Patents

Literature

134 results about "Viscous friction" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Uncertain mechanical arm fixed time track following control method with input saturation

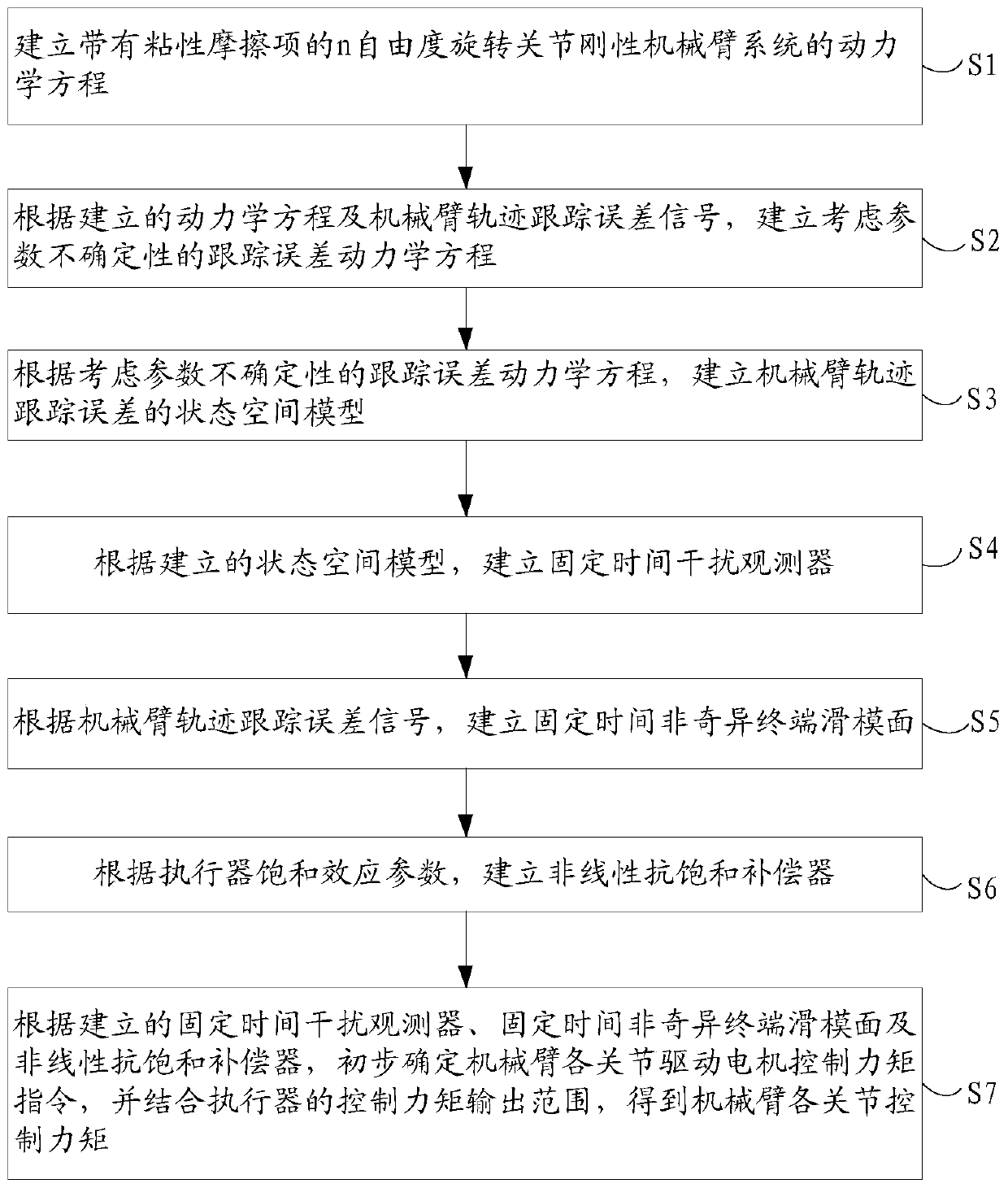

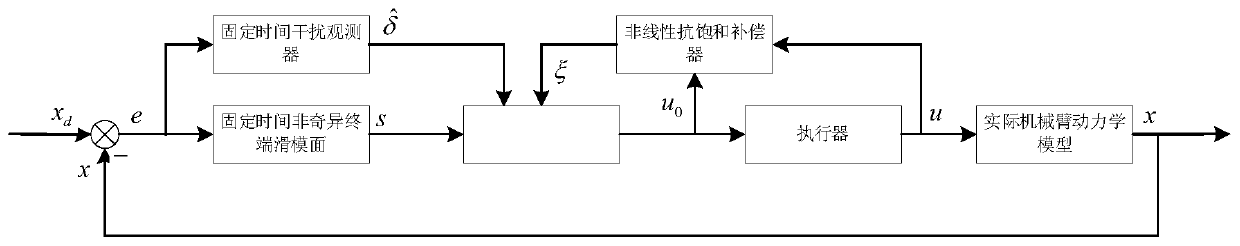

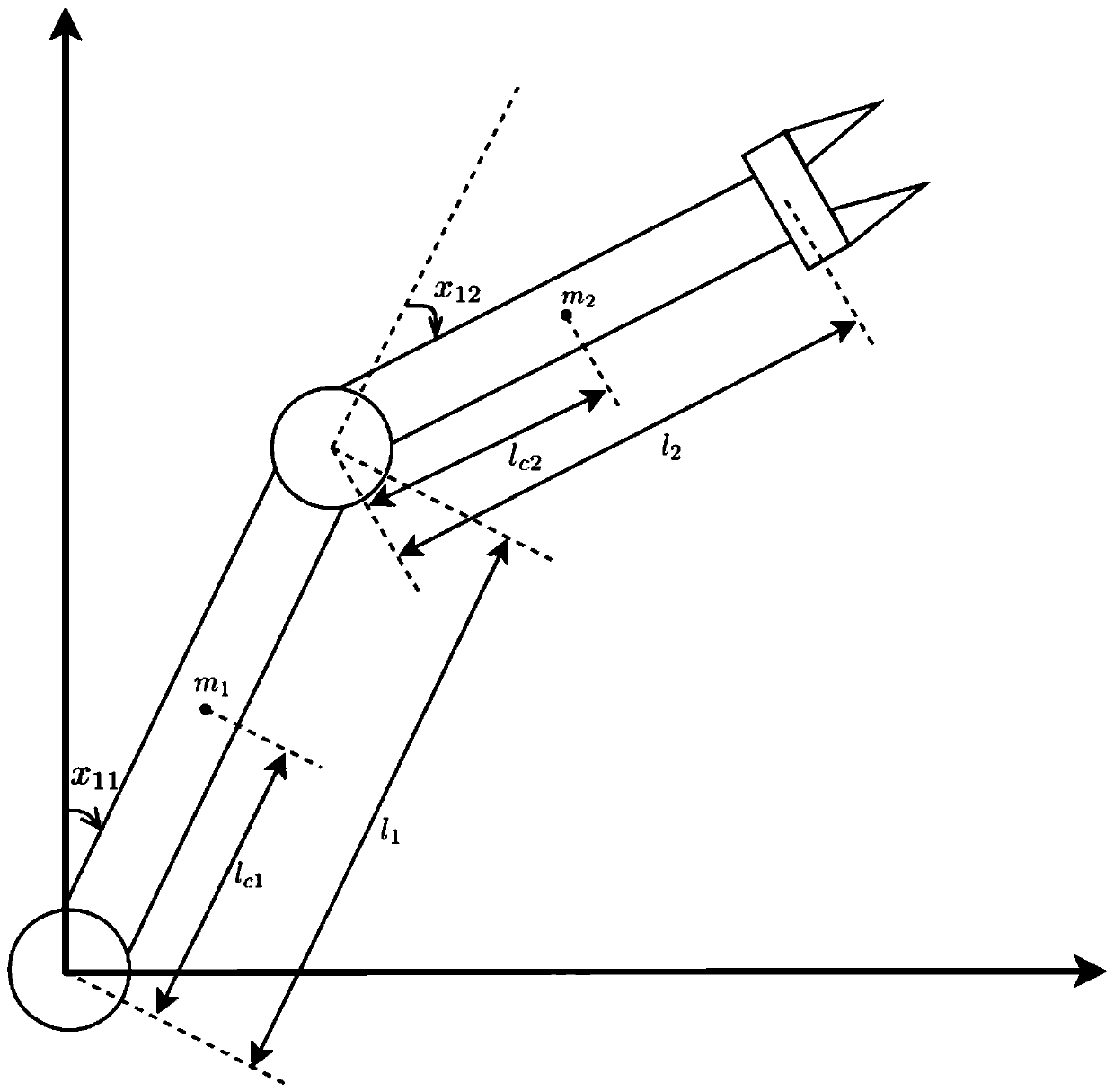

The invention provides an uncertain mechanical arm fixed time track following control method with input saturation, which can overcome influences of mechanical arm control input saturation effect anduncertainty, and improves robustness of a system. The method comprises the following steps: establishing a kinetic equation of an n-freedom rotary joint rigid mechanical arm system with a viscous friction item; according to the established kinetic equation and a mechanical arm track error following signal, establishing a following error kinetic equation which takes parameter uncertainty into consideration; establishing a state space model of mechanical arm track following errors; establishing a fixed time disturbance observer according to the established space model; establishing a fixed timenon-singular terminal sliding mode surface according to the mechanical arm track following error signal; preliminarily determining each joint drive motor control moment instruction of a mechanical arm, and integrating a moment output range of a performer, thereby obtaining each joint control moment of the mechanical arm. The invention relates to the field of mechanical arm control.

Owner:UNIV OF SCI & TECH BEIJING

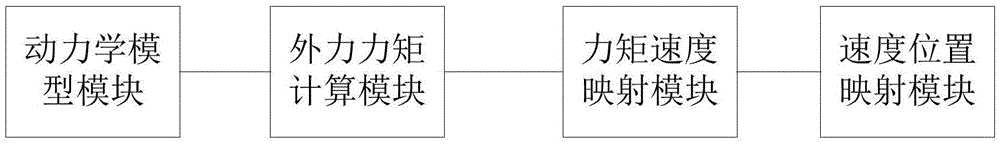

Zero-force control method and system for robot

ActiveCN105479459AReduce system costReduce system complexityProgramme-controlled manipulatorControl mannerStatic friction

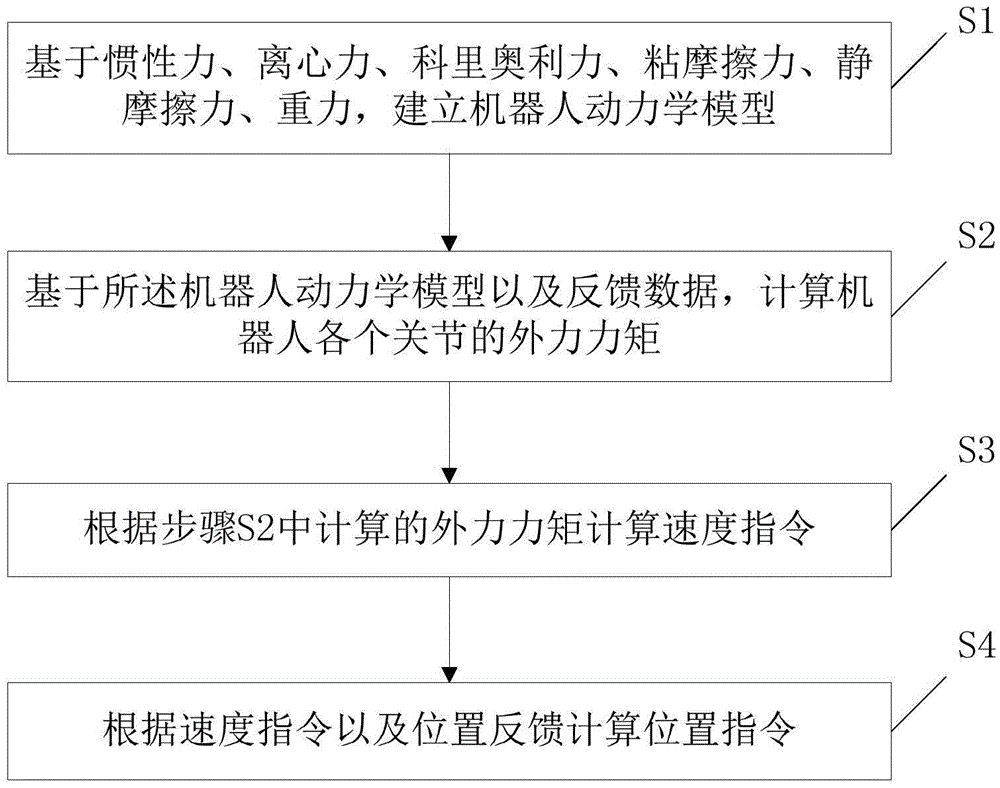

The invention relates to a zero-force control method and system for a robot. The zero-force control method comprises the following steps: S1, a robot kinetic model is built on the basis of inertia force, centrifugal force, coriolis force, viscous friction force, static friction force and gravity; S2, external force moments of all the joints of the robot are calculated on the basis of the robot kinetic model and feedback data; S3, a speed command is calculated according to the external force moments calculated in the step 2; and S4, a position command is calculated according to the speed command and position feedback. Through the building of the kinetic model, the external force moments of all the joints can be directly calculated, without the assistance of a power-assisted sensor or a torque sensor, so that the cost and the complexity of the system are reduced; by the adoption of a position command control manner instead of a direct torque control manner, the design difficulty in the safety and the stability of the system is reduced; and in addition, since inertia force is considered when the external force moments are calculated, the zero-force control method and system can be suitable for robots with greater dead weight.

Owner:SHENZHEN INOVANCE TECH +1

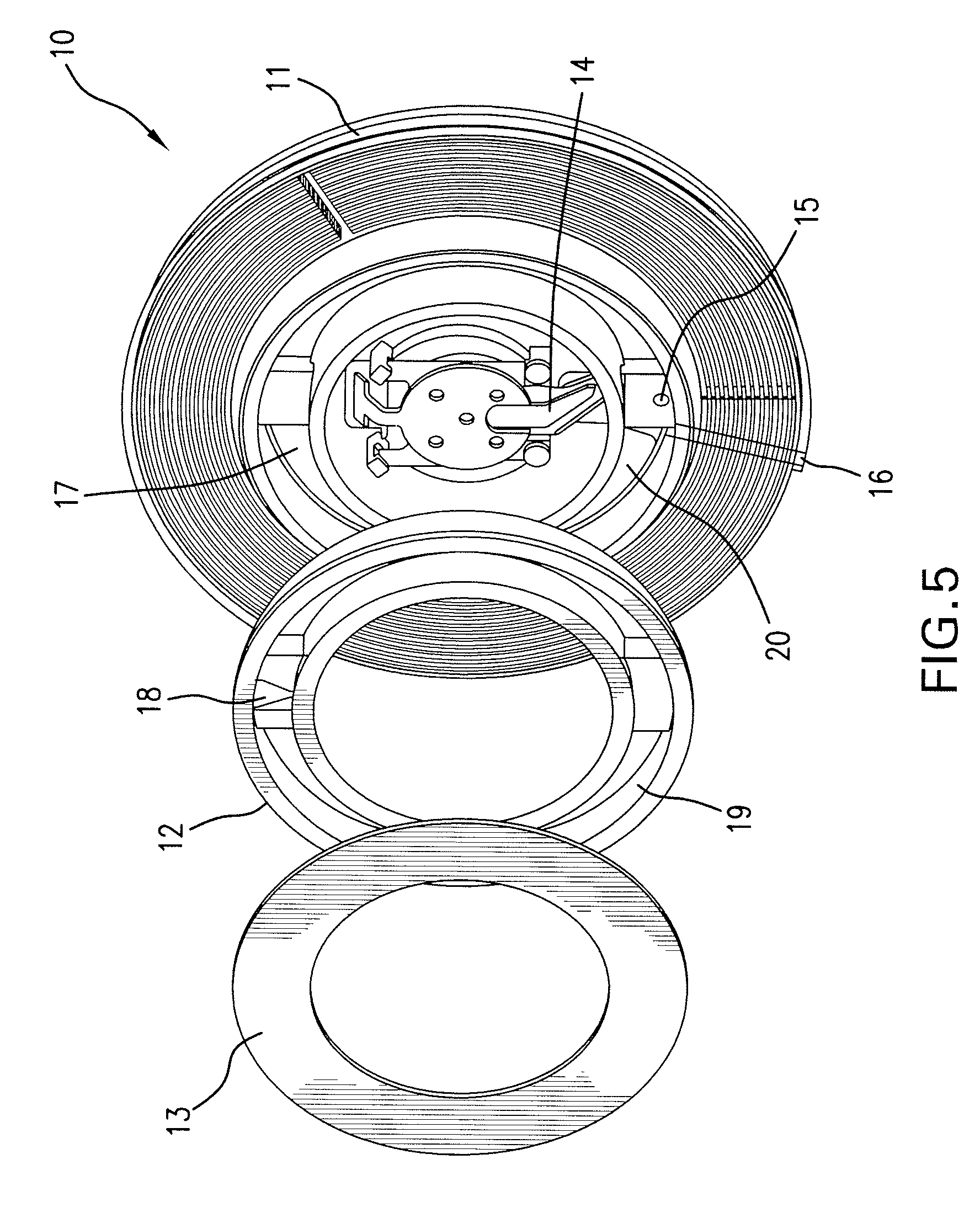

Viscous friction clutch for driving a cooling fan in a motor vehicle

Owner:MAHLE INT GMBH

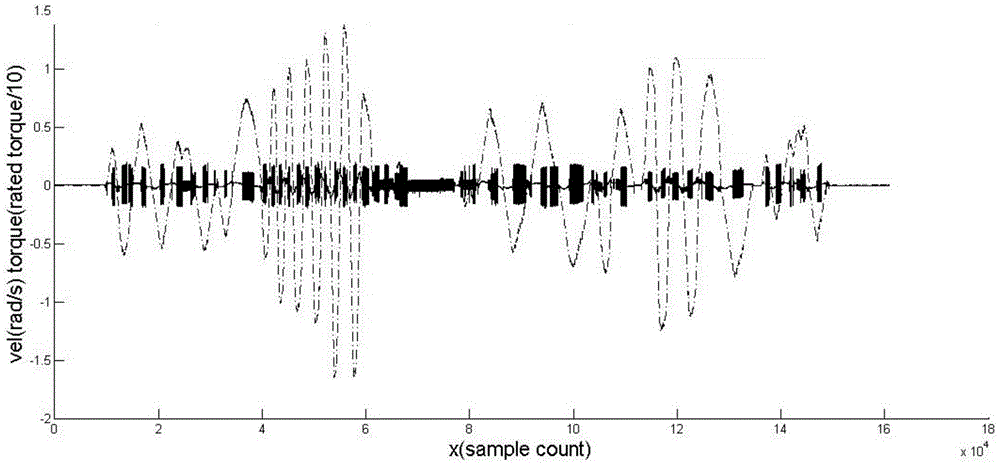

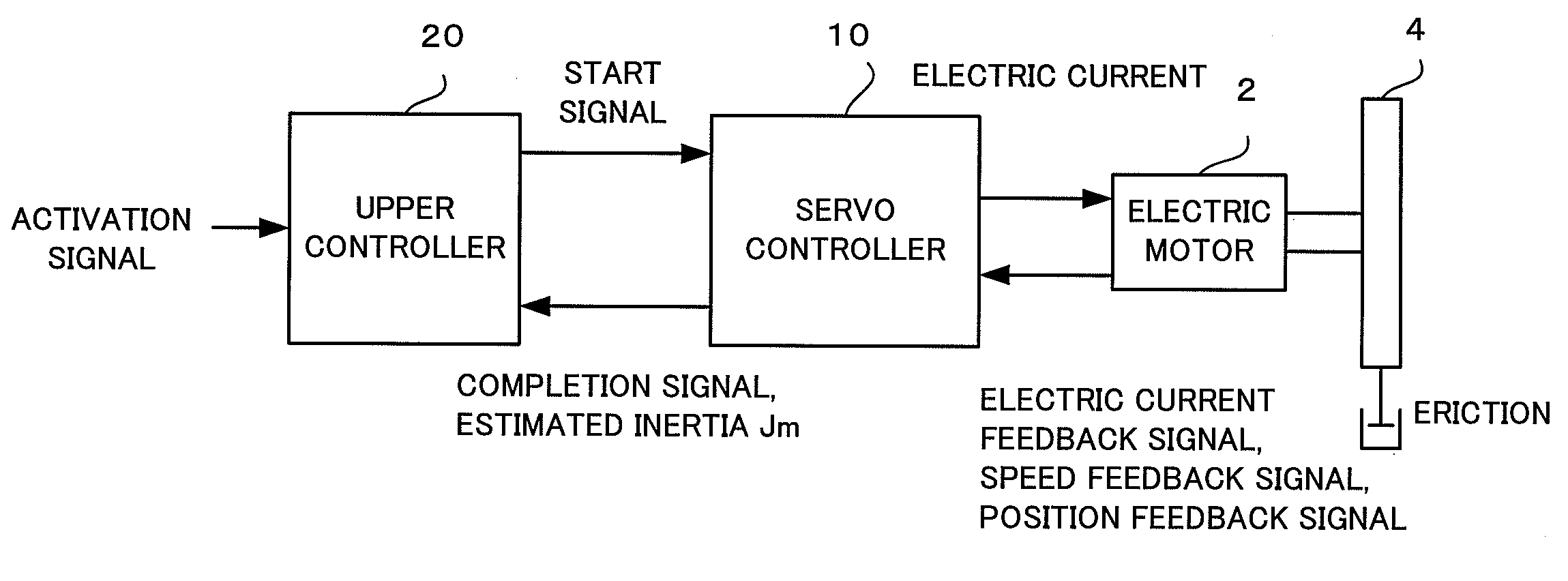

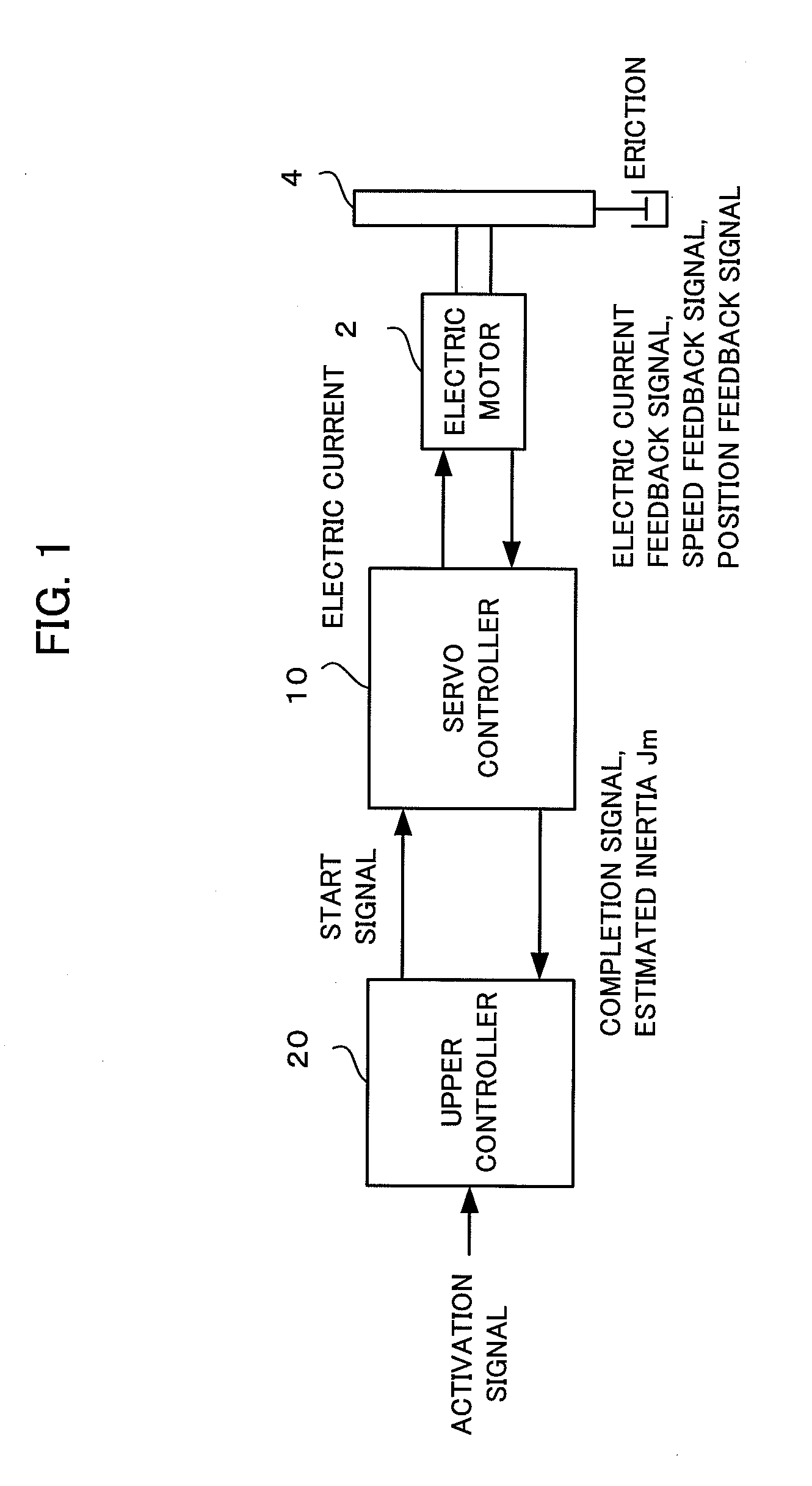

Controller of electric motor having function of estimating inertia and friction simultaneously

ActiveUS20110050146A1Improve estimation accuracyConvenient and accurateDigital data processing detailsFilamentary/web record carriersTransformerViscous friction

A controller estimates Coulomb friction itself together with inertia and viscous friction, and reduces the influence of the Coulomb friction on the accuracy of the estimated inertia. In addition, the controller estimates inertia, viscous friction and Coulomb friction simultaneously with sequential adaptation in which a Fourier transformer is not used but an inverse transfer function model is used in order to minimize the estimated error. Data sampled for a predetermined time need not be accumulated, as a result, a large amount of data memory is unnecessary.

