Patents

Literature

295results about How to "Large loading capacity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

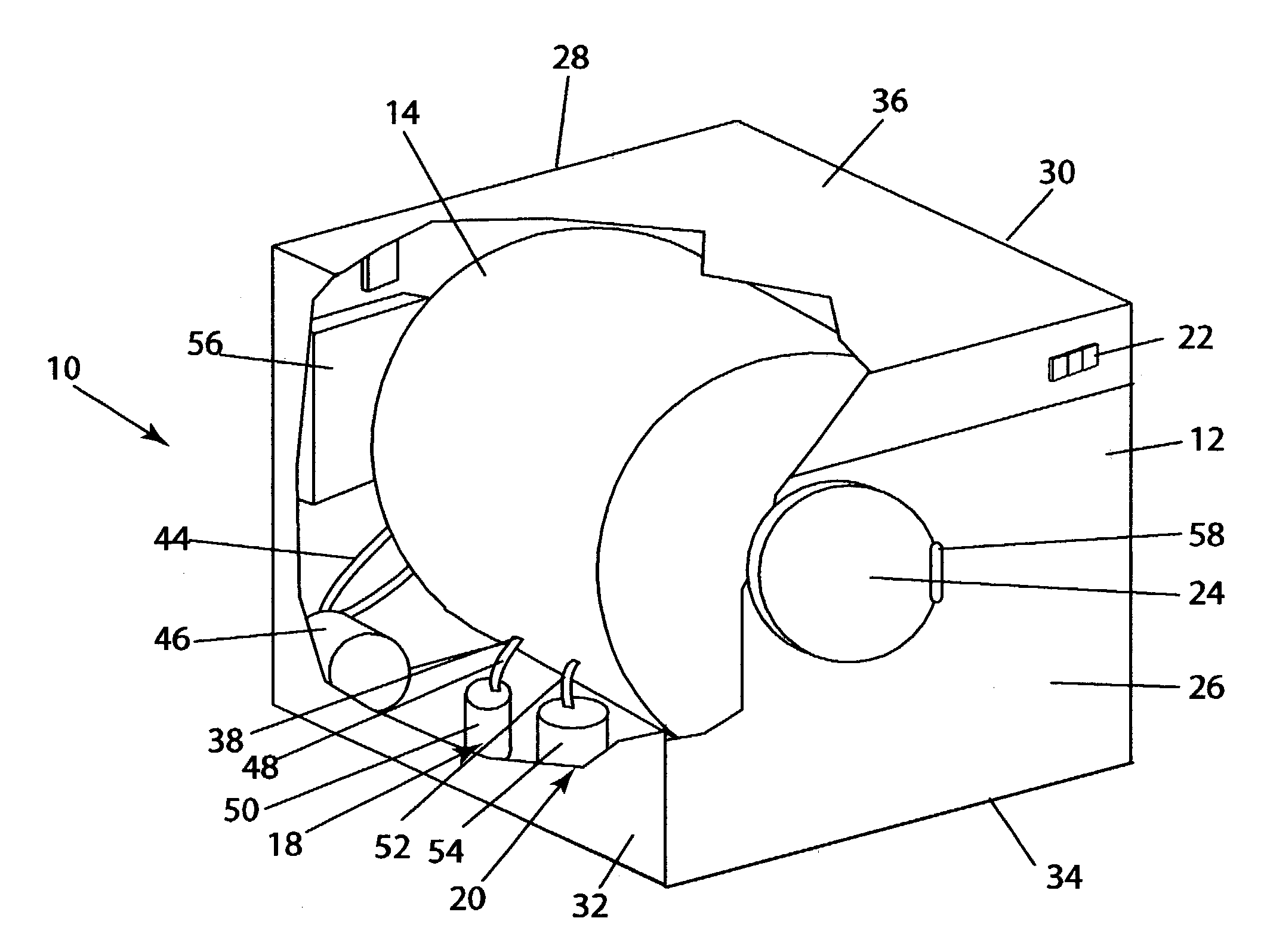

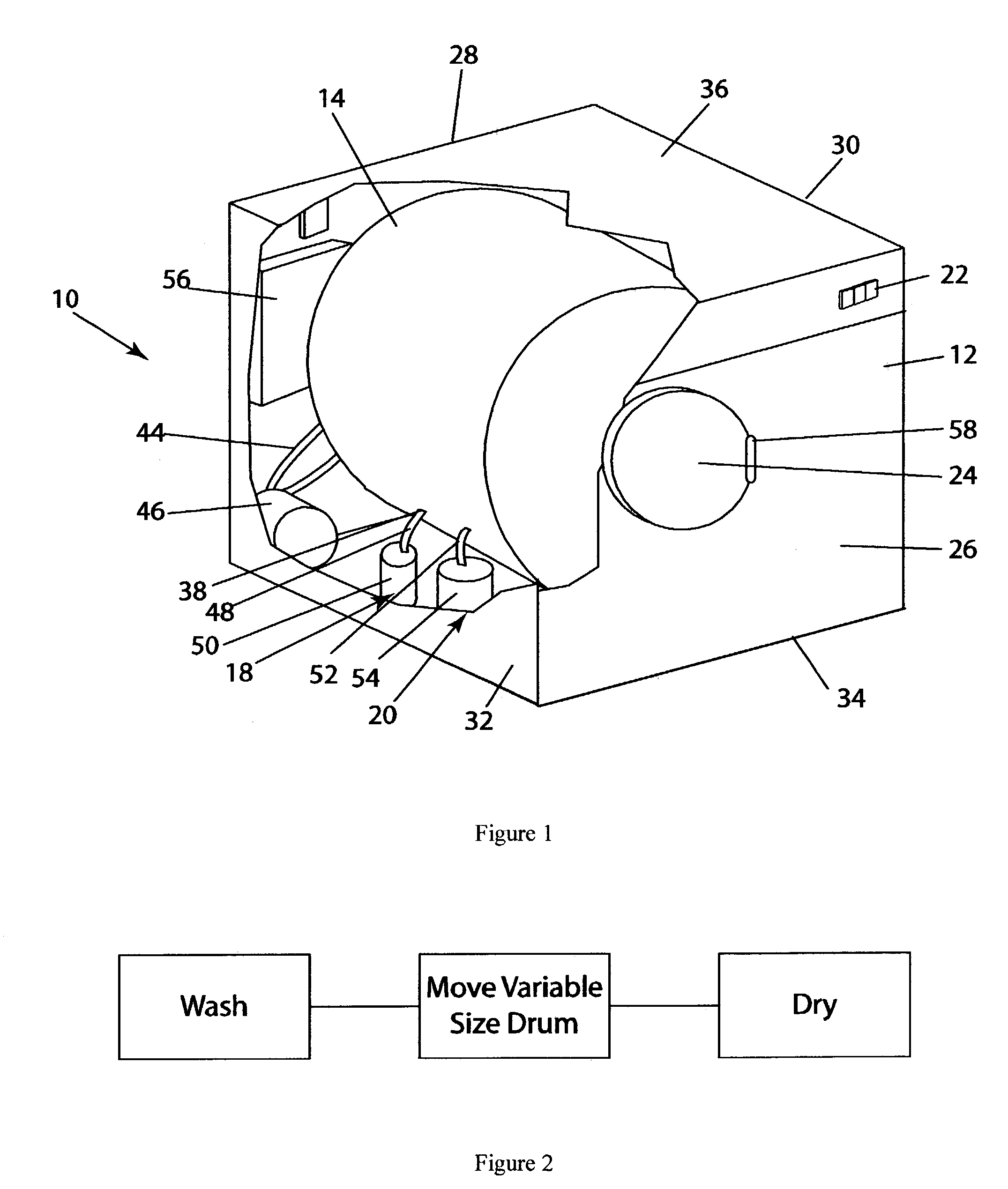

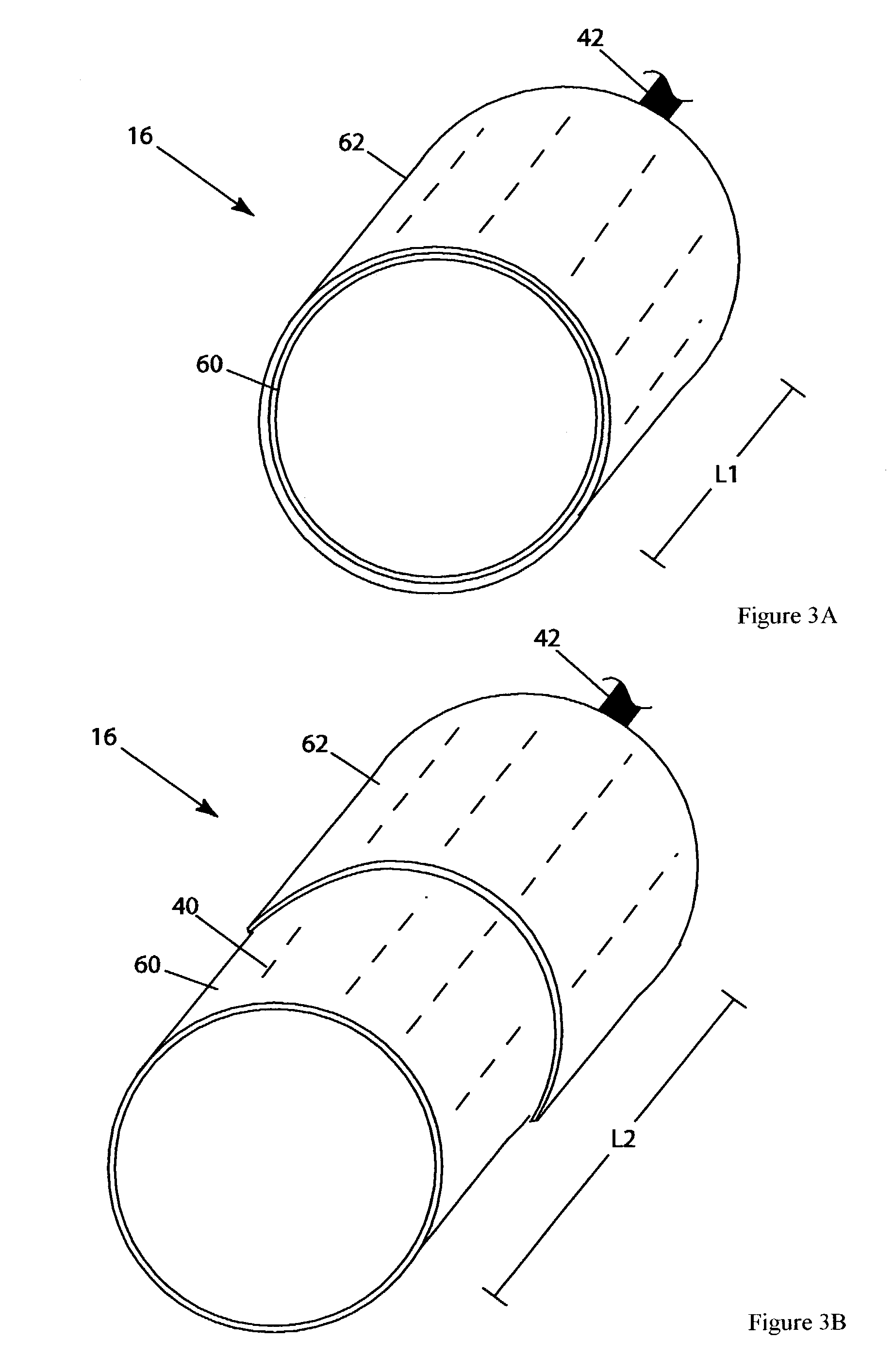

Combined washer dryer

InactiveUS7380423B1Large load capacityDry ability be improveOther washing machinesControl devices for washing apparatusAerospace engineeringWater treatment system

A combined washer dryer is provided. The combined washer dryer comprises an outer drum; a rotatable cylindrical variable size inner drum arranged coaxially within the outer drum and movable from a first position to a second position; a water handling system adapted to intake water into the inner drum and to remove water from the outer drum; an air handling system adapted to intake air into the inner drum and to remove air from the outer drum; and a control system adapted to control the movement of the variable size inner drum.

Owner:MUSONE JOHN P

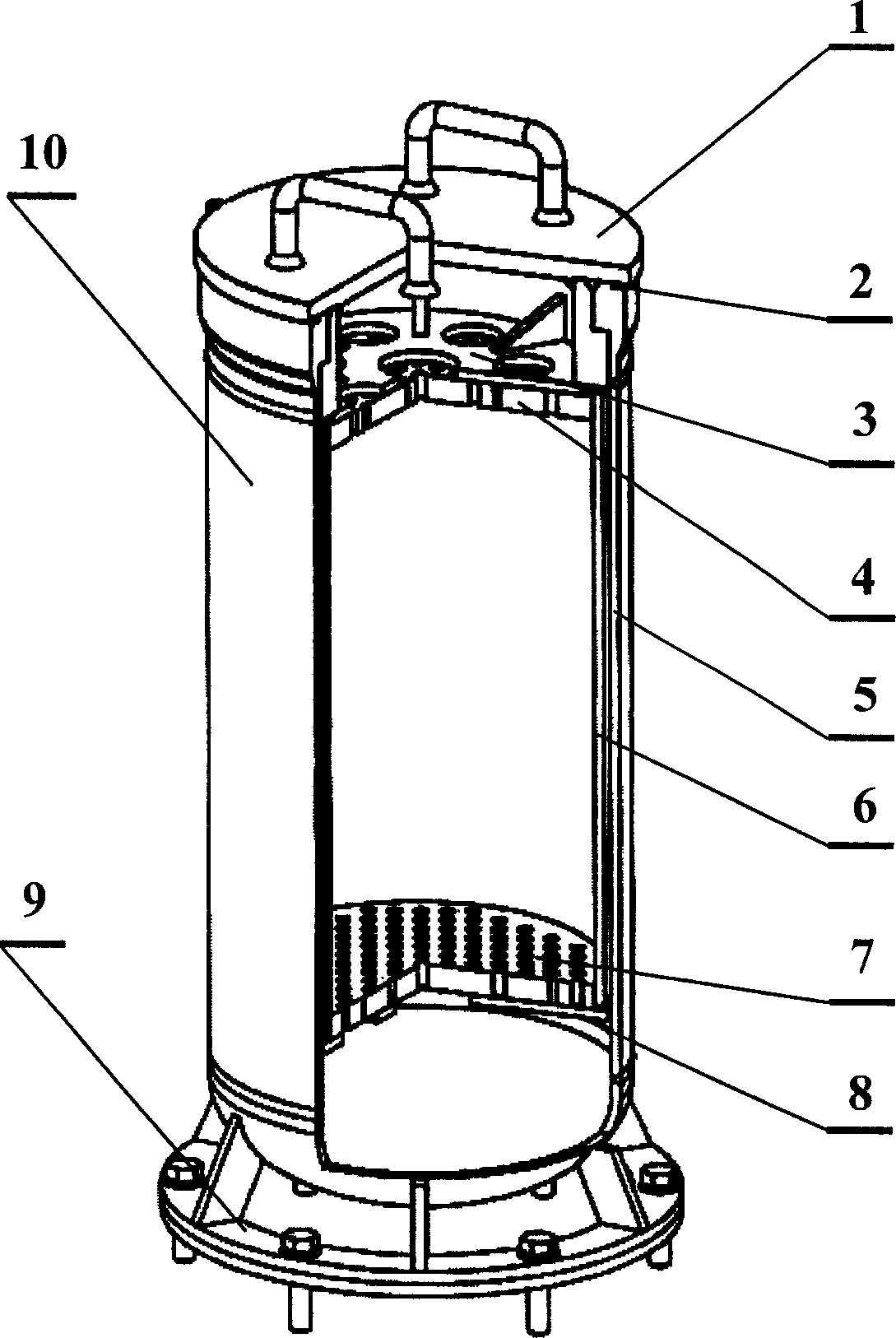

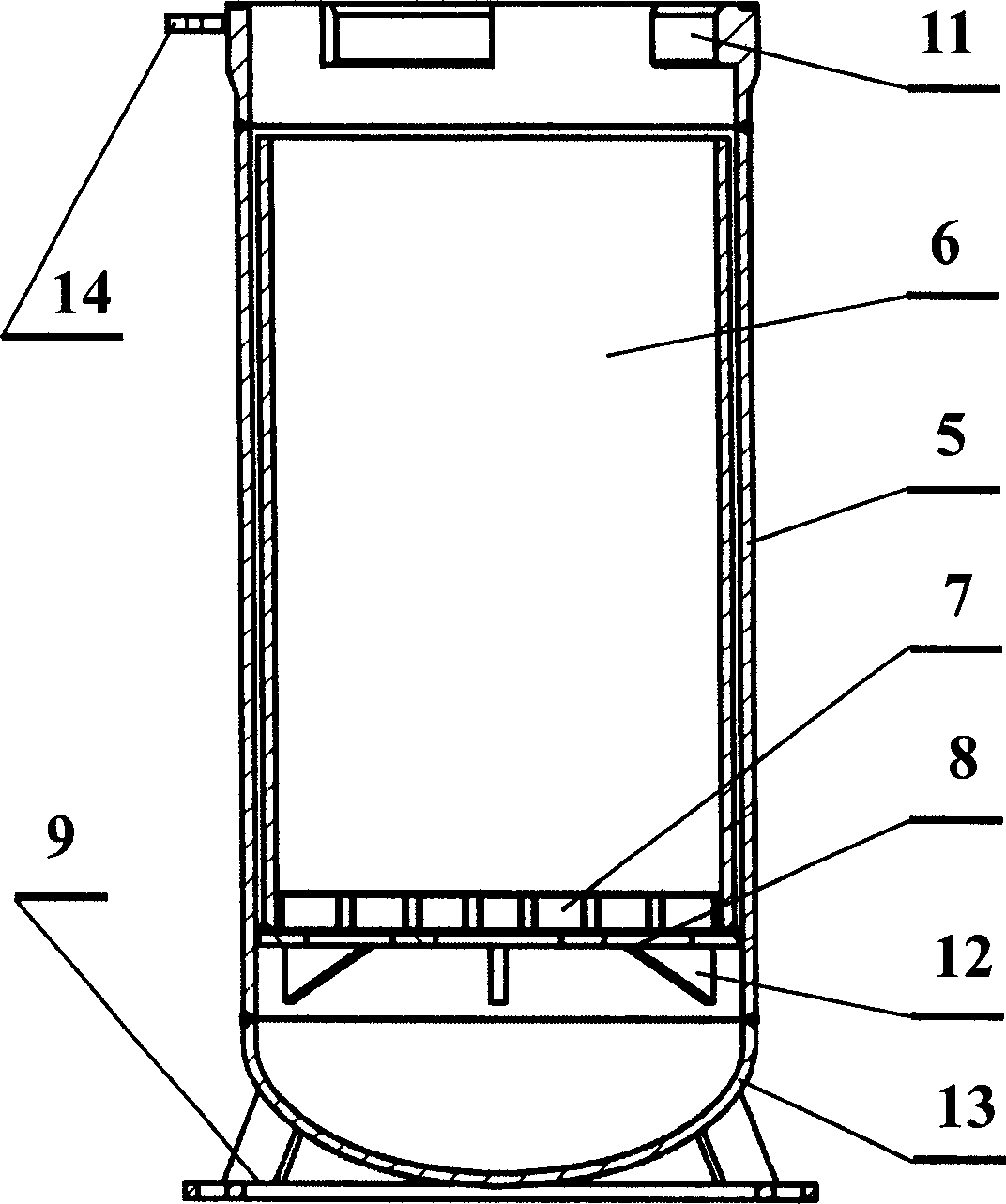

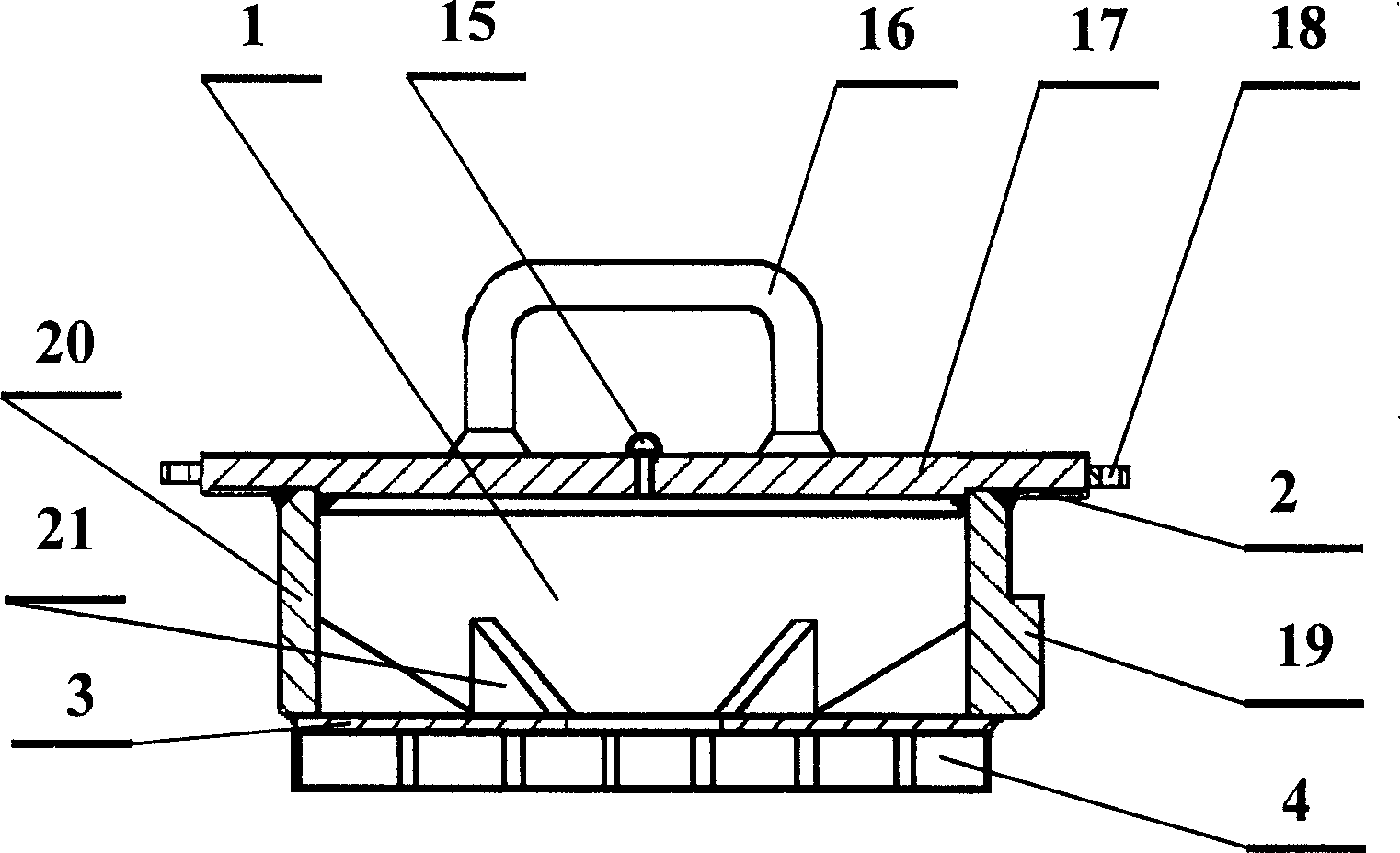

Anti-knock container

ActiveCN1632445AOpen and close flexible and convenientNot easy to wearAmmunition storageDetonatorEngineering

The invention belongs to storage and transportation equipment for detonating materials (detonators), in particular to an anti-explosion container. The anti-explosion container includes an upper cover, a cylinder and a fixed bracket. It is characterized in that the cylinder is composed of an outer cylinder and an inner cylinder, wherein the outer cylinder is a cylinder with an open upper end and a closed lower end. The lower part of the inner cylinder is provided with a lower wave breaking plate. , the upper cover is composed of a top cover plate and a cover wall, wherein the lower end of the cover wall is provided with an upper wave dissipation plate, the cover wall and the upper port of the outer cylinder are connected by splines, and the top cover plate is provided with explosion-venting bolts. The invention can not only ensure safety when the detonating equipment and explosives are transported in the same vehicle, but also can seal the harmful gas generated by the explosion in the container in case of an explosion in the container, and discharge the harmful gas after it is transported to a suitable place. In order to avoid polluting the environment and causing casualties and damage to surrounding personnel and facilities. It has the advantages of flexible and convenient opening and closing, large loading capacity, long service life, and good anti-explosion and explosion-proof performance.

Owner:蒋友明

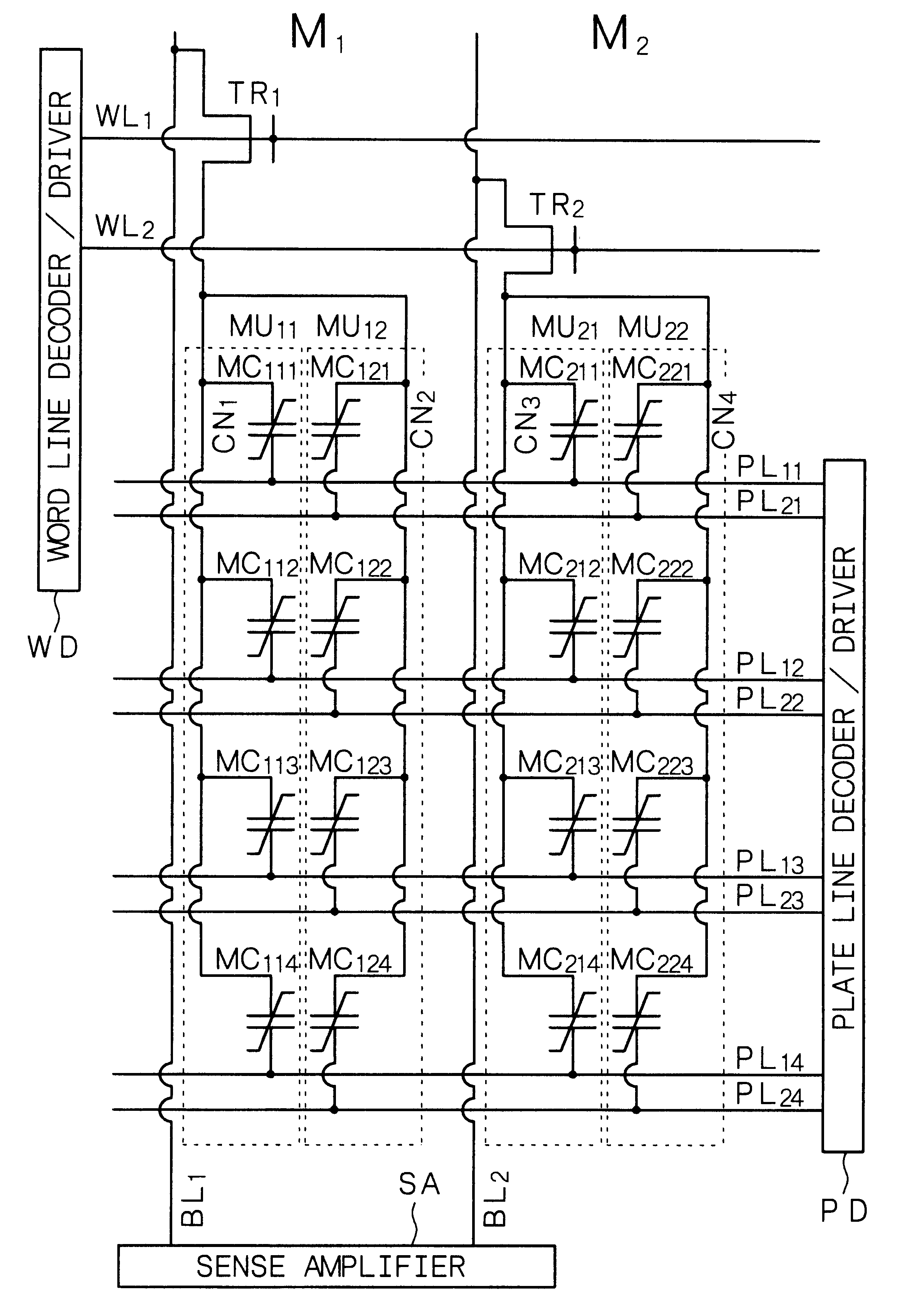

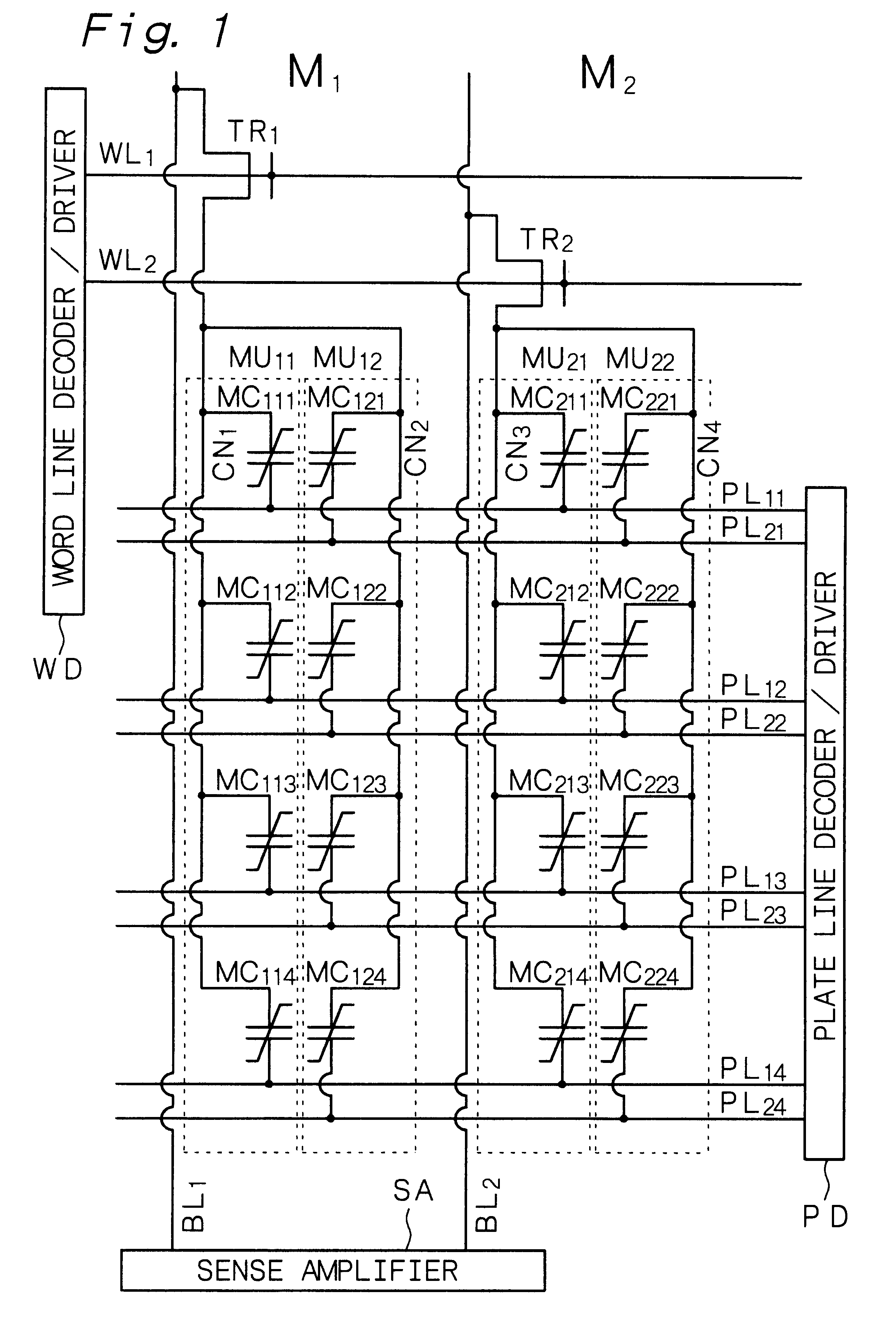

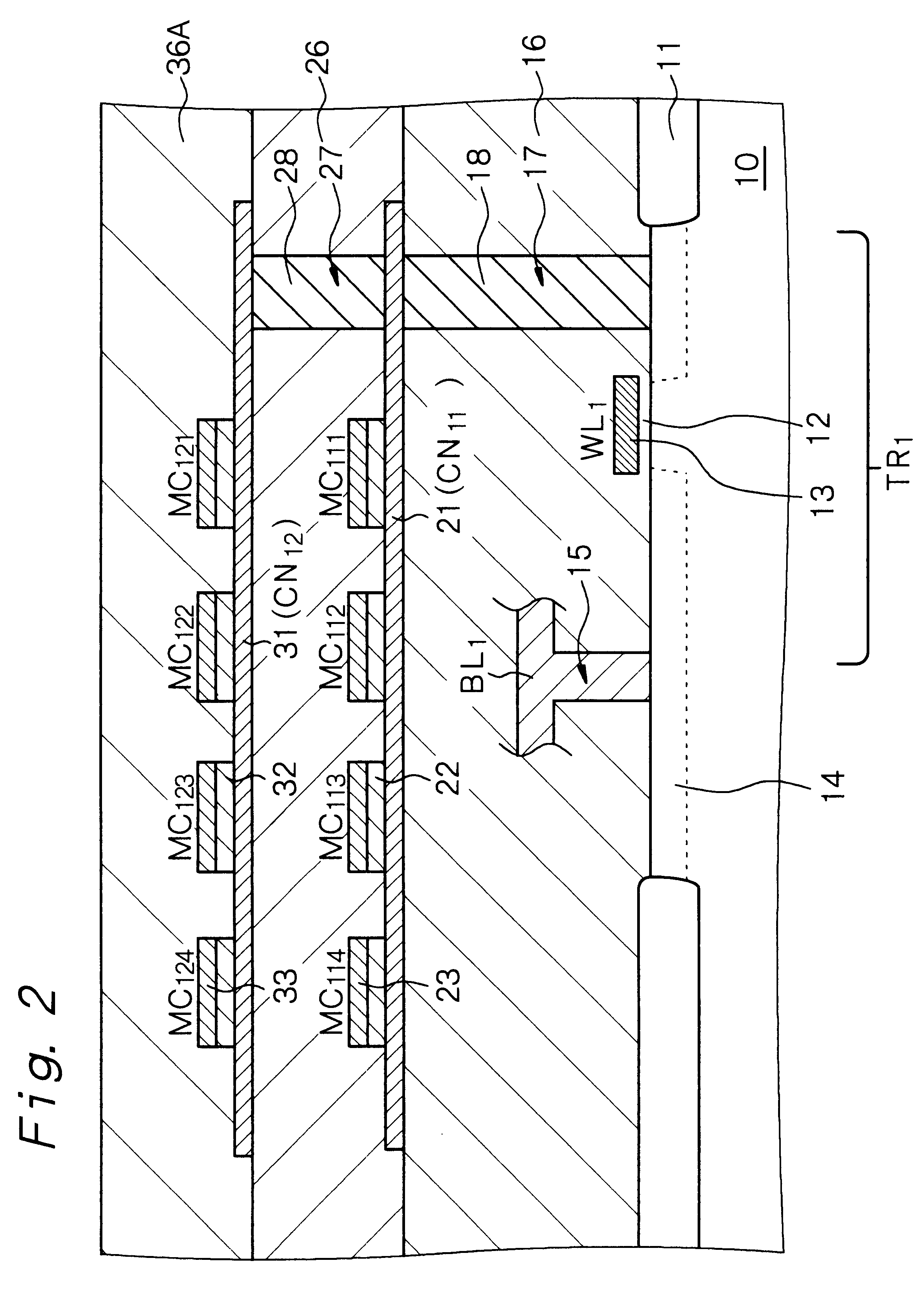

Ferroelectric-type nonvolatile semiconductor memory and operation method thereof

A ferroelectric-type nonvolatile semiconductor memory comprising (A) a bit line, (B) a transistor for selection, (C) memory units in the number of N, each memory unit including memory cells in the number of M wherein N>=2 and M>=2, and (D) plate lines in the number of MxN, in which the memory units in the number of N are stacked through an insulating interlayer, each memory cell includes a first electrode, a ferroelectric layer and a second electrode, the first electrodes are in common in each memory unit, and the common first electrode is connected to the bit line through the transistor for selection, and the second electrode of the m-th memory cell in the n-th memory unit is connected to the [(n-1)M+m]-th plate line wherein m=1, 2 . . . M and n=1, 2 . . . N.

