Patents

Literature

607results about How to "Solve the lack of hardness" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

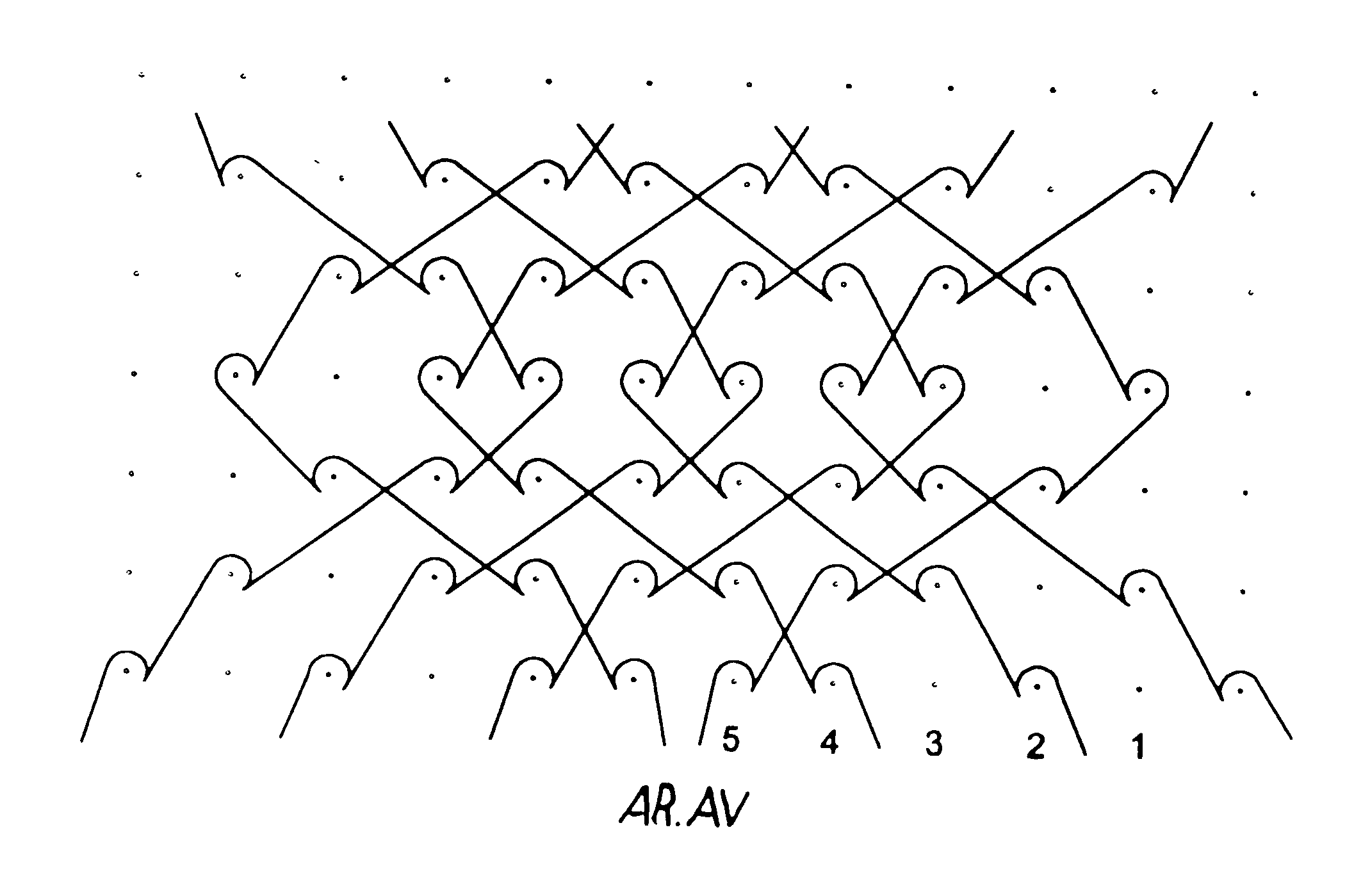

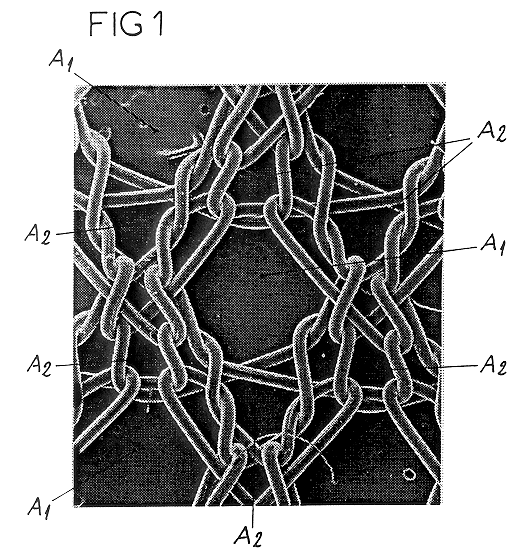

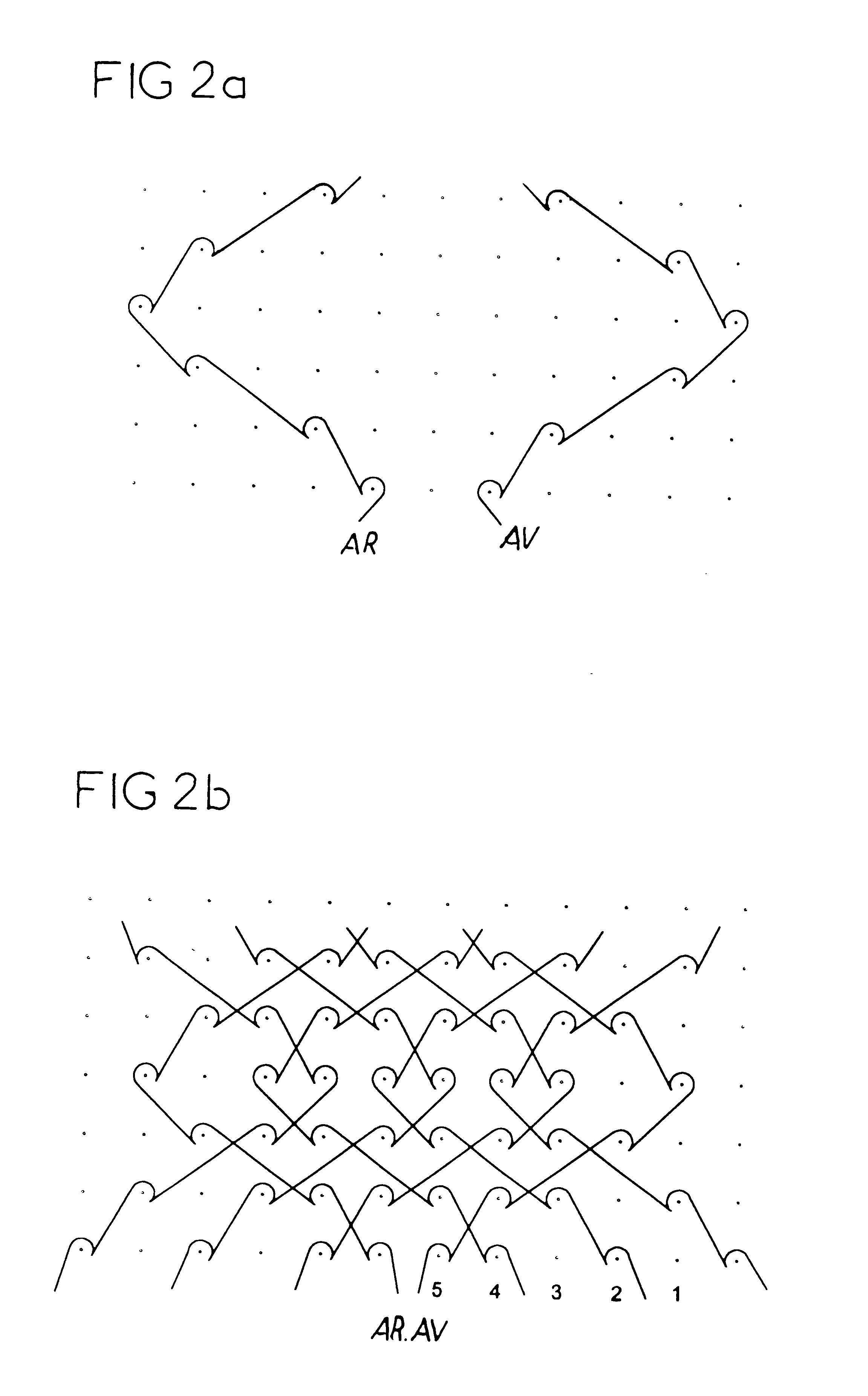

Isoelastic prosthetic filet stitch fabric

This knit is produced on the basis of a biocompatible polymer material monofilament, whose pattern is defined by a front lap and a rear lap of yarns knitted together and determines a plurality of cells each having a substantially polygonal shape. The pattern gives the knit a multidirectional tensile behavior such as obtained by a front lap capable of being obtained by knitting according to a scheme 5-4 / 4-3 / 2-1 / 0-1 / 1-2 / 3-4 and by a rear lap capable of being obtained by knitting according to a scheme 0-1 / 1-2 / 3-4 / 5-4 / 4-3 / 2-1.

