Air motor and electrostatic coating device

A technology of air motors and nozzles, applied in electrostatic spraying devices, spraying devices, spraying devices with movable outlets, etc., can solve problems such as protruding, and achieve the effect of improving driving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

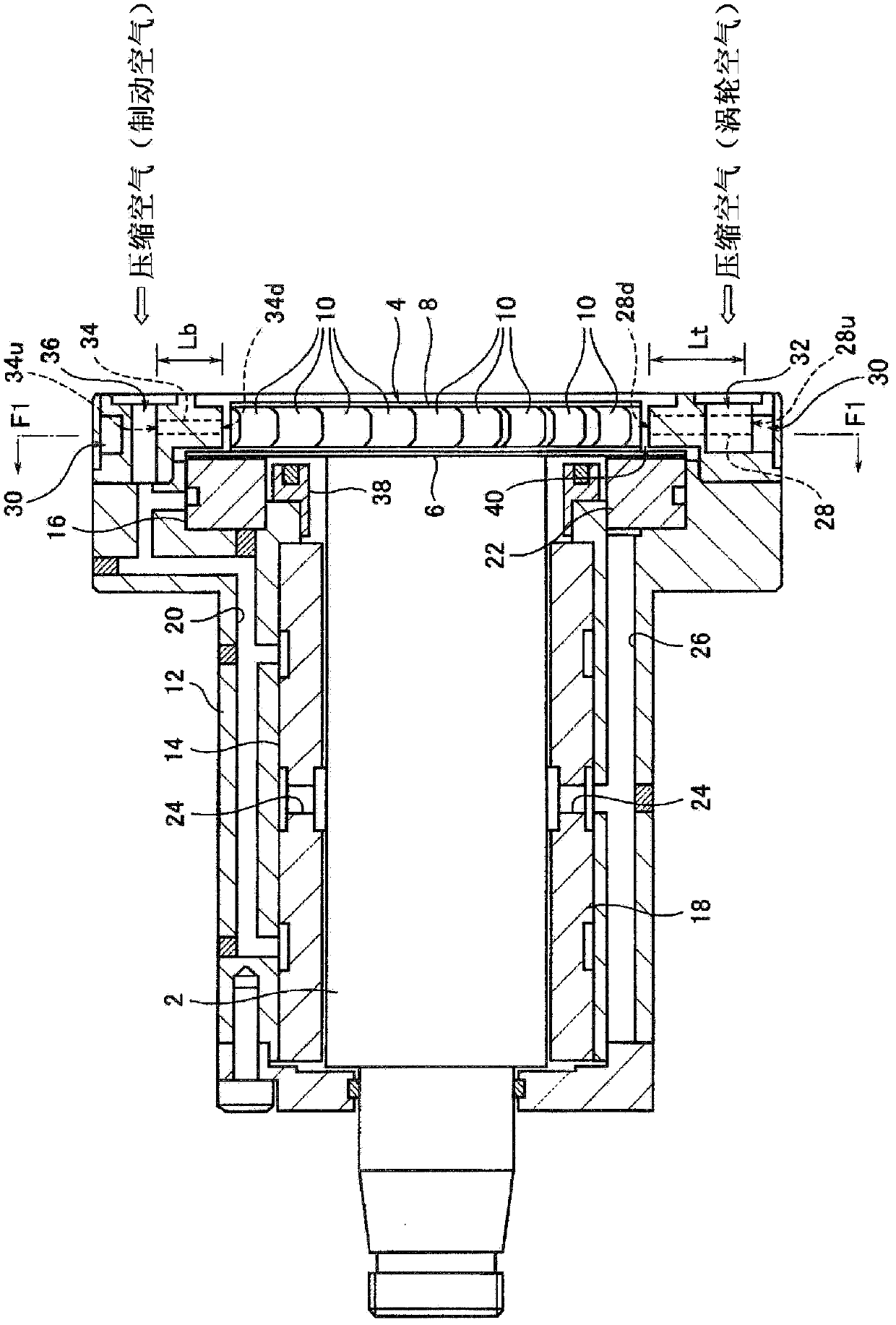

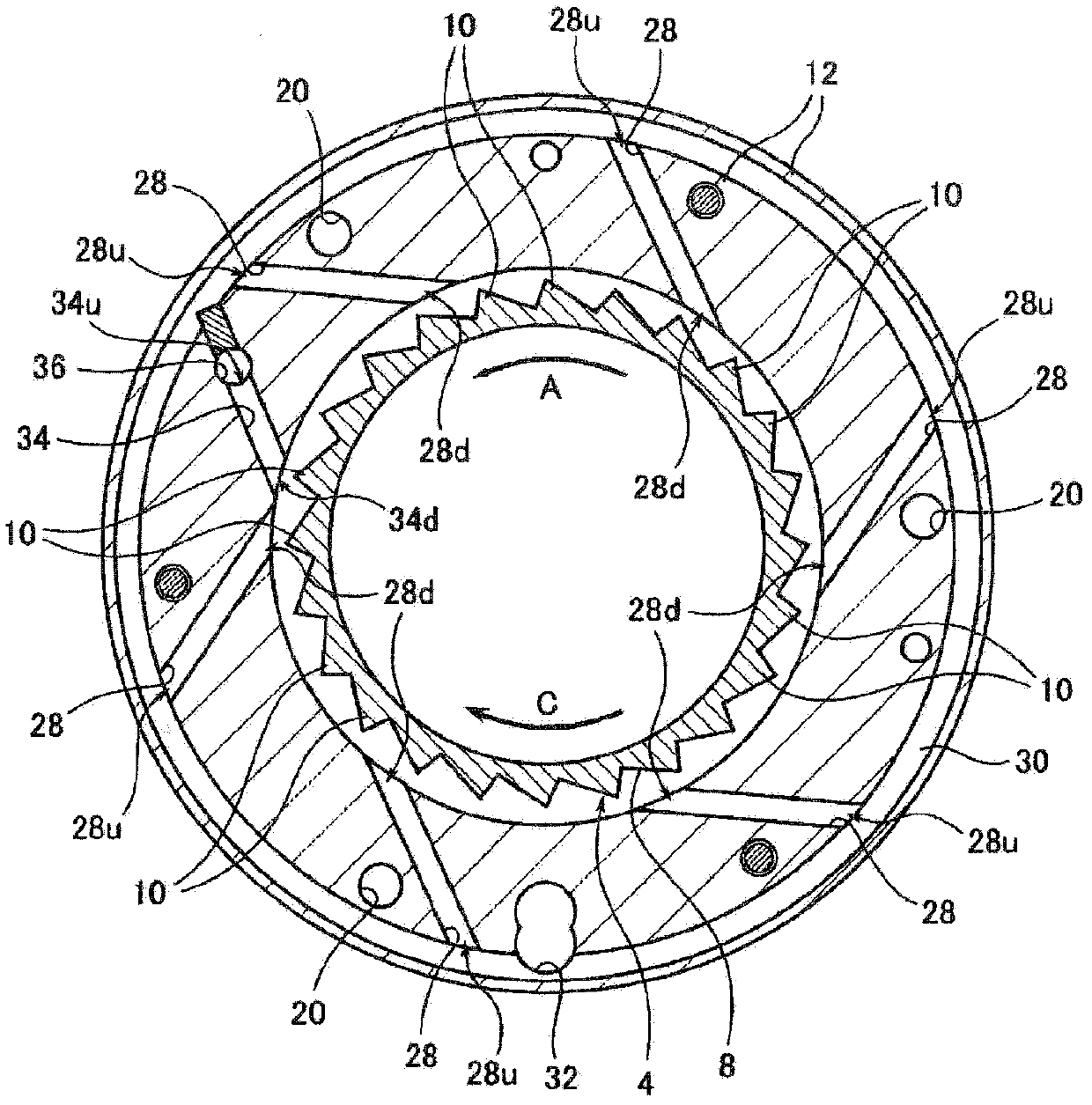

[0075] Next, one embodiment of the air motor of the present invention will be described with reference to the drawings. In addition, the air motor of this embodiment can be assumed to be, for example, mounted on a spindle device used in an electrostatic spraying process, or a drive unit such as a spindle of a machine tool using a small-diameter tool that requires high-speed rotation, but the mounted device is not limited to these devices.

