Patents

Literature

1644 results about "Sucrose measurement" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A 25 °Bx sucrose solution has 25 grams of sucrose per 100 grams of liquid; or, to put it another way, 25 grams of sucrose sugar and 75 grams of water exist in the 100 grams of solution. The Brix degrees are measured using an infrared sensor.

Natural fruit and vegetable enzyme beverage blended thick slurry and production method thereof

The invention provides a natural fruit and vegetable enzyme beverage blended thick slurry and a production method thereof. One or more kinds of fruits and vegetables are squeezed into juice, the separated fruit and vegetable residue and peels, seeds and pulps of the fruits and vegetables are added with sugar and are fermented and proliferated by yeasts to form yeast cells, so that yeast polypeptide amino acid is prepared; fruit and vegetable juice is added with saccharose and the yeast polypeptide amino acid and then is subjected to synchronous fermentation of yeasts and lactic acid bacteria; fermentation liquid is added with saccharose, high fructose corn syrup and soaked white fungus, the mixture is ground, homogenized, heated and sterilized, and then is subjected to hot filling and is sealed, wherein the shelf life is more than one year, the terminal product is not added with any food additive and is not added with nutrient supplements artificially, and is a pure natural heath drinking. The yeasts and the lactic acid bacteria are utilized for fermenting fruits and vegetables, a number of enzyme metabolites are produced and accumulated, and compared with nutrition and functional components contained in fruit and vegetable raw materials and microorganisms, the natural fruit and vegetable enzyme beverage blended thick slurry has beneficial efficacies of promoting digestion, enhancing immunity, delaying senescence of a human body and the like.

Owner:兰敬墨

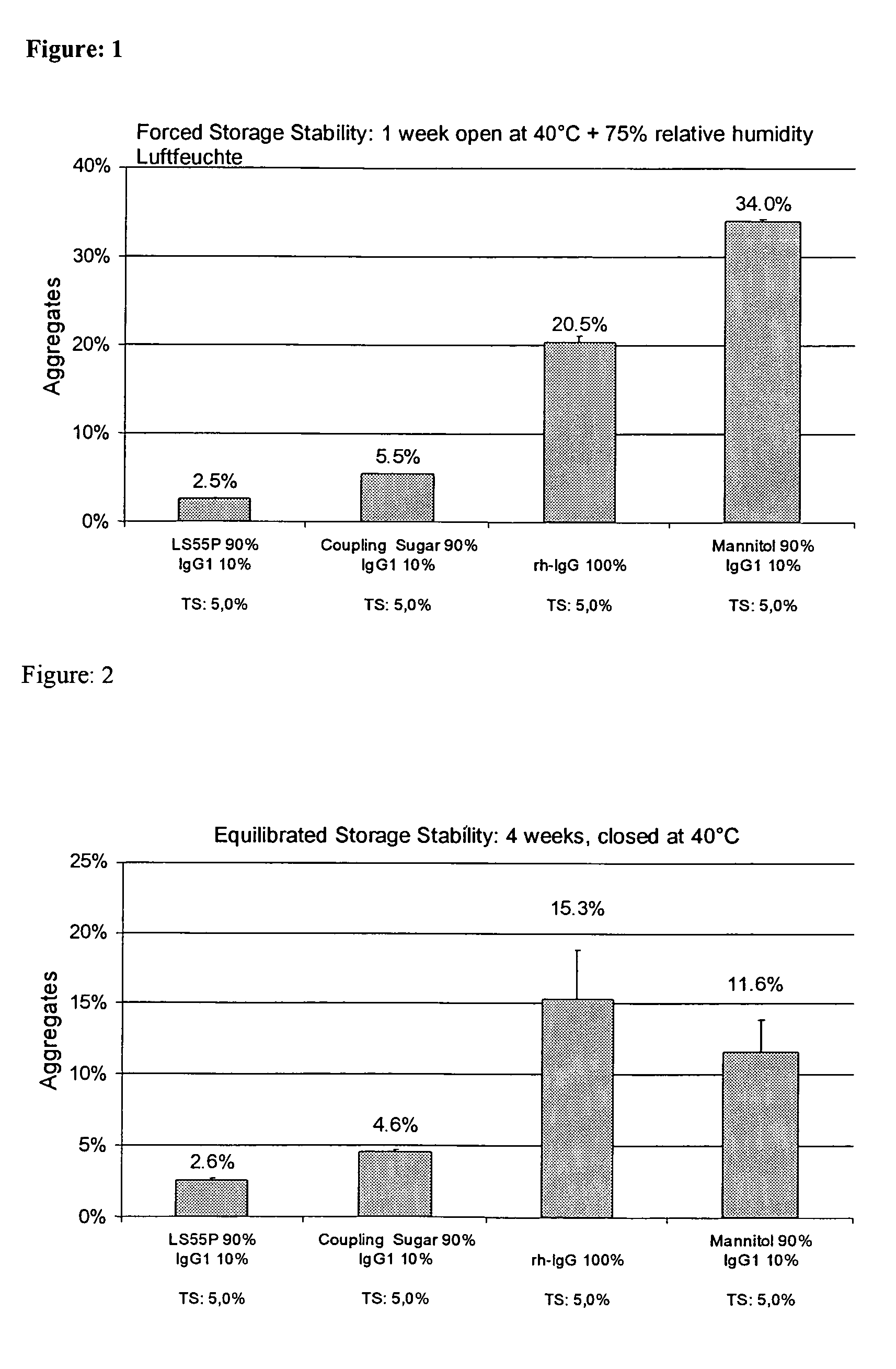

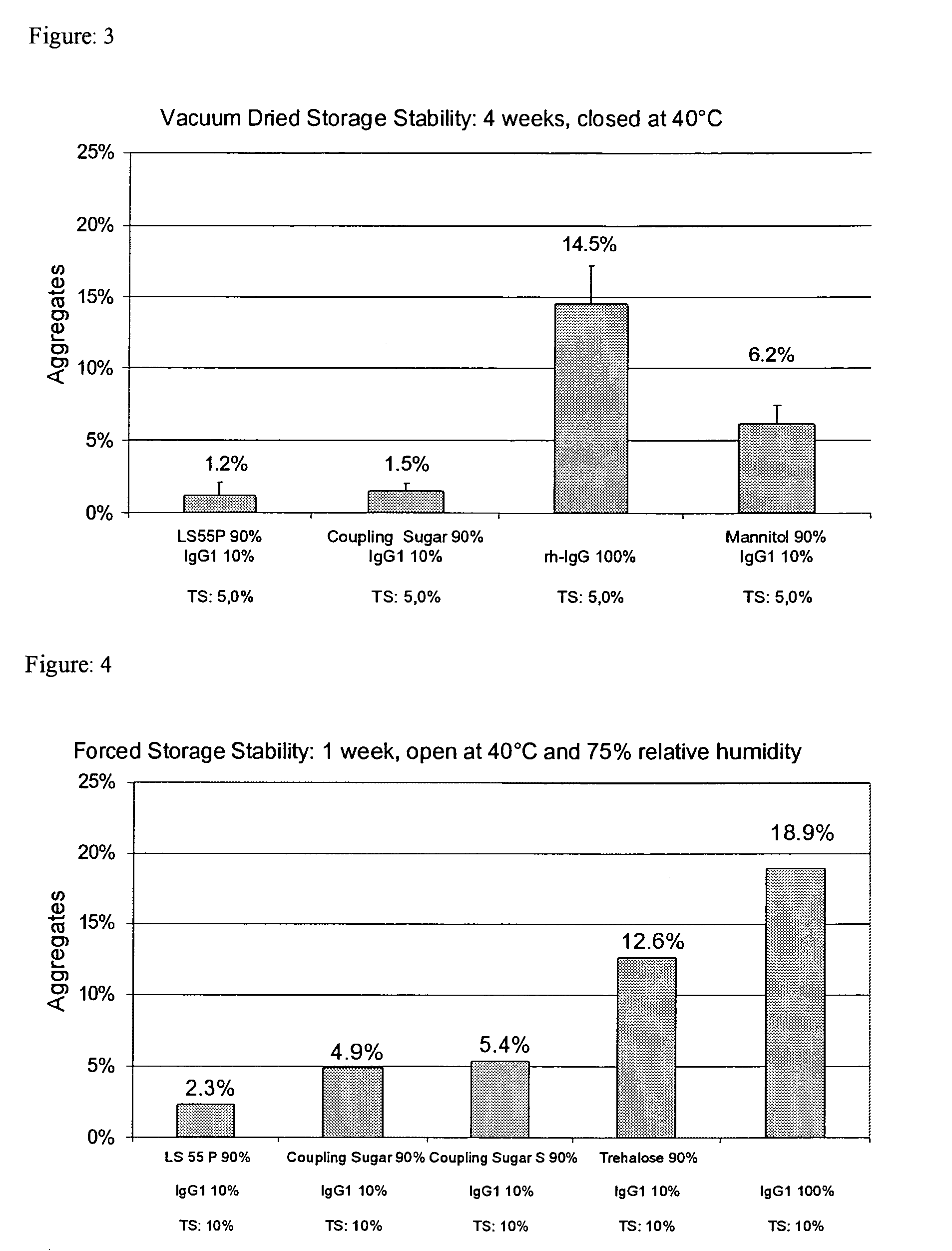

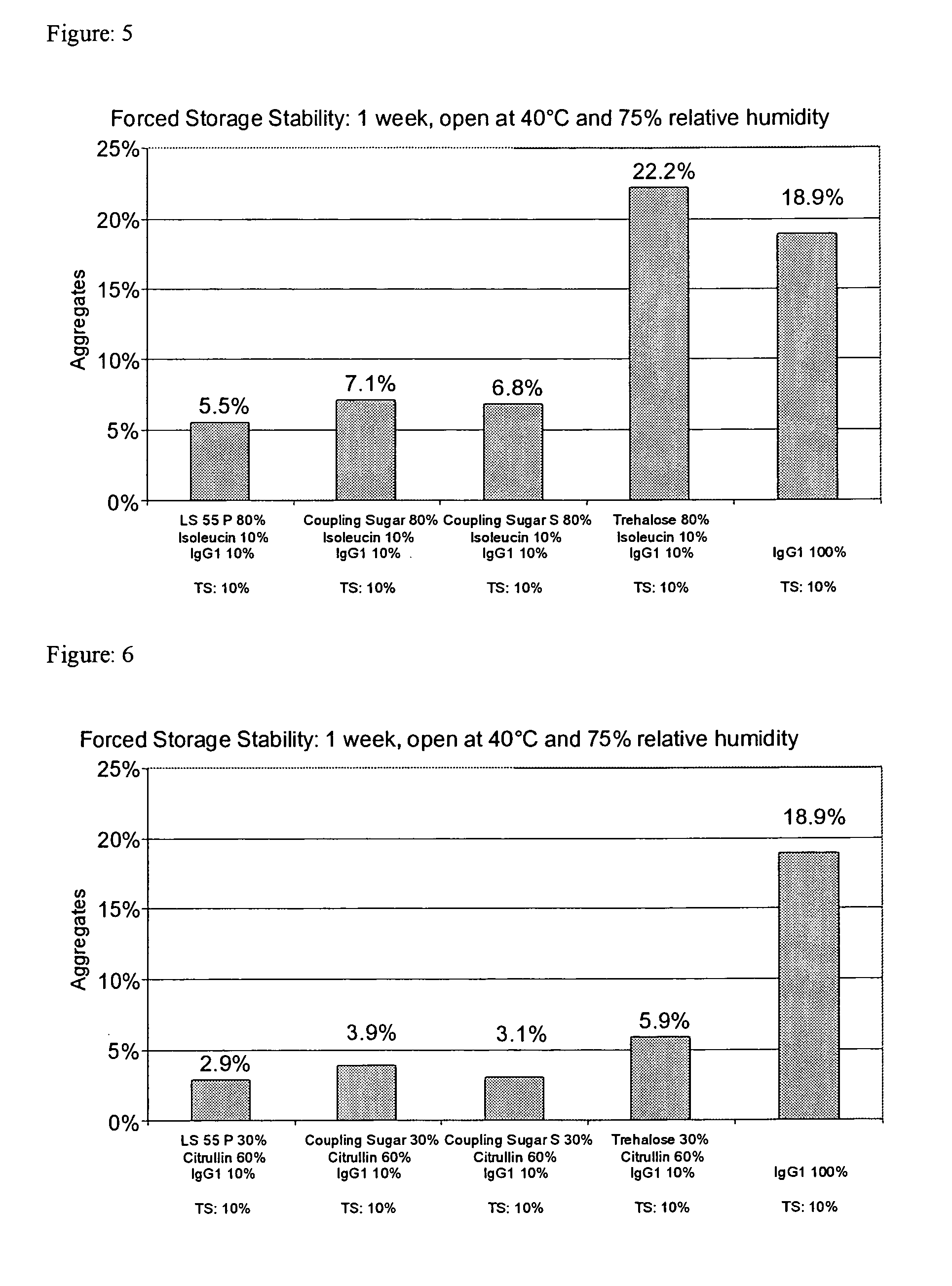

Powder comprising new compositions of oligosaccharides and methods for their preparation

