Patents

Literature

252 results about "Press cake" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A press cake or oil cake is the solids remaining after pressing something to extract the liquids. Their most common use is in animal feed. Some foods whose processing creates press cakes are olives for olive oil (pomace), peanuts for peanut oil, coconut flesh for coconut cream and milk (sapal), grapes for wine (pomace), apples for cider (pomace), and soybeans for soy milk (used to make tofu) (this is called soy pulp) or oil. Other common press cakes come from flax seed (linseed), cottonseed, and sunflower seeds. However, some specific kinds may be toxic, and are rather used as fertilizer, for example cottonseed contains a toxic pigment, gossypol, that must be removed before processing.

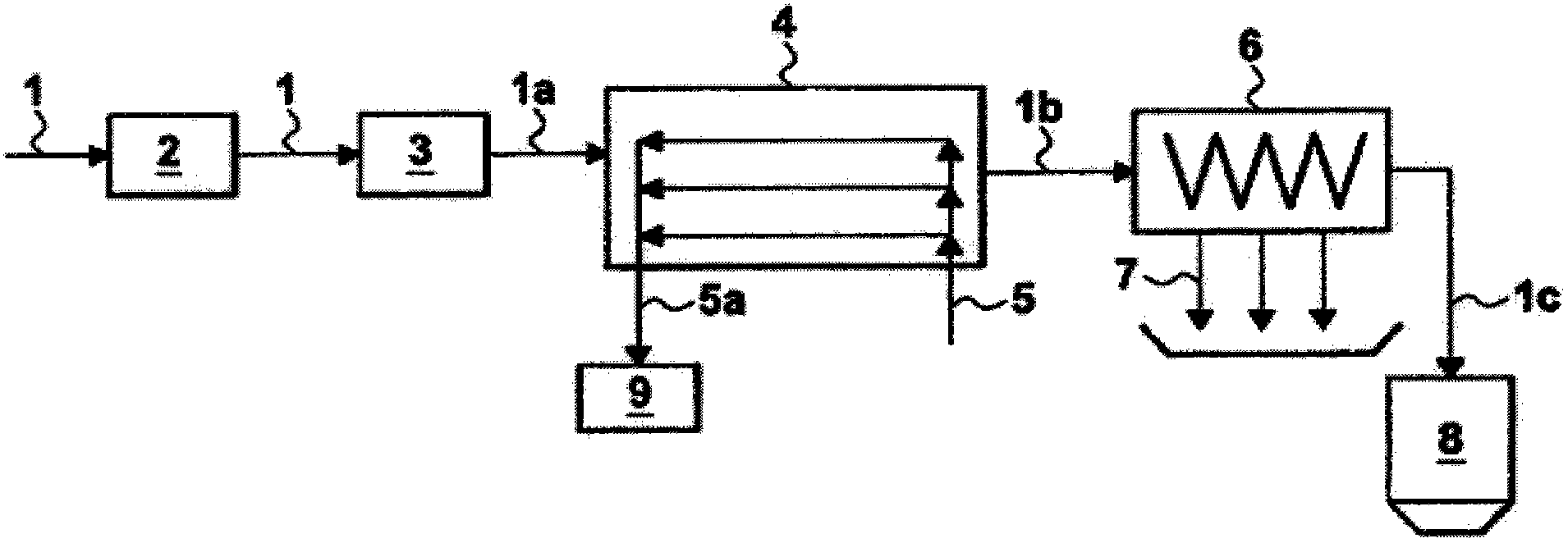

Process for the fractionation of oilseed press cakes and meals

A process for the fractionation of oilseed cakes and meals (e.g. rapeseed cake, soybean meal, and cottonseed cake) is disclosed. This invention describes a fractionation process, in which the said cake or meal is subjected to enzymatic treatment with polysaccharidases with intermittent wet milling, followed by heat treatment to facilitate separation of insoluble from soluble phase by centrifugal forces. Sequential centrifugation and ultrafiltration steps are carried out in order to yield a fibre-rich fraction, at least three protein-rich fractions, in the case of oilseed cakes at leas one emulsified oil fraction, a sugar-rich fraction, and a phytate-rich fraction. This invention also describes the use of the above-mentioned fractions in food, feed, nutraceutical and pharmaceutical applications.

Owner:BIOVELOP INT

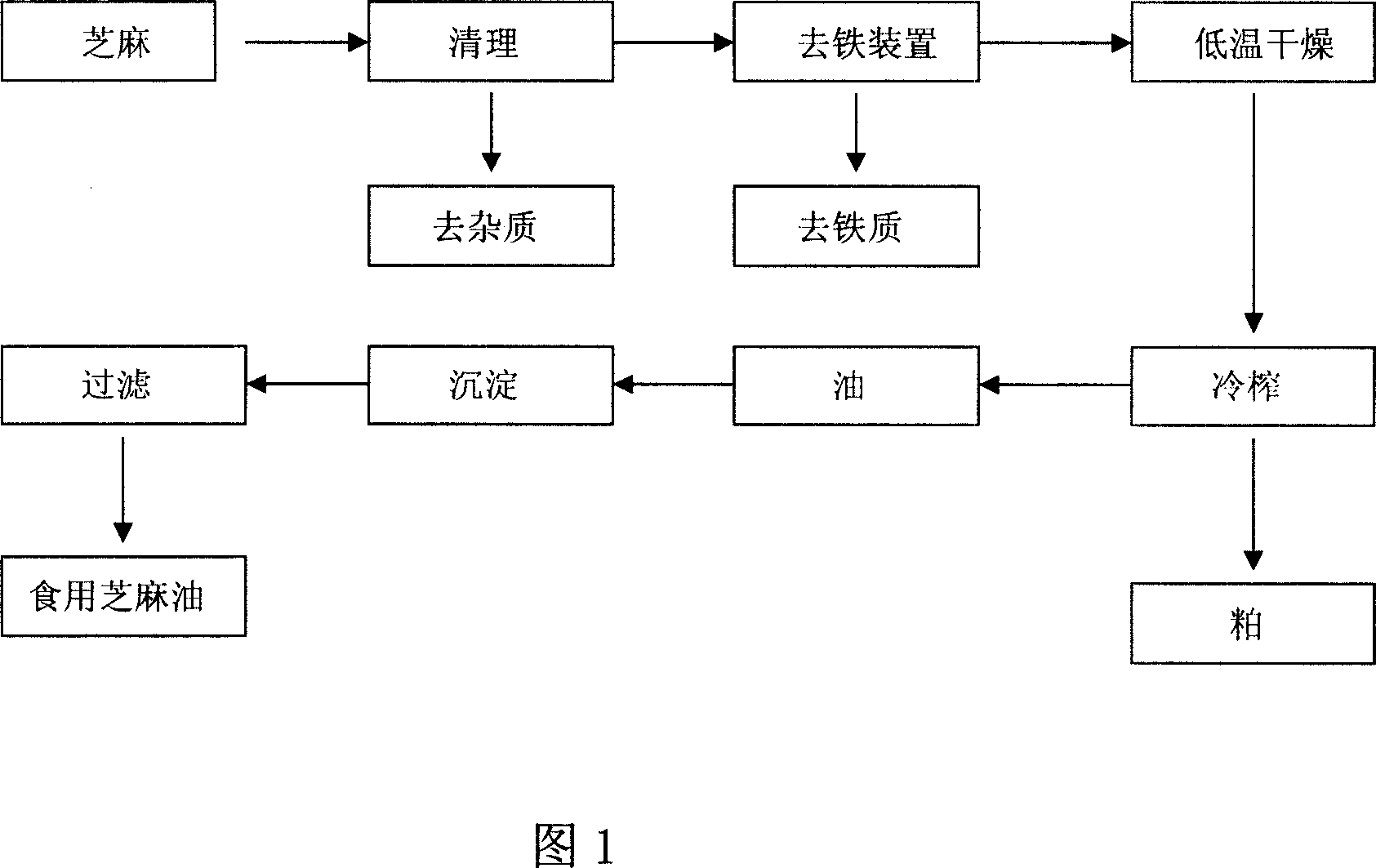

Low temperature method for cold pressing sesame oil

ActiveCN1958761ANo pollution in the processSimple processFatty-oils/fats productionEngineeringPress cake

This invention provides a method for cold-pressing sesame oil at low temperatures. The cold-pressing method is simple, and the nutritious ingredients and active substances in sesame oil are largely retained. The pressed sesame oil is fragrant, clear and bright. The method comprises: (1) cleaning sesame, and air-drying by a dryer below 50 deg.C to a water content of 6-10 wt.%; (2) loading into an oil press at 5-35 deg.C, pressing, and discharging sesame oil below 50 deg.C; (3) precipitating, and fine-filtering at 20-40 deg.C to obtain natural and edible sesame oil. The method has such advantages as simple and rational process, and no environmental pollution. The proteins in the cold-pressed cakes are not denatured, and can be further developed and utilized.