Owner:FANUC LTD

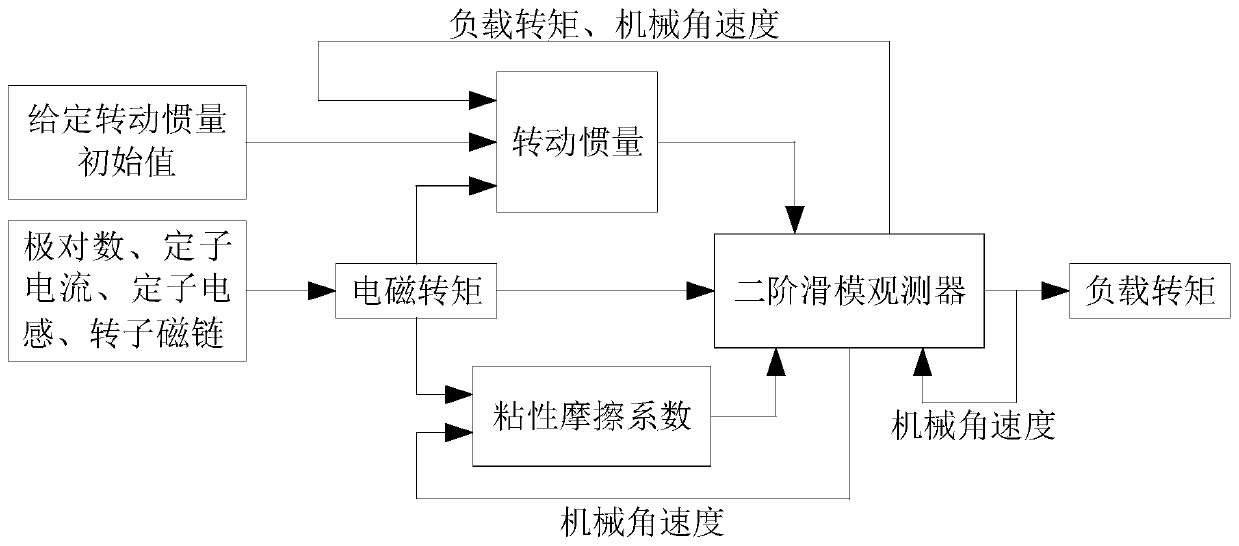

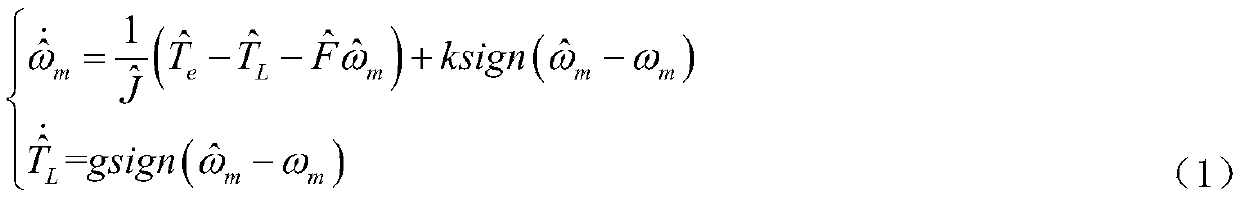

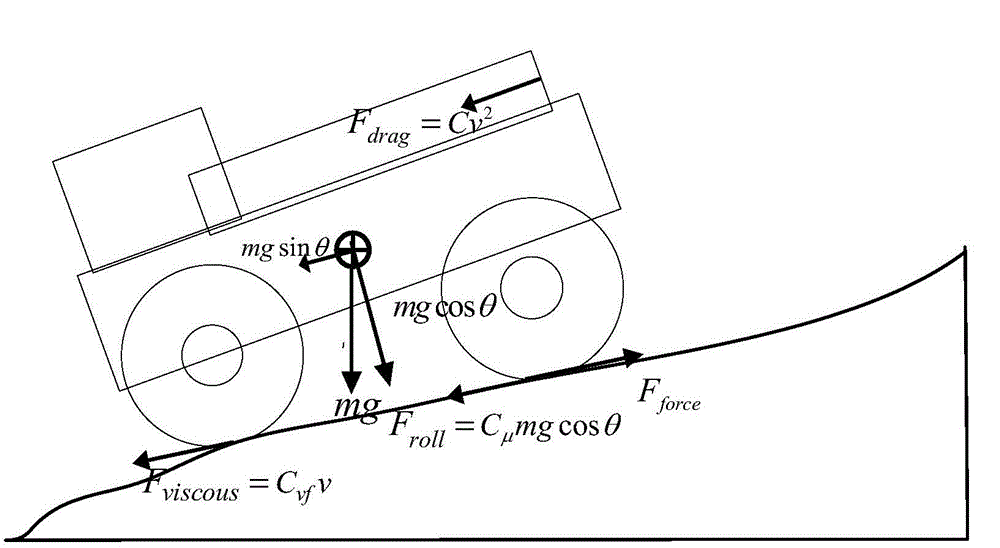

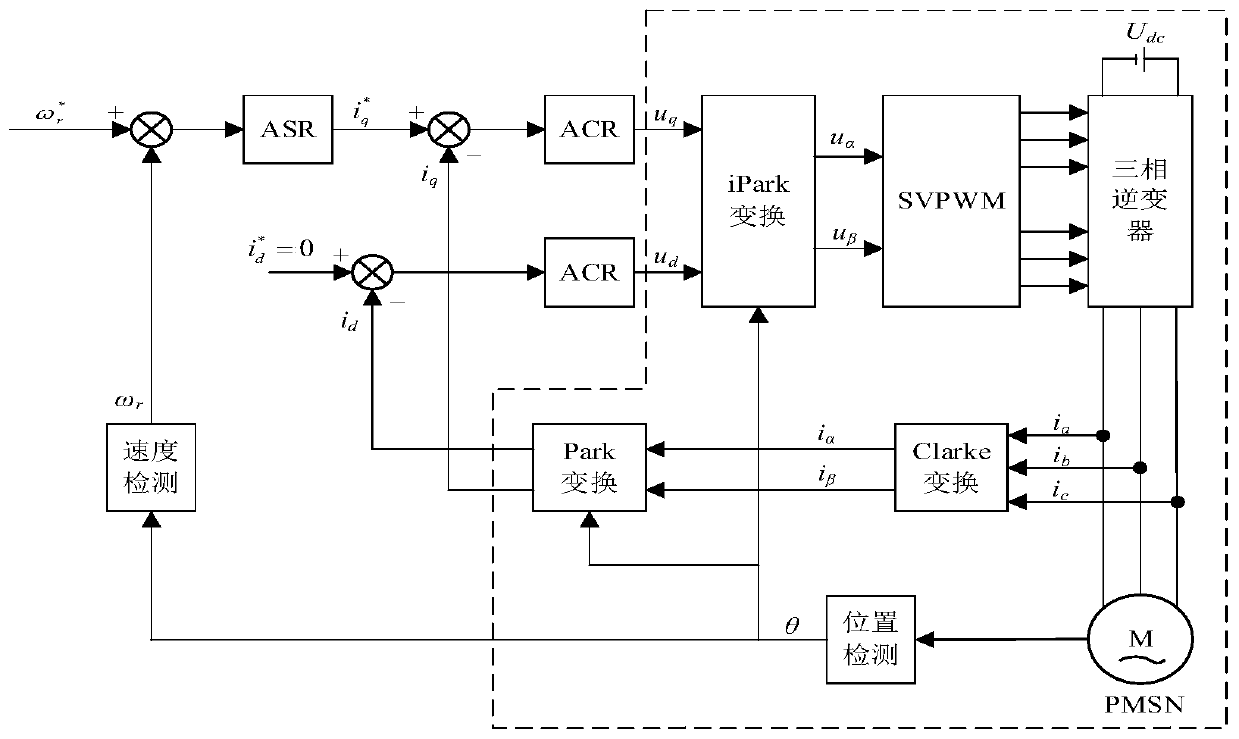

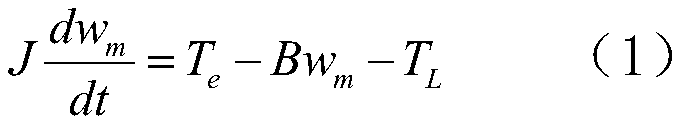

Method for identifying parameters of permanent magnet synchronous motor based on second-order sliding mode observer

InactiveCN110557070ASuppress chatterImprove estimation accuracyElectronic commutation motor controlVector control systemsLoad torquePermanent magnet synchronous motor

The invention relates to the technical field of motor parameter identification, and specifically relates to a method for identifying parameters of a permanent magnet synchronous motor based on a second-order sliding mode observer. The method comprises the steps of first, acquiring parameters of the permanent magnet synchronous motor under a dq-axis reference coordinate system; second, constructingan expandable sliding mode observer by taking the mechanical angular velocity and the load torque as observation objects; third, constructing a second-order sliding mode observer to identify the loadtorque of the permanent magnet synchronous motor by taking the mechanical angular velocity and the load torque as observation objects on the basis of the second step, and fourth, identifying the rotational inertia of the permanent magnet synchronous motor by adopting a direct calculation method or a PI regulator method on the basis of the identified load torque. According to the invention, changes of rotational inertia, the electromagnetic torque and the viscous friction are considered, and the buffeting can be effectively restrained while the precision of the load torque is guaranteed.

Owner:山东深川变频科技股份有限公司

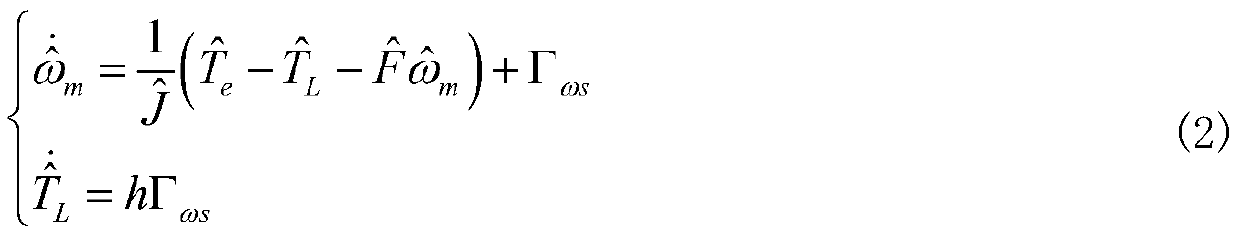

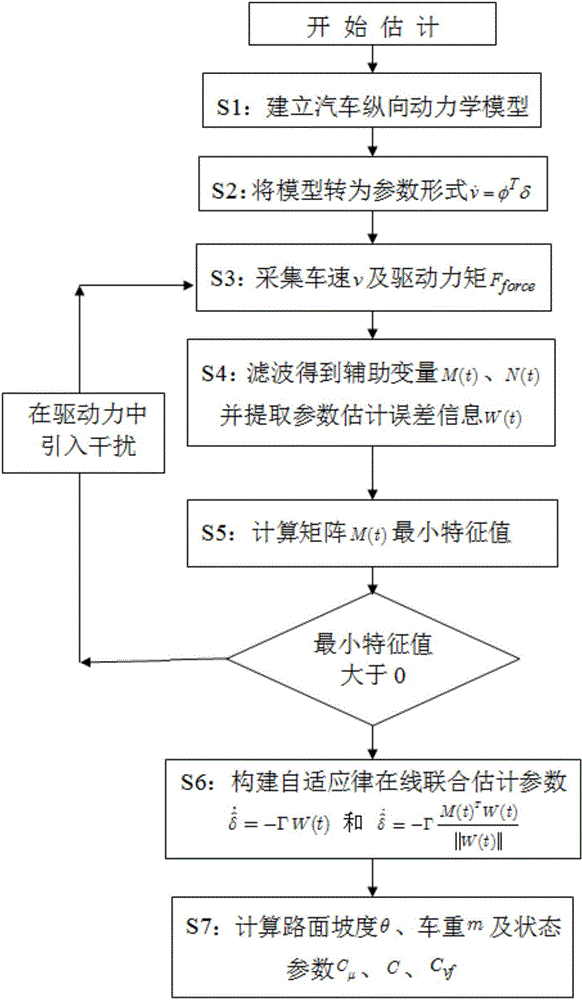

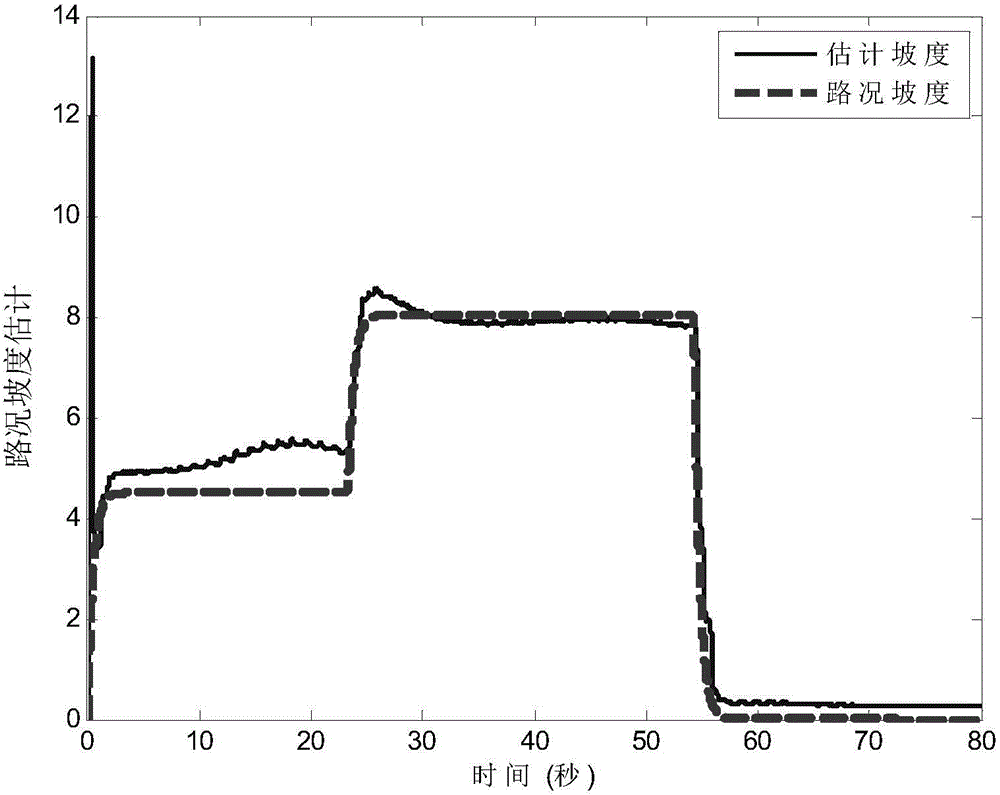

Road gradient and car state parameter combined estimation method based on parameter estimation error

The invention relates to a road gradient and car state parameter combined estimation method based on a parameter estimation error, and belongs to the field of vehicle engineering. The method comprises the steps of firstly establishing a car driving longitudinal kinetic model according to a car kinetics theory and the newton second law; measuring a car speed and a driving force of an engine by virtue of a car-borne sensor, and adopting the measured car speed and the driving force as input quantities of an estimation algorithm; filtering the car driving longitudinal kinetic model, and extracting a parameter estimation error; judging whether an excitation condition is satisfied: estimating an unknown parameter vector by utilizing a vector designing self-adaptive law containing the parameter estimation error if the excitation condition is satisfied; adding random interference to the driving force if the excitation condition is not satisfied, and returning for re-measurement; finally calculating estimated values of a road gradient, car weight, viscous friction coefficient, rolling friction coefficient and air resistance coefficient by virtue of basic mathematical manipulation. By adopting the method, the cost is reduced, the accumulation of measurement noise can be avoided, and the precision is improved; the calculation quantity is reduced.

Owner:KUNMING UNIV OF SCI & TECH

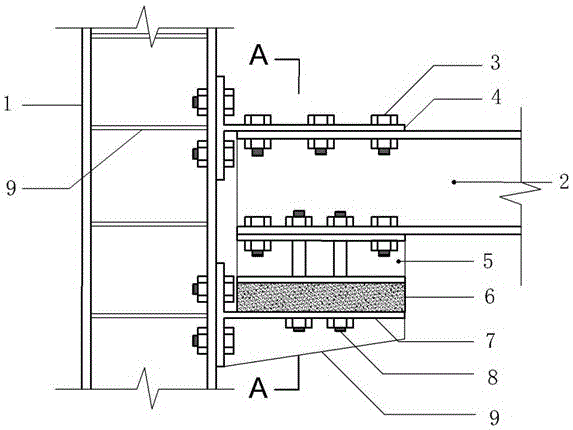

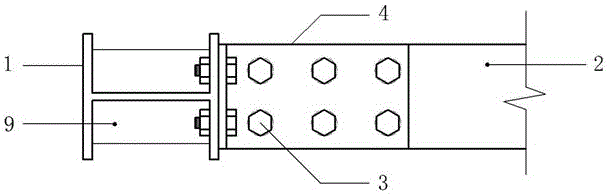

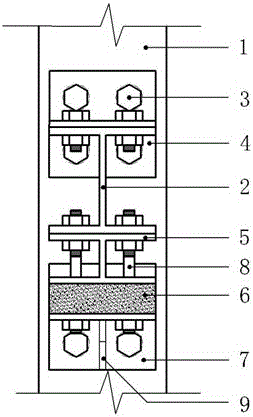

Energy dissipation beam column joint for building steel structure

InactiveCN106567457AReduce economic lossSimple structureBuilding constructionsProtective buildings/sheltersViscous frictionEngineering

The invention relates to an energy dissipation beam column joint for a building steel structure. The energy dissipation beam column joint comprises a frame beam column, T-shaped connection parts, a viscous friction damper, a small I-shaped steel connection part, a metal energy dissipation bar and the like. Connection of the beam end comprises the upper T-shaped connection part, a frame beam, the small I-shaped steel connection part, the viscous friction damper and the lower T-shaped connection part. Except that the viscous friction damper and the small I-shaped steel connection part as well as the lower T-shaped connection part are bonded through strong glue, the others are all connected through high-strength bolts. The upper T-shaped connection part and the lower T-shaped connection part are connected with the frame beam through high-strength bolts. The whole metal energy dissipation bar penetrates through the lower flange of the frame beam to the lower T-shaped connection part and is fixed through a nut. When horizontal seismic force is small, the viscous friction damper can provide certain lateral resisting stiffness. When horizontal seismic force is large, relative sliding occurs to all layers of the viscous friction damper, the metal energy dissipation bar is driven to be subjected to bending deformation, joint energy dissipation is achieved, and a mixed energy dissipation system is formed. The energy dissipation beam column joint is simple in structure, significant in energy dissipation and seismic mitigation effect and suitable for various connection positions and does not occupy additional space.

Owner:TONGJI UNIV

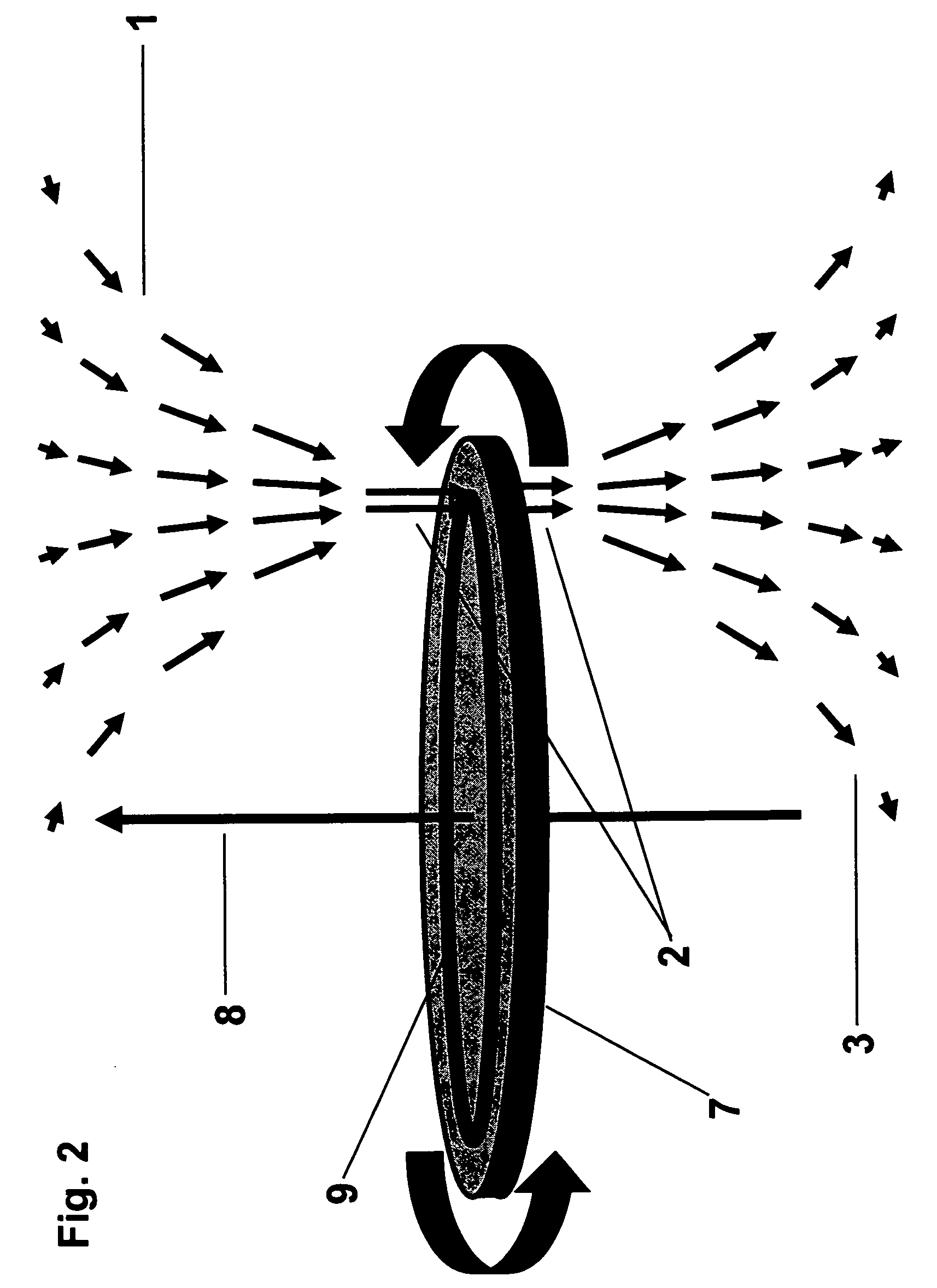

Gun, artillery and rocket jet engines, steam turbines, internal combustion engines and air vehicles with additional magnetic device

InactiveCN106158230AReduce the temperatureIncrease the speed of diffusionInternal combustion piston enginesCombustion-air/fuel-air treatmentShock waveMagnetic tension force

The invention provides gun, artillery and rocket jet engines, steam turbines, internal combustion engines and air vehicles with an additional magnetic device. A magnet is included, translational motion, through Lorentz force, rotation and vibration of fluid molecules near the magnet in the direction of being perpendicular to the micro-flow direction of fluid are strongly inhibited, and pressure and temperature of the fluid molecules in the direction of being perpendicular to the micro-flow direction of the fluid are significantly lowered, so that the speed that the fluid molecules diffuse in the needed micro-flow direction is significantly increased. Viscous friction, turbulent shear stress, friction force and heat conduction in a boundary layer and shock waves, resistance generated by the shock waves and negative influences of heating on relative movement between air flow and an object are eliminated fundamentally in the microcosmic level or at least weakened greatly. By equipping the magnet on various gun, artillery and rocket engines, jet engines, turbines, gasoline engines, diesel engines and the like, radial pressure and temperature must be significantly lowered, the initial speed of pills is significantly increased, the power and the speed of the rock engines and the jet engines are increased, the energy utilization rate of the gas turbines, the turbines and the internal combustion engines is increased, and various resistances borne by the air vehicles and heating of the air vehicles are significantly reduced.

