Omnibearing detection method for large-diameter aspherical mirror

An aspheric mirror and detection method technology, which is applied in the direction of measuring devices, optical instrument testing, and testing optical performance, can solve the problems of troublesome post-processing, high precision of auxiliary mirrors, and difficult production, and achieve convenient purchase, high precision, and low price Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

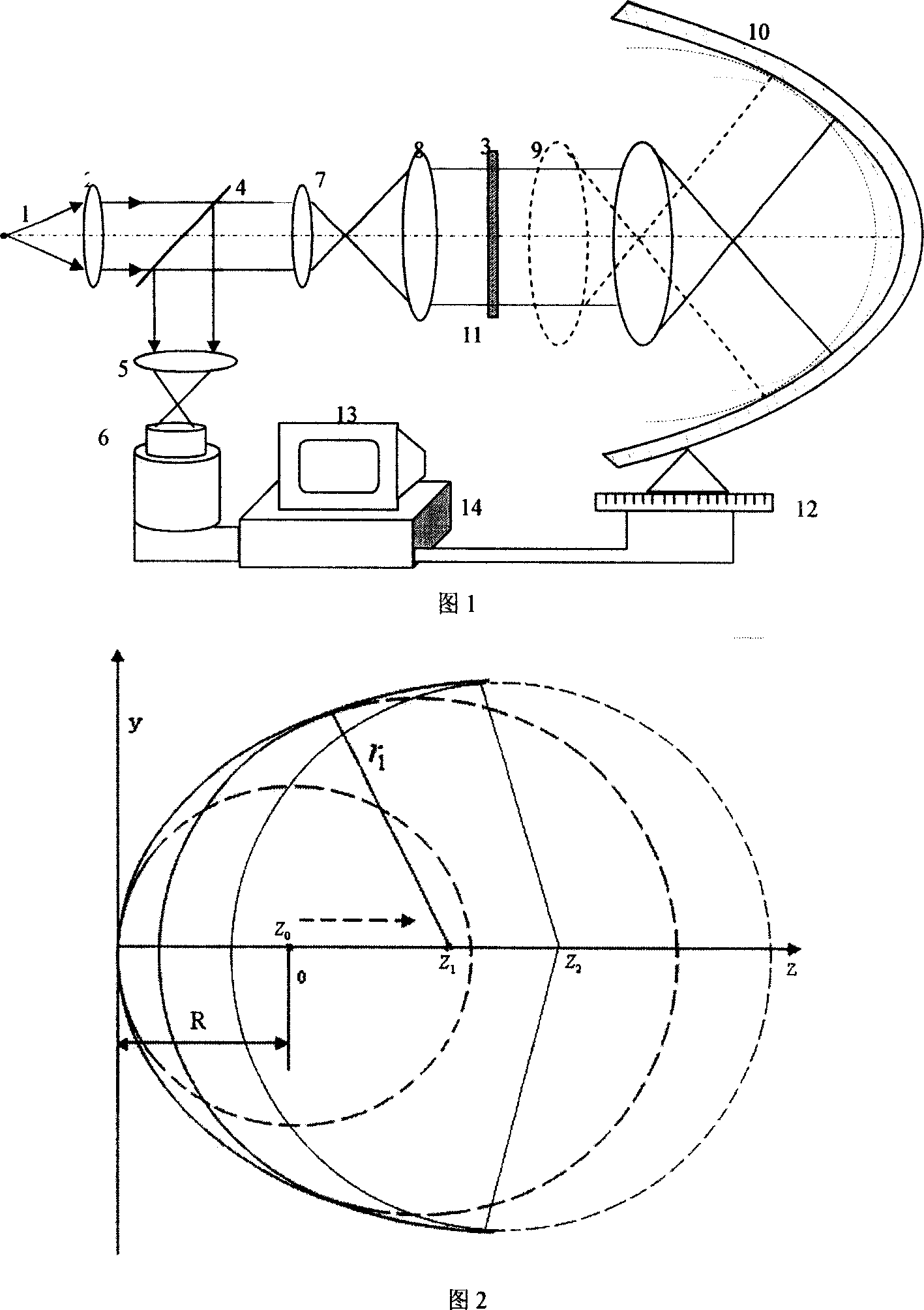

[0028]As shown in FIG. 1 , the system is mainly composed of an interferometer (such as a Fizeau interferometer), a spherical lens 9 , an aspheric mirror 10 to be tested, an electronically controlled translation stage 11 , a digital driver 12 and a computer system 14 . The interferometer is mainly composed of a laser light source 1 , a collimating lens 2 , a plane standard lens 3 , a beam splitting prism 4 , an imaging lens 5 and a CCD detector 6 . The standard spherical lens 9 is located between the interferometer and the measured aspheric mirror 10, and the optical axes of the three are on the same straight line. One of the implementation methods is to place the measured aspheric mirror 10 on an electronically controlled translation platform, and the computer system 14 controls it to move precisely in the direction of the optical axis through the digital driver 12, so that the measured aspheric mirror 10 is connected with the interferometer and the spherical surface. The sphe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com