Patents

Literature

81 results about "Sugar refining" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A sugar refinery is a refinery which processes raw sugar into white refined sugar or that processes sugar beet to refined sugar. Many cane sugar mills produce raw sugar, which is sugar that still contains molasses, giving it more colour (and impurities) than the white sugar which is normally consumed in households and used as an ingredient in soft drinks and foods.

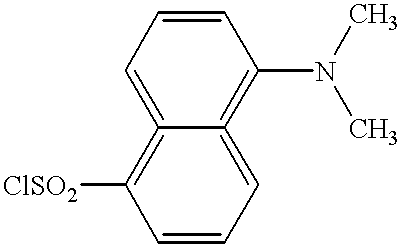

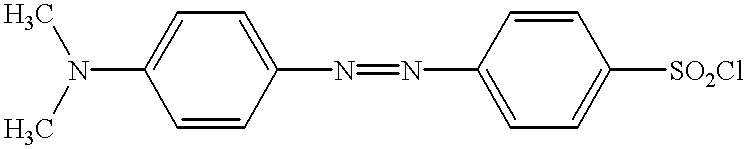

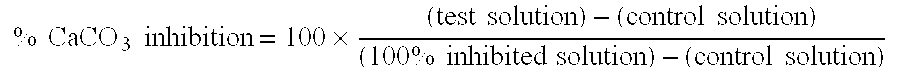

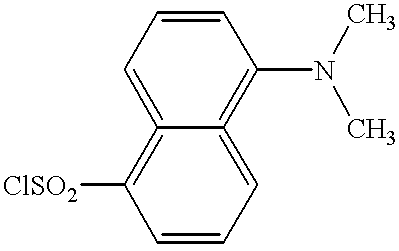

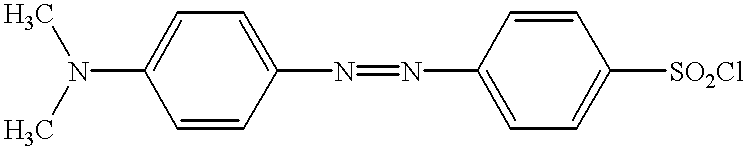

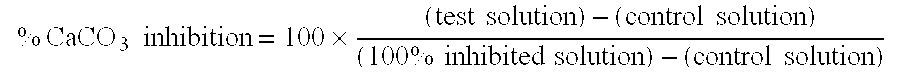

Detectable polymers and methods for detecting polymers in Aqueous systems

InactiveUS6251680B1High molecular weightDecrease in levelAnalysis using chemical indicatorsOrganic detergent compounding agentsThiolPaper production

Polymers having amine-thiol terminal moieties are provided. The amine-thiol terminal moieties are imparted by using amine-thiols as chain transfer agents in aqueous addition polymerizations. The polymers are useful as mineral dispersants, as water-treatment additives for boiler waters, cooling towers, reverse osmosis applications, sugar refining, paper production, geothermal processes and oil wells, and as detergent additives acting as builders, anti-filming agents, dispersants, sequestering agents and encrustation inhibitors.

Owner:ROHM & HAAS CO

Sludge bagasse active carbon and preparation method thereof

ActiveCN103241737AImprove adsorption capacitySolve the defect of poor adsorption performanceSludge treatmentOther chemical processesSludgeSugar refining

The invention relates to sludge bagasse active carbon and a preparation method thereof. The sludge bagasse active carbon is prepared from sewage treatment sludge and sugar refining industrial waste bagasse. The bagasse is added into the sludge to improve the carbon content of the sludge and the adsorptive property of sludge base active carbon, so that the problem that the adsorptive property of the sludge base active carbon is poor is solved; and the sludge is subjected to heavy metal removal to improve the using safety of the sludge base active carbon. The process comprises the following steps of: carrying out heavy metal removal on the sludge by adopting a certain technical means; drying the sludge and the bagasse, and then uniformly mixing the sludge and the bagasse according to a certain proportion; adding an activating agent ZnCl2 solution with a certain concentration to carry out immersion and activation; then carrying out pyrolysis under the protection of an inert gas; and washing and drying to obtain the active carbon. According to the preparation method, the active carbon is prepared from the sludge and the bagasse, the active carbon with good adsorptive property is prepared, and the resource utilization of the two types of industrial solid wastes is achieved at the same time, so that the sludge bagasse active carbon has good economic, social and ecological benefits.

Owner:GUANGXI UNIV

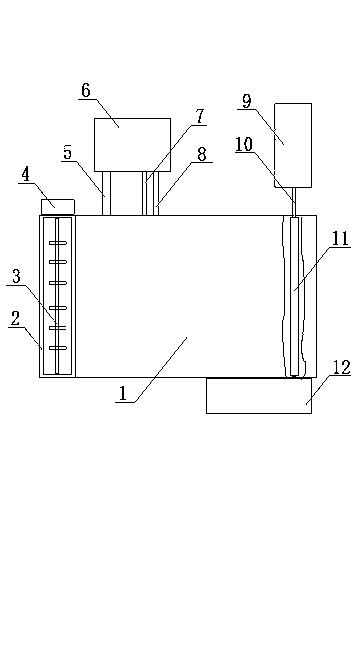

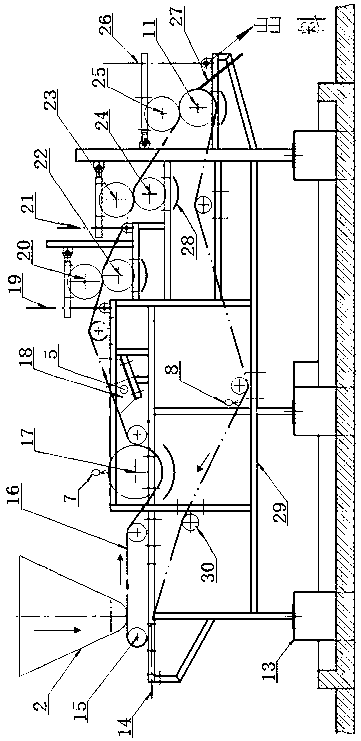

High-efficiency energy-saving belt filter press

InactiveCN103007614ANot easy to runSolve slipperyChemical industryMoving filtering element filtersChemical industrySlag

The invention discloses a high-efficiency energy-saving belt filter press which comprises a frame, a filter press belt, a hopper and a motor, and is characterized in that a material equalizing regulation device is arranged at a discharging end of the frame; the filter press belt is a double-layer filter cloth belt; a four-stage press filtering mechanism is arranged on the discharged filter press belt at intervals; a vacuum suction filtration disc for vacuumizing by utilizing a vacuum pump is arranged below the filter press belt behind a mesh cage roller; a tail gas cleaning mesh-cleaning roller and a filter press belt gas ejector pipe are respectively arranged on the mesh cage roller and on a belt return part of the filter press belt. The machine is uniform in feeding, long in service life, stable in performance, good in dewatering effect and high in yield, and the filter belt is difficult to block; the slag adhered to the mesh cage roller and the filter press belt is subjected to air injection cleaning by utilizing the vacuum pump tail gas, and water and electric energy are saved; and the machine is suitable for squeezing and dewatering manioc waste, cassava residues, bean dregs and distillers grains and water-containing raw materials in the industries such as municipal sludge, chemical industry, oil refining, papermaking and sugar refining.

Owner:陆汉克

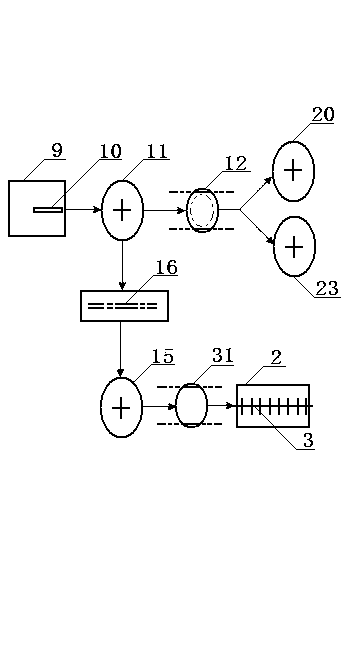

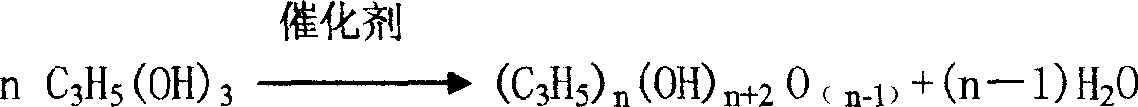

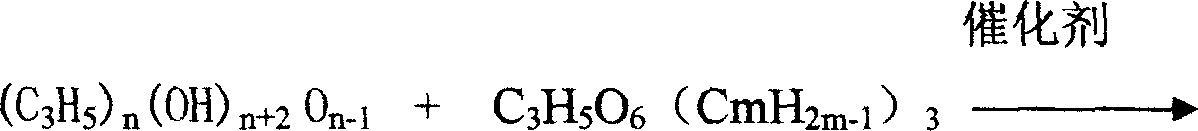

Preparation method of industrial defoaming agent

InactiveCN1721031AGood defoamingGood anti-foam performanceFoam dispersion/preventionGlycerolSugar refining

The preparation method for industrial defoaming agent belongs to organic chemical industry field. First polymerize the glycerin to polyglycerol with polymerization degree of 2-10 under activator, add glycerin fatty acid ester or fatty acid for determined mass rate to process ester interchange and obtain the product. It is simple in technique, has good defoaming and foam inhibiting effect, gets raw material easily and fits to many techniques, such as paper making, sugar refining and fermentation.

