Patents

Literature

691results about How to "Prevent fading" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

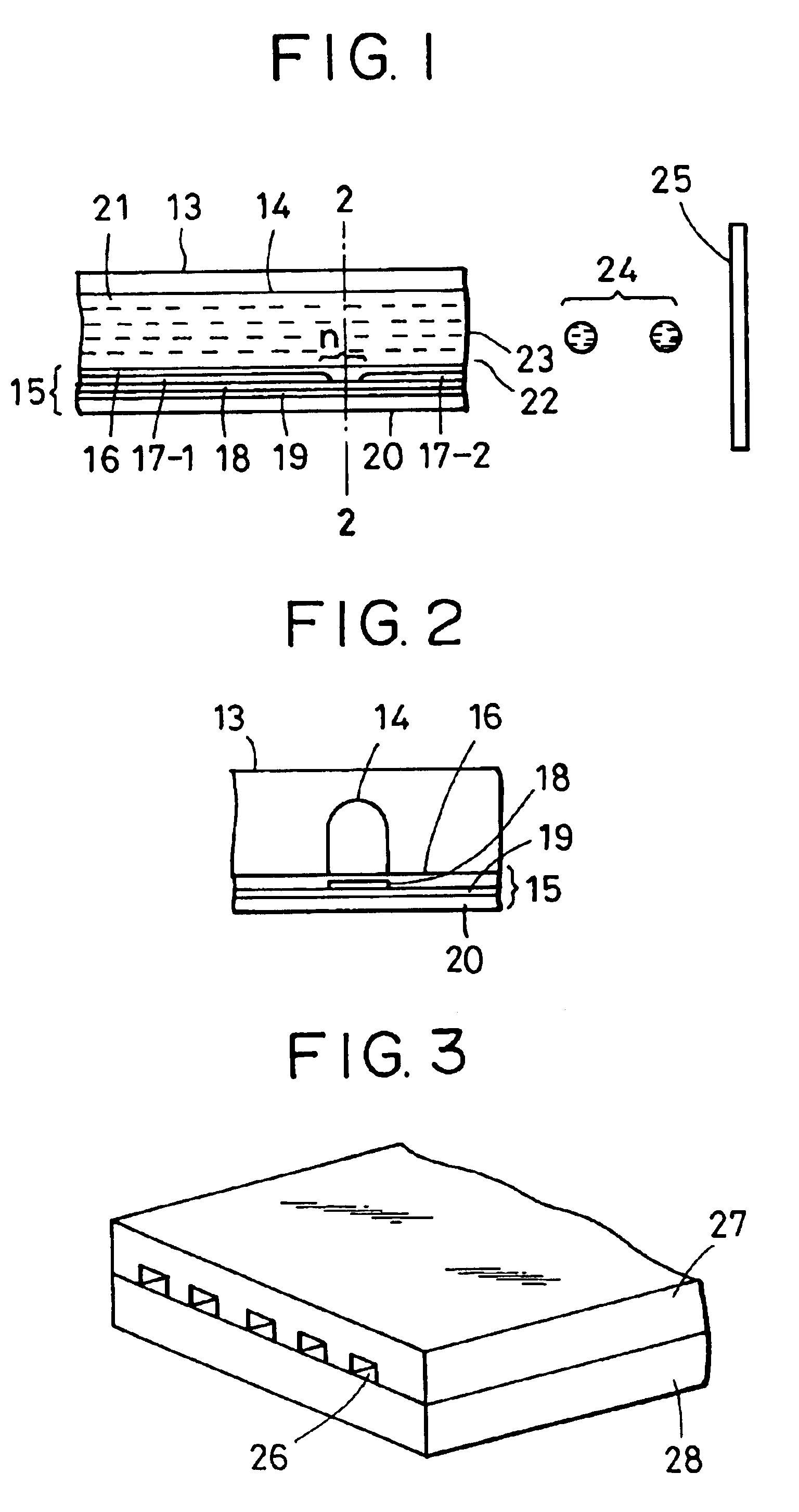

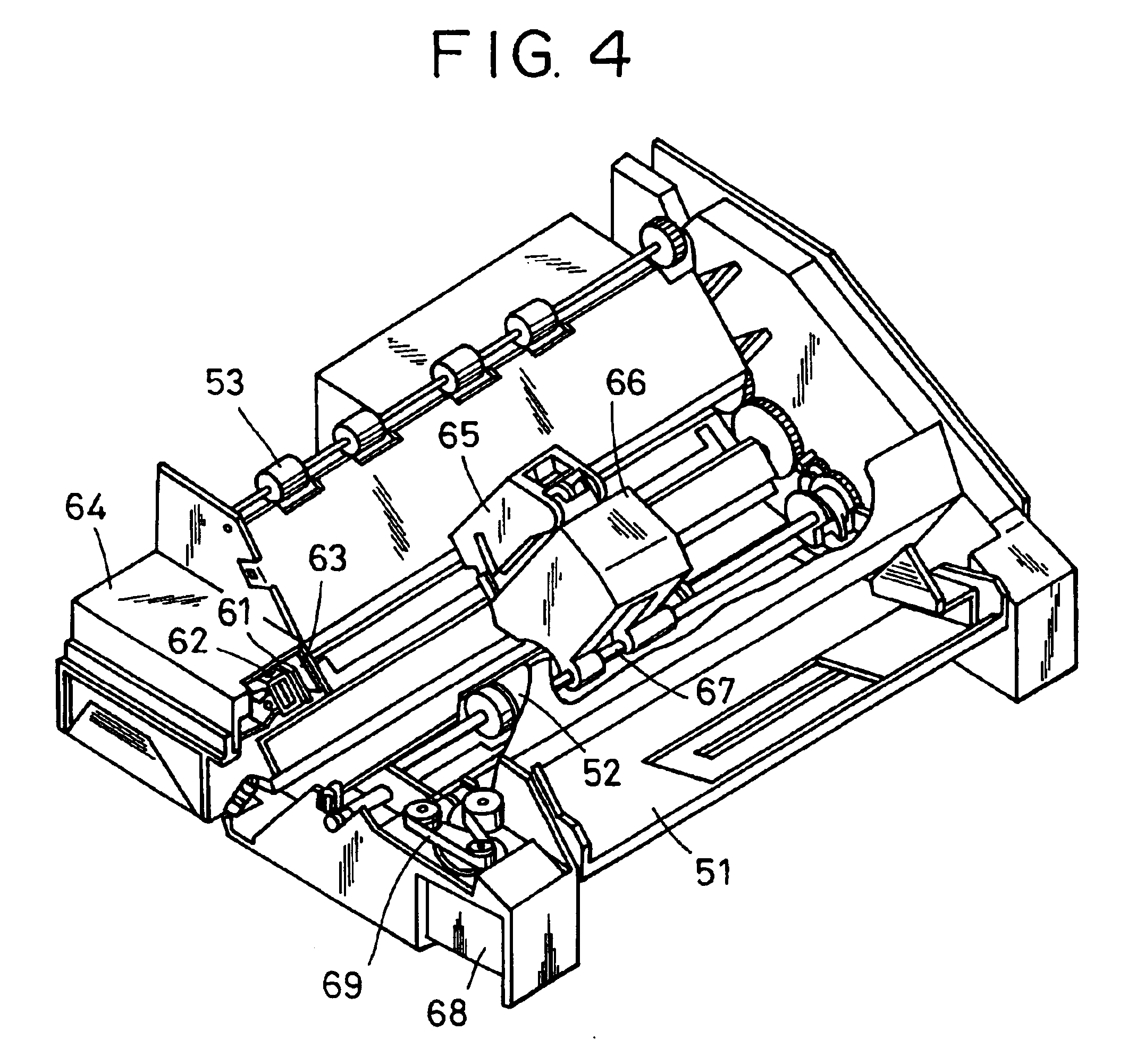

Ink, recording method, recording unit, ink cartridge, ink set, and recording apparatus

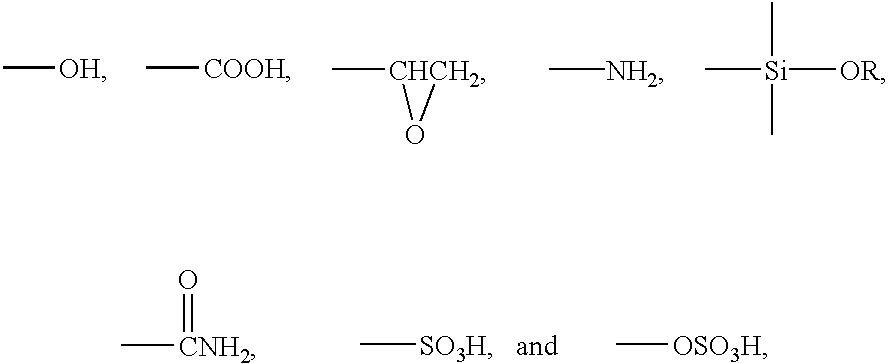

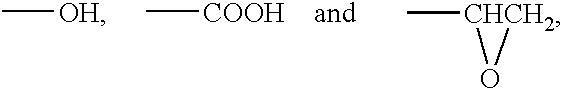

InactiveUS6843839B2Excellent toneIncreased durabilityMonoazo dyesOrganic chemistryWater basedImage density

Magenta ink exhibiting excellent coloration on various recording materials is provided according to the present invention. The magenta ink can realize high image densities and can produce images having superior light resistance. The magenta ink contains first and second coloring materials represented by the following general formulae 1 and 2, respectively, and a water-based medium

