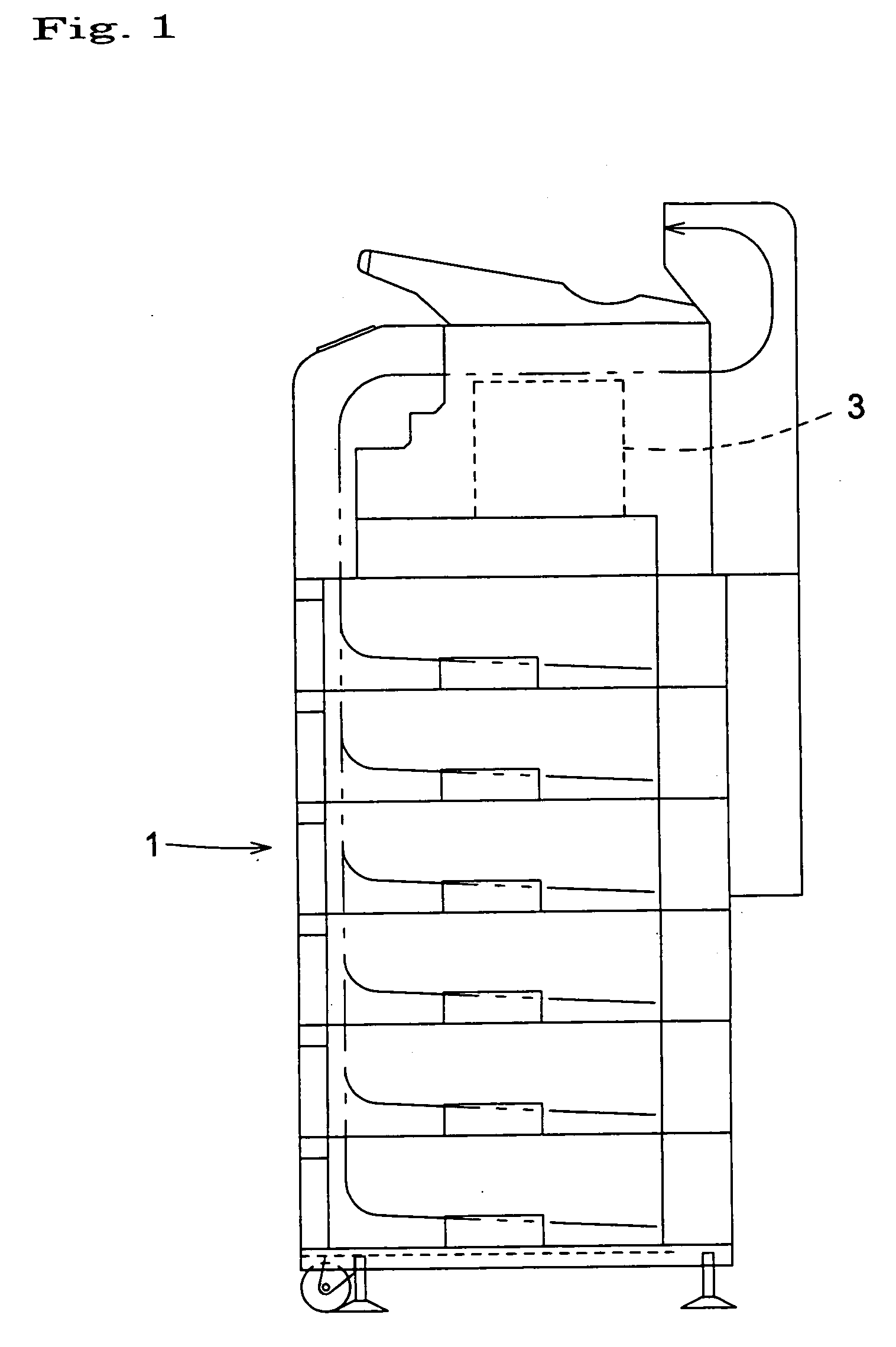

Automatic paper feed apparatus

InactiveUS7029003B2Reliable preventionEasy constructionArticle feedersArticle separationEngineeringFriction force

The present invention provides an automatic paper feed apparatus which can reliably prevent papers from being discharged in an overlapped state in spite of simple construction. The automatic paper feed apparatus comprises a paper feed roller for automatically feeding a plurality of papers in order from an uppermost one, with the plurality of papers being contained in a cassette in a stacked state. A holding member having flexibility is provided so that the holding member comes into contact with the uppermost paper to generate a friction force that is weaker than that between the paper feed roller and the uppermost paper.

Owner:YUYAMA MFG CO LTD

Drawer assembly as well as domestic appliance and base thereof

The invention provides a drawer assembly as well as a domestic appliance and a base thereof. Specifically, the drawer assembly comprises a drawer, a drawer chamber, guide rails and at least one supporting piece, wherein the drawer chamber is configured into a containing drawer; the inner wall face of the drawer chamber comprises two side wall faces, and the two side wall faces are opposite to eachother and are not parallel to each other; the two guide rails are respectively arranged on the two side wall faces, and the drawer is connected with the guide rails arranged on the two side wall faces; the supporting piece is arranged between at least one of the two side wall faces and the guide rail arranged on the side wall face; the supporting pieces are configured into supporting guide rails,so that the guide rail arranged on one of the two side wall faces tends to be parallel to the guide rail arranged on the other side wall face. According to the drawer assembly in the scheme, the guide rails arranged at the two sides of the drawer can be installed on the two non-parallel side wall faces in parallel without being restricted by the parallelism between the side wall faces, so that the parallelism between the guide rails at the two sides of the drawer is improved, the drawer is smoother, and the slidable stroke of the drawer is maximized; furthermore, the abrasion of the guide rails is reduced, and the product quality is improved.

Owner:WUXI LITTLE SWAN ELECTRIC CO LTD

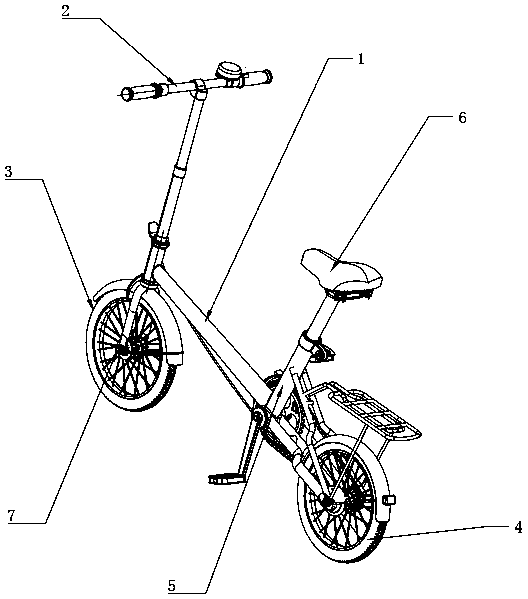

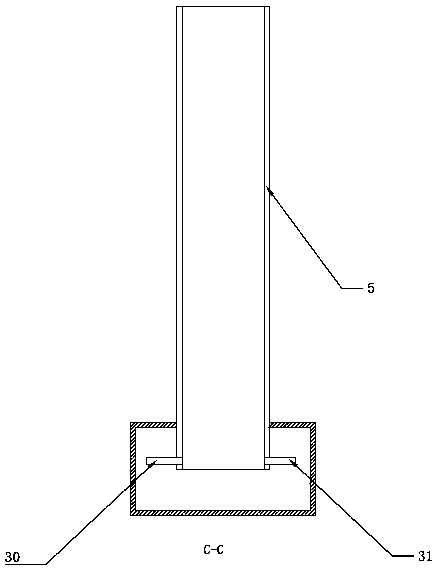

Bicycle using air brake

InactiveCN107933807AIncrease pressureIncrease the differential pressureFluid braking transmissionCycle brakesVehicle frameEngineering

