Method for preparing environmentally responsive monodisperse cyclodextrin polymer hollow microspheres

A cyclodextrin polymer, environment-responsive technology, which is applied in the field of preparation of monodisperse cyclodextrin polymer hollow microspheres, achieves the effects of increasing permeability and simple post-processing process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

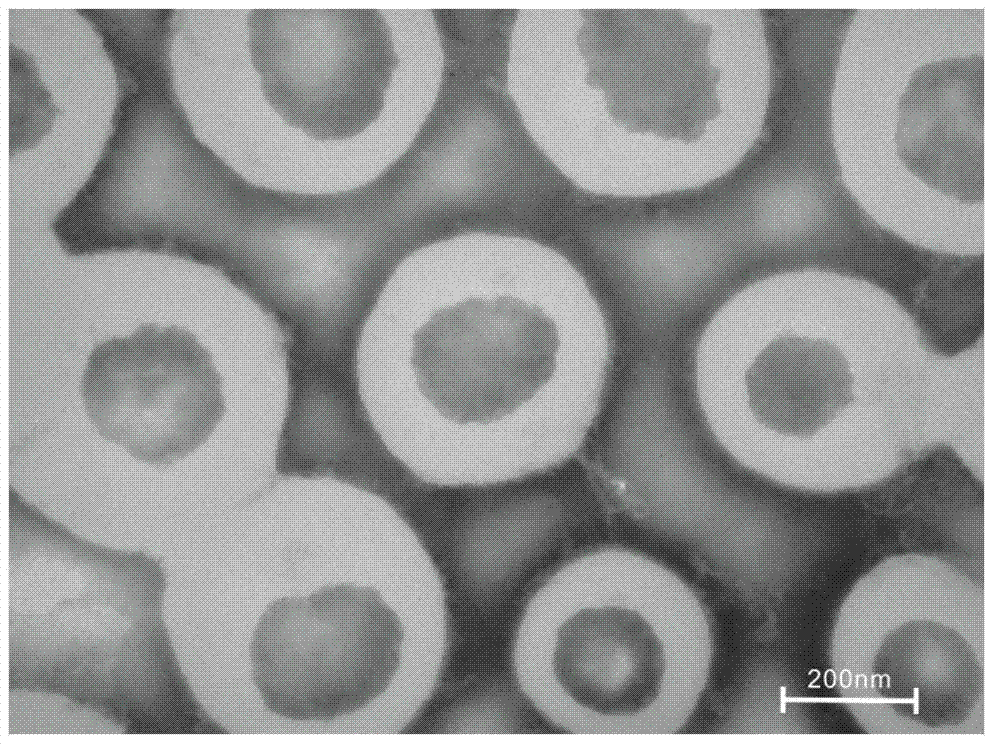

[0035] Example 1: Prepare 50 mL of N-isopropylacrylamide aqueous solution with a concentration of 10 g / L, add 30 mg of methacrylic acid to it, pour the mixed solution into a 100 mL round bottom flask, and place it in an oil bath at 60°C for magnetic stirring At the same time, nitrogen gas was introduced, and after 20 minutes, 2 mL of potassium persulfate aqueous solution with a concentration of 4 mg / mL was added to the solution with a syringe. 2mL aqueous solution of sodium dialkylbenzene sulfonate, and then add 2mL aqueous solution of monovinylcyclodextrin with a concentration of 0.08g / mL and 2mL aqueous solution of cross-linking agent N,N-methylenebisacrylamide (concentration: 10mg / mL), polymerized at 60°C, N 2 Under atmosphere for 10h. After the reaction, stir and cool to room temperature, adjust the pH value of the solution to 9.4 with 1:1 diluted ammonia water under the monitoring of the pH meter, stir at room temperature for 4 hours, and then put the sample into a dial...

Embodiment 2

[0036] Example 2: Prepare 50 mL of N-isopropylacrylamide aqueous solution with a concentration of 20 g / L, add 100 mg of ethacrylic acid to it, pour the mixed solution into a 100 mL round bottom flask, and place it in an oil bath at 80°C for magnetic stirring At the same time, nitrogen gas was introduced, and after 20 minutes, 2 mL of azobisisobutylamidine hydrochloride (V-50) aqueous solution with a concentration of 5 mg / mL was added to the solution with a syringe. Add 2 mL of sodium lauryl sulfate aqueous solution with a concentration of 12 mg / mL to the syringe first, and then add 2 mL of polyvinyl cyclodextrin aqueous solution with a concentration of 0.15 g / mL and cross-linking agent ethylene glycol dimethacrylic acid Ester 25 μL, polymerized at 80 °C, N 2 Under the atmosphere for 8h. After the reaction, stir and cool to room temperature, adjust the pH value of the solution to 10.0 with 1:1 diluted ammonia water under the monitoring of the pH meter, stir at room temperature...

Embodiment 3

[0037] Example 3: Prepare 50 mL of N-isopropylacrylamide aqueous solution with a concentration of 15 g / L, add 60 mg of maleic anhydride to it, pour the mixed solution into a 100 mL round bottom flask, and place it in an oil bath at 70°C for magnetic stirring At the same time, nitrogen gas was introduced, and after 20 minutes, 2 mL of azobisisobutylamidine hydrochloride (V-50) aqueous solution with a concentration of 4.5 mg / mL was added to the solution with a syringe, and after 3 to 5 minutes, the solution appeared light blue. First add 2 mL of sodium dodecylbenzenesulfonate aqueous solution with a concentration of 10 mg / mL into it with a syringe, and then add 2 mL of polyvinyl cyclodextrin aqueous solution with a concentration of 0.15 g / mL and cross-linking agent ethylene glycol di Methacrylate 15 μL, polymerized at 70 °C, N 2 Under atmosphere for 12h. After the reaction, stir and cool to room temperature, adjust the pH value of the solution to 9.8 with 1:1 diluted ammonia wa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com