Patents

Literature

115results about How to "Light smell" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Odorless ultraviolet-curing wood lacquer and preparation method thereof

ActiveCN102352173AEnvironmental protection is goodReduce heavy metal contentEpoxy resin coatingsPolyesterBenzene

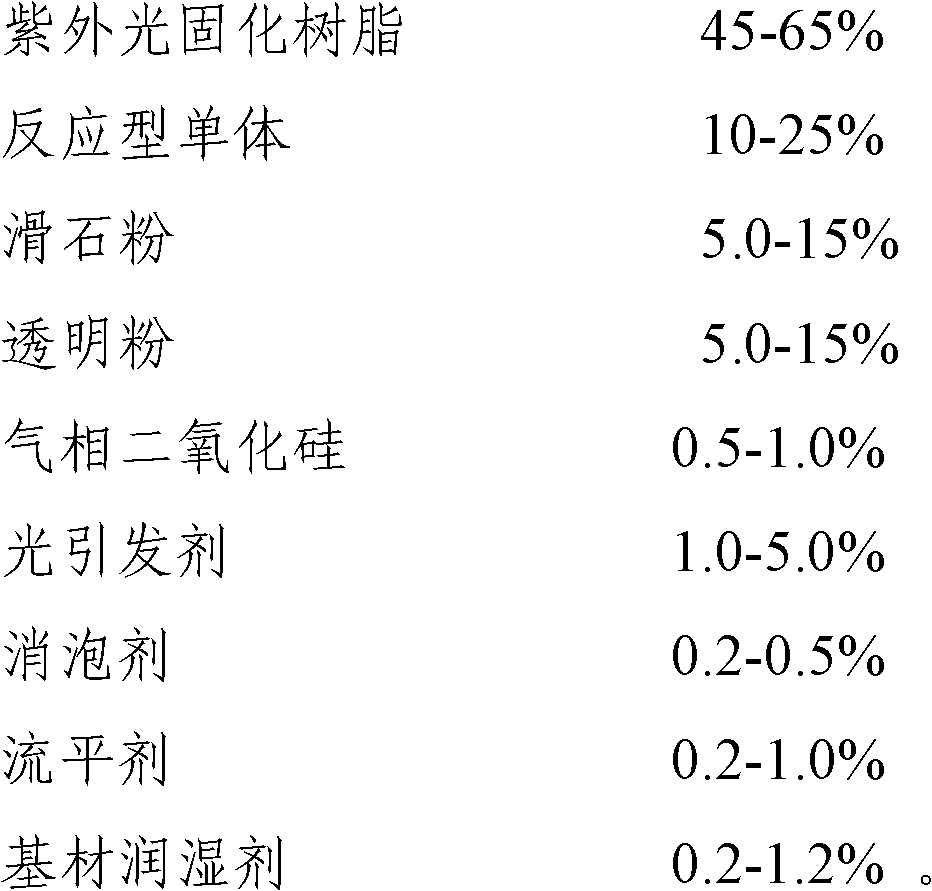

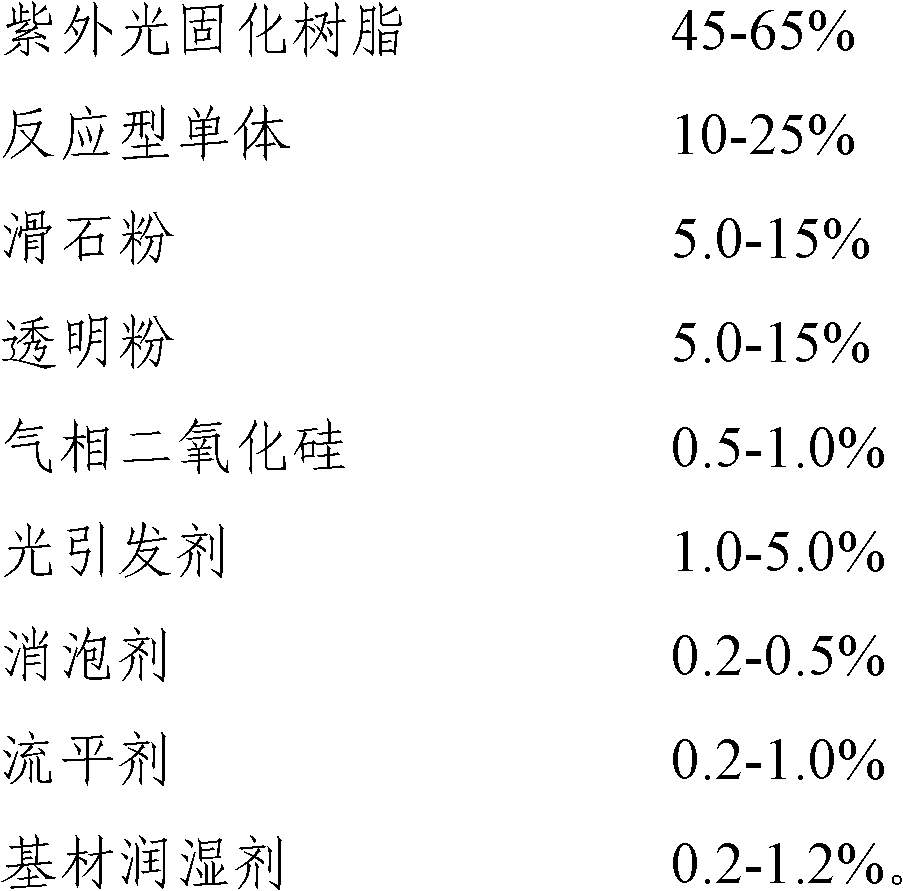

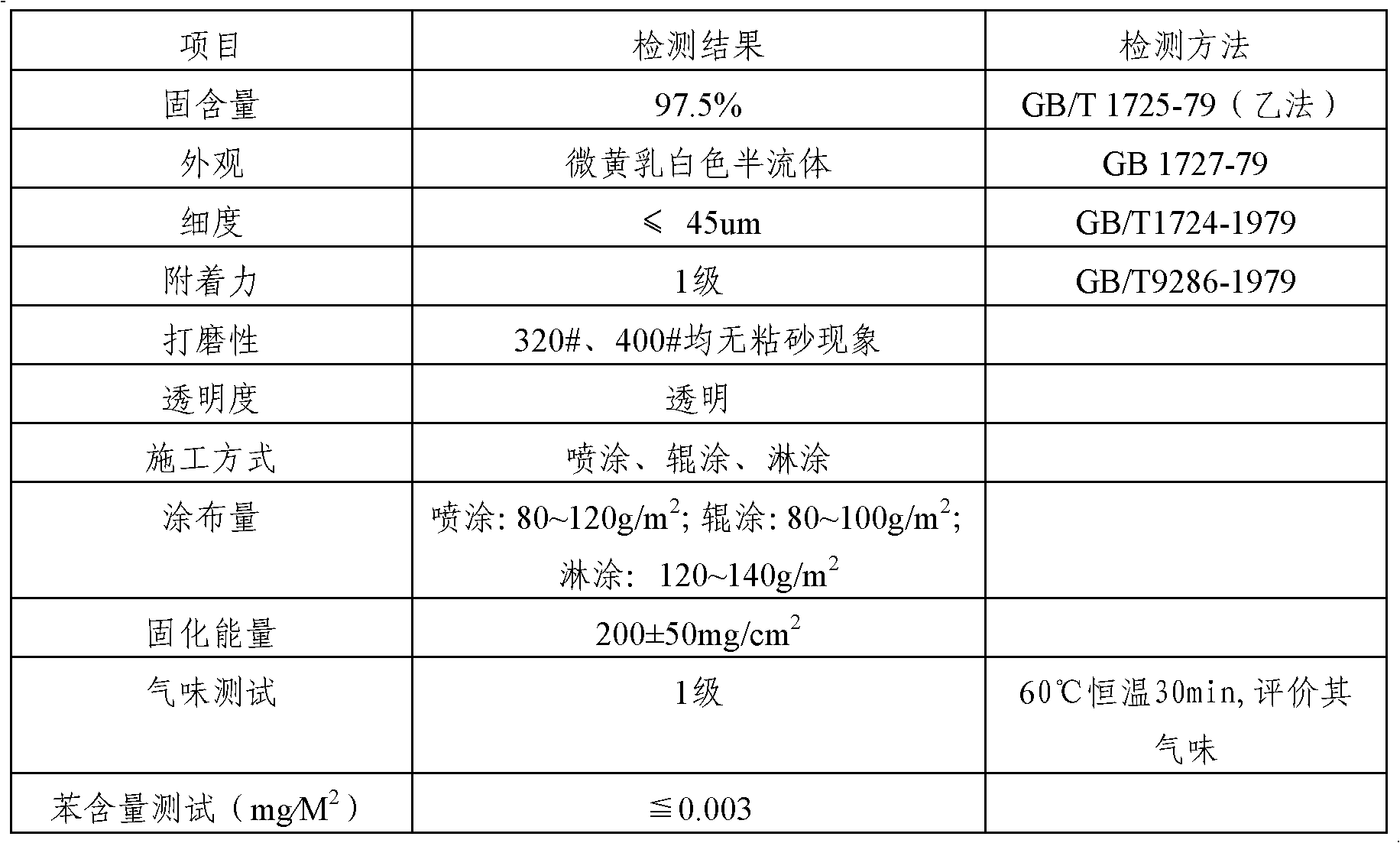

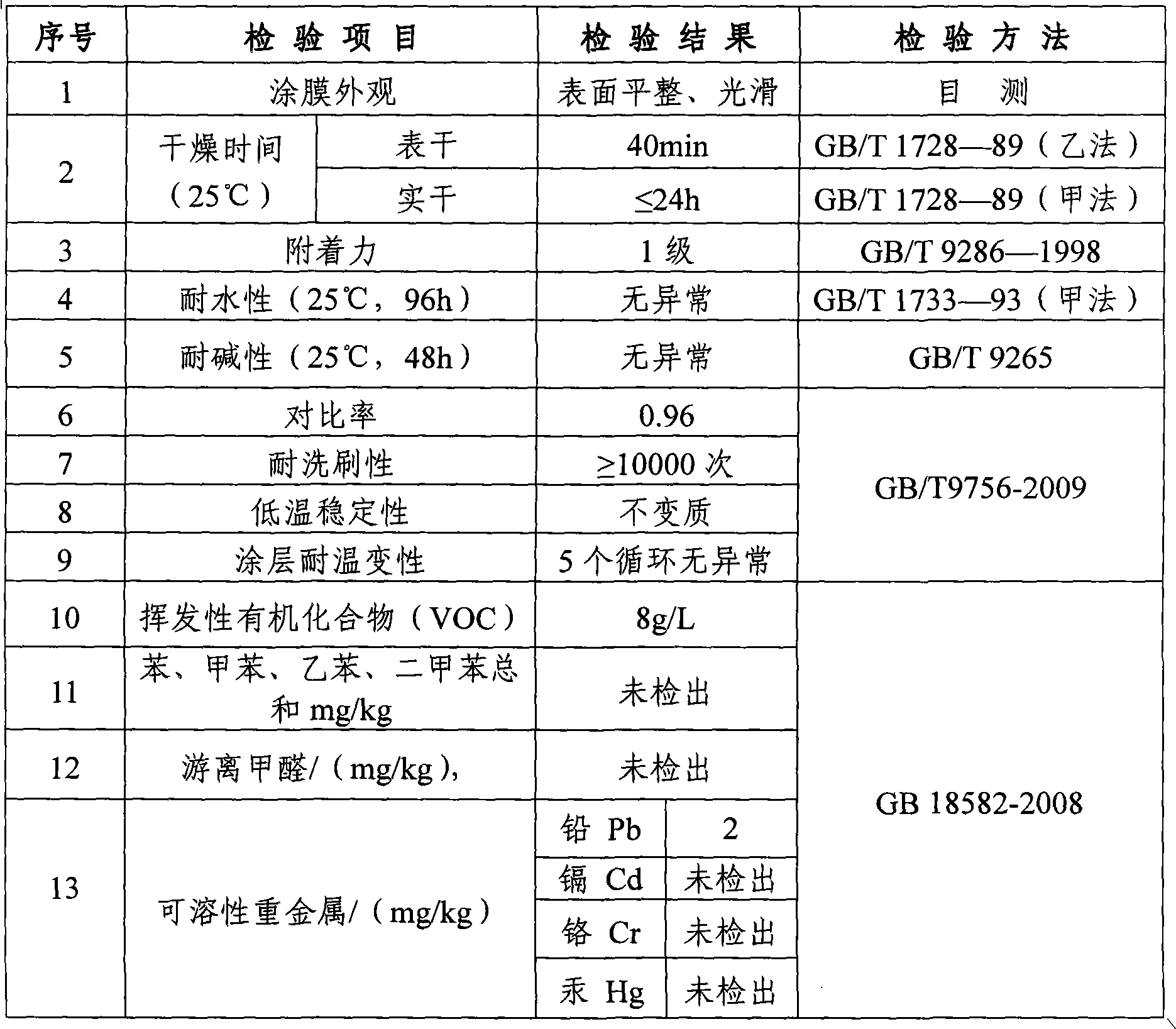

The invention relates to an odorless ultraviolet-curing wood lacquer and a preparation method thereof. The wood lacquer is prepared from the following components in percentage by weight: 45-65% of ultraviolet-curing resin, 10-25% of reactive monomer, 5.0-15% of talcum powder, 5.0-15% of transparent powder, 0.5-1.0% of gas-phase silicon dioxide, 1.0-5.0% of photoinitiator, 0.2-0.5% of defoaming agent, 0.2-1.0% of leveling agent and 0.2-1.2% of wetting agent. The odorless ultraviolet-curing wood lacquer does not have irritating odor before and after construction, does not contain benzene, and can be used immediately after construction; and meanwhile, the surface effect and fullness are not inferior to those of nitrocellulose dope, unsaturated paint or polyester paint.