Owner:SONY CORP

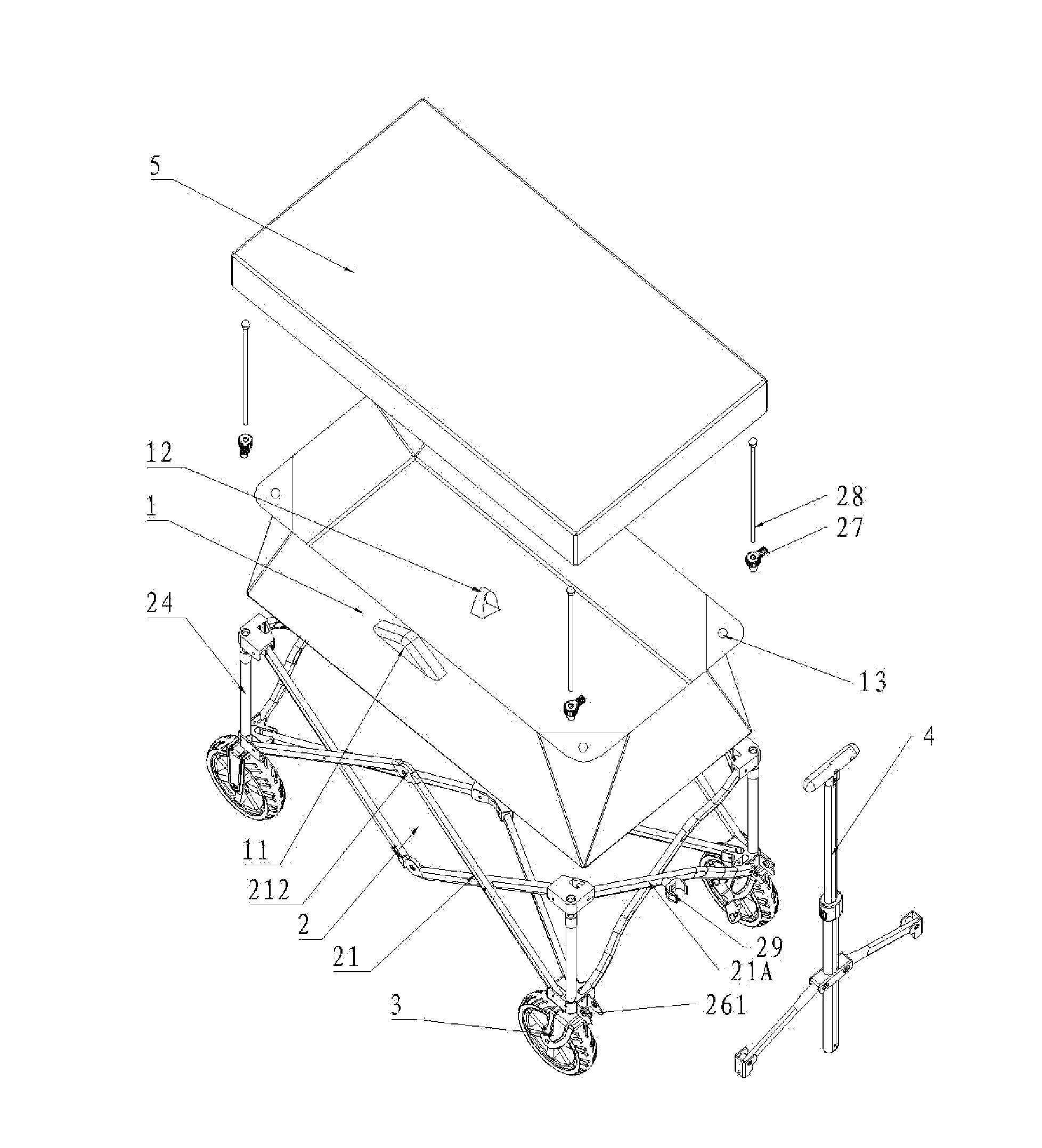

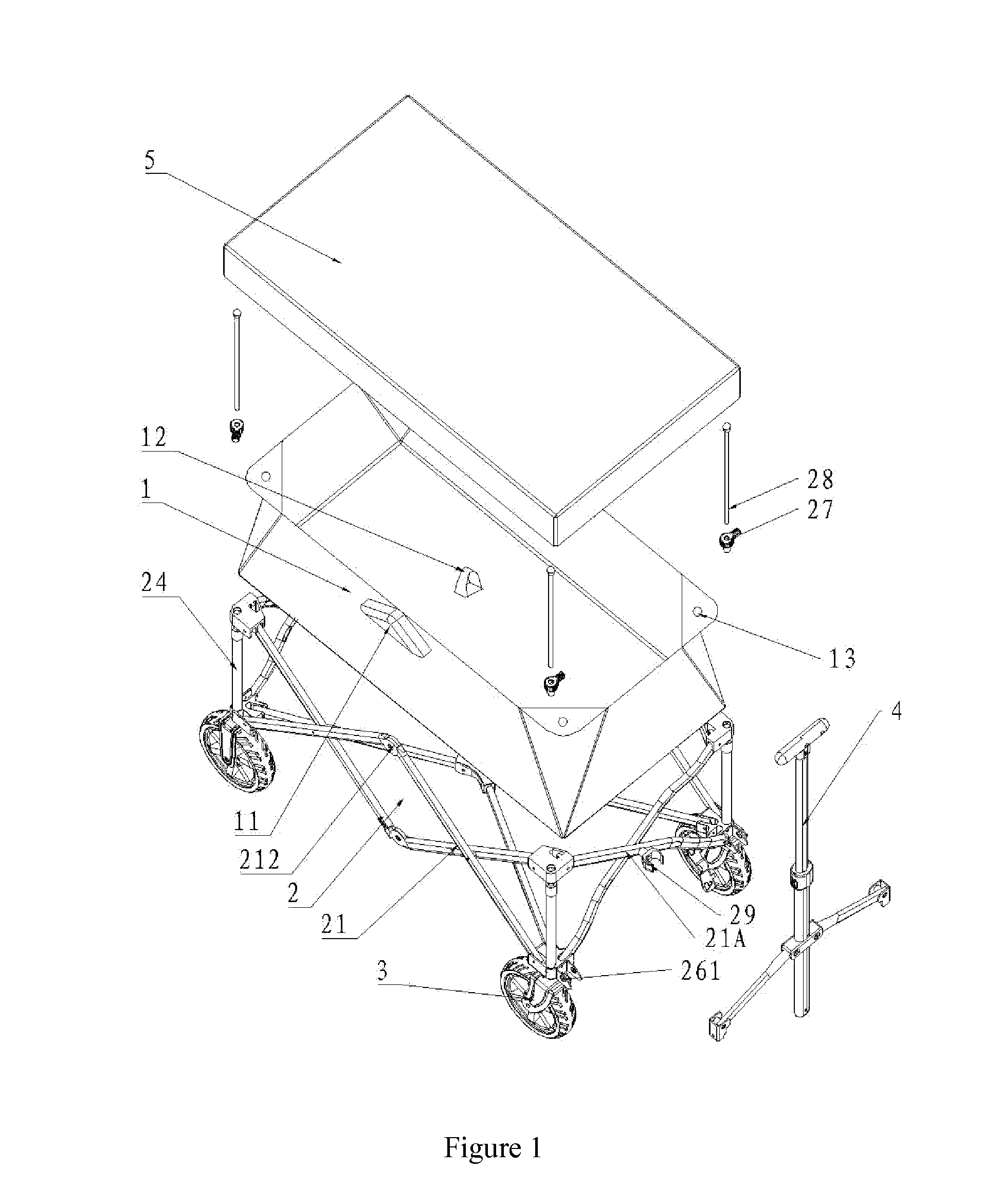

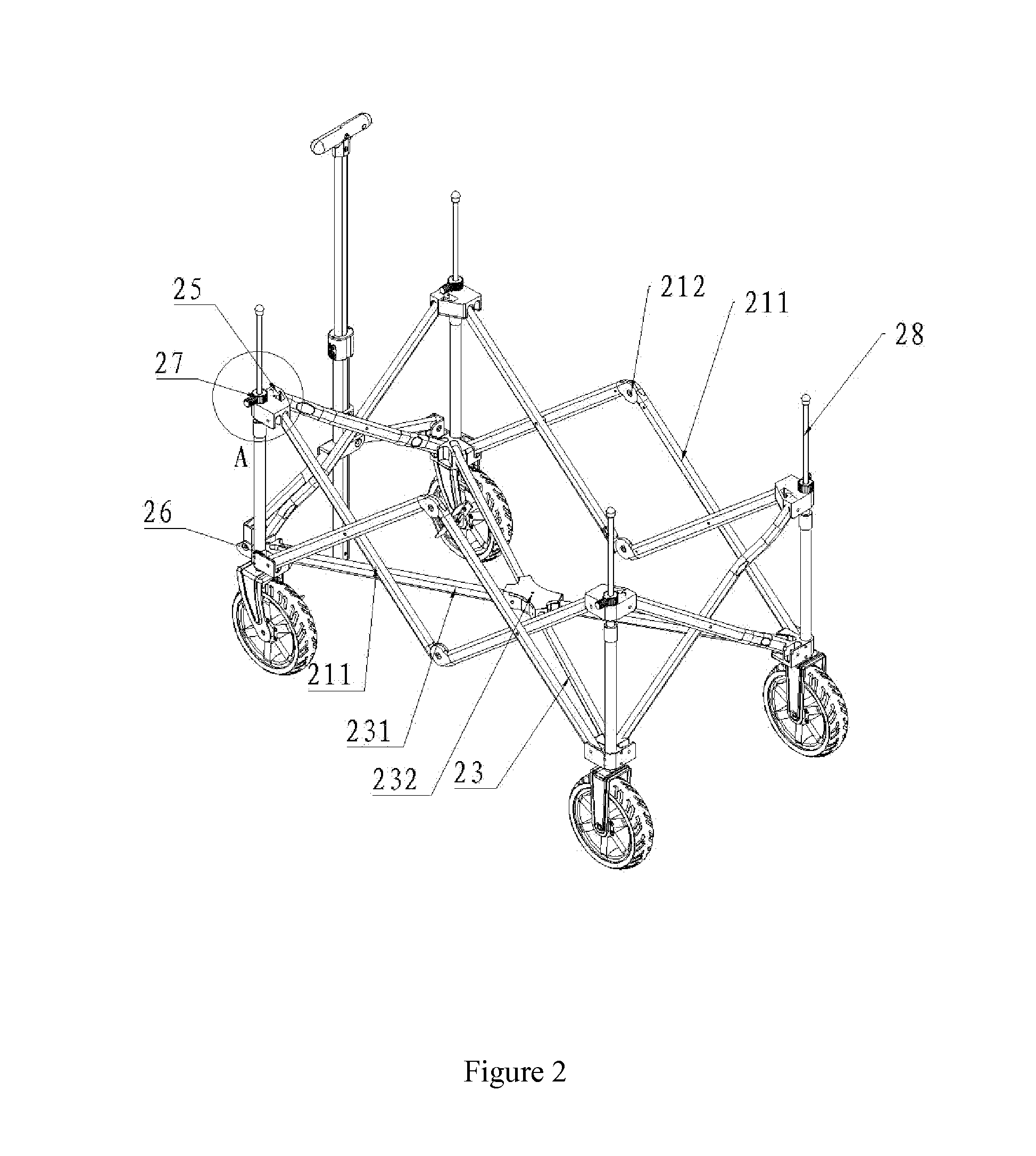

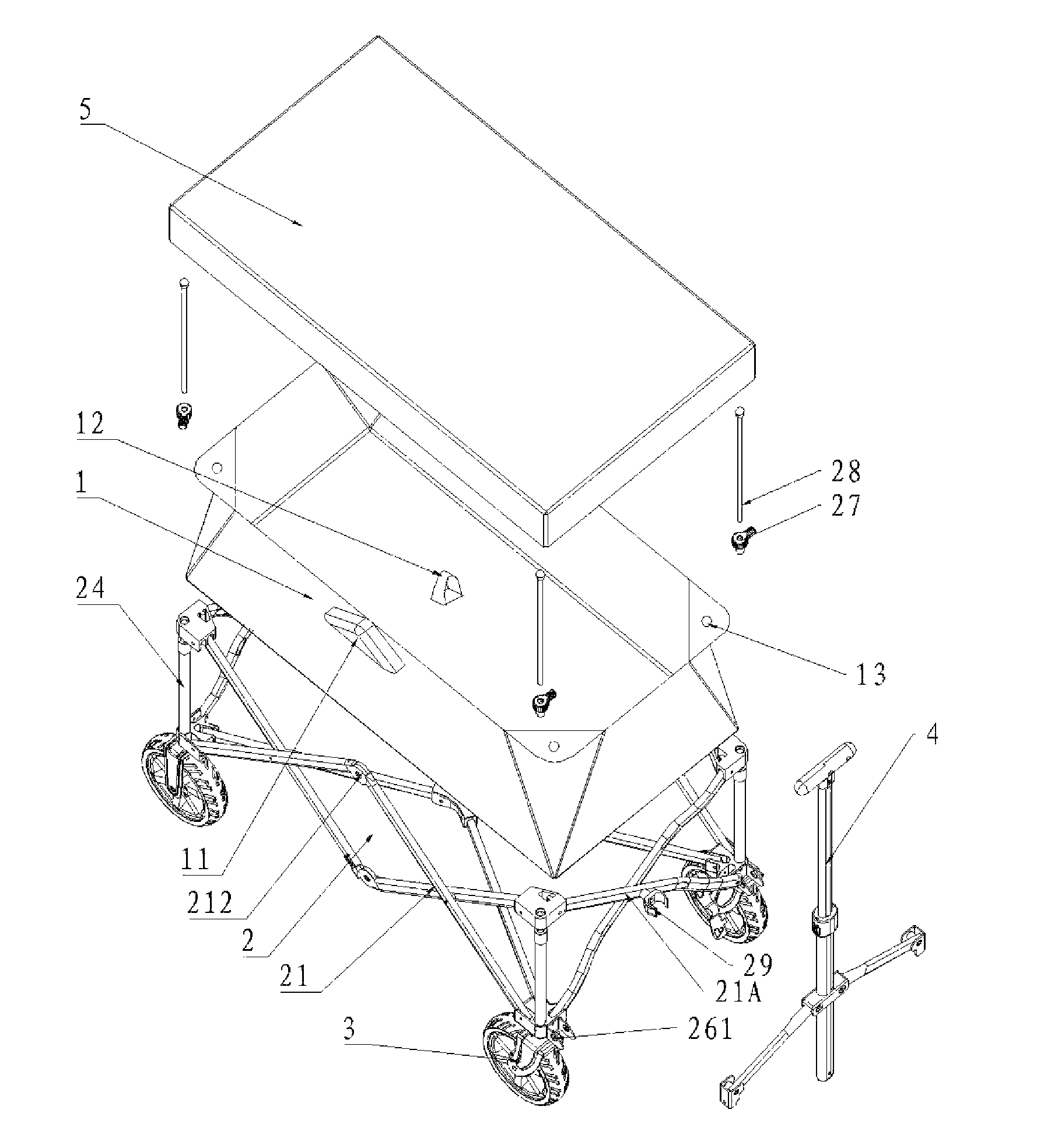

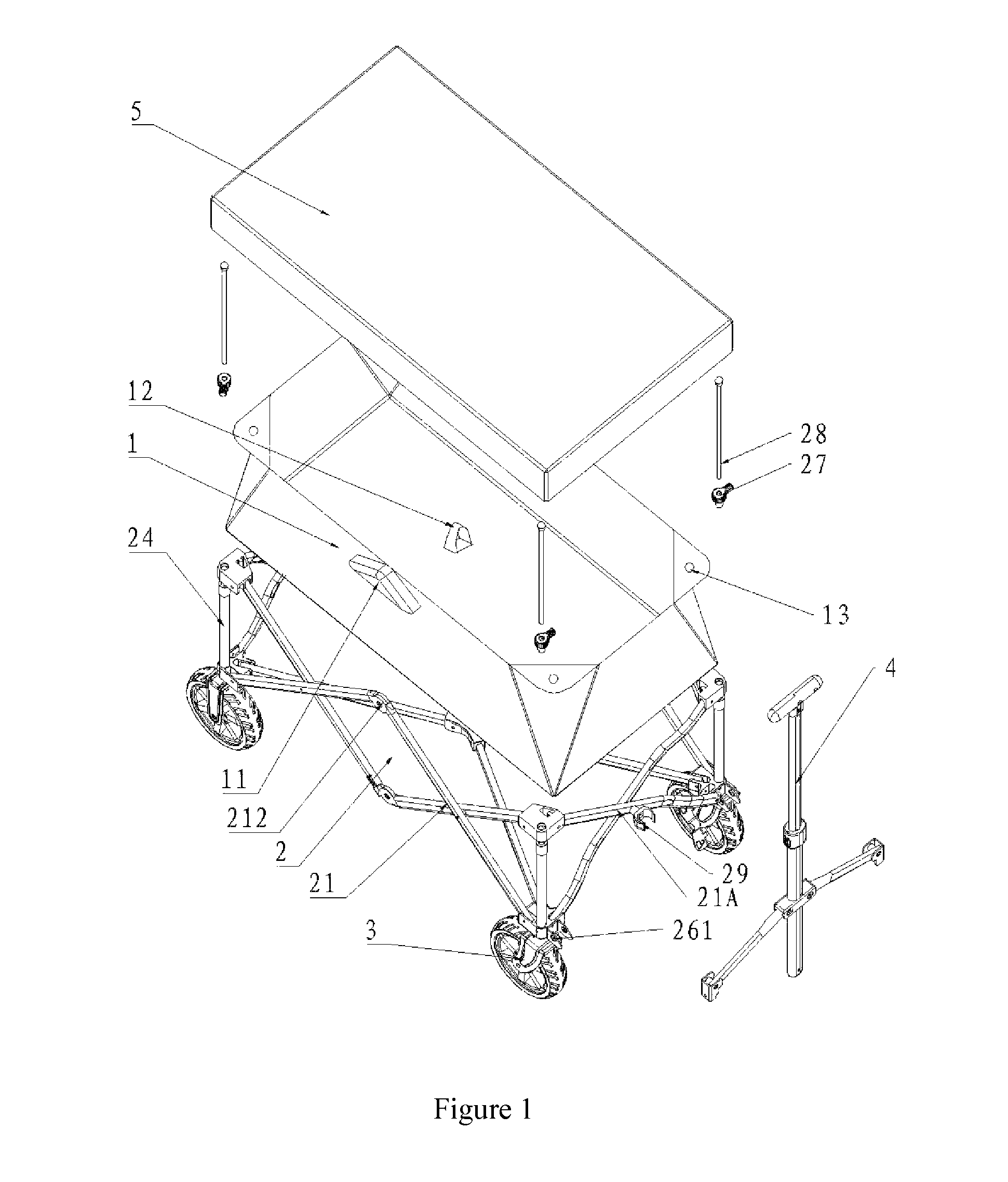

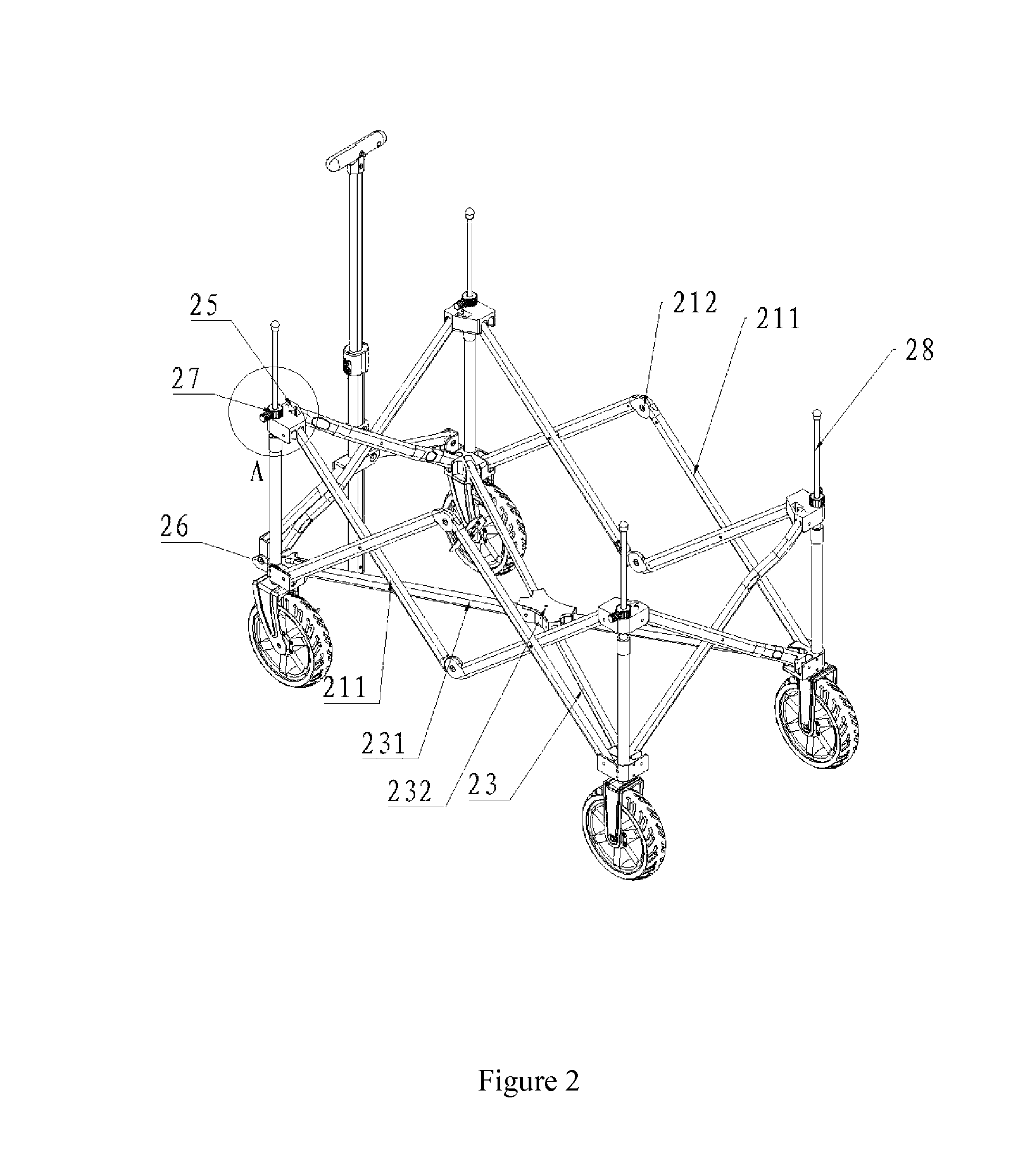

Folding trolley

InactiveUS20150151771A1Increase edge strengthLarge load capacityCarriage/perambulator accessoriesHand carts with one axisEngineeringFuselage

A folding trolley includes a folding trolley frame and a storage pocket. Said trolley frame includes side brackets and a bottom support bracket; said side bracket comprises two cross connecting rods hinged at the central point; said bottom support bracket includes bottom support rods and a central hinged seat. the side bracket is a multi-stage connecting rod structure, including at least two pairs of corresponding hinged connecting rods; the ends of the connecting rods are hinged to form pocket support ends; said storage pocket is provide with downward openings; a pulling member corresponding to the location of said central hinged seat and used for folding the trolley body is provided at the interior bottom of said storage pocket. The trolley can realize convenient fold of the whole body, increase edge strength of the storage pocket, and ease using operation for different users, and has stable structure and larger loading capacity.

Owner:JIN XUGANG

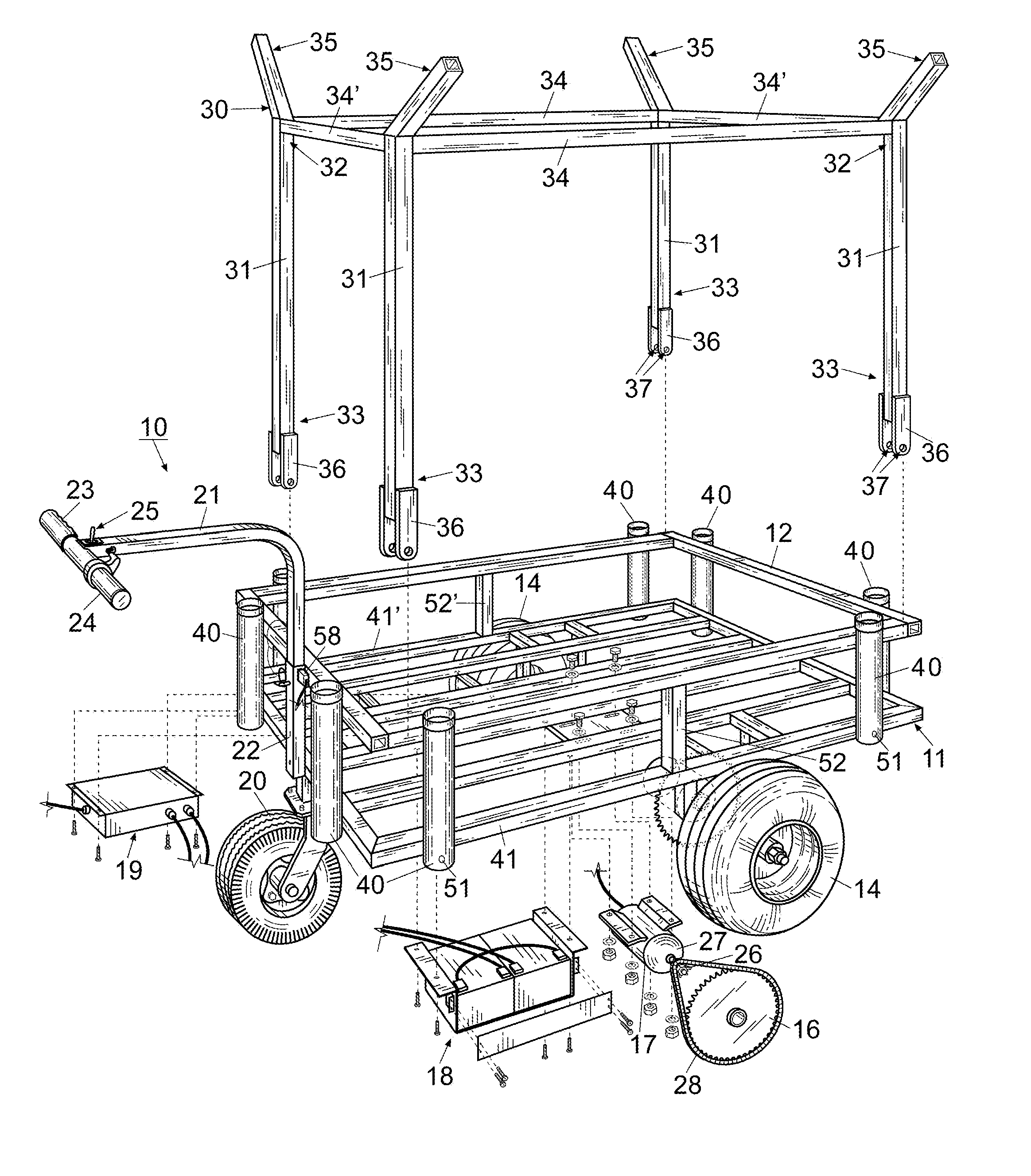

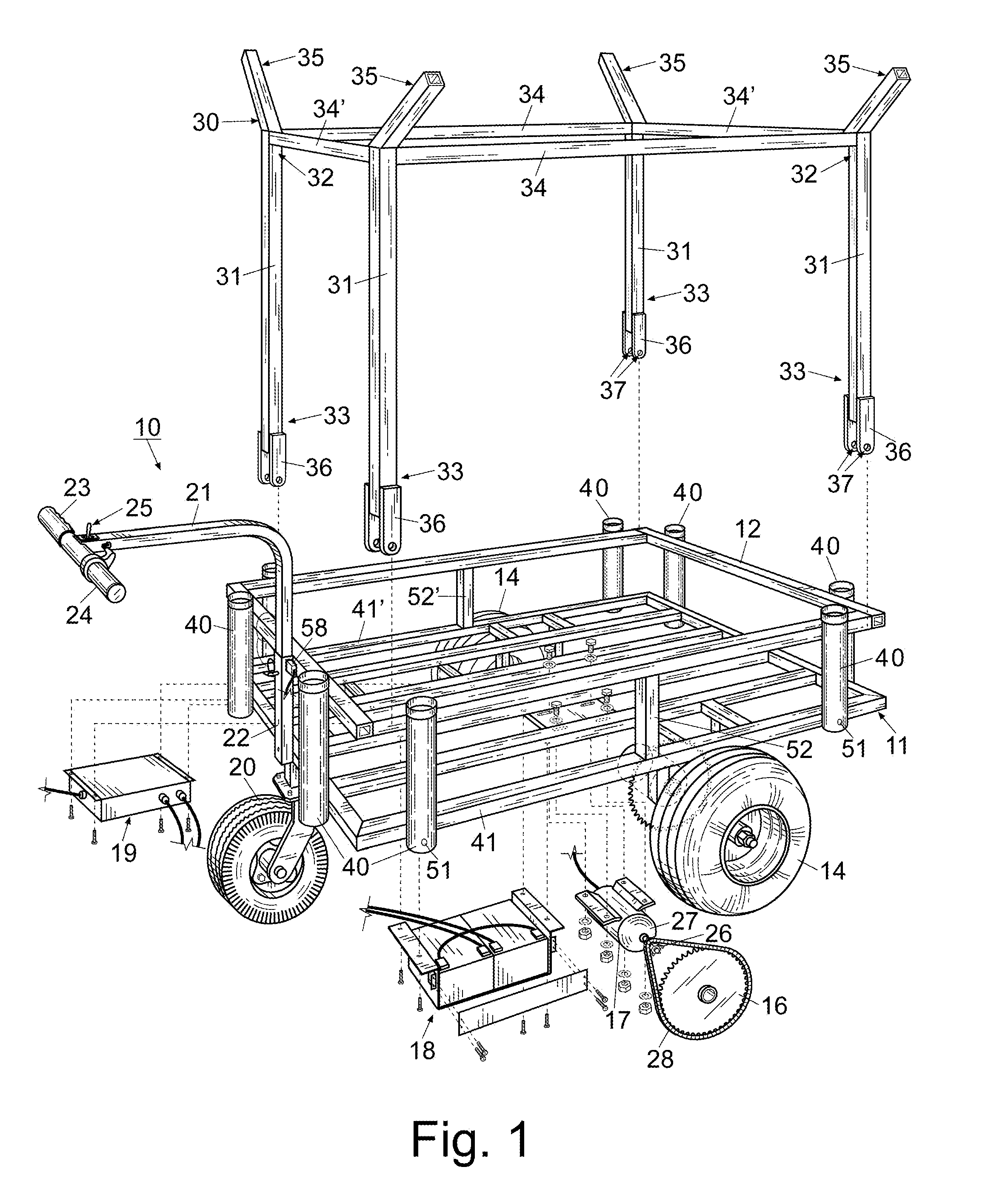

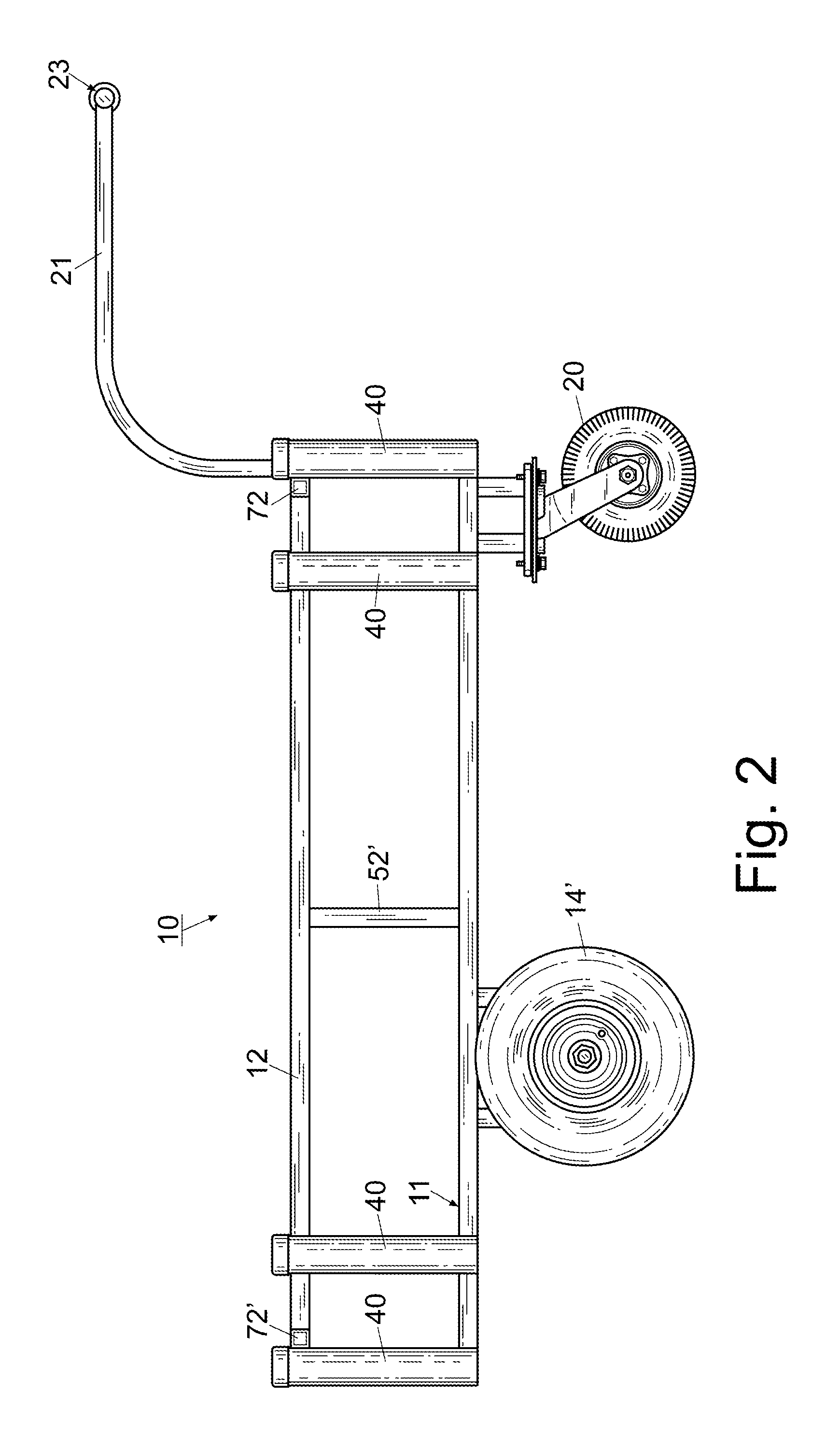

Electric utility cart

ActiveUS8746377B1Large loading capacityIncrease and decrease its speedCyclesCarriage/perambulator with multiple axesPickup truckEngineering

An electric utility cart to assist in transportation and hauling various items is disclosed. The utility cart includes a handle with a throttle to control the speed of the cart during use. A single 360° rotatable front wheel in combination with a pair of wide rear wheels which are joined to a differential allows the cart to turn in tight circles. A directional switch proximate the handle allows the user to drive the cart in either a forward or rearward direction. An auxiliary rack can be mounted on the cart as needed for carrying surf boards or other large items. A hitch rod allows the cart to be suspended and transported by a conventional vehicle such as a car, SUV or pickup truck having a typical tubular hitch.

