Low temperature method for cold pressing sesame oil

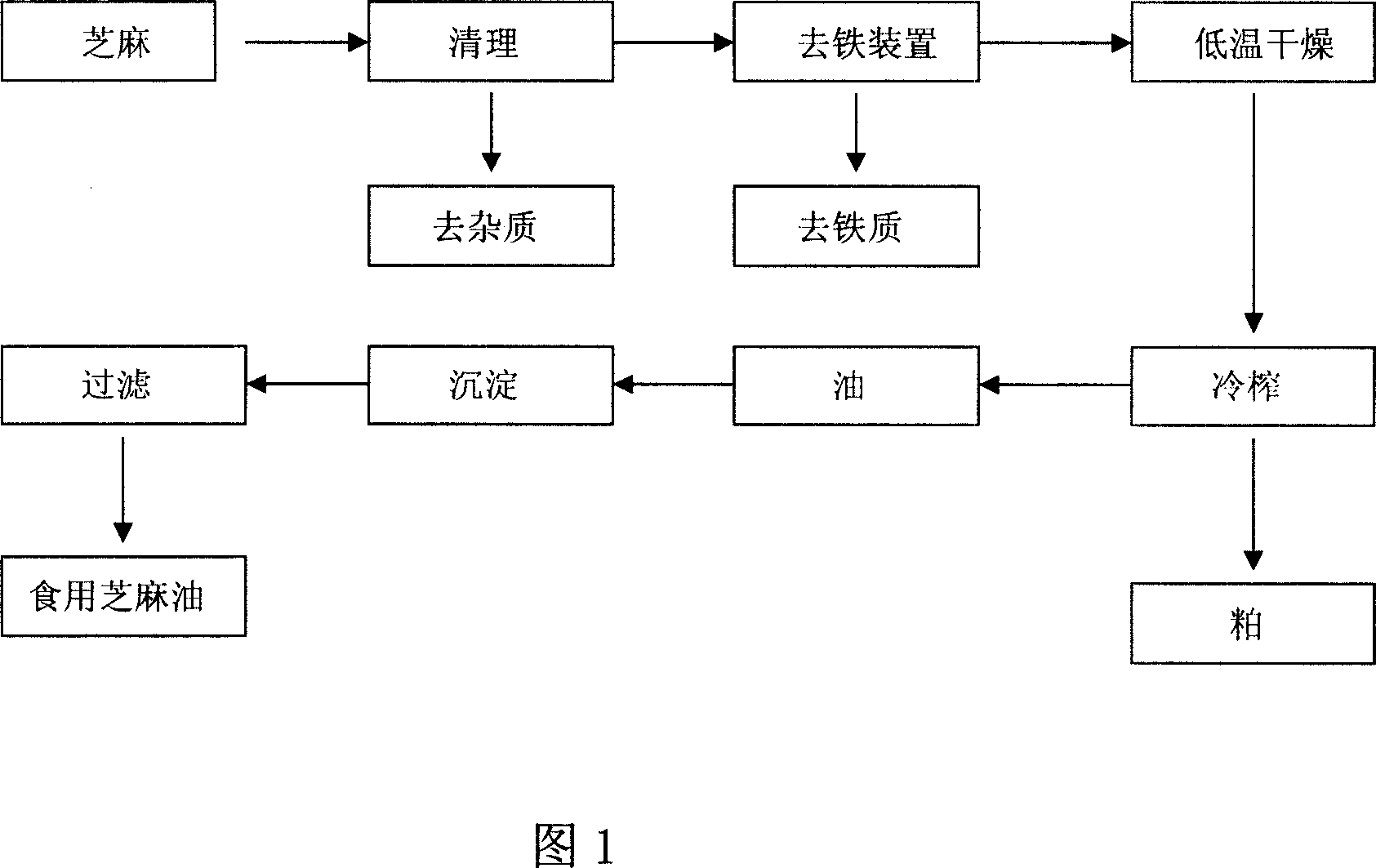

A technology of sesame oil and sesame oil, which is applied in the directions of fat oil/fat production and fat generation, can solve the problems of limited use range, dark color of sesame oil, etc., and achieves the effects of clear color, light smell and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] Appropriate amount of sesame seeds are removed through cleaning equipment to remove various impurities. After cleaning, the raw materials do not contain stones and iron substances, and the impurity content is less than 0.5%. Hot air drying, sesame temperature is 40 ℃ when drying. Water was removed from the sesame seeds to reduce the moisture content to 7% (W / W). Then enter the screw press machine to extract oil, the temperature of the sesame oil for feeding is 30°C, the screw speed is 20 rpm, and the oil outlet temperature is 45°C. The pressed oil is precipitated and finely filtered at 35°C to become pure natural edible sesame oil. The pressed cake can be further developed and utilized as food raw materials. The oil yield of this embodiment is 46.6%, the residual oil in the cake is 13.3%, and the production capacity is 5.55kg / h.

Embodiment 2

[0022] Appropriate amount of sesame seeds are removed through cleaning equipment to remove various impurities. After cleaning, the raw materials do not contain stones and iron substances, and the impurity content is less than 0.5%. Hot air drying, sesame temperature is 40 ℃ when drying. Water was removed from the sesame seeds to reduce the moisture content to 7% (W / W). Then enter the screw press machine for oil extraction, the temperature of the sesame oil fed into the feed is 35°C, the screw speed is 40 rpm, and the oil outlet temperature is 45°C. The pressed oil is precipitated and finely filtered at 30°C to become pure natural edible sesame oil. The pressed cake can be further developed and utilized as food raw materials. The oil yield of this embodiment is 43.0%, the residual oil in the cake is 16.1%, and the production capacity is 7.36kg / h.

Embodiment 3

[0024] Appropriate amount of sesame seeds are removed through cleaning equipment to remove various impurities. After cleaning, the raw materials do not contain stones and iron substances, and the impurity content is less than 0.5%. Hot air drying, sesame temperature is 40 ℃ when drying. Water was removed from the sesame seeds to reduce the moisture content to 8% (W / W). Then enter the screw press machine for oil extraction, the temperature of the sesame oil fed into the feed is 10°C, the screw speed is 20 revs / min, and the oil outlet temperature is 40°C. The pressed oil is precipitated and finely filtered at 10°C to obtain pure natural edible sesame oil. The pressed cake can be further developed and utilized as food raw materials. The oil yield of this embodiment is 40.5%, the residual oil in the cake is 21.1%, and the production capacity is 5.45kg / h.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com