Patents

Literature

99results about How to "Improve loss factor" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

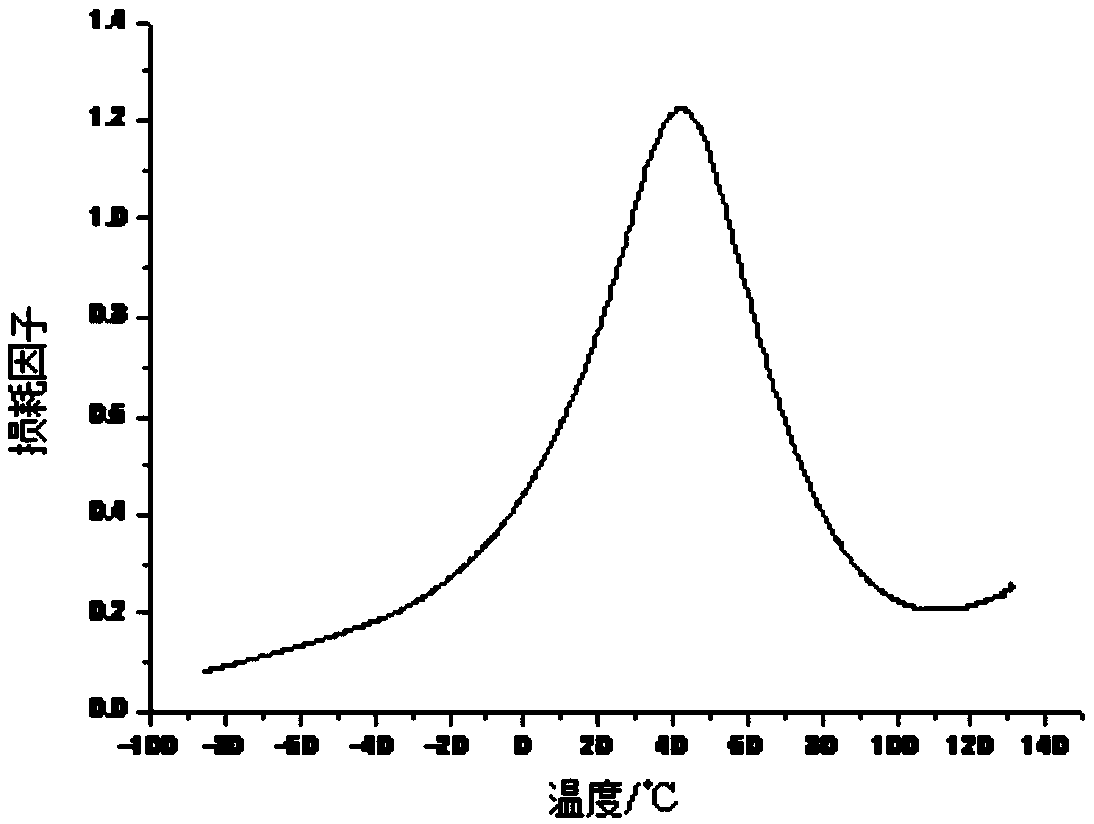

High shock-resistant, wear-resistant sport shoe sole material and manufacturing method thereof

InactiveCN101885865AWide glass transition temperature rangeImprove loss factorSolesActive agentButadiene-styrene rubber

The invention relates to a method for manufacturing a rubber sole material, in particular to a method for manufacturing a medium- and high-grade sport shoe sole with higher requirements on shock resistance and wear resistance. The high shock-resistant, wear-resistant sport shoe sole material consists of butadiene rubber, natural rubber, styrene butadiene rubber, brominated butyl rubber, softening oil, a reinforcing agent, an activating agent, a coupling agent, a vulcanizing agent, a vulcanization accelerator, a tackifier and an age resister. On the basis of the rubbers, the softening oil and the reinforcing agent, a series of the high shock-resistant, wear-resistant shoe sole materials are prepared by screening rubber composition ratio, the coupling agent, the accelerator and an active agent and controlling the process reasonably; and in a dynamic viscoelastic property test, the maximum value of a dissipation factor is 0.3 to 0.5, and the DIN abrasion is less than or equal to 120 mm<3>. The high shock-resistant, wear-resistant shoe sole material has the advantages of alleviation of the shock to a brain during a strenuous exercise, high shock resistance, high wear resistance, improvement on wet skid resistance and increase of comfortableness during the strenuous exercise.

Owner:CHINA LEATHER & FOOTWEAR IND RES INST

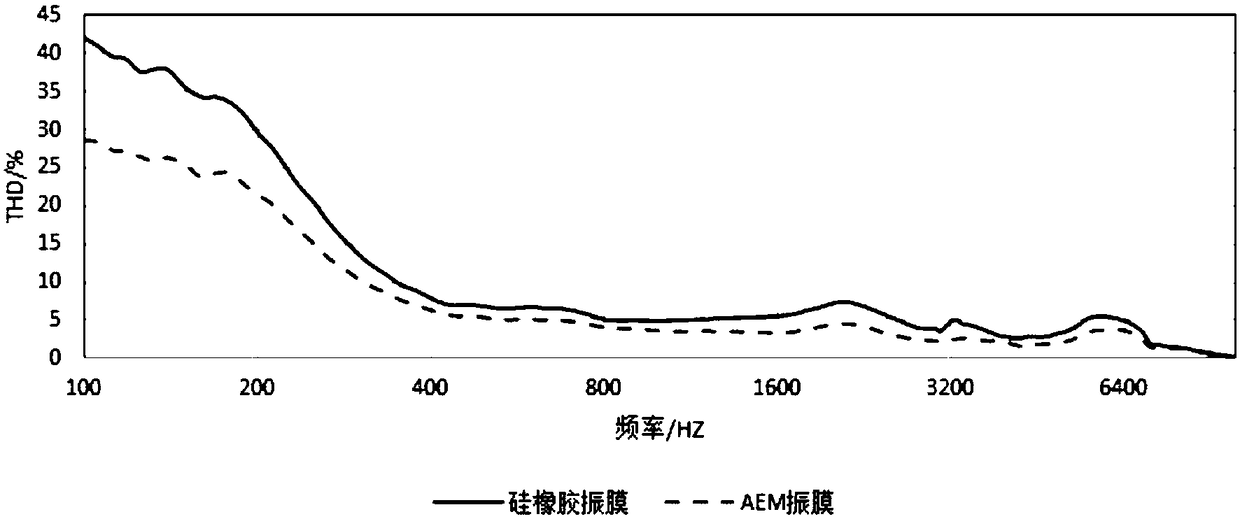

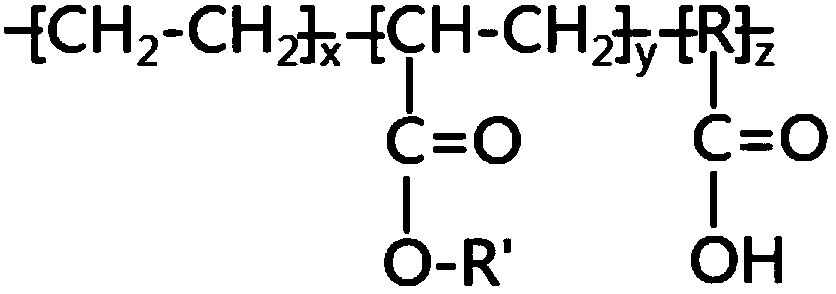

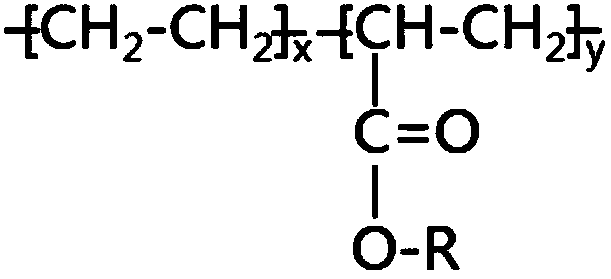

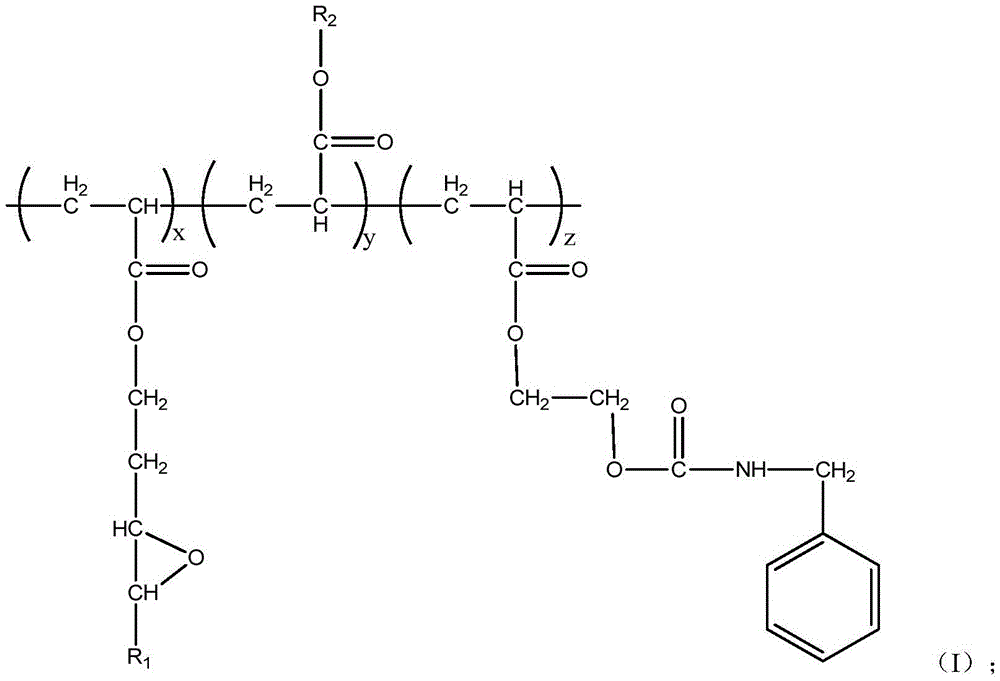

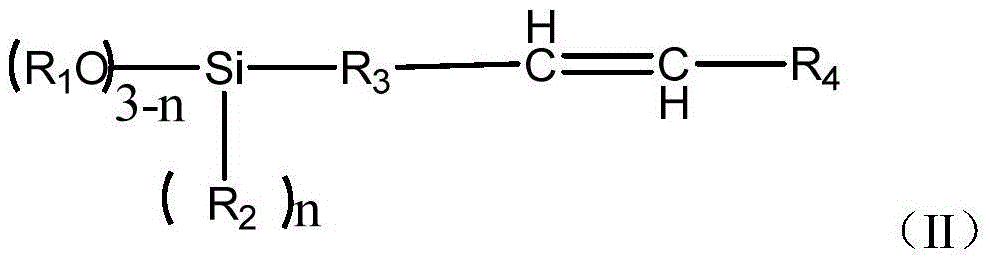

Diaphragm for sounding device, sounding device and assembling method thereof

PendingCN109218924AImprove loss factorReduced chemical structure symmetryDiaphragm extensionsPlane diaphragmsChemical structureCarboxylic acid

The invention discloses a diaphragm for a sounding device, a sounding device and an assembling method thereof. The diaphragm includes a diaphragm layer prepared by subjecting at least one of an ethylene-acrylate copolymer and an ethylene-acrylic ester-carboxylic acid copolymer to crosslinking reaction. The molecular structure of the diaphragm includes a vinyl-acrylic group. The group reduces the chemical structure symmetry of a material, reduces tacticity, and increase steric hindrance, so that the diaphragm has a high loss factor and the sounding device has a good damping effect.

Owner:GOERTEK INC

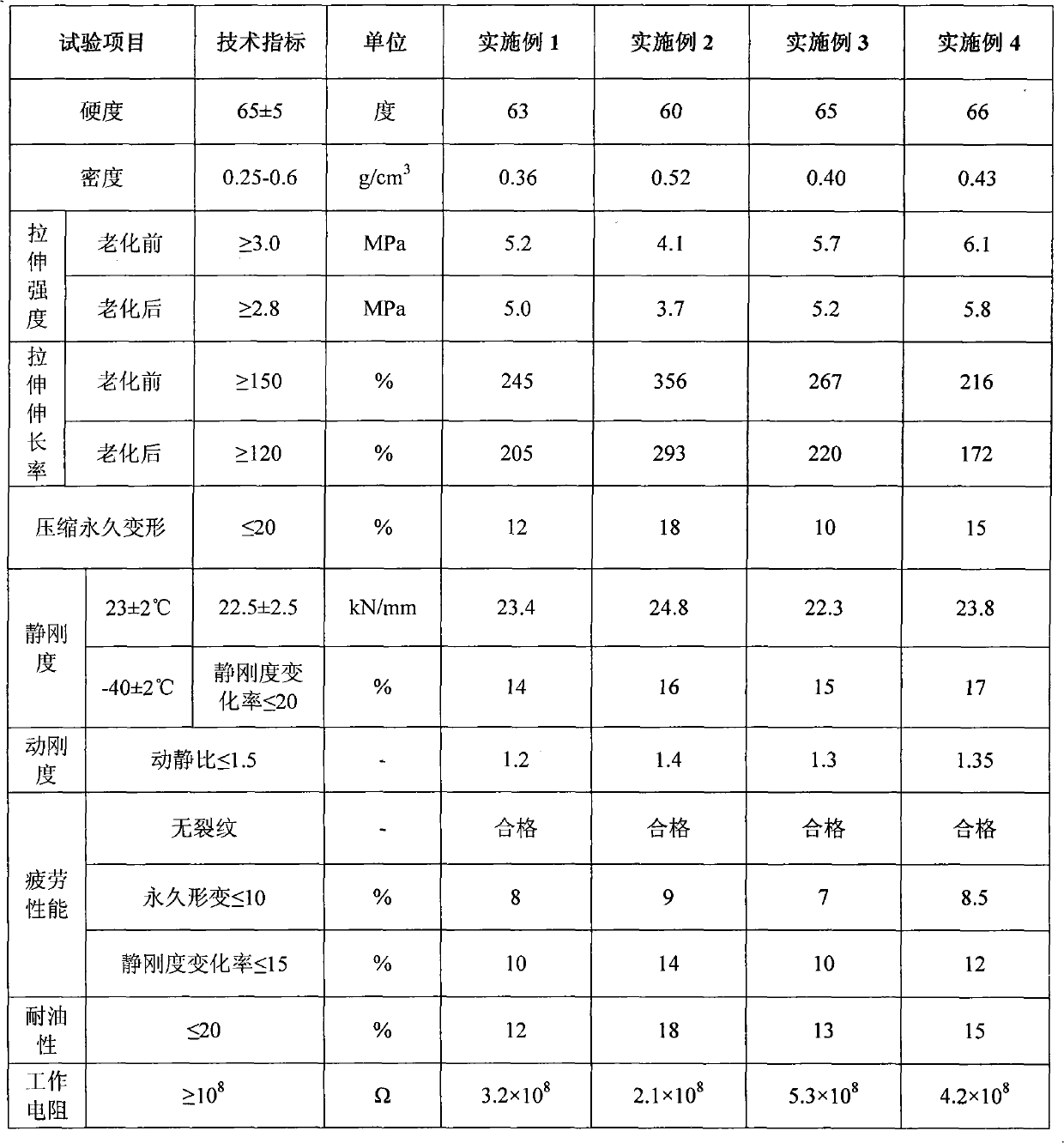

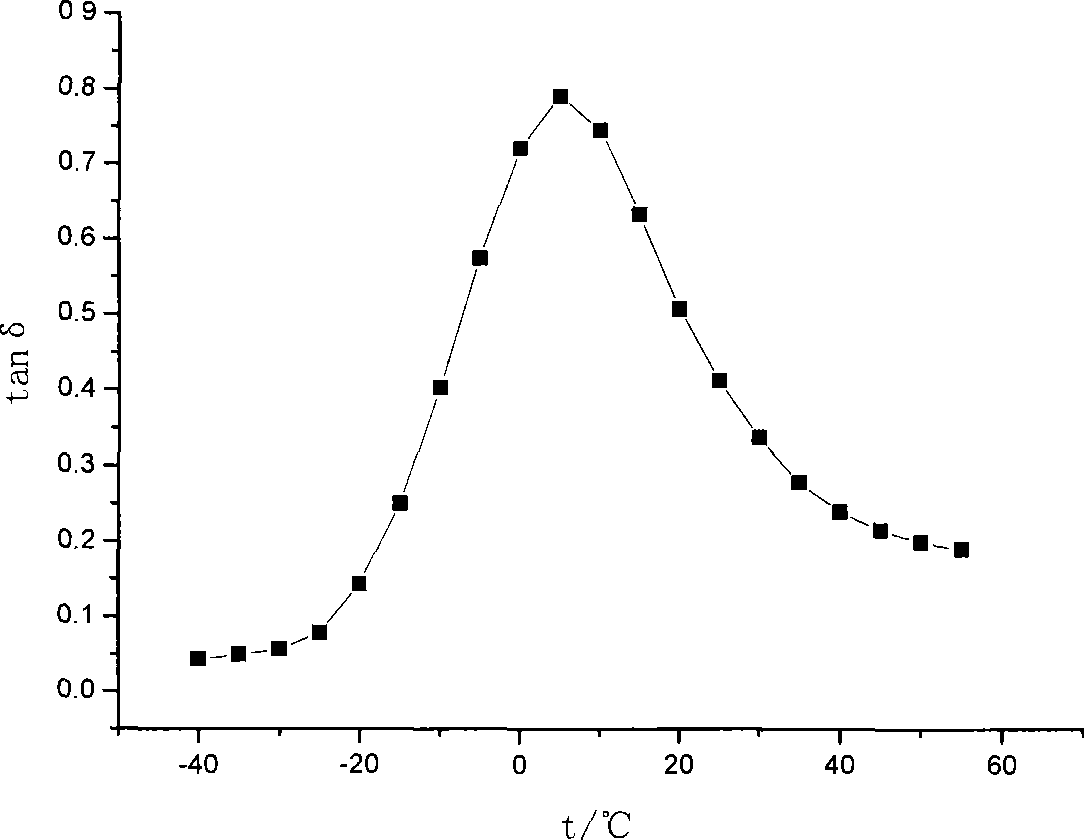

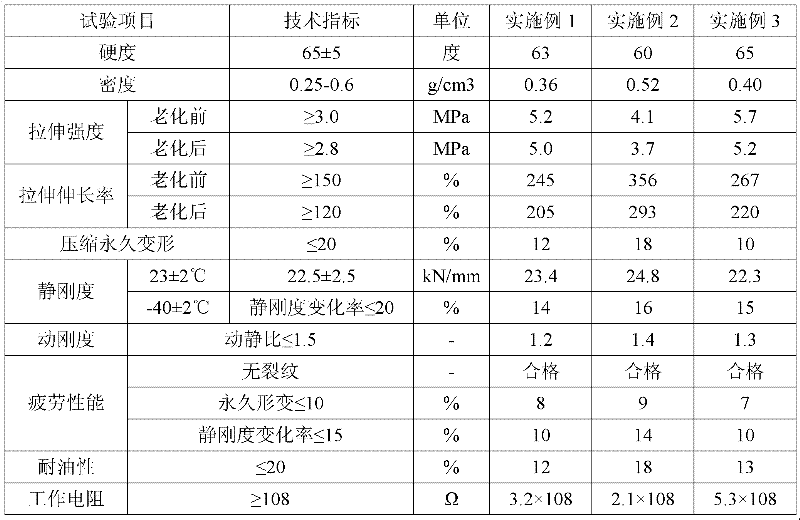

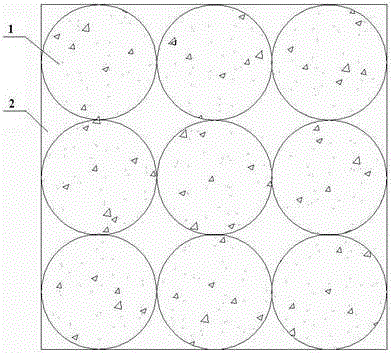

Microporous polyurethane elastomer shock absorption element for high-speed railway and preparation method thereof

The invention discloses a microporous polyurethane elastomer shock absorption element for a high-speed railway. The shock absorption element is characterized by being prepared by stirring and mixing a mixture I and a quasi-prepolymer II at the temperature of between 35 and 55 DEG C for 2 to 5 minutes to obtain a mixture, wherein the mixture I consists of the following components in part by weight: 23 to 40 parts of polyether polyol A, 5 to 10 parts of chain extender, 0.1 to 0.5 part of water, 0.2 to 0.55 part of silicone oil foam homogenizing agent and 0.15 to 0.3 part of catalyst, and the quasi-prepolymer II is prepared by reacting 2.5 to 8 parts of modified nanokaolin, 24 to 30 parts of polyether glycol and 30 to 40 parts of polyisocyanate; pouring the mixture into a die which is pre-heated to 45 to 70 DEG C and is coated with a de-molding agent for molding, de-molding, and curing at the temperature of between 80 and 100 DEG C for 10 to 20 hours. The indexes of the shock absorption element meet the requirements of the HE / 3328-2006 standard.