Owner:BLUE COMET VENTURES

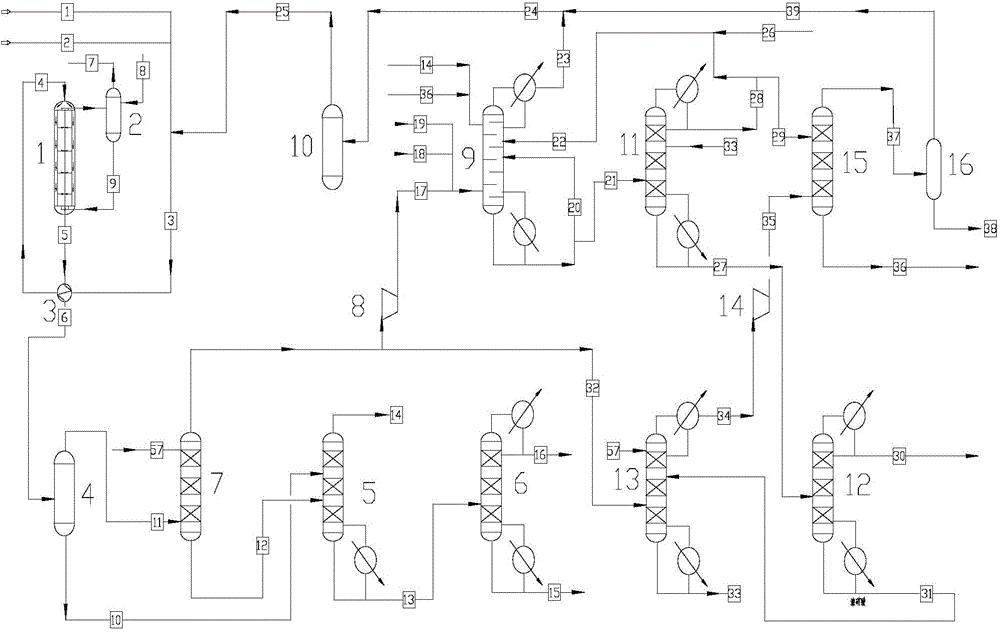

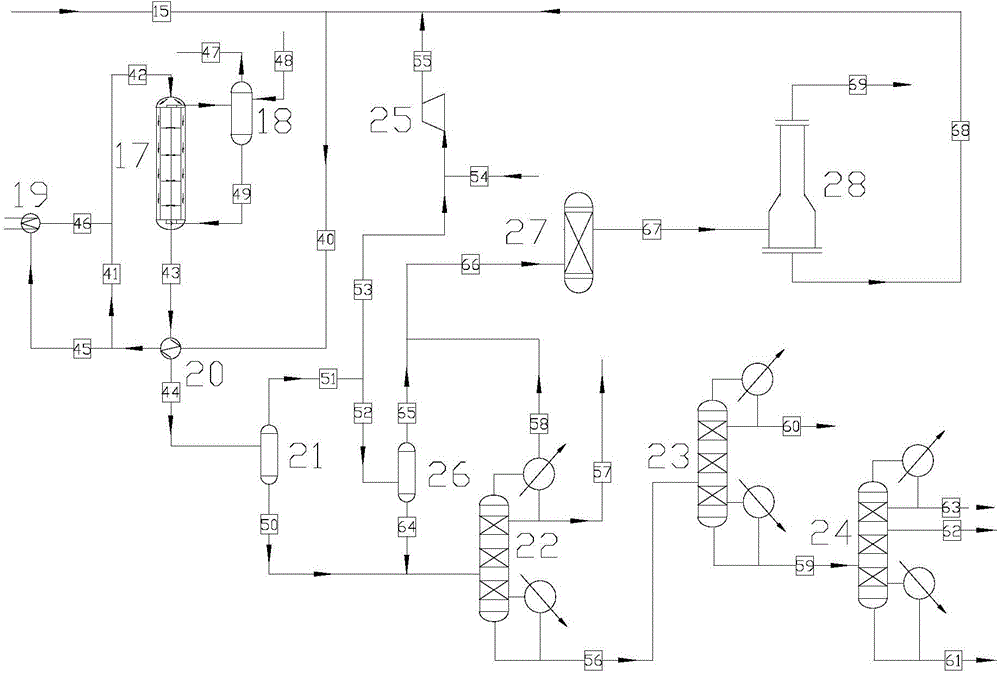

Technology and device system for producing dimethyl oxalate by high-pressure carbonylation of industrial synthesis gases and producing ethylene glycol through dimethyl oxalate hydrogenation

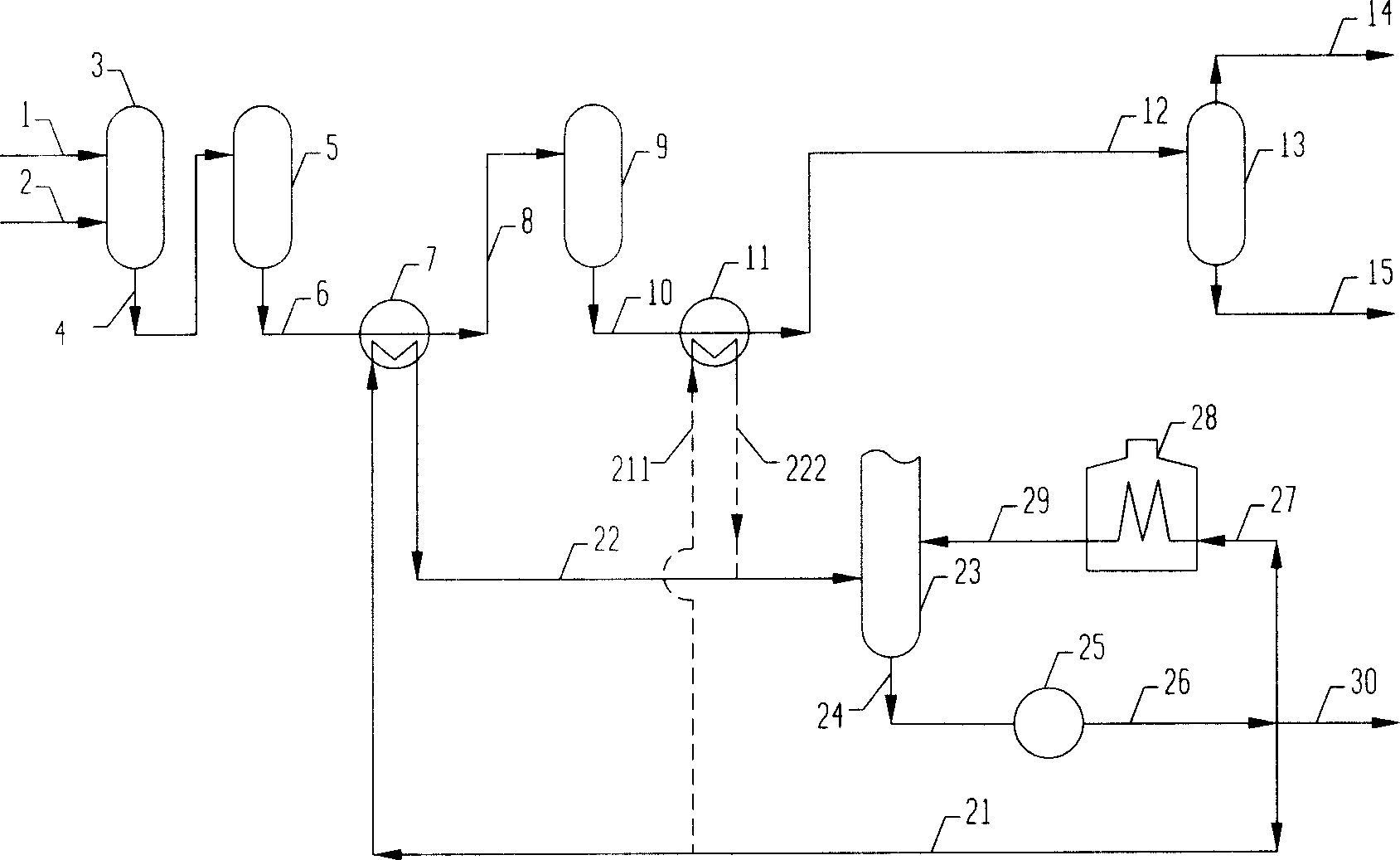

ActiveCN104098441AConducive to large-scale productionSmall volume requirementOrganic compound preparationEnergy inputSeparation technologyHigh pressure

The invention relates to a technology and a device system for producing dimethyl oxalate by high-pressure carbonylation of industrial synthesis gases and producing ethylene glycol through dimethyl oxalate hydrogenation. The technology comprises the following steps: adopting industrial NO, O2 and methanol as raw materials for an esterification reaction to produce methyl nitrite; adopting industrial CO and methyl nitrite for a carbonylation reaction in a plate reactor to produce carbonylation products, which mainly include dimethyl oxalate and dimethyl carbonate; separating the carbonylation products to obtain dimethyl carbonate products; subsequently adding hydrogen into dimethyl oxalate in the plate reactor to produce ethylene glycol products; conducting the coupling recovery treatment on waste acids in the esterification reaction and purge gases in the carbonylation reaction for recycling. The device system comprises an esterification reaction system, a carbonylation reaction system, a coupling recovery system for purge gases and waste acids and a hydrogenation reaction system. The technology has the characteristic that device consumption is remarkably reduced, and particularly the nitric acid waste liquid recycling and purge gas recycling technologies as well as the separation technologies thereof are highly coupled; recycling of the raw materials in reaction waste gases is realized, and the effect is remarkable.

Owner:SHANGHAI WUZHENG ENG TECH CO LTD

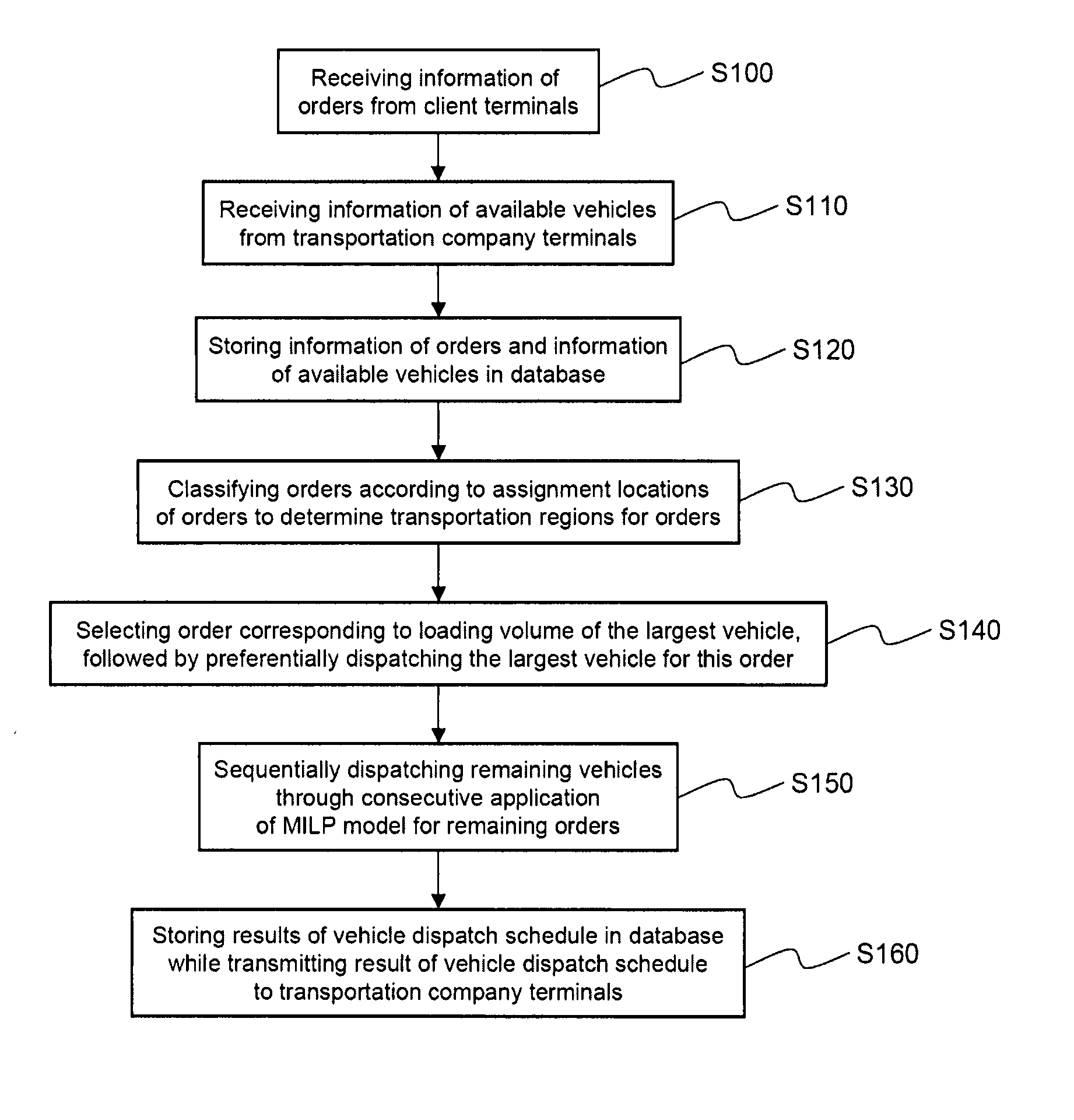

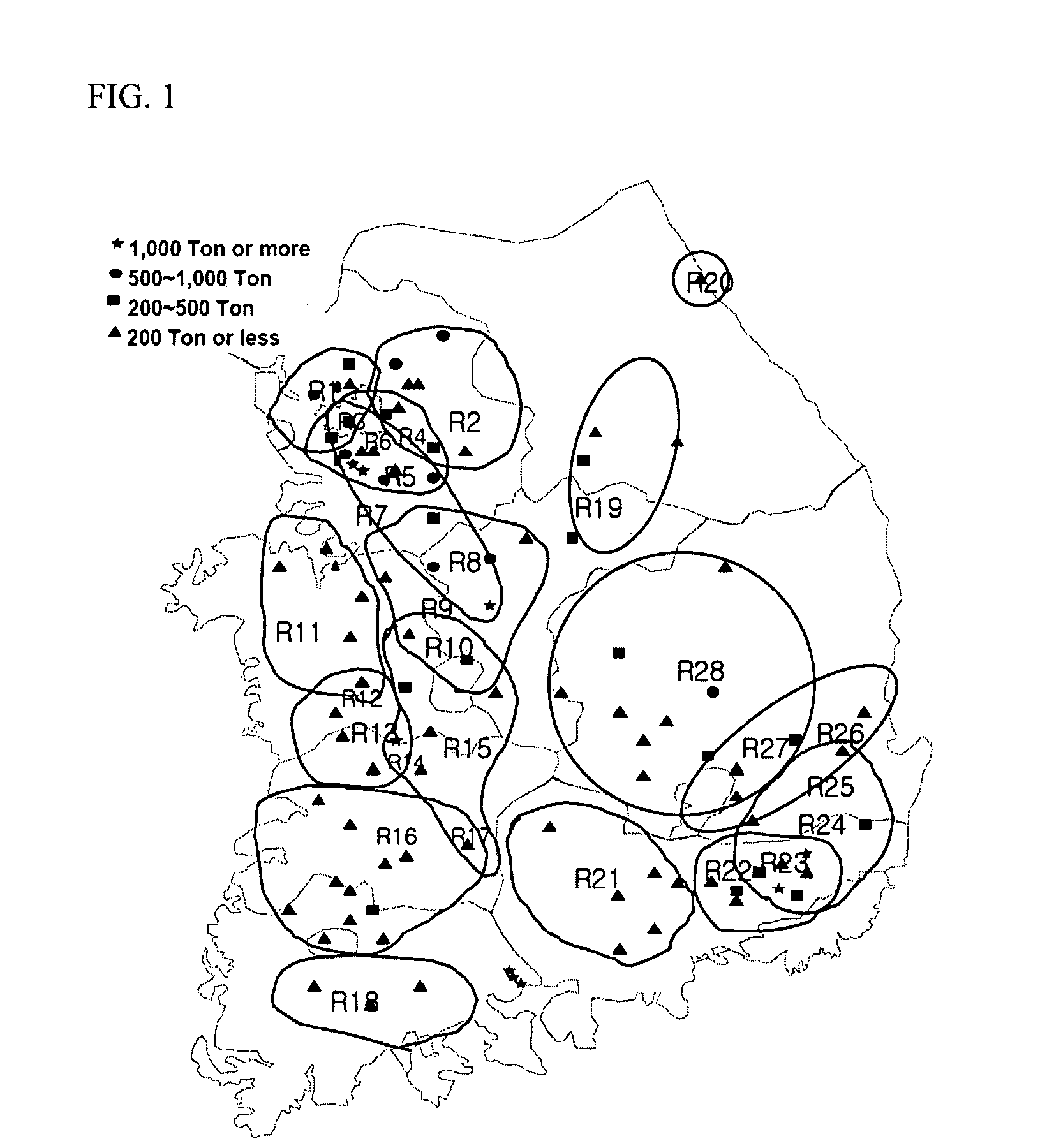

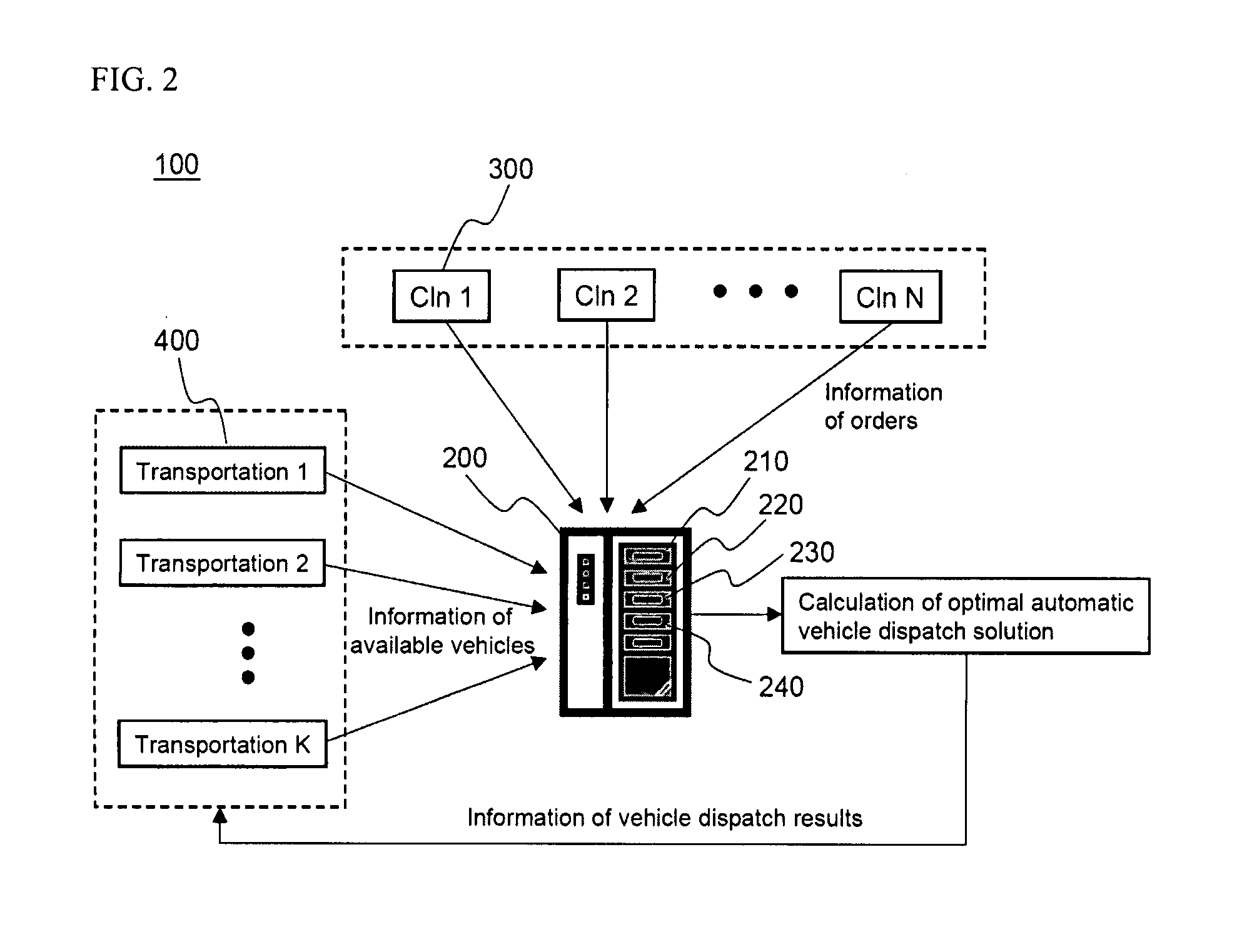

Method for optimal multi-vehicle dispatch and system for the same

ActiveUS20070194912A1Increase in delivery timeIncrease in consolidation costData processing applicationsRadio/inductive link selection arrangementsTransport timeTransport engineering

A vehicle dispatch system enables optimal dispatch of a plurality of vehicles with information of available vehicles from transportation company terminals and information of orders from client terminals under restrictive conditions such as vehicle sizes, minimum loading rates, and a maximum number of assignment locations, based on transportation regions preset in consideration of transportation times, past order quantities, and order congestion degrees, such that a relevant vehicle can perform delivery of freight within a predetermined transportation region to minimize a total transportation cost for each transportation region. The system minimizes a delivery distance of each vehicle, increases a loading volume of the vehicle to reduce an empty rate of vehicles, and minimizes the number of dispatched vehicles, thereby reducing the total transportation cost.

Owner:LG CHEM LTD

Folding trolley

InactiveUS9056621B1Convenient and easy foldImprove edge strengthHand carts with multiple axesHand cart accessoriesWhole bodyEdge strength

A folding trolley includes a folding trolley frame and a storage pocket. Said trolley frame includes side brackets and a bottom support bracket; said side bracket comprises two cross connecting rods hinged at the central point; said bottom support bracket includes bottom support rods and a central hinged seat. the side bracket is a multi-stage connecting rod structure, including at least two pairs of corresponding hinged connecting rods; the ends of the connecting rods are hinged to form pocket support ends; said storage pocket is provide with downward openings; a pulling member corresponding to the location of said central hinged seat and used for folding the trolley body is provided at the interior bottom of said storage pocket. The trolley can realize convenient fold of the whole body, increase edge strength of the storage pocket, and ease using operation for different users, and has stable structure and larger loading capacity.

Owner:JIN XUGANG

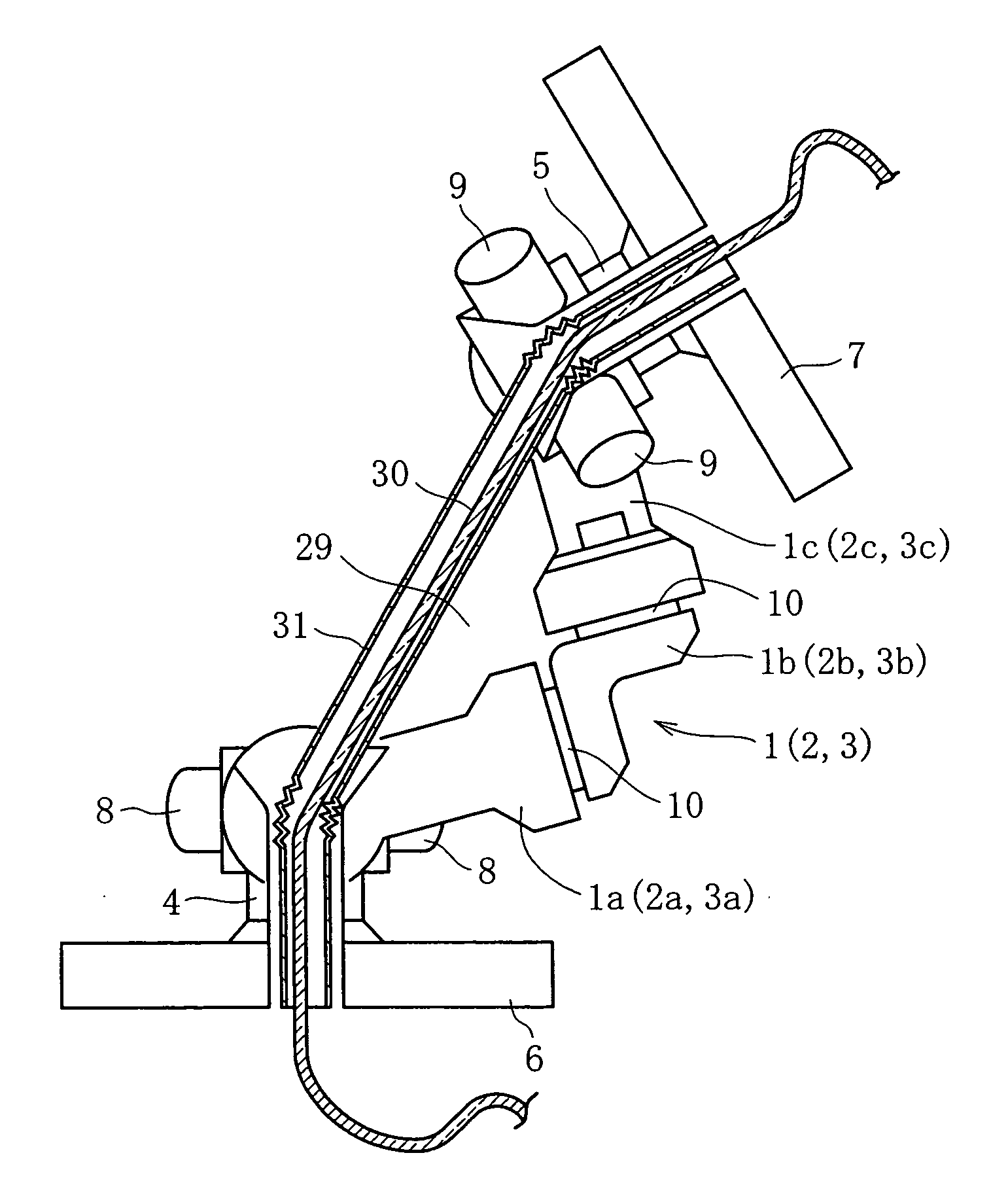

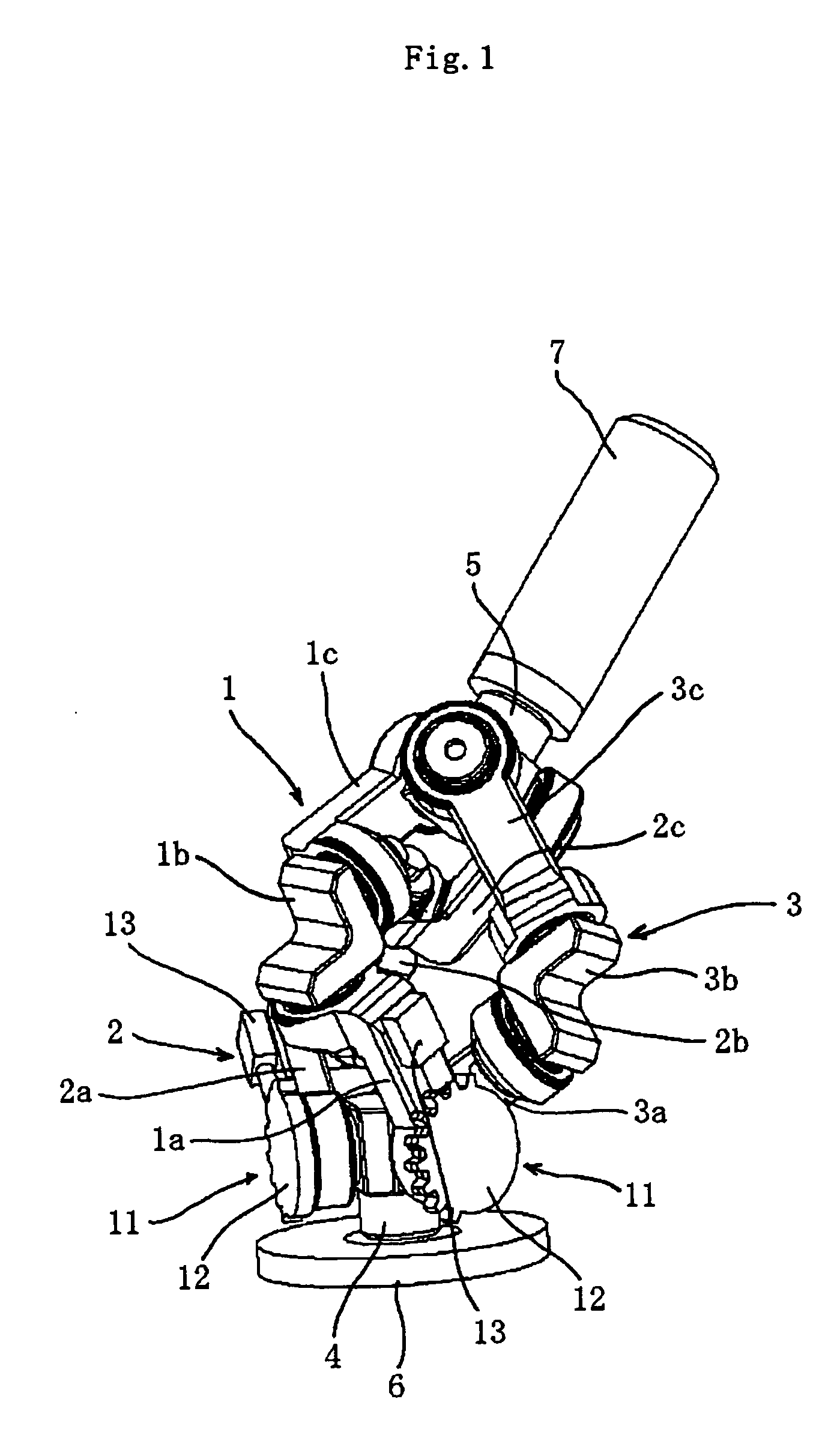

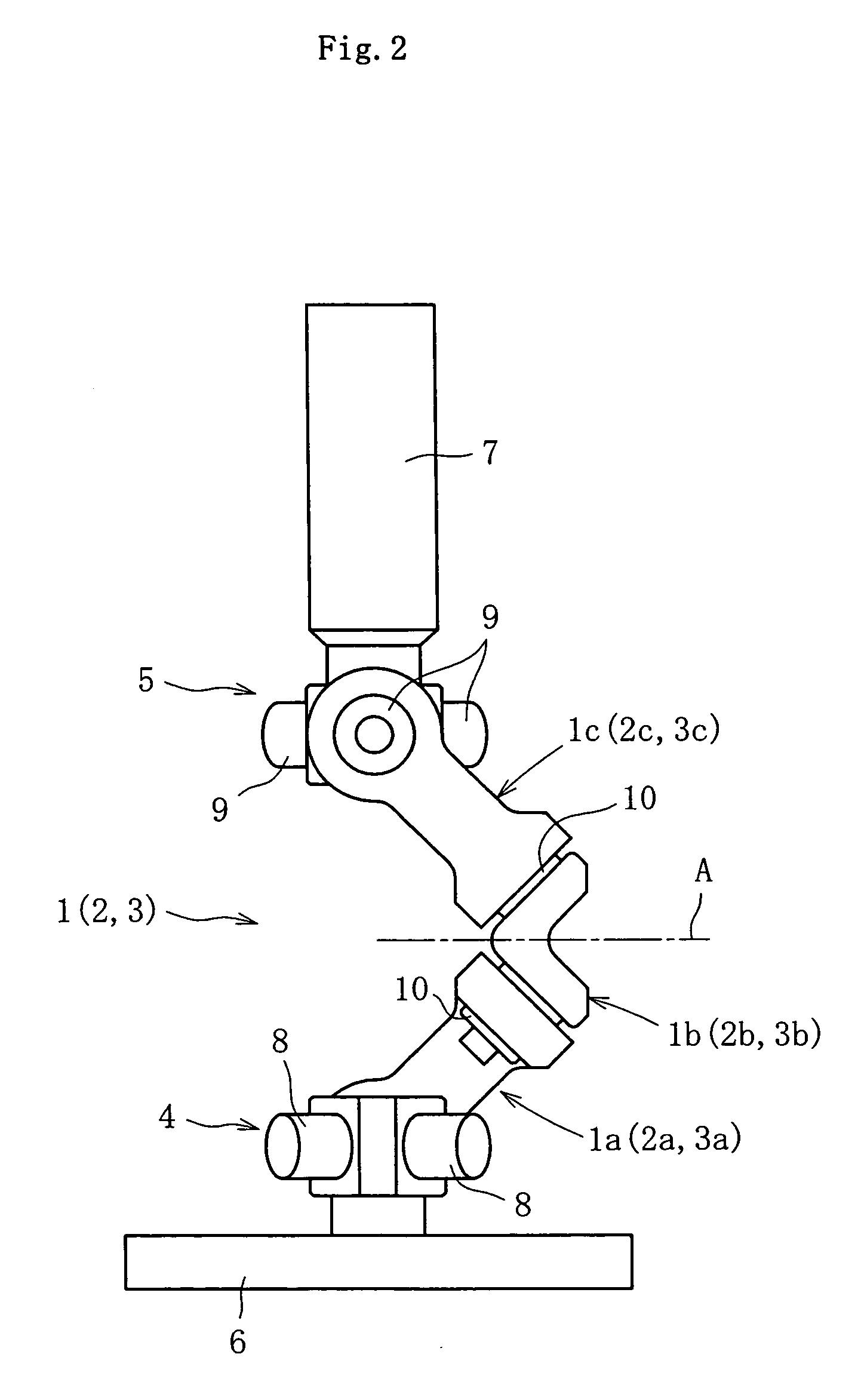

Linkage System

InactiveUS20080028881A1Large loading capacityImprove rigidityManual control with multiple controlled membersProgramme-controlled manipulatorEngineeringLoad capacity

A linkage system is provided which is equipped with a compact and high-rigidity link mechanism with a large load capacity. The linkage system includes three or more link mechanisms. Each link mechanism consists of a center link member and end link members rotatably coupled to the center link member and to link hubs that are provided to an input member and an output member, respectively. An input side and an output side of a center cross-sectional plane of each link mechanism are geometrically identical. One or more of revolute joints of two or more of the link mechanisms that are coupled to the input member are provided with a stopping mechanism for stopping the output member at a given position.