Owner:温木盛

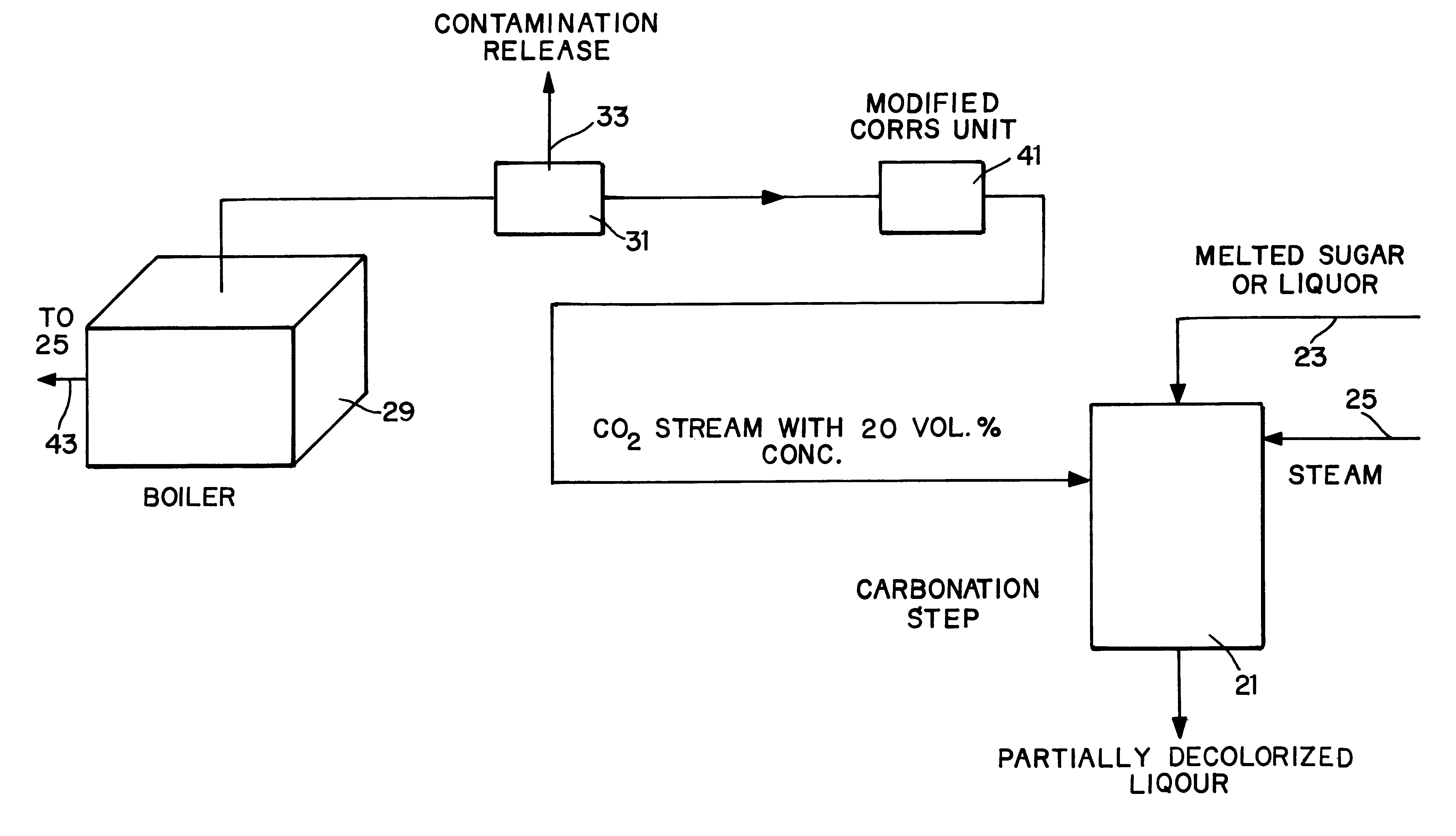

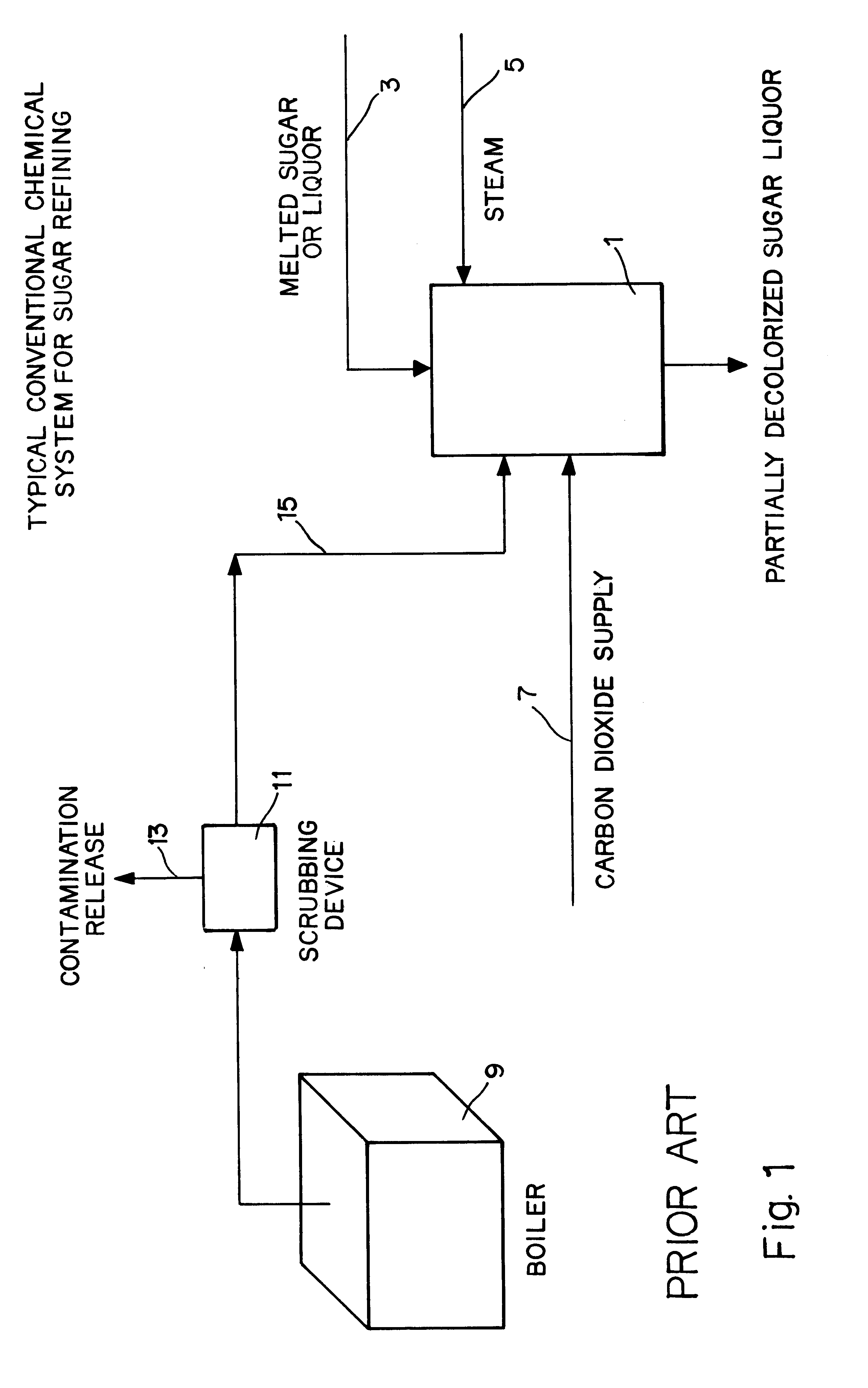

System and method for refining sugar

InactiveUS6176935B1Speed up the processEasily incorporated into existing refineryPurification using alkaline earth metal compoundsSugar crystal separationFlue gasSugar refining

A sugar refining process uses carbon dioxide obtained from a module containing a plurality of gas-permeable polymeric membranes. Flue gas from a boiler is scrubbed, and then passed through the gas-separation module. The output of the module contains an enhanced concentration of carbon dioxide, in the range of about 20% by volume. The carbon dioxide enhanced gas is then directed into a reactor in which raw sugar is exposed to carbon dioxide to cause carbonation, an essential step in the decolorization of the raw sugar. The same boiler used to produce the carbon dioxide is also used to produce steam which drives the reaction. The present invention provides carbon dioxide for carbonation in a highly efficient manner, as the gas separation membrane has no moving parts and requires little maintenance. The invention is especially suited for retrofitting existing sugar refining plants, to improve their efficiency, at a relatively small cost.

Owner:AIR LIQUIDE AMERICA INC +1

Colorimetric or fluorometric-detectable polymers containing pendant amine groups

InactiveUS6218491B1Minimize contaminationLow residual monomer contentOrganic detergent compounding agentsScale removal and water softeningThiolFluorescence

Polymers having amine-thiol terminal moieties are provided. The amine-thiol terminal moieties are imparted by using amine-thiols as chain transfer agents in aqueous addition polymerizations.The polymers are useful as mineral dispersants, as water-treatment additives for boiler waters, cooling towers, reverse osmosis applications, sugar refining, paper production, geothermal processes and oil wells, and as detergent additives acting as builders, anti-filming agents, dispersants, sequestering agents and encrustation inhibitors.

Owner:ROHM & HAAS CO

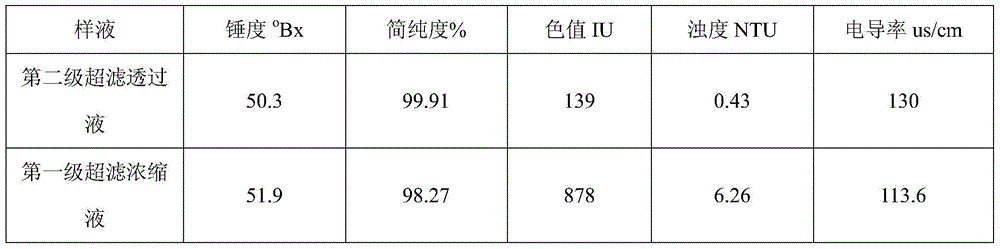

Membrane technology-based refined sugar clear-syrup impurity removal and decoloring technology

InactiveCN104404174AReduce turbidityHigh purityPurification by physical meansFiltrationMembrane technology

The invention discloses a membrane technology-based refined sugar clear-syrup impurity removal and decoloring technology. The technology comprises the following steps of carrying out press filtration on syrup to obtain clear syrup, before evaporation, feeding the clear syrup to a microfiltration device, carrying out microfiltration on the clear syrup by a microfiltration device to obtain a microfiltred concentrate liquid and a microfiltred penetrating liquid, removing the microfiltred concentrate liquid, collecting the microfiltred penetrating liquid, feeding the microfiltred penetrating liquid into a ultrafiltration device, carrying out further condensation treatment on the primary ultrafiltration concentrate liquid, carrying out sterilization to obtain a sugar liquid, and feeding the last ultrafiltration concentrate liquid into follow-up processes of sugar refining. The technology does not produce a waste liquid, is free of a chemical reagent, has no damage to the human body, improves syrup purity, reduces syrup turbidity and is conducive to crystallization.

Owner:GUANGXI UNIV

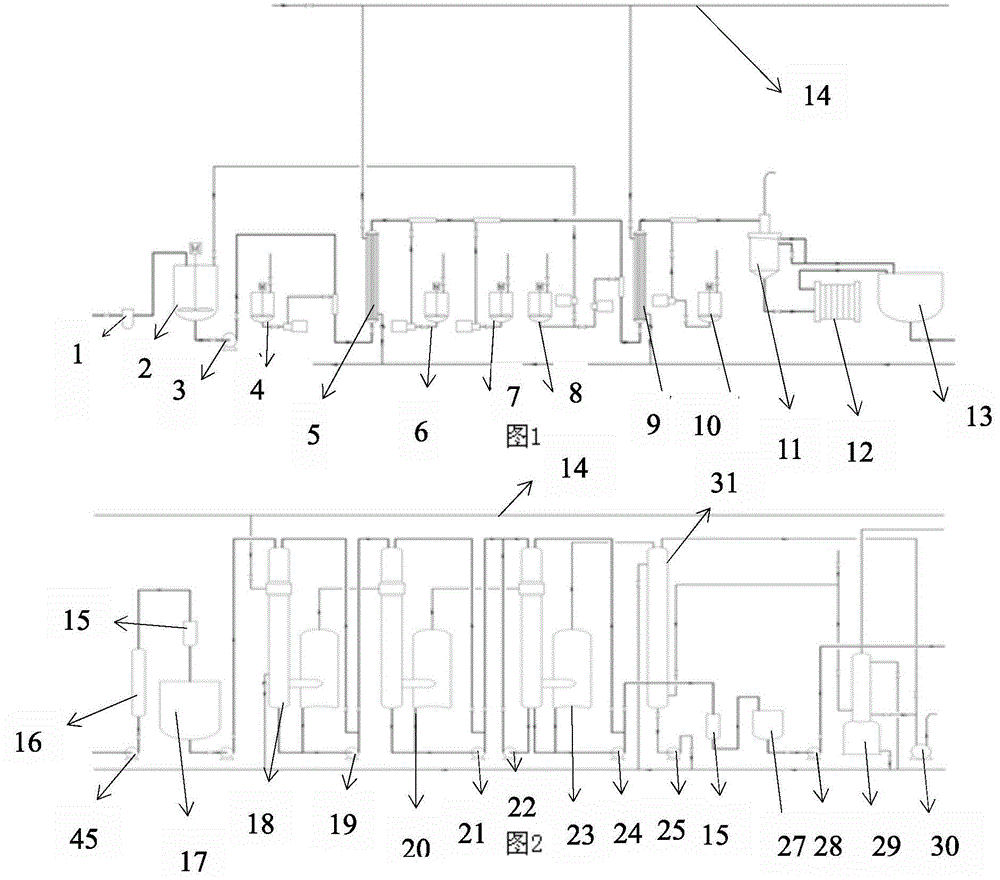

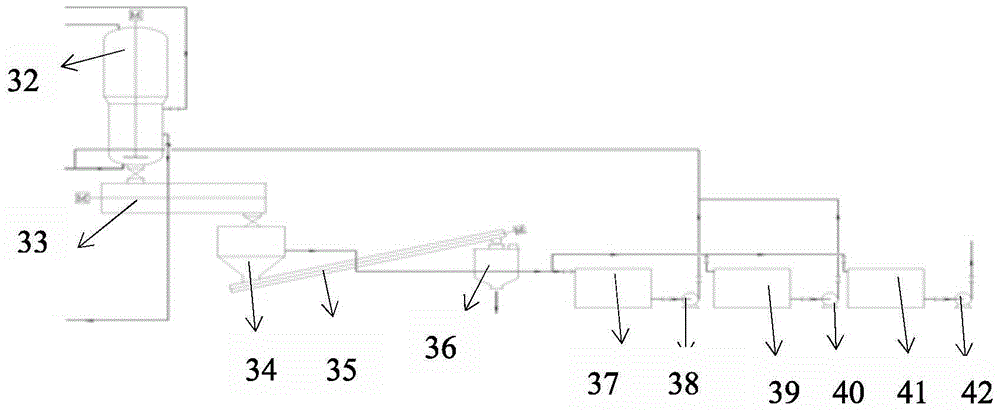

Cane sugar manufacture production system

InactiveCN103981291ALow investment costReduce manufacturing costSucrose extractionSugar juice boiling/evaporationIndustrial equipmentSettling basin

The invention discloses a cane sugar manufacture production system. The production system is characterized by comprising a cleaning system, a discoloring system, an evaporation system, a sugar boiling system and a purging and drying system; the system device comprises a pipeline filter, a mixed juice tank, a mixed juice pump, a static mixer, a heater, a rapid settling basin, a dosing storage tank, a filter press, a falling film evaporator, a condenser, a discoloring column, a bag filter, a sugar boiling crystallizing tank, a syrup tank, a help-crystallization box, a purging box, a conveyor, a drying machine, a gas-liquid separator, a honey jar, a clear juice pump, a syrup pump, a circulating pump and a vacuum pump. According to the cane sugar manufacture production system, a stove drying system and a carbonation system in the original sugar refining design are canceled, a novel process is adopted, novel industrial equipment is introduced, and the system can serve as a scientific research platform for performing a novel cane sugar manufacture process or an industrial production line for producing raw sugar, primary white granulated sugar, high-grade sugar and refined sugar.