Owner:SOFRADIM PROD SAS

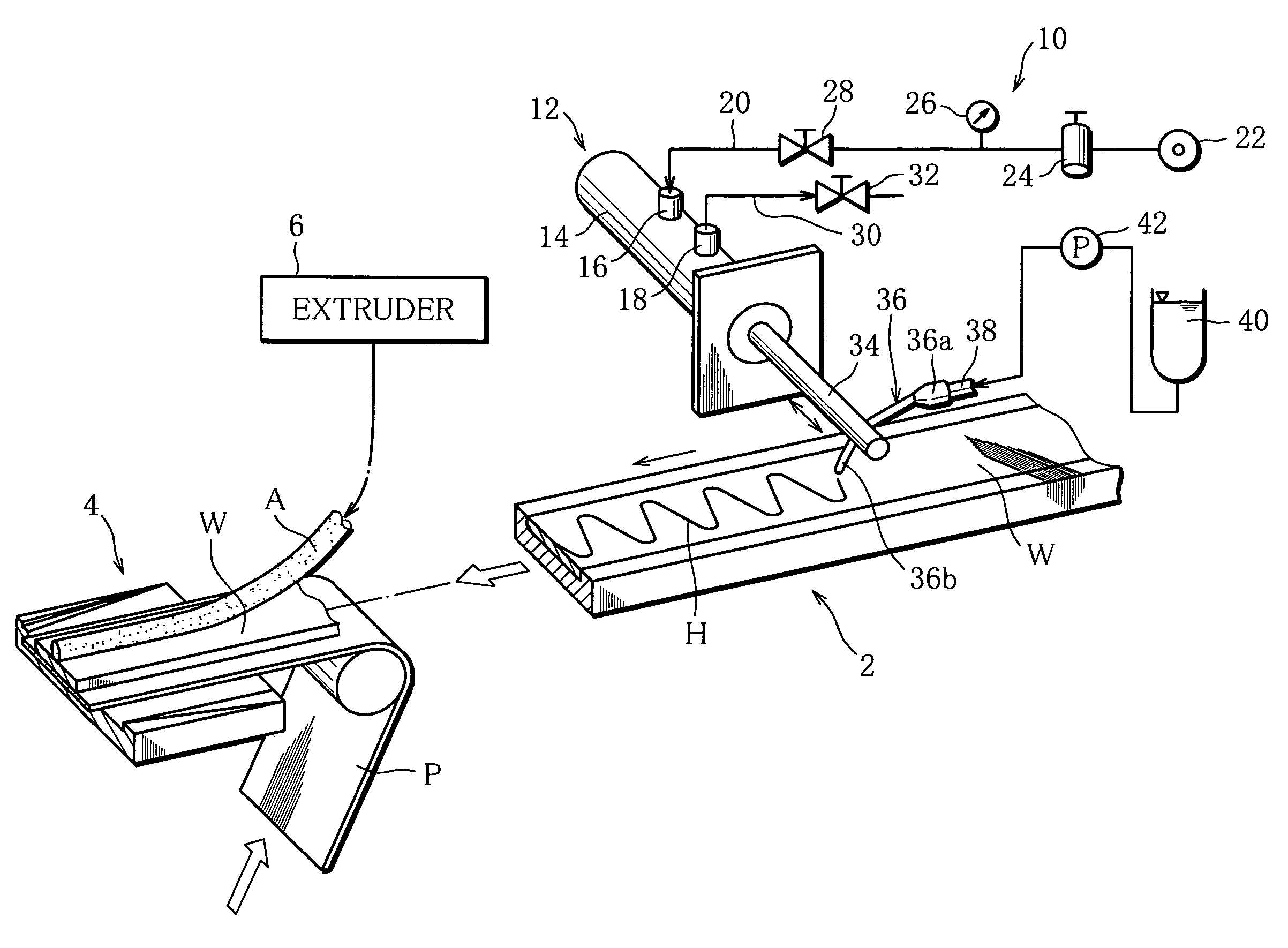

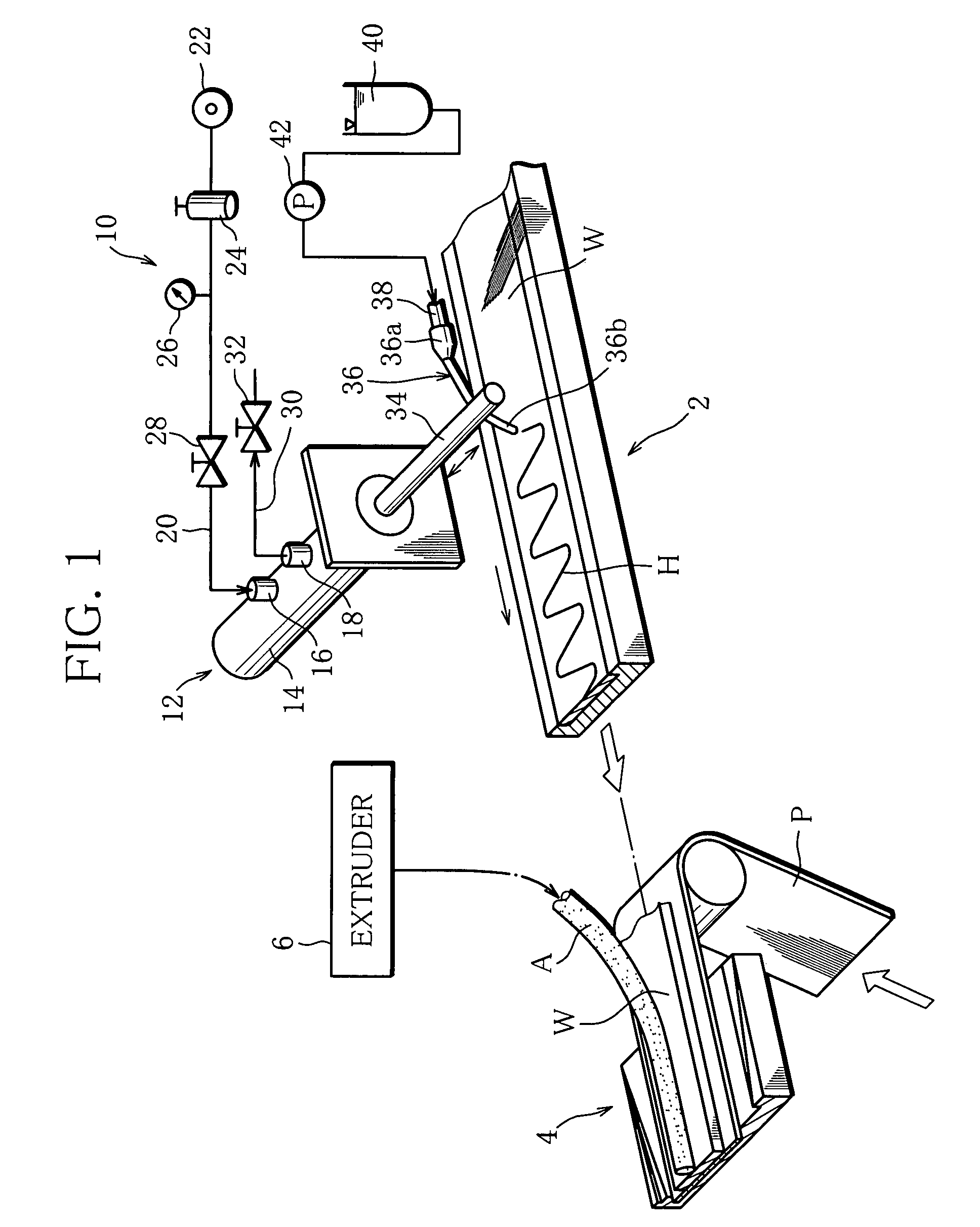

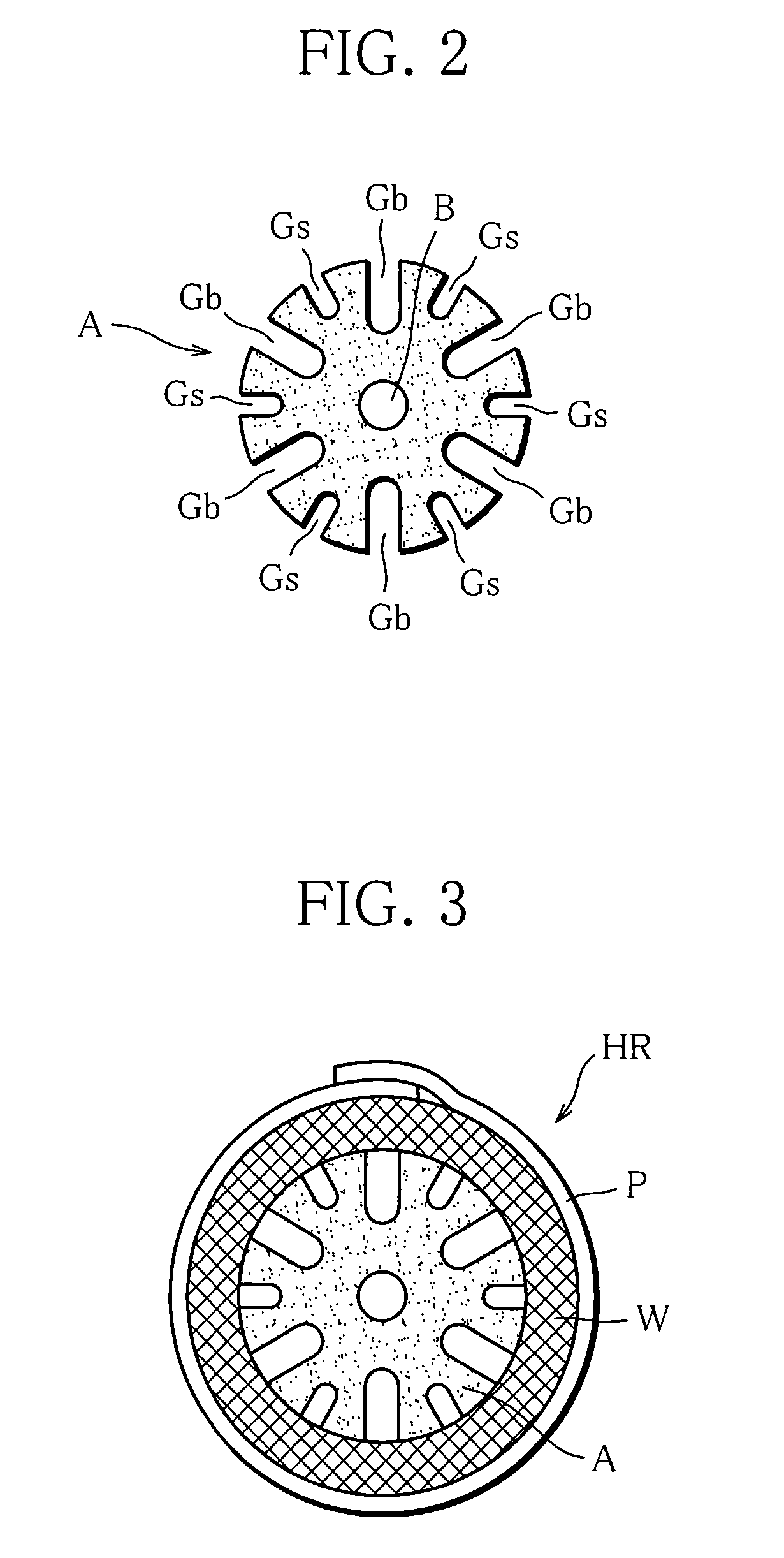

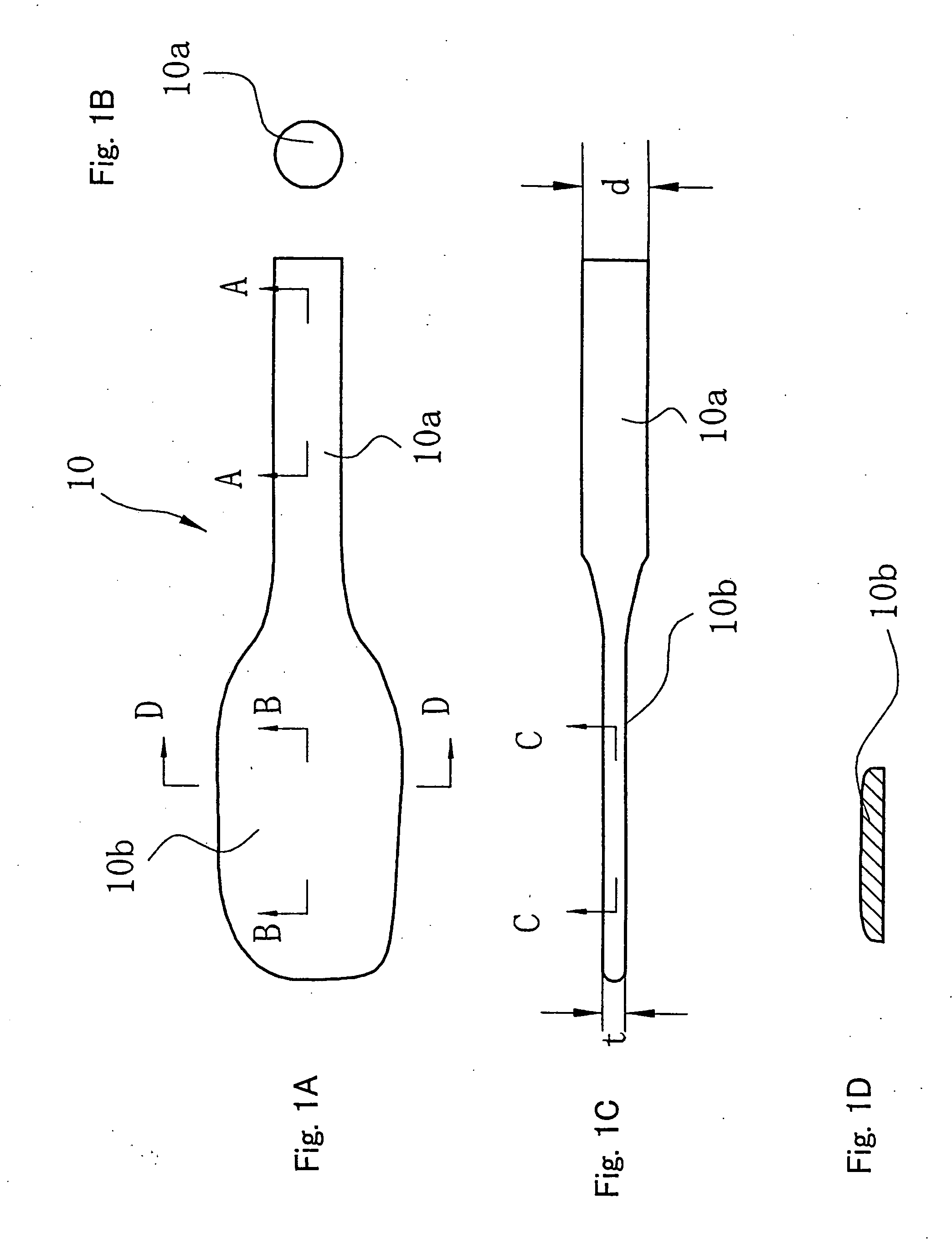

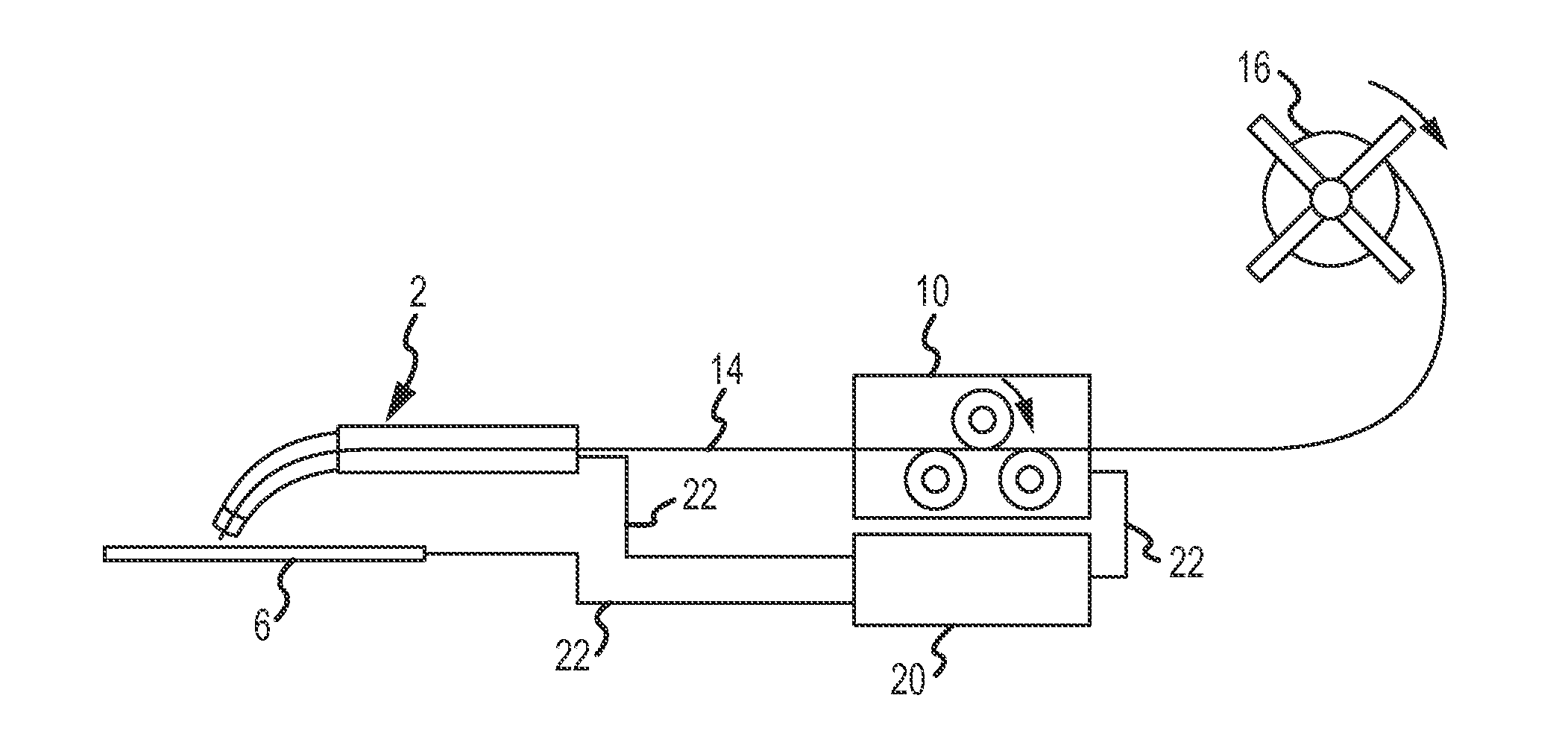

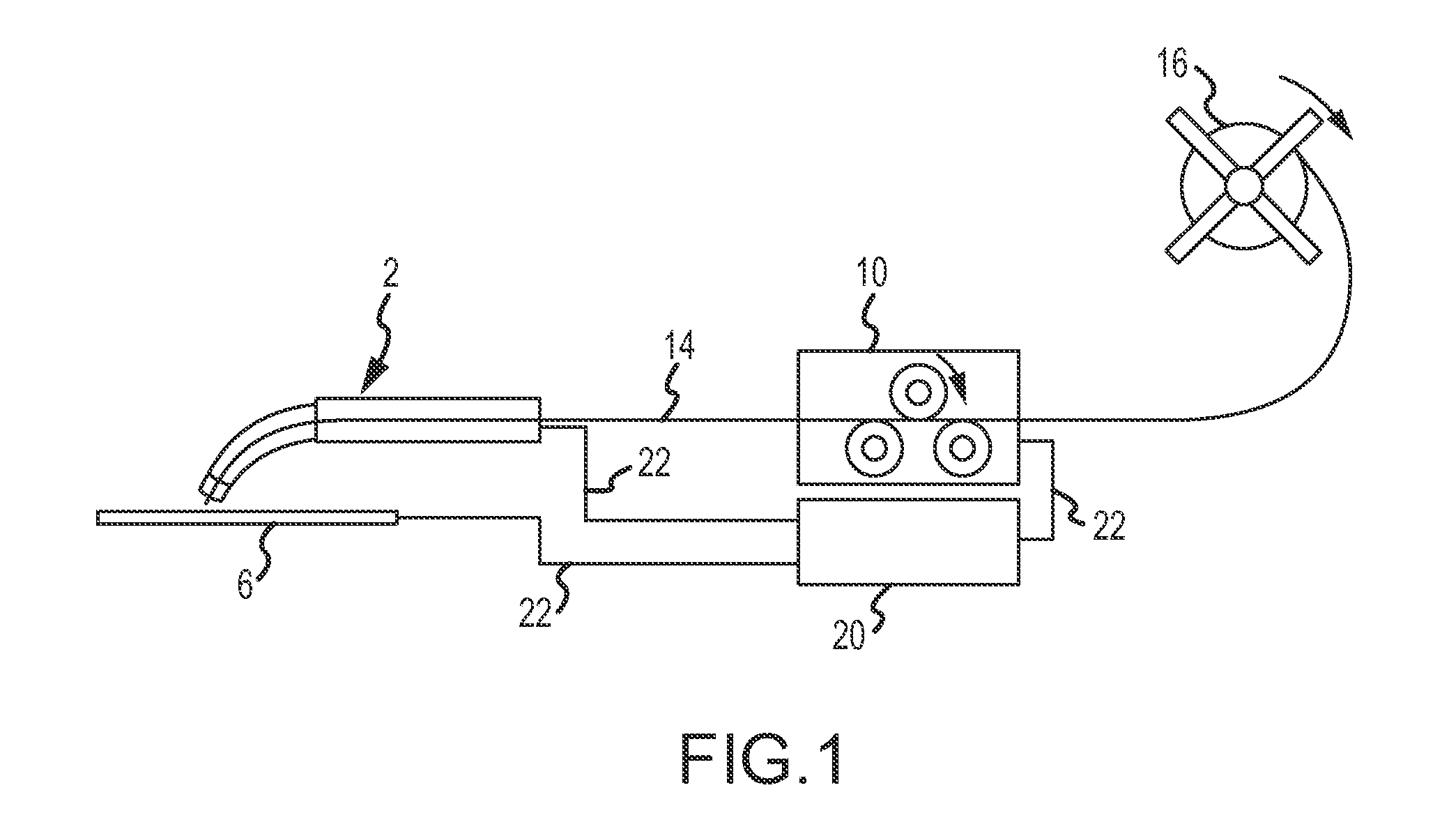

Manufacturing machine for manufacturing heat-source rod and method of manufacturing same

InactiveUS7692123B2High bonding strengthSolve the lack of hardnessNon-fibrous pulp additionNatural cellulose pulp/paperFiberWater flow

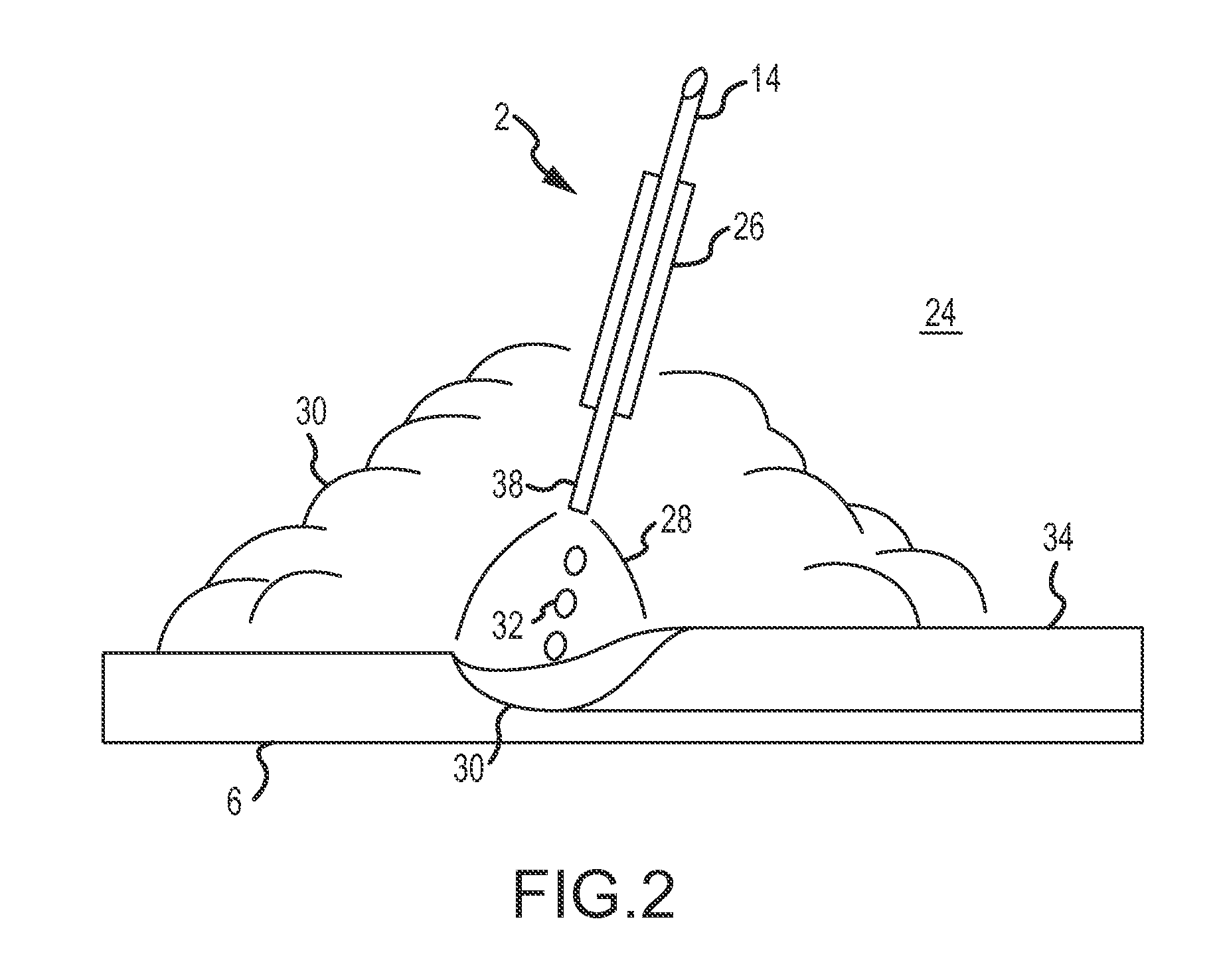

A manufacturing machine manufactures a heat-source rod having a rod-like extrusion-molded article made from a combustible material with axial grooves in the cylindrical surface thereof and a heat-insulating web enveloping the article, and is provided with a apparatus 10 for spouting water to the web W in the process of the web W being fed to a wrapping section 4. The spout apparatus 10 includes an air vibrator 12 with a vibrating rod 34, and a flexible nozzle 36 attached to the rod 34 to extend across the rod 34 and supplied with water from a rate regulating pump 42. While the web W is being fed, the end of the nozzle 36 spouts water to the web W, reciprocating widthways relative to the web W due to vibration of the rod 34, and the water spouted dissolves a binder used in the web W to bind heat-insulating fiber, thereby forming a wet band H, where the wet band H has a waveform continuing along the longitudinal direction of the web W and provides a adhesive region for bonding the article.

Owner:JAPAN TOBACCO INC

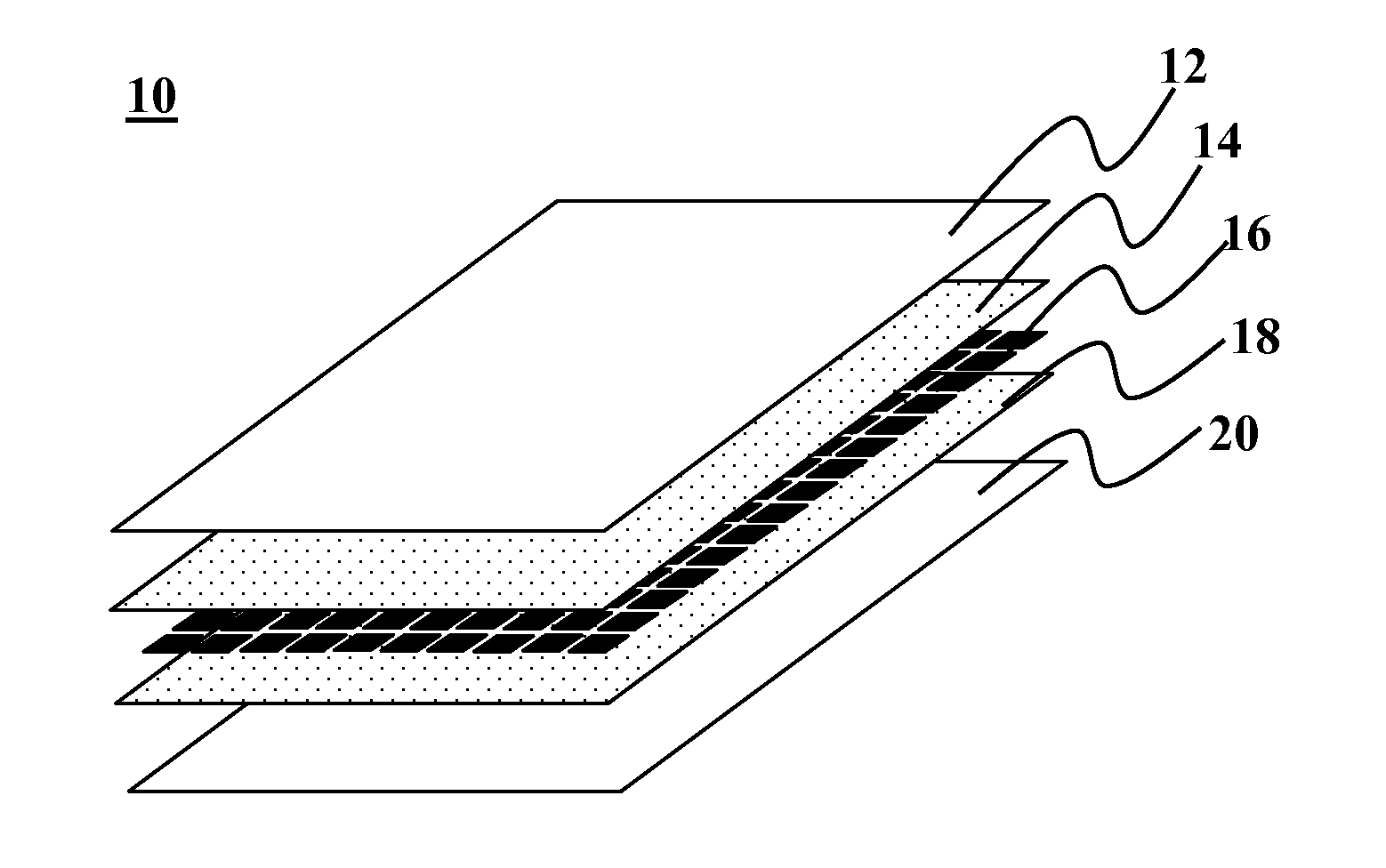

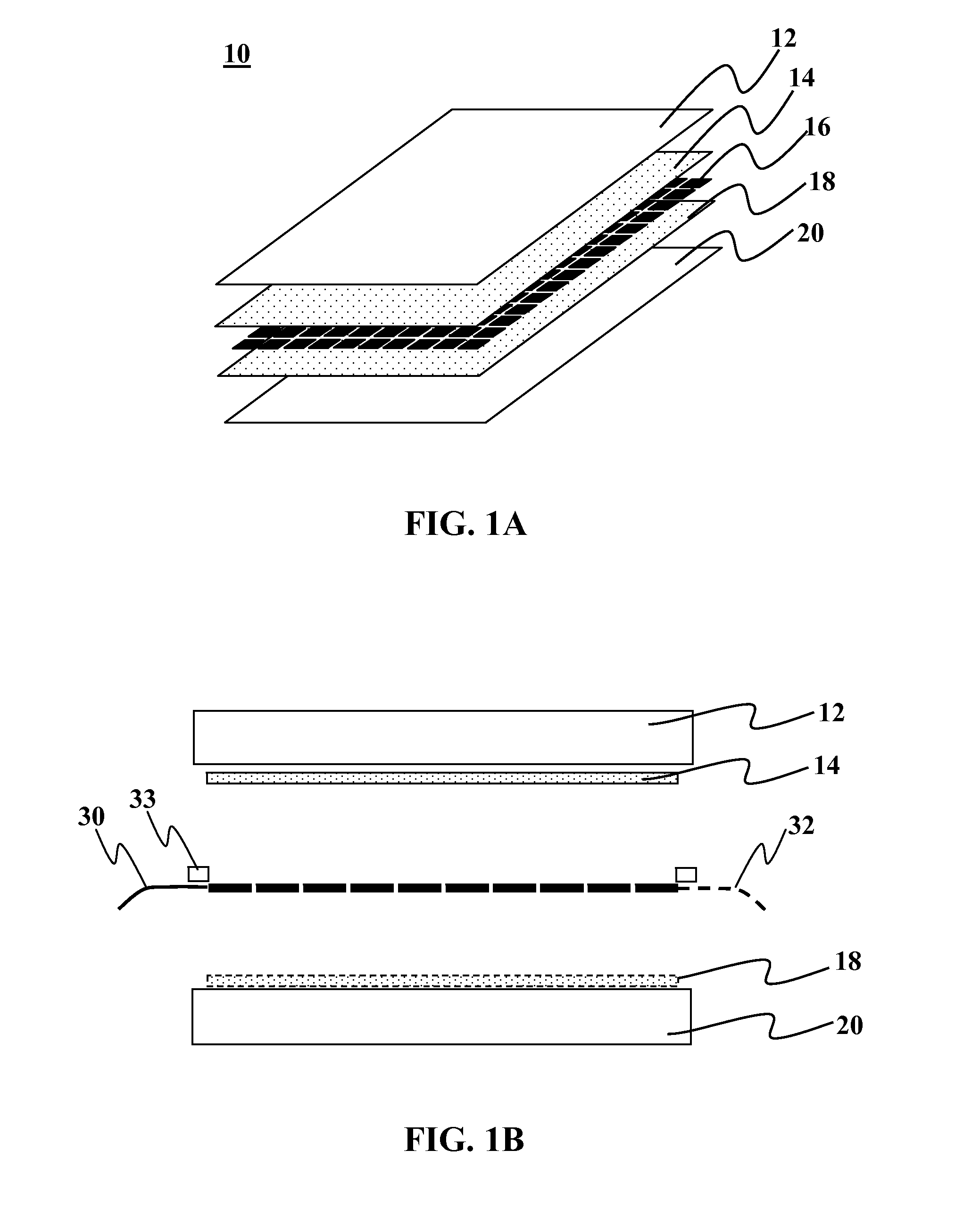

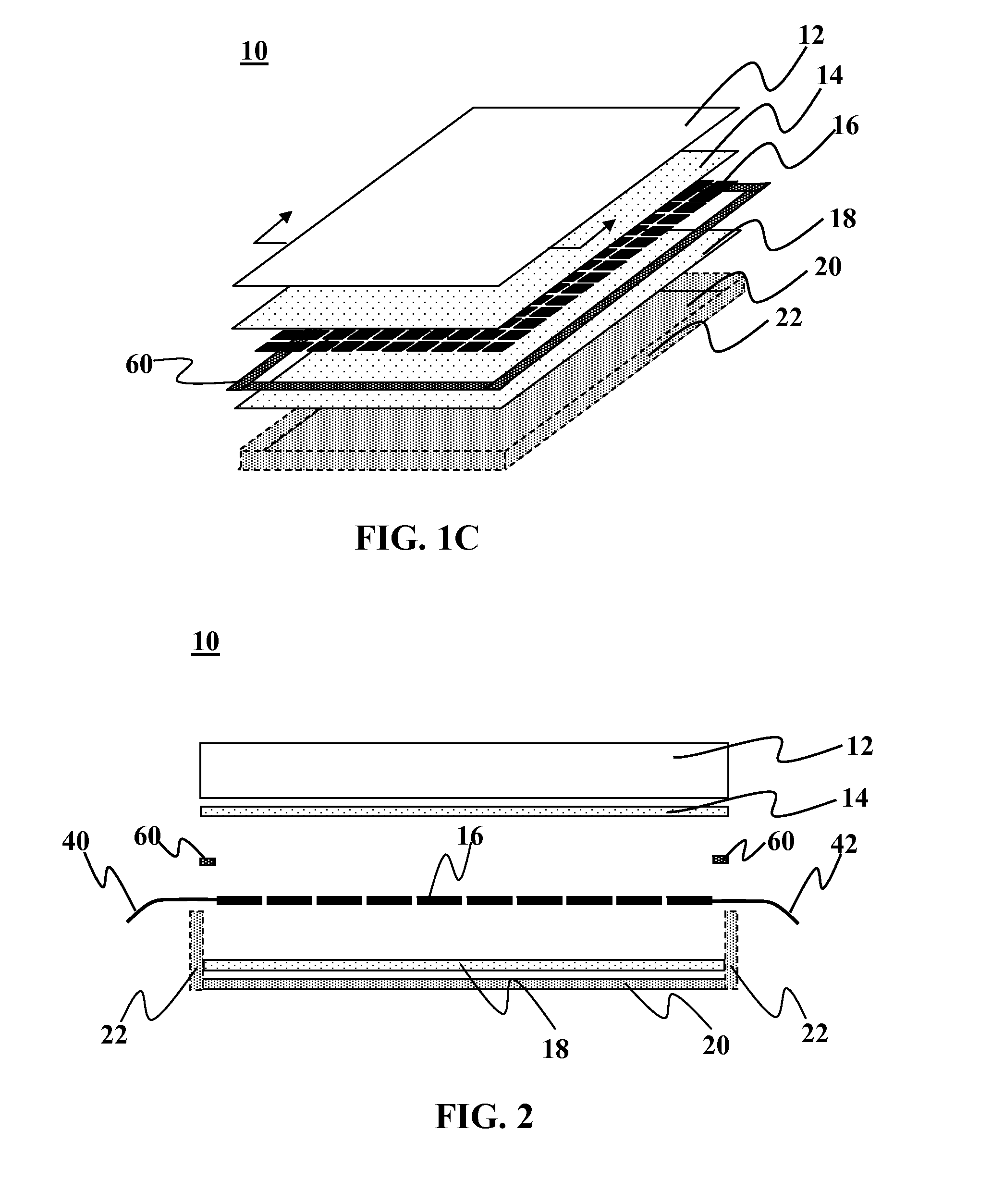

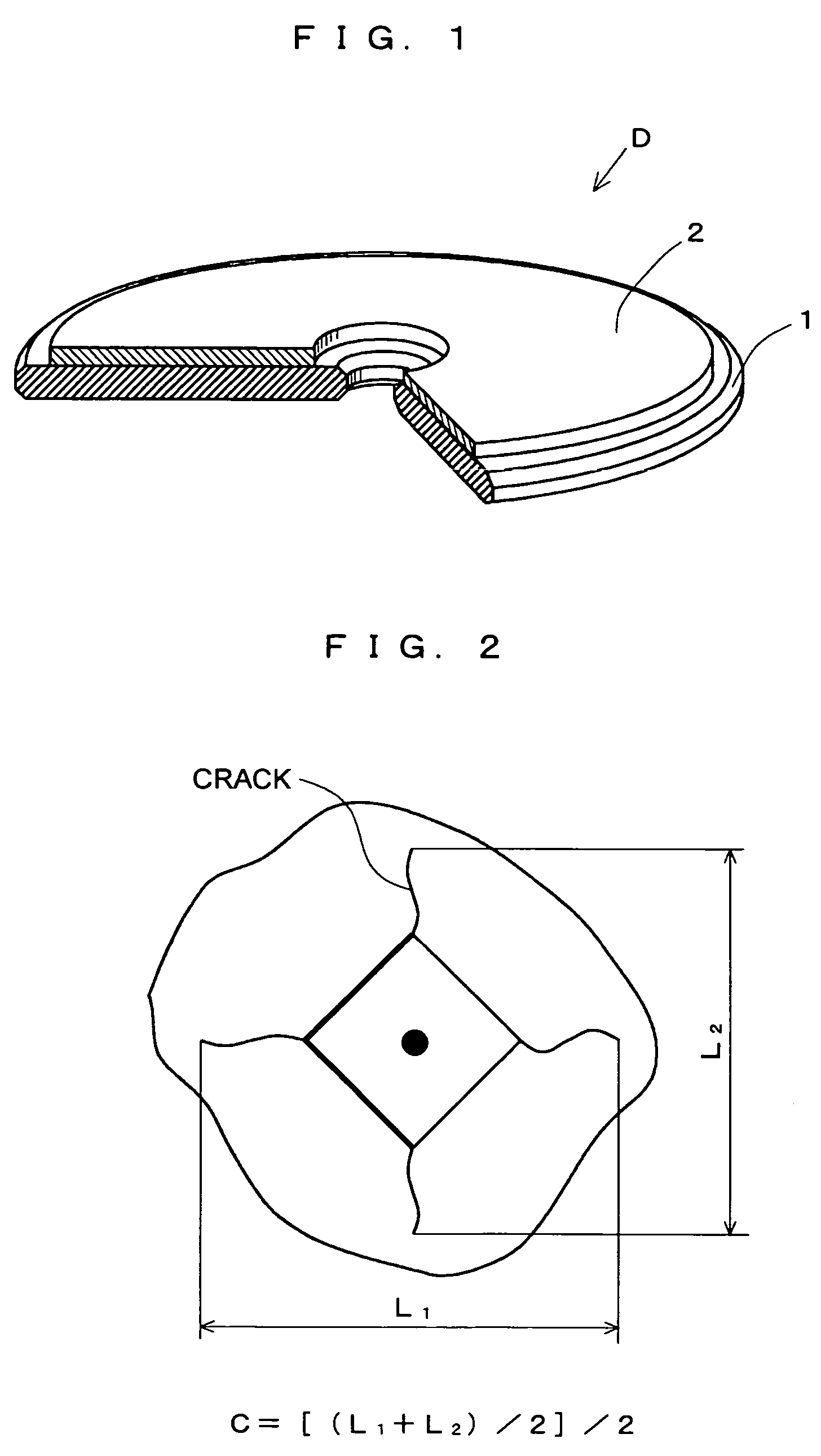

Impact Resistant Thin-Glass Solar Modules

InactiveUS20100065116A1Reduce manufacturing costReduce redundant partsSynthetic resin layered productsElectrical equipmentEngineeringThin glass

Methods and devices are provided for solar module designs. In one embodiment, a durable thin glass solar module is provided. The system comprises of a photovoltaic module with at least one layer comprised of a thin glass layer with protection which protects against microcracks (radial and concentric) which may form during hail impacts.

