Patents

Literature

45results about How to "Reflect characteristics" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

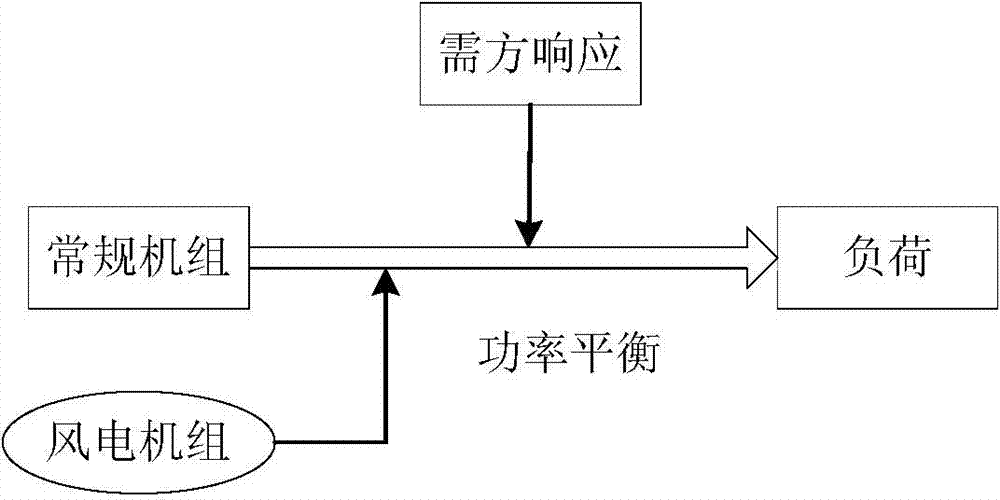

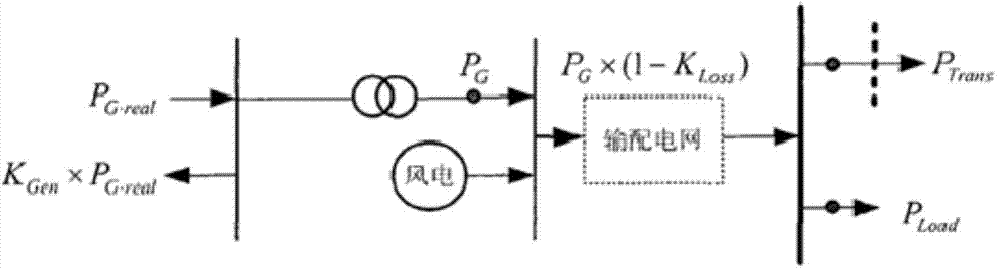

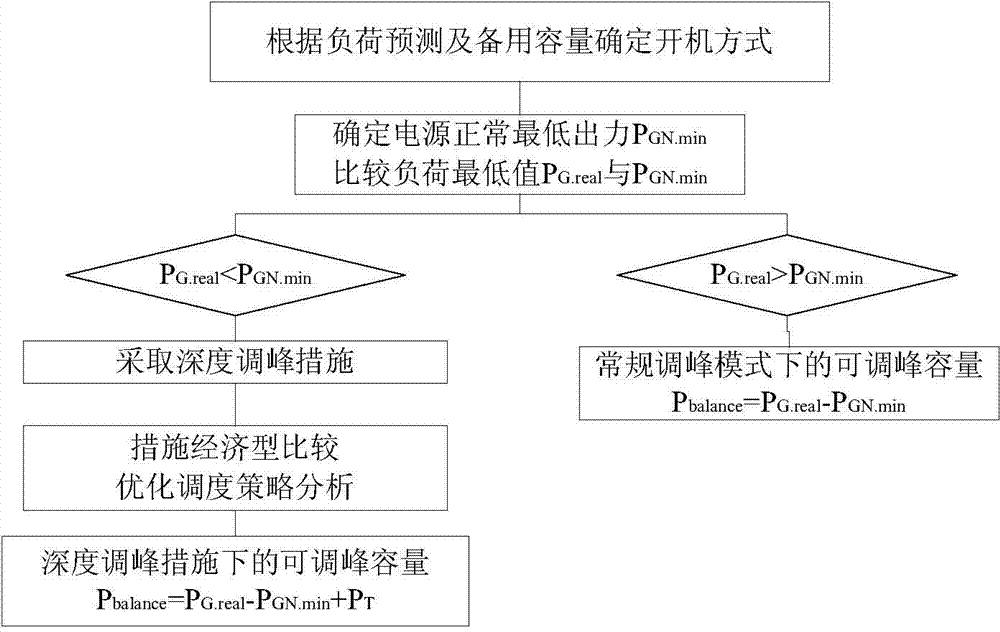

Large-scale grid-connected wind power consumption method based on demander response

ActiveCN103580063ASolve grid-connected consumptionSolve the problem of abandoned windEnergy industrySingle network parallel feeding arrangementsElectricityPower station

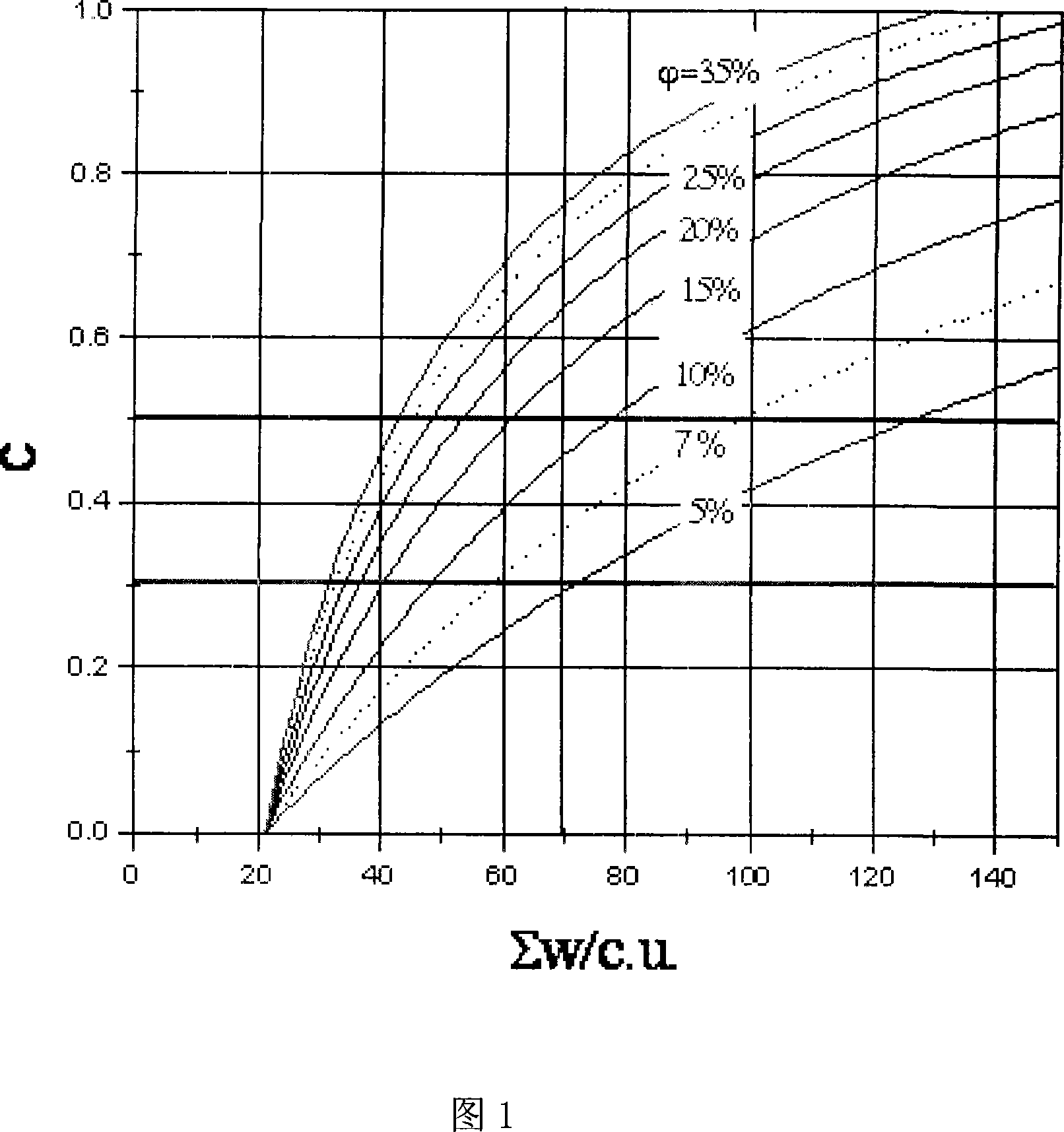

The invention relates to the research field that a demander response participates in large-scale grid-connected wind power consumption, in particular to a large-scale grid-connected wind power consumption based on the demander response. The method comprises the steps of establishing high-energy-consumption enterprises of mining, metal smelting, petroleum processing, heating and the like nearby areas with rich wind power, utilizing adjustable and interruptible high-energy-consumption loads for participating in wind power pitch peaks, locally absorbing wind power resources, and avoiding large-scale and remote wind power transmission. Therefore, power grid losses are reduced, the power utilization cost of high-energy-consumption users is saved, output consumption of a wind power plant is increased, and occurrences of the wind abandoning phenomenon are reduced. The method can objectively and comprehensively reflect the output characteristics of large-scale power wind and the user power utilization load characteristics, the sizes of the adjustable and interruptible high-energy-consumption loads are accurately calculated, then the capacity of the newly-increased wind power consumption scale is determined, and the current large-scale wind power grid-connected consumption problem and the wind abandoning problem are solved.

Owner:STATE GRID CORP OF CHINA +1

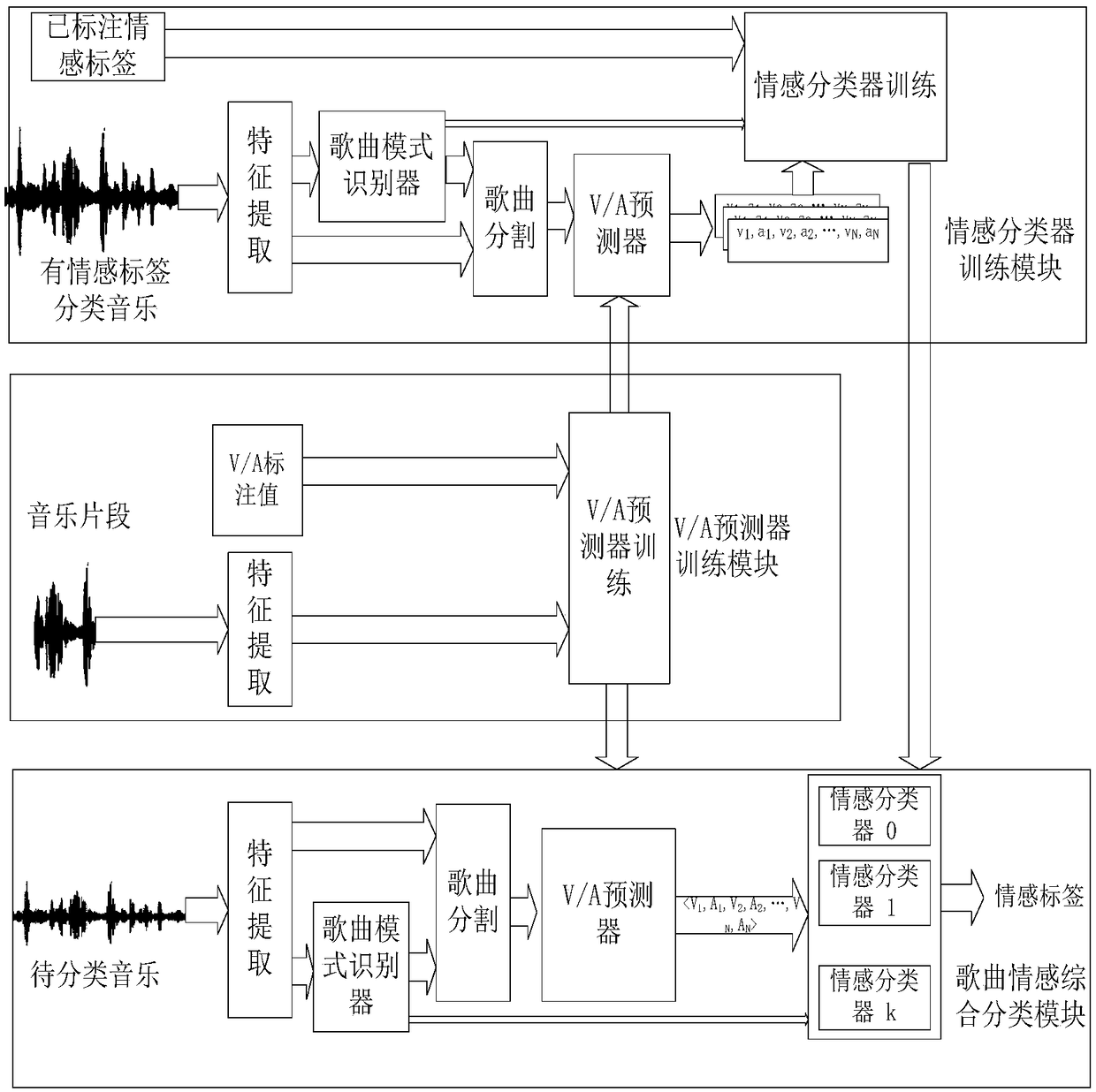

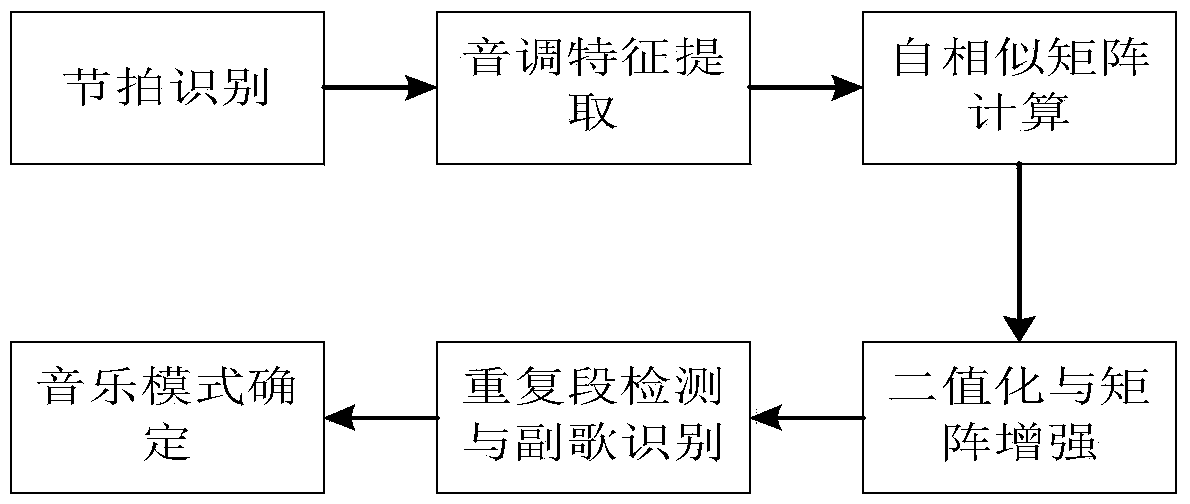

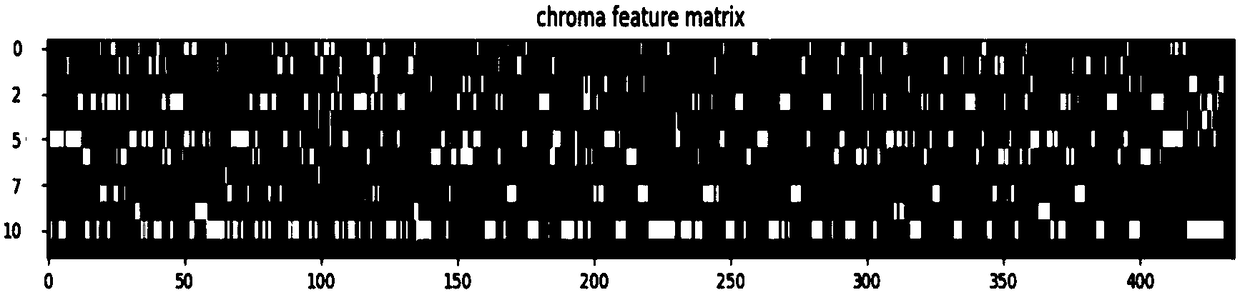

Popular song emotion integration and classification method

InactiveCN108648767AReflect the emotional cognitive processReflect characteristicsElectrophonic musical instrumentsSpeech analysisInformation processingFeature extraction

The invention discloses a popular song emotion integration and classification method, and relates to the field of audio information processing. The method comprises the following steps: firstly, judging a music chorus appearance mode of a piece of music, and confirming different popular music modes; then, segmenting a song into N pieces of segments via a flexible segmenting method, and predictinghappiness and an intense degree of each segment; and implementing emotion integration of the whole piece of music by selecting various classifiers in accordance with the mode of a piece of popular music as well as happiness and intense degree results of the N music segments, so that an emotion label of the whole piece of music is obtained. The method provided by the invention has the advantages that V / A emotional evolution characteristics are extracted via the flexible segmenting technique and the characteristics are separately processed, so that the targeting performance of training on the popular song emotion classifiers of different structures is enhanced; and the method, which conducts song emotion classification via the structures of the popular songs and the emotional evolution characteristics, is better in effect of reflecting emotion cognition processes and features of human beings to music in comparison with methods which simply conduct integration on the basis of statistic characteristics of the whole piece of music.

Owner:COMMUNICATION UNIVERSITY OF CHINA

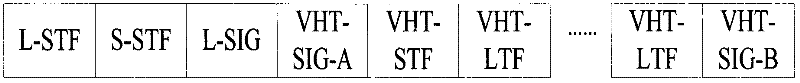

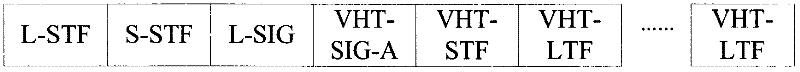

Wireless frame transmission method and device

ActiveCN102201891AReflect characteristicsThe number is reasonableError preventionRadio transmissionThroughputReal-time computing

The invention discloses a wireless frame transmission method and a wireless frame transmission device. The wireless frame transmission method comprises the following steps of: transmitting a null data packet (NDP) to a receiver, wherein the NDP comprises at least two very high throughput (VHT) long training fields (VHT-LTF), and the maximum number of the VHT-LTFs is determined according to the number of the VHT-LTFs which can be supported by at least one receiver. By the transmission method and the transmission device, the maximum number of the VHT-LTFs in the NDP is determined.