Owner:GUANGXI UNIV +1

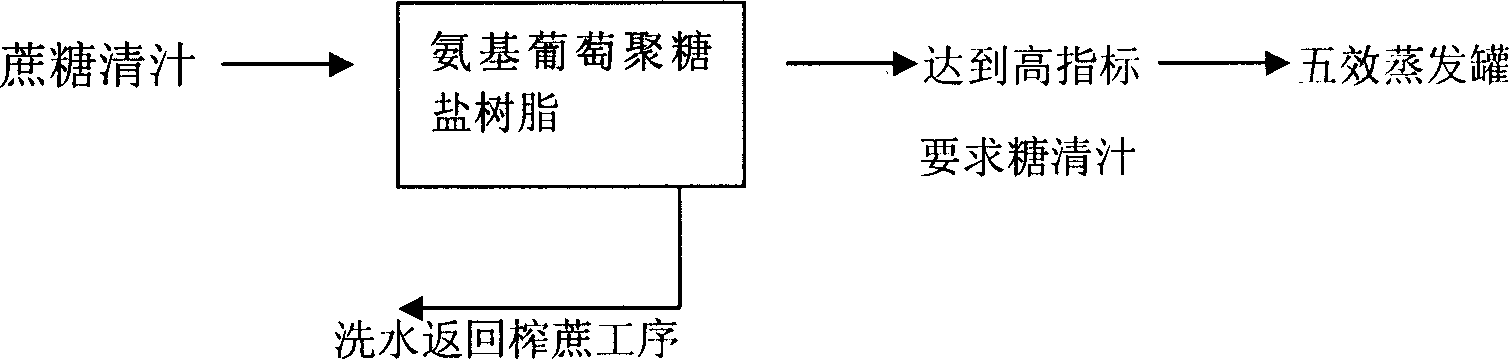

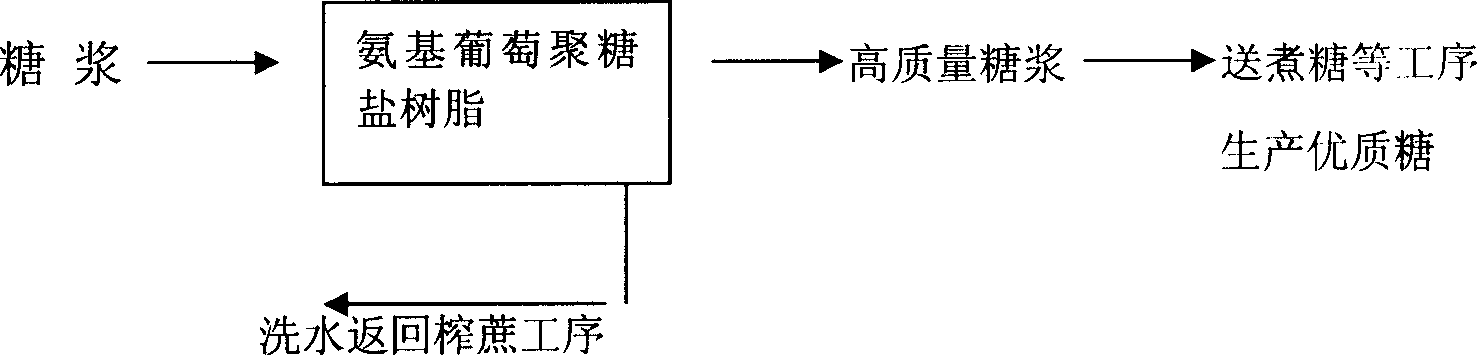

Purification and decolouring agent cane juice, syrup and its preparation method and application in sugar refining technology

InactiveCN1757756AEasy to handleEasy to operatePurification using adsorption agentsAcetic acidSugar refining

A purifying and decoloring agent for the cane juice or syrup in sugar refinery is prepared from chitosan through catalytic reaction between chitosan and the solution of acetic acid, citric acid or hydrochloric acid to obtain the polyose aminogluconate, and polymerizing to obtain aminoglucosan salt insoluble in water and deluted acid.

Owner:张永达 +3

Low-cost ganoderma lucidum cultivation method

InactiveCN107047066APromote growthImprove qualityAlkali orthophosphate fertiliserAmmonium orthophosphate fertilisersCelluloseAnimal science

The invention provides a low-cost ganoderma lucidum cultivation method. A large amount of bagasse is added in a culture medium, the bagasse is a by-product of sugar refining, when added in the culture medium, the bagasse can provide cellulose, sugar and other nutrients, all the bagasse, soybean cakes and traditional Chinese medicine leftovers are by-products of food and medicines, and the cost is low and is significantly reduced; vitamins are added, the growth of ganoderma lucidum can be promoted, and the quality of ganoderma lucidum is improved; the leftovers of traditional Chinese medicines improving the immunity effect are added, and the quality of ganoderma lucidum is further improved; at the same time, by improving the time, temperature, illumination and humidity in ganoderma lucidum cultivation process, the cultivation time of ganoderma lucidum is shortened, and the cost is further reduced.

