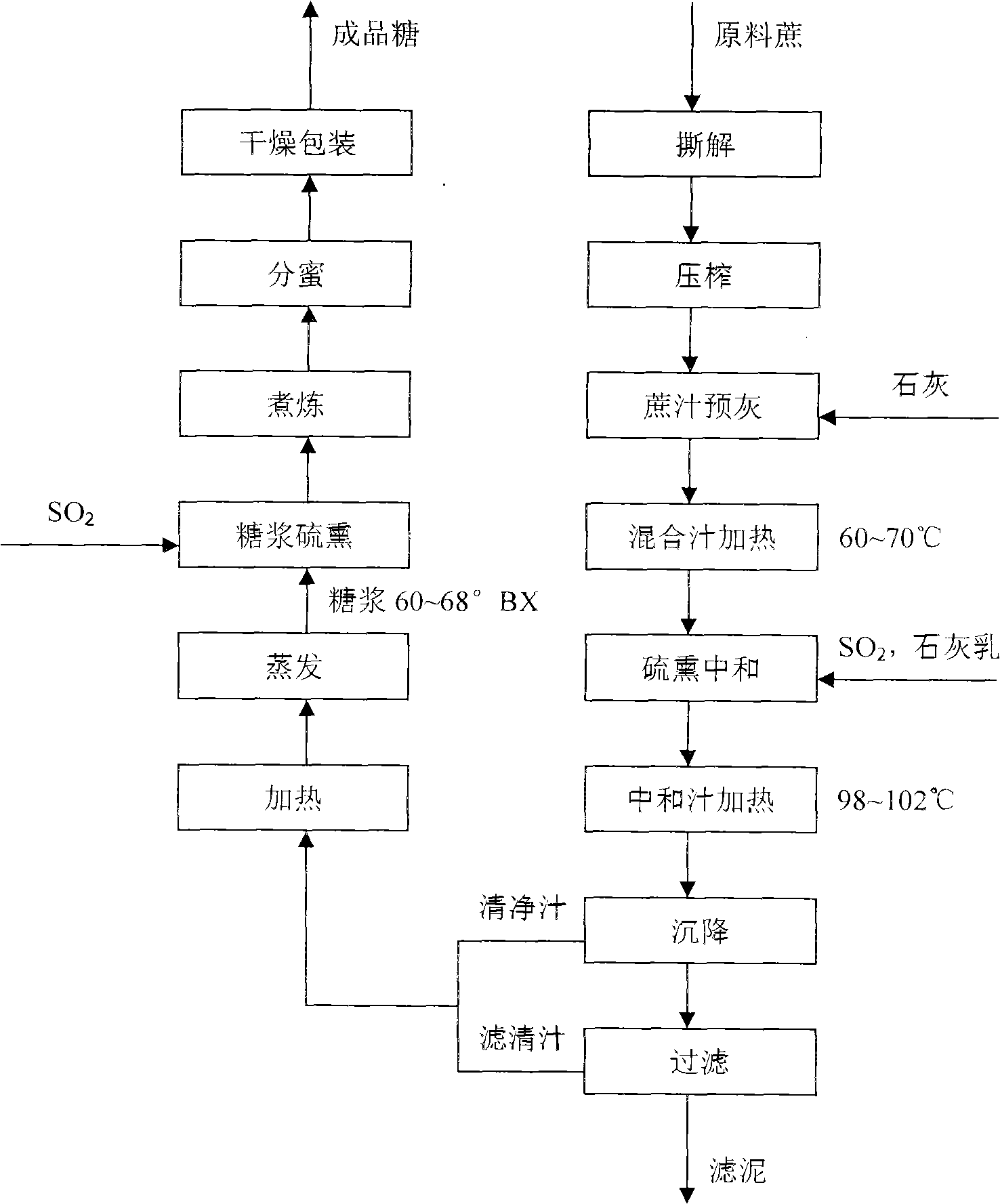

Production method of sulfurless superior saccharose

A production method and sucrose technology, which are applied in sucrose production, sugar production, and juice purification, etc., can solve the problems of irreplaceable sulfur fumigation decolorization effect, stay in the research stage, and sugar conversion loss, etc., and achieve equipment reduction and operation. Easy, promote calcium loss effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