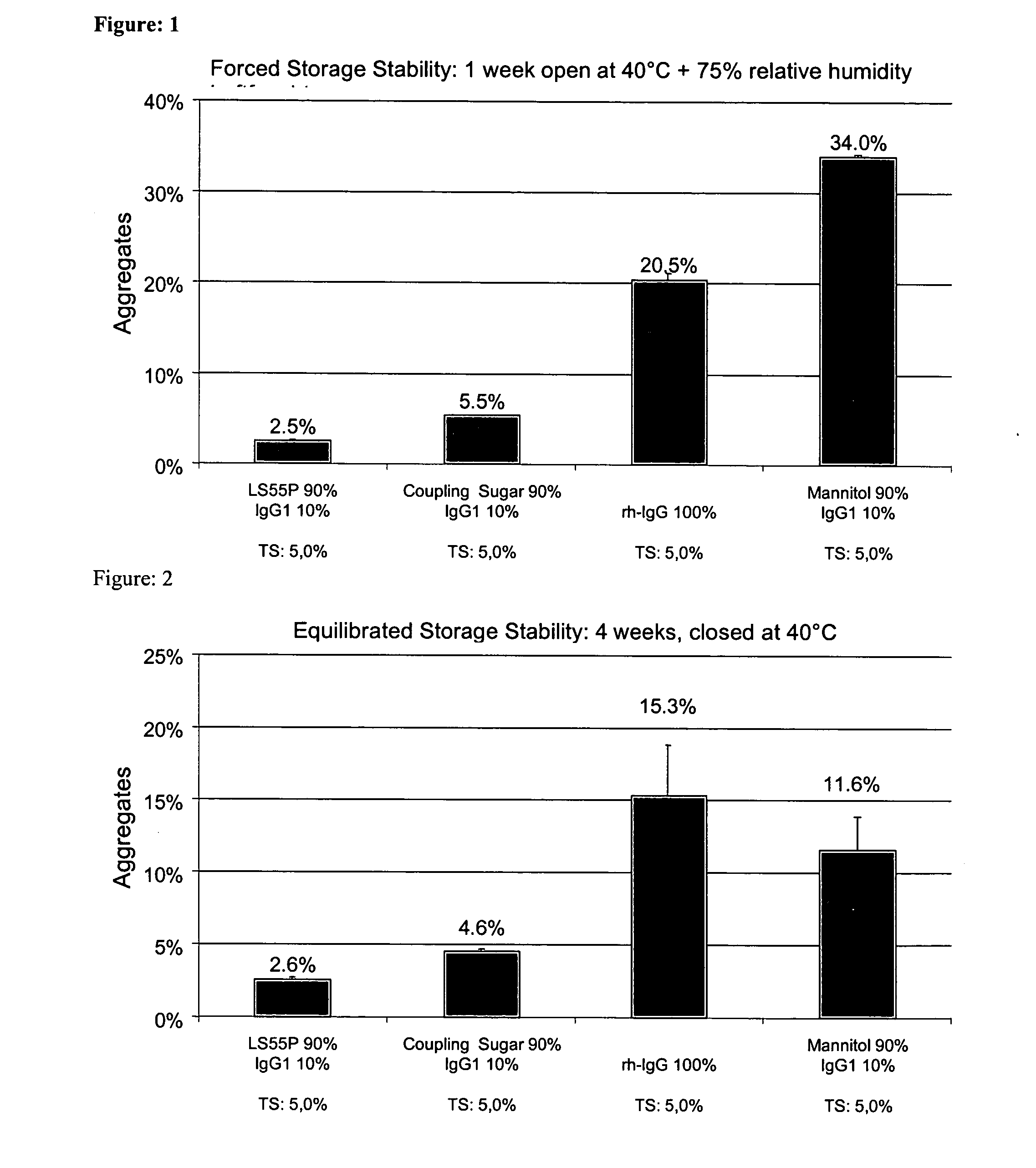

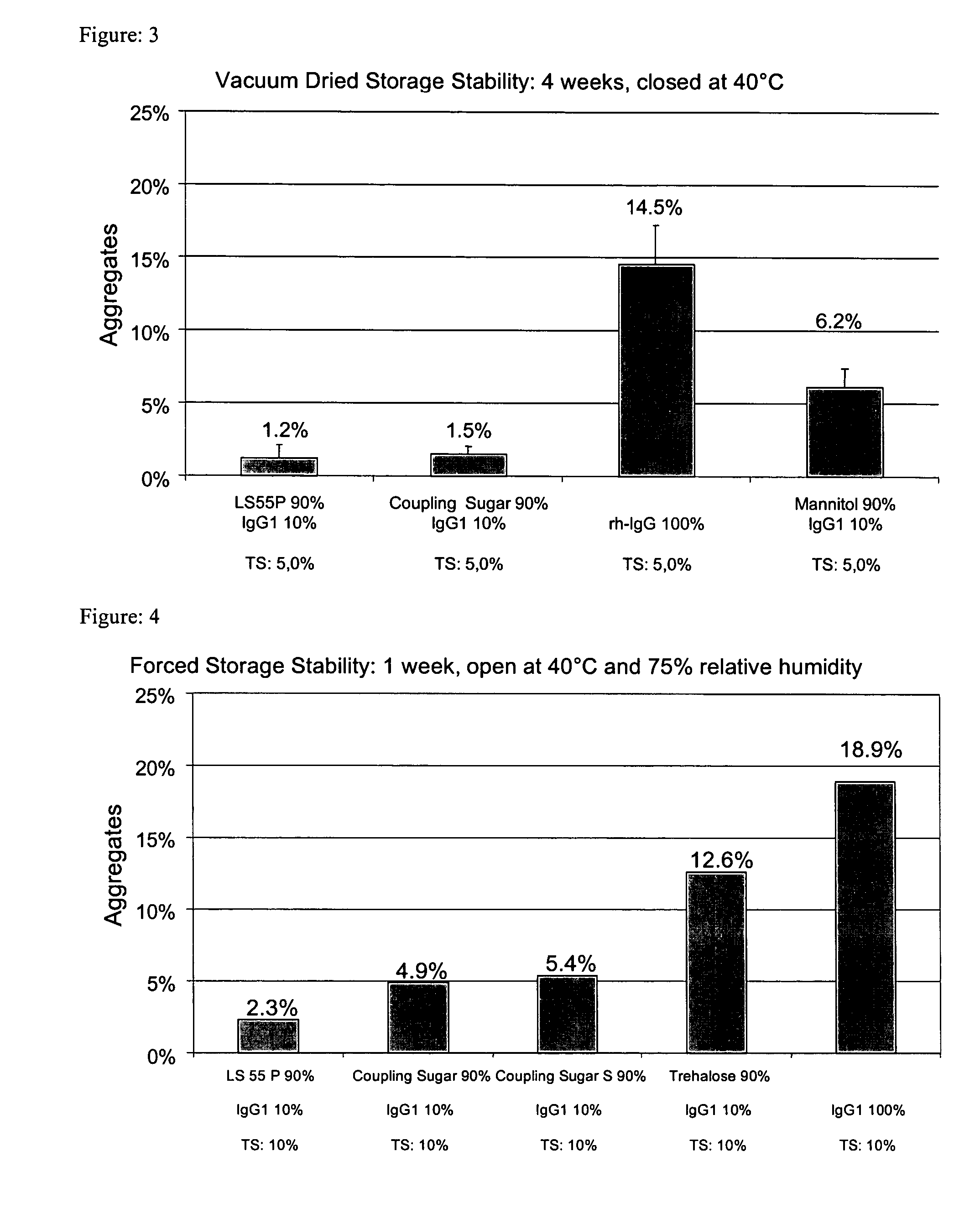

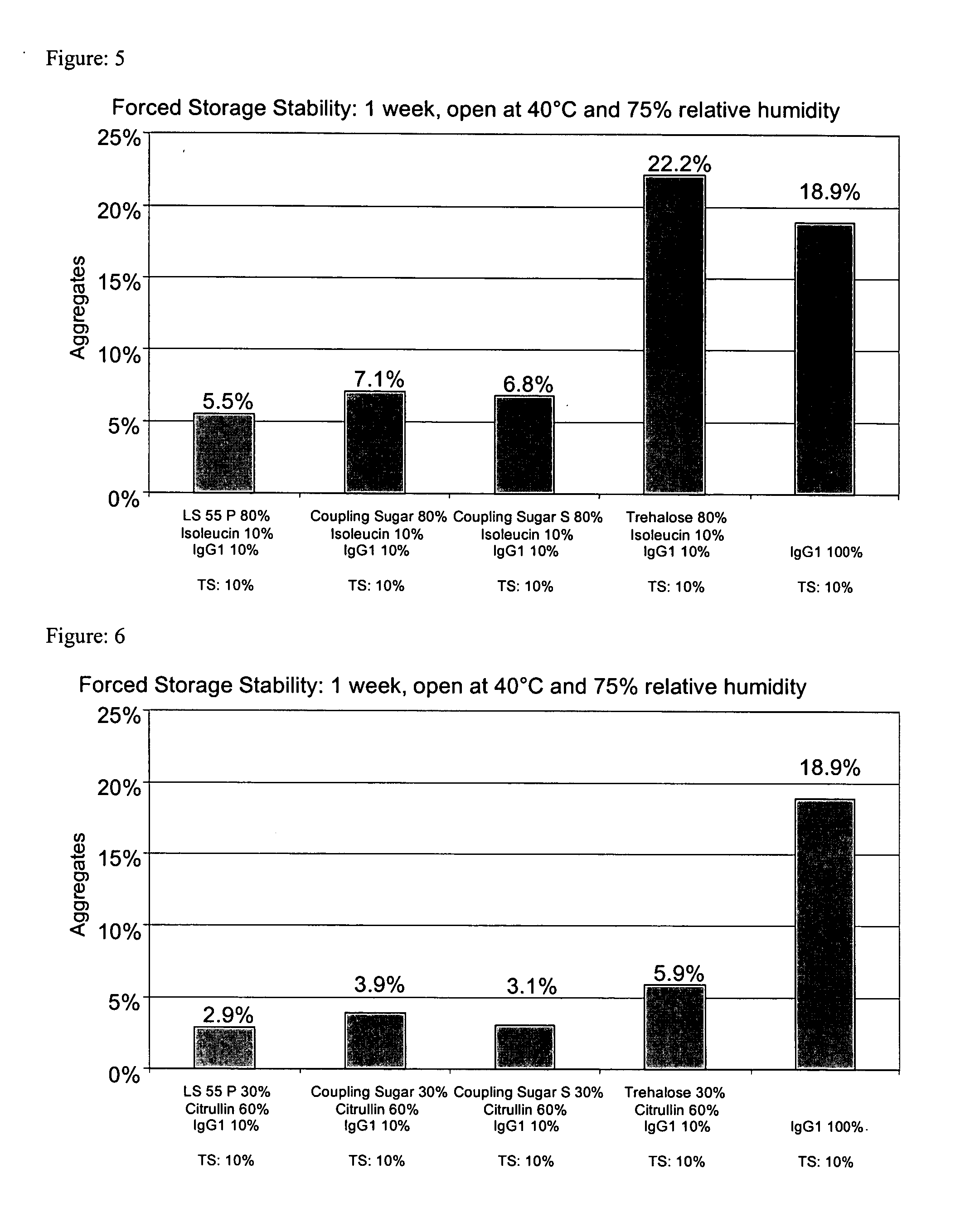

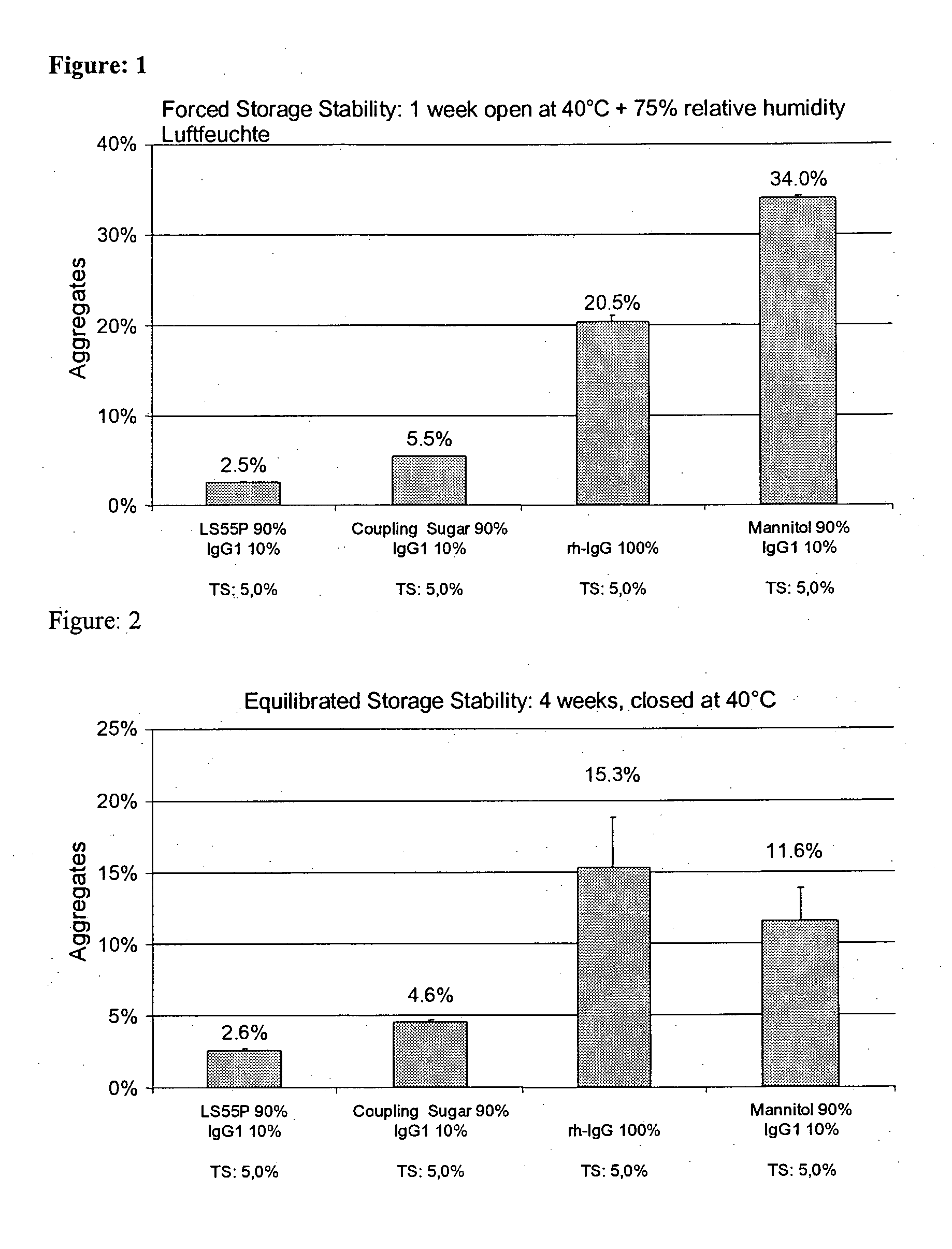

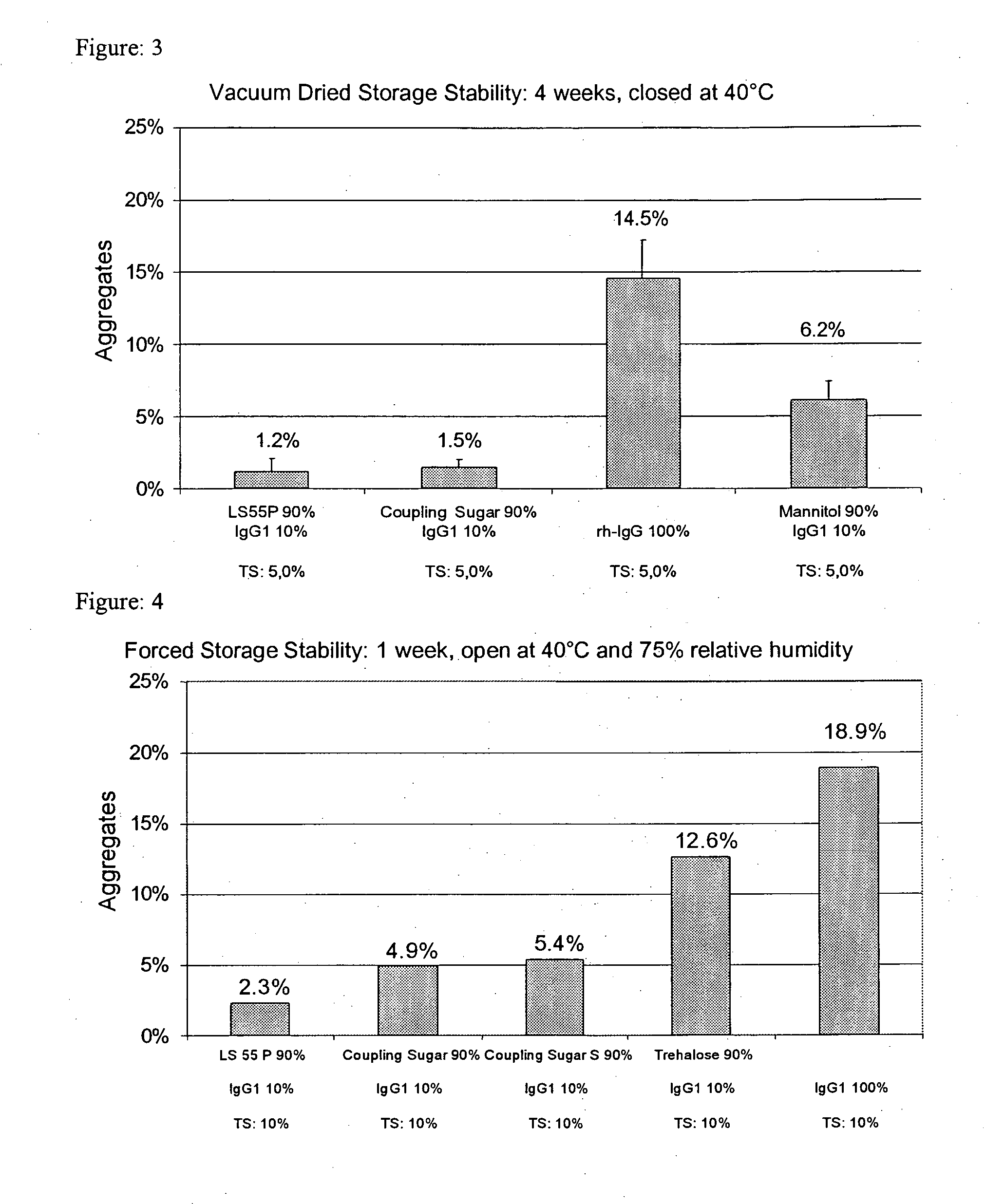

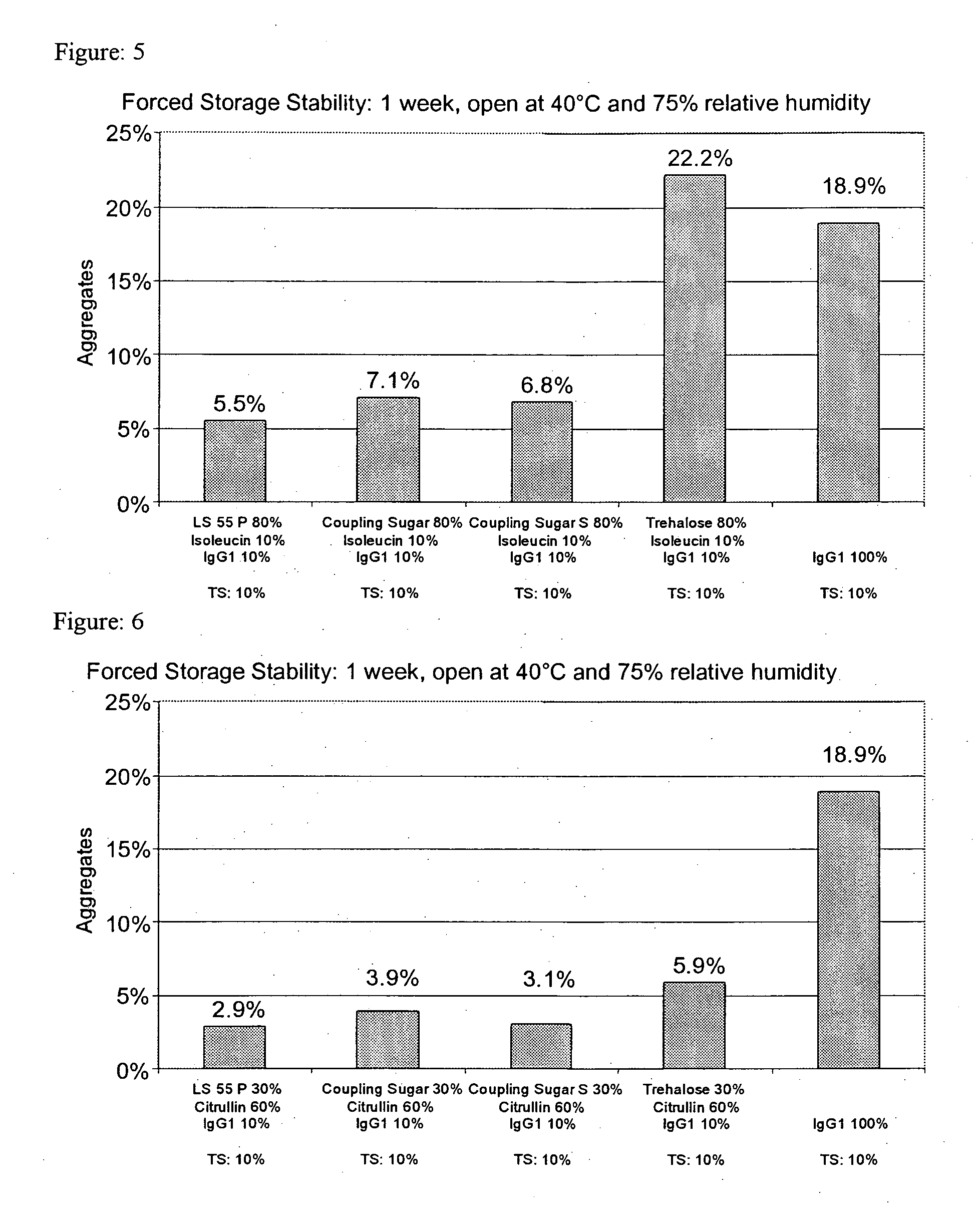

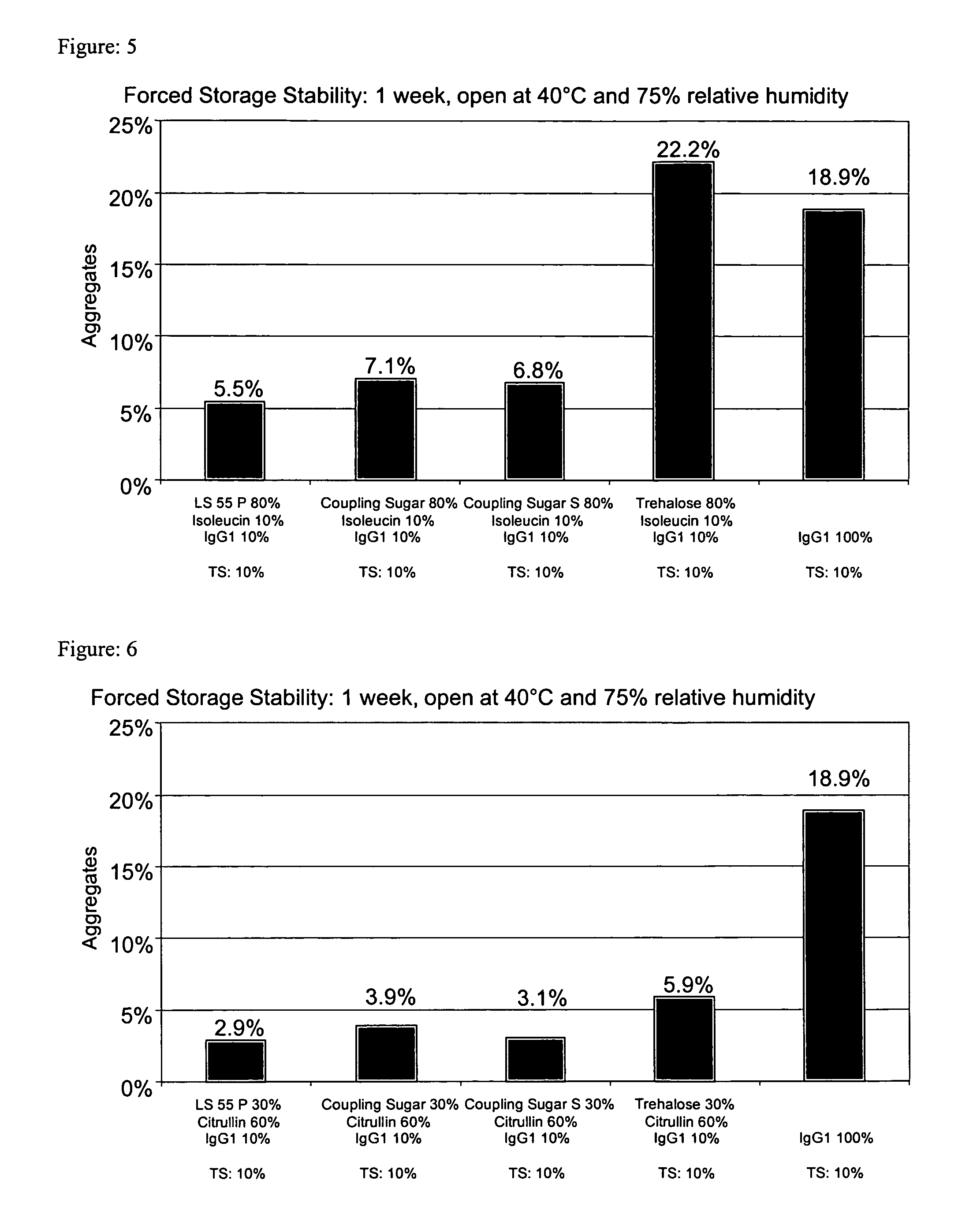

ActiveUS20050250704A1Improve long-term stabilityHigh yieldPowder deliveryBiocideGlucosylsucroseSucrose measurement

