Upper paper guider of printer

A technology for printers and paper guides, applied in printing devices, printing, etc., can solve the problem of large differences in the pressing force of printing media on the lower paper guide roller, aggravate the wear of the rubber ring on the surface of the lower paper guide roller, and reduce the size of the printer's lower paper guide Service life and other issues, to achieve the effect of not easy to scratch ink, compact and reasonable structure, simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

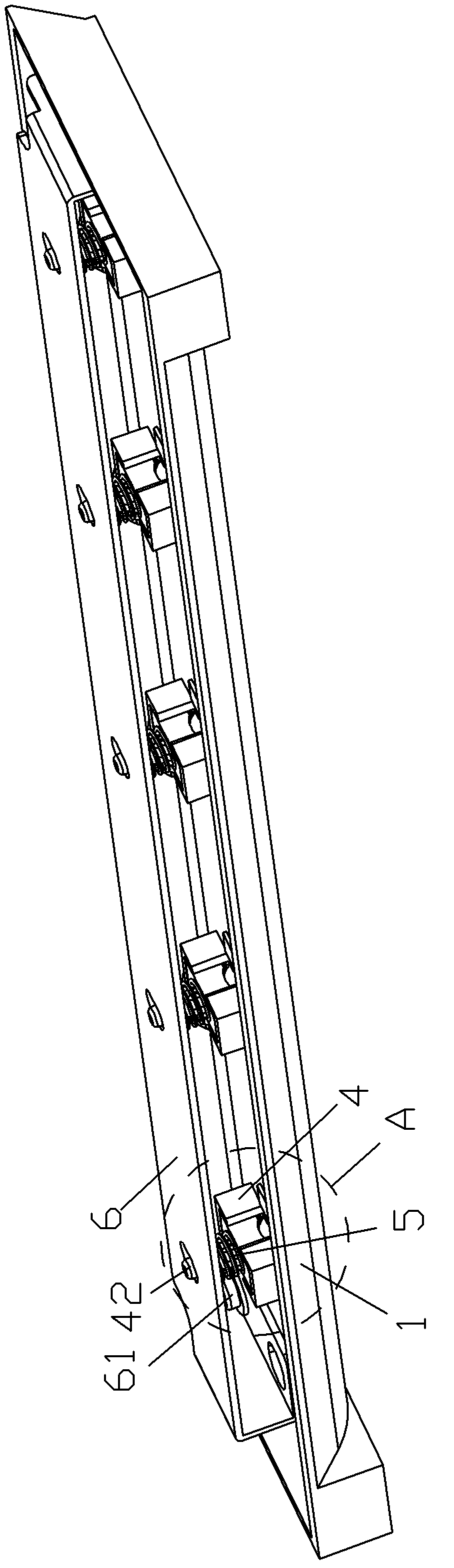

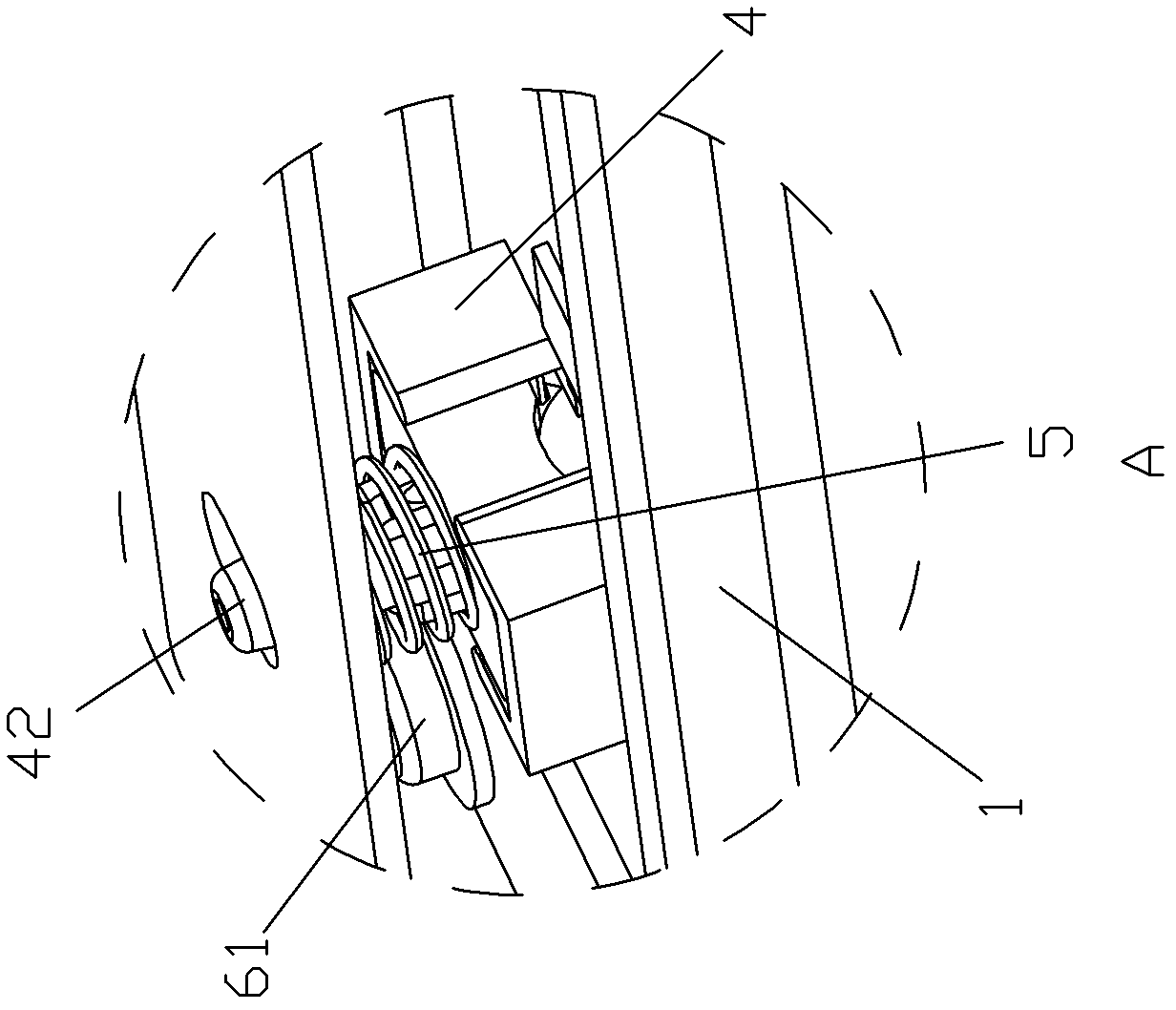

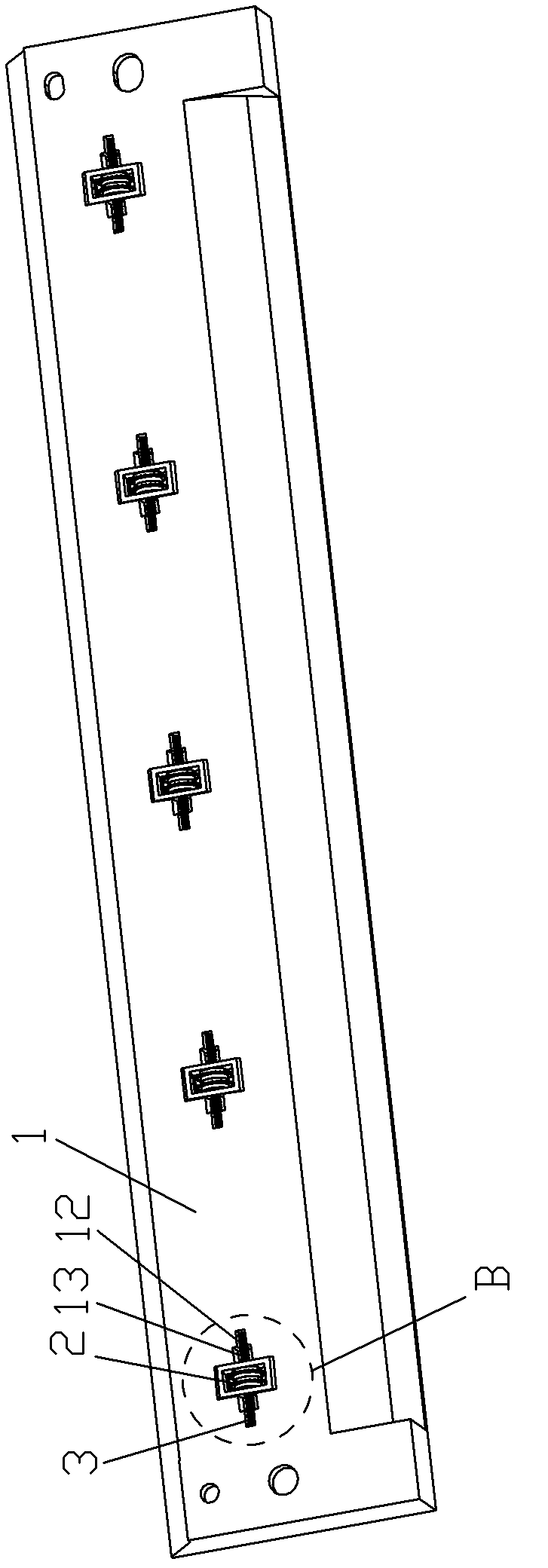

[0030] refer to Figure 1~Figure 16 , a paper guide on a printer of the present invention, which includes a main board 1 and a star wheel 2, the star wheel 2 is composed of a toothed wheel 22 and a smooth wheel 21 injected on the toothed wheel 22, and the star wheel 2 Pass through the elastic shaft 3 and rest in the installation groove 14 on the main board 1 through the elastic shaft 3, the smooth wheel 21 of the star wheel 2 is topped with a briquetting block 4, and the contact between the briquetting block 4 and the star wheel 2 The end face is provided with a groove 41 for accommodating the toothed wheel 22 , the top of the pressing block 4 is connected with a compression spring 5 , and the other end of the compression spring 5 is connected to the bottom of the pressing plate 6 fixedly installed on the main board 1 . The top of the pressure block 4 protrudes upwards with a sleeve 42 that is sleeved with the compression spring 5. The diameter of the sleeve 42 is less than th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com