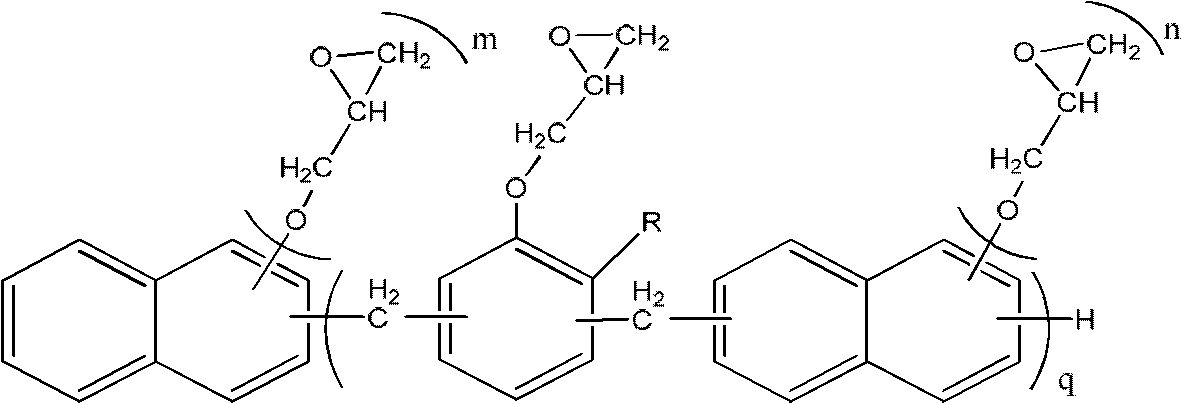

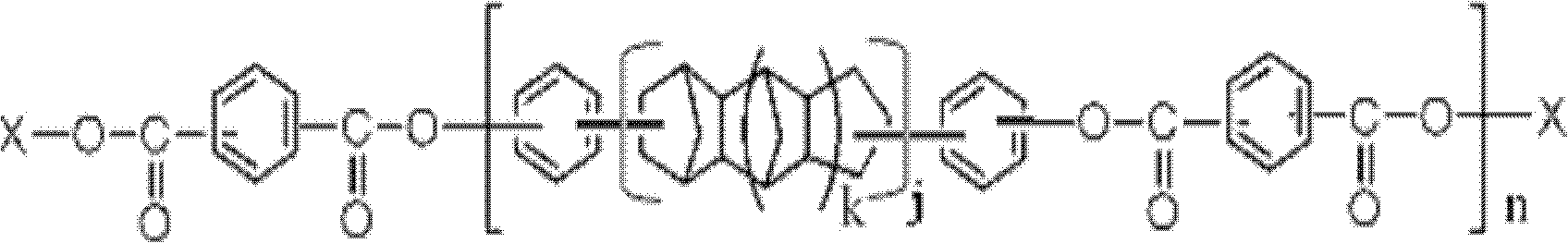

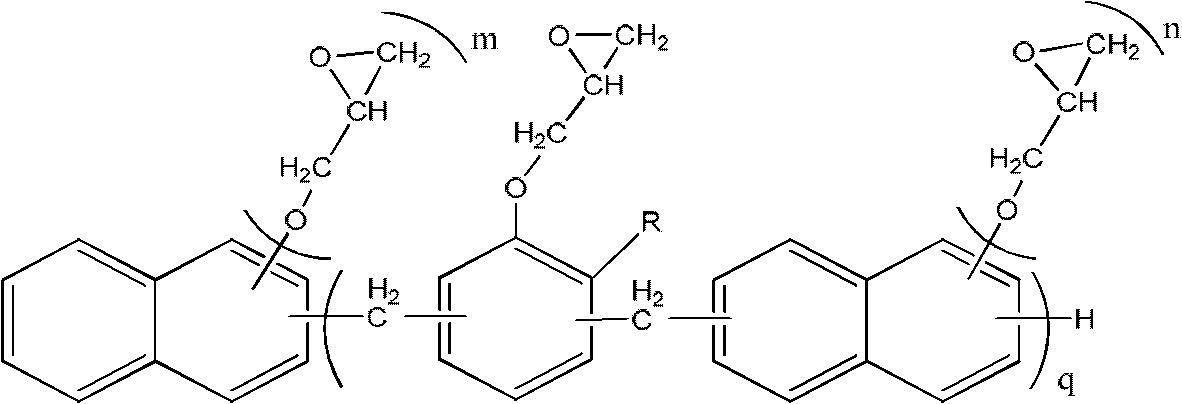

Epoxy resin composition as well as prepreg and copper-foil-clad laminated board prepared by using same

A technology of epoxy resin and prepreg, which is applied in the direction of synthetic resin layered products, layered products, metal layered products, etc., and can solve the problems of lower water absorption, low water absorption, low glass transition temperature and dielectric loss tangent, etc. , to reduce water absorption, low water absorption, excellent dielectric properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0063] Take a container, add 100 parts by weight of naphthol type novolac epoxy resin NC-7300L, then add an equivalent part by weight of active ester curing agent HPC-8000-65T, stir, add an appropriate amount of DMAP, and solvent toluene, continue to stir evenly into glue. Use glass fiber cloth (type 2116, thickness 0.08mm) to impregnate the above glue solution, and control it to an appropriate thickness, then dry to remove the solvent to prepare a prepreg. A plurality of prepregs prepared are stacked on each other, a piece of copper foil is laminated on each side of the prepreg, and put into a hot press machine to solidify to form the copper-clad laminate. The physical data are shown in Table 1.

Embodiment 2~3

[0065] The manufacturing process is the same as in Example 1, and the formula composition and physical property data are as shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| epoxy equivalent | aaaaa | aaaaa |

| epoxy equivalent | aaaaa | aaaaa |

| epoxy equivalent | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com