Owner:合肥燕庄食用油有限责任公司

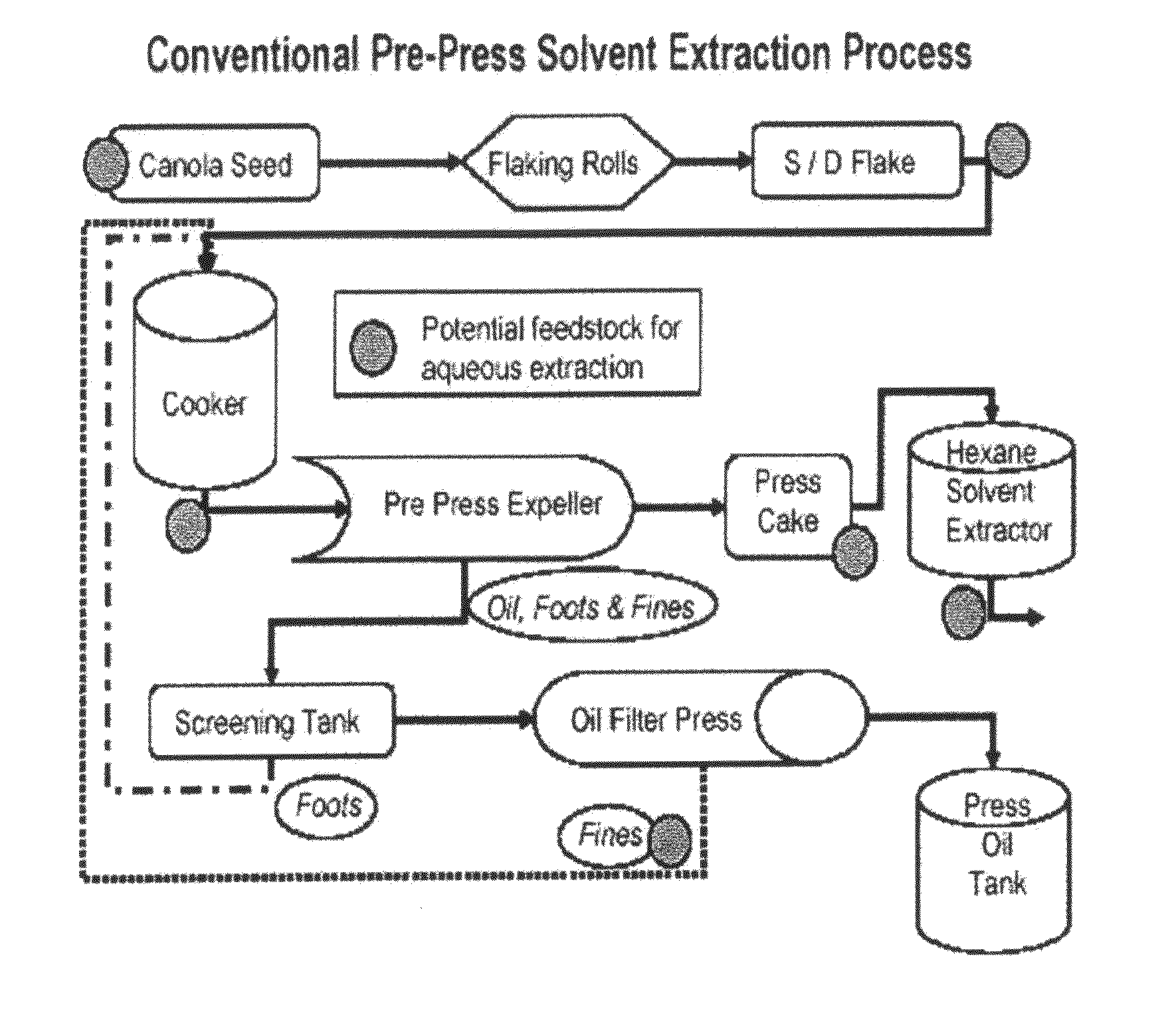

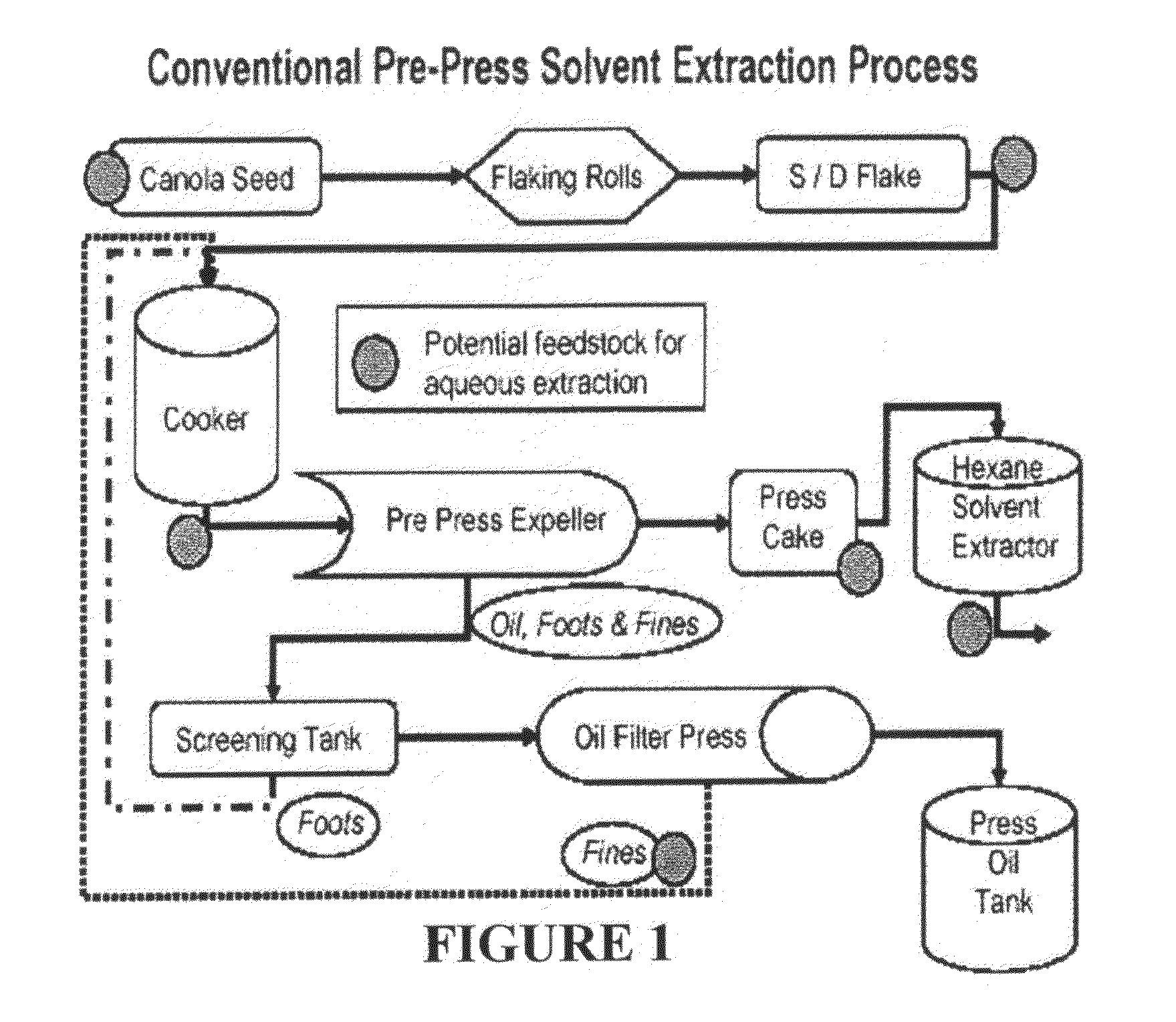

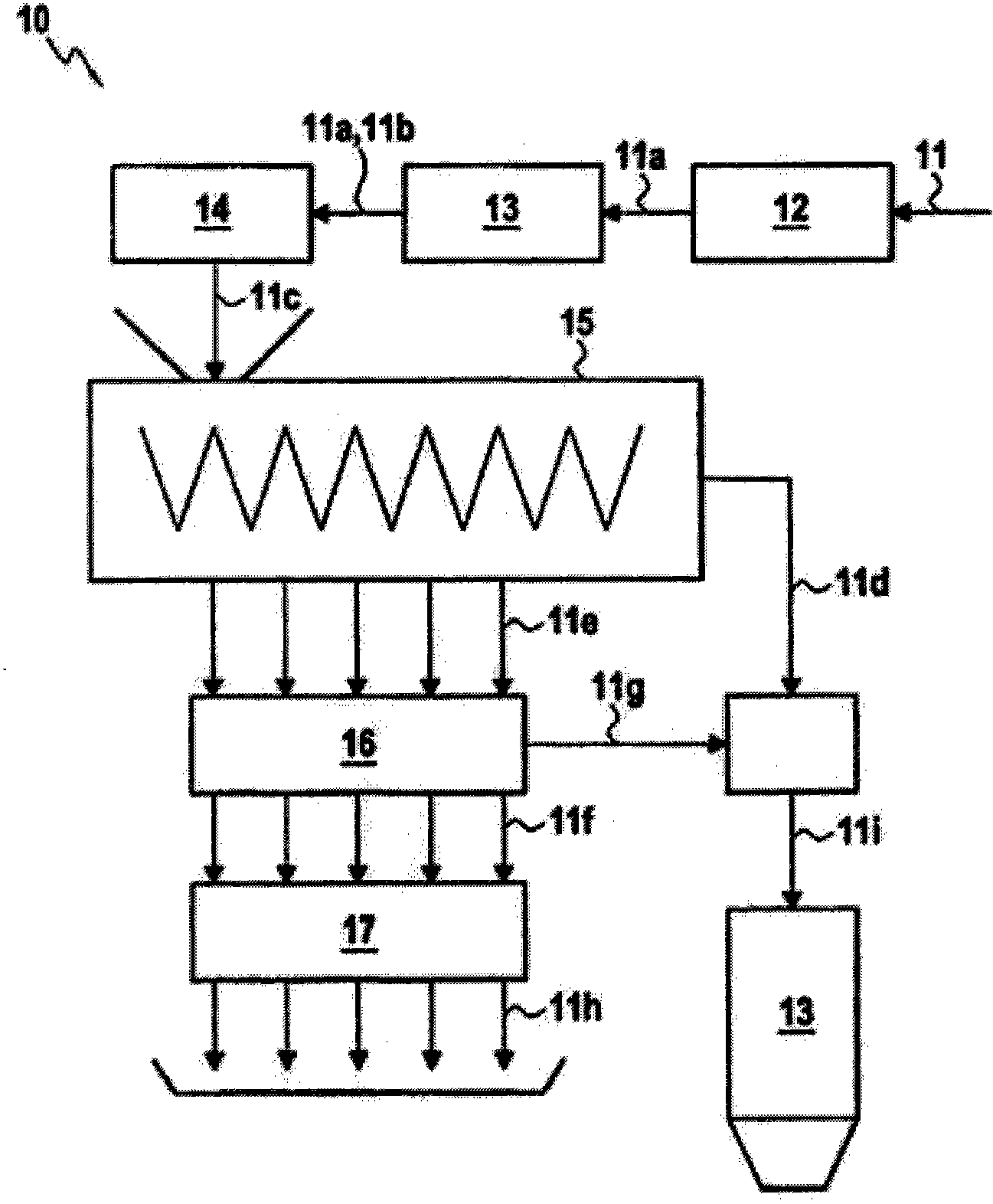

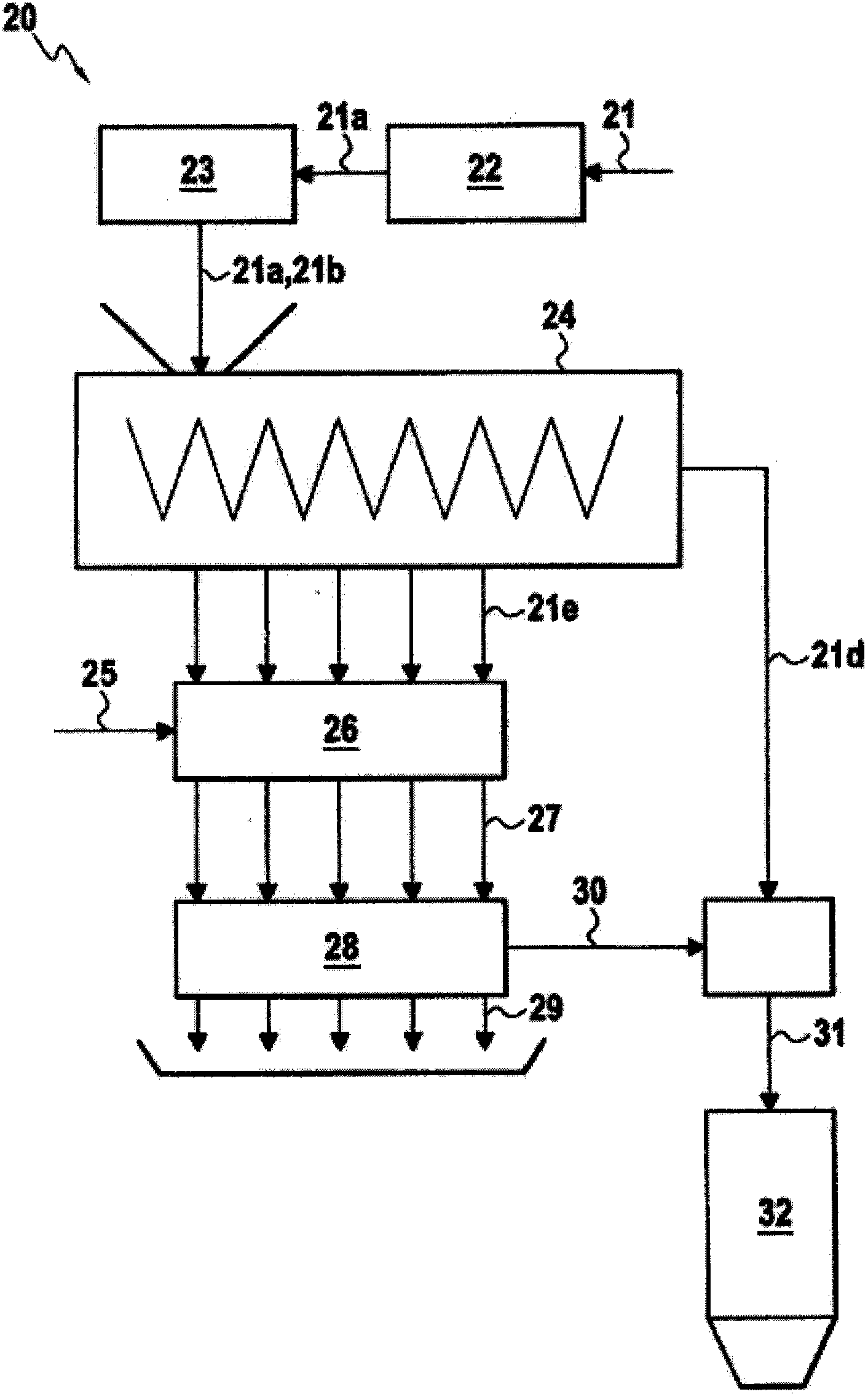

Aqueous processing of oilseed press cake

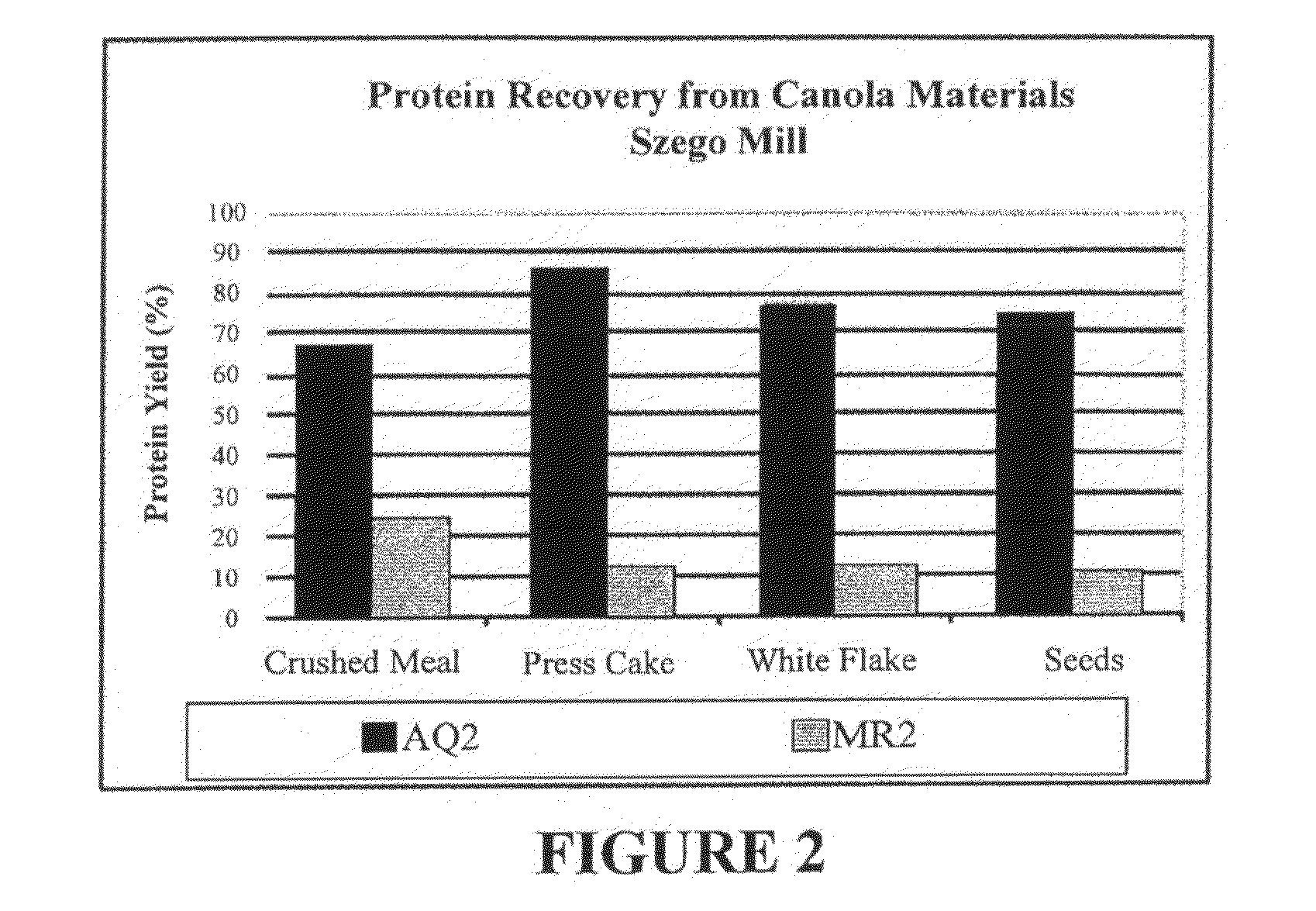

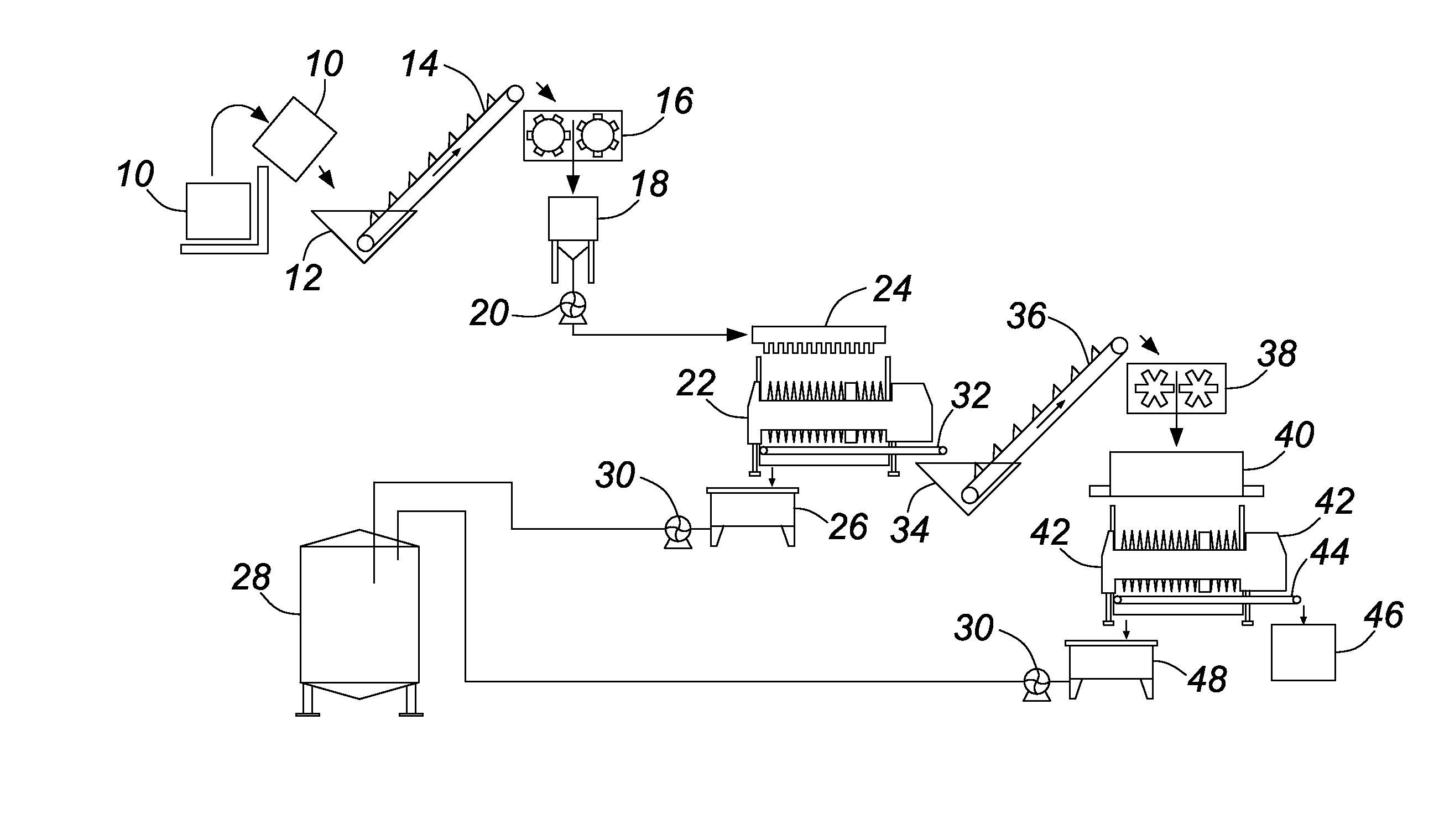

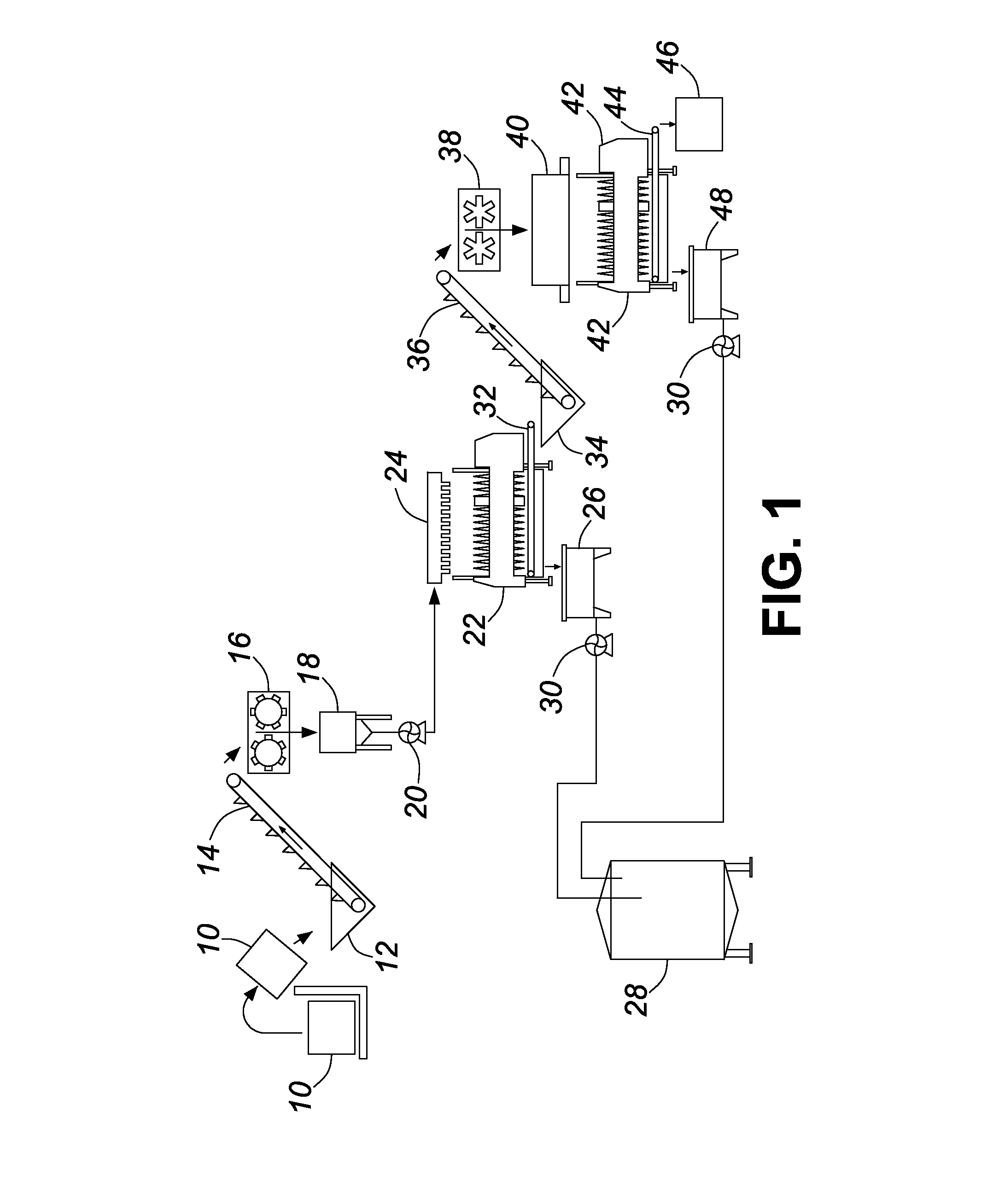

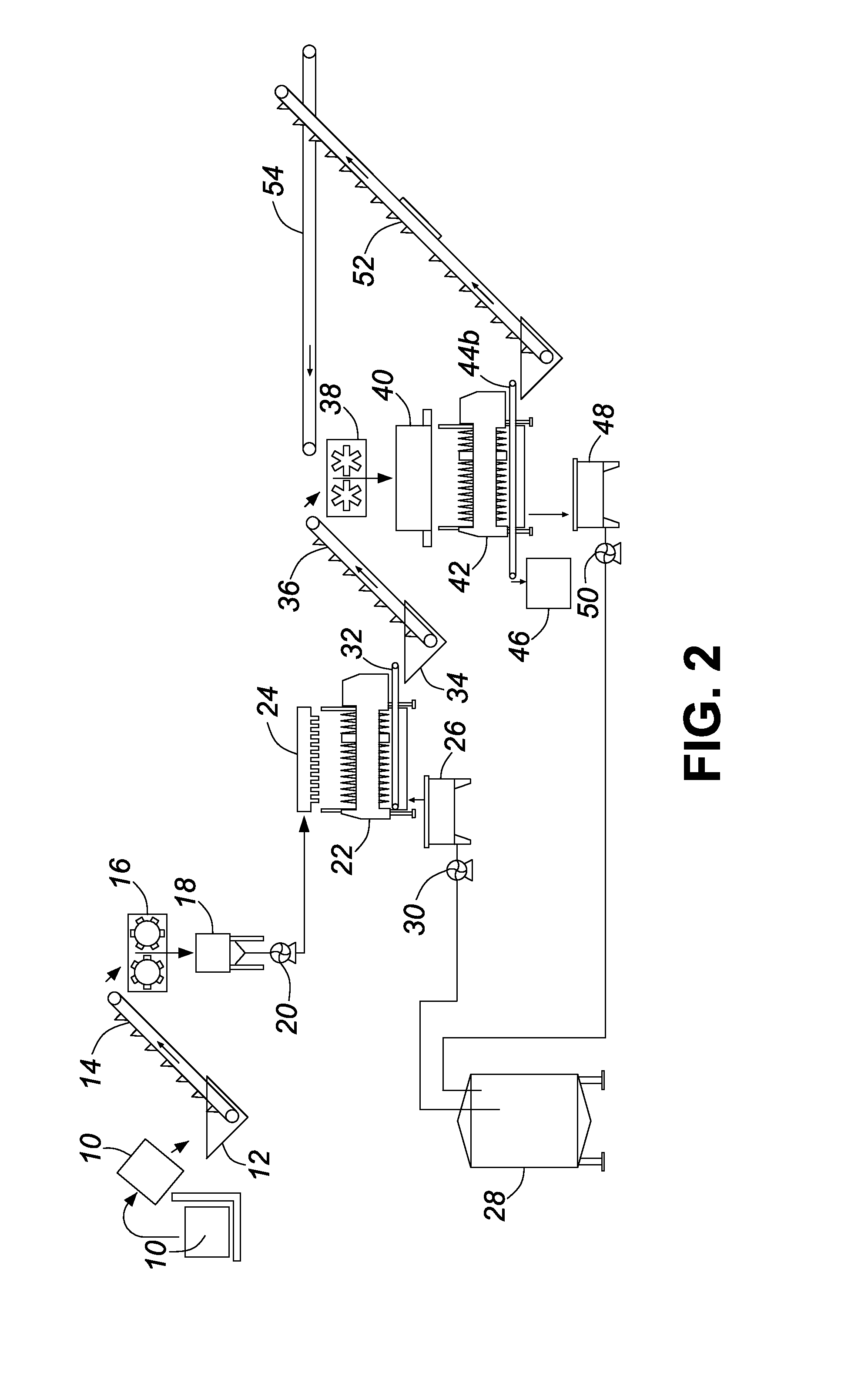

ActiveUS20100234569A1High level of proteinLarge particle sizeButter manufactureEdible oils/fatsVegetable matterSubject matter

The subject invention relates in part to novel steps in canola and other oil seed processing, including milling to achieve a significant particle size reduction, extraction of higher levels of protein from the starting material, the use of presscake as a starting material, and the production of a precipitated protein concentrates containing a nutritionally significant amount of oil. The subject invention also provides optimal pH ranges for extraction and recovery steps in these novel processes. The subject processes can be applied to, and offer similar advantages to, other oilseeds and vegetable matter, such as sunflower seeds and flax seeds. The subject invention also includes novel feed compositions.

Owner:CORTEVA AGRISCIENCE LLC

Method for manufacturing high-metal-sense aluminum silver paste

ActiveCN101708553AFlat surfaceNarrow particle size distributionPigment physical treatmentHigh carbonSteel ball

The invention discloses a method for manufacturing high-metal-sense aluminum silver paste, which is realized in a way that: high-carbon steel balls with the diameters of 0.4-1.0 mm are used as the milling medium of the ball mill, fine spherical aluminum powder (d50 is smaller than 5 mum), an organic solvent and lubricant are evenly mixed according to the weight proportion of 40:300:1, ball-milling is carried out in the ball mill for 25-50 hours, pressure filter is carried out on the discharged material, and the filtrate returns to the ball milling process for cycle use; press cakes enter the sieve classification process, the material passing through a 500-mesh sieve enters a wet whirl classification process and then pressure filter is carried out, and the filtrate returns to the sieve process for cycle use; and the press cakes enter the kneading process to be surface-treated, and then is packed to obtain the high-metal-sense aluminum silver paste. In the invention, small steel balls are used for carrying out mild transformation operation on the fine spherical aluminum powder for a long time, oil for the ball mill and oil for sieving are used separately, and the material passing through the 500-mesh sieve is processed in a wet classification way, so that the flaky aluminum pigment particles have the advantages of smooth surface and narrow particle size distribution, thereby ensuring the high metal sense of the aluminum paste.

Owner:长沙奥特金属颜料有限公司

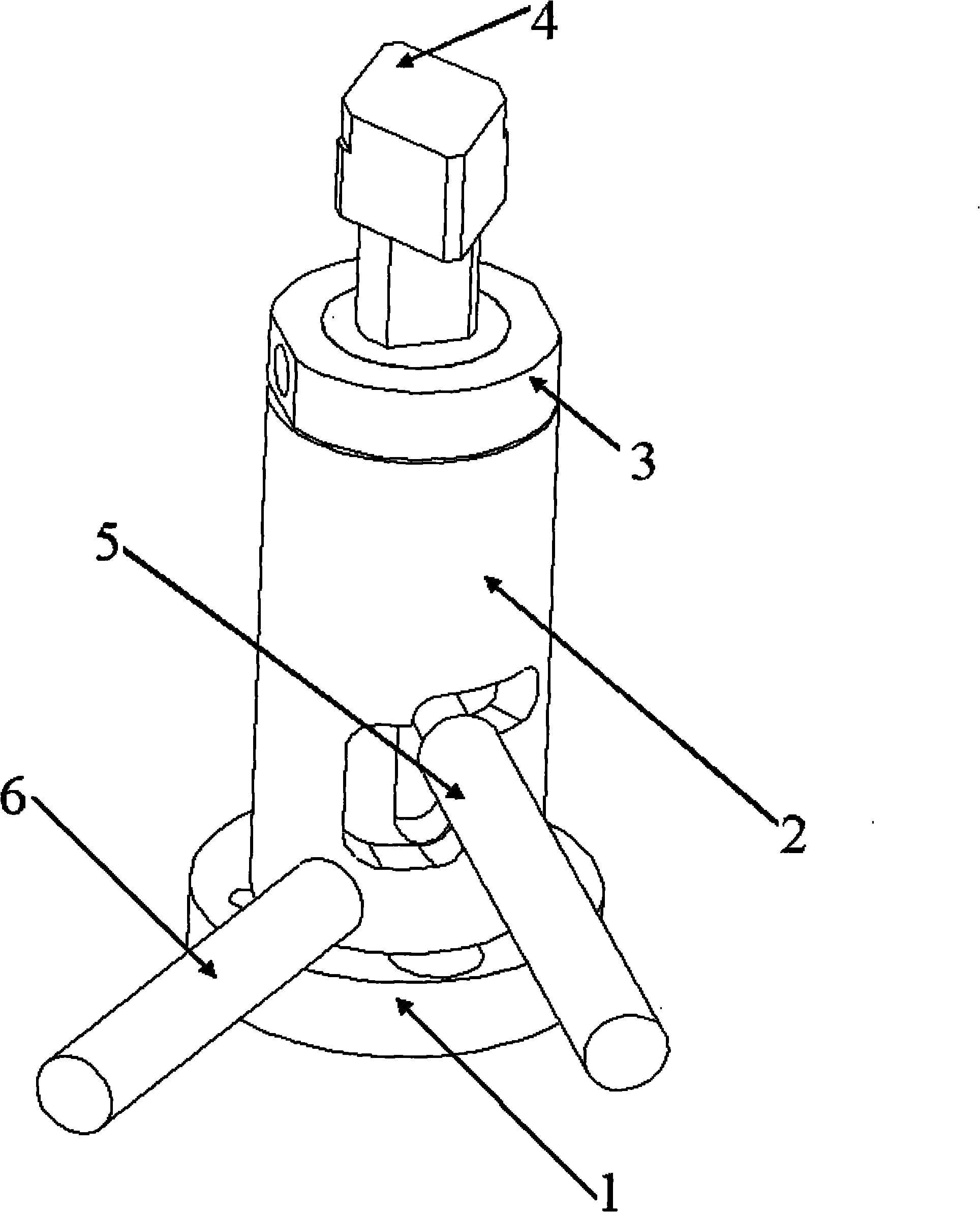

Method and Apparatus for Pressing Fruit