Owner:ZTE CORP

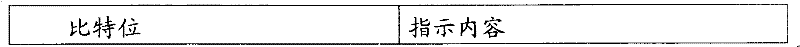

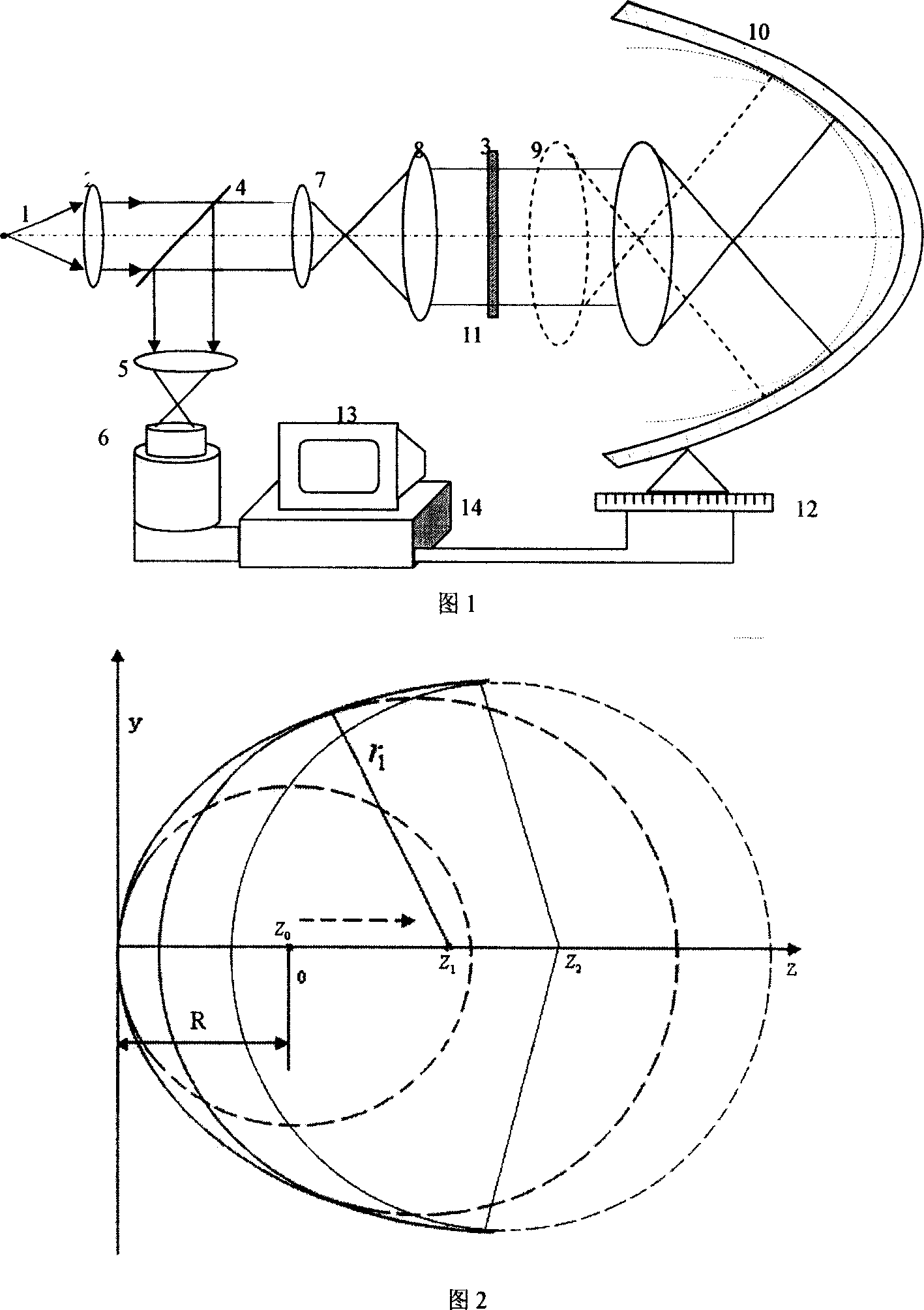

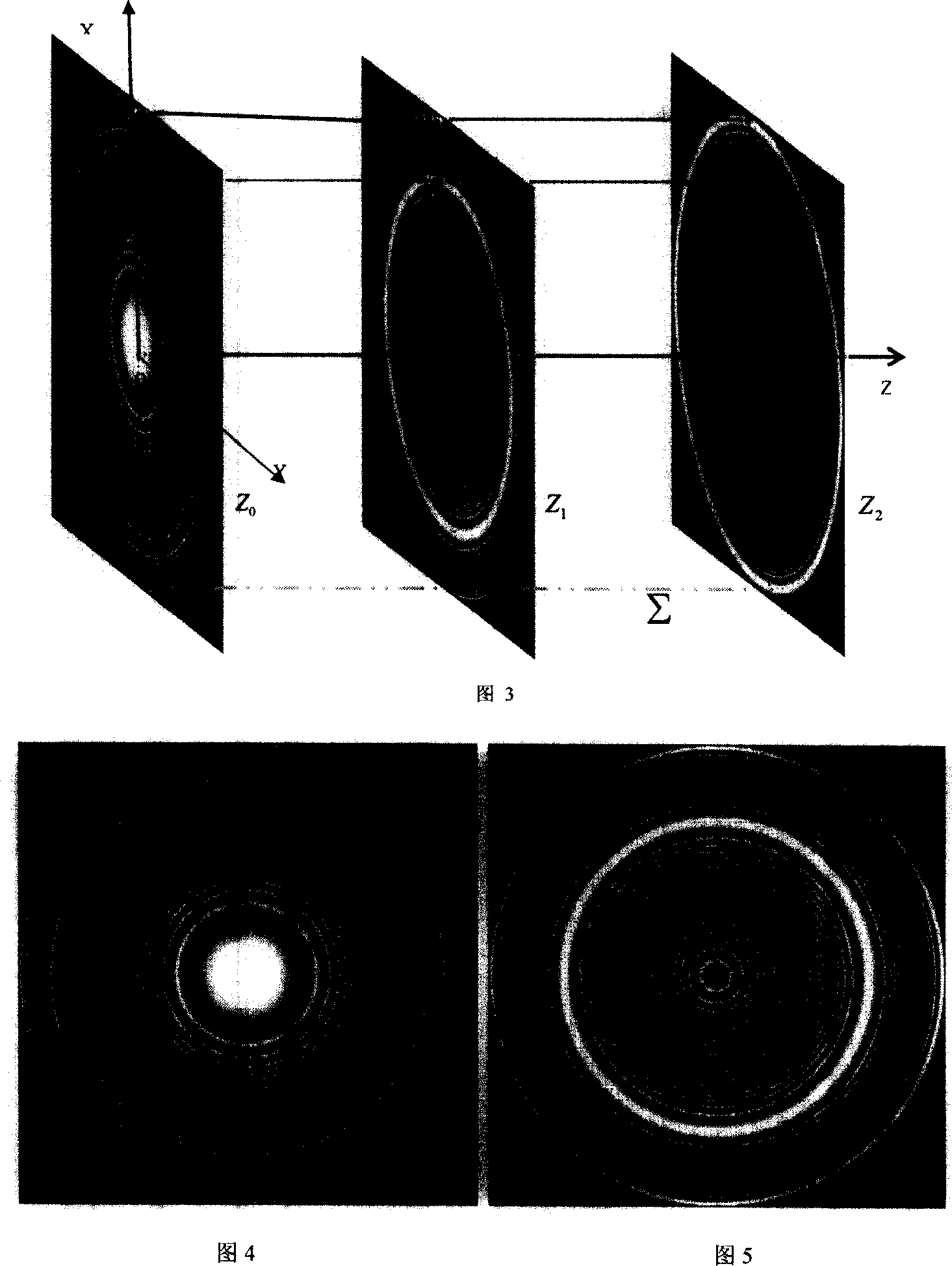

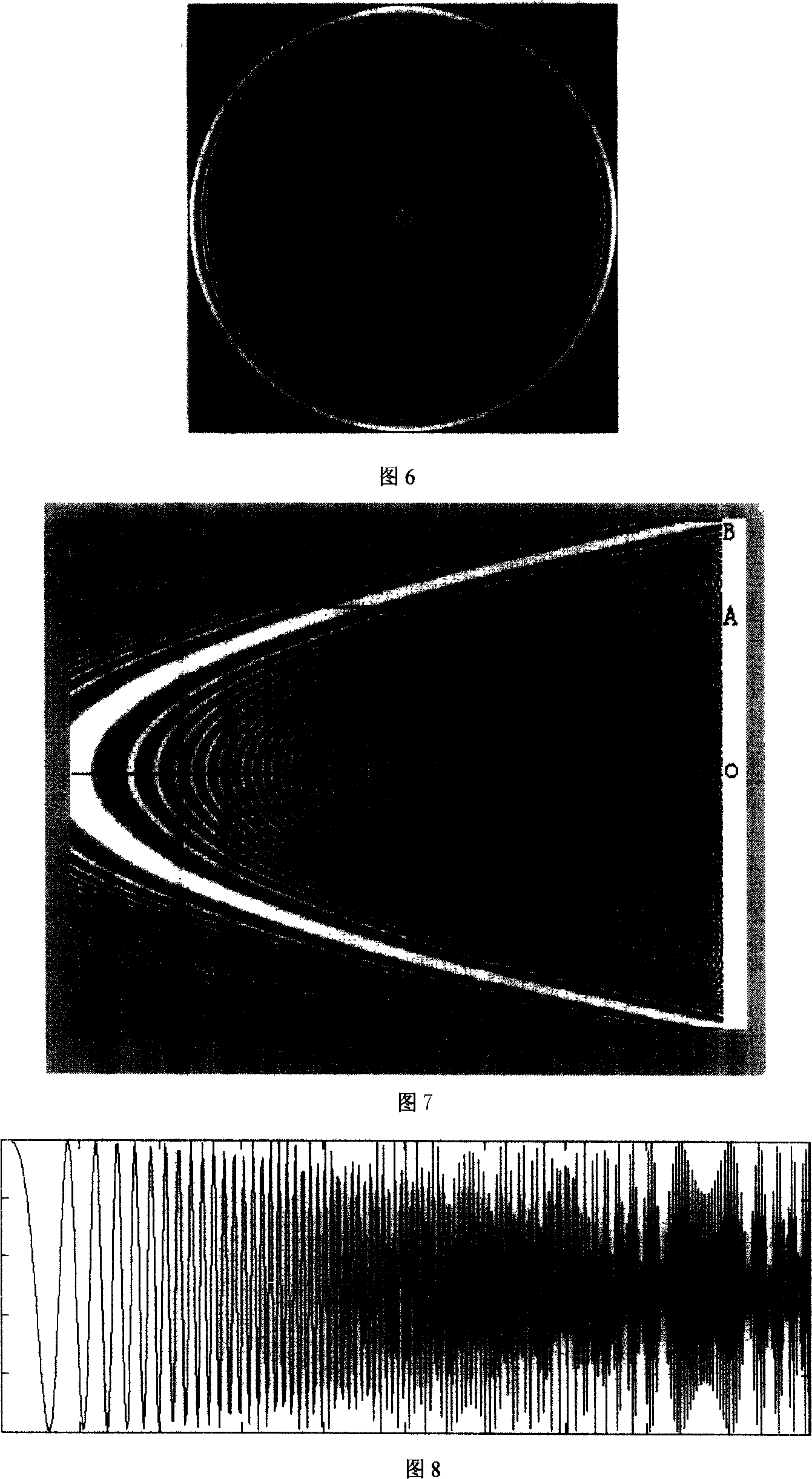

Omnibearing detection method for large-diameter aspherical mirror

InactiveCN1995943ASimple structureHigh precisionTesting optical propertiesContinuous scanningData treatment

The big caliber nonspherical lens inspection controls the moving conoscope through the computer, continuously scanning the big caliber nonspherical lens along the symmetrical axis, acquiring the interference thread changing through time. The generated reference ball surface wave automatically matching with the nonspherical ball surface to be inspected, the best matching zone with low frequency distinguishable interference thread, moving from the center to the edge in the scanning process. Through acquiring the best matching point data to make overall caliber restructuring before the wave, it can acquire the overall information of the nonspherical surface. It is free from design and nonspherical surface compensator, and junction of sub caliber, providing an efficient tool to overall inspection for big caliber nonspherical lens with broad prospect.

Owner:SICHUAN UNIV

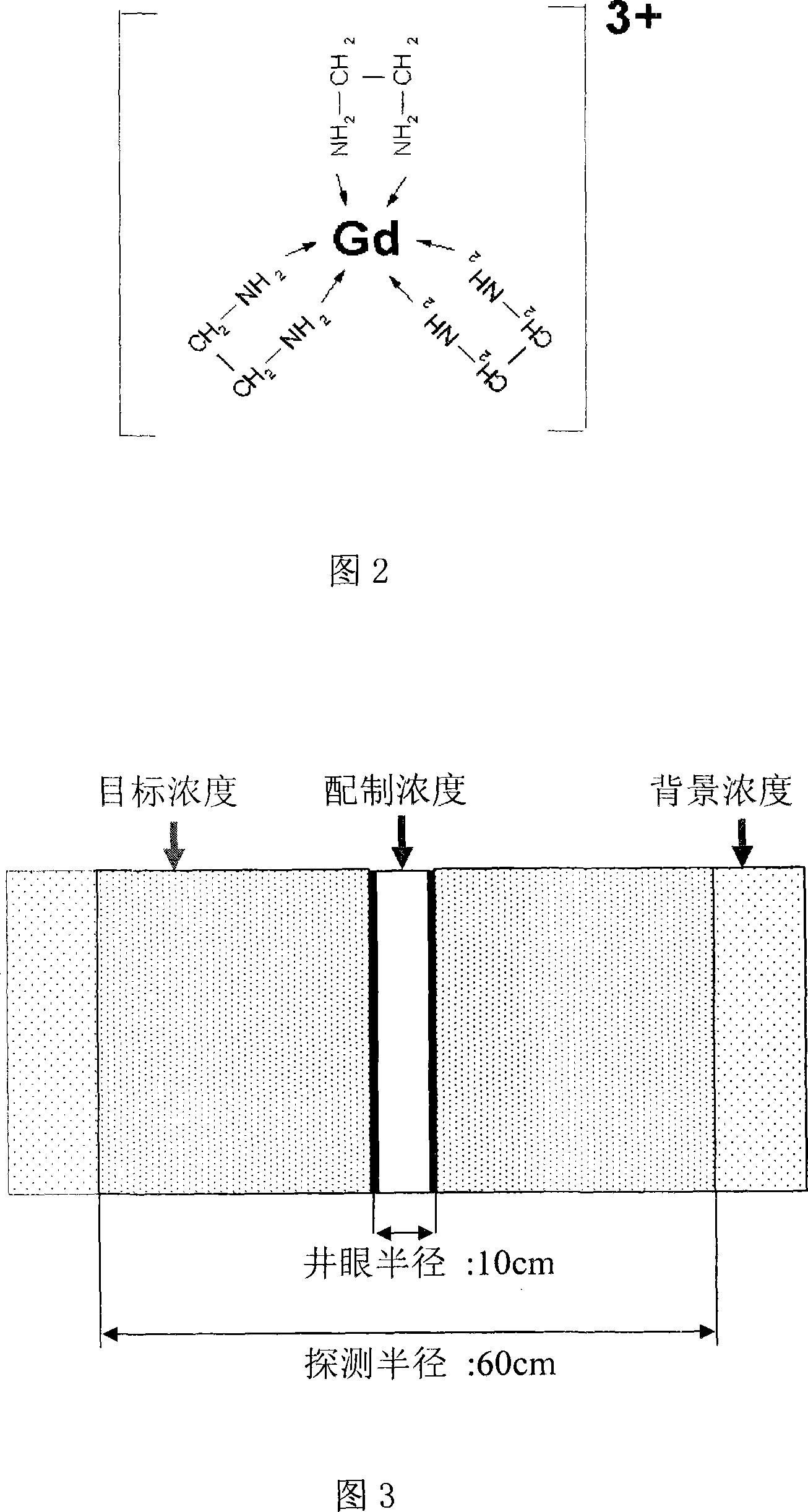

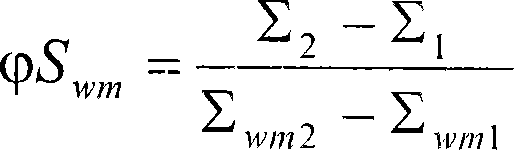

Pulse neutron double spectrum tracing remaining oil saturation logging method

ActiveCN101135733AReflect characteristicsAccurate identificationNuclear radiation detectionEnvironmental geologyOil water

The method comprises: a) before infiltrating the tracer agent into the target layer, using a pulsed neutron dual-spectrum saturation logger to collect the well logging base value data; 2) infiltrating the tracer agent containing Gadolinium into stratum, and measuring the data after infiltration; 3) making the tracer to squeeze into the stratum, and measuring the data after squeezing; 4) processing and explaining the data.

Owner:XIAN AOHUA ELECTRONICS INSTR +1

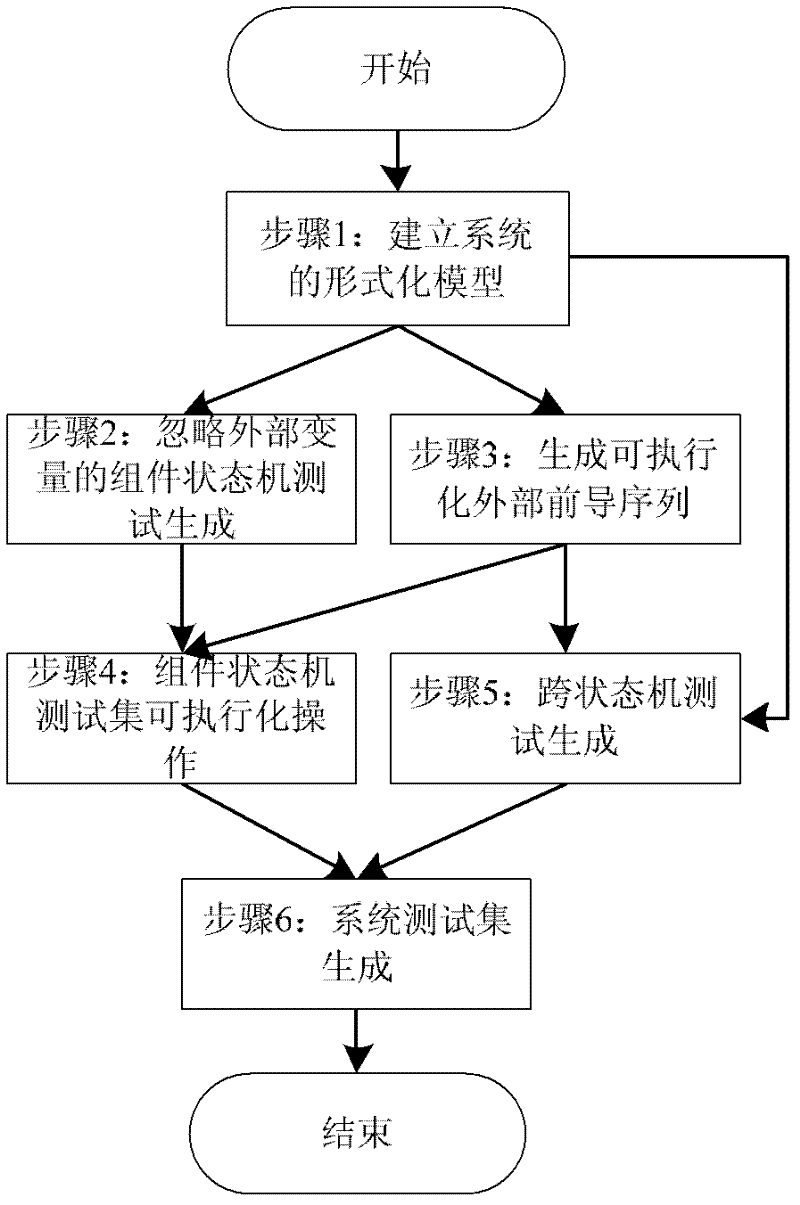

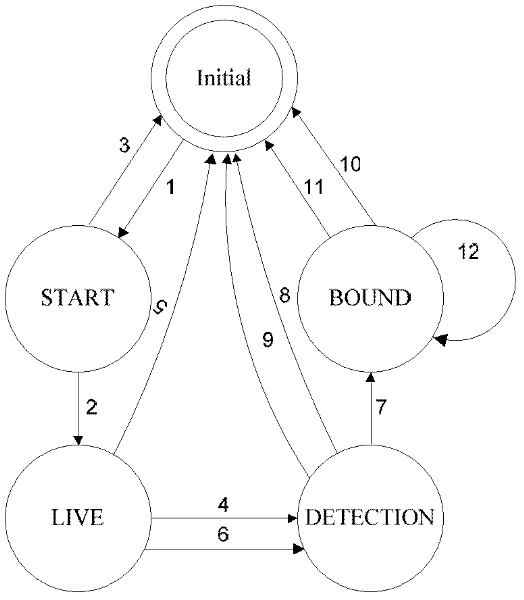

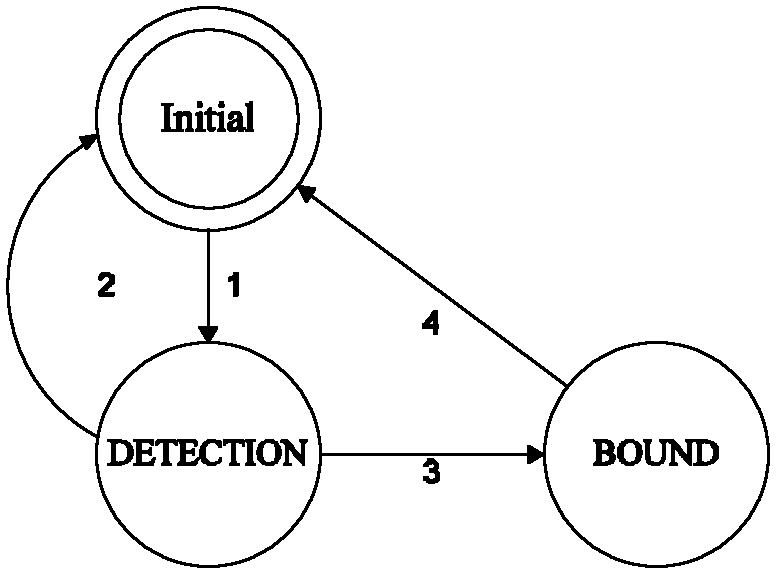

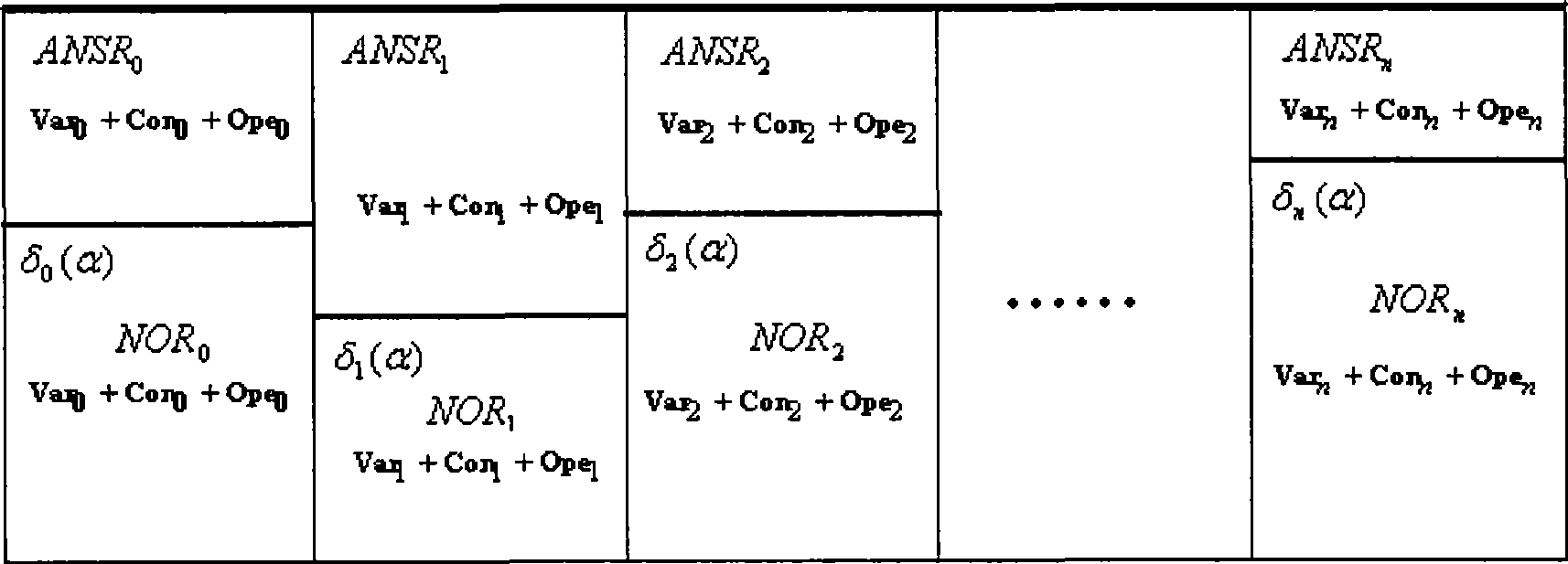

Protocol test generating method of parallel expansion finite-state machine based on variable dependence

ActiveCN102404167AReflect characteristicsFix non-executable issuesData switching networksPathPingParallel Extensions

The invention relates to the technical field of a network protocol test and discloses a protocol test generating method of a parallel expansion finite-state machine based on variable dependence. The protocol test generating method comprises the following steps of 1. in a computer, describing a protocol specification of tested network equipment as a parallel expansion finite-state machine model; 2. generating a component state machine abstract test set by adopting a test generation technology of the expansion finite-state machine ignoring the variable dependence; 3. aiming at external variables, generating an executable external leader sequence; 4. carrying out executable processing on the component state machine abstract test set by linking the external leader sequence; 5. generating a cross-state machine abstract test set with respect to the external variables; and 6. combining the abstract test set processed in the step 4 and the abstract test set generated in the step 5, deleting a repeated or an included test sequence and obtaining the abstract test set of a protocol state machine. By adopting the protocol test generating method, the non-executable problem of the path caused by the variable dependence is solved, and the state explosion is avoided.

Owner:TSINGHUA UNIV

Emulation method of high fidelity onboard foresight weather radar low-altitude wind shear signal

ActiveCN101950017ALow system requirementsReflect characteristicsWave based measurement systemsJet aeroplaneParticulates

The invention relates to an emulation method of high fidelity onboard foresight weather radar low-altitude wind shear signals, which belongs to the technical field of emulation of radar echo signals and comprises the following steps of: (1) establishing a wind shear wind field model by using wind field emulation software; (2) computing reflectivity factors of wind shear wind fields according to density information of an emulation wind field; (3) initializing an emulation scene; (4) determining opposite position information of scattering particulates in the scanning orientation and an airplane; (5) computing the amplitude and the phase position information of echo signals of the scattering particulates of the wind field; (6) superposing echoes of the scattering particulates to form an echo signal in the scanning orientation; and (7) updating a scanning angles of an antenna, and judging scanning range, if the scanning range is exceeded, outputting emulation results, and otherwise, repeating the steps. The invention has the advantages of simple method, good emulation effect, echo emulation of onboard foresight weather radar wind shear targets at high fidelity, and the like.