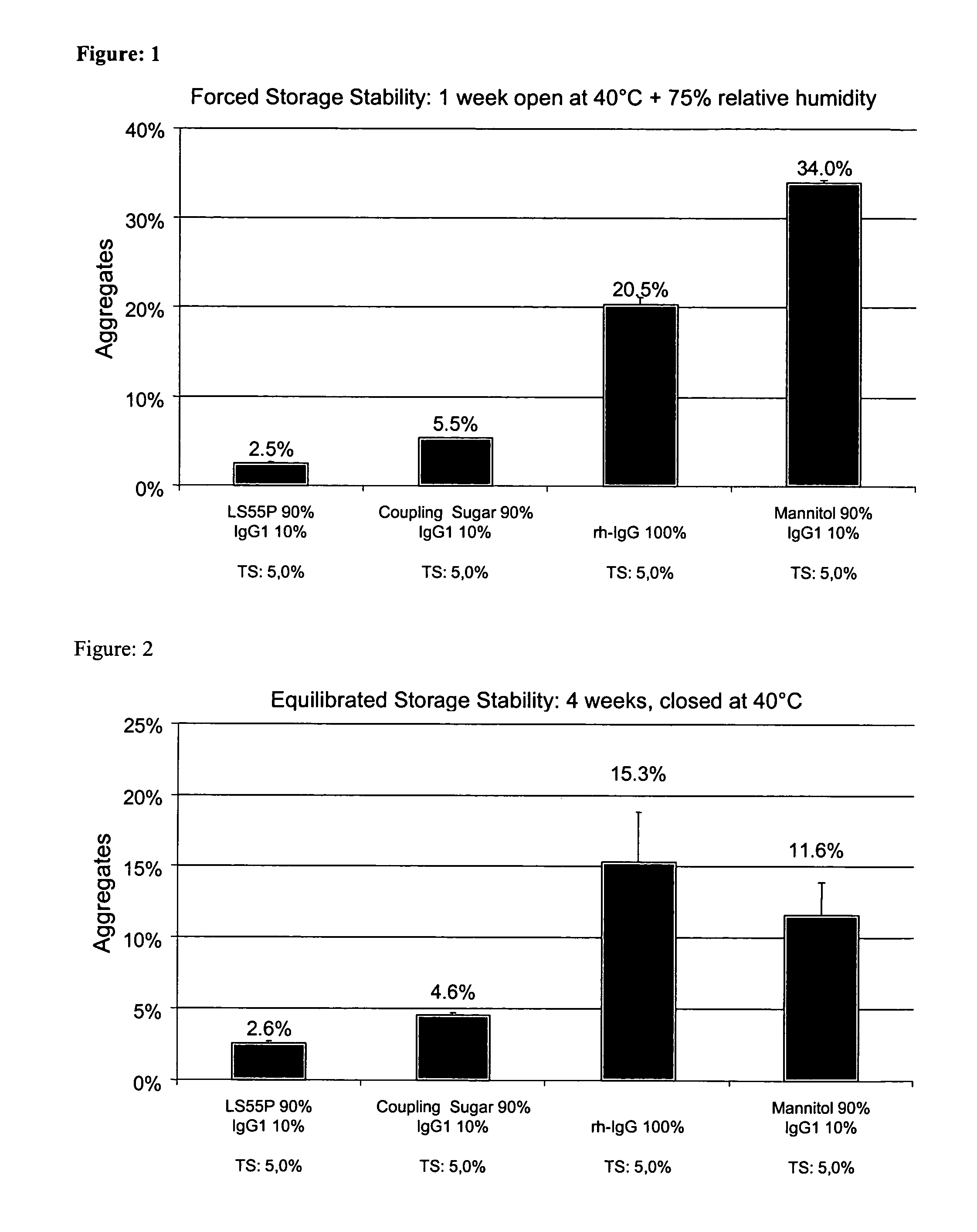

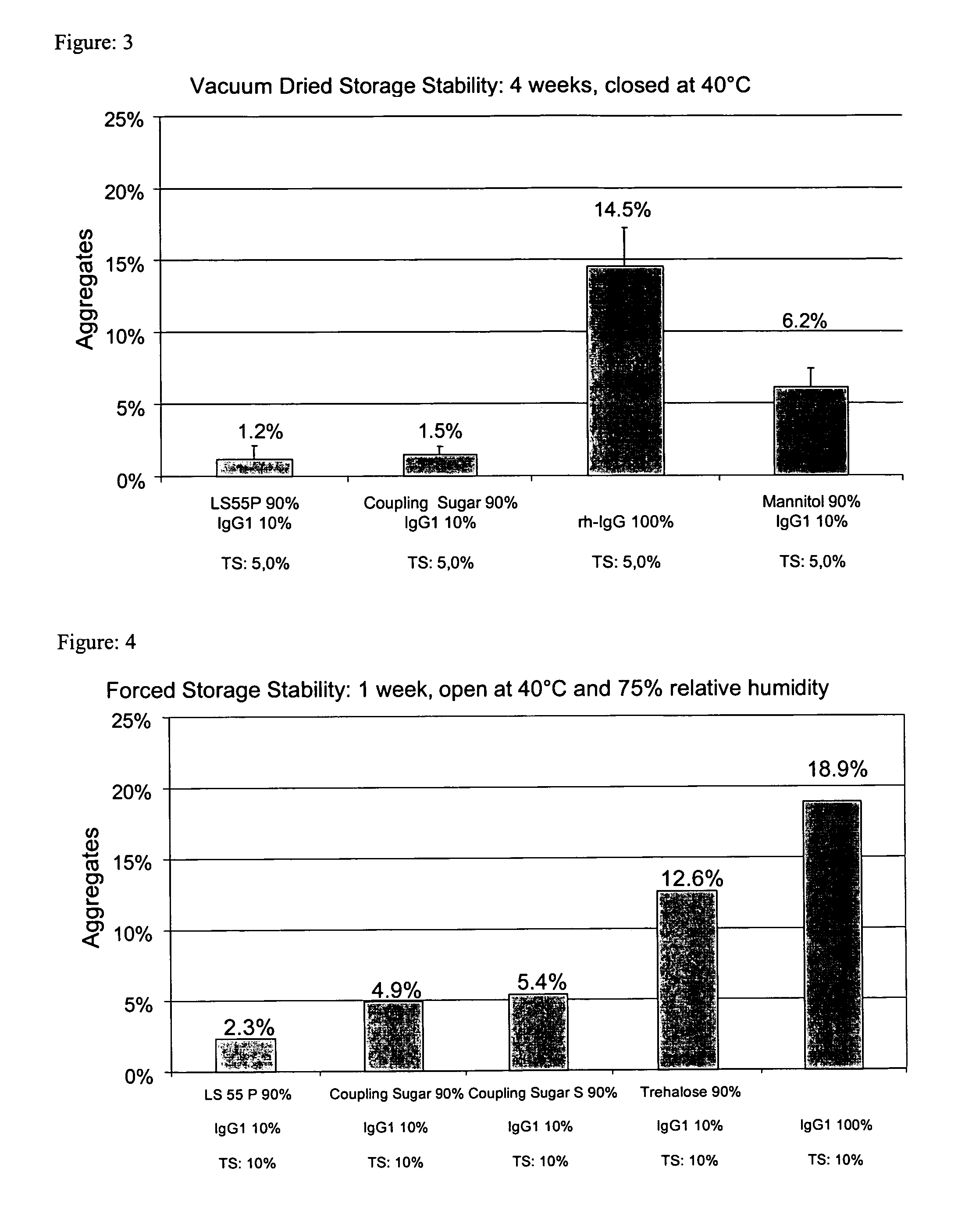

The present invention concerns powders containing a pharmaceutical active substance and a combination of excipients comprising at least one 1,4 O-linked saccharose derivative selected from the compounds: 1,4 O-linked D-Gal-saccharose (lactosucrose), 1,4 O-linked D-Glu-saccharose (glucosyl sucrose), or 1,4 O-linked Glu-Glu-saccharose (maltosyl sucrose) in combination with at least one further excipient. The other excipient is preferably an amino acid, a peptide and / or a mono-, di- and / or oligosaccharide, wherein the oligosaccharide may be a second 1,4 O-linked saccharose derivative, provided that this is different from the first.

Owner:BOEHRINGER INGELHEIM PHARM KG

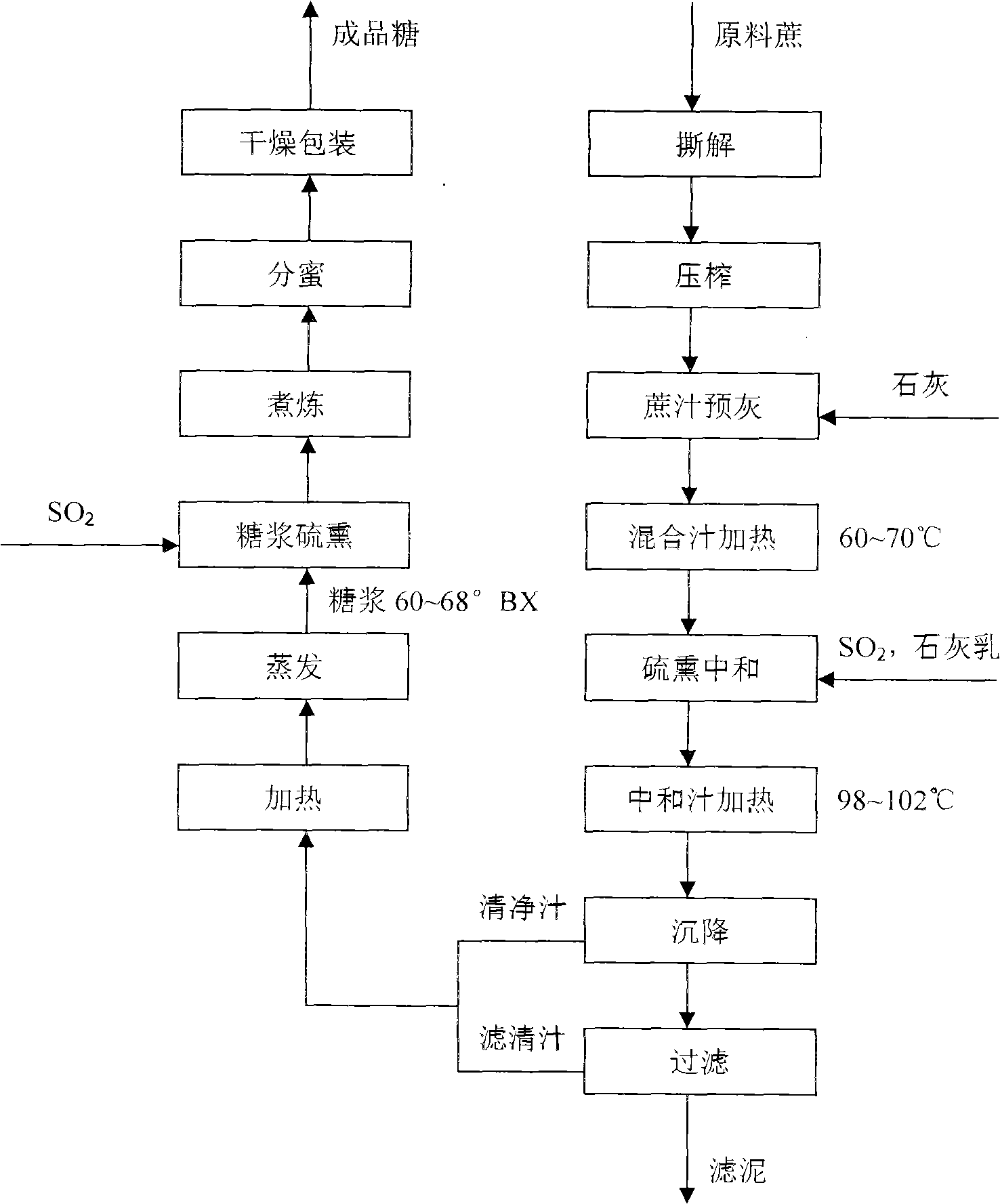

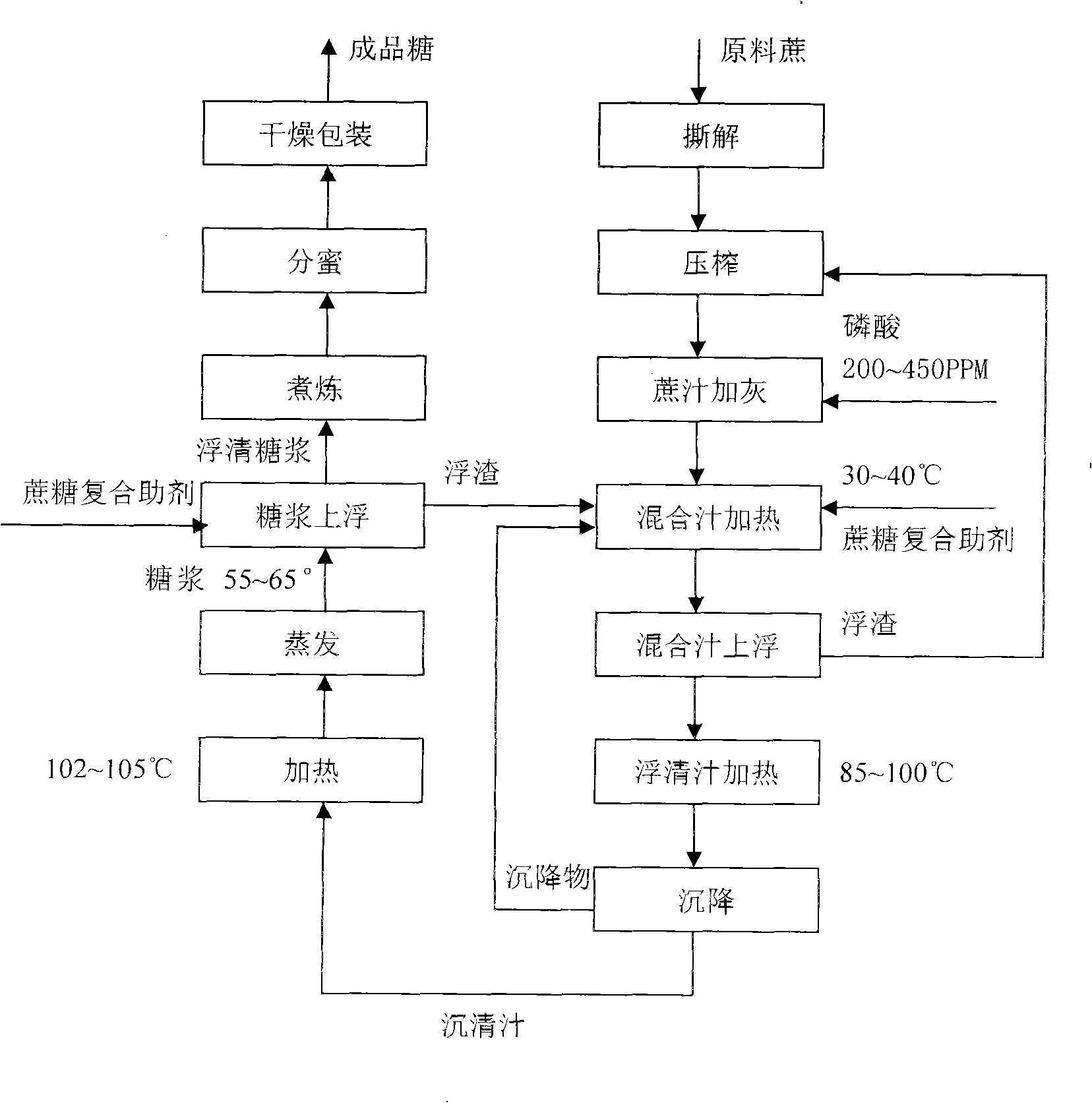

Production method of sulfurless superior saccharose

InactiveCN101323885AHigh purityPurity is higher than mixed puritySugar crystallisationSugar juice purificationRetention timeFiltration

The invention relates to a production method of high-quality sugar, specifically to an improvement of a technology of sugar refinement and purification. High-quality white granulated sugar products are obtained after sugar canes are torn, pressed, cane juice is defecated, mixed juice is heated, a cane sugar complex auxiliary agent is added, the mixed juice is stirred up, floating juice is heated, sedimentated and vaporized, phosphoric acid and the cane sugar complex auxiliary agent are added, syrup is stirred up, the process of honey separation is carried out, the mixture is boiled, refined, crystallized, dried and packed. As the method of the invention adopts a low-temperature technology and a floating treatment method of adding the phosphoric acid, lime and the cane sugar auxiliary agent to lead the floating juice to reach or exceed the effect of the floating juice by original traditional technology, and utilizes a syrup floating principle and a scruff repressing method to substitute the sediment, filtration and stoving technology in the prior art, and cancels such technologies and equipment thereof as filtration, neutralization and sulfur dioxide gas system, retention time in cane juice production process is shortened, sulfur is used as a clarifier during the whole technical process, and sugar without sulfur is produced, thus improving product quality as well as reducing cost.

Owner:高晓军 +1

A preparing method of an active-carbon/graphene composite

A preparing method of an active-carbon / graphene composite is disclosed. The active-carbon / graphene composite is prepared by uniformly mixing raw materials comprising 45-90% by weight of biomass, 5-50% by mass of carbonitride and 5-10% by mass of a transition-metal-containing compound, heating the material mixture at 300-500 DEG C for 2-5 h to obtain a gray block material with a fluffy structure, and heating the block material in a protective gas atmosphere at 600-900 DEG C for 5-60 min. The biomass is any one or a mixture of straw, saccharose residue, saw dust and rice straw. The method utilizing the biomass for directly synthesizing the active-carbon / graphene composite material is simple. Raw materials are simple and easily available. The obtained active-carbon / graphene composite material has the specific capacitance meeting requirements of electrode materials and is suitable for large-scale production and application.

Owner:WUHAN INSTITUTE OF TECHNOLOGY

Spray-dried powder comprising at least one 1,4 O-linked saccharose-derivative and methods for their preparation

ActiveUS20050250705A1Improve long-term stabilityImprove liquidityPowder deliveryBiocideCompound (substance)Lactose

The present invention relates to a spray-dried powder and method for its manufacture. A spray dried powder containing a pharmaceutical active substance and one or more 1,4 O-linked saccharose derivatives chosen from the compounds: 1,4 O-linked D-gal-saccharose (lactosucrose), 1,4 O-linked D-glu-saccharose (glucosyl sucrose) or 1,4 O-linked glu-glu-saccharose (maltosyl sucrose). Preferred combinations are such that they contain glucosyl and maltosyl sucrose.