InactiveUS20140224137A1For quick ejectionQuickly and easily loadedJuice extractionEggs preservationThin layerEngineering

A method and apparatus for extracting juice from a previously de-juiced fruit mass which as been pressed within a primary press, the previously de-juiced fruit mass being discharged from the primary press and then being broken-up and mixed externally of the primary press, and then pressed again preferably by using a secondary thin layer repressing press which permits the repressed press cake to be quickly and easily loaded and emptied.

Owner:WETTLAUFER DALE +2

Strawberry soilless culture medium

InactiveCN103070059AThe physical and chemical properties of the matrix are stableNutritional balanceAgriculture gas emission reductionCultivating equipmentsFragariaSlag

The invention provides a strawberry soilless culture medium, relates to the technical field of planting and aims at reasonably using organic and inorganic wastes such as chicken excrement, slag and mushroom cultivating residues, saving resources, protecting the environment and realizing the goals of fertilizer saving, water saving, labor saving, pesticide saving, high yield, high quality and cleanness during soilless culture of pollution-free strawberries. The strawberry soilless culture medium comprises 60 percent of slag and 40 percent of mushroom cultivating residues by mass percentage, 40kg of fermented chicken excrement and 15kg of sesame-seed press cake are additionally per unit square meter medium, and the slag is additionally used for bedding according to a standard of 10m<2> / mu. By combining organic raw materials such as the mushroom cultivating residues, the chicken excrement and the slag with inorganic raw materials and by making the best use of materials, a formula for preparing the strawberry soilless culture medium is developed, so as to improve the nutrition conditions and the physical and chemical properties of the medium and lay a good foundation for the normal growth and development of the strawberries.

Owner:阜阳市王冰生态农业科技有限公司

Pressed cake and preparing method thereof

InactiveCN106982900APlay a puffing effectNutritious and balancedDough treatmentBakery productsEdible oilPress cake

The invention relates to a pressed cake. The pressed cake is mainly prepared from pastes prepared from vegetables or fruits, flour, seasoning accessories, edible oil and water. The preparing method of the pressed cake comprises the steps of mixing main raw materials to prepare a pasty premixed raw material, and then shaping and baking the premixed raw material to complete preparation of the pressed cake. According to the pressed cake, a puffing technology is not adopted, but cavities are formed in both the inside and the surface of the obtained pressed cake, thus the puffing effect is achieved, the pressed cake which is more 'crisp' and 'crunchy' compared with a traditional pressed cake is obtained, and the vegetables and the fruits are added in the pressed cake as the raw materials for preparation, so that the nutrition is richer and more balanced.