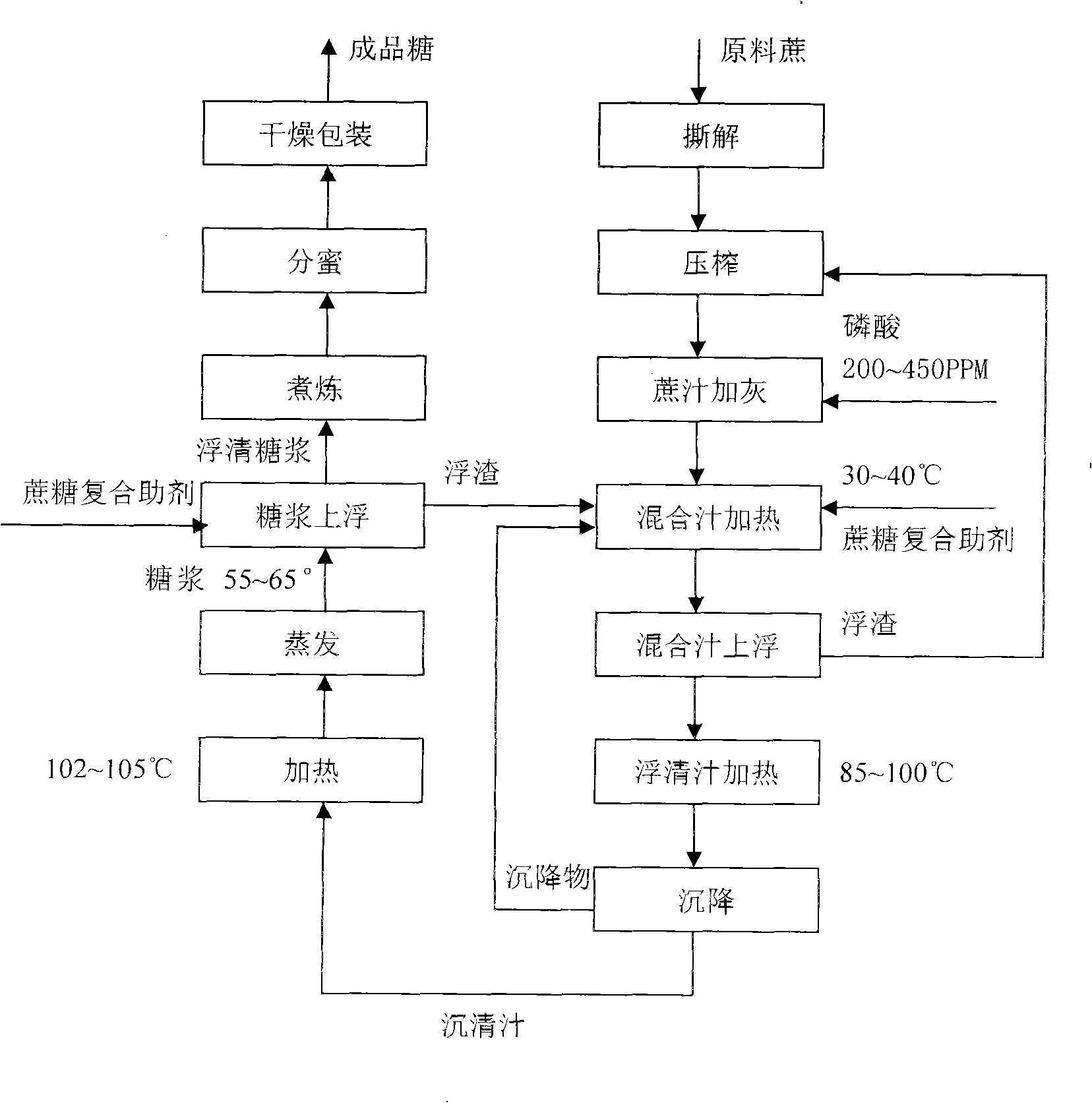

Method used

Image

Examples

Embodiment 1

[0046] Take 500ml of virgin juice from a sugar factory, add 350PPM / L phosphoric acid, add lime milk, add 10mg of chitosan with a molecular weight of 10,000 to 1 million as a sucrose compound additive, and control the pH value between 6.8 and 7.2 , shake and stir, then heat to 35°C, add the bubble solution of the simple bubble-making mechanism, add 1-5PPM polyacrylamide, and observe that the flocs float up quickly. To meet the clear juice requirements of the color value required for sugar production.

Embodiment 2

[0048] In a sugar factory, a φ3000 floater is used. According to the production process, a φ3000 floater system is installed in the press room, adding 300-350PPM phosphoric acid, lime milk, and sucrose compound additives (molecular weight between 50,000 and 3 million. Chitosan, 0.5g per cubic meter of syrup), foamed with a pressure-melting foaming system, after adding 15PPM polyacrylamide, the scum began to float, the concentration of the scum was high, and the amount was small, accounting for about 5% of sugarcane juice quantity. Compared with cane juice, the purity of floating clear juice is 1.73AP higher, and the color value is 233IU lower than that of the original clear juice. When entering the next process, it can produce first-grade white sugar.

Embodiment 3

[0050] After the sugarcane raw material enters the factory, it is torn apart and squeezed multiple times, and the obtained cane juice is directly added with lime, and the amount of phosphoric acid added is 350PPM, and the pH value is adjusted to neutral, and then heated to about 34-37°C, adding sucrose compound additives - Chitosan with a molecular weight of 10,000 to 1 million is added in an amount of 1 to 100 mg / kg sugarcane juice, and enters the low-temperature floater, and the scum returns to the middle conveyor belt of the press, and enters the press process. The floating clear juice is pumped for secondary heating, heated to about 90-95°C, and enters the fast settler, and the sediment is discharged to the mixing reaction tank, and after being mixed with the raw cane juice, it also enters the floater for retreatment, and the settled juice is heated to 102°C After ~105°C, enter the evaporating tank for concentration, and after concentration to 55~60°BX, add phosphoric acid ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com