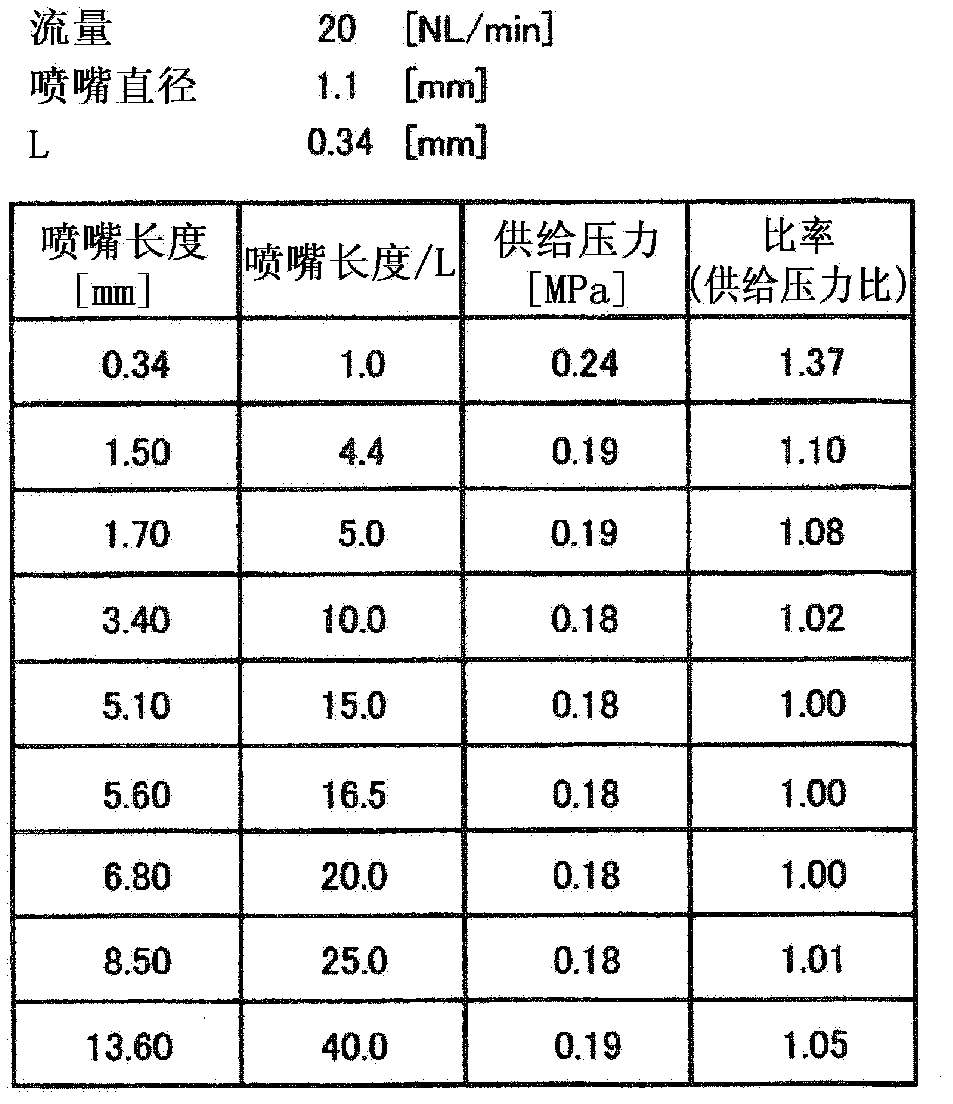

[0076] Furthermore, the air motor of this embodiment limits the length (nozzle length) of the nozzle portion constituting such an air motor to a size within a predetermined range, and the basic structure other than the nozzle portion of the air motor does not have the structure of a known air motor. question. Therefore, in this embodiment, the structure of the air motor (spindle device with air turbine) mounted on the electrostatic spray gun of the electrostatic sprayer as described above ( figure 1 and figure 2 ) is assumed to be an ex...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com