Owner:CANON KK

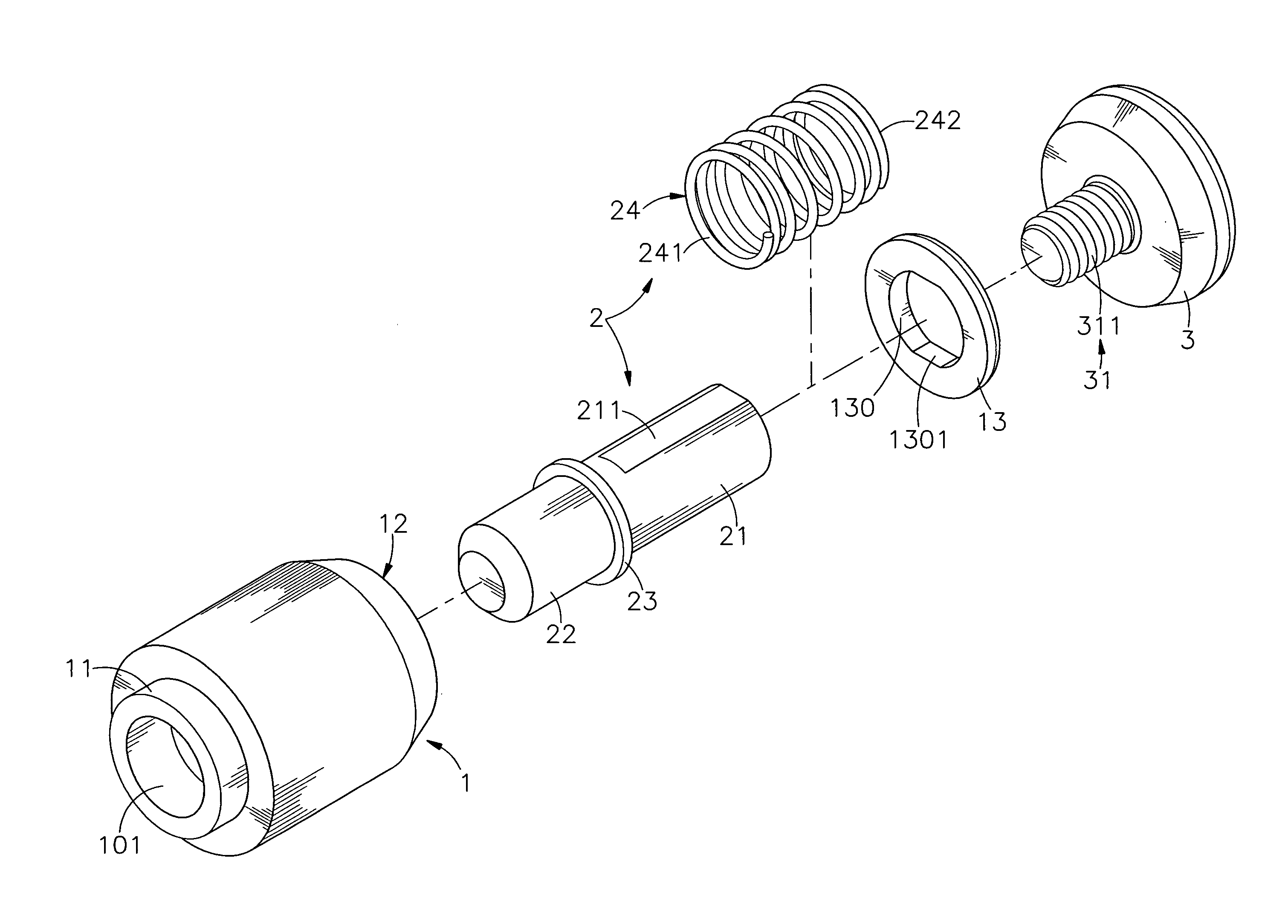

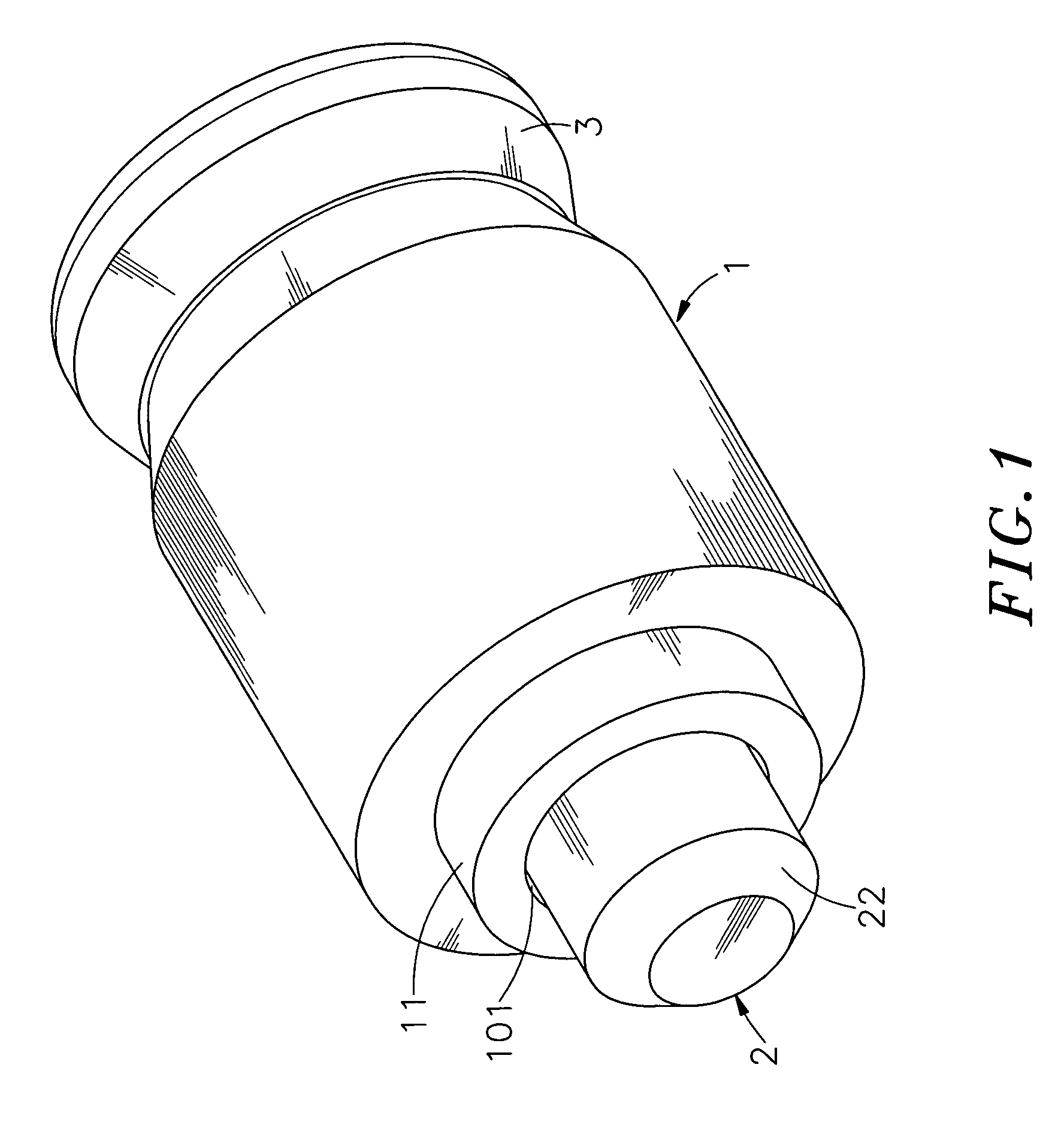

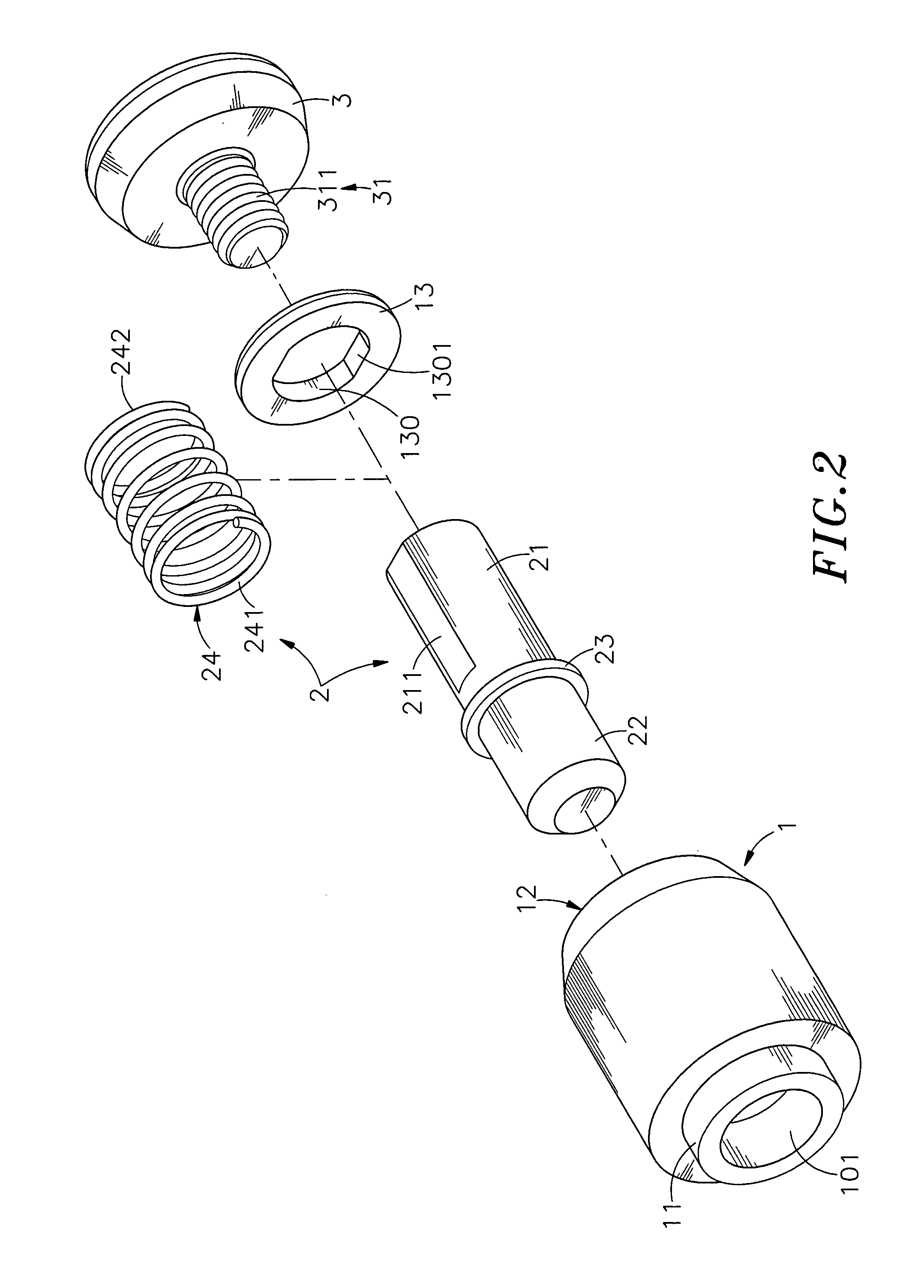

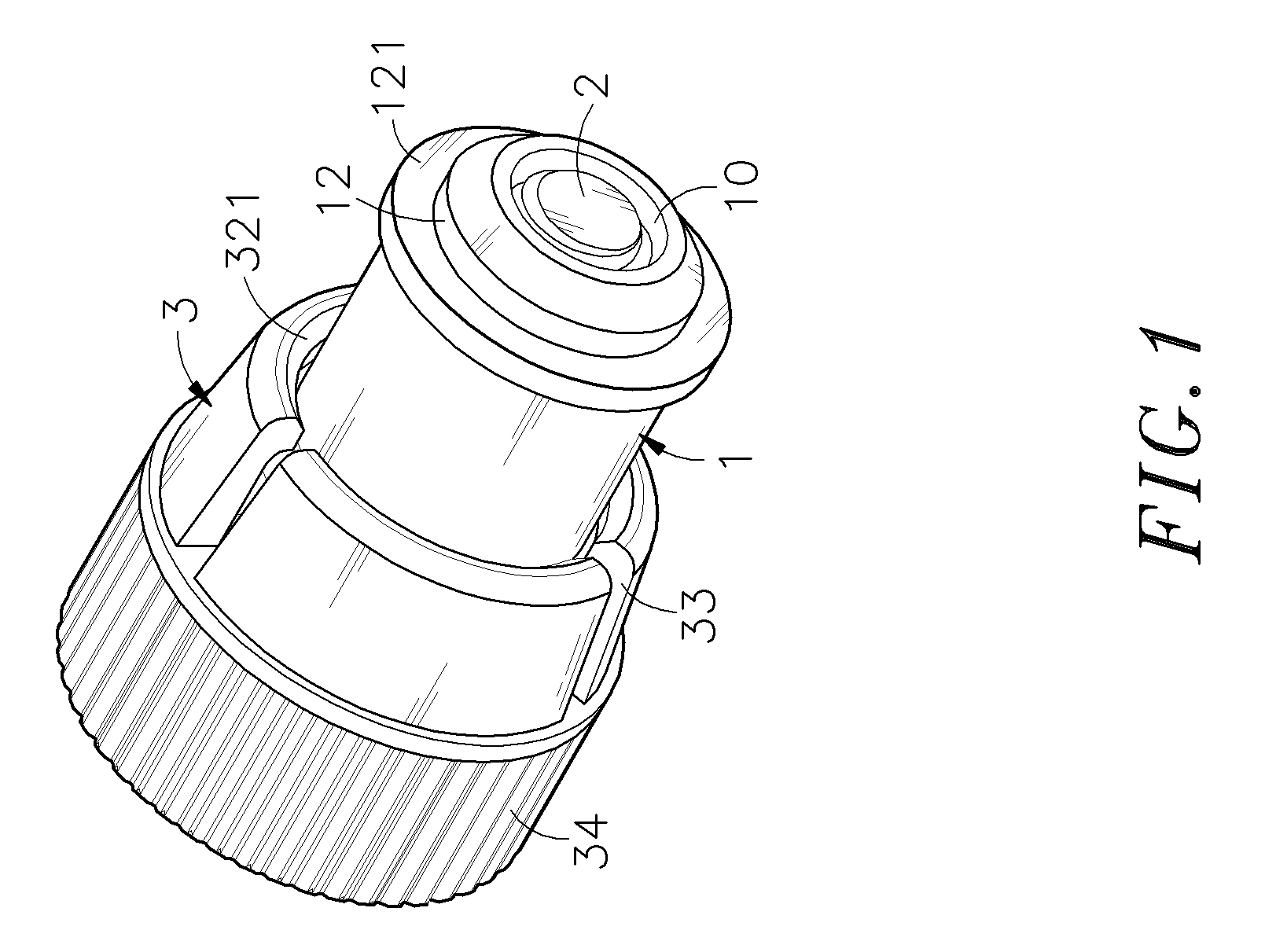

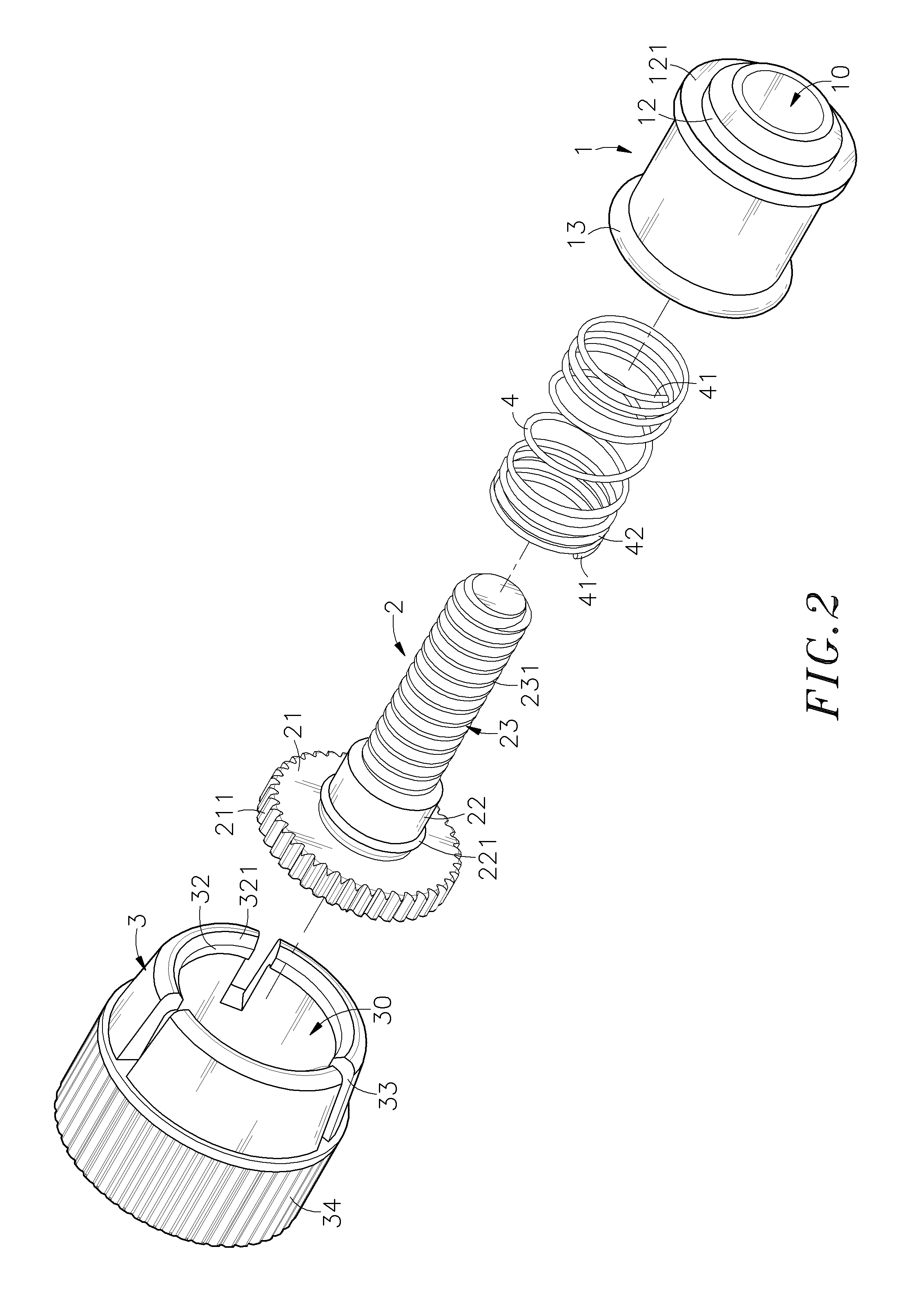

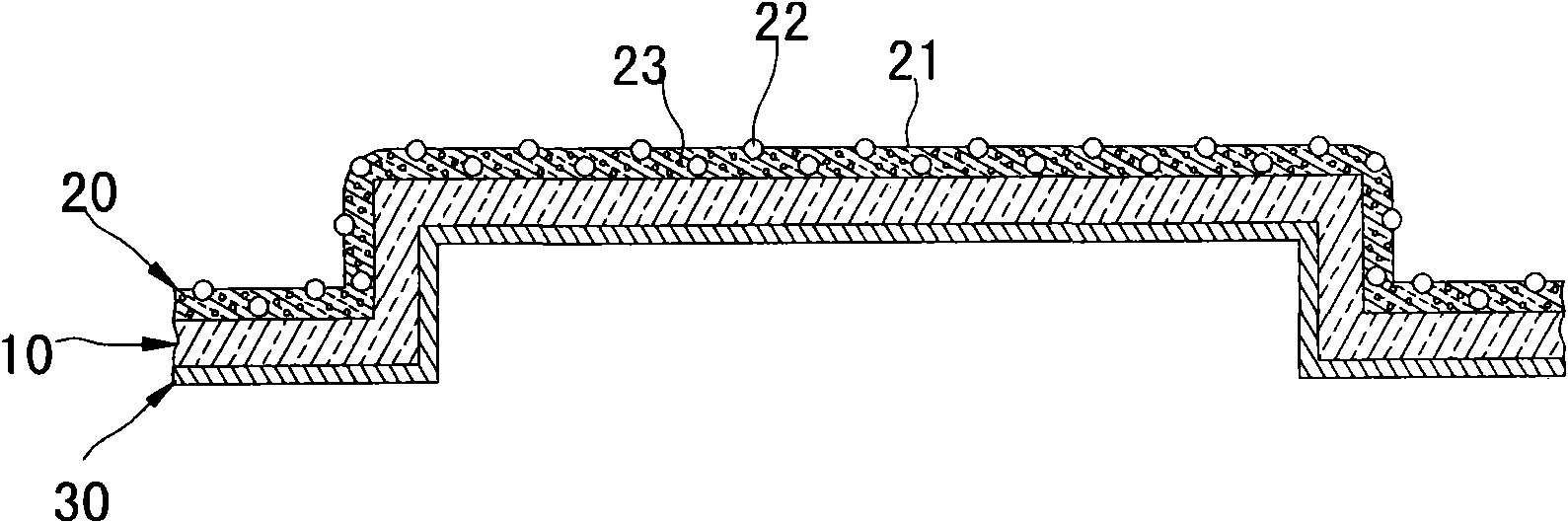

Captive fastener

A captive fastener includes a mounting base member bonded to a first panel frame, a locking shank loaded with a spring member and axially movably mounted in the mounting base member hole for engaging into a mounting through hole of a second panel frame to detachably lock the second panel frame to the first panel frame, and a driving member, which is coated with a color index coating for identification and connected to the locking shank after bonding the mounting base member to the first panel frame and operable to move the locking shank between a locking position where the first panel frame and the second panel frame are locked and an unlocking position where the first panel frame is detachable from the second panel frame.

Owner:HANWIT PRECISION IND LTD

Polyethylene wood plastic and preparation method thereof

The invention relates to a polyethylene wood plastic and a preparation method thereof and belongs to the technical field of plastic compound modifying processing. The invention provides a formula of the polyethylene wood plastic and a preparation method for a section bar; extruding temperature and extruding speed are increased; a polyethylene wood plastic section bar produced according to the preparation method has excellent high-temperature resistance; and according to the technical scheme, the polyethylene wood plastic comprises the following raw materials in parts by weight: 30-40 parts of polyethylene, 50-70 parts of wood flour, 0.5-2 parts of maleic anhydride grafted polyethylene, 0.8-1.5 parts of polyethylene wax, 1-3 parts of zinc stearate, 2-6 parts of toner, 0.5-1 part of antioxidant, 0.4-0.9 part of anti-ultraviolet light absorber UV-531 and 0.5-1.2 parts of stearic acids. The preparation method provided by the invention is suitable for the extruding molding of the polyethylene wood plastic section bar.

Owner:山西峰岩新型建材股份有限公司

Ink-jet recording material and preparation method thereof as well as method for preparing ink absorption layer coating liquid

ActiveCN102092209ALow priceIncrease polarityStarch dervative coatingsConjugated diene hydrocarbon coatingsPolymer scienceAdhesive

The invention provides an ink-jet recording material and a preparation method thereof as well as a method for preparing an ink absorption layer coating liquid, and relates to an ink-jet material and a preparation method thereof as well as a method for preparing an ink absorption layer coating liquid, so that the problems of poor ink absorption effect, nonuniform color distribution of printed images, unclear printed images and higher preparation cost of the existing ink-jet recording material can be solved. The ink-jet recording material is prepared from the ink-jet layer coating liquid which is prepared from PVC (polyvinyl chloride) serving as a base material, a 20-30% polyacrylic acid emulsion serving as a primer, an inorganic nano-pigment with the thickness of 10-100nm, a dispersing agent, acetic acid, deionized water and an adhesive aqueous solution. The prepared ink-jet recording material prepared through PVC material corona treatment, PVC substrate glue coating, drying, ink absorption layer coating and drying has the advantages that that the printed image is clear, the ink droplet does not diffuse, and the color is distributed uniformly; and the ink-jet recording material has excellent performances of color definition, color saturation, glossiness and the like. The raw material cost and the manufacture cost are low, so the ink-jet recording material is advantageous to industrial production, popularization and application.

Owner:HARBIN INST OF TECH

Colorful mortar for wall face

InactiveCN101508542AImprove water retentionImprove the lubrication effectCelluloseWeather resistance

The invention provides color mortar for wall facings, which is characterized in that the color mortar consists of the following raw materials in percentage by weight: 20 to 25 percent of cement, 50 to 60 percent of quartz sand, 10 to 20 percent of ground limestone, 2 to 4 percent of emulsion powder, 0.3 to 0.5 percent of lignocellulose, 0.3 to 0.5 percent of thixotropic lubricant, 0.15 to 0.2 percent of cellulose ether and 1 to 5 percent of inorganic pigment. The color mortar has the advantages of good weather resistance, firm and durable color and luster, good ultraviolet resistance, good binding force with various non-polar bottom layer materials, difficult cracking, and good hydrophobicity.

Owner:上海英硕聚合材料股份有限公司

Surface treating method for metal workpieces

InactiveCN101205616APrevent fadingAvoid the effects of stainingAnodisationMetallic material coating processesAnodic oxidationMetal

The invention provides a surface treatment method for a metal workpiece, which includes the following steps: the metal workpiece is provided, and the metal workpiece is provided with a welding zone which is formed during welding; the surface of the metal workpiece is conducted with anodic oxidation treatment to form an anode oxidation film on the surface of the metal workpiece; the metal workpiece is immersed in activate fluid to conduct activating treatment to the welding zone; the surface of the metal workpiece is washed by water; the metal workpiece is dipped in dyeing liquor for dyeing treatment; the surface of the workpiece is washed by water; the surface of the workpiece is dipped in hole sealing solution for hole sealing treatment.