Owner:ANHUI UNIVERSITY +1

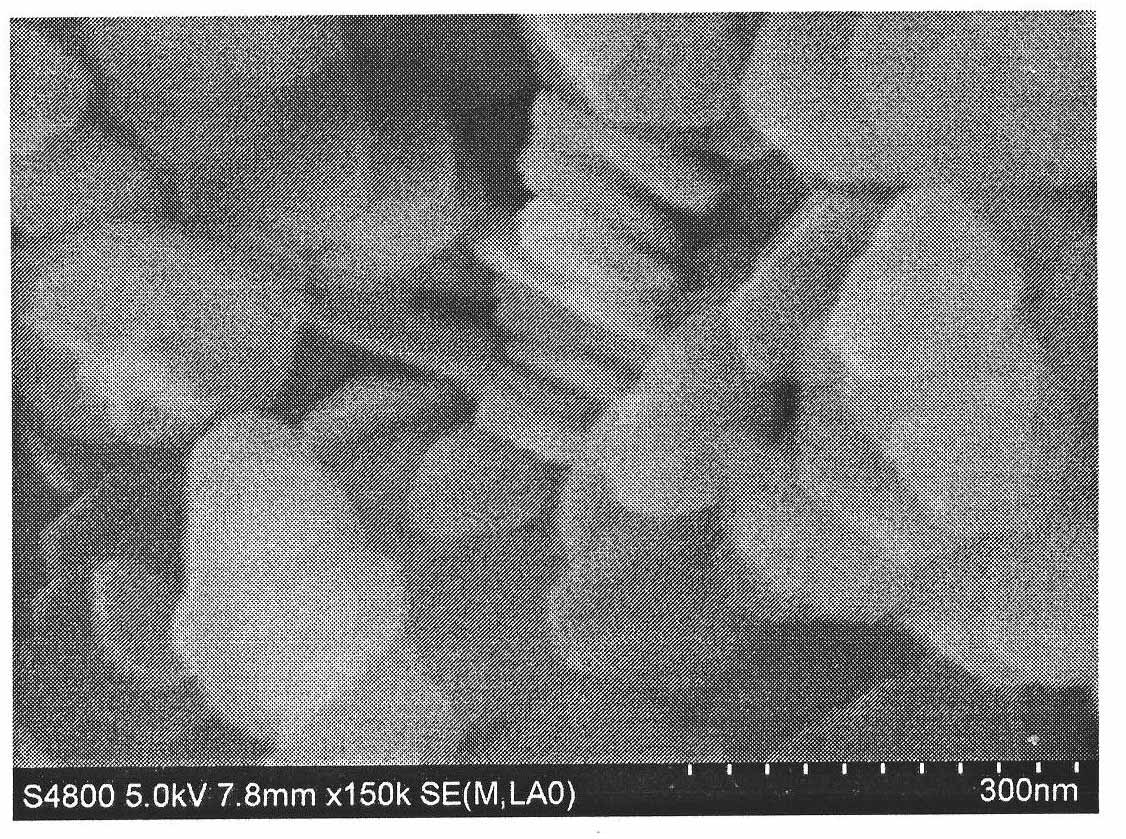

Crosslinking-type rubber-base damping material and preparing method thereof

The invention discloses a cross bonding type rubber group damping material and preparing method, which comprises the following steps: choosing rubber material; adding into phenols organic small molecule as damping function additive and proper organic inclusive agent; supplying good mechanical property for rubber group damping material; improving damping property of material. The loss factor (eta) of material is higher, which can express good tensile strength and extension at break.

Owner:BEIJING UNIV OF CHEM TECH

Bituminous concrete capable of self-healing fast under microwave action, manufacturing method and repairing method thereof

InactiveCN105036614AExtended service lifeImprove maintenance efficiencyMicrowave - actionFerrite powder

The invention relates to bituminous concrete capable of self-healing fast under microwave action, a manufacturing method and a repairing method thereof. The microwave self-healing bituminous concrete is prepared from, by mass, 83.8-88.3% of thick and thin aggregates, 2.3-7.9% of limestone mineral powder, 4.4-5.8% of bitumen, 2.1-8.5% of soft magnetic ferrite powder and 0-0.3% of fibers. Through stirring, the soft magnetic ferrite powder is evenly dispersed in bitumen mortar, the loss factor of the bituminous under microwaves is increased to over 0.16, when microwaves act on the damaged road surface made of the microwave self-healing bituminous concrete, soft magnetic ferrite has dielectric loss and magnetic loss effects on the microwaves, the bitumen mortar converts microwave electromagnetic energy into heat energy, the temperature of the bituminous concrete fast and evenly rises to 45 DEG C-85 DEG C after the bituminous concrete is heated for certain time, and fast self-healing of the bituminous concrete can be achieved by means of the heat repair function of the bitumen.

Owner:TONGJI UNIV

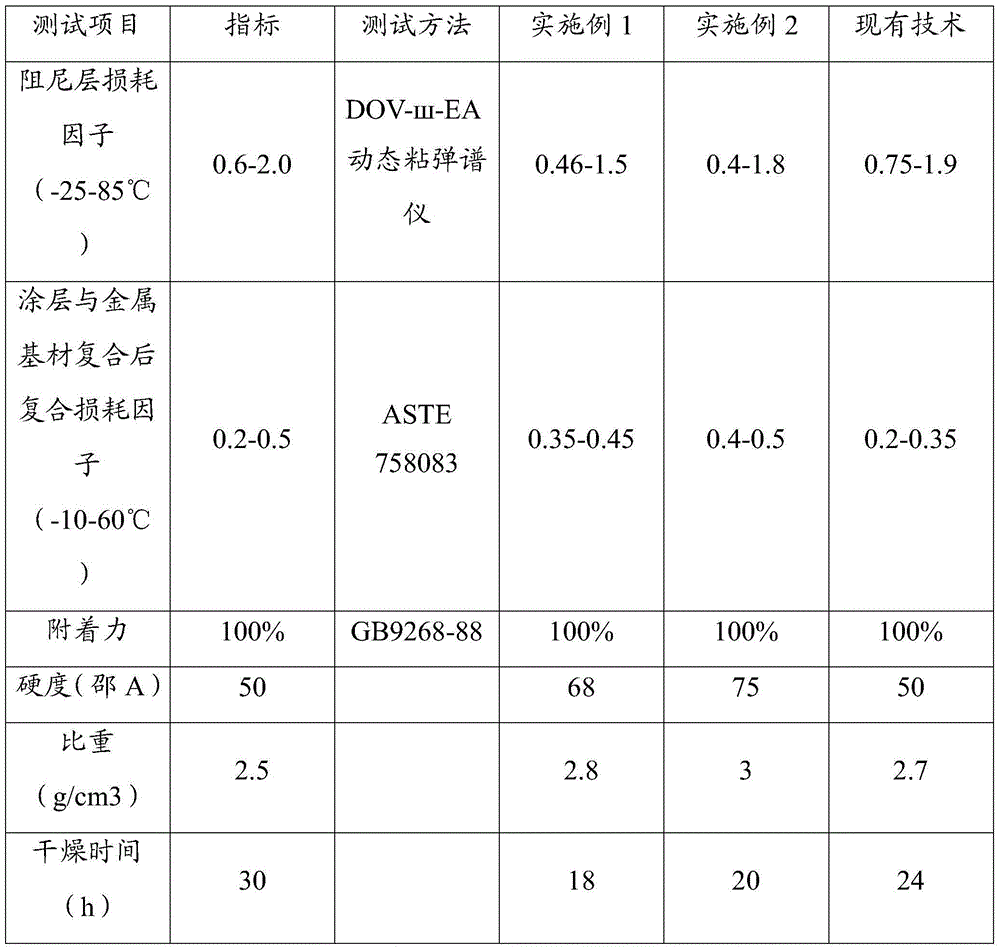

Preparation and application of thermal conductive wide temperature range damping coating

ActiveCN106590203AImprove thermal conductivityLarge specific surface areaPolyurea/polyurethane coatingsPreservativeFilm-forming agent

The invention provides preparation and application of a thermal conductive wide temperature range damping coating. The thermal conductive wide temperature range damping coating is prepared from the following components in parts by mass: 75-125 parts of a main material and 14-39 parts of additive; the main material is prepared from the following components in parts by mass: 30-50 parts of acrylic emulsion, 35-55 parts of filler, 10-20 parts of thermal conducting filler and 10-25 parts of deionized water; the additive is prepared from the following components in parts by mass: 1-5 parts of dispersant, 1-3 parts of anti-sedimentation agent, 0.2-1 part of defoamer, 0.1-1.5 parts of thickener, 0.5-1.8 parts of film forming agent and 0.06-0.2 part of preservative. According to the preparation and the application, the acrylic emulsions with a core-shell structure and an IPN structure are adopted, the structures can enable a polymer to have a micro-phase separation structure after film formation, and the problem of mutual separation of damping peaks due to phase separation easily caused by blending of traditional polymers is overcame; and in addition, various polymerized emulsions are blended and are in gradient Tg distribution, so that a damping temperature range can be widened to the greatest extent, the prepared damping coating is wide in damping temperature range, can be suitable for variation of air temperature and reaches a wide temperature range from 20 DEG C to 100 DEG C.

Owner:BMF NANO MATERIAL TECHNOLOGY CO LTD

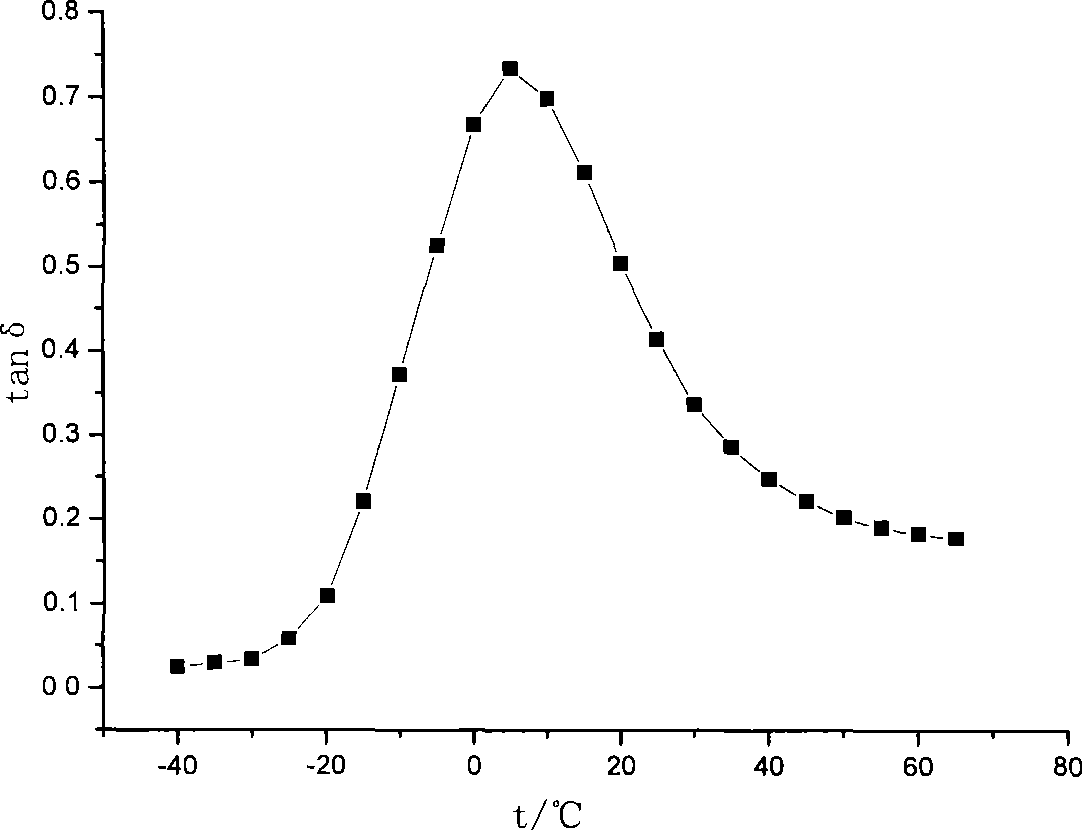

Polyester type polyurethane damping material and preparation method

The invention provides a polyester polyurethane damping material with dimethyl structure with the same carbon number on main chain and a preparation method thereof. The preparation method comprises the following steps: A. allowing polyester glycol dehydrated in vacuum to react with diisocyanate to synthesize a prepolymer; and B. allowing the prepolymer to react with a chain extender or block and graft to synthesize the polyester polyurethane damping material with dimethyl structure with the same carbon number on the main chain; choosing 3,3'-dichloro-4,4'-diaminodiphenylmethane, 3,5- dimethythiotoluene diamine, 1,4-butanediol or trimethylolpropane as the chain extender for room temperature vulcanization. The polyester polyurethane damping material has good thermal stability, acid and alkali resistance, hydrolytic resistance, weatherability and high damping property. Meanwhile, the polyester main chain contains ester group with strong polarity, and forms a plurality of hydrogen bonds with urethane group to improve intermolecular acting force, thus the polyester polyurethane has good mechanical property. High-performance damping materials for use under different temperature can be obtained by adjusting position of damping peak by changing molecular weight of the polyester glycol and by adding liquid packing. The preparation method is simple with low energy consumption.

Owner:HEBEI ENERGY RES INST

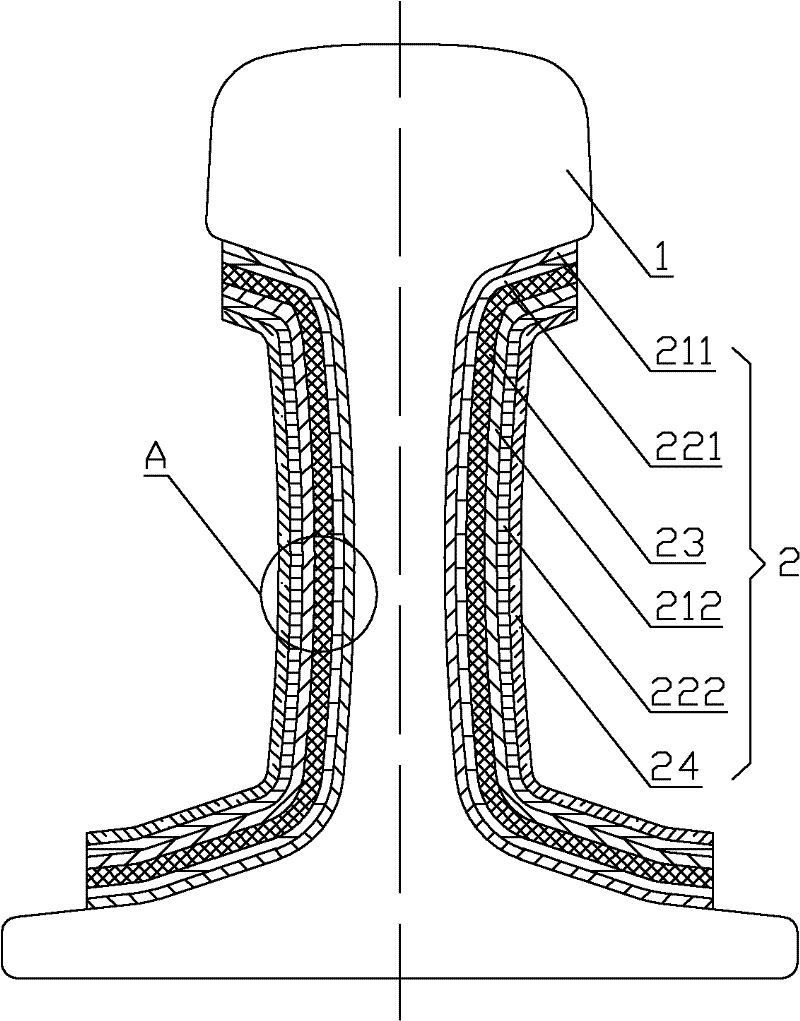

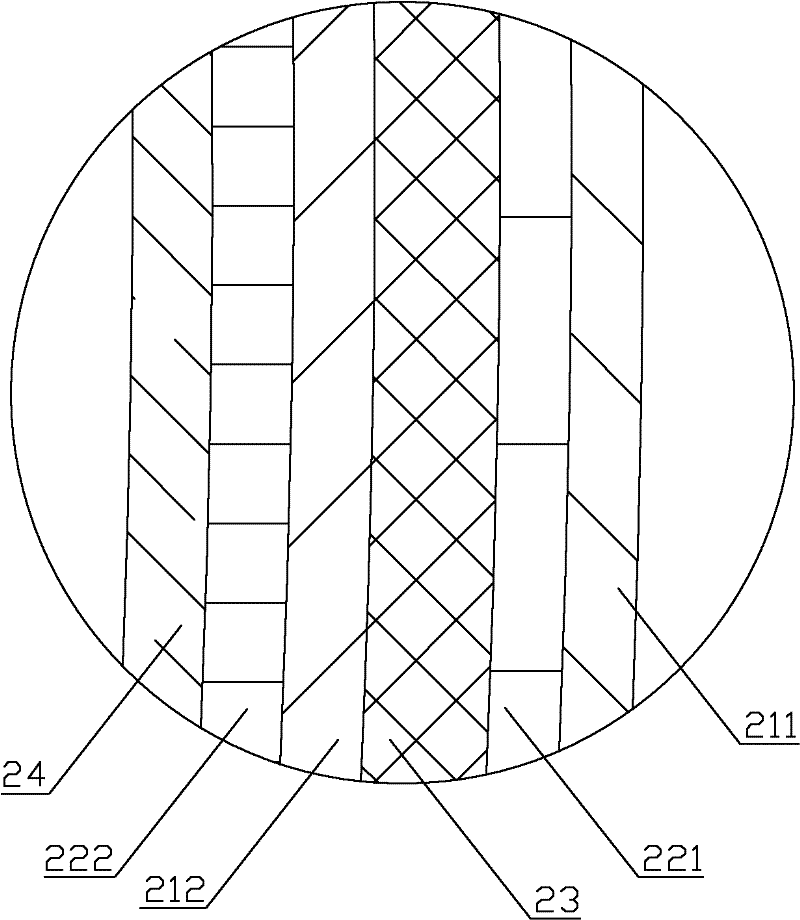

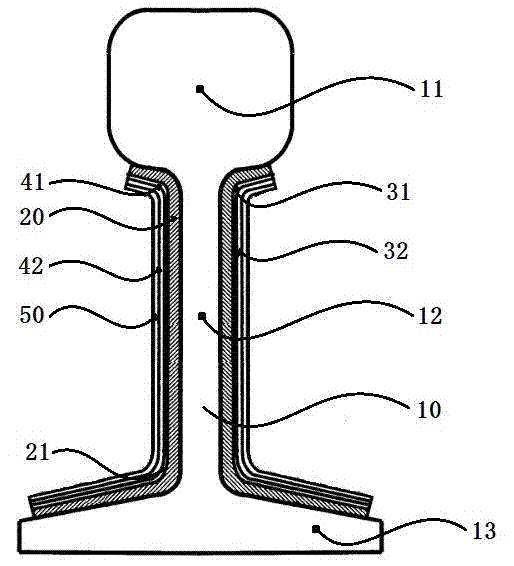

Steel rail and damping absorber thereof

The invention discloses a steel rail and a damping absorber thereof. The disclosed damping absorber comprises a damping layer and a metal constraining board layer, as well as a magnetic material layer, wherein the damping layer, the metal constraining board layer and the magnetic material layer are laid at the rail waist of the steel rail in sequence from inside to the outside; since magnetic material layer has higher specific gravity and vibration-absorbing mass effect, the damping absorber has more obvious vibration absorbing effect; meanwhile, since the damping layer and the metal constraining board layer are closely stuck on the rail waist more reliably under the action of the magnetic attraction between the magnetic material layer and the rail body, the ineffective stickiness caused by rust and flaw removal can be effectively prevented in construction and and the potential safety hazard of falling off of the damping absorber can be eliminated, and therefore the reliability of the damping absorber is improved effectively and the denoising effect of the steel rail is increased.