The invention discloses a bicycle using an air brake. The bicycle is characterized by comprising a frame, wherein the frame is provided with a handle, a front wheel, a rear wheel, a mounting rod and aseat, axles are arranged on the front wheel and the rear wheel, one sides of the axles are connected to a brake assembly, the brake assembly comprises a brake part fixedly connected to the axles, a ring-shaped brake groove is formed in the brake part, one end, near a fixed bracket, of the brake groove is fixedly connected to an elastic rubber, the elastic rubber is in sealed connection with a brake block groove, the elastic rubber is fixedly connected to a plurality of brake blocks, a communication pipe is arranged on the wall surface of the brake groove, the brake assembly also comprises thefixed bracket fixed to the wheels, the fixed bracket rotates around and is in sealed connection with the brake part, the brake block groove is formed in the fixed bracket, a piston cylinder is arranged in the mounting rod, the piston cylinder is communicated with the communication pipe, a piston is arranged in the piston cylinder, and the piston is connected to a foot pedal for a user to compressthe air by foot pedaling. The bicycle solves the problems that the friction force of the existing bicycle brake is not uniform and the braking of the front and rear wheels cannot be simultaneously achieved.

Owner:尚宇新

Stainless steel cable tie

InactiveCN103671373AIncrease frictionIncrease frictional resistancePipe supportsElectrical apparatusMetallurgySteel ball

A stainless steel cable tie comprises a locking-buckling mechanism and a cable tie strip. The two ends of the locking-buckling mechanism are provided with a tie inlet and a tie outlet respectively, the tie inlet and the tie outlet are mutually communicated, a steel ball roller path is formed between the tie inlet and the tie outlet, and a steel ball is arranged in the steel ball roller path; the height of the steel ball roller path is increased in the direction from the tie inlet to the tie outlet and shrinks at the tie outlet; one end of the cable tie strip is fixed to the tie inlet, and the other end of the cable tie strip is a free end extending out of the tie outlet; frictional barbs are arranged on the inner wall, between the tie inlet and the tie outlet, of the locking-buckling mechanism, and frictional barbs are further arranged at the position, between the tie inlet and the tie outlet, of the cable tie strip. The frictional barbs can increase friction and be matched mutually so that frictional resistance can be greater after binding, and binding can be firmer. In this way, the problems that in the prior art, tie bodies make contact with each other through smooth surfaces, the friction between the tie bodies is quite small, and the cable tie will slide in the long-term using process.