Owner:DAWU HONGYUAN AGRI TECH CO LTD

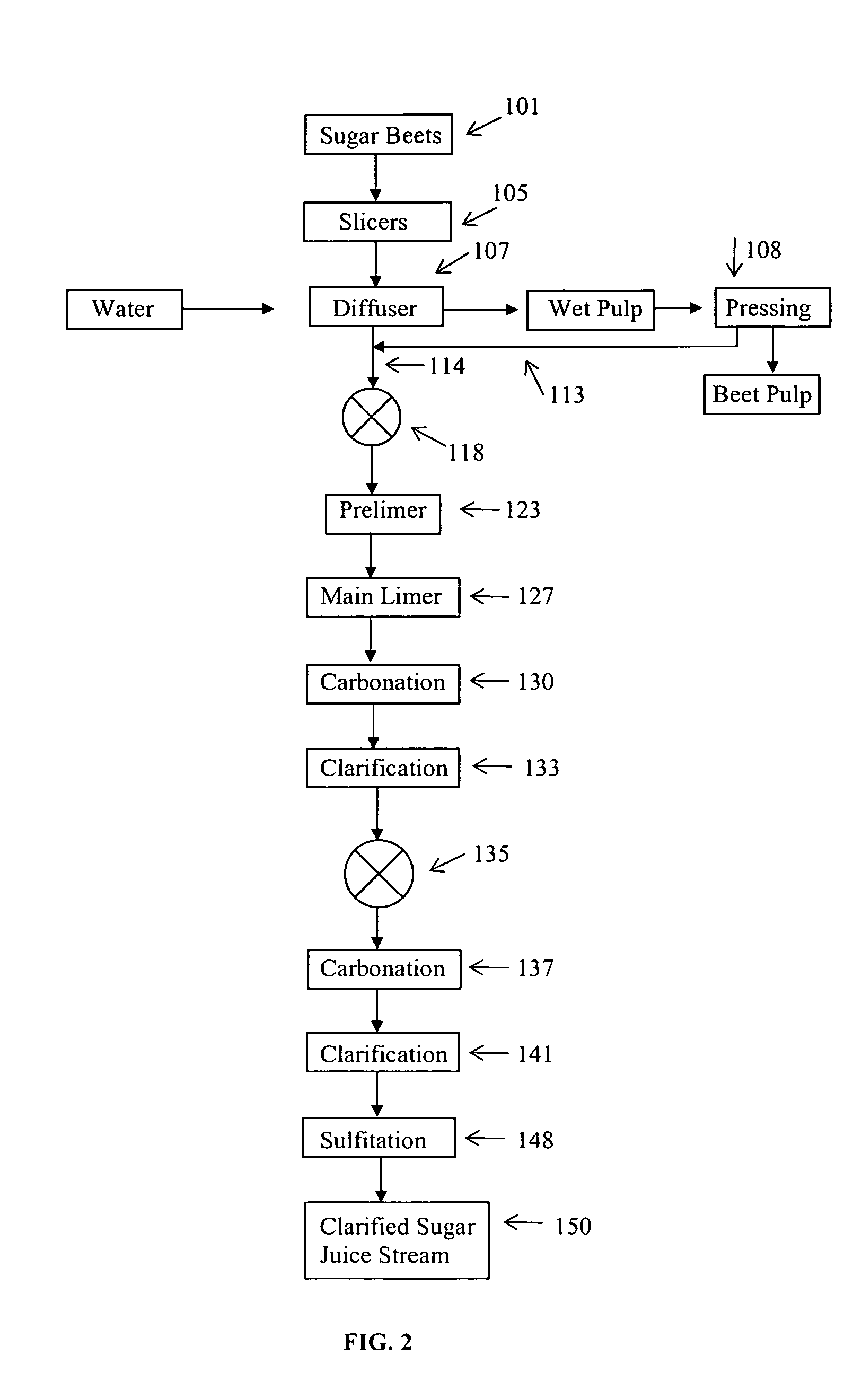

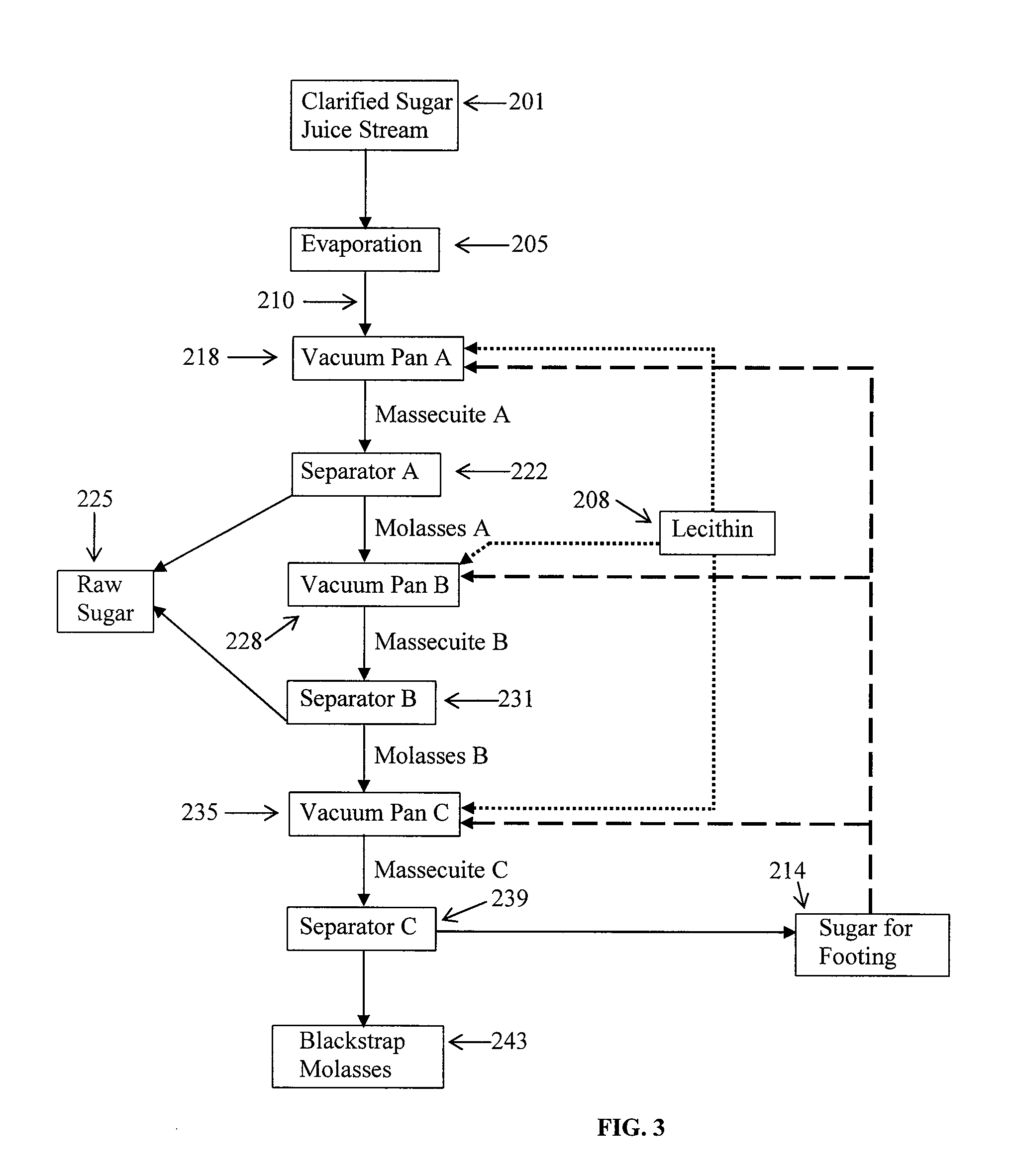

Composition and sugar refining process

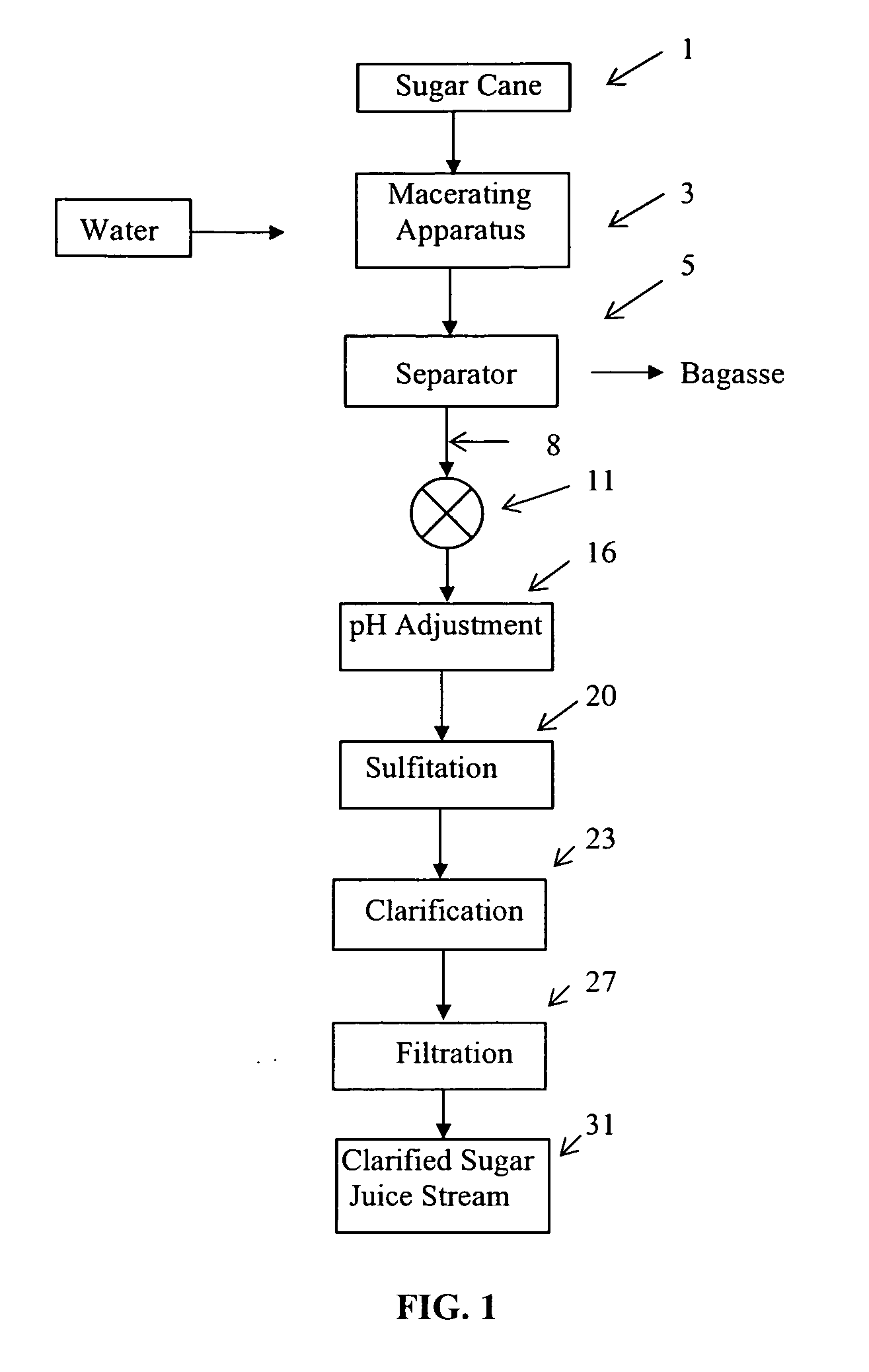

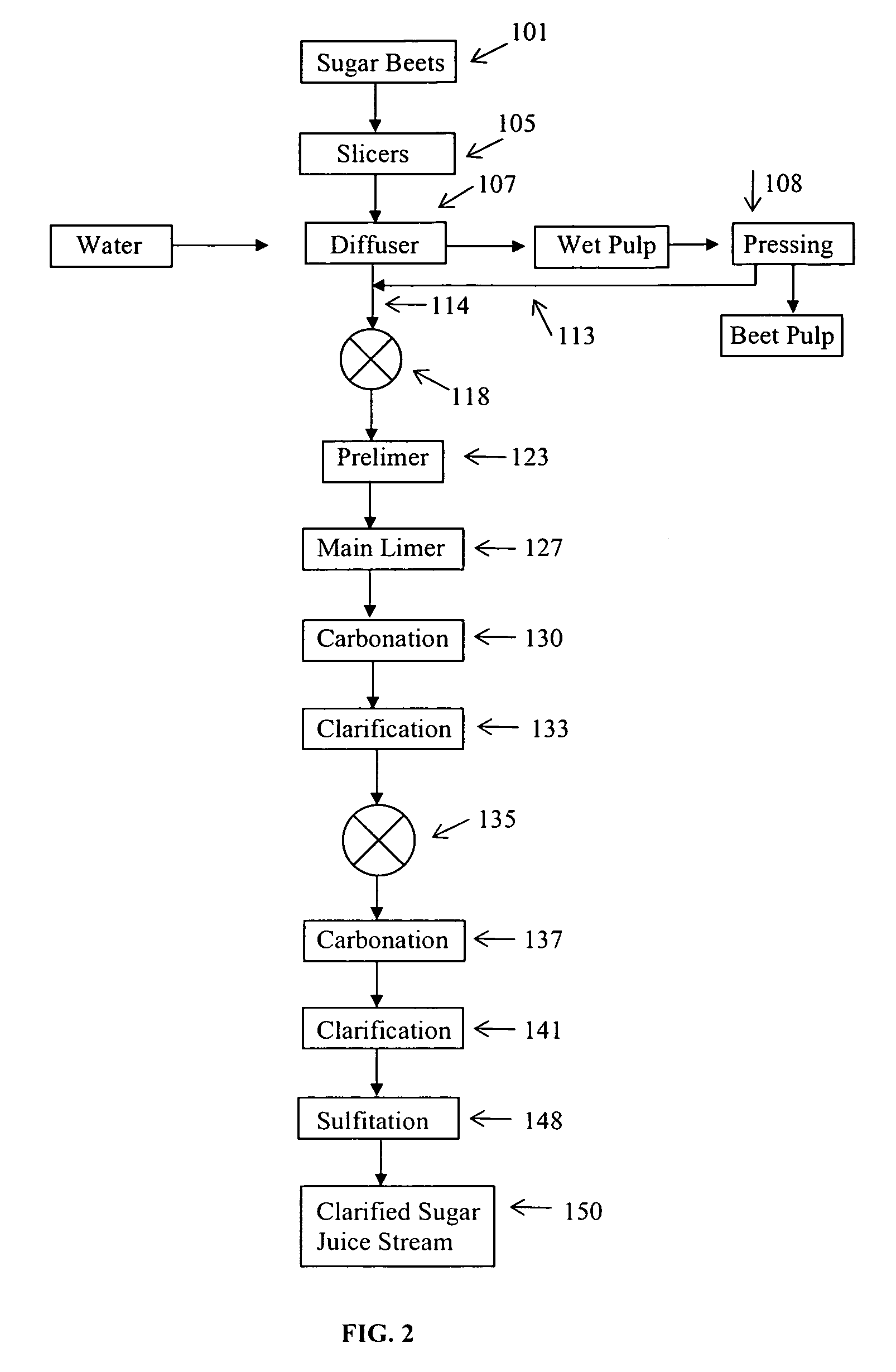

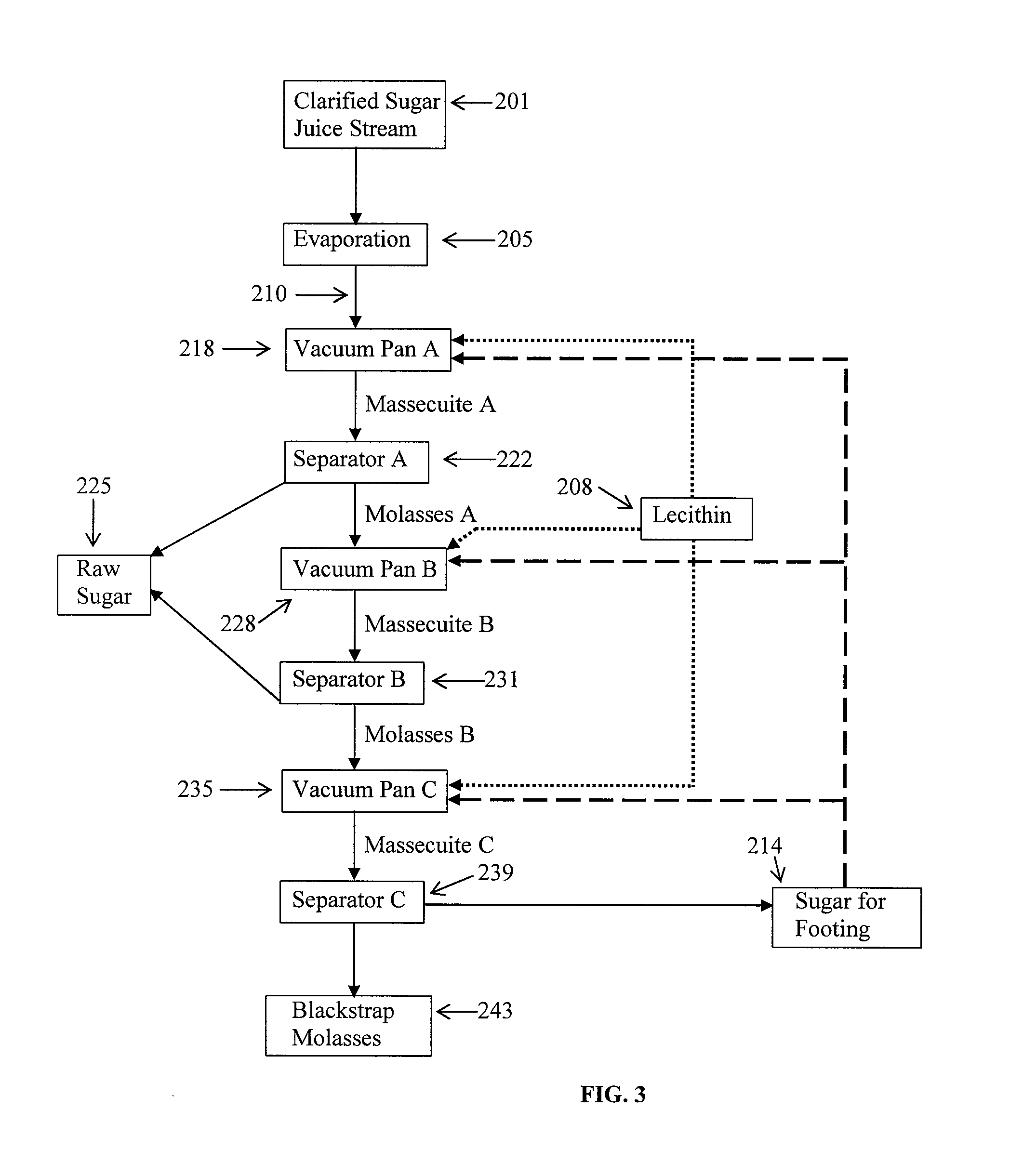

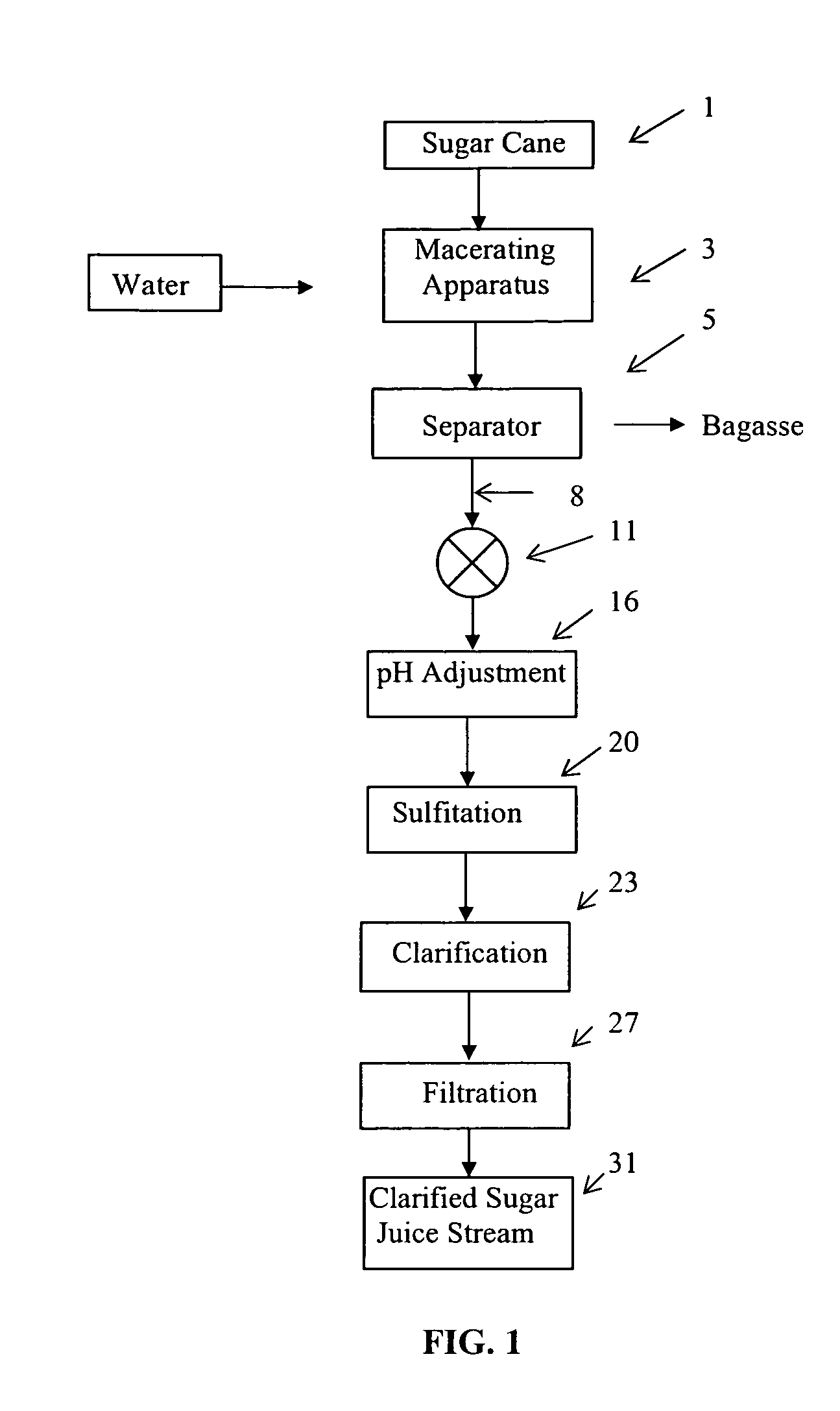

InactiveUS20070277814A1Increase productionSugar productsSugar crystallisationSugar refiningRefined sugar

Disclosed is a lecithinated sugar composition wherein lecithin is present in the sugar composition at not more than about 200 parts per million. Also disclosed is a process for increasing the yield of raw sugar from a clarified sugar juice stream. Further disclosed is a process for increasing the yield of refined sugar from raw sugar.

Owner:SOLAE LLC

Method for producing well-composted organic raw materials by using sugar refining filter mud and bagasse

InactiveCN104529579AImprove permeabilityGood aerobic fermentation stateBio-organic fraction processingClimate change adaptationOrganic manureSugar refining

The invention provides a method for producing well-composted organic raw materials by using sugar refining filter mud and bagasse. The method comprises the steps of blending the sugar refining filter mud, of which the weight ratio is 90.01-99.9%, and the bagasse, of which the weight ratio is 0.1-9.99%, so as to form a filter mud fermentation material, then, putting the filter mud fermentation material in a fermentation tank or stacking the filter mud fermentation material into window shapes on the ground surface, carrying out aerobic fermentation, stirring with fermentation equipment during fermentation, carrying out fermentation composting, and dehydrating, so as to obtain the well-composted organic raw materials. The method provided by the invention can be used for effectively utilizing the sugar refining filter mud and the bagasse and is good in fermentation effect and small in floor area, meanwhile, secondary pollution resulting from bad smell can be avoided, and the aims of high efficiency and environment-friendliness are achieved.

Owner:GUANGXI LIYUANBAO SCI & TECH

Composition and sugar refining process

Disclosed is a lecithinated sugar composition wherein lecithin is present in the sugar composition at not more than about 200 parts per million. Also disclosed is a process for increasing the yield of raw sugar from a clarified sugar juice stream. Further disclosed is a process for increasing the yield of refined sugar from raw sugar.

Owner:SOLAE LLC

Bio-fertilizer for fruit trees and preparation method of bio-fertilizer