Owner:STANCEL ROBERT +3

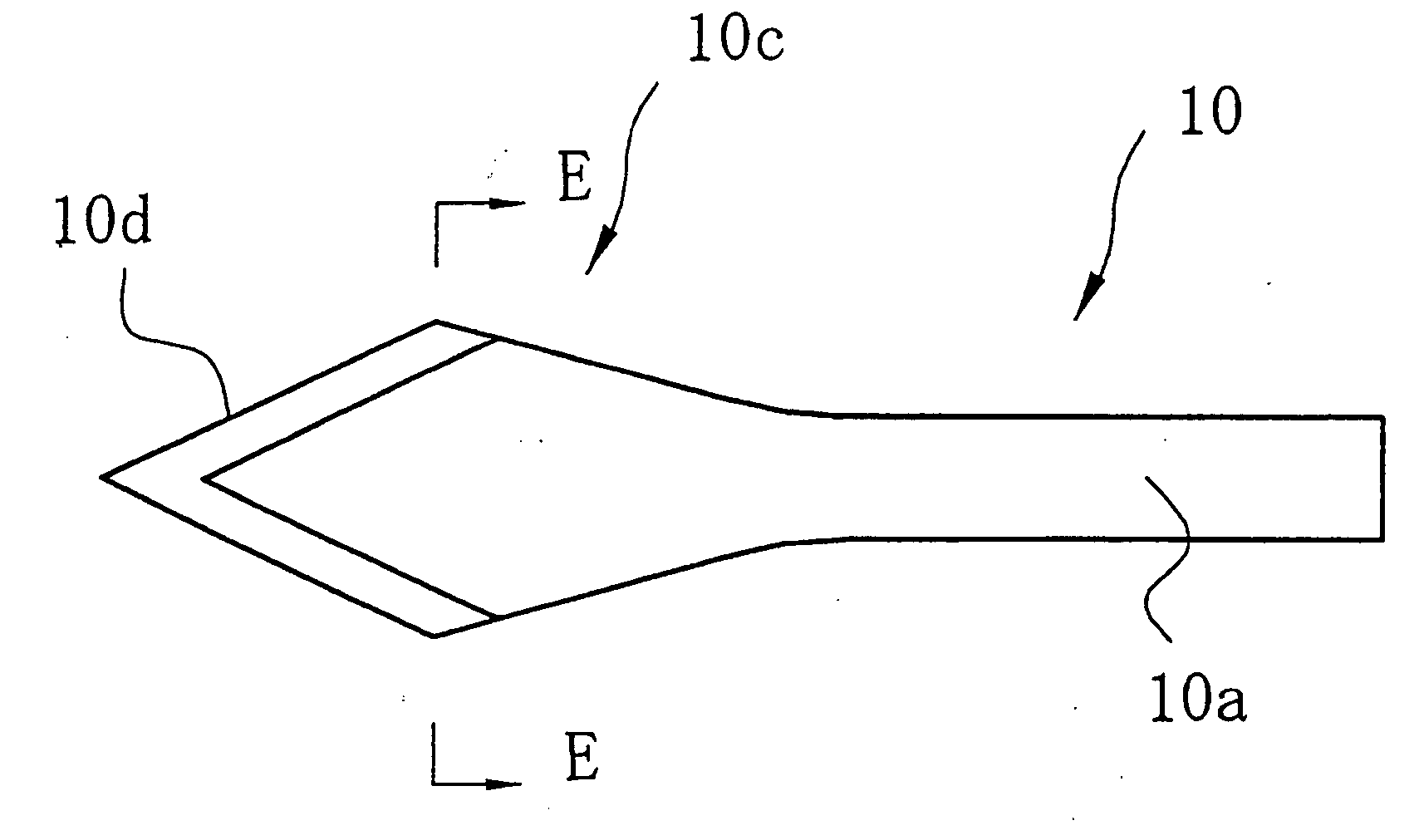

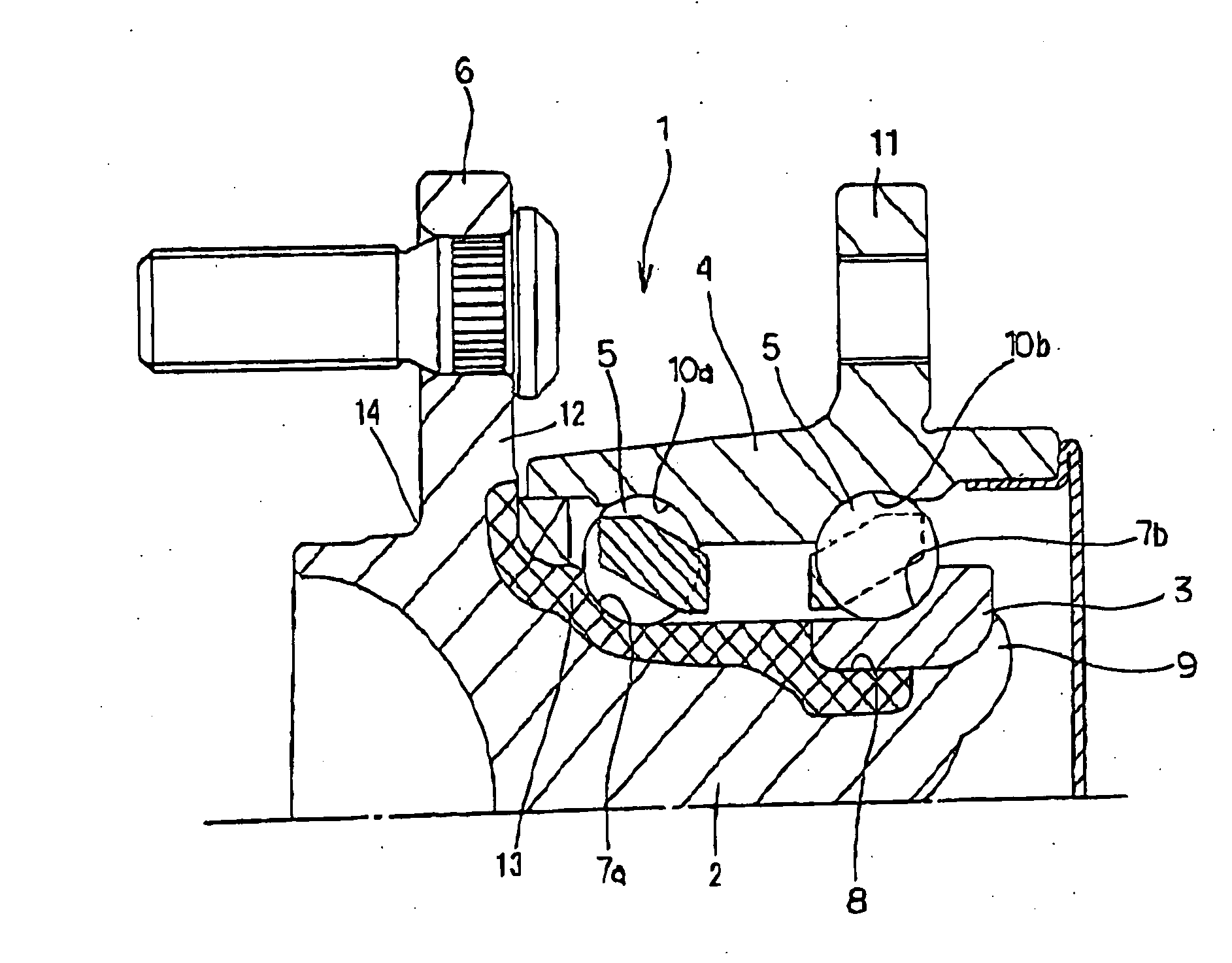

Medical knife

ActiveUS20070179515A1Excellent corrosion resistanceSufficient hardness and sharpnessIncision instrumentsEye surgeryCorrosion resistantAustenitic stainless steel

A work 10 made of a hard wire rod of austenitic-stainless steel is pressed at a rolling reduction of 60% or greater, into a paddle-shaped end 10b, and then subjected to work hardening, making the hardness of the end 10b 550 Hv or greater. Afterwards, the paddle-shaped end 10b is cut through machining, forming a main body 10c of a medical knife and cutting blades 10d. As a result, a medical knife, which is easily fabricated, is corrosion resistant, has sufficient hardness and sharpness, high toughness preventing cracks, can be provided.