Owner:SHENZHEN FUTAIHONG PRECISION IND CO LTD

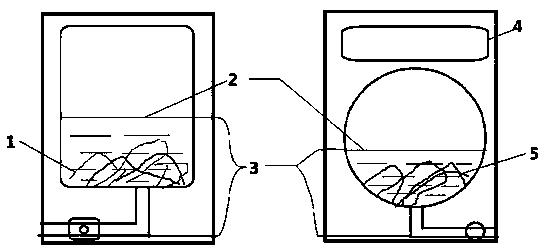

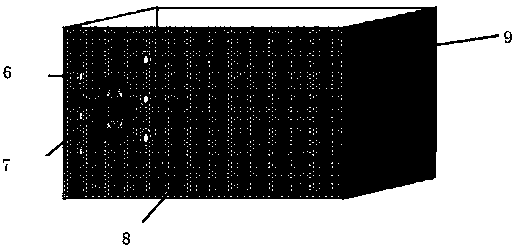

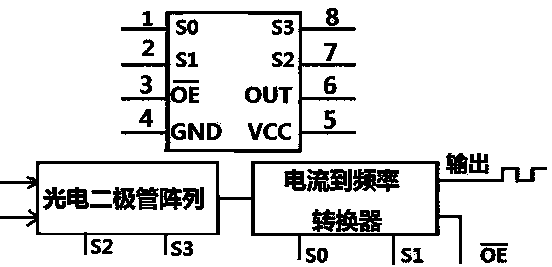

Anti-fading washing control method

ActiveCN104195787AResolve detectionSolve the disadvantages of missed alarmOther washing machinesControl devices for washing apparatusLaundry washing machineControl engineering

The invention discloses an anti-fading washing control method. According to the method, an impeller type washing machine or a tumbling-box washing machine is included. The washing machine comprises a washing machine body. An inner washing barrel, an outer barrel and a controller are mounted in the washing machine body. The washing machine body is further provided with a color sensor. The color sensor detects washing water in the washing process and feeds back a detected result to the controller. The controller analyzes the detected result and then judges whether follow-up operation for preventing fading and mutual dyeing needs to be conducted. The anti-fading washing machine can judge whether woven products fade or not accurately in time.

Owner:HISENSE(SHANDONG)REFRIGERATOR CO LTD

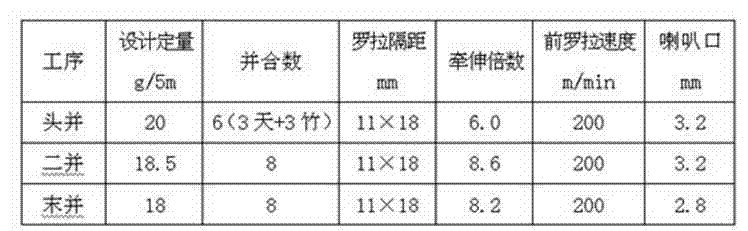

Natural bamboo fiber shirt fabric and manufacture method thereof

The invention provides natural bamboo fiber shirt fabric which has silky gloss, good feel and drapability, and is rich in graceful feeling, antibiosis, moisture-adsorption and ventilating. Warps and wefts of the fabric are both natural fiber / bamboo viscose blended yarns, the blending ratio of the warps and the wefts is 1:1, the warp density is 512 / 10cm, and the weft density is 338.5 / 10cm. A manufacture method of the natural bamboo fiber shirt fabric comprises the following steps: a, blending: opening picking, carding cotton, drawing out, roving and spun yarn; b, drum yarn dying: tube loosening, pretreatment, dying, dehydration and drying, wherein the pretreatment comprises bleaching and enzyme treatment; during bleaching: soda ash is 1-3g / L, hydrogen peroxide is 1-2g / L, the temperature is 95 DEG C, the time is 35-45min; and during the enzyme treatment, HontonezymePA is 1-1.5g / L, pH value is 4.5-5.5, the bath ratio is 1:15, and the time is 25-35min; and during dying, the drum yarn density is 0.33-0.35g / cm<3>, and MegafixB type reactive dying is adopted; c, weaving: winding, warp pulp connection, drawing in or warp tying and weaving; and d, after treatment: singeing, desizing, sizing and preshrinking.

Owner:JIANGSU YDTEX GRP LTD

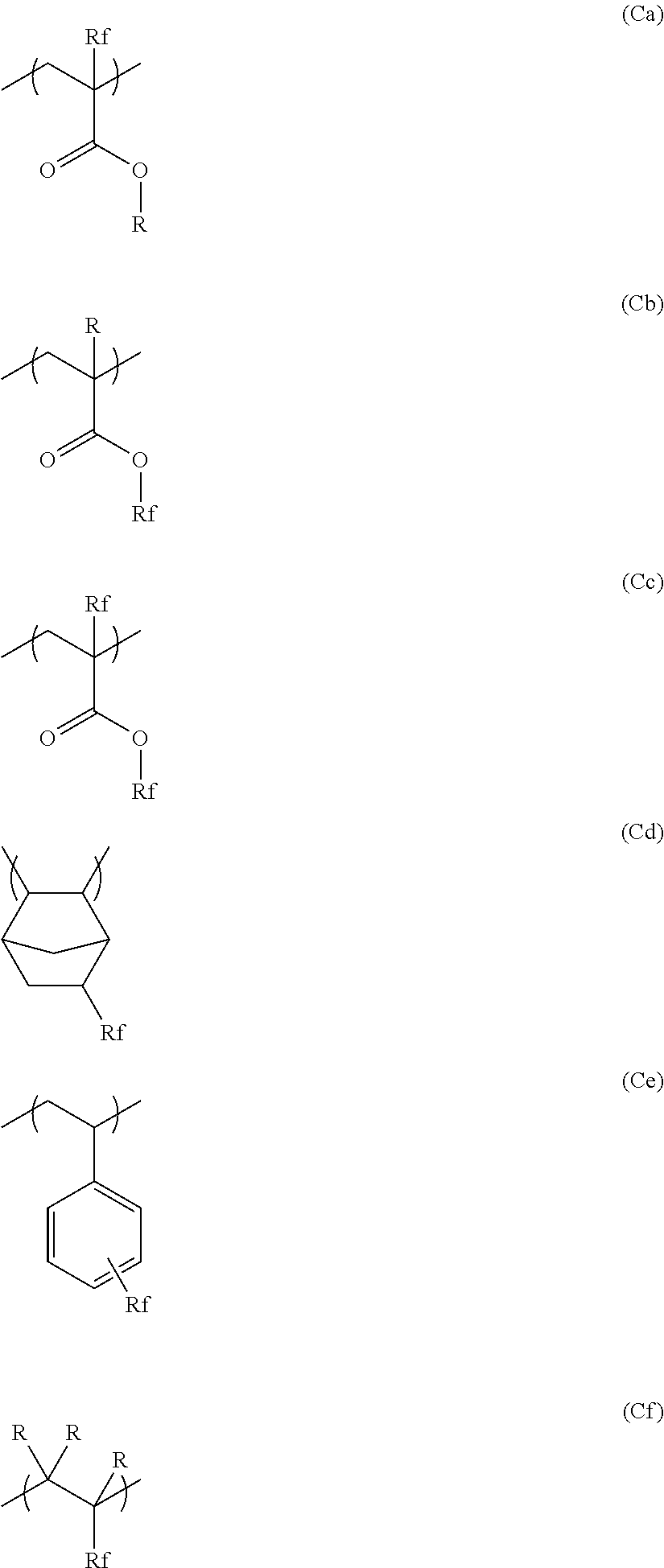

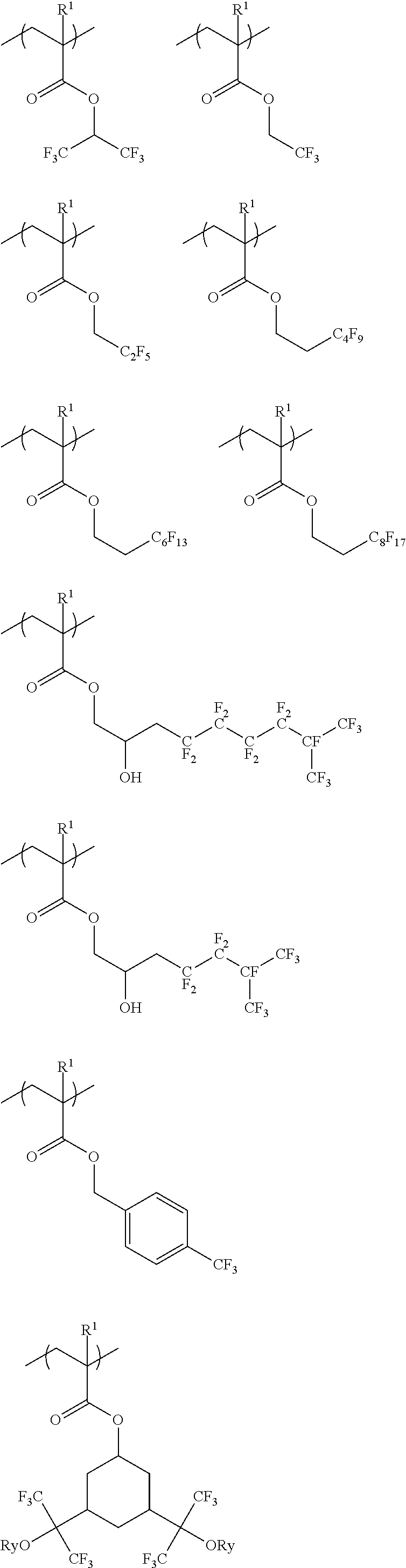

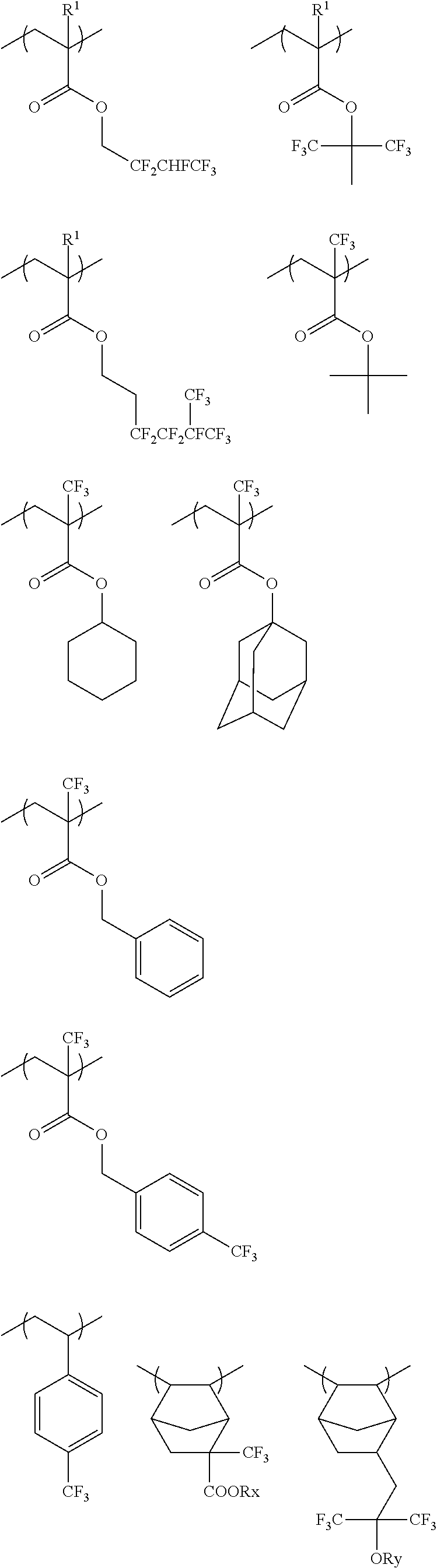

Composition for imprints, pattern and patterning method

InactiveUS20110183127A1Hardly worsening mold transferabilityImprove coating uniformityLayered productsDecorative surface effectsSiliconContamination

A composition for imprints comprising a polymerizable monomer, a photopolymerization initiator, and a polymer having a functional group with at least one of a fluorine atom or a silicon atom and having a polymerizable functional group, wherein the polymer has a weight-average molecular weight of at least 2000 and the amount of the polymer is from 0.01 to 20% by mass relative to the polymerizable monomer, is excellent in patternability and mold releasability, capable of forming good patterns and free from a problem of mold contamination.