Owner:NTN CORP

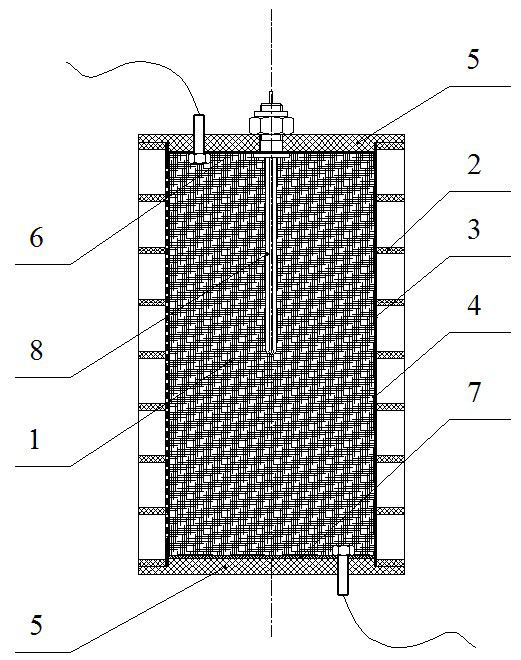

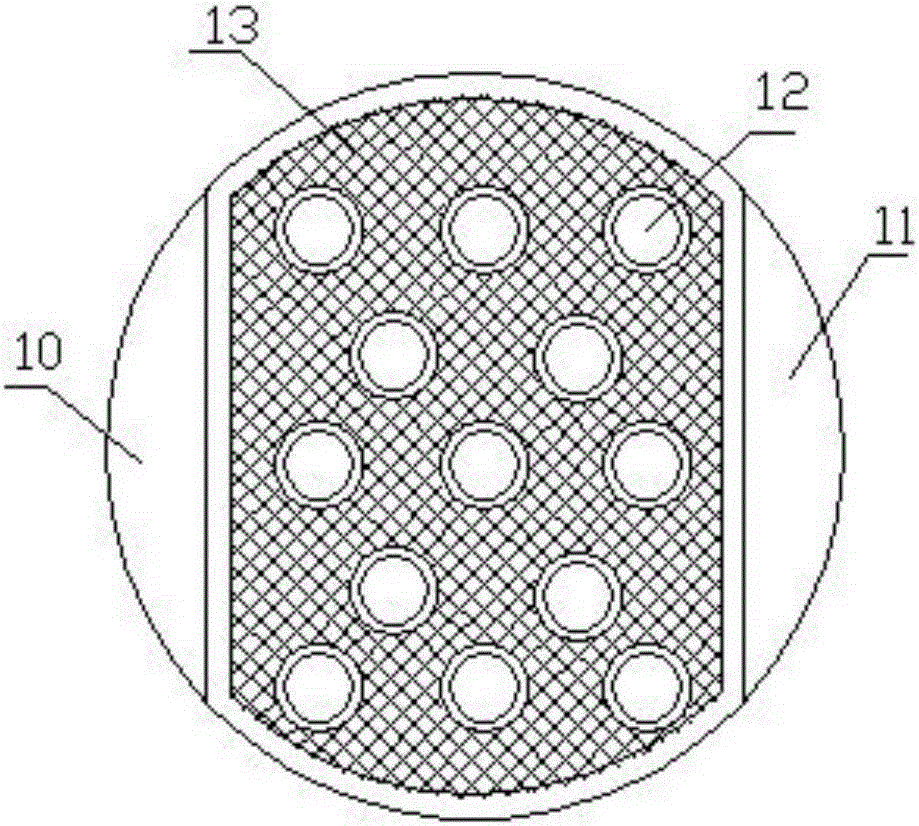

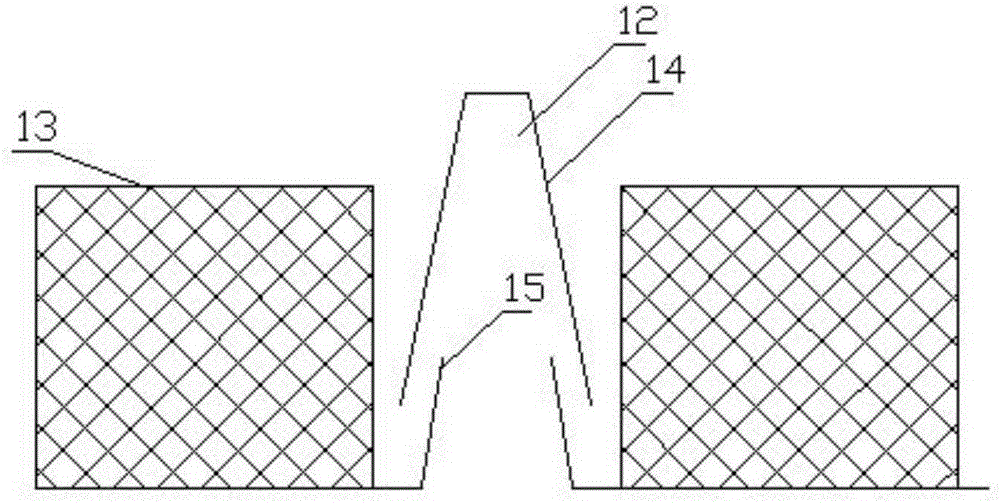

Electrothermic purifying filter element for treating high-air-quantity VOCs (volatile organic chemicals) waste gas

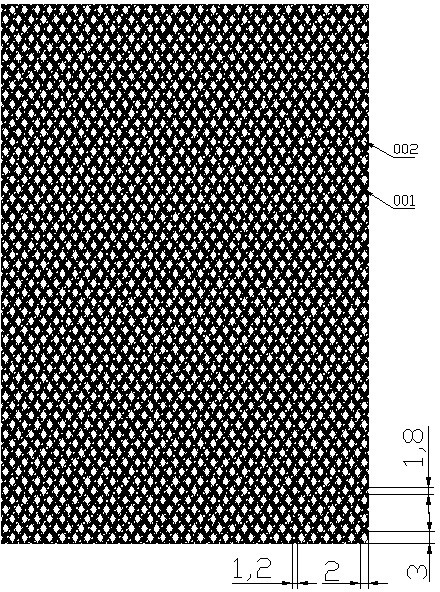

ActiveCN102600697AReduce wind resistanceRealize processingDispersed particle separationActivated carbonFiber

An electrothermic purifying filter element for treating high-air-quantity VOCs (volatile organic chemicals) waste gas comprises a containment structure and an adsorption bed layer filled in the containment structure, and is characterized in that activated carbon eyelet fabrics or / and porous activated carbon fiber cloth (felt) are overlapped to form the adsorption bed layer, an electrode A and an electrode B are arranged on two optional opposite end surfaces or positions close to the end surfaces of the adsorption bed layer, current can be led into the adsorption bed layer via the two electrodes, a couple is arranged in the adsorption bed layer, the temperature of the adsorption bed layer is tested in an electrothermic temperature rising process, the containment structure comprises a sealing portion, an air inlet surface and an air outlet surface, and each of the air inlet surface and the air outlet surface is made of one layer or multiple layers of mesh or porous materials. The air resistance of the electrothermic purifying filter element for treating the high-air-quantity VOCs waste gas is reduced, the high-air-quantity organic waste gas is treated by small equipment, filling quantities of adsorption materials in units of the adsorption bed layer are increased, adsorption period is long, energy consumption caused by frequent desorption and adsorption switching of the equipment due to low filling quantities of the adsorption materials is avoided, the adsorption materials are filled compactly, resistivity of the adsorption bed layer is uniform and identical, and potential safety hazards caused by local over heat are avoided.

Owner:李鑫焱

Method of recovering heat in hydrocarbon hydrogenating conversion process

InactiveCN101067095AReduce consumptionSmall scaleExothermal chemical reaction heat productionExothermal chemical reactions for heatingThermal energyHydrogen

The present invention relates to method of recovering heat in hydrocarbon hydrogenating conversion process. The low temperature heat absorbing oil and the reaction resultant are heat exchanged to form high temperature heat absorbing oil, which enters to the bottom of the fractionating tower so as to mix with the liquid phase material flow inside the fractionating tower before being shunt into low temperature heat absorbing oil for reuse. The process is especially suitable for hydrogenating conversion of coal tar, and has the advantages of high heat utilizing rate, reduced hydrogen circulating system scale and reduced the scale of reboiling furnace in the fractionating tower. In addition, the heat absorbing oil heat exchanger may be used as the heater for starting the reactor or sulfurizing to reduce heat load of the heating furnace.

Owner:何巨堂 +1

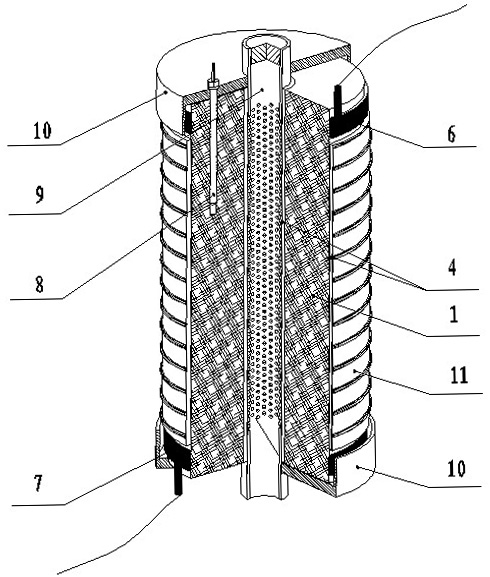

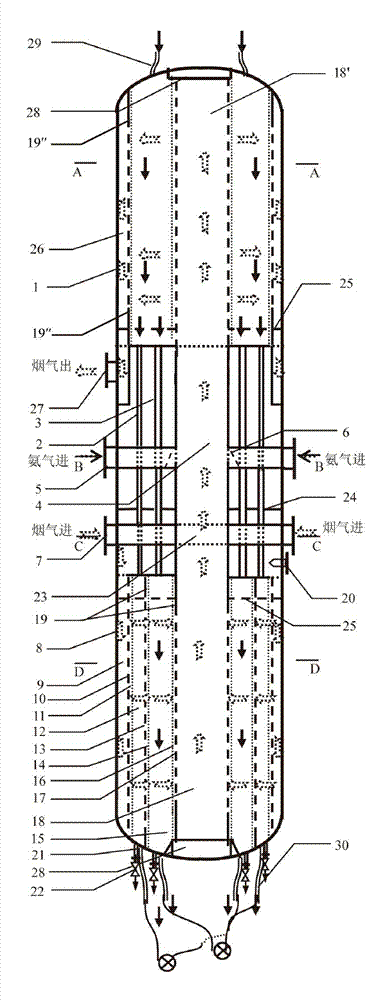

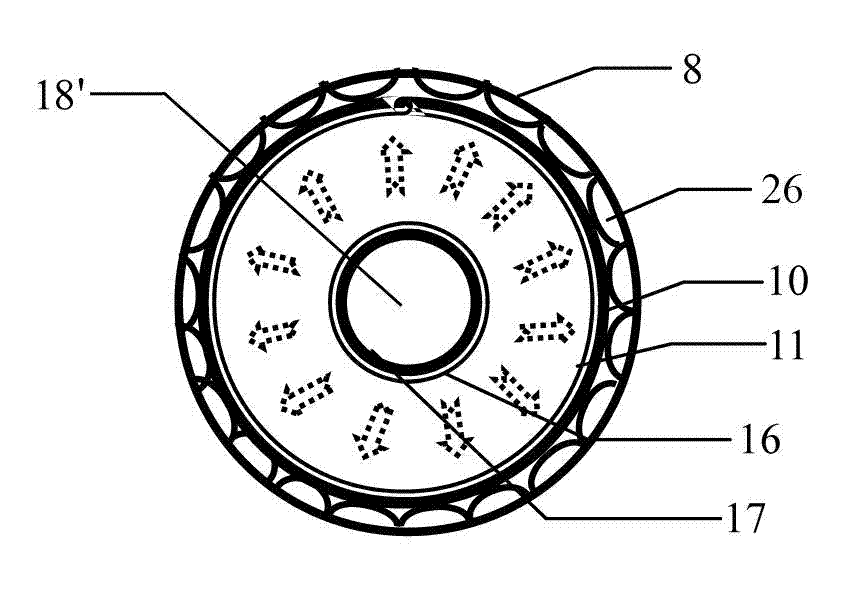

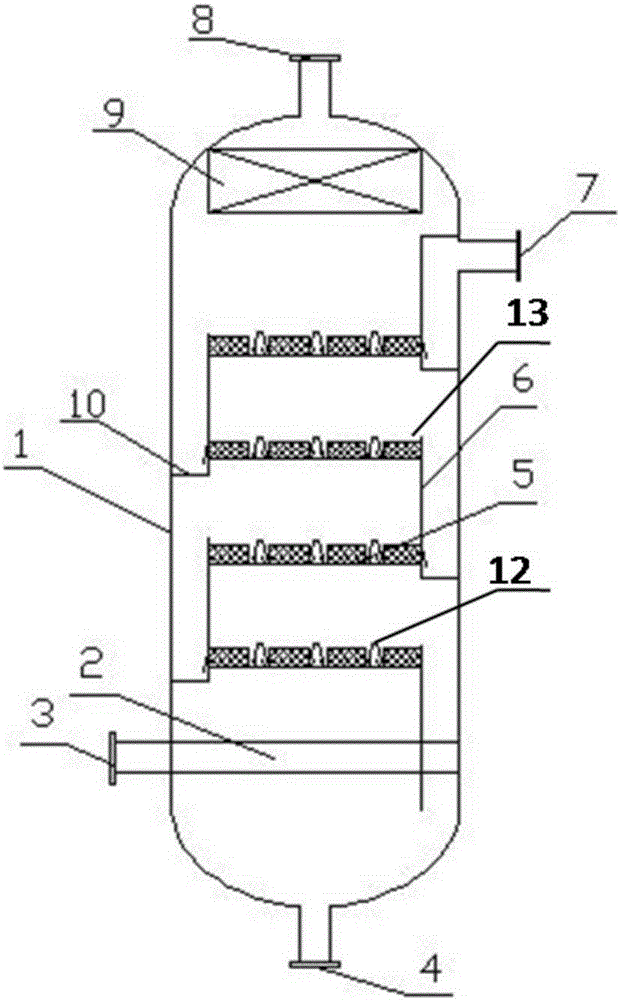

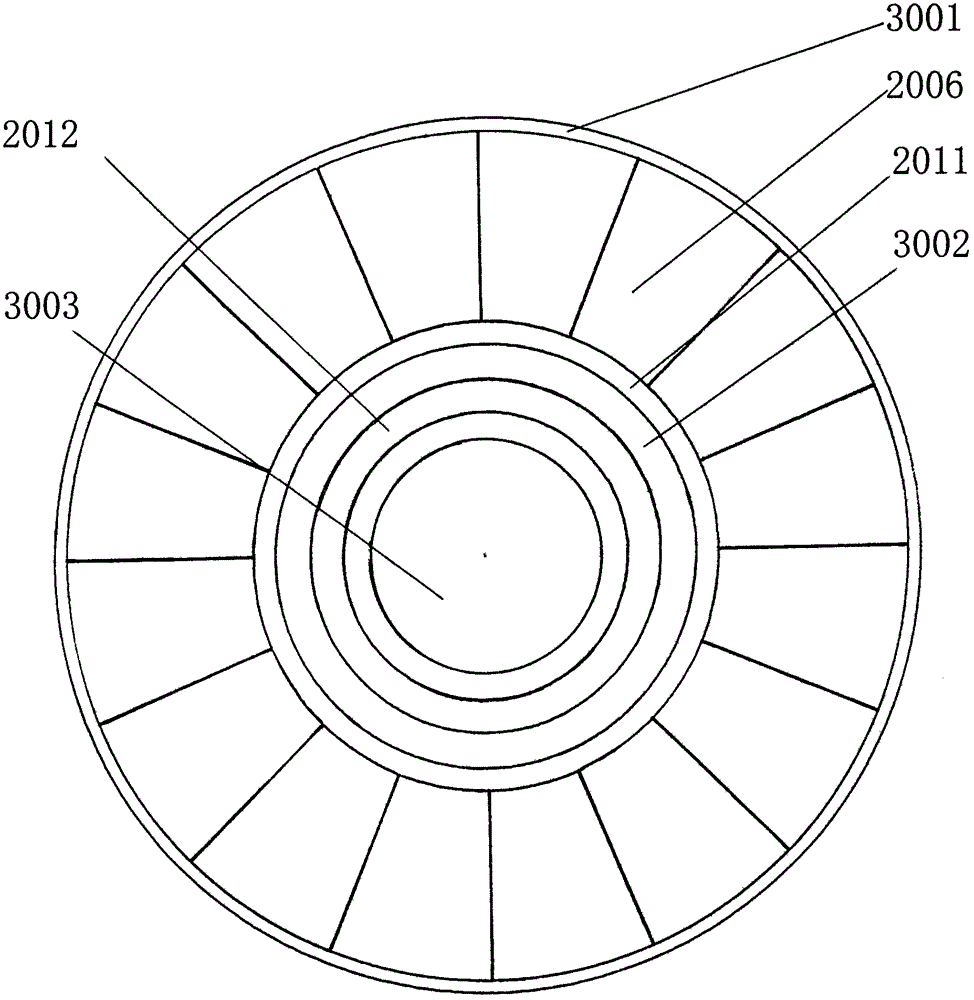

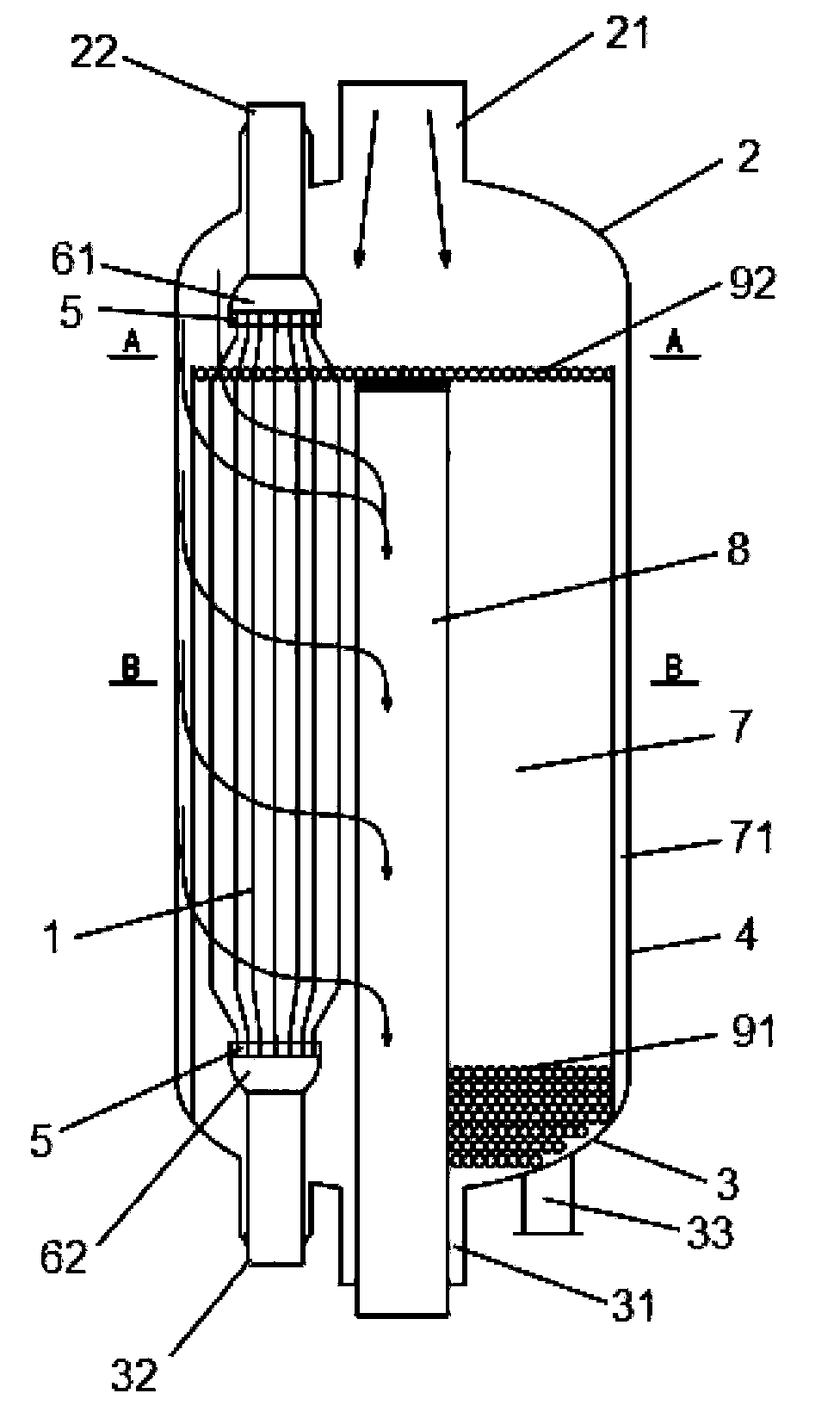

Axial and radial cross flow moving bed reactor and activated coke flue gas desulfurization and denitration technology thereof

ActiveCN102824846ACombined removalAchieve efficient utilizationDispersed particle separationAir quality improvementThermodynamicsFlue gas

An axial and radial cross flow moving bed adsorption reactor and an activated coke flue gas desulfurization and denitration technology thereof are used for realizing the purposes that SO2, NOx, mercury, dioxin and other pollutants in flue gas are unitedly removed and integrally purified in an adsorption reactor, and belong to the technical field of comprehensive waste flue gas treatment. The adsorption reactor is a combined type double-section double-inverse U-type axial and radial cross flow moving bed, awherein desulfurization area is arranged at a lower section of the axial and radial cross flow moving bed, an annular internal activated coke particle layer and an annular external activated coke particle layer are arranged, and the desulfurization area is divided into a coarse desulfurization area and a fine desulfurization area; a denitration area is arranged at an upper section of the axial and radial cross flow moving bed, and an activated coke particle layer is arranged; an ammonia spray pipe is arranged between the upper section and the lower section; and flue gas is filled along a double-port counter annular gas flow channel structure, the flue gas of the lower section centripetally flows to be desulfurized, and the flue gas of the upper section centrifugally flows to be denitrated. According to the reactor and the technology, desulfurization and denitration are realized in one adsorption reactor, so the adsorption reactor has the advantages of efficient utilization of activated coke, uniform flue gas mixing, sufficient gas-solid contact, stability and reliability in operation, operation cost saving and the like.

Owner:SHANGHAI LONGKING ENVIRONMENTAL PROTECTION

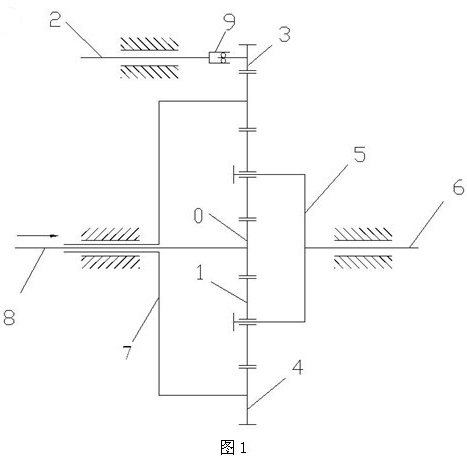

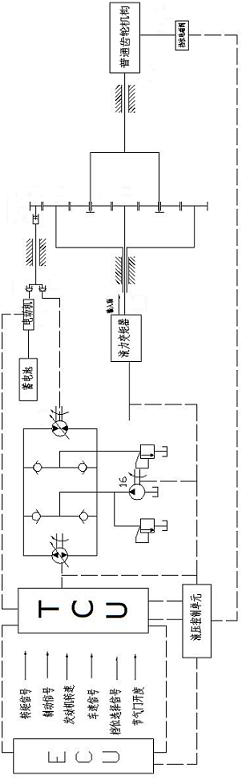

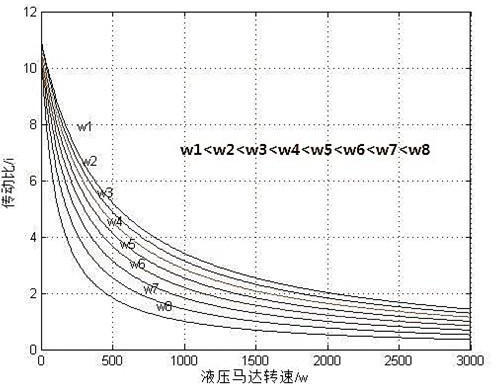

A planetary gear stepless transmission

InactiveCN102287498AChange gear ratioHigh torque transmissionToothed gearingsGear wheelControl theory

The invention discloses a novel gear continuously variable transmission, aiming to provide a continuously variable transmission with large transmission torque, high transmission efficiency, good reliability and good fuel economy. The present invention includes a first input shaft, a second input shaft, a one-way clutch, a gear, a planetary ring gear, a planetary gear, a first planetary carrier, a sun gear, a second planetary carrier and an output shaft, and the planetary gear continuously variable transmission passes through The power input of two degrees of freedom of the first input shaft and the second input shaft realizes the function of stepless speed change. The invention has the advantages of simple structure and convenient manufacture, and can effectively realize the stepless speed change function.

Owner:NANJING INST OF TECH

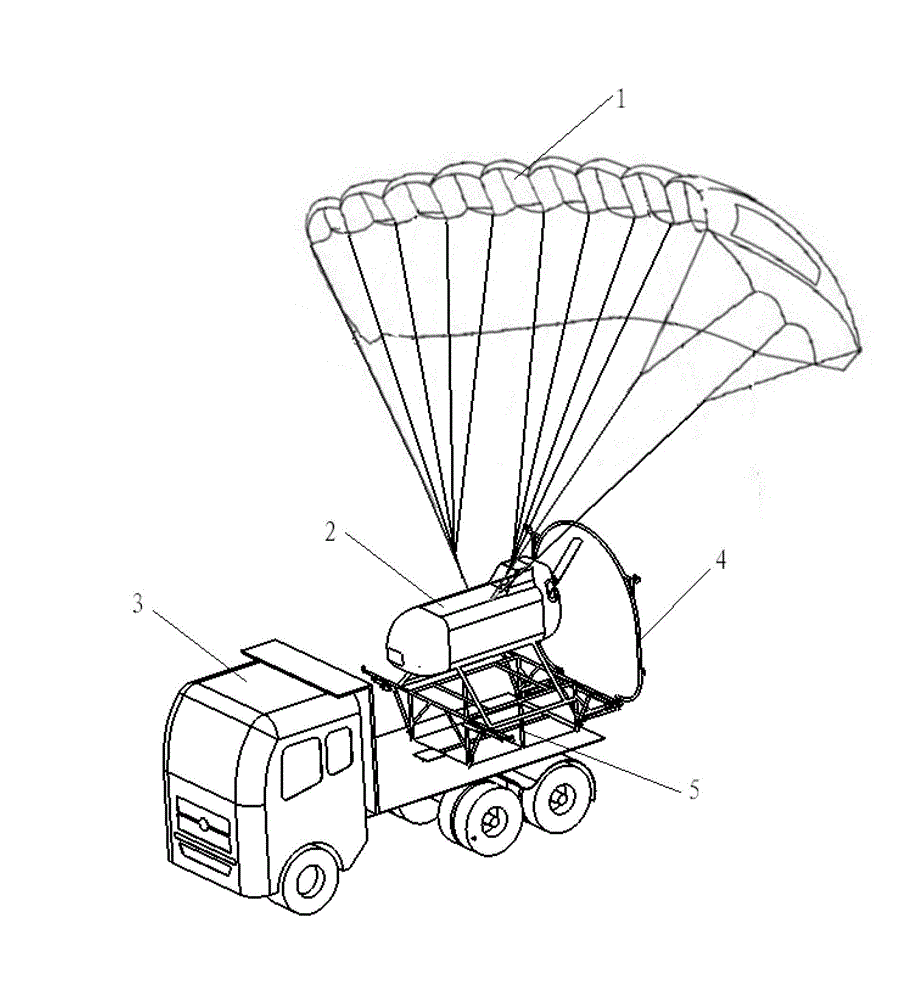

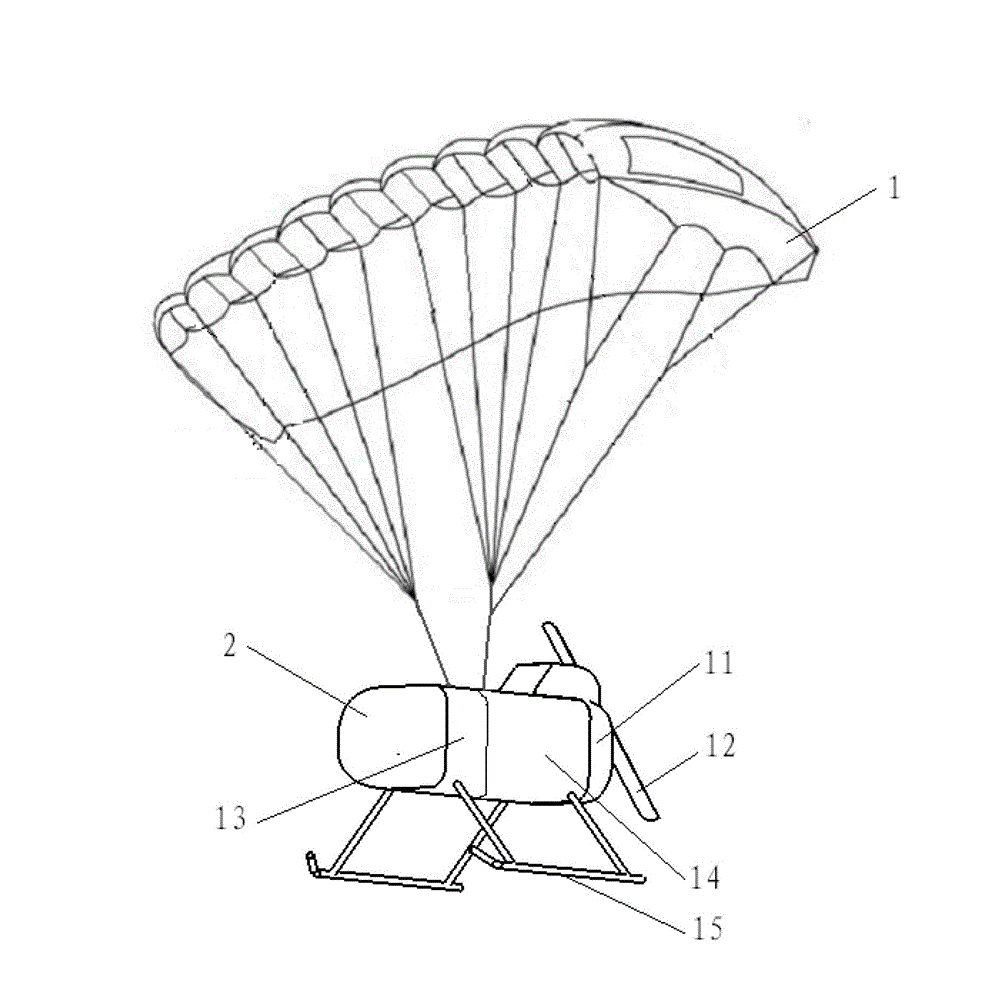

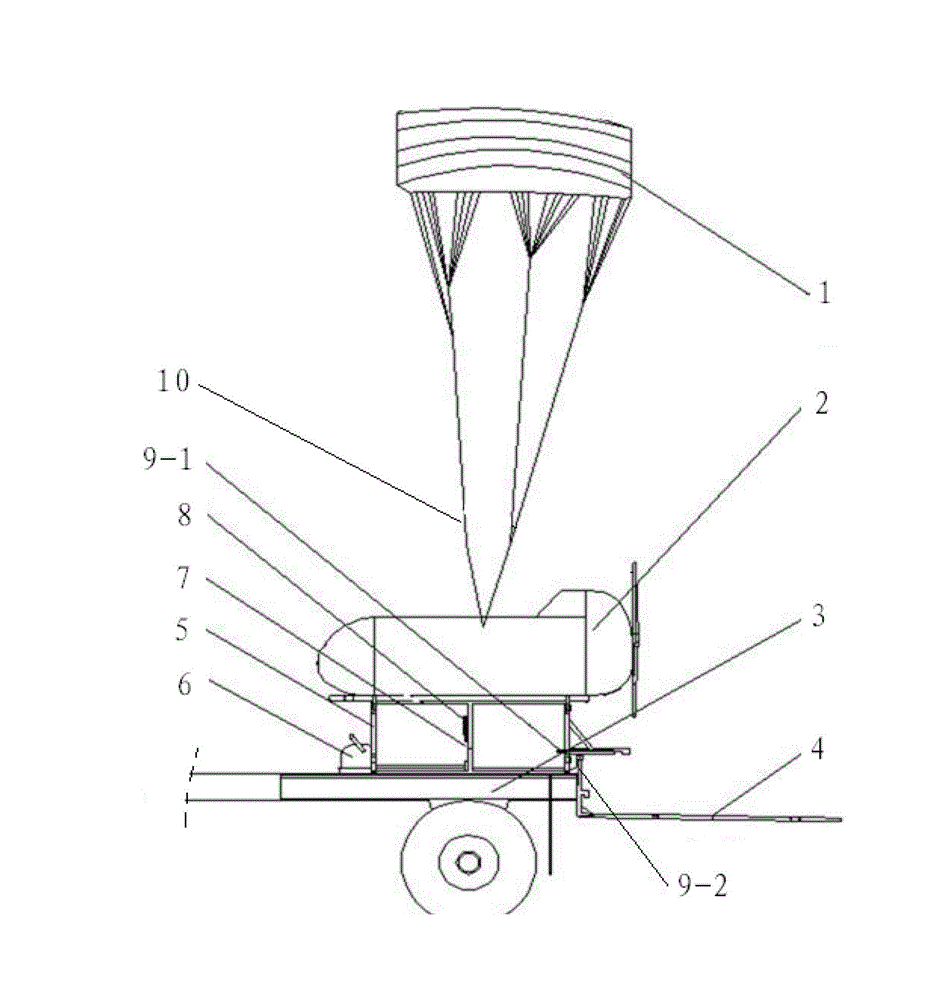

Multifunctional unmanned aerial vehicle provided with flexible stamping parafoil

InactiveCN102910288AVarious launch methodsVersatilityLaunching/towing gearMicrolight aircraftsWide fieldModularity

The invention provides a multifunctional unmanned aerial vehicle provided with a flexible stamping parafoil, which mainly comprises the flexible stamping parafoil (1), a cabin body (2), a propeller (12) and a skid type landing gear (15); the lower part of the flexible stamping parafoil (1) is connected with the cabin cabin (2) through parafoil ropes (10); a control mechanism (13), a modularized mission cabin (14) and an engine (11) are mounted inside the cabin body (2); the propeller (12) is mounted at the tail part of the cabin body (2); the skid type landing gear (15) is mounted at the lower part of the cabin body (2); and equipment required for different purposes is carried in the modularized mission cabin. The multifunctional unmanned aerial vehicle provided with the flexible stamping parafoil has the benefits of safety, reliability, multiple launching manners, long cruise time, wide flying range, small size, light weight, convenience in use, and wide field of use, and is an ideal unmanned aircraft.

