Polyphenyl ether-polyorganosiloxane photo-crosslinking thin film based on graft copolymer and preparation method of polyphenyl ether-polyorganosiloxane photo-crosslinking thin film

A graft copolymer, polysiloxane optical technology, applied in the field of polyphenylene ether-polysiloxane photo-crosslinked film and its preparation, can solve the problems of high temperature resistance and high loss damping performance in wide temperature range , to achieve the effects of good capacity expansion, high loss performance and excellent damping performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

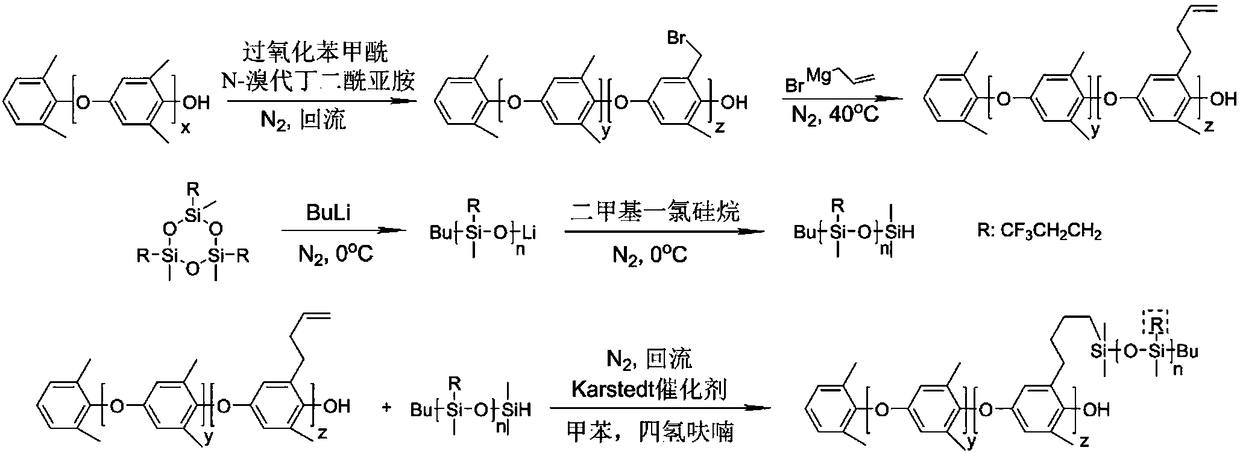

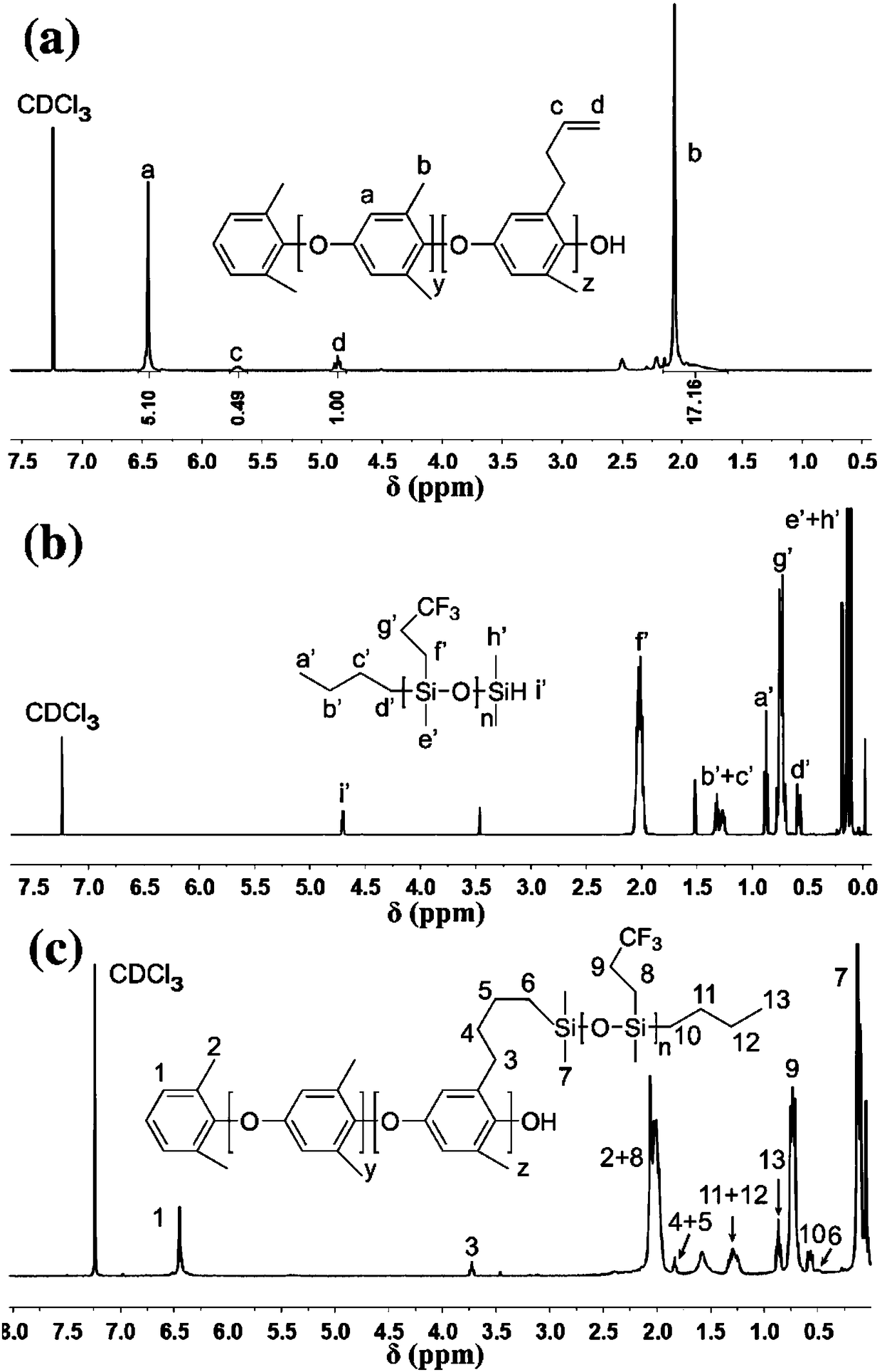

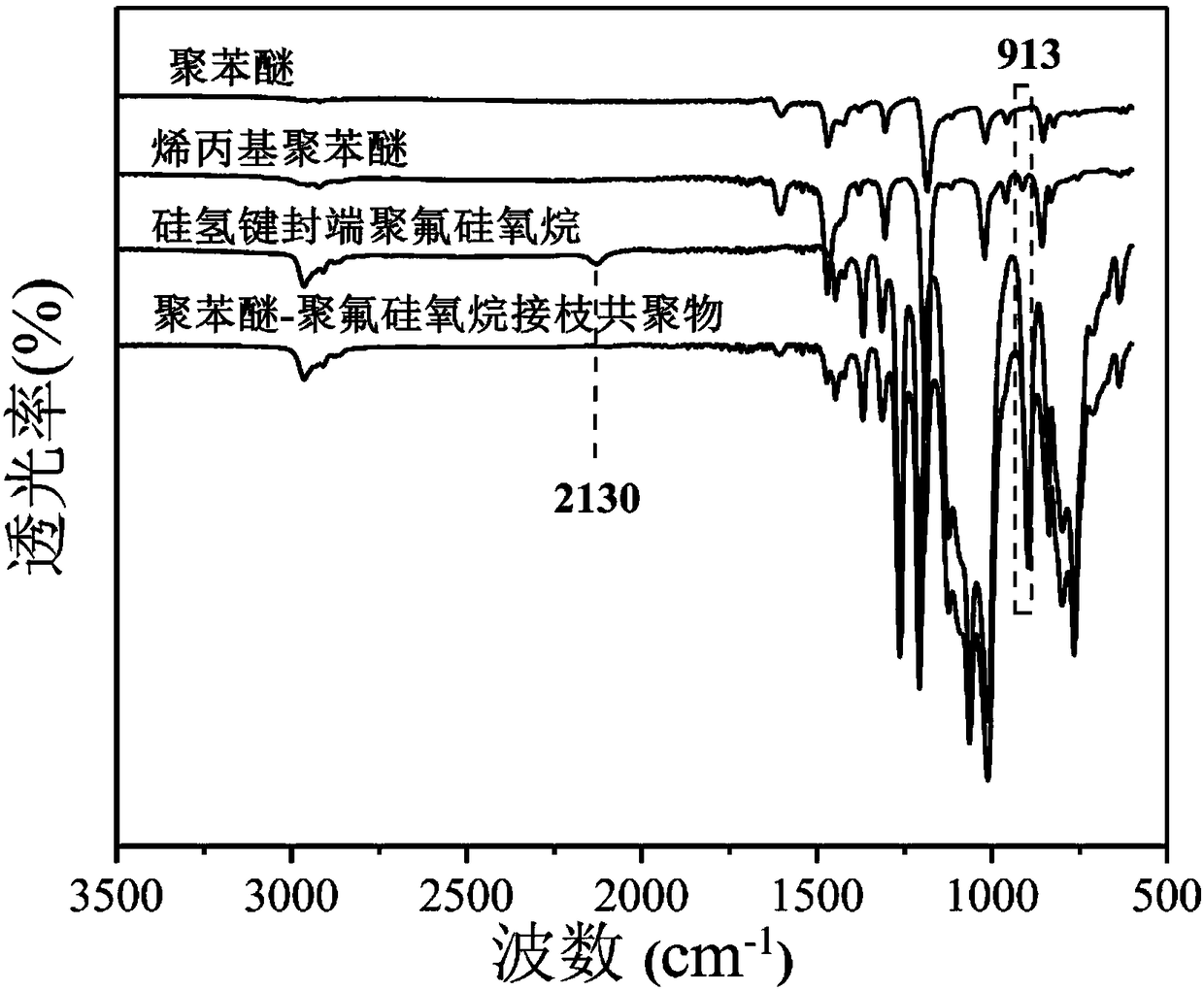

[0061] (1) Preparation of allyl polyphenylene ether

[0062] Under the condition of nitrogen protection, dissolve 10g of polyphenylene ether in 100mL of chlorobenzene, then add 1g of benzoyl peroxide and 4g of N-bromosuccinimide in sequence, heat and reflux for 1.5h; precipitate the product with methanol, After washing, filtering and drying, brominated polyphenylene ether was obtained. Dissolve 10g of brominated polyphenylene ether in 500mL of tetrahydrofuran at a temperature of 40°C under nitrogen protection, and then add 20mL of allylmagnesium