Owner:STATE GRID SHANDONG ELECTRIC POWER

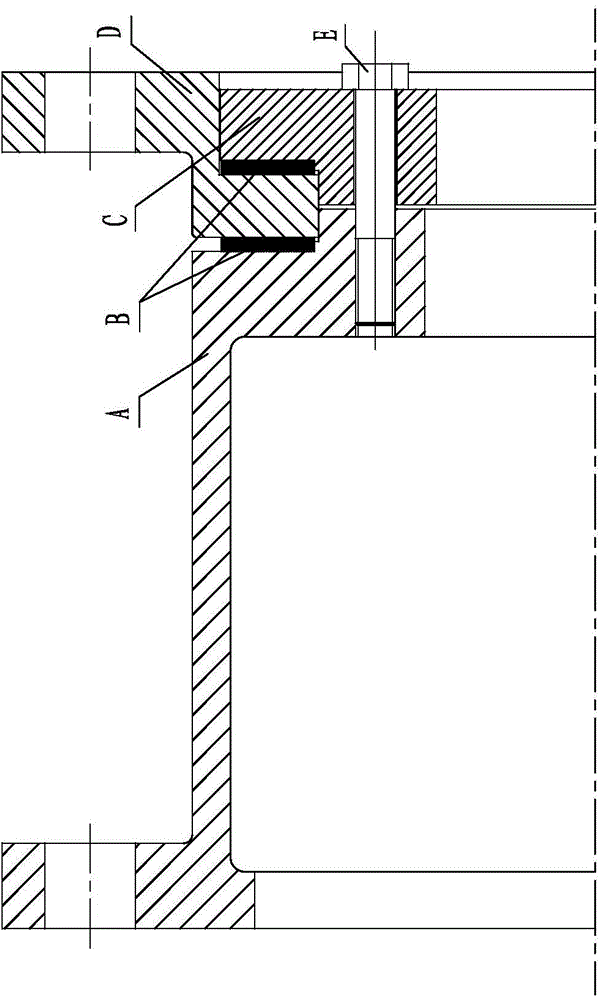

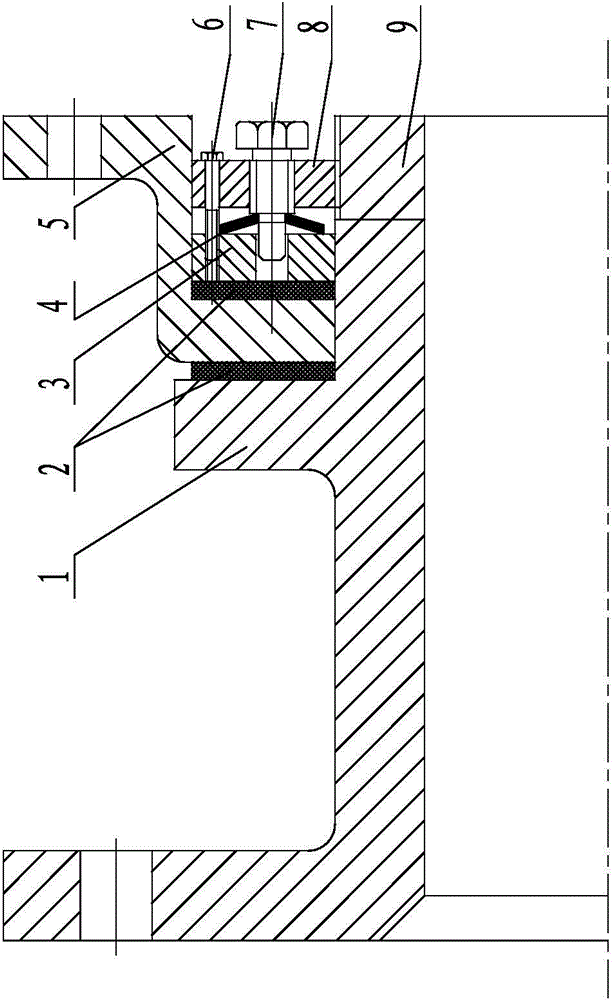

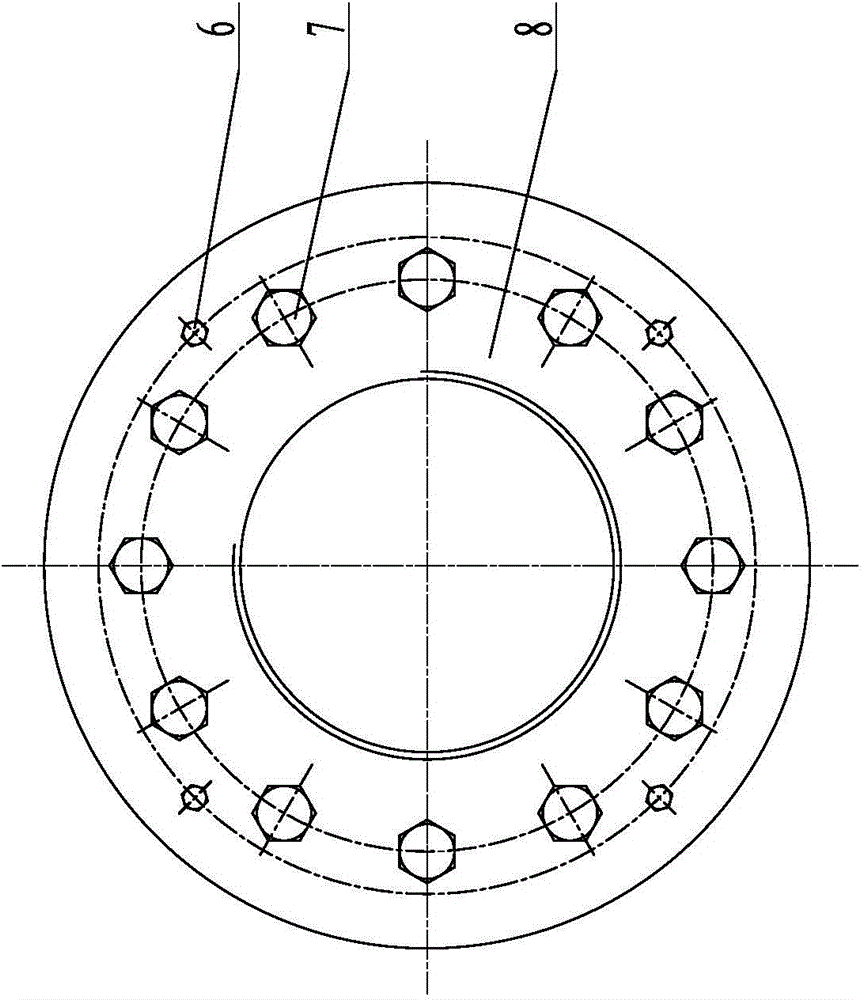

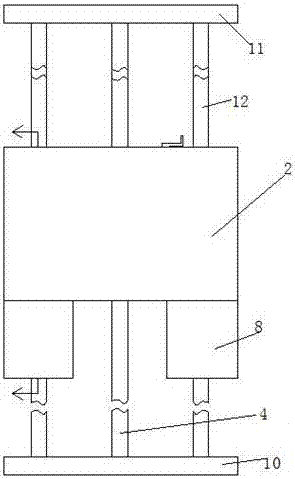

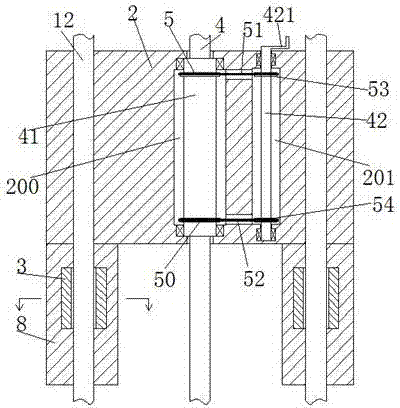

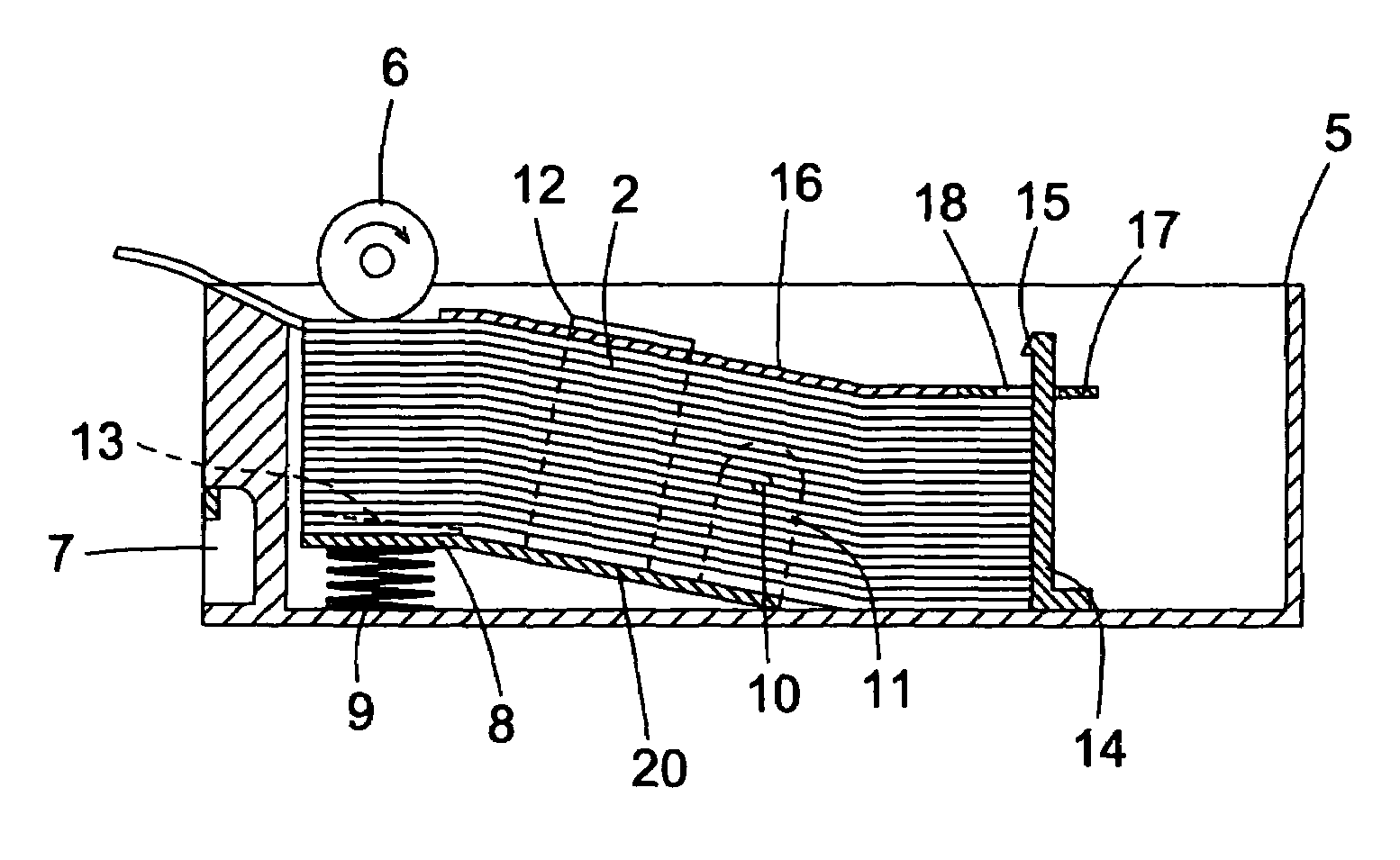

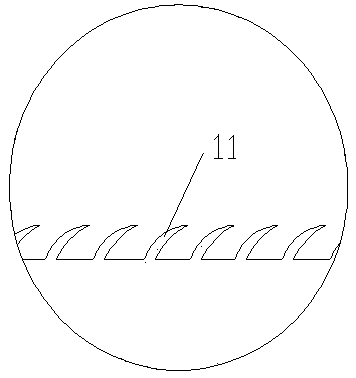

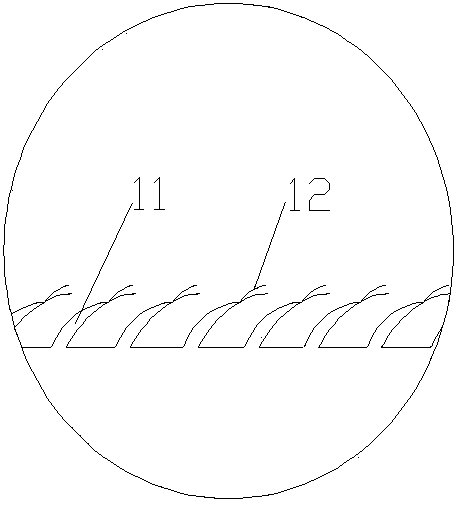

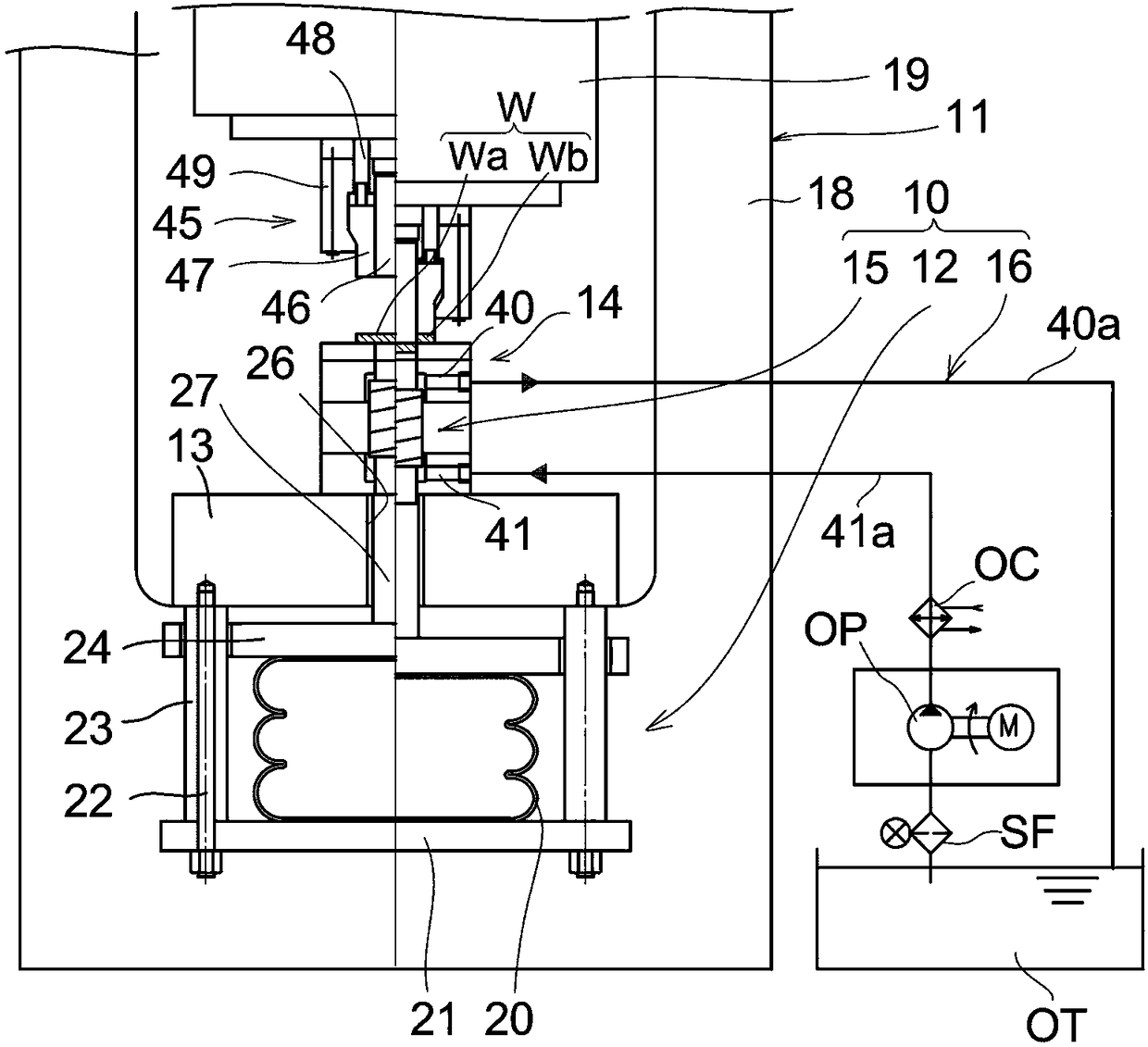

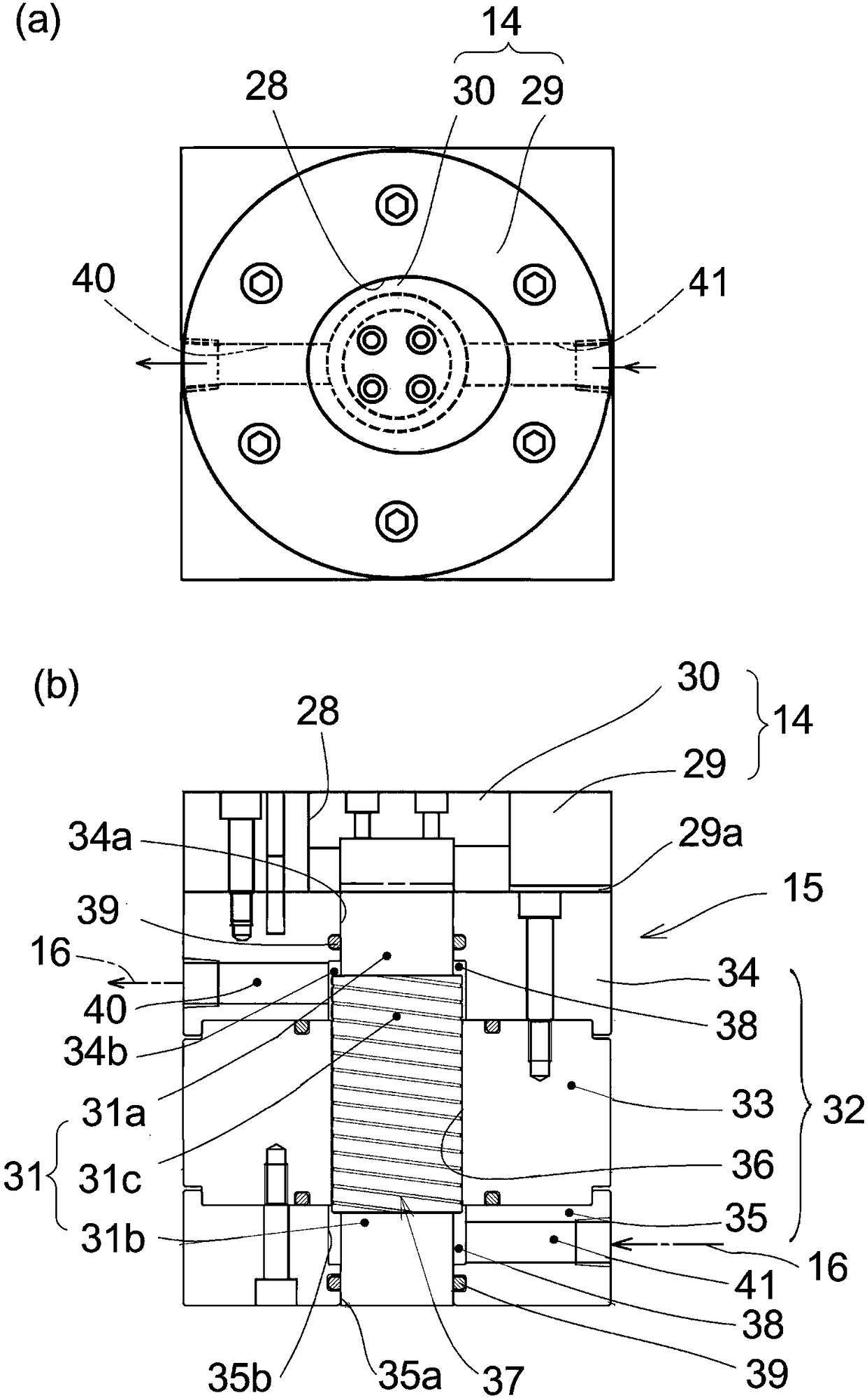