Owner:QINGDAO ZHANCHEN NEW MATERIAL

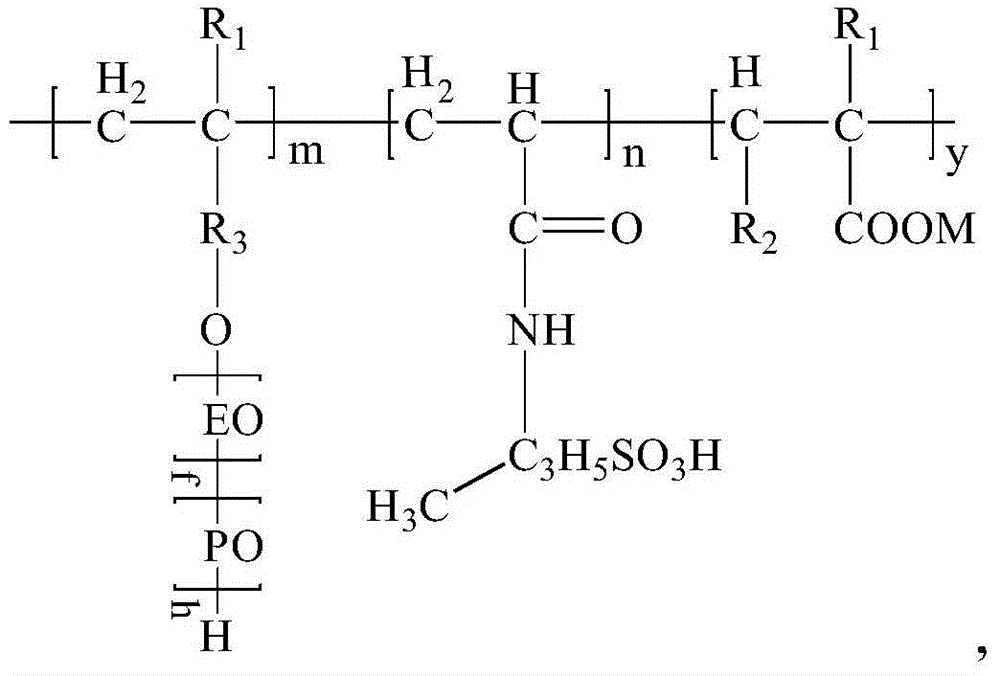

Bamboo charcoal odor-cleaning and formaldehyde-removing emulsion paint and preparation method thereof

ActiveCN102086325AReduce harmImprove freeze-thaw resistanceEmulsion paintsHazardous substanceMicrosphere

The invention provides a bamboo charcoal odor-cleaning and formaldehyde-removing emulsion paint. The emulsion paint comprises the following components in parts by weight: 100-400 parts of waterborne resin, 1-5 parts of defoaming agent, 1-5 parts of preservative, 1-10 parts of dispersant, 100-300 parts of pigment, 100-400 parts of filler, 1-10 parts of nanometer thickener, 1-10 parts of flatting agent, 5-20 parts of nanometer inorganic anionic formaldehyde-removing additive, 40-100 parts of nanometer polymer hollow microspheres, 10-20 parts of bamboo vinegar and 0-350 parts of water. The bamboo charcoal odor-cleaning and formaldehyde-removing emulsion paint can be coated on the wall and wood; the paint film is characterized by light odor, low volatile organic compound (VOC), good hiding power and adhesion, washing and wiping resistance and the like; the harmful substances such as formaldehyde and benzene can be removed; the cost is low, the construction property is good, the environmental friend is good; and the emulsion paint is a product which combines decorative function, functionality and environmental friend together perfectly.

Owner:濮阳展辰新材料有限公司

High-efficiency decontamination laundry detergent

InactiveCN104479893ANot dimWon't turn yellowInorganic/elemental detergent compounding agentsNon-ionic surface-active compoundsPreservativeWhitening Agents

The invention relates to a laundry detergent, and particularly relates to a high-efficiency decontamination laundry detergent. The high-efficiency decontamination laundry detergent comprises the following components in percentage by weight: 15%-20% of surface active agents, 2%-5% of acidic auxiliary agents, 0.2%-0.6% of flake caustic soda, 0.3%-0.5% of sterilizing agents, 0.3%-0.5% of chelating agents, 0.4%-0.6% of fluorescent whitening agents, 0.2%-0.4% of preservative agents, 1%-2% of thickening agents, 1%-2% of anti-redeposition agents, 0.2%-0.4% of rosemary essential oil, 0.5%-1% of perfume fixatives, 2%-4% of tea saponins and the balance of deionized water. The laundry detergent disclosed by the invention is mild in smell, capable of removing multiple stubborn stains and high in decontamination capacity; in addition, a fabric can not be darkened and yellowed after being washed by using the laundry detergent.

Owner:QINGDAO HOUKE INFORMATION ENG

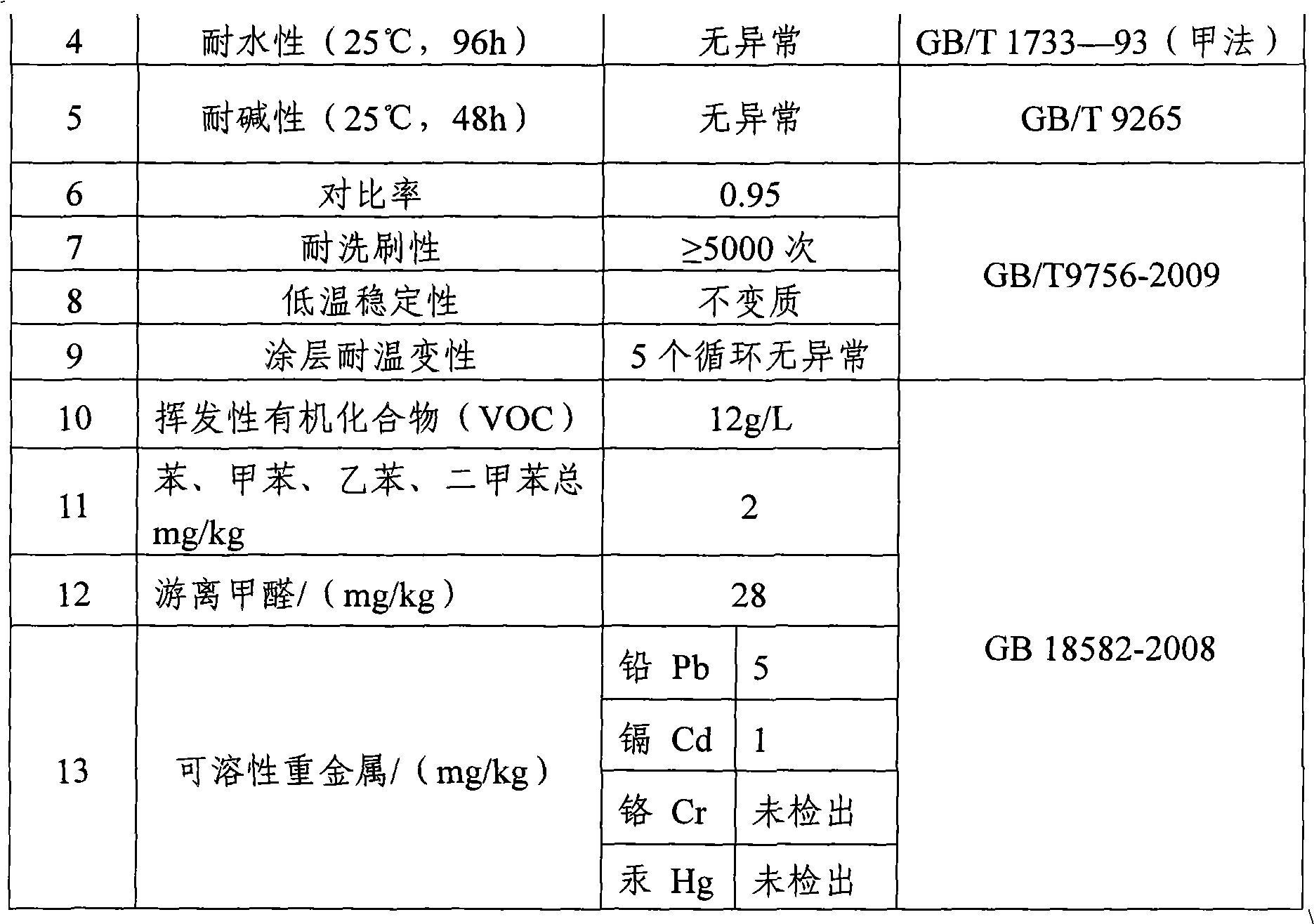

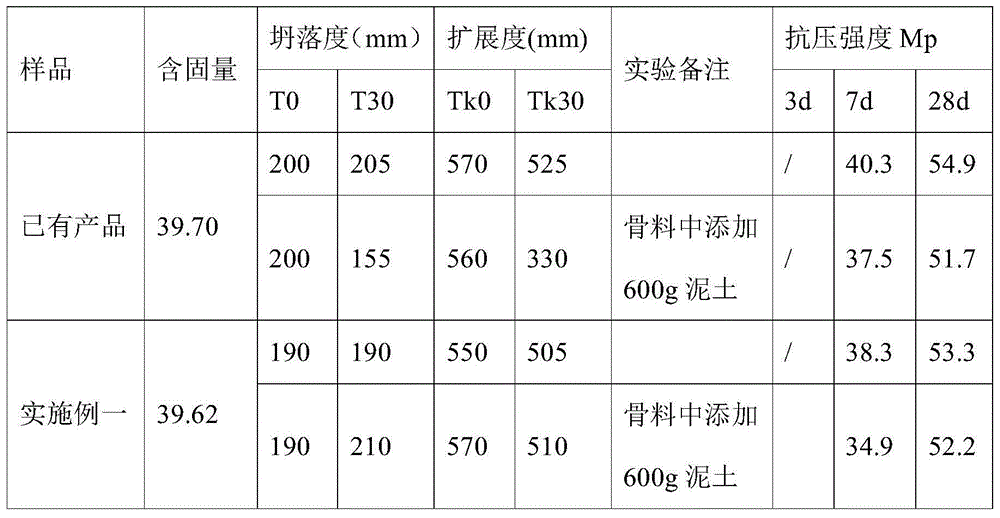

Polycarboxylate superplasticizer with mud preventing effect and preparation method of polycarboxylate superplasticizer

ActiveCN104530324AImprove performanceHigh initial water reduction effectSuperplasticizerWater reducer

The invention discloses a polycarboxylate superplasticizer with a mud preventing effect. The structural general formula of the polycarboxylate superplasticizer is as shown in the description, wherein R1 is H or CH3, R2 is H or COOM, R3 is an alkyl of C1 to C3, and M is H, Na, K or NH4. The invention also provides a preparation method of the polycarboxylate superplasticizer with the mud preventing effect. The superplasticizer synthesized by use of the process is applied to concrete within the aggregate mud content range of 0-8%, and a good application effect can be obtained through direct use without physical compounding.

Owner:SHAANXI KZJ NEW MATERIALS

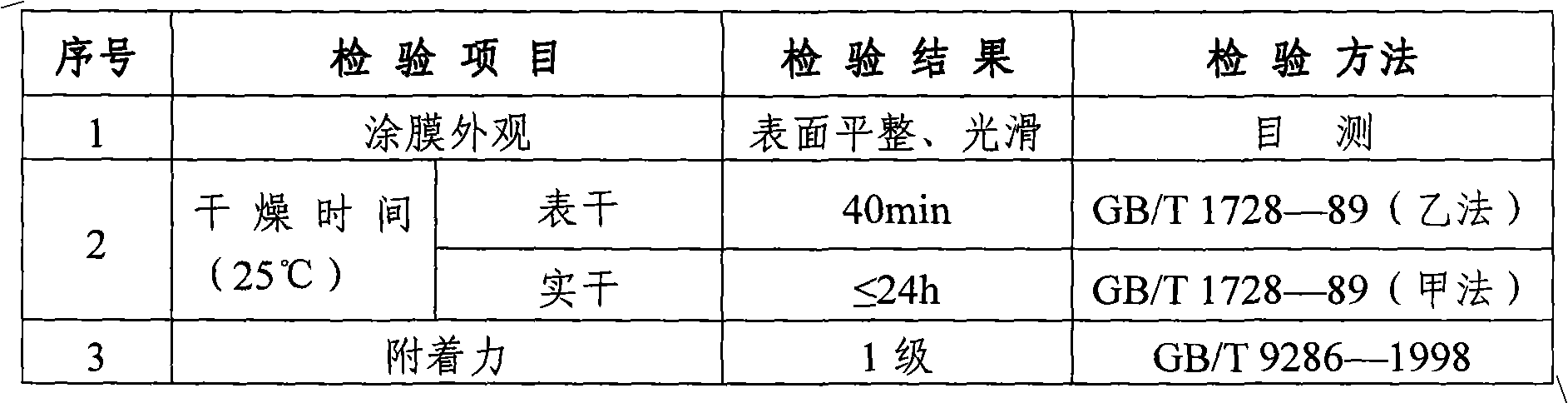

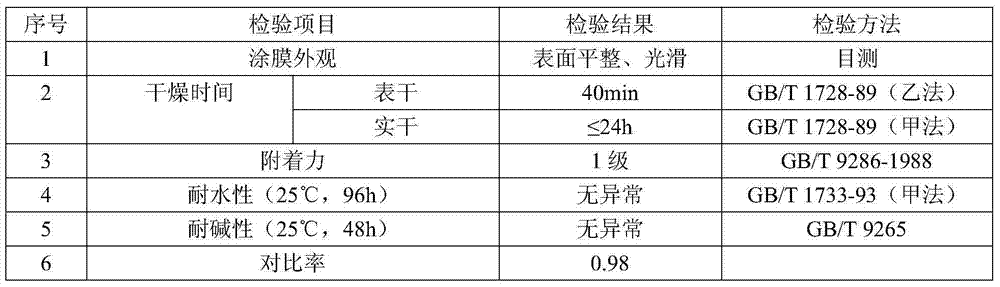

Environment-friendly latex paint and preparation method thereof

InactiveCN108329765AStrong adhesionLight smellAntifouling/underwater paintsPaints with biocidesFiberWeather resistance

The invention discloses an environment-friendly latex paint and a preparation method thereof, and relates to the technical field of latex paint. The latex paint is prepared from the following raw materials in parts by weight: 85-105 parts of styrene-acrylic emulsion, 35-45 parts of nano-silica sol, 20-25 parts of diatom ooze, 10-15 parts of nano-TiO2, 10-15 parts of tourmaline anion powder, 10-15parts of glutinous rice glue, 7-8 parts of plant dehydrated filaments, 7-8 parts of antibacterial powder, 4-6 parts of active powder, 4-6 parts of essential oil components, 20-22 parts of an aid and 70-75 parts of deionized water. The latex paint has relatively powerful adhesive force, a paint film has light smell, low VOC and high adhesive force and is combined with the wall stably, peeling and bursting of the paint surface are not easily produced, and weather resistance of the latex paint is greatly improved.