Owner:田景华

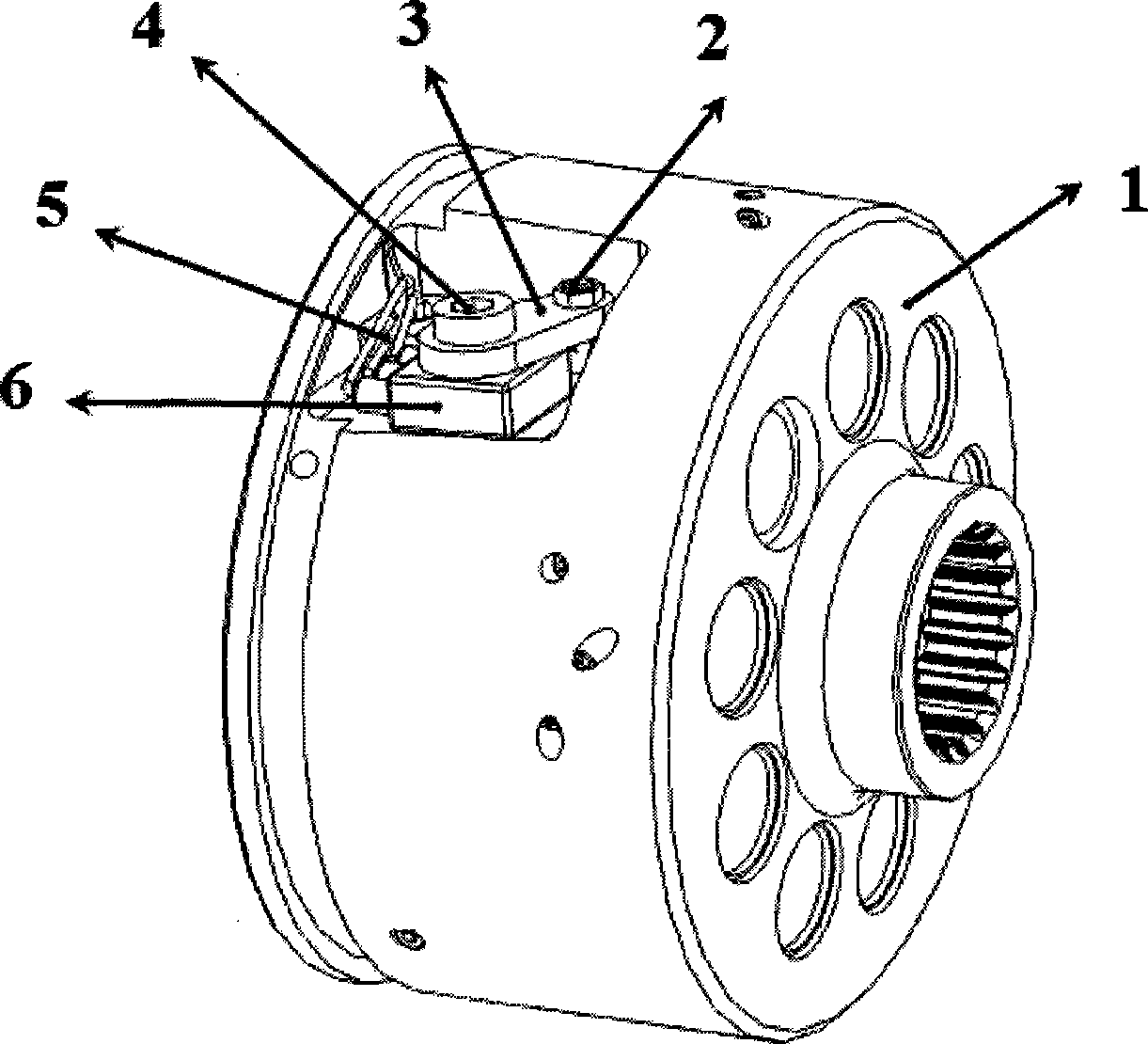

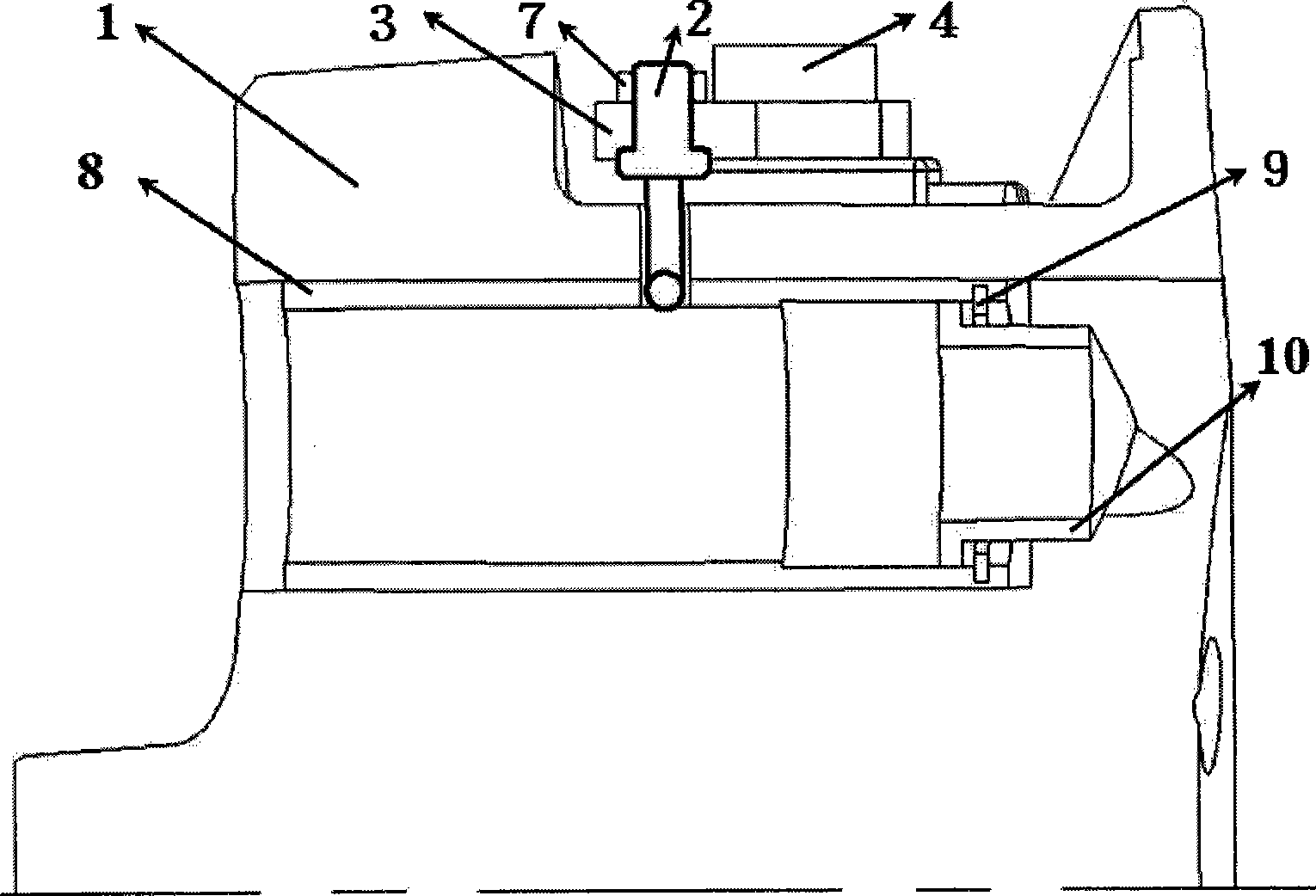

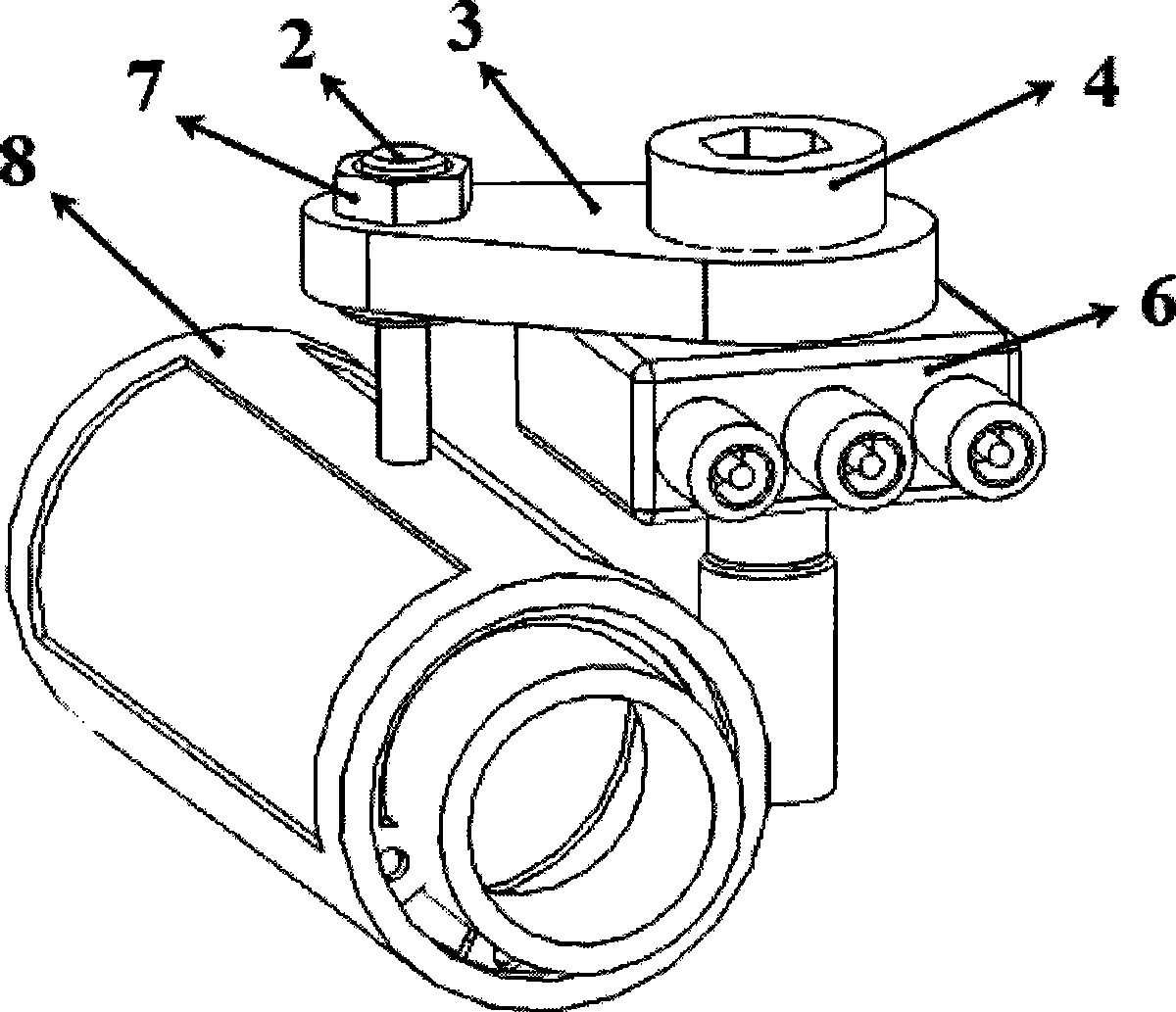

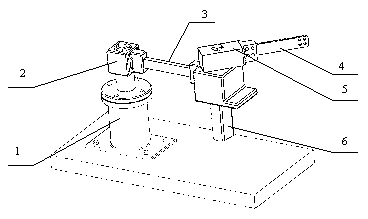

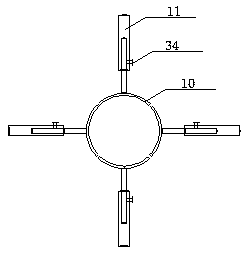

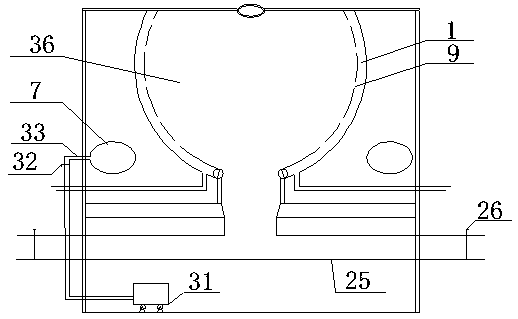

Apparatus for measuring plunger sub-oil film viscous friction

InactiveCN101413838AIngenious designClever applicationFluid pressure measurement by electric/magnetic elementsPlunger pumpViscous friction

The invention discloses a device for measuring viscous friction force of an oil film of a plunger pair in a plunger pump. The device comprises a cylinder body, an induction feeler lever, a connecting rod, a fastening screw, a sensor cable, a friction force sensor, a fixing nut, a plunger bushing, a spring closing ring, a flow guide rod and a check valve component. The flow guide rod and the plunger bushing are connected together by the spring closing ring to form a floating bushing assembly supported by static pressure, the viscous force in the 3D direction of the oil film is induced by the induction feller lever and is transmitted to the friction force sensor by the connecting rod with higher rigidity, and the cable of the friction force sensor is led to the central position of the cylinder body by a neck groove on the cylinder body, and the cable is led out by a main shaft of the plunger pump. The structure of the device reasonably uses a void part between plunger chambers on the cylinder body, which causes the friction force sensor with larger volume to have sufficient mounting space and ensures reliable and stable structure and reliable performance; and the ingenious design and the application of the integral mechanical structure realizes compact structure and reduced volume.

Owner:ZHEJIANG UNIV

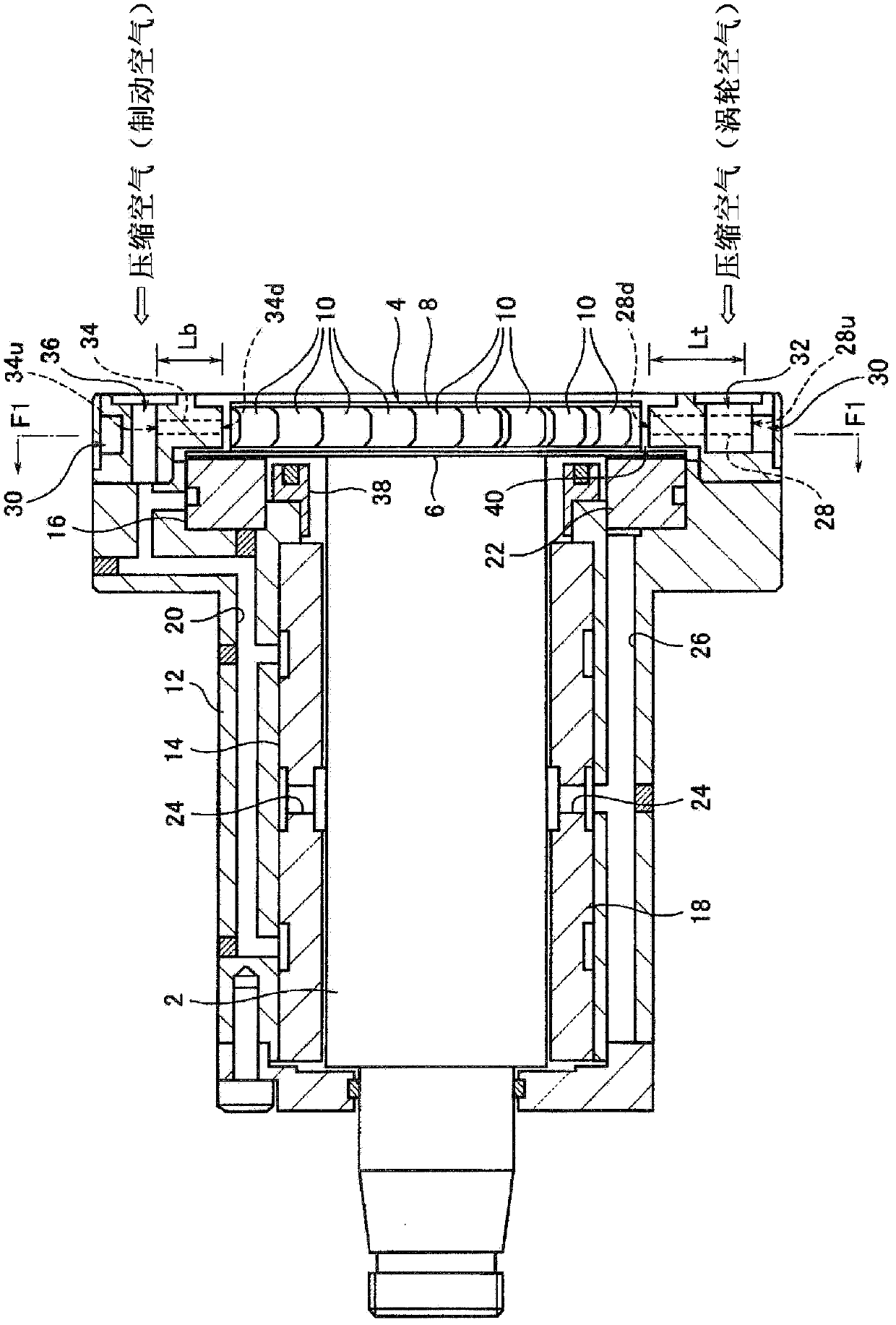

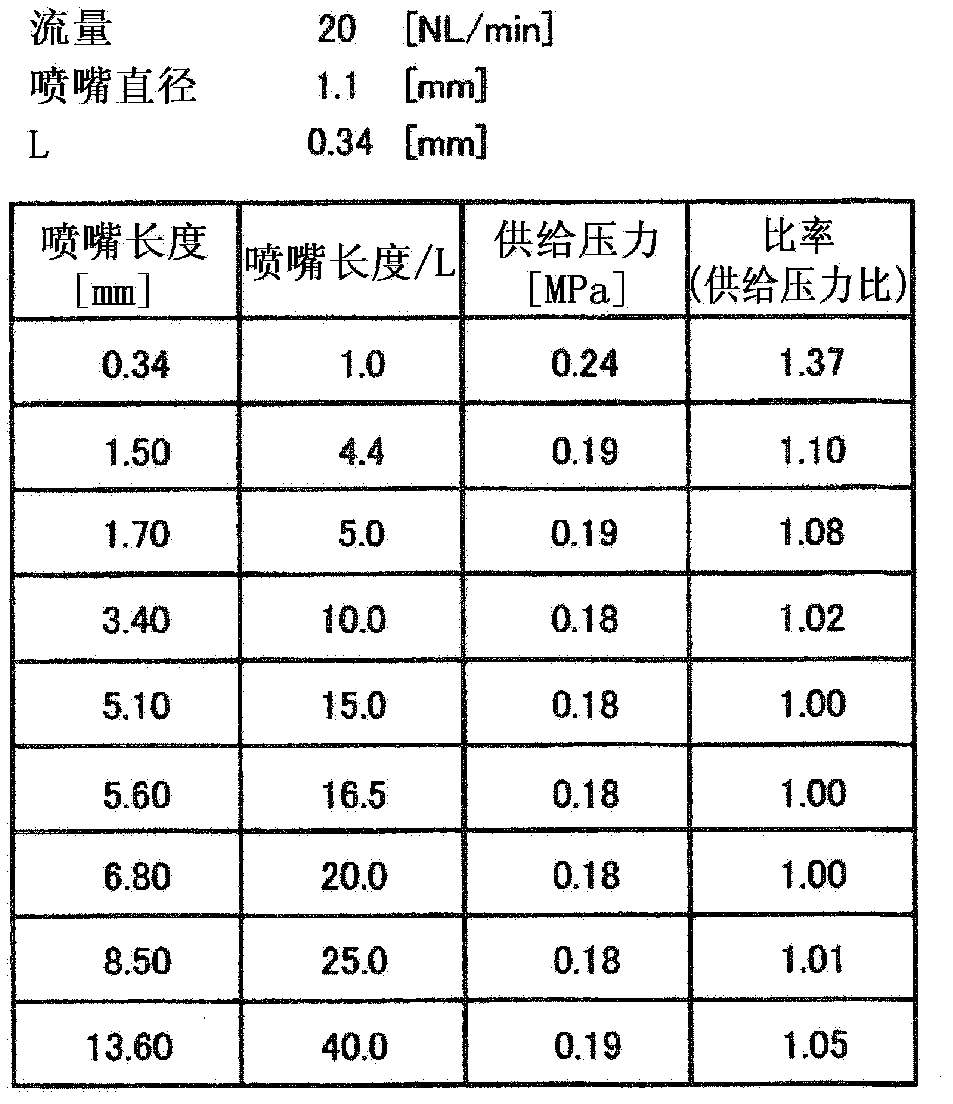

Air motor and electrostatic coating device

ActiveCN102639816AImprove driving efficiencyMovable spraying apparatusNon-positive displacement enginesImpellerTurbine blade

Owner:NSK LTD

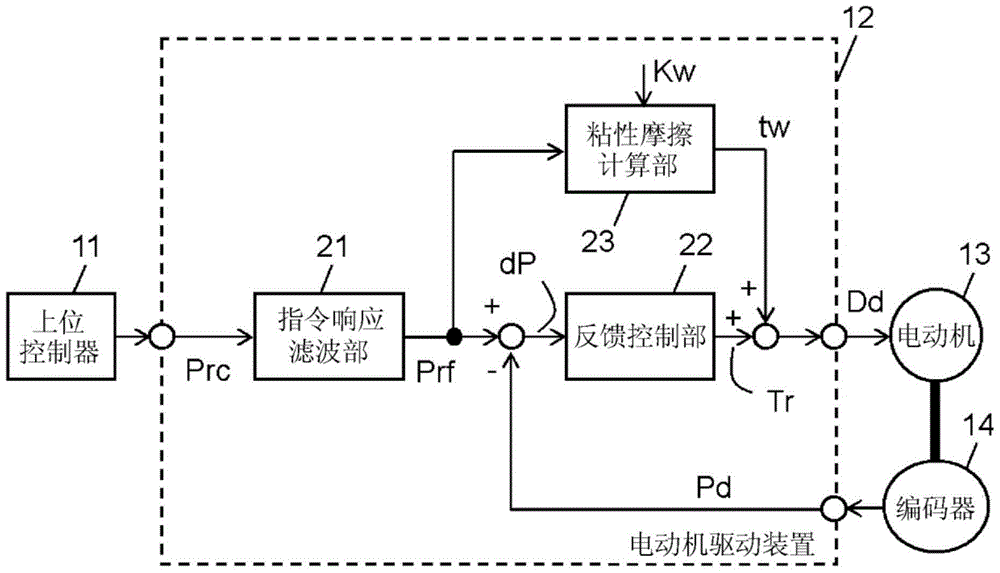

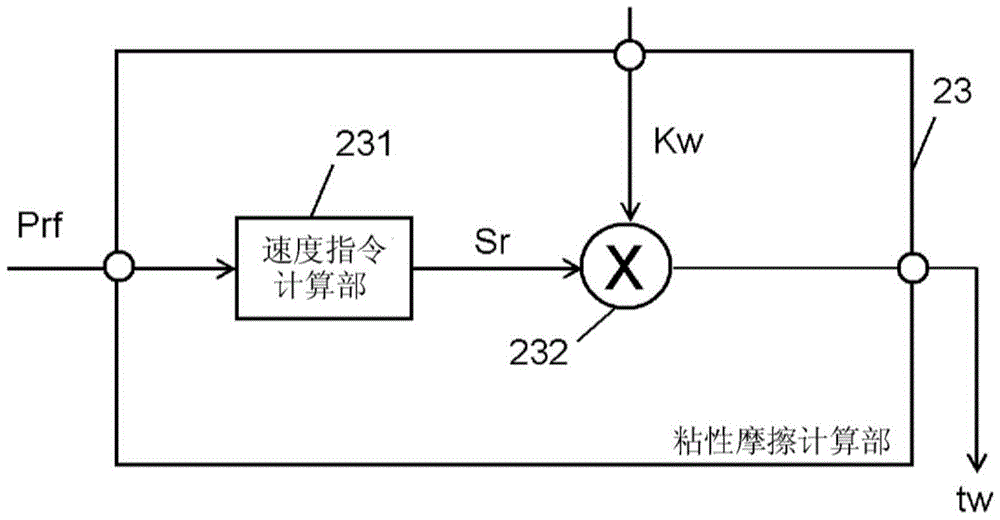

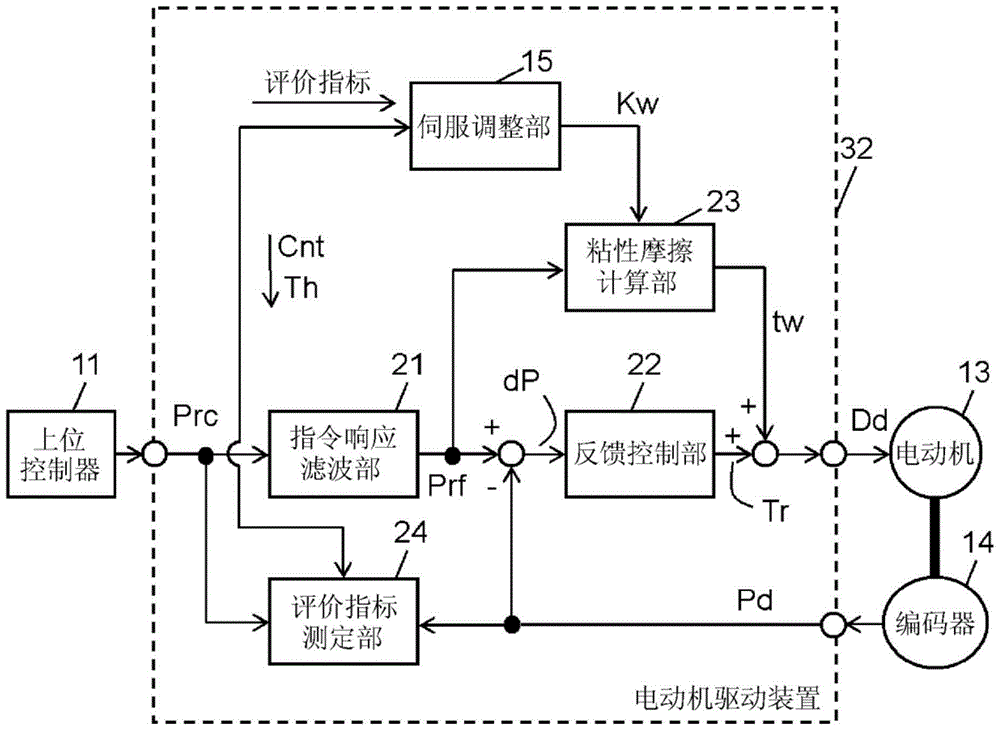

Motor drive device

ActiveCN105191116ALower latencyEvenly compensatedElectric motor controlGeneral control strategiesMotor driveViscous friction

A motor drive device according to the present invention drives a motor while carrying out feedback control so that an actual operation follows a command. The motor drive device comprises: a feedback control unit for carrying out feedback control by outputting a torque command; and a viscous friction calculation unit for calculating a viscous friction torque compensation value by multiplying a speed command by a viscous friction coefficient. The motor drive device drives a motor on the basis of a drive signal created by adding the viscous friction torque compensation value to the torque command. The motor drive device is provided with an evaluation index measurement unit for measuring an overshoot amount and positioning stabilization time by inputting a position command and a motor position or a load position, and a servo adjustment unit for carrying out positioning operations a plurality of times by changing a viscous friction coefficient and determining a viscous friction coefficient so that the overshoot amount is a designated value or the positioning stabilization time is the minimum value.

Owner:PANASONIC INTELLECTUAL PROPERTY MANAGEMENT CO LTD

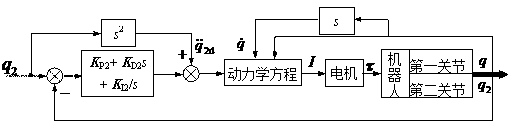

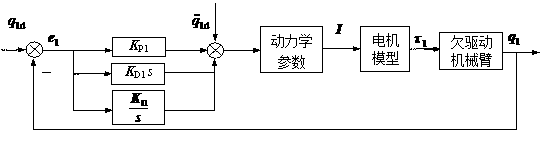

Location control method of 2R underactuated planar mechanical arm based on subdivision control

InactiveCN103128737ASmooth motionThe control object is universalProgramme-controlled manipulatorUnderactuated robotsResearch Object

The invention discloses a location control method of a 2R underactuated planar mechanical arm based on subdivision control. The location control method of the 2R underactuated planar mechanical arm based on subdivision control comprises the following steps: establishing an underactuated planar mechanical arm mechanics module with a driving first joint and a driven second joint, and considering Coulomb friction force and viscous friction force of joints in the module. To an underactuated robot, the friction of the driving joint can be directly compensated by a motor, but the driven joint can not be compensated, and the friction force of the driven joint is utilized. By adopting a time scale method and a proportion integration differentiation (PID) control method, the location control method of the 2R underactuated planar mechanical arm based on subdivision periodically starts joint space and location control to the 2R underactuated planar mechanical arm, and further achieves positioning control to the tail end of the robot. A research objective of the location control method is an underactuation system which includes entirely free joints, and so that the location control method of the 2R underactuated planar mechanical arm based on subdivision control has the advantages of being simplified in a mechanical device and pervasive in the control objective. The location control method of the 2R underactuated planar mechanical arm based on subdivision control utilizes a simple and feasible control method to realize the location control of the 2R underactuated planar mechanical arm, avoids to adopt complex and profound nonlinear control methods, and achieves the purposes of being distinct in train of thought, simple to programming and easy to achieve.

Owner:SHANGHAI PAXING INFORMATION TECH

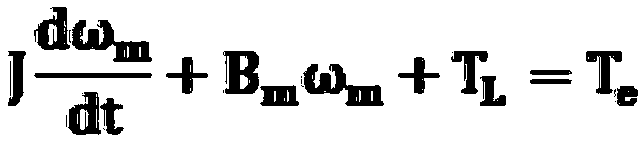

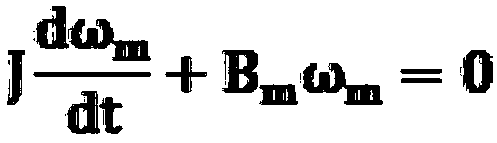

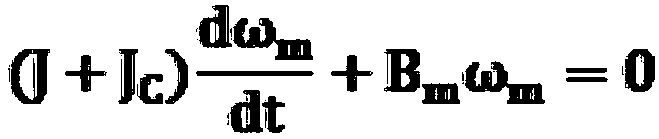

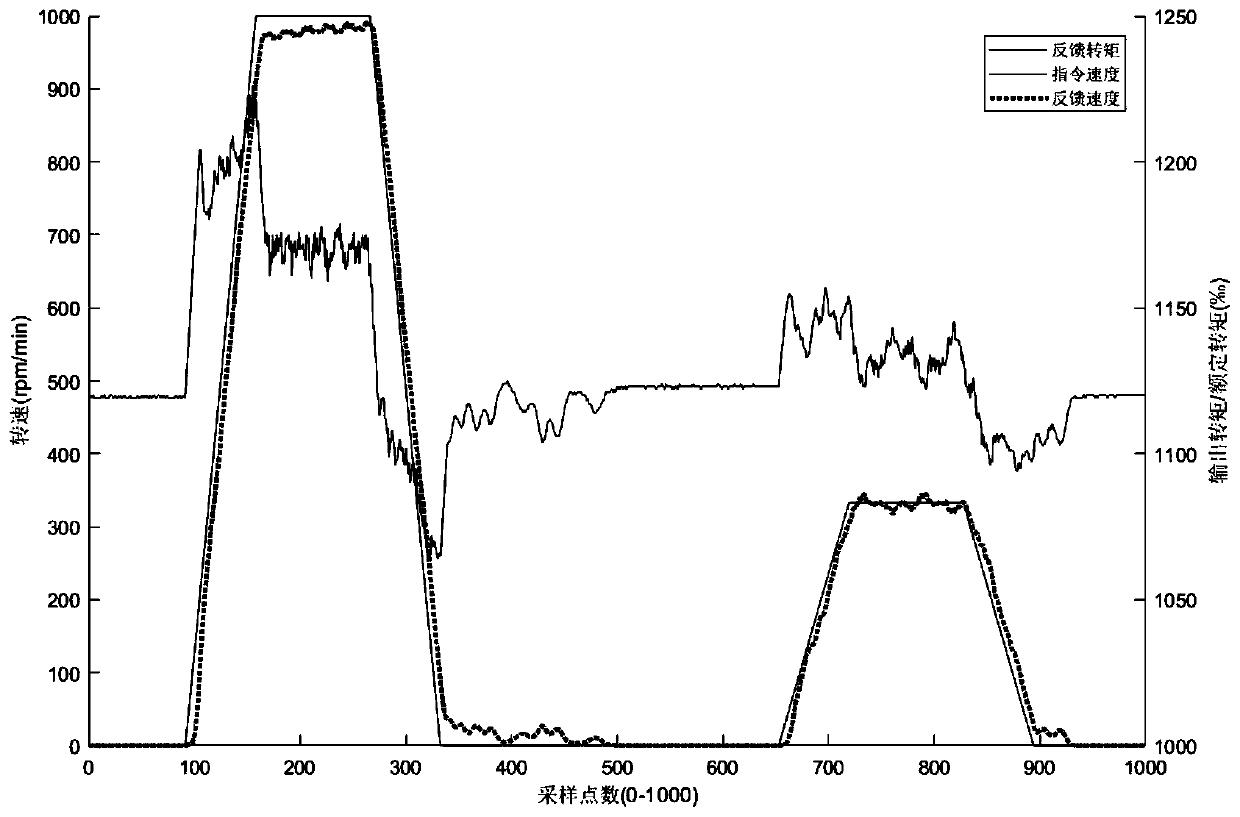

Electromechanical servo system parameter identification method based on large-inertia friction load

InactiveCN108448988AHigh precisionEstimate moment of inertia in real timeElectronic commutation motor controlVector control systemsElectric machineryViscous friction

The invention relates to an electromechanical servo system parameter identification method based on large-inertia friction load. The method is characterized in that, to begin with, under a motor no-load operation state, determining an initial mechanical movement equation offline through a velocity reduction method, and serving the equation as controller parameters; and then, under a motor with-inertia operation state, determining a mechanical movement equation with inertia online through the same velocity reduction method, and calculating motor rotor rotational inertia J and viscous friction coefficient Bm online by utilizing the initial mechanical movement equation and the mechanical movement equation with inertia. The method can realize online identification, that is, the rotational inertia and the viscous friction coefficient of a motor rotor are calculated in real time during the system operation process, and the control strategy is adjusted according to characteristics in different time periods to allow the servo system to have excellent performance.