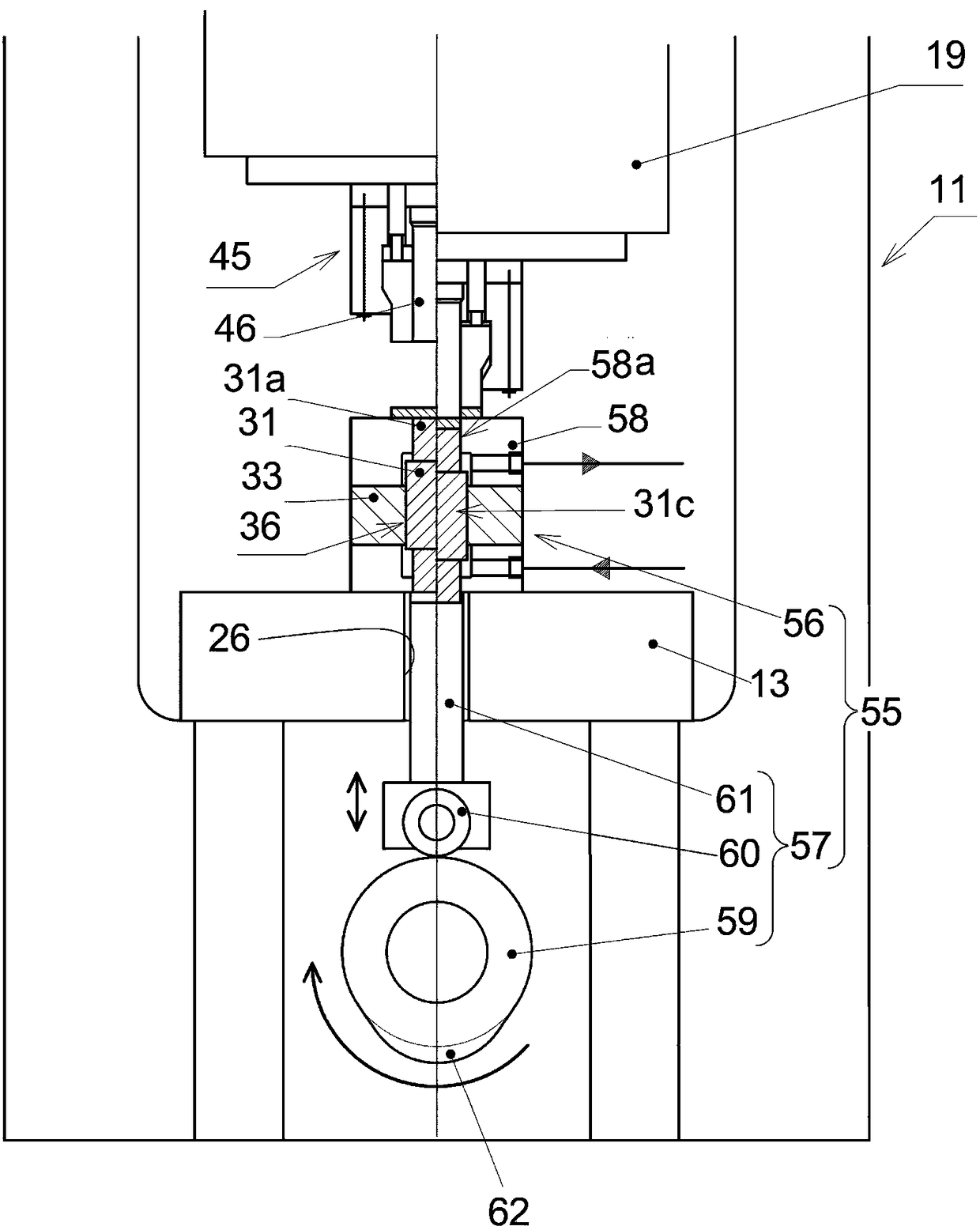

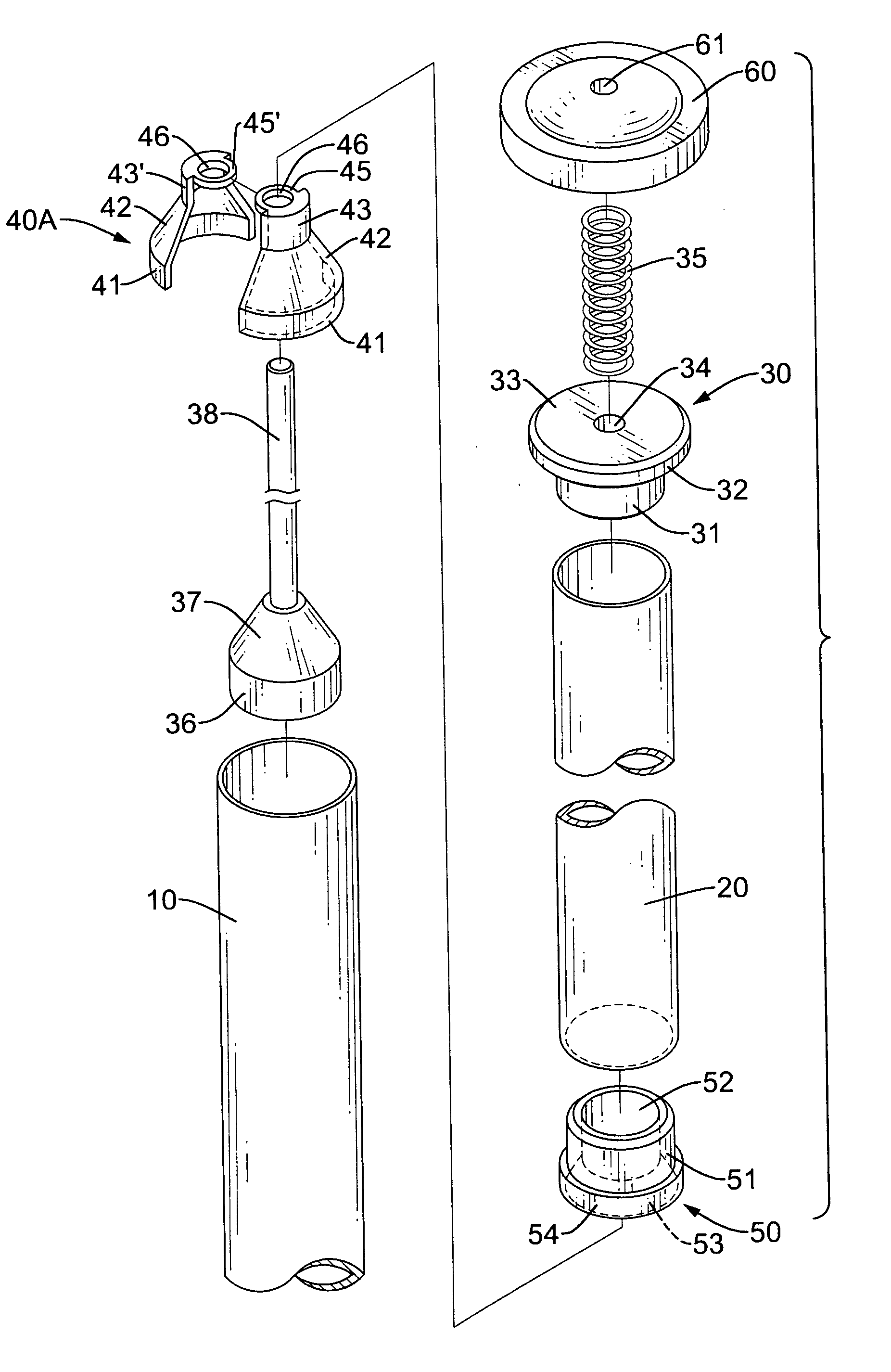

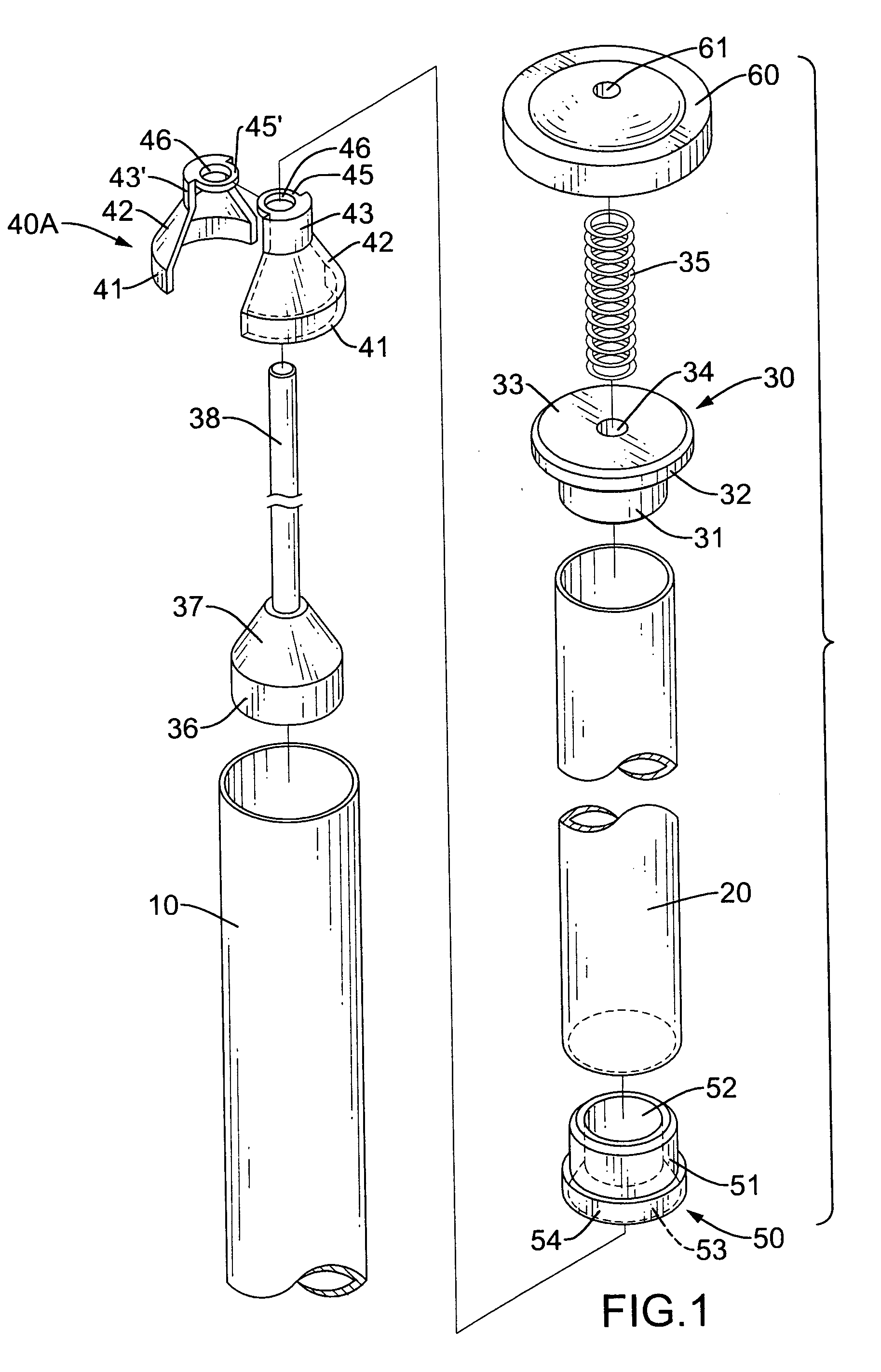

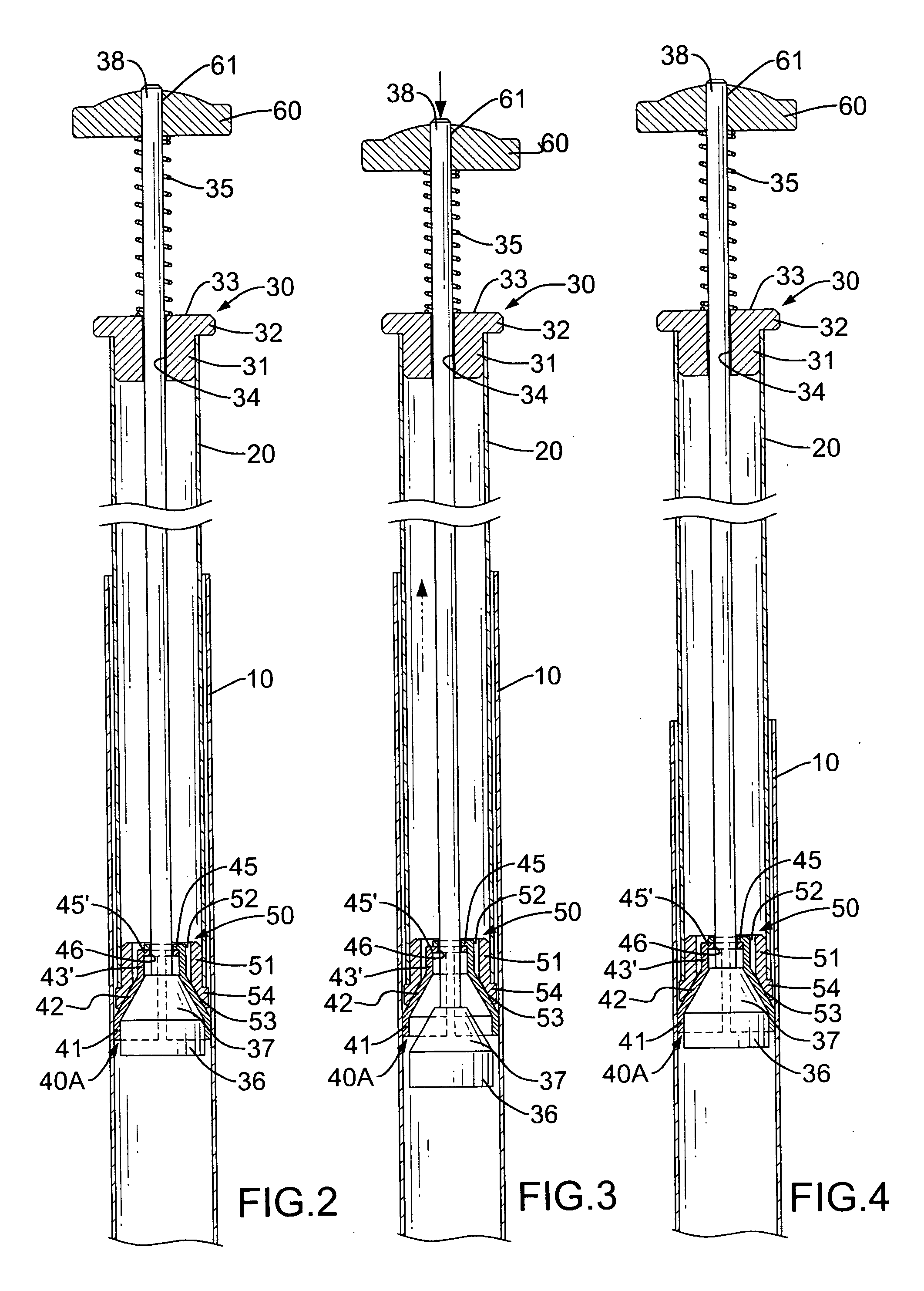

Sliding frictional force generation mechanism and manufacture method thereof, mold buffer device and metal die

The invention provides a sliding frictional force generation mechanism and a manufacture method thereof, a mold buffer device and a metal die. The sliding frictional force generation mechanism can stably exert greater load and is highly endurable and applied to mold buffer of a pressure machinery. A friction mold buffer (15) comprises a shaft sleeve (33) with a friction hole (36), a friction pin (31) embedded to freely slide in an axial direction in the friction hole (36) and a supply system (16) used for supplying lubricating oil as a cooling medium between the friction hole (36) and the friction pin (31). The friction hole (36) and the friction pin (31) are embedded in the state of interference fit. A mold buffer device (10) is in series connection with the friction mold buffer (15) andan air buffer device (12).

Owner:AIDA ENG LTD

Automatic paper feed apparatus

InactiveUS20050156371A1Reliable preventionEasy constructionArticle feedersArticle separationEngineeringFriction force

The present invention provides an automatic paper feed apparatus which can reliably prevent papers from being discharged in an overlapped state in spite of simple construction. The automatic paper feed apparatus comprises a paper feed roller for automatically feeding a plurality of papers in order from an uppermost one, with the plurality of papers being contained in a cassette in a stacked state. A holding member having flexibility is provided so that the holding member comes into contact with the uppermost paper to generate a friction force that is weaker than that between the paper feed roller and the uppermost paper.

