Method for preparation of ethylene from hydrogenation of acetylene and reaction tower for the method

A technology of acetylene hydrogenation and reaction tower, which is applied in the fields of hydrogenation to hydrocarbons, chemical instruments and methods, organic chemistry, etc., and can solve problems such as difficulty in removing heat from overheating reactions, difficulty in uniform mixing of liquid and solid, and easy blockage of gas distributors, etc. , to achieve the effect of solving mercury pollution, expanding the coal chemical industry route, and avoiding the overheating of the fixed bed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] A method for producing ethylene by hydrogenation of acetylene, comprising the steps of:

[0032] 1) Pack the granular catalyst and evenly load it on the tray, and purge the reaction pipeline and equipment with inert gas. After the oxygen content is qualified, the liquid phase solvent N-methyl-2-pyrrolidone is pumped in from the liquid phase inlet And move from top to bottom, when the liquid level at the bottom of the reaction tower reaches 50%, the liquid phase solvent is continuously extracted from the liquid phase outlet, sent to the regeneration or heat exchange unit for treatment, and then returned to the liquid phase inlet for recycling.

[0033] The nitrogen is switched to a mixed gas with a volume ratio of hydrogen and acetylene of 5:1, which is pressurized by the compressor and enters from the gas phase inlet at the lower part of the reaction tower, and moves from bottom to top in the reaction tower after being distributed by a gas distributor;

[0034] 2) The g...