InactiveCN107417433AWide variety of sourcesSimple preparation processExcrement fertilisersBiological combination treatmentSodium BentoniteMicrobial agent

The invention discloses a bio-fertilizer for fruit trees. The bio-fertilizer for fruit trees consists of the following raw materials in parts by weight: 100-135 parts of fruit tree wastes, 2-6 parts of a microbial agent, 60-70 parts of animal dung, 0.5-2 parts of microelements, 20-28 parts of bentonite, 8-12 parts of humic acid, 18-30 parts of sugar refining waste liquid, 10-15 parts of Ludwigia octovalvis, 5-14 parts of medical stone, 30-48 parts of edible fungi leftovers, 12-18 parts of vermiculite powder and 6-10 parts of christina loosestrife herb. The invention further discloses a preparation method of the bio-fertilizer. By scientific proportioning, the finished product has abundant nutrient substances and long-lasting fertilizer efficiency. The prepared finished product is high in absorption rate; growth of harmful microorganisms such as fungi, bacteria and viruses in soil can be inhibited, the yield and quality of fruit can be improved, the use amount is small, and the production cost is reduced.

Owner:NINGBO YINZHOU DUOFAN INT TRADE

Process for refined production of stevioside

InactiveCN105061527AAvoid damageImprove securitySugar derivativesSugar derivatives preparationSolubilityFiltration

A process for refined production of stevioside comprises the following steps: (1) mixing stevioside raw sugar and edible ethanol solution and performing stirring backflow until the stevioside raw sugar is fully dissolved; (2) performing immediate filtration of the obtained solution and crystallizing filtrate obtained after the filtration; performing refiltration after the crystallization and obtaining crystal I and filtrate I; (3) after the obtained crystal I is dried, mixing the obtained crystal I and the edible ethanol solution, and performing stirring backflow until the crystal I is fully dissolved; (4) performing immediate filtration of the obtained solution and crystallizing the filtrate obtained after the filtration; performing refiltration after the crystallization and obtaining crystal II and filtrate II; (5) performing concentration and drying of the obtained filtrate II; (6) drying the crystal II obtained through the step (4), and obtaining the product. By utilizing the fact that components of stevioside are different in solubility in the edible ethanol solution, rebaudioside A is separated and extracted, stevioside with the purity of rebaudioside A over 97% is obtained, and the use of solvents class 2 such as methanol and isopropanol is avoided.