Owner:CIVIL AVIATION UNIV OF CHINA

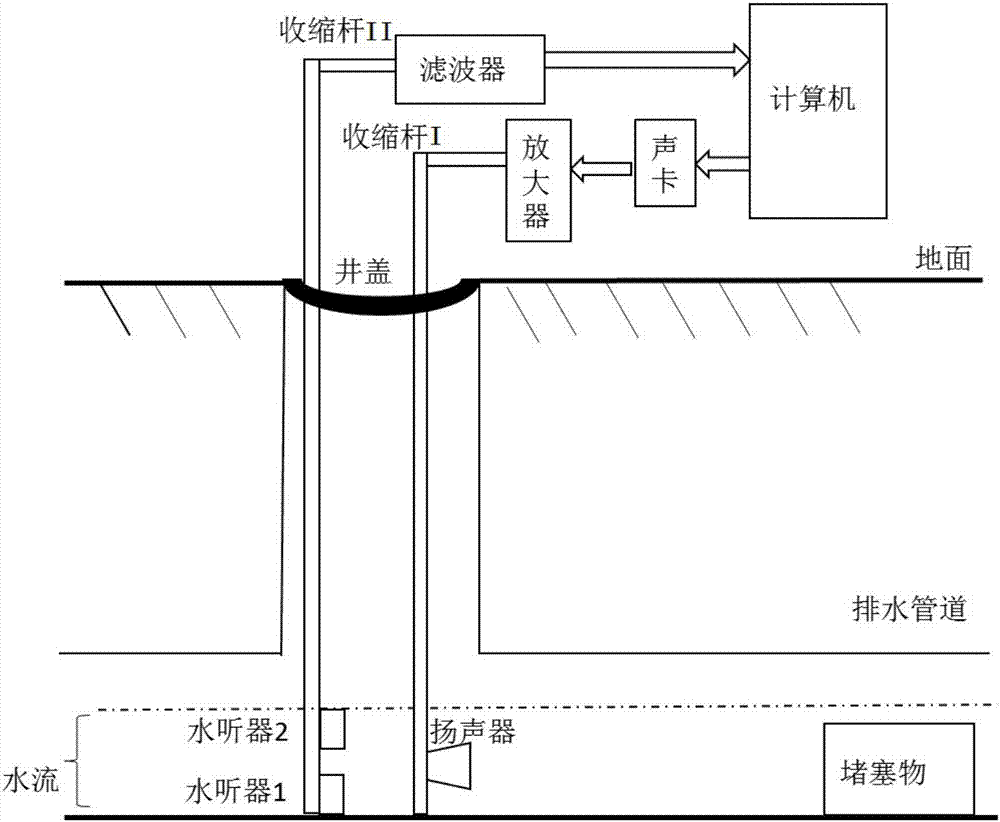

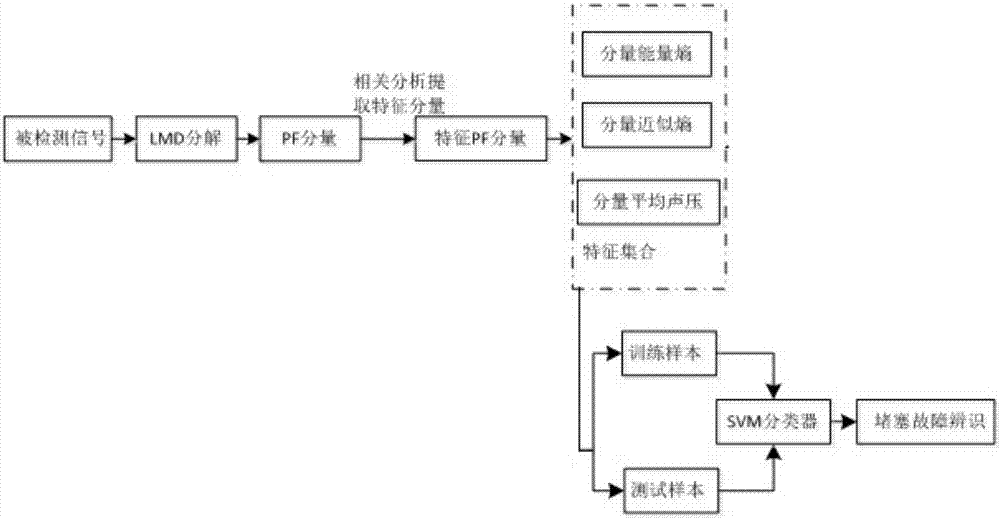

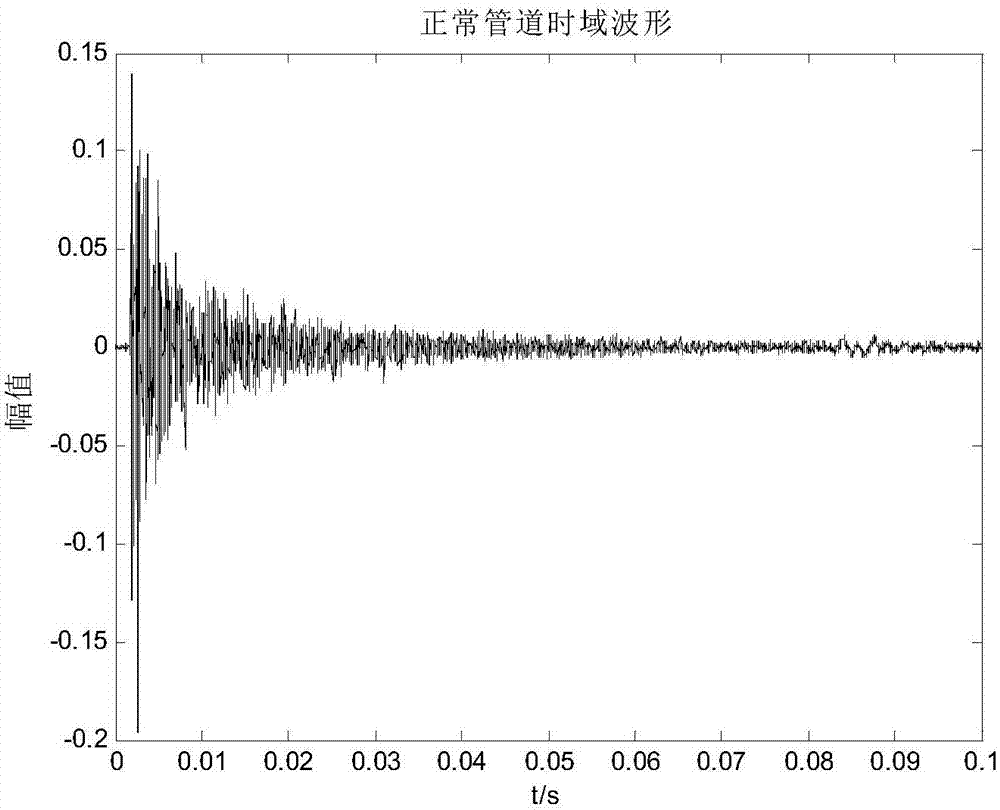

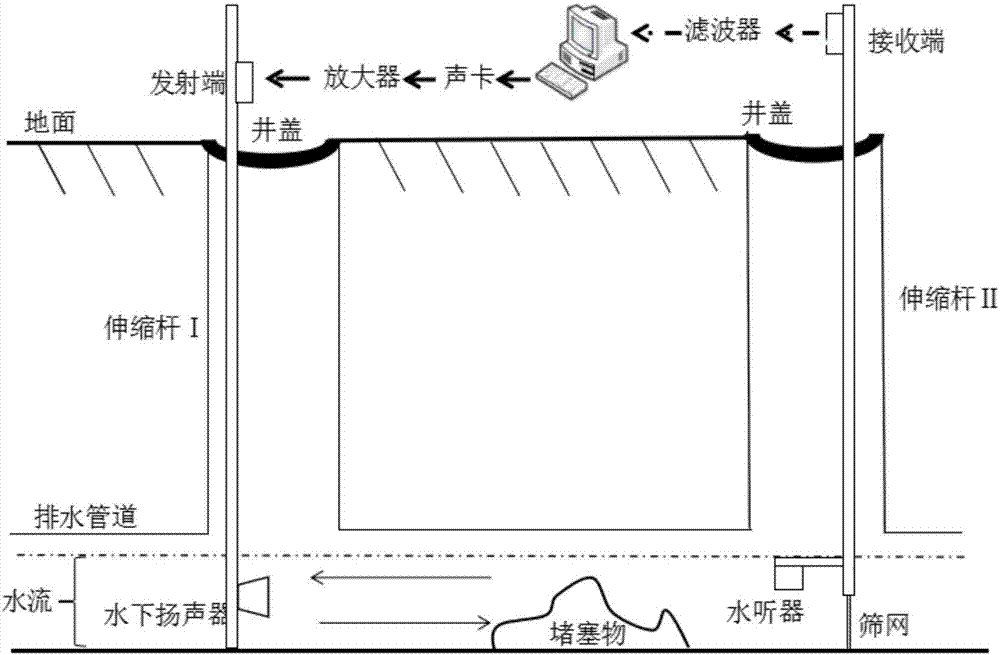

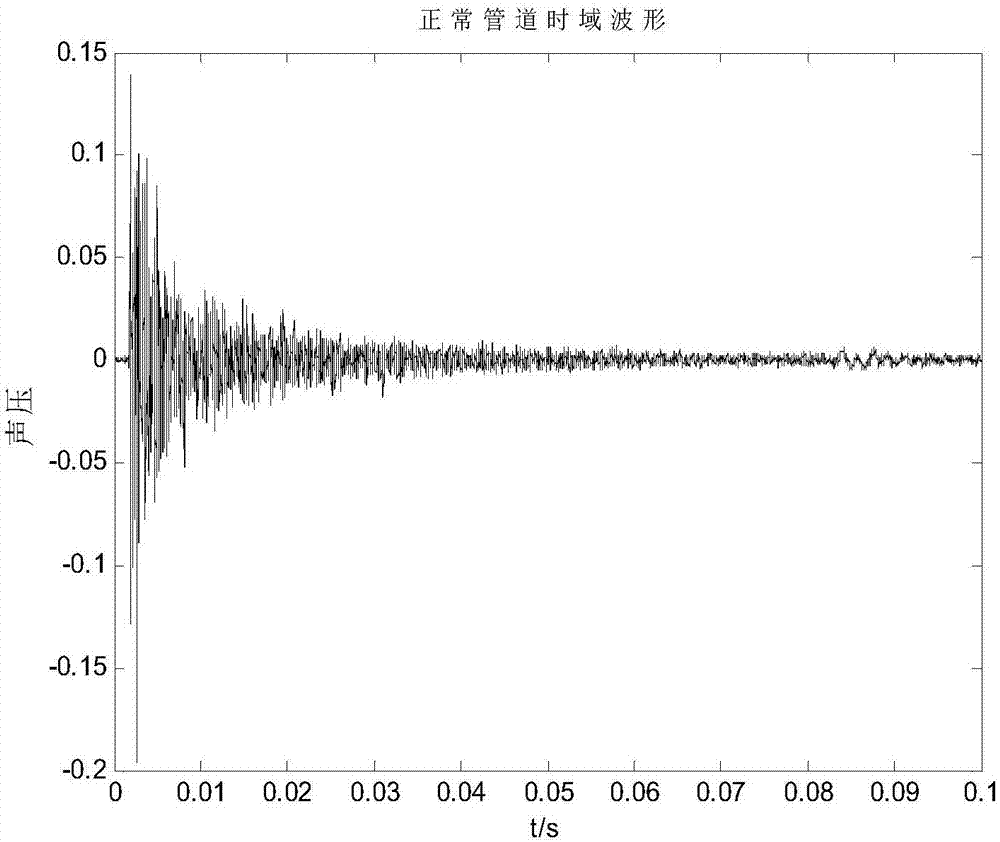

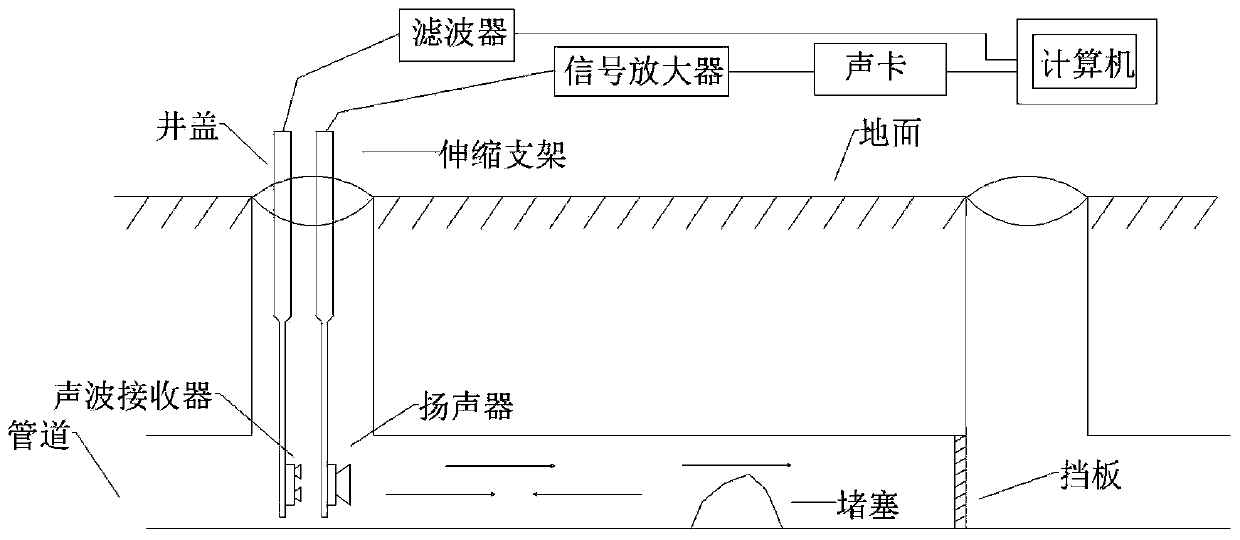

Detection method of detection device for drainage pipeline blockage faults

ActiveCN107218518AOvercoming Disadvantages of Fault DetectionHighlight failure conditionsPipeline systemsCorrelation coefficientDecomposition

The invention discloses a detection method of a detection device for drainage pipeline blockage faults. The method comprises the steps that the detection device for the drainage pipeline blockage faults is arranged; a computer obtains a signal of a normal / blocked pipeline from the receiving end; acoustic response signals in two working conditions of a drainage pipeline are acquired; LMD decomposition is conducted on the acoustic response signals of the normal pipeline and the blocked pipeline; correlation coefficients of all PF components of the normal pipeline and an original signal and correlation coefficients of all PF components of the blocked pipeline and the original signal are calculated by adopting a Pearson correlation coefficient method, and each component of which the correlation coefficient exceeds 15% is taken as an effective PF component signal; energy entropy indexes, approximate entropy indexes and average acoustic pressure indexes of the effective PF components of the normal pipeline and the blocked pipeline are calculated to serve as a characteristic set; an optimal parameter of the characteristic set is sought through a K-CV method; the steps are repeated, and fault identification is conducted on other sections of the pipeline by adopting an SVM classifier with the trained parameter. According to the detection method, the detection procedure is conveniently conducted, and the accuracy and reliability of a detection result are improved.

Owner:KUNMING UNIV OF SCI & TECH

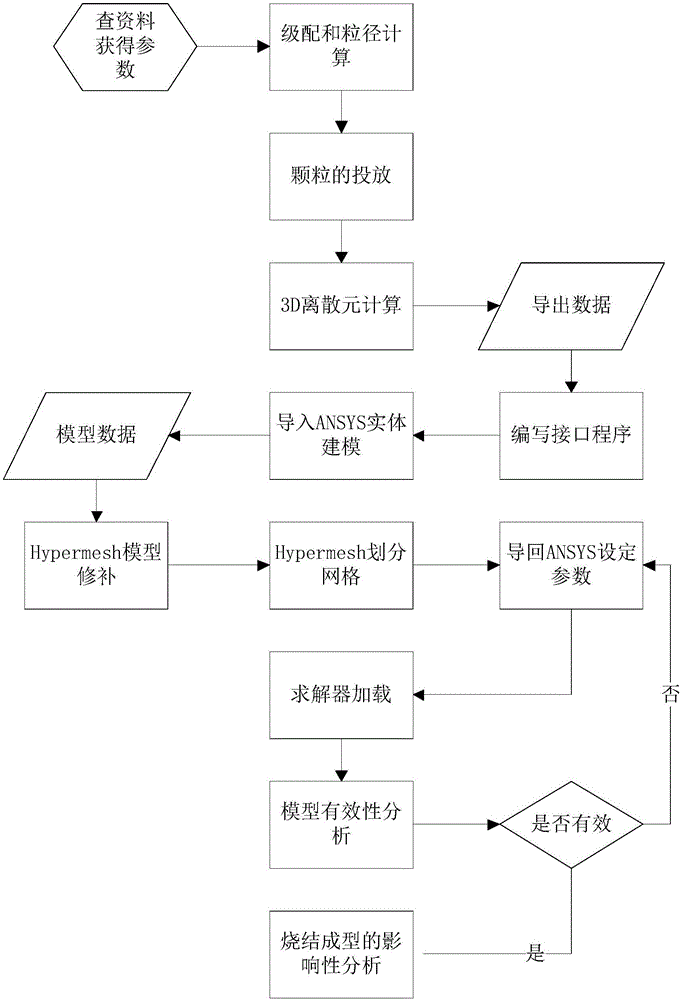

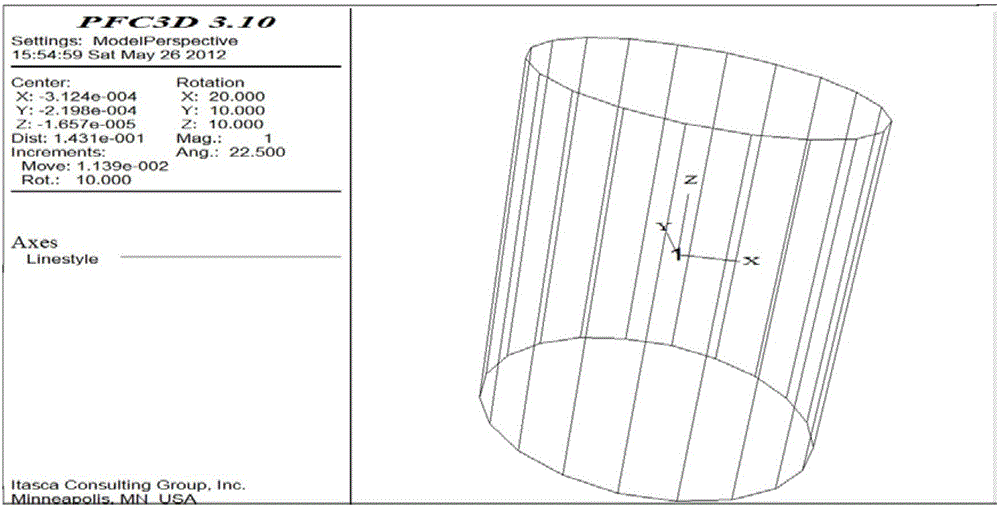

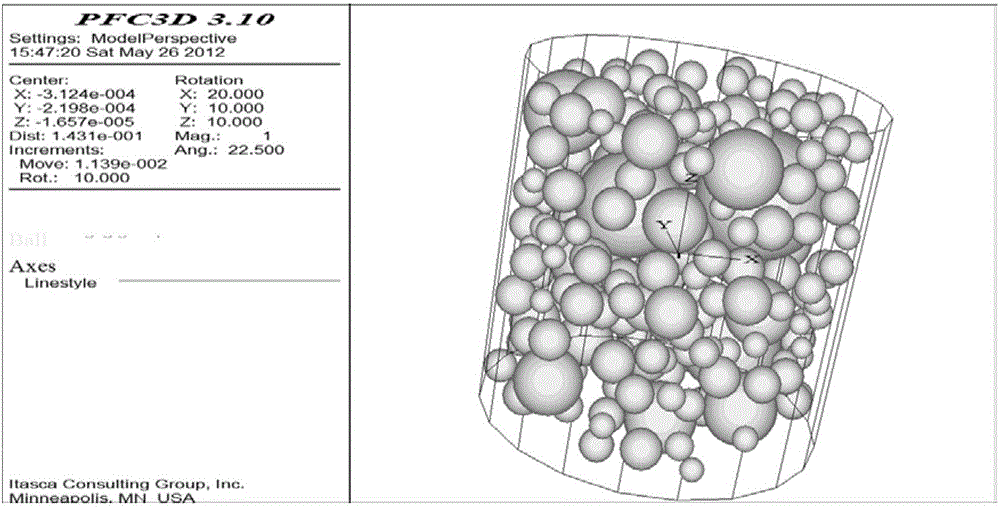

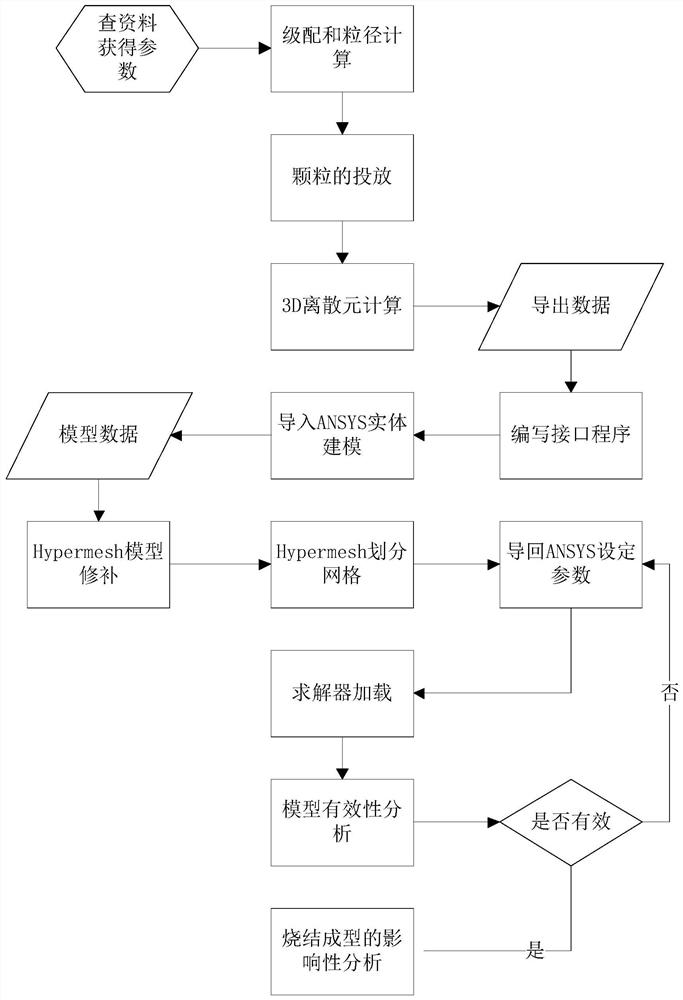

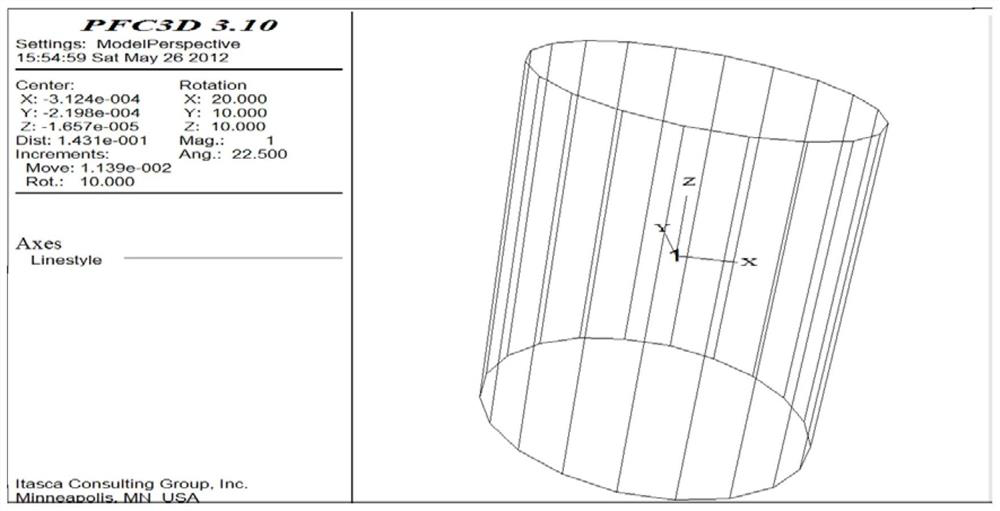

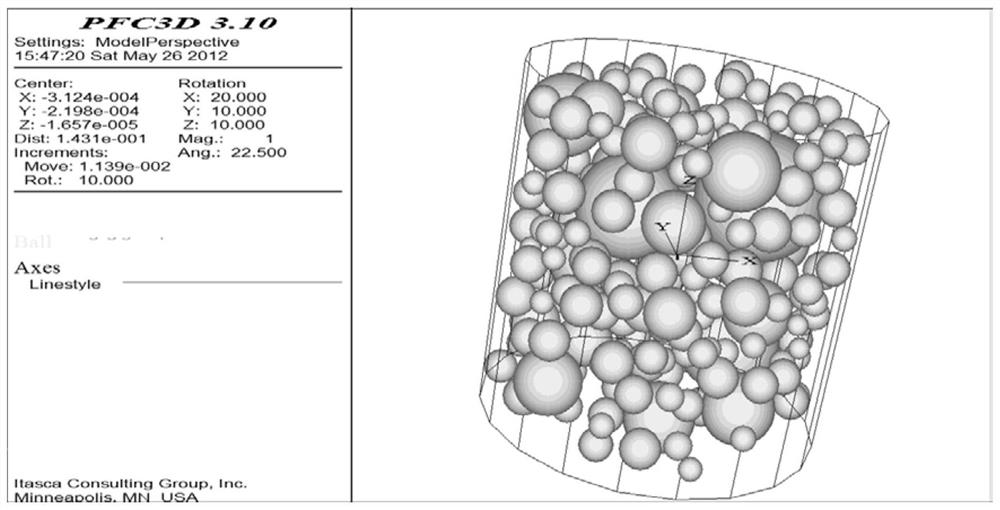

Powder metallurgy random particle size distribution 3D (three-dimensional) finite element modeling and simulation method

ActiveCN106777807AReflect characteristicsAccurate modelingDesign optimisation/simulationSpecial data processing applicationsElement modelElement modeling

The invention discloses a powder metallurgy random particle size distribution 3D (three-dimensional) finite element modeling and simulation method which includes the steps: firstly, acquiring the content and the particle size range of all components according to a powder metallurgy formula, calculating the average density of material particles according to the density and the content of different components, and acquiring the sizes and the number of the particles under a particle size belt; secondly, throwing the particles by PFC3D software, discretizing a random model and deriving throwing coordinates and particle sizes; thirdly, leading the coordinates and the particle sizes into ANSYS software and building a random 3D finite element model; fourthly, leading the finite element model into Hypermesh, dividing grids and finally loading a solver for finite element simulation to simulate the random model of a powder metallurgy random particle size distribution process. Main parameters include maximum particle size and minimum particle sizes. By making full use of randomization of discrete elements and strong analysis functions of finite elements, the model is visual, simple and high in practicability and conforms to application and research of present powder metallurgy in terms of sinter molding.