Owner:BOEHRINGER INGELHEIM PHARM KG

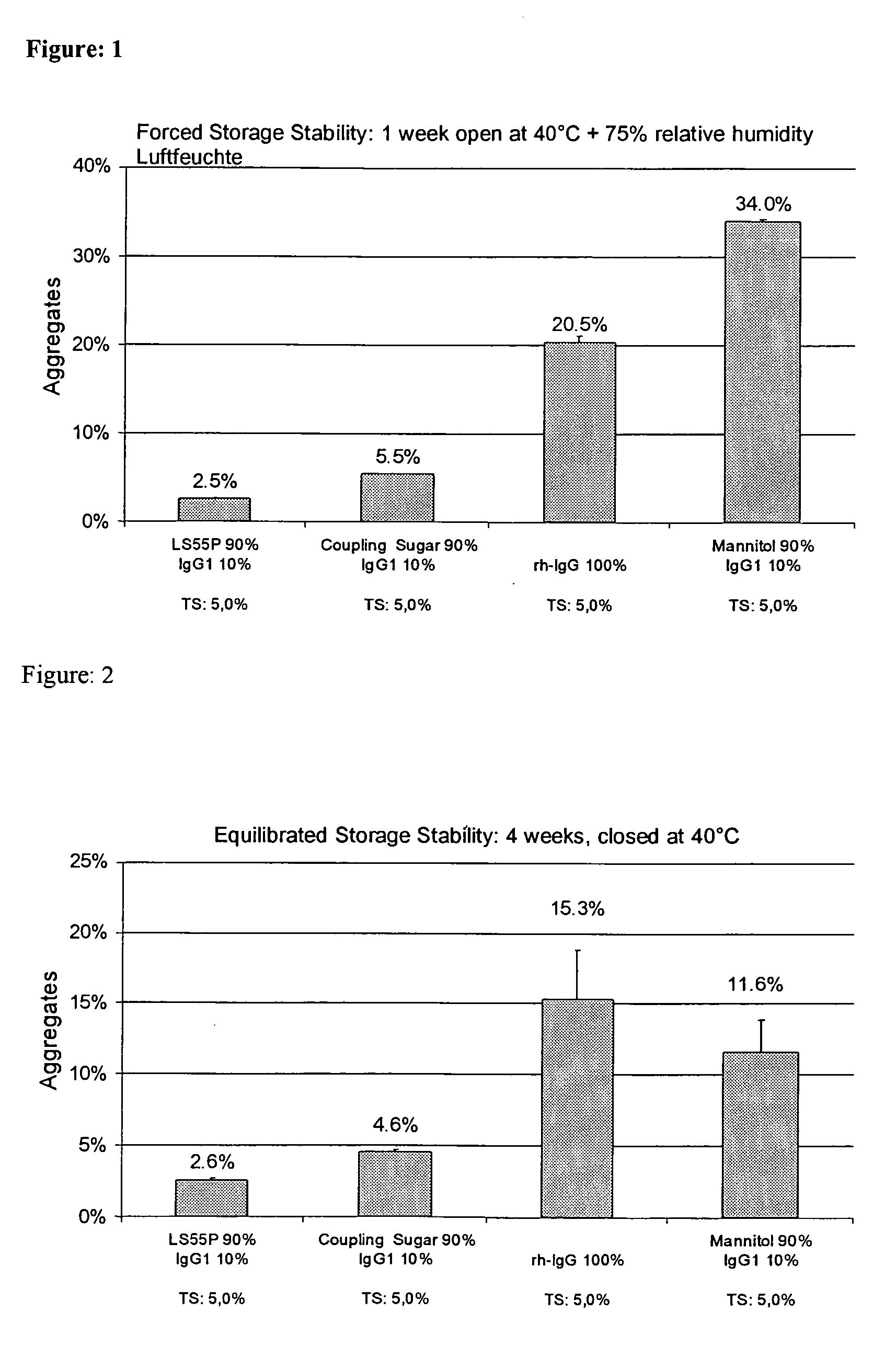

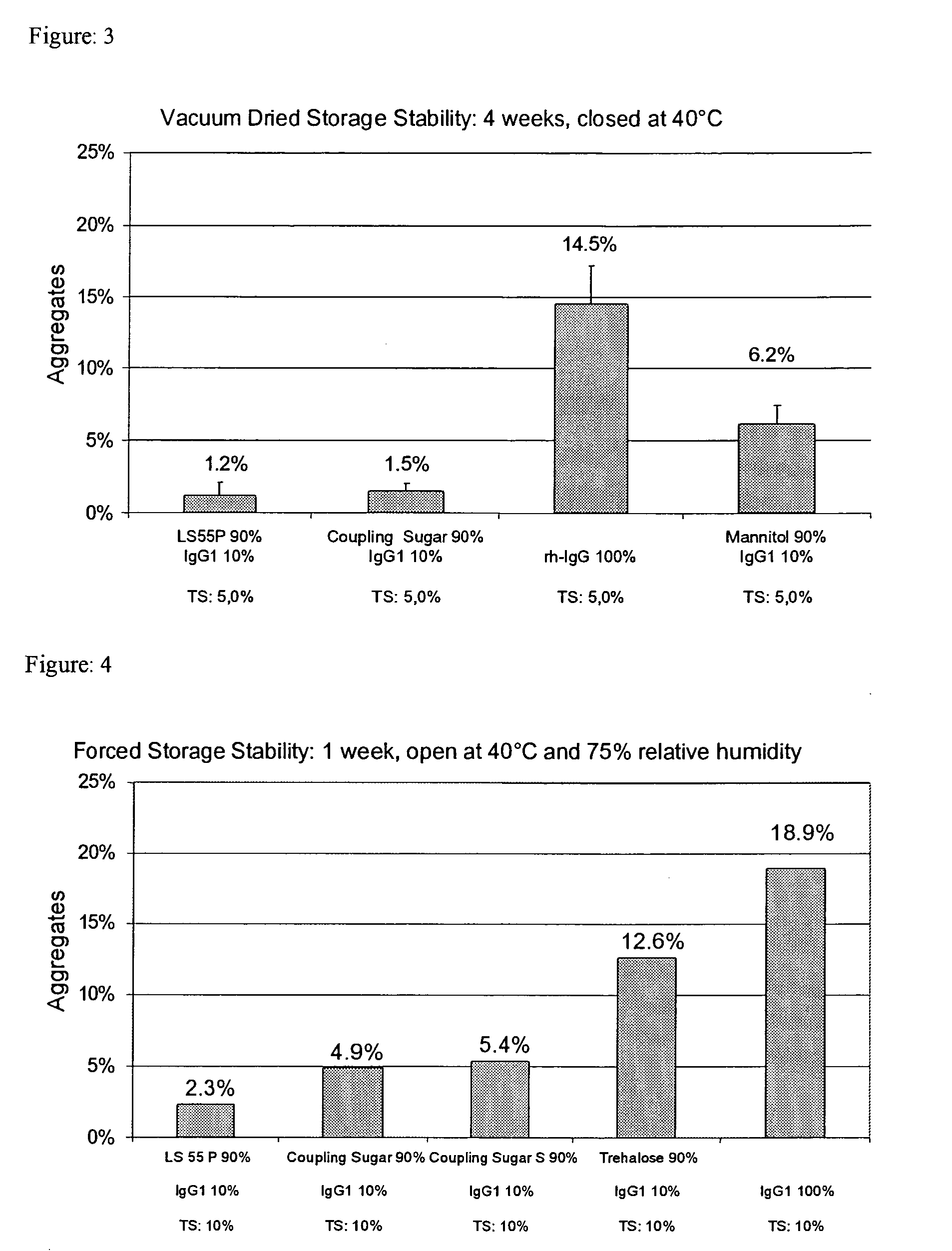

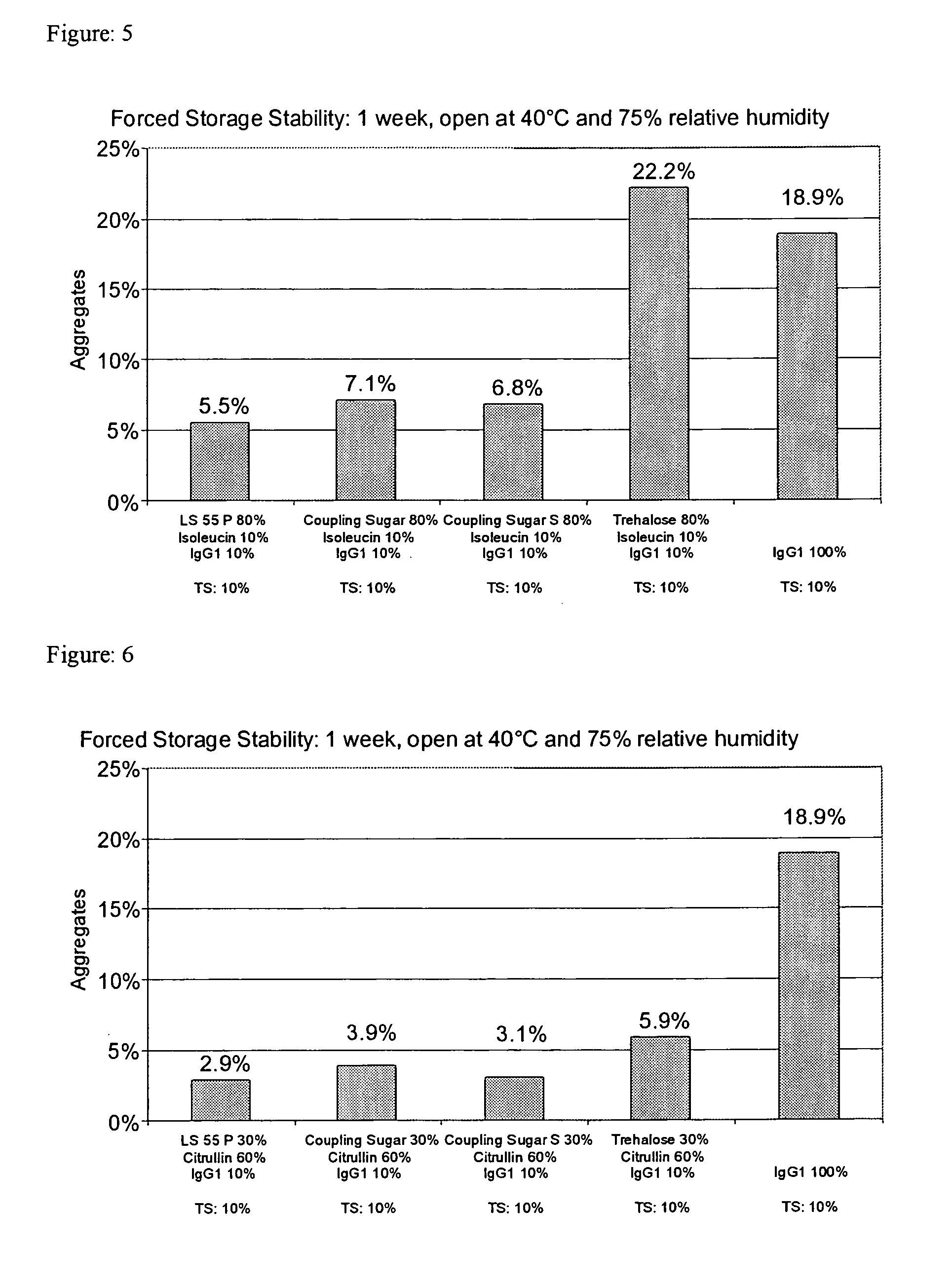

1,4 O-linked saccharose derivatives for stabilization of antibodies or antibody derivatives

ActiveUS20050255119A1Improve liquidityImprove processing stabilityPowder deliveryHybrid immunoglobulinsSaccharophagus degradansSpray dried

The present invention relates to compositions, preferably powdered compositions such as spray-dried or freeze-dried powders, containing an antibody or and antibody derivative and one or more 1,4 O-linked saccharose derivatives chosen from the compounds: 1,4 O-linked D-gal-saccharose (lactosucrose), 1,4 O-linked D-glu-saccharose (glucosyl sucrose) or 1,4 O-linked glu-glu-saccharose (maltosyl sucrose). Preferred combinations are those which contain lactosucrose or a combination of glucosyl and maltosyl sucrose.

Owner:BOEHRINGER INGELHEIM PHARM KG

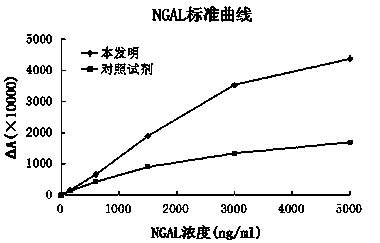

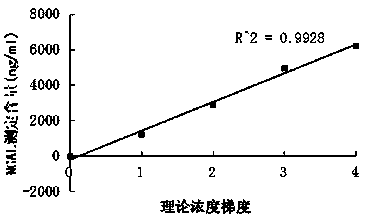

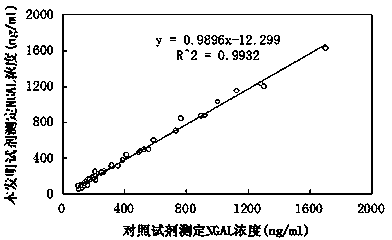

Kit for detecting content of neutrophil gelatinase-associated lipocalin (NGAL)

ActiveCN104198732AComposition is simpleGood test sensitivityBiological testingLatex particlePolyethylene glycol

The invention discloses a kit for detecting the content of neutrophil gelatinase-associated lipocalin (NGAL). The kit comprises a reagent R1, a reagent R2 and an NGAL reagent reference standard substance, wherein the reagent R1 comprises the following components: 10mM-100mM of Tris, 50mM-200mM of NaCl, 0.05%-1% of BSA (Bovine Serum Albumin), 0.01%-0.1% of Tween-20, 0.5%-3% of PEG (Polyethylene Glycol) and 0.1% of NaN3; the reagent R2 comprises the following components: 10mM-100mM of Tris, 50mM-200mM of NaCl, 0.05%-1% of BSA, 0.01%-0.1% of Tween-20, 0.1% of NaN3, 1%-10% of saccharose and 0.1%-1% of NGAL antibody sensitization latex particles; the NGAL reagent reference standard substance comprises the following components: 10mM-100mM of Tris, 50mM-200mM of NaCl, 0.05%-1% of BSA, 0.01%-0.1% of Tween-20, 0.5mM-5mM of EDTA (ethylenediamine tetraacetic acid) and 0.1% of NaN3. The kit is simple in reagent composition, high in test sensitivity, wide in linear range, high in stability, low in test cost, high in accuracy and convenient to popularize.

Owner:NINGBO RUI BIO TECH

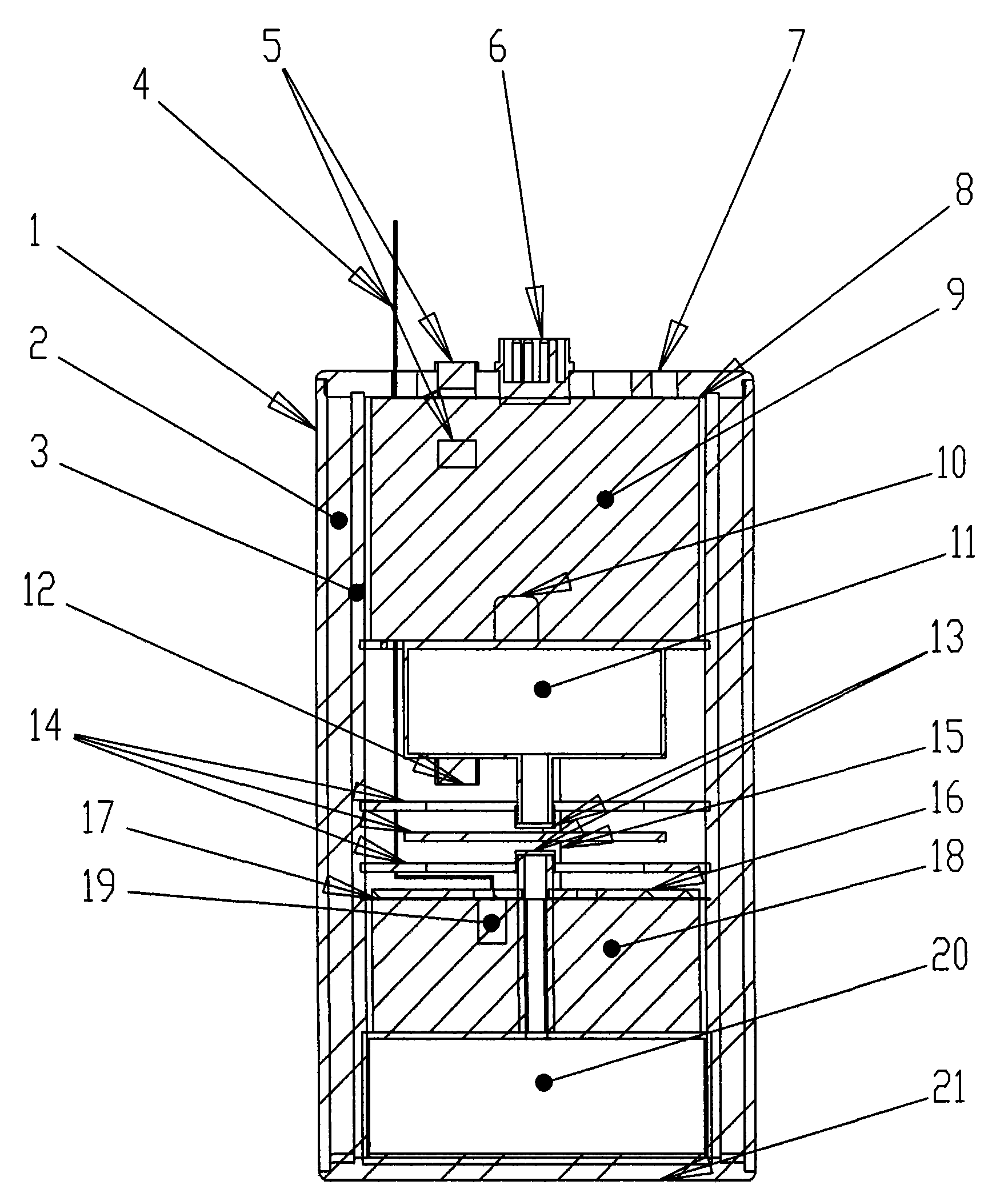

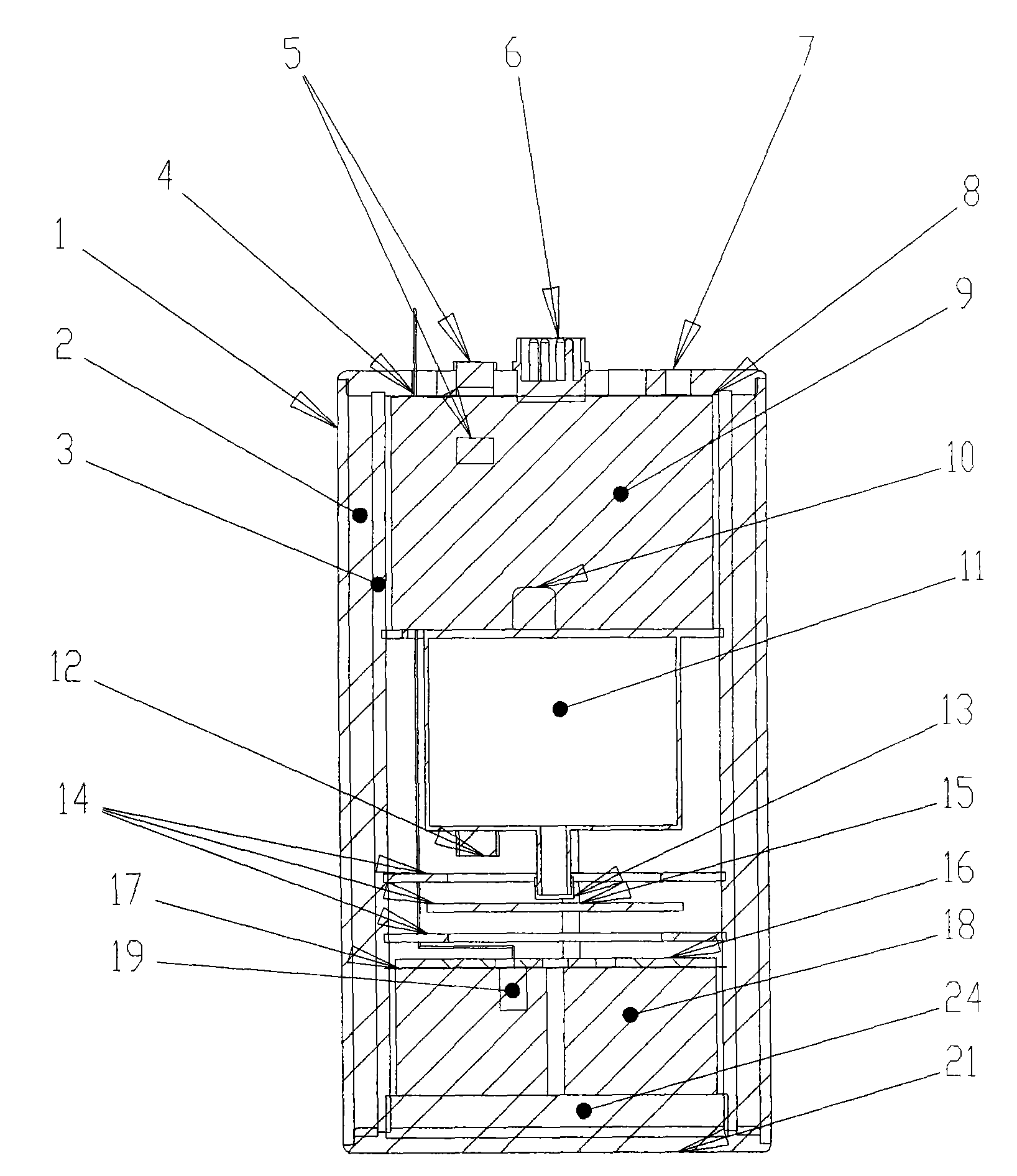

Steam hot aerosol fire-extinguishing composite and application method and fire extinguishing device thereof

ActiveCN101554520AWide variety of sourcesLess corrosiveFire rescueFire extinguisherSodium bicarbonateEpoxy

The invention provides a steam hot aerosol fire-extinguishing composite which contains 30-80wt percent of oxidant, 10-60wt percent of fuel additive and 2-30wt percent of cohesion solidification molding auxiliary agent. The oxidant can be one or more of the following substances: potassium salt, strontium salt, ammonium salt, magnesium salt, nitrocellulose and nitroglycerin; the fuel additive can be one or more of the following substances: azos, azoles, amino-guanidine nitrate, sodium bicarbonate, melamine, cyanoguanidine, carbamide, hexamine, triaminoguanidine nitrate, olefin, saccharose, aluminium powder, magnesite powder and magnesium-aluminium alloy power; the cohesion solidification molding auxiliary agent can be one or more of the following substances: phenol formaldehyde resin, ethoxyline resin, glycidyl azide, urethane rubber, hydroxyl-terminated polybutadiene, polyisobutylene, acetyl tributyl citrate, carboxymethyl cellulose, polyvinyl alcohol phenolic resin and acrylic resin. The invention also provides a fire extinguishing method and a fire extinguishing device adopting the composite. The invention has strong fire extinguishing capacity and fewer hazardous materials and can be applied to different places.

Owner:JIANGXI TSINGHUA IND CO LTD

Non-antibiotics compound feed for suckling pig

InactiveCN103689273APromote growth efficiencyImprove conversion rateAnimal feeding stuffAnimal scienceDL-methionine

The invention provides a non-antibiotics compound feed for a suckling pig. The non-antibiotics compound feed comprises the following components in parts by weight: 430 to 450 parts of extruded corn, 80 to 90 parts of fermented soybean meal, 150 to 160 parts of expanded soybean meal, 150 to 180 parts of milk powder with high protein, 20 to 30 parts of plasma protein, 1 to 3 parts of yeast nucleotide, 40 to 50 parts of super steamed fish meal, 12 to 15 parts of monocalcium phosphate, 1.5 to 1.75 part of 50% choline, 25 to 30 parts of saccharose, 3 to 5 parts of composite acidifier, 5 to 8 parts of stone powder, 3 to 5 parts of 98.5% L-lysine, 2 to 3 parts of table salt, 1 to 1.5 part of threonine, 0.2 to 0.3 part of 98.5% DL-methionine, 0.5 part of multifunctional complex enzyme preparation, 0.4 part of decavitamin for pig, 0.25 part of antioxidant, 0.2 to 0.3 part of combined microecologics, 1 to 1.5 part of nanometer montmorillonite, 1 part of plant extract, and 2 parts of compound trace element.