Owner:王新喜

Puffing expression method for producing oil with low oil-containing oil-bearing material

InactiveCN101245284AImprove product qualityAvoid excessive denaturationFatty-oils/fats productionPress cakeImpurity

The invention relates to a method for extracting oil by swelling and pressing low oil content oil seeds and is characterized by comprising the following steps: 1) clearing: impurities are removed from the oil seeds; 2) quality-adjusting: the temperatures and water contents are adjusted for the oil seeds; 3) the oil seeds are pressed and swelled; 4) enzyme killing and drying are carried out for the pressed and swelled oil seeds; 5) most of the oil is pressed from the dried oil seeds; the oil seeds can be crushed and then the quality adjusting can be done after the clearing of the step 1); after the step 2) of quality-adjusting, the bloom rolling can be done to the oil seeds and then the pressing and swelling can be done. The method adds the procedures of pressing and swelling before the traditional one time pressing and obtains pure physical pressed oil with high quality and pressed cakes which can be directly used for feed processing, which increases the processing amount of a press and reduces the power consumption and wearing. The method is mainly used for producing small-scale pressed oil and pressed cakes with good qualities and raw materials of low oil content oil seeds such as soybeans and rice bran.

Owner:中机康元粮油装备(北京)有限公司

Method for preparing vegetable oil through physical adsorption

ActiveCN104673492AReach the food standardEasy to operateFatty-oils/fats refiningFatty-oils/fats productionOil and greaseOrganic solvent

The invention discloses a method for preparing vegetable oil through physical adsorption. The method comprises the following steps: performing clearing, conditioning and pressing to obtain a press cake and crude oil; performing degumming treatment on the crude oil with a sepiolite degumming agent, performing deacidifying treatment on the degummed oil with a sepiolite deacidifying agent, performing decoloring treatment on the deacidified oil with a sepiolite decoloring agent, performing dehydrating treatment on the decolored oil with a sepiolite dehydrating agent, and separating to obtain dehydrated oil; and filtering and sealing and storing the finished product of vegetable oil, wherein an organic solvent is fed into the used sepiolite for circular treatment, a filter cake is obtained by filtering and then calcined and ground and crushed, and the crushing particle size is 100-200 meshes; and the sepiolite can be reused after drying. Food-grade sepiolite is adopted to perform physical adsorption refining treatment on the vegetable oil, the operation is easy and convenient, the energy consumption and the loss are low, few nutrients of grease are lost, the adsorption material can be recycled, and the edible standard of vegetable oil can be reached.

Owner:INST OF OIL CROPS RES CHINESE ACAD OF AGRI SCI

Method for producing foamless frying rapeseed oil of national fourth-level standard

InactiveCN101735884AIncrease productionIncrease temperatureFatty-oils/fats refiningFatty-oils/fats productionSalting outRapeseed

The invention discloses a method for producing foamless frying rapeseed oil of a national fourth-level standard. The method comprises the following steps: in an oil pre-pressing workshop, firstly, performing flaking on rapeseeds to obtain material flakes; secondly, steaming and frying the material flakes to obtain cooked flakes, and drying the cooked flakes; thirdly, pre-pressing the cooked flakes to obtain pre-pressed oil and pre-pressed cakes; and finally refining the pre-pressed oil and leaching out the pre-pressed cake; in a leaching plant, firstly leaching out crude oil and wet seeds from the pre-pressed cakes; secondly, drying the wet seeds to obtain dry seeds, and evaporating the leached crude oil through a first evaporator, a second evaporator and a third stripping tower in sequence to obtain leached oil; and finally refining the leached oil; and in a refining plant, refining the pre-pressed oil and the leached oil respectively: firstly performing primary hydration, standing and precipitating the oil to obtain oil residue; secondly, salting out the oil residue to obtain crude oil and waste oil residue; thirdly, performing secondary hydration on the crude oil; fourthly, performing centrifugal separation on the crude oil to obtain half-finished oil and the oil residue; fifthly, performing continuous desolvation on the half-finished oil under vacuum and filtering the half-finished oil after the desolvation to obtain finished oil; and finally cooling the finished oil and metrically putting the finished oil in storage. The rapeseed oil produced by the method of the invention cannot foam during frying, so that the application fields and the market sale are expanded.

Owner:江苏广原油脂有限公司

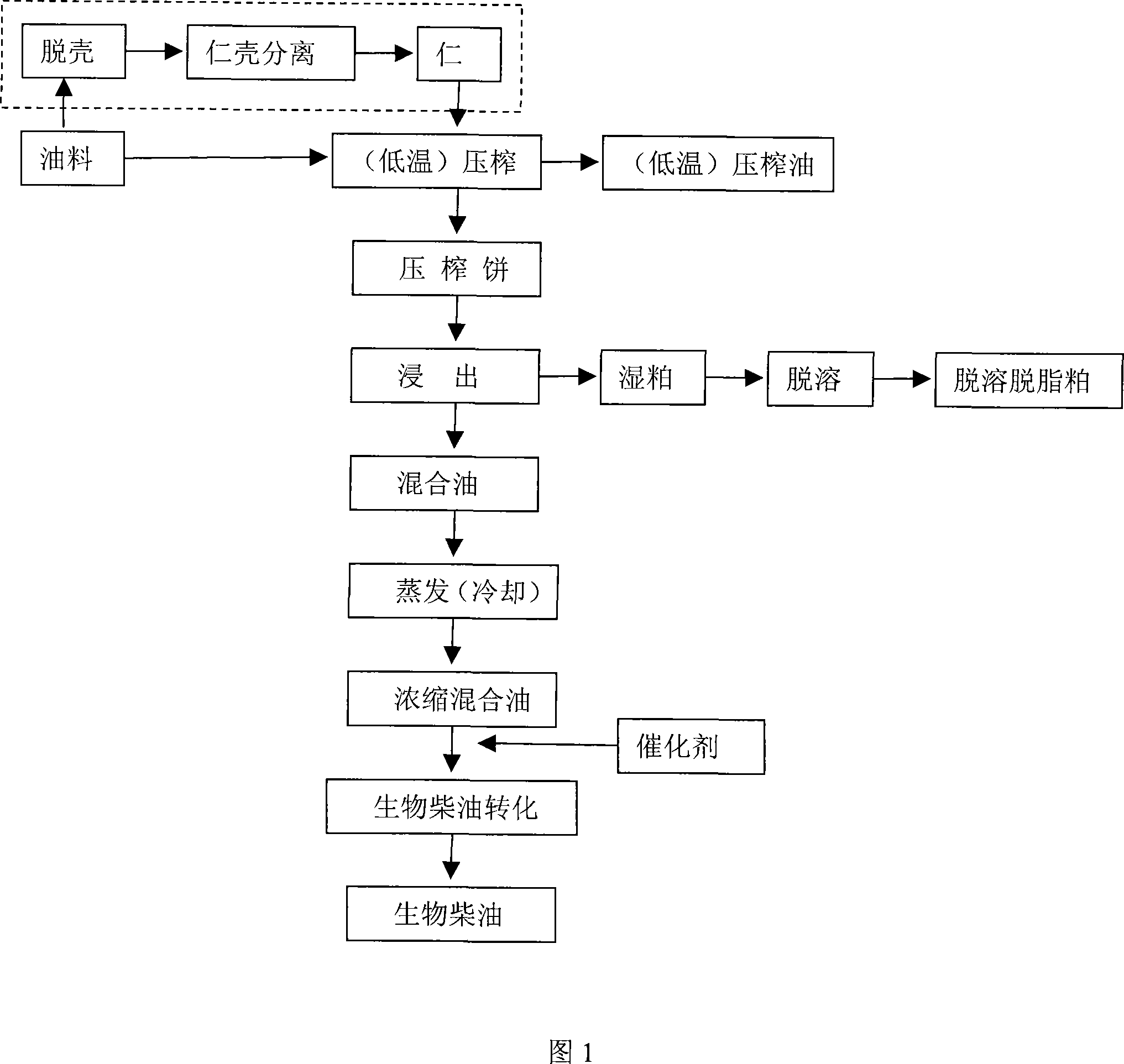

Method for extracting conversion biodiesel from oil pressing cake

InactiveCN101161784AQuality improvementHigh priceFatty oils/acids recovery from wasteBiofuelsBiodieselVegetable oil

The invention relates to a method for extracting transformation biodiesel from oil-bearing press cake and solves the problems of complex pretreatment and high energy consumption, etc. of the prior art which mainly adopts animal and vegetable oil as raw materials. The invention realizes direct pressing of shelled oilseeds or unshelled oilseeds through a low-temperature screw oil press or a common oil press to obtain press cake and expressed oil; the press cake is leached out through adopting organic solvent with the leaching out solvent ratio ranging between 0.8:1 and 2.0:1 and the leaching out time ranging from 60 min to 200 min; the leached out oil mixtures is converted into 60 percent to 90 percent concentrated oil mixtures after evaporation or cooling and separation, while the leached out wet meal containing solvent is converted into degreased meal with the residual oil rate being less than or equal to 1 percent after exsolution; catalyst which accounts 1 percent to 10 percent of the weight of the concentrated oil mixtures is added in the concentrated oil mixtures for biodiesel transformation with the products separated to obtain biodiesel crude product and glycerol; finally, the biodiesel crude product is made into biodiesel product after distillation. The invention which omits steps such as steam stripping and refining has the characteristics of simple process and low energy consumption, etc.

Owner:INST OF OIL CROPS RES CHINESE ACAD OF AGRI SCI

Process for preparing hazelnut oil

InactiveCN101338246AEasy to separateHigh extraction rateFatty oils/acids recovery from wasteFatty-oils/fats productionSolventPress cake

The invention relates to a preparation method of hazelnut oil. Firstly, shelling hazelnut nutlets are cold-pressed by an oil press in low temperature to get pressed hazelnut oil and pressed cake. The pressed cake is then crushed to 40-60 meshes to get pressed cake powder. A method of carbon dioxide supercritical extraction is used to extract the pressed cake powder to get extracted hazelnut oil. The pressed cake powder is extracted under the pressure of 24-26MPa and the temperature of 50-60 DEG C in the carbon dioxide flow rate of 110-130 L / h for 2-3 hours. The pressed hazelnut oil and the extracted hazelnut oil are mixed together to get the hazelnut oil. During the preparation of the hazelnut oil, the invention firstly presses partial hazelnut oil in the hazelnut nutlets by using the low temperature cold-pressing method, then extracts the rest hazelnut oil in the pressed cake gained by pressing the hazelnut nutlets by using the carbon dioxide supercritical extraction method, has a high extraction rate, is easy to separate the oil and the cake, does not have solvent residue in the product, and is safe to be manufactured.

Owner:铁岭三能科技有限公司

Strong-flavor rapeseed oil processing method

InactiveCN106244316AImprove qualityUnique fragranceFatty-oils/fats refiningFatty-oils/fats productionOil processingAdditive ingredient

The invention discloses a strong-flavor rapeseed oil processing method, which comprises: pounding agastache rugosa, dianthus chinensis l, peppermint, melissaofficinalis l, osmanthus fragrans and camellia japonica l, adding water, decocting, and filtering to obtain an ingredient liquid; selecting high-quality rapeseed, peeling to obtain rapeseed kernel, heating for a certain time with steam, adding edible salt, uniformly mixing, adding to the ingredient liquid, soaking for a certain time, filtering, adjusting the water content of the rapeseed kernel, carrying out a microwave pretreatment, cooling, and carrying out cold pressing to obtain pressed oil and pressed cake; and carrying out degumming, alkali refining, decoloring and deodorizing on the pressed oil to obtain the strong-flavor rapeseed oil. According to the present invention, the strong-flavor rapeseed oil processing method is provided, wherein the low temperature cold pressing is used, the oil yield is high, the prepared strong-flavor rapeseed oil has advantages of rich flavor, high nutritional value, good oxidation stability and no pollution, the pure nature property of the rapeseed oil is ensured, and the requirements of green food are met.

Owner:BENGBU QIONGHUAI GRAIN & OIL

Processing method of aromatic oxidation-resistant rapeseed oil

InactiveCN104629896AImprove oil yieldHigh nutritional valueFatty-oils/fats productionEdible oils/fatsRapeseedOxidation resistant

The invention discloses a processing method of aromatic oxidation-resistant rapeseed oil. The processing method comprises the following steps: adding liquorice roots, chrysanthemum, immature bitter oranges, dried tangerine peels, perilla fruits and peppermint into water, decocting, and filtering to obtain a preparing liquid; husking rapeseeds to obtain rapeseed kenels, adding the rapeseed kenels into the preparing liquid, soaking, filtering, adjusting the content of water in the rapeseed kenels, refrigerating the rapeseed kenels, and pretreating with microwaves; cooking the rapeseed kenels pretreated with microwaves, and carrying out cold pressing to obtain pressed oil and a pressed cake; washing the pressed oil with water, and decoloring to obtain the aromatic oxidation-resistant rapeseed oil. Because the rapeseed kenels are pretreated with microwaves and cold pressed, the rapeseed oil is high in yield and nutritional value and good in quality and oxidation stability.