Owner:YUYAMA MFG CO LTD

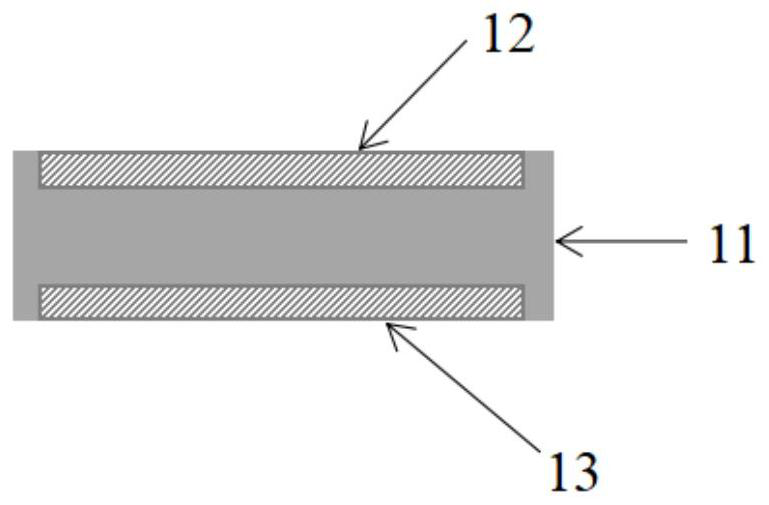

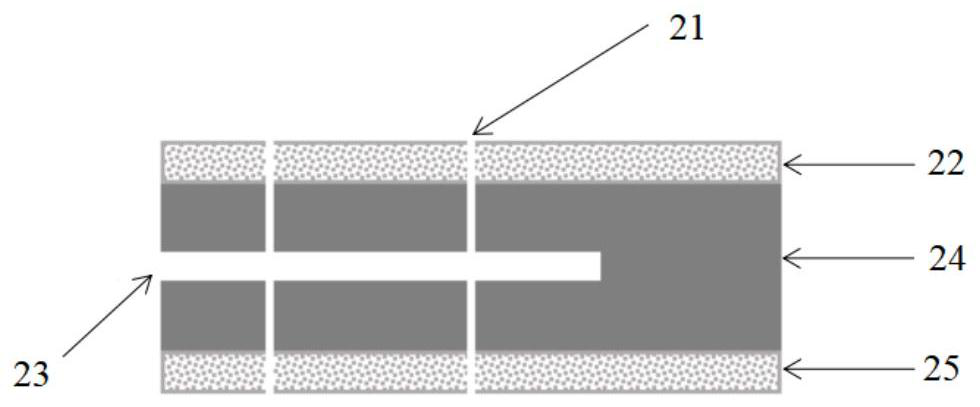

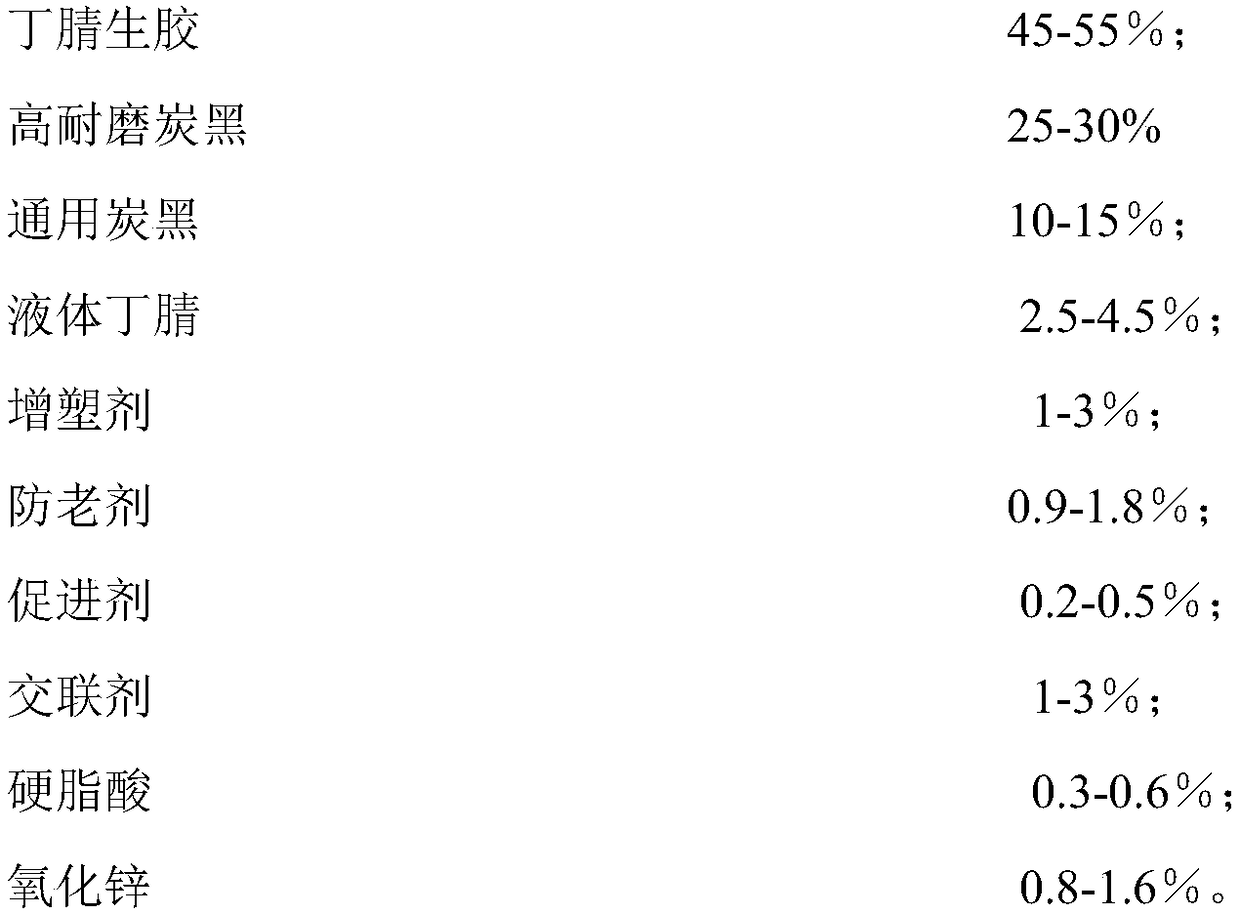

Rubber covered roller of island structure and preparation method thereof

ActiveCN108948459AIncrease coefficient of frictionImprove wear resistanceDomestic articlesPolymer scienceHardness

Owner:南京金三力辊业科技有限公司

Telescopic tube assembly for a clothes rack

A telescopic tube assembly includes an outer tube, an inner tube slidably received in the outer tube, an abutting device provided under the bottom cap and having a first flange, a first conical abutting face formed on top of the first flange, a hollow cylinder formed on top of the first conical abutting face and a first through hole defined through the hollow cylinder, and a drive rod extending into a second through hole in a stop. The drive rod has a second conical abutting selectively engaged with the first conical abutting face of the abutting device such that movement of the stop is able to selectively expand the first conical abutting face to allow the first flange to abut the inner periphery of the outer tube to position the inner tube relative to the outer tube.

Owner:WANG CHI CHUNG

Paper currency transfer structure for paper currency sorter

InactiveCN103787101AUniform frictionSmooth transmissionCoin/currency accepting devicesArticle feedersPulp and paper industryTorsion spring

A paper currency transfer structure for a paper currency sorter comprises a pressing wheel and a transmission wheel; the paper currency transfer structure also comprises a supporting part, a moving part, a pivot shaft and a torsion spring; the pivot shaft is fixed on the supporting part; the moving part pivots around the pivot shaft to be connected with the supporting part; the torsion spring is in sleeving connection with the pivot shaft; the pressing wheel is fixed on the moving part; torsion is applied to the moving part of the torsion spring and accordingly the pressing wheel can be pressed on the transmission wheel.

Owner:HONG FU JIN PRECISION IND (SHENZHEN) CO LTD +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com