Owner:HUNAN AGRICULTURAL UNIV

Preparation method of saccharose-free functional powdered peony seed oil

ActiveCN105053276AHigh in alpha-linolenic acidHigh nutritional valueEdible oils/fatsAcute hyperglycaemiaOil processing

The invention belongs to the technical field of oil processing, and particularly relates to a preparation method of saccharose-free functional powdered peony seed oil. The method comprises the following steps: (1) dissolving wall materials with distilled water, and heating and stirring to obtain a solution A; (2) adding food functional factors and an emulsifier into peony seed oil, and mixing and stirring uniformly to obtain an emulsion; (3) shearing and emulsifying the emulsion obtained in the step (2) to obtain an emulsion solution; (4) adding the solution A obtained in the step (3) into the emulsion solution obtained in the step (3), and homogenizing at high pressure to obtain a solution B; and (5) spray-drying the solution B obtained in the step (4), thereby obtaining the powdered peony seed oil. The powdered peony seed oil prepared by the method can be compounded with different nutritive substances according to demands of different groups of special people; as the peony seed oil is high in content of alpha-linolenic acid, the powdered peony seed oil is high in nutritive value; and due to containing no saccharose, the powdered peony seed oil is suitable for patients with hyperglycemia and diabetes to take.

Owner:HEZE YAO & SHUN PEONY BIOTECH

1,4 O-linked saccharose derivatives for stabilization of antibodies or antibody derivatives

ActiveUS7611709B2Improve liquidityEasy to processPowder deliveryHybrid immunoglobulinsFreeze-dryingSaccharophagus degradans

Disclosed are applications of oligosaccharides / oligosaccharide mixtures for the production and stabilization of pharmaceutical compositions, chiefly powders, that contain antibodies or antibody derivatives as pharmaceutical active substance. The production of powders is accomplished through spray drying or freeze drying. Also disclosed are the corresponding antibody-containing powders as well as processes for their production.

Owner:BOEHRINGER INGELHEIM PHARM KG

Biological potassic fertilizer special for potatoes and preparation method thereof

ActiveCN102190524AReduce pollutionConducive to survivalBio-organic fraction processingOrganic fertiliser preparationAgricultural scienceSaccharum

Owner:INST OF SOIL FERTILIZER & WATER SAVING AGRI GANSU ACAD OF AGRI SCI

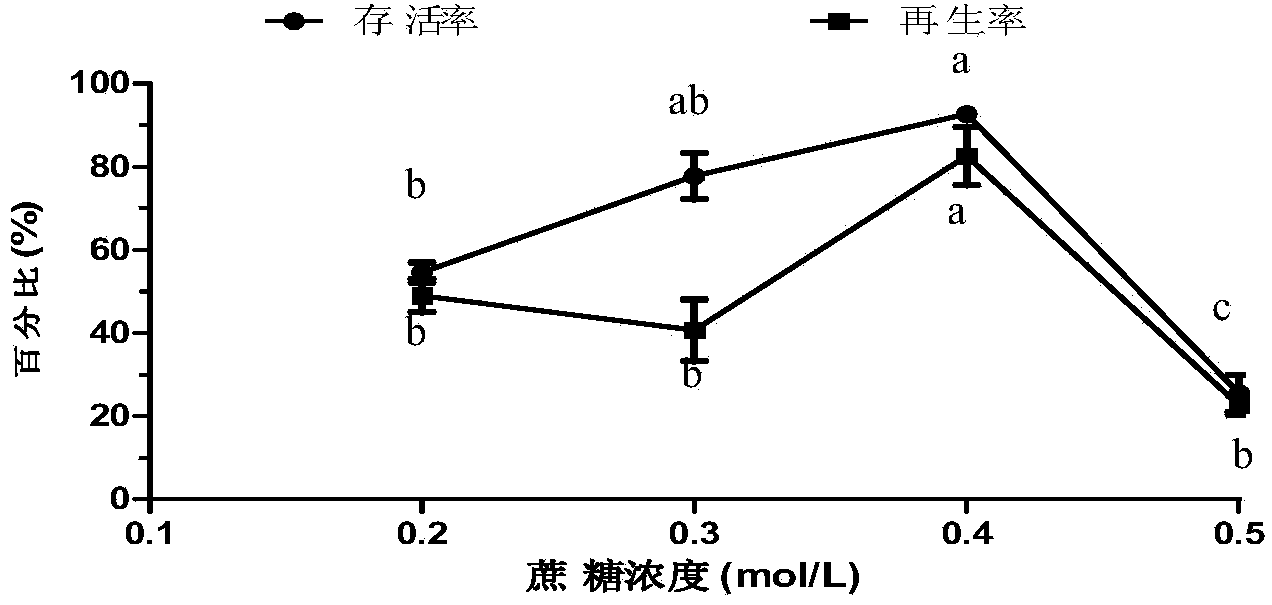

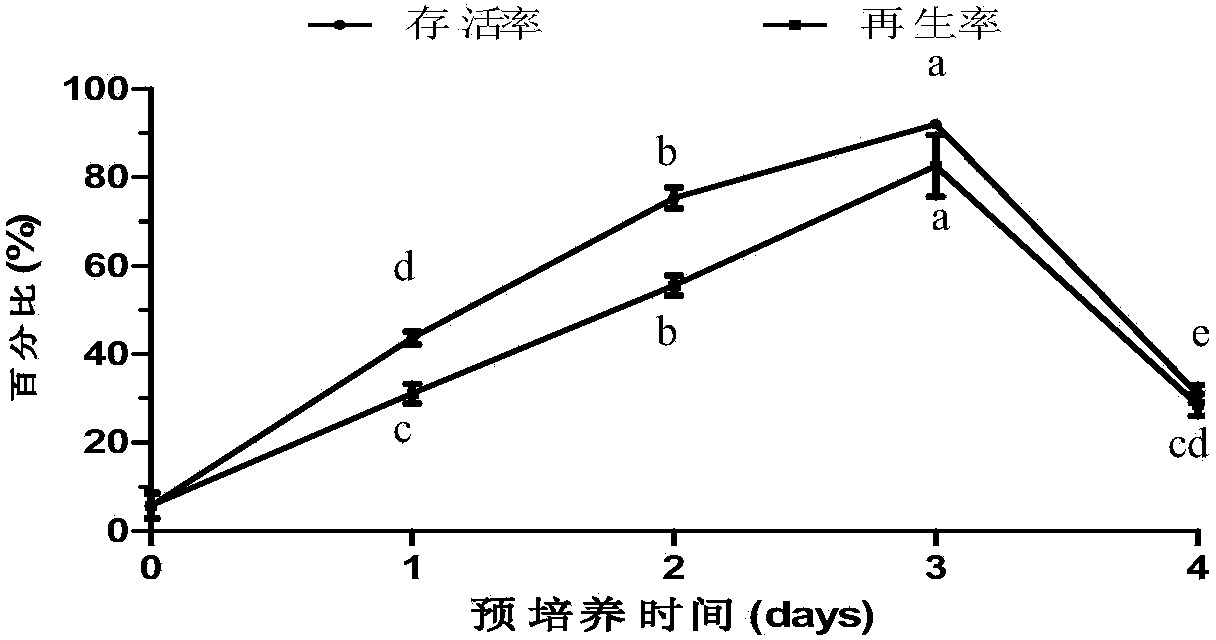

Ultralow temperature storage and regeneration culture method of in vitro stem tip of Jerusalem artichoke

ActiveCN104012524AAvoid lossAvoid dangerDead plant preservationPlant tissue cultureSaccharumGermplasm

The invention provides an ultralow temperature storage and regeneration culture method of an in vitro stem tip of Jerusalem artichoke. The method comprises the following steps: obtaining materials; peeling to obtain the stem tip; pre-culturing saccharose; loading a loading liquid; carrying out dehydration treatment by using PVS2 (Plant Vitrification Solution) vitrification protective liquid; carrying out ultralow temperature cryopreservation; unfreezing and washing; and recovering regenerative culture. By adopting the ultralow temperature storage technology by a droplet vitrification method, the vitro stem tip of a test-tube plantlet of Jerusalem artichoke stored at the ultralow temperature is defrosted and recovered in cultivation and is directly regenerated to form a seedling. The method is a long-term safe, stable, reliable and simple and effective method for storing germplasm resources of Jerusalem artichoke, wherein the survival rate can reach over 90%, the regeneration rate can reach over 80% and the regenerated plant is good in recovery growth.

Owner:INST OF CROP SCI CHINESE ACAD OF AGRI SCI

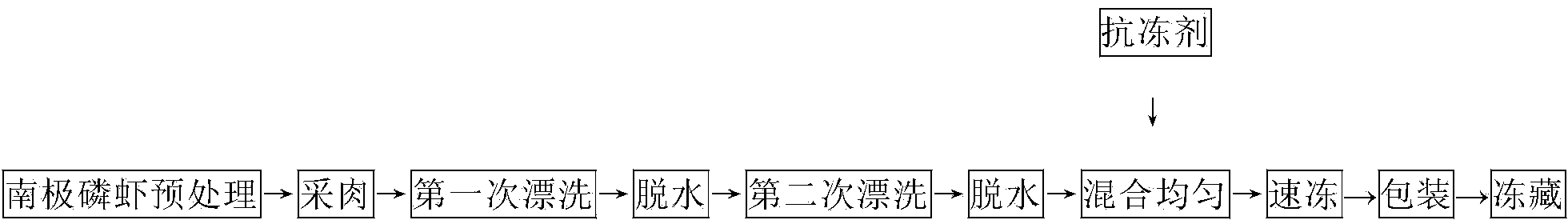

Production process of on-board euphausia superba mince

ActiveCN103549510AReduced fluorine and enzyme contentImprove qualityFood freezingFood ingredient as anti-freezing agentCarrageenanAdditive ingredient

The invention discloses a production process of on-board euphausia superba mince. The production process of on-board euphausia superba mince particularly comprises the following steps of rinsing euphausia superb twice after flesh extraction, dehydrating, adding an antifreeze agent, and storing frozen euphausia superb mince at minus 24 DEG C after quick-freezing; rinsing the euphausia superb mince by fresh water or seawater again which contains 0.1-0.3% of CaC12 for one time, and then rinsing the euphausia superb mince by fresh water or seawater for the second time, thus improving the jelly strength and the whiteness of the euphausia superba mince and reducing the loss of fluorine content and nutritional components; and adding 3-5% of saccharose, 3-5% of sorbitol, 0.2-0.3% of polyphosphates, 0.1-0.3% of sodium alginate tech grade as well as 0.2-0.4% of carrageenan, thus reducing the possibility of the protein denaturation of the euphausia superba mince during the freezing process, and improving the euphausia superba mince quality and yield.

Owner:SHANGHAI OCEAN UNIV

Spray-dried powder comprising at least one 1,4 O-linked saccharose-derivative and methods for their preparation

ActiveUS7723306B2Improve liquidityHigh proportionPowder deliveryOrganic active ingredientsGlucosylsucroseLactose

The present invention relates to a spray-dried powder and method for its manufacture. A spray dried powder containing a pharmaceutical active substance and one or more 1,4 O-linked saccharose derivatives chosen from the compounds: 1,4 O-linked D-gal-saccharose (lactosucrose), 1,4 O-linked D-glu-saccharose (glucosyl sucrose) or 1,4 O-linked glu-glu-saccharose (maltosyl sucrose). Preferred combinations are such that they contain glucosyl and maltosyl sucrose.

Owner:BOEHRINGER INGELHEIM PHARMA KG

Apricot solid drink and preparation method thereof

InactiveCN101536805AIncrease the juice yieldGood instant solubilityFood preparationCarboxymethyl celluloseAdditive ingredient

The invention relates to an apricot solid drink and a preparation method thereof. The ingredients of the apricot solid drink are 10-50% of apricot powder, 20-60% of maltodextrin, 10-30% of saccharose, 0.05-0.10% of citric acid, 0.1-0.2% of xanthan gum, 0.1-0.3% of sodium carboxymethyl cellulose, 0.03-0.1% of sodium alginate and 0.5-1.4% of amorphous silicon dioxide. The preparation method comprises the steps of pre-treating, washing and colour-protecting, blanching and cooling, pulping, zymohydrolysis, glue milling, homogenizing, spray drying, material mixing and granulating, packaging, and sterilizing. The solid drink has high fruit content, natural flavour, excellent stability, and convenient carry and use, thereby meeting requirements of modern consumption and having broad market prospect.

Owner:BEIJING ACADEMY OF AGRICULTURE & FORESTRY SCIENCES

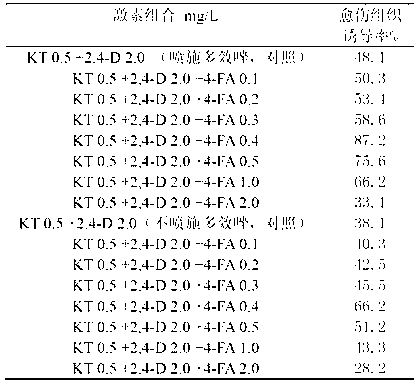

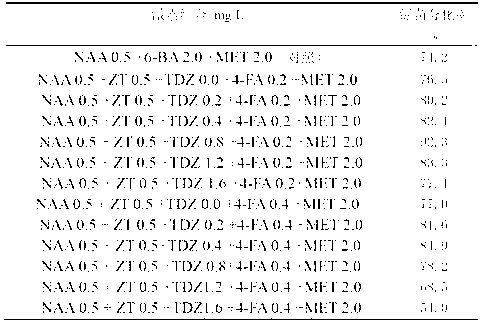

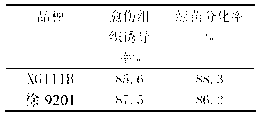

Method for improving frequency of callus induction and plant differentiation rate in japonica rice anther culture

InactiveCN103210844AImprove work efficiencyEasy to operateHorticulture methodsPlant tissue culturePollenBiology

The invention relates to a rice anther culture improvement technology, and in particular relates to a method for improving the frequency of callus induction and plant differentiation rate in japonica rice anther culture. The method comprises the following steps that: 200g / 667m<2> of 10% of paclobutrazol wettable powder and 50-60L of water are mixed for spraying treatment before sampling, the spraying of the paclobutrazol and low-temperature treatment cause multiple pollen cells in the anther to be in the later monokaryotic stage, novel cytokinin 4-FA is introduced into a callus inducing medium, under the synergistic action of the 4-FA, KT, and 2,4-D, division is easily started in the dark culture after inoculation, and the frequency of callus induction is greatly improved. By using the anther culture method, the frequency of callus induction in the japonica rice anther culture is obviously improved to exceed 85.0%. A differential medium comprises the following ingredients: an MS (Murashige and Skoog) basic culture medium, 0.5mg / L of NAA, 0.5mg / L of ZTO, 0.8mg / L of TDZ, 0.2mg / L of FA, 0.2mg / L of MET, 30g / L of saccharose, and 8g / L of agar powder; and after the novel hormones of ZT, 4-FA and TDZ are introduced, light cultivation is carried out, and plant differentiation rate can reach more than 86%.

Owner:JIANGSU XUHUAI DISTRICT XUZHOU AGRI SCI INST

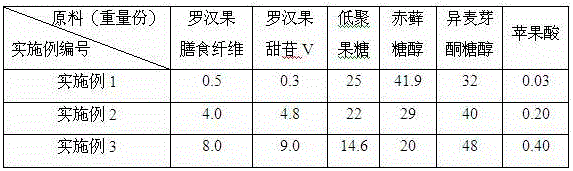

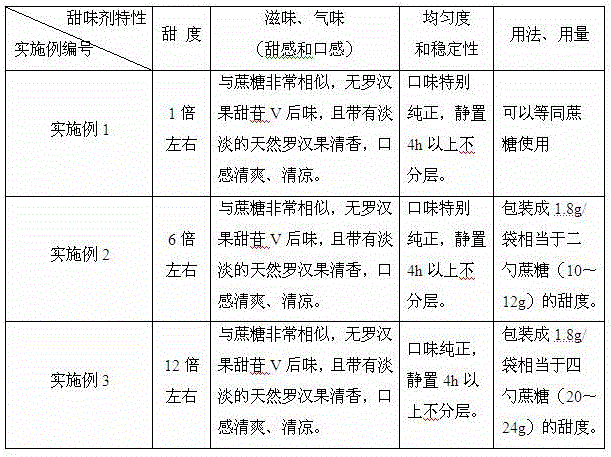

Natural plant product compound sweetening agent and preparation method thereof

InactiveCN106333336ARefreshing tasteShorten the sweetness timeFood ingredient as taste affecting agentFood ingredient as mouthfeel improving agentFiltration membraneIsomalt

Owner:HUNAN AIDALUN TECH CO LTD

Novel rose jam and preparation method of rose jam

The invention relates to a rose jam and a preparation method of the rose jam, belonging to the technical field of food. The rose jam is prepared from the following ingredients in parts by weight: 30-50 parts of dry roses, 150-170 parts of wine, 230-250 parts of saccharose, 70-90 parts of lemon juice, 3-5 parts of sodium carboxymethylcellulose, 3-5 parts of agar and 1500-1700 parts of water. Simultaneously, the invention also discloses a preparation process of the rose jam. The jam provided by the invention is hermosa pink, soft and delicate in taste, moderate in sweet and sour, and easy to coat, has natural and rich rose fragrance, not only keeps functional ingredients of the dry roses, but also has the nutritional ingredients of the wine additionally, as well as has the effects of maintaining beauty, keeping young and caring health.

Owner:河南宝莱健生物工程有限公司

Rose jam and preparation method of rose jam

The invention relates to a rose jam and a preparation method of the rose jam, belonging to the technical field of food. The rose jam is prepared from the following ingredients in parts by weight: 30-50 parts of dry roses, 150-170 parts of wine, 230-250 parts of saccharose, 70-90 parts of lemon juice, 3-5 parts of sodium carboxymethylcellulose, 3-5 parts of agar and 1500-1700 parts of water. Simultaneously, the invention also discloses a preparation process of the rose jam. The jam provided by the invention is hermosa pink, soft and delicate in taste, moderate in sweet and sour, and easy to coat, has natural and rich rose fragrance, not only keeps functional ingredients of the dry roses, but also has the nutritional ingredients of the wine additionally, as well as has the effects of maintaining beauty, keeping young and caring health.

