Aqueous sunscreen thermal insulation coating and preparation method thereof

A technology for sun protection and heat insulation and a production method, which is applied in the direction of radiation-absorbing coatings, polyurea/polyurethane coatings, coatings, etc., can solve problems such as poor waterproof performance and uneven coating composition, and achieve high adhesion, convenient operation, low smell effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

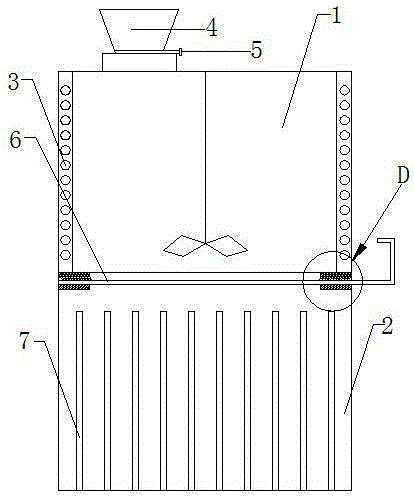

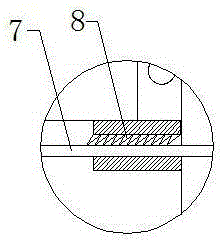

[0024] Embodiment one: A water-based sunscreen and heat-insulating coating and a production method thereof, comprising the following components in parts by weight: 200 parts of water-based polyurethane, 40 parts of ultraviolet absorbers, 30 parts of infrared absorbers, 10 parts of copper powder, 20 parts of molybdenum powder, ceramic micro 20 parts of beads, 30 parts of hollow microspheres, 3 parts of defoamer, 5 parts of leveling agent, 4 parts of dispersant, 15 parts of silicone hydrophobic agent, 3 parts of curing agent, silicate, carbonate and sulfuric acid as filler Three kinds of salts, specifically magnesium silicate, calcium carbonate, and calcium sulfate are used, and an appropriate amount of water is used as a solvent. The above-mentioned various raw materials are added to the agitator 1 according to the determined parts and stirred, and heated and mixed during the stirring process.

[0025] A method for making a water-based sunscreen and heat-insulating coating, co...

Embodiment 2

[0033] Embodiment two: A water-based sunscreen and heat-insulating coating, comprising the following components in parts by weight: 150 parts of water-based polyurethane, 60 parts of ultraviolet absorbers, 25 parts of infrared absorbers, 20 parts of copper powder, 15 parts of molybdenum powder, 30 parts of ceramic microbeads, 20 parts of hollow microspheres, 5 parts of defoaming agent, 3 parts of leveling agent, 8 parts of dispersing agent, 10 parts of silicone hydrophobic agent, 5 parts of curing agent, the solvent is water, and the filler is magnesium silicate and calcium carbonate.

[0034] The preparation method of the coating of the second embodiment is the same as that of the first embodiment.

Embodiment 3

[0035] Embodiment three: A water-based sunscreen and heat-insulating coating, comprising the following components in parts by weight: 180 parts of water-based polyurethane, 50 parts of ultraviolet absorbers, 28 parts of infrared absorbers, 15 parts of copper powder, 18 parts of molybdenum powder, 25 parts of ceramic microbeads, 25 parts of hollow microspheres, 4 parts of defoaming agent, 4 parts of leveling agent, 6 parts of dispersant, 12 parts of silicone hydrophobic agent, 4 parts of curing agent, the solvent is water, and the filler is calcium carbonate and calcium sulfate.

[0036] The preparation method of the coating of the third embodiment is the same as that of the first embodiment.

[0037] The invention improves the sunscreen and heat insulation effect of the paint by adding ultraviolet absorbers, infrared absorbers, hollow microspheres and ceramic microspheres into the raw materials of the paint, and the combination of the four better improves the sunscreen and he...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com