Embodiment 2

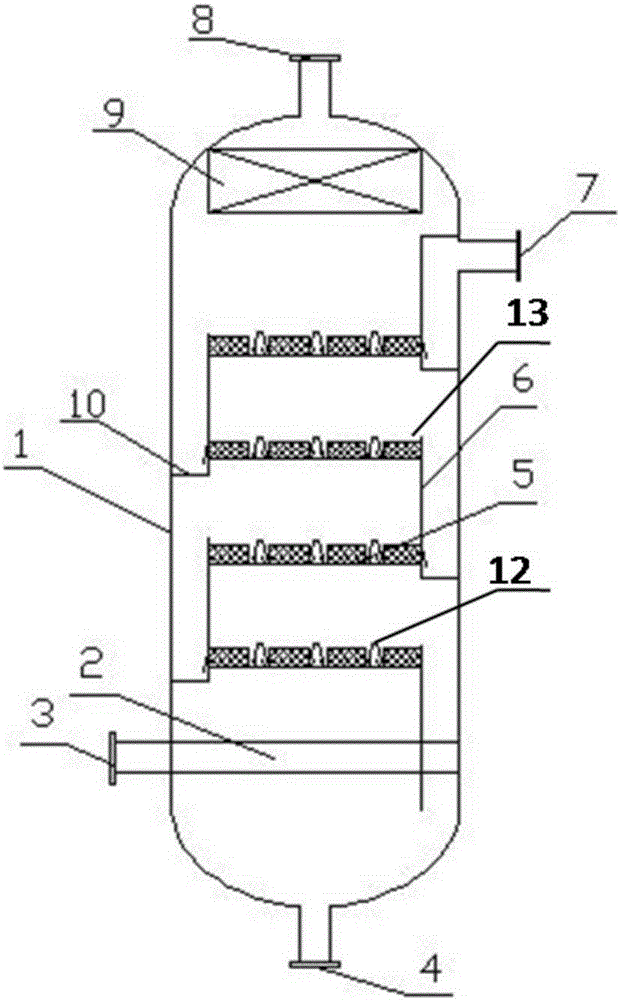

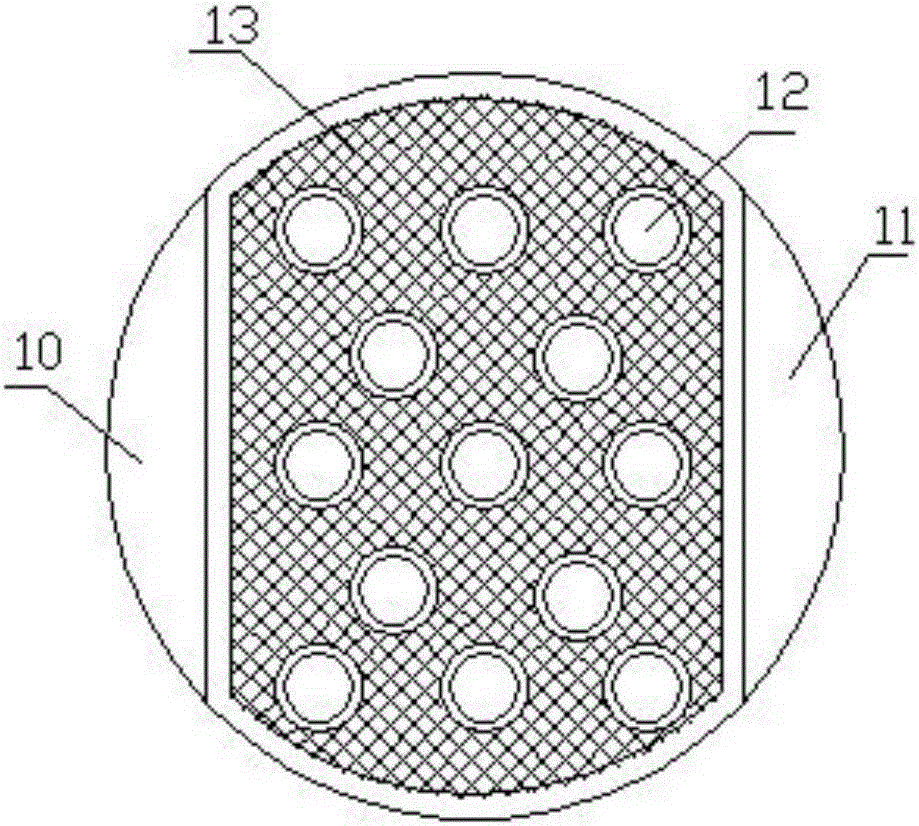

[0040] A reaction tower used in the hydrogenation of acetylene to produce ethylene, the reaction tower is gas-liquid-solid three-phase mass transfer equipment, the diameter of the reaction tower is 600mm, and the total height is 5m. like Figure 1-3 As shown, its structure includes tower body 1, liquid phase inlet and outlet 7, 4, gas phase inlet and outlet 3, 8, tray 5, gas distributor 2, gas-liquid separator 9, downcomer 6;

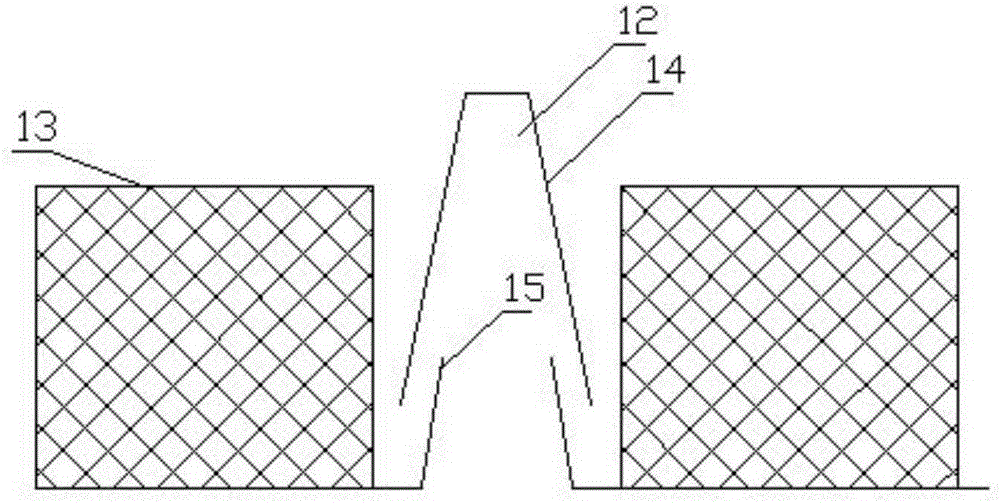

[0041] Wherein, tray 5 is provided with 10 layers altogether, and spacing is 300mm; It comprises overflow port 11, liquid receiving plate 10 and reaction unit; Be provided with a plurality of spraying devices 12 in the reaction unit, and described spraying device comprises air riser 15 and spraying device Cover 14, the opening ratio of the injection device is 13%. Described gas riser 15 is conical, hollow, small head upwards, high 50mm; Described injection cover 14 is conical structure, and top evenly opens injection hole, and the bottom and tower tray...

PUM

| Property | Measurement | Unit |

|---|---|---|

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com