Owner:河南宝莱健生物工程有限公司

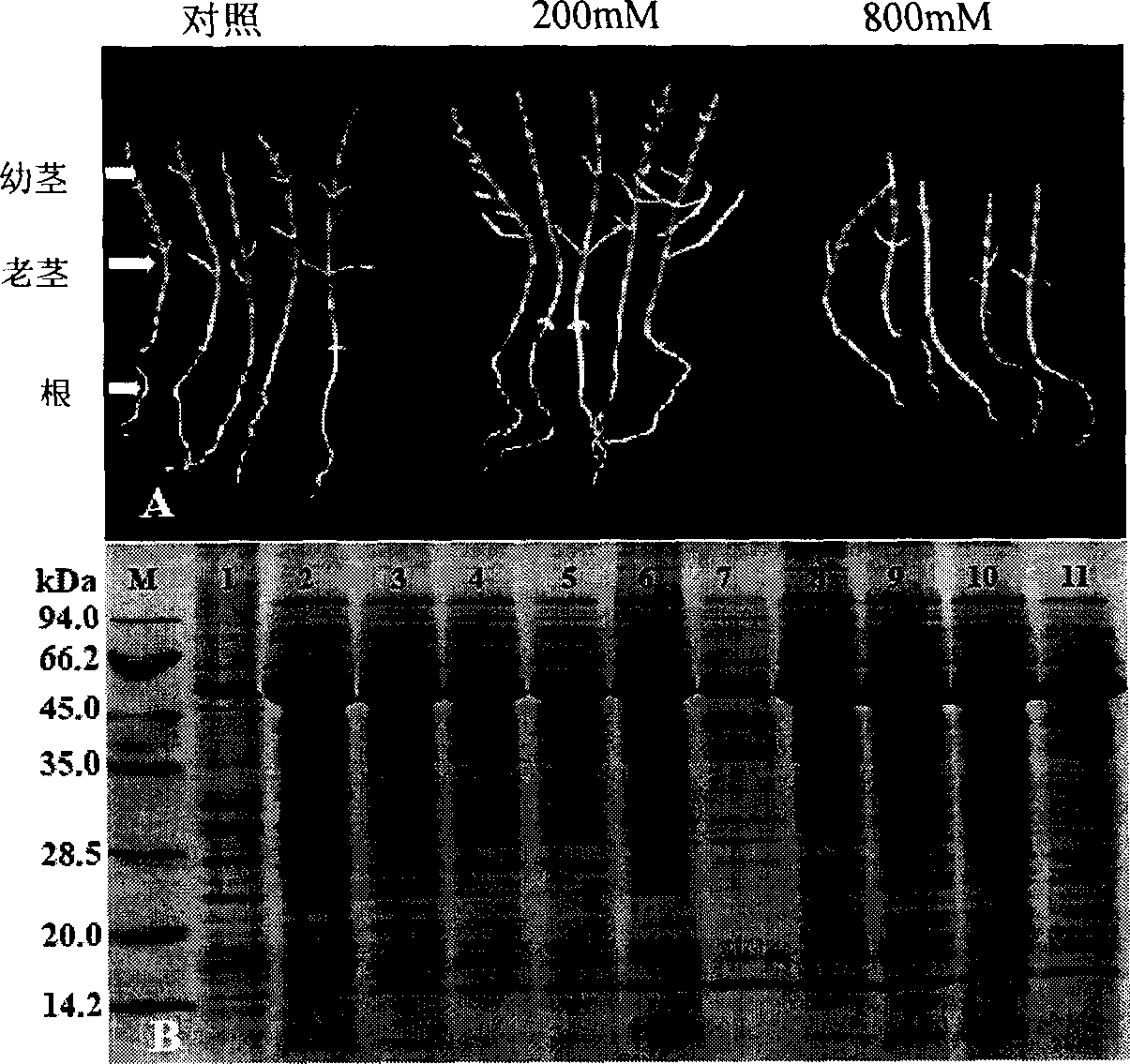

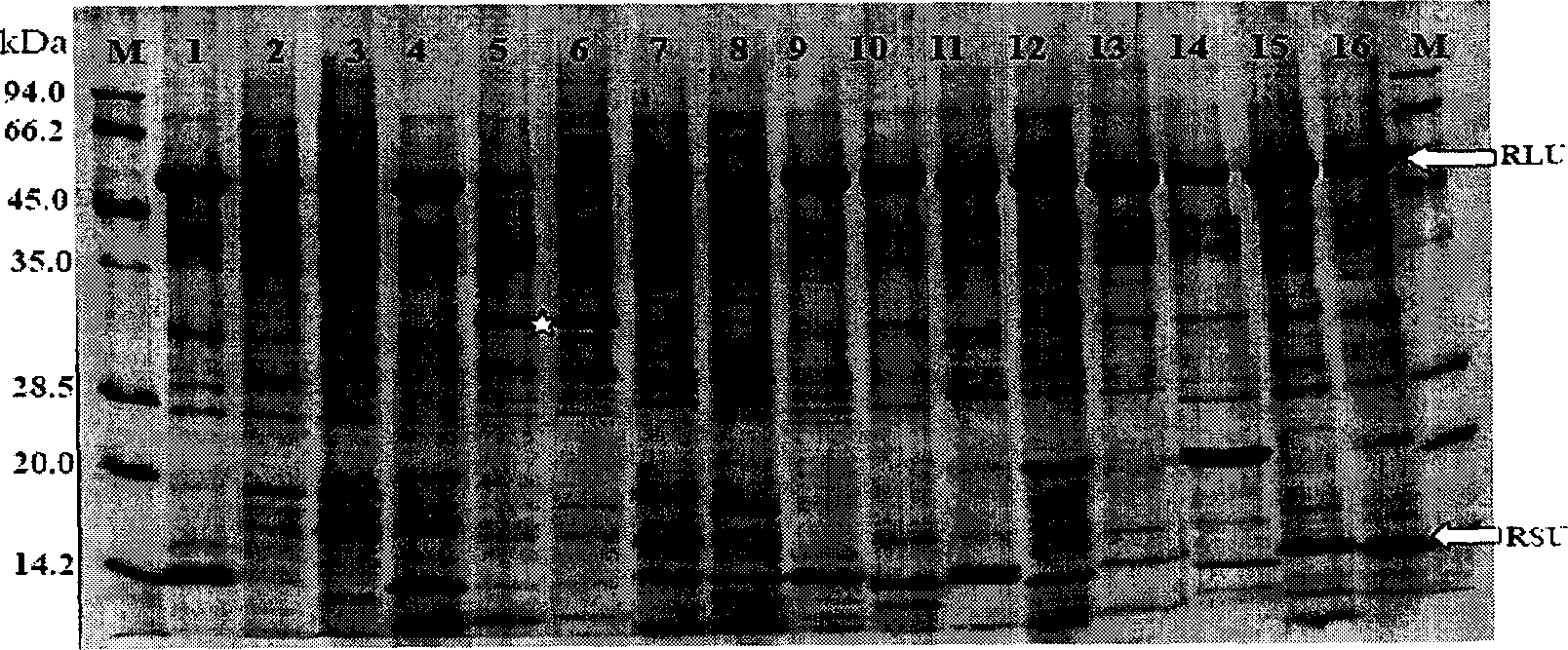

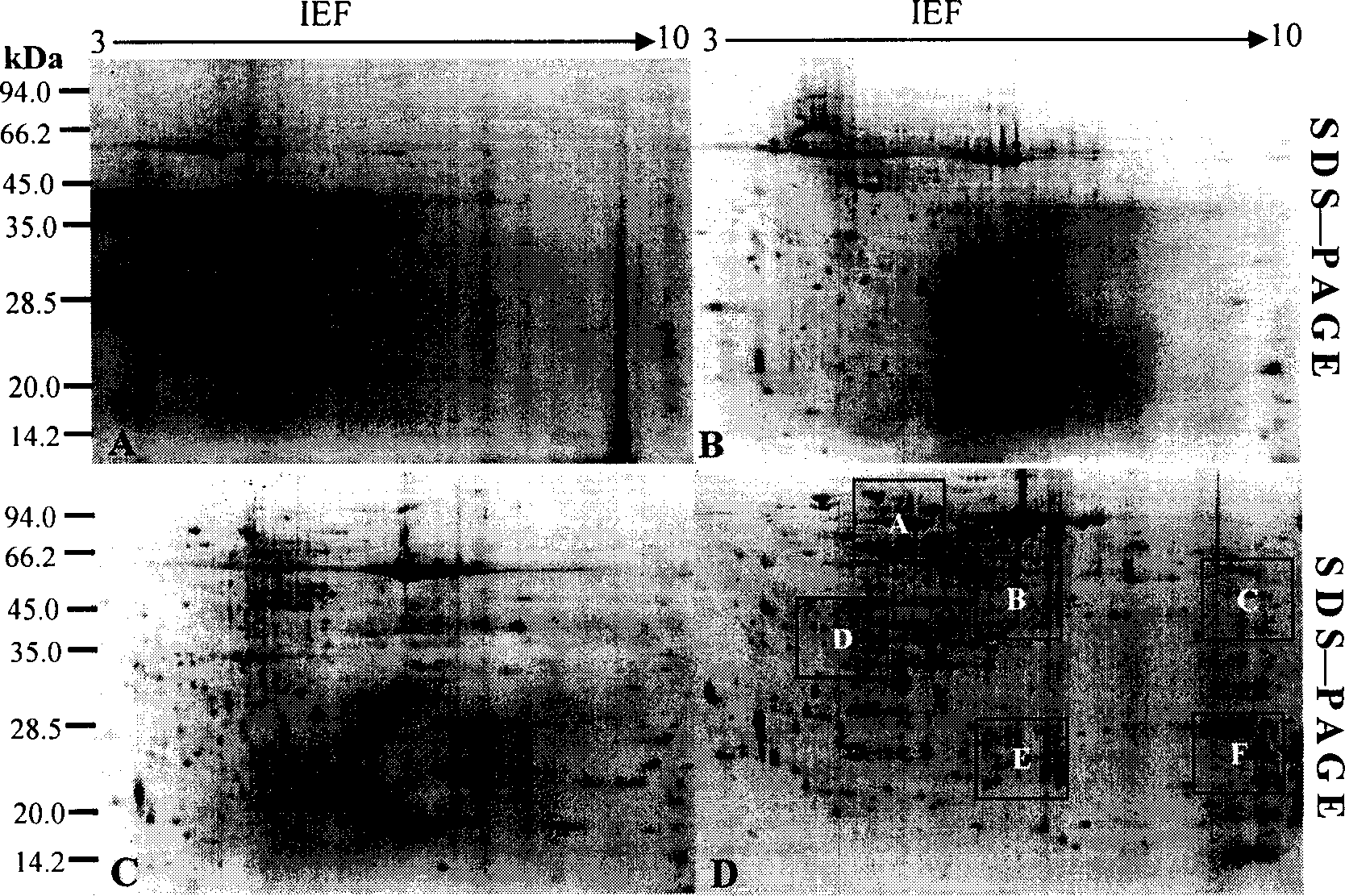

Extraction method of plant total protein and special extract for the same

InactiveCN1908007AHigh extraction rateQuality improvementPreparing sample for investigationPlant peptidesEthylenediamineHalophyte

the invention discloses an extracting method of total plant protein and specific extracting liquid, which comprises the following parts with pH value at 7.5-8.5: 80-120mM EDTA, 80-120mM trimethyl aminomethane, 40-60mM sodium tetraborate and 40-60mM vitamin C, 0.8-1.2% polyvinyl polypyrrolidon,0.8-1.2% Triton-100, 1.5-2.5% 2-mercaptoethanol and 28-32% saccharose solution.

Owner:INST OF BOTANY CHINESE ACAD OF SCI

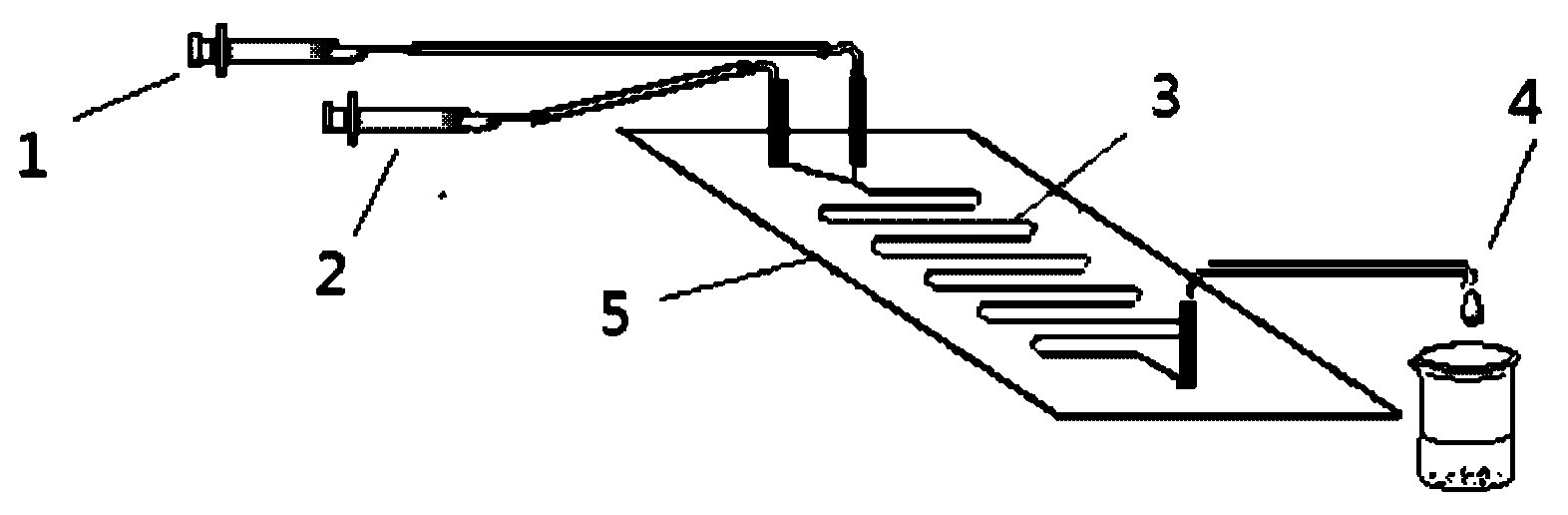

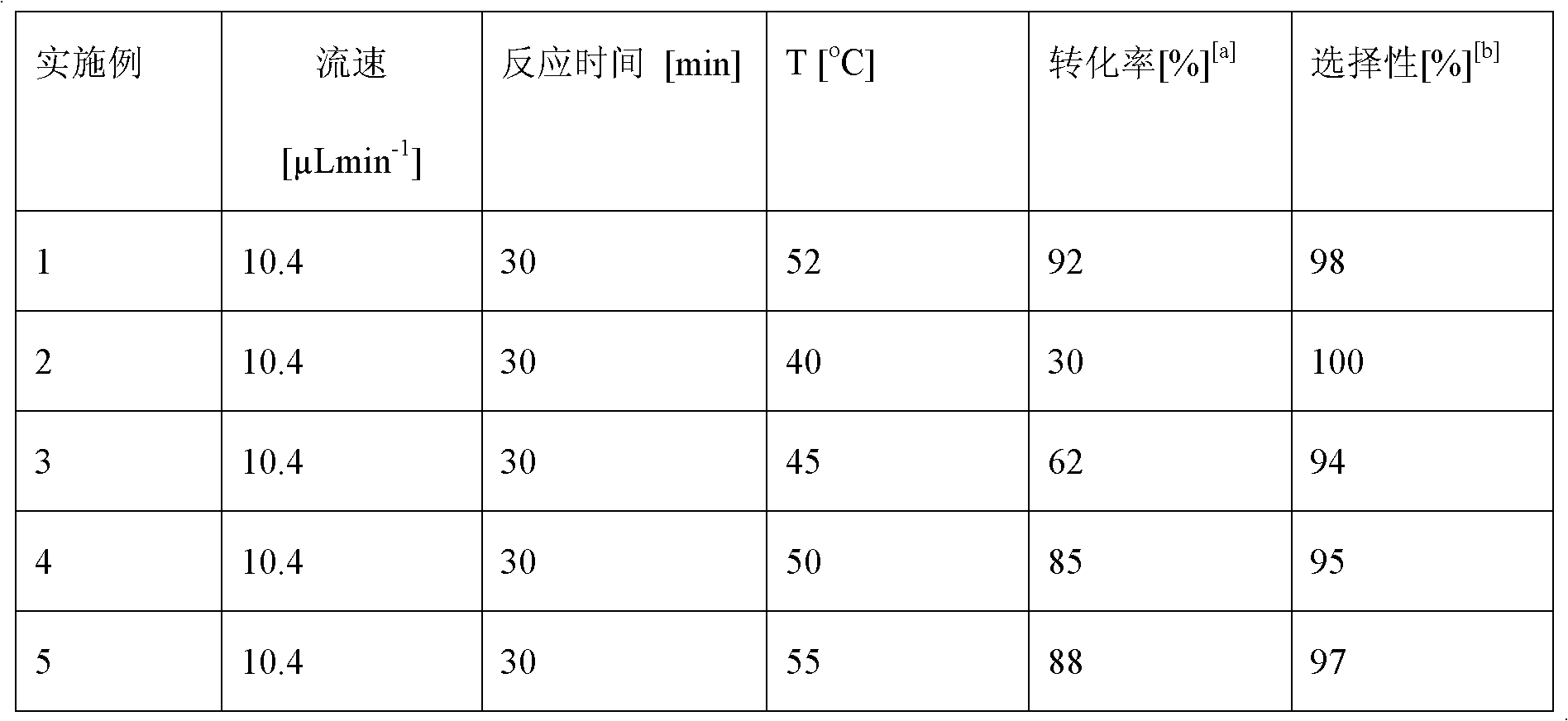

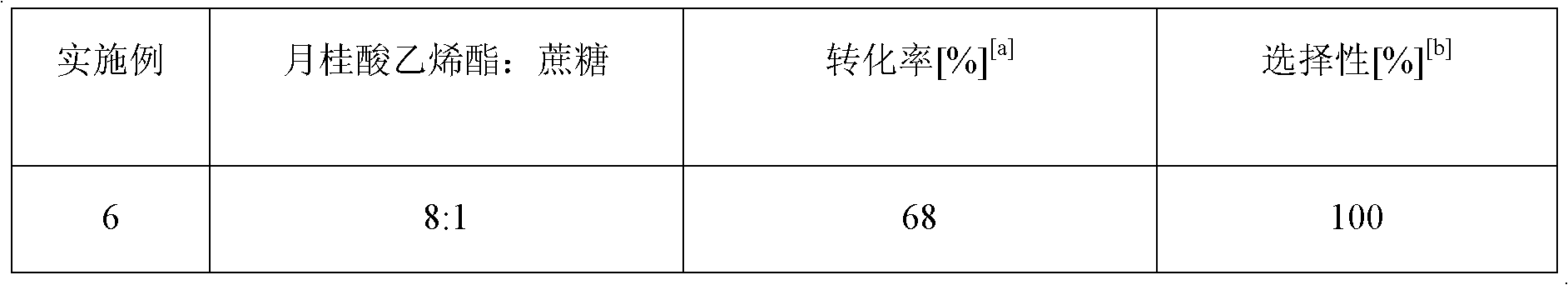

Method for on-line synthesizing saccharose-6-laurate by lipase catalysis

ActiveCN103184256AReduce usageShort reaction timeBioreactor/fermenter combinationsBiological substance pretreatmentsMicrofluidic channelSucrase

The invention provides a method for on-line synthesizing saccharose-6-laurate by lipase catalysis, comprising: using saccharose and vinyl laurate, with a mol ratio of 1:8-12, as raw materials, using 0.5-10g of Lipozyme TLIM as a catalyst, and using a mixed solvent of tertiary amyl alcohol and DMSO as a reaction solvent, uniformly filling Lipozyme TLIM in a reaction channel of a microfluidic channel reactor, wherein the internal diameter of the reaction channel of the microfluidic channel reactor is 0.8-2.4mm, and the length of the reaction channel is 0.5-1.0m; continuously introducing the raw materials and the reaction solvent into the reaction channel to perform acylation reaction under 40-55 DEG C for 20-35min, on-line collecting the reaction solution, and then obtaining the saccharose-6-laurate after conventional post-treatment on the reaction solution. The method of the invention has advantages of short reaction time, high selectivity and high yield.