Owner:湖南威嘉生物科技有限公司

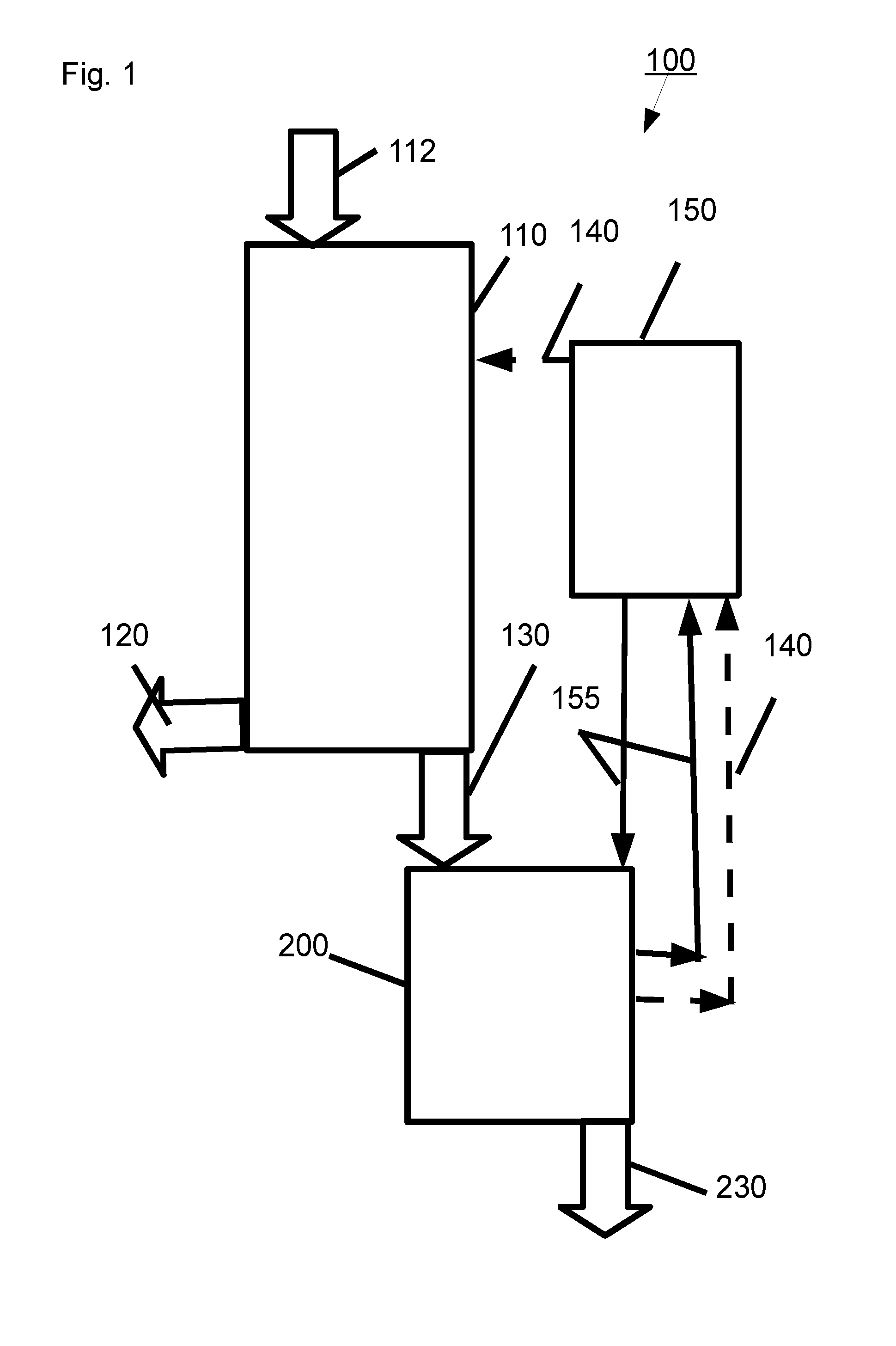

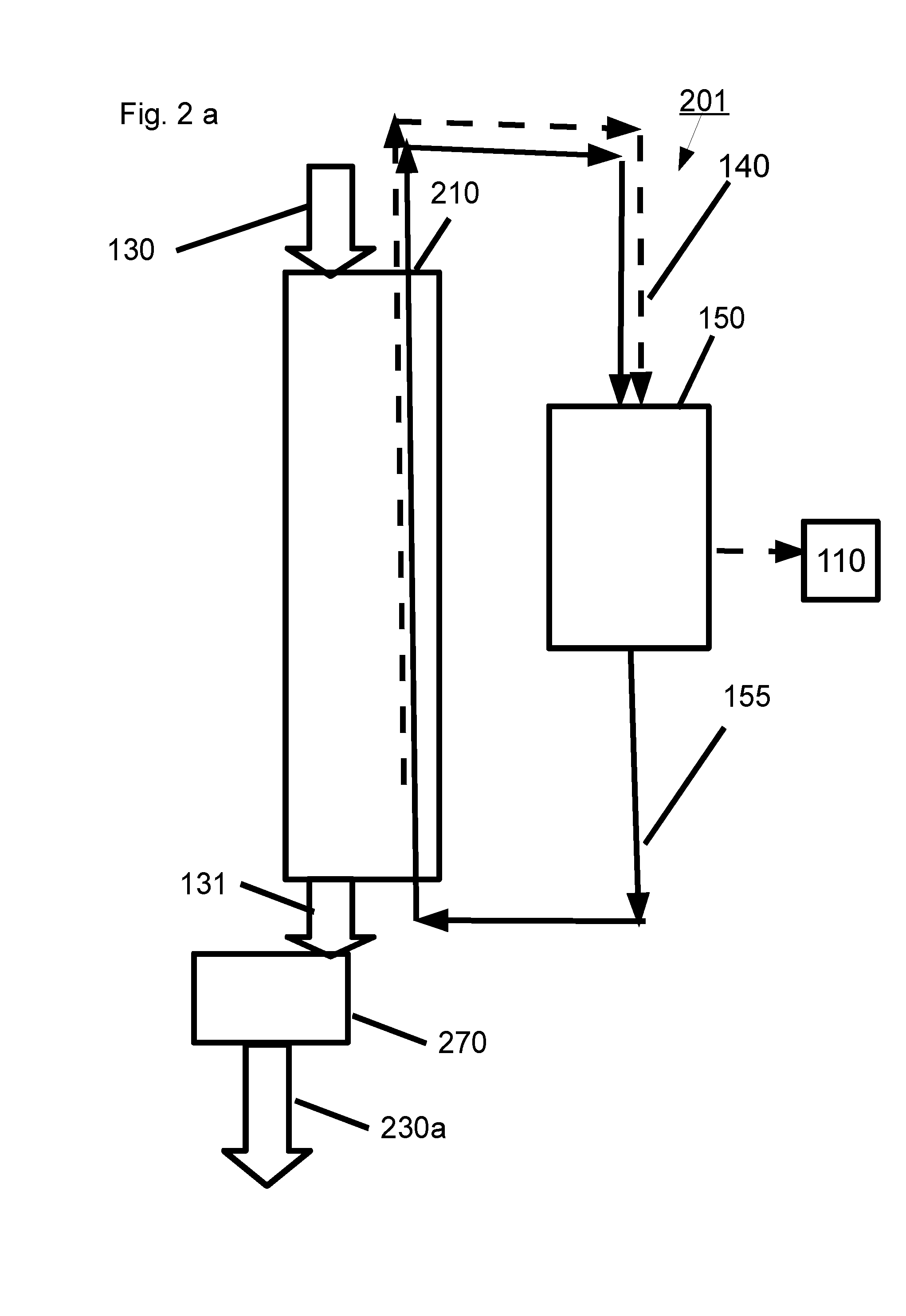

Systems and methods for sugar refining

InactiveUS20140202452A1High economic valueImprove processing efficiencySolid sorbent liquid separationPurification using ion-exchange materialsSugar refiningSolvent

A method comprising: (a) extracting a sugar mixture in an aqueous solution of at least 30% HCL / [HCl+water] by weight with an extractant including an S1 solvent; (b) increasing a monomeric sugar to oligomeric sugar ratio in the mixture to produce a monomeric sugar enriched mixture comprising at least 65% monomeric sugars by weight relative to total sugars; and (c) separating an S1 / HCl liquid phase comprising more than 30% HCl / [HCl+water] from said sugar mixture.

Owner:VIRDIA

Ruminant animal concentrated feed and preparation method thereof

InactiveCN106721195AImprove palatabilityHigh nutritional valueAnimal feeding stuffAccessory food factorsNutritive valuesBiotechnology

Ruminant animal concentrated feed is composed of, by weight, 50-80% of sugarcane tip leaves, 15-30% of cassava leaves and 5-20% of molasses. A preparation method of the ruminant animal concentrated feed includes of smashing of the sugarcane tip leaves and cassava leaves, pre-spraying, steam explosion, primary fermentation, secondary fermentation, drying, smashing and granulating. With sugar-refining industry by-products and cassava by-products being raw materials, the ruminant animal concentrated feed is prepared by the adoption of a method of steam explosion and biological fermentation combination; the obtained feed contains rich protein, further contains kinds of amino acid, flavonoid substances, sugar, grease, alcohol and others, and is high in nutritive value, good in palatability and good in digestion performance. In addition, the ruminant animal concentrated feed contains fungi, active ferment and kinds of digestive enzymes beneficial to intestines, can improve intestinal flora of animals and enhance the immunity of the animals, and is a animal protein feed having a health-care function.

Owner:GUANGXI UNIV

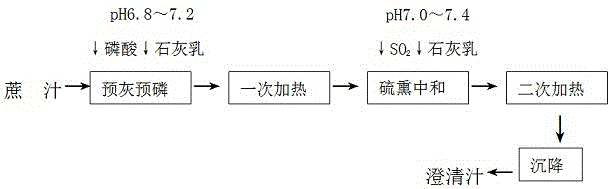

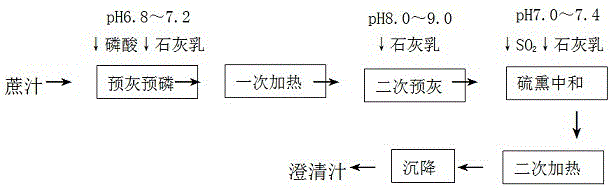

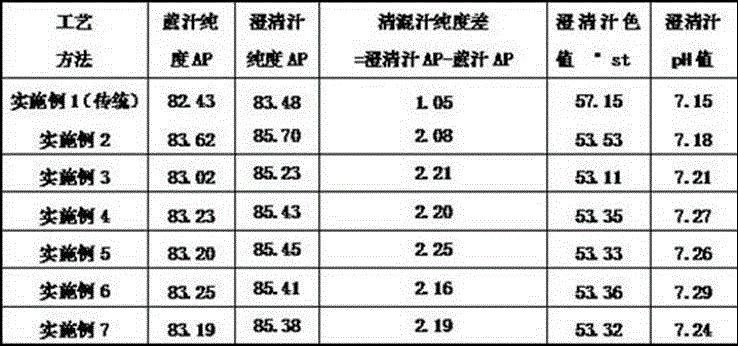

Sulfurous method sugar refining segmented preliming clarifying process

InactiveCN106282420AAdequate responseHigh recovery ratePurification using alkaline earth metal compoundsSulfurPhosphoric acid

The invention discloses a sulfurous method sugar refining segmented preliming clarifying process. The process includes the steps of preliming and pre-phosphorizing, primary heating, secondary preliming, stoving and neutralization, secondary heating and sedimentation. The segmented preliming technology is adopted in the clarifying process, preliming is carried out on cane juice after squeezing and juicing and before stoving and neutralization, after squeezing and juicing, phosphoric acid and lime milk are added into the cane juice at the same time, the pH value is controlled to be 6.8-7.2, and therefore protein and other colloidal substances in the cane juice are agglomerated in advance; secondly, lime milk is added before stoving and neutralization, the pH value is controlled to be 8.0-9.0, and it is avoided that much soluble calcium bisulfate is formed in the sulfur absorbing process of the cane juice. The technical scheme overcomes the defect that a traditional sulfurous method clarifying process is low in clarifying efficiency, product quality can be effectively improved, the sugar recovery rate can be effectively increased, and process energy consumption is reduced.

Owner:NANNING SUGAR INDUSTRY CO LTD

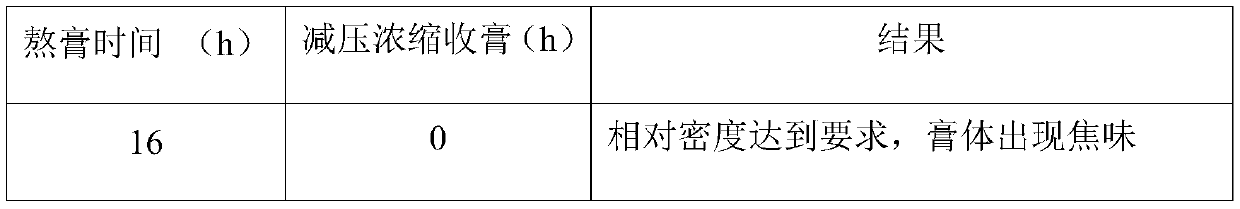

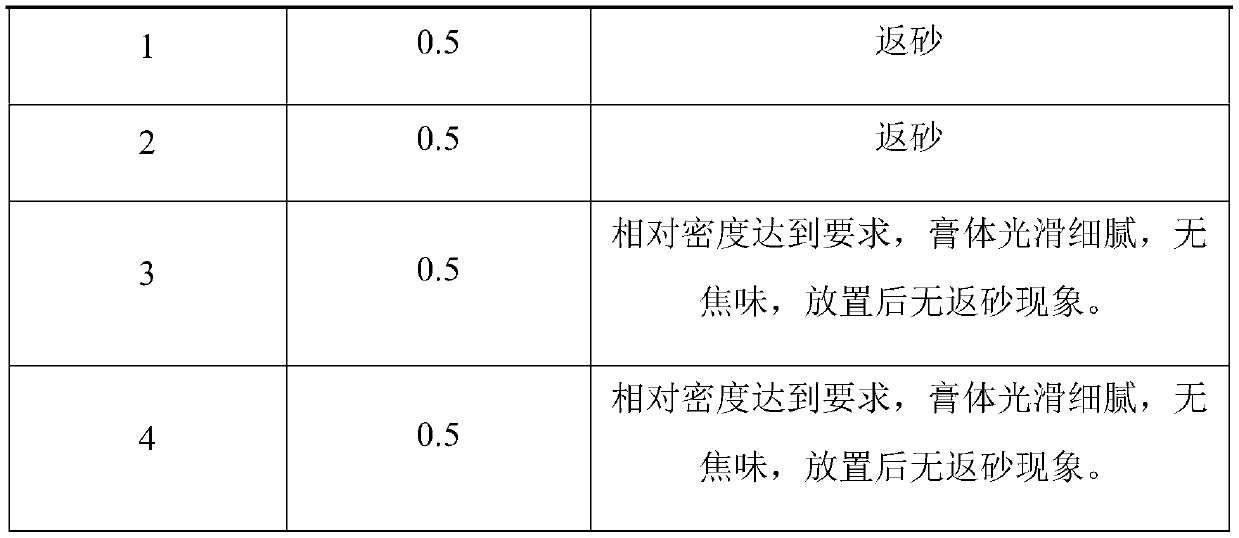

Paste composition and preparation method and application thereof

InactiveCN109999091AGood sleep effectPromote digestionNervous disorderAerosol deliverySugar refiningDigestion

The invention belongs to the field of traditional Chinese medicine compositions or traditional Chinese medicine health care products, and relates to a paste composition and a preparation method and application thereof. Specifically, the preparation method of the paste composition comprises the steps of preparation of a pure paste, sugar refining, paste decocting and reduced-pressure concentrationfor paste collection. According to the preparation method of the paste composition, reduced-pressure concentration is conducted in the paste collection process, and the preparation time for the pastecomposition is greatly shortened; meanwhile, the quality of the paste composition is excellent, the drawing and flagging effect is better, the paste body is smooth and delicate, no burnt smell is caused, and the sand returning phenomenon does not occur after placement. The invention further relates to the paste composition prepared by means of the paste composition preparation method and the application of the paste composition in preparing sleep aiding or digestion aiding foods or medicines.