Owner:BEIJING RES INST OF PRECISE MECHATRONICS CONTROLS

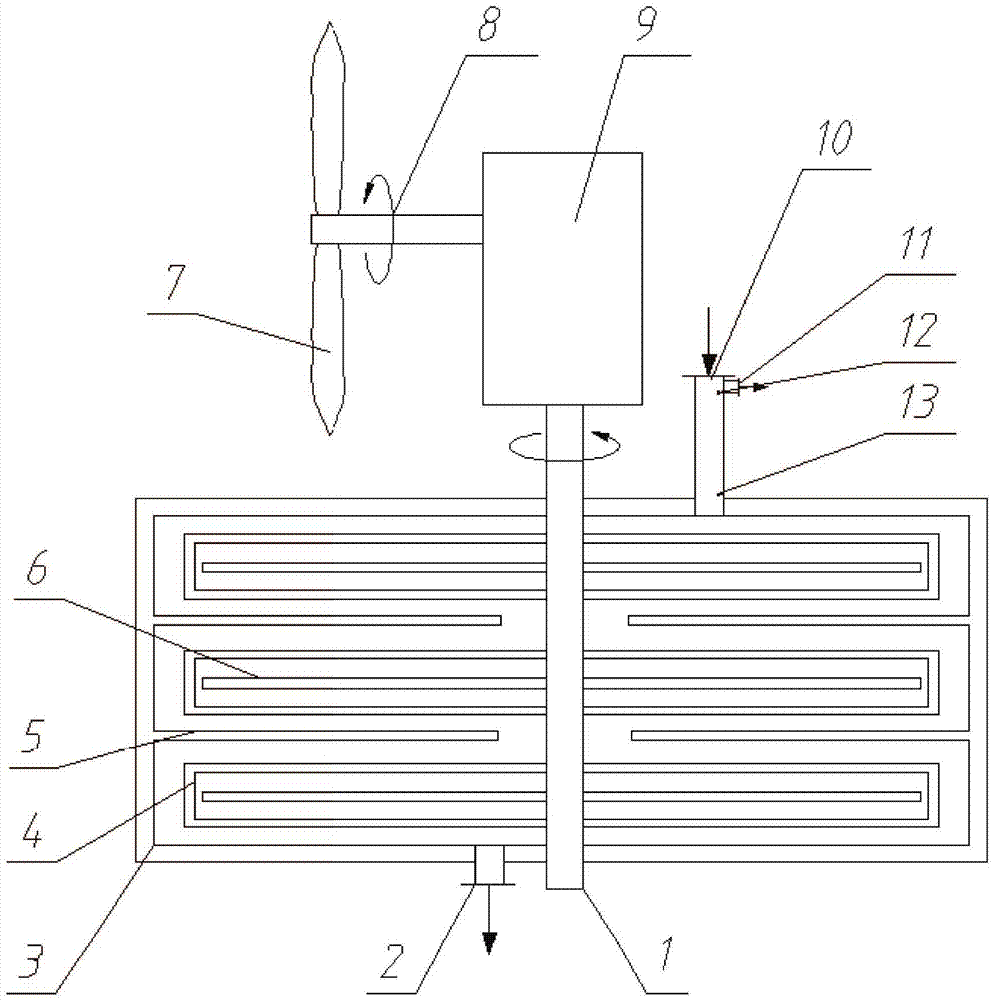

Wind-power rotary disc type viscous friction water heater

InactiveCN104266340ASimple processAvoid electric heatingEnergy industryWind motor combinationsMechanical energyEngineering

The invention relates to a wind-power rotary disc type viscous friction water heater which comprises a fan, a gear case and a friction water heater body. The friction water heater body comprises a disc rotary shaft, a heating chamber, a rotary disc, a water cavity, a baffling plate, a cold water inlet and a hot water outlet. The fan rotates under the wind power effect, the rotary kinetic energy of the fan can be steered by the gear case at variable speed and then is transferred to the disc rotary shaft, and the disc rotary shaft drives the rotary disc to rotate at certain rotation speed. The rotary disc is arranged in the heating chamber, the heating chamber is full of a high-viscosity fluid, and the rotary disc and the high-viscosity fluid produce heat serving as a heat source for heating through friction when the rotary disc rotates. Water flows into the friction water heater body through the cold water inlet, the water and the fluid in the heating chamber perform heat exchange through a dividing wall to improve the temperature, and the water flows out of the hot water outlet when being needed by a user. The wind-power rotary disc type viscous friction water heater utilizes wind power mechanical energy to directly produce hot water, an electric heating link is avoided, a water heating process can be simplified, energy utilization rate can be improved, and the wind-power rotary disc type viscous friction water heater is suitable for domestic, industrial and ship hot water supply in regions rich in wind energy.

Owner:HAINAN UNIVERSITY

Off-line identification method for moment of inertia of permanent magnet synchronous motor

InactiveCN111464097AEliminate the effects ofImprove recognition accuracyElectronic commutation motor controlVector control systemsElectric machineClassical mechanics

The invention discloses an off-line identification method for moment of inertia of a permanent magnet synchronous motor. The method comprises the steps of planning a speed instruction given by a speedring to enable the motor to operate for twice identification; sampling a feedback current value and a rotor position from a servo system at the same time when the motor runs in a controllable stroke;and inputting the current feedback signal and the rotor position signal into a designed model to calculate the moment of inertia so as to obtain a relatively accurate inertia identification result. According to the method, the problems that the influence caused by viscous friction cannot be ignored by a traditional off-line identification method, errors are introduced by differential operation inthe calculation process, and the application occasions are limited are solved. According to the method, the accuracy of an identification result can be effectively improved, and the total inertia ofthe system can be rapidly and accurately identified in an occasion with a load.

Owner:SOUTH CHINA UNIV OF TECH

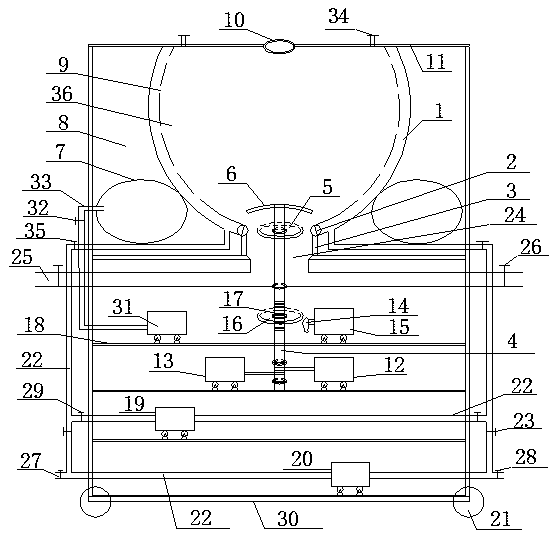

Plant root and soil separating and washing device

ActiveCN108185457AAvoid damageHigh precisionDigger harvestersCleaning using liquidsPlant rootsHigh pressure water

The invention relates to a plant root and soil separating and washing device, and belongs to the technical field of plant washing apparatuses. The plant root and soil separating and washing device comprises a root and soil separating device, a root system flushing device, a root system rinsing device and a root system dehumidifying device. According to the plant root and soil separating and washing device disclosed by the invention, soil structure is broken in two manners of wrapping type extruding and impacting roots of plant bodies by external force; loose soil at the roots is flushed in alldirections in a manner of orifice high-pressure water outputting; silts adhered to the surfaces of the root systems are rinsed by viscous friction of a positive and negative rotating flow; and the evaporation rate of the water content of surface layers of the root systems is accelerated in a manner of orifice ventilation. According to the growth characteristics of plant root systems, certain uniform pressure and certain viscous friction are provided to perform plant root and soil separating and washing, so that the accuracy of study on shape characteristics, physiological functions and growthand development law of the root systems is improved; and the plant root and soil separating and washing device disclosed by the invention is high in automation degree, easy and simple to operate, lowin workload and high in practicality.

Owner:KUNMING UNIV OF SCI & TECH

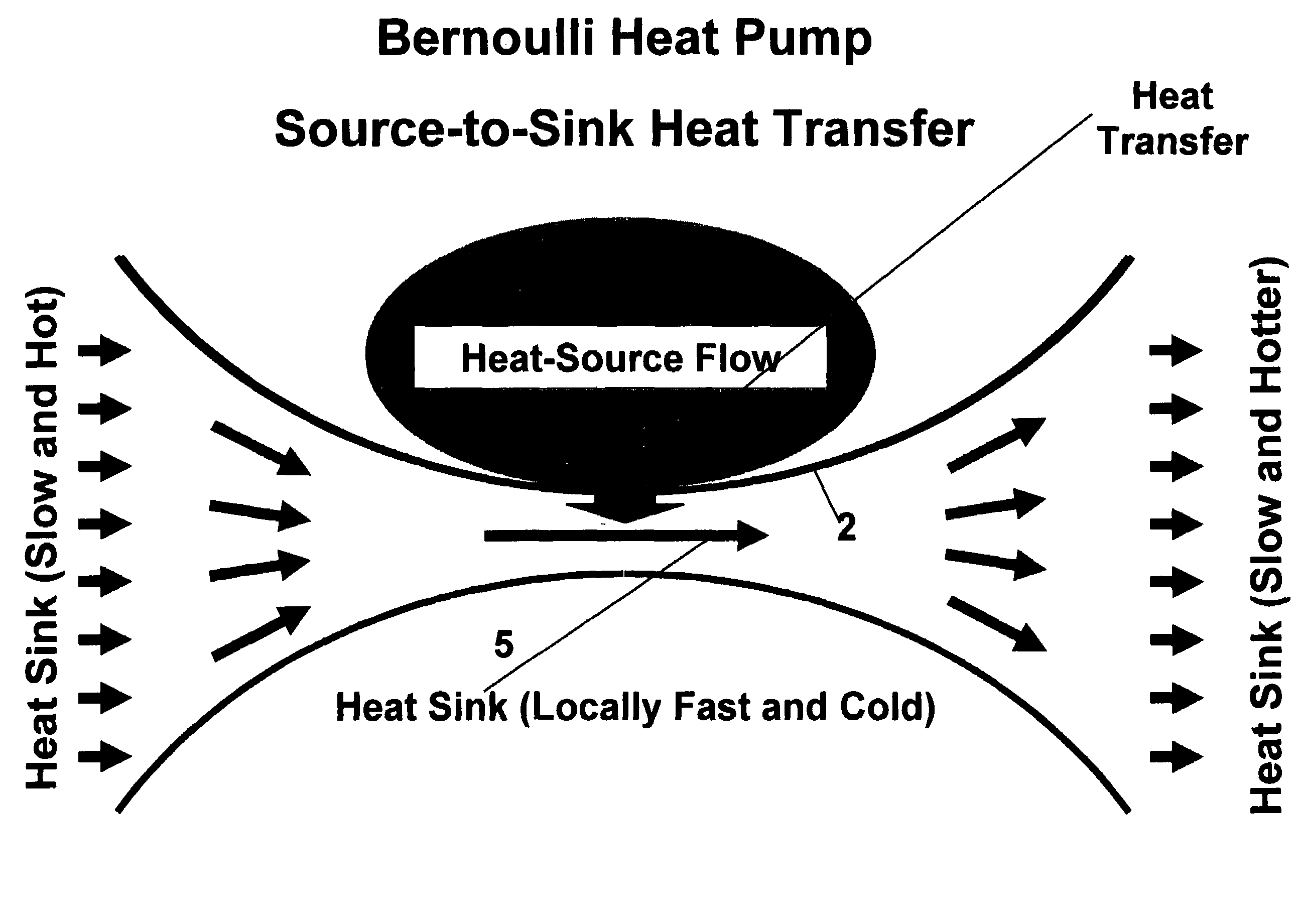

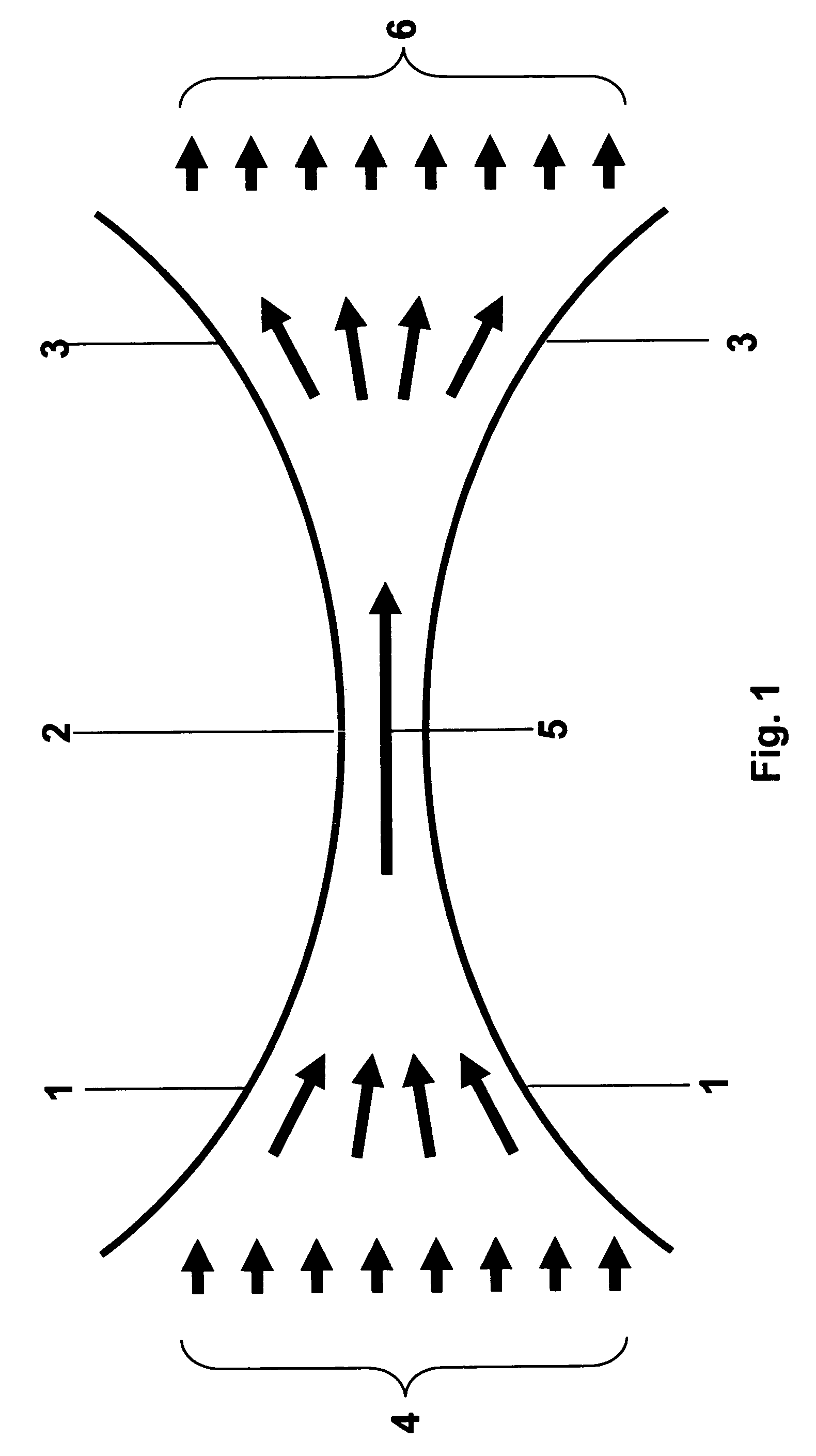

Rare-gas-based Bernoulli heat pump and method

InactiveUS20080028774A1Efficient heat transferMinimizes fluid flow lossDomestic cooling apparatusCompression machines with reversible cycleDiffusionPrandtl number

Heat pumps move heat from a source to a warmer sink, with Bernoulli heat pumps accomplishing this movement by reducing the temperature in a portion of the generally-warmer heat-sink flow. Heat flows spontaneously from the generally cooler heat-source flow into the locally cold portion of the heat-sink flow, which is the neck of a Venturi. The temperature reduction results from the Bernoulli conversion of random gas-particle motion (temperature and pressure) into directed motion (flow). This invention is a Bernoulli heat pump in which the heat transfer into the Venturi neck exploits unusual thermodynamic transport properties of rare-gases. Rare gases, especially mixtures of them, possess unusually small Prandtl numbers and thereby facilitate the diffusion of random particle motion (heat) relative to the diffusion of directed particle motion (viscosity), viscous friction being responsible for most of the power consumed by a Bernoulli heat pump.

Owner:MACHFLOW ENERGY INC

System identification device

InactiveUS8005630B2Inhibition effectSmall operationForce measurementLinear/angular speed measurementAudio power amplifierViscous friction

Owner:YASKAWA DENKI KK

Motor, and motor control system

InactiveUS20170268524A1Fewer spinsAvoid seizuresElectric motor controlRolling contact bearingsMaximum torqueFriction torque

This invention prevents seizure of a dynamic pressure gas bearing caused upon swinging contact between a motor shaft and a sleeve and an increase in contact friction torque. It also detects rotation of auxiliary bearings. A motor includes auxiliary bearings in series with a dynamic pressure gas bearing, and a non-contact detent torque generation mechanism parallel to the auxiliary bearings suppresses rotation of the auxiliary bearings. Where Ta denotes rotation-time viscous friction torque of the dynamic pressure gas bearing, Tka denotes contact friction torque possibly causing damage to the dynamic pressure gas bearing, Tb denotes rotation friction torque of the auxiliary bearings, and Tdmax denotes maximum torque generated when rotation of the auxiliary bearings is suppressed by the non-contact detent torque generation mechanism, (Ta+Tka)>(Tb+Tdmax)>(Ta), and the rotation detecting means detects the rotation of the auxiliary bearings.