bromide tetrahydrofuran solution (1mol / L) dropwise to it. After the dropwise addition, React at 40°C for 3 hours; precipitate the product with methanol, wash, filter and dry to obtain allylated polyphenylene ether.

[0063] (2) Preparation of silicon-hydrogen bond-terminated polysiloxane

[0064] Dissolve 5.8mL of trifluoropropylmethylcyclotrisiloxane in 2mL of anhydrous tetrahydrofuran, then add 13.5mL of n-butyllithium solution (1....

Embodiment 2

[0073] The allyl polyphenylene ether prepared in 8.1g embodiment 1, the polyphenylene ether-polysiloxane graft copolymer prepared in 1g embodiment 1, 0.9g vinyl polytrifluoropropyl methylsiloxane , 1.07g of trimethylolpropane tris(3-mercaptopropionate) and 0.27g of (2,4,6-trimethylbenzoyl)diphenylphosphine oxide were dissolved in 500mL of tetrahydrofuran to obtain solution E.

[0074] Level the solution E on the polytetrafluoroethylene carrier, irradiate it under a UV lamp with a wavelength of 365nm for 5 minutes, take out the sample, and dry it fully to obtain a graft copolymer modified polyphenylene ether-polysiloxane photocrosslinker. Linked film. Its thermogravimetric analysis (TGA) curve, loss factor-temperature curve (obtained by dynamic mechanical analysis DMA test) and cold-field scanning electron microscope (SEM) photos of the brittle fracture section are shown in the attached Figure 4 , attached Figure 5 And attached Figure 6 .

Embodiment 3

[0076] The allyl polyphenylene ether prepared in 7.65g embodiment 1, the polyphenylene ether-polysiloxane graft copolymer prepared in 1.5g embodiment 1, 0.85g vinyl polytrifluoropropyl methylsiloxane Alkanes, 1.02 g of trimethylolpropane tris(3-mercaptopropionate) and 0.26 g of (2,4,6-trimethylbenzoyl)diphenylphosphine oxide were dissolved in 500 mL of tetrahydrofuran to obtain solution E.

[0077] Level the solution E on the polytetrafluoroethylene carrier, irradiate it under a UV lamp with a wavelength of 365nm for 5 minutes, take out the sample, and dry it fully to obtain a graft copolymer modified polyphenylene ether-polysiloxane photocrosslinker. Linked film. Its thermogravimetric analysis (TGA) curve, loss factor-temperature curve (obtained by dynamic mechanical analysis DMA test) and cold-field scanning electron microscope (SEM) photos of the brittle fracture section are shown in the attached Figure 4 , attached Figure 5 And attached Figure 6 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| thermal decomposition temperature | aaaaa | aaaaa |

| thermal decomposition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com