Patents

Literature

412 results about "Failure risk" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Failure to include risks in the risk register on the grounds that they do not fit the PIM-based concept of a risk. Failure to take into account other risk attributes that may be important to risk prioritisation, e.g. urgency of response, value of risk responses, clarity of risk ownership or relationships with other risks.

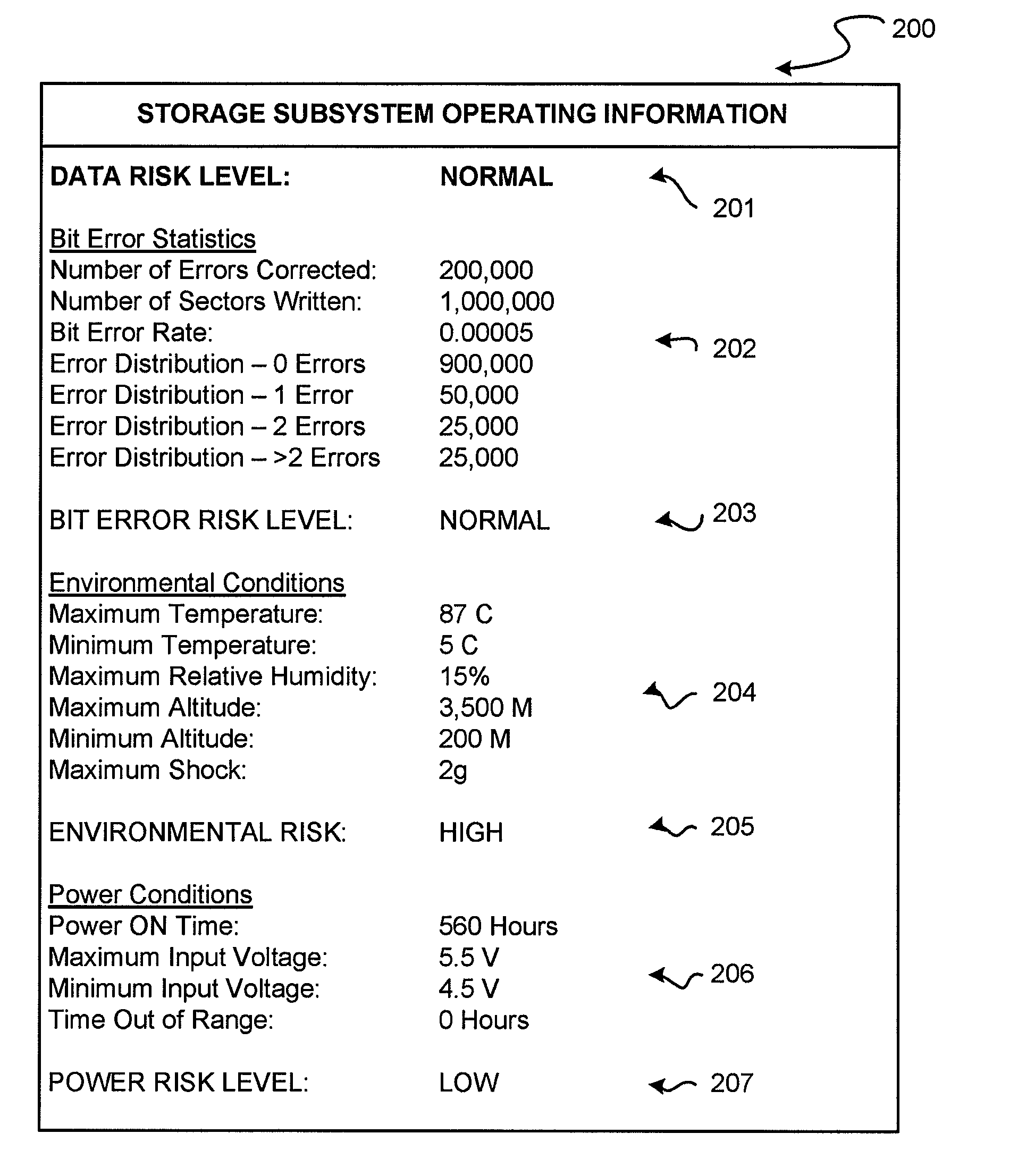

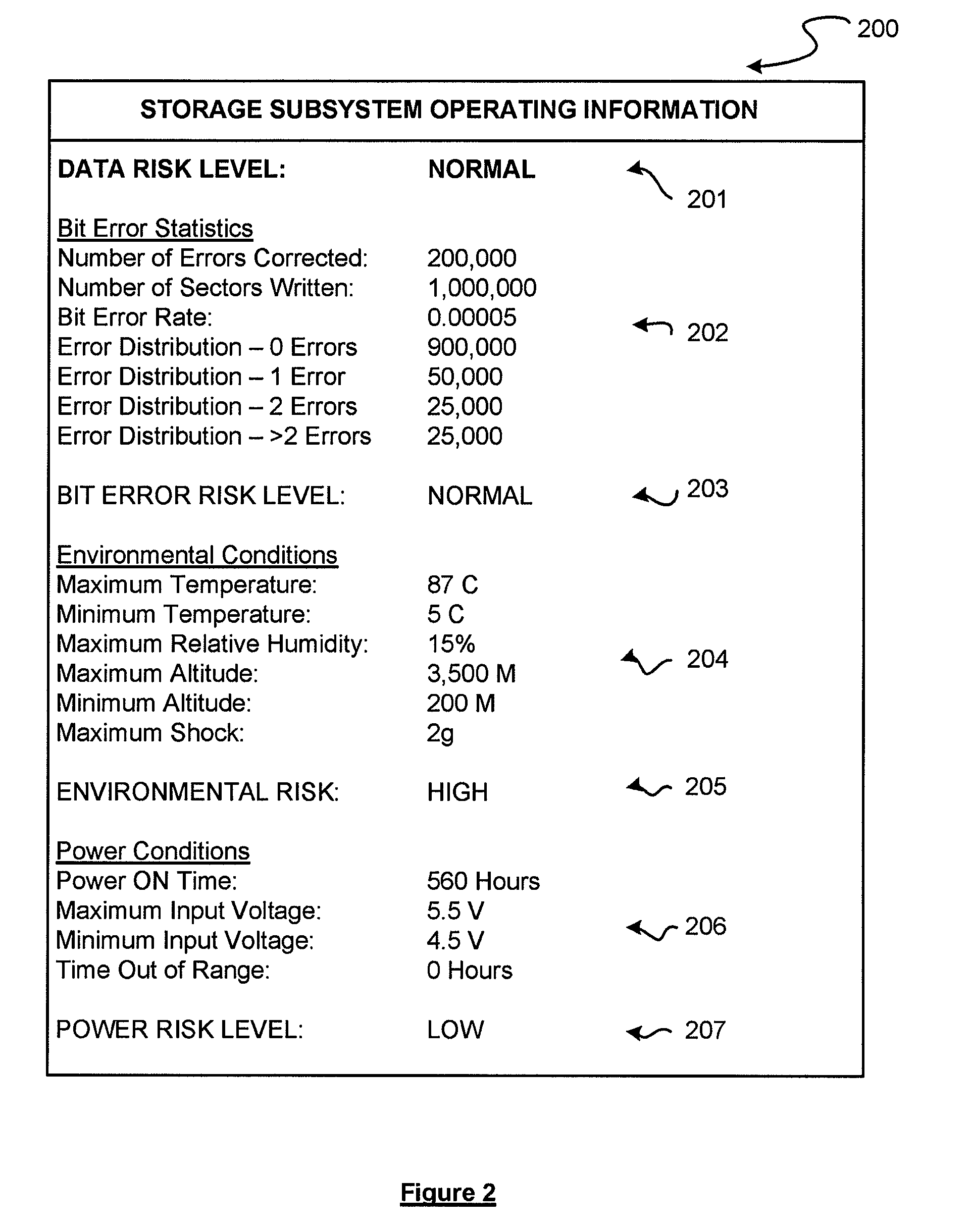

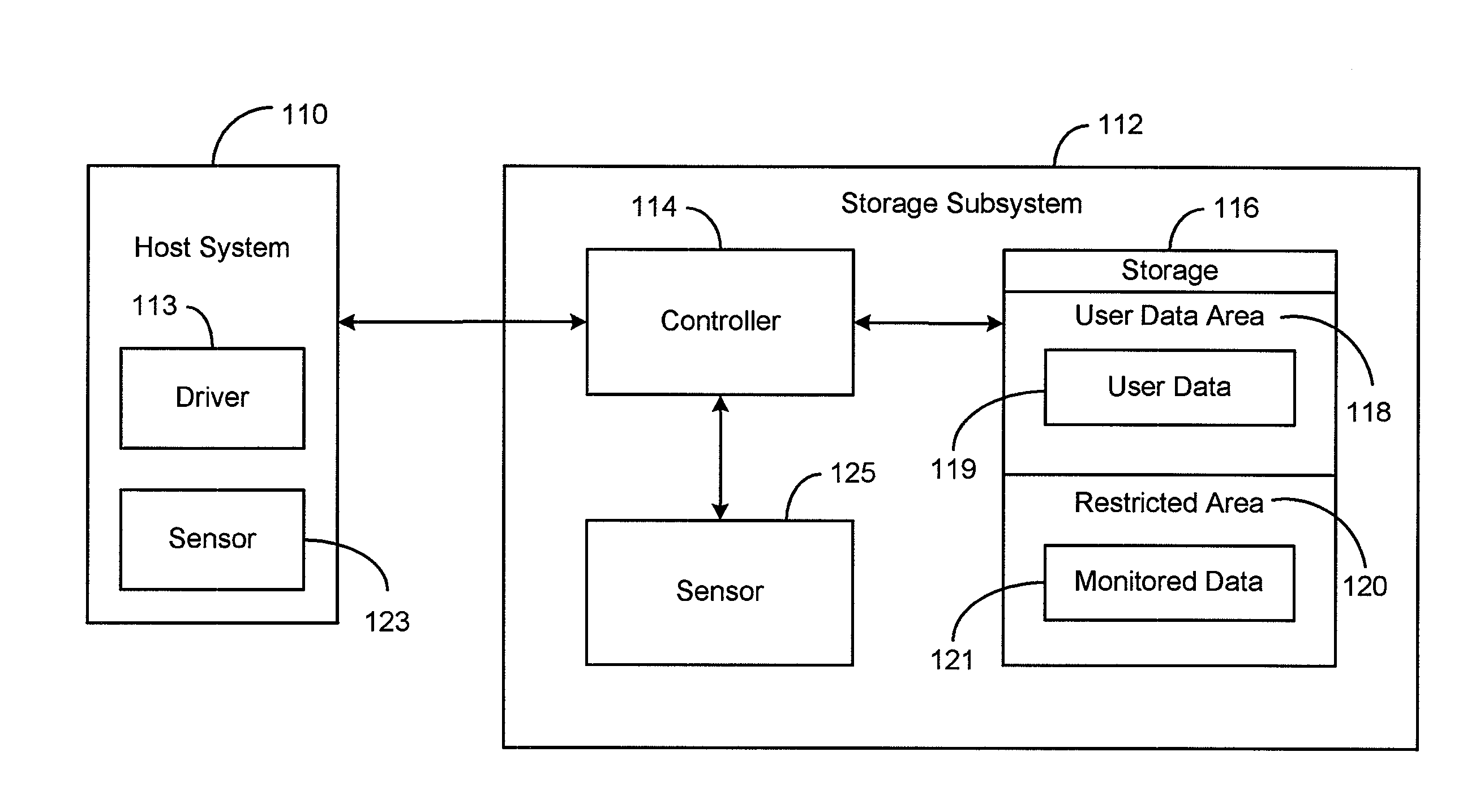

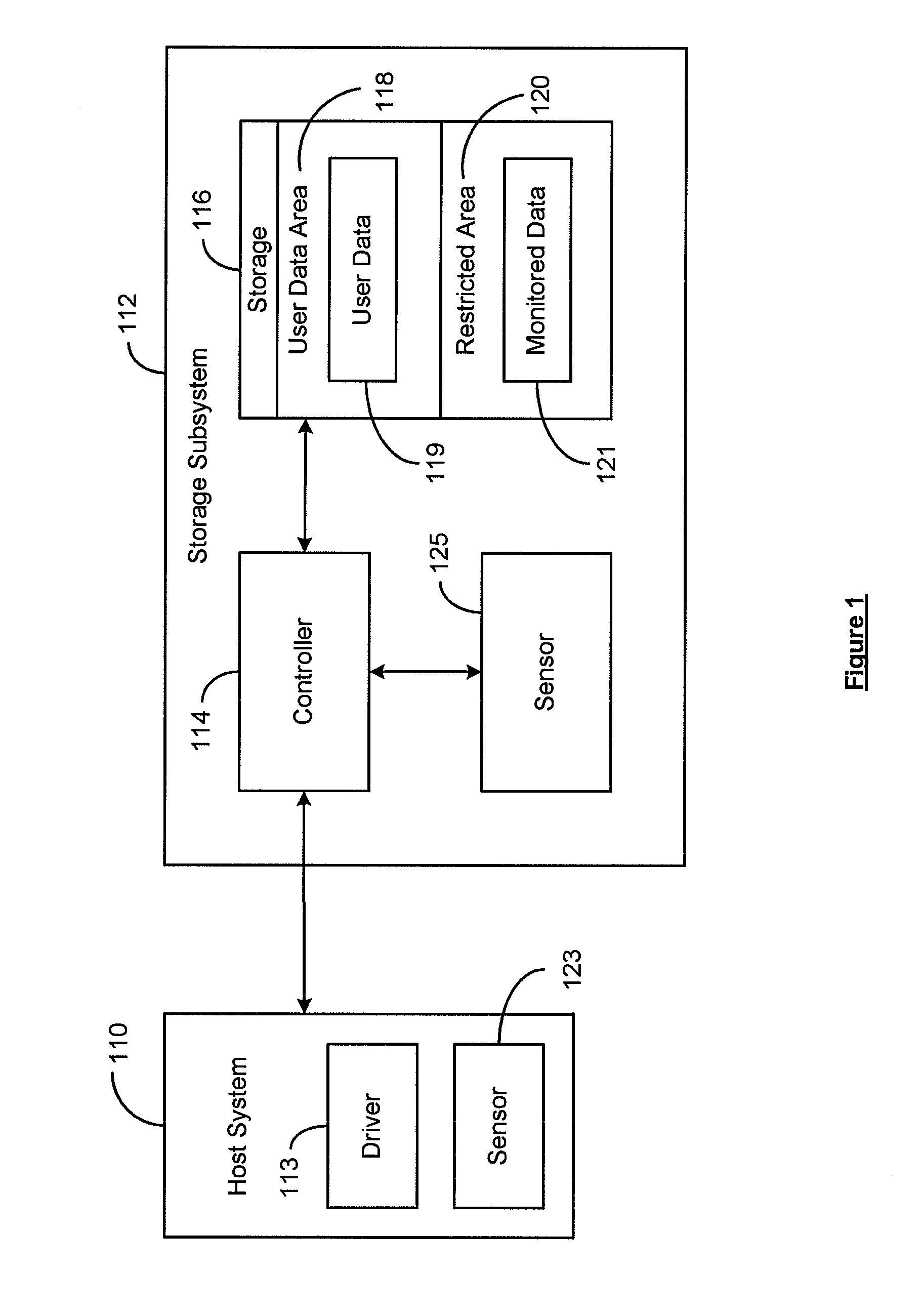

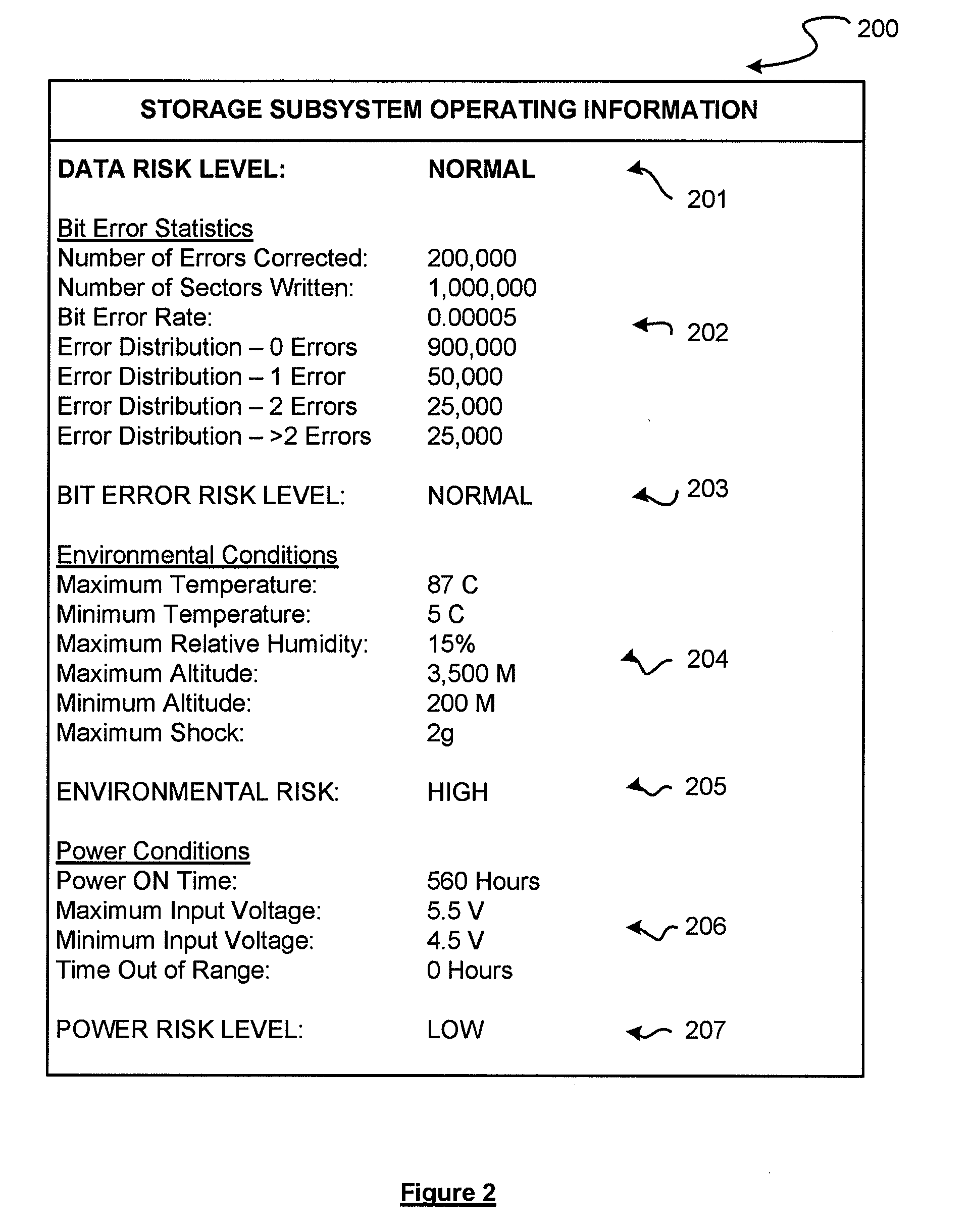

Solid state storage subsystem that maintains and provides access to data reflective of a failure risk

Owner:WESTERN DIGITAL TECH INC

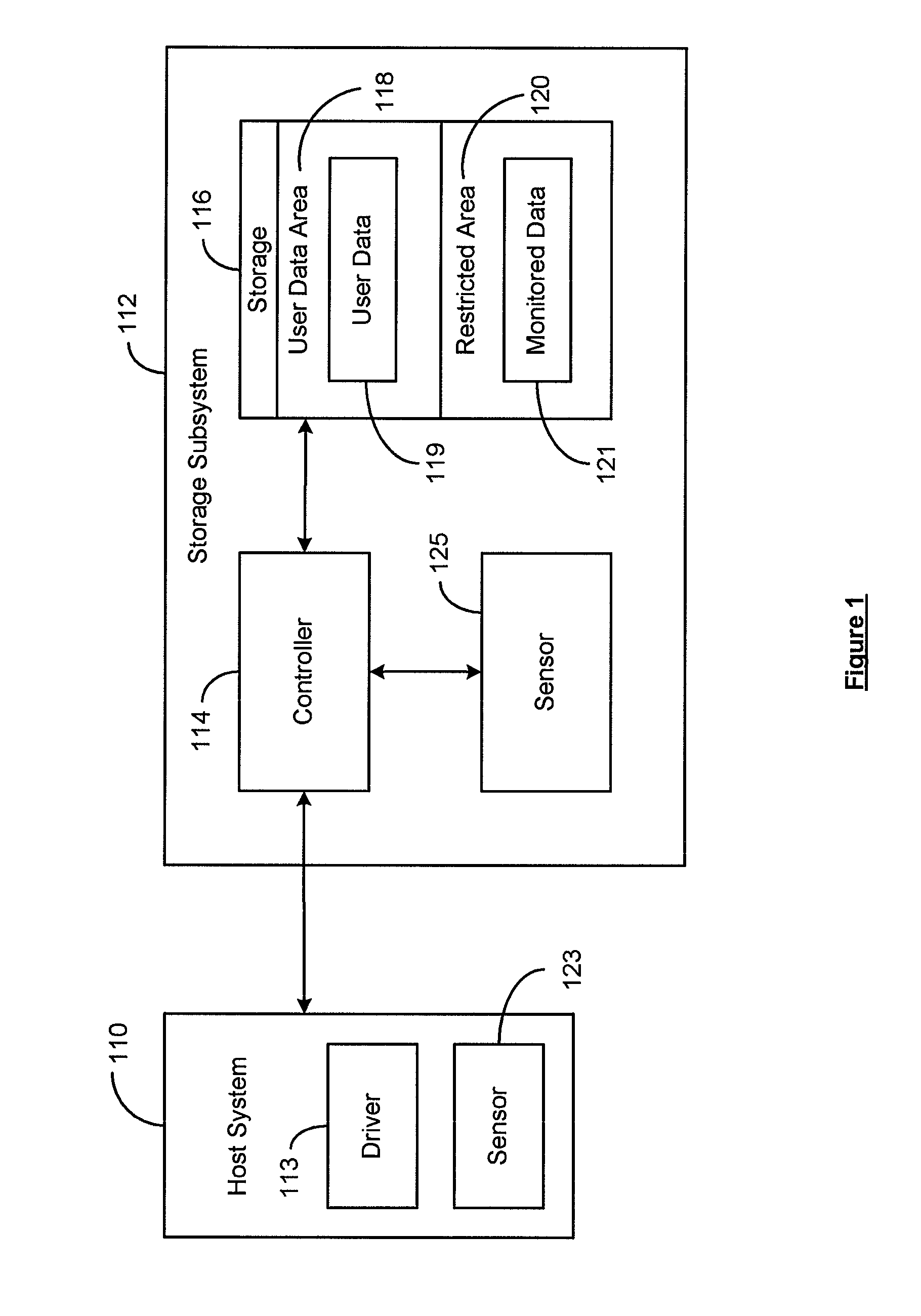

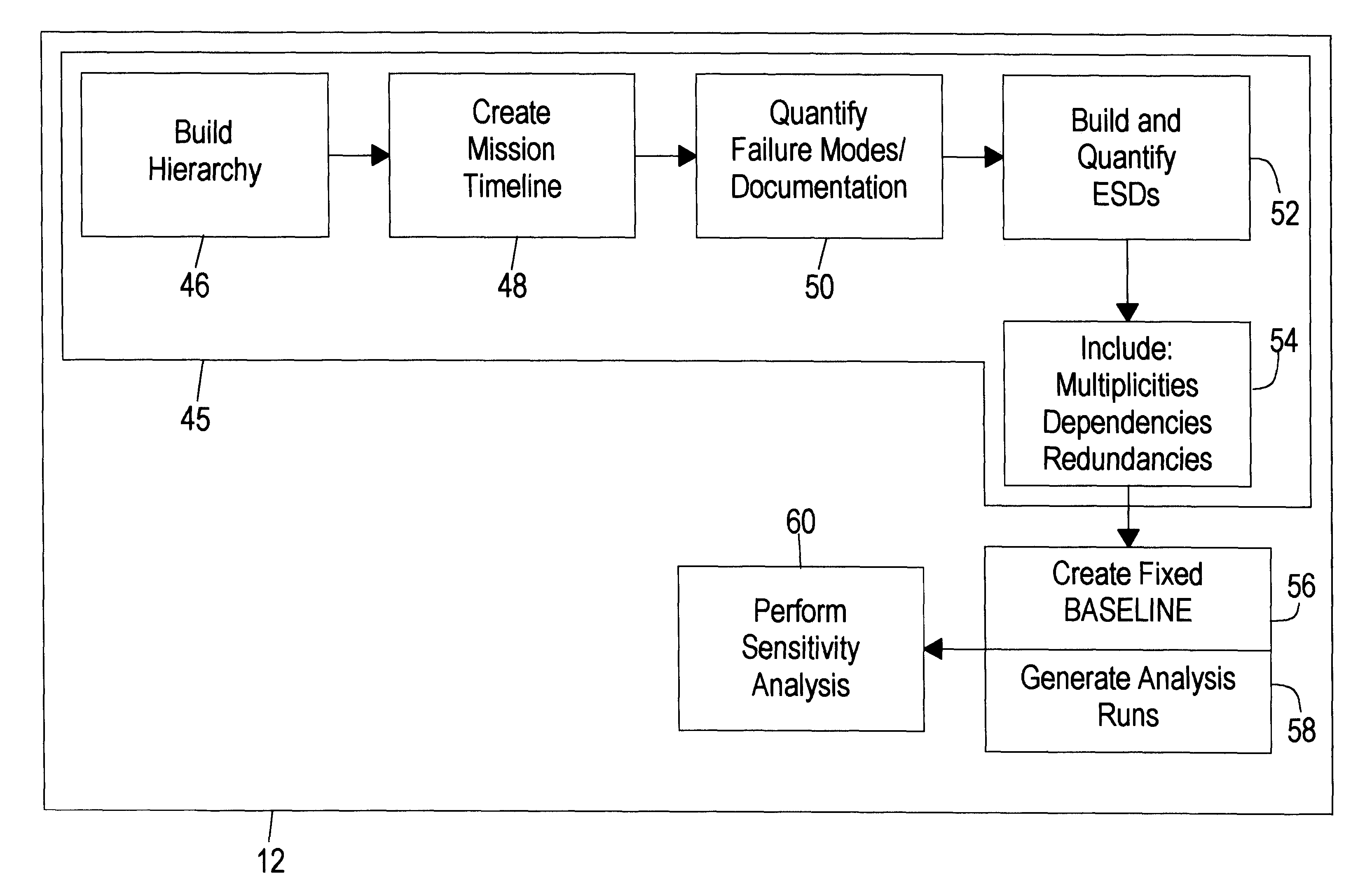

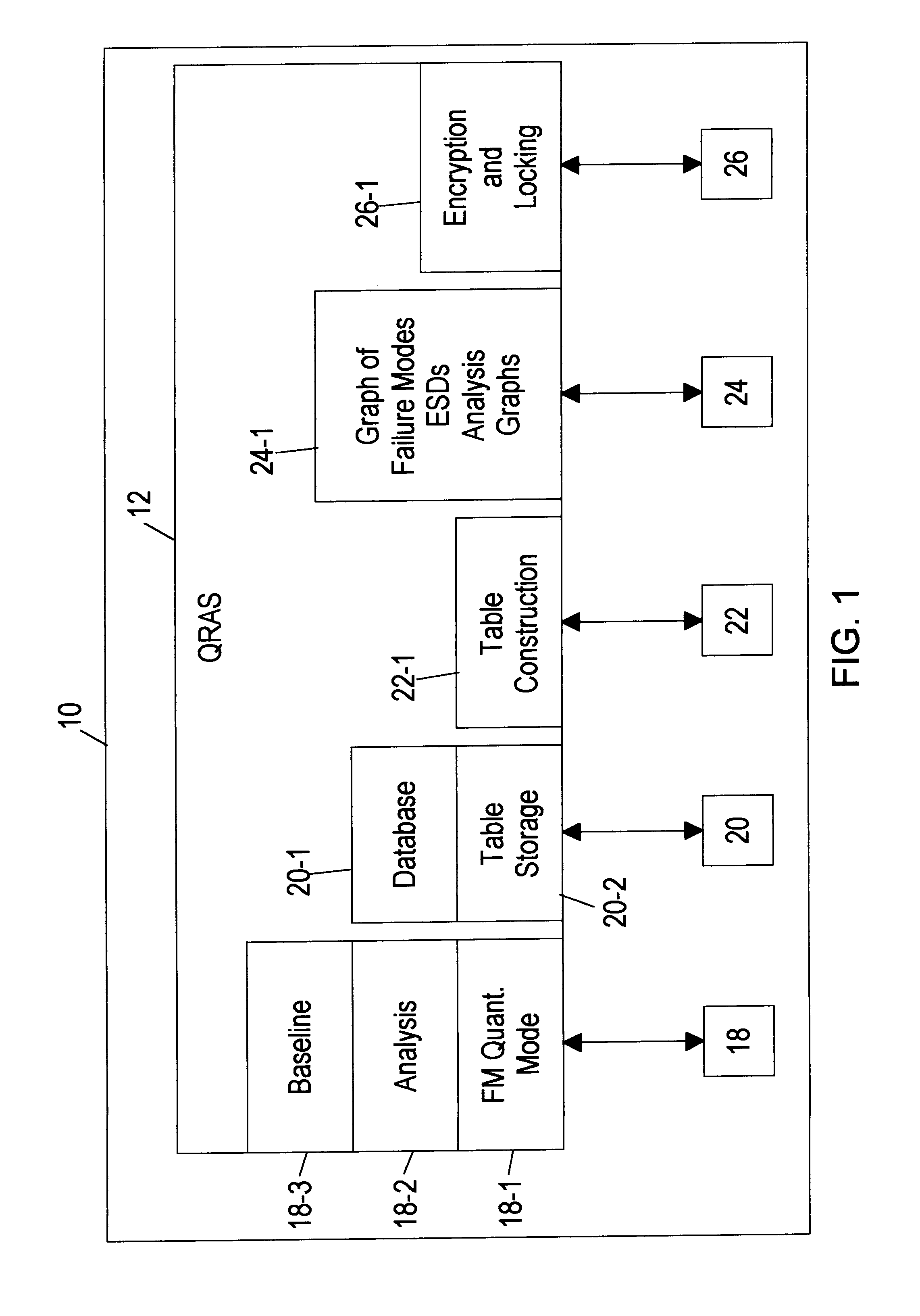

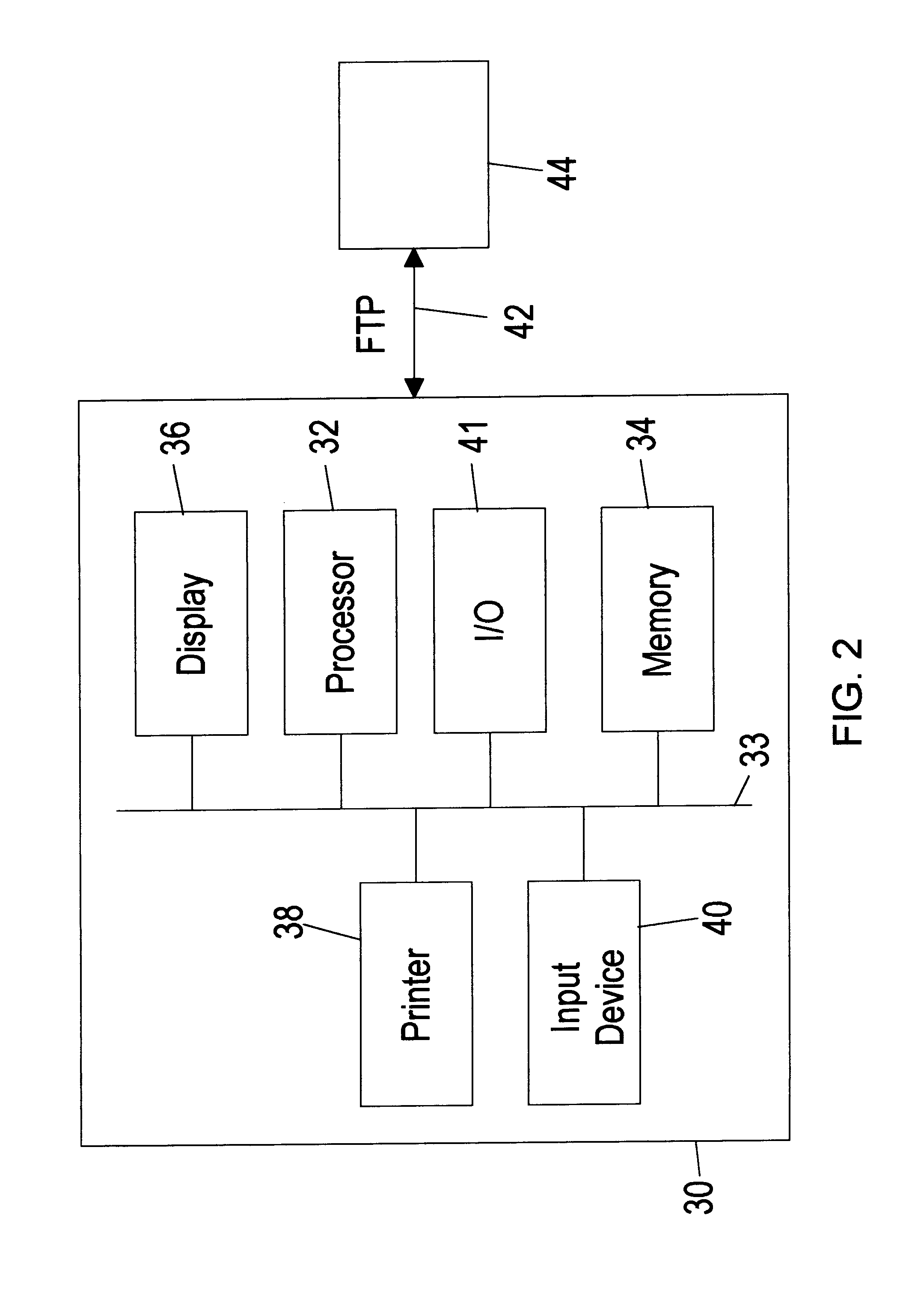

Quantitative risk assessment system (QRAS)

A quantitative risk assessment system (QRAS) builds a risk model of a system for which risk of failure is being assessed, then analyzes the risk of the system corresponding to the risk model. The QRAS performs sensitivity analysis of the risk model by altering fundamental components and quantifications built into the risk model, then re-analyzes the risk of the system using the modifications. More particularly, the risk model is built by building a hierarchy, creating a mission timeline, quantifying failure modes, and building / editing event sequence diagrams. Multiplicities, dependencies, and redundancies of the system are included in the risk model. For analysis runs, a fixed baseline is first constructed and stored. This baseline contains the lowest level scenarios, preserved in event tree structure. The analysis runs, at any level of the hierarchy and below, access this baseline for risk quantitative computation as well as ranking of particular risks. A standalone Tool Box capability exists, allowing the user to store application programs within QRAS.