Owner:东莞东阳光保健品研发有限公司

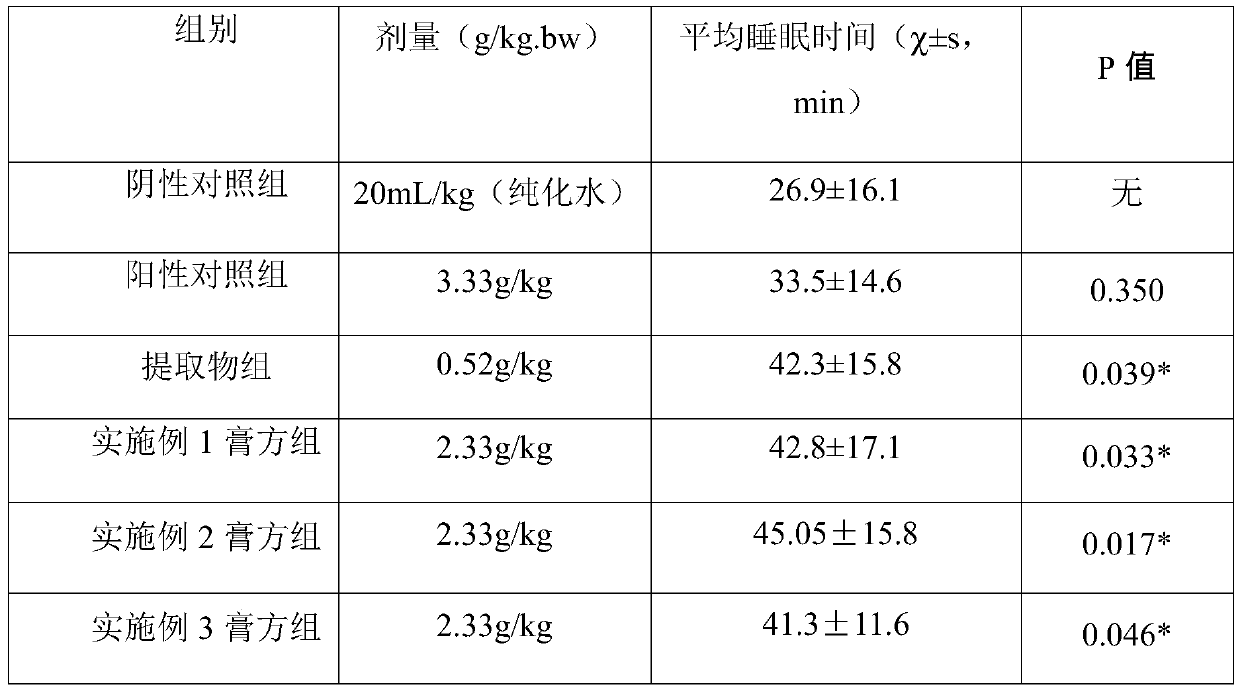

Preparation method for multi-functional high-efficiency flocculating agents

InactiveCN101525175AEasy to separatePlay a multifunctional roleWater/sewage treatment by flocculation/precipitationSugar refiningNitrogen gas

The invention relates to a preparation method for multi-functional high-efficiency flocculating agents, comprising the following steps: acrylamide, dimethyl cyclosiloxane, sodium carbonate, carbamide and de-ionized water which are selected are prepared according to the proportion, and are input to a batching tank by a centrifugal pump and are dissolved for forming the mixture, and then the mixture is transported to a polymeric kettle by the centrifugal pump, and then high-purity nitrogen is input from the bottom part of the polymeric kettle, evocating agents are added from a ball valve at the top part of the polymeric kettle, nitrogen is input for 15 minutes and then is stopped inputting, and the ball valve is closed at the top part of the polymeric kettle, so as to lead the mixture to be polymerized and to form colloid, 80 DEG.C of hot water is added to a kicked of the polymeric kettle, hydrolysis is carried out to the colloid for four hours, compressed air is used for compressing the material, dispersants are added at the same time, a pelletizer is used for pelleting, and then double-plastid vibration is carried out, a drier is used for frying, and the dried flocculating agents are packaged according to the granularity required by costumers for forming finished products. The preparation method is widely applied to industries such as industrial solid and liquid separation, sewage disposal, paper making, petroleum, petroleum, petroleum, geology, geology, buildings, packing industry, sugar refining, liquor making, etc.

Owner:徐兴伟

Preparation method for plant cirrus fermentation liquid glucose

The invention belongs to the field of biomass energy, and relates to a preparation method for a plant cirrus fermentation liquid glucose. The preparation method provided by the invention hydrolyzes the cirrus, and particularly comprises the technologies of cirrus cleaning, smashing, ammonium salt processing, calcium oxalate catalyzing and hydrolyzing and the like. The preparation method for the plant cirrus fermentation liquid glucose provided by the invention has the following advantages: (1) the cost is low, and the raw material source is wide; (2) the preparation technology is simple, the input is less, and large-scale popularization and application are facilitated; (3) the uncertainty of the microorganism enzyme fermentation sugar refining technology is avoided, and the technical risk is reduced; (4) the sugar conversion rate is high, the produced residue quantity is less, and the preparation method is an environment friendly technology. The plant cirrus fermentation liquid glucose prepared by the invention can be used as a raw material for producing alcohol, and the market prospect is wide.

Owner:TAICANG BIQI NEW MATERIAL RES & DEV

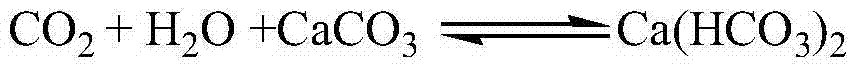

Method for treating carbonic acid method sugarhouse filter mud by using boiler flue gas

ActiveCN103586255APromote resource utilizationAvoid pollutionWaste processingSolid waste disposalCalcium bicarbonateEcological environment

The invention discloses a method for treating carbonic acid method sugarhouse filter mud by using boiler flue gas. The method comprises the steps of mixing carbonic acid method sugar refining filter mud with water according to a mass ratio of 1:(0.1-1):10; then introducing boiler flue gas, controlling the pressure of the boiler flue gas to be 0.01-0.10Mpa, and controlling the pH value of the mixture to be 5.0-7.5; performing sedimentation for demixing to obtain a solution on the upper layer, and performing burning treatment to obtain solid particles on the lower layer; filtering and then embedding the solid particles or using the solid particles as a building material. According to the method disclosed by the invention, CO2 in the boiler flue gas is used to ensure that calcium carbonate is generated into calcium bicarbonate, organic impurities adsorbed by the calcium carbonate are released, organic substances are enriched in water, and solid-liquid separation facilitates resource utilization; the organic substances are dried through the flue gas and then are burnt, so that pollution can be thoroughly solved while increasing fuels; the CO2 and heat energy in the flue gas are fully used to protect the ecological environment.

Owner:SOUTH CHINA UNIV OF TECH

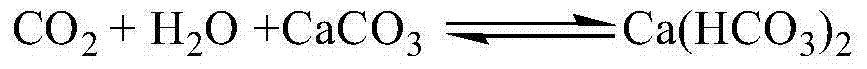

Method for applying lime sludge of sugar refining waste to flue gas desulfurization

InactiveCN103071382ALow running costImprove environmental benefitsCalcium/strontium/barium sulfatesDispersed particle separationSludgeSugar refining

The invention relates to a method for applying lime sludge of sugar refining waste to flue gas desulfurization. The method is characterized in that solid waste lime sludge generated by a sugar refinery adopting a carbonic acid method serves as a flue gas desulfurization agent, and is smashed to form lime sludge liquid; the lime sludge liquid is pumped into an absorption tower by a sludge pump; original flue gas from a deduster enters the absorption tower for desulfurization reaction; a pH value of the lime sludge liquid is controlled at 4.5-5.5; the temperature of the flue gas is controlled; desulfurization is achieved by multi-stage spraying; calcium sulfite generated in the reaction is subjected to forced oxidation by air blown in by an oxidation fan, in a circulating sludge tank at the bottom of the absorption tower; and gypsum is generated finally. According to the method, the lime sludge serves as the flue gas desulfurization agent for the first time; a brand-new recycling approach is provided for the solid waste lime sludge generated by the sugar refinery adopting the carbonic acid method; a more economical desulfurization agent is provided for the flue gas desulfurization of a heat-engine plant; purposes of treatment of wastes with processes of the wastes against one another, energy conservation and emission reduction are achieved; an environmental benefit and an economic benefit are increased; and the system operation cost is saved for an enterprise greatly.

Owner:山东星光生物科技有限公司

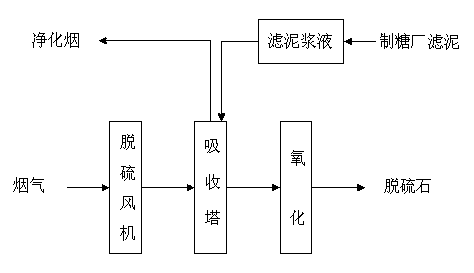

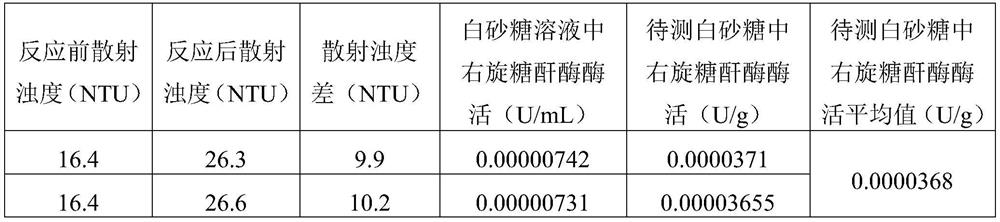

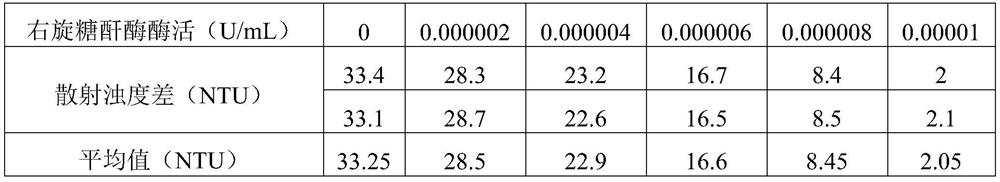

Anti-dextran monoclonal antibody D24 and application thereof in determination of enzyme activity of dextranase in sugar product

ActiveCN113201072AUndisturbedEasy to operateImmunoglobulinsMaterial analysisAntiendomysial antibodiesSugar refining

The invention discloses an anti-dextran monoclonal antibody D24 and application of the anti-dextran monoclonal antibody D24 in determination of dextranase activity in a sugar product, and belongs to the technical field of sugar refining. The anti-dextran monoclonal antibody D24 disclosed by the invention is generated by a dextran hybridoma cell strain D24 with the preservation number of CGMCC No. 21002. The anti-dextran monoclonal antibody D24 can be used for determining the enzyme activity of dextranase in a sugar product. The invention provides a method for determining the enzyme activity of dextranase in a sugar product. The method is simple to operate and low in detection limit.