Owner:FUJIFILM CORP

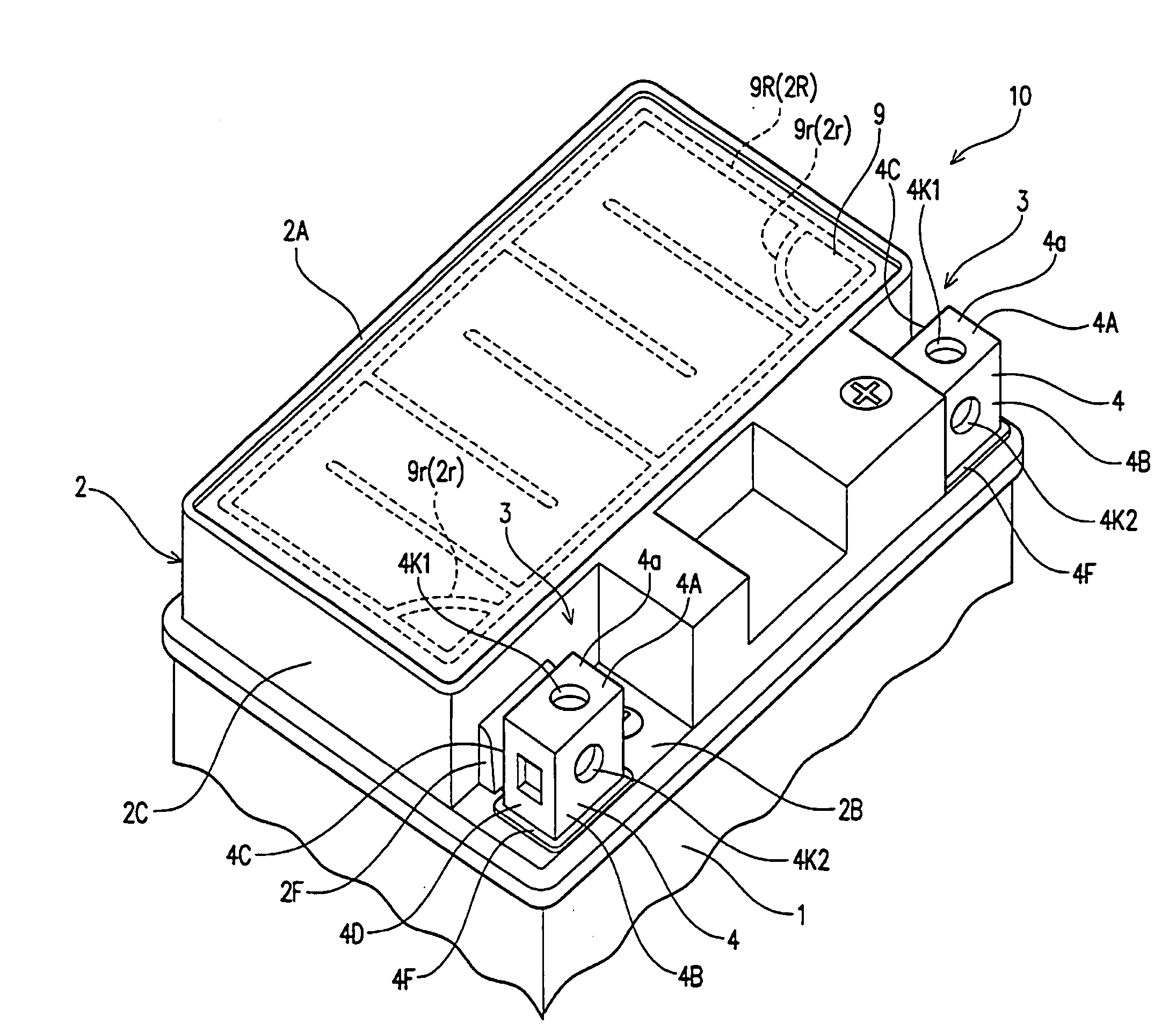

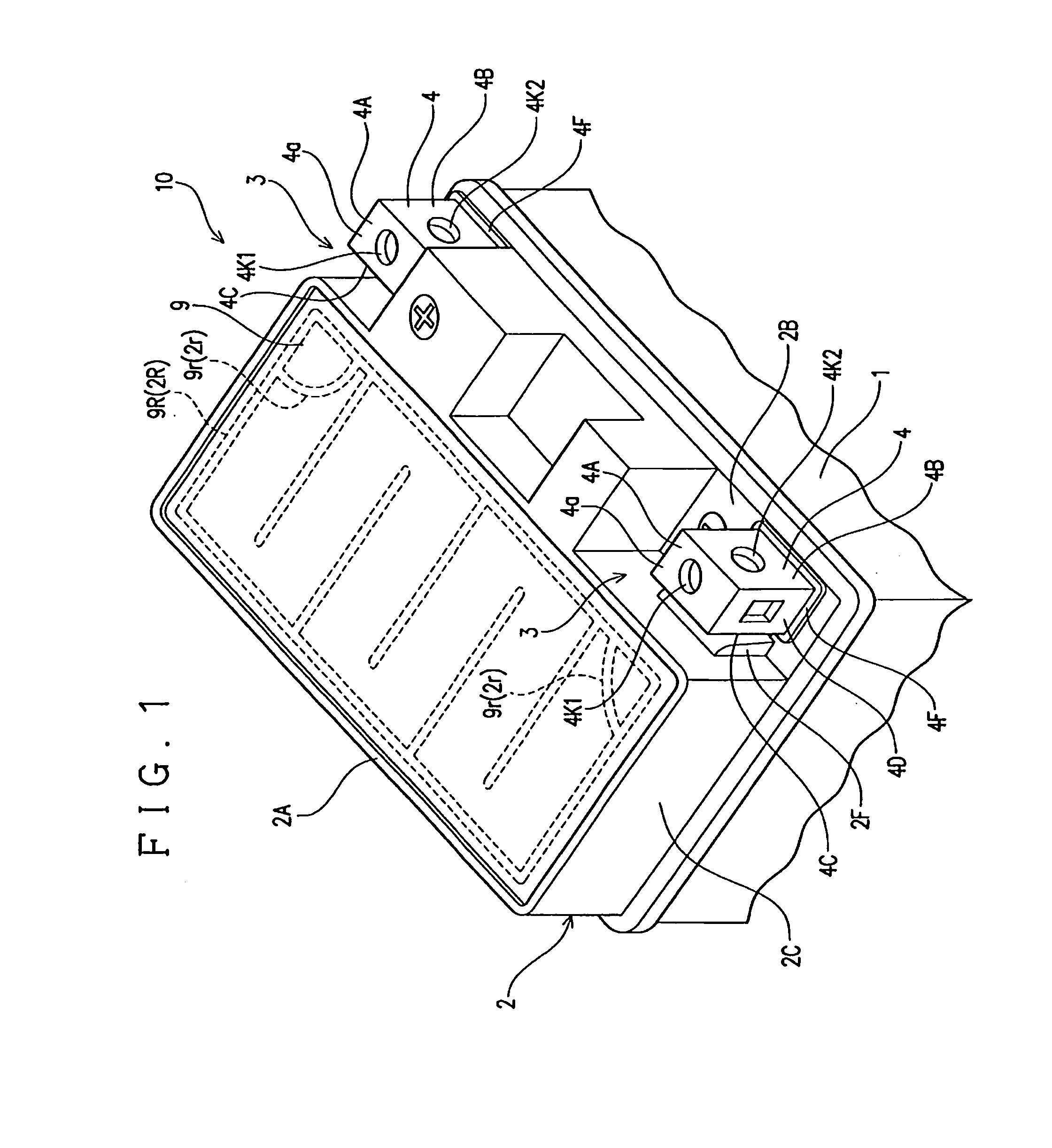

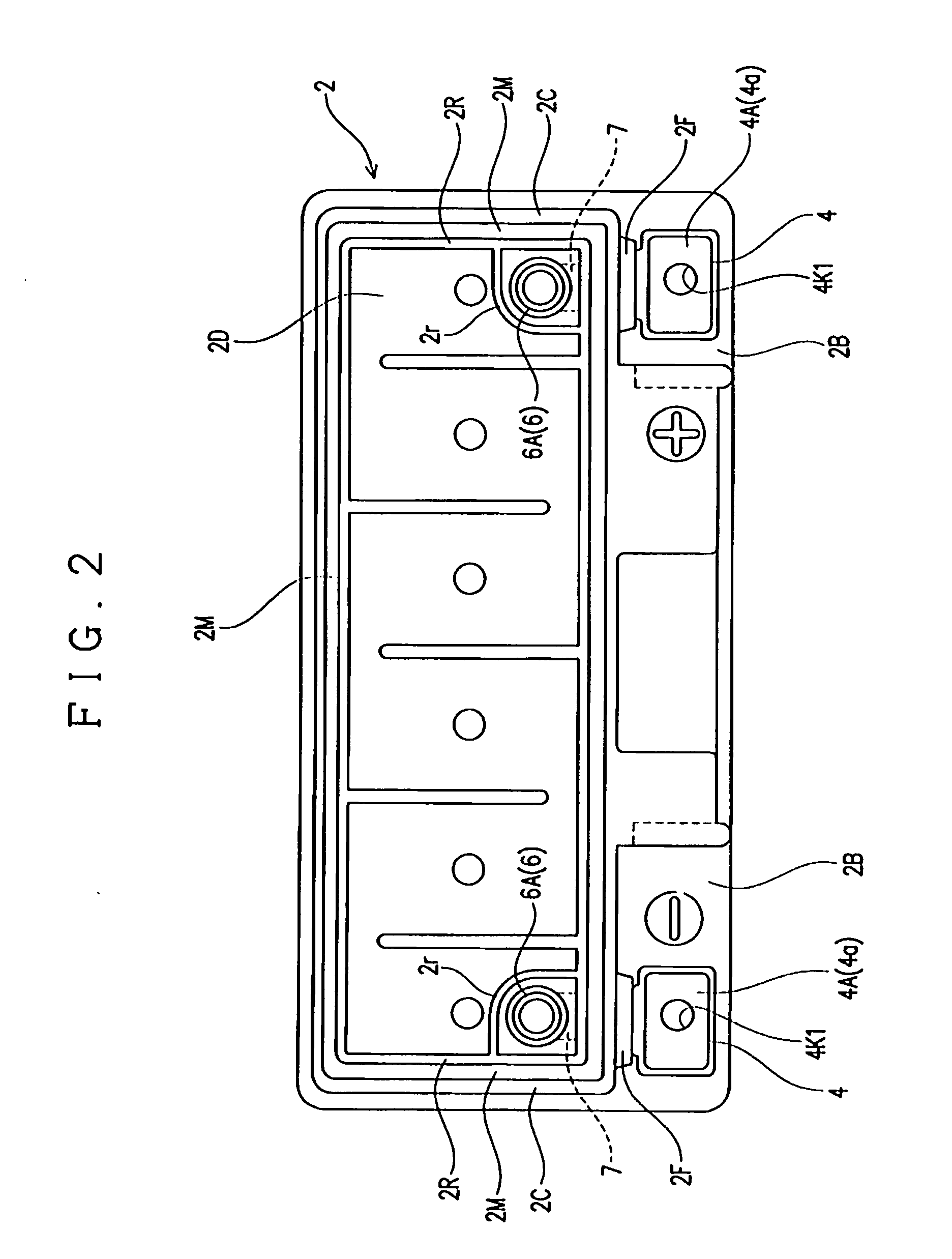

Storage battery

InactiveUS20090042098A1Easy and speedy fabrication workAvoid problemsCell lids/coversSynthetic resinMechanical engineering

There is provided storage battery that is capable of enabling an easy and speedy fabrication work as well as preventing a terminal thereof from fading or decaying for a long time. A storage battery includes: a lid made of a synthetic resin for closing a container and having cutout portions or recesses; terminals disposed respectively in the cutout portions or the recesses; bushings each having a tubular shape located inside the lid; electrode poles extending from the container for taking out power, the electrode poles respectively inserted into the bushings and welded thereto; conductive portions each for electrically connecting an upper side of the bushing and a lower side of the terminal disposed in parallel with the bushing in a horizontal direction in each of the cutout portions or the recesses; and an auxiliary lid for covering the bushing disposed inside the lid from above. The terminal, the bushing and the conductive portion are monolithically molded to form a terminal portion of the corresponding terminal in each of the cutouts or the recesses. Annular protrusions protrude outwards from a side wall of the conductive portion. At least a lower portion of the bushing and the conductive portion of the terminal portion in each of the cutouts or the recesses are embedded in the lid by insert molding.

Owner:HONDA MOTOR CO LTD

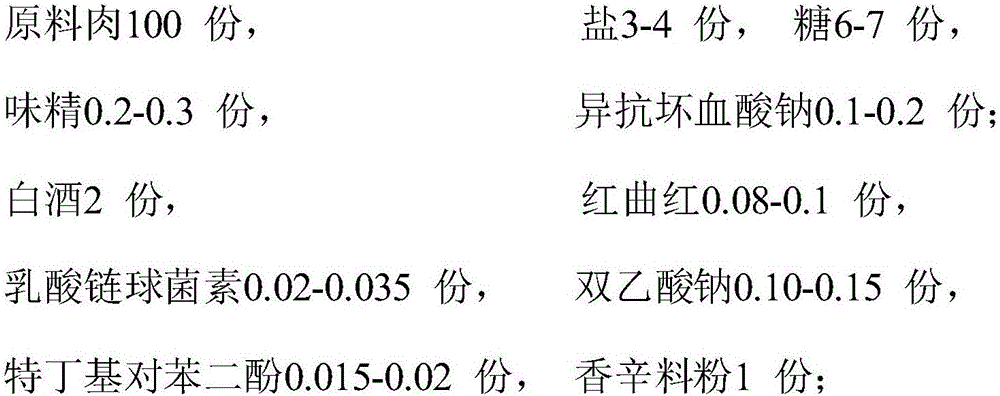

Nitrite-substituted meat processing method

InactiveCN106071907AGood effectGood muscle toneFood ingredient as antioxidantFood ingredient as taste affecting agentBetaninEthyl maltol

The invention discloses a nitrite-substituted meat processing method, and belongs to the technical field of food processing. The nitrite-substituted meat processing method comprises the following steps: selecting raw materials, carrying out pickling treatment and processing a meat product, so that the final products of the meat product are prepared; and the nitrite is substituted by a nitrite substitute during the step of carrying out pickling treatment. The nitrite substitute comprises the following components in parts by weight: 4-5 parts of monascorubin, 0.7-1.3 parts of betanin, 4-6 parts of potassium sorbate, 2-3 parts of D-sodium isoascorbate, 1.5-2.5 parts of nisin, 9-11 parts of sodium lactate, 1-2 parts of natamycin, 5-6 parts of natural vitamin E, 1-2 parts of a rosemary extract, 0.5-1.5 parts of sage essential oil, 1-2 parts of tea polyphenols, 15-16 parts of L-sodium glutamate, 0.5-1.5 parts of flavoring 5'-disodium ribonucleotide, 40-43 parts of a yeast extract, 4-5 parts of sodium tripolyphosphate and 0.5-1.5 parts of ethyl maltol. The nitrite-substituted meat processing method disclosed by the invention is simple, easy to operate and free of nitrite addition; and the prepared meat products are very good in qualities, color, luster and taste.

Owner:邯郸市锦园食品有限公司

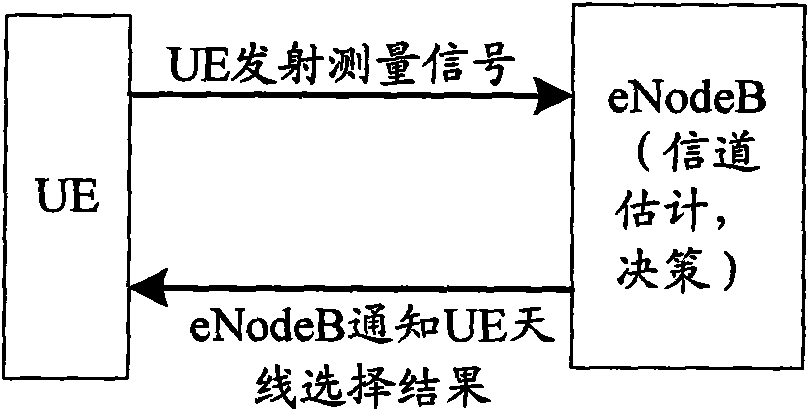

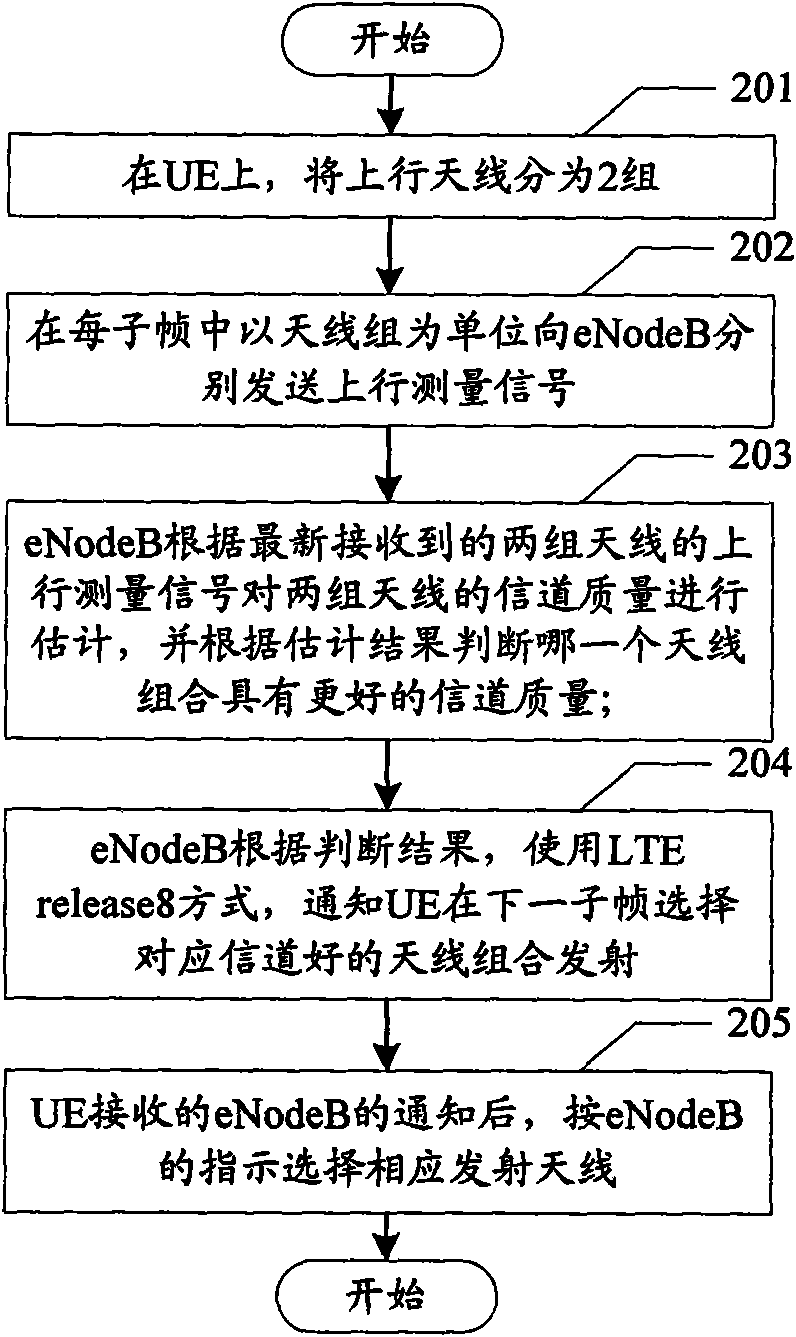

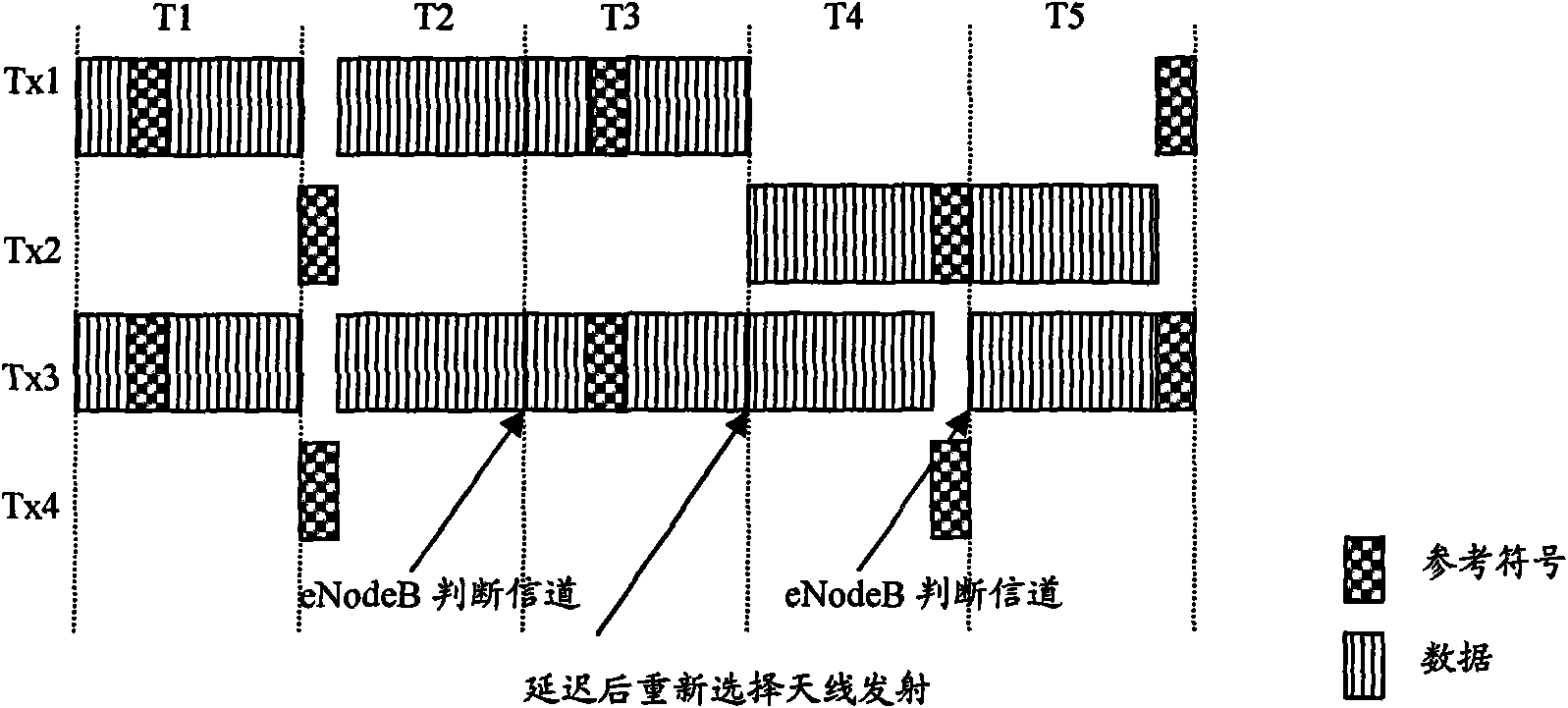

Antenna selection method and device for mobile terminal

InactiveCN101944940AReduce modificationReduce signaling overheadSpatial transmit diversityHigh level techniquesTransmission performanceSelection method

The invention discloses an antenna selection method and an antenna selection system for a mobile terminal, and is used for solving the technical problem of antenna selection under an LTE-A protocol version. By considering power conservation of the terminal and cost problem, four antennas are grouped or sorted according to channel quality estimation results thereof so as to select a group of antennas or two antennas with the highest channel quality estimation for transmission. The antenna selection method and the antenna selection system can use an antenna selection signaling in an LTE release8 protocol version, have little modification of the system and low signaling overhead, and also can support a flexible antenna grouping mode by increasing DCI so as to improve the sensitivity to the channel quality and enhance transmission performance.