Owner:NAT AERONAUTICS & SPACE ADMINISTATION U S GOVERNMENT AS REPRESENTED BY THE ADMINISTATOR +1

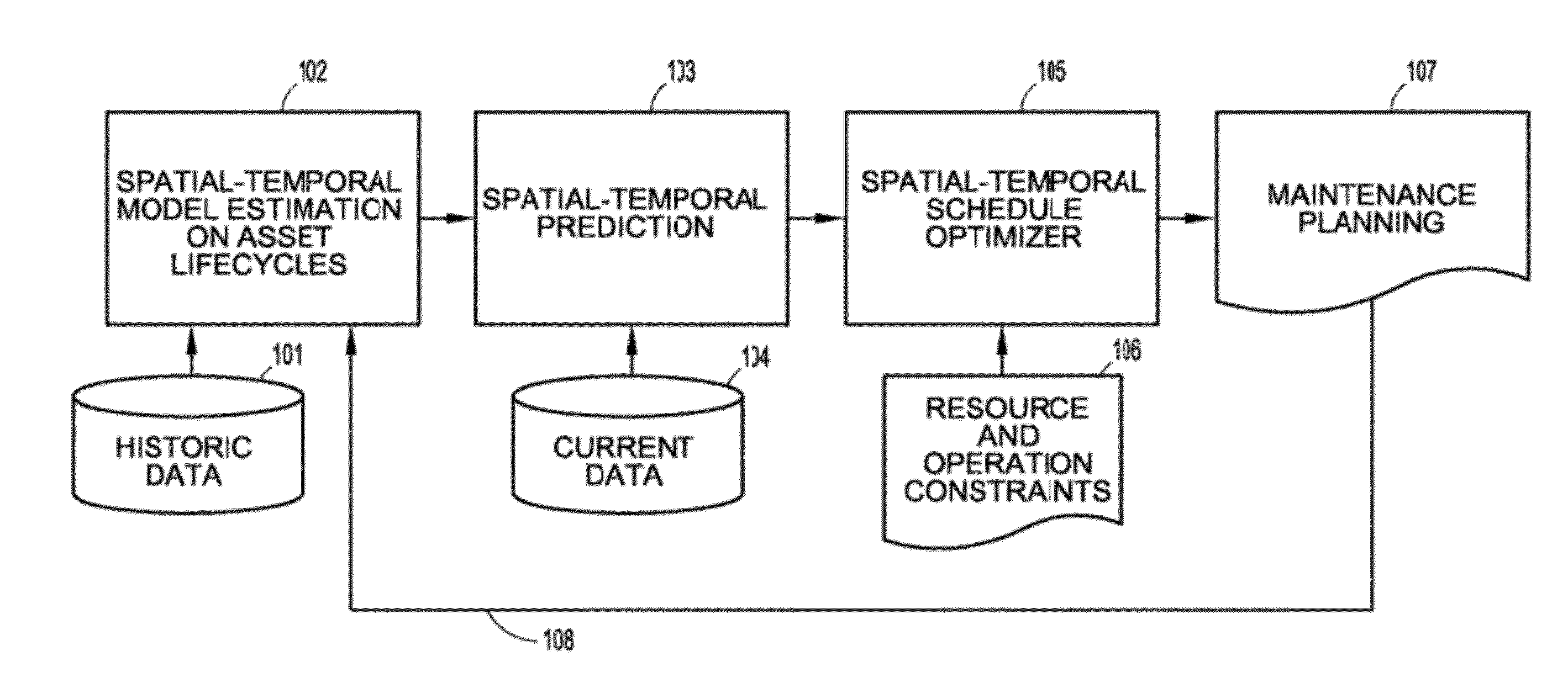

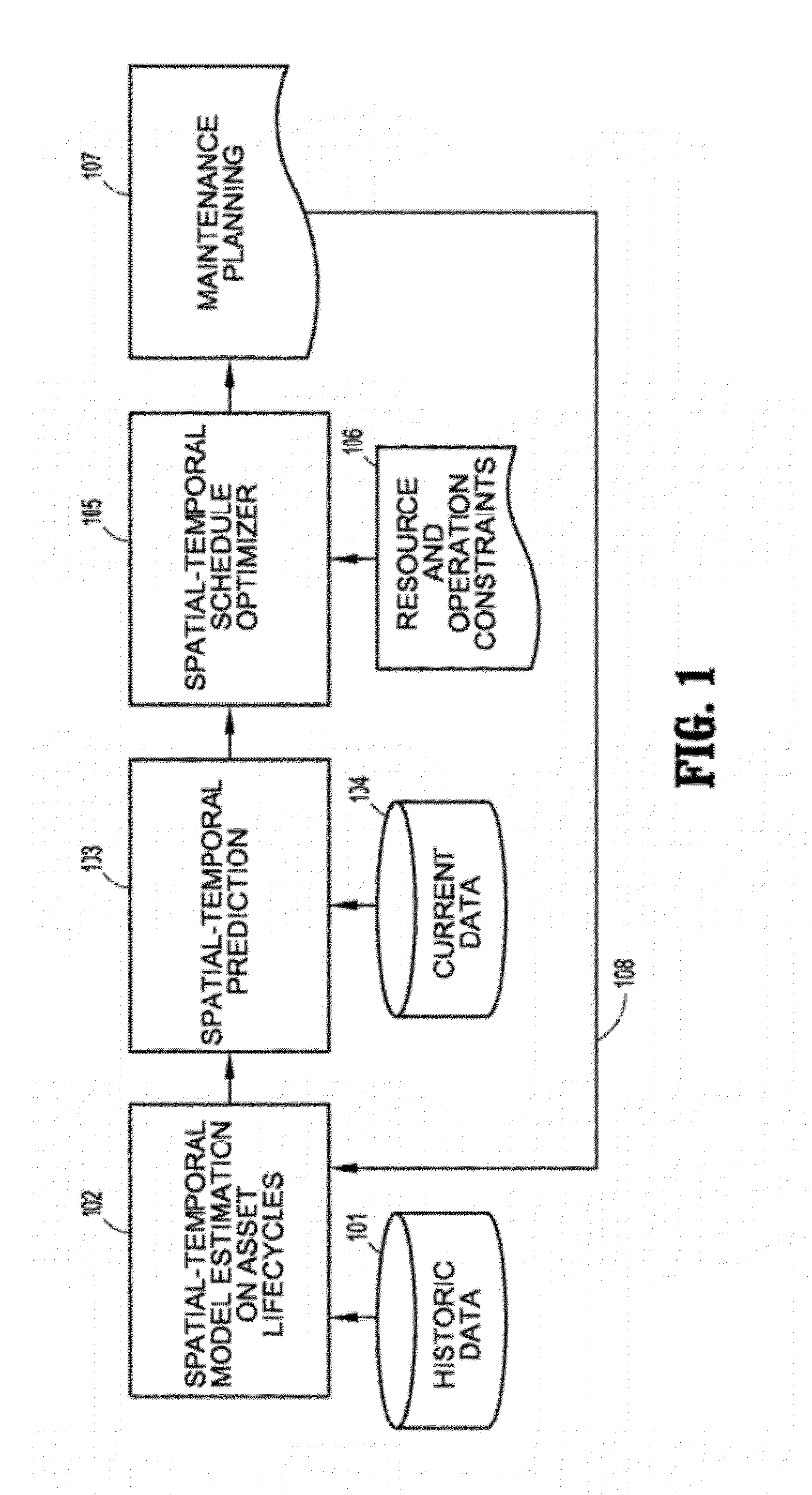

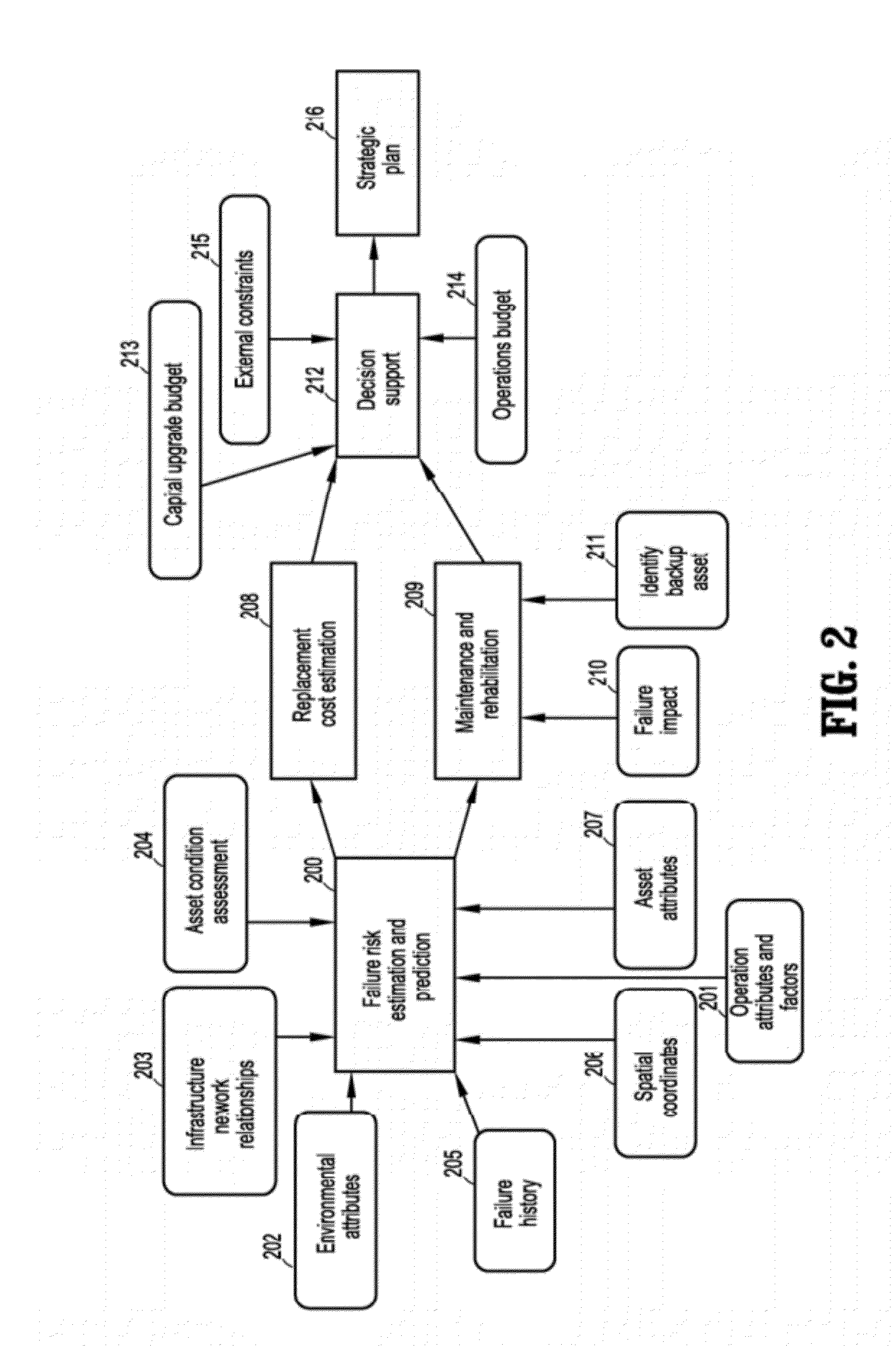

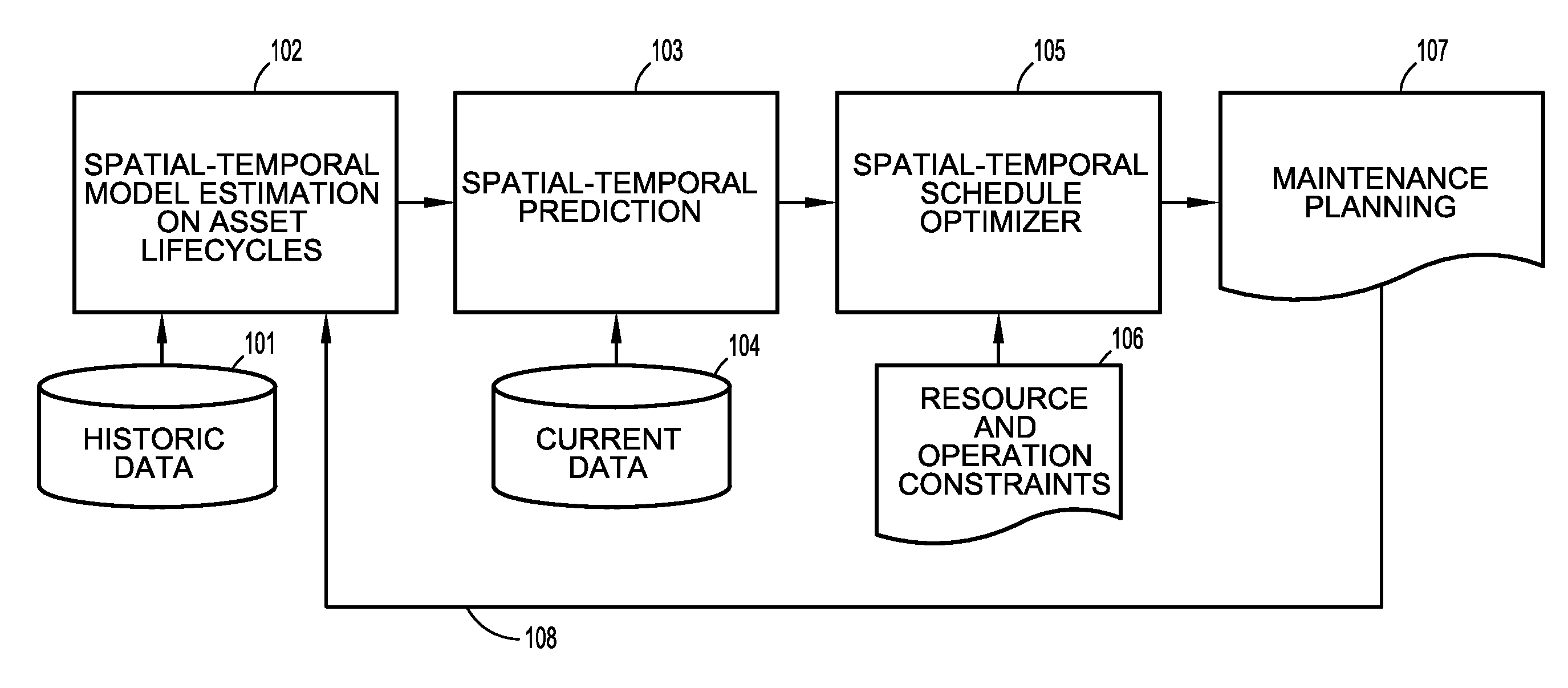

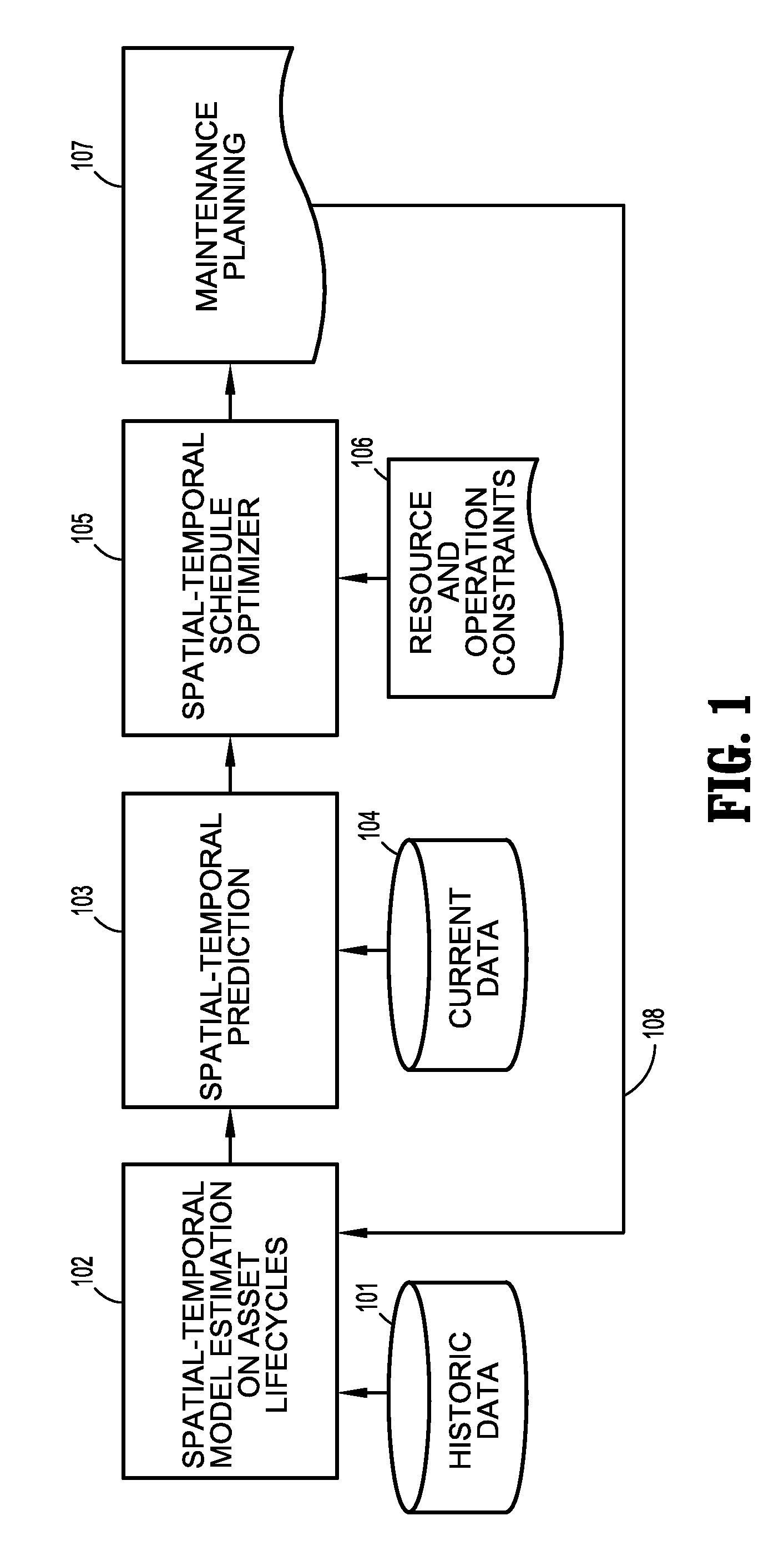

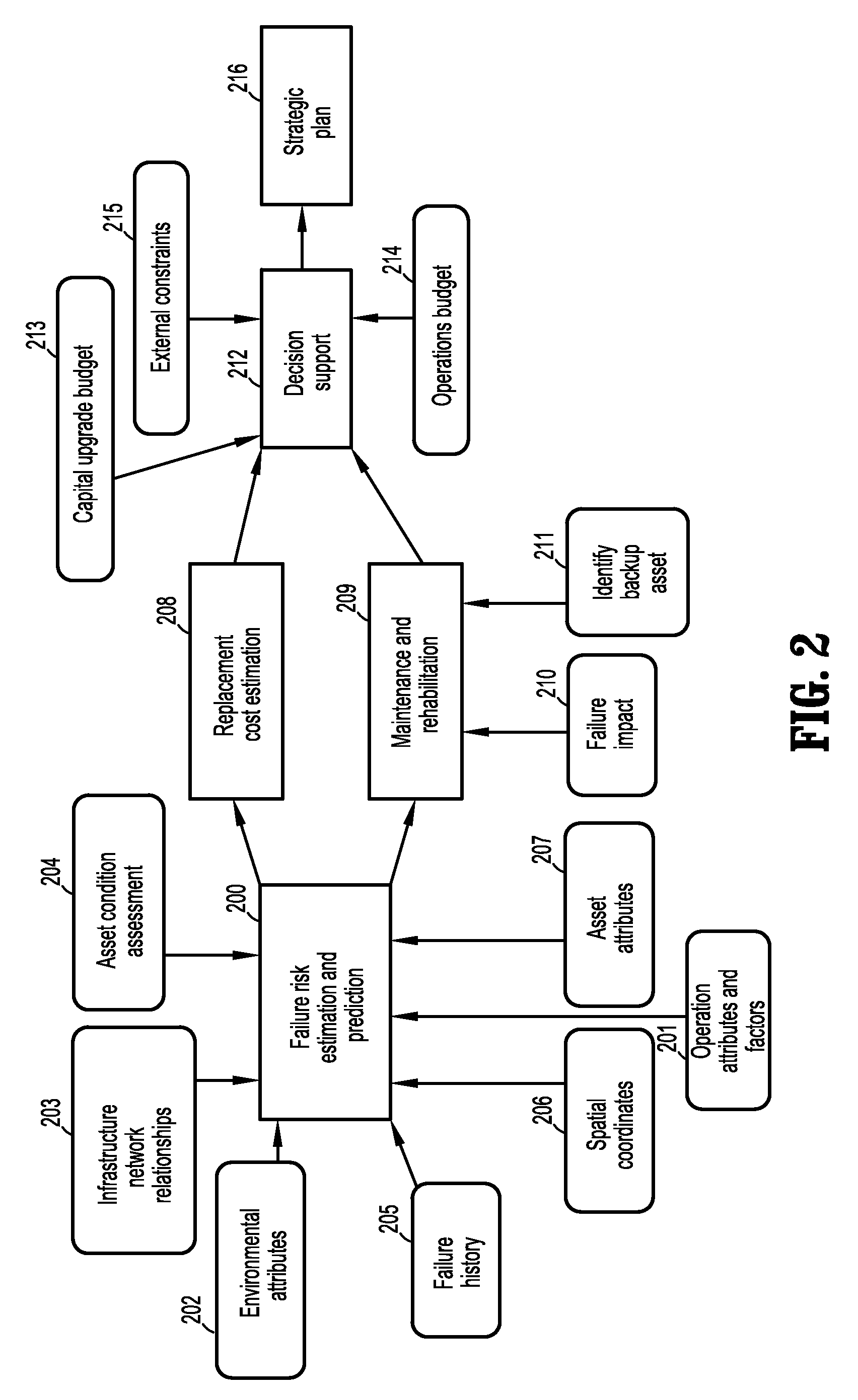

Spatial-Temporal Optimization of Physical Asset Maintenance

A method for determining a maintenance schedule of geographically dispersed physical assets includes receiving asset data including infrastructure relationships between the assets, modeling failure risk of the assets based on spatial, temporal and network relationships, and producing the maintenance schedule according to a combination of the risk model, asset data, maintenance, and external operation constraints. The maintenance schedule may be corrective and / or strategic.

Owner:IBM CORP

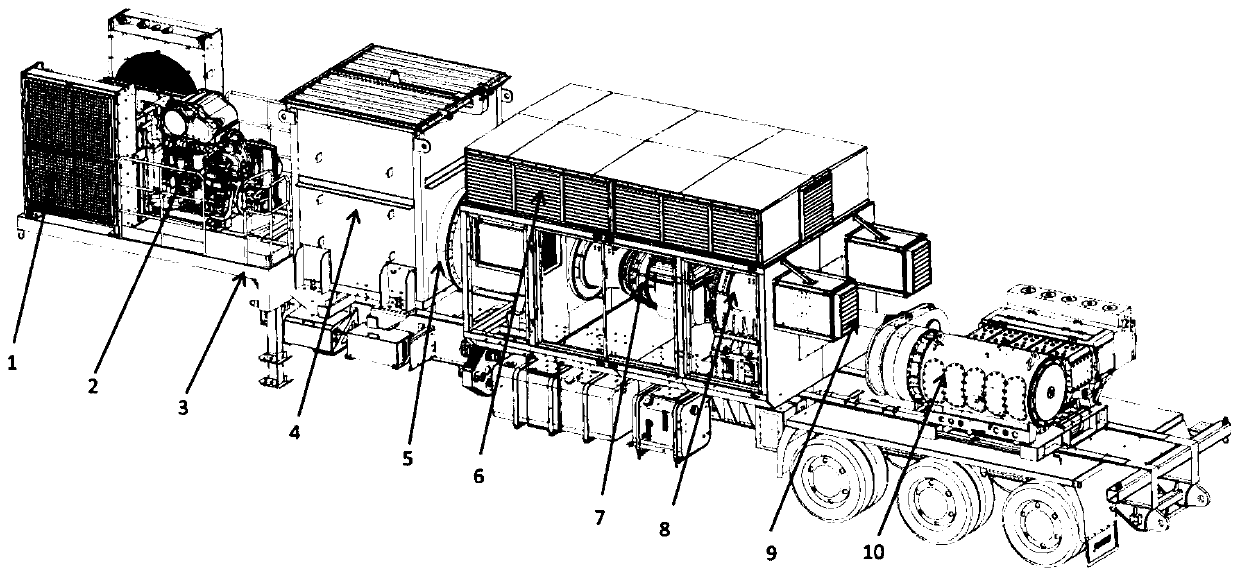

Turbine fracturing semitrailer

PendingCN110485983AReduce volumeReduce weightEngine manufactureEngine fuctionsTransmission lossFailure risk

The invention discloses a turbine fracturing semitrailer. The turbine fracturing semitrailer comprises a semitrailer body, a turbine engine, a reduction gearbox, a transmission mechanism and a plungerpump; the turbine engine, the reduction gearbox, the transmission mechanism and the plunger pump are arranged on the semitrailer body, the output end of the turbine engine is connected with the reduction gearbox, and the reduction gearbox is connected with the plunger pump through the transmission mechanism in a transmission mode. The turbine fracturing semitrailer has the beneficial effects thatthrough linear connection of the turbine engine, the reduction gearbox, the transmission mechanism and the plunger pump in the power-transmission direction, excessive transmission loss can be avoided, and efficient transmission performance is guaranteed; and the whole semitrailer is small in size, light in weight, low in the use cost, and low in failure risks.

Owner:YANTAI JEREH PETROLEUM EQUIP & TECH CO LTD

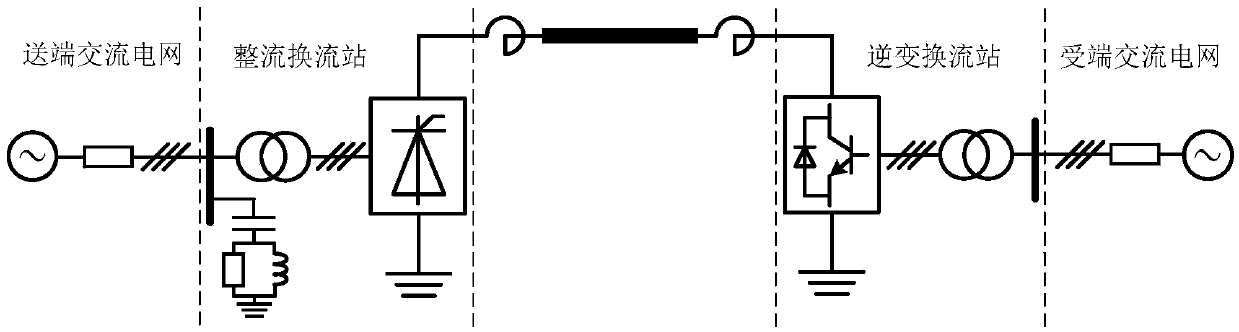

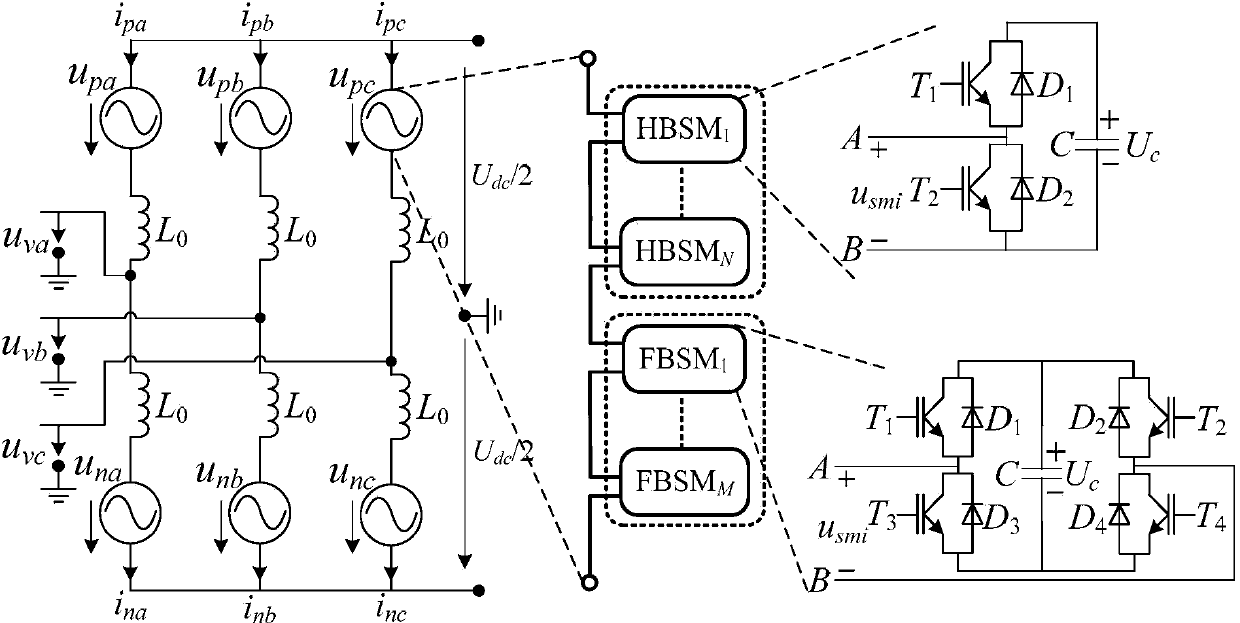

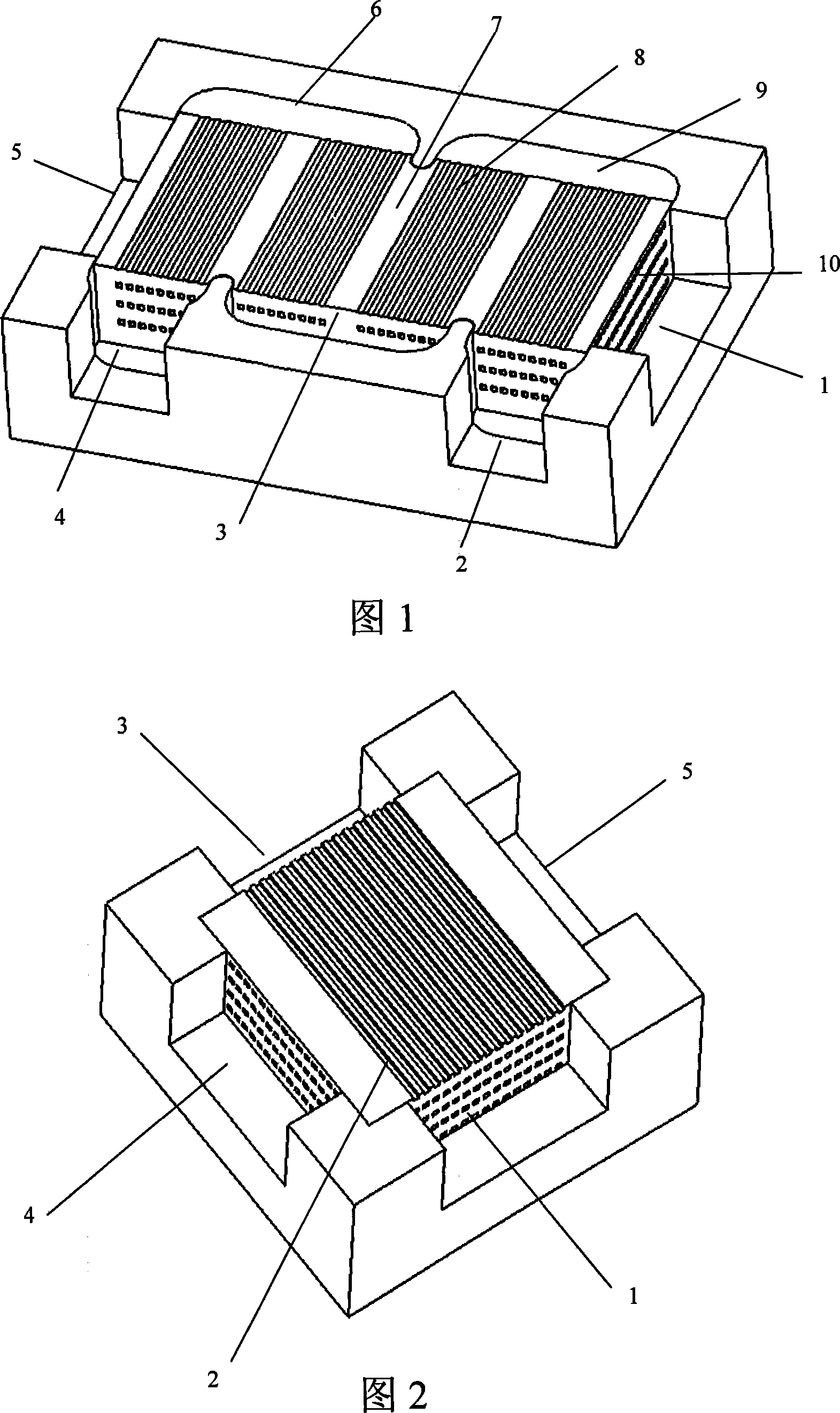

Mixed MMC-based mixed direct current power transmission system

InactiveCN103701145ANo risk of commutation failureWith DC fault self-clearing capabilityAc-dc conversionElectric power transfer ac networkHybrid typeFull bridge

The invention discloses a mixed MMC-based mixed direct current power transmission system, comprising a rectifying converter station and an inversion converter station, wherein the inversion converter station adopts a mixed MMC. The direct current power transmission system has the active and reactive decoupling control capacity, can transmit power to a reactive network without the phase change failure risk and has direct current fault self-cleaning capacity; under the condition that a feeding end alternating current system has a fault; the mixed MMC has the capacity of outputting a negative level by using a full-bridge submodule, the direct current voltage output by the system can be reduced under the premise of ensuring the controllability and stability of the system, the direct current voltage can be matched with the direct current voltage of a rectifying station, and the direct current power is maintained to be continuously transmitted; due to the optimization on the number of two types of submodules in the mixed MMC, the use number of power electronic components is greatly reduced and the investment cost is reduced under the condition that the mixed modularized multi-level converter meets the stable and transient operation demands of the direct current system.