Owner:GUANGDONG ACAD OF SCI INST OF BIOENGINEERING

Sugar production process using boiler flue gas as clarificant

InactiveCN100494407CImprove the purification effectHigh purityPurification using alkaline earth metal compoundsLime productionCO2 contentSugar refining

The present invention is sugar refining process with boiler fume as the clarifier, and the sugar refining process includes the steps of extracting crude sugar liquid, purifying crude sugar liquid and producing high quality sugar. During purifying crude sugar liquid, calcium oxide or regenerated filtering mud are added, and boiler fume with CO2 content of 6-17 is introduced for reaction with calcium oxide or regenerated calcium oxide to produce calcium carbonate adsorbing non-sugar impurity in the sugar liquid, with the volume ratio between boiler fume and crude sugar liquid being 100-300, and the mass ratio between boiler fume and calcium oxide or regenerated filtering mud being 5-30. The present invention has high sugar liquid purifying effect, sugar liquid purity raised by 2-13 %, reduced lime consumption, reduced CO2 exhaust of boiler, and raised economic utility and environment utility.

Owner:SOUTH CHINA UNIV OF TECH

Sugar refining technology for premature-falling apples

InactiveCN105671213AAchieve recyclingRealize developmentPurification using alkaline earth metal compoundsPurification by physical meansCalcium hydroxideAdjuvant

The invention discloses a sugar refining technology for premature-falling apples. The method comprises the following steps: carrying out pretreatment: slicing the premature-falling apples; carrying out squeezing: conveying the obtained premature-falling apple slices to a squeezer, squeezing out juice through thrice squeezing, enabling the juice to flow out of screen openings in the wall of a squeezer cavity, and collecting the juice in a first vessel; carrying out filtering: conveying the obtained juice to a filter so as to obtain pure juice, and separating the premature-falling apple leavings into a second vessel; carrying out clarifying: heating the obtained juice, adding lime cream to the heated juice for neutralization, adding a calcium hydroxide emulsion and an acetic solution to the juice, carrying out stirring, carrying out an isothermal reaction for 25 to 35 minutes, then, adding a flocculating adjuvant into the mixture, and carrying out isothermal standing, so as to obtain clarified sugar juice; and finally, carrying out concentration, thereby obtaining a product, i.e., sugar syrup. Compared with the existing sugar refining technologies, the sugar refining technology has the advantages that the premature-falling apples serve as a raw material, thus, the development and utilization of the premature-falling apples are achieved, the wasting of resources is reduced, and the sugar refining technology for different materials is achieved, so that the sugar refining technology is a new development direction.

Owner:宁金萍

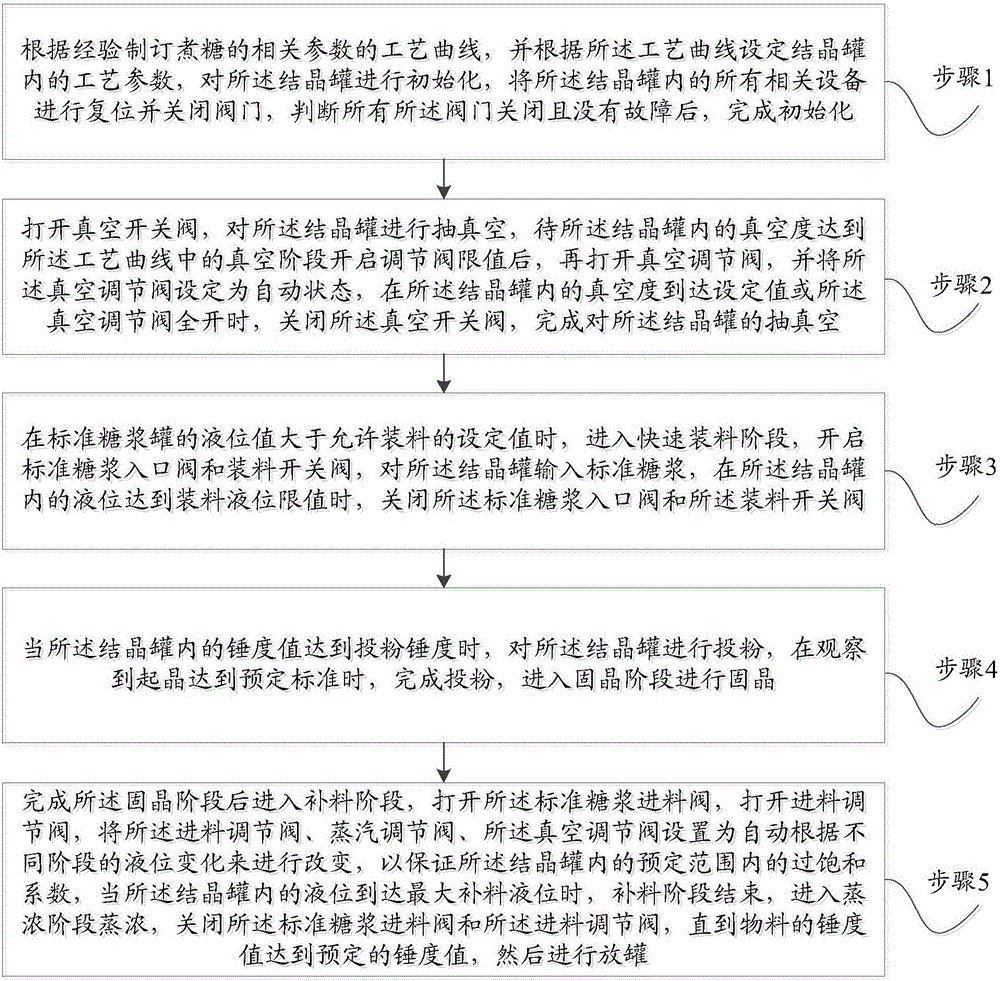

Automatic sugar refining method

InactiveCN106191323AImprove qualityReduce lossSugar crystallisationSugar juice boiling/evaporationBrixInlet valve

The invention discloses an automatic sugar refining method. The method includes the steps that a process curve of related parameters of sugar boiling is drawn up according to experience, and a crystallizing tank is initialized; the crystallizing tank is vacuumized; when liquid level value of a standard syrup tank is larger than a set value allowing charging, a standard syrup inlet valve and a charging switching valve are started, standard syrup is input into the crystallizing tank, and when the liquid level in the crystallizing tank reaches the charging liquid level limiting value, the tandard syrup inlet valve and the charging switching valve are closed; when brix degree in the crystallizing tank reaches a powder putting value, powder is put, when the brix degree reaches the preset standard, powder putting is completed, solid phase crystallization and material supplementation are carried out, inspissations is carried out then, the tandard syrup inlet valve and the charging switching valve are closed, and tank discharging is carried out until the brix value of the materials reaches the preset brix value. Existing sugar boiling experience is adopted, the process curve is manufactured, process parameters of related equipment in different stages are set according to the process curve, sugar is boiled automatically, and the automatic sugar refining method is high in adaptability and efficiency.

Owner:HANGZHOU HOLLYSYS AUTOMATION

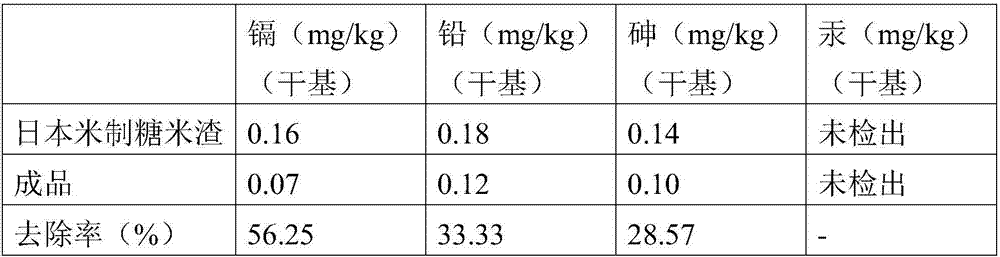

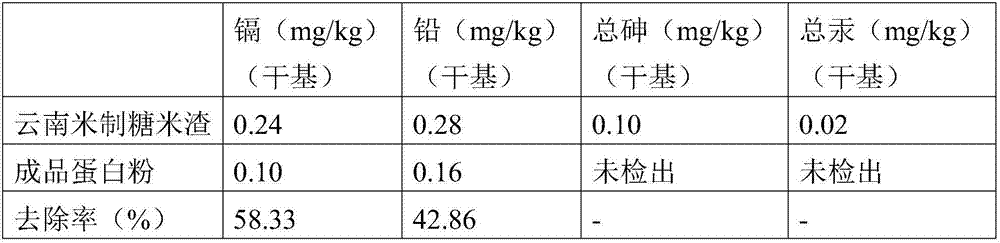

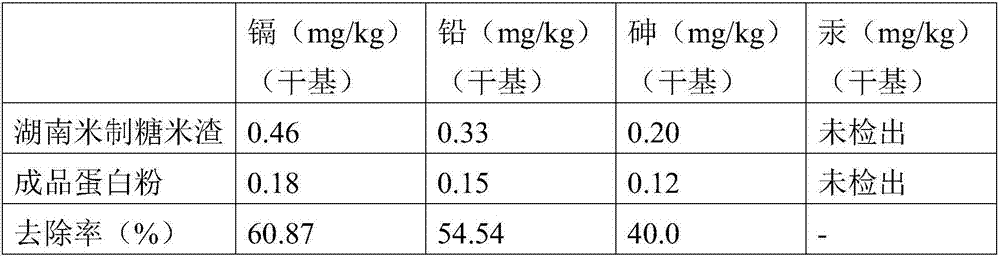

Method for removing heavy metal from rice protein through surfactant

The invention discloses a method for removing heavy metal from rice protein through a surfactant. The method comprises the following steps of (1) pretreating sugar refining rice residues; (2) adding a composite surfactant; (3) performing plate-frame pressure filtration, performing subsequent drying treatment on plate-frame filter cakes to obtain finished products of protein powder, and collecting plate-frame filtrate so as to obtain production waste water; and (4) adding a composite flocculant to the waste water, performing horizontal spiral sedimentation centrifuging, performing activated carbon treatment on supernatant, and performing plate-frame filtration so as to obtain filtrate which can be used as reclaimed water in the production process to be recycled. According to the method disclosed by the invention, materials are treated through the composite surfactant under weak alkali condition, reaction conditions are mild, requirements for production equipment are not high, ordinary production equipment can meet the requirements, the production cost is low, the heavy metal removal effects are notable, and the popularization properties of the technique are improved.

Owner:JIANGNAN UNIV

Method for pile fermentation of bagasse

InactiveCN106348963AWide variety of sourcesLow costCalcareous fertilisersAlkali orthophosphate fertiliserSlagSugar refining

The invention provides a method for pile fermentation of bagasse. The method comprises the following steps: proportioning the following raw materials in parts by weight: 1,000 to 1,200 parts of the bagasse, 20 to 30 parts of calcined lime, 80 to 120 parts of phosphatic fertilizer, 1 to 2 parts of monopotassium phosphate and 0.001 part of EM bacteria, and performing pile fermentation. According to the method for pile fermentation of the bagasse, slag, i.e. the bagasse, obtained by squeezing sugarcanes for sugar refining can be effectively used. The raw materials are readily available, and the cost is low; the whole pile fermentation process is simple, and the finally obtained organic fertilizer can be used for planting of crops such as vegetables, so that the growing effect of the crops is effectively enhanced, and the application of chemical fertilizer is reduced. The method is environment-friendly, pollution residue-free and suitable for being popularized in sugarcane planting and sugar refining districts.

Owner:北海市绿品生态农业科技有限公司

Fermentation method of utilizing sugar refining tailing and tryptophan mother liquid to produce biological feed

PendingCN109793097AHigh protein contentHigh nutritional valueFood processingAnimal feeding stuffSodium bicarbonateSugar refining

The invention provides a fermentation method of utilizing sugar refining tailing and tryptophan mother liquid to produce biological feed. The fermentation method includes: sequentially adding tryptophan mother liquid, corn pulp and ammonium sulfate into a mixing tank, using alkali liquid to adjust pH of fermentation raw materials, sequentially adding corn bran, pond sediment and sodium hydrogen carbonate, stirring well in the mixing tank, dividing a material mixture into two parts, respectively adding bacillus subtilis and yeast into the two parts of the material mixture, respectively performing facultative anaerobic fermentation on two kinds of the material mixtures added with different zymophytes, mixing after fermentation is completed, performing anaerobic fermentation again, directly bagging and sealing a re-fermentation material mixture after fermentation is finished, or smashing and packaging after drying. By the fermentation method, the problem of downstream treatment difficultyof the sugar refining tailing and the tryptophan mother liquid in the process of tryptophan production is solved, and environment protection pressure of amino acid production is relieved.

Owner:HENAN JULONG BIOLOGICAL ENG CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com