Owner:ANHUI ZHAOLAOWU GREASE

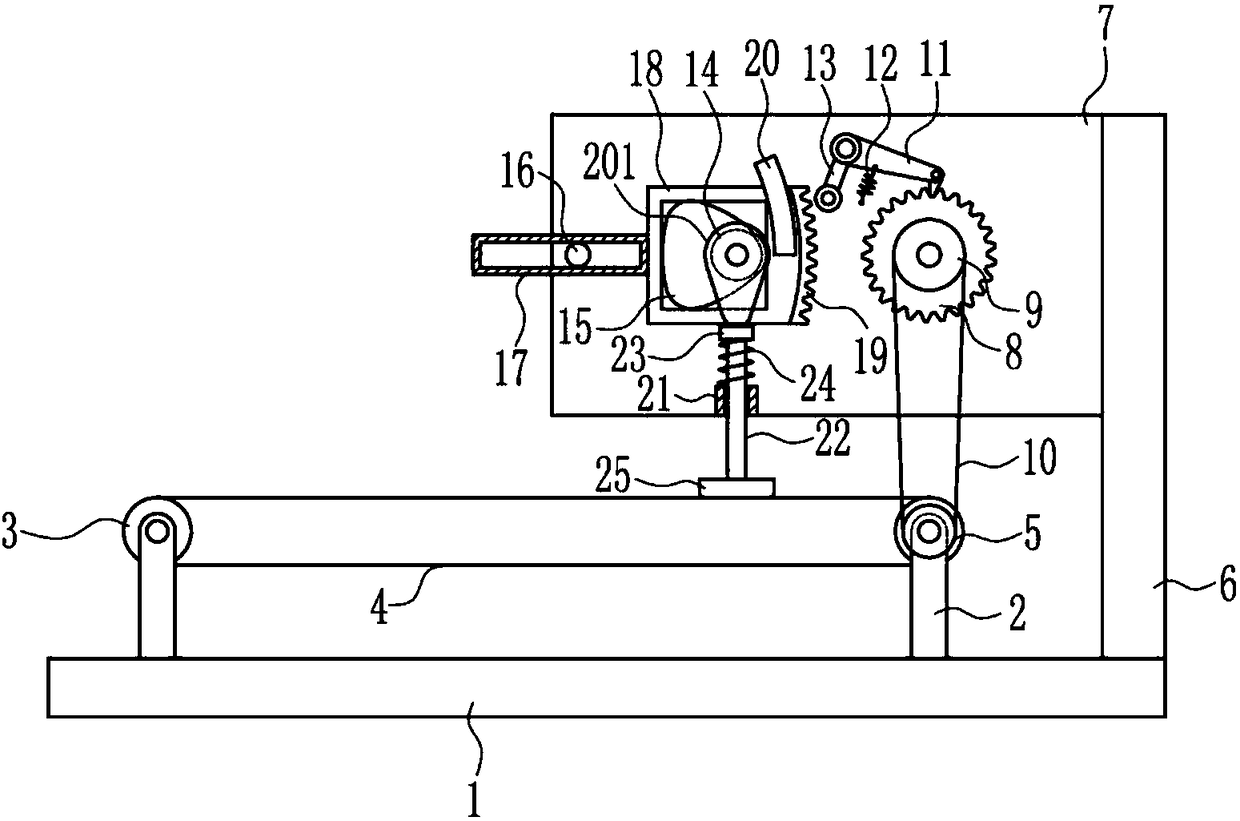

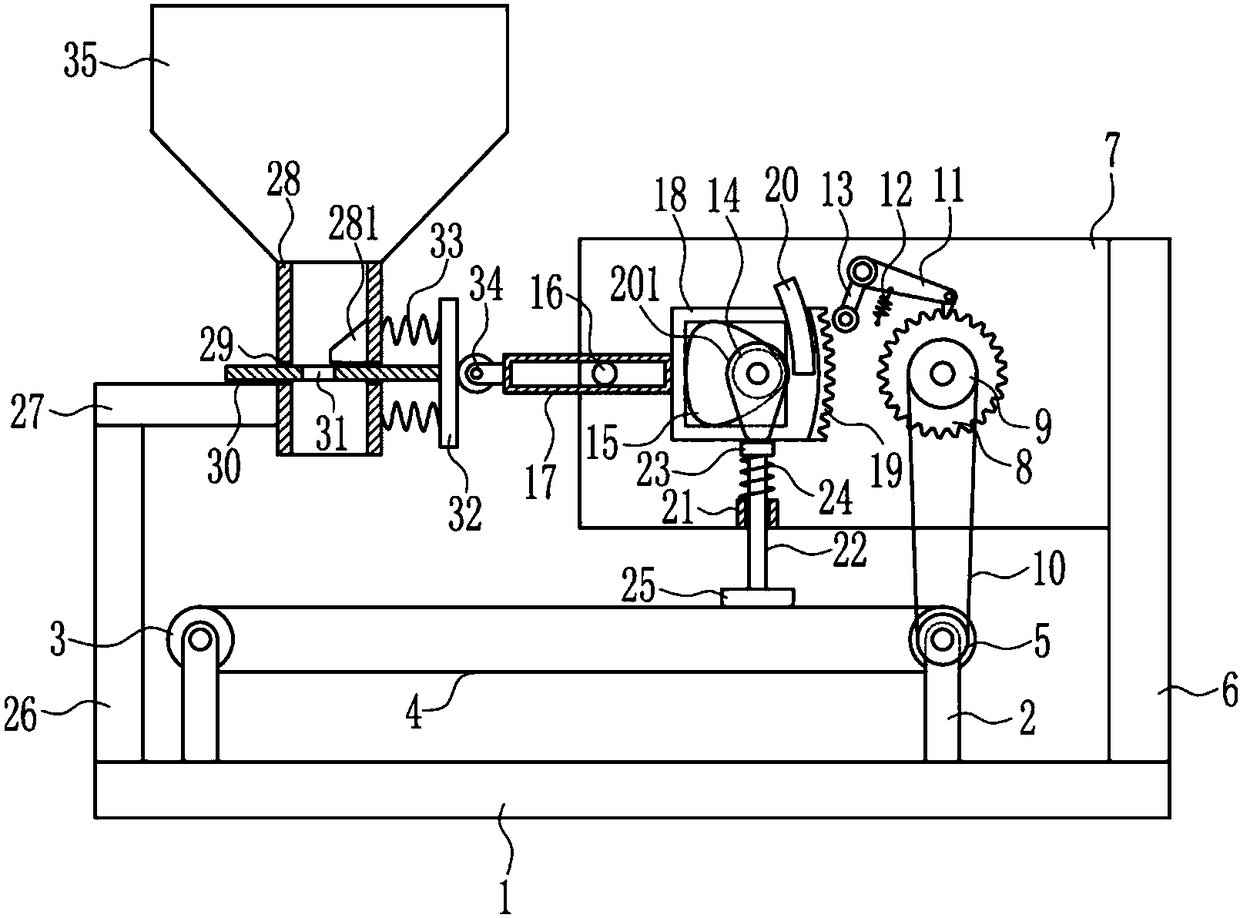

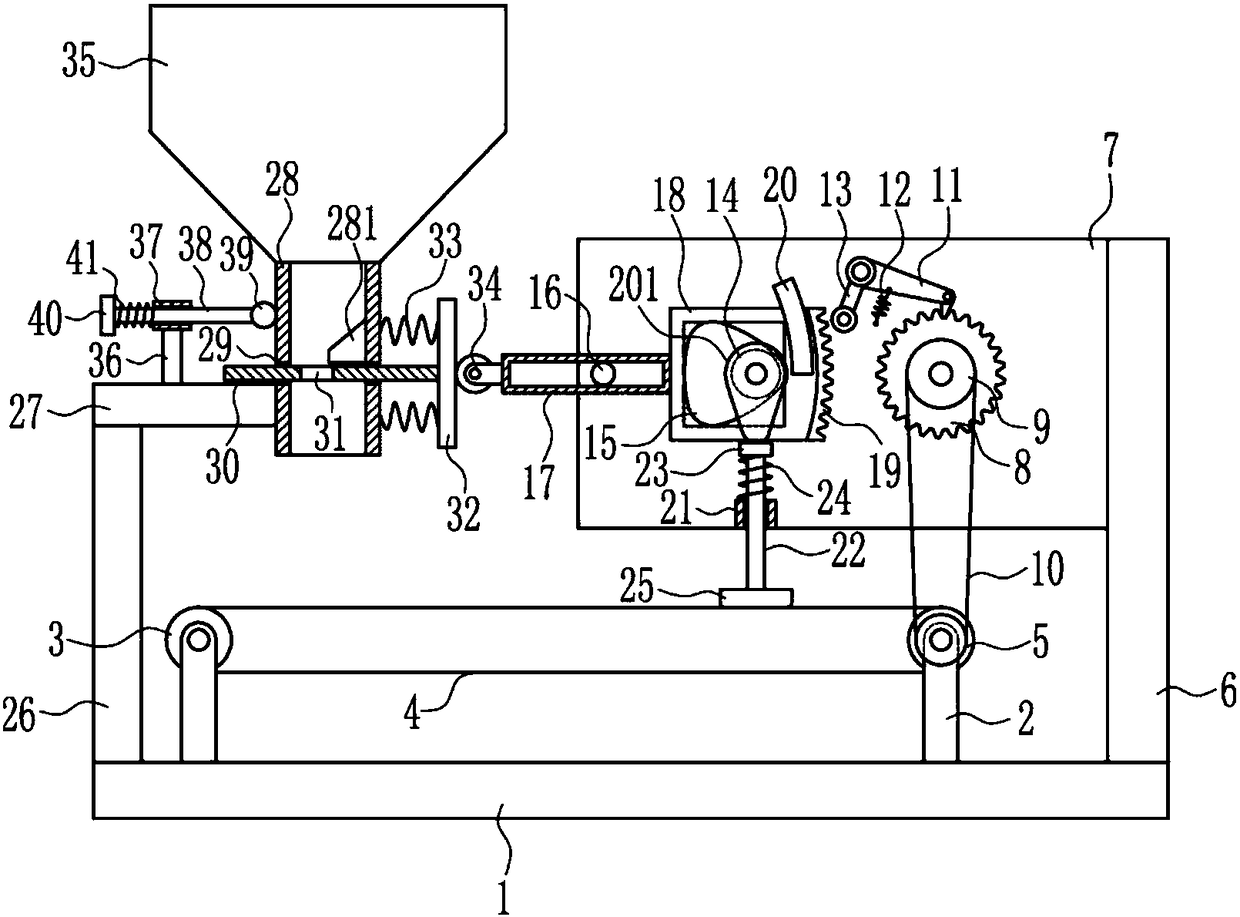

Solid fertilizer intermittent breaking equipment used for gardens

The invention relates to a breaking equipment, in particular to a solid fertilizer intermittent breaking equipment used for gardens. The breaking equipment has the technical problem that the solid fertilizer intermittent breaking equipment, which has the advantages of high breaking efficiency and sufficiency in breaking, used for the gardens is provided. The solid fertilizer intermittent breakingequipment has the beneficial effects that the solid fertilizer intermittent breaking equipment used for gardens comprises a bottom plate and the like, wherein the left side and the right side of the top of the bottom plate are respectively connected with an installation rod; the top of each installation rod is rotatably provided with a roller; a conveyor belt is connected between the left roller and the right roller; the front side of the right roller is connected with a first belt pulley; the right side of the top of the bottom plate is connected with a bracket. According to the breaking equipment, the rotor rotates to drive a moving plate to move between left and right, so that solid fertilizer in a discharging hopper intermittently falls to the conveyor belt, a rack drives a gear to intermittently rotate so as to drive the conveyor belt to intermittently move rightwards, so that the solid fertilizer on the conveyor belt can be efficiently broken by a press cake, and therefore, the effects of high breaking efficiency and sufficient breaking are achieved.