Owner:ZHEJIANG UNIV +1

Solid state storage subsystem that maintains and provides access to data reflective of a failure risk

ActiveUS20090204852A1Hardware monitoringReliability/availability analysisSolid-state storageOperation mode

A storage subsystem is disclosed that maintains (a) statistics regarding errors detected via an ECC (error correction code) module of the storage subsystem; and / or (b) historical data regarding operating conditions experienced by the storage subsystem, such as temperature, altitude, humidity, shock, and / or input voltage level. The storage subsystem, and / or a host system to which the storage subsystem attaches, may analyze the stored data to assess a risk of a failure event such as an uncorrectable data error. The results of this analysis may be displayed via a user interface of the host system, and / or may be used to automatically take a precautionary action such as transmitting an alert message or changing a mode of operation of the storage subsystem.

Owner:WESTERN DIGITAL TECH INC

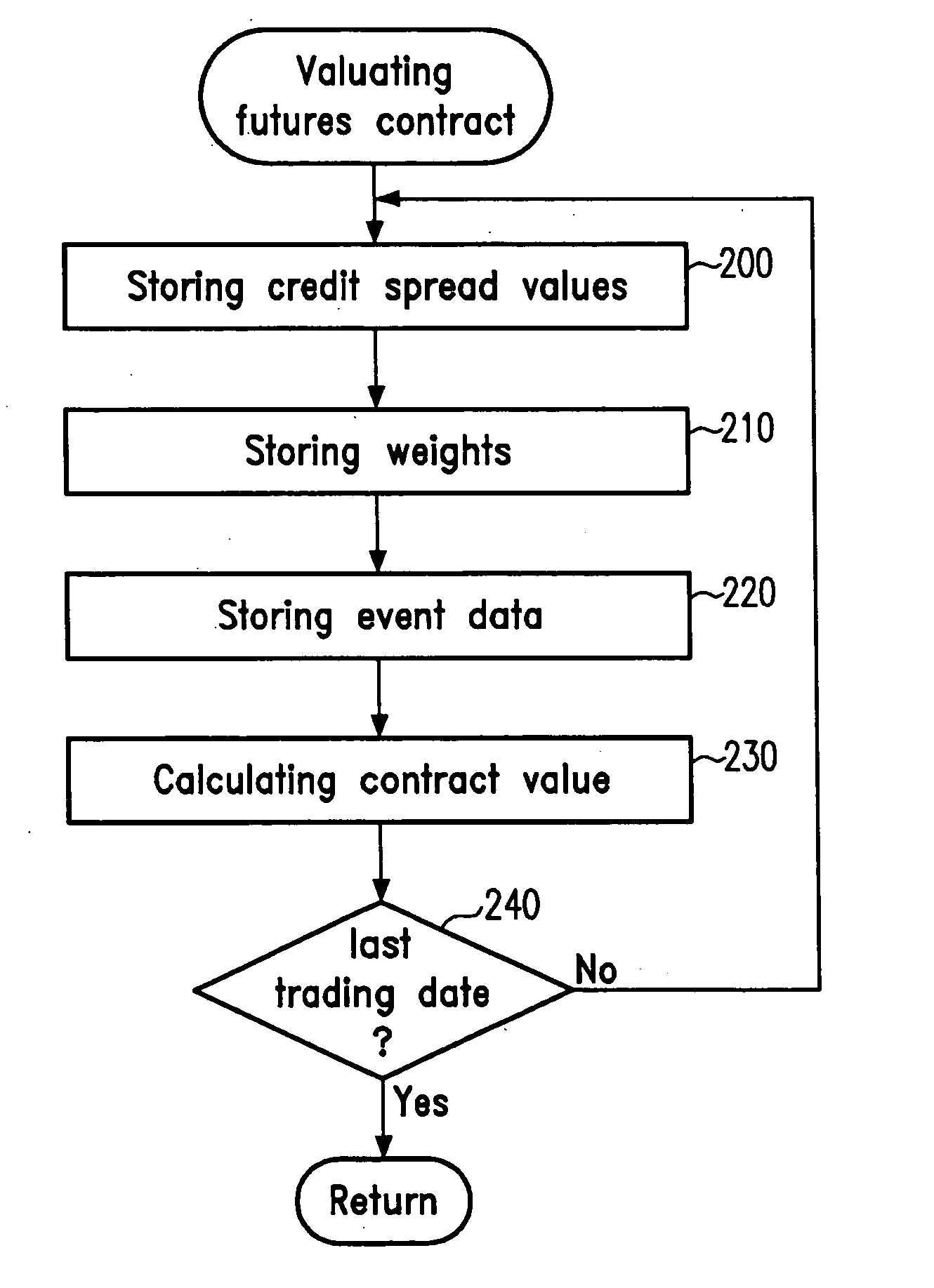

Resource amount determination technique

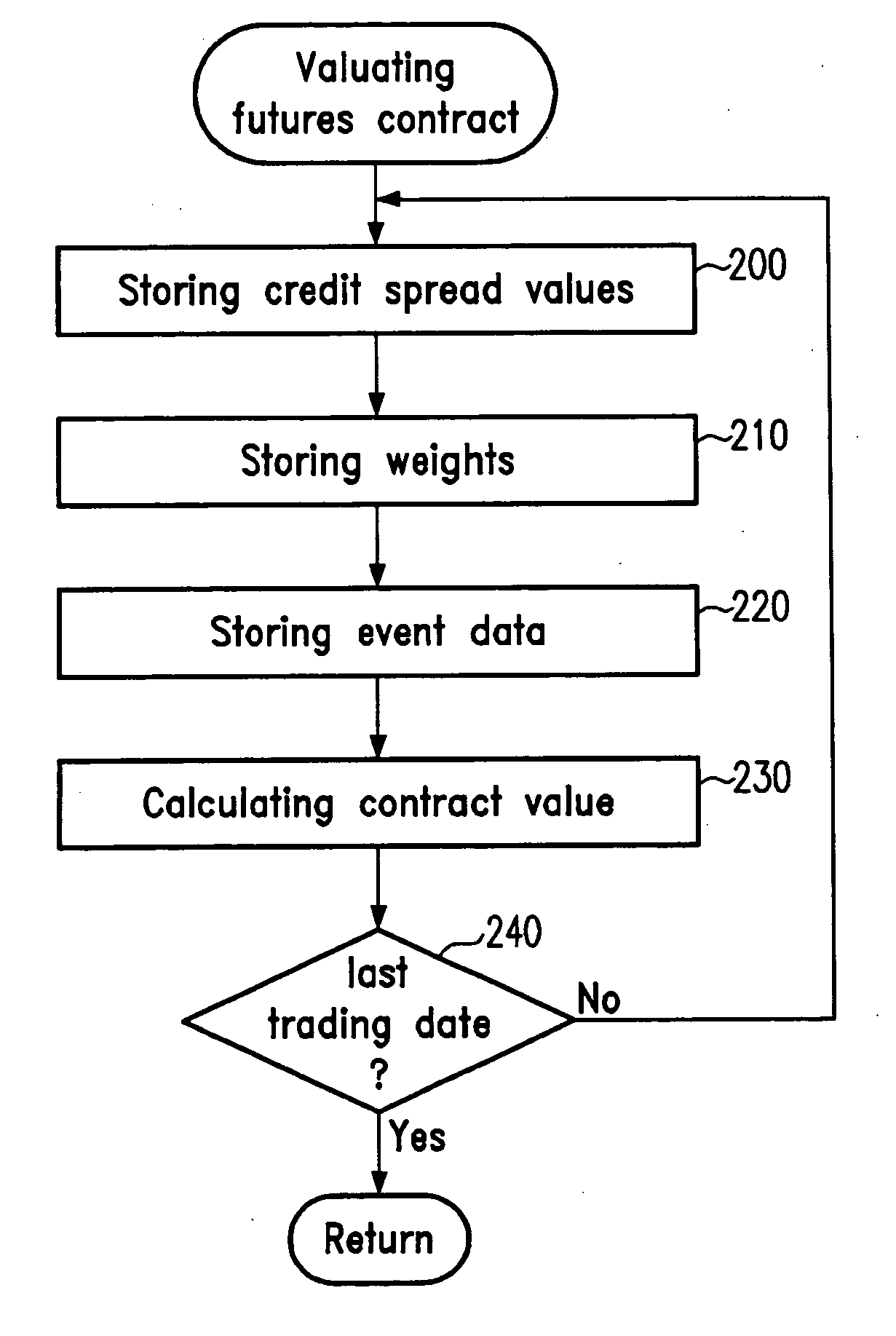

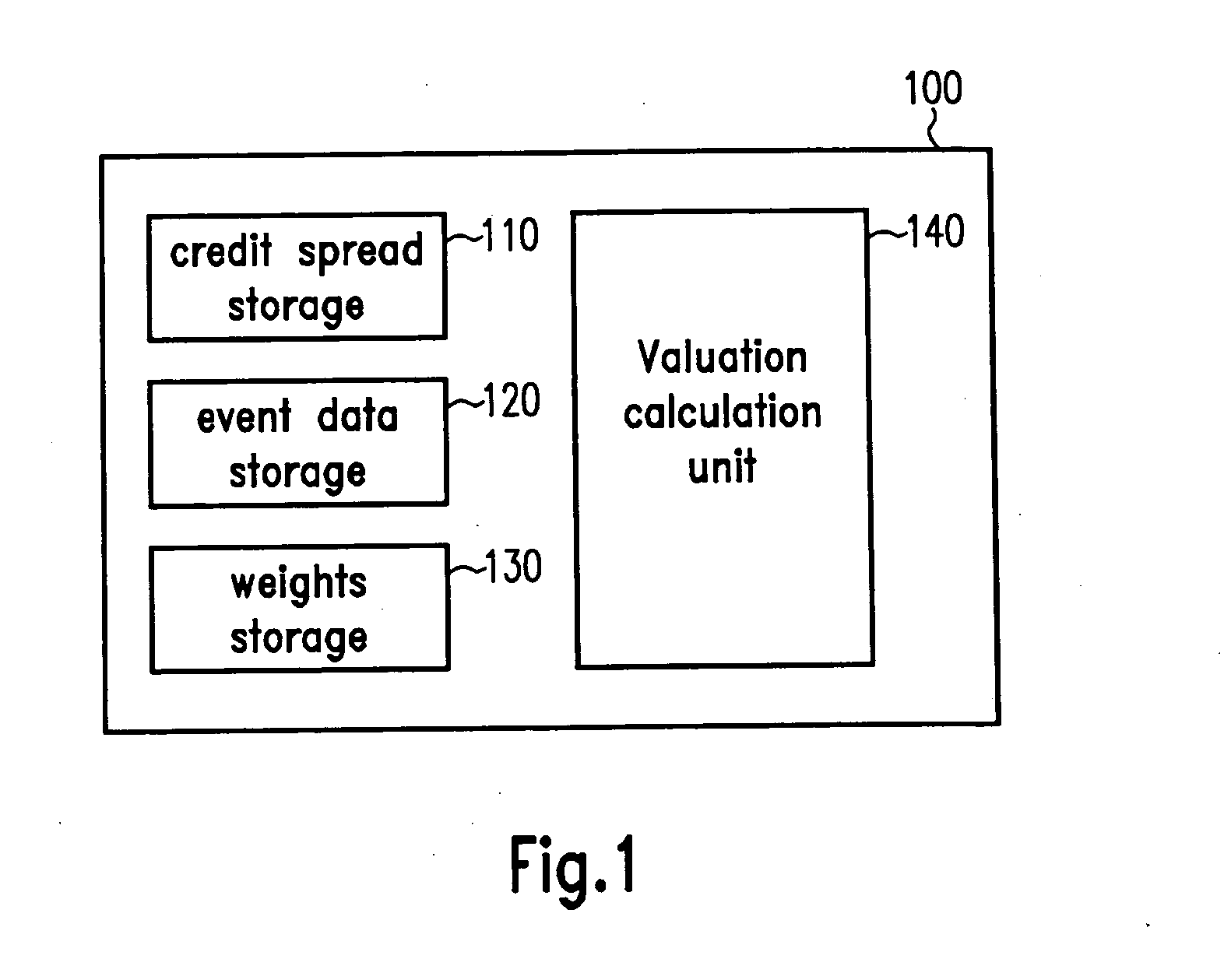

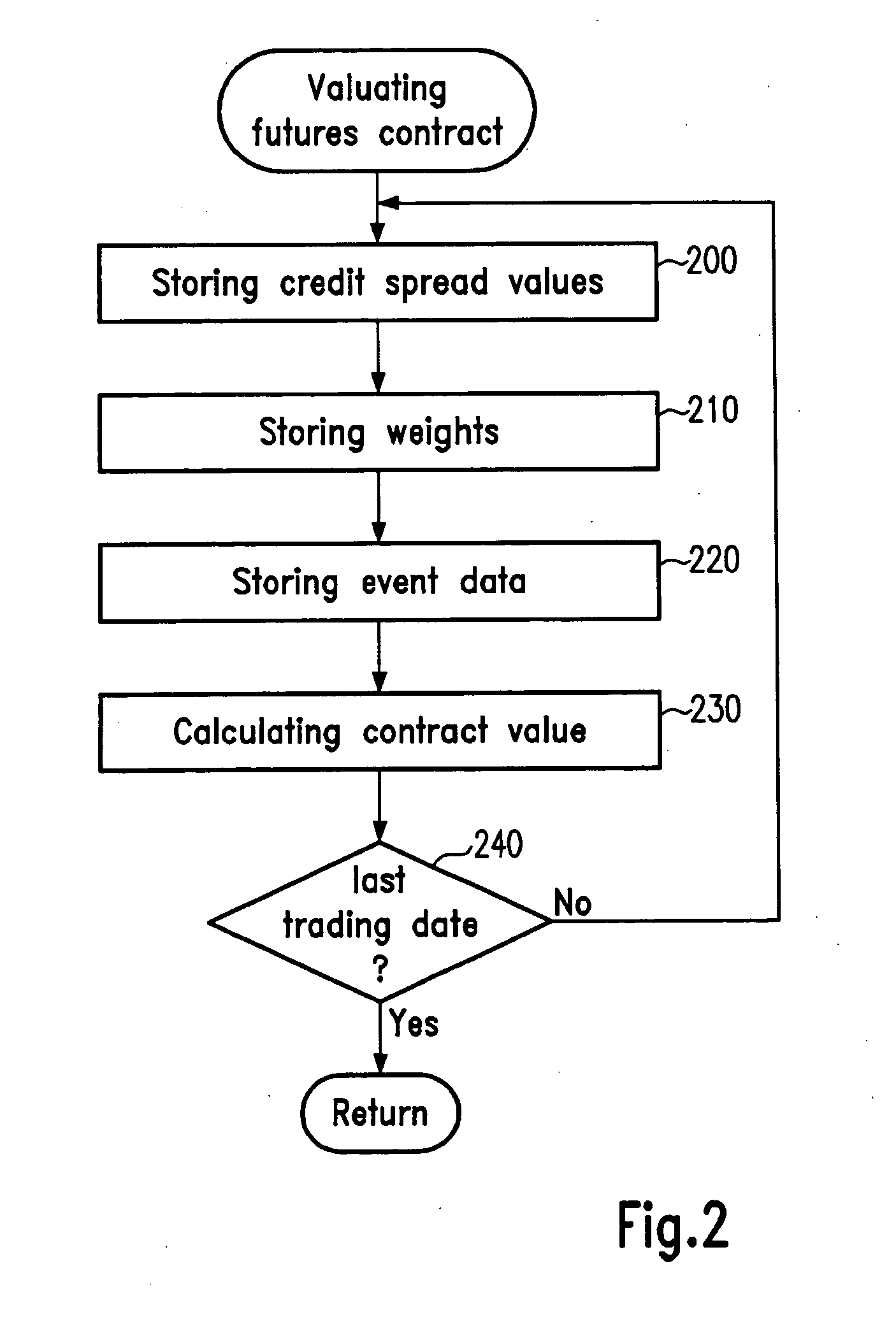

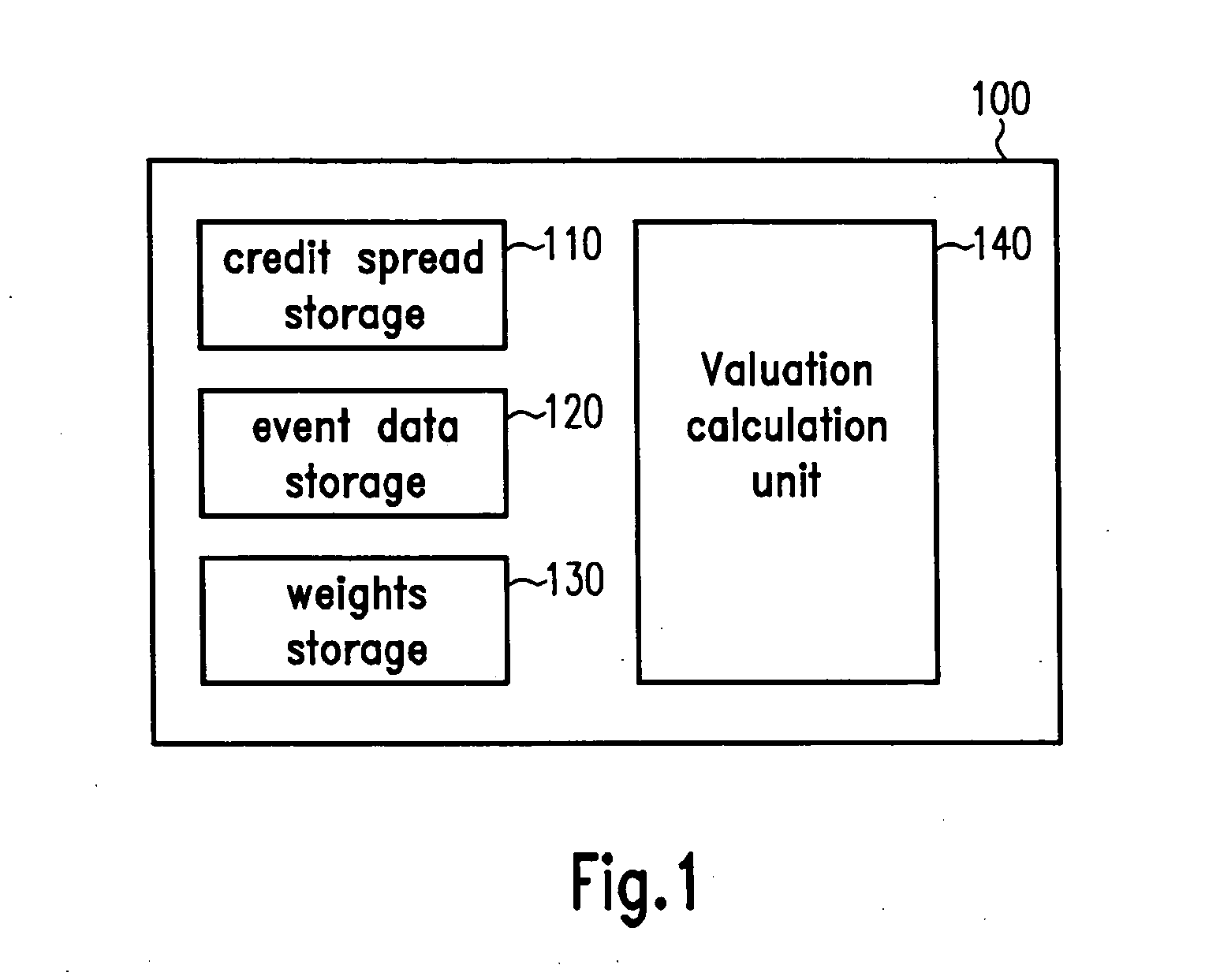

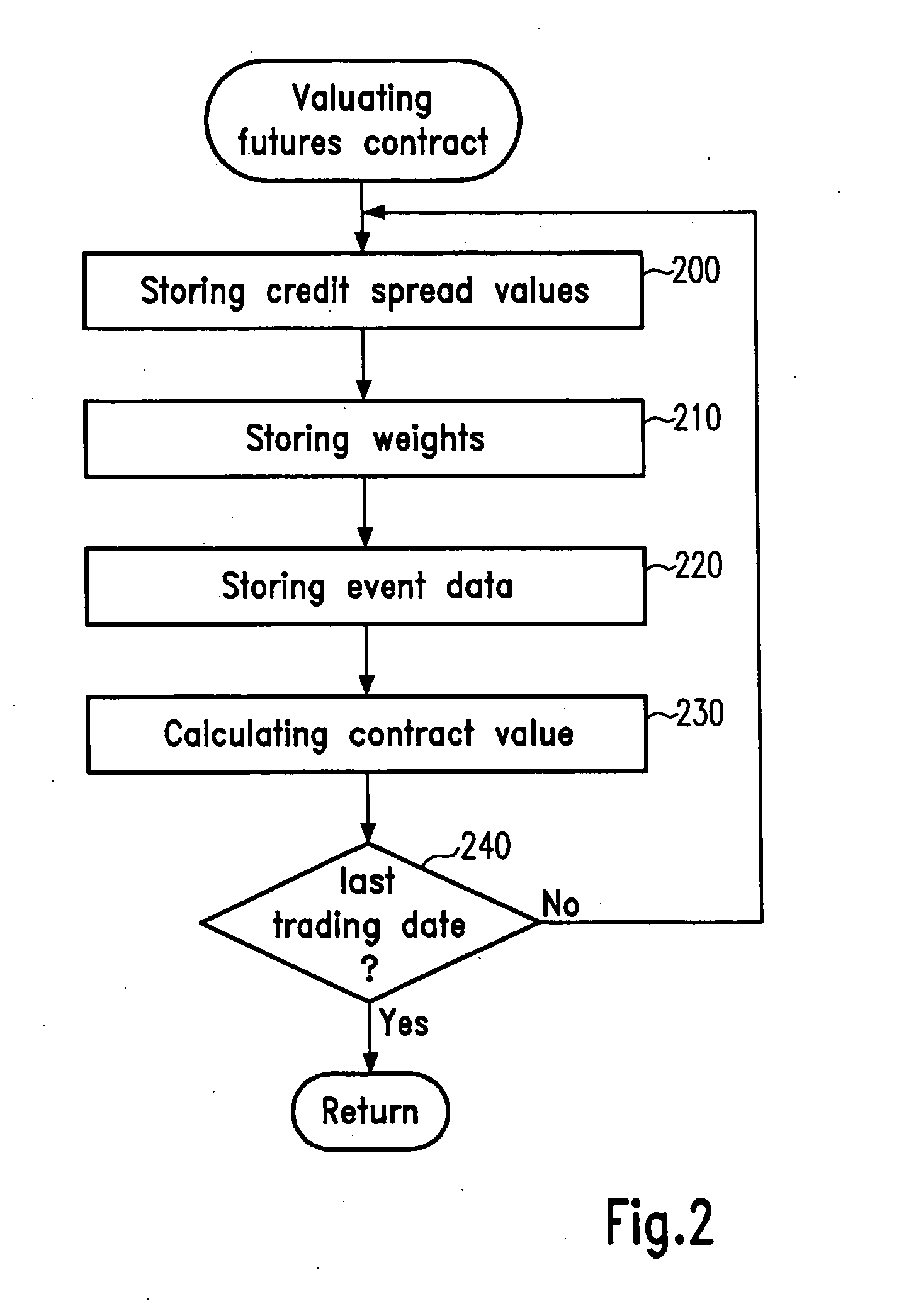

A data processing system and method are provided for repetetively determining a resource amount for counterbalancing the transfer of a failure risk pertaining to a bundle of constructs that may individually fail. The system has a data storage for storing reference values of the bundle of constructs for distinct individual time instances during the resource amount determination. The reference values indicate a value of a respective reference construct or a value of a reference bundle of constructs. The system further has a calculation unit connected to the data storage for calculating a value of the resource amount for an individual time instance based on the reference values. The technique is suitable for valuing a futures contract that is based on a basket of credit default swaps as underlyings.