Owner:MANI INC

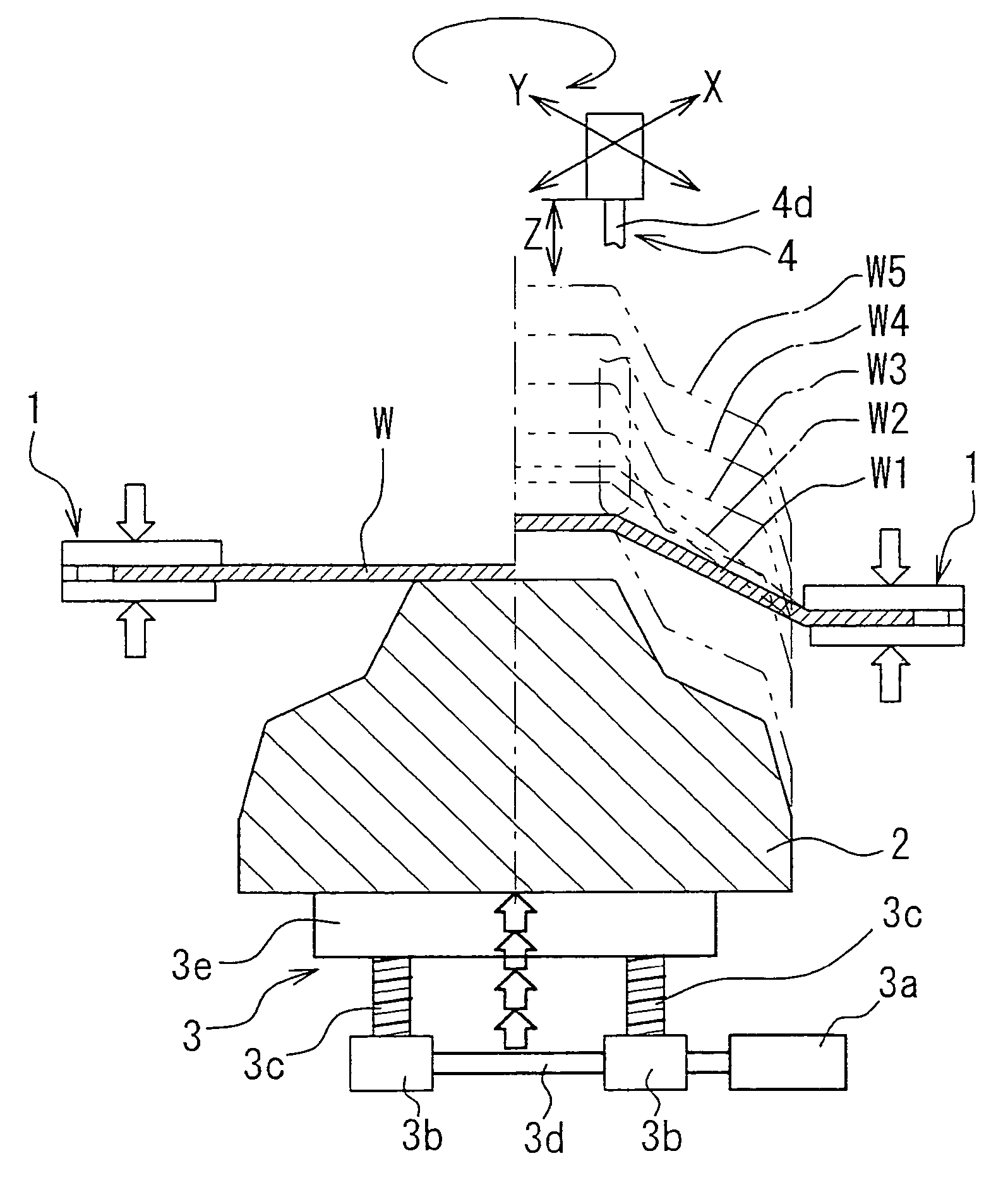

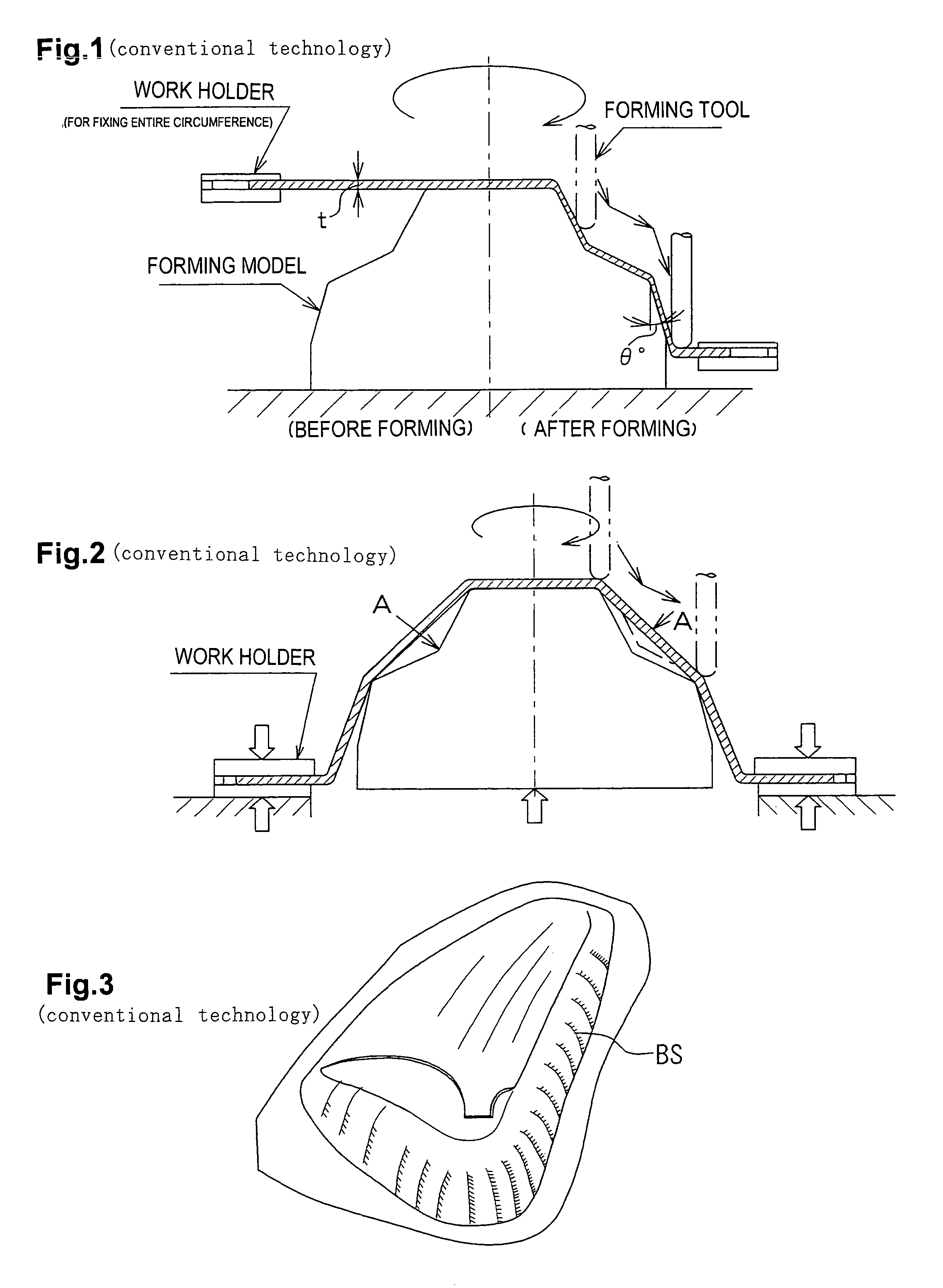

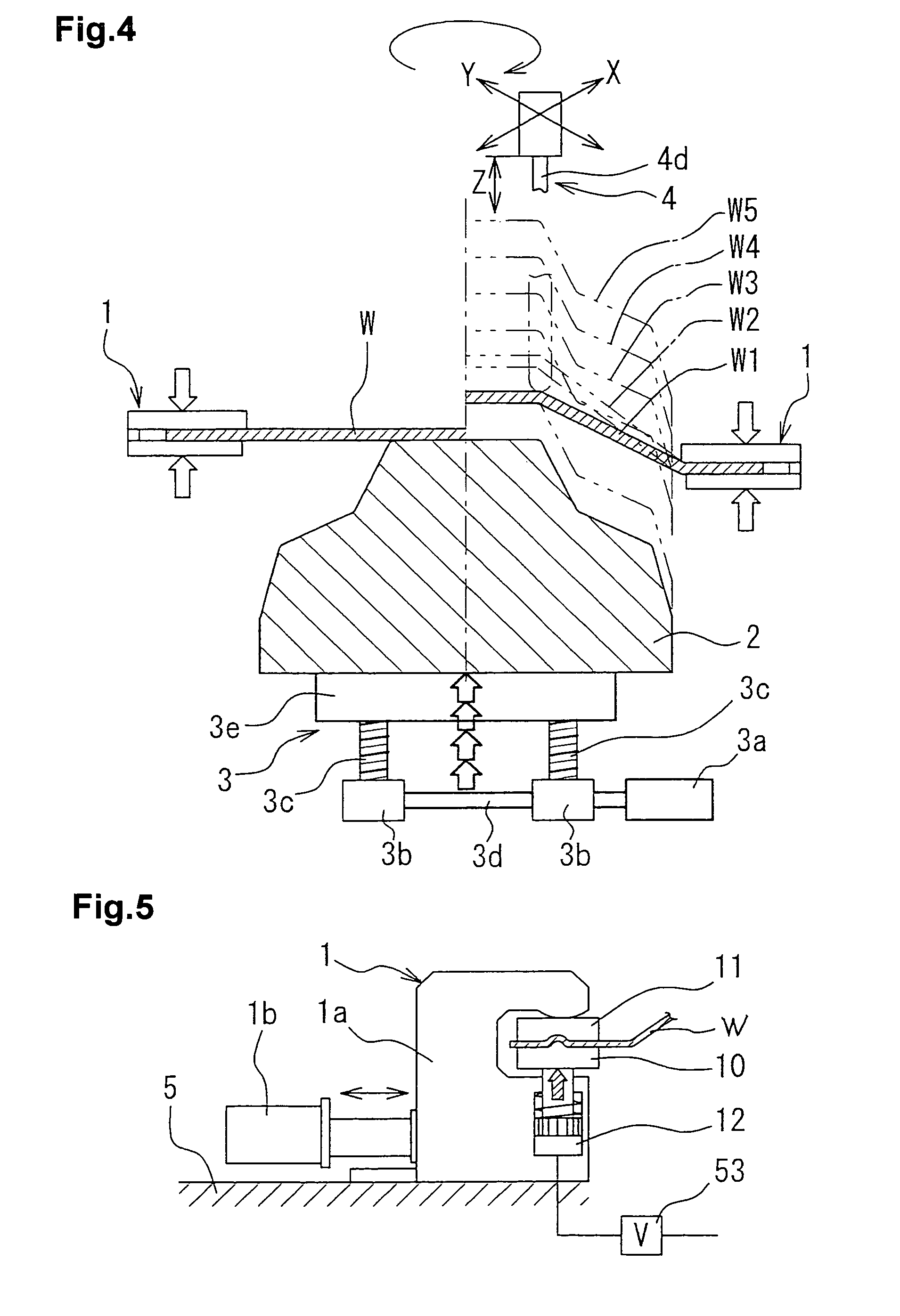

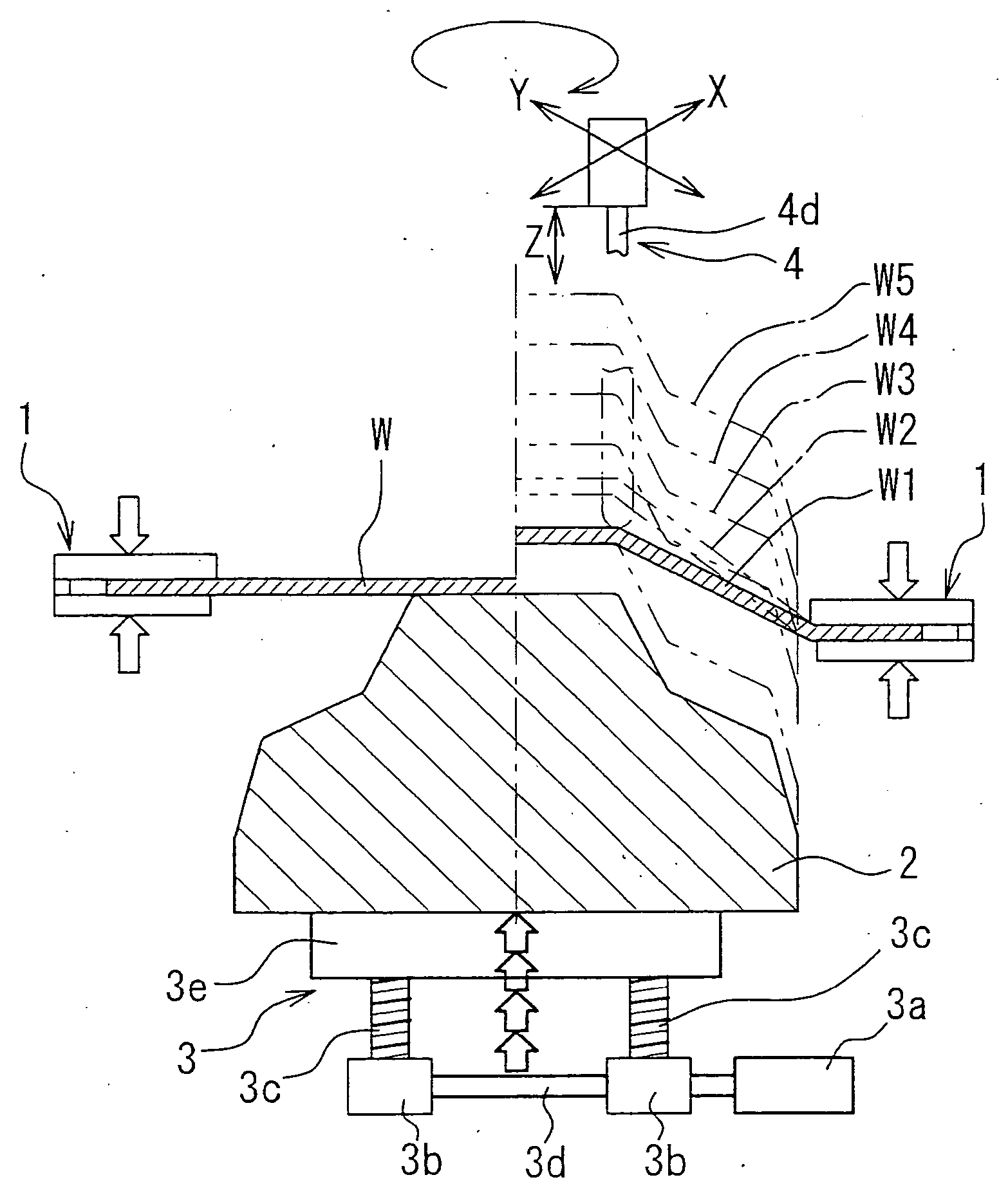

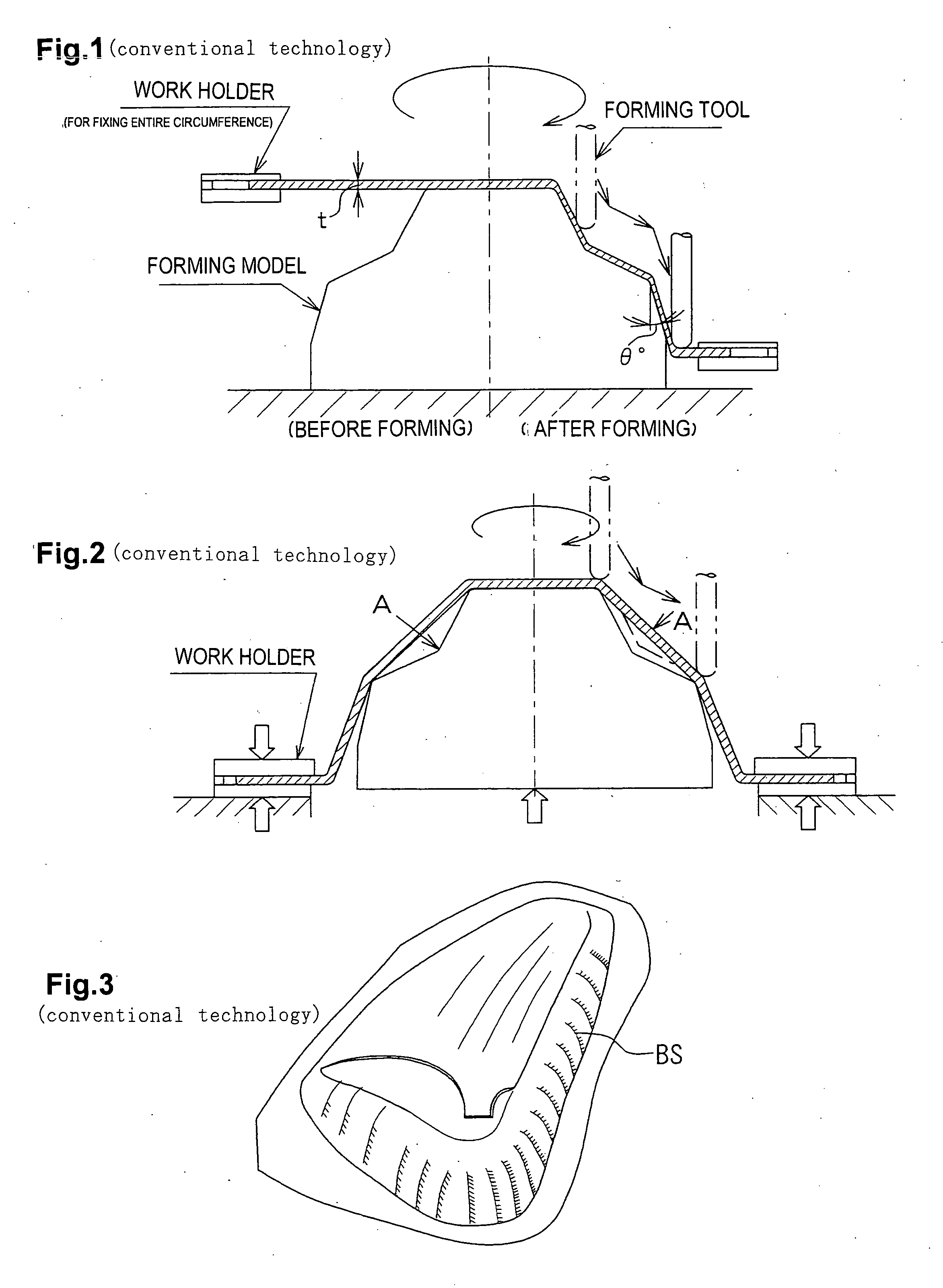

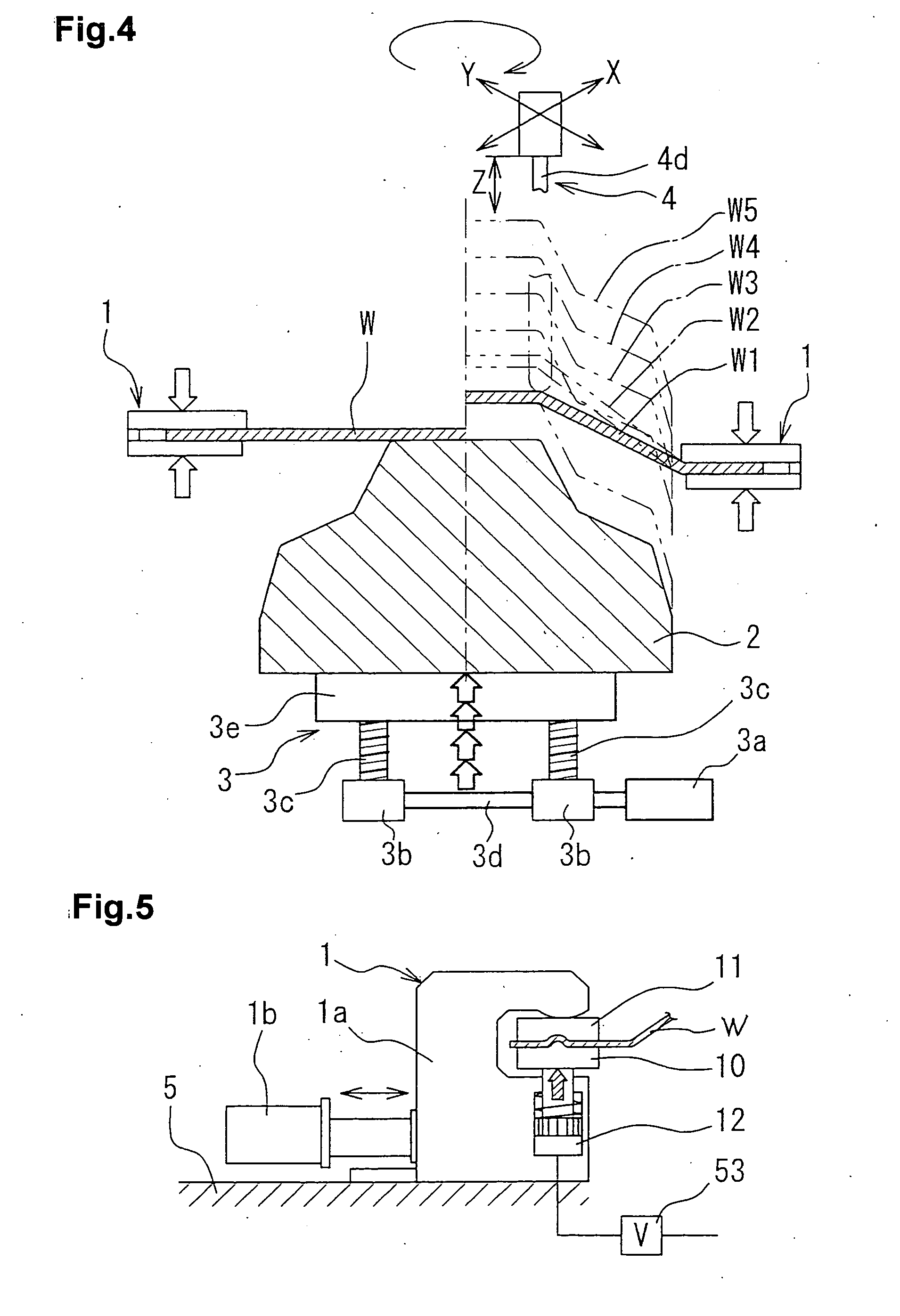

Method and apparatus for forming sheet metal

InactiveUS7536892B2Improve accuracyShort timeMetal-working feeding devicesPositioning devicesMechanical engineeringMetal

In order to provide a method and apparatus for forming a sheet metal, in which a three-dimensional product such as a prototype for commercialized press-forming can be formed in short time without limitations as to the shape and with high accuracy, preventing body wrinkles or reduction of the sheet thickness,a process of: performing drawing-forming to a predetermine height by pushing the forming punch having a desired shape in the sheet thickness direction with the edges of the blank workpiece being clamped; performing shape-forming with the shaping tool in the opposite side to the forming punch by increasing a clamping pressure to lock movement of a material with the forming punch being pushed; performing drawing-forming again by decreasing the clamping pressure and raising the forming punch by a desired height; and performing shape-forming with the shaping tool by increasing the clamping pressure to lock movement of a material, is repeated at least once.

Owner:AMINO CORP (JP)

Ultraviolet-cured hard coating and application thereof

ActiveCN102236113AImprove wear resistanceImprove antifouling performanceLayered productsPolyurea/polyurethane coatingsUltravioletPliability

The invention discloses an ultraviolet-cured hard coating and an application thereof. The ultraviolet-cured hard coating comprises a transparent supporting body and a scratch-proof coating coated on the transparent supporting body; the scratch-proof coating comprises the following components in part by weight: 5 to 90 parts of light-cured prepolymer, 5 to 90 parts of thinning agent, 1 to 10 parts of photoinitiator, 0 to 80 parts of active thinning agent, 0 to 20 parts of inorganic nanopadding and 0 to 18 parts of aid. By the invention, the defects that the conventional hard coating is not hard enough, the scratch resistance and the wear resistance are limited, the flexibility is relatively low and the like are overcome; and the ultraviolet-cured hard coating has relatively low surface energy, relatively good antifouling effect, high strength, relatively good scratch resistance and wear resistance, and excellent adhesion, flexibility and transparence.

Owner:中国航天科技集团公司第四研究院第四十二所

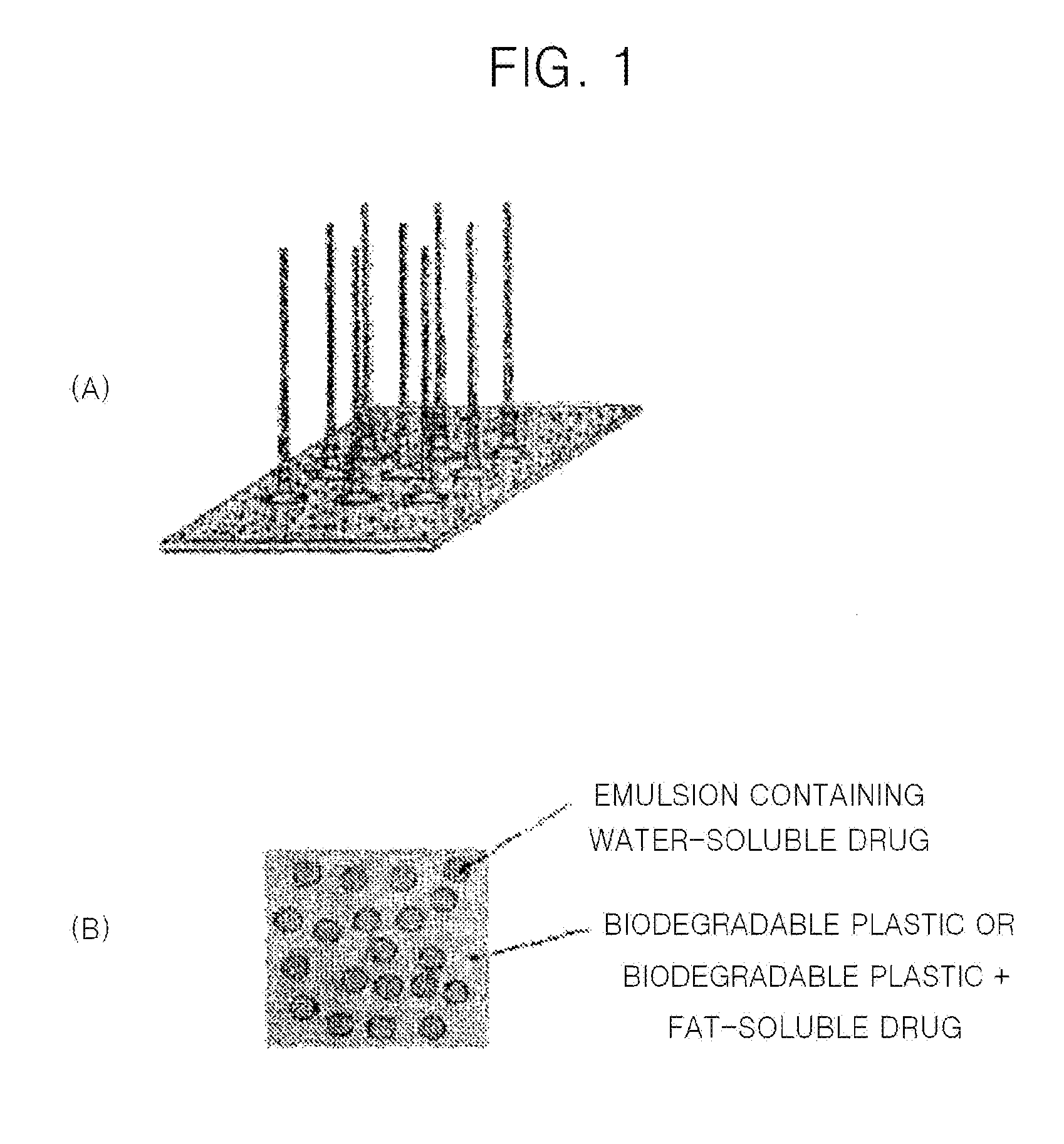

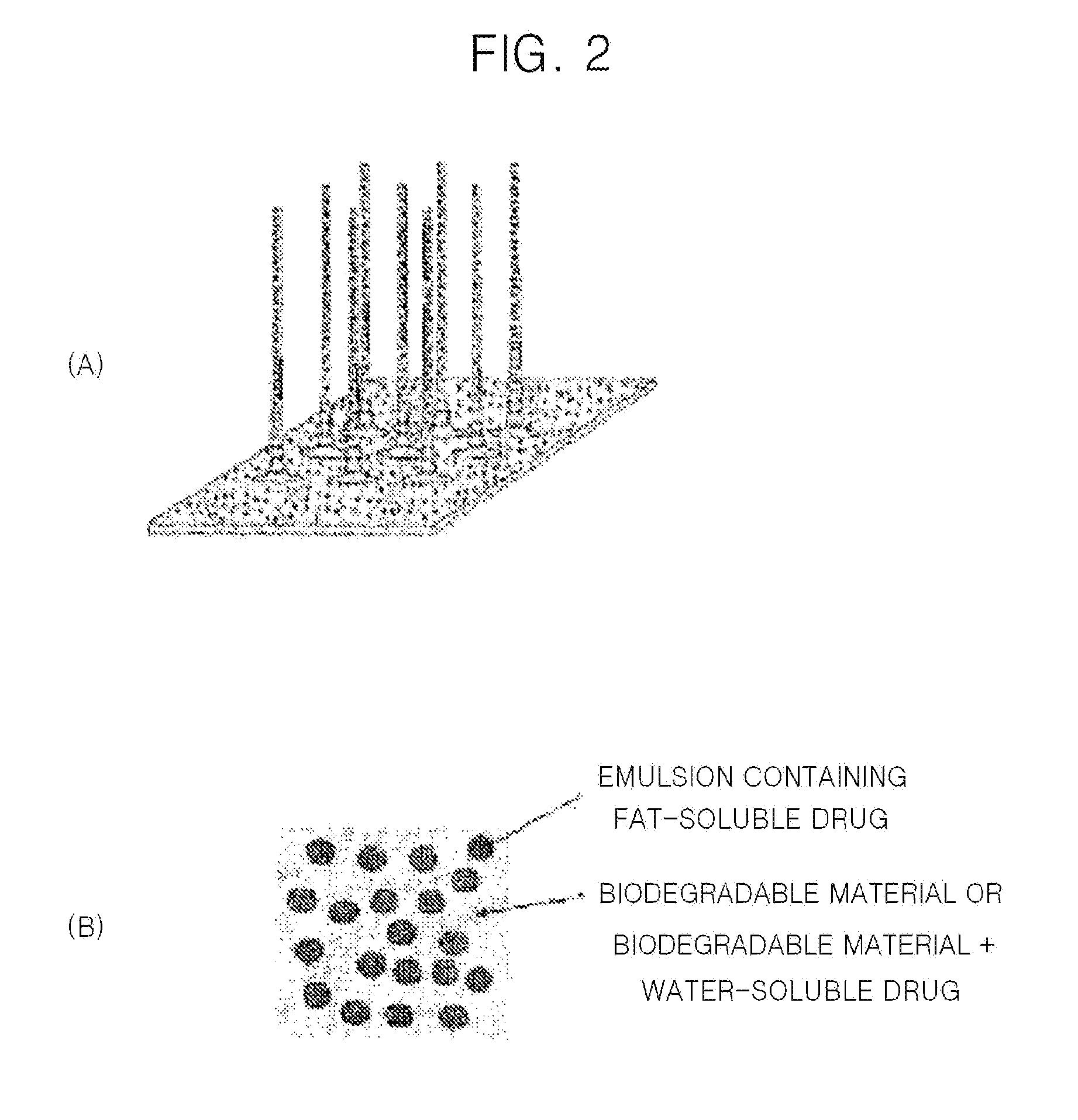

Solid microstructure that enables multiple controlled release and method of maufacturing same

InactiveUS20110177139A1Sufficient effective lengthSolve the lack of hardnessBiocideMicroneedlesEmulsionControl release

Provided are a method of manufacturing a solid microstructure capable of controlling multidrug release by mixing a biocompatible or biodegradable material with microparticles or nanoparticles and / or an emulsion as drug carriers and a solid microstructure structure manufactured using the same.

Owner:NURIM WELLNESS

Glass composition, glass substrate employing it for an information recording medium, and information recording medium employing it

ActiveUS20050215414A1Excellent specific elastic modulusLow alkali elutionBase layers for recording layersRecord information storageRecording mediaChemistry

A glass substrate used as a substrate of an information recording medium such as a magnetic disk, magneto-optical disk, DVD, or MD, and a glass composition used to make such a glass substrate, contains the following glass ingredients: 40 to 70% by weight of SiO2; 1 to 20% by weight of Al2O3; 0 to 10% by weight, zero inclusive, of B2O3; SiO2+Al2O3+B2O3 accounting for 60 to 90% by weight; a total of 3.0 to 15% by weight of R2O compounds, where R═Li, Na, and K; a total of 2.0 to 15% by weight of R′O compounds, where R═Mg, and Zn; and a total of 1.0 to 20% by weight of MOx (TiO2+ZrO2+LnxOy), where LnxOy represents at least one compound selected from the group consisting of lanthanoid metal oxides, Y2O3, Nb2O5, and Ta2O5. Here, the following condition is fulfilled: 0.070<(total content of R′O compounds) / (SiO2+Al2O3+B2O3)<0.200.

Owner:HOYA CORP

Method and apparatus for forming sheet metal

InactiveUS20060272378A1Short timeImprove accuracyMetal-working feeding devicesPositioning devicesWrinkle skinEngineering

In order to provide a method and apparatus for forming a sheet metal, in which a three-dimensional product such as a prototype for commercialized press-forming can be formed in short time without limitations as to the shape and with high accuracy, preventing body wrinkles or reduction of the sheet thickness, a process of: performing drawing-forming to a predetermine height by pushing the forming punch having a desired shape in the sheet thickness direction with the edges of the blank workpiece being clamped; performing shape-forming with the shaping tool in the opposite side to the forming punch by increasing a clamping pressure to lock movement of a material with the forming punch being pushed; performing drawing-forming again by decreasing the clamping pressure and raising the forming punch by a desired height; and performing shape-forming with the shaping tool by increasing the clamping pressure to lock movement of a material, is repeated at least once.

Owner:AMINO CORP (JP)

Ultraviolet-cured anti-dazzle hard film and application thereof

InactiveCN103205190AGood anti-glare effectGood compatibilityPolyurea/polyurethane coatingsPolyester coatingsUltravioletReactive diluent

The invention provides an ultraviolet-cured anti-dazzle hard film and application thereof. The ultraviolet-cured anti-dazzle hard film comprises a transparent supporter and an anti-dazzle hard film coating coated on at least one surface of the transparent supporter. A formula for the coating comprises, by weight, 5 to 90 parts of an ultraviolet-cured resin, 5 to 90 parts of a solvent, 1 to 10 parts of a photoinitiator, 0 to 80 parts of a reactive diluents, 1 to 40 parts of an anti-dazzle particle and 0 to 6 parts of an auxiliary agent. Compared with the prior art, the invention has the following advantages: the ultraviolet-cured resin contains a certain amount of an organic silicon resin, which enables the antifouling property of the surface of the anti-dazzle hard film to be improved; and the selected organic particle has good compatibility with the ultraviolet-cured resin, so transmission loss of light is reduced, which enables clarity of displaying by the anti-dazzle hard film to be improved. The ultraviolet-cured anti-dazzle hard film has good anti-dazzling performance, a good antifouling effect, high hardness, good scratch resistance, excellent flexibility and high resolution.

Owner:HUBEI INST OF AEROSPACE CHEMOTECHNOLOGY

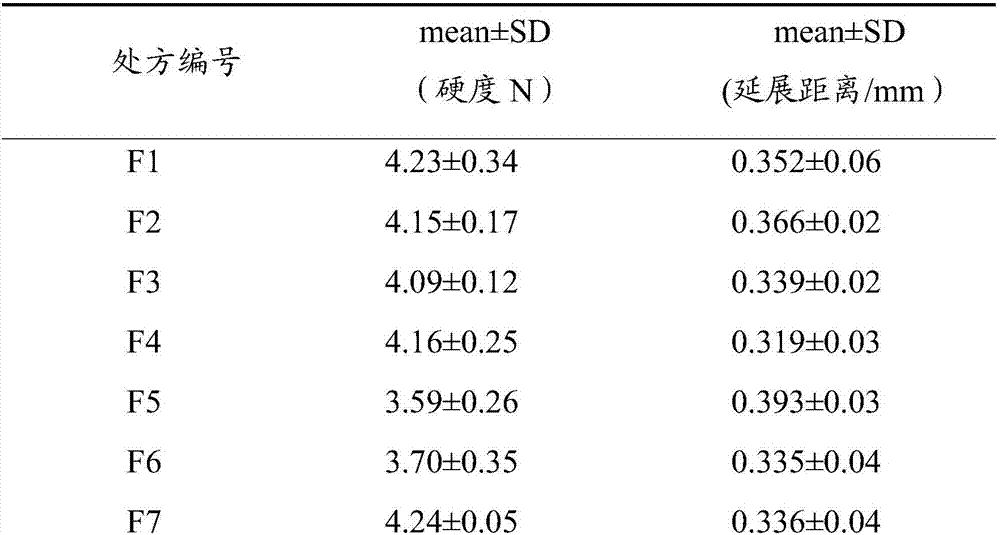

Tocotrienol-containing powder, a process for preparing it and a tablet comprising compressed said powder into a tablet form

InactiveUS6562372B1Flowability is restrainedSolve the lack of hardnessPowder deliveryAnimal feeding stuffCelluloseEmulsion

A tocotrienol-containing powder prepared by a process wherein an oil containing a tocotrienol is treated with a lecithin, a cellulose and an emulsifying agent in water to form an emulsion, a powder substance is mixed with the formed emulsion to form a suspension and then the formed suspension is spray-dried. The powder containing tocotrienol, which has excellent storage stability and free flowability, can be used in preparing a tablet which comprises the powder compressed into a tablet form.