Owner:BEIHANG UNIV

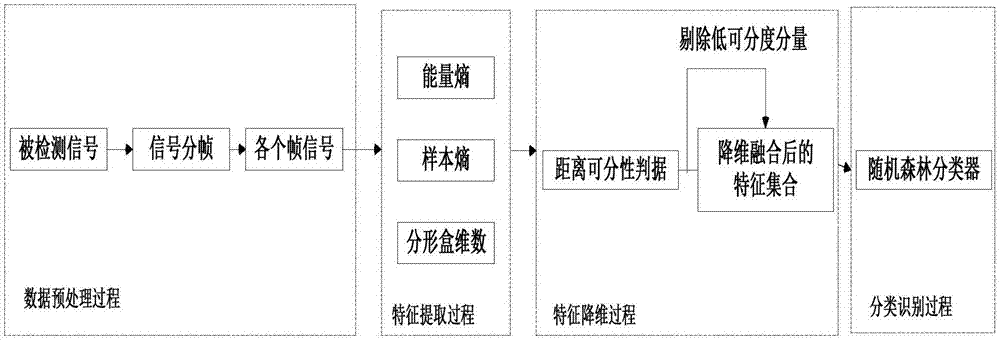

Detecting method for blocking failure of water drainage pipeline

ActiveCN107355686AReliable extraction resultsOptimize the detection processCharacter and pattern recognitionPipeline systemsVIT signalsApproximate entropy

The invention discloses a detecting method for blocking failure of a water drainage pipeline. The detecting method for blocking failure of the water drainage pipeline comprises the following steps that a detecting device for the blocking failure of the water drainage pipeline is installed; a known pipeline failure-free section / a pipeline failure section are selected for detecting, and signals under two working conditions are obtained by a computer from the receiving end; acoustic response signals of the water drainage pipeline under the two working conditions are obtained; SVD is conducted on the acoustic response signals; an energy entropy index and an approximate entropy index are extracted; the extraction results of the two indexes are merged as a initial eigenvector set; a within-class discrete matrix and a between-class discrete matrix are obtained by using a distance separable criterion method for an obtained energy entropy eigenvector set, an approximate entropy eigenvector set and the initial eigenvector set; the weight of the energy entropy index and the approximate entropy index are calculated; all the eigenvector sets are weighted to obtain a new eigenvector set; a random forest classifier is trained with the eigenvector set, and a failure identification model is obtained. According to the detecting method for blocking failure of the water drainage pipeline, accuracy and reliability of the detecting result are improved.

Owner:KUNMING UNIV OF SCI & TECH

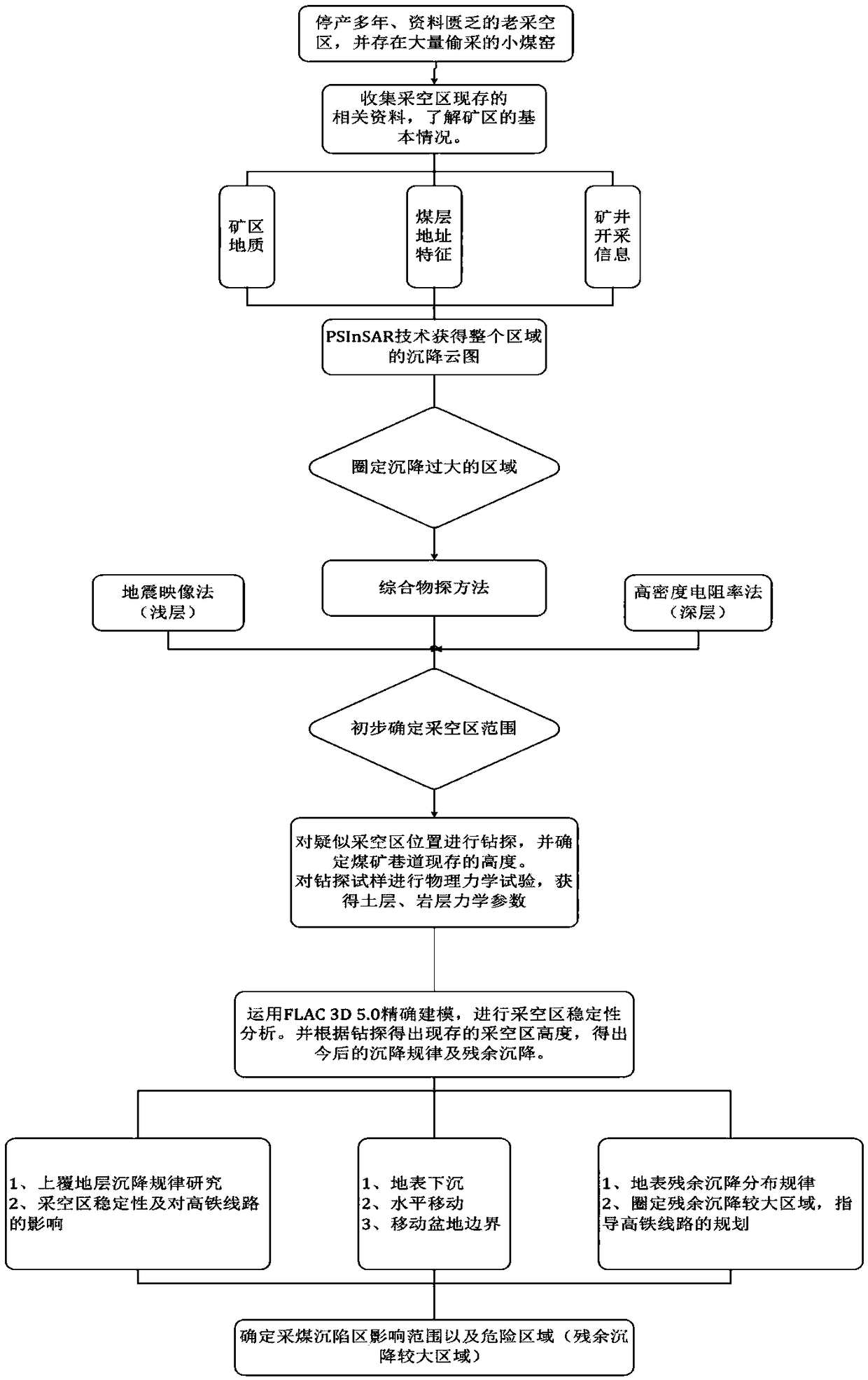

Method for determining unknown goaf range and old goaf residual settlement

ActiveCN109029343AReduce dependencyPracticalHeight/levelling measurementGeophysical prospectingGeological disaster

The invention belongs to the technical field of the high-speed railway geological disaster, and specifically relates to a method for determining unknown goaf range and old goaf residual settlement. The method comprises the following steps: firstly collecting goaf related documents such as peripheral coal seam distribution, mining and coverage resource coditions, and then drawing a settlement cloudatlas, and determining a suspicious goaf range; treating the suspicious goaf range by adopting the PSP-InSAR deformation measurement technology; form the suspicious goaf region delineated by the InSAR technology measurement, initially determining a fact that the goaf is existent under the region if the goaf abnormity is detected by using the geophysical prospecting technology measure, and performing the drilling; and performing indoor physical mechanics test for a sample taken out through drilling, and acquiring the mechanics parameter of each stratum covered on the goaf, thereby preparing for the subsequent modelling; performing precise modelling, performing mutual verification on a numerical analysis result and the settlement result of the InSAR, finally obtaining the influence range and the residual settlement of the old goaf. The method disclosed by the invention is scientific in design, accurate in measurement result, friendly in application environment, and wide in market prospect.

Owner:深科空间(青岛)建设工程技术有限公司

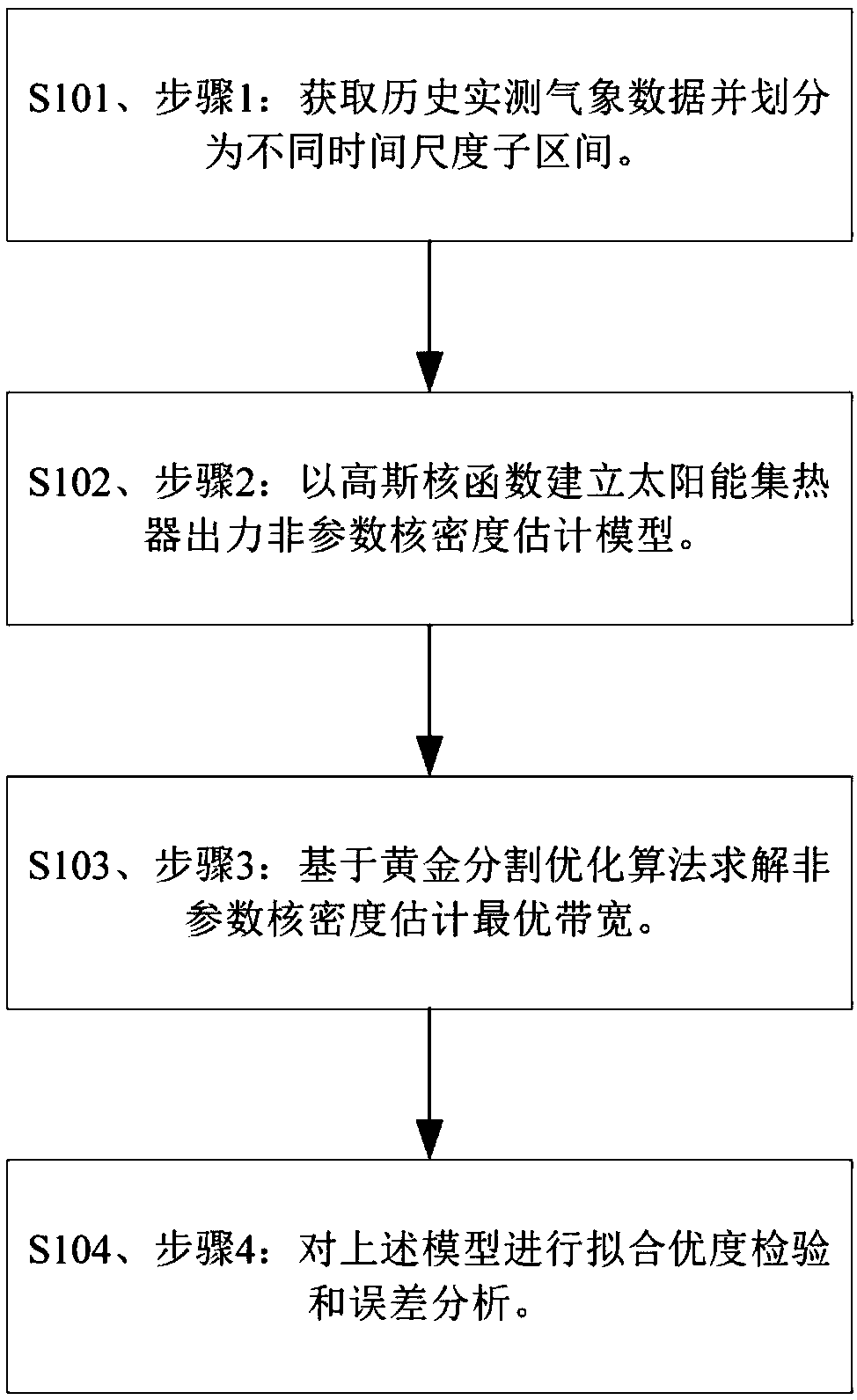

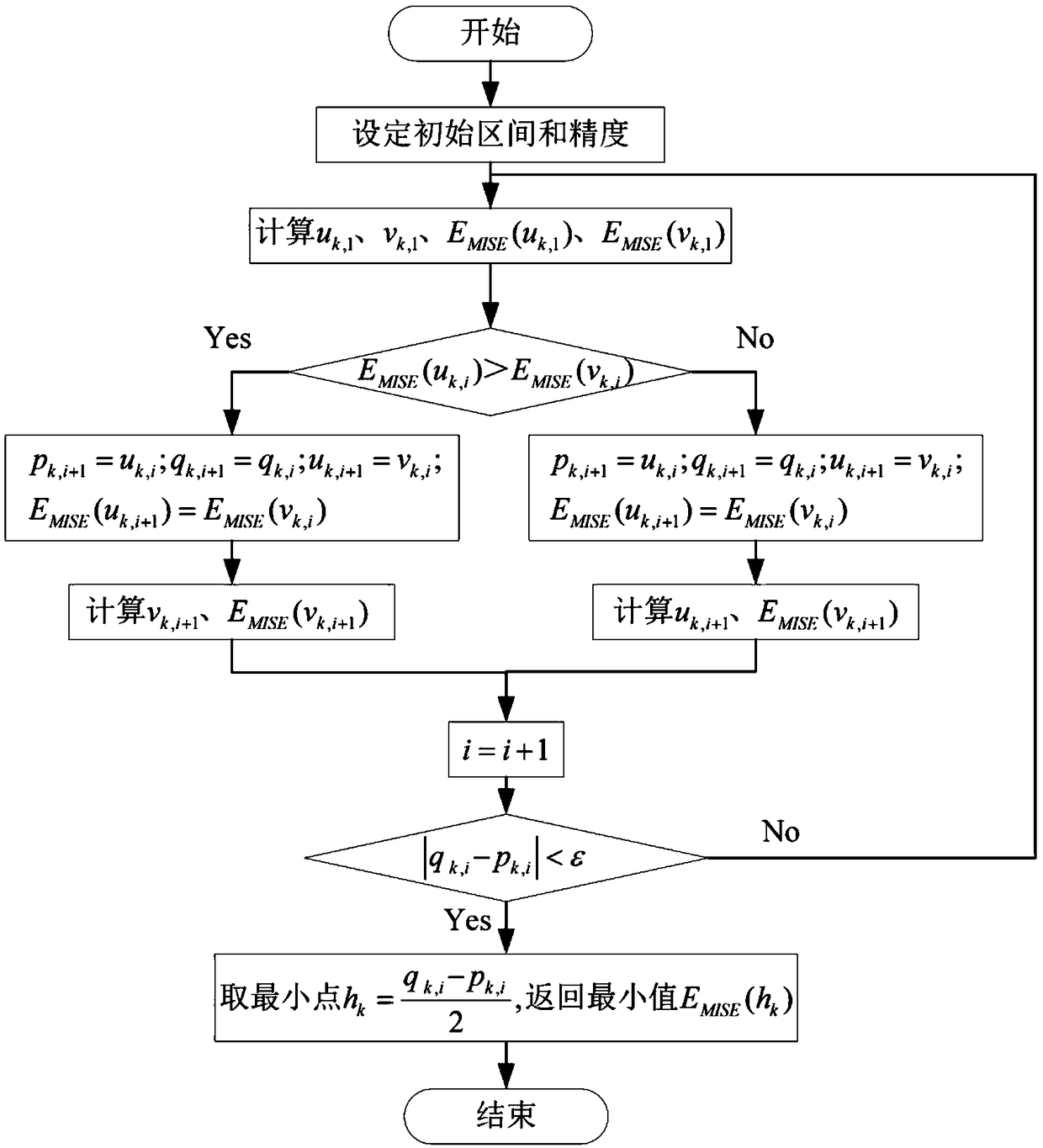

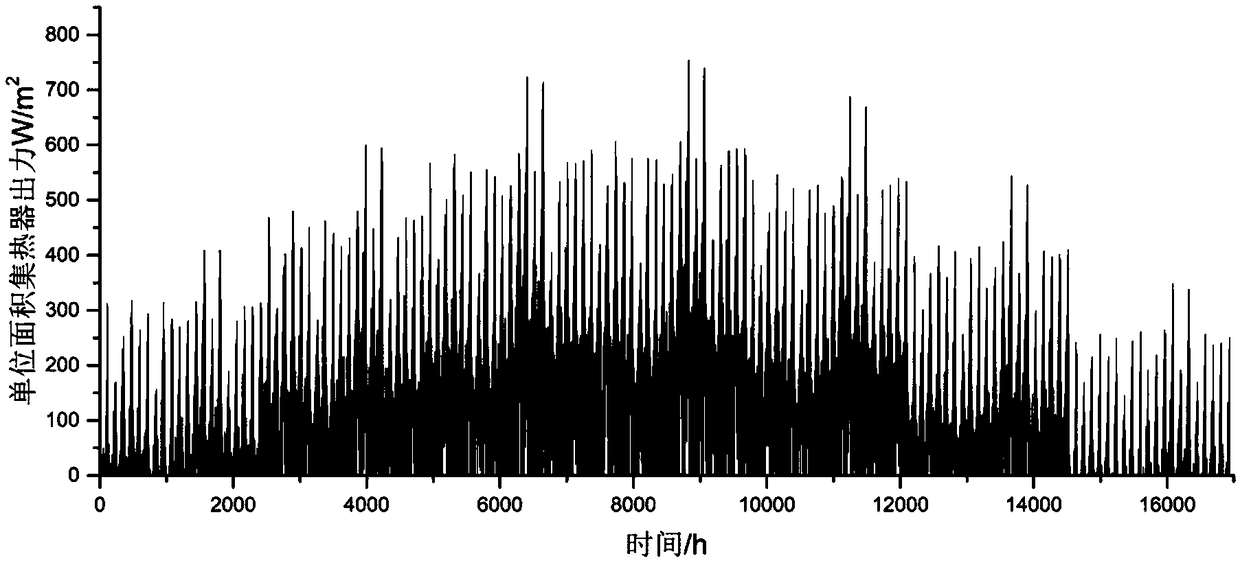

Solar collector output probability modeling method based on nonparametric kernel density estimation

ActiveCN109325273AReflect characteristicsReflect the law of changeDesign optimisation/simulationSpecial data processing applicationsCollector deviceVariable kernel density estimation

The invention discloses a solar collector output probability modeling method based on non-parametric kernel density estimation. The method comprises the following steps of: 1. obtaining hourly meteorological data measured in history and counting according to different years; 2. solving the output value and the bandwidth value of the unit area collector through a non-parametric kernel density estimation model of the output of the solar collector; 3. modifying the nonparametric kernel density estimation model. The method of the present invention can accurately reflect the random characteristicsand variation law of the output of the collector under different time scales, and can be used for planning and reliability research of the photothermal system under the condition of lacking historicaloperation data in the early stage.

Owner:TIANJIN UNIV

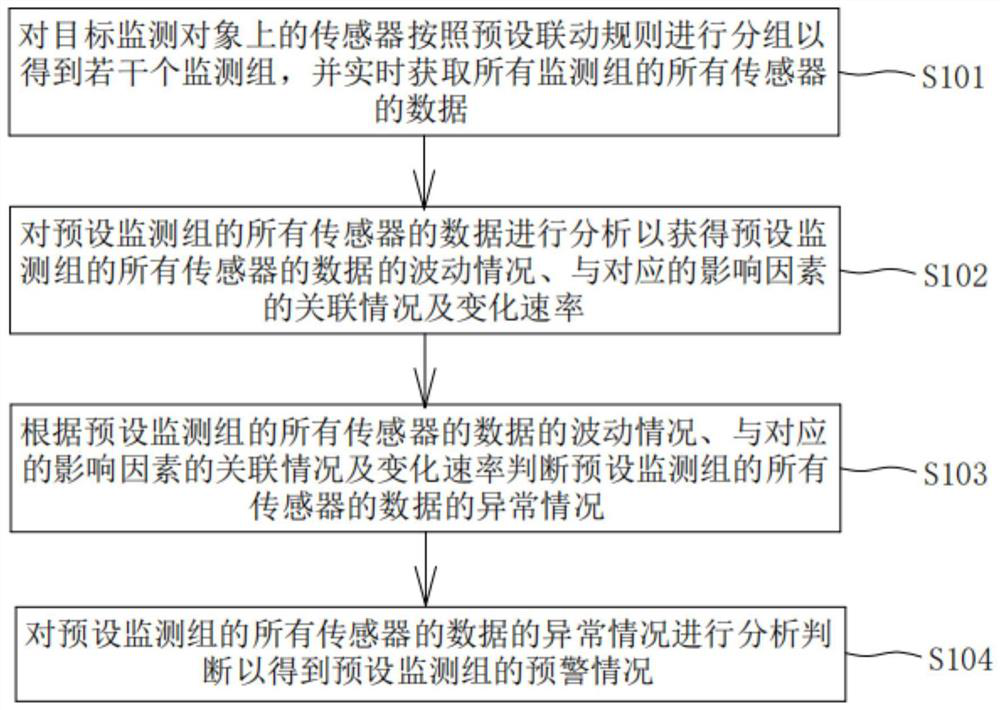

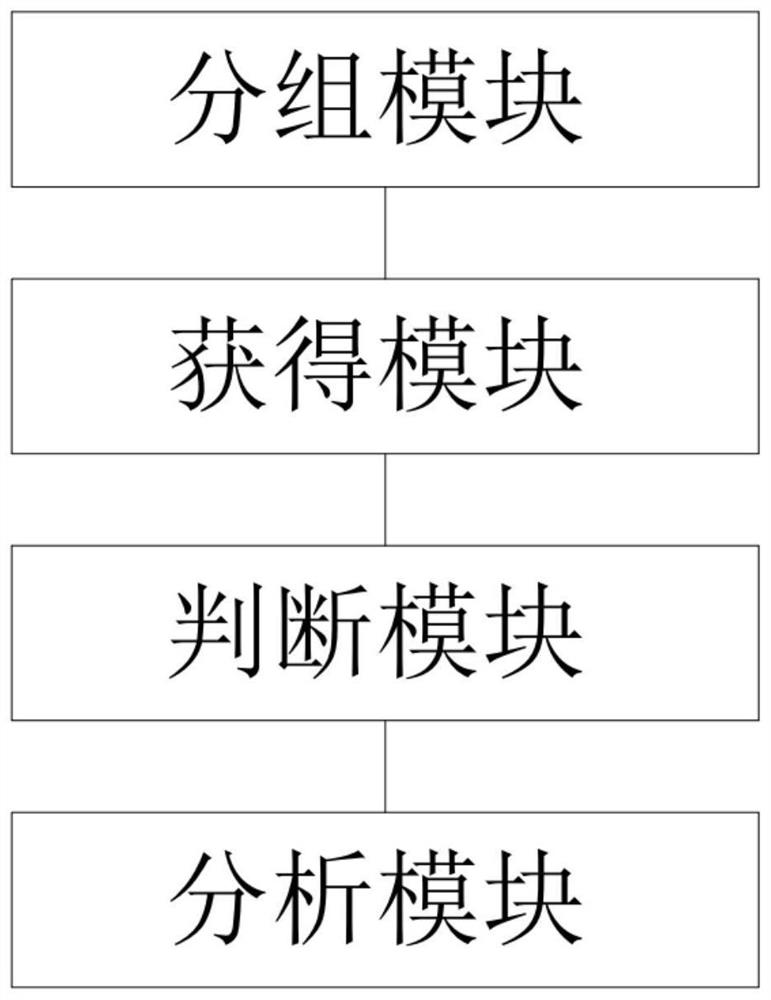

Linkage early warning management method and system, storage medium and equipment

PendingCN114446020AHigh data correlationReflect characteristicsClimate change adaptationForecastingReliability engineeringReal-time computing

The invention provides a linkage early warning management method and system, a storage medium and equipment, and the method comprises the steps: carrying out the grouping of sensors on a target monitoring object according to a preset grouping rule, so as to obtain a plurality of monitoring groups, and obtaining the data of all sensors of all monitoring groups in real time; analyzing the data of all the sensors of the preset monitoring group to obtain fluctuation conditions of the data of all the sensors of the preset monitoring group, association conditions of corresponding influence factors and change rates; according to the fluctuation condition of the data of all the sensors of the preset monitoring group, the association condition of the corresponding influence factors and the change rate, the abnormal condition of the data of all the sensors of the preset monitoring group is judged; and analyzing and judging abnormal conditions of the data of all the sensors of the preset monitoring group to obtain an early warning condition of the preset monitoring group. According to the invention, comprehensive and efficient linkage early warning management can be conveniently carried out on different monitoring items or different monitoring parts on the monitoring object.