Owner:DEUT BORSE

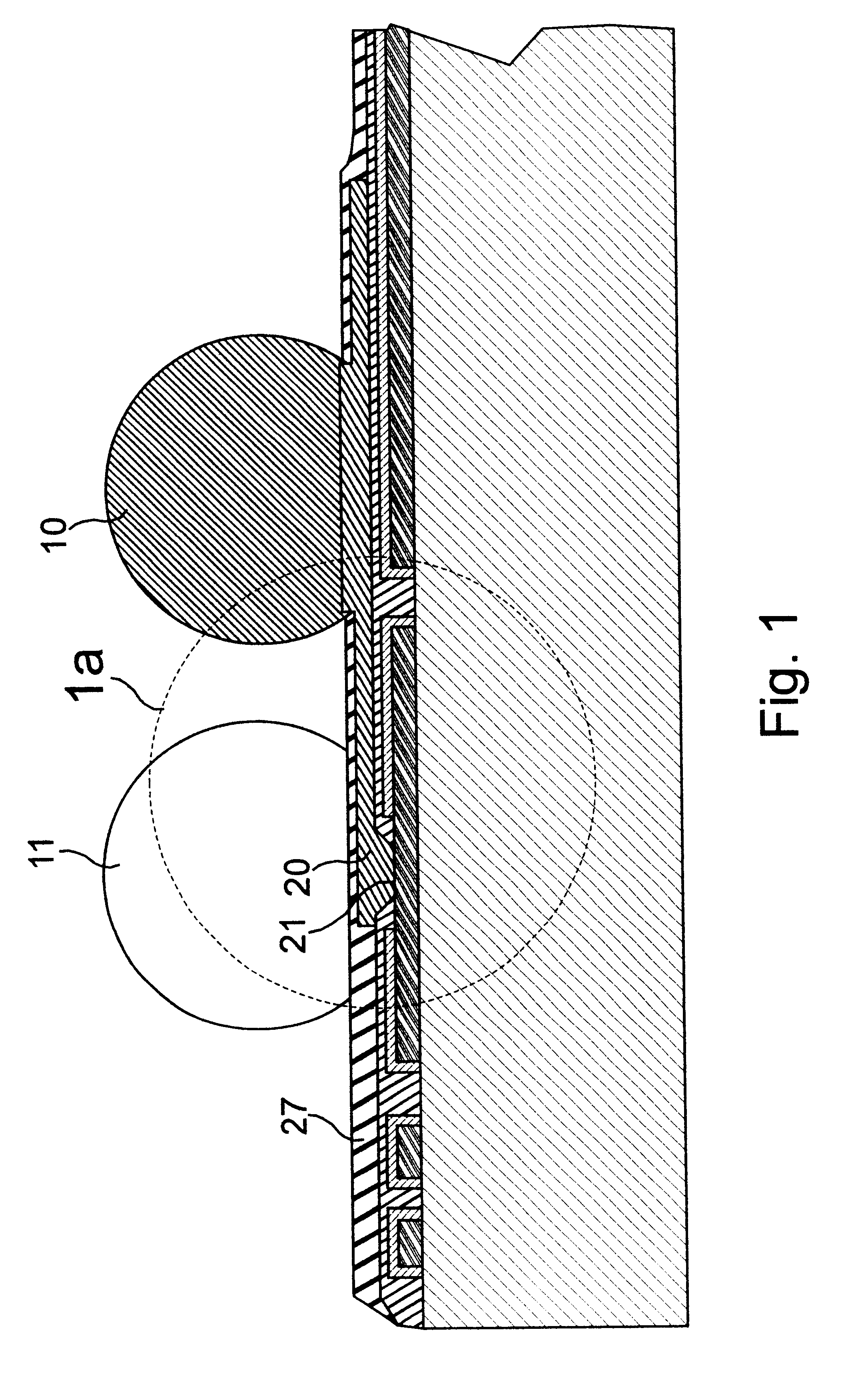

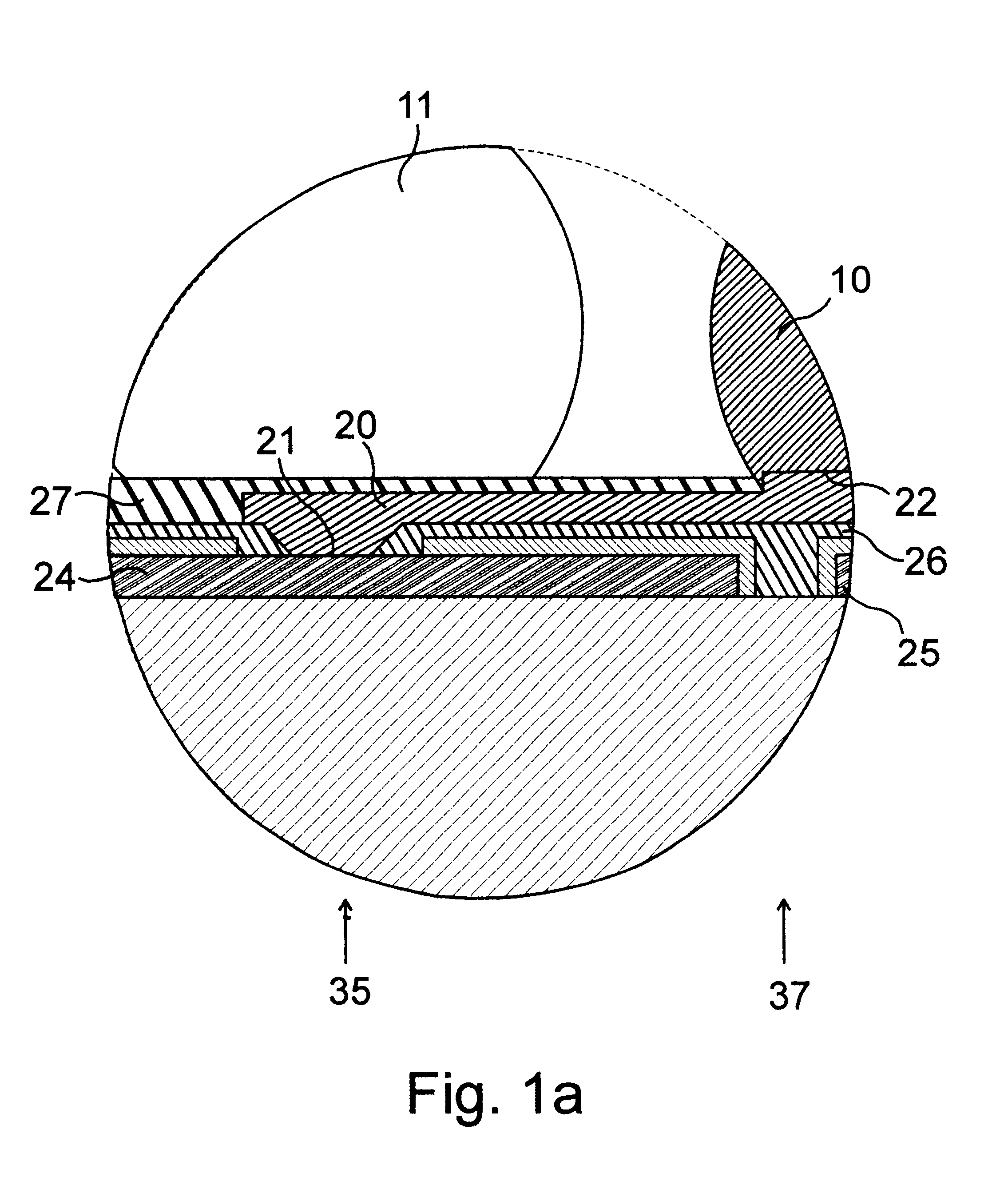

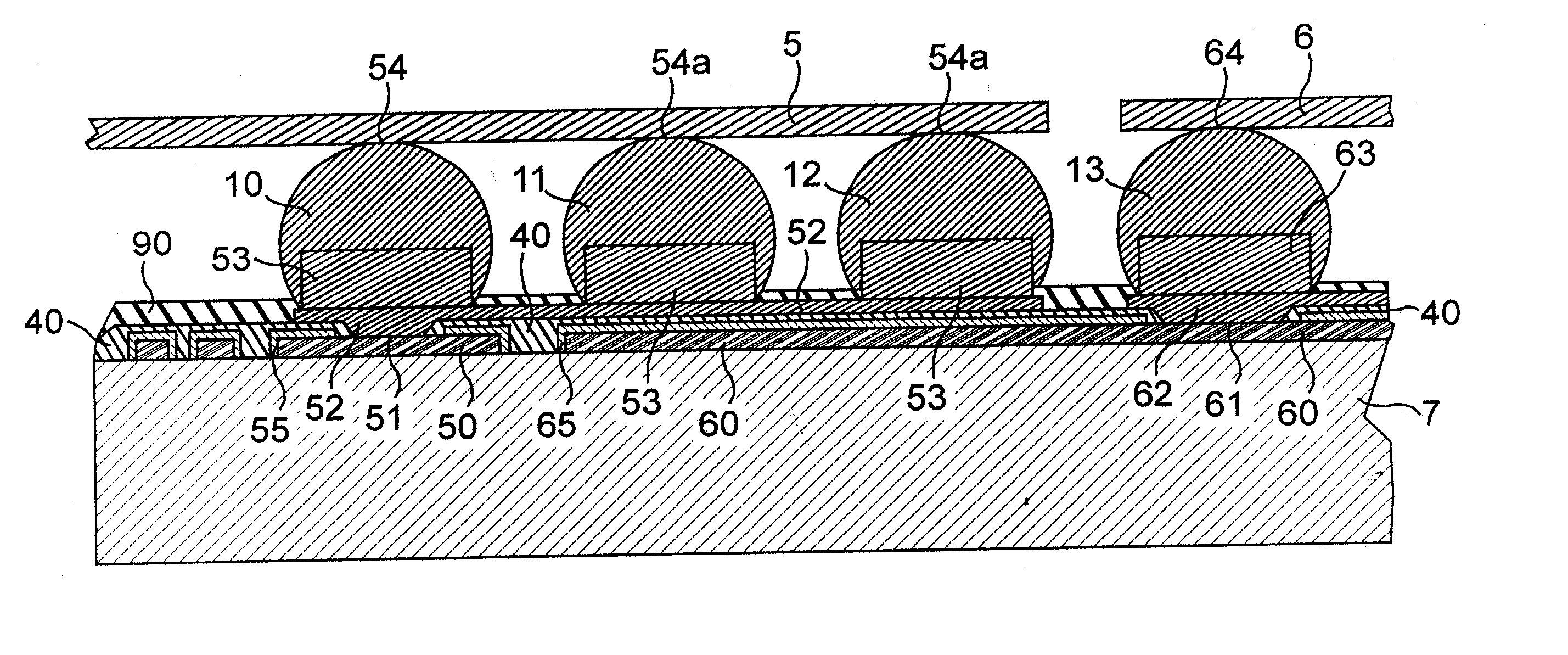

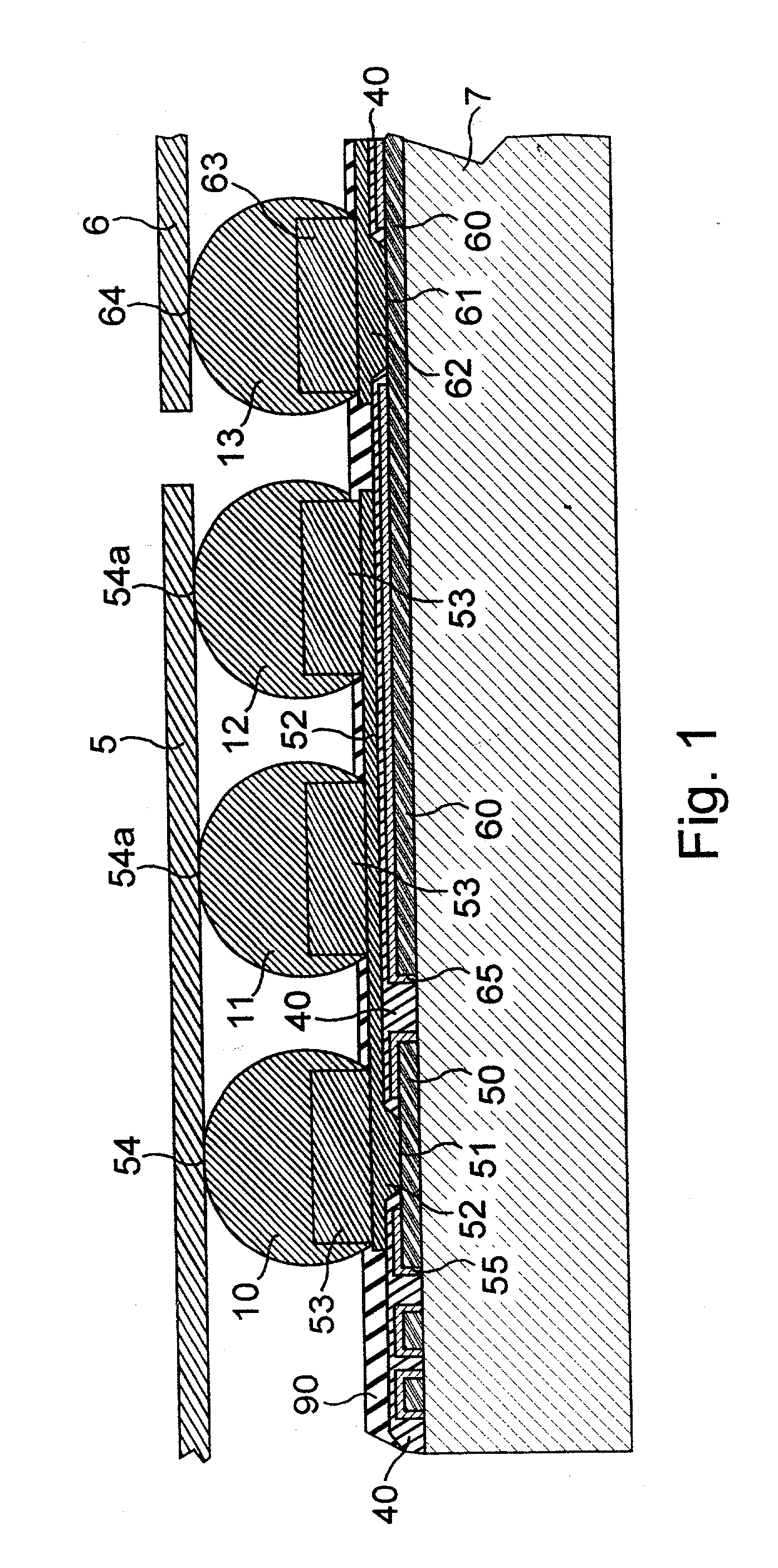

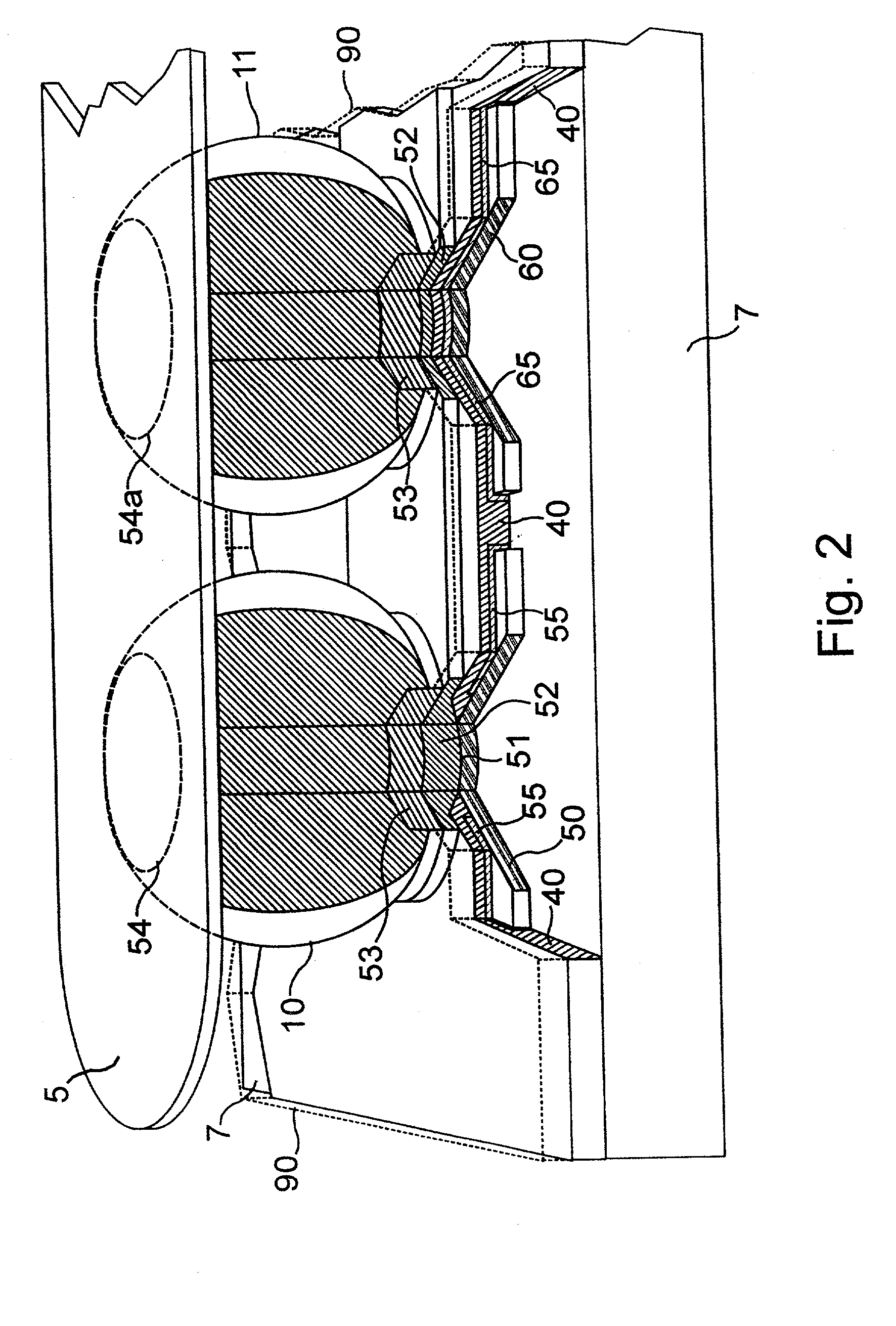

MOSFET device with multiple gate contacts offset from gate contact area and over source area

Careful repositioning of MOSFET gate contacts and increasing of their number makes MOSFET gate contacts more durable and reliable without requiring changes in either the leadframe design or the assembly process. Extension of the under-bump metal laterally from the gate contact with the gate pad metallization out to two or more gate pads not overlying the gate pad metallization minimizes the risk of delamination of the metallization due to thermal and mechanical stresses in assembly and operation. Use of more than one gate pad further reduces such failure risks. Positioning the gate pads sufficiently close to the original gate contact permits use of the same leadframe design and assembly process as would be used for a single gate pad placed directly over the gate contact. The result is a reliable, durable MOSFET gate contact compatible with current assembly methods.

Owner:SEMICON COMPONENTS IND LLC

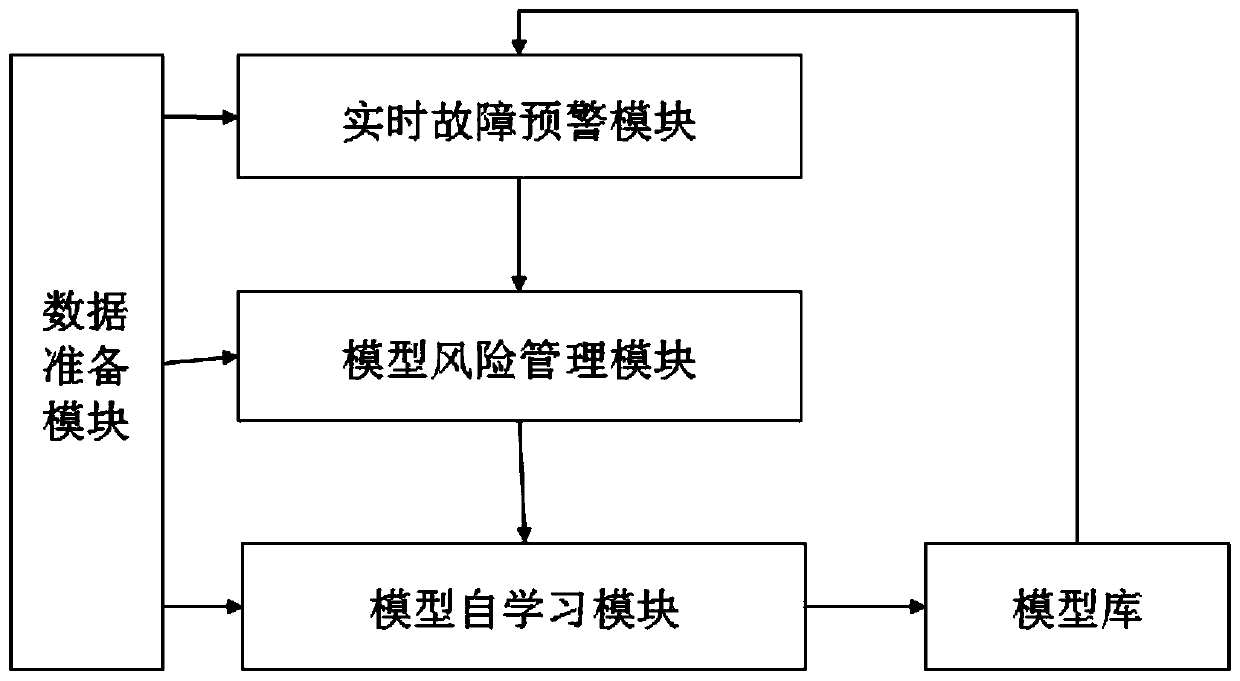

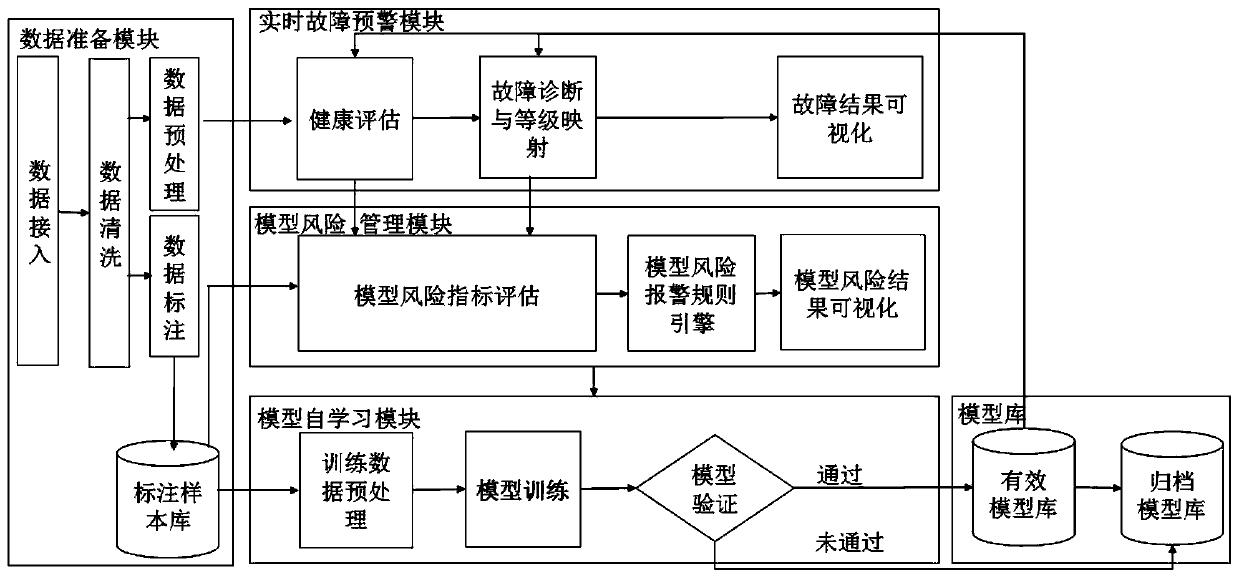

Equipment failure early-warning system based on model lifecycle management

ActiveCN109947088APre-warning results are consistently accurateEnable predictive maintenanceElectric testing/monitoringResourcesEarly warning systemReal-time data

The invention relates to an equipment failure early-warning system based on model lifecycle management. The system comprises a data preparation module, a real-time failure early-warning module, a model risk management module, a model self-learning module and a model base, wherein the data preparation module reads in and preprocesses external real-time data and transmits the processed external real-time data to the real-time failure early-warning module and the model risk management module for analysis; the real-time failure early-warning module predicts failure risks and generates early-warning information and maintenance suggests; the model risk management module evaluates reliability of model results; the model self-learning module reads in accumulated annotation samples and retrains models in the real-time failure early-warning module. The system can realize failure early-warning of equipment, online monitoring of model lifecycle and dynamic update of models, and the continuity reliability of model results is guaranteed; besides, running data and operation data are introduced simultaneously, so that early-warning errors are smaller.

Owner:CYBERINSIGHT TECH CO LTD

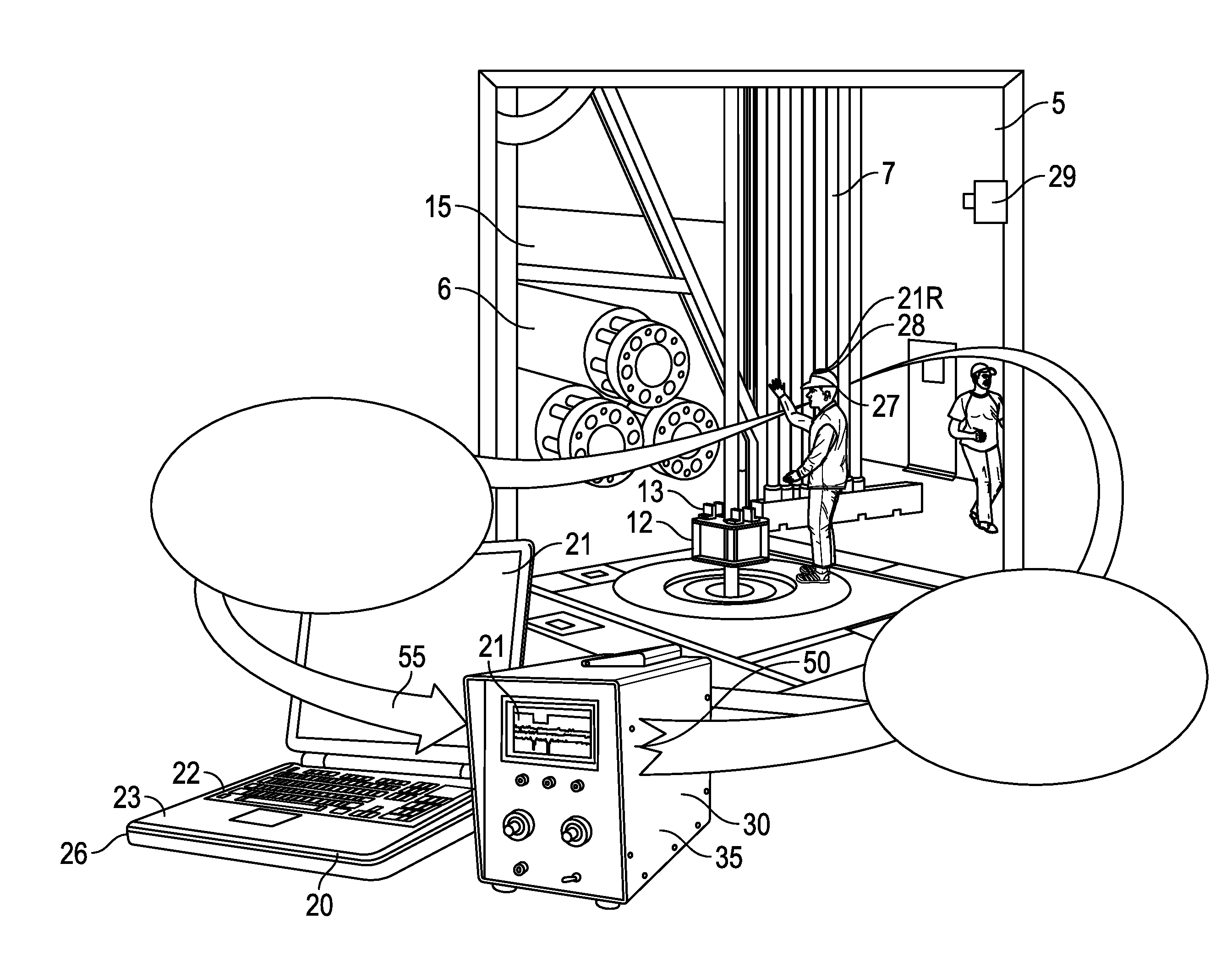

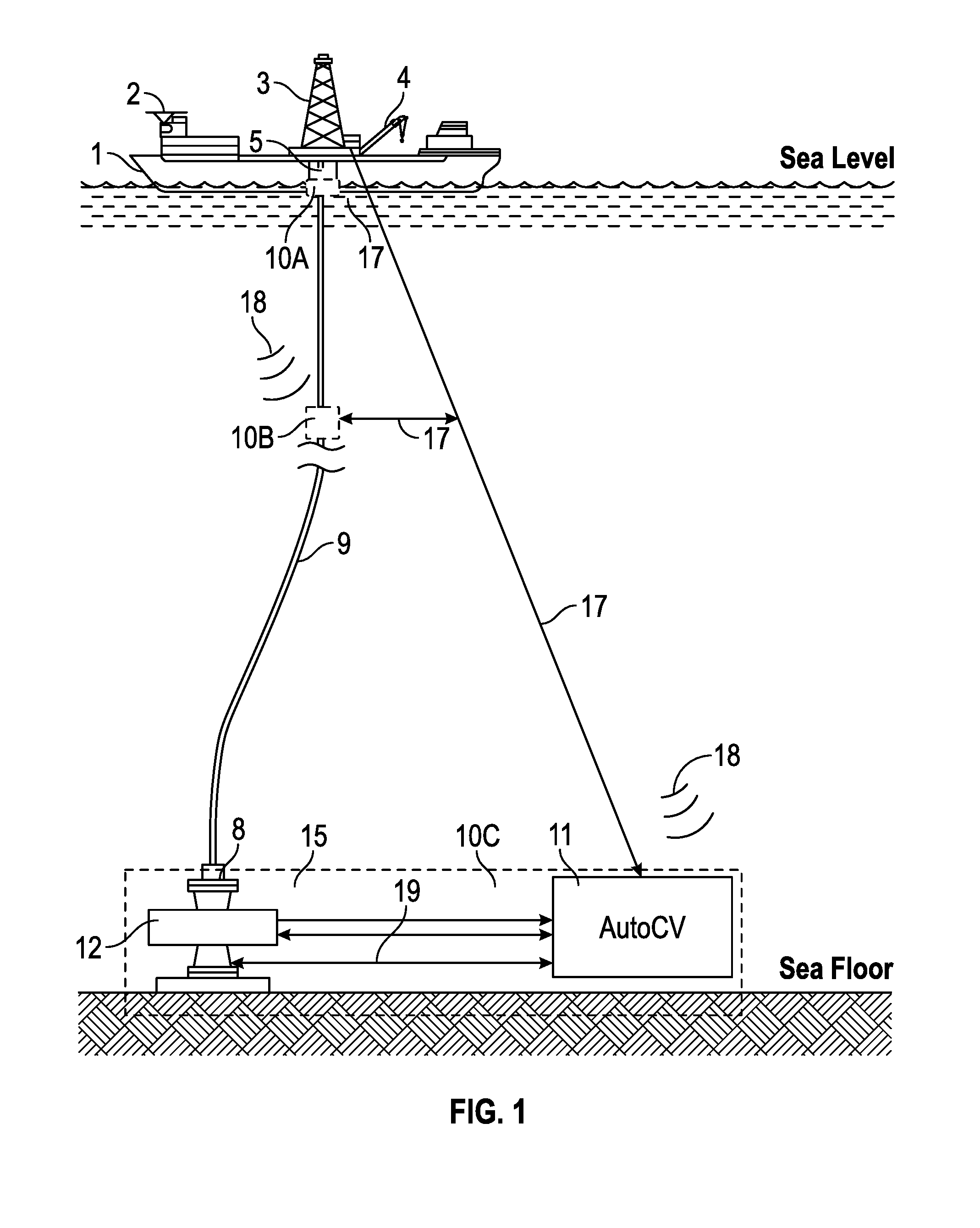

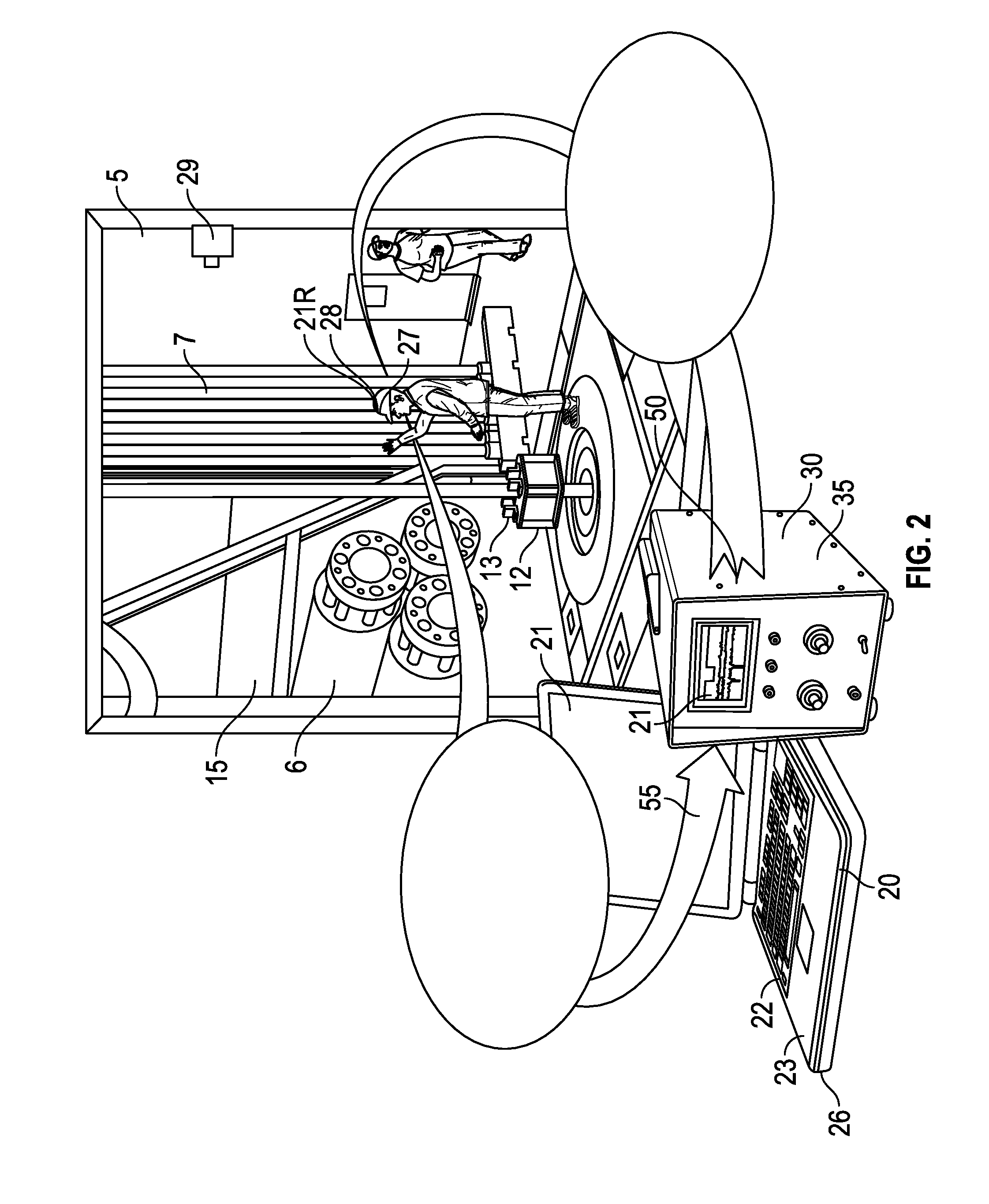

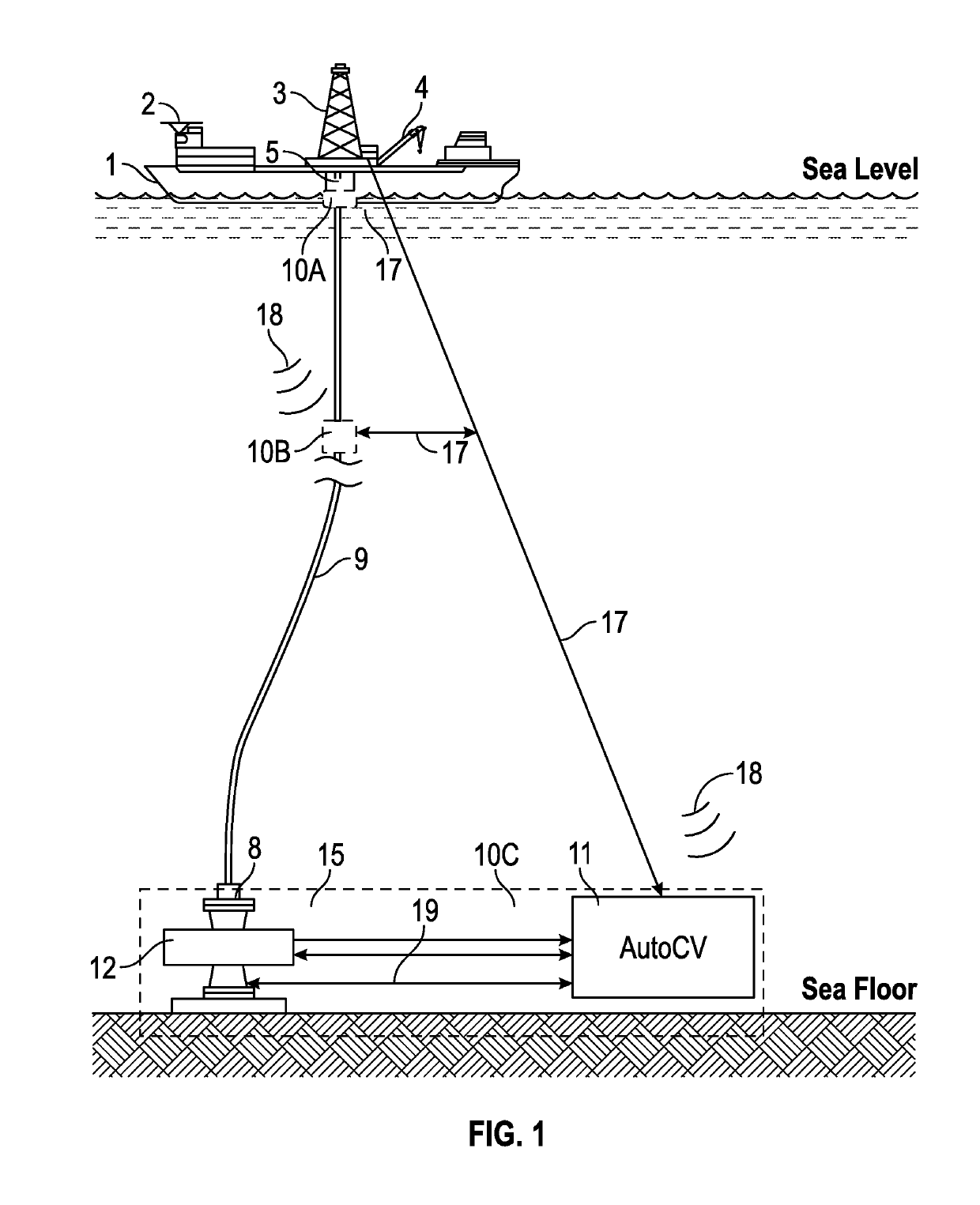

Stress engineering assessment of risers and riser strings

InactiveUS20160237804A1Limit any harmful consequenceIncrease the gapSurveyDrilling rodsData acquisitionFailure risk

Riser stress-engineering-assessment equipment to verify the integrity and the in-deployment-integrity of a riser string by knowing the status, details and location of each riser joint and by monitoring the deployment parameters. When the failure risk exceeds an acceptable level, the equipment activates a local and / or a remote alarm using voice, sound and lights. The system comprises a computer with communication means, a material properties and geometry detection system, a data acquisition system acquiring deployment and other parameters, a database comprising of riser historical data and captured expert knowledge, a failure-criteria calculation to calculate maximum-stresses under different loads and the combined effects of the different loads to determine if the riser string is still fit-for-deployment.

Owner:STYLWAN IP HLDG LLC

Construct separation for resource amount determination

A technique is provided for managing bundles of constructs that may individually fail. Each bundle has a repetitively updated resource amount for counterbalancing a transfer of a failure risk pertaining to the respective bundle. Construct data is stored and a value of the resource amount is calculated for an individual time instance based on the construct data. It is determined whether a construct of a first bundle has failed. If not, a value of a resource amount for the first bundle is calculated, but if a construct has failed, a second bundle is generated that includes all constructs of the first bundle except for the construct having failed, and a value of a resource amount for the second bundle is calculated. The technique is particularly suitable for managing futures contracts that are based on a basket of credit default swaps as underlyings.