Owner:ZTE CORP

Useful aramid blends

InactiveUS20120183747A1Excellent mechanical and flame resistance and printability propertyPrevent fadingChemical protectionHeat protectionYarnPolyamide

The present invention relates to a fabric comprising a warp system and a weft system. The warp system comprises at least one flame retardant yarn comprising aramid fibers and the weft system comprises at least one core spun yarn. The flame retardant yarn of the warp system is covered by at least 70% of the weft system.The fabric according to the present invention has an ink receptive surface and a thermal protection surface, and has particularly excellent mechanical, flame resistance and printability properties due to the structure of its weft and warp systems and the materials used and is particularly useful in confection of combat uniforms. Furthermore, the fabric according to the present invention is also exceptionally abrasion resistant, which prevents the fading of a printed image thereon.

Owner:EI DU PONT DE NEMOURS & CO

Nano silver face pack for beauty treatment

PendingCN101129308AGood effectReduce concentrationCosmetic preparationsToilet preparationsMedicineGreen tea extract

The invention discloses a multifunctional beauty treatment face pack which comprises the following constituents (by weight percent): nano colloidal silver 0. 0005-0. 0015%, aloe extract 4. 0-8. 0%, natto gum 0. 5-1. 55, ginkgo extract 0. 3-0. 5%, green tea extract 0. 1-0. 3% and lavandula angustifolia extract 0. 05-0. 15%.

Owner:全昌均 +1

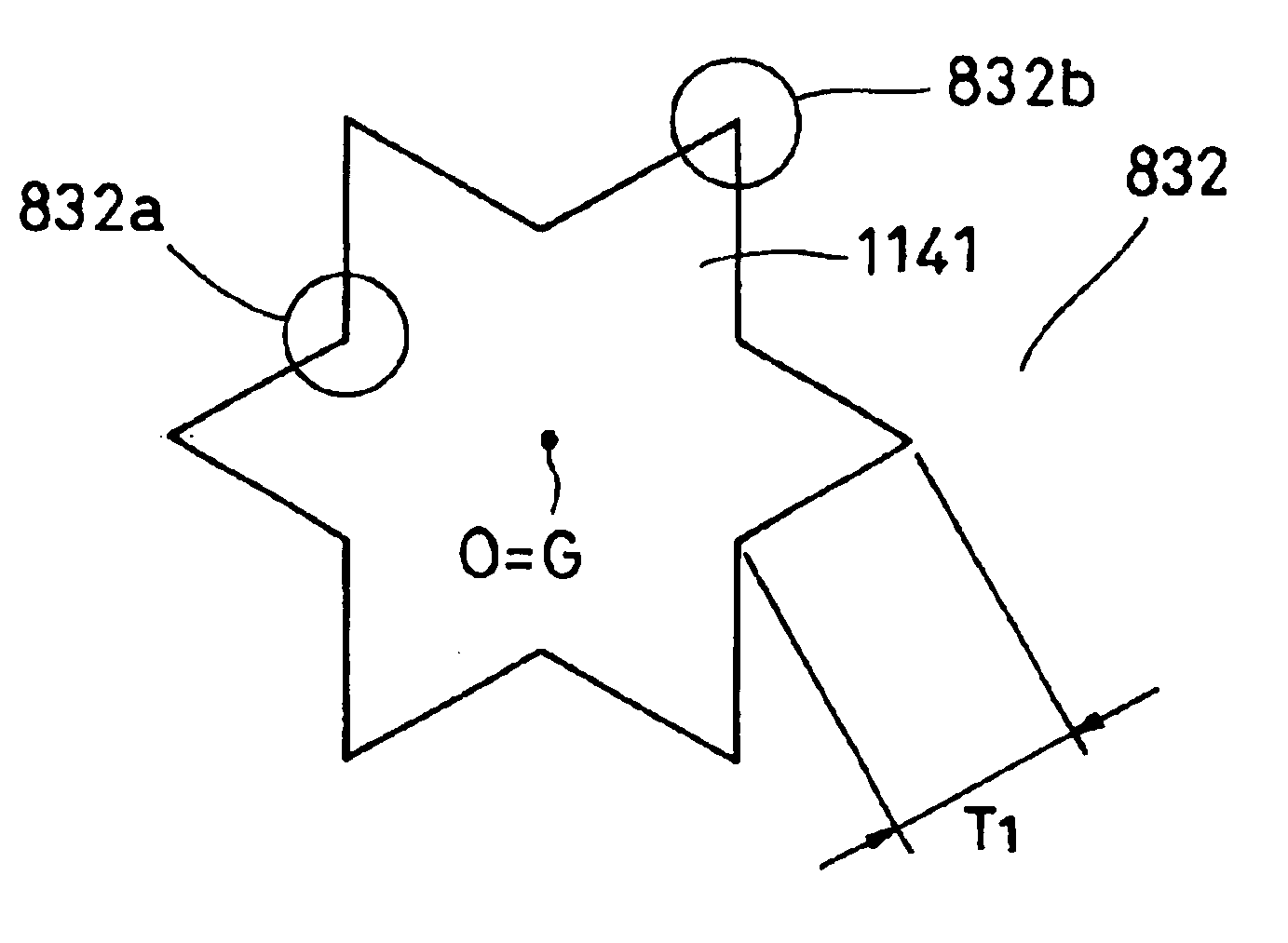

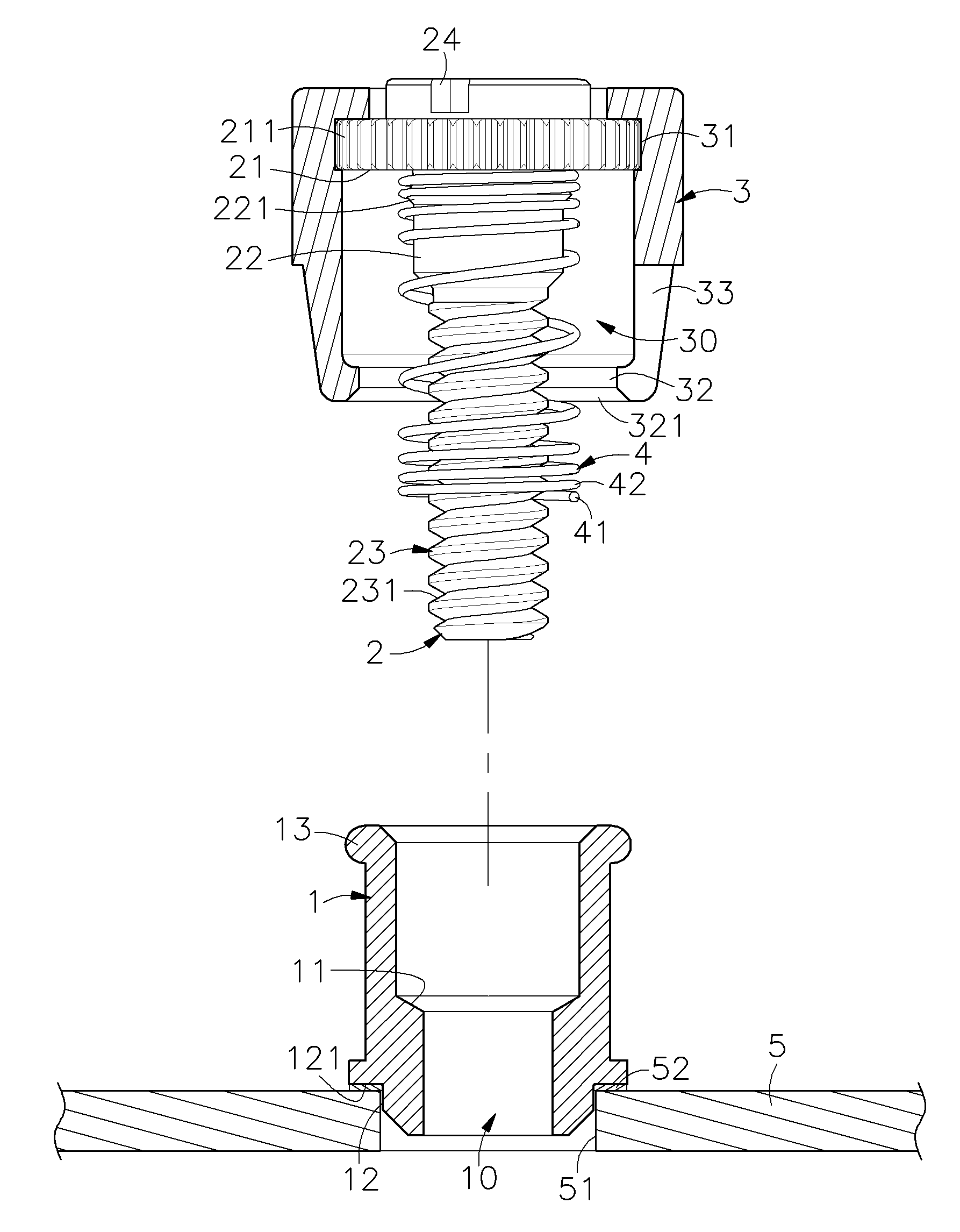

Plate member fastener

A plate member fastener includes a barrel bonded to a mounting through hole of a first metal plate member through a reflow bonding process, a screw member, which is inserted through the barrel after bonding of the barrel to the first metal plate member and threaded into a screw hole of a second metal plate member to joint the first and second metal plate members together, a cap molded on the head of the screw member and axially movably coupled to the barrel for gripping by a user to rotate the screw member into or out of the screw hole of the second metal plate member, and a spring member sleeved onto the shank of the screw member and stopped between the head of the screw member and a step inside the barrel to force the cap outwards relative to the barrel.

Owner:WANG KUO CHUNG

Melon and fruit fresh-keeping liquid and preparation method thereof

InactiveCN101199298AImprove stabilityReduce manufacturing costFruit and vegetables preservationSucroseFiltration

The invention is a melon-fruit preservative solution which is composed of chitosan solution (2.5-5.0w percent), gelatin (2.0-5.0w percent), glycerol (0.5-1.0w percent), cane sugar (0.5-1.0w percent), tragantine (5.0-10.0w percent) and plant rosemary extract (80.0-85.0w percent). The chitosan solution is the saturated liquid of chitosan in acetic acid with concentration of one percent; the plant rosemary extract is distillate of the plant rosemary with temperature of 90-103 DEG C received by distillation after the filtration and slag removal through being soaked in water with the volume 40 times greater than that of plant rosemary. The invention has advantages of easy material getting, simple preparation method, low production cost, small energy consumption, innocuity to human bodies, non environment pollution, long preserving time for melon and fruit-in particular to high-grade fruit and good effects.

Owner:DALIAN POLYTECHNIC UNIVERSITY

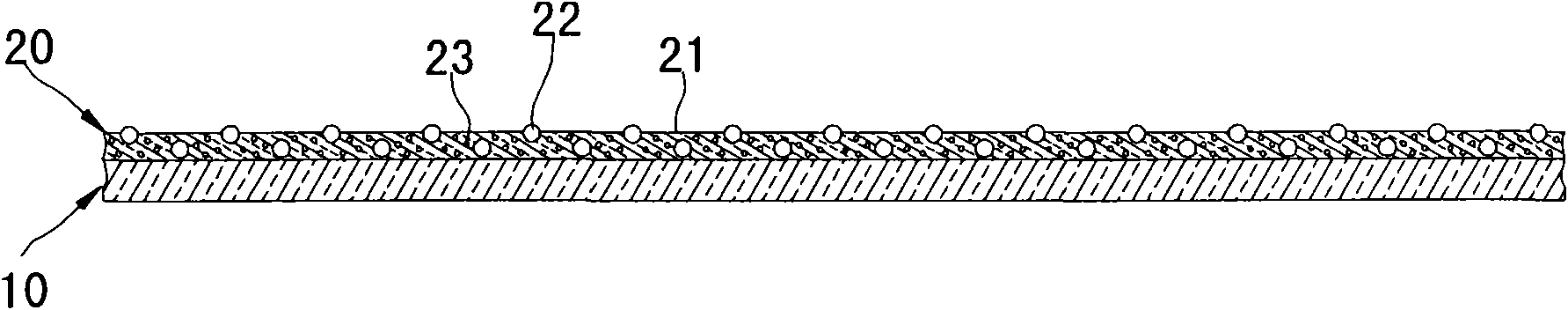

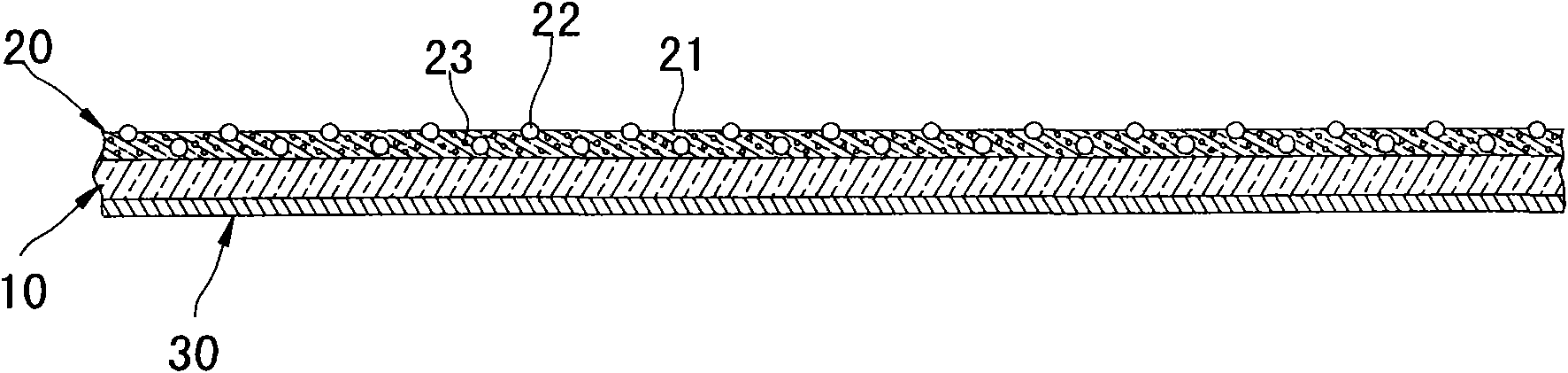

Thin film structure and manufacturing method thereof

ActiveCN101596803AFeel comfortableImprove scratch resistance and abrasion resistanceLiquid surface applicatorsSynthetic resin layered productsUltraviolet lightsThermal treatment

The invention discloses a thin film structure and a manufacturing method thereof for intromode decoration process. The method comprises the steps of coating a coating containing at least two kinds of elastic resin particles on the surface above the thin film, wherein the two kinds of resin particles contains first resin particles for increasing the fluffy feeling and second resin particles for increasing the scratch and abrasion resistances, then forming an ink layer on the surface below the thin film and molding the thin film into a predetermined shape through thermal treatment, molding and laminating a plastic base material under the ink layer in the form of injection molding, and finally hardening the coating by using ultraviolet light. Hereby, the thin film has fluffy feeling as well as scratch and abrasion resistances.

Owner:ENTIRE TECH CO LTD

Nano silicon dioxide modified polyurethane composite material

The invention discloses a nano silicon dioxide modified polyurethane composite material comprising the raw materials: polytetrahydrofuran glycol, hydroxyl-terminated polyepichlorohydrin, isocyanate, epoxy resin, a chain extender, 1H,1H,8H,8H-dodecafluoro-1,8-octanediol, a catalyst, polypropylene, a maleic anhydride grafted ethylene-octene copolymer, an acrylonitrile-styrene-butadiene copolymer, ethylene-propylene-diene rubber, organic modified nano silicon dioxide, tetrapod-like zinc oxide whiskers, graphene oxide, carbon nanotubes, expanded graphite, tris(2-chloroethyl) phosphate, triphenyl phosphite, tris(2,4-di-tert-butylphenyl)phosphite, di(octane phenol polyoxyethylene)phosphate, polythiazole, and a silane coupling agent. The nano silicon dioxide modified polyurethane composite material provided by the invention has the advantages of excellent heat resistance, good flame retardancy, good water resistance, and high strength.

Owner:CHUZHOU GLOBAL POLYURETHANE TECH CO LTD

Method for bleaching grey down feather

InactiveCN101705612AThe whiteness is obviously improvedDown damage is smallBleaching apparatusIonChemistry

The invention discloses a method for bleaching grey down feather. The method comprises the following steps: firstly, using ferrous ions to conduct pretreatment on down feather to be treated, then conducting selective oxidation bleaching on the down feather, and finally using thiourea dioxide to conduct reduction bleaching on the down feather, and using clear water to wash the down feather, and drying. The method can effectively eliminate the natural pigment in the down feather, and has less damage to the down feather; the selective oxidation bleaching and reduction bleaching by using the thiourea dioxide (TDO) are combined to treat the down feather; after the TDO is applied to conduct reduction bleaching under the mild condition on the down feather treated by selective oxidation bleaching, thus improving the whiteness of the down feather, leading the decolorization and bleaching of the grey down feather to achieve high-level whiteness, and inhibiting the color reversion of the down feather; and the TDO is an acid reducing agent, can play the role of strong reducing property under the acidulous and neutral conditions, is suitable for the stability condition of the protein fiber in the down feather, and has little damage to the fiber. The whole process for decolorizing and bleaching the down feather is conducted at low temperature, thus not only ensuring the little damage to the fiber, and good bulkiness, but also being beneficial to energy conservation and environmental protection.

