Method for treating carbonic acid method sugarhouse filter mud by using boiler flue gas

A technology for boiler flue and sugar factory filter mud, applied in waste treatment, separation methods, chemical instruments and methods, etc., can solve the problems of plant metabolic process changes, ozone layer destruction, waste of resources, etc., to fully utilize resources and protect ecology Environmental and CO2 emission reduction effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

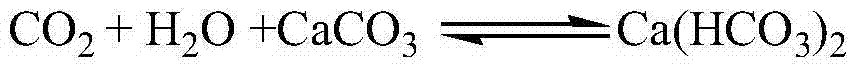

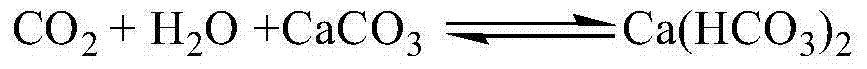

Method used

Image

Examples

Embodiment 1

[0019] Boiler flue gas is taken from the flue gas produced by the boiler in the sugar factory after burning coal. After dust removal, water or alkaline water washing, gas-water separation pretreatment, and then removal of solids, suspended impurities and sulfides, the main content of N 2 , CO 2 , CO and O 2 and other mixed gases, where CO 2 The content is 15-18% (volume percentage), and the gas pressure is 0.01-0.10MPa.

[0020] Take 1000kg of carbonic acid sugar filter mud (moisture mass percentage is about 65%), add 100kg of water, stir evenly, pass into the boiler flue gas until the pH of the material mixed with carbonic acid sugar filter mud and water is 7.5, and the sedimentation The upper layer solution is sprayed onto the bagasse, and the flue gas (flue gas temperature 190-200°C) after the boiler air preheater is dried and then burned in the boiler, and the solid particles in the lower layer are filtered and then buried; according to the measurement method in the inte...

Embodiment 2

[0025] Boiler flue gas is taken from the flue gas produced after burning oil in the boiler of the sugar factory. After dust removal, clean water or alkaline water washing, gas-water separation pretreatment, and then removal of solids, suspended impurities and sulfides, the main content of N 2 , CO 2 , CO and O 2 and other mixed gases, where CO 2 The content is 11-17% (volume percentage), and the gas pressure is 0.01-0.10MPa.

[0026] Take 1000kg of carbonic acid sugar filter mud (moisture mass percentage is about 55%), add 10000kg of water, stir evenly, pass through the boiler flue gas until the pH of the material mixed with carbonic sugar filter mud and water is 7.0, and the sedimentation point The upper layer solution is sprayed onto the bagasse, and the flue gas (flue gas temperature 190-210 ℃) after the boiler air preheater is dried and then burned in the boiler, and the solid particles in the lower layer are filtered and used as building materials without odor; accordin...

Embodiment 3

[0031] Boiler flue gas is taken from the flue gas produced by the boiler in the sugar factory after burning natural gas. After dust removal, clean water or alkaline water washing, and gas-water separation pretreatment, solids, suspended impurities and sulfides are removed to obtain mainly N 2 , CO 2 , CO and O 2 and other mixed gases, where CO 2 The content is 10-15% (volume percentage), and the gas pressure is 0.01-0.10MPa.

[0032] Take 1000kg of carbonic acid sugar filter mud (moisture mass percentage is about 58%), add 1000kg of water, stir evenly, pass into the boiler flue gas until the pH of the material mixed with carbonic acid sugar filter mud and water is 6.0, and the sedimentation The upper layer solution is sprayed onto the bagasse and the flue gas (flue gas temperature 160-180 ℃) after the boiler air preheater is dried and then burned in the boiler, and the solid particles in the lower layer are filtered and used as building materials without odor; according to t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com