Owner:JIANGXI FASHION TECH

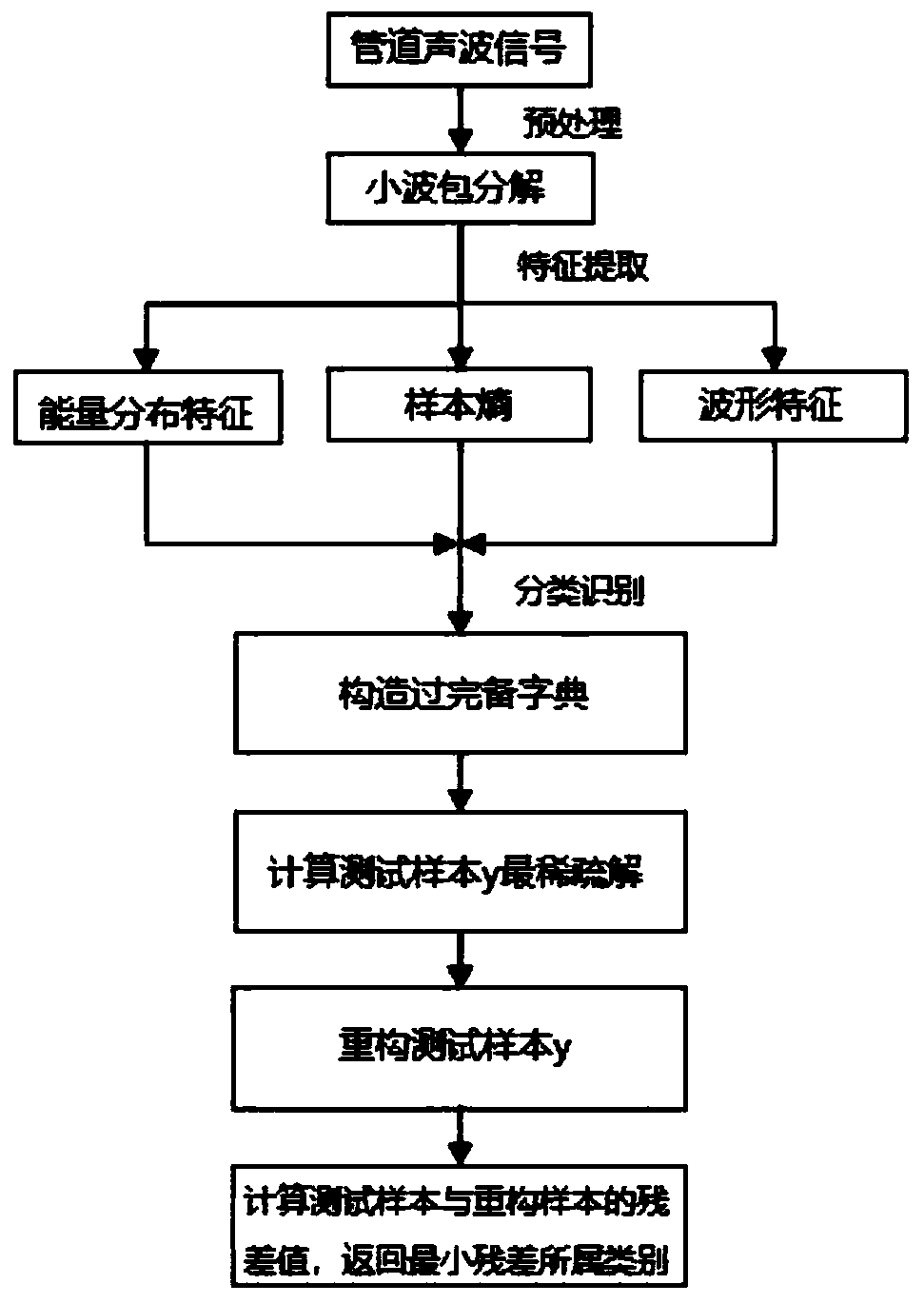

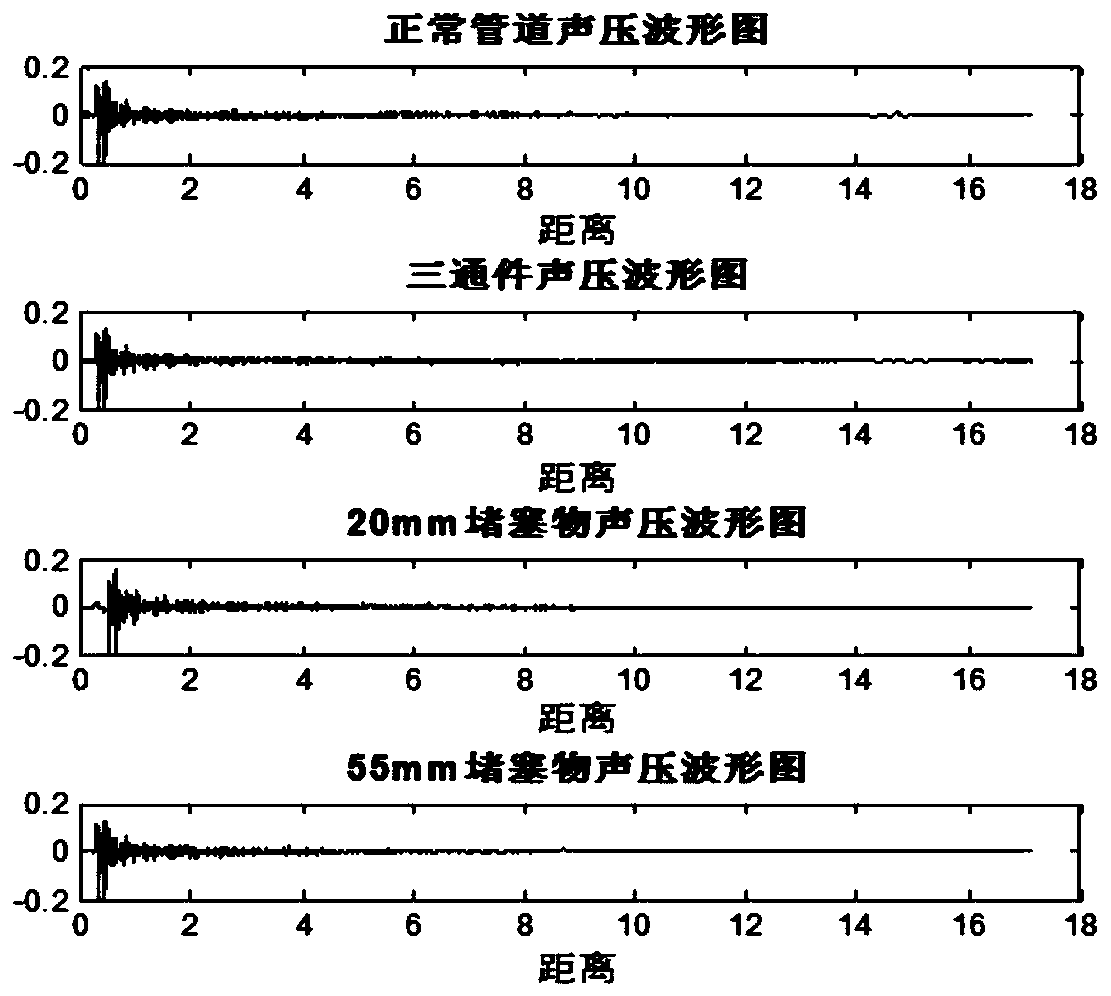

Acoustic active detection-based diagnosis method for blockage faults and pipeline tee joints in buried drainage pipelines

ActiveCN109827081AOvercoming Disadvantages of Fault DetectionReduce pollutionMaterial analysis using acoustic emission techniquesPipeline systemsFeature vectorDiagnosis methods

The invention discloses an acoustic active detection-based diagnosis method for blockage faults and pipeline tee joints in buried drainage pipelines, and belongs to the field of pipeline fault diagnosis. The diagnosis method comprises the following steps of selecting a corresponding pipeline and detecting the pipeline by a detector, and acquiring signals under four working conditions from a receiving end by a computer; performing wavelet packet decomposition on an acquired acoustic signal; extracting the energy distribution feature, the sample entropy and the waveform feature of each frequencyband component, and forming feature vectors with multiple feature cascades to represent the signals under the different working conditions; establishing a super complete dictionary with the feature vectors of training samples collected in advance; and acquiring reconstruction signals of detection signals in different classes by employing a sparse representation method on the basis of the super complete dictionary, and calculating the residual values of test samples and the reconstruction signals of the test samples to realize recognition of the blockage degree and tee joints in the pipeline.The diagnosis method disclosed by the invention is capable of recognizing the blockages of different degrees and the pipeline tee joints in the pipeline, and the accuracy of a recognition result is increased; and the diagnosis method has certain robustness on the change of the external environment.

Owner:KUNMING UNIV OF SCI & TECH

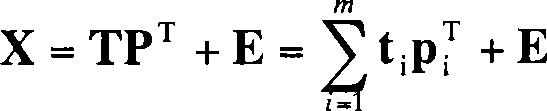

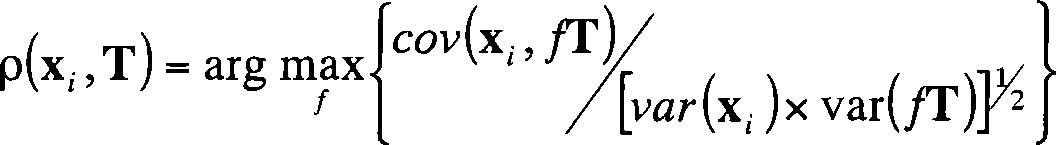

Fault separation technique for chemical production abnormal sub-domain

InactiveCN101477372AReflect characteristicsReflect appearanceElectric testing/monitoringData informationStatistical analysis

The invention relates to a technical method for separating abnormal subdomain fault in chemical production, which is a novel fault separating method and is realized by using statistical analysis theory. The method comprises the following steps: extracting a principal element from data information acquired by a process; classifying data into information related with the principal element and information in weak relation with the principal element according to the correlation of a variable and the principal element; establishing a statistical process control limit for diagnosis of the fault respectively according to the two classes of data; determining a domain of normal data as a normal subdomain and a domain of abnormal data as an abnormal subdomain; and iterating the processes in the abnormal subdomain until the fault is converged to be separated. The method classifies the process data according to the correlation of the process data and a principal element array, can reflect characteristics and presentation of the fault information better, and improve relative accuracy and reliability of fault separation by statistical analysis. The method has the advantages of advanced technique, theoretical principle existence, and strong actual application and operability.

Owner:SHENYANG INSTITUTE OF CHEMICAL TECHNOLOGY

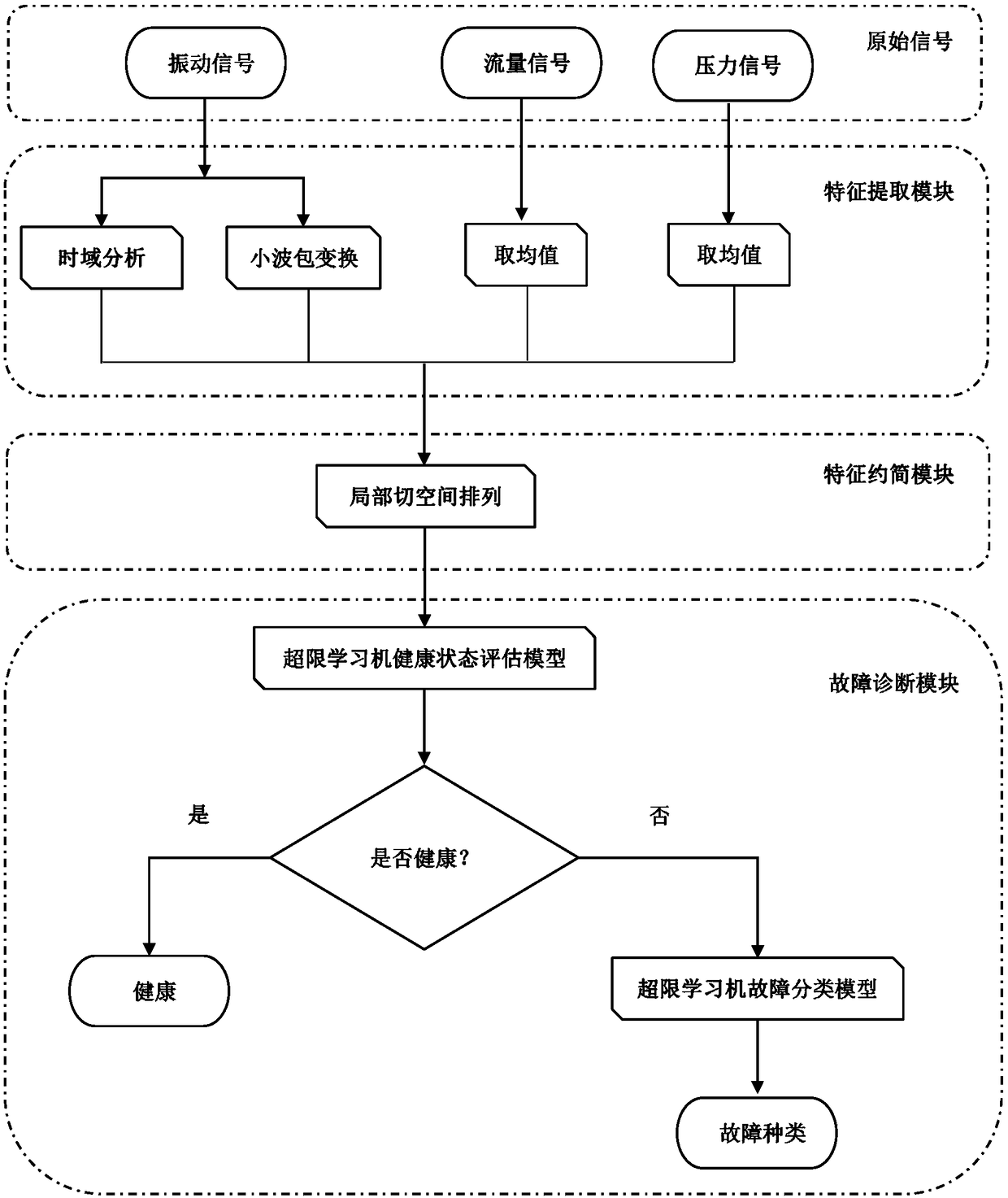

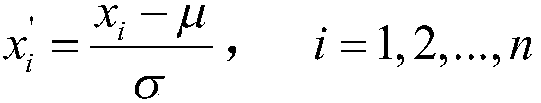

Method for diagnosing multiple faults of hydraulic pumps on basis of extreme learning machines

InactiveCN108153987AReflect characteristicsFew parametersDesign optimisation/simulationSpecial data processing applicationsFault toleranceFeature extraction

The invention discloses a method for diagnosing multiple faults of hydraulic pumps on the basis of extreme learning machines. The method for diagnosing the multiple faults of the hydraulic pumps is implemented by a feature extraction module, a feature reduction module and a fault diagnosis module. The method includes sequentially carrying out feature extraction, feature reduction and fault diagnosis on vibration signals, outlet flow signals and outlet pressure signals of an optional pump case to ultimately diagnose the multiple faults of the hydraulic pumps. The method for diagnosing the multiple faults of the hydraulic pumps has the advantages of reliable, accurate and simple diagnosis, high robustness and fault tolerance, good generalization capacity and the like.

Owner:TAIYUAN UNIV OF TECH

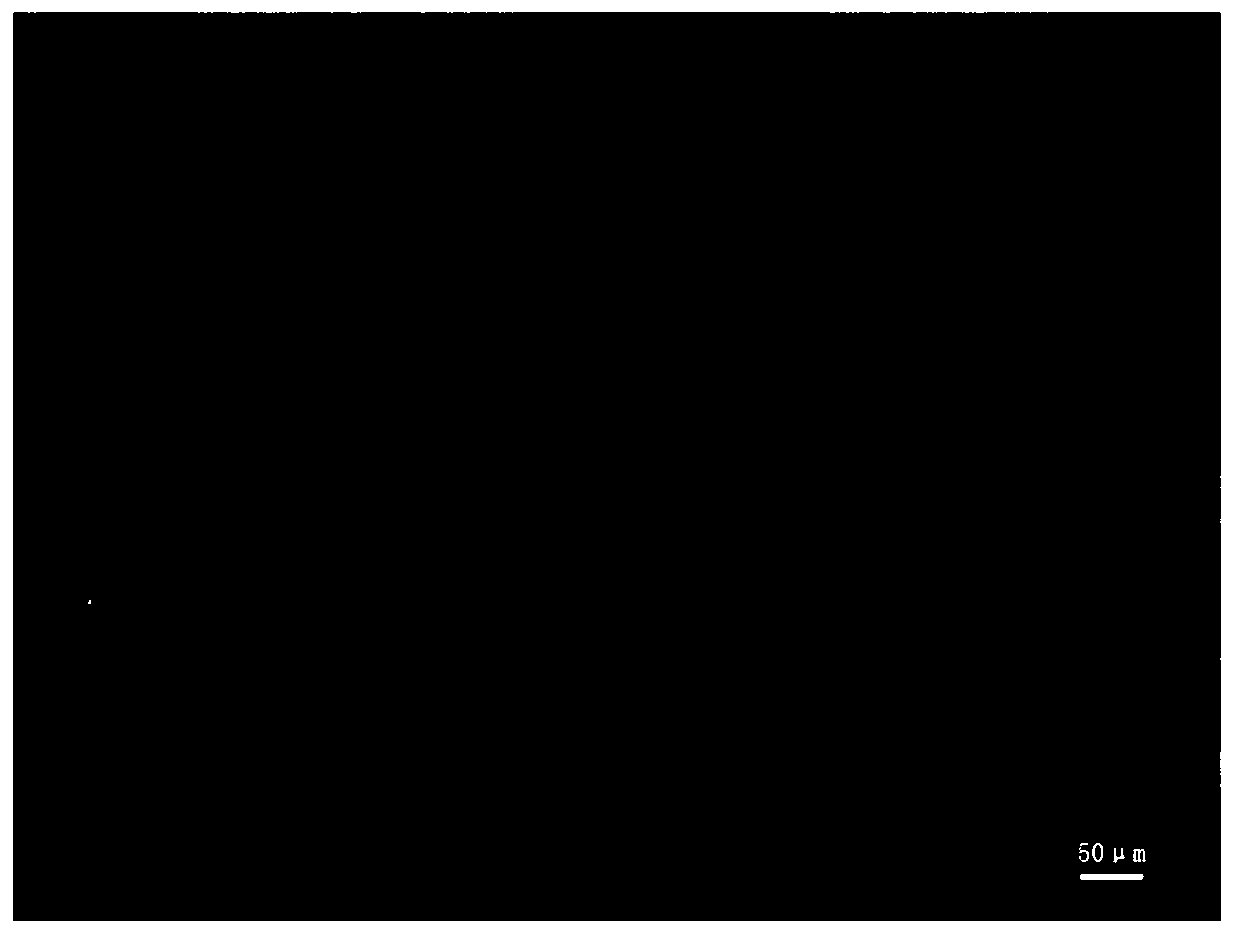

3D culture system of primary tumor cells, and culture method and application of 3D culture system

ActiveCN110607279AAchieve superior growthReflect characteristicsMicrobiological testing/measurementCulture processCell-Extracellular Matrix3D cell culture

The invention provides a 3D culture system of primary tumor cells, and an application of the 3D culture system. The 3D culture system comprises lower layer gelatin, a middle layer cell substrate and an upper layer culture medium, wherein the middle layer cell substrate comprises improved agarose gel, a condition culture medium containing addition factors and tumor cells; the improved agarose gel comprises low melting-point agarose, polylysine and an extracellular matrix; the lower layer gelatin comprises agarose gel and a conditioned medium; and the upper layer culture medium is the conditionculture medium containing the addition factors. The 3D culture system provided by the invention can screen tumor cells and normal epithelial cells, besides, can realize preferential growth of the tumor cells, is high in culture success rate, can really reflect the properties of entire tumor cell groups, and can accurately represent the growth condition of in vivo tumors, and after the 3D culture system is used for medicine susceptibility detection, the obtained results are high in reliability, and clinical promotion is facilitated.

Owner:SHENZHEN YOUSHENGKANG MEDICAL LAB CO LTD

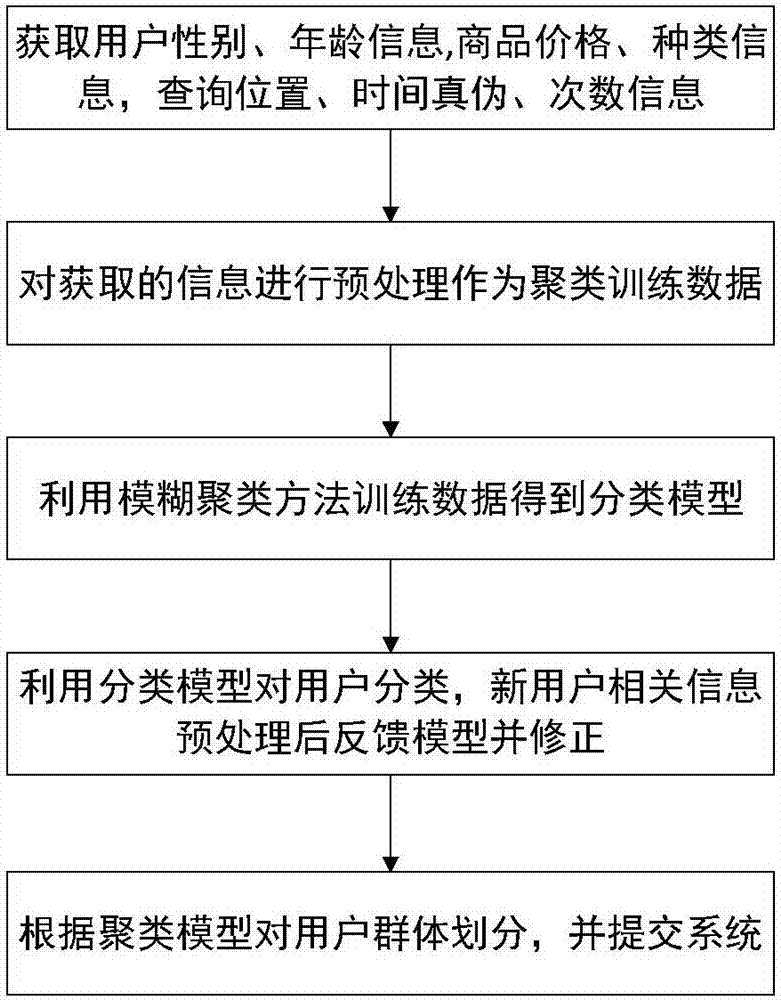

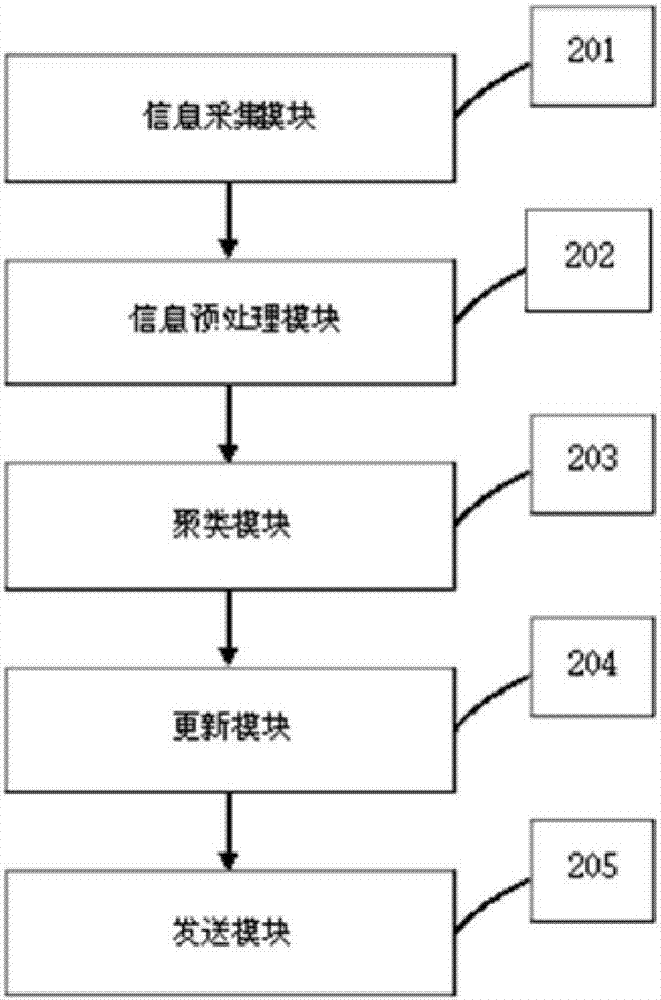

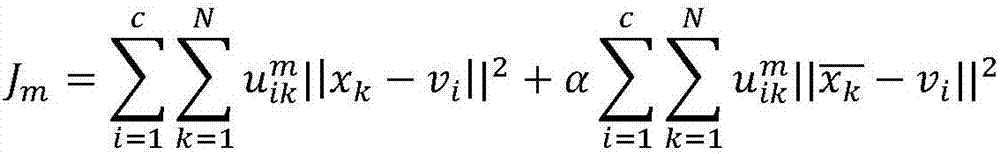

User group division method based on anti-fake traceability system and system thereof

InactiveCN107220831AFully excavatedTargetedCharacter and pattern recognitionMarket data gatheringLibrary scienceUser group

The invention provides a user group division method based on an anti-fake traceability system and a system thereof. A user inquires commodity authenticity through the anti-fake traceability system. Through combining characteristic information of the user, characteristic information of a commodity, and query information, a user group is divided so that later marketing of a merchant and manufacturer production possess pertinence. Information acquired by the anti-fake traceability system is fully excavated and system creativity is increased.