Owner:FUJI CHEM IND CO LTD

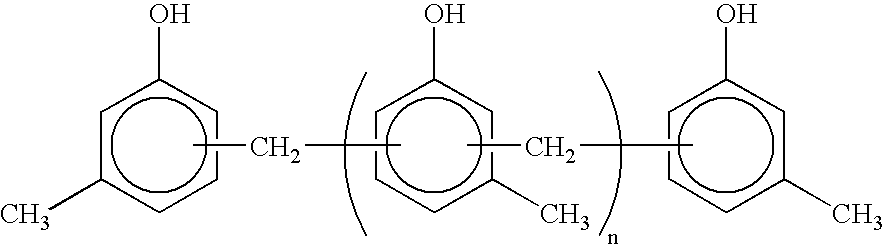

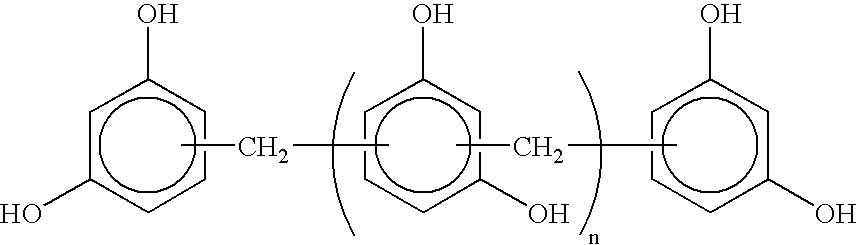

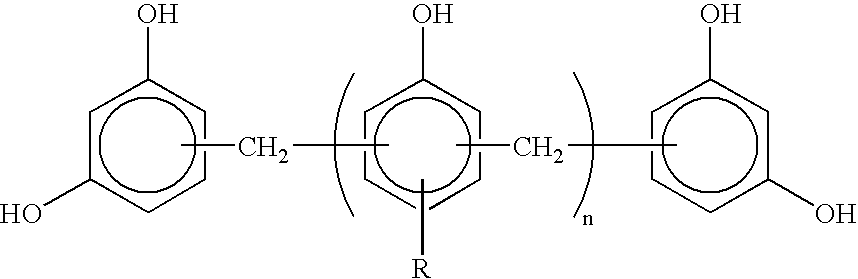

Rubber composition and tire using same

InactiveUS20080009570A1Solve the lack of hardnessReduce consumptionOrganic chemistrySpecial tyresPolymer scienceCresol

The present invention provides a rubber composition with superior properties with respect to processability, low fuel consumption, complex modulus, and durability, and tires prepared by using the rubber composition. The rubber composition of the present invention comprises: 2 to 2.9 parts by weight of (B) sulfur, 0.6 to 10 parts by weight of (C) at least one compound selected from the group consisting of a cresol resin, a resorcin condensate, and a modified resorcin condensate, and 10 to 55 parts by weight of (D) a carbon black and / or silica, based on 100 parts by weight of (A) a rubber component comprising a natural rubber and / or isoprene rubber and at least two kinds of synthetic rubbers selected from the group consisting of butadiene rubber, modified butadiene rubber, styrene-butadiene rubber, and modified styrene-butadiene rubber. The tire of the present invention is prepared by using the rubber composition.

Owner:SUMITOMO RUBBER IND LTD

Glass composition, glass susbstrate employing it for an information recording medium, and information recording medium employing it

ActiveUS7687419B2Excellent specific elastic modulusLow alkali elutionMagnetic materials for record carriersBase layers for recording layersRecording mediaChemistry

A glass substrate used as a substrate of an information recording medium such as a magnetic disk, magneto-optical disk, DVD, or MD, and a glass composition used to make such a glass substrate, contains the following glass ingredients: 40 to 70% by weight of SiO2; 1 to 20% by weight of Al2O3; 0 to 10% by weight, zero inclusive, of B2O3; SiO2+Al2O3+B2O3 accounting for 60 to 90% by weight; a total of 3.0 to 15% by weight of R2O compounds, where R=Li, Na, and K; a total of 2.0 to 15% by weight of R′O compounds, where R=Mg, and Zn; and a total of 1.0 to 20% by weight of MOx (TiO2+ZrO2+LnxOy), where LnxOy represents at least one compound selected from the group consisting of lanthanoid metal oxides, Y2O3, Nb2O5, and Ta2O5. Here, the following condition is fulfilled:0.070<(total content of R′O compounds) / (SiO2+Al2O3+B2O3)<0.200.

Owner:HOYA CORP

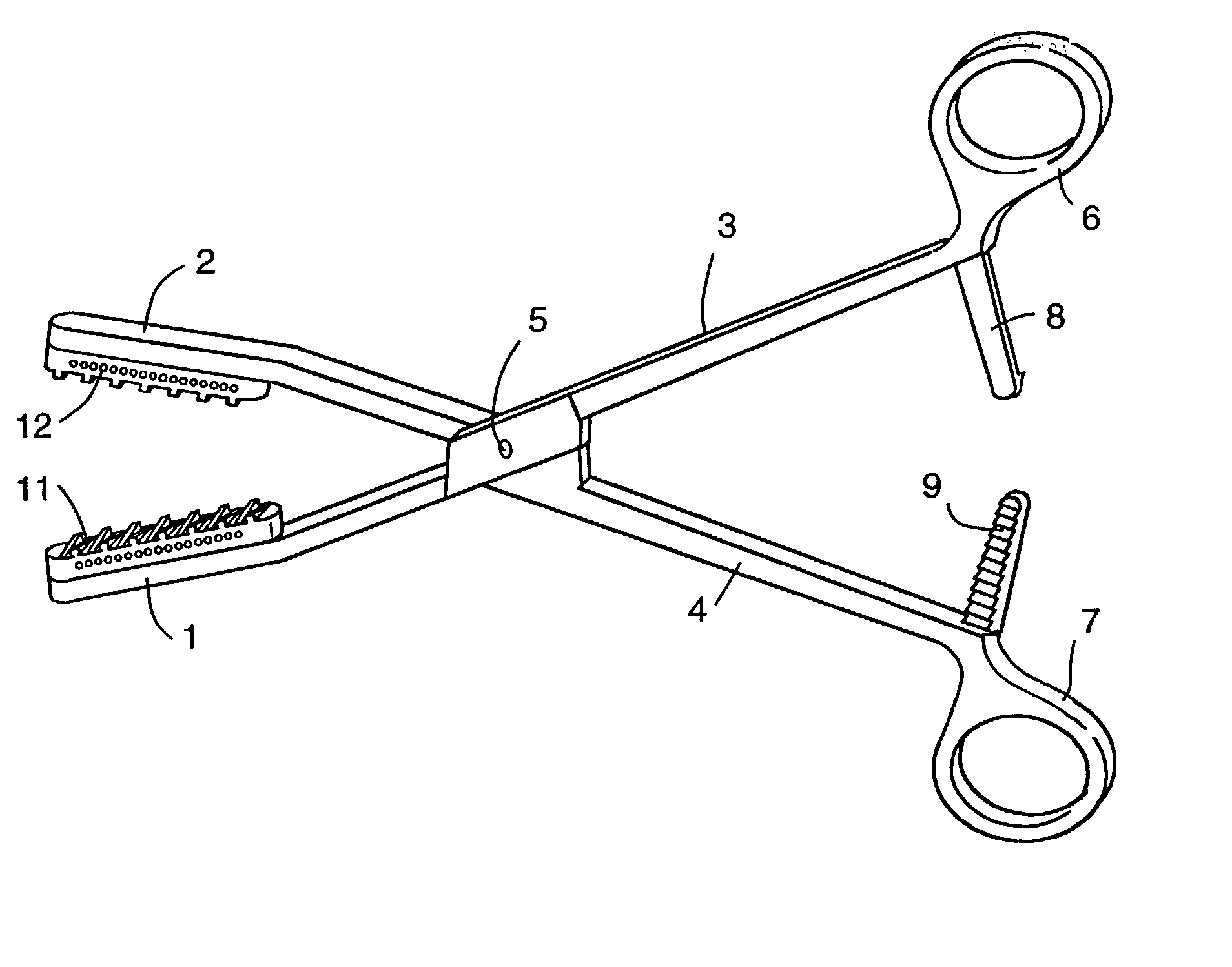

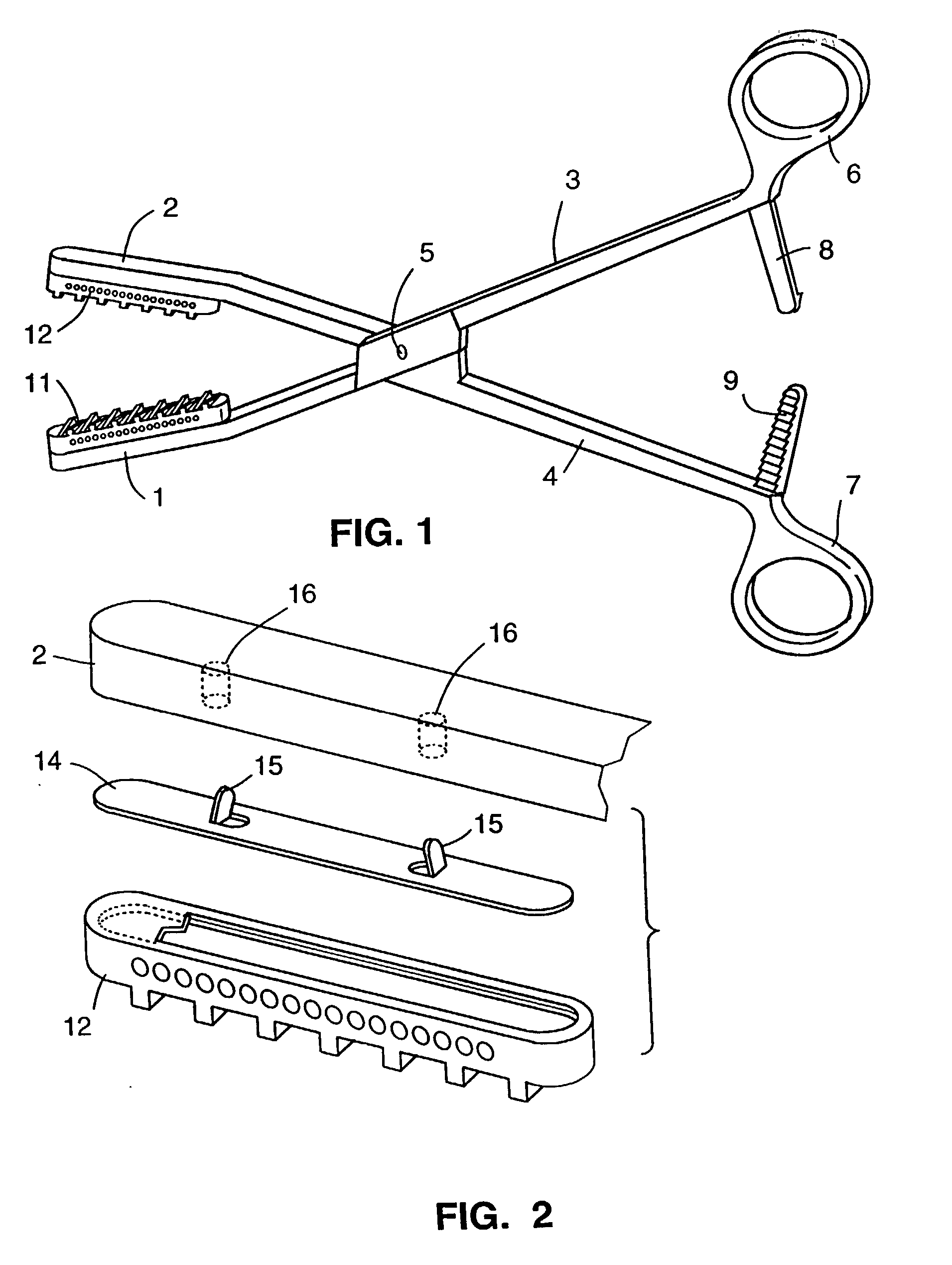

Surgical clamp pad with interdigitatin teeth

InactiveUS20020183785A1Great tractionMinimizing trauma and damageSurgical forcepsWound clampsSurgical ClampsSurgical department

Opposable surgical clamp members having opposable resilient pads with wedge-shaped and cylindrical protrusions extending from the surfaces of the pads and the use of such members for occluding vessels and other tubular body structures are described. The protrusions are arranged such that when the members are moved toward one another, the protrusions of one pad interdigitate with the protrusions of the other pad. Upon engagement with a vessel, portions of the vessel are forced into the interdigital spaces providing for improved gripping of the vessel. The protrusions also resist lateral or transverse movement of a clamped vessel relative to the pads. The existence of through holes under the pad surface alters the relative resiliency of the pad, allowing for an overall pad resiliency that minimizes trauma to a clamped vessel while allowing the local resiliency of the protrusions themselves to be of a hardness to avoid excessive deflection and retain the desired shape and gripping ability.

Owner:VITALTEC INT

Curable dental mill blanks and related methods

The invention features a dental mill blank constructed from an uncured, self-supporting, hardenable organic composition. The invention also provides a method of making a dental appliance. The method involves machining an uncured dental mill blank into an uncured shaped article and then at least partially curing the shaped article. The shaped article may be cured in multiple steps with or without additional machining steps in between the curing steps.

Owner:3M INNOVATIVE PROPERTIES CO +1

Medicinal preparation containing 5-methyl-1-phenyl-2-(1h)-pyridone as active ingredient

ActiveUS20040048902A1Oral convenienceImprove complianceBiocideOrganic chemistryBULK ACTIVE INGREDIENTTraditional medicine

A tablet characterized by comprising 5-methyl-1-phenyl-2-(1H)-pyridone as the main ingredient and, based on the main ingredient, 10 to 50 wt. % excipient, 5 to 40 wt. % disintegrator, 1 to 10 wt. % binder, 0.5 to 5 wt. % lubricant, 2 to 6 wt. % coating basis, and 0.05 to 3 wt. % light-shielding agent, wherein the odor or bitterness of the 5-methyl-1-phenyl-2-(1H)-pyridone is masked and the light stability is improved.

Owner:INTERMUNE INC

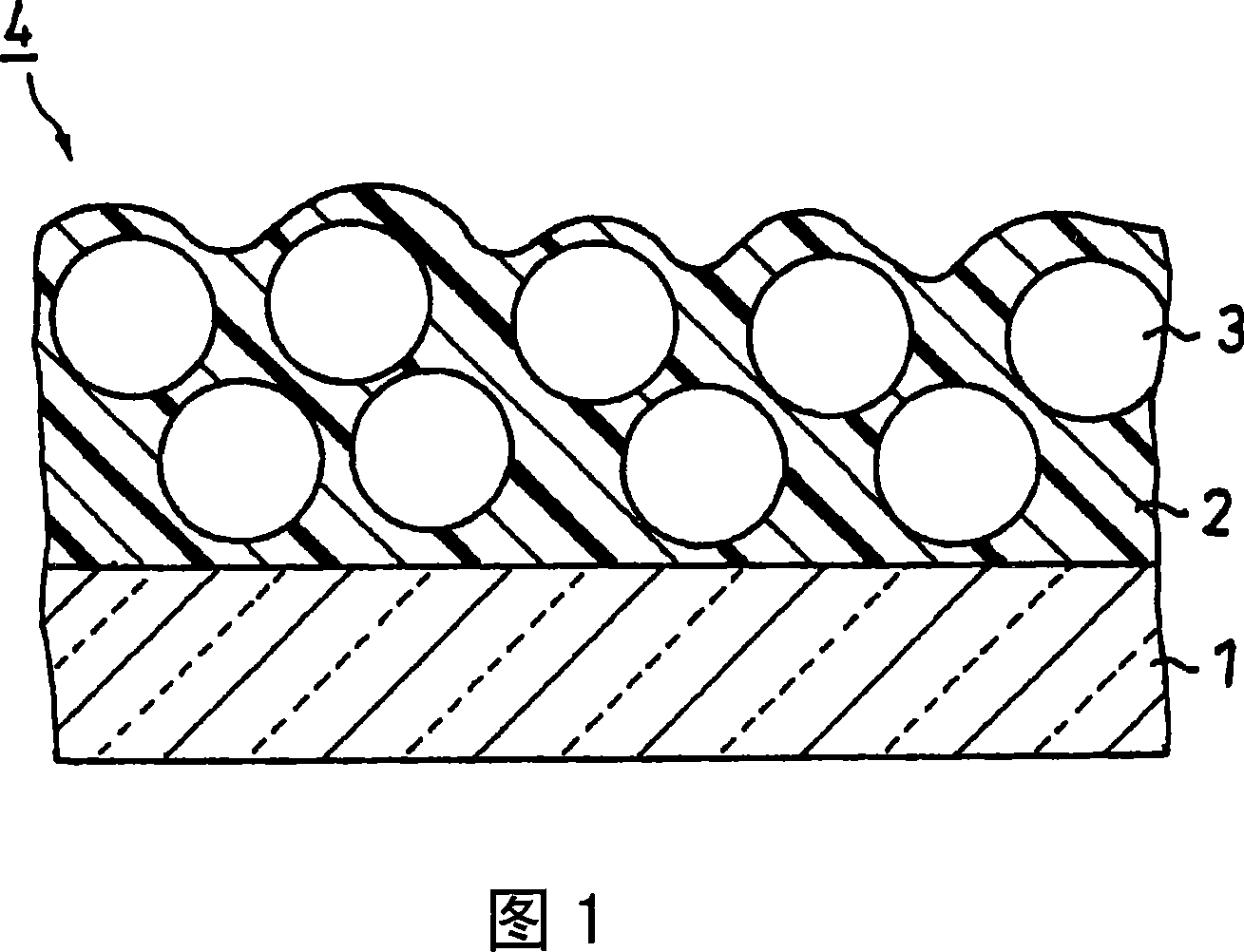

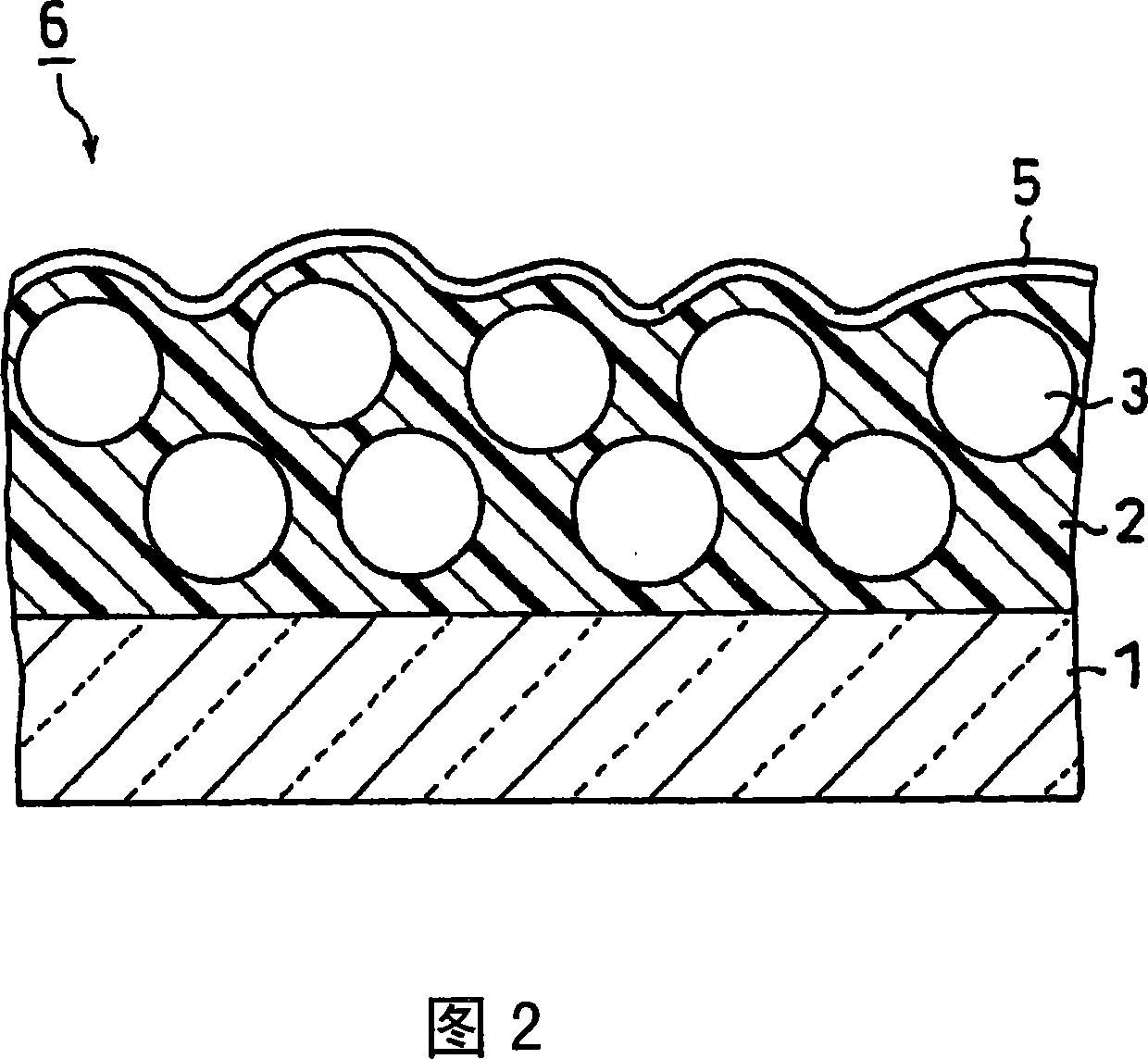

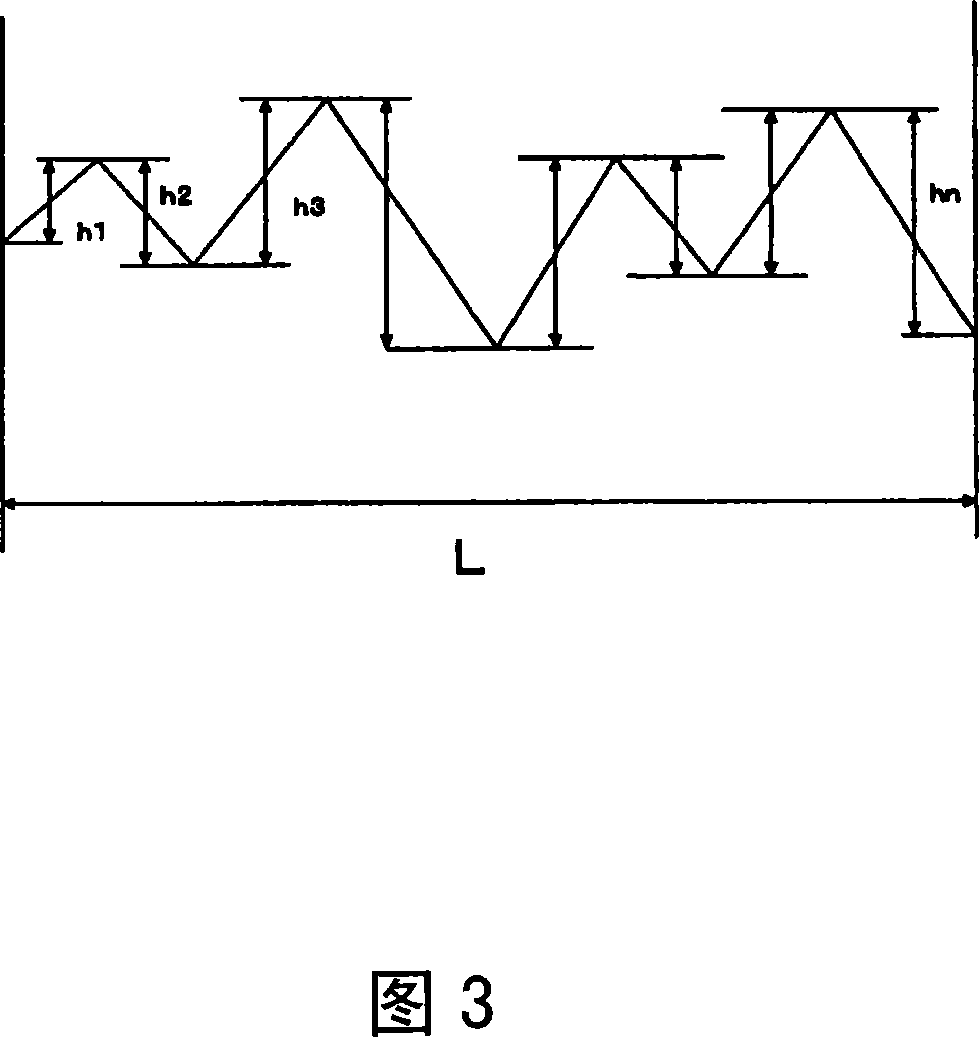

Hard-coated antiglare film, method of manufacturing the same, optical device, polarizing plate, and image display

InactiveCN101046520ASolve the lack of hardnessHigh hardnessSynthetic resin layered productsPolarising elementsCoated surfaceHardness

A hard-coated antiglare film is provided that has high hardness, high scratch resistance, and good antiglare properties. In the hard-coated antiglare film of the present invention including a transparent plastic film substrate, a hard-coating layer containing fine particles is formed on at least one surface of the transparent plastic film substrate, the hard-coating layer has a thickness in the range of 15 to 30 mum, the fine particles have a weight average particle size of 30 to 75% of a thickness of the hard-coating layer, the average tilt angle thetaa of the unevenness of the hard-coating layer surface is in the range of 0.4 DEG to 1.5 DEG , and the hard-coating layer is formed using a resin for forming the hard-coating layer containing three specific resin components.