Owner:萧山区质量计量监测中心 +1

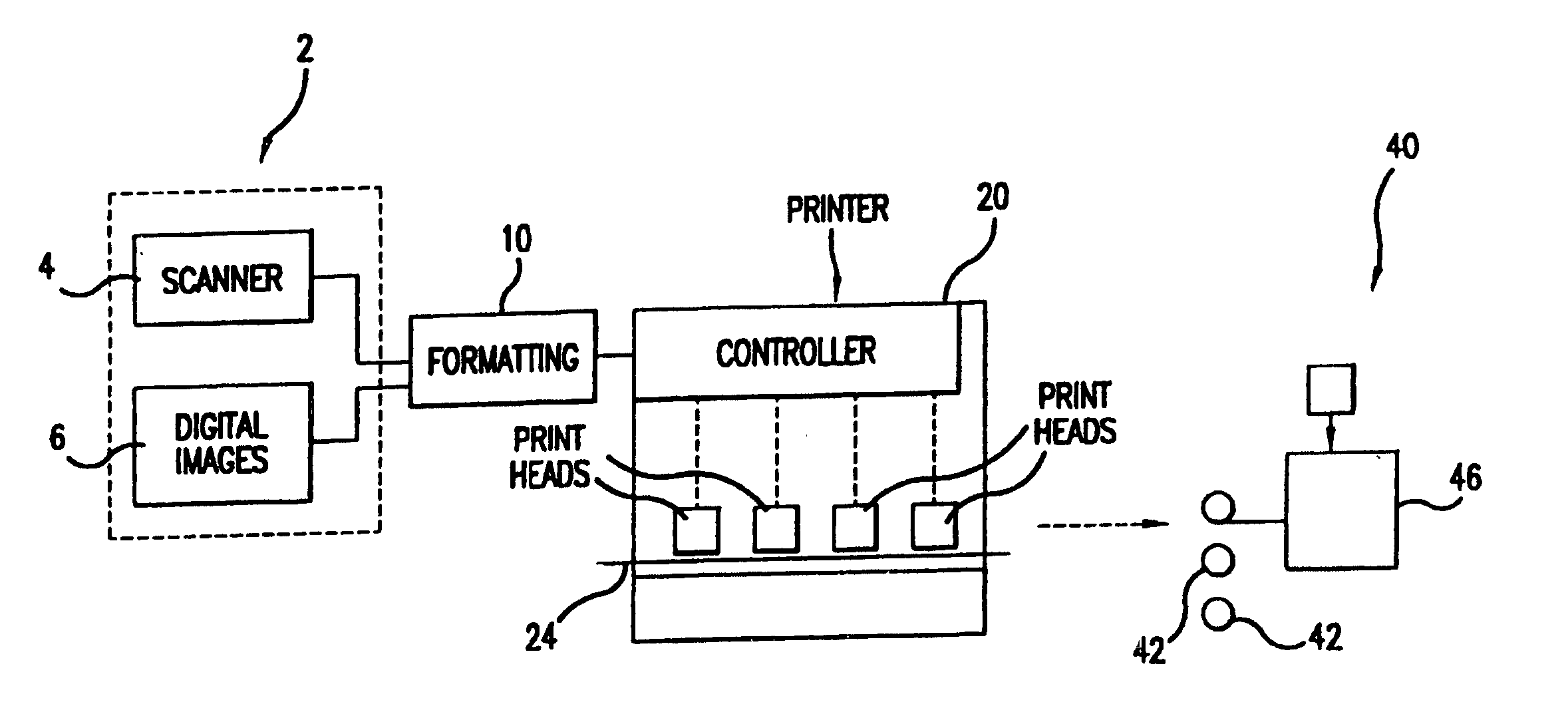

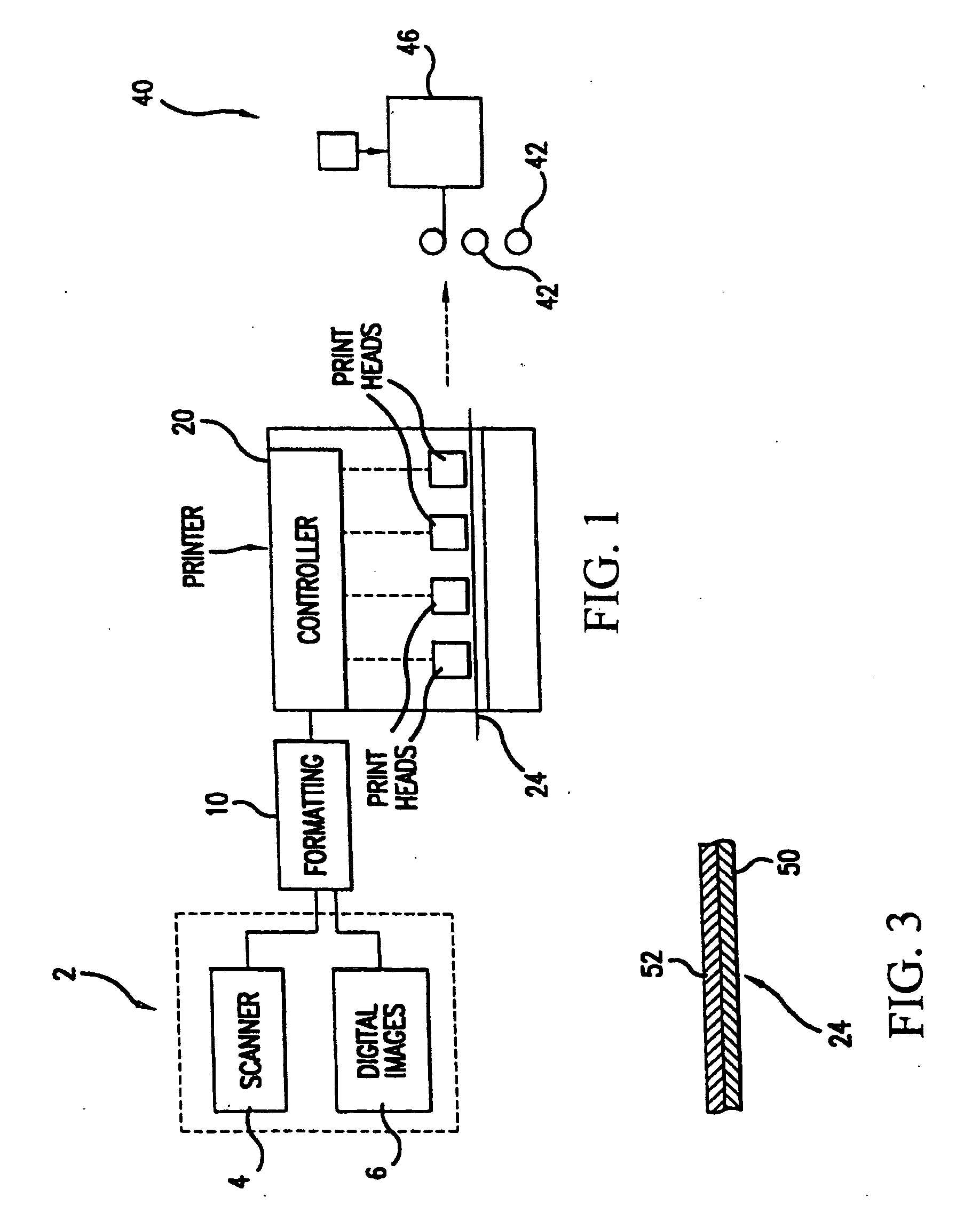

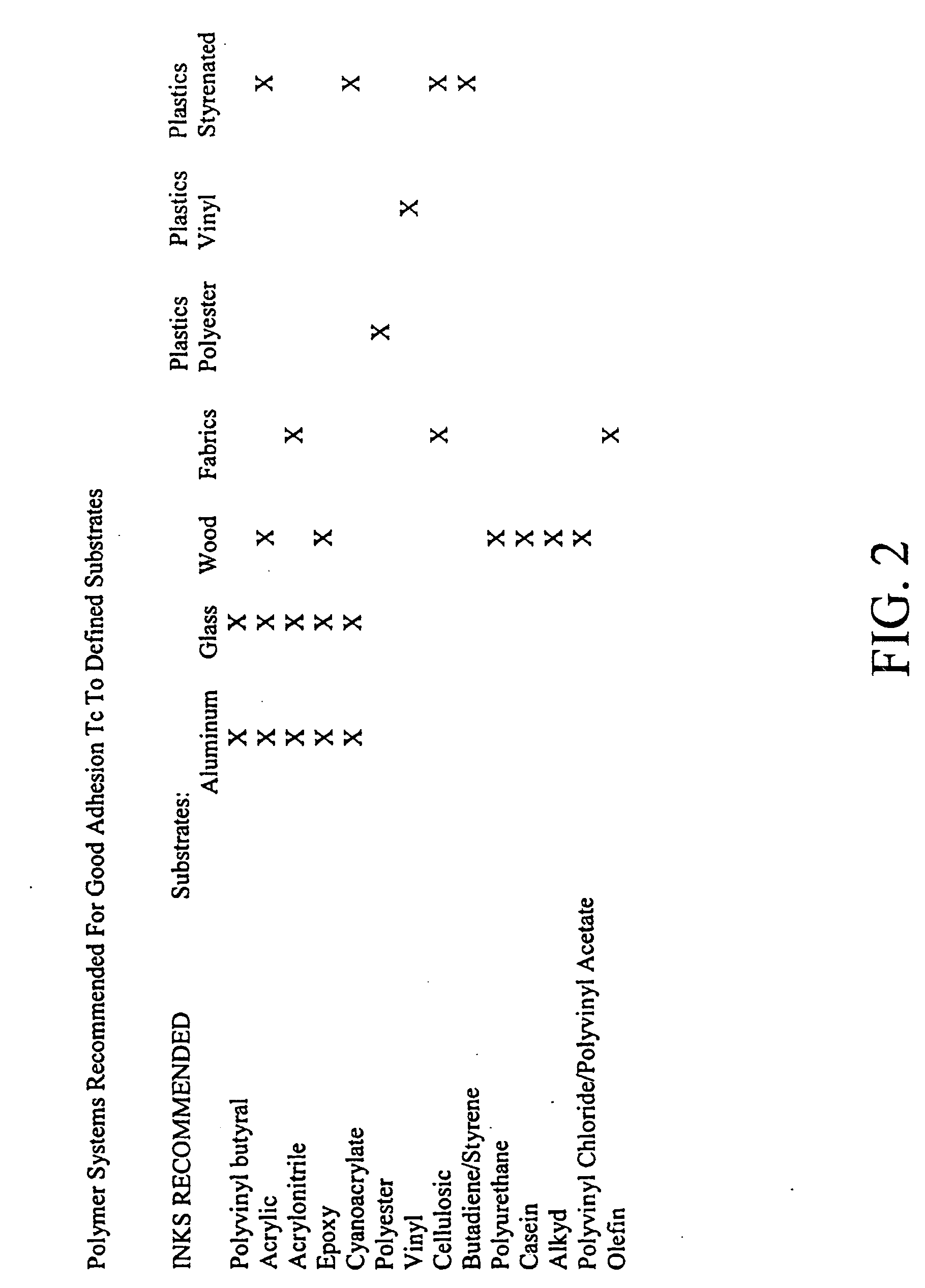

Insert molded print product on demand

A system and process for high speed molding to place printed images, particularly printed color images, on molded objects using a print medium composed of a substrate carrying a coating, the coating being adapted to retain printing inks and formulated to be releasable from the substrate after a molding process. Alternatively, the coating may be formulated to adhere to the substrate after the molding process. The portion of the print medium placed inside may be separated into segments or left in a continuous strip prior to placement in the mold. Images may also be placed on objects by printing directly on the surface of a mold, causing ink from the image to bond to the object formed upon closing the mold and injecting molded material into the mold cavity.

Owner:NAT PEN CORP

Thermosetting powder coating composition

InactiveUS6506843B1Good effectMaintain gloss retentionPretreated surfacesPolyurea/polyurethane coatingsRoom temperatureResin-Based Composite

To provide a thermosetting powder coating composition which comprises a powder of a composite resin comprising a vinylidene fluoride polymer having crosslinkable functional group and a methyl methacrylate polymer and having a melt flow rate of 1 to 1,000 g / 10 min when measured at 130° C. at a load of 2.1 kg. The coating composition has advantages that the preparation thereof is easy because pulverization can be carried out at room temperature as well as at low temperatures, the composite resin has excellent compatibility with various curing agents and the composition gives a coating film having excellent properties.

Owner:DAIKIN IND LTD

Method for inhibiting fading and enhancing color intensity of color-treated hair

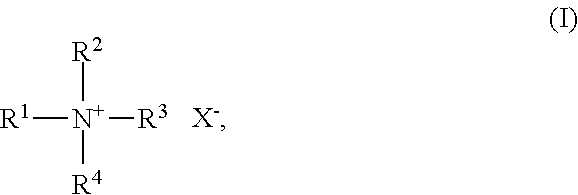

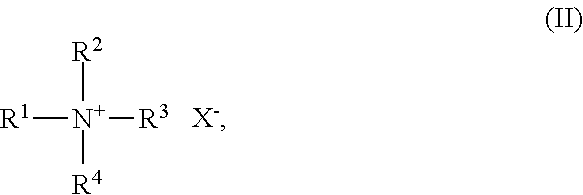

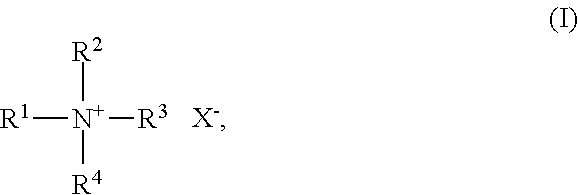

InactiveUS20110044924A1Increase in colour intensityInhibit from colorCosmetic preparationsCationic surface-active compoundsPolymer chemistryFiber

The invention provides a method for inhibiting color fading in color-treated keratinous fibers, which method includes treating the keratinous fibers with a color-fade inhibiting-effective effective amount of a monoalkyl quaternary ammonium salt. The invention also provides a method for enhancing the intensity of color in color-treated keratinous fibers, which method includes treating the keratinous fibers with a color intensity enhancing effective amount of an alkyl a quaternary ammonium salt. Additionally provided are products for inhibiting the fading of color and increasing the intensity of color in color-treated keratinous fibers.

Owner:ALBERTO-CULVER

Fabric dirt pretreatment agent containing steady biological enzyme complex and low-activity substance and preparation method thereof

ActiveCN101514306ALow cost performanceLow market priceSurface-active detergent compositionsDetergent perfumesFatty alcoholPollution

The invention relates to a fabric dirt pretreatment agent containing a steady biological enzyme complex and a low-activity substance and a preparation method thereof. A product of the invention takes fatty alcohol polyoxyethylene ether (7), fatty alcohol polyoxyethylene ether (9), sodium fatty alcohol-polyoxyethyleneether sulfate (70 percent), fatty alcohol polyoxyethylene ether (JFC), polyacrylate, sodium citrate, boric acid, propylene glycol, prolease, calcium chloride, isothiazolinone, essence, and deionized water as raw materials; and the method adopts a polymer to ensure that the prolease forms a polymer complex in a system by researching biological enzyme stabilization technology, which ensures the long-term effective activity of biological enzyme, ensures that the product can achieve stronger detergency when the content of an active substance is 10 percent or so and has steady quality during the storage, and achieves the aims of saving resources and protecting environment. The product is neutral, and has unique advantages in preventing fading, reducing the damage of clothes, protecting skin, and reducing pollution.

Owner:北京绿伞科技股份有限公司

A preparing method of ceramic inkjet ink

A preparing method of ceramic inkjet ink is disclosed. The method is characterized in that the ink is prepared from an inclusion type cadmium sulfoselenide colourant or an inclusion type cadmium sulfide colourant; and the inclusion type cadmium sulfoselenide colourant is one or more of a zirconium silicate inclusion type cadmium sulfoselenide colourant, a silicon dioxide inclusion type cadmium sulfoselenide colourant and a zirconium dioxide inclusion type cadmium sulfoselenide colourant. The inclusion type cadmium sulfide colourant is one or more of a zirconium silicate inclusion type cadmium sulfide colourant, a silicon dioxide inclusion type cadmium sulfide colourant and a zirconium dioxide inclusion type cadmium sulfide colourant. Compared with the prior art, the ink is prepared by using the inclusion type cadmium sulfoselenide colourant creatively, the technical constraint that application of the zirconium silicate inclusion type cadmium sulfoselenide colourant for preparation of inkjet ink is difficult is overcome at a stroke, the color of the inkjet ink can be configured as a series of colors from yellow to orange to crimson, and the inkjet ink is rich in color, various in choice, suitable for various ceramic products and dark in color development.