Owner:COPAL ELECTRON CO LTD

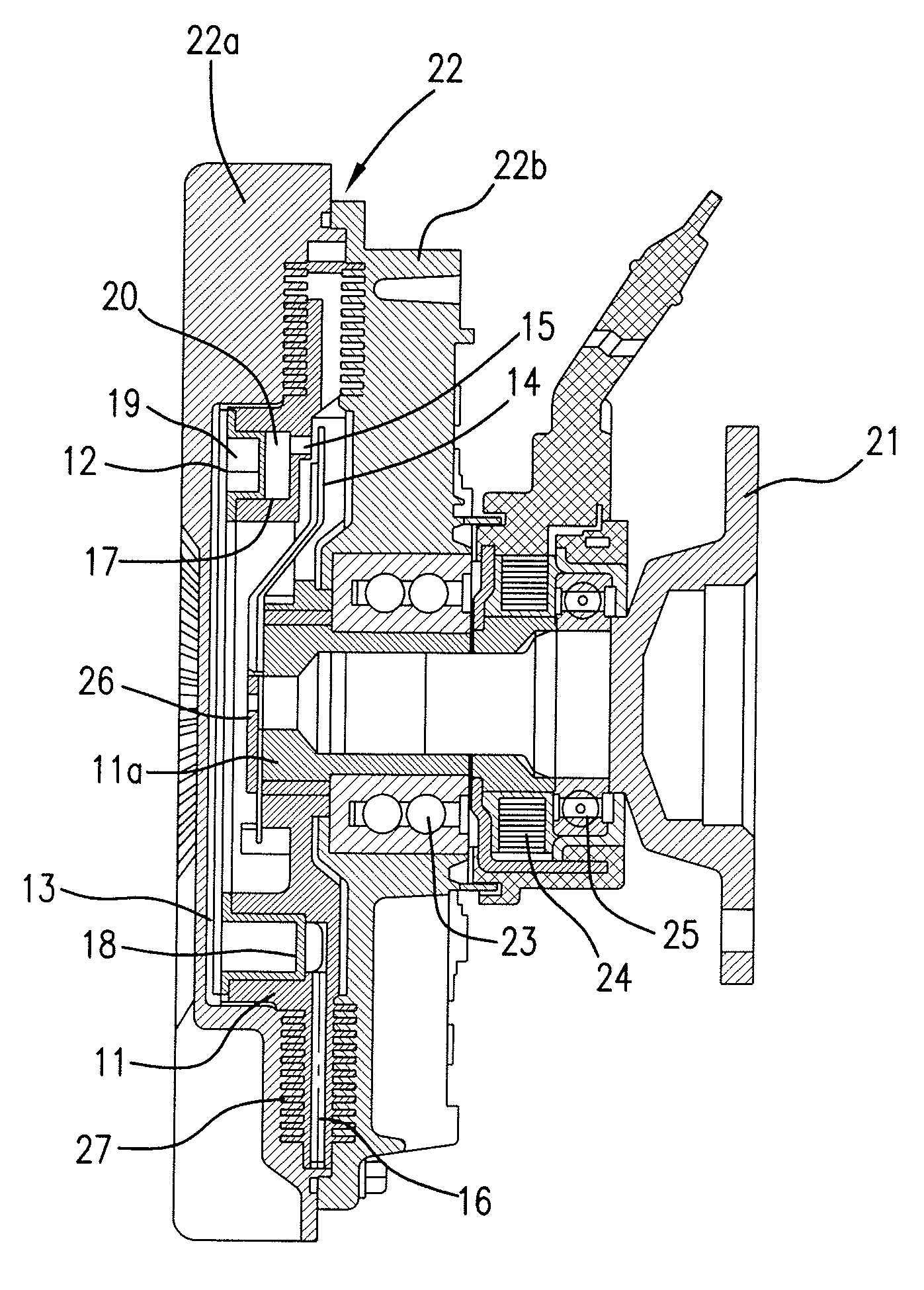

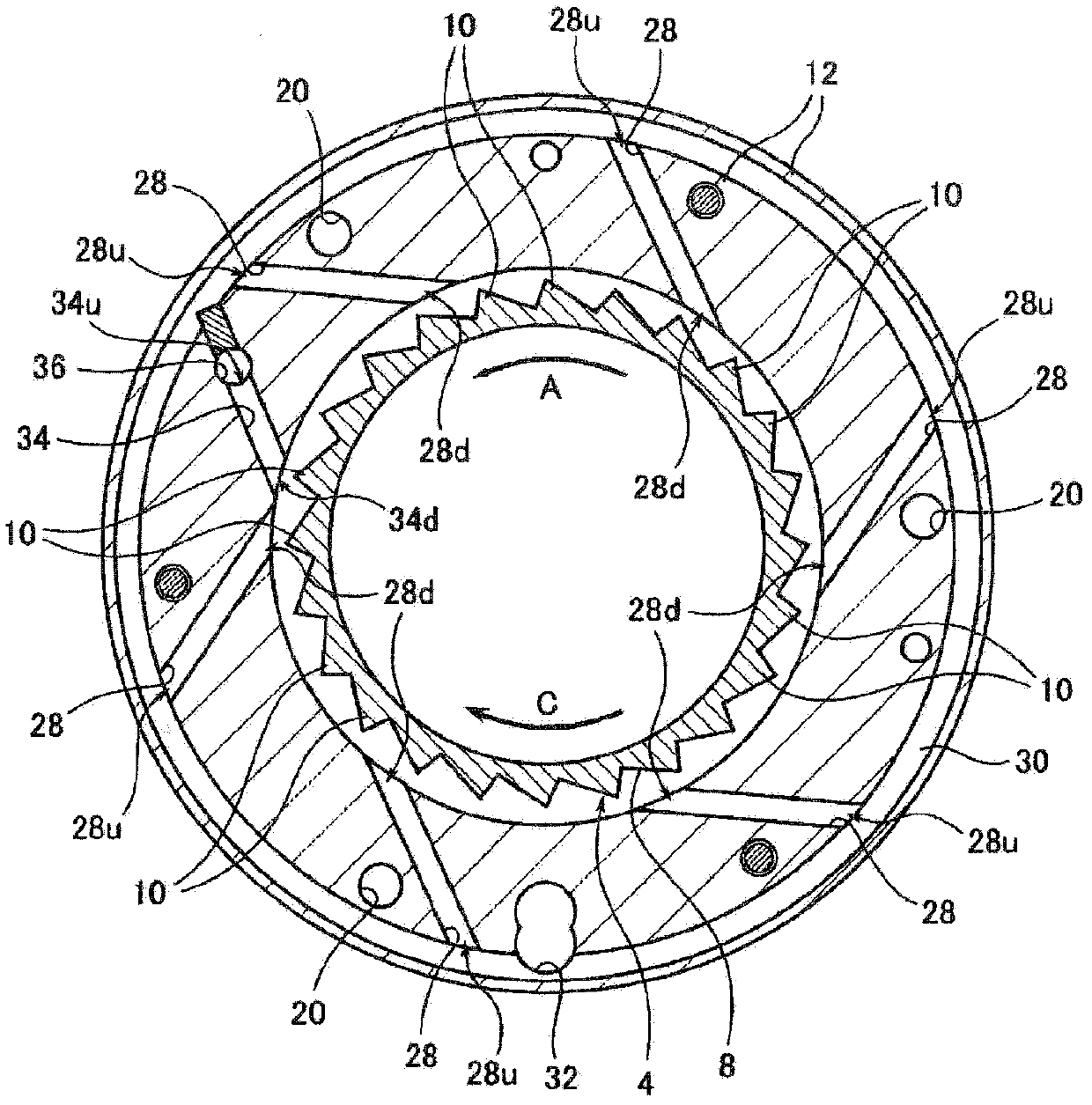

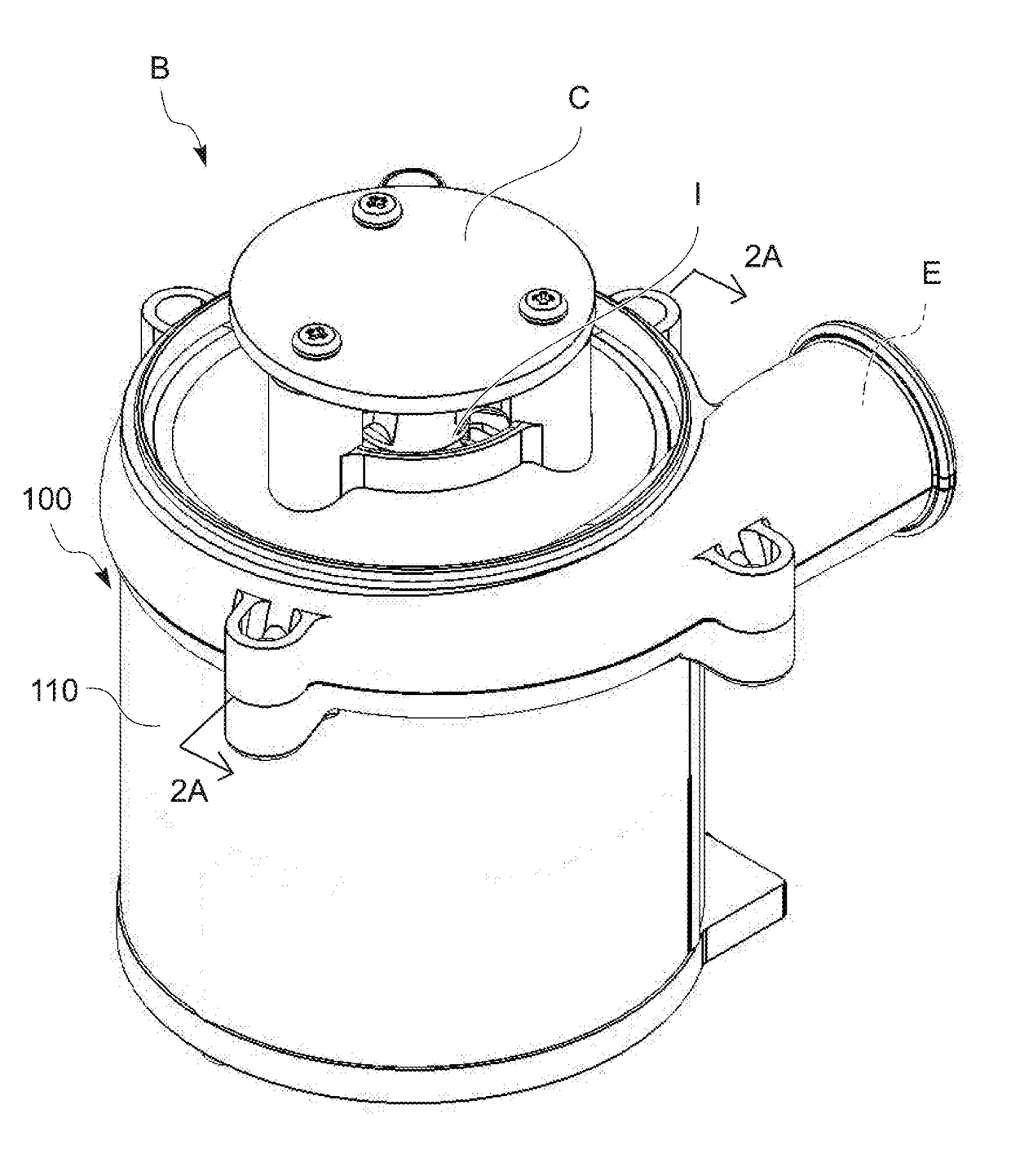

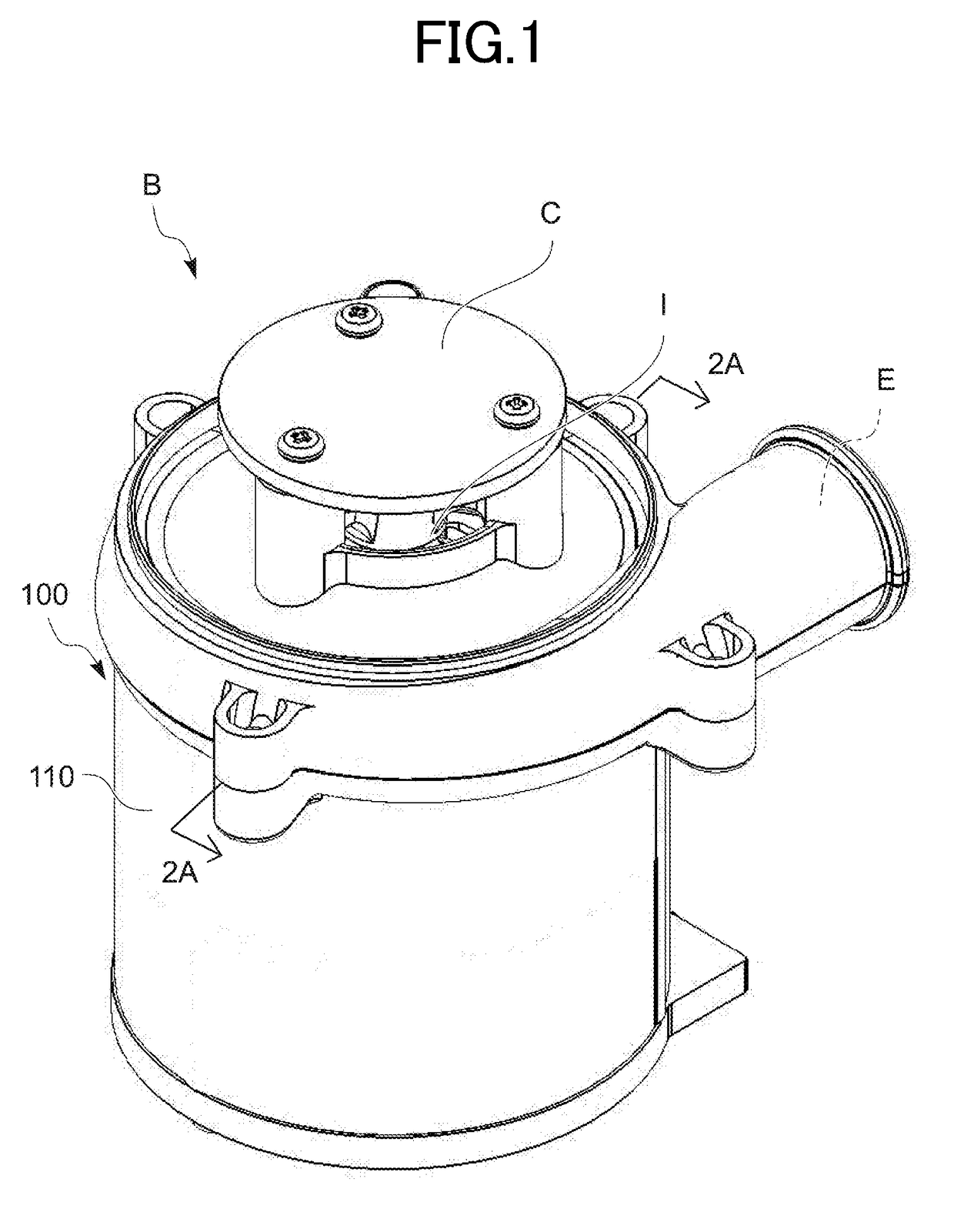

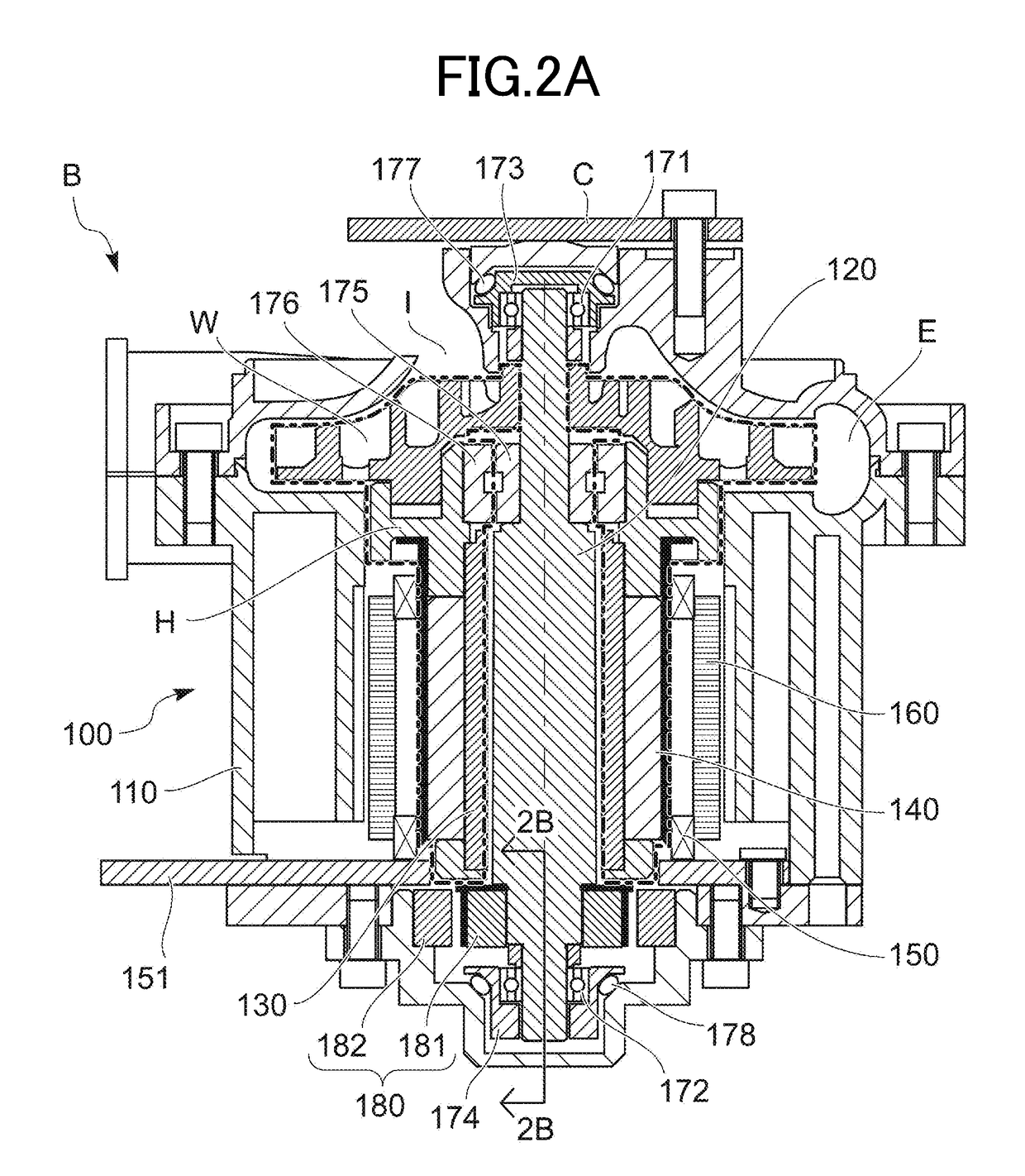

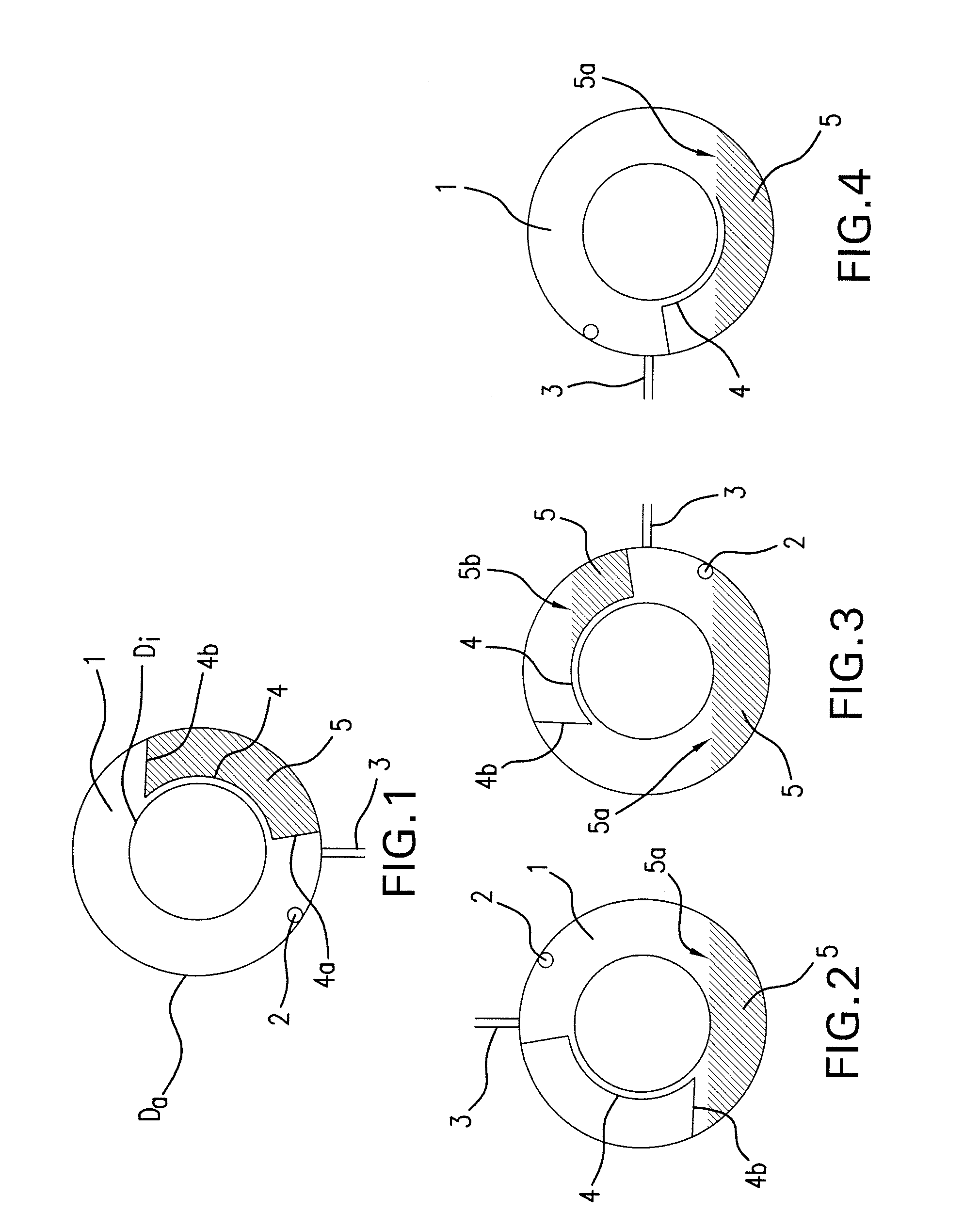

Viscous friction clutch for driving a cooling fan in a motor vehicle

A viscous friction clutch for driving a cooling fan in a motor vehicle is disclosed, wherein the viscous friction clutch comprises a driving pulley and a housing, a supply chamber and a working chamber, a device for supplying shear fluid from the supply chamber to the working chamber and a device for returning the shear fluid from the working chamber to the supply chamber.

Owner:BEHR GMBH & CO KG

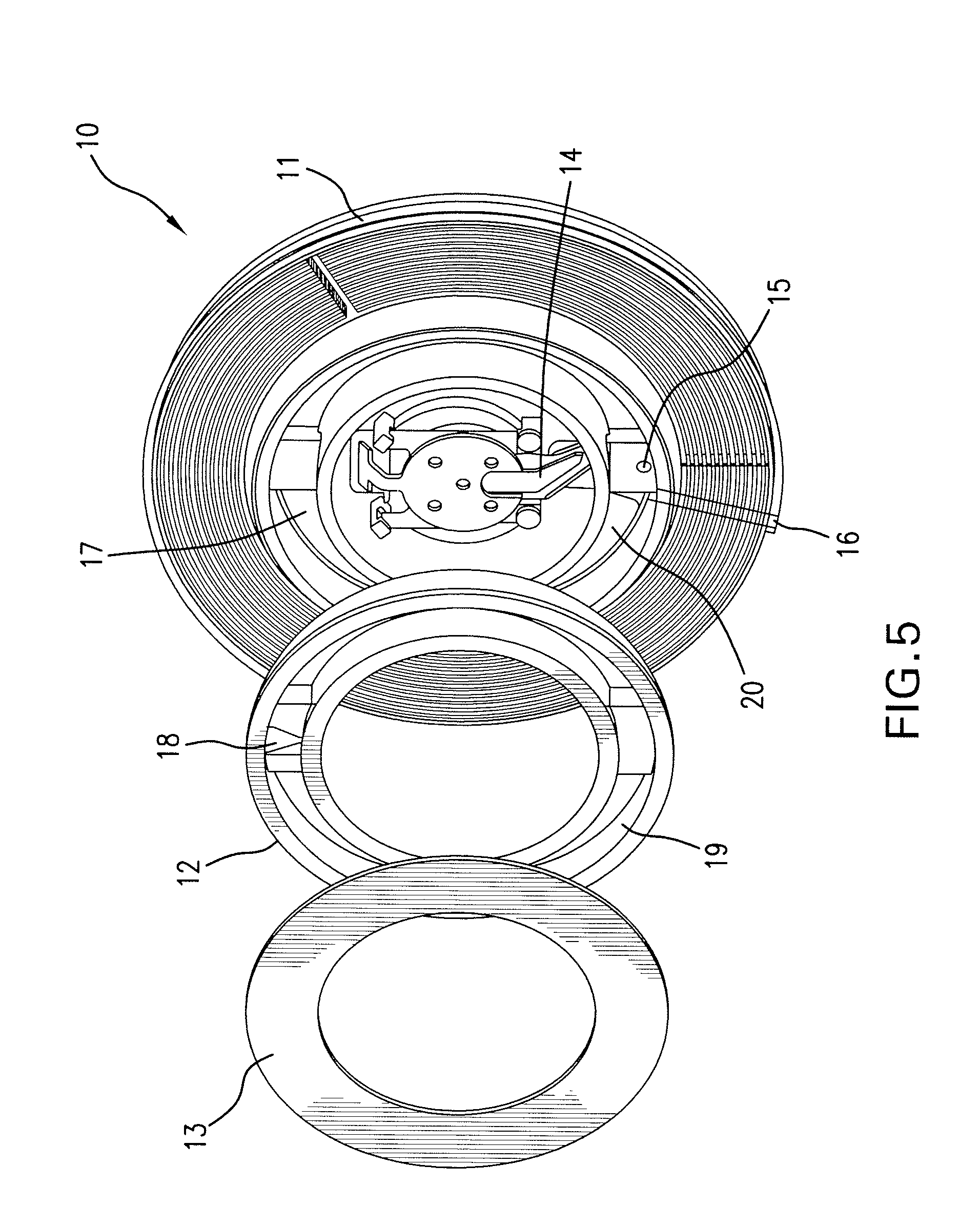

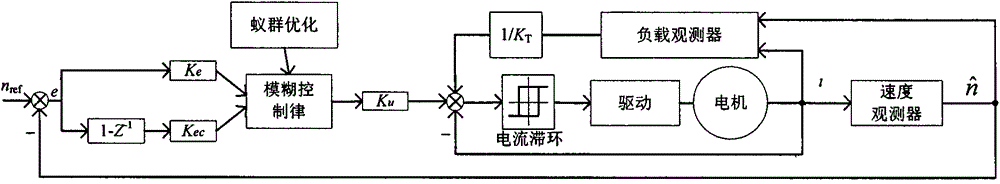

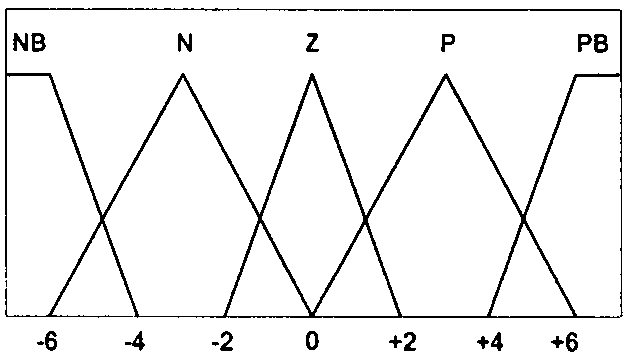

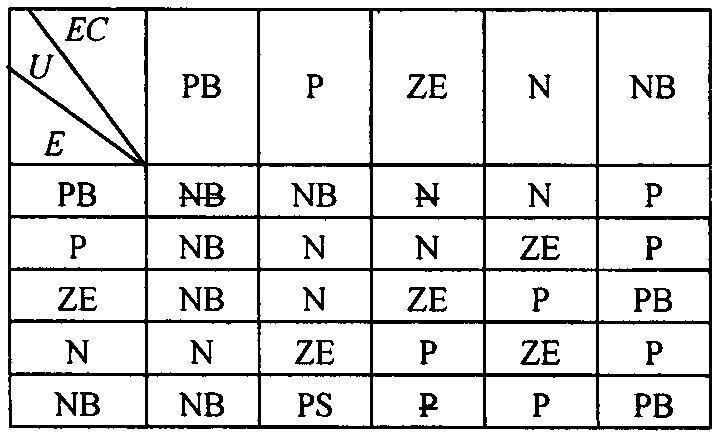

Ant colony optimization reduced order fuzzy controller

InactiveCN103560723AFew fuzzy rulesQuick responseTorque ripple controlSingle motor speed/torque controlOvervoltageHysteresis

The invention belongs to the field of intelligent control application and relates to reduced order fuzzy intelligent motor controllers, in particular to a reduced order fuzzy motor controller based on the ant colony optimization. The controller comprises an inner closed loop and an outer closed loop. The inner closed loop is a current hysteresis controller body and the outer closed loop is a fuzzy controller body. The reduced order fuzzy motor controller is characterized in that a velocity error and a velocity change error are adopted by the fuzzy control strategy and serve as input, fuzzy output serves as input of a current loop after an ambiguity solving change factor Ku acts on the fuzzy output, the number of fuzzy rules which are optimized through the ant colony optimization is 22, load torque estimation can be conducted by the current hysteresis controller body through observation of change of rotational inertia and a viscous friction coefficient, so that compensation control over a current is achieved, the effect that the torque ripple is restrained is achieved, the control strategy is achieved through a TMS320LF2407A chip, parameters of the chip can be corrected online, and the overvoltage and overcurrent protection functions can be achieved.