Owner:武汉南沙工贸有限公司

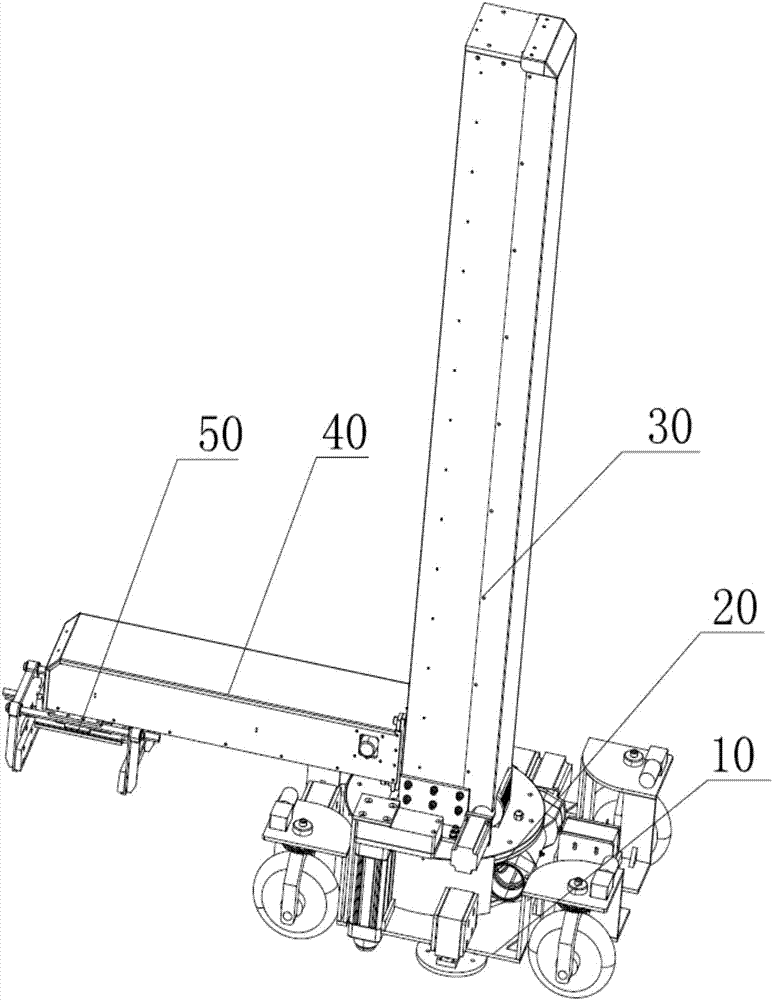

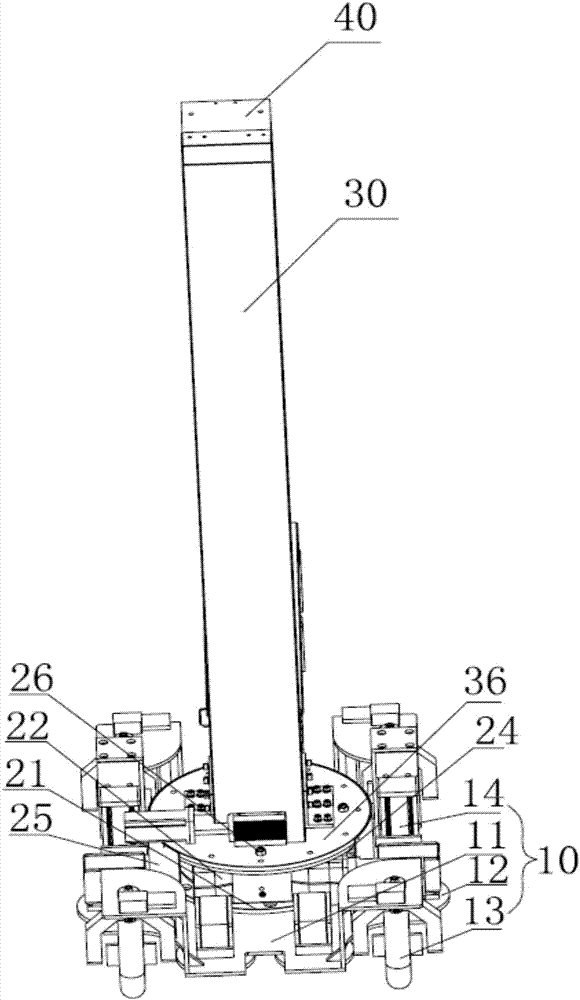

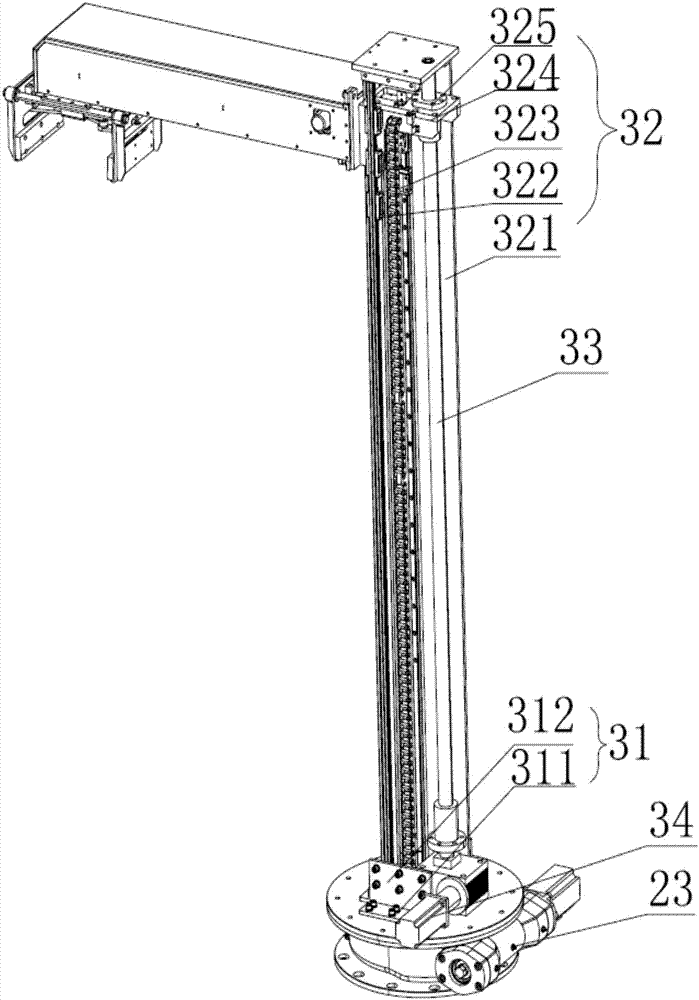

Portable bricklaying robot capable of being disassembled and assembled

ActiveCN107060355AAchieve fixationAchieve positioningBuilding material handlingManipulatorEngineeringSlide plate

The invention provides a portable bricklaying robot capable of being disassembled and assembled. The portable bricklaying robot comprises a lifting aerial ladder, a rotary pedestal, a liftable machine body and a top bricklaying module which are sequentially connected and capable of being singly disassembled and assembled. The rotary pedestal comprises a base, a first drive device, a gear set and a rotary supporting disc which are connected with one another. The liftable machine body comprises a second drive device, a first lead screw, a longitudinal guide rail structure and a plurality of first fixing plates. The top bricklaying module comprises a supporting plate and further comprises a plurality of second fixing plates, a second lead screw, a transverse guide rail mechanism, a third drive mechanism, a rotary grabbing device and a fourth drive device which are fixed to the supporting plate. The supporting plate is provided with a guide rail groove, a sliding plate fixing plate and a hole groove matched with the first lead screw. The portable bricklaying robot capable of being disassembled and assembled is simple in structure, easy to disassemble and assemble, liftable, low in weight, large in bricklaying weight and range which are capable of being achieved and good in grabbing effect.

Owner:HUAWAY IOT TECH

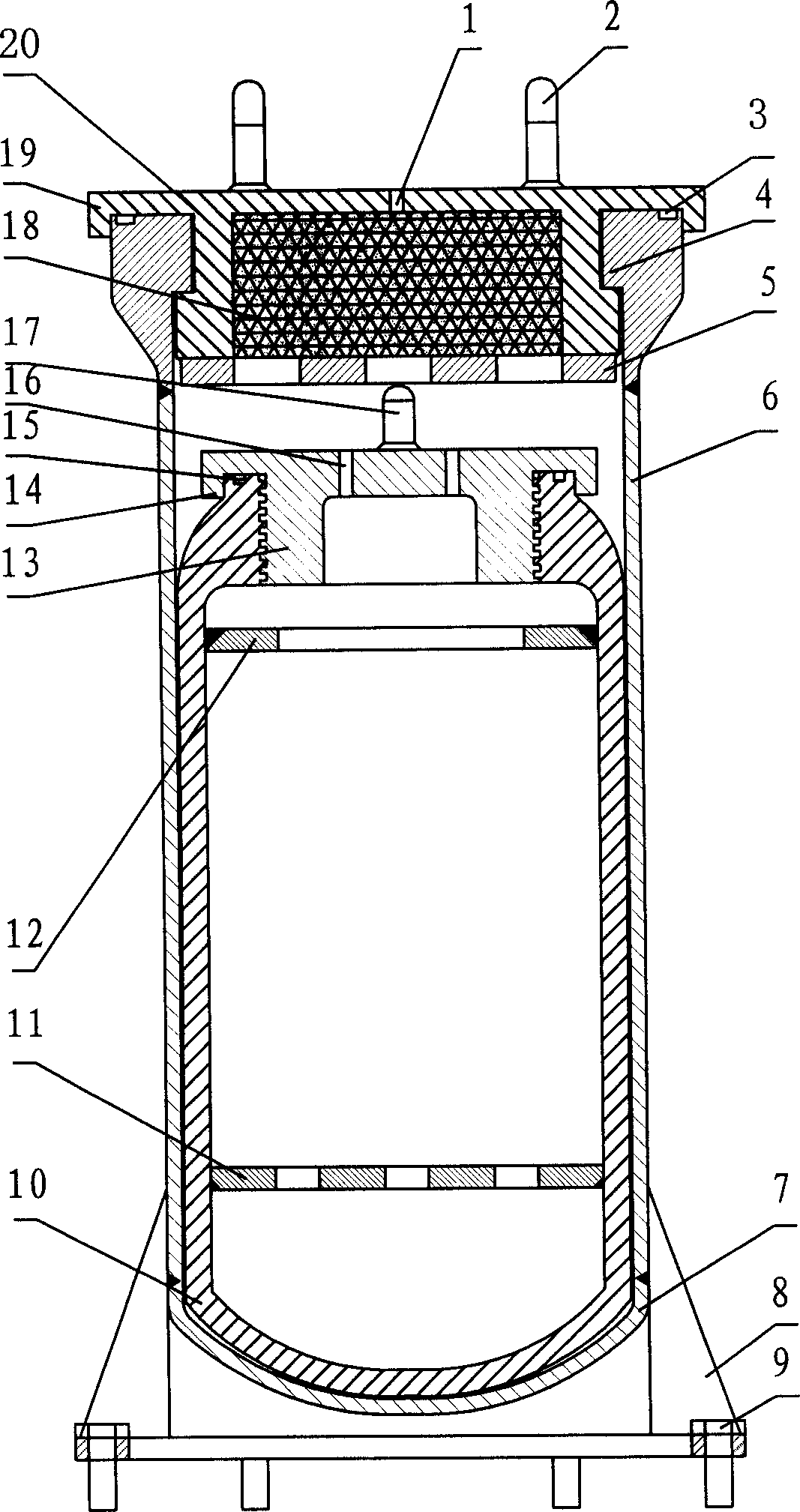

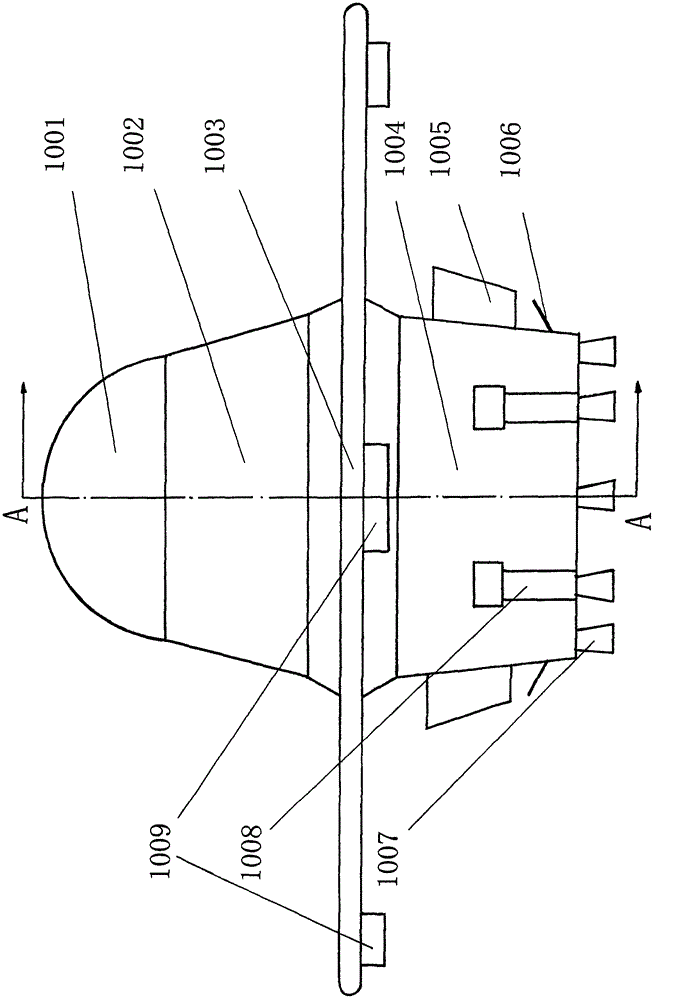

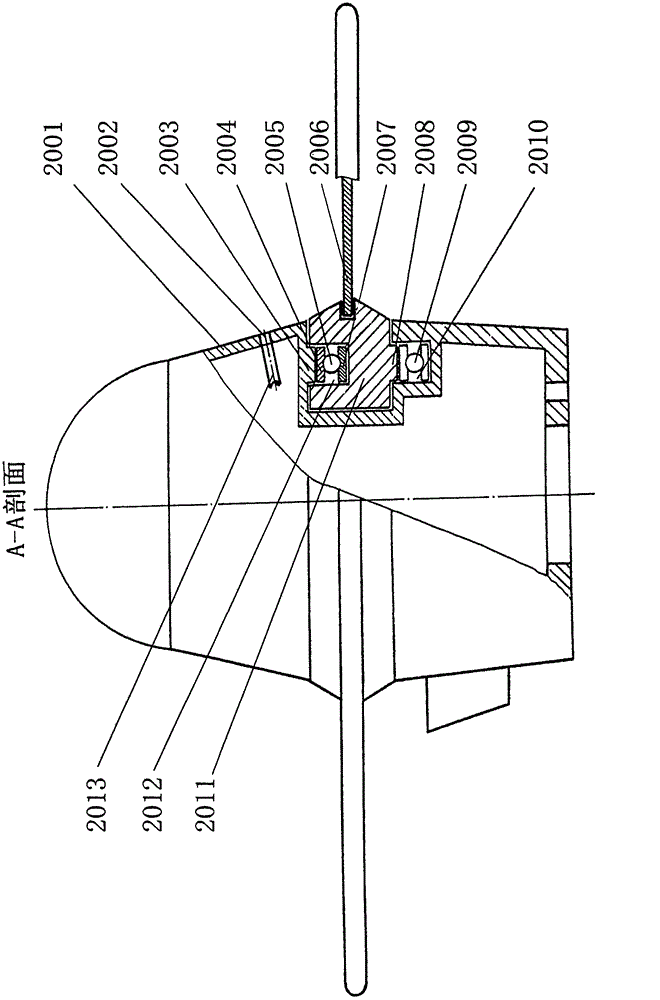

Anti-explosive container

ActiveCN1888810ANot easy to wearFlexible opening and closingAmmunition storageMechanical engineeringDetonator

A blast resistant container relates to outside canister, fixed board and top plate. There is handle and blast-release hole on top plate; outside canister connects with top plate by spline. The top plate owns wave absorber plate and the bottom of outside canister owns some supported vertical plate fixed with fixed board. Outside canister owns inside canister and it is made up by inner top plate and inside closed canister without coping, and the inside of the top bottom compounds with the inside wall of the inner top plate by thread bayonet. Inner top plate owns handle and at least two blast-release holes, and its rim owns hook side for the outer rim of top bottom to inside canister; and the top and down bottom of the inside canister owns up and down wave absorber plate. It is safe for carrying the blast starting equipment and detonator in the same carrying vehicle and reduces the influence for the ambience, people and establishment when the canister blasts. It is easy for starting and stopping, large capability, long life and good blast resistant performance to be able to demolish equipment dedication carrying vehicle.

Owner:ZHEJIANG LUJIESHUN COMPARTMENT MFG

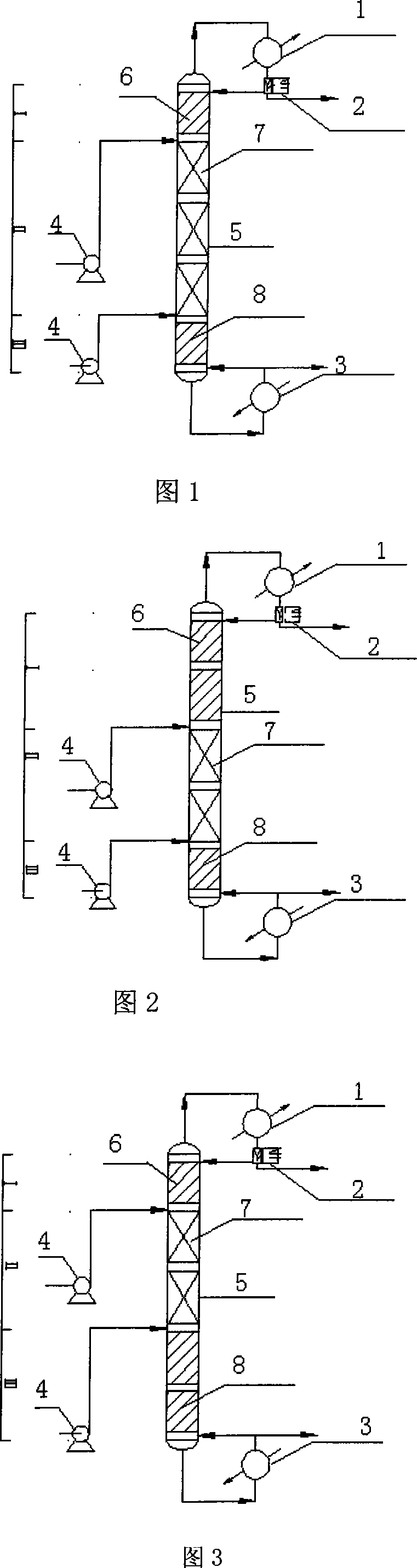

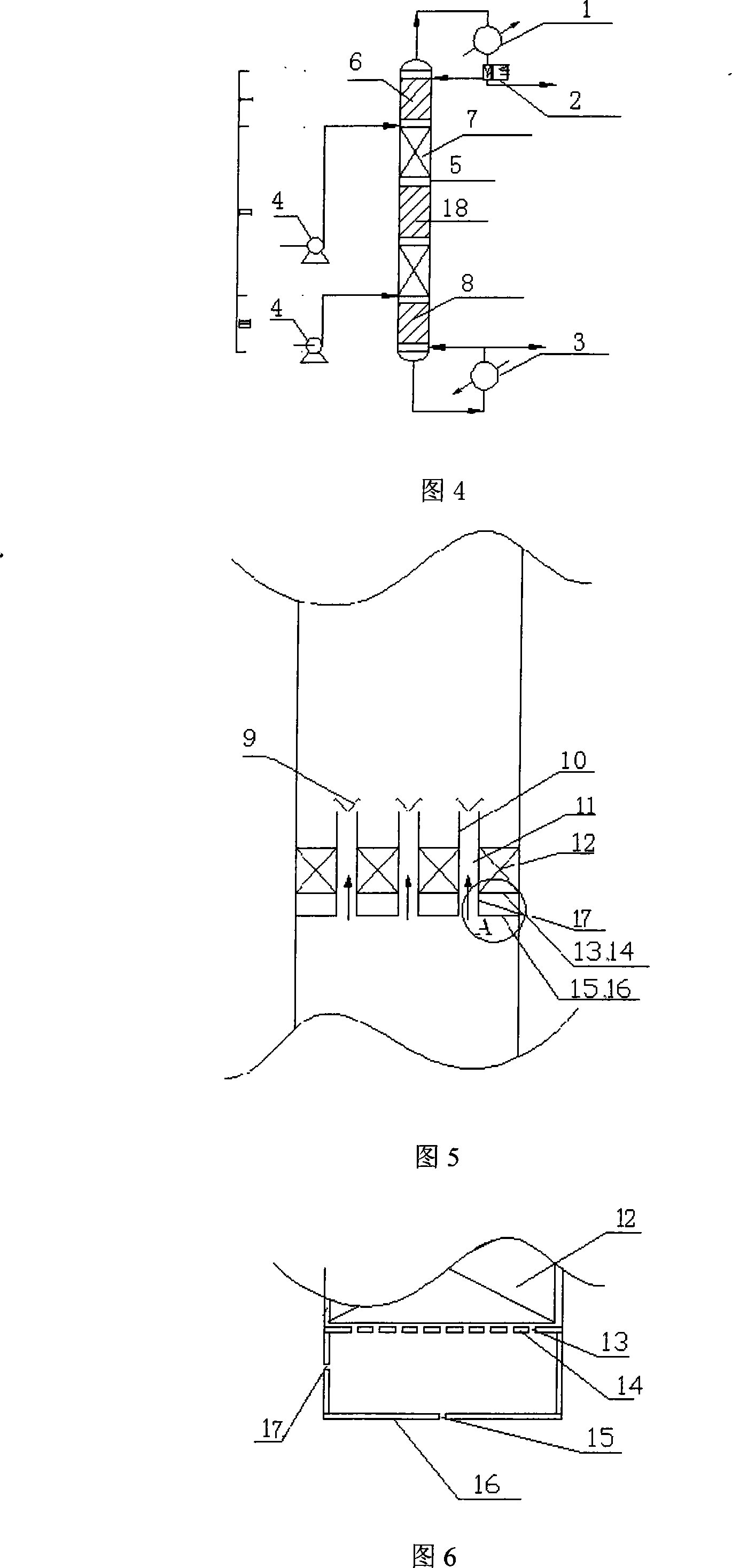

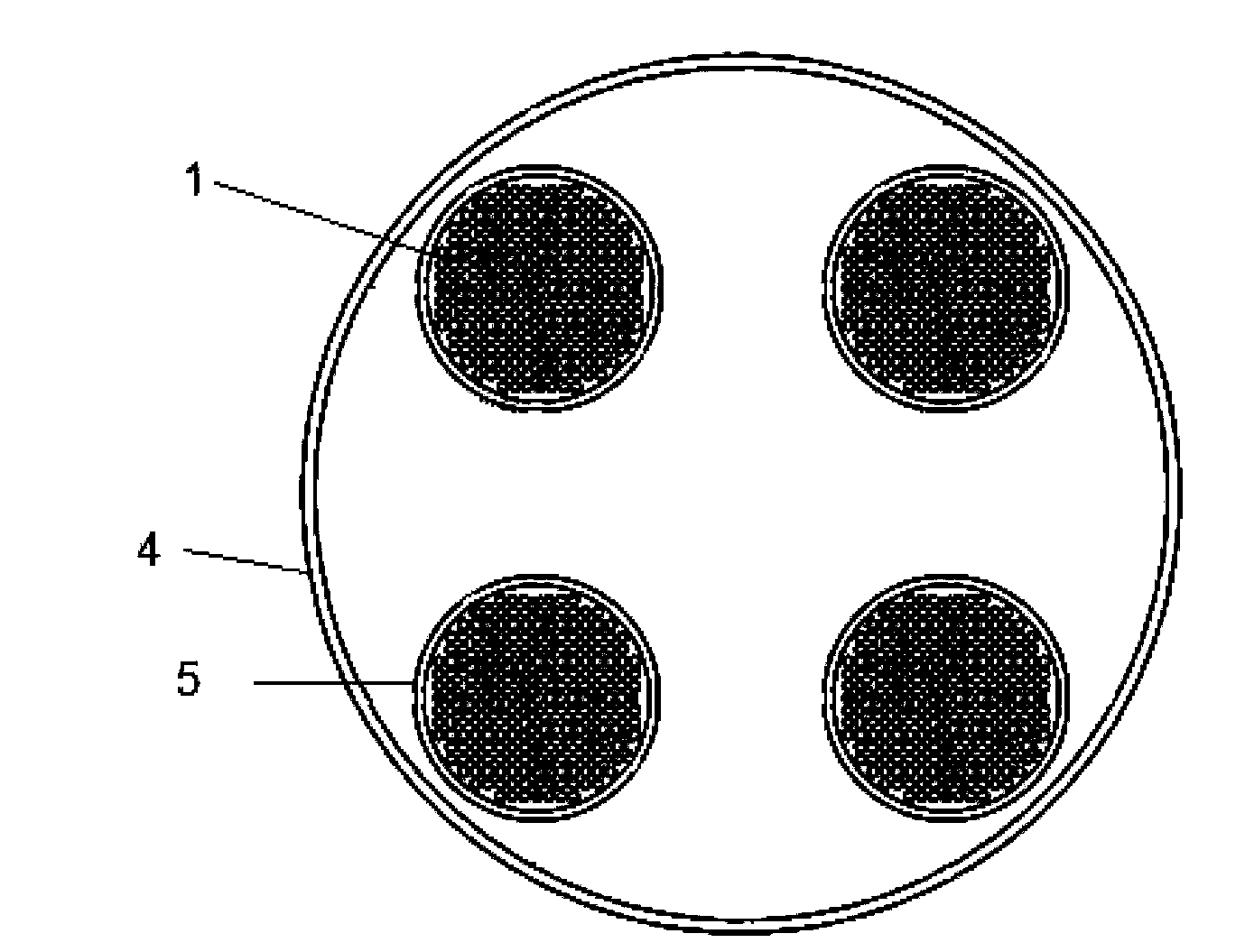

Method for preparation of ethylene from hydrogenation of acetylene and reaction tower for the method

ActiveCN105175208AImprove conversion rateReduce manufacturing costHydrocarbon by hydrogenationChemical/physical processesSlurry reactorThree-phase

Owner:北京锦泰诚瑞科技发展有限公司

System and method for producing n-butyl acetate by using methyl acetate and n-butyl alcohol ester exchange reaction

InactiveCN101219950ASimple processEasy to operatePreparation by ester-hydroxy reactionChemical industryReboilerTransesterification

The invention discloses a method and a system for utilizing transesterification of methyl acetate and n-butanol to prepare n-butyl acetate. The reaction system substantially consists of a reboiler, a catalytic distillation column, a condenser, a feeding pump and a reflux ratio controller; among which, the catalytic distillation column is provided with a liquid collecting plate, a gas exit tube, a catalyst packet, a supporting plate and a catalytic reaction segment consisting of bottom plates. An overflow outlet is arranged on a tube wall of the gas exit tube at the lower end of the liquid collecting place and is higher than the catalyst packet. A lacrimal foramen is arranged on the bottom plate; the catalyst packet and a sieve hole is arranged on the supporting plate; a liquid leaking hole is arranged on the tube wall of the gas exit tube between the supporting plate and the bottom plate. The preparation method is to add the methyl acetate and n-butanol into the column respectively from the top and bottom of the catalytic reaction area. A molar ratio of the methyl acetate to the n-butanol is 0.5:5, a reaction temperature is 50 DEG C to 90 DEG C, and a reflux ratio is 0.5 to 30 under a normal pressure operation. The technical proposal of the invention enhances the conversion rate of the methyl acetate, simplifies the operation procedure and overcomes the problem of equipment corrosion.

Owner:TIANJIN UNIV

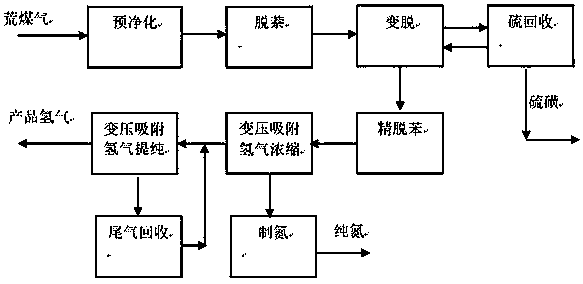

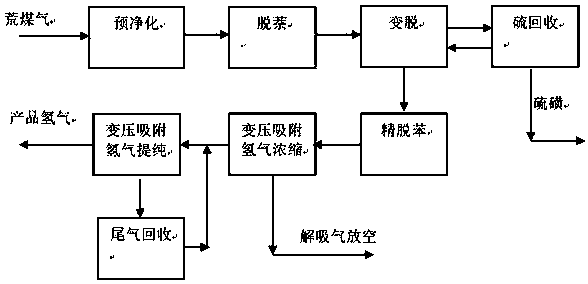

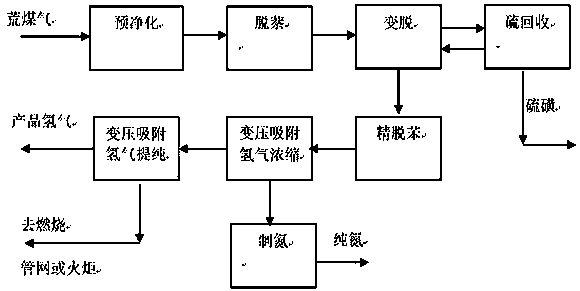

Low-energy-consumption high-yield method for preparing hydrogen from raw gas

InactiveCN107758615AReduce consumptionEmission reductionNitrogen purification/separationHydrogen separation using solid contactSulfurNitrogen

The invention discloses a low-energy-consumption high-yield method for preparing hydrogen from raw gas. The method comprises the following procedures: pre-cleaning; naphthalene removal; transformationand desulfurization; sulfur recovery; refined debenzolization; pressure swing adsorption for hydrogen production; recovery of tail gas; nitrogen production; etc. After pretreatment and naphthalene removal, raw gas is allowed to enter the procedure of transformation and desulfurization so as to obtain more hydrogen and increase the yield of hydrogen, and then desulfurization is carried out in a desulfurization tower; then pure hydrogen is prepared through the procedure of refined debenzolization and the procedure of pressure swing adsorption for hydrogen production; through the procedures of tail gas recovery and nitrogen production, effective hydrogen in desorbed gas is recovered, and hydrogen yield is further increased; and pure nitrogen with a purity of 99% or more is further prepared through a nitrogen production unit. The method provided by the invention substantially reduces the energy consumption of an apparatus for hydrogen production from raw gas, increases hydrogen yield, recovers almost all the effective hydrogen component in the desorbed gas, realizes recovery and graded utilization of each component in the raw gas while guaranteeing low energy consumption and high yield, and by-produces sulfur, pure nitrogen and the other products while preparing pure hydrogen.