Owner:HEFEI FANTENG ENVIRONMENTAL PROTECTION TECH CO LTD

Edible mixed oil for increasing intelligence

The invention provides intelligence-enhancing edible blend oil, relates to the edible blend oil, and solves the problems that the prior edible oil does not contain omega-3 unsaturated fatty acid, and intake shortage of the omega-3 unsaturated fatty acid in a human body is caused by only eating the prior edible oil, and the problems of heavy smell, poor mouthfeel and low absorption rate of flaxseed oil. The edible blend oil consists of edible flaxseed oil, edible sesame oil, edible walnut oil, edible sunflower oil and edible perilla oil. The edible blend oil has the advantages of light smell, good mouthfeel, low viscosity and easy absorption, contains the omega-3 unsaturated fatty acid accounting for 30 to 42 percent of total content of fatty acid, has high content of the omega-3 unsaturated fatty acid, can improve the intake of the omega-3 unsaturated fatty acid in the human body through eating the blend oil so as to supply cerebral nutrients, improve intelligence and protect eyesight.

Owner:韩福臻

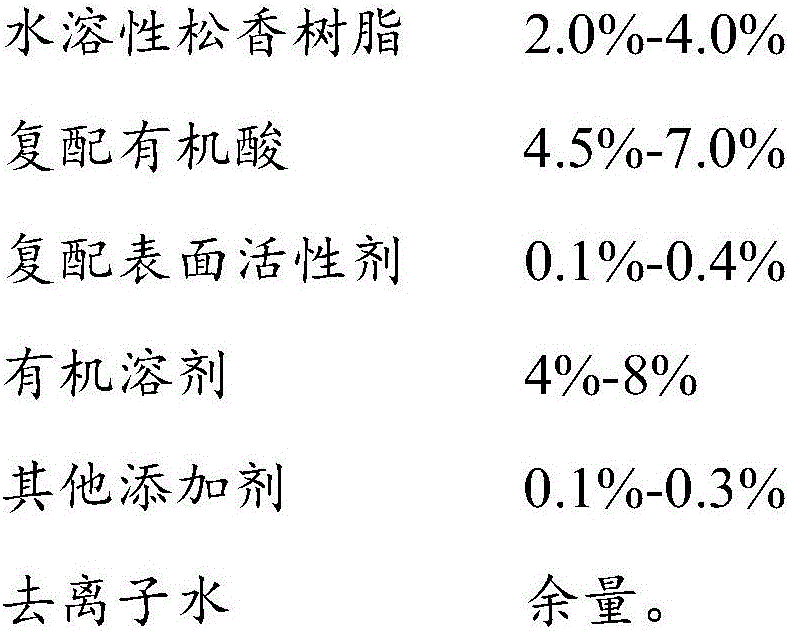

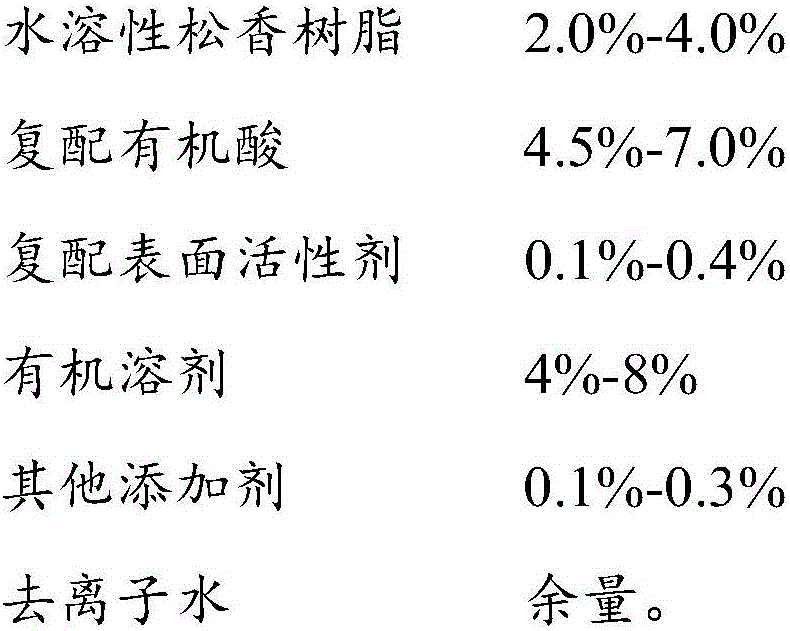

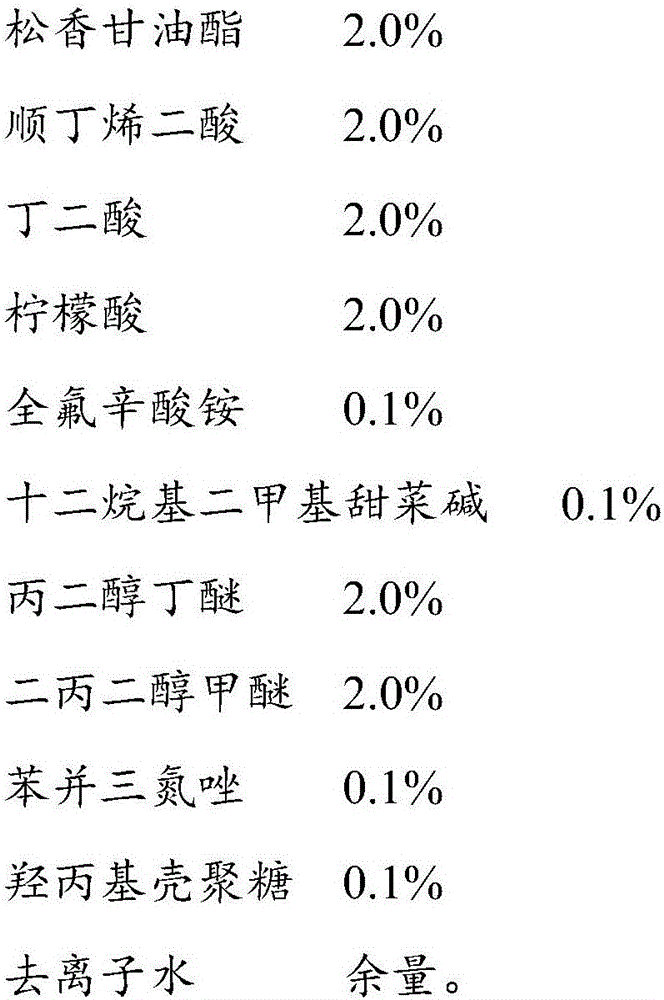

Water-base scaling powder and preparation method and application thereof

ActiveCN106493487AGood weldabilityExcellent tin penetration performanceWelding/cutting media/materialsSoldering mediaWater basedTin

The invention discloses water-base scaling powder and a preparation method and application thereof. The water-base scaling powder is prepared from, by mass, 2.0-4.% of water-soluble rosin resin, 4.5-7.0% of formulated organic acid, 0.1-0.4% of formulated surfactant, 4-8% of organic solvent, 0.1-0.3% of other additives and the balance deionized water. On one hand, the water-base scaling powder is completely suitable for a wave-soldering welding technology, and has the advantages that the weldability is high, the tin penetration property is excellent, postwelding residues are few on the plate surface, the surface insulation resistance is extremely high and the water-base scaling powder is easy to clean; on the other hand, the water-base scaling powder is mild in smell, and in the welding process, the scaling powder is low in smog, high in wettability, free of flashing point and safe to use, and the affinity of the scaling powder is good for water. The preparation method is environmentally friendly and safe, harmless to human body and free of flashing point, the technological conditions are easy to control, and the properties of the prepared water-base scaling powder are stable.

Owner:SHENZHEN UNIBRIGHT TECH

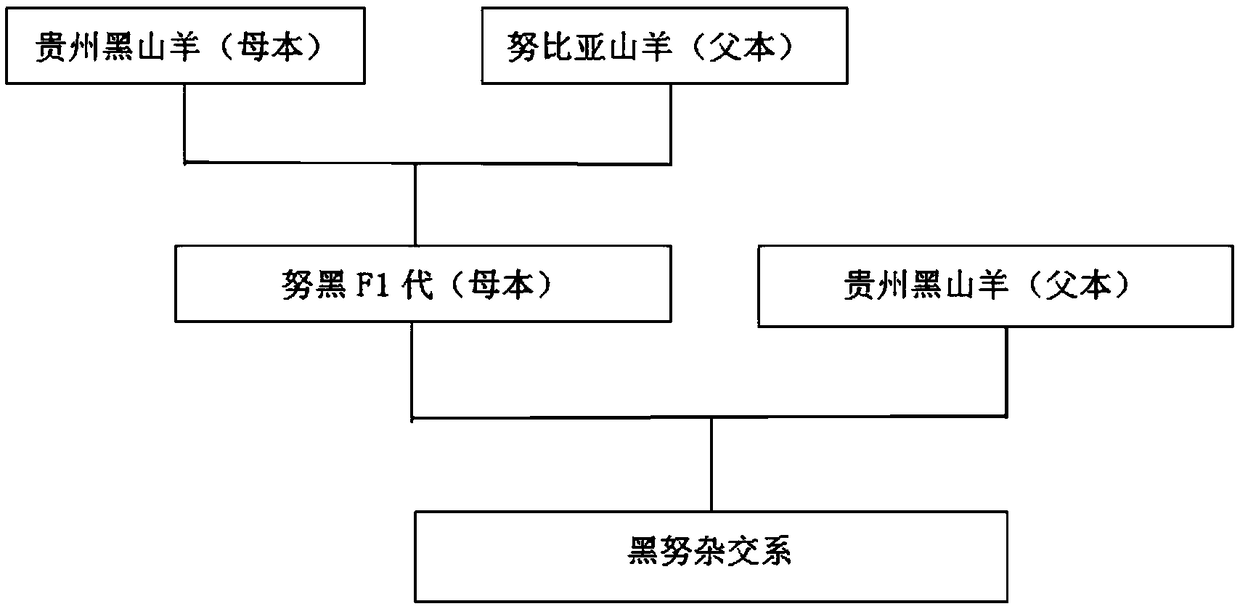

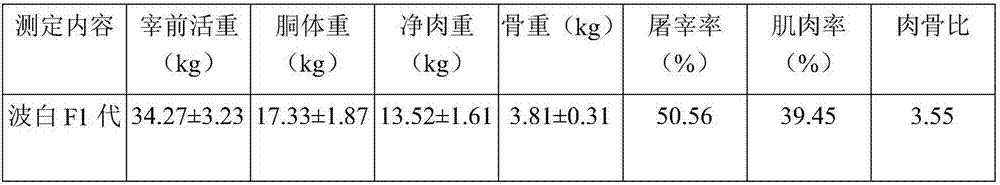

Method for cultivating hybrid new line of Guizhou black goat and Nubian goat

InactiveCN109496983AImprove reproductive performanceImprove reproductive abilityAnimal husbandryF1 generationBiology

The invention discloses a method for cultivating a hybrid new line of Guizhou black goat and Nubian goat. An offspring with high meat yield, high fecundity and fast growth rate is obtained through hybridization breeding of Guizhou black goat and Nubian goat, and the offspring with fast growth rate, high fecundity and high meat yield can be obtained by hybridization of the Guizhou black goat and the Nuhei F1 generation; then the Nuhei hybrid sheep is obtained by hybridization of a Guizhou black goat ram and the F1 generation; and finally, the Heinu hybrid sheep is subjected to transverse fixation of three generations, and the hybrid line sheep with high fecundity and fast growth can be obtained. The sheep retains the specific advantages of the Guizhou black goat, such as high reproductive rate, light mutton taste, delicious meat and good quality of skin, and inherits the advantages of the Nubian goat, such as tall property, fast growth rate and strong fecundity.