Owner:吴权武

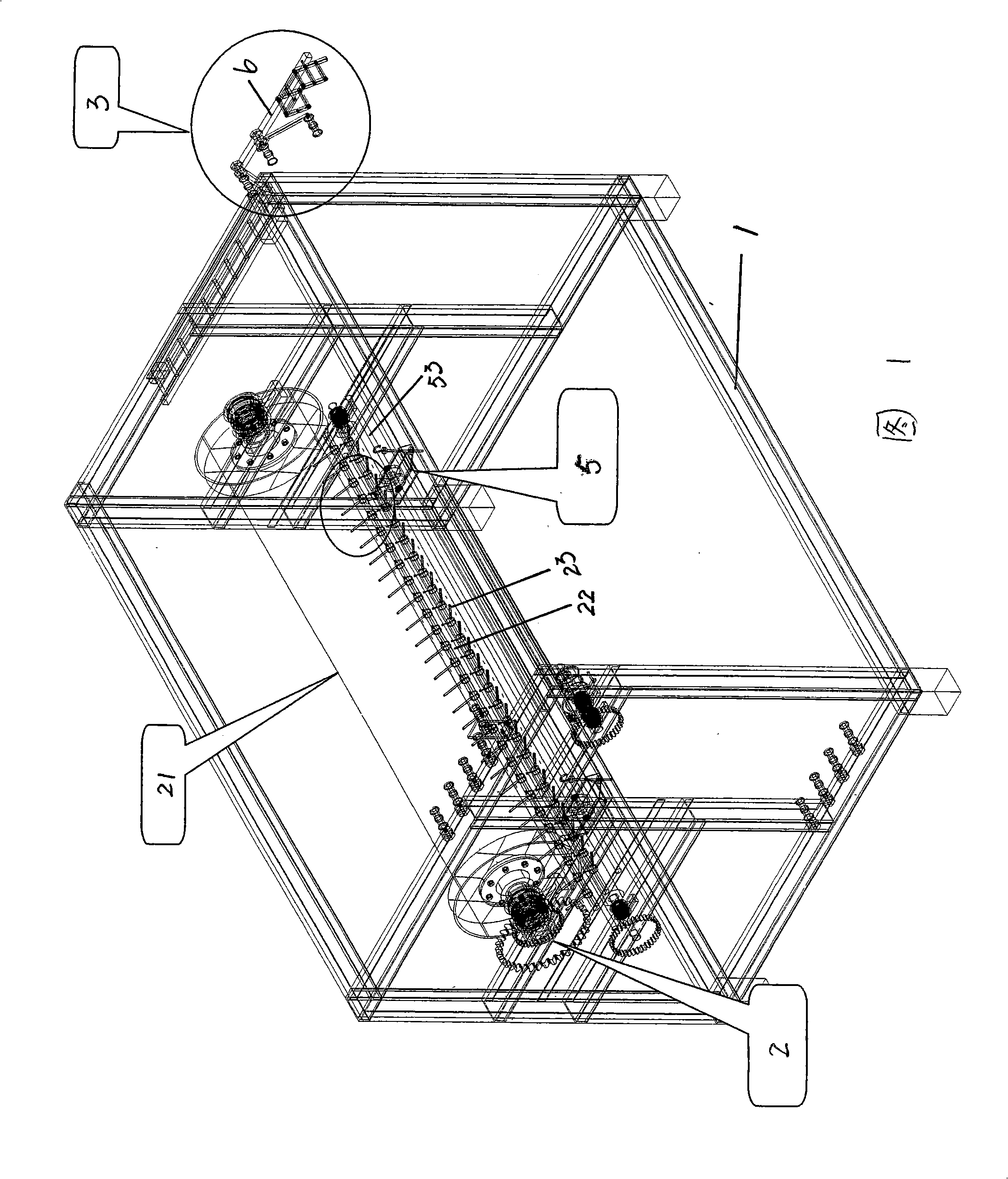

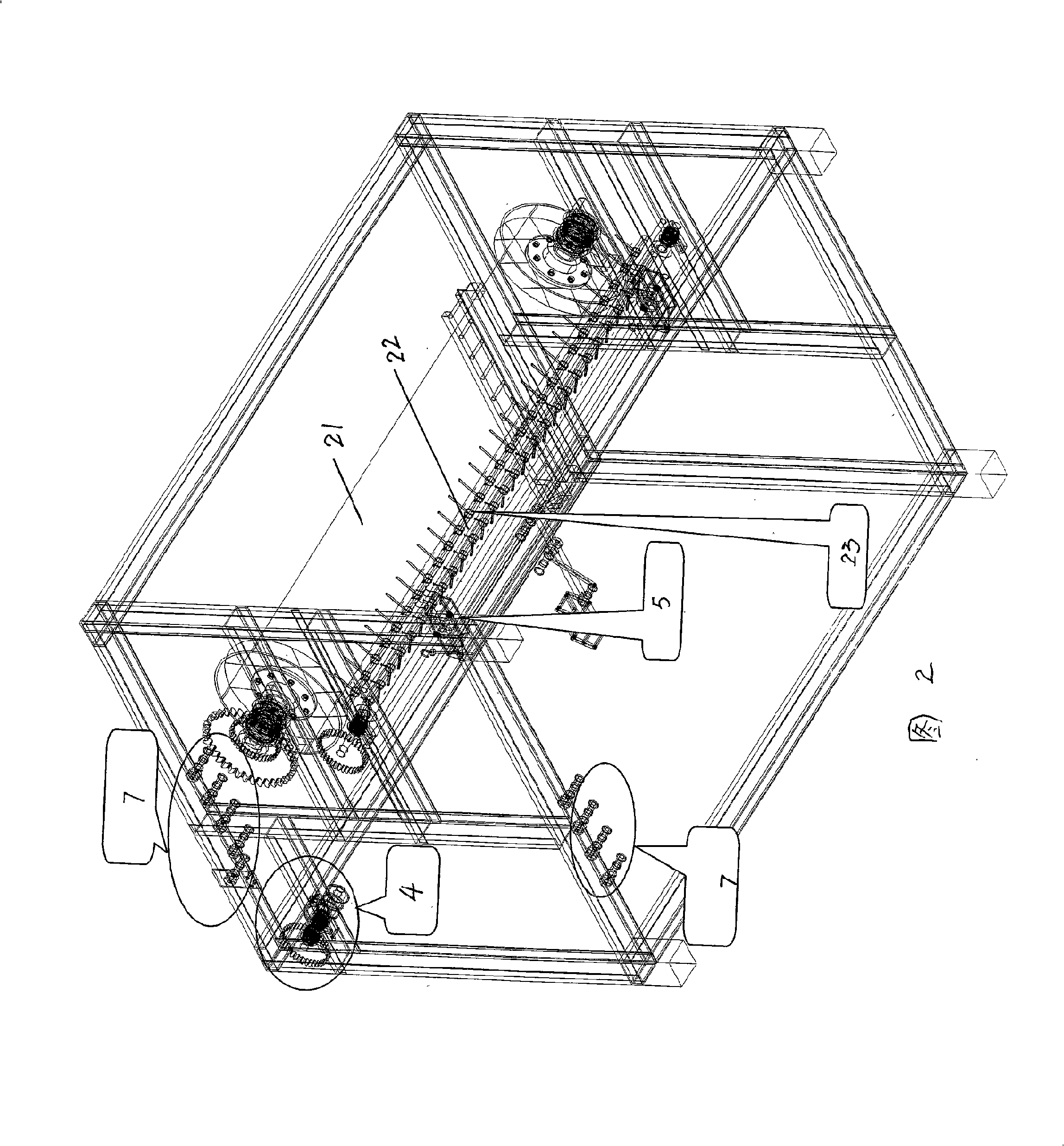

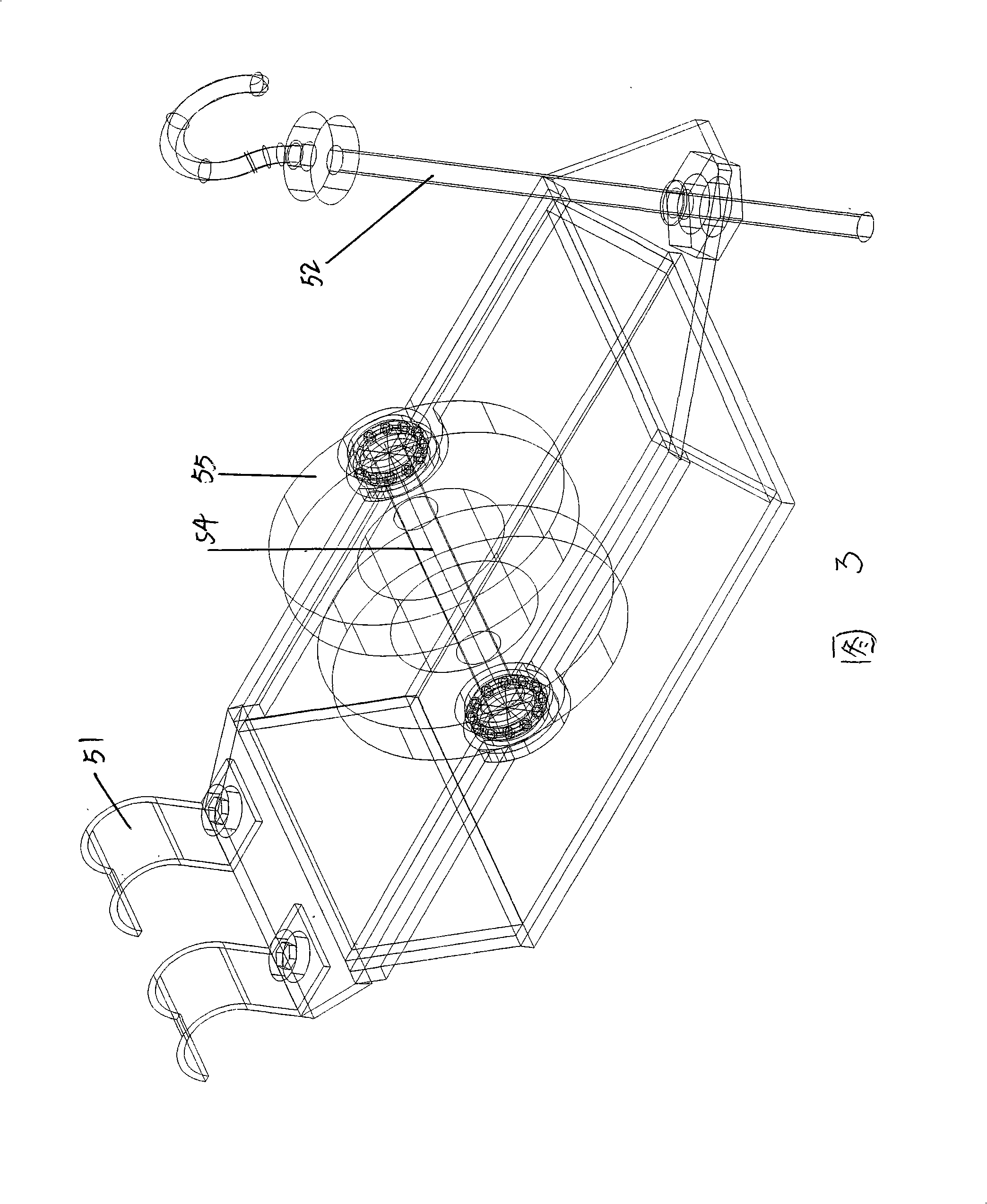

Metal slide fastener and manufacturing technology and metal slide fastener surface gold paint seal treatment machinery

InactiveCN101263948AThe process is easy to operateImprove processing qualitySlide fastenersPretreated surfacesEpoxyManufacturing technology

The invention relates to a metal zipper, the manufacture technology and a sealing and treating machine for the oil on the surface of the metal zipper, belonging to the technical field of daily necessities. A layer of oil is covered on the surface of the metal zipper; the oil comprises double-component epoxy resin varnish, epoxy curing agent and epoxide diluent with the weight ratio of 1:1 to 1.5:2.5 to 3.5. The metal zipper has the functions of rusting prevention, color losing resistance and anti-oxidizing discoloration with the advantages of good rigidity, friction resistance, scratch resistance and chemical corrosion resistance.

Owner:JIANGSU CMZ ZIPPER SCI & TECH CO LTD

Shell and preparation method thereof

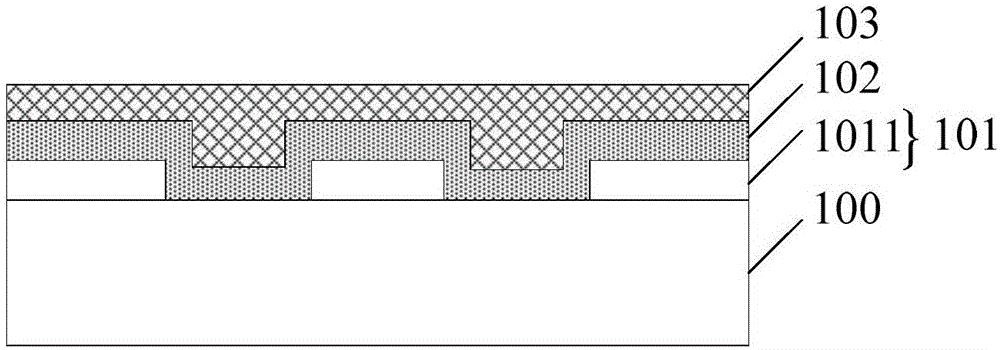

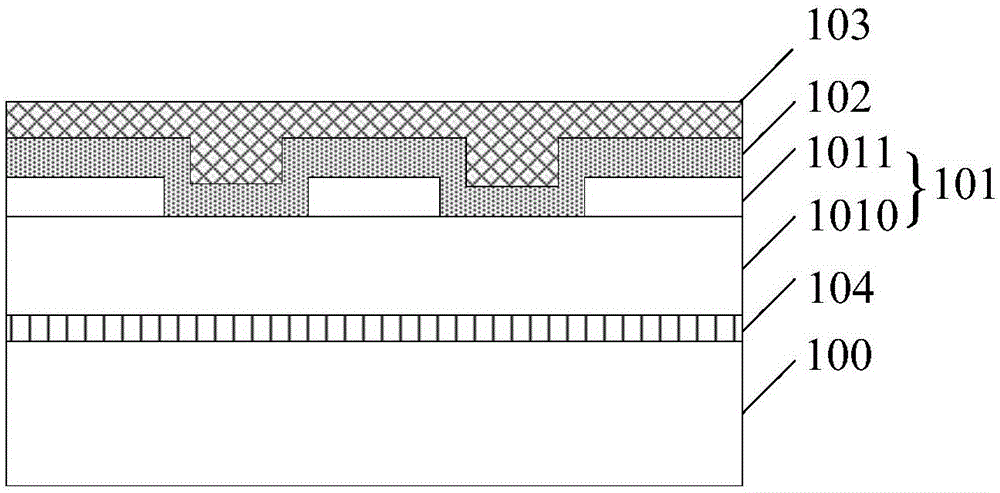

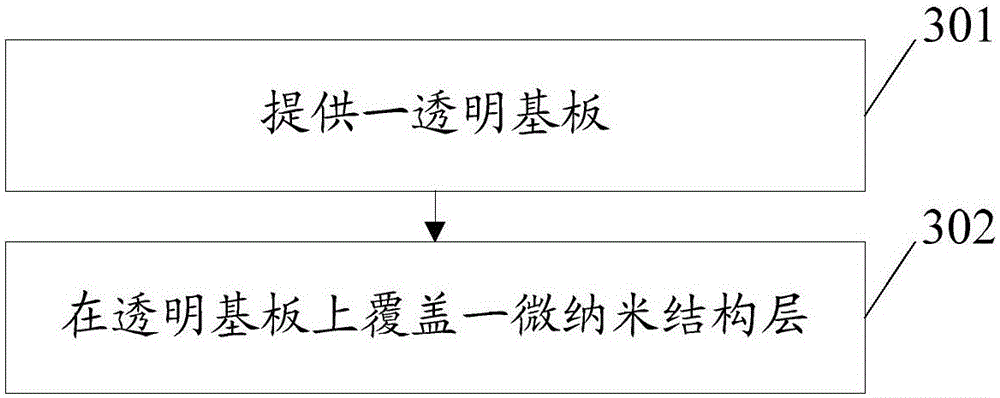

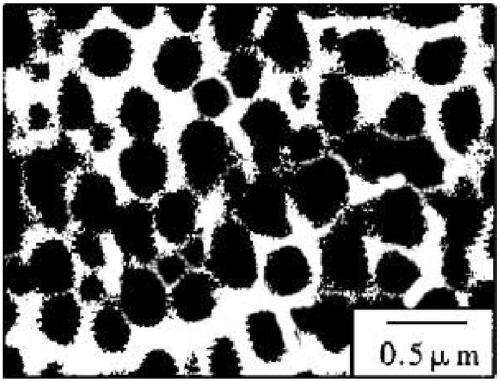

InactiveCN105120019AHigh precisionPrevent fadingVacuum evaporation coatingSputtering coatingMicro nanoChange patterns

The invention discloses a shell and a preparation method thereof, and belongs to the field of shells. The shell is applied to electronic equipment. The shell comprises a transparent substrate and a micro-nano structure layer covering the transparent substrate. The micro-nano structure layer is arranged at a side, near the electronic components in the electronic equipment, of the transparent substrate. The micro-nano structure layer is a micro-nano pattern composed of micro-nano trenches and bosses. The shell comprises the transparent substrate and the micro-nano structure layer covering the transparent substrate, the micro-nano structure layer is a micro-nano pattern composed of micro-nano trenches and bosses, the micro-nano pattern is composed of micro-nano trenches and bosses and is a stereoscopic and changing pattern, and the micro-nano structure ensures high pattern accuracy. As the micro-nano pattern is disposed at the inner side of the shell, users are not affected when using the shell, and the failure risk such as pattern fading or film fall-off is avoided.

Owner:HUAWEI TECH CO LTD

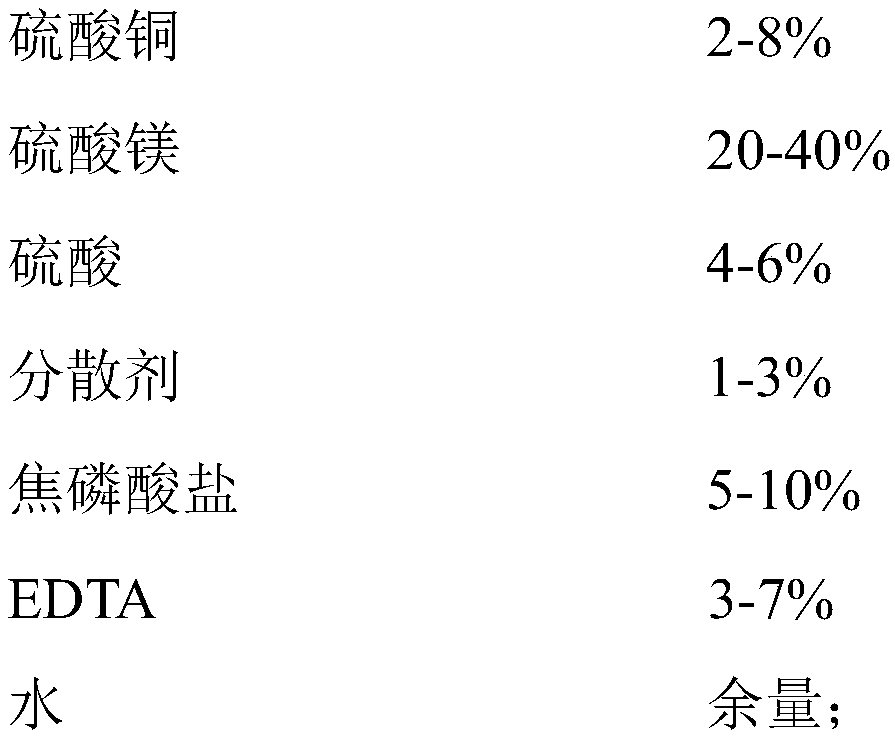

Section aluminum anode oxide film copper salt electrolytic coloring production process

ActiveCN109056027APrevent fadingChange structureSurface reaction electrolytic coatingElectrolysisPyrophosphate

The invention discloses a section aluminum anode oxide film copper salt electrolytic coloring production process. The section aluminum anode oxide film copper salt electrolytic coloring production process comprises the following treatment steps of oil removing, washing, washing, anodizing, washing, washing, an activation working procedure, an electrolytic coloring, washing, washing, hole sealing and a washing treatment working procedure and is characterized in that an electrolytic coloring agent in the electrolytic coloring step comprises, by weight percent, 2%-8% of copper sulfate, 20%-40% ofmagnesium sulfate, 4%-6% of sulfuric acid, 1%-3% of a dispersing agent, 5%-10% of pyrophosphate, 3%-7% of EDTA and the balance water, a bath solution in an electrolytic coloring trough is composed of30g / L-50g / L of the electrolytic coloring agent, 18 g / L-25 g / L of free sulphuric acid, 5g / L-25 g / L of copper sulfate pentahydrate and the balance water, and in the electrolytic coloring treatment step, the temperature of the bath solution in the electrolytic coloring trough is 20 DEG C-22 DEG C, the voltage is 16v-19v, and the coloring time is 0.5min-0.8min. A coloring film layer color system of section aluminum prepared through the coloring production process is complete, uniform, stable and good in quality, a color fading problem does not exist in the using process, relatively high corrosionresistance is achieved, and volume production can be formed.