Owner:SICHUAN TECHAIRS

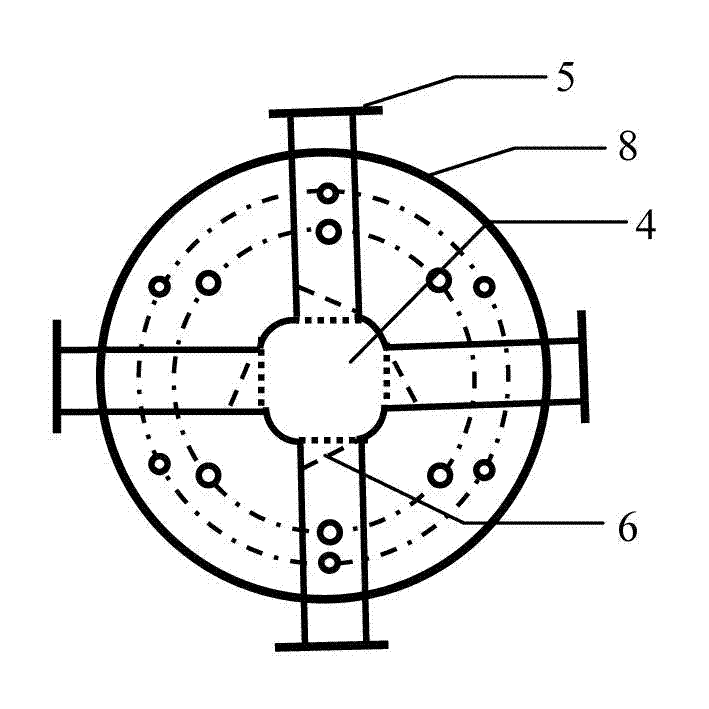

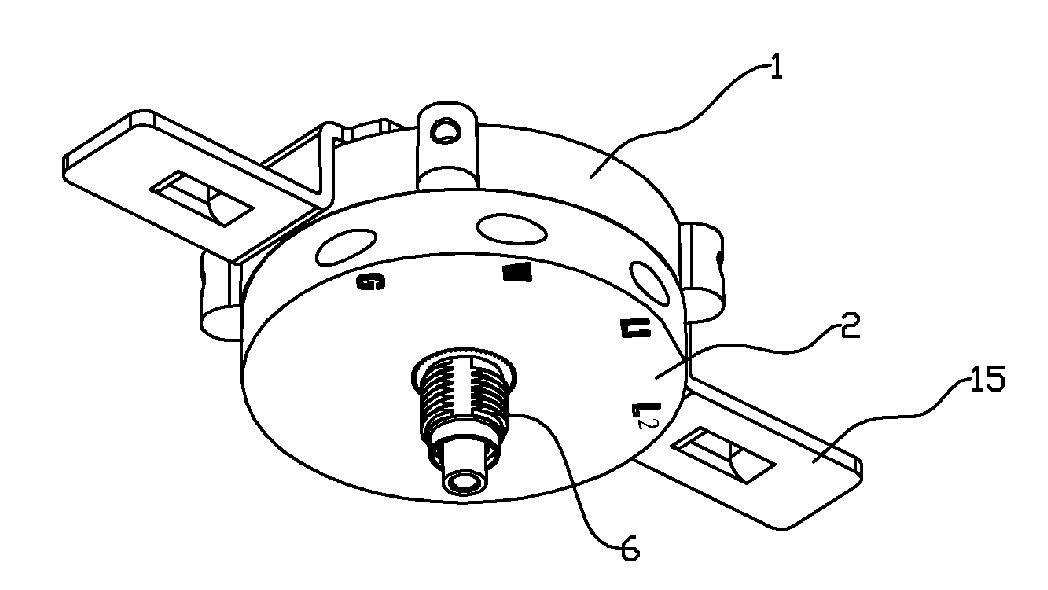

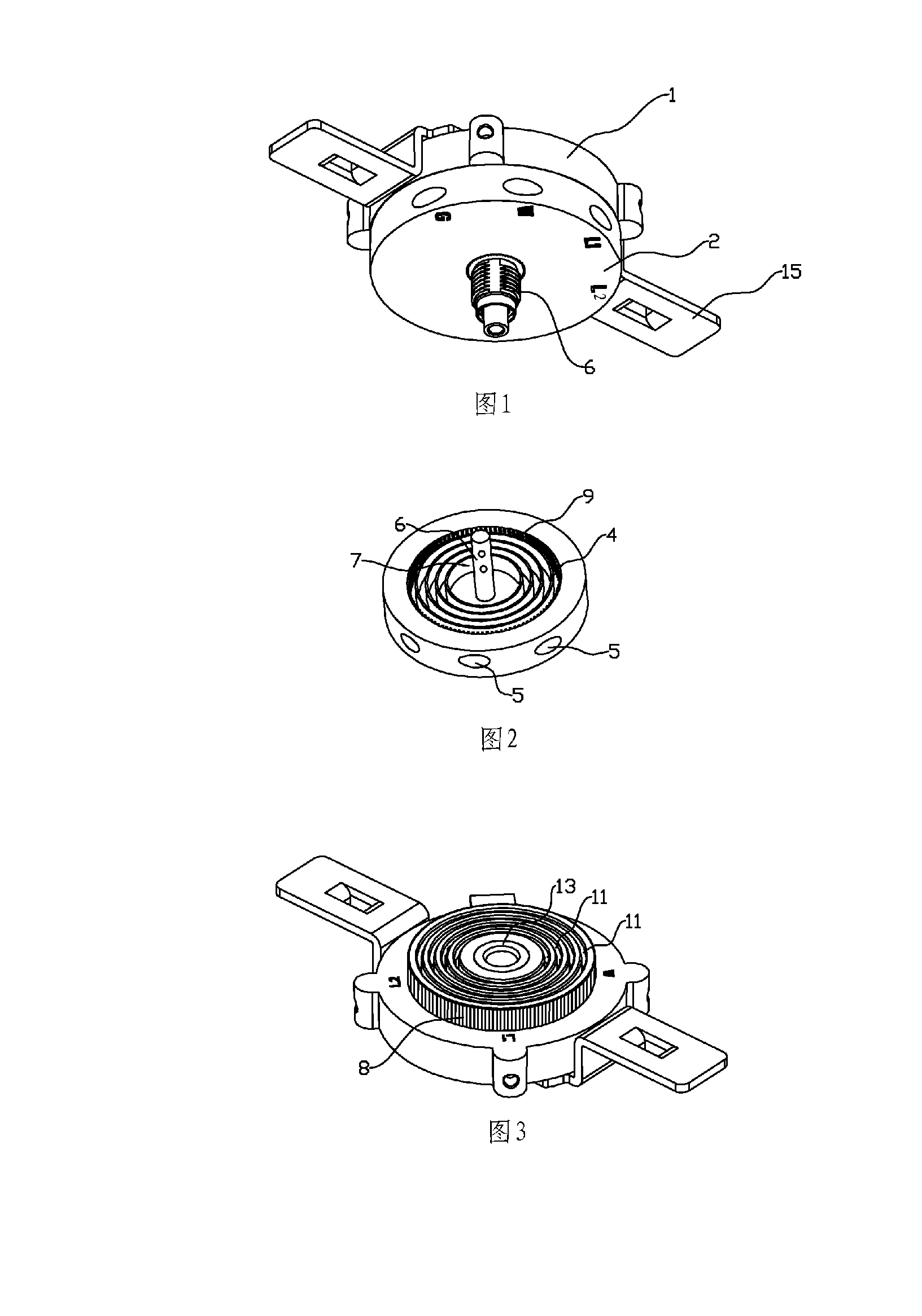

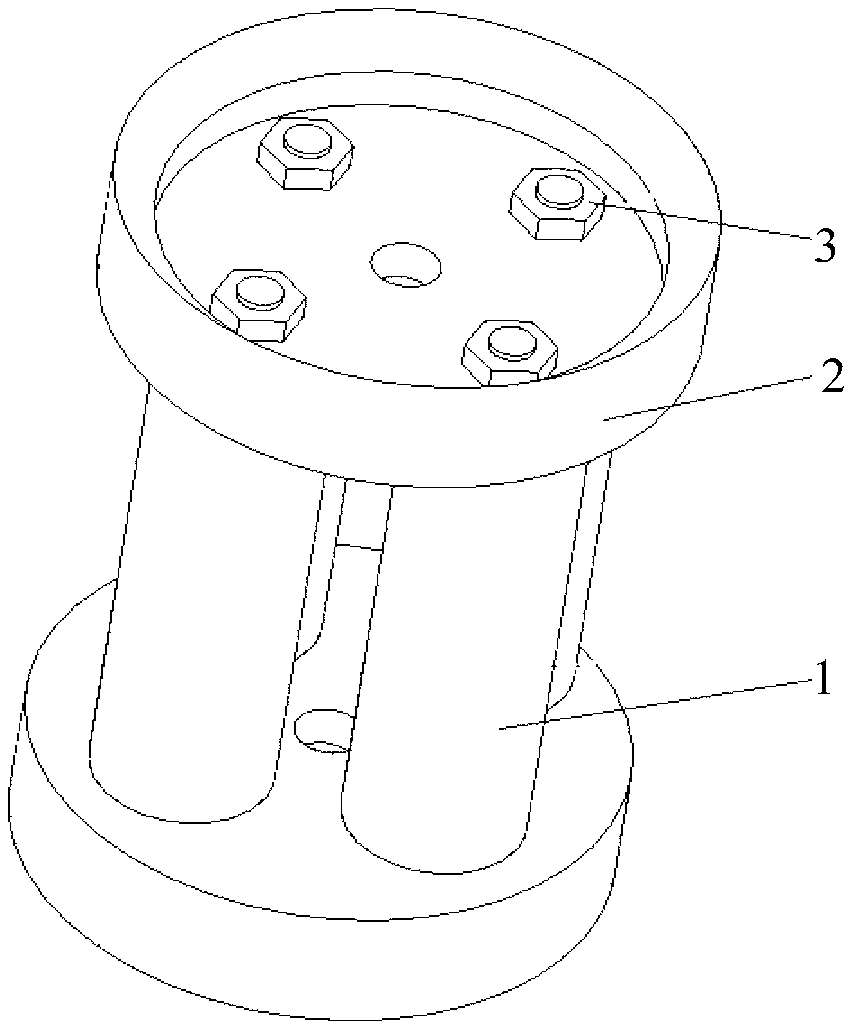

Quick Connection Device for Electric Appliance

InactiveUS20120196471A1Easy to useHeavy weightRotary current collectorCoupling device detailsElectricityHeavy load

A quick connection device for electric appliance includes a base (1) and a plug (2), the base (1) has several grooves (11), each groove (11) has a contact (3) connected with electrical wires, the base (1) has a center hole (12), the plug (2) has several conductive rings (4) mated with the grooves (11), the outside of the plug (2) has wiring interface (5) electrically connected with the conductive rings (4), the plug (2) has a connecting rod (6) which is able to be inserted into the center hole (12), the connecting rod (6) has a lock structure (7) fixed to the center hole (12). The electric appliance, such as a fan and a droplight, is fixed to the plug (2), then the plug (2) is fixed to the base (1) by the connecting rod (6), the plug (2) is separated from the base (1) by unlocking the lock structure (7), the device is operated quickly and easily, and it can carry a heavy load.

Owner:FOSHAN CITY NANHAI AREA MEIPIN METAL & ELECTRICAL

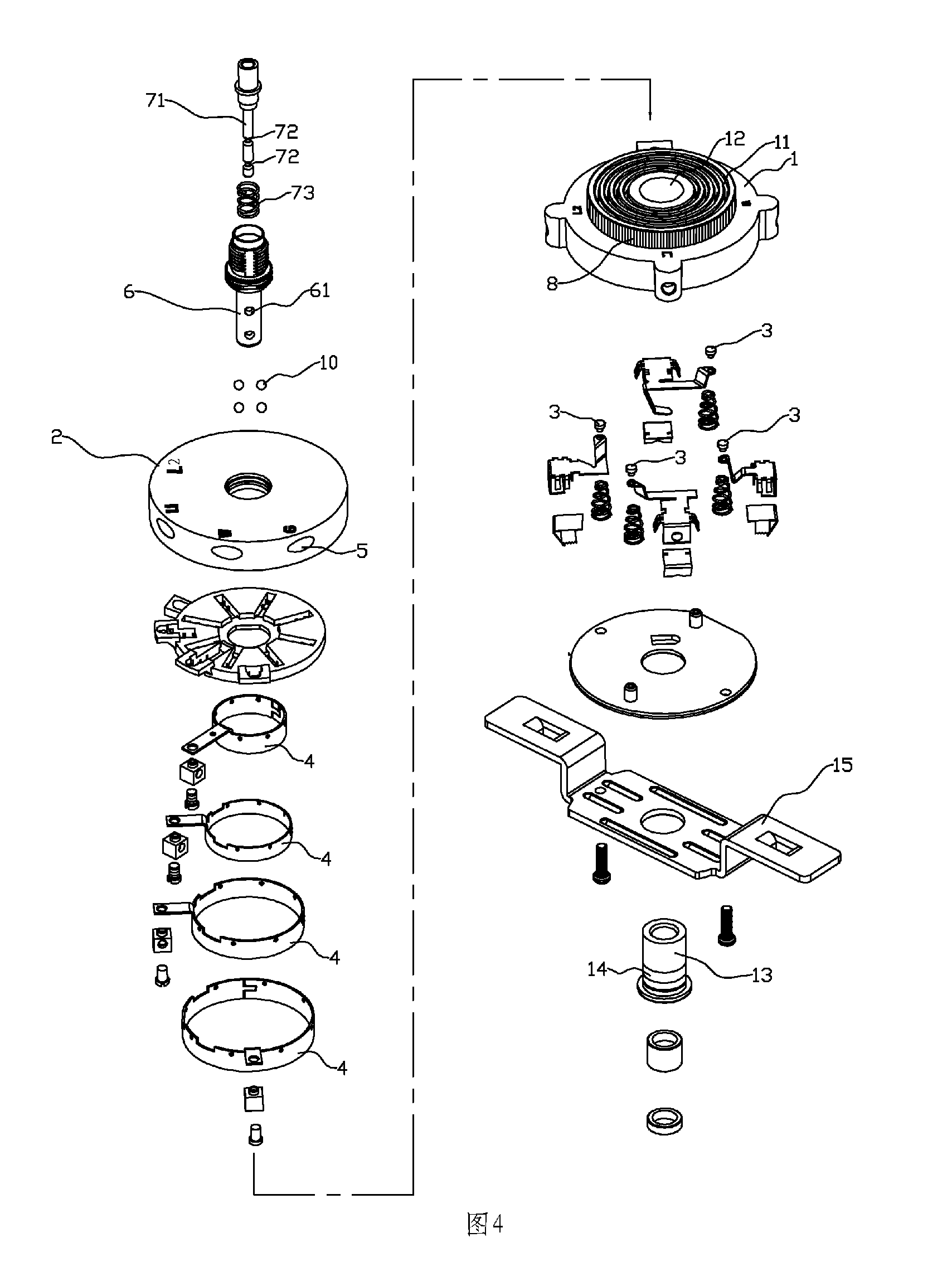

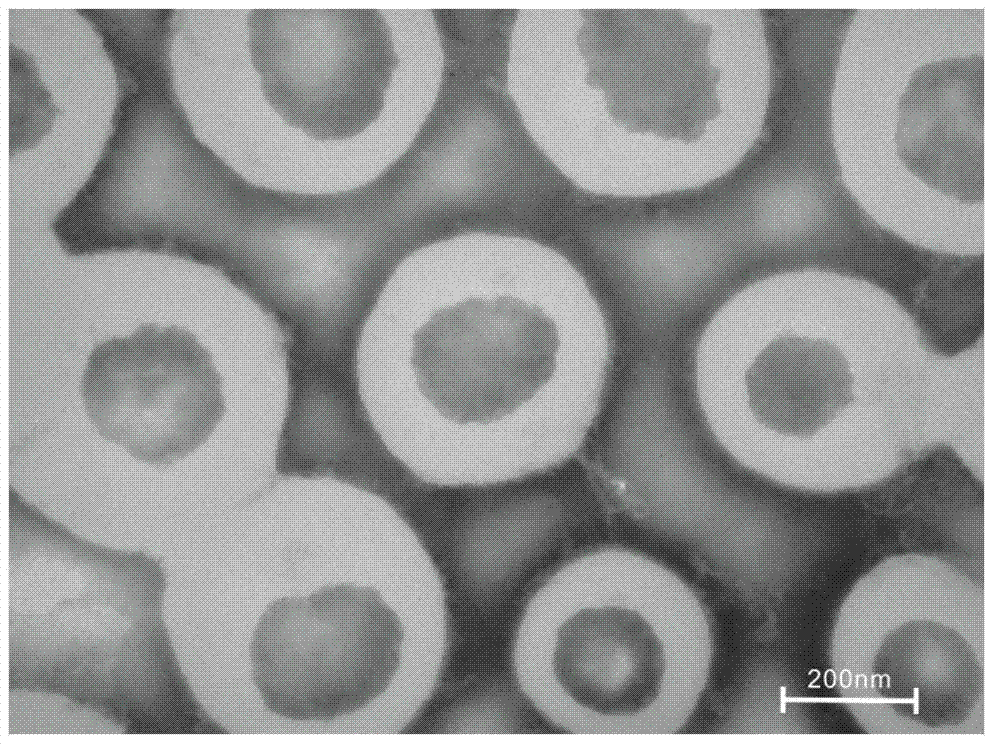

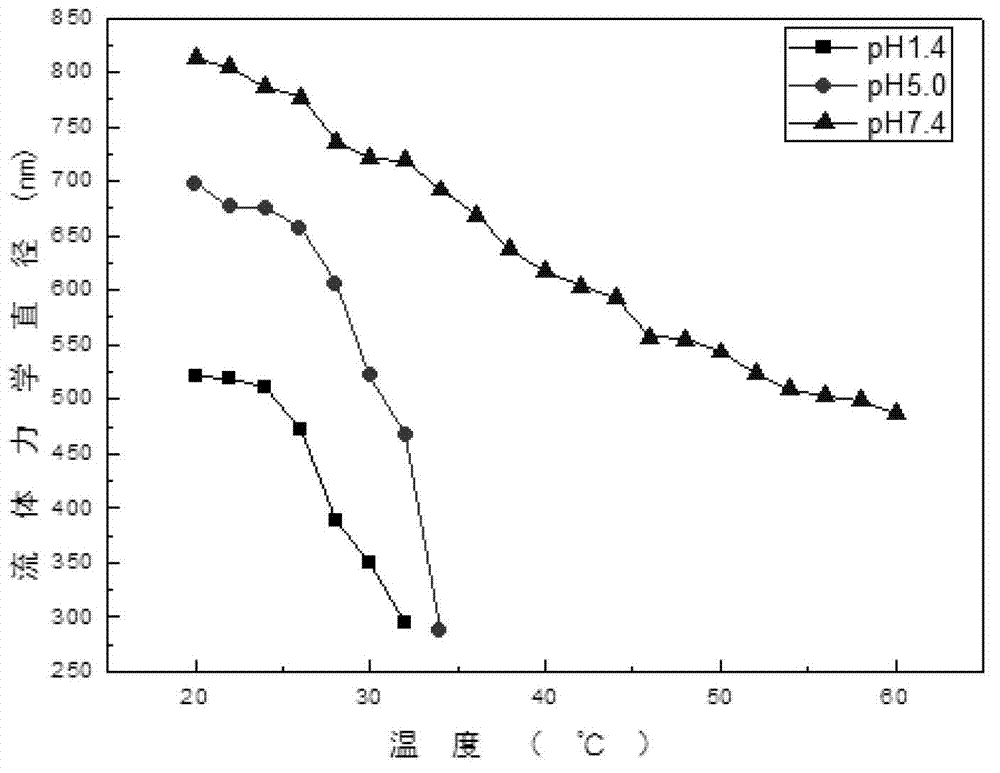

Method for preparing environmentally responsive monodisperse cyclodextrin polymer hollow microspheres

The invention relates to a method for preparing environmentally responsive monodisperse cyclodextrin polymer hollow microspheres. In the process of preparing multi-cavity poly (N-isopropylacrylamide-cyclodextrin) hollow microspheres, the hollow microspheres are endowed with environmental responsiveness, and in the process of preparing crosslinking cores, acid monomers are added to be copolymerized with NIPAM monomers so as to obtain acidic cores; and after cyclodextrin monomers and a crosslinking agent are added into the acidic cores so as to obtain core / shell-structured microspheres, the core / shell-structured microspheres are treated by using alkali liquor, and an ionization effect generated by acid-base neutralization accelerates the collapse of cores and the swelling of crosslinking shell layers, so that the permeability of the shell layers subjected to swelling is enhanced, therefore, a situation that PNIPAM (core) chains in the shell layers quickly escape so as to obtain microspheres is facilitated, and PNIPAM and acid ingredients in the microspheres also endow the hollow microspheres with pH and temperature responsiveness. The method disclosed by the invention solves the problems existing in hollow microsphere preparation implanted by using the existing 'self-removable' technique.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

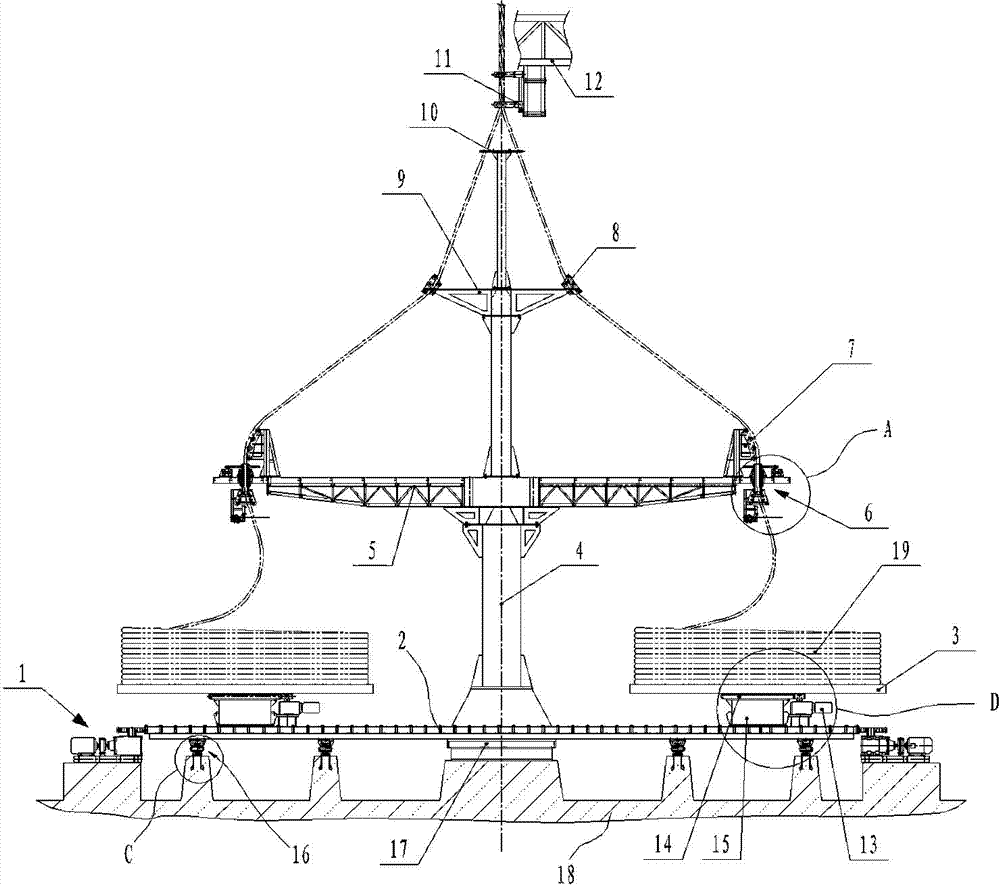

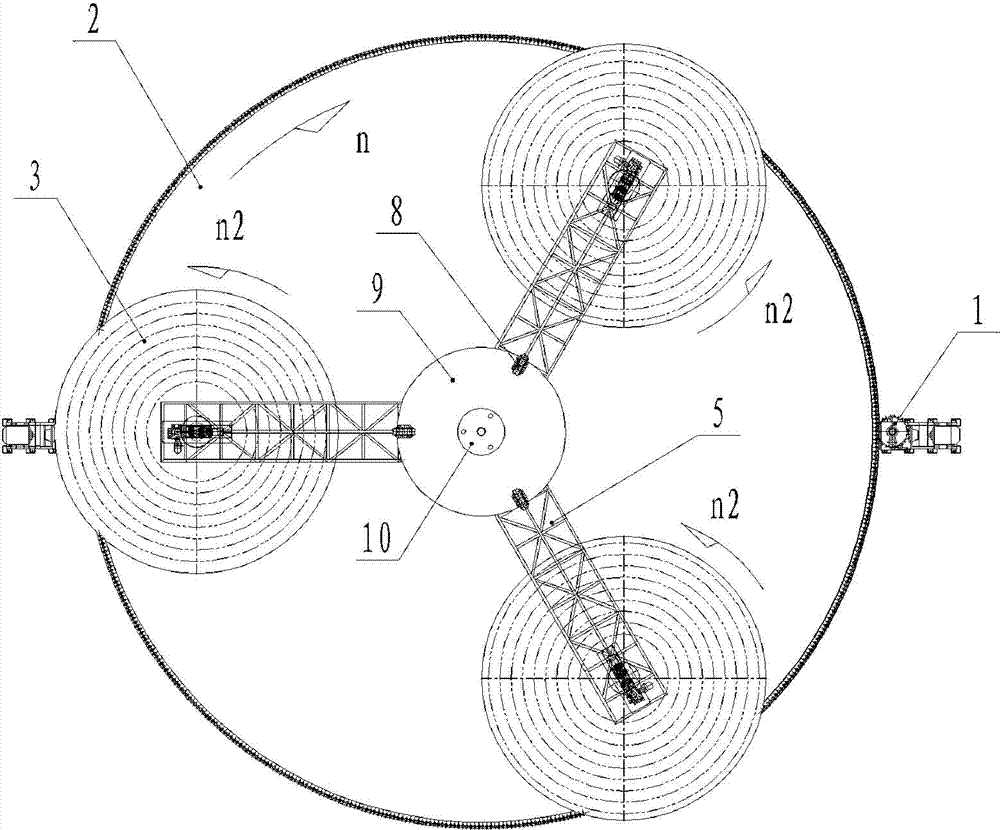

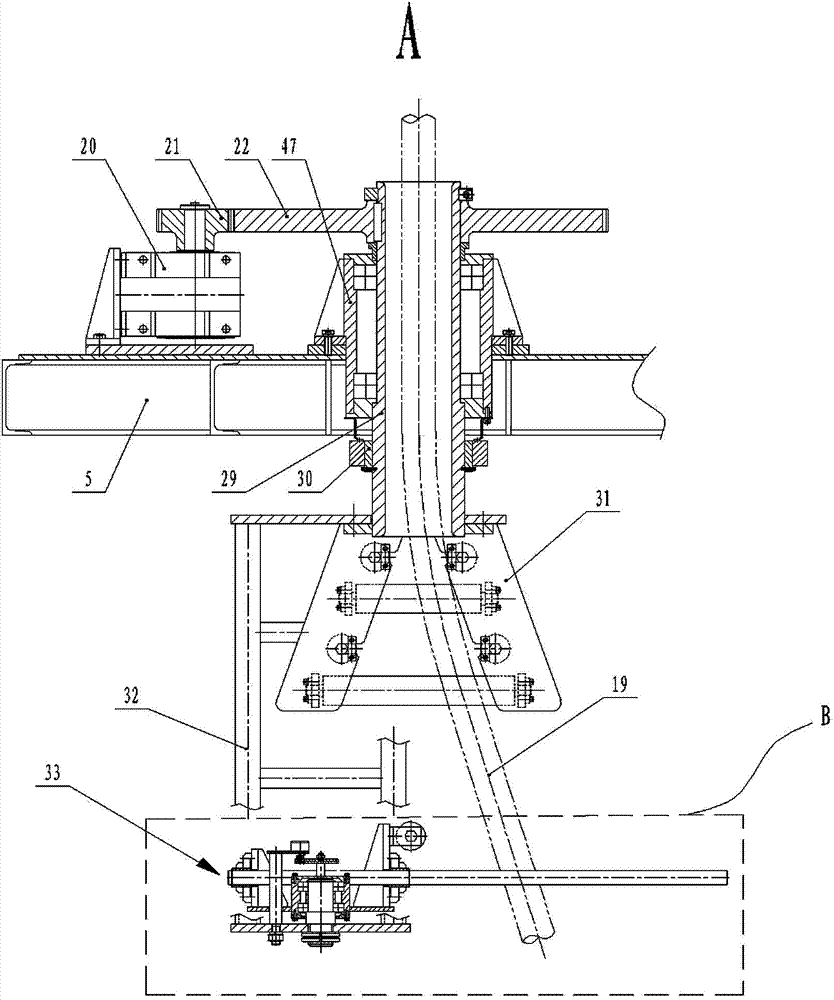

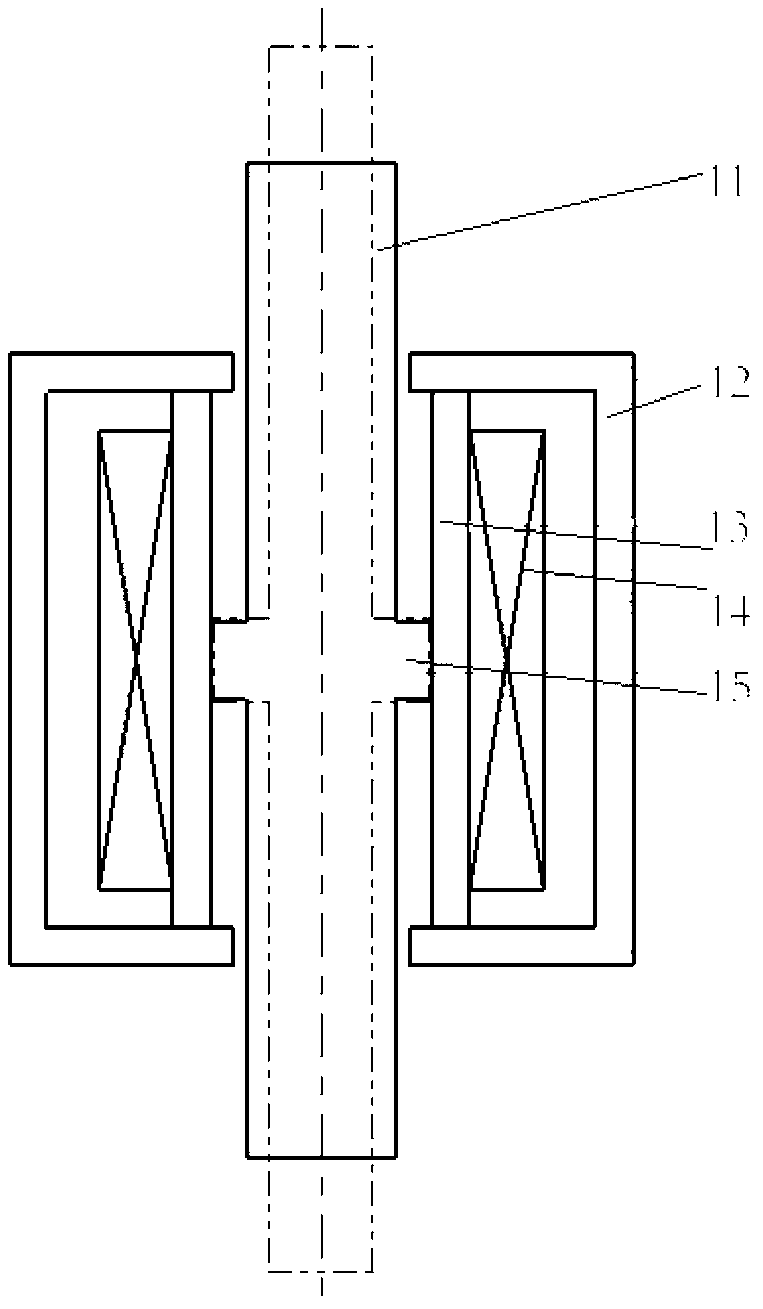

Vertical type cable former with back-twist control function

InactiveCN103578652ALarge loading capacityEnsure that the stranding meets the needs of the production processCable/conductor manufactureElectric cablesWire wrap

The invention relates to a vertical type cable former with the back-twist control function. The vertical type cable former with the back-twist control function comprises a base (18), wherein a rotary table support (17) and supporting wheel devices (16) are arranged on the base; a twisting rotary table (2) is connected to the rotary table support (17) and the supporting wheel devices (16); the rotary table support is further connected with a vertical column (4); the upper end of the vertical column is connected with a wire distribution plate (10) in a matched mode. The vertical type cable former with the back-twist control function is characterized in that a set of winding tray bases (15) are evenly distributed on the twisting rotary table, each winding tray base is connected with a winding rotary table (14), each winding rotary table is connected with a winding tray (3) and a winding tray drive device (13), the vertical column is connected with supporting frames (5), and the front side of each supporting frame is connected with a back-twisting device (6). The vertical type cable former with the back-twist control function has the advantages that the load capacity of wire spool cable cores is increased, the back-twisting and twisting of the cable cores can be achieved by 100%, insufficient or over back-twisting is avoided, and the production quality of submarine cables is ensured.