Owner:GUIZHOU UNIV

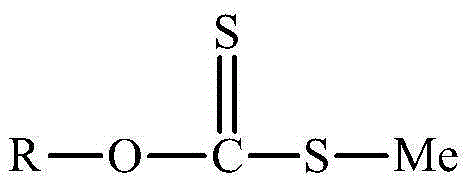

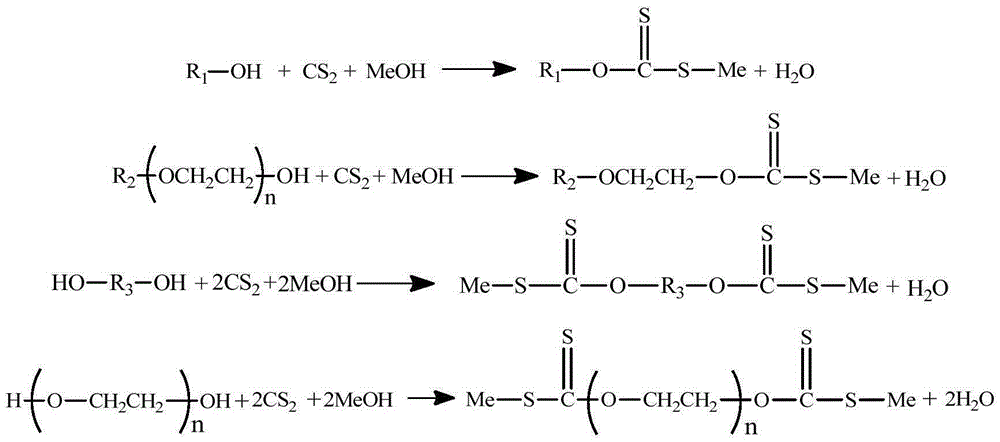

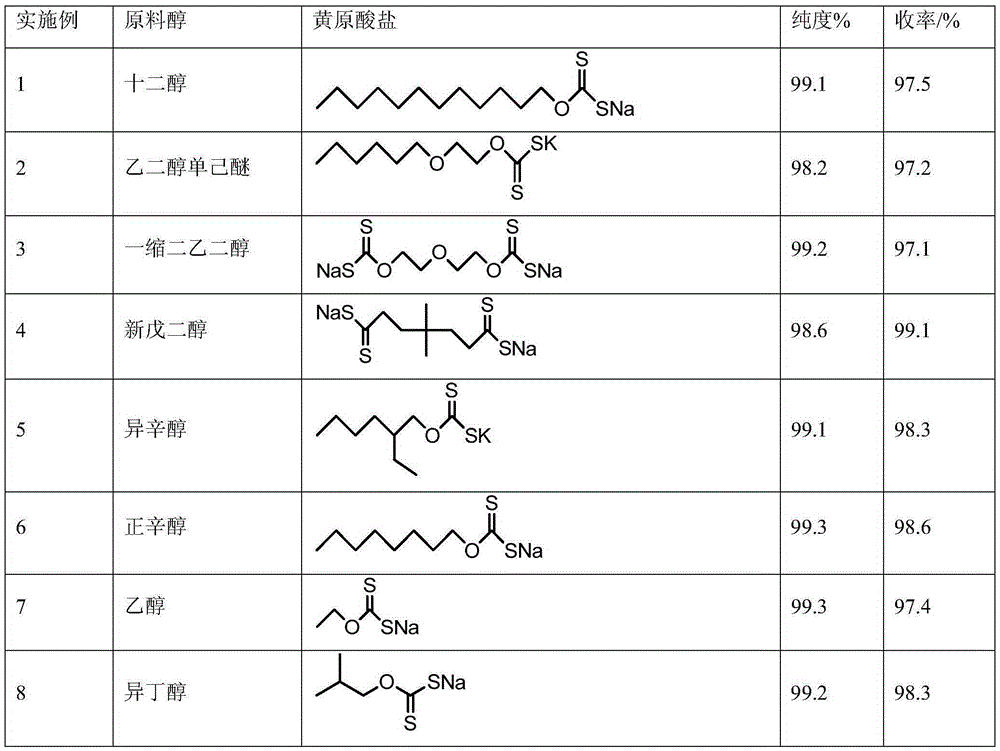

Preparation method of xanthate

The invention discloses a preparation method of xanthate. According to the preparation method, tetrahydrofuran is taken as the reaction medium, monohydric alcohol or dihydric alcohol and caustic alkali carry out reactions at a temperature of 0 to 30 DEG C, finally desolvation is performed to obtain high purity xanthate, and the yield is high. The obtained xanthate has the advantages of little odor, higher purity, and higher yield, and is especially suitable for being used to prepare high grade xanthate with a carbon chain having a carbon number of 6 or more, ethyl xanthate, and dixanthate.

Owner:CENT SOUTH UNIV

Low-viscosity modified polyester acrylate and preparation method thereof

The invention provides a preparation method of low-viscosity modified polyester acrylate. The preparation method comprises the following steps: 1) dissolving polybasic acid, polyol, a catalyst and anantioxidant into a solvent of a reaction kettle, and leading nitrogen for protection, heating to 135-145DEG C, and insulating until the acid value is close to 5mgKOH / g; 2) cooling the reaction kettleto 75-85DEG C, adding acrylic acid and a polymerization inhibitor into the reaction kettle, then heating to 120-125DEG C, and further reacting in the reaction kettle until the acid value is less than10mgKOH / g; and 3) vacuumizing the reaction kettle, removing reflux solvent, cooling to 75-85DEG C and discharging after the solvent is removed cleanly to obtain polyester acrylate. The invention further provides a low-viscosity modified polyester acrylate production prepared by using the preparation method. The polyester acrylate is low in viscosity, not only can be used as an oligomer, but also can be used as an activity dilution monomer, and in addition, the polyester acrylate is light in odor and small in stimulation, thus having small damage to a human body.