Owner:宁夏宁苗生态建设集团股份有限公司

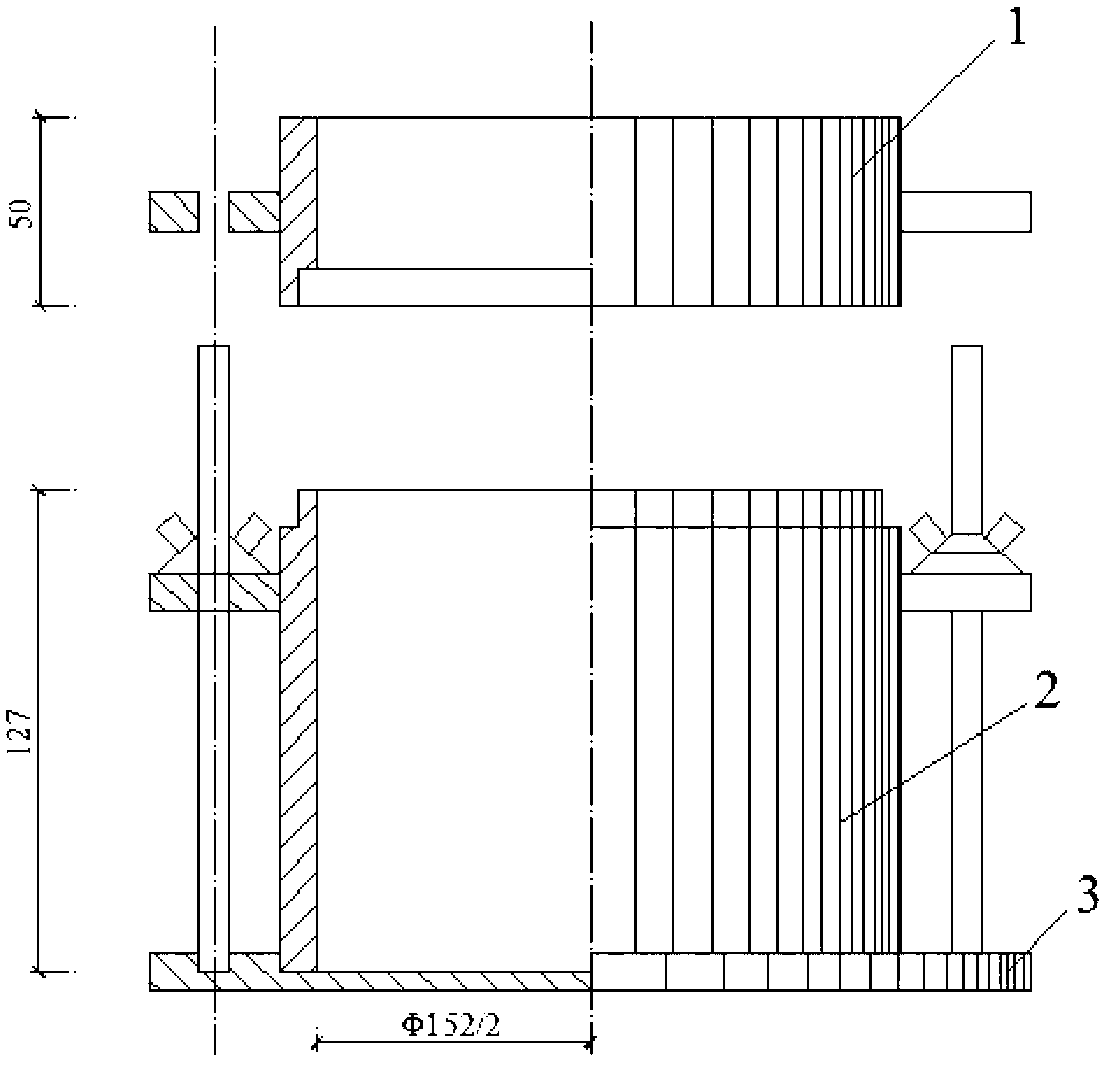

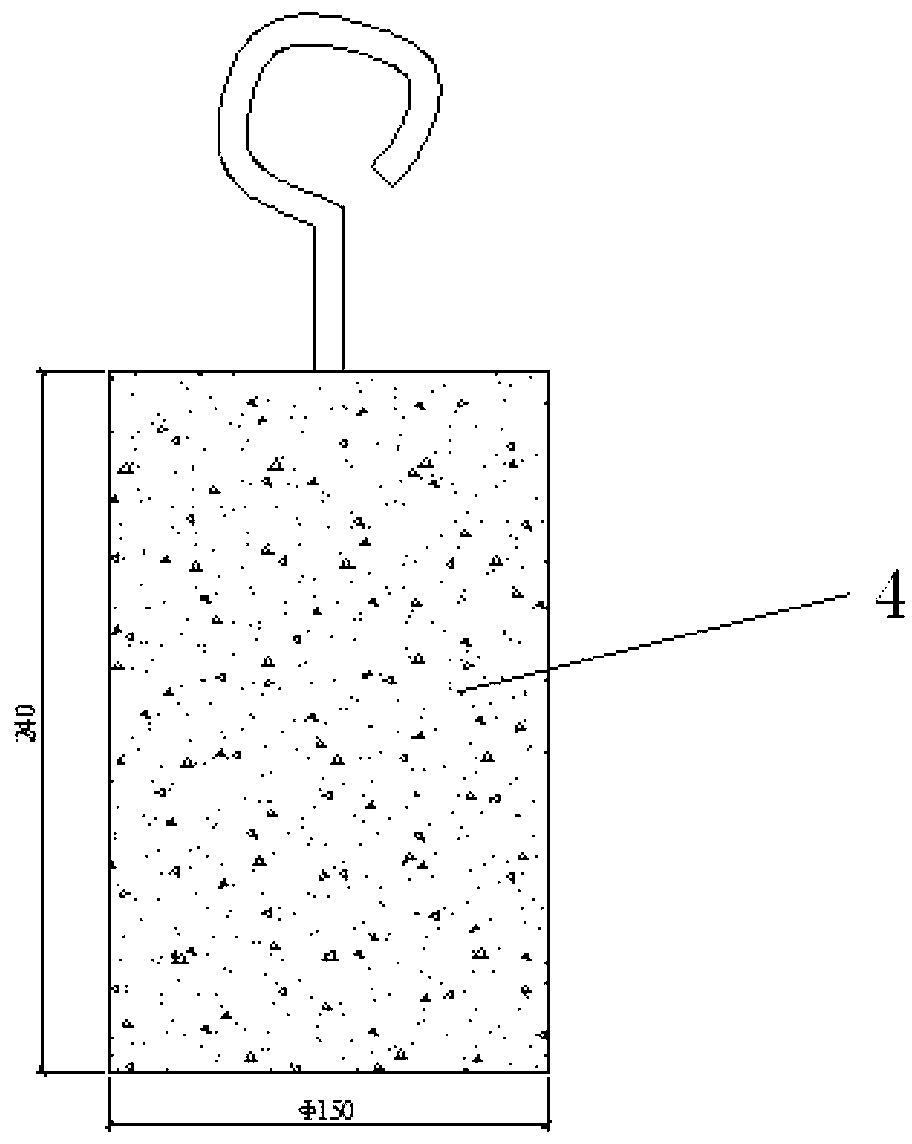

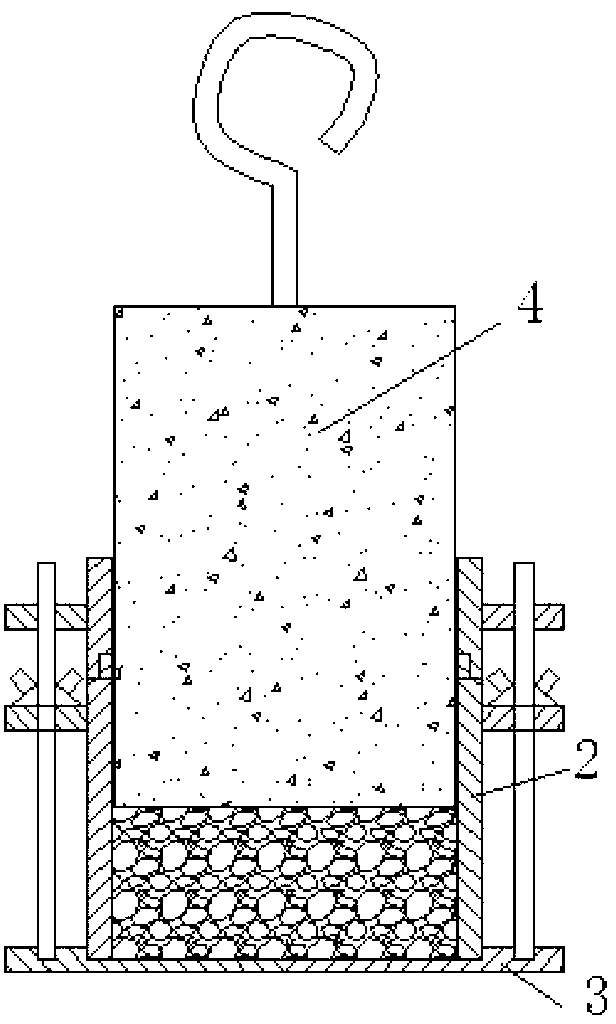

Method for determining road roller compacted concrete composition based on pressing vibration method

ActiveCN103344750AImprove compactionMeet construction requirementsMaterial testing goodsRoller-compacted concreteGraduated cylinder

The invention discloses a method for determining a road roller compacted concrete composition based on a pressing vibration method. The method comprises the following steps of: placing samples into a volume tube in two layers, placing on-load press cakes on the surfaces of the samples, starting a vibrating table, measuring the head room of the volume tube, respectively determining the height of a first layer and the height of a second layer, leveling the surfaces of the samples, removing the samples and the volume tube together from the vibrating table, weighing the mass of the volume tube and the samples, taking out the samples, determining the volume of the roller compacted concrete sample, removing the sample, weighing, determining the water content, calculating the dry density, and with the dry density of the sample as the vertical coordinate and the water content of the sample as the horizontal coordinate, selecting the composition with large compactness and thickness satisfying the requirements as the compacted concrete composition according to test. The method disclosed by the invention ensures that the road roller compacted concrete composition has large compactness, meanwhile, the thickness of the road roller compacted concrete also can meet the construction requirements, and the method is simple and feasible to operate.

Owner:TSINGHUA UNIV +1

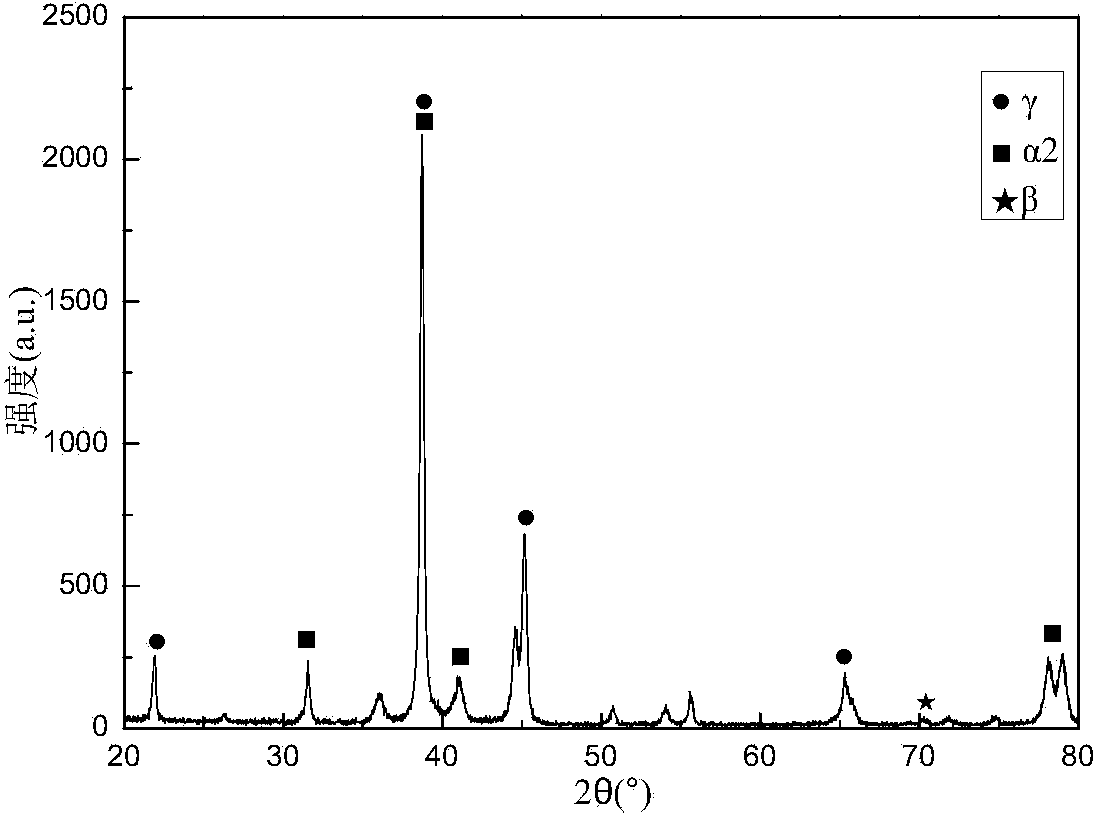

Cr and V alloying beta phase solidifying high Nb-TiAl alloy and preparation method thereof

The invention relates to a Cr and V alloying beta phase solidifying high Nb-TiAl alloy and a preparation method thereof, and belongs to the field of alloy technology. The alloy comprises the following elements by mole: 43%-45% of Al, 5%-15% of Nb, less than or equal to 0.5% of Cr, less than or equal to 0.5% of V, and the balance of Ti and inevitable impurities. The preparation method comprises the following steps: raw materials are subjected to briquetting forming according to constitutions, titanium sponges are placed on the edge of the inner side of a mould when briquetting is conducted, a high purity aluminium layer, an aluminium niobium intermediate alloy layer, an electrolytic chromium piece layer, an aluminium vanadium intermediate alloy layer and a titanium sponge layer are arranged from bottom to top in a layering manner; pressing cakes are placed into a water-cooling copper crucible vacuum induction suspension smelting furnace capable of centrifugal pressure casting for vacuum smelting to obtain melts and the melts are enabled to be mixed uniformly; the melts are cast in a metal casting mould that is preheated in advance and centrifugally rotates for centrifugal rotating and casting and cooled with the furnace. According to the invention, a TiAl alloy that is homogeneous and fine in structure and has no obvious segregation is obtained.

Owner:BEIJING UNIV OF TECH

Bean flour press cakes and making method thereof

InactiveCN106212590ARich in nutrientsSolve rough tasteDough treatmentBakery productsPearl barleySugar

The invention relates to bean flour press cakes and a making method thereof. The cakes are prepared from, by weight, 40-50 parts of flour, 30-40 parts of soybean flour, 8-10 parts of red date powder, 8-10 parts of rhizoma dioscoreae powder, 6-9 parts of pearl barley powder, 3-6 parts of white sugar, 110-140 parts of spring water, 8-12 pieces of eggs, 8-10 parts of edible oil and 2-5 parts of lard oil. By using purely natural spring water and adding eggs and edible oil, the obtained press cakes are more crispy and delicious. By adopting soybean flour, red date powder, rhizoma dioscoreae powder and pearl barley powder besides flour and eggs, the obtained press cakes contain rich nutrients; besides, sesame seeds are spread on the cakes, so that color, aroma and taste are all good.

Owner:山西绿德农业科技股份有限公司

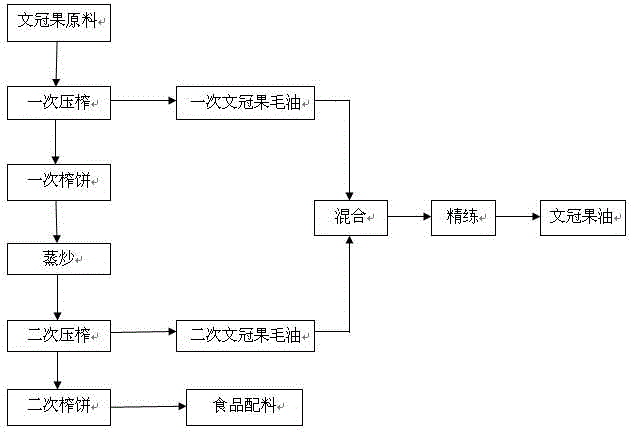

Method for preparing shiny-leaved yellowhorn oil by secondary pressing

ActiveCN104789345AGuaranteed qualityImprove qualityFatty-oils/fats refiningFatty-oils/fats productionPress cakeRaw material

The invention discloses a method for preparing shiny-leaved yellowhorn oil by secondary pressing. The method comprises the following steps: preparing a shiny-leaved yellowhorn raw material; primarily pressing the prepared shiny-leaved yellowhorn raw material to obtain primary shiny-leaved yellowhorn crude oil and primary pressed cakes; steaming and frying the crushed primary pressed cakes; secondarily pressing the steamed and fried primary pressed cakes to obtain secondary shiny-leaved yellowhorn crude oil and secondary pressed cakes; mixing the primary and secondary shiny-leaved yellowhorn crude oil to obtain the pressed crude oil; sequentially alkali-refining, dehydrating, decoloring and deodorizing the obtained pressed crude oil to obtain a finished product shiny-leaved yellowhorn oil. Compared with a conventional primary pressing method, the method for preparing shiny-leaved yellowhorn oil by secondary pressing disclosed by the invention greatly improves the oil yield of pressing the shiny-leaved yellowhorn, so that the quality of the shiny-leaved yellowhorn oil is guaranteed. Compared with an aqueous enzymatic method, the method disclosed by the invention is simple in process, less in corollary equipment, flexible in production and suitable for small scale production.

Owner:WUHAN POLYTECHNIC UNIVERSITY

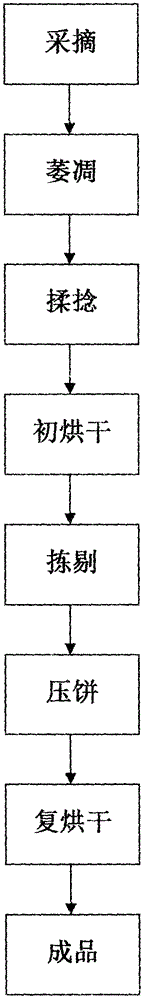

Making method of Xinyang white tea and making method of white tea cakes

InactiveCN106615255ADecreased green energyNice appearancePre-extraction tea treatmentEconomic benefitsPress cake

The invention relates to a making method of Xinyang white tea, and a making method of white tea cakes, and belongs to the technical field of processing of white tea. The making method comprises the following steps of performing picking, performing withering, performing rolling, performing primary drying, performing picking for removal, pressing cakes, and performing redrying so as to obtain finished products. The raw materials of the Xinyang white tea are one or more of Fuding dabaicha, Xinyang species, C.sinensis cv.Baihaozao, Fuyun No.6, C.sinensis cv.Bixiangzao, Wuniuzao, Pingyangtezao, and Xinyang No.10. The processing technology is unique, the made white tea is good in quality, plump and hard in shape, much in tea leaf grading, grayish green and bright in color, and fragrant in flesh flowers and rich in honey fragrance, orange and bright in soup, mellow, fresh, and sweet in taste, and tender in leaf base. Loose and crispy white tea is pressed to obtain tea cakes, so that the size is reduced the shape is beautiful, and the made white tea is convenient to store and carry. In a storage process, a slight enzymatic reaction is also generated, so that the made white tea is thick, mellow and rich in fragrance, and sweet in aftertaste, and the made white tea is well loved by consumers. The making method disclosed by the invention has remarkable economic benefits.

Owner:周开启

Joint production method of edible rice bran oil and rice polishings protein

InactiveCN101220314ALight colorReduce lossesPeptide preparation methodsFatty-oils/fats productionFiltrationRice Bran Extract

The invention relates to a co-production method of edible rice bran oil and rice bran protein, which is characterized in that: the rice bran which is within 2 hours after rice milling is processed by using a dryer at 50 DEG C to 70 DEG C, the water content of the rice bran is dried to 2 percent to 10 percent; the cooling is carried out till the normal temperature, a piece of low-temperature oil pressing equipment is directly used, the pressing temperature is 20 DEG C to 80 DEG C and a screw rod is controlled to the rotation speed of 10 to 40r / min for carrying out the low-temperature pressing so as to obtain the low-temperature pressed crude oil and a low temperature pressed cake; the rice bran crude oil is treated with precipitation and fine filtration so as to obtain the rice bran oil; the low temperature pressed cake is smashed and filtered by using a 80-mesh screen so as to obtain the half-defatted rice bran protein powder. The method which is provided by the invention can keep the active substances in the oil material, the nutritional value is improved, the color of the rice bran oil is shallow; the invention has unique taste of the rice bran and no chemical reagent pollution or residue, the protein loss is less, the degeneration degree of the protein is low, and the utilization value of the protein of the cake is improved.