Owner:DEUT BORSE

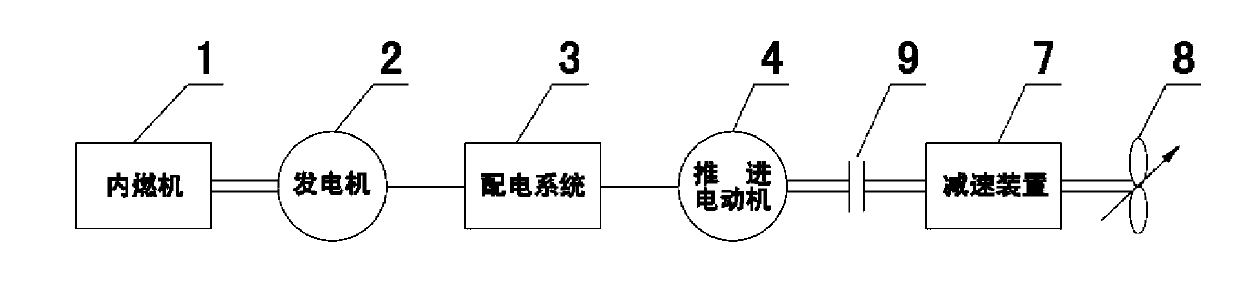

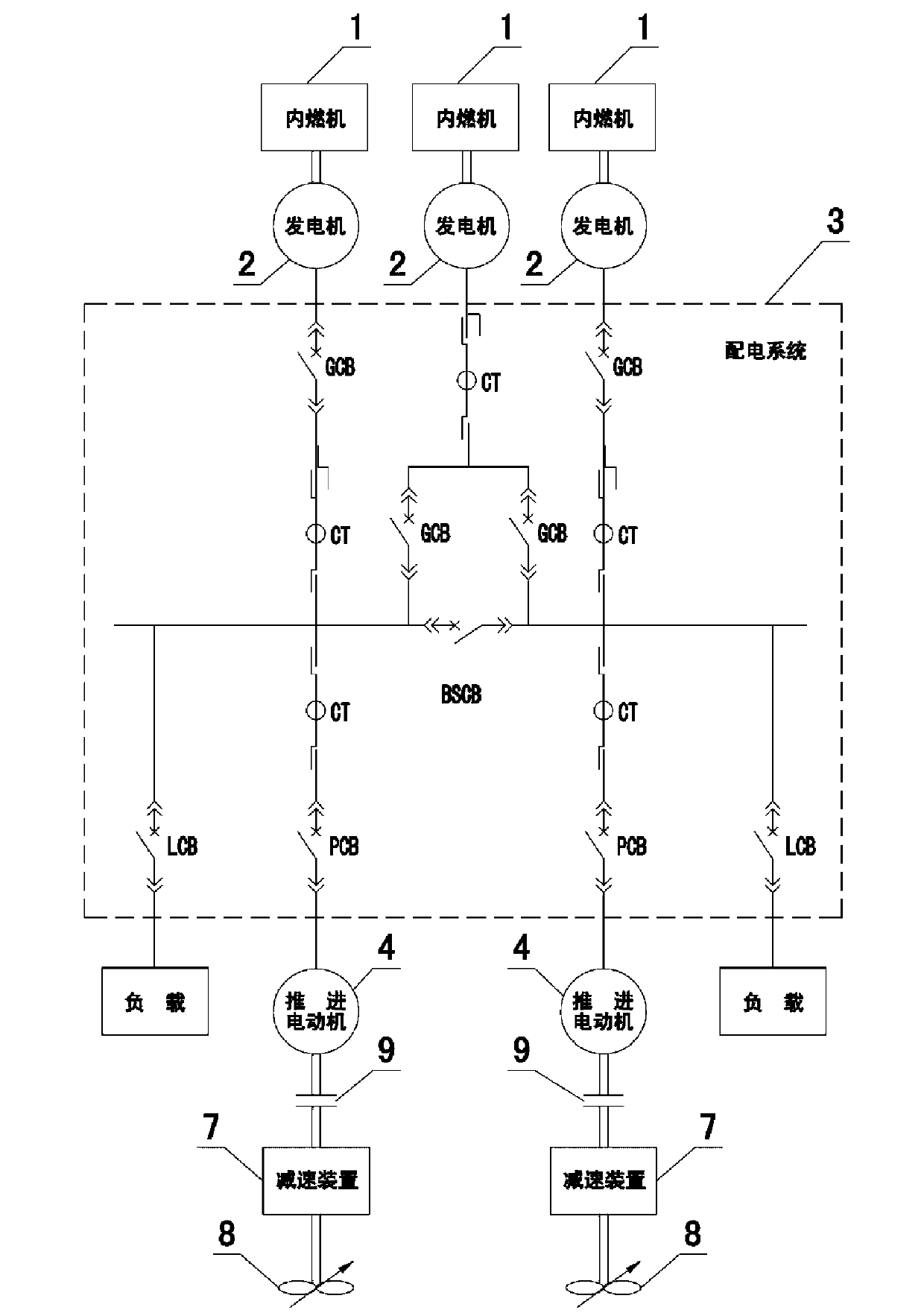

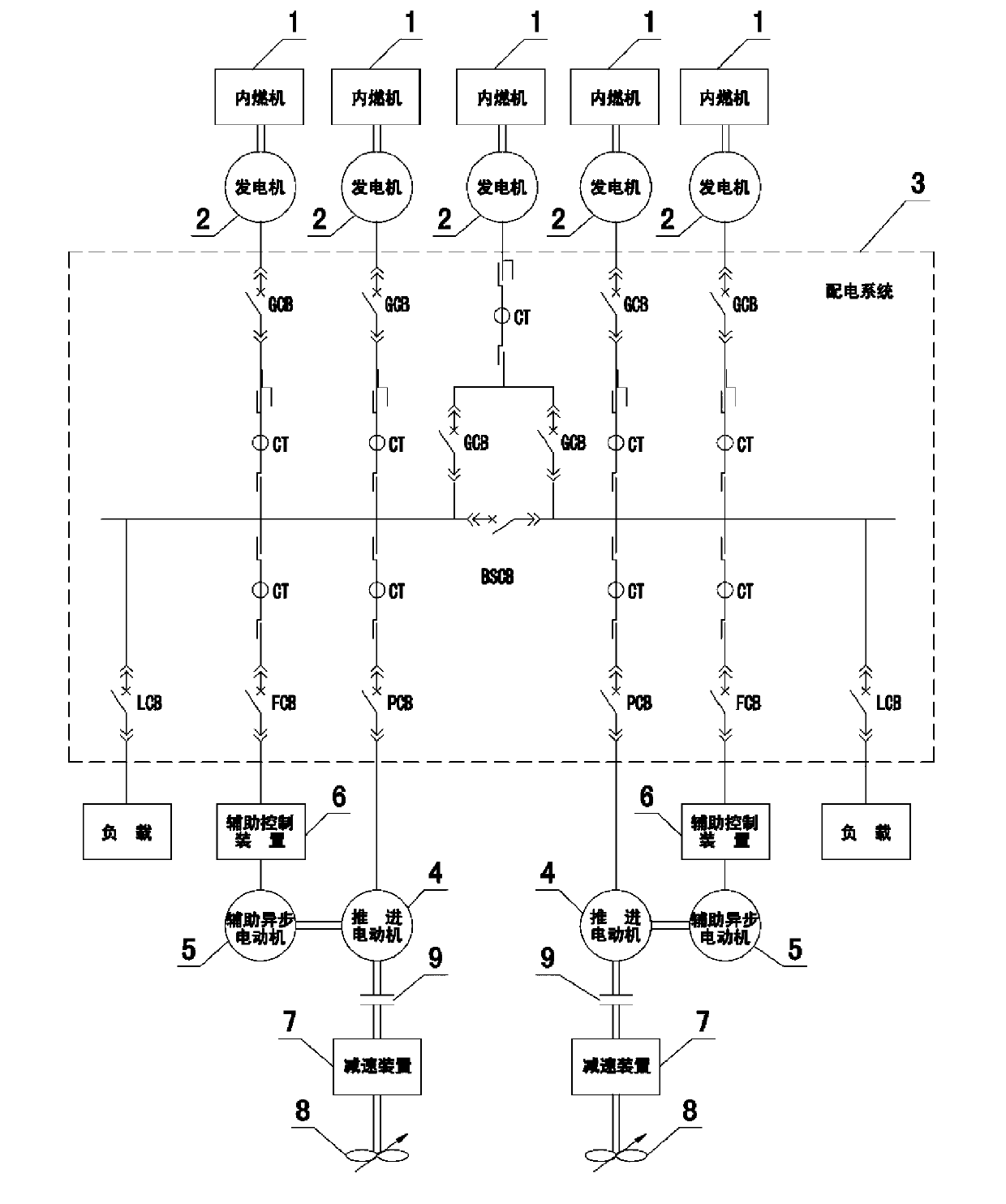

Novel electric propulsion system

InactiveCN101767645ASolve problems with high risk of failureSolve the large voltage drop of the gridPropulsion power plantsPropulsive elementsSynchronous motorDistribution power system

The invention discloses a novel electric propulsion system. The system comprises an internal combustion engine, an electric generator, an electric distribution system, a propulsion motor and a propeller, wherein the electric generator is in cable connection with the propulsion motor through the electric distribution system; the propulsion motor is connected with the propeller through a clutch and a speed reducer; both the electric generator and the propulsion motor are synchronous motors; and the propeller is an adjustable pitch propeller. The novel electric propulsion system effectively solves the problems of high investment cost, electric loss, severe harmonic pollution, difficult maintenance and high failure risk due to the adoption of a variable frequency technique by the electric propulsion system in the prior art and also solves the problems of high voltage drop in a system power grid and big torque born by a starting transient mechanical shaft due to the high starting transient current in the electric propulsion system in the prior art. The novel electric propulsion system has little investment, convenient installation and maintenance, a low running cost, high system reliability, low failure risk in a use process and a remarkable economic benefit.

Owner:浙江欣亚磁电发展有限公司

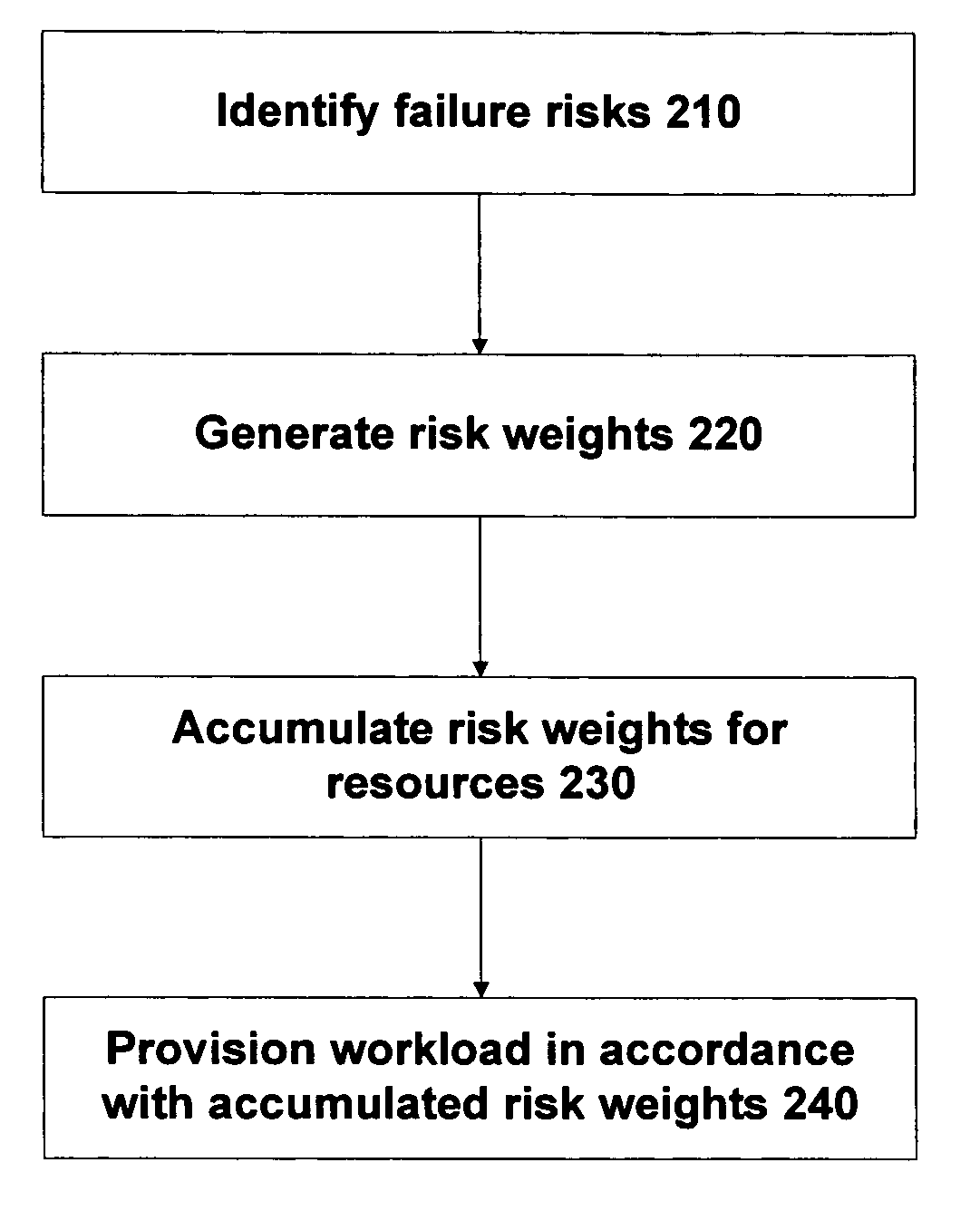

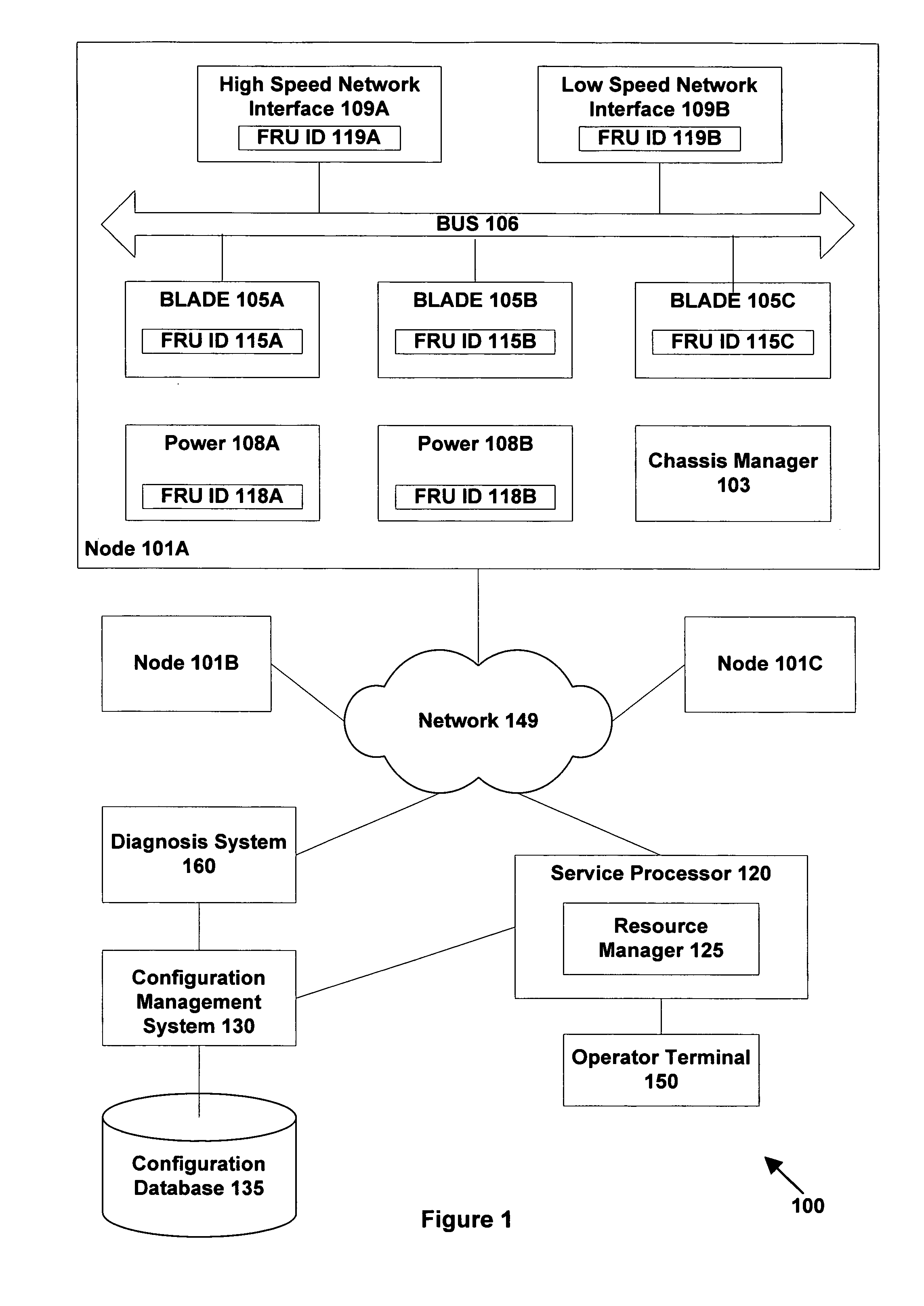

Method and apparatus for managing workload across multiple resources

ActiveUS7669087B1Longer expected resolution timeReduce riskReliability/availability analysisResource managementResource based

A method for operating a system comprising multiple resources. The method comprises identifying for each resource a set of one or more failure risks for that resource. For each identified failure risk, a likelihood of failure is combined with an expected resolution time to provide a risk weight for the identified failure risk. For each resource, the risk weights for each failure risk are accumulated to provide an accumulated risk weight for the resource. A resource manager provisions workload across the multiple resources based on the accumulated risk weights for each resource.

Owner:ORACLE INT CORP

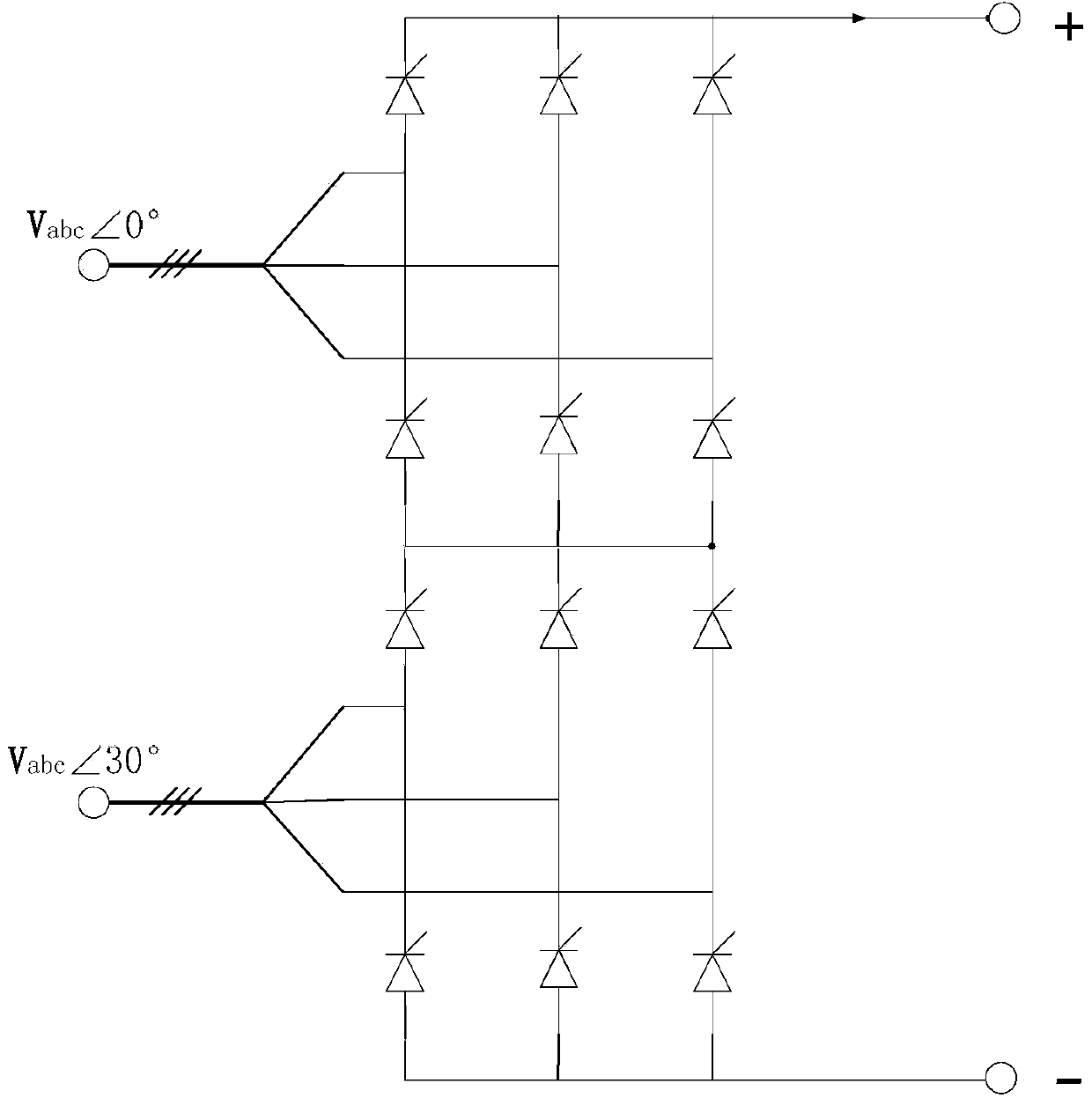

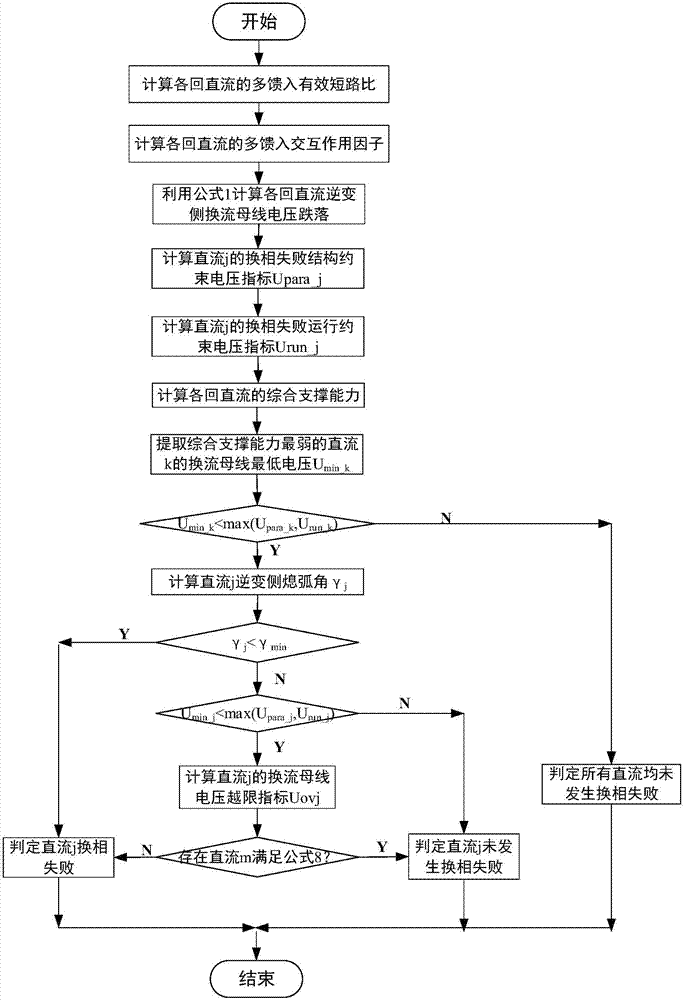

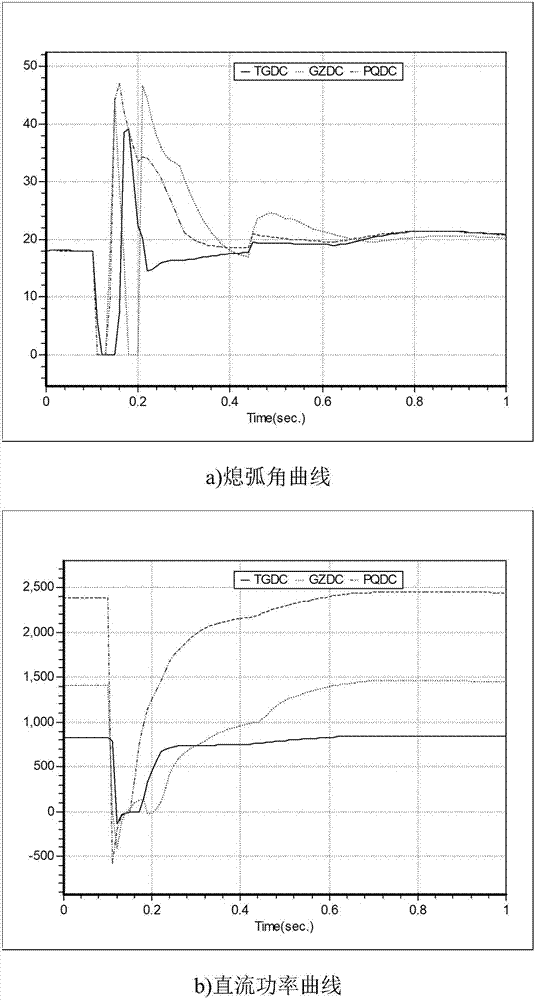

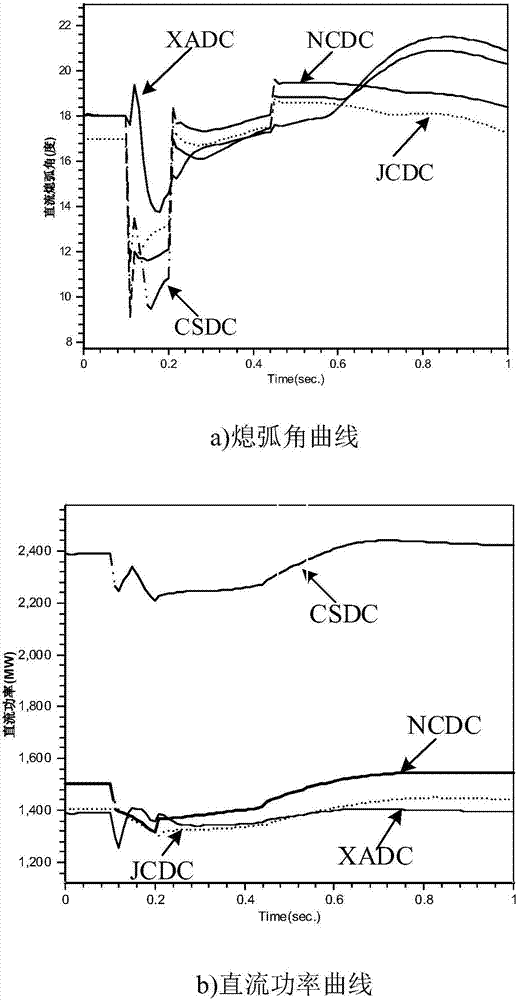

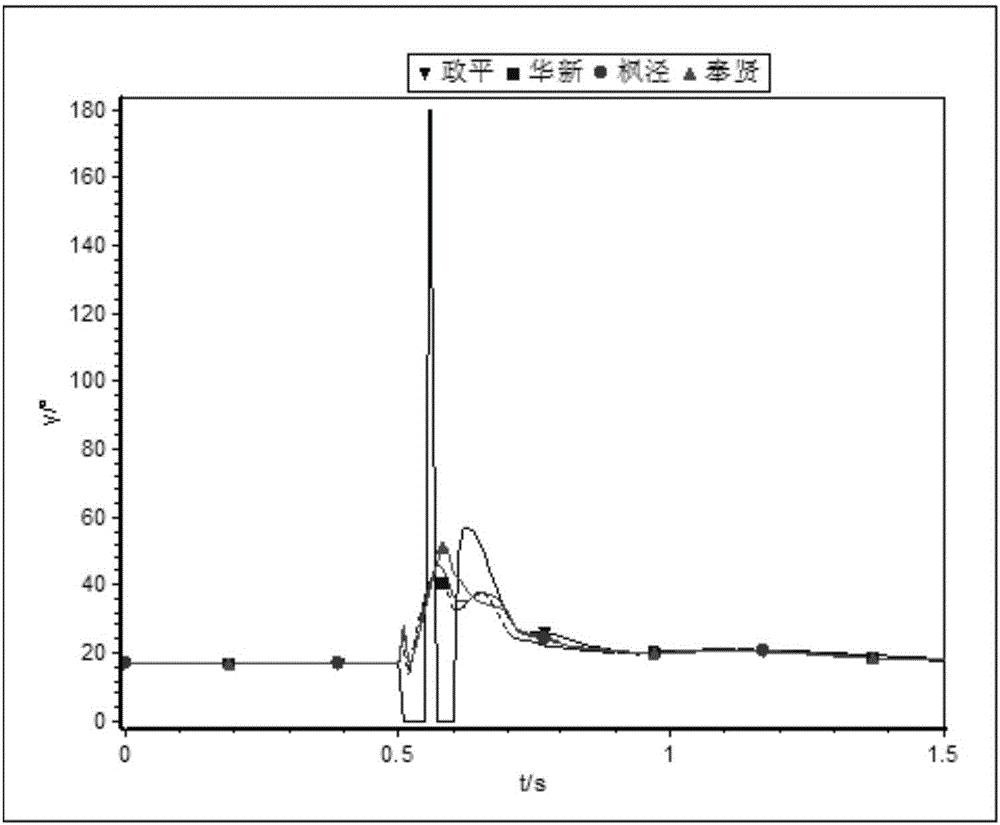

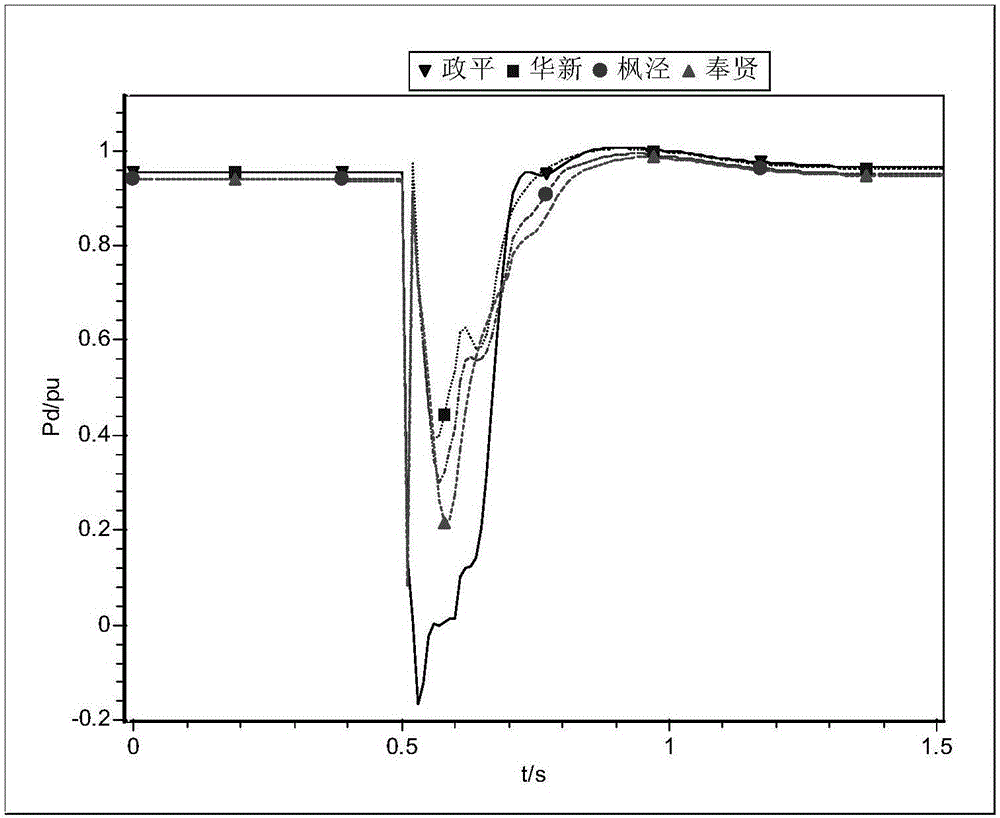

Multi-infeed direct current commutation failure quick assessment method

ActiveCN107394807AQuick scanAvoid errors of judgmentElectric power transfer ac networkSingle network parallel feeding arrangementsTime domainPower-system automation

The invention discloses a multi-infeed direct current commutation failure quick assessment method, and belongs to the technical field of power system automation. The multi-infeed direct current commutation failure quick assessment method comprehensively considers the interaction influence among multiple loops of direct current, the self operating state and the structure parameter of the direct current, and the capability of the alternating current power grid of supporting a direct current inversion station commutation bus, based on the flow result in the initial operating mode and the structure parameter of the multi-infeed direct current power grid, and can realize quick assessment of the multiple loops of direct current commutation failure risk which may be caused by the three-phase short circuit fault of a multi direct current infeed alternating current power grid on the premise of carrying out no transient stable time domain simulation. The multi-infeed direct current commutation failure quick assessment method can effectively avoid misjudgment caused by depending on voltage drop of the direct current inversion station commutation bus.

Owner:NARI TECH CO LTD +3

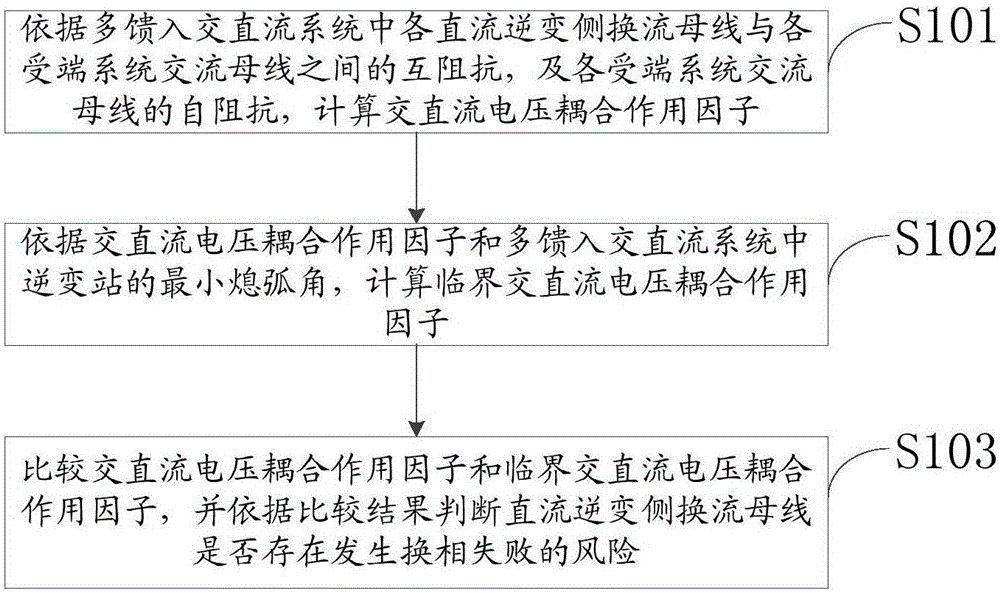

Method and system for assessing risk of multi-feed-in alternating AC/DC system commutation failure

PendingCN106803153ASimple implementation stepsRapid assessmentResourcesElectric power systemEnd system

The invention provides a method and system for assessing a risk of a multi-feed-in AC / DC system commutation failure. The method includes calculating an AC / DC voltage coupling effect factor and a critical AC / DC voltage coupling effect factor; and comparing the AC / DC voltage coupling effect factor and the critical AC / DC voltage coupling effect factor, and judging whether a risk of a commutation failure exists in a DC inverter side current conversion bus according to a comparison result. Compared with the prior art, the method and system for assessing the risk of a multi-feed-in AC / DC system commutation failure judge whether the risk of a commutation failure exists in the DC inverter side current conversion bus after a fault occurs in an AC bus of a receiving end system according to the comparison result of the AC / DC voltage coupling effect factor and the critical AC / DC voltage coupling effect factor, do not need to perform whole-network fault monitoring on an electric power system, greatly reduce the work amount of calculation and can rapidly assess whether a commutation failure risk exists in the DC inverter side current conversion bus.