Owner:广州五行材料科技有限公司

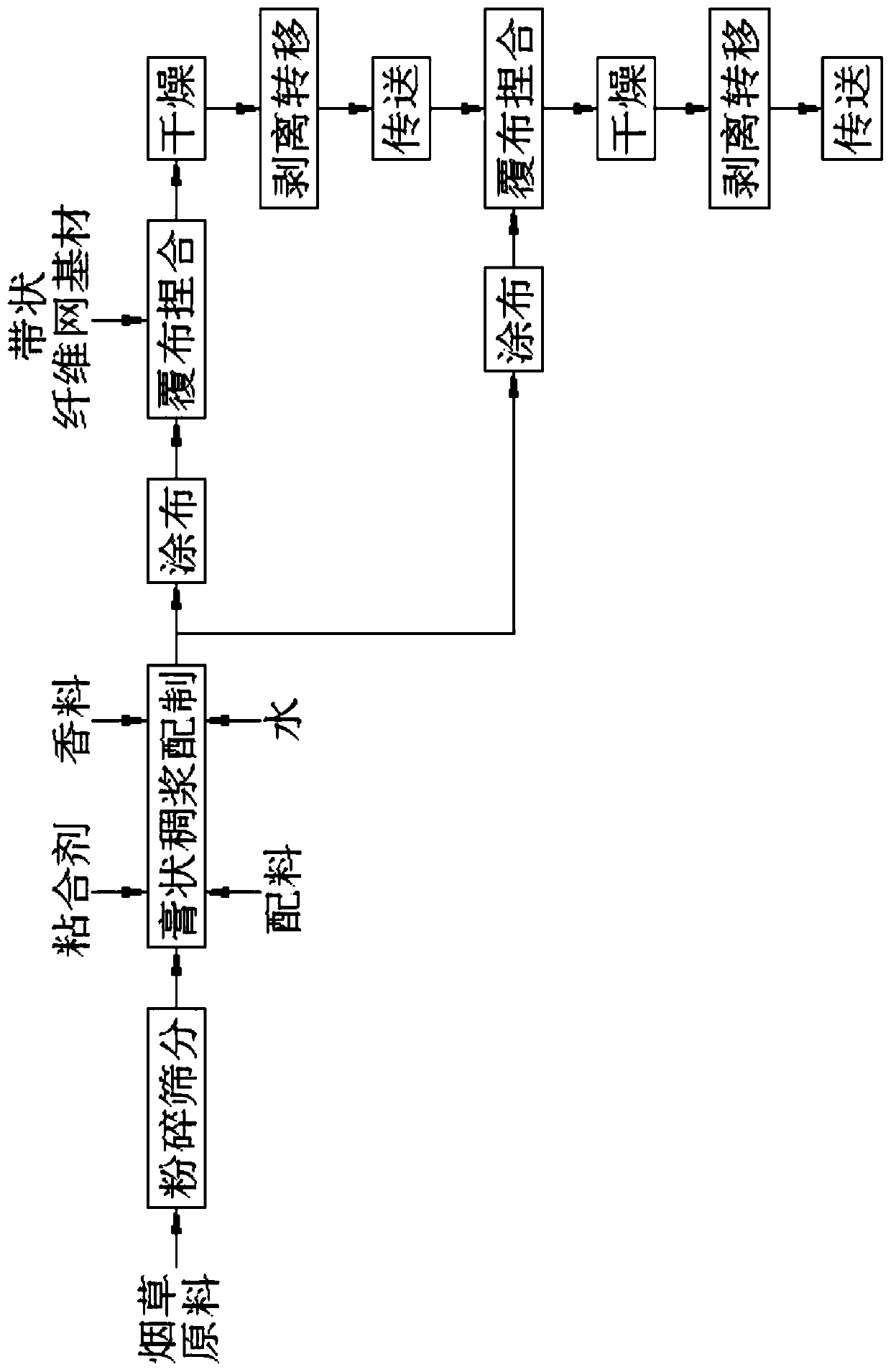

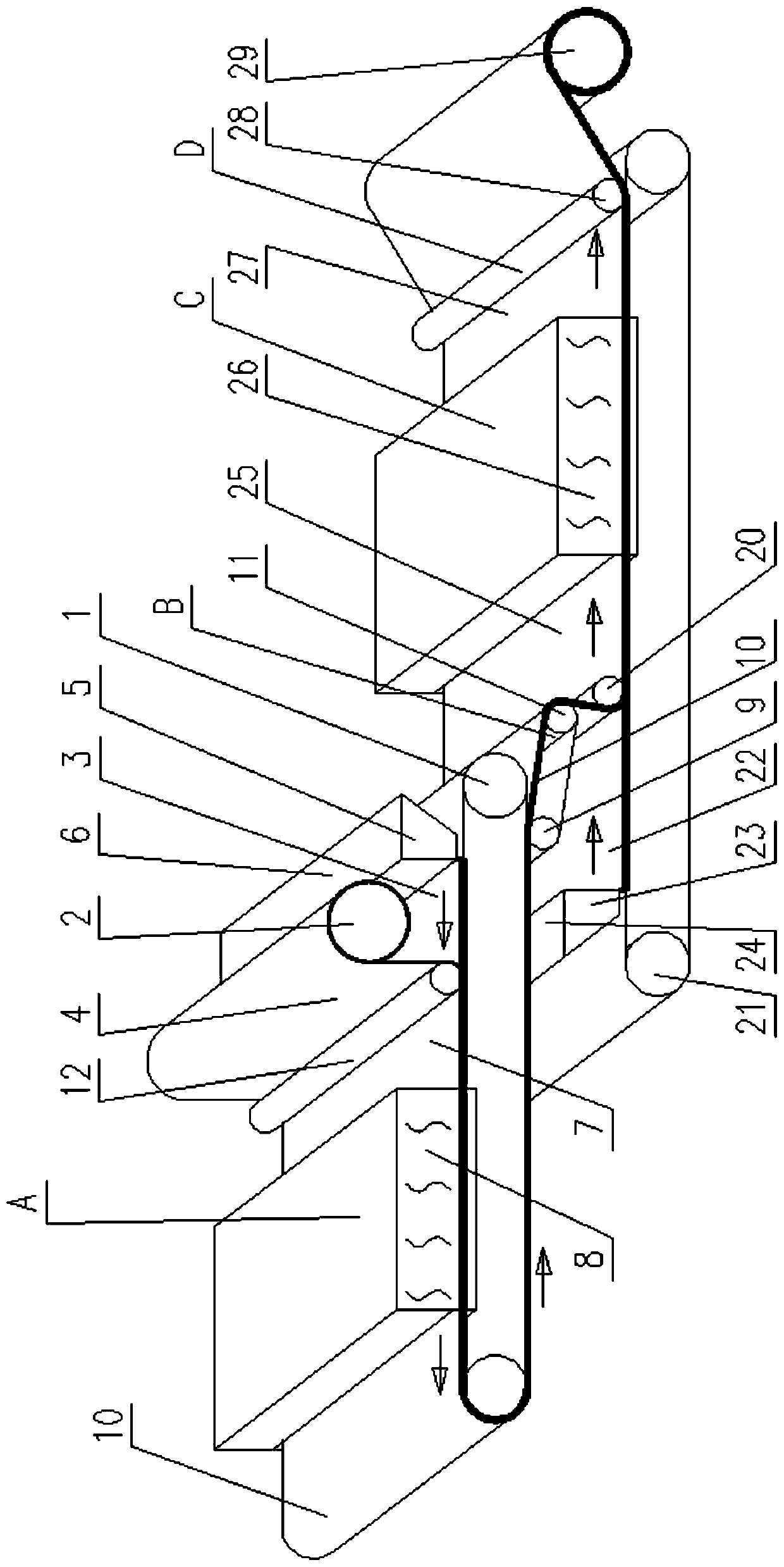

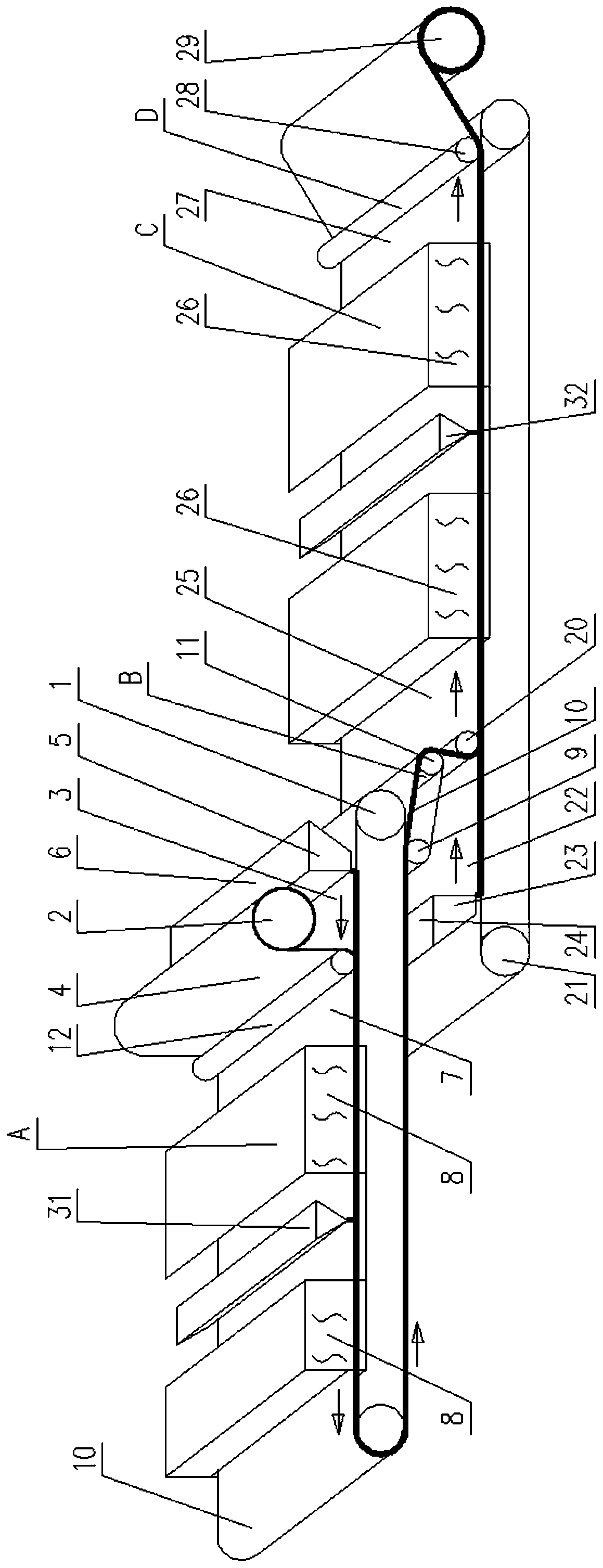

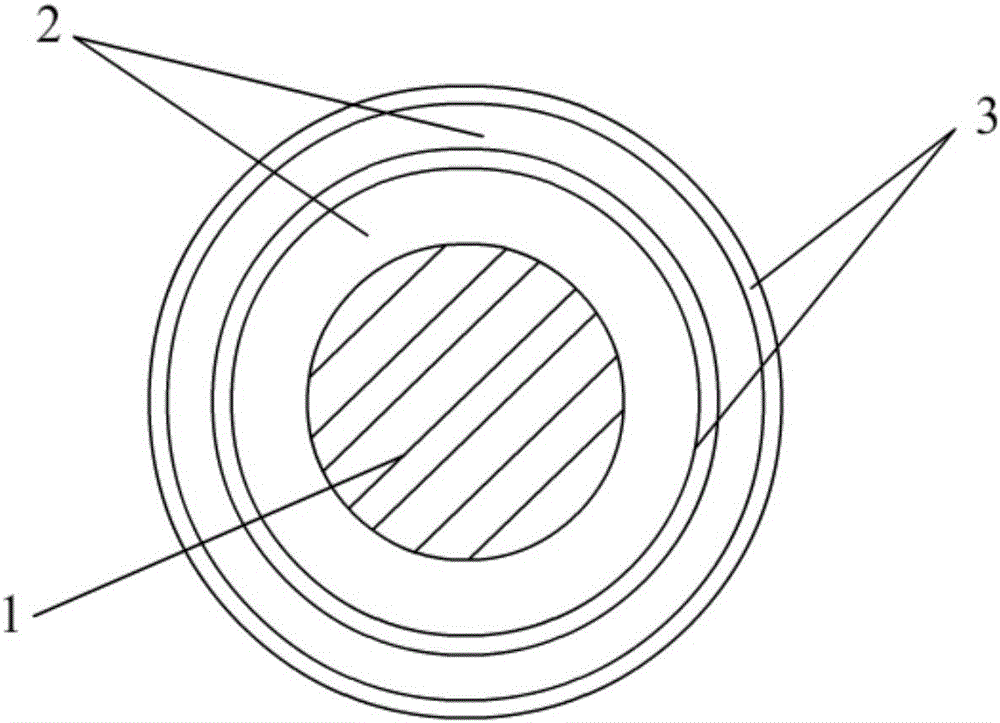

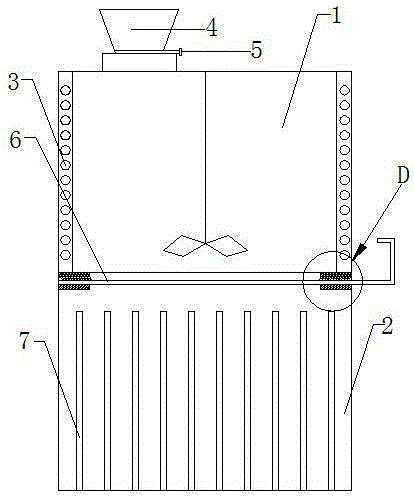

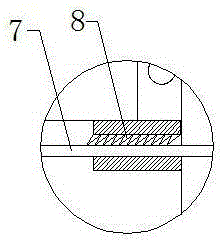

Forming method and forming equipment for ternary composite reconstituted tobacco sheets

PendingCN111134352AReduces the effects of odor inhalationImprove physical strengthTobacco preparationTobacco treatmentFiberPowder mixture

The invention relates to a forming method and forming equipment for ternary composite reconstituted tobacco sheets. The equipment comprises a primary coating composite device, a primary stripping conveying device, a secondary coating composite device and a secondary stripping conveying device. The method comprises the following steps of: coating a tobacco mixture on a first conveying surface in acoating and compounding manner to form a strip-shaped slurry sheet, and coating a fiber net-shaped base material on the surface of the strip-shaped slurry sheet under the condition of smaller tensionto form a strip-shaped binary compound reconstituted tobacco sheet, coating the secondary conveying surface with the tobacco mixture, and coating the surface of the strip-shaped slurry sheet with thestrip-shaped binary composite reconstituted tobacco sheet under the condition of small tension to form the ternary composite reconstituted tobacco sheet. The middle layer of the produced reconstitutedtobacco sheet is a prefabricated strip-shaped fiber net base material, the upper layer and the lower layer are tobacco powder mixtures, the coating rate can be increased, the cigarette smell can be improved, the consistency of finished products can be improved, the tensile strength can be improved, the thickness can be reduced, and the processability can be enhanced.

Owner:YUNNAN KUNCHUAN TOBACCO EQUIP CO LTD

Synthetic method for sorbitan octoate emulsifier

ActiveCN106588830AHigh selectivityHigh purityOrganic chemistryTransportation and packagingHydroxyl valueSaponification value

The invention discloses a synthetic method for a sorbitan octoate emulsifier. The synthetic method is characterized by being prepared from commercially available D-sorbitol, caprylic acid, a metal tin catalyst, a basic catalyst and a granular magnesium silicate adsorbent, which serve as raw materials, through processes of etherification, etherate refinement, esterification, deacidification, ester refinement and the like. According to the method, the metal tin catalyst is rationally selected and used; a product in the etherification process is subjected to adsorption and refinement treatment by utilizing the granular magnesium silicate adsorbent; unreacted caprylic acid is removed in vacuum at a high temperature; and a final product is subjected to adsorption and refinement treatment by utilizing the granular magnesium silicate adsorbent, so that the sorbitan octoate emulsifier which has the acid value less than 2.0 mgKOH / g, the color luster less than or equal to 100 Hazen, the hydroxyl value equal to 230-300 mgKOH / g and the saponification value equal to 180-210 mgKOH / g, is light in smell, high in transparency, low in fatty acid residue content, difficult in acid backflow and high in stability, and has good solubilizing, emulsification-facilitating, tackifying and anticorrosion-enhancing effects and safe and mild performance is obtained; and the method is suitable for the fields of daily chemicals and cosmetics, and the like.

Owner:ZHANGJIAGANG GREAT CHEM

Sorbitan caprylate emulsifier

InactiveCN106749118ALight smellHigh transparencyOrganic chemistryTransportation and packagingIon contentSynthesis methods

The invention aims to provide a synthesis method of sorbitan caprylate emulsifier. The synthesis method is characterized by comprising the following steps: taking commercially available D-sorbitol and caprylic acid as raw materials, performing etherification and esterification, then vacuumizing, adding water, vacuumizing according to the vapor distillation principle, deacidifying in vacuum through a falling film evaporator to remove the caprylic acid, and finally adsorbing through granular magnesium silicate to prepare the sorbitan caprylate emulsifier. According to the invention, the material addition and proportioning in the reaction process are reasonably adjusted, the reaction temperature and time in deacidification and other working procedures are optimally selected, and the process is reasonable and simple to operate. The sorbitan caprylate emulsifier prepared by the invention is faint in smell, light in color, high in transparency, low in acid value, low in fatty acid residue, low in sodium ion content, less prone to acidification and favorable in stability; and meanwhile, the sorbitan caprylate emulsifier has the advantages of solubilization, emulsification assistance, tackification, corrosion resistance synergy, safe and mild performance and favorable compatibility, thereby being applicable to the fields of daily chemical cosmetics and the like.

Owner:ZHANGJIAGANG GREAT CHEM

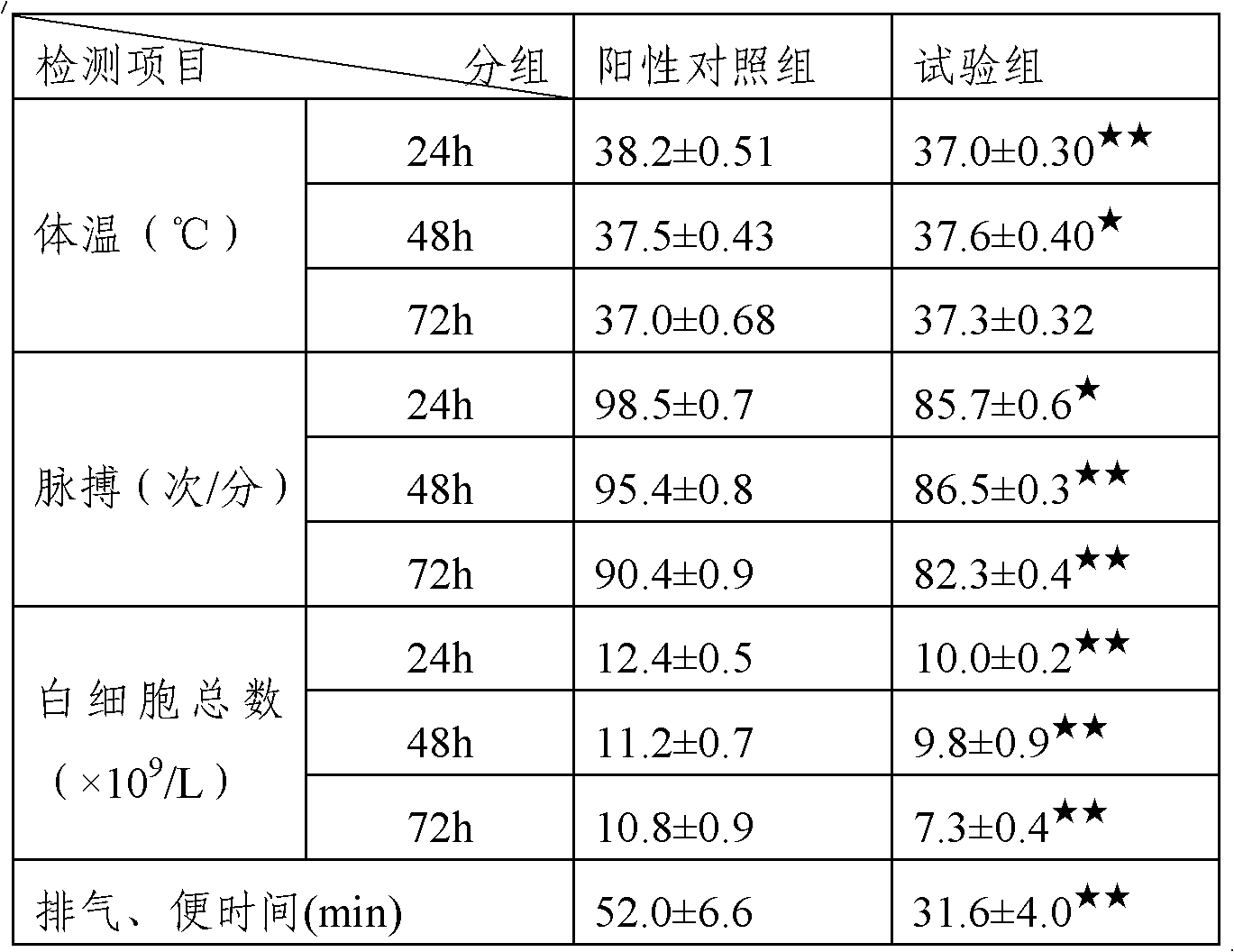

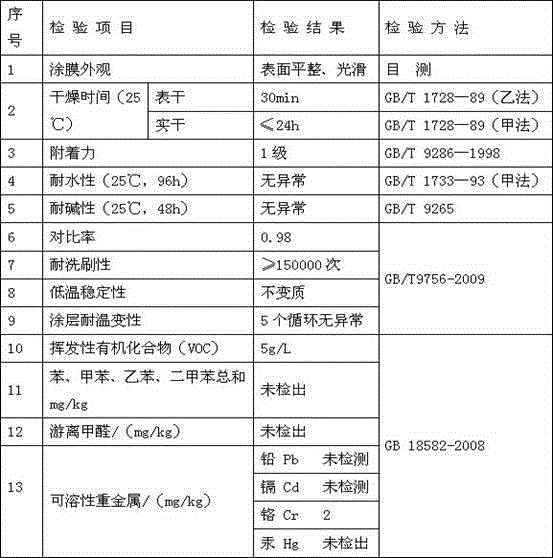

Chinese medicine composition for treating sepsis and preparation method thereof

The invention relates to a Chinese medicine composition for treating sepsis and a preparation method thereof. The Chinese medicine composition comprises active ingredients prepared from the following traditional Chinese medicines in parts by weight: 10-20 parts of radix bupleuri, 10-20 parts of radix scutellariae, 10-20 parts of radix salviae miltiorrhizae, 1-5 parts of Chinese rhubarb, 5-10 parts of coptis chinensis, 8-10 parts of radix paeoniae rubra, 5-10 parts of ginseng, 8-10 parts of root of rehmannia, 10-20 parts of honeysuckle, 5-10 parts of fruit of trifoliate orange and 5-10 parts of liquorice. According to the Chinese medicine composition disclosed by the invention, fungi, toxicity and inflammation are treated simultaneously by utilizing synergistic effect of various ingredients, various ways and various target points of the traditional Chinese medicines; in addition, the Chinese medicine composition has unique and exact effects of controlling sepsis in early stage and turning and cutting off the disease development, and has excellent remote effects.