Owner:ZHEJIANG UNIV OF TECH

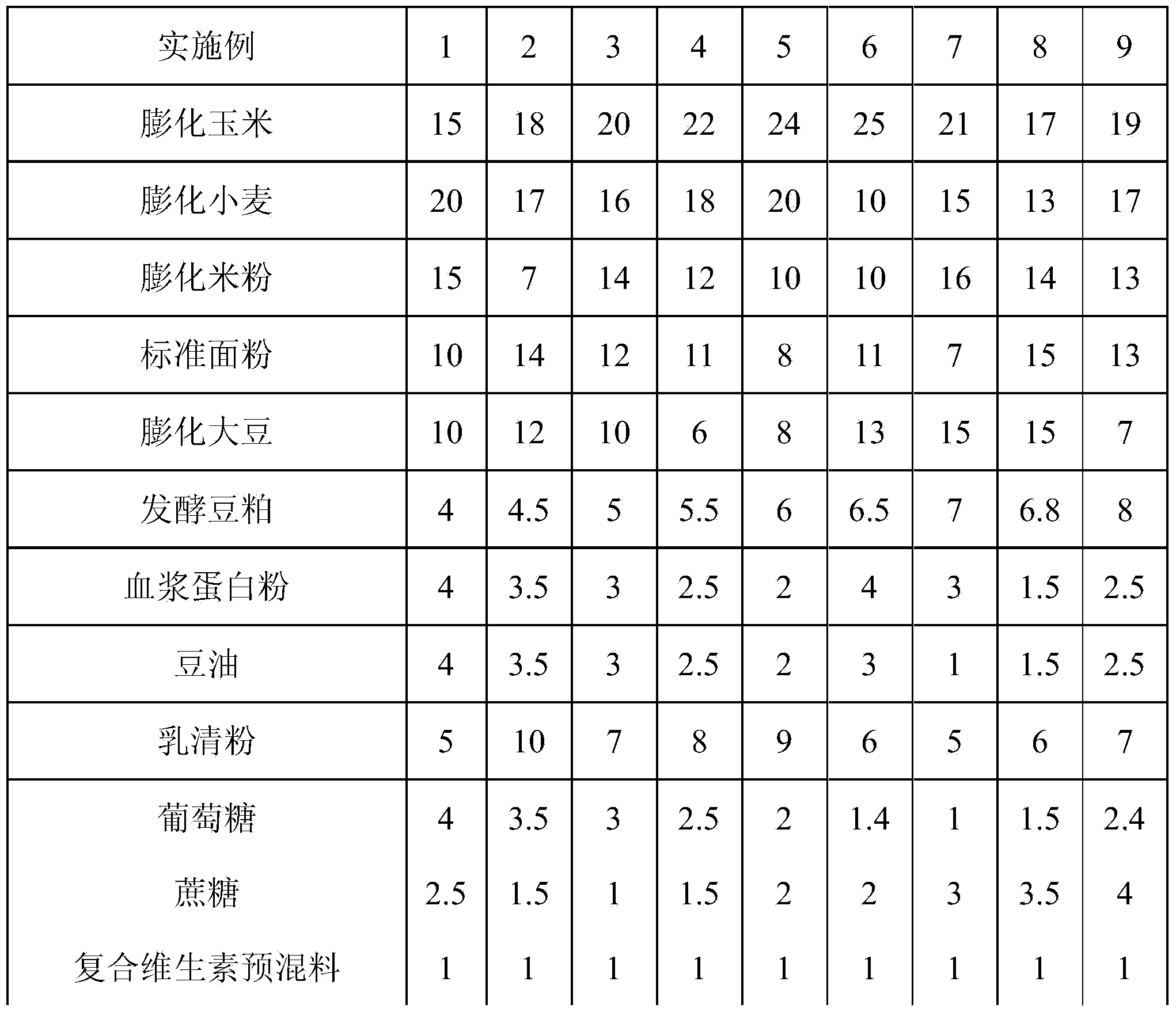

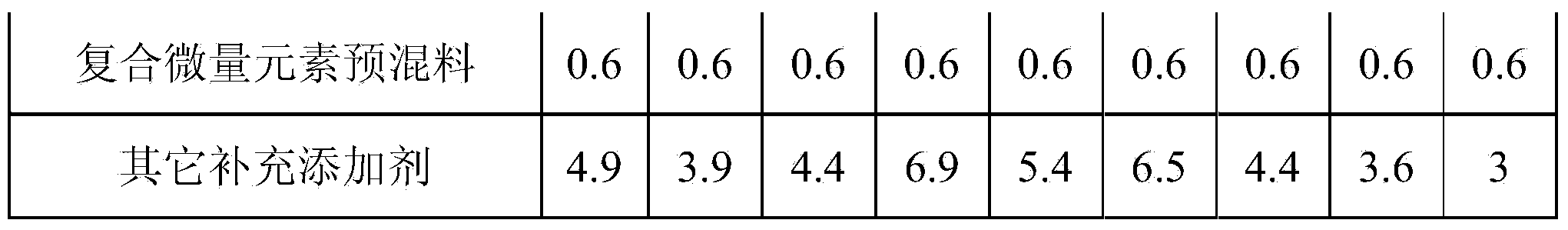

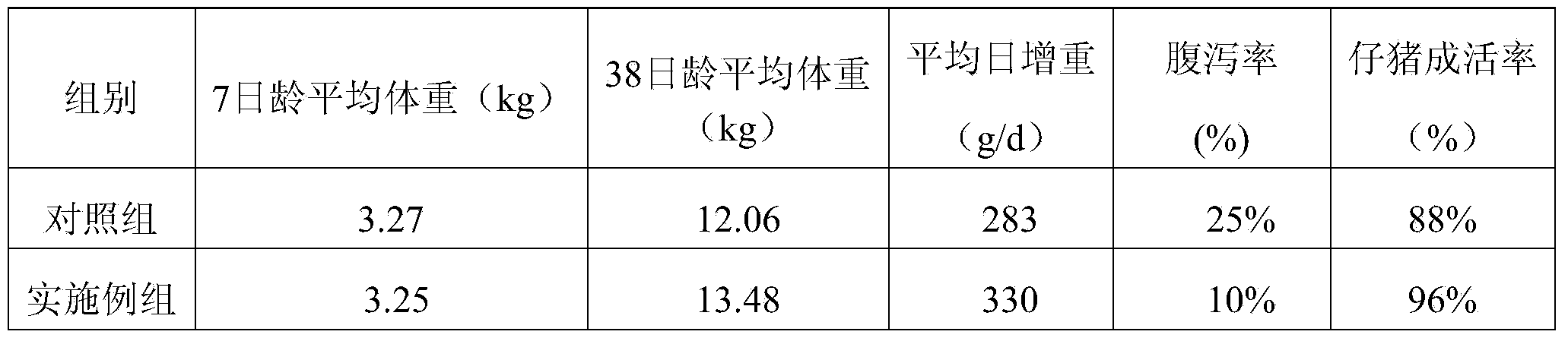

Creep compound feed applicable to 7-38-days-old piglets and preparation method of creep compound feed

InactiveCN104041712AImprove palatabilityIncrease feed intakeAnimal feeding stuffD-GlucoseGlucose polymers

The invention provides a creep compound feed applicable to 7-38-days-old piglets and a preparation method of the creep compound feed. The creep compound feed applicable to 7-38-days-old piglets is prepared from the following components by weight percent: 15-25% of puffed corns, 10-20% of puffed wheat, 5-15% of puffed rice flour, 5-15% of standard flour, 6-15% of puffed soybeans, 4-8% of fermented soybean meal, 1-4% of plasma protein powder, 1-4% of soybean oil, 5-10% of whey powder, 1-4% of glucose, 1-4% of saccharose, 1.0% of compound vitamin premix, 0.6% of compound microelement premix and 4-6% of other supplement additives. The invention provides a creep compound feed applicable to the 7-38-days-old piglets and the preparation method of the creep compound feed. The creep compound feed is capable of effectively meeting the nutritional requirements before and after weaning of the piglets, effectively reducing stress of the piglets after weaning and improving the feed intake of the piglets after weaning.

Owner:SHAANXI SHIYANG AGRI TECH

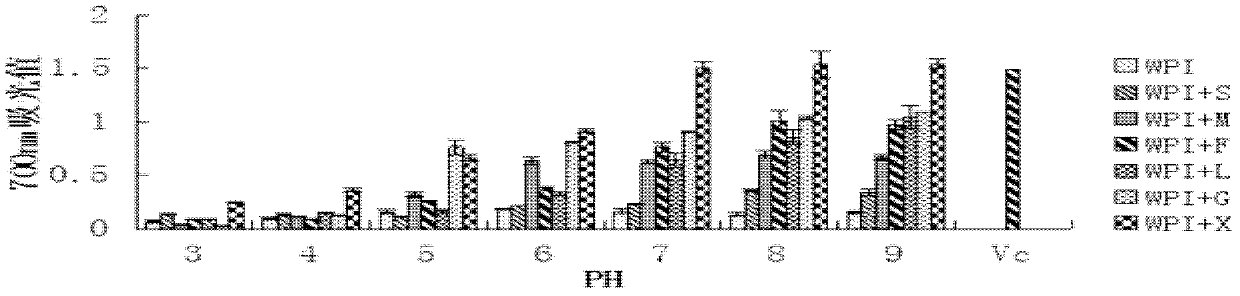

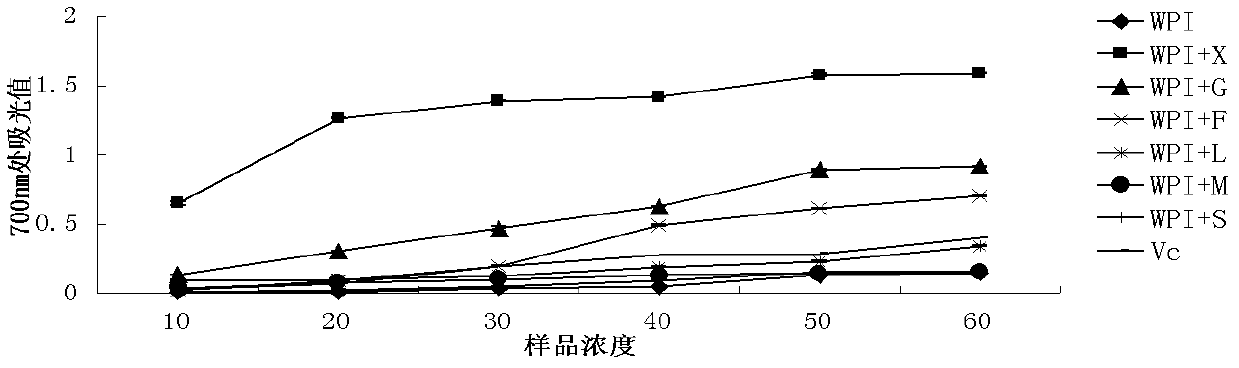

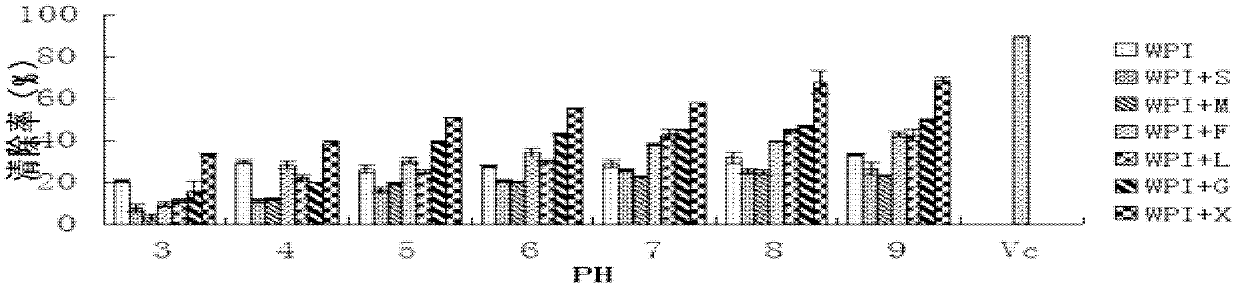

Glycosylated modifying method for improving antioxidant activity of whey protein

InactiveCN103304657AImprove reducibilityImprove cleanlinessPeptide preparation methodsAnimals/human peptidesDPPHMaltose

The invention relates to a glycosylated modifying method for improving the antioxidant activity of a whey protein. The method comprises the following step of: by using xylose, glucose, fructose, lactose, maltose, saccharose and the whey protein as reaction raw materials, performing a damp and hot glycosylated reaction according to a certain proportion. The result shows that the reducing capacity of a whey protein-xylose compound, the DPPH free radical scavenging capacity, the.OH free radical scavenging capacity and the anti-lipid peroxidation capacity are improved to the maximum extent along with increase of pH. SDS-PAGE displays that the molecular weight of the whey protein-xylose compound after reaction is remarkably increased. Fourier Transform Infrared Spectroscopy (FTIR) results show that amides I and II in the whey protein-xylose compound are remarkably reduced. The method provided by the invention aims to obtain the glycosylated modifying method for the whey protein with stronger antioxidant function. The antioxidant function characteristic of the whey protein is improved, a novel functional whey protein ingredient is developed, and the application range is expanded and a novel functional additive is increased.

Owner:NORTHEAST FORESTRY UNIVERSITY +2

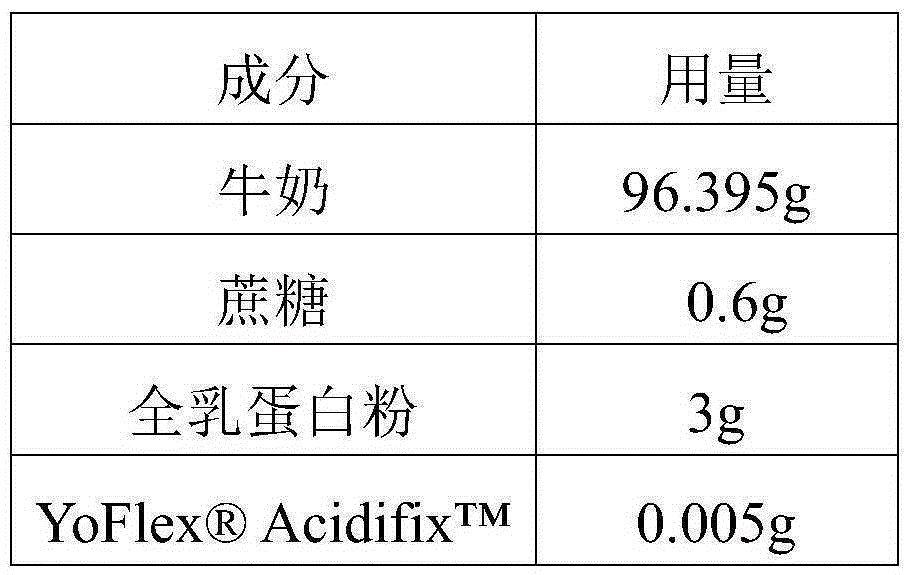

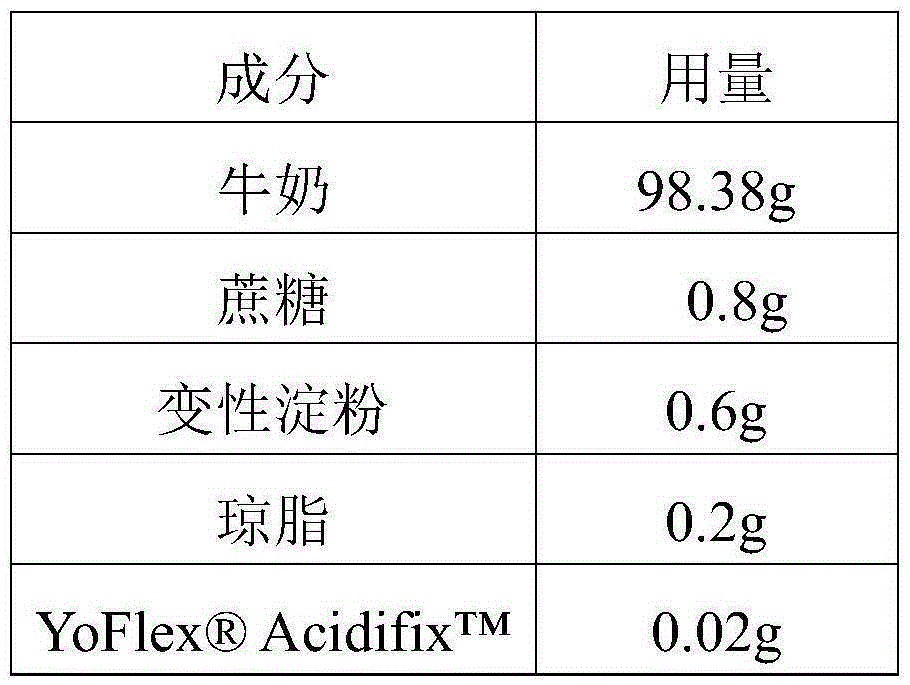

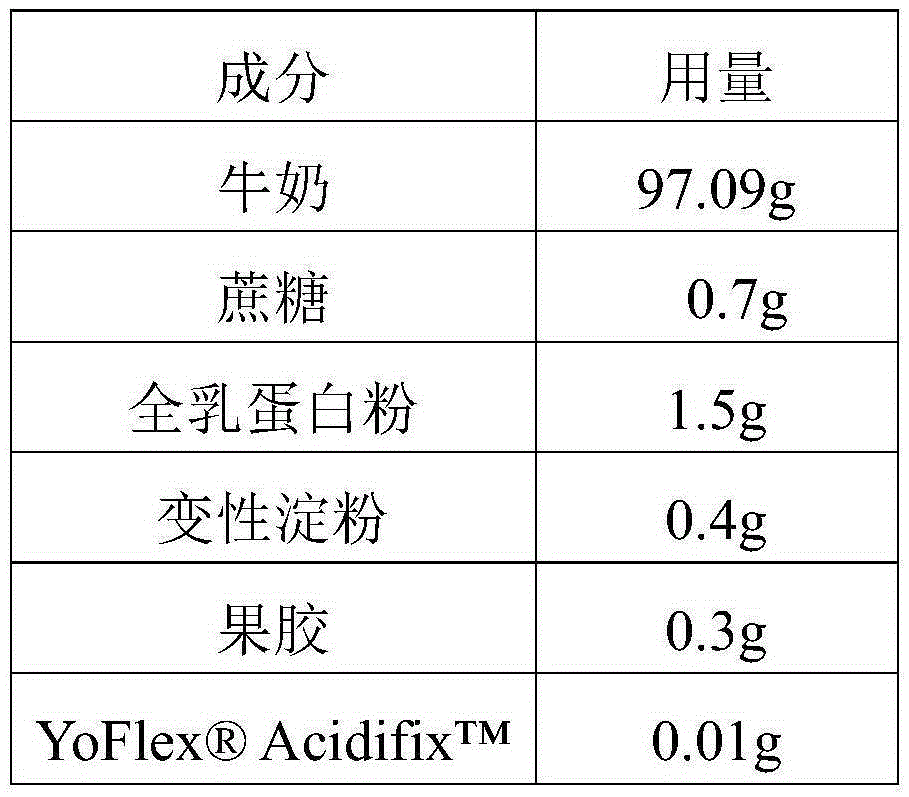

Living bacterium type room temperature yoghurt and making method thereof

ActiveCN105325541AViable count is stableConsistent tasteMilk preparationLactic acid bacteriumRoom temperature

The invention discloses living bacterium type room temperature yoghurt and a making method thereof. Raw materials of the living bacterium type room temperature yoghurt comprise conventional raw materials of yoghurt, wherein the content of saccharose accounts for 0.6%-0.8% of the total mass of the raw materials, the content of protein in the raw materials accounts for 2.95%-4.69% of the total mass of the raw materials, and a fermenting agent with the shop sign of YoFLex<R> Acidifix<TM> is adopted as a fermenting agent of the yoghurt. The making method specifically comprises the steps that 1, the raw materials except the fermenting agent are mixed; 2, the materials obtained in the step 1 are homogenized and sterilized to obtain a fermenting matrix; 3, the fermenting matrix obtained in the step 2 is cooled, and the fermenting agent is added for fermentation; 4, sweet substances which do not contain the saccharose are added in the fermented matrix obtained in the step 3, the mixture is stirred evenly, filling is performed, and then the living bacterium type room temperature yoghurt is obtained. The yoghurt breaks through the technical barrier that room temperature yoghurt has no living bacterium, and the acidity, the state, the mouthfeel and the lactic acid bacterium number are kept stable when the yoghurt is placed at the room temperature within the quality guarantee period.