Owner:TIANJIN POLYTECHNIC UNIV

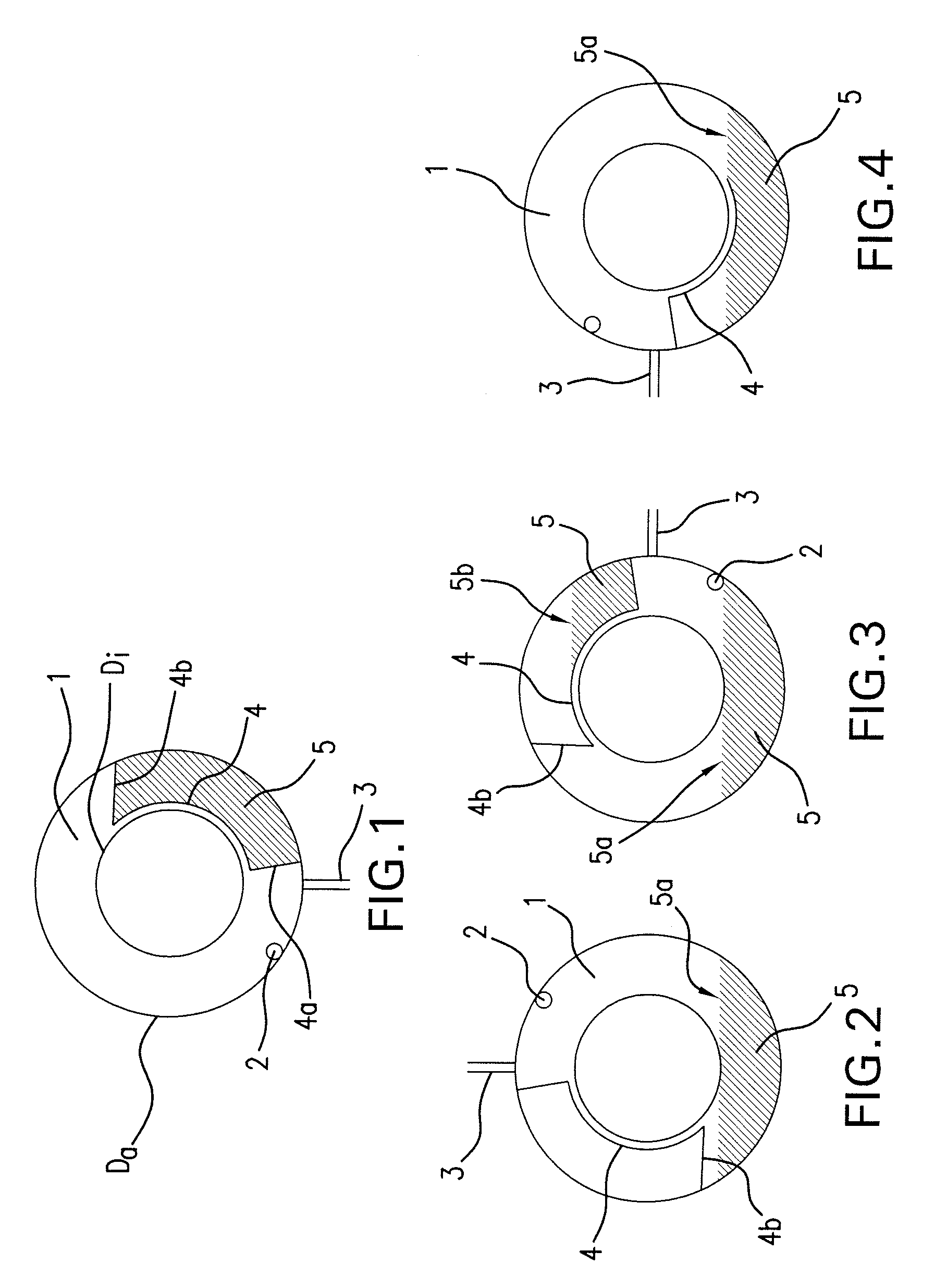

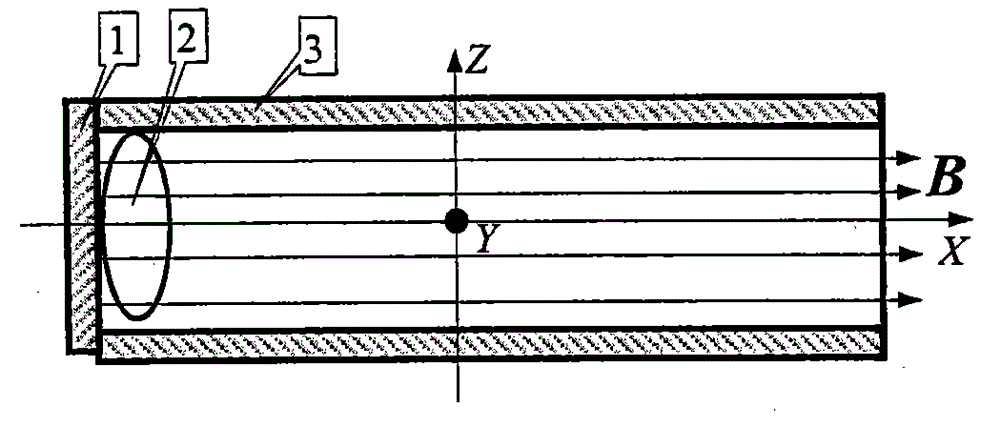

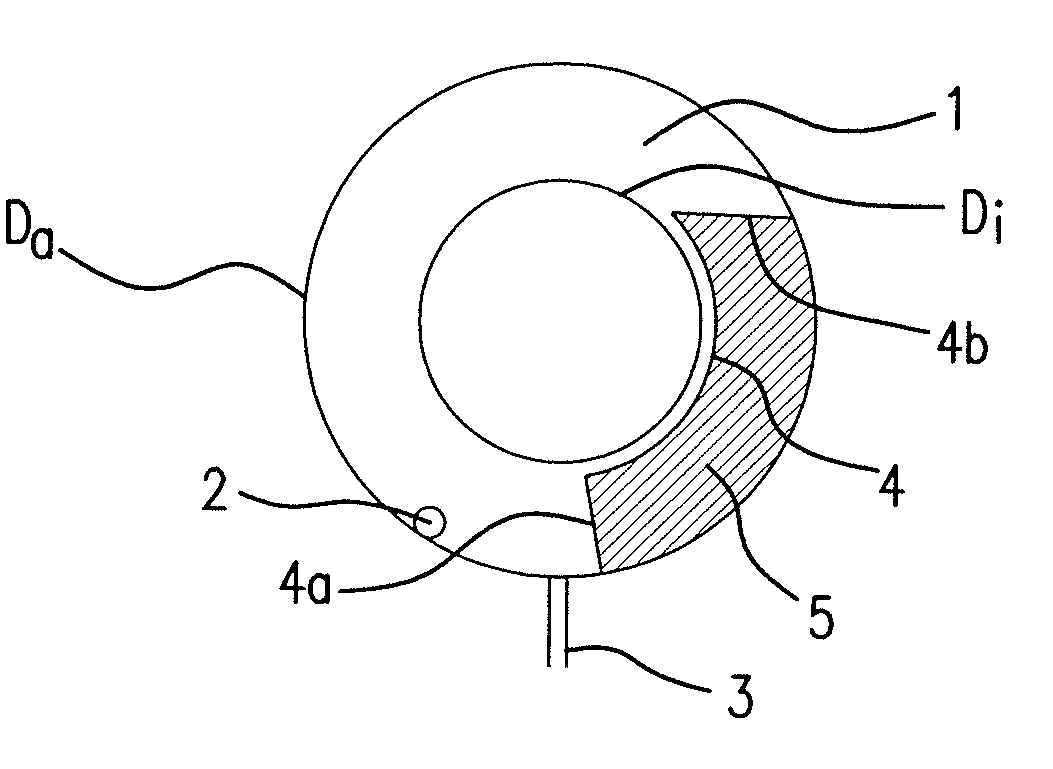

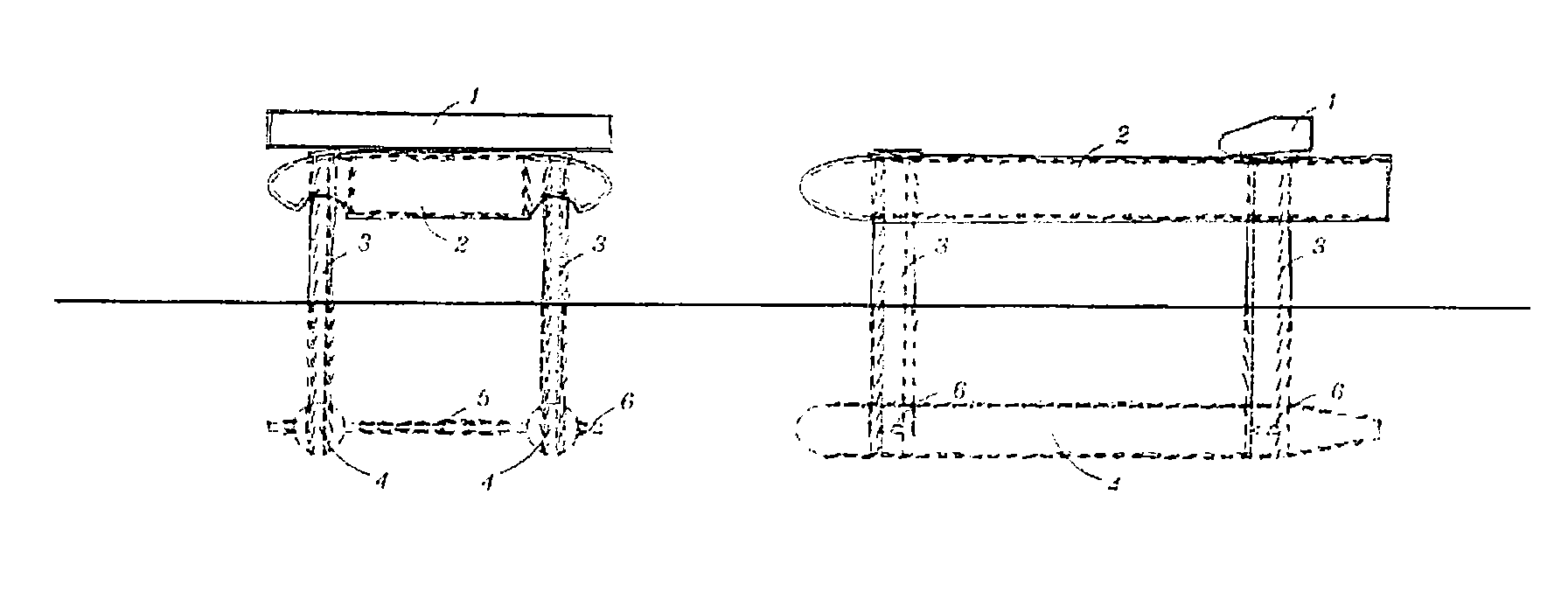

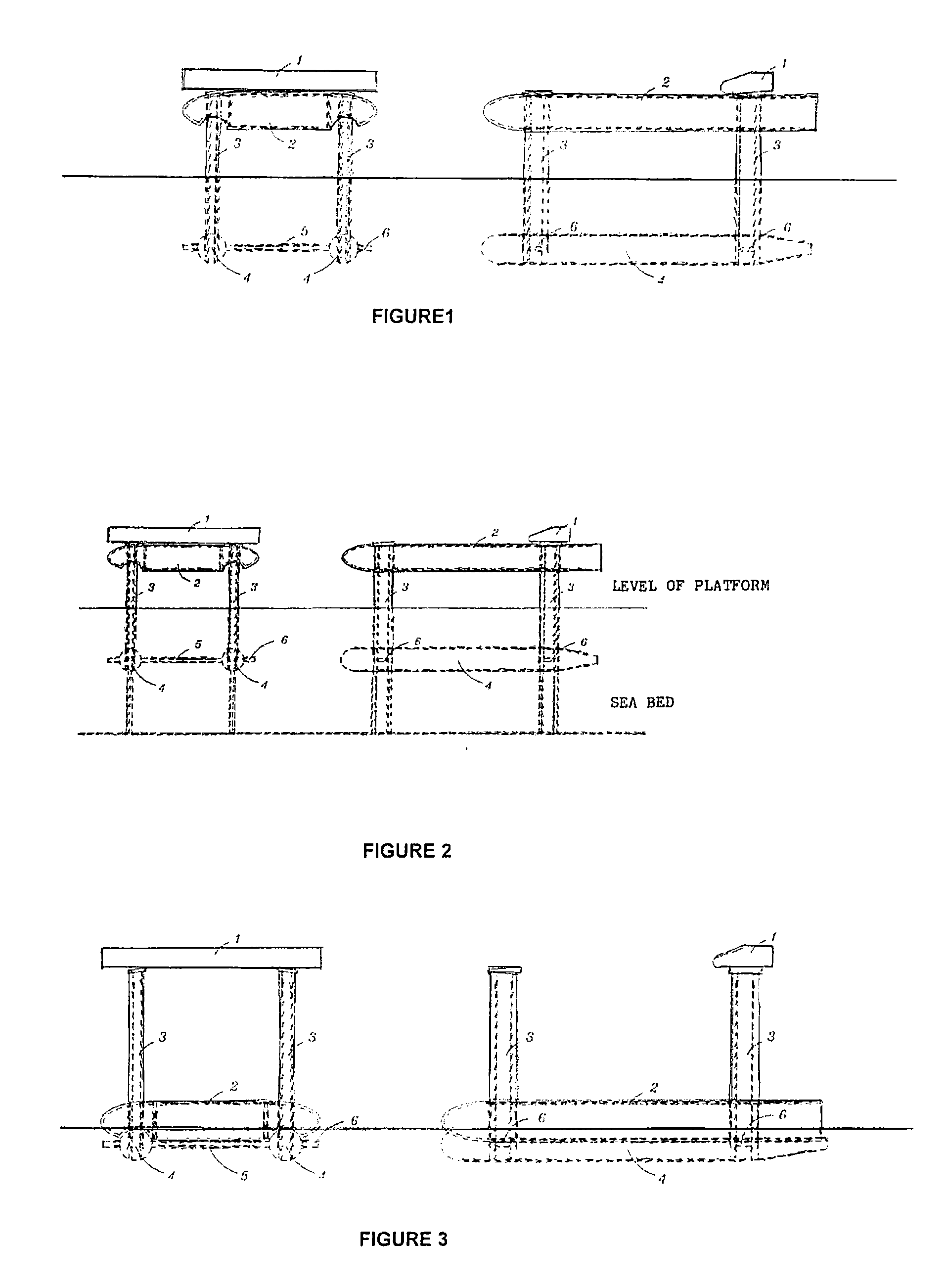

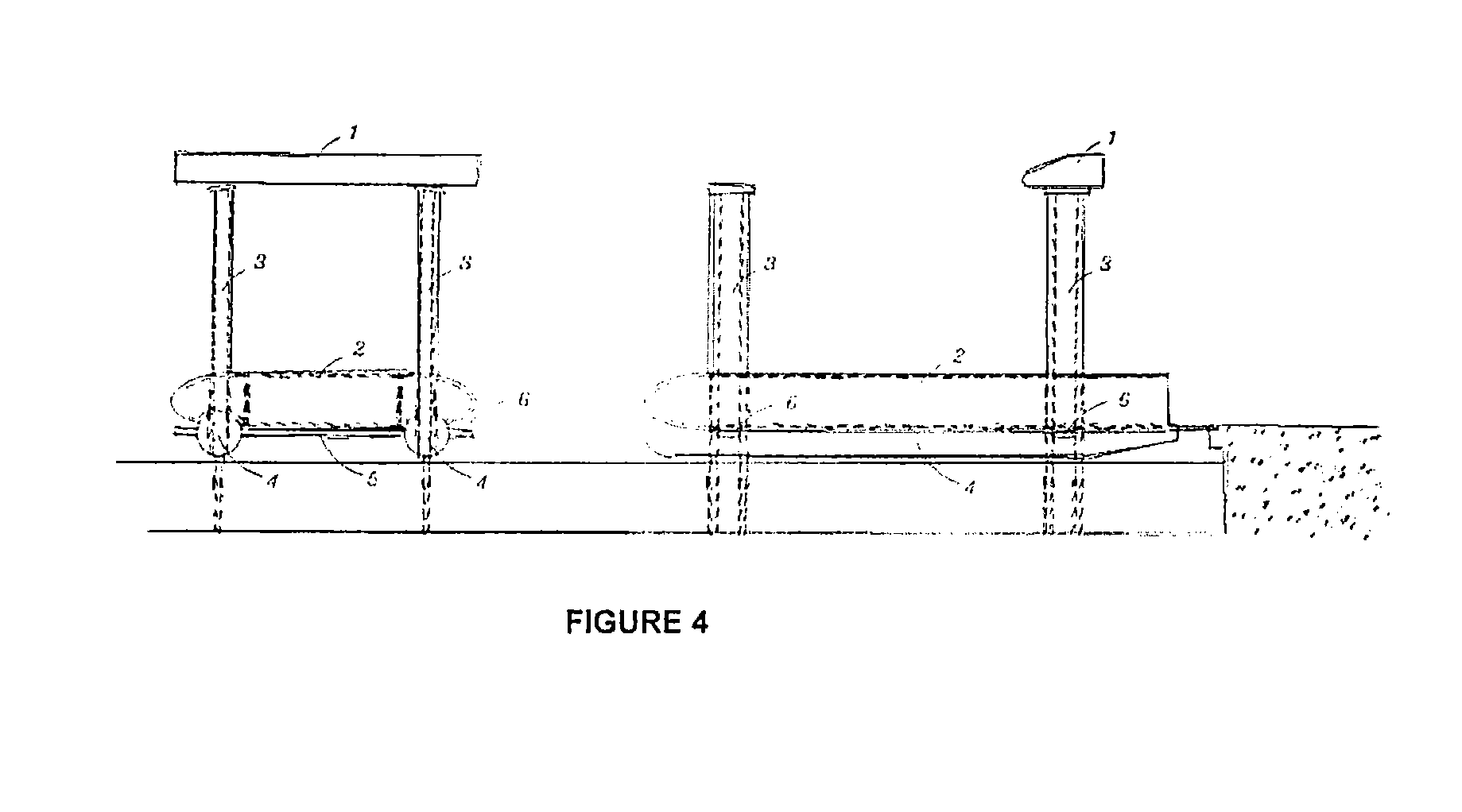

Vessel with submersible hulls

InactiveUS20120304909A1Reduce usageReduce viscous resistanceWatercraft hull designFloating buildingsPorosityMarine engineering

New design of vessel with submersible hulls which can transport large cargos at high speed sailing above the waves and which is made up of two parallel submerged bodies (4), clearly cylindrical in cross-section or as hydrodynamic as possible, joined by hydrodynamic profiles (5).Four hydrodynamic legs (3) are located in the confluence between the cylinders (4) and the profiles (5) capable of supporting a platform or loading zone (2) which can move (up or down) on the legs (3) which have a system of vertical displacement so as to raise itself above the level of the waves.The parallel bodies of submerged displacement (4) joined to the hydro-dynamic profiles (5) can be completely covered with a textile of permeable sheets of porosity less than the size of a molecule of water and greater than that of a molecule of air and air can be pumped into the interior. The air molecules escape via the pores breaking the outer layer and separating the water molecules from the submerged area so as to reduce viscous friction to a significant degree.The lower works can be raised to the level of the sea to load and material in their interior or to enter shallow water ports.

Owner:GRUPO DE ING OCEANICA

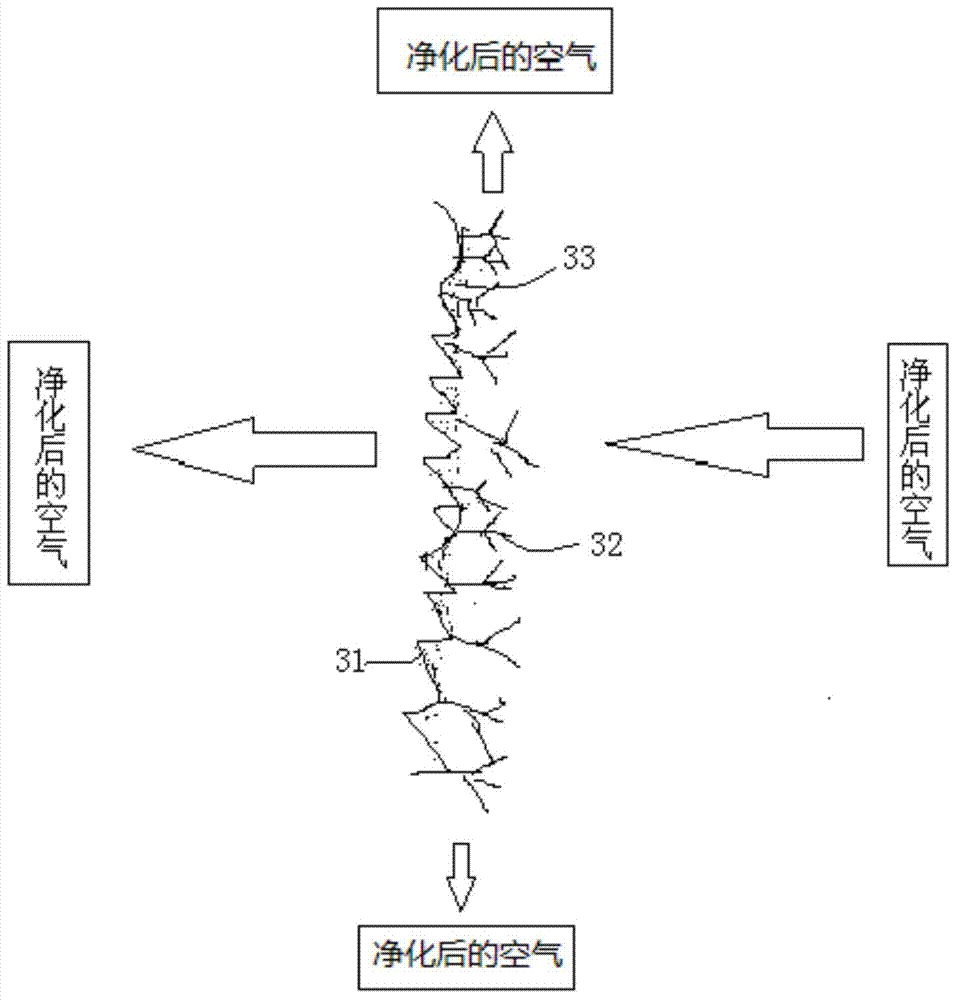

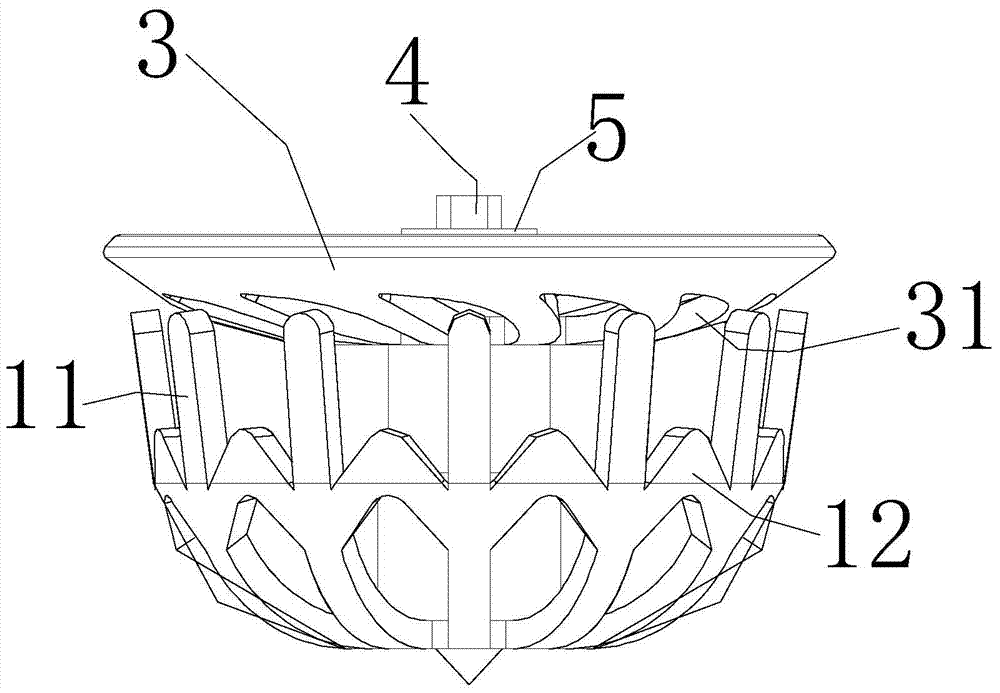

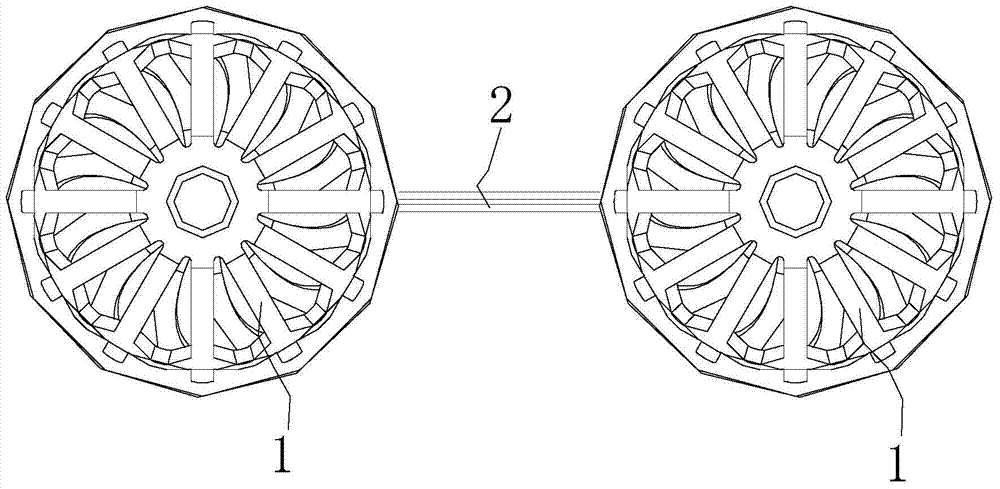

Air purification method and device

InactiveCN103657262AImprove purification effectAdd inertial collisionDispersed particle separationParticulatesGas phase

The invention discloses an air purification method, which comprises the steps that (1) the air flowing randomness is increased, and turbulent flow is formed or enhanced; (2) the turbulent flow air is in contact with a purification surface. The invention also discloses an air purification device, which comprises a turbulent flow forming and enhancing device and the purification surface, wherein the purification surface is a viscous surface, and the viscous friction stress of the viscous surface on particles in the air is obviously greater than the viscous friction stress of gas phase substances in the air on the particles. The method and the device provided by the invention have the following advantages and beneficial effects that through the turbulent flow formation of the air and the turbulent flow enhancement, the inertia collision between the particles in the air and the viscous surface is effectively enhanced, the sedimentation effect at the maximum efficiency is generated, in addition, the contact occasion between the particles in the air and the viscous surface is increased, particles which are not sedimented are effectively pasted by the viscous surface and are removed, so the air purification effect can be effectively improved.