Owner:无锡曙辉药业有限公司

Water-phase preparation method of low-impurity light-smell polysulfide silane coupling agent

InactiveCN103804410AReduce manufacturing costLess impuritiesGroup 4/14 element organic compoundsPtru catalystDistillation

The invention aims at provide a water-phase preparation method of a low-impurity light-smell polysulfide silane coupling agent. The water-phase preparation method comprises the following specific steps: a, synthesis of a sodium polysulfide aqueous solution, namely adding sodium bisulfide or sodium sulfide, sodium hydroxide, sodium chloride, sulfur and water to a reaction device capable of stirring and heating, stirring and heating to the range from 70 to 80 DEG C, and preserving heat; b, addition of catalyst, namely feeding a catalyst aqueous solution into the sodium polysulfide aqueous solution; c, synthesis of coarse product, namely dropwise adding chloropropyltriethoxysilane to the sodium polysulfide aqueous solution, controlling the temperature of the reaction system within the range from 75 to 95 DEG C, and preserving heat after finishing dropwise adding; d, phase separation, namely separating the organic phase of the upper layer and the water phase of the lower layer and filtering the organic phase of the upper layer; e, purification of the organic phase, namely purifying the filtered organic phase by means of filtering or distillation, and then obtaining the product, namely, the polysulfide silane coupling agent.

Owner:南京曙光硅烷化工有限公司

Preparation method of environment-friendly biological insecticide

InactiveCN106561757APromote growthAvoid harmBiocideBio-organic fraction processingCypermethrinPlant growth

The invention discloses a preparation method of environment-friendly biological insecticide. The environment-friendly biological insecticide is composed of nicotine, derris, ammonium sulfate, monoammonium phosphate, potassium sulfate, borax, zinc sulfate, ferrous sulfate, calcium powder, a rooting agent, chicken manure, humic acid, K7 rare earth, zeolite powder, azone, chitosan, fresh ginger, herba geranii, artemisiae annuae herba, fructus cnidii, tripterygium wilfordii, radix stemonae, pod pepper, garlic, alkyl sodium sulfonate, ginkgo nut extract, pymertrozine, menthol, dimethylbenzene, cypermethrin, lemon essence and deionized water. Compared with the prior art, the preparation method of the environment-friendly biological insecticide has the advantages that plant fermentation extraction is adopted, ingredients beneficial for plant growth are adopted, and the environment-friendly biological insecticide is weak in smell and harmless to human bodies, protects the environment, kills pests, facilitates growth of plants and has the application and popularization value.

Owner:INNER MONGOLIA UNIV FOR THE NATITIES

Low-carbon organic-inorganic hybridization super swabbing resistant and stain resistant inner wall latex paint and preparation method thereof

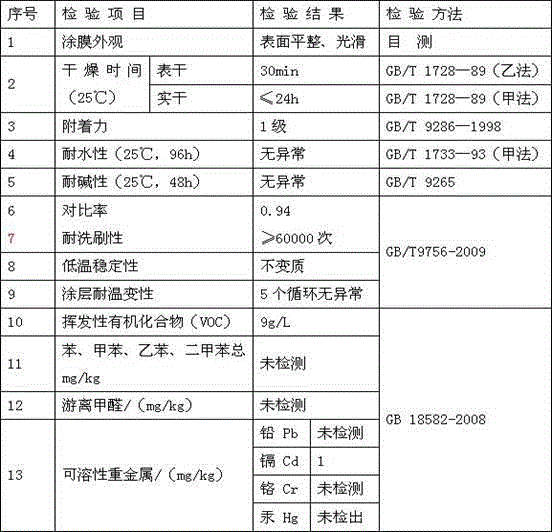

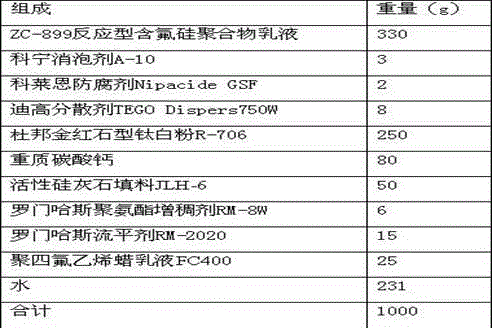

InactiveCN104449365ALarge displacementImprove hydrophilicityAntifouling/underwater paintsPaints with biocidesCarbon.organicRutile

The invention relates to a low-carbon organic-inorganic hybridization super swabbing resistant and stain resistant inner wall latex paint and a preparation method thereof. The low-carbon organic-inorganic hybridization super swabbing resistant and stain resistant inner wall latex paint contains the following components in percentage by weight: 20-45% of a reactive polymer emulsion containing fluorine and silicon, 15-45% of water, 0.1-0.3% of a preservative, 0.5-0.8% of an anti-mildew agent, 0.5-1% of a moist dispersant, 0.2-0.5% of a defoamer, 20-30% of rutile titanium pigment, 5-15% of calcium carbonate, 1-3% of a polytetrafluoroethylene wax emulsion, 5-10% of an active superfine wollastonite filler, 0.5-1% of a polyurethane thickening agent and 1-2% of a leveling agent. The low-carbon organic-inorganic hybridization super swabbing resistant and stain resistant inner wall latex paint provided by the invention overcomes defects of poor swabbing resistance and insufficient substrate protection of an existing product, has excellent covering power, adhesive power and swabbing resistance, can resist swabbing for more than 150000 times, has good constructability and environmental protection performance, and is mainly applied to decoration and protection of surfaces of wall bodies, woods and the like.

Owner:上海展辰涂料有限公司 +4

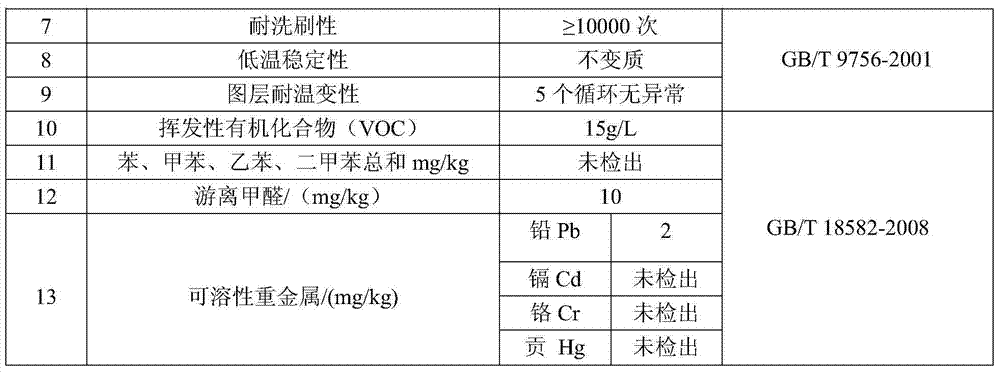

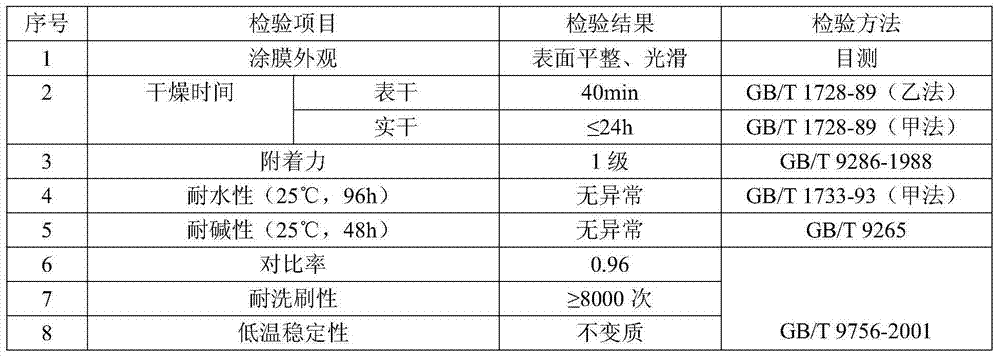

Antibacterial latex paint

InactiveCN104497663ALight smellGood water solubilityAntifouling/underwater paintsPaints with biocidesSolubilityWater based

The invention belongs to the field of a wall coating for indoor decoration, and particularly relates to an antibacterial latex paint. The antibacterial latex paint is characterized by being prepared from the following raw materials in parts by mass: 150-350 parts of water-based acrylic acid, 1-5 parts of defoaming agents, 2-4 parts of preservative agents, 5-10 parts of dispersing agents, 150-300 parts of pigments, 150-350 parts of fillers, 2-9 parts of thickening agents, 1-10 parts of levelling agents, 6-15 parts of nanometer inorganic negative ion antibacterial agents, 50-90 parts of nanometer polymer hollow microspheres, 50-90 parts of bamboo vinegar, 1-5 parts of cosolvents, 10-20 parts of citronella oil and 100-350 parts of water. The antibacterial latex paint disclosed by the invention can be coated on a wall and a wood. A paint film has the advantages of mild smell, good water solubility, low VOC, good covering power, low cost and optimal environment-friendly property. The antibacterial latex paint disclosed by the invention is a product which perfectly combines three themes, namely decoration, functionality and environmental friendliness, and has long-term continuous bacteriostatic effect.

Owner:QINGDAO JIASHANG CREATIVE CULTURE

Anti-cracking antioxidant antirust epoxy finish paint and preparation method thereof

InactiveCN104312384AWell mixedUniform and stable performanceAnti-corrosive paintsEpoxy resin coatingsEpoxyPliability

The invention relates to an antirust paint, in particular to an anti-cracking antioxidant antirust epoxy finish paint and a preparation method thereof. The finish paint is prepared from the following raw materials in parts by weight: 40-50 parts of polybutadiene epoxy resin, 28-40 parts of polyamide resin, 10-13 parts of acrylate / C10-30 alkyl acrylate cross-linking copolymer, 1-1.5 parts of zinc diricinoleate, 20-28 parts of butyl acetate, 4-6 parts of dimethylaminoethyl methacrylate, 12-15 parts of n-butyl alcohol, 10-14 parts of calcium carbonate, 1-3 parts of dilauryl thiodipropionate, 4-5 parts of tung oil, 18-22 parts of an antirust pigment, and 2-3 parts of an auxiliary. The paint slurry in the finish paint is uniform and stable in properties, light in smell, and excellent in adhesive force, flexibility, wear resistance, impact resistance and other mechanical performances after complete curing; the paint film can keep good flexibility after long time use, and is low in possibility of cracking and oxidation; compared with the conventional epoxy antirust finish paint, the finish paint is durable, wear-resisting, capable of realizing long-standing antirust protection, and suitable for the assorted finish paint of various high-performance special antirust primer, epoxy zinc-rich paint and epoxy micaceous iron antirust paint.

Owner:合肥宏图彩印有限公司

Method for synthesizing environment-friendly type urea-formaldehyde plastics resin

InactiveCN101200529AMake full use of resourcesProtect physical and mental healthSodium carbonateOrganic acid

A synthetic method of environment-friendly urea moulding compound resin relates to urea formaldehyde and the synthetic method of modifying urea formaldehyde by tripolycyanamide. Firstly, a ph8-9 formaldehyde solution added with urea or urea and tripolycyanamide reacts under the temperature of 60 to 90 DEG C and when the reaction liquid turns into ivory-white thick liquid, water with the basically same pH value of the reaction liquid is added for even mixing or reaction under the temperature of 70 to 90 DEG C for 0.5 to 1.5 hours; then organic acid is used to adjust pH to 5-6 and further reaction goes on under the temperature of 70 to 90 DEG C; when the reaction liquid turns into ivory-white thick liquid; afterwards, sodium carbonate solution is used to adjust the pH of the reaction liquid to 7-8 and water with the basically the same pH value of the reaction liquid is added for even mixing; finally, the ivory-white thick resin liquid is sent to the sequent procedures and processed into the urea moulding compound. In the method, excessive formaldehyde is converted into resin as much as possible, thus reducing the air pollution and protecting workers health; at the same time, the formaldehyde residue of the urea moulding compound is greatly reduced, so the present invention is worthy the name of environment-friendly process compared with the traditional process.