Owner:BEIJING HUANTIE UNITED NOISE CONTROL TECH

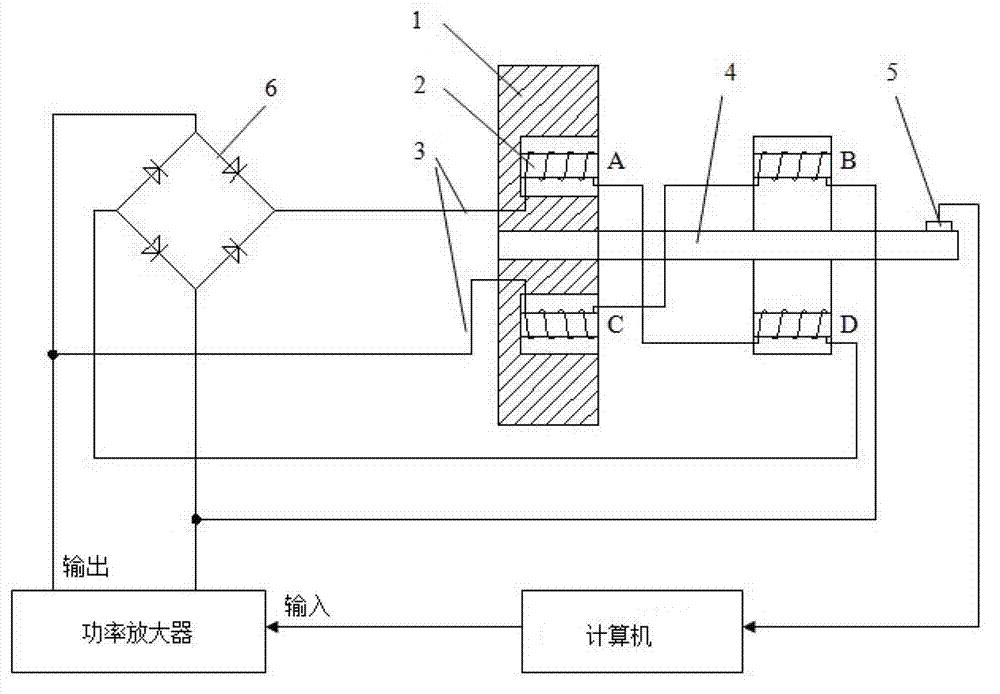

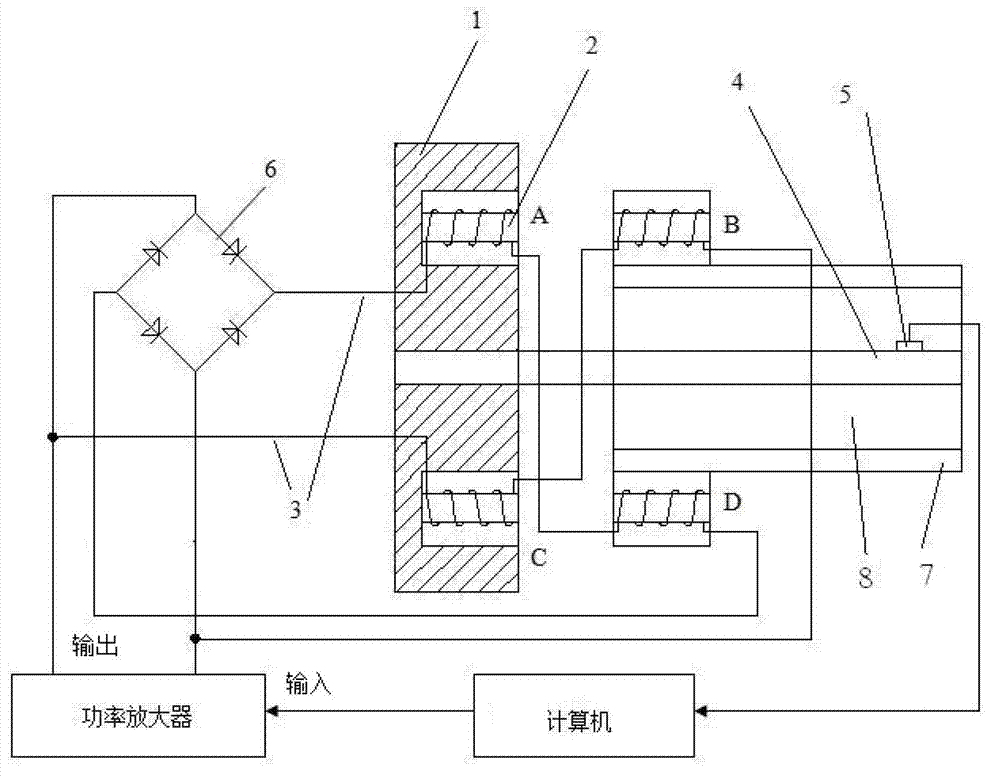

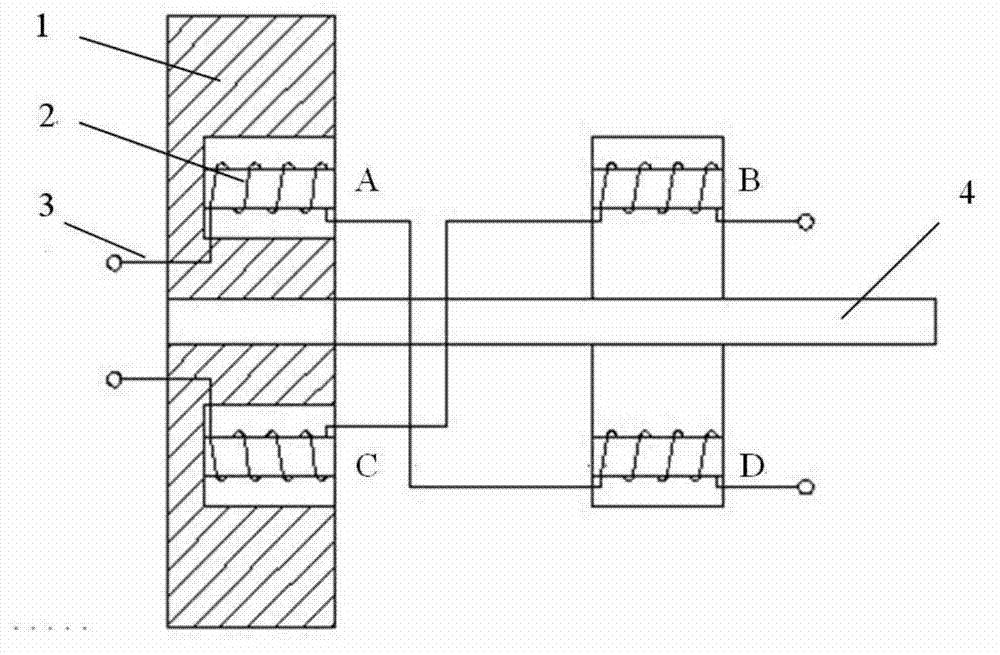

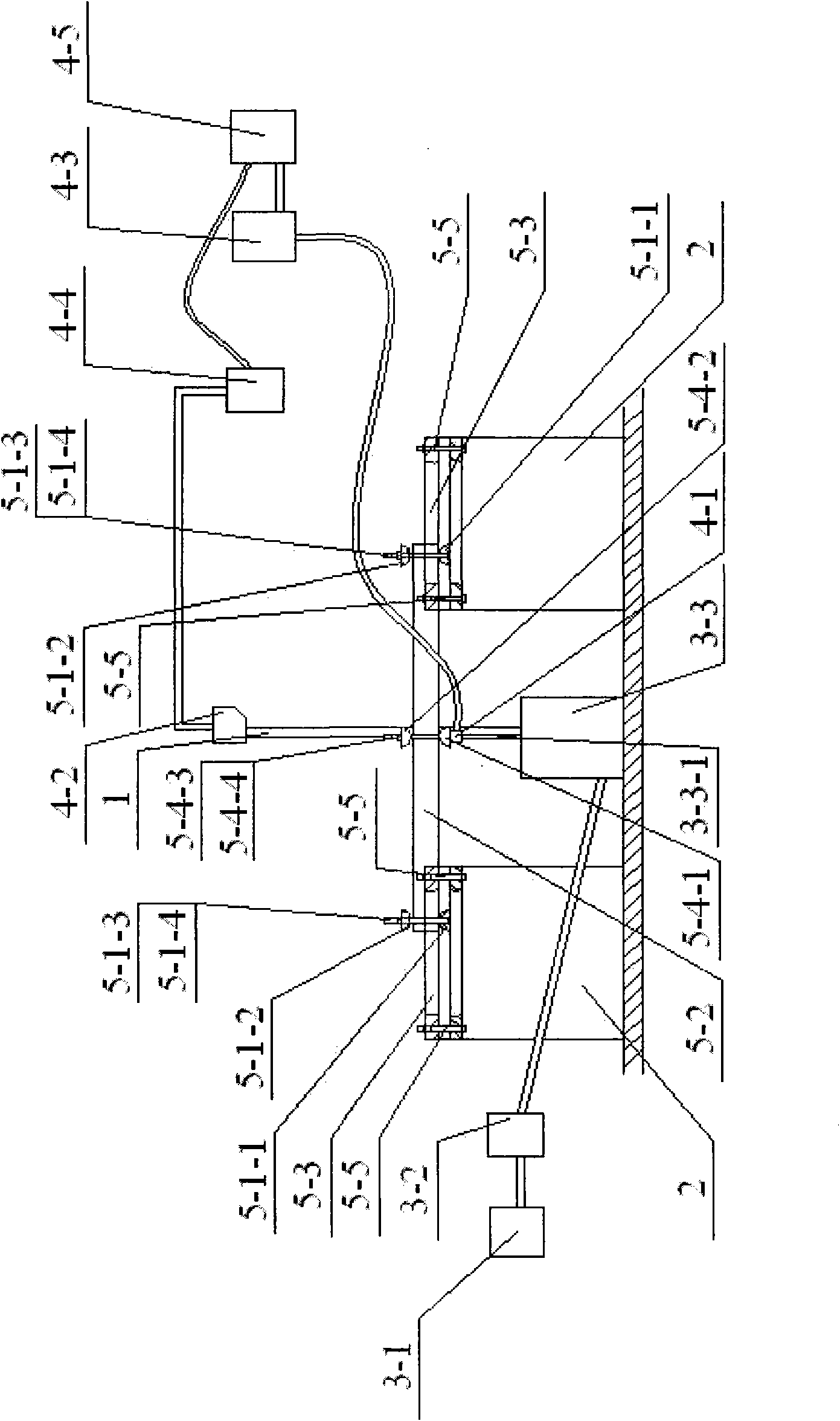

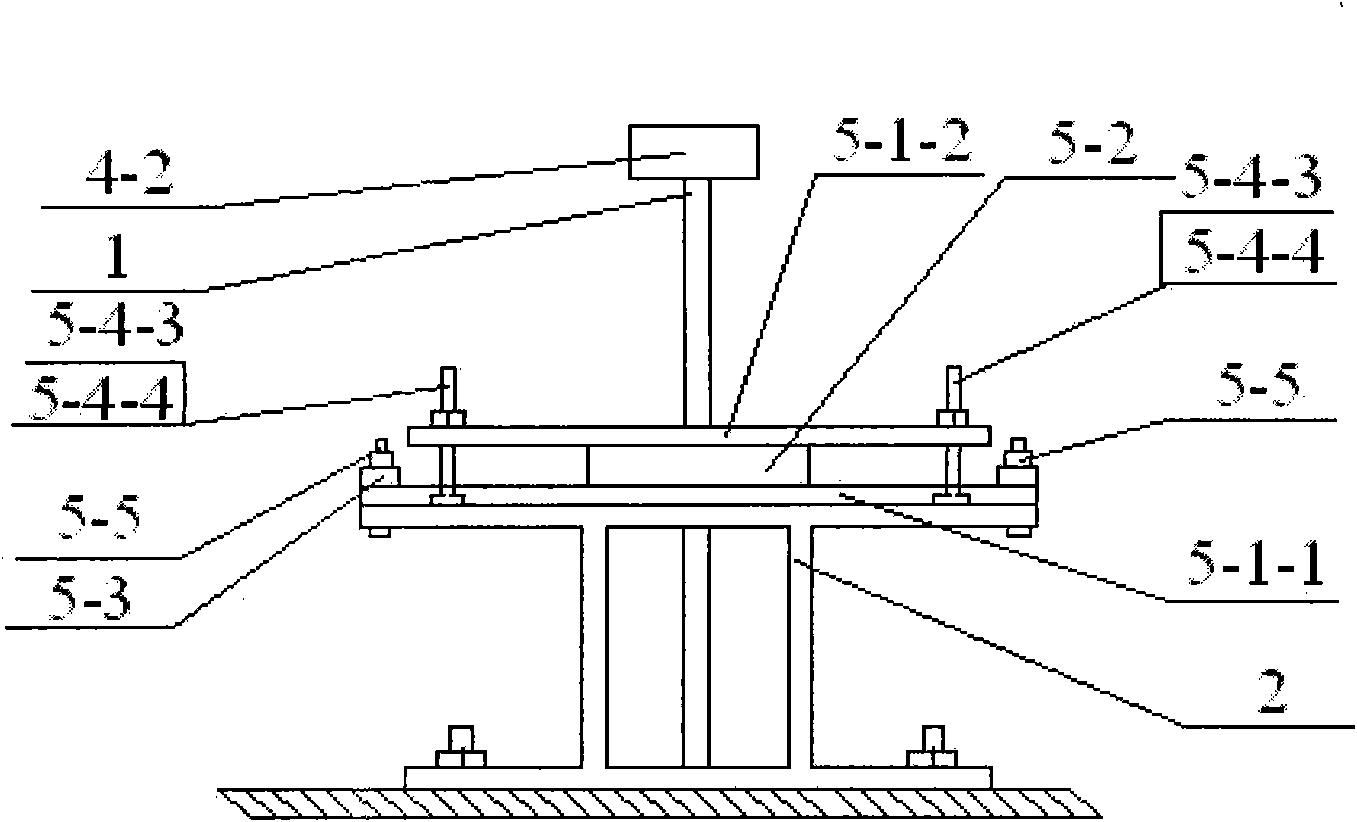

Initiative electromagnetic control system for slab and girder structure vibration

ActiveCN103244603AChange polarityChange the strength of the magnetic fieldNon-rotating vibration suppressionAudio power amplifierControl system

The invention discloses an initiative electromagnetic control system for slab and girder structure vibration. The initiative electromagnetic control system comprises a mechanical portion and a control portion. The mechanical portion comprises a wall made of nonferromagnetic materials, a slab and girder structure and electromagnets. One end of the slab and girder structure is connected with the wall, a displacement sensor is arranged on the slab and girder structure, and the electromagnets include electromagnets A, B, C and D. The control portion comprises a computer, a power amplifier and a full-wave rectification circuit without a filter. The computer is connected with the displacement sensor, an input end of the power amplifier is connected with the computer, one path of an output end of the amplifier is connected with the electromagnets A and D through a bridge rectification circuit without a filter while the other path of the same is directly connected with the electromagnets B and C. When the slab and girder structure vibrates, magnetic pole polarity and magnetic field intensity of the electromagnets can be automatically changed to attenuate the vibration quickly, so that damages to a mechanical system caused by vibration are reduced.

Owner:QINGDAO TECHNOLOGICAL UNIVERSITY

Modified carcass ply compound of all-steel radial tire

InactiveCN103012870AGood viscosity increasing effectImprove adhesionSpecial tyresCopper platingMooney viscosity

The invention provides a modified carcass ply compound of an all-steel radial tire. According to the modified carcass ply compound, resorcin is replaced with phenolic resin. The resorcin is replaced with modified phenolic resin Penacolite B-20-S, modified phenolic resin Elaztobond A250 and phenolic resin TYC-0219, the Mooney viscosity of a sizing material is increased, and the scorch time is prolonged; except for the condition that the resin TYC-0219 enables the vulcanizing time to be prolonged obviously, and little difference of other resin exists; the tensile strength and the stretching stress of vulcanized rubber are reduced slightly, and other physical and mechanical properties are not changed much; and storage moduli and loss factors are all reduced; and the drawing force between the sizing material and a coppered steel wire is increased obviously.

Owner:QINGDAO UNIV OF SCI & TECH

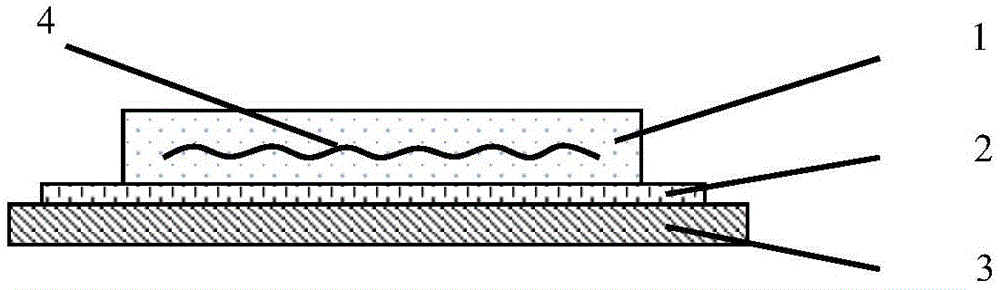

Composite damping coating

ActiveCN104129132AWide damping temperature rangeImprove damping performanceSynthetic resin layered productsMetal layered productsEpoxyOrganic solvent

The invention discloses a composite damping coating comprising a damping layer and a constraining layer. The damping layer is a solvent-free modified polyurethane damping coating, and the constraining layer is a solvent-free modified epoxy resin constraining coating. According to the composite coating provided by the invention, the constraining layer is used for reducing sound, and the damping layer is used for insulating sound, such that frequency from a sound source can be reduced, and muting and noise reduction purposes can be achieved. The coating provided by the invention has the characteristics of wide damping temperature range, high loss factor after being combined with a metal plate material, good damping effect, and the like. Also, the coating does not contain an organic solvent. The coating has the advantages of normal-temperature curing and convenient and fast construction. The coating is non-toxic and flame-retardant.

Owner:GUANGZHOU POWER SUPPLY BUREAU GUANGDONG POWER GRID CO LTD

Silanization processing method of silicon powder and high damping concrete containing silanized silicon powder

The invention discloses a silanization processing method of silicon powder and a high damping concrete containing silanized silicon powder, relating to a method for processing silicon powder and a concrete containing the silicon powder. The invention solves the problem that traditional concrete structural materials have low damping capacity. The silanization processing method of silicon powder comprises the following steps: immersing constantly dried silicon powder in KH 550 silane coupling agent water solution with the temperature of 80 DEG C for 1h, and then filtering, airing, and drying to constant weight to obtain the silanized silicon powder; each cubic meter of the high damping concrete containing the silanized silicon powder is made of 480 kg of cement, 28.8 kg of silanized silicon powder, 200 kg of water, 638 kg of sand, 1042 kg of stones and 2.4 kg of FDN efficient water reducer. By adding the silanized silicon powder into common concrete materials, the invention improves the damping performance of the concrete material and structure, thereby realizing the aim of improving self-shock resistance of the structure without a control device.

Owner:刘铁军

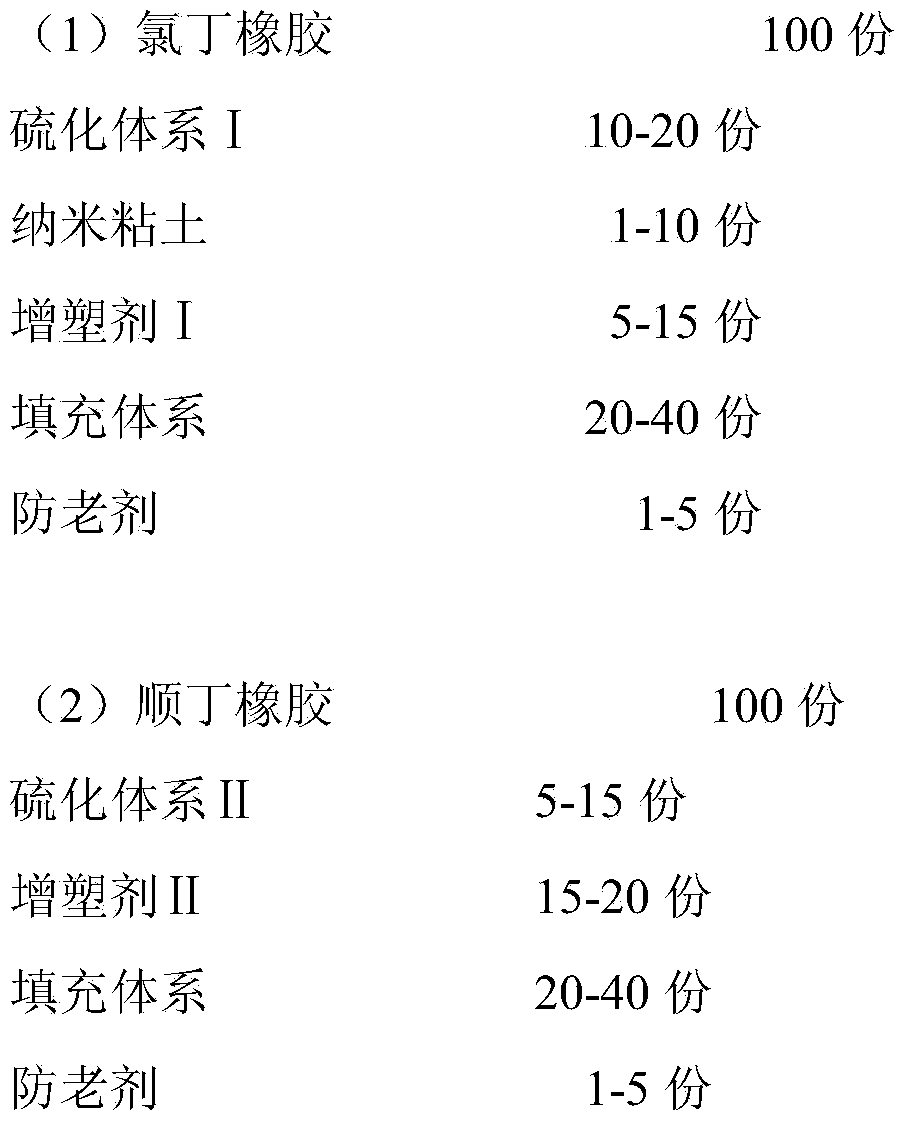

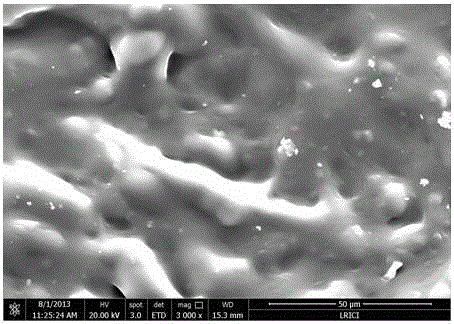

High-temperature underwater sound transmission rubber material and preparation method thereof

ActiveCN103589025AImprove sound transmission performanceImprove stabilityRubber materialVulcanization

The invention relates to a high-temperature underwater sound transmission rubber material and a preparation method thereof. The crystallization of chloroprene rubbers is restrained through selecting the chloroprene rubbers with slow crystallization speed and using butadiene rubbers (BR) with a certain ratio, so that the sound transmission performance and the temperature stability of the rubber material are improved; a certain parts of nanometer clay are added in a formula system to improve the water tightness of the sound transmission material; quick low-temperature and low-pressure vulcanization (100-120 DEG C, 30-40 minutes) of the rubber material is realized through optimizing the rubber material formula and the processing technique design. The underwater sound transmission rubber material with high sound transmission performance, high temperature stability, high water tightness and excellent physical and mechanical properties can be prepared through the method. The material can satisfy the requirements of a coating material of ship underwater sound equipment, and is an excellent underwater sound transmission material.