Owner:SYSU CMU SHUNDE INT JOINT RES INST +1

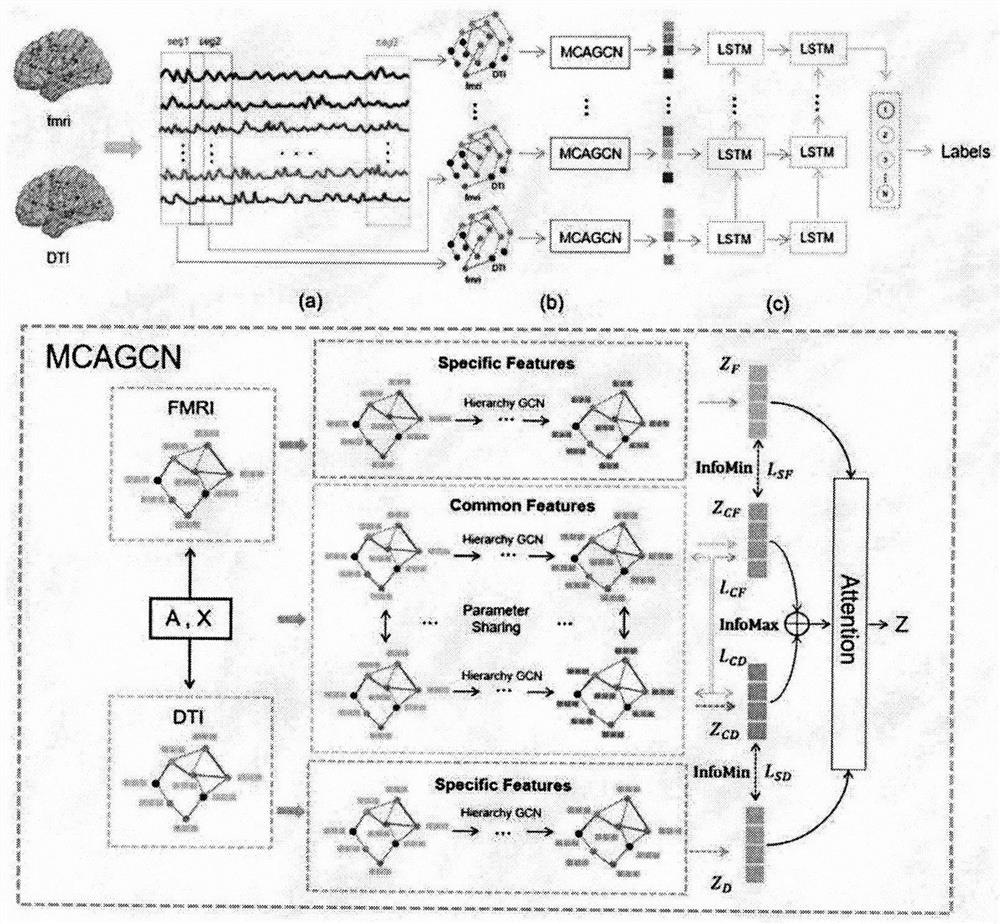

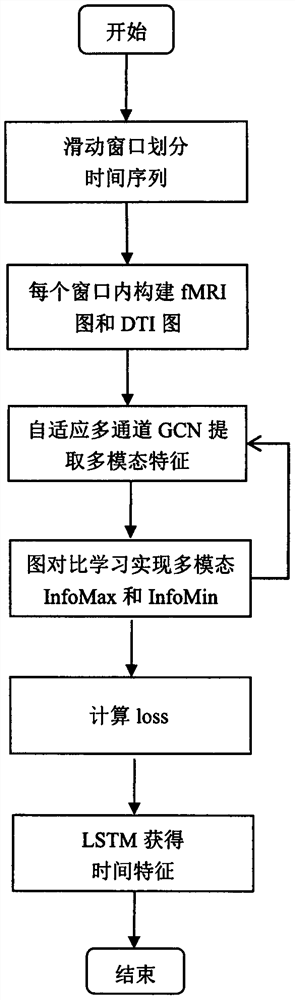

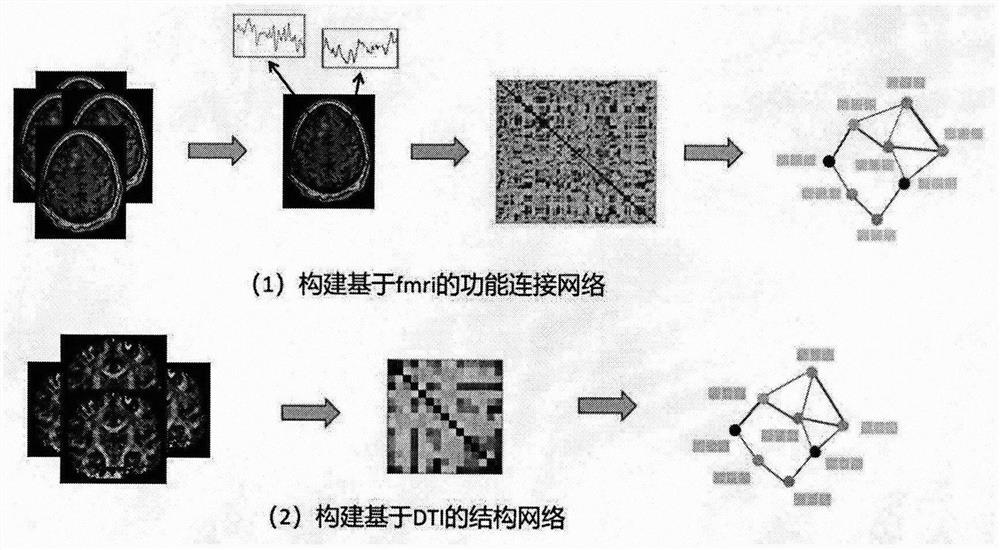

Adaptive multi-channel graph convolutional network of joint graph contrast learning

PendingCN114299006AEffective digging timeEffective Mining FeaturesImage analysisCharacter and pattern recognitionBrain networkComputer science

The invention discloses a self-adaptive multi-channel graph convolutional network method combined with graph contrast learning. Multi-modal big data is often composed of multiple data of different structural forms, and the data often have the characteristics of complementarity, mutual verification and fusion. How to accurately and efficiently extract complementary information among multi-modal data is a main target of multi-modal research. However, most of methods for performing multi-mode fusion only pay attention to complementary information among multiple modes at present, but often neglect specific information under a single mode. In addition, how to extract abundant and distinctive expressions from multiple modes by using a graph convolutional network is rarely researched at present. Therefore, the invention discloses a self-adaptive multi-channel graph convolutional network method combined with graph contrast learning, a framework takes brain network research as a background, time and space information of a brain network can be mined, and unique and shared features of multiple modes can be effectively fused.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

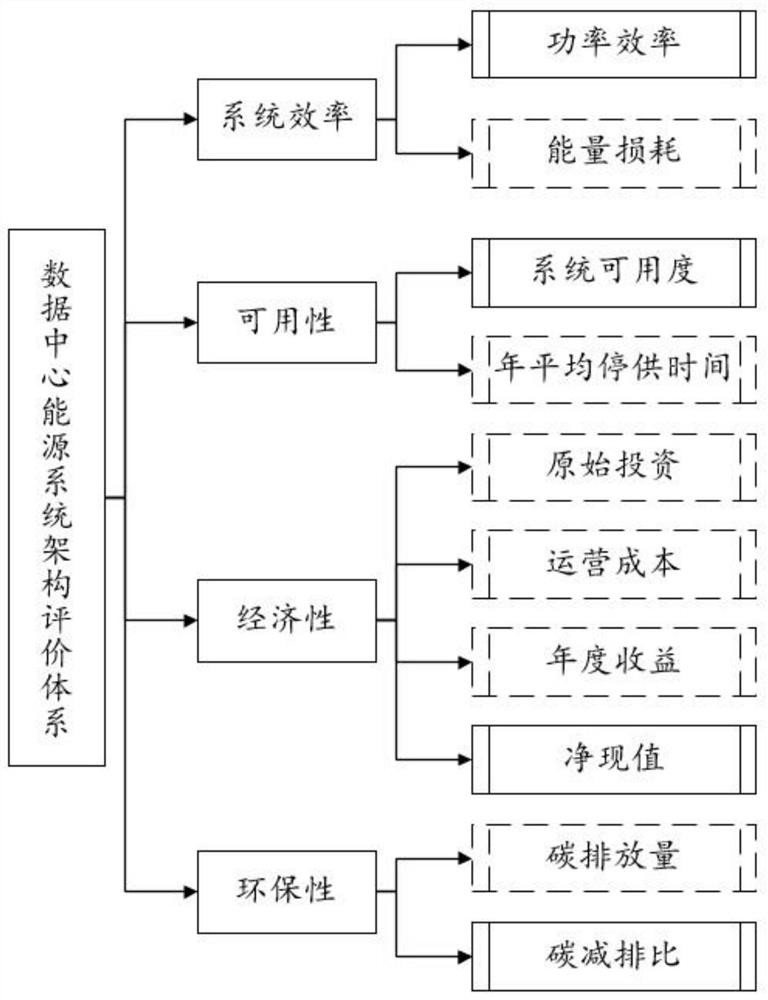

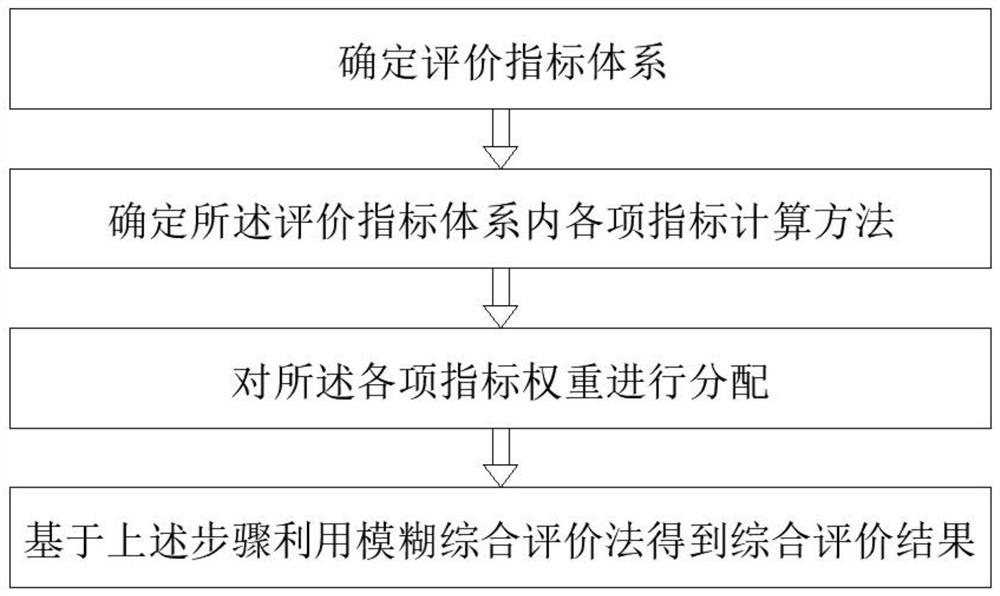

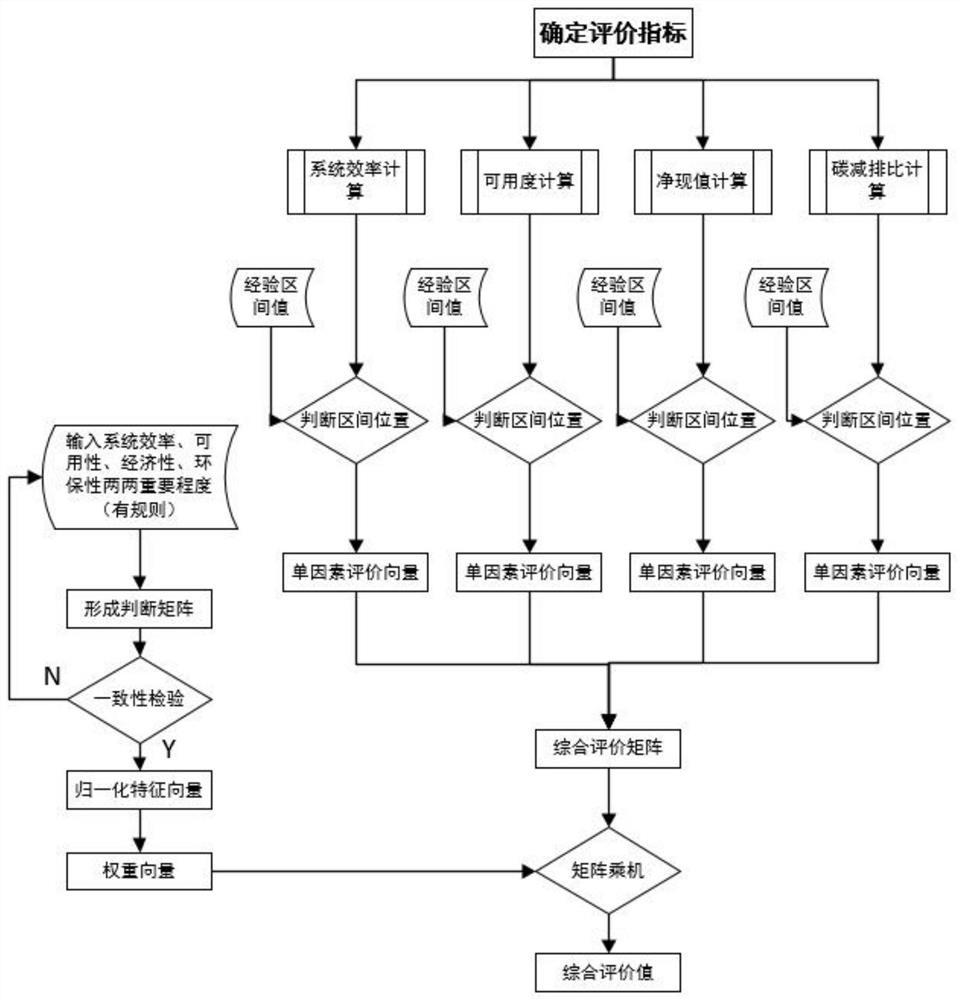

Data center energy system comprehensive evaluation method

PendingCN112561319AReflect characteristicsComprehensive evaluationTechnology managementFuzzy logic based systemsEvaluation resultEngineering

Disclosed is a comprehensive evaluation method for a data center energy system, common evaluation indexes of an existing data center are comprehensively considered, four evaluation indexes suitable for the data center energy system are selected, and the characteristics of the data center energy system can be comprehensively reflected; meanwhile, a specific calculation method of each evaluation index is given, a quantitative calculation result can be obtained, and single-factor evaluation on each index is obtained according to an expert experience method; an index weight value by using a methodof'analytic hierarchy process + fuzzy comprehensive evaluation method ', is determined and a comprehensive evaluation result is acquired. And finally, comprehensive, scientific and reasonable evaluation on the energy system architecture is realized.

Owner:TSINGHUA UNIV +1

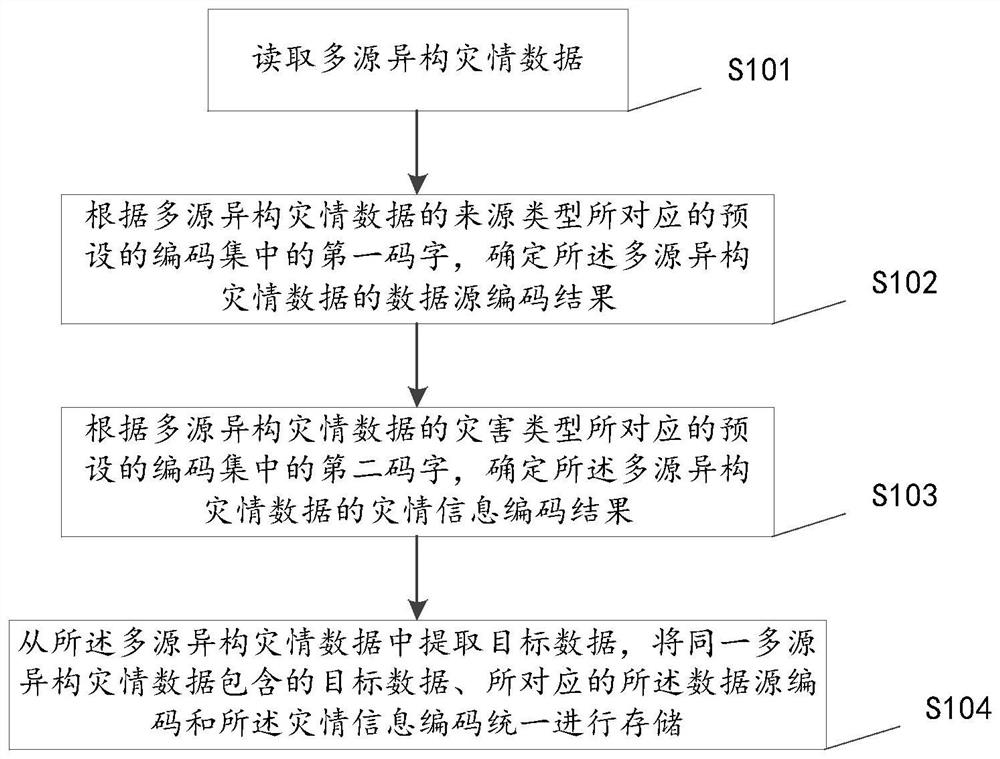

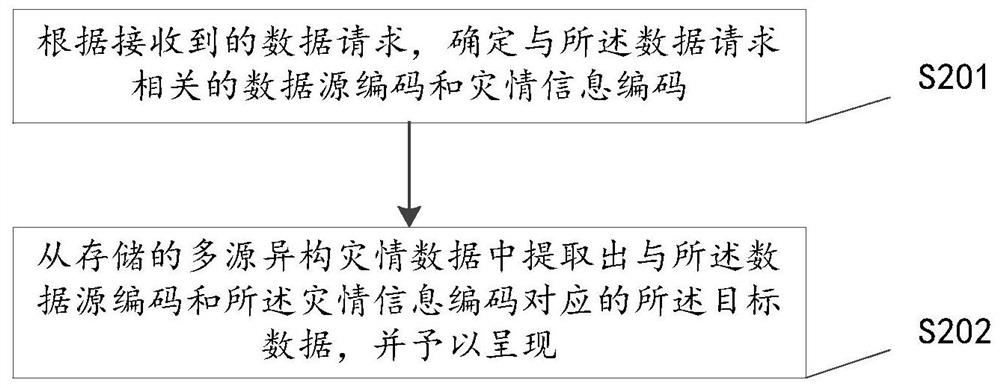

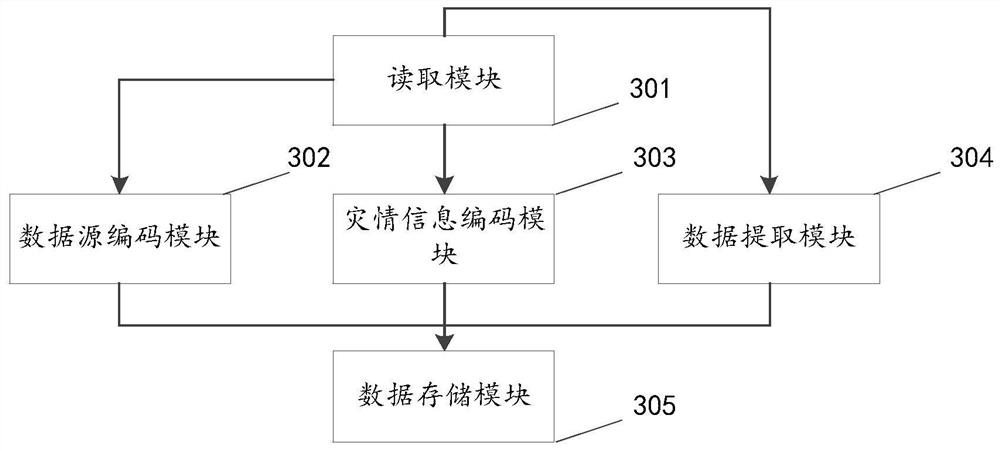

Multi-source heterogeneous disaster data processing and presenting method and device

PendingCN111680021AEasy to organizeOrganized presentationDatabase management systemsNatural language data processingData OriginSource encoding

One or more embodiments of the invention provide a multi-source heterogeneous disaster data processing and presenting method and device; the method includes determining A data source coding result according to a data source type; according to disaster types in the data, determining a disaster information coding result; extracting target data from the multi-source heterogeneous disaster data; storing the target data, the data source code and the disaster information code in a unified manner; building the relevance among the target data, the data source and the disaster information; according tothe invention, the characteristics and attributes of disaster data of different sources and different disaster types can be reflected more comprehensively; source information and disaster informationof the multi-source heterogeneous disaster data are completely stored as much as possible in a coding mode; unified fusion of the heterogeneous disaster information and the heterogeneous disaster information is achieved, and the multi-source heterogeneous disaster data can be managed and presented more orderly.