Owner:滁州市十扬环保塑木科技有限公司

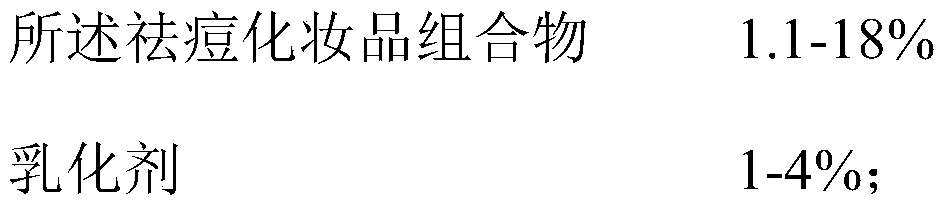

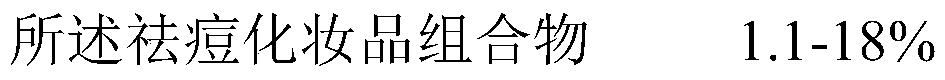

Acne-removing cosmetic composition and applications thereof

InactiveCN109718138AInhibitory activityGrowth inhibitionCosmetic preparationsToilet preparationsSkin barrier functionNormal cell

The invention relates to an acne-removing cosmetic composition and applications thereof. The acne-removing cosmetic composition is prepared from the following raw materials in parts by weight: 0.5-5 parts of zostera marina extract, 0.1-3 parts of horse fat and 0.5-10 parts of honeysuckle flower extract. The acne-removing cosmetic composition can reconstruct the skin structure, form a normal cell structure, maintain and regulate the water-oil balance of the skin, improve the skin barrier function and play a role in removing acne, has low recurrence rate, light smell, light color, and can adaptto market demands.

Owner:BEIHAO STEM CELL & REGENERATIVE MEDICINE RES INST CO LTD

Environmentally-friendly waterproof material for buildings

InactiveCN110669401AImprove environmental performanceAvoid destructionCoatingsFiberCellulose acetate

The invention discloses an environmentally-friendly waterproof material for buildings, and relates to the technical field of building materials. The raw materials of the waterproof material comprise,by weight, 25-45 parts of acrylic acid, 8-14 parts of an elastic fiber, 4-10 parts of a filler, 1-6 parts of a solvent, 1-3 parts of a defoamer, 15-35 parts of an epoxy resin adhesive, 10-30 parts ofan epoxy resin curing agent, 8-16 parts of a thickener, 2-10 parts of an antioxidant, 3-6 parts of a compatilizer, 2-8 parts of an antistatic agent, 6-12 parts of a lubricant and 4-12 parts of a pigment, and the elastic fiber is one or more of cellulose acetate, cellulose acetate butyrate and microcrystalline cellulose. The environmentally-friendly waterproof material for buildings is prepared from environmentally-friendly raw materials, so the environmentally-friendly performance of the building material is improved; the building material has a light smell after being used, so the pollution to the environment and human bodies is reduced, and a comfortable living environment is provided for people; and the building material has certain waterproofness, so the building material can be prevented from being damaged by water vapor, and the service life of the building material is prolonged.

Owner:HANGZHOU BAOLI SPORTS FACILITIES ENG

Synthesis method of high-purity fatty acid monoethanolamine

InactiveCN102516109AHigh purityLight smellOrganic compound preparationCarboxylic acid amides preparationSynthesis methodsSURFACTANT BLEND

The invention belongs to the technical field of synthesis of a surfactant in organic chemistry, and particularly relates to a synthesis method of a high-purity fatty acid monoethanolamine, which comprises the following steps of: 1) preparation of a fatty acid methyl ester; 2) post-treatment refining of the fatty acid methyl ester; and 3) amidation reaction. The fatty acid monoethanolamine prepared by the method has the advantages of high purity, light odor, low amine value, light color and the like.

Owner:广州花语精细化工有限公司

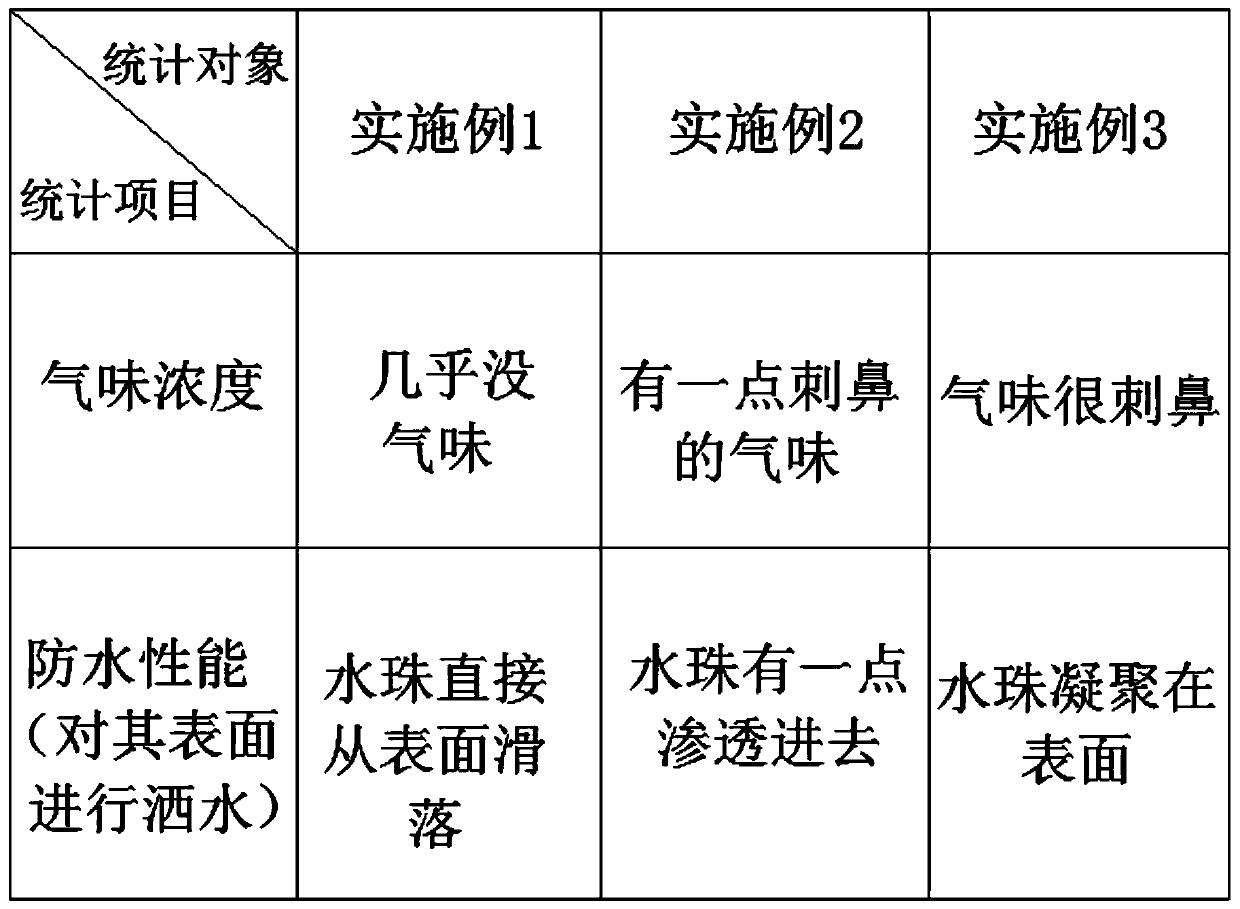

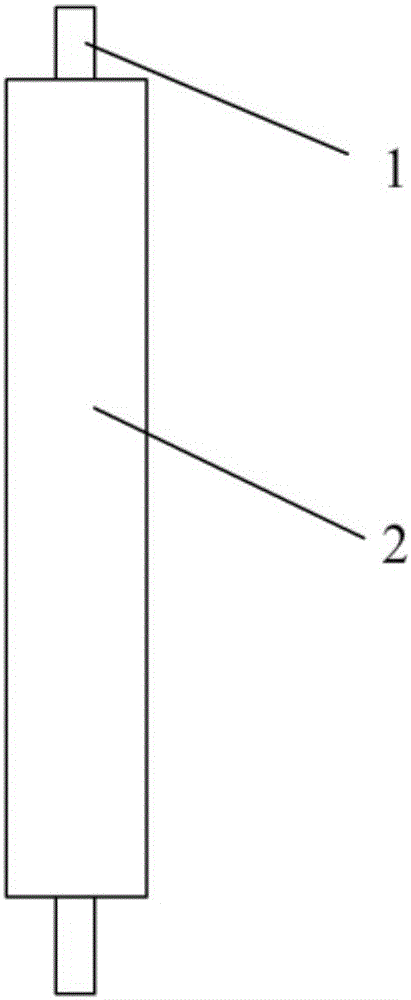

Electric wire applied in transformer substation

InactiveCN106057340ALight smellImprove smellInsulated cablesPower cablesSedum hispanicumElectrical conductor

The invention discloses an electric wire applied in a transformer substation. The electric wire comprises an electric conductor, an insulating cover and a coating, wherein the electric conductor is linear; the insulating cover wraps the surface of the electric conductor along the linear direction and two ends of the insulating cover are opened; and coating solution is coated on the surface of the insulating cover so as to form the coating after air drying. A preparation method of coating solution for a high-voltage cable comprises the following steps: selecting 32-55 parts of fresh sedum hispanicum blades by weight, 61-80 parts of calathea insignis blades by weight and 54-75 parts of laggera pterodonta petals by weight; carrying out a series of processing to obtain the coating solution; coating the coating solution on the surface of the insulating cover of the cable; and air drying the surface of the cable. Through above processing, the probability of damaging the cable by rodents can be decreased, the safety of high-voltage electricity in the transmission process can be ensured, and the electric shock accidents can be decreased.

Owner:王小凤

Preparation method of nerve-calming and smokeless mosquito-repellent incense

InactiveCN106070370ANo pollution in the processImprove cleanlinessBiocidePest repellentsTurpentine OilIrritation

The invention relates to a preparation method of nerve-calming and smokeless mosquito-repellent incense and belongs to the technical field of articles for daily life. Aiming at the problems of the existing mosquito-repellent incense that bad undesirable odor is generated in a combustion process, medicine liquid has certain irritant odor and generated smoke pollutes the environment, spina date seeds are firstly treated to remove colloid substances so that the spina date seeds can be sufficiently combusted; meanwhile, anthracite and potassium permanganate are added to assist combustion; the flavor generated by the spina date seeds and cinnabar has a nerve-calming effect; effective mosquito-killing components in substances, including cloves, acorus gramineus and the like, are extracted; an extracting solution has a faint scent flavor and is mixed with a combustion matrix; sodium alginate is used as a binding agent, turpentine oil is used as a diluting agent and bleached soil is used as a fire retardant, so that the prepared mosquito-repellent incense has the faint scent flavor and no smoke; and meanwhile, the mosquito-repellent incense has the nerve-calming effect. The prepared mosquito-repellent incense has a good mosquito-killing effect, has no damages to human bodies and does not cause environment pollution.

Owner:陈建峰

Aqueous sunscreen thermal insulation coating and preparation method thereof

InactiveCN106609102AProtect healthPrevent fadingPolyurea/polyurethane coatingsRadiation-absorbing paintsThermal insulationUltraviolet

The invention discloses an aqueous sunscreen thermal insulation coating and a preparation method thereof. The aqueous sunscreen thermal insulation coating comprises, by weight, 150-200 parts of waterborne polyurethane, 40-60 parts of an ultraviolet absorber, 25-30 parts of an infrared absorber, 10-20 parts of copper powder, 15-20 parts of molybdenum powder, 20-30 parts of ceramic beads, 20-30 parts of hollow beads, 3-5 parts of a defoamer, 3-5 parts of a leveling agent, 4-8 parts of a dispersant, 10-15 parts of an organosilicone hydrophobic agent, 3-5 parts of a curing agent, an appropriate amount of a solvent and an appropriate amount of a filler. The aqueous sunscreen thermal insulation coating has the advantages of good sunscreen and heat insulation effects, excellent water resistance, good heat radiation and reflection effects, energy saving, environmental friendliness, economy, safety and hygiene. The coating produced by the method can achieve accurate feeding and blending and has the best stirring effects. The preparation method can directly cool the stirred coating, greatly improves production efficiency and has low operation complexity.

Owner:丹阳市海信涂料化工厂

Traditional Chinese medicine composition for treating uremia

InactiveCN105055964AConvenience dietImprove sleepingUrinary disorderPlant ingredientsOfficinalFibrosis

The invention relates to a traditional Chinese medicine composition for treating the uremia, and belongs to the technical field of traditional Chinese medicine preparing. The composition comprises orally-taken medicine and external application medicine. The orally-taken medicine comprises, by weight, 3 parts to 8 parts of first-class ginseng, 3 parts to 8 parts of semen plantaginis, 3 parts to 8 parts of capillary artemisia, 3 parts to 8 parts of herba cistanche, 3 parts to 8 parts of mulberries, 3 parts to 8 parts of fructus psoraleae, 5 parts to 10 parts of lalang grass rhizomes, 5 parts to 10 parts of semen cuscutae, 5 parts to 15 parts of lophatherum gracile, 5 parts to 10 parts of bighead atractylodes rhizomes, 10 parts to 20 parts of raw radix astragalis and 10 parts to 30 parts of fried sticky rice. The external application medicine comprises, by weight, 50 parts to 80 parts of raw garlic and 20 parts to 50 parts of mirabilite. The preparing method of the orally-taken medicine includes the steps that refluxing is carried out on the traditional Chinese medicinal materials with the weight parts through ethyl alcohol with the volume ten times that of the traditional Chinese medicinal materials, and extracting, separating and drying are carried out for standby application. The preparing method of the external application medicine includes the step that the traditional Chinese medicinal materials with the weight parts are mixed in proportion to be mashed to be pasty for standby application. According to the traditional Chinese medicine composition, oral taking and external application are combined; after continuous taking is carried out, the functions of clearing away heat, cooling blood, eliminating toxins, warming and activating meridians and promoting blood circulation to remove blood stasis are achieved, fibrosis of kidney tissues is relieved, the kidney functions are gradually restored finally, and the curing effect is achieved.