Owner:CHINA ELECTRIC POWER RES INST +1

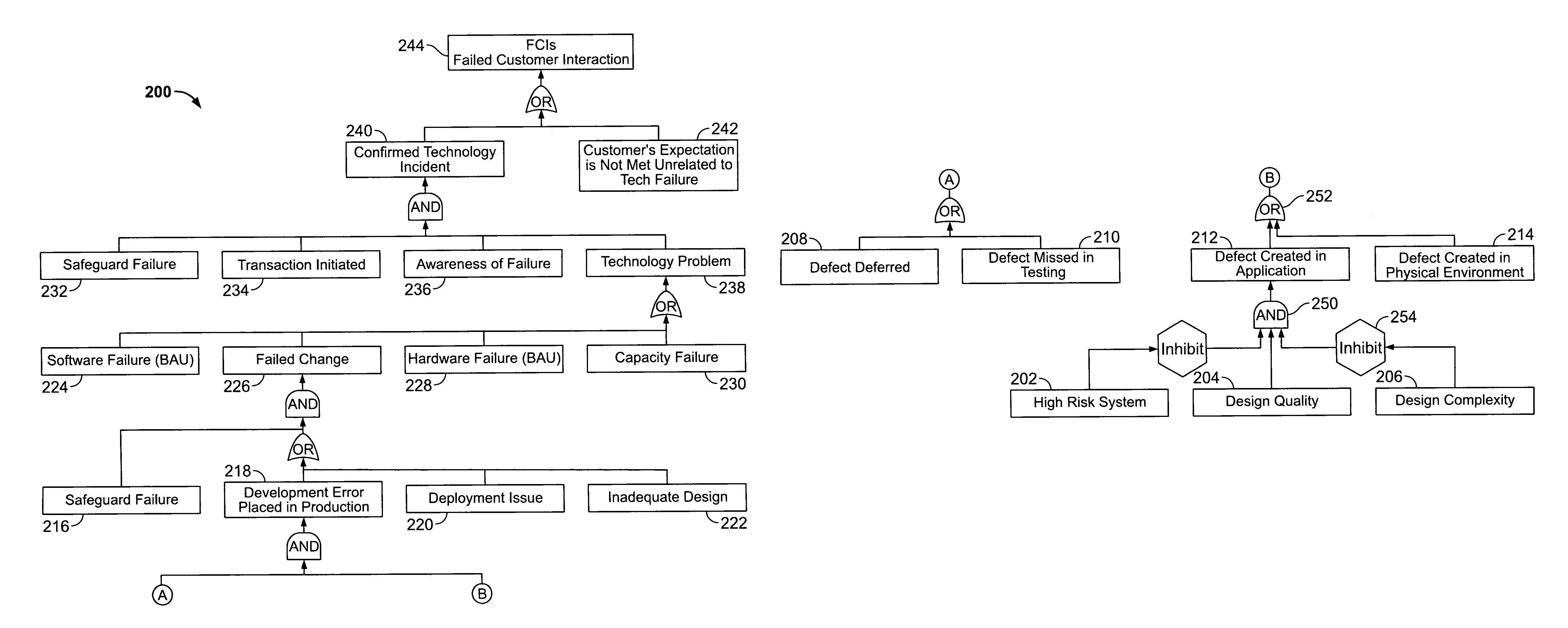

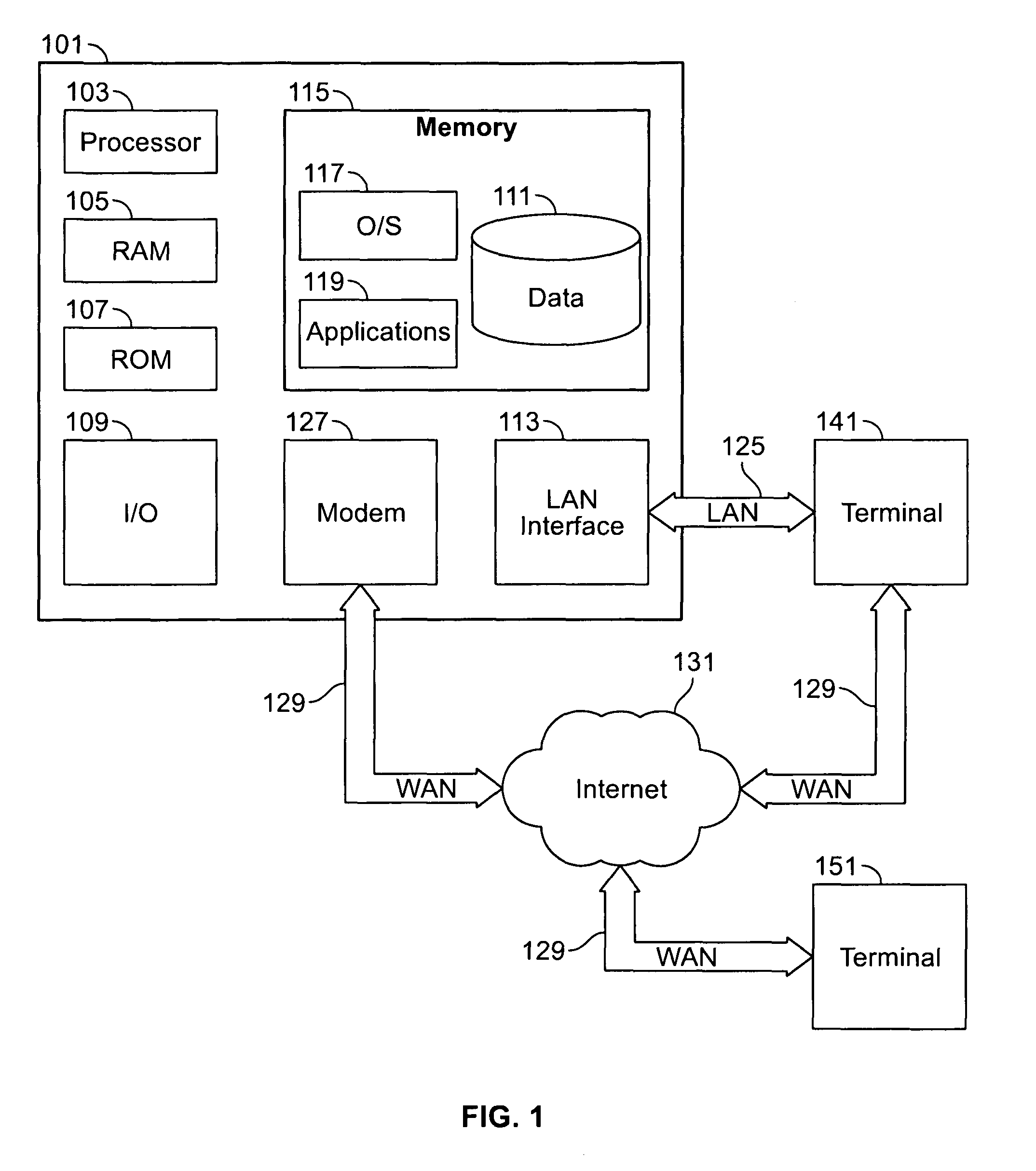

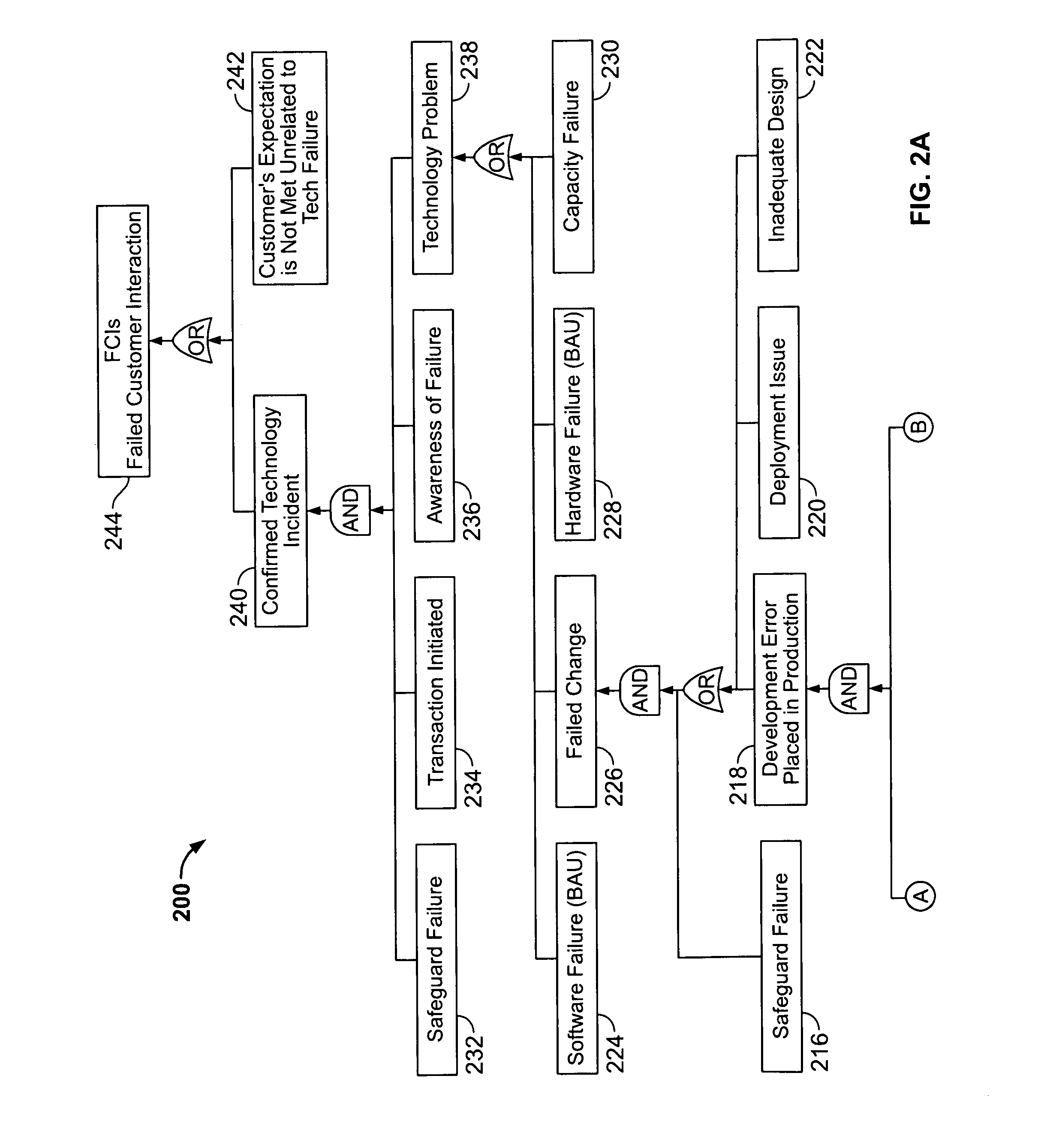

Customer impact predictive model and combinatorial analysis

Systems and methods for objective Deployment Failure risk assessments are provided, which may include fault trees. Systems and methods for the analysis of fault trees are provided as well. The risk assessments system may involve the development of a fault tree, assigning initial values and weights to the events within that fault tree, and the subsequent revision of those values and weights in an iterative fashion, including comparison to historical data. The systems for analysis may involve the assignment of well-ordered values to some events in a fault tree, and then the combination those values through the application of specialized, defined gates. The system may further involve the revision of specific gates by comparison to historical or empirical data.

Owner:BANK OF AMERICA CORP

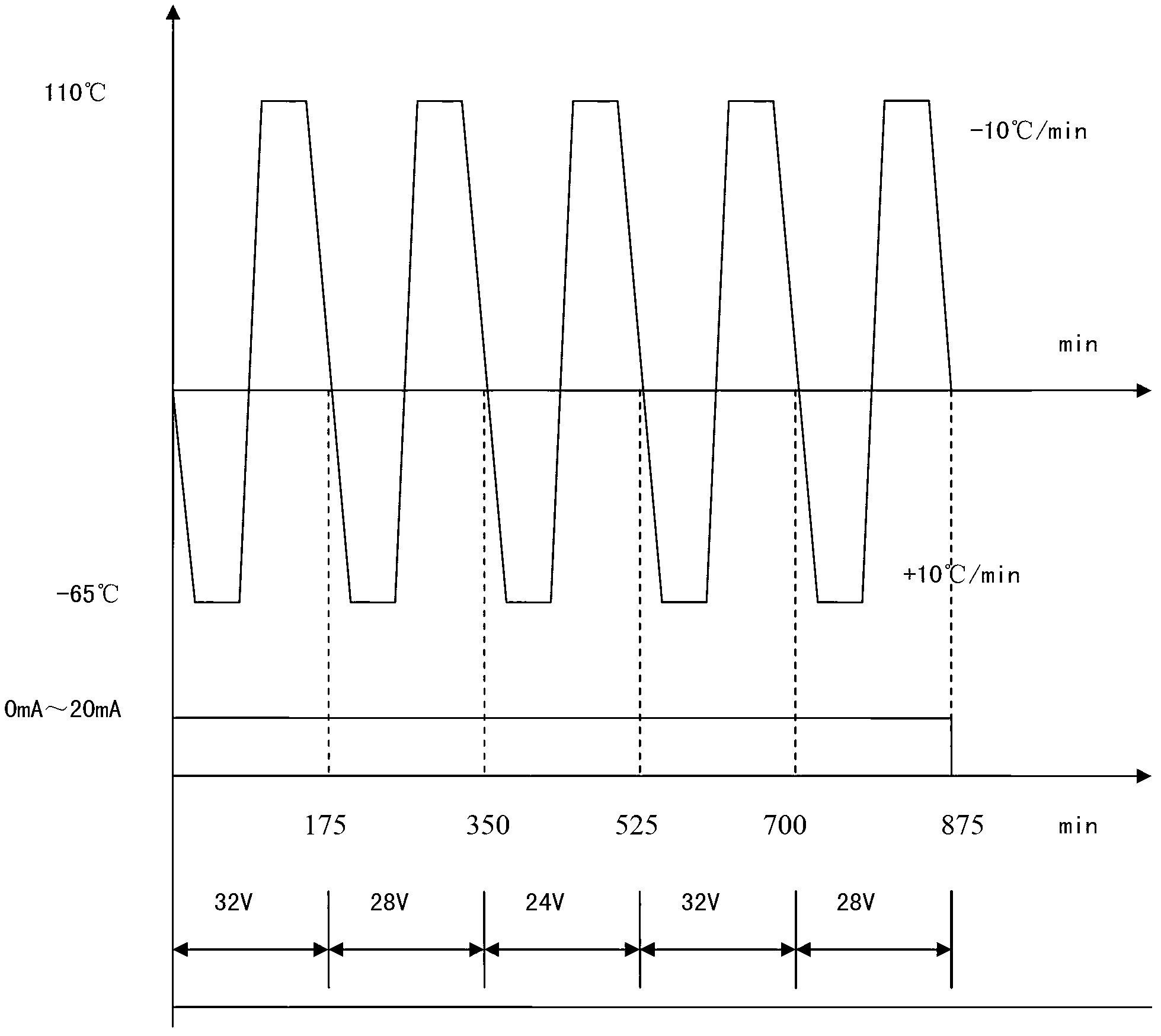

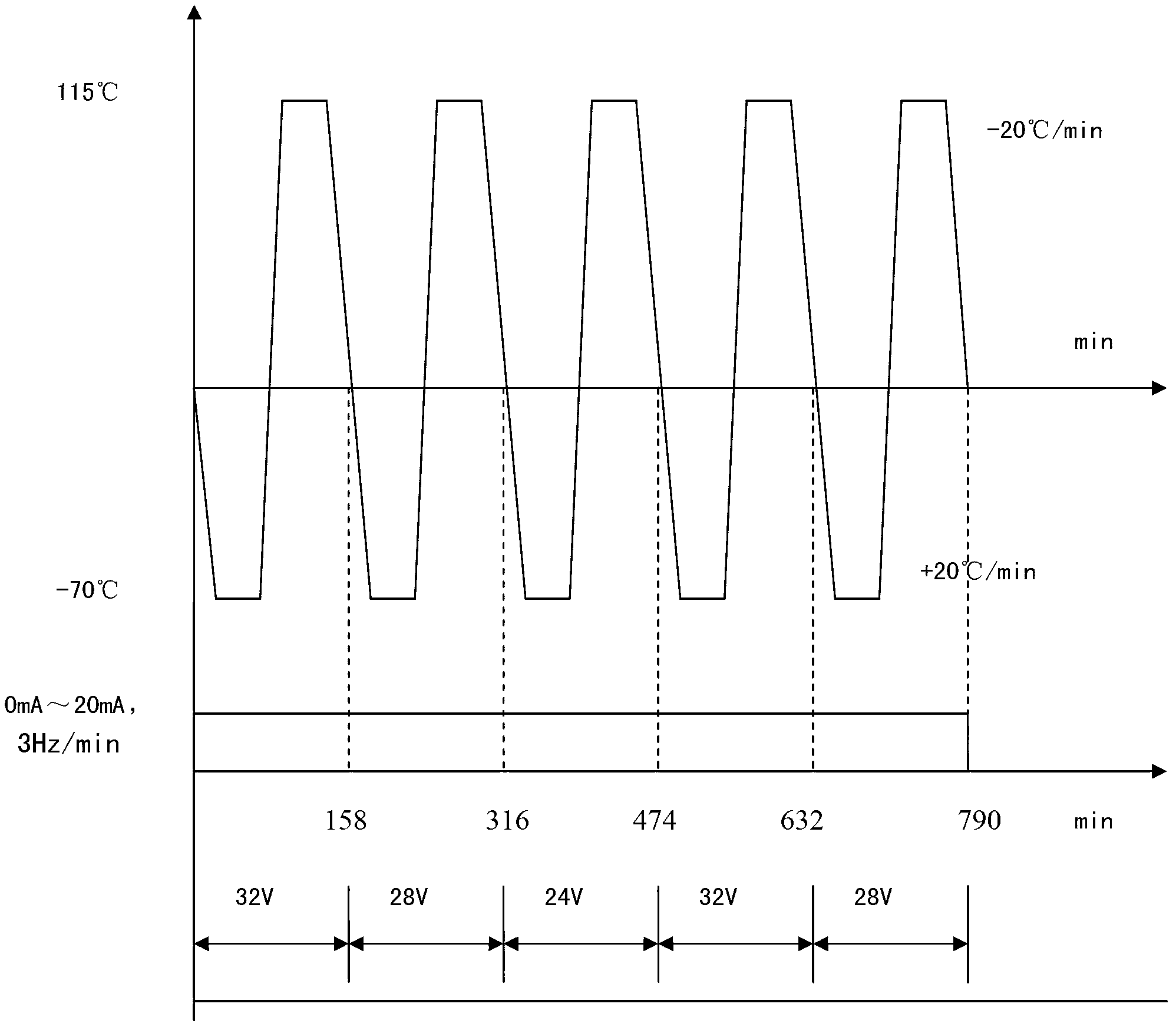

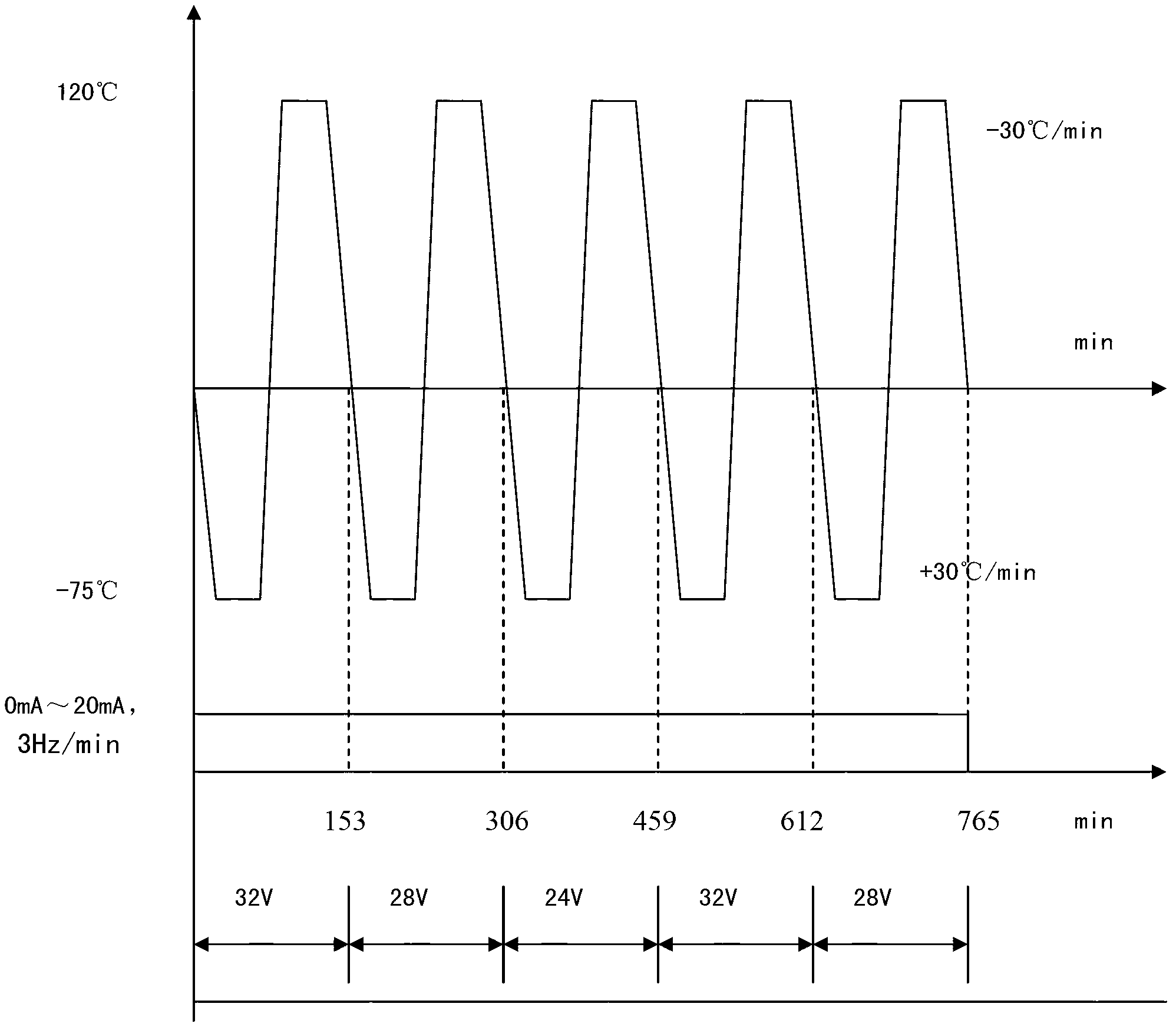

Method for testing potential failure risks of antiskid braking control boxes by aid of quick temperature variation

InactiveCN103294052ATrigger failureImprove development efficiencyElectric testing/monitoringTest chamberEngineering

The invention discloses a method for testing potential safety risks of antiskid braking control boxes by the aid of quick temperature variation. The method includes determining high-temperature numerical values of an antiskid braking control box in quick temperature variation tests; determining low-temperature numerical values of the antiskid braking control box in the quick temperature variation tests; determining a quick temperature variation rate; determining working currents applied to the antiskid braking control box in test procedures and determining temperature holding durations of the antiskid braking control box under high-temperature and low-temperature conditions; establishing a quick temperature variation test profile according to a determined high temperature of a test chamber, a determined low temperature of the test chamber and a determined temperature variation rate of the test chamber; performing five cycle quick temperature variation tests according to the established test profile; comprehensively applying an antiskid braking working current to truly stimulate potential failure risks of the antiskid braking control box. The method has the advantages that the comprehensive environmental test chamber is utilized, the temperatures are accessorily controlled via liquid nitrogen, the potential failure risks of the antiskid braking control box during temperature variation can be stimulated within two days, and accordingly purposes of improving the development efficiency, saving energy and reducing consumption are achieved.

Owner:XIAN AVIATION BRAKE TECH

Supporting gate contacts over source region on mosfet devices

InactiveUS20030189248A1Reliable and durable and economicalTransistorSemiconductor/solid-state device detailsMOSFETEngineering

Increasing the number of MOSFET gate bump contacts makes MOSFET gate contacts more durable and reliable. Extension of the under-bump metal laterally from the gate contact with the gate pad metallization out to two or more gate pads overlying the source pad metallization reduces the risk of delamination of the metallization due to thermal and mechanical stresses in assembly and operation. Use of more than one gate pad further reduces such failure risks. The result is a reliable, durable MOSFET gate contact.

Owner:SEMICON COMPONENTS IND LLC

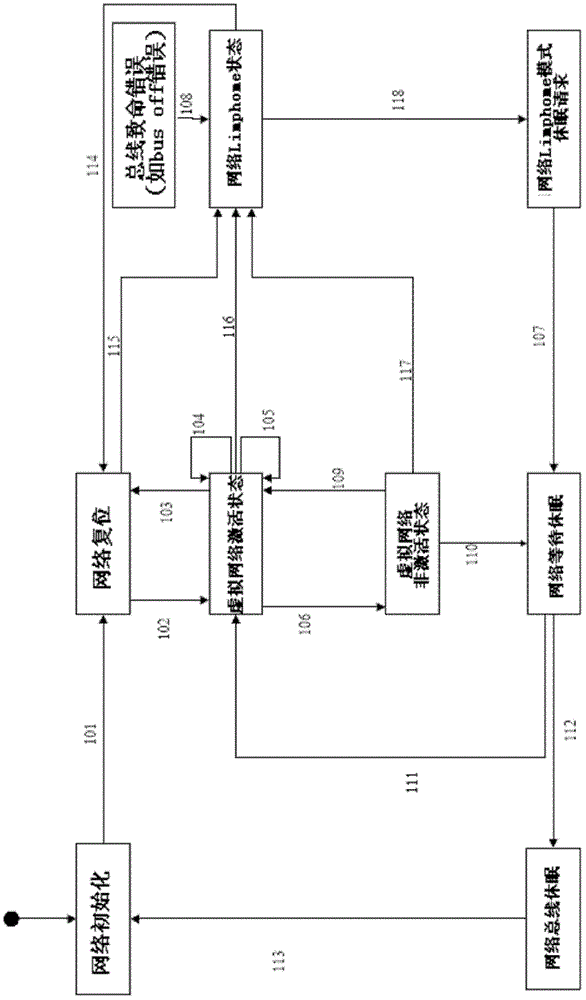

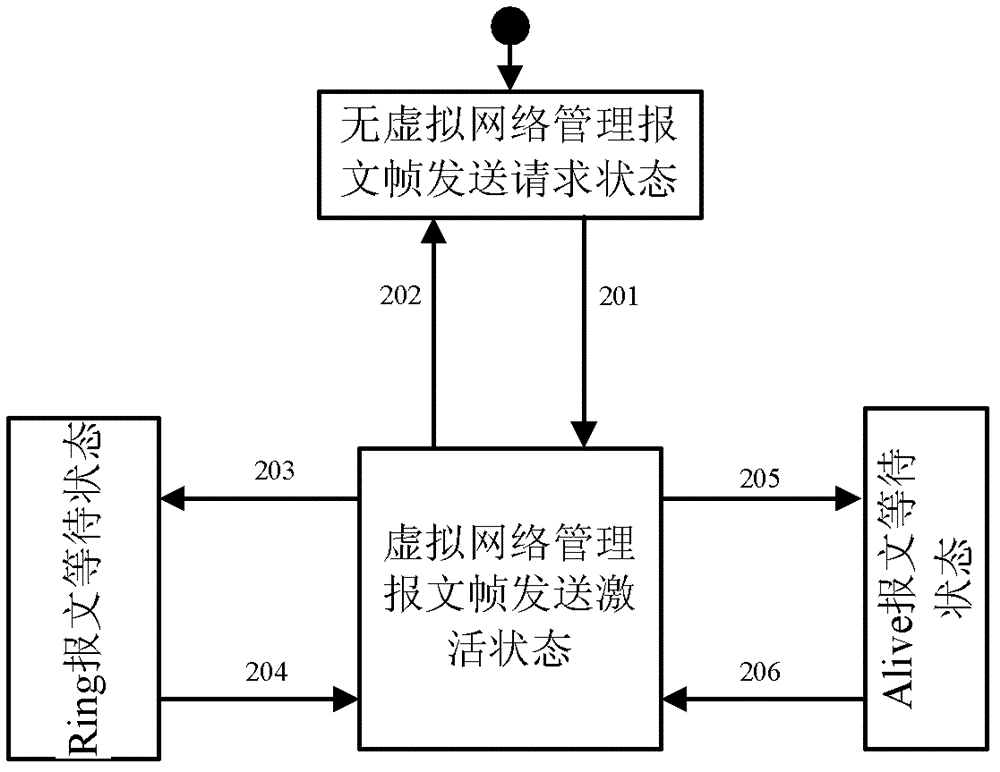

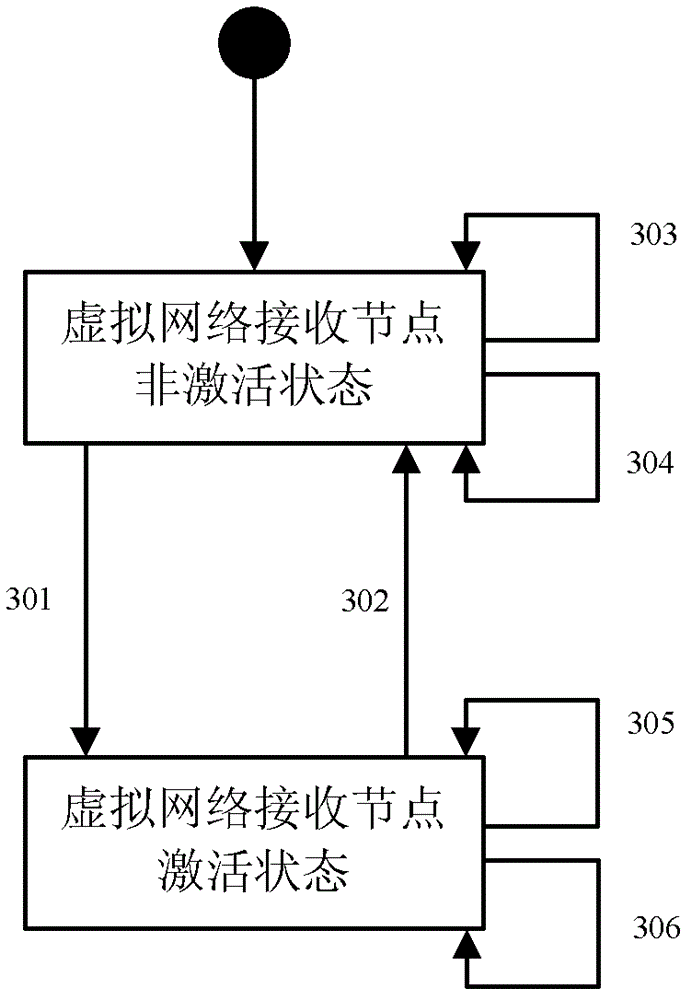

Open systems and the corresponding interfaces for automotive electronics (OSEK) network management-based controller area network (CAN) management method

InactiveCN102801551AEasy to manageSolve the high load rateData switching networksArea networkNetwork management

The invention discloses an open systems and the corresponding interfaces for automotive electronics (OSEK) network management-based controller area network (CAN) management method. The CAN management method is implemented under the coaction of an OSEK network conversion processing module and an application layer-network interface processing module. All electronic control unit (ECU) nodes of an automobile body are connected through a CAN bus. The OSEK network conversion module comprises a failure processing module, a dormancy and initialization processing module and a virtual network processing module. The process of converting the network statuses of the ECU nodes comprises the following steps of: (a) network initialization; (b) network resetting; and (c) conversion between different virtual network statuses of the ECU nodes. A virtual network concept is put forward, a virtual network is dynamically constructed according to the actual needs of each ECU node, and modules without communication requirements can continue to be dormant. The problem of high CAN bus load rate caused by a great number of ECU nodes is solved, network management is optimized, and bus load, electrical interference and bus failure risks are reduced.