Owner:BEIJING UNIV OF CHEM TECH

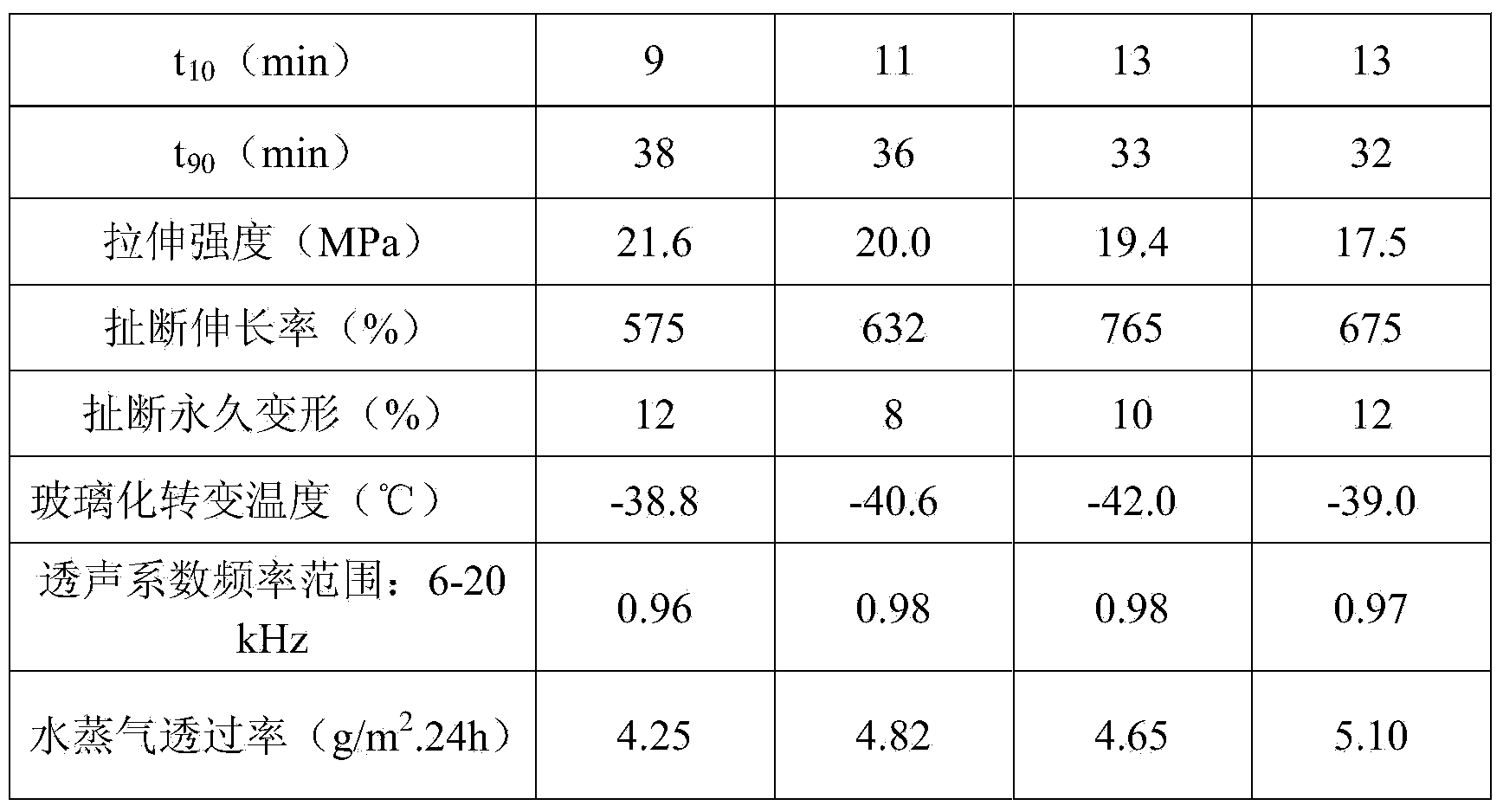

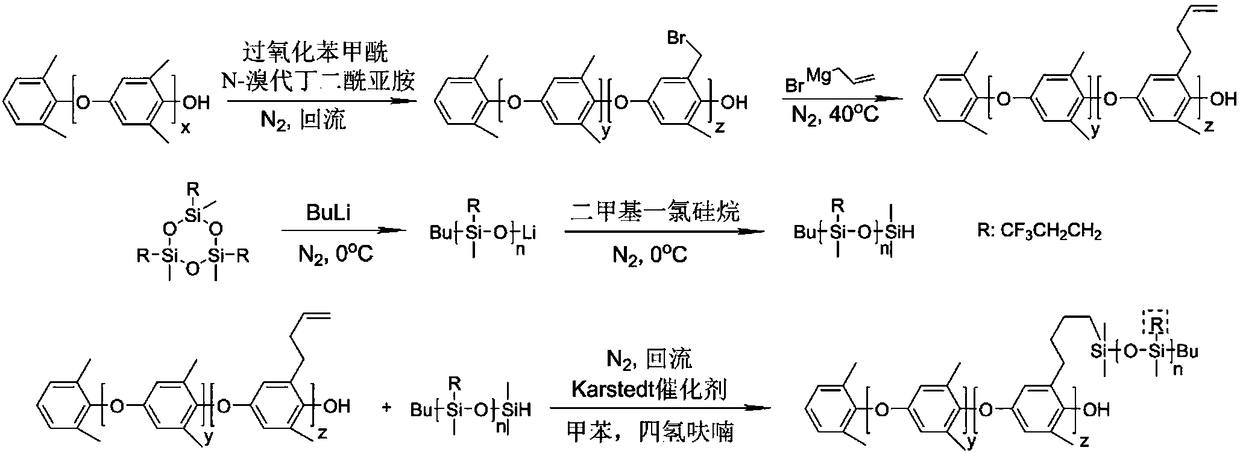

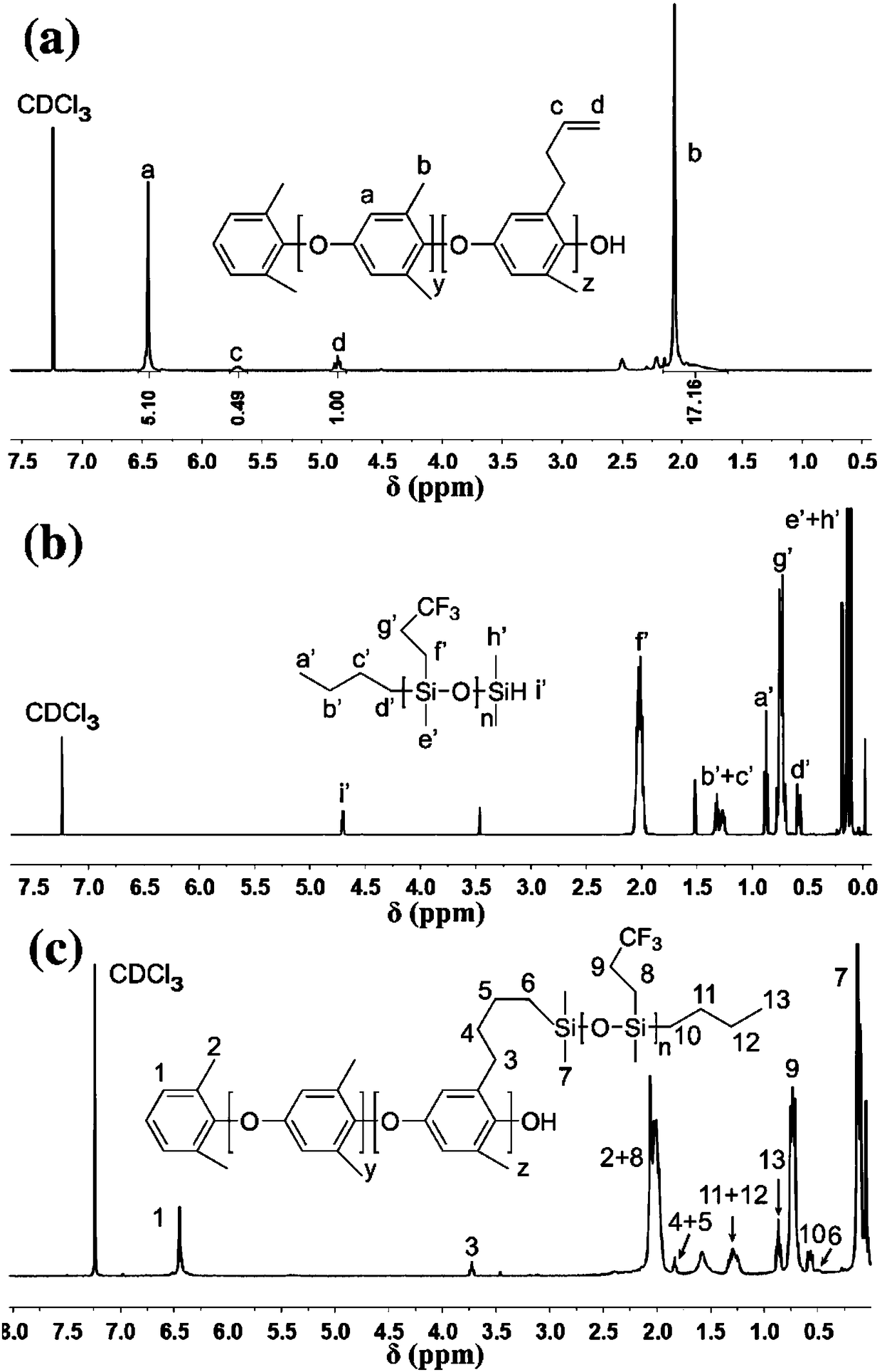

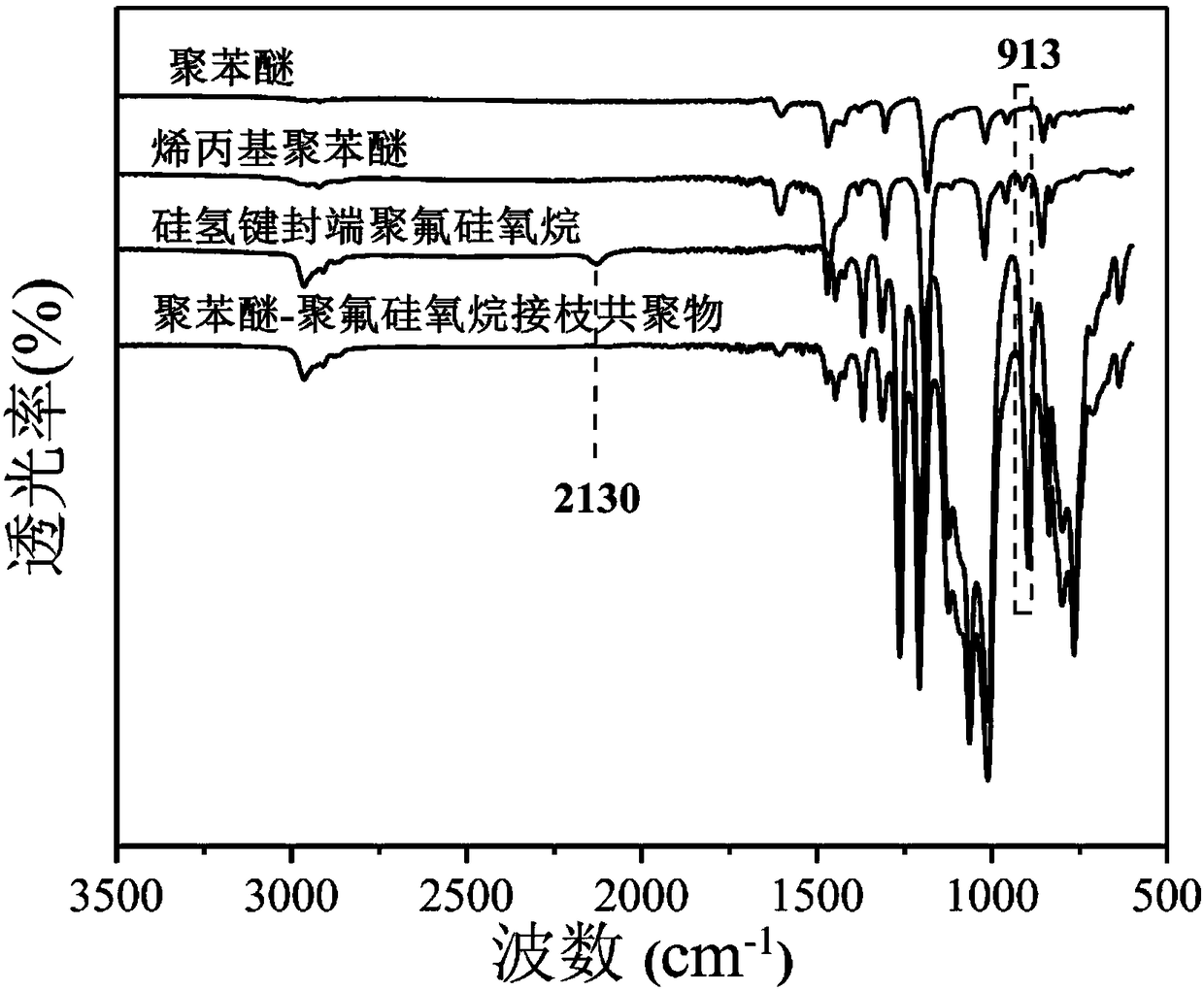

Polyphenyl ether-polyorganosiloxane photo-crosslinking thin film based on graft copolymer and preparation method of polyphenyl ether-polyorganosiloxane photo-crosslinking thin film

The invention discloses a polyphenyl ether-polyorganosiloxane photo-crosslinking thin film based on a graft copolymer and a preparation method of the polyphenyl ether-polyorganosiloxane photo-crosslinking thin film. The preparation method comprises the following steps: (1) preparing allylated polyphenyl ether; (2) synthesizing silicon-hydrogen bond terminated polysiloxane by taking n-butyllithiumas an initiator and taking chlorodimethylsilane as an end capping agent; (3) carrying out copolymerization on the allylated polyphenyl ether and the silicon-hydrogen bond terminated polysiloxane to prepare a polyphenyl ether-polyorganosiloxane graft copolymer; and (4) blending the polyphenyl ether-polyorganosiloxane graft copolymer with polyphenyl ether and polyorganosiloxane, and carrying out photo-crosslinking to obtain a photo-crosslinking thin film. Compared with the prior art, the polyphenyl ether-polyorganosiloxane photo-crosslinking thin film based on the graft copolymer not only has awide effective damping temperature range, but also has good heat resistance and high loss factors, the damping property is shown in a temperature range from 152 DEG C to 223 DEG C, the effective damping temperature range is greater than 60 DEG C, and the loss factor (tan delta) is greater than or equal to 0.9. In addition, the photo-crosslinking preparation method is adopted, and has the advantages of rapidness, high efficiency and energy conservation.

Owner:SUZHOU UNIV

Biobased micro-porous polyurethane material and preparation method thereof

The invention discloses a biobased micro-porous polyurethane material and a preparation method thereof. The method comprises a component A preparation process, a component B preparation process and a component A and component B mixing process, wherein the component A preparation process comprises the following steps: stirring 20 to 41 parts by weight of polyether polyol, 3 to 11 parts by weight of chain extender, 0.01 to 0.52 part by weight of water, 0.15 to 0.59 part by weight of silicone oil, and 0.12 to 0.33 part by weight of catalyst for not less than 5 minutes; and degassing under a negative pressure condition until the degree of vacuum does not change any more, and sealing for storage. Compared with the prior art, according to the invention, a pre-polymer method is adopted, MDI (diphenylmethane diisocyanate) with low price, good prepolymer stability and short production period and biobased polyether polyol with environmental friendliness and regenerability are preferably used for preparing a micro-porous elastic body, thus environmental friendliness and use performance are taken into consideration, and the market developing space is great.

Owner:安徽绿能技术研究院有限公司

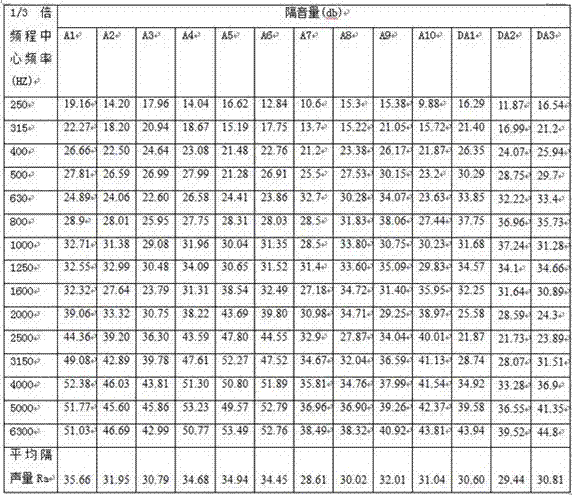

Sound insulation material composition and vehicle sound insulation sheet

ActiveCN106916363AImprove sound insulationIncrease energy lossVehicle componentsSound producing devicesPlasticizerVibration absorption

The present application provides a sound insulation material composition and a vehicle sound insulation sheet, wherein the sound insulation material composition comprises, by weight, 50-300 parts of EVA, 10-300 parts of mica powder, 10-300 parts of dolomite, 10-50 parts of a thermoplastic resin, 10-100 parts of a toughening agent, 3-60 parts of a compatibilizer, 30-300 parts of a flame retardant agent, 10-80 parts of a plasticizer, and 100-500 parts of barium sulfate. The present invention further provides the vehicle sound insulation sheet. According to the present invention, by adding the sheet-like mica powder and the massive dolomite to the sound insulation material according to a certain weight ratio, the processing performance of the sound insulation material composition can be improved, and the effects of vibration absorption and sound insulation of the vehicle sound insulation sheet can be improved.