Owner:彭健智

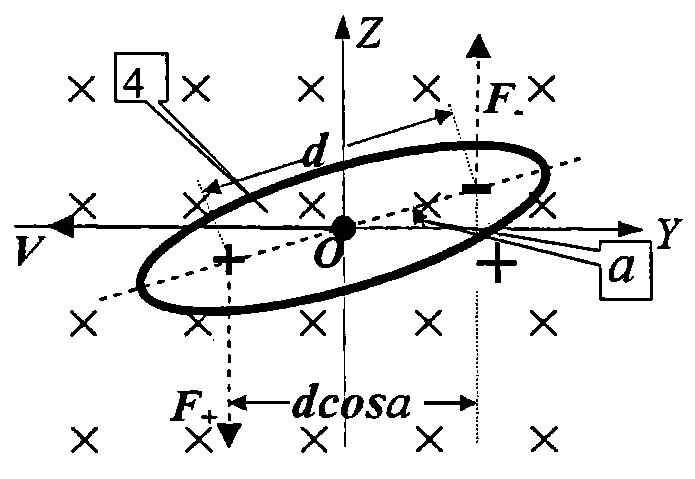

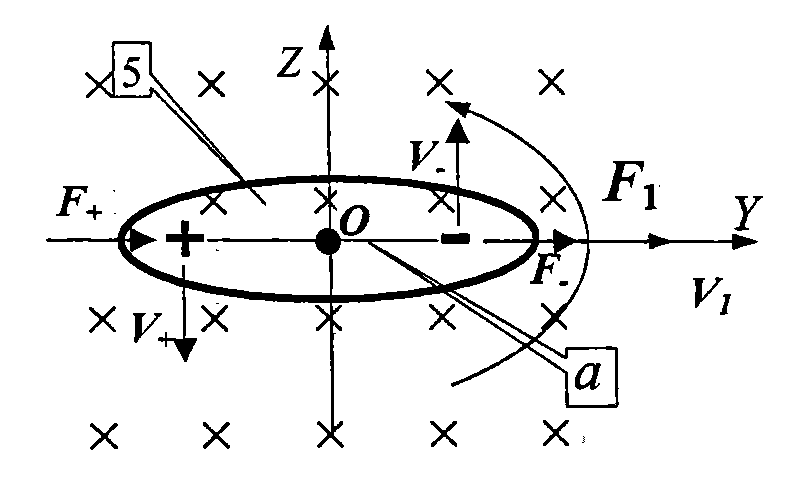

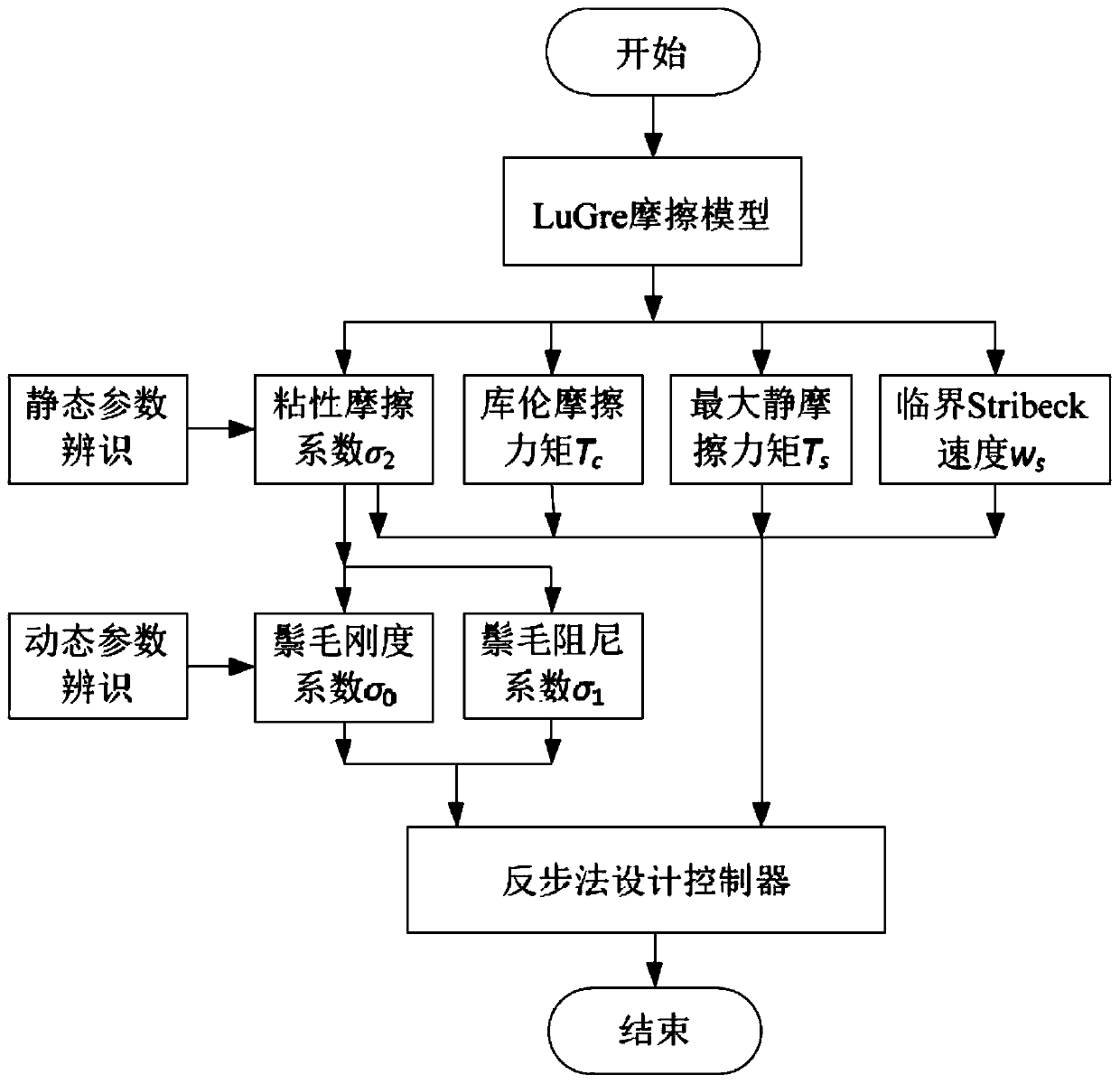

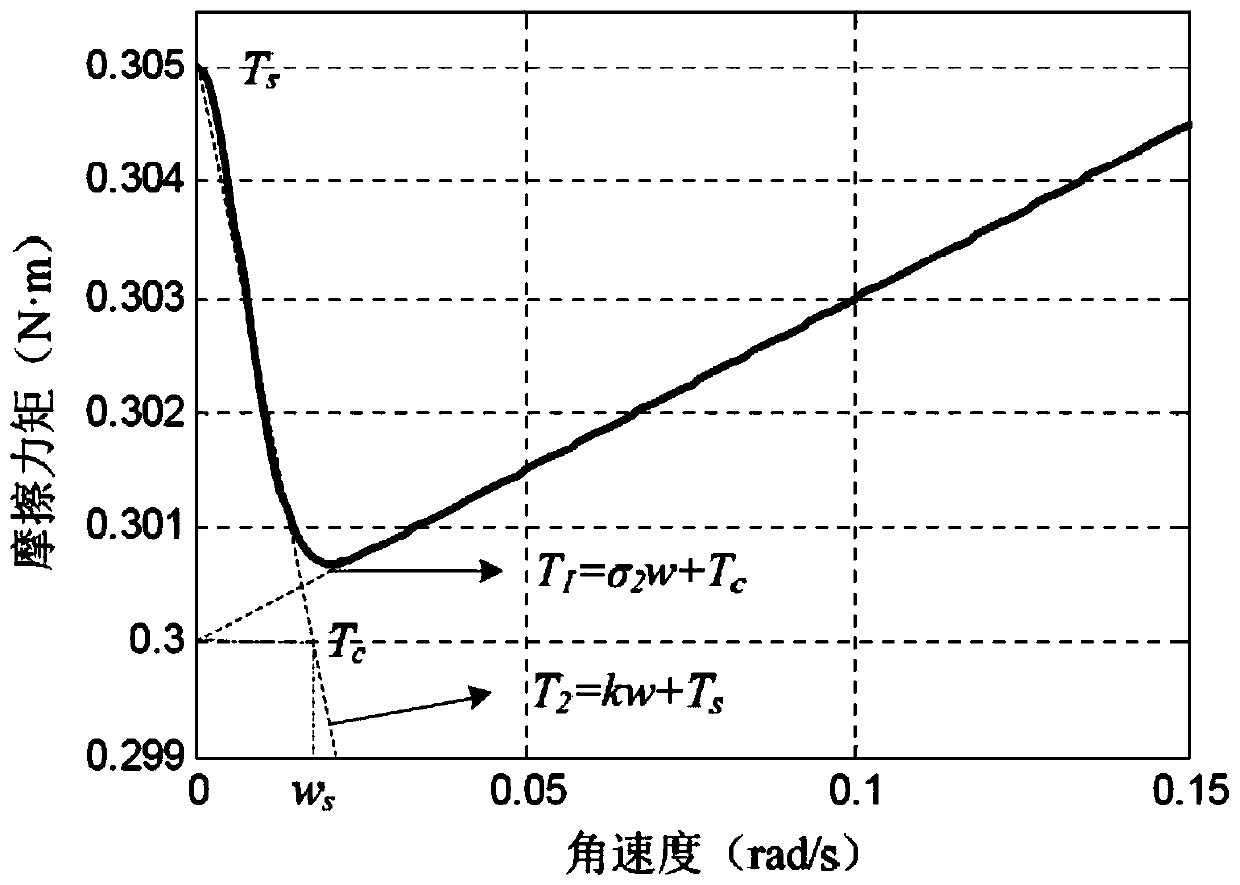

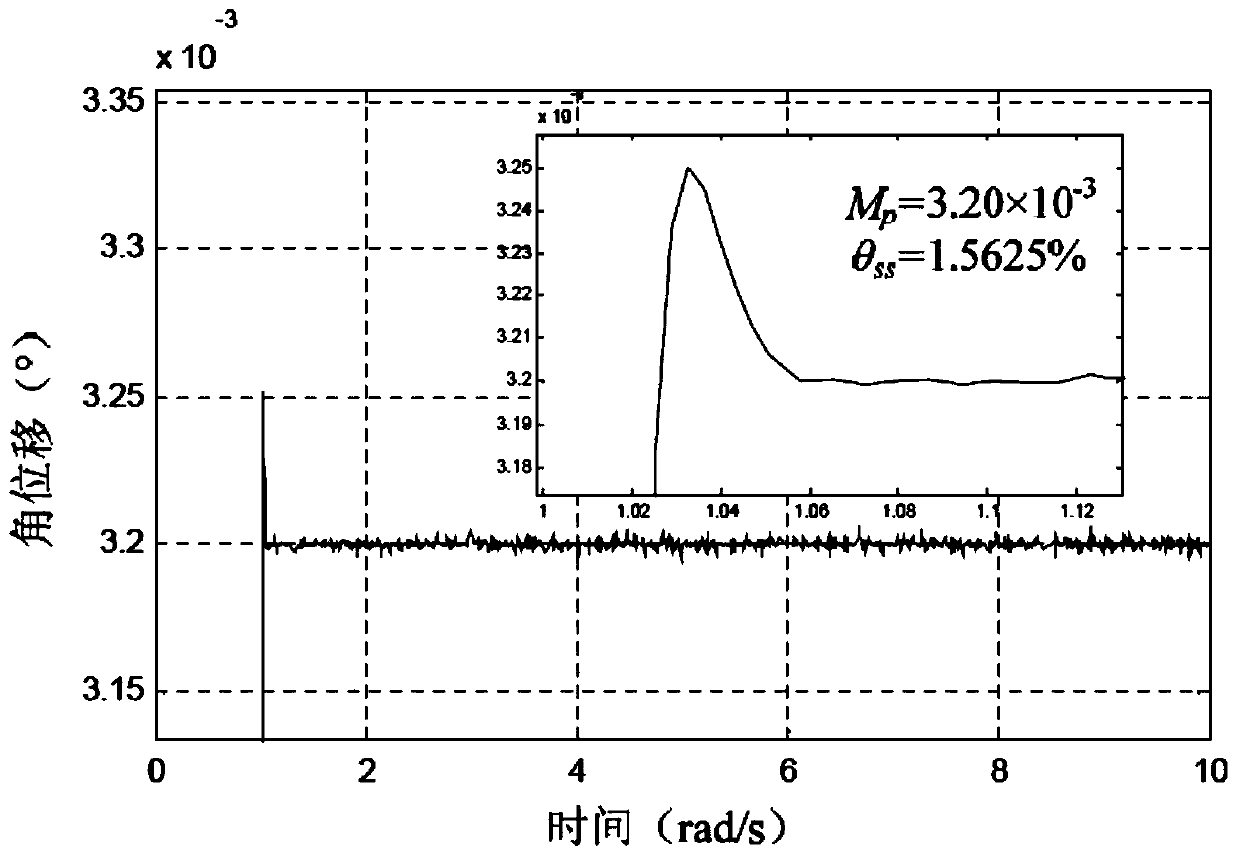

Lorentz inertial stabilization platform friction recognition and compensation control method

PendingCN111580539AResolve interferenceHigh stability and precisionAttitude controlFriction torqueFrictional coefficient

The invention discloses a friction recognition and compensation control method for a Lorentz inertially stabilized platform. Aiming at the non-linear friction force between a bearing and a stator whenthe Lorentz inertial stabilization platform works, LuGre friction models of static and dynamic friction characteristics under platform deflection are established. Measuring a Stribeck curve through aconstant-speed deflection experiment, carrying out data fitting by adopting a linear regression equation based on a least square method, and identifying static parameters of the model; based on the viscous friction coefficient in the static parameters, the micro bristle deformation idea is adopted, the pre-sliding phenomenon is equivalent to second-order damping oscillation motion, and the dynamic parameters are solved by measuring the step response of the system. According to identified static and dynamic parameters, a Lyapunov function is constructed by adopting a back-stepping recursion thought, the design of a nonlinear feedback compensation controller is completed, and the problem of interference of nonlinear friction torque on rotor deflection is solved. The invention belongs to thefield of inertially stabilized platform control, and is suitable for recognition and compensation control of nonlinear friction torque of a platform.

Owner:BEIJING INSTITUTE OF PETROCHEMICAL TECHNOLOGY

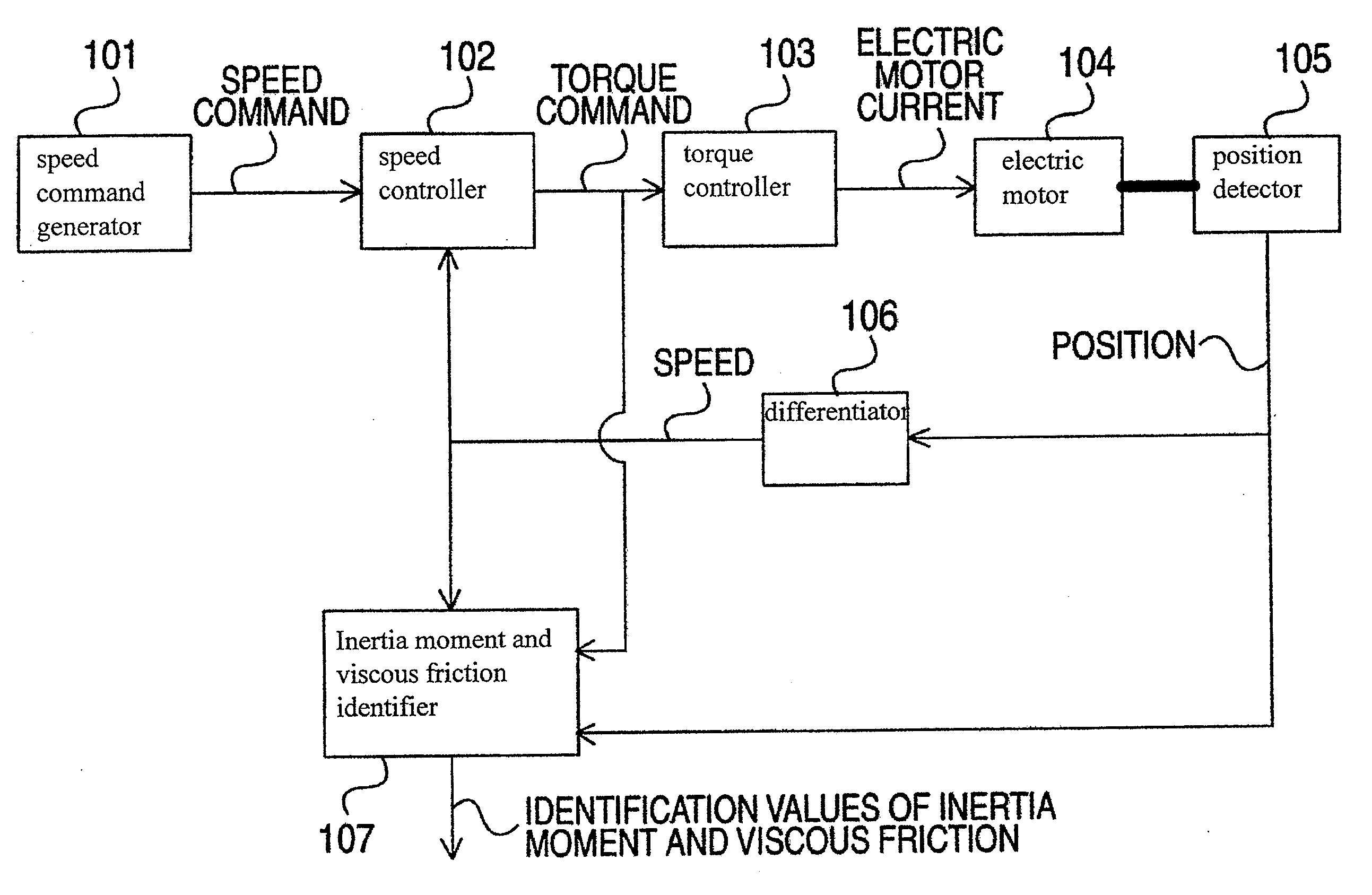

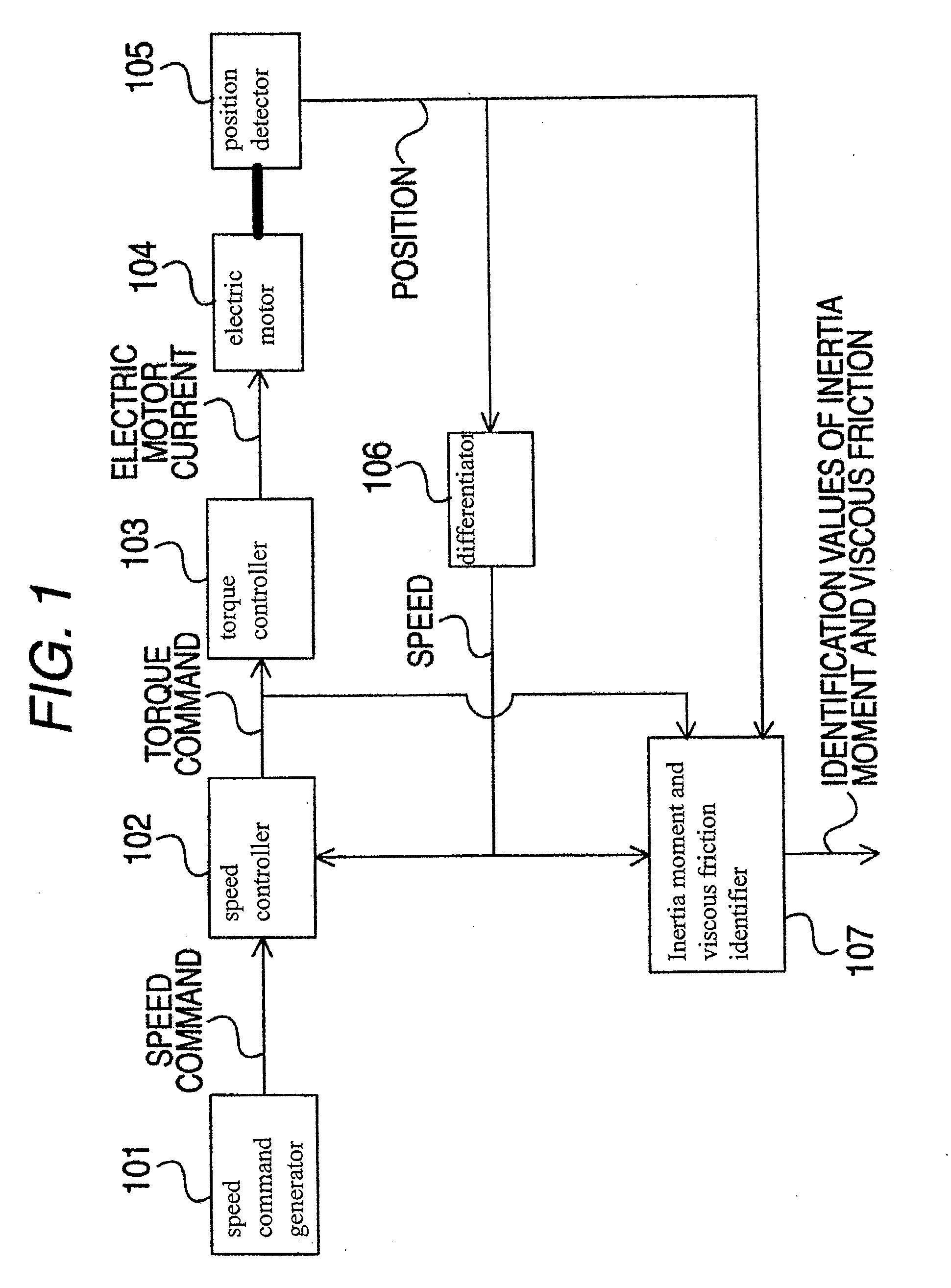

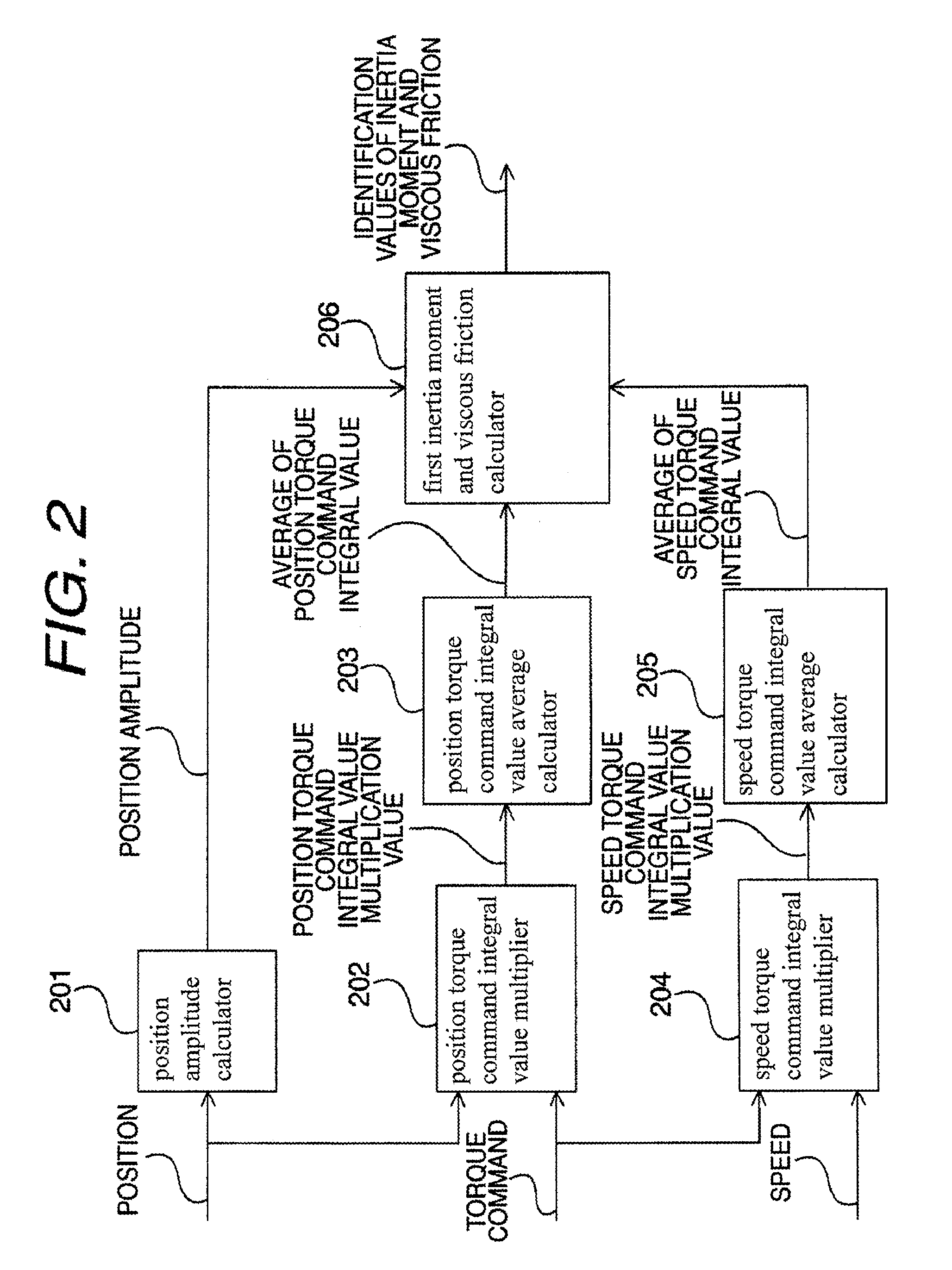

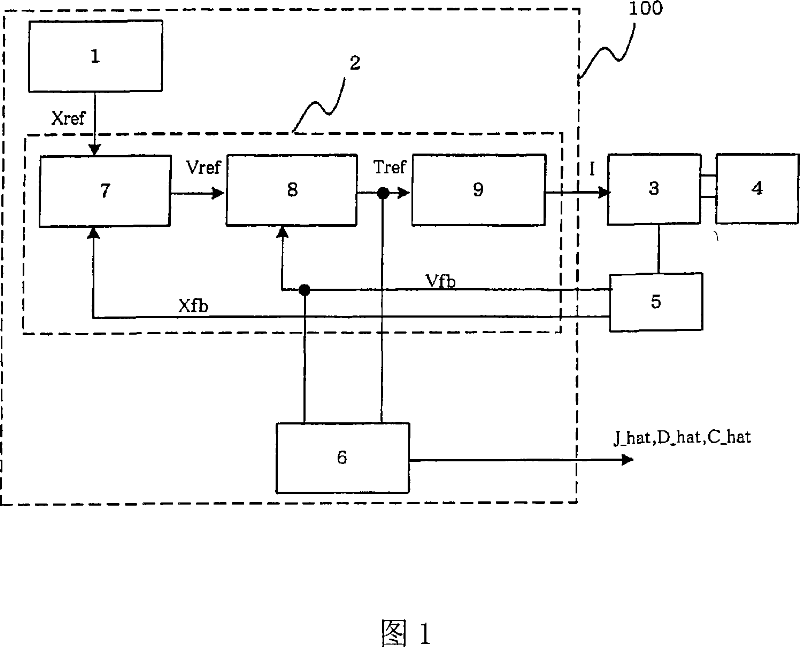

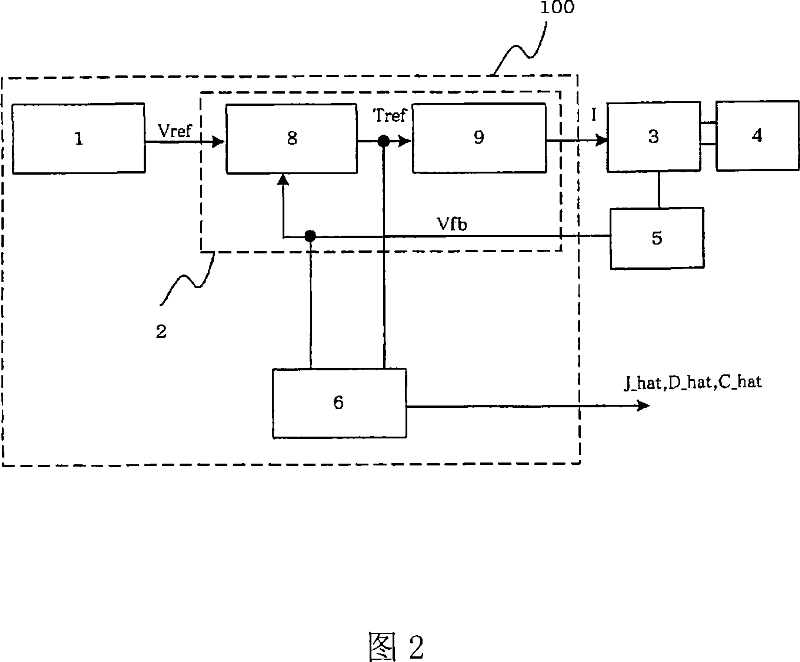

Motion controller and system identifying method

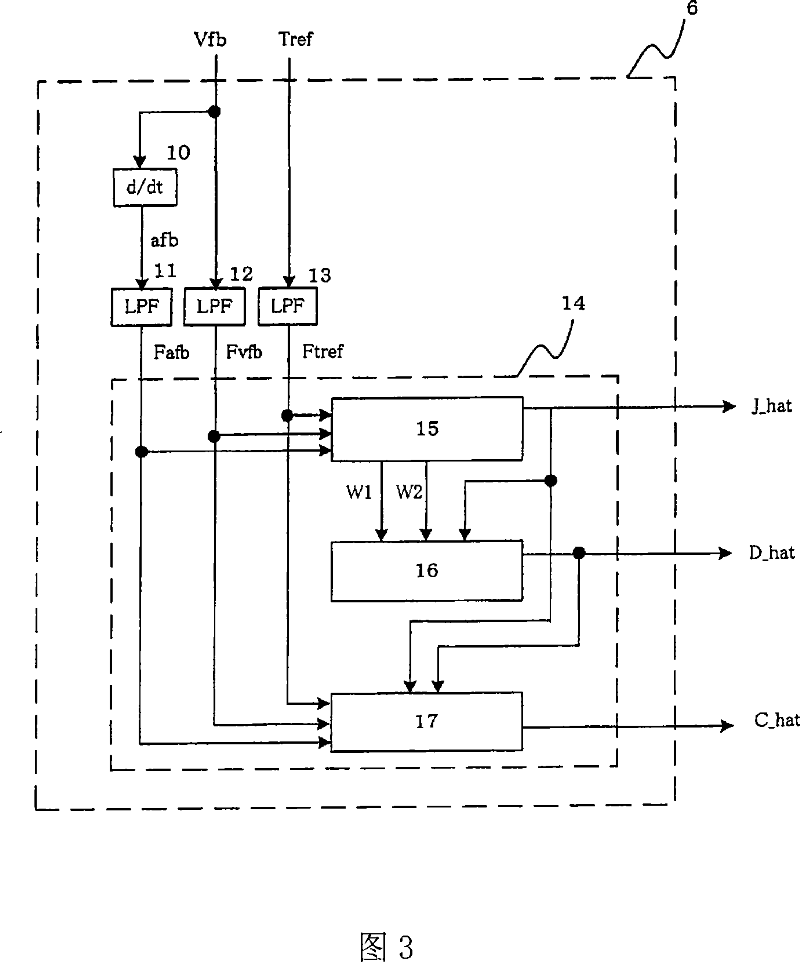

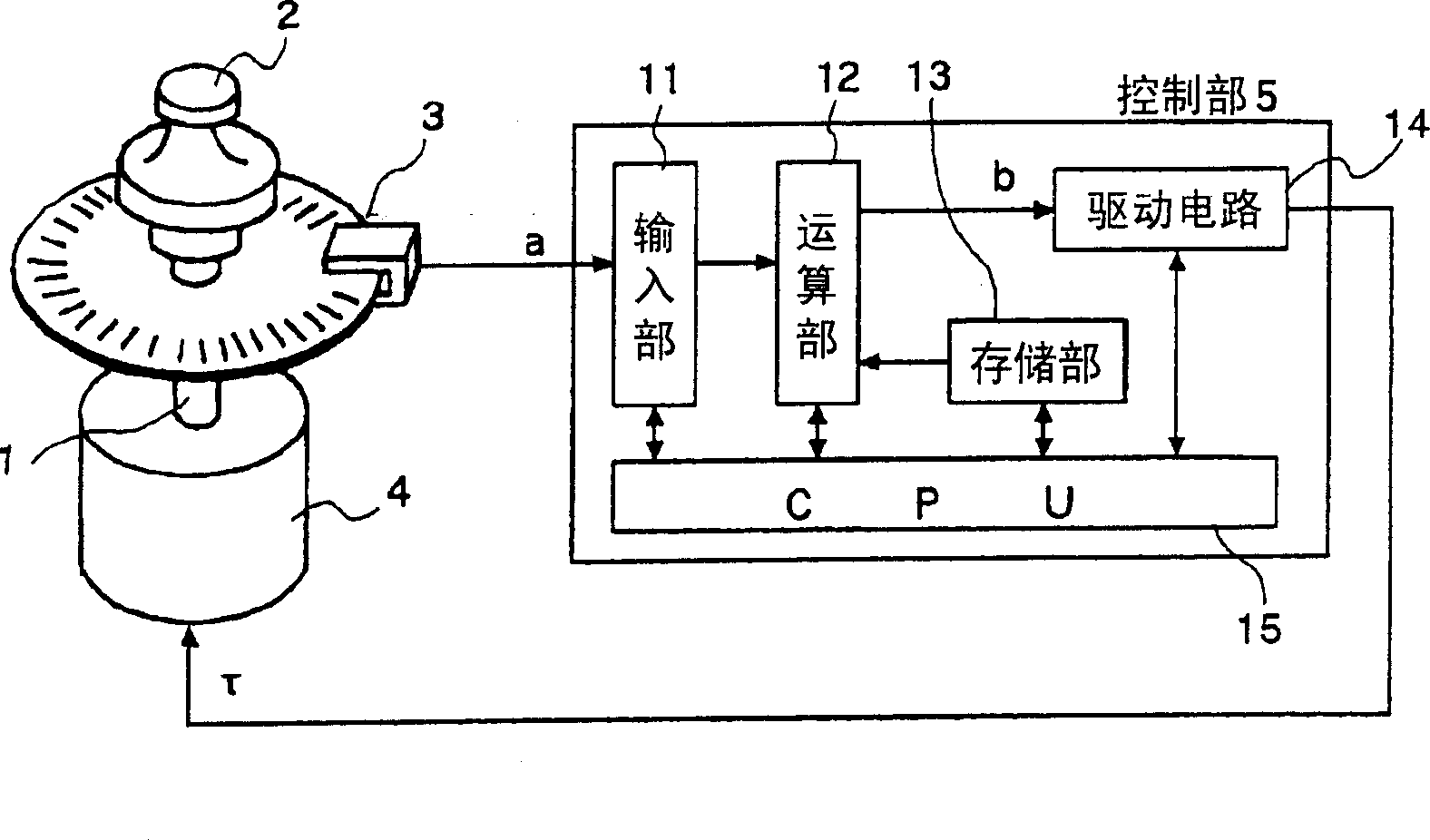

InactiveCN101044673AEasy to identifyReduce the impact of interferenceElectric motor controlMotor parameters estimation/adaptationDifferentiatorViscous friction

A motion controller accurately identifies system constants, such as inertia, viscous friction coefficient, and constant disturbance, without requiring operation, even in cases where viscous friction and / or constant disturbance are present. An identifier includes a time-differentiator for calculating an acceleration detection value afb by time-differentiating a speed detection value Vfb, a first filter for calculating Fafb by filtering the acceleration detection value afb, a second filter for calculating Fvfb by filtering the speed detection value Vfb, a third filter for calculating Ftref by filtering a torque command value Tref, and a JDC estimator for calculating an inertia identification value J_hat, a viscous friction coefficient identification value D_hat, and a constant disturbance identification value C_hat of a control object by performing time-differentiation and four arithmetic operations based on Ftref, Fvfb and Fafb.