Owner:FOSHAN HAIHUA SURFACE TREATMENT TECH CO LTD

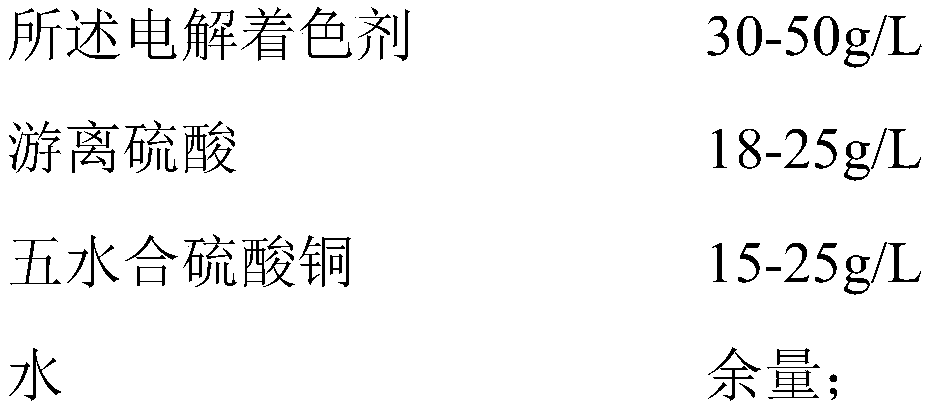

Laser engraving method of plastic component

InactiveCN103029498AAvoid peeling paintInhibit sheddingEngravingEnvironmental resistanceMaterial consumption

The invention relates to a laser engraving method of a product, in particular to a plastic component laser engraving method for engraving any pattern or mark in an elastic workpiece with one layer being lucent. Laser engraving is carried out inside the plastic component at least comprising one layer of transmission material. The method comprises the following steps of starting a laser engraving machine; measuring the size of the plastic component to be engraved; editing the patterns and characters; calculating points of the patterns; calling in a picture file, selecting product dimensional specification and setting parameters; and carrying out the engraving. Due to the adoption of the laser engraving method of the plastic component, not only can the display effect of the patterns and characters of the traditional process be realized, but also the defects of the traditional process such as paint dropping, dropping, color fading, non-abrasion resistance, short service life, easiness for storing dirt, environmental pollution and incapability of individualized production can be solved; and moreover, a novel high-efficient and environment-friendly technique for producing any pattern and character with no material consumption can be realized, and a broad individualized exhibition platform can be provided for the individualized times.

Owner:东莞市光威激光科技有限公司

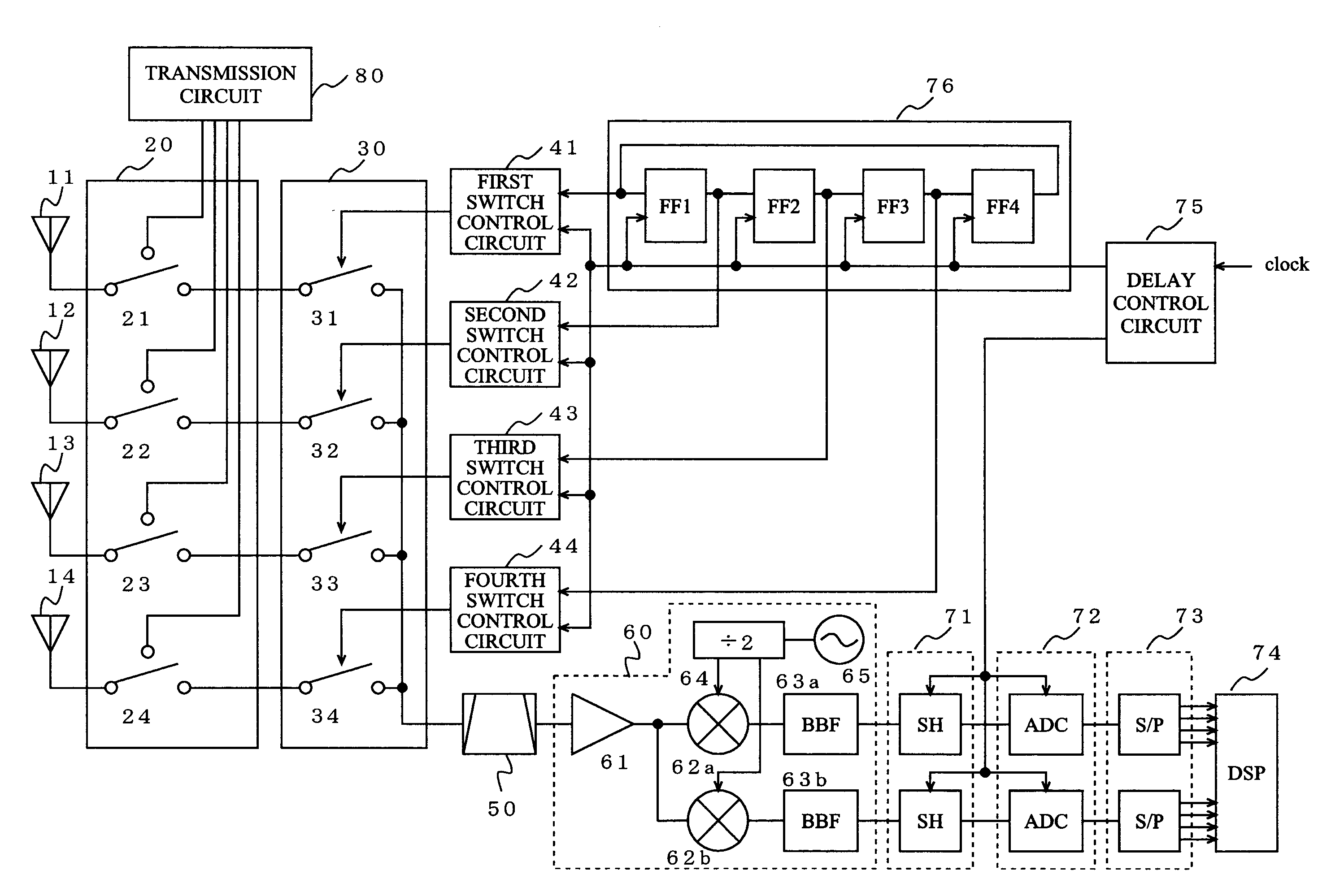

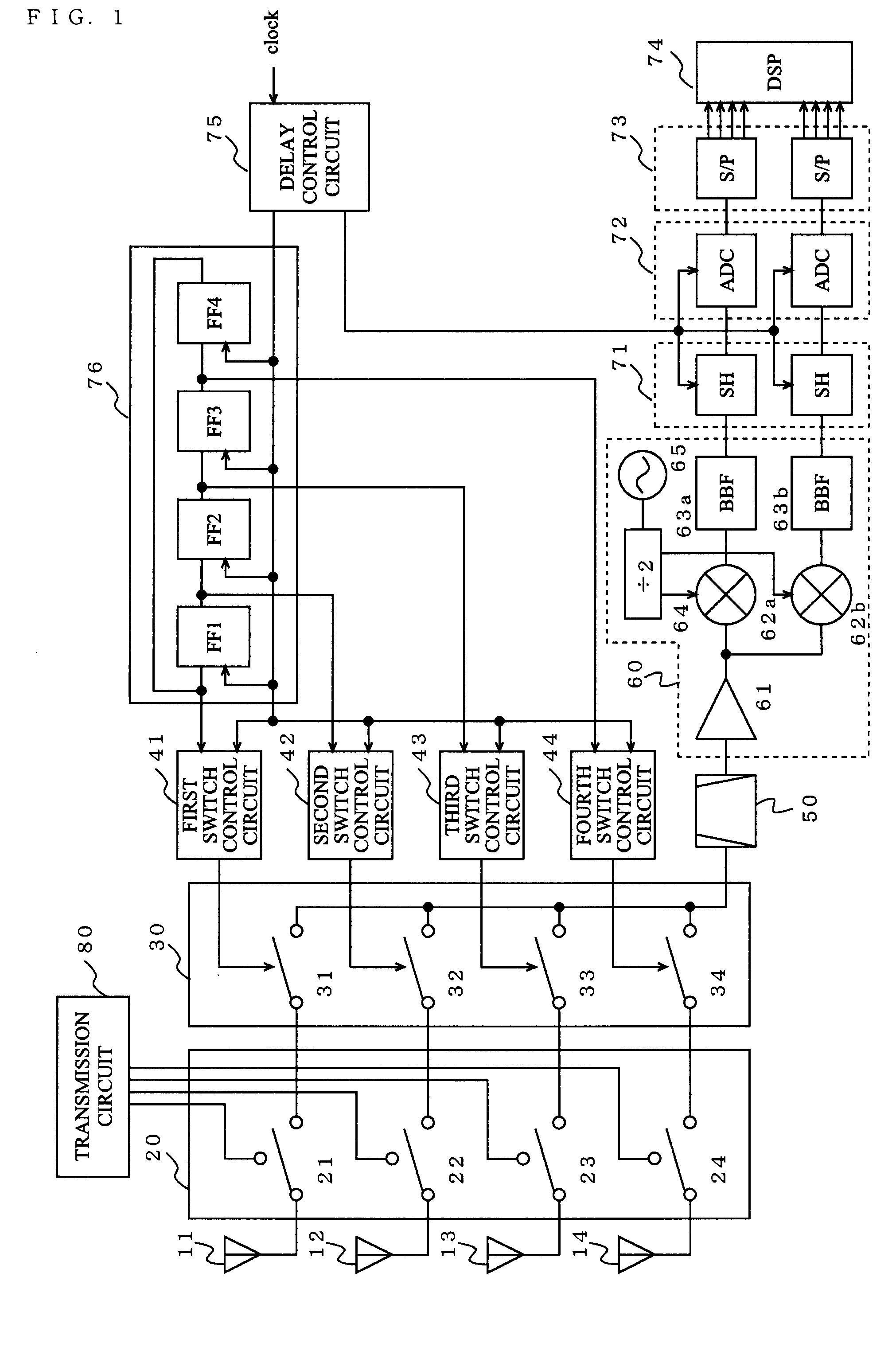

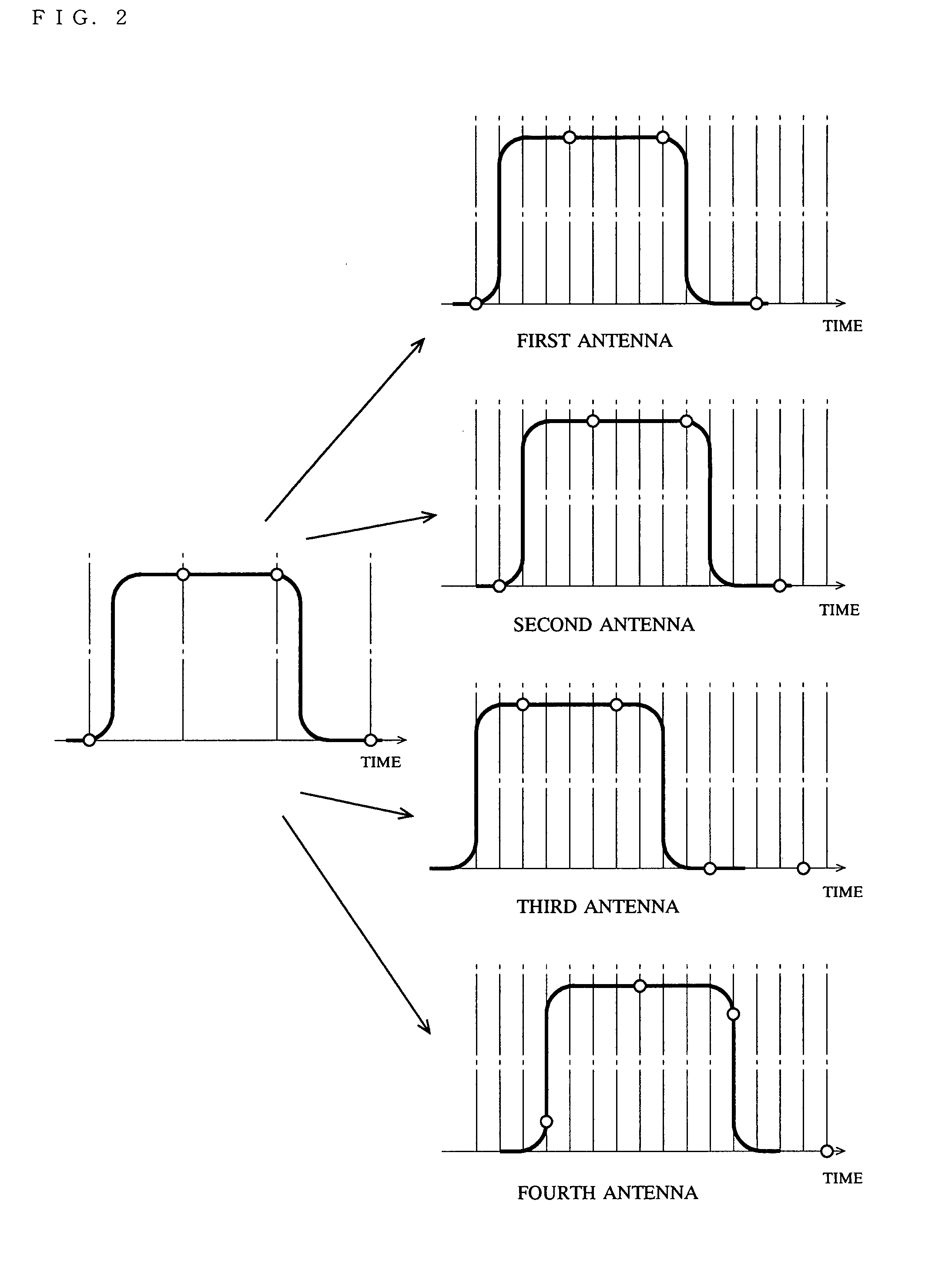

Multi-antenna communication apparatus

ActiveUS20070280297A1Prevent fadingIncrease the frequency bandSpatial transmit diversityPolarisation/directional diversityControl circuitSample and hold

Reception signals received by first to fourth antennas 11 to 14 are sequentially selected one by one repeatedly in accordance with first to fourth switches 31 to 34 being controlled by first to fourth switch control circuits 41 to 44, respectively, so as to be inputted to a signal shaping section 60. The reception signals having been shaped by the signal shaping section 60 are sampled by a sample-and-hold section 71 and AD-converted by an AD converter 72 in accordance with a time at which the reception signals are sequentially selected. The resultant signals are converted into parallel signals by a serial-parallel conversion section 73. Thus, the parallel signals are obtained as the reception signals of the first to the fourth antennas 11 to 14.

Owner:PANASONIC CORP

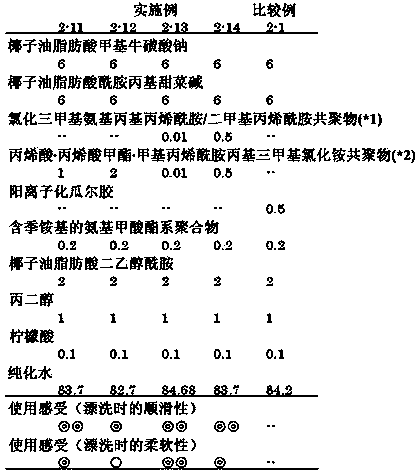

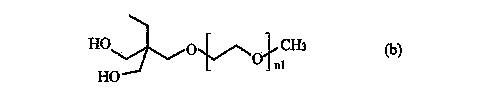

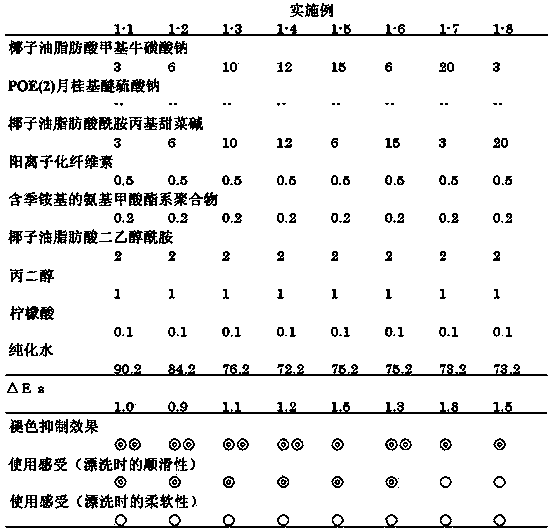

Shampoo composition

A shampoo composition excellent in fading-inhibiting effect and use feeling is provided. The shampoo composition is characterized by comprising: (i) an anionic surfactant which is a taurine-derivative surfactant; (ii) an amphoteric surfactant which is an alkylamide betaine surfactant; (iii) a cationic conditioning polymer; and (iv) a quaternary ammonium group-containing silylated urethane polymer.

Owner:SHISEIDO CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com