Owner:BYD CO LTD

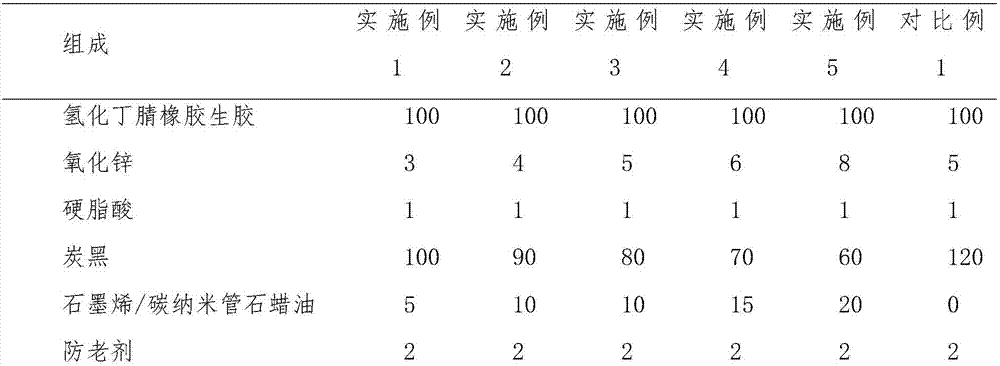

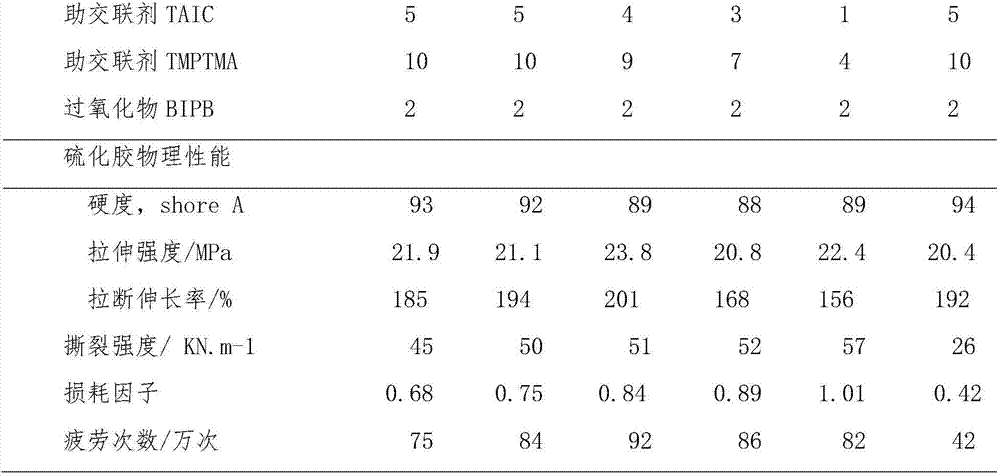

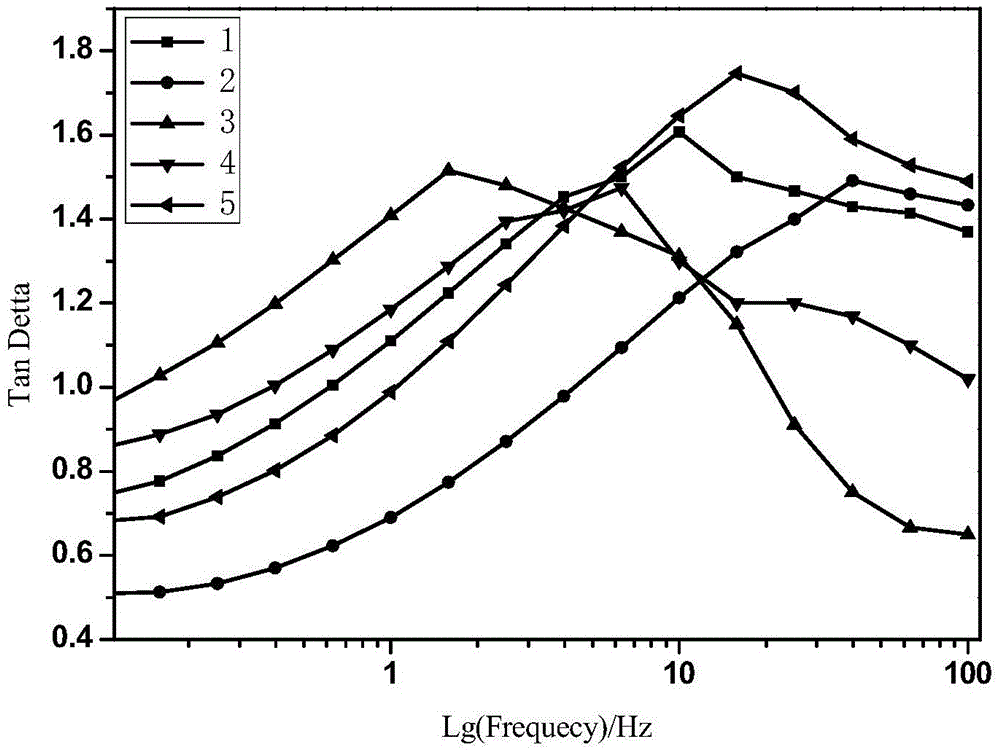

Graphene-containing HNBR (hydrogenated butadiene-acrylonitrile rubber) nanocomposite and preparation method

The invention belongs to the technical field of rubber materials and relates to a graphene-containing HNBR (hydrogenated butadiene-acrylonitrile rubber) nanocomposite and a preparation method. The graphene-containing HNBR nanocomposite is a mixture of crude HNBR, carbon black, graphene / carbon nanotube paraffin oil, an anti-aging agent, an assistant crosslinker and a vulcanizing agent. According tothe graphene-containing HNBR nanocomposite, high-frequency loss factor of HNBR is greatly increased, high-frequency vibration fatigue resistance of the HNBR material is improved, tear resistance of the HNBR is further improved, and therefore, the graphene-containing HNBR nanocomposite has the advantages beyond traditional filler. The graphene-containing HNBR nanocomposite adopts a simple technology, is low in cost, facilitates industrial production, is widely adaptive and has better economic benefit and social benefit.

Owner:AVIC BEIJING INST OF AERONAUTICAL MATERIALS

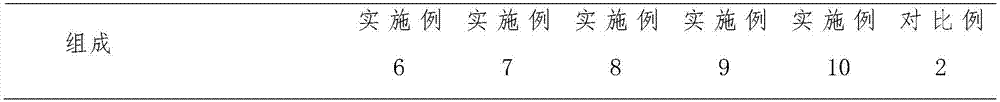

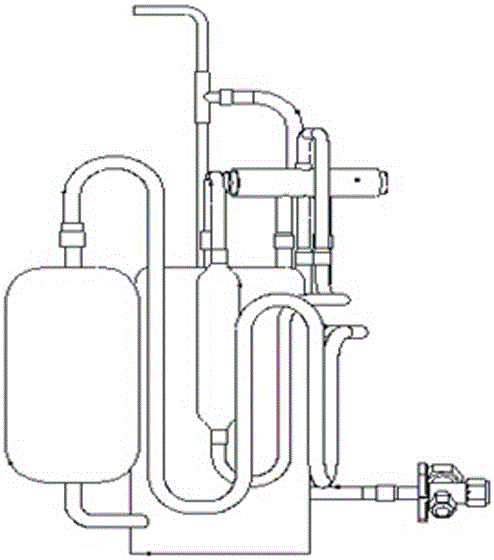

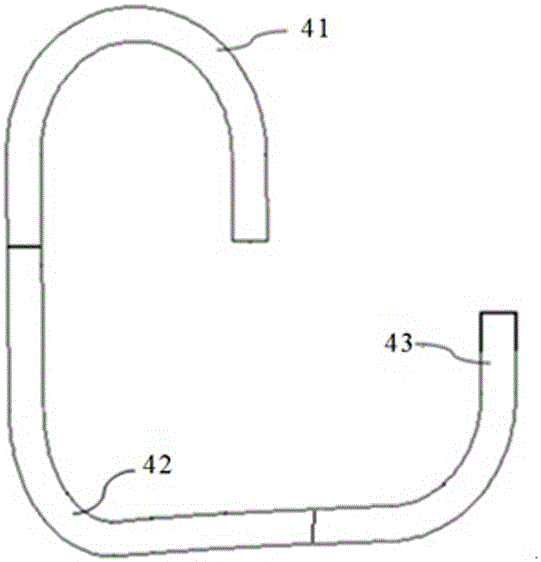

Air conditioner outdoor unit piping, method for forming damping material on piping and air conditioner outdoor unit

InactiveCN105757828AImprove loss factorGood damping performanceLighting and heating apparatusNoise suppressionPipingMechanics

The invention discloses an air conditioner outdoor unit piping, a method for forming a damping material on the piping and an air conditioner outdoor unit.The air conditioner outdoor unit piping comprises an air suction pipe section and an exhaust pipe section, and the damping material which has the damping and denoising properties is formed on the outer surfaces of the air suction pipe section and the exhaust pipe section.According to the air conditioner outdoor unit piping, the method for forming the damping material on the piping and the air conditioner outdoor unit, due to the fact that the damping material which has the damping and denoising properties is sprayed on the outer surfaces of the air suction pipe section and the exhaust pipe section of the air conditioner outdoor unit, vibration of the air suction pipe section and the exhaust pipe section can be weakened, and noise caused by vibration is reduced; the piping design on the air suction pipe section and the exhaust pipe section is simple; meanwhile, airflow noise caused by refrigerant circulating in the air suction pipe section and the exhaust pipe section can be reduced, vibration and noise of the air conditioner outdoor unit can be reduced, and the refrigerating efficiency of the air conditioner outdoor unit is improved.

Owner:HISENSE (SHANDONG) AIR CONDITIONING CO LTD

UV polymerization type body foamed damping material and preparation method thereof

ActiveCN105585985AImprove performanceLower glass transition temperatureNon-macromolecular adhesive additivesGraft polymer adhesivesFoaming agentSolvent free

The invention discloses a UV polymerization type body foamed damping material. The UV polymerization type body foamed damping material comprises components in parts by weight as follows: 20-30 parts of an acrylate copolymer, 70-75 parts of a reactive diluent, 0.5-0.8 parts of a photoinitiator and 1-5 parts of hollow inorganic nanoparticles. The high-performance damping material is prepared through UV polymerization, and a solvent-free and pollution-free product is realized thoroughly. The hollow inorganic nanoparticles are taken as an inorganic body foaming agent, the product density can be controlled precisely according to requirements through control of adding amount of the hollow inorganic nanoparticles, and the loss factor of the product can be controlled and increased. The damping material has the advantages of excellent initial adhesion, persistent adhesion, peel strength, interfacial wettability and high loss factor.

Owner:WUHAN OXIRAN SPECIALTY CHEM CO

Preparation method of graphene composite silicon-carbon-nitrogen precursor ceramics

The invention relates to a preparation method of graphene composite silicon-carbon-nitrogen precursor ceramics, wherein the preparation method includes the following steps: (1) stirring polysilazane (PSZ) and graphene evenly in an N2 atmosphere to obtain a mixed solution; (2) rising the temperature of the mixed solution obtained by the step (1) with the heating rate of 3-5 DEG C / min from room temperature to 300-800 DEG C, and solidifying for 1-8 h; (3) carrying out crushing ball milling of the material solidified in the step (2) in a vibrating ball mill, and allowing the powder to pass througha 100-200 mesh sieve; (4) carrying out press molding of the powder obtained in the step (3) under the pressure of 5 MPa-15 MPa, carrying out cold isostatic pressing, and under the pressure of 150-250MPa, maintaining the pressure for 200-400 s to obtain a green body; and (5) carrying out heat treatment of the green body obtained in the step (4) under N2 atmosphere protection at the temperature of1000 DEG C-1300 DEG C, carrying out heat preservation for 2 h-6 h, and thus obtaining the product. The graphene material is introduced in the preparation process of a precursor, a real part and a virtual part of the relative complex dielectric constant of the ceramic material obtained by heat treatment are increased, the loss factor is increased and the reflection loss of the material is improved.

Owner:SHANDONG UNIV

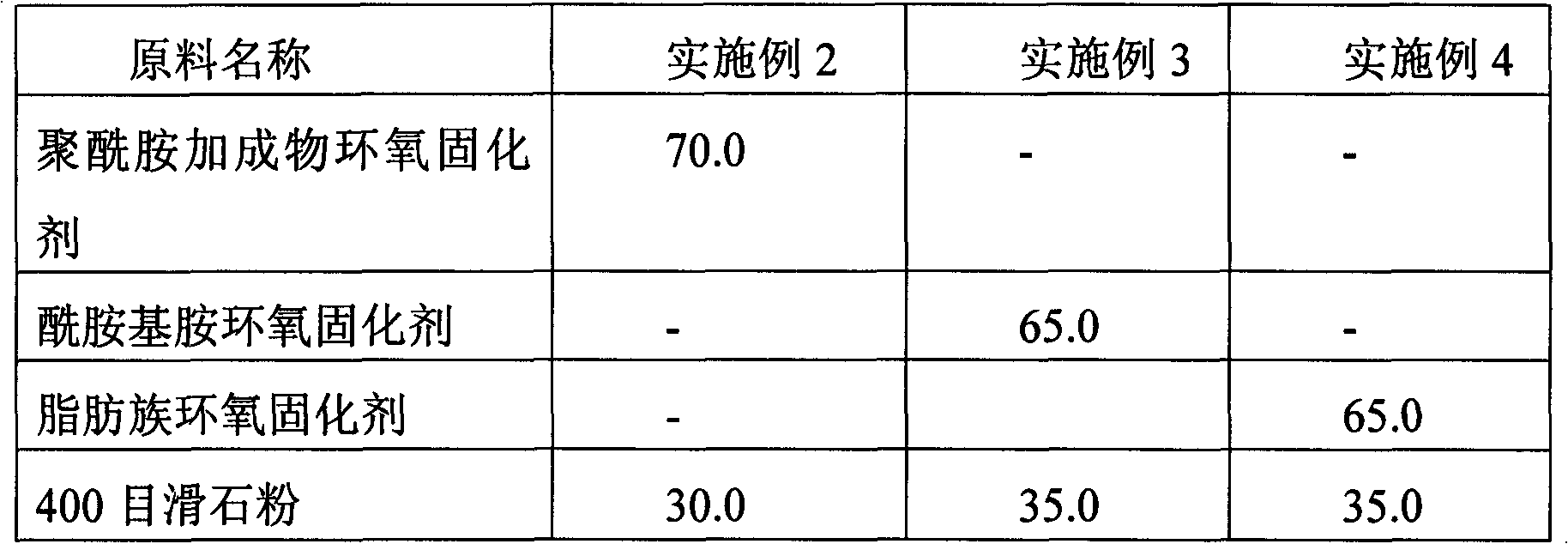

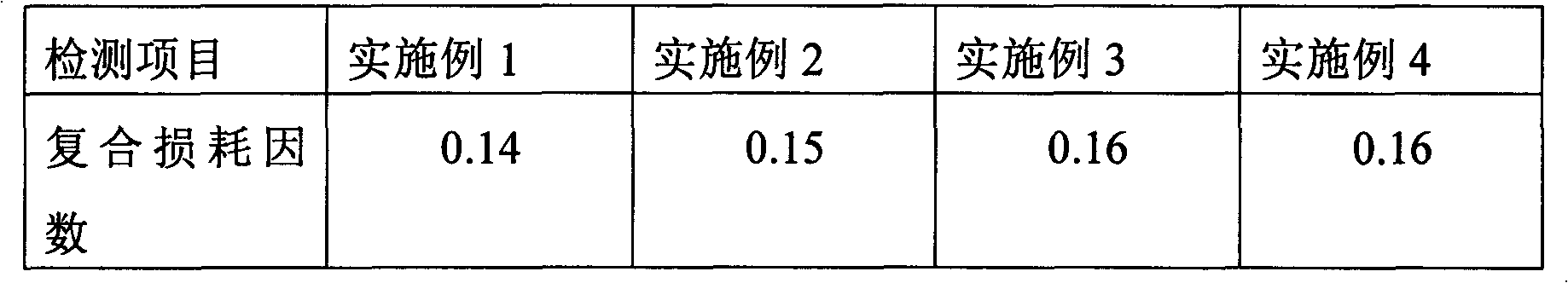

Double-component solvent-free damping coating and its preparation method

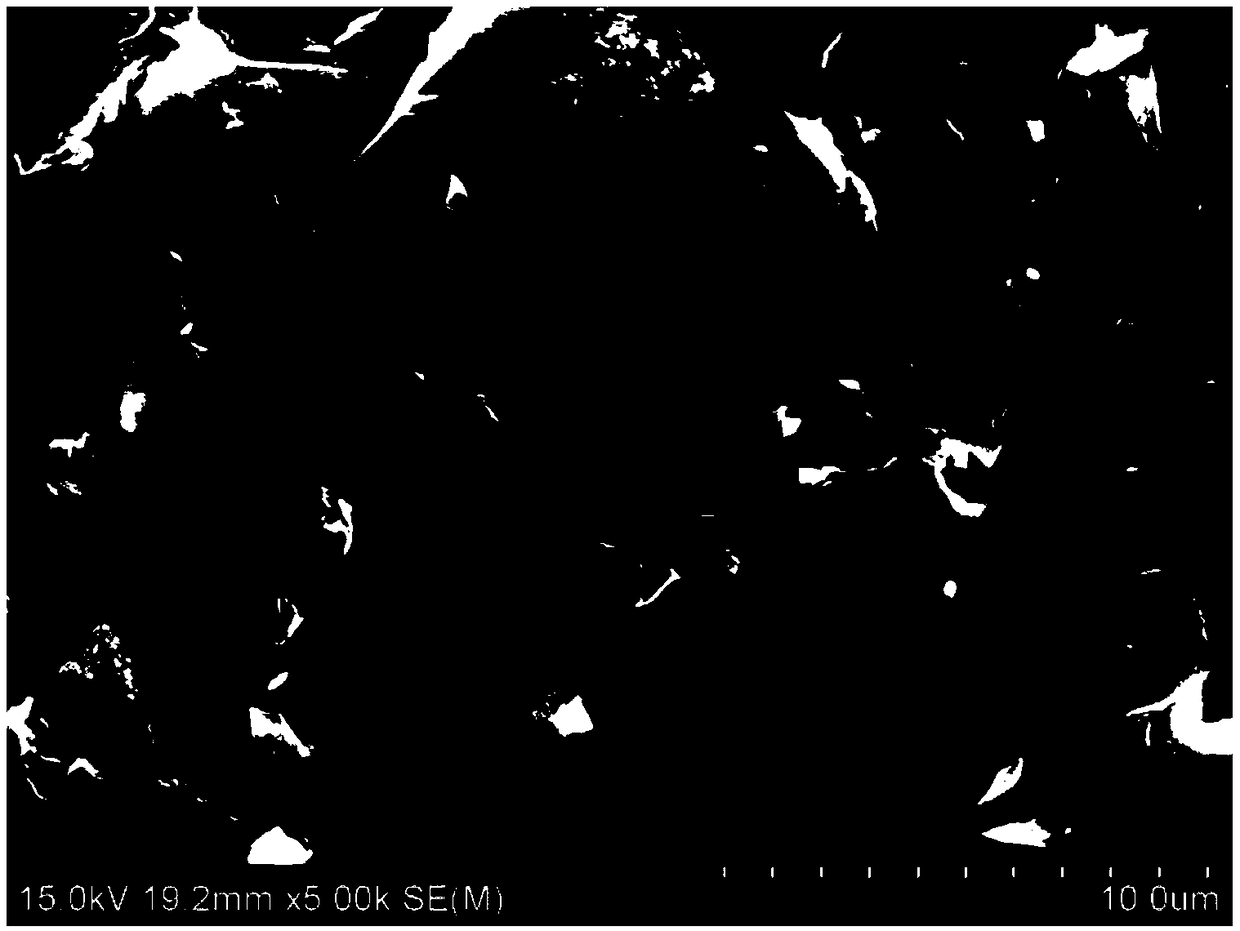

InactiveCN102876195AImprove loss factorSuitable for anti-vibration and anti-noiseAnti-corrosive paintsEpoxy resin coatingsEpoxySolvent free

The invention relates to a double-component solvent-free damping coating and its preparation method. The method comprises the following steps: 1, paint preparation: uniformly stirring and mixing a modified epoxy resin and a standard epoxy resin, adding an antifoaming agent, continuously uniformly stirring, sequentially adding composite sheet mica, 400 mesh calcium carbonate, graphite powder, the antifoaming agent and a dust preventive, uniformly stirring, grinding twice through using a three-roll machine, and examining the viscosity to obtain the paint of the solvent-free damping coating when the viscosity satisfies a case that no flowing appears after the scraping of 5mm of a coat; 2, curing agent preparation: adding an epoxy curing agent into talcum powder under stirring, and continuously stirring for 1-2h to obtain a uniform slurry which is the curing agent of the solvent-free damping coating; and 3, coating preparation: uniformly mixing the paint obtained in step 1 with the curing agent obtained in step 2 according to a weight ratio of the paint to the curing agent of 2:1 to obtain the solvent-free damping coating. Compared with coatings prepared through the prior art, the coating prepared in the invention has the advantages of easy construction, zero content of VOC, curing at normal temperature, high loss factor, high corrosion and vibration resistances, and the like.