Owner:YASKAWA DENKI KK

Force-applying input device

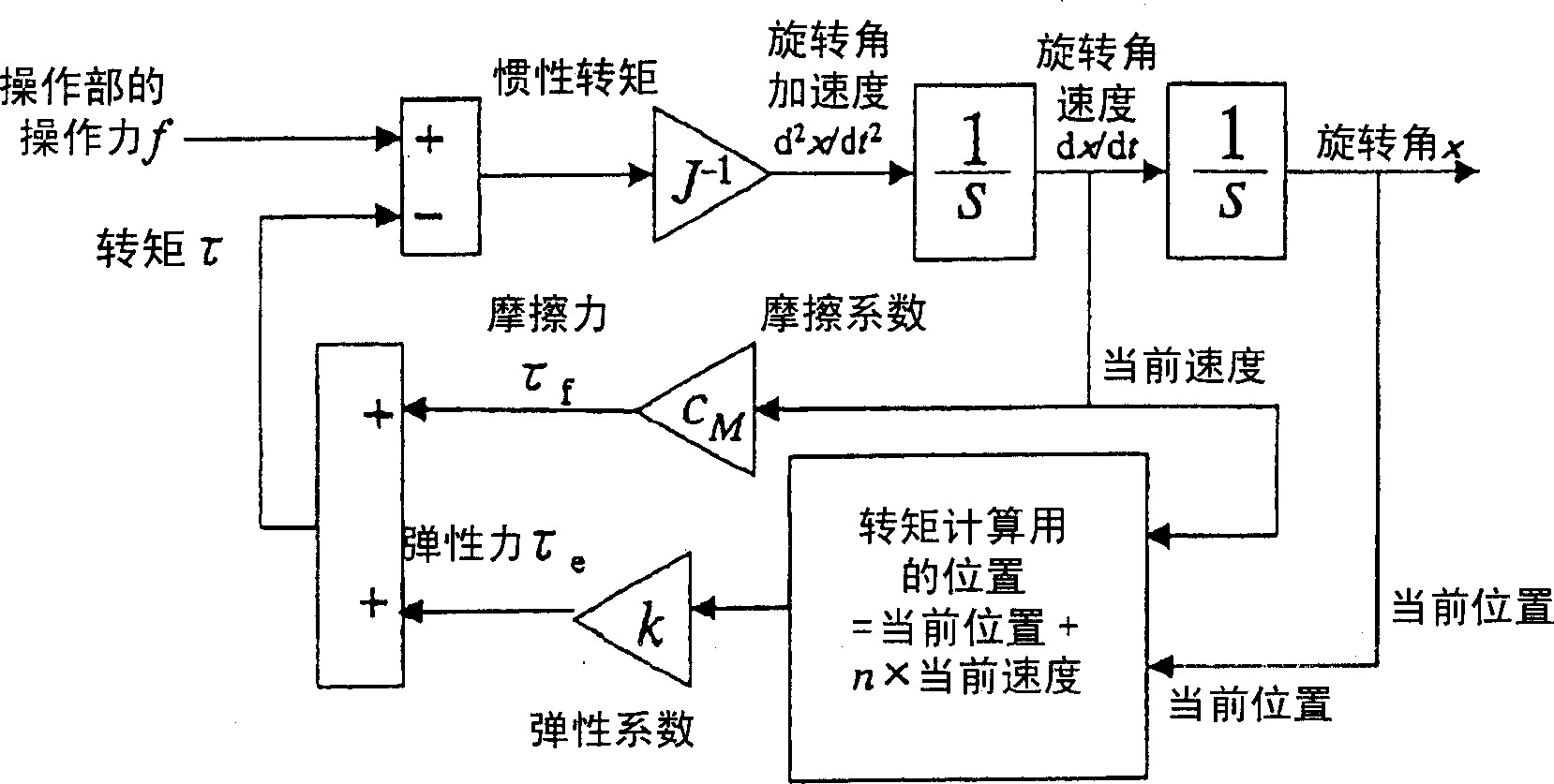

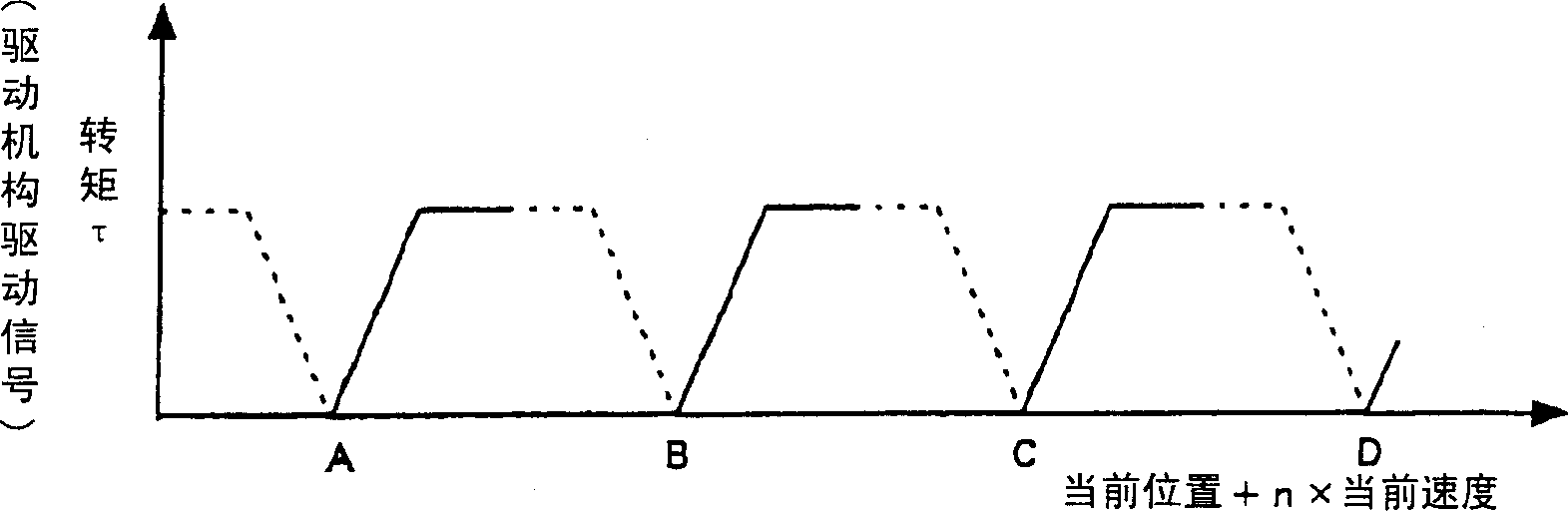

InactiveCN1523480AInput/output for user-computer interactionControlling membersFrictional coefficientSensing applications

Provided is an inner force sense application type input device capable of applying inner force sense to an operation part when operating the operation part and capable of stably controlling the inner force sense. A product of current speed dx / dt and a coefficient (n) is added to a current position (x) and the added value is multiplied by an elastic coefficient (k) to calculate a torque component [tau]e corresponding to the current position (x) of an actuator driving signal [tau]. The current speed dx / dt is multiplied by a viscous friction coefficient Cm to calculate a torque component [tau]f corresponding to the current speed dx / dt.

Owner:ALPS ALPINE CO LTD

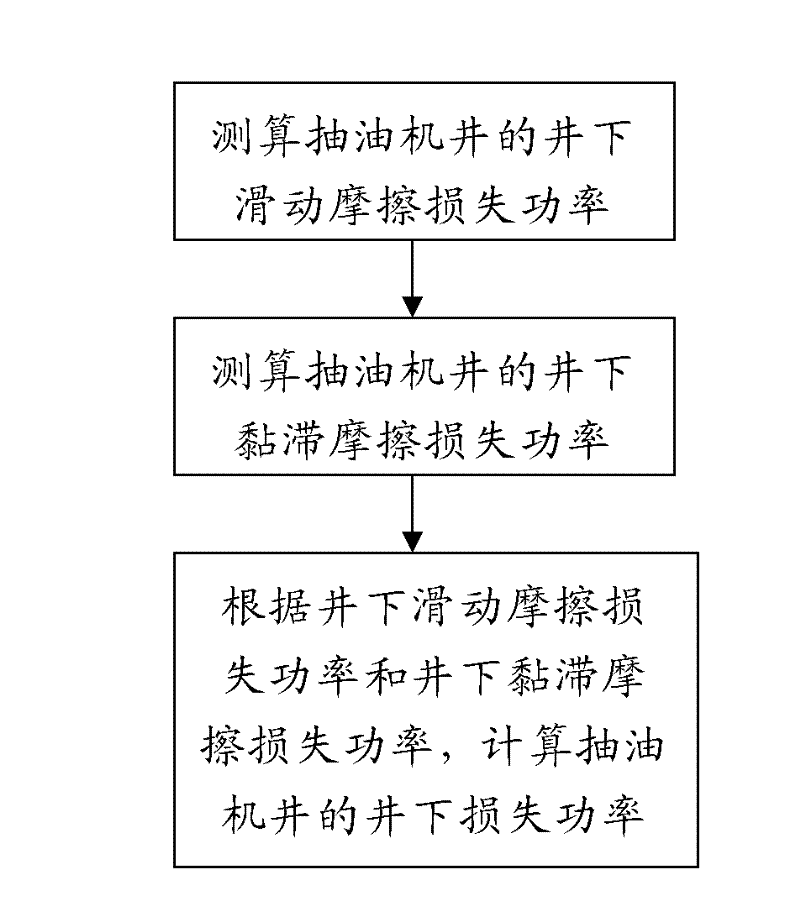

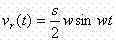

Method for measuring and calculating downhole power loss of rod-pumped wells

InactiveCN102507059AAvoid hard-to-determine problemsSolving problems that become difficult to solveWork measurementTorque measurementViscous frictionOil production

The invention relates to the technical field of oil production, in particular to a method for measuring and calculating downhole power loss of rod-pumped wells, which mainly solves problems that existing measurement and calculation methods are incapable of reflecting components of downhole power loss objectively, incapable of properly handling irregularity of well deflection tracks and the defect that viscosity of crude oil varies along with temperature. The method includes the following steps: measuring and calculating downhole sliding friction power loss of the rod-pumped wells; measuring and calculating downhole viscous friction power loss of the rod-pumped wells; and measuring and calculating the downhole power loss of the rod-pumped wells according to the measured and calculated downhole sliding friction power loss and downhole viscous friction power loss. The method reflects components of the downhole power loss objectively, effectively prevents affection of irregularity of well deflection tracks and the defect that viscosity of crude oil varies along with temperature onto measurement and calculation of the downhole power loss, is capable of accurately measuring and calculating the downhole power loss of specific mechanical production systems, and thereby laying a fine foundation for calculation and improvement of input power and efficiency of the mechanical production systems.

Owner:CHINA PETROLEUM & CHEM CORP +2

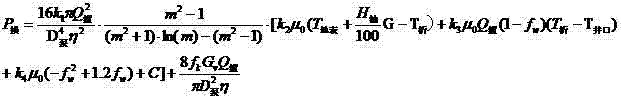

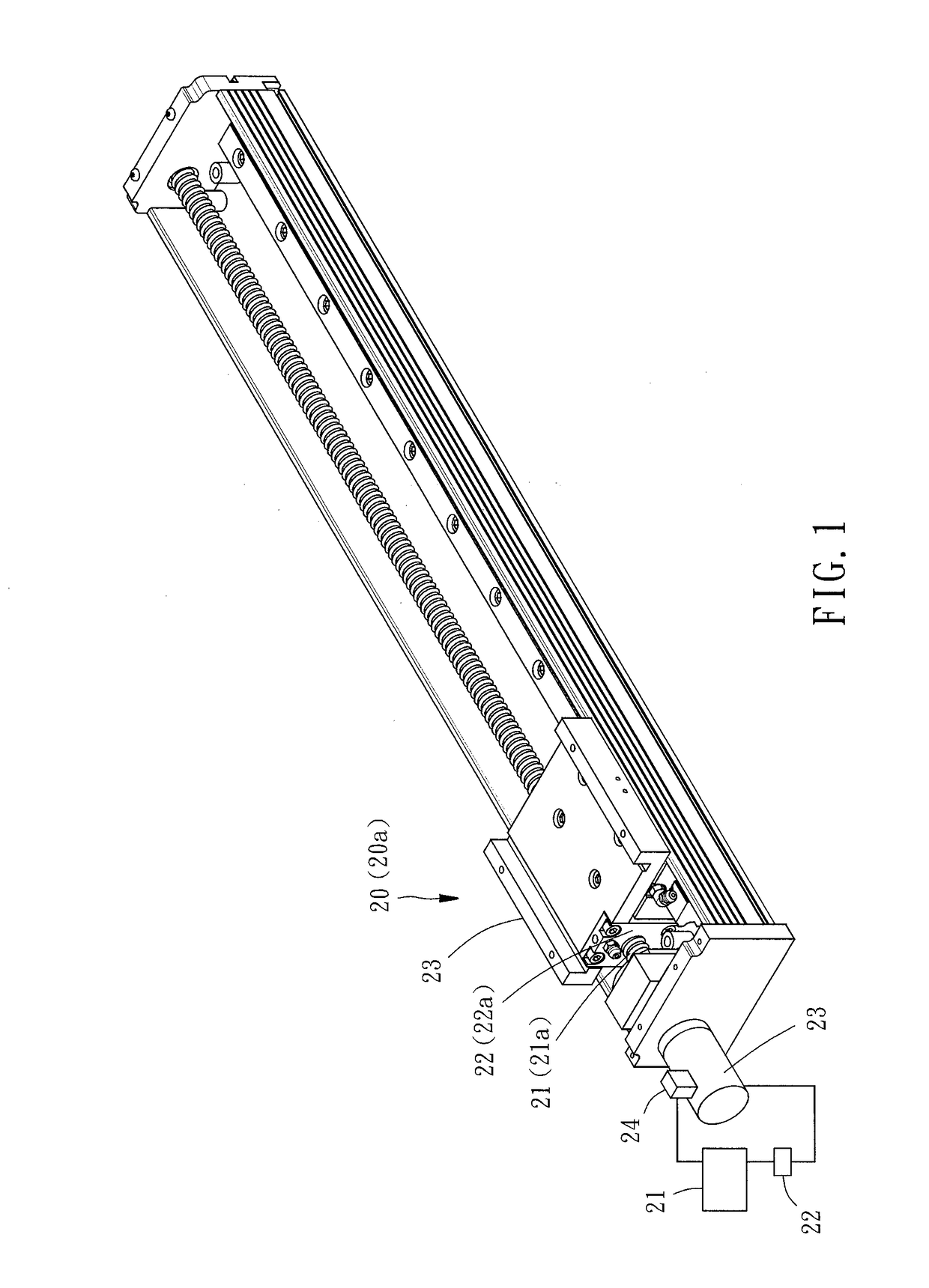

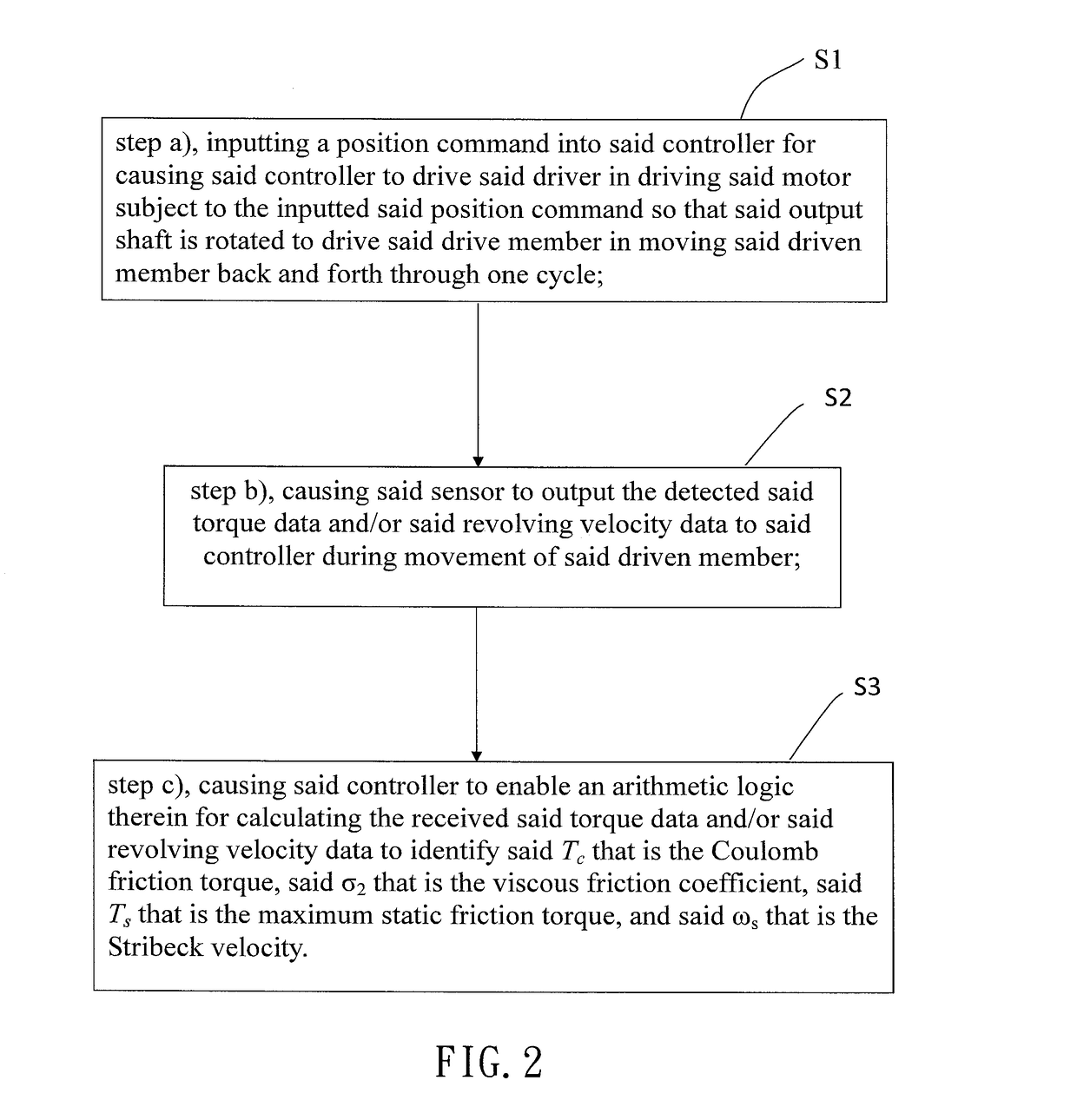

Method for identifying friction parameter for linear module

InactiveUS20170261529A1Eliminate useMuch easier and much in practiceProgramme controlMeasurement of torque/twisting force while tighteningFriction torqueReciprocating motion

A method for identifying friction parameters for a linear module is disclosed. Since an acting interval of a friction is determined by a relative velocity between two contacting surfaces, and when the relative velocity is much greater than a Stribeck velocity, there is only a Coulomb friction and a viscous friction exist between the contacting surfaces, it is possible to use a measured torque signal of this interval to identify a Coulomb friction torque, a the linear module's friction torque, and the linear module's equivalent inertia. When the relative velocity between the two contacting surfaces is smaller than the Stribeck velocity, it is possible to identify a maximum static friction torque and the Stribeck velocity by referring to the three known parameters. Thereby, all the friction parameters can be identified within one reciprocating movement of the linear module, making the method highly feasible in practice.

Owner:HIWIN TECH

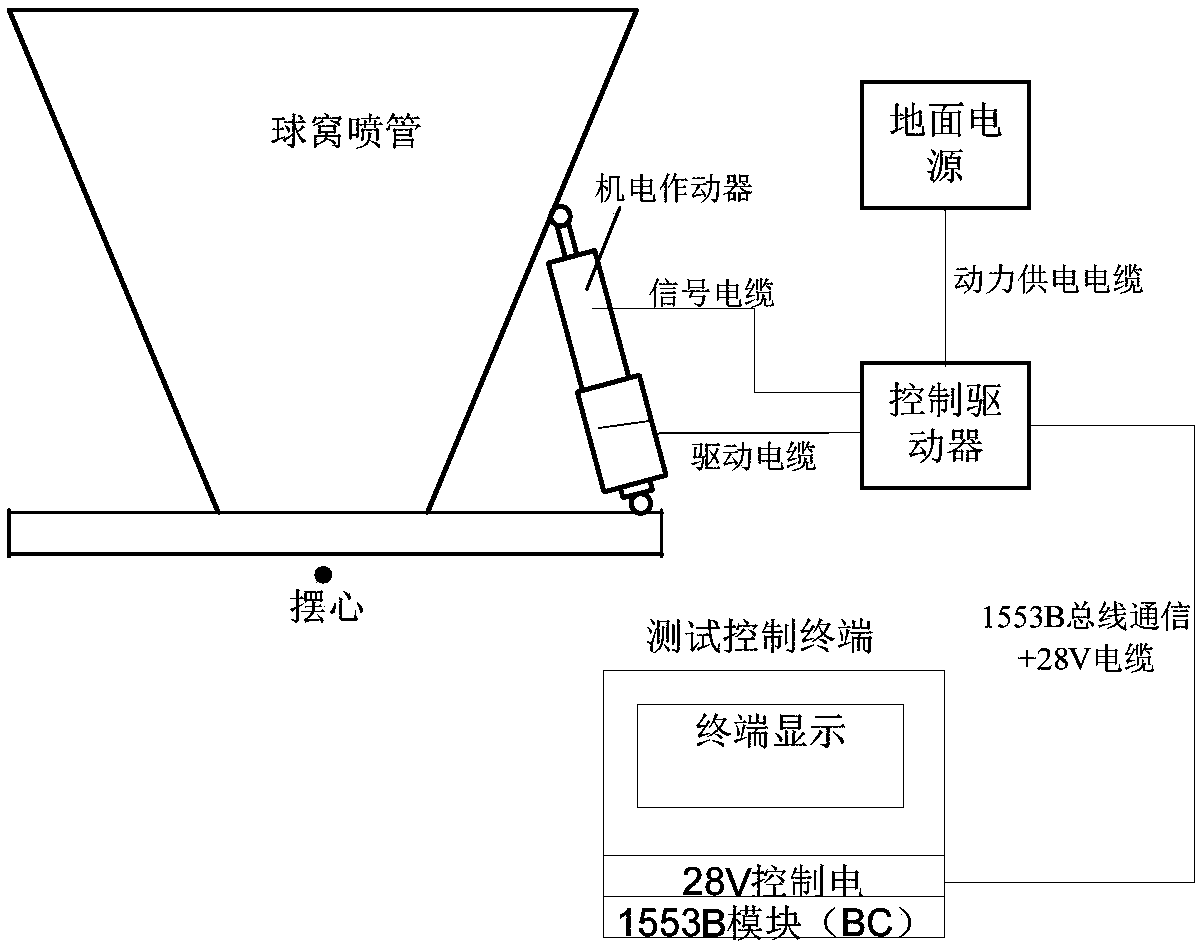

A ball socket nozzle load characteristic identification method for servo system load matching

ActiveCN109725659ALoad-matched ball-and-socket nozzle load characteristic matchingMatching Load CharacteristicsMechanical power/torque controlControl vectorViscous friction

The invention belongs to the technical field of electromechanical servo systems, and particularly relates to a ball socket nozzle load characteristic identification method for servo system load matching. The method comprises a coulomb friction torque identification method, a viscous friction torque identification method, an elastic torque identification method and an inertia torque calculation method. By means of the method, accurate load characteristic parameters of a large ball socket nozzle can be identified, matching of the servo system and the load characteristics of the ball socket nozzle is achieved, and the performance requirement for thrust vector control of a solid rocket is met.

Owner:BEIJING RES INST OF PRECISE MECHATRONICS CONTROLS

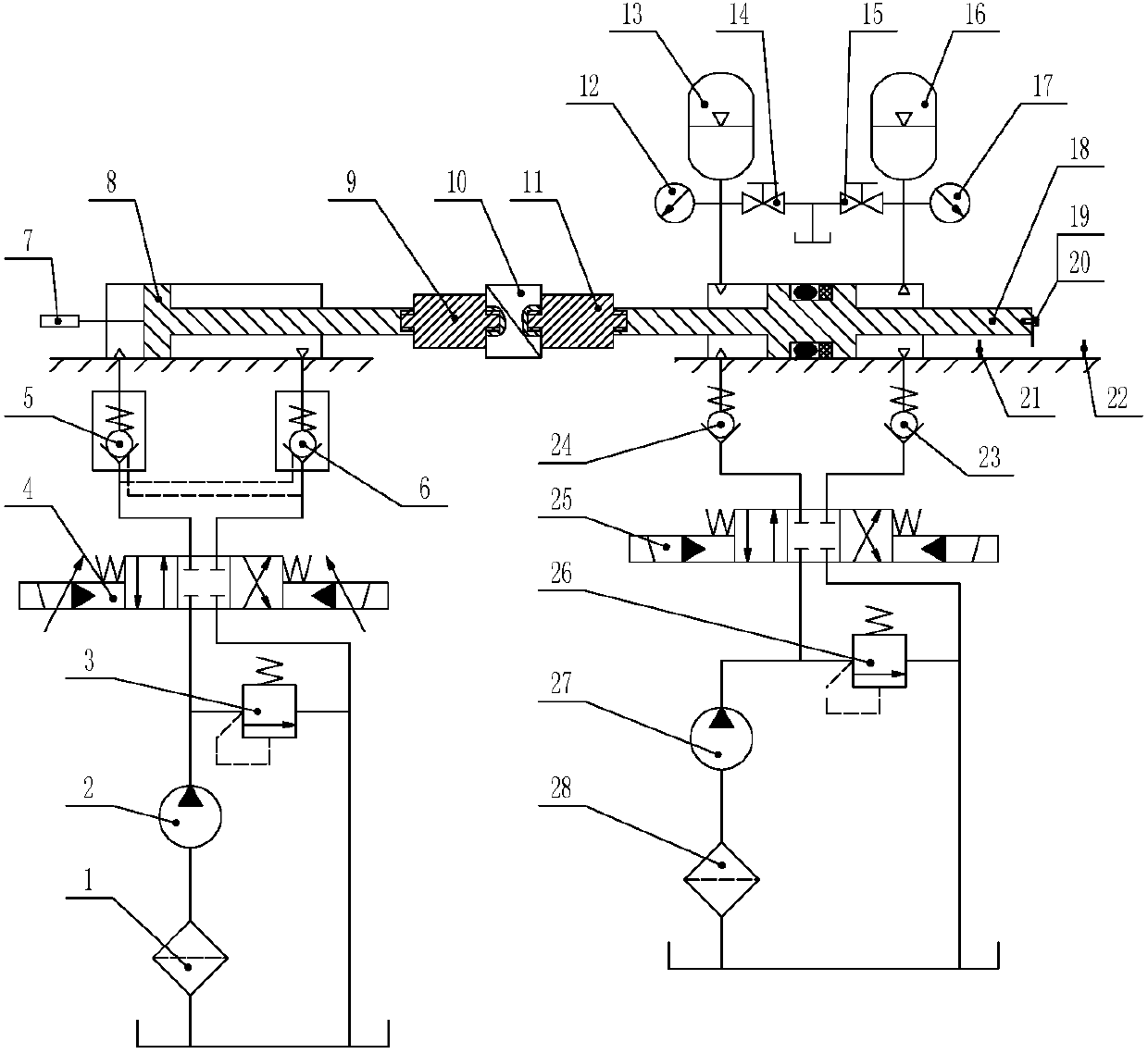

System and method for testing sealing friction force and viscous friction coefficients of hydraulic linear moving element

InactiveCN108223492AMovement speed controllableMeasuring resistanceFluid-pressure actuator testingWater basedDifferential pressure

The invention belongs to the technical field of hydraulic testing, and particularly relates to a system and method for testing sealing friction force and viscous friction coefficients of a hydraulic linear moving element. The testing problems of viscous friction force and viscous friction coefficients of a high-water-based hydraulic element are solved. The system for testing the testing sealing friction force and the viscous friction coefficients of the hydraulic linear moving element is characterized in that a driving part comprises a filter I, a driving pump, an overflow valve I, an electro-hydraulic proportional directional valve, a hydraulic control one-way valve I, a hydraulic control one-way valve II, a displacement sensor and a driving oil cylinder, and a tested part comprises a pressure gauge I, an energy accumulator I, a stop valve I, a stop valve II, an energy accumulator II, a pressure gauge II, a tested cylinder, a shifting piece, a travel switch I, a travel switch II, a one-way valve I, a one-way valve II, an electro-hydraulic reversing valve, an overflow valve II, a liquid filling pump and a filter II. According to the system and method for testing the testing sealingfriction force and the viscous friction coefficients of the hydraulic linear moving element, the sealing friction resistance and the friction coefficients under different differential pressure and movement speeds can be measured.

Owner:TAIYUAN UNIV OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com