Owner:安徽长江精工装备科技有限公司

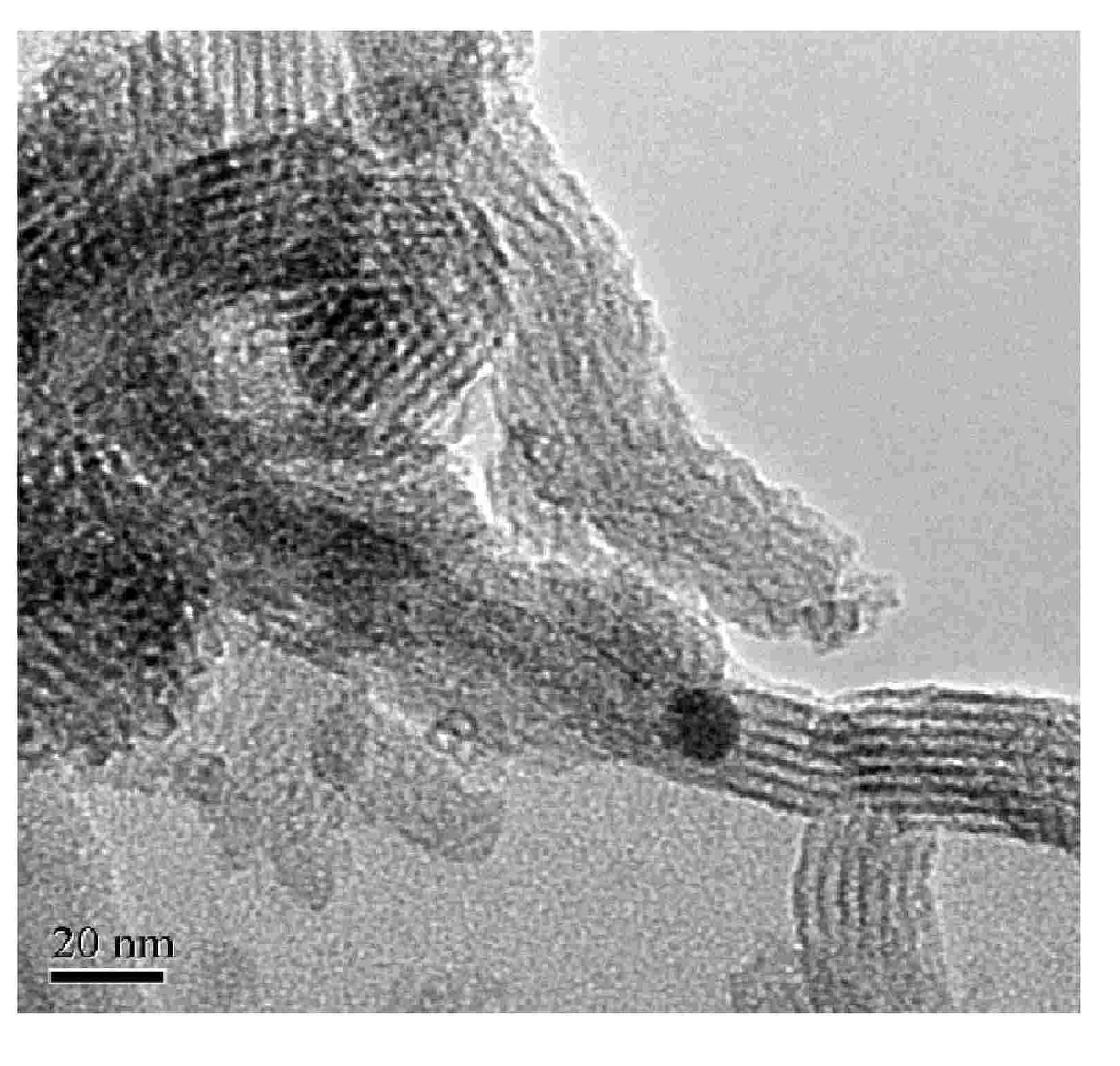

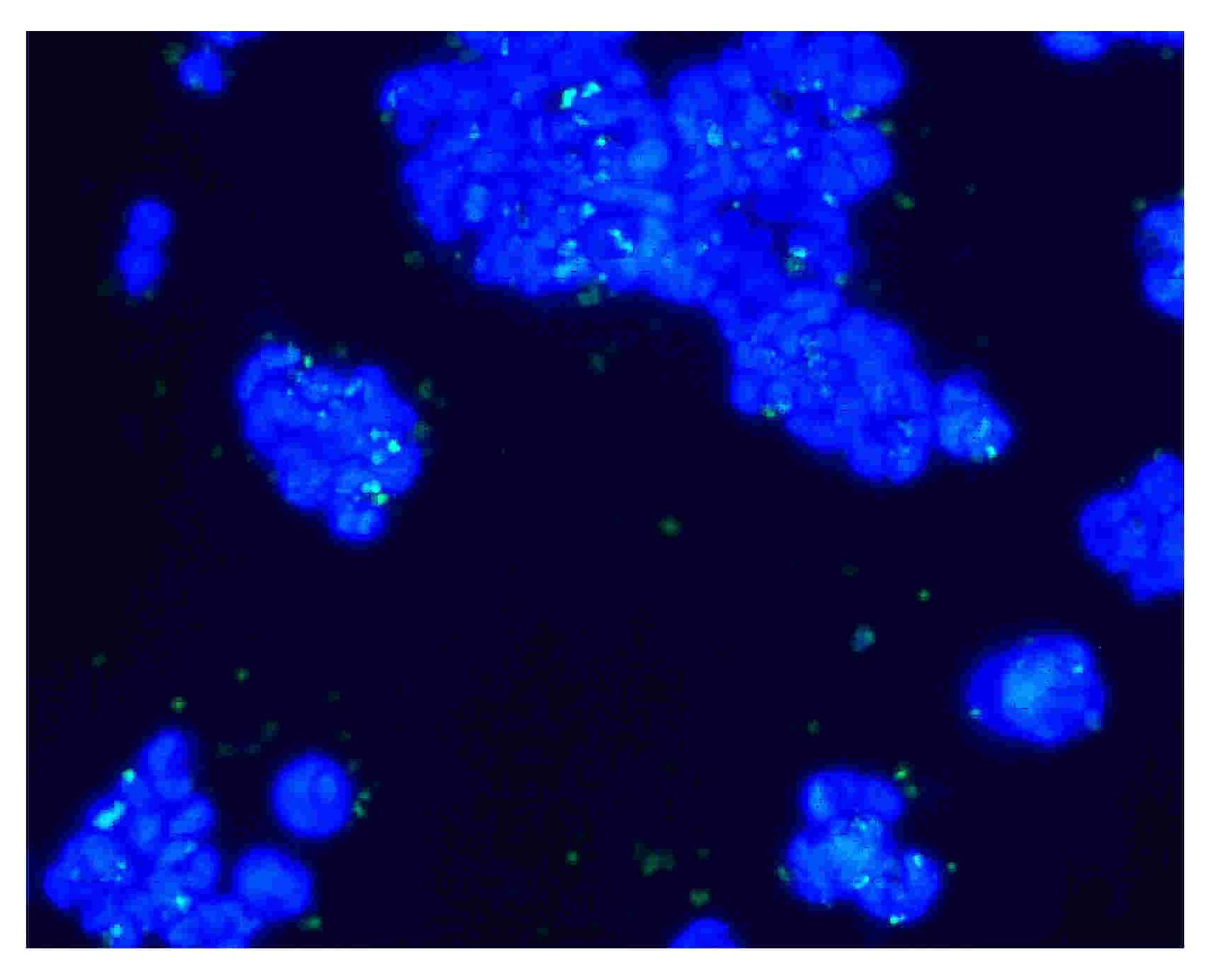

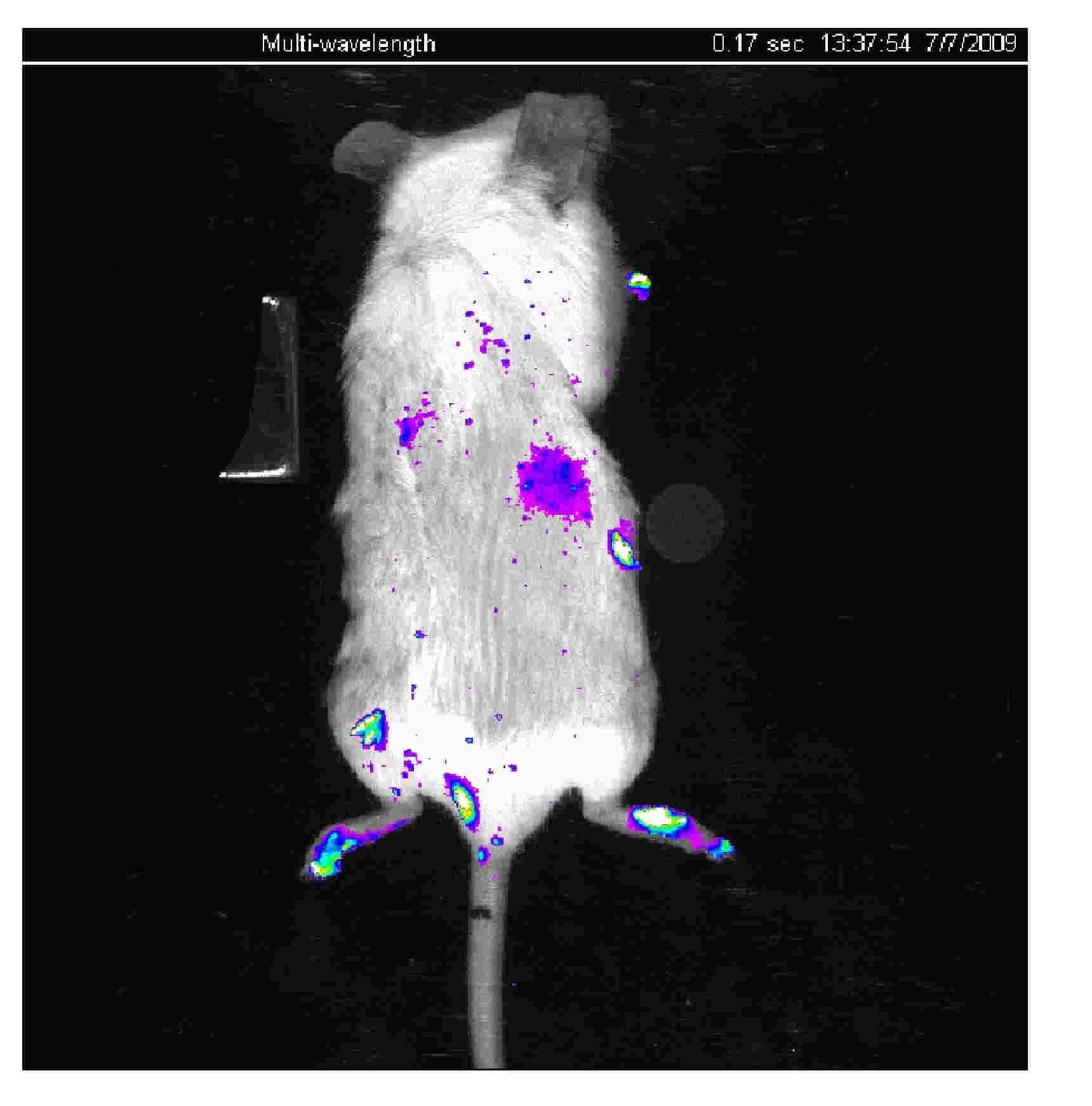

Magnetic targeting carrier capable of carrying gene and drug, preparation method and application thereof

InactiveCN101797387AFree from degradationNot easy to degradeGenetic material ingredientsInorganic non-active ingredientsControl releasePharmaceutical drug

The invention discloses a magnetic targeting carrier capable of carrying genes and drugs, a preparation method and an application thereof. The invention is a carrier which has stability, safety and targeting and has controlled release behavior for non-viral magnetic gene therapy and drug therapy. The carrier material of the invention is characterized in that the carrier material is a bunchy silica mesoporous material with magnetism; the length-diameter ratio is not less than 3; the loading capability is big; the material has a protective effect on loaded genes and carriers and superparamagnetism, is not easy to agglomerate, and can control release speed of genes and drugs in vitro; and the surface thereof is easy to modify various functional groups, thus having wide adaptability. The invention also provides a preparation method of the carrier. When in use, therapeutic short chain DNA, siRNA or drugs enter in holes or are combined with surface modified functional genes by a soaking mode, then reach a targeted tissue by guidance of an applied magnetic field, and release the short chain DNA, siRNA or drugs carried thereby under the action of an alternating magnetic field, thus achieving the purpose of magnetic targeting controlled therapy.

Owner:CENT SOUTH UNIV

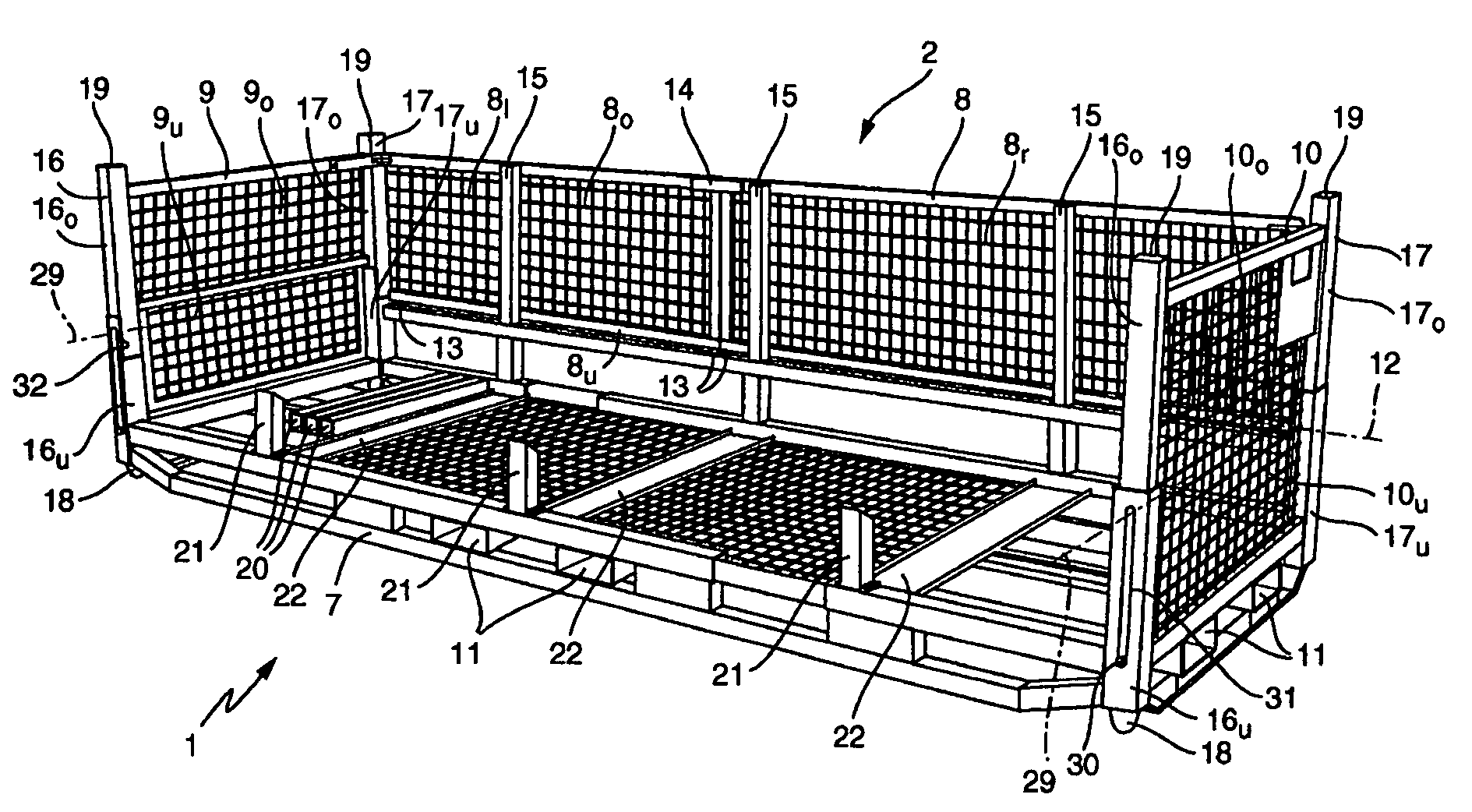

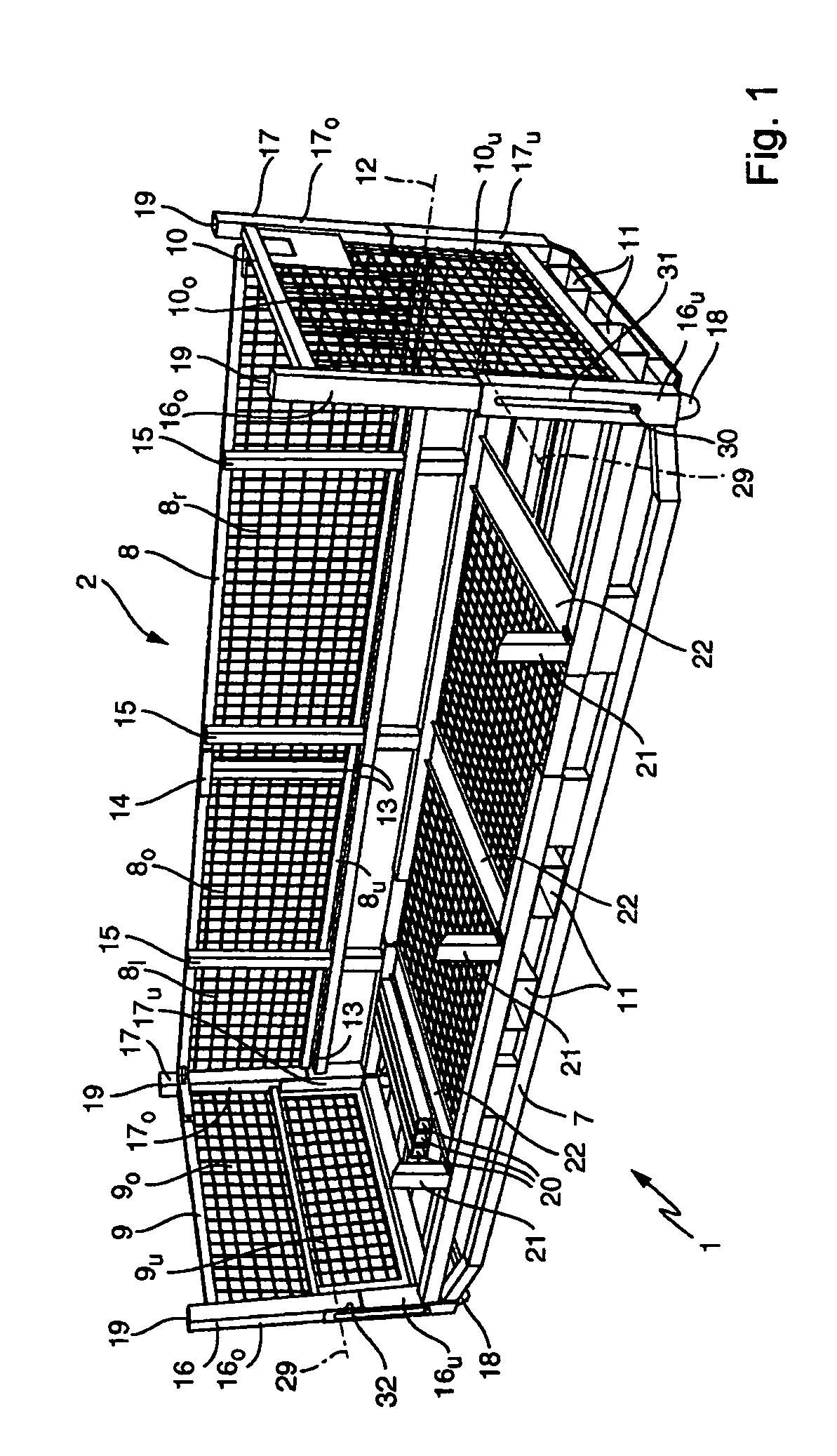

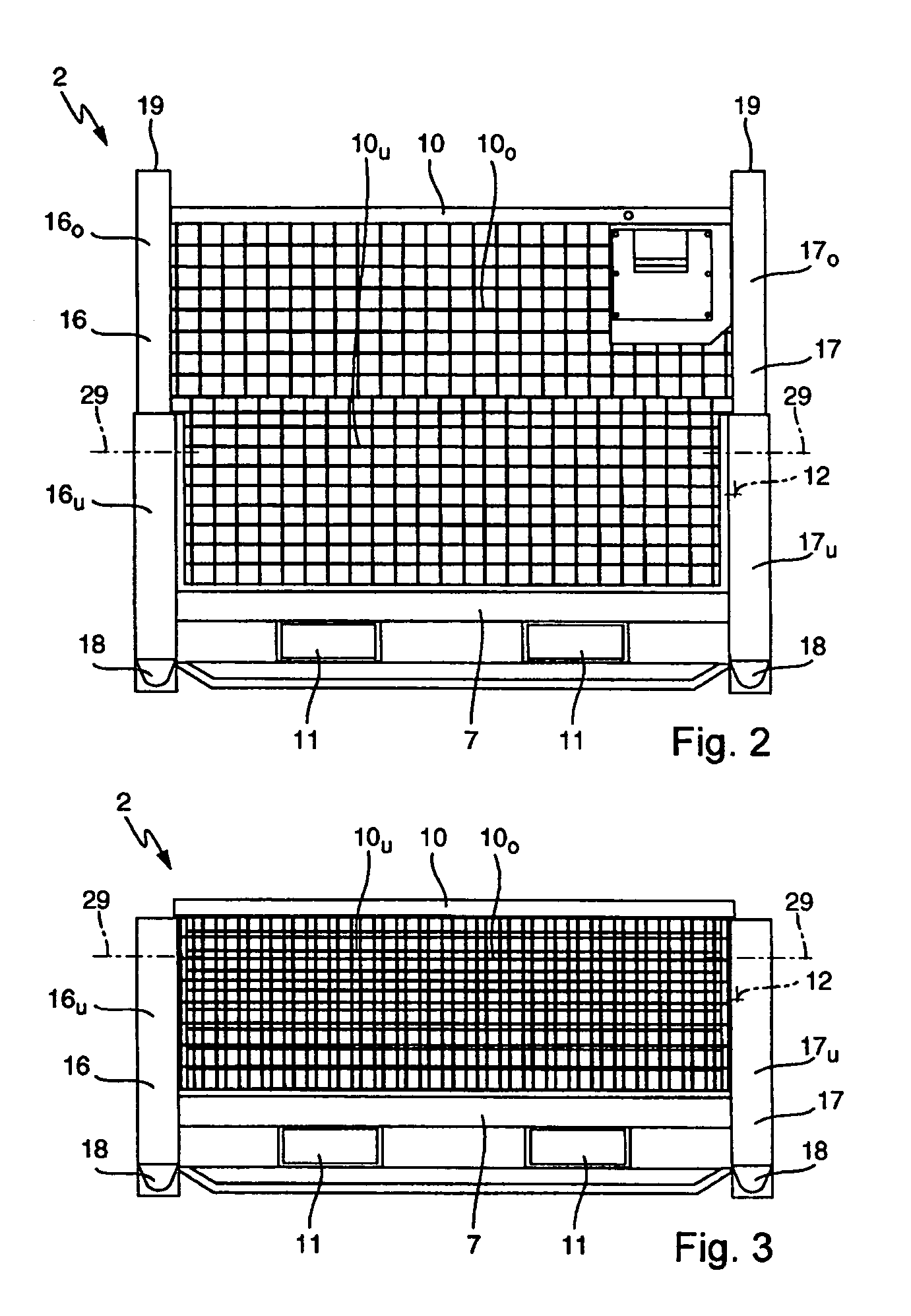

Shipping system

InactiveUS7328804B2Lower the volumeLarge loading capacityLarge containersOther accessoriesTransit systemEngineering

The present invention relates to a shipping system (1) for shipping articles, comprising a shipping box (2) which can be converted between an in-use state in which it can be loaded with articles and a not-in-use state in which it has a reduced height in comparison with the in-use state while having the same base area, and comprising multiple positioning elements that are stackable one above the other, each having at least one holding fixture arranged side-by-side to hold a section of one of the articles. The shipping box (2) is designed to accommodate at least one stack of positioning elements in the in-use state and in the not-in-use state it is designed to accommodate the positioning elements.

Owner:J EBERSPAECHER GMBH & CO KG

Large-size high-speed invisible flying saucer

InactiveCN105314111AIncrease the moment of inertiaReduce oil supplyAircraft navigation controlJet type power plantsCircular discNacelle

The invention discloses a flying saucer and two smoke- and fire-free engines. The flying saucer is composed of a cabin and a disk which rotates round the cabin. The disk includes a disk-shaped wing and a rotary engine. The cabin includes a driving cabin, a passenger cabin and a device cabin. The rotary engine sucks air which is mixed with water, and then the mixture is jetted out horizontally through jet tubes installed on the edge of the disk according to the sprayer principle, so that a generated reactive force enables the disk to rotate at a high speed, thereby generating an upward raising force on the disk. Four fixing wings are installed outside the device cabin to eliminate reverse rotation of the cabin. A vector engine and a diesel power generating set are installed in the device cabin under the disk. The vector engine sucks large amount of air through an air inlet duct in the passenger cabin to form vacuum above the passenger cabin, which enables air pressure difference between an upper surface and a lower surface of the disk to be increased, thereby generating a huge raising force. The sucked air is compressed to form high-pressure gas which is discharged into vector jet tubes and is jetted out, wherein the directions and the angles of the vector jet tubes are adjustable to generate pushing forces in different directions, thereby achieving maneuvering flight of the flying saucer.

Owner:周彦辉

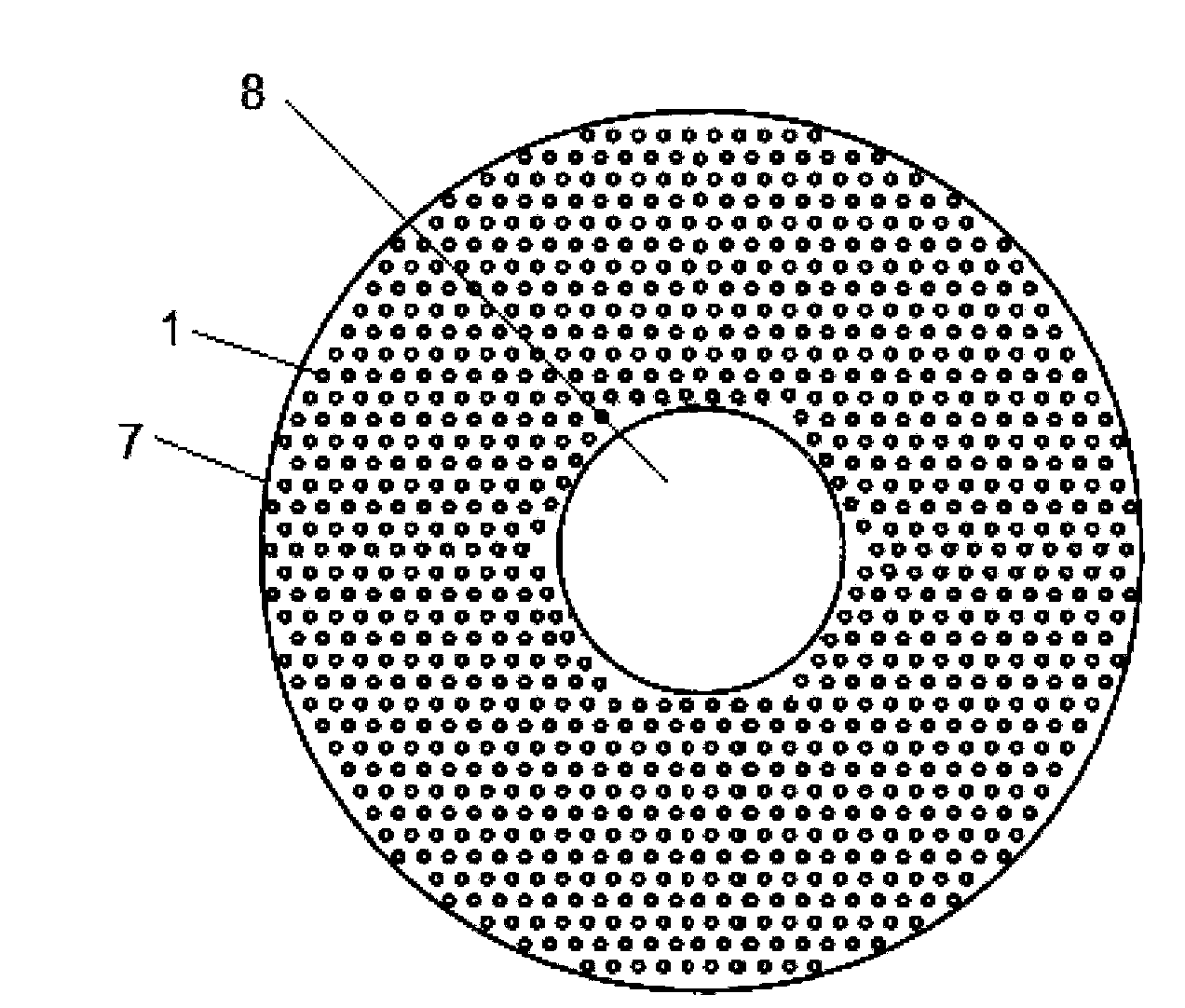

Isothermal fixed bed reactor loading catalyst among heat exchange tubes

ActiveCN104096514ALarge loading capacityAchieve uniform temperature effectChemical/physical processesFixed bedProcess engineering

The invention provides an isothermal fixed bed reactor loading a catalyst among heat exchange tubes, and the isothermal fixed bed reactor comprises a pressure-bearingg casing, the plurality of heat exchange tubes installed in the pressure-bearing casing, and the catalyst; gaps among the plurality of heat exchange tubes form a catalyst filling zone, and a gas inlet, the gaps among the plurality of heat exchange tubes and a gas outlet form a gas channel. The isothermal fixed bed reactor loads the catalyst among the plurality of heat exchange tubes, the catalyst loading quantity is large; the heat exchange tubes can quickly remove the reaction heat, the whole bed basically reaches the even temperature effect and is free of excess temperature and occurrence of side reactions, and the isothermal fixed bed reactor enables a reaction gas to axially radially flow in the bed, can maximize the use of the and can use a more active small particle catalyst.