Owner:NITTO DENKO CORP

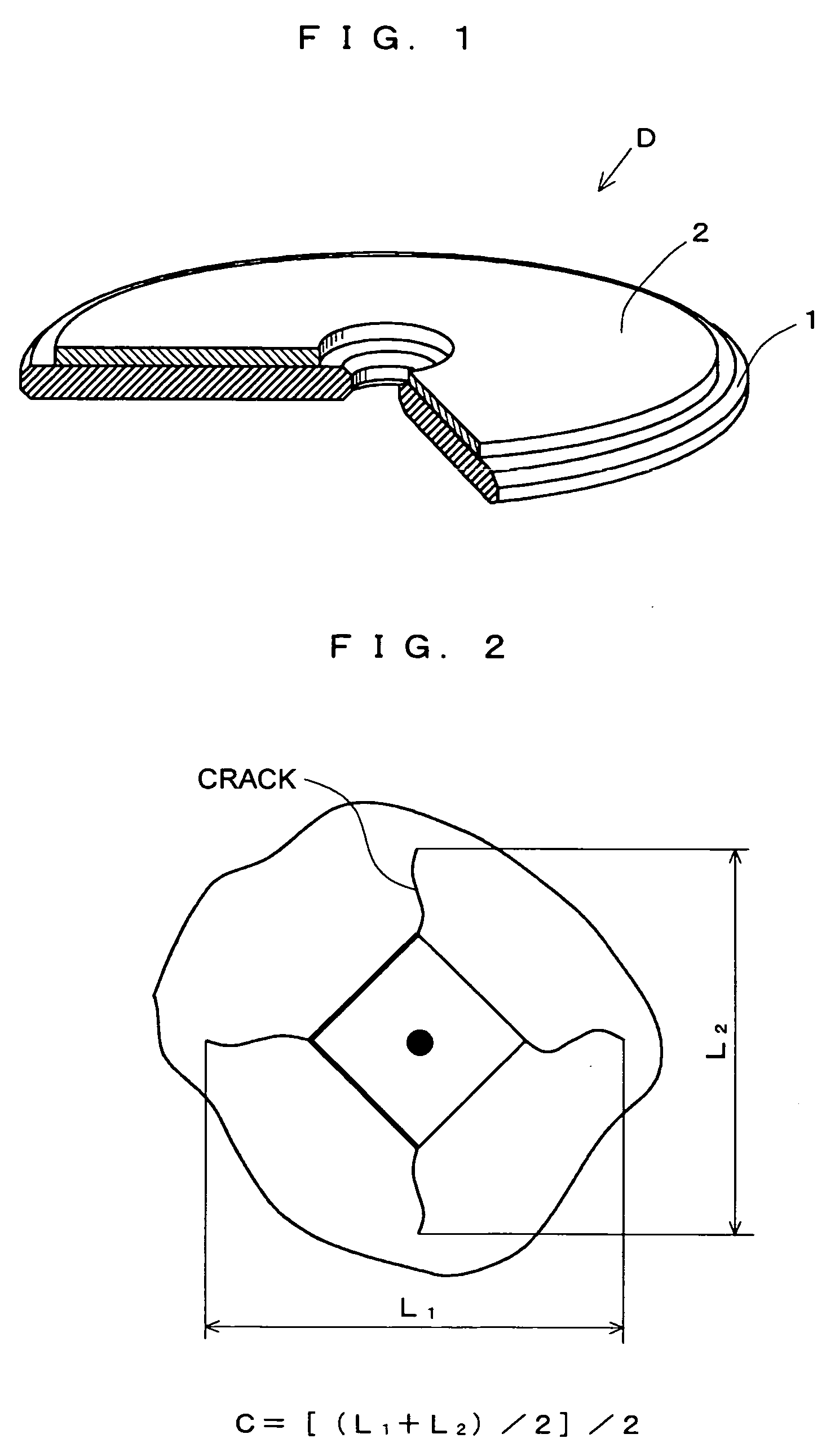

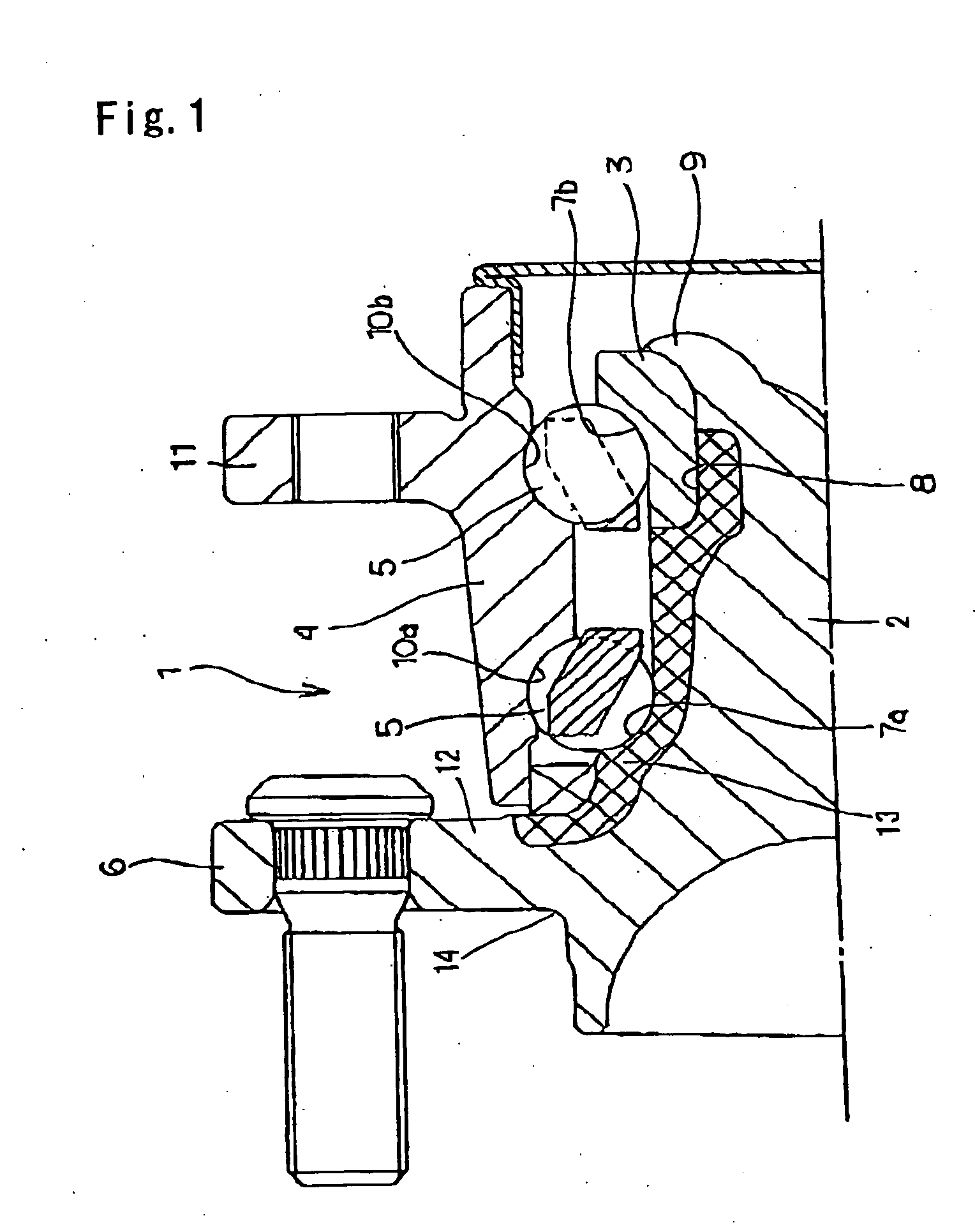

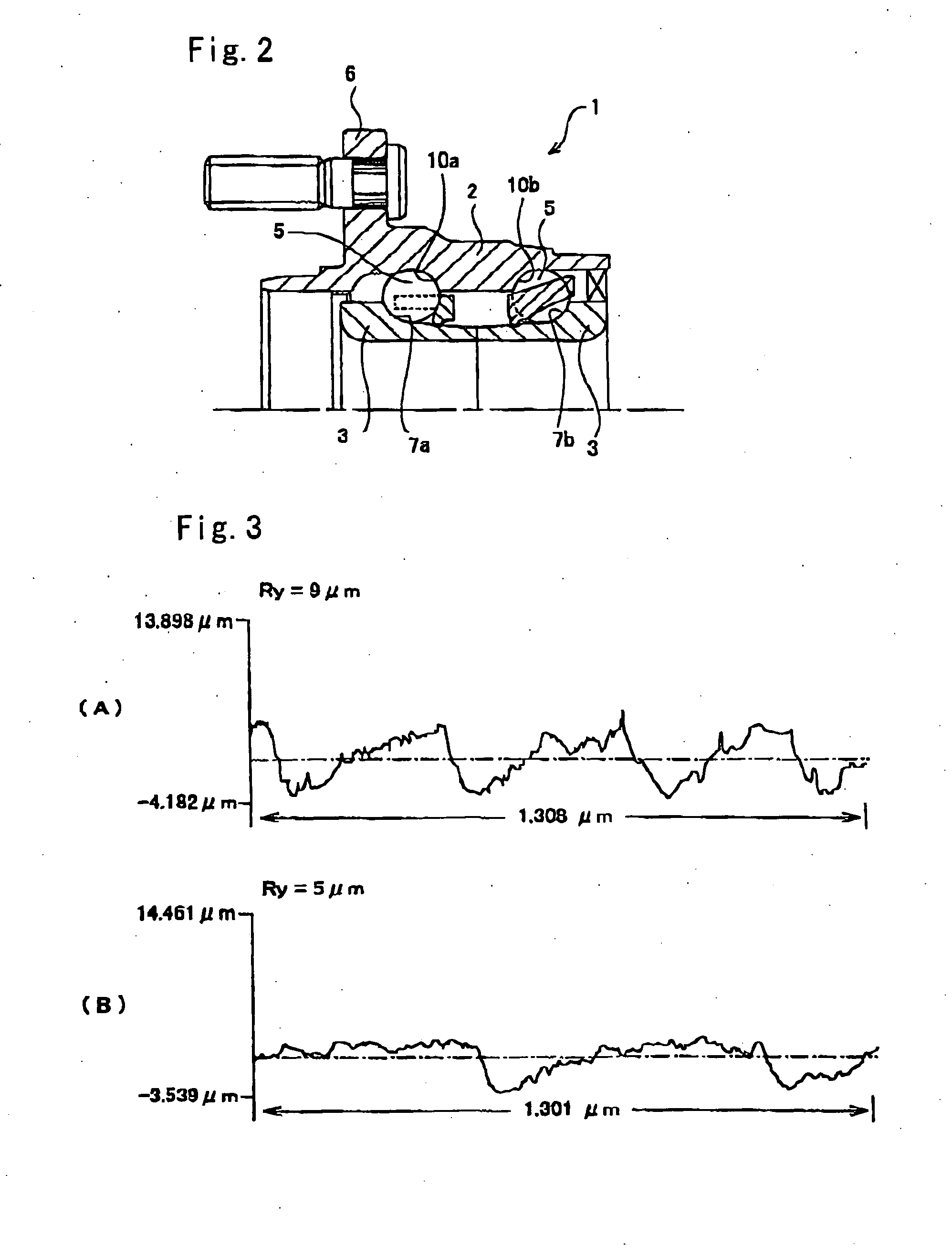

Wheel-support rolling bearing unit

InactiveUS20050141799A1Reduced deformabilityEasy to crackRolling contact bearingsBearing assemblySurface roughnessHardness

In a wheel-support rolling bearing unit, in order to made a flange 6 thinner and thus lighten the bearing unit without impairing fatigue strength, machinability, and workability after forging, the composition of the alloy steel constituting the flange attached member (hub ring 2), the surface hardness of the root portion 14 on the axial outside surface side of the flange 6, and the surface roughness, are stipulated to thereby improve the durability ratio (fatigue limit strength / tensile strength) of the flange 6. In one aspect, the member is made from an alloy steel containing C: 0.5 to 0.65 weight %, Mn: 0.3 to 1.5 weight %, Si: 0.1 to 1.0 weight %, Cr: 0.01 to 0.5 weight %, S: 0.35 weight % or less, and any one type or more selected from 0.01 to 0.2 weight % of V, 0.01 to 0.15 weight % of Nb, and 0.01 to 0.15 weight % of Ti, with the rest being Fe and inevitable impurities, and the oxygen contents is 15 ppm or less. Moreover, the surface hardness of the inner raceway 7a formed with the hardened layer, is between Hv 650 and 780, and the surface hardness of a portion not formed with the hardened layer is between Hv 230 and 300.

Owner:NSK LTD

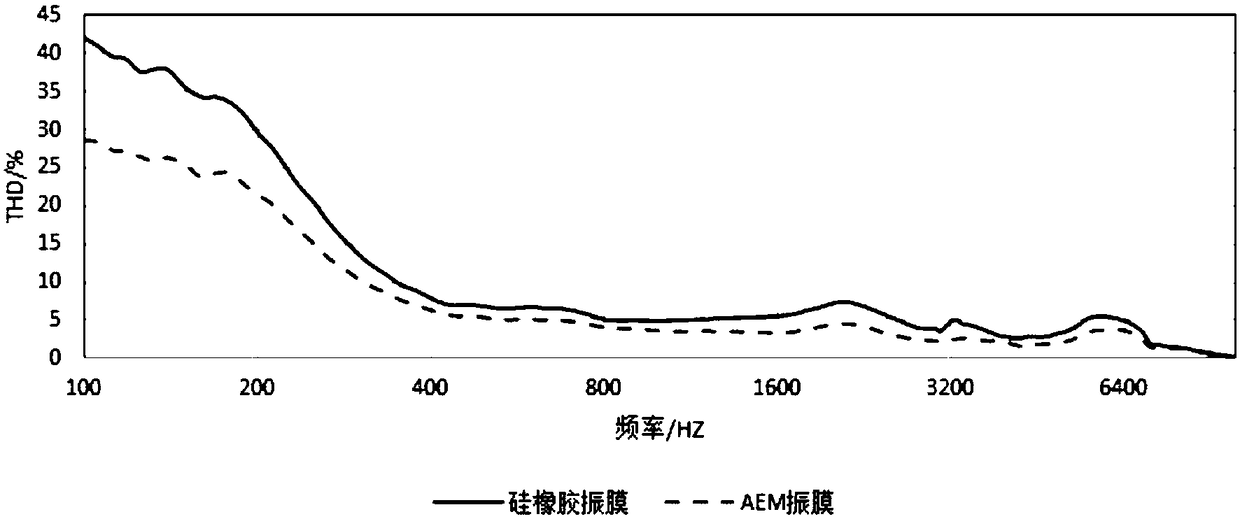

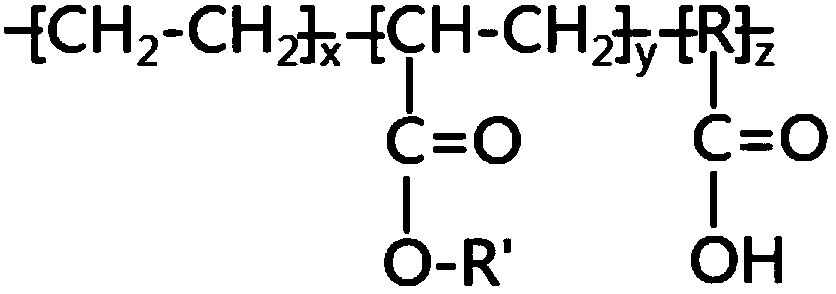

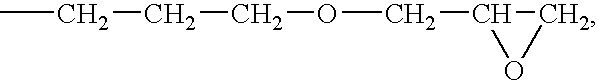

Diaphragm for sounding device, sounding device and assembling method thereof

PendingCN109218924AImprove loss factorReduced chemical structure symmetryDiaphragm extensionsPlane diaphragmsChemical structureCarboxylic acid

The invention discloses a diaphragm for a sounding device, a sounding device and an assembling method thereof. The diaphragm includes a diaphragm layer prepared by subjecting at least one of an ethylene-acrylate copolymer and an ethylene-acrylic ester-carboxylic acid copolymer to crosslinking reaction. The molecular structure of the diaphragm includes a vinyl-acrylic group. The group reduces the chemical structure symmetry of a material, reduces tacticity, and increase steric hindrance, so that the diaphragm has a high loss factor and the sounding device has a good damping effect.