Owner:殷永洲

Cultivation method of novel Guizhou white goat hybrid strain

InactiveCN107372332AImprove meat qualityIncrease meat productionAnimal husbandryBoer goat breedBiology

The invention discloses a cultivation method of a novel Guizhou white goat hybrid strain. According to the method, a Guizhou white goat and a Boer goat are hybridized, growth of a hybrid later generation is accelerated, the meat yield of the hybrid later generation is improved, a blood relationship of the Guizhou white goat is further introduced, so that meat quality id improved, the Guizhou white goat and a white Boer goat are horizontally and fixedly mated to obtain a Guizhou white goat of a novel strain, so that the obtained white Boer goat of the novel strain is high in meat yield and rapid to grow, the cultivation method ensures that meat is tender, delicious, juicy and fresh, mutton odor is light, and goat skin quality is excellent, and economic and breeding values are improved.

Owner:GUIZHOU UNIV

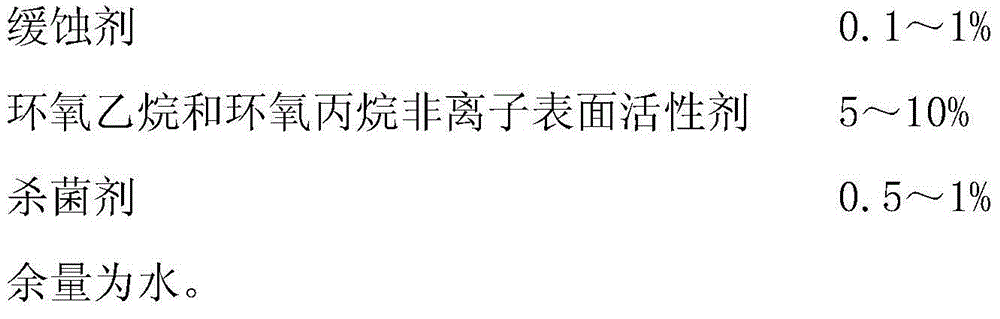

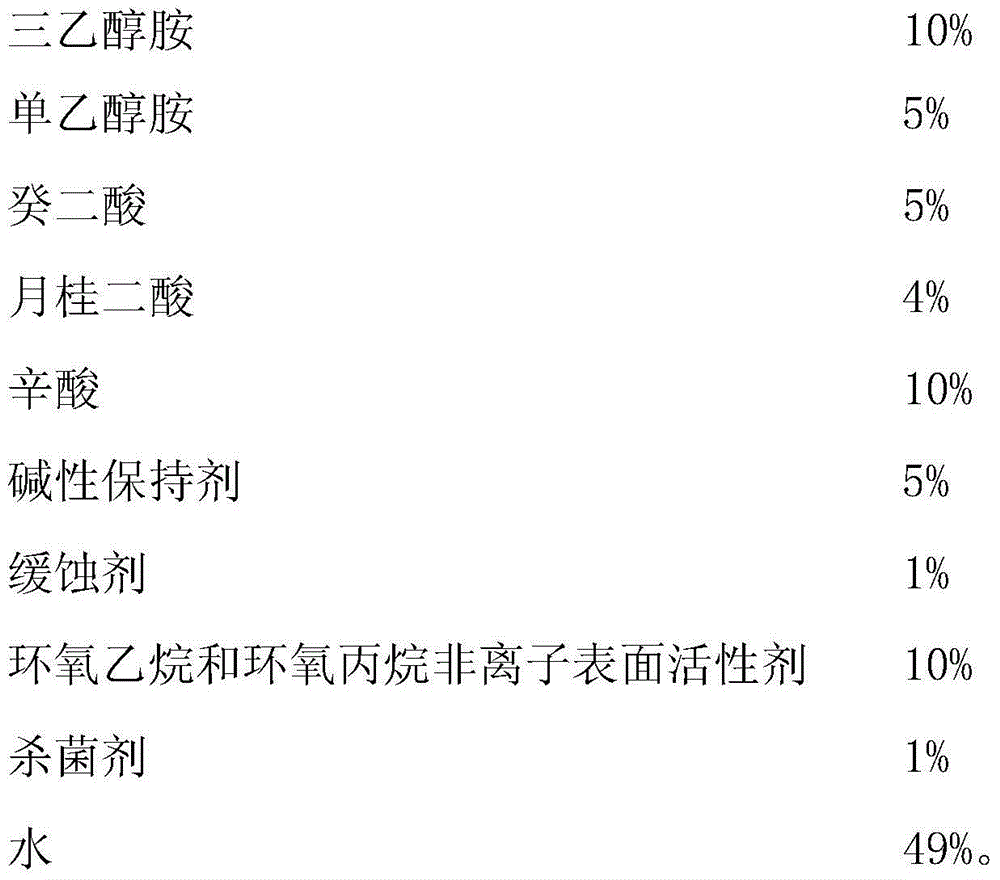

Low-skin-allergy synthetic metal cutting fluid and preparation method thereof

InactiveCN104087407AReduce stimulationReduce generationLubricant compositionOctanoic AcidsIrritation

The invention relates to a cutting fluid for metal working and a preparation method thereof, particularly a low-skin-allergy synthetic metal cutting fluid which comprises 1-10% of triethanolamine, 1-10% of monoethanolamine, 2-10% of decanedioic acid, 4-10% of dodecanedioic acid, 4-10% of octanoic acid, 3-8% of alkaline retaining agent, 0.1-1% of corrosion inhibitor, 5-10% of epoxyethane and epoxypropane nonionic surfactant, 0.5-1% of bactericide and the balance of water. The preparation method comprises the following steps: proportioning the raw materials of the cutting fluid in percentage by weight, adding the pure water, triethanolamine, monoethanolamine, decanedioic acid and dodecanedioic acid into a reaction kettle, continuously stirring for 30 minutes, adding the octanoic acid, alkaline retaining agent, corrosion inhibitor, epoxyethane and epoxypropane nonionic surfactant and bactericide, and continuously stirring for 30 minutes, thereby obtaining the low-skin-allergy synthetic metal cutting fluid. Compared with the prior art, the low-skin-allergy synthetic metal cutting fluid has the advantages of low skin allergy, low fog, favorable lubricating property, favorable dirty oil drainage property and lower irritation for skin of operators.

Owner:马思特(上海)化学有限公司

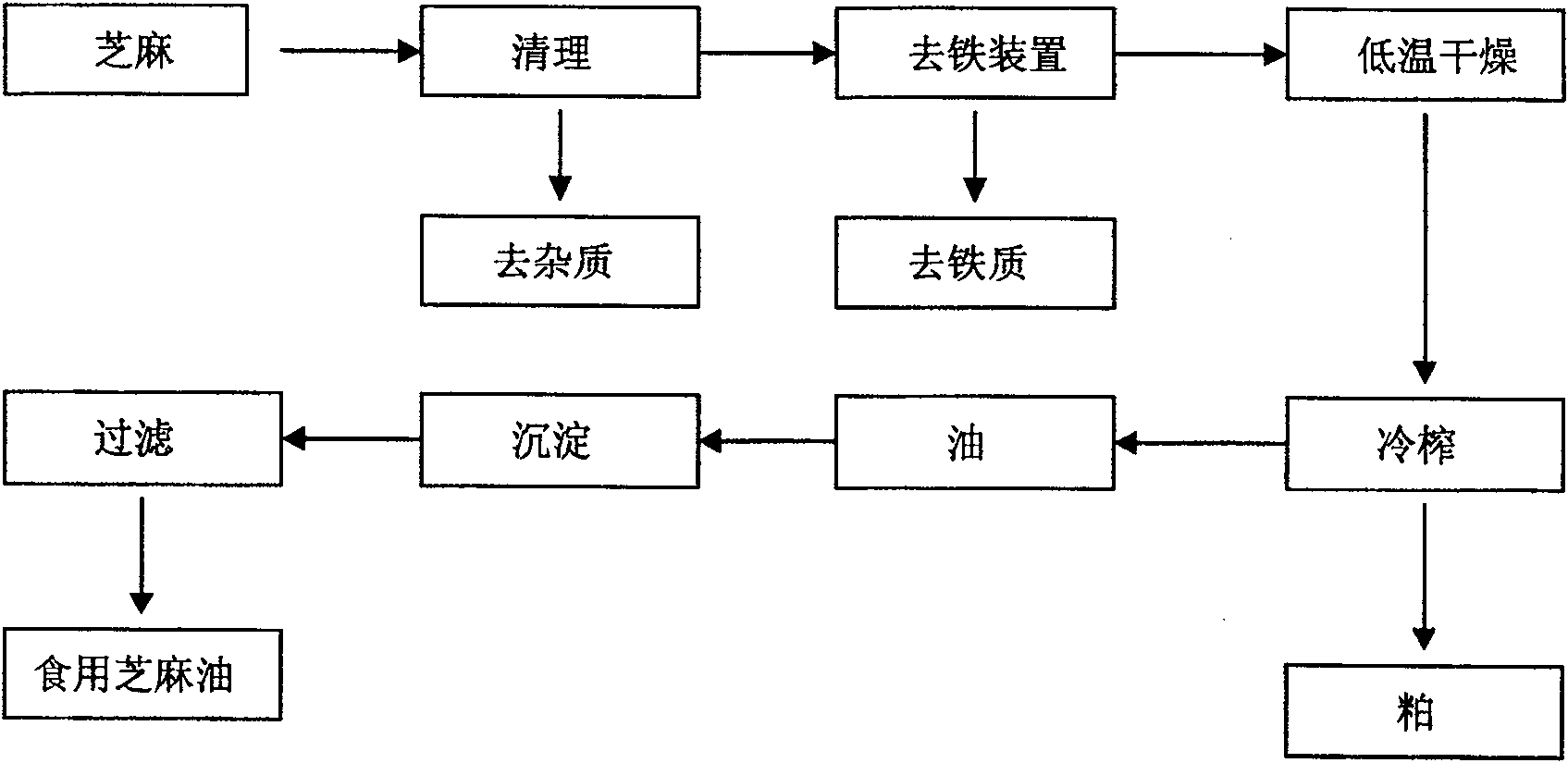

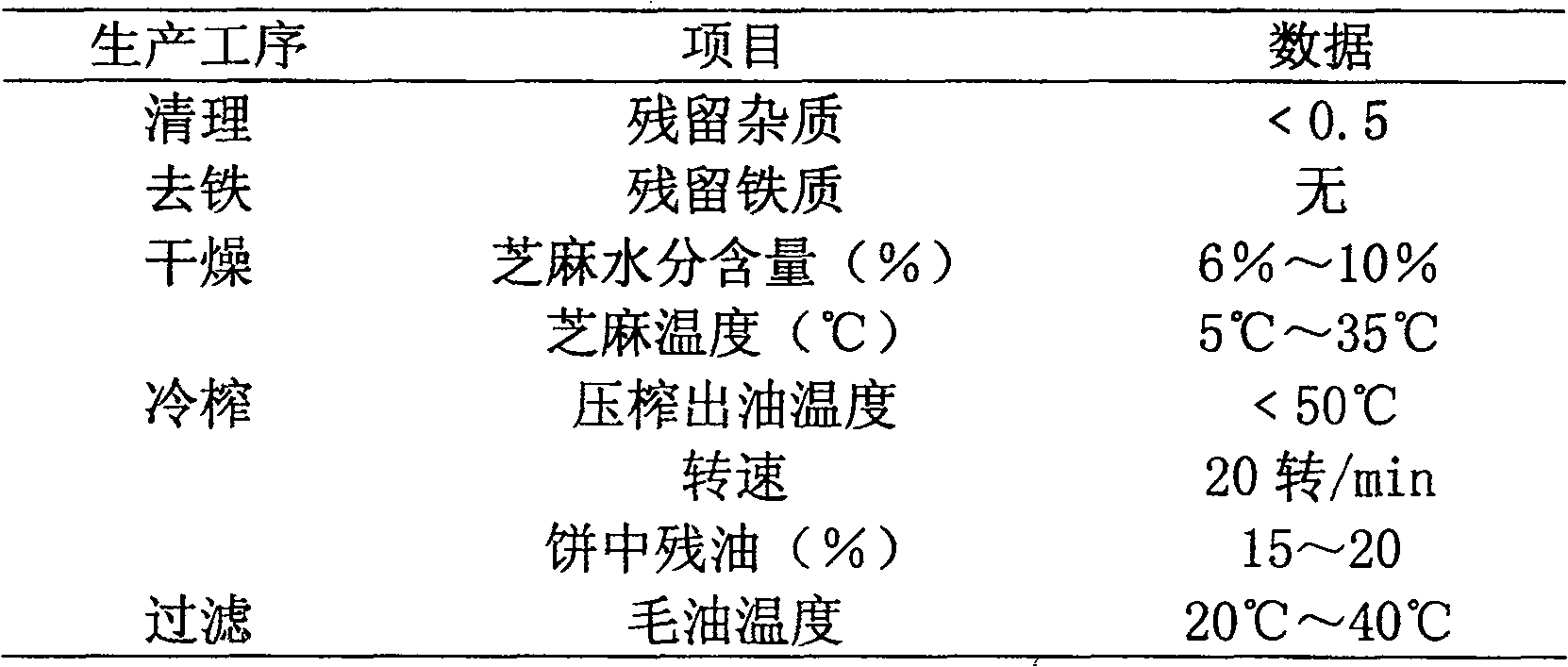

Low temperature method for cold pressing sesame oil

The invention provides a low-temperature cold-pressing method for sesame oil. The cold-pressing method for sesame oil is simple and easy, and the nutritive components, active substances in the oil and the fragrance of the sesame itself are not lost during the pressing process, and the pressed sesame oil is rich in fragrance and clear in color. The method is to firstly clean the sesame and remove the slag, and then dry it with hot air in a drying equipment. The temperature of the sesame is less than 50°C, and the moisture content of the sesame is reduced to 6wt%-10wt%. ~35°C, the oil output temperature is below 50°C; the final squeezed oil is precipitated and finely filtered at 20°C~40°C to obtain pure natural edible sesame oil. The invention has the advantages of simple process, scientific and reasonable, and no pollution to the environment; the protein in the cold-pressed cake is not denatured and can be further developed and utilized.

Owner:合肥燕庄食用油有限责任公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com