Owner:SHANGHAI DATONG HIGH TECH MATERIALS

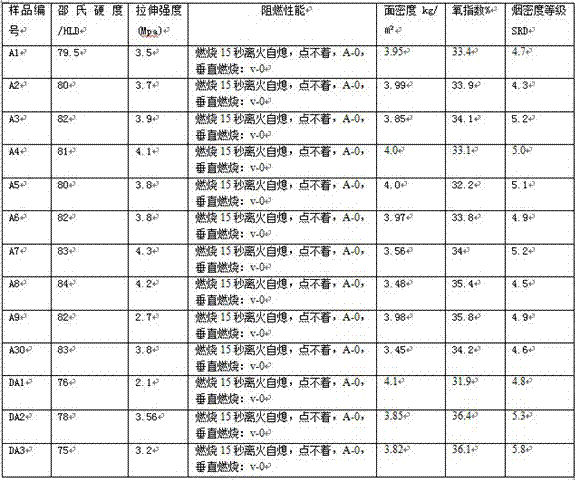

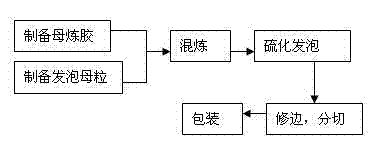

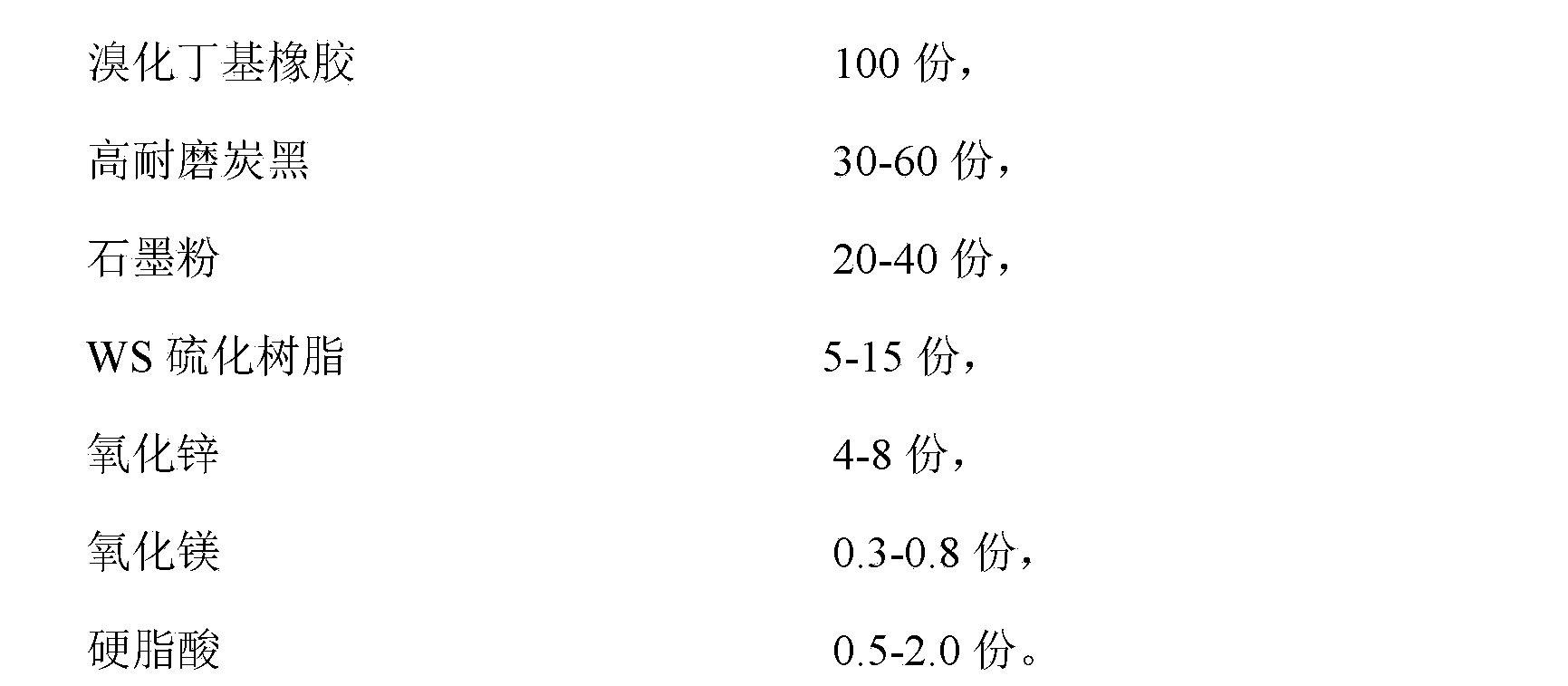

Composite foam sound insulation material and preparation method thereof

The invention discloses a composite foam sound insulation material. The material is composed of the following components in parts by weight: 49 parts of halogenated butyl rubber sulfurization system, 120 parts of sound insulation material master batch, and 40 parts of foaming master batch; wherein the halogenated butyl rubber sulfurization system comprises the following components in parts by weight: 30 parts of halogenated butyl rubber, 12 parts of promoter, 2 parts of promoter, 2 parts of anti-coking agent, 1 part of promoter, and 3 parts of sulfurization agent; the foaming master batch comprises the following components in parts by weight: 20 parts of halogenated butyl rubber and 20 parts of foaming agent; the sound insulation material master batch comprises the following components in parts by weight: 50 parts of halogenated butyl rubber, 50 parts of sound insulation material, and 20 parts of plasticizer. The invention also discloses a preparation method of the composite foam sound insulation material. The composite foam sound insulation material has the advantages of good sound insulation and sound absorbing property, light weight, and excellent heat insulation property, and at the same time has the characteristics of adaptability to various appearances in the actual use, excellent elasticity, fire retardant property, environment-friendliness, and chemical corrosion resistance.

Owner:李巍巍 +1

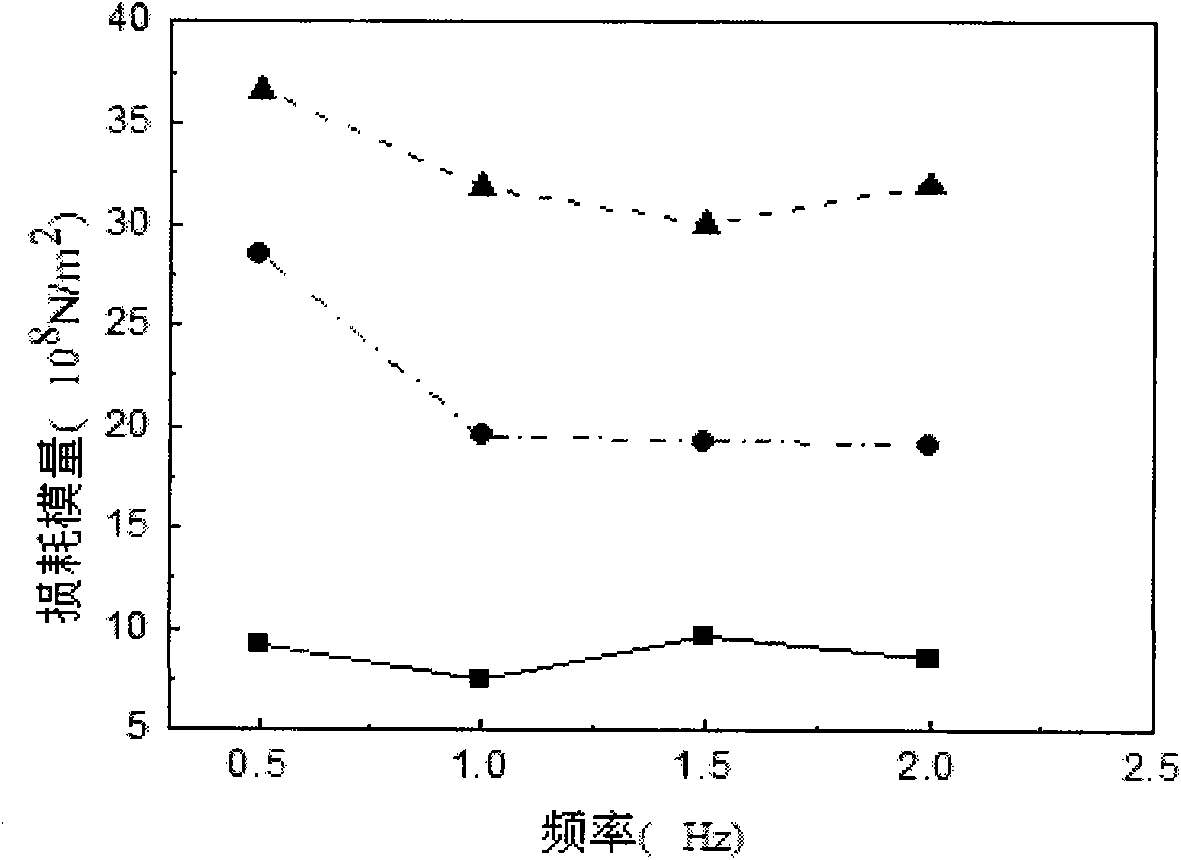

Low-frequency damping visco-elastic material

The invention relates to a low-frequency damping visco-elastic material which is a low-frequency vibration high-energy consumption visco-elastic material used in civil engineering structures, high-voltage transmission systems, machinery, vehicle shock (vibration) reduction projects. The visco-elastic material is prepared by mixing by using a main body rubber, a reinforcing system, a vulcanization system, an anti-aging system, and a softening-plasticizing system. As a result of large amounts of tests, the low-frequency damping visco-elastic material has good energy consumption and anti-aging performances under an application environment with a frequency of 0.1-10Hz and a temperature of -20 DEG C to 50 DEG C. Loss factor is 0.5-1.0, and a durability life reaches 80 years.

Owner:东南大学常州研究院

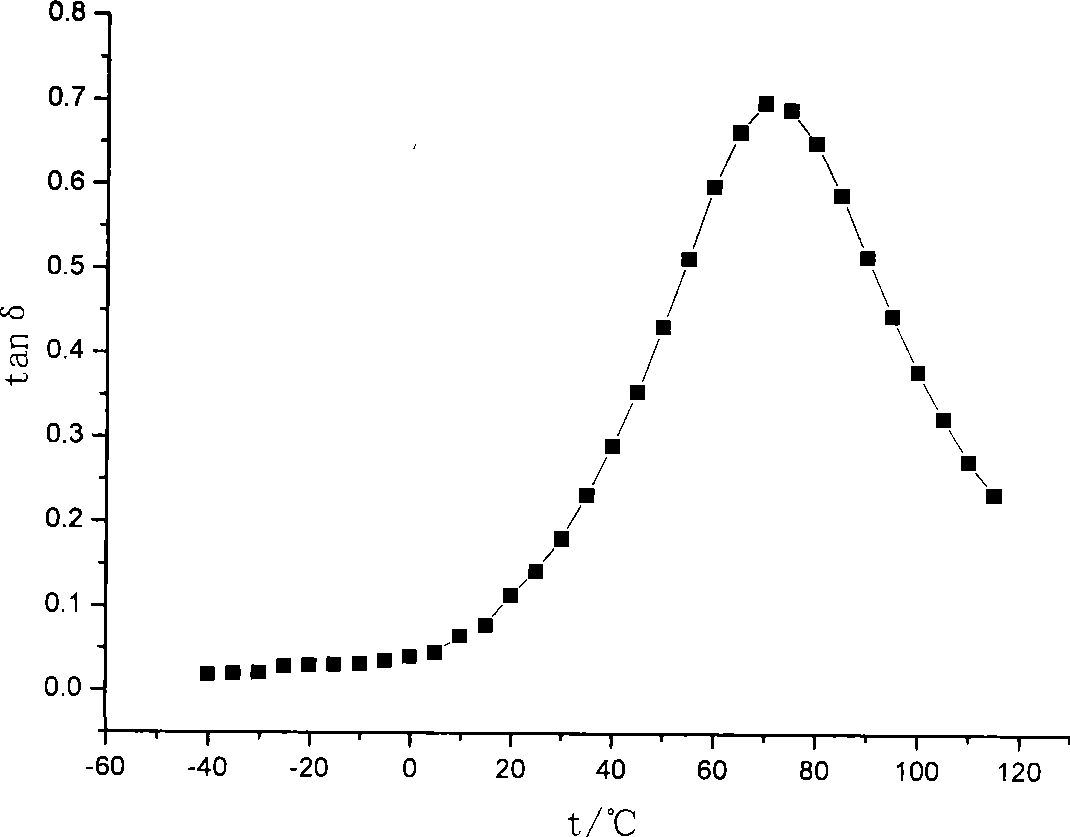

Organosilicon-type polyurethane damping material and preparation method thereof

ActiveCN109021196AHigh damping loss factorImprove low temperature brittlenessHydrolysisMechanical property

The invention provides an organosilicon-type polyurethane damping material and a preparation method thereof. The damping material is synthesized by methyl propylene oxide, a molecule main chain has ahomo-carbon dimethyl structure and a homo-silicon dimethyl structure, and terminal alkenyl ether alcohol is synthesized by using enol and isobutylene oxide, the diol having the homo-carbon dimethyl structure and the homo-silicon dimethyl structure is synthesized with the double-end hydrogen silicone oil having the homo-silicon dimethyl, a polyurethane prepolymer is synthesized by the raw materialand the diisocyanate, the prepolymer is reacted with a chain extender, and the organosilicon-type polyurethane damping material is obtained. The damping material prepared by the invention has good mechanical properties and damping properties, and at the same time, the low temperature brittleness, heat resistance and hydrolysis resistance of the material are improved by the introduction of the organosilicon, and the application of the material in the fields of sophisticated weapons, spaceflight aircrafts, navigation, construction, and environmental protection and the like.

Owner:ENERGY RESOURCES INST HEBEI ACADEMY OF SCI

Dispersion layer composite damping material with vacant-shell foam ceramic balls as aggregate

ActiveCN105330201AImprove the protective effectImprove attenuation performanceCeramicwareClaywaresCompression moldingAttenuation coefficient

The invention belongs to the technical field of national defense engineering protection materials, and especially relates to a dispersion layer composite damping material with vacant-shell foam ceramic balls as aggregate and with a civil air defense command work layered structure. The purpose of the invention is to use a dispersion layer material with large attenuation coefficient, high cost performance and stable performances to substitute sandy soil and other local materials used at present in order to improve the comprehensive protection ability of the layered protection structure. The dispersion layer material is prepared through mixing the vacant-shell foam ceramic balls, highly adhesive and elastic asphalt base and polyphenyl particles according to a certain ratio, and through carrying out compression molding, wherein the vacant-shell foam ceramic balls are a hollow foam ceramic structure, and have the characteristics of high amount of porosity and small density. The cavity diffraction and foam compression destroy energy dissipation of the vacant-shell foam material and the intrinsic damping of the highly adhesive and elastic asphalt base are fully used in the invention, so the attenuation coefficient of the prepared dispersion layer material is 4.2, the density is 0.85g / cm<3>, the wave velocity is 120m / s, and the comprehensive protection ability of the civil air defense command engineering layered structure is greatly improved.