Owner:GOERTEK INC

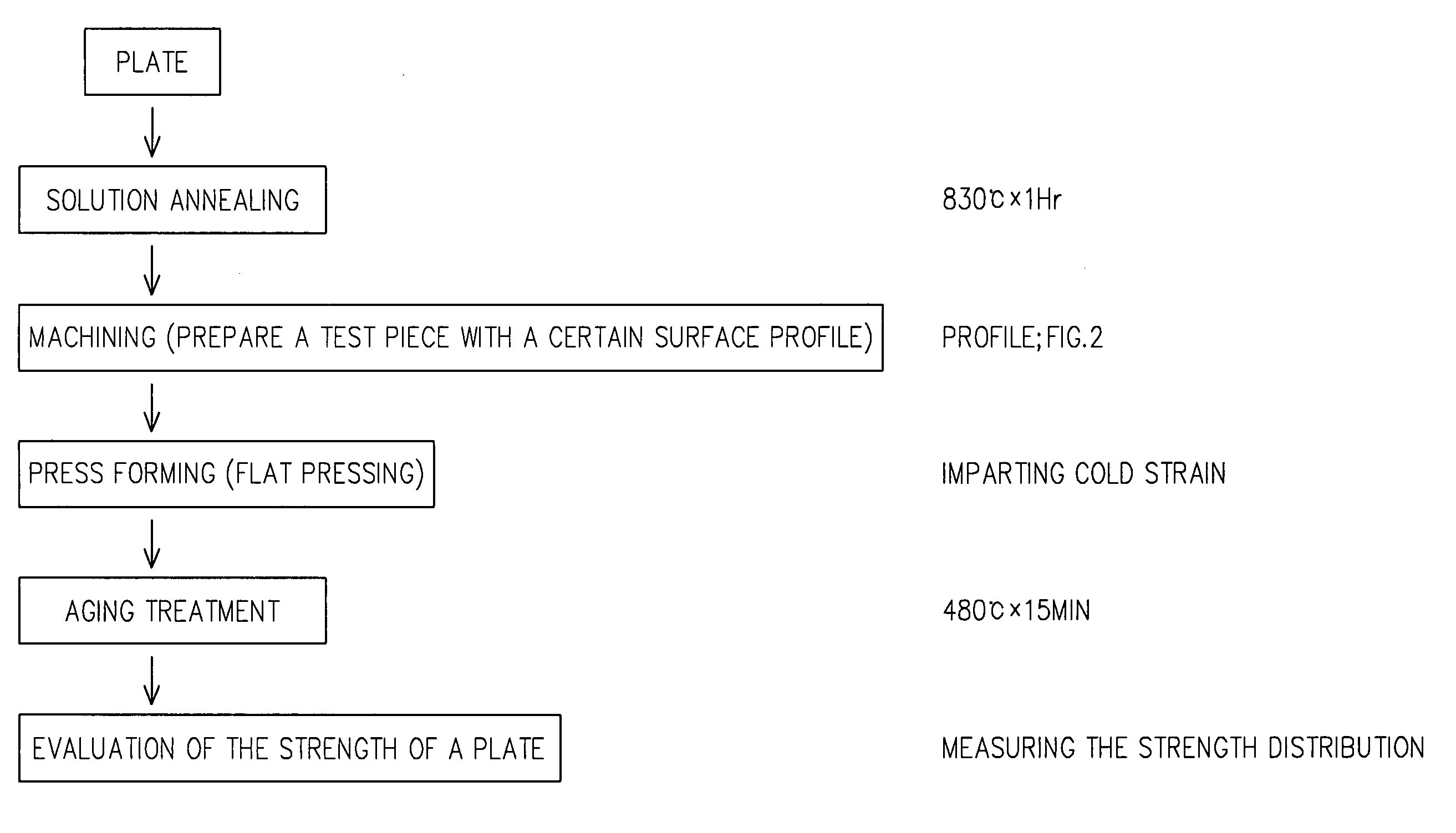

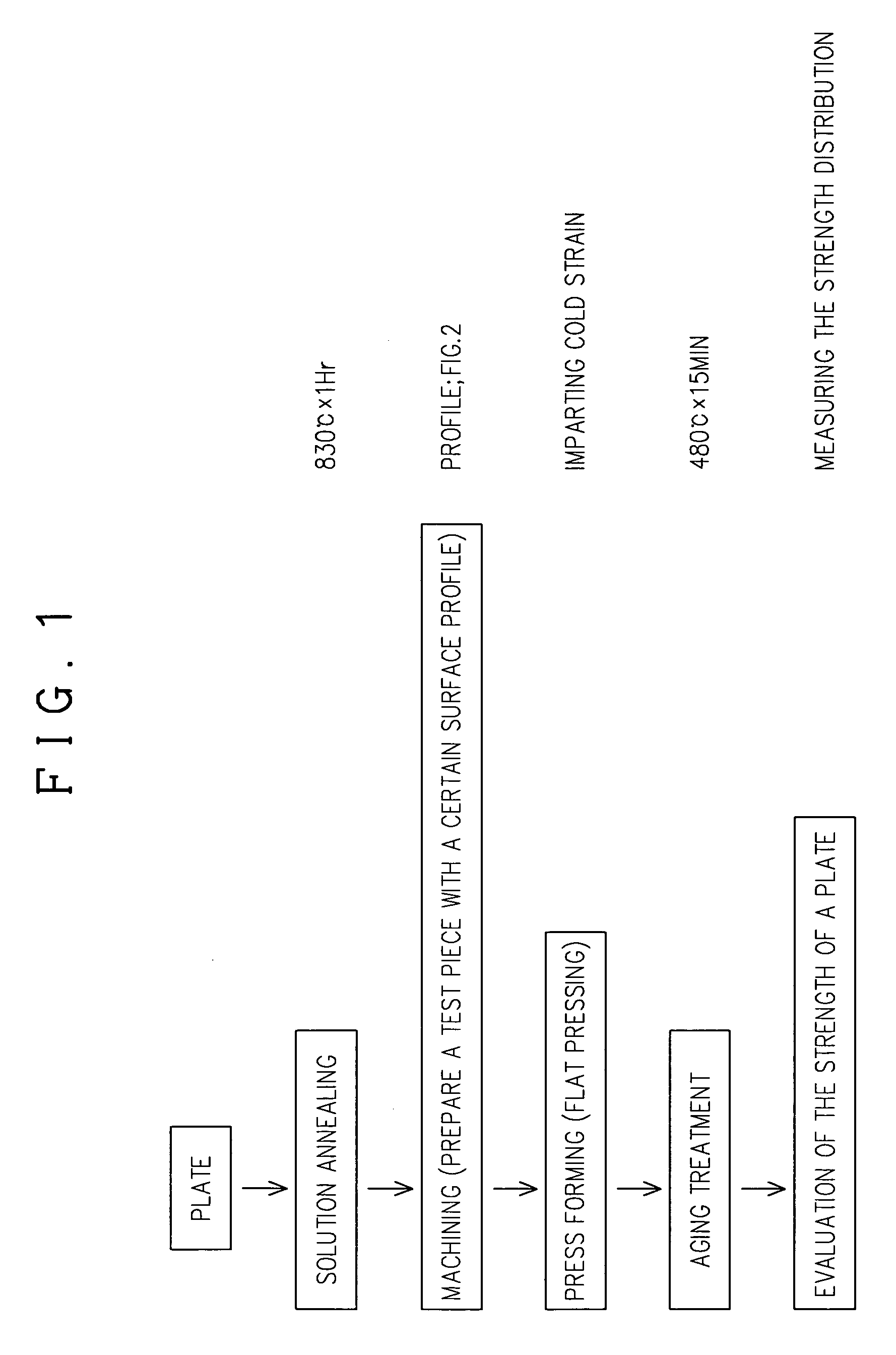

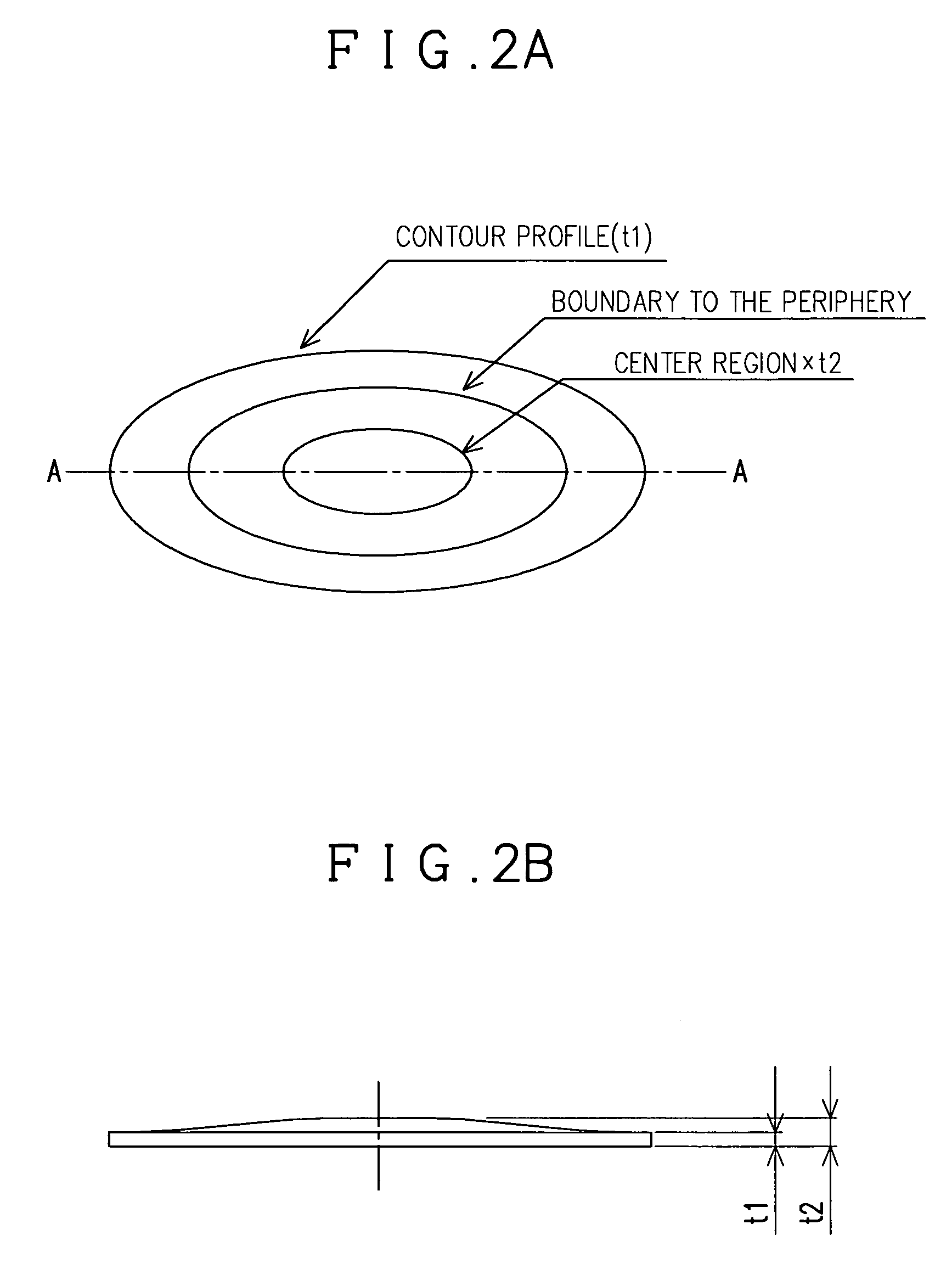

Process for making a work piece from a beta-type titanium alloy material

A process for making a work piece from a β-type titanium alloy material includes subjecting the β-type titanium alloy material to cold working with controlling the reduction rate thereof to vary the reduction rate depending on a position across a plain direction of the β-type titanium alloy material, and then subjecting the β-type titanium alloy material to an aging treatment.

Owner:NIPPON STEEL CORP

Rasagiline Orally Disintegrating Compositions

InactiveUS20090111892A1Reduce brittlenessSolve the lack of hardnessBiocideOrganic active ingredientsAlcohol sugarsPharmacology

This invention provides a solid pharmaceutical composition comprising rasagiline or a pharmaceutically acceptable salt of rasagiline, and particles having a non-filamentous microstructure of at least two sugar alcohols. This invention also provides a solid pharmaceutical composition comprising rasagiline or a pharmaceutically acceptable salt of rasagiline, a mixture of a disintegrant, a flow agent and particles having a non-filamentous microstructure of at least two sugar alcohols, a supplemental sugar alcohol, a supplemental flow agent, and a supplemental disintegrant. This invention further provides a method of treating a subject afflicted with Parkinson's disease comprising administering to the subject a therapeutically effective amount of the solid pharmaceutical composition, thereby treating the subject. Finally, this invention provides a process of making such solid pharmaceutical compositions.

Owner:TEVA PHARMA IND LTD

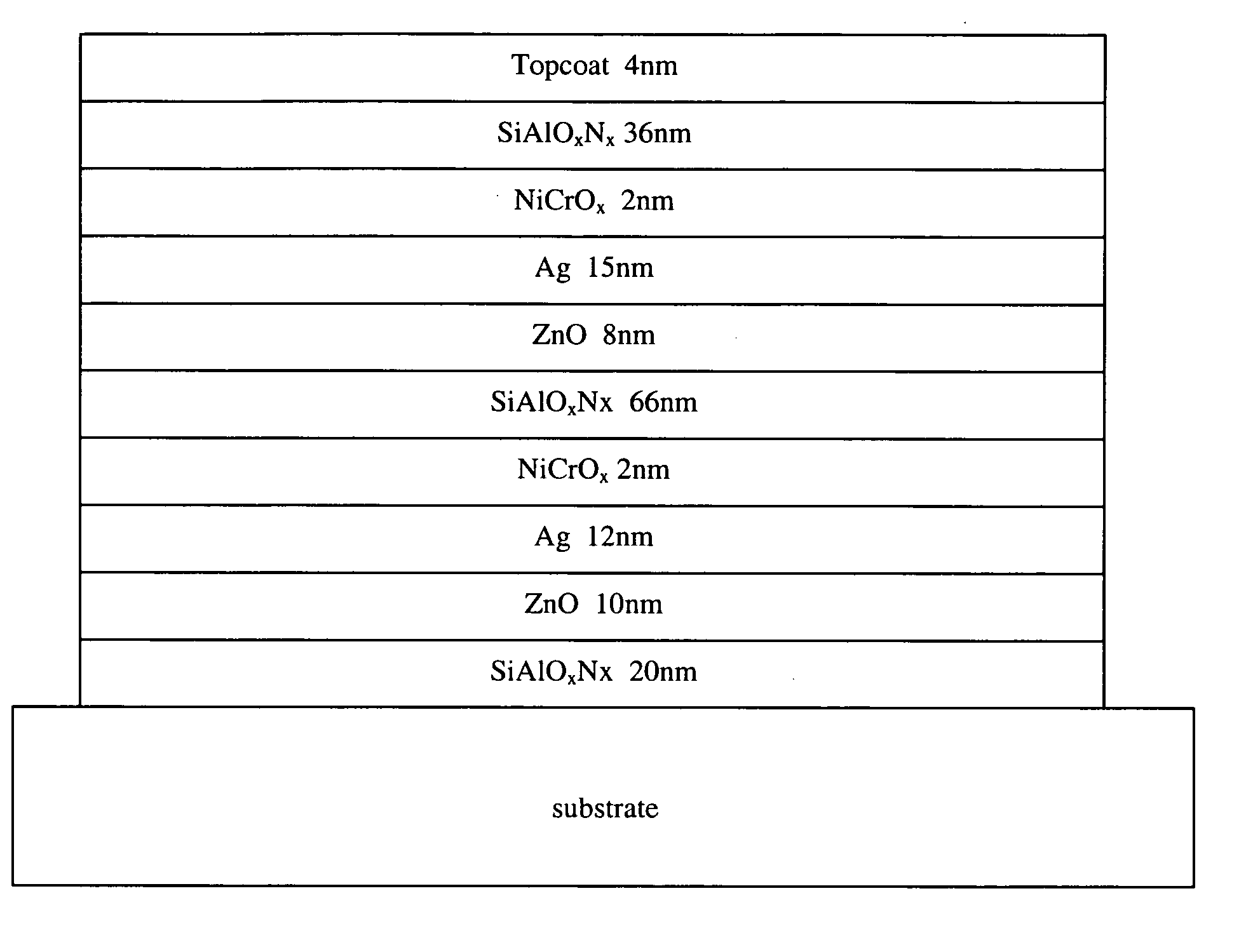

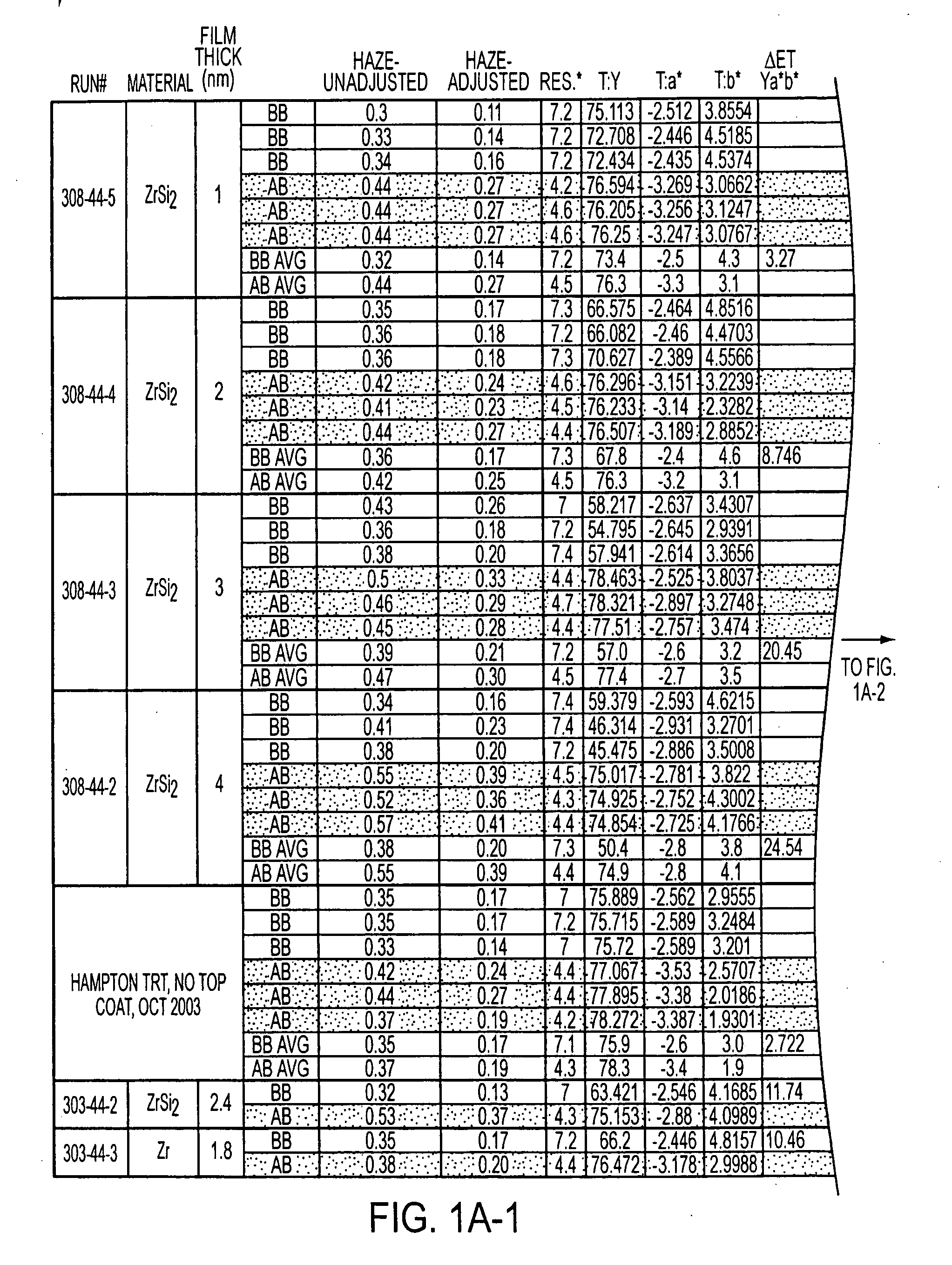

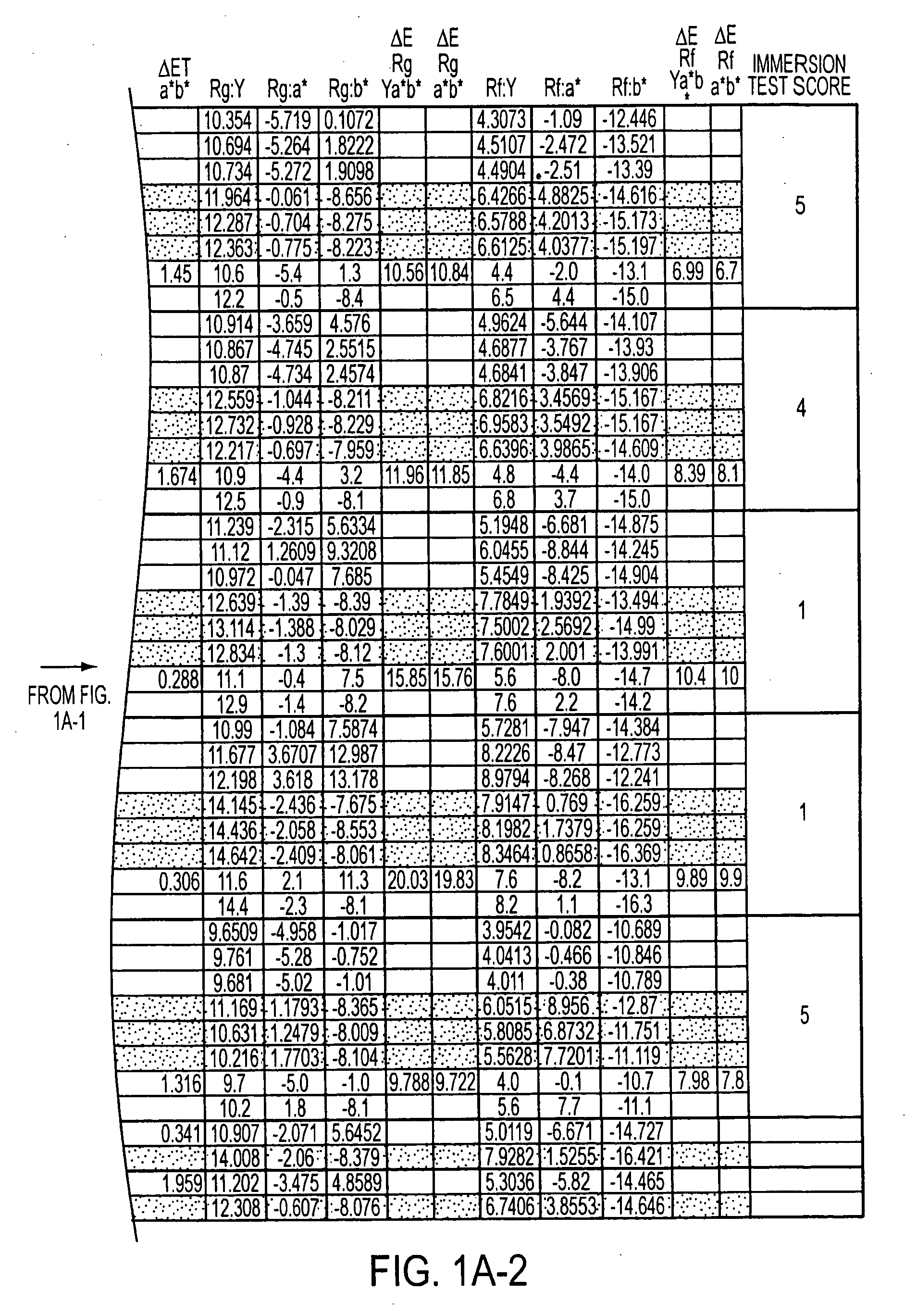

Protective layer for optical coatings with enhanced corrosion and scratch resistance

InactiveUS20050196632A1Reduce harmSolve the lack of durabilitySynthetic resin layered productsVacuum evaporation coatingOptical coatingMetal silicide

An oxidizable metal silicide or metal aluminide is used as one of the outer layers of an optical coating to provide a corrosion and scratch resistant barrier. This layer is initially deposited in an unoxidized or partially oxidized state. In this chemical state it provides corrosion protection to the layers underneath. The metal compound or intermetallic layer has hardness properties greater than most metals and therefore provides significant scratch protection.