Owner:SHANGHAI INT ENG CONSULTING

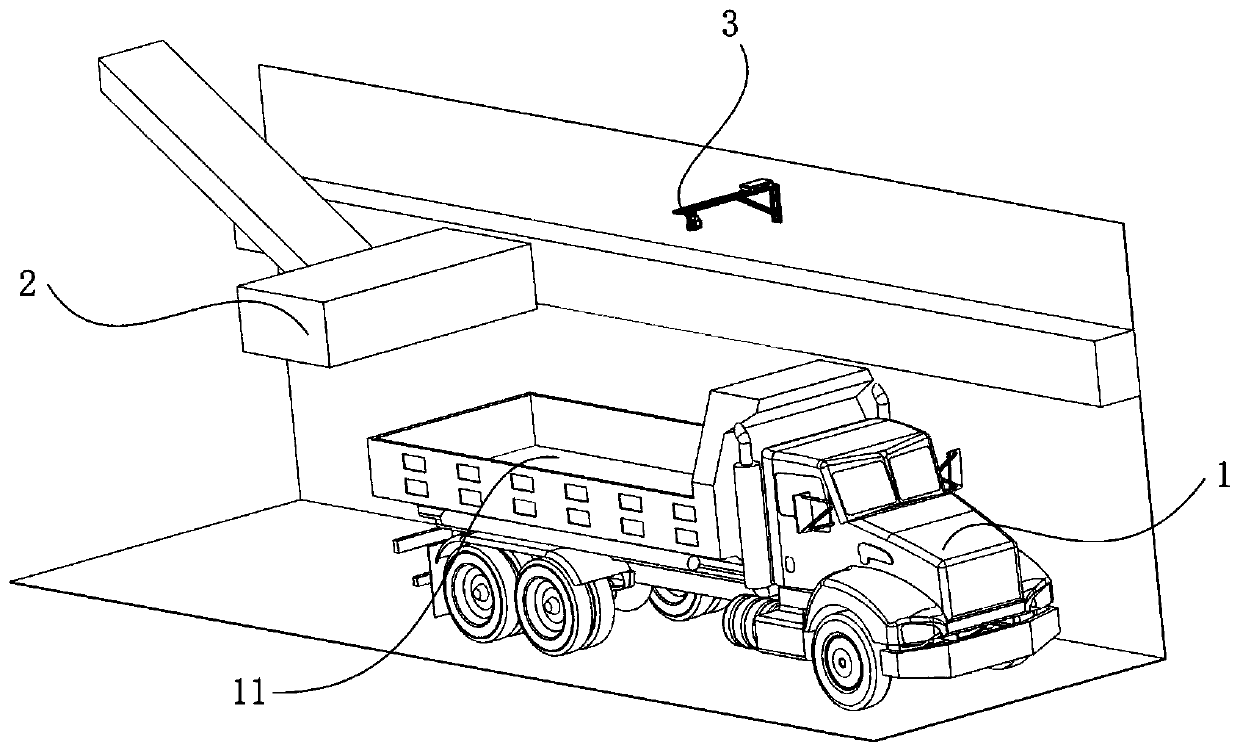

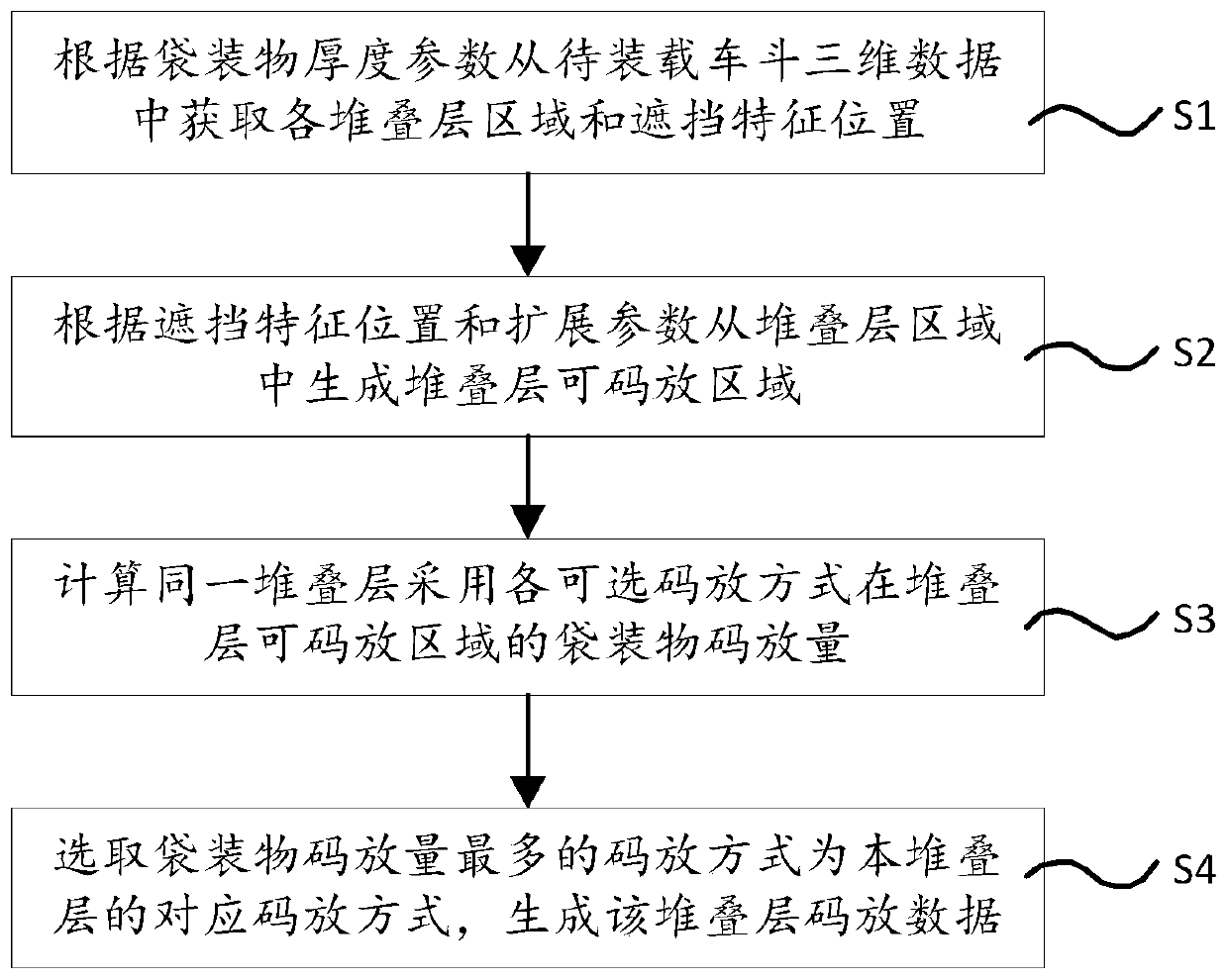

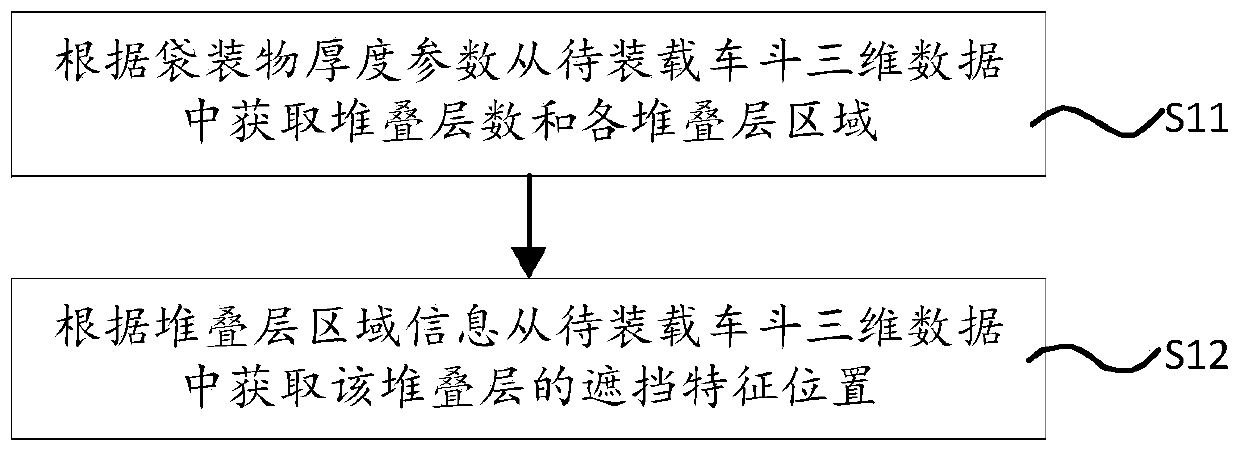

Bagged object loading method, loading device and storage medium

ActiveCN109784449ALarge loading capacityExpand your audienceCo-operative working arrangementsLoading/unloadingEngineeringTruck

The invention discloses a bagged object loading method, which is used for stacking bagged objects to an automatic loading system of a to-be-loaded car hopper, and comprises the following steps of: obtaining each stacking layer area and a shielding characteristic position from three-dimensional data of the to-be-loaded car hopper according to the thickness parameters of the bagged objects; generating a stacking layer stackable area from the stacking layer area according to the shielding feature position and the expansion parameter; calculating the stacking amount of the bagged objects in the stacking area of the stacking layer by adopting each optional stacking mode in the same stacking layer; selecting a stacking mode with the largest stacking quantity of the bagged objects as a corresponding stacking mode of the stacking layer. By means of the technical scheme, the stacking layer stacking data is generated, multiple types of vehicle stacks can be supported, under the condition that safety is guaranteed, the loading capacity of vehicles is expanded to the maximum extent, the effect of fully utilizing space is achieved, the audience groups of truck loading drivers are greatly increased, and the loading capacity of trucks is improved.

Owner:杭州明度智能科技有限公司

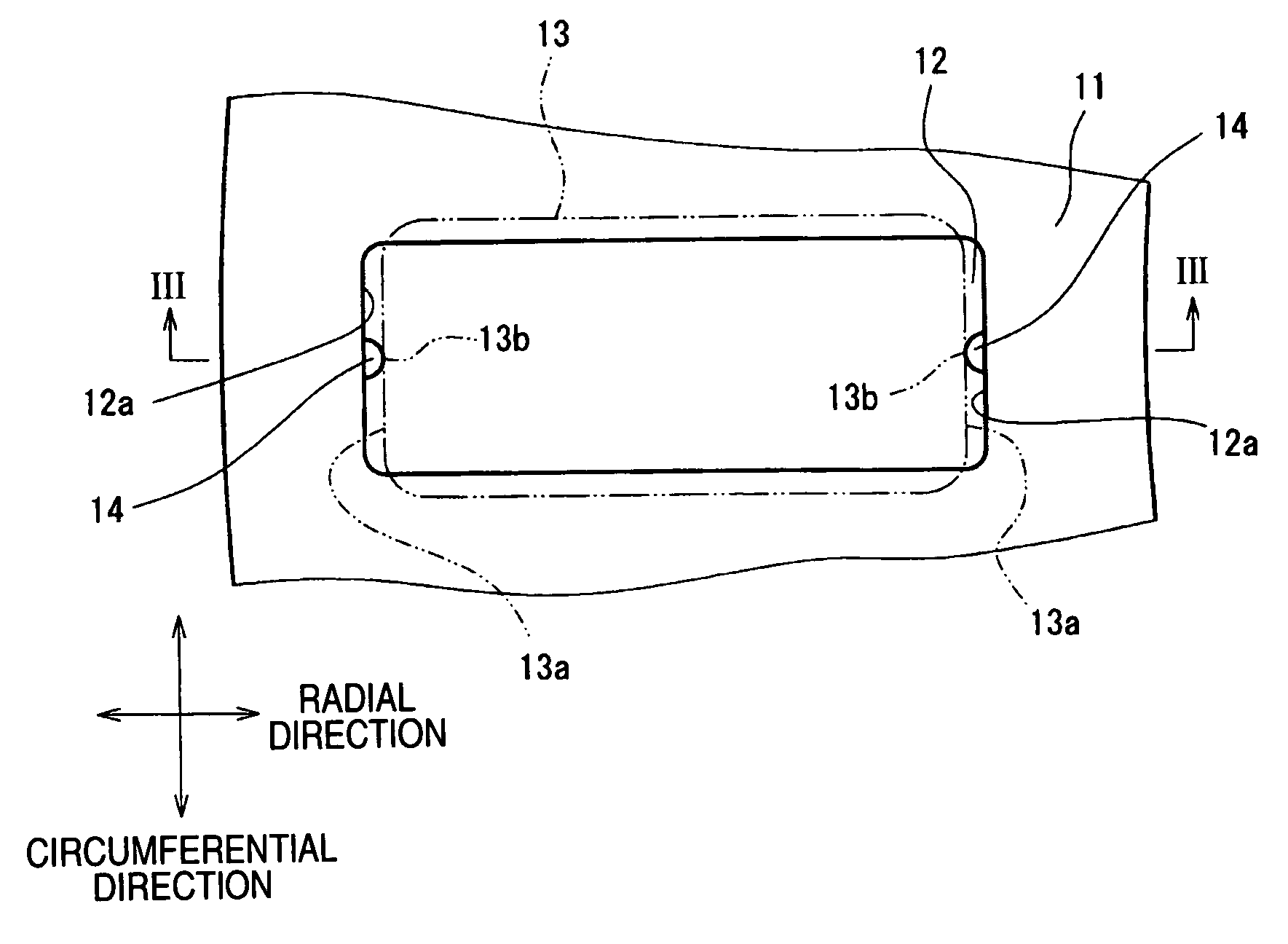

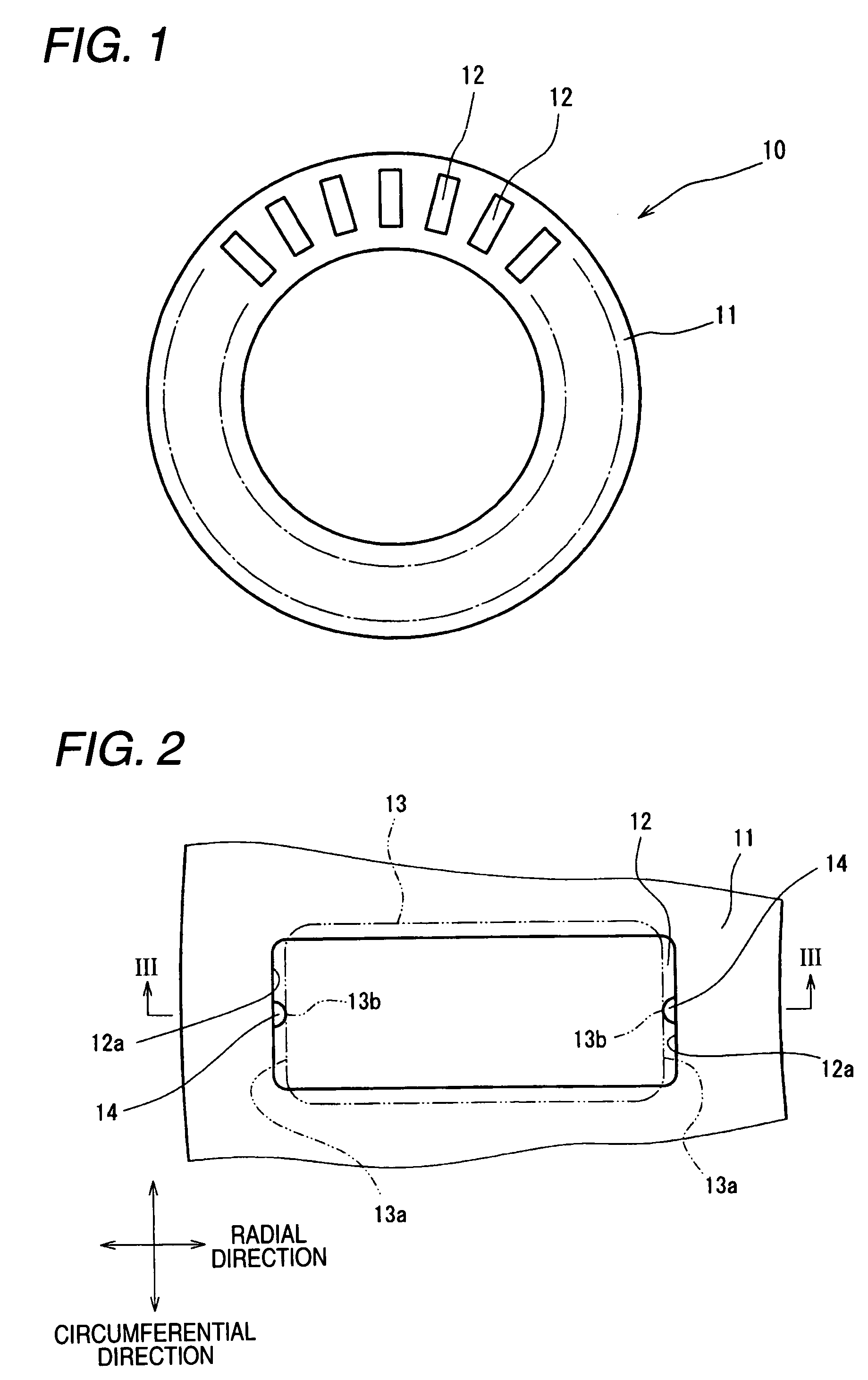

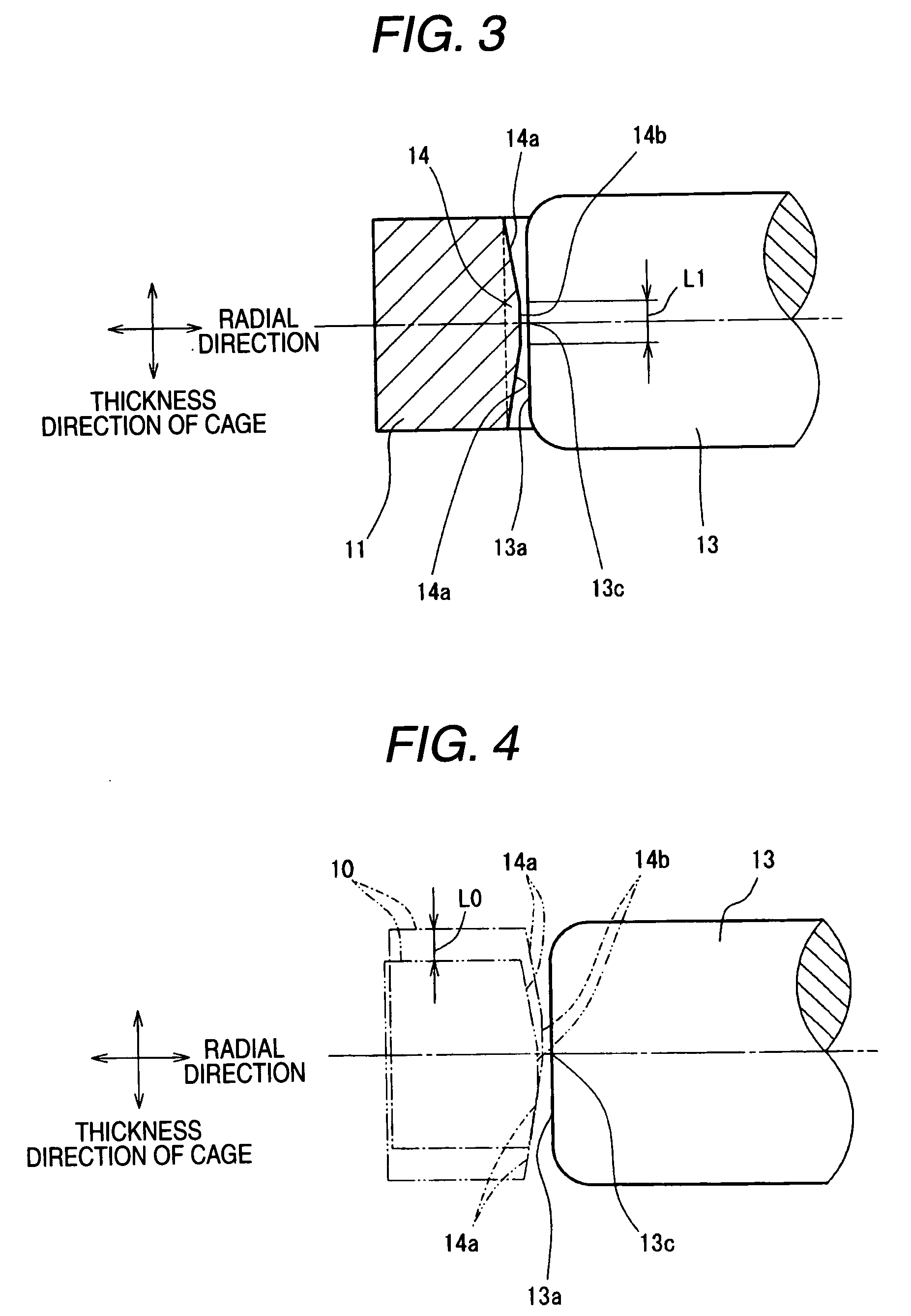

Roller thrust bearing cage and manufacturing method thereof

InactiveUS20060126984A1Reduce rotation torqueReduce weightRoller bearingsBearing componentsThrust bearingEngineering

Owner:JTEKT CORP

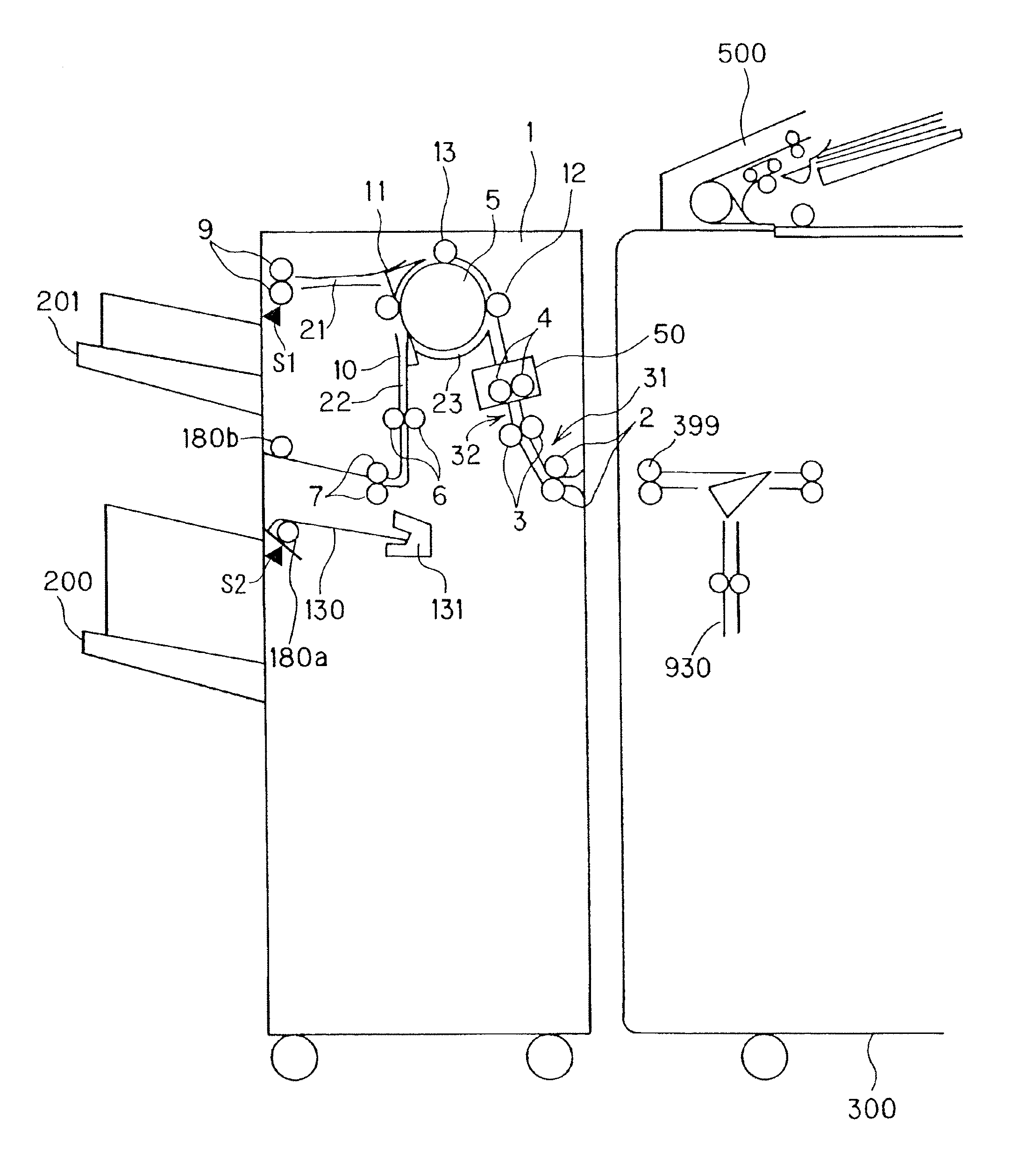

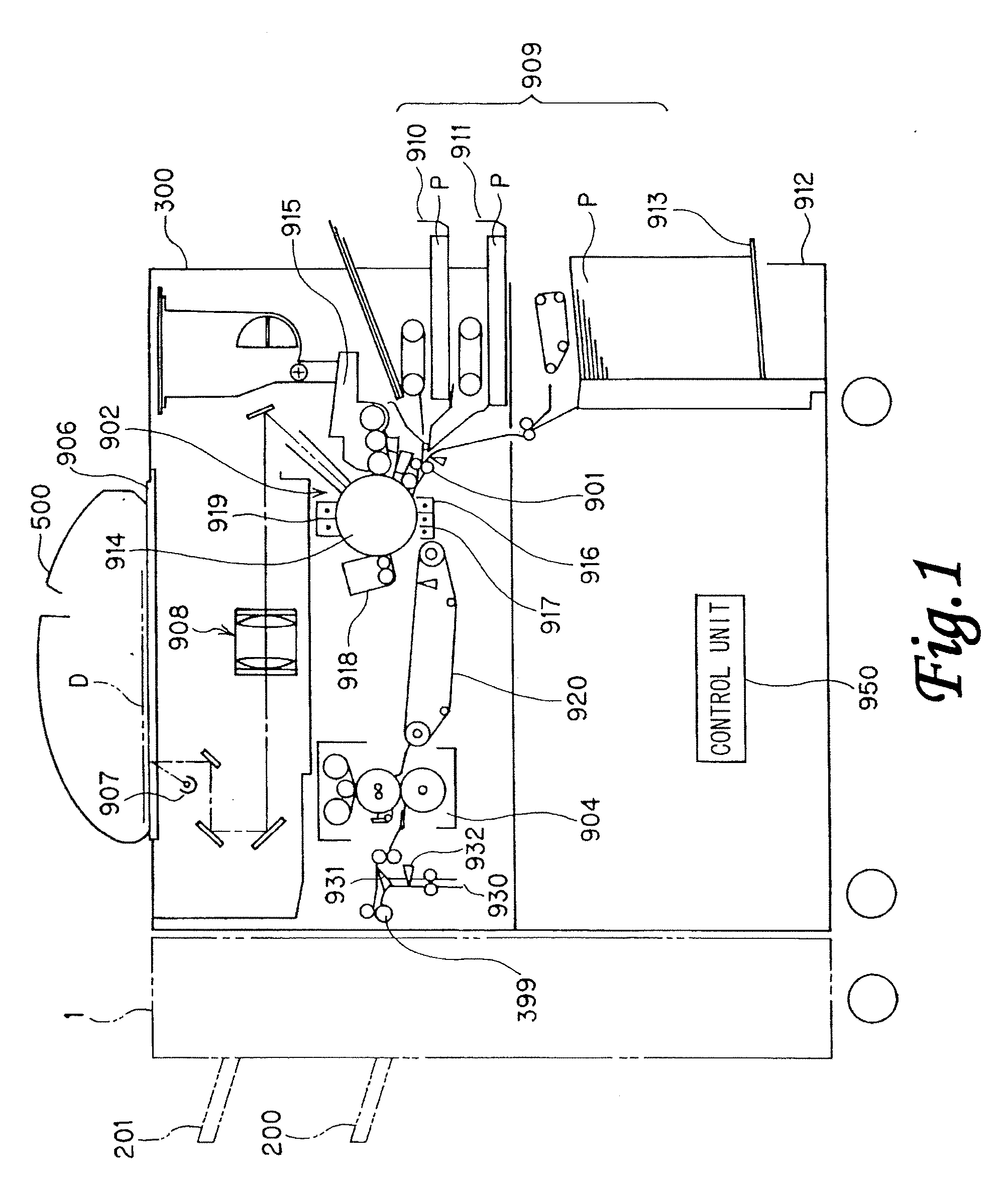

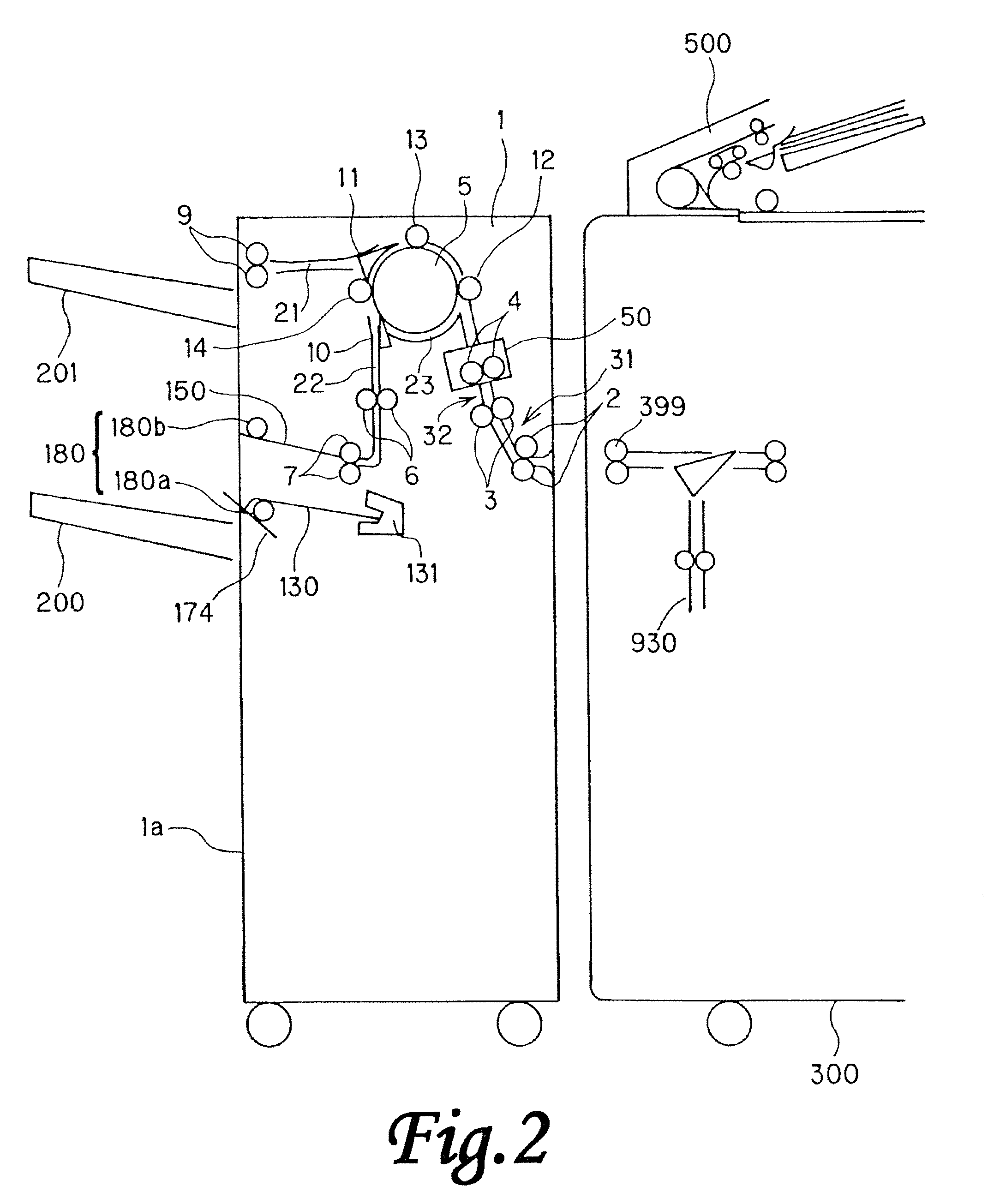

Sheet stacking apparatus, sheet processing apparatus and image forming apparatus

InactiveUS20070045948A1Increase the maximum loadIncrease costDigital data processing detailsFunction indicatorsLower limitNormal mode

A recording material stacking apparatus equipped with a plurality of discharge ports and a plurality of stacking trays can be set to normal mode and large capacity stacking mode each having a different maximum loading capacity. A stacking tray on the upper side has a plurality of lower limit positions and uses a lower limit position located on the upper side when normal mode is selected. On the other hand, it uses a lower limit position located on the lower side when the large capacity stacking mode is selected. The lower limit position located below a stacking tray on the upper side when this large capacity stacking mode is selected exists at a position in which it blocks a lower discharge port of sheets Selection of the large capacity stacking mode and normal mode is executed according to a result of computation from data input through an input portion.

Owner:CANON KK

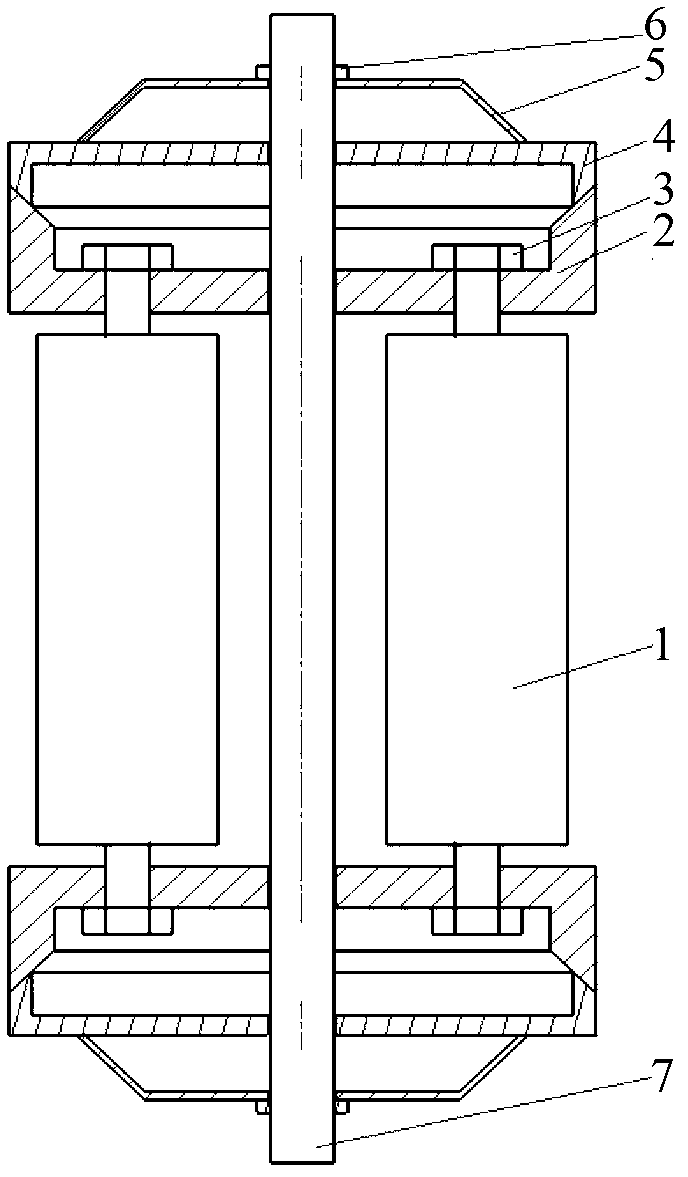

Electric rotating machine based on super magnetostriction material

InactiveCN102983778AHigh precisionImprove reliabilityPiezoelectric/electrostriction/magnetostriction machinesElectric machineMagnetostriction

The invention provides an electric rotating machine based on super magnetostriction material. The electric rotating machine based on the super magnetostriction material comprises a precompression system, a stator and two rotors, wherein the precompression system comprises an output shaft, two springs and two spring fixing pieces, the two rotors are respectively connected with two ends of the stator, the output shaft penetrates the center of the stator and the centers of the rotors and is connected with the stator and the rotors in a sleeved mode, the springs are respectively sleeved on two ends of the output shaft and press the rotors tightly, and the spring fixing pieces are connected with the output shaft and press the springs tightly. The stator comprises two stator driving ends, a plurality of super magnetostriction units and a plurality of fixing pieces, wherein the super magnetostriction units are evenly arranged between the two stator driving ends, two ends of each super magnetostriction unit are respectively connected with the stator driving ends through the fixing pieces, and the stator drives the rotors to rotate by friction. The electric rotating machine based on the super magnetostriction material has the advantages of being high in accuracy, free of noise, fast in response, big in bearing capacity, big in working bandwidth, good in stability, high in reliability, free of fatigue, free of overheating failure and the like.

Owner:SHANGHAI JIAO TONG UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com