Owner:CATARC TIANJIN AUTOMOTIVE ENG RES INST CO LTD

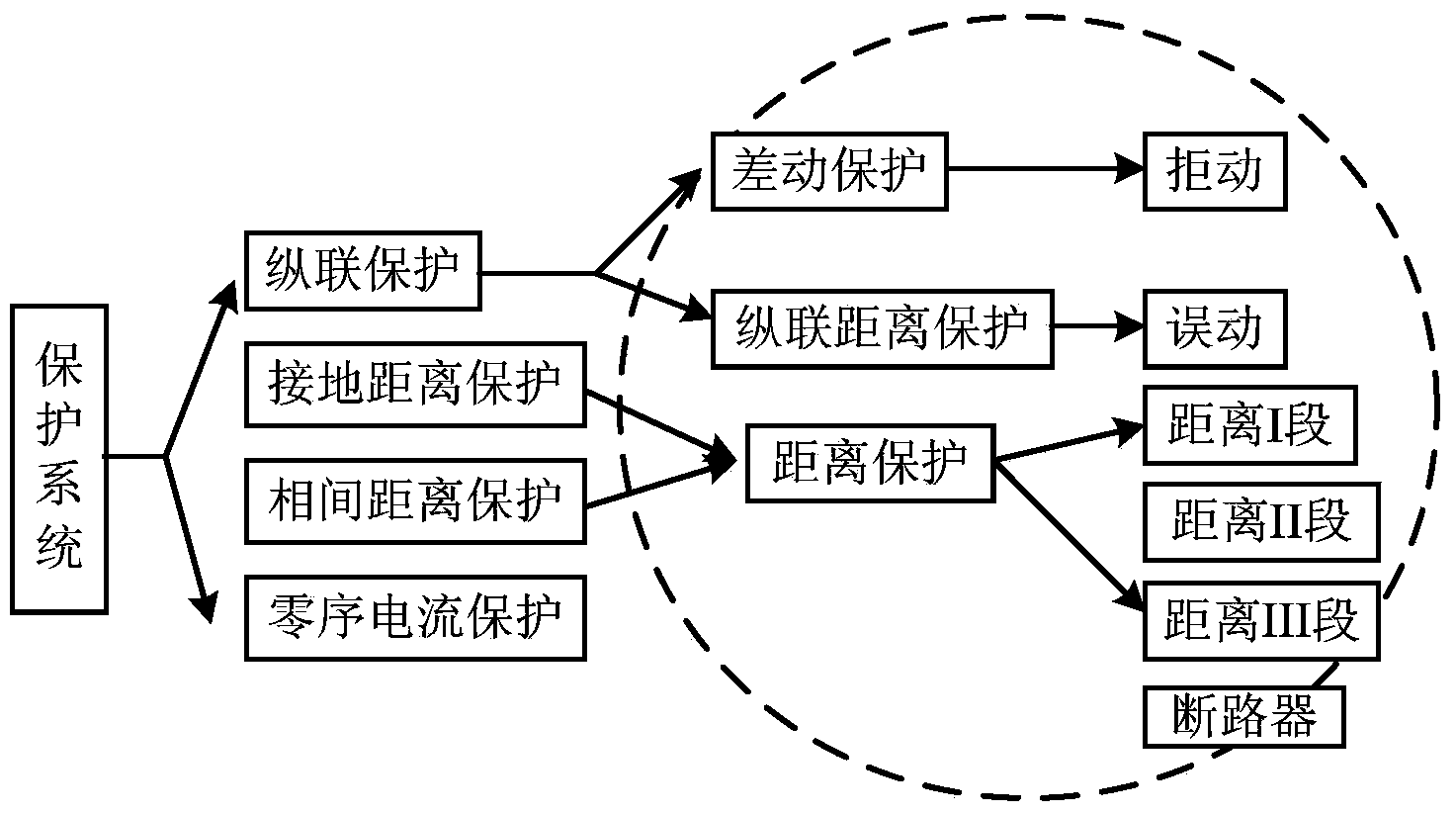

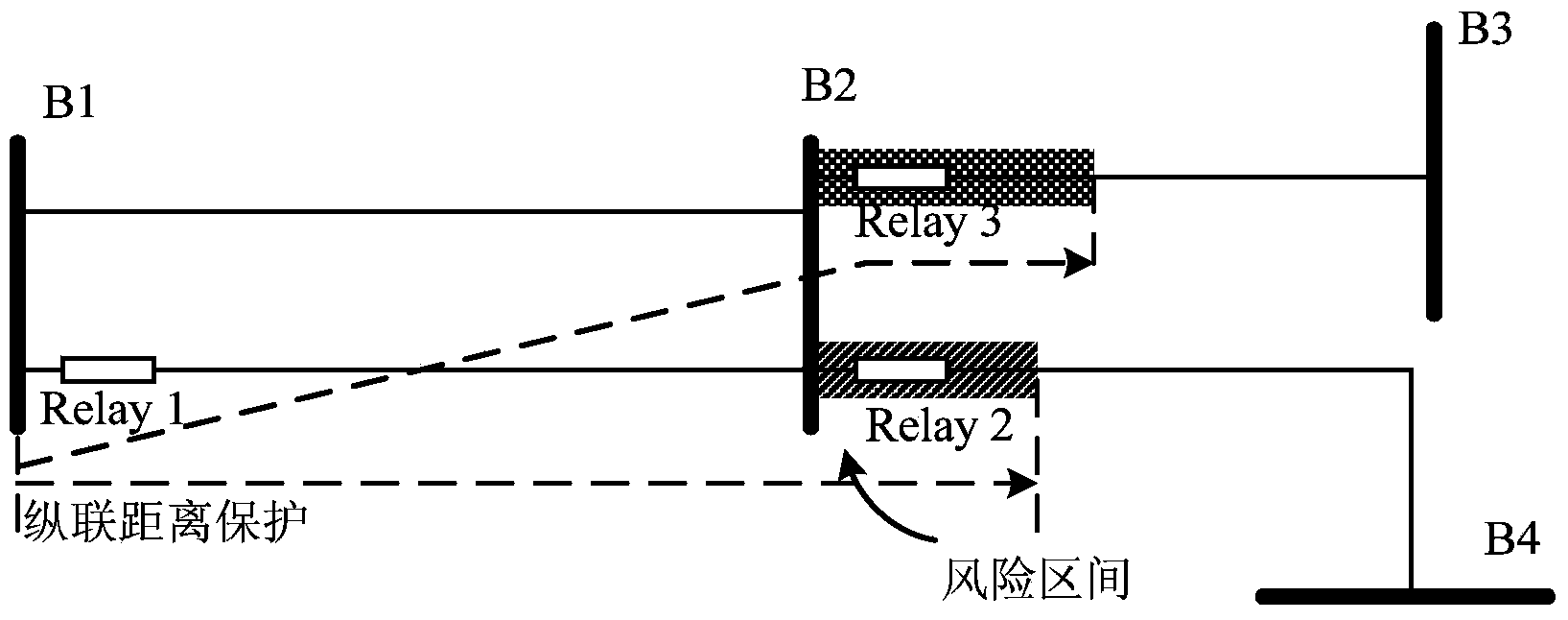

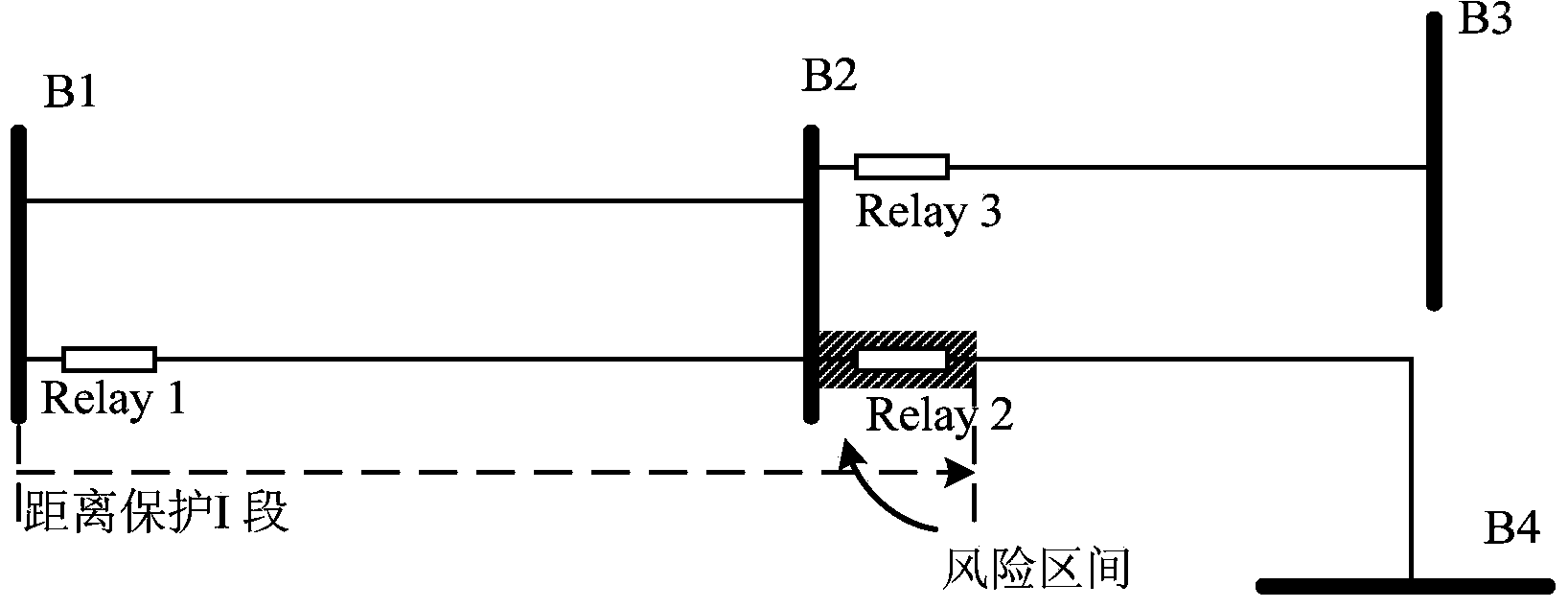

Multi-mode hidden-fault risk analysis method of relaying protection system

ActiveCN103488873AImprove calculation accuracyImprove reliabilitySpecial data processing applicationsCascading failureEngineering

The invention belongs to the field of relaying protection and risk analysis of power systems, and discloses a multi-mode hidden-failure risk analysis method of a relaying protection system. The method comprises the steps of building a multi-mode hidden-failure model of the relaying protection system; according to the multi-mode hidden-failure model, performing risk analysis on power grid N-k failures caused by relaying protection hidden failures, and obtaining risk index values of hidden failures of the relaying protection system. According to the method, simplified modeling analysis is performed on the hidden failures of the protection system; the multi-mode hidden-failure model is built by analyzing the characteristics of protection hidden failures with various typical modes; a power N-k grid failure analysis method is provided by aiming at the risk analysis problem of the hidden failures. An N-k failure probability solving method based on an improved functional group decomposition method and an event tree analysis method is adopted during the analysis, and corresponding cascading failure risk indexes are set up; the calculation accuracy of the power grid N-k failure probability is improved, and risk assessment and analysis can be performed on the hidden failures of the relaying protection system.

Owner:POWER DISPATCHING CONTROL CENT OF GUANGDONG POWER GRID CO LTD

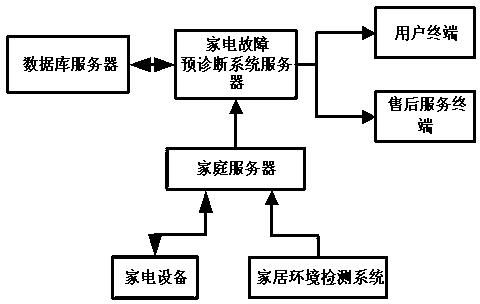

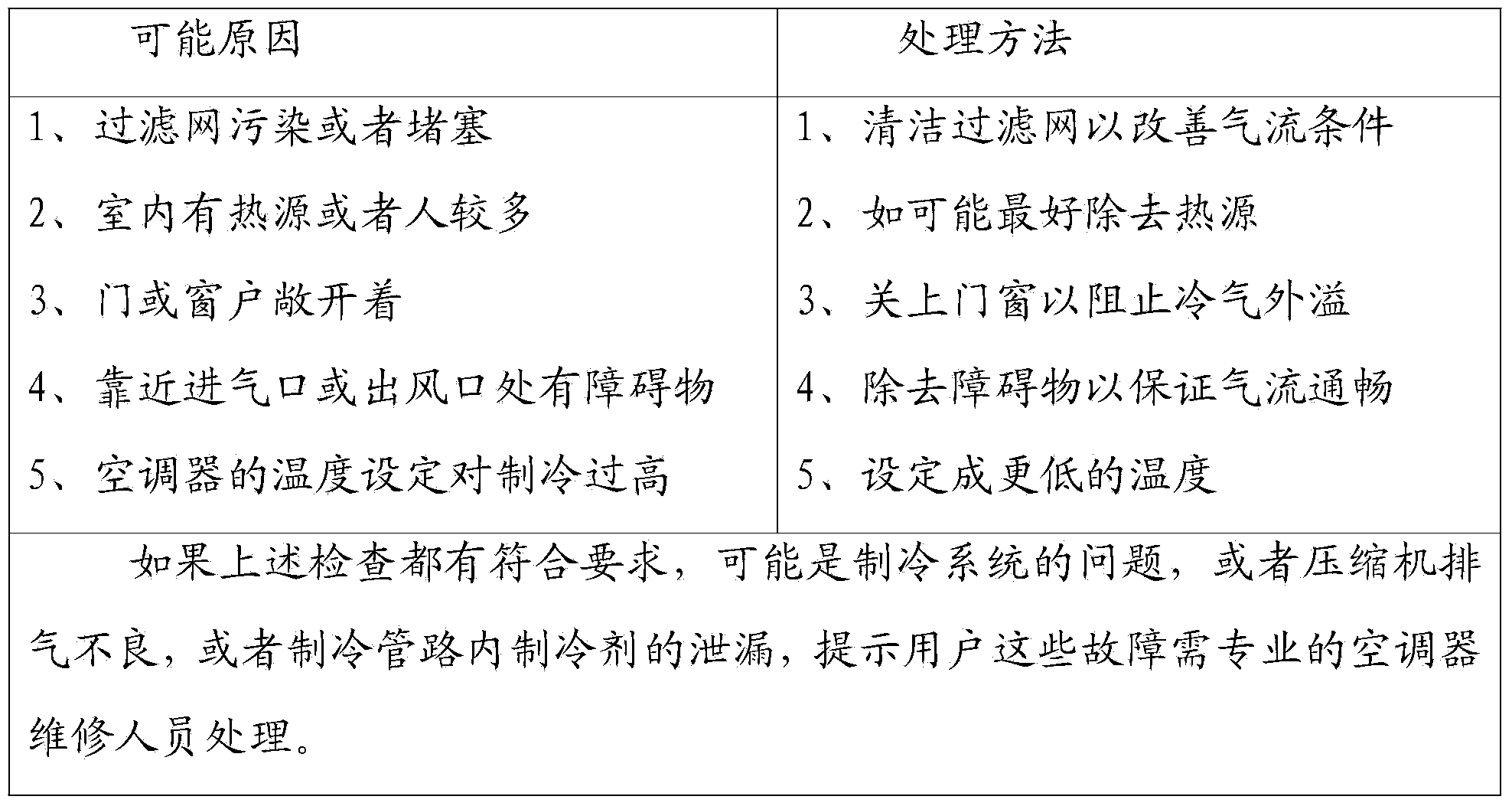

System and method for estimating failure risk of household appliance

InactiveCN103592919ASatisfaction GuaranteedImprove satisfactionProgramme total factory controlFailure causesFailure risk

The invention relates to a system and method for estimating the failure risk of a household appliance. A household appliance failure pre-diagnosis system server is compared with a preset failure risk estimating model through self information uploaded by the household appliance and household environment information detected by a household environment detection system, whether the household appliance has the failure risk is judged, and if yes, the information and failure causes of the household appliance with the failure risk are sent to a user and an after-sales service department. On one hand, the user can timely discover the failure risk of the household appliance and deal with the failure risk timely in order to reduce repairing cost and shorten repairing time, and meanwhile, energy consumption caused by the failure risk in the rime range can be lowered. On the other hand, the after-sales service department can timely discover problems and provide after-sales service for the user timely in order to improve the degree of satisfaction of the user.

Owner:QINGDAO UNIV

Spatial-temporal optimization of physical asset maintenance

A method for determining a maintenance schedule of geographically dispersed physical assets includes receiving asset data including infrastructure relationships between the assets, modeling failure risk of the assets based on spatial, temporal and network relationships, and producing the maintenance schedule according to a combination of the risk model, asset data, maintenance, and external operation constraints. The maintenance schedule may be corrective and / or strategic.

Owner:IBM CORP

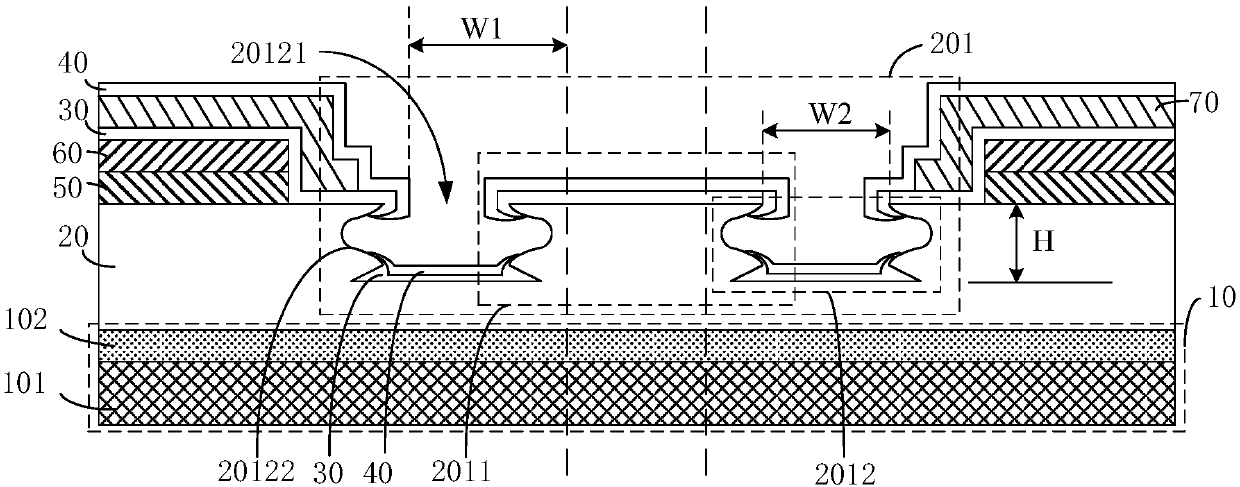

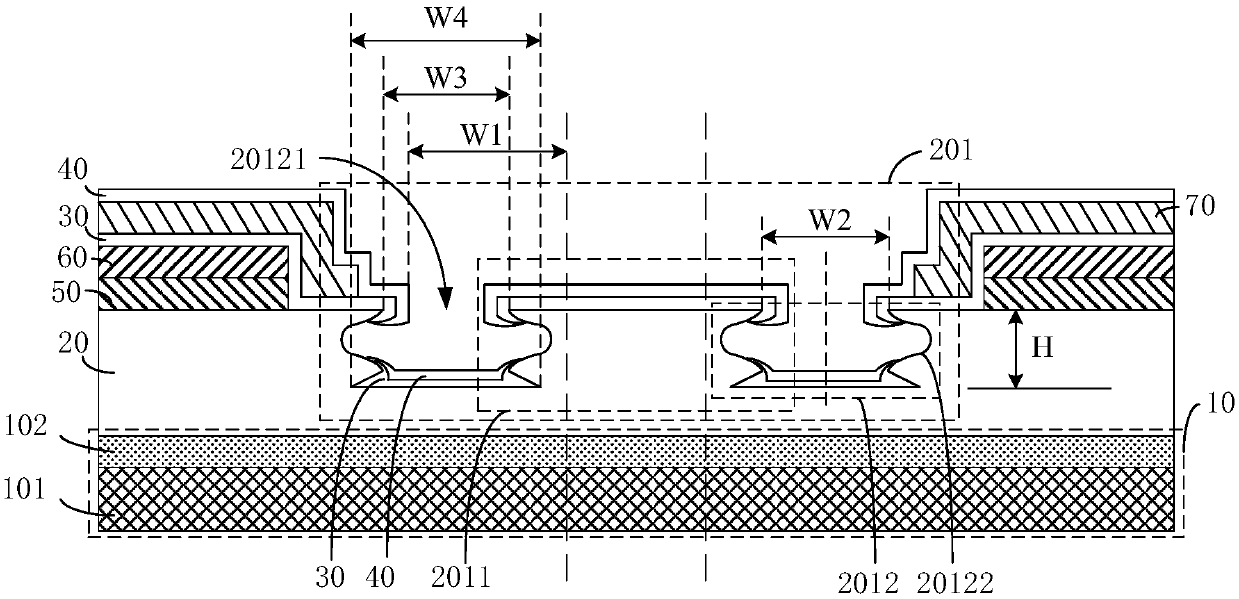

Display panel, mask and display equipment

ActiveCN109638019AExtended service lifeReduce the risk of package failureFinal product manufactureSemiconductor/solid-state device detailsEngineeringFailure risk

The invention discloses a display panel, a mask and display equipment. The display panel comprises a substrate, a first flexible layer, a first inorganic layer and a second inorganic layer which are sequentially laminated from bottom to top, wherein a crack baffle structure is arranged on the first flexible layer and comprises a cutting part and inner concave parts, the inner concave parts are arranged at two sides of the cutting part, each inner concave part comprises an opening and an inner cavity, the inner cavity extends from the opening towards the first flexible layer, the first inorganic layer and the second inorganic layer are broken at the openings of the inner concave parts, the inner concave parts are used for preventing cracks of the first inorganic layer and the second inorganic layer from extending towards two sides of the crack baffle structure when the display panel is cut by the cutting part, so that the package failure risk is reduced. Due to the existence of the crack baffle structure, the mask for fabricating the display panel is not needed to be shielded excessively, the complexity of the fabrication process and the fabrication cost are reduced, and the servicelifetime of the mask is prolonged.

Owner:WUHAN CHINA STAR OPTOELECTRONICS SEMICON DISPLAY TECH CO LTD

Drilling system failure risk analysis method

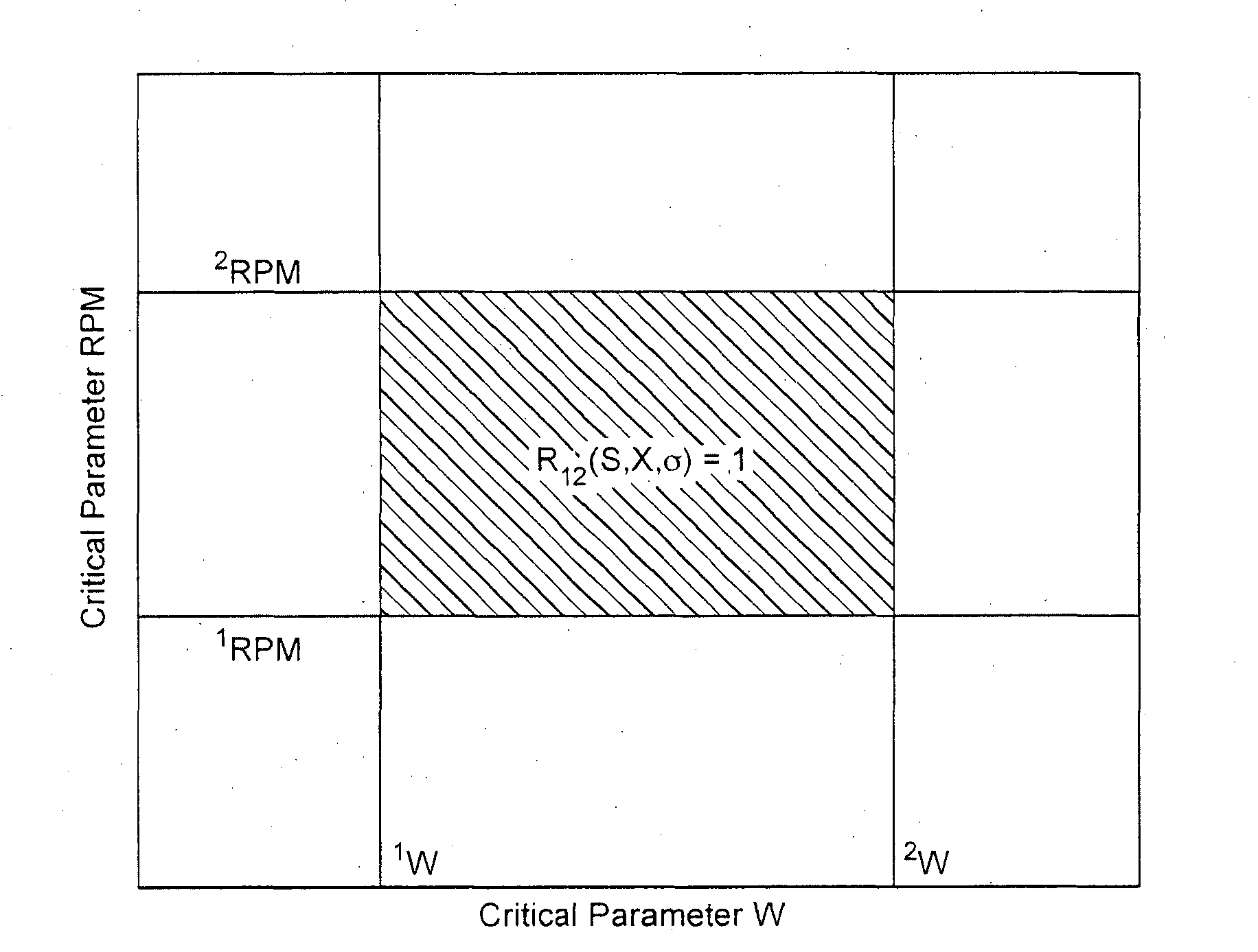

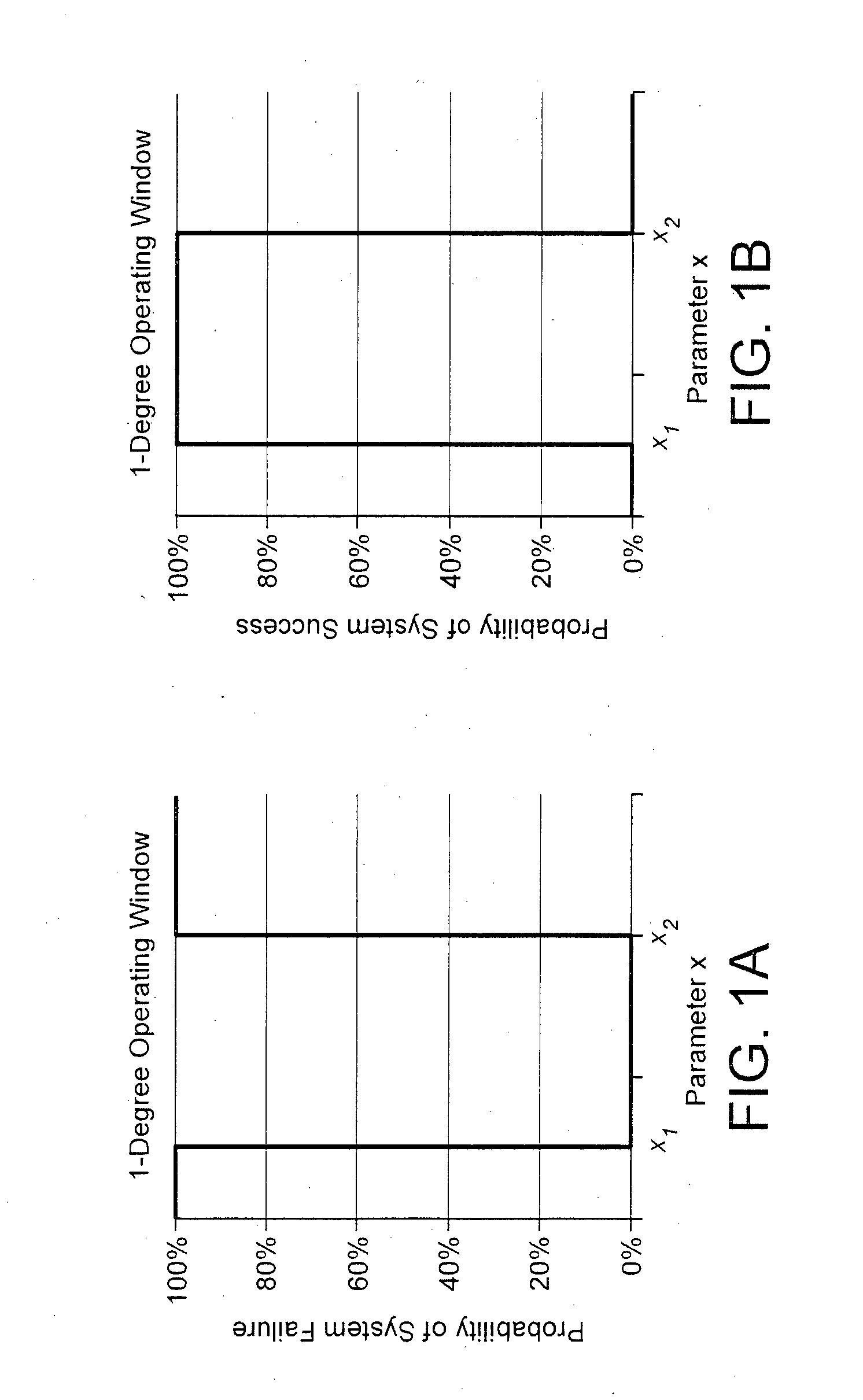

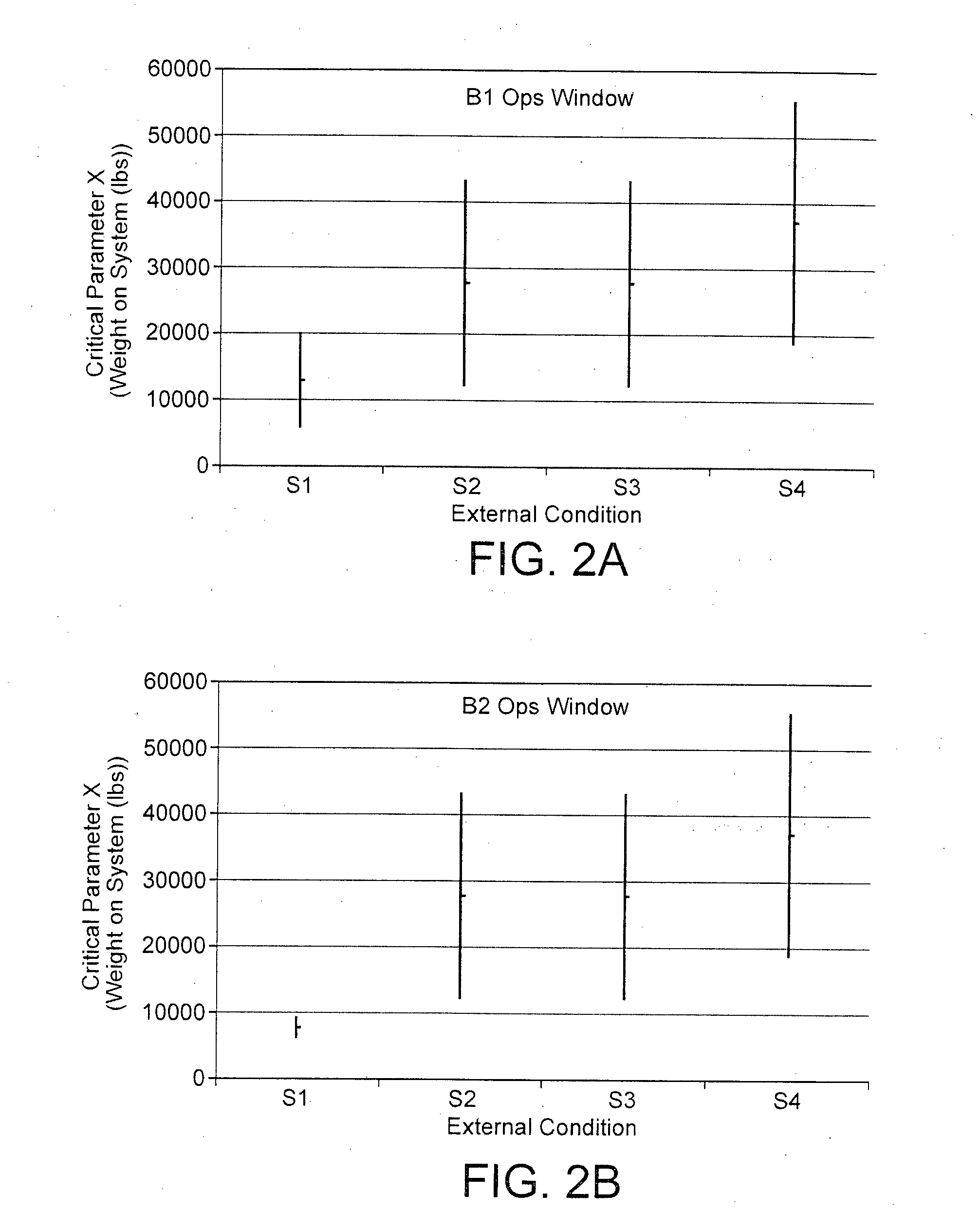

ActiveUS20150081221A1Minimizing and reducing and capping riskImprove performanceElectric/magnetic detection for well-loggingSeismology for water-loggingProbit modelRisk profiling

There is disclosed a method for assessing risk associated with drilling a section of a wellbore in a formation using a drilling system, comprising: providing a probabilistic model for the risk of the drilling system triggering a failure mode during drilling; and assessing the risk of the drilling system triggering one of said failure modes during drilling of the section based on said model. A further such method comprises: defining the critical control parameters for the drilling system; and identifying one or more failure modes of the drilling system associated with each critical control parameter which may arise during drilling the section of the formation.