Owner:BRIGHT DAIRY & FOOD CO LTD

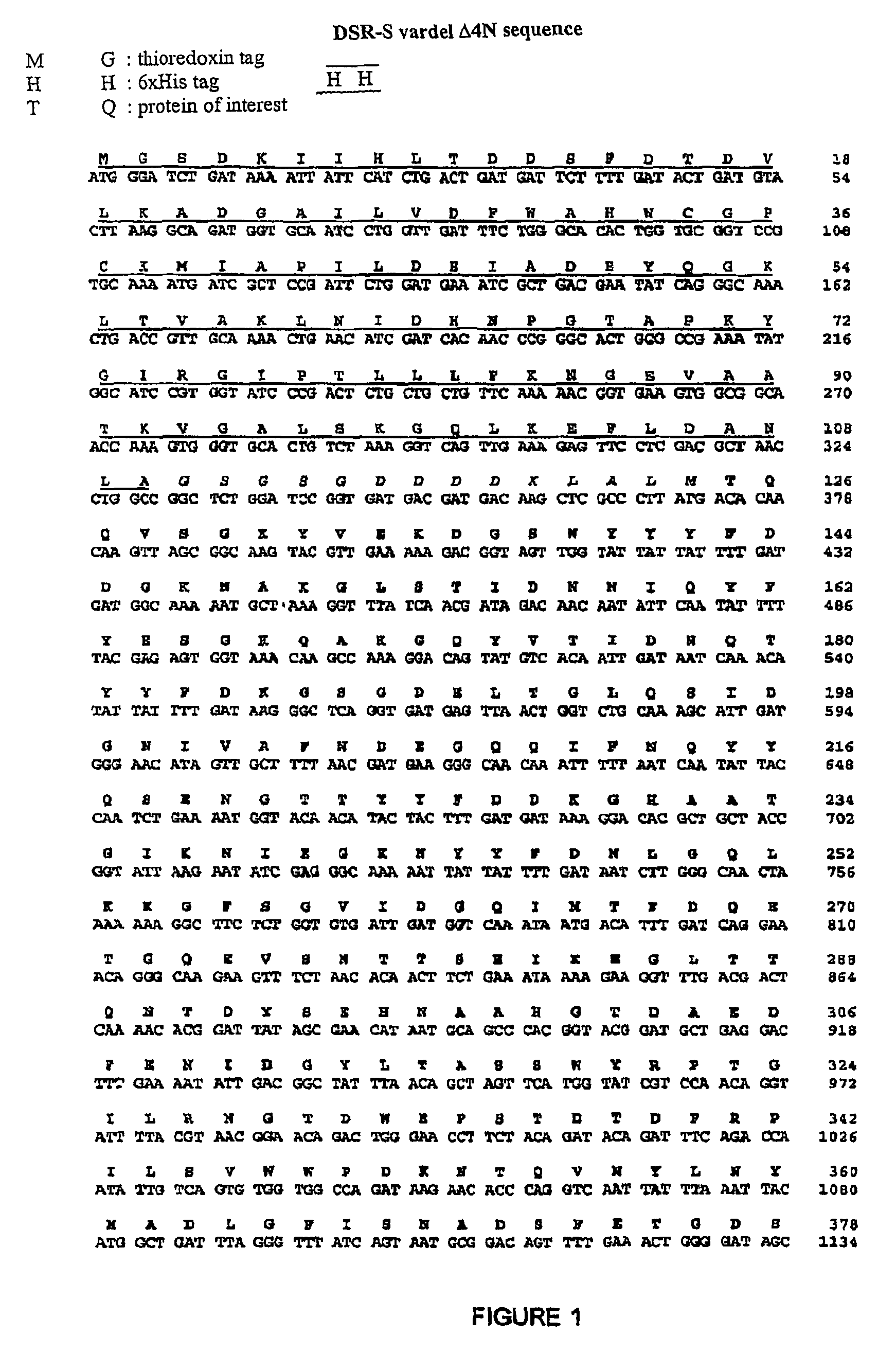

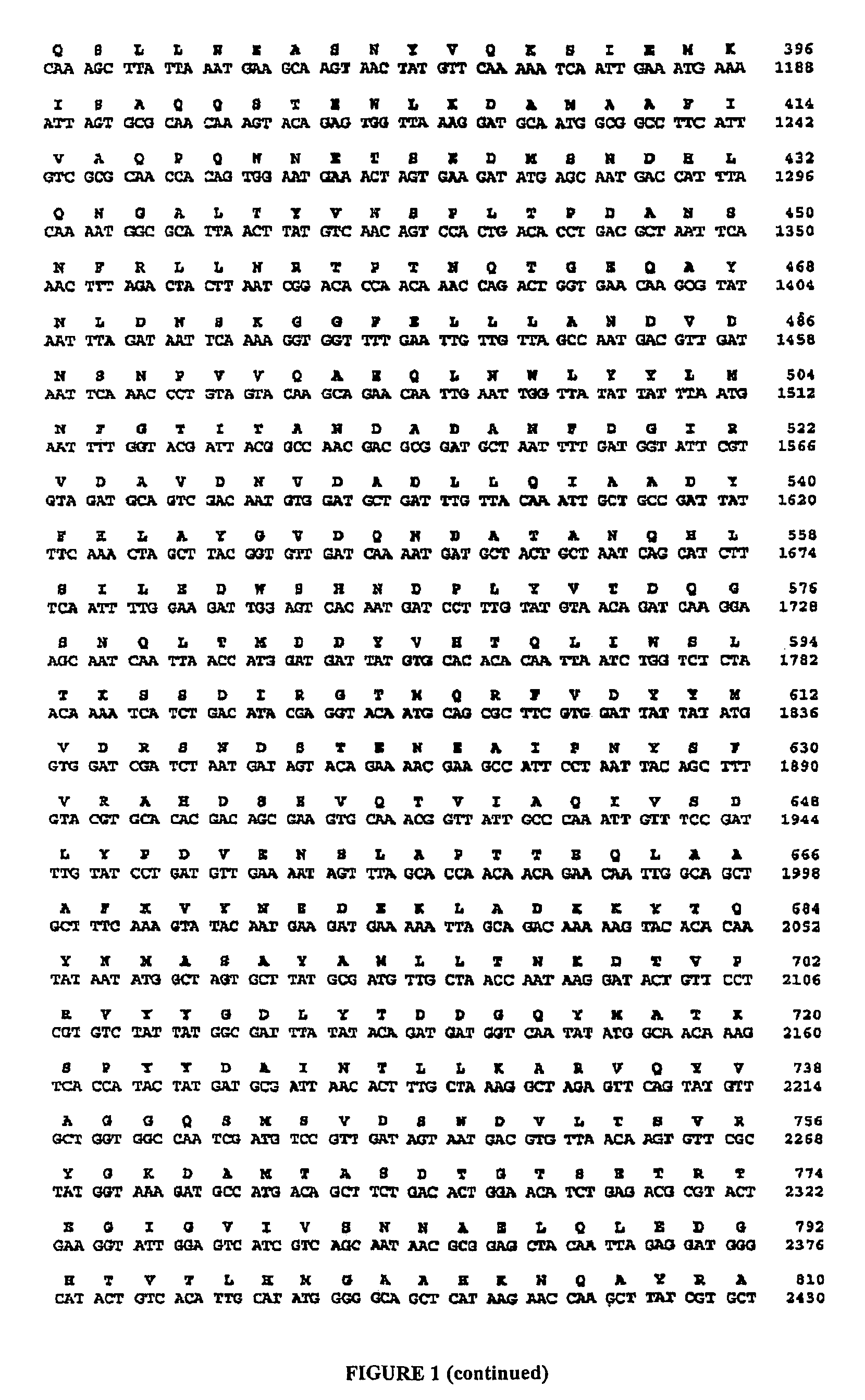

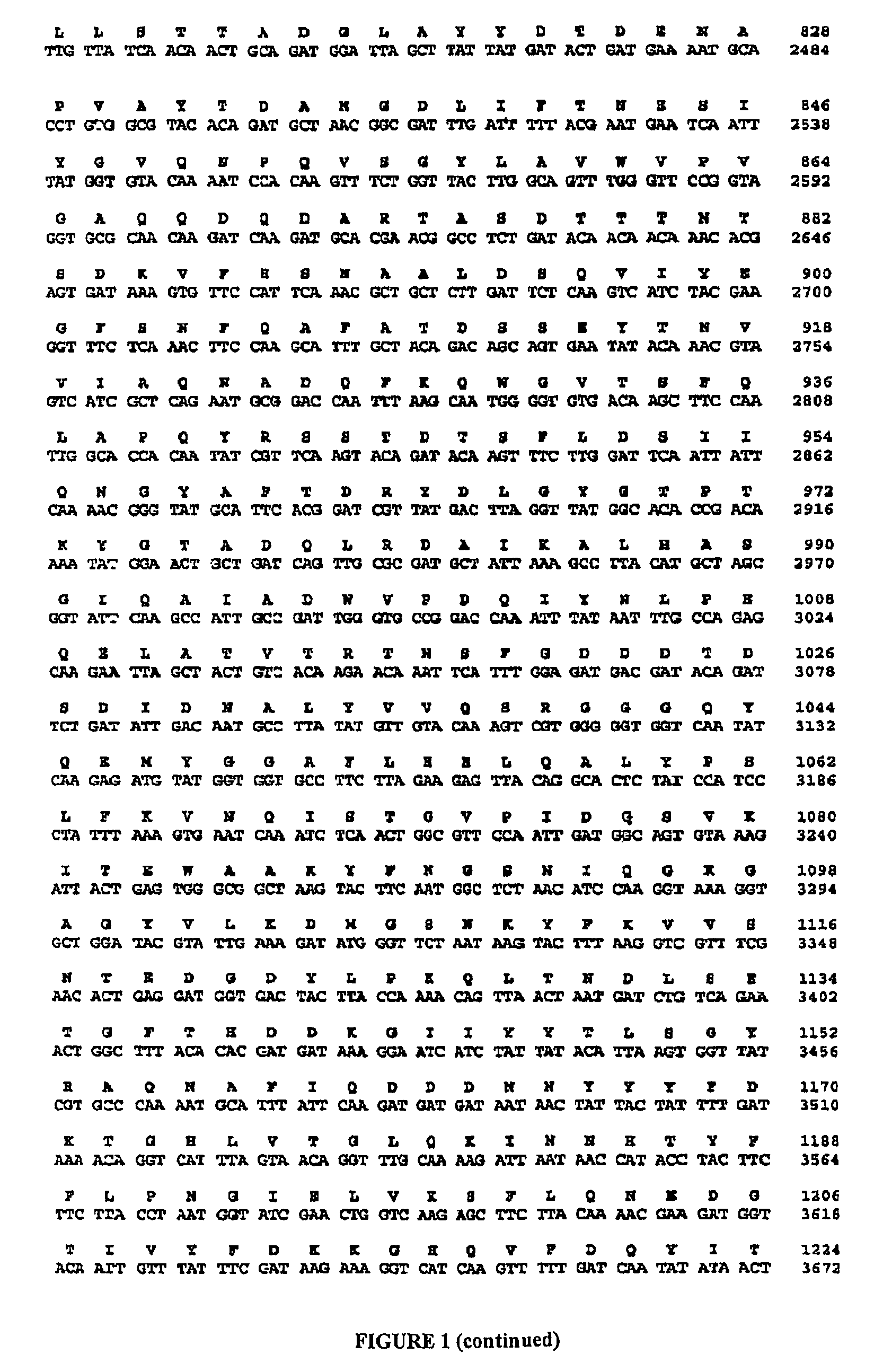

Construction of new variants of dextransucrase DSR-S by genetic engineering

The present invention relates to a recombinant process for the production of truncated or mutated dextransucrases while conserving the enzymatic activity or their specificity in the synthesis of the α-1,6 bonds. The present invention relates to nucleic acid sequences of truncated or mutated dextransucrases, vectors containing the nucleic acid sequences and host cells transformed by sequences encoding truncated or mutated dextransucrases. In another aspect, the invention concerns a method for producing, in a recombinant manner, truncated or mutated dextransucrases which conserve their enzymatic activity or which conserve their specificity in the synthesis of α-1,6 bonds and can produce, from saccharose, dextrans with high molar mass and modified rheological properties compared with the properties of dextran obtained with the native enzyme and isomalto-oligosaccharides with a controlled molar mass and dextrans. The dextrans and isomalto-oligosaccharides of the invention can be used namely as texturing agents or as prebiotics.

Owner:INST NAT DE RECH POUR LAGRICULTURE LALIMENTATION & LENVIRONNEMENT +2

Rapid vitrification preservation and frozen refrigeration method for little yellow croakers and special refrigerating fluid

InactiveCN104522141APlay a role in keeping freshAvoid breakingMeat/fish preservation by freezing/coolingCell wallIce crystals

The invention aims at providing a rapid vitrification preservation and frozen refrigeration method for little yellow croakers and special refrigerating fluid. The refrigerating fluid is characterized by comprising the following components in percentage by weight: 10-18 percent of sodium chloride, 8-25 percent of 98-percent ethanol, 10-30 percent of glycerin, 3-5 percent of edible saccharose, 0.2-1 percent of sodium tripolyphosphate and the balance of water. The refrigerating fluid can be maintained in a liquid state from room temperature to the temperature of 40 DEG C below zero. According to the method, when the little yellow croakers are subjected to low temperature preservation, breakage of cell walls caused by formation of ice crystals can be avoided, so that the aim of preserving the aquatic products is achieved, and bacteria and microbes carried by the fish bodies can be killed by adopting extremely low temperature. Therefore, after the little yellow croakers are subjected to vitrification refrigeration, fresh and delicious meat is ensured. According to the method, refrigeration and preservation can be finished in one step the process is simple, the cost is low, and the application is flexible.

Owner:DALIAN BOYUAN SCI & TECH CO LTD

Pollen filling agent for plant pollination and preparing technology and using method of pollen filling agent

ActiveCN104137771AImprove germination rateQuality improvementPlant genotype modificationFiller ExcipientPollen

The invention belongs to the technical field of filling agents and discloses a pollen filling agent for plant pollination and a preparing technology and a using method of the pollen filling agent. The pollen filling agent is mainly characterized in that the pollen filling agent for plant pollination comprises water, white carbon black, saccharose or fructose or glucose or sorbitol, vitamin B1, an equivalent mixture of vitamin B6 and niacin or niacinaminde, borax or boric acid, gibberellin GA3 or GA4 + 7, cytokinin 6-BA or forchlorfenuron, ethyl alcohol with the concentration of at least 95%, phosphoric acid or citric acid. The pollen filling agent for plant pollination is prepared by common raw materials and can be suitable for various plants, cost is low, raw materials are sufficient, environment pollution is avoided from production to application, residue problems are avoided for agricultural products, through added nutrition, growth promotion matter and proper moisture, the germination rate and the germination quality of pollen are improved, the using effect under a dry weather environment is improved, and the quality and the efficiency of hand pollination are greatly improved.

Owner:岑建卫

Compound colour conserving method for prolonging storage period of dehydrated lettuce slices

The invention relates to a compound colour conserving method for prolonging the storage period of dehydrated lettuce slices, belonging to the technical field of fruit and vegetable processing. The method in the invention comprises the following steps: pretreating lettuce utilized as a raw material, soaking with a colour conserving solution, and conserving the colour by adopting a mixed solution of lactose, saccharose and table salt, thus not only can the colour conserving cost be reduced, but also the colour and lustre of the lettuce slices preserved at different temperatures; then blanching,carrying out secondary soaking, and drying; and finally packaging and storing, wherein the storage temperature is 4-22 DEG C. In the invention, the degradation of chlorophyll in the processing process of each step is ensured to reach the minimum, so as to realize a good green conserving effect in the storage period.

Owner:NINGBO HAITONG FOOD SCI & TECH CO LTD +1

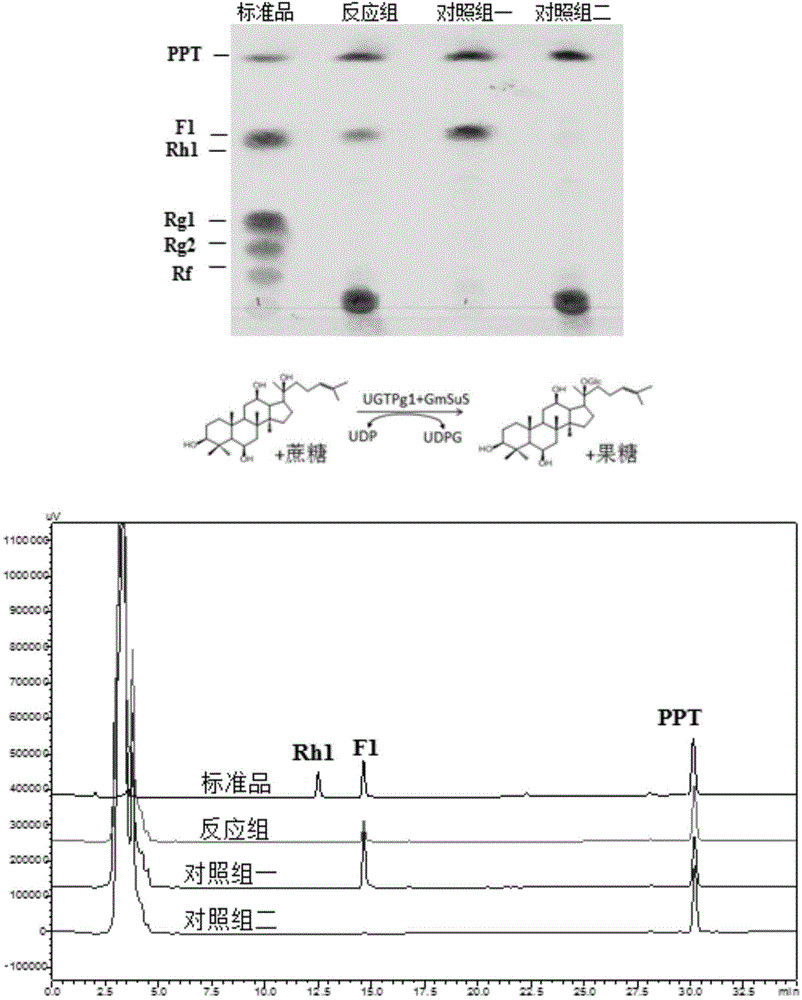

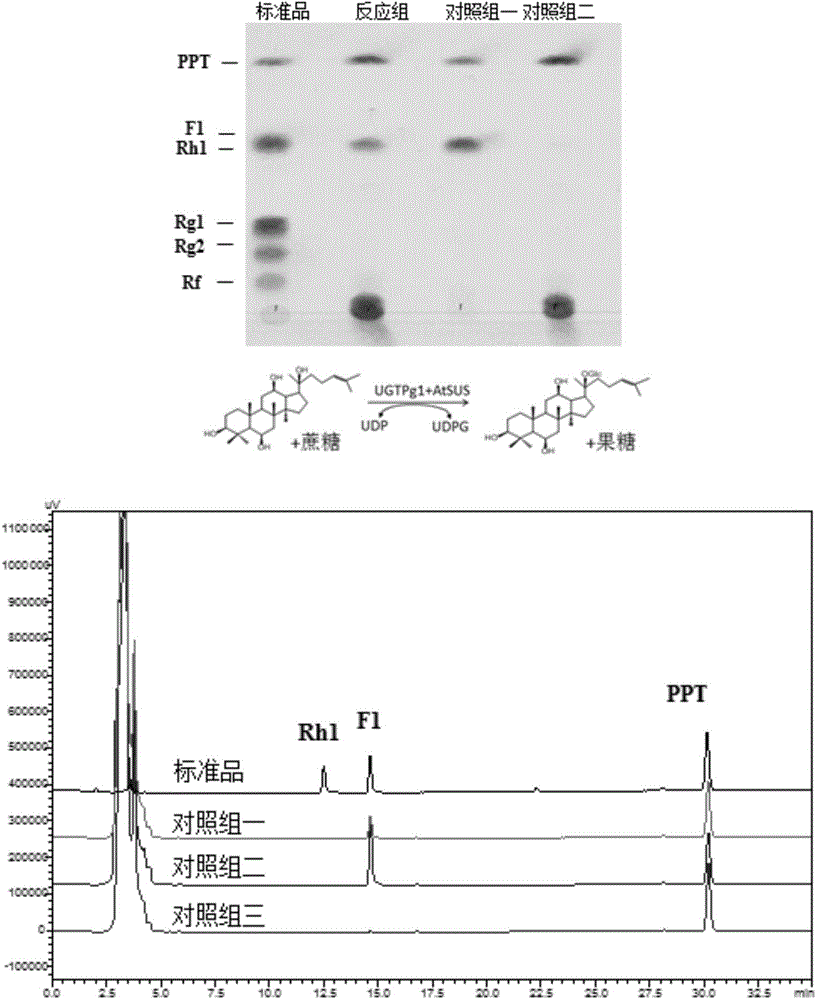

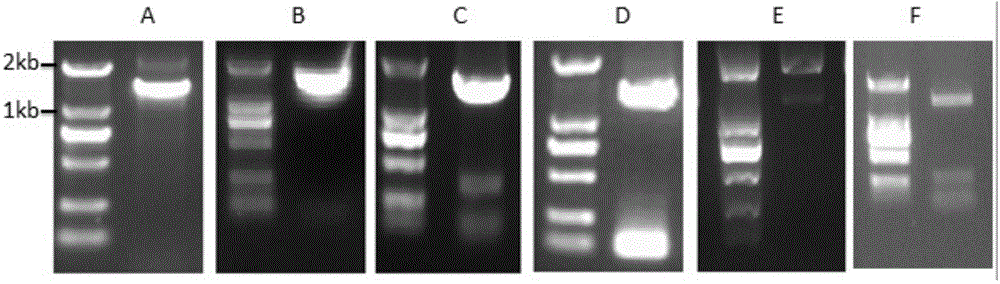

Novel catalytic system for preparing rare ginsenosides and application thereof

ActiveCN105087739AHigh catalytic efficiencyReduce use costFungiBacteriaSucrose synthetaseProtopanaxadiol

The invention discloses a co-catalytic reaction system for preparing rare ginsenosides. The co-catalytic reaction system comprises glycosyltransferase GT (a); sucrose synthase SUS (b); uridine diphosphate UDP (c); and saccharose (d). Experiments show that in the presence of the saccharose and little UDP, an enzyme combination composed of the glycosyltransferase and the saccharose is capable of replacing an in-vitro reaction system to synthesize UDP sugar, one of expensive materials for the rare ginsenosides, and efficiently and economically converting substrates such as protopanoxadiol or protopanaxatriol into the rare ginsenosides, wherein the UDP is about 1 / 4 of the UDP sugar in price and is 1% of its original dosage; thus, preparation cost of the rare ginsenosides is greatly saved, and large-scale commercial preparation of the ginsenosides is better facilitated.

Owner:SYNBIOTECH (SUZHOU) CO LTD

Popular searches

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com