Owner:马涛 +1

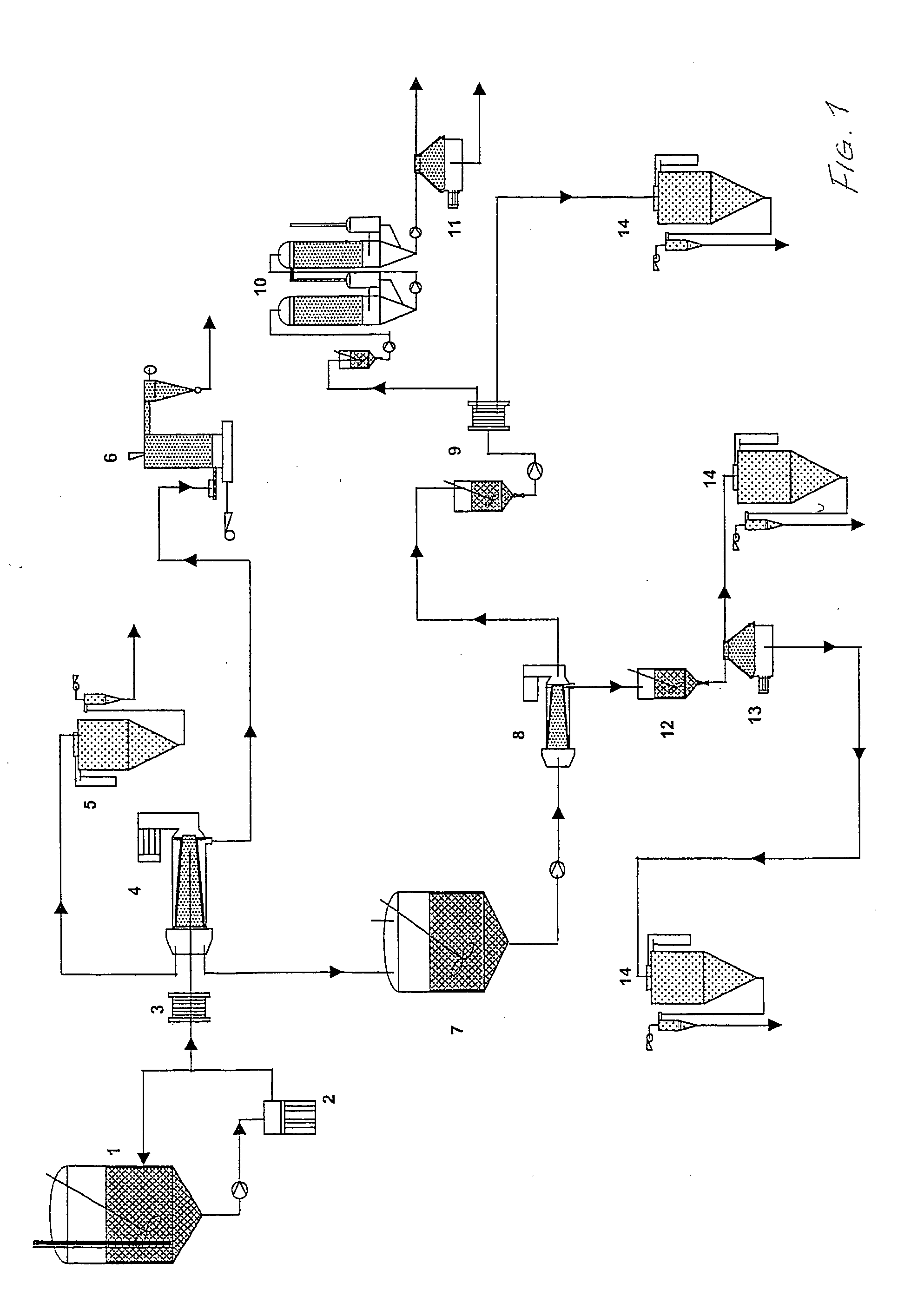

Beet processing process and unit

The invention relates to a beet processing process comprising at least the following steps: washing of the beets; partial pressing of the beets for the production, on the one hand, of a sugar-containing press cake at more than 20% relative to the dry matter content and, on the other hand, of a sugar juice at a concentration greater than 15% dry matter content; separation of the press cake and of the sugar juice. The invention also relates to animal nutrition, fermentation substrates and edible sugar based on the products obtained from this beet processing process.

Owner:LESAFFRE & CIE

Pressed cake and manufacturing method thereof

InactiveCN106234503ARich in nutrientsRich taste roughDough treatmentBakery productsMonosodium glutamateCooking oil

The invention particularly relates to a pressed cake and a manufacturing method thereof. The pressed cake is prepared from the following raw materials in parts by weight: 90 to 120 parts of flour, 8 to 10 parts of smashed peanuts, 120 to 150 parts of spring water, 8 to 12 eggs, 8 to 10 parts of cooking oil, 2 to 5 parts of lard oil, 1 to 1.4 parts of salt, 0.2 to 0.5 part of five-spice powder, 0.2 to 0.3 part of Sichuan pepper powder, 0.2 to 0.5 part of monosodium glutamate and 0.2 to 0.5 part of chicken essence. The pressed cake is manufactured by adopting purely natural spring water, and the egg and the lard oil are added into the raw materials, so that the manufactured pressed cake is more crispy and delicious; the smashed peanuts and the eggs are added into the raw materials, so that the manufactured pressed cake is rich in abundant nutriments; moreover, sesame or green vegetables are scattered on a flour cake; therefore, the pressed cake is complete in colour, flavour and taste.

Owner:山西绿德农业科技股份有限公司

D shape guide pin top and bottom positioning structure of hole position check tool

ActiveCN101858718AImprove convenienceMechanical measuring arrangementsPosition checkArchitectural engineering

The invention relates to a D shape guide pin top and bottom positioning structure of hole position check tool, comprising a detection pin, a rotating sleeve and a D shape guide pin sliding support; wherein the D shape guide pin sliding support is sheathed at the outer side of the detection pin, the lower end face thereof is provided with a larger-diameter step face with a bolt hole; the rotating sleeve is sheathed at the outer side of the D shape guide pin sliding support, the upper side of the rotating sleeve is provided with a limit press cake; the outer side of the rotating sleeve is fixed with a rotating handle pin, the wall of the rotating sleeve is provided with an inversed 'L' shape first through hole, the wall of the D shape guide pin sliding support is provided with a vertical second through hole, one end of an up-down shifting pin is respectively fixed on the detection pin by virtue of the through holes on the rotating sleeve and the D shape guide pin sliding support. In the invention, the rotating sleeve is sheathed at the outer side of the D shape guide pin sliding support, so that the previous detection pin which only can move up and down and can not be fixed at certain position can be fixed at one specific position, thus improving convenience of operation.

Owner:ROYAL GAUGE IND

Processing method for increasing cold pressing oil yield of aromatic peanut kernels

InactiveCN106350204AImprove oil yieldStrong oil yieldFatty-oils/fats refiningFatty-oils/fats productionFiltrationPress cake

The invention discloses a processing method for increasing a cold pressing oil yield of aromatic peanut kernels. The processing method comprises the following steps: decocting lavender, chamomile, mint, violet, sweet-scented osmanthus, jasmine and trigonella foenum-graecum with water, filtering to form batching liquid, selecting the high-quality peanut kernels for baking and peeling, cooling to the room temperature, breaking the peanut kernels into particles, adding ground salt after steam heating for a period of time, performing uniform mixing and centrifugation, adding the centrifuged peanut kernel particles into the batching liquid for soaking, adjusting the moisture content of the peanut kernel particles after filtration, performing microwave treatment, performing cold pressing after cooling to form press oil and press cakes, and performing water washing and decoloration on the press oil to form the peanut oil. The processing method for increasing the cold pressing oil yield of the aromatic peanut kernels is high in oil yield, green and nutritional, guarantees pure nature of the peanut oil and meets requirements for green food, and the fragrance is strong.

Owner:BENGBU QIONGHUAI GRAIN & OIL

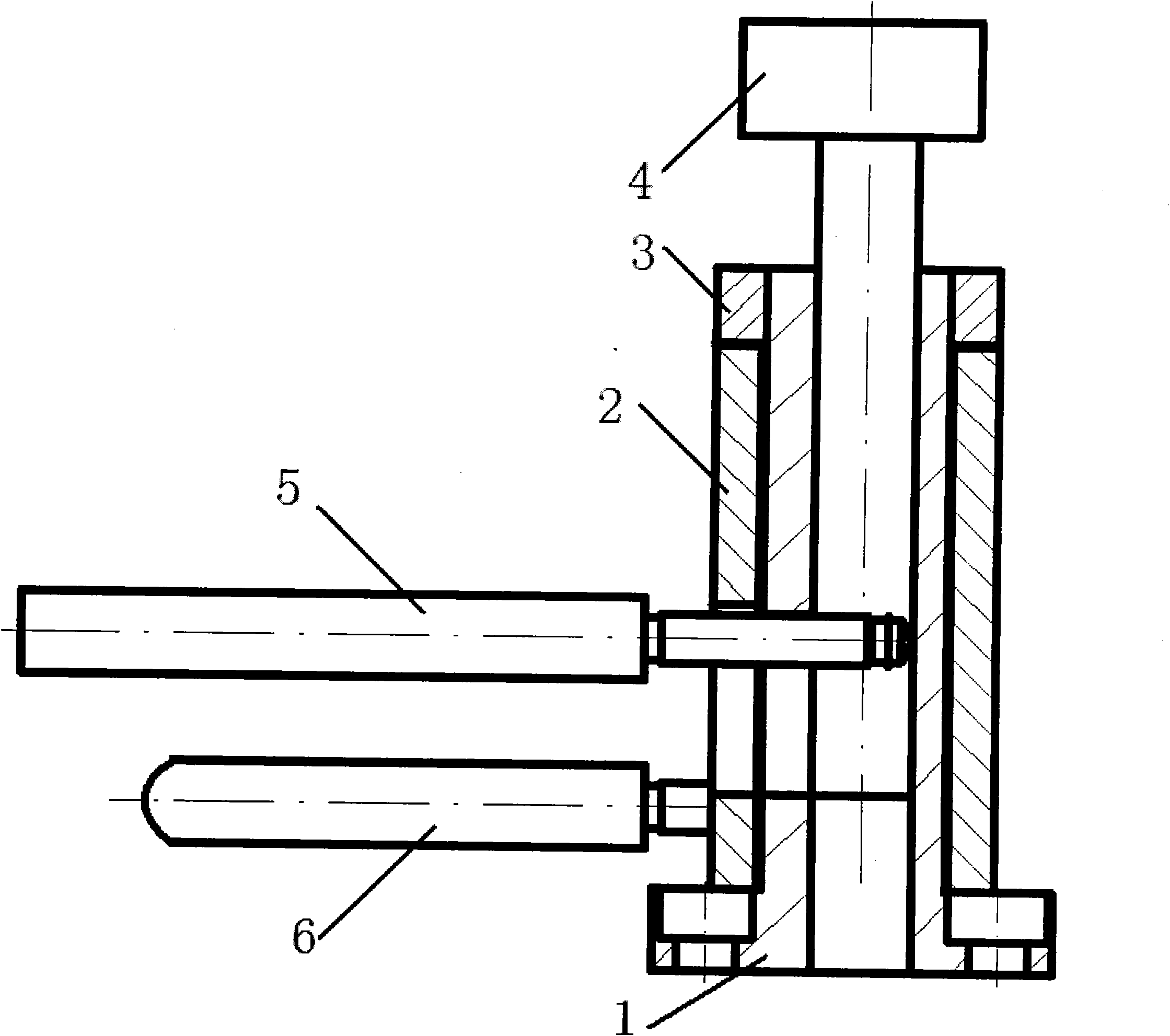

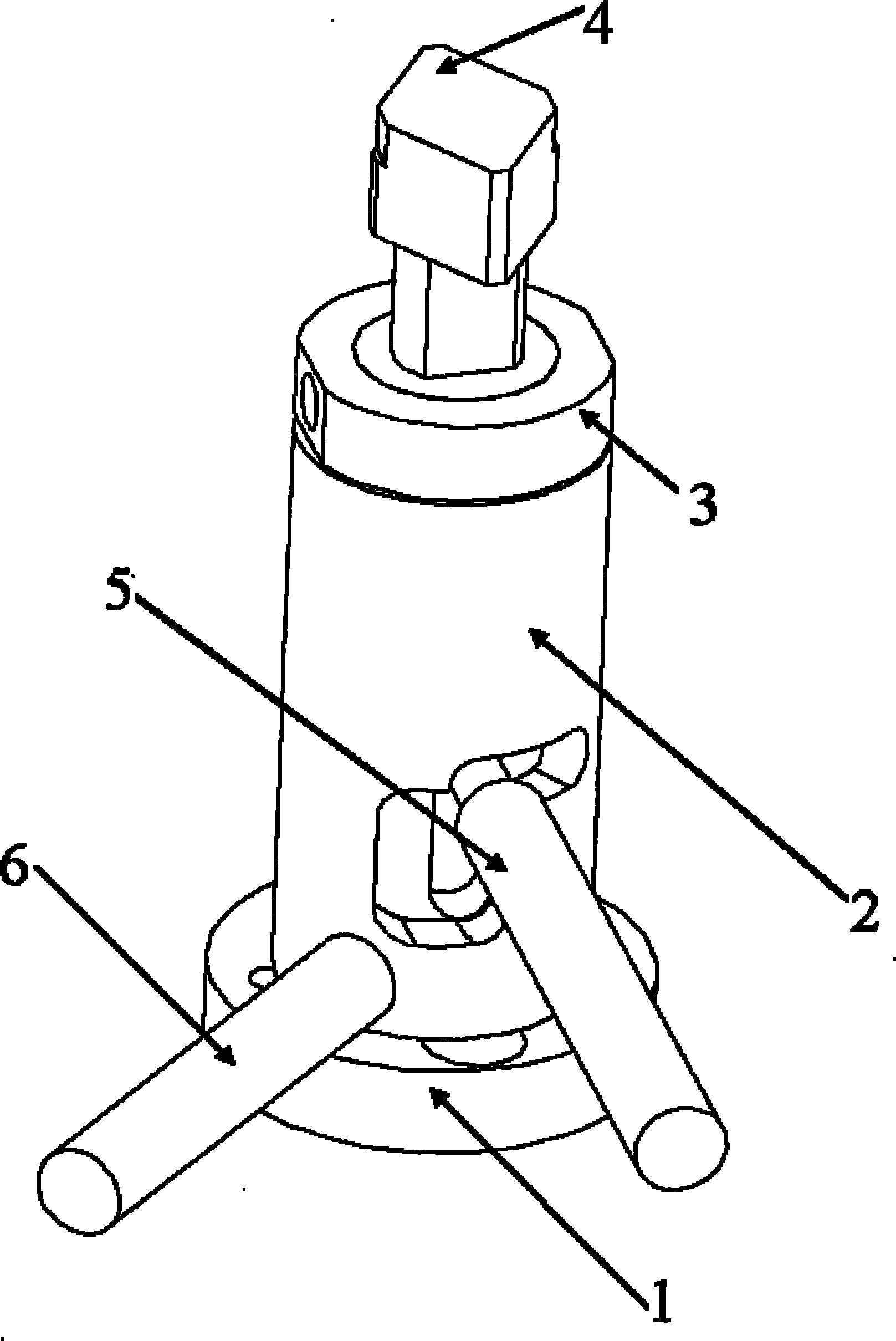

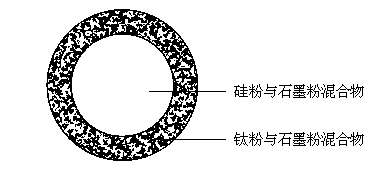

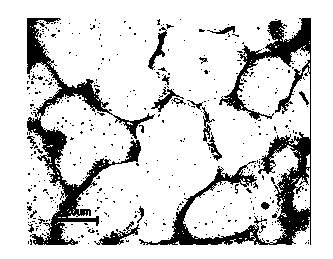

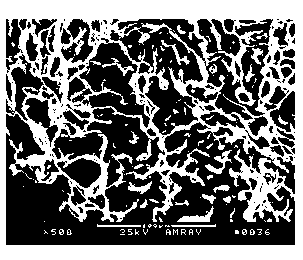

In-situ SiC-TiC particle mixing enhanced aluminum-based composite material and preparation process thereof

The invention relates to the technical field of non-continuous enhanced metal-based composite materials, and in particular relates to an in-situ SiC-TiC particle mixing enhanced aluminum-based composite material and a preparation process thereof. For overcoming the defects of high preparation cost, complicated process and poor wettability and compatibility of particles and substrates in the prior art, the invention provides the in-situ SiC-TiC particle mixing enhanced aluminum-based composite material and the preparation process thereof. The preparation process comprises the following steps: firstly, preparing in-situ reaction system press cakes: dividing the designed press cakes into inner and outer layers, wherein the mass ratio of the inner layer to the outer layer is 3:10, and then pressing by a pressure machine; then, preparing Al-4.5Cu based alloy by taking pure Al and Al-50% Cu as raw materials; and finally adding the press cakes in Al-4.5Cu melt to carry out in-situ reaction. Compared with the prior art, the preparation method disclosed by the invention has the advantages that the in-situ produced SiC particles are fine and reach micron scale.