Owner:BEIJING UNIV OF POSTS & TELECOMM

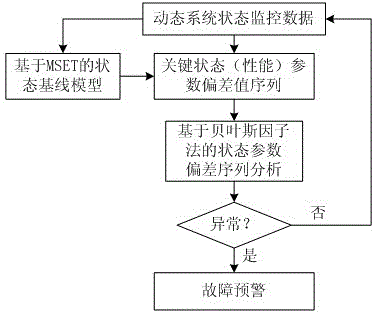

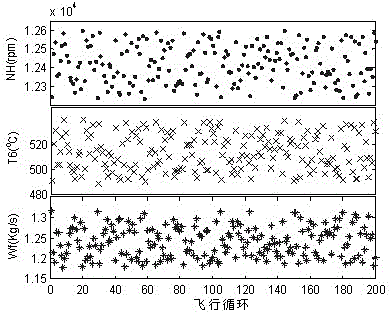

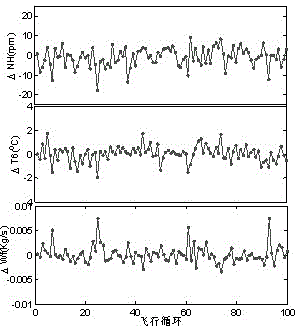

System failure early warning method based on baseline model and Bayesian factor

ActiveCN102880170BGet rid of dependenceSimple modelElectric testing/monitoringAdaptive controlState parameterSystem failure

The invention discloses a system failure early warning method based on a baseline model and the Bayesian factor. The system failure early warning method based on the baseline model and the Bayesian factor can be applied to a dynamic complex system and particularly applied to early detection and warning of aerospace vehicle equipment failure. The method includes: using the multivariate state estimation technique to excavate the system 'individuation' baseline model on the basis of system state monitoring data; and using an actual measurement value of a system state parameter to subtract a baseline value so as to obtain a deviation value of a state parameter, analyzing a deviation value sequence by the aid of a Bayesian factor method, monitoring abnormalities of a sequence structure, and timely giving out failure early warning. The system failure early warning method based on the baseline model and the Bayesian factor solves the problems that dynamic complex system performance parameter deviation value dispersion is large, failure early characteristics are easily buried in noise, warning can be given out at the early stage of system failure, and sensitivity and robustness of the monitoring system are improved. Besides, the baseline model is easy to implement from the perspective of engineering, and the method is high in university and capable of meeting the requirements of the dynamic system on real-time monitoring.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

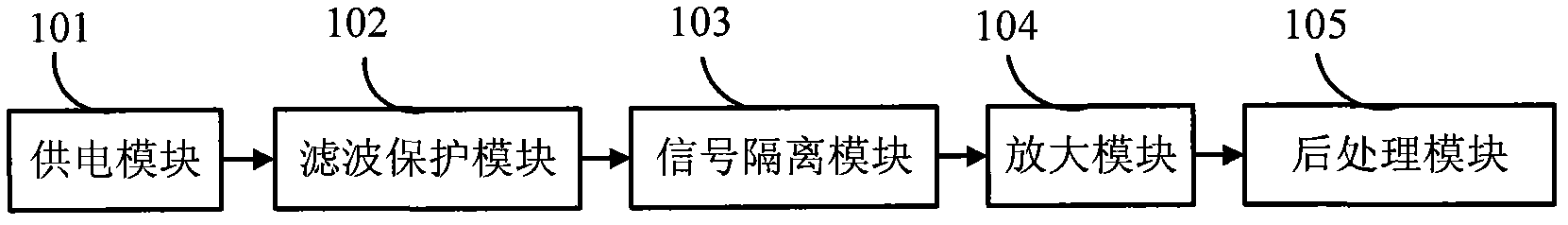

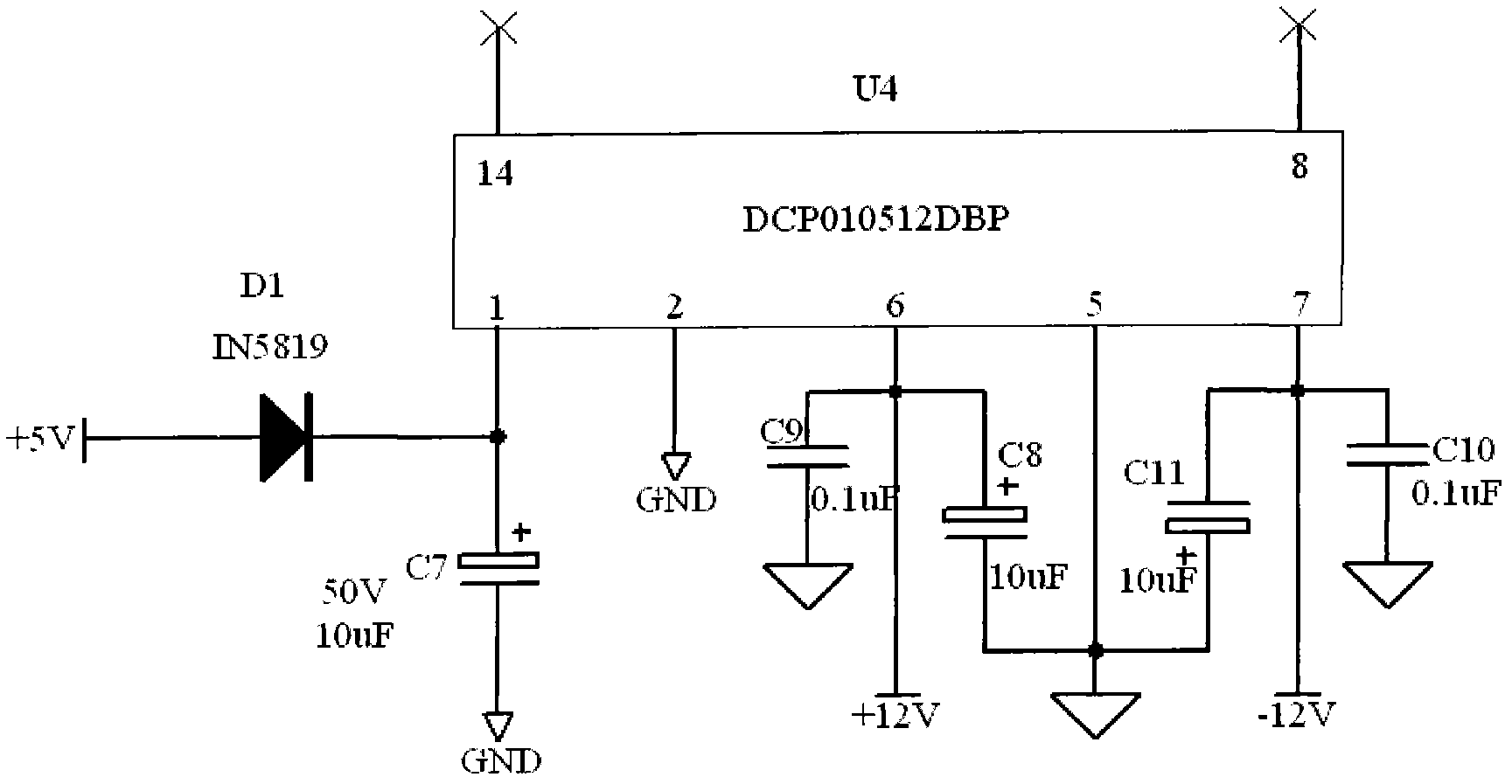

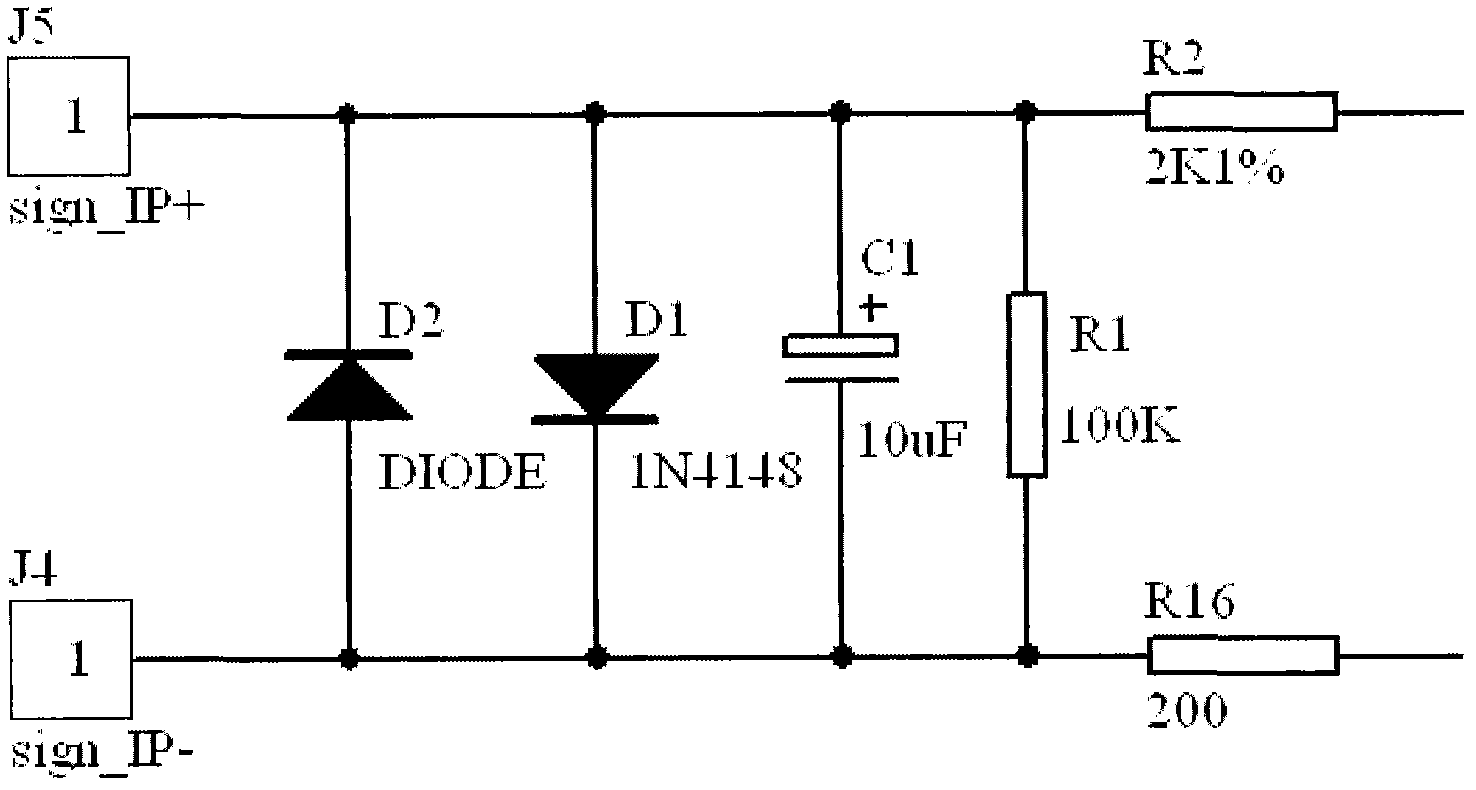

Signal isolation and amplification device

InactiveCN102064779AEffective isolationAchieve isolationAmplifier combinationsEngineeringSignal processing

The invention discloses a signal isolation and amplification device. The device comprises a power supply module, a filter protection module, a signal isolation module and an amplification module, wherein the power supply module is used for ground isolation of a power supply and voltage transformation of power supply voltage provided by the power supply; the filter protection module is connected with the power supply module and used for voltage limiting protection and filter of the transformed power supply voltage; the signal isolation module is connected with the filter protection module and used for signal isolation and zero point correction of the signals processed by the filter protection module; and the amplification module is connected with the signal isolation module and used for amplification of the signals processed by the signal isolation module. The signal isolation and amplification device has low temperature drift, low null drift and high precision, and is suitable for isolation and amplification of the high-precision signals in a semiconductor single crystal silicon furnace signal acquisition process.

Owner:BEIJING JINGYI CENTURY ELECTRONICS

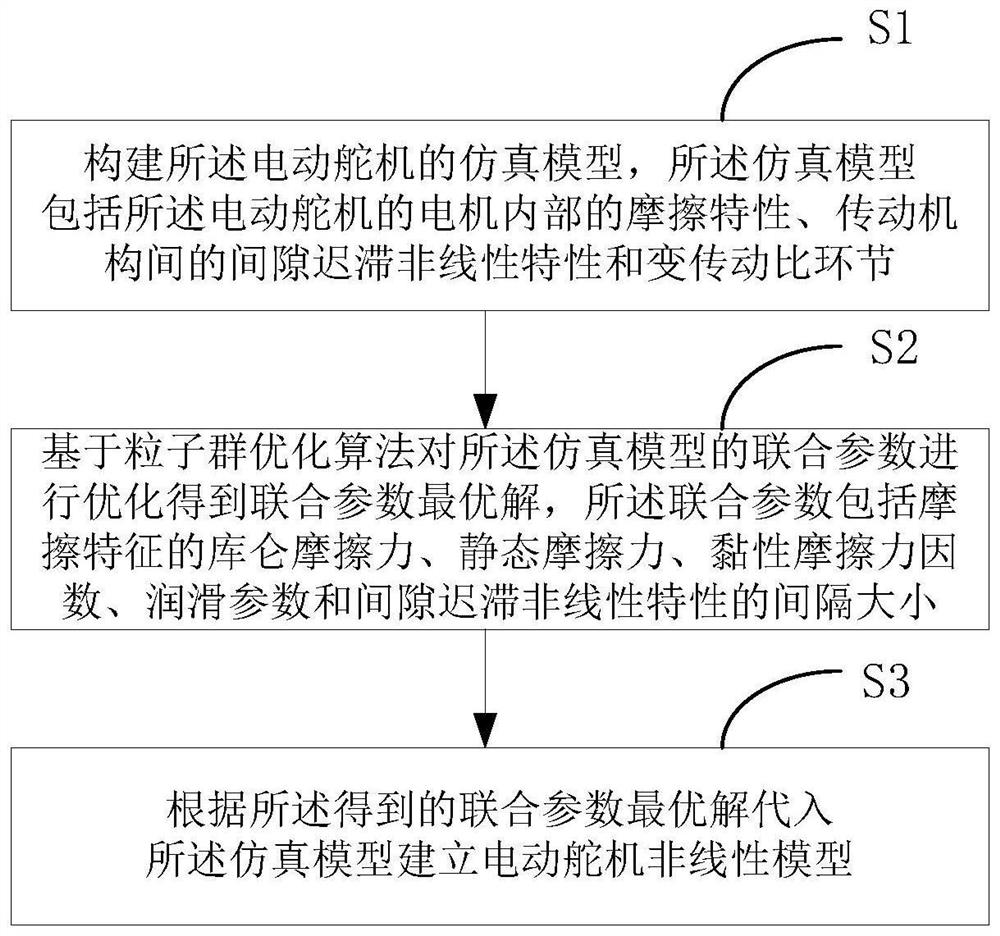

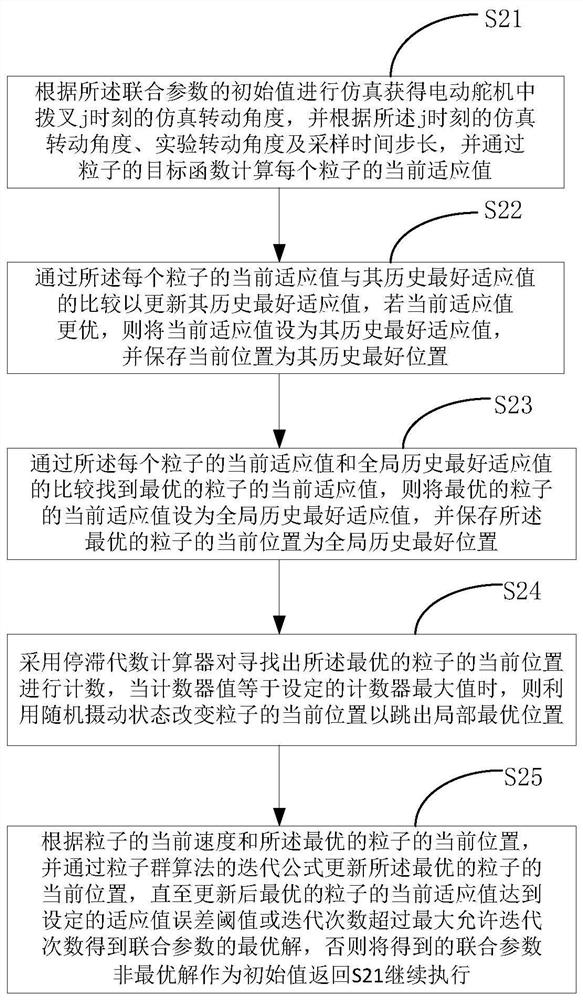

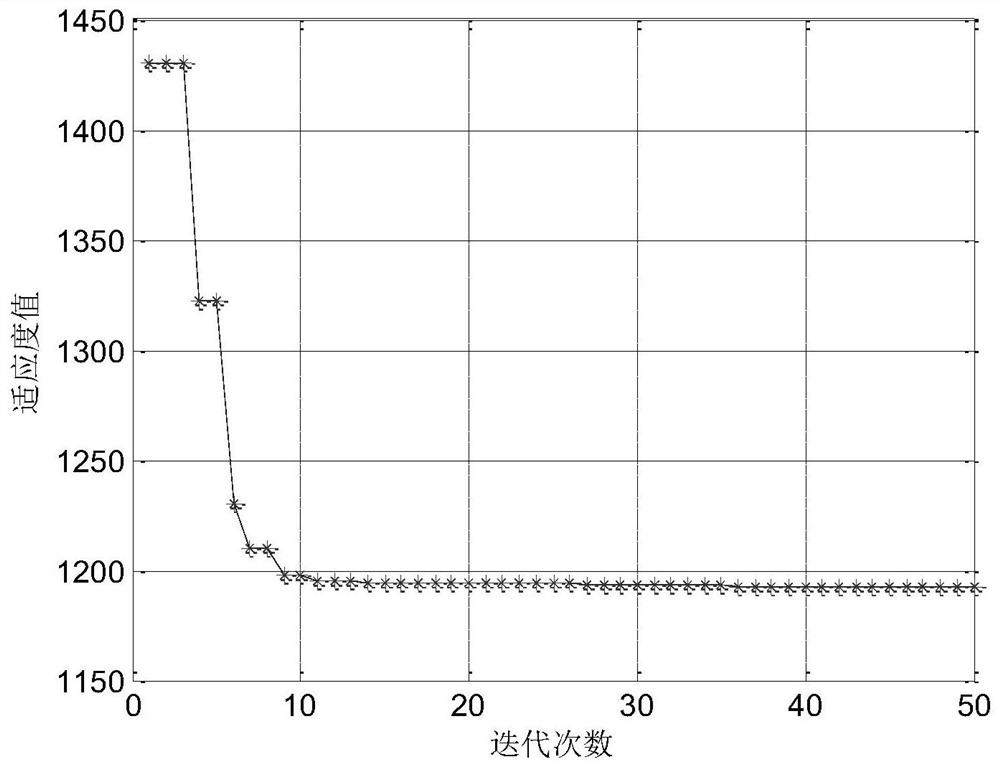

Method for establishing electric steering engine nonlinear model based on particle swarm optimization algorithm

ActiveCN113704949AAvoid local optimaReflect characteristicsInternal combustion piston enginesArtificial lifeNonlinear modelModelSim

The invention relates to a method for establishing an electric steering engine nonlinear model based on a particle swarm optimization algorithm, and belongs to the technical field of motor control. The method comprises the following steps: S1, constructing a simulation model of the electric steering engine, wherein the simulation model comprises a friction characteristic in a motor of the electric steering engine, a gap hysteresis nonlinear characteristic between transmission mechanisms and a variable transmission ratio link; s2, optimizing joint parameters of the simulation model based on a particle swarm optimization algorithm to obtain an optimal solution of the joint parameters, wherein the joint parameters comprise coulomb friction force Fc of friction characteristics, static friction force Fs, a viscous friction force factor B, a lubrication parameter omega s and an interval size b of gap hysteresis nonlinear characteristics; and S3, substituting the obtained joint parameter optimal solution into the simulation model to establish an electric steering engine nonlinear model. According to the invention, the problem that the model cannot truly reflect the characteristics of a modeling object due to poor accuracy of a simulation model in traditional electric steering engine modeling is solved.

Owner:BEIJING MECHANICAL EQUIP INST

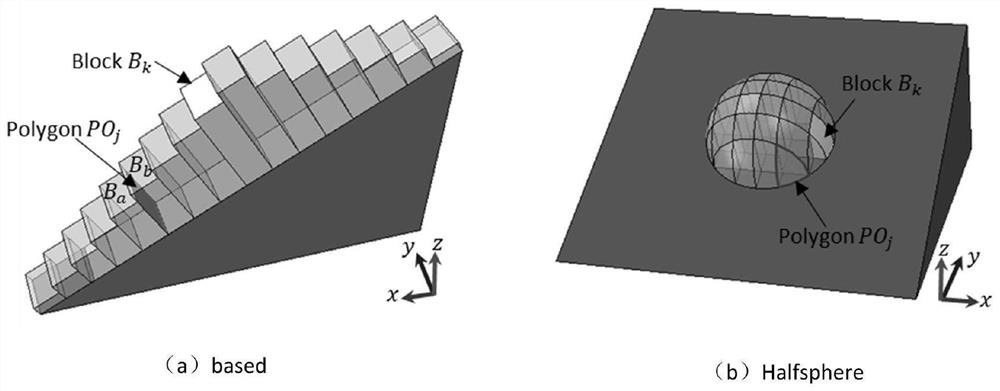

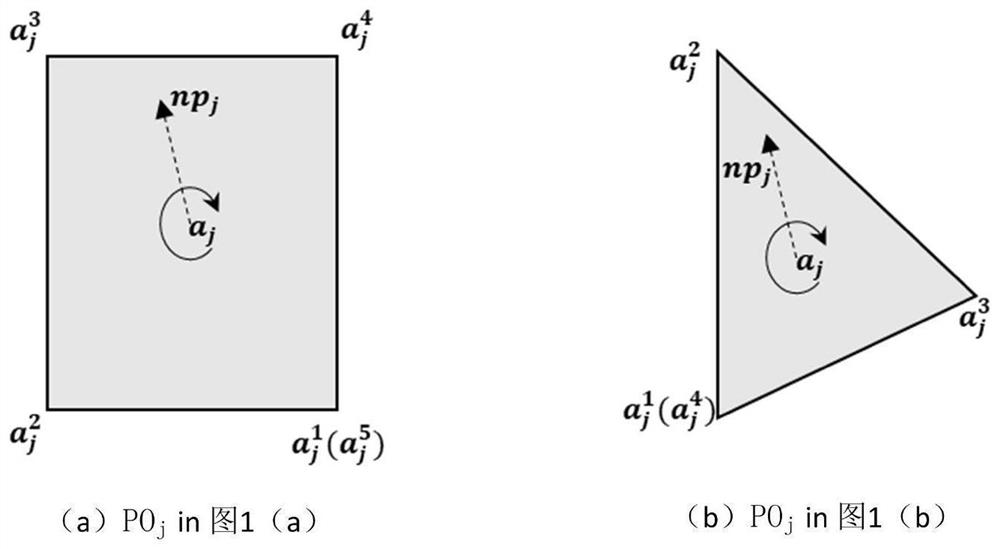

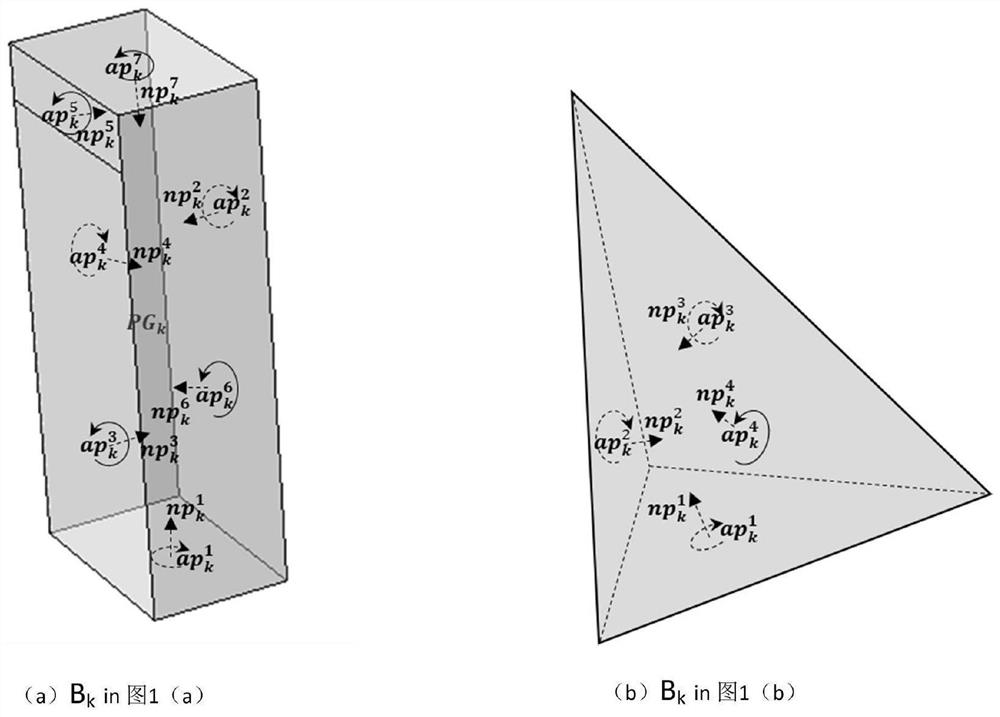

Three-dimensional analysis method for stability of toppled rock slope

PendingCN112231898AReduce mistakesReflect characteristicsClimate change adaptationDesign optimisation/simulationSlope stability analysisClassical mechanics

The invention belongs to the field of rock slope stability analysis, and particularly relates to a three-dimensional analysis method for the stability of a toppled rock slope, which comprises the following steps: defining a toppled body, performing block division on the toppled body, and establishing a block system which comprises at least one block; establishing a force balance equation and a moment balance equation of the block body; constructing a standard optimization model by taking the force balance equation and the moment balance equation of the block body as constraint conditions, andcalculating the slope stability safety coefficient of the toppling body through the standard optimization model. On the basis of a force and moment balance equation, a boundary meeting a yield condition inequality equation is taken as a constraint condition, and the maximum value of a slope stability safety coefficient is taken as a target function, so that three-dimensional analysis of the stability of the toppled rock slope is converted into optimization solution, errors are reduced, and the mechanical characteristics and the stability characteristics of the three-dimensional analysis of thestability of the toppled rock slope can be better reflected.