Owner:HALLIBURTON ENERGY SERVICES INC

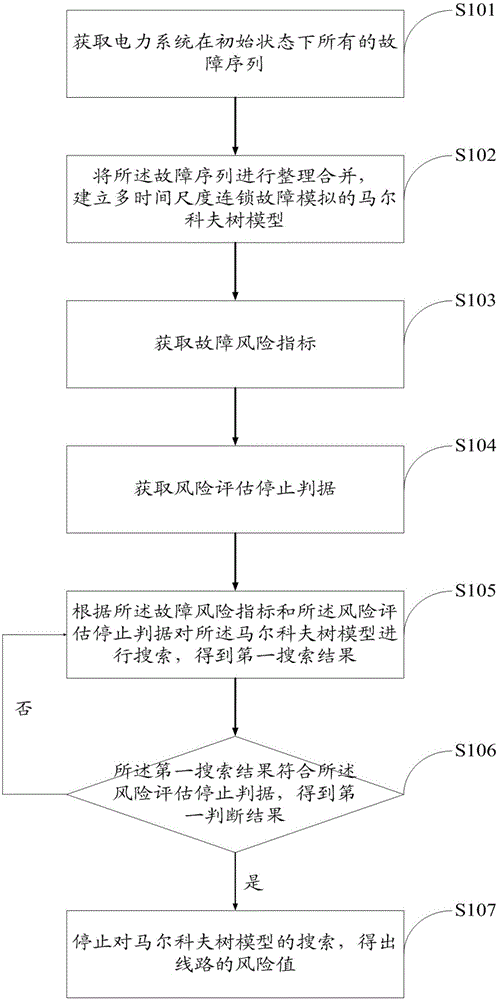

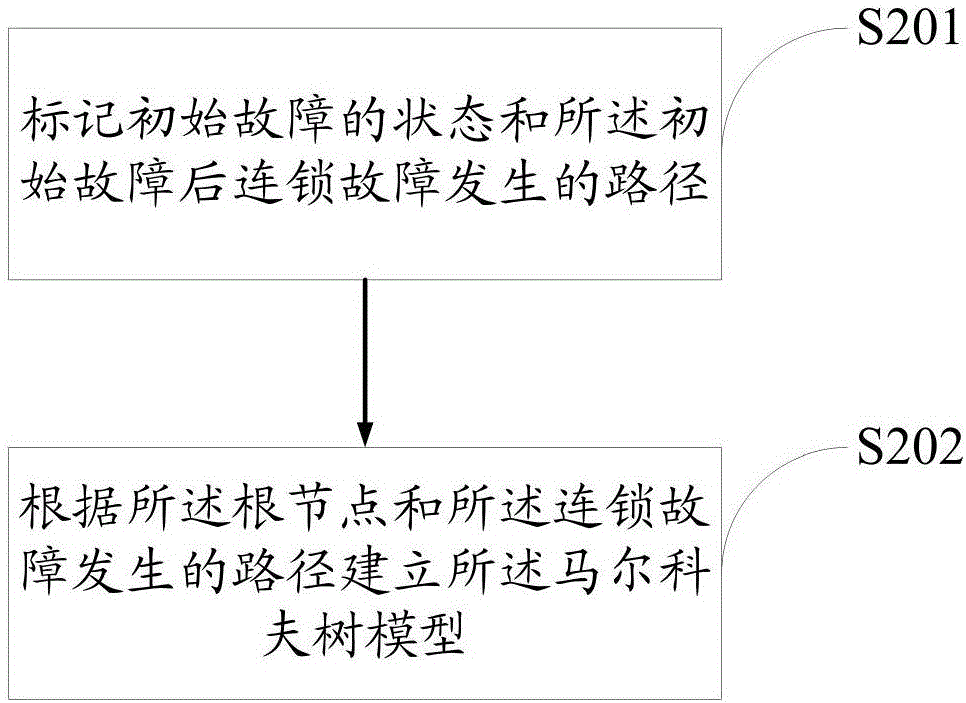

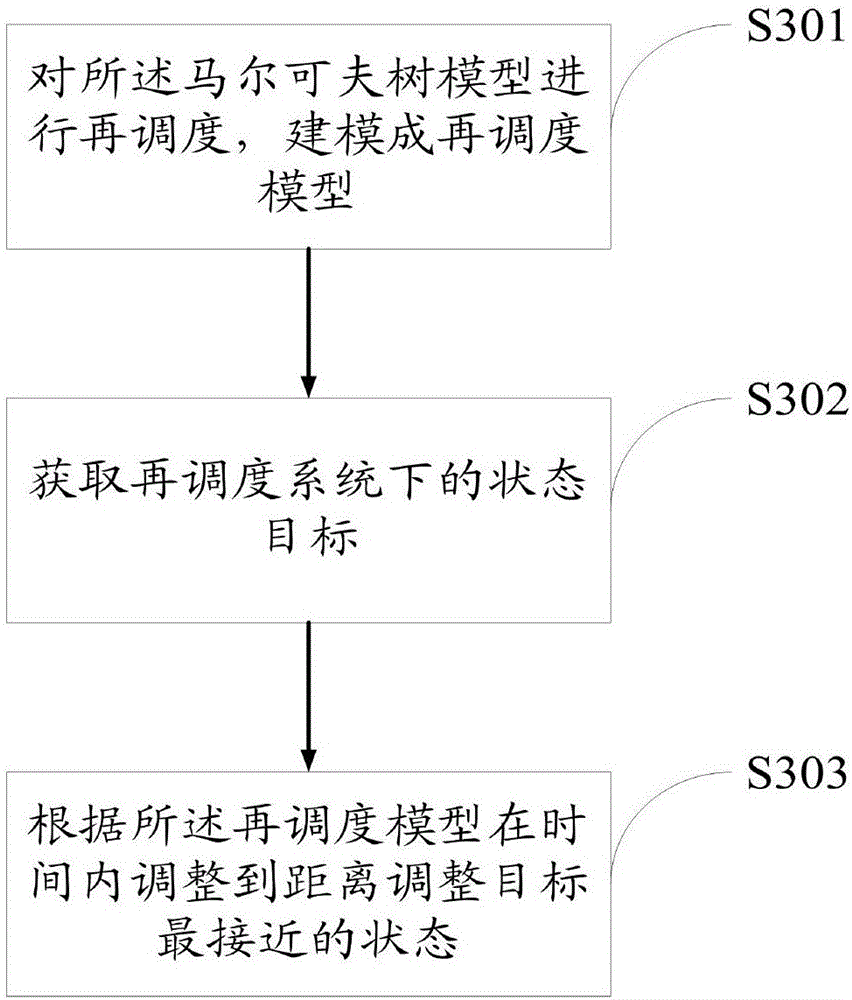

Power system cascading failure risk assessment method and power system cascading failure risk assessment system

The invention discloses a power system cascading failure risk assessment method and a power system cascading failure risk assessment system. The method comprises the following steps: acquiring all failure sequences of a power system in an initial state; sorting and combining all the failure sequences, and building a Markov tree model of multi-time-scale cascading failure simulation; acquiring failure risk indicators; acquiring a risk assessment stop criterion; searching for the Markov tree model according to the failure risk indicators and the risk assessment stop criterion to get a first search result; judging whether the first search result is in accordance with the risk assessment stop criterion to get a first judgment result; and when the first judgment result indicates that the first search result is in accordance with the risk assessment stop criterion, stopping searching for the Markov tree model, and getting the risk value of a line. By using the risk assessment method and the risk assessment system, maximum coverage of the possible development path space of cascading failure can be realized under the condition of limited computing resources, and therefore, the computation efficiency is improved significantly.

Owner:STATE GRID SICHUAN ELECTRIC POWER CORP ELECTRIC POWER RES INST +1

Complex supply network robust performance analyzing method based on topological structure

InactiveCN103870642AReflect characteristicsReflect the law of changeResourcesSpecial data processing applicationsModeling and simulationAnalysis method

The invention discloses a complex supply network robust performance analyzing method based on a topological structure. The method comprises the following steps: firstly providing a complex supply network topological structure model, and then applying the established model to perform the static robust performance analysis and dynamic robust performance analysis of a complex supply network, wherein the complex supply network topological structure model comprises mechanisms of increase, local selection and preferential connection; during the static robust performance analysis, structure robust performance of the supply network is analyzed by virtue of simulating and depicting different damages of the supply network by virtue of a computer; during the dynamic robust performance analysis, the dynamic robust performance of the network is analyzed by virtue of introducing external perturbation and a dynamic perturbation propagate algorithm. By means of modeling and simulation, the robust performance of the complex supply network suffering from different damages and perturbation can be effectively analyzed, and a solution conception is provided for a supply chain practitioner to reduce the supply failure risk.

Owner:HUZHOU TEACHERS COLLEGE

Stress engineering assessment of risers and riser strings

ActiveUS20190228777A1Limit any harmful consequenceDesign optimisation/simulationSpeech recognitionData acquisitionEngineering

Riser stress-engineering-assessment equipment to verify the integrity and the in-deployment-integrity of a riser string by knowing the status, details and location of each riser joint and by monitoring the deployment parameters. When the failure risk exceeds an acceptable level, the equipment activates a local and / or a remote alarm using voice, sound and lights. The system comprises a computer with communication means, a material properties and geometry detection system, a data acquisition system acquiring deployment and other parameters, a database comprising of riser historical data and captured expert knowledge, a failure-criteria calculation to calculate maximum-stresses under different loads and the combined effects of the different loads to determine if the riser string is still fit-for-deployment.

Owner:STYLWAN IP HLDG LLC

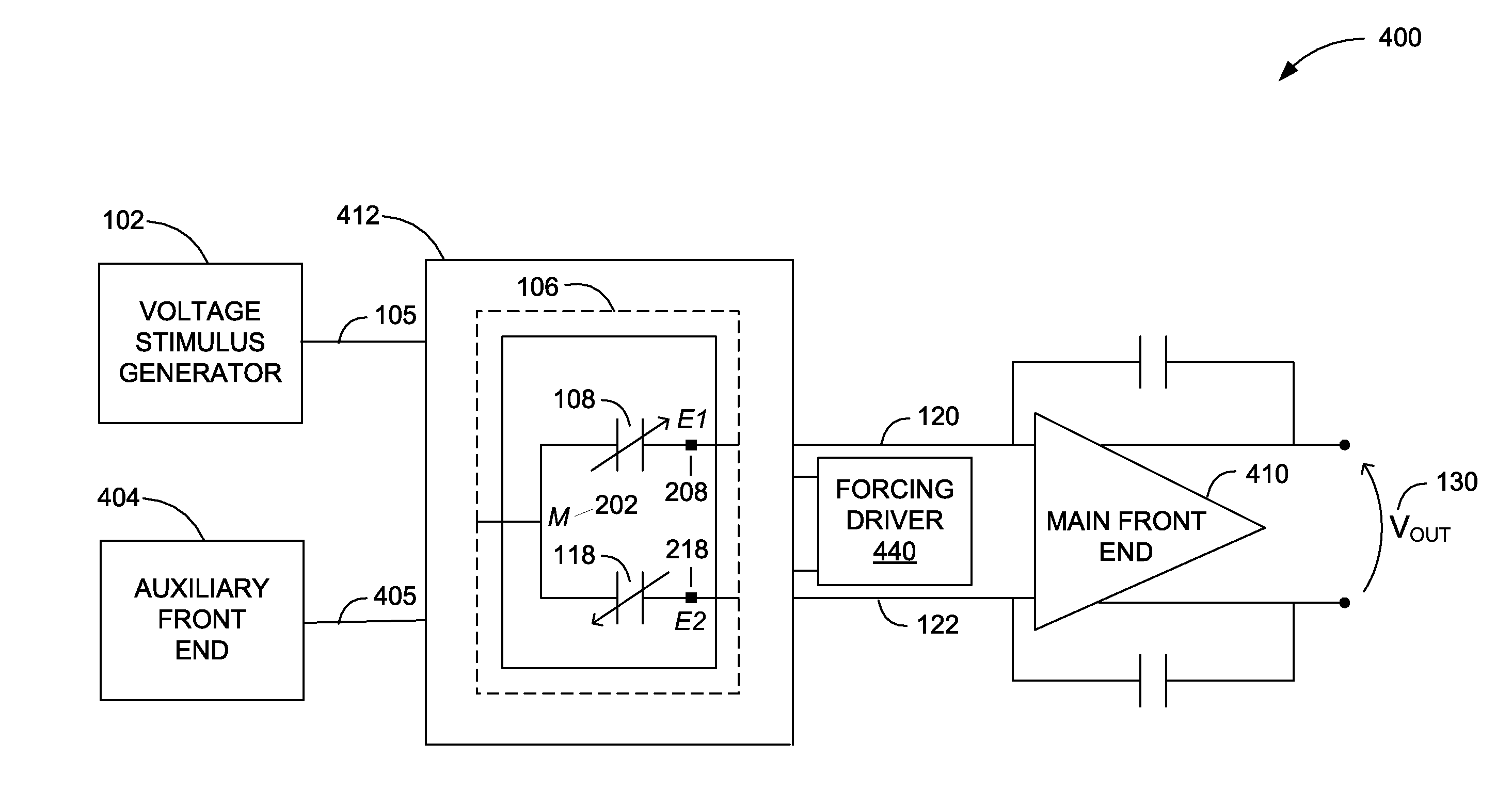

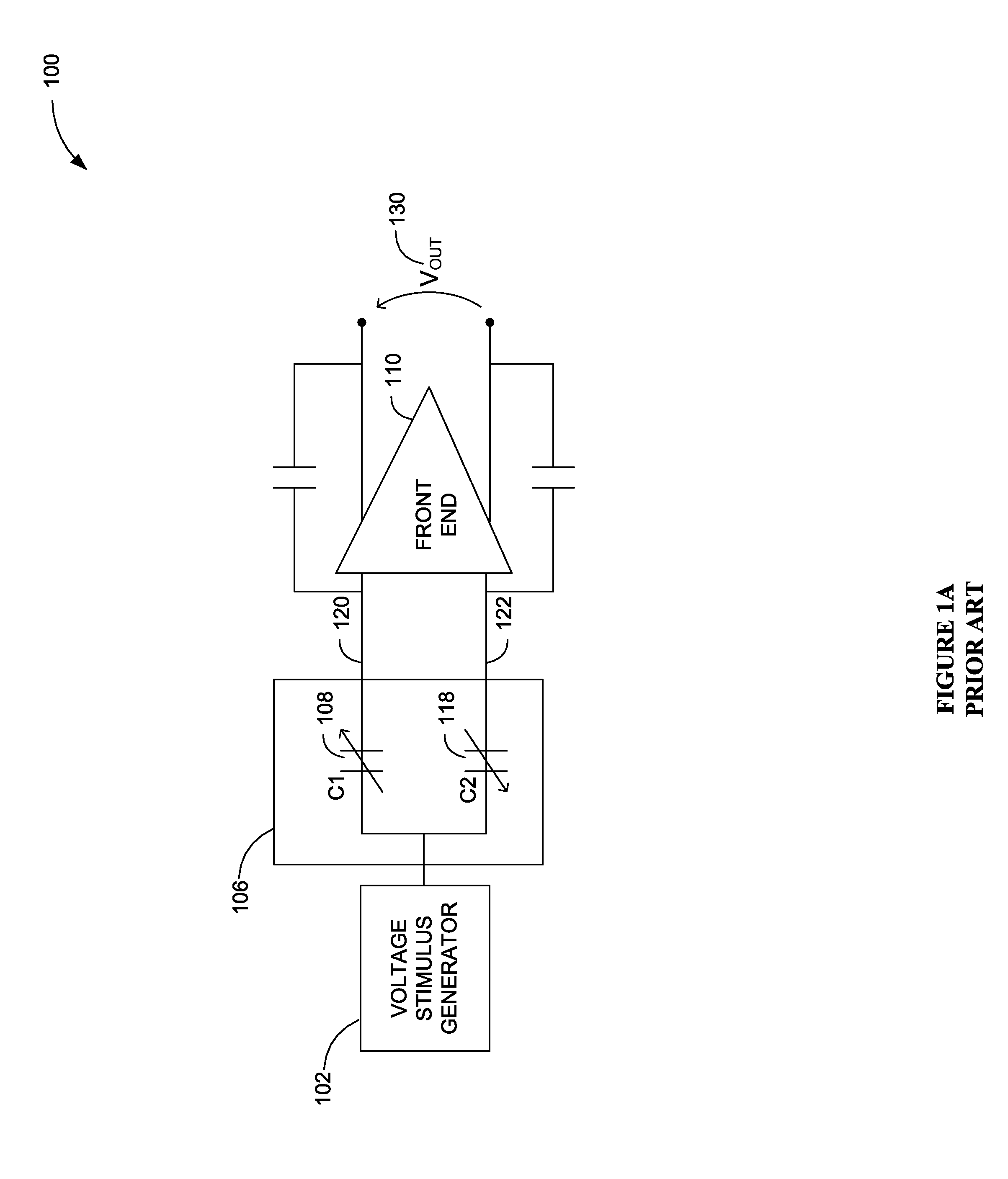

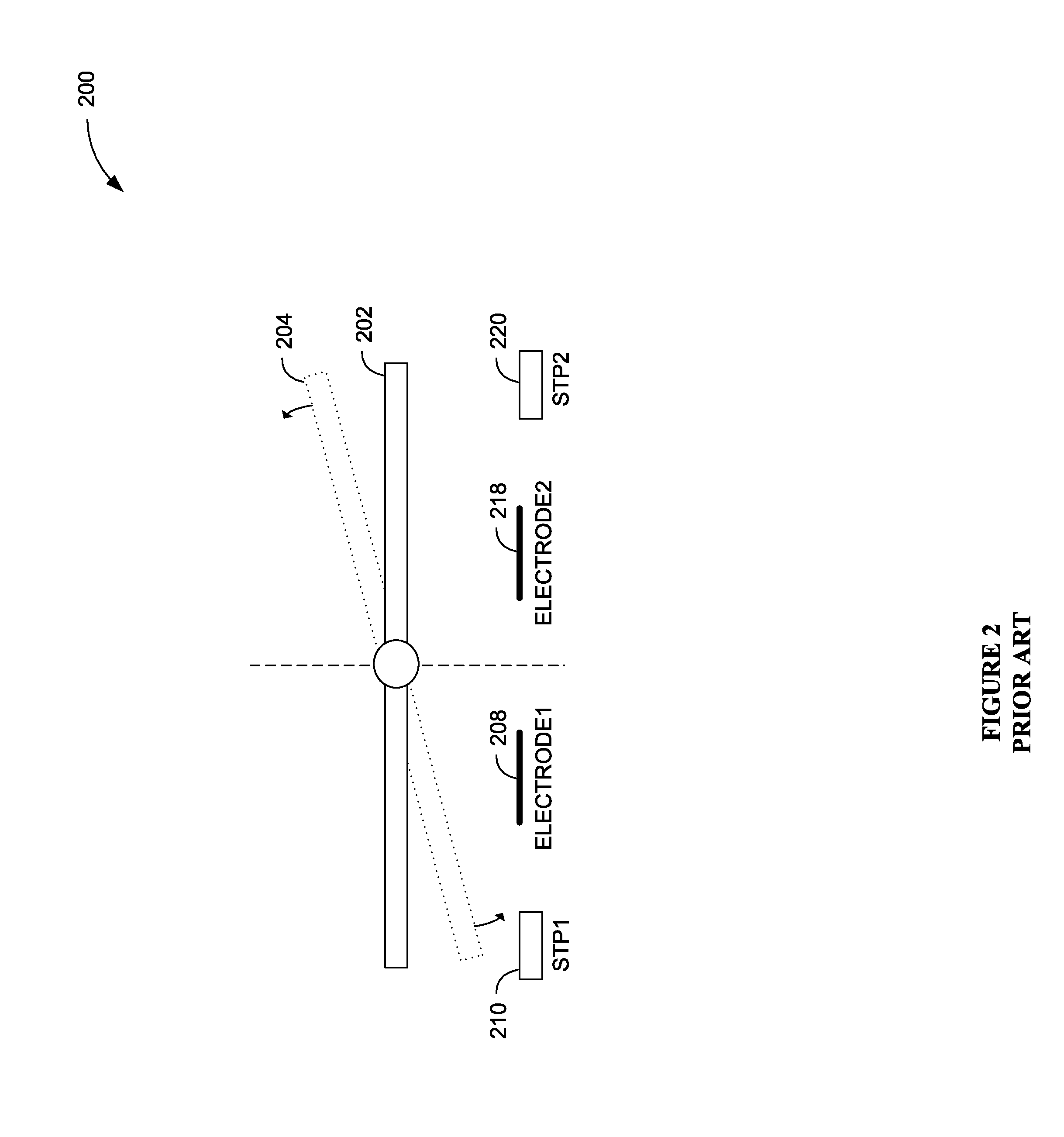

Systems and methods to determine stiction failures in MEMS devices

ActiveUS20150096377A1Improve reliabilityStress protectionAcceleration measurementTesting/calibration of speed/acceleration/shock measurement devicesHigh pressureAnalog front-end

Various embodiments of the invention provide for stiction testing in MEMS devices, such as accelerometers. In certain embodiments, testing is accomplished by a high voltage smart circuit that enables an analog front-end circuit to accurately read the position of a movable proof-mass relative to a biased electrode in order to allow the detection of both contact and release conditions. Testing allows to detect actual or potential stiction failures and to reject defective parts in a Final Test stage of a manufacturing process where no other contributors to stiction issue can occur, thereby, minimizing stiction failure risks and extending the reliability of MEMS devices.

Owner:HANKING ELECTRONICS LTD

Continuous heat-storage type fume residual heat recovering device

InactiveCN101122446AImprove thermal conductivityIncrease the heat transfer specific surface areaStationary plate conduit assembliesFailure riskThermal transmittance

A continuous regenerative flue gas residual heat recycle device belongs to the industrial furnace energy saving field. The device is made from high heat resistance and conduction materials. A gas passage in the device is separated into mutually independent multistory spaces. Flue gas passages and air (gas) passages are arranged in a stratified and staggered way (that is a layer of flue gas passage is connected with a layer of air (gas) passage in the height direction, a staggered arranged sandwich structure). Every layer of gas flow passage is a honeycomb channel, which is made from high thermal conductivity materials. The hest recycle device has the advantages mentioned below. First, the heat exchange rate is fast. The thermal conductivity rate of a regenerator is high. And heat exchange between flue gas and air can be done rapidly. Second, the device can work continuously. Communication is not required in the wind supply and the smoke exhaust. And the system is simple. Third, utmost waste recovery is really realized. No heat and fuel loss caused by volume effect is made during the communication. Fourth, with a long service life, the device can be flexibly arranged. And the device has relative small relevance with the furnace, which makes the failure risk lowered and is convenient for the engineering management.

Owner:UNIV OF SCI & TECH BEIJING

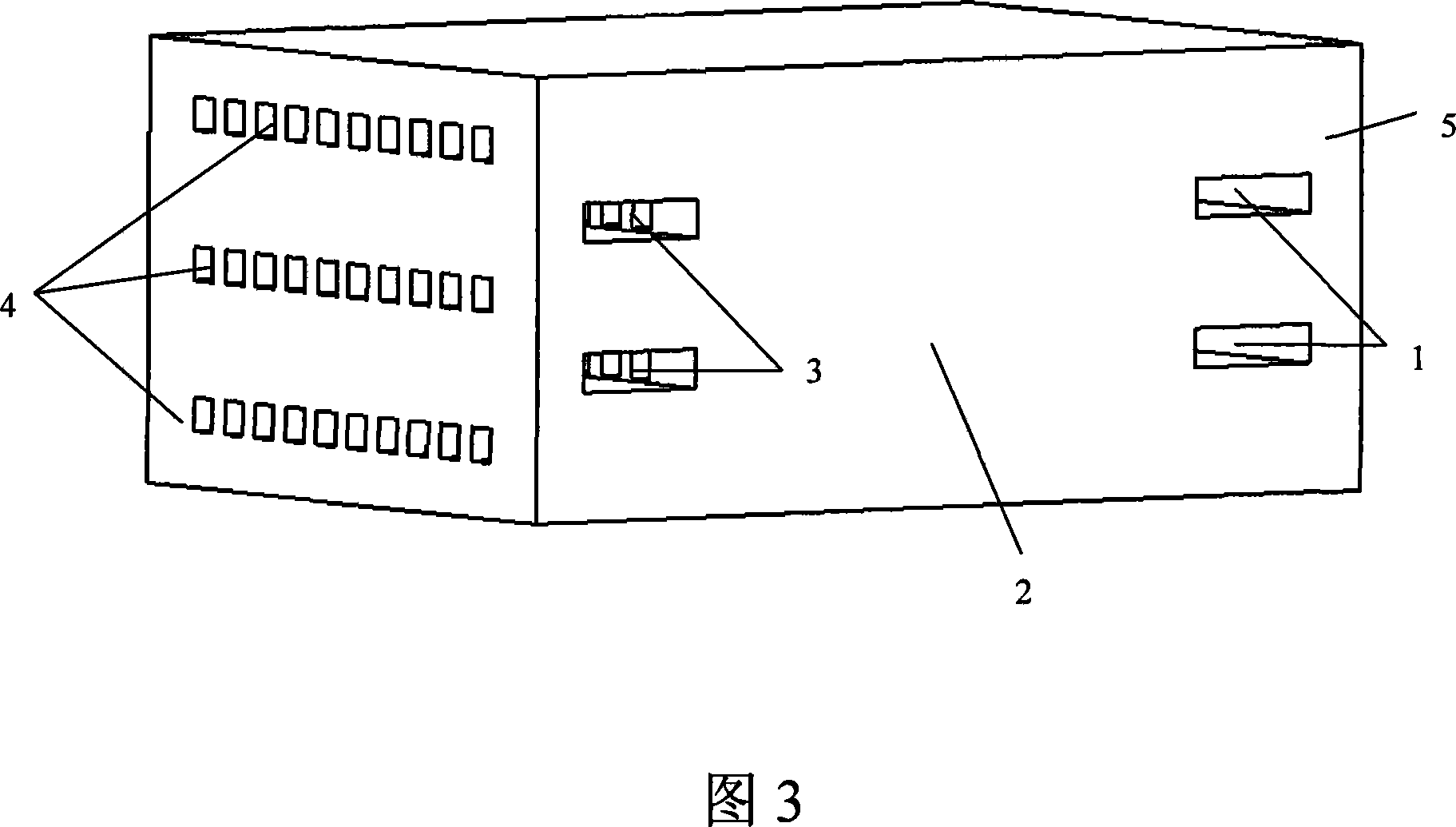

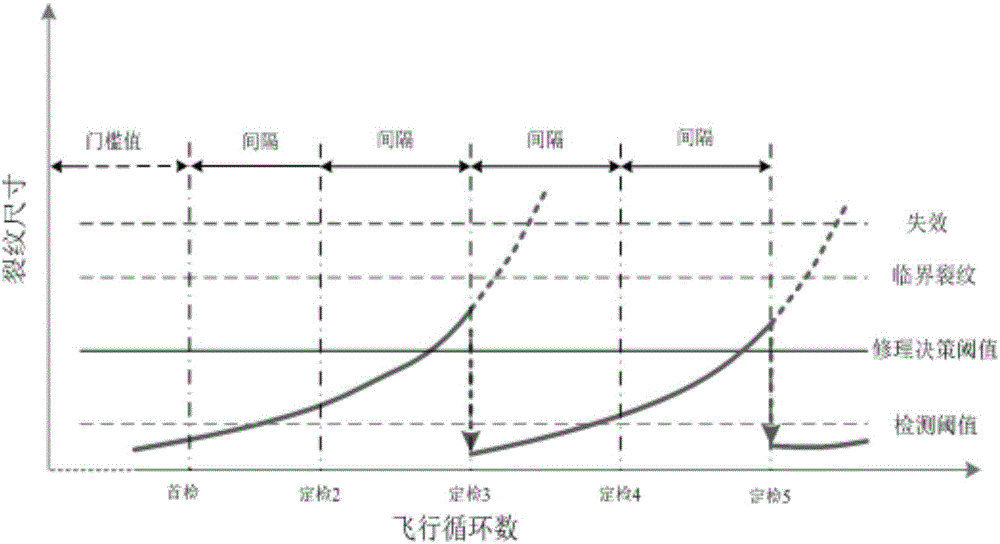

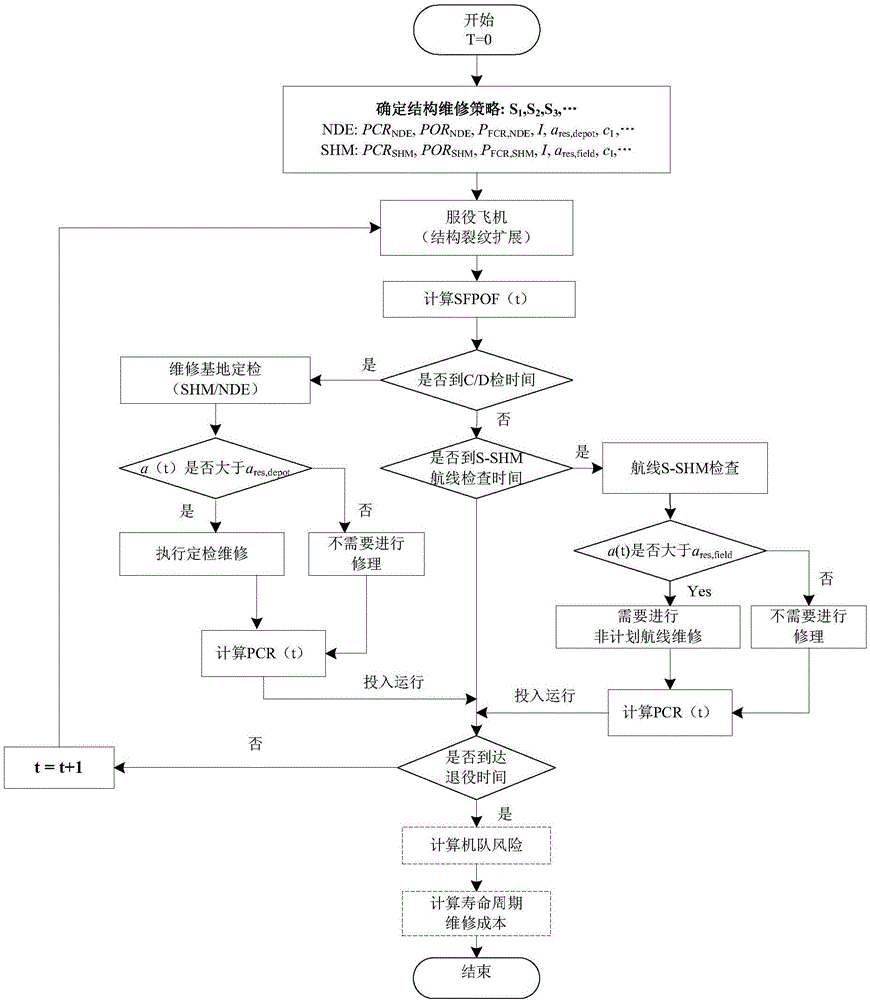

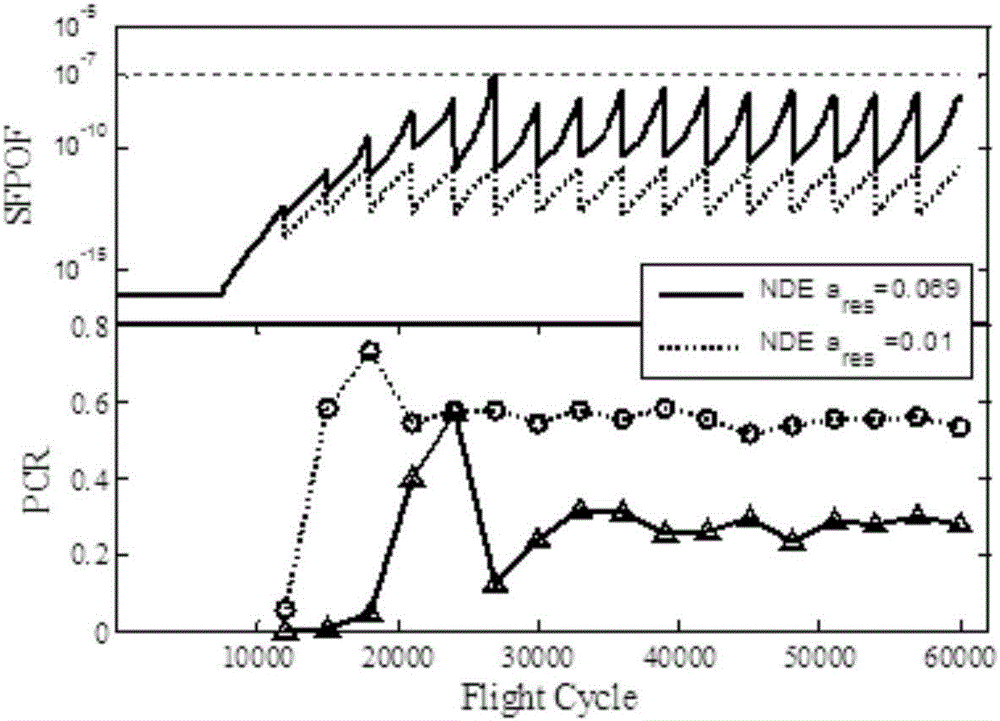

Aircraft structure checking task planning method based on risk and cost analysis

InactiveCN106295897AMeet minimum security requirementsEfficient integrationForecastingCumulative riskFailure risk

The invention discloses an aircraft structure checking task planning method based on risk and cost analysis. The checking mode comprises traditional structure non-destructive detection and structure health monitoring. The method comprises the steps that based on the principle of probability damage tolerance analysis, the calculation model of single flight failure probability of an aircraft structure element is established; based on the model, a cumulative risk calculation model of a fleet in a certain period of time is established; in the existing aircraft structure plan maintenance mode, the maintenance cost calculation model of the aircraft structure element in the service life cycle is established, wherein the calculation model comprises structure checking cost, repair cost and false alarm cost; the single flight failure risk and fleet cumulative risk are used as the risk assessment indicators of a structure maintenance policy; under the premise that a safety risk requirement is satisfied, the optimal structure checking policy can be determined according to the analysis of the structure whole service life cycle maintenance cost. The optimal structure checking interval and repair threshold can be determined based on the tradeoff between the structure failure risk and the service life cycle maintenance cost.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com