Owner:XIAN TECH UNIV

Rapeseed pre-pressing technology

The invention discloses a rapeseed pre-pressing technology comprising processes of removing impurities and cleaning rapeseed, implementing vacuum breaking on the rapeseed, extruding and swelling, adding bran, carrying out low-temperature pre-pressing and extracting pre-pressed cakes under a nitrogen environment, and the like, thus finally obtaining pre-pressed crude oil, extracted crude oil and rapeseed dregs. The technology can be used for improving oil output and reducing oil content in the pre-pressed cakes, and avoid shortcomings that the quality of the crude oil and the cake dregs is influenced by high temperature; in addition, after the technology is adopted, energy consumption and equipment investment are reduced, and the production cost is reduced.

Owner:YOUYANG COUNTY KANGYOU GRAIN OIL

Processing method of strongly-aromatic rapeseed oil

InactiveCN106833872ALight colorImprove stabilityFatty-oils/fats refiningFatty-oils/fats productionResidual oilRapeseed

The invention discloses a processing method of strongly-aromatic rapeseed oil. The processing method comprises following steps: (1), cleaning and flaking; (2), seed stir-frying; (3), squeezing; (4), crude oil refining. According to the method, after pressed oil preparation,residual oil of press cakes and residual oil of extraction meal are both in a lower level and reach 8.2% and 0.7% respectively; after the rapeseeds are stir-fried with the method, protein in embryos of the rapeseeds can be denatured sufficiently, vitta in the rapeseed protein is sufficiently opened, plasticity is improved, so that the press cakes and follow-up extraction mealcontain less residual oil, and the pressed oil is lighter in color, has strong rapeseed oil aroma and has specific aroma and smooth taste of the strongly-aromatic rapeseed oil.

Owner:张晓娟

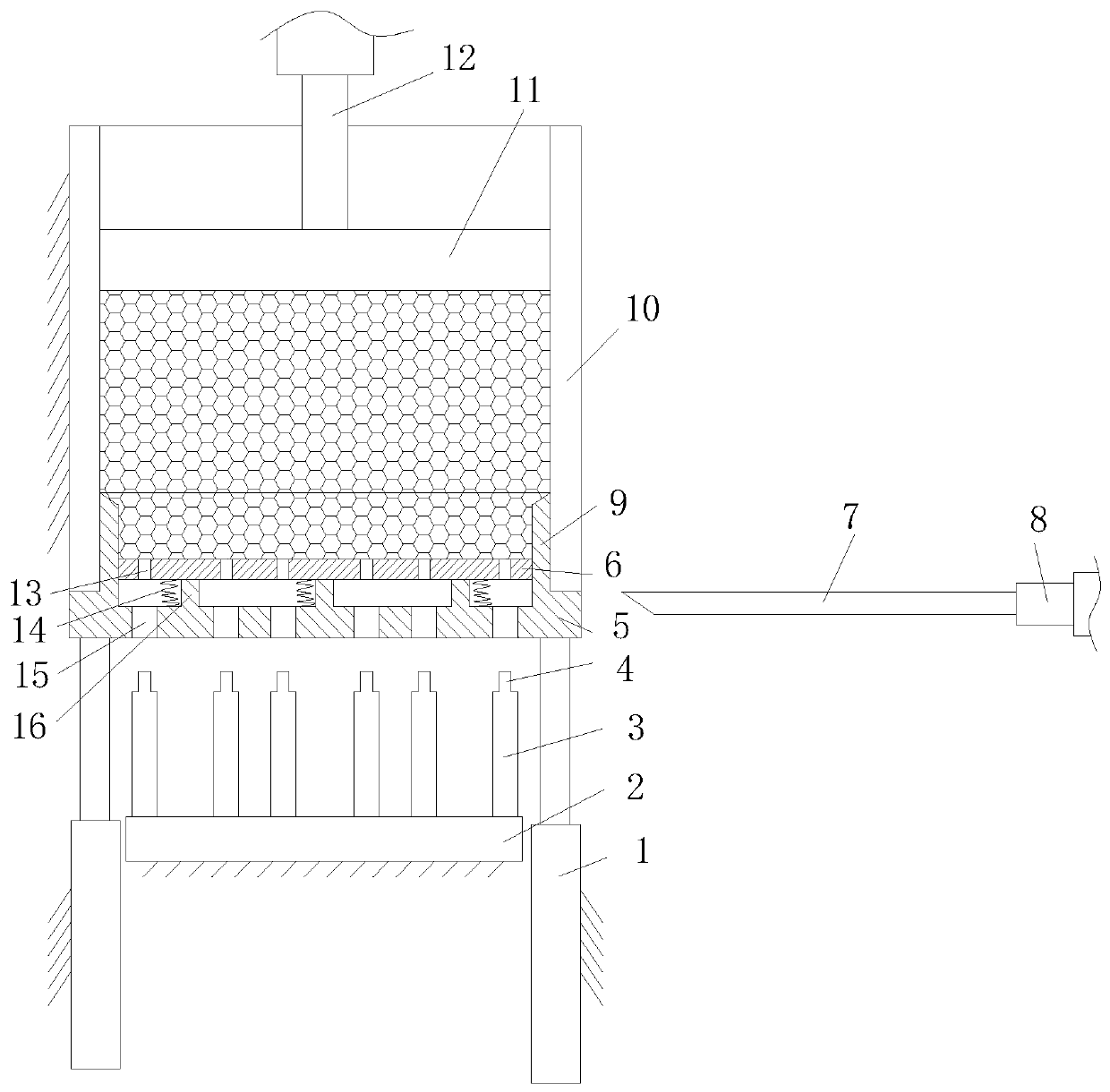

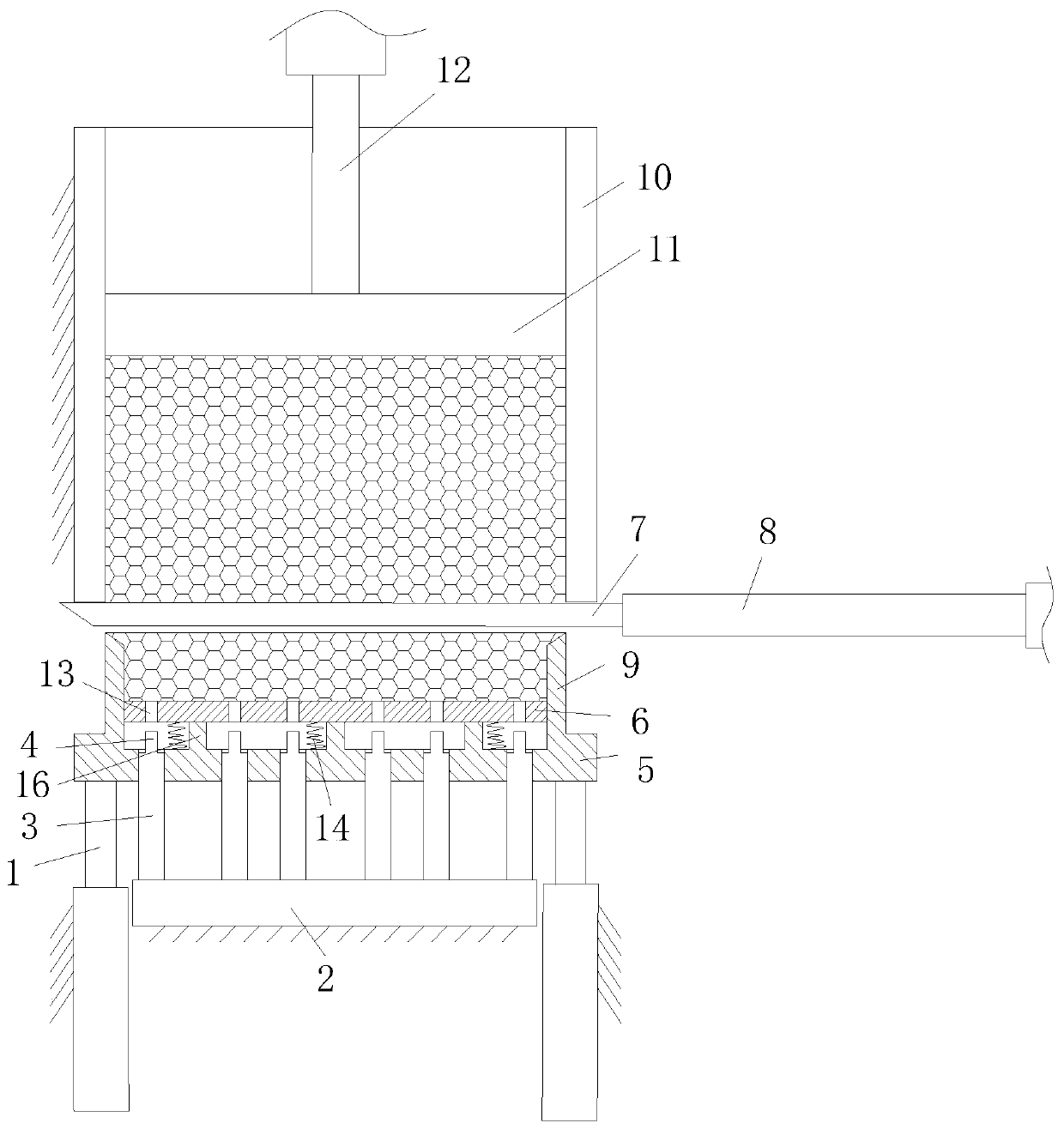

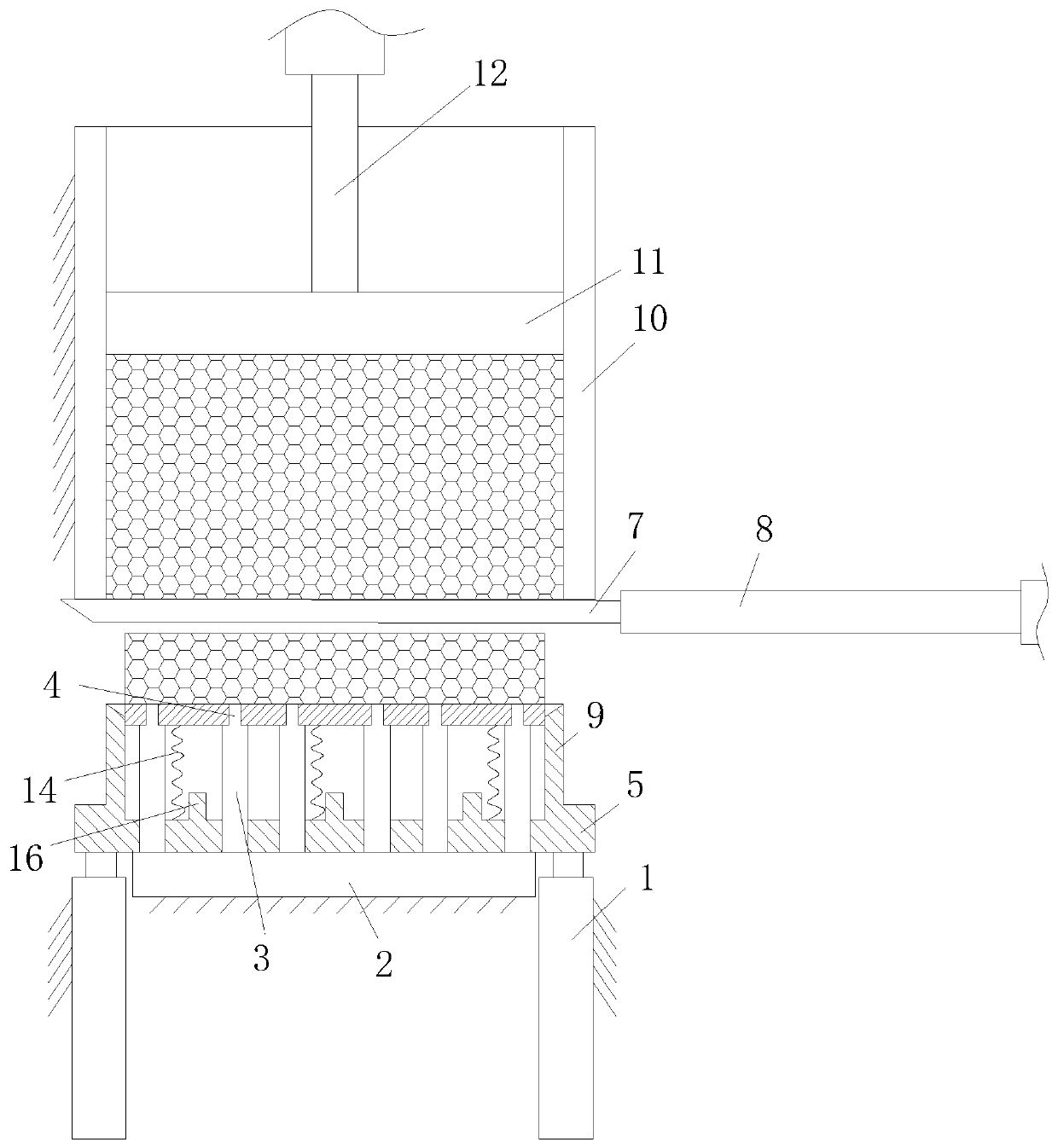

Animal oil residue cake pressing device

ActiveCN110341228AEasy to compressAvoid cloggingMetal working apparatusPressesHydraulic cylinderPulp and paper industry

The invention relates to the technical field of oil residue pressing cakes, in particular to an animal oil residue cake pressing device. The animal oil residue cake pressing device comprises a machineframe, wherein an oil residue storage box is fixedly connected to the machine frame, the two ends of the oil residue storage box communicate with each other, a pressing plate which is horizontally placed is arranged in the oil residue storage box, a third hydraulic cylinder which is vertically arranged is connected above the pressing plate, the third hydraulic cylinder is fixedly connected to themachine frame, a supporting mechanism is arranged at the bottom of the oil residue storage box, and a cutting mechanism is arranged on one side of the oil residue storage box; the cutting mechanism comprises a second hydraulic cylinder fixedly connected to the machine frame and horizontally arranged, and a horizontally-arranged cutting knife is fixedly connected to a piston rod of the second hydraulic cylinder, and the top surface of the cutting knife is tangent to the end surface of the oil residue storage box; and the supporting mechanism is arranged at the bottom of the oil residue storagebox, so that oil residues can be better compressed. Due to the ingenious and reasonable structural design, filter holes can be dredged once every time cakes are cut, the filter holes are effectivelyprevented from being blocked, and meanwhile, the oil residue cakes can be conveniently taken out, and a continuous cake making process can be completed.

Owner:ANHUI JIAYUAN GREASE

Utilization method of acid remelted iron powder

The invention relates to a utilization method of acid remelted iron powder, which sequentially comprises the following steps of: (1) mixing materials: uniformly stirring 30-50 parts by mass of acid remelted iron powder, 50-70 parts by mass of iron scales and not more than 10 parts by mass of coke powder, adding 1-15 parts by mass of water and 3-5 parts by mass of binder humic acid, and uniformly mixing; (2) pressing cakes: sending the mixed material into a cake pressing machine by using a belt, extruding into pressed cakes under the pressure of 25+ / -5 MPa, and baking or naturally airing the pressed cakes; and (3) delivering into a kiln: loading the pressed cakes in a pot, tamping the pot with coke, sealing the material pot, maintaining the temperature for 8+ / -1 h at a temperature of 1300+ / -100 DEG C, cooling for 6+ / -1 h into sponge iron, and discharging out of the kiln. The utilization method of acid remelted iron powder has the advantages of low cost and high efficiency.

Owner:SHANXI TAIGANG STAINLESS STEEL CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com