Owner:CHINA INST OF WATER RESOURCES & HYDROPOWER RES

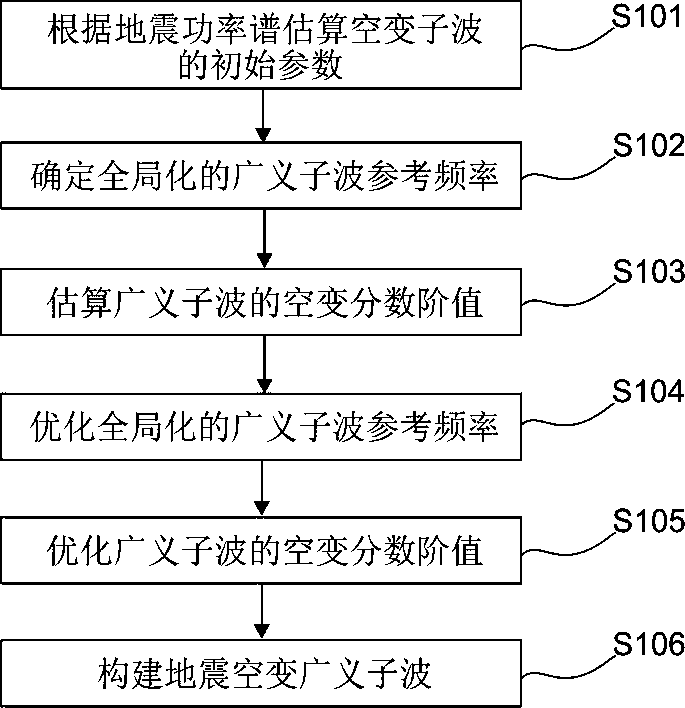

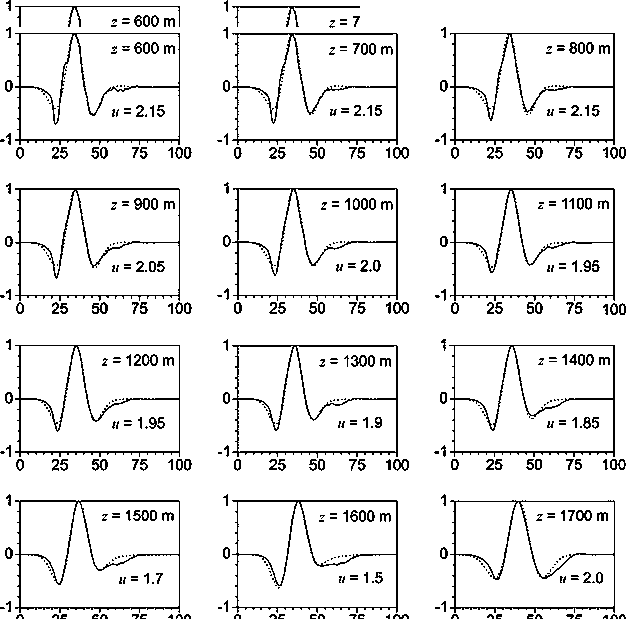

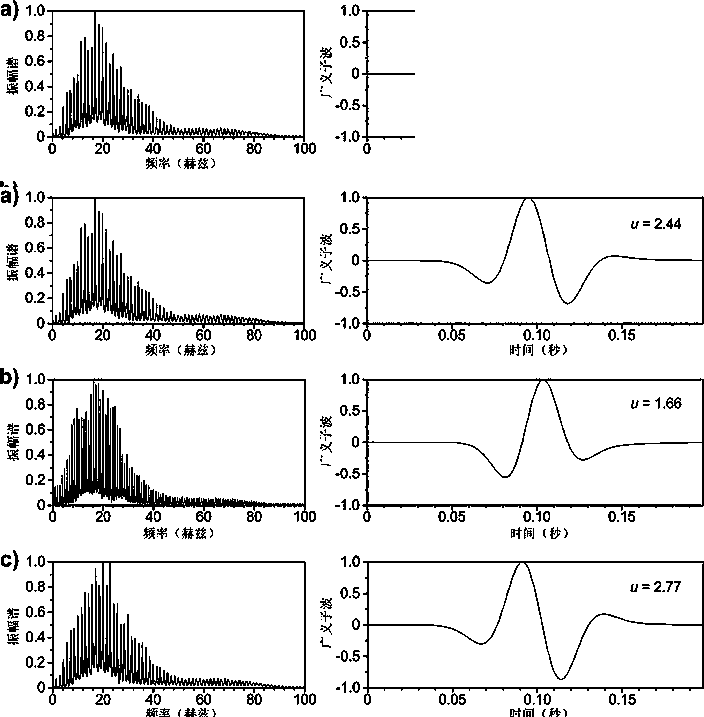

Seismic data space-variant generalized wavelet extraction method

ActiveCN111427080ATruly reflect attenuationTrue reflection of phase distortionSeismic signal processingPhase distortionGeophysics

The invention relates to a seismic data space-variant generalized wavelet extraction method, and aims to solve the problem that seismic wavelets extracted in the prior art cannot truly reflect energyattenuation, phase distortion and spatial change characteristics of seismic signals, and the method comprises the following steps: (1) estimating initial parameters of space-variant wavelets accordingto a seismic data power spectrum; (2) determining a global generalized wavelet reference frequency; (3) estimating a space-variant fractional order value of the generalized wavelet; (4) optimizing the global generalized wavelet reference frequency; (5) optimizing the space-variant fractional order value of the generalized wavelet; and (6) constructing a space-variant seismic generalized wavelet.The invention has the advantages that the extraction method is stable in operation and high in anti-noise capacity, the extracted seismic generalized wavelet is concise in form, and the extracted wavelet can truly reflect space-variant features such as absorption attenuation of seismic signals in the stratum medium propagation process.

Owner:王仰华

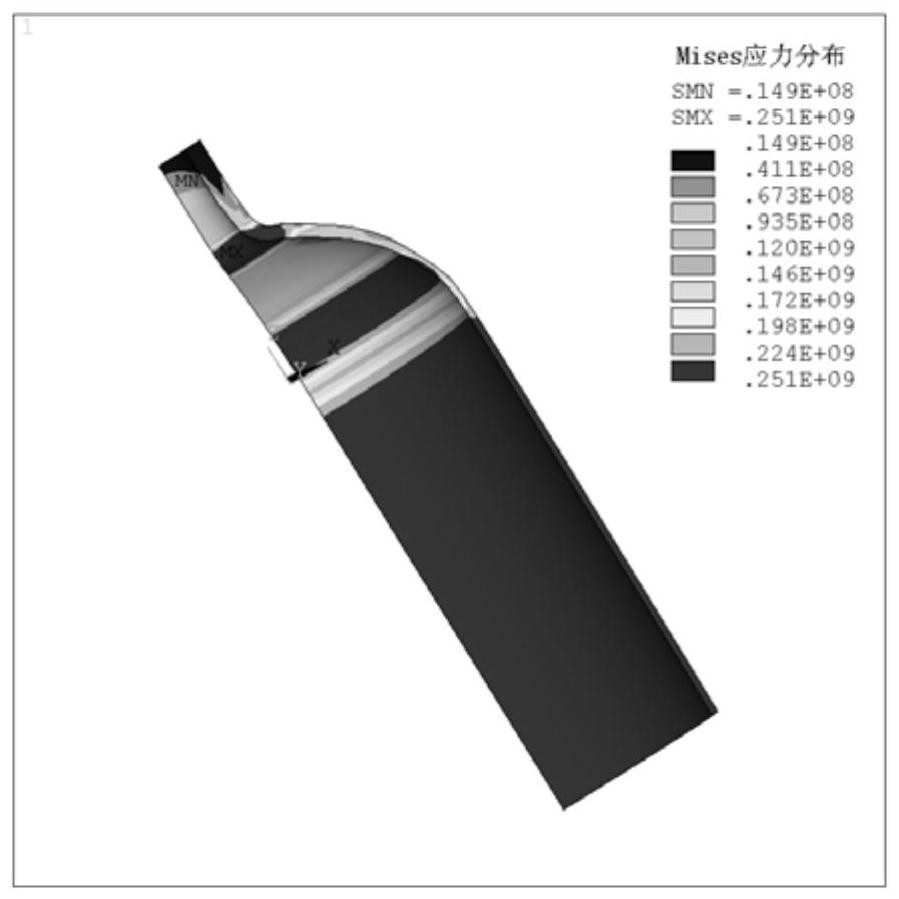

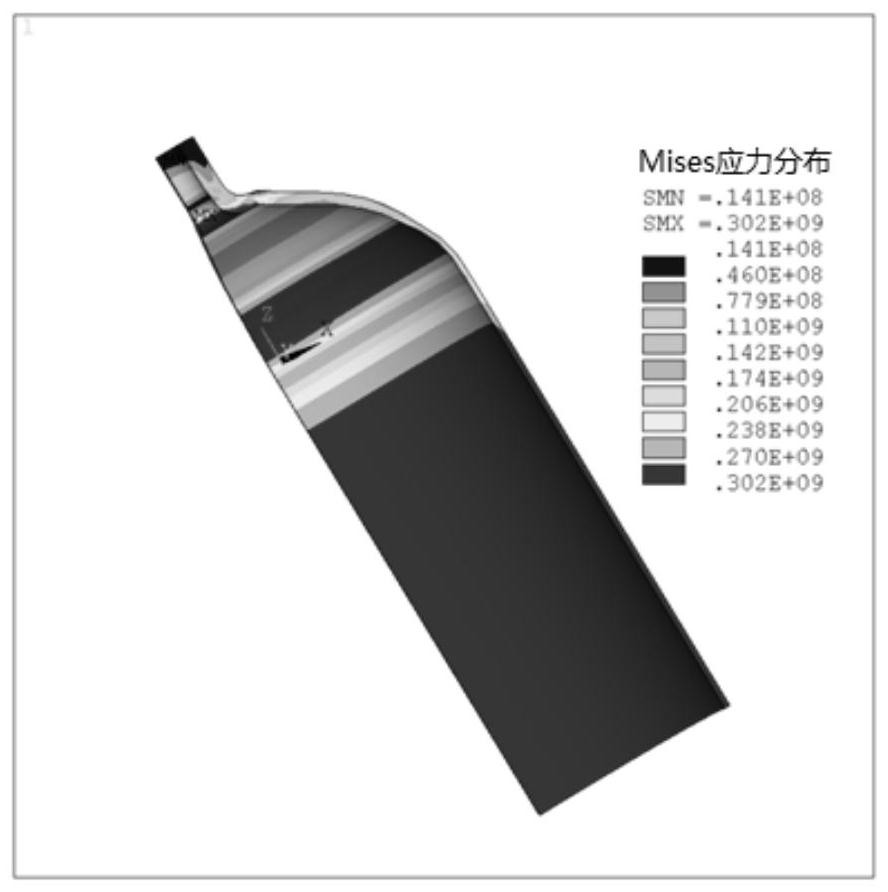

Low-temperature composite gas cylinder design method

ActiveCN112446112ARapid designImprove design efficiencyGeometric CADDesign optimisation/simulationElement modelThermodynamics

A low-temperature composite gas cylinder design method comprises the following steps: 1, designing laying parameters; 2, calculating the normal-temperature strength and the low-temperature strength ofthe gas cylinder by utilizing a grid theory, judging whether the normal-temperature strength and the low-temperature strength meet requirements or not, if not, returning to the step 1, and if yes, entering a step 3; 3, establishing a finite element model for the gas cylinder, calculating the stress state of the lining of the gas cylinder under normal temperature and low temperature working pressure, the stability of the lining under normal temperature and low temperature zero pressure and the stress in the fiber direction of the outermost layer of the winding layer under low temperature working pressure, and judging whether the Mises stress of the lining under normal temperature and low temperature working pressure does not exceed the yield limit of the material; judging whether the lining structure is complete and stable at normal temperature and low temperature and zero pressure; judging whether the stress in the fiber direction of the outermost layer of the winding layer is not greater than sigma d1 / n under low-temperature working pressure; if yes, the gas cylinder design meets the requirement; otherwise, if the design of the gas cylinder does not meet the requirements, redesign is needed. The design is comprehensive, and it can be guaranteed that the gas cylinder performance meets the requirement.

Owner:BEIJING INST OF ASTRONAUTICAL SYST ENG

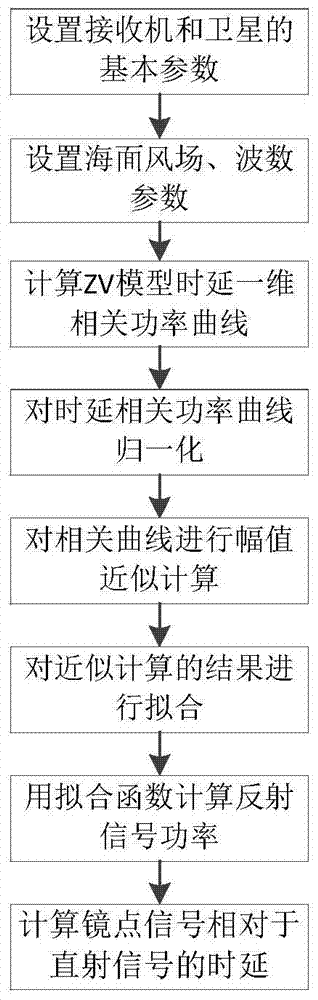

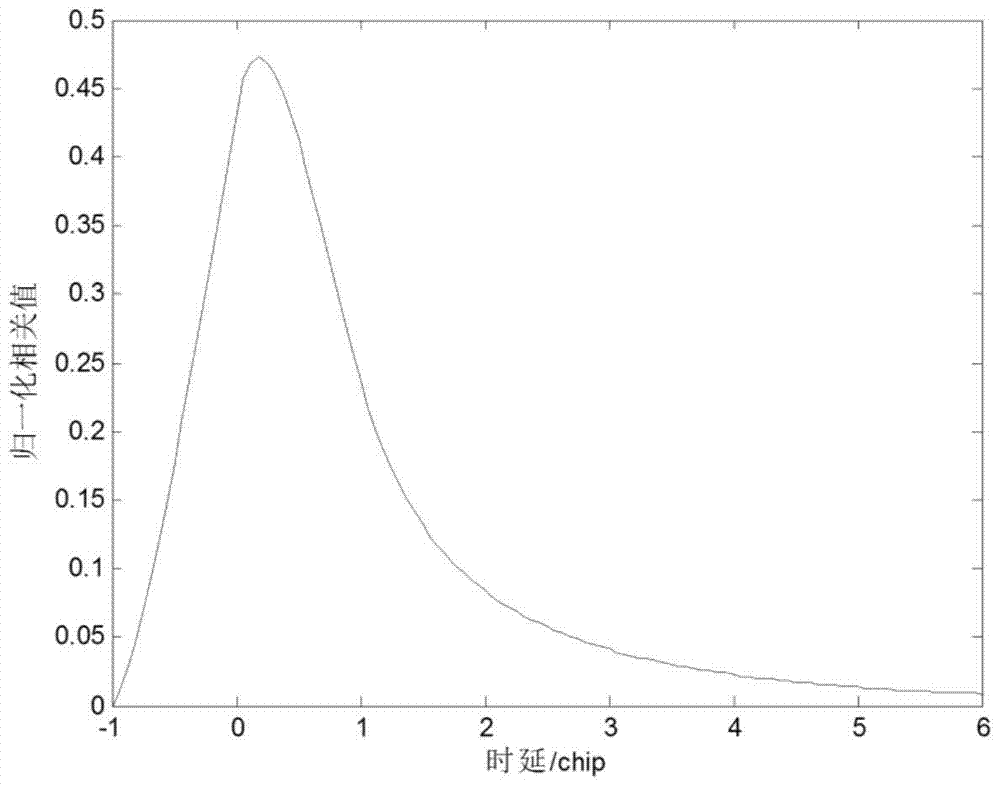

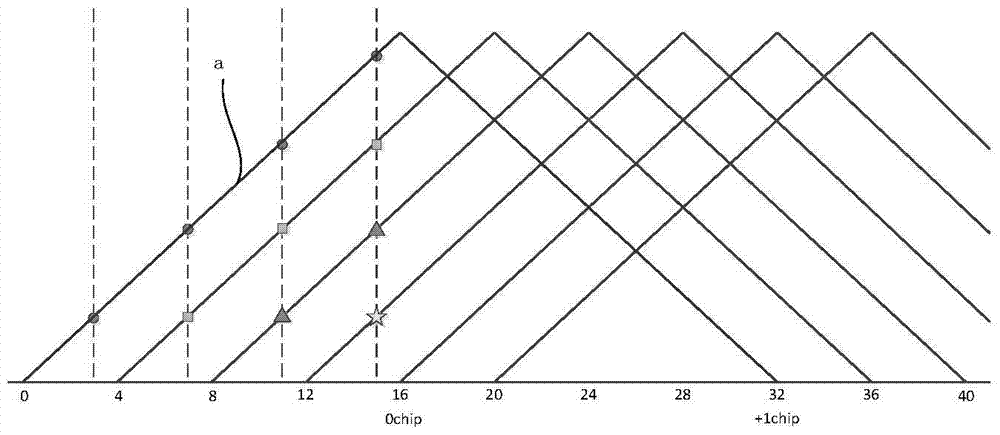

A method for generating airborne GNSS ocean reflection signals

InactiveCN105182308BSimplify complex phenomenaReflect characteristicsRadio wave reradiation/reflectionTime delaysOn board

The invention discloses an on-board GNSS marine reflection signal generation method. Marine reflection signals received by a GNSS receiver are in the form of the superposition of different time-delay reflection signals. Therefore, a time delay correlation curve of the marine reflection signals is formed through the superposition of the correlation curves of different time-delay reflection signals. Based on the above principle, it can be assumed that the amplitude values of n equal-delay-interval reflection signals are figured out based on the approximately fitting method, so that the powers of the reflection signals relative to direct signals can be further figured out. After that, the time delays of the n reflection signals relative to direct signals are figured out. The Doppler frequencies of the direct signals can be directly adopted as the Doppler frequencies of the reflection signals. In this way, the generation of GNSS marine reflection signals is realized based on the factors of time delay, Doppler frequency and power. The above generation method for complicated marine reflection signals is simplified based on the approximately fitting method, so that the simulation of the reflection signals is practicable and feasible. Therefore, the method lays a foundation for the development of GNSS reflection signal simulators.

Owner:BEIHANG UNIV

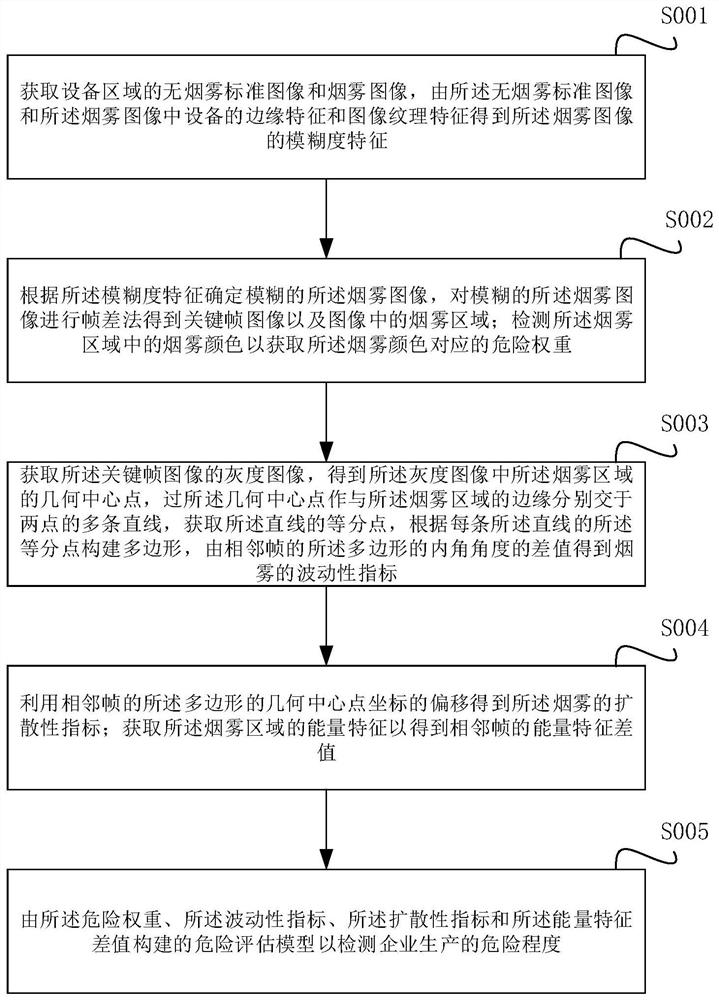

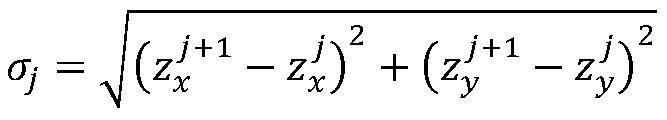

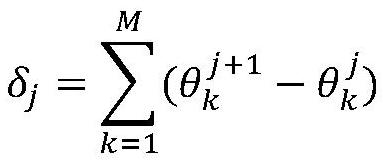

Chemical enterprise safety risk early warning method and system based on visual perception

PendingCN114155439AFast and Accurate FeaturesFast and accurate edge detail changesImage analysisCharacter and pattern recognitionVision basedSmoke Emission

The invention relates to the technical field of artificial intelligence, in particular to a chemical enterprise safety risk early warning method and system based on visual perception. The method comprises the following steps: acquiring a fuzzy smoke image according to ambiguity features, and detecting the smoke image to obtain a key frame image and a danger weight of a smoke color in the image; obtaining a geometric center point of the smoke area, drawing a plurality of straight lines through the geometric center point, obtaining equal division points of each straight line to construct a polygon, and obtaining a volatility index of smoke according to a difference value of interior angles of the polygon; obtaining the diffusivity index of the smoke according to the offset of the coordinates of the geometric center point, and obtaining an energy characteristic difference value according to the energy characteristics of the smoke area; and acquiring the danger degree by a danger evaluation model constructed by the danger weight, the volatility index, the diffusivity index and the energy characteristic difference value. By constructing the polygon of the smoke area, the dynamic change characteristics and edge detail changes of the smoke can be quickly and accurately reflected, the prediction result of the danger degree can be reduced, and dangerous accidents are avoided.

Owner:河南鑫安利安全科技股份有限公司

A 3D finite element modeling and simulation method for random particle size distribution in powder metallurgy

ActiveCN106777807BReflect characteristicsAccurate modelingDesign optimisation/simulationSpecial data processing applicationsElement modelElement modeling

The invention discloses a powder metallurgy random particle size distribution 3D (three-dimensional) finite element modeling and simulation method which includes the steps: firstly, acquiring the content and the particle size range of all components according to a powder metallurgy formula, calculating the average density of material particles according to the density and the content of different components, and acquiring the sizes and the number of the particles under a particle size belt; secondly, throwing the particles by PFC3D software, discretizing a random model and deriving throwing coordinates and particle sizes; thirdly, leading the coordinates and the particle sizes into ANSYS software and building a random 3D finite element model; fourthly, leading the finite element model into Hypermesh, dividing grids and finally loading a solver for finite element simulation to simulate the random model of a powder metallurgy random particle size distribution process. Main parameters include maximum particle size and minimum particle sizes. By making full use of randomization of discrete elements and strong analysis functions of finite elements, the model is visual, simple and high in practicability and conforms to application and research of present powder metallurgy in terms of sinter molding.

Owner:GUILIN GUIBEI MACHINE

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com