Owner:AGC FLAT GLASS NORTH AMERICA INC

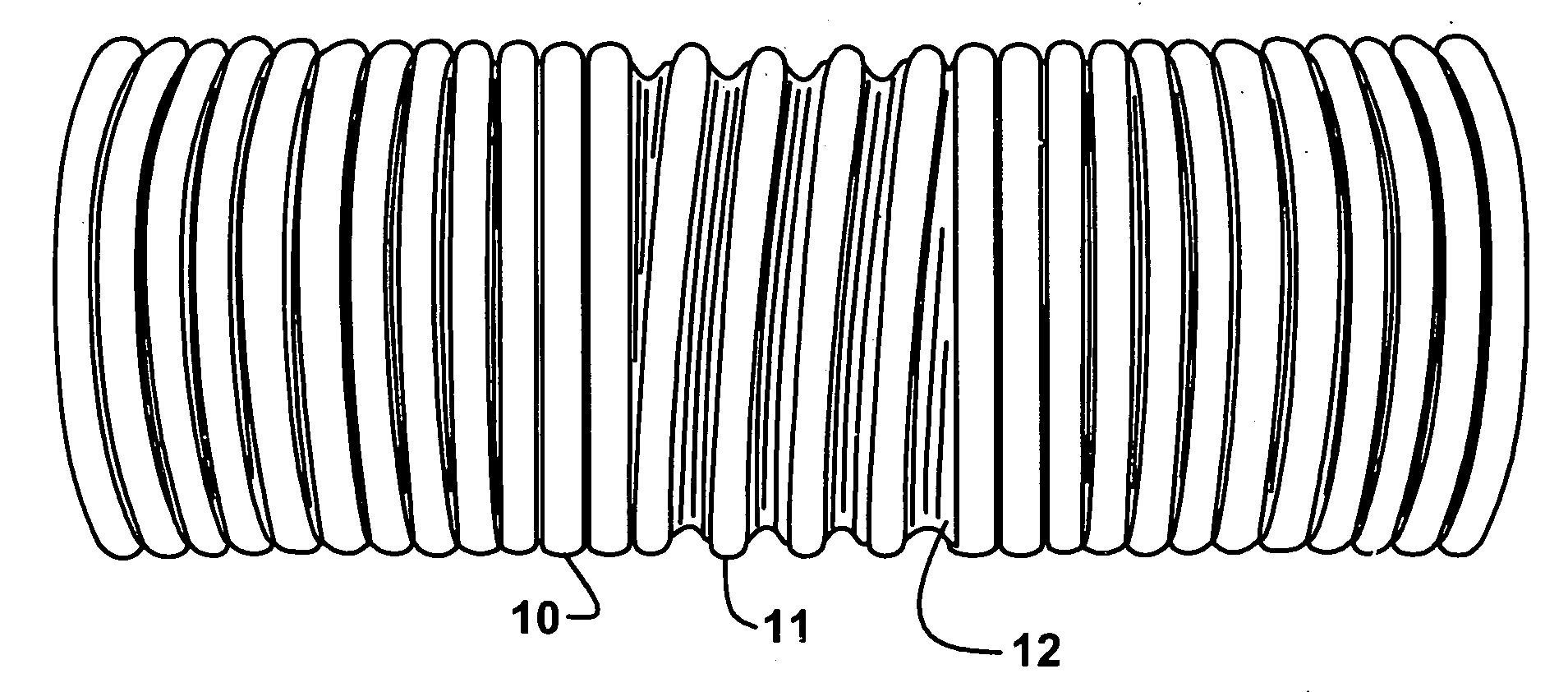

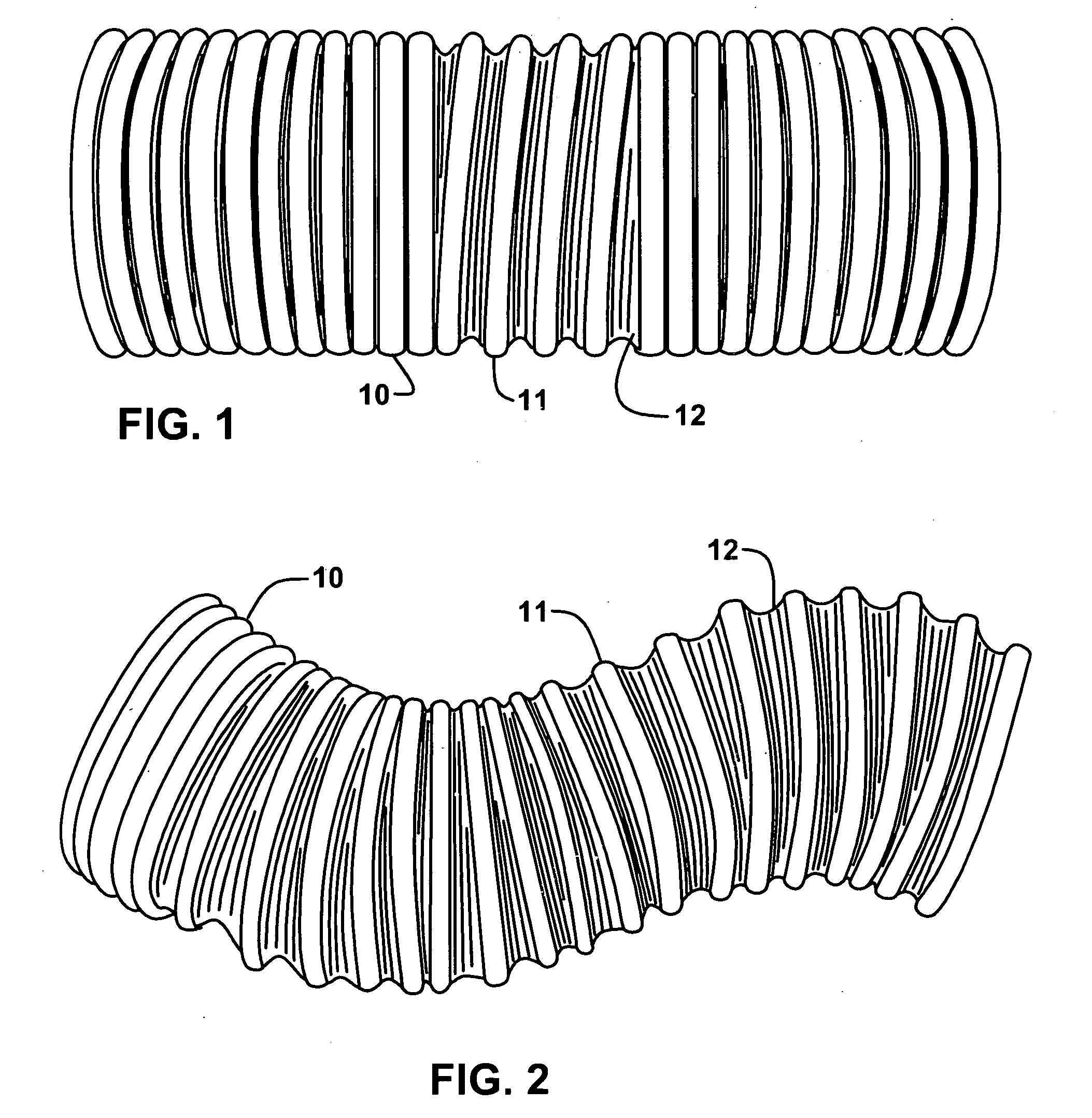

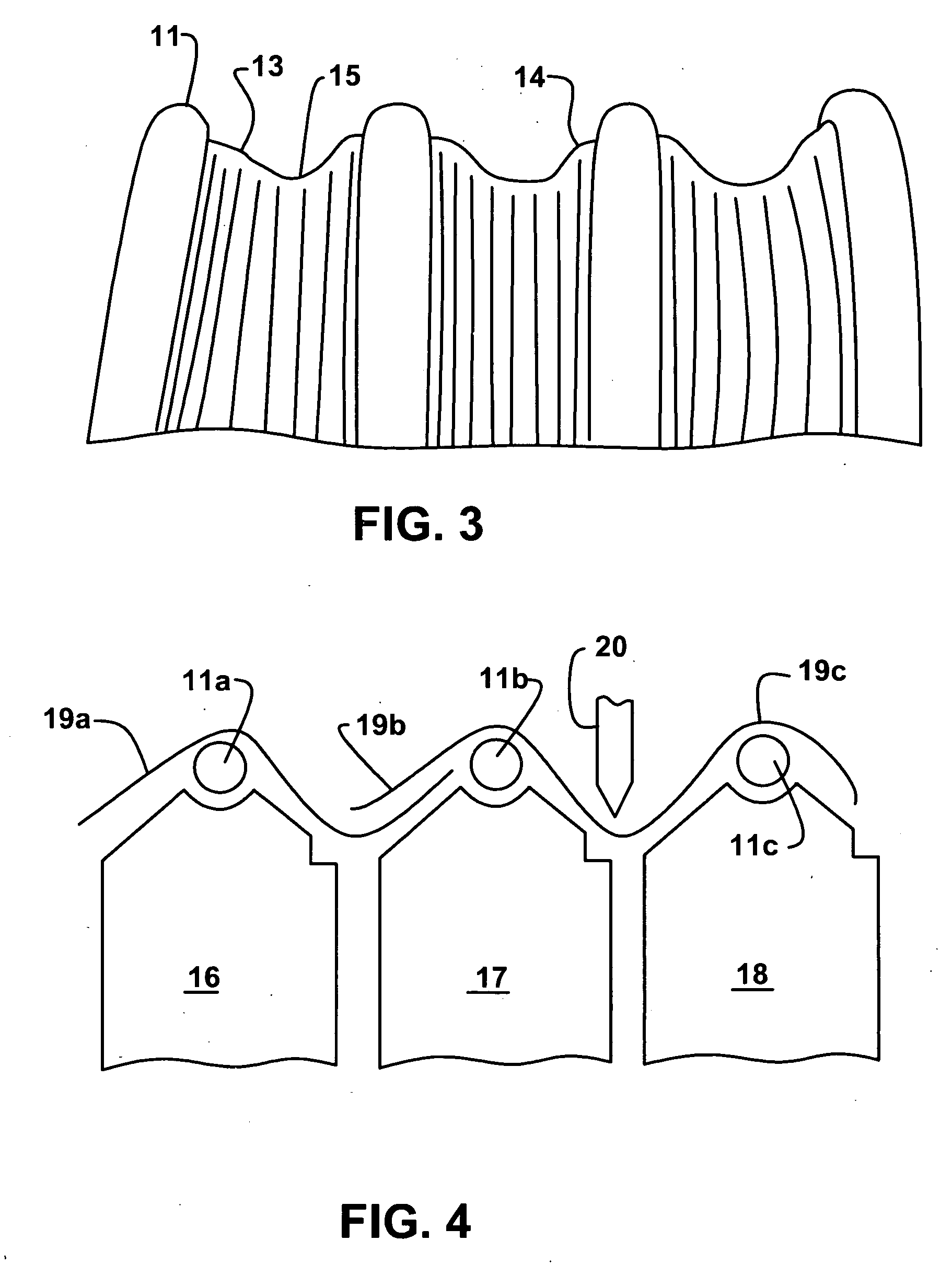

Crush resistant stay put hose

InactiveUS20100108170A1Improve wear resistanceImprove efficiencyFlexible pipesTubular articlesLiving hingeBiomedical engineering

A crush resistant and stay put hose is provided. There is a helical member having a plurality of coils and a wall surface of one or more thermoplastic polymer layers. The layers extend from one coil to the next and the wall surface between the coils has at least one living hinge. When one portion of the hose is in an extended condition, the hose remains in the extended condition without reverting to the unextended condition. Methods of making the hose are also disclosed.

Owner:FLEXIBLE TECH INC

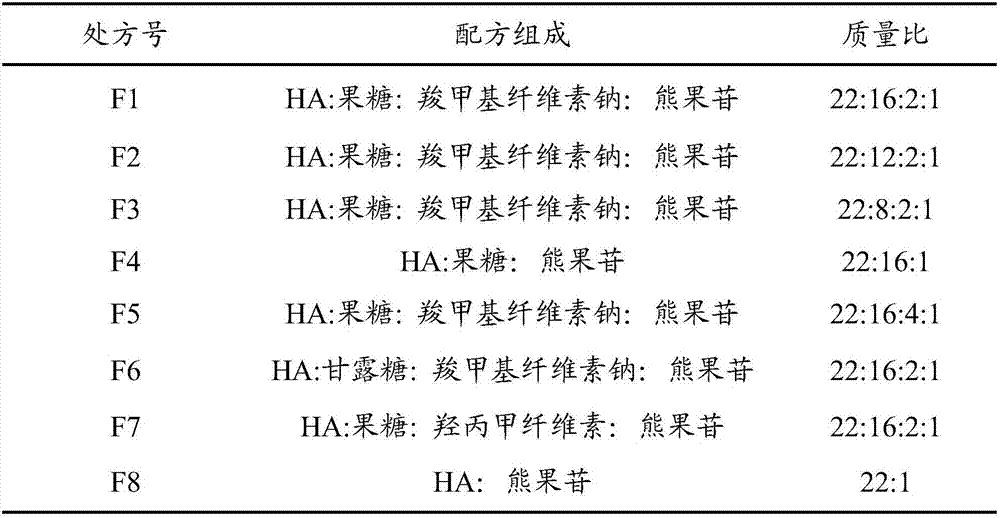

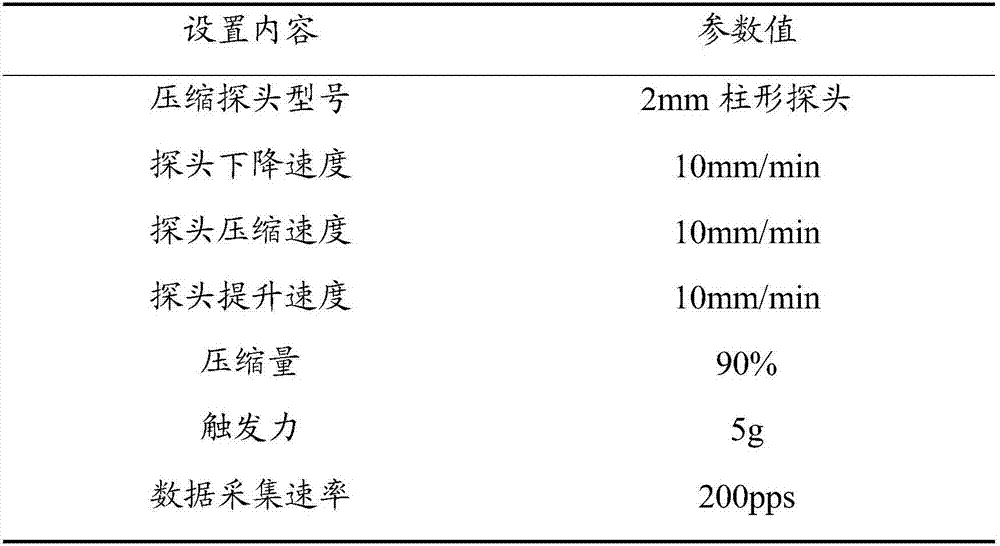

Soluble microneedle patch used for skin whitening and preparation method thereof

ActiveCN107375008AHigh mechanical strengthSolve the lack of hardnessCosmetic preparationsToilet preparationsSolubilitySodium hyaluronate

The invention relates to a soluble microneedle patch used for skin whitening and a preparation method thereof. The soluble microneedle patch comprises a needle point and a substrate, the needle point comprises the following raw materials in parts by weight: 1 part of arbutin, 15-30 parts of hyaluronic acid or its salt, and 5-25 parts of a forming material; wherein the hyaluronic acid or its salt is hyaluronic acid or sodium hyaluronate; and the forming material is selected from at least one of fructose, mannose, carboxymethylcellulose sodium and hydroxypropyl methylcellulose. The soluble microneedle patch has good mechanical strength, hardness and dissolvability, avoids the disadvantage that a traditional skin-caring mode cannot perform arbutin advantage, and has obvious effects for lightning color spots and whitening skin.

Owner:GUANGZHOU NEWORLD PHARMA CO LTD +1

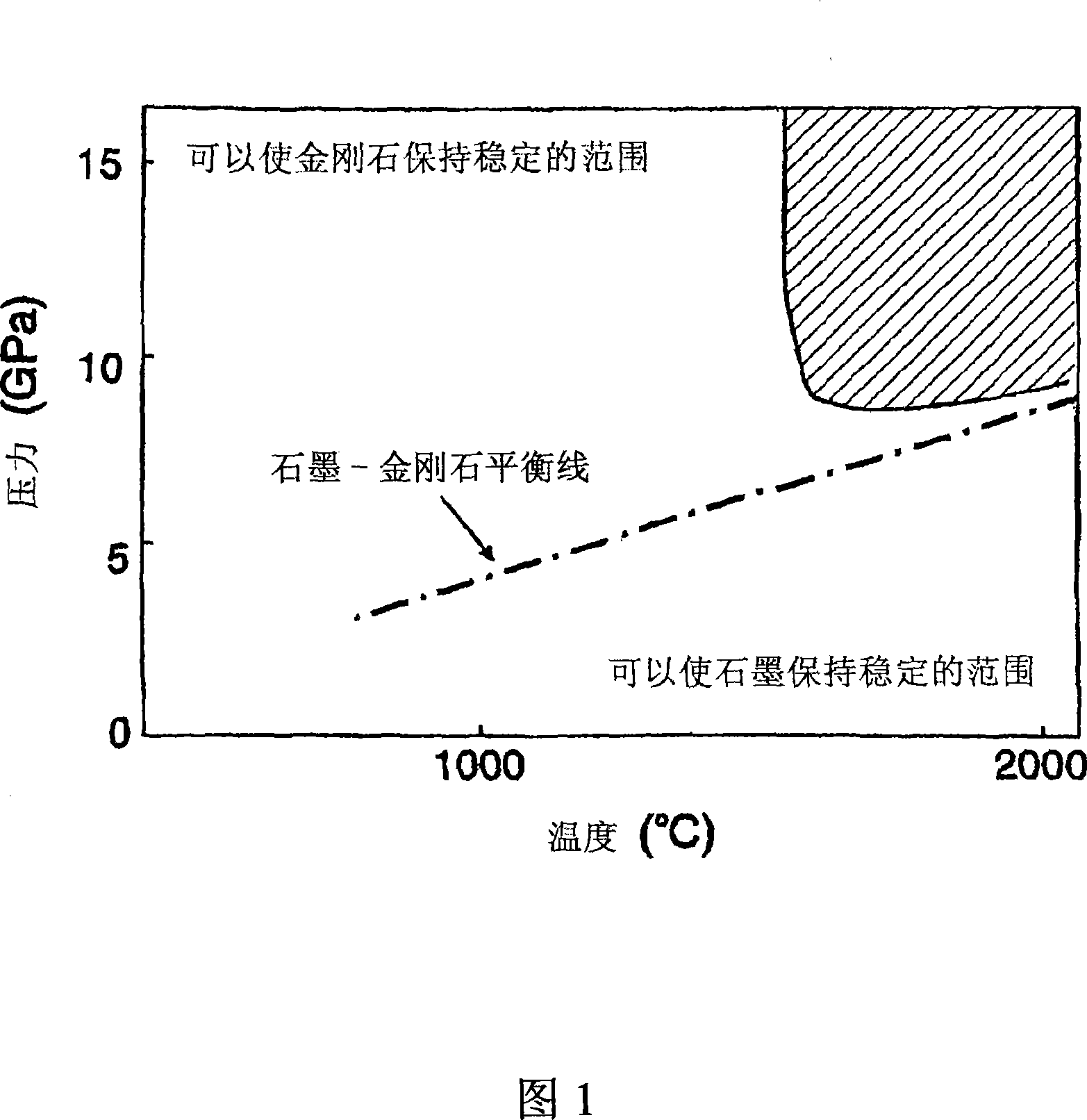

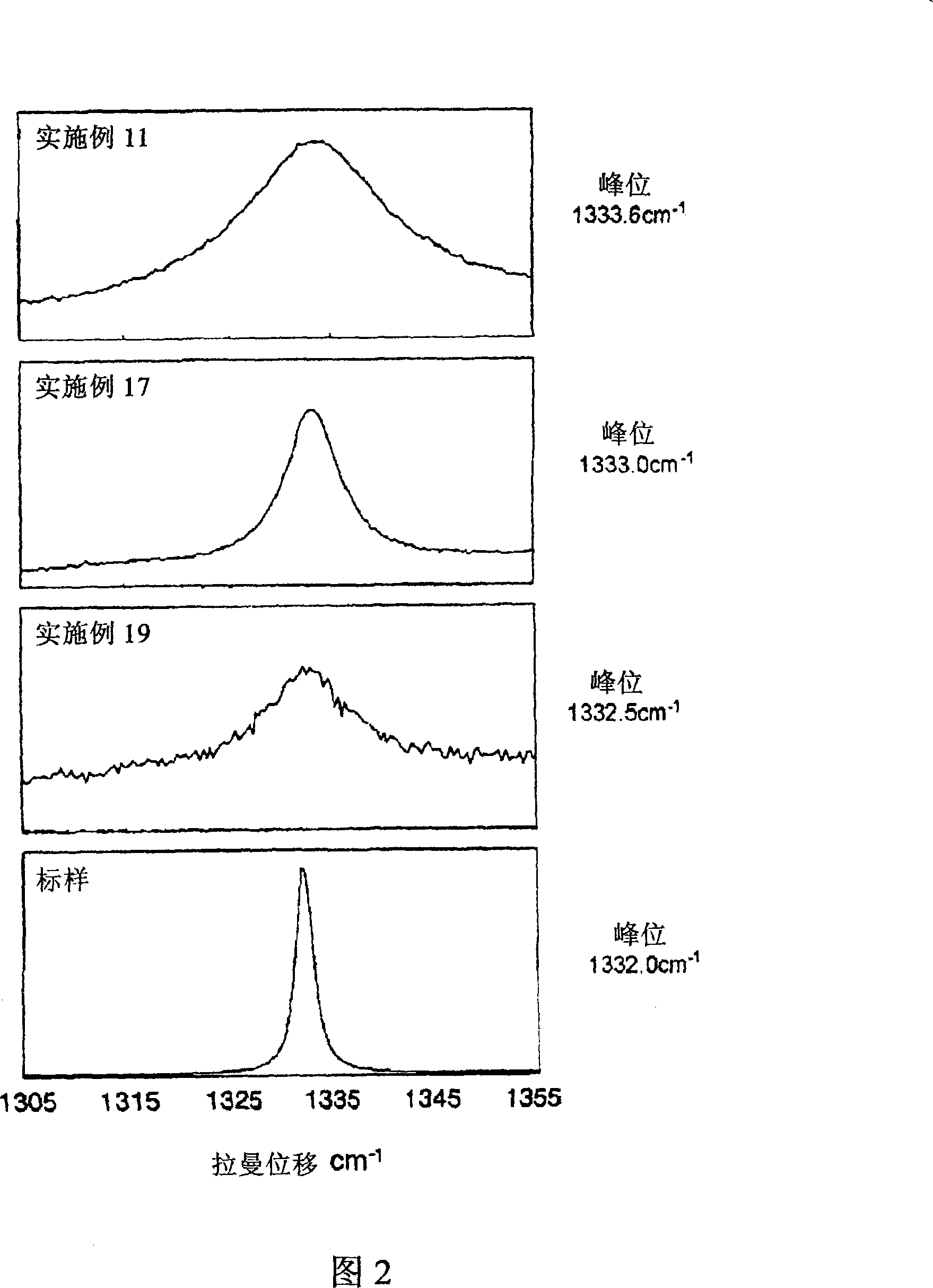

High-hardness polycrystalline diamond and process for producing the same

ActiveCN101228095AStable and cheap offerSolve the hardnessUltra-high pressure processesTurning toolsParticulatesUltra high pressure

The present invention provides a dense and homogeneous polycrystalline diamond having sufficient strength, hardness and heat resistance, which can be used in cutting tools, shapers, dies and other machining tools, excavation bits, etc., and a polycrystalline diamond made of the polycrystalline diamond A cutting tool that forms a cutting edge. The polycrystalline diamond consists essentially of only diamond, and is directly converted into diamond and sintered from a raw material composition containing non-diamond-type carbon material under ultra-high pressure and ultra-high temperature and without the use of sintering aids or catalysts formed, wherein the polycrystalline diamond has a mixed microstructure comprising diamond fine grains with a maximum grain size of 100 nm or less and an average grain size of 50 nm or less and a grain size of 50 nm to 10,000 nm Flake or granular diamond coarse grains.

Owner:SUMITOMO ELECTRIC IND LTD

Material for probe pins

ActiveUS20060197542A1Solve the lack of hardnessImprove oxidation resistanceSemiconductor/solid-state device testing/measurementElectrical measurement instrument detailsTungstenIridium

Probe pins related to the present invention are formed from a material which consists essentially of one or more elements selected from the group consisting of platinum, iridium, ruthenium, osmium, palladium and rhodium. A material obtained by adding one or more elements selected from the group consisting of tungsten, nickel and cobalt to this metal may also be used.

Owner:TANAKA PRECIOUS METAL IND

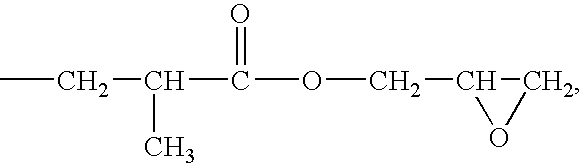

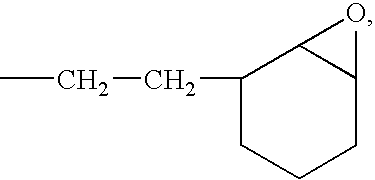

Active Energy Ray-Curable Organopolysiloxane Resin Composition, Optical Transmission Component, And Manufacturing Method Thereof

ActiveUS20080032061A1Superior adhesionHigh optical transmittanceCladded optical fibreFibre mechanical structuresChemistrySilorane Resins

An active energy ray (e.g. UV rays)-curable organopolysiloxane resin composition comprises (A) 100 parts by weight of an organopolysiloxane resin containing epoxy groups and aromatic hydrocarbon groups, (B) 0.05 to 20 parts by weight of a photo acid generator, (C) 0.01 to 20 parts by weight of a photosensitizer or photo-radical generator, and (D) 0 to 5,000 parts by weight of an organic solvent. An optical transmission component made of the above-mentioned composition cured by irradiation with active energy rays (for example, UV rays). A method for manufacturing an optical transmission component by irradiating the above-mentioned composition with active energy rays (for example, UV rays).

Owner:DOW TORAY CO LTD +1

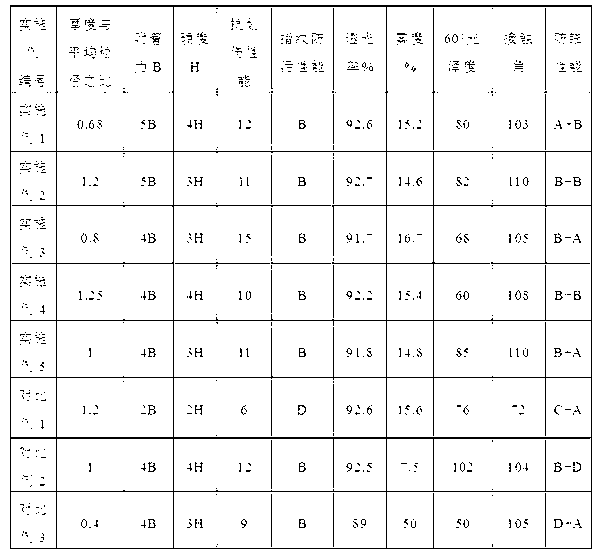

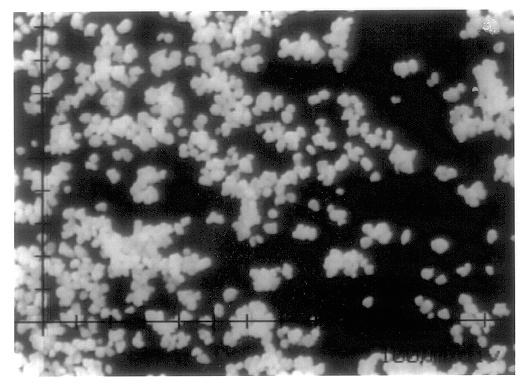

RE-containing prealloy powder

ActiveCN1986116AGood composition uniformitySufficient sintering reactivityRare-earth elementScanning electron microscope

The present invention relates to a kind of pre-alloyed powder and its application in making diamond tool. The pre-alloyed powder consists of at least two selected from Fe, Co, Cu and Ni as basic components, one or several of Mn, Ti, Sn, Mo, W and WC, and one or two of RE, such as La and Ce. It contains at most 80 % of Fe, at most 40 % of Co, at most 80 % of Cu, at most 40 % of Ni, at most 8 % of M and 0-5 % of RE, where, M is one or several of Mn, Ti, Sn, Mo, W and WC and RE is La and / or Ce. The pre-alloyed powder has also inevitable impurity. Scanning electronic microscope measurement shows that the pre-alloyed powder has basic particle size smaller than 15 micron and oxygen content not more than 2 %. The pre-alloyed powder is used as adhesive in making diamond tool.

Owner:GRIPM ADVANCED MATERIALS CO LTD

In-service weld repairs using metal arc welding under oil (MAWUO) of pipelines, tanks, and vessels

InactiveUS20120111837A1Minimizing debrisReduce porosityArc welding apparatusPipeline systemsCombined useGas metal arc welding

Apparatus and methods of repairing an in-service pipeline, tank, and / or vessel are provided. Generally, a metal arc welding under oil process employing an automated metal arc welding setup with a continuous wire feed is utilized. The process may be used in connection with a smart pig to perform in-situ internal repairs of in-service pipelines, tanks, and / or vessels. For example, a pipeline pig or other device is contemplated that employs an internal power supply, a navigation system, and a metal arc welding under oil system that is able to travel vast distances within a pipeline to reach pipeline segments that are either buried underground, under highways, or underwater making access very difficult. Once at its desired location, the pipeline pig performs in-situ welding or other internal repairs to the in-service pipeline. The disclosed apparatus and methods provide great flexibility to the repair of pipelines, tanks, and / or vessels.

Owner:COLORADO SCHOOL OF MINES

Artificial stone panel and manufacturing method thereof

InactiveCN101328039AGood wear resistanceNoble and elegant decorative effectCalcium carbonateArtificial stone

The invention discloses a artificial stone plate prepared by adding cobalt naphthenate accelerator, methylethylketone, light stabilizer, paint and antioxidant into unsaturated polyester resin. The preparation method includes the following steps: firstly modifying the aluminium hydroxide and / or calcium carbonate to get surface modified aluminium hydroxide and / or calcium carbonate or pure aluminium hydroxide powder, then adding cobalt naphthenate accelerator, methylethylketone, light stabilizer, paint and antioxidant into unsaturated polyester resin, uniformly mixing and stirring the mixture in a high speed stirring reactor, adding surface modified aluminium hydroxide and / or calcium carbonate powder or pure aluminium hydroxide powder, stirring and casting the mixture into a mould after vacuum defoamtion, heating up to 60-80 DEG C and curing to get the artificial stone and marble panel.

Owner:覃庆峰

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com