Owner:UNIT 61489 OF PLA

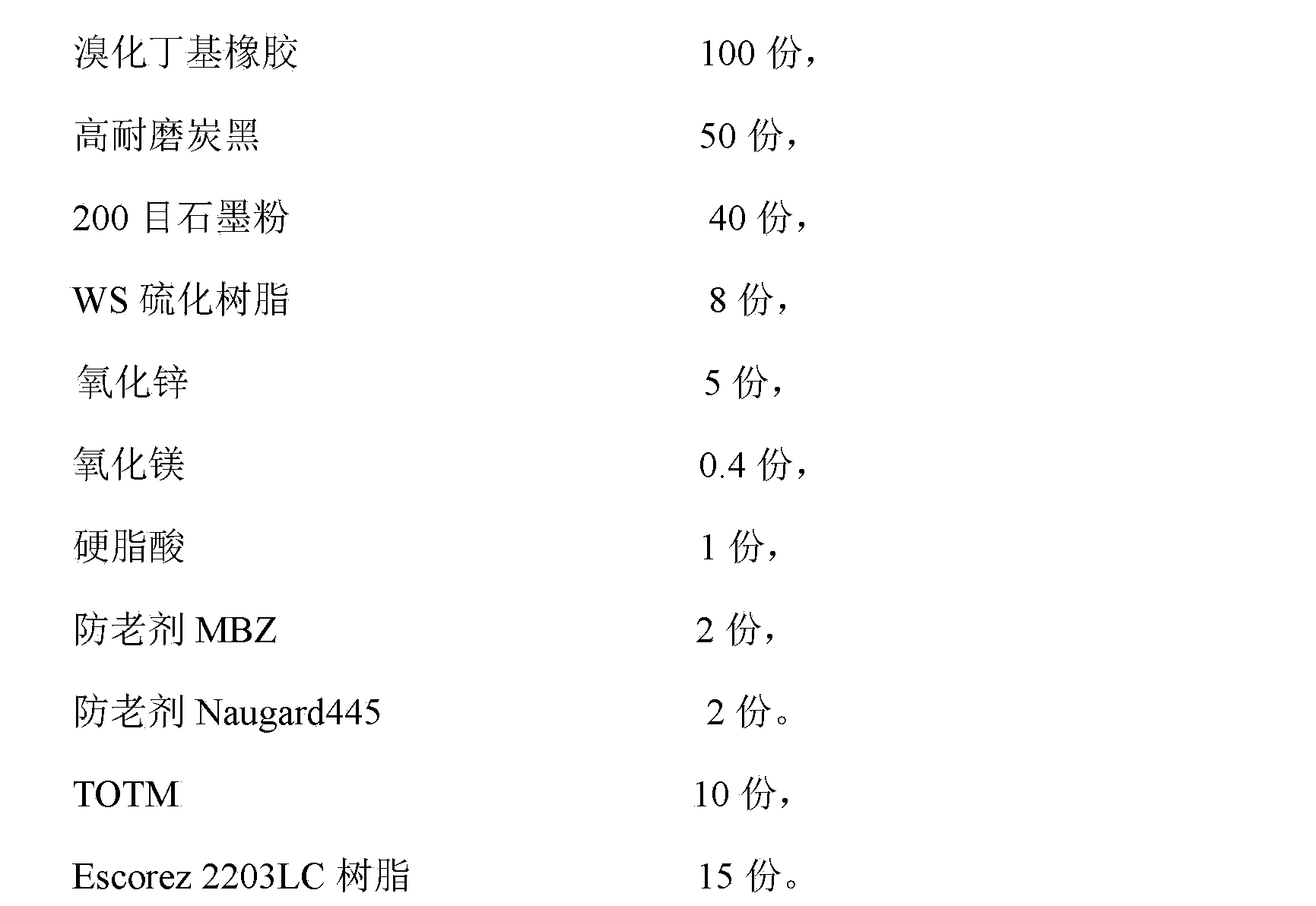

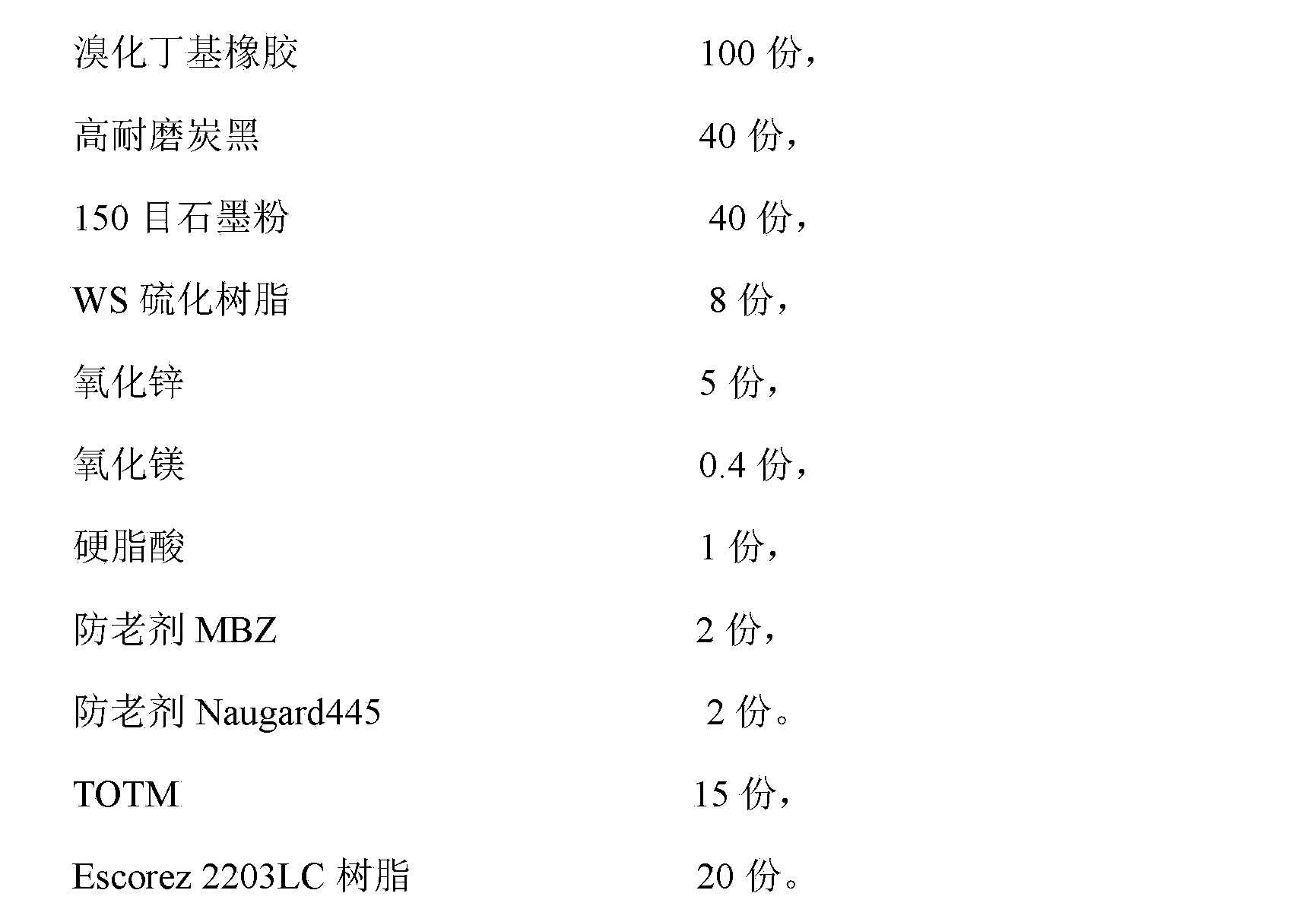

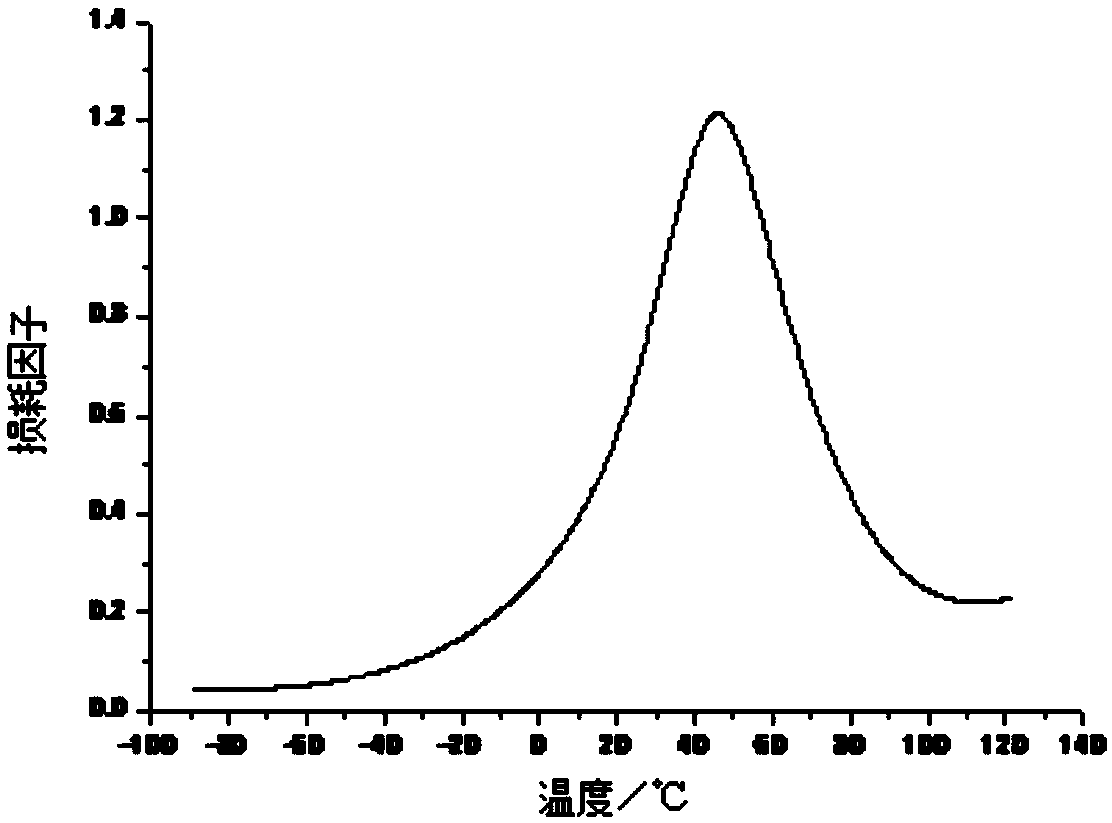

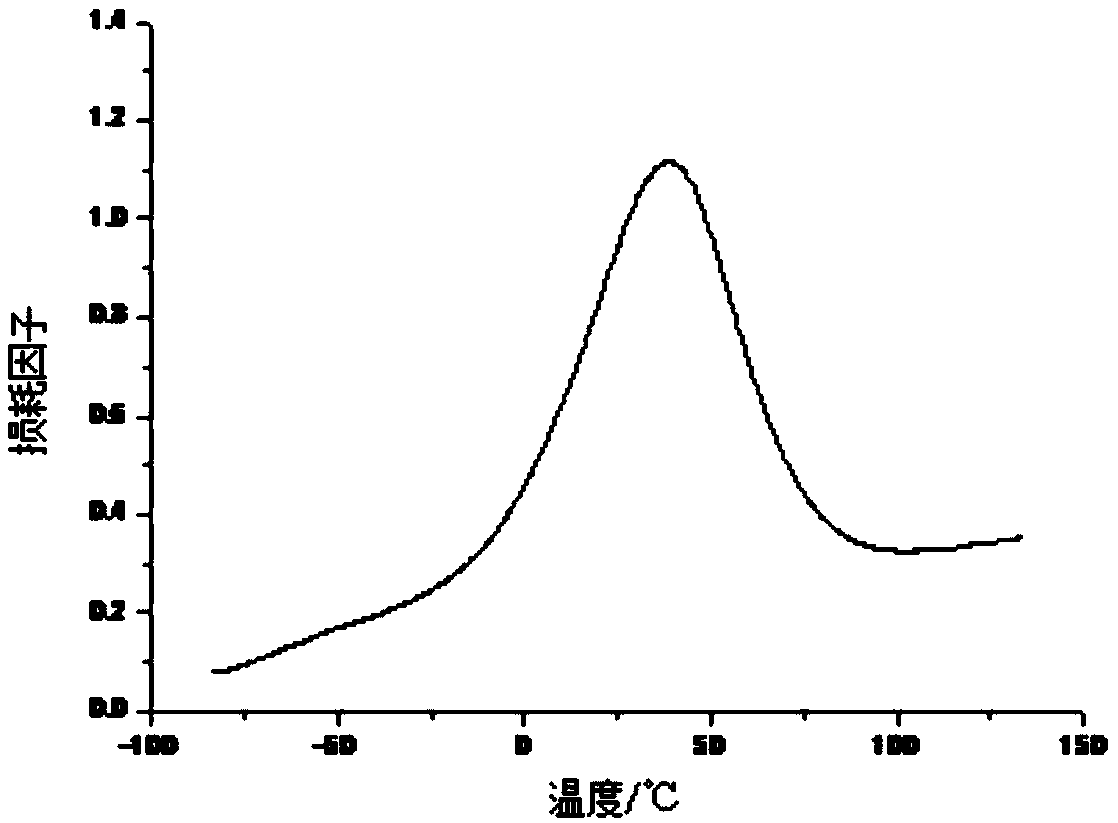

Preparation method of novel normal-temperature low-pressure-change high-damping material

The invention relates to a preparation method of a novel normal-temperature low-pressure-change high-damping material. The preparation method of the novel normal-temperature low-pressure-change high-damping material comprises the following steps of S1, selecting components according to the proportion as below: 55 to 76.5 percent of butyl rubber, 5 to 7 percent of phenolic resin, 3 to 5 percent ofzinc oxide, 1 to 1.5 percent of stearic acid, 1.5 to 2 percent of anti-aging agent, and 8 to 34.5 percent of modified silicon earth filler; S2, according to the material proportions of the S1, sequentially adding the materials into an open mill according to the sequences of the butyl rubber, the zinc oxide, the stearic acid, the anti-aging agent, the phenolic resin and the modified silicon earth filler, mixing and discharging slices; S3, using a press vulcanizer for vulcanizing and forming a rubber compound in the S2.

Owner:航天长征睿特科技有限公司

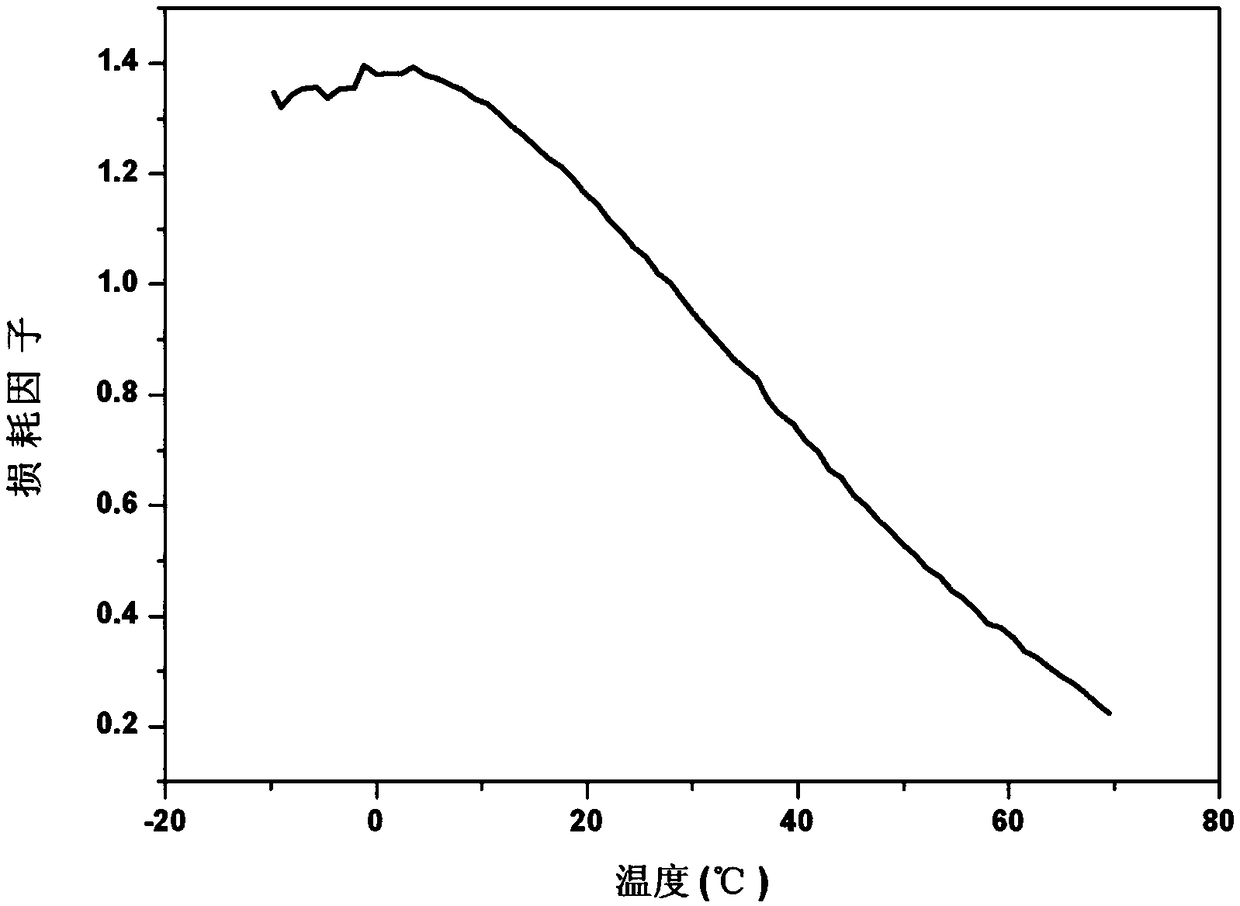

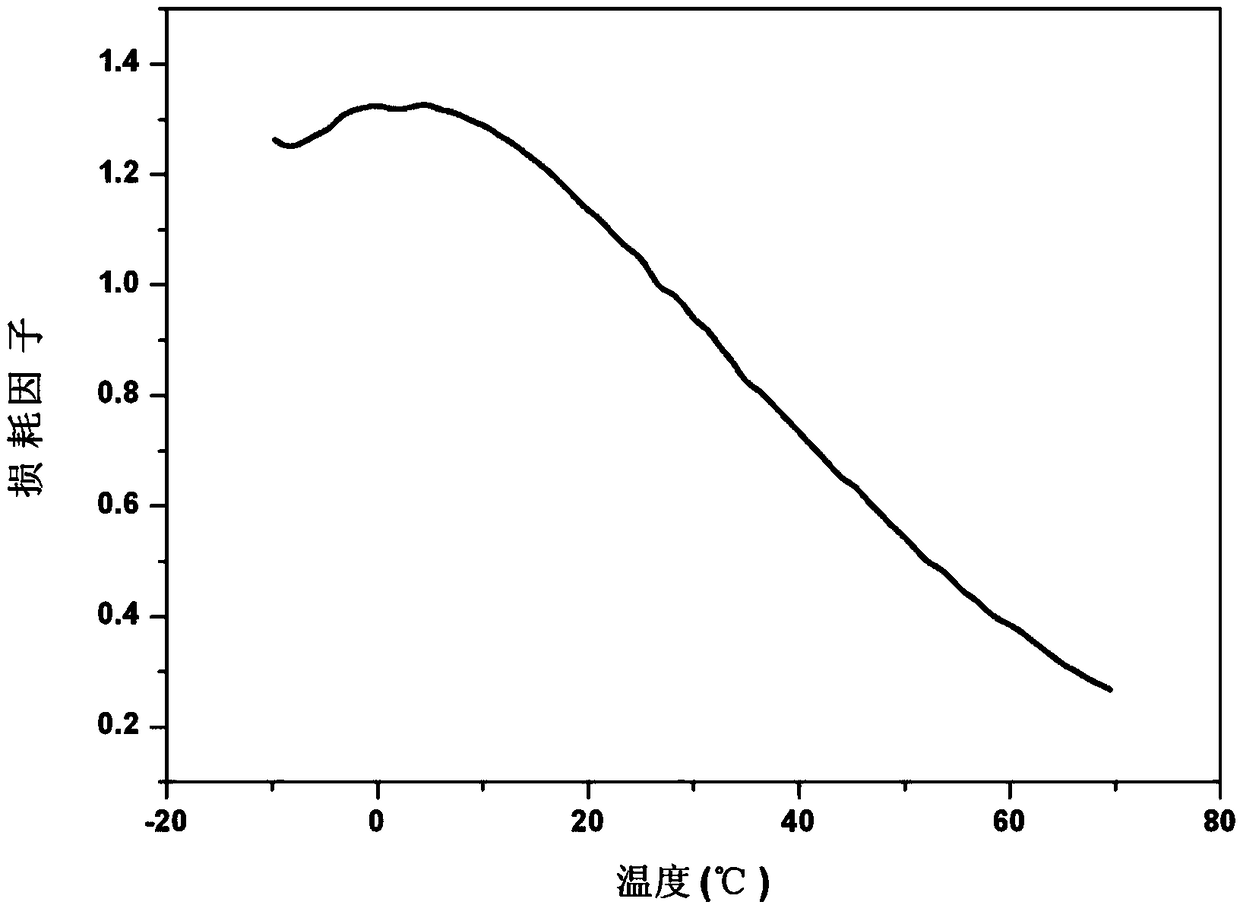

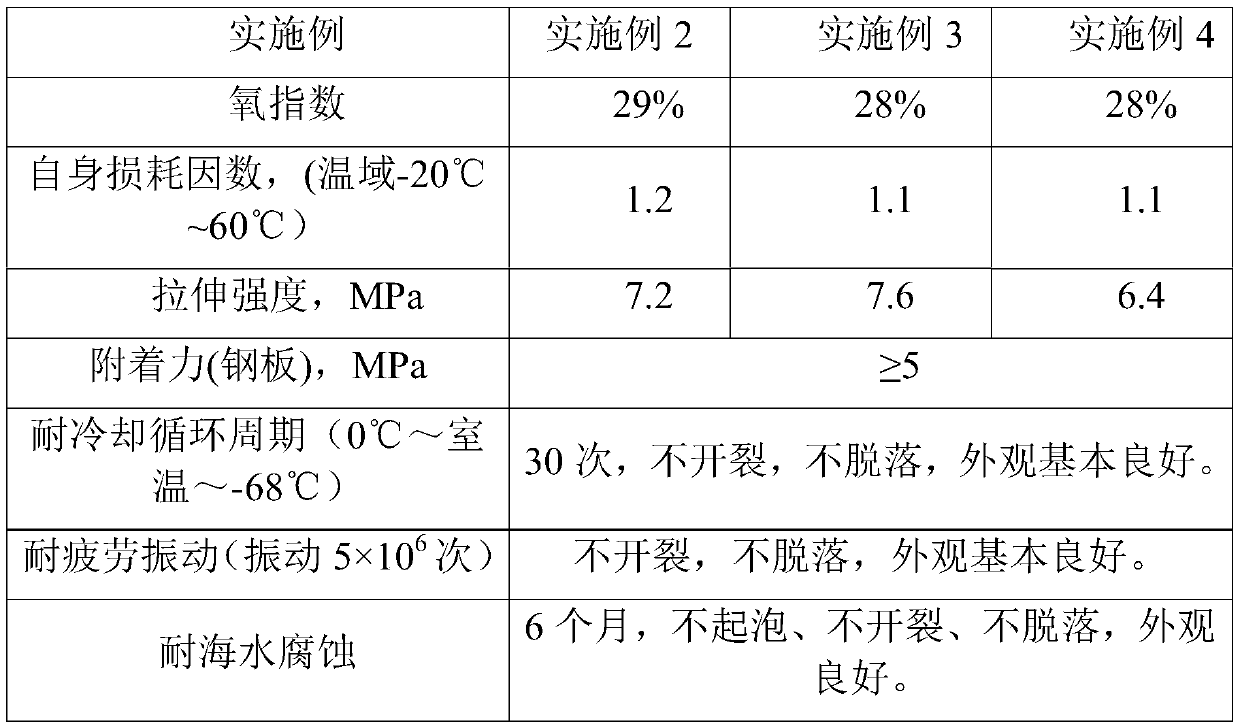

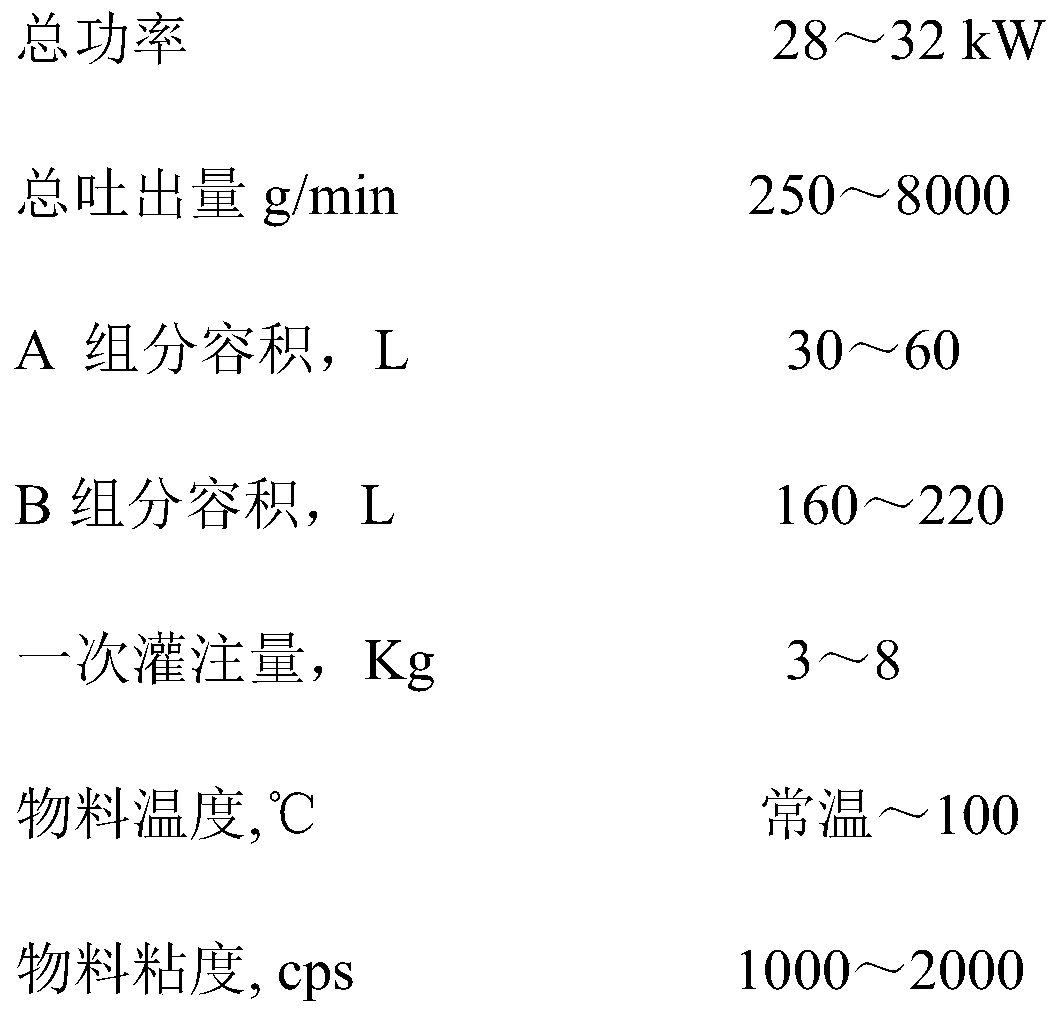

Ship perfusion sealing damping vibration attenuation material and preparation method thereof

ActiveCN111533883ASeawater corrosion resistanceImprove damping performanceHydroxyl-terminated polybutadieneEther

The invention provides a ship perfusion sealing damping vibration attenuation material which comprises a component A and a component B. The component A comprises the following raw materials: oligomerpolyol and polyisocyanate; the component B is prepared from the following raw materials: oligomer polyol and a chain extension cross-linking agent, wherein the oligomer polyol comprises at least two compounds selected from the group consisting of hydroxyl-terminated polybutadiene, polytetrahydrofuran ether glycol, polycaprolactone glycol and polycarbonate glycol. According to the ship perfusion sealing damping vibration attenuation material, polytetrahydrofuran ether glycol is blended with marine environment corrosion resistance with hydroxyl-terminated polybutadiene, polycaprolactone glycol and polycarbonate glycol which are used for effectively controlling mechanical vibration and noise, the prepared damping vibration attenuation material has a wide damping temperature range and a high loss factor and is resistant to seawater corrosion and is suitable for a ship perfusion sealing construction process.

Owner:QINGDAO AIR NEW MATERIALS

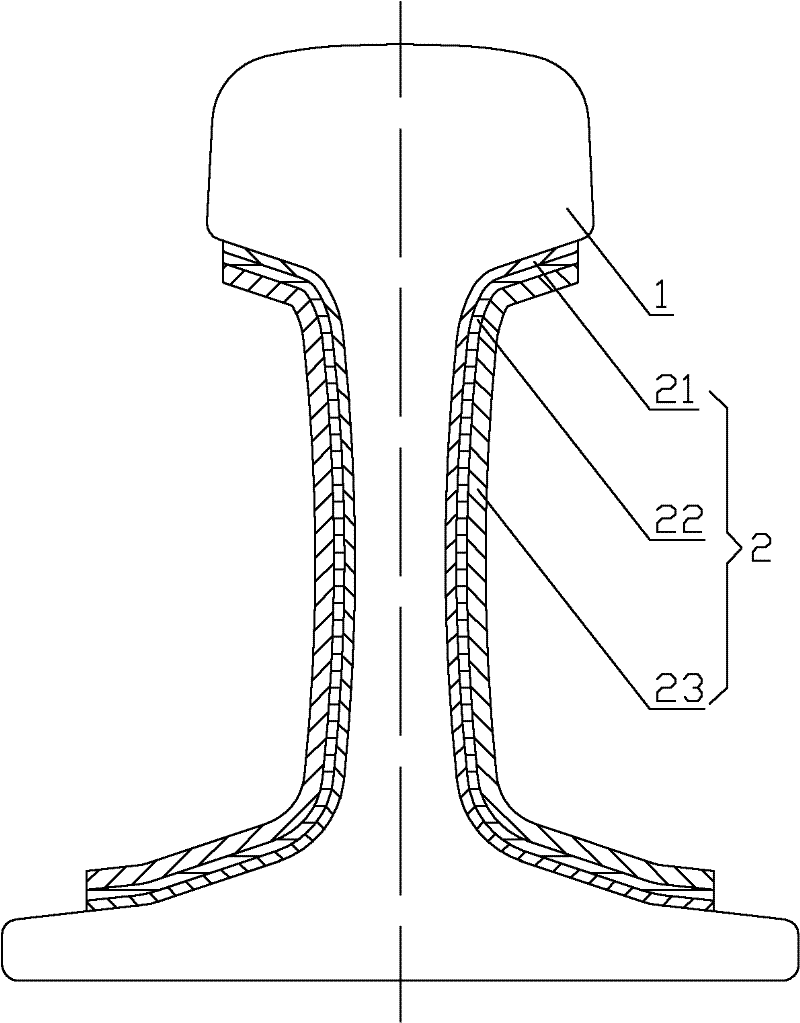

Damping steel rail

InactiveCN103498392AControl low and medium frequency vibrationNoise controlRailsLight railEngineering

The invention relates to a damping steel rail which comprises a steel rail body, wherein the steel rail body comprises a waist rail, a top rail located at the upper end of the waist rail, and a rail base located at the lower end of the waist rail, a layered structural body is arranged on the surface of the waist rail and extends to the top rail and the rail base along the waist rail, and the layered structural body is provided with an elastic energy consumption layer, a magnetic absorption layer, a damping layer, a restraint layer and a protective layer from inside to outside along the surface of the waist rail. According to the damping steel rail, a dynamic vibration absorbing and restraint damping composite structure is adopted, the vibration absorbing and silencing frequency range can be widened remarkably, and medium-and-low-frequency vibration and noise of the steel rail can be effectively controlled especially. The damping steel rail is especially suitable for new line laying or old line reformation of city subways, light rails, interurban railways, high speed railways and the like.

Owner:EAST CHINA JIAOTONG UNIVERSITY

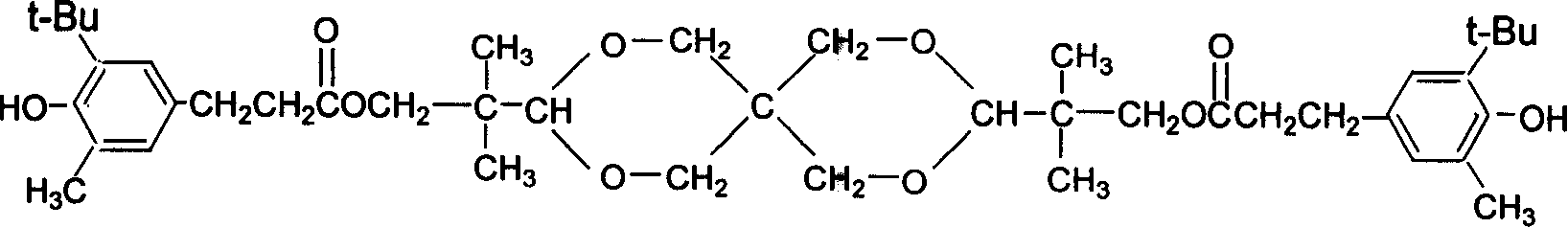

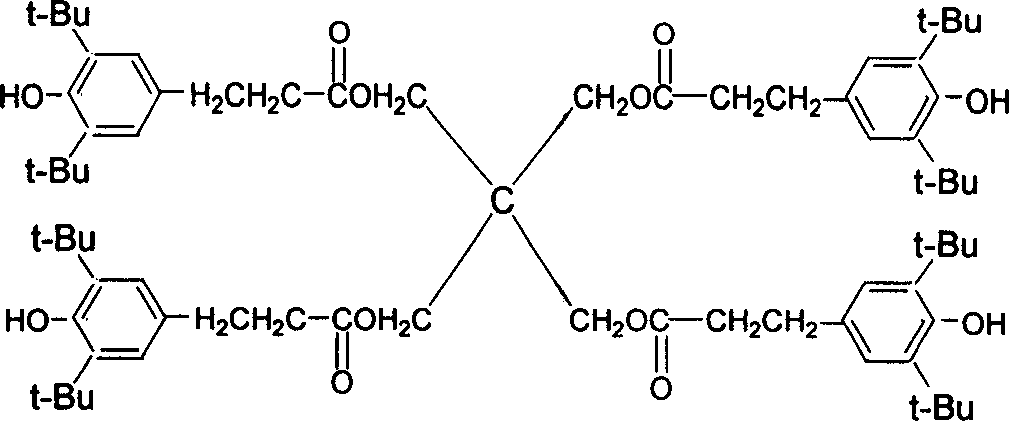

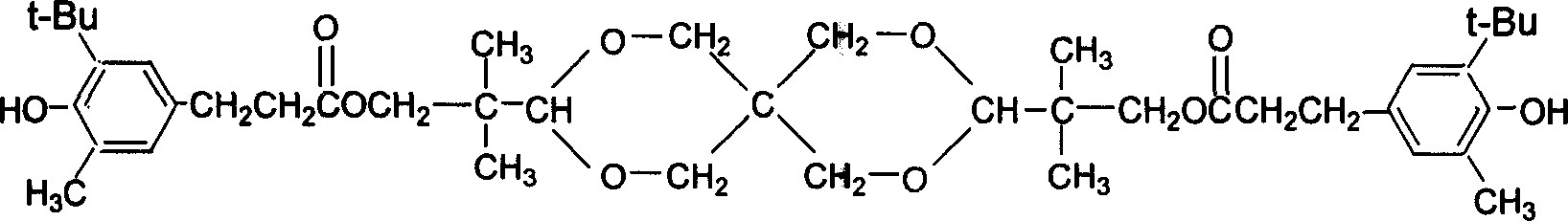

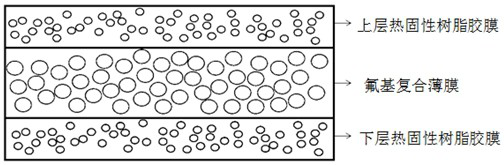

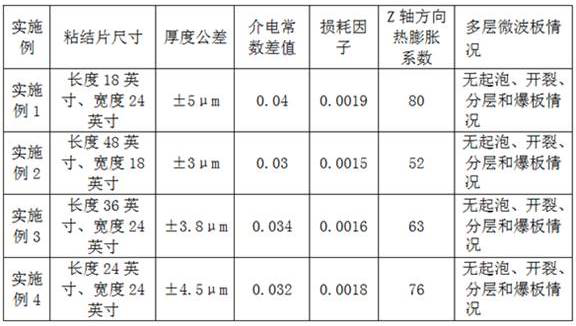

A method for preparing a low-loss and high-uniform adhesive sheet and a multi-layer microwave board

ActiveCN113861864BSmall coefficient of thermal expansionLow loss factorNon-macromolecular adhesive additivesFilm/foil adhesivesElastomerPolymer science

The invention relates to a low loss and high uniformity adhesive sheet and a method for preparing a multilayer microwave board. The adhesive sheet is composed of an upper thermosetting resin film and a lower thermosetting resin film of a fluorine-based composite film; the upper thermosetting resin film and The components of the lower thermosetting resin film are thermosetting resin, initiator and filler. In order to achieve specific functions, thermoplastic elastomers, flame retardants, antioxidants and plasticizers can be added to it; among them, thermosetting resin and thermoplastic elastic The body is the matrix, the cross-linking agent, flame retardant, antioxidant and plasticizer are the additives, and the filler is the reinforcing material; the additives and reinforcing materials are randomly distributed in the matrix; the thermosetting resin film is semi-cured or uncured. In the cured state, it has certain fluidity and is prepared on the upper and lower surfaces of the fluorine-based composite film through a coating process. The components of the invention exhibit high uniformity and do not contain fiberglass cloth, thus avoiding the impact of the "glass fiber effect" on high-frequency signal transmission.

Owner:CHINA ELECTRONICS TECH GRP NO 46 RES INST

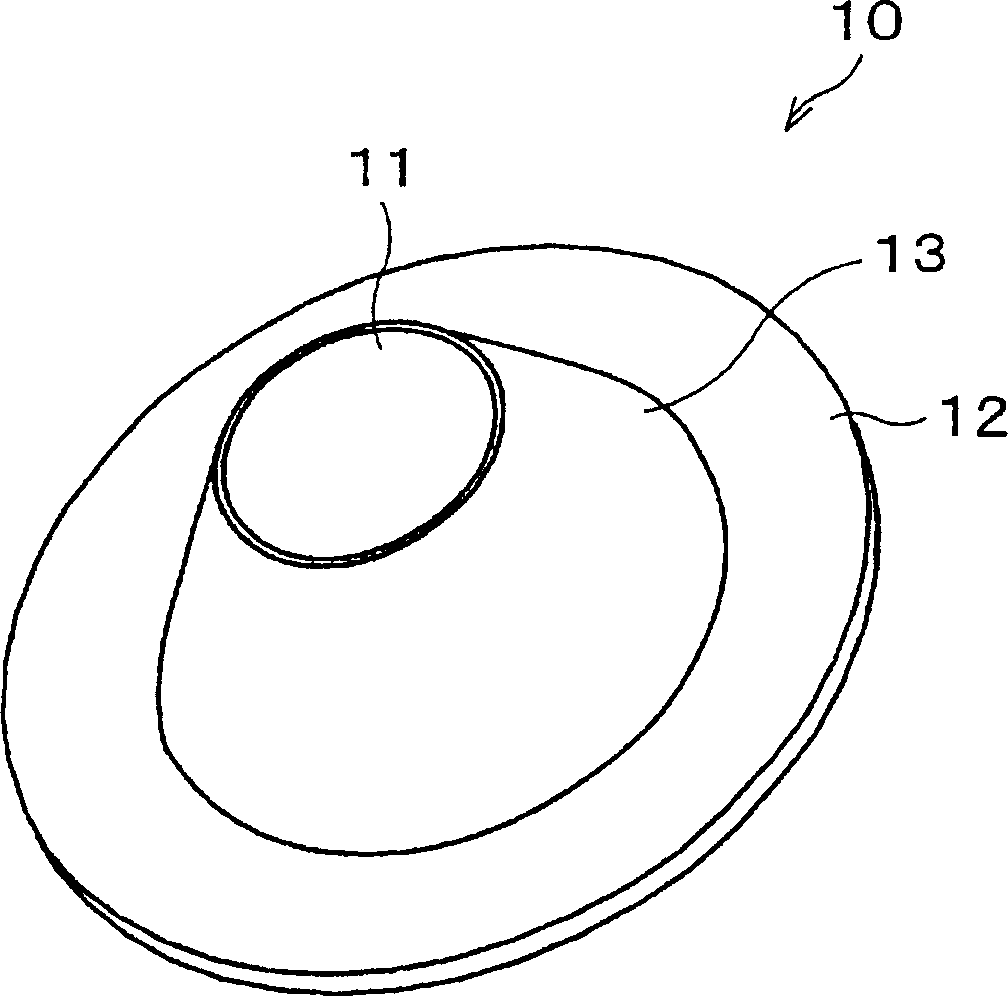

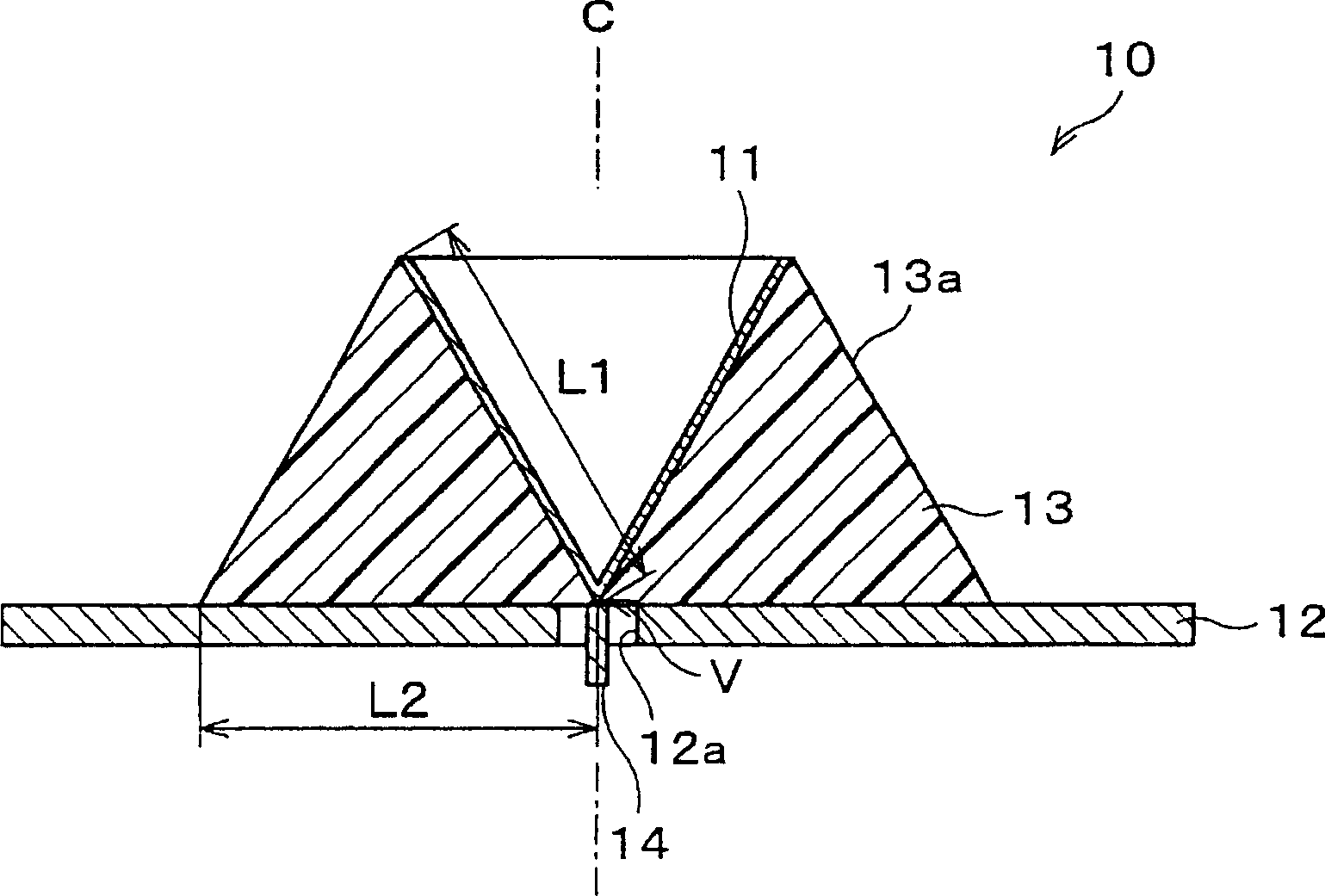

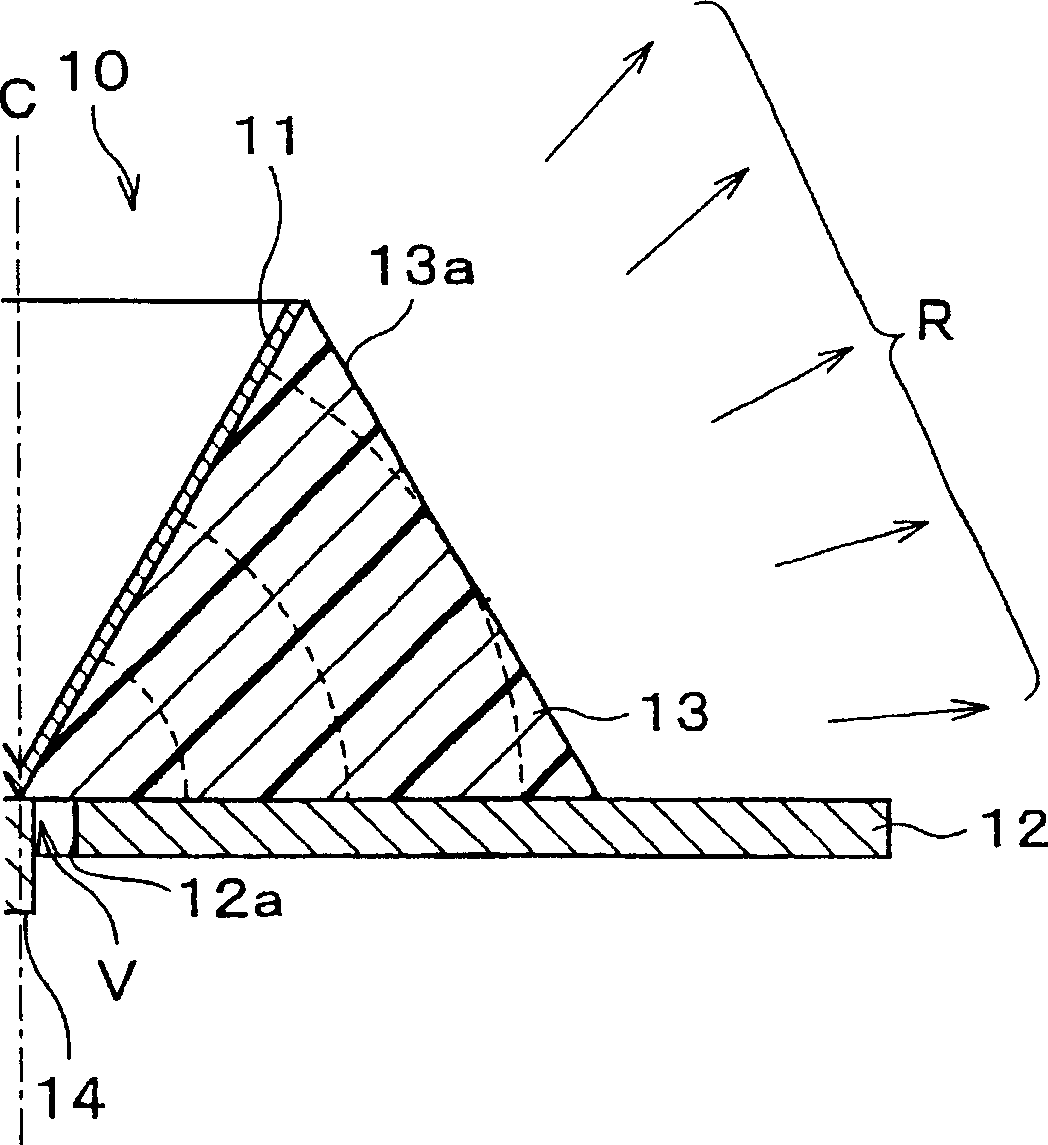

Dielectric antenna

InactiveCN1842939ALow dielectric constantImprove loss factorRadiating elements structural formsElongated active element feedDielectricConoid

A mono-conical antenna as a dielectric antenna includes: a feed electrode having a conical surface; a grounding electrode having a flat surface positioned at the vertex side of the conical surface with respect to the conical surface; and a dielectric member arranged between the conical surface and the flat surface. The outer circumference of the dielectric member has a shape spreading from the conical surface side toward the flat surface side. Thus, the size of the dielectric antenna can be reduced and the dielectric antenna can have a wide range of a frequency band suppressing the maximum value of the VSWR to a